Permanent antistatic flame-retardant polyamide-6 bulked continuous filament textured carpet yarn and preparation method

A technology of bulked filament and carpet yarn, which is applied in the manufacture of fire-retardant and flame-retardant filament, single-component polyamide rayon, yarn, etc. The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Equipment and raw materials: three-screw BCF spinning unit, polyamide 6 slices, PA6BCF oil agent, PA6 color masterbatch (black: PA005, green: PA609), polyether ester amide antistatic agent containing zinc salt, containing Hydrophobic treatment of melamine cyanurate (MCA) and melamine polyphosphate (MPP) flame retardants, modified composite flame retardant masterbatch of nano-zinc oxide, the above three materials are pre-dried.

[0033] Flame-retardant fiber spinneret: 43 holes / trilobal shape, leaf width 0.32mm, leaf length 0.85mm; antistatic fiber spinneret: 43 holes / circle, diameter 0.6mm.

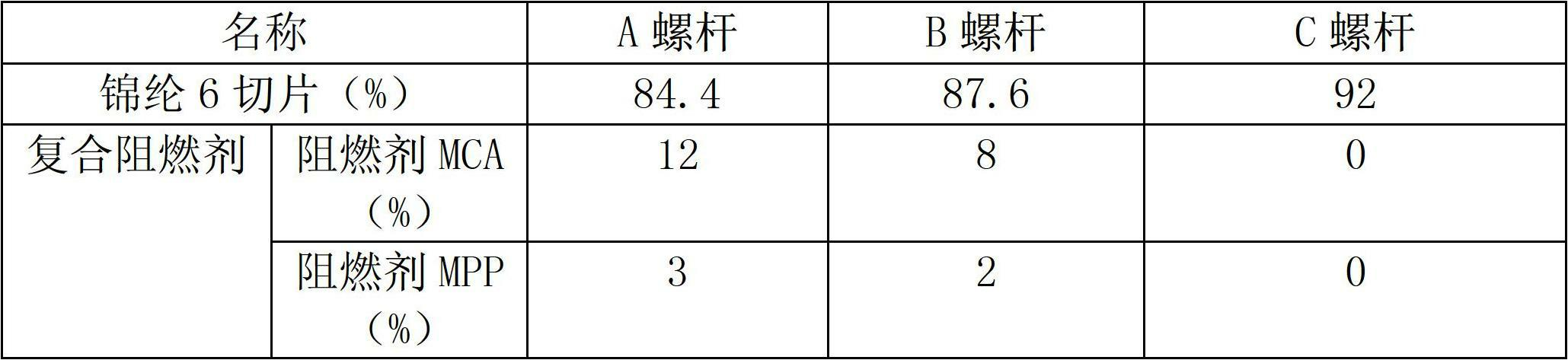

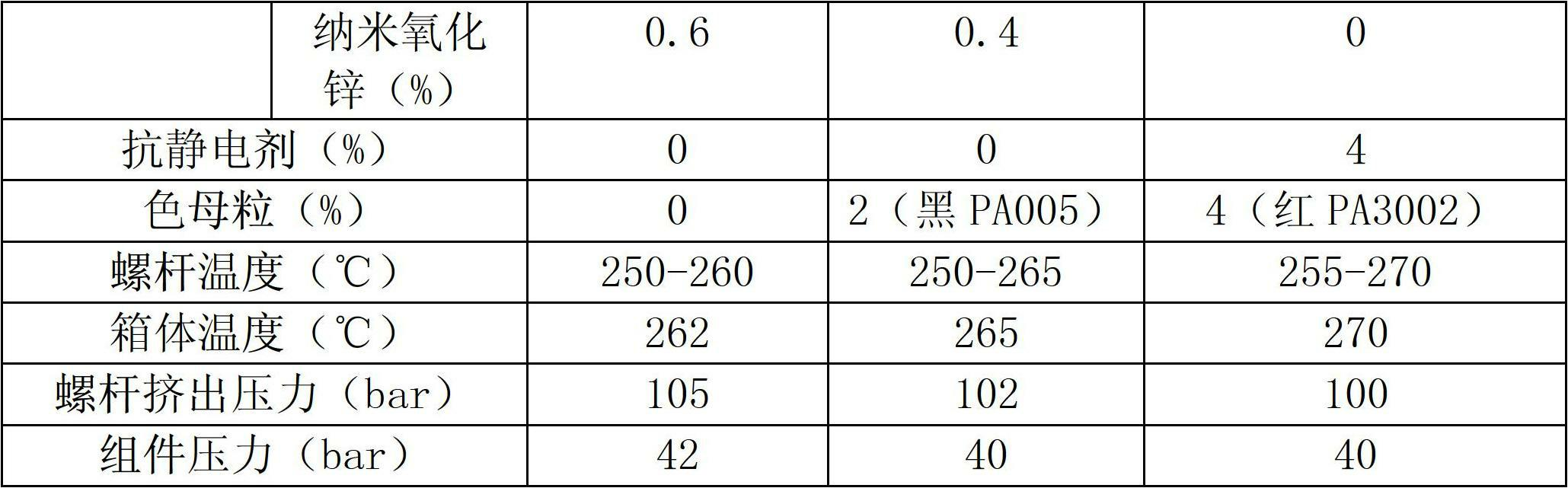

[0034] Spinning conditions:

[0035]

[0036]

[0037] crafting process:

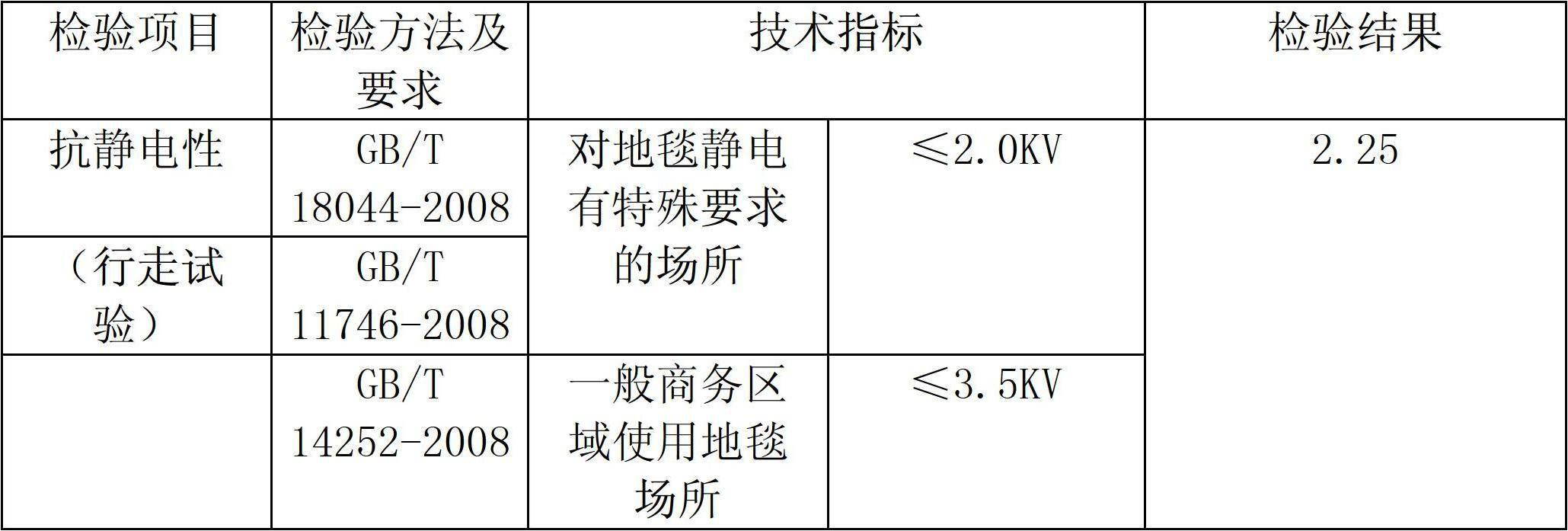

[0038] Add the separately measured nylon 6 slices and the pre-dried modified flame retardant, modified antistatic agent, and color masterbatch to the three feeding hoppers of the three-screw BCF spinning unit according to the requirements specified in the above table, according to the above table The...

Embodiment 2

[0047] Equipment and raw materials: three-screw BCF spinning unit, polyamide 6 chips, PA6BCF oil agent, PA6 masterbatch (black: PA005, bright red: PA348, green: PA609), polyether ester amide antistatic agent containing zinc salt, Modified composite flame retardant masterbatch containing melamine cyanurate (MCA) and melamine polyphosphate (MPP) flame retardants treated with coupling agent hydrophobization, and nano-zinc oxide. The above three materials are all pre-dried .

[0048] Flame-retardant fiber spinneret: 23 holes / trilobal shape, leaf width 0.3mm, leaf length 0.8mm; antistatic fiber spinneret: 23 holes / circle, diameter 0.6mm.

[0049] Spinning conditions:

[0050]

[0051]

[0052] crafting process:

[0053] Add the separately measured nylon 6 slices and the pre-dried modified flame retardant, modified antistatic agent, and color masterbatch to the three feeding hoppers of the three-screw BCF spinning unit according to the requirements specified in the above tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com