Pouring flow inoculation feeding device

A technology of feeding device and inoculation with flow, which is applied in the field of non-hand-held pouring inoculation feeding device with flow, can solve the problems of difficult quantitative and uniform control of feeding amount, high labor intensity of operators, and spheroidization decline in pouring time, and achieves relative position Reliable, simple structure, universal and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

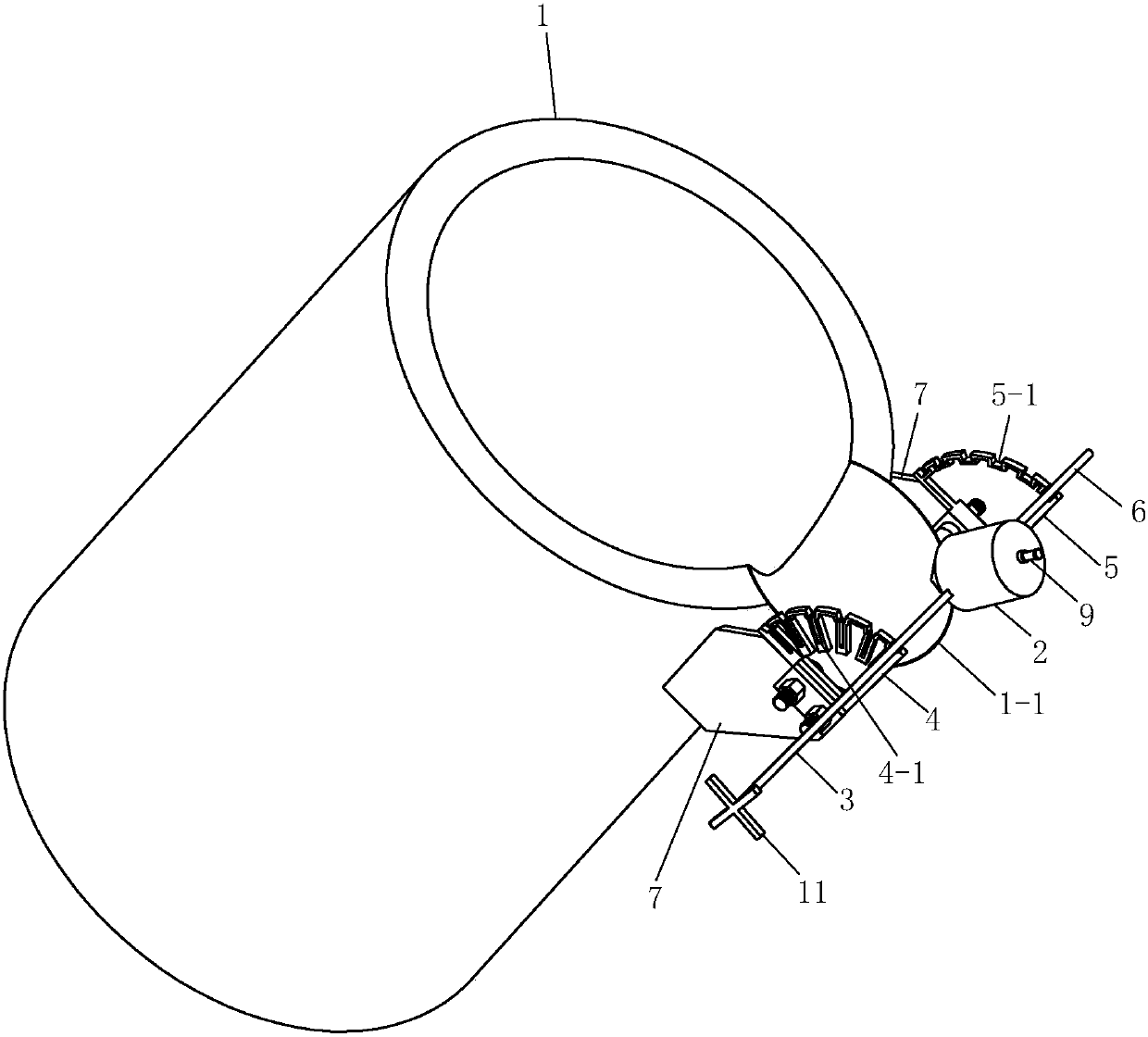

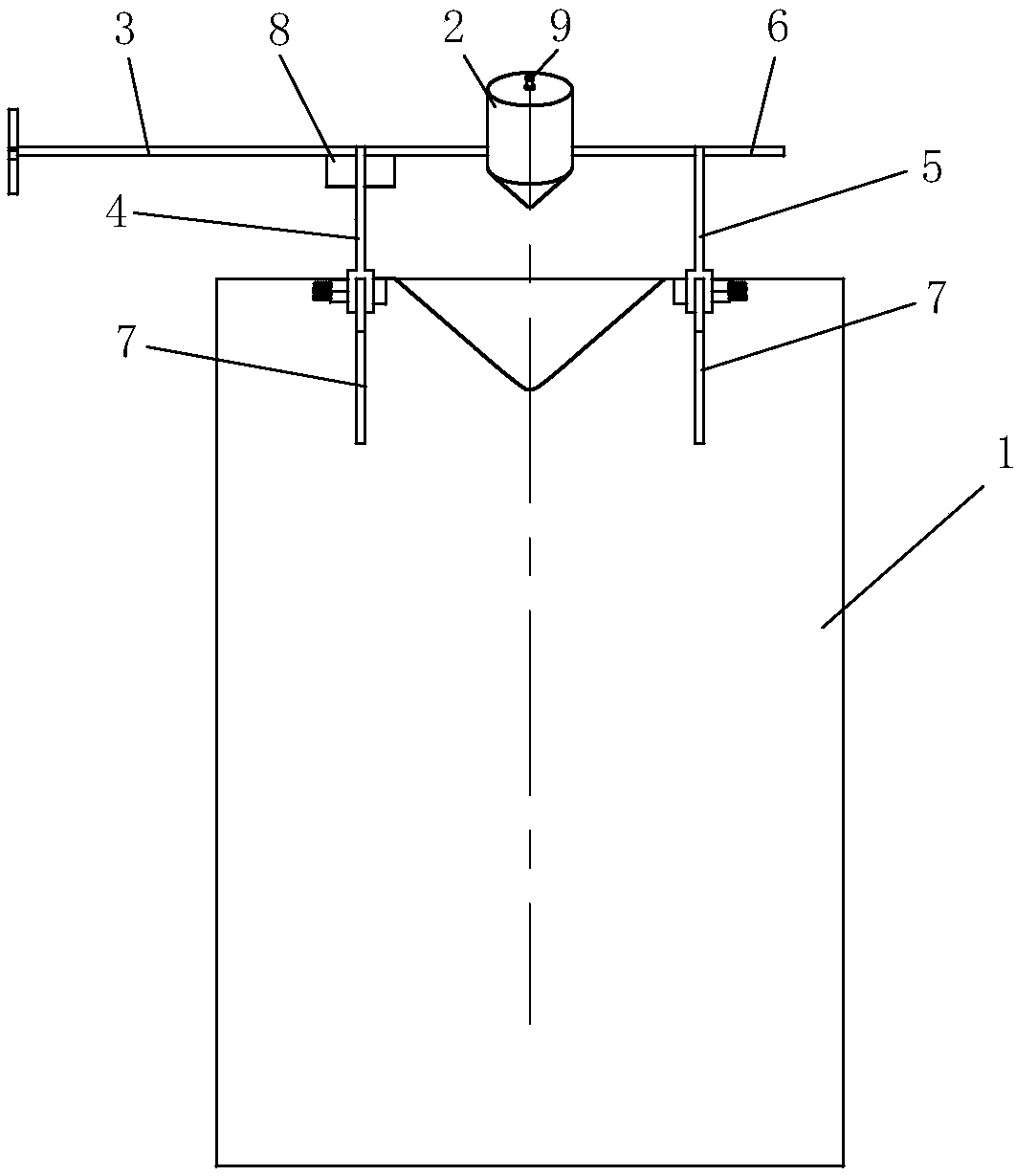

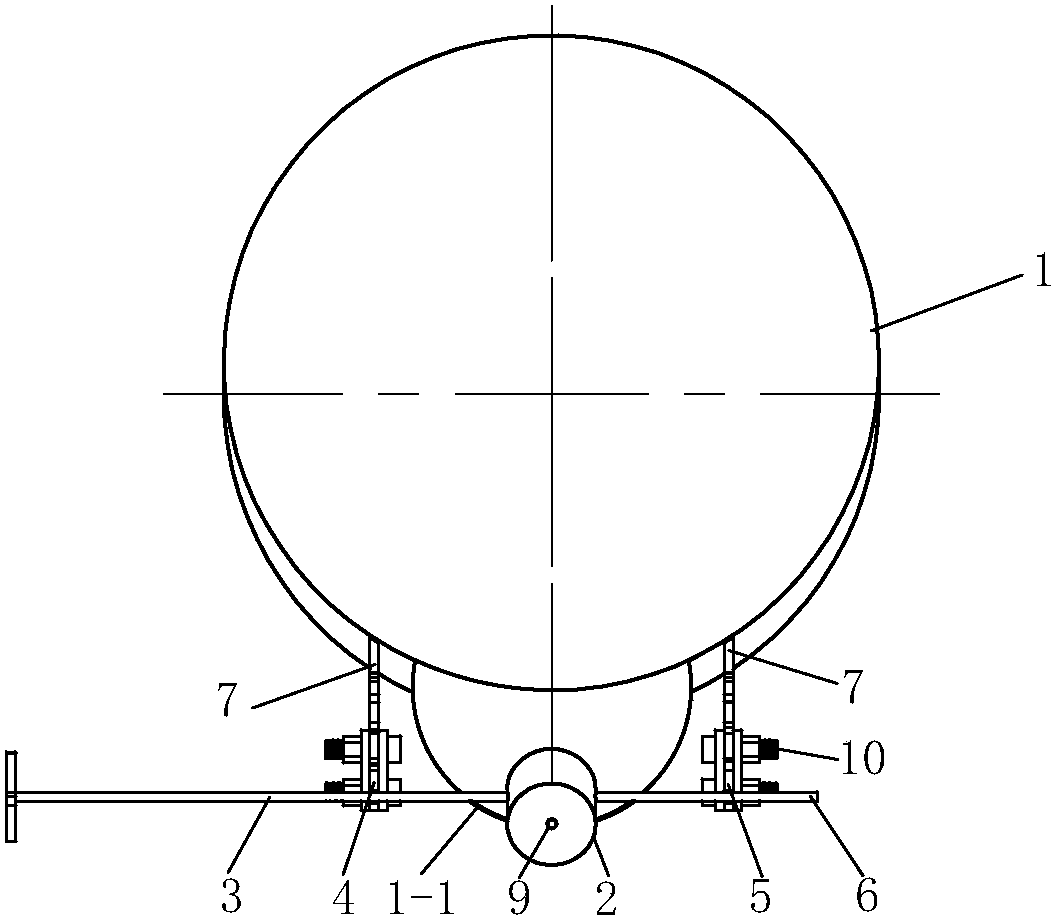

[0017] See Figure 1 to Figure 7 , the present embodiment has a ladle 1 and a hopper 2 for storing the inoculant, the two sides of the hopper 2 are respectively fixed with a first support rod 3 and a second support rod 6 with the same diameter, and the first support rod 3 and the second support rod 6 On the same center line, and the center line passes below the center of gravity of the hopper 2. A handle 11 is provided on the end of the first support rod 3 . The lower part of the hopper 2 is a cone, the top of which has a feed port, the feed port is provided with a screw-connected plug 9, and the bottom of the hopper 2 has a discharge port 2-1.

[0018] The outer wall of the ladle 1 and the parts on both sides of the ladle mouth 1-1 are welded with support plates 7, and the two support plates 7 are respectively connected by bolts 10 to a first fan-shaped groove plate 4 and a second fan-shaped groove plate 5. The positions of the first fan-shaped slot plate 4 and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com