Manufacture of metal tubes

A seamless tube and tube blank technology, applied in the field of metal tubes, can solve problems such as deterioration of internal surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

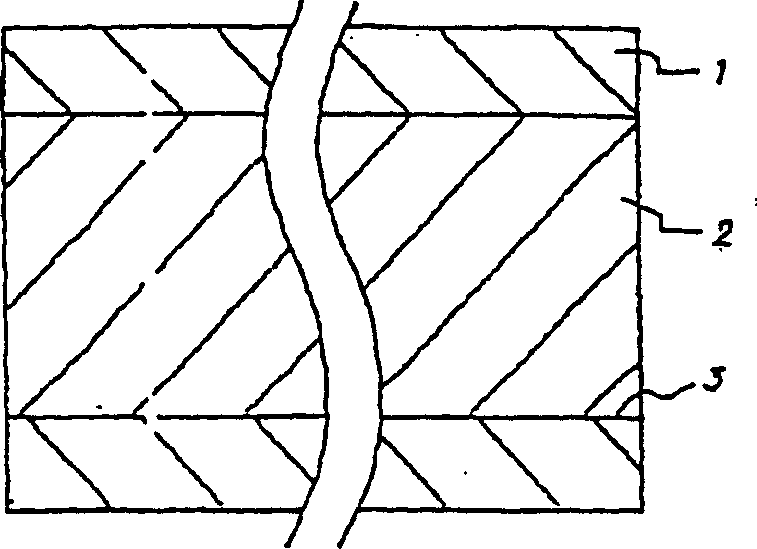

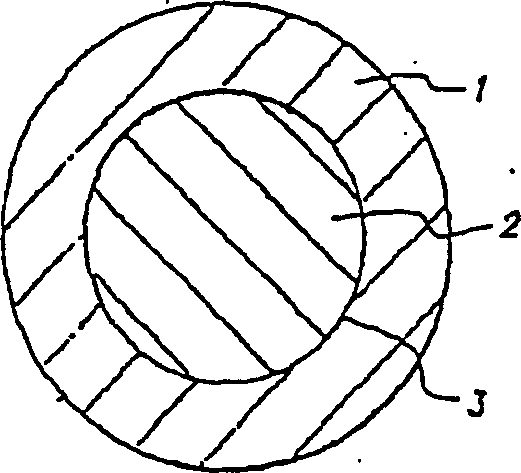

[0018] In a preferred aspect, the present invention provides a method of making tubes of shape memory alloys, such as binary nitinol and its modified ternary and quaternary compositions, with precisely controlled outer diameter (OD) and inside diameter (ID), wall thickness, and improved OD and ID finish. The method includes:

[0019] 1. To provide an assembly comprising (a) a metal tube stock and (b) an elongated metal core surrounded by the tube stock and in wired contact with a minimum clearance, and between the core and the tube Between can advantageously use a lubricant;

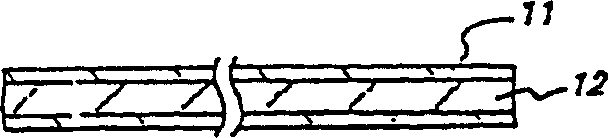

[0020] 2. Elongation of the assembly by machining which can be carried out at an elevated temperature (thermal working) where the core and the blank have similar plastic flow rates until the tube blank has been converted to the desired diameter A pipe, or cold stretched from an annealed state;

[0021] 3. heat treating the elongated component while straightening the component under longitudinal stress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com