Patents

Literature

33results about How to "The production method is practical" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method of Chinese herbal medicine health tea

InactiveCN101336704ADoes not affect formDoes not affect colorPre-extraction tea treatmentFood preparationUltrafiltrationChinese drug

A processing method for Chinese medicine health tea, is that the health Chinese herbal medicine is prepared into the concentrated Chinese herbal medicine extract or discolored concentrated Chinese herbal medicine extract, which is sprayed into tea in a spraying way. The process includes: preparing the concentrated Chinese herbal medicine extract; spraying and drying first; spraying the concentrated Chinese herbal medicine extract into tea in different proportions for one to five times in the spraying way, spraying every time and first drying every time, and first drying tea with the concentrated Chinese herbal medicine extract by a drying device at different temperature respectively; drying again and perfuming, namely, adding the tea with the Chinese herbal medicine extract after sprayed and dried first into a baking cage to be dried again and perfumed; packing and storing. The preparation of the discolored concentrated Chinese herbal medicine extract includes: pulverizing the health Chinese medicine components, soaking in water, then extracting by a diacolation or microwave extracting process, concentrating and separating by a refrigeration or ultrafiltration concentrating technic. The Chinese medicine health tea having the original shape and color of tea, and a certain health care effect, is prepared by the process.

Owner:邓智深

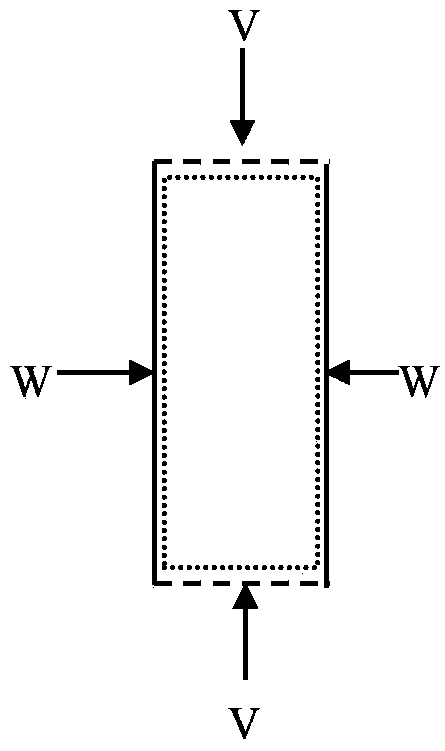

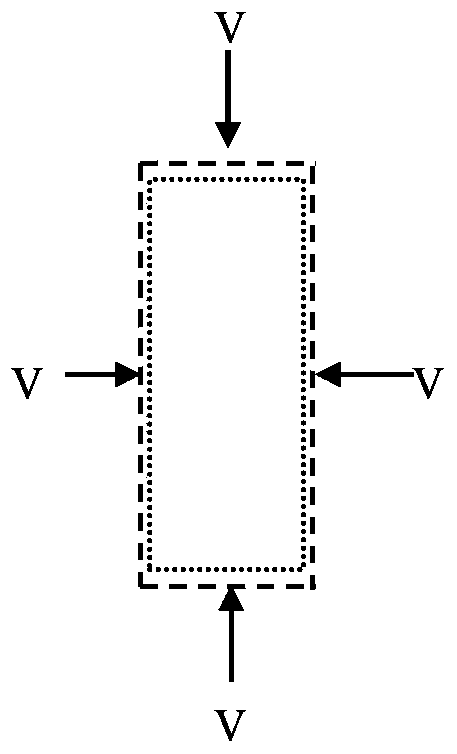

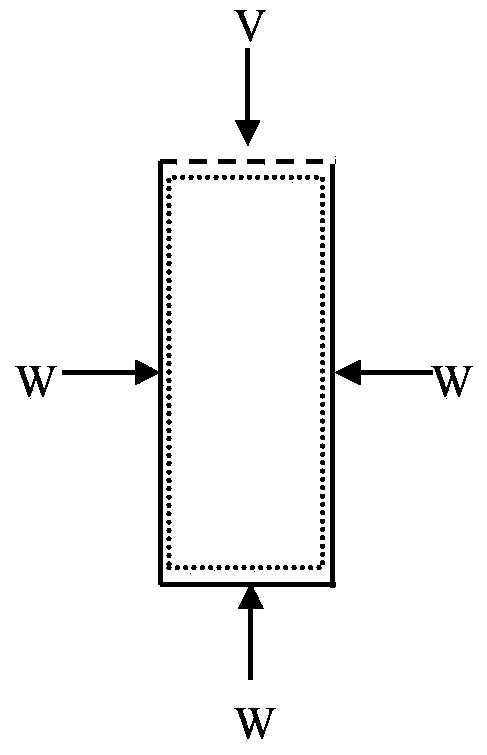

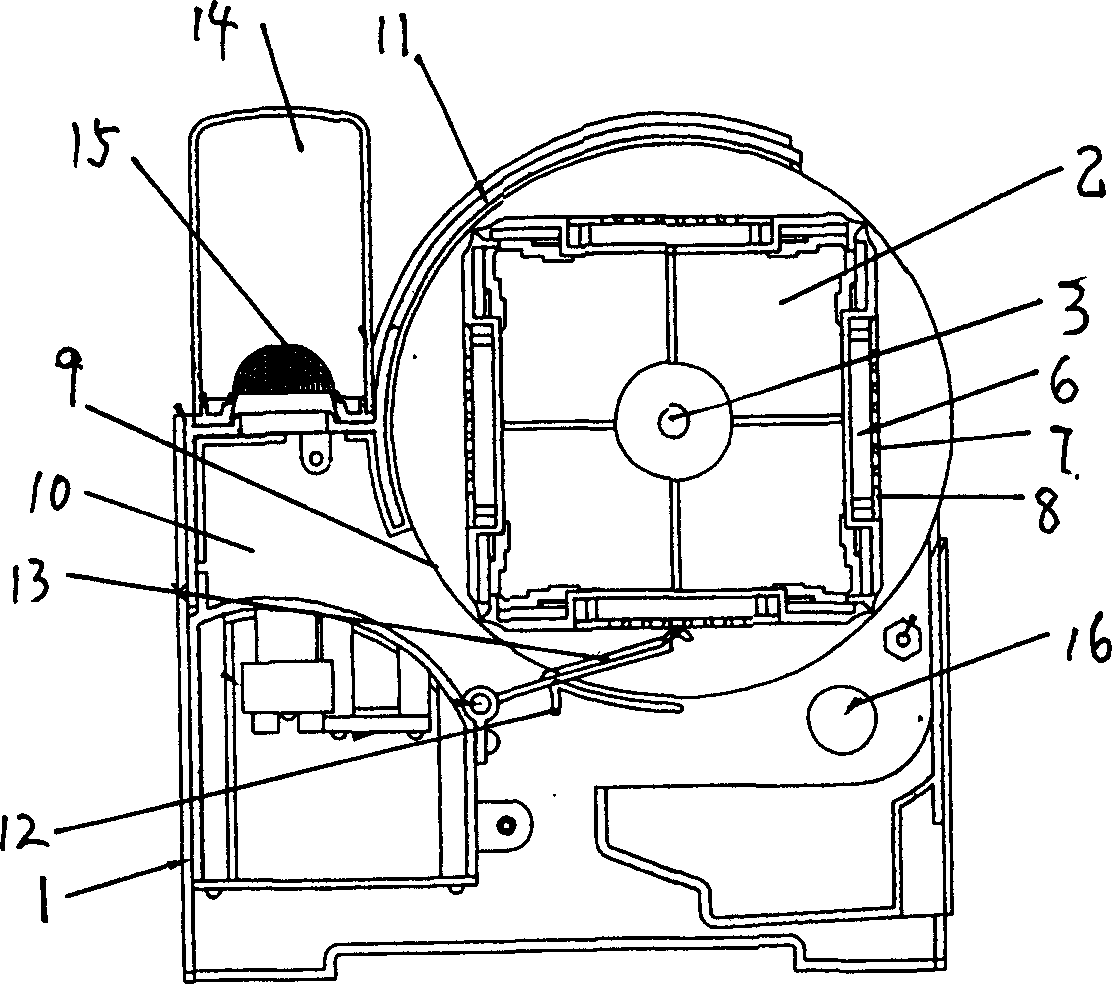

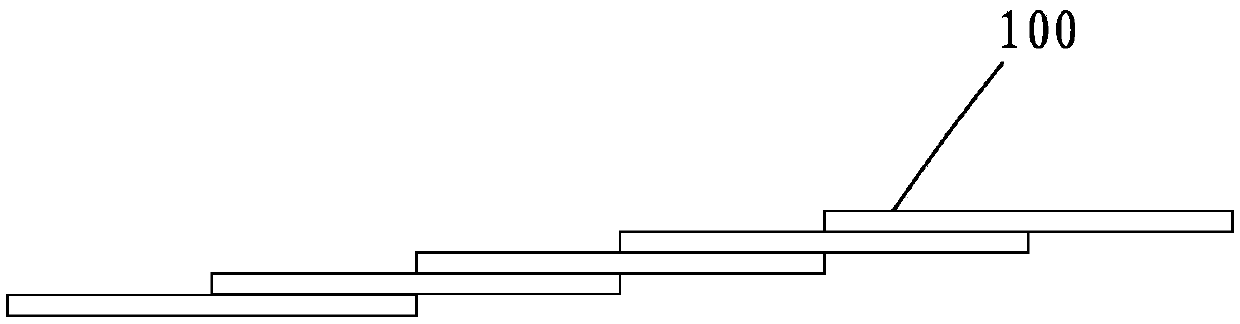

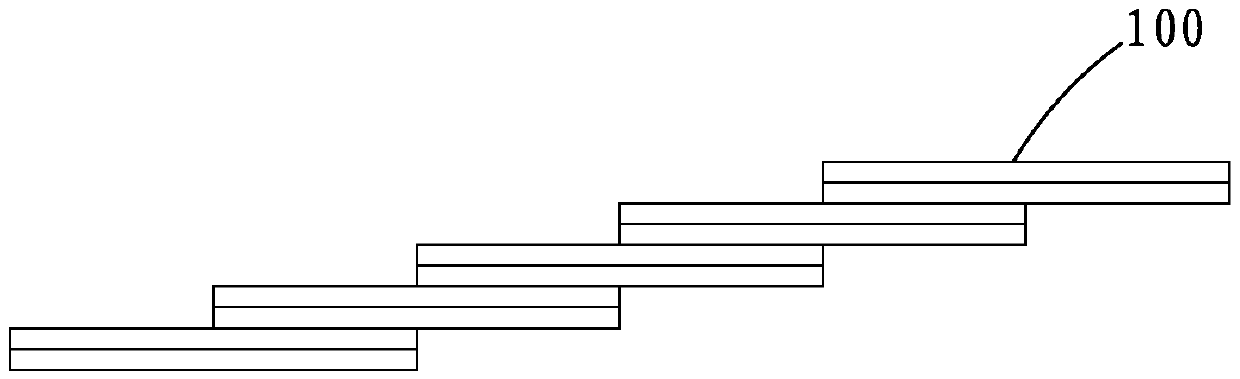

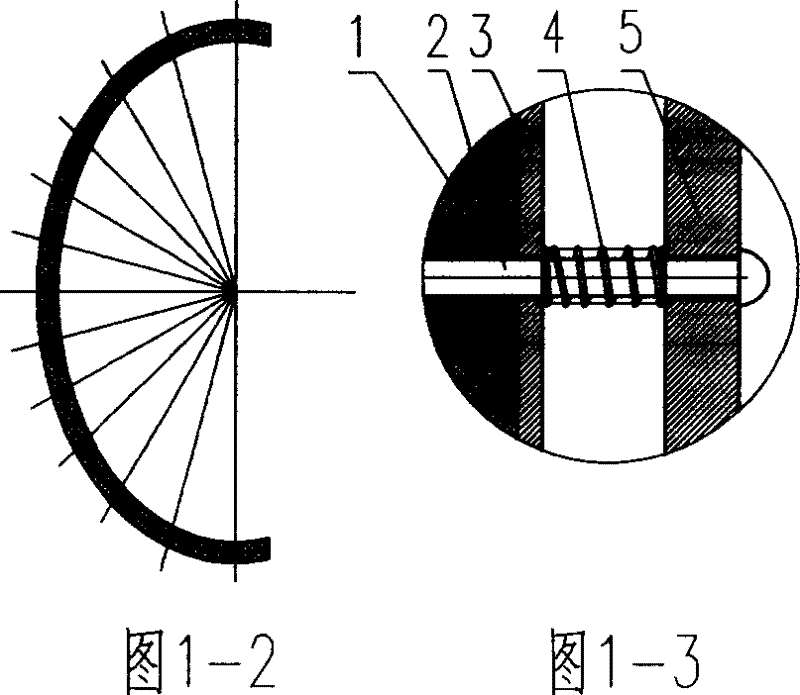

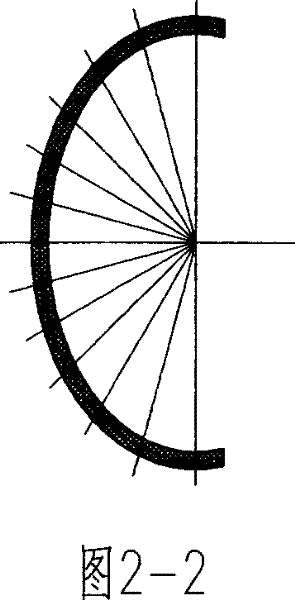

Arc battery cell, arc single cell, arc cell combination structure and manufacturing method

InactiveCN103401024ARealize a variety of designsNo internal short circuitFinal product manufactureElectrolyte accumulators manufactureElectrical batteryBattery cell

The invention discloses an arc battery cell, an arc single cell, an arc cell combination structure and a manufacturing method. According to the invention, the battery cell is required to be bent in the perpendicular direction of a connecting line of opposite open ends, the limit in the arc bending direction is performed, so that the external bending acting force cannot damage an internal structure of the battery, the defects of internal short circuit, increase of the internal resistance, reduction of capacity, unstable size and the like cannot be caused, and the batch production of cells is easy to realized. The bending degree of the battery cell is larger, and the manufactured single cell and cell combination structure can be combined and matched variously, so that diversified designs of the cell product are achieved. The manufacturing method of the battery cell is obtained by adjusting a conventional manufacturing method of the cell, the cell is not required to be heated during bending, and accordingly, the manufacturing method is simpler, practical, efficient and low in manufacturing cost.

Owner:GUANGZHOU FULLRIVER BATTERY NEW TECH

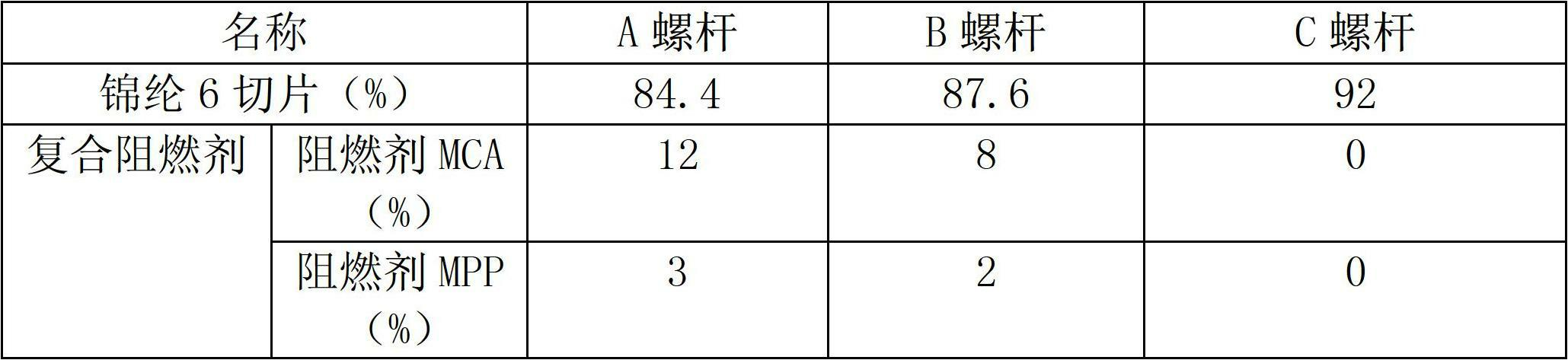

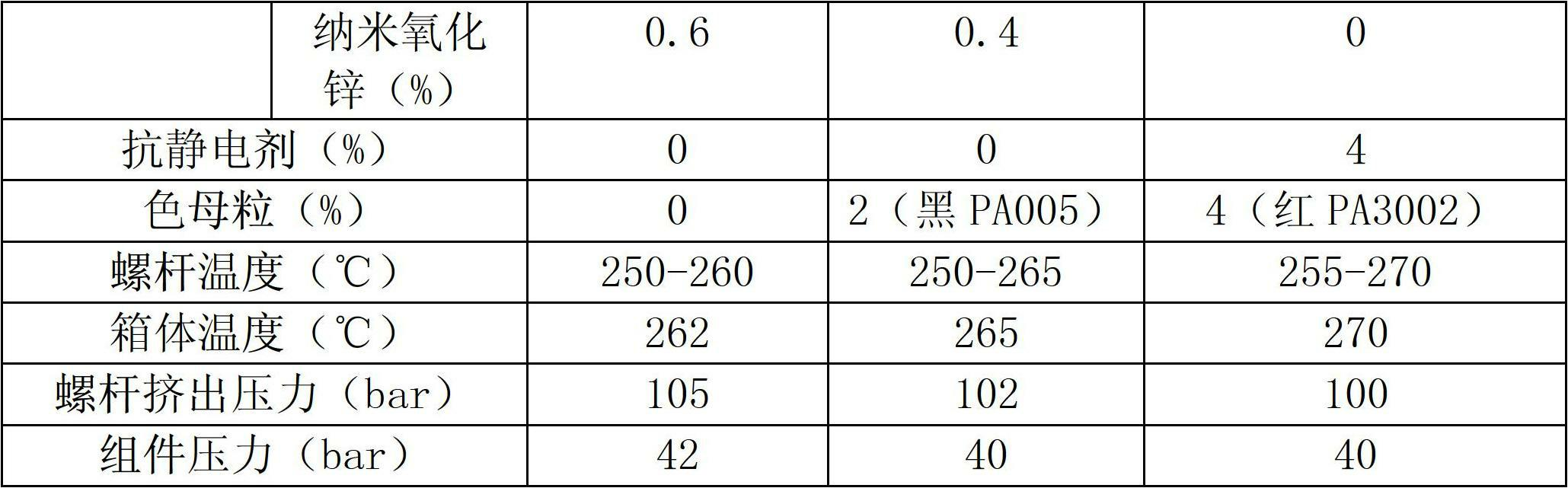

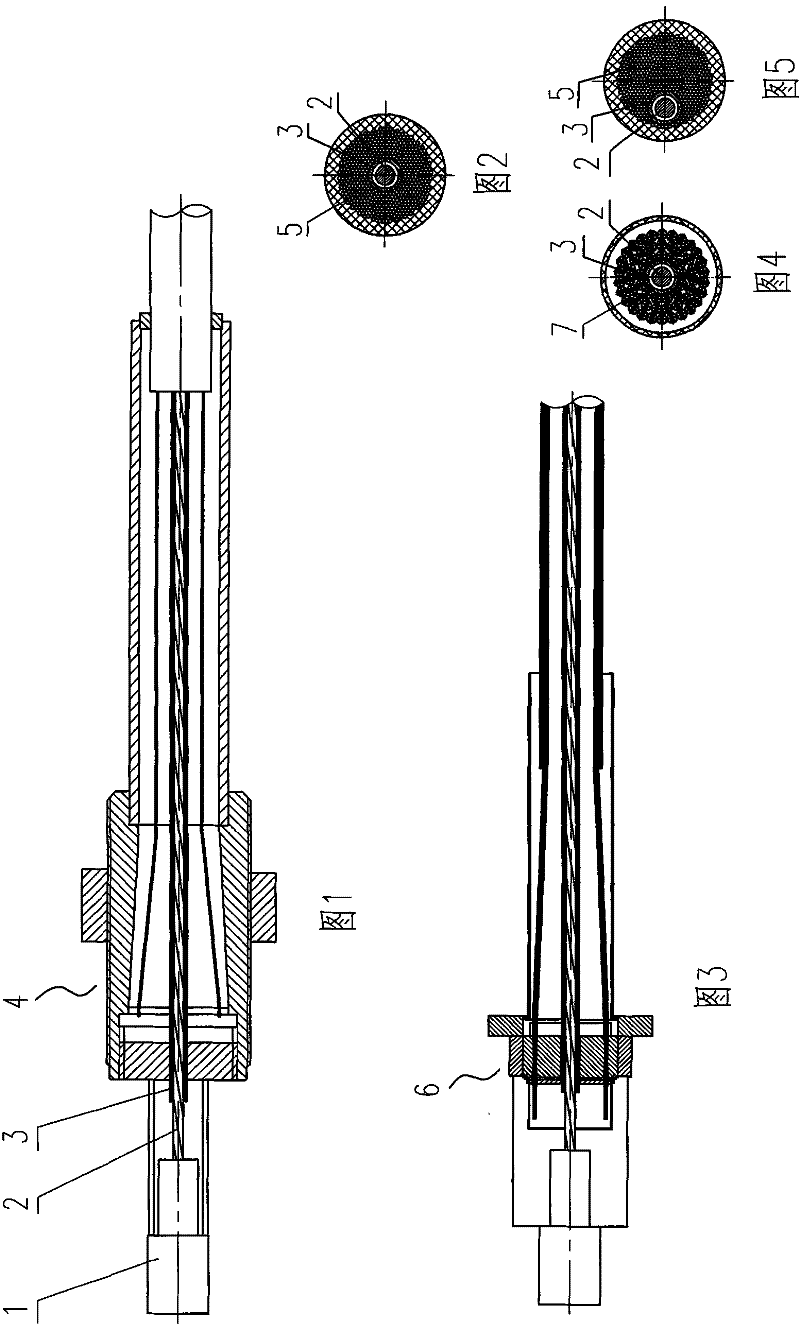

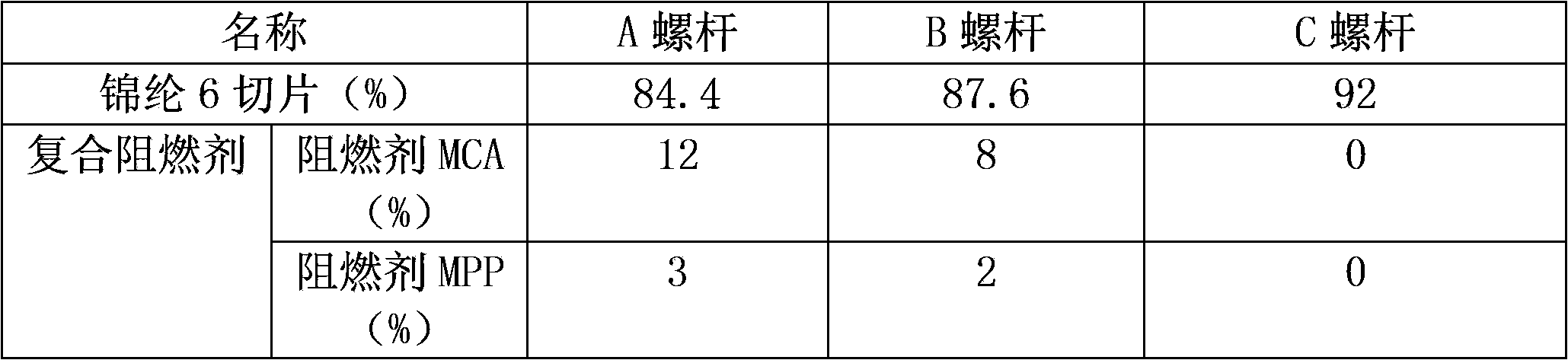

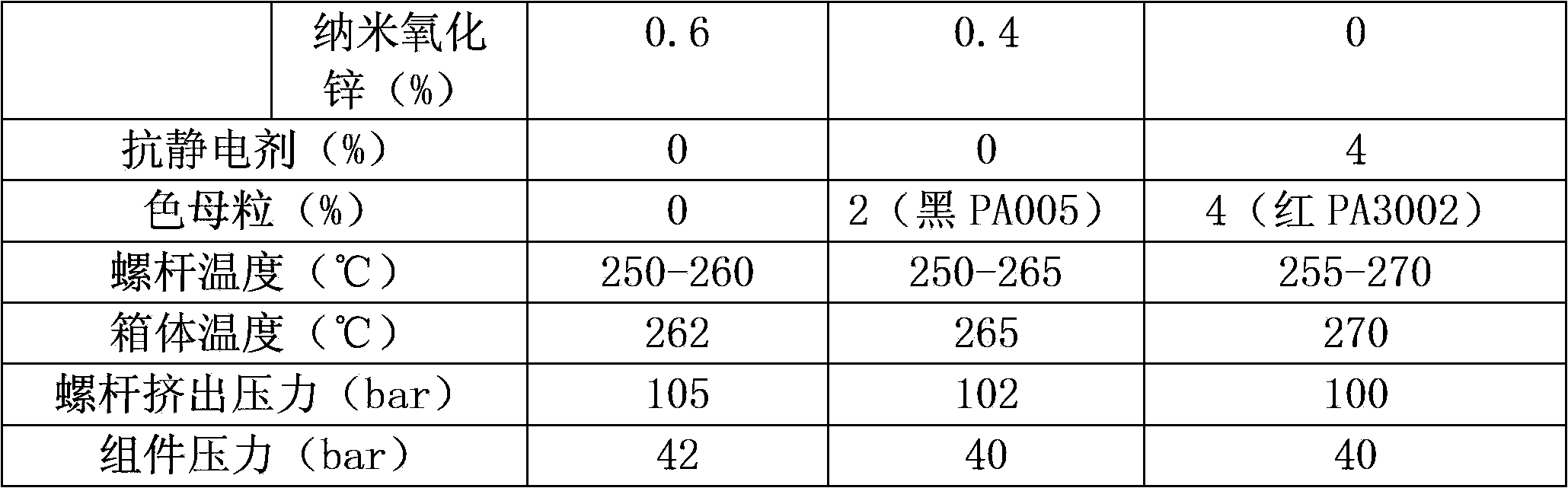

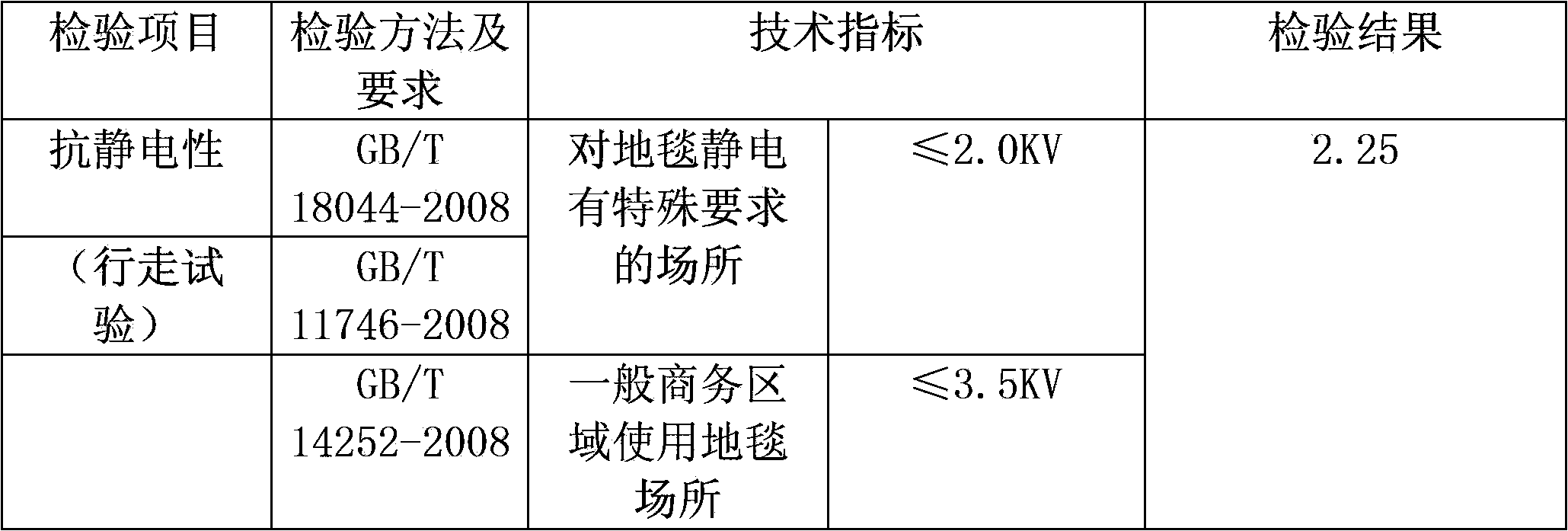

Permanent antistatic flame-retardant polyamide-6 bulked continuous filament textured carpet yarn and preparation method

ActiveCN102660819APermanent antistaticGuaranteed wear resistanceFlame-proof filament manufactureYarnComposite functionPolyamide

The invention relates to a permanent antistatic flame-retardant polyamide-6 bulked continuous filament textured carpet yarn and a preparation method. The permanent antistatic flame-retardant polyamide-6 bulked continuous filament textured carpet yarn comprises a carpet yarn body, wherein the carpet yarn body consists of two tows of flame-retardant polyamide-6 bulked continuous filaments in different colors or the same color and a tow of antistatic polyamide-6 bulked continuous filaments; single fibers in the three tows of polyamide-6 bulked continuous filaments are random three-dimensional crimped fibers; different types of fibers are randomly mixed and intertwined; and periodical net knots are arranged on the surface of the carpet yarn body. The preparation method is implemented by one step through a tri-screw bulked continuous filament (BCF) spinning machine set. The product substantially maintains the characteristics of abrasion resistance, stain resistance, resilience and the like of polyamide-6, and also has a permanent antistatic function and a flame-retardant function. According to the preparation method, the characteristics of a production process of the tri-screw BCF spinning machine set are utilized, so that the aim of spinning the antistatic flame-retardant polyamide-6 textured carpet yarn by one step is fulfilled, and the production process is simple, practical and efficient.

Owner:CHANGZHOU LINGDA SPECIAL FIBER

Sweet peppery taste salted egg and its production method

A salted egg is prepared from eggs of fowls, liquor with high alcohol content, white sugar, hot pepper and flavouring through boiling eggs, adding white sugar and said liquor, loading the eggs and soup in a ceramic container, sealing and preserving.

Owner:TIANJIN CHINESE & BRITISH NANOMETER TECH DEV

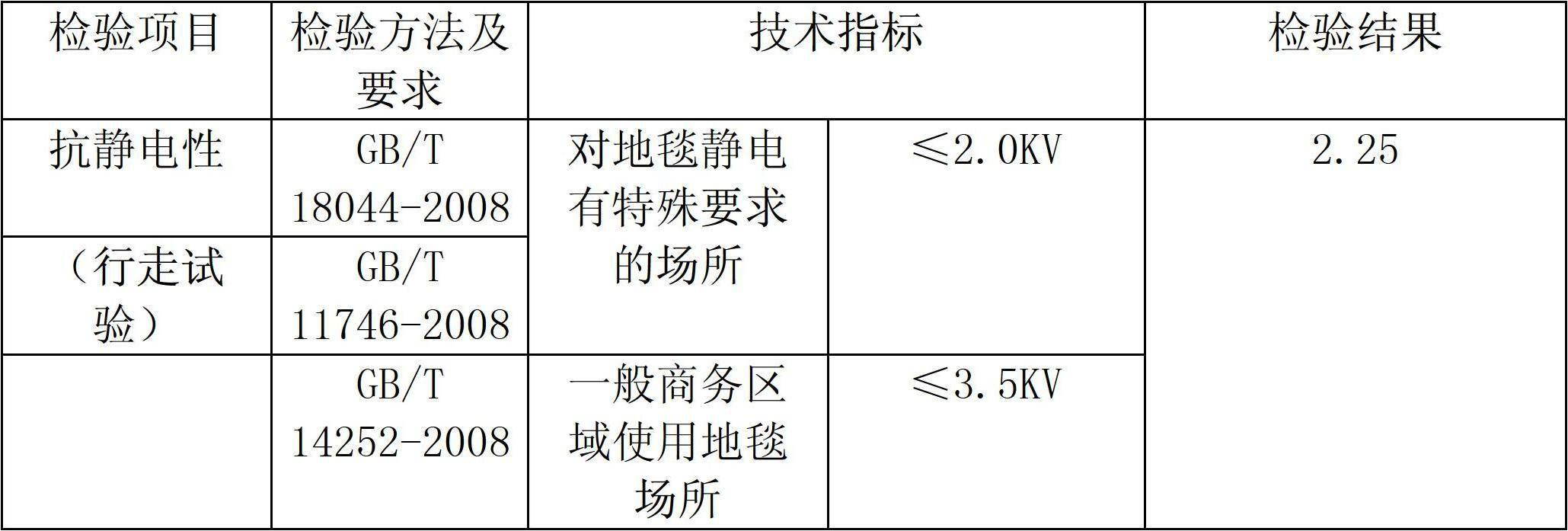

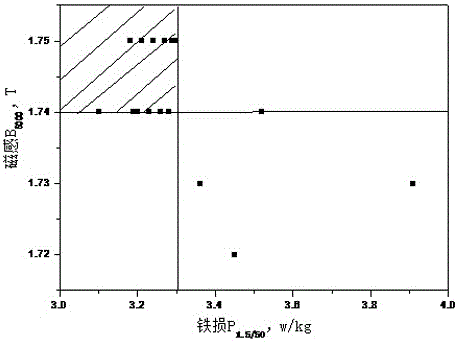

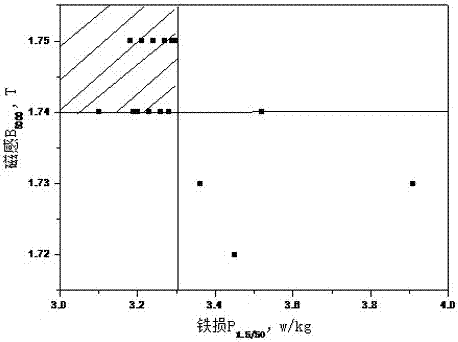

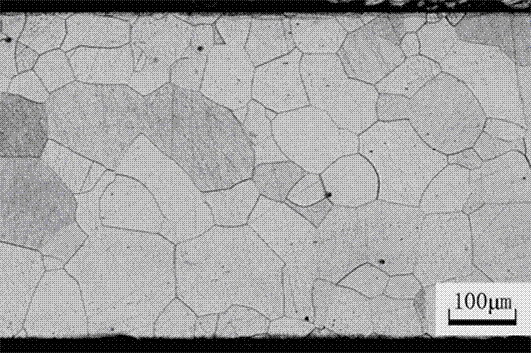

Non-oriented silicon steel for high-power-factor motor and production method

Non-oriented silicon steel for a high-power-factor motor is prepared from, by weight, 0-0.0020% of C, 1.70-1.90% of Si, 0.10-0.20% of Mn, 0-0.05% of P, 0-0.0030% of S, 0.25-0.35% of Al, 0.05-0.50% of Cr and 0-0.0020% of N. A production method includes the steps that pure steel is smelted into ingots; the ingots are heated; hot rolling is conducted; coiling is conducted; normalizing is carried out; acid pickling is conducted; cold rolling is conducted; finished products are annealed at the N2+H2 atmosphere; cooling, coating and finishing are conducted through conventional methods. The thickness of the silicon steel is 0.50 mm, iron loss P1.5 / 50 is smaller than or equal to 3.3 W / kg, and B5000 is larger than or equal to 1.74 T. A motor simulation result shows that the silicon steel can be used for manufacturing the high-power-factor motor, relatively high motor efficiency is obtained, and components are simple.

Owner:武汉钢铁有限公司

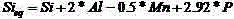

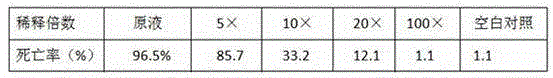

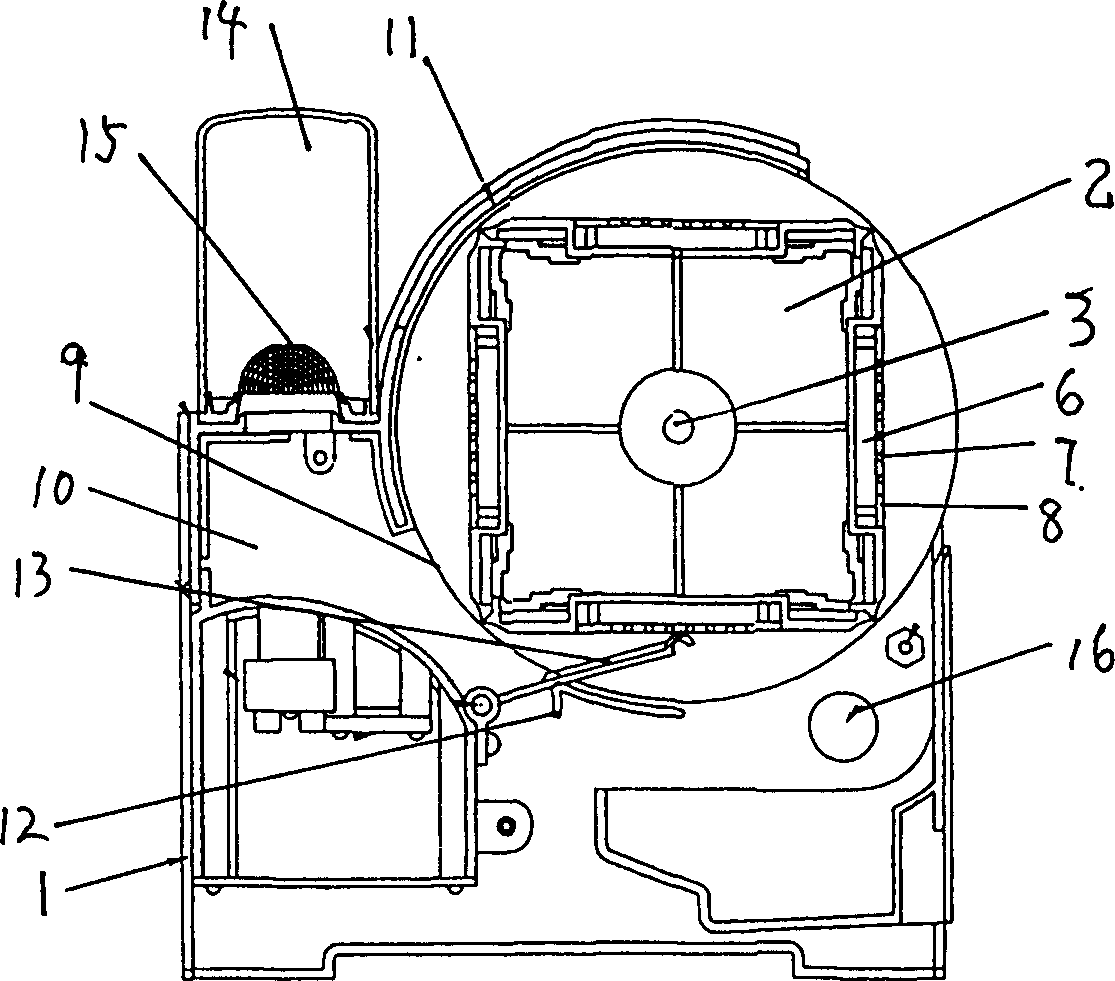

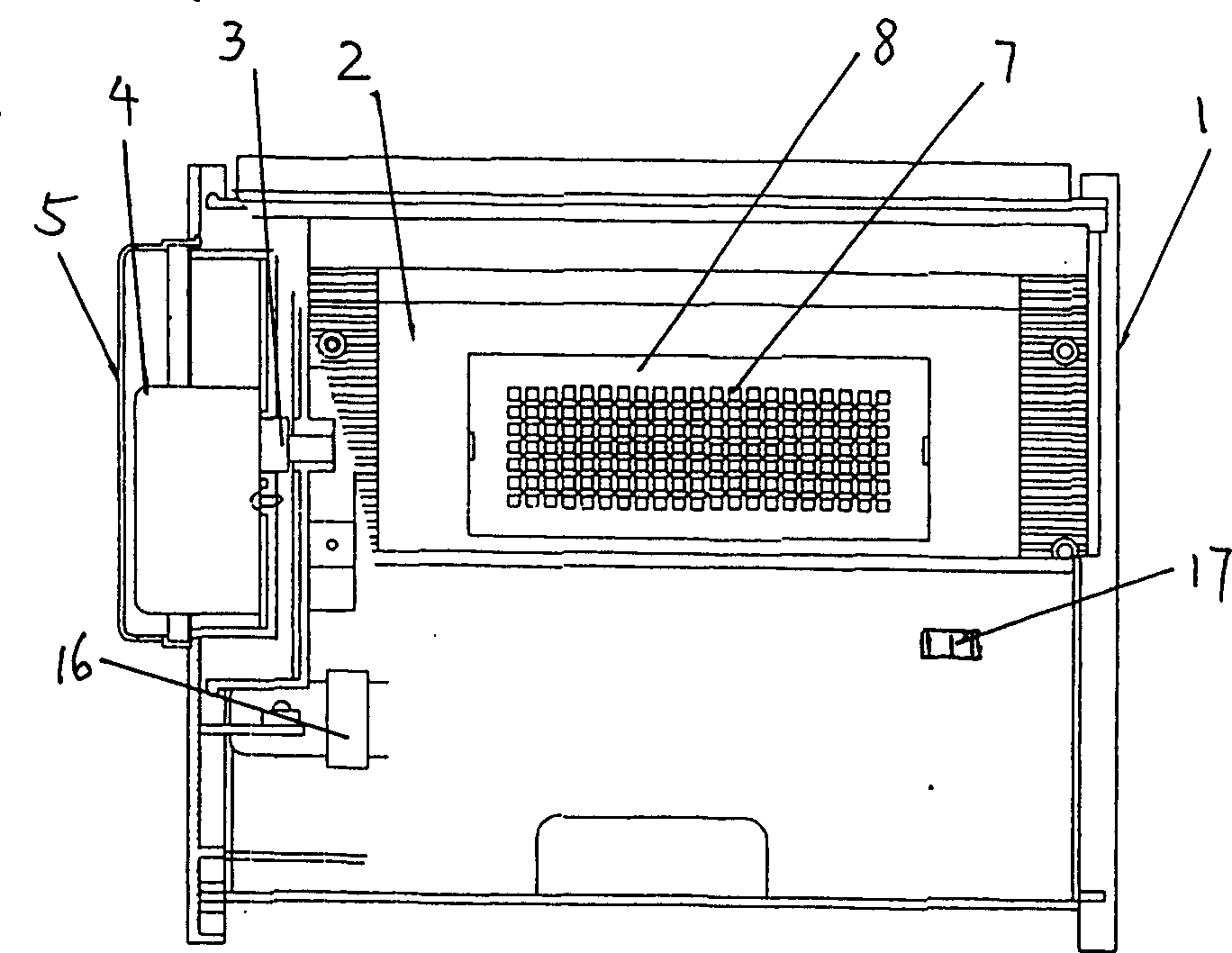

Fly trapping agent and its manufacturing method and fly trapping method and fly catcher

InactiveCN1555706AWide variety of sourcesThe production method is practicalBiocideAnimal repellantsFruit juiceLow speed

A fly attractant is prepared from rice flour, fish, fruit juice, sugar, sodium pyrosulfite and water through parching the rice flour and proportionally and sequentially mixing it with others. A method for attracting fly and appliance for capturing fly are also disclosed. Said fly attractant is put on a drum rotating at low speed. A transparent fly collecting channel can collecting the fly on said drum and send them in a fly collecting box.

Owner:胡锡林

Paper pulp production method by utilizing alternaria tenuis to biodegrade lignin

The invention relates to a paper pulp production method by utilizing alternaria tenuis to biodegrade lignin. Combined with machining, the method comprises steps of: immersing fragmented raw materials into a water tank containing alternaria tenuis bacterial liquid; maintaining a temperature at 30-45 DEG C; and decomposing for 6-48 h. The production process of the invention uses no chemical, generates no pollution, saves water, has low material loss, low energy consumption and a cost only 40% of that of an existing chemical pulping method. The method can be used to produce paper pulp using raw materials of wheat straw, straw, reed, Chinese alpine rush, bagasse, bamboo and timber, etc., and realizes zero discharge of water for paper pulp production. Produced paper pulp has excellent quality and no chemical toxin, and can be used for manufacturing of daily used paper like food package paper and medicine packing paper, etc.; besides the production process has no pollution. The method has high economic benefit and social benefit, and is a high-tech with value for ecological balance.

Owner:张健

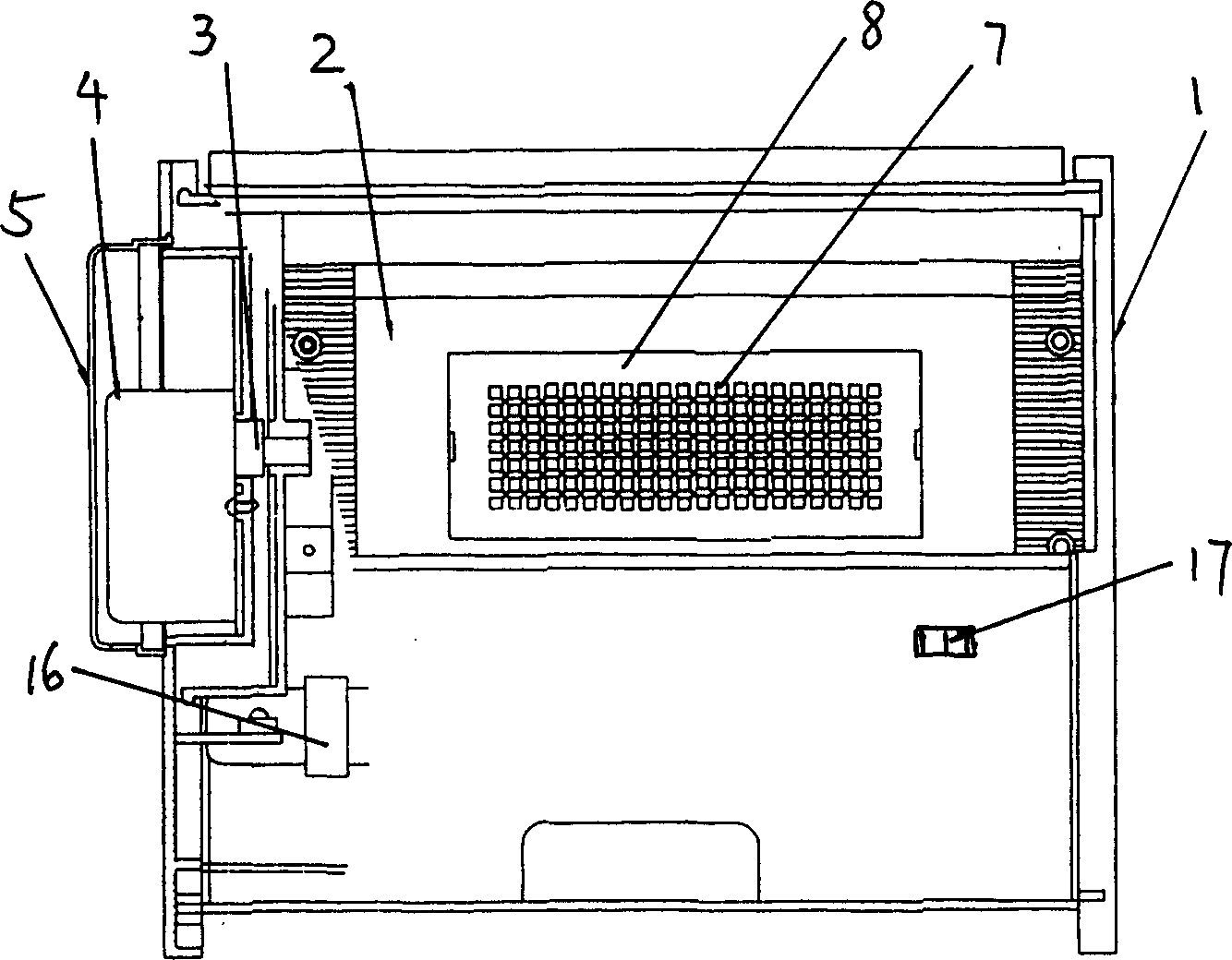

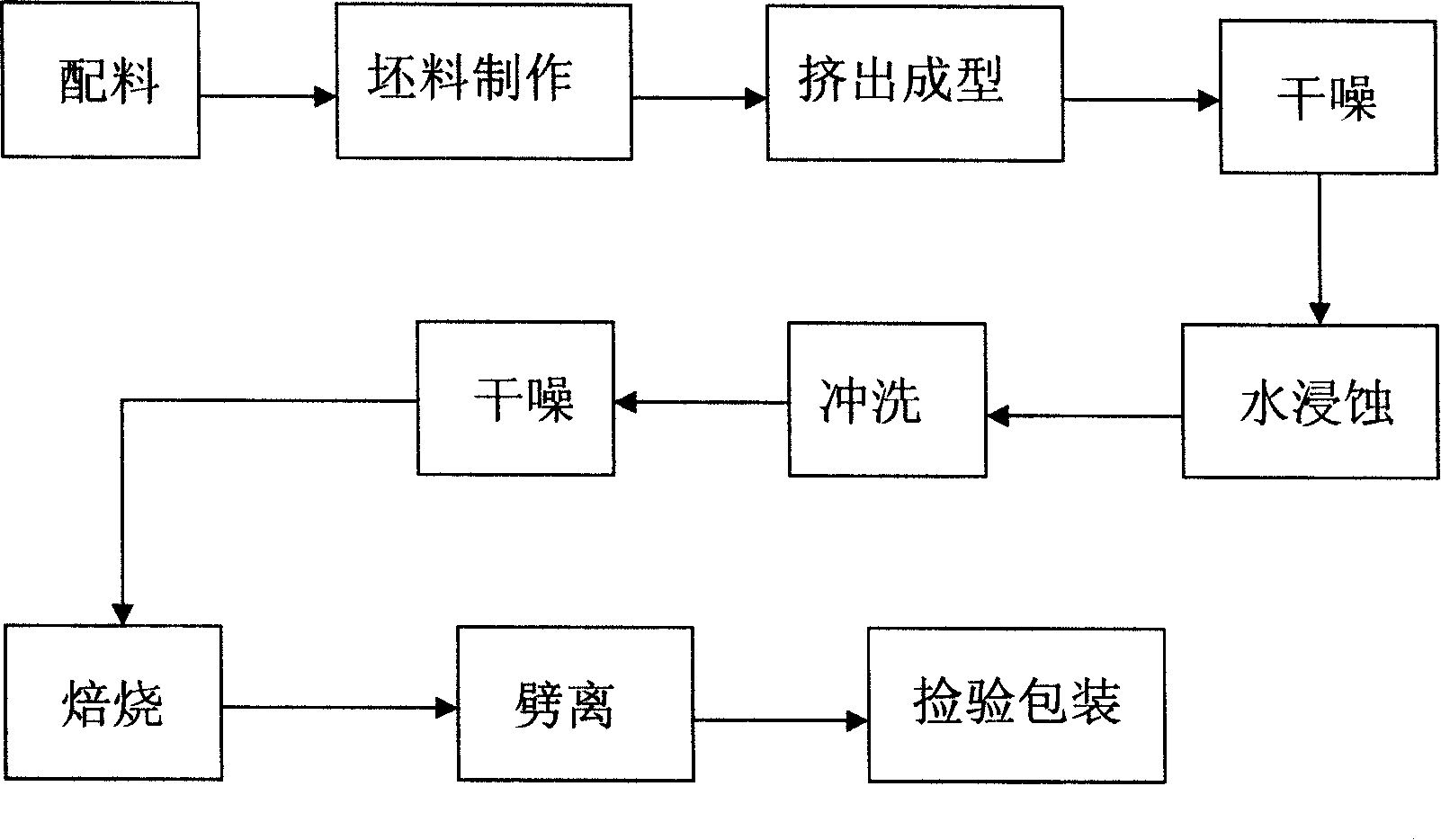

Natural water erosion face ceramic decoration split tile and its production method

InactiveCN101173552AUnique artistic effectSatisfy the pursuit of natureCovering/liningsSidewalk pavingsAdobeBrick

The invention relates to a ceramic decorative detached brick with natural water erosion surface, comprising an adobe made of same or different colored blanks, the brick surface is water erosion surface, namely a plurality of rugged pits or cambered surfaces or natural round pitting surfaces different depth generated due to water immersion and erosion are arranged on the surface of the brick. Compared with the prior detached brick, the production method is characterized in that the water erosion and flushing process are added between the drying process and the calcination process, the drying process is as follow: immersing the dry adobe surface of detached brick under water 1 to 3mm for 1 to 10 minutes, when the immersed part fully softened, washing the brick surface with fresh water, thus a plurality of rugged pits or cambered surfaces or water erosion surfaces with the depth of 0.1 to 3mm are formed on the brick surface, then calcining the adobe after drying. The surface of the brick produced with the method has smooth rugged pits which are similar to the stone surface eroded or flushed by water, and appears the unique artistic effect; furthermore, the brick surface has no scratch; the appearance is beautiful, and the brick body is higher in strength and more corrosion resistant.

Owner:柳州市奋进建筑材料有限责任公司

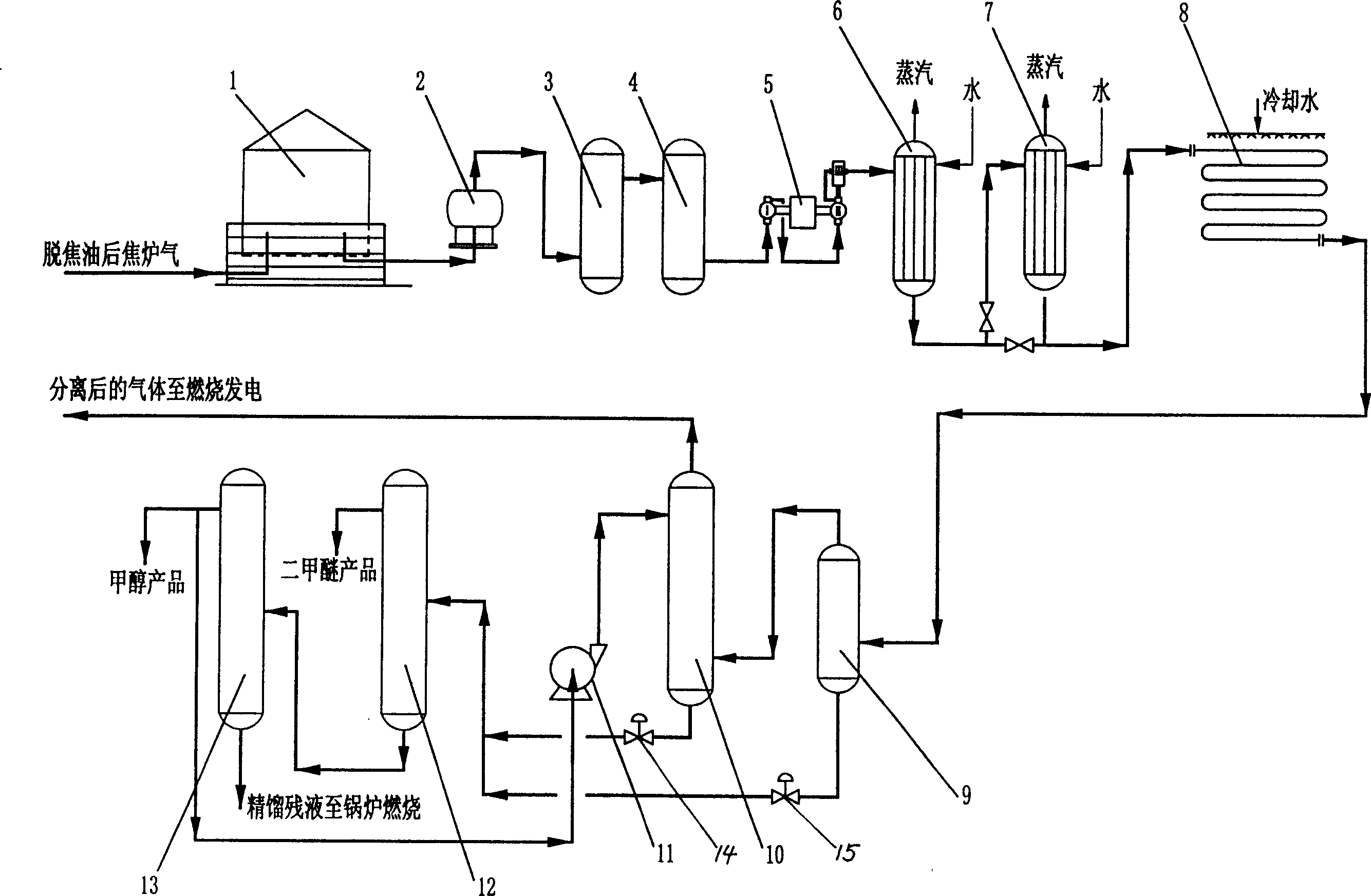

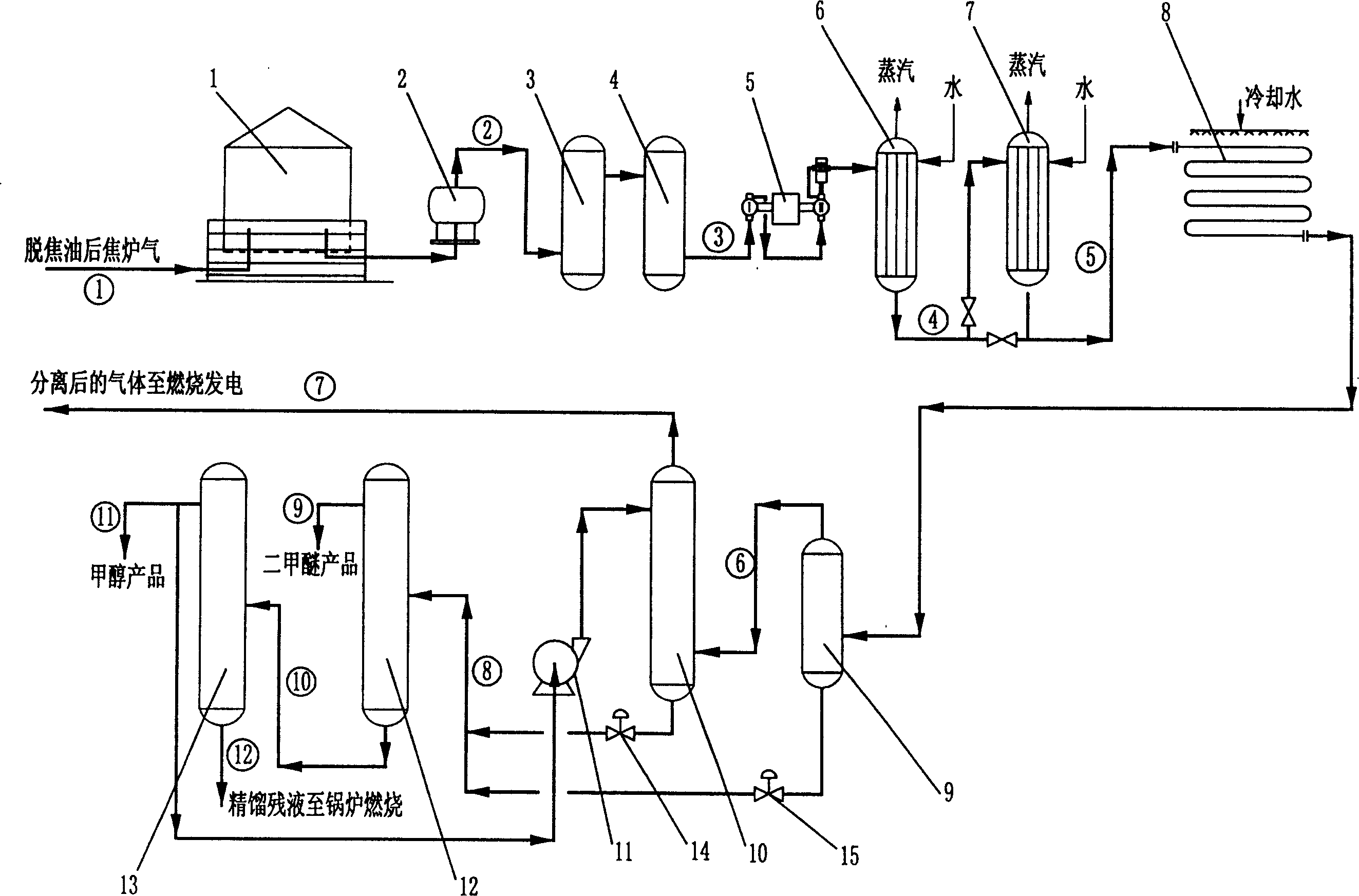

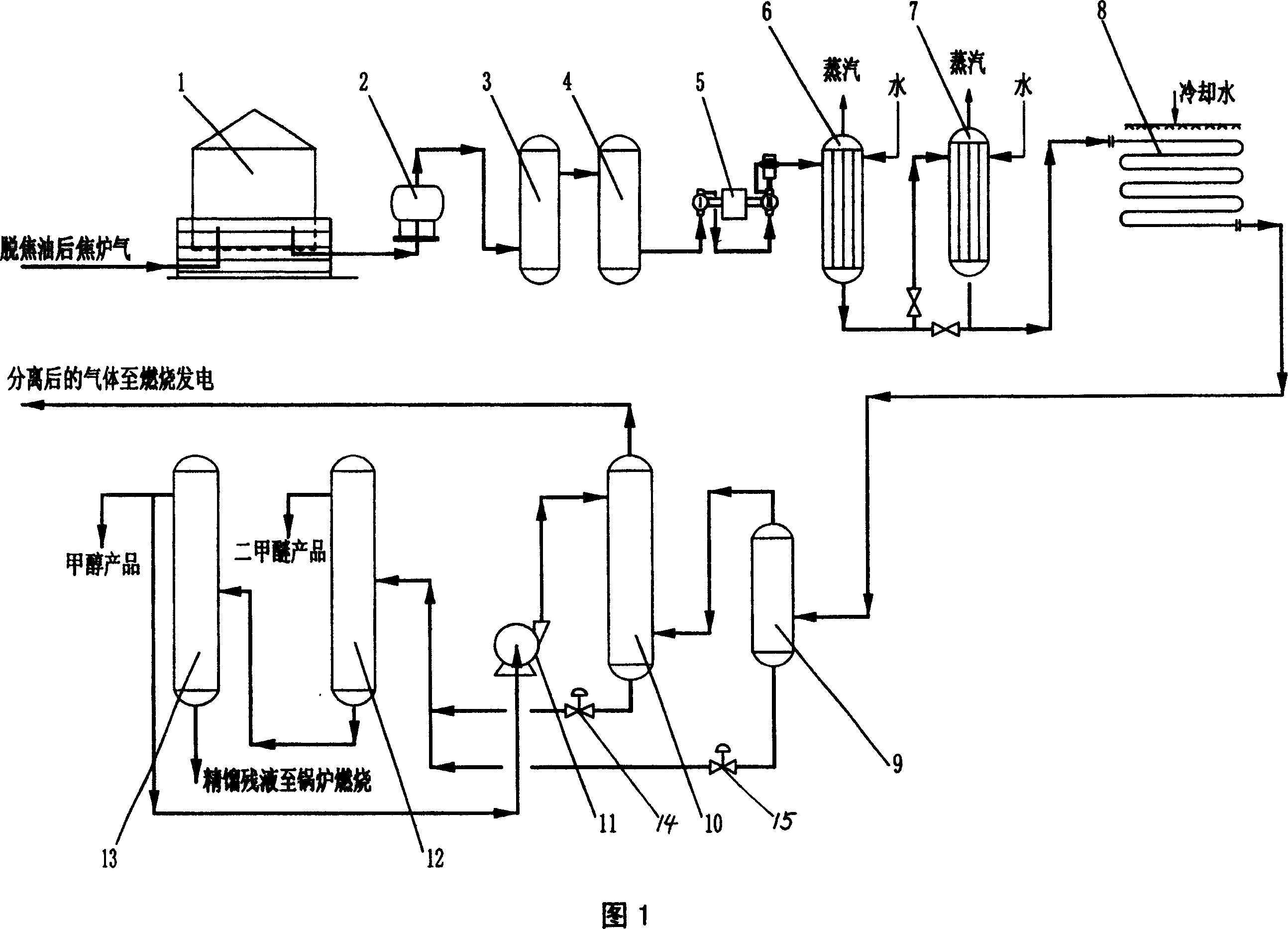

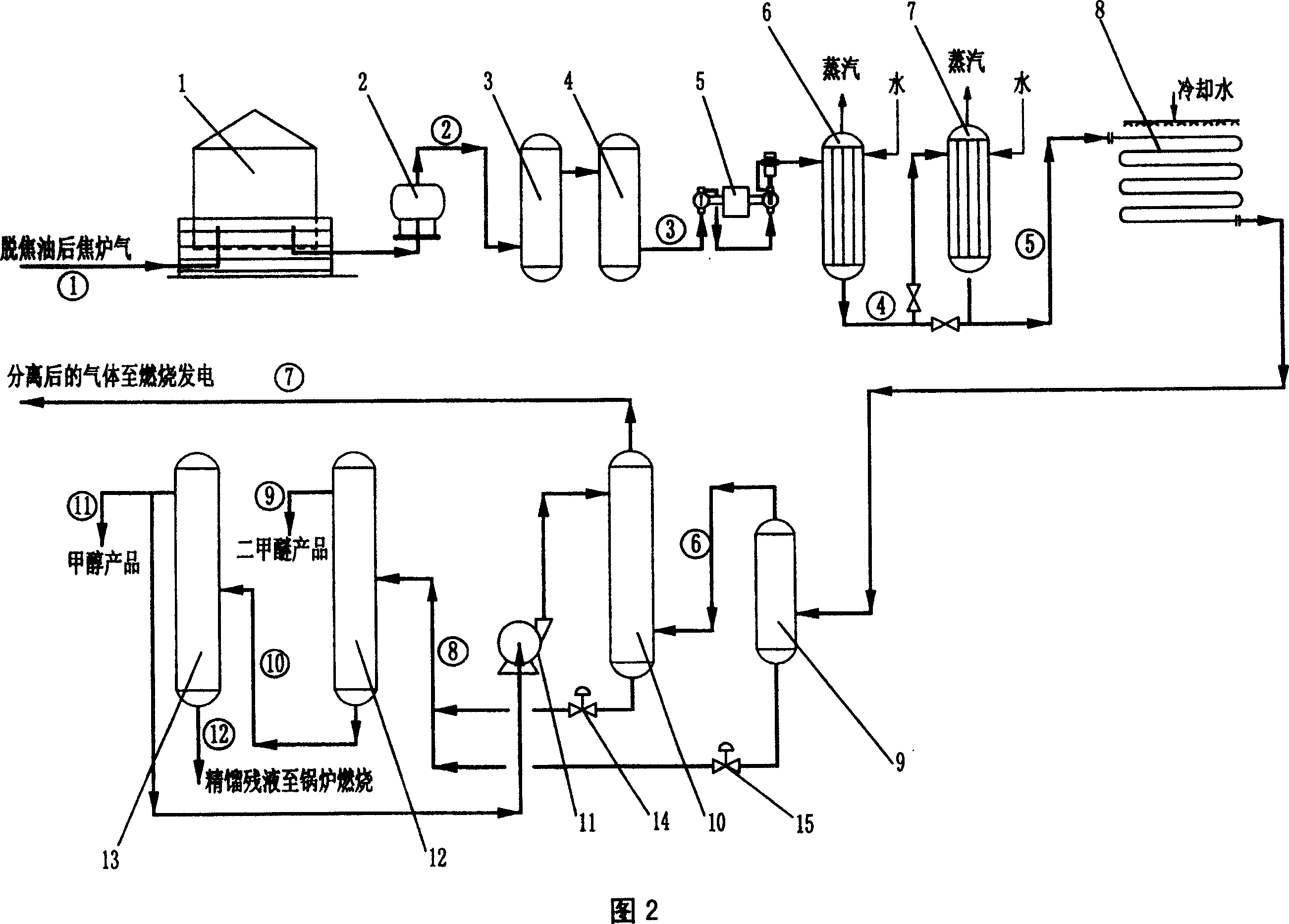

Production method of non-convertible combined methanol and dimethyl ether from coke oven gas

ActiveCN1876614ABroad application spaceAdvanced production methodsEther preparation by compound dehydrationCogenerationPollution

The invention relates the producing method of coking gas non-convertible cogeneration methanol dimethyl ether, solving the problems of high dissipating energy, high cost and low conversion ratio. The method comprises the following steps: making coking gas decoking and desulfurizing, pressurizing them and putting them into converter, synthesizing methanol with copper as accelerating agent, transferring heat, cooling, separating, getting methanol, dimethyl ether and water, putting them into rectifying tower, getting methanol and dimethyl. The method is advanced and simple, and the product can replace diesel fuel, liquefied petroleum gas and Freon. The product is new pattern pollution-free energy and basis chemical engineering material.

Owner:河南广硕化工科技有限公司

Production method of high-alumina mullite cast steel bricks

The invention discloses a production method of high-alumina mullite cast steel brick. The production flow is as follow: purchasing raw materials; crushing and processing the raw materials; preparing; mixing; forming green bricks; drying the green bricks; sintering; inspecting; packaging and putting the bricks into storage. The production method uses high bauxite as the main raw material which is abundant in resource and great in storage, and the high-alumina mullite cast steel bricks are strong in chemical stability and good in physical performance. In addition, the product produced by the method disclosed by the invention has stronger anti-erosion capability and good thermal stability. The production process is simple and convenient to operate and is beneficial to batch production.

Owner:姜斌峰

Indometacin eyedrops

InactiveCN1517089AFormulation scienceSimple production methodOrganic active ingredientsSenses disorderSodium sulfitePolyethylene glycol

An indometacin eyedrops for treating ophthalmopathy including the non-infective inflammation caused by operating is prepared from indometacin, polyethanediol-400, sodium sulfite, borax, boric acid and the water for injection.

Owner:赵珊

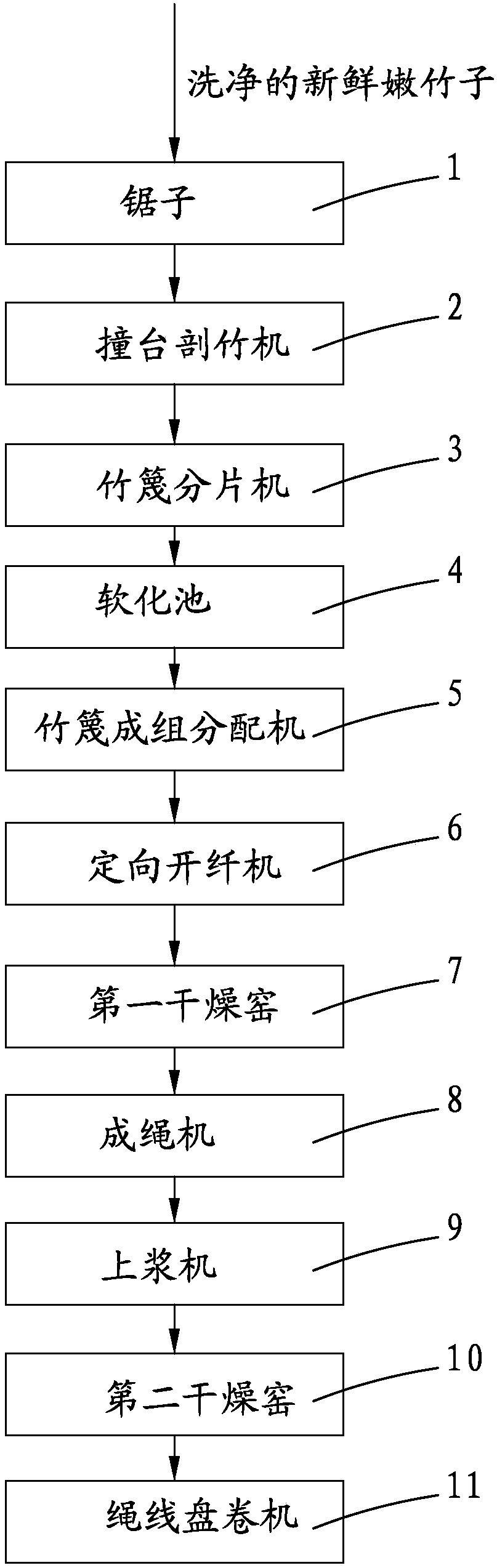

Preparation method and system for bamboo fiber rope

PendingCN109093797AImprove efficiencyIncrease profitWood treatment detailsCane mechanical workingChemistryYarn

The invention provides a preparation method and system for a bamboo fiber rope. The preparation method comprises the following steps that fresh bamboo is taken; branches and bamboo leaves are removed;the bamboo is sawed into bamboo tubes with the fixed length through a disc saw; the bamboo tubes are divided into bamboo chips through a collision table bamboo splitting machine; the bamboo chips aresubjected to bamboo strip dividing treatment through a bamboo strip dividing machine; bamboo strips are placed into a softening pool for to be softened; the softened bamboo strips ae combined and stacked through a bamboo strip group allocation machine; splitting is conducted through a directional splitting machine, and ramie-strip-shaped bamboo fibers are obtained; the ramie-strip-shaped bamboo fibers are pre-dried in a drying kiln; the pre-dried ramie-strip-shaped bamboo fibers are twisted into a rope through a rope forming machine; then slurry coating treatment is conducted through a sizingmachine; then bamboo fiber rope yarn is dried through the drying kiln; and finally, the bamboo fiber rope yarn is rolled through a rope yarn rolling machine to obtain the e bamboo fiber rope yarn. The unique process combination is adopted, the original ecological bamboo fiber rope yarn can be manufactured, and the obtained bamboo fiber rope yarn is basically uniform in evenness, high in strength,good in rigidity, good in antimicrobial property and breathability, high in instantaneous water absorption property, and good in elastic elongation performance.

Owner:JIYANG COLLEGE OF ZHEJIANG A & F UNIV

Paper pulp production method by soft rot fungus biodegradation of lignin

InactiveCN102517950AReduce lossImprove qualityPaper recyclingWaste paper working-upWater savingSocial benefits

The invention relates to a paper pulp production method by soft rot fungus biodegradation of lignin. With the combination of machining, crushed raw materials are immersed in water tank filled with a soft rot fungus liquid for biodegradation. The biodegradation is carried out at the temperature of 30-45 DEG C for 6-48 hours. According to the method, no chemicals are used in the production process. The method provided by the invention has advantages of no pollution, water saving, little material loss and low energy consumption. The cost by the method is only 40% of that by a conventional chemical method for pulping. Wheat straw, straw, reed, Eulaliopsis binata, tobacco rod, bagasse, bamboo, timber and the like are used as raw materials for paper pulp production. In addition, zero discharge of water for paper pulp production is realized. The paper pulp produced by the method is excellent in quality, contains no chemical toxicant, can be used to produce daily paper such as food packing paper, medical packing paper and the like. In addition, there is no pollution during the production process. The method provided by the invention has very high economic benefits and social benefits and is an ecological balanced high-tech value-promotion technology.

Owner:张健

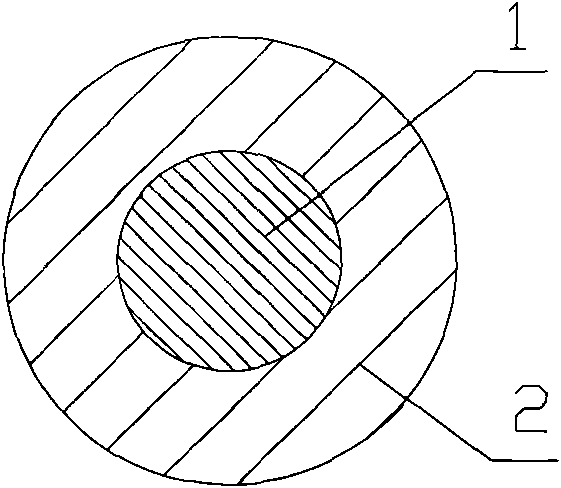

Conductive terylene short fiber production technology

InactiveCN101265619APhysicochemically stableStable chemical propertiesElectroconductive/antistatic filament manufactureFilament/thread formingFiberYarn

The invention provides a conductive terylene short fiber production technique, which is characterized in that the skin component is PET, the core component is PET with 10-25% carbon soot nanometer particles; in the production process, the two skin and core components respectively adopt different screws which carry out fusion and extrusion and then are injected into the composite with skin and core structure in an accurate frequency conversion timing manner, and then carry out working procedures such as spinning, winding, severing, packing and so on as the routing of chip spinning; at last, the conductive terylene short fiber of the invention is obtained. Adding 0.6% conductive fiber in antistatic blended yarn can permanently remove the static electrification. The laundry resistance is higher than 200 times.

Owner:CHANGSHU FEITENG CHEM FIBER

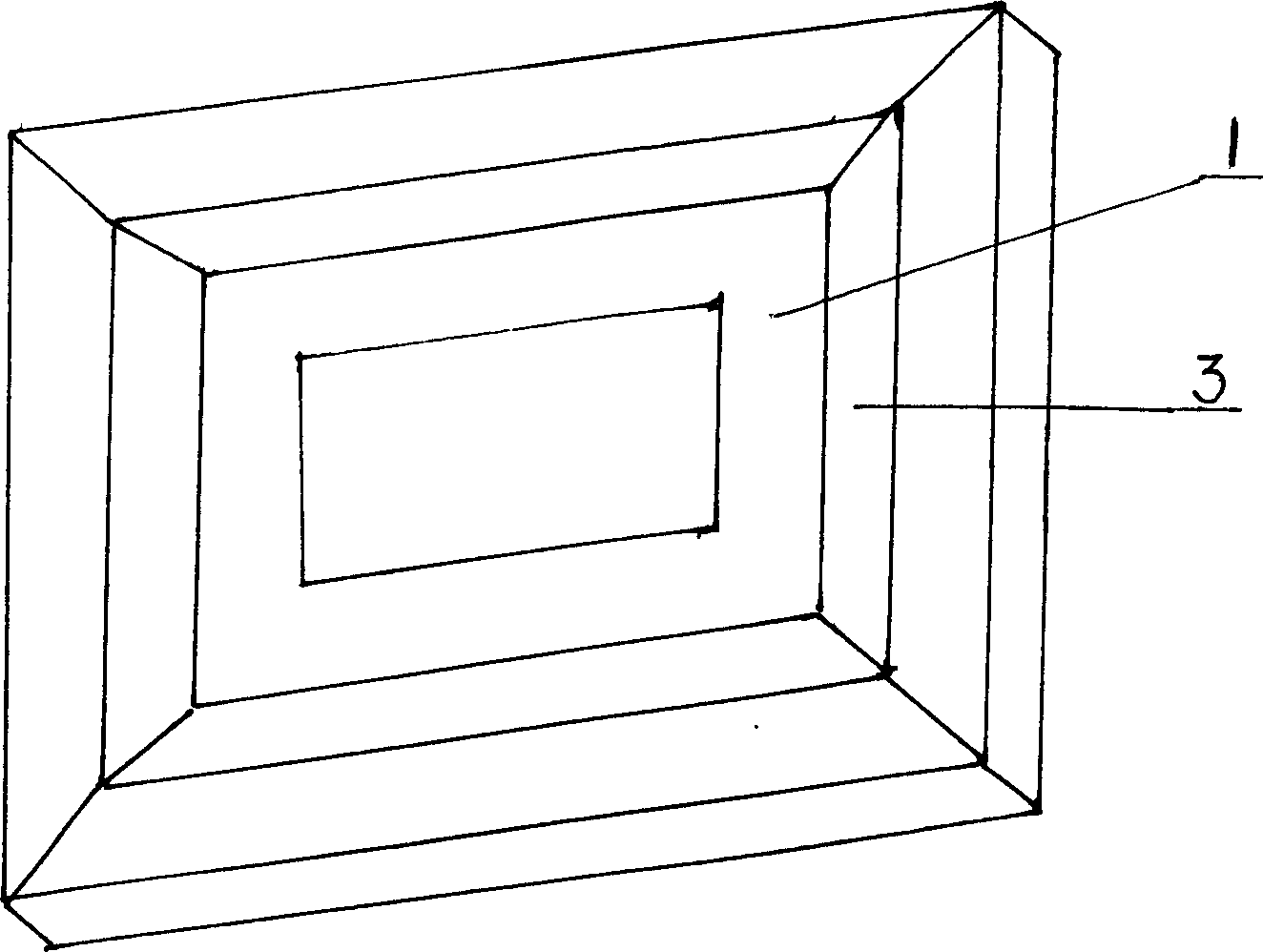

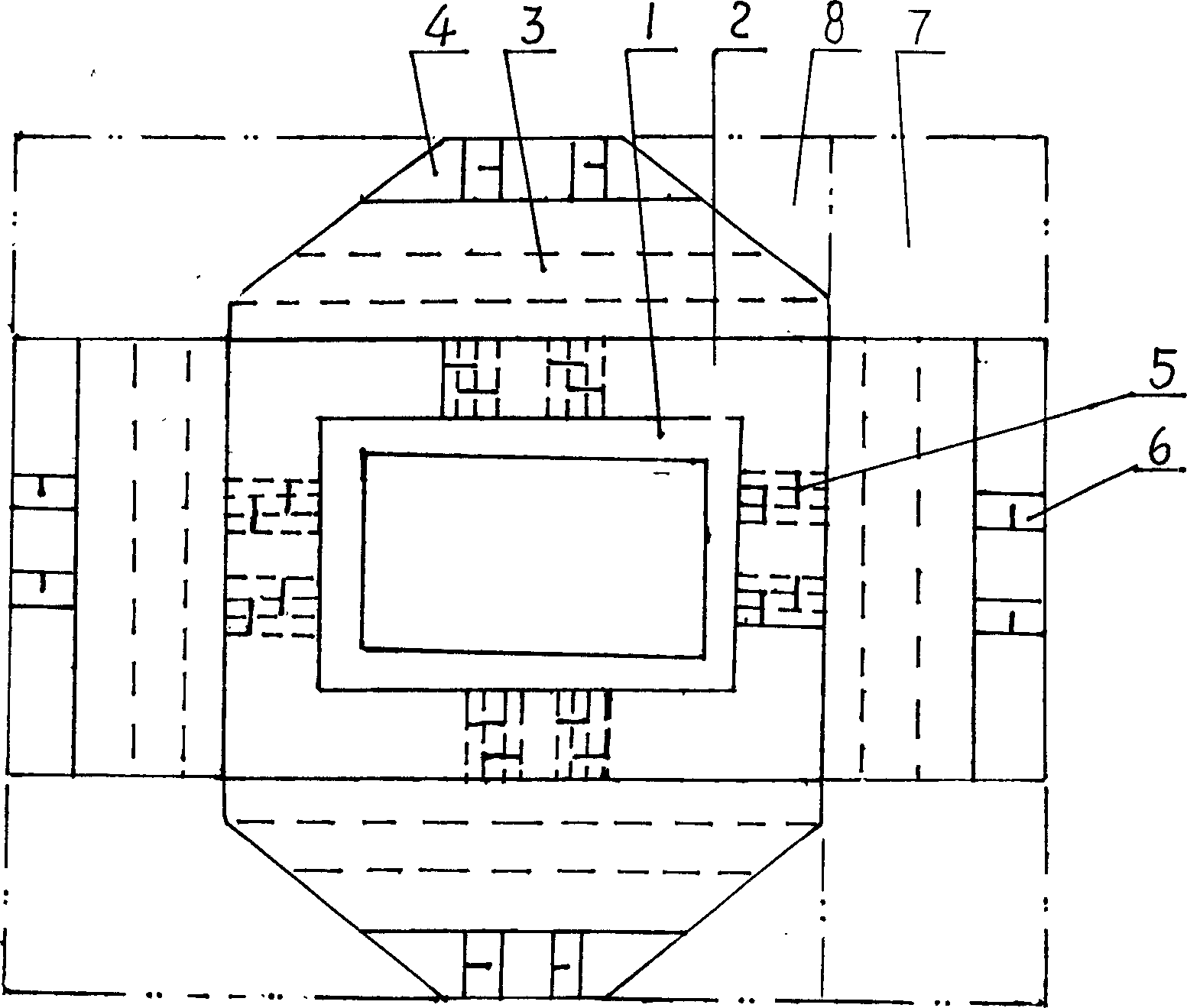

Method for making convenient self-back-up frame

The picture frame making process features the paper-like material. The picture frame has preserved part for picture in the middle part and three peripheral areas including inserting hole area, folding area and inserting tongue area in the peripheral. Via folding the folding area inwards and inserting the inserting tongues into the inserting holes, the picture frame is produced. The present invention makes the frame and the picture form one integral, and when the picture is mounted, it may be rolled. The present invention has convenient storage and transportation, easy hanging and low mounting cost.

Owner:谢世平

Formula and extraction process of composite natural purple pigment

The invention discloses a formula of a composite natural purple pigment. The composite natural purple pigment is prepared from 250 g of beetroot, 25 g of clitoria ternatea flowers, 25 g of peeled lemons and 1,500 g of water. An extraction process comprises the following steps that the beetroot is washed to completely remove sand, peeling is not needed, the air-dried beetroot and peeled lemons arejuiced and filtered by a 100-mesh fine sieve, then a mixture is put into a pot to be boiled with a big fire and then concentrated with a small fire to the weight required by the formula, and after natural precipitation, an uppermost pure part is taken for use; fresh red-pulp dragon fruits are peeled, diced, juiced and then filtered by the 100-mesh fine sieve, a filter residue is put into the pot to be boiled with a big fire and then concentrated with a small fire to the weight required by the formula, and after natural precipitation, an uppermost pure part is taken for use; water which is 20 times the weight of the clitoria ternatea flowers is added to the clitoria ternatea flowers, after a clitoria ternatea flower liquid is boiled with a big fire, cooking is conducted with a small fire for 10 minutes, sieving is conducted after braising is conducted for 20 minutes, the clitoria ternatea flower liquid continues to be cooked to 1 / 3 of the original volume with a big fire and then is cooked to be in a thick state with a small fire, finally, natural precipitation is conducted for at least 60 minutes, and an upper pure part is taken for use; the extracted beetroot red pigment and clitoria ternatea flower blue pigment (a combination of red-pulp dragon fruit red and clitoria ternatea flower blue) are uniformly mixed and loaded into a sterilized dark essential oil bottle, and the purple natural pigment is formed.

Owner:匠人之心(北京)食品有限公司

Hair painting manufacturing method

InactiveCN103395336AEasy to prepareThe production method is practicalSpecial artistic techniquesEngineeringCorrosion prevention

The invention discloses a hair painting manufacturing method. According to the specific technical scheme, the hair painting manufacturing method includes the first step of collecting hair, the second step of conducting disinfection, cleaning, corrosion prevention processing and drying, the third step of preparing method, namely, manufacturing the required hair into powder and hair with different lengths through professional tools and dyeing the hair, the fourth step of preparing an on-spot sketching script or a picture and preparing a base plate, the fifth step of brushing dedicated glue onto portions which need to be expressed on the base plate and spraying and placing the hair powder to the face of a painting through a screen, the sixth step of conducting reinforcing and forming through painting fixing agents so that the hair powder and the hair with the different lengths can not fall, and the seventh step of arranging a liner plate or an outer frame as required. The manufacturing method is simple and practical, a craft picture manufactured through the hair painting manufacturing method is vivid and expressive, and the hair painting manufacturing method is of great artistic value and deserves popularization and application.

Owner:王前明

Production method of non-convertible combined methanol and dimethyl ether from coke oven gas

ActiveCN1331832CBroad application spaceAdvanced production methodsOrganic compound preparationHydroxy compound preparationFree energiesCogeneration

The invention relates the producing method of coking gas non-convertible cogeneration methanol dimethyl ether, solving the problems of high dissipating energy, high cost and low conversion ratio. The method comprises the following steps: making coking gas decoking and desulfurizing, pressurizing them and putting them into converter, synthesizing methanol with copper as accelerating agent, transferring heat, cooling, separating, getting methanol, dimethyl ether and water, putting them into rectifying tower, getting methanol and dimethyl. The method is advanced and simple, and the product can replace diesel fuel, liquefied petroleum gas and Freon. The product is new pattern pollution-free energy and basis chemical engineering material.

Owner:河南广硕化工科技有限公司

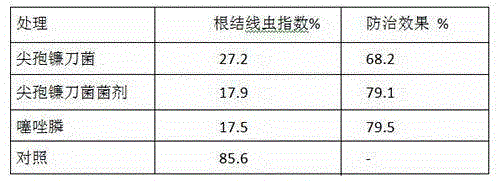

Preparation method and applications of fusarium oxysporum inoculant

The invention discloses a preparation method and applications of a fusarium oxysporum inoculant. The inoculant is prepared by the following steps: taking fusarium oxysporum as the mother inoculant, inoculating a fermentation liquid containing fusarium oxysporum to a solid culture medium to carry out solid fermentation, and fully and evenly mixing the fermentation products with diatomite and fosthiazate particles so as to obtain the inoculant. The inoculant has the advantages that: fusarium oxysporum can colonize in plants, but does not cause diseases, is an internal bio-control bacterium, and has a unique advantage on preventing and treating root-knot nematode; furthermore, because of the endoparasitism characteristic, fusarium oxysporum is seldom affected by competitions from other external micro-organisms, thus the preventive effect can be stably exerted; fusarium oxysporum can be directly used to prevent and treat root-knot nematode and cooperatively used with fosthiazate, can effectively control the harms caused by root-knot nematode, at the same time prominently reduces the usage amount of fosthiazate, promotes the crop growth, and realizes high yield, safe, and harmless vegetable production.

Owner:INST OF VEGETABLE & FLOWERS CHINESE ACAD OF AGRI SCI

A kind of non-oriented silicon steel for high power factor motor and its production method

Non-oriented silicon steel for a high-power-factor motor is prepared from, by weight, 0-0.0020% of C, 1.70-1.90% of Si, 0.10-0.20% of Mn, 0-0.05% of P, 0-0.0030% of S, 0.25-0.35% of Al, 0.05-0.50% of Cr and 0-0.0020% of N. A production method includes the steps that pure steel is smelted into ingots; the ingots are heated; hot rolling is conducted; coiling is conducted; normalizing is carried out; acid pickling is conducted; cold rolling is conducted; finished products are annealed at the N2+H2 atmosphere; cooling, coating and finishing are conducted through conventional methods. The thickness of the silicon steel is 0.50 mm, iron loss P1.5 / 50 is smaller than or equal to 3.3 W / kg, and B5000 is larger than or equal to 1.74 T. A motor simulation result shows that the silicon steel can be used for manufacturing the high-power-factor motor, relatively high motor efficiency is obtained, and components are simple.

Owner:武汉钢铁有限公司

Fly trapping agent and its manufacturing method and fly trapping method and fly catcher

InactiveCN1268210CWide variety of sourcesThe production method is practicalBiocideAnimal repellantsFruit juiceLow speed

A fly attractant is prepared from rice flour, fish, fruit juice, sugar, sodium pyrosulfite and water through parching the rice flour and proportionally and sequentially mixing it with others. A method for attracting fly and appliance for capturing fly are also disclosed. Said fly attractant is put on a drum rotating at low speed. A transparent fly collecting channel can collecting the fly on said drum and send them in a fly collecting box.

Owner:胡锡林

Luminous reflective concrete floor tile and its producing method

The production process of luminous reflective concrete floor tile includes making base layer of common concrete material including cement, sand and stone, concrete additive and water, and through mixing, molding and vibrating; mixing the luminous reflective layer materials including cement, graded glass beads, luminous powder, color powder, concrete additive, dispersive glue powder and water via stirring; pouring the mixture on the freshly formed base layer; vibrating to densify and combine the base layer and the luminous reflective layer; demolding and curing. The luminous reflective concrete floor tile may be produced in plant or in site, and may be used widely in expressway, highway, sports ground, warehouse, building and other places needing luminous or fluorescent indication and warning.

Owner:潘英豪

Processing method of Chinese herbal medicine health tea

InactiveCN101336704BDoes not affect formDoes not affect colorPre-extraction tea treatmentFood preparationUltrafiltrationChinese drug

A processing method for Chinese medicine health tea, is that the health Chinese herbal medicine is prepared into the concentrated Chinese herbal medicine extract or discolored concentrated Chinese herbal medicine extract, which is sprayed into tea in a spraying way. The process includes: preparing the concentrated Chinese herbal medicine extract; spraying and drying first; spraying the concentrated Chinese herbal medicine extract into tea in different proportions for one to five times in the spraying way, spraying every time and first drying every time, and first drying tea with the concentrated Chinese herbal medicine extract by a drying device at different temperature respectively; drying again and perfuming, namely, adding the tea with the Chinese herbal medicine extract after sprayed and dried first into a baking cage to be dried again and perfumed; packing and storing. The preparation of the discolored concentrated Chinese herbal medicine extract includes: pulverizing the health Chinese medicine components, soaking in water, then extracting by a diacolation or microwave extracting process, concentrating and separating by a refrigeration or ultrafiltration concentrating technic. The Chinese medicine health tea having the original shape and color of tea, and a certain health care effect, is prepared by the process.

Owner:邓智深

Production method for preparing highland barley bran and potentilla anserina jelly rich in beta-glucan

The invention relates to a production method for preparing highland barley bran and potentilla anserina jelly rich in beta-glucan. The highland barley bran and potentilla anserina jelly is prepared through the following production technologies of firstly, preparing materials, preparing mixed powder, preparing an enzymolysis saccharification solution, adding ingredients to highland barley bran andthe potentilla anserina enzymolysis saccharification solution, performing stirring, performing dissolving, performing cooling to obtain a mixture, and fishing out a jelly box. According to the production method, the highland barley bran and the potentilla anserina are adopted for processing and making the jelly, so that the mouth feel of conventional jelly is achieved; and nutrients of the highland barley bran and the potentilla anserina are added, so that the jelly is rich in beta-glucan, the varieties are increased, and the flavor is improved. The production method is reasonable and practical, simple to operate, good in effect, and favorable for extensive popularization.

Owner:青海金祥生物科技发展有限责任公司

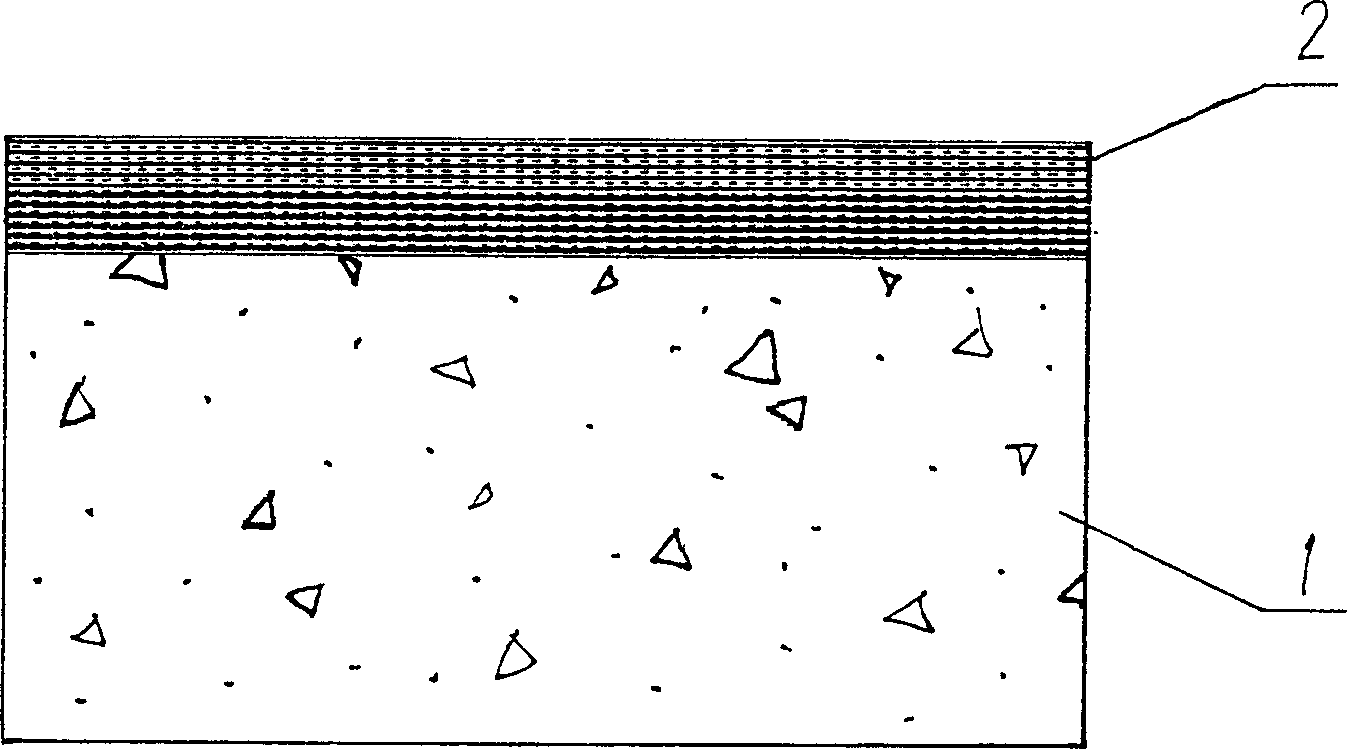

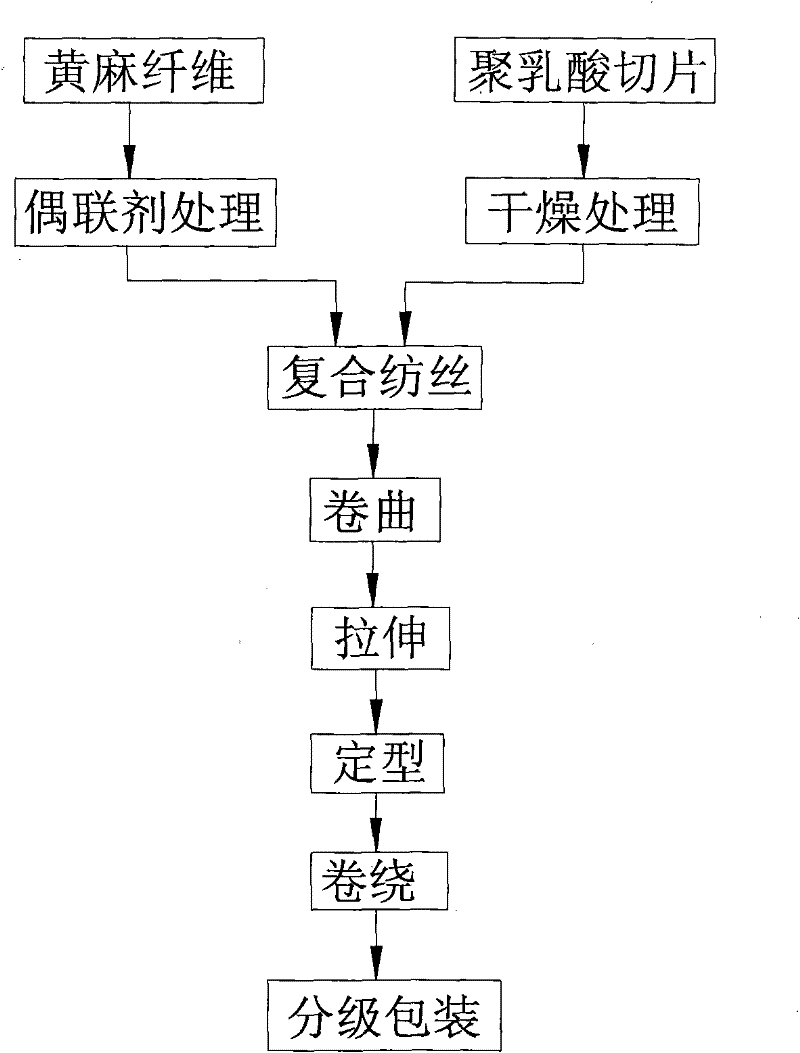

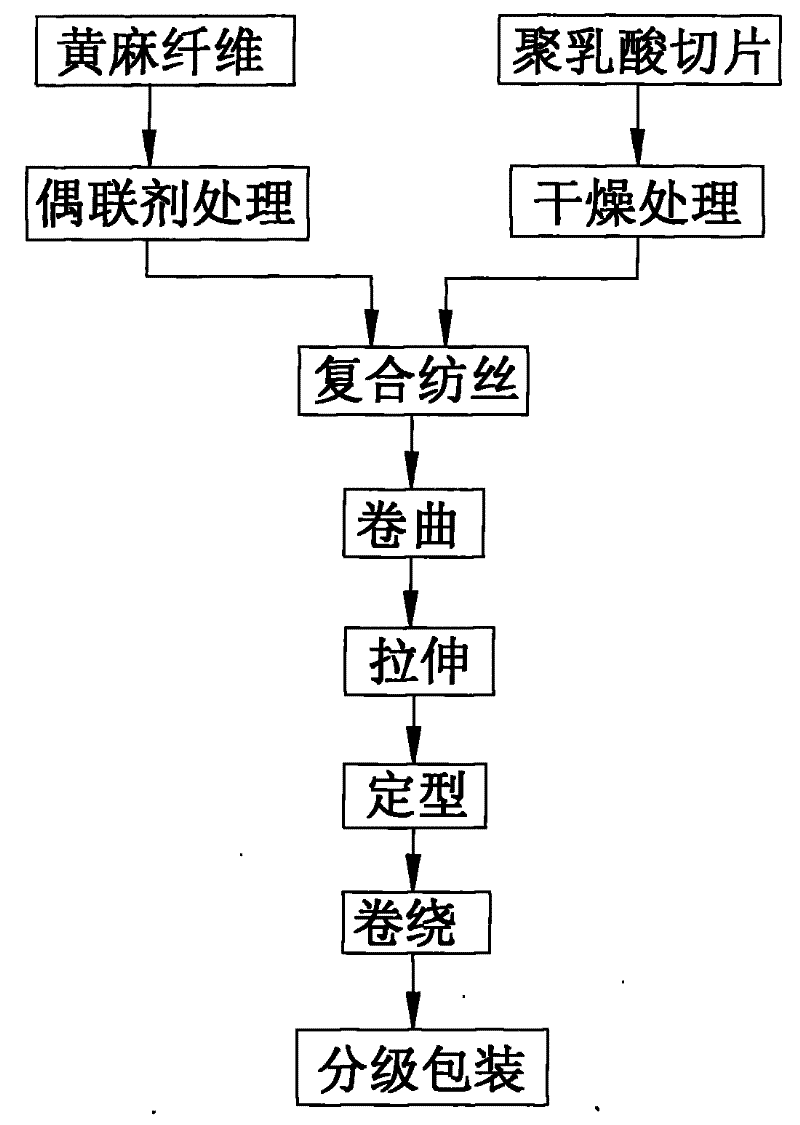

Manufacturing method of sheath-core fibrilia

ActiveCN101671866BGood touchMeet fiber requirementsConjugated cellulose/protein artificial filamentsFilament/thread formingFiberPolylactic acid

The invention provides a manufacturing method of an environment-friendly sheath-core fibrilia with nice feeling. The sheath-core fibrilia comprises a core layer of fibrilia, wherein the fibrilia is treated with silane coupling agent and the external of fibrilia is covered with a layer of polylactic acid. The manufacturing method thereof comprises the steps of: A) cutting the polylactic acid into pieces and drying, dipping the fibrilia into silane coupling agent and then drying, B) conjugating spinning the polylactic acid pieces and the dried fibrilia from the step A) with a conjugating spinning machine to make into sheath-core conjugating spinning component, C) orderly winding, drawing and forming the sheath-core conjugating spinning component to make into sheath-core fibrilia, D) orderly winding and packaging the sheath-core fibrilia. The sheath-core fibrilia of the invention is environment-friendly and has a nice feeling, meeting the demand of people on fiber. The manufacturing method thereof is simple, useful and highly efficient.

Owner:CHERY COMML VEHICLE ANHUI

Traditional Chinese medicine mask for skin firming and wrinkle removal and preparation method thereof

InactiveCN104257579AAvoid slackIncrease elasticityCosmetic preparationsToilet preparationsSide effectSkin elasticity

The invention discloses a traditional Chinese medicine mask for skin firming and wrinkle removal and a preparation method thereof. The traditional Chinese medicine mask is prepared from the following raw materials in parts by weight: 5-15g of Chinese ginseng, 5-10g of saffron crocus, 10-25g of angelica sinensis, 8-15g of atractylodes macrocephala rhizome, 10-20g of glycyrrhiza uralensis, 5-20g of radix ampelopsis, 5-25g of mint, 5-15g of semen cuscutae, 5-15g of fructus evodiae, 5-20g of rhizoma kaempferiae, 5-10g of radices trichosanthis, 5-15g of radix angelicae and 20-45g of semen coicis. The traditional Chinese medicine mask for skin firming and wrinkle removal is low in side effect and sufficient in absorption, has the effects of increasing skin elasticity, repairing fine winkles and reconstructing skin texture, and can be used for a long time as a skin care product.

Owner:朱翠帮

Formula and extraction process of composite natural green pigment

InactiveCN110115335AImprove securityFix fadingNatural extract food ingredientsFood extractionGramGardenia

The invention discloses a formula and an extraction process of a composite natural green pigment. The composite natural green pigment is extracted from raw materials by taking clear water as a mediumand a physical method without adding of any chemical substance, and the problems of fading and color change caused by illumination and air oxidation of a chlorophyll green pigment in the prior art aresolved. In order to achieve the purpose, the formula of the composite natural green pigment is prepared from 35 grams of gardenia, 15 grams of butterfly peas and 1500 grams of water, wherein the weight of raw juice is 64%-67%, and the weight is 10% by weight after concentration; 15 grams of butterfly peas and 35 grams of gardenia (or 30 grams of honeysuckle and 20 grams of butterfly peas) are poured into 1500 grams of water, and the mixture is boiled with big fire; a cover is put on, the boiling continues for 10 minutes with a small fire, uncovered standing is executed for 20 minutes after fire stopping, and 100-mesh sieving is executed; the boiling continues with big fire until 1 / 3 of the original volume is left b, and then the boiling is executed with small fire to reach a thick state;and natural precipitation is executed for at least 60 minutes, and the upper-portion pure part is taken and charged into a pastry bag, extruded into a sterilized refined oil bottle and refrigerated for later use.

Owner:匠人之心(北京)食品有限公司

Barrier strip having reinforced rib and method for making the same

InactiveCN101225642BImprove wind load capacityPlay an auxiliary role in strengtheningProtective constructionElastomerEngineering plastic

The invention relates to a barrier strip with stiffeners, comprising a barrier plate made by PC, PE and other engineering plastics, and one to one hundred strips of stiffeners distributed axially in the barrier plate; wherein, the stiffener can expand freely in the barrier plate; the two end of the stiffener provided with a elastic body are anchored by headings, or fixed by nuts after opening screw, or fixed on the anchor plate via clamping and gripping tightly by jaws after opening taper holes on the anchor plate; the elastic body sleeved on the two ends of the stiffener are rubber or springs. The barrier strip is characterized in that one to one hundred strips of stiffeners are put into the barrier plate made by engineering plastics in axial direction, and can expand freely in the barrier plate while making the barrier plate of the barrier strip, then the elastic body are put on both ends of the stiffener which are anchored on the anchor plate. The barrier strip with stiffeners has the advantages of uneasy crack, high wind resistance and load ability, long service life, improved engineering and traffic safety.

Owner:LIUZHOU OVM MASCH CO LTD

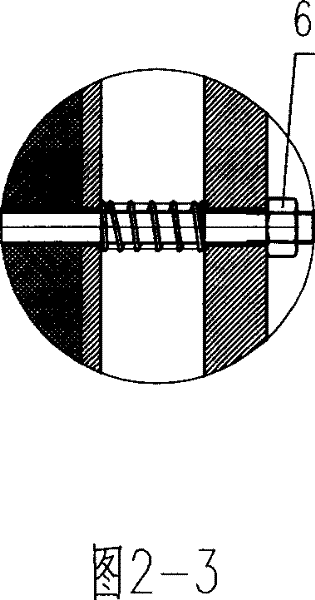

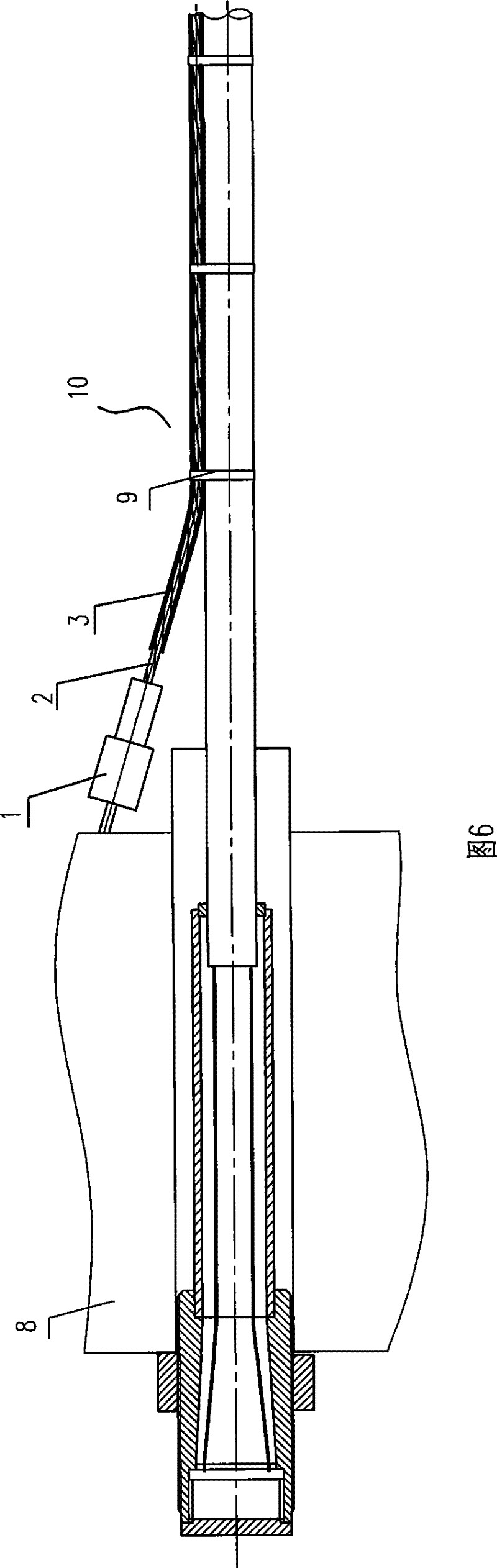

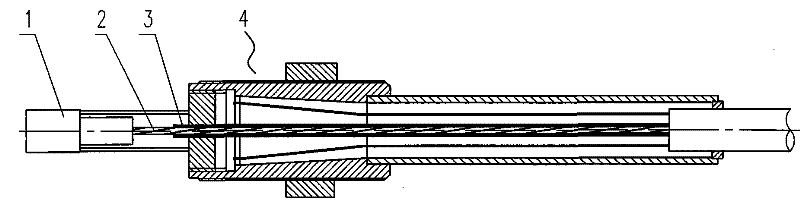

Axial vibration damping system for stayed cable, stayed cable equipped with the system and manufacturing method thereof

ActiveCN101372827BGood vibration reduction effectGood vibration dampingBridge structural detailsShock proofingAxial vibrationVibration damper

An axial vibration damping system for inhaul cables comprises vibration dampers, a vibration damping cable and a vibration damping cable sheath. The vibration damping cable is installed in the vibration damping cable sheath and can be freely telescopic in the vibration damping cable sheath; two ends of the vibration damping cable are both connected and provided with a vibration damper, or one endof the vibration damping cable is provided with a vibration damper while the other end has no vibration damper, and the end without a vibration damper is anchored with the inhaul cable or anchored onthe bridge fixed structure while the vibration damper is fixed on the anchor end of the inhaul cable system or the bridge fixed structure. The inhaul cable with the axial vibration damping system forinhaul cables comprises a vibration damping system and a cable system taking steel wires, steel strands or steel wire ropes as the cable body. The axial vibration damping system for inhaul cables is axially installed in the inhaul cable system. The manufacturing method for the system comprises the steps as follows: arranging the vibration damping cable sheath with the vibration damping cable in the cable body of the inhaul cable system to integrate with the cable body; arranging the vibration damper at one end or both ends of the vibration damping cable and arranging and fixing the vibration damper on the anchor end of the inhaul cable system or the bridge fixed structure. The system has good damping effect.

Owner:LIUZHOU OVM MASCH CO LTD

Permanent antistatic flame-retardant polyamide-6 bulked continuous filament textured carpet yarn and preparation method

ActiveCN102660819BGuaranteed wear resistanceMaintain stain resistanceFlame-proof filament manufactureYarnYarnSingle fiber

The invention relates to a permanent antistatic flame-retardant polyamide-6 bulked continuous filament textured carpet yarn and a preparation method. The permanent antistatic flame-retardant polyamide-6 bulked continuous filament textured carpet yarn comprises a carpet yarn body, wherein the carpet yarn body consists of two tows of flame-retardant polyamide-6 bulked continuous filaments in different colors or the same color and a tow of antistatic polyamide-6 bulked continuous filaments; single fibers in the three tows of polyamide-6 bulked continuous filaments are random three-dimensional crimped fibers; different types of fibers are randomly mixed and intertwined; and periodical net knots are arranged on the surface of the carpet yarn body. The preparation method is implemented by one step through a tri-screw bulked continuous filament (BCF) spinning machine set. The product substantially maintains the characteristics of abrasion resistance, stain resistance, resilience and the like of polyamide-6, and also has a permanent antistatic function and a flame-retardant function. According to the preparation method, the characteristics of a production process of the tri-screw BCF spinning machine set are utilized, so that the aim of spinning the antistatic flame-retardant polyamide-6 textured carpet yarn by one step is fulfilled, and the production process is simple, practical and efficient.

Owner:CHANGZHOU LINGDA SPECIAL FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com