Patents

Literature

888results about "Pigment addition to spinning solution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

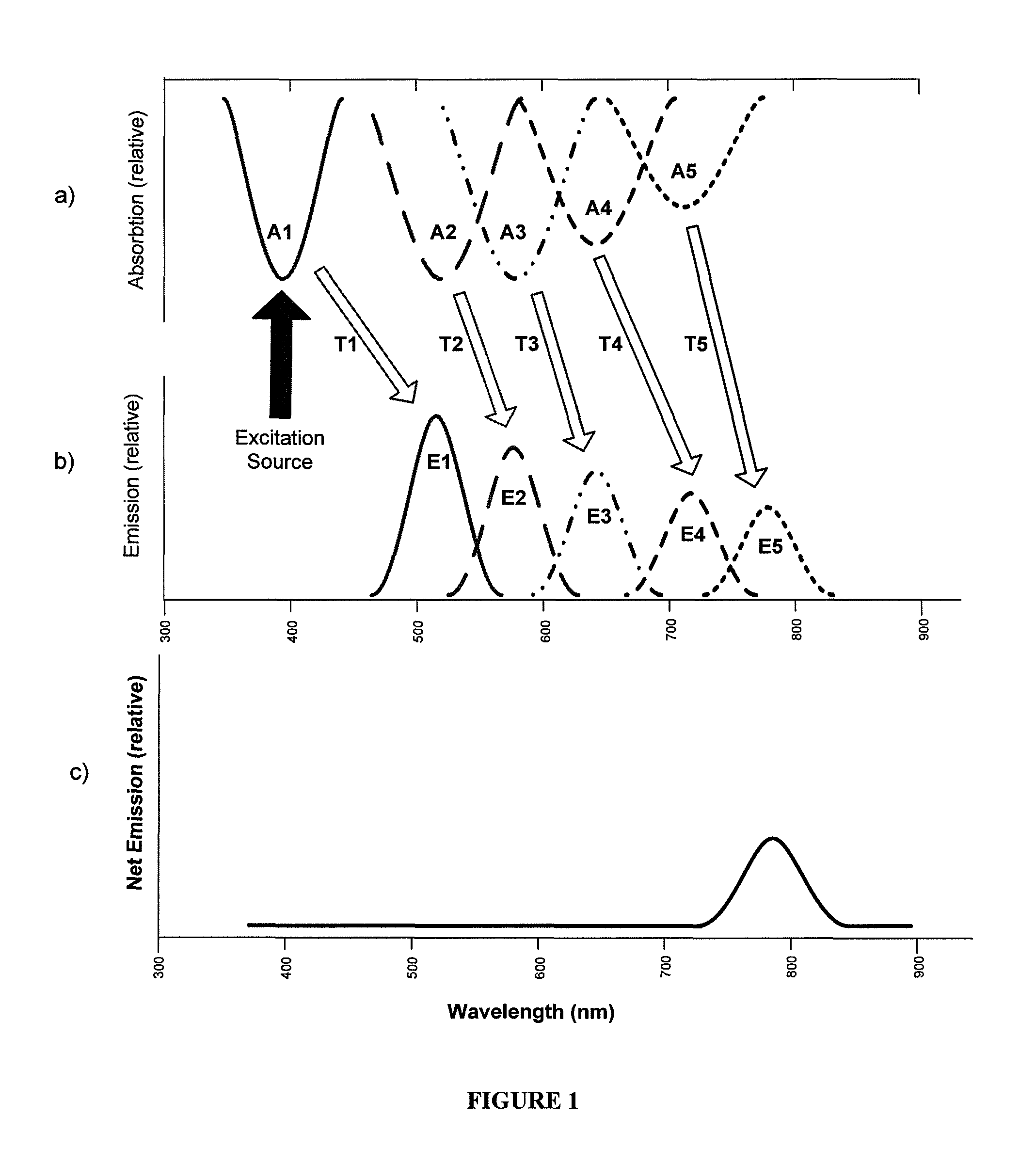

Photoluminescent fibers, compositions and fabrics made therefrom

Disclosed are photoluminescent fibers containing photoluminescent phosphorescent materials and photoluminescent fluorescent materials whose emission signature lies partly or fully in the infrared region of the electromagnetic spectrum. Also disclosed are the use of the inventive fibers, fabrics made therefrom, and objects containing the fiber.

Owner:PERFORMANCE INDICATOR LLC

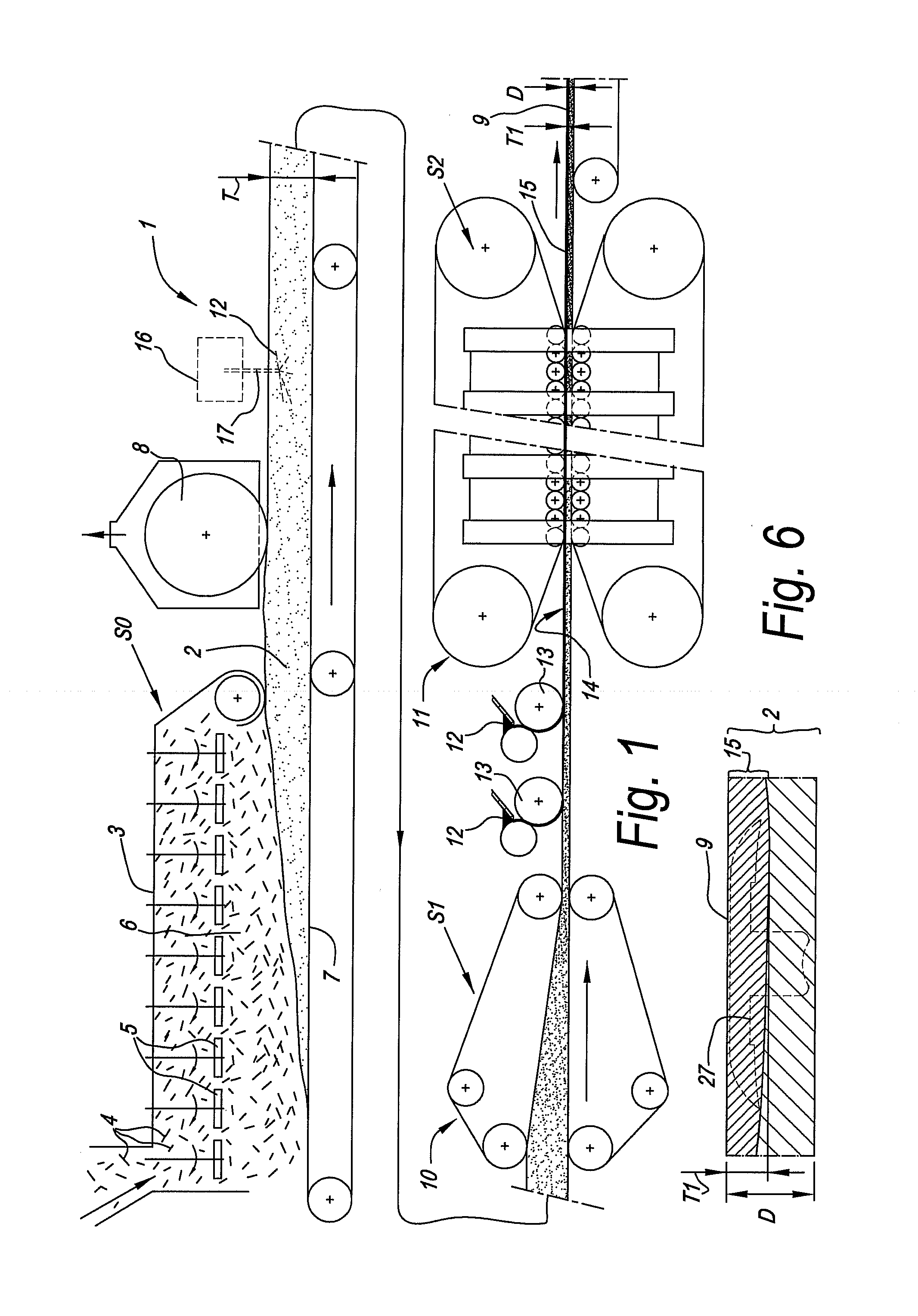

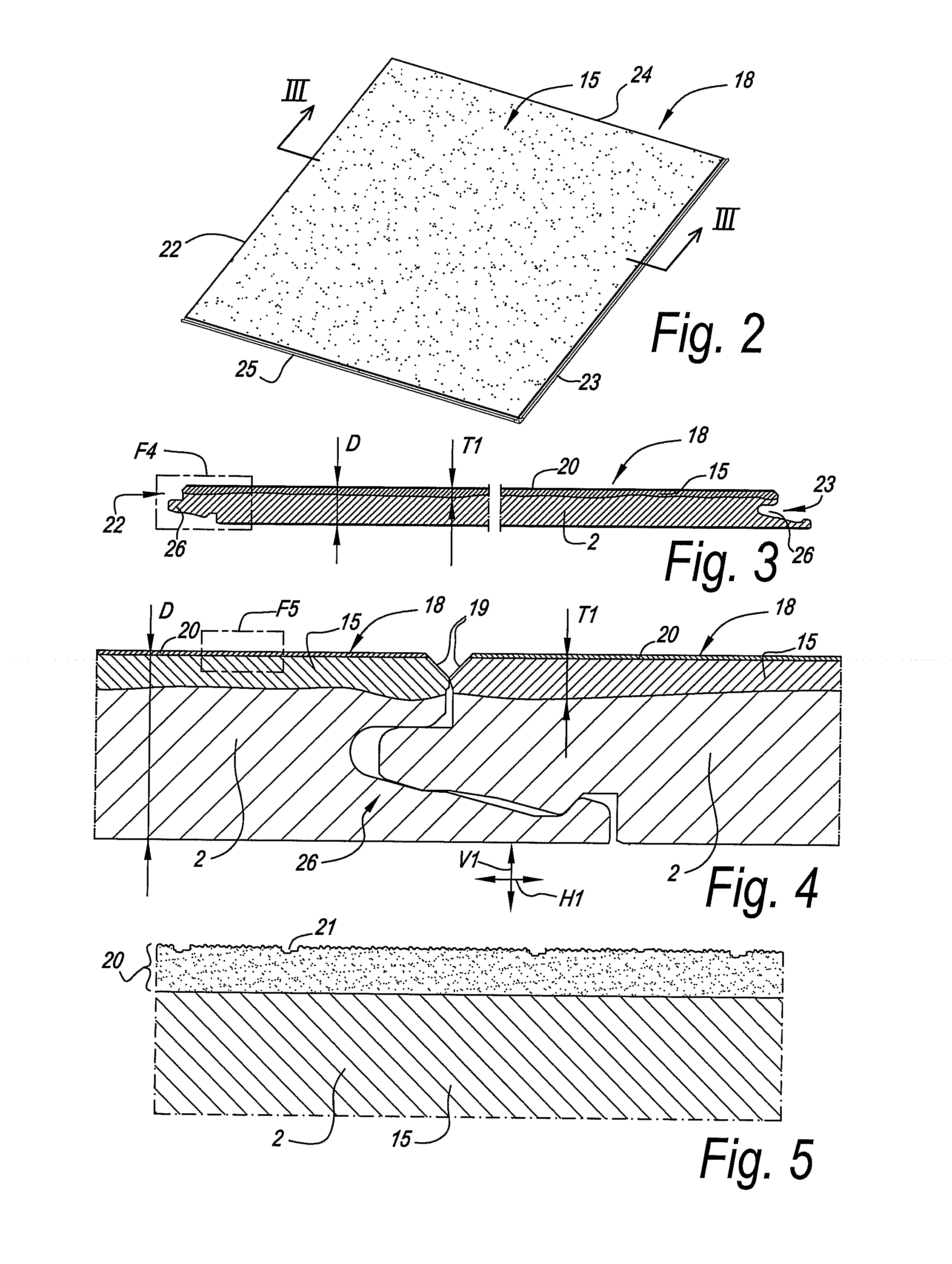

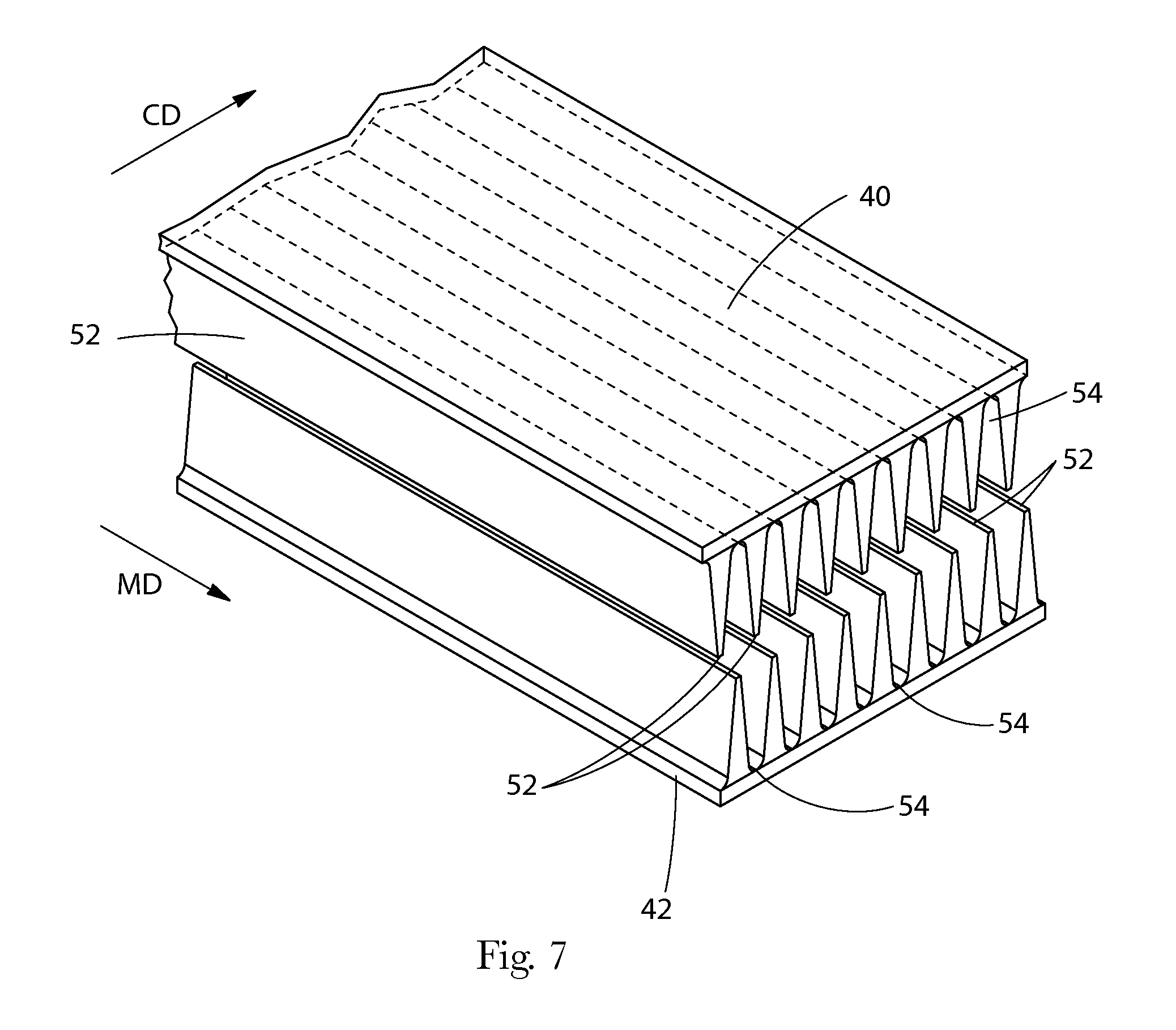

Method for manufacturing panels and panels obtained hereby

InactiveUS20110311806A1Simply formedFine surfaceLayered productsMonocomponent cellulose artificial filamentVolumetric Mass DensityEngineering

A method for manufacturing panels including a substrate on the basis of a pressed material mass, whereby it is started from a material mass to be densified, wherein the density of this material mass, in one or more densifying steps, is at least doubled. Prior to one or more of these densifying steps, a colorant is added to the material mass.

Owner:FLOORING IND LTD

Transfer method and transfer apparatus

InactiveUS20060243377A1Simple structureReduce capacityElectrical apparatusDecorative surface effectsOptoelectronics

A transfer method includes the steps of placing a donor substrate including a support base and a transfer layer provided on the support base onto a receptor substrate such that the transfer layer faces the receptor substrate, evacuating a space between the receptor substrate and the donor substrate that are placed one on the other, and transferring the transfer layer onto the receptor substrate by applying a radiant ray onto the donor substrate in an evacuated atmosphere.

Owner:SONY CORP

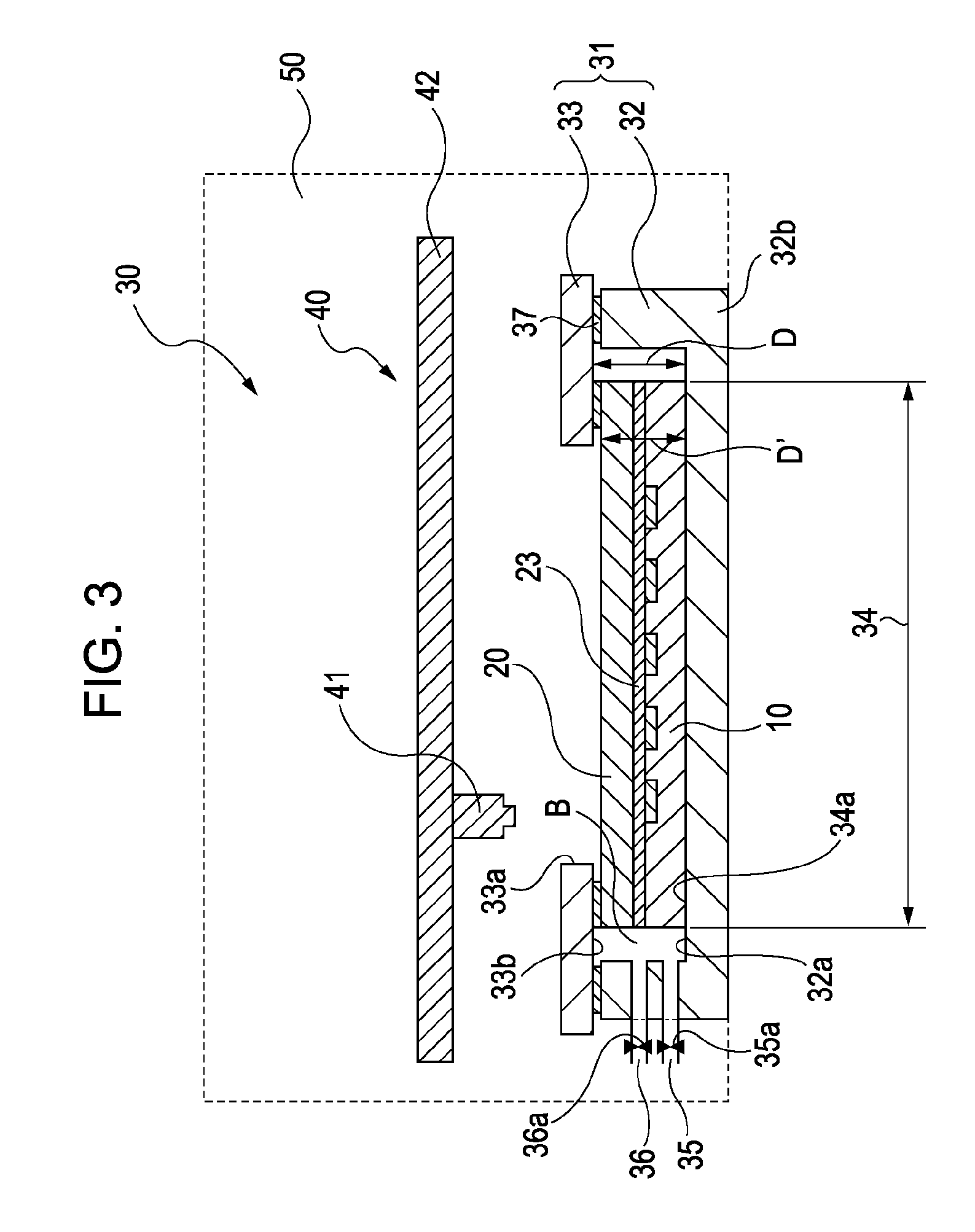

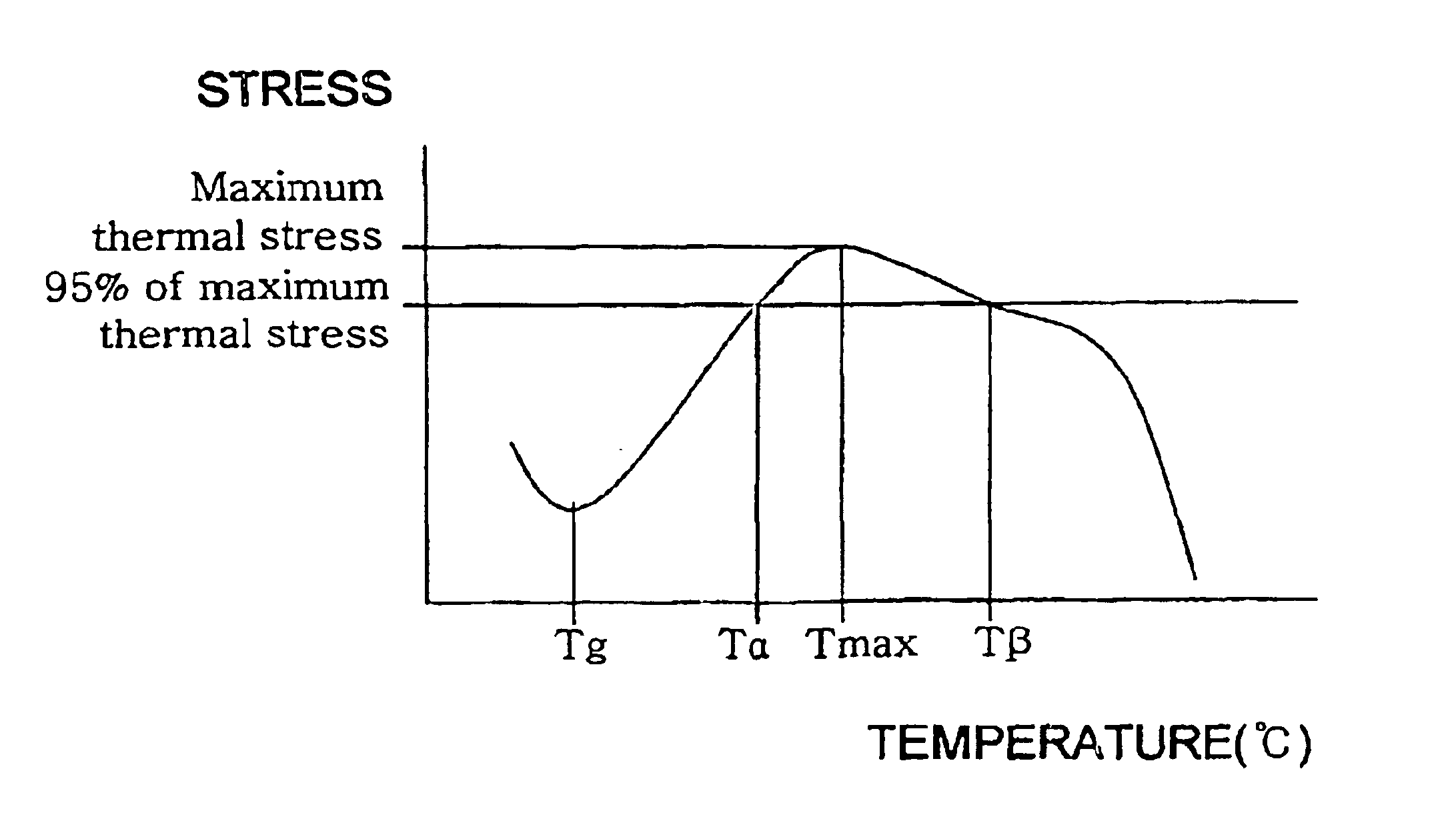

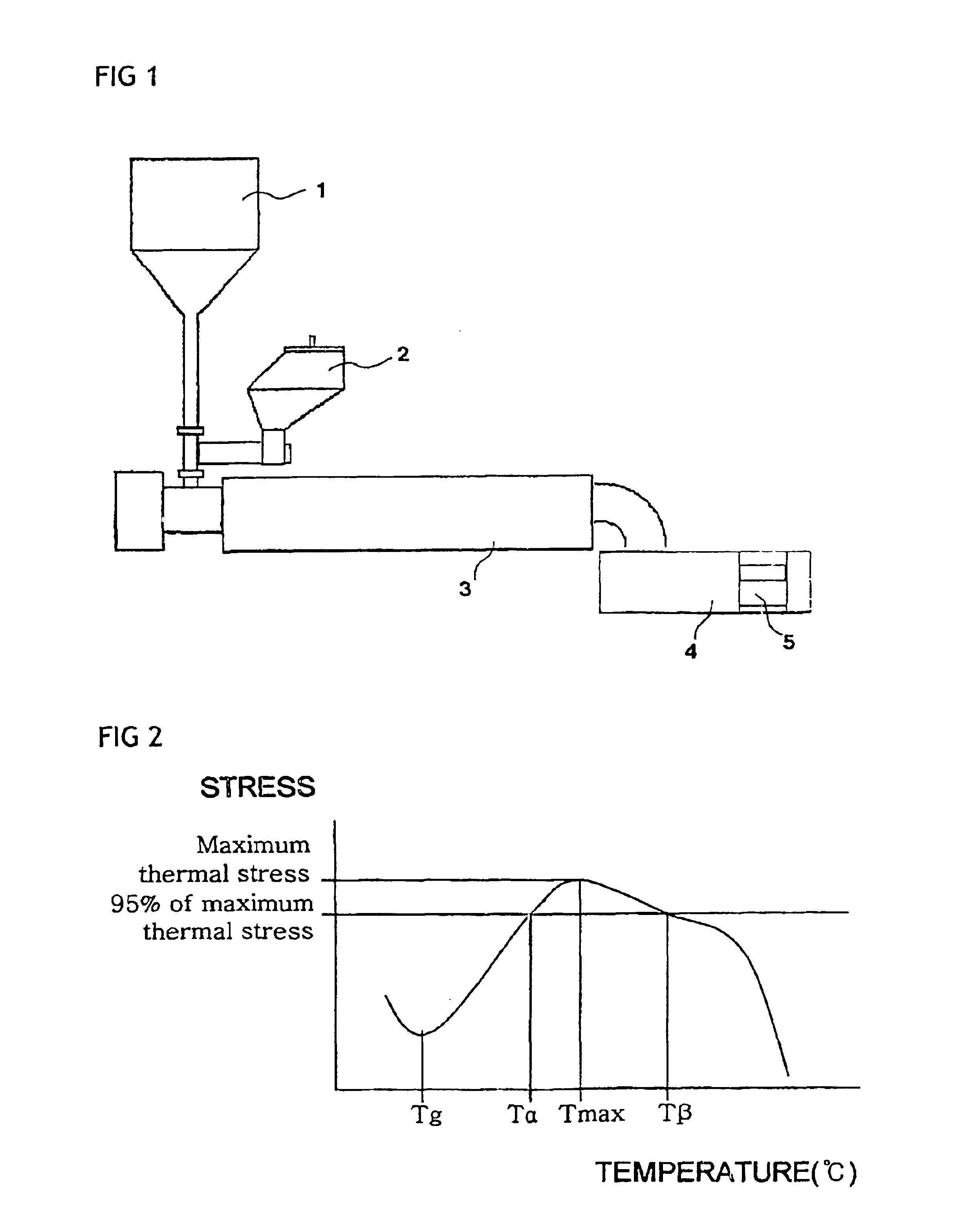

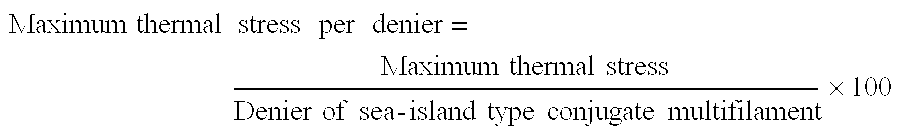

Sea-island typed conjugate multi filament comprising dope dyeing component and a process of preparing for the same

InactiveUS6838172B2Improve shrinkageImprove fastnessFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterYarn

The present invention relates to a dope dyed sea-island type conjugate multifilament. In the dope dyed sea-island type conjugate multifilament, which comprises easy soluble polymer as a sea component and polyester as an island component, the island component contains a dope dyed component selected from the group consisting of carbon black, pigments and dyestuffs and the temperature range (Tα-Tβ) showing more than 95% of the maximum thermal stress of yarns is from 120° C. to 210° C. The dope dyed sea-island type conjugate multifilament of the present invention has an excellent thermal shrinkage property and excellent wash fastness and light fastness, and the dyeing process thereof can be omitted after producing a woven or knitted fabric because a dope dyed component is contained in the island component (ultra fine yarn). The dope dyed sea-island type conjugate multifilament of the present invention is useful as yarns for warp knit fabrics used in production of women's apparel.

Owner:KOLON IND INC

Thermoplastic fibers exhibiting durable high color strength characteristics

InactiveUS6849330B1Reduce extractionQuick and efficient changeoverFireproof paintsSynthetic resin layered productsYarnPolymer science

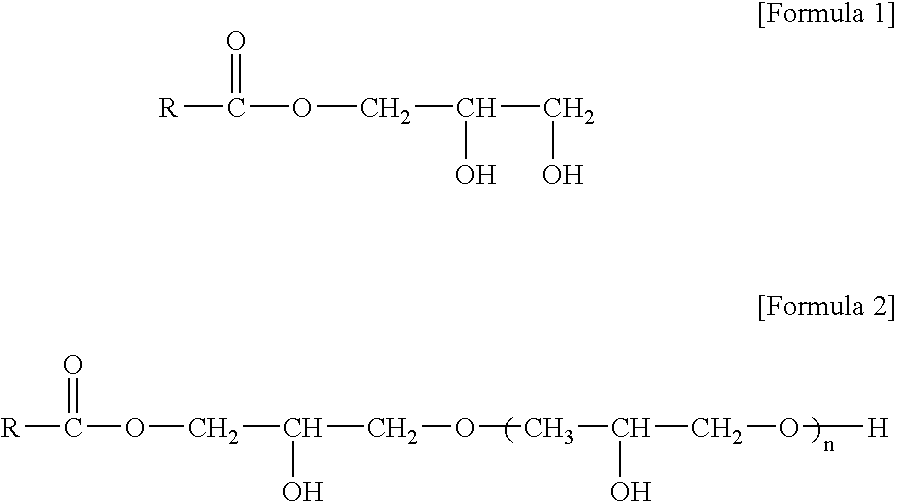

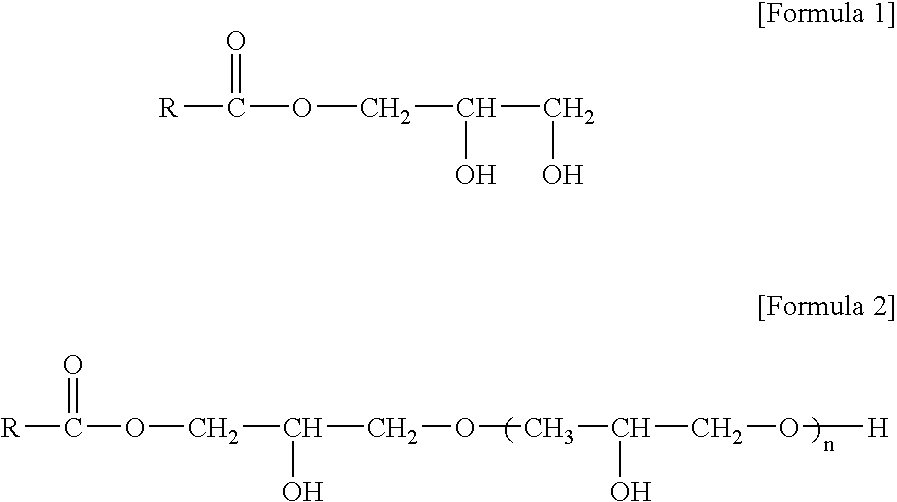

Improvements in permitting brighter colorations within polypropylene fibers and / or yarns while simultaneously providing more efficient production methods of manufacturing of such colored fibers as well are provided. Generally, such fibers and / or yarns have been colored with pigments, which exhibit dulled results, or dyes, which exhibit high degrees of extraction and low levels of lightfastness. Such dull appearances, high extraction levels, and less than stellar lightfastness properties negatively impact the provision of such desirable colored polypropylene fibers and / or yarns which, in turn, prevents the widespread utilization of such fibers and yarns in various end-use applications. Thus, it has surprisingly been determined that brighter colorations, excellent extraction, and more-than-acceptable lightfastness characteristics can be provided, preferably, through manufacture with certain polymeric colorants that include poly(oxyalkylene) groups thereon. Fabric articles comprising such novel fibers and / or yarns are also encompassed within this invention.

Owner:MILLIKEN & CO

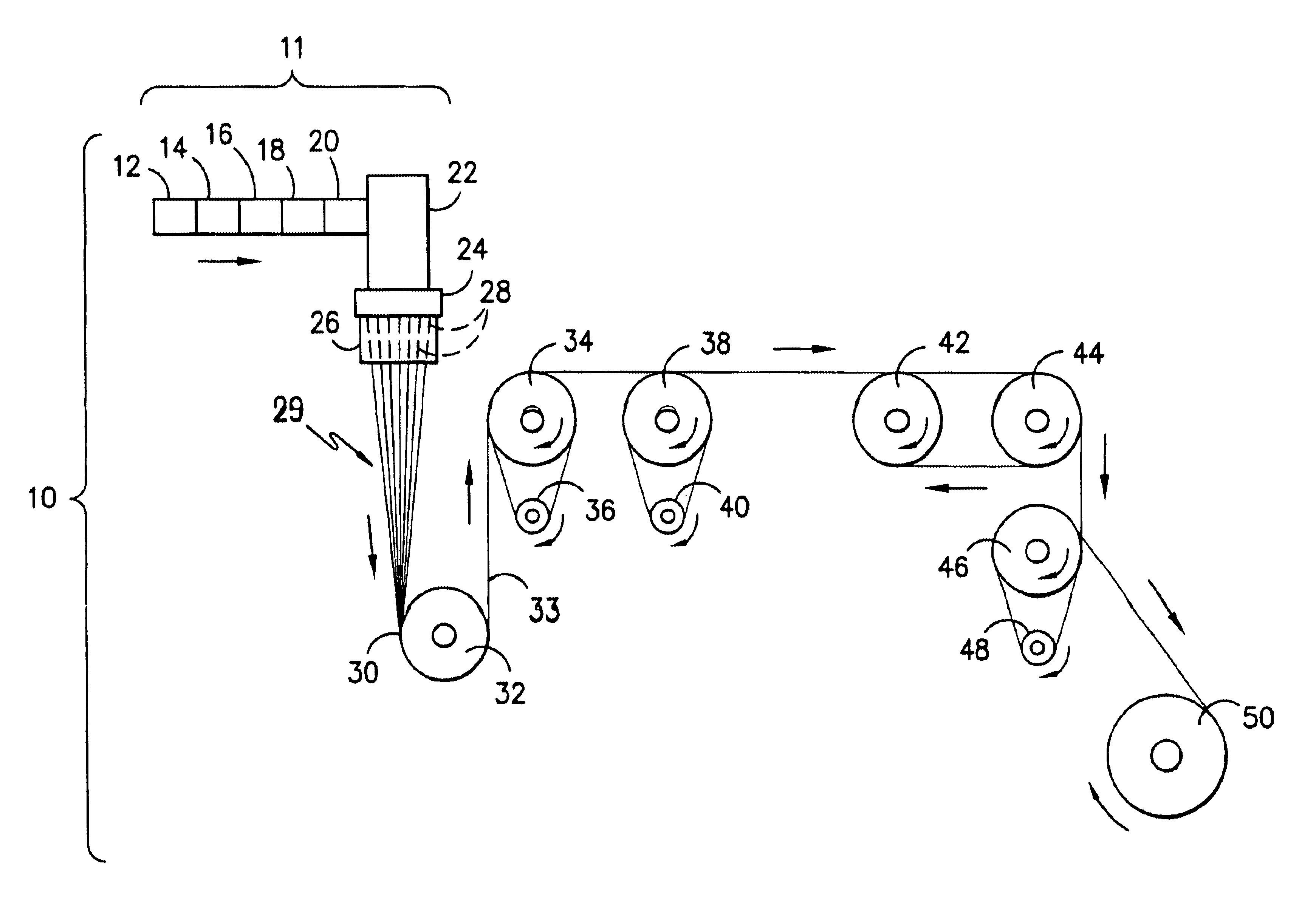

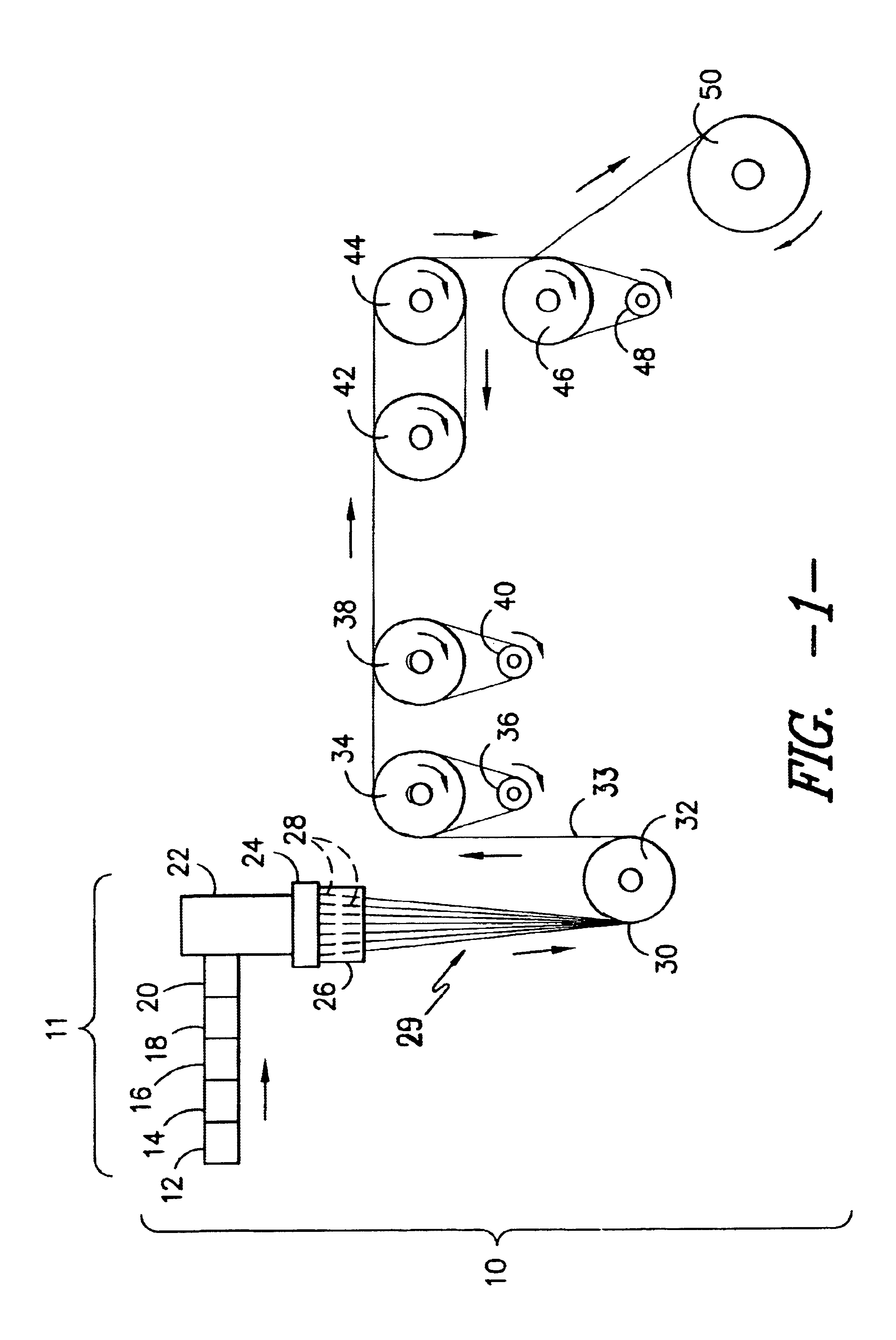

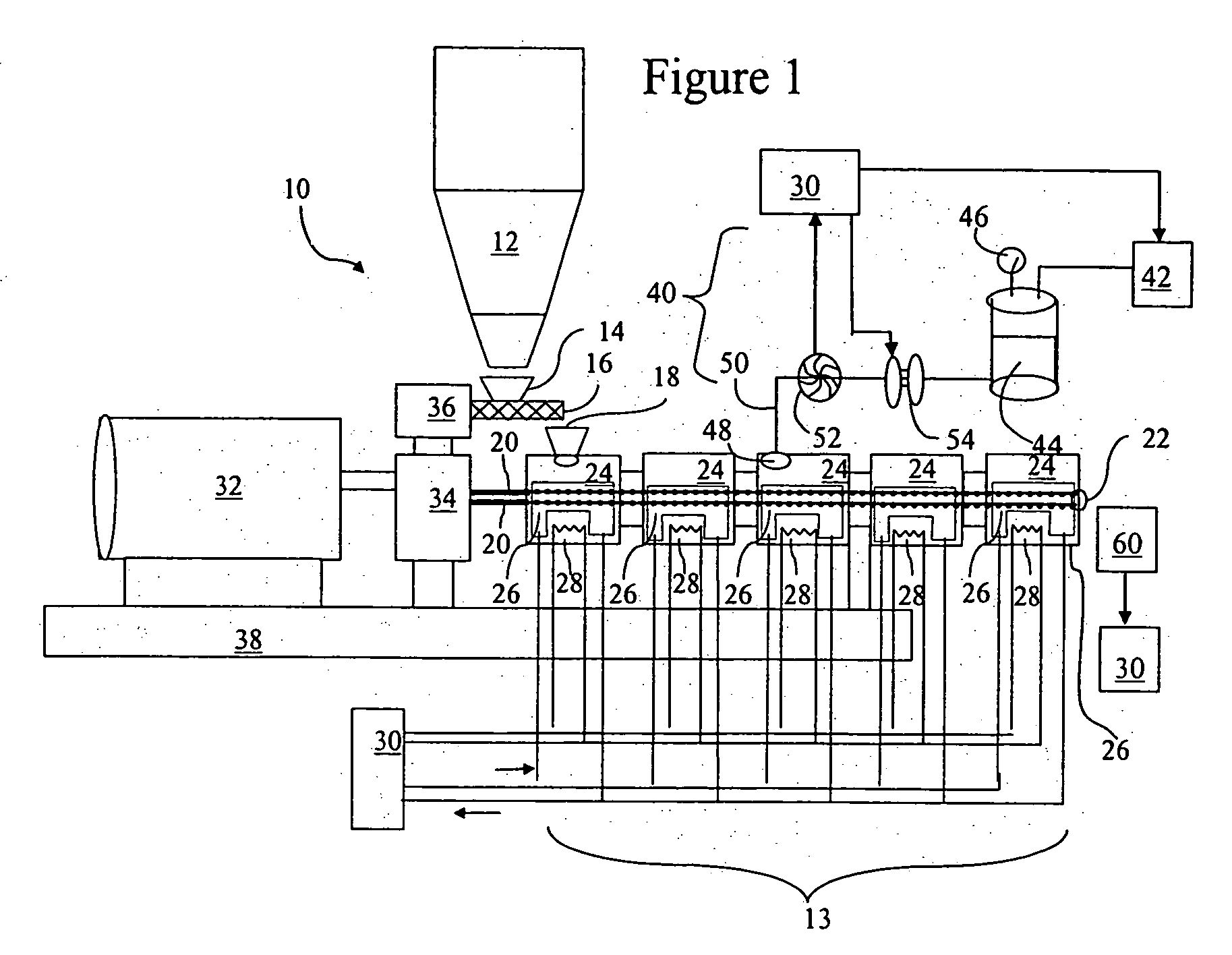

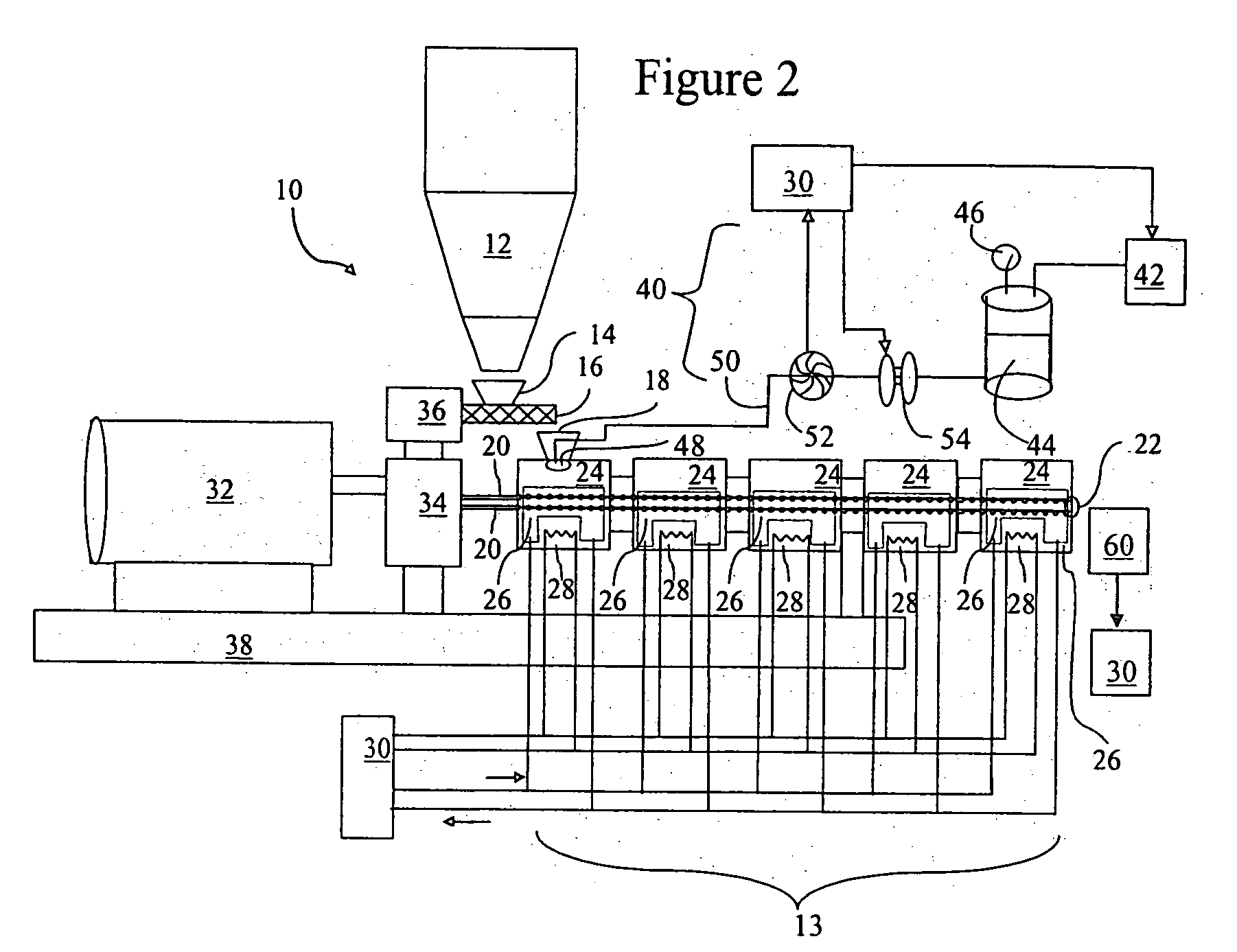

Methods and systems for manufacturing the manufacture of layered three-dimensional forms

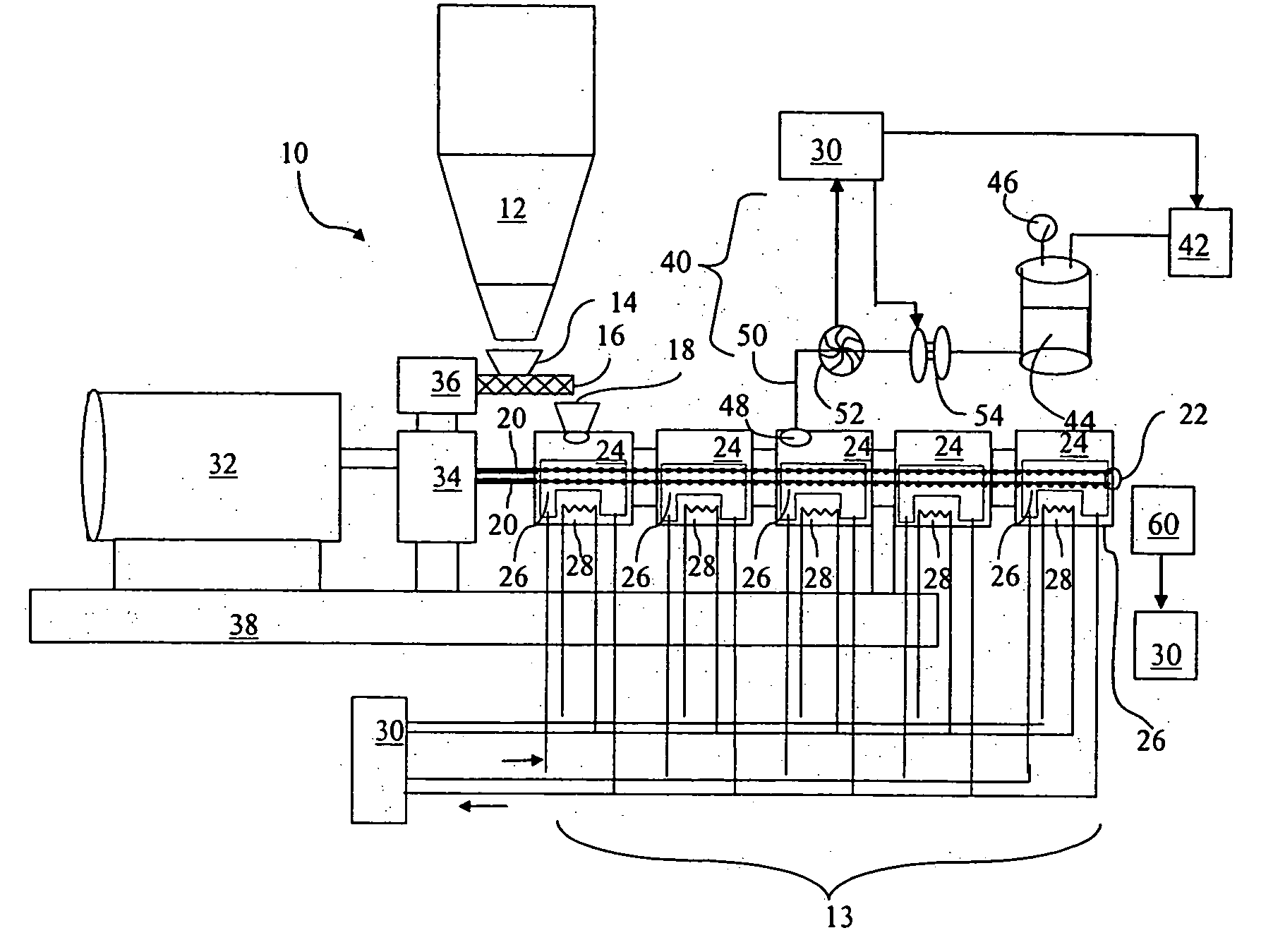

ActiveUS20080237933A1Efficiently reclaim and re-useEfficient use ofAdditive manufacturing apparatusArtificial filament recoveryParticulatesBiological activation

New methods and systems for manufacturing a three-dimensional form, comprising steps of providing a plurality of particulates; contacting the particulates with an activation agent; contacting particulates having the activation agent with a binder material that is activatable by the activation agent; at least partially hardening the binder for forming a layer of the three-dimensional form; and repeating these steps to form the remainder of the three-dimensional form. Following sequential application of all required layers and binder material to make the form, the unbound particles are appropriately removed (and optionally re-used), to result in the desired three-dimensional form. The invention also contemplates a novel method for preparing a form, where unbound particulates free of binder material are re-claimed.

Owner:EXONE

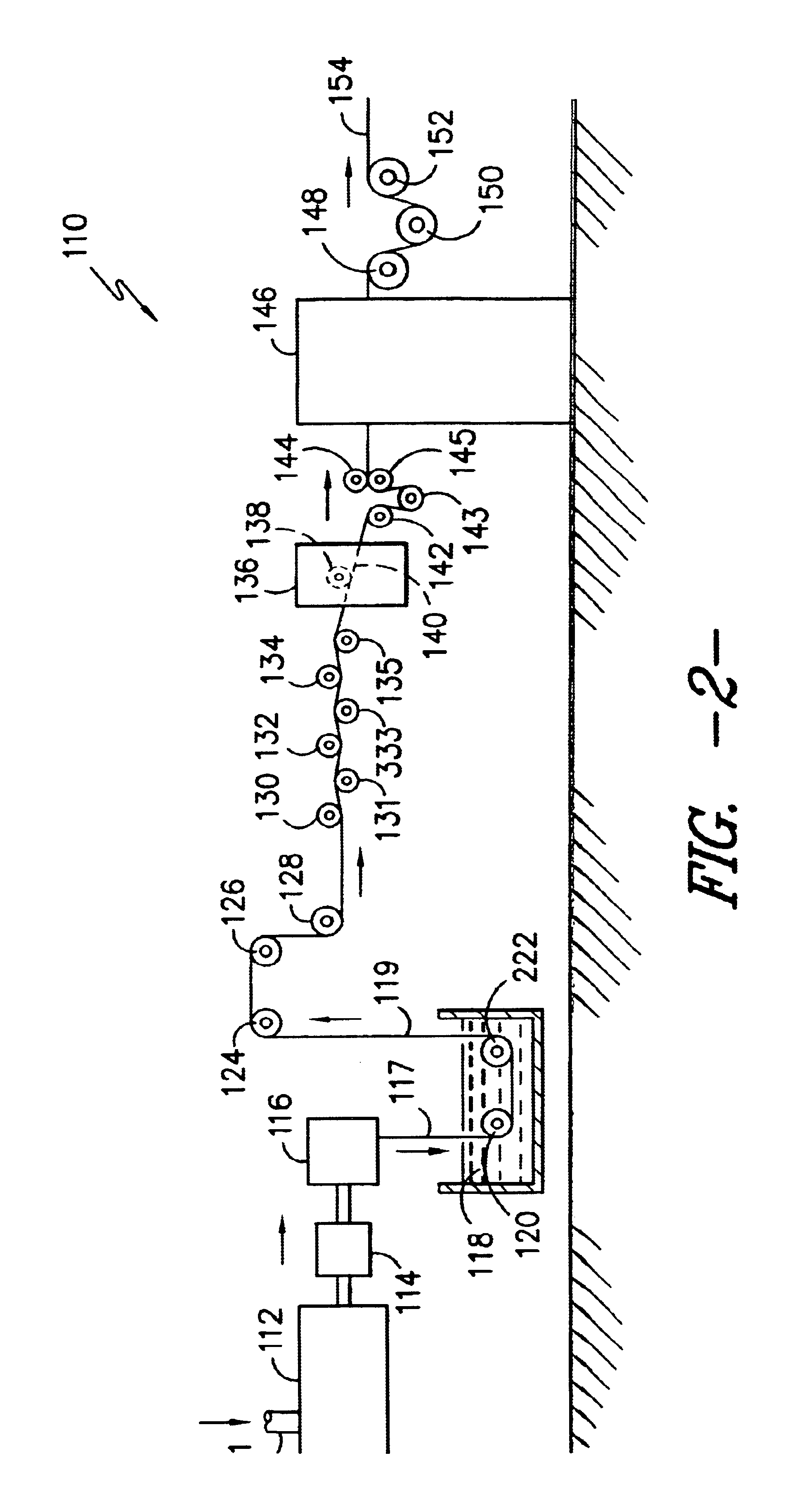

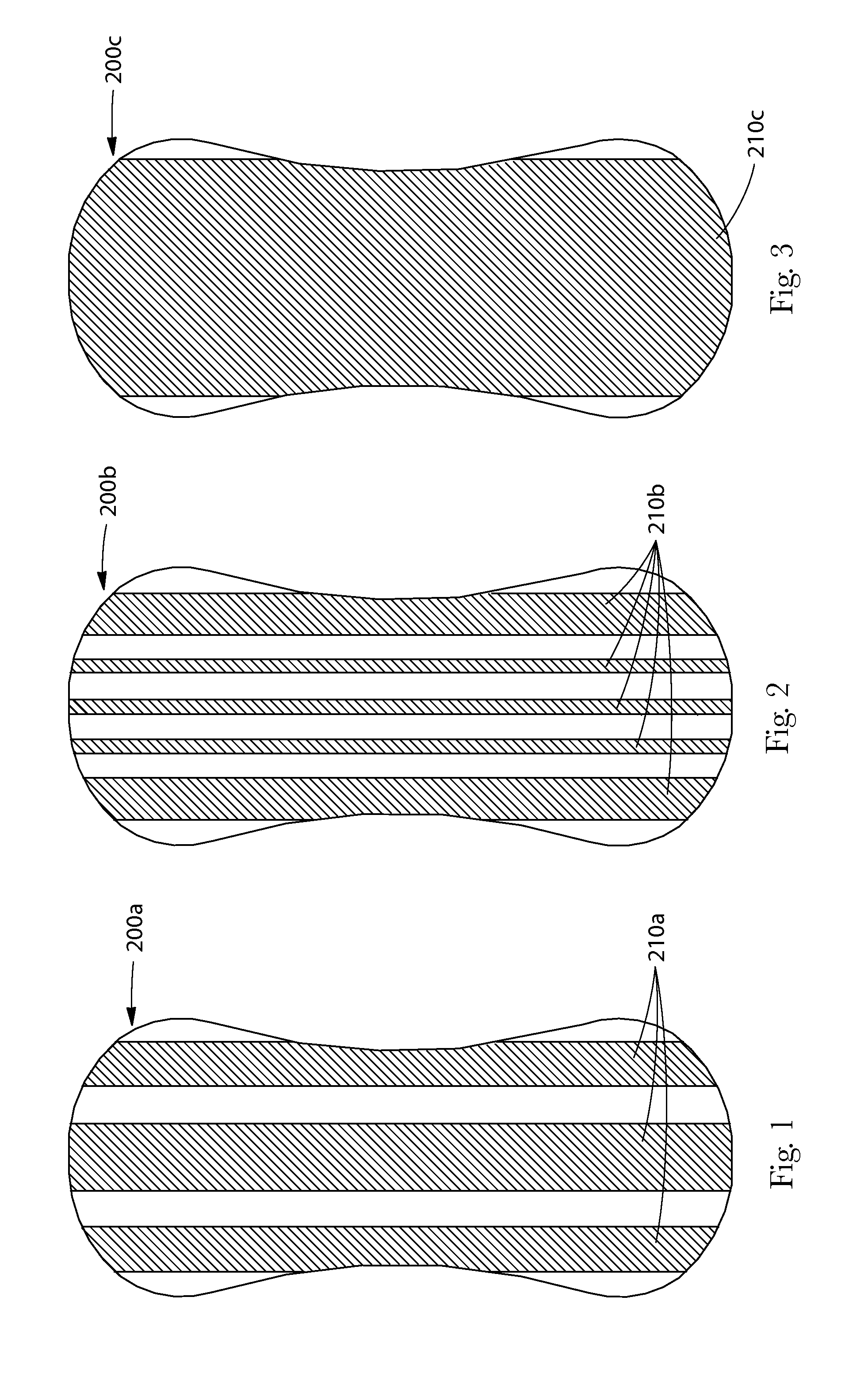

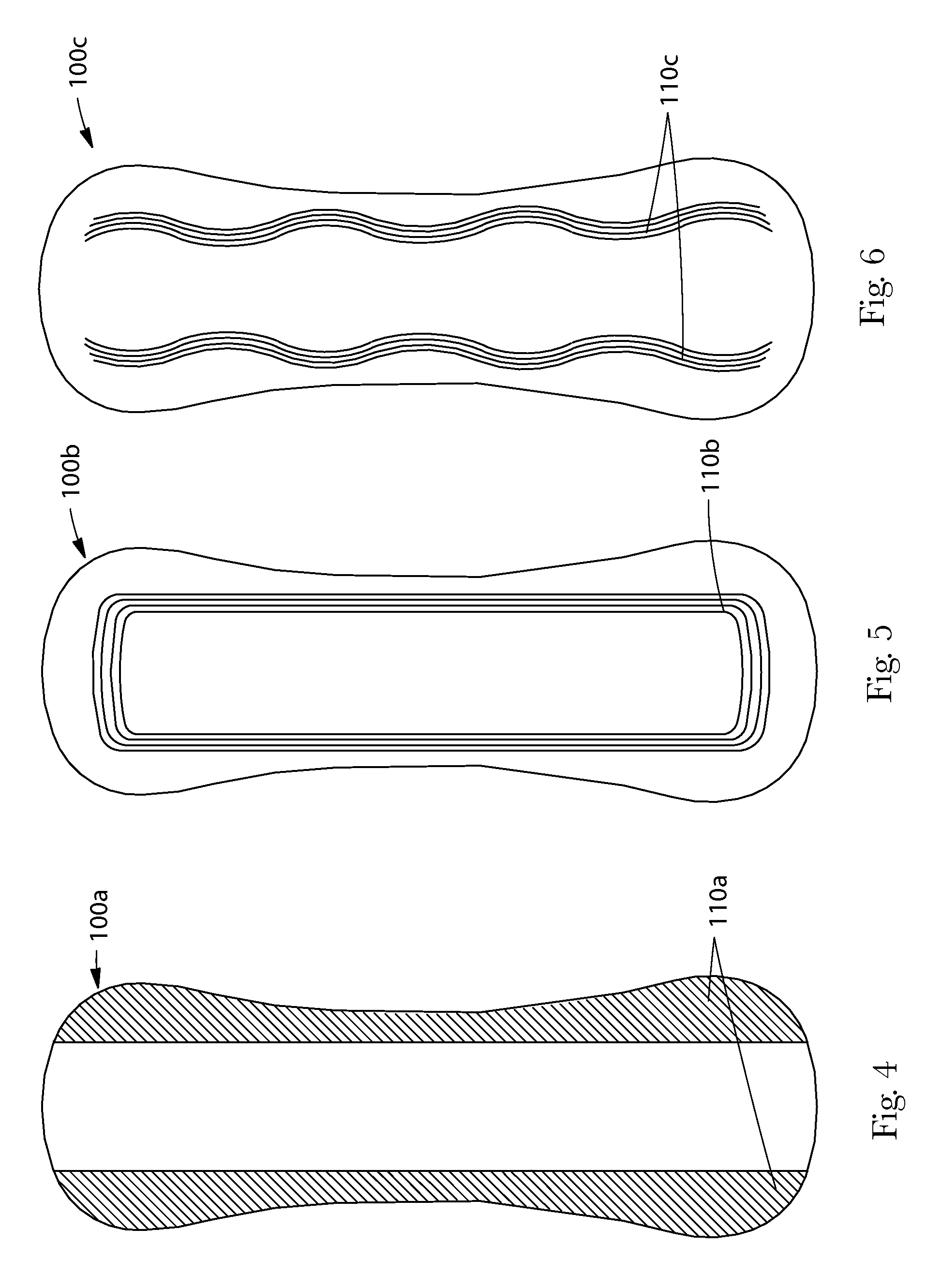

Method of Producing a Web Substrate Having Activated Color Regions in Deformed Regions

Owner:THE PROCTER & GAMBLE COMPANY

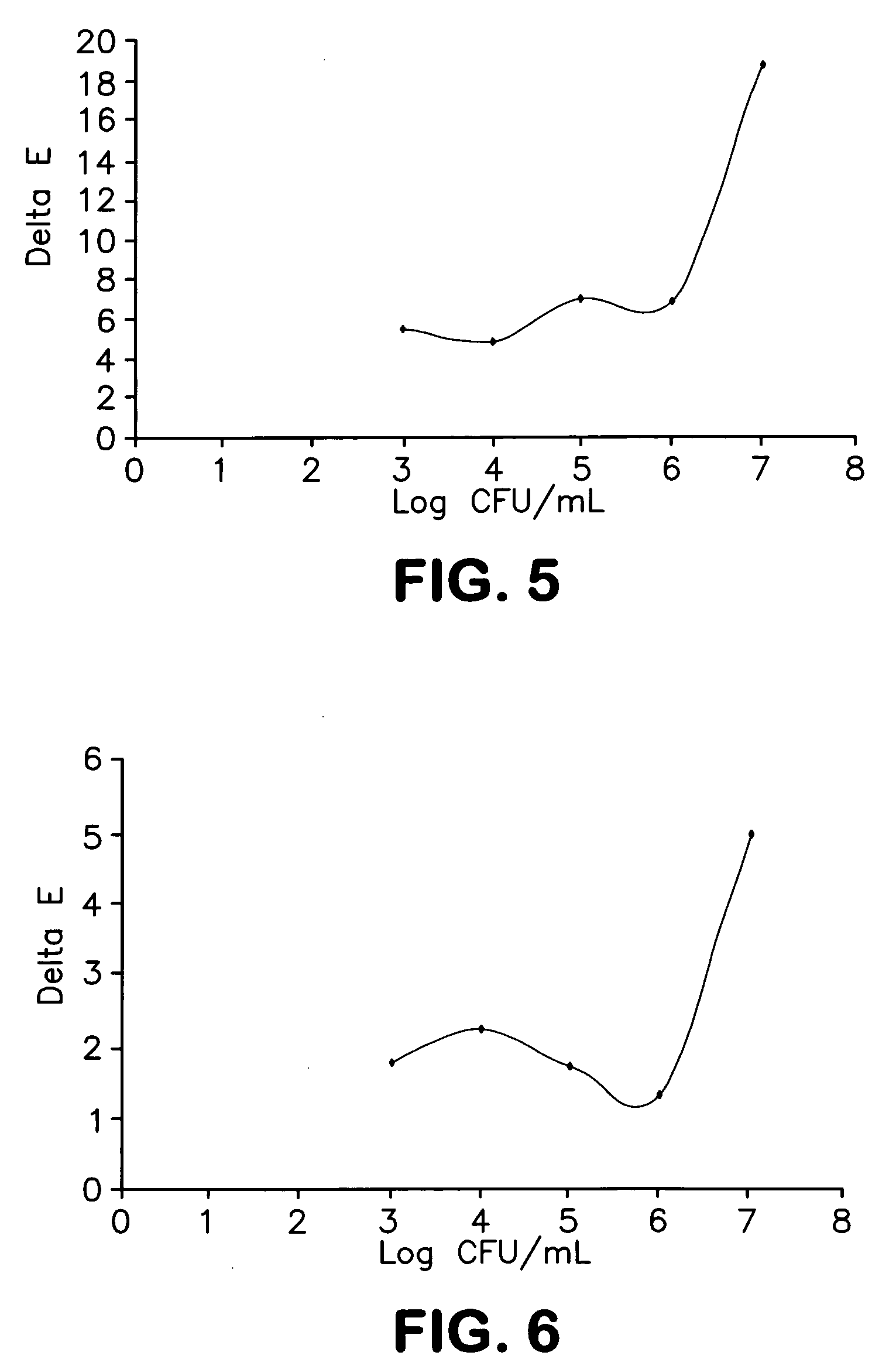

Detection of microbe contamination on elastomeric articles

ActiveUS20060134613A1Bioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismOxidation-Reduction Agent

An elastomeric article that contains a chromogen that undergoes a detectable change in color in the presence of one or more microbes is provided. For example, in one embodiment, the chromogen is a solvatochromic dye (e.g., Reichardt's dye) that undergoes a color change in the presence of bacteria or other microbes. More specifically, such dyes may respond to differences in polarity between microbe components (e.g., cell membrane, cytoplasm, etc.) and the environment outside the cell. Alternatively, other mechanisms may be wholly or partially responsible for the interaction between the dye and the microbe, such as acid-base reactions, redox reactions, and so forth.

Owner:O&M HALYARD INC

Reaction of carbon black with diazonium salts, resultant carbon black products and their uses

Processes for preparing a carbon black product having an organic group attached to the carbon black. In one process at least one diazonium salt reacts with a carbon black in the absence of an externally applied electric current sufficient to reduce the diazonium salt. In another process at least one diazonium salt reacts with a carbon black in a protic reaction medium. Carbon black products which may be prepared according to process of the invention are described as well as uses of such carbon black products in plastic compositions, rubber compositions, paper compositions, and textile compositions.

Owner:CABOT CORP

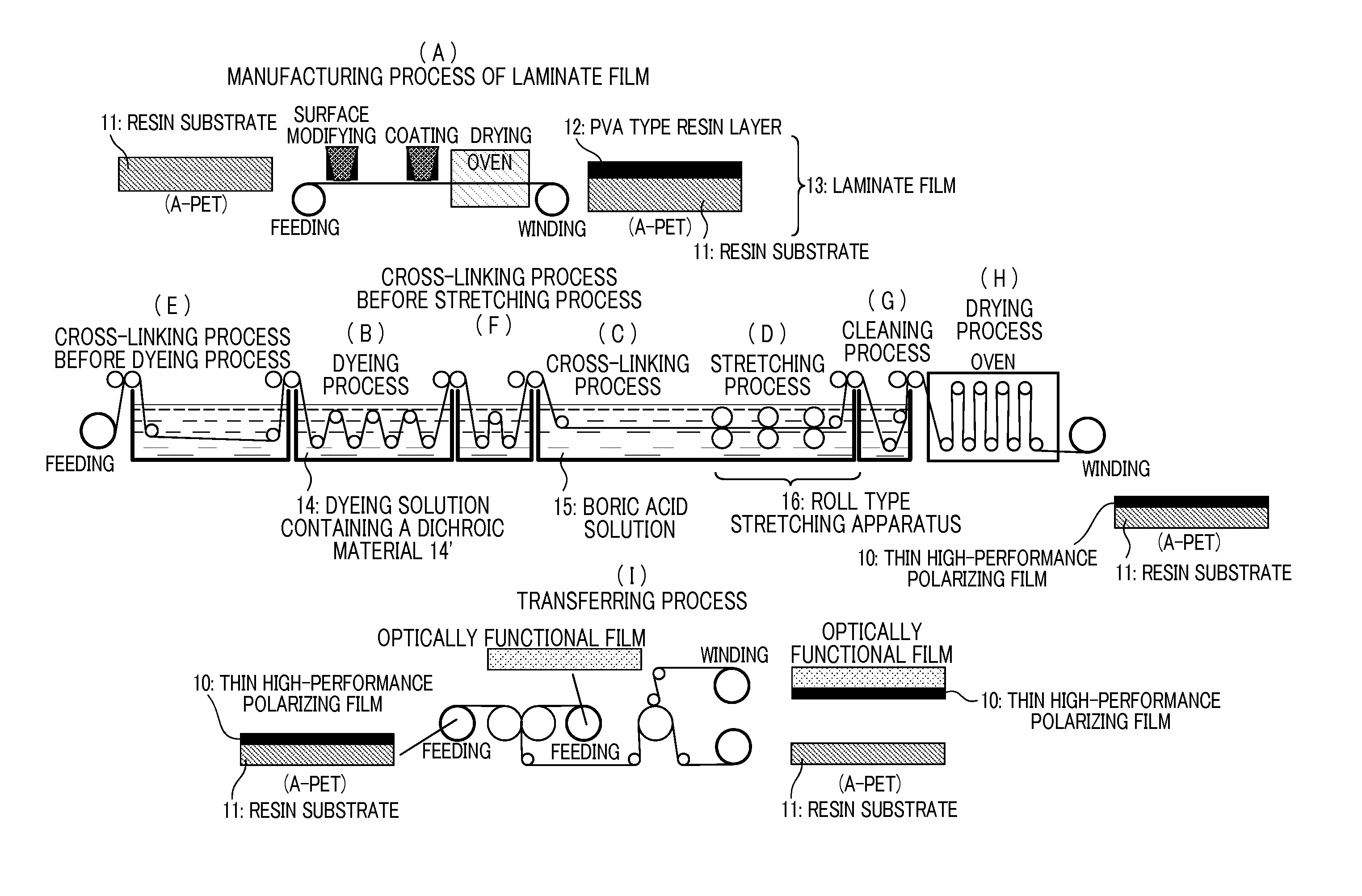

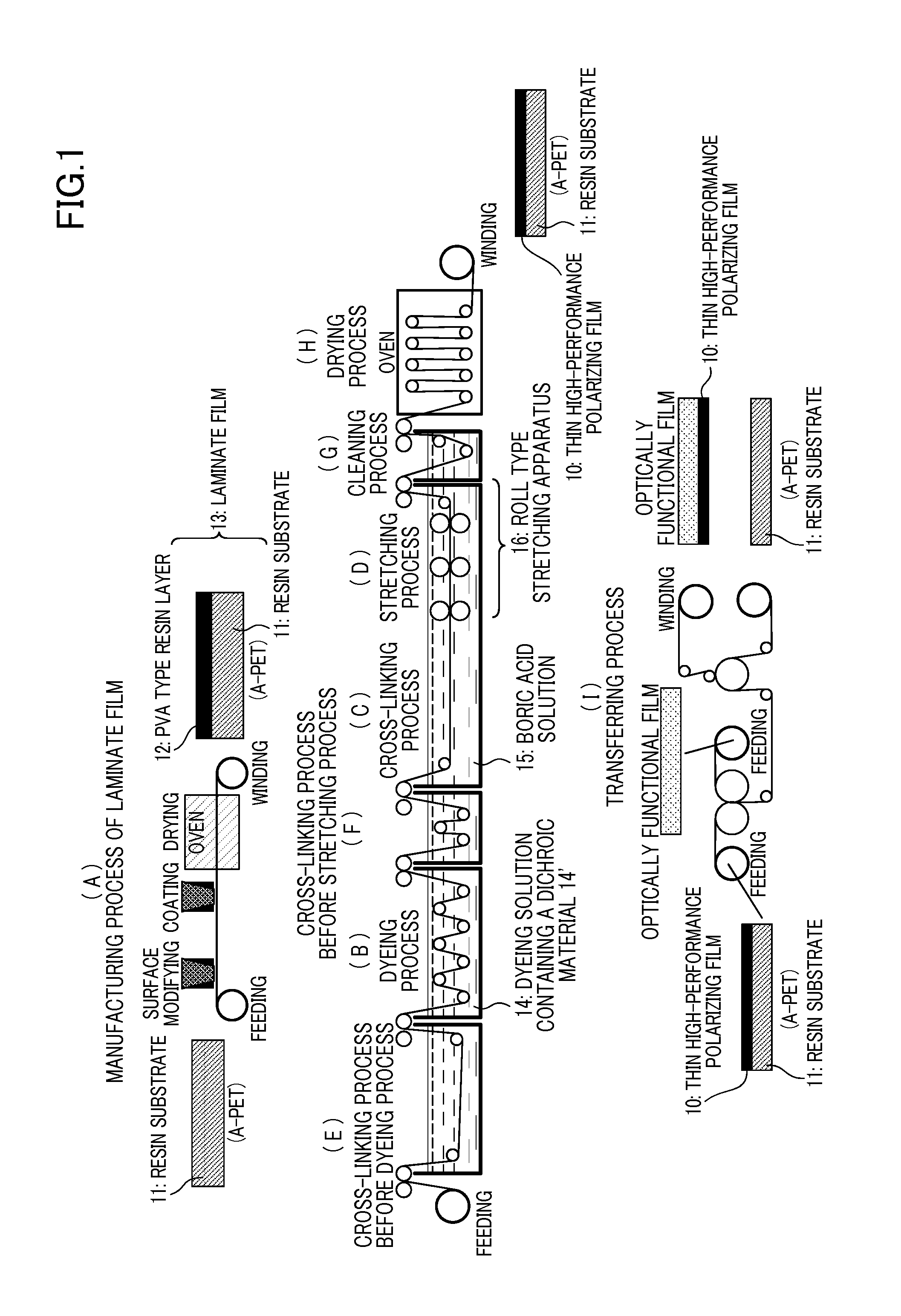

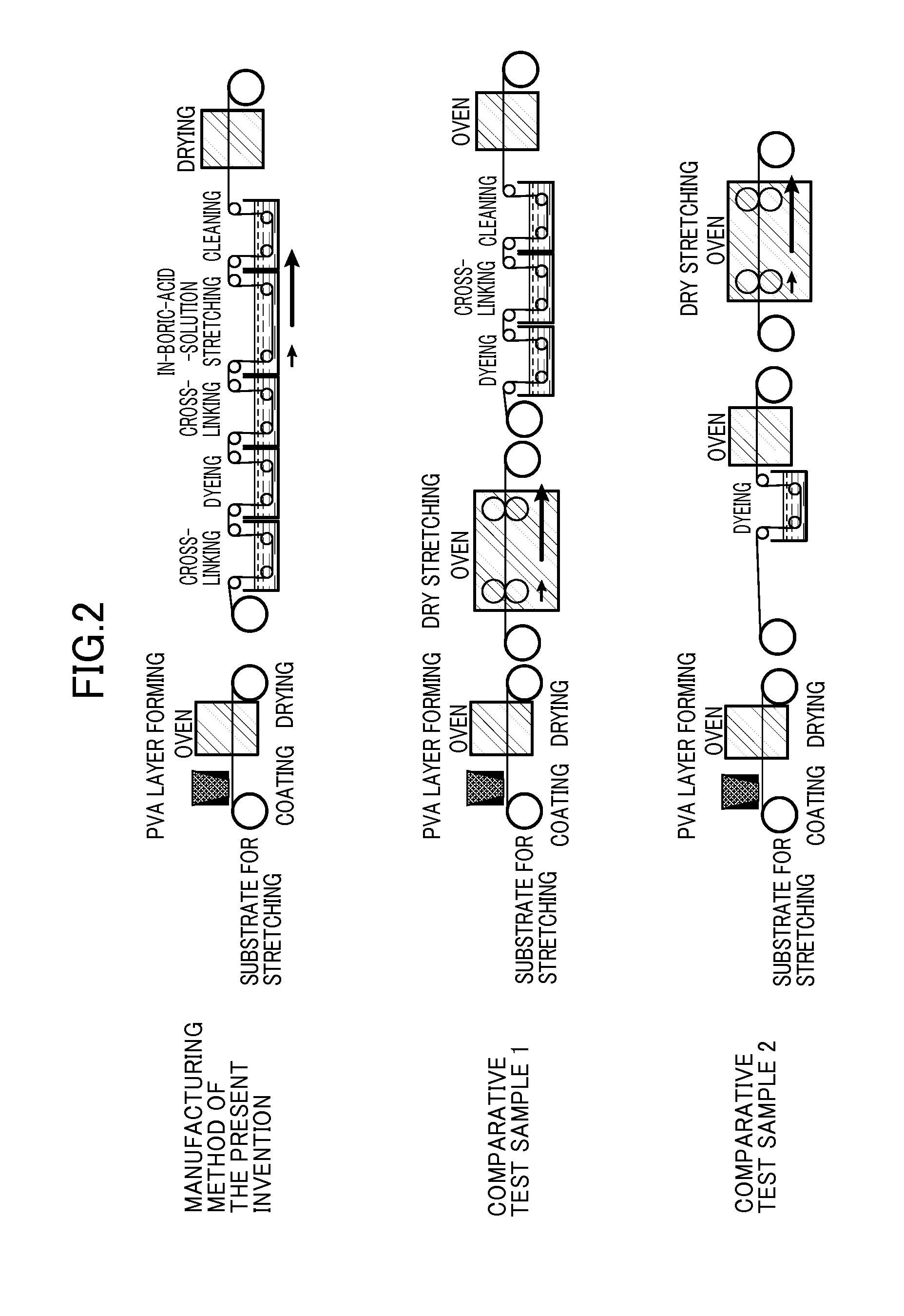

Thin high-performance polarizing film and method for manufacturing the same

InactiveUS20110315306A1High magnificationReduced optical performanceMonocomponent cellulose artificial filamentPolarising elementsStretch ratioBoric acid

A method for manufacturing a thin high-performance polarizing film includes coating a polyvinyl alcohol type resin on a resin substrate having a thickness of at least 20 μm and then drying the resin to thereby form a polyvinyl alcohol type resin layer, immersing thus produced polyvinyl alcohol type resin layer in a dyeing solution including a dichroic material to thereby have the dichroic material impregnated in the polyvinyl alcohol type resin layer, stretching the polyvinyl alcohol type resin layer having the dichroic material impregnated therein together with the resin substrate in a boric acid solution such that a total stretching ratio of 5.0 or more of the original length is achieved.

Owner:NITTO DENKO CORP

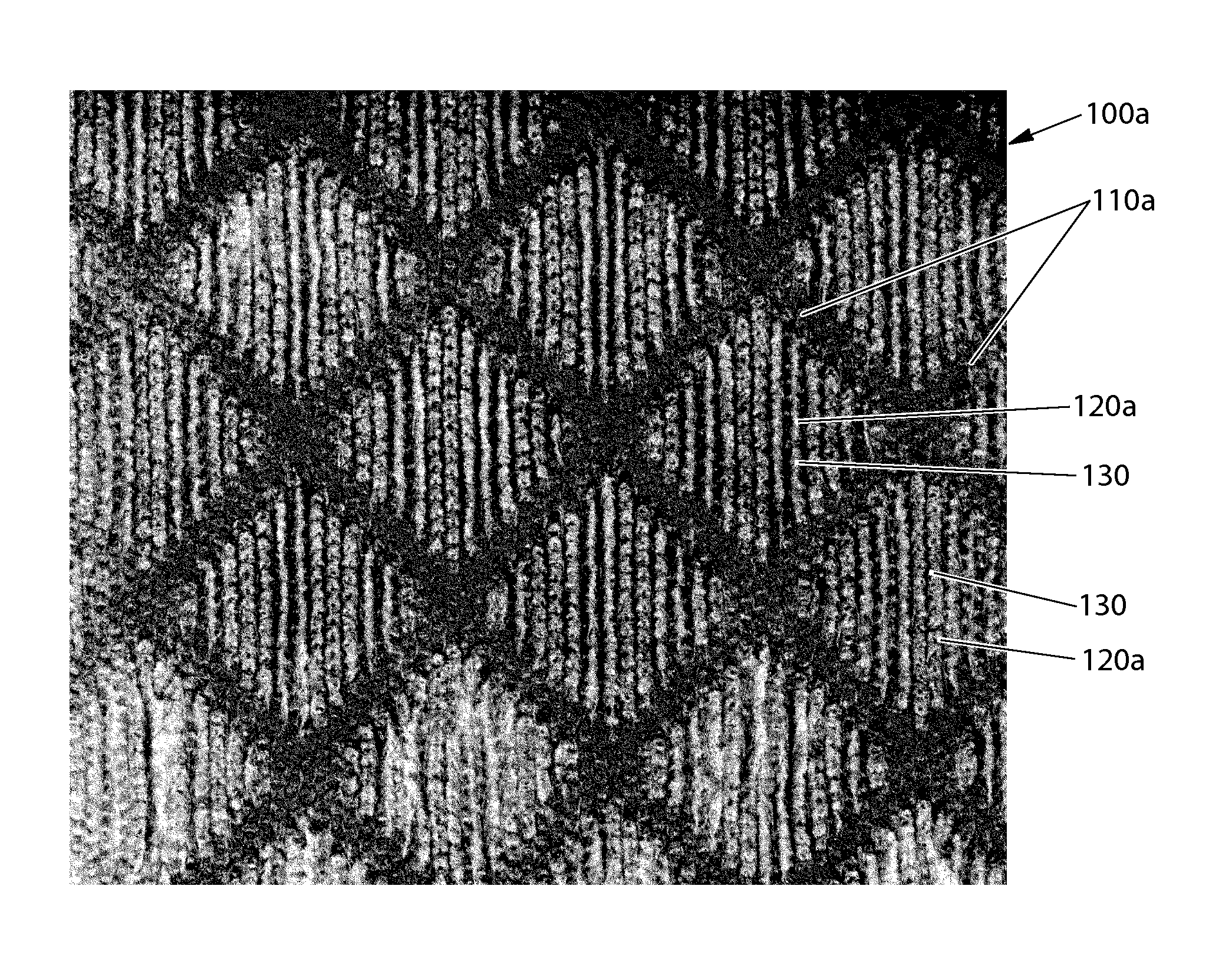

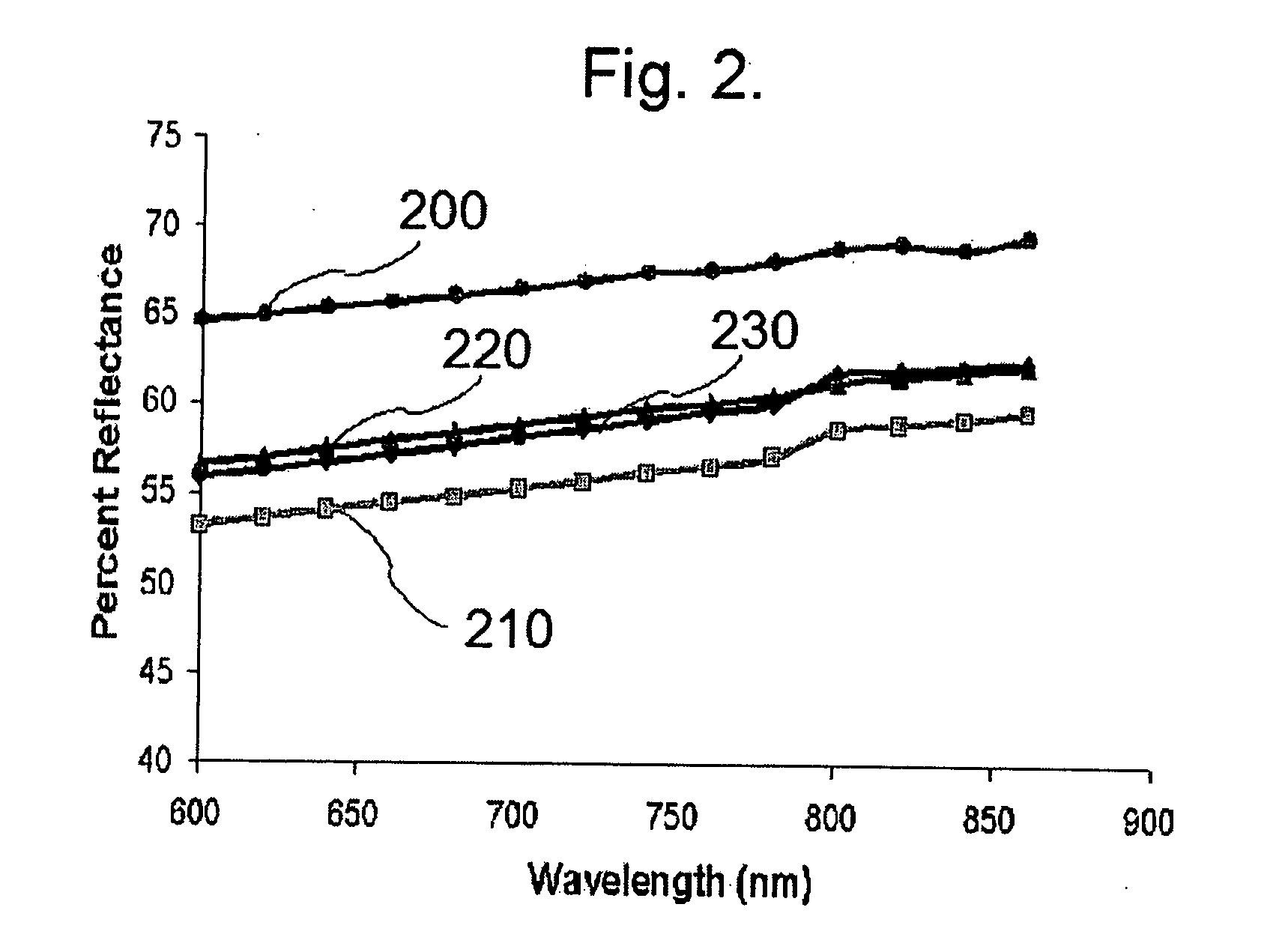

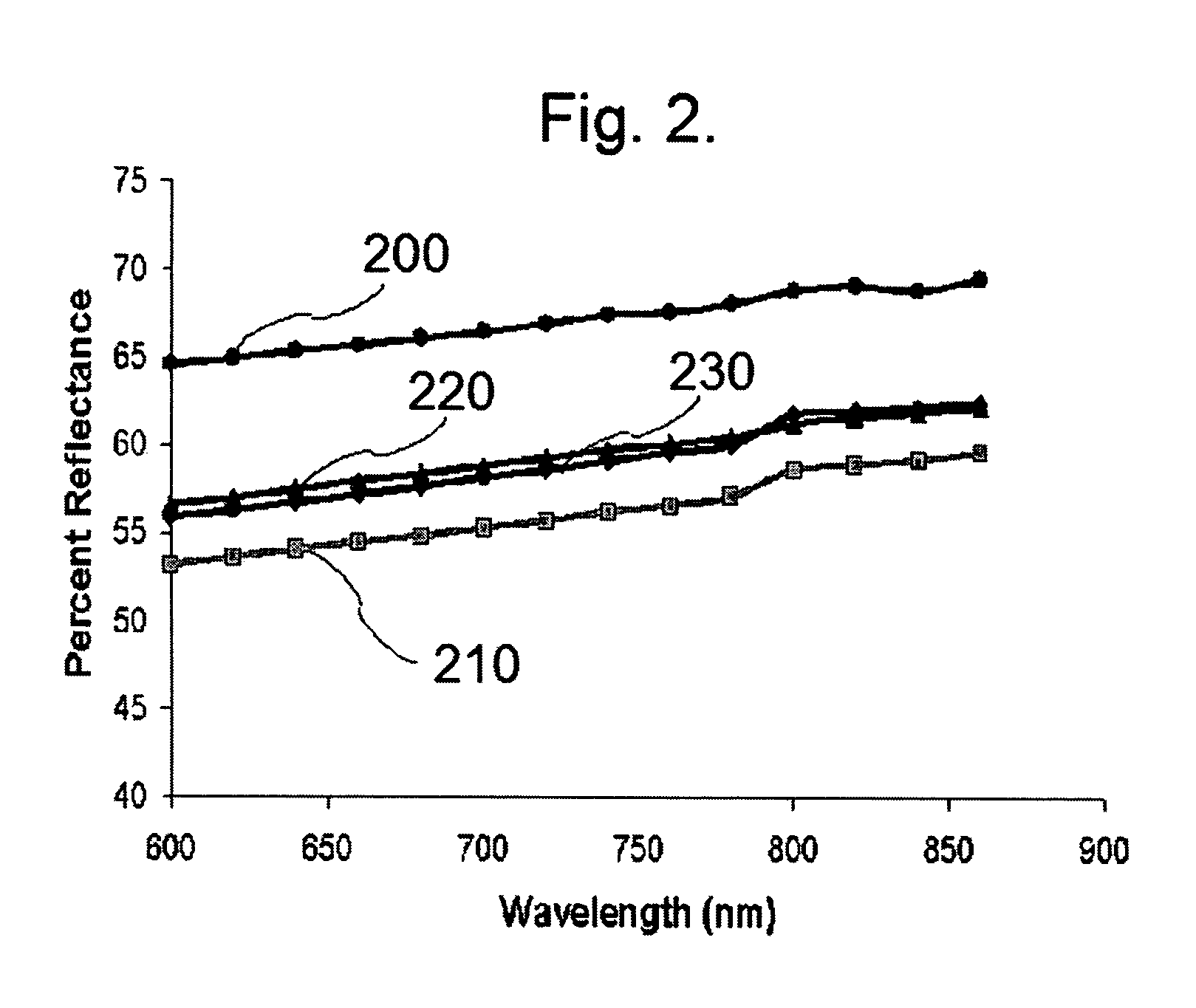

Polymer fibers, fabrics and equipment with a modified near infrared reflectance signature

InactiveUS20060234050A1Readily dyed and printedHigh dye absorption propertyFilament/thread formingCamouflage devicesPolyamideNear infrared reflectance

A modified synthetic polymer filament and multifilament yarn of polyamide or polyester filament containing a carbon black polymer additive, and fabrics from these yarns, are disclosed. These melt spun filaments are especially well-suited for use in garments and equipment where a modified Near Infrared Reflectance (NIR) signature is desired. The yarn and fabrics made from this yarn may be advantageously dyed or printed to provide a camouflage fabric for use in desert sand dominated environments, urban environments and multi-terrain environments.

Owner:INVISTA NORTH AMERICA S A R L

Fibers with chemical markers and physical features used for coding

Disclosed are fibers which contain identification fibers. The identification fibers can contain a one or more of chemical markers and one or more distinct features, or taggants, which may vary among the fibers or be incorporated throughout all of the fibers. The chemical markers and distinct features can be representative of specific supply chain information. The supply chain information can be used to track the fibers from manufacturing through intermediaries, conversion to final product, and / or the consumer. The disclosed embodiments also relate to the method for making and characterizing the fibers. Characterization of the fibers can include identifying chemical markers and distinct features and correlating the chemical markers and distinct features to manufacturer-specific taggants to determine supply chain information.

Owner:EASTMAN CHEM CO

Anti-oxidative color masterbatch and preparation method and application thereof

InactiveCN103289184AImprove uniformityImprove stabilityMonocomponent polyolefin artificial filamentPigment addition to spinning solutionMasterbatchWeather resistance

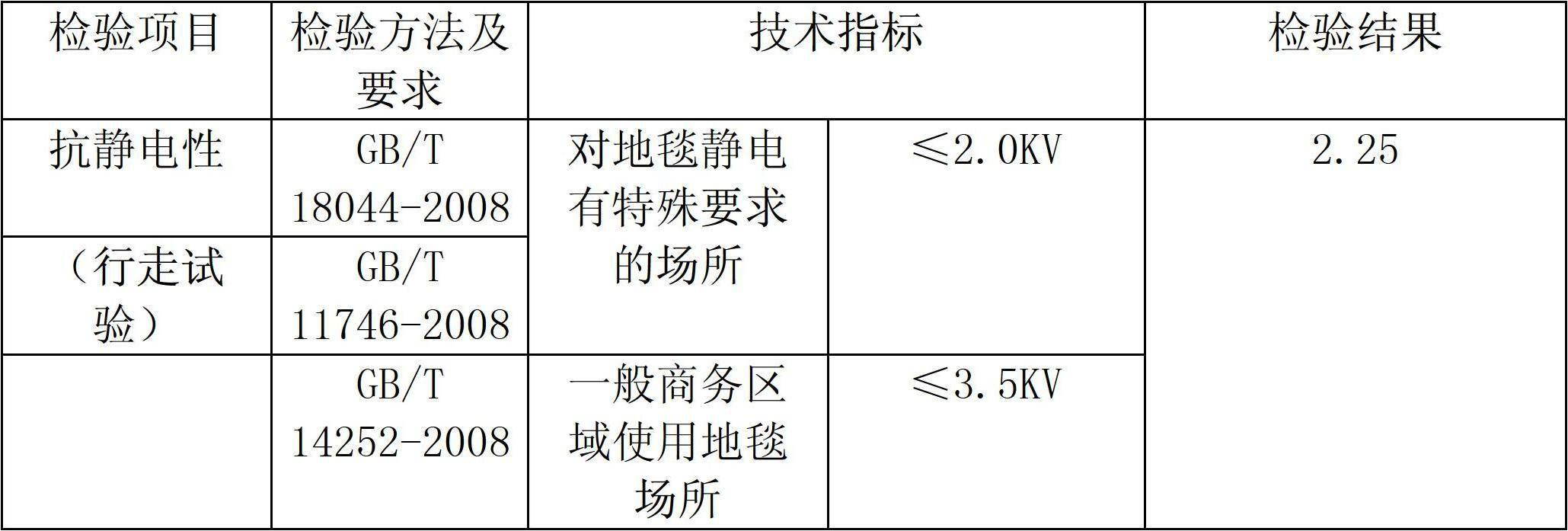

The invention discloses an anti-oxidative color masterbatch. The anti-oxidative color masterbatch comprises the following raw materials in percentage by weight: 10-70% of pigment, 1-22% of antioxidant composition, 5-30% of dispersion and lubrication agent, 20-60% of carrier resin and 0-15% of filler, wherein the antioxidant composition comprises a hindered phenolic antioxidant and one or more of a phosphite antioxidant, a thio antioxidant and a light stabilizer. The invention further discloses a preparation method and application of the anti-oxidative color masterbatch. The anti-oxidative color masterbatch disclosed by the invention has the advantages of good uniformity, good stability, good processability, good mobility and good heat and weather resistance; the preparation method of the anti-oxidative color masterbatch has the advantages of simplicity, no pollution to factory buildings and no pollution to operating personnel; and during use, the dispersion is easy, the adding dosage is small, the service lives of plastic products can be prolonged remarkably, the brightness of colors of the plastic products can be increased, and the fading time of the plastic products can be delayed.

Owner:SHANGHAI RONGXIN CHEM IND CO LTD

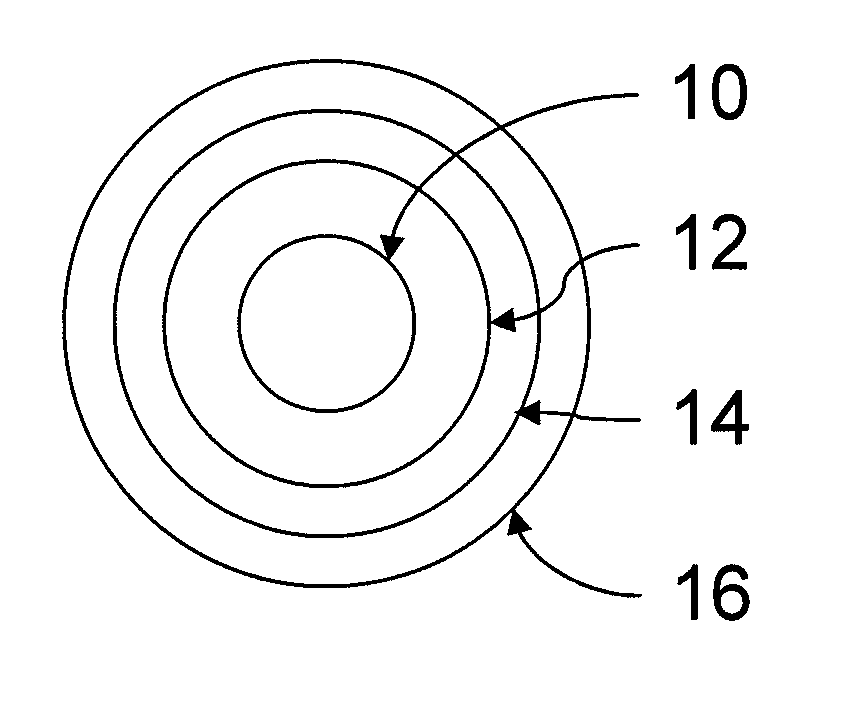

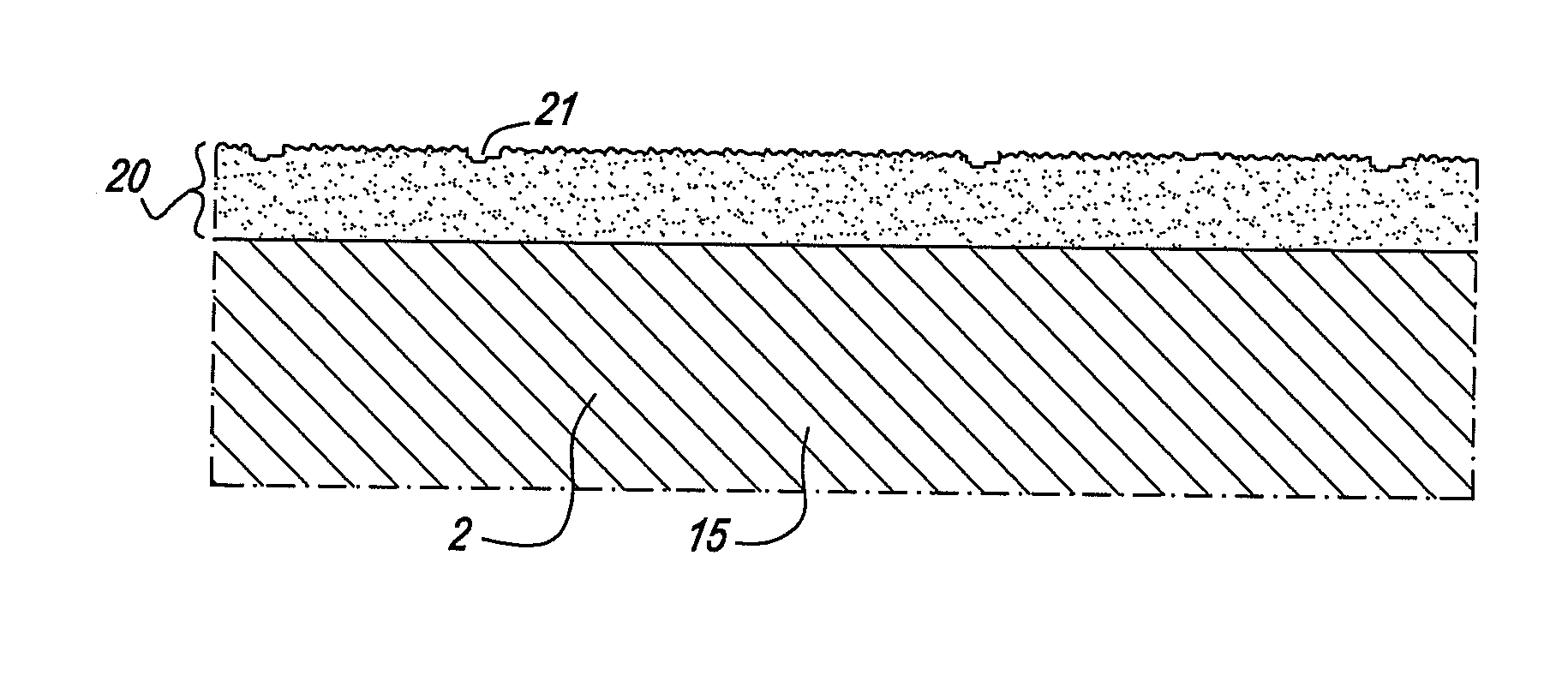

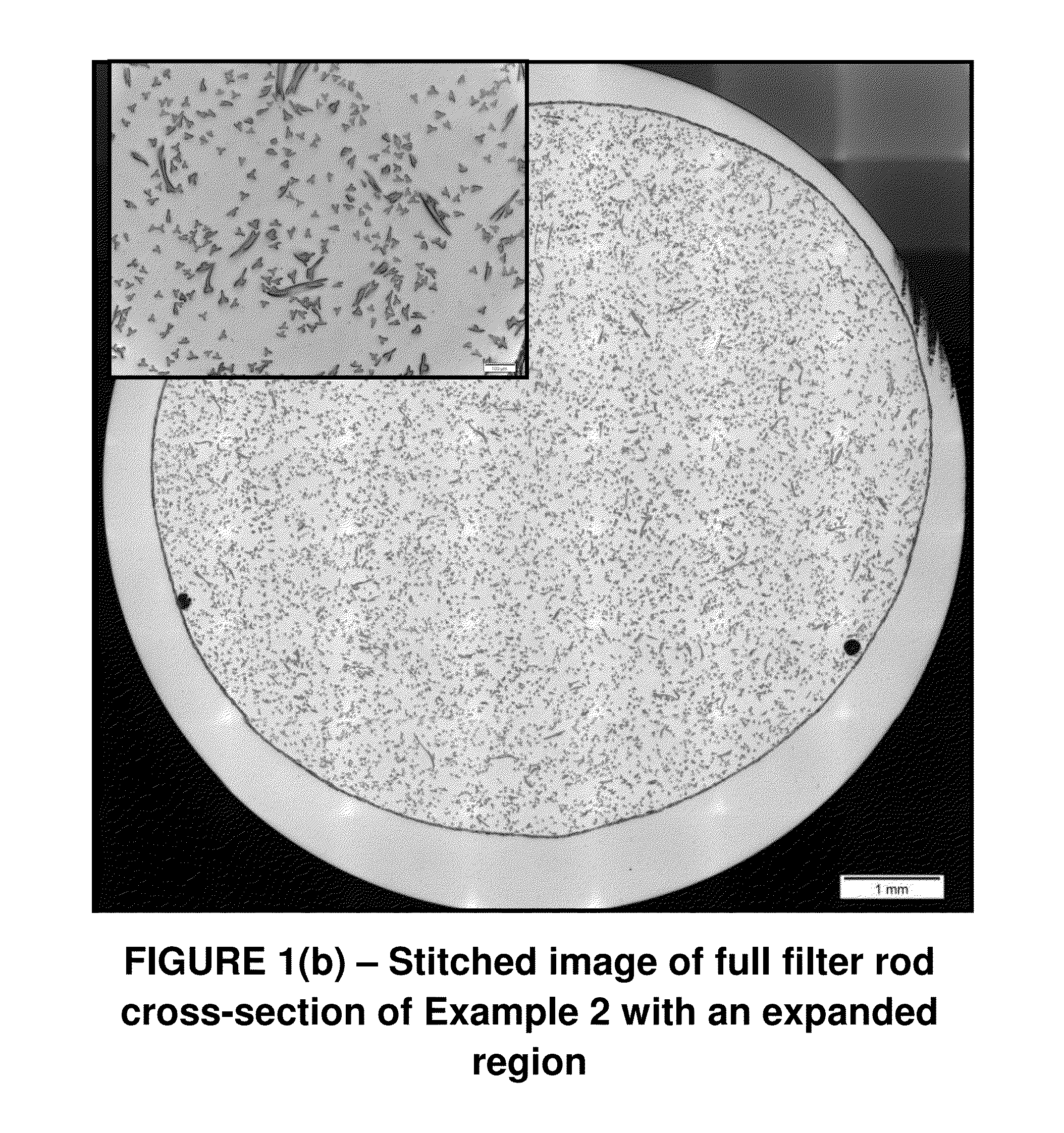

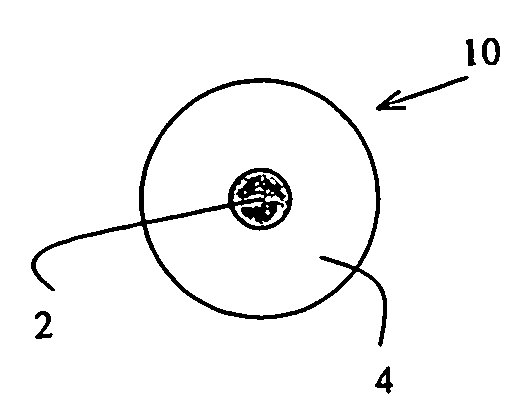

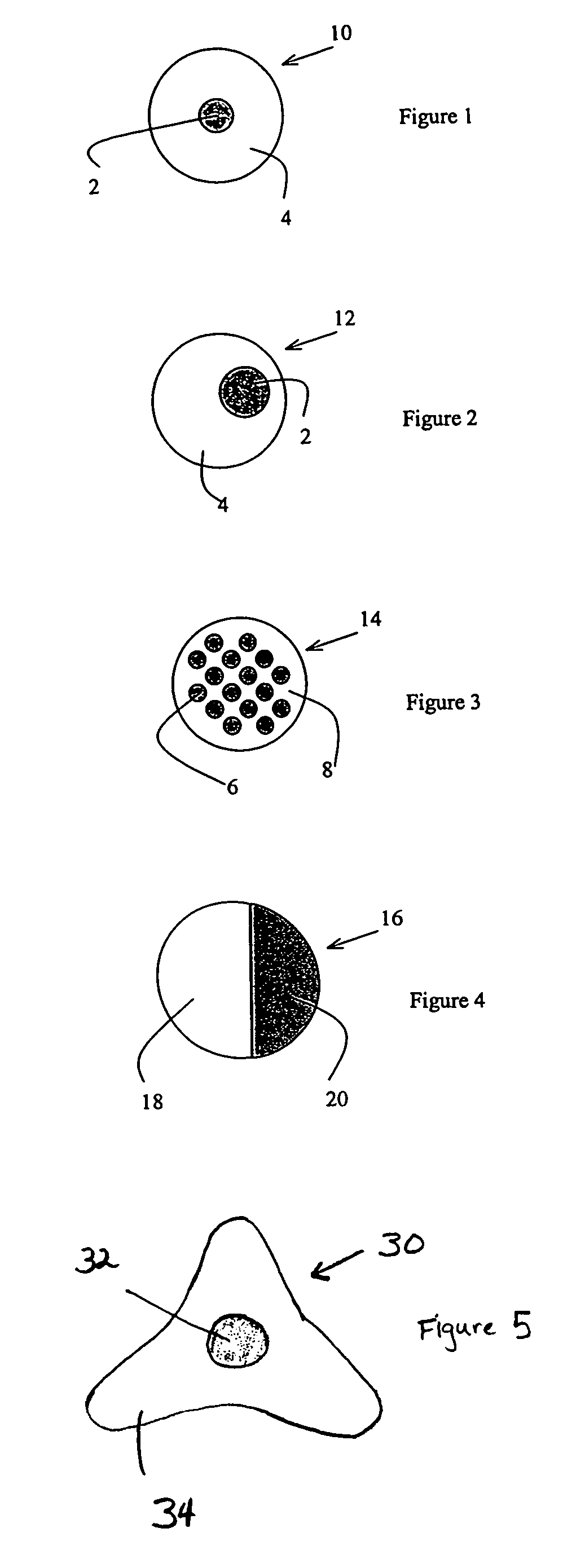

Multicomponent fiber including a luminescent colorant

InactiveUS7338877B1Reduced colorant loadingReduce manufacturing costFilament/thread formingSemiconductor/solid-state device manufacturingFiberPolymer chemistry

The present invention is directed to multicomponent fibers having a non-luminescent first polymeric component and a second polymeric component comprising a luminescent colorant. The second component comprises less than about 50 percent of the total cross-section of the fiber. The fibers of the present invention may be incorporated into fabrics useful in the manufacture of safety apparel and equipment.

Owner:FIBER INNOVATION TECH

Color master batch for polyolefin grass fiber and its preparation method

InactiveCN101187076AReduce dosageGood weather resistanceGround pavingsMonocomponent polyolefin artificial filamentYarnParaffin wax

The invention relates to a technology of color master batches for a polyolefin yarn fiber, which comprises pigments, plastic additives and carrier resin, wherein the plastic additives comprise dispersed lubricant, an antioxidant, a light stabilizer, a coupling agent and liquid paraffin. The process for preparation is that the pigments, a part of plastic additives and the carrier resin are added into a high-speed mixer to be mixed, and then the coupling agent and the liquid paraffin are added to be stirred in a high speed, and at last the above stirred mixture is sent to a twin-screw extruder to be extruded, cooled, dried and granulated. The invention has the characteristics of less dosage, excellent weathering resistance, easy dispersing and excellent processability, and is suitable for the yarn fiber which takes polyethylene, polypropylene and other copolymer as base materials.

Owner:EAST CHINA UNIV OF SCI & TECH

Web Substrate Having Activated Color Regions in Deformed Regions

The present invention relates to a web substrate comprising an activatable colorant and at least one deformed region. A first activated color region is produced in the web substrate upon exposure to a first external stimulus and a second activated color region is produced within the first activated color region upon exposure to a second external stimulus. The second activated color region coincides with the deformed region.

Owner:THE PROCTER & GAMBLE COMPANY

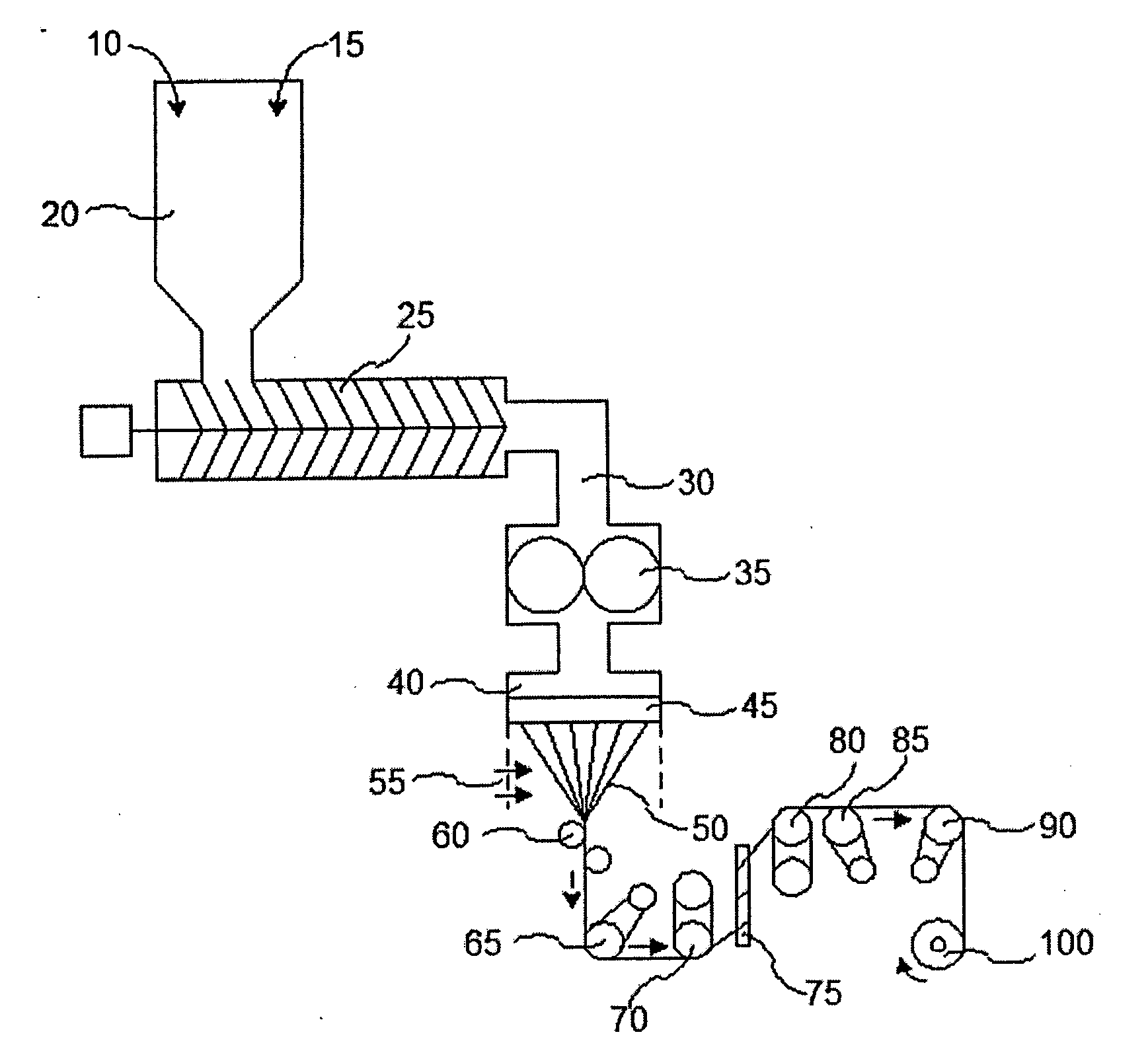

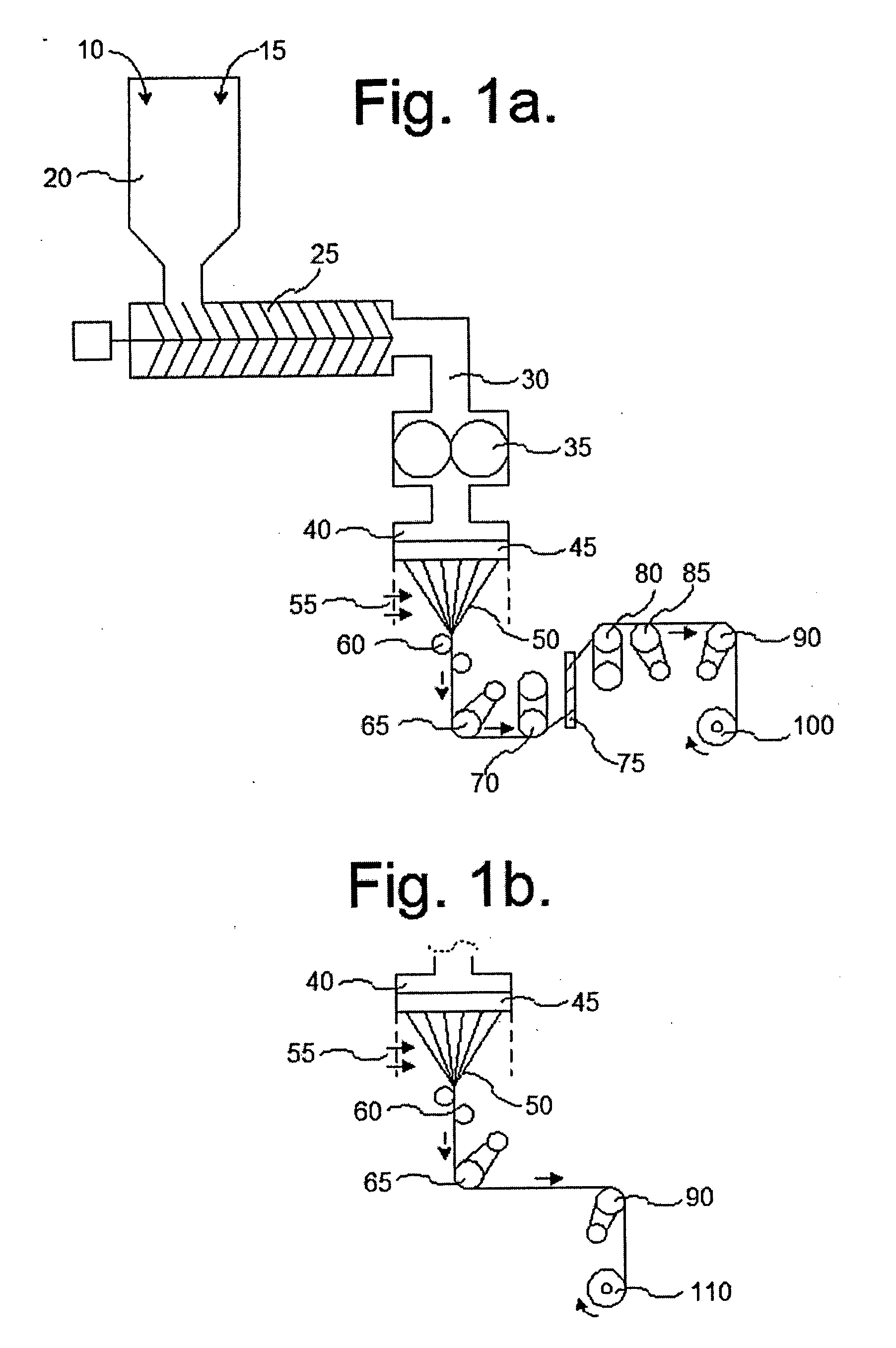

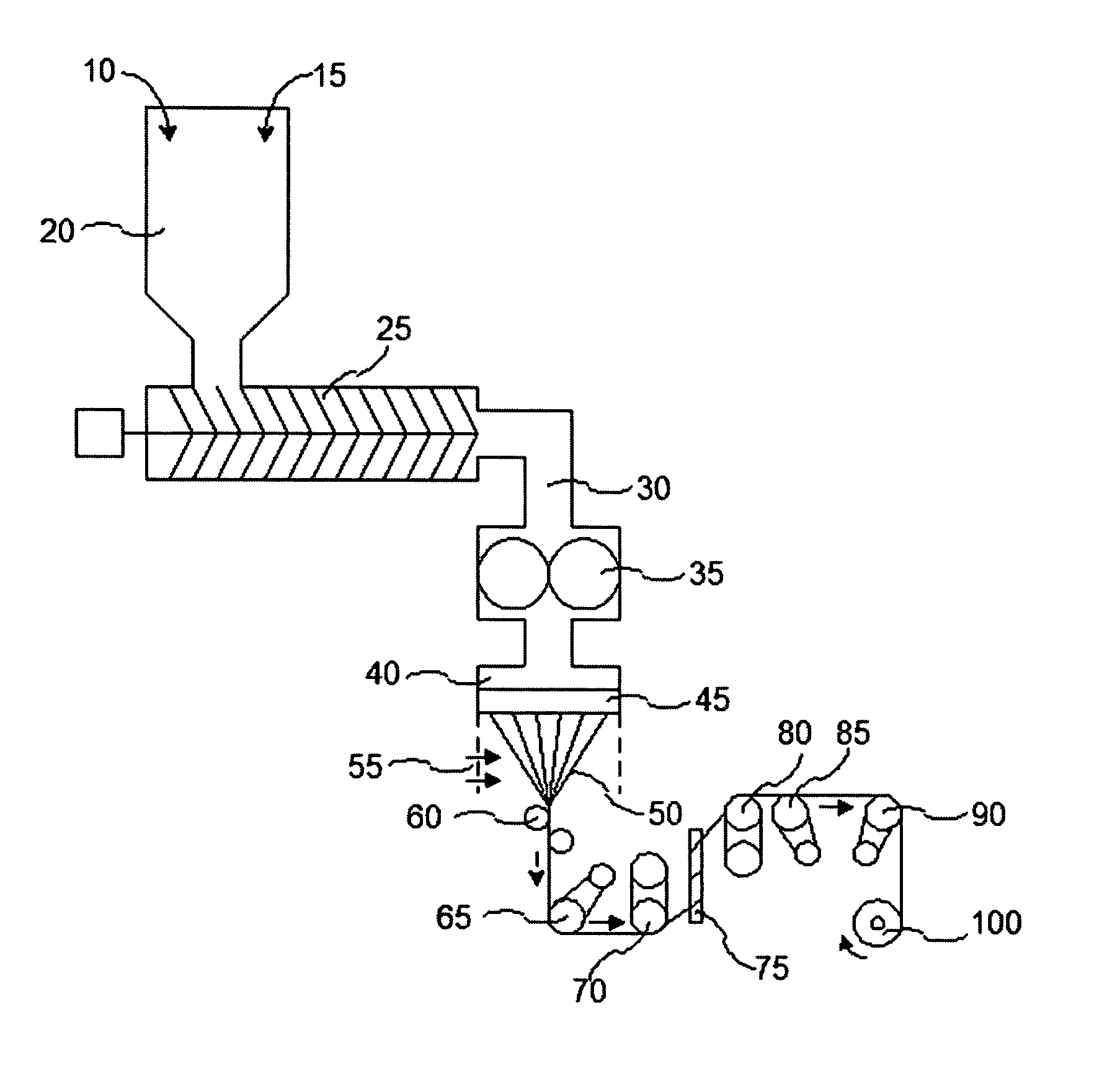

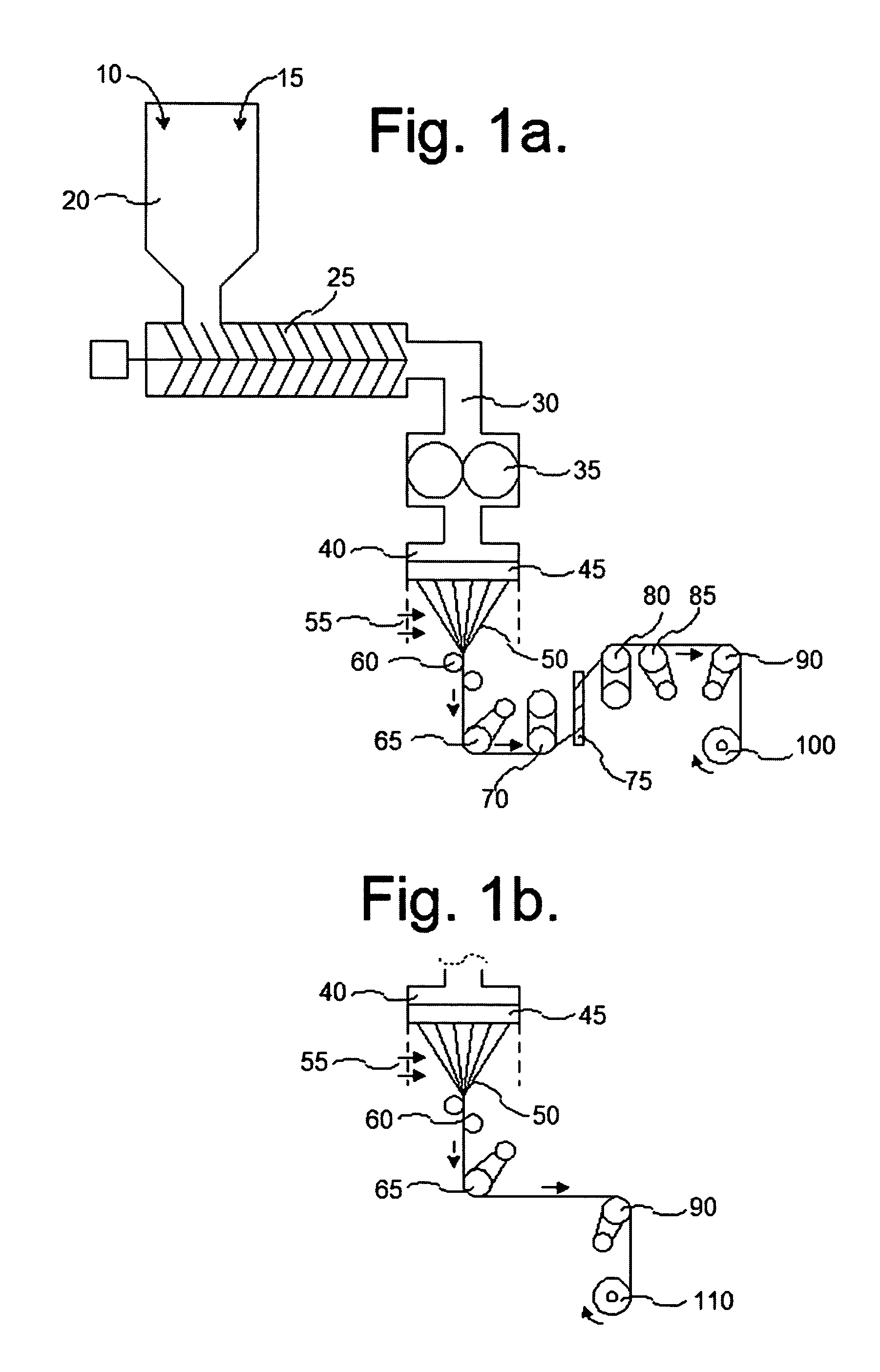

Process for manufacturing powder coating compositions introducing hard to incorporate additives and/or providing dynamic color control

InactiveUS20050212159A1Sufficiently dispersedGood colorMonocomponent cellulose artificial filamentPowdery paintsMaterials sciencePowder coating

An extrusion process for manufacturing thermosetting powder coating compositions is disclosed. A base material is fed to an extruder body such as from a pre-mix hopper; in one embodiment, hard to incorporate additives, such as pigments, are added to the base material after they exit from the pre-mix hopper and before they exit from the extruder body. In another embodiment, hard to incorporate additives in a dried form are added with the base material. The combined base material and hard to incorporate additives are mixed through at least a portion of the extruder body to form a homogeneous thermosetting powder coating composition. The output of the extruder body may be monitored for composition accuracy, wherein the amount of hard to incorporate additives added is dynamically adjusted based upon the monitored output. The process may be repeated for thermosetting powder coating compositions having distinct hard to incorporate additives utilizing a common base material in the pre-mix hopper. Use of one or more hyperdispersed pigments in the formation of a powder coating is also disclosed.

Owner:PPG IND OHIO INC

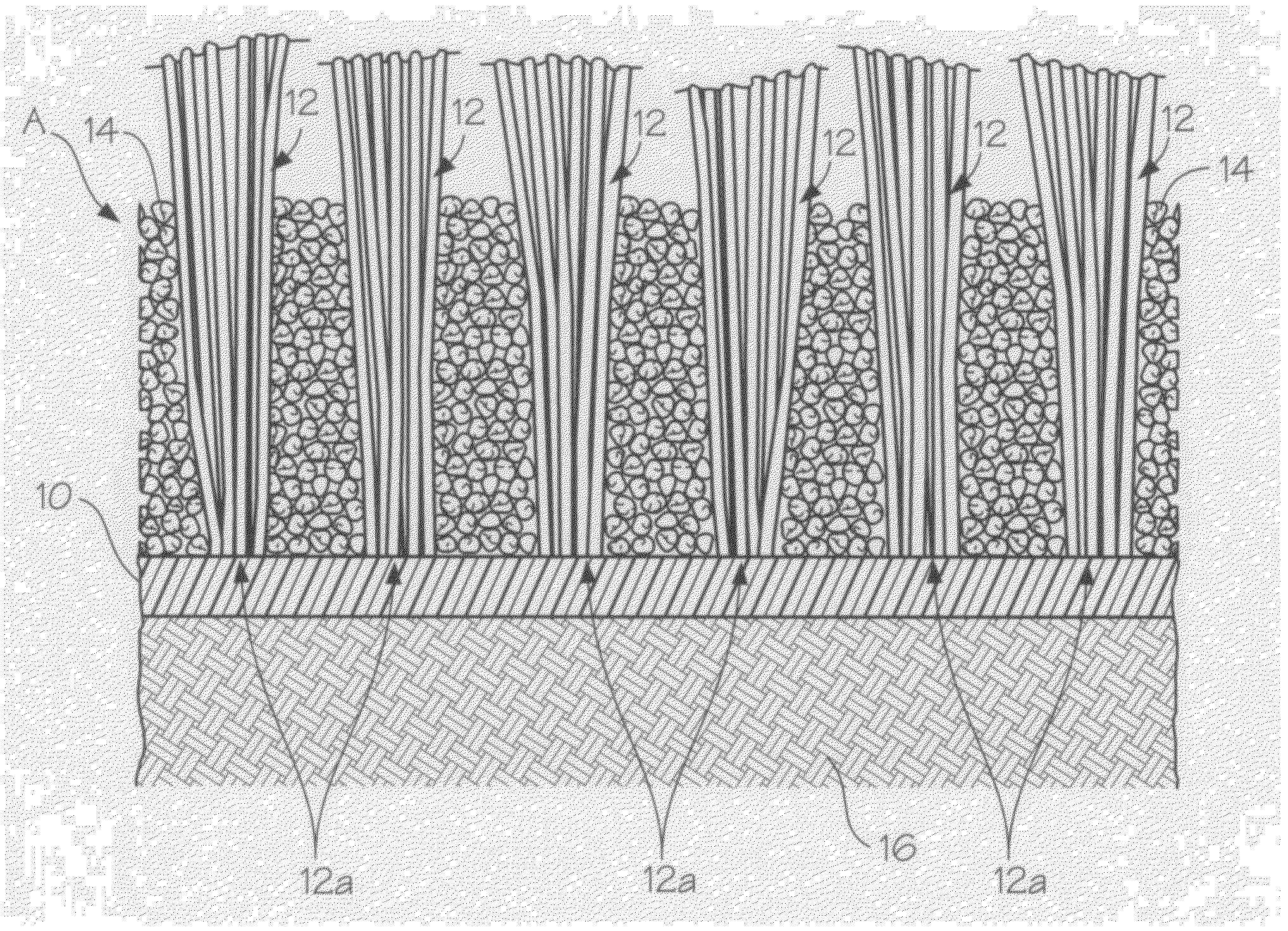

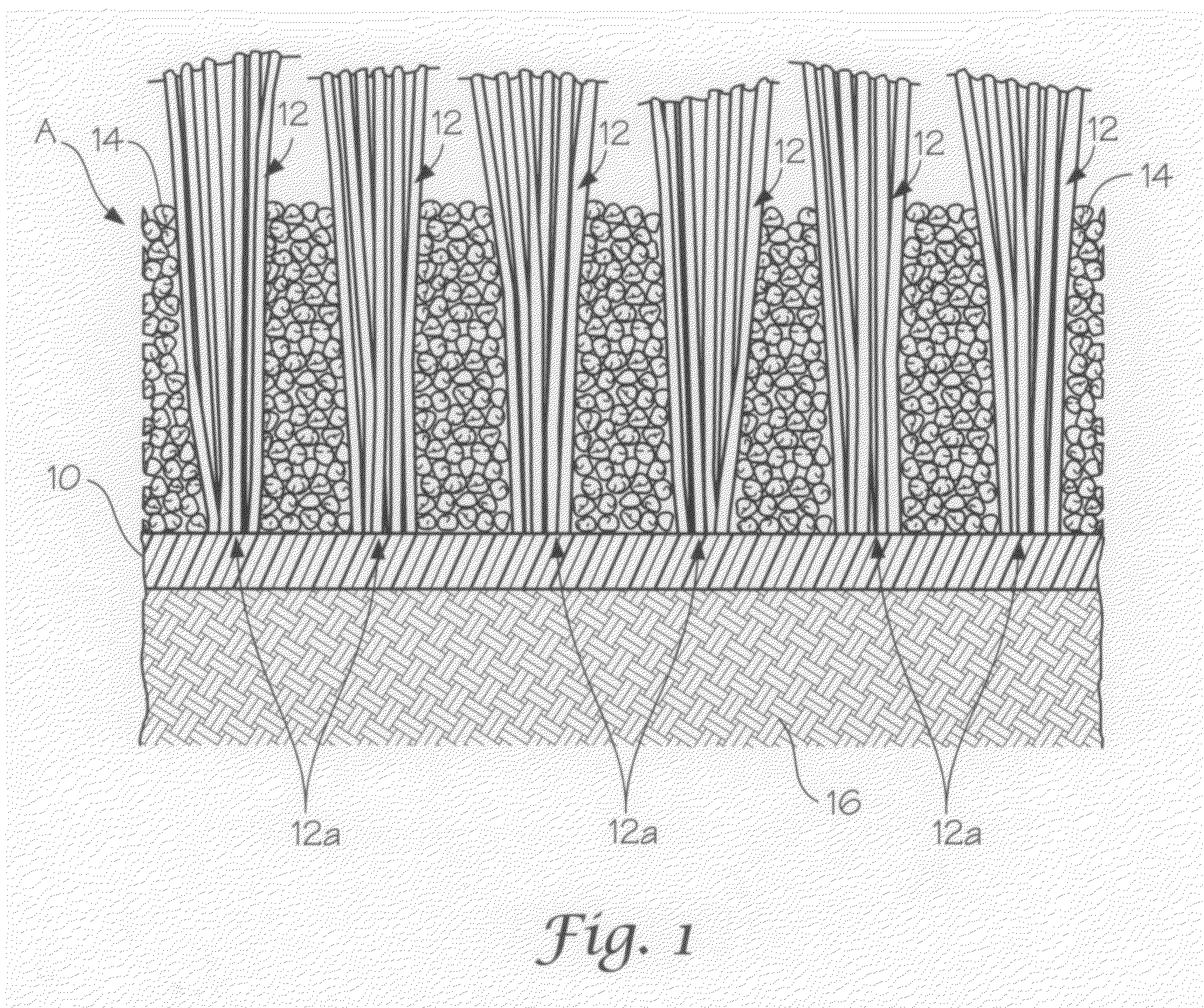

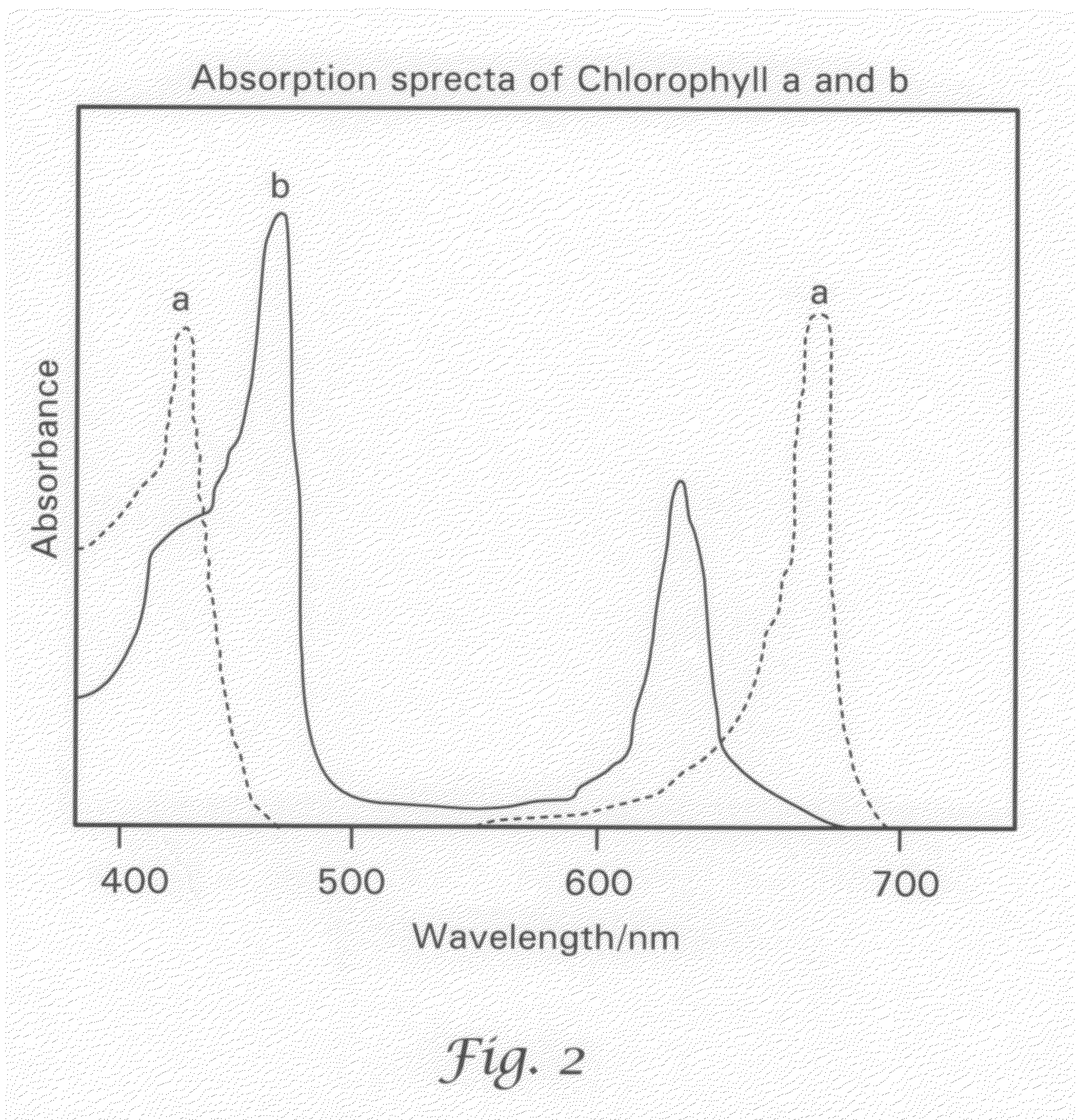

Chlorophyll cooling agent for synthetic turf components

InactiveUS20130034671A1Good lookingReduce heatDead plant preservationArtificial flowers and garlandsArtificial turfEngineering

An artificial turf is disclosed having a base and a plurality of synthetic fibers attached to and extending upward from the base, the fibers comprising a chlorin-based organic colorant and the colorant reflects infrared radiation in the range of 700 to 1,100 nm.

Owner:CHLOROCOOL

Method for producing terylene fibre with pearly lustre

InactiveCN101381903AImprove performanceAdd lessFilament/thread formingPigment addition to spinning solutionPolyesterLight extinction

The invention relates to a method for preparing polyester fibers with pearly luster. The method comprises the following steps: (1) pearlescent pigment agglomerate and full-dull PET fiber forming resin slice are blended according to the weight ratio of 5-20 to 80-95; and after drying, the water content is less than 100PPM, and the slice is delivered to a feeding port of an extruder and enters an screw extruder for heat fusing and compression; (2) the temperature is controlled to between 290 and 305 DEG C, fusant extruded out by the rotary screw rod enters a metering pump through a distributing pipe and a static mixer, delivered to a spinning component, filtered by a sea sand layer and pressed into a spinning plate to form fusant current which is cooed to form in a spinning cabinet, and the surface of a filament bundle is covered by a spinning finish; and 3. the spinning speed pre-extension is between 2, 500 and 3, 500m / min, the winding carry rate is between 5 and 15 percent for wind-forming, and the full-dull pearlescent polyester fiber POY is obtained. The manufacturing process is easily realized, and is convenient to improve the pearlescent fiber spinning effect and simultaneously provides the fibers with light extinction performance, and the pearlescent pigment has excellent performance and little feed rate.

Owner:DONGHUA UNIV

Method for preparing colorized fire-retardant delustering hollow polyester filament

ActiveCN101597816AWith colorFlame retardantFlame-proof filament manufactureHollow filament manufactureFiberState of art

The invention relates to a method for preparing a polyester filament, in particular to a method for preparing a colorized fire-retardant delustering hollow polyester filament. The method mainly solves the technical problem of the prior art that color master batches and a delustering agent added into a fire-retardant slice can influence the viscosity of a fused mass during the spinning and the friction to a device in the processing process so that colorized, fire-retardant and delustering finished polyester fiber and the like cannot be prepared. The preparation method comprises the following steps: adding a copolymerization fire retardant in the process of preparing a polyester slice to form the fire-retardant slice; performing pre-crystallization on and drying the fire-retardant slice, the color master batches and delustering master batches, and evaporating the water content; mixing the fire-retardant slice with the color master batches and the delustering master batches, passing the mixture into a double screw extruder to perform heating melting, performing filter mixing and measuring allocation on the fused mass, and spinning the fused mass into tows; and performing cooling molding on the tows through lateral blow, and obtaining a finished product after oil tanker oiling, drafting, networking and winding.

Owner:ZHEJIANG HUAXIN ADVANCED MATERIALS

Polymer fibers, fabrics and equipment with a modified near infrared reflectance signature

ActiveUS7008694B1Readily dyed and printedHigh dye absorption propertyFilament/thread formingCamouflage devicesTerrainPolyamide

A modified synthetic polymer filament and multifilament yarn of polyamide or polyester filament containing a carbon black polymer additive, and fabrics from these yarns, are disclosed. These melt spun filaments are especially well-suited for use in garments and equipment where a modified Near Infrared Reflectance (NIR) signature is desired. The yarn and fabrics made from this yarn may be advantageously dyed or printed to provide a camouflage fabric for use in desert sand dominated environments, urban environments and multi-terrain environments.

Owner:INV PERFORMANCE MATERIALS LLC

Method of producing color change in a substrate

ActiveUS20120242009A1X-ray/infra-red processesElectric discharge heatingColor changesElectromagnetic radiation

The present invention relates to a method of producing color change in a substrate. The substrate includes an activatable colorant and a region that is heated prior to activating the activatable colorant. The substrate is exposed to electromagnetic radiation producing a first activated color region in the heated region and a second activated color region in a non heated region. The first activated color region appears in a different shade than the second activated color region.

Owner:THE PROCTER & GAMBLE COMPANY

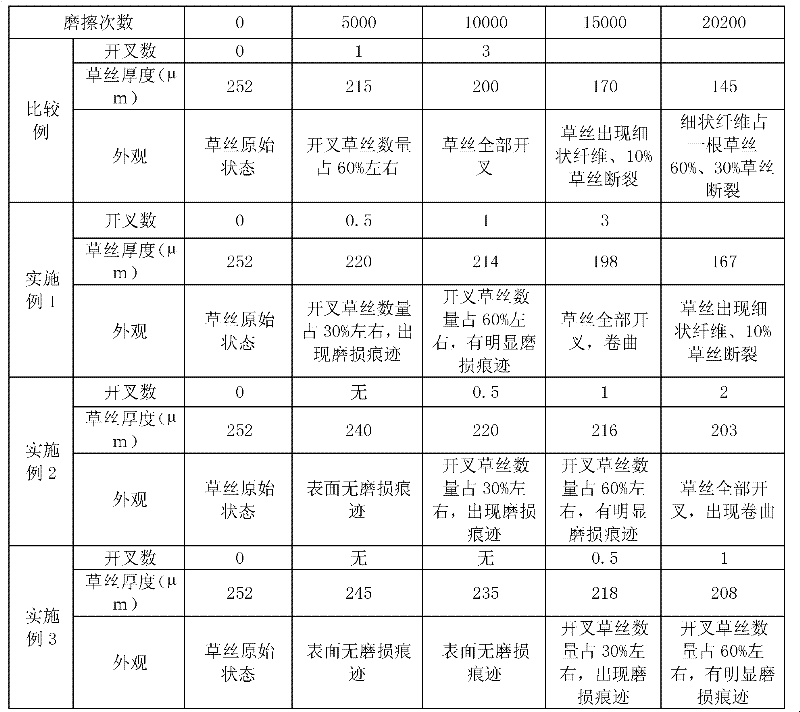

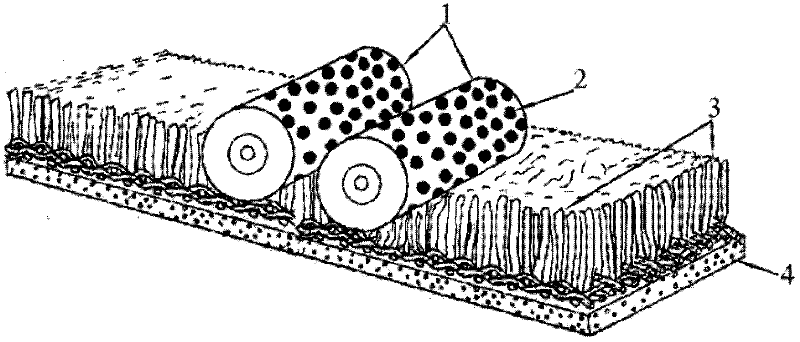

Wear-resistant artificial turf fiber

ActiveCN102493011AReduce wear rateImprove wear resistanceArtificial filament heat treatmentGround pavingsMasterbatchFiber

The invention relates to a wear-resistant artificial turf fiber made of the following raw materials by weight: 60 to 95 parts of matrix resin, 1 to 10 parts of wear-resistant masterbatch, 1 to 10 parts of color masterbatch, and 2 to 5 parts of age resister; and the wear-resistant masterbatch contains silicone powder. The wear-resistant artificial turf fiber has a greatly improved wear resisting property, thereby being suitable for places such as schools and the like where the wear-resistant artificial turf fiber is required to be used frequently for a long time. The wear-resistant artificial turf fiber has the advantages that the preparation method is simple; and the cost is low.

Owner:TAISHAN SPORTS IND GRP +1

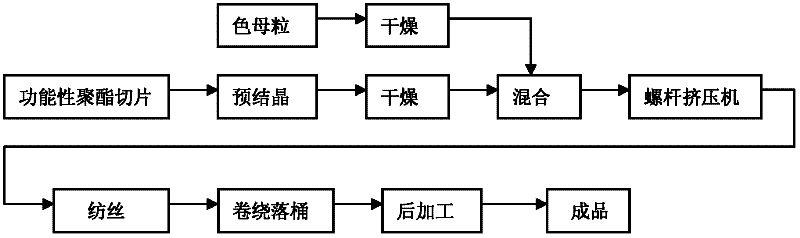

Method for producing differential terylene color yarns

InactiveCN102392317AReduce pollutionHigh fastnessFilament forming substance formingMelt spinning methodsYarnPolyester

The invention discloses a method for producing differential terylene color yarns. The method comprises the following steps of: pre-crystallizing a functional polyester chip at the temperature of between 144 and 146 DEG C for 20 to 60 minutes, and drying at the temperature of between 149 and 151 DEG C for 4 to 6 hours, so that the moisture content of the dried functional polyester chip is less than or equal to 17 ppm; and drying masterbatches for 1 to 2 hours, mixing the dried masterbatches and the dried functional polyester chip fully, adding the mixture into a screw extrusion spinning machine, spinning by using a spinneret plate of the screw extrusion spinning machine, winding and dropping into a bucket, and processing to obtain the differential terylene color yarns. In the method, the masterbatches are added into the functional polyester chip to be spun into the color yarns, the masterbatches and the functional polyester chip are mixed uniformly in a mode of dynamic mixing or static mixing in a screw extruder, and the color yarns are produced through the spinneret plate. By the method, the color fastness and stability of the products are improved, the production cost is reduced, and environmental pollution is reduced.

Owner:ZHEJIANG SANZHI TEXTILES

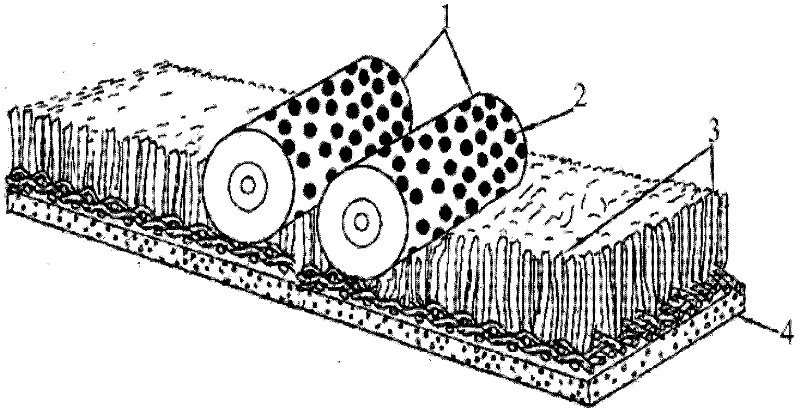

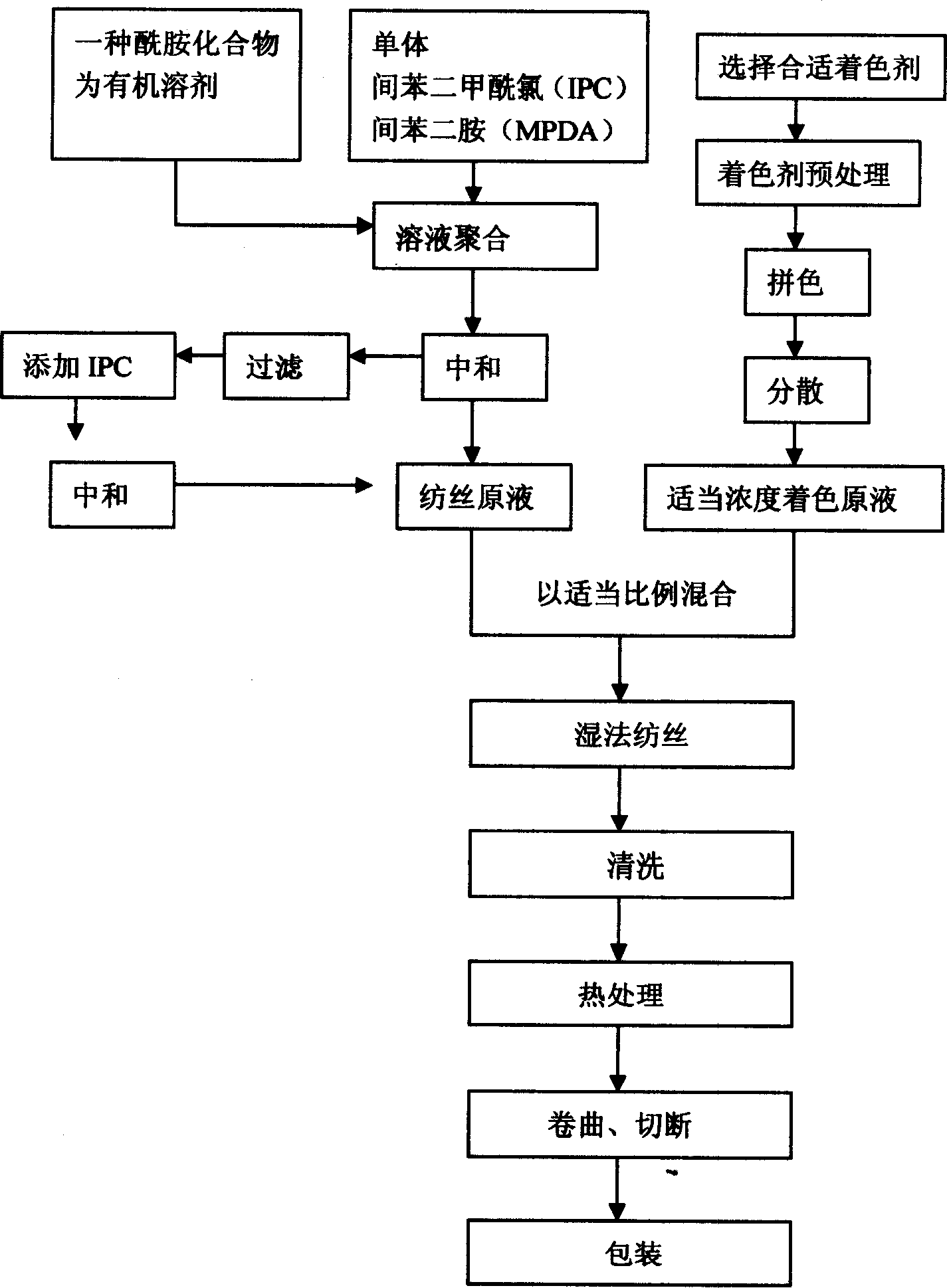

Spun dyeing meta-aramid short fiber and its preparation process

ActiveCN1847475AWet spinning methodsPigment addition to spinning solutionOrganic solventWater insoluble

The present invention relates to spun dyeing meta-aramid short fiber and its preparation process, and belongs to the field of aramid short fiber and its preparation technology. The preparation process includes the following steps: 1. synthesizing meta-aramatoc polyamide solution as the spinning fluid; 2. pre-treating selected colorants, matching color and dispersing to obtain coloring fluid in proper concentration; 3. mixing the spinning fluid and the coloring fluid; 4. wet spinning the mixed fluid to form continuous tow by means of water solution coagulation bath at 10-35 deg.c; and 5. water washing, stoving, heat treatment, curling and cutting. The pigment of the present invention is treated into grain and agglomerate, whose maximum diameter determines the physical and mechanical performance, spinnability and post-processing performance of the fiber, and is water insoluble and organic solvent insoluble, resulting in no loss during the fiber production.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

Reaction of carbon black with diazonium salts, resultant carbon black products and their uses

Owner:CABOT CORP

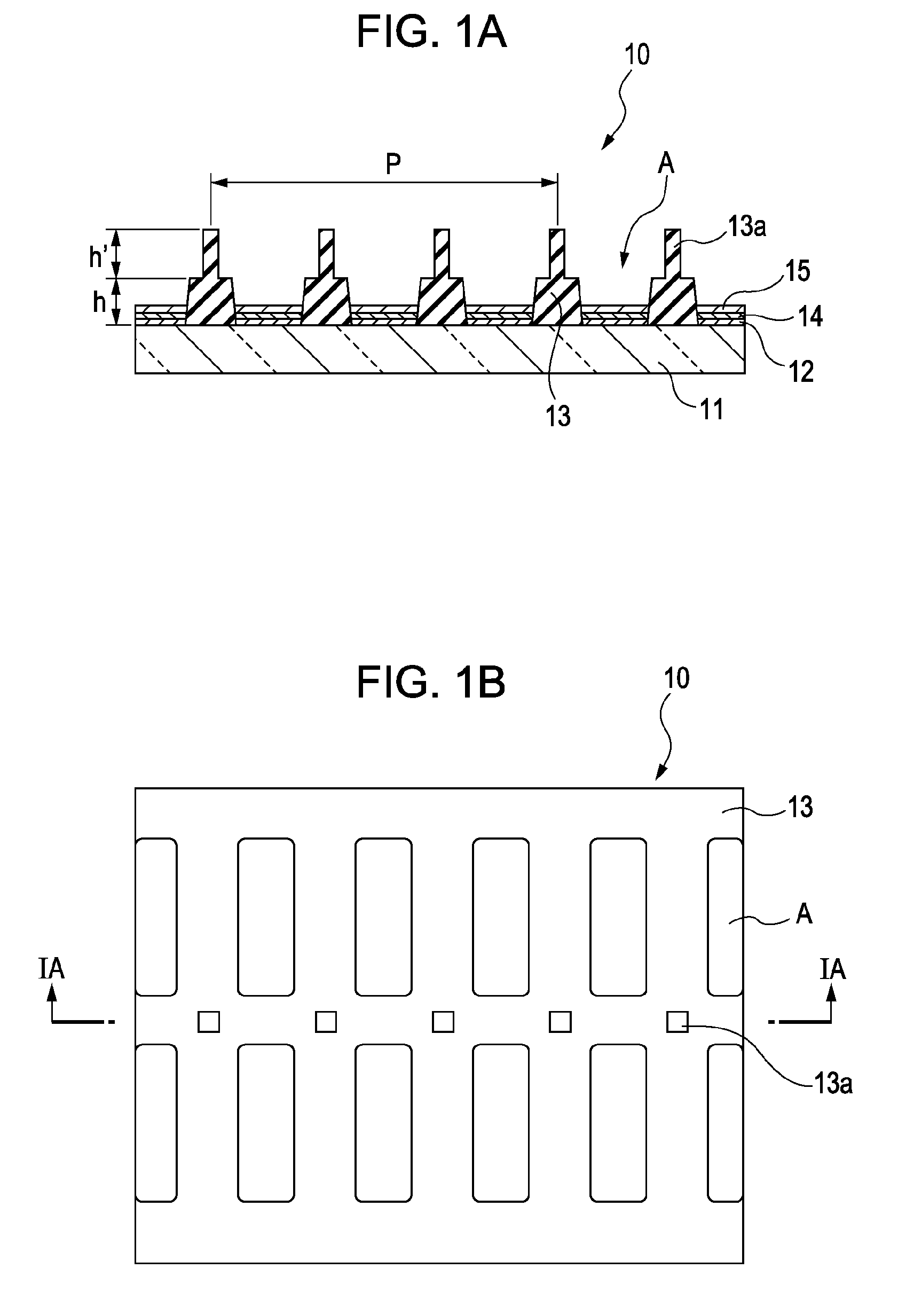

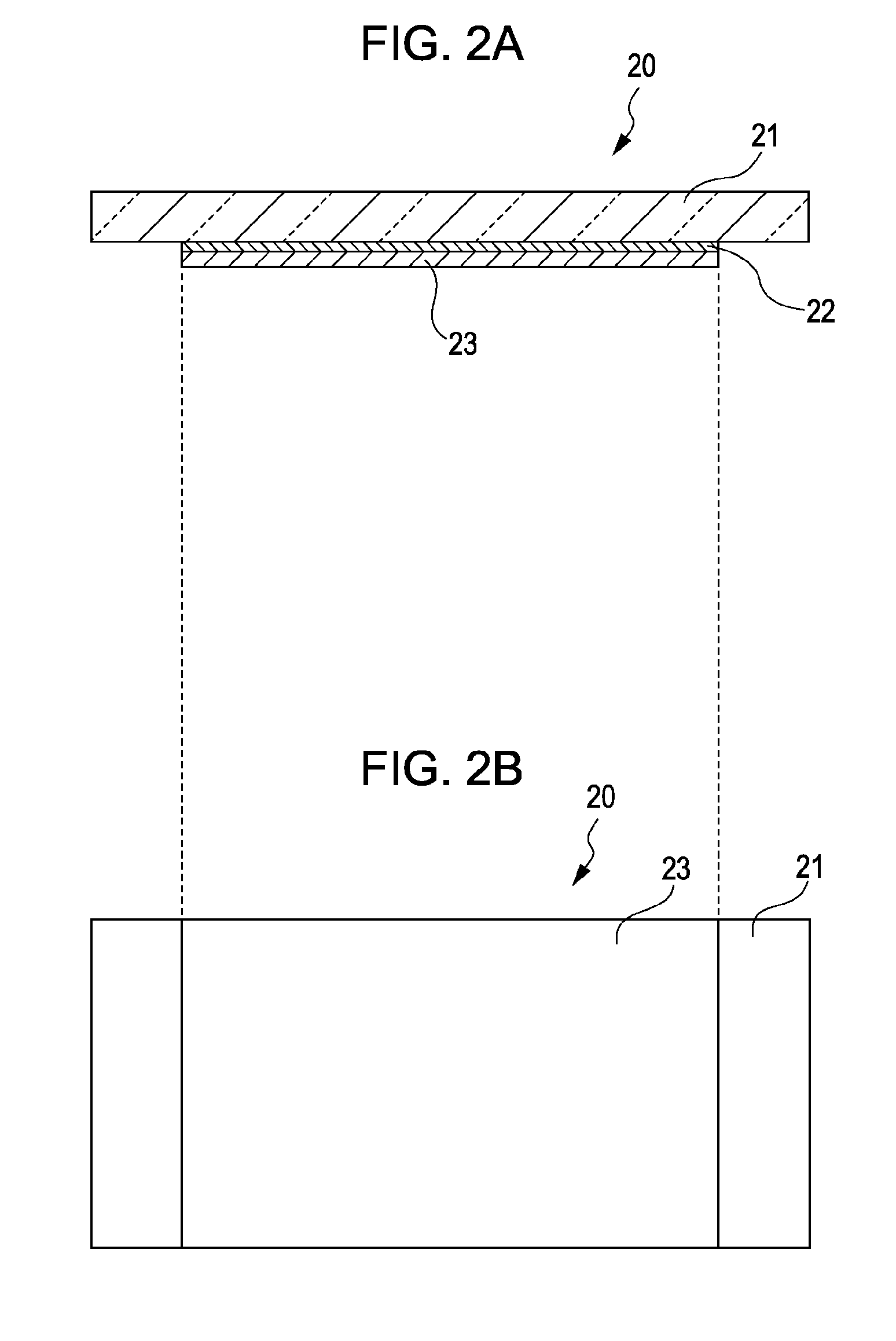

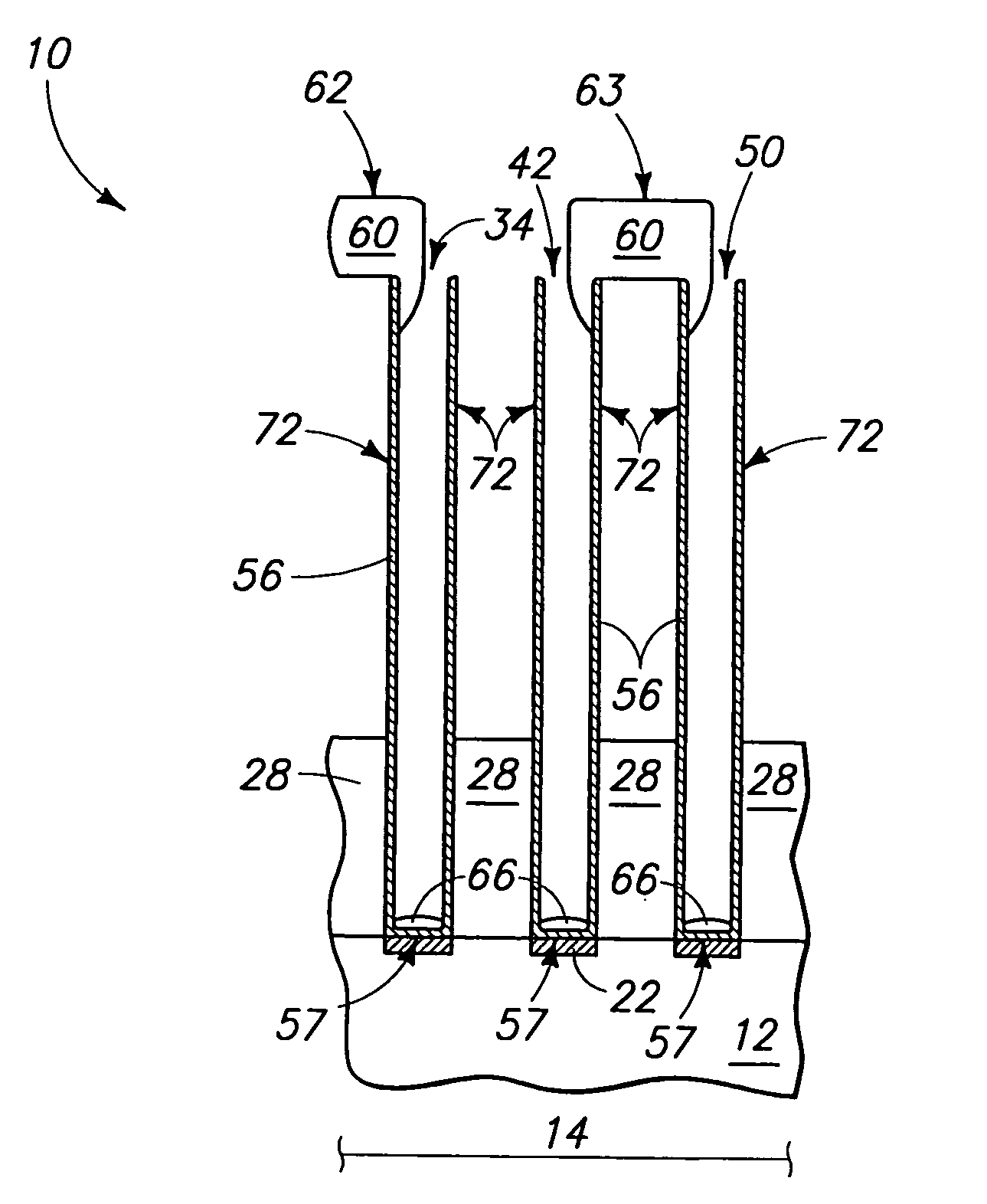

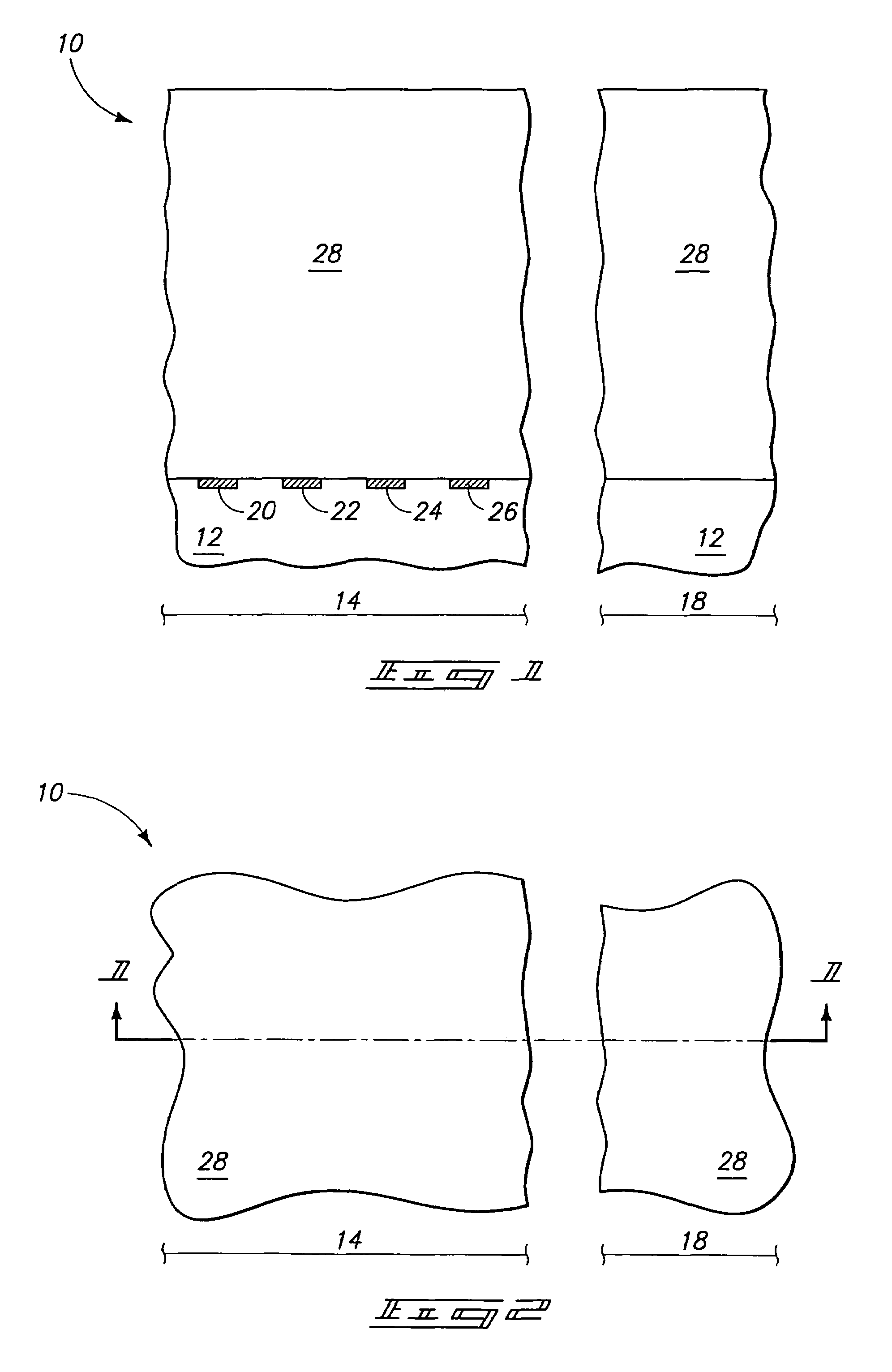

Methods of forming a plurality of capacitors

InactiveUS7445990B2Semiconductor/solid-state device manufacturingConjugated synthetic polymer artificial filamentsDielectricEngineering

A plurality of capacitor electrode openings is formed within capacitor electrode-forming material. A first set of the openings is formed to a depth which is greater within the capacitor electrode-forming material than is a second set of the openings. Conductive first capacitor electrode material is formed therein. A sacrificial retaining structure is formed elevationally over both the first capacitor electrode material and the capacitor electrode-forming material, leaving some of the capacitor electrode-forming material exposed. With the retaining structure in place, at least some of the capacitor electrode-forming material is etched from the substrate effective to expose outer sidewall surfaces of the first capacitor electrode material. Then, the sacrificial retaining structure is removed from the substrate, and then capacitor dielectric material and conductive second capacitor electrode material are formed over the outer sidewall surfaces of the first capacitor electrode material formed within the first and second sets of capacitor openings.

Owner:ROUND ROCK RES LLC

Process for coloring a textile substrate

InactiveUS7018429B1Good light fastnessDurable lightfastnessPretreated surfacesDyeing processYarnUltraviolet protection

The present invention relates to methods of imparting color and ultraviolet protection to synthetic yarns or substrates. More specifically, the present invention is directed to a method of solution dyeing a polymeric material during polymerization to form a base color shade, and subsequently dyeing the polymeric material by either yarn dyeing or piece dyeing. Ultraviolet protection is also provided in the solution dyeing step, by introducing an ultraviolet stabilizing agent into the polymer. The base shade may then be transformed into a useful color pallet with enhanced lightfastness properties by applying a final color shade late in the fabric formation process.

Owner:SAGE AUTOMOTIVE INTERIORS INC

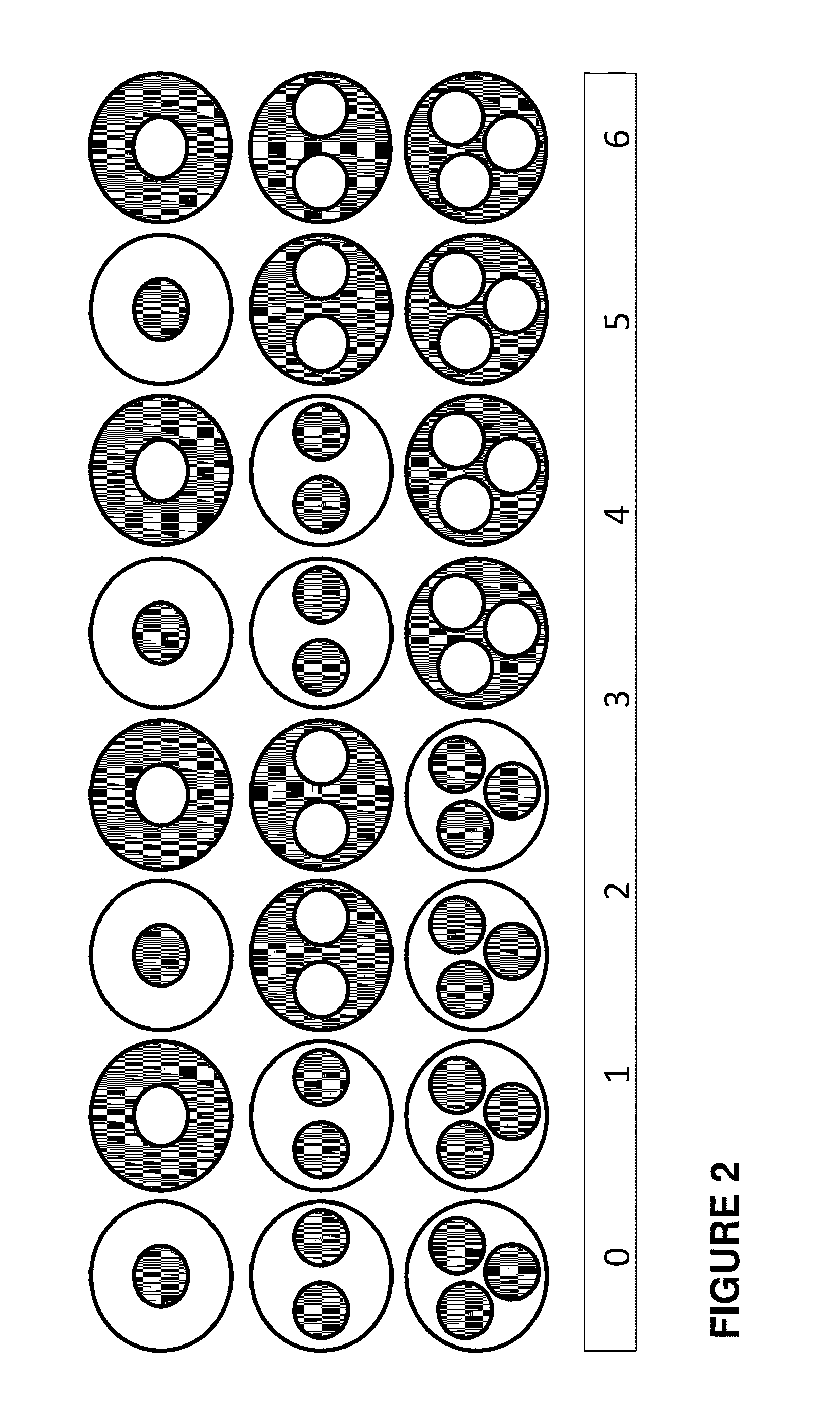

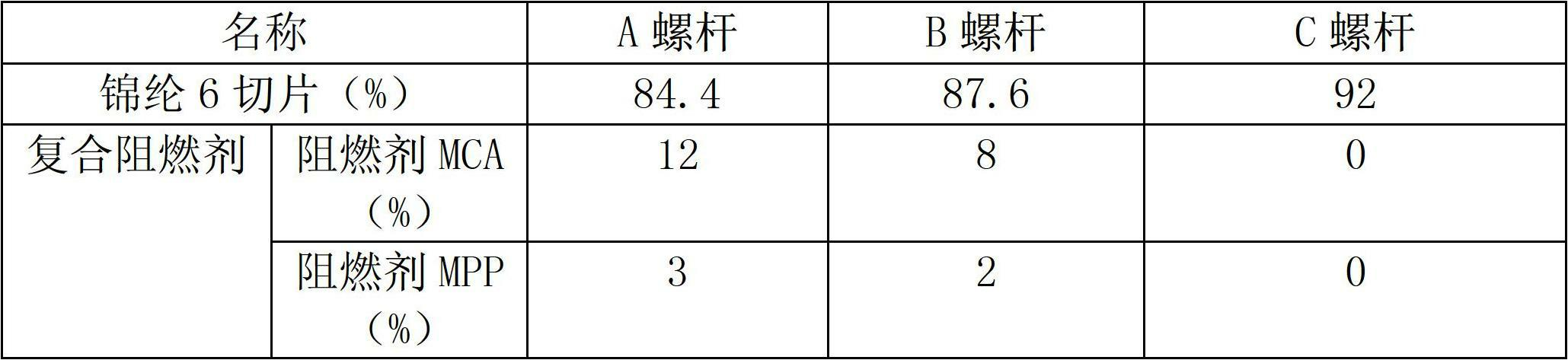

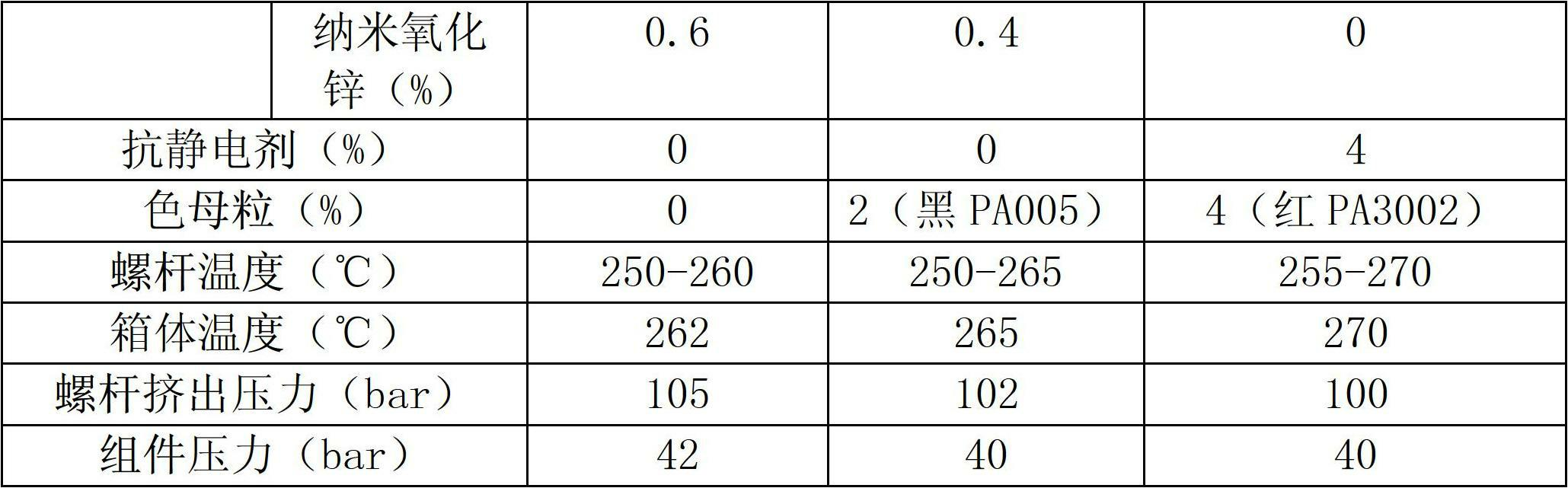

Permanent antistatic flame-retardant polyamide-6 bulked continuous filament textured carpet yarn and preparation method

ActiveCN102660819APermanent antistaticGuaranteed wear resistanceFlame-proof filament manufactureYarnComposite functionPolyamide

The invention relates to a permanent antistatic flame-retardant polyamide-6 bulked continuous filament textured carpet yarn and a preparation method. The permanent antistatic flame-retardant polyamide-6 bulked continuous filament textured carpet yarn comprises a carpet yarn body, wherein the carpet yarn body consists of two tows of flame-retardant polyamide-6 bulked continuous filaments in different colors or the same color and a tow of antistatic polyamide-6 bulked continuous filaments; single fibers in the three tows of polyamide-6 bulked continuous filaments are random three-dimensional crimped fibers; different types of fibers are randomly mixed and intertwined; and periodical net knots are arranged on the surface of the carpet yarn body. The preparation method is implemented by one step through a tri-screw bulked continuous filament (BCF) spinning machine set. The product substantially maintains the characteristics of abrasion resistance, stain resistance, resilience and the like of polyamide-6, and also has a permanent antistatic function and a flame-retardant function. According to the preparation method, the characteristics of a production process of the tri-screw BCF spinning machine set are utilized, so that the aim of spinning the antistatic flame-retardant polyamide-6 textured carpet yarn by one step is fulfilled, and the production process is simple, practical and efficient.

Owner:CHANGZHOU LINGDA SPECIAL FIBER

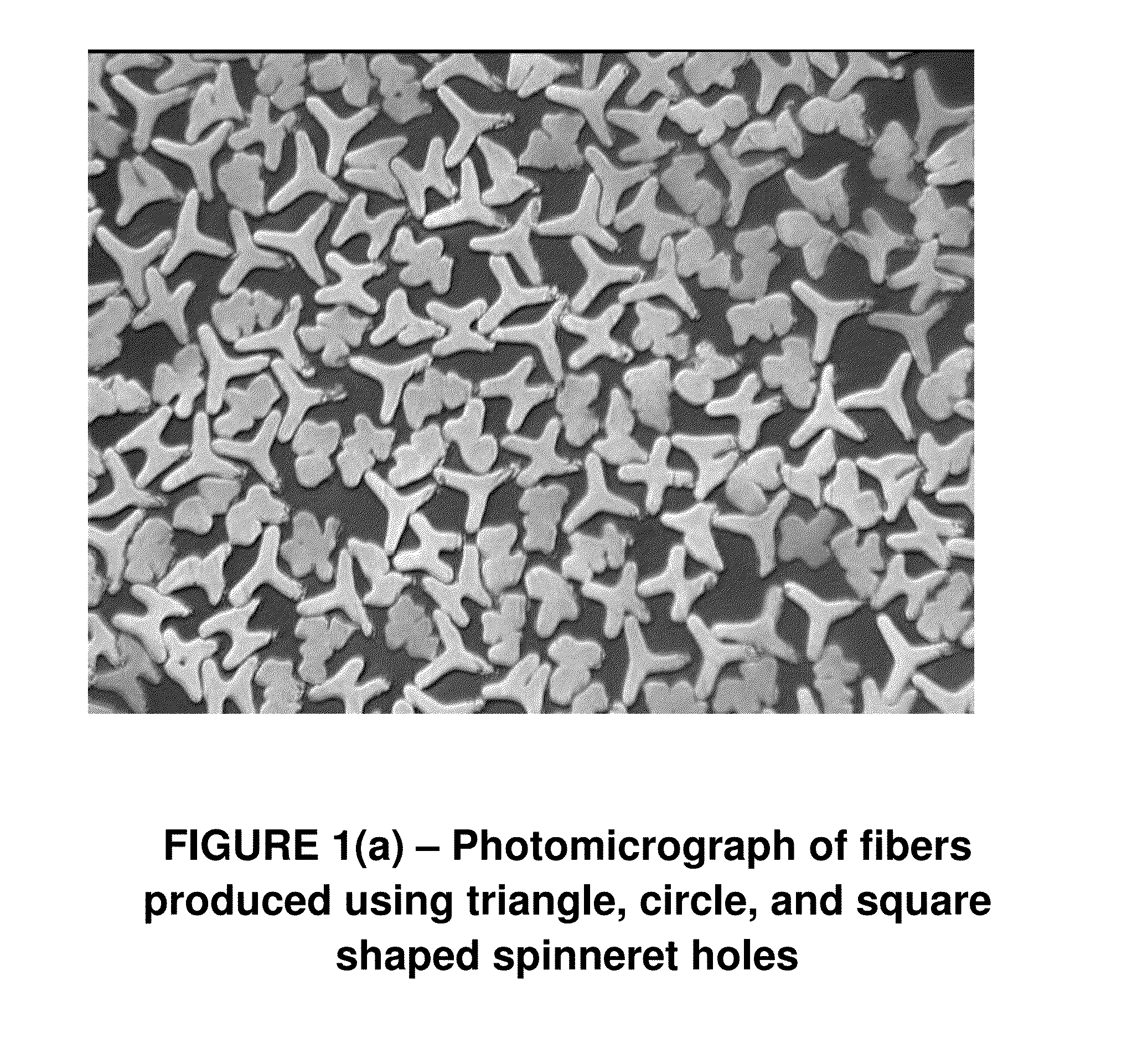

Polyolefin fiber and method of producing the same

ActiveUS20090093180A1Desirable maintenanceDesirable of whitenessFilament/thread formingGlass/slag layered productsYarnPolymer science

A polyolefin fiber includes 0.2 to 5.0 wt % of hydrophilic additive, and 0.05 to 3.00 wt % of titanium dioxide (TiO2). The polyolefin fiber may further include 0.2 to 1.0 wt % of spin finish provided on a surface thereof. The polyolefin fiber is spun to have a circular section, a modified cross-section including an X-shaped section, a Y-shaped section, a deltaic section, an oval section, a diamond section, a bladebone-shaped section, and a combined section thereof, or a combined section of the circular section and the modified cross-section. A method of producing a polyolefin fiber includes (a) melt extruding a composition which contains 93 to 99 wt % of polyolefin resin, 0.2 to 5.0 wt % of hydrophilic additive, and 0.05 to 3.00 wt % of any one titanium dioxide (TiO2) of rutile titanium dioxide, anatase titanium dioxide, and brookite titanium dioxide at 240 to 300° C. and performing winding at a spin speed of 500 to 2,000 mpm to produce a undrawn yarn, and (b) drawing the undrawn yarn at a draw ratio of 1.0 to 5.0, crimping the drawn yarn to 5.5 to 9.0 ea / cm by using a crimper, attaching 0.2 to 1.0 wt % of spin finish to a surface of the fiber by spraying or dipping, heat setting the spin finish at 100 to 130° C. for 3 to 10 min, and cutting the resulting polyolefin fiber to predetermined lengths. A method of producing a polyolefin fiber includes melt extruding a composition which contains 93 to 99 wt % of polyolefin resin, 0.2 to 5.0 wt % of hydrophilic additive, and 0.05 to 3.00 wt % of any one titanium dioxide (TiO2) of rutile titanium dioxide, anatase titanium dioxide, and brookite titanium dioxide at 230 to 270° C., winding at a spin speed of 40 to 300 mpm to produce a undrawn yarn, drawing the undrawn yarn at a draw ratio of 1.0 to 5.0, crimping the drawn yarn to 5.5 to 9.0 ea / cm by using a crimper, attaching 0.2 to 1.0 wt % of spin finish to a surface of the fiber by spraying or dipping, heat setting the spin finish at 100 to 130° C. for 3 to 10 min, and cutting the resulting spin finish to predetermined lengths. The polyolefin fiber has desirable maintenance of hydrophilicity and whiteness after rinsing is performed by using water and low foaming property and excellent carding workability required to produce non-woven fabrics (particularly, spunlace non-woven fabrics). The polyolefin fiber improves clearness of point and embossing patterns during thermal point bonding and thermal embossing processes.

Owner:KOLON GLOTECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com