Selected zone laser melting and rapid forming method for metal parts and apparatus thereof

A technology for selective laser melting and metal parts, applied in the field of metal parts forming and processing, it can solve the problems of poor dimensional accuracy and surface finish of metal parts, achieve good mechanical properties, prevent cracks and pores, and have a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

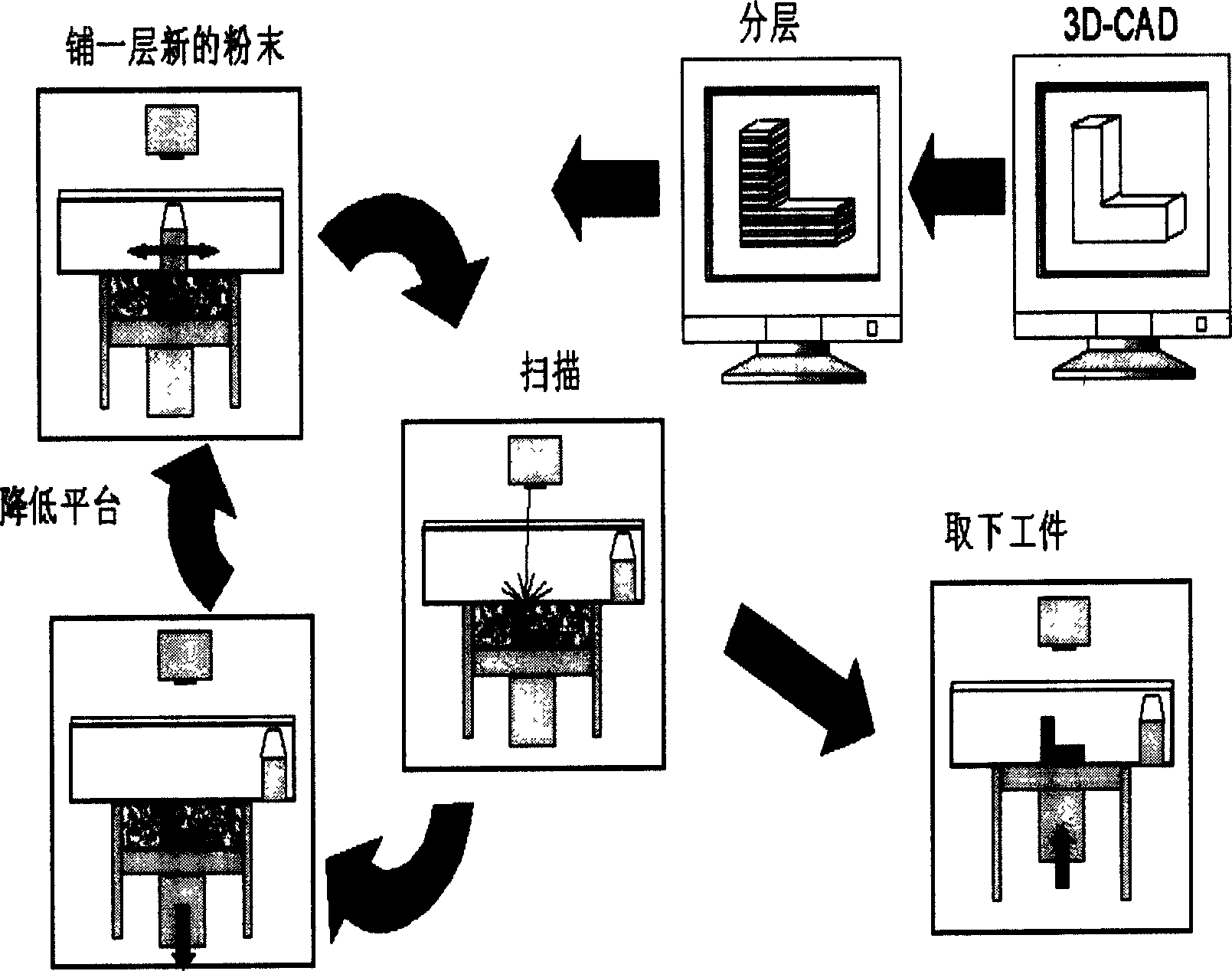

Method used

Image

Examples

Embodiment 1

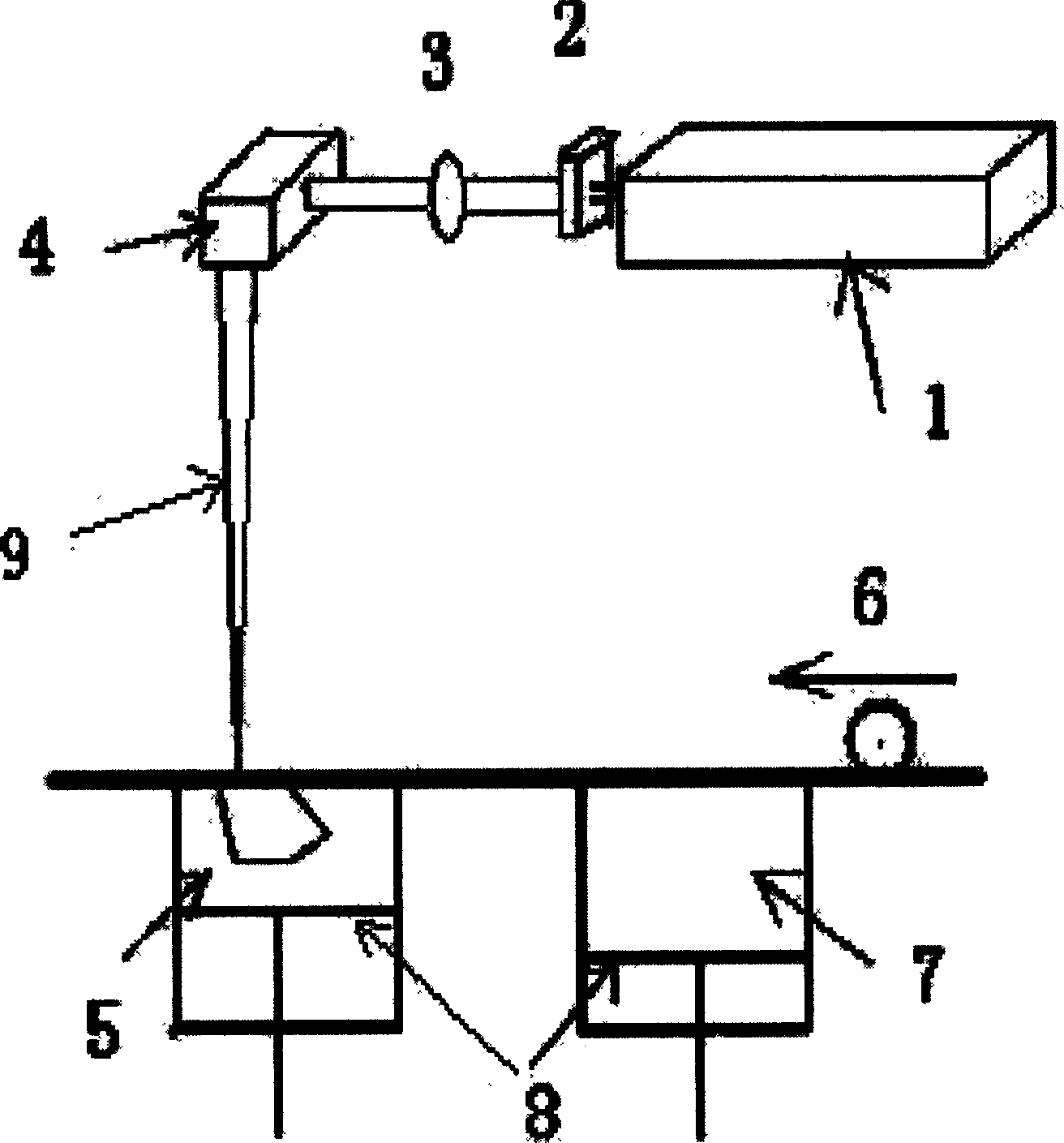

[0027] Such as figure 2 As shown, the metal parts selective laser melting rapid prototyping device adopts the front focusing method, including the beam focusing system composed of the laser 1, the beam expander 2, the focusing mirror 3, and the scanning galvanometer 4. The formed part cylinder 5 passes through the powder spreading roller 6 and powder The cylinders 7 are connected, and the molding cylinder 5 and the powder cylinder 7 are connected with a lifting piston 8. Forming part cylinder 5, powder spreading roller 6, powder cylinder 7, lifting piston 8, corresponding control drive components and computer constitute a powder laying system. Among them, laser 1 adopts semiconductor-pumped YAG laser and its attached power supply and water cooling system. The laser power is 100 watts, the wavelength is 1.06 μm, and the beam quality factor is M 2 = 1.5, the laser output spot is 3-6mm; the scanning galvanometer 4 adopts X and Y double galvanometers, the effective width is 24-3...

Embodiment 2

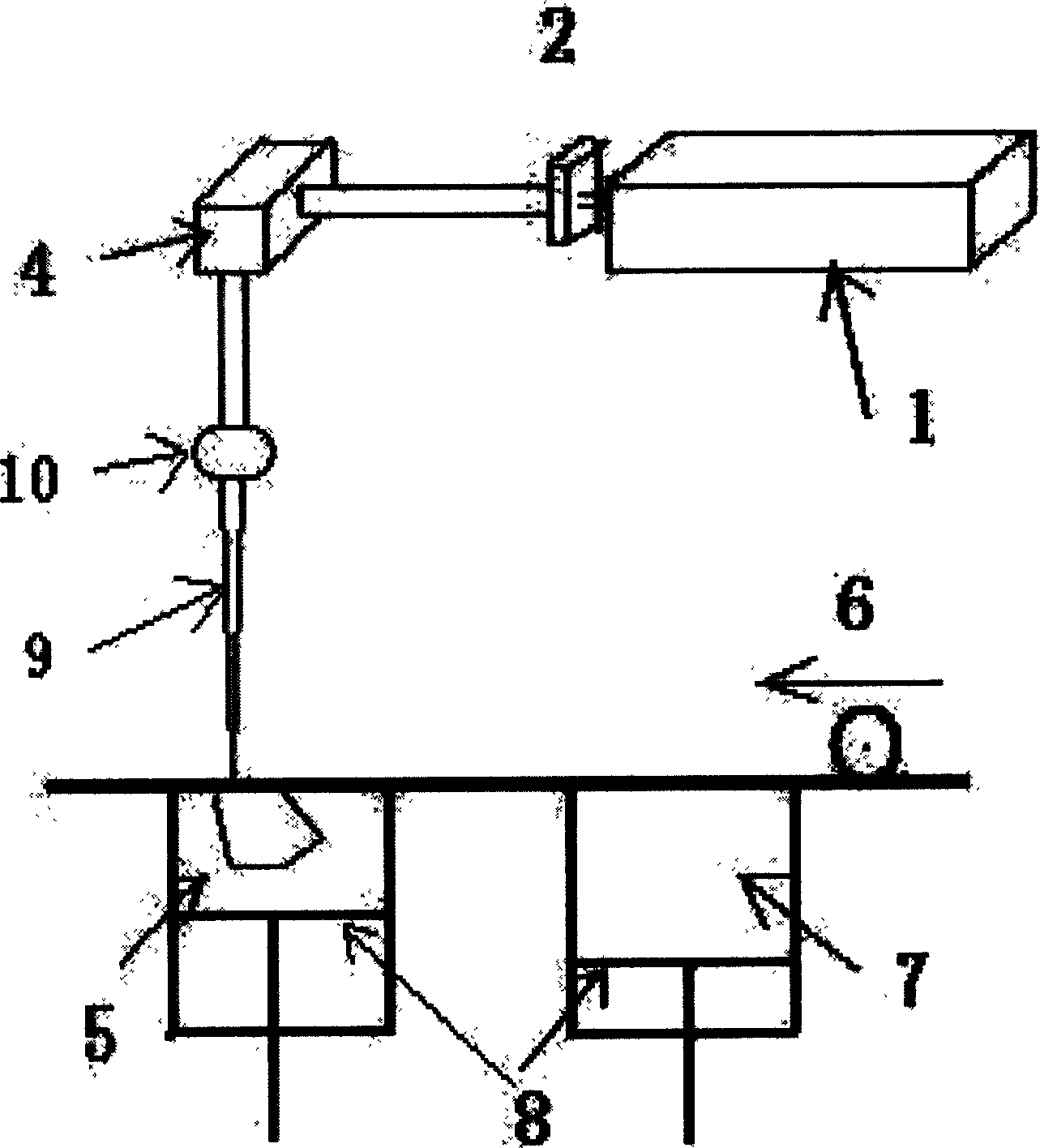

[0029] Such as image 3As shown, the selective laser melting rapid prototyping device for metal parts adopts the post-focusing method. The beam focusing system includes a beam expander 2, a scanning galvanometer 4 and an Fθ combination lens 10. The laser 1 adopts a fiber laser. Wherein, the focal length of the Fθ combination lens 10 is f=160-200 mm. The laser 9 is output from the laser 1, and after being expanded by the beam expander 2, it is first irradiated on the surface of the scanning galvanometer 4, and then focused by the Fθ combination lens 10, which is the interaction point between the laser 9 and the metal powder in the cylinder 5 of the molded part. The plane movement of the focus point can be realized by the slight swing of the scanning galvanometer 4 . The metal powder in the powder cylinder 7 is made of stainless steel powder material, and the particle size of the powder is less than 10 μm. Other structures are the same as in Embodiment 1.

Embodiment 3

[0031] Laser 1 in the selective laser melting rapid prototyping device for metal parts adopts a semiconductor-pumped YAG laser and its attached power supply and water cooling system. The laser power is 150 watts and the beam quality factor is M 2 =1.1; the alloy powder in the powder cylinder 7 is made of nickel-based alloy powder material, and the particle size of the powder is less than 10 μm. Other structures are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com