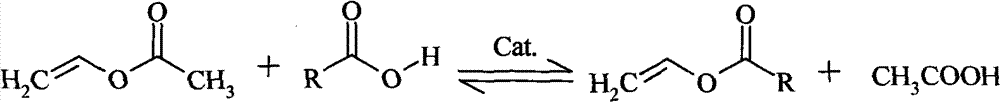

Preparation method of vinyl ester carboxylic acid

A technology of vinyl carboxylate and vinyl acetate, applied in the field of chemistry, can solve the problems of difficult recovery, high price, causing pollution, etc., and achieve the effects of simple preparation method, low equipment corrosion, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

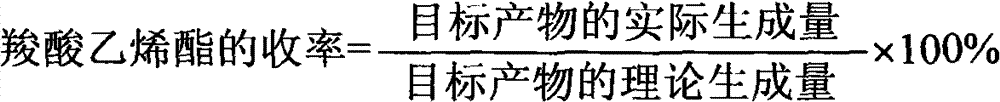

Examples

Embodiment 1

[0029] Weigh 25g of activated carbon and place it in a flask, add 30% HNO 3 The solution was heated and stirred in a water bath at 60°C for 4 hours, the activated carbon in the solution was filtered out, the activated carbon was repeatedly washed with distilled water until the filtrate was neutral, and dried for later use. Weigh 5g of pretreated activated carbon and place it in a flask, and add 50g of distilled water; weigh 0.25g of PdCl 2 , dissolved in concentrated HCl and poured into a flask, stirred and impregnated in a water bath at 80°C for 6h, filtered and washed until the filtrate was neutral, and dried to a constant weight to obtain 1 # Loaded PdCl 2 / C solid catalyst.

Embodiment 2

[0031] Weigh 25g of activated carbon and place it in a flask, add 30% HNO 3 The solution was heated and stirred in a water bath at 60°C for 4 hours, the activated carbon in the solution was filtered out, the activated carbon was repeatedly washed with distilled water until the filtrate was neutral, and dried for later use. Weigh 5g of pretreated activated carbon and place it in a flask, and add 50g of distilled water; weigh 0.25g of PdCl 2 , dissolved in concentrated HCl, poured into a flask, added 0.2g NaCl, stirred and impregnated in a water bath at 80°C for 6h, filtered and washed until the filtrate was neutral, dried the solid to constant weight, and obtained 2 # Loaded PdCl 2 -NaCl / C solid catalyst.

Embodiment 3

[0033] Weigh 25g of activated carbon and place it in a flask, add 30% HNO 3 The solution was heated and stirred in a water bath at 60°C for 4 hours, the activated carbon in the solution was filtered out, the activated carbon was repeatedly washed with distilled water until the filtrate was neutral, and dried for later use. Weigh 5g of pretreated activated carbon and place it in a flask, and add 50g of distilled water; weigh 0.25g of PdCl 2 , dissolved in concentrated HCl and poured into a flask, added 0.2g KCl, stirred and impregnated in a water bath at 80°C for 6h, filtered and washed until the filtrate was neutral, dried the solid to constant weight, and obtained 3 # Loaded PdCl 2 - KCl / C solid catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com