Fabric internally-enhanced block polyolefin waterproof roll

A waterproofing membrane, fabric reinforcement technology, applied in the direction of layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of weak bonding of upper and lower thermoplastic polyolefin layers and unreliable long-term use of welding seams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

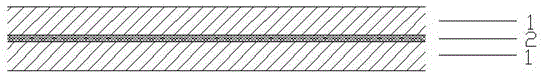

[0029] ⑴ Coil structure: figure 1 It is an embodiment of the composition and structure of the reinforced block polyolefin waterproof membrane in the fabric of the present invention, see figure 1 , the coil is composed of a two-block polyolefin layer 1 and a fabric reinforcement layer 2, and its arrangement sequence is: block polyolefin layer 1, fabric reinforcement layer 2, block polyolefin layer 1 , the three-layer structure conforms to one body, and the preferred total thickness is 1.2-2.0mm. This example is 1.5 mm.

[0030] (2) Components and parts by mass of block polyolefin layer

[0031] 60 parts of block polyolefin (OBC), 40 parts of polyolefin, 60 parts of flame retardant, 2 parts of compatibilizer, 5 parts of pigment, 0.5 part of antioxidant, and 0.5 part of light stabilizer.

[0032] Block polyolefin adopts INFUSE 9010 from Dow Chemical.

[0033] The polyolefin is linear low density polyethylene 7042 from Yangzi Petrochemical.

[0034] The flame retardant is sur...

Embodiment 2

[0044] ⑴ Coil structure: figure 1 It is an embodiment of the composition and structure of the reinforced block polyolefin waterproof membrane in the fabric of the present invention, see figure 1 , the coil is composed of a two-block polyolefin layer 1 and a fabric reinforcement layer 2, and its arrangement sequence is: block polyolefin layer 1, fabric reinforcement layer 2, block polyolefin layer 1 , the three-layer structure is combined into one body, and the preferred total thickness is 1.2-2.0mm. This embodiment is 1.2mm.

[0045] (2) Components and parts by mass of block polyolefin layer

[0046] 50 parts of block polyolefin (OBC), 50 parts of polyolefin, 50 parts of flame retardant, 2 parts of compatibilizer, 5 parts of pigment, 0.5 part of antioxidant, and 0.5 part of light stabilizer.

[0047] The block polyolefin is INFUSE 9530 from Dow Chemical.

[0048] The polyolefin was ExxonMobil's linear low density polyethylene LL1001XV.

[0049] The flame retardant is surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com