Patents

Literature

43results about "Mandrel separation arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

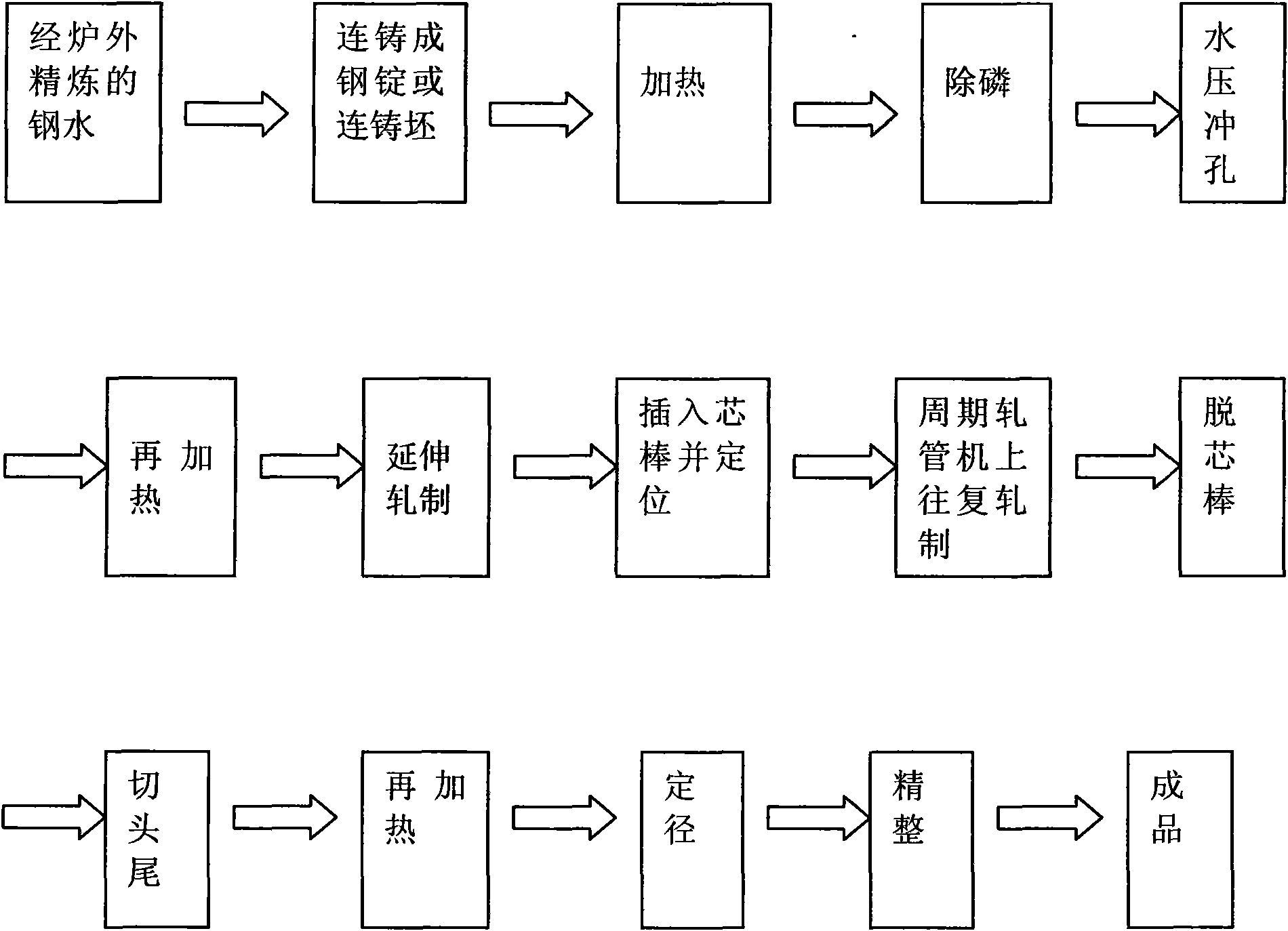

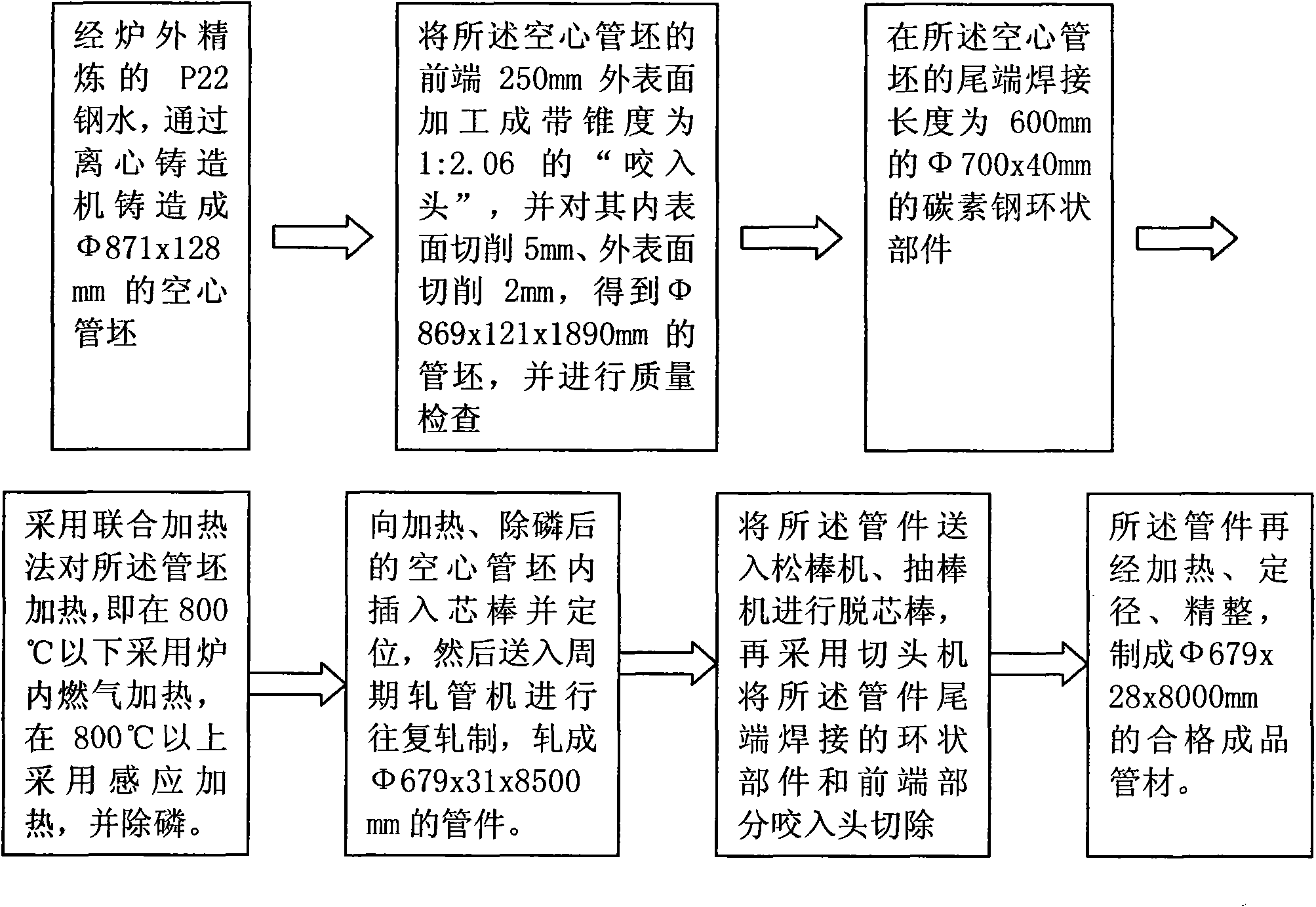

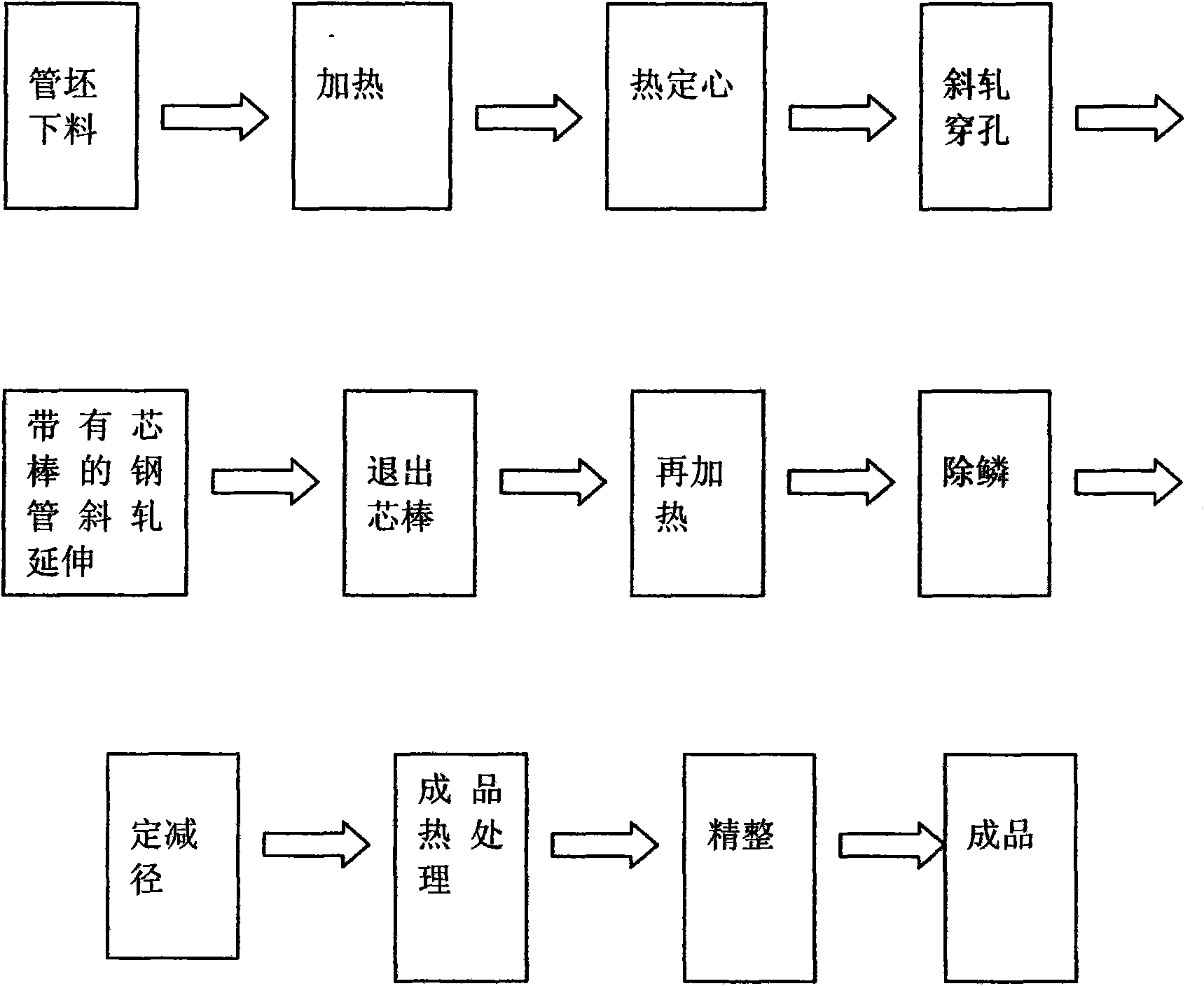

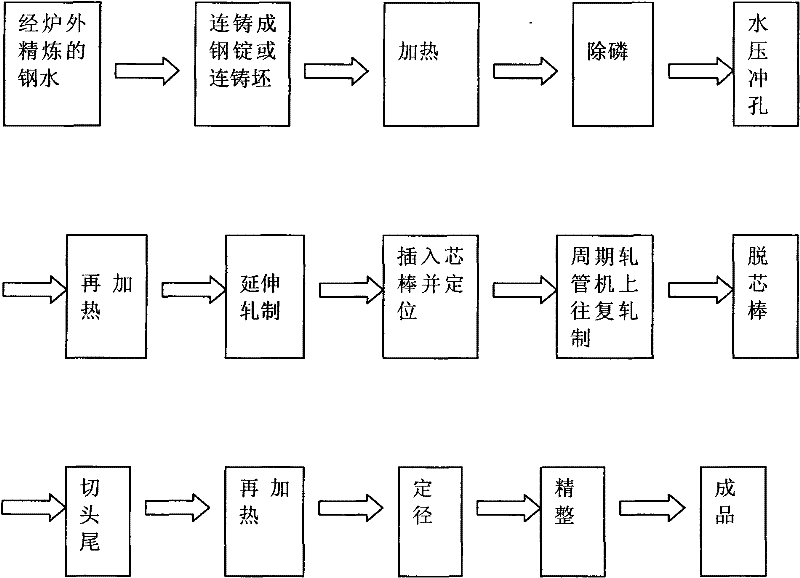

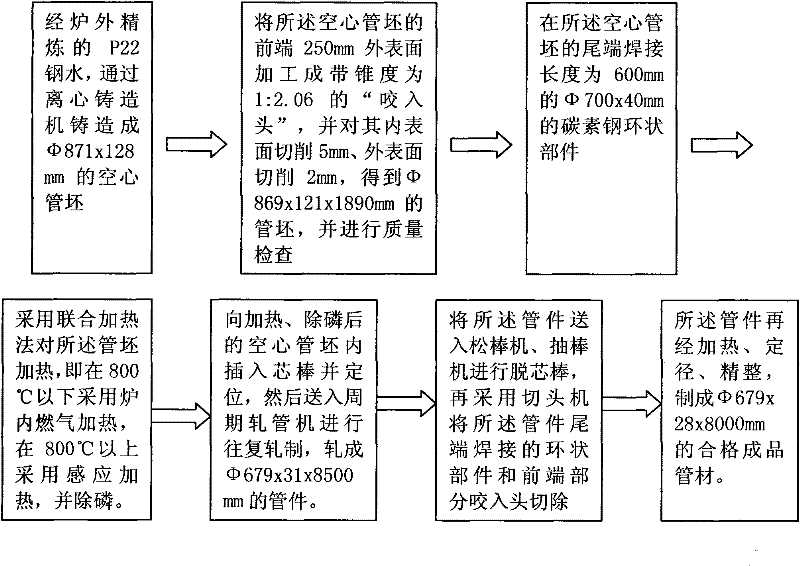

New technique for manufacturing high alloy steel seamless pipe with heavy calibre by adopting pilger mill

InactiveCN101579703ALow investment costLow running costMandrel separation arrangementsMetal rolling arrangementsPunchingPipe fitting

Owner:北京蓝海科融新技术有限公司

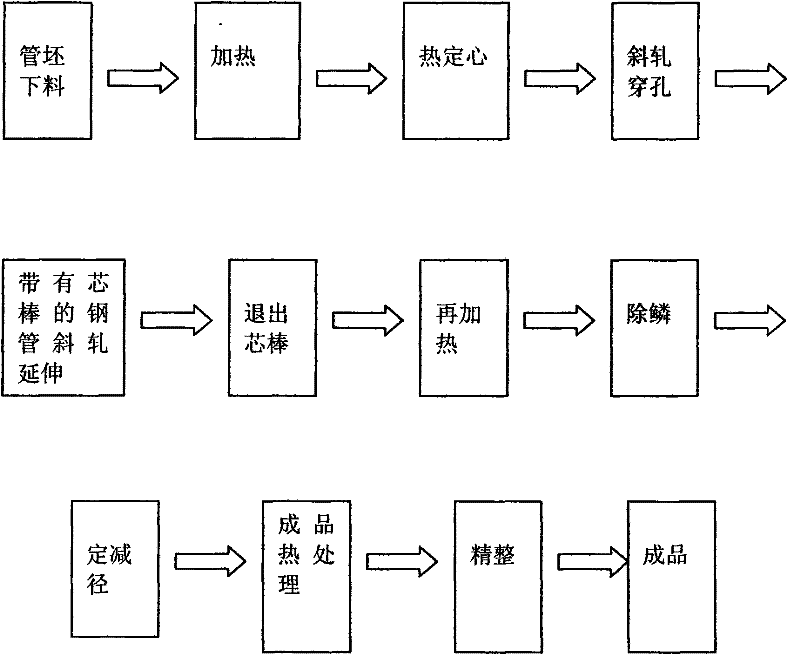

Method for rolling tube by hot-rolled seamless tube restraint core rod continuous rolling mill

InactiveCN101209458AAvoid breakingAvoid internal and external surface holesMandrel separation arrangementsRollsContinuous rollingCarbon steel

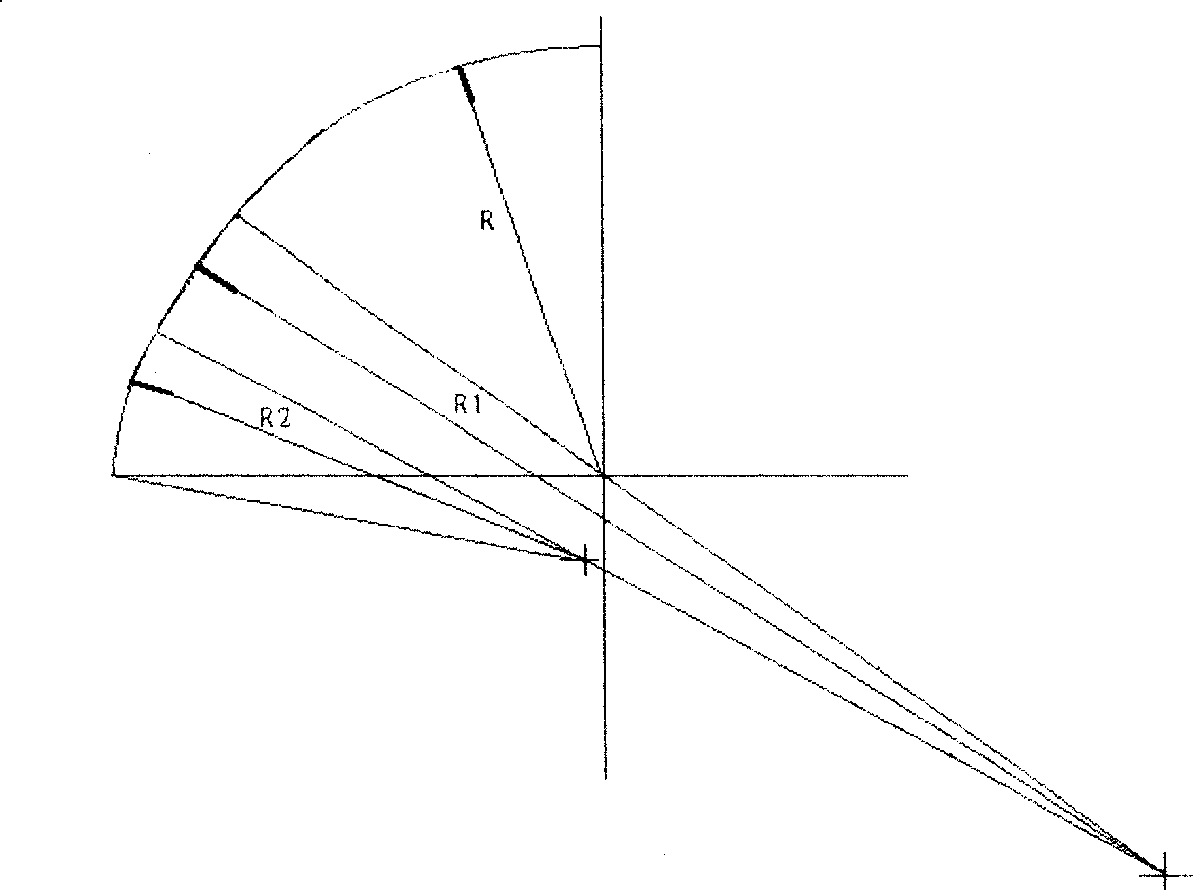

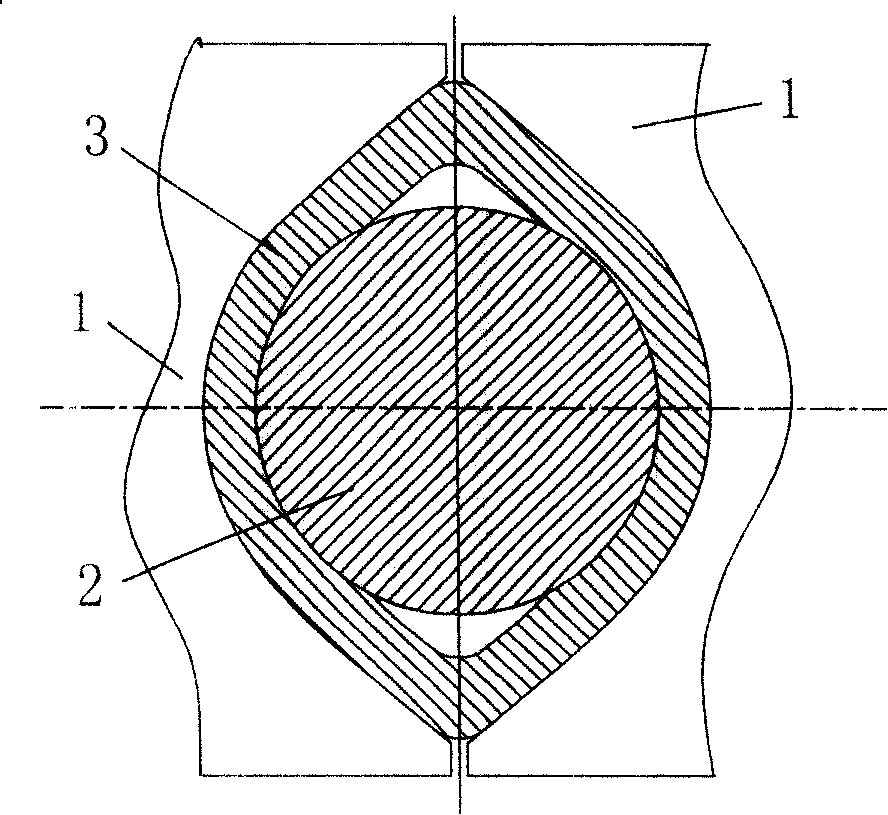

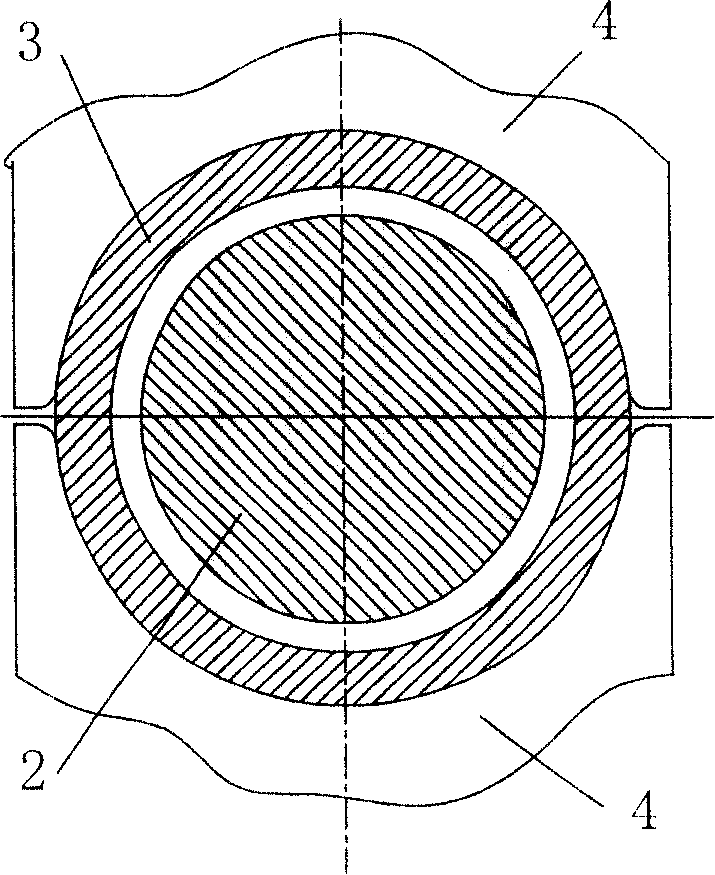

The invention relates to a hot rolling continuous mill with seamless steel pipes and retained mandrels and a method of rolled pipes with the hot rolling continuous mill with seamless steel pipes and retained mandrels. The continuous mill comprises five mill rolls of a mill stand and mandrels and the mill roll consists of a hole; the continuous mill is characterized in that the hole pattern of a third mill roll and a fourth mill roll are in the shape of an oval while the fifth mill roll is in the shape of a perfect circle; the ovality of the pipe is gradually increased in the hole patterns of the third mill roll and the fourth mill roll and the circumference of the pipe is more than that of the perfect circle of the fifth mill roll so as to ensure that the pipe and the mandrel can form a clearance in a fifth mill stand and a pierced billet can be smoothly pulled out so as to separate the pipe and the mandrel. The invention ensures that the pipe and the mandrel can form the clearance in the fifth mill stand in the continuous mill with retained mandrels through the improvement of the hole pattern of the mill roll of the continuous mill and the pierced billet can be smoothly pulled out to separate the pipe and the mandrel, with no breakage of the pierced billet and no holes caused in the outer and inner surfaces. The invention can produce high-alloy steel pipes excluding stainless steel pipes and general carbon steel pipes and has a relatively wide scope of application.

Owner:BAOSHAN IRON & STEEL CO LTD

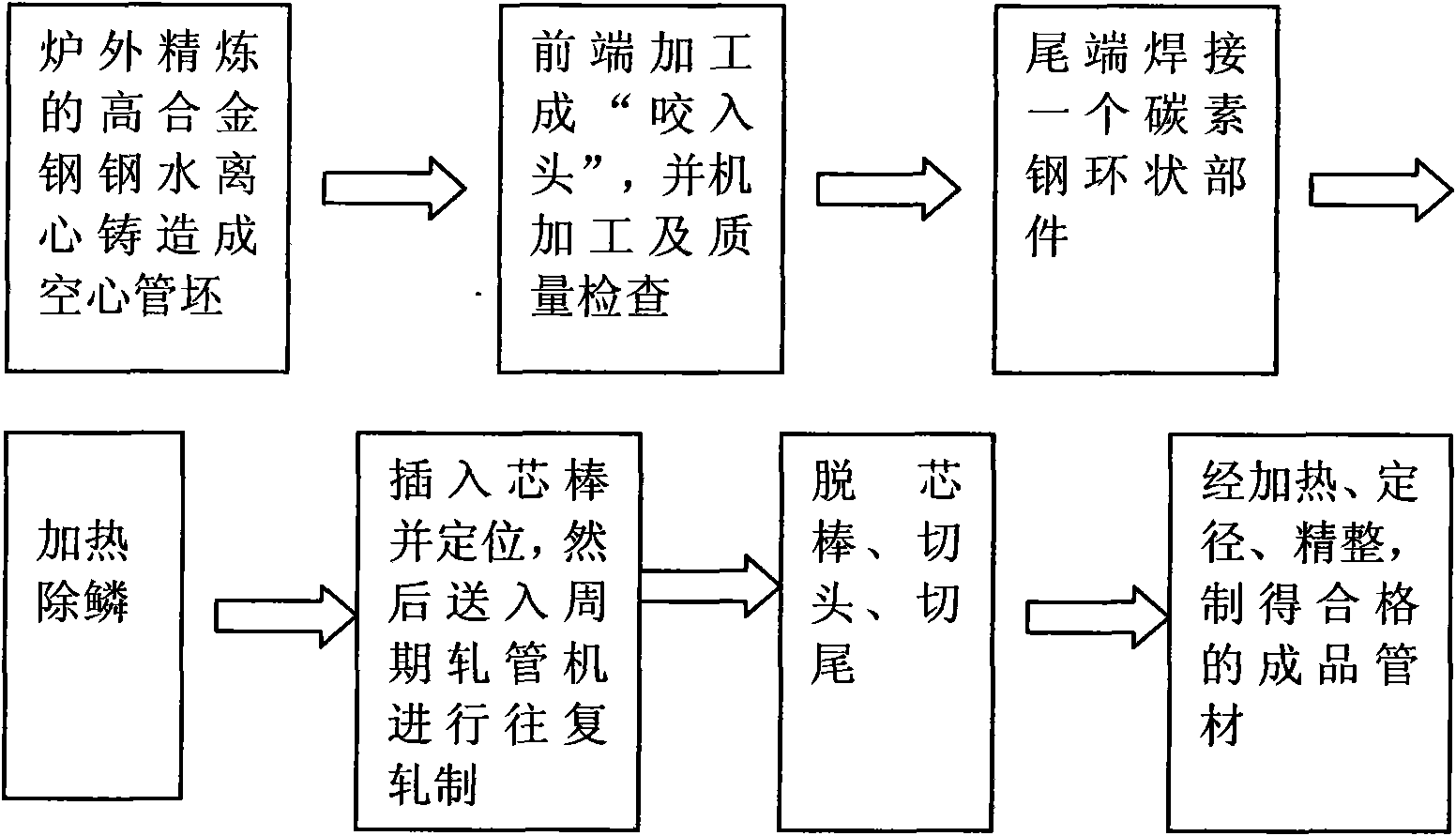

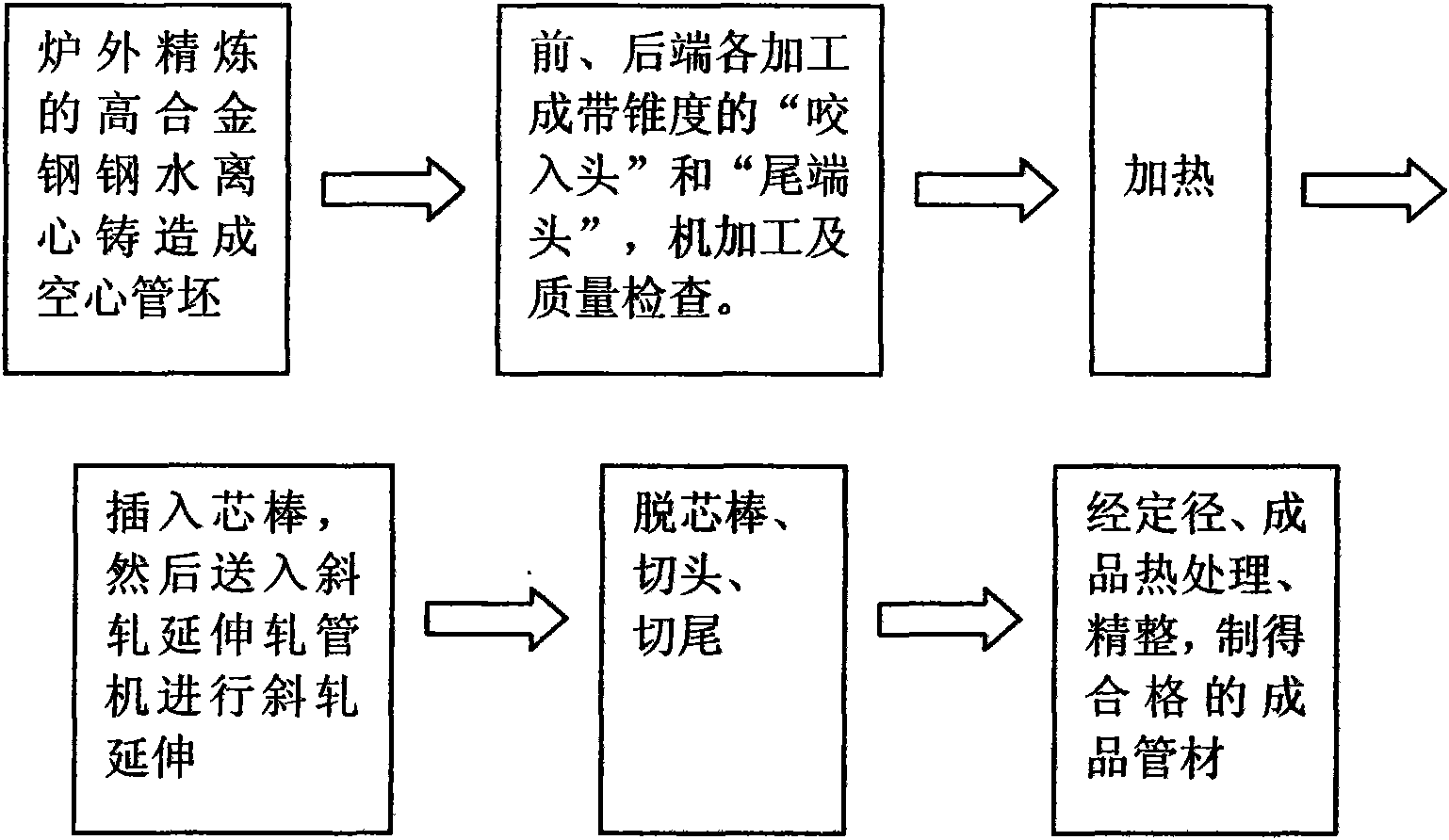

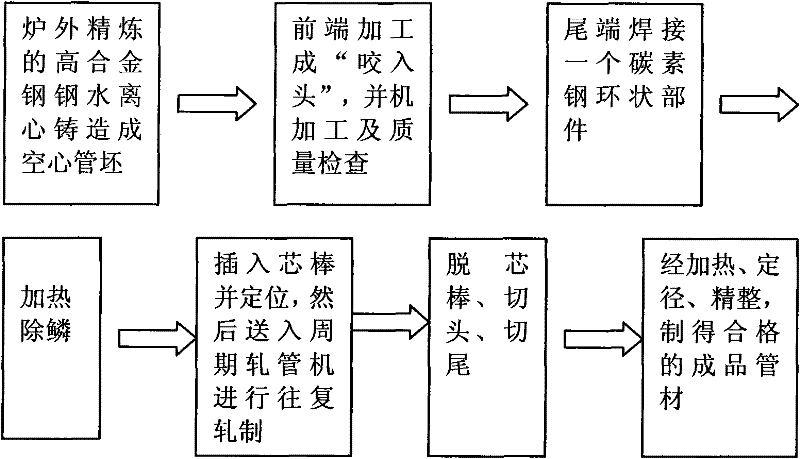

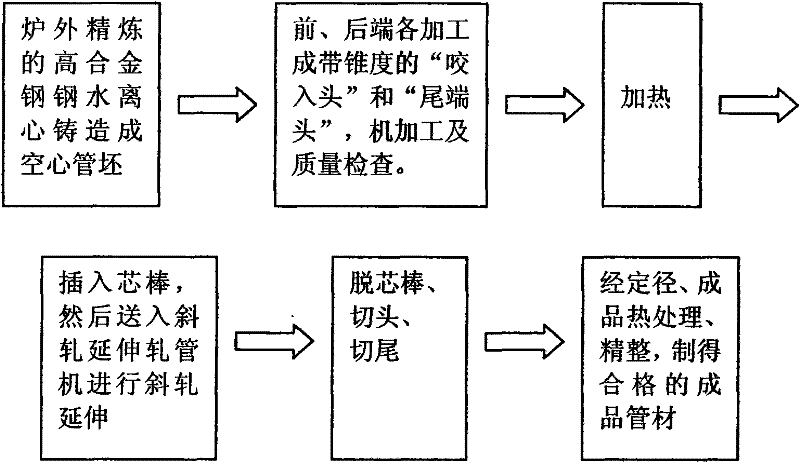

New technique for producing high alloy steel high-end pipe by adopting cross rolling elongation technology

InactiveCN101579702ALow equipment investment costLow running costMandrel separation arrangementsMetal rolling arrangementsPipe fittingMaterial Perforation

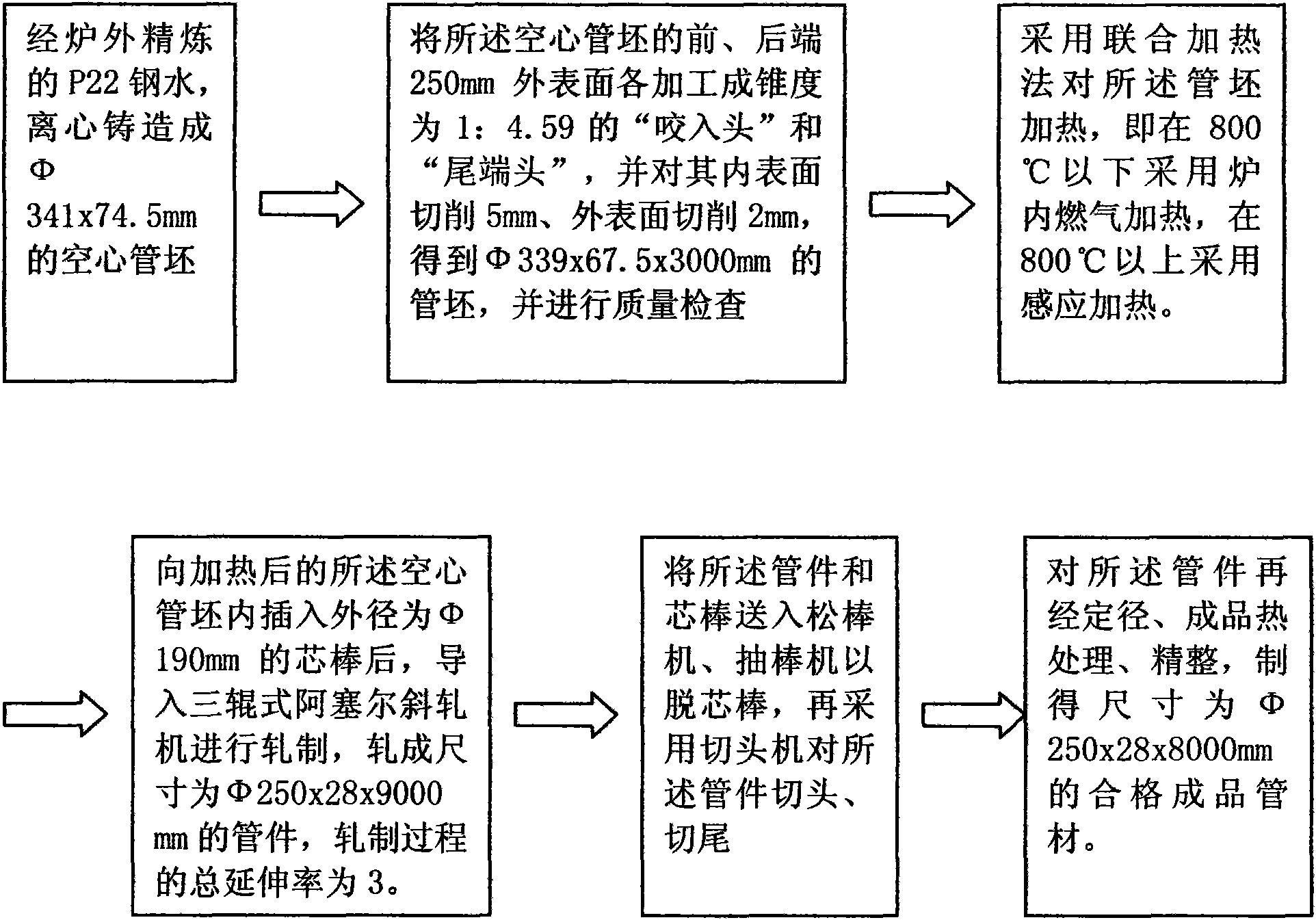

The invention relates to a new technique for producing a high alloy steel high-end seamless pipe by adopting cross rolling elongation technology without perforation, comprising: molten high alloy steel which is externally refined is made into a hollow shell by centrifugal casting; the outside surfaces of the front and the rear ends of the hollow shell are respectively processed to be a 'gripping head' and a 'tail end head' with conicity, and machining and quality inspection are carried out on the inside and the outside surfaces as well as the 'gripping head' and the 'tail end head' of the hollow shell; heating is carried out; a mandril is inserted into the heated hollow shell, and then the hollow shell is sent into a cross rolling elongating mill for cross rolling, so that the pipe fittings having the wall thickness, the diameter and the length being in accordance with the requirements can be produced; the mandril is removed, and the head and the tail are cut off; finally, the qualified finished pipes can be obtained after sizing, heat treatment for finished product and finishing operation. The technique has short process flow and does not need cross rolling perforation, thus reducing the cost and improving the quality; due to small tapered treatment for the front and the rear ends, 'tail triangle' is avoided when the medium-thick walled pipes are produced, and the performance of secondary gripping is improved, thus improving the quality of the product and the production efficiency.

Owner:北京蓝海科融新技术有限公司

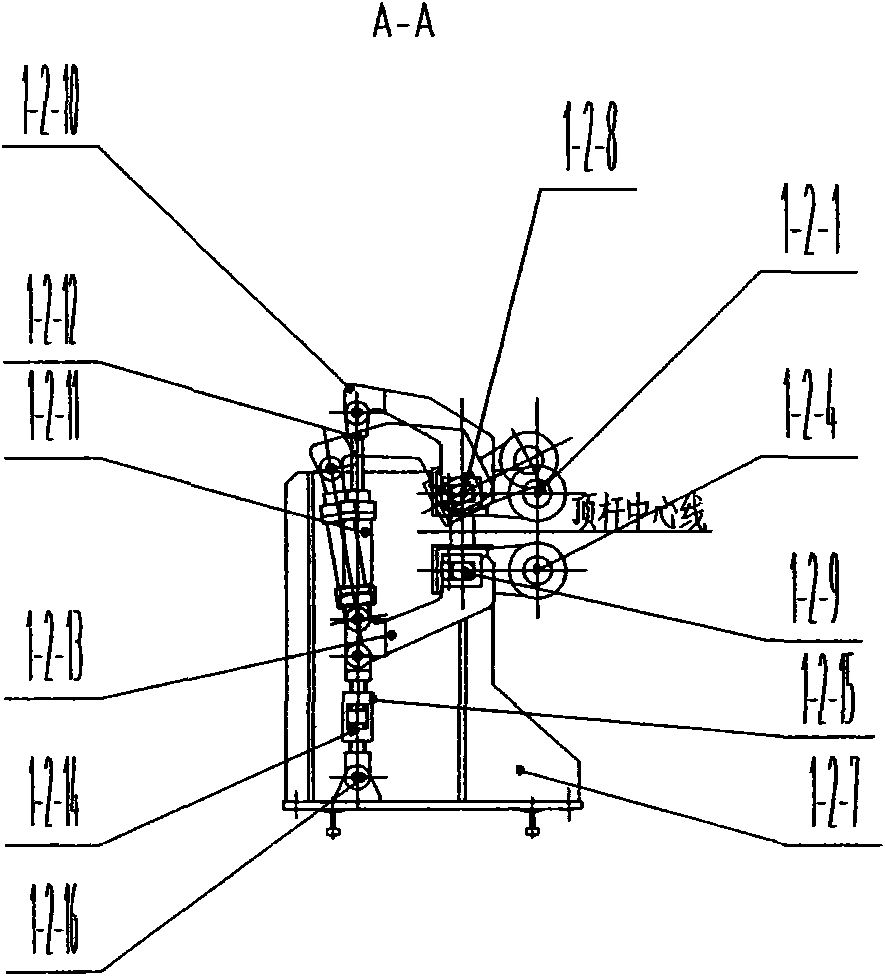

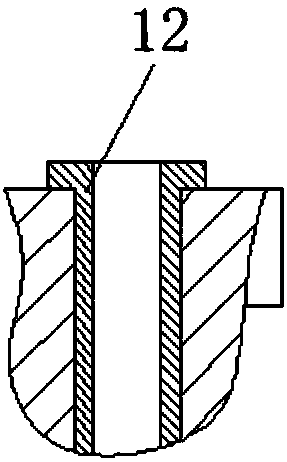

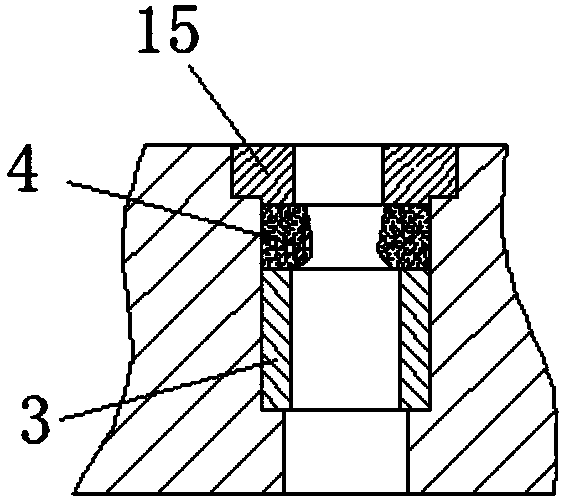

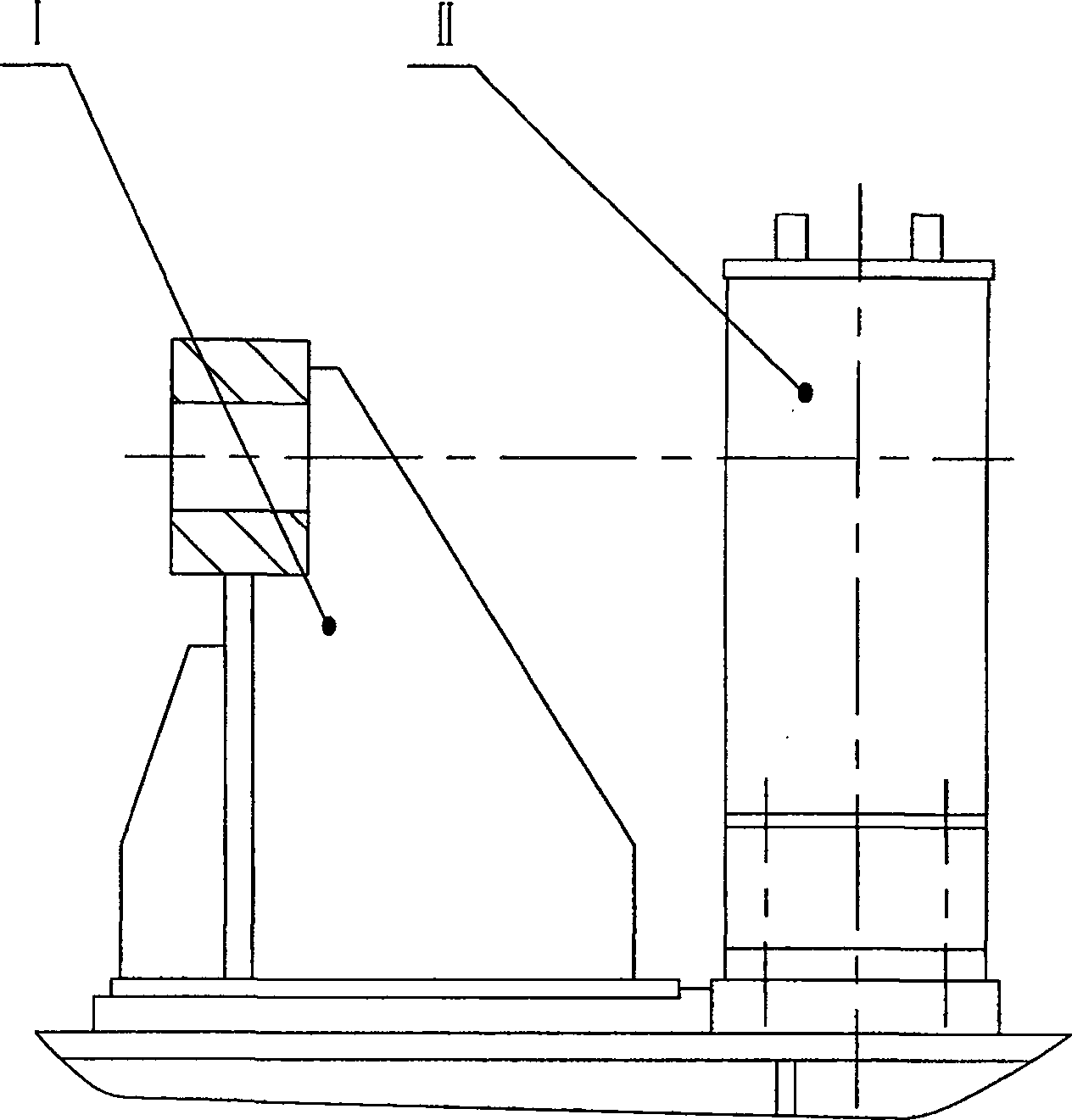

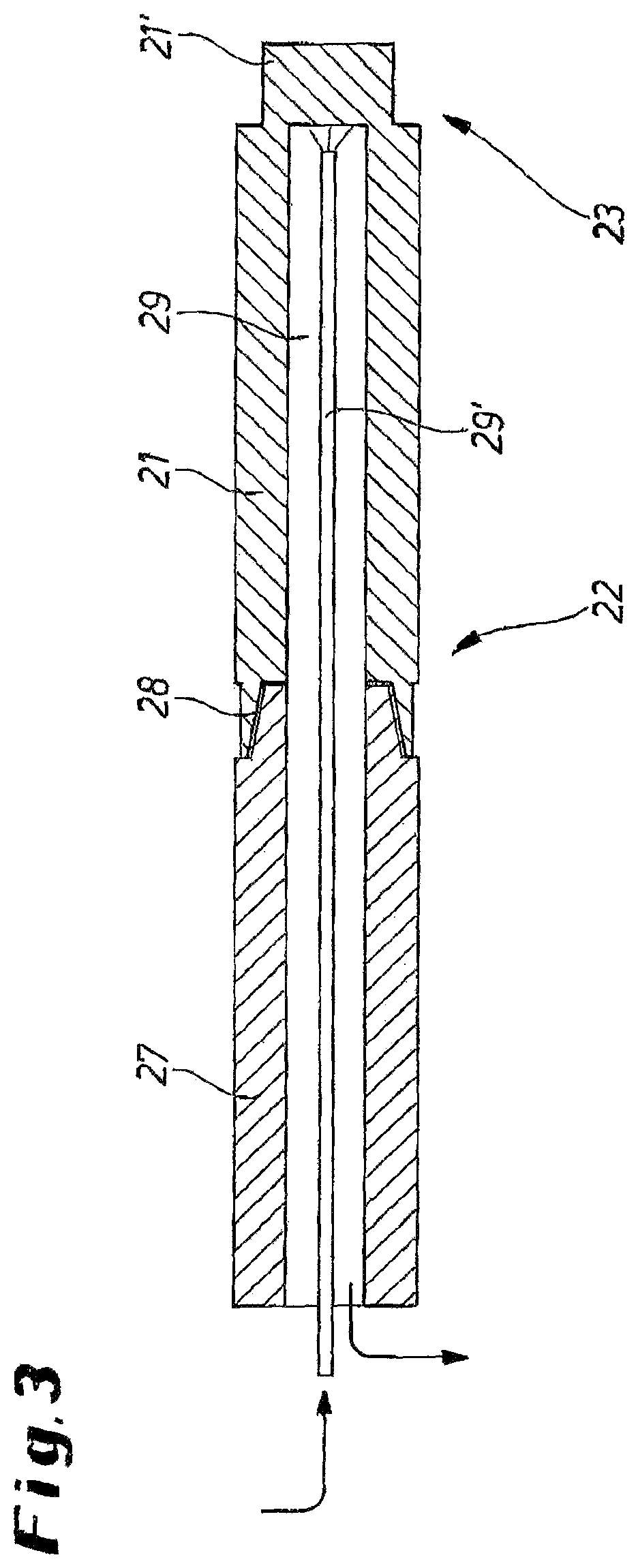

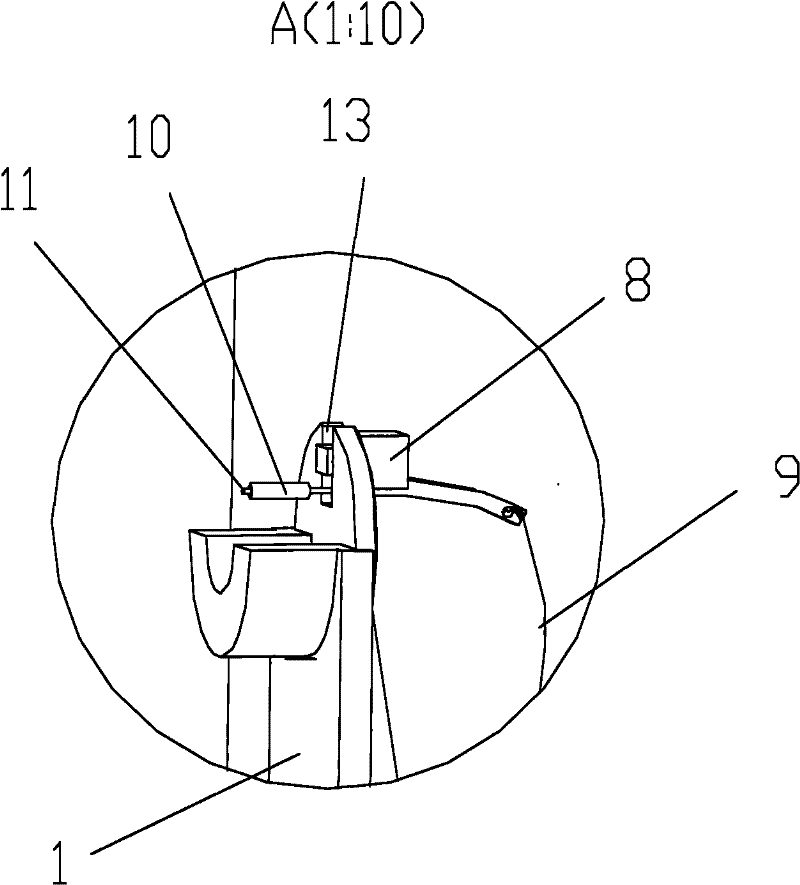

Disconnection device for punch refrigerant top

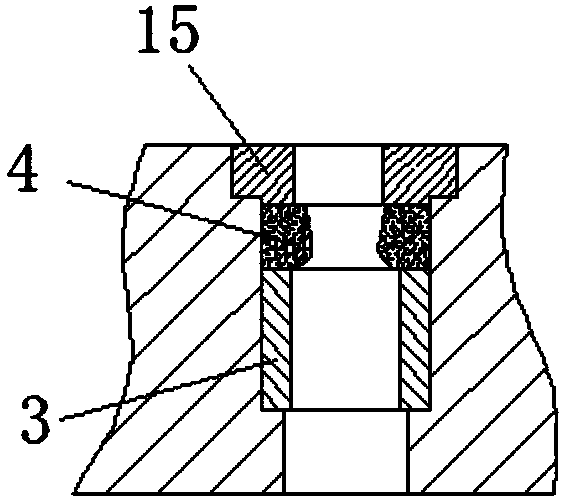

InactiveCN101204713AImproves wall thickness uniformityShorten the lengthMandrel separation arrangementsMandrelsEngineeringMaterial Perforation

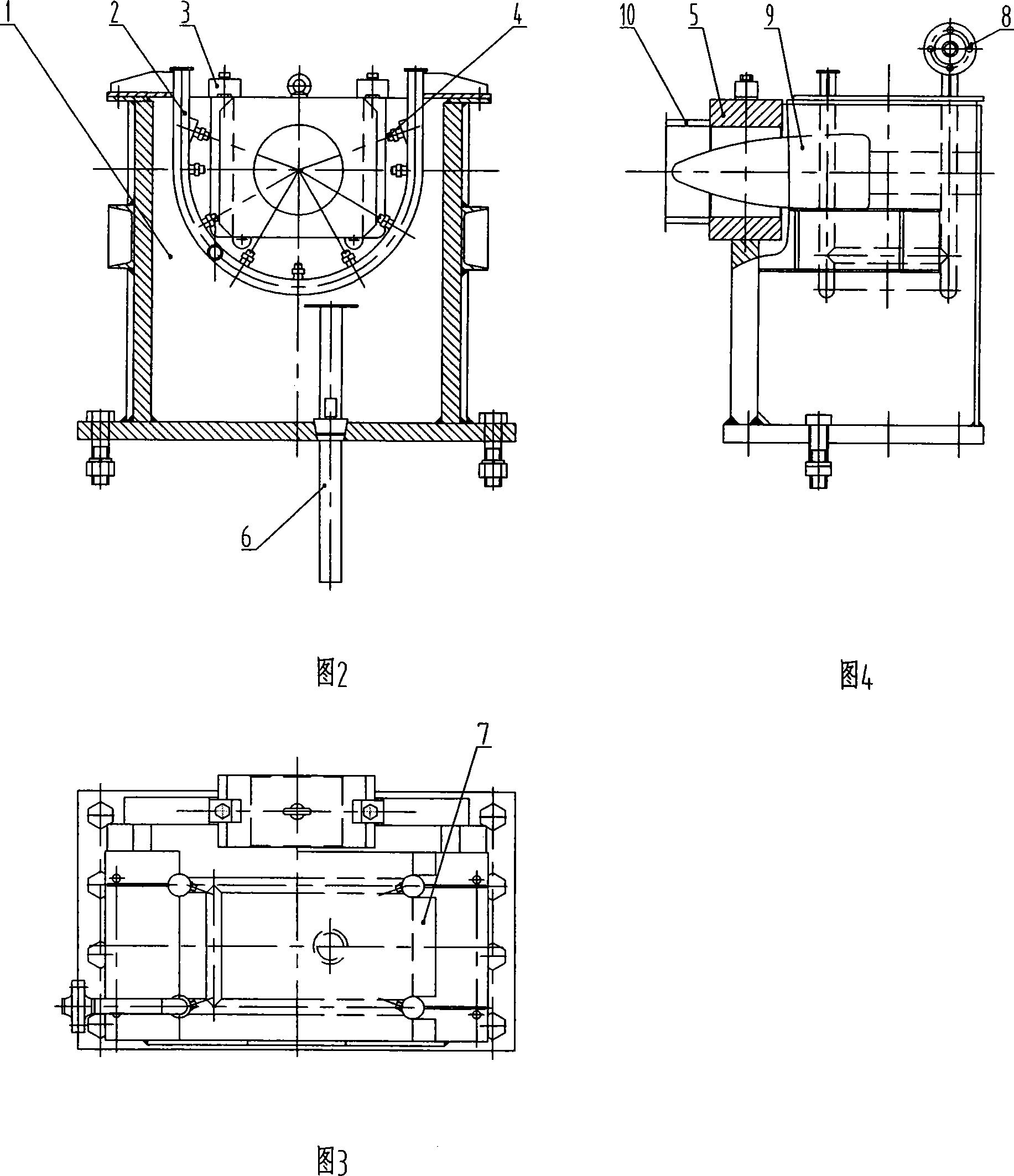

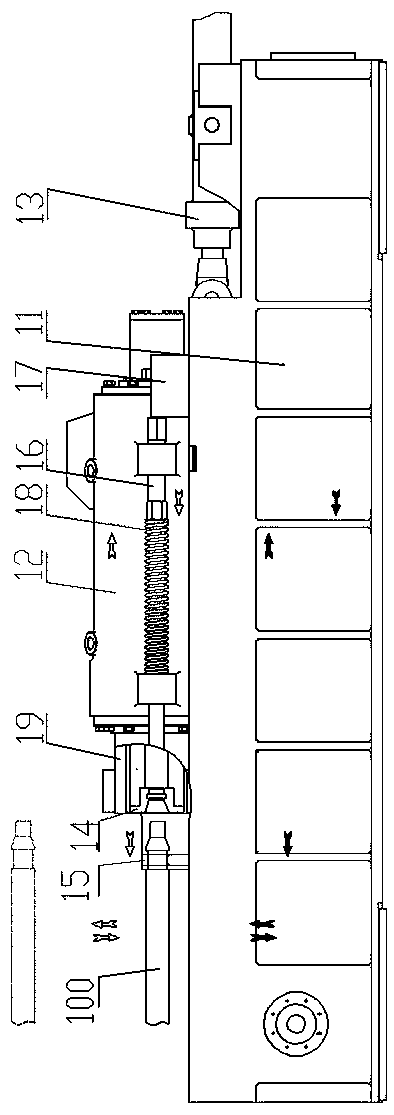

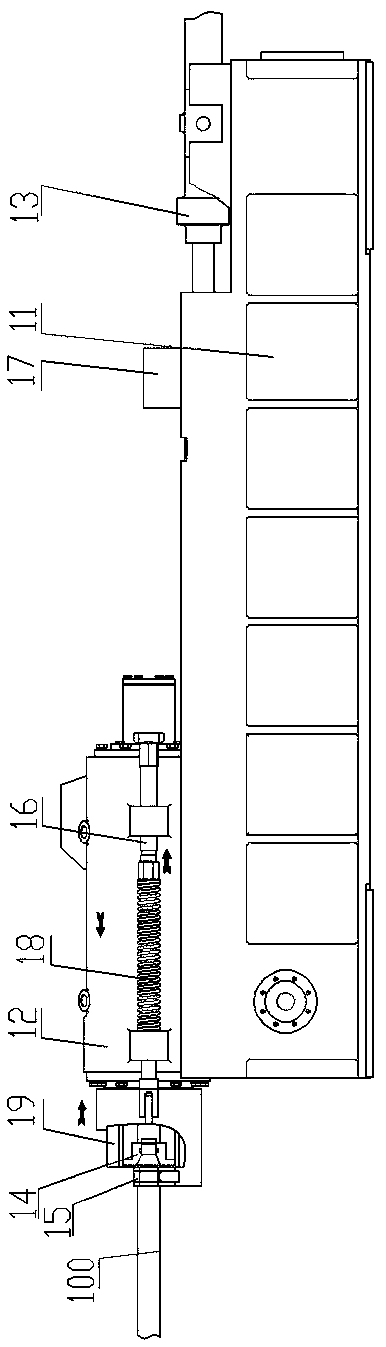

The invention discloses a tube detaching device used in a perforator and being capable of cooling the piercing plug of a perforator, which relates to the device for cooling the piercing plug of a hot rolling perforator and tube detaching equipment. In prior art, a cooling water tank and a tube detaching device take up two positions respectively, after perforation, the length of a tubular billet is up to 10 meter with which a mandril and an outlet platform both with enough length are needed to be matched. The increased length of mandril not only results in the poor rigidity of the mandril, influences the quality of wall thickness of the tubular billet, but also results in lengthening of the outlet platform and enlarging the land occupation. In the invention, the cooling water tank and the tube detaching device are designed in integration; a water nozzle is positioned in the cooling water tank; the water nozzle is connected with flow pipe through a flange; an offlet is positioned at the bottom of the cooling water tank; therefore, one position can realize two functions that are tube detaching and piercing plug cooling, which not only reduces the length of the mandril, enhances the rigidity of the mandril, improves the uniformity of wall thickness of the tubular billet but also reduces the lengths of a first and a second segments of the outlet platform, thus ensuring the more compact structure of the device.

Owner:TAIYUAN HEAVY IND

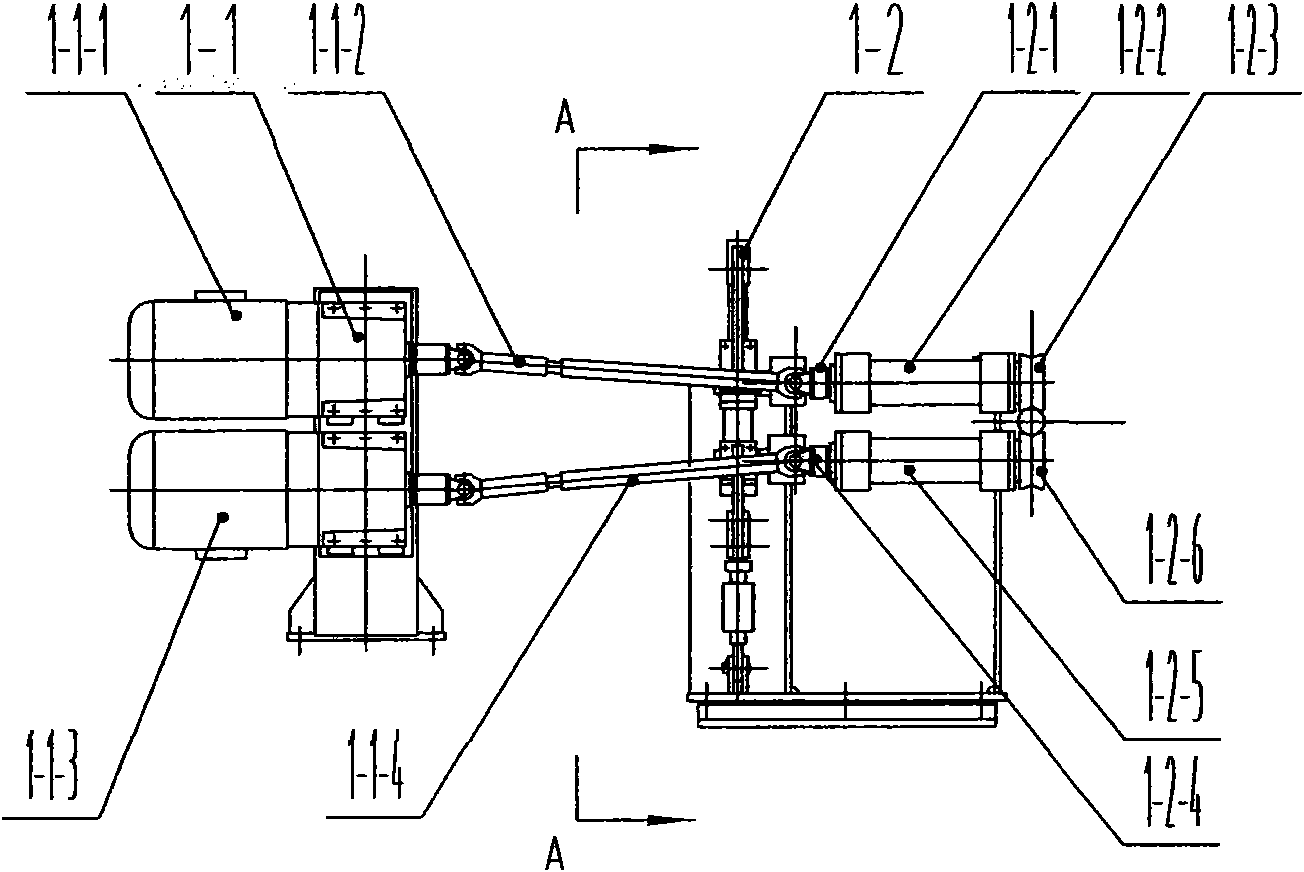

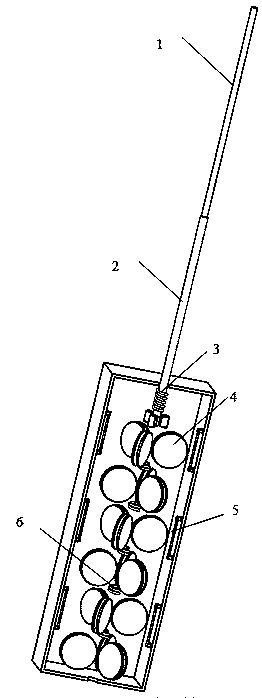

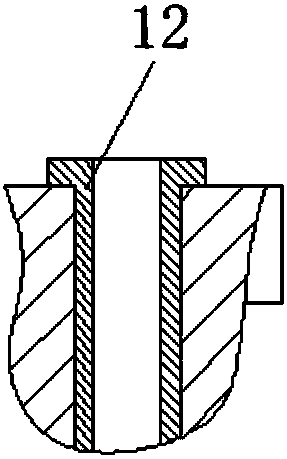

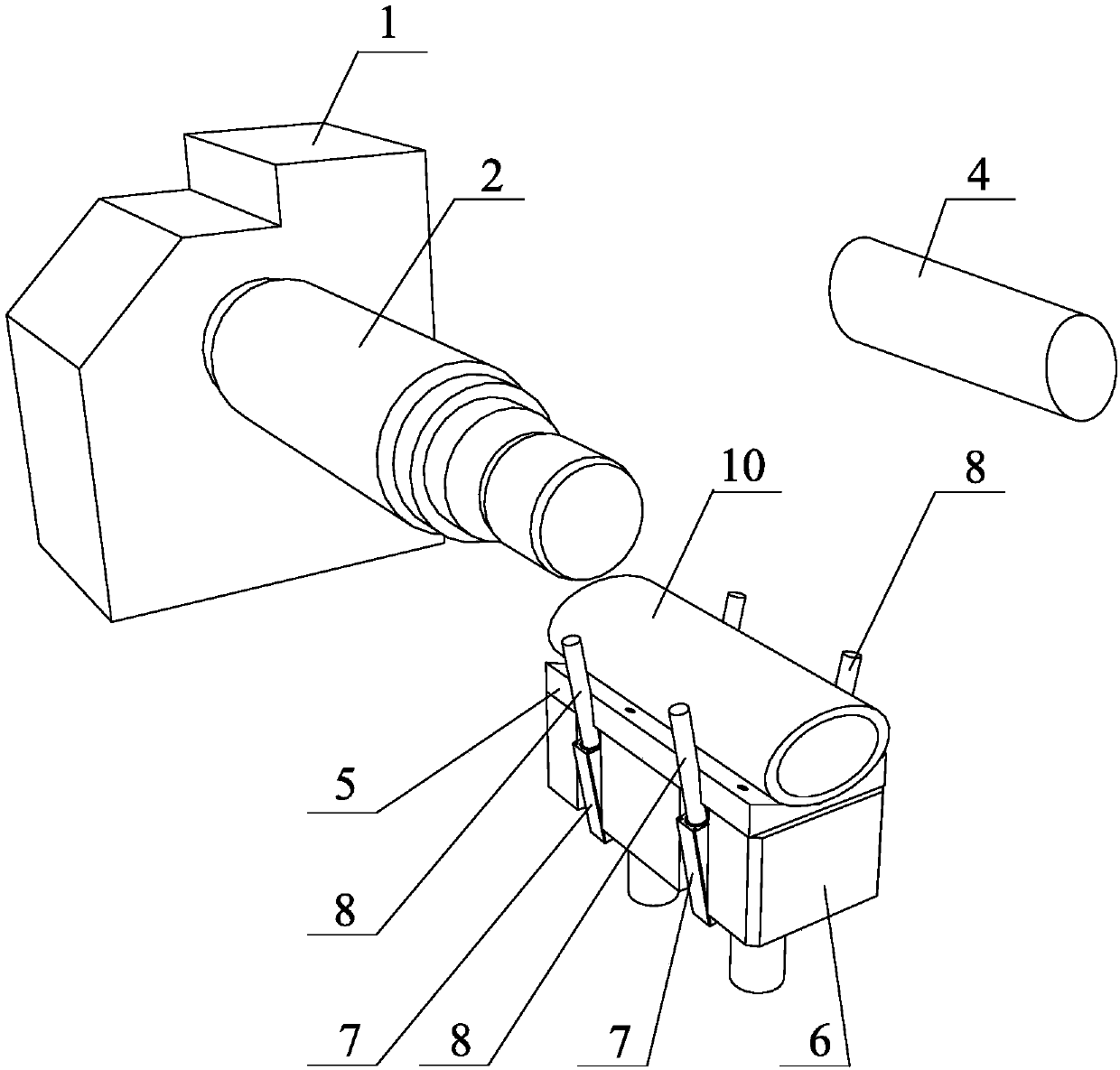

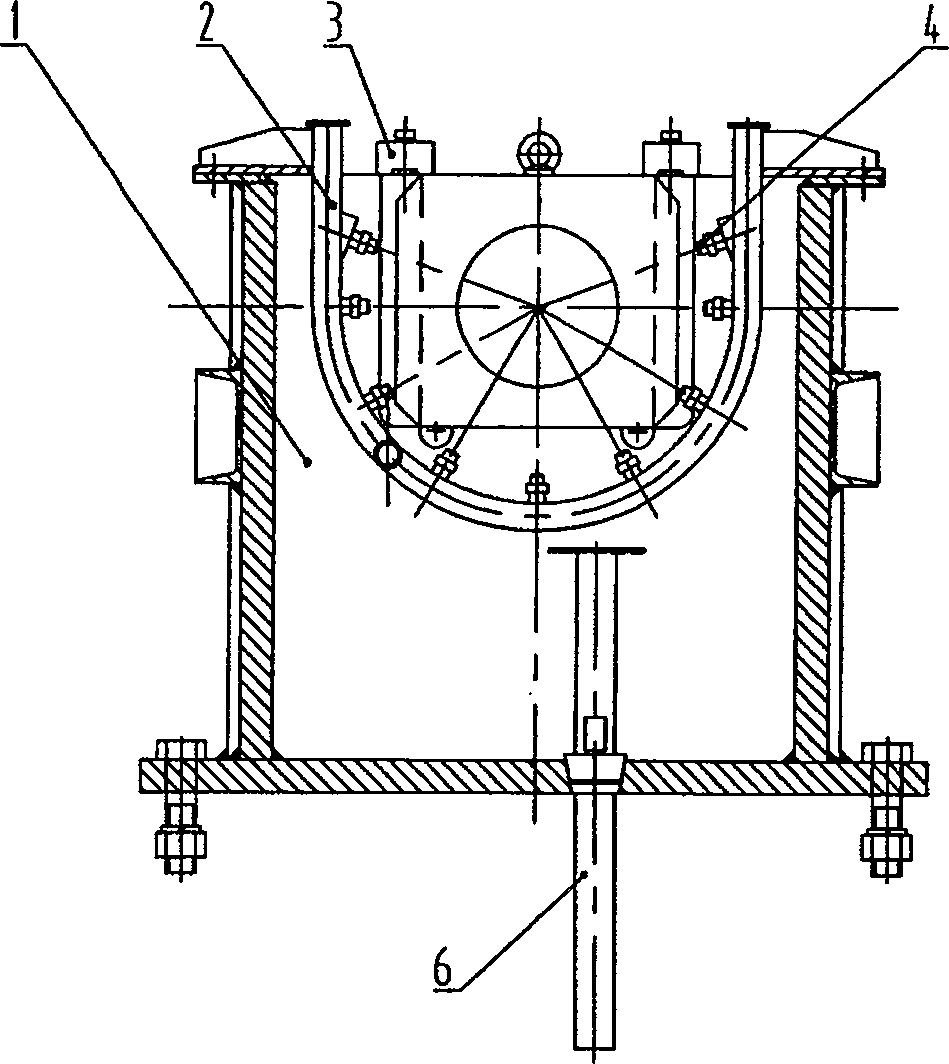

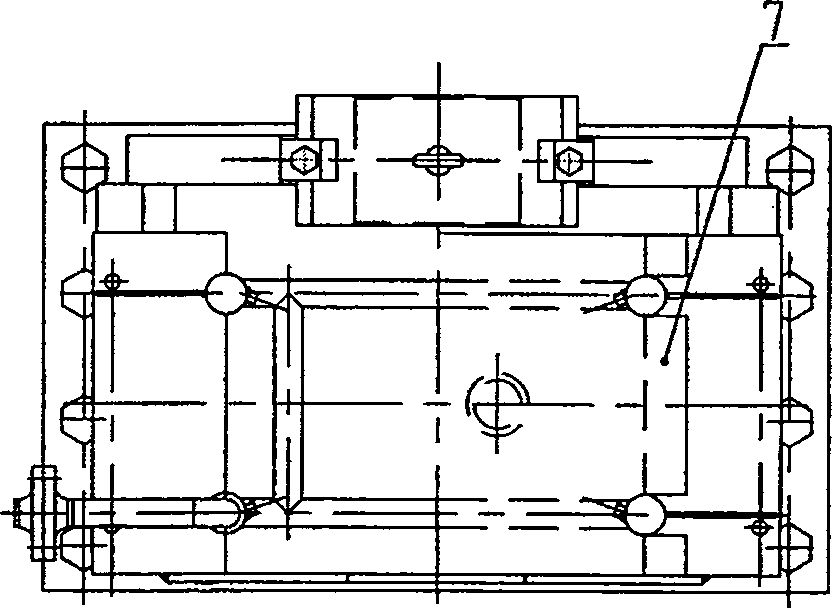

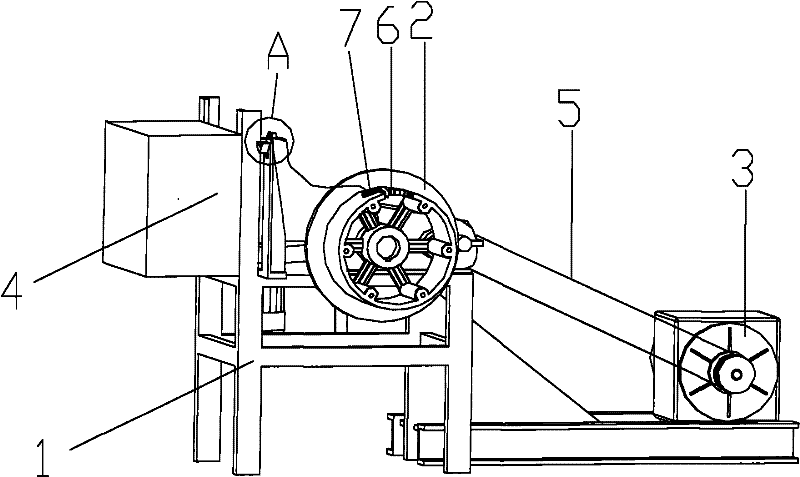

Evacuation device for mandril of perforator

InactiveCN101559448AQuality improvementIncrease productionMandrel separation arrangementsMetal rolling arrangementsHydraulic cylinderMaterial Perforation

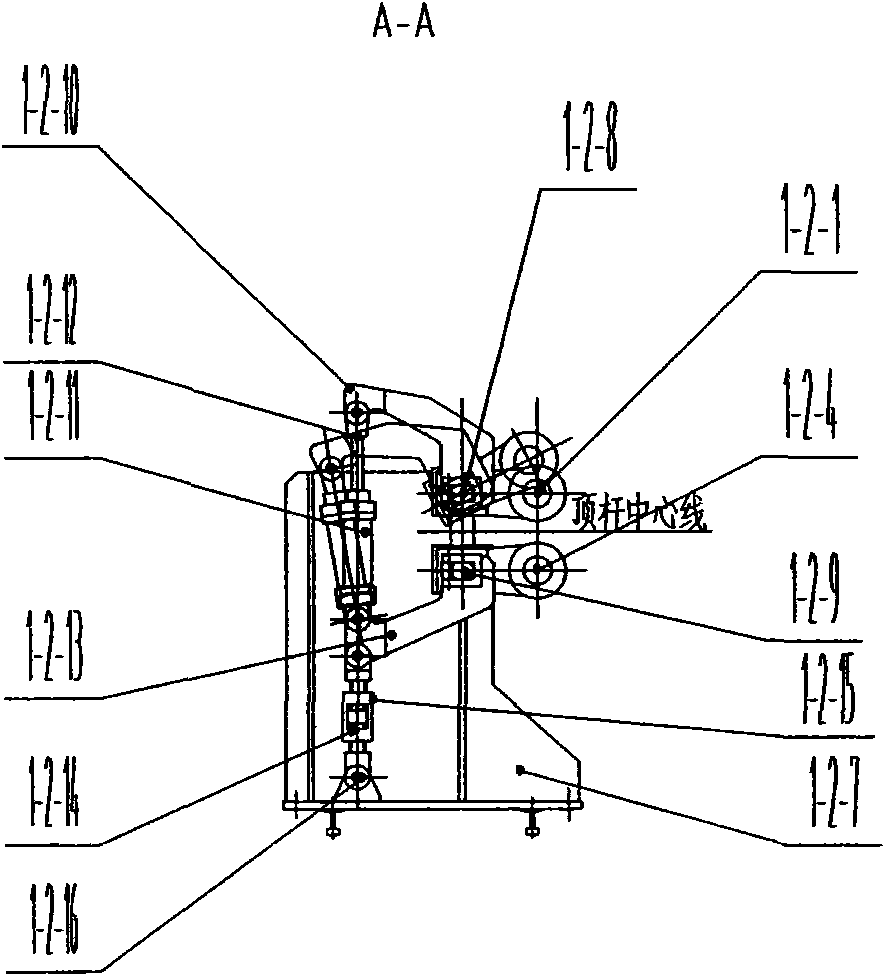

The invention discloses an evacuation device for a mandril of a perforator, and relates to steel rolling machines. The evacuation device comprises a pinch device and a baffle plate; the pinch device consists of a transmission device and a pinch roll mechanism; the transmission device consists of two sets of motors and a universal spindle; and the pinch roll mechanism mainly comprises upper and lower pinch roll shafts connected with the motors and the universal spindle, upper and lower pinch rolls connected with the upper and lower pinch roll shafts, upper and lower swinging arm sleeves sleeved with the upper and lower pinch rolls, upper and lower pressure arms connected with the upper and lower swinging arm sleeves through minor axes, a hydraulic cylinder hinged with the upper and lower pressure arms, and a telescoping mechanism hinged with the lower pressure arm and connected with a base through a hinge shaft. The evacuation device can make the mandril after perforation evacuate from a steel tube, thereby improving the quality of the steel tube, being capable of using a plurality of the mandrils, circularly cooling the mandrils and improving the processing property of the perforator.

Owner:TAIYUAN HEAVY IND

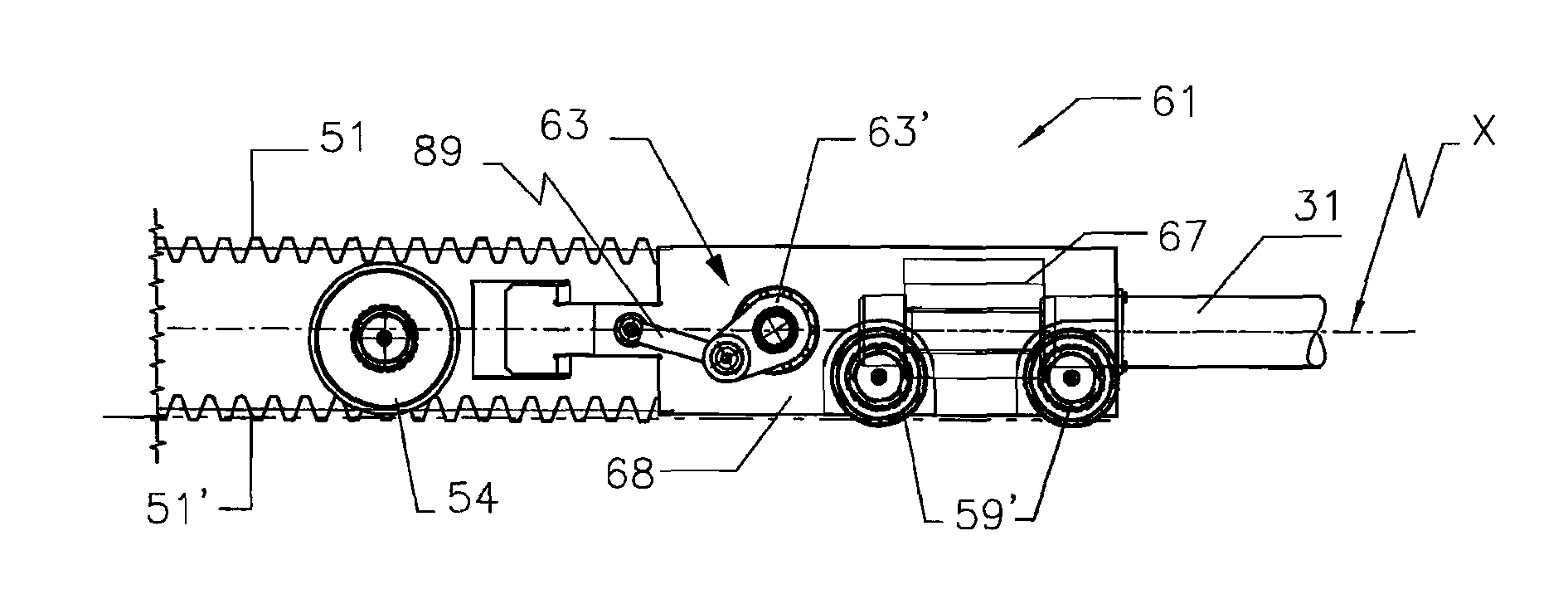

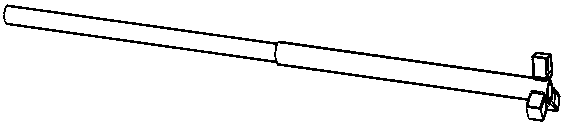

Mandrel conveying device for a tube rolling mill

ActiveUS20130008219A1Improve productivityCost-effectiveMandrel separation arrangementsMandrelsEngineeringRolling mill

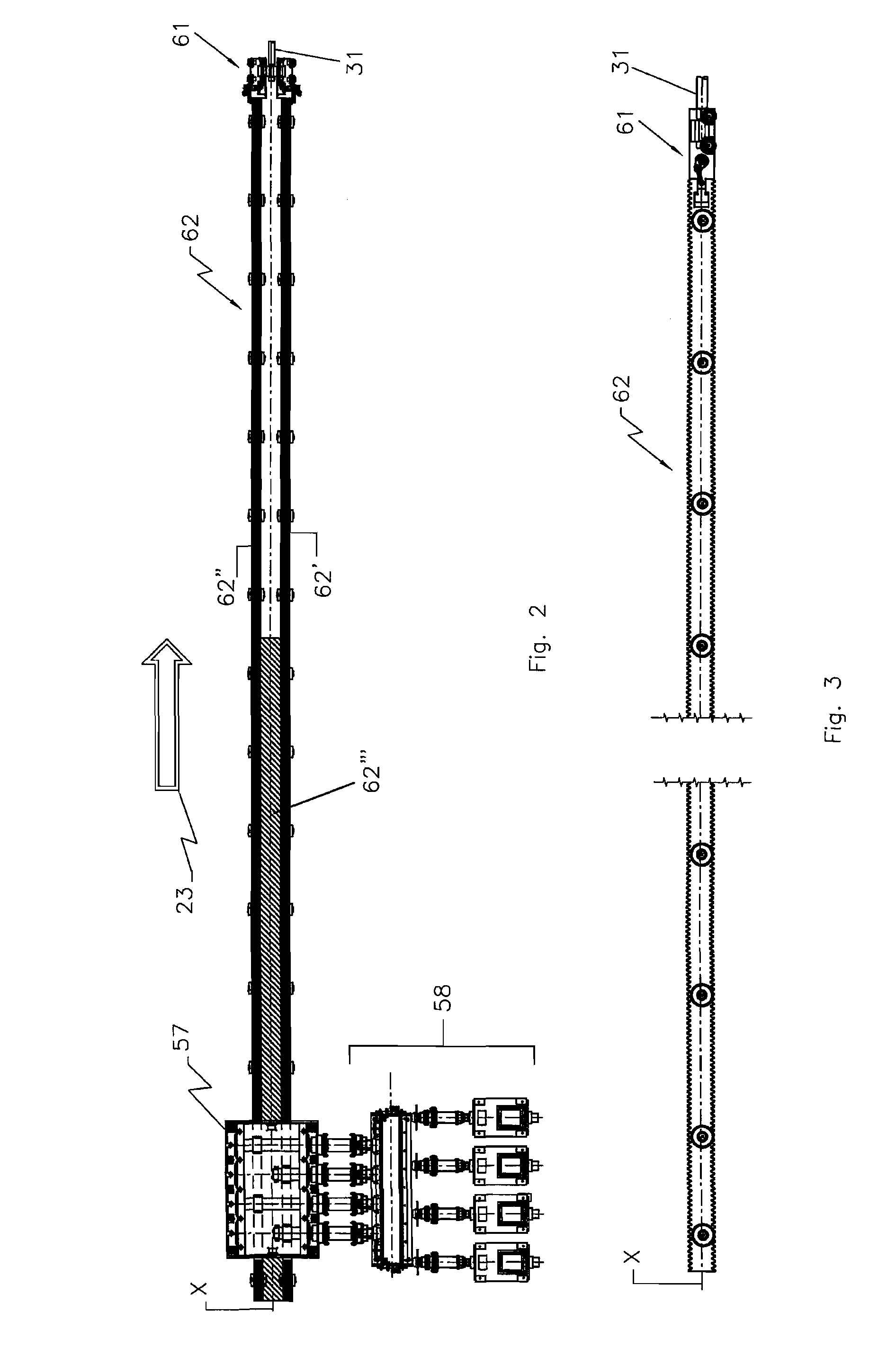

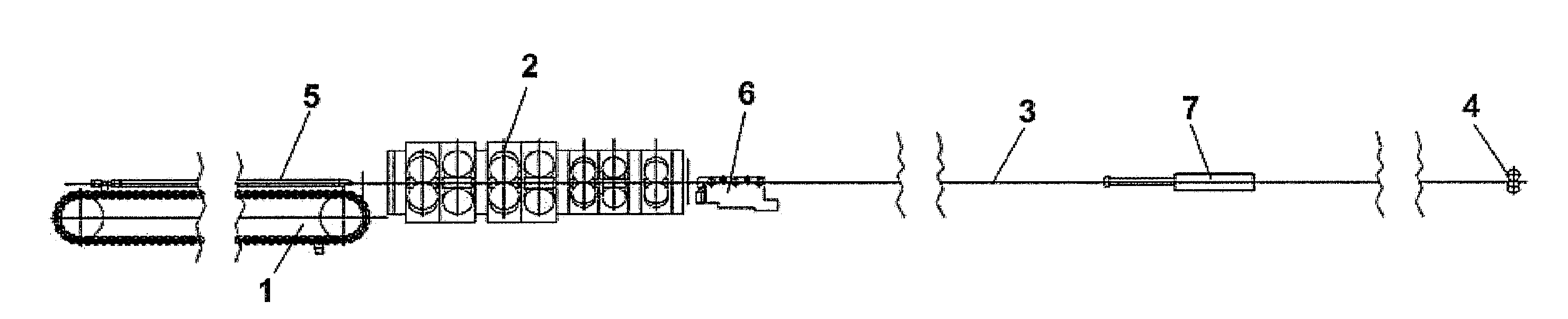

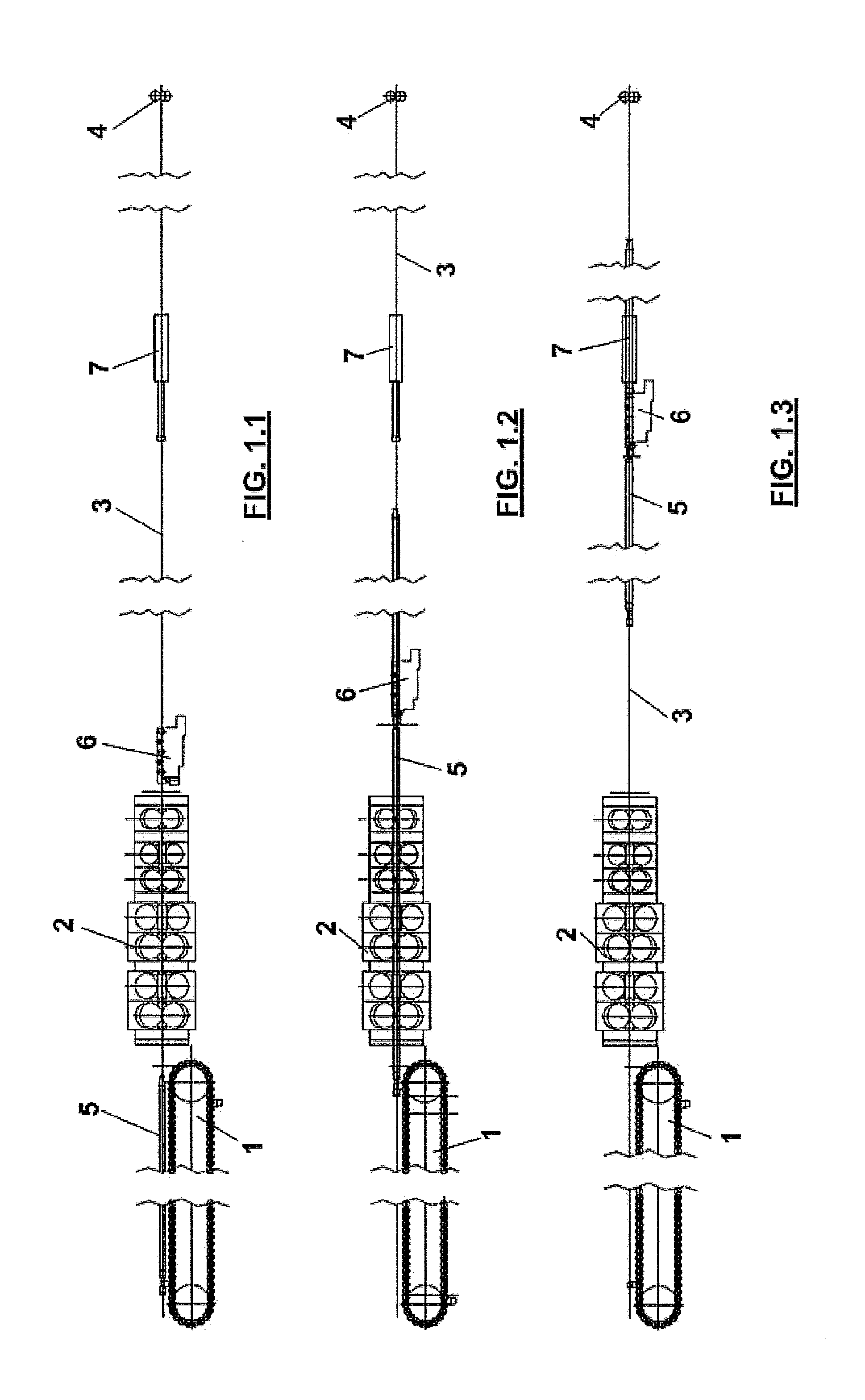

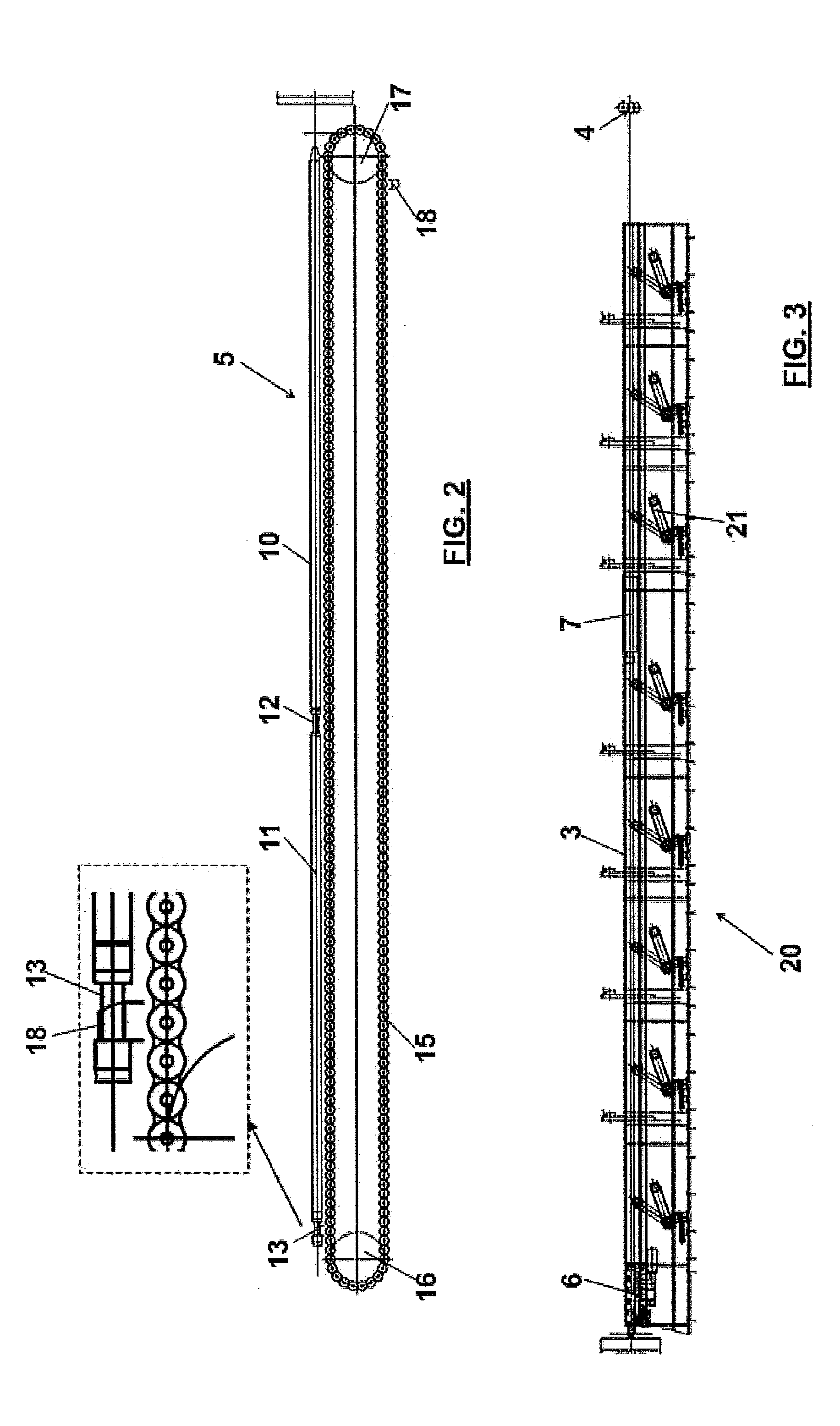

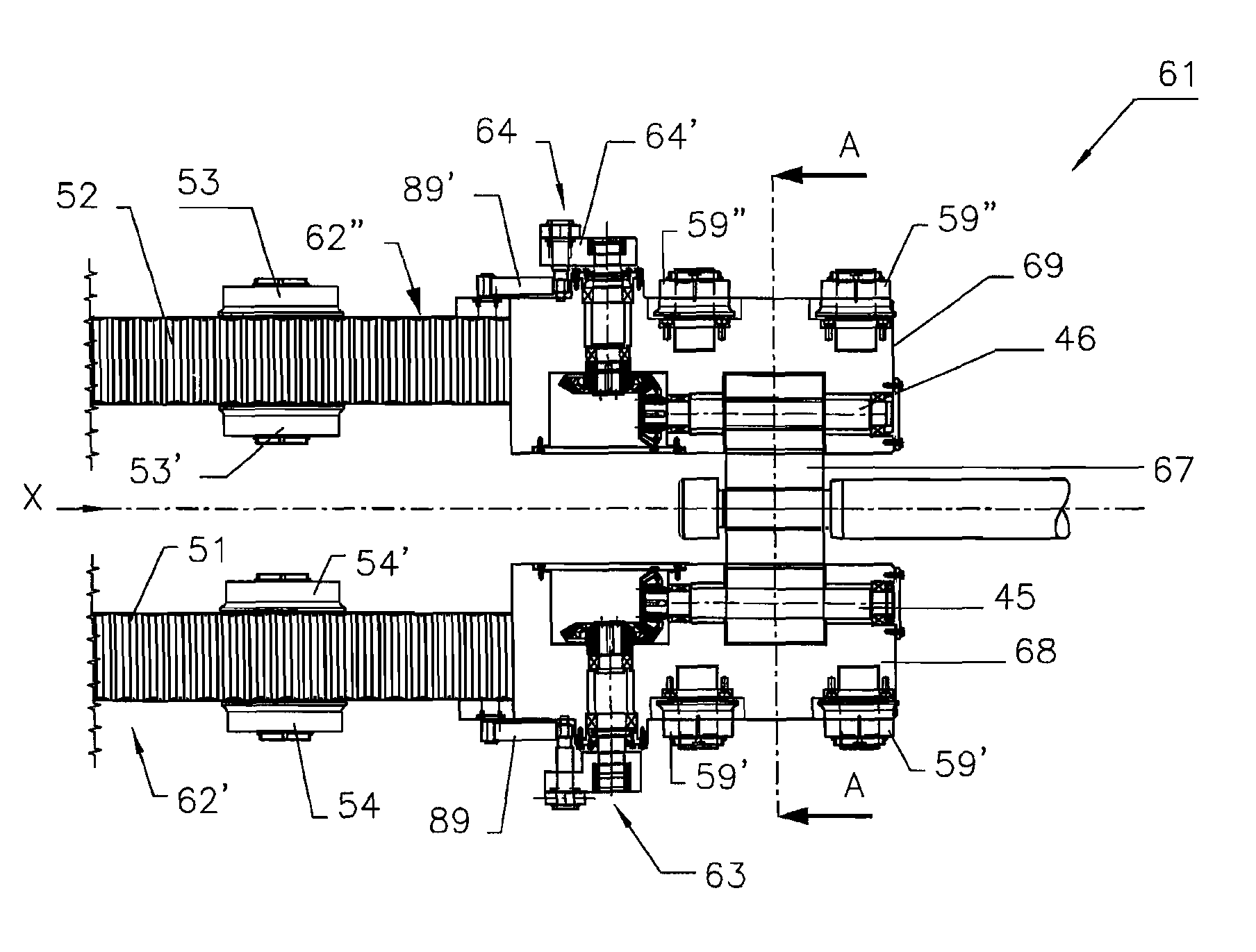

A rolling plant (R) for rolling tubes having a multi-stand rolling mill (5) with two or more rolls, in order to implement a controlled speed mandrel rolling process, comprises a hooking and releasing device (61) which is arranged in the inlet area of the rolling mill (5) to cooperate with the rear tang of the mandrel (31) and a hooking and releasing device (71) which is arranged in the outlet area of the rolling mill (5) to cooperate with the front tang of the mandrel (31) in coordinated manner with the first hooking and releasing device (61).

Owner:DANIELI & C OFF MEC SPA

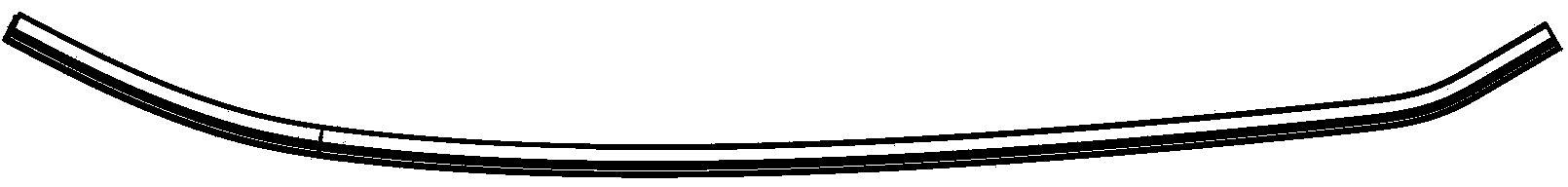

Pipe bending machine

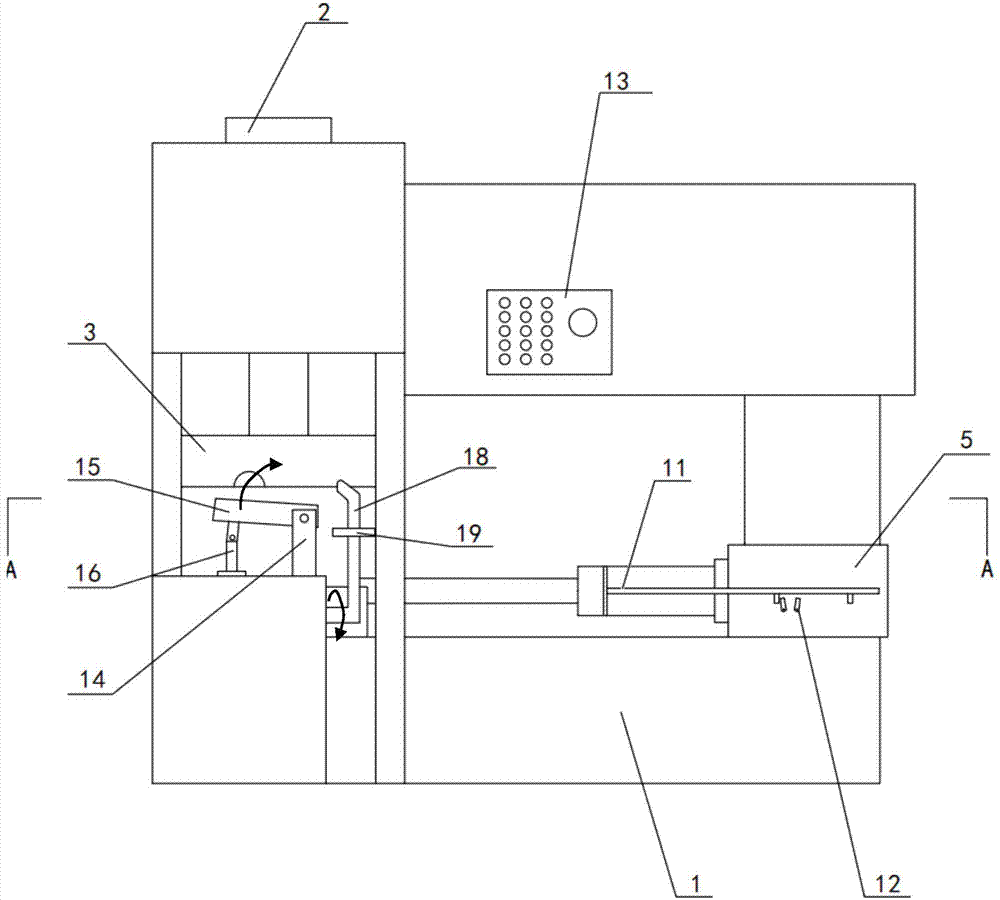

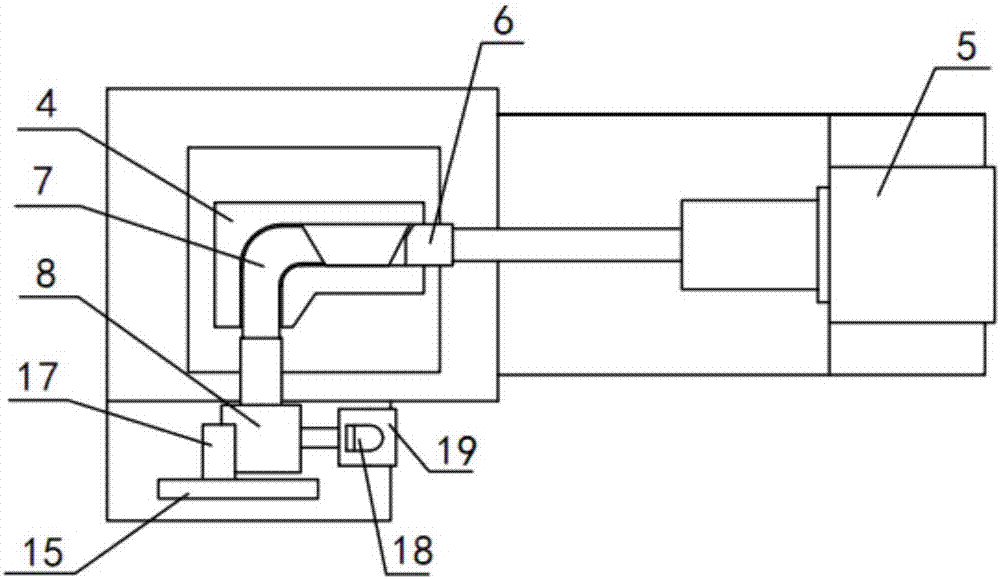

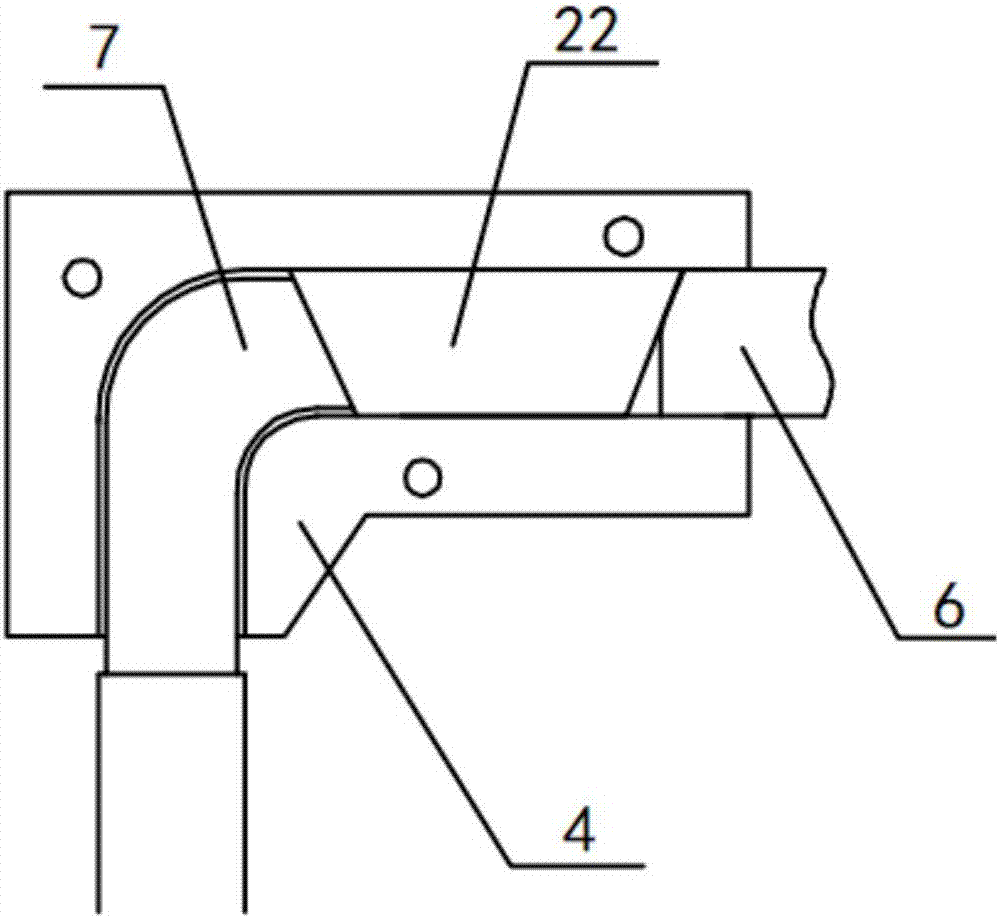

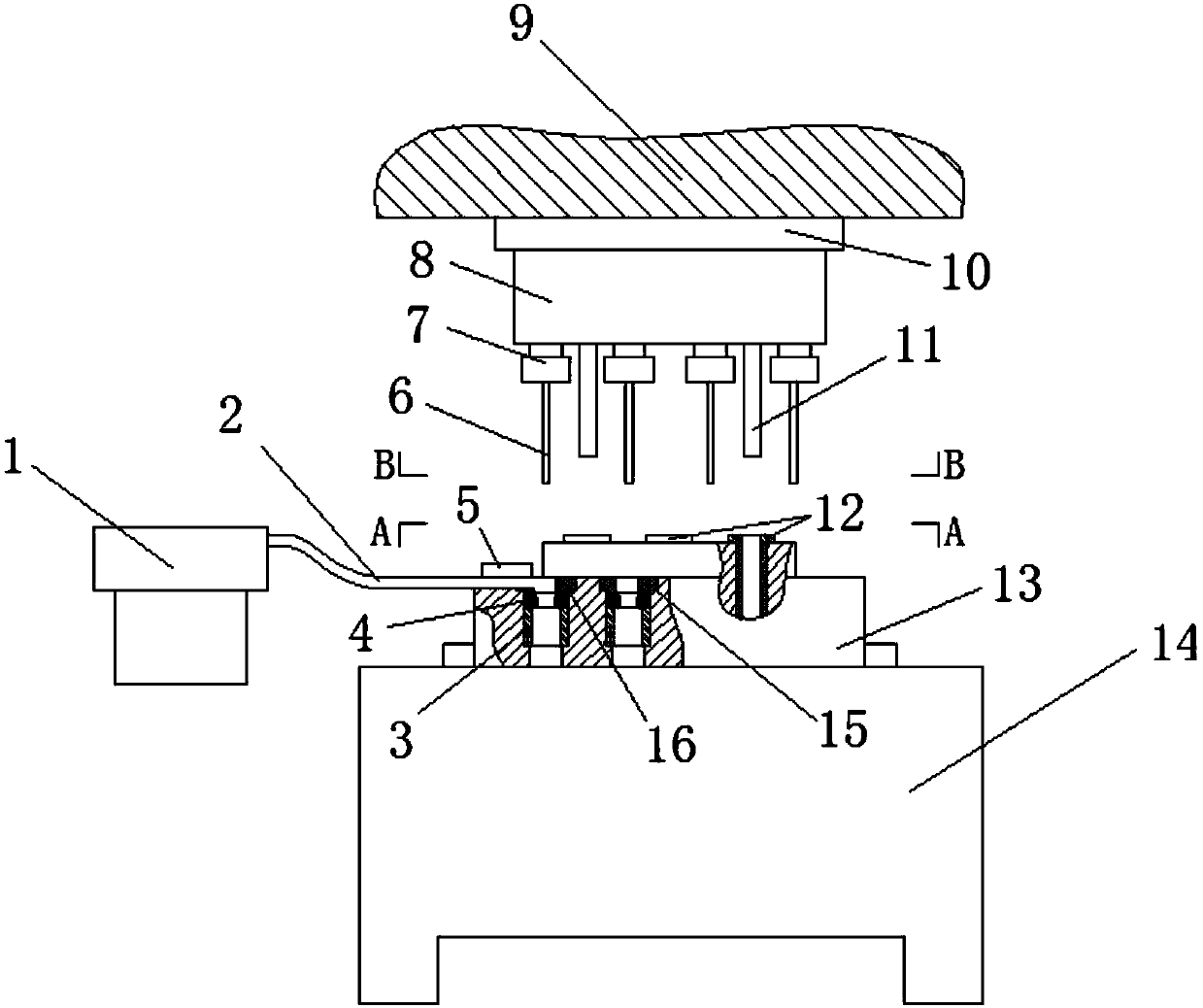

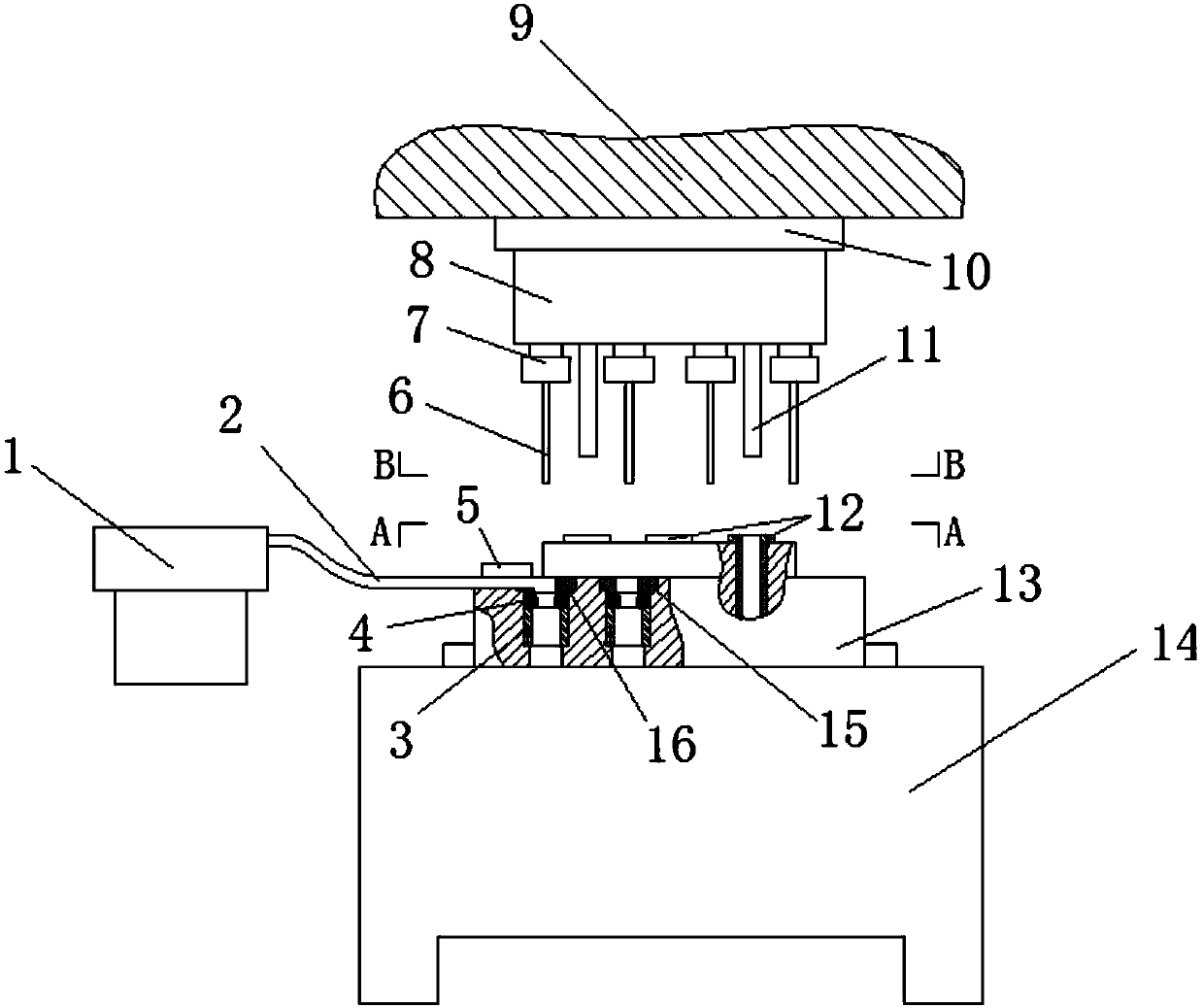

InactiveCN107876604AQuick exit without injuryReduce labor intensityMandrel separation arrangementsEngineeringUltimate tensile strength

The invention provides a pipe bending machine. A vertically arranged down-pressing oil cylinder is arranged on one side of the bed, an upper die is arranged at the lower end of the down-pressing oil cylinder, and a lower die is arranged directly below the upper die. The upper die and the lower die Model grooves are respectively arranged on the mating surfaces of the molds, and a push cylinder is horizontally arranged on the other side of the bed, and a push head is arranged at the front end of the push rod of the push cylinder, and a mold core is arranged inside the lower mold, and a mold core is arranged inside the mold. The tail end of the core is connected to the base, and the base is connected to the rotating shaft of the turning motor. A discharge device is arranged beside the base at the tail end of the mold core. The discharge device includes a fixed plate, a rotating plate and a telescopic oil cylinder. The two ends of the plate are respectively connected with the fixed plate and the piston rod of the telescopic oil cylinder, and a material shifting block is installed on the side of the mold core of the rotating plate. The pipe bending machine can improve production efficiency and reduce labor intensity of workers.

Owner:YANGZHOU PIPE FITTING FACTORY

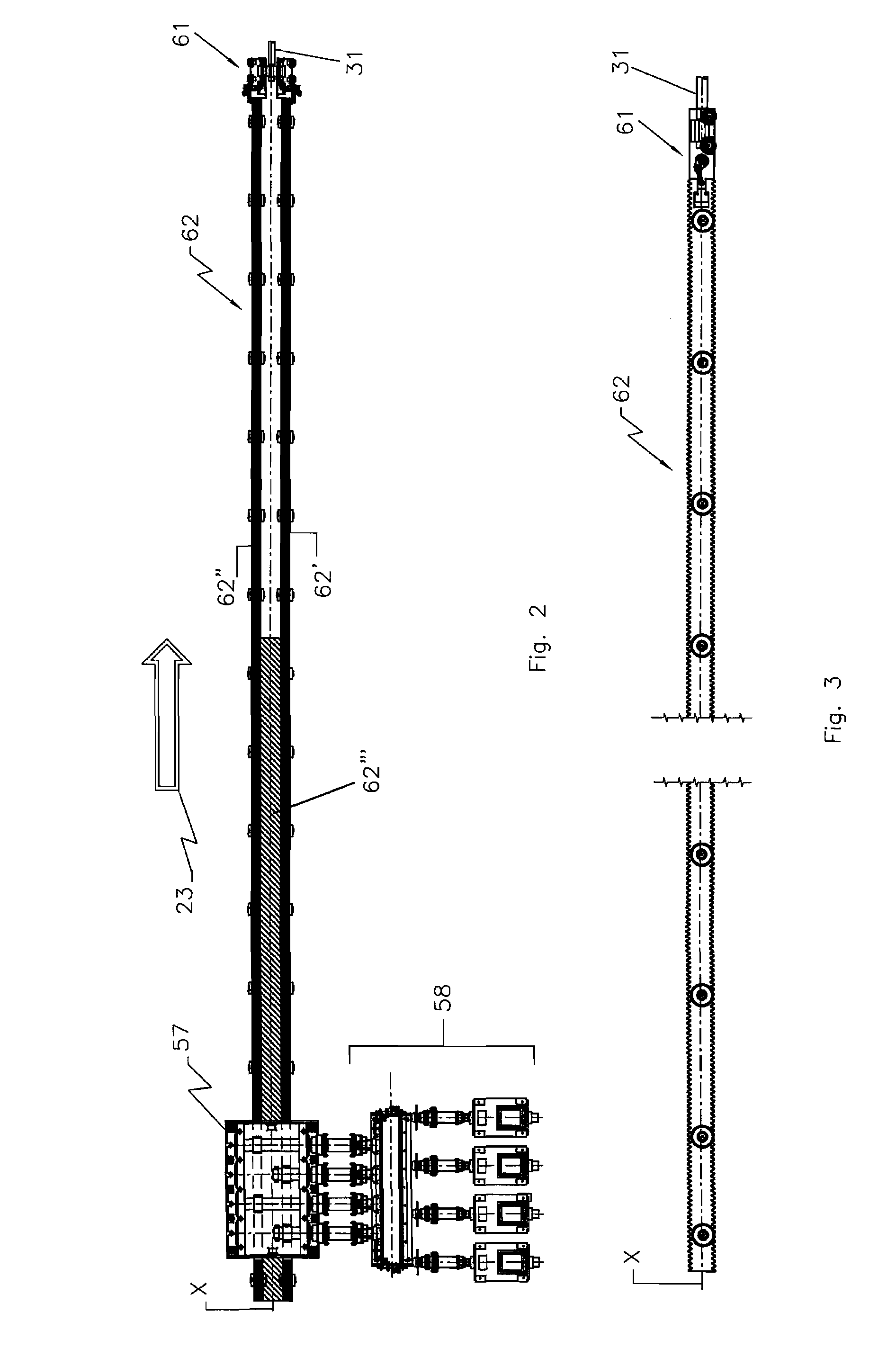

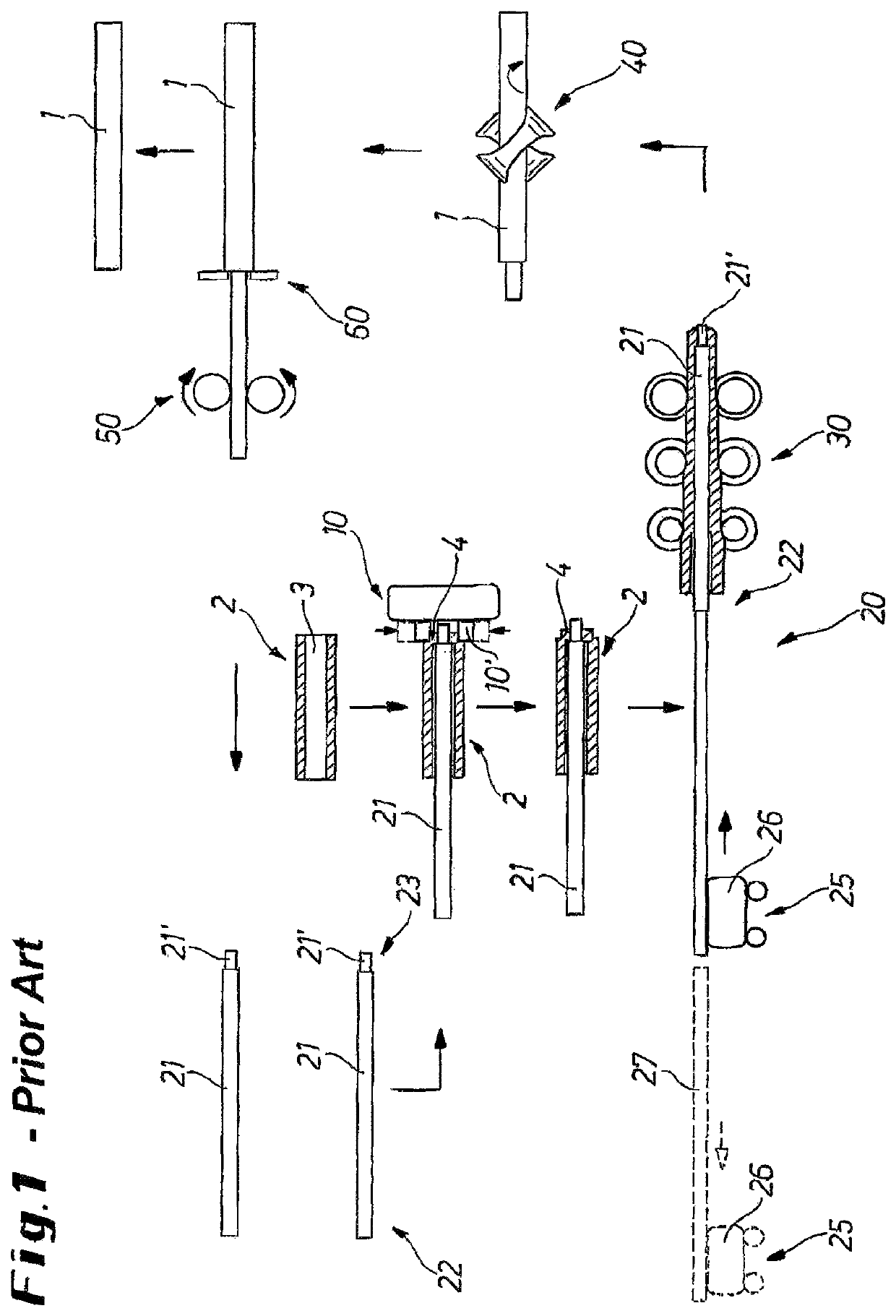

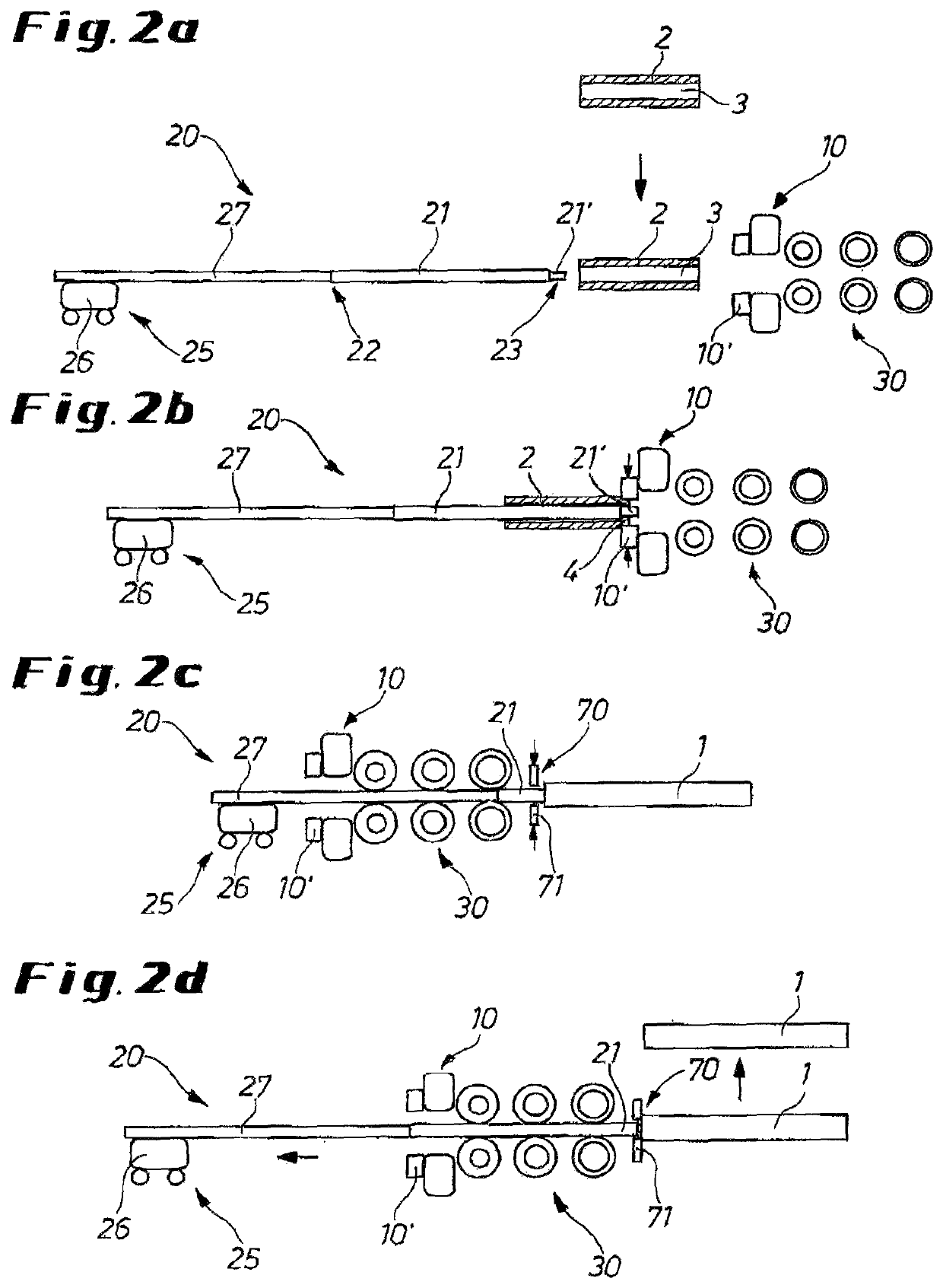

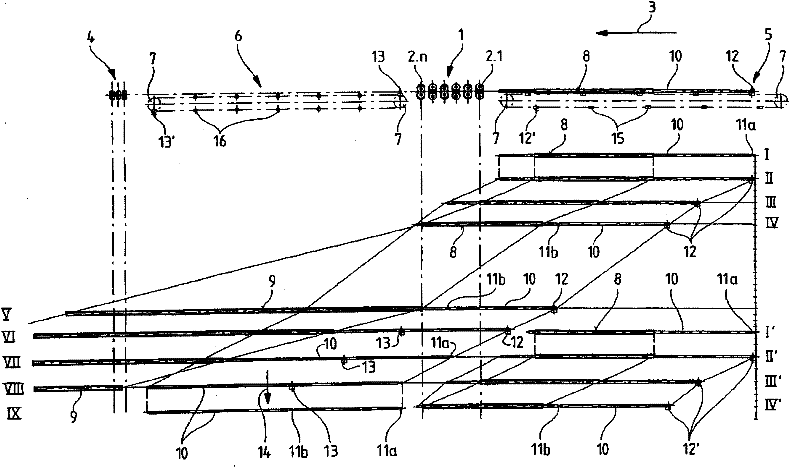

Rolling process and relating longitudinal, multi-stand rolling mill of continuous, restrained type for hollow bodies

ActiveUS20120103049A1Improve productivityRaise quality standardsMandrel separation arrangementsMandrelsMaterials scienceRolling mill

A longitudinal, multi-stand rolling mill of the continuous, restrained type for rolling hollow bodies is described, which comprises a main rolling mill (2) and an extracting rolling mill (4) in line and downstream of the main rolling mill, at a distance from the main rolling mill larger than the maximum length of the hollow body and of the spindle, and in which the spindle is extracted at the outlet of the main rolling mill in the gap between said main rolling mill and extracting rolling mill, and is laterally unloaded.

Owner:DANIELI & C OFF MEC SPA

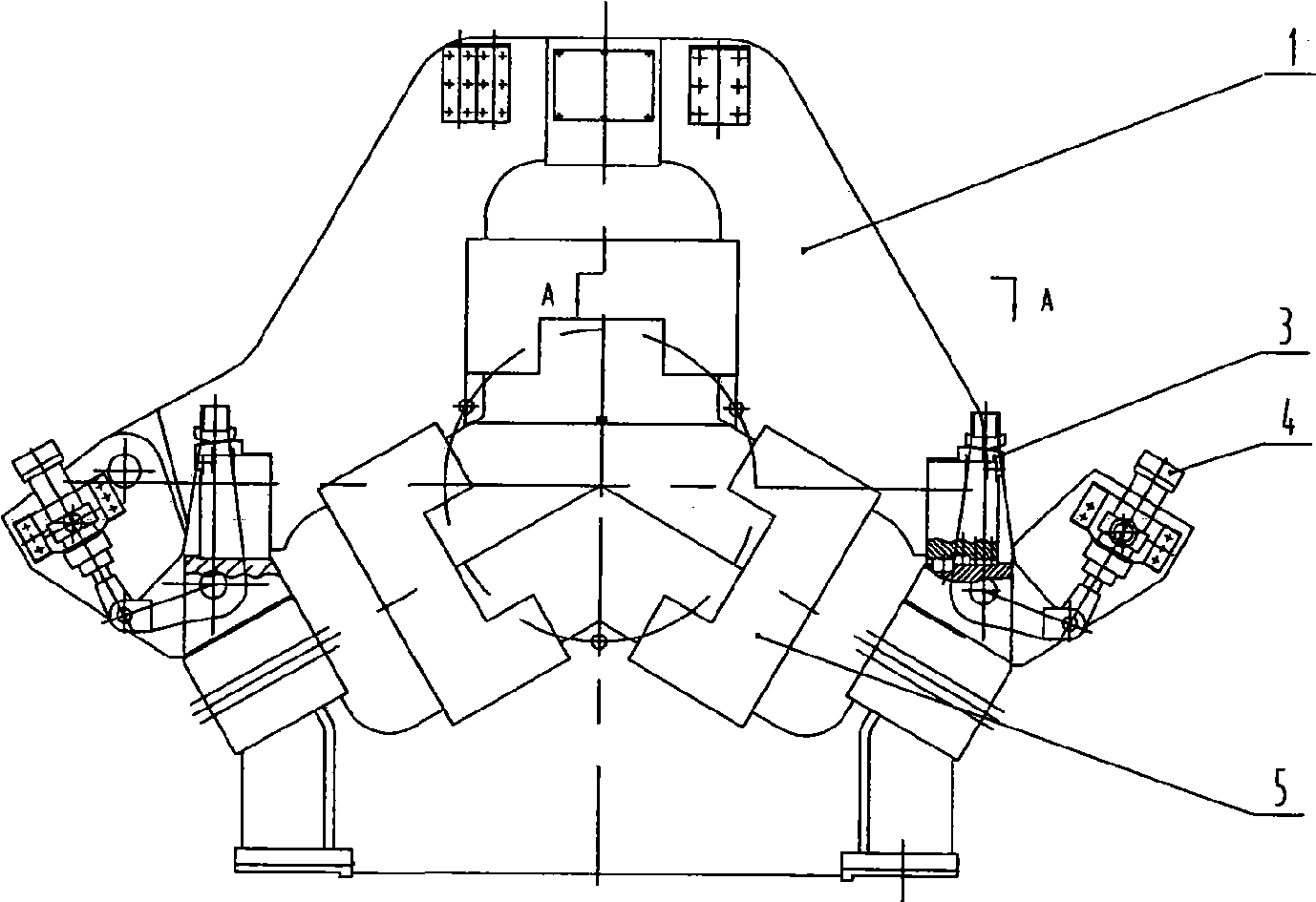

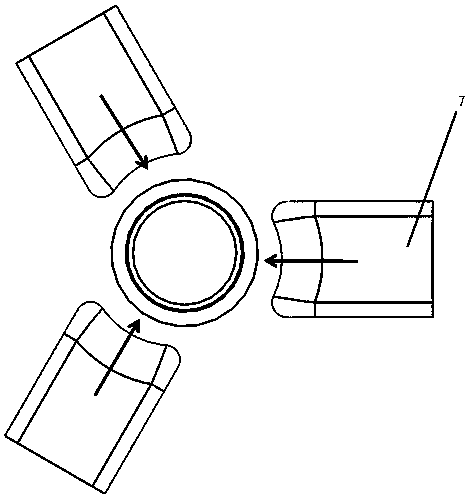

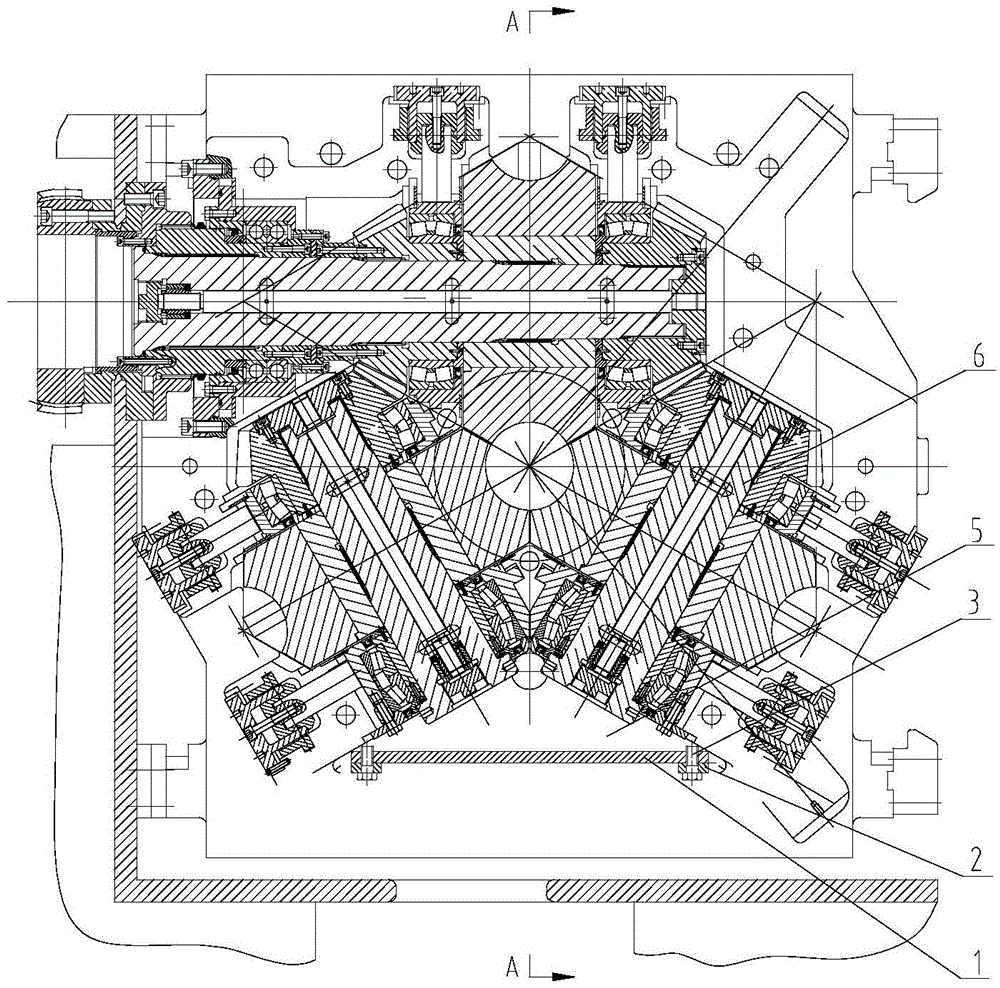

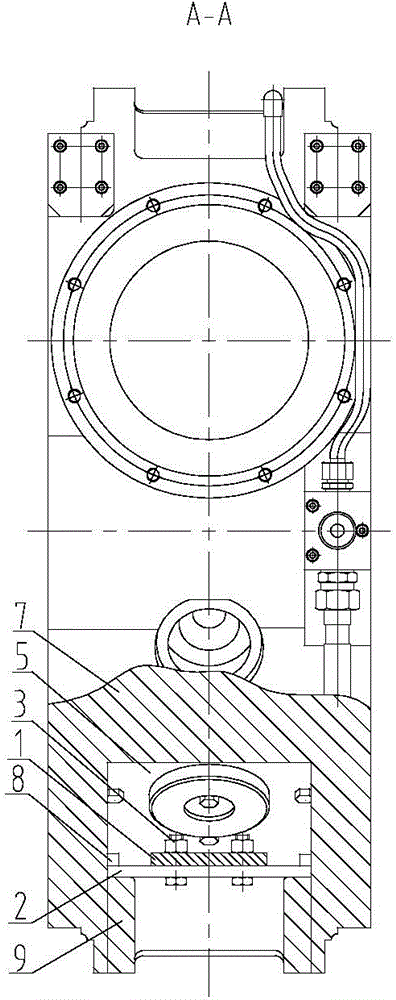

Three-roller tube-rolling machine

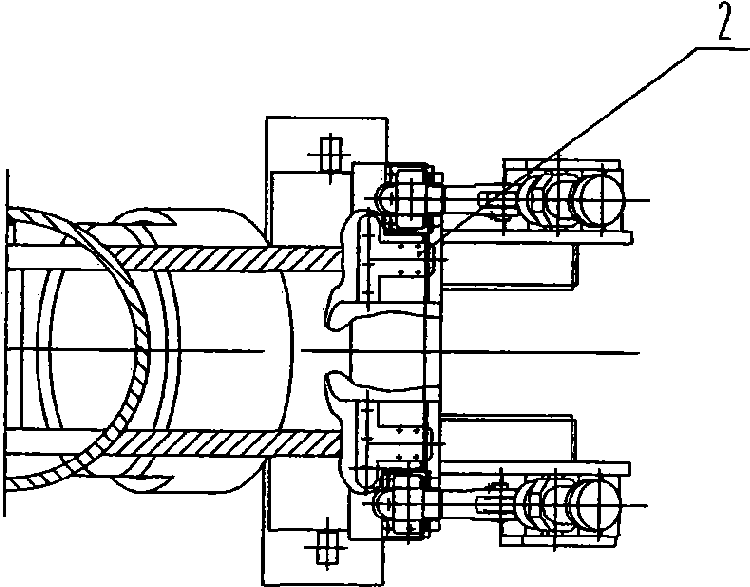

ActiveCN101474634AImprove rigidityNo bouncingMetal rolling stand detailsGuiding/positioning/aligning arrangementsDrive shaftEngineering

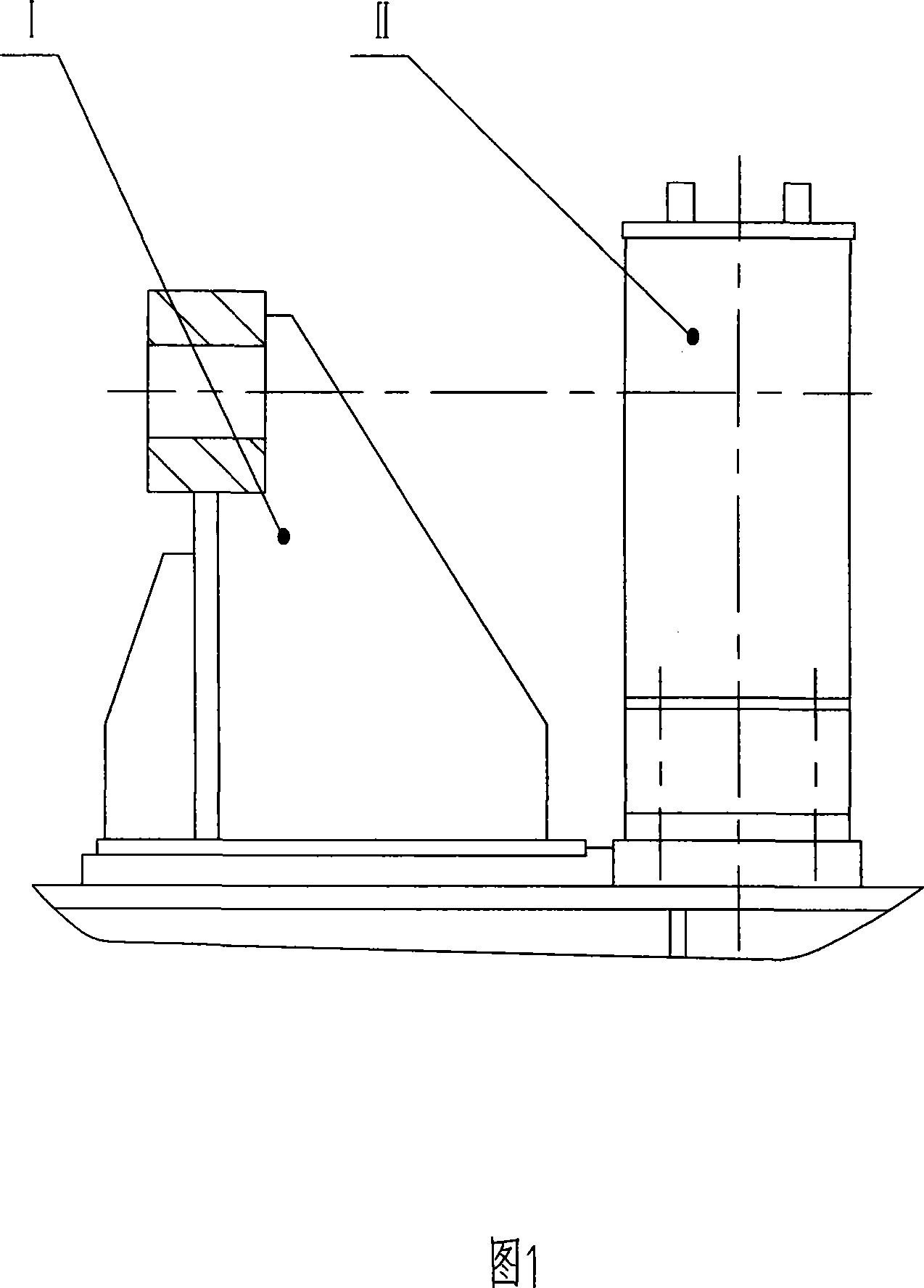

A three-roller tube mill relates to hot-rolled seamless steel tube equipment. The existing three-roller tube mill is a small-sized tube mill which is provided with a closed frame, changes a roll in an off-line manner, and can only produce seamless tubes with the diameter shorter than 219mm. The three-roller tube mill comprises three rotating drums and three rollers which are arranged in the frame, and main motors which are connected with the rollers by main speed reducers and main transmission shafts. The fame is an open frame consisting of an upper part and a lower part and provided with three cylinders which form an angle of 120 degrees with each other; the three rollers and the three rotating drums are respectively arranged in the three cylinders; and the three rollers are respectively connected with the three main motors and the main speed reducers by the transmission shafts. The three-roller tube mill has the advantages that the fame has good rigidity and high strength; the transmission device does not easily resonate and has good stability; the tube mill body is provided with an inlet auxiliary device and an outlet auxiliary device; the roller shape can satisfy metal flowability very well, thus causing the production of large-diameter steel tubes possible.

Owner:TAIYUAN HEAVY IND

Composite stretch forming method for corrugated tube blanks

InactiveCN107855372AImproves wall thickness uniformityReduce cleaningMandrel separation arrangementsEngineeringThin walled

The invention discloses a composite stretch forming method for corrugated tube blanks. The method comprises the following steps: the tube blanks are sent to feeding blocks during forming, an upper machine board drives a servo motor linkage module to press downward, core rods drive the tube blanks to disengage from the feeding blocks and enter female die cavities, and stretch the tube blanks, downward pressing motion stops after the stretching motion is completed, then the servo motor linkage module rises and returns, a material returning block performs material returning motion to make the tube blanks disengage from the lower ends of the core rods when the tube blanks exist, and one stretching cycle is completed after the rising motion is completed; the servo motor linkage module rotates apreset angle after the last stretching cycle is completed, the core rods go forward for one station relative to female dies on a lower pedestal, and then stretching motion in the next cycle is carried out; and the tube blanks are stretched to reach a need thin wall state after cycle stretching motion is carried out with the frequency corresponding to the quantity of the female dies. The method greatly shortens the production period and increases the production efficiency, and the wall thickness of the produced seamless thin wall tube blanks has a good uniformity.

Owner:ZHEJIANG GARDEN ELECTRONICS EQUIP

Novel plastic processing method for high-performance magnesium alloy seamless long pipe material

InactiveCN109092898AEnough to shapeImprove mechanical propertiesMandrel separation arrangementsRollsThermal insulationHeat losses

The invention provides a novel plastic processing method for a high-performance magnesium alloy long pipe material, comprising the steps of: using a far-infrared heating lamp tube to heat a roll, inserting a mandrel after a pipe blank is heated, using three hammerheads for synchronous tightening, and after mouth shrinkage, ensuring a certain pressing force between the mandrel and the inner wall ofthe pipe blank; when an induction coil is working, enabling the mandrel to drive the pipe blank after the mouth shrinkage into the roll, and conducting reduced-diameter reduced-wall plastic deformation processing on the pipe blank; and after the rolled pipe is subjected to rod removal by a rod conveying set, segmenting the pipe into n sections based on needs. According to the invention, an induction heating manner is used for heating the pipe blanks instead of traditional resistance heating, thereby realizing on-line heating and on-line rolling. An induction heating way is employed for supplementing heat in multiple rolling passes, thereby overcoming the difficulty that magnesium alloy is extremely sensitive to temperature during plastic deformation and precisely controlling the temperature during rolling. Meanwhile, since the rolling process is finished in a thermal insulation box, heat loss with air is weakened.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Mandrel conveying device for a tube rolling mill

ActiveUS9205473B2Cost-effectiveCost-effective to to operateMandrel separation arrangementsMandrelsEngineeringHooking

A rolling plant (R) for rolling tubes having a multi-stand rolling mill (5) with two or more rolls, in order to implement a controlled speed mandrel rolling process, comprises a hooking and releasing device (61) which is arranged in the inlet area of the rolling mill (5) to cooperate with the rear tang of the mandrel (31) and a hooking and releasing device (71) which is arranged in the outlet area of the rolling mill (5) to cooperate with the front tang of the mandrel (31) in coordinated manner with the first hooking and releasing device (61).

Owner:DANIELI & C OFF MEC SPA

Rotatable composite automatic stretching device

InactiveCN107639124AImproves wall thickness uniformityReduce cleaningMandrel separation arrangementsEngineeringHeat treating

The invention discloses a rotatable composite automatic stretching device which comprises a lower machine table, an upper machine table, a lower base and a servo motor linkage module, wherein the upper machine table is arranged above the lower machine table, the lower base is arranged on the lower machine table, and the servo motor linkage module is arranged on the upper machine table. A pluralityof female dies are uniformly and circumferentially distributed on the lower base, upper bases are uniformly and circumferentially distributed on servo motor linkage module, the number of the upper bases is as same as that of the female dies, the circumference positions of the upper bases are one-to-one correspondence to that of the female dies, core rods are arranged on the upper base, the core rods are matched with the female dies in the downward pressing process, so that tube blanks are stretched, the female dies are provided with cavities, and the inner diameter sizes of the female die cavities are sequentially reduced from the female dies correspondingly arranged below feeding blocks to the female dies correspondingly arranged below discharging blocks. According to the device, the processes such as cleaning and heat treatment in the original multi-pass stretching process are saved, a production period is greatly shortened, and production efficiency is improved.

Owner:ZHEJIANG GARDEN ELECTRONICS EQUIP

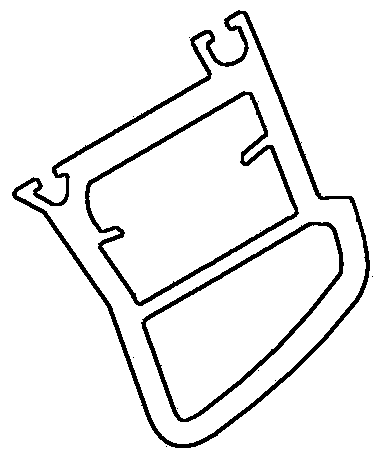

Core drawing mechanism

ActiveCN104043679ACompact structureSimple structureMandrel separation arrangementsProduct processingAutomation

A core drawing mechanism comprises a horizontally arranged frame, a guide rail positioned on the frame and horizontally extending, and a vertical seat positioned on the frame, the frame is provided with a rodless cylinder driving the vertical seat to move along the guide rail, the vertical seat comprises a vertical portion vertical to the extension direction of the guide rail, the vertical portion is provided with a driving cylinder, a piston rod of the driving cylinder is downward vertically arranged, is connected with a plug board and can drive the plug board to move up and down, the plug board can be inserted into a side groove extending up and down of the core rod of a product and exposed to two sides of the product, the frame is also provided with a product fixing device positioned outside one end of the guide rail, and the product fixing device is used for fixing the product when the plug board drives the core rod to move. The core drawing mechanism has the advantages of compact structure, small size, rapid and efficient drawing of the core rod out of the product, simple structure, processing convenience, low product cost, time and labor saving, and improvement of the product processing automation degree.

Owner:NINGBO XINTAI MACHINERY

Liquid resin molding system

A liquid resin molding system has a stationary platen and a movable platen mounted for undergoing movement relative to the stationary platen. A mold has at least one cavity and includes a first mold member attached to the movable platen and a second mold member attached to the stationary platen. An injection nozzle is attached to the movable platen and is configured to receive a liquid resin and to inject the liquid resin into the mold cavity. A nozzle touch mechanism is attached to the movable platen for pressing the injection nozzle against the mold.

Owner:NISSEI PLASTIC IND CO LTD

Evacuation device for mandril of perforator

InactiveCN101559448BQuality improvementIncrease productionMandrel separation arrangementsMetal rolling arrangementsHydraulic cylinderMinor axis

The invention discloses an evacuation device for a mandril of a perforator, and relates to steel rolling machines. The evacuation device comprises a pinch device and a baffle plate; the pinch device consists of a transmission device and a pinch roll mechanism; the transmission device consists of two sets of motors and a universal spindle; and the pinch roll mechanism mainly comprises upper and lower pinch roll shafts connected with the motors and the universal spindle, upper and lower pinch rolls connected with the upper and lower pinch roll shafts, upper and lower swinging arm sleeves sleevedwith the upper and lower pinch rolls, upper and lower pressure arms connected with the upper and lower swinging arm sleeves through minor axes, a hydraulic cylinder hinged with the upper and lower pressure arms, and a telescoping mechanism hinged with the lower pressure arm and connected with a base through a hinge shaft. The evacuation device can make the mandril after perforation evacuate froma steel tube, thereby improving the quality of the steel tube, being capable of using a plurality of the mandrils, circularly cooling the mandrils and improving the processing property of the perforator.

Owner:TAIYUAN HEAVY IND

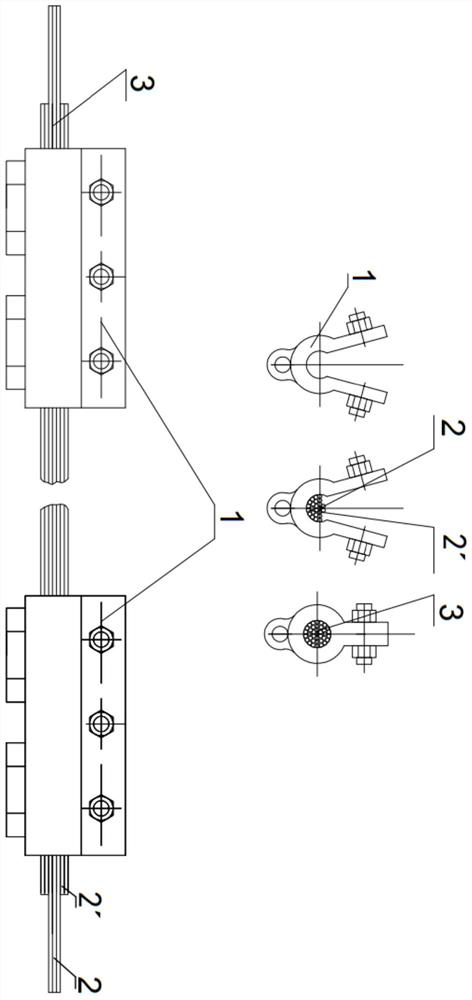

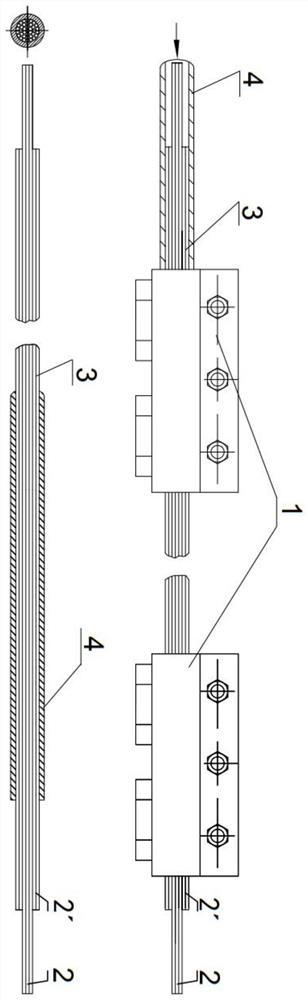

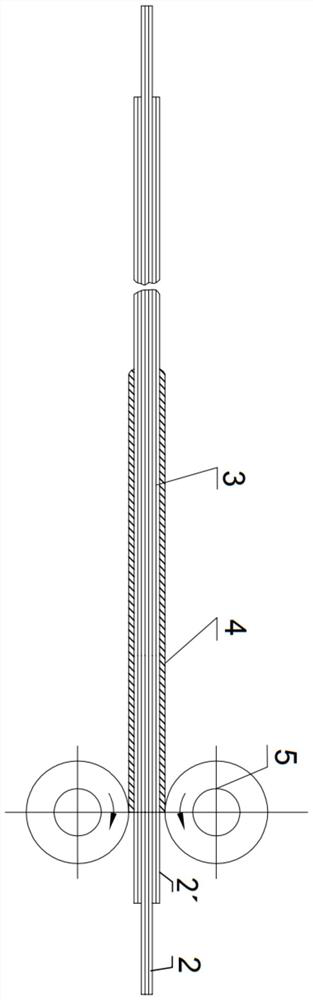

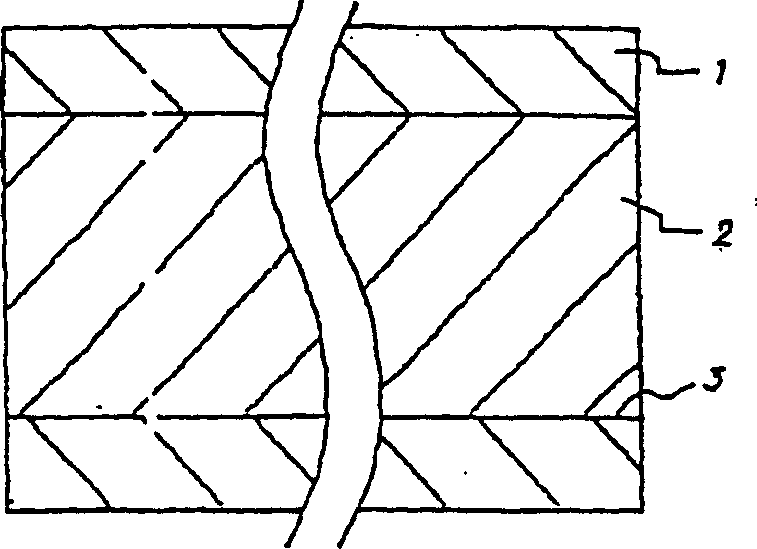

Bundled steel wire core rod as well as metal pipe wall-reducing extension method and device

ActiveCN111633047AEasy to achieve wall reduction and extension deformation processingAvoid damageDrawing mandrelsMandrel separation arrangementsStructural engineeringMachining

The invention provides a bundled steel wire core rod as well as a metal pipe wall-reducing extension method and device, and belongs to the technical field of metal pipe machining. The bunched steel wire core rod is composed of a plurality of hard steel wires, the number, the length and the shape of the hard steel wires are determined according to the inner diameter size and the length of a machined pipe, and the steel wires are clamped together through a plurality of core rod clamps to form the bunched steel wire core rod. According to the method, the pipe penetrating into the core rod is placed on a reducing machine, and a gap between the pipe and the core rod is eliminated; then the pipe is conveyed to a drawing machine for wall reduction and extension; and after the drawing is finished,the rod is removed. The rod removing process comprises the following two steps of 1, blocking short steel wires by using a stop plate, clamping long steel wires in the core rod by using a jaw of a rod removing trolley, and pulling out the long steel wires to loosen the short steel wires in the core rod; and 2, blocking the pipe by the stop plate, and dragging the short steel wires out by the rodremoving trolley to complete rod removing. The inner surface of the pipe is subjected to finishing according to requirements after the rod removing is finished, so that the pipe with longitudinal ribswith different heights on the inner wall is obtained.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Coil unloading system and coil unloading method

ActiveCN109954761APrevent fallingRealize automatic controlMandrel separation arrangementsEngineeringMechanical engineering

Owner:BAOSHAN IRON & STEEL CO LTD

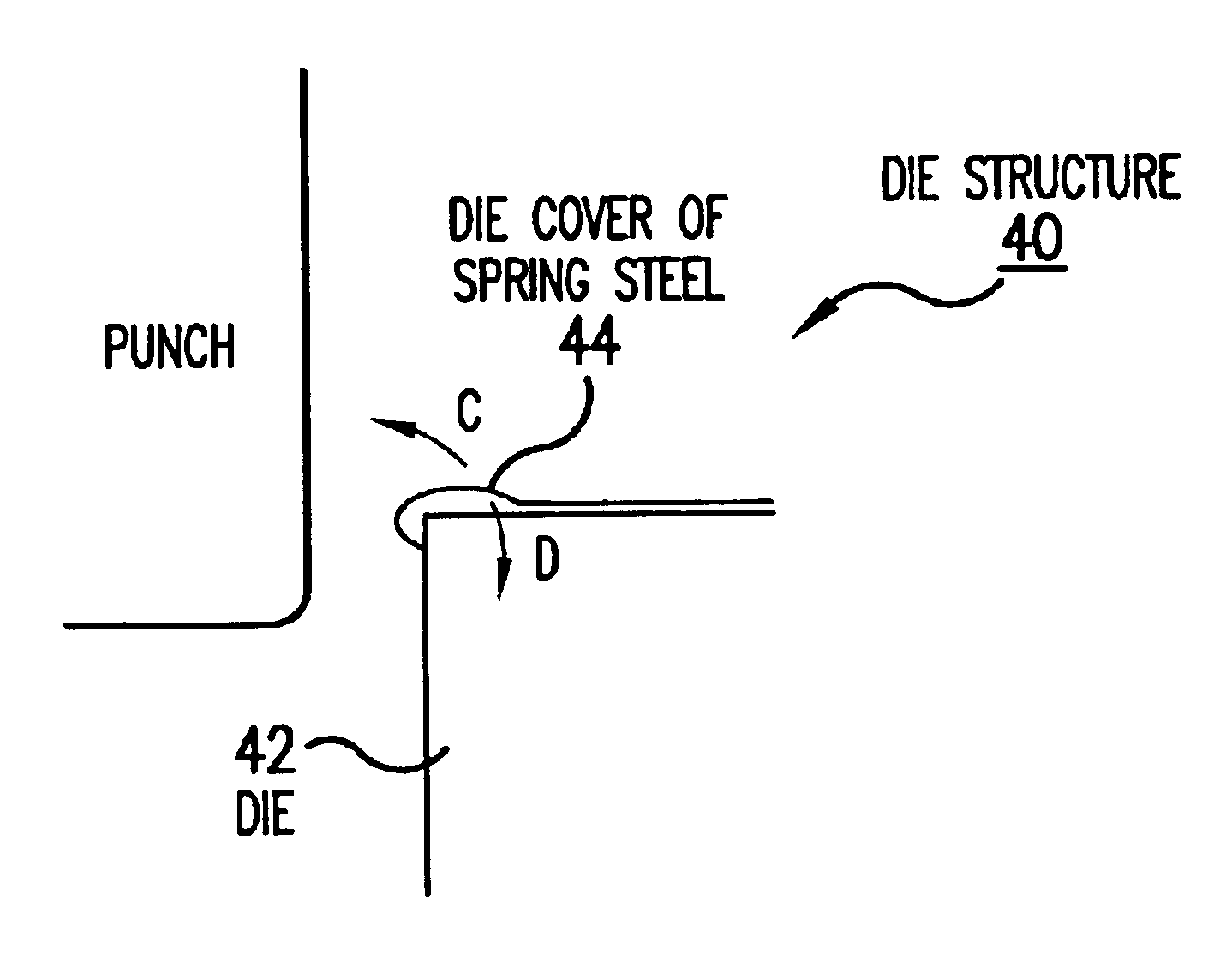

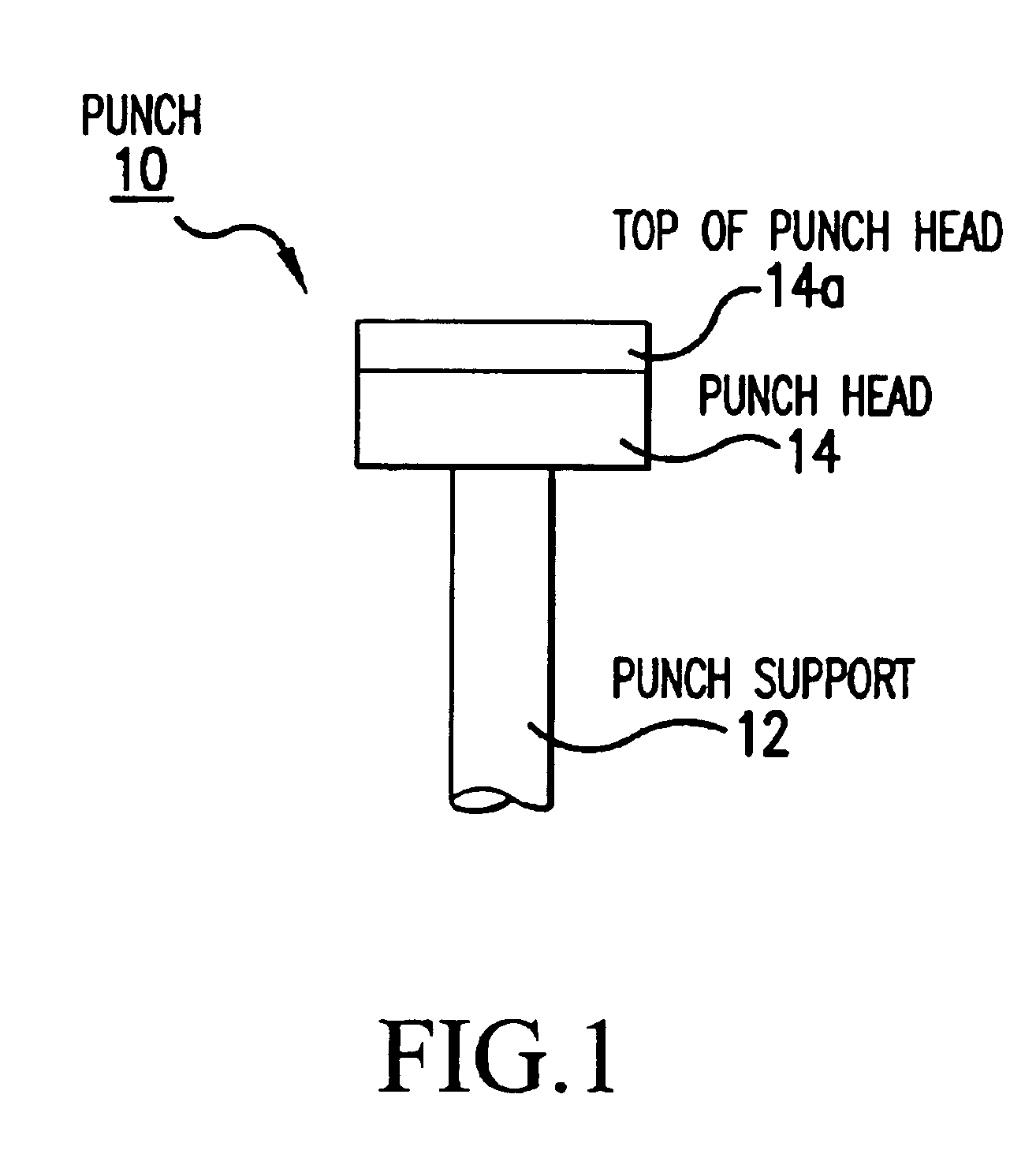

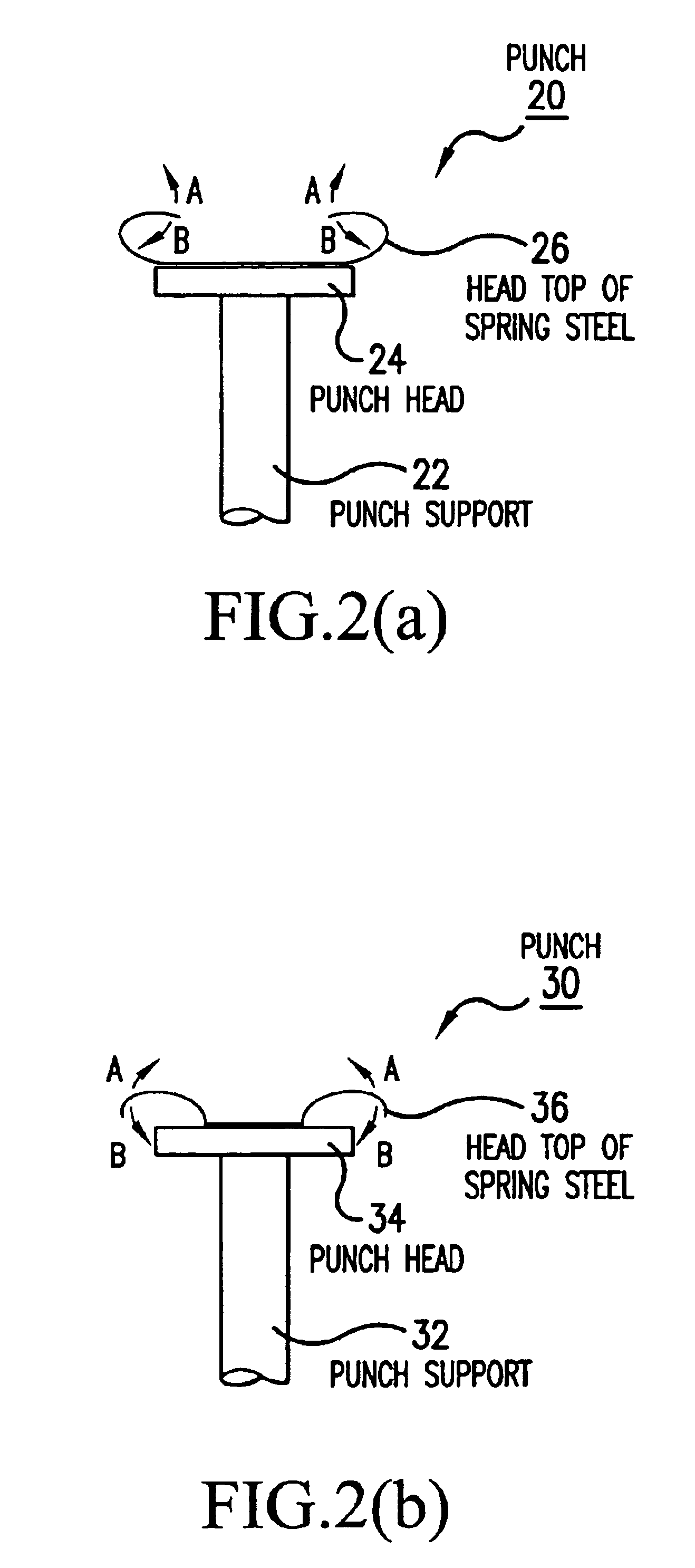

Ironing dies

InactiveUS6860134B2Easy to disassembleImprove production efficiencyShaping toolsMandrel separation arrangementsEngineeringHigh pressure

Owner:WE PLAN +1

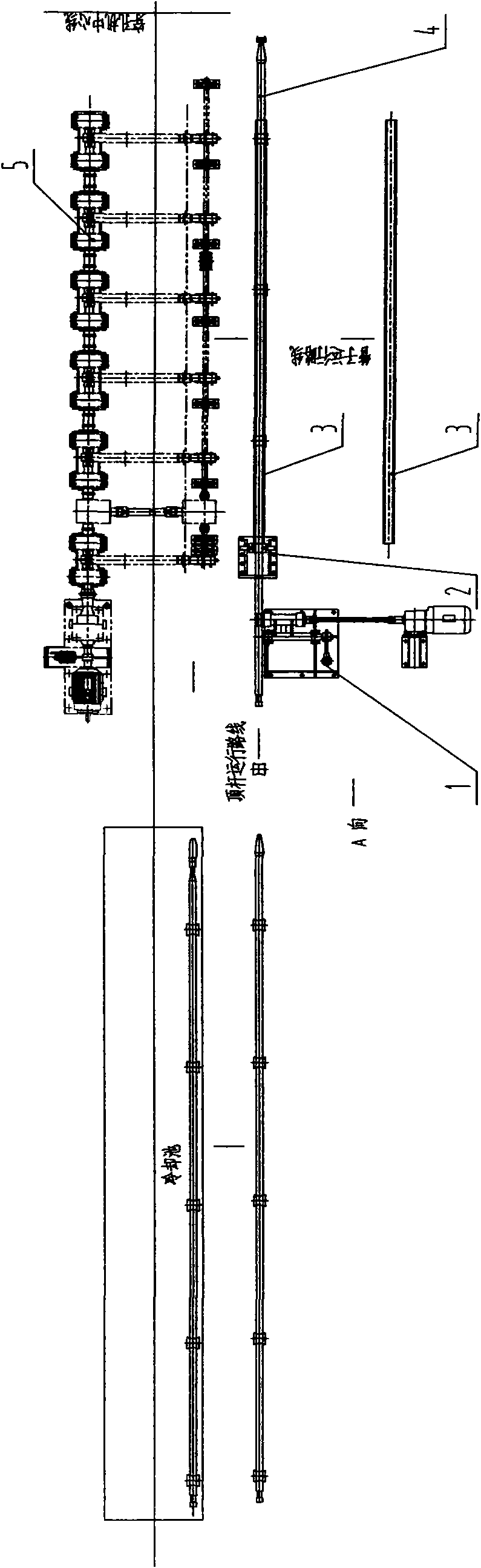

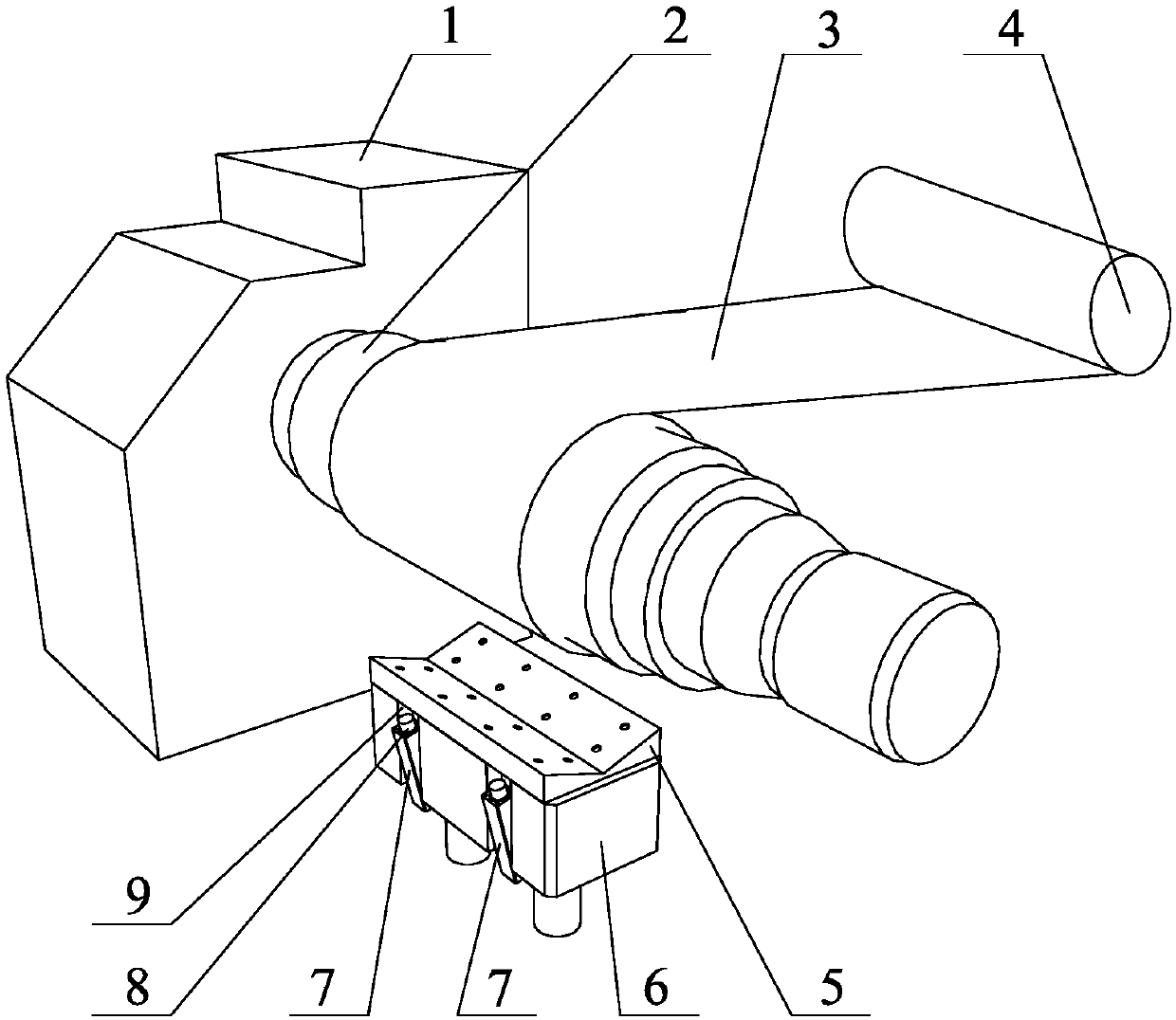

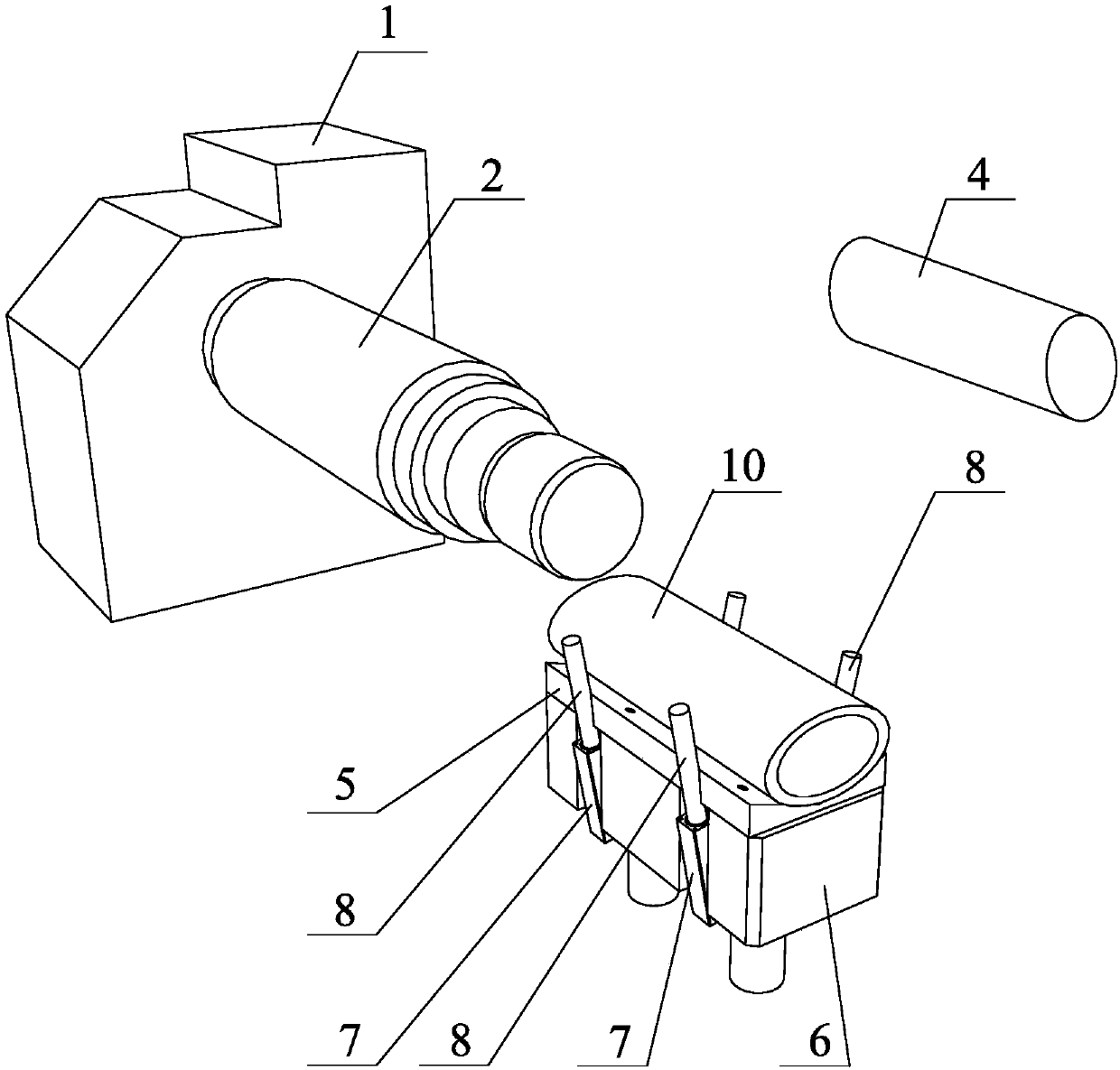

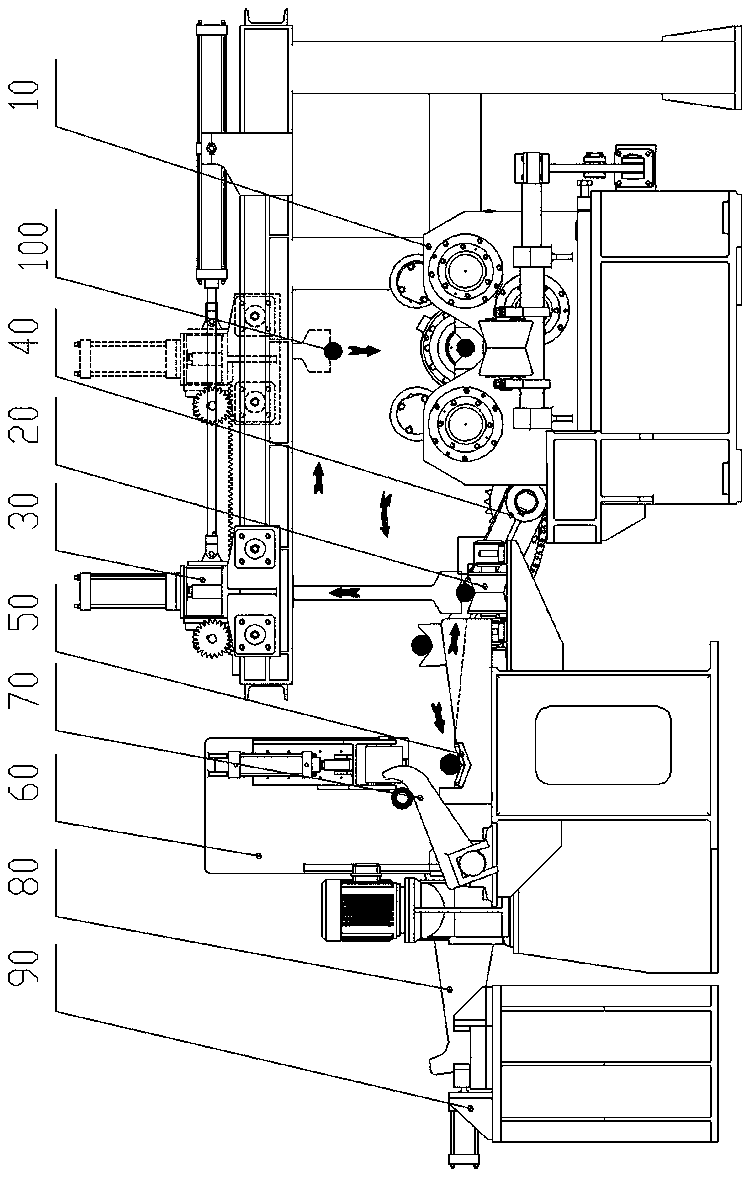

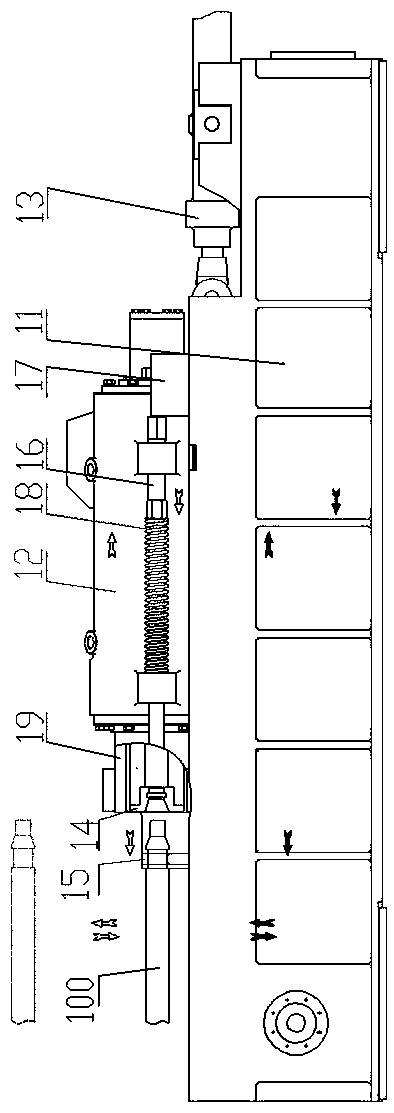

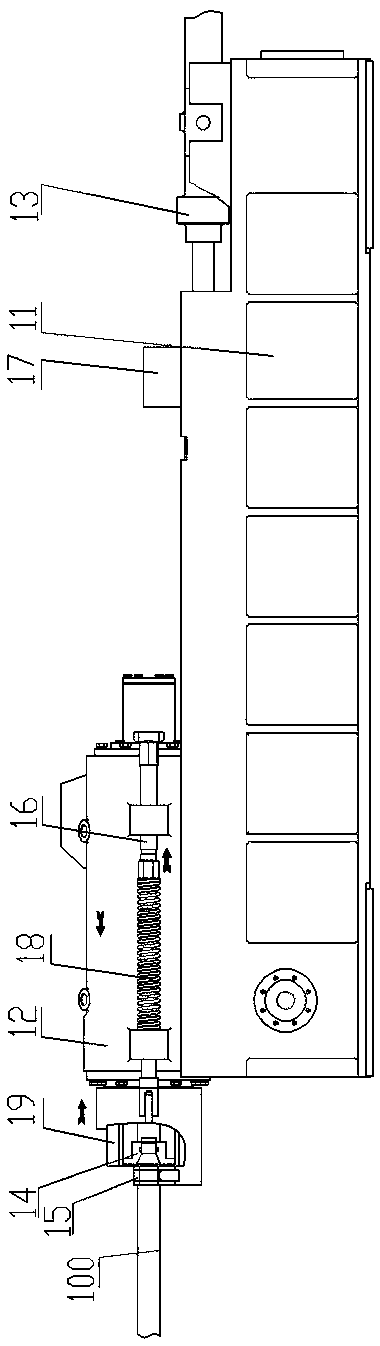

Automatic circulating equipment and method for perforating machine core rods

ActiveCN107716555ARealize online recyclingReduce long-distance round-trip timeMandrel separation arrangementsMandrelsShortest distanceEngineering

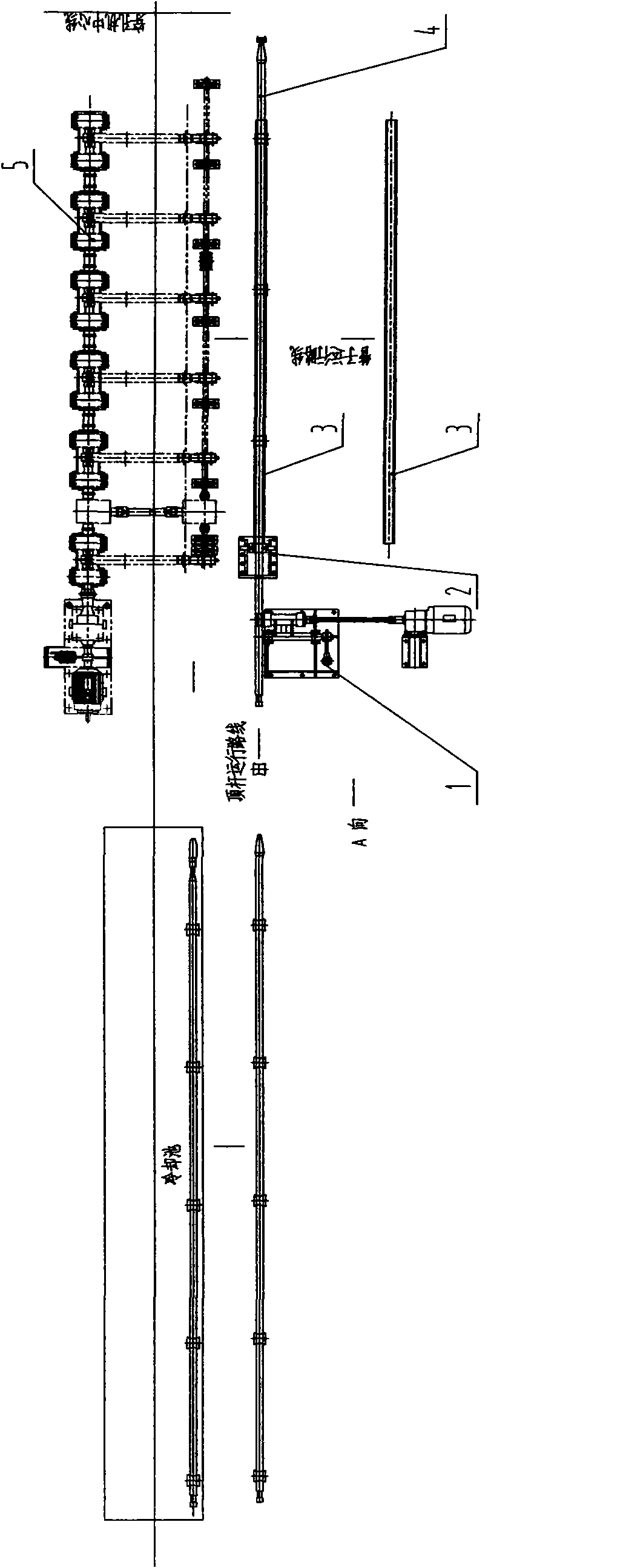

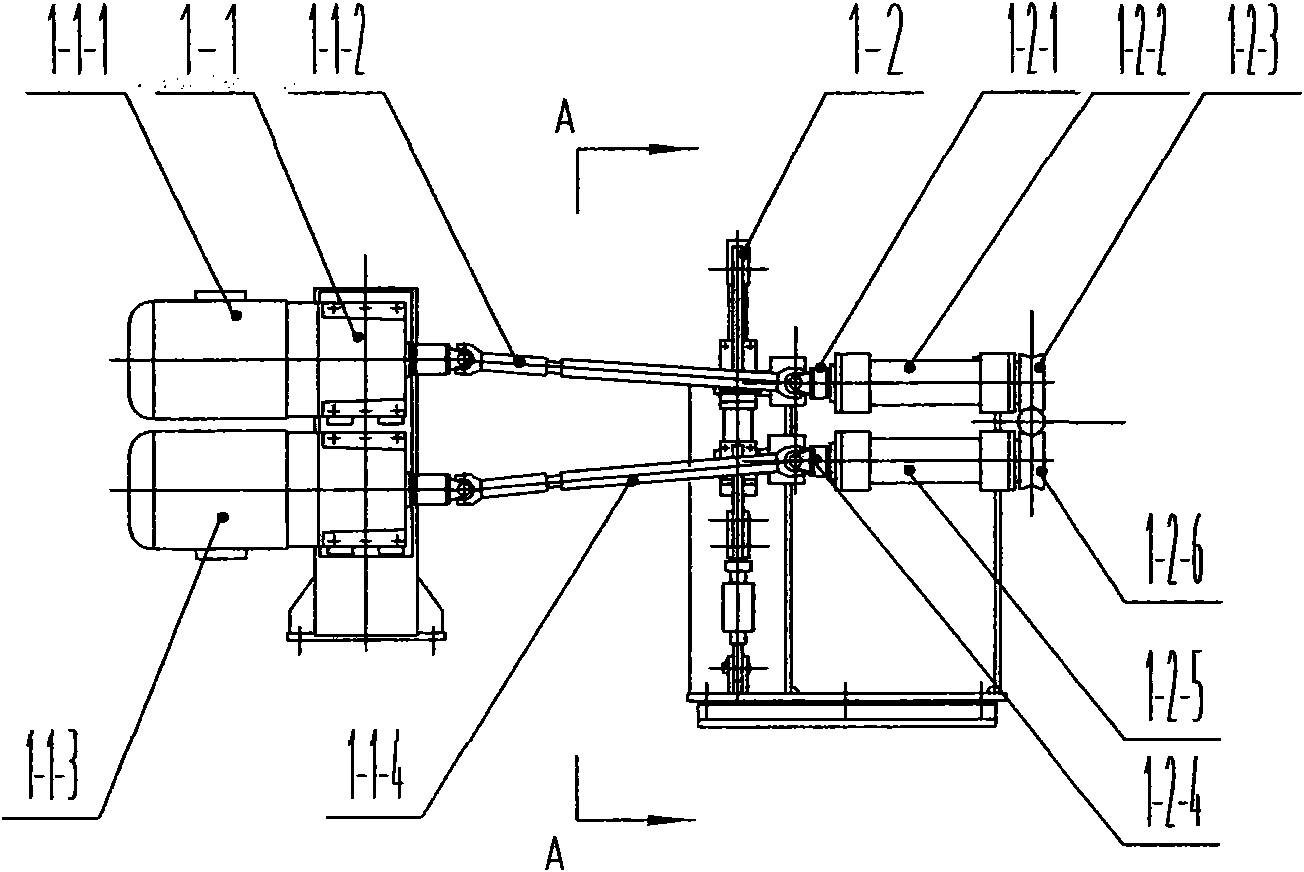

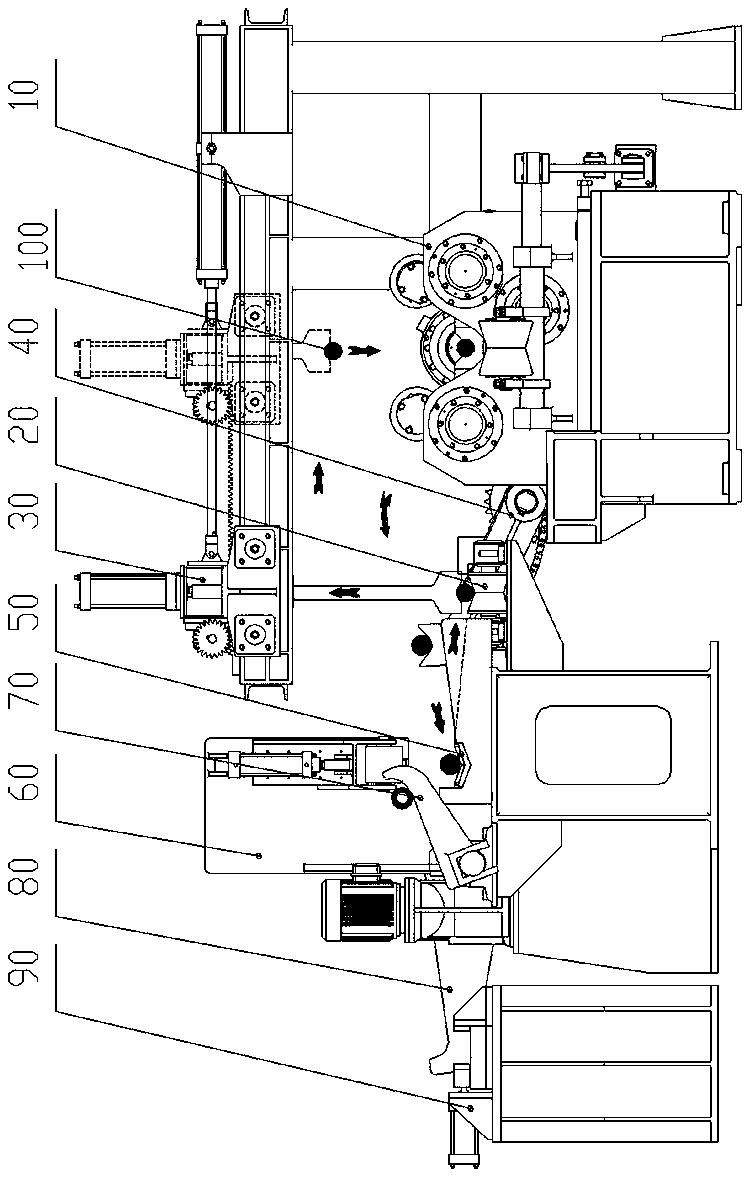

The invention discloses automatic circulating equipment for perforating machine core rods. The automatic circulating equipment comprises a perforating machine is used for driving the corresponding core rod to penetrate a pipe material and further comprises a return roller way, a first material delivering mechanism, a second material delivering mechanism, a rod breaking-away roller way, a rod breaking-away device, a third material delivering mechanism and a fourth material delivering mechanism, wherein the return roller way is used for carrying the to-be-used core rod; the first material delivering mechanism is used for delivering the core rod on the return roller way into the perforating machine; the second material delivering mechanism is used for delivering the pipe material provided with the corresponding core rod in a penetrated manner to the rod breaking-away roller way; the rod breaking-away roller way is used for carrying the pipe material provided with the corresponding core rod in a penetrated manner; the rod breaking-away device is used for breaking the pipe material on the rod breaking-away roller way away from the core rod which is arranged in the pipe material in a penetrating manner; the third material delivering mechanism is used for delivering the pipe material on the rod breaking-away roller way to the next procedure; and the fourth material delivering mechanism is used for delivering the core rod on the rod breaking-away roller way to the return roller way. By means of the automatic circulating equipment, online cyclic use of the three core rods can be achieved at the same time; after perforating is completed, a trolley body only needs to retreat for a short distance, the head of the corresponding core rod extends out of the outer edge of a machine main body, and perforating of the next time can be conducted; and the long-distance round-trip time of the trolley body is shortened.

Owner:常州常宝精特钢管有限公司

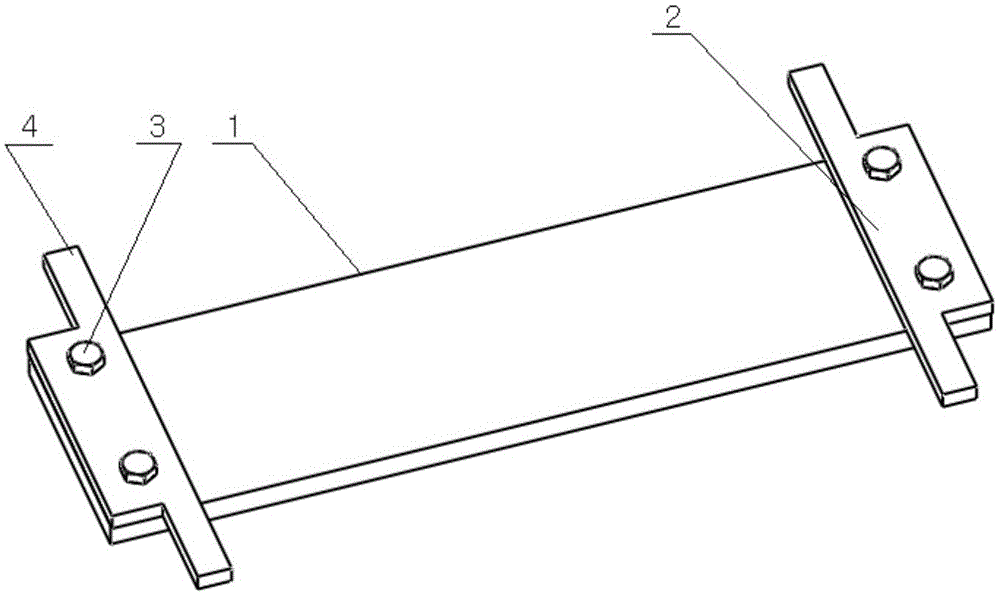

Method for preventing extracting mill frame driven shaft from shedding

ActiveCN104858262APrevent the problem of falling off and getting stuck in the drain of the archway and cannot be drawn outIncrease productionMandrel separation arrangementsRolling safety devicesDrive shaftPulp and paper industry

The invention provides a method for preventing an extracting mill frame driven shaft from shedding. A protective rack composed of a rectangular baffle plate, supporting plates with bosses and bolts is manufactured, and baffle blocks are respectively welded to raised edges at two sides of a groove at the lower part of the frame. In installation, a baffle plate of which one end is fixed to the supporting plate is put into the groove at the lower part of the frame, the other supporting plate is fixed to the other end of the baffle plate by bolts, the baffle plate and the supporting plates are orderly and transversely arranged in the groove of the frame from top to bottom, sides of the two supporting plates clings to inner walls at the two sides of the groove, the bottom surfaces of the supporting plates presses upon the upper surfaces of the raised edges at two sides of the groove, and the bosses of the supporting plates are blocked by the baffle blocks at the bosses. The method can effectively prevent an extracting roller mill frame driven shaft from shedding and being blocked by a water outlet of a memorial archway, thoroughly prevent a driven shaft shedding-caused production stopping accident, improve a unit yield, greatly reduce labor and resource waste and reduce treatment workload and labor intensity.

Owner:ANGANG STEEL CO LTD

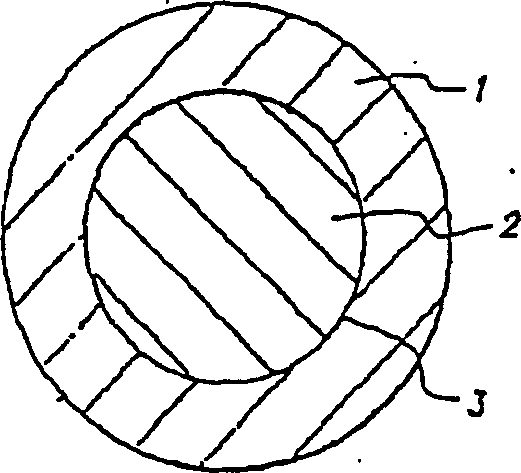

Manufacture of metal tubes

InactiveCN1287922CWide variation in lengthDrawing mandrelsMandrel separation arrangementsSurface finishMachining

The manufacture of seamless tubes in which the process includes providing an assembly having a metal tube blank (1), and an elongate metal core (2) of shape memory effect material which is surrounded and contacted by the tube blank (1) with a minimal gap. The assembly is elongated by mechanical working thereof at an elevated temperature until the tube blank (1) has been converted into a tube of desired dimensions. After the elongation step, the core (2) is subjected to a treatment which results in the core being in a stretched condition throughout its length, and does not substantially stretch the tube (1). The core is removed from the tube, and subsequently subjected to drawing passes over a nondeformable mandrel thereby refining the precision of diametric and wall dimensions with improved ID and OD surface quality. There is also decoring and reinserting to improve final dimensions which results in the ability to fabricate smaller, longer tubes.

Owner:敏忆有限公司

An automatic circulation device and method for perforated mandrel rod

ActiveCN107716555BRealize online recyclingReduce long-distance round-trip timeMandrel separation arrangementsMandrelsStructural engineeringPipe

The invention discloses automatic circulating equipment for perforating machine core rods. The automatic circulating equipment comprises a perforating machine is used for driving the corresponding core rod to penetrate a pipe material and further comprises a return roller way, a first material delivering mechanism, a second material delivering mechanism, a rod breaking-away roller way, a rod breaking-away device, a third material delivering mechanism and a fourth material delivering mechanism, wherein the return roller way is used for carrying the to-be-used core rod; the first material delivering mechanism is used for delivering the core rod on the return roller way into the perforating machine; the second material delivering mechanism is used for delivering the pipe material provided with the corresponding core rod in a penetrated manner to the rod breaking-away roller way; the rod breaking-away roller way is used for carrying the pipe material provided with the corresponding core rod in a penetrated manner; the rod breaking-away device is used for breaking the pipe material on the rod breaking-away roller way away from the core rod which is arranged in the pipe material in a penetrating manner; the third material delivering mechanism is used for delivering the pipe material on the rod breaking-away roller way to the next procedure; and the fourth material delivering mechanism is used for delivering the core rod on the rod breaking-away roller way to the return roller way. By means of the automatic circulating equipment, online cyclic use of the three core rods can be achieved at the same time; after perforating is completed, a trolley body only needs to retreat for a short distance, the head of the corresponding core rod extends out of the outer edge of a machine main body, and perforating of the next time can be conducted; and the long-distance round-trip time of the trolley body is shortened.

Owner:常州常宝精特钢管有限公司

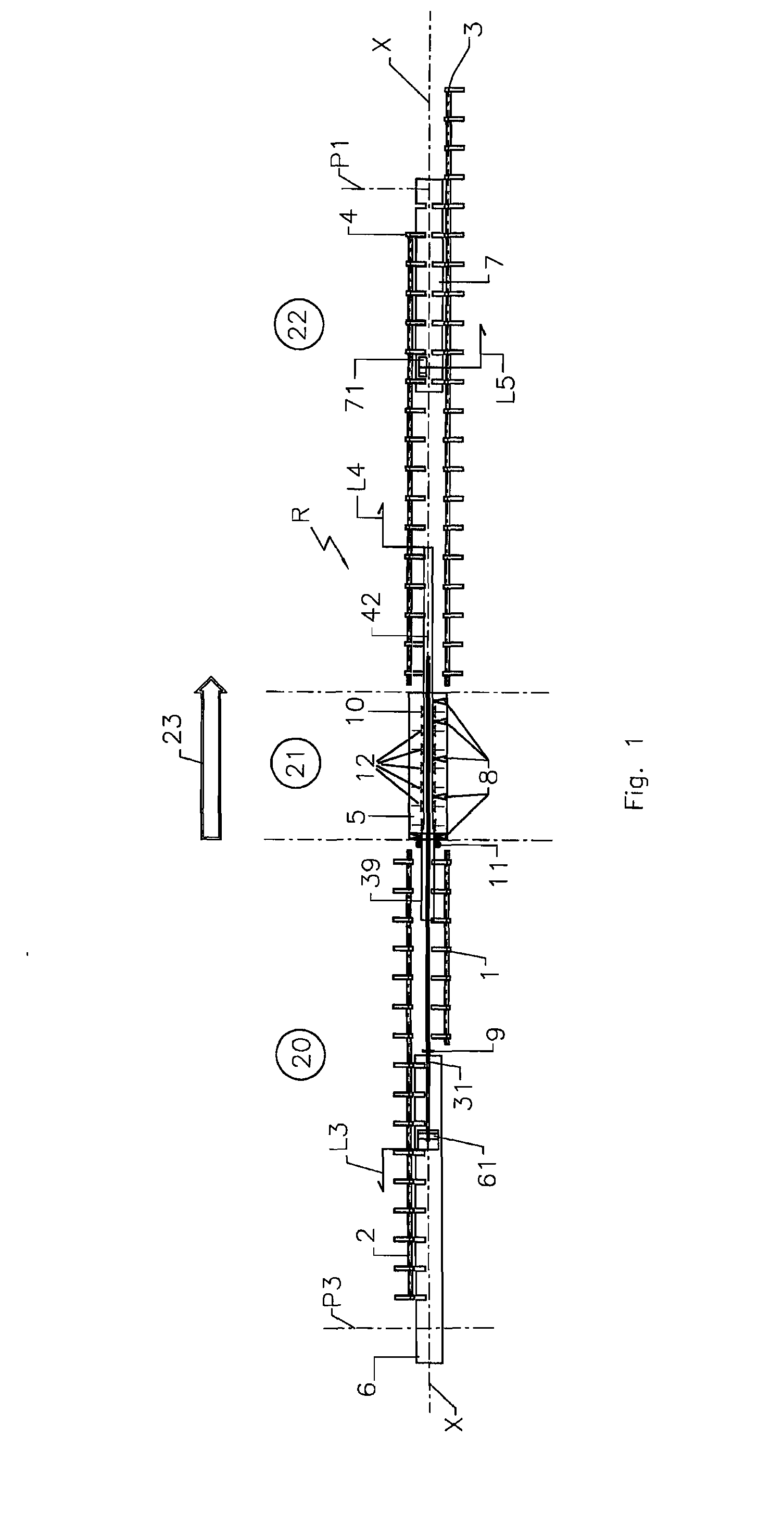

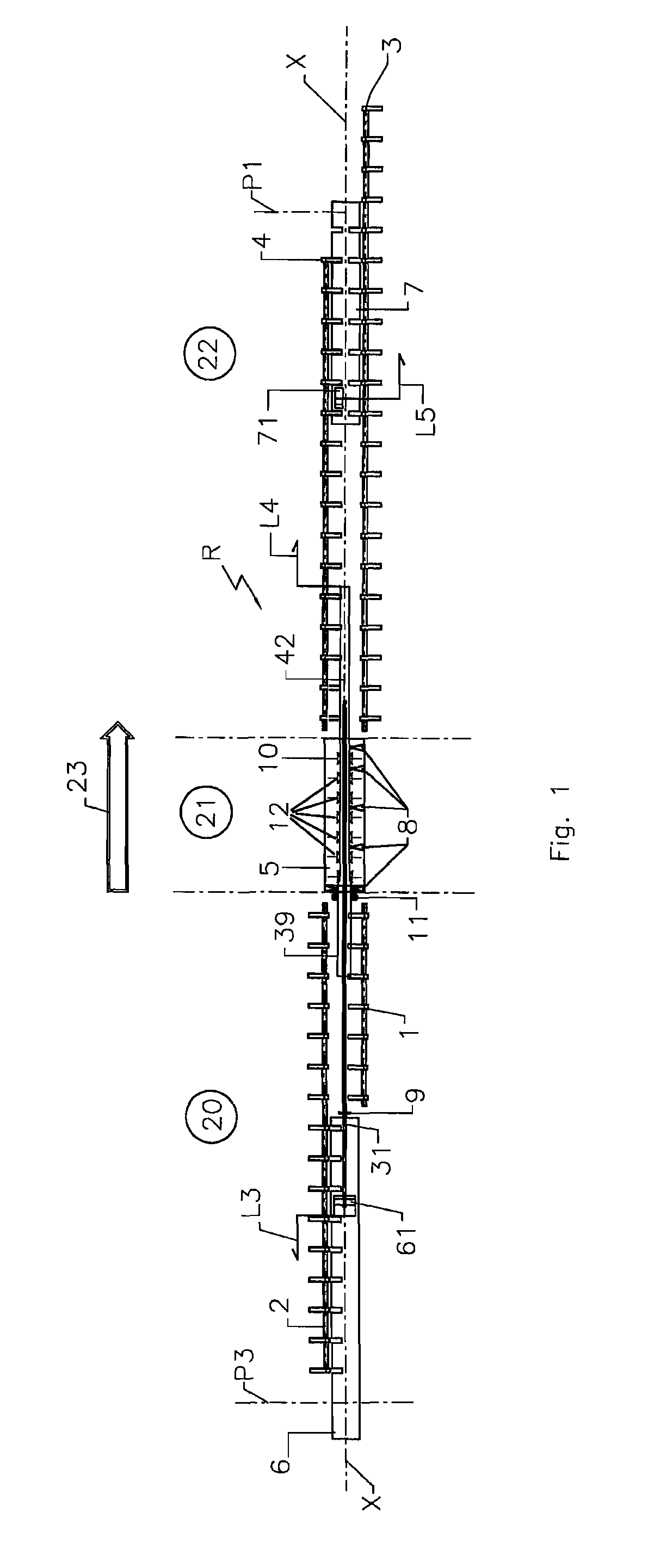

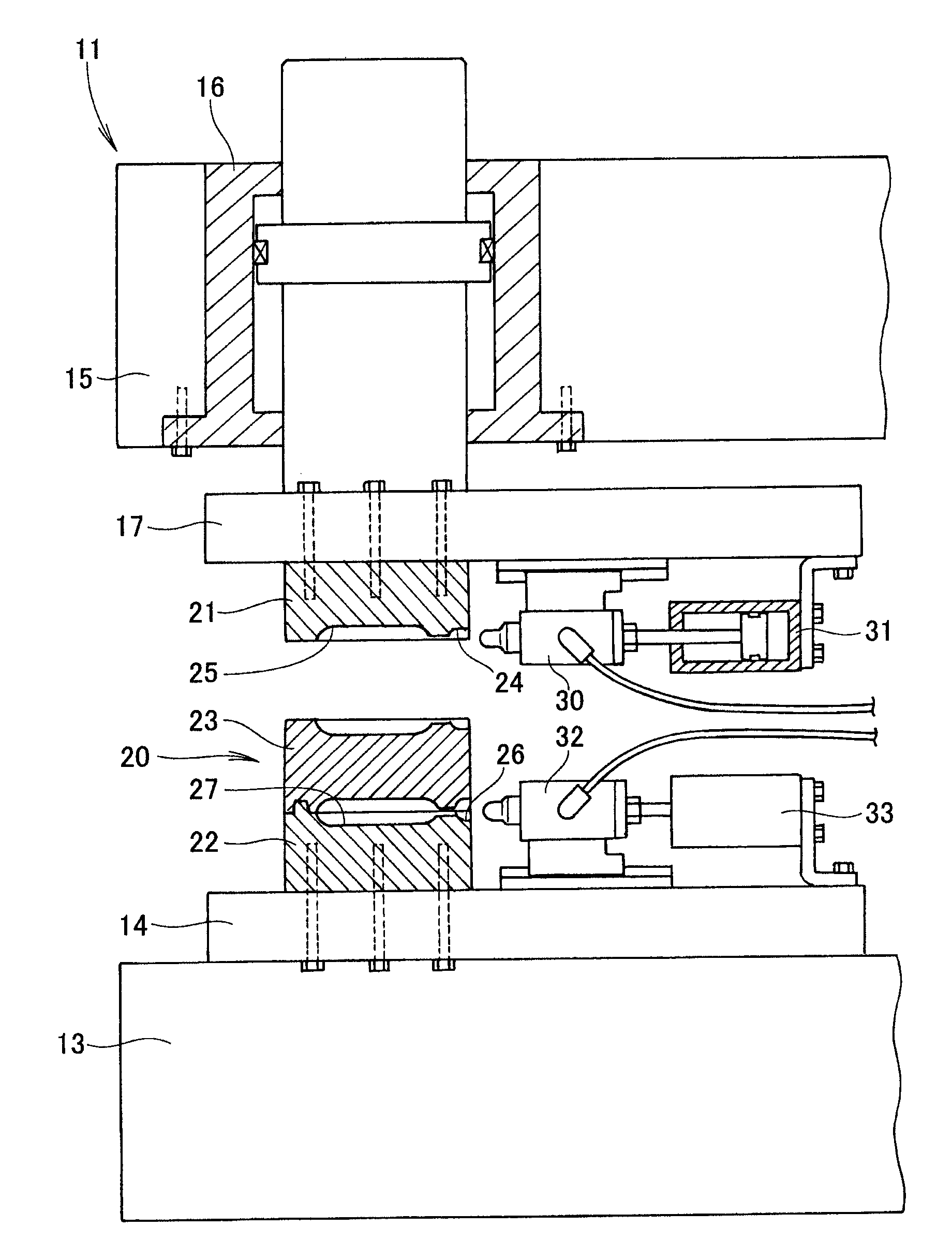

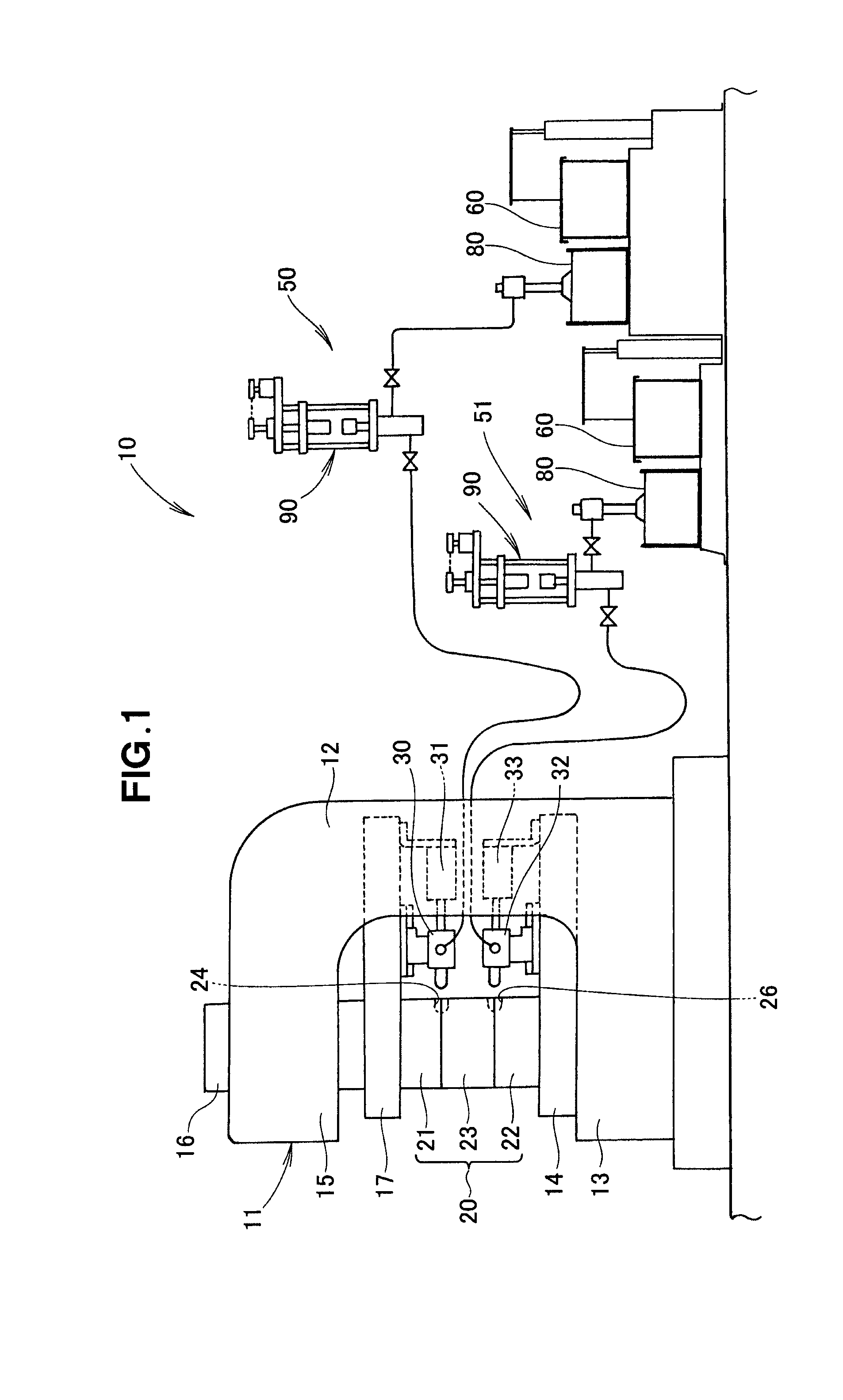

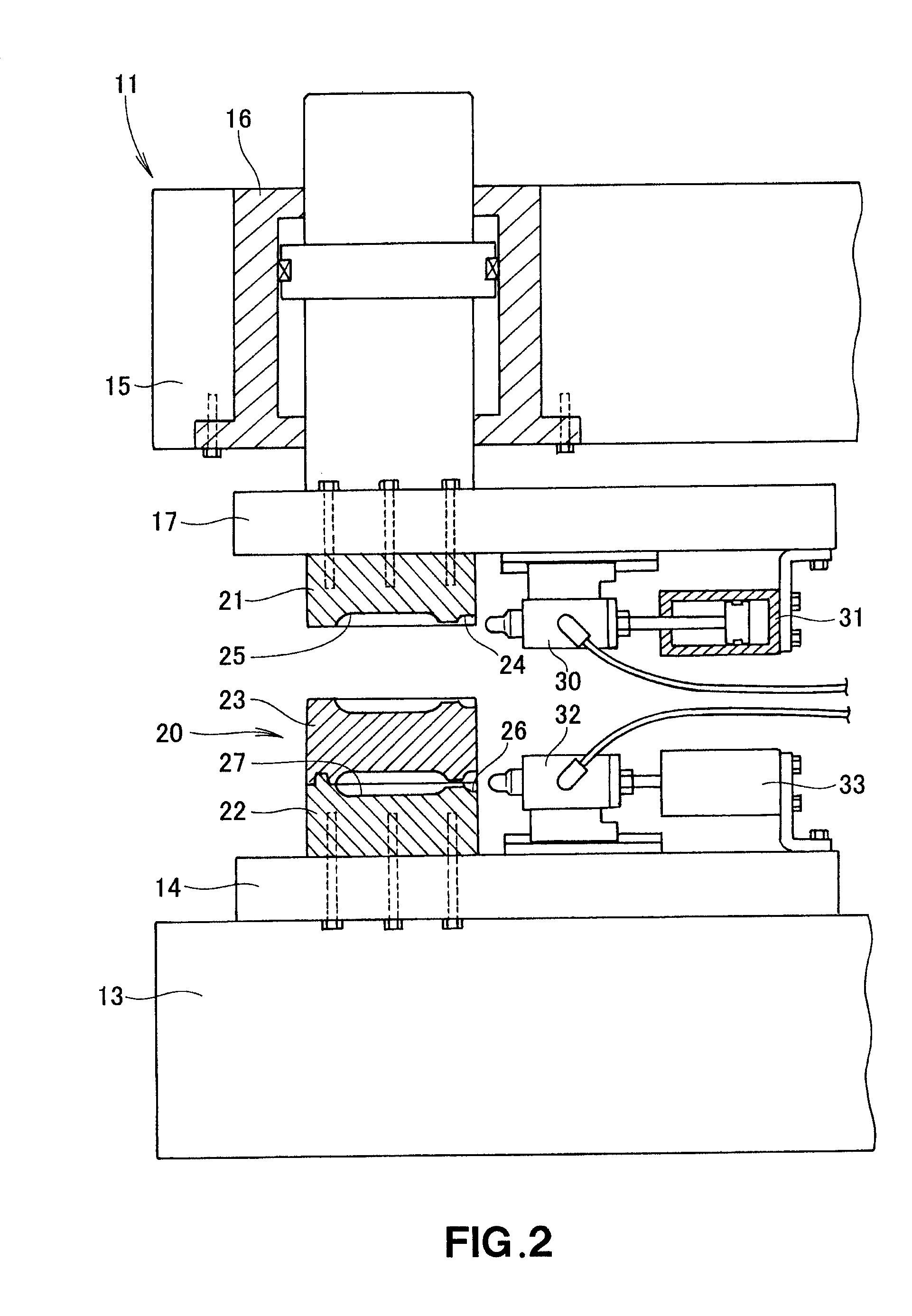

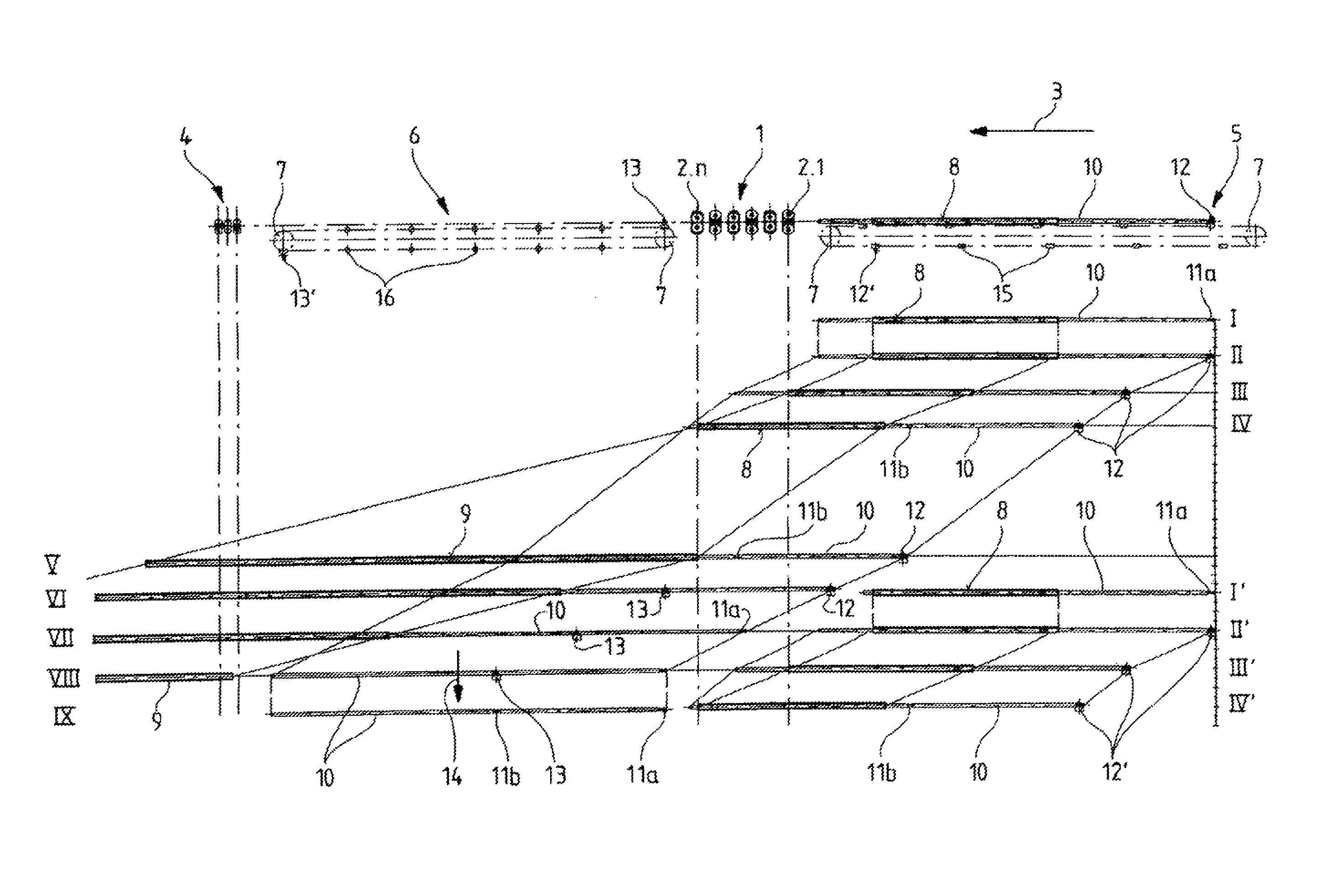

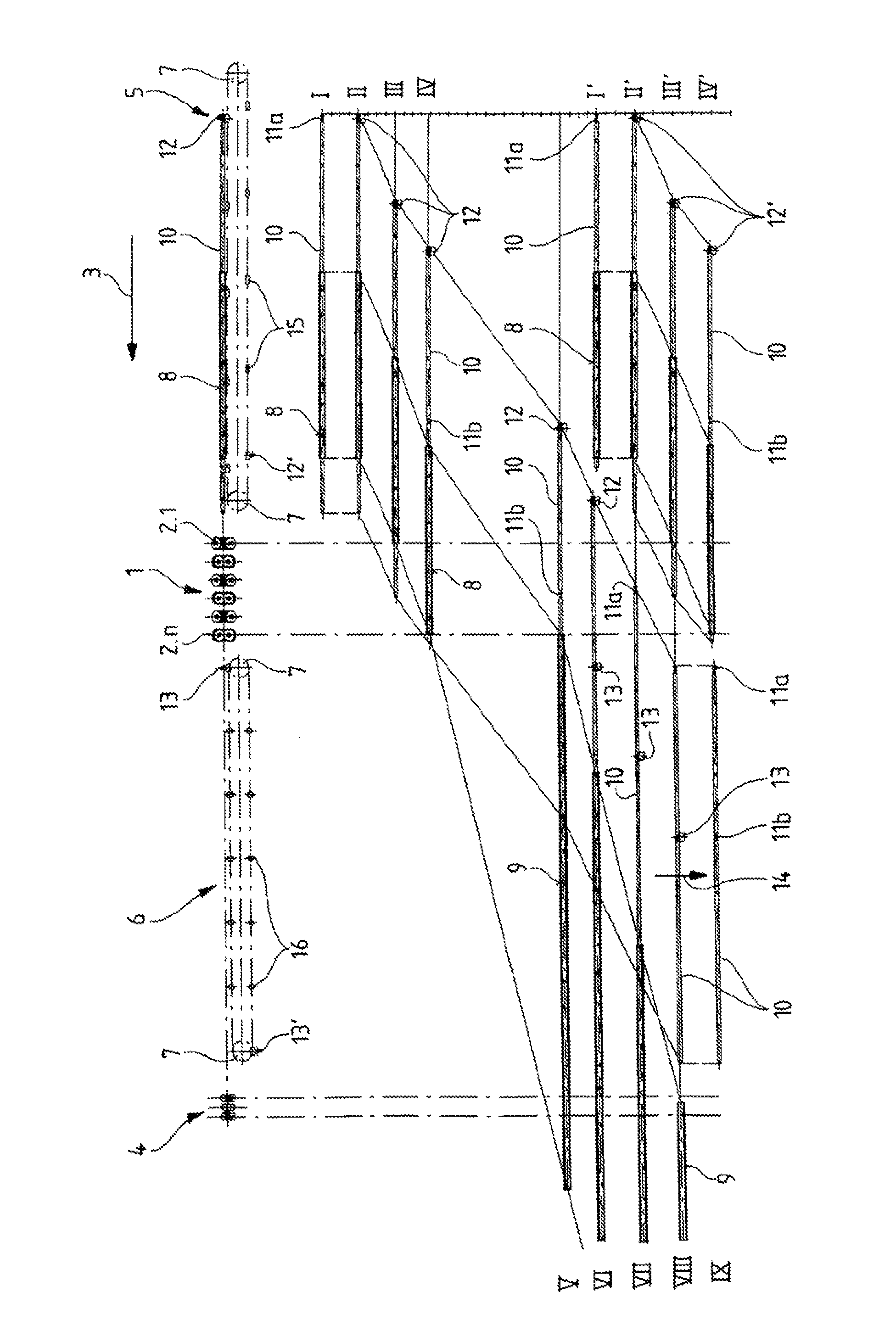

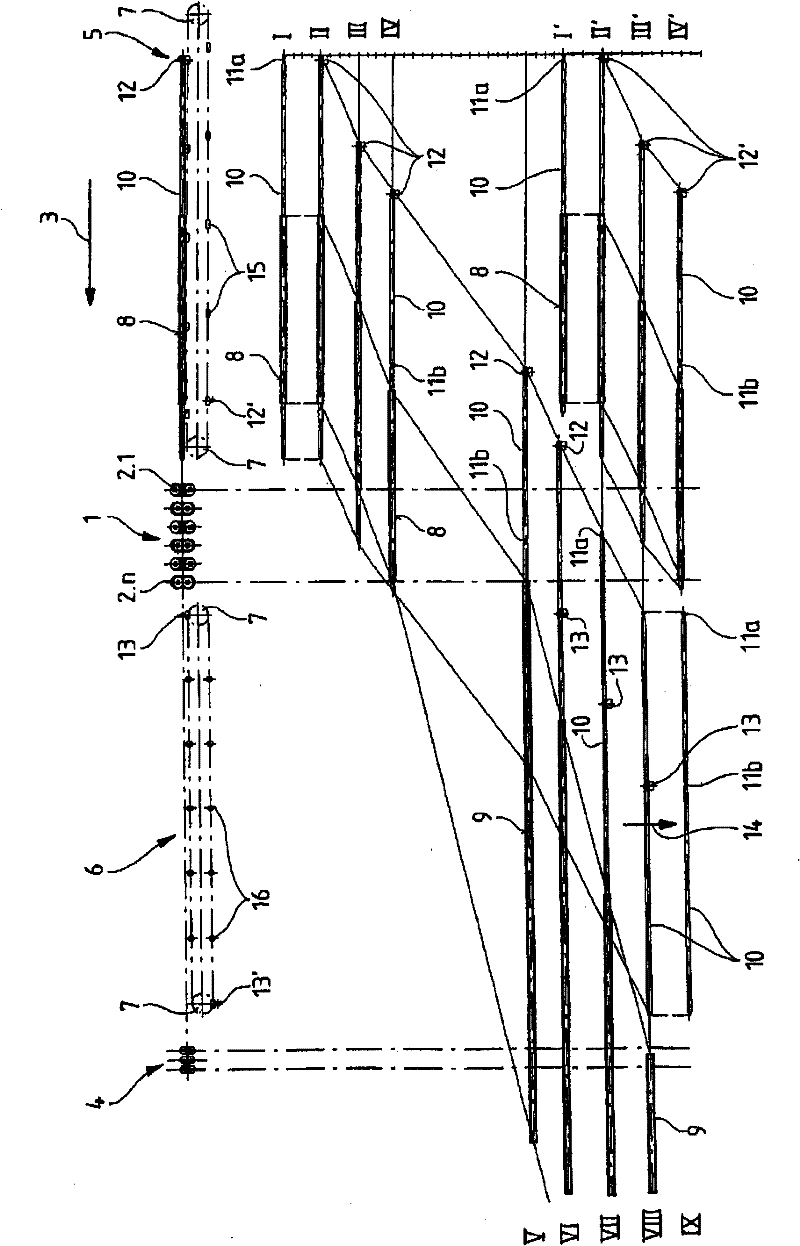

Method of and rolling mill for making seamless steel pipe

ActiveUS8904839B2Increase chanceMandrel separation arrangementsWork manipulationProduction rateWork in process

The invention relates to a method and a rolling mill for producing a seamless steel pipe in a continuous rolling process, where semi-finished material is first formed into a hollow block (8) in a rotary rolling mill, said block then being rolled in a multi-tooled continuous rolling mill (1) over a previously inserted mandrel (10) to form a tube blank (9), wherein the mandrel (10) receiving the hollow block and held by a mandrel holding and transporting device (5) disposed on the entry side is fed into the continuous rolling mill (1) and is transported back to the entry side after the tube blank has been rolled off of the mandrel (10) on an extracting rolling mill (4) connected downstream of the continuous rolling mill. An aim of the invention is to allow high production rates at the same product quality, particularly at a low drop in the temperature of the tube blanks. The aim is achieved in that the mandrel (10) with the tube blank (9) is released by the entry-side mandrel holding and transporting device (5) after exiting the last tool (2.n) of the continuous rolling mill (1) and thus is transferred to an accompanying second mandrel holding and transporting device (6) connected downstream and held by the same until the tube blank (9) is rolled off by means of the extracting rolling mill (4).

Owner:SMS MEER

New technique for manufacturing high alloy steel seamless pipe with heavy calibre by adopting pilger mill

InactiveCN101579703BLow investment costLow running costMandrel separation arrangementsMetal rolling arrangementsSizingMaterials science

Owner:北京蓝海科融新技术有限公司

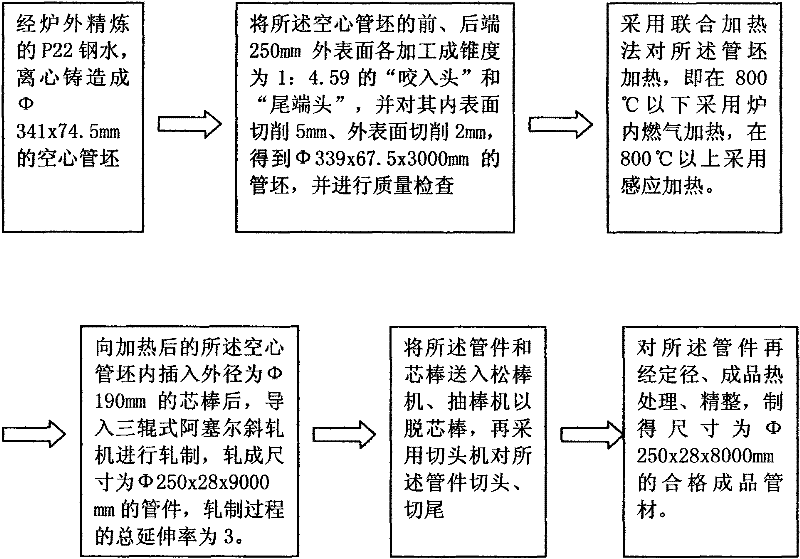

New technique for producing high alloy steel high-end pipe by adopting cross rolling elongation technology

InactiveCN101579702BLow equipment investment costLow running costMandrel separation arrangementsMetal rolling arrangementsPipe fittingMaterial Perforation

The invention relates to a technique for producing a high alloy steel high-end seamless pipe by adopting cross rolling elongation technology without perforation, comprising: molten high alloy steel which is externally refined is made into a hollow shell by centrifugal casting; the outside surfaces of the front and the rear ends of the hollow shell are respectively processed to be a 'gripping head' and a 'tail end head' with conicity, and machining and quality inspection are carried out on the inside and the outside surfaces as well as the 'gripping head' and the 'tail end head' of the hollow shell; heating is carried out; a mandril is inserted into the heated hollow shell, and then the hollow shell is sent into a cross rolling elongating mill for cross rolling, so that the pipe fittings having the wall thickness, the diameter and the length being in accordance with the requirements can be produced; the mandril is removed, and the head and the tail are cut off; finally, the qualified finished pipes can be obtained after sizing, heat treatment for finished product and finishing operation. The technique has short process flow and does not need cross rolling perforation, thus reducing the cost and improving the quality; due to small tapered treatment for the front and the rear ends, 'tail triangle' is avoided when the medium-thick walled pipes are produced, and the performance of secondary gripping is improved, thus improving the quality of the product and the production efficiency.

Owner:北京蓝海科融新技术有限公司

Disconnection device for punch refrigerant top

InactiveCN100537068CImproves wall thickness uniformityShorten the lengthMandrel separation arrangementsMandrelsMaterial PerforationFlange

The invention discloses a tube detaching device used in a perforator and being capable of cooling the piercing plug of a perforator, which relates to the device for cooling the piercing plug of a hot rolling perforator and tube detaching equipment. In prior art, a cooling water tank and a tube detaching device take up two positions respectively, after perforation, the length of a tubular billet is up to 10 meter with which a mandril and an outlet platform both with enough length are needed to be matched. The increased length of mandril not only results in the poor rigidity of the mandril, influences the quality of wall thickness of the tubular billet, but also results in lengthening of the outlet platform and enlarging the land occupation. In the invention, the cooling water tank and the tube detaching device are designed in integration; a water nozzle is positioned in the cooling water tank; the water nozzle is connected with flow pipe through a flange; an offlet is positioned at the bottom of the cooling water tank; therefore, one position can realize two functions that are tube detaching and piercing plug cooling, which not only reduces the length of the mandril, enhances the rigidity of the mandril, improves the uniformity of wall thickness of the tubular billet but also reduces the lengths of a first and a second segments of the outlet platform, thus ensuring the more compact structure of the device.

Owner:TAIYUAN HEAVY IND

Method and apparatus for making seamless pipe

ActiveUS10632514B2Quality improvementEasy constructionDrawing diesMandrel separation arrangementsEngineeringStructural engineering

The invention relates to a device and a method for producing a pipe (1) from a hollow block (2) which has an opening (3). The device has a rolling mill (30) for rolling the hollow block (2) via a rolling rod (21) introduced into the opening (3) of the hollow block (2), whereby the pipe (1) is produced. A retaining device (70) for retaining the pipe (1) is provided behind the rolling mill (30), and the device is further designed such that the rolling rod (21) can be drawn out of the pipe (1) after the rolling process while the pipe (1) is retained by the retaining device (70).

Owner:SMS GRP GMBH

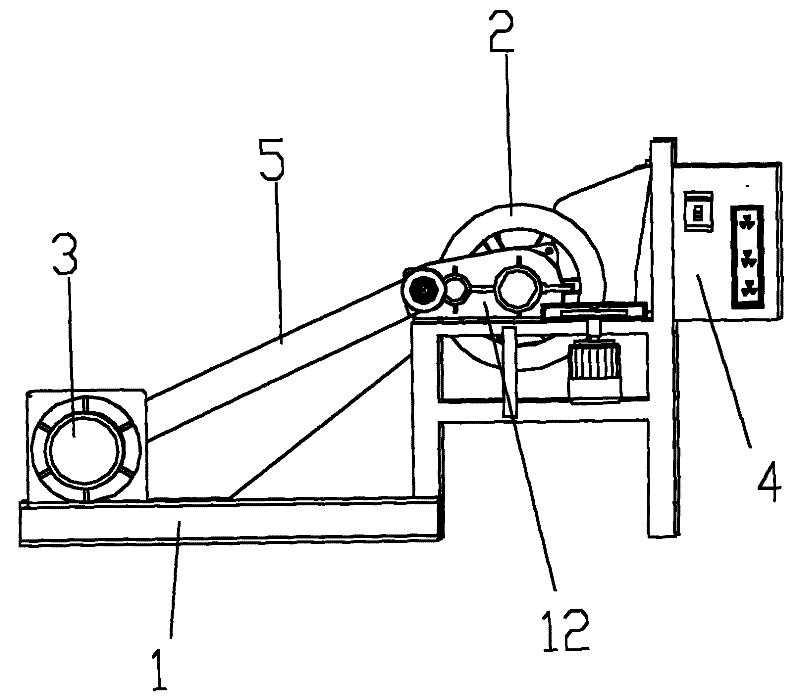

Pullout device for steel wire drawing die

InactiveCN102218456AImprove work efficiencySimple structureMandrel separation arrangementsEngineeringReducer

The invention discloses a pullout device for a steel wire drawing die. The device comprises a support, a bull wheel, a motor, an electric control box, a hook, a locating piece and a speed reducer. Wherein, the motor, the electric control box, the bull wheel and the speed reducer are installed on the support, with the motor connected to the speed reducer through a belt and the speed reducer in connection with the bull wheel. The electric control box controls the forward and backward movement of the motor. The bull wheel is provided with a gap where the hook is hooked, and the support is equipped with a u-shaped groove on which the locating piece is stuck, with the hook and the locating piece connected by a hinge. In operation, one end of the steel wire is fixed on the locating piece to make one end face of the drawing die close to the end of the u-shaped groove, so that when the motor puts the bull wheel in motion, the steel wire is pulled so as to pull out the drawing die from the steel wire. With a motor serving as the driving force, the pullout device for a steel wire drawing die in the invention has high operation efficiency, simple structure and low cost.

Owner:JIANGSU SHENWANG GROUP

Method for producing a seamless steel pipe and rolling mill for performing the method

The invention relates to a method and a rolling mill for producing a seamless steel pipe in a continuous rolling process, where semi-finished material is first formed into a hollow block (8) in a rotary rolling mill, said block then being rolled in a multi-tooled continuous rolling mill (1) over a previously inserted mandrel (10) to form a tube blank (9), wherein the mandrel (10) receiving the hollow block and held by a mandrel holding and transporting device (5) disposed on the entry side is fed into the continuous rolling mill (1) and is transported back to the entry side after the tube blank has been rolled off of the mandrel (10) on an extracting rolling mill (4) connected downstream of the continuous rolling mill. An aim of the invention is to allow high production rates at the same product quality, particularly at a low drop in the temperature of the tube blanks. The aim is achieved in that the mandrel (10) with the tube blank (9) is released by the entry-side mandrel holding and transporting device (5) after exiting the last tool (2.n) of the continuous rolling mill (1) and thus is transferred to an accompanying second mandrel holding and transporting device (6) connected downstream and held by the same until the tube blank (9) is rolled off by means of the extracting rolling mill (4).

Owner:SMS MEER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com