Patents

Literature

72results about How to "Efficient production method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

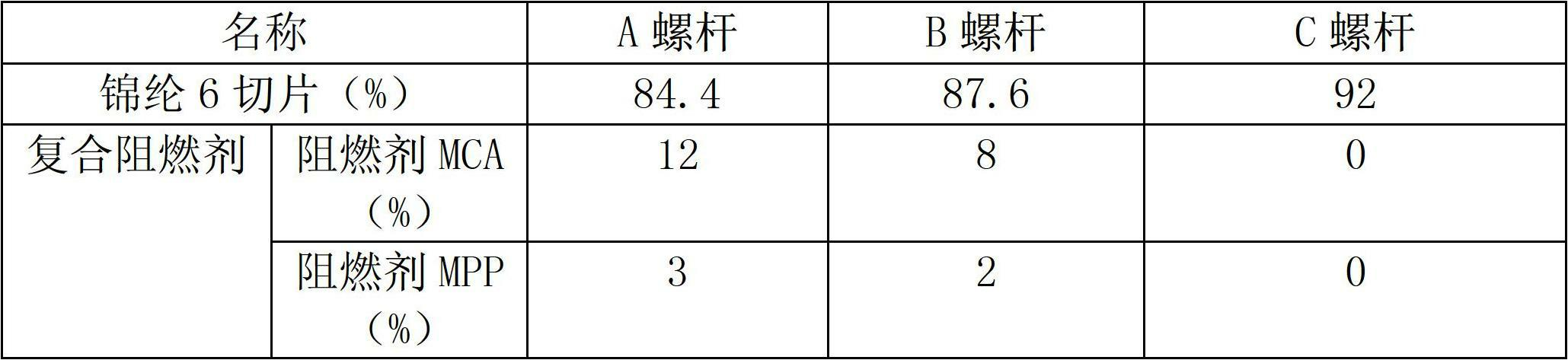

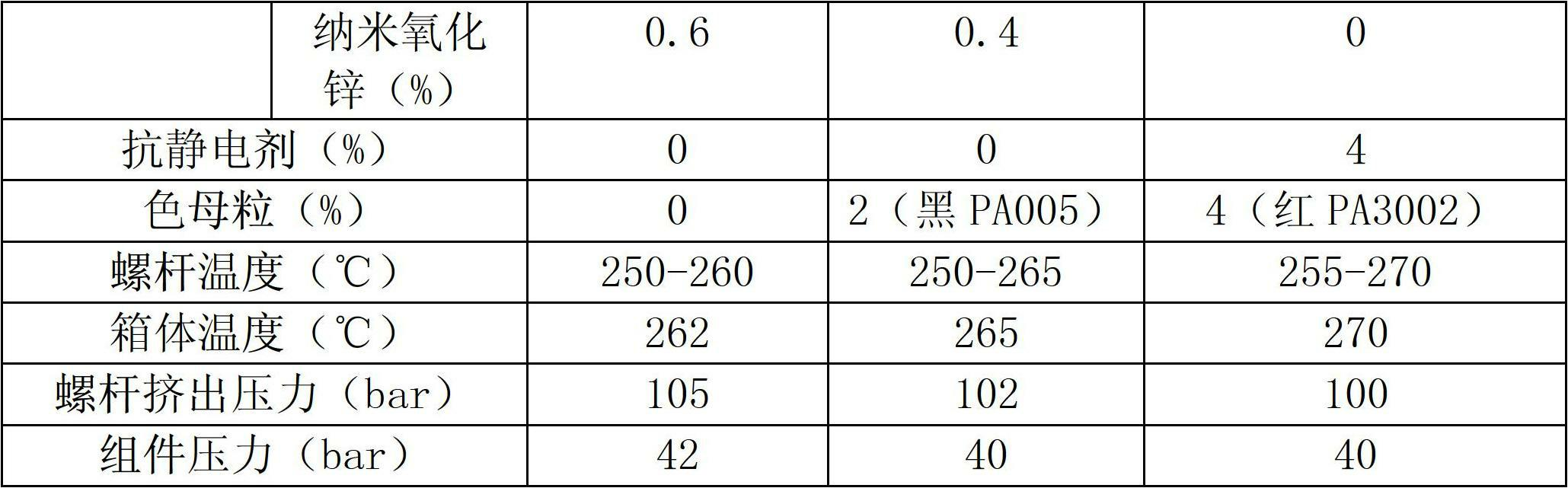

Permanent antistatic flame-retardant polyamide-6 bulked continuous filament textured carpet yarn and preparation method

ActiveCN102660819APermanent antistaticGuaranteed wear resistanceFlame-proof filament manufactureYarnComposite functionPolyamide

The invention relates to a permanent antistatic flame-retardant polyamide-6 bulked continuous filament textured carpet yarn and a preparation method. The permanent antistatic flame-retardant polyamide-6 bulked continuous filament textured carpet yarn comprises a carpet yarn body, wherein the carpet yarn body consists of two tows of flame-retardant polyamide-6 bulked continuous filaments in different colors or the same color and a tow of antistatic polyamide-6 bulked continuous filaments; single fibers in the three tows of polyamide-6 bulked continuous filaments are random three-dimensional crimped fibers; different types of fibers are randomly mixed and intertwined; and periodical net knots are arranged on the surface of the carpet yarn body. The preparation method is implemented by one step through a tri-screw bulked continuous filament (BCF) spinning machine set. The product substantially maintains the characteristics of abrasion resistance, stain resistance, resilience and the like of polyamide-6, and also has a permanent antistatic function and a flame-retardant function. According to the preparation method, the characteristics of a production process of the tri-screw BCF spinning machine set are utilized, so that the aim of spinning the antistatic flame-retardant polyamide-6 textured carpet yarn by one step is fulfilled, and the production process is simple, practical and efficient.

Owner:CHANGZHOU LINGDA SPECIAL FIBER

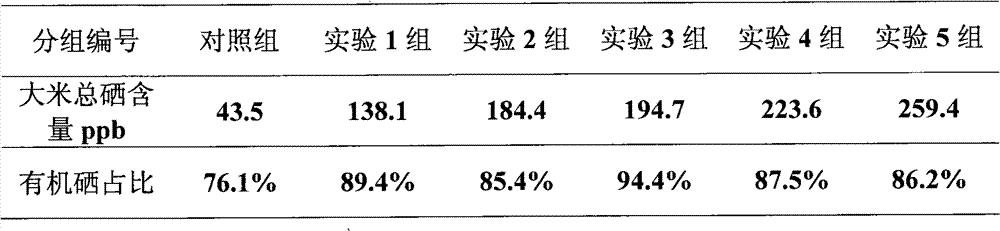

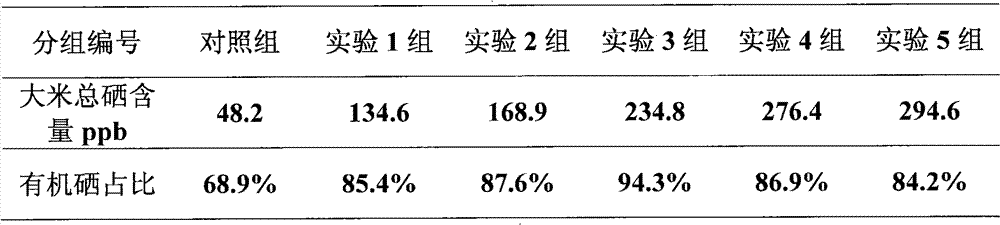

Method for producing organic selenium-enriched rice

ActiveCN102511346AImprove conversion rateImprove securityRice cultivationFertilizer mixturesNutrientBiology

The invention discloses a method for producing organic selenium-enriched rice, wherein the organic selenium-enriched rice is planted according to a normal rice cultivation method. The method is characterized in that the method comprises the steps of: carrying out root dipping treatment to rice seedlings by using selenium-enriched nutrient before transplanting the rice seedlings, transplanting therice seedlings into a big field, planting according to a conventional rice planting method, harvesting organic selenium-enriched paddy, and processing the organic selenium-enriched paddy to obtain the organic selenium-enriched rice. The selenium-enriched nutrient comprises substances with effective application dose, wherein the substances contain selenium and potassium sulfate,. The selenium content of the rice, obtained by the method, is 50-300mug / kg and is improved by 2-10 times in comparison with that of common rice, organic selenium ratio is greater than or equal to 80% and the standard of the organic selenium-enriched rice is achieved.

Owner:宁夏硒产业发展有限责任公司

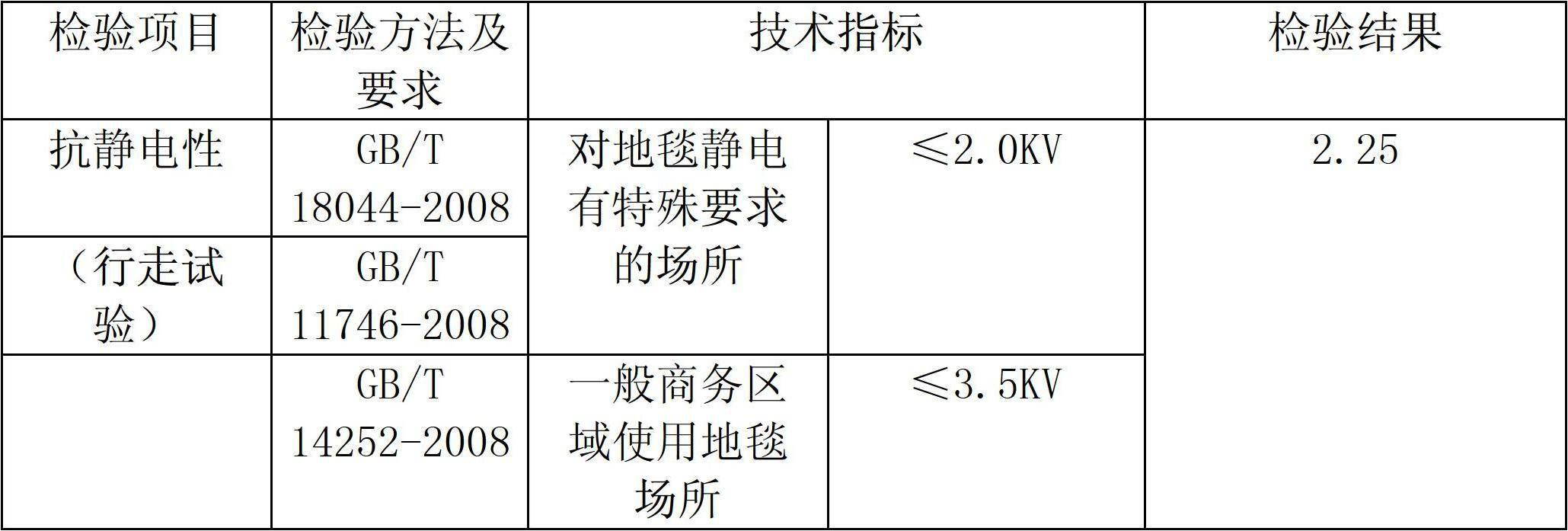

Method for producing pentaerythritol oleate under catalysis of granular solid superacid

InactiveCN102875374ANo pollutionHigh yieldOrganic compound preparationCarboxylic acid esters separation/purificationPentaerythritolAcid catalyzed

The invention discloses a method for producing pentaerythritol oleate under catalysis of granular solid superacid, and relates to a method for synthesizing ester base oil in biodegradable lubricating oil. The method comprises the following steps of: mixing pentaerythritol and oleic acid in a mass ratio of 1:(7.2-9.5), adding the granular solid superacid, and reacting at the temperature of between 140 and 240DEG C for 4 to 10 hours in the vacuum degree of 100-1,000Pa; filtering by using a 200-12,500 mesh filter screen or filter plate; and heating crude grease to the temperature of between 160 and 280DEG C, removing unreacted acid or alcohol, keeping the vacuum degree of the system ranging from 1 to 500Pa, and distilling under reduced pressure for 40 to 120 minutes to obtain the pentaerythritol oleate. The pentaerythritol oleate produced by the method has excellent low temperature fluidity, lubricity, viscosity-temperature characteristics, oxidation safety, cleanness and good biodegradability, and the method is an environment-friendly and high-efficiency production method having advantages of simple treatment, short production period, high esterification rate and high product yield.

Owner:SICHUAN SIPO CHEMICAL CO LTD

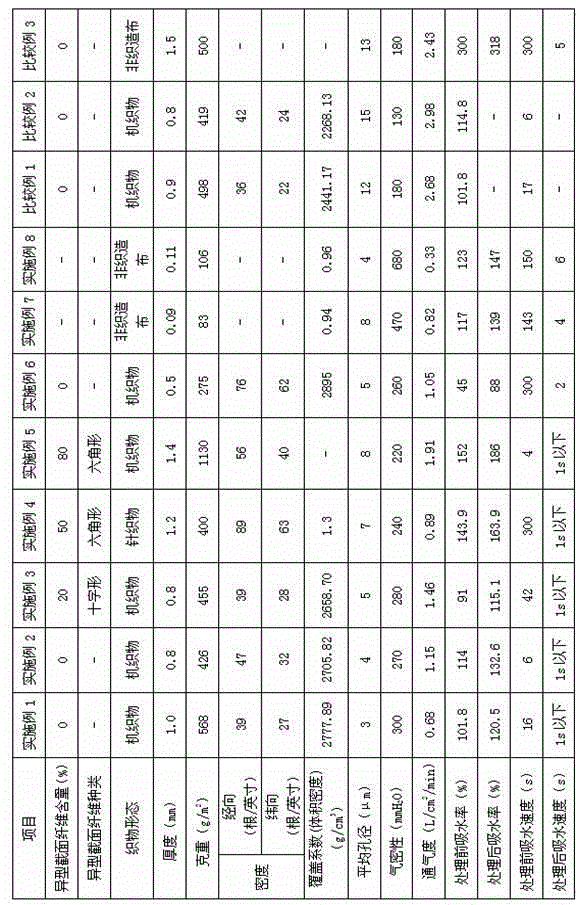

Diaphragm cloth for water electrolyser and producing method thereof

ActiveCN104746202AImprove air tightnessImprove hydrophilicityPhysical treatmentHeating/cooling textile fabricsFiberHigh density

The invention discloses diaphragm cloth for a water electrolyser and a producing method thereof. The diaphragm cloth is high density woven fabric formed by polyphenylene sulfide fiber with the diameter ranging from 4 mum to 12 mum, the thickness of the diaphragm cloth is 0.2-3.0 mm, and the gram weight is 200-600 g / m<2>. The diaphragm cloth has the advantages of being high in air tightness, good in hydrophilia, good in ion permeability, low in cost, safe, environment-friendly and light in weight. The producing method is quick, efficient, free of pollution, simple in operation and capable of saving energy.

Owner:TORAY IND INC

Diaphragm cloth for water electrolyser and method for producing diaphragm cloth

InactiveCN103938337AImprove air tightnessImprove hydrophilicityCellsOrganic diaphragmsFiberEngineering

The invention discloses a piece of diaphragm cloth for a water electrolyser and a method for producing the diaphragm cloth. The diaphragm cloth is a woven fabric or a non-woven fabric or a knitted fabric made of polyphenylene sulfide fiber, the average aperture of the diaphragm cloth is smaller than 10 micrometers, and the venting quality of the diaphragm cloth is 2 L / cm<2> / min or lower under the pressure of 3 KPa. The diaphragm cloth has the advantages of being high in gas tightness, hydrophilcity and ion permeability, and has the advantages of being low in cost, safe, environmentally friendly, light in weight, rapid and efficient in production, free of pollution, easy to operate and capable of saving energy at the same time.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Sodium doped graphite phase carbon nitride prepared by one-step synthesis and application thereof

ActiveCN106582765AImprove photocatalytic activityNarrow BandwidthPhysical/chemical process catalystsWater/sewage treatment by irradiationSodium bicarbonateOrganic dye

The invention belongs to the technical field of semiconductor photocatalysis, and particularly relates to a sodium doped graphite phase carbon nitride prepared by one-step synthesis and application thereof. The preparation method comprises the steps of placing melamine and sodium hydrogen carbonate into a ball milling agitator for ball-milling for 8 hours, taking out the mixture, placing the mixture in a alumina crucible with lid for calcination to acquire a solid, washing the solid with 3% salpeter solution, deionized water and ethanol for three times, then drying and grinding to acquire the sodium doped graphite phase carbon nitride. The preparation method has the advantages of being low in material cost, simple in processing process, and high in preparation efficiency. The prepared sodium doped graphite phase carbon nitride has a decreased forbidden band gap. The photocatalytic degradation speed of organic dye RhB is increased by leaps and bounds.

Owner:CENT SOUTH UNIV

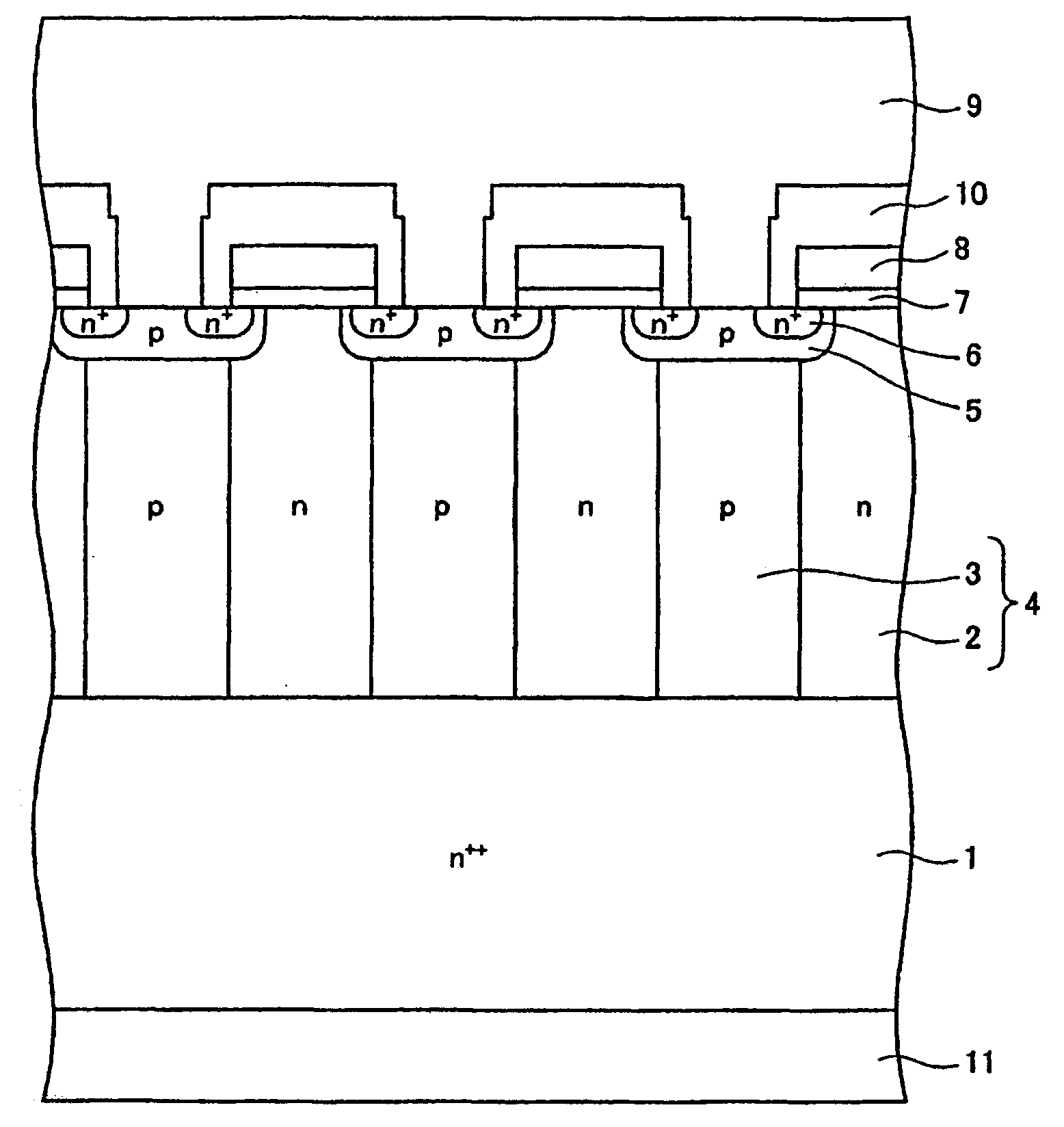

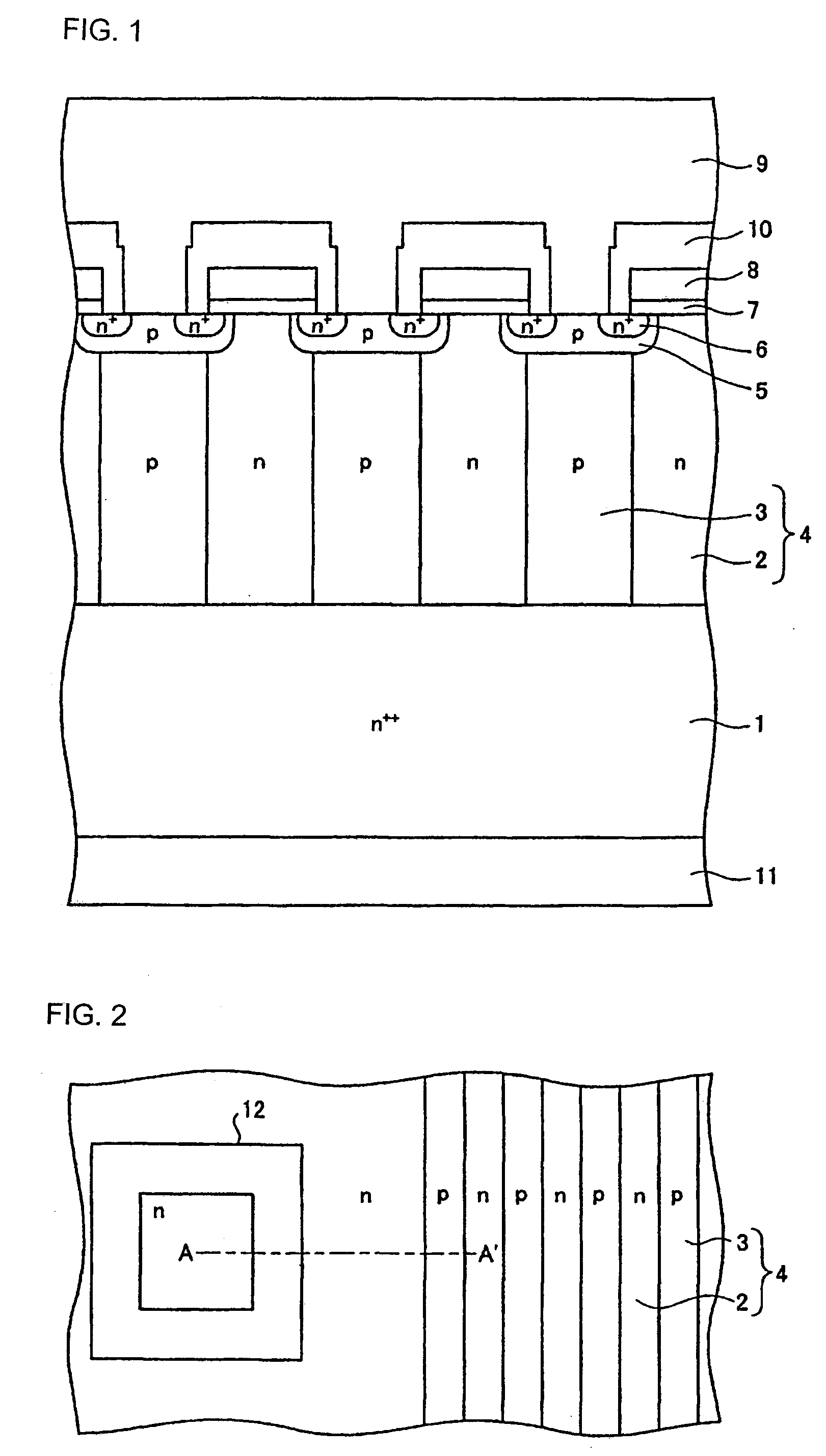

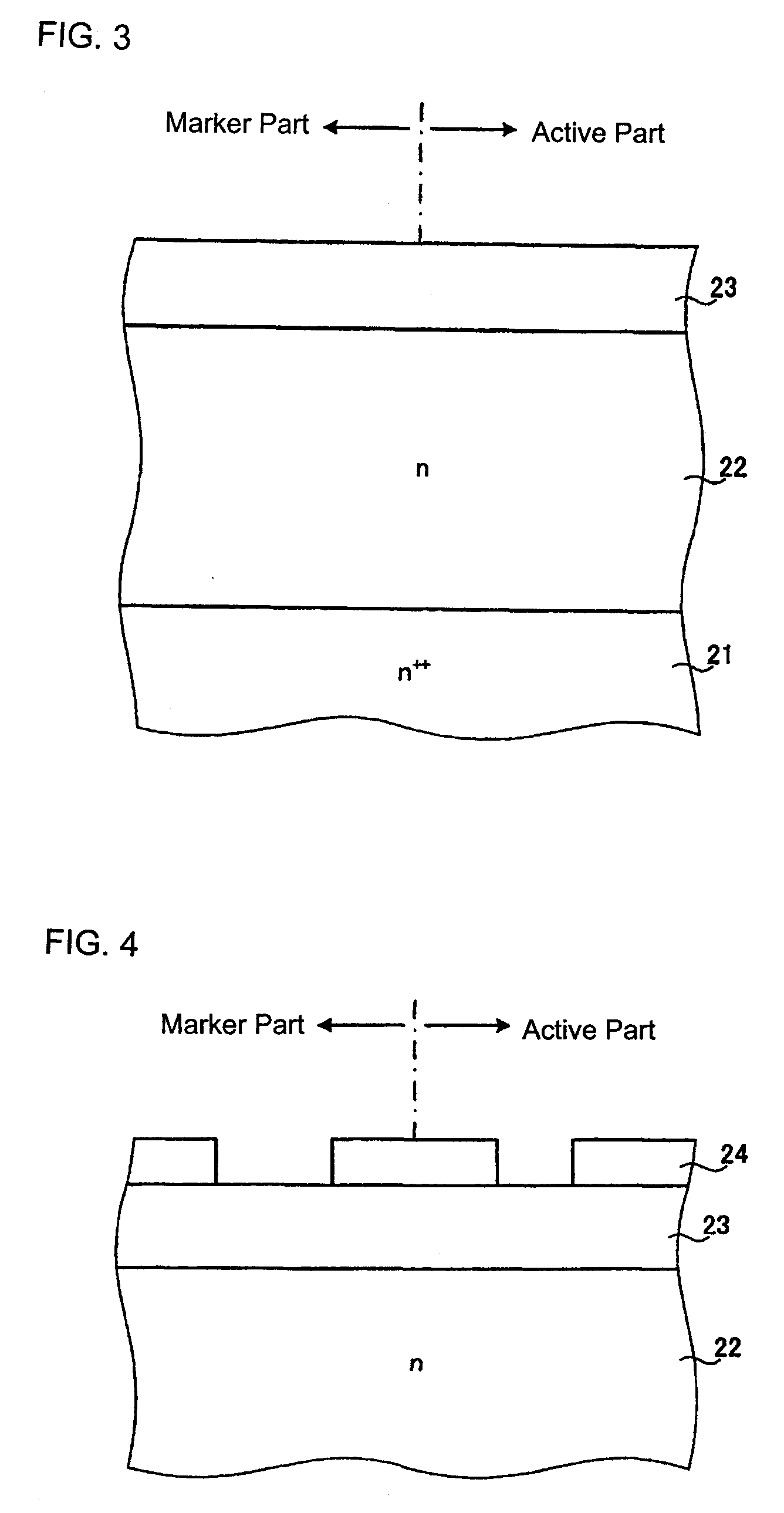

Method of producing semiconductor device

ActiveUS20090294917A1Improve efficiencyEasy to disassembleSemiconductor/solid-state device detailsSolid-state devicesManufacturing technologyEngineering

A semiconductor device is manufactured by forming a mask having a first opening and a second opening wider than the first opening on a principal surface of a first conductivity type semiconductor substrate, etching semiconductor portions of the first conductivity type semiconductor substrate exposed in the first and second openings to thereby form a first trench in the first opening and form a second trench deeper than the first trench in the second opening, and filling the first and second trenches with a second conductivity type semiconductor to concurrently form an alignment marker for device production and a junction structure of alternate arrangement of the first conductivity type semiconductor and the second conductivity type semiconductor. In this manner, it is possible to provide a semiconductor device in which a parallel pn structure and an alignment marker can be formed concurrently to improve the efficiency of a manufacturing process.

Owner:FUJI ELECTRIC CO LTD

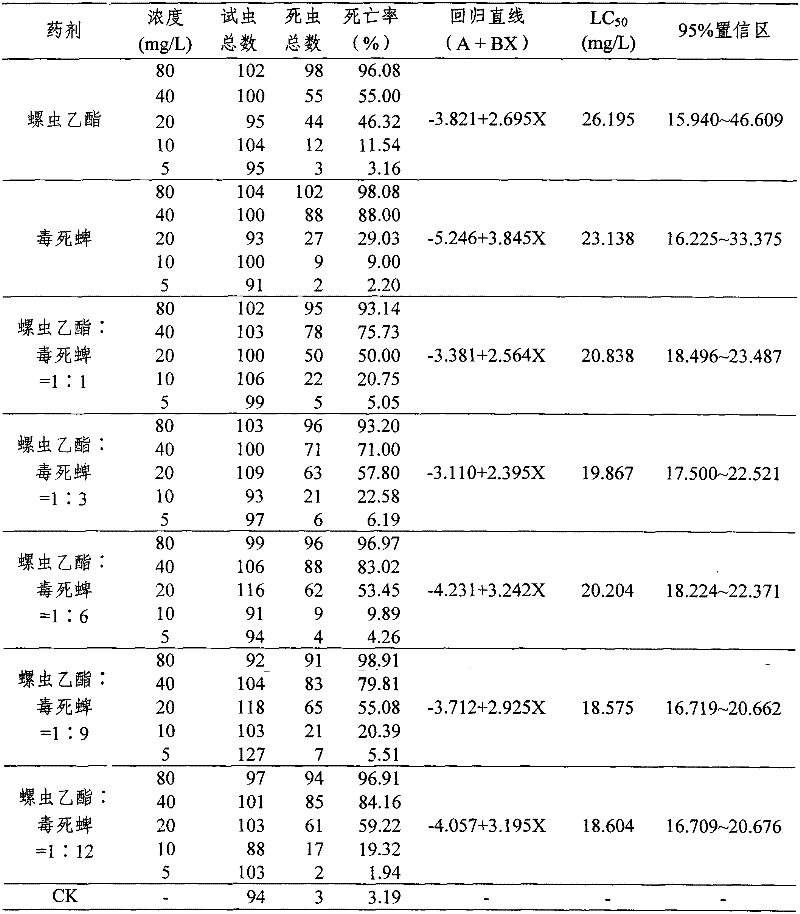

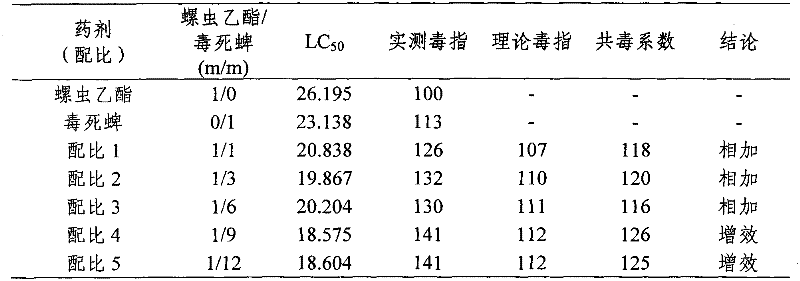

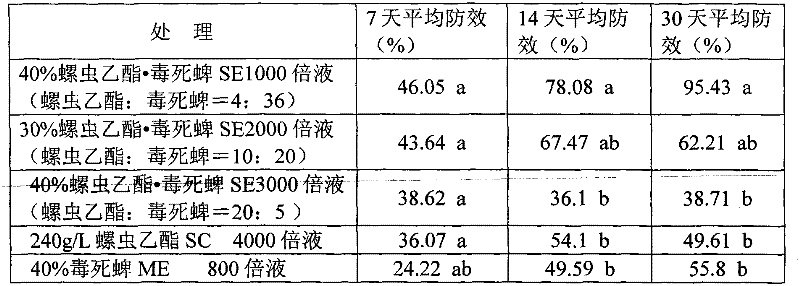

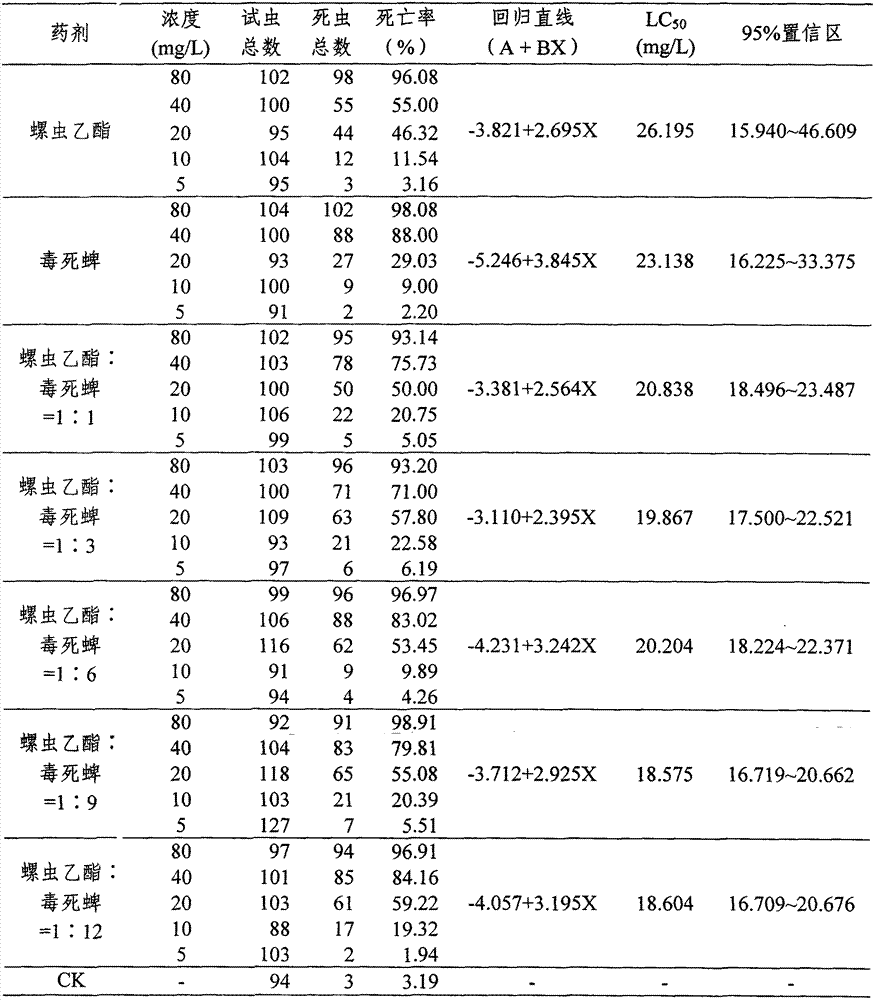

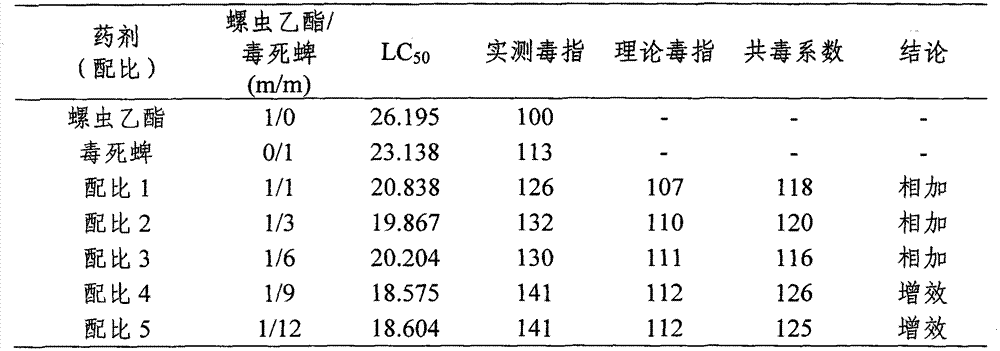

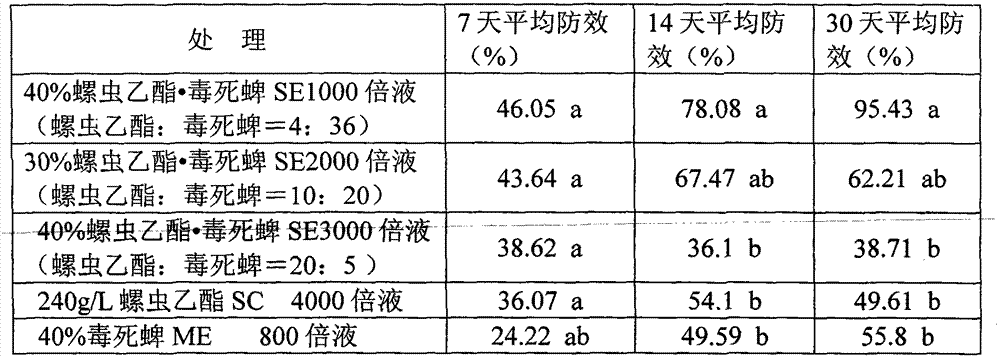

Compounded insecticidal suspension emulsion with chlorpyrifos and spirotetramat and preparation method of compounded insecticidal suspension emulsion

The invention discloses a compounded insecticidal suspension emulsion with chlorpyrifos and spirotetramat and a preparation method of the compounded insecticidal suspension emulsion. The compounded insecticidal suspension emulsion comprises the following contents in percentage by weight: 2-30% of spirotetramat, 10-40% of chlorpyrifos, 5-20% of organic solvent and the balance water, and is formed by adopting the following steps of mechanical stirring, sanding and high-speed homogeneity cutting. The compounded insecticidal suspension emulsion has a stable property and a high medicine effect, and can be used for preventing injurious insects such as scale insects of oranges, cotton and apples, bemisia tabaci of vegetables, and the like. According to the invention, the compounded insecticidal suspension emulsion has the advantages that the water is used as the main dispersion medium, the pollution to the environment is small, the situations of oil deposition, sediment and the like when the compounded insecticidal suspension emulsion is stored for two years under normal temperature are not existed, the service life of a storage rack is long and is non-flammable, the storage and the transportation is safe, compared with using the spirotetramat alone, the cost is low, and the like.

Owner:ZHEJIANG XINNONG CHEM CO LTD +1

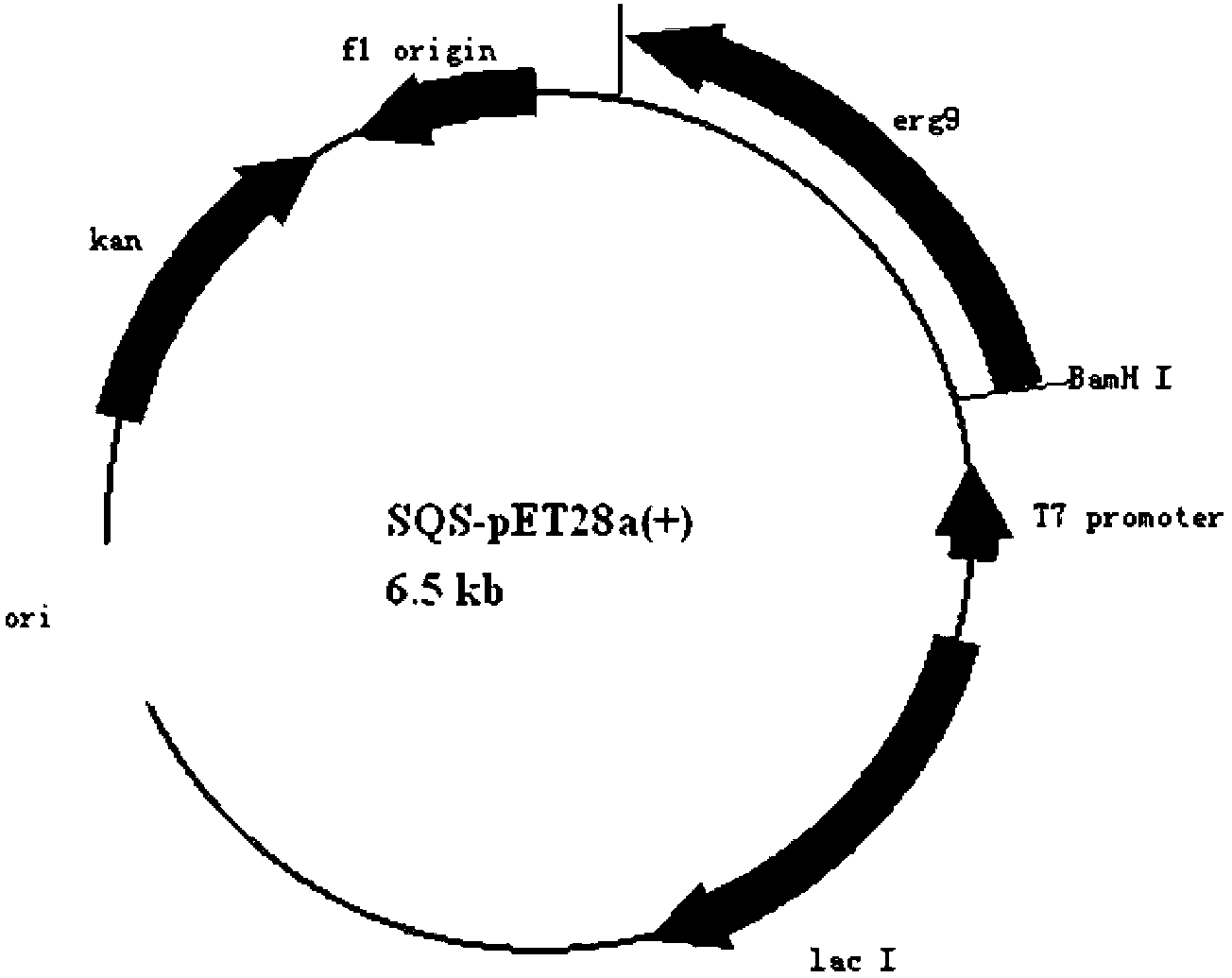

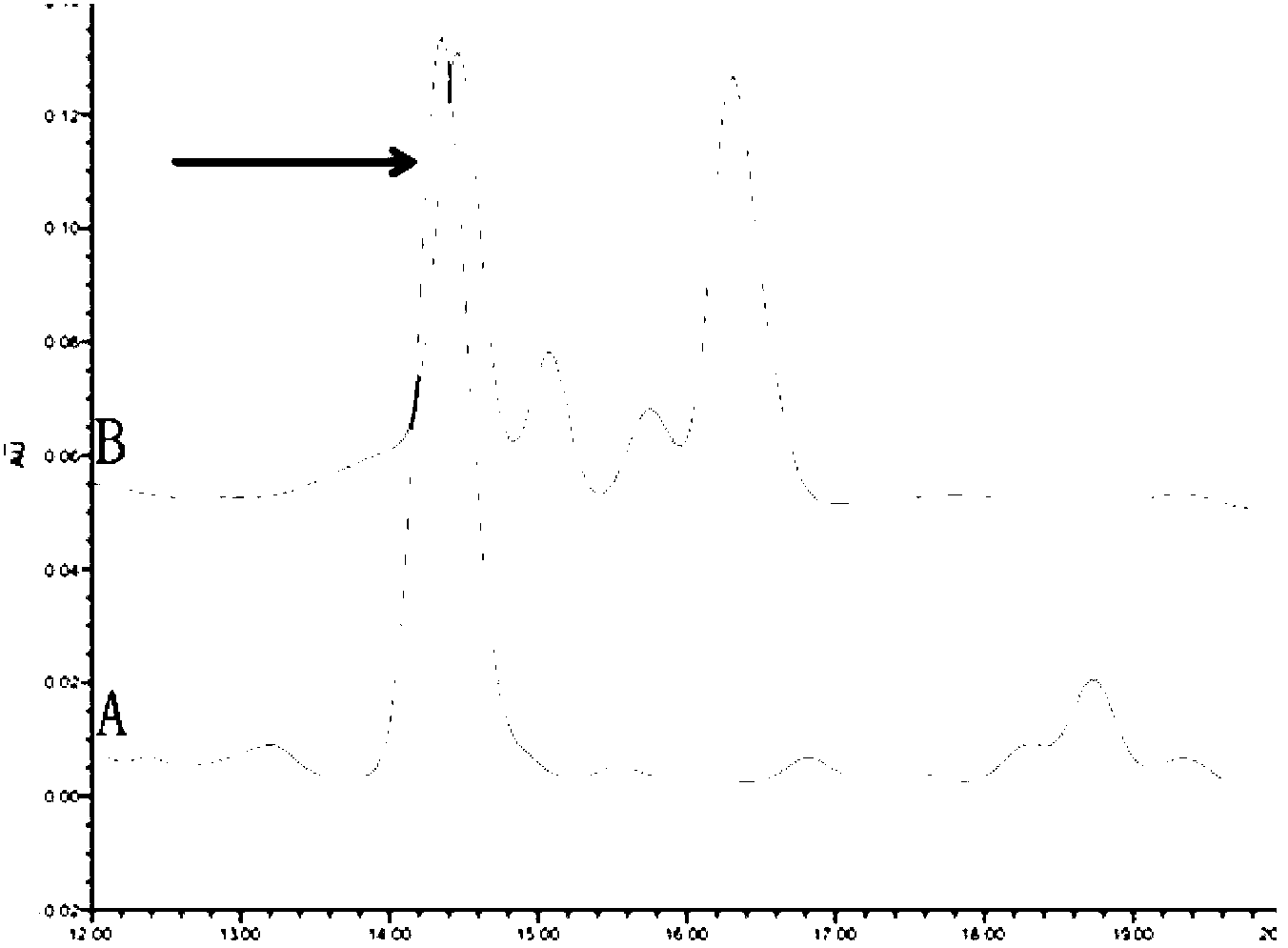

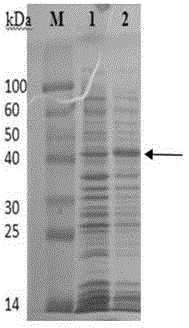

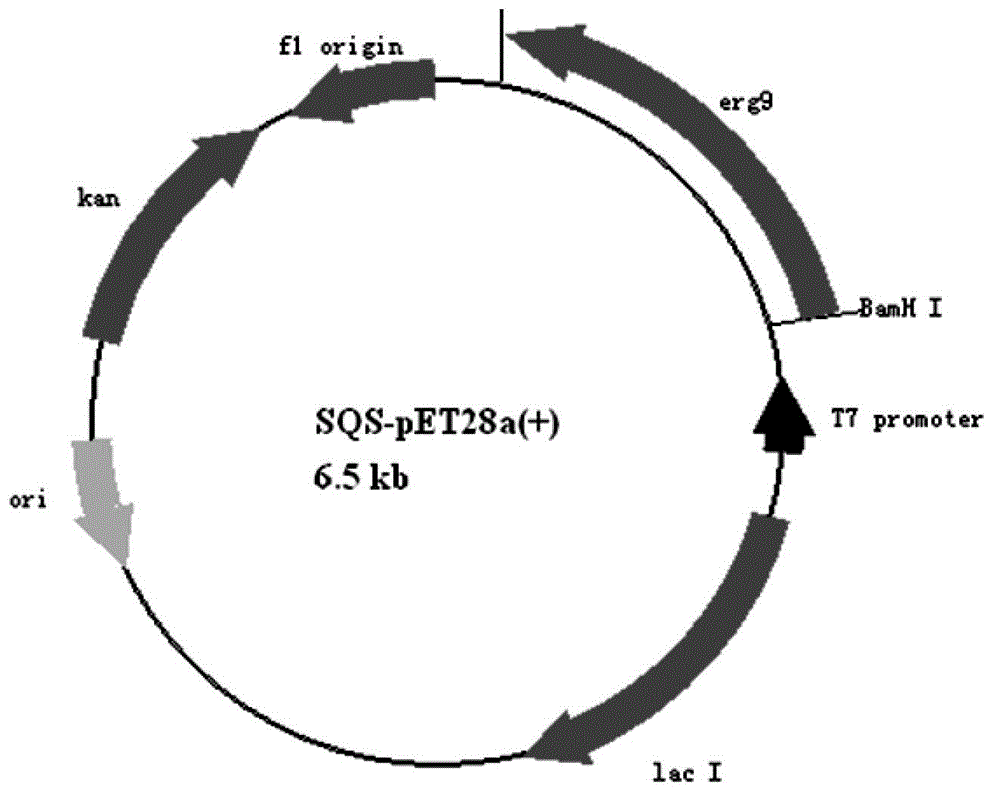

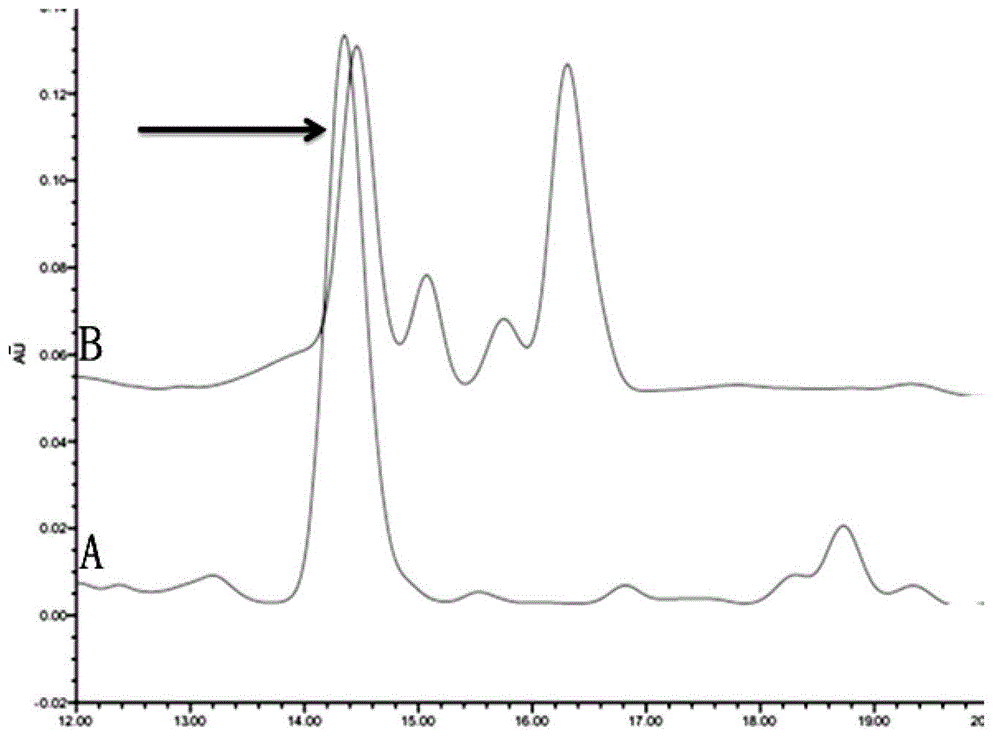

Production method of squalene

ActiveCN103266137ASimple production methodIncrease productionBacteriaMicroorganism based processesSqualene SynthetaseMethods of production

The invention relates to a production method of squalene, and in particular relates to a method for cloning a squalene synthetase gene and co-expressing in escherichia coli so as to establish a recombinant strain capable of synthesizing squalene. The production method of squalene, provided by the invention, is simple and efficient, the established escherichia coli engineering bacteria can be used for producing squalene with a high yield and can be widely applied to the fermentation production of squalene, the output of squalene is increased, and then the large-scale application of squalene is facilitated.

Owner:QINGDAO VLAND BIOTECH GRP

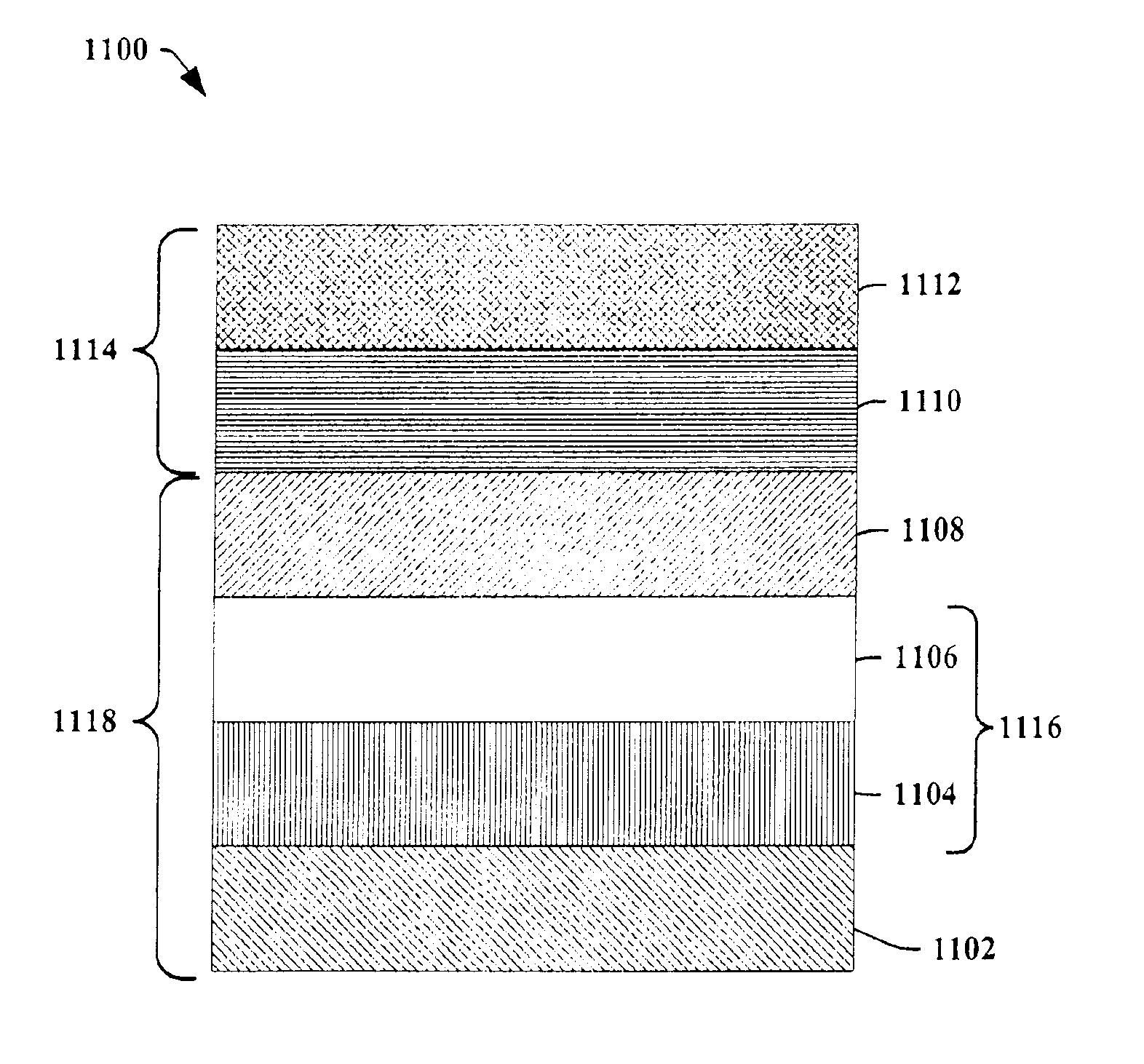

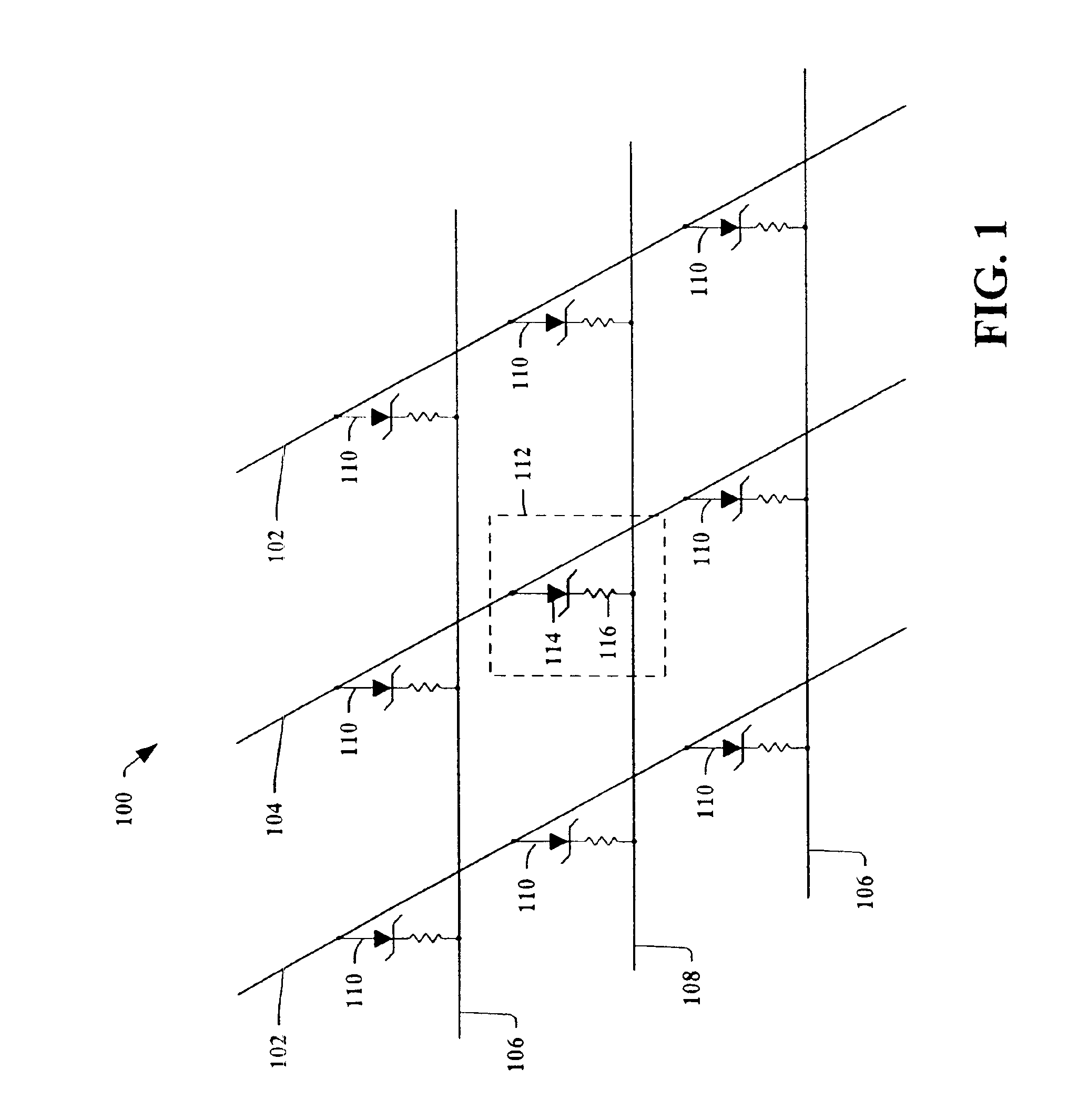

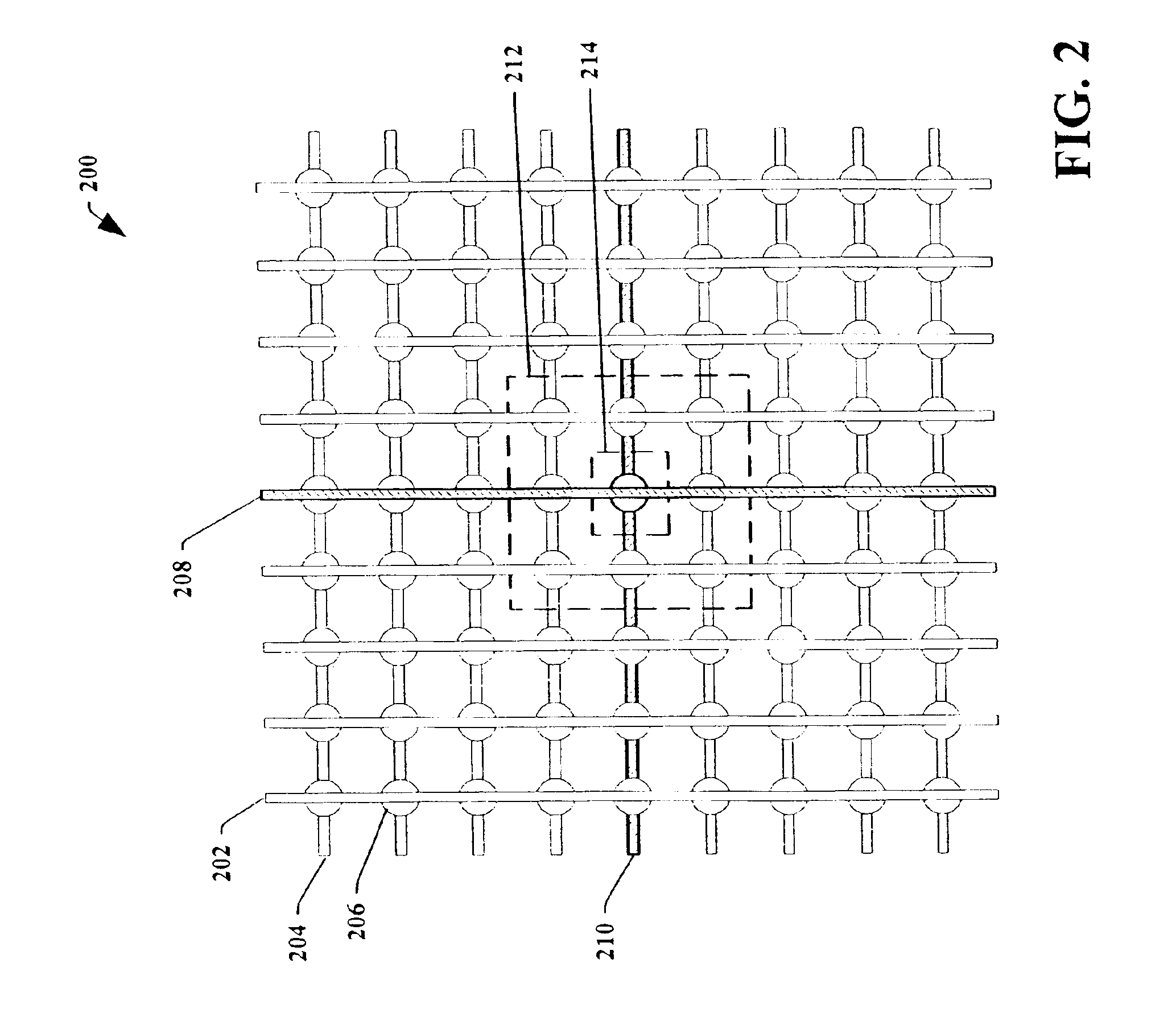

Control of memory arrays utilizing zener diode-like devices

InactiveUS6943370B2Easy to manufactureLow production costSemiconductor/solid-state device detailsNanoinformaticsZener diodeEngineering

The present invention facilitates semiconductor devices by aiding the efficiency in the way individual devices change states in a semiconductor array. State change voltages can be applied to a single device in the array of semiconductor devices without the need for transistor-type voltage controls. The diodic effect of the present invention facilitates this activity by allowing specific voltage levels necessary for state changes to only occur at the desired device. In this manner, an array of devices can be programmed with varying data or states without utilizing transistor technology. The present invention also allows for an extremely efficient method of producing these types of devices, eliminating the need to manufacture costly external voltage controlling semiconductor devices.

Owner:MONTEREY RES LLC

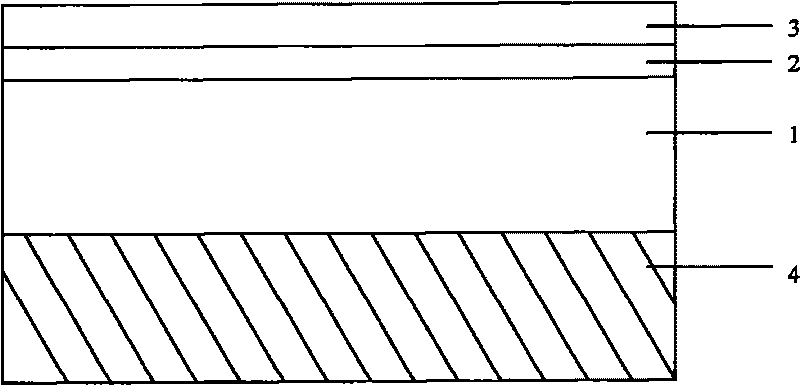

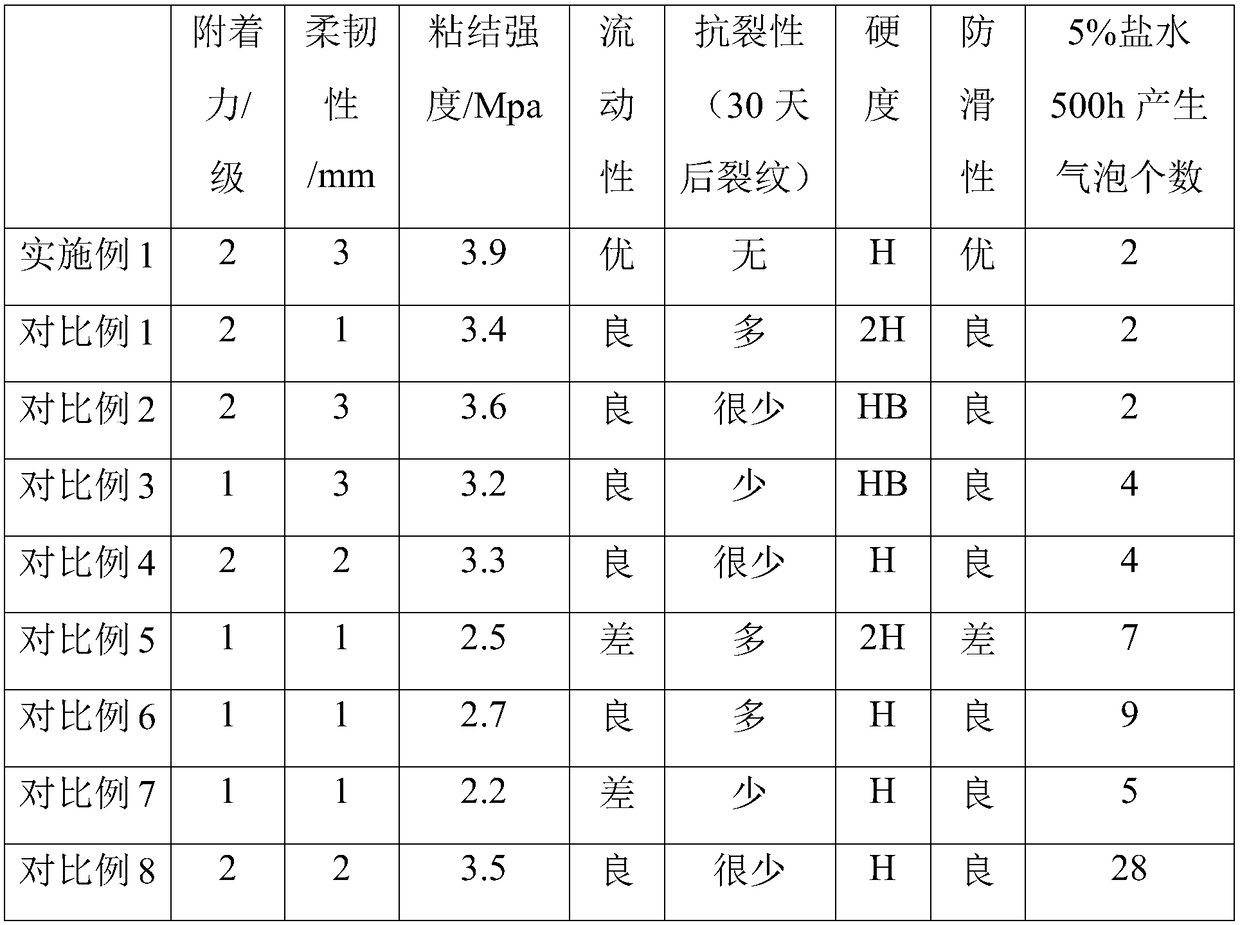

Chromium-plated plastic product

InactiveCN101700703AReduce consumptionSimple production methodSynthetic resin layered productsVacuum evaporation coatingTitaniumTitanium oxide

The invention relates to a chromium-plated plastic product, belonging to the new material and surface technical field. The chromium-plated plastic product comprises the matrix material and chromium-plated layer and is characterized in that the chromium-plated plastic product also comprises organic coating layer and titanium oxide film layer; the matrix material, organic coating layer, chromium-plated layer and titanium oxide film layer are arranged from inside to outside; the thickness of the organic coating layer is 10-20mu m; the thickness of the chromium-plated layer is 2-3mu m; and the thickness of the titanium oxide film layer is 2-4mu m. The vacuum-deposited chromium plastic product of the invention which can replace the plastic electroplating product has three-layer structure, the modification of the structure leads the product to have the advantages of low cost, no toxicity and simple procedure and solve the technical problem that the prior art for preparing plastic chromium-electroplated product has severe pollution, complicated technology and high cost.

Owner:HUZHOU HARTEC JINTAI AUTOMOTIVE PARTS

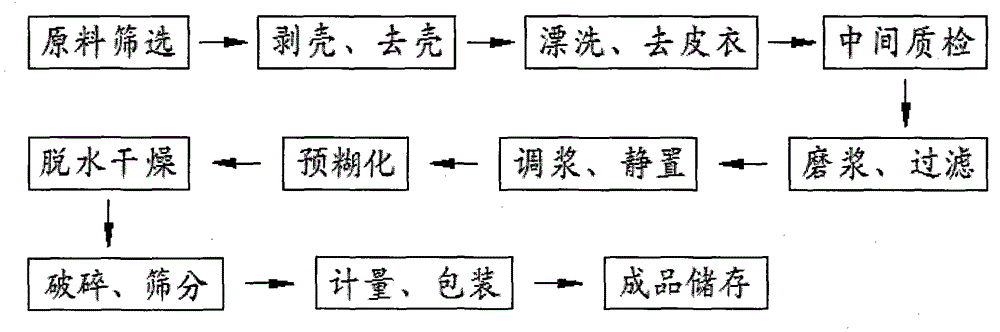

Method for producing whole ginkgo powder

The invention provides a method for producing whole ginkgo powder. The method comprises the steps of screening a raw material, shelling, rinsing and removing coating, performing intermediate inspection, pulping, filtering, mixing and standing, pre-gelatinizing, dewatering and drying, crushing and screening, metering and packing, and storing a finished product. The safe and sanitary whole ginkgo powder with stable quality is produced continuously in large scale without any chemical synthesis agent, and can be directly eaten or used as an intermediate raw material of other food, medicine, feed and the like; the whole ginkgo powder has good rehydration performance, high dissolution rate and high cohesiveness, and can reserve more nutrients so that the flavor and mouthfeel are closer to those of fresh ginkgo; and the production method is efficient, energy-saving, reliable and more friendly to the ecological environment.

Owner:无锡捷尔机械有限公司

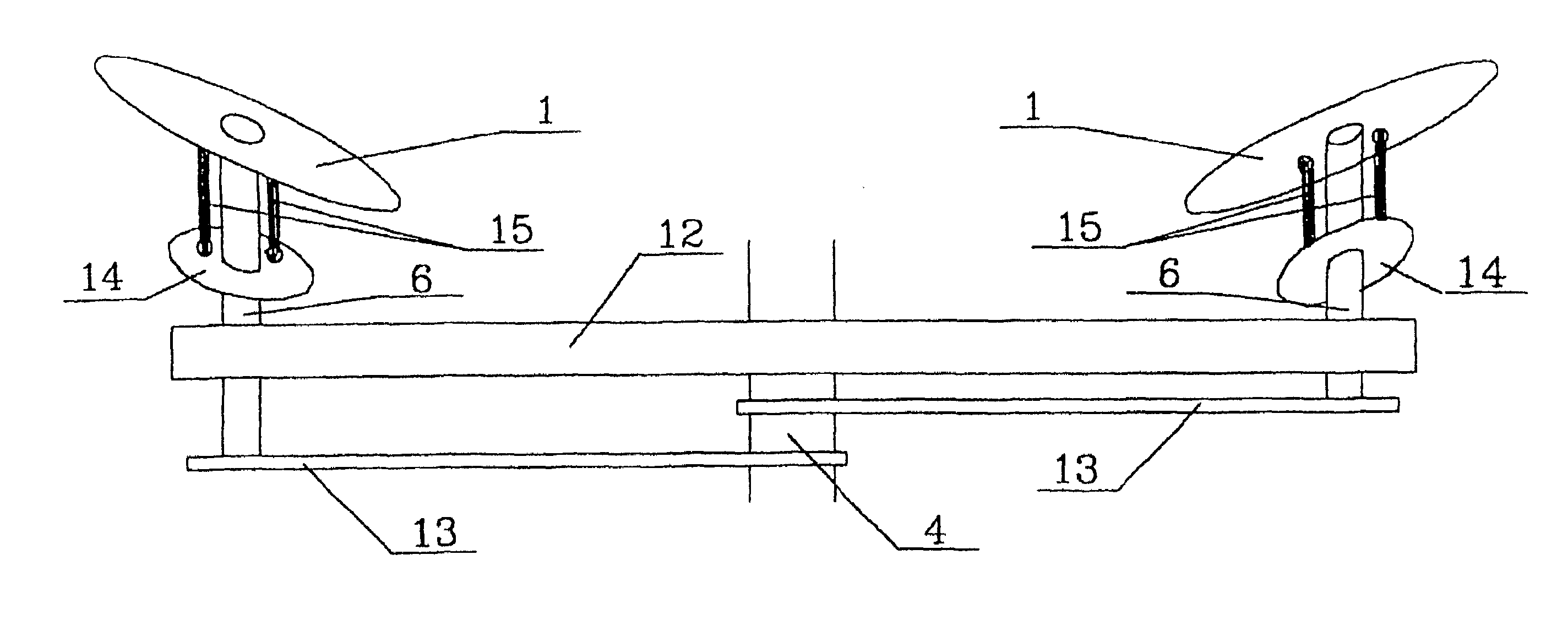

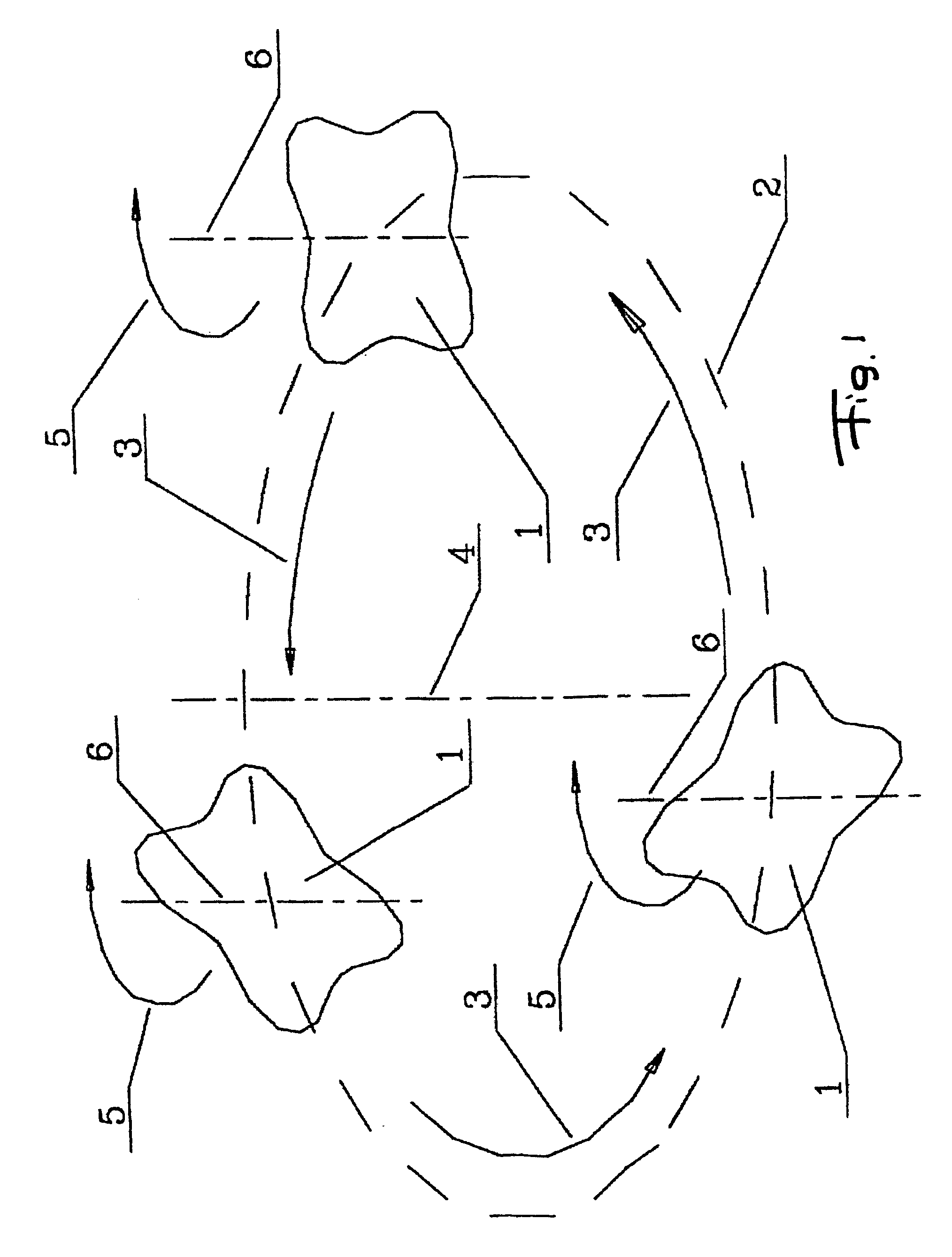

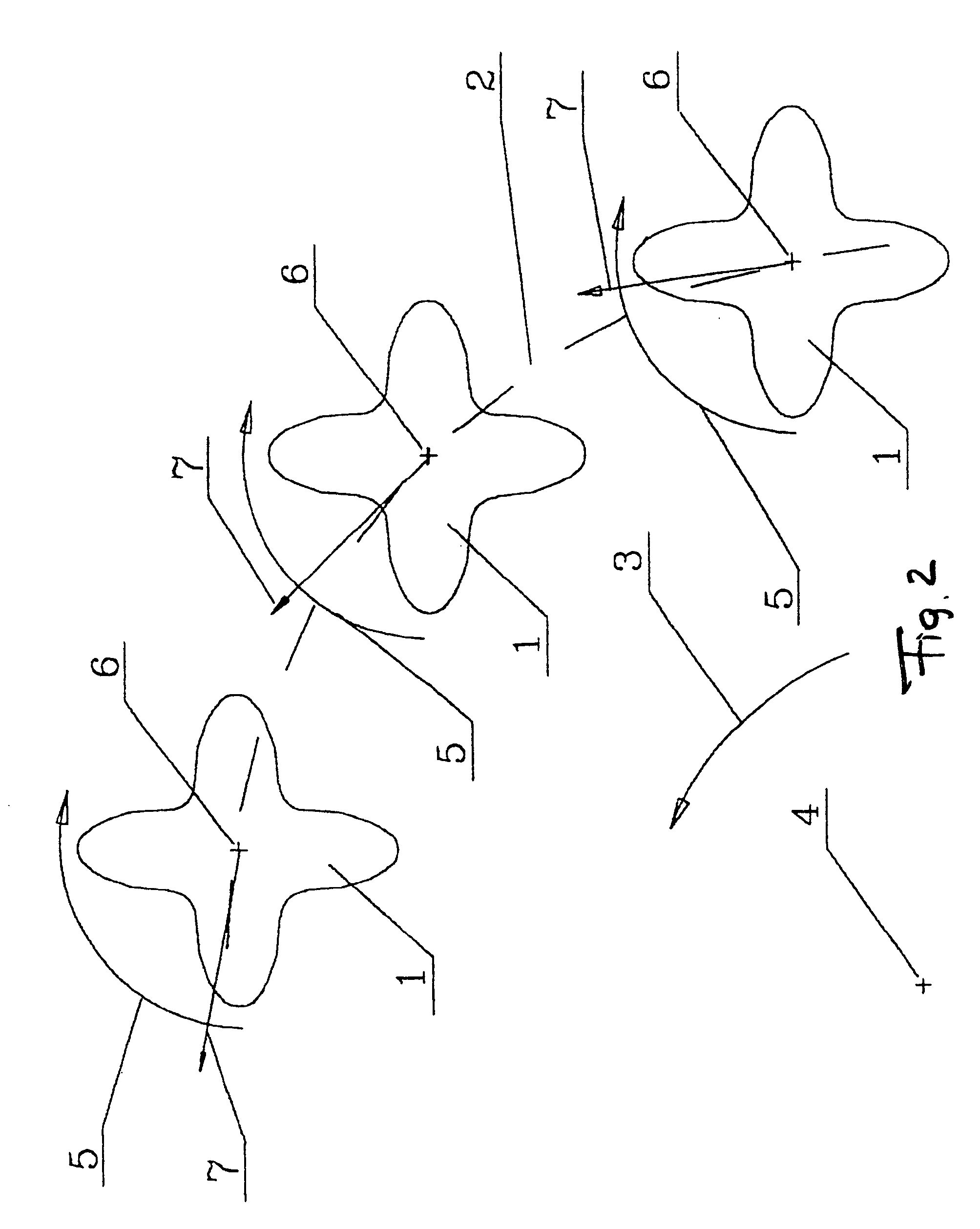

Method for producing a lift and a horizontal thrust

A method of producing a lifting force and a horizontal force by aerodynamic surfaces includes the steps of moving aerodynamic surfaces along a circumference and providing their oscillations; rotating each of the aerodynamic surfaces synchronously with the movement along the circumference, in a direction which is opposite to it, relative to an axis of rotation which is parallel to an axis of the movement along the circumference, with an angular speed which is equal to an angular speed of the movement along the circumference, and performing oscillations of each of the aerodynamic surfaces synchronously with a rotation relative to mutually perpendicular axes located correspondingly in two mutually perpendicular planes which intersect along an axis of rotation of the aerodynamic surfaces, wherein one of them passes through an axis of the movement along the circumference and the axis of rotation.

Owner:AKARO ANDREY IGOREVICH +3

Production method of squalene

ActiveCN103266137BSimple production methodEfficient production methodBacteriaMicroorganism based processesEscherichia coliSqualene Synthetase

The invention relates to a production method of squalene, and in particular relates to a method for cloning a squalene synthetase gene and co-expressing in escherichia coli so as to establish a recombinant strain capable of synthesizing squalene. The production method of squalene, provided by the invention, is simple and efficient, the established escherichia coli engineering bacteria can be used for producing squalene with a high yield and can be widely applied to the fermentation production of squalene, the output of squalene is increased, and then the large-scale application of squalene is facilitated.

Owner:QINGDAO VLAND BIOTECH GRP

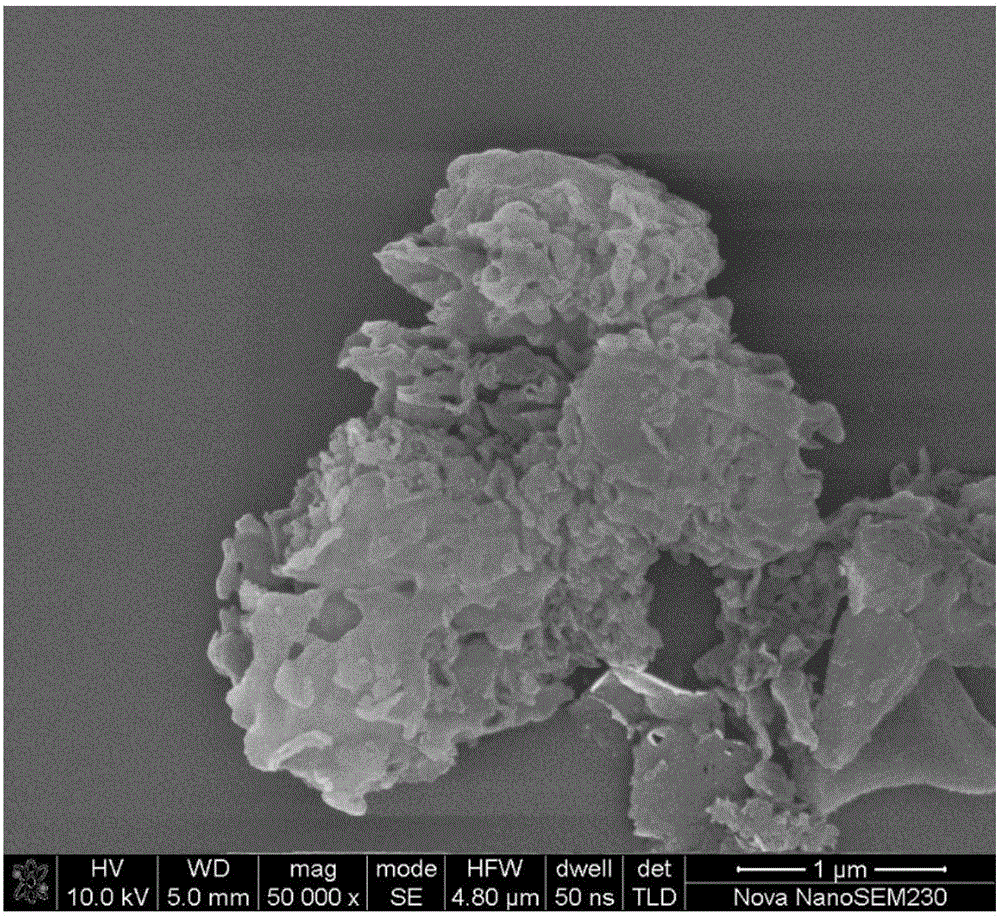

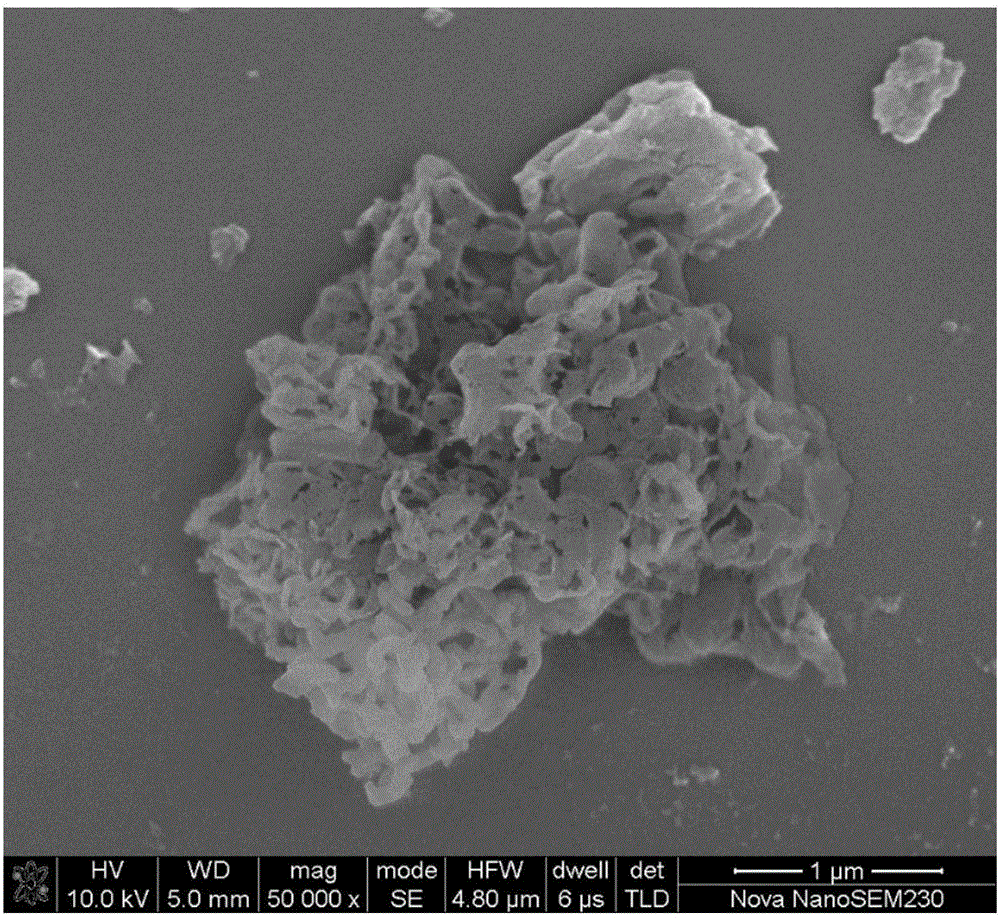

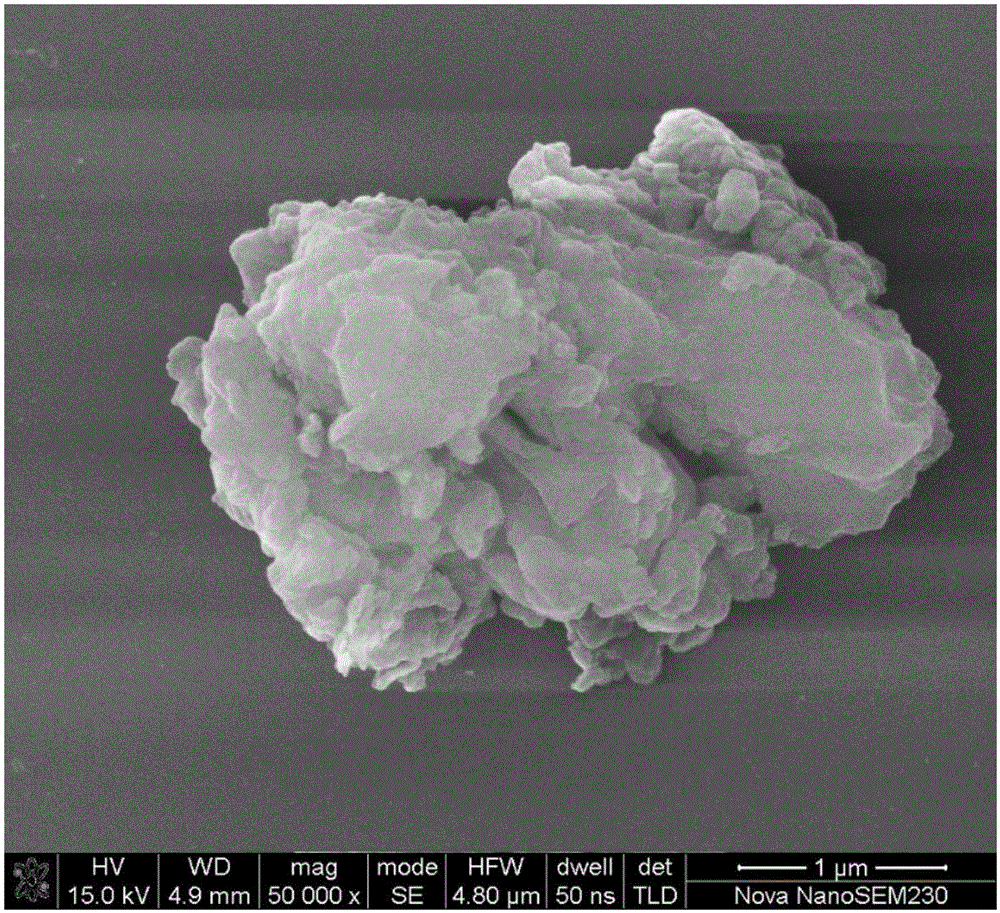

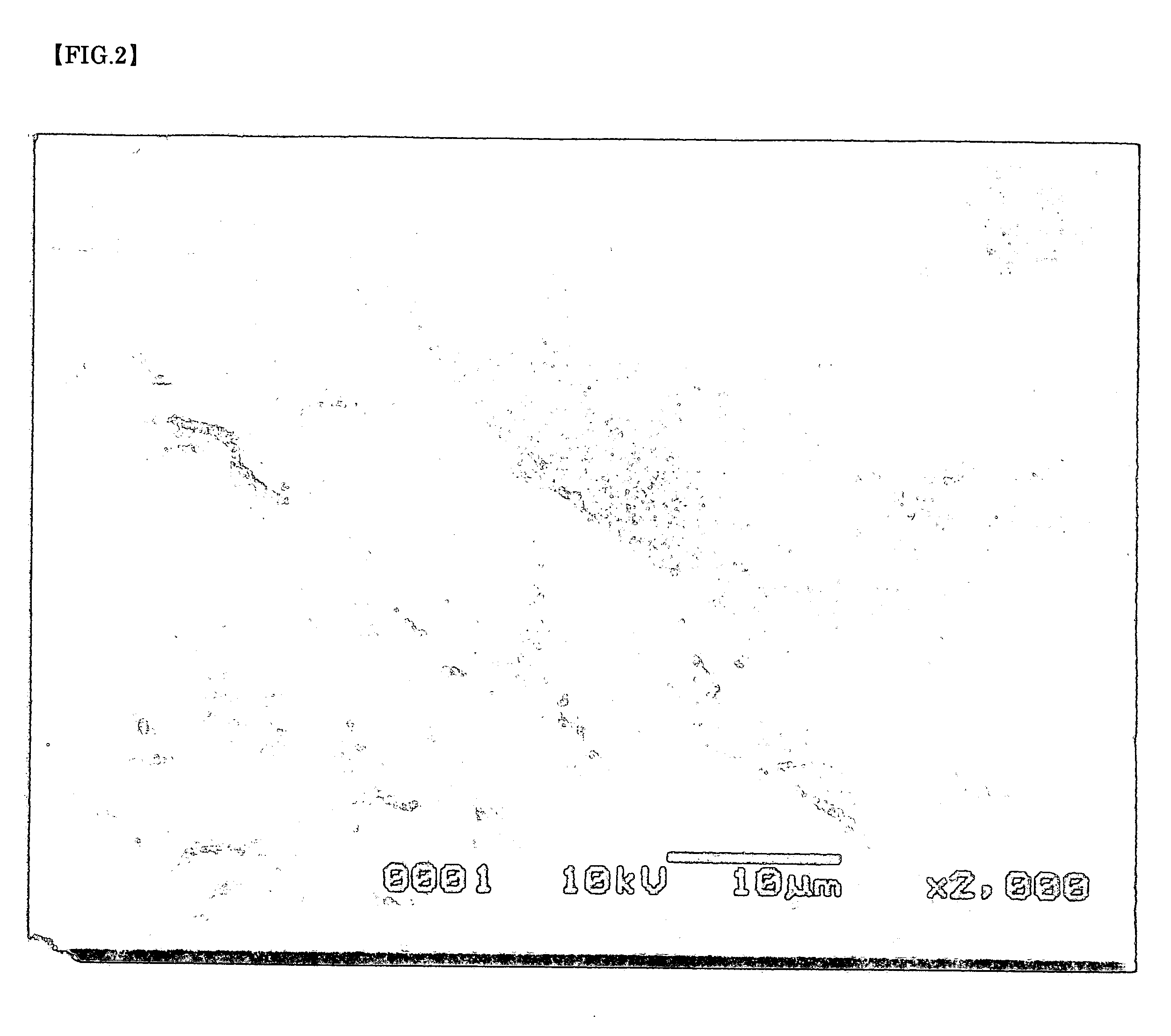

Particles with silver carried and producing method thereof

InactiveUS20050126970A1Short timeEffective disinfectionBiocideLoose filtering material filtersAdditive ingredientSem micrographs

To provide particles for water disinfection which are hard to be suspended and are hard to be diffused in water which is suitable for use of disinfecting water and which are capable of developing disinfection effect fully and method of producing the same. Particles for water disinfection in which silver is coated on a garnet surface or a particle surface whose main ingredient is garnet are used. When said particles are used, preferable embodiment of silver is that the granular lumps of silver are carried continuously and discontinuously forming a group on a garnet surface as shown in SEM photographs of FIG. 4. Effective production method of such particles can be conducted by the electroless plating method in which garnet particles are immersed in a mixed solution composed of reducing solution in which at least any one of potassium sodium tartarate, glucose, or acetardehyde as a reducing agent is dissolved in water, silver nitrate solution, and ammonium solution.

Owner:YOSHIAKI MAEDA

Low-flourine frozen Antarctic krill mince and preparation method thereof

ActiveCN105454403AHigh nutritional valueImprove securityFood freezingFood ingredient as anti-freezing agentProtein contentProtein food

The invention belongs to the field of development of protein raw materials of aquatic food, and particularly relates to low-flourine frozen Antarctic krill mince and a preparation method thereof. Meat of thawed frozen Antarctic krill products or fresh and live Antarctic krill are separated, collected and chopped, fluorine rich in krill protein is continuously removed, protein is settled and separated simultaneously, an anti-freezing denaturant is added after the products are adjusted to be neutral, and the low-flourine frozen Antarctic krill mince is obtained through quick freezing; the water content of the krill mince is 78%-82%, and the content of fluorine is lower than 100 mg / Kg on the dry basis; the crude protein content is 72-80 g / 100 g on the dry basis, the content of crude fat is 22-30 / 100 g on the dry basis, and the content of phospholipid is 450-480 mg / g on the basis of lipids. By means of the preparation method, industrialization is easy to realize, the prepared product has high nutrition value and good safety, is convenient to store and transport and can be widely used as a main material or an auxiliary material of aquatic protein food for various processing methods.

Owner:OCEAN UNIV OF CHINA

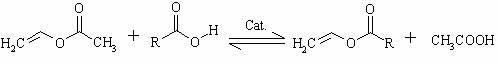

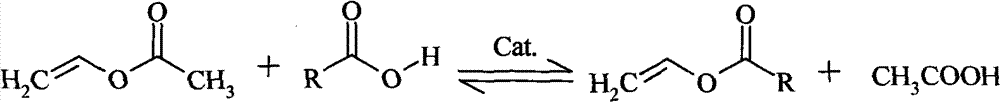

Preparation method of vinyl carboxylate

ActiveCN102627558AReduce dosageHigh catalytic activityPhysical/chemical process catalystsOrganic compound preparationEnvironmental resistanceCarboxylic salt

The invention relates to a preparation method of a vinyl carboxylate. According to the method, a carboxylic acid and vinyl acetate are subjected to a vinyl group exchange reaction under refluxing in the presence of a supported HgSO4 / C solid catalyst to obtain a reaction solution containing a corresponding vinyl carboxylate. The method which allows the catalyst to be simply prepared, have a high catalytic activity and be easily separated from products is a high-efficiency environmental-protection production method.

Owner:JIANGSU YIDA CHEM +1

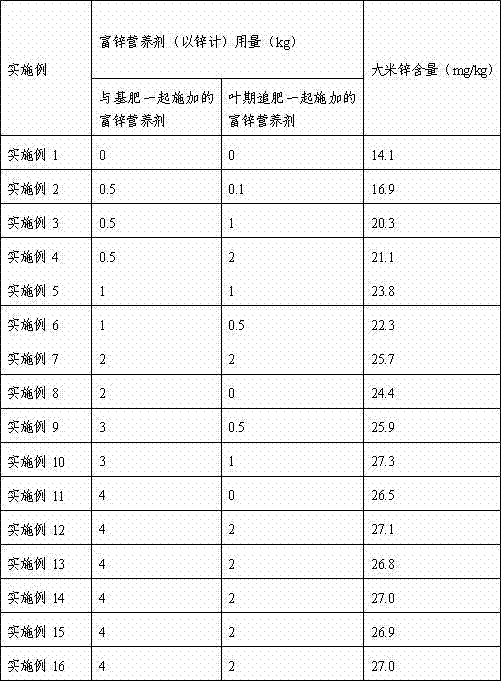

Zinc-rich nutrient for rice, preparation method thereof and method for producing zinc-rich rice with nutrient

ActiveCN103787770AGuaranteed nutritionTo achieve the purpose of enriching zincRice cultivationFertilizer mixturesOrganic fertilizerZinc

The invention discloses a zinc-rich nutrient for rice, a preparation method thereof and a method for producing zinc-rich rice with the nutrient. The zinc-rich nutrient comprises the following components in parts by weight: 0.5-25.5 parts of a zinc source by zinc weight, 0.3-1.8 parts of bio-organic fertilizer, 1.8-2.5 parts of humic acid and 0.01-0.05 part of a fertilizer binding agent. The zinc-rich nutrient is applied in the rice planting process. The rice produced by the method has the zinc content of 18.2-27.5 mg / kg and can be directly cooked or processed into other rice products to be eaten.

Owner:MICROHARBOR BIOTECH JIANGSU

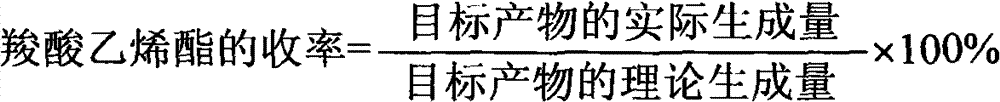

Preparation method of vinyl ester carboxylic acid

InactiveCN102775298AIncrease dispersionReduce dosagePhysical/chemical process catalystsOrganic compound preparationActivated carbonVinyl acetate

The invention provides a preparation method of vinyl ester carboxylic acid. The method comprises in the presence of activated carbon load PdCl2 or an activated carbon load PdCl2-alkali halide solid catalyst, enabling carboxylic acid and vinyl acetate to undergo a vinyl exchange reaction in a backflow state, and obtaining reaction liquid containing corresponding vinyl acetate. According to the method, the catalyst is prepared simply and conveniently, the catalytic activity is high, and the catalyst is separated from a product easily. The preparation method is an efficient, green and environment-friendly production method.

Owner:NANJING FORESTRY UNIV

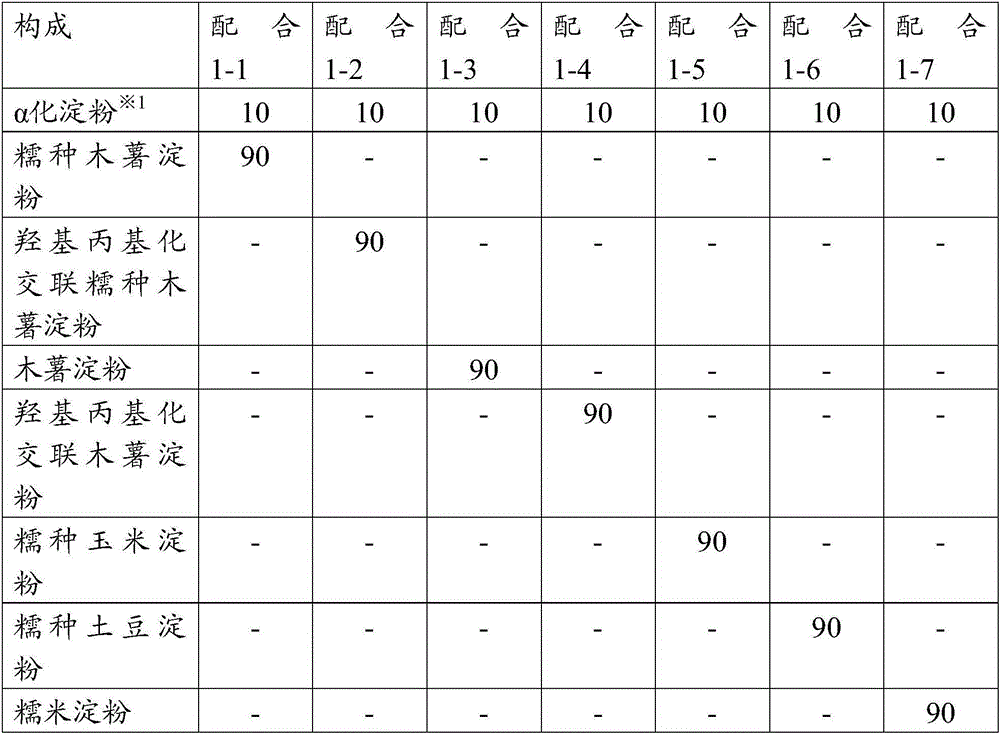

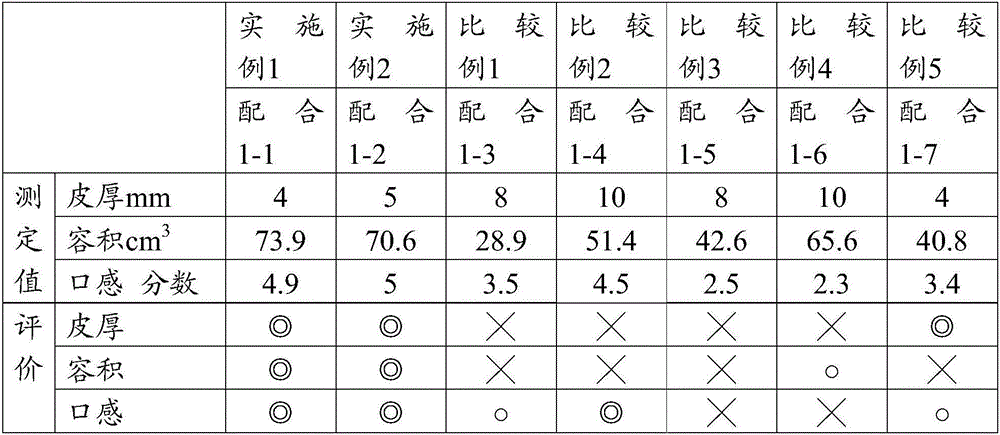

Cream puff and production method thereof

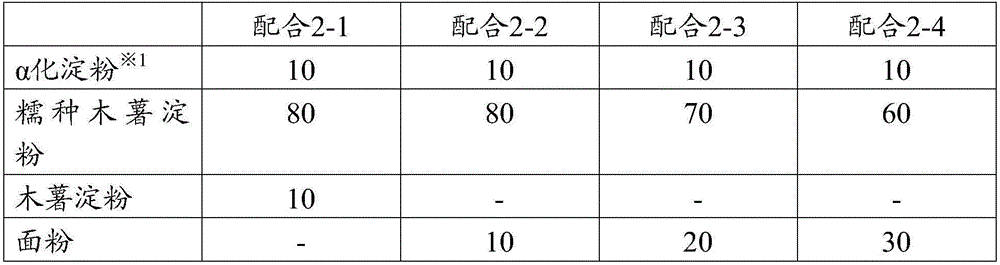

ActiveCN106572665AExcellent glutinous tasteEfficient production methodDough treatmentBakery productsAmylopectinRaw material

According to the present invention, a starchy raw material to be contained in cream puffs contains, with respect to 100 parts by mass of the starchy raw material: (A) 70-92 parts by mass of a starch having an amylopectin content of 80 mass% or higher, and (B) 8-20 parts by mass of a pregelatinized starch so as to satisfy A+B<=100 parts by mass; or (A) 70-92 parts by mass of the starch having an amylopectin content of 80 mass% or higher, and (B) 8-20 parts by mass of the pregelatinized starch so as to satisfy A+B<100 parts by mass, wherein, as the remaining portion of the starchy raw material, (C) 22 parts by mass or less of a grain flour is blended, and at least 8 parts by mass of the starch having an amylopectin content of 80 mass% or higher is a glutinous tapioca starch. Cream puff dough is prepared by using this starchy raw material as the starchy raw material for cream puff production, and cream puffs having an excellent rice-cake texture, a large volume, and a thin puff shell are produced by using the dough and are provided.

Owner:MATSUTANI CHEM INDS CO LTD +1

Production of thin-film label

InactiveCN1982045AInexpensive and how to makeEfficient production methodPaper/cardboard articlesPaper/cardboard layered productsPaper sheetComposite material

A process for preparing film label includes such steps as providing a film, vacuum evaporating of a metal layer on the film surface, printing a chemical corrosion resistant protecting layer whose shape is a needed graphics or pattern, chemical corroding to remove uncovered metal layer, and attaching the obtained metal graphics or pattern onto a paper substrate.

Owner:李华容

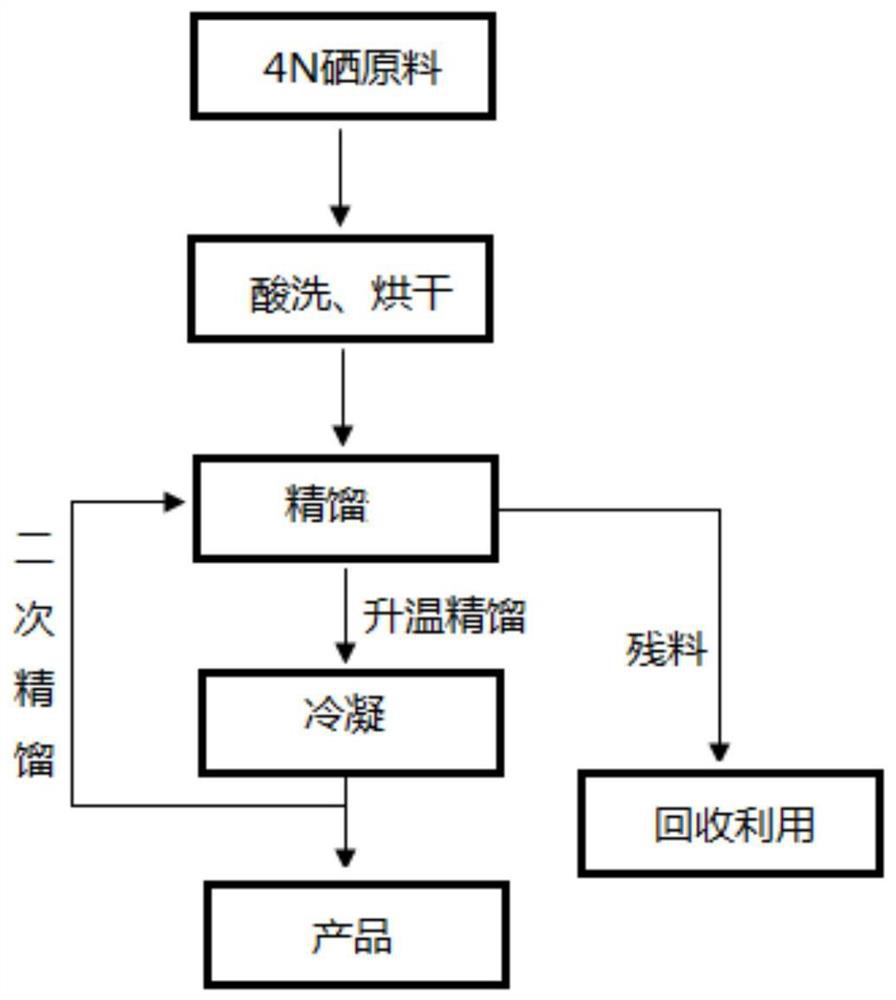

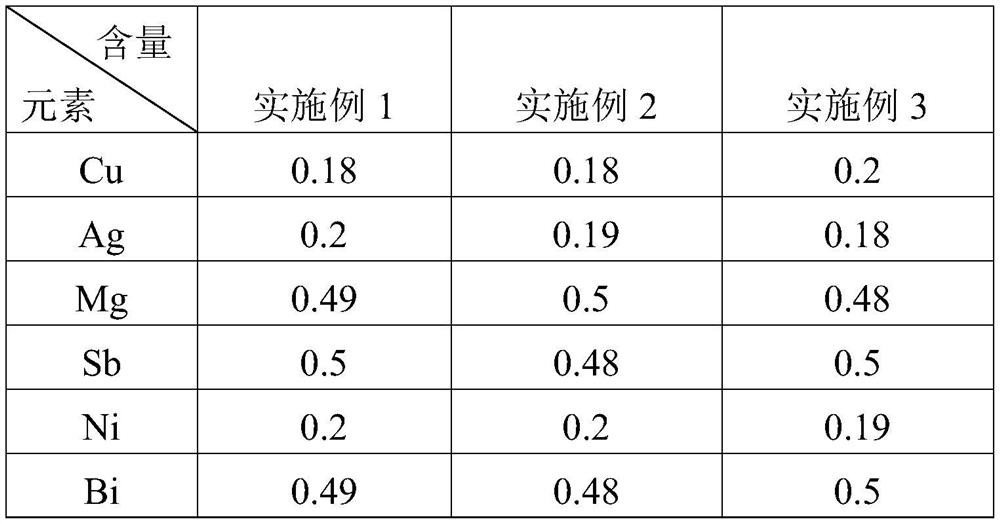

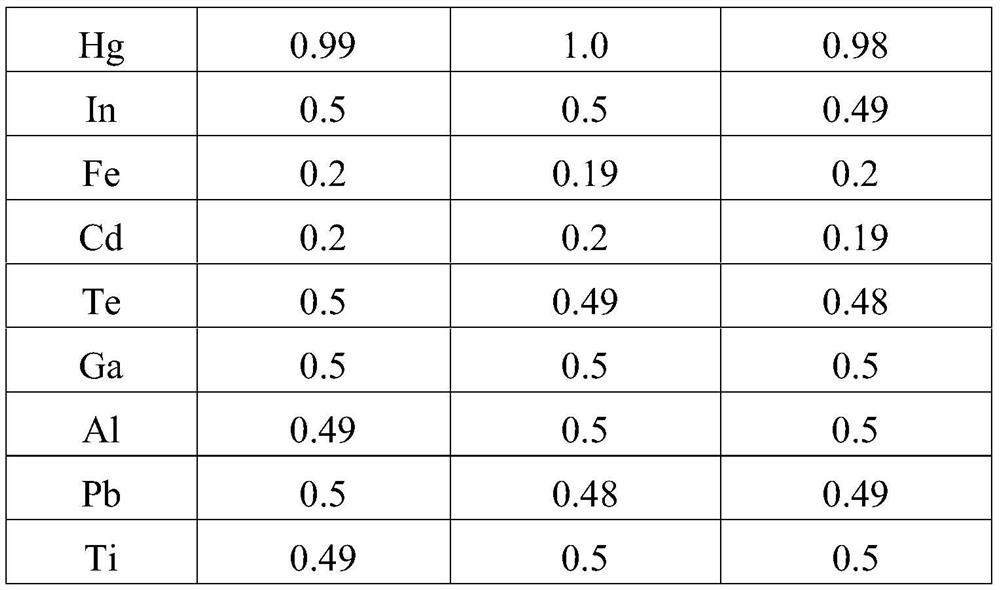

Production method of 5N selenium

InactiveCN113460975AHigh purityReduce contaminationElemental selenium/telluriumOrganic chemistryImpurity

The invention provides a 5N selenium production method, which comprises: S1, crushing a 4N selenium raw material into 4N selenium particles, pre-treating the 4N selenium particles, and removing impurities in the 4N selenium particles; and S2, carrying out gas-phase normal-pressure rectification on the pretreated 4N selenium particles, and cooling the rectified product to obtain 5N selenium. According to the production method, high-purity 5N selenium can be obtained, and the production method is efficient, environmentally friendly, low in investment and capable of saving energy. Meanwhile, compared with gas-phase vacuum rectification, the production method of the 5N selenium disclosed by the invention adopts gas-phase normal-pressure rectification. The process is simpler and easier to operate, can directly produce the 5N selenium particles, reduces contamination of the granulation process, and is suitable for producing a large number of 5N selenium particles.

Owner:江西中晶新材料有限公司

Preparation method of mulberry leaf metallothionein

InactiveCN105859875ATake advantage ofHigh purityPeptide preparation methodsMetallothioneinsEnzyme digestionProtein target

The invention discloses a preparation method of mulberry leaf metallothionein. The preparation method of the mulberry leaf metallothionein is completed through the six steps of mulberry leaf protein extracting, protein fusion vector expression constructing, biomembrane separating, orientated metal ion releasing, enzyme digestion eluting and purifying, refining and freeze-drying. A protein source of the mulberry leaf metallothionein is extracted and separated from pure plants, the plant protein resources are fully utilized, and compared with MT raw materials from other sources, the advantages of being reliable in raw material source, simple in extraction process, low in cost, green, safe and the like are achieved; when concentrated liquid protein is induced with metal ions, a metallic element which is necessary for a human body is selected as a fusion vector expression body, and therefore the target product can be stably expressed in a soluble and high-yield mode; the target protein and quantitative releasing of the metal ions can achieve classified expression to obtain purified MT protein molecules with the different structures; the extraction process cycle is short, the handling capacity is high, and the target product obtained through reacting has the advantages of being high in recycling rate, few in loss, high in purity, free of secondary pollution and the like.

Owner:邹汉志

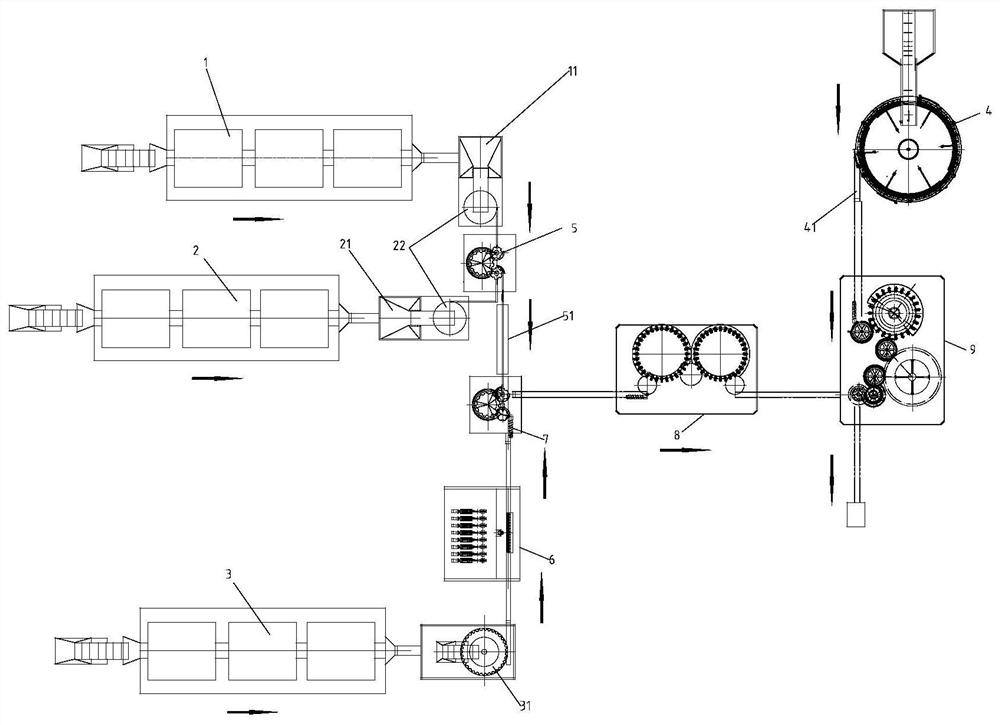

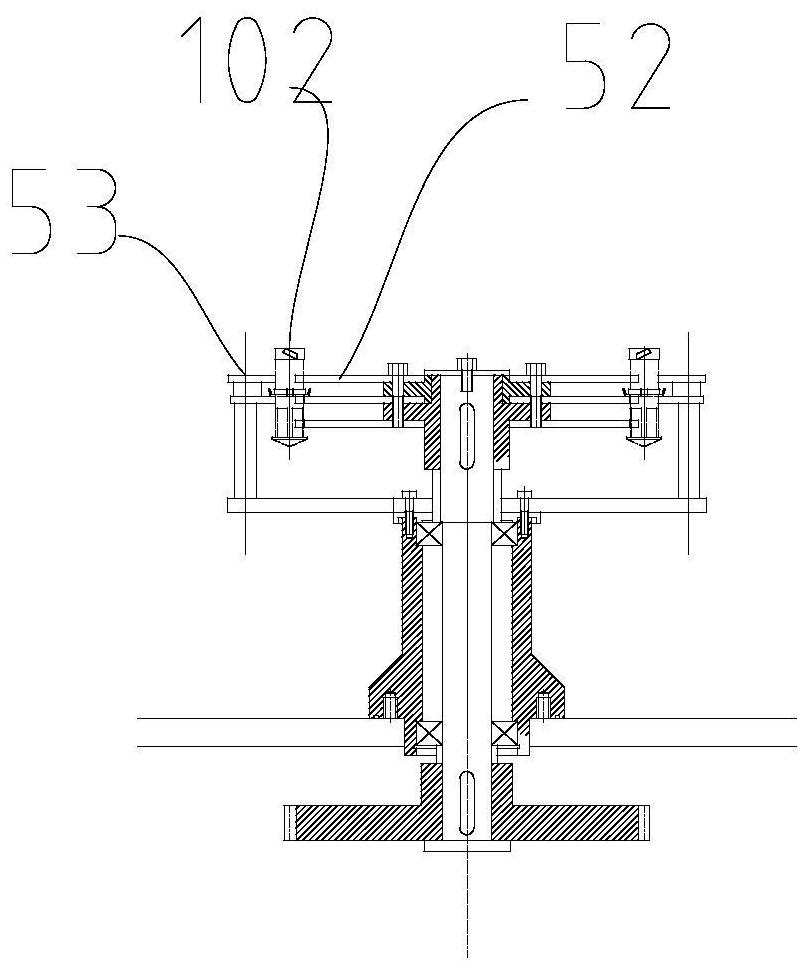

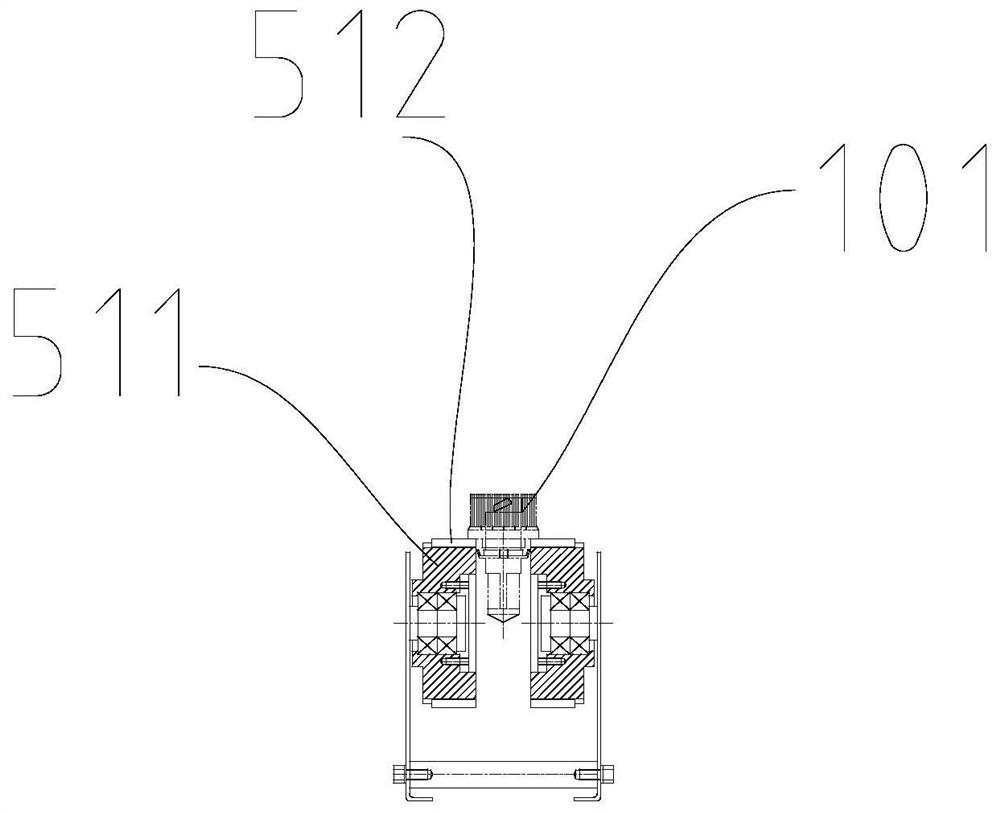

Ready-to-prepare beverage production line and process

ActiveCN112062081ARealize automated productionComplete production methodBottle-handling machinesProcess engineeringBottle cap

The invention relates to a ready-to-prepare beverage production line and process. The ready-to-prepare beverage production line comprises an ejector rod cleaning machine, a bottle cap cleaning machine, a sealed cup cleaning machine, a filling machine, a bottle cap ejector rod cap screwing machine, a sealed cup storage finishing machine, a sealed cup screwing machine, a combined sealed cup washingand drying machine, a water bottle finishing machine and a water bottle washing, filling and sealing machine. A discharging port of the ejector rod cleaning machine is connected with a material storage hopper of an ejector rod storage finishing machine. A discharging port of the bottle cap cleaning machine is connected with a material storage hopper of a bottle cap storage finishing machine, and an outlet of the material storage hopper of the ejector rod storage finishing machine and an outlet of the material storage hopper of the bottle cap storage finishing machine are connected with two feeding ports of the bottle cap ejector rod cap screwing machine through a spiral oscillation finishing machine separately. A discharging port of the bottle cap ejector rod cap screwing machine is connected with a feeding port of the sealed cup screwing machine through a belt conveyor. According to the ready-to-prepare beverage production line and process, all the components are combined through thebottle cap ejector rod cap screwing machine, the sealed cup screwing machine and the water bottle washing, filling and sealing machine, a finished product of instant beverage is finally formed, full-automatic production of ready-to-prepare beverage can be achieved through the ready-to-prepare beverage production device, and defects in the prior art are overcome.

Owner:CHANGSHA PINGXIN PHARMACY PACKING MACHINERY

Production method of instant seasoned mulberry leaves

The invention discloses a production method of instant seasoned mulberry leaves. The method comprises the following steps of picking fresh mulberry leaves, and performing blanching and color protection on the picked mulberry leaves; rapidly putting the blanched and color-protected mulberry leaves into flowing ozone water to be cooled, and then putting the cooled mulberry leaves into a dehydrator to be dehydrated until no water flows out when the mulberry leaves are pinched by the hands; fully immersing the cooled and sterilized mulberry leaves into prepared seasoning juice, and performing stirring for 50-60 seconds to obtain seasoned mulberry leaves; putting the seasoned mulberry leaves in an ozone sterilization cabinet for ozone drying and sterilization until the moisture content of the mulberry leaves is 60-70% by micro-drying; putting the mulberry leaves subjected to seasoning and secondary low-temperature sterilization into a sterilized packaging bag, vacuumizing the bag, and sealing the bag; and putting the bag into ultrahigh-pressure sterilization equipment for low-temperature sterilization to obtain the instant seasoned mulberry leaves. According to the preparation method, three times of low-temperature sterilization are adopted, so that the microorganism killing rate can be guaranteed, the nutritional active ingredients of the final instant seasoned mulberry leaves canbe greatly reduced, the taste is crisp and tasty, the texture is hard and crisp, and the nutrition, taste and quality form of the instant seasoned mulberry leaves are greatly improved.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI

Compounded insecticidal suspension emulsion with chlorpyrifos and spirotetramat and preparation method of compounded insecticidal suspension emulsion

The invention discloses a compounded insecticidal suspension emulsion with chlorpyrifos and spirotetramat and a preparation method of the compounded insecticidal suspension emulsion. The compounded insecticidal suspension emulsion comprises the following contents in percentage by weight: 2-30% of spirotetramat, 10-40% of chlorpyrifos, 5-20% of organic solvent and the balance water, and is formed by adopting the following steps of mechanical stirring, sanding and high-speed homogeneity cutting. The compounded insecticidal suspension emulsion has a stable property and a high medicine effect, and can be used for preventing injurious insects such as scale insects of oranges, cotton and apples, bemisia tabaci of vegetables, and the like. According to the invention, the compounded insecticidal suspension emulsion has the advantages that the water is used as the main dispersion medium, the pollution to the environment is small, the situations of oil deposition, sediment and the like when the compounded insecticidal suspension emulsion is stored for two years under normal temperature are not existed, the service life of a storage rack is long and is non-flammable, the storage and the transportation is safe, compared with using the spirotetramat alone, the cost is low, and the like.

Owner:ZHEJIANG XINNONG CHEM CO LTD +1

Environment-friendly anticorrosion abrasion-resistant luminescent marking coating production method

InactiveCN109082185AEnvironmentally friendly anti-corrosion and wear-resistant luminescent marking paint production method Efficient production methodEfficient production methodRubber derivative coatingsLuminescent paintsAcrylic resinRare earth

The invention discloses an environment-friendly anticorrosion abrasion-resistant luminescent marking coating production method which includes the steps: 1) adding solvents to completely dissolve chlorinated rubber, acrylic resin and modified piperylene-based hydrocarbon resin; 2) uniformly stirring anti-yellowing a polyurethane prepolymer, a chain extender, an antioxidant, long-lasting polyurethane luminous powder to obtain mixture; 3) adding pigments, fillers and additives into the mixture prepared in the step 2) to uniformly stir materials; 4) adding composite rare earth in the step 3), 5) grinding the materials uniformly dispersed in the step 4), and packaging the grinded materials. The environment-friendly anticorrosion abrasion-resistant luminescent marking coating production method is efficient and suitable for industrial production, a coating is environmentally friendly, high in comprehensive performance, excellent in abrasion resistance and anticorrosion water resistance and long in service life and can continue to emit light for a long time without light, and a driver can be timely, continuously and remarkably reminded and warned.

Owner:南宁市高科交通设施有限公司

Selenium-enriched paddy seedling and cultivation method thereof and produced organic selenium-enriched rice

ActiveCN102150538BIncrease selenium contentImprove conversion rateFertilising methodsRice cultivationPlant nutritionSeedling

The invention discloses a selenium-enriched paddy seedling and a cultivation method thereof and produced organic selenium-enriched rice. The total content of selenium in each seedling is between 4.6 and 360 mu g when the selenium-enriched paddy seedling is transplanted. The method comprises the following steps of: adding a nano selenium plant nutrition agent into seedling raising soil in seedlingdisks or seedling raising fields at the paddy seedling raising stage; and cultivating the selenium-enriched paddy seedling by a paddy seedling raising method. The content of the selenium in the organic selenium-enriched rice is between 100 and 300 mu g / kg, wherein the organic selenium content is more than or equal to 80 percent. The rice is rich in selenium elements, and the whole content is unified. By the method, the proportion of organic selenium is improved, the problem of low stability of the content of the selenium in the rice which grows in different batches in the prior art is solved,the uniformity of the content of the selenium in the rice is ensured, and the standardized large-scale production can be realized.

Owner:SUZHOU SETEK

Culture medium for identifying infectious microbes of erythromycin fermentation liquid, preparation method of culture medium, and method for identifying infectious microbes

InactiveCN109609585AThe test result is simpleWith a clear purposeMicrobiological testing/measurementBeef extractCulture mediums

The invention discloses a culture medium for identifying infectious microbes of erythromycin fermentation liquid, a preparation method of the culture medium, and a method for identifying infectious microbes. The culture medium comprises the following raw materials of sodium chloride, a beef extract, yeast cream, glucose, peptone and magnesium sulphate. The preparation method comprises the following steps of enabling the raw materials to dissolve in distilled water, adjusting pH, dropwise adding a phenol red solution to the culture medium until the culture medium is deep red, subpackaging the deep red culture medium into clean empty test tubes, sealing the test tubes with rubber plugs or test tube caps, and performing sterilization so as to obtain the culture medium for identifying infectious microbes of erythromycin fermentation liquid. The method for identifying infectious microbes comprises the following steps of inoculating erythromycin fermentation liquid samples needing examination with the culture medium, performing culture, examining sample taking smear under a microscope, and through examining the microbe type of microbe strains on the smear, judging whether the erythromycin fermentation liquid contains the infectious microbes or not. The culture medium disclosed by the invention is definite in purpose, and coordinated and rich in nutrients, the preparation method is simple, quick, convenient and efficient, and the method for identifying the infectious microbes is simple, effective and high in accuracy degree.

Owner:YILI CHUANNING BIOTECH CO

Slag fiber cotton production method

InactiveCN105236729AUnique production methodReduce manufacturing costGlass making apparatusFiberSlag

The present invention provides a slag fiber cotton production method, which comprises that: thermal liquid state floating slag in a melting furnace is subjected to re-upgrading, the re-graded slag enters a quenching and tempering furnace, acidity coefficient is adjusted to 1.26, the thermal liquid state slag enters a centrifuge, and inorganic fiber filaments with a diameter of 7 [mu]m are drawn under centrifugal hot wind blowing pressure; when the thermal liquid state slag is blown into the inorganic fiber filaments, a mist-like dust preventing oil agent is blown and sprayed on the inorganic fiber filaments, a water soluble thermosetting type powder phenol formaldehyde resin binder is uniformly sprayed on the inorganic fiber filaments, and wind separation is performed, such that the fibers settles in a cotton collection chamber; and the cotton collection chamber makes the fibers be uniformly distributed on a conveyor belt through the provided negative pressure so as to be output, the material is conveyed into a curing furnace, and pressurization shaping and other processes are performed to prepare the cotton felt and the structure cotton product. According to the present invention, the thermal liquid state slag is directly upgraded to prepare the inorganic fiber filaments, such that the production method is unique, the production cost is low, the production method is superior, the energy sources are circularly and comprehensively utilized and the effects of energy saving and consumption reducing are achieved during the production, and the ecology and the environment are protected.

Owner:湖北铸邦环保科技材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com