Magnetic composite nano microsphere capable of emitting fluorescence and preparation thereof

A technology of magnetic composite nanometer and nanometer microspheres, which can be applied in the fields of luminescent materials, chemical instruments and methods, etc., and can solve the problems such as the decrease of fluorescence intensity and the difficulty in controlling the adsorption amount of quantum dots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) In a 500ml three-necked bottle, add 5.0g ferric oxide powder with a particle size of 10nm, add 200ml deionized water, stir and disperse at 500rpm for 2 hours, add 2.1g citric acid dihydrate, use 1mol / 1 ammonia solution to adjust the pH value to 6.0, continue to stir for 5 hours, separate with a magnet, and wash 3-5 times with deionized water, and finally disperse ferroferric oxide in 200ml deionized water to obtain a solid content of 2.0wt%. of magnetic fluid.

[0029] (2) In a 500ml three-neck bottle, add 40ml of deionized water, 160ml of absolute ethanol in sequence, add 2g of the prepared magnetic fluid, and then add 4ml of 25wt% concentrated ammonia water and 0.2ml of ethyl orthosilicate at 500rpm After continuous stirring at 25° C. for 8 hours, the magnetic separation was followed by washing three times with deionized water and three times with absolute ethanol.

[0030] (3) In a 150ml round-bottomed beaker, disperse all the above-mentioned silica-coated magn...

Embodiment 2

[0033] (1) In a 500ml three-necked bottle, add 5.0g of ferric oxide powder washed with deionized water, add 200ml of deionized water, stir and disperse at 500rpm for 2 hours, add 2.1g of citric acid dihydrate, use 1mol / l ammonia solution to adjust the pH value to 6.0, continue to stir for 5 hours, separate with a magnet, and wash 3-5 times with deionized water, and finally disperse ferroferric oxide in 200ml deionized water to obtain a solid content of 2.0wt % ferrofluid.

[0034] (2) In a 500ml three-necked bottle, add 80ml cyclohexane, 28ml polyethylene glycol octylphenyl ether (Triton X-100), 20ml hexanol, 2g of the prepared magnetic fluid, and then add 12ml to Ionized water and 0.6ml of 25% concentrated ammonia water, stirred at 25°C and 500rpm for 20 minutes, then added 0.2ml of tetraethyl orthosilicate, continued to stir for 12 hours, then washed twice with acetone and deionized water after magnetic separation 3 times, washed 3 times with absolute ethanol.

[0035] (3...

Embodiment 3

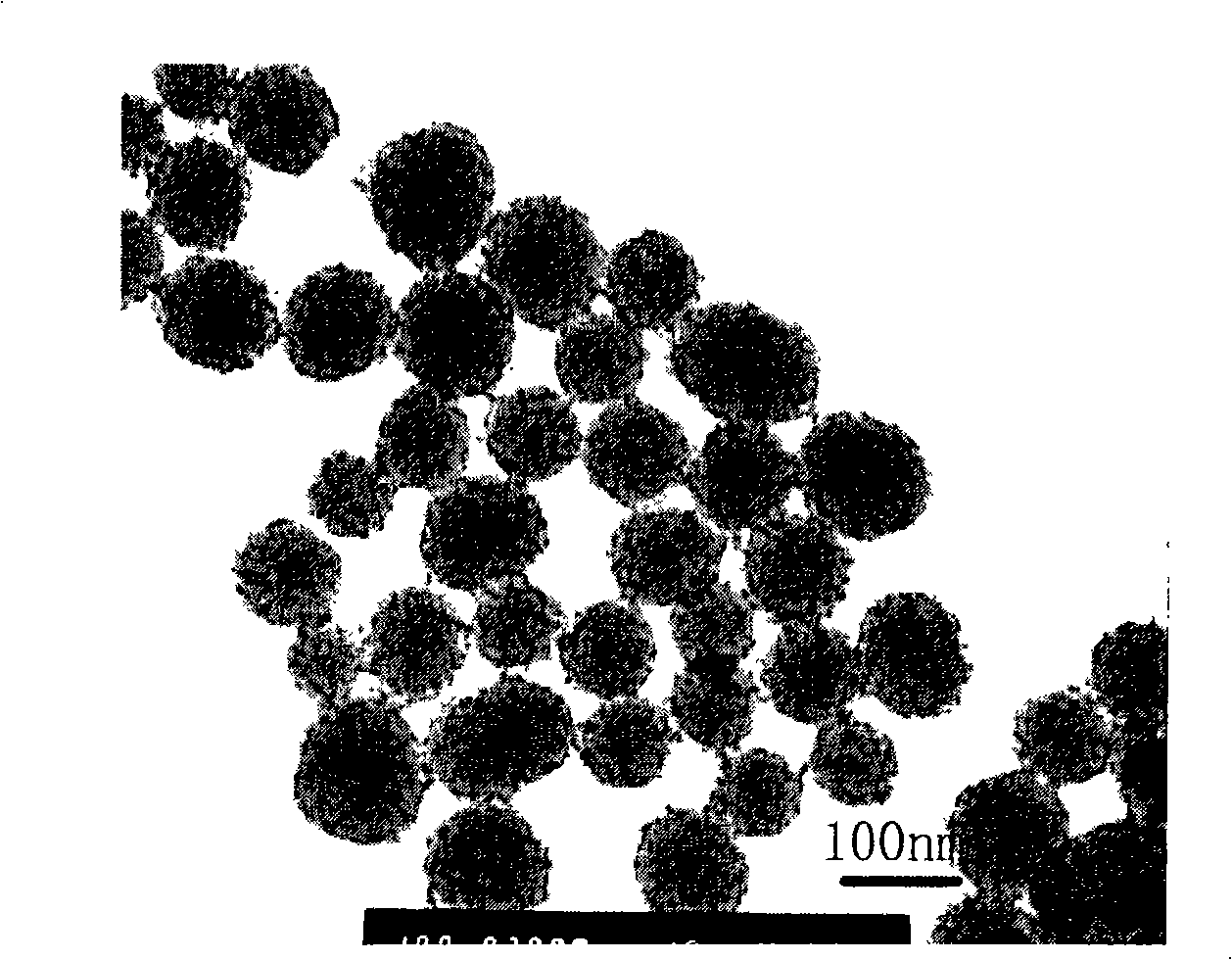

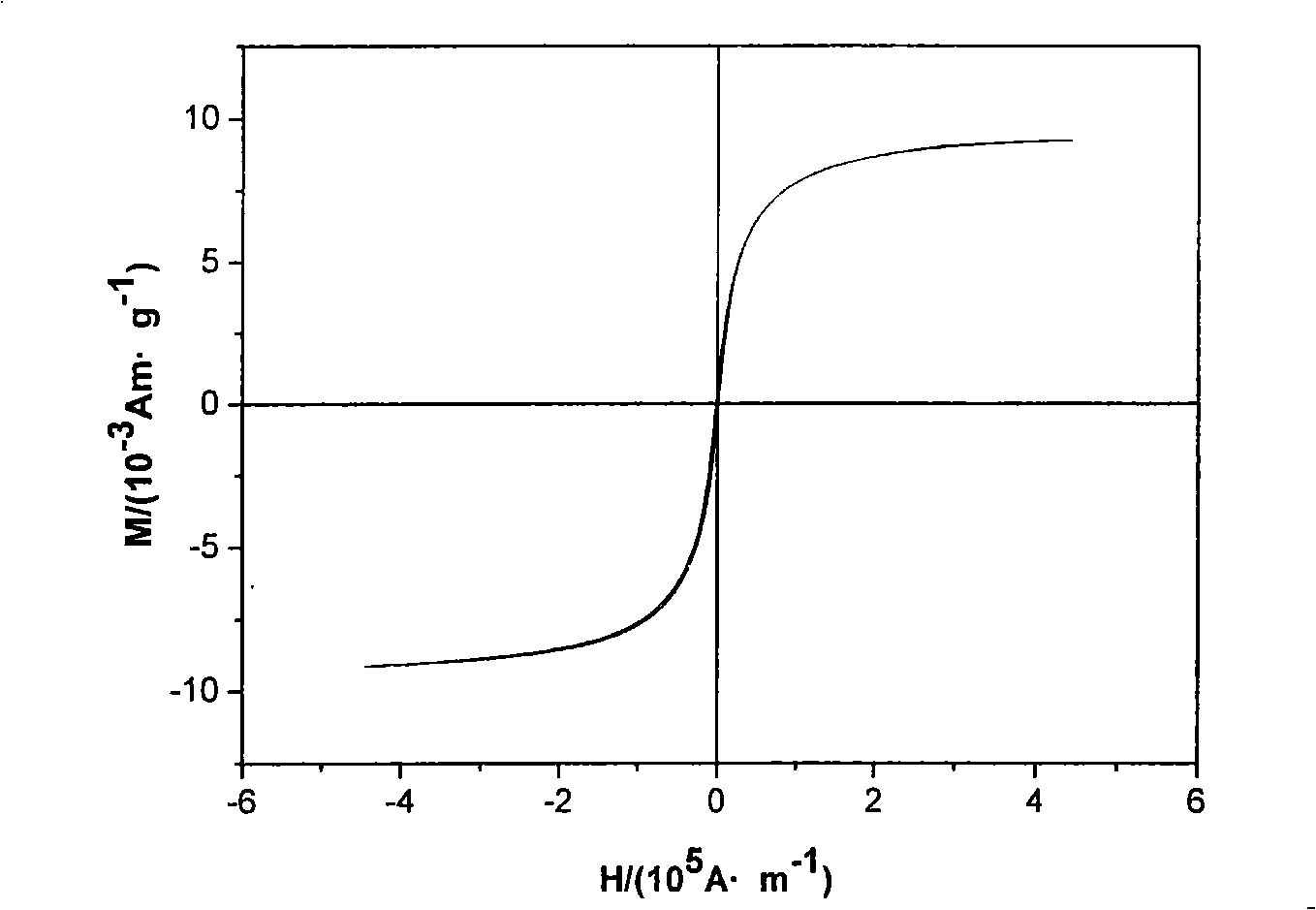

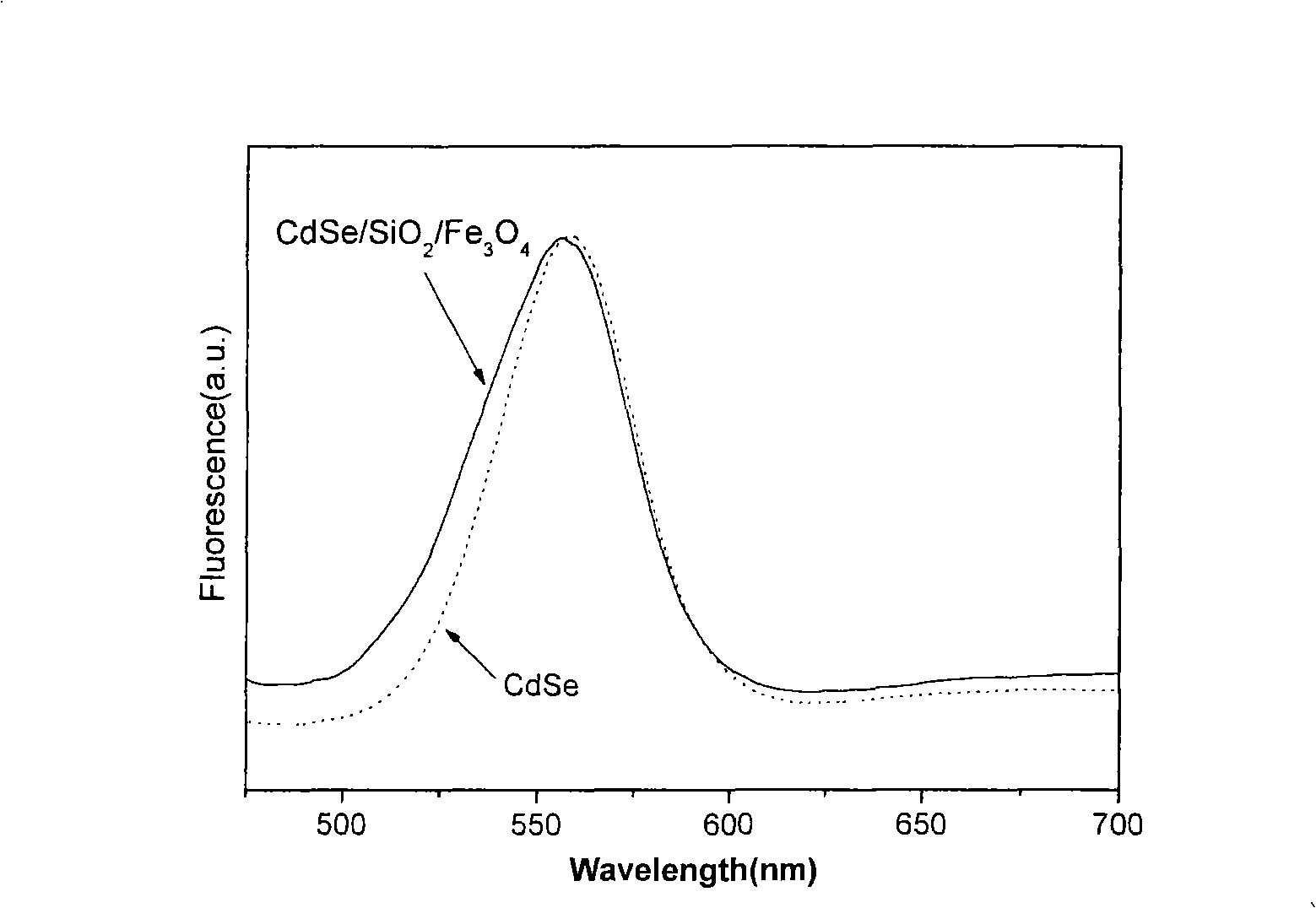

[0038] Change the consumption of the tetraethyl orthosilicate of the step (2) of embodiment (1) into 0.8ml, all the other conditions are exactly the same, obtain particle diameter and be the CdSe / SiO of 100nm 2 / Fe 3 o 4 Fluorescent magnetic composite nanospheres. Its TEM, hysteresis loop diagram and fluorescence spectrum are as follows figure 1 , figure 2 and image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com