Manufacturing method of light-load automobile aluminum alloy wheel hub

The technology of an aluminum alloy wheel hub and its manufacturing method, which is applied in the field of aluminum alloy wheels, can solve the problems of high manufacturing process cost and difficult promotion and use, and achieve the effects of reducing processing steps, wide promotion range, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A kind of manufacturing method of light load automobile aluminum alloy wheel provided by the present invention, the steps are as follows:

[0030] The first step, rim production:

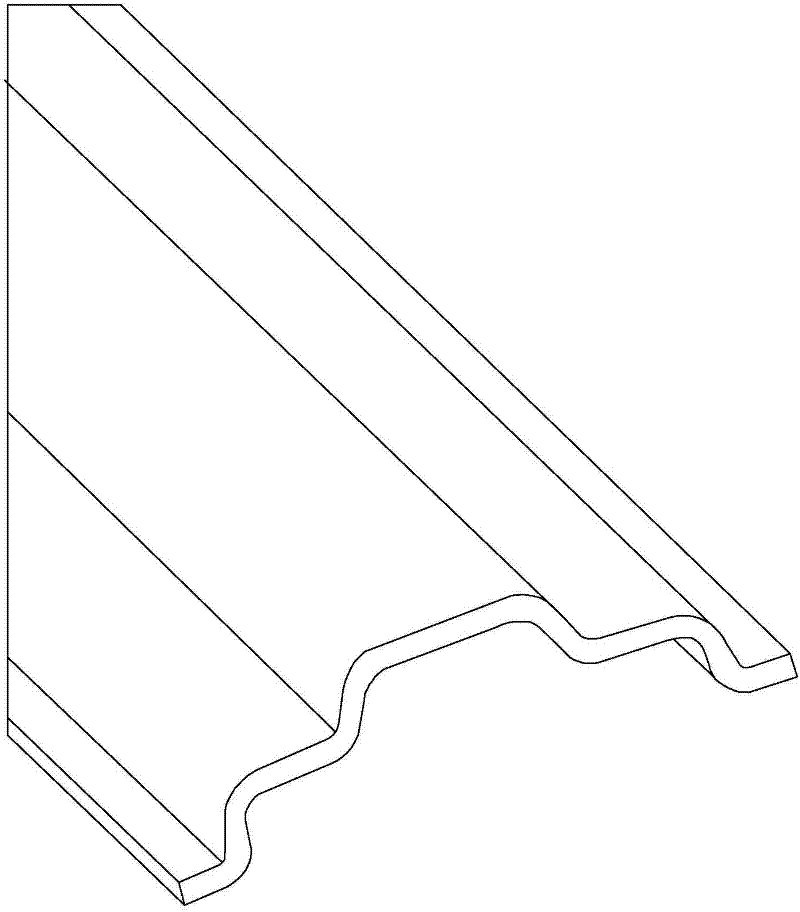

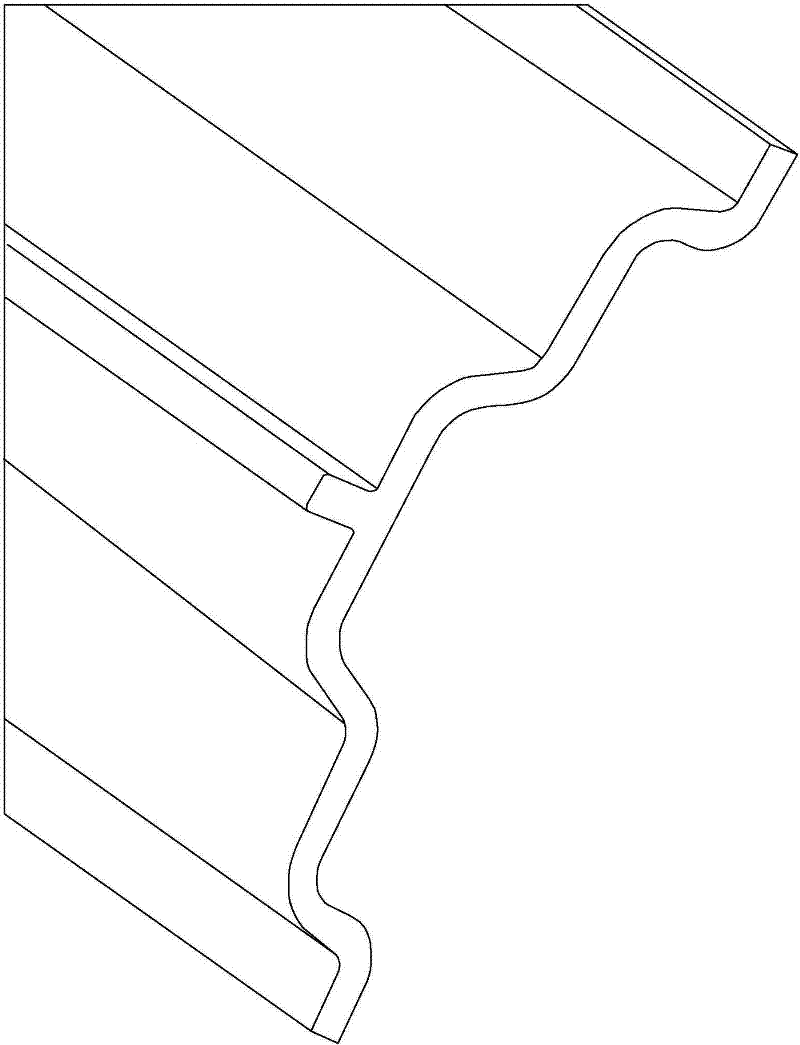

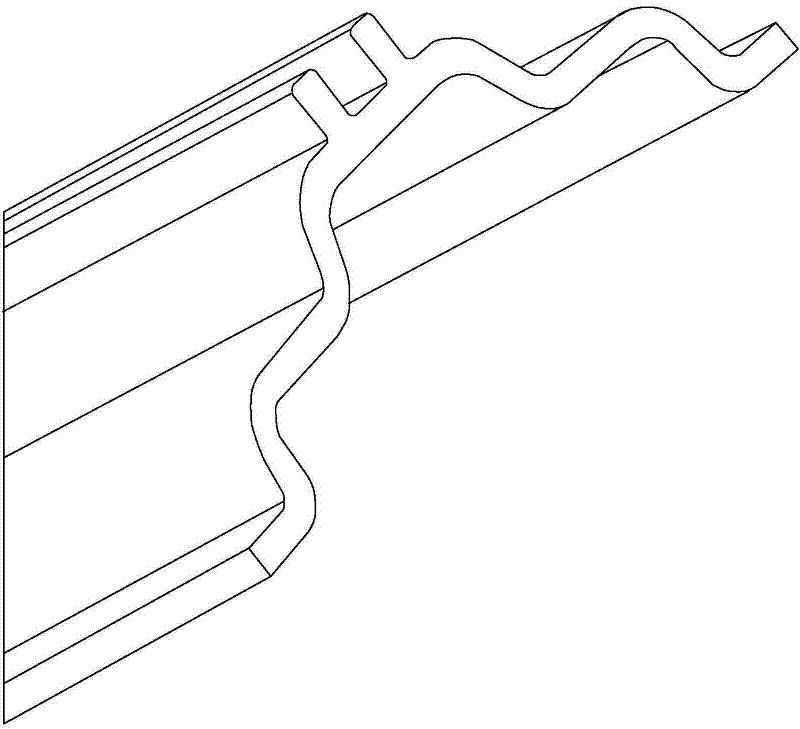

[0031] According to the design requirements, select profiles with different cross-sections extruded from aluminum alloy materials, such as figure 1 , figure 2 with image 3 Shown are profiles of three different cross-sections. 2.5 ~ 3mm thick extruded aluminum alloy profiles of type 5052 or 6061 can be selected. Different thicknesses can be set for each part according to the force requirements of the hub. Cut the material according to the length and size requirements, and then roll the aluminum alloy profile into a cylinder, such as Figure 4 , Figure 5 with Image 6 shown. The butt seam of the cylindrical body is stirred and welded, and then the cylindrical body is calibrated by a circular calibration machine to ensure the beating accuracy of the assembly position. In order to imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com