Patents

Literature

535results about How to "Good for mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

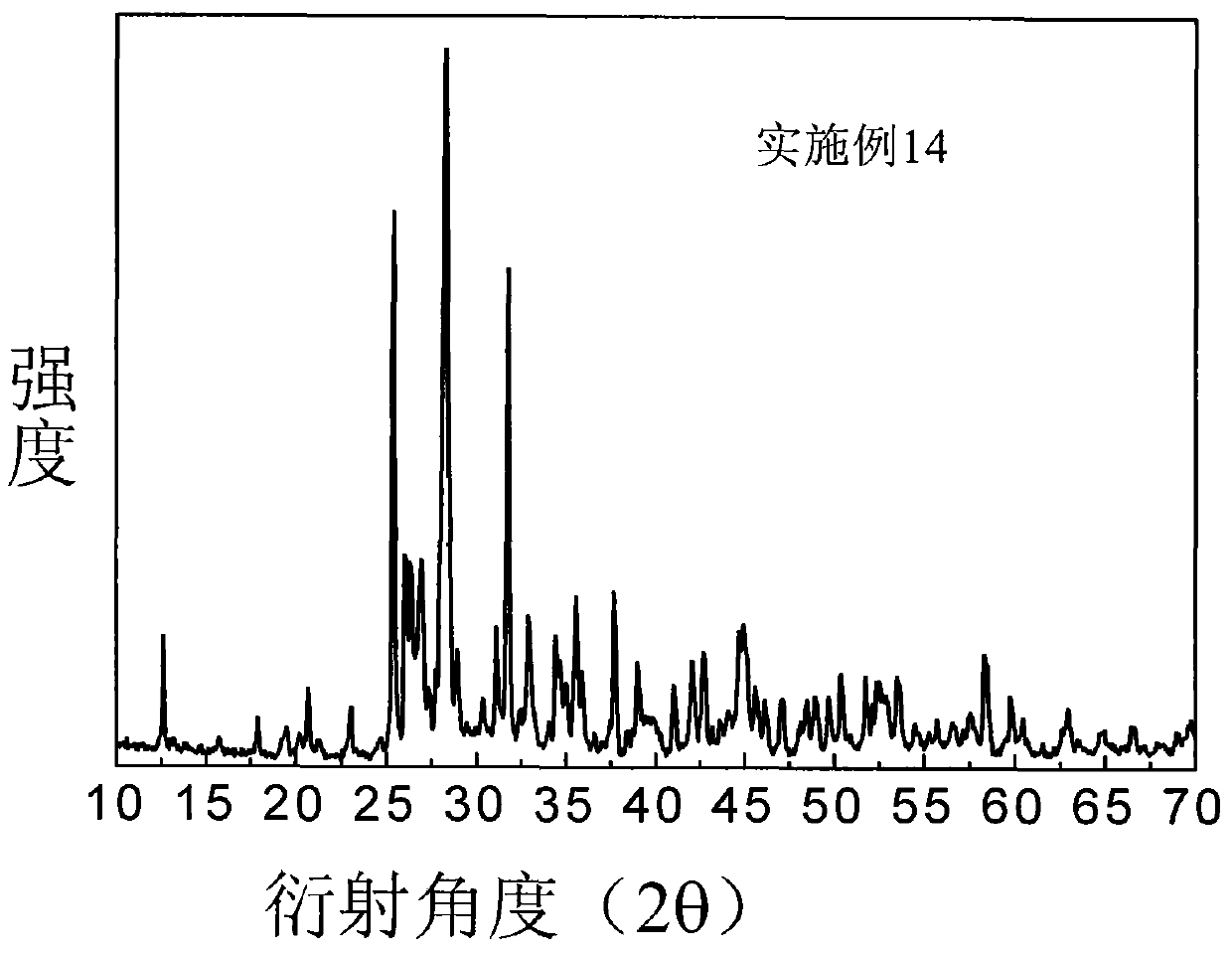

Silicon dioxide composite anode material for lithium ion battery, as well as preparation method and application of silicon dioxide composite anode material

ActiveCN104022257AImprove electronic conductivityImprove efficiencyCell electrodesSecondary cellsLithium electrodeVolume effect

The invention discloses a silicon dioxide composite anode material for a lithium ion battery, as well as a preparation method and an application of the silicon dioxide composite anode material. The silicon dioxide composite anode material is prepared from the components of silicon dioxide powder and a conductive carbon layer with the surface of the silicon dioxide powder is uniformly and densely coated. With the adoption of the silicon dioxide composite anode material, the original component structure of an SiO material system is kept, so that the lower volume effect is ensured; the silicon dioxide dense carbon layer coating structure is successfully realized by adopting the technologies of mixing kneading, sheet rolling, press forming and the like, and thus the first coulombic efficiency of the silicon dioxide composite anode material is remarkably increased, and can reach a theoretical value being larger than 77 percent, and the cycle performance and the conductive characteristic are also remarkably improved, so that the silicon dioxide composite anode material is suitable for being charged and discharged with the large rate and can be applied to the power market.

Owner:BTR NEW MATERIAL GRP CO LTD +1

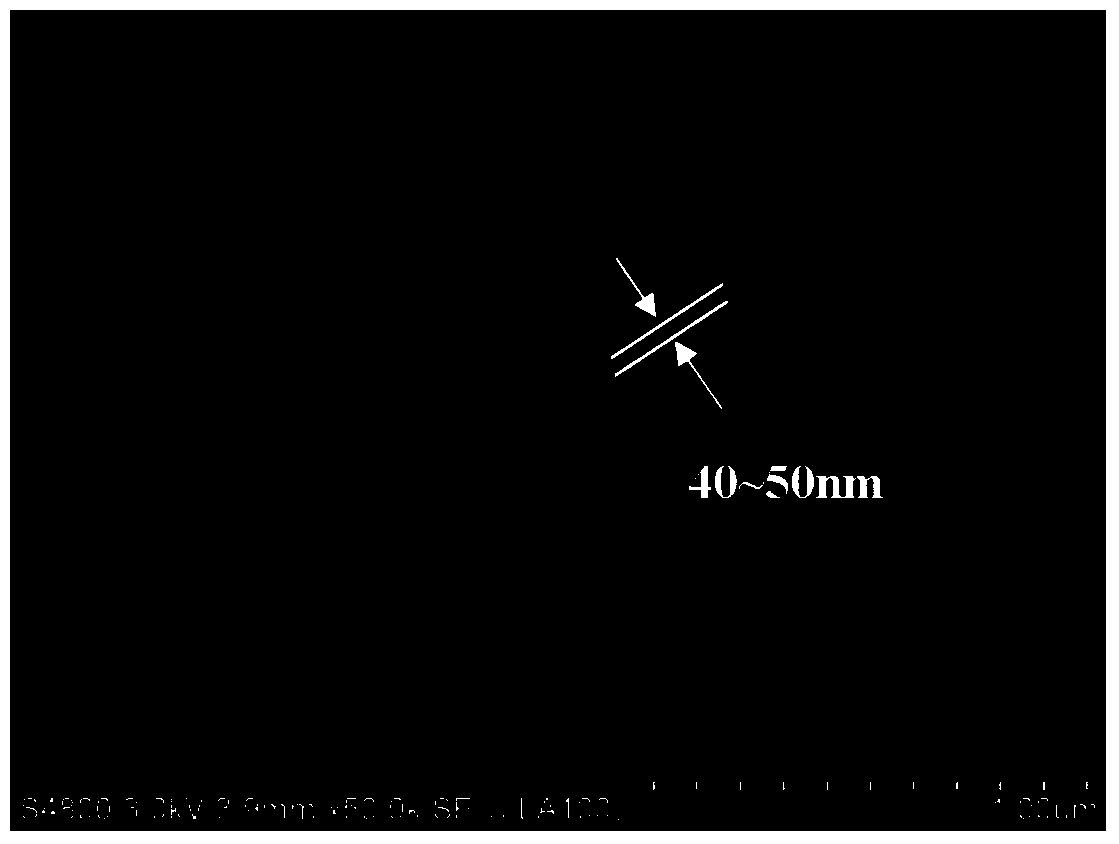

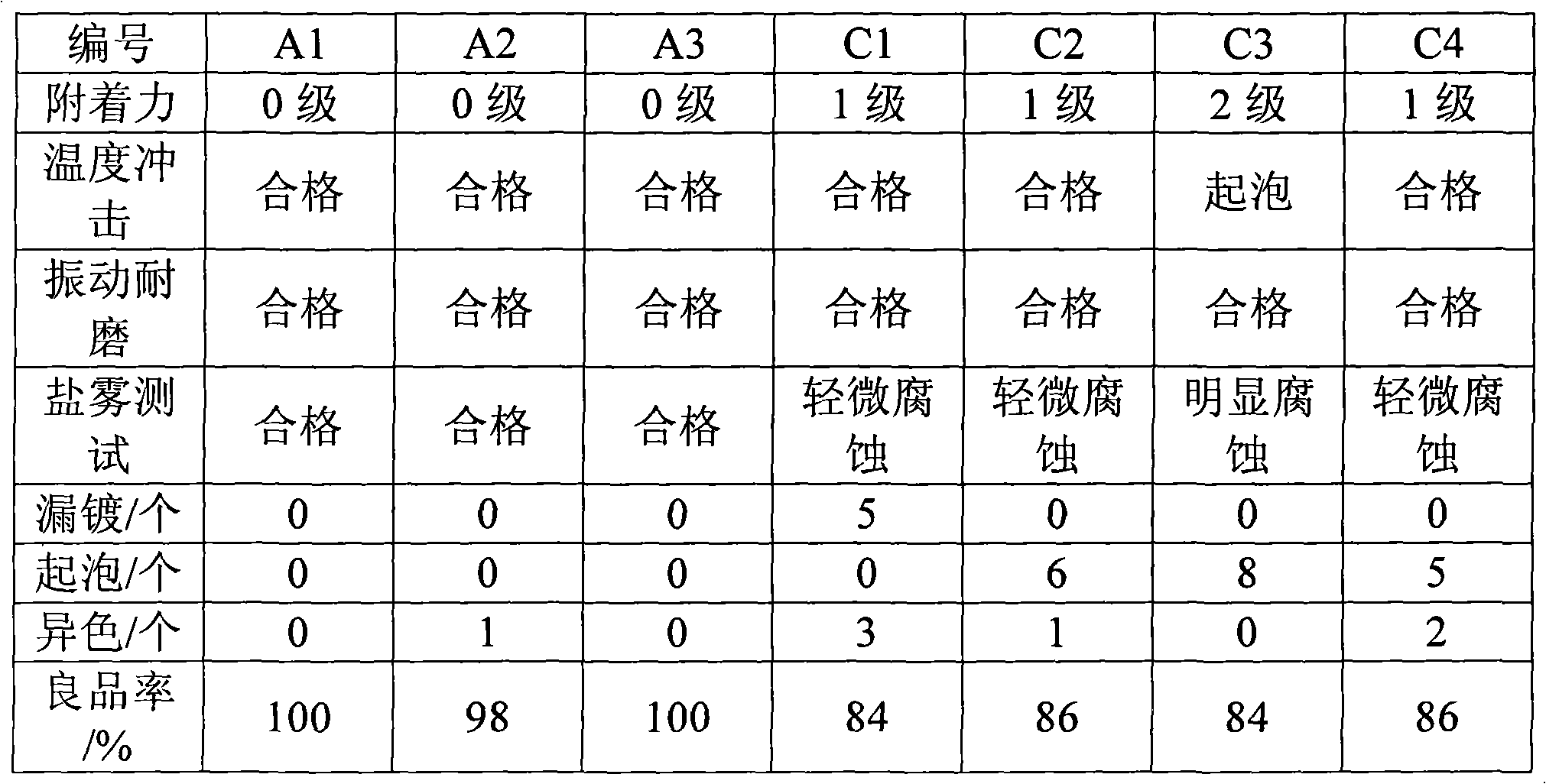

Aluminum alloy surface treatment method

InactiveCN101922010ALess prone to missing platingNot prone to foamingHot-dipping/immersion processesAnodisationAcid etchingLaser etching

The invention provides an aluminum alloy surface treatment method which comprises the steps of sequentially carrying out pretreatment, chemical plating and electroplating on an aluminum alloy matrix, wherein the pretreatment comprises the steps of sequentially carrying out anode oxidation, laser etching, erosion and acid etching on the aluminum alloy matrix. By using the method for forming electroplating texture on the surface of an aluminum alloy, the obtained product has natural texture, is not subject to skip plating, bubbling and discoloration phenomena and has a good decorative effect. Besides, the method has the advantage of simple operation, realizes the unshaded treatment and the convenient maintenance by using the technology of anode oxidation plus electroplating, and facilitates the mass production.

Owner:BYD CO LTD

Realization method based on CPCI bus technology of dual module hot spare system switching

ActiveCN102001348AImprove scalabilityImprove operational efficiencyAutomatic systemsRedundant hardware error correctionSoftware engineeringMechanical engineering

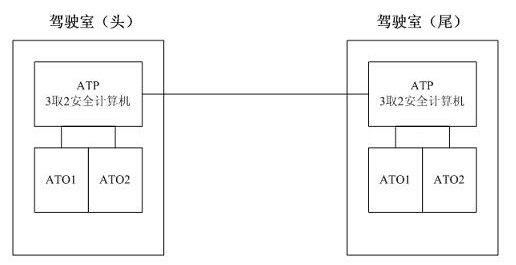

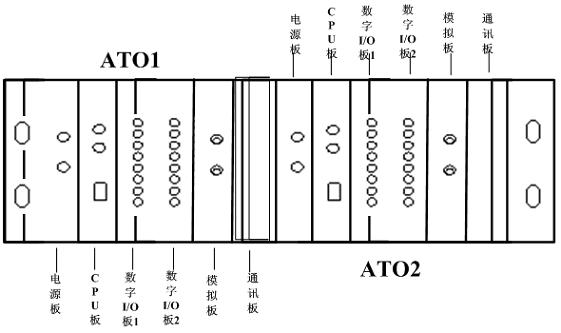

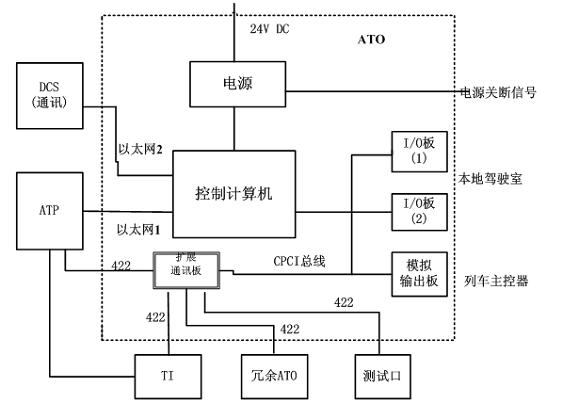

The invention relates to a realization method based on the CPCI bus technology of the dual module hot spare system switching. The realization method is characterized by comprising the following steps: 1) the cabs at the head and tail of a train are separately provided with an ATP and two ATOs, the ATP adopts 2-out-of-3 architecture, the same ATOs (ATO1, ATO2) are hot spares to each other; 2) when the train runs normally, only the ATPs and ATO of the front head cab in the advancing direction work, the tail cab is powered off; when the train enters a turning section, a driver in the head cab of the original advancing direction presses an AR button on the driving platform to power on the ATPs and ATO of the tail cab; the ATPs and ATO of the head cab and the ATPs and ATO of the tail cab exchange information, the driving privilege is exchanged according to the driving direction so that the original tail cab is reversed to become the head cab, the ATPs and ATO of the original head cab are powered off; and 3) the redundancy automatic switching of one ATO adopts the dual module hot spare mode. The system of the invention has simple hardware configuration, lower system cost and abundant interfaces and is convenient to test and debug.

Owner:NANJING NRIET IND CORP

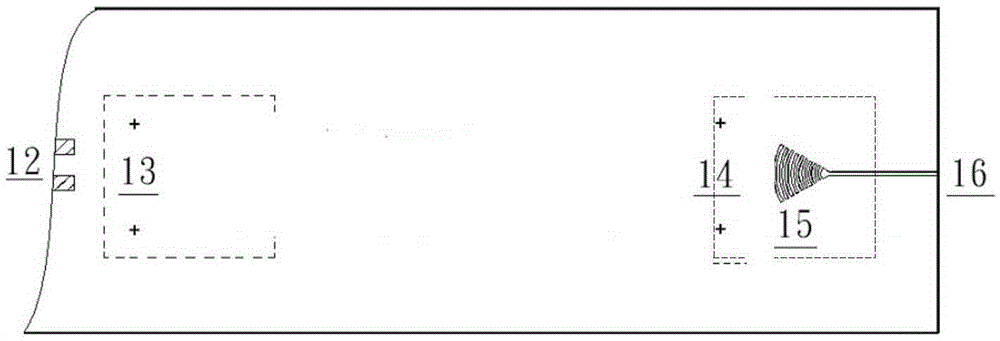

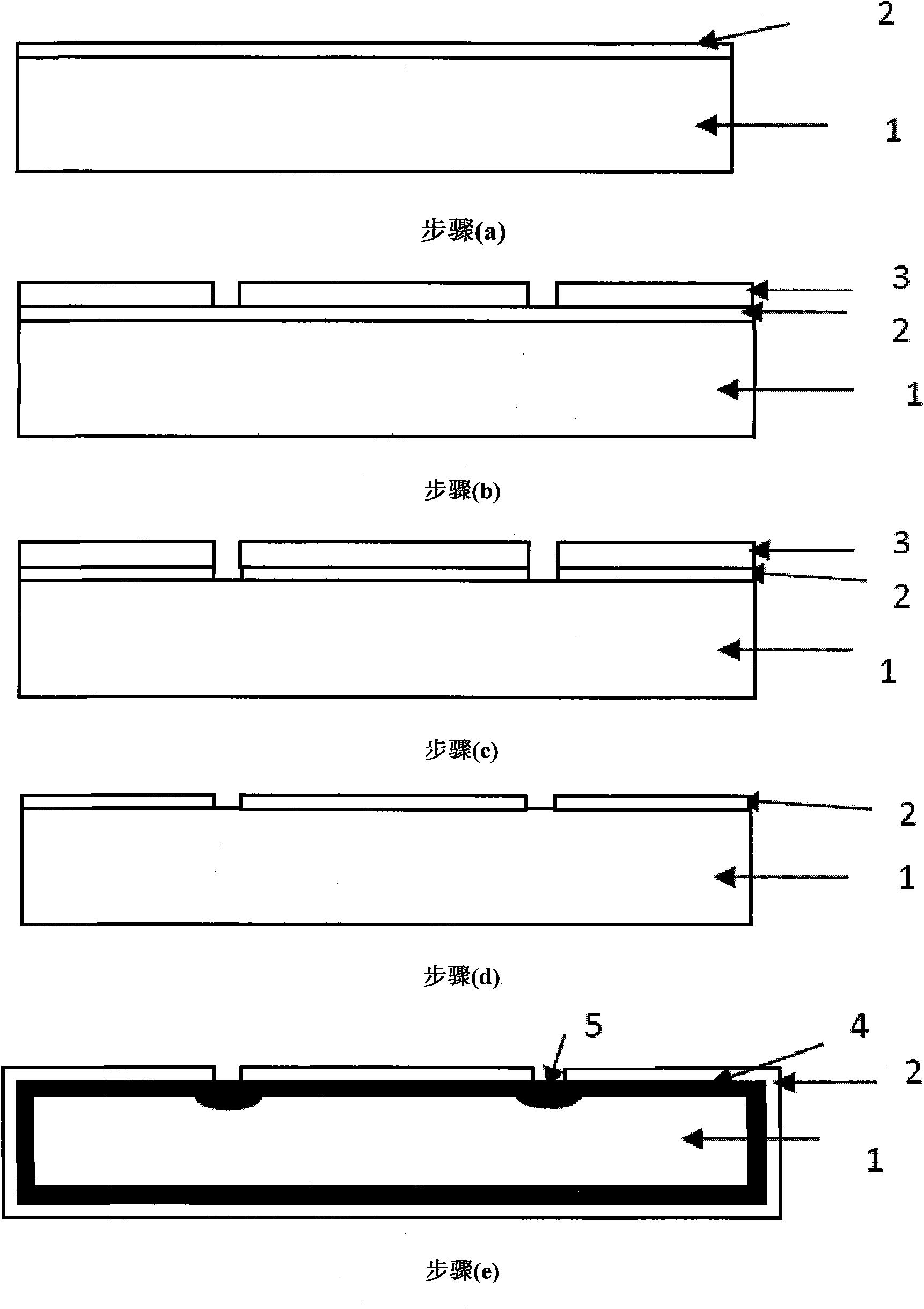

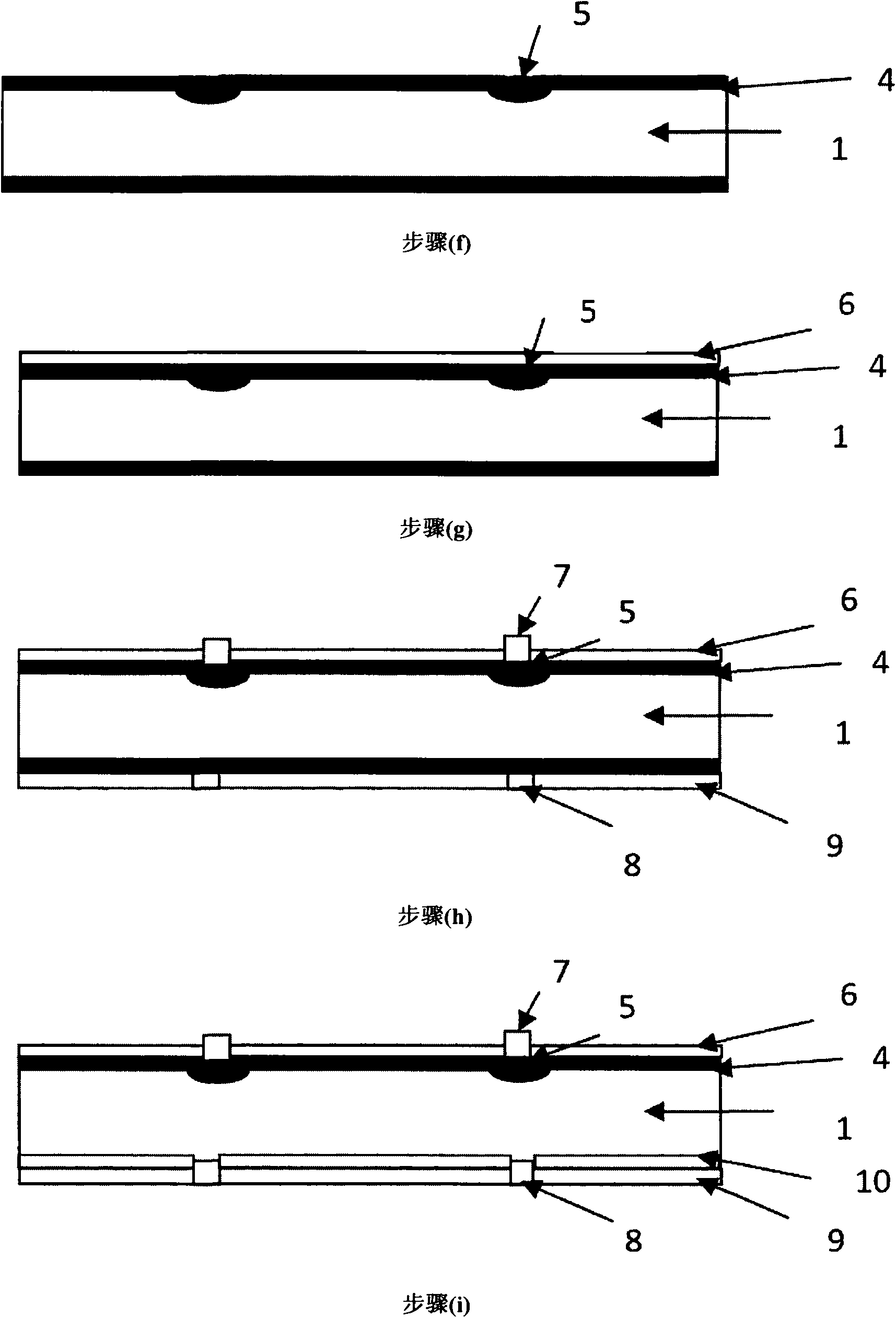

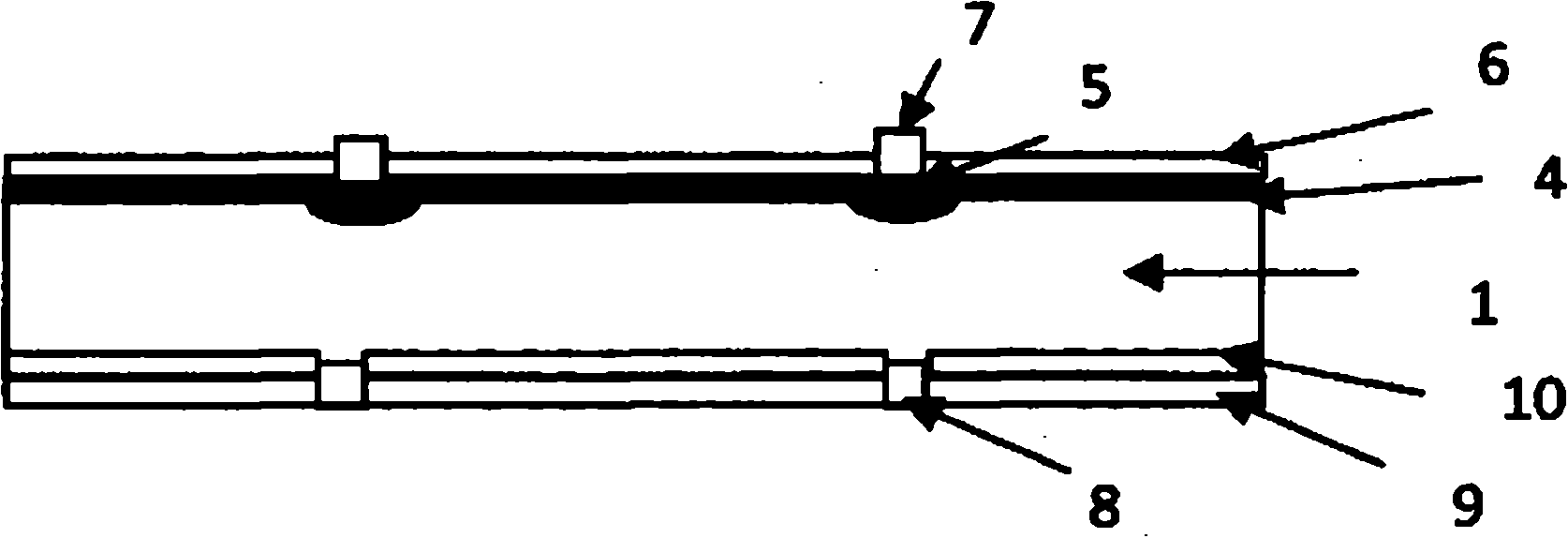

Laser and grating coupler packaging structure and method

ActiveCN105259623AGuaranteed placement accuracyEfficient couplingLaser detailsSemiconductor laser optical deviceGratingEngineering

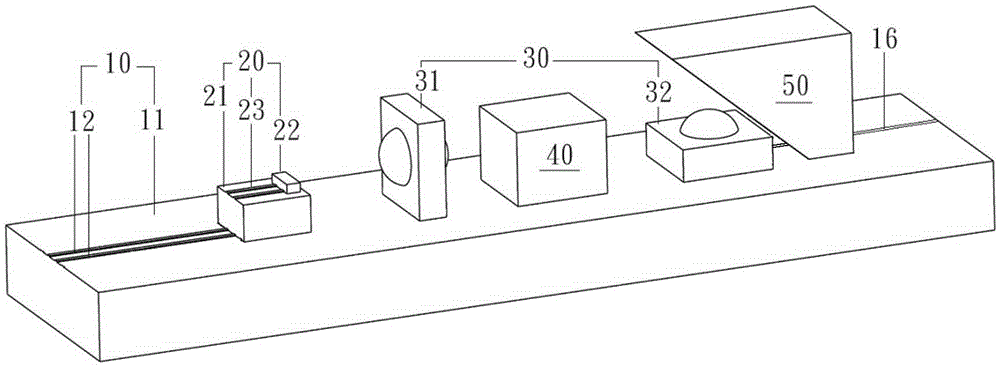

The invention provides a laser and grating coupler packaging structure and method. The packaging structure comprises a laser unit, a collimating lens, an isolator and a reflection prism, wherein the laser unit, the collimating lens, the isolator and the reflection prism are mounted on a silicon-based photoelectric chip. The silicon-based photoelectric chip comprises a first electrode, first and second marks, a grating coupler and a waveguide layer which are all arranged at the surface; the laser unit comprises a transitional substrate and a laser; the collimating lens comprises a first lens and a second lens, the first lens is vertical to the surface, the second lens is arranged at the surface at the position of the second mark, and thus, the grating coupler is placed in the central area of the main axis of the optical path of the second lens; and the isolator is mounted at the surface between the first lens and the second lens, so that diverging light output by the laser is collimated by the first lens, then reflected to the reflection prism through the isolator, deflected by the reflection prism for certain angle, and gathered by the second lens, and the gathering point is placed at the surface of the grating coupler. Thus, technical problems in accurate in-place packaging are solved, convenience is provided for preparation, and the yield rate is improved.

Owner:WUHAN TELECOMM DEVICES

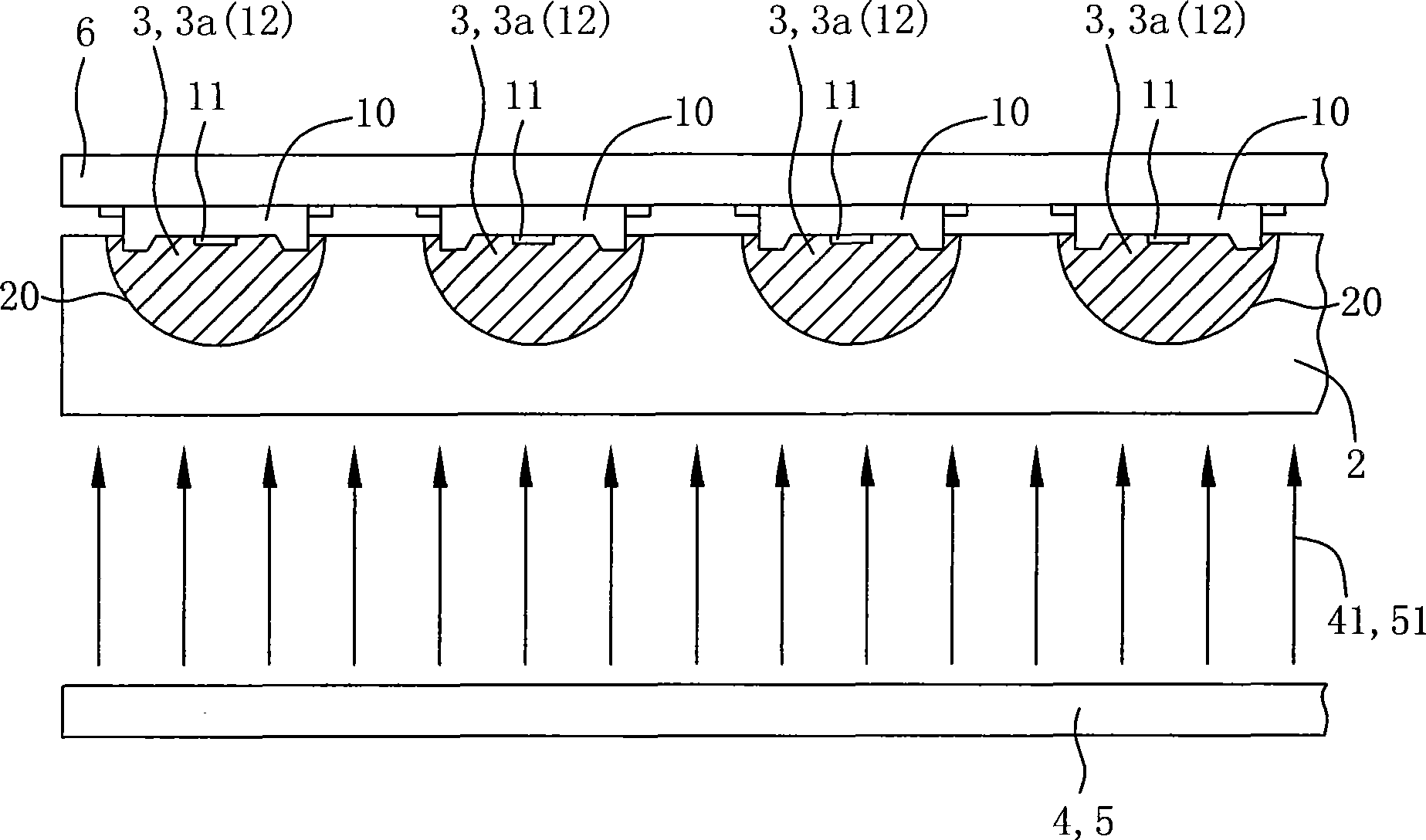

Forming method of resin lens in LED module

InactiveCN101386194AShorten the curing timeLow costPoint-like light sourceOptical articlesEpoxyPlastic materials

The invention provides a method for forming resin lenses in an LED component, which comprises the following steps: manufacturing a mould corresponding to the lens by a material with light transmittance, which contains plastic materials, such as PP, PET, PC, PE, or glass and the like; selecting liquid light-transmittance resin material for forming the lens, such as polyurethane, epoxide resin, silica gel, polyacrylic resin or co-polymer thereof and the like; quickly solidifying the liquid light-transmittance resin under irradiation of electron beam, or adding light trigger in the materials to solidify the liquid light-transmittance resin under irradiation of ultraviolet ray. By being combined with the LED component, the resin can be injected in the mould corresponding to the lens, and the resin material inside the mould is irradiated by the electron beam or the ultraviolet ray from the outside of the light-transmittance mould, so that the resin material can be quickly solidified and formed into the lens. Therefore, the solidifying process of the lens can be accelerated, and the solidified forming time of the resin can be effectively shortened.

Owner:ISOTECH PRODS

Manufacturing method of light-load automobile aluminum alloy wheel hub

The invention discloses a method for manufacturing an aluminum alloy wheel hub of a light-loaded automobile. The steps are as follows: A. Making the rim: according to requirements, select profiles of different cross-sections extruded from aluminum alloy materials, and then roll the profiles into a circle Cylinder, welding the butt joint, then rounding, and finally flanging the wheel lip; B. Spoke production: the circular aluminum plate is stretched or spun to make the aluminum plate reach the designed shape of the spoke, and then the spoke Stamping and processing various through holes; C. Manufacturing of the wheel hub: assembling the spokes in the inner circle of the rim; D. Completing the manufacturing: machining the lip parts of the wheel to complete the final manufacturing of the hub. The wheel rim in the present invention adopts the wheel rim profile that can be produced in large quantities to make the wheel rim. A large number of processing steps are reduced, manufacturing costs are saved, mass production is easier, and it can be directly entered into the ranks of low-end cars, making the promotion range of aluminum alloy wheels wider.

Owner:苏竞

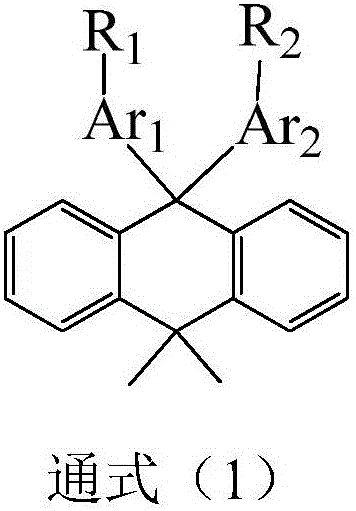

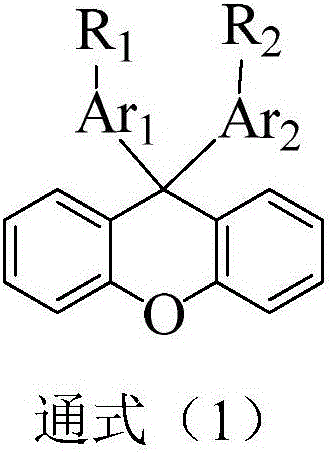

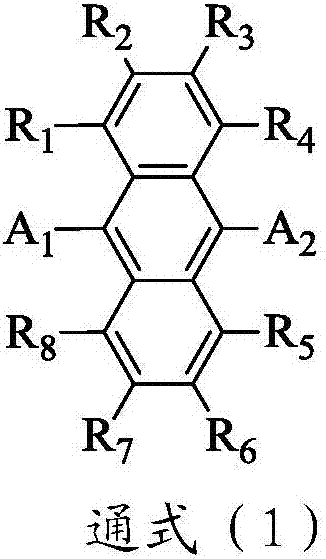

Dimethylanthracene-containing organic compound and application thereof

ActiveCN106467486ADestroy crystallinityInhibit aggregationOrganic chemistrySolid-state devicesOrganic electroluminescenceThermal stability

The invention discloses a dimethylanthracene-containing compound and an application of the dimethylanthracene-containing compound on an organic electroluminescent device. A structural general formula of the organic compound is shown as a general formula (1). The compound has high glass transition temperature and molecular thermal stability, and appropriate HOMO and LUMO energy level and high Eg, by optimizing a device structure, the photoelectric property of the OLED device and the life of the OLED device are effectively increased.

Owner:JIANGSU SUNERA TECH CO LTD

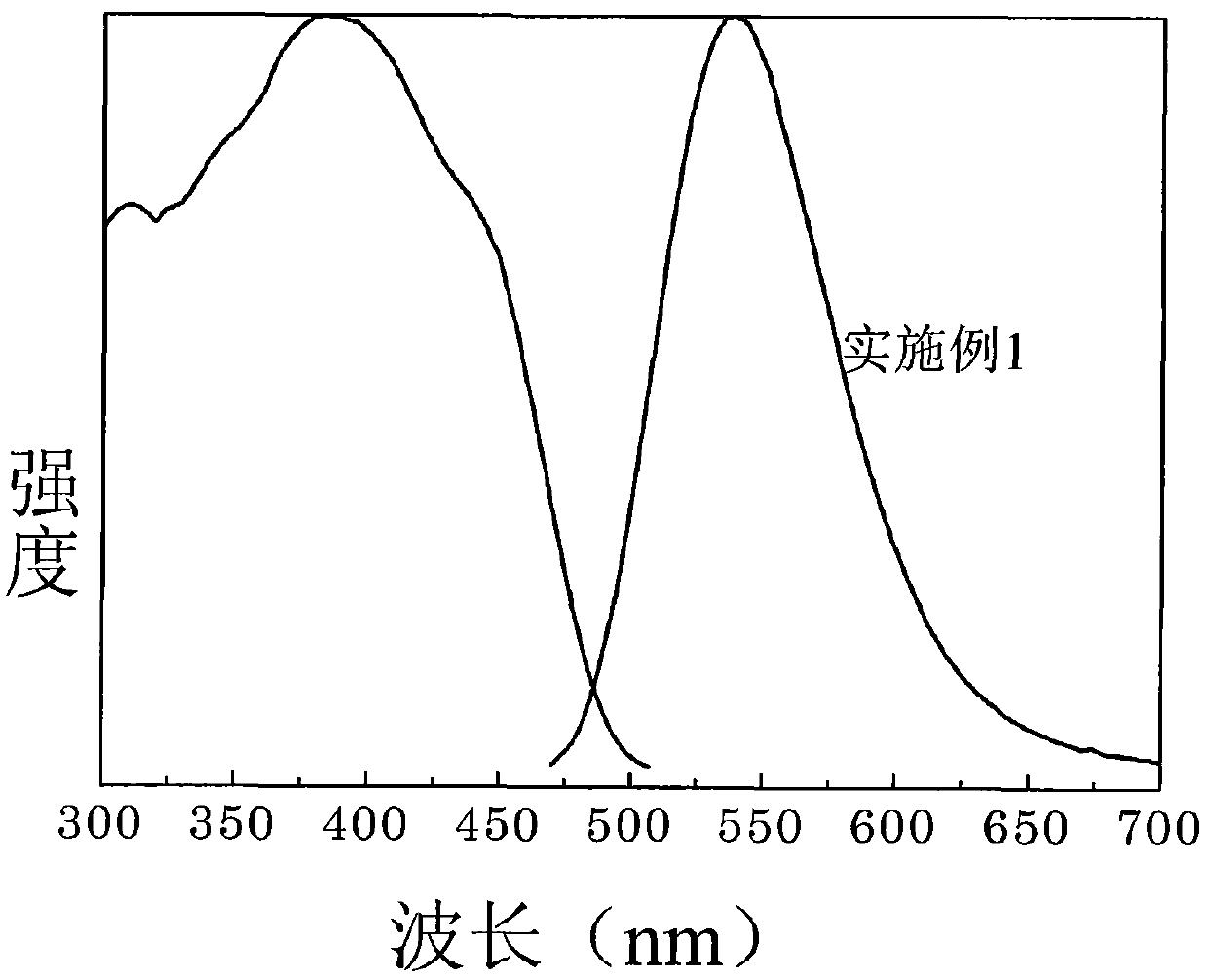

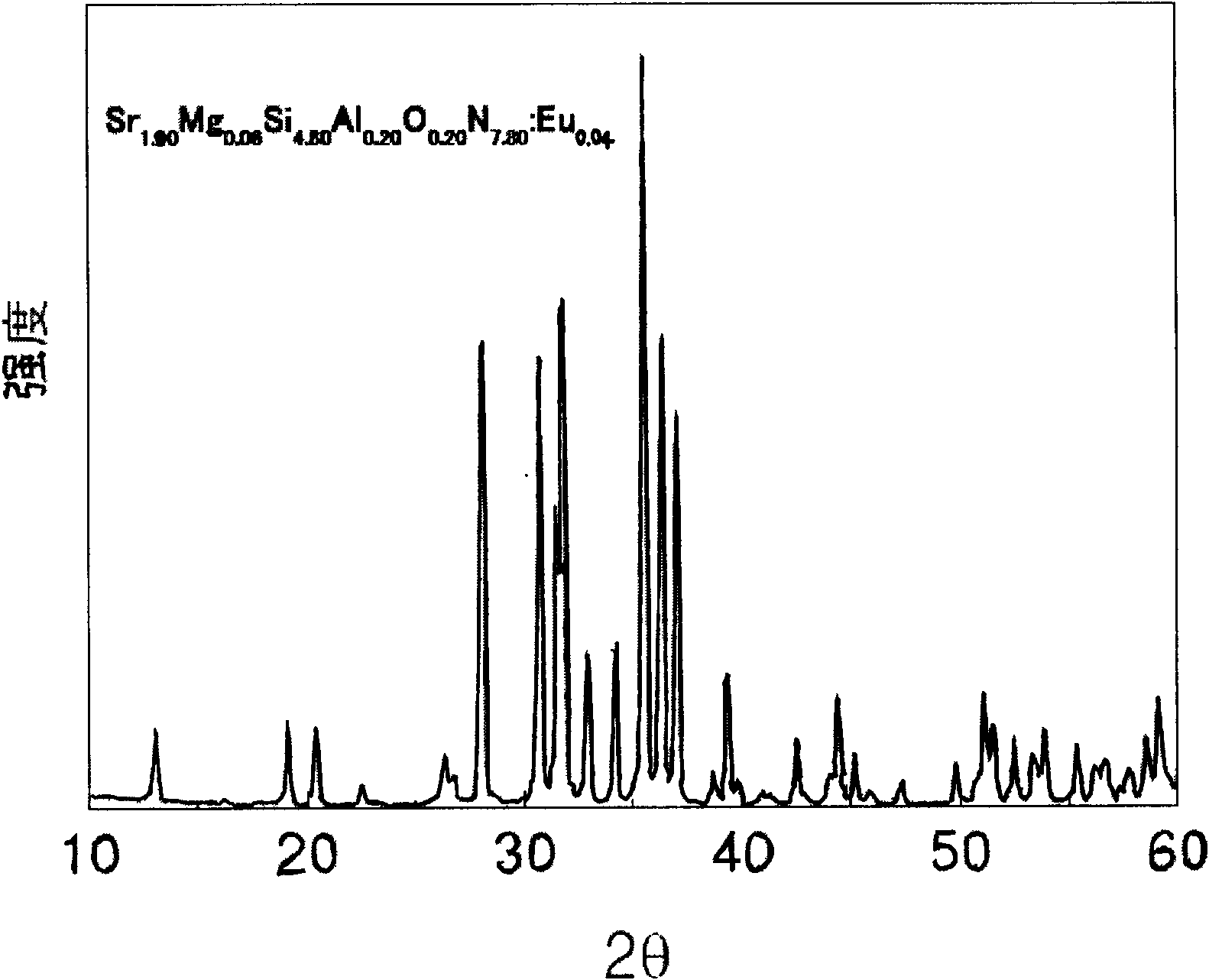

Nitrogen oxide compound fluorescent material and illuminating or displaying light source therefrom

ActiveCN101029230AImprove energy conversionSimple processLuminescent compositionsSemiconductor devicesOxygen compoundLight source

Owner:BEIJING ZHONGCUN YUJI TECH

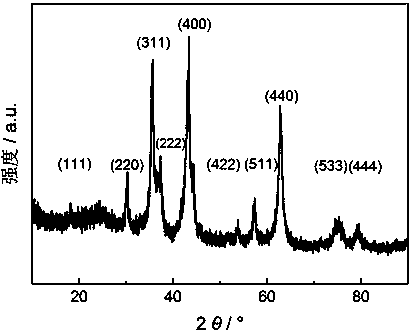

Transitional metal oxide/nitrogen-doped ordered mesoporous carbon composite material and preparation method thereof

ActiveCN108840370AIncrease capacityIncrease active pointMaterial nanotechnologyIron compoundsHexamethylenetetramineSugars carbohydrates

The invention discloses a transitional metal oxide / nitrogen-doped ordered mesoporous carbon composite material and a preparation method thereof. The preparation method comprises the following steps: carrying out inert gas calcining and removing a template to obtain nitrogen-doped ordered mesoporous carbon first by taking a mesoporous molecular sieve SBA-15 as the template, a saccharide carbohydrate as a carbon source and urea and hexamethylenetetramine as a nitrogen source; and then adding a transitional metal salt solution and introducing inert gas to calcine to obtain the transitional metaloxide / nitrogen-doped ordered mesoporous carbon composite material. The preparation method disclosed by the invention is low in cost and easy to operate. The nitrogen-doped ordered mesoporous carbon prepared by the method is clear in pore, proper in pore diameter and large in specific surface area, and nanoparticles of the transitional metal oxide are uniformly distributed and high in capacity. Thetransitional metal oxide / nitrogen-doped ordered mesoporous carbon composite material is excellent in electrochemical property and has a wide market prospect in the fields such as catalysts, electricity and heat conduction and energy-storage materials.

Owner:SHANDONG JIANZHU UNIV

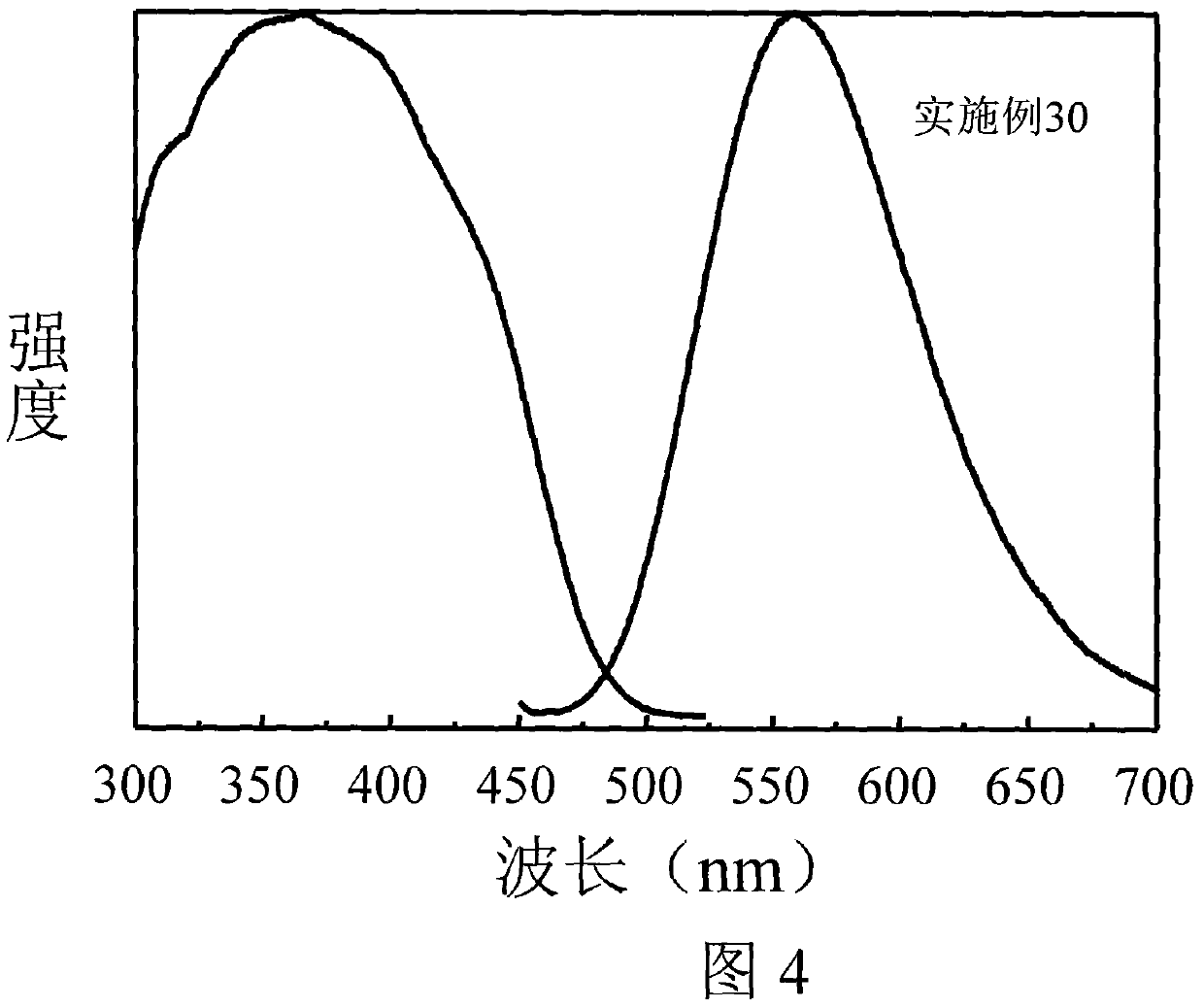

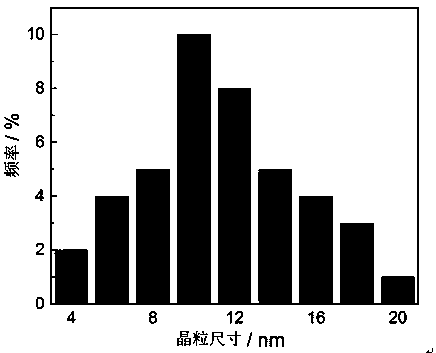

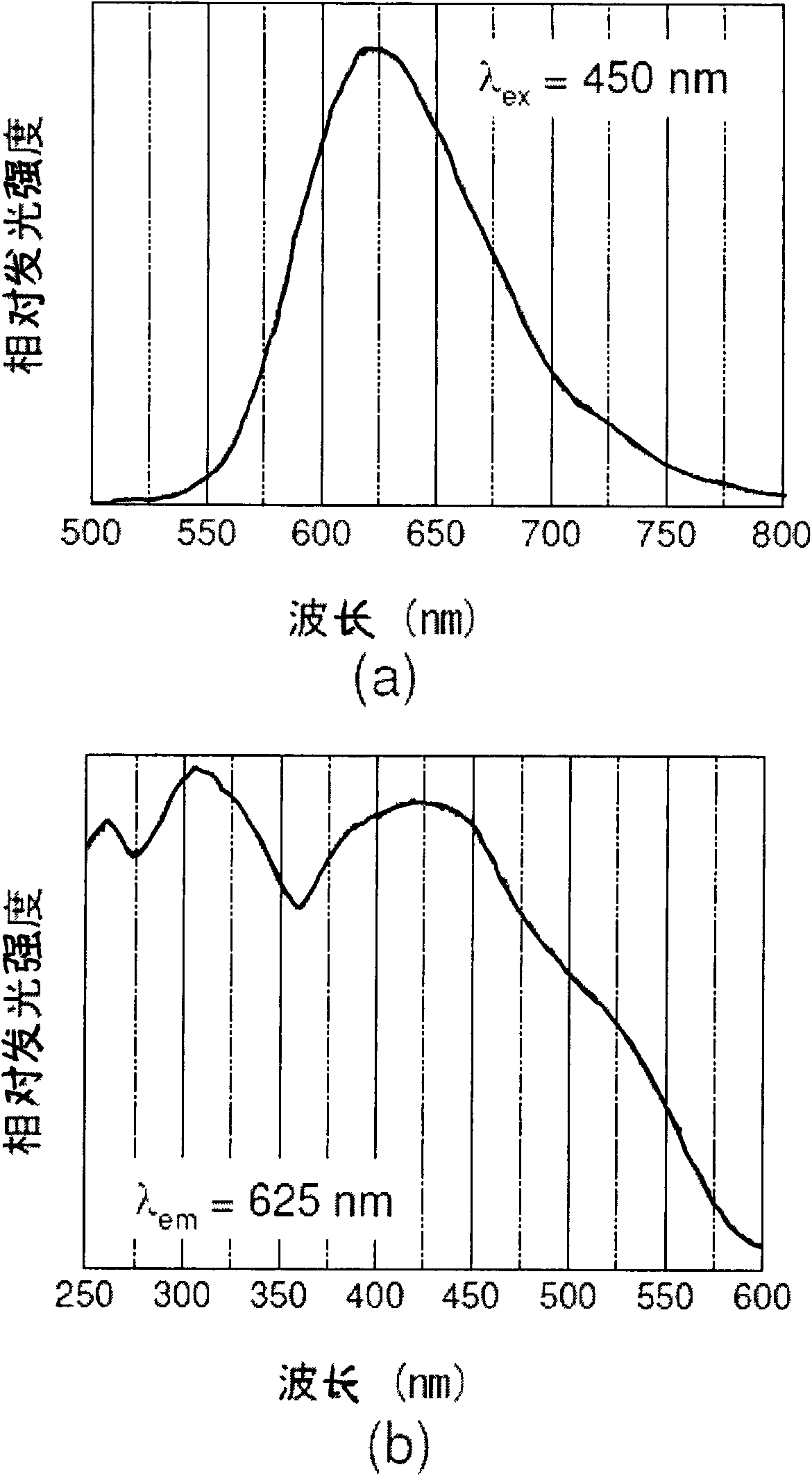

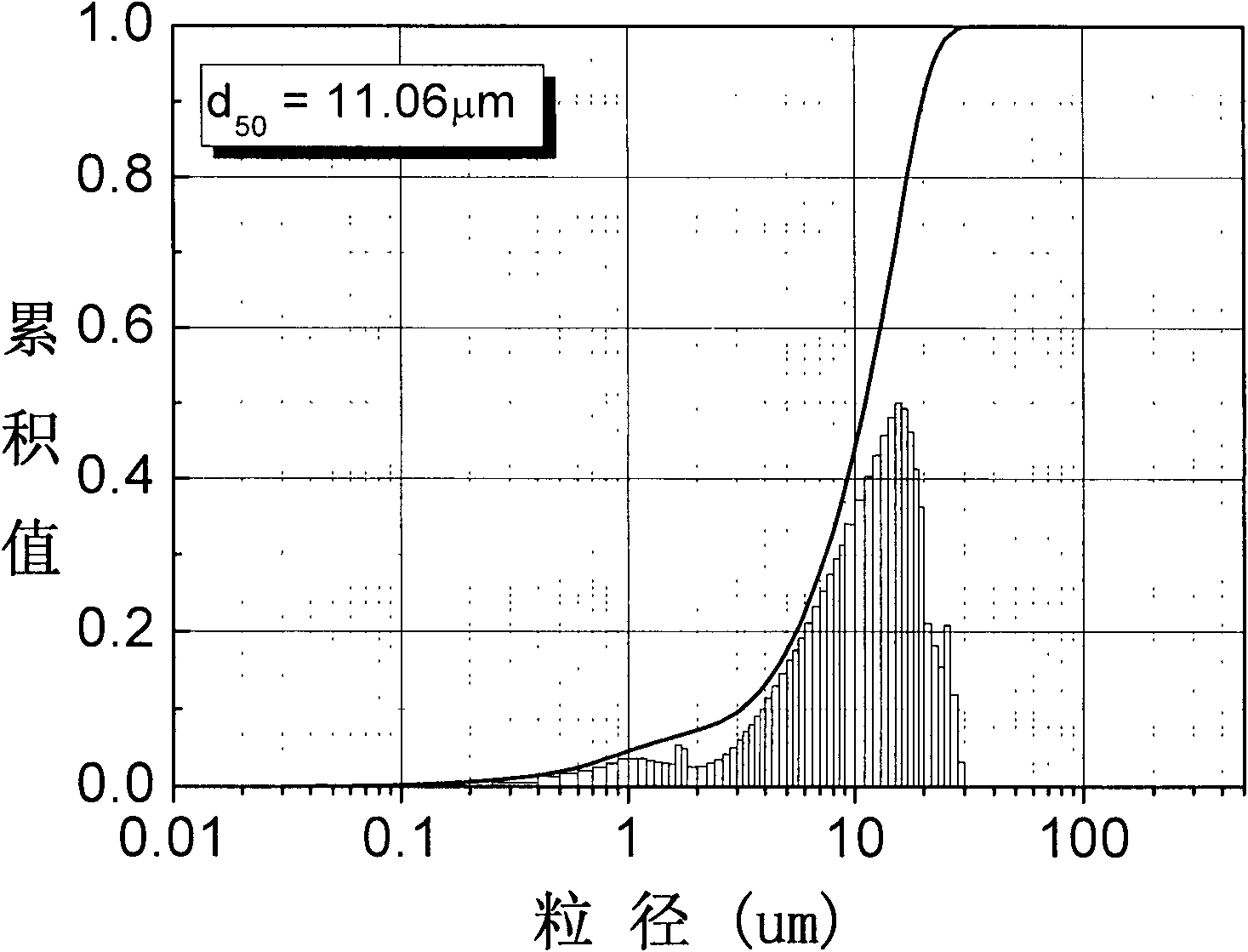

Nitrogen oxides luminescent material and preparation method and application thereof

ActiveCN101671562AImprove energy conversionSimple processGas discharge lamp usageLuminescent compositionsUltravioletLight source

The invention relates to a nitrogen oxides luminescent material and a preparation method and an application thereof, belongs to the semiconductor field. The chemical formula of the nitrogen oxides luminescent material is AxByOzN(2 / 3x+4 / 3y-2 / 3z):R, wherein A is one or more of Be, Mg, Ca, Sr, Ba, Zn, Li and Na, and B is one or more of Si, Ge, Zr, Ti, B, Al, Ga and In and contains at least Si. The luminescent material has stable chemical property and excellent luminescent performance, can be used as the blue / green-to-red nitrogen oxides luminescent material of white-light LED which can be excited by ultraviolet LED or blue light LED; the excitation wavelength is 300-500nm, the luminescent wavelength is 470-700nm, and the luminescent material can be used to prepare white light LED lighting sources or display sources by combining the blue light LED or ultraviolet or near-ultraviolet LED.

Owner:BEIJING YUJI SCI & TECH

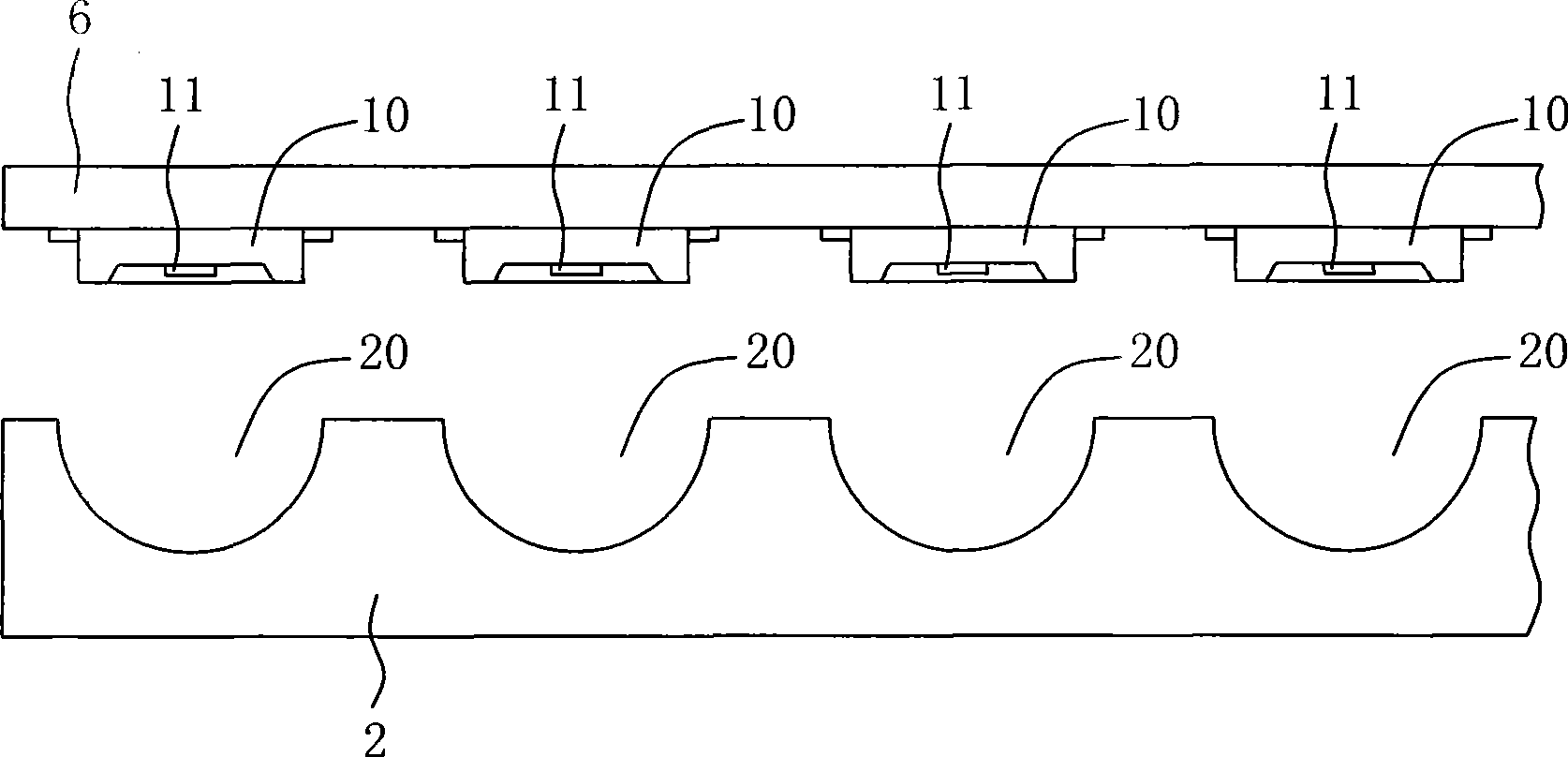

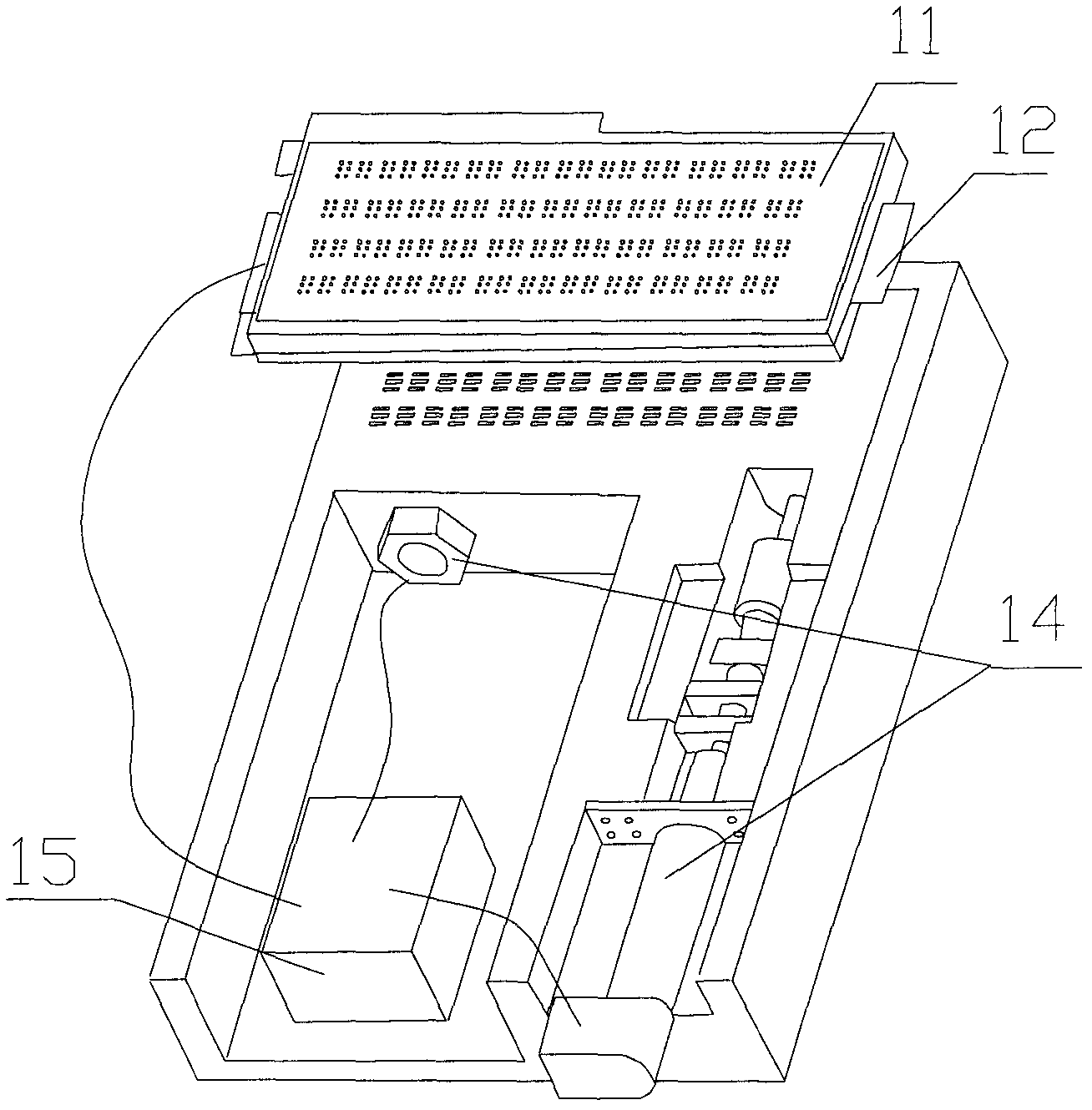

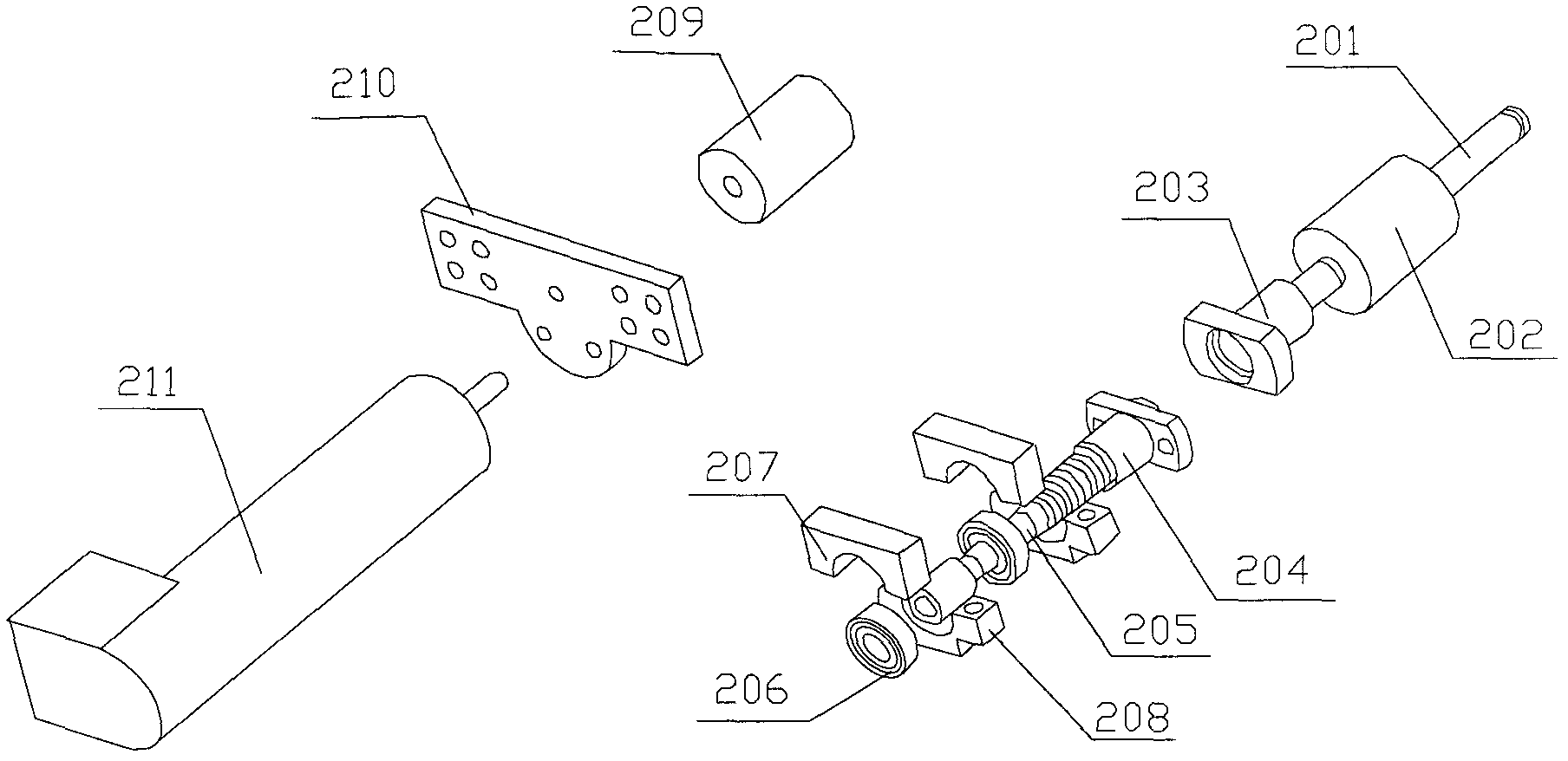

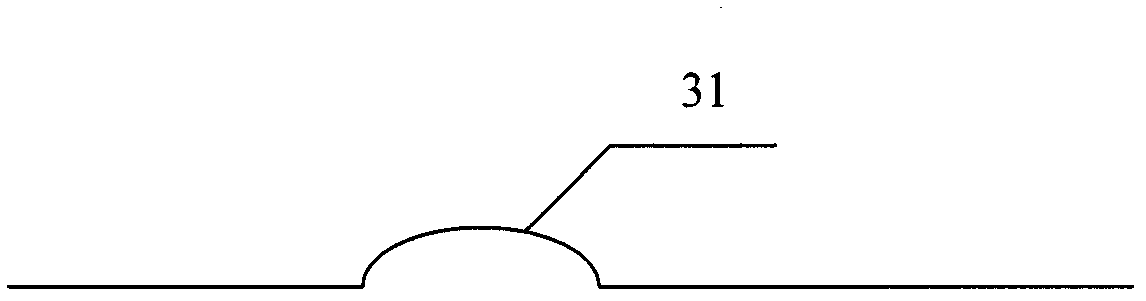

Electronic book for blind people

InactiveCN102222430AReduce in quantityReduce manufacturing costTeaching apparatusComputer moduleControl line

The invention provides an electronic book for blind people, which comprises a display module used for displaying Braille characters, an array valve module, a driving module and a control module, wherein the display module comprise basic points for displaying Braille characters; the array valve module comprises a plurality of valve sets, wherein on-off of the valve sets is used for controlling projection and not projection of the corresponding basic points; the driving module is used for generating power for the display module to display Braille characters; the control module is used for controlling the on-off of corresponding valve set of each basic point by switch tube through longitude control line and latitude control line according to the received electronic data, and controlling the driving module to work. By employing a technical scheme of the invention, when displaying multiple lines of Braille characters, quantity of required switch tube is greatly reduced, production cost of the electronic book for blind people is greatly reduced. The electronic book for blind people is convenient for large scale production, which facilitates visual impairment people to enjoy the pleasureof reading.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

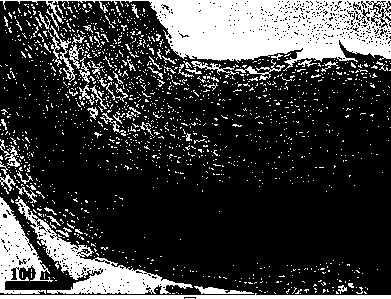

Hyperpure silver powder for solar cell conductive silver paste and preparing method of hyperpure silver powder

The invention relates to a hyperpure silver powder for solar cell conductive silver paste and a preparing method of the hyperpure silver powder. The preparing method comprises the steps that a mixed reaction solution A of silver nitrate and a dispersing agent and an ascorbic acid mixed reducing solution B are prepared; the solution A and the solution B are preheated at a constant temperature in a water bath kettle, the solution A and the solution B are stirred in a magnetic mode and then mixed for conducting reduction reaction; aftertreatment and a plasma process are conducted on obtained silver powder to obtain the hyperpure silver powder which meets the demand of the solar cell conductive silver paste. A plasma technology is applied so that the prepared silver powder is high in purity, the purity is larger than or equal to 99.99%, the ohmic contact of the silver powder and a silicon substrate can be facilitated when the silver paste is sintered, and a dense membrane is formed. Under the premises that the purity is improved and the characteristics of the silver powder are not changed, the prepared silver powder is made to have the average grain diameter of 0.1-5 micrometers, grain diameter distribution is narrow, dispersity is good, tap density is larger than or equal to 4.5g / cm<3>, and the photoelectric converting efficiency of solar cells can be better improved. A plasma aftertreatment process is simple, and mass production is facilitated.

Owner:QINGDAO CUP NEW MATERIALS CO LTD

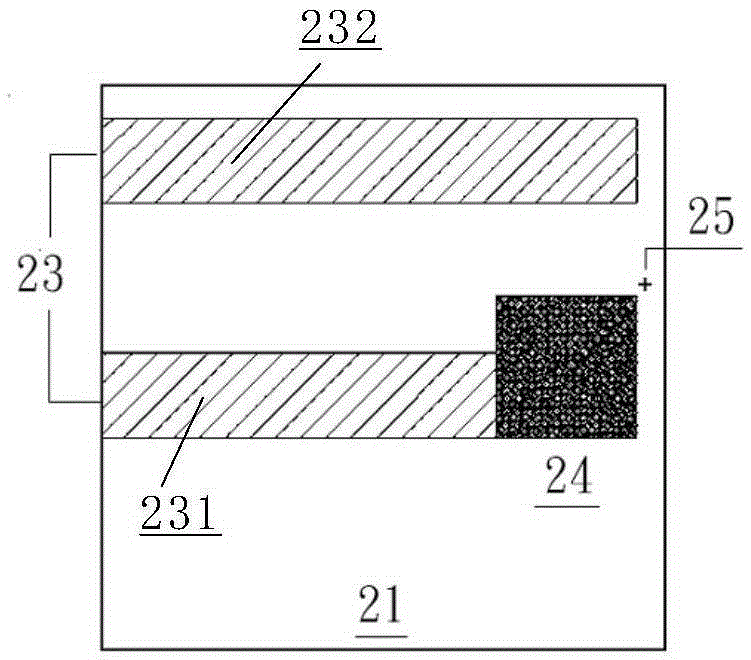

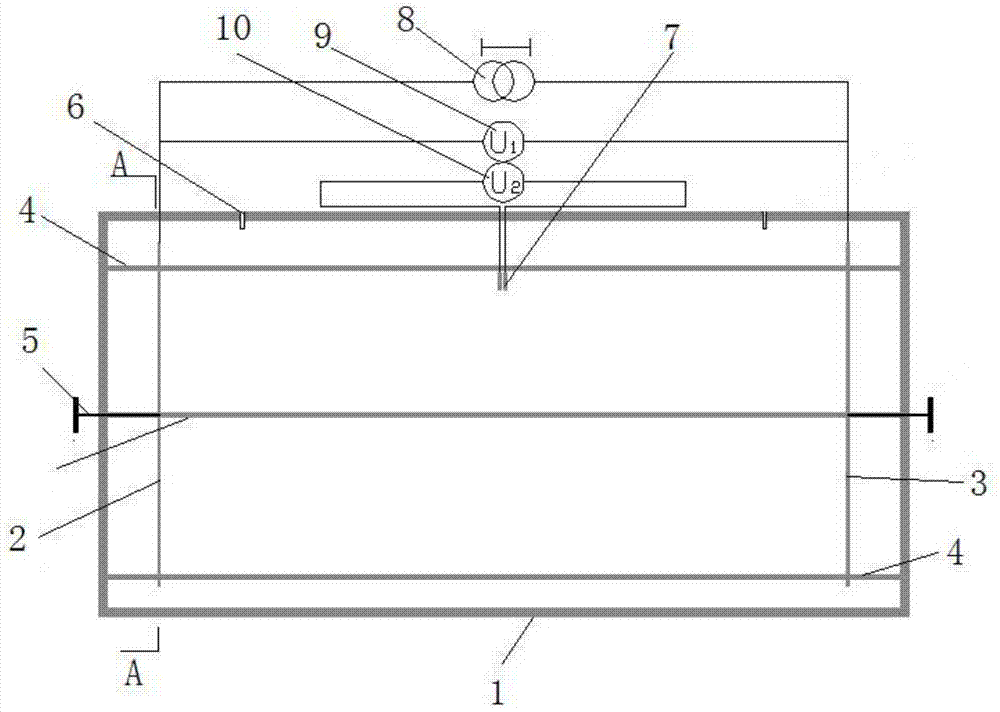

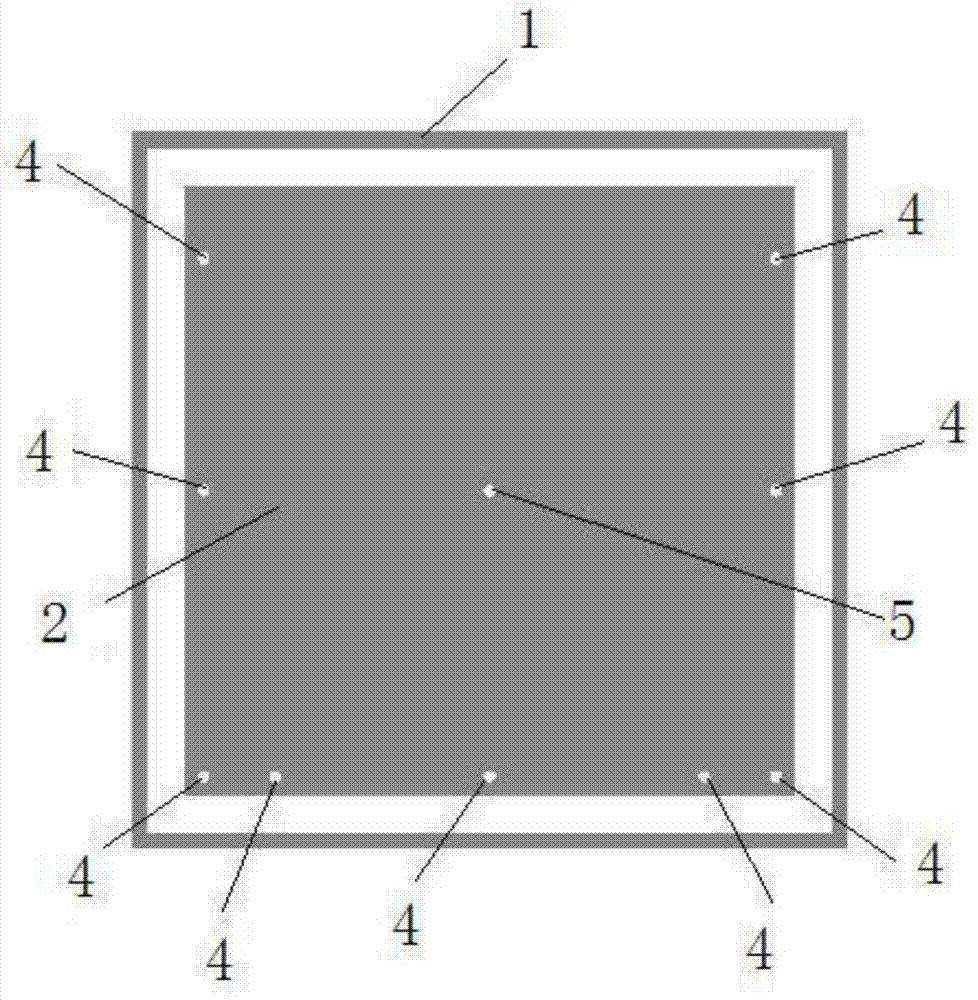

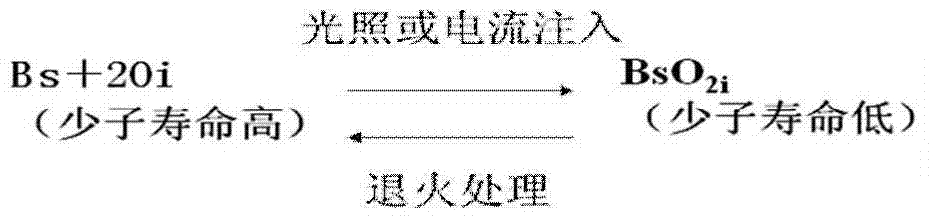

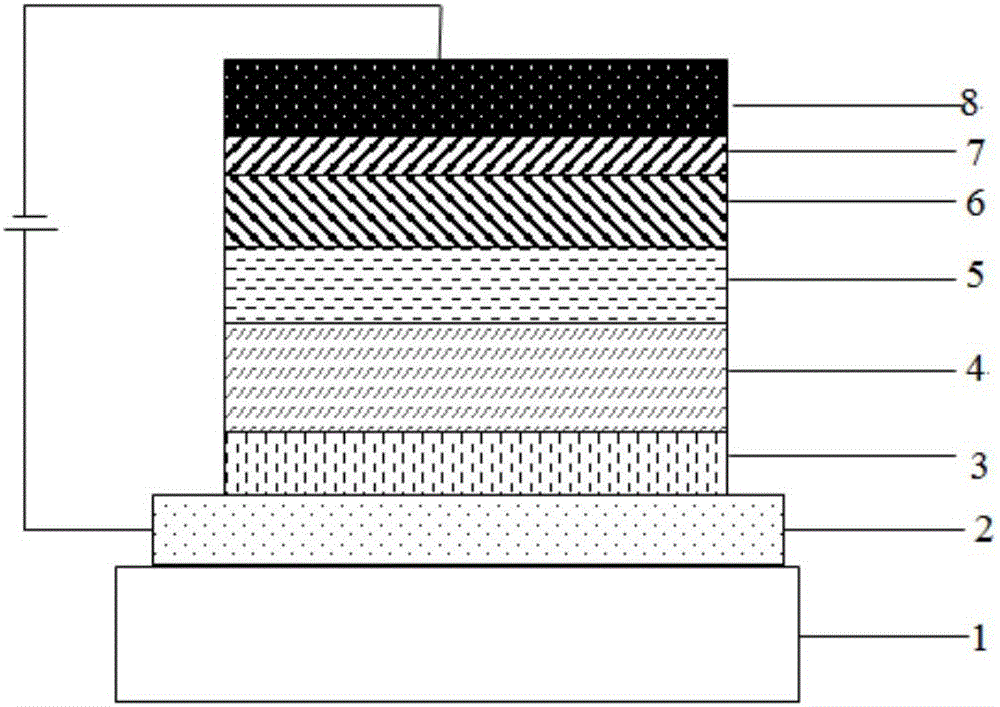

Device reducing light degradation of solar cell and method thereof

ActiveCN104505424AReduce light-induced attenuationNo change in electrical propertiesFinal product manufacturePhotovoltaic energy generationElectricityProduction line

The invention discloses a device reducing light degradation of a solar cell and a method thereof. The device is simple in structure and is easy to product in volume. The device comprises a thermostat, a left conducting plate, a right conducting plate, and a plurality of insulating support rods. The insulating support rods are installed in the thermostat. Two ends of the insulating support rod are respectively disposed on the left side surface and the right side surface of the thermostat. The left conducting plate and the right conducting plate are disposed in the thermostat and are installed on the insulating support rods. A constant current DC power supply is connected between the left conducting plate and the right conducting plate. A first voltmeter is connected with the left conducting plate and the right conducting plate. The middle of the internal of the thermostat is also provided with two pieces of sheet metal. A second voltmeter is connected between the two pieces of sheet metal. Beneficial effects of the device are that production technology of a production line is not changed, devices and equipment which are very expensive and occupy large land are not needed, original electrical performance and efficiency of a cell piece are not changed, the device is simple in structure, easy in mass production, obvious in effect, little in power consumption, high in yield, and high in reliability.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

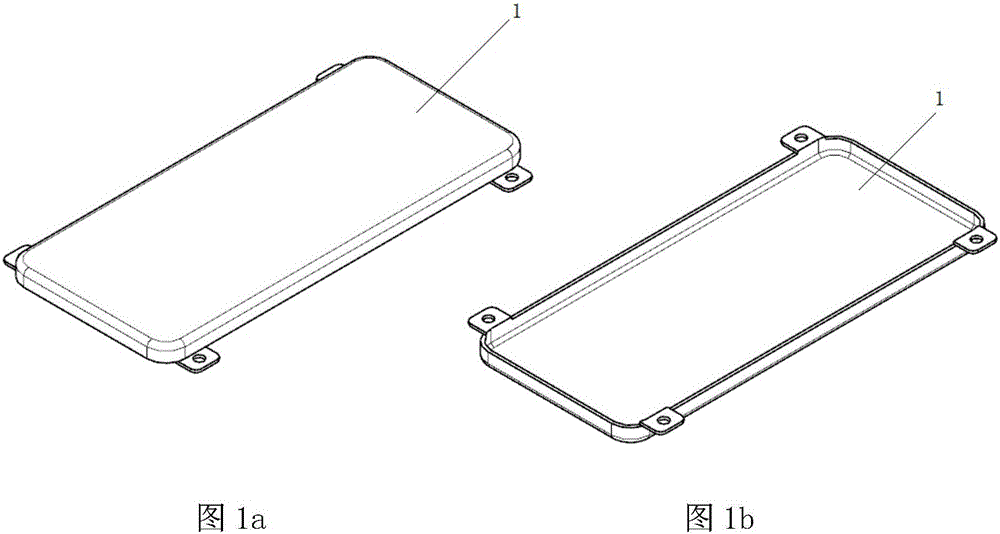

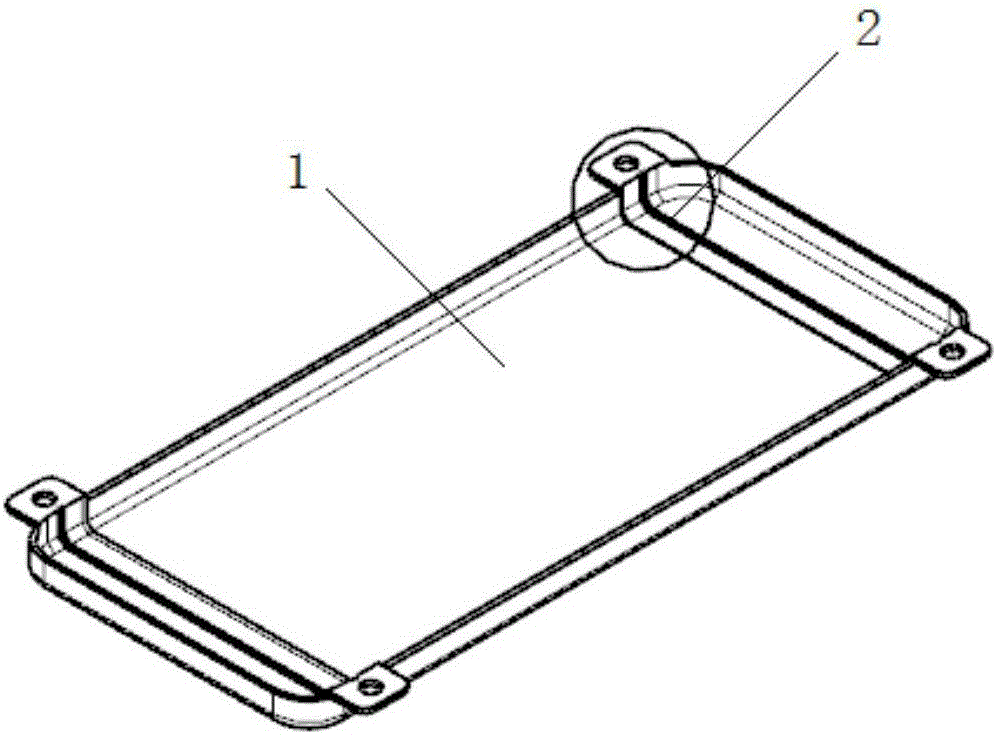

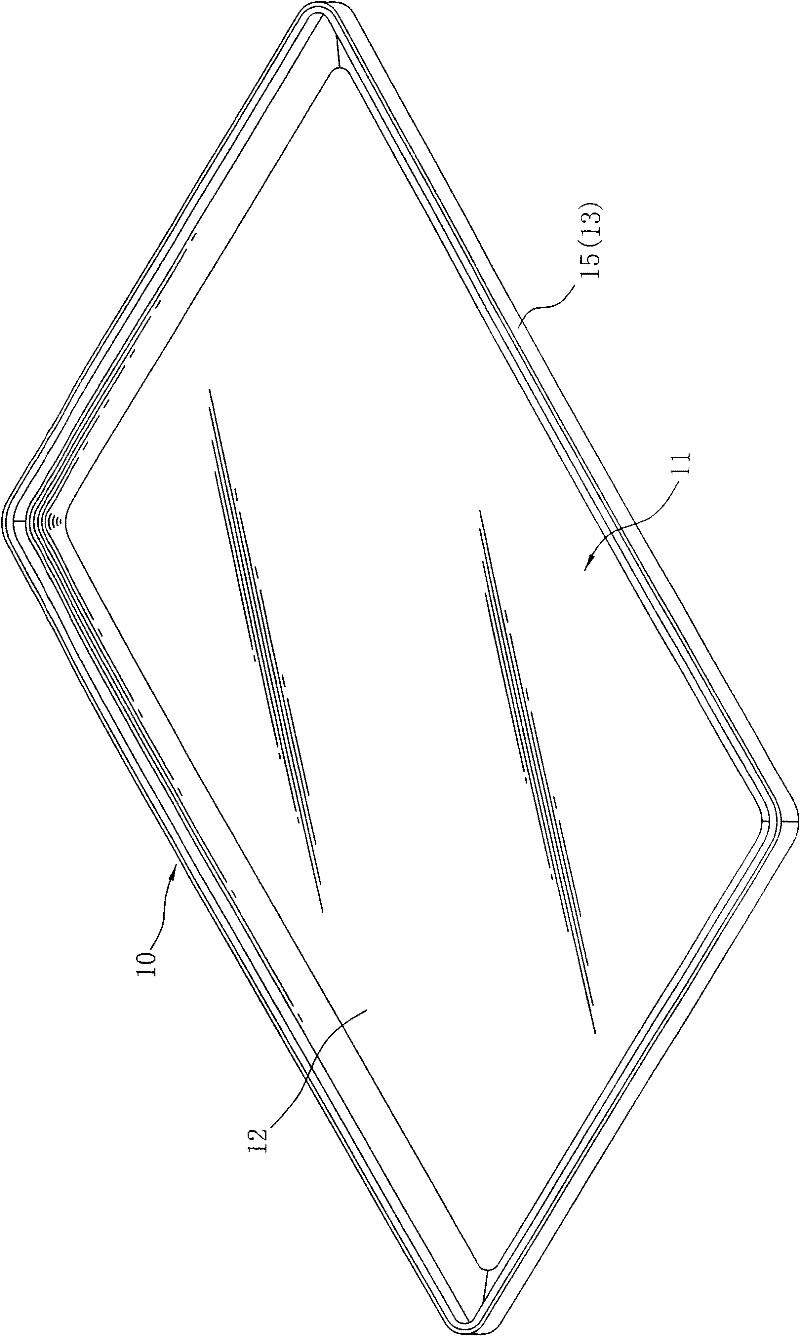

3C electronic product shell and manufacturing method thereof

InactiveCN105979741AEliminates the problem of slitting bit exposureMeet the appearance quality requirementsCasings/cabinets/drawers detailsMetal casingsEngineeringInjection moulding

The invention discloses a 3C electronic product shell and a manufacturing method thereof. The 3C electronic product shell comprises a metallic structure, an antenna slot penetrates through the back and the front of the metallic structure, the antenna slot comprises a slot cavity and an antenna cutting position slit penetrating through the front of the metallic structure from the slot cavity, the antenna cutting position slit is filled with a nonconductive matter, an integrally inject-molded plastic structure layer is arranged on the back of the metallic structure, and the slot cavity is filled with at least part of the plastic structure layer. The 3C electronic product shell is favorable for completely solving the problem that the antenna cutting position on the surface of the electronic product metal shell is exposed, so that the electronic product metal shell is coherent in overall appearance and strong in metallic texture; and the 3C electronic product shell is simple in manufacturing process, low in cost and suitable for large-scale production, meets the requirement of 3C electronic product structures for appearance quality, and simultaneously has the advantages of easiness in manufacturing, low cost and practicability.

Owner:GUANGDONG JANUS SMART GRP CO LTD

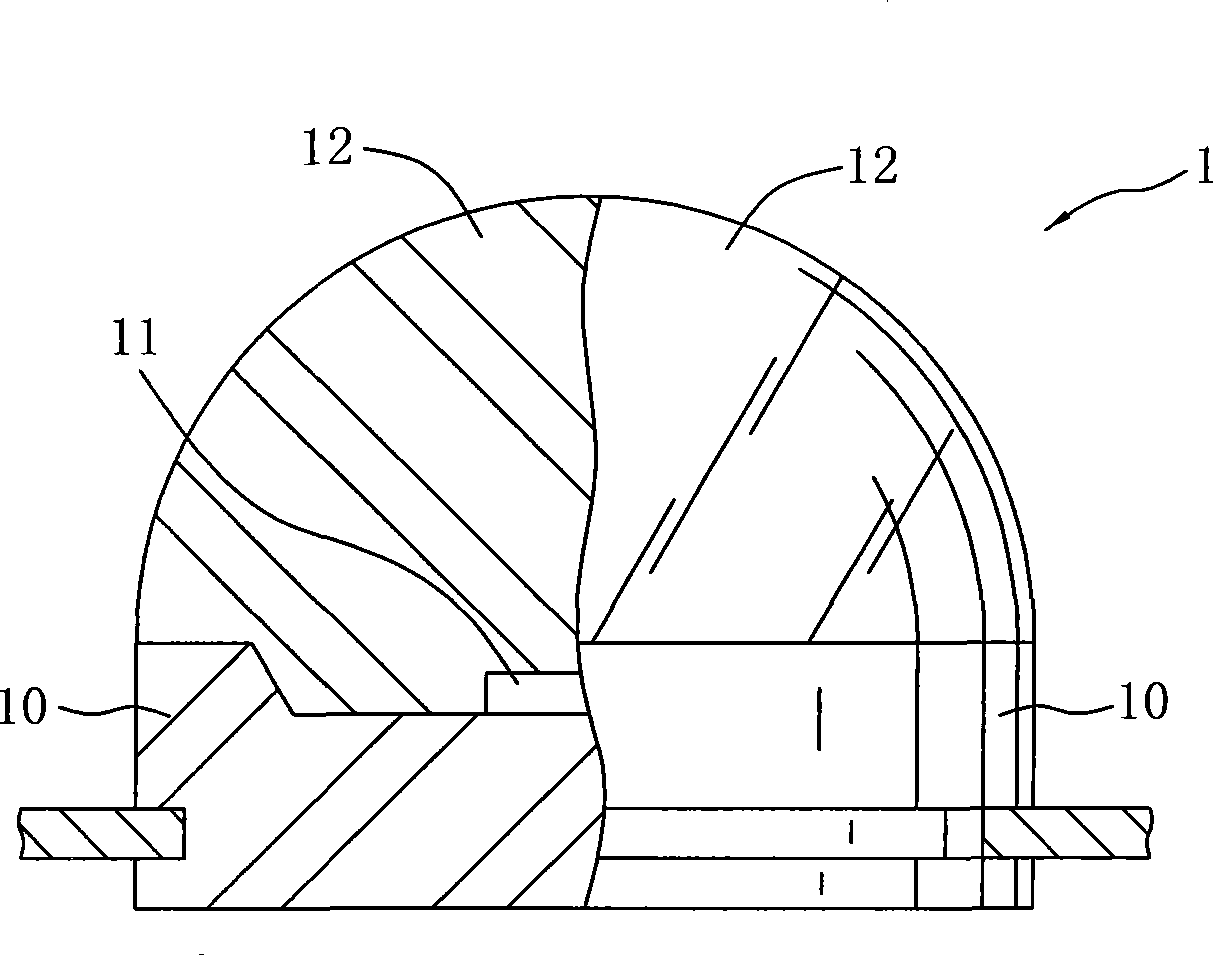

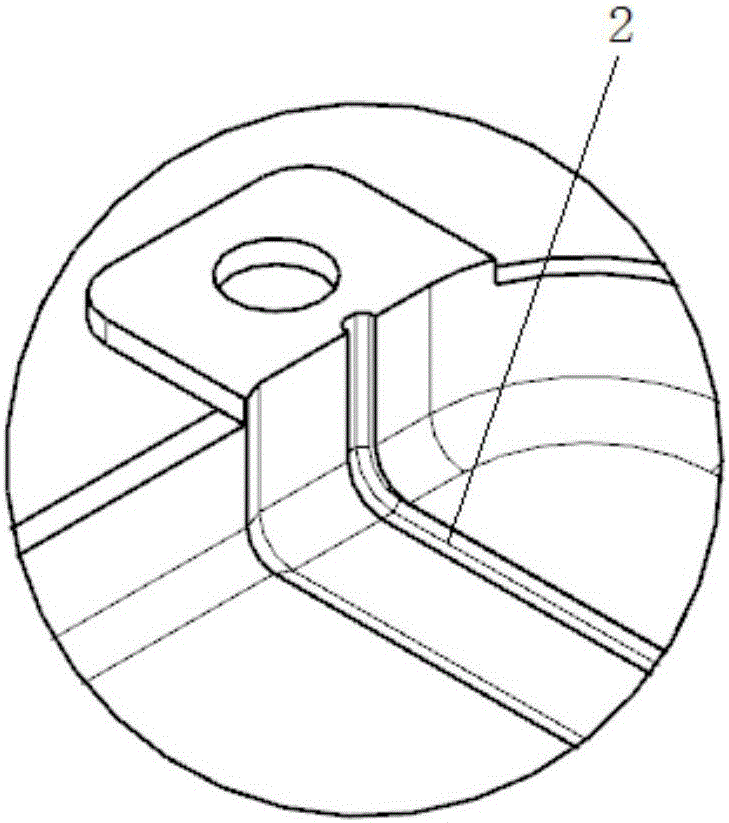

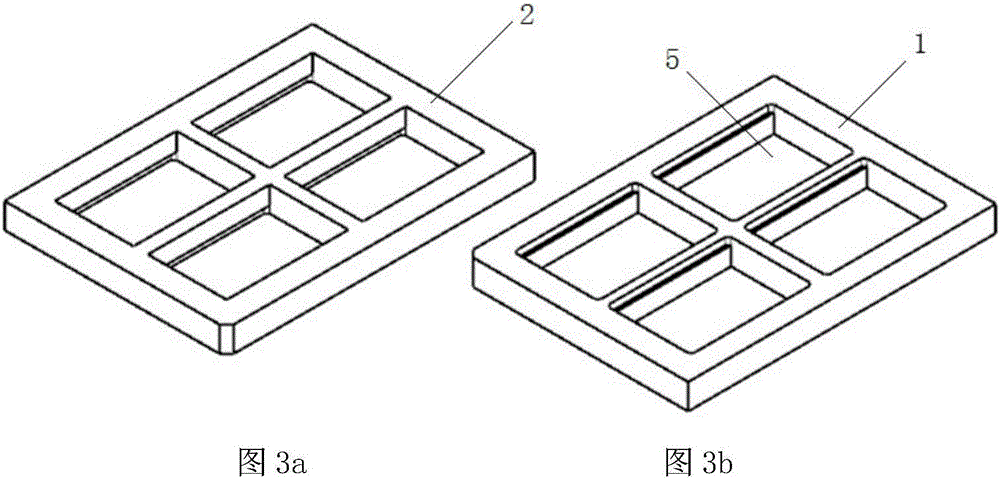

Glass heating graphite mold and production method thereof

ActiveCN106746526AImprove molding qualityGood for mass productionGlass reforming apparatusGlass productionGraphiteMaterials science

The invention discloses a glass heating graphite mold and a production method thereof. The mold comprises a front mold and a rear mold, wherein the front mold comprises a front mold base and a front mold core made of a graphite material; the rear mold comprises a rear mold base and a rear mold core made of the graphite material; a cavity matched with the front mold core is formed in the front mold base; the front mold core is arranged in the cavity of the front mold base; a cavity matched with the rear mold core is formed in the rear mold base; the rear mold core is arranged in the cavity of the rear mold base; intermediate areas of opposite surfaces of the front mold core and the rear mold core are three dimensional curved surfaces suitable for processing to obtain hot bending glass during mold closing; edge areas of the opposite surfaces of the front mold core and the rear mold core are respectively provided with a plurality of supporting insert via holes; supporting inserts are arranged in the supporting insert via holes; when the mold is closed, the supporting inserts, which are oppositely arranged, on the front mold core and the rear mold core, make contact with one another, so that the effects of positioning and supporting the mold cores are realized, and the pressures of the mold cores are borne. According to the glass heating graphite mold disclosed by the invention, large-scale mass production is easily realized while the molding quality of the graphite mold is improved.

Owner:DONGGUAN HUAQING OPTICAL TECH

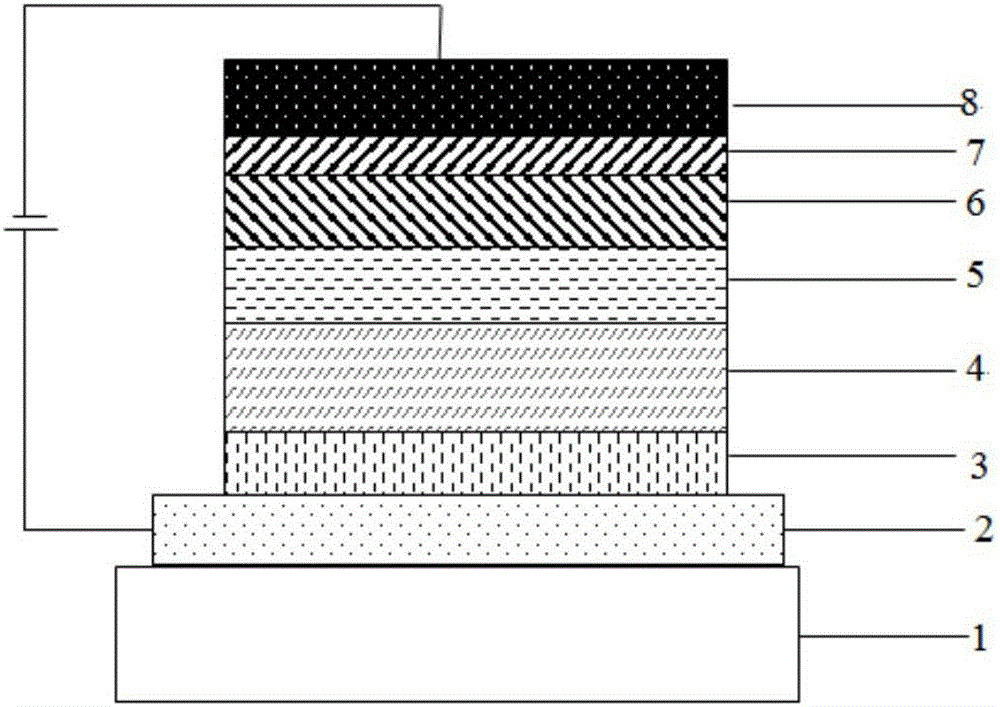

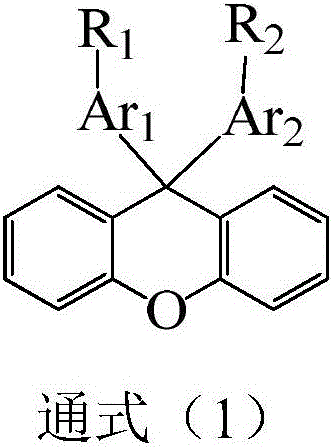

Organic compound containing xanthene and application thereof

ActiveCN106467526ADestroy crystallinityInhibit aggregationOrganic chemistrySolid-state devicesVitrificationThermal stability

The invention discloses an organic compound containing xanthene and an application thereof. A structural general formula of the organic compound is shown as a general formula (1). The vitrification temperature of the organic compound is high, the molecular thermal stability is strong, the organic compound has appropriate HOMO and LUMO energy level and high Eg, and the photoelectric property of an OLED device and life of the OLED device are effectively increased through optimization of a device structure.

Owner:JIANGSU SUNERA TECH CO LTD

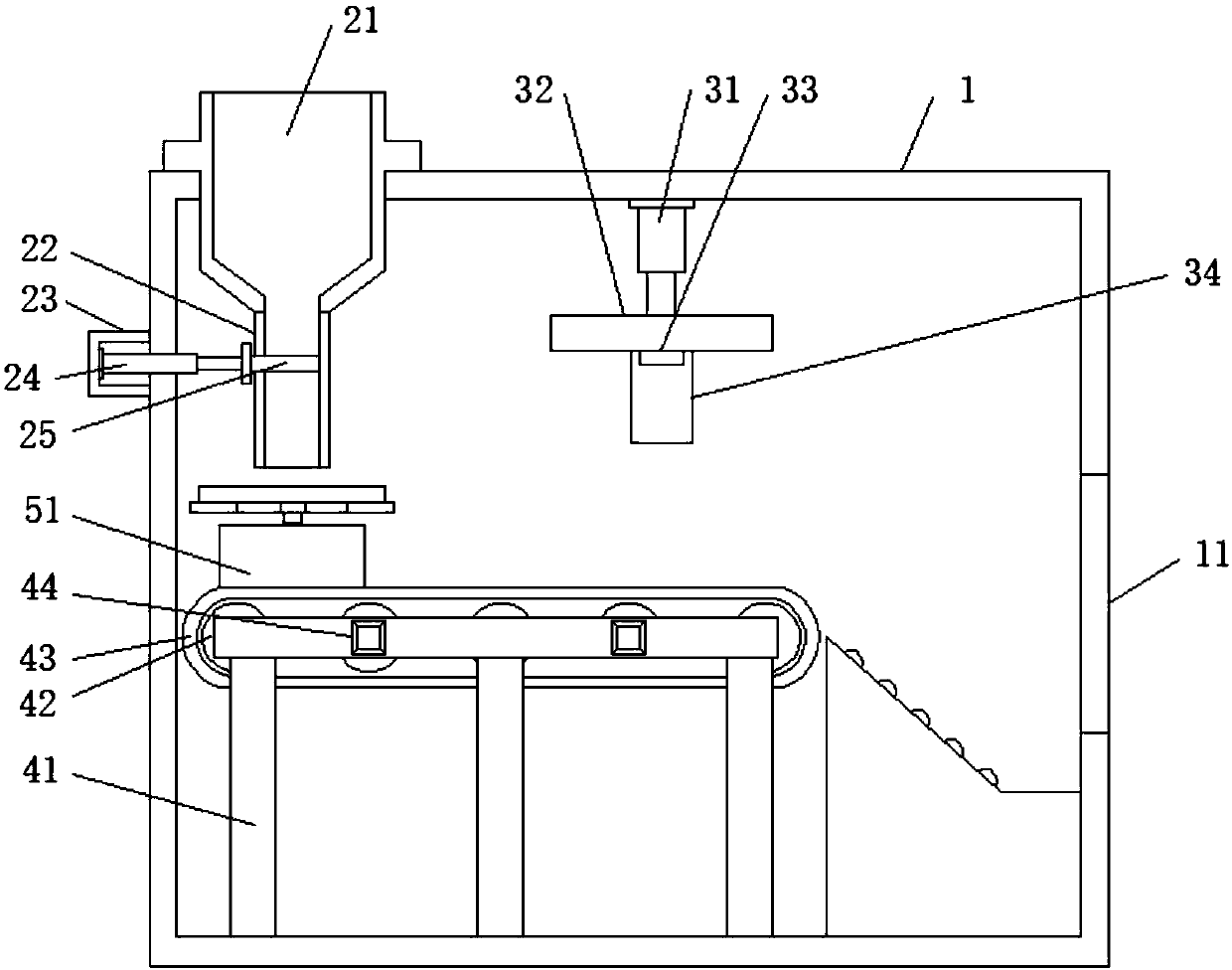

Full-automatic LED package machine

ActiveCN107910287AConvenient order placementEasy to moveSemiconductor/solid-state device manufacturingConveyor partsEngineeringAutomatic processing

The invention discloses a full-automatic LED package machine. The full-automatic LED package machine comprises a hollow-structure shell and also comprises a feeding mechanism, a package mechanism, a transmission mechanism and an adjustment mechanism, wherein the feeding mechanism is arranged at one side of the top of the shell, the package mechanism is arranged on an inner wall of the other side of the top of the shell, the adjustment mechanism moves with the transmission mechanism, the transmission mechanism comprises a support rack, a transmission shaft, a conveying belt and a third drivingdevice, the transmission shaft is rotatably connected to the top of the support rack, the conveying belt sleeves the transmission shaft, the third driving device drives the transmission shaft to rotate, the adjustment mechanism comprises a hollow fixed seat, the hollow fixed seat is fixedly arranged at the top of the transmission shaft, a positioning rod and a fourth driving device are arranged onan inner wall of the bottom of the hollow fixed seat, a first gear is arranged on an output shaft of the top of the fourth driving device, a fixed block is welded at a middle position of the positioning rod and is perpendicular to the positioning rod, and a rotation rod is rotatably connected with one side of the fixed block and is parallel to the positioning rod. The full-automatic LED package machine is reasonable in design and low in manual operation cost, full-automatic processing is achieved, the LED package efficiency and package accuracy are improved, and mass production is facilitated.

Owner:ZHONGSHAN MULINSEN ELECTRONICS CO LTD

Automatic-drive vehicle positioning method

InactiveCN109085821AGood for mass productionPosition/course control in two dimensionsVehiclesAutopilotVisual perception

The invention discloses an automatic-drive vehicle positioning method. The automatic-drive vehicle positioning method comprises the following steps that S1, a guideboard is mounted; S2, automatic recognizing is conducted; S3, database comparison is conducted; and S4, position output is conducted. According to the automatic-drive vehicle positioning method, through the guideboard arranged on a roadand a unique corresponding coding arranged on the guideboard, the coding corresponds to the position, and is stored in a database, and the coding can be recognized by a vision or other sensors, and therefore the position is determined through comparison with the database. According to recognition to the guideboard by the sensor, the relative position between a vehicle and the guideboard can be determined by the position of the guideboard in the field of vision, and the included angle between the vehicle and the current road can be determined by further analysis. In the current automatic driving field, the problem about positioning accuracy and real-time positioning limiting the volume production prospect of automatic driving is solved, and the automatic-drive vehicle positioning method can promote the volume production of automatic driving.

Owner:苏州上善知源汽车电子有限公司

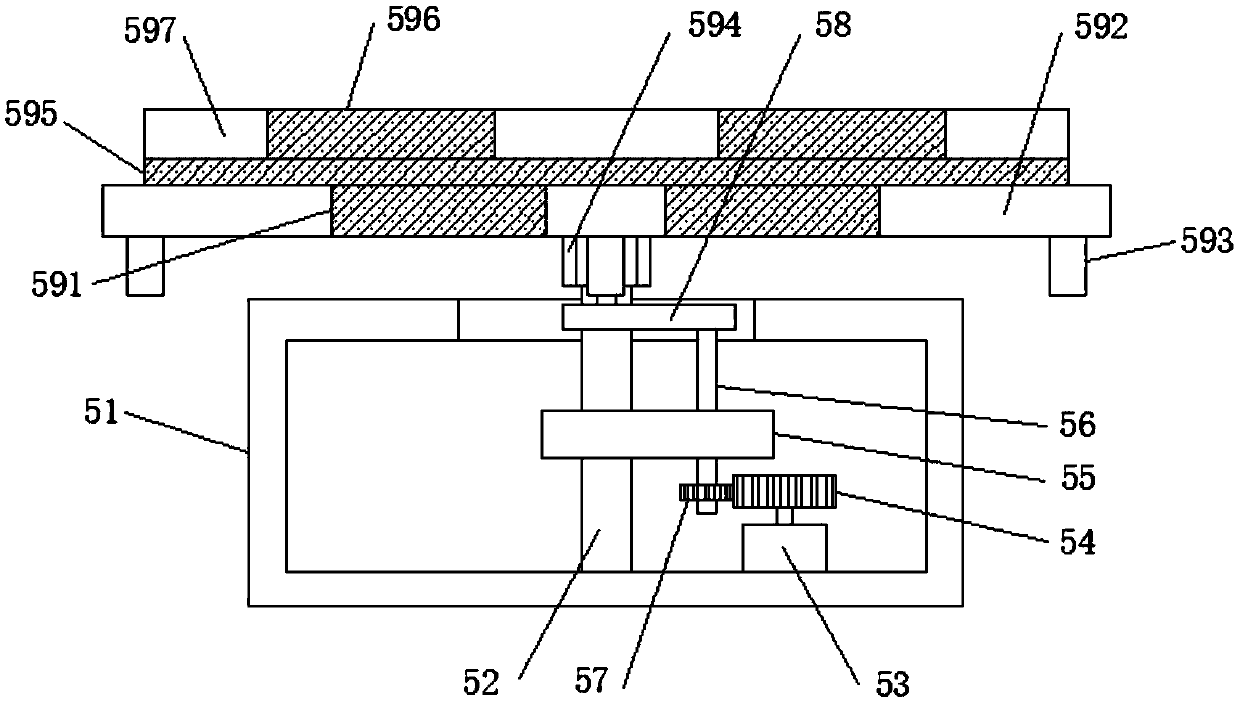

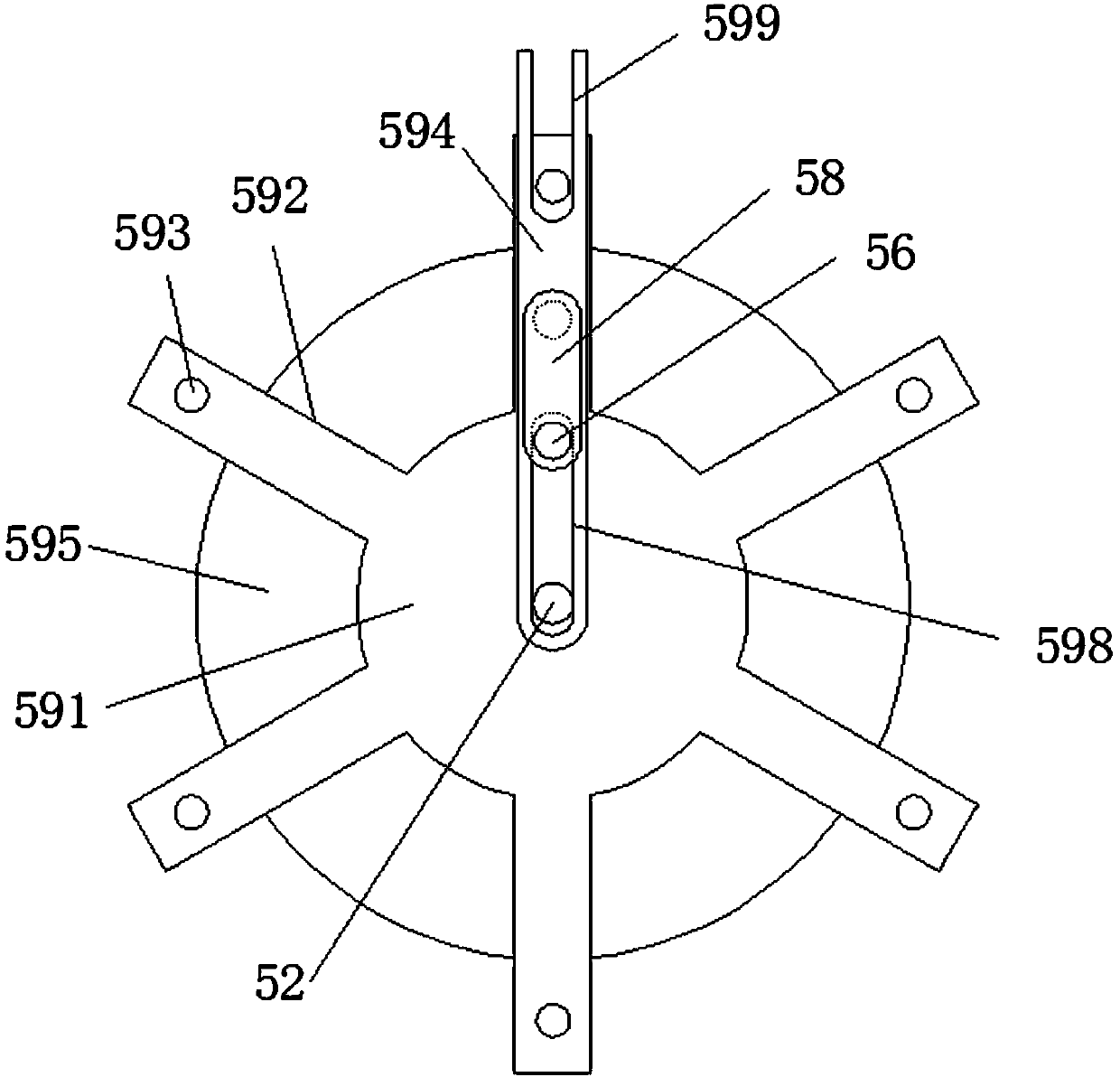

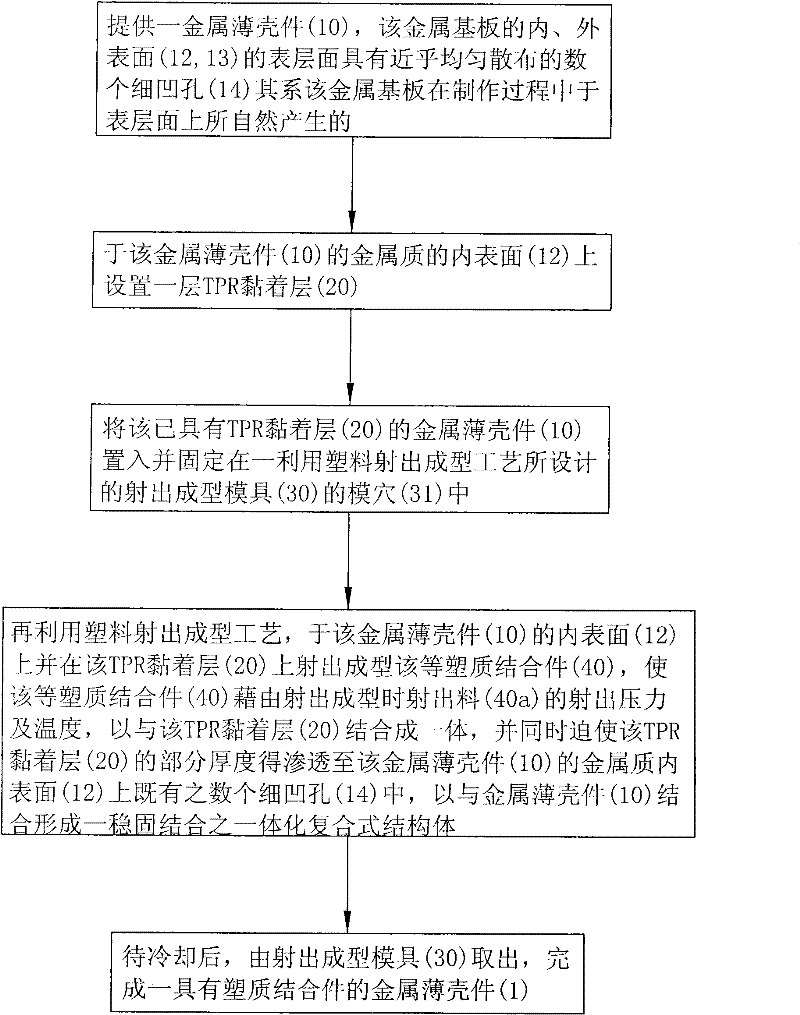

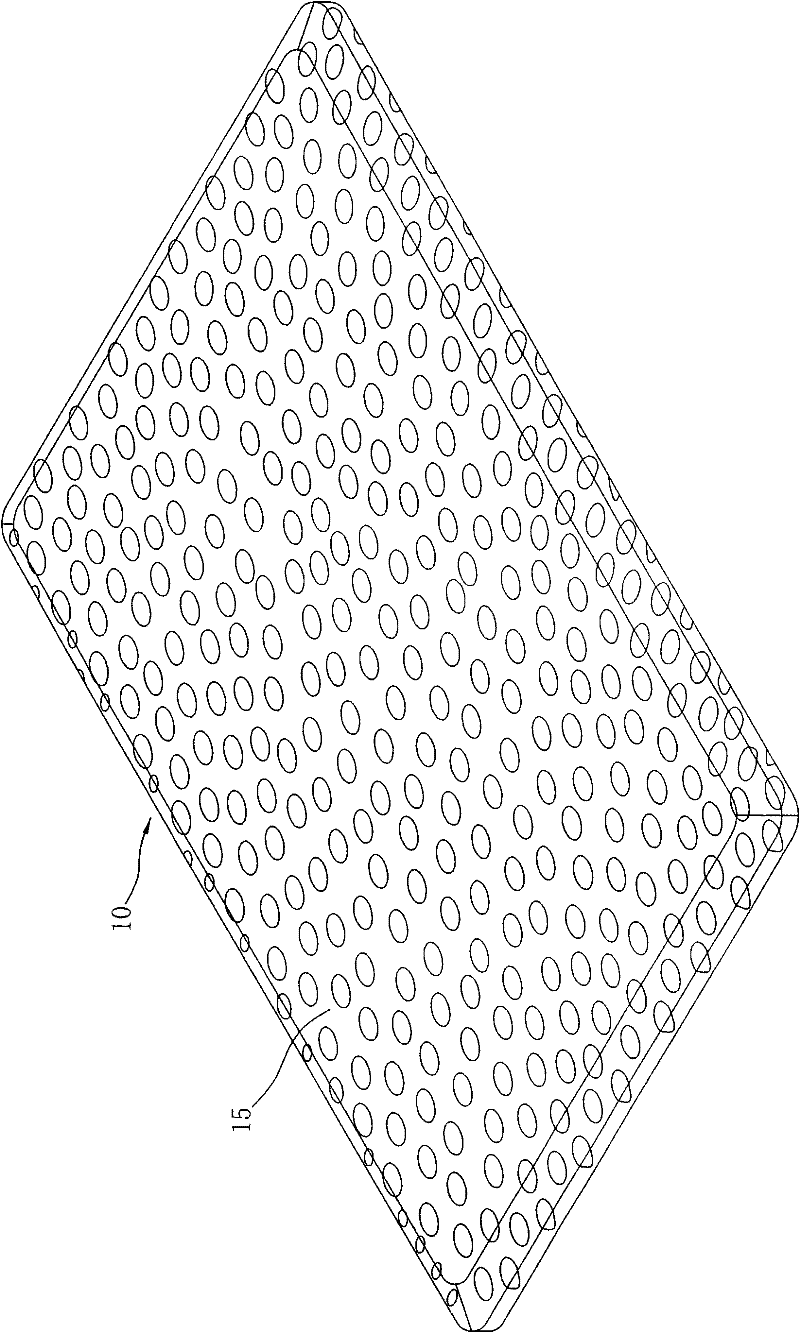

Thin plastic shell with plastic binder and manufacturing method thereof

InactiveCN102215653ASimplification of manufacturing process and forming moldIncrease productivityMetal casingsMetal layered productsThin metalPetroleum resin

The invention relates to a thin metal shell with a plastic binder and a manufacturing method thereof. The manufacturing method comprises the following steps of: providing a molded thin metal shell one surface of which can be provided with an outer decorative coating layer through processing; arranging a TPR (Thermoplastic Rubber) adhesion layer with the thickness of about 400-500 mum on the unprocessed metal surface of the thin metal shell, wherein the TPR adhesion layer is a thermoplastic rubber film synthesized from a butadiene-styrene block copolymer and hydrocarbon petroleum resin; embedding the thin metal shell with the plastic binder and fixing in a cavity of an injection molding die with a corresponding matching shape; injection-molding the plastic binder on the TPR adhesion layer of the thin metal shell by using a metal injection molding process. Therefore, the plastic binder has the pressure and the temperature of the material injected during injection molding so as to be molten and integrated with the TPR adhesion layer, and meanwhile, the thickness of part of the TPR adhesion layer, for example 10% and about 40-50 mum, is forced to permeate into the existing thin concave holes in the metal surface of the thin metal shell.

Owner:铂邑科技股份有限公司

Process for preparing selective emitter solar crystalline silicon solar cell

InactiveCN101916801AGood for mass productionStrong process controllabilityFinal product manufactureSemiconductor devicesAmorphous siliconCrystalline silicon

The invention discloses a process for preparing a selective emitter solar crystalline silicon solar cell, which comprises the following steps of: selecting a silicon wafer, plating a layer of amorphous silicon film serving as a diffused semi-blocking layer on a diffusing surface, making a mask complementary with a front electrode on the amorphous silicon film, corroding the amorphous silicon film not covered by the mask by adopting alkali liquor to obtain a front electrode pattern, removing the mask on the amorphous silicon film, performing selective phosphorus diffusion on the silicon wafer under the blocking of the amorphous silicon film to obtain doped layers with different concentrations, and finally performing subsequent treatment to prepare the solar cell. The preparation process is concise and low in cost, is convenient to be compatible with the conventional solar cell equipment without large-scale equipment change, and is suitable for large-scale mass production; and the amorphous silicon film is adopted as the semi-blocking layer of selective diffusion, so the process controllability is high and the repeatability is high.

Owner:SUN YAT SEN UNIV

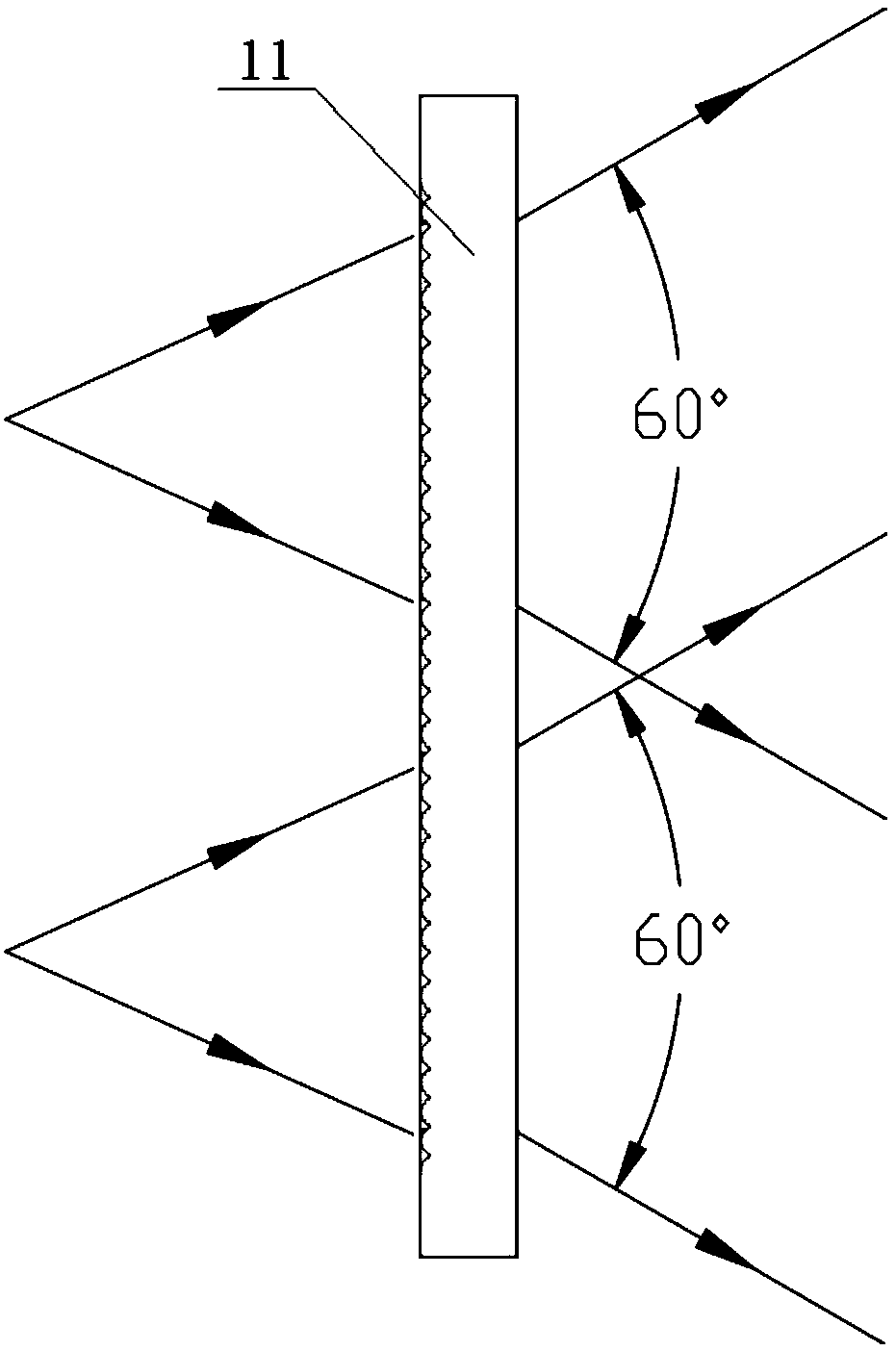

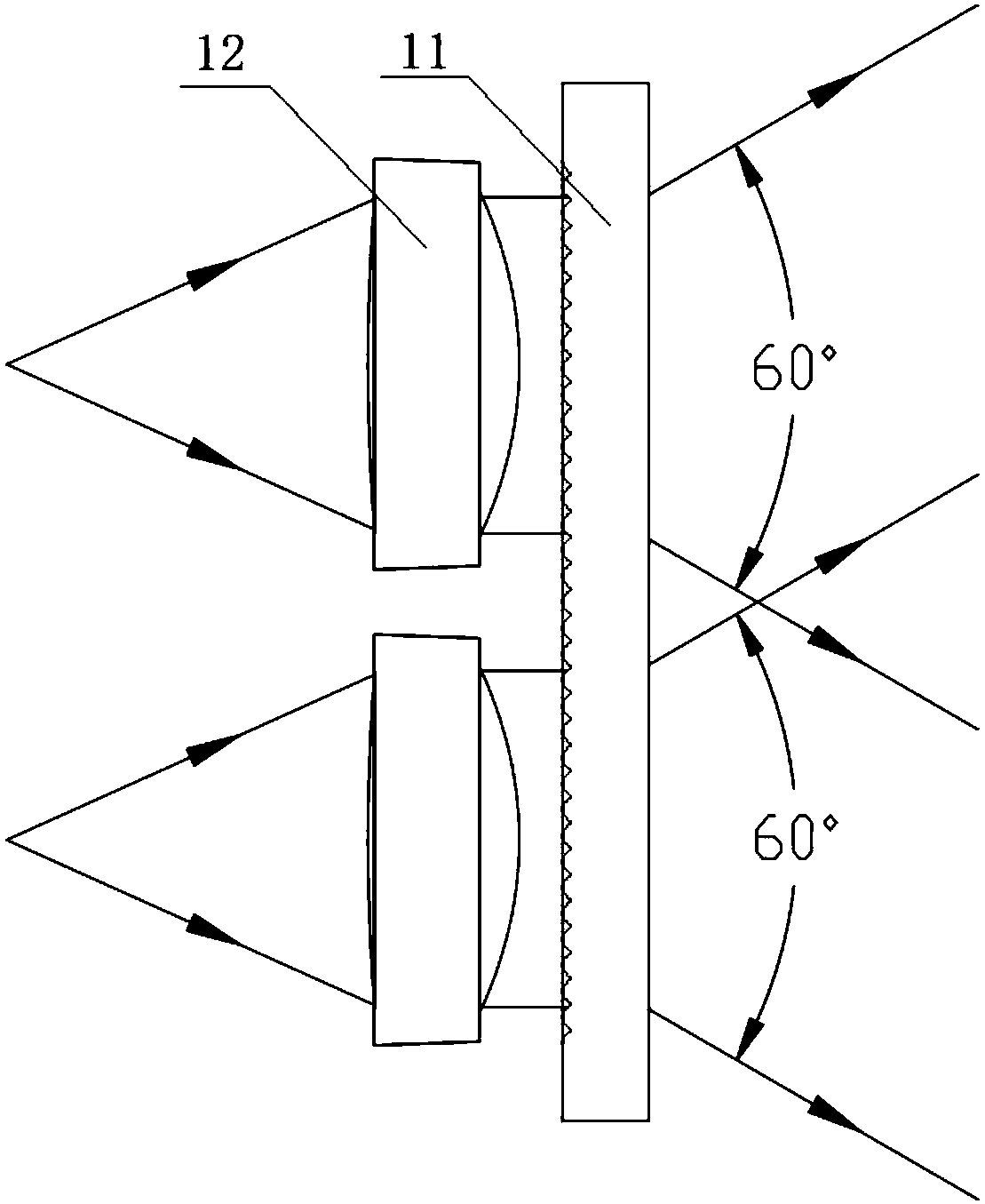

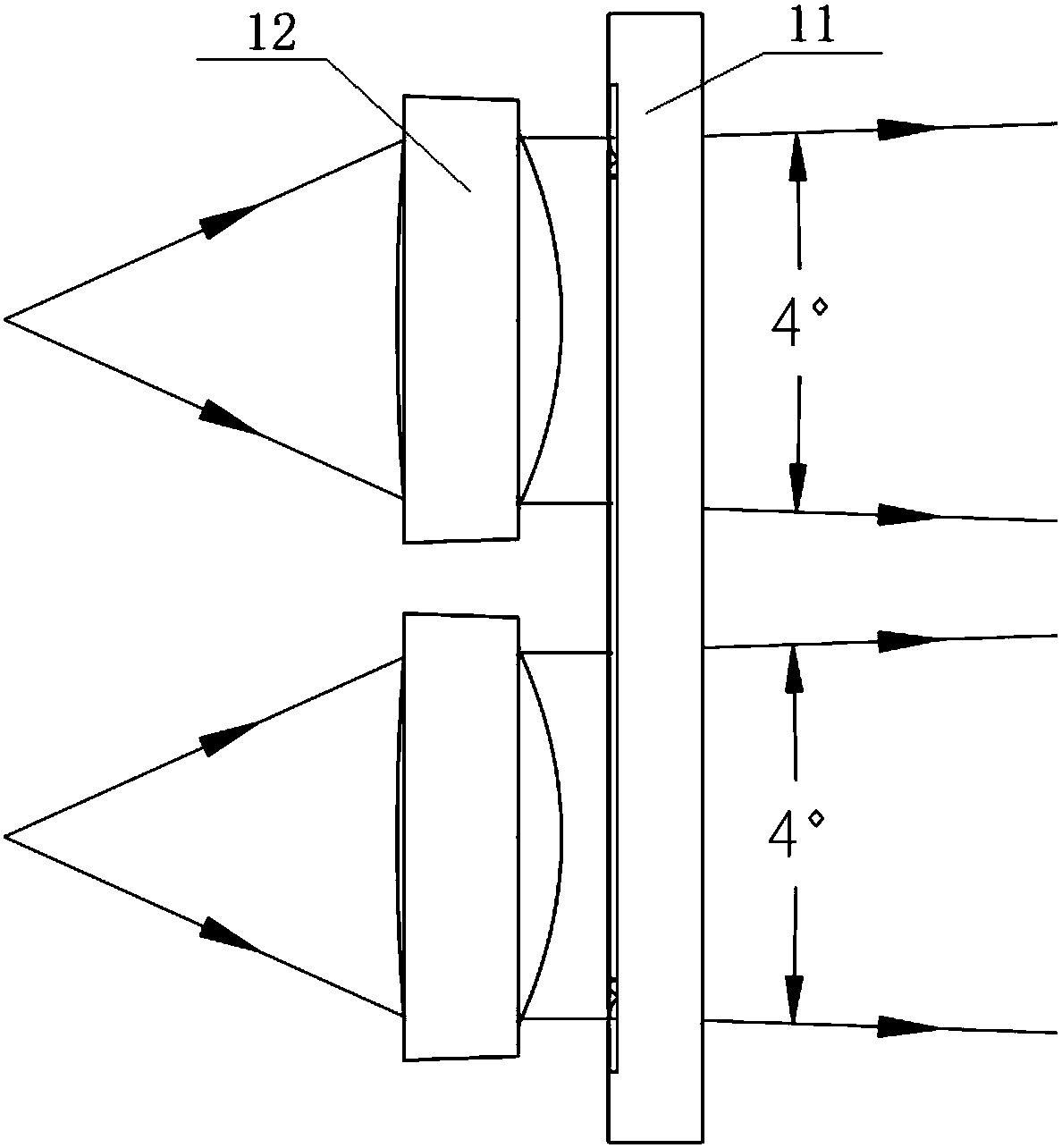

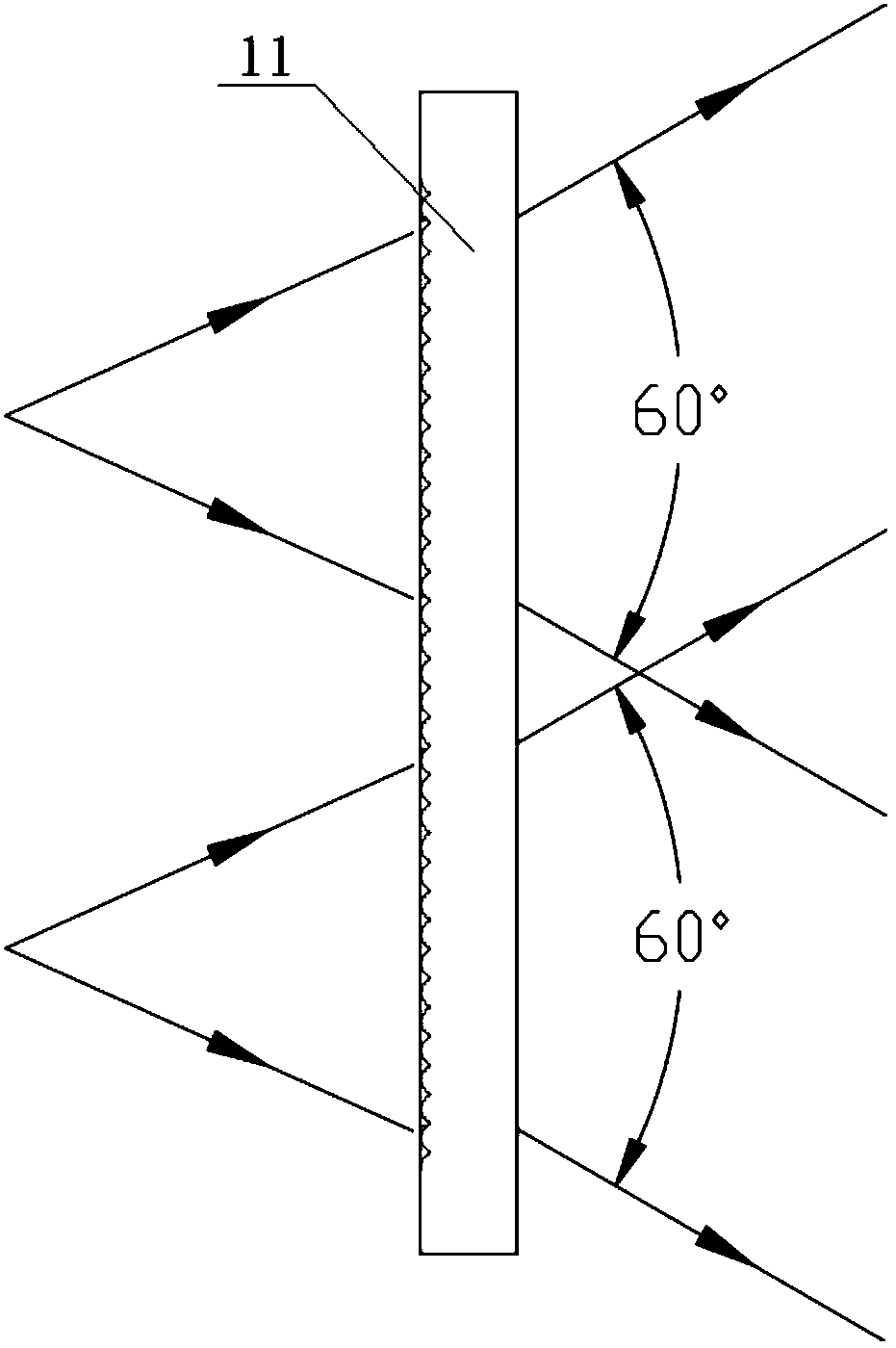

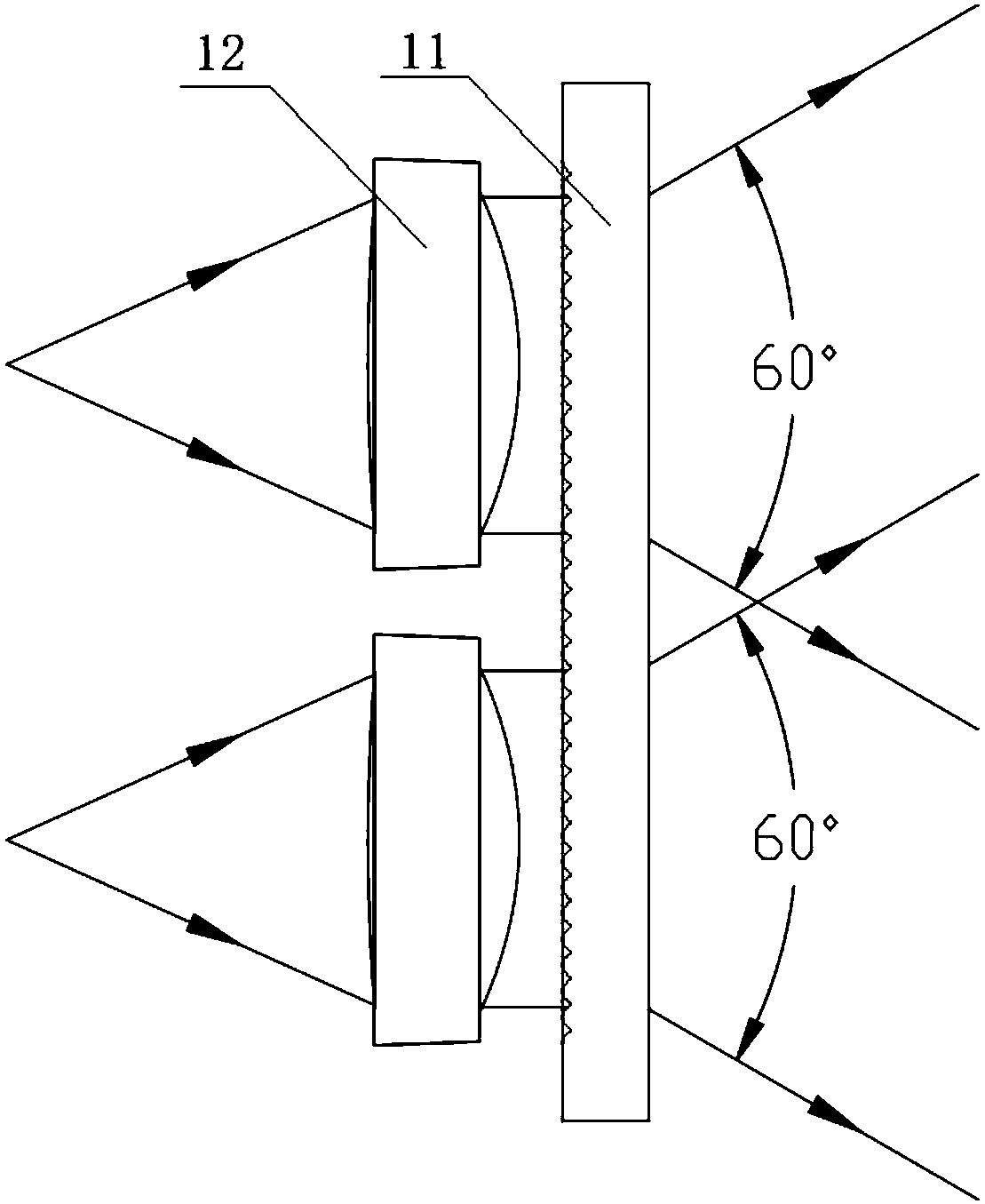

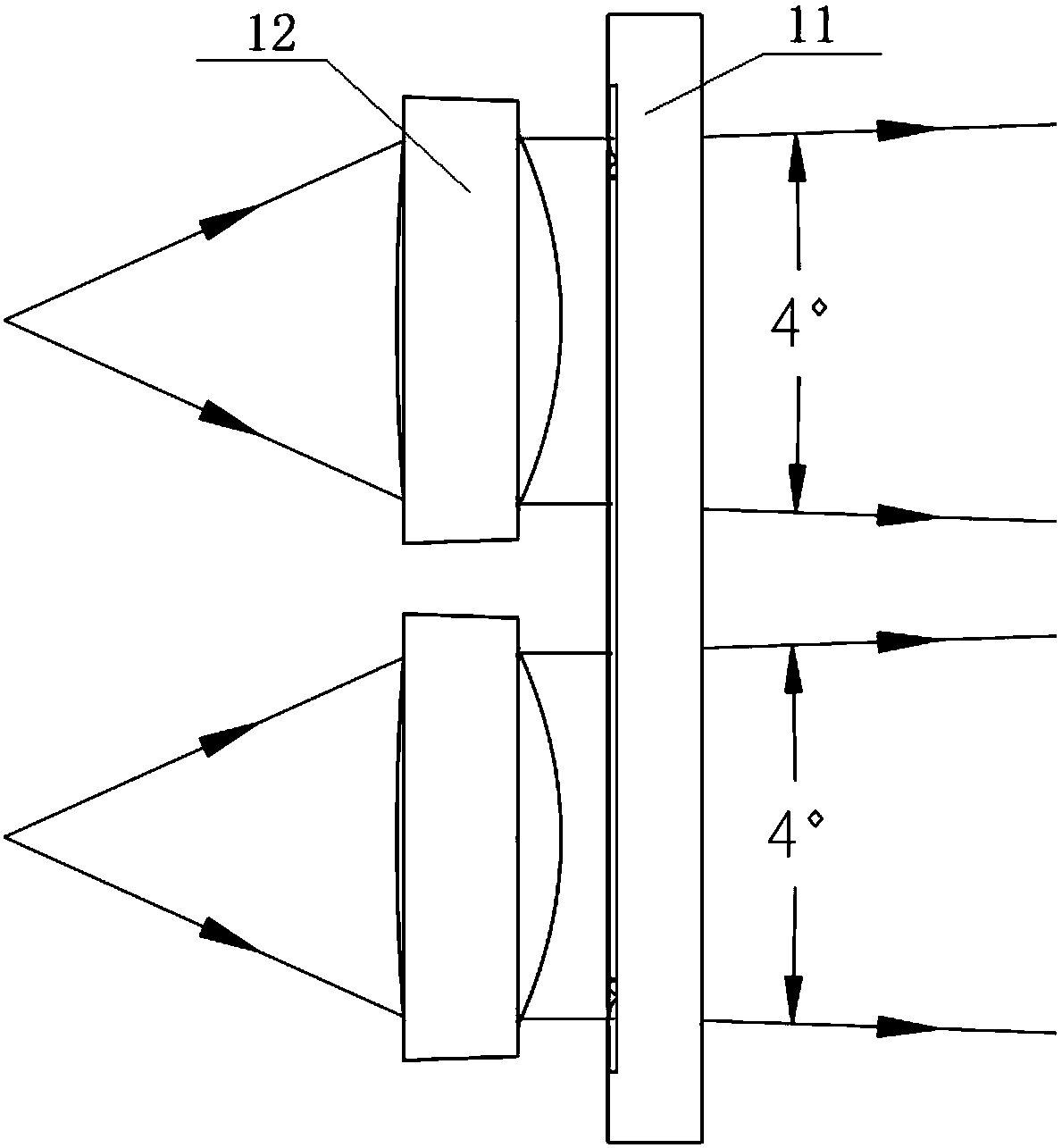

Area array laser radar and mobile platform

PendingCN108318874AUniform treatmentSolve the problem of complex light scanning structure and low refresh rateWave based measurement systemsRadarLight beam

The invention relates to an area array laser radar and a mobile platform. An emission lens comprises an optical reshaping structure arranged in a light emission direction of an emission light source,wherein the optical reshaping structure comprises at least one columnar lens; a length direction of a columnar bulge arranged on one side, close to the emission light source, of each columnar lens isperpendicular to a divergence direction of an emission beam; and the emission beam is a uniform beam with a set divergence angle and a set shape after passing through the optical reshaping structure.The invention further provides the area array laser radar which comprises an area array light emission mechanism, an area array light receiving mechanism and a master control board, wherein the area array light emission mechanism comprises an emission light source, a driving emission circuit and the emission lens. The invention further provides the mobile platform. The problem of the nonuniform emission beam of an emission system of the common area array laser radar is solved, and the testing and operating safety and accuracy are improved.

Owner:BENEWAKE BEIJING TECH CO LTD

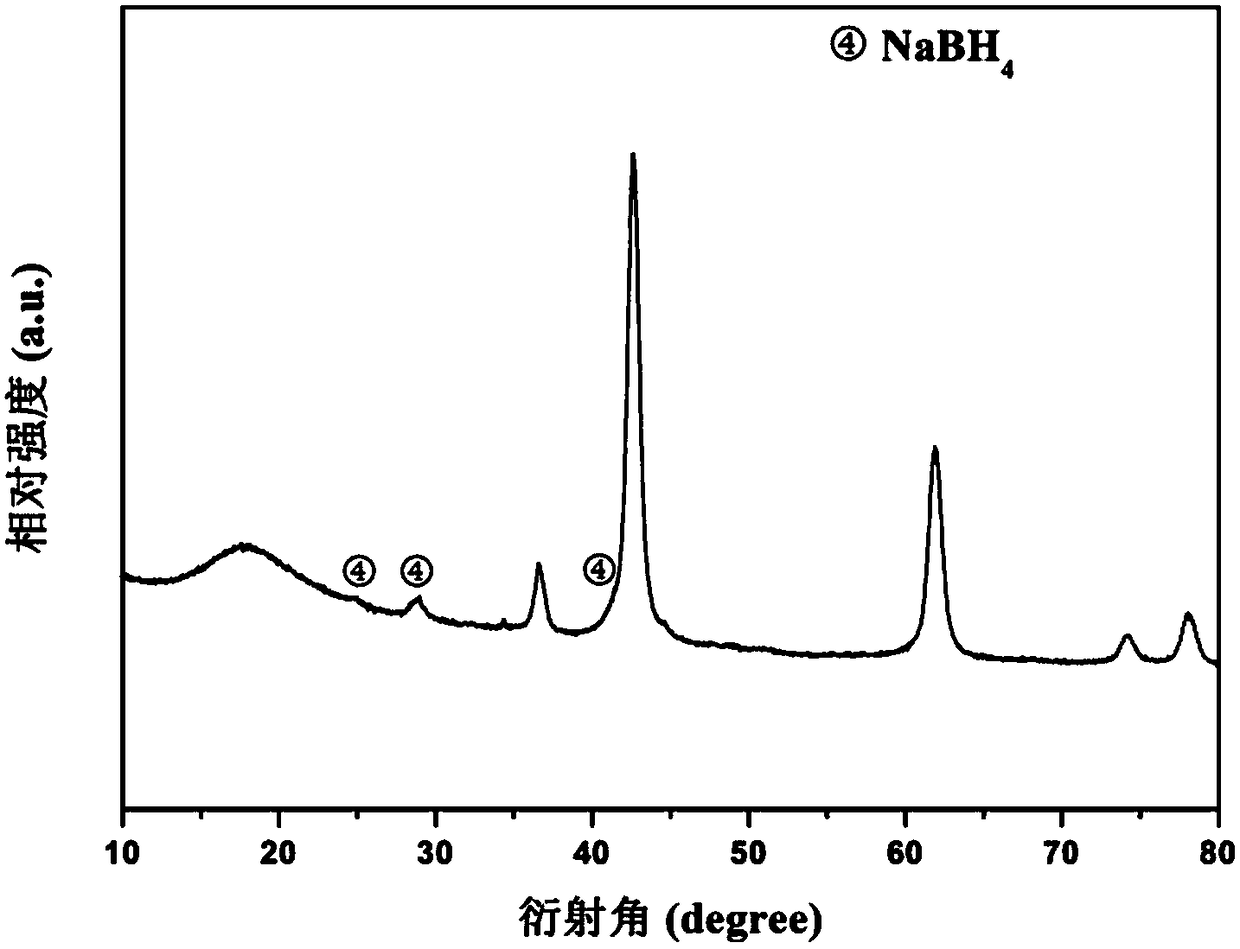

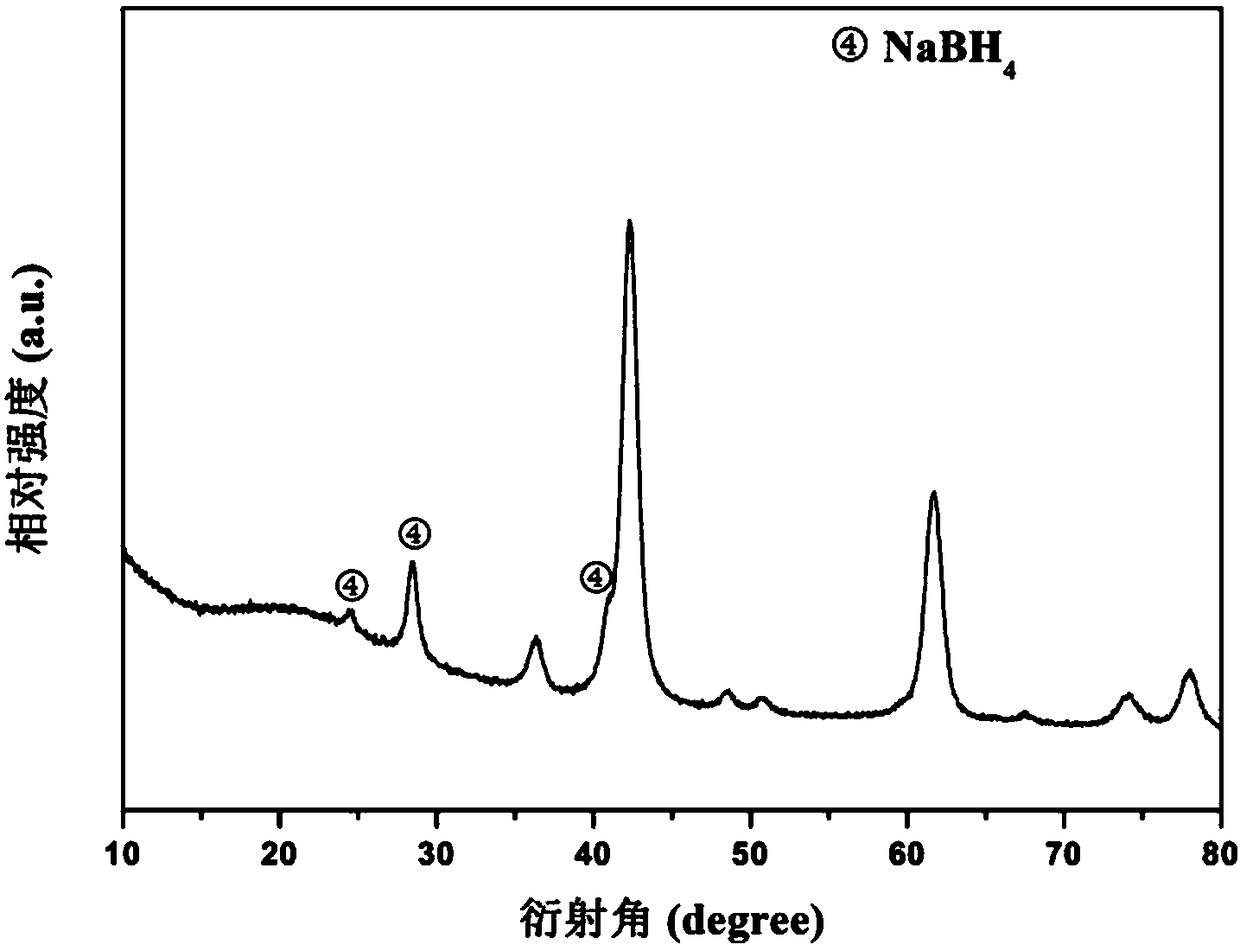

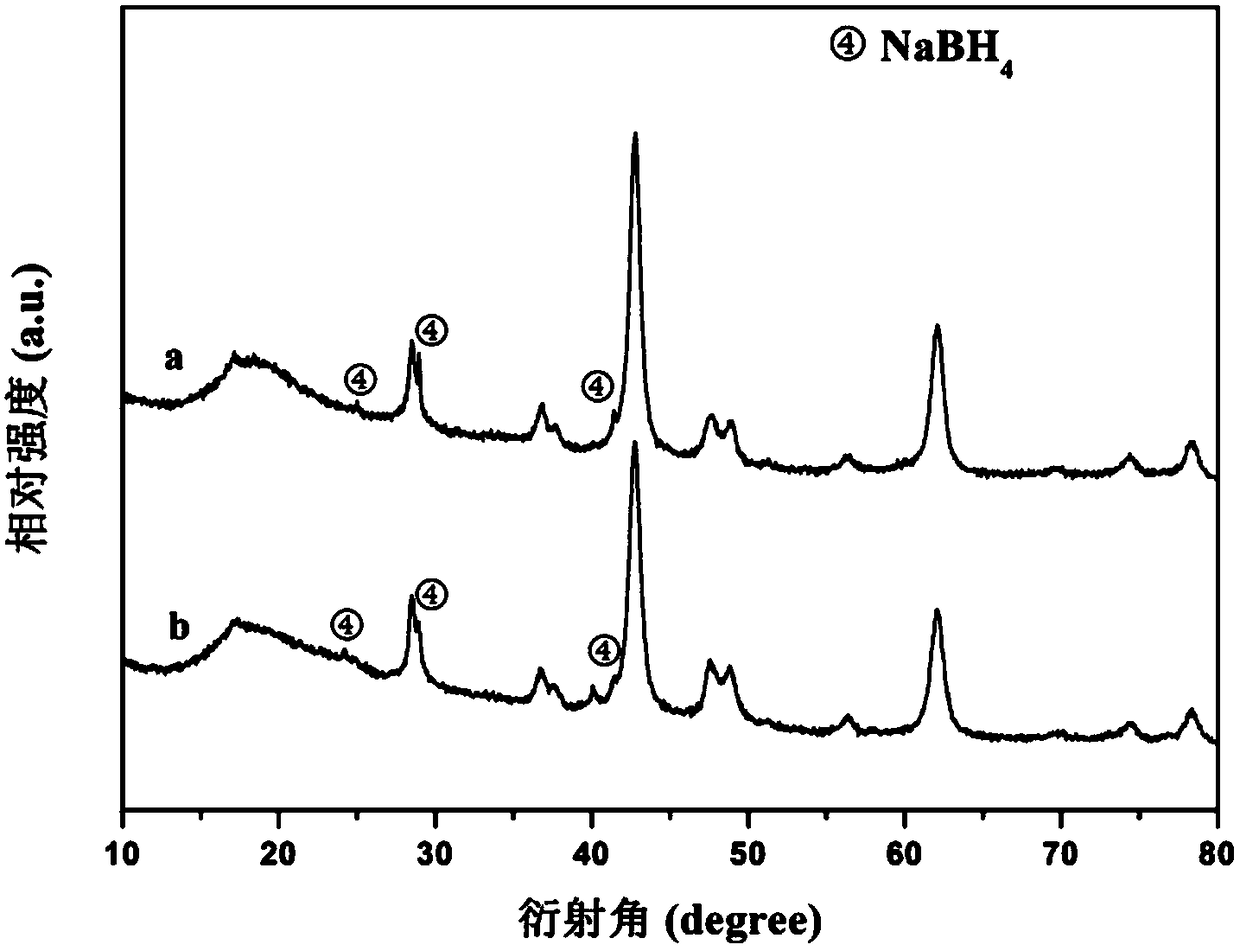

Method for directly synthesizing sodium borohydride by solid phase ball milling at room temperature

ActiveCN108545699AThe reaction process is controllable and adjustableSimple processMonoborane/diborane hydridesSolid phasesMagnesium hydride

The invention discloses a method for directly synthesizing sodium borohydride by solid phase ball milling at room temperature. Under the condition of the room temperature, a ball mill is used for solid phase ball milling of a mixture of a reducing agent, a sodium supplement and a reduced material and purification to obtain the sodium borohydride; the reducing agent comprises one or more of magnesium, magnesium hydride, aluminum, calcium silicide and magnesium silicide; the sodium supplement includes at least one of sodium hydroxide, sodium hydride and sodium carbonate; the reduced material iscrystal water-contained sodium tetraborate or sodium tetraborate or a mixture of the crystal water-contained sodium tetraborate or the sodium tetraborate, the solid phase ball milling is carried out in a mixed atmosphere of argon and hydrogen or an argon atmosphere or a hydrogen atmosphere. The method has the advantages of short production process, mild reaction condition, low cost, high output, no pollution, high safety factor and easy industrial production.

Owner:SOUTH CHINA UNIV OF TECH

Chinese caterpillar fungus bionic culturing method

The invention relates to a bionic culture method for winter worm summer herb mycelium, which comprises: separating and pure culturing monospore, preparing liquid medium, inoculating the pure culture bacterium of mycelium, static culturing the superficial-layer liquid for six months; harvesting the mycelium; wherein, breaking the mycelium into monocellular or multicellular mycelium every month during the culture process. This invention needs no fermentor or other dear devices, and reduces cost more than 50% for 1g dry mycelium.

Owner:江西荣善绿色中药有限公司

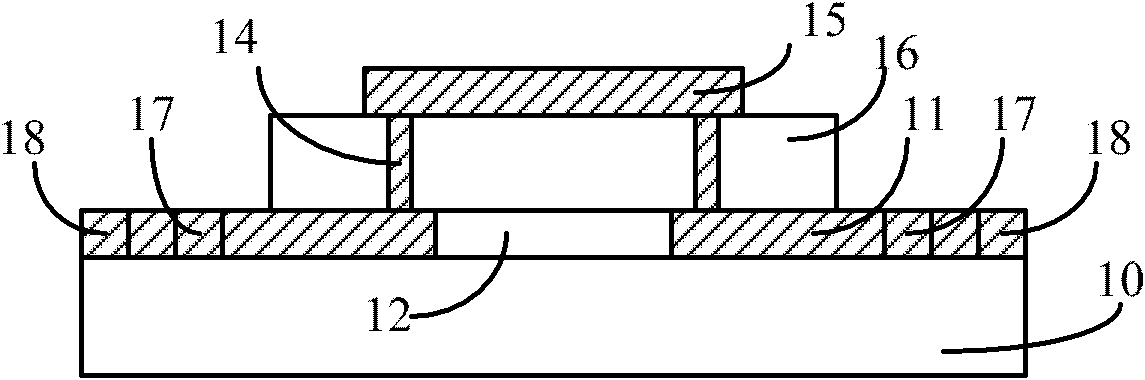

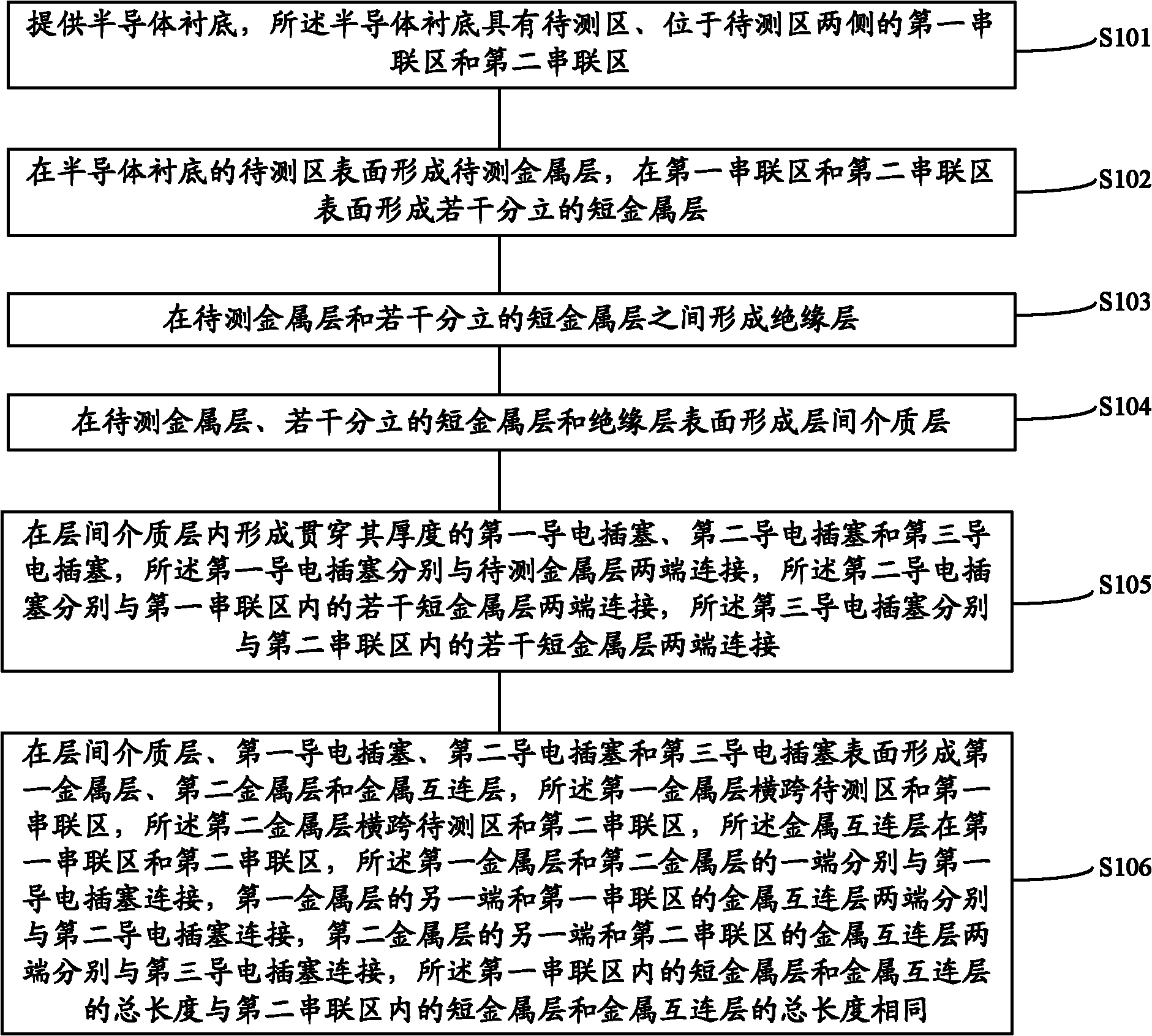

Semiconductor failure analysis structure, forming method of semiconductor failure analysis structure and failure time detection method thereof

ActiveCN103187403AImprove accuracyIncrease resistanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringFailure analysis

The invention provides a semiconductor failure analysis structure, a forming method of the semiconductor failure analysis structure and a failure time detection method thereof. The semiconductor failure analysis structure comprises a semiconductor substrate, a metal layer to be tested, a first metal layer, a second metal layer, a first conductive plug, a plurality of first resistance metal layers, a plurality of second resistance metal layers, a plurality of second conductive plugs and a plurality of third conductive metal layers. The semiconductor substrate is provided with an area to be tested, a first serial area and a second serial area. The metal layer to be tested, the first metal layer and the second metal layer are placed on the semiconductor substrate. The first conductive plug placed in an interlayer dielectric layer enables the first metal layer, the second metal layer and the metal layer to be tested to be connected in series. The plurality of first resistance metal layers are arranged in the first serial area. The plurality of second resistance metal layers are arranged in the second serial area. The plurality of second conductive plugs are placed in the interlayer dielectric layer of the first serial area. The plurality of third conductive metal layers are arranged in the interlayer dielectric layer of the second serial area. The first conductive plug, the second conductive plugs and the third conductive plugs enable the metal layer to be tested, the first metal layer, the second metal layer, the plurality of first resistance metal layers and the plurality of second resistance metal layers to be sequentially connected in series.

Owner:SEMICON MFG INT (SHANGHAI) CORP

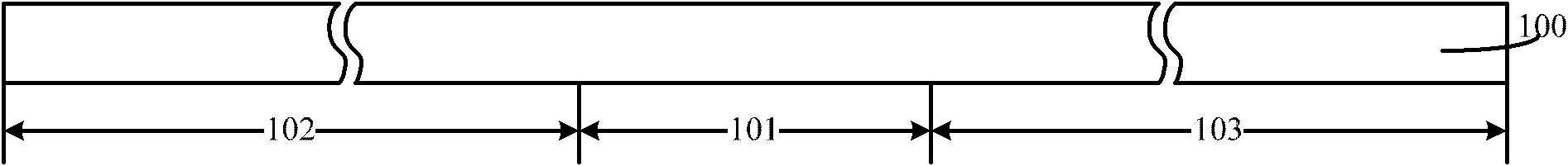

Transmitting lens, area array laser radar, and movable platform

PendingCN108549085AImprove measurement accuracy and measurement efficiencyImprove stabilityElectromagnetic wave reradiationLight sourceOptoelectronics

The invention relates to a transmitting lens, an area array laser radar, and a movable platform. The transmitting lens comprises an optical shaping structure which is set in a light transmitting direction of a transmitting light source. The optical shaping structure comprises at least one cylindrical lens, and the length direction of a cylindrical projection disposed at one side, close to the transmitting light source, of the cylindrical lens is perpendicular to the divergent direction of a transmitting light beam. The transmitting light beam becomes a uniform light beam with a set divergenceangle and a set shape after passing through the optical shaping structure. The invention also provides the area array laser radar, and the laser radar comprises an area array light transmitting mechanism, an area array light receiving mechanism, and a main control board. The area array light transmitting mechanism comprises a transmitting light source, a drive transmitting circuit and the transmitting lens. The invention also provides the movable platform. The invention solves a problem that transmitted beams of a transmitting system of a conventional area array laser radar are not uniform, and the testing and operation safety and accuracy are improved.

Owner:BENEWAKE BEIJING TECH CO LTD

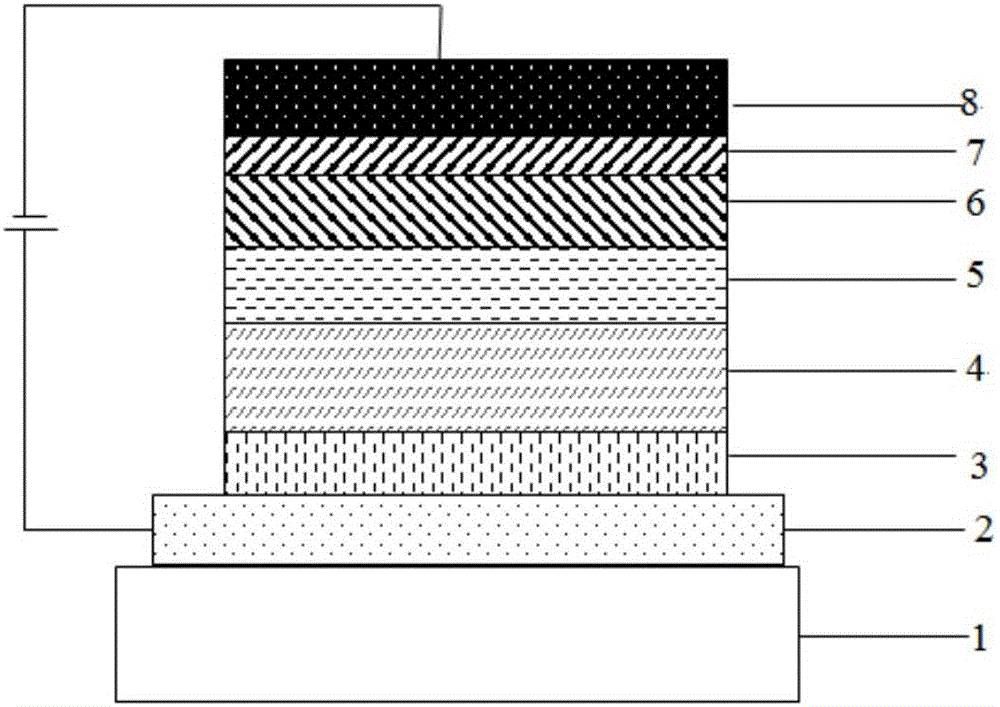

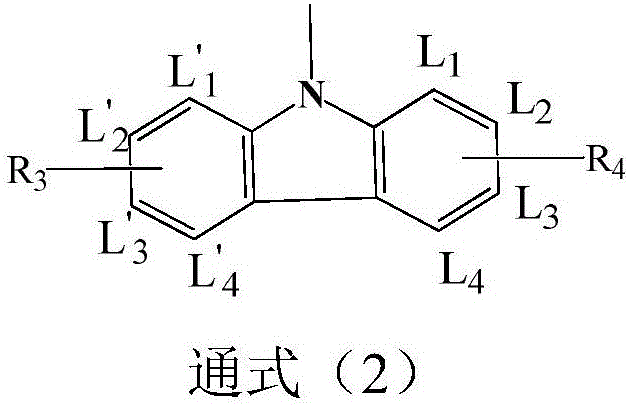

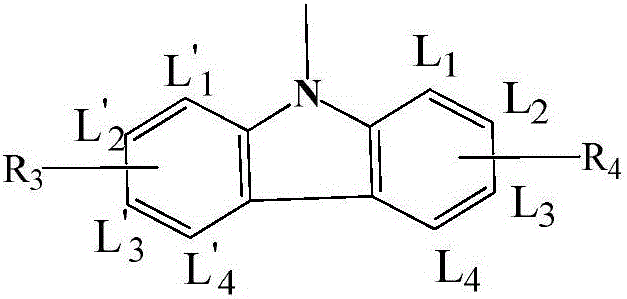

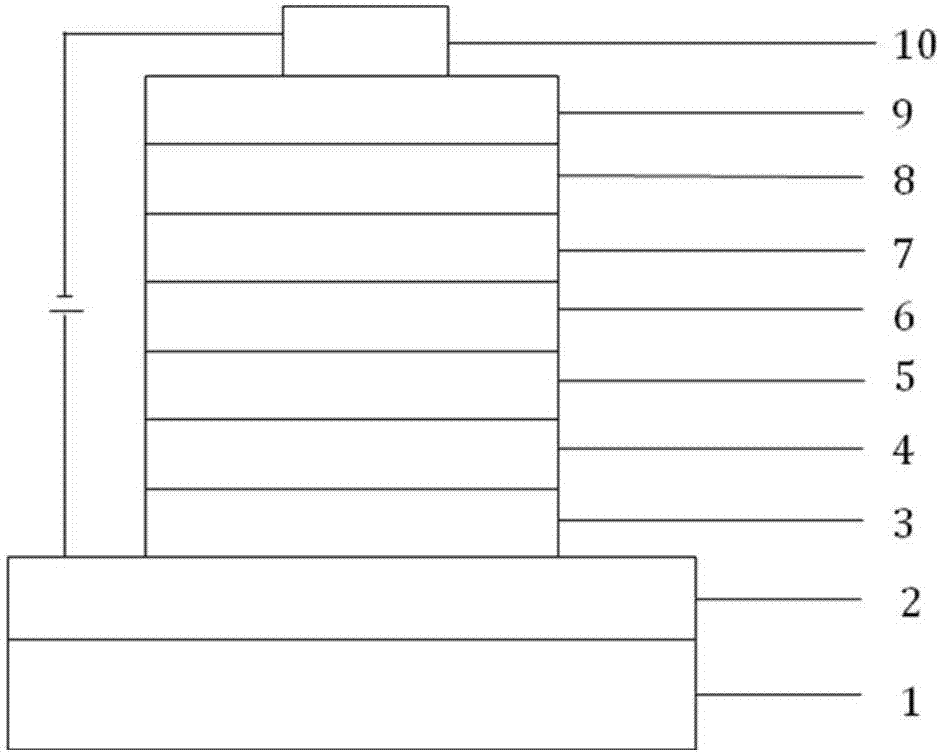

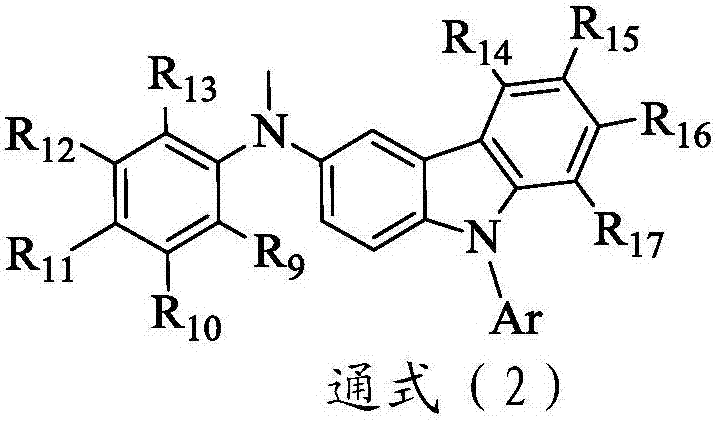

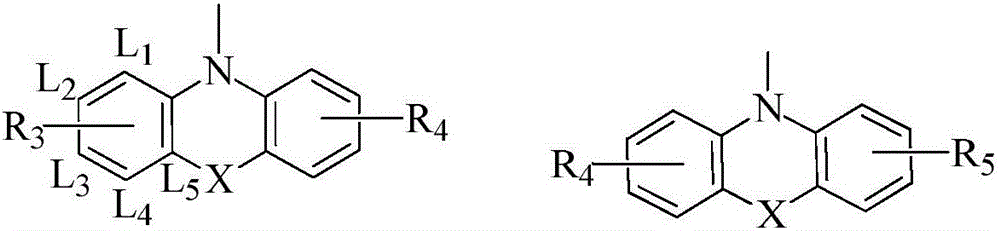

Organic electroluminescent device taking anthracene as core compound, and applications thereof

InactiveCN108003089ADestroy crystallinityInhibit aggregationOrganic chemistrySolid-state devicesAnthraceneChain structure

The invention discloses an organic electroluminescent device taking anthracene as core compound, and applications thereof. The organic electroluminescent device taking anthracene as core compound comprises a cavity transmission layer, a luminescent layer, and an electron transmission layer; and anthracene is taken as the core compound. Anthracene is combined with a branch chain structure represented by general structure (2), so that it is convenient for energy transmission among host and guest materials, and device high efficiency can be achieved easily; and in addition, the core compound possesses relatively high glass transition temperature and molecule heat stability, and appropriate HOMO and LUMO energy level, device structure optimization is capable of improving OLED device photoelectric properties and prolonging OLED device service life effectively.

Owner:VALIANT CO LTD

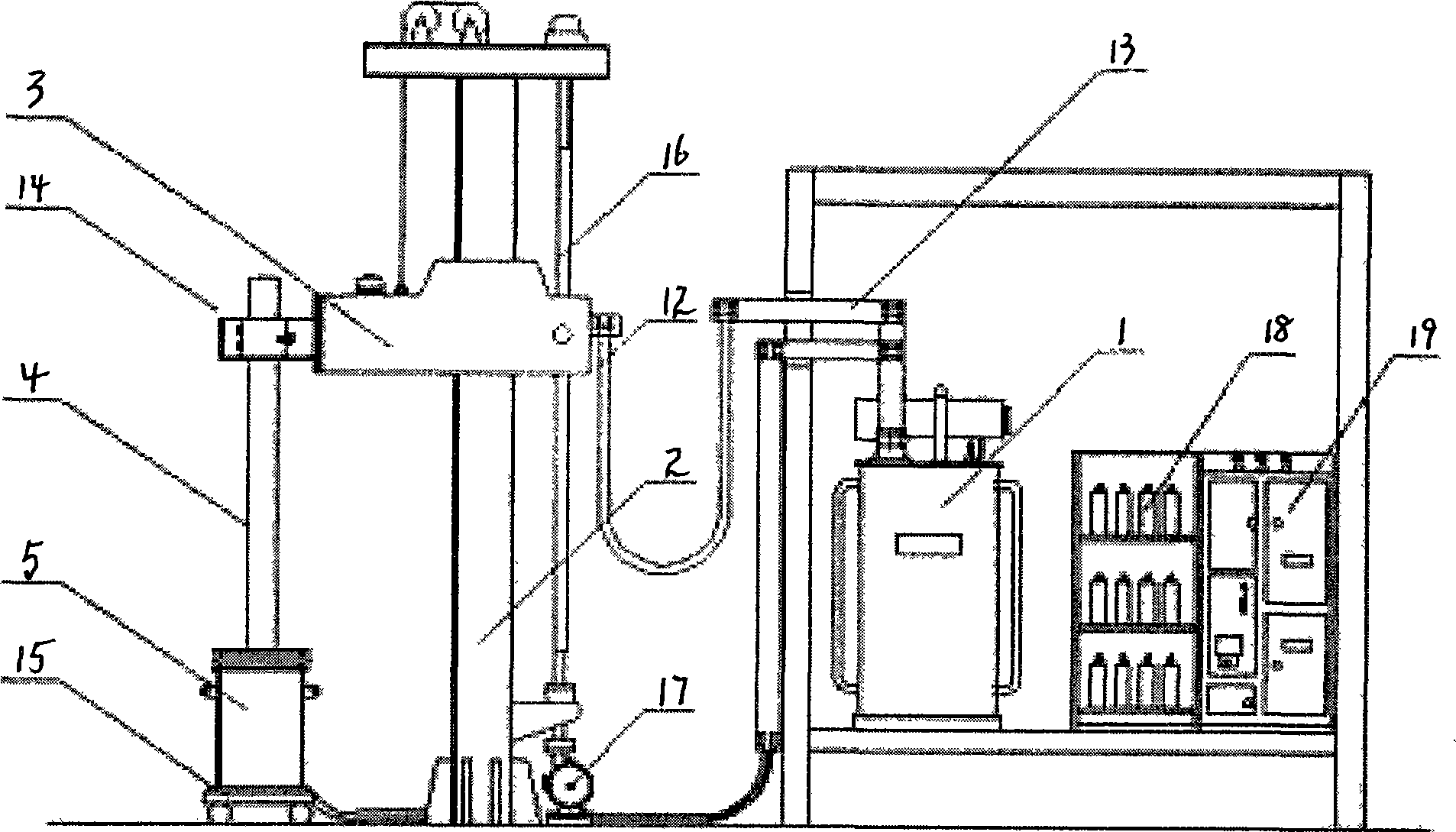

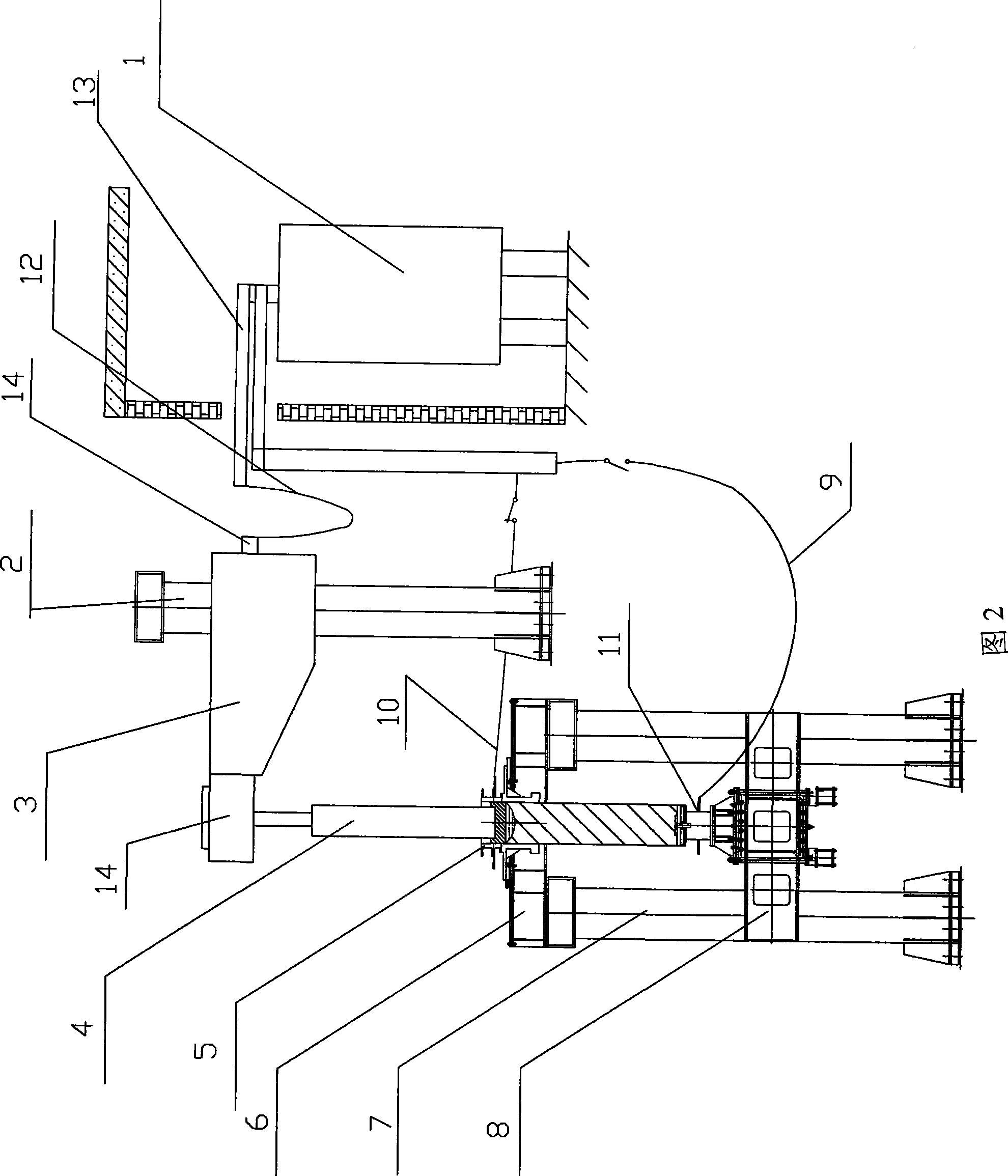

Conductive and continuous casting type electroslag remelting furnace for crystallizer

The invention relates to a crystallizer conducting continuous casting type electroslag remelting furnace which comprises a stripping system, a crystallizer system, an electrode, an electrode elevating system and a power supply system. The stripping system comprises a stripping upright column (7), a stripping platform (8) and a bottom water tank (10). The crystallizer system comprises a crystallizer platform (6) and a crystallizer (5). The electrode elevating system adopts two independent cross arm upright columns (2) and cross arms (3). The power supply system comprises a transformer (1), a short network (13), a cross arm cable (12), a crystallizer cable (11) and a bottom water tank cable (9), wherein one end of the cross arm cable (12) is connected with an electrode holder (14) through the short network (13), the other end of the cross arm cable (12) is connected with the transformer (1) through the short network (13), one end of the crystallizer cable (11) and one end of the bottom water tank cable (9) are connected with the crystallizer (5) and the bottom water tank (11) respectively, and the other end of the crystallizer cable (11) and the other end of the bottom water tank cable (9) are connected with the transformer (1). The crystallizer conducting continuous casting type electroslag remelting furnace has the advantages of low production electricity consumption, high production efficiency, simple production process, and higher yield than that of a continuous casting billet.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

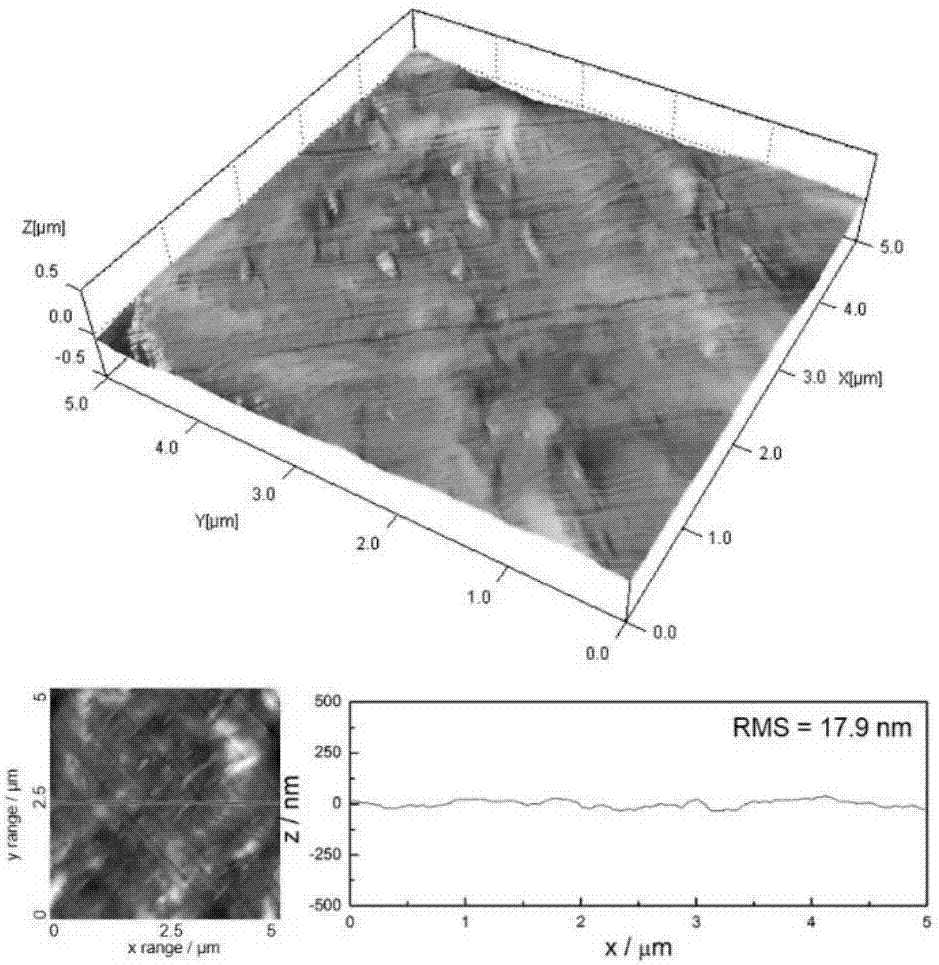

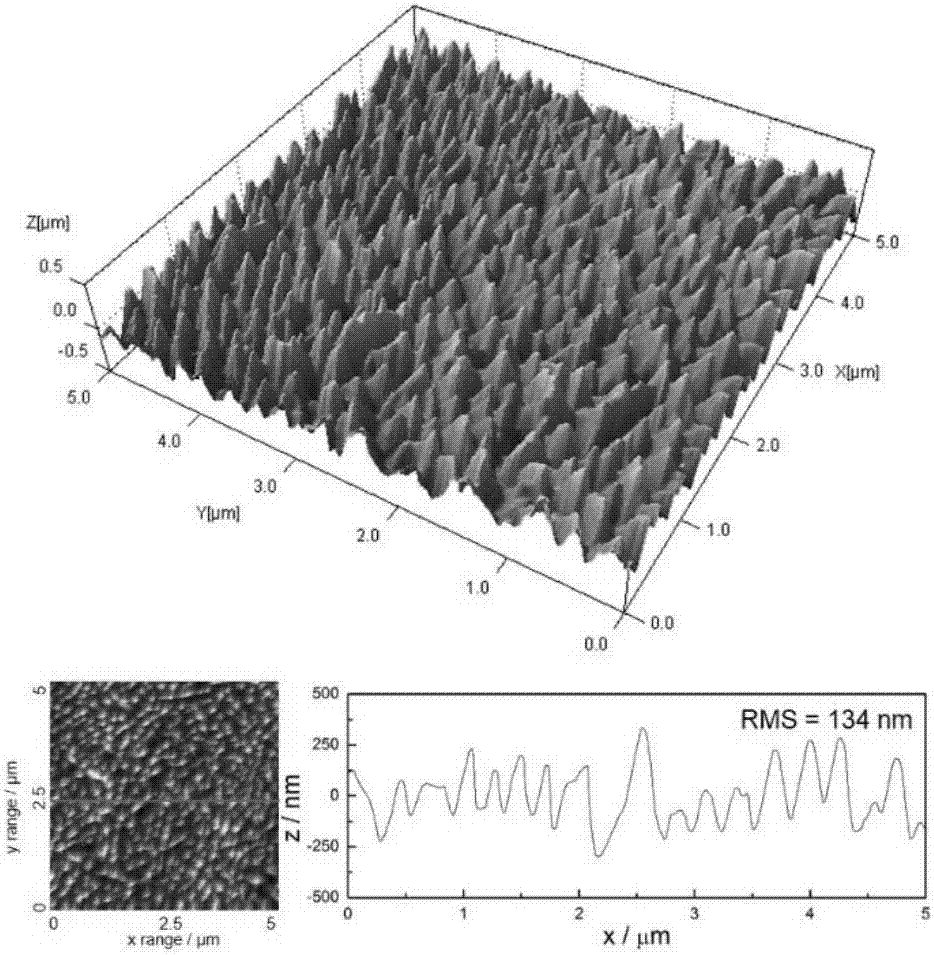

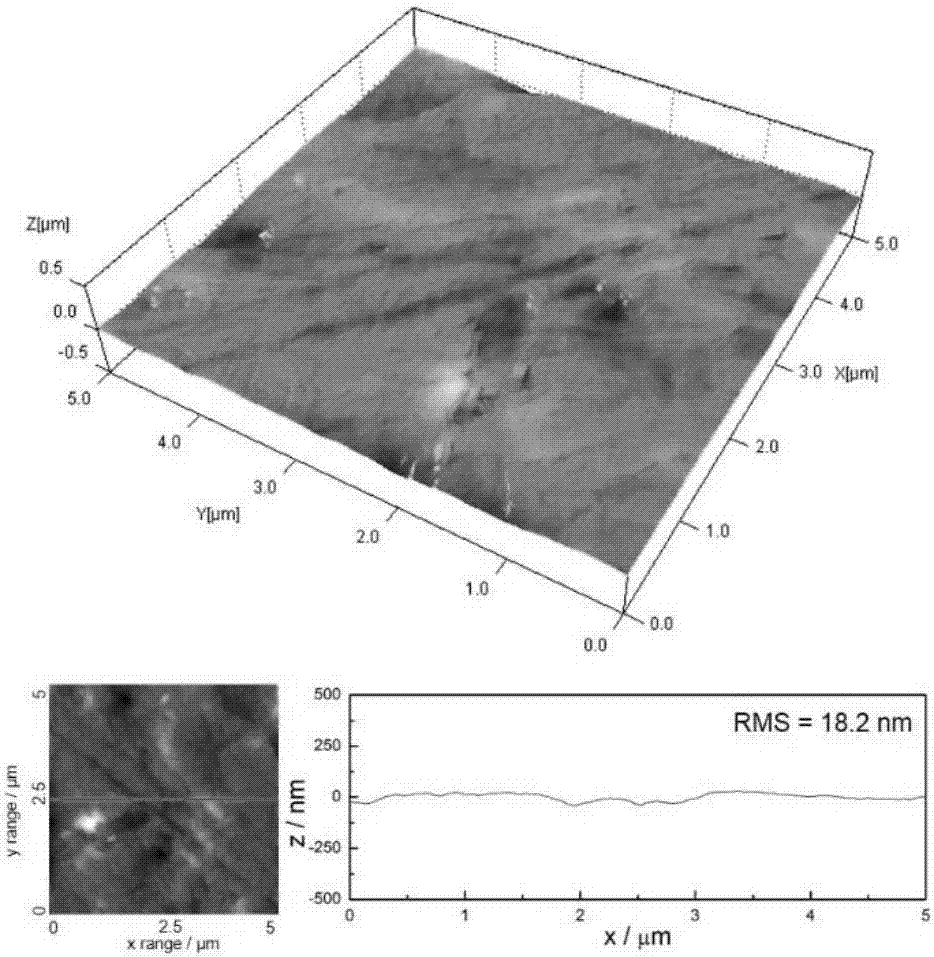

High molecular material surface modification method and its product and application

ActiveCN107189096AAchieve covalently grafted loadingAchieve biomimetic surface modificationAfter treatmentCompound (substance)

The invention discloses a high molecular material surface modification method and its product and application. The surface modification method particularly relates to a biomedical polymer material surface treated on the basis of plasma immersion ion injection and a surface covalent grafting bioactive molecule after treatment so as to realize its bionic modification; the method particularly includes steps of 1), treating the high molecular material through gas plasma immersed ion injection; 2), incubating the treated high molecular material in the solution containing biological molecules. The high molecular material with modified gas plasma immersion ion injection surface has good stability; the grafting ability still cannot be significantly declined even though the high molecular material is stored in the air for a long time, and the high molecular material does not use chemical crosslinking agent; the whole surface modification technique is simple in process, low in cost, and suitable for batch and industrial production. The method and its product have wide application prospects in medical implant materials, functional materials, bioactive materials and other domain.

Owner:SHENZHEN INST OF ADVANCED TECH

Organic compound with xanthene and application thereof in OLED (organic LED) devices

ActiveCN106478610ADestroy crystallinityInhibit aggregationOrganic chemistrySolid-state devicesVitrificationThermal stability

The invention discloses an organic compound with xanthene and application thereof in OLED (organic LED) devices; the organic compound has a structural general formula shown as in formula (1). The organic compound provided herein has high vitrification temperature and high molecular thermal stability, has suitable HOMO and LUMO energy levels and high Eg, and by optimizing device structure, it is possible to effectively improve photoelectric properties of OLED devices and prolong the lives of the OLED devices.

Owner:JIANGSU SUNERA TECH CO LTD

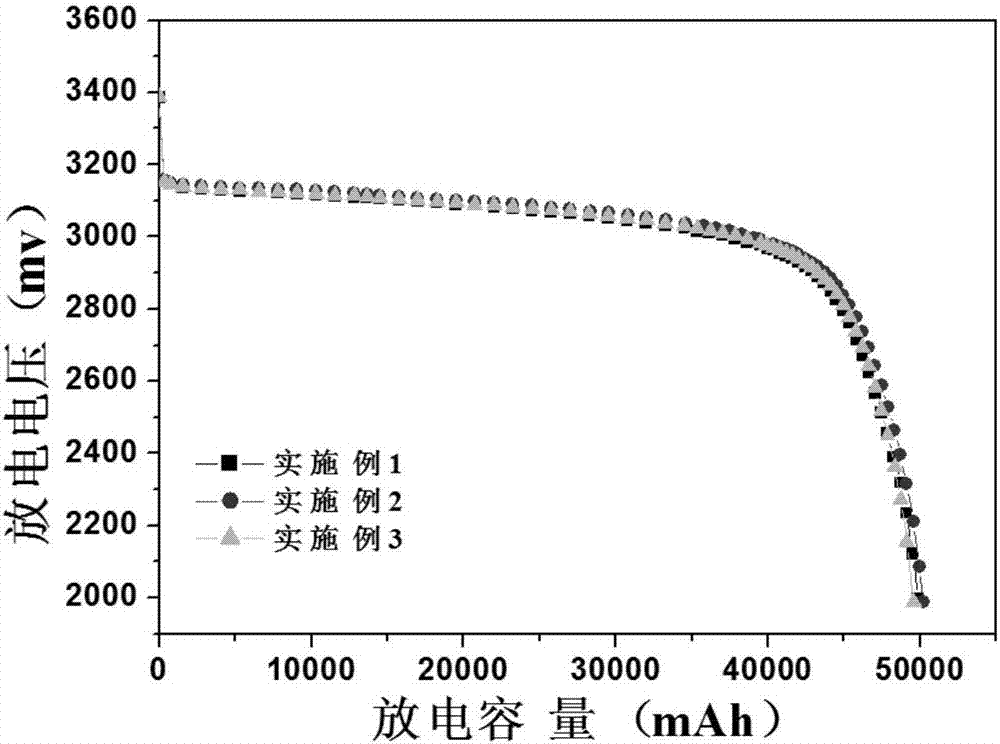

Lithium iron phosphate system lithium ion battery and preparation method thereof

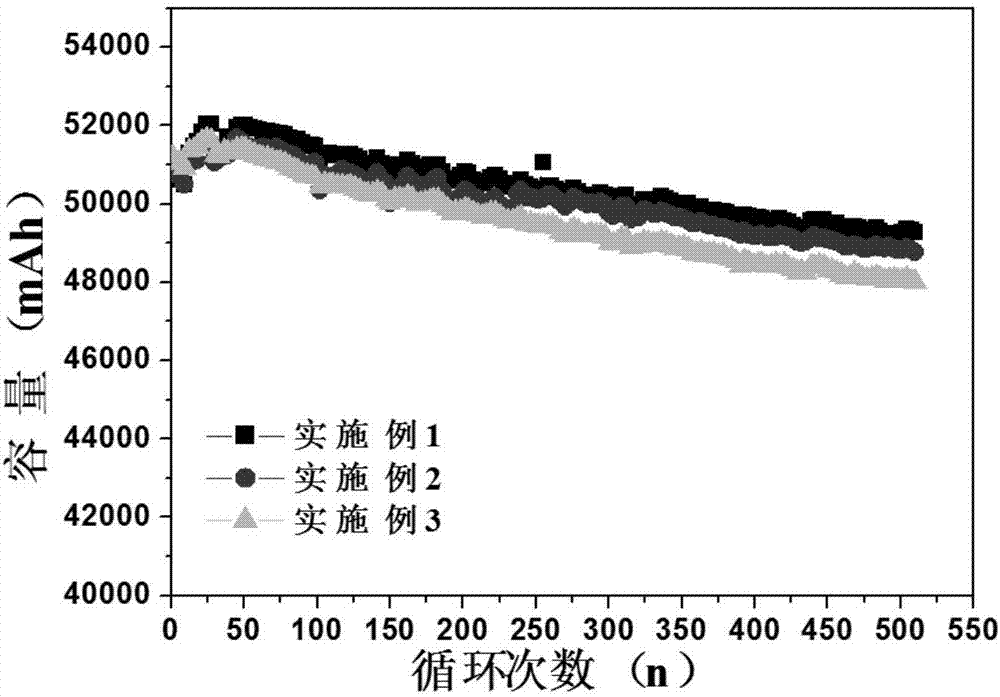

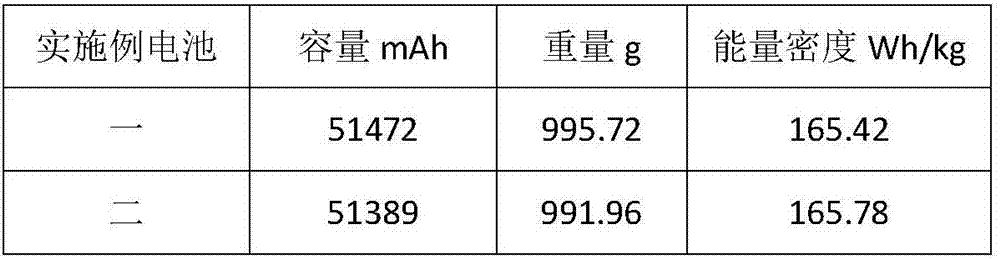

InactiveCN107046131AIncrease energy densityImprove electrochemical performancePhosphatesCell electrodesMicrosphereSodium-ion battery

The invention discloses a lithium iron phosphate system lithium ion battery. The lithium iron phosphate system lithium ion battery comprises a shell, a lamination core body arranged in the shell, and an electrolyte solution injected into the shell; the lamination core body comprises a positive plate, a negative plate, and a diaphragm arranged between the positive plate and the negative plate; a cathode material comprises a cathode active substance; an anode material comprises an anode active substance; the cathode active substance is lithium iron phosphate; the anode active substance comprises at least one ingredient selected from natural graphite, artificial graphite, mesophase carbon microsphere, and polymer carbon; the electrolyte solution comprises at least one or a plurality of electrolytes selected from LiPF6, LiBF4, and LiAsF6. The lithium iron phosphate system lithium ion battery is excellent in cycling performance, and is high in energy density; and large-scale production of the lithium iron phosphate system lithium ion battery can be easily realized.

Owner:SOUNDON NEW ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com