Method for producing differential terylene color yarns

A production method and differentiated technology, which is applied to the melting of filament raw materials, melt spinning, filament forming treatment, etc., can solve the problems of high energy consumption, large environmental pollution, unstable product performance, etc., and reduce environmental pollution , Reduce production costs, improve color fastness and stabilize performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

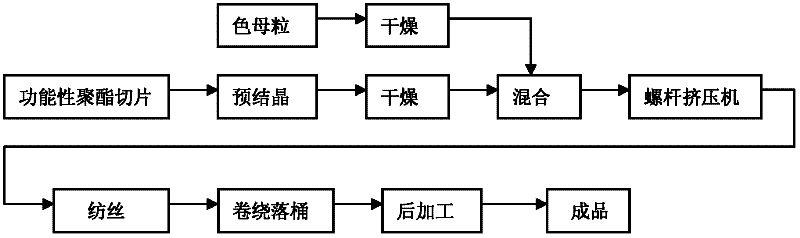

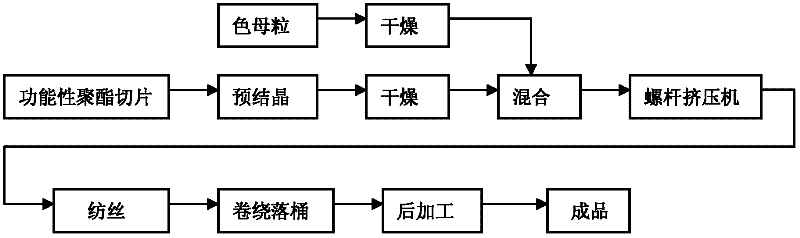

[0015] Example 1: Production of 75D / 36F light red flame-retardant functional polyester shaped fiber.

[0016] Such as figure 1 As shown, take 3000kg of functional polyester polyester raw material (flame-retardant polyester chip) and 97kg of light red masterbatch, pre-crystallize the flame-retardant polyester chip at a temperature of 145°C for 40min, and then dry it at a temperature of 150°C for 5h , the moisture content of the dried flame-retardant polyester chips is ≤17ppm, and then the light red masterbatch is dried for 2 hours, then the dried light red masterbatch is fully mixed with the dried flame-retardant polyester chips, and then added to the screw extrusion spinning machine In the spinning machine, the spinning is carried out through the special-shaped spinneret of the screw extrusion spinning machine, and then it is wound and dropped into the barrel and then processed to obtain differentiated colored polyester yarn. In the screw extrusion spinning machine, the screw...

Embodiment 2

[0019] Embodiment two: produce 100D / 36F purple negative ion functional polyester fiber.

[0020] Take 5000kg of functional polyester polyester raw materials (anion polyester chip) and 203kg of purple color masterbatch, pre-crystallize the anion polyester chip at a temperature of 144°C for 45min, then dry at a temperature of 149°C for 4.5h, the dried The moisture content of the negative ion polyester chip is ≤17ppm, and then the purple color masterbatch is dried for 1.5h, and then the dried purple color masterbatch is fully mixed with the dried negative ion polyester chip, then added to the screw extrusion spinning machine, passed The special-shaped spinneret of the screw extrusion spinning machine is used for spinning, and then after winding and falling into the barrel, it enters post-processing to obtain differentiated polyester colored yarn.

Embodiment 3

[0021] Embodiment 3: Production of 300D / 96F light yellow anti-ultraviolet functional polyester shaped fiber.

[0022] Take 15000kg of functional polyester raw material (anti-ultraviolet polyester chip) and 458kg of light yellow masterbatch, pre-crystallize the anti-ultraviolet polyester chip at a temperature of 146°C for 45min, then dry it at a temperature of 151°C for 5h, after drying The moisture content of the anti-ultraviolet polyester chips is ≤17ppm, and then the light yellow masterbatch is dried for 2 hours, and then the dried light yellow masterbatch is fully mixed with the dried anti-ultraviolet polyester chips, and then added to the screw extrusion spinning machine , through the special-shaped spinneret of the screw extrusion spinning machine for spinning, and then after winding and falling into the barrel, it enters post-processing to obtain differentiated colored polyester yarn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com