Method of lock catch type vacuum rolling metal composite plate

A metal clad plate, vacuum rolling technology, applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., to increase the composite strength, improve the rolling stability, and reduce the oxidation of the joint interface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

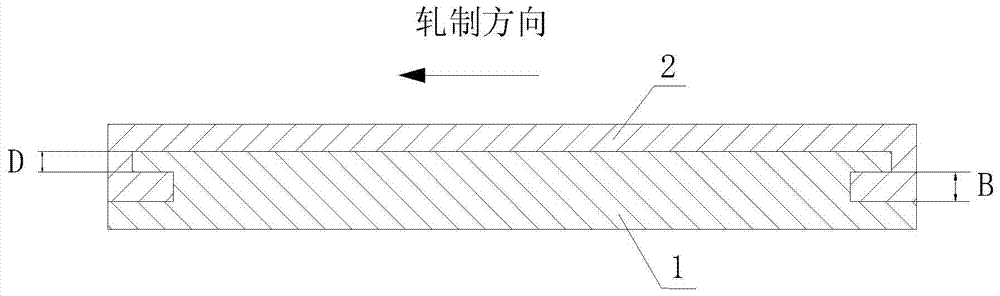

[0033] like Figure 1~3 The method of locking type vacuum rolling metal clad plate shown in, realizes through the following steps:

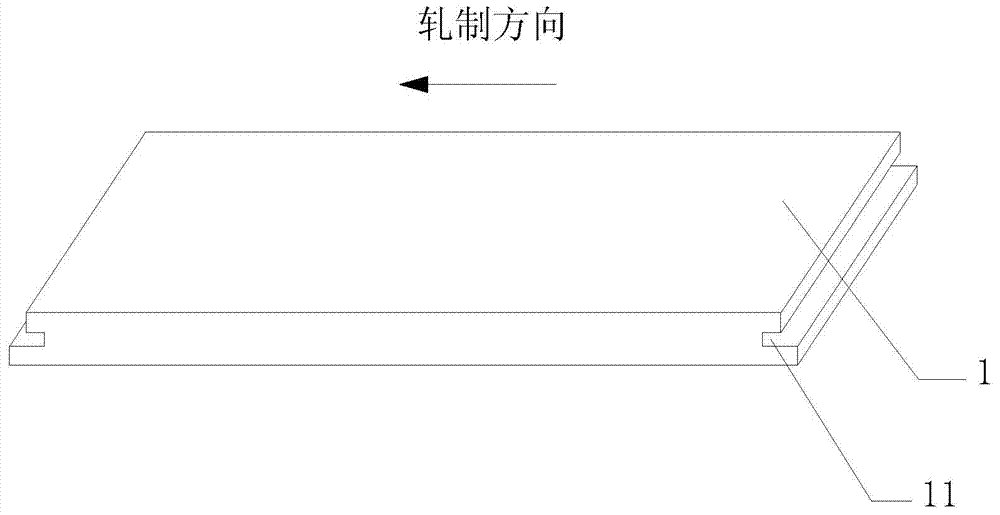

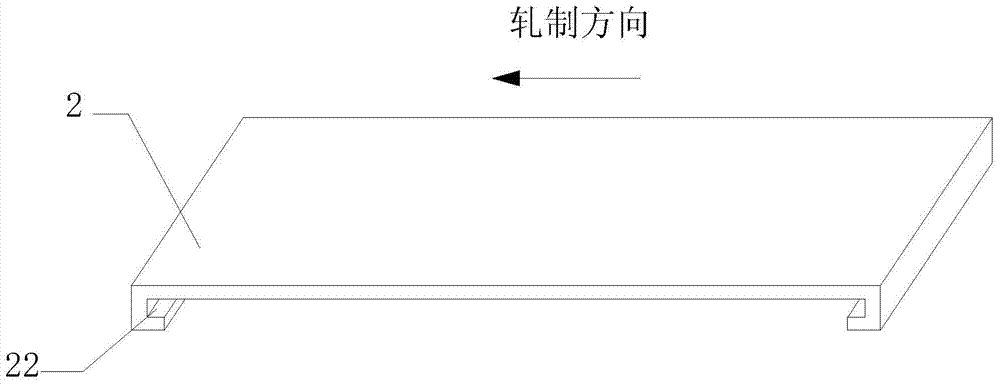

[0034] 1) Select the base plate 1 and the cladding plate 2 with the same width for processing, respectively process the through grooves 11 on both end faces of the base plate 1 perpendicular to the rolling direction, so that the longitudinal section of the base plate 1 after processing is I-shaped; The L-shaped fitting strips 21 are respectively welded at the positions corresponding to the grooves 11 at the two ends of the cladding plate 2 perpendicular to the rolling direction; With corresponding cooperation, the grooves 11 at both ends of the substrate 1 have the same depth;

[0035] 2) Clean the surface to be compounded of the substrate 1 and the cladding 2 to remove surface oil stains; slide the L-shaped fitting strips 21 at both ends of the cladding 2 into the grooves 11 at both ends of the substrate 1 along the direction perpendicular to t...

Embodiment 2

[0044] like Figure 2~4 As shown, the present embodiment is substantially the same as embodiment 1, except that embodiment 2 is to prepare stainless steel-carbon steel double-sided composite panels by this method, that is, substrate 1 adopts a Q345 carbon steel plate with a length of 1200mm × width of 600mm × thickness of 60mm; 2 Two pieces of 304 stainless steel plates are used with a thickness of 10mm; a groove 11 is processed on the carbon steel substrate 1 with a width of 30mm at the bottom, and the distance between the groove 11 and the upper surface of the carbon steel substrate 1 is 15mm; L is processed on both sides of the stainless steel cladding plate 2 Shape fitting bar 21, L-shaped fitting bar 21 height is 15mm. Slide the L-shaped fitting strip 21 into the groove 11 perpendicular to the rolling direction, so that the two cladding plates 2 are attached to the upper and lower surfaces of the base plate 1 respectively to form a composite slab, and the two sides of the...

Embodiment 3

[0046] like Figure 1~3 As shown, this embodiment is substantially the same as that of Embodiment 1, except that in Embodiment 3, a carbon steel extra-thick composite plate is prepared by this method, that is, both the base plate 1 and the cladding plate 2 are Q345 carbon steel plates with a length of 1000 mm × width of 600 mm × thickness of 200 mm , processing a groove 11 on the substrate 1 with a bottom width of 25mm, and the groove 11 is 50mm away from the upper surface of the substrate 1; L-shaped fitting strips 21 are processed on both sides of the cladding plate 2, and the size of the L-shaped fitting strip 21 is the same as that of the groove 11 consistent size. Slide the L-shaped fitting strip 21 into the groove 11 along the direction perpendicular to the rolling direction, so that the base plate 1 and the cladding plate 2 form a composite slab, and weld the sealing and welding plates on both sides of the composite slab, so that the base plate 1 and the cladding plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com