Highly-dispersed support core-shell structure Pd @ Ni/WC direct alcohol fuel cell catalyst and preparation method thereof

A core-shell structure, fuel cell technology, applied in the direction of fuel cells, battery electrodes, structural parts, etc., can solve the problems of anode catalysts restricting the industrialization process of direct alcohol fuel cells, limited cost reduction, and poor stability. Facilitate large-scale production, reduce usage and cost, and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

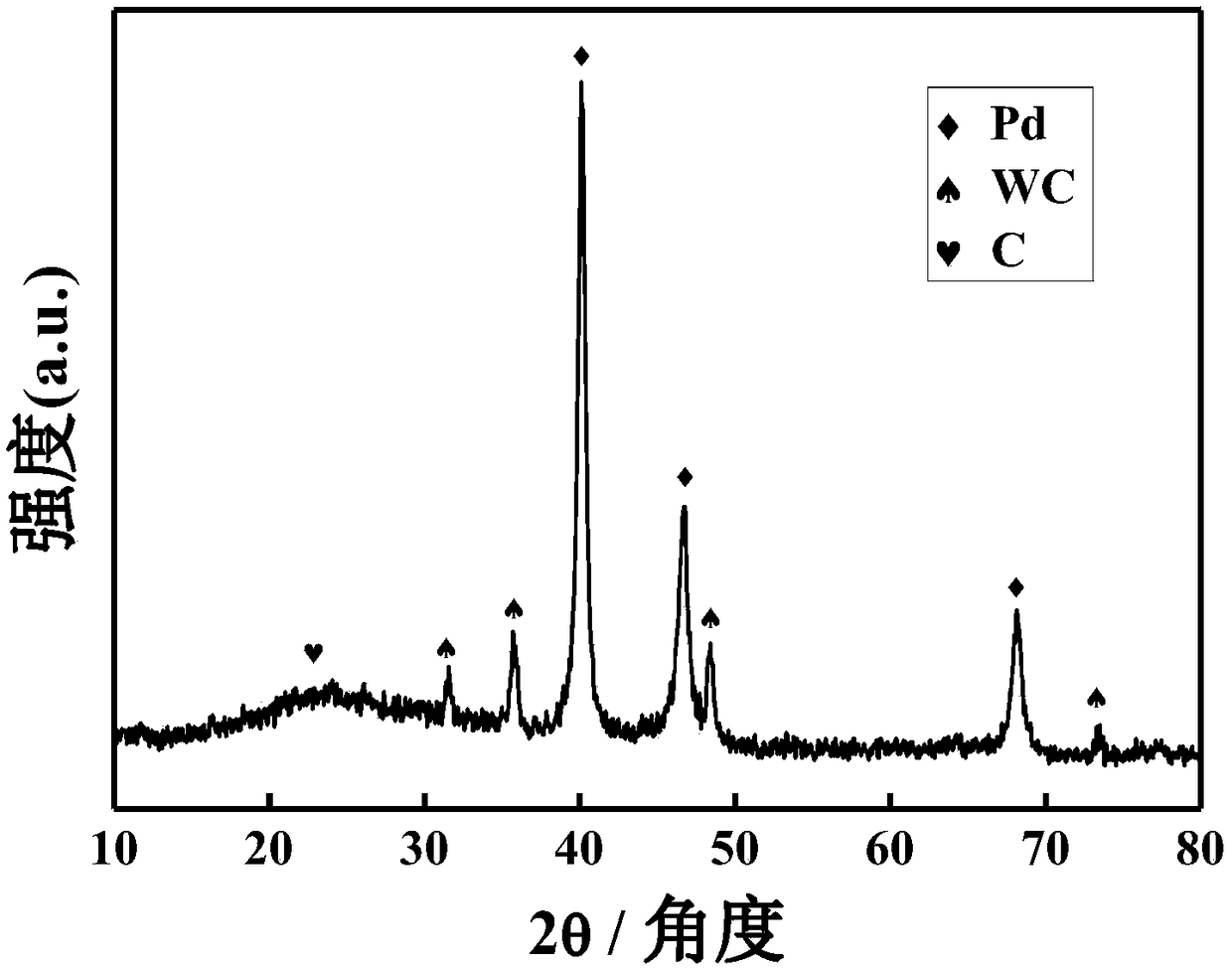

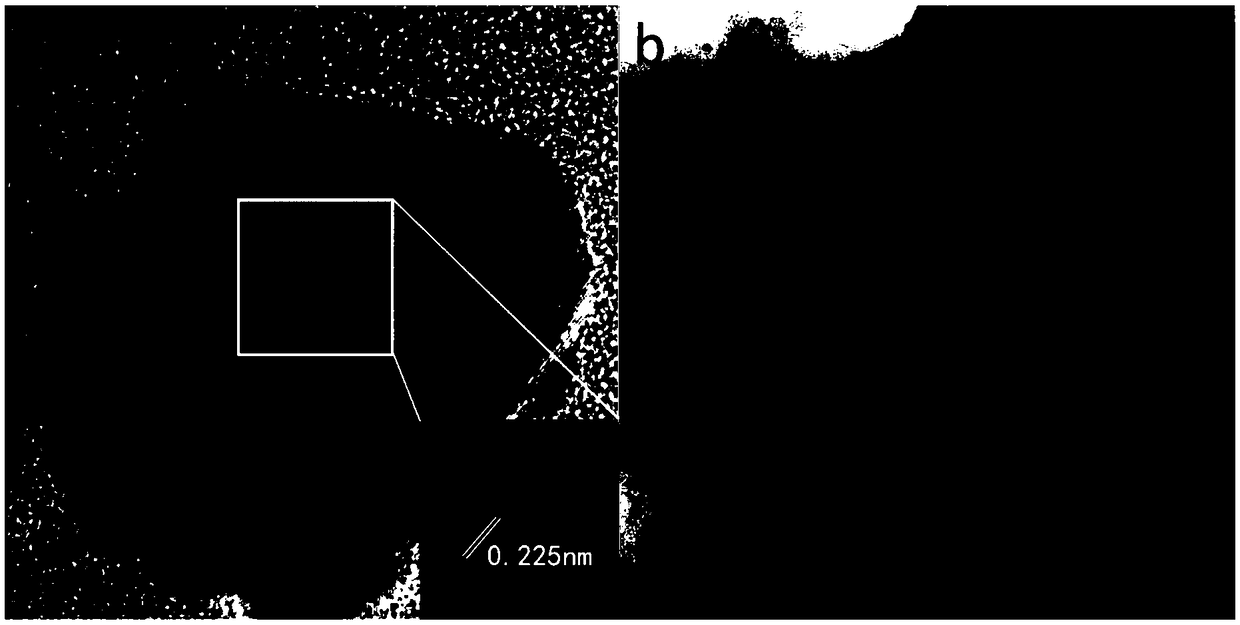

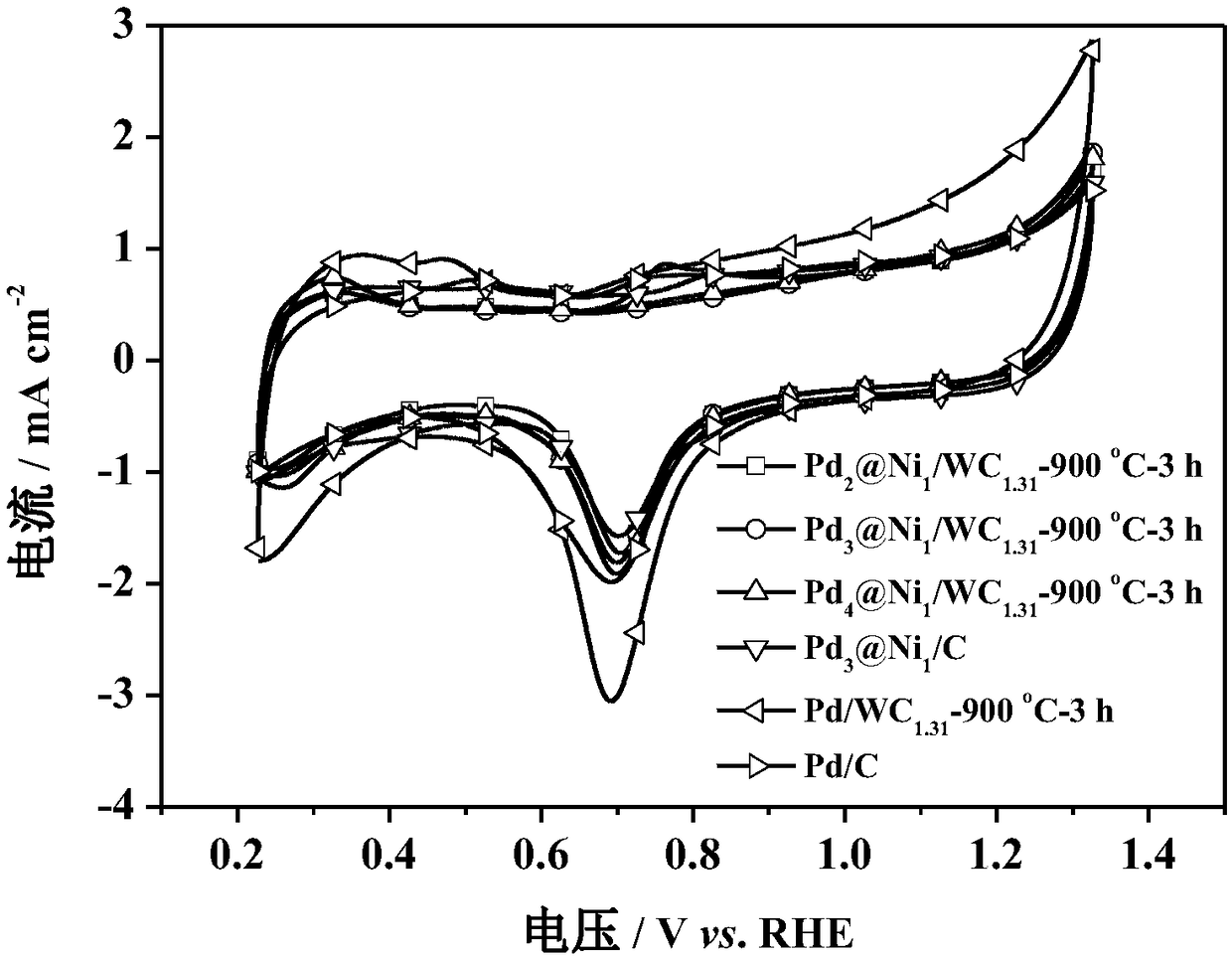

[0041] Example 1: Pd 2 @Ni 1 / WC 1.31 -900℃-3h(Pd 2 @Ni refers to the molar ratio of Pd and Ni is 2:1, WC 1.31 Indicates tungsten carbide, the mass ratio of tungsten source and carbon source is 1:1.31, the calcination temperature is 900°C, and the calcination time is 3h)

[0042] Weigh 1g of ammonium metatungstate, dissolve 1.31g of glucose in deionized water at 80°C, adjust the pH to 11 with NaOH, add 2g of SiO 2 The sol (diameter 20nm, mass fraction 40%) was stirred at 80°C for 3h; dried at 120°C for 5h to obtain a precursor solid. The above precursor solids were placed in a tube furnace, N 2 Under atmosphere at 5°C min -1 The rate is programmed to 550°C, then at 2°C min -1 The rate was programmed to raise the temperature to 900°C, react at a constant temperature for 3 hours, and cool naturally to obtain a precursor composite material. Put the above precursor composite material in 2M NaOH solution, stir at 80°C for 12h, suction filter, wash, and vacuum dry at 80°C fo...

Embodiment 2

[0045] Example 2: Pd 3 @Ni 1 / WC 1.31 -900℃-3h(Pd 3 @Ni means the molar ratio of Pd and Ni is 3:1, WC 1.31 Indicates tungsten carbide, the mass ratio of tungsten source and carbon source is 1:1.31, the calcination temperature is 900°C, and the calcination time is 3h)

[0046] Weigh 1g of ammonium metatungstate, dissolve 1.31g of glucose in deionized water at 80°C, adjust the pH to 11 with NaOH, add 2g of SiO 2 The sol (diameter 20nm, mass fraction 40%) was stirred at 80°C for 3h; dried at 120°C for 5h to obtain a precursor solid. The above precursor solids were placed in a tube furnace, N 2 Under atmosphere at 5°C min -1 The rate is programmed to 550°C, then at 2°C min -1 The rate was programmed to raise the temperature to 900°C, react at a constant temperature for 3 hours, and cool naturally to obtain a precursor composite material. Put the above precursor composite material in 2M NaOH solution, stir at 80°C for 12h, suction filter, wash, and vacuum dry at 80°C for 6h...

Embodiment 3

[0049] Example 3: Pd 4 @Ni 1 / WC 1.31 -900℃-3h(Pd 4 @Ni means the molar ratio of Pd and Ni is 4:1, WC 1.31 Indicates tungsten carbide, the mass ratio of tungsten source and carbon source is 1:1.31, the calcination temperature is 900°C, and the calcination time is 3h)

[0050] Weigh 1g of ammonium metatungstate, dissolve 1.31g of glucose in deionized water at 80°C, adjust the pH to 11 with NaOH, add 2g of SiO 2 The sol (diameter 20nm, mass fraction 40%) was stirred at 80°C for 3h; dried at 120°C for 5h to obtain a precursor solid. The above precursor solids were placed in a tube furnace, N 2 Under atmosphere at 5°C min -1 The rate is programmed to 550°C, then at 2°C min -1 The rate was programmed to raise the temperature to 900°C, react at a constant temperature for 3 hours, and cool naturally to obtain a precursor composite material. Put the above precursor composite material in 2M NaOH solution, stir at 80°C for 12h, suction filter, wash, and vacuum dry at 80°C for 6h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com