Patents

Literature

378results about "Mould controlling devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

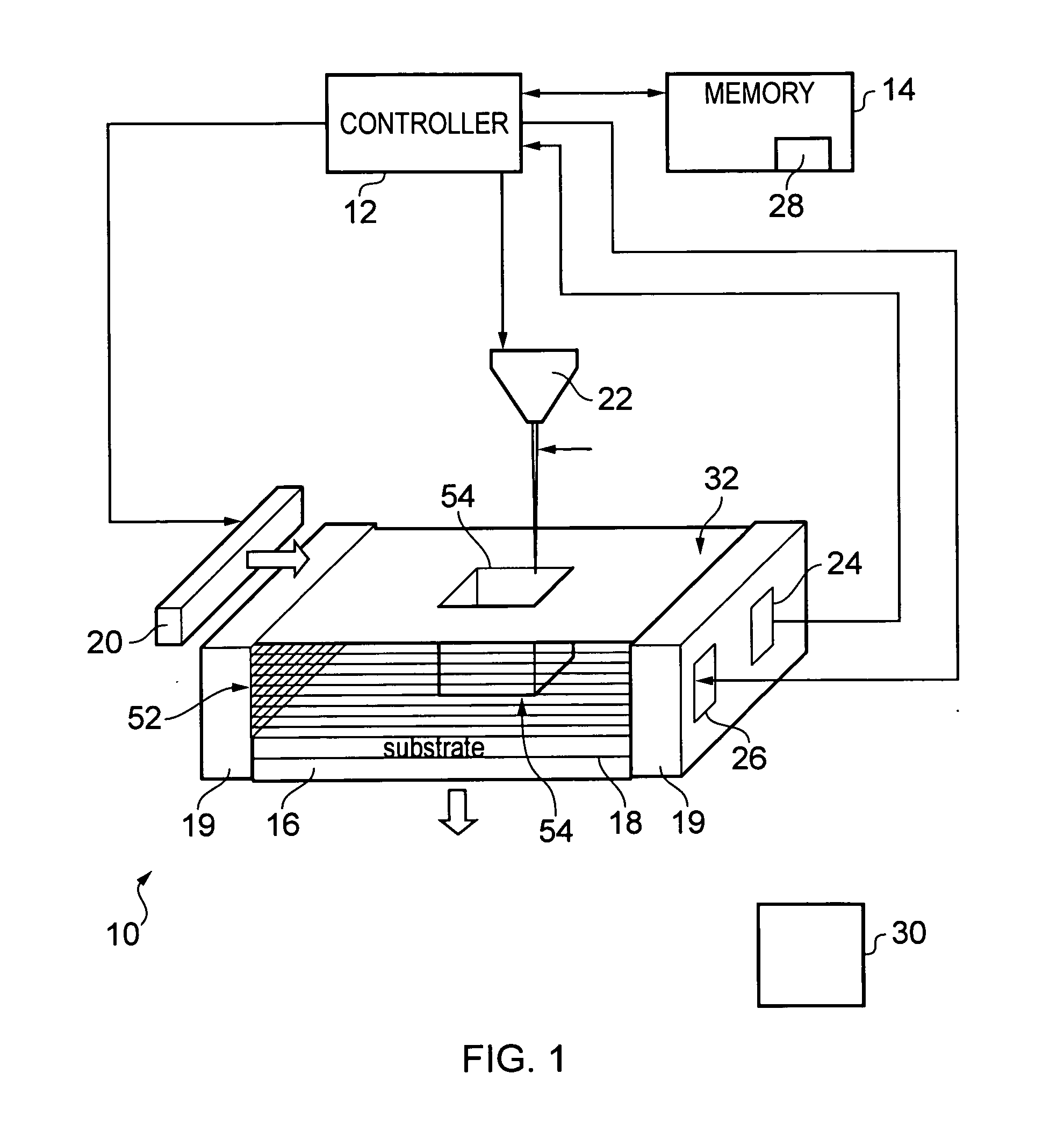

Method, apparatus, computer readable storage medium and computer program for forming an object

InactiveUS20110042031A1Polycrystalline material growthAdditive manufacturing apparatusComputer programFreezing point

A method for forming an object, including providing at least a first material having a melting point at a first temperature and a second material having a melting point at a second temperature; heating at least a portion of the first and second materials above the first and second temperatures to form a substantially molten alloy, the molten alloy having a solidifying point at a third temperature, the third temperature being less than the first temperature and the second temperature; and providing substantially solid further material to at least a portion of the molten alloy, the further material having a melting point at a temperature greater than the third temperature.

Owner:UNIV OF SHEFFIELD

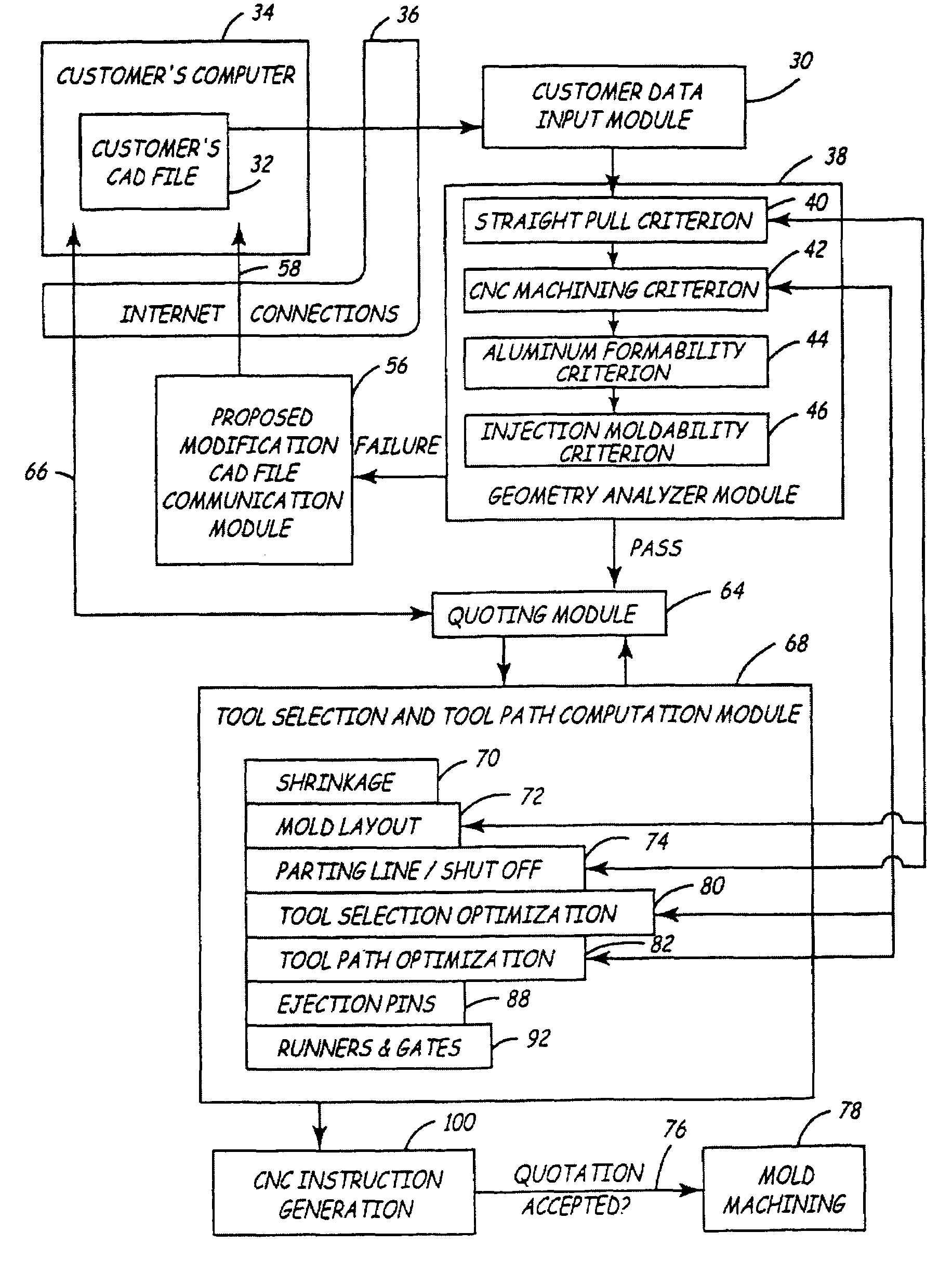

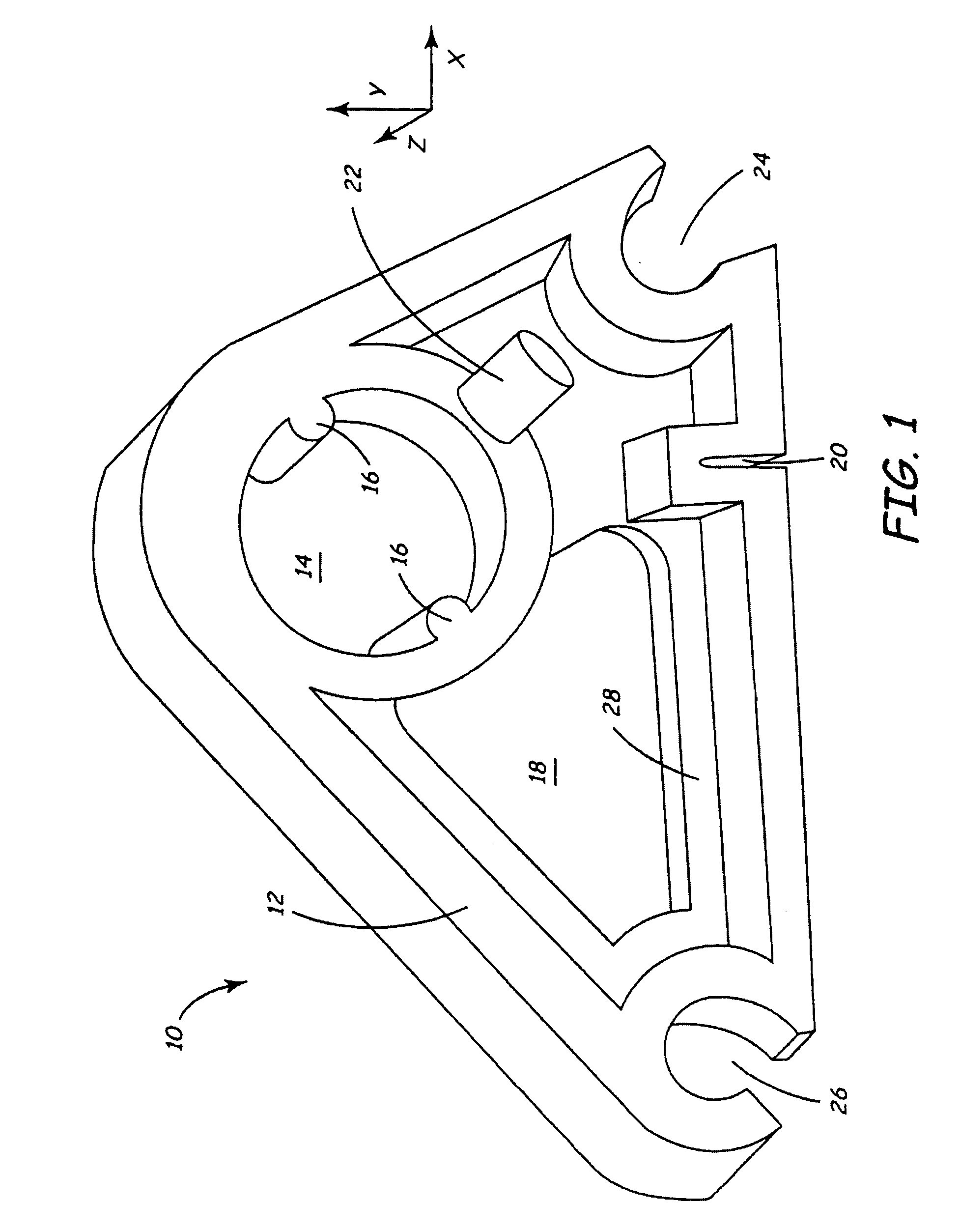

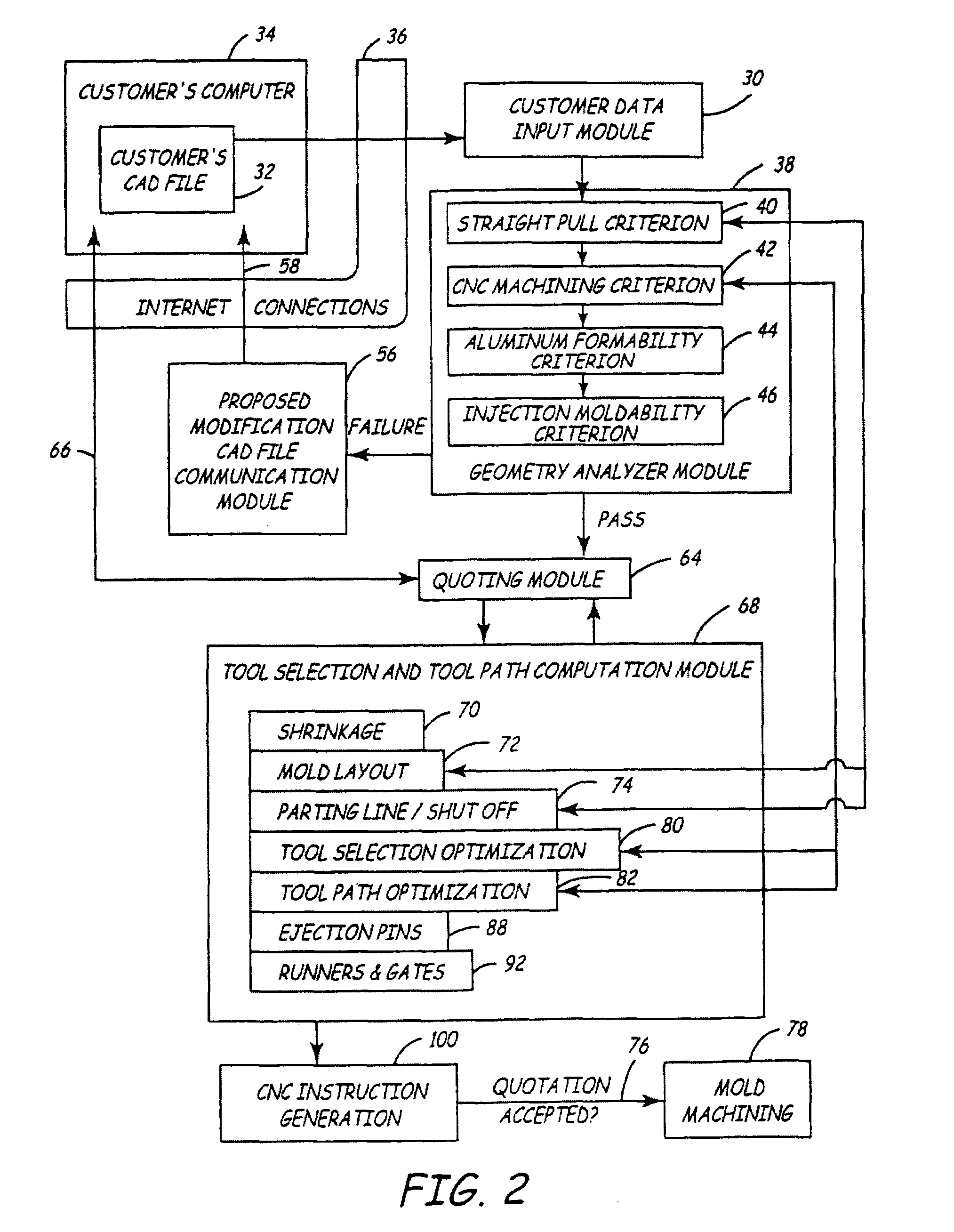

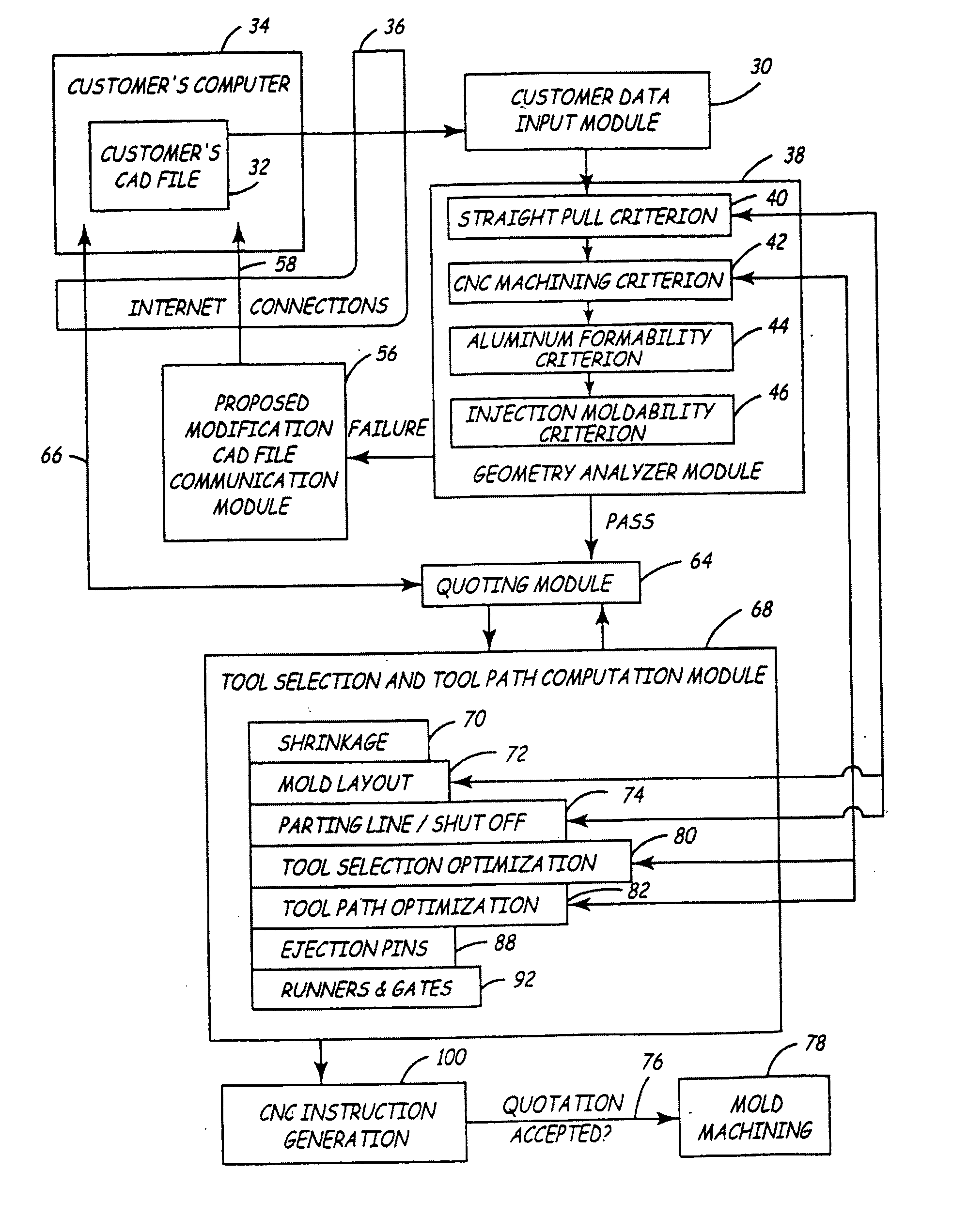

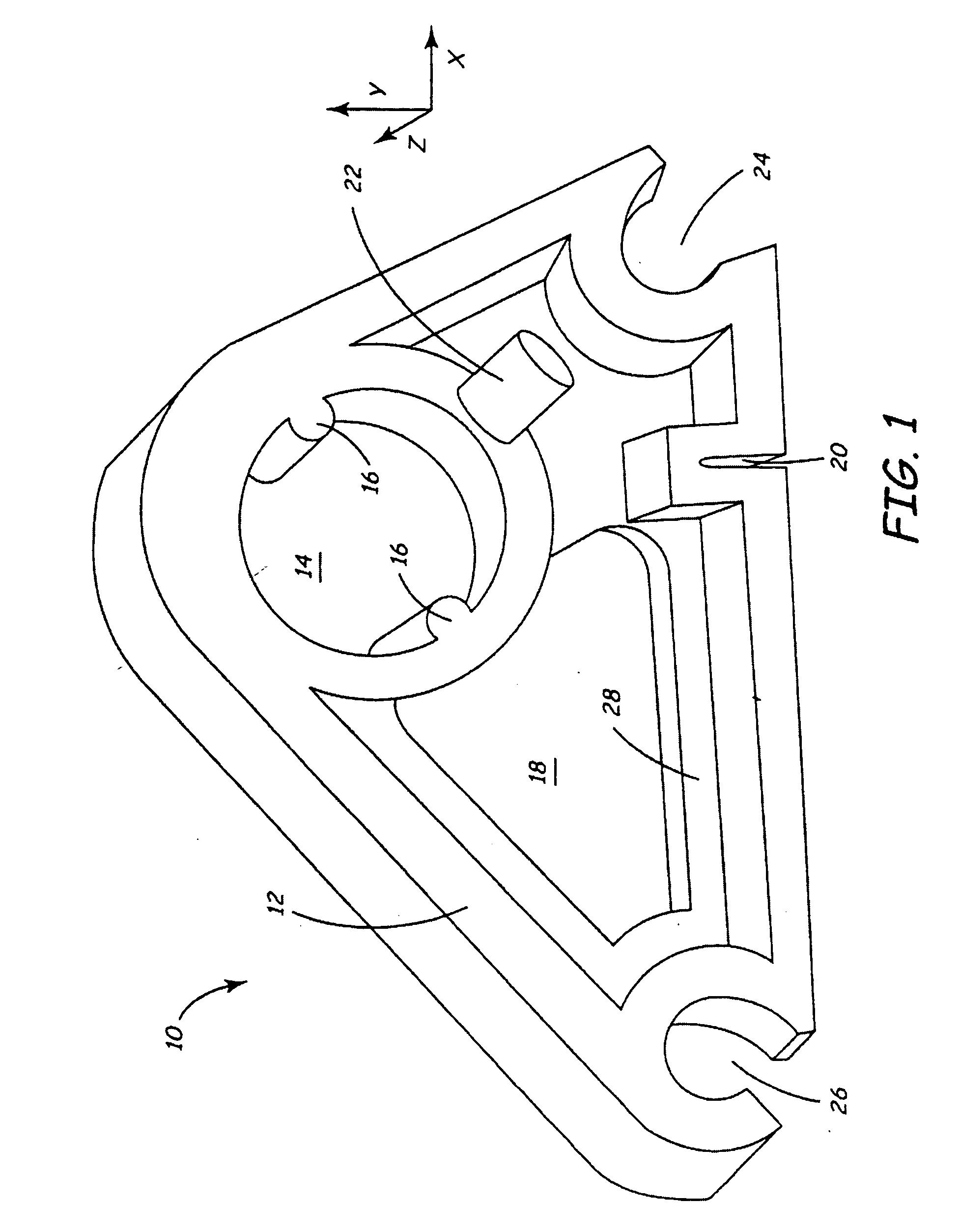

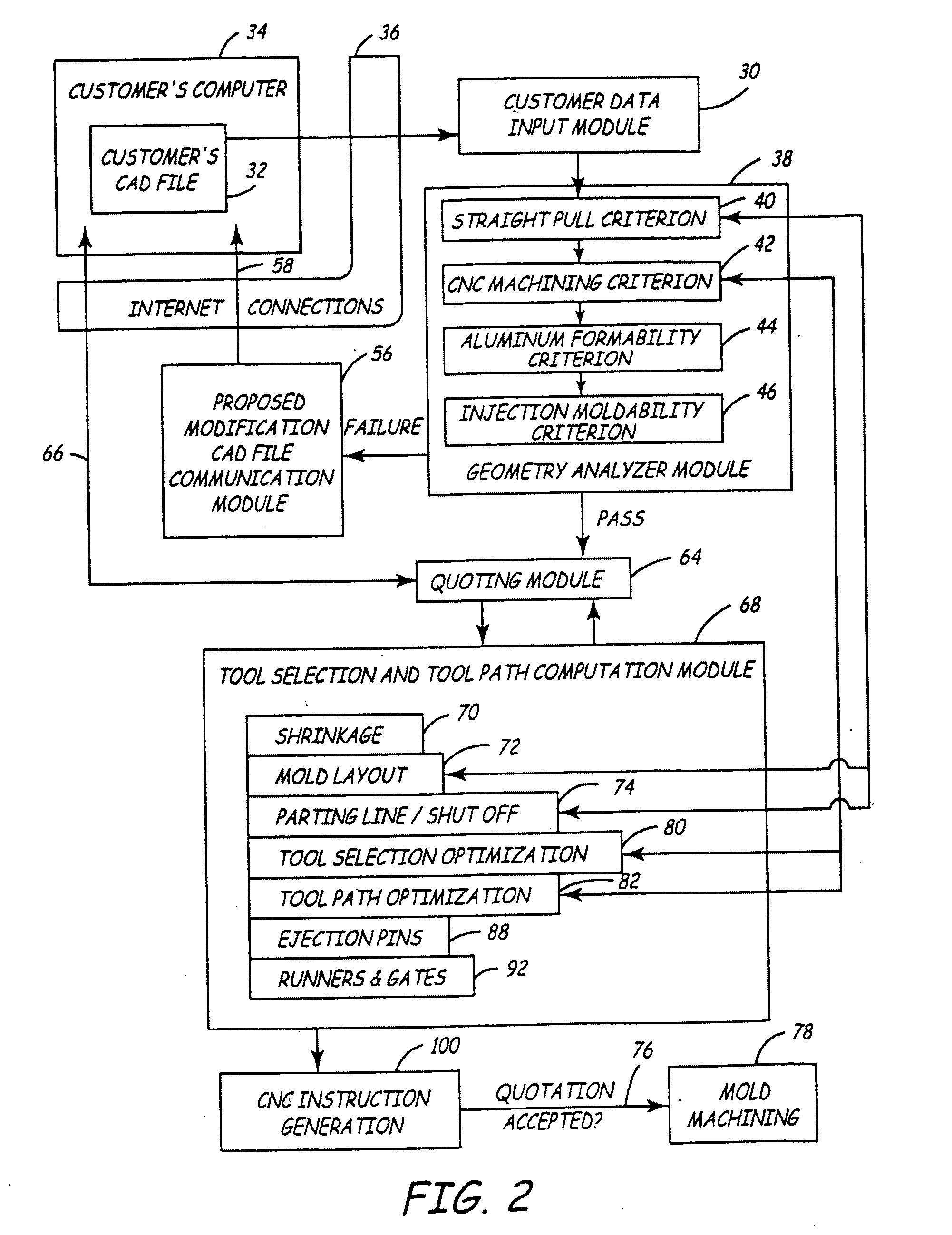

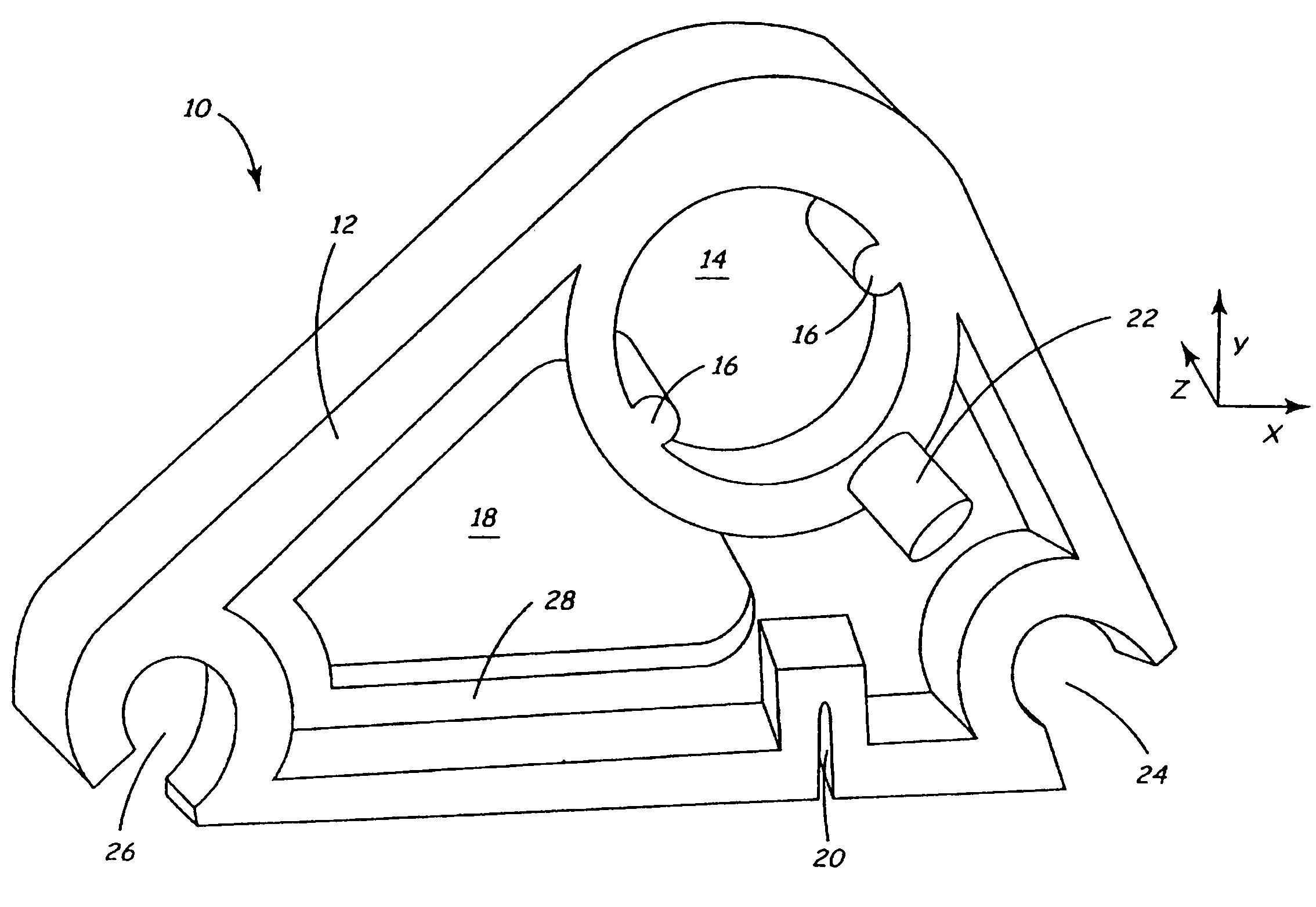

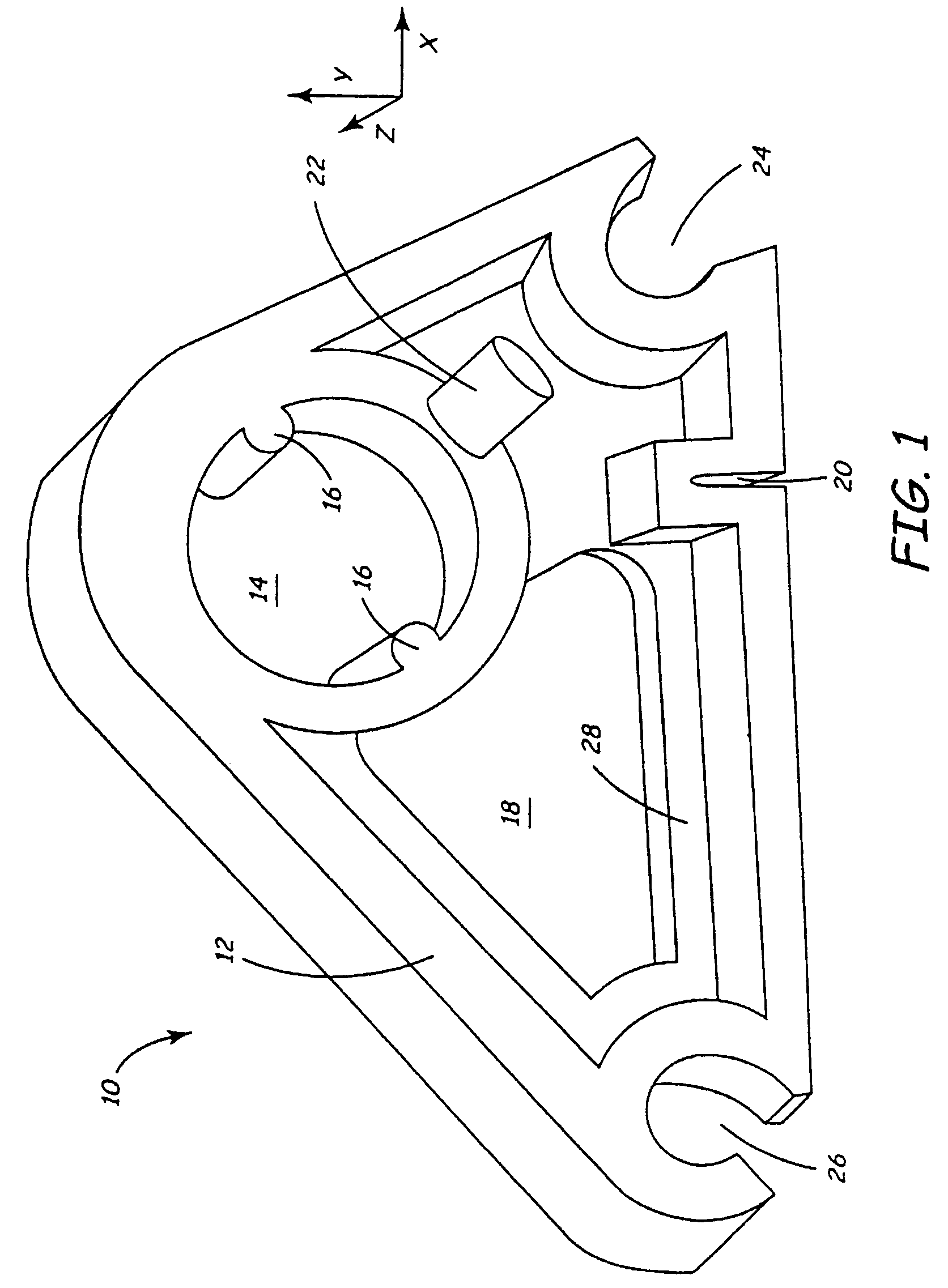

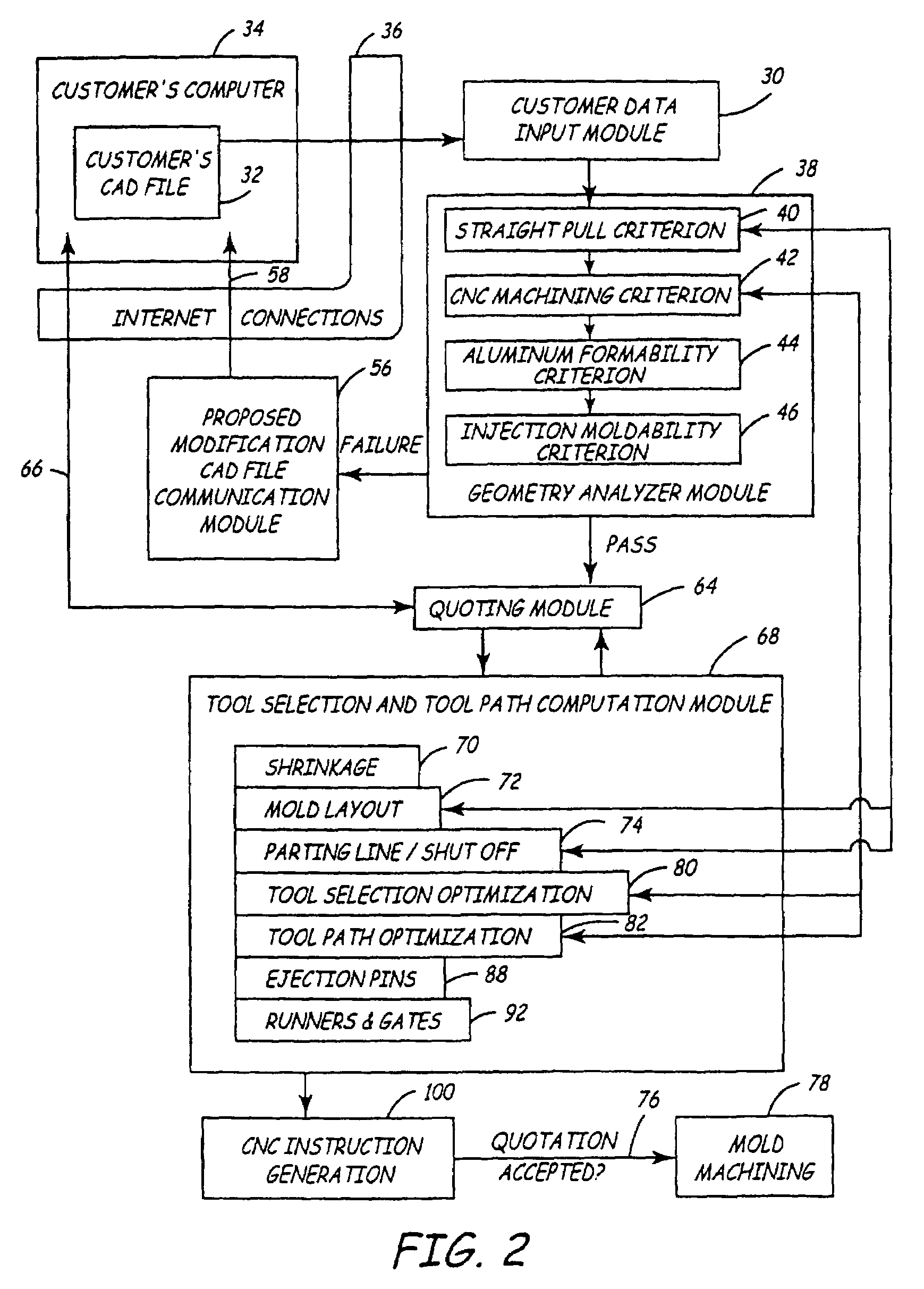

Automated quoting of molds and molded parts

InactiveUS7496528B2Increase flexibilityImprove interactivityBuying/selling/leasing transactionsMould controlling devicesSurface finishGraphics

Owner:PROTOLABS INC

Automated quoting of molds and molded parts

InactiveUS20050125092A1Increase flexibilityImprove interactivityBuying/selling/leasing transactionsMould controlling devicesSurface finishGraphics

A customer sends a CAD file for the part to be molded to the system. The system assesses the CAD file to determine various pieces of mold manufacturing information. One or more acceptability criteria are applied to the part, such as whether the part can be manufactured in a two-piece, straight-pull mold, and whether the mold can by CNC machined out of aluminum. If not, the system sends a file to the customer graphically indicating which portions of the part need modification to be manufacturable. The system provides the customer with a quotation form, that allows the customer to select several parameters, such as number of cavities, surface finish and material, which are independent of the shape of the part. The quotation module then provides the customer with the cost to manufacture the mold or a number of parts. Budget-driven quotation is possible, wherein proposed modifications in the molding process are controlled by the budget of the customer. Interactivity is also achieved, with the customer being able to modify the quotation interactively by modifying one or more of the initially selected parameters, including selecting a different budgeted amount.

Owner:PROTOLABS INC

Automated quoting of molds and molded parts

InactiveUS7590466B2Buying/selling/leasing transactionsMould controlling devicesSurface finishGraphics

Automated, custom mold manufacture for a part begins by creating and storing a collection of information of standard tool geometries and surface profiles machinable by each of the standard tool geometries. A customer sends a CAD file for the part to be molded to the system. The system assesses the CAD file to determine various pieces of mold manufacturing information. One or more acceptability criteria are applied to the part, such as whether the part can be manufactured in a two-piece, straight-pull mold, and whether the mold can by CNC machined out of aluminum. If not, the system sends a file to the customer graphically indicating which portions of the part need modification to be manufacturability. The system provides the customer with a quotation form, that allows the customer to select several parameters, such as number of cavities, surface finish and material, which an independent of the shape of the part.

Owner:PROTOLABS INC

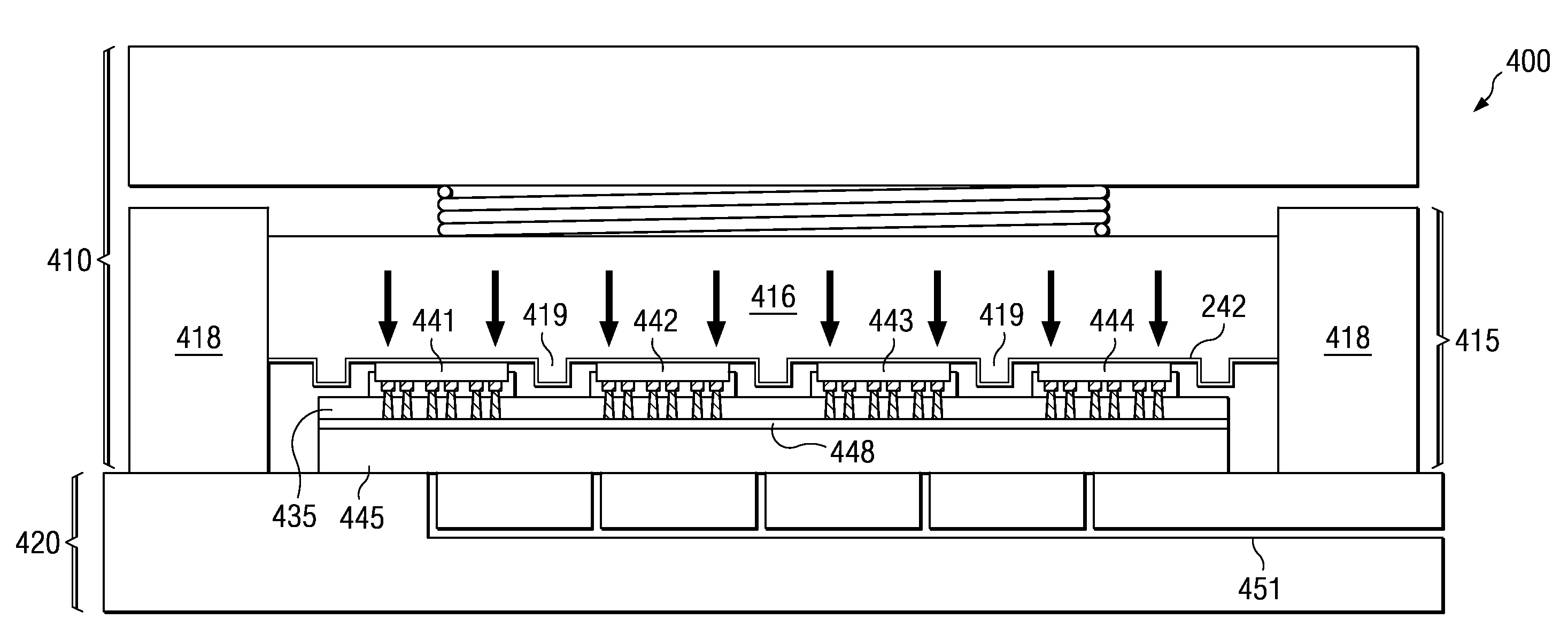

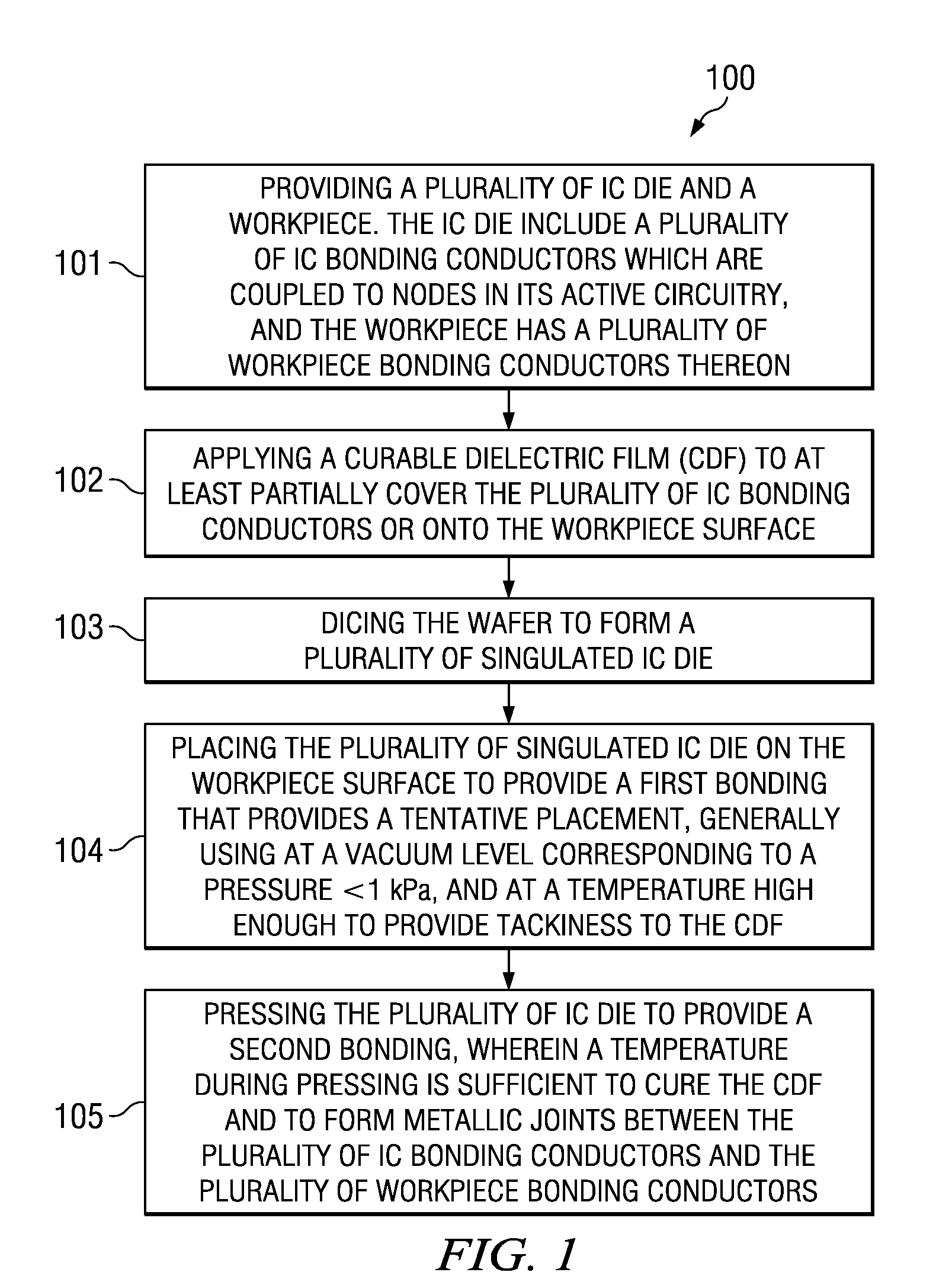

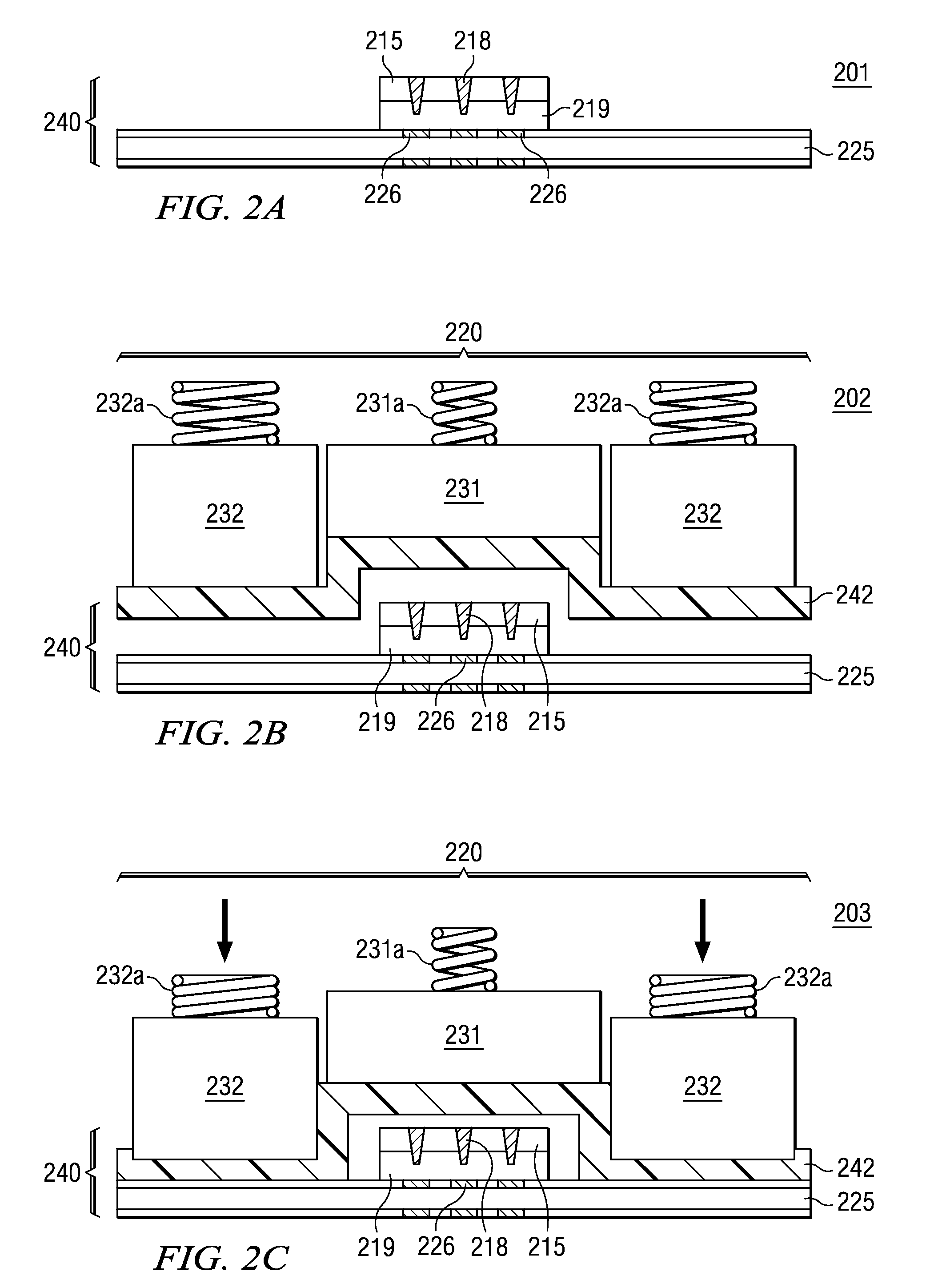

Combined metallic bonding and molding for electronic assemblies including void-reduced underfill

ActiveUS20090291524A1Small sizeReducing joint misalignmentCasting safety devicesSolid-state devicesElectrical conductorDielectric membrane

A method for forming electronic assemblies includes providing a plurality of IC die each having IC bonding conductors and a workpiece having workpiece bonding conductors. A curable dielectric film is applied to the IC bonding conductors or the workpiece surface. The plurality of IC die are placed on the workpiece surface so that the plurality of IC bonding conductors are aligned to and face the plurality of workpiece bonding conductors to provide a first bonding. The placing is performed at a vacuum level corresponding to a pressure <1 kPa, and at a temperature sufficient to provide tackiness to the curable dielectric film. The plurality of IC die are then pressed to provide a second bonding. A temperature during pressing cures the curable dielectric film to provide an underfill and forms metallic joints between the plurality of IC bonding conductors and the plurality of workpiece bonding conductors.

Owner:TEXAS INSTR INC

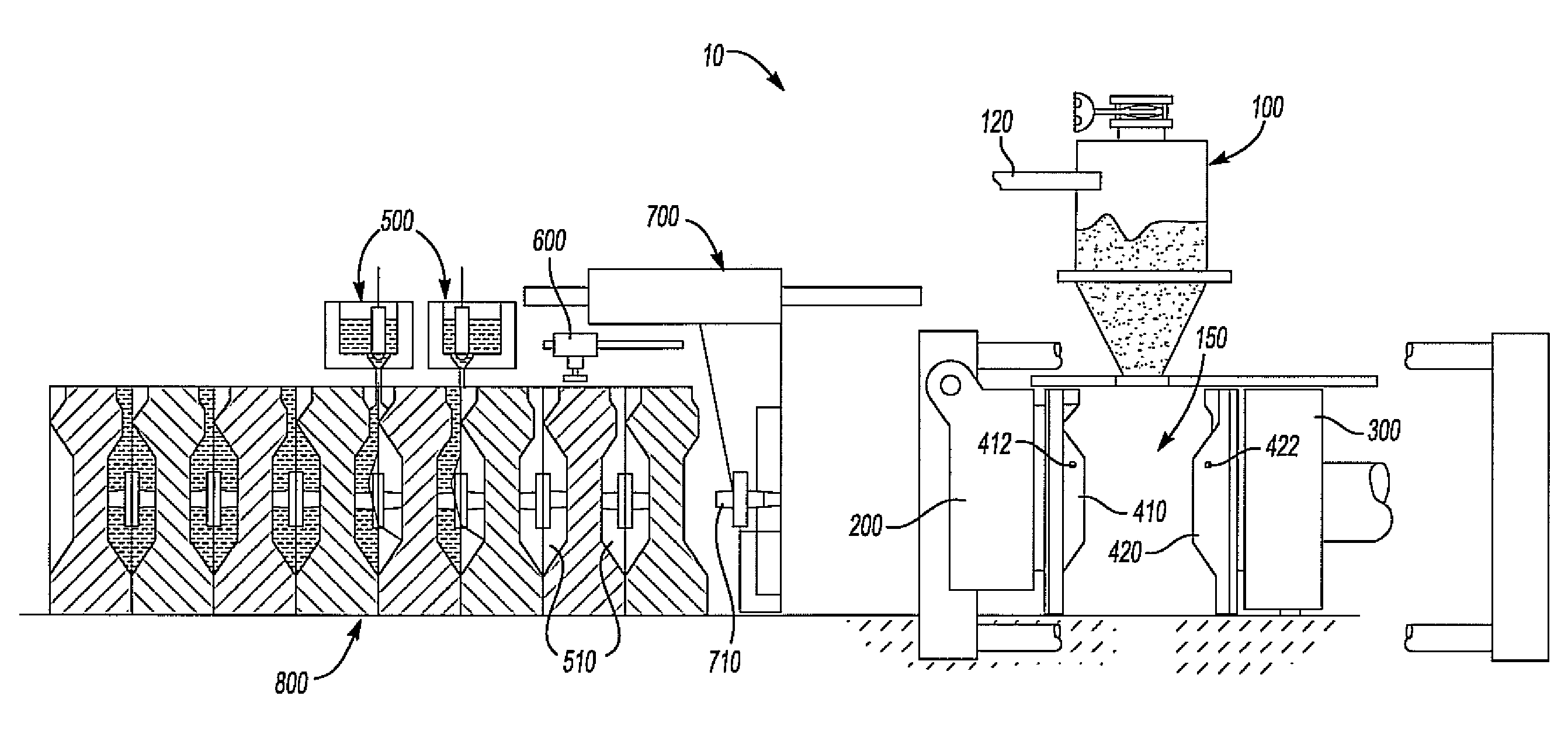

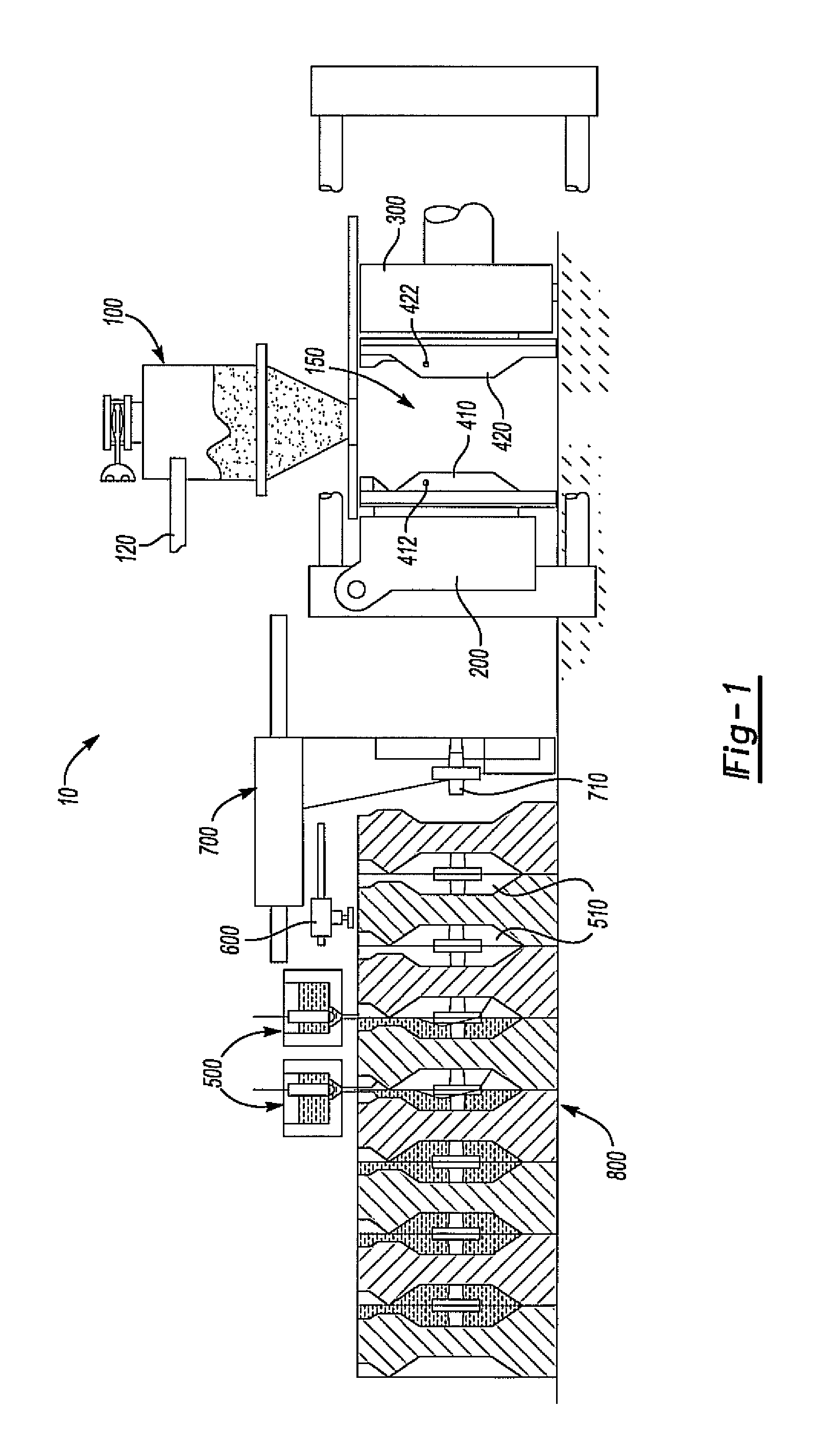

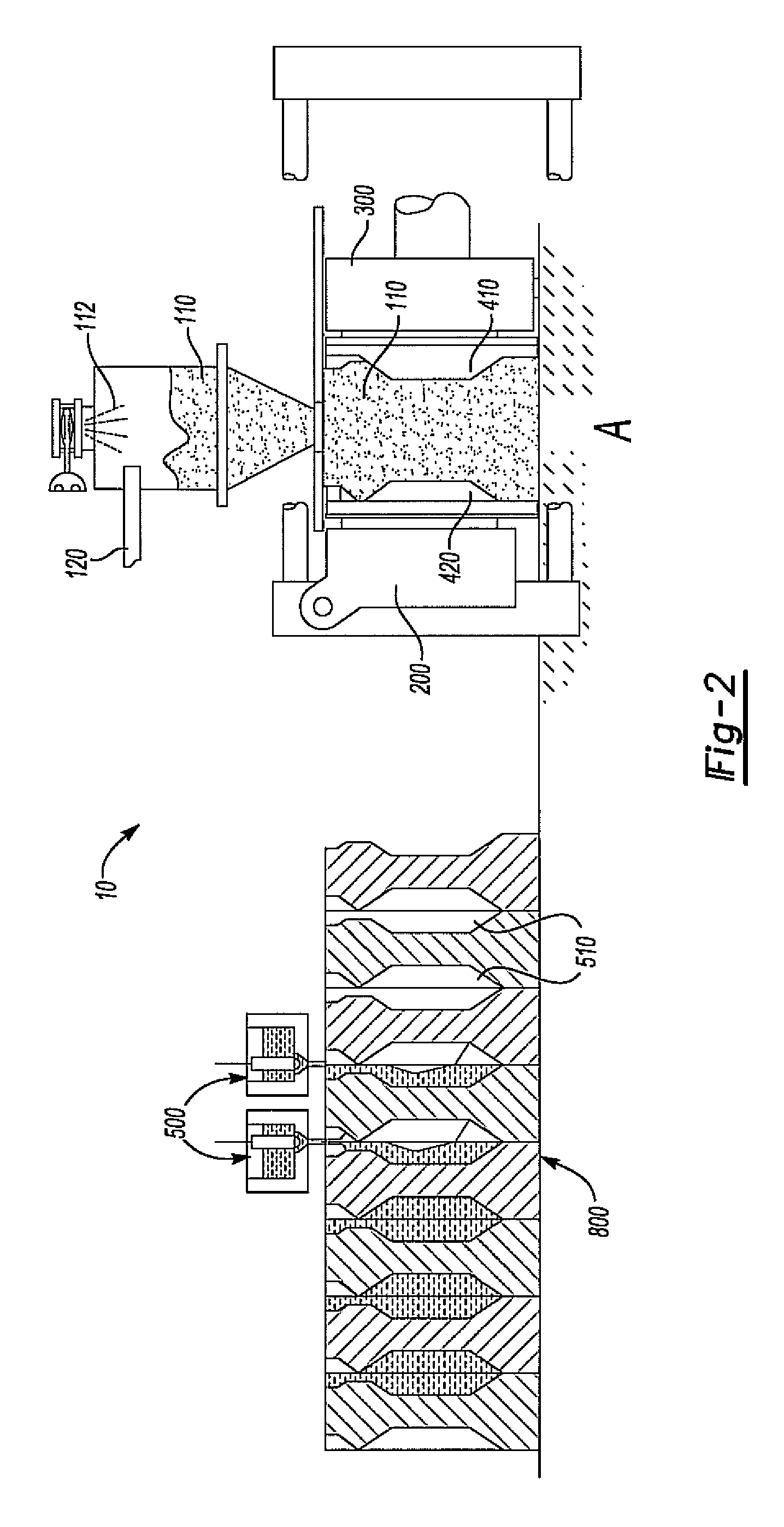

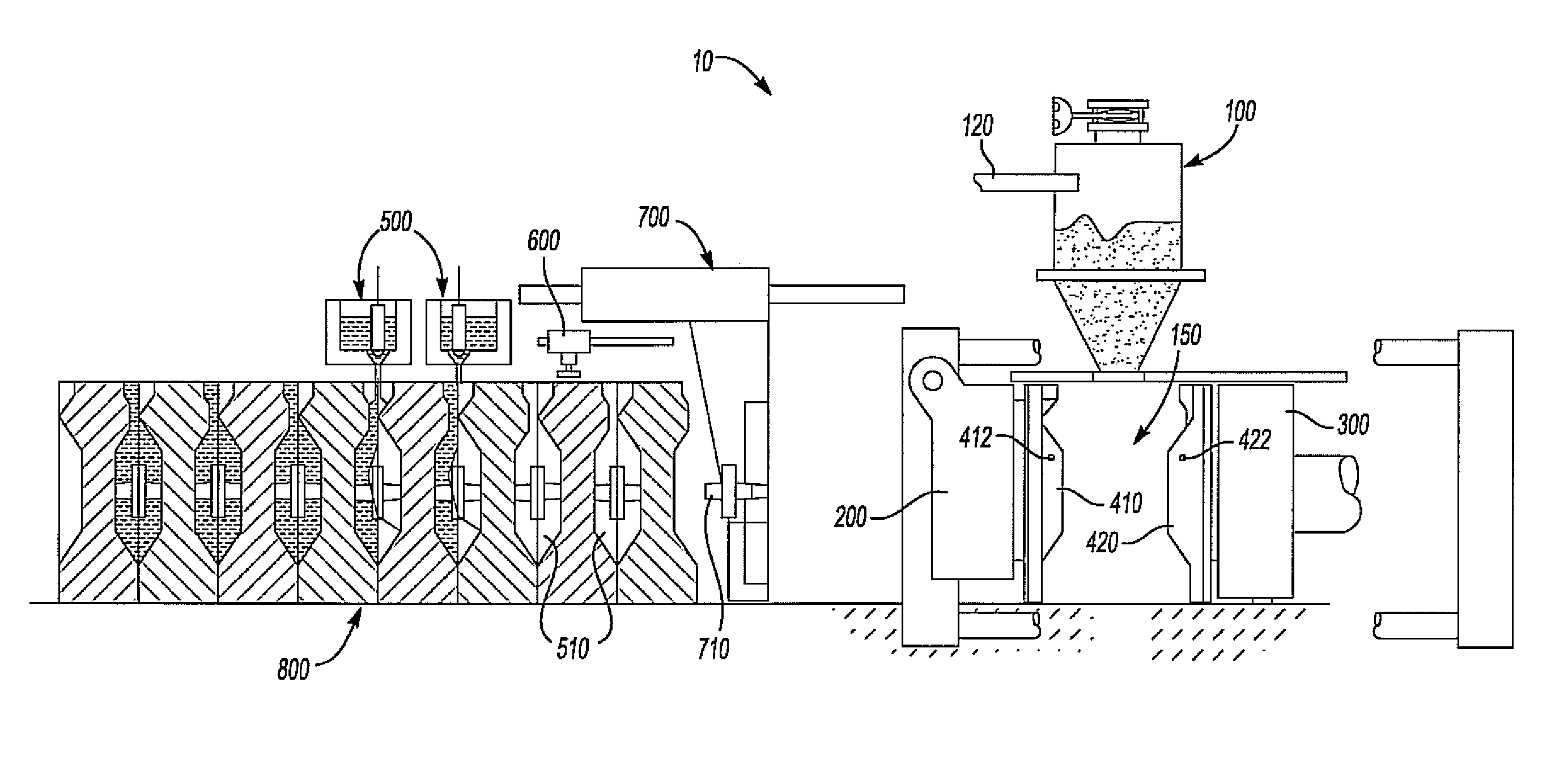

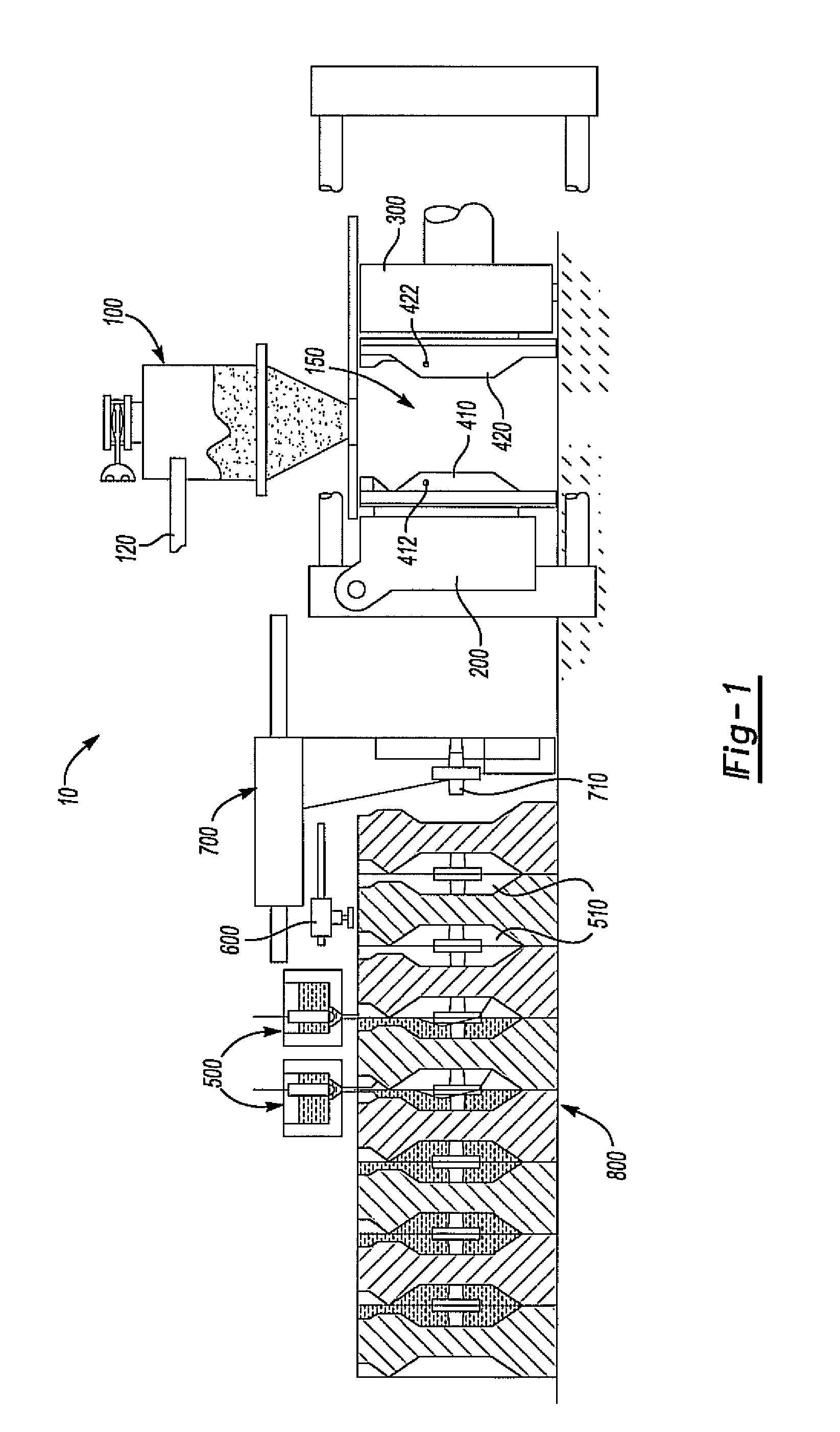

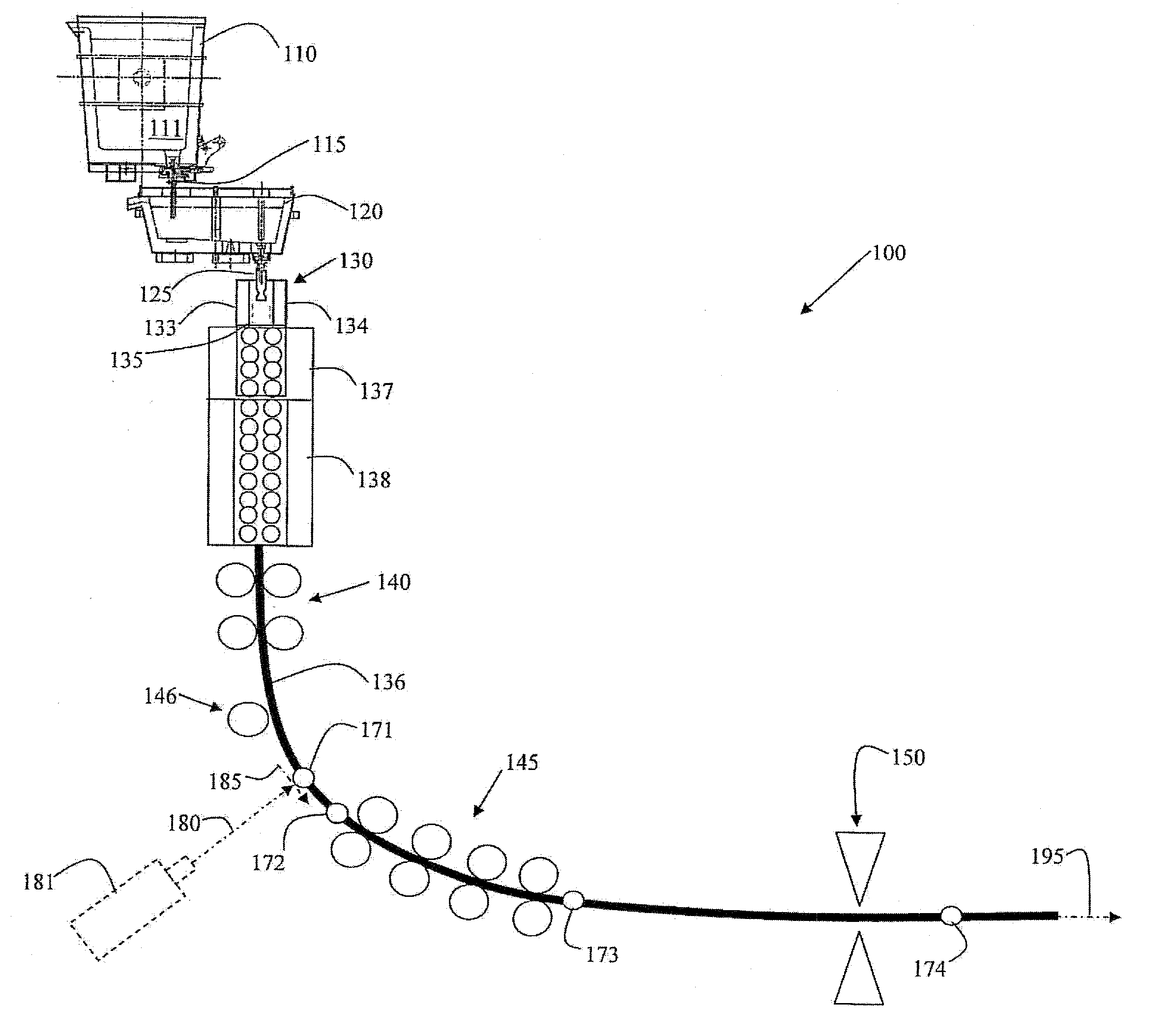

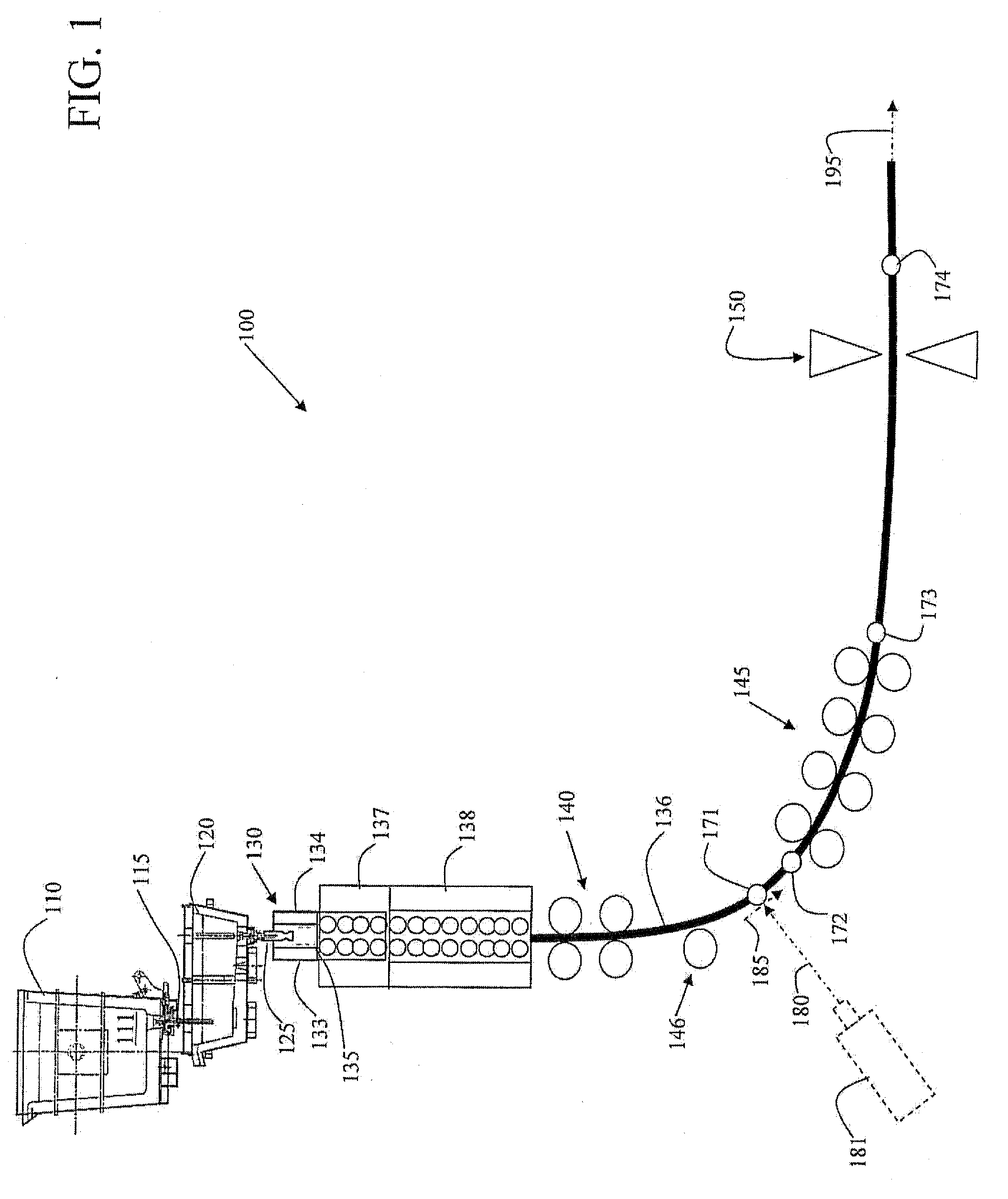

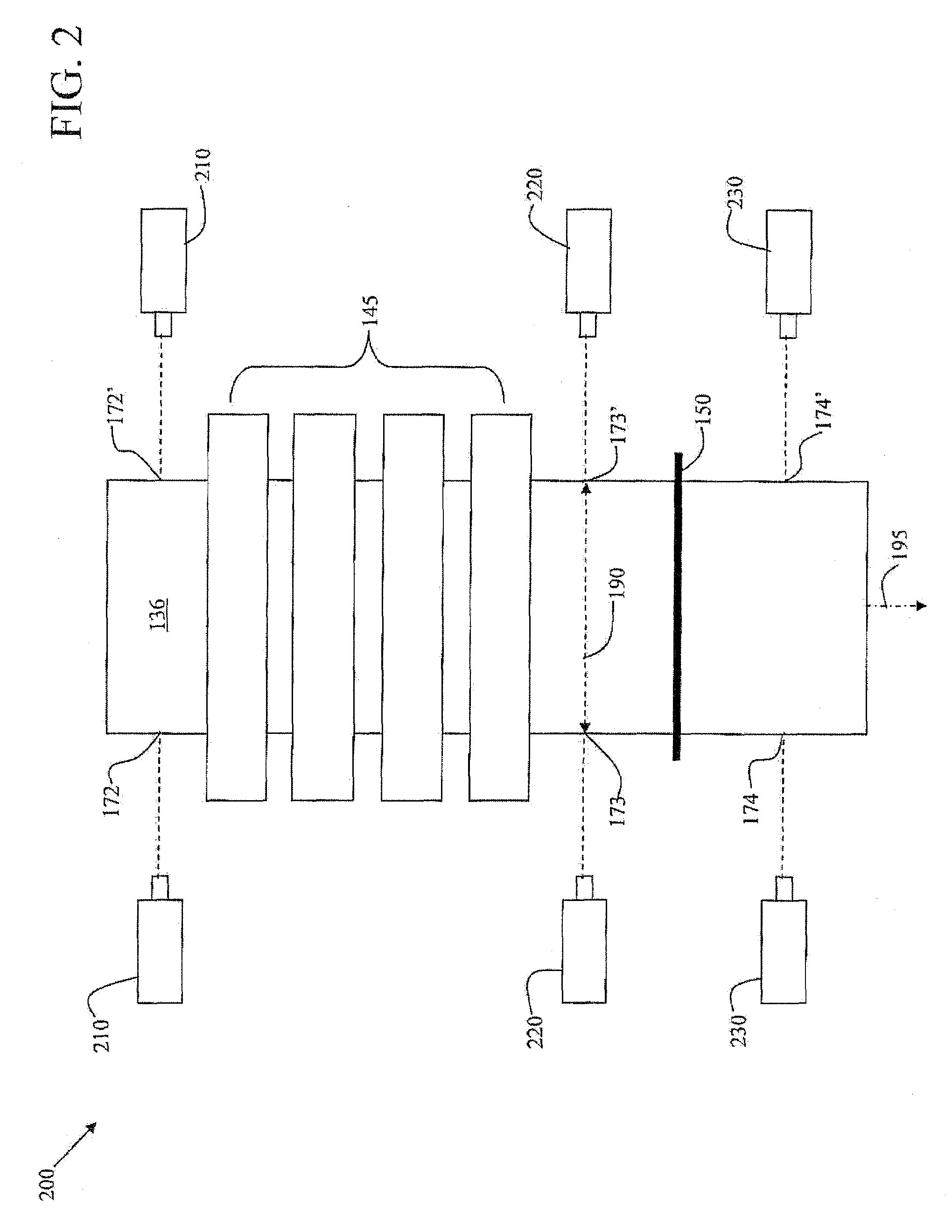

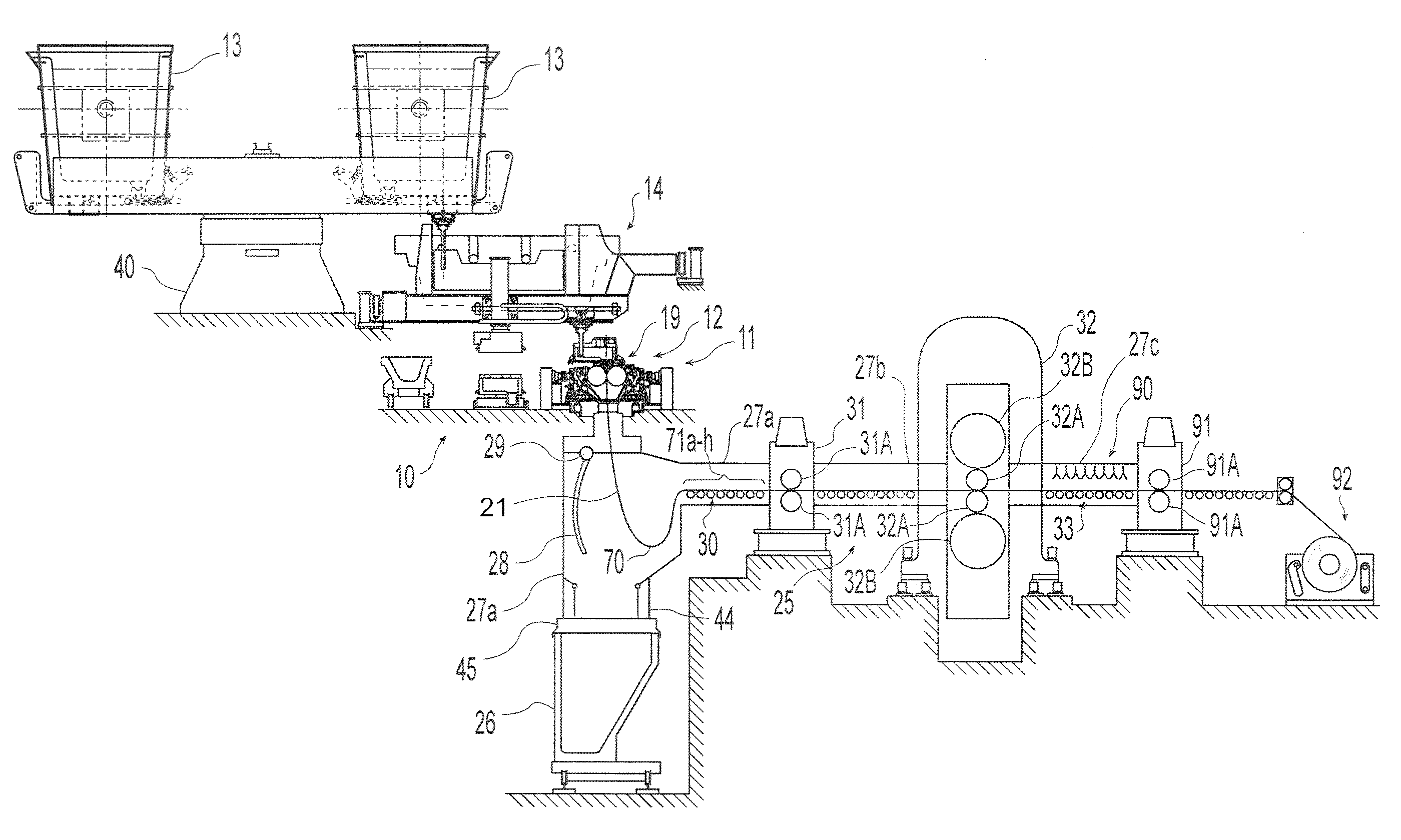

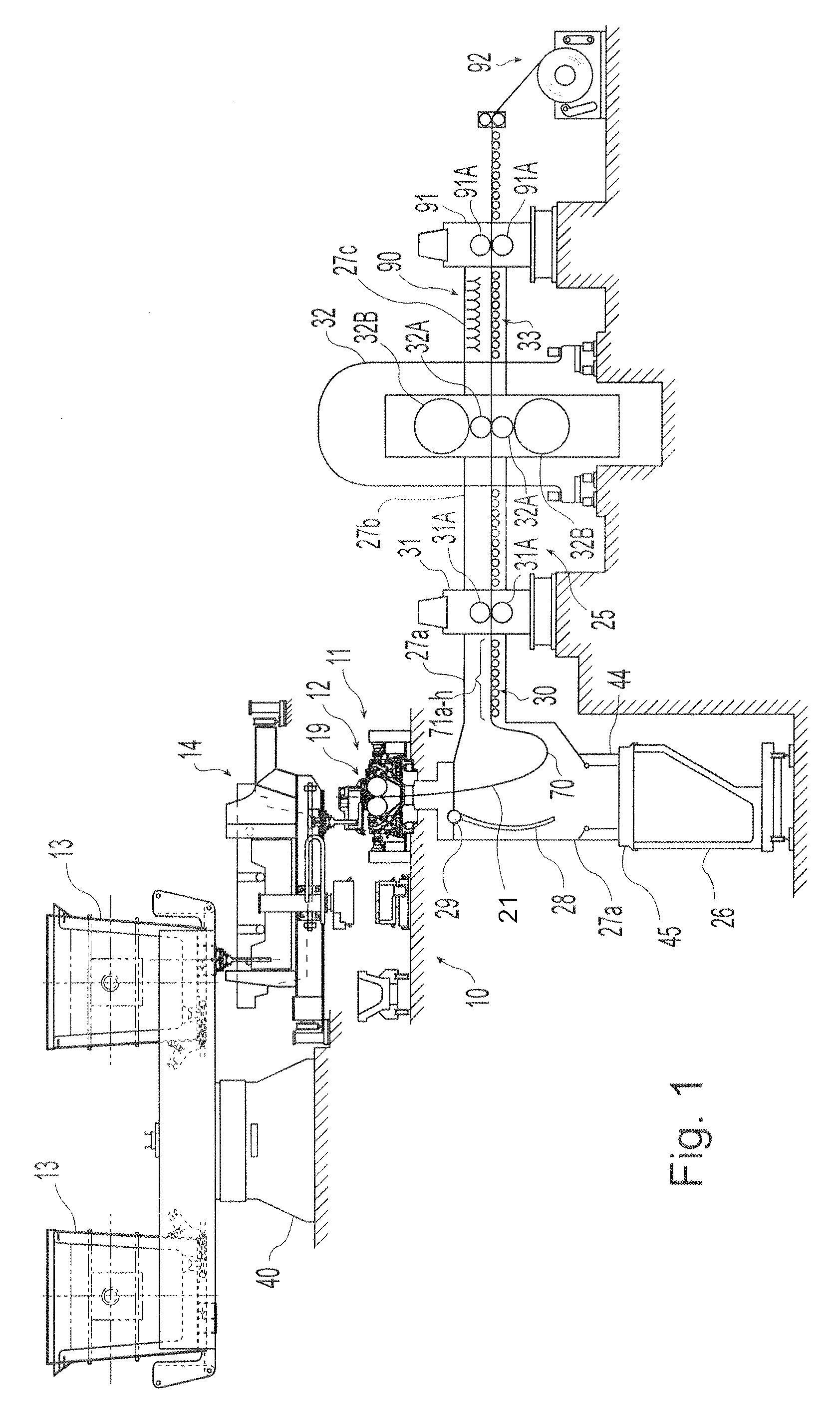

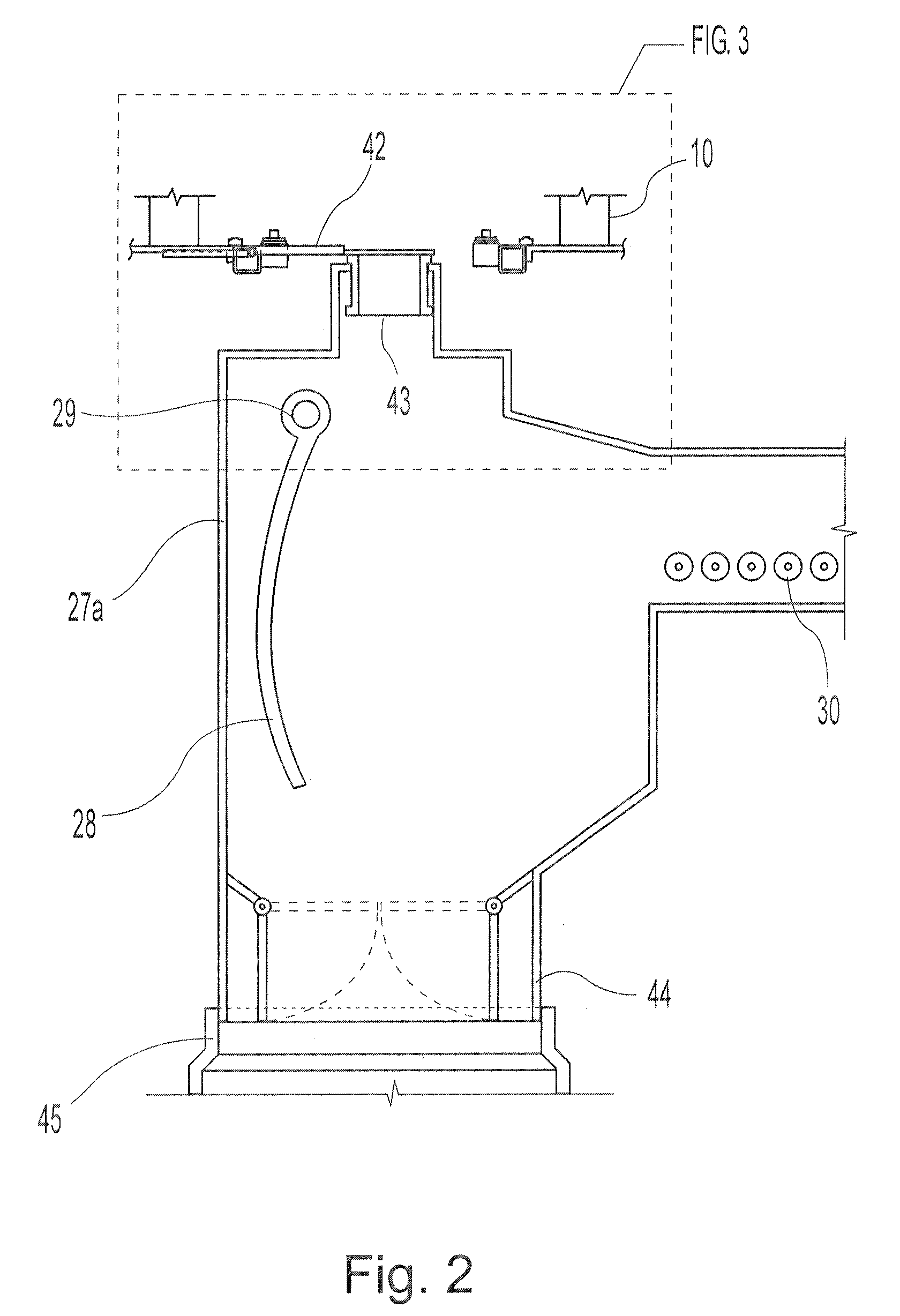

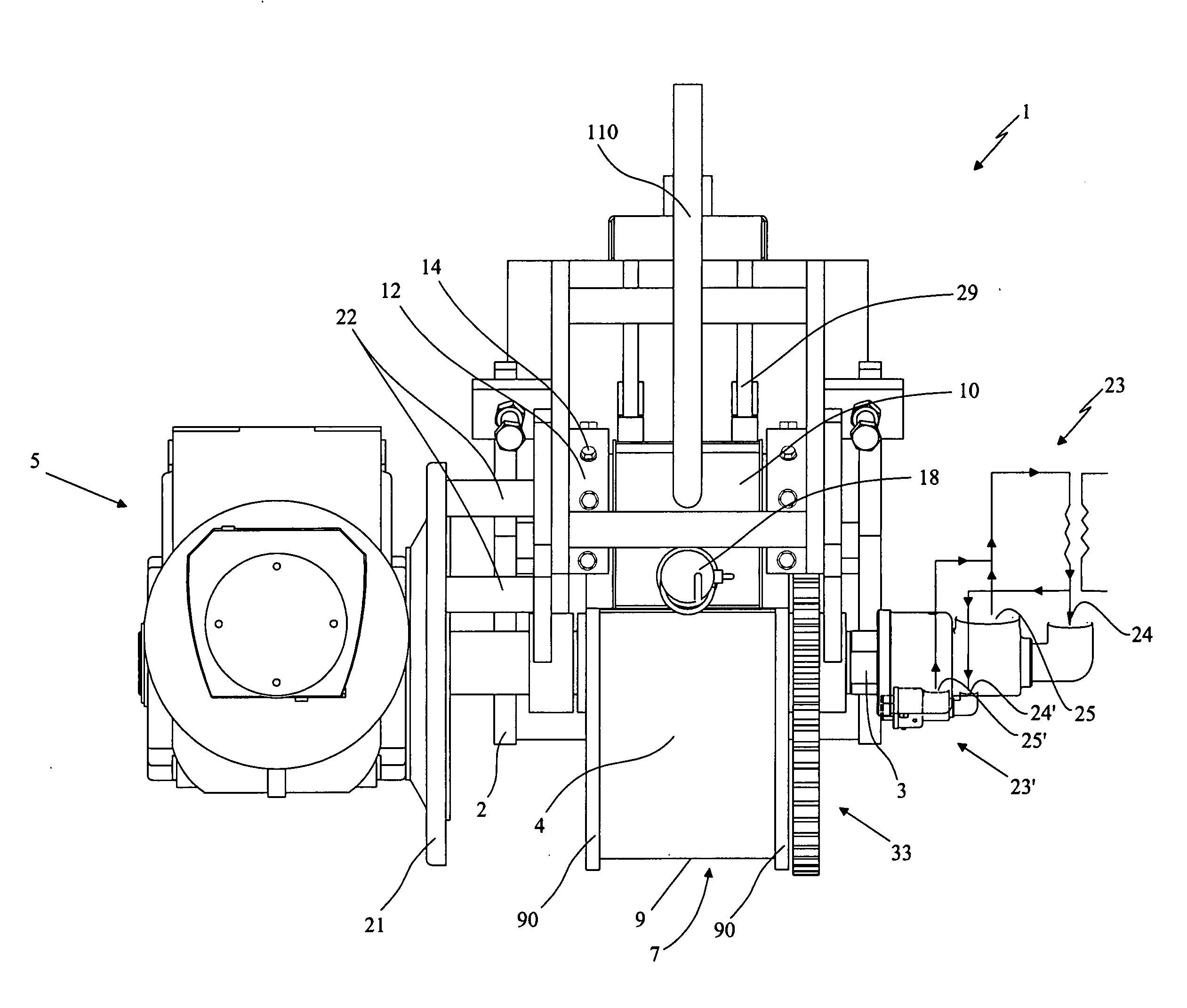

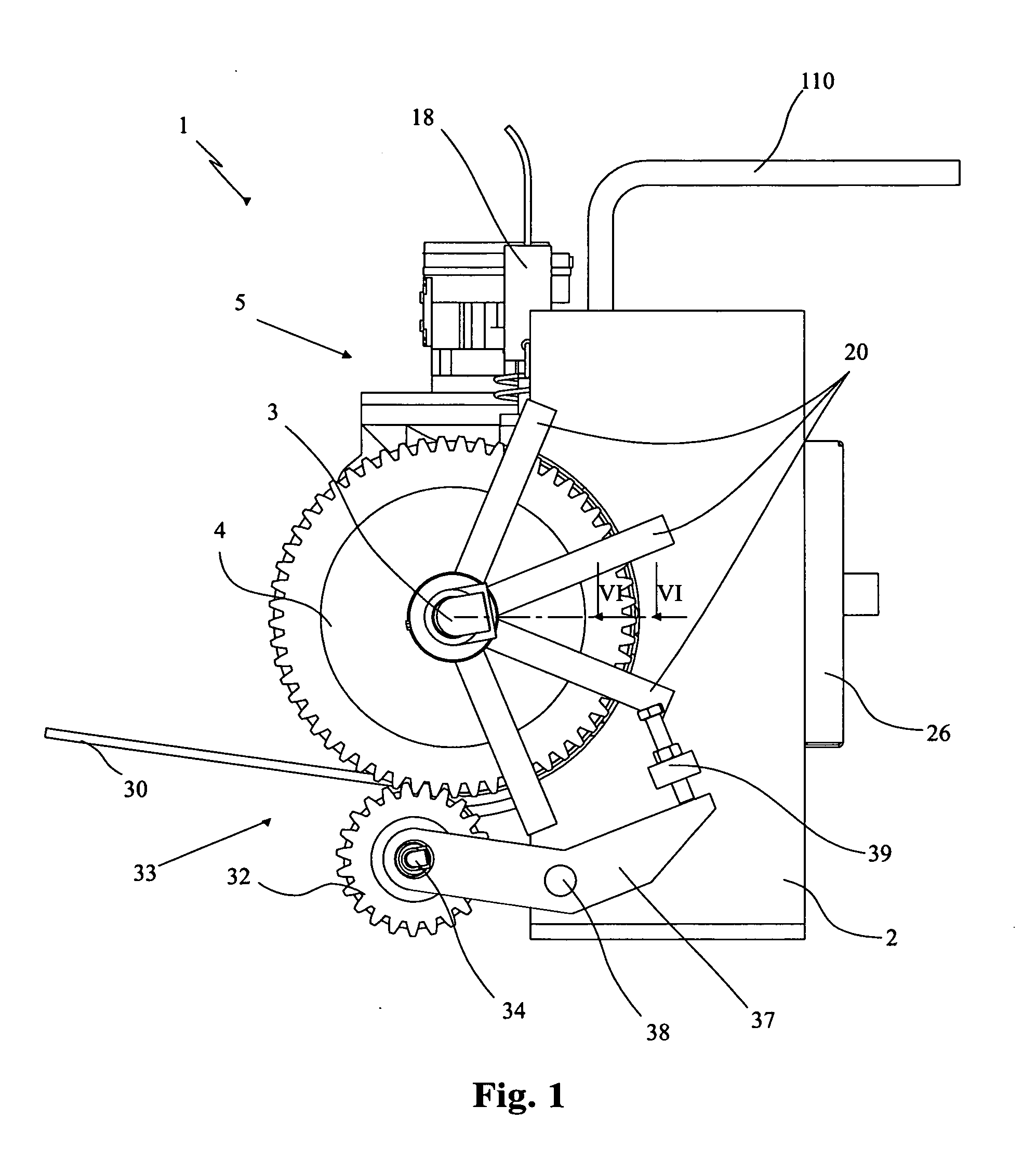

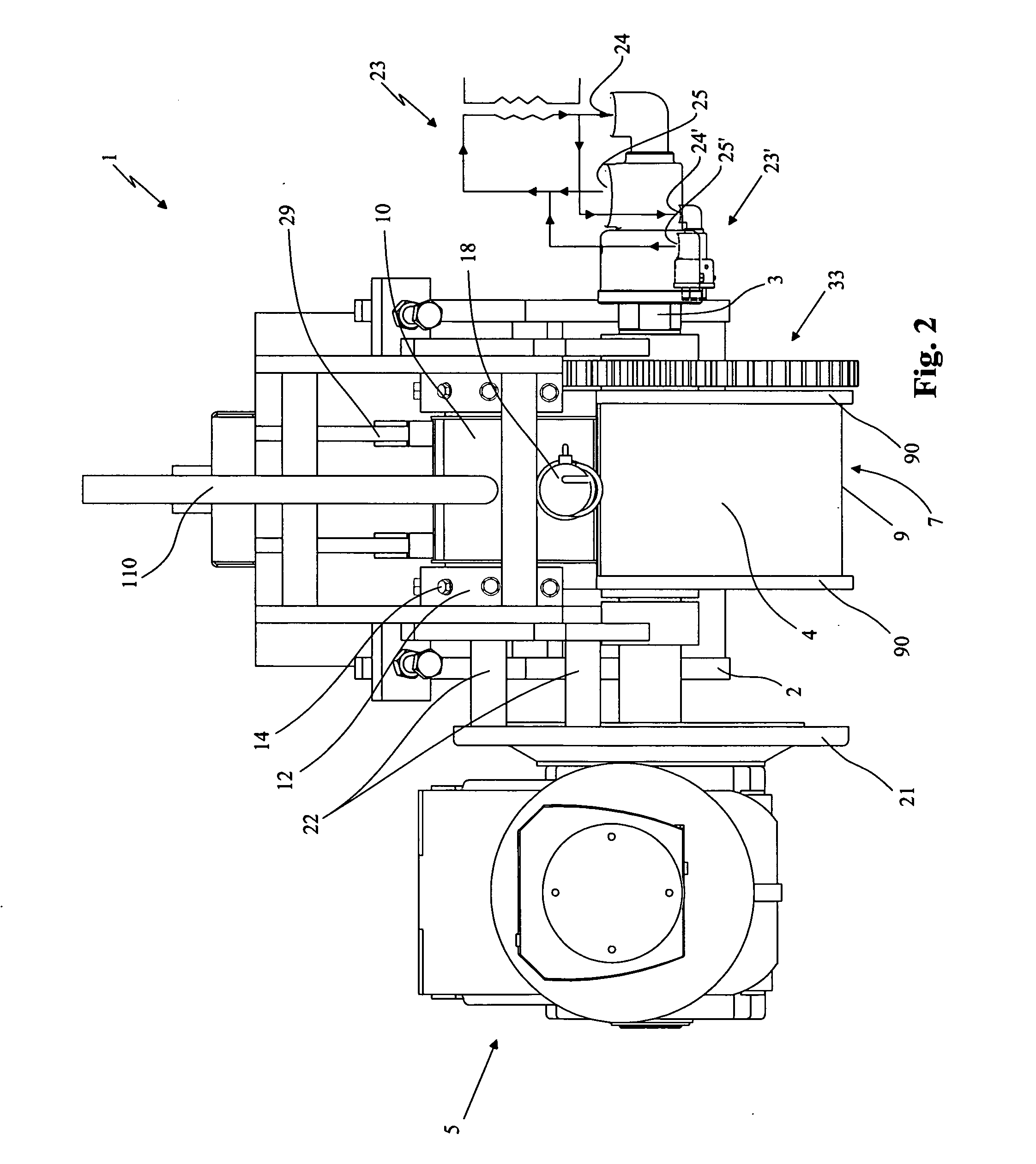

Molding and casting machine

ActiveUS20080135205A1Improved swing movementEasy to adjustPig casting plantsCasting safety devicesMolding machineSand casting

Disclosed is a sand casting molding machine for double indexing molds in a mold string. The machine can include a shot chamber having sand, a swingable squeeze head, a lateral squeeze head, a core setter, a mold hold down, a mold retention device and a mold string conveyor.

Owner:THYSSENKRUPP WAUPACA

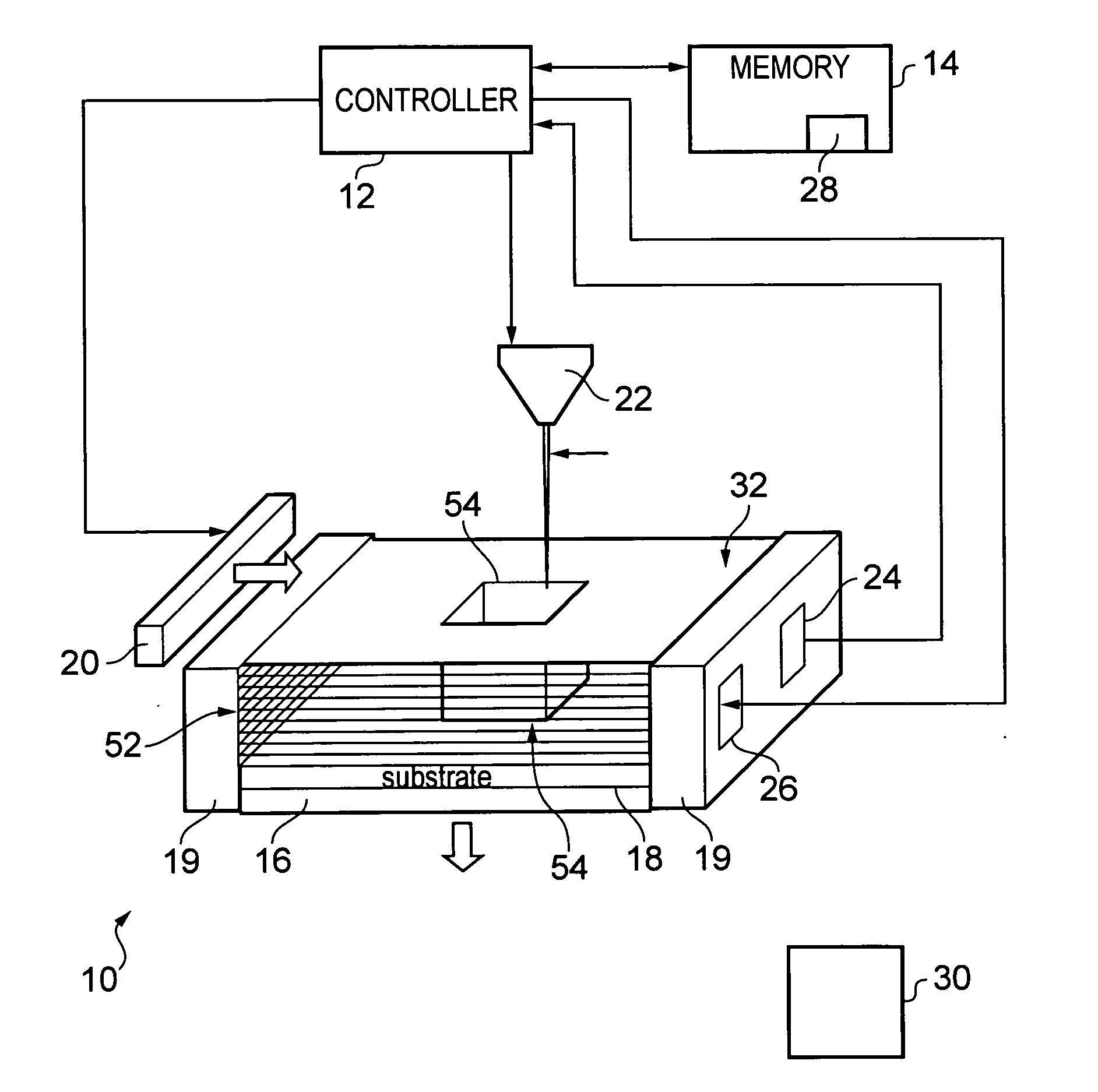

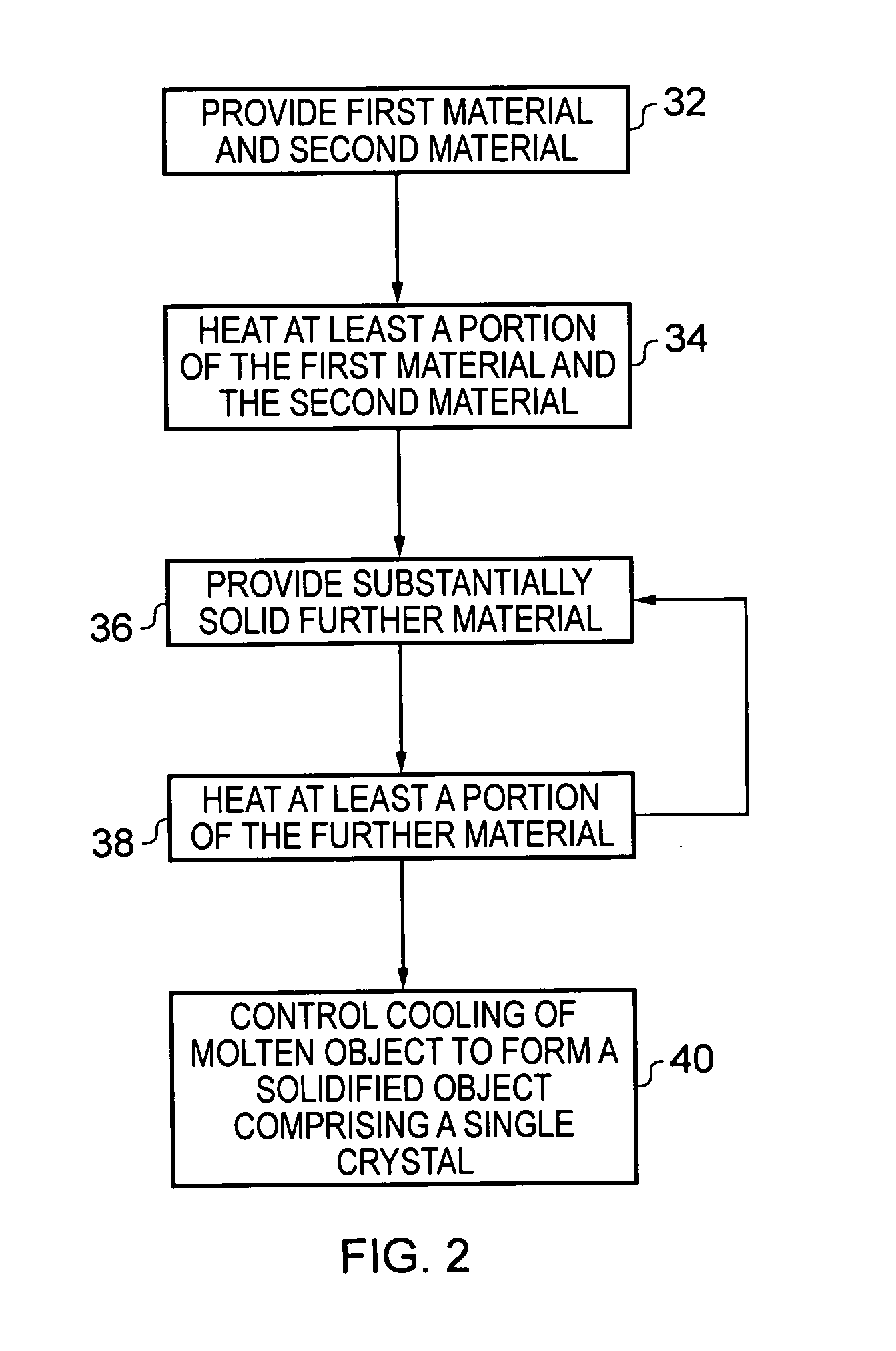

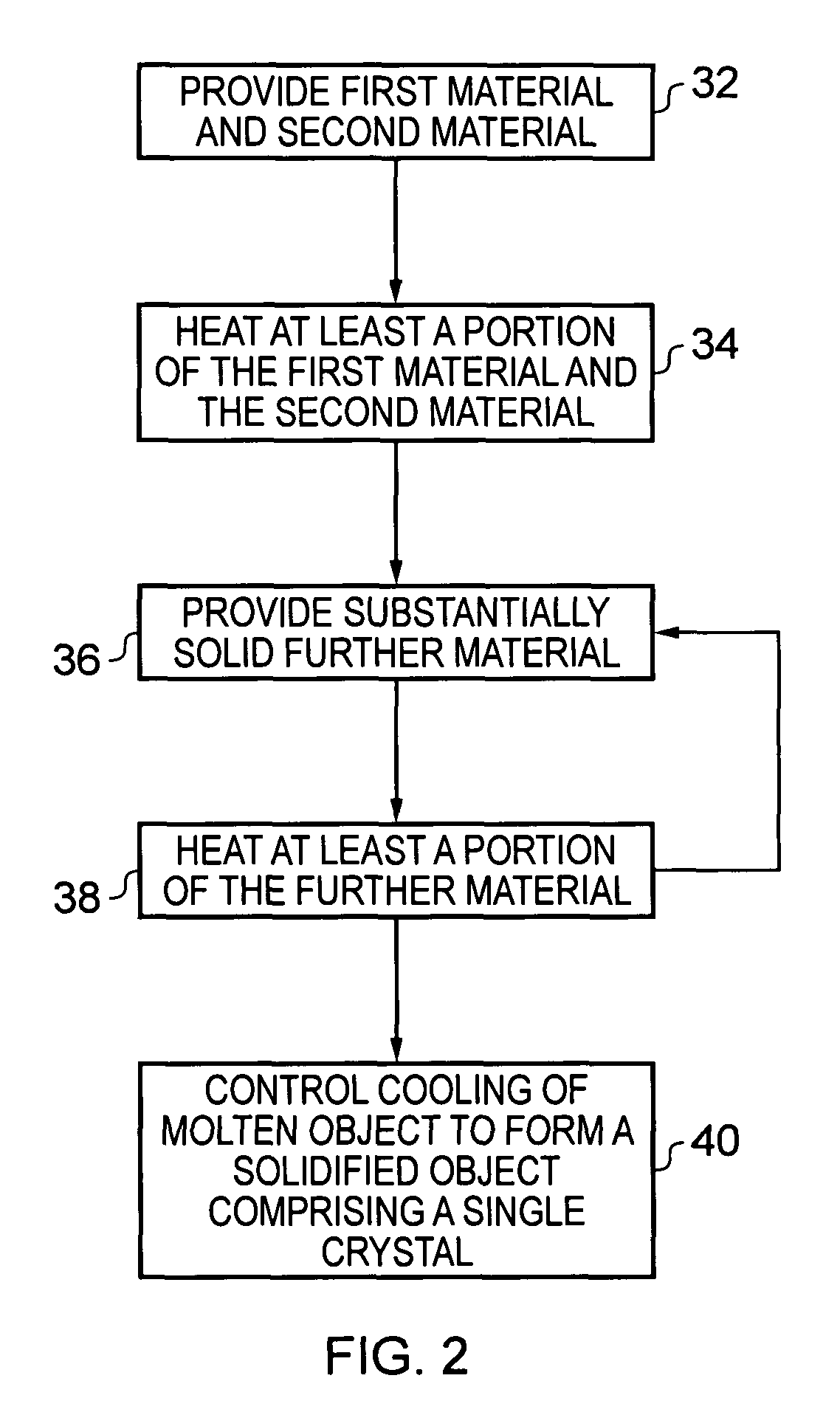

Method for forming an object

InactiveUS8186414B2Polycrystalline material growthAdditive manufacturing apparatusFreezing pointMelting point

A method for forming an object, including providing at least a first material having a melting point at a first temperature and a second material having a melting point at a second temperature; heating at least a portion of the first and second materials above the first and second temperatures to form a substantially molten alloy, the molten alloy having a solidifying point at a third temperature, the third temperature being less than the first temperature and the second temperature; and providing substantially solid further material to at least a portion of the molten alloy, the further material having a melting point at a temperature greater than the third temperature.

Owner:UNIV OF SHEFFIELD

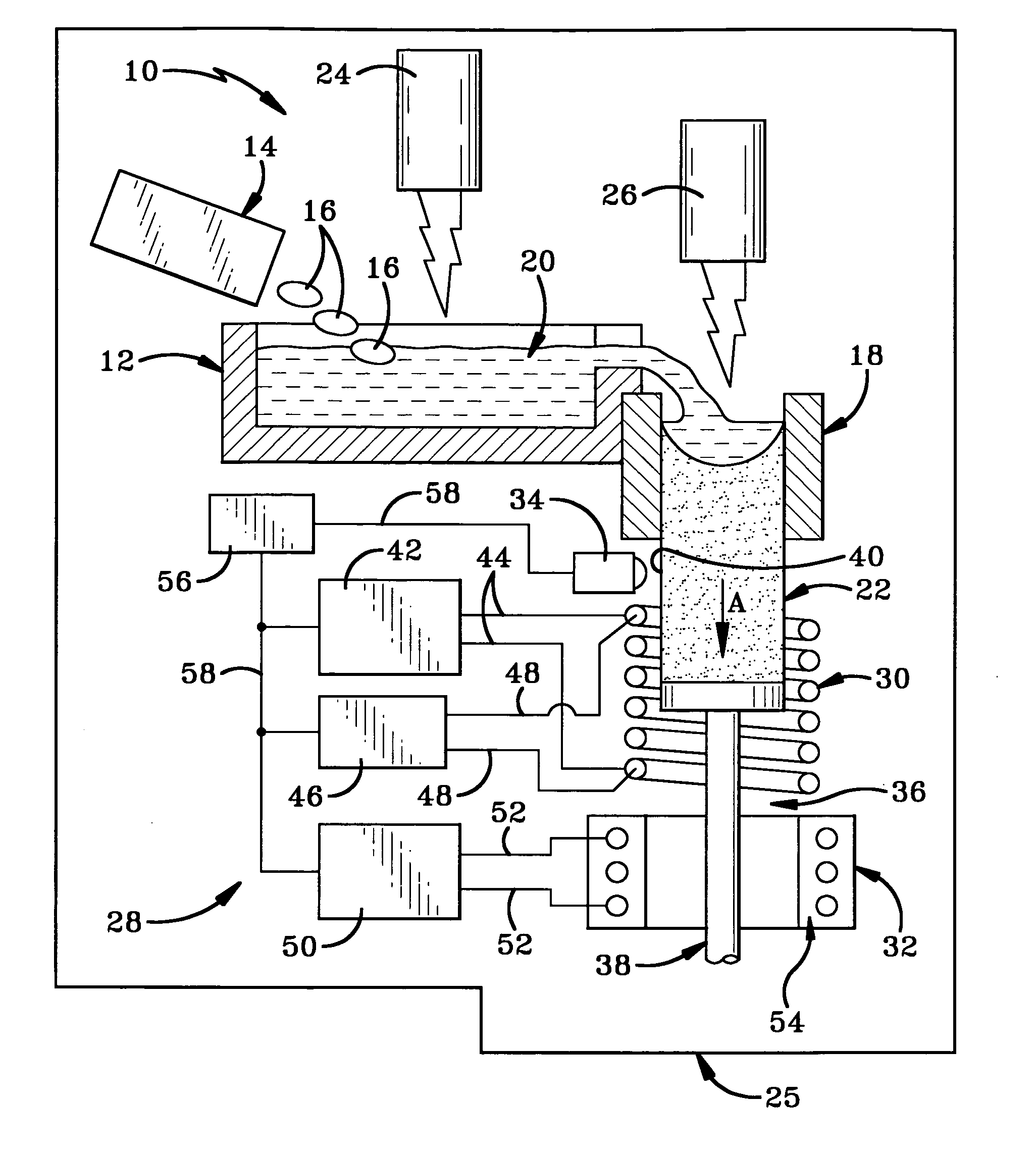

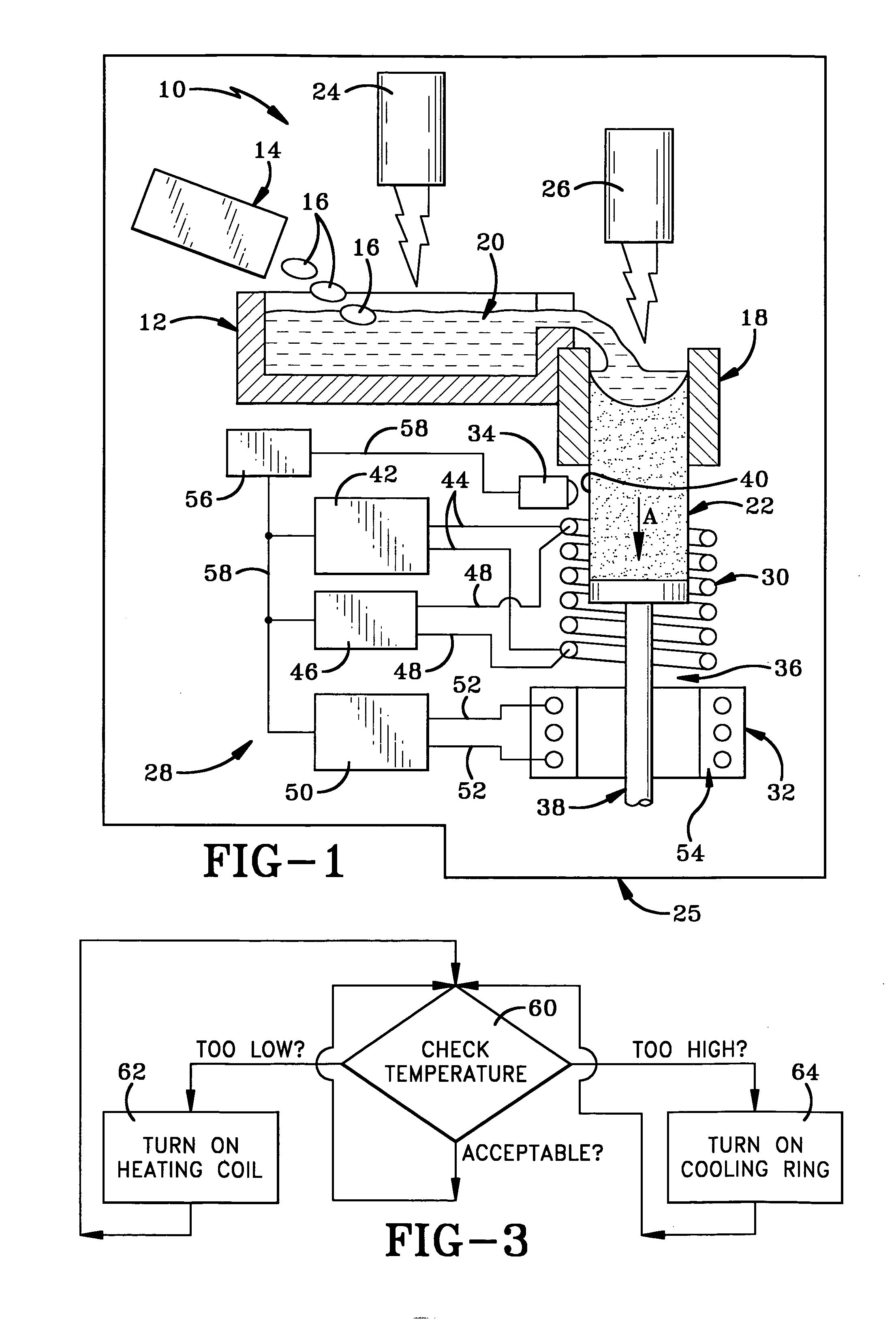

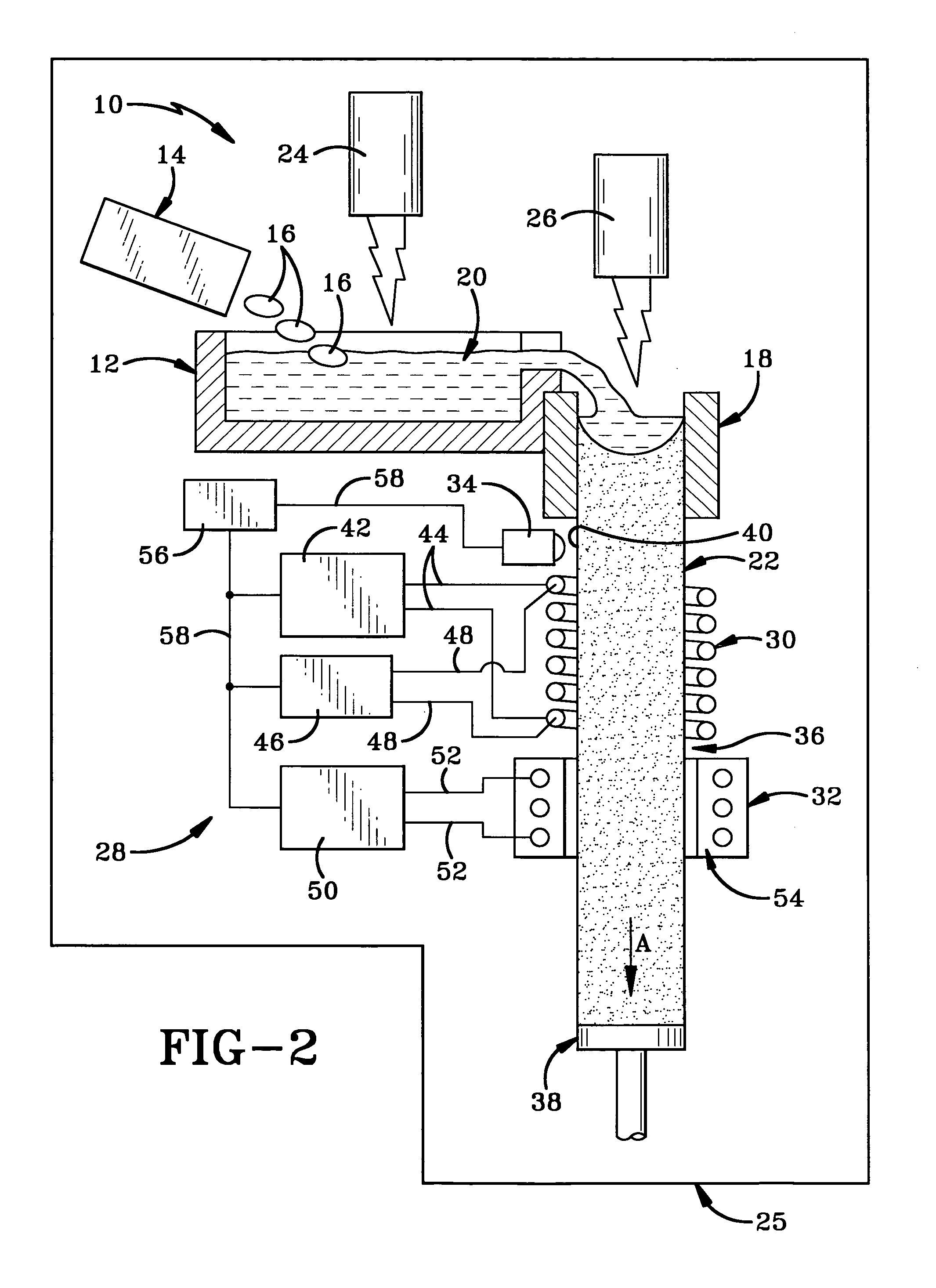

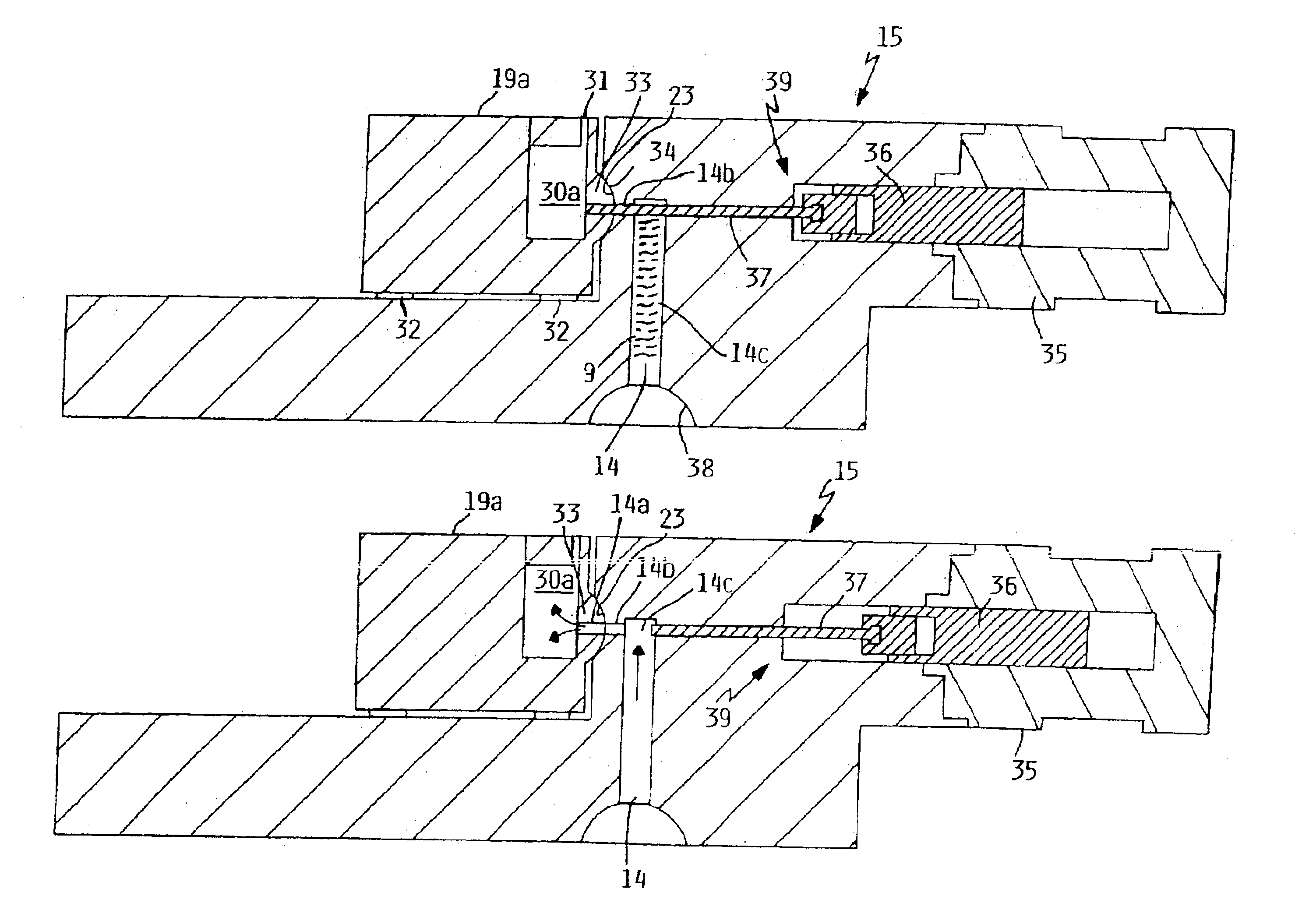

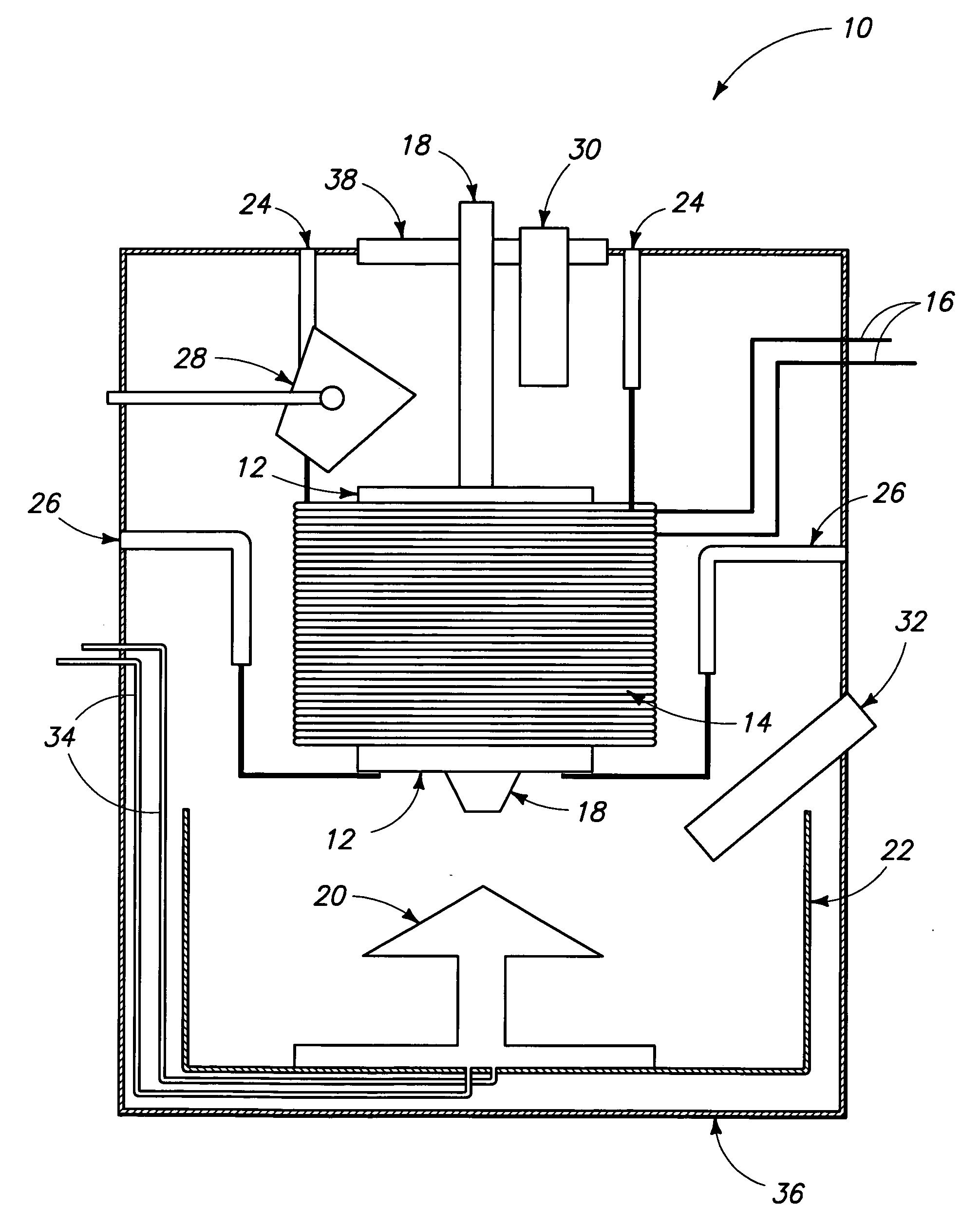

Method and apparatus for temperature control in a continuous casting furnace

ActiveUS20080035298A1Lighting and heating apparatusCasting safety devicesTemperature controlCasting mold

A continuous casting furnace includes a temperature control mechanism for controlling the temperature of a metal cast as it exits a continuous casting mold in order to provide improved characteristics of the metal cast. The temperature control mechanism includes a temperature sensor for sensing the temperature of the metal cast, and a heat source and cooling device for respectively heating and cooling the metal cast in light of the temperature of the metal cast. A control unit determines if the temperature of the metal cast is within a predetermined range and controls the heat source and cooling device accordingly. The heat source may double as a cooling device or the cooling device may be separate from the heat source.

Owner:HOWMET AEROSPACE INC

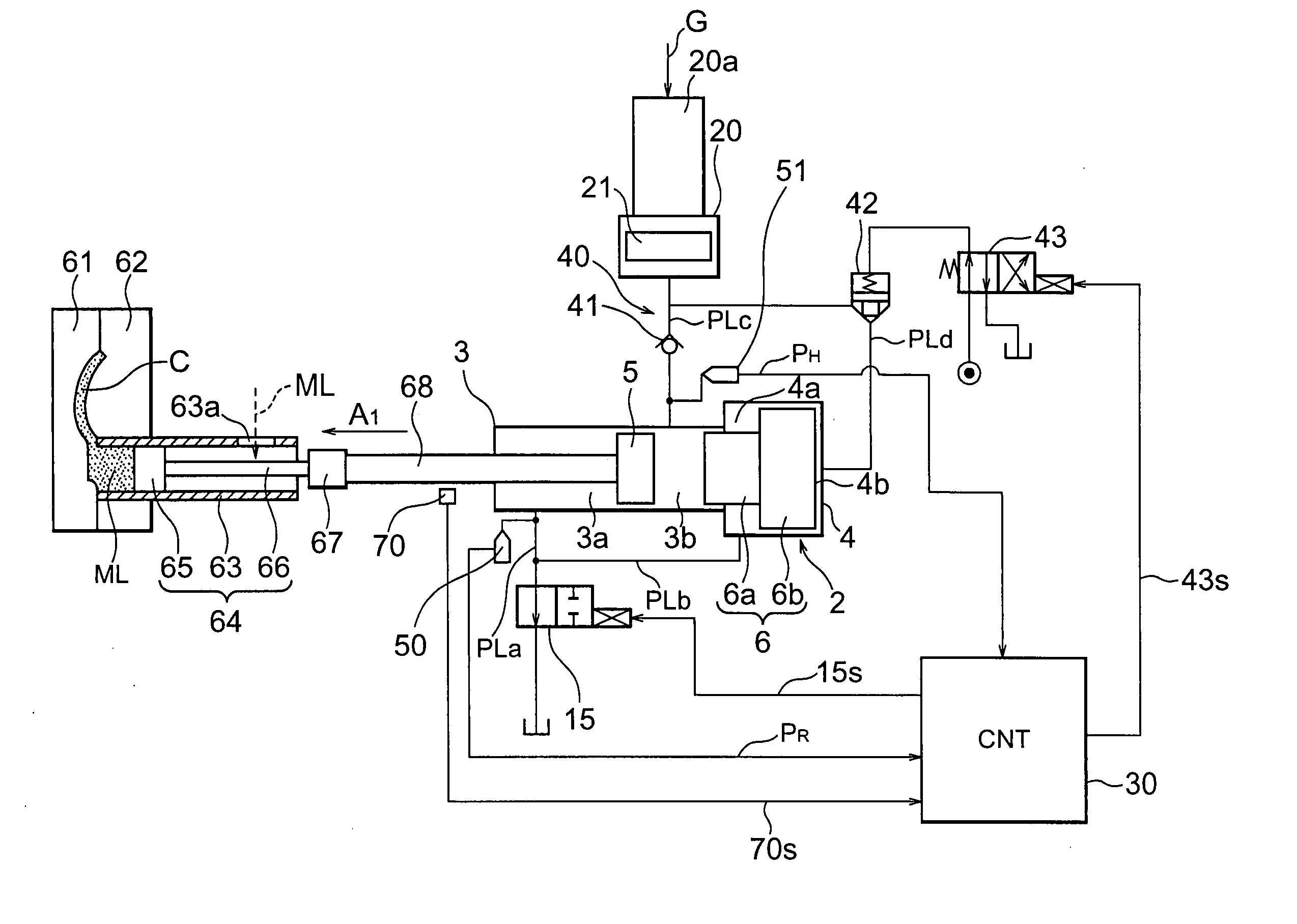

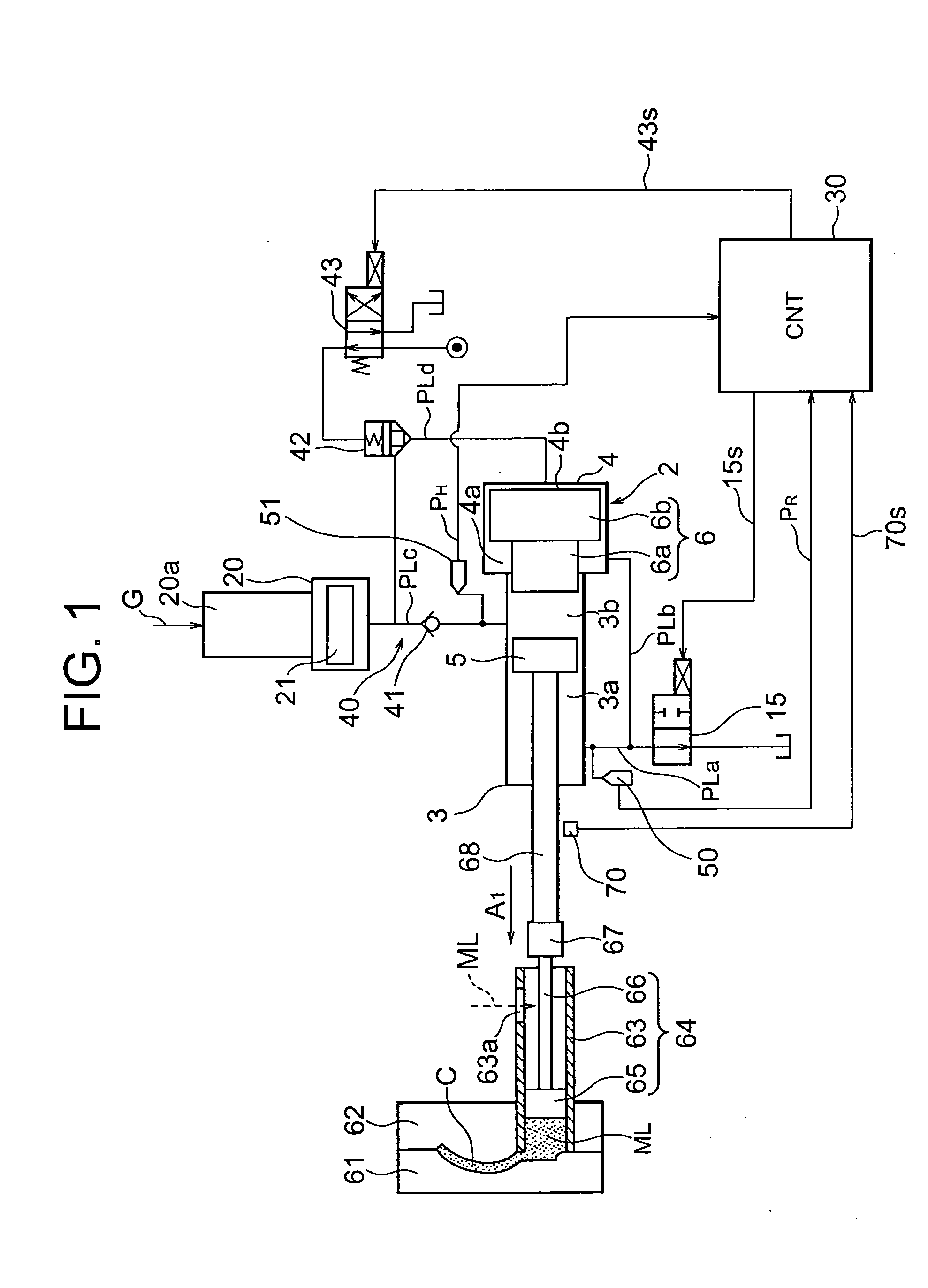

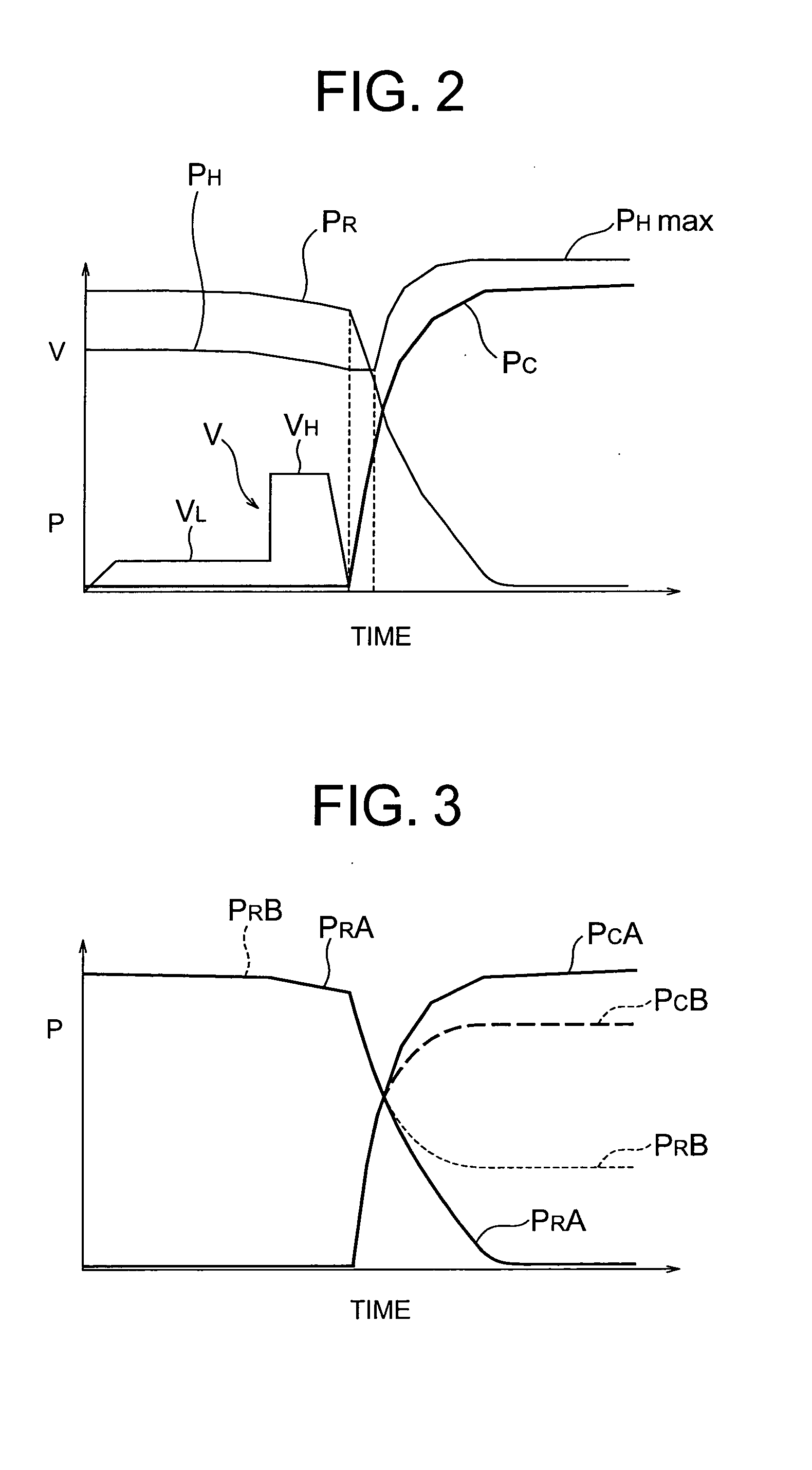

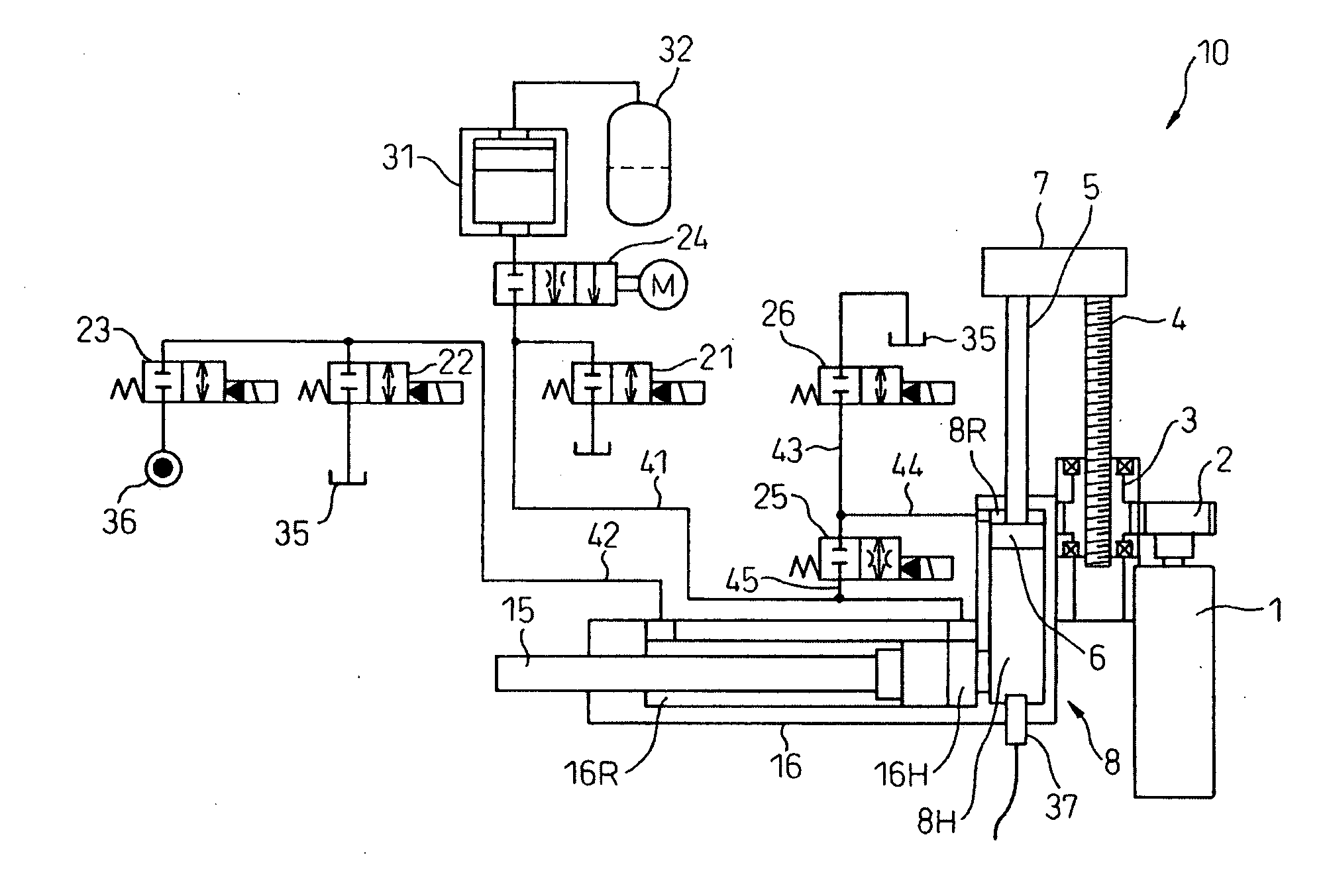

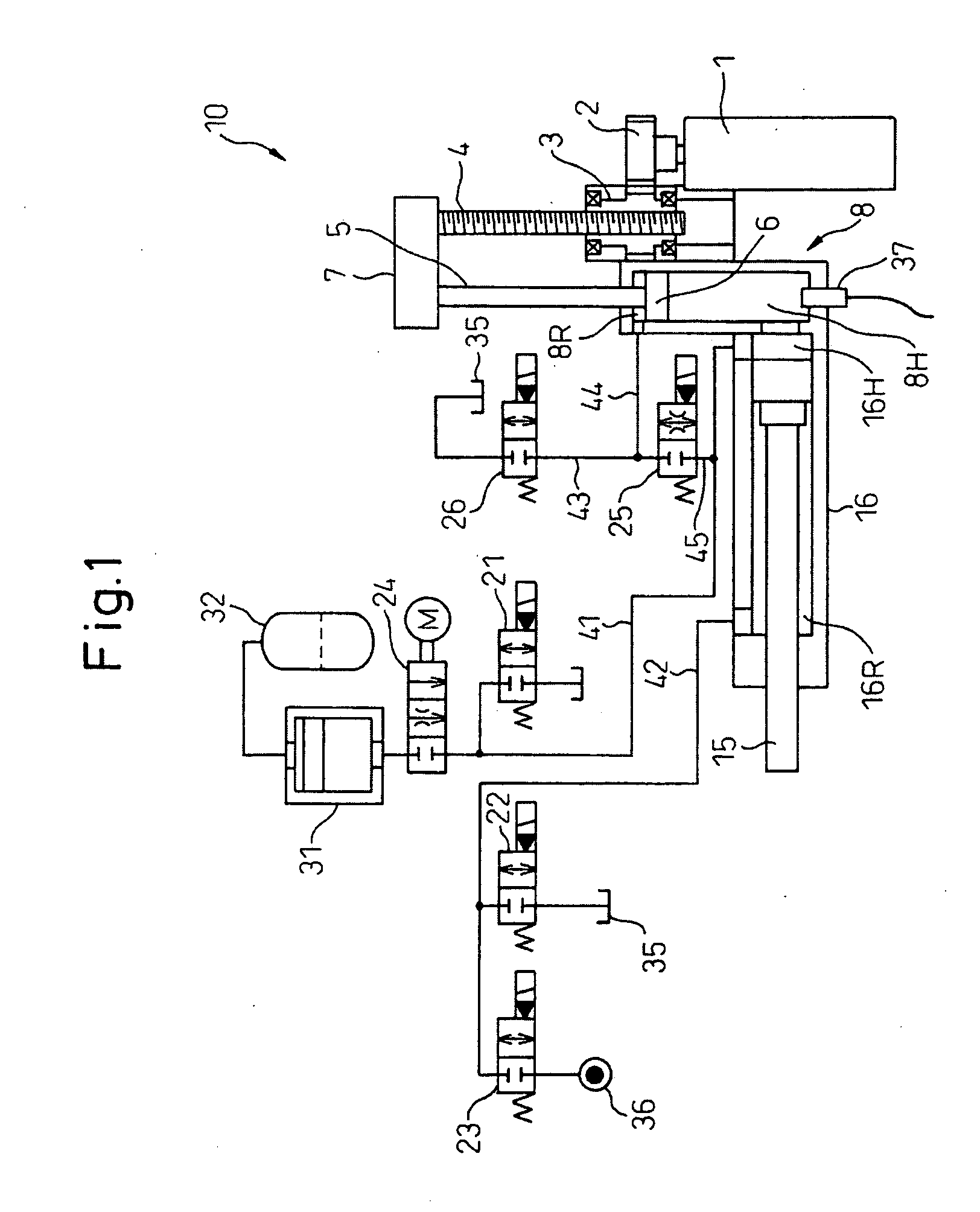

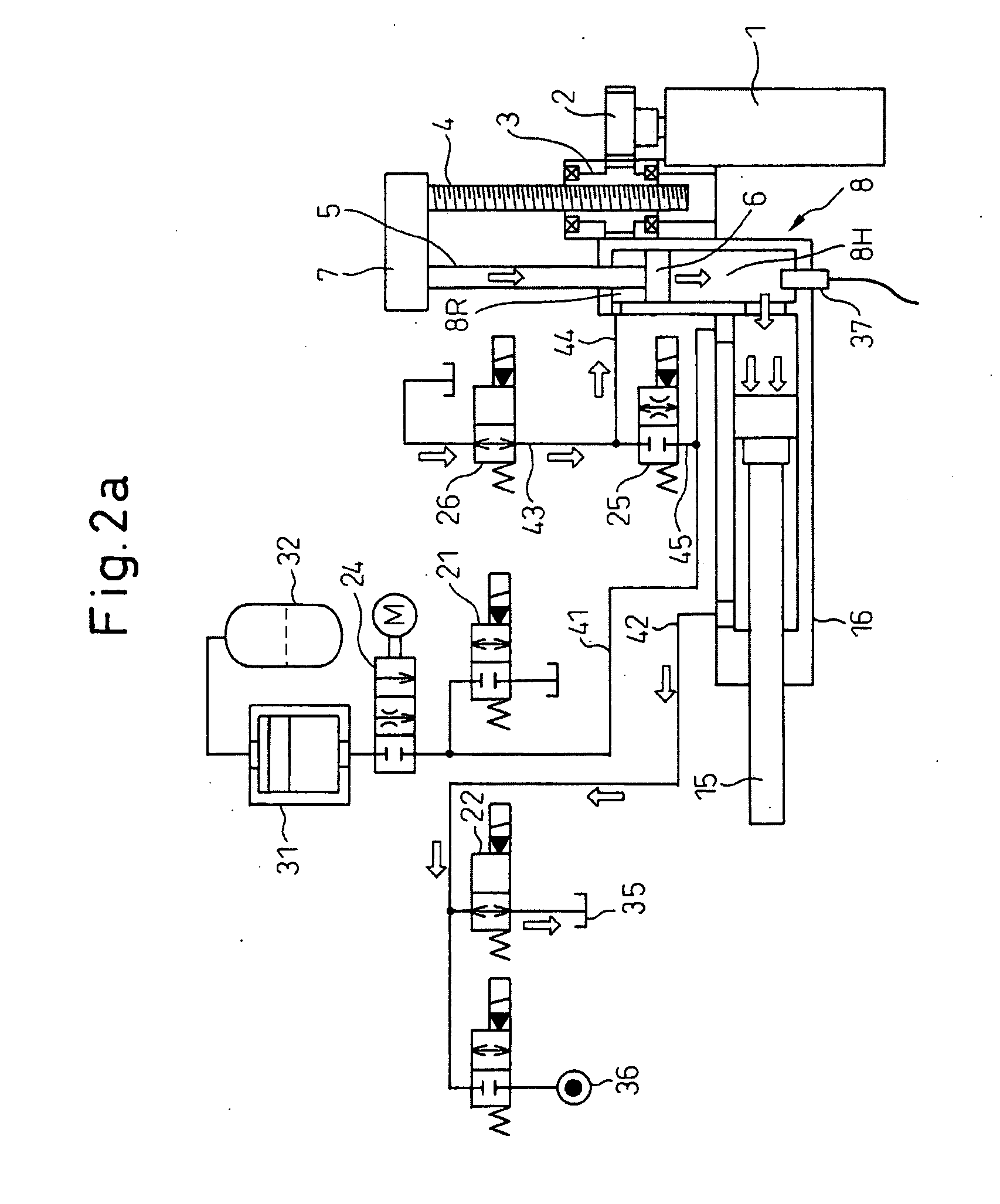

Injection system and casting method of die casting machine

An injection system of a die casting machine giving the necessary casting pressure without adjusting the accumulator side, provided with an injection cylinder including an injection piston linked with the injection plunger and a booster piston arranged behind the injection piston, an accumulator for supplying a pressurized liquid of a predetermined pressure, a liquid pressure circuit for supplying the pressurized liquid from the accumulator to the injection cylinder, driving the injection piston, then driving the booster piston, a control valve for controlling a flow rate of the pressurized liquid discharged from the front side of the injection piston of the injection cylinder so as to control a flow rate of the injection piston, and controlling the pressure of the pressurized liquid at the front side of the injection piston by the timing of closing the control valve to determine the final value of the casting pressure.

Owner:TOSHIBA MASCH CO LTD

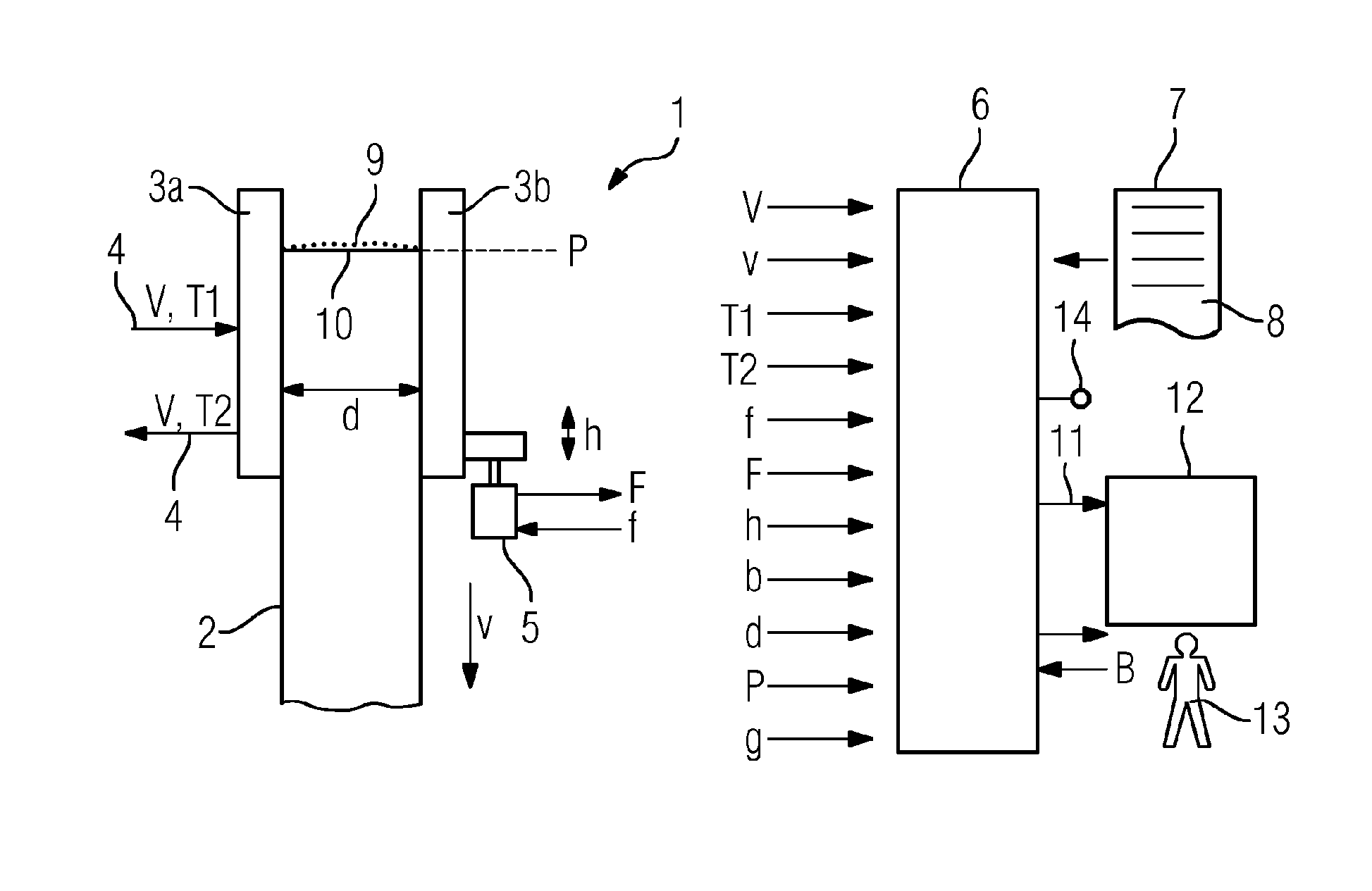

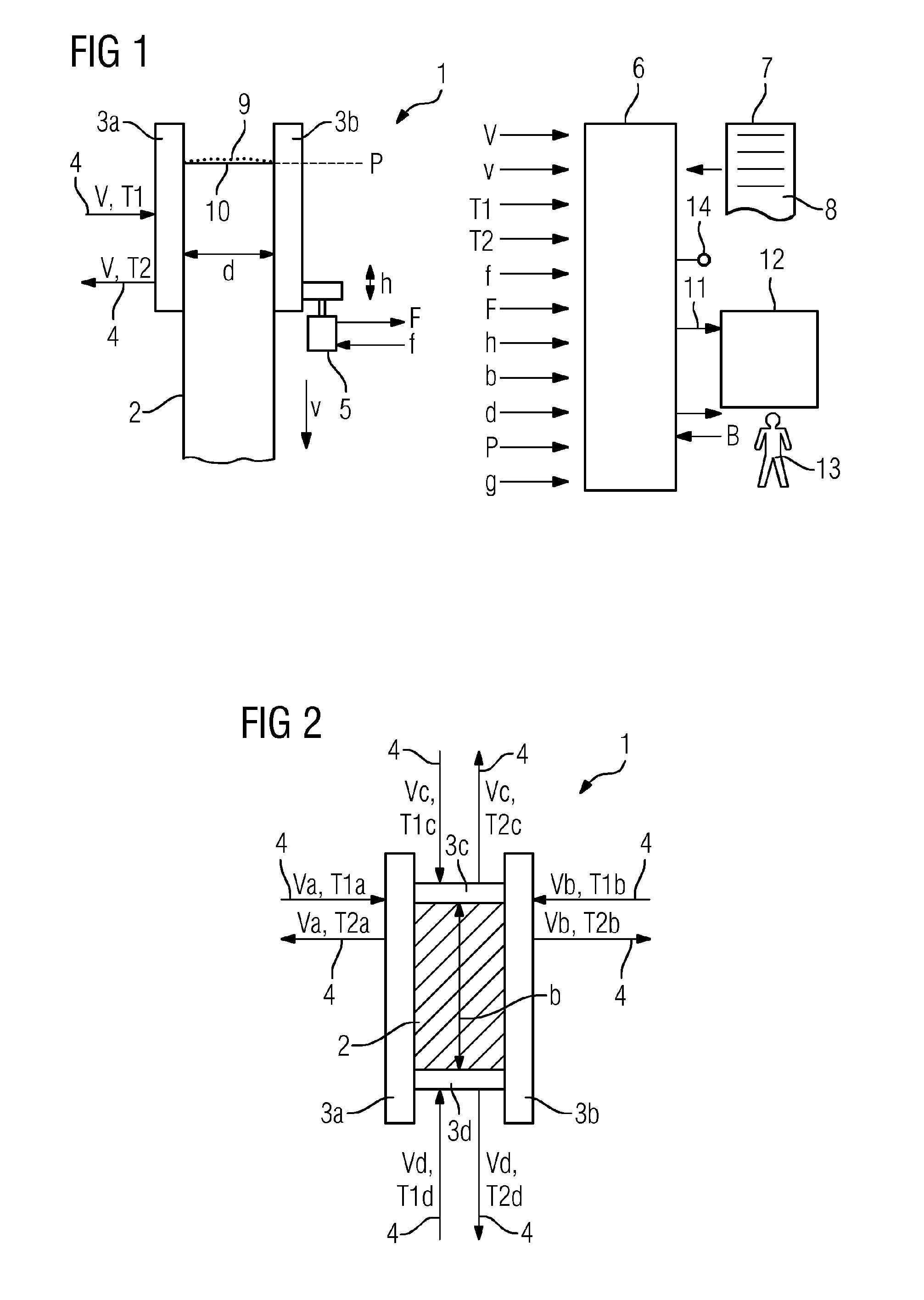

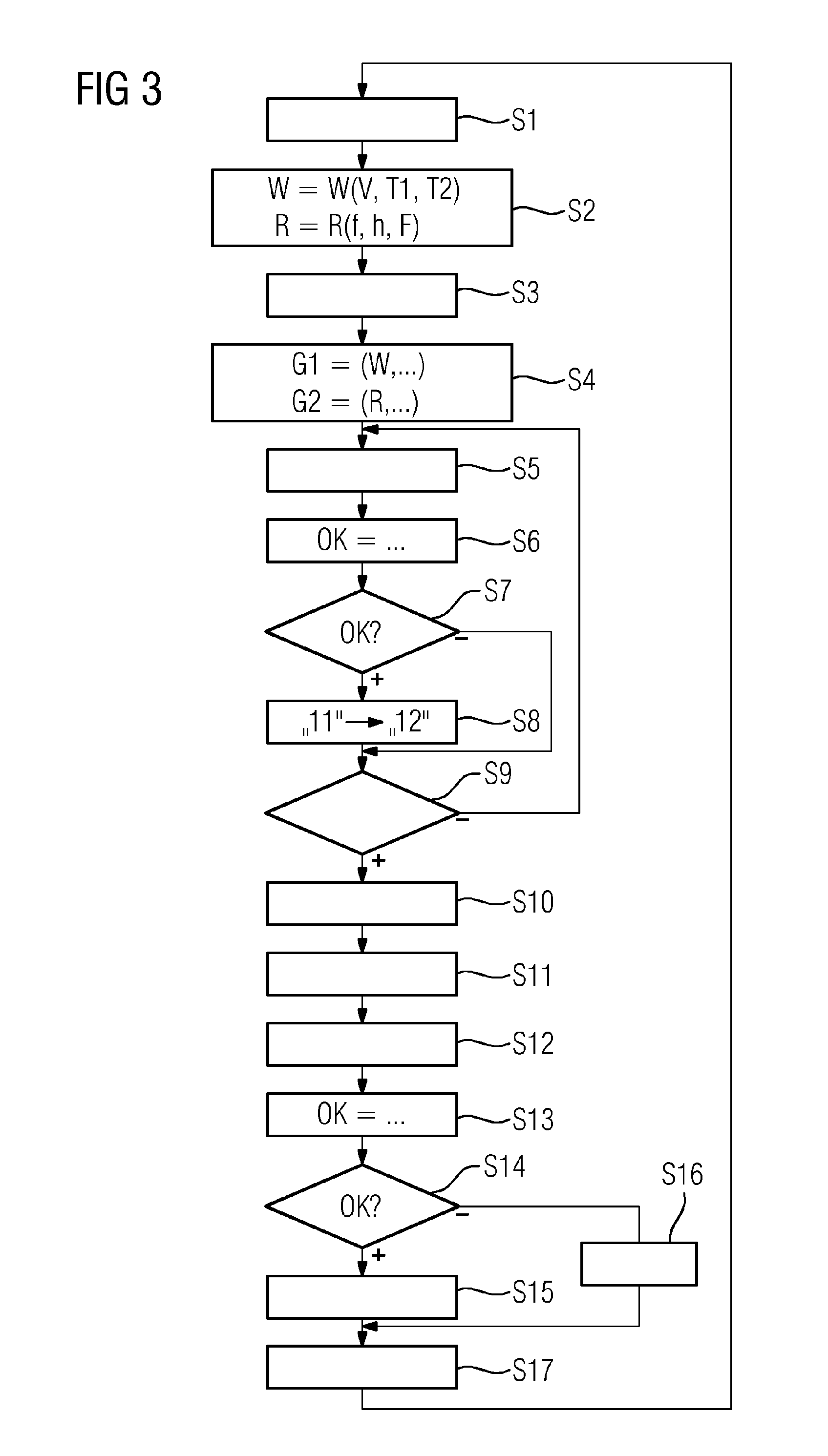

Monitoring method for a continuous casting mould including building up a database

InactiveUS20150314368A1Casting safety devicesMould controlling devicesStability criterionMaterials science

A monitoring device (6) records variables that are characteristic of operating parameters of a continuous casting mold (1) for casting a metal strand (2). The monitoring device (6) records at least some of the characteristic variables by independently performing measurements during the casting of the metal strand (2). The monitoring device (6) forms groups (G1, G2) of operating parameters and independently tests whether the operating parameters of the respective group (G1, G2) satisfy a respective predetermined stability criterion. The monitoring device (6) accepts the operating parameters into a database (12). The monitoring device (6) determines those data records (11) contained in the database (12) that coincide in their input variables with the basic operating parameters and determines admissible operating parameter ranges for supplementary operating parameters. The monitoring device (6) independently tests whether the supplementary operating parameters lie within the admissible operating parameter ranges.

Owner:PRIMETALS TECH AUSTRIA GMBH

Molding and casting machine

ActiveUS7806161B2Easy to moveEasy to adjustPig casting plantsCasting safety devicesMolding machineSand casting

Disclosed is a sand casting molding machine for double indexing molds in a mold string. The machine can include a shot chamber having sand, a swingable squeeze head, a lateral squeeze head, a core setter, a mold hold down, a mold retention device and a mold string conveyor.

Owner:THYSSENKRUPP WAUPACA

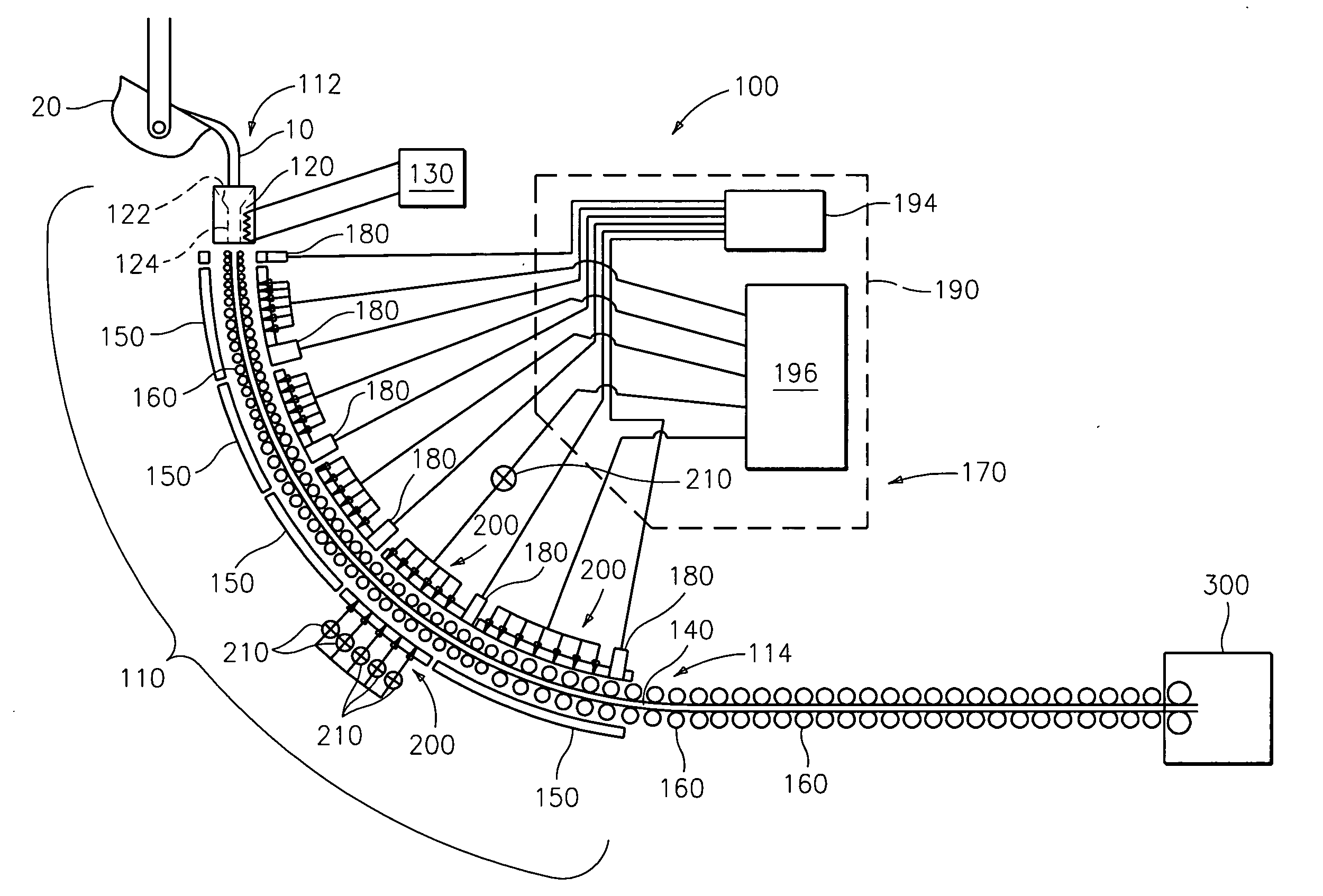

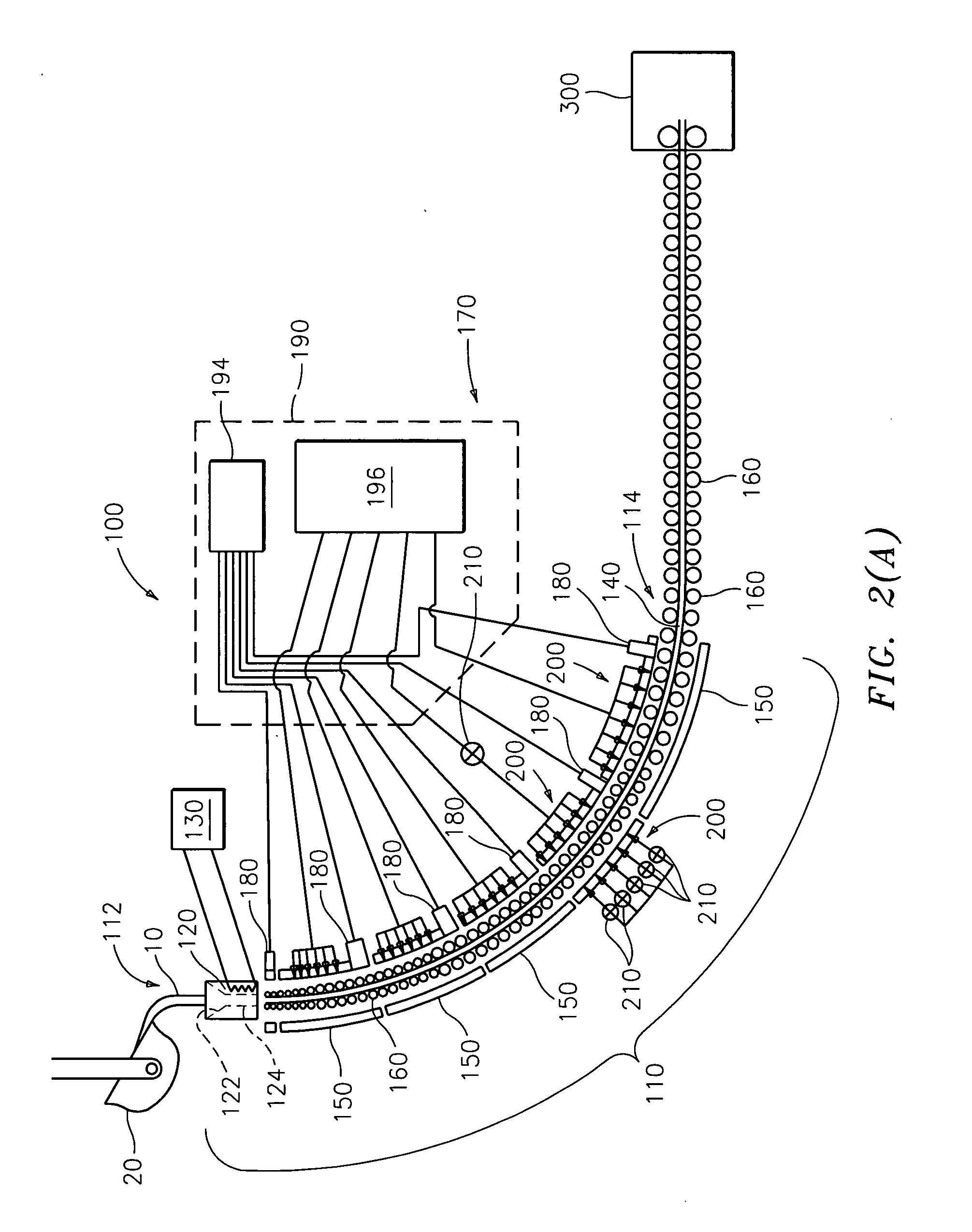

Method and system for tracking and positioning continuous cast slabs

ActiveUS20080264598A1Keep in touchReduce thicknessCasting safety devicesMould controlling devicesControl signalComputer vision

A system and method for tracking and positioning a continuous cast strand in a casting plant. Lateral positions and, optionally, elevational positions of a cast strand are monitored by sensors as casting proceeds and are fed to a computer-based system as corresponding position information where the information is stored as associated data. The computer-based system processes the associated data and generates corresponding control signals which are used to control at least one correcting device to maintain desired orientation of the cast strand as casting proceeds.

Owner:NUCOR CORP

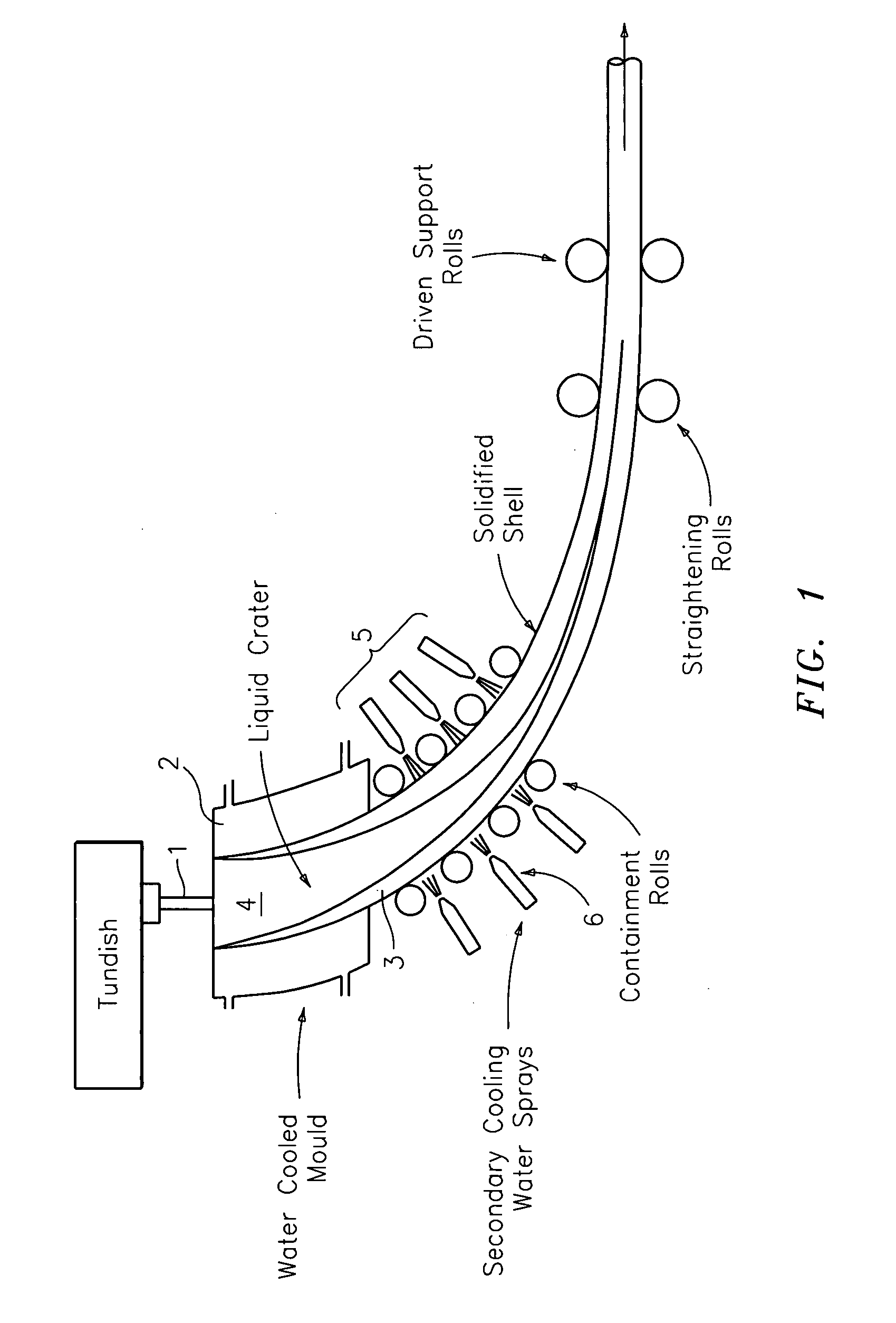

Active temperature feedback control of continuous casting

InactiveUS20070251663A1Uniform surface temperatureImprove efficiencyTemperature control using plurality of sensorsCasting safety devicesEngineeringFeedback control

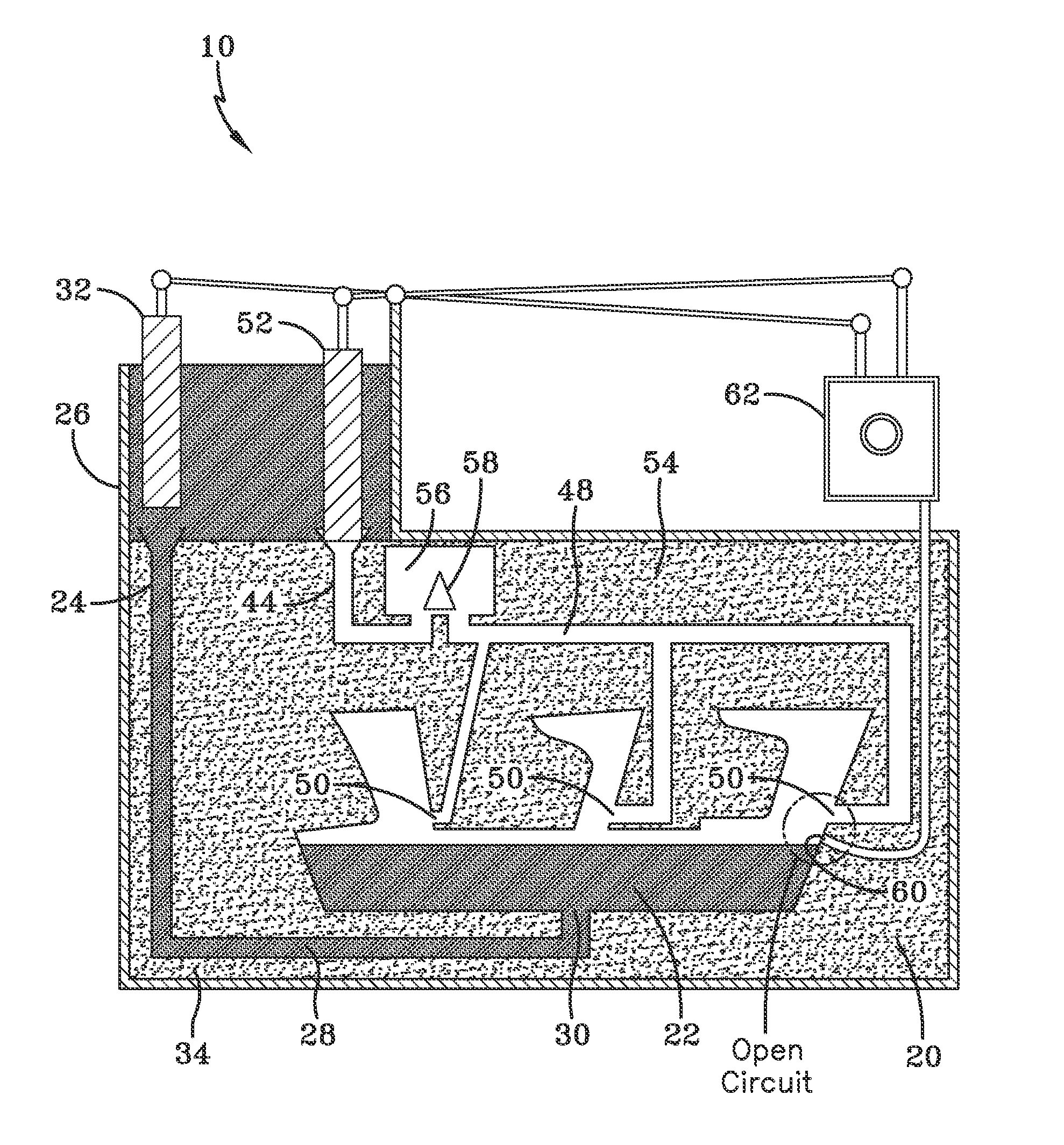

The invention includes a system, method and machine readable program for dynamically controlling the casting of a material. Generally, the systems and methods described herein include an active control feedback system or aspects thereof including a temperature sensing device that is well-suited for the harsh environment of the interior of a caster such as a caster for casting metal. Temperature measurement can be accomplished either directly or indirectly. The system is configured to compare the measured temperature with an ideal casting temperature. The temperature sensing device is operably coupled to a cooling device that modulates a flow of coolant to dynamically cool the material being cast. In accordance with one embodiment of the invention, the cooling device includes a plurality of nozzles for delivering one or more cooling fluids to the material being cast.

Owner:ROSEMOUNT AEROSPACE +1

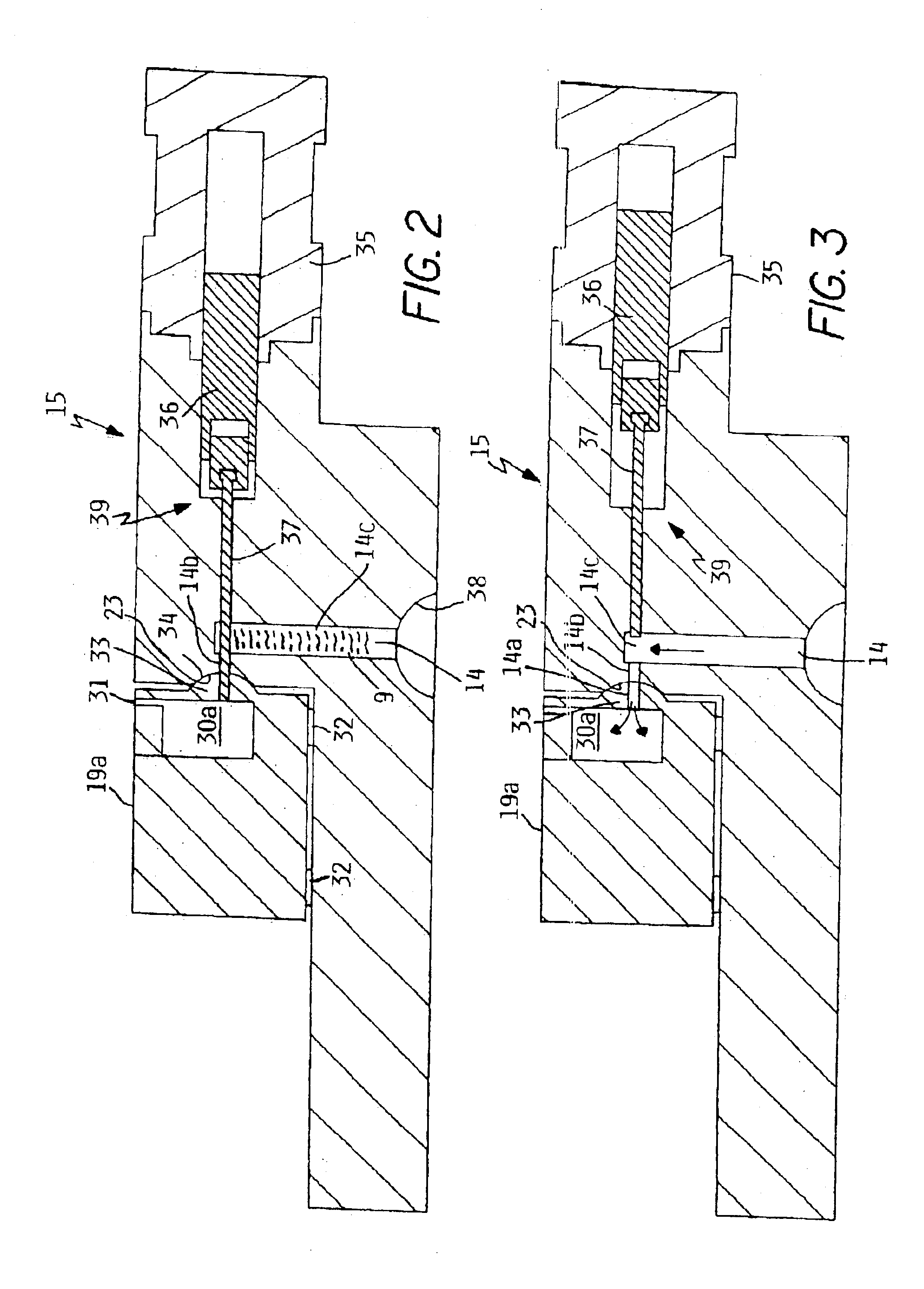

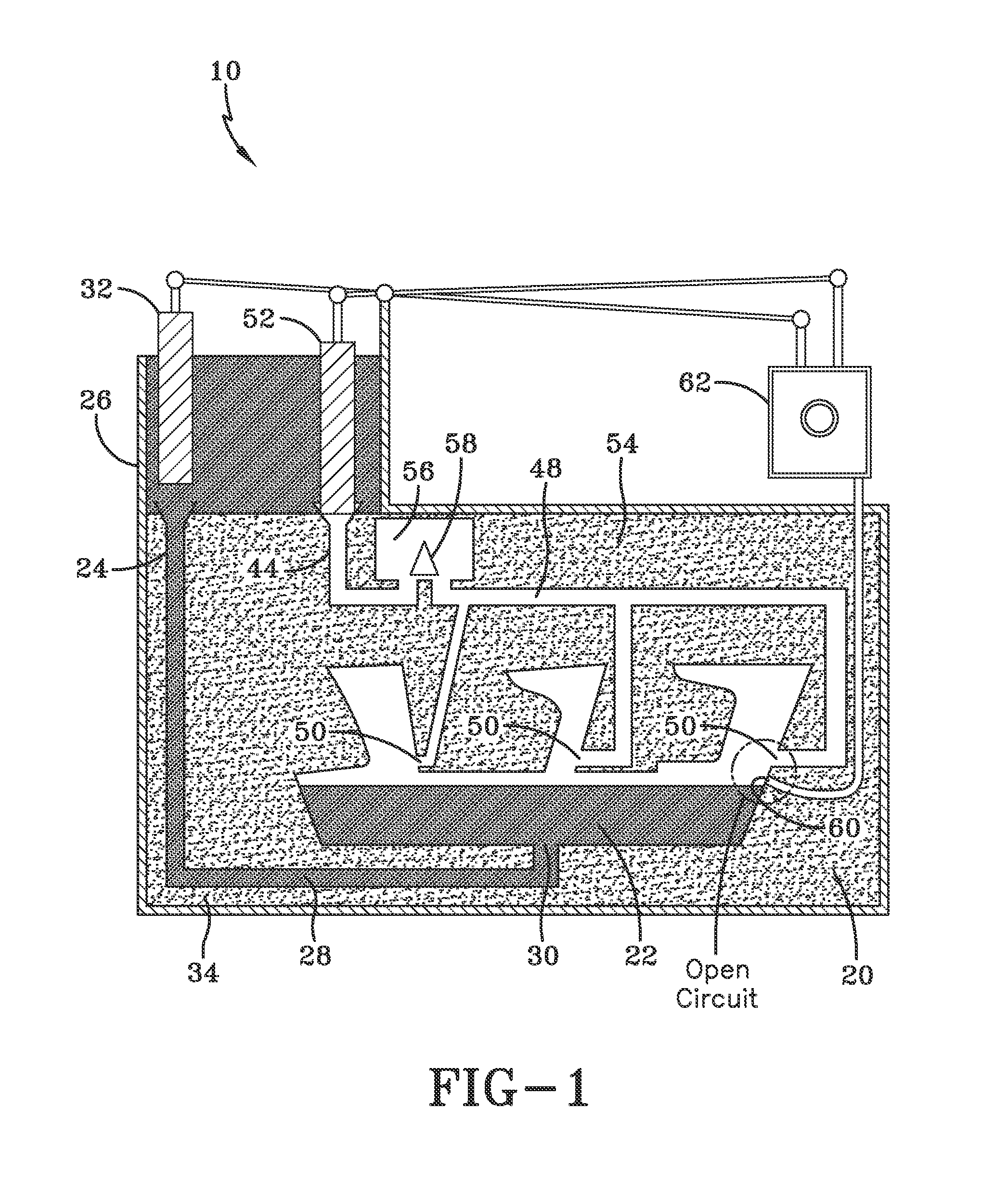

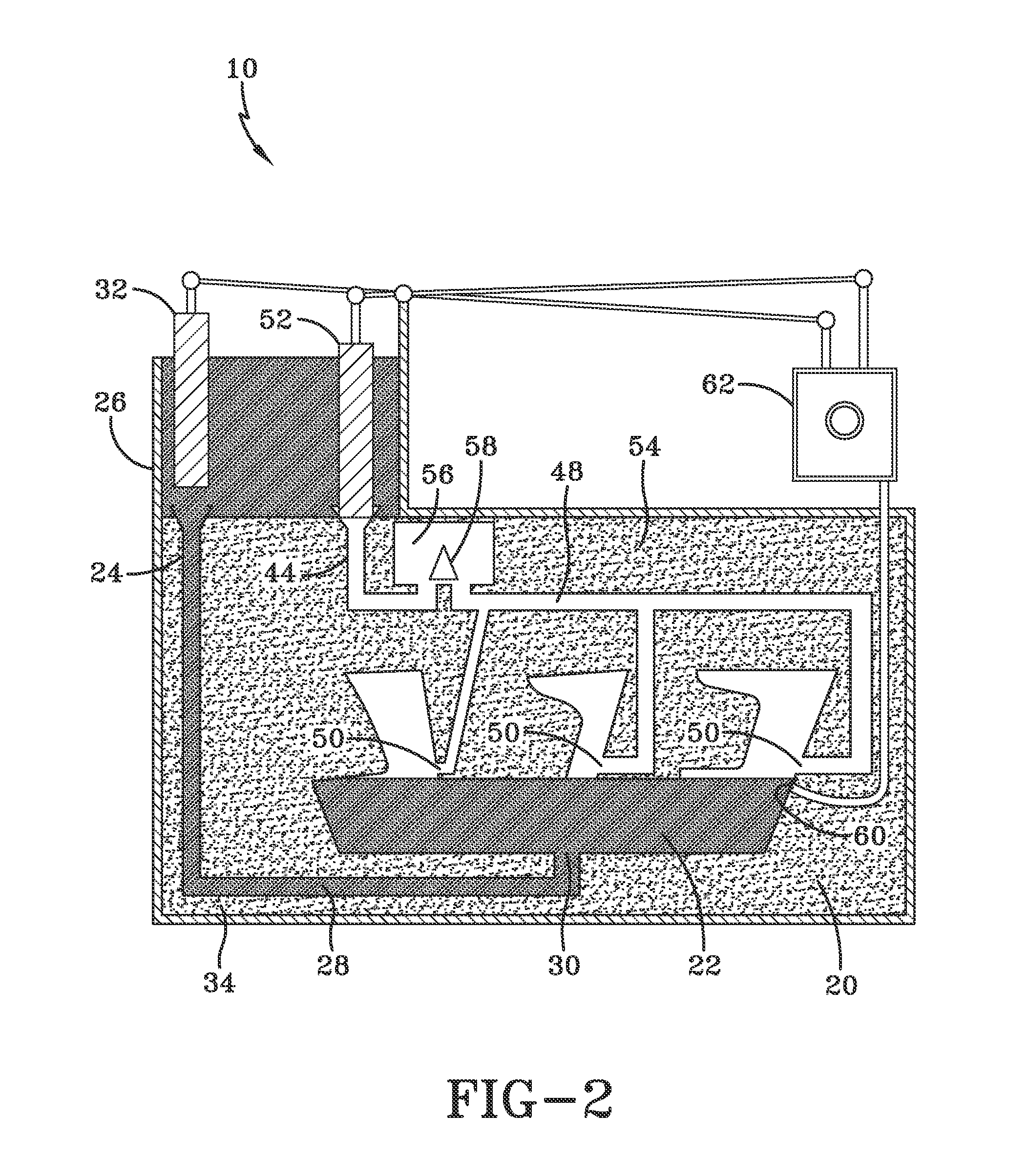

Apparatus and method of forming parts

InactiveUS6896031B2Minimizes shrinkageAvoid enteringMolten metal pouring equipmentsMolten metal supplying equipmentsMolten stateCasting

A closed system and method that includes a source of pressurizeable molten lead connected to a mold having a mold cavity therein with the mold maintainable at sufficiently low temperature so that a charge of molten lead located in the mold cavity solidifies to thereby form a solidified casting in the mold cavity. A housing having a runner, is maintainable at sufficiently high temperature to maintain the molten lead in a molten state so that the mold cavity can be refilled with a fresh charge molten lead when a solidified casting is removed therefrom without introducing air to the closed system. A shut-off valve, having an open position to allow a charge of molten lead to flow into the mold cavity and a closed position to prevent molten lead from flowing out of the runner as the molten lead in mold cavity solidifies with the shut-off valve configurable to intensify the pressure of the lead in the mold cavity.

Owner:WATER GREMLIN

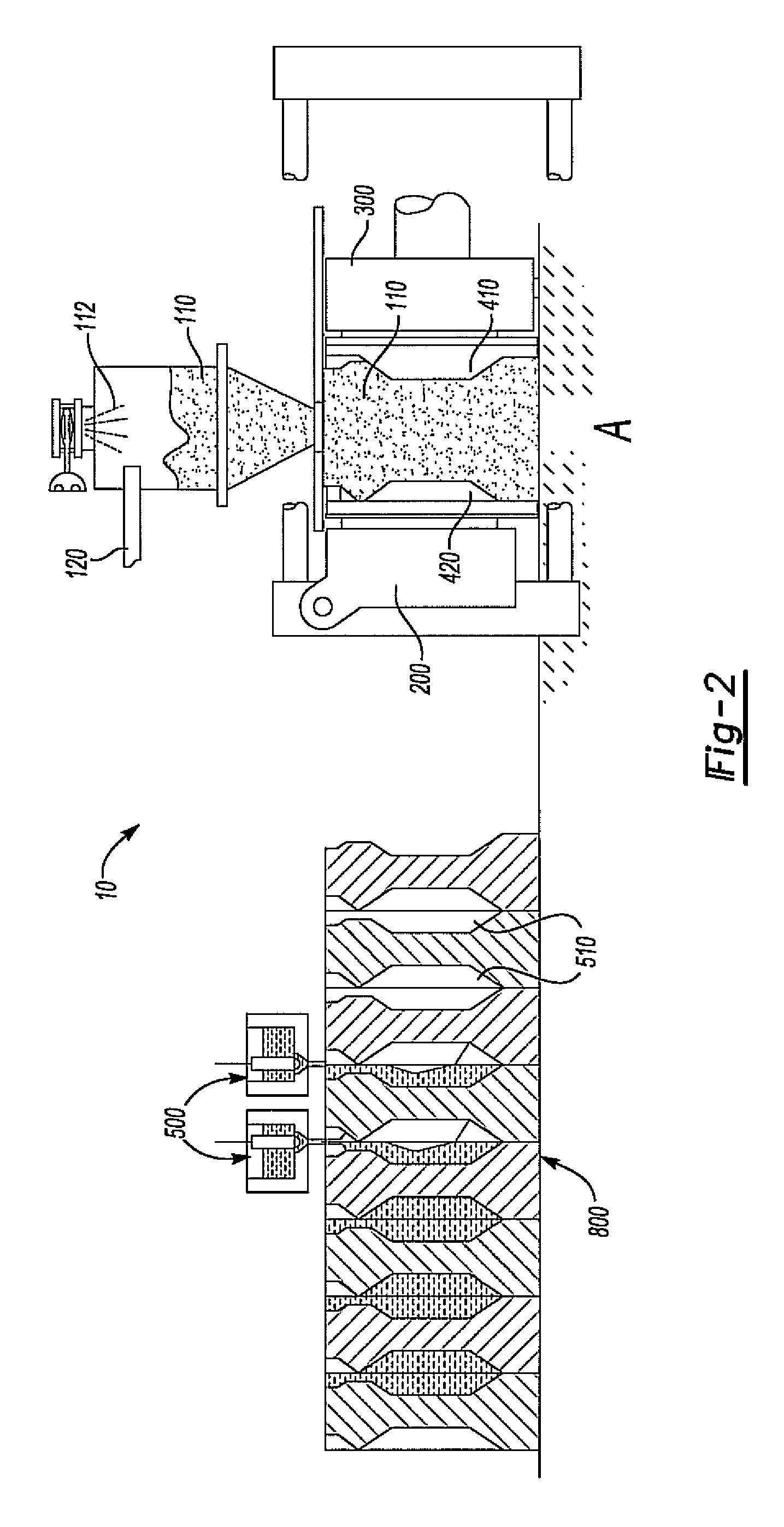

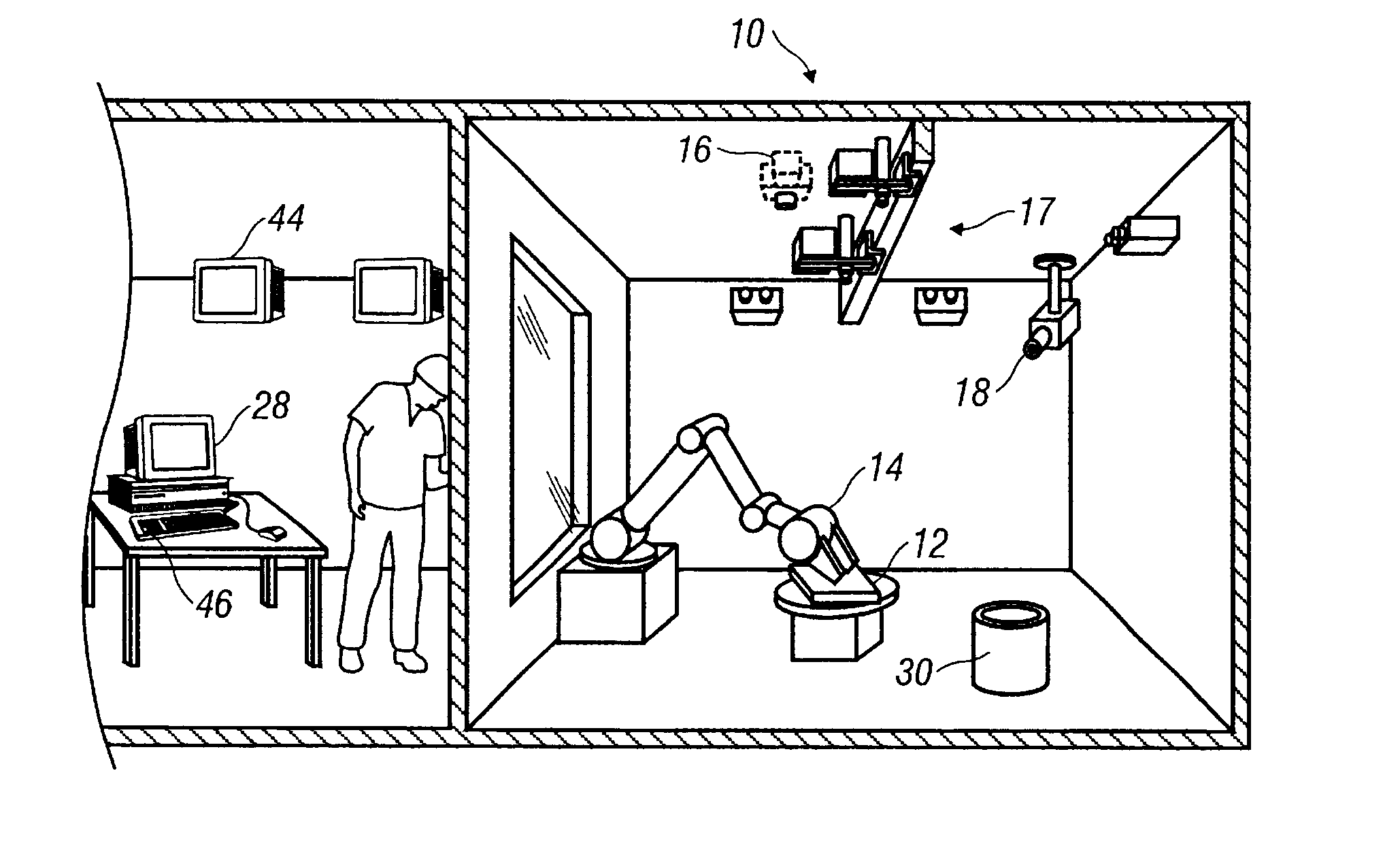

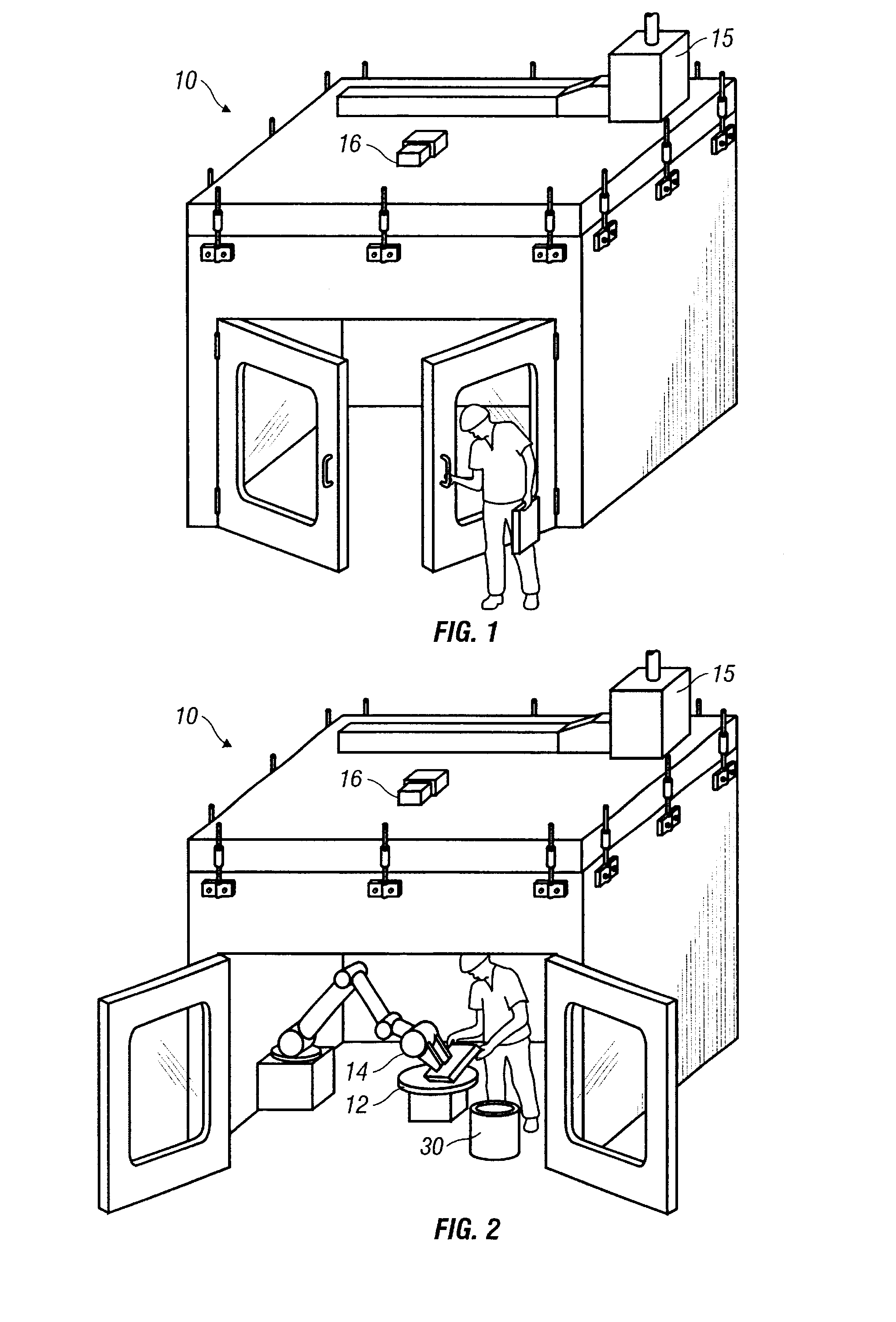

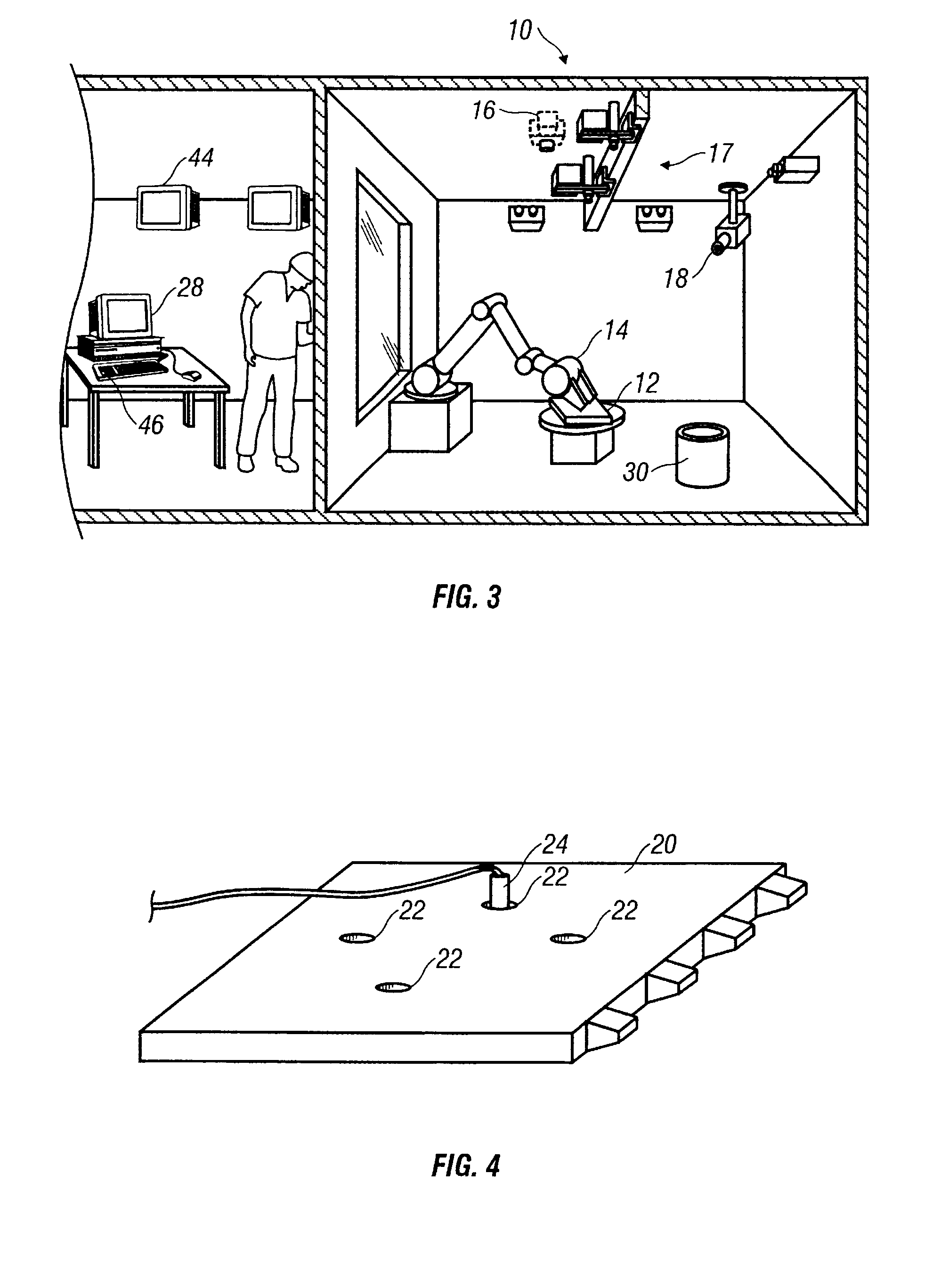

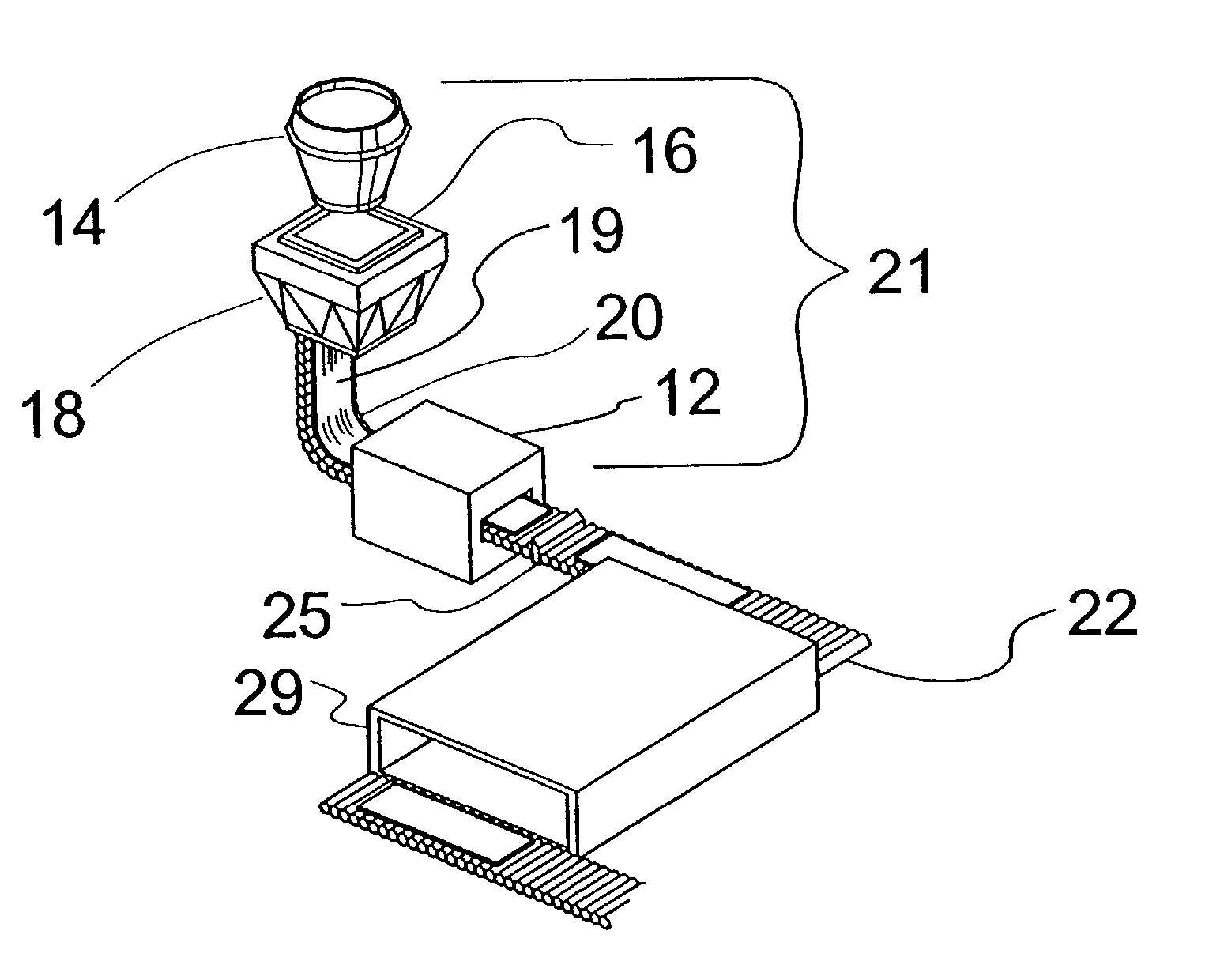

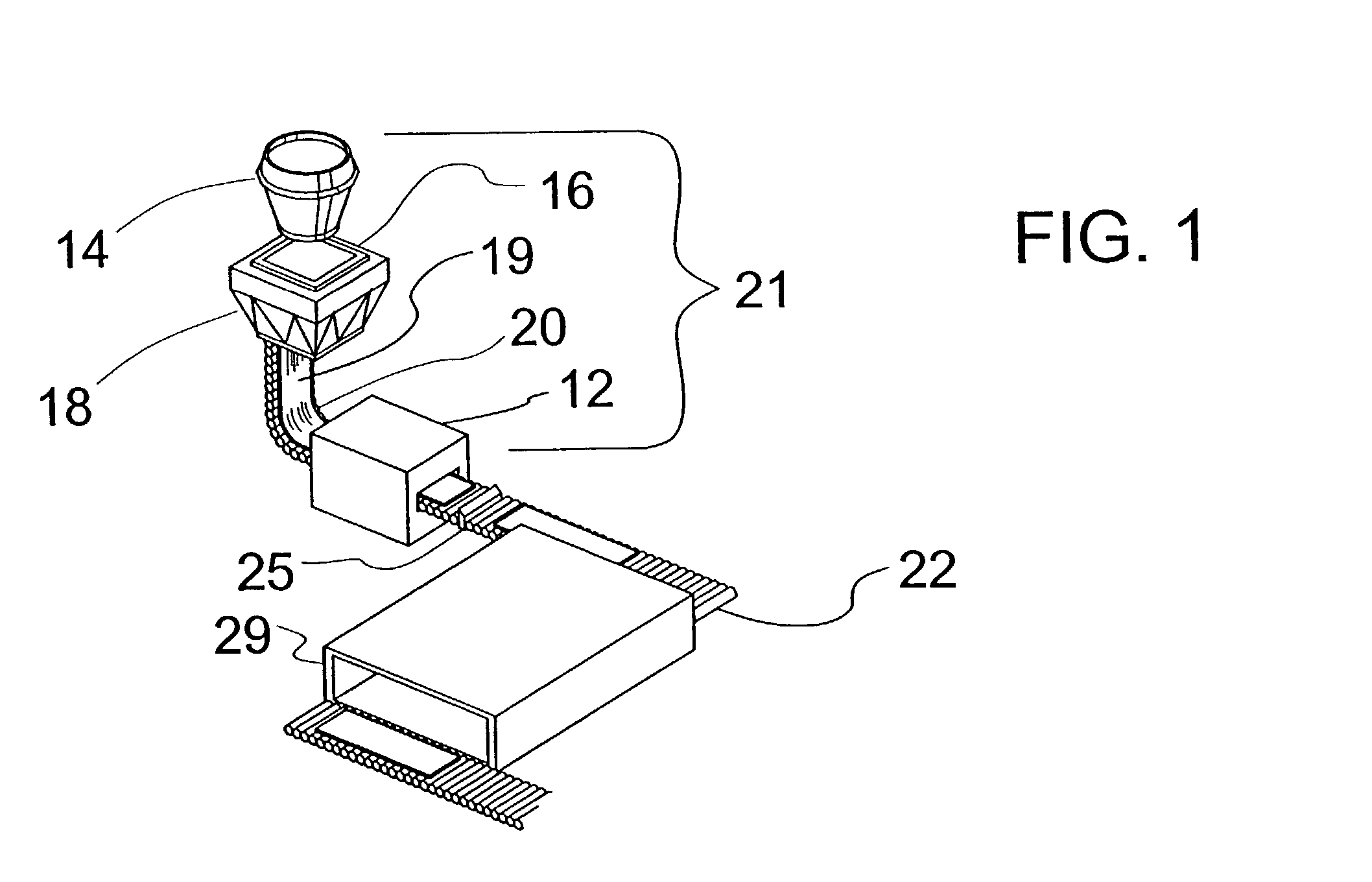

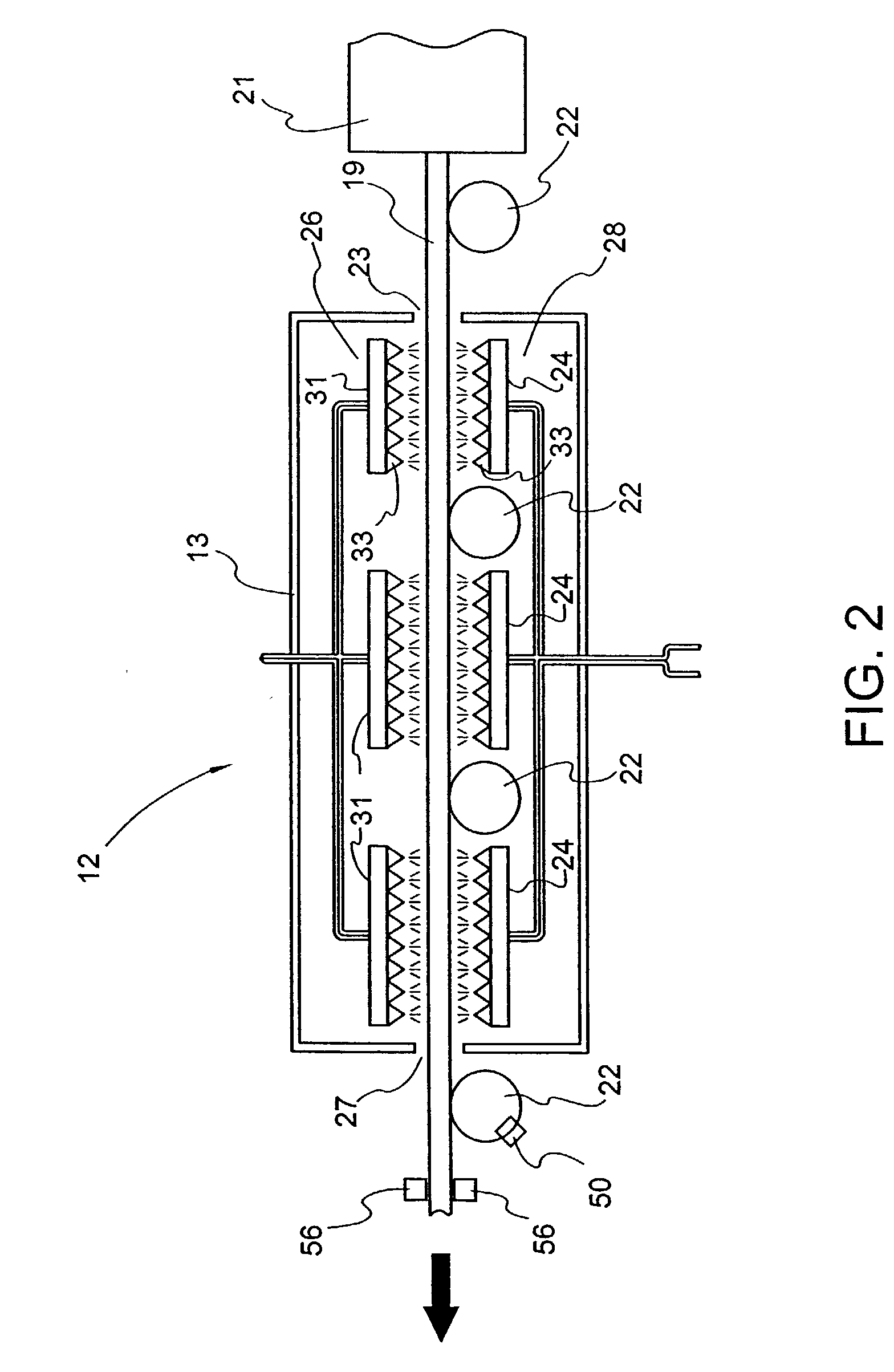

Automated spray form cell

InactiveUS6640878B2High sensitivityAccurate distributionMolten spray coatingCasting safety devicesStress inducedAutomotive industry

Owner:FORD MOTOR CO

Differential quench method and apparatus

InactiveUS20020129921A1Facilitate transverse temperature equalizationReduce surface temperatureTemperature control deviceCasting safety devicesSurface layerMetallurgy

Surface defects in rolled steel are remedied by quenching a surface layer of the steel product downstream of the caster and upstream of the reheat furnace by transversely differentiated quenching to match the transverse temperature profile of the steel product. The flow rate of the quench spray is differentially adjustable across the width and optionally the length of the steel product. An array of spray nozzles controlled in transversely or longitudinally arranged groups provides the quench spray.

Owner:UNTRA PREMIUM OILFIELD SERVICES LTD

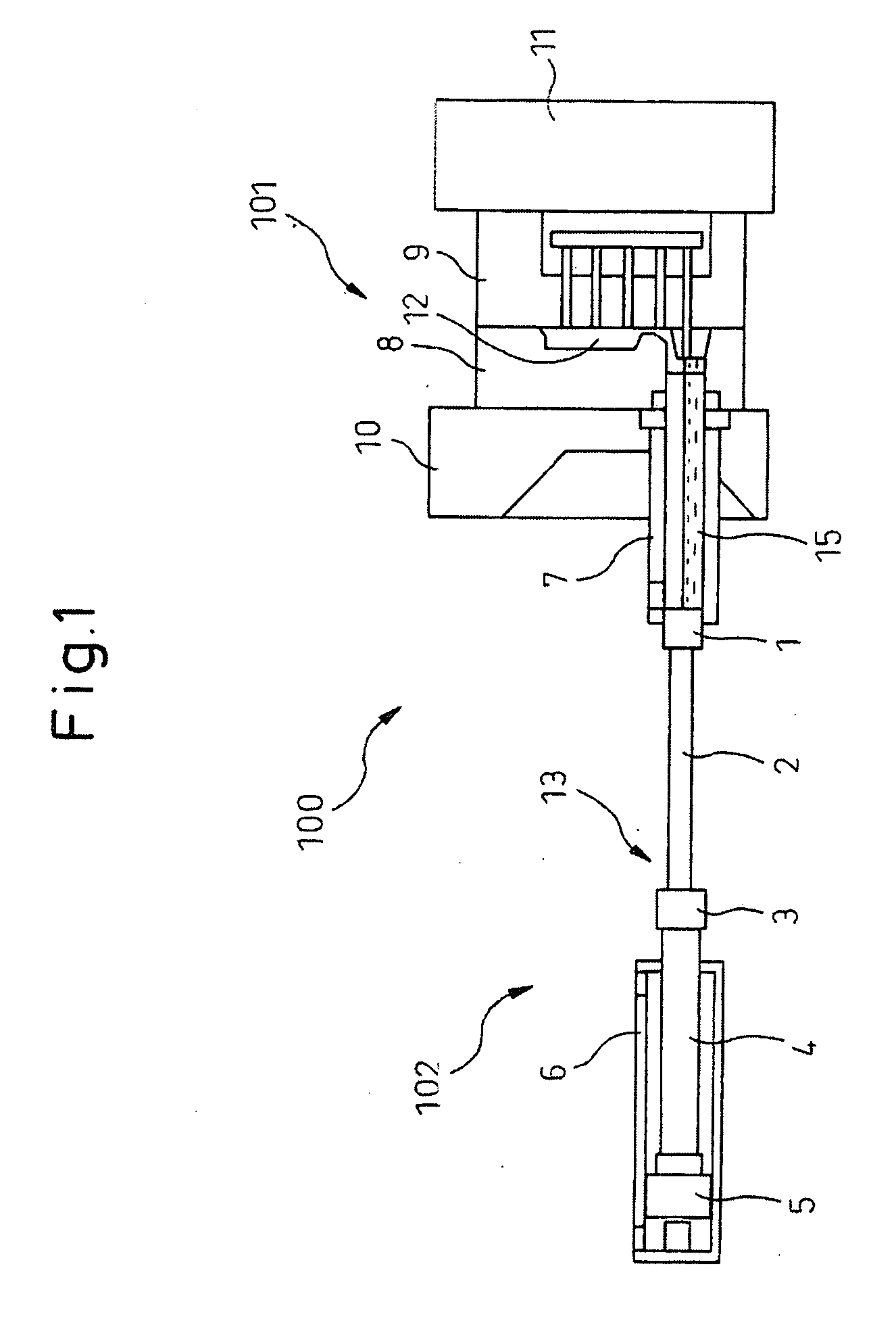

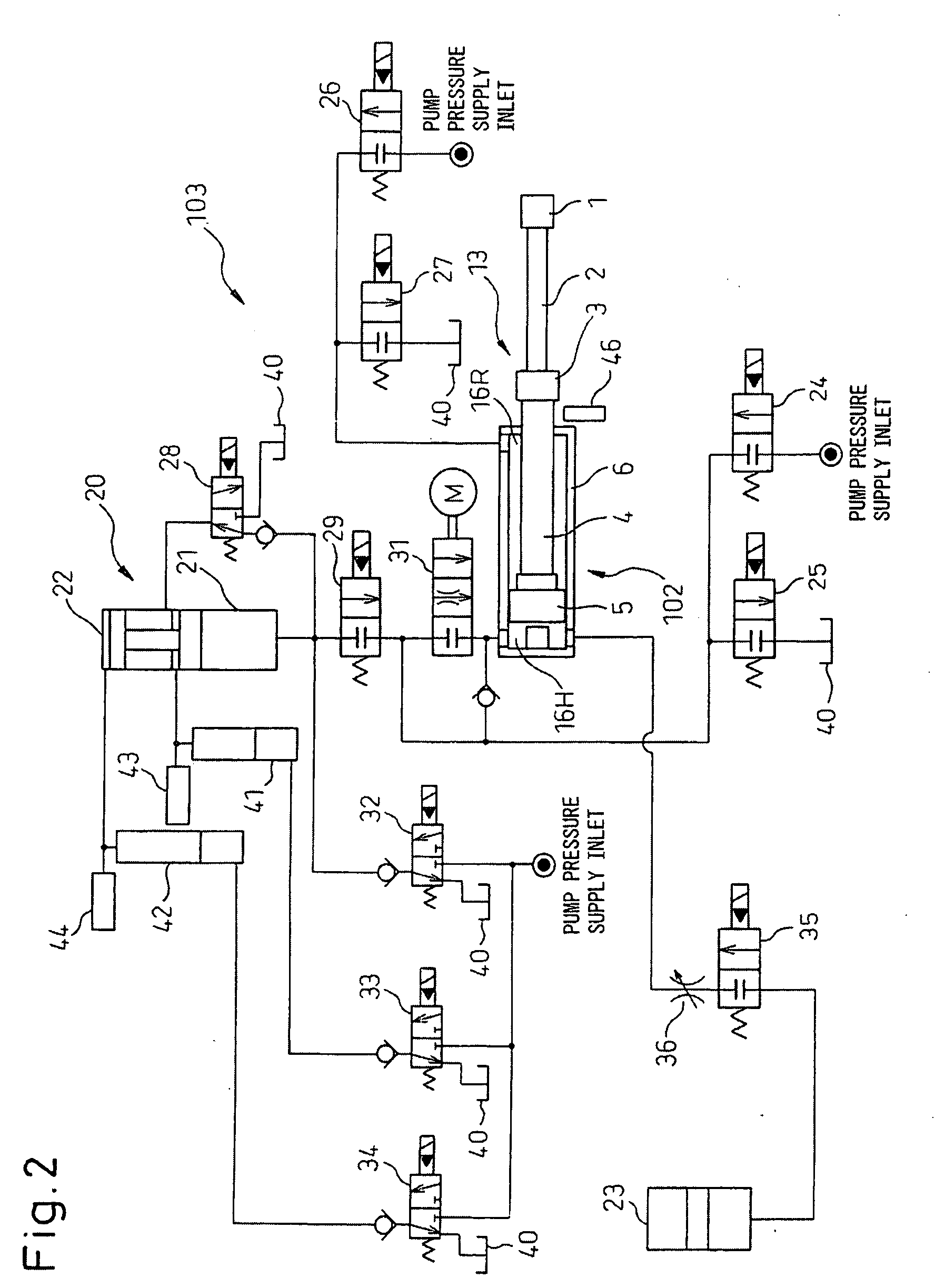

Injection device for die casting machine

InactiveUS20090242161A1Reducing necessary maximum torqueLower injection costsMoulding plantsCasting safety devicesHydraulic cylinderPower flow

In a hybrid injection system of a die casting machine, the occurrence of a large electric power loss can be prevented by avoiding a large current at a pressure-holding step and the size of a motor is reduced.In an injection system comprising an injection cylinder (16) housing an injection piston (15) for injecting molten metal to a mold and an electric booster (8) of hydraulic cylinder type, a head chamber (8H) to the electric booster communicates fluidly with a head chamber (16H) of the injection cylinder, causing a booster piston rod (5) to be housed in the electric booster (8) to move linearly and thus pressing under pressure to move the injection piston to perform injection molding. Because a stop valve (25) is provided in a pipe that causes the head chamber (16H) of the injection cylinder to communicate with a rod chamber (8R) of the booster (8), it is possible for the pressure of the hydraulic oil to act on a head area of the electric booster at a pressure-increasing step for increasing pressure of the molten metal, and for pressure of the hydraulic oil to act on a rod area of the electric booster at a pressure-holding step for holding pressure of the molten metal.

Owner:UBE MASCH CORP LTD

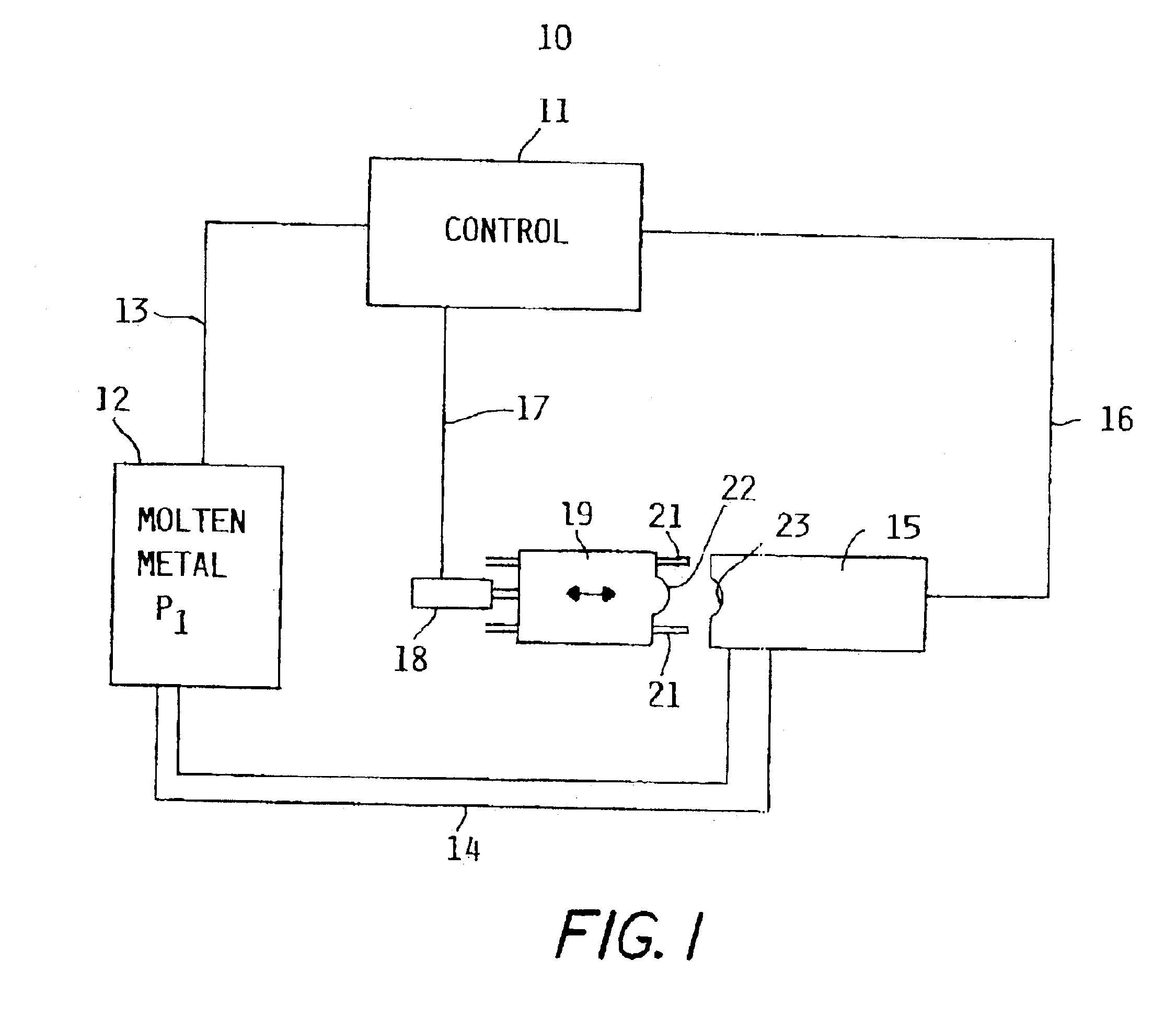

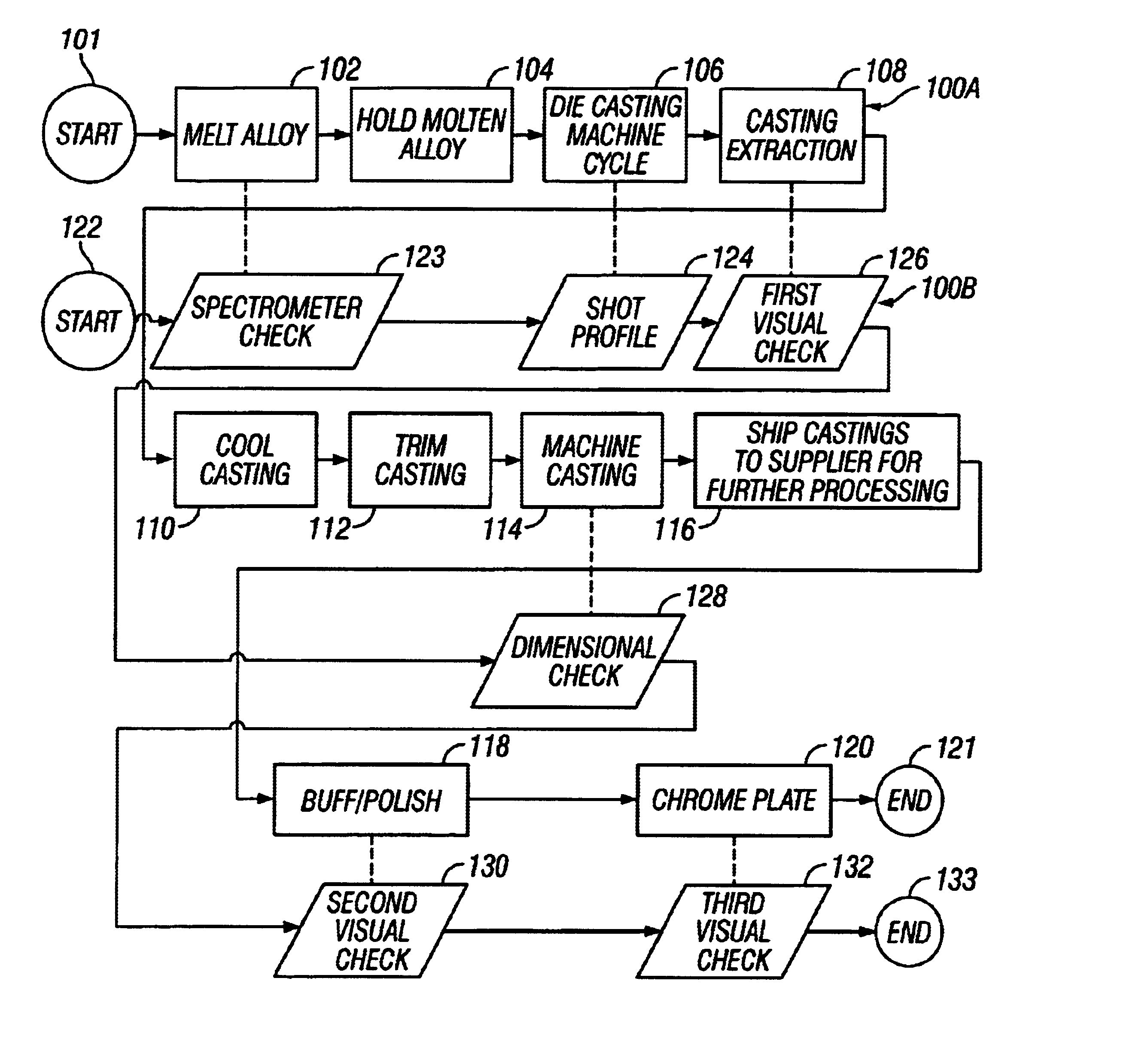

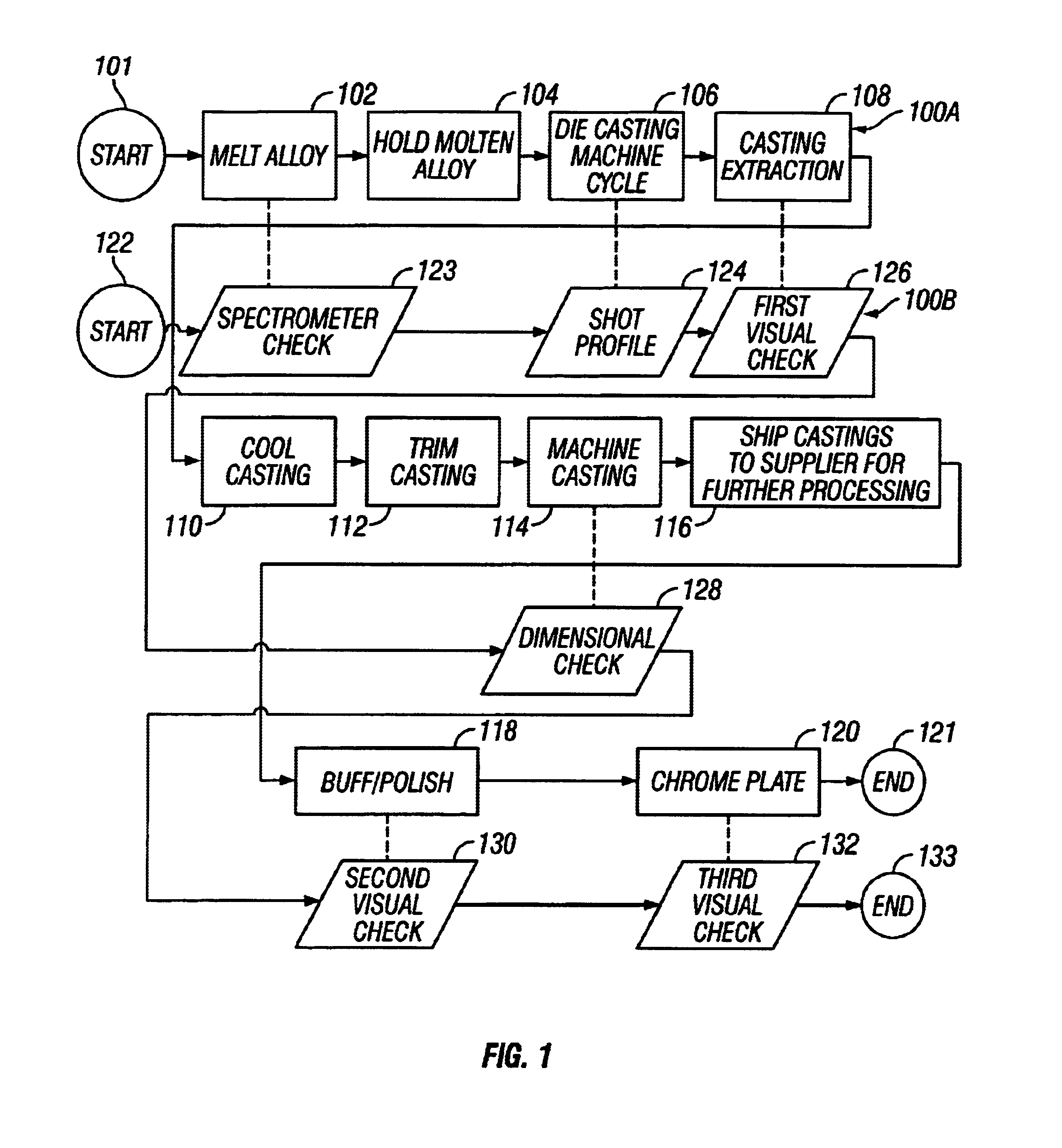

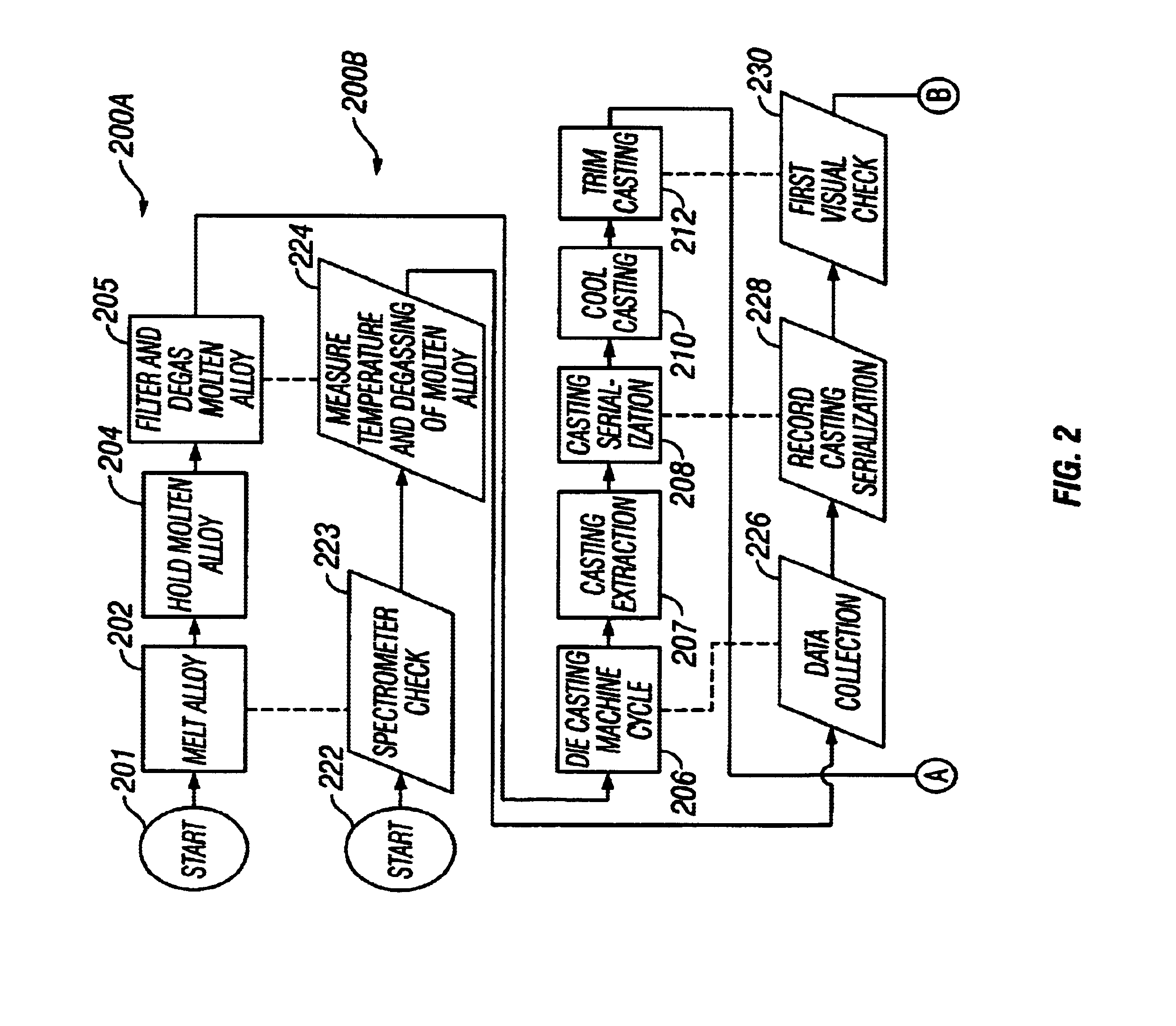

Die casting process incorporating computerized pattern recognition techniques

A die casting process using pattern recognition techniques to identify those die castings manufactured under conditions likely to produce a die casting which would subsequently prove unacceptable for use. By promptly identifying such die castings, they may be discarded before being shipped to a remote facility for further processing. As a result, the rejection rate of die castings at the remote facility may be reduced and the raw materials used to form the discarded die castings may be more readily recycled.

Owner:PACE IND LLC A DELAWARE CO

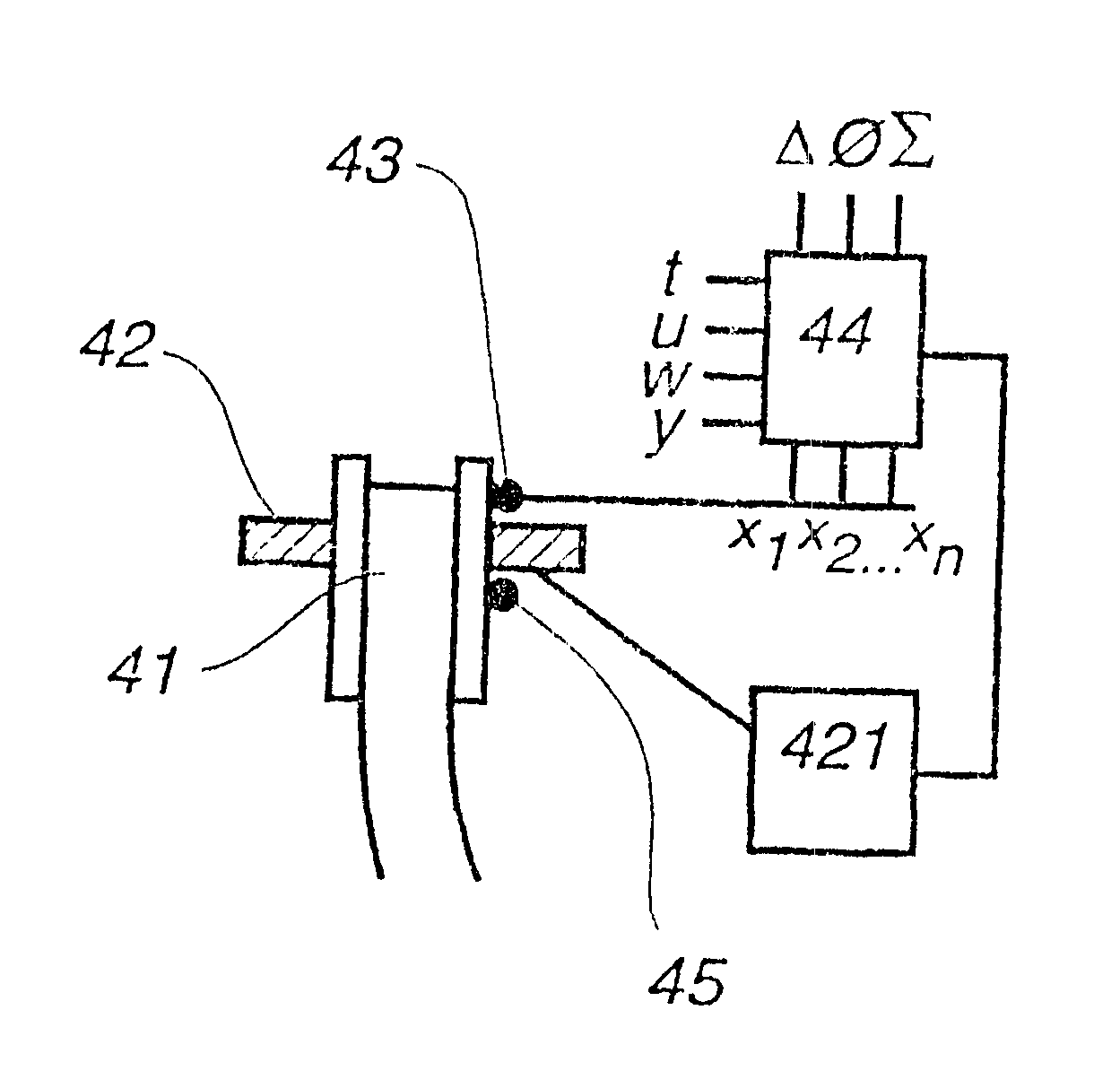

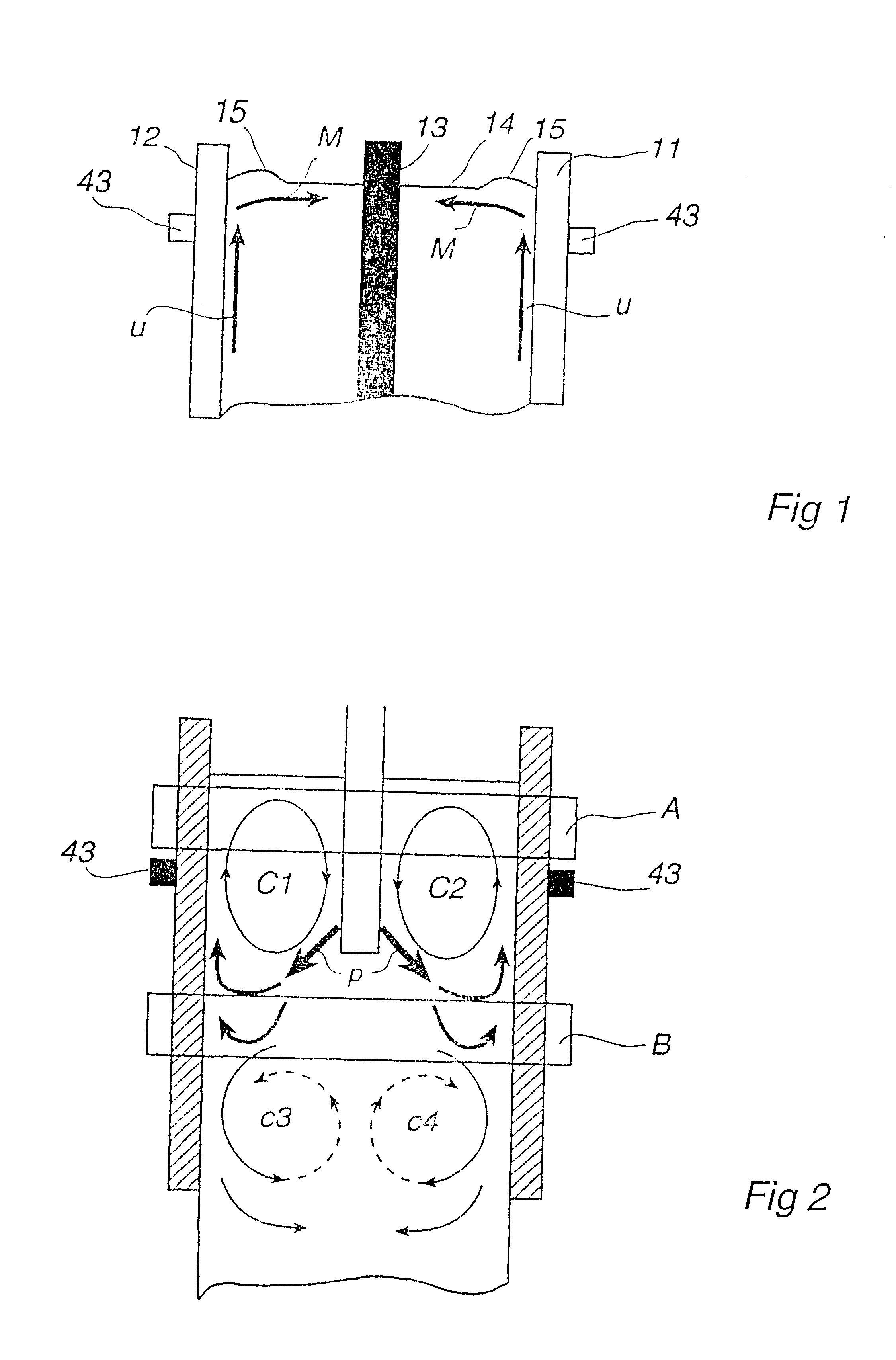

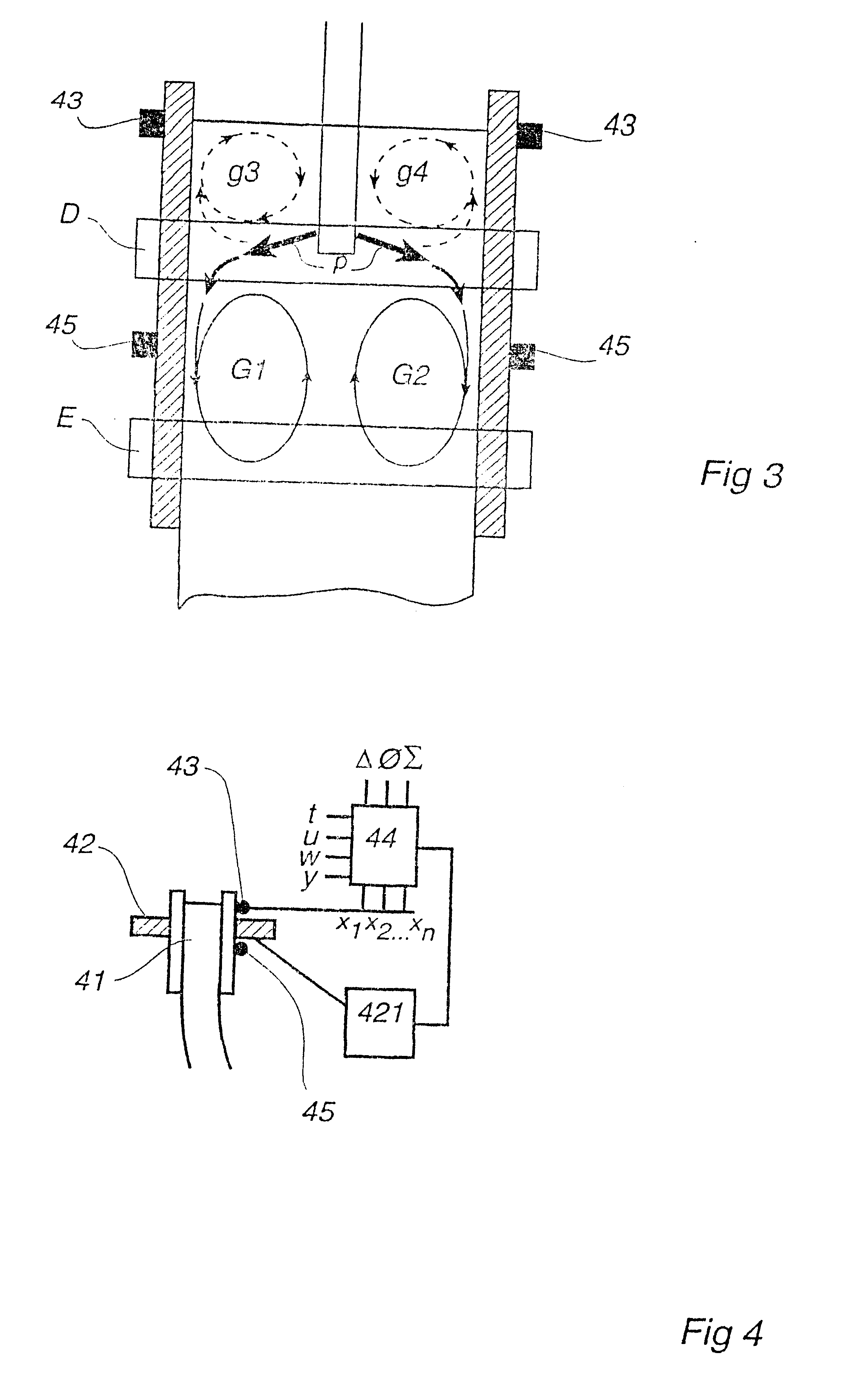

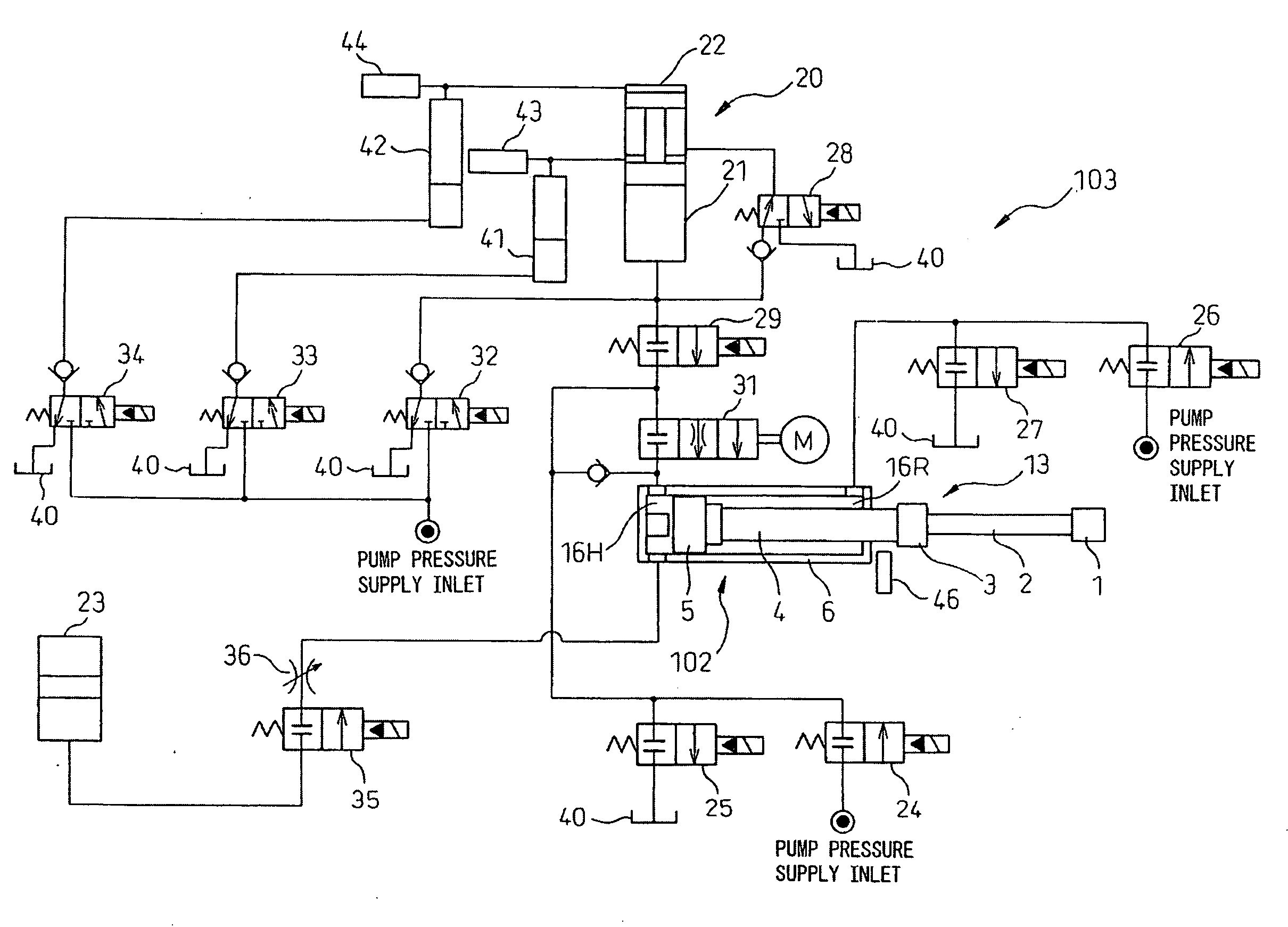

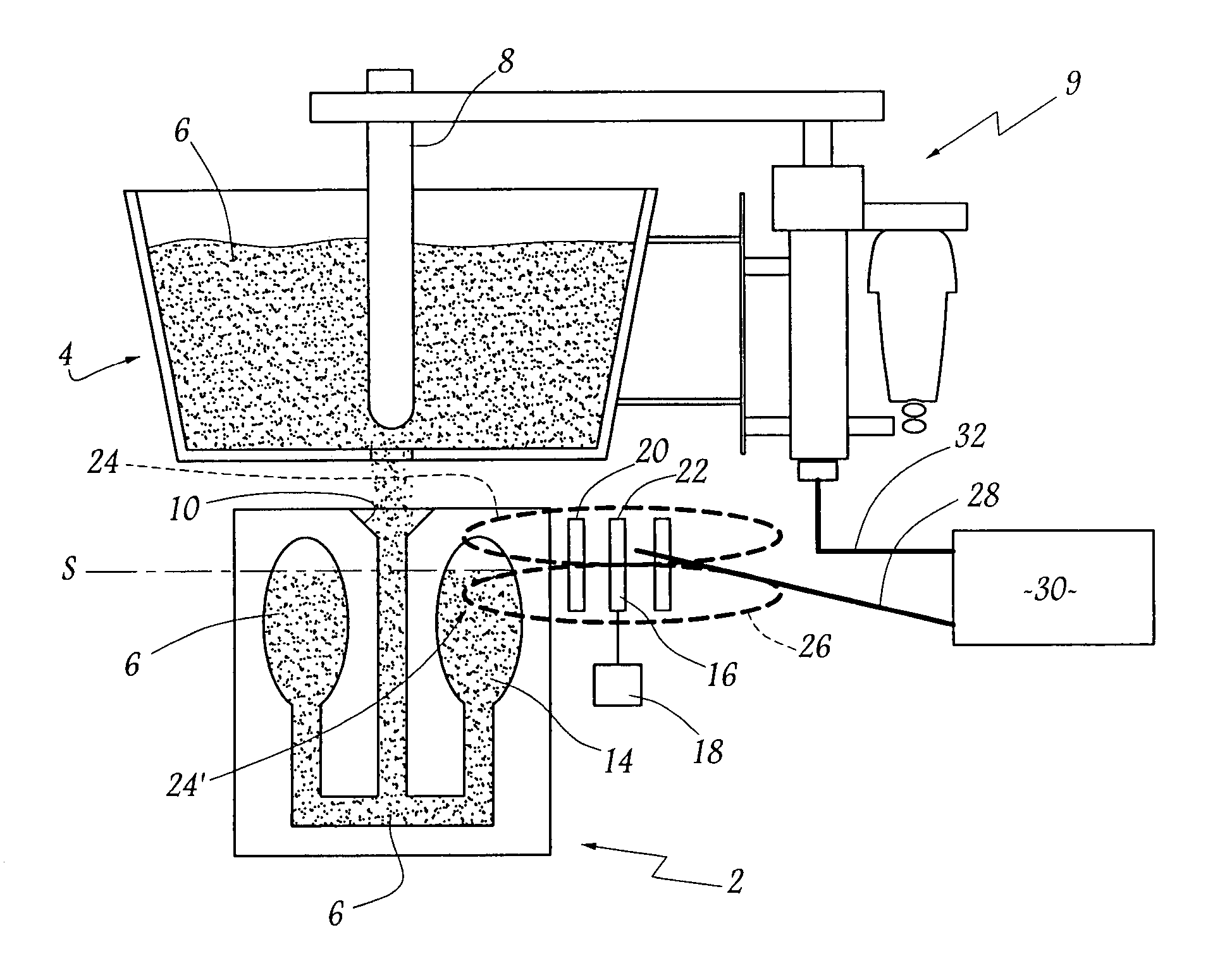

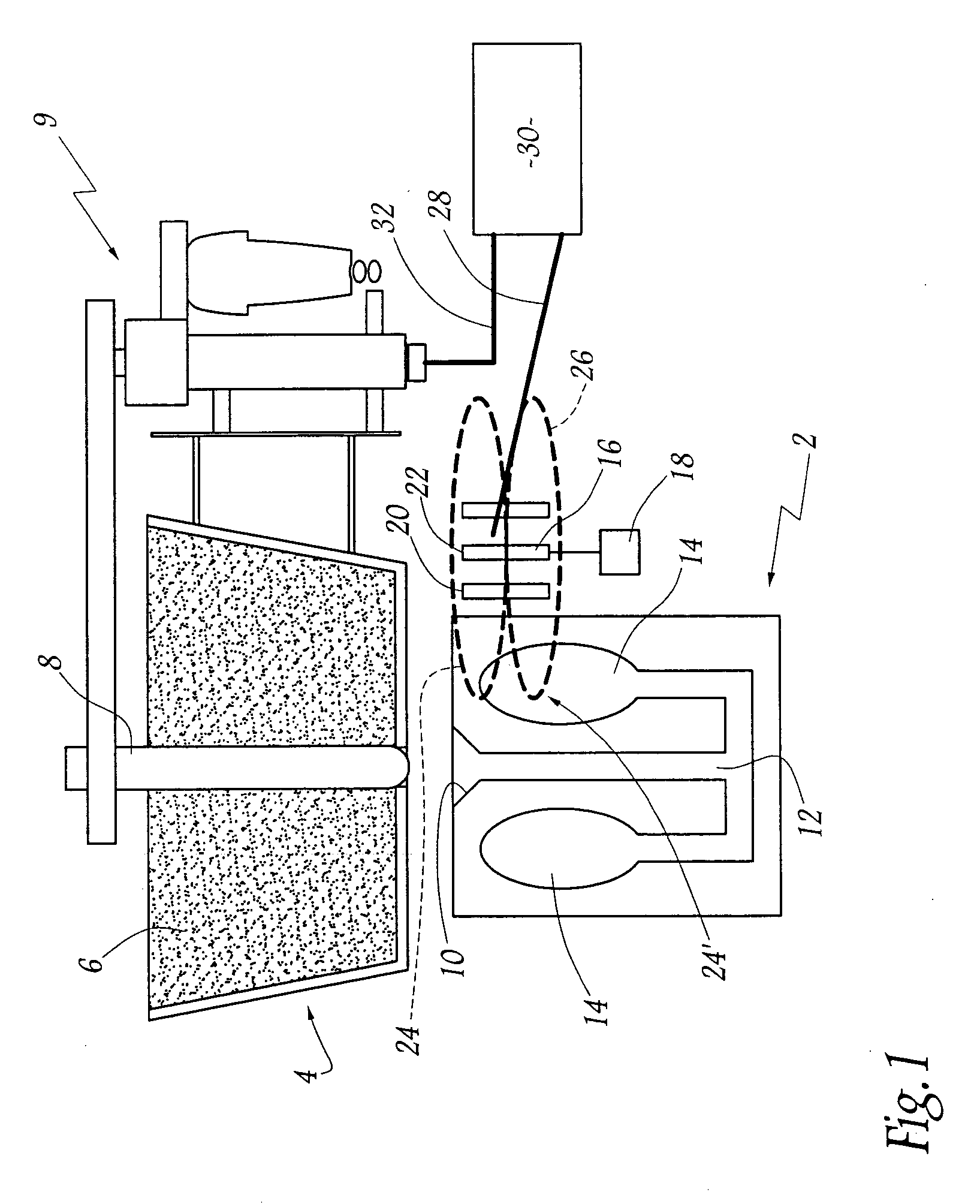

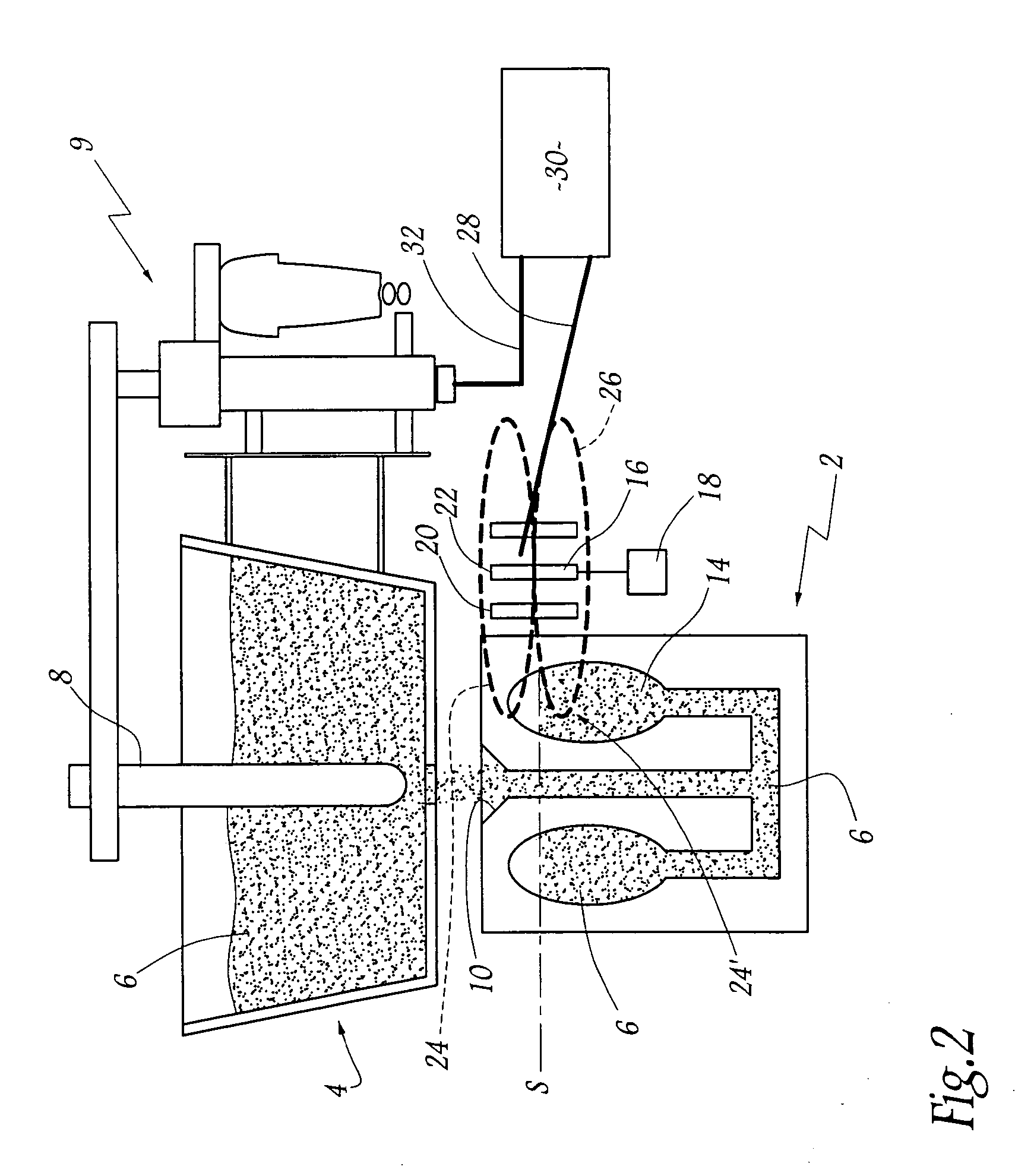

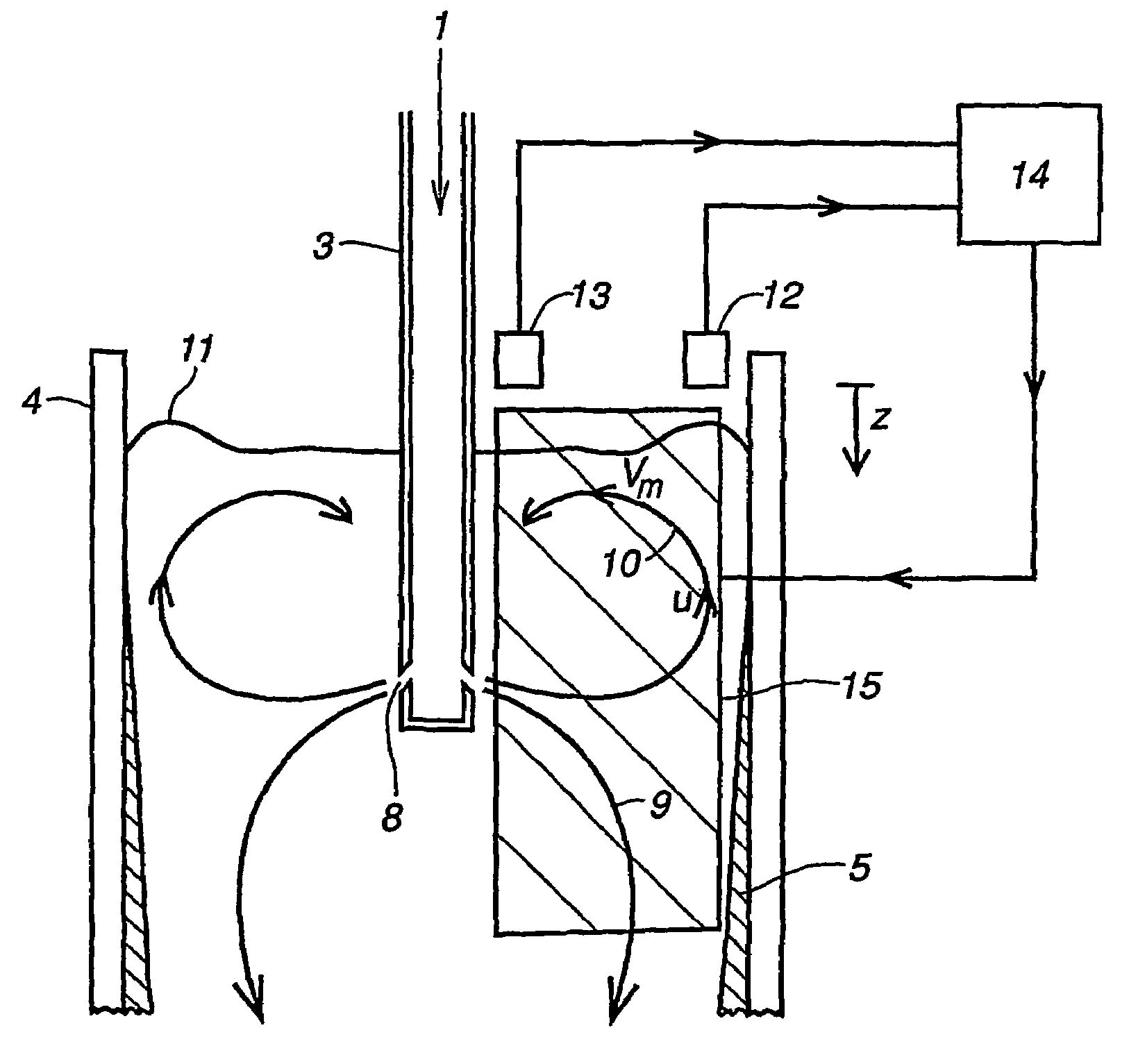

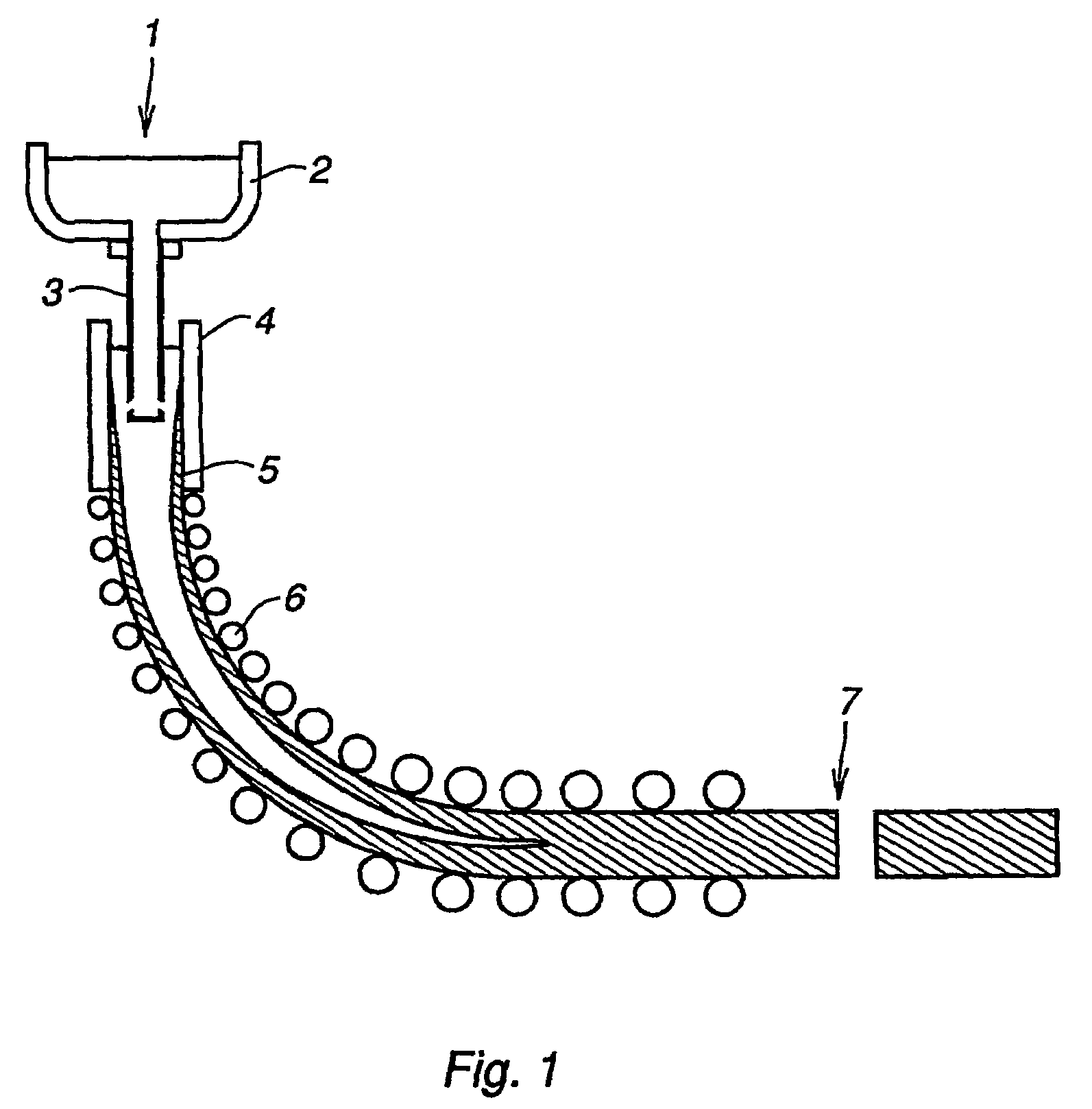

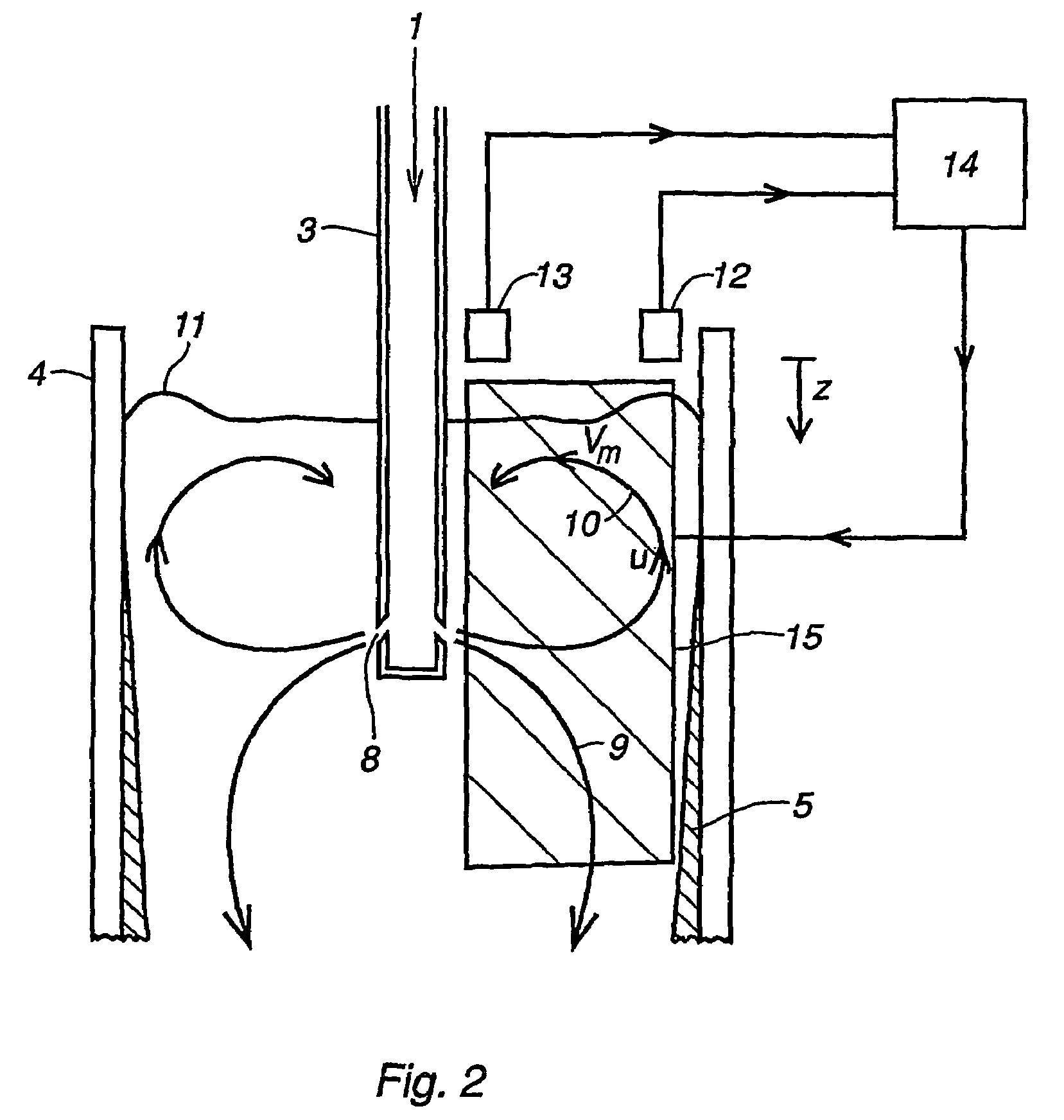

Method and device for control of metal flow during continuous casting using electromagnetic fields

InactiveUS6494249B1Improve productivityImprove abilitiesCasting safety devicesMould controlling devicesVolumetric Mass DensityElectromagnetic field

A method and a device for continuous or semi-continuous casting of metal. A primary flow (P) of hot metallic melt supplied into a mold is acted upon by at least one static or periodically low-frequency magnetic field to brake and split the primary flow and form a controlled secondary flow pattern in the non-solidified parts of the cast strand. The magnetic flux density of the magnetic field is controlled based on casting conditions. The secondary flow (M, U, C1, C2, c3, c4, G1, G2, g3, g4, O1, O2, o3, o4) in the mold is monitored throughout the casting and upon detection of a change in the flow, information on the detected change monitored flow is fed into a control unit (44) where the change is evaluated and the magnetic flux density is regulated based on this evaluation to maintain or adjust the controlled secondary flow.

Owner:ABB (SCHWEIZ) AG

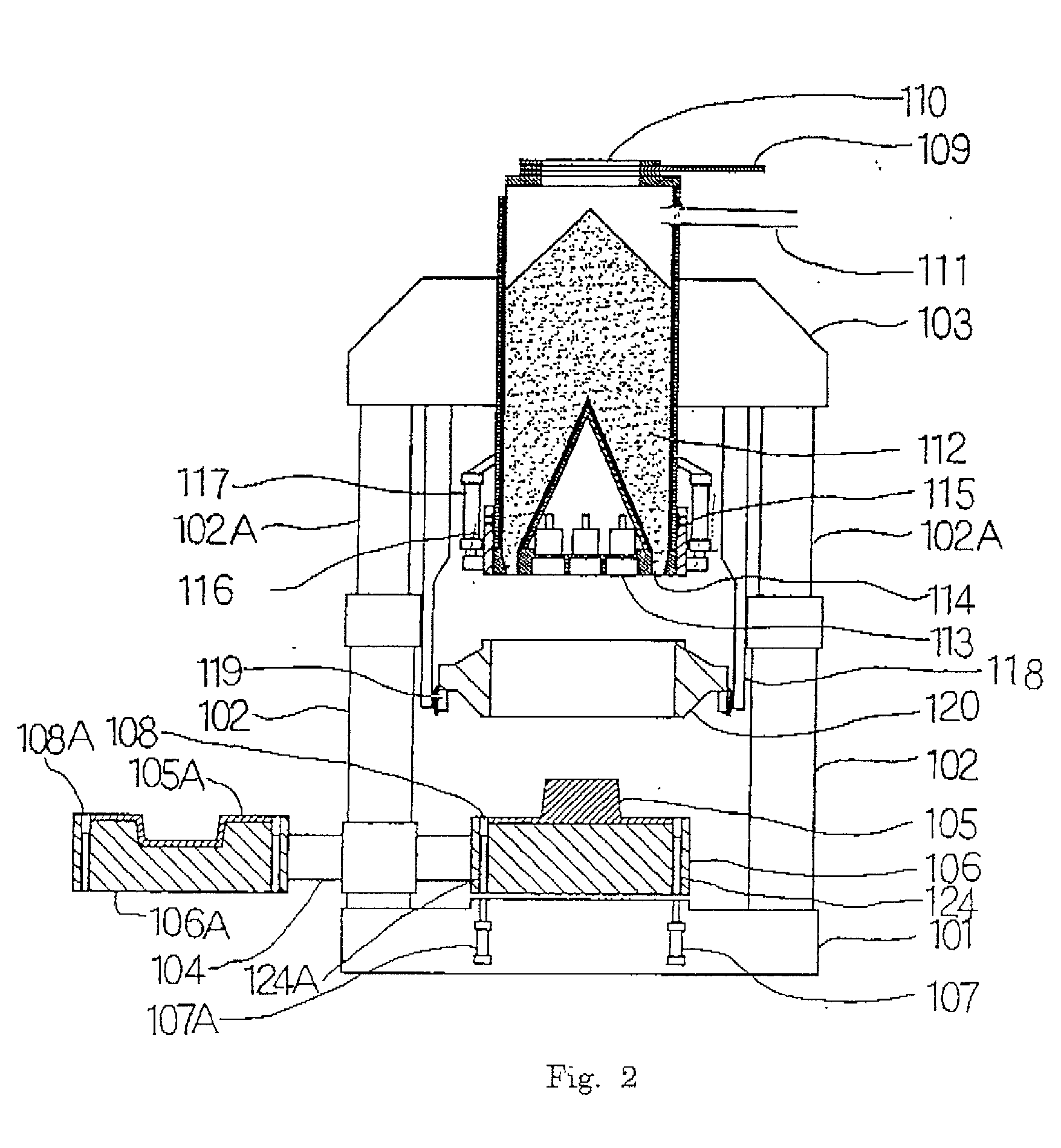

Die casting machine and die casting method

InactiveUS20100000699A1Fast injection moldingHigh speedCasting safety devicesMould controlling devicesThermodynamicsDie casting

A die casting machine that suppresses the occurrence of surge pressure, prevents the occurrence of burrs and spouting of molten metal, and further minimizes variations in the quality of a molded product on site.The die casting machine comprises a mold (101) that cast-molds a product, an injection cylinder (102) for injecting molten metal (15) to the mold, and a hydraulic device (103) for pressing under high pressure the injection cylinder. The hydraulic device comprises a piston ACC (20) that supplies hydraulic oil to press under pressure a piston (13) of the injection cylinder (102) and an injection cylinder inlet valve (31). The piston ACC comprises a high pressure fast pressure-raising piston accumulator (22, 322) and a low-pressure injection piston accumulator (21, 321).

Owner:UBE MASCH CORP LTD

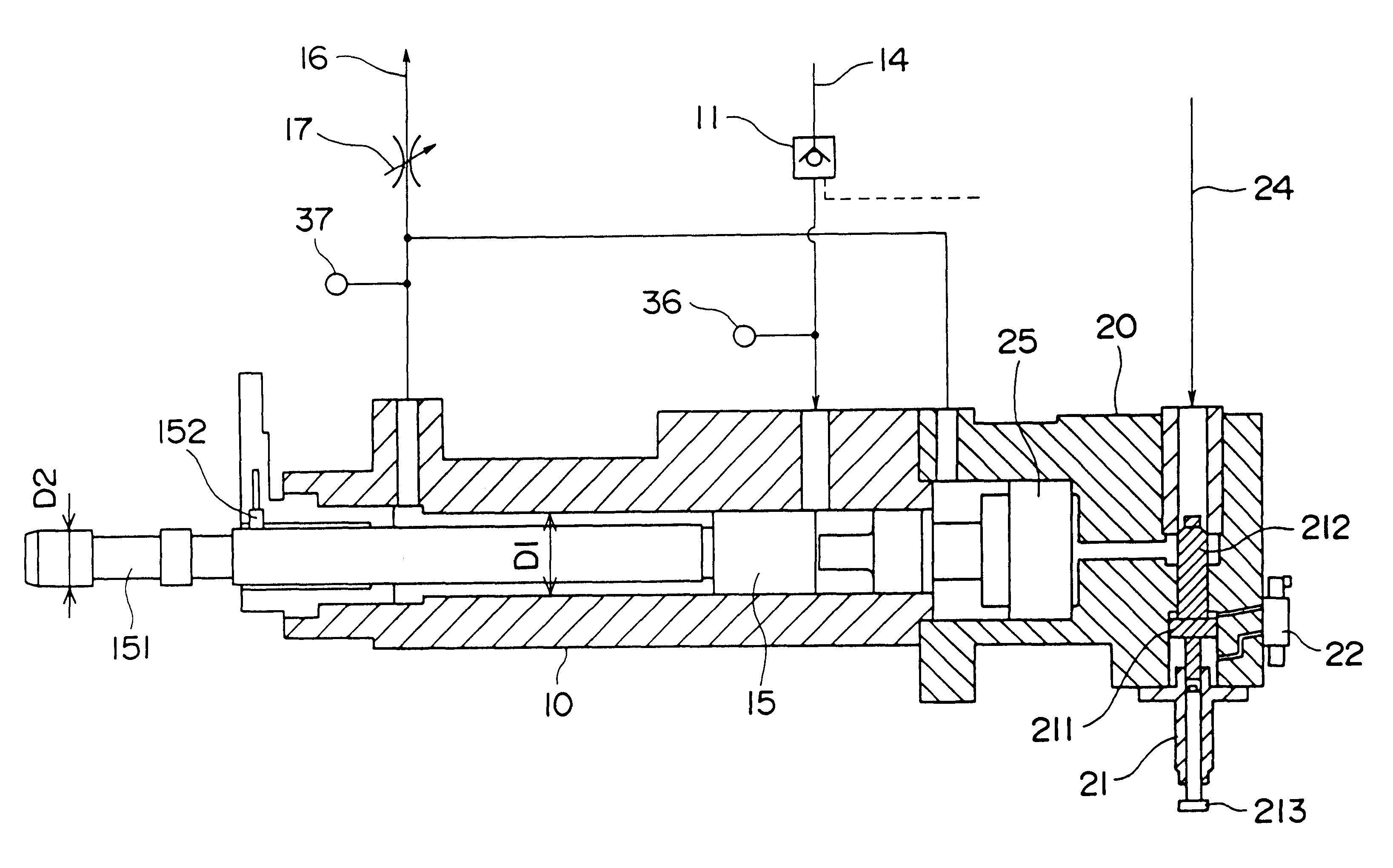

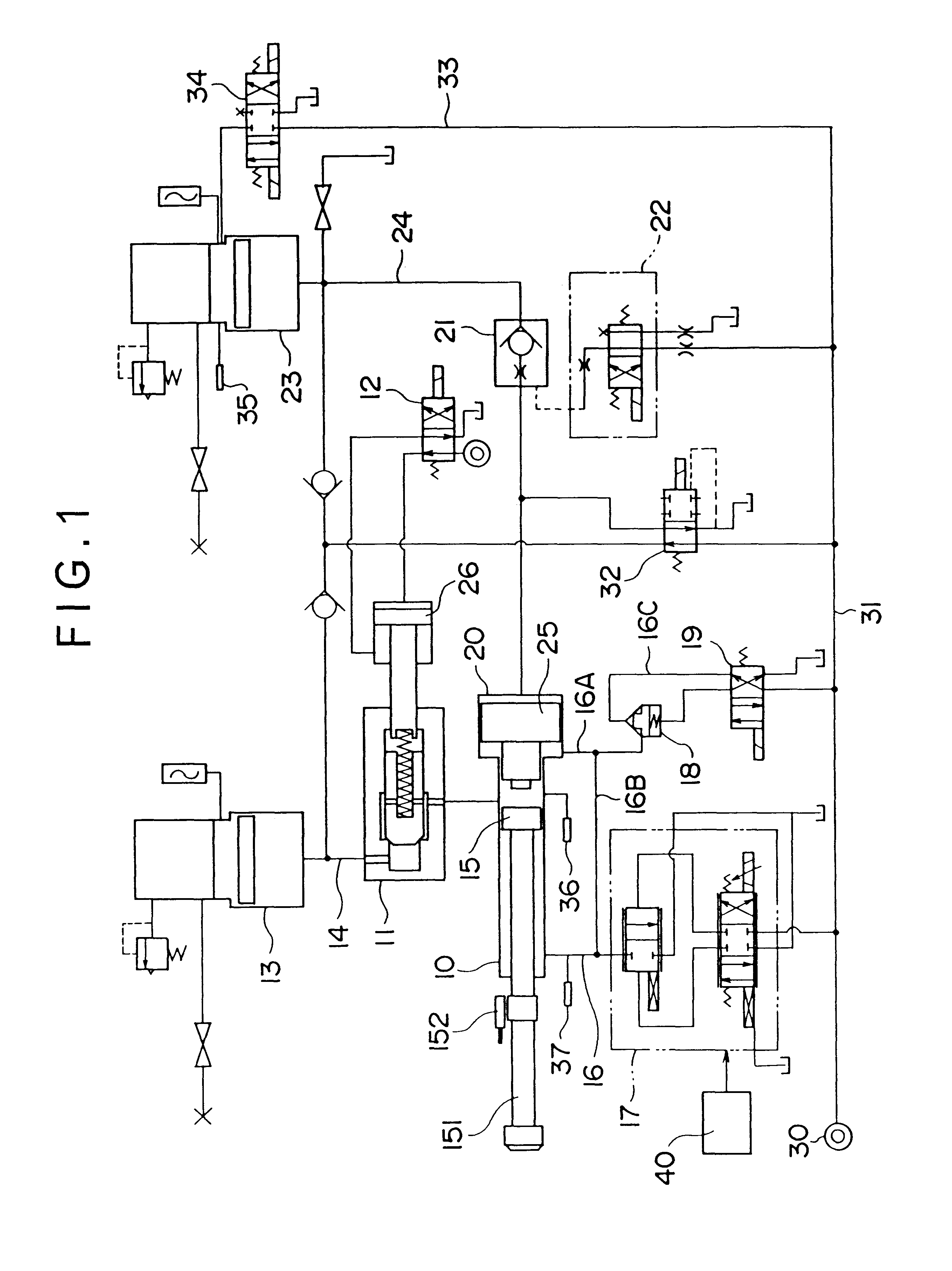

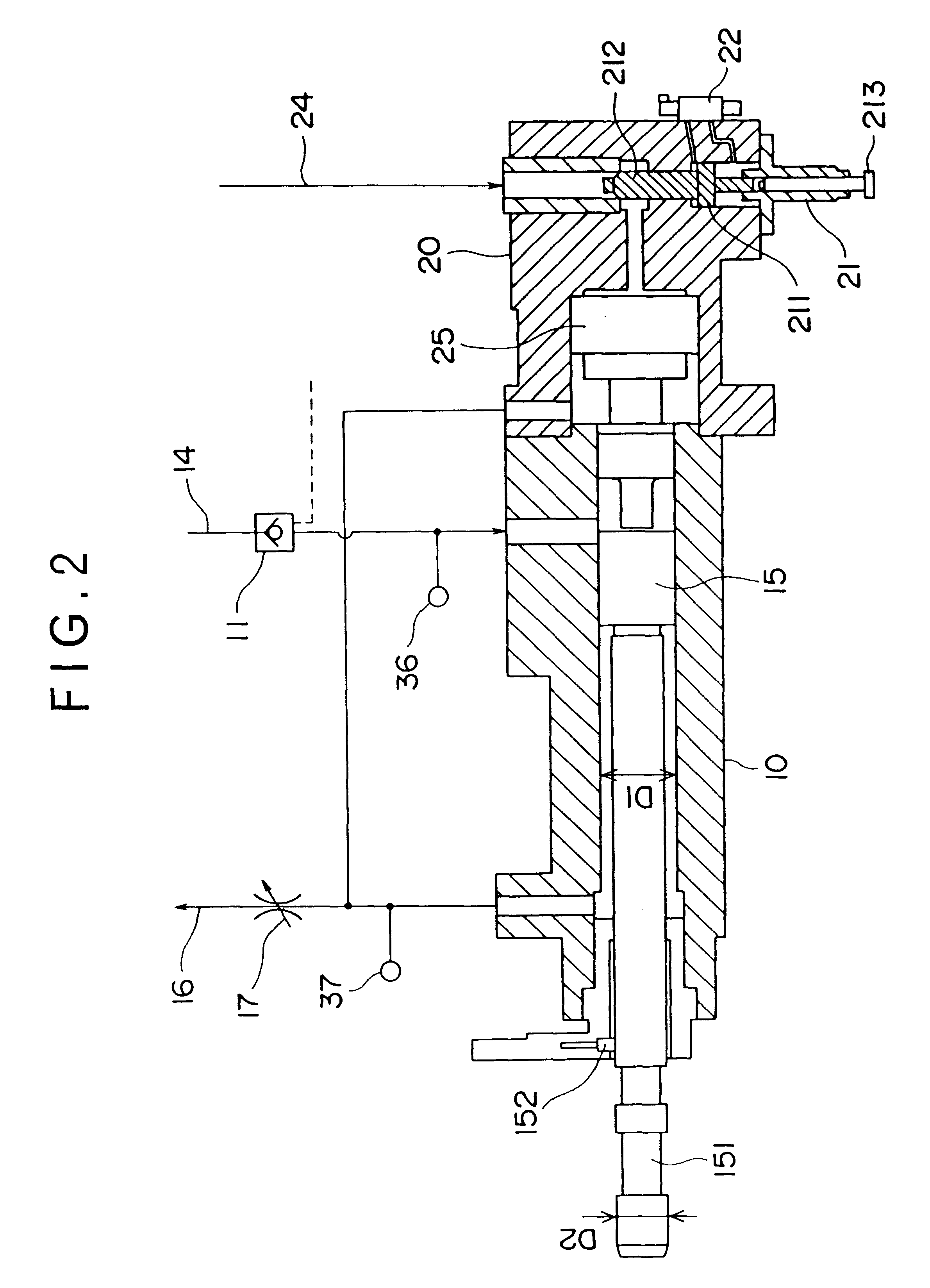

Injection control method and device of die-casting machine

In a die-casting machine having an injection cylinder device (10) for injecting molten material to a casting die and a boost cylinder device (20) for boosting a hydraulic oil supplied to the injection cylinder device (10), back-pressure of the injection cylinder device (10) and back-pressure of the boost cylinder device (20) are synchronously controlled by a flow-rate control valve (17) capable of continuously adjusting flow-rate of the hydraulic oil discharging channel (16). Accordingly, boosting characteristic can be made in accordance with burr critical boost curve, thereby avoiding burr occurrence in die-casting products in advance. Therefore, high-quality die-casting products without burrs can be manufactured even in a high-speed casting method or using low-accuracy dies.

Owner:TOSHIBA MASCH CO LTD

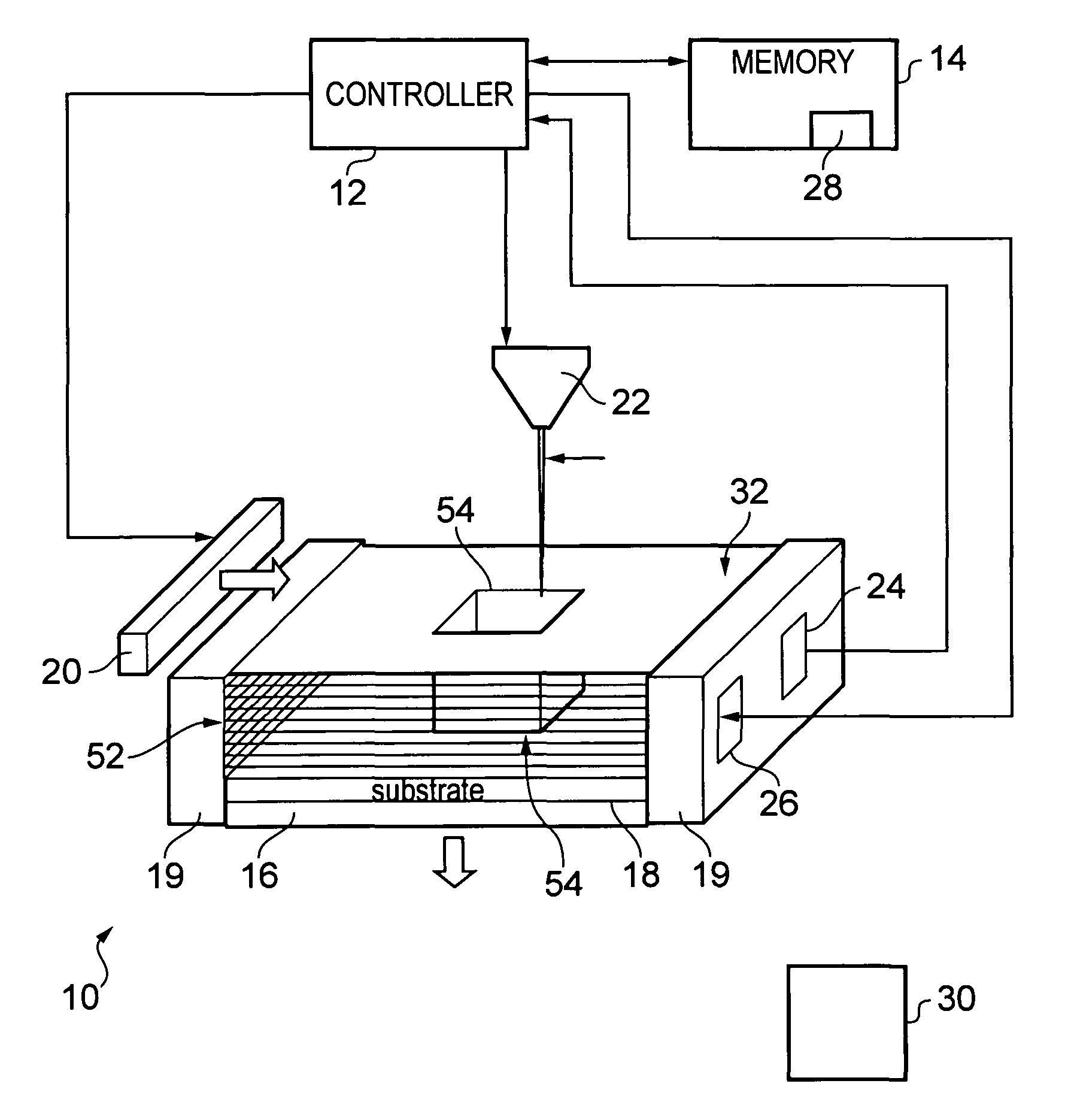

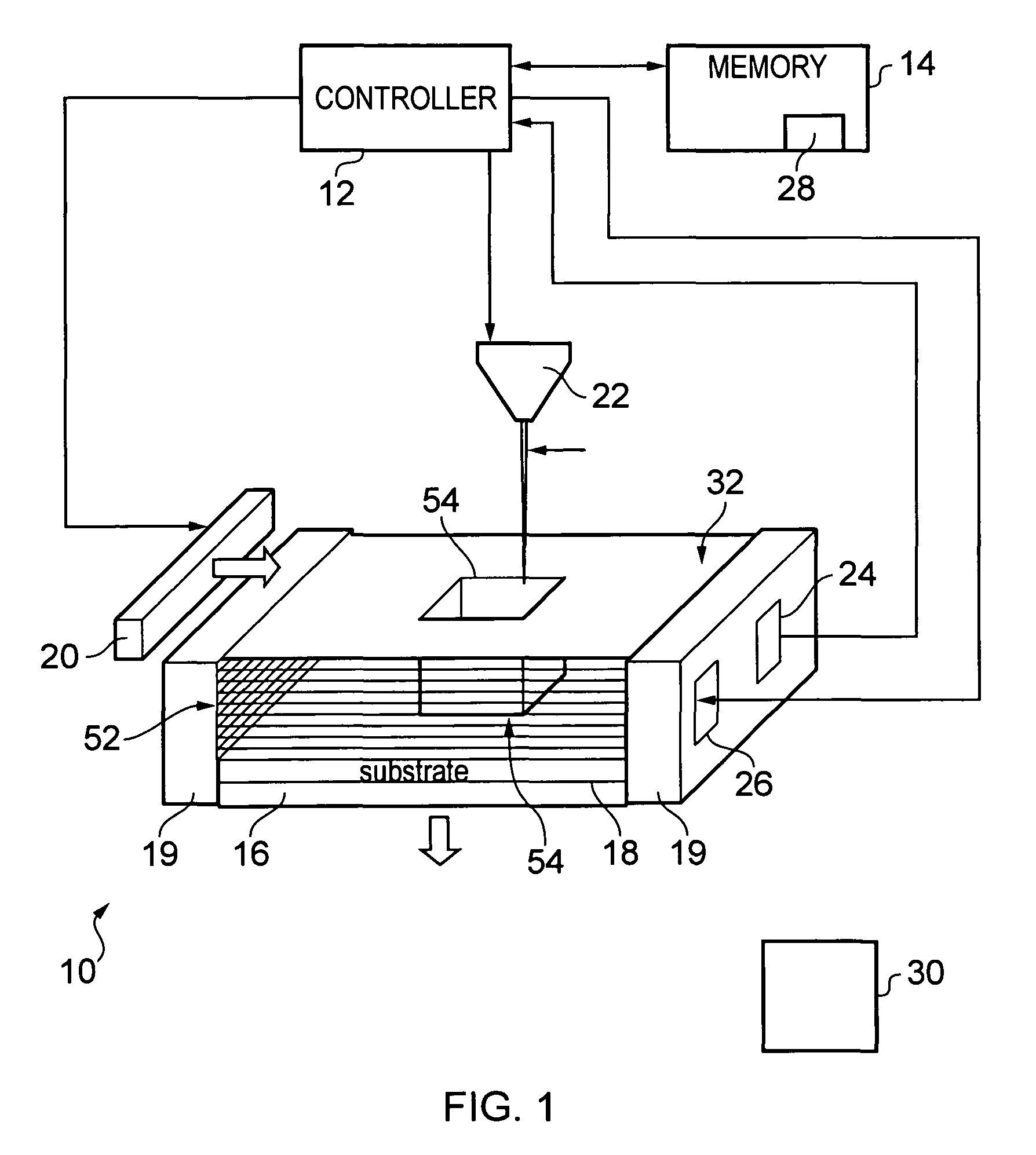

Sensor aided direct gating for metal casting

A mold system and method for producing a casting. The mold system utilizes multiple channels, each channel comprising a sprue and gating system, to feed the mold cavity at different heights. When a lower portion of the mold is filled, a controller is signaled to initiate filling of the mold through a second channel positioned above the lower portion. This mold system desirably provides the hottest molten metal to the last portion of the casting to freeze with or without the use of risers, eliminating casting defects. The system also enables the controlled pouring of dissimilar metal castings.

Owner:GENERAL ELECTRIC CO

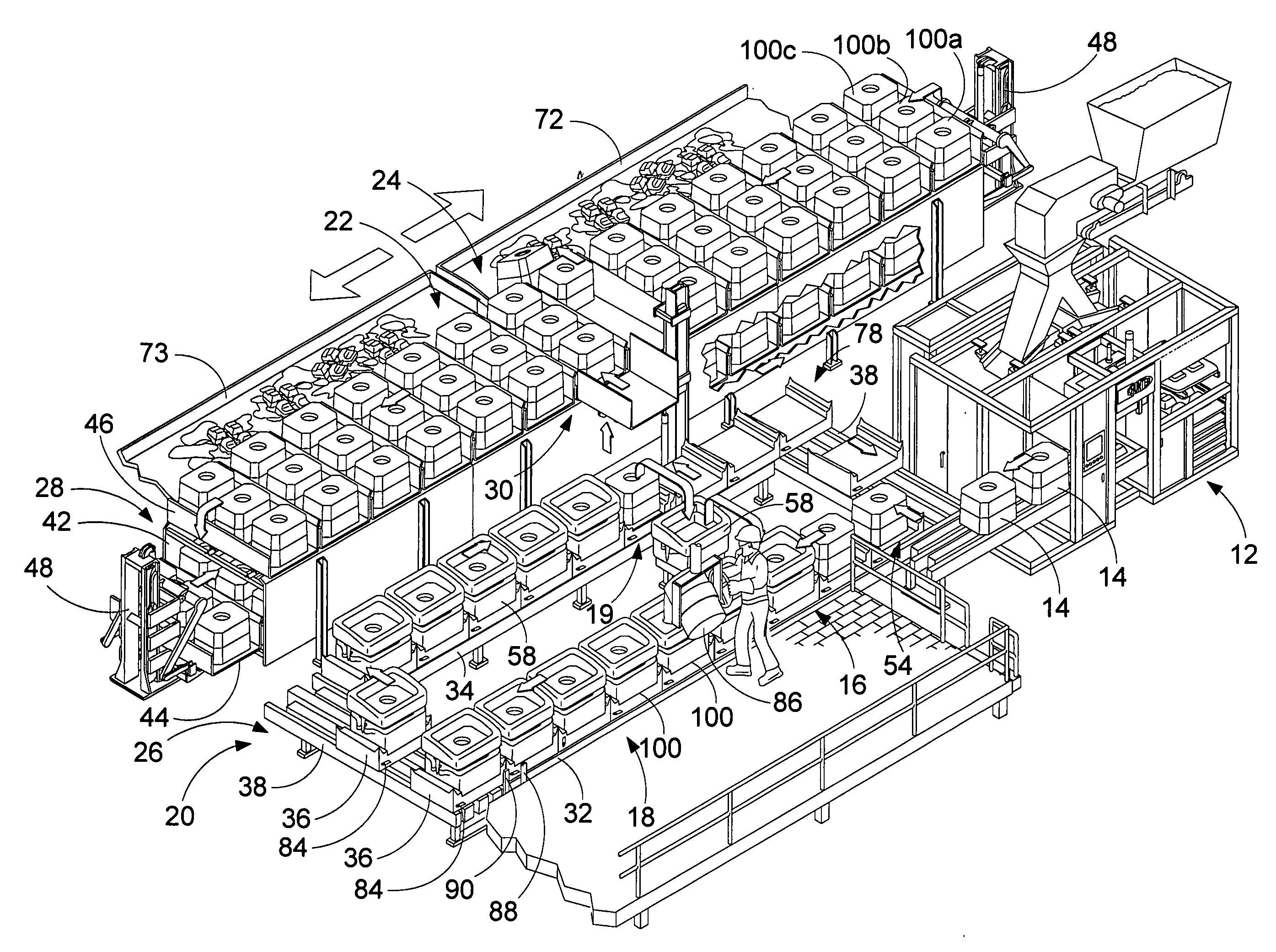

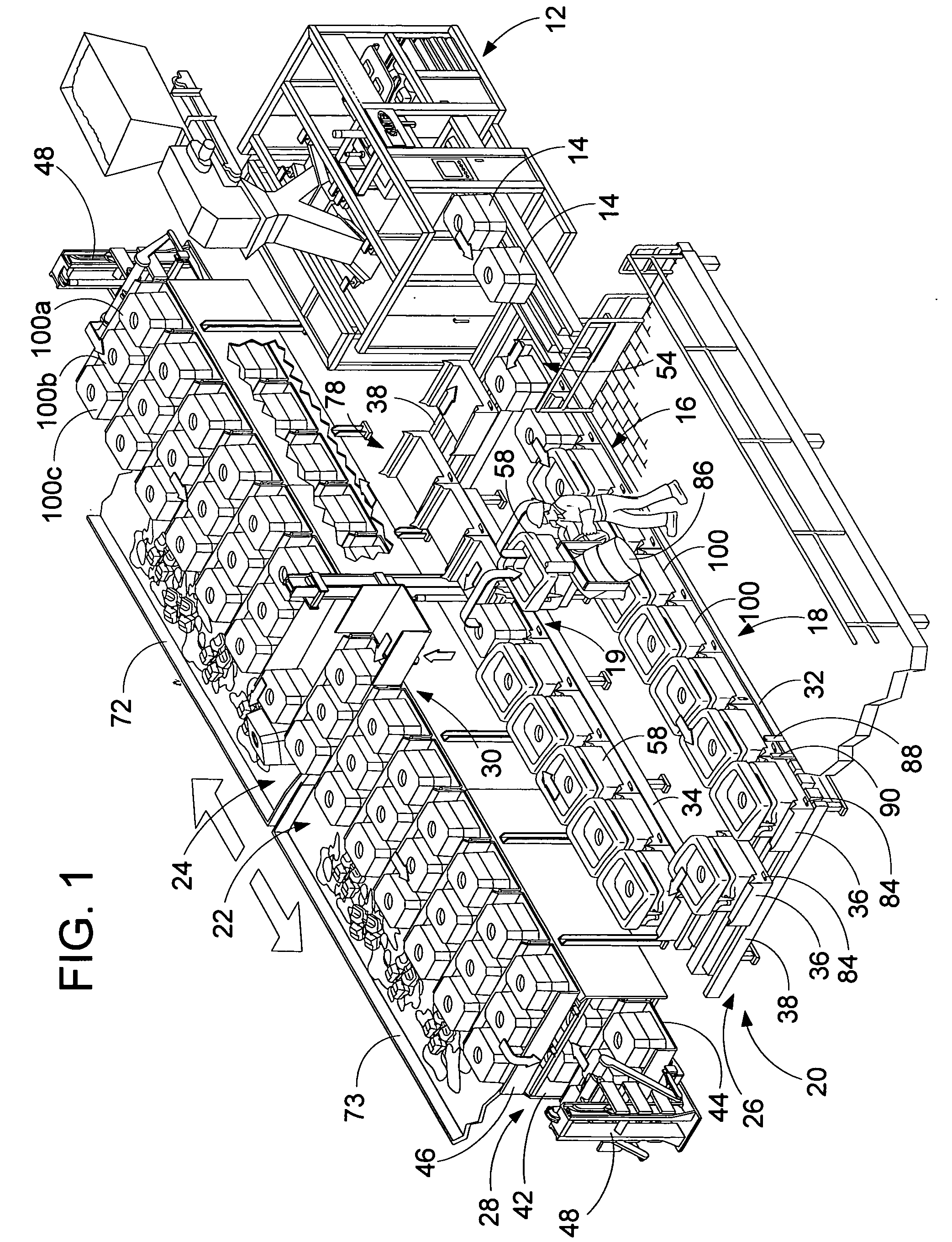

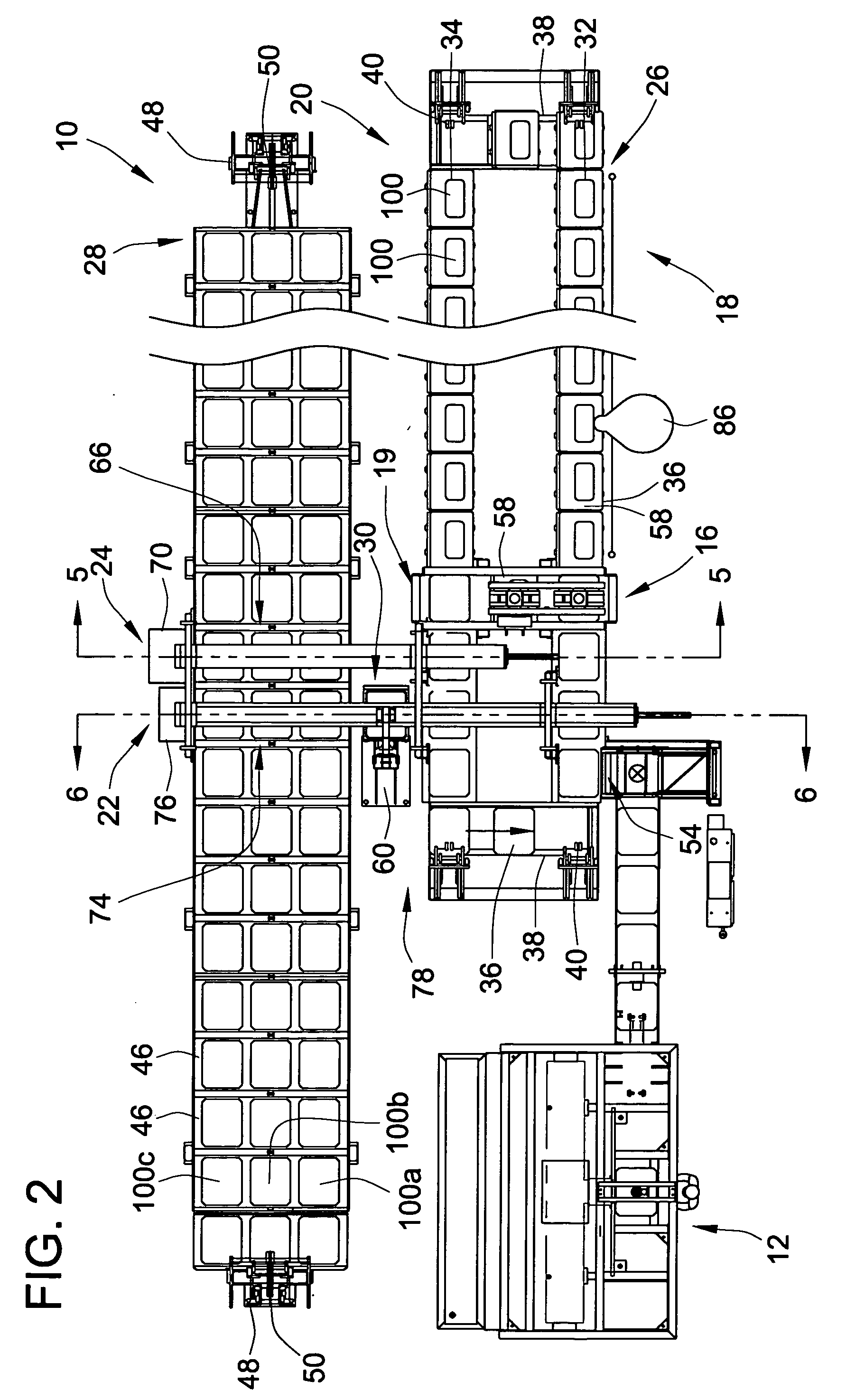

Foundry mold handling system with multiple dump outputs and method

ActiveUS20050109478A1Problem can be addressedPig casting plantsCasting safety devicesFoundryControl system

A mold handling system for carrying and transporting sand molds comprises a mold handling conveyor with multiple mold exits to provide different outputs for the sand molds. The mold handling system may include flags which can be used to mark selected molds to segregate the sand molds into different groups. A control system responds to flag sensors and tracks the molds to selectively control output of sand molds through the mold exits. Methods of handling sand molds using a mold handling system are also disclosed.

Owner:HUNTER AUTOMATED MACHINERY

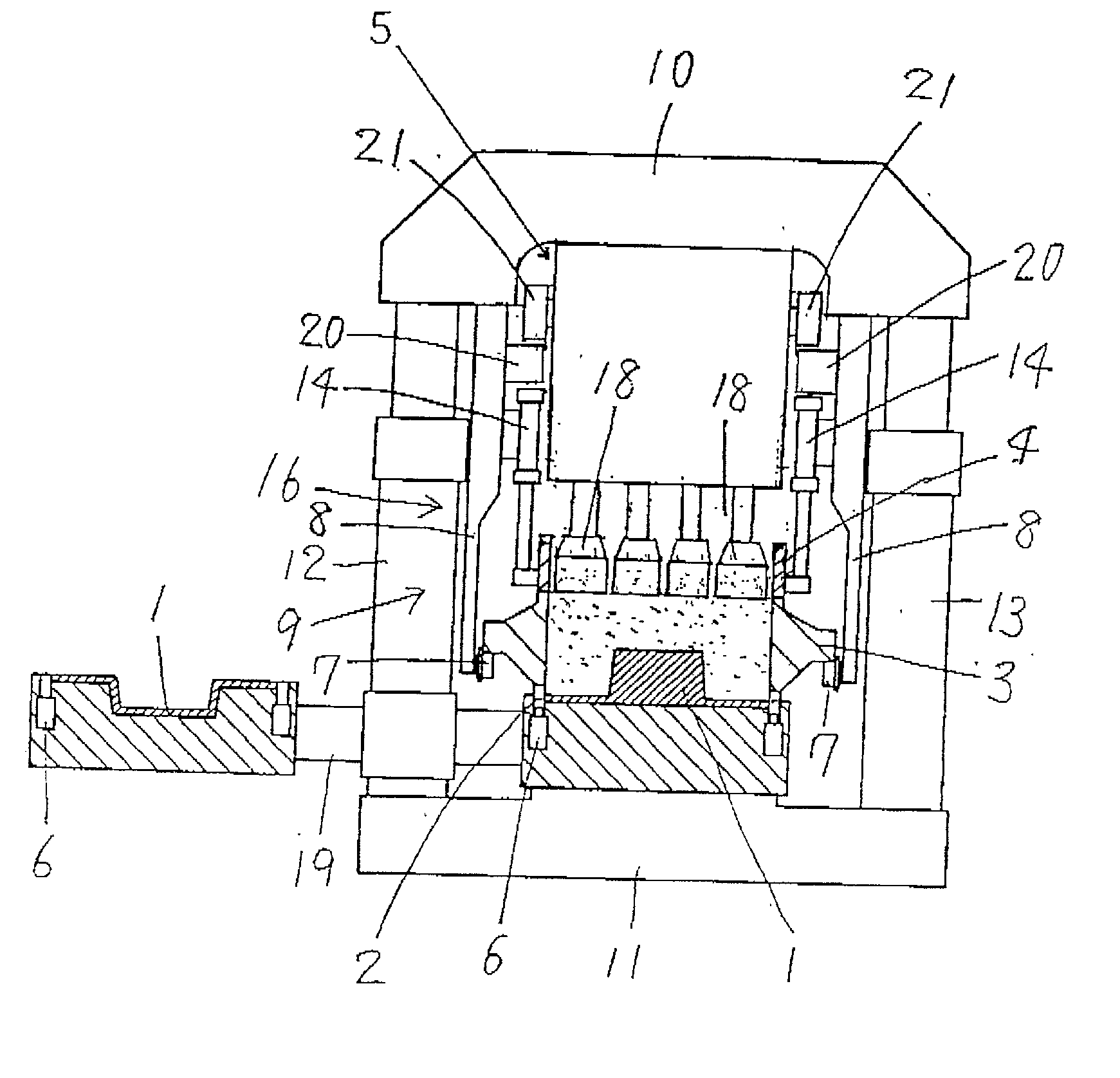

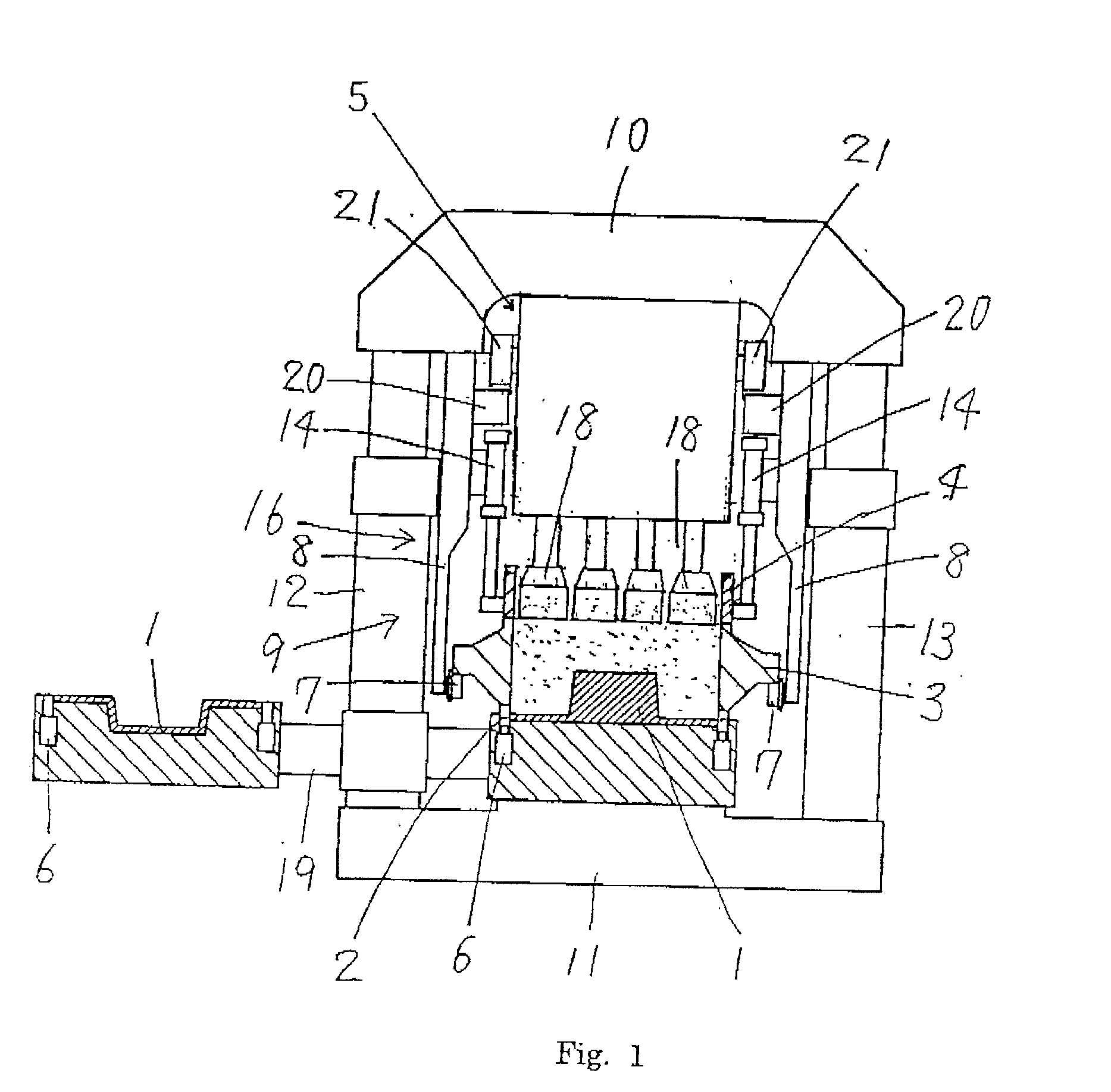

Method and apparatus for compacting molding sand

InactiveUS20020129917A1Good effectIncrease pressureMoulding machinesMould controlling devicesEngineeringMechanical engineering

A method for compacting molding sand in a mold space defined by a pattern plate, which is fixed in a horizontal position when the molding sand is compacted, a leveling frame disposed for vertical sliding movement around the outer periphery of the pattern plate, a frame member disposed for vertical movement above the leveling frame, and a filling frame disposed for vertical movement above the frame member. The method comprises the steps of feeding molding sand into the mold space, primarily compacting the molding sand in the mold space from above by compacting means while at least the leveling frame is being set so that it cannot be lowered, and secondarily compacting the molding sand in the mold space from above by the compacting means while the leveling frame, the frame member, and the filling frame are set so that these elements can be lowered.

Owner:SINTOKOGIO LTD

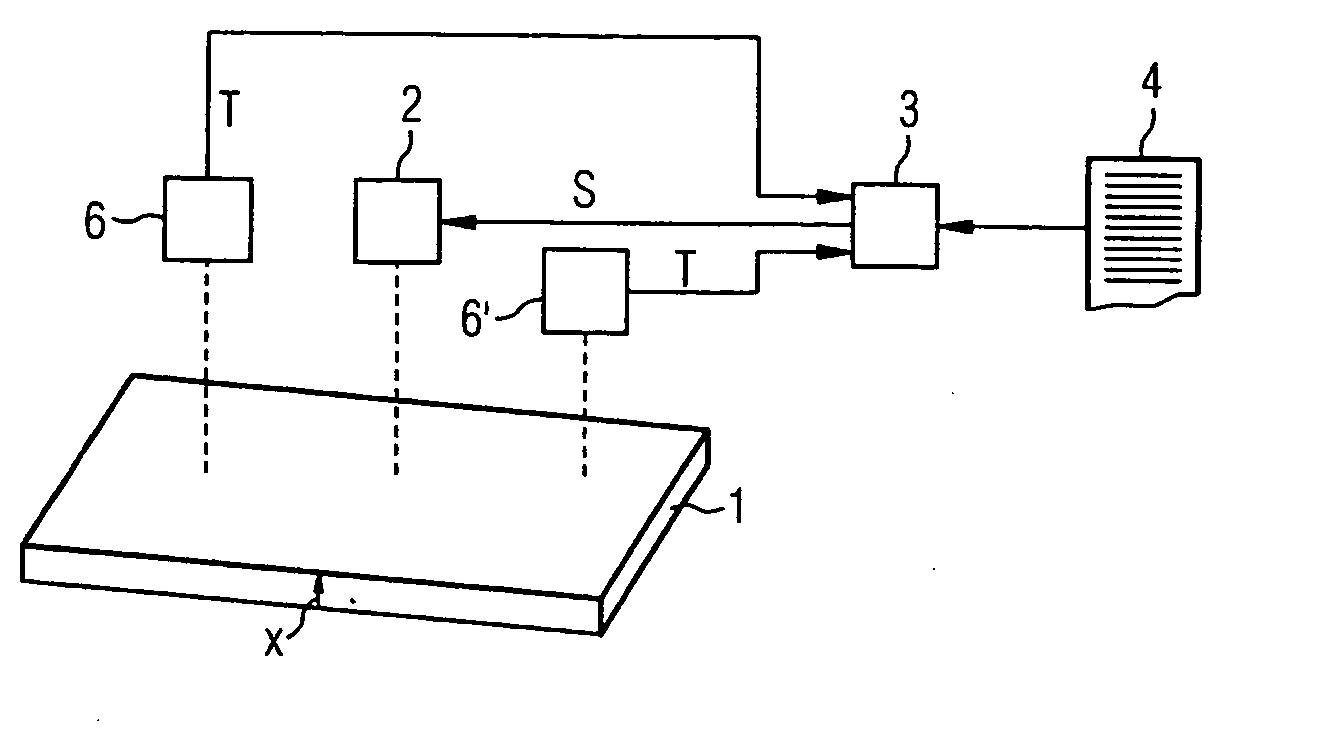

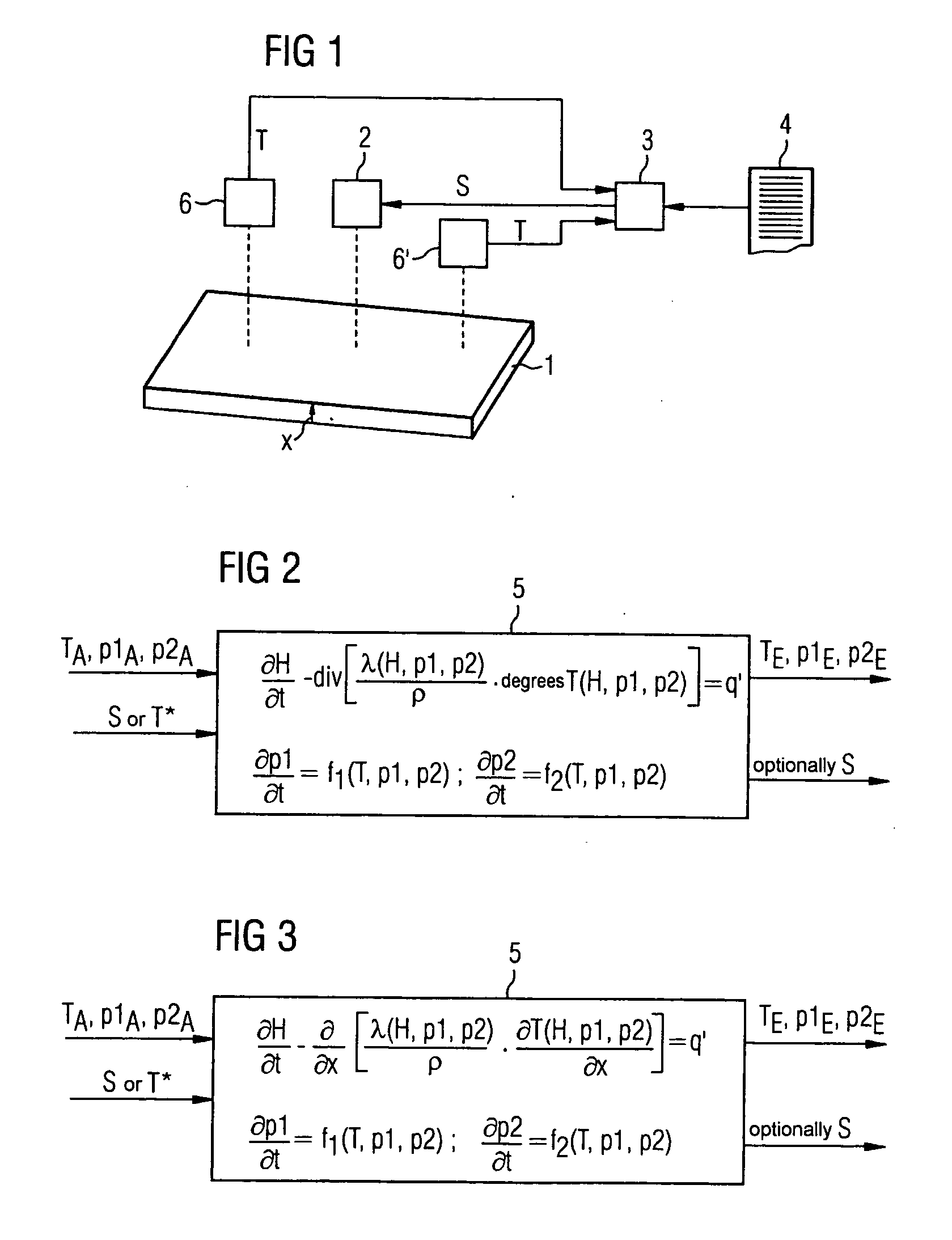

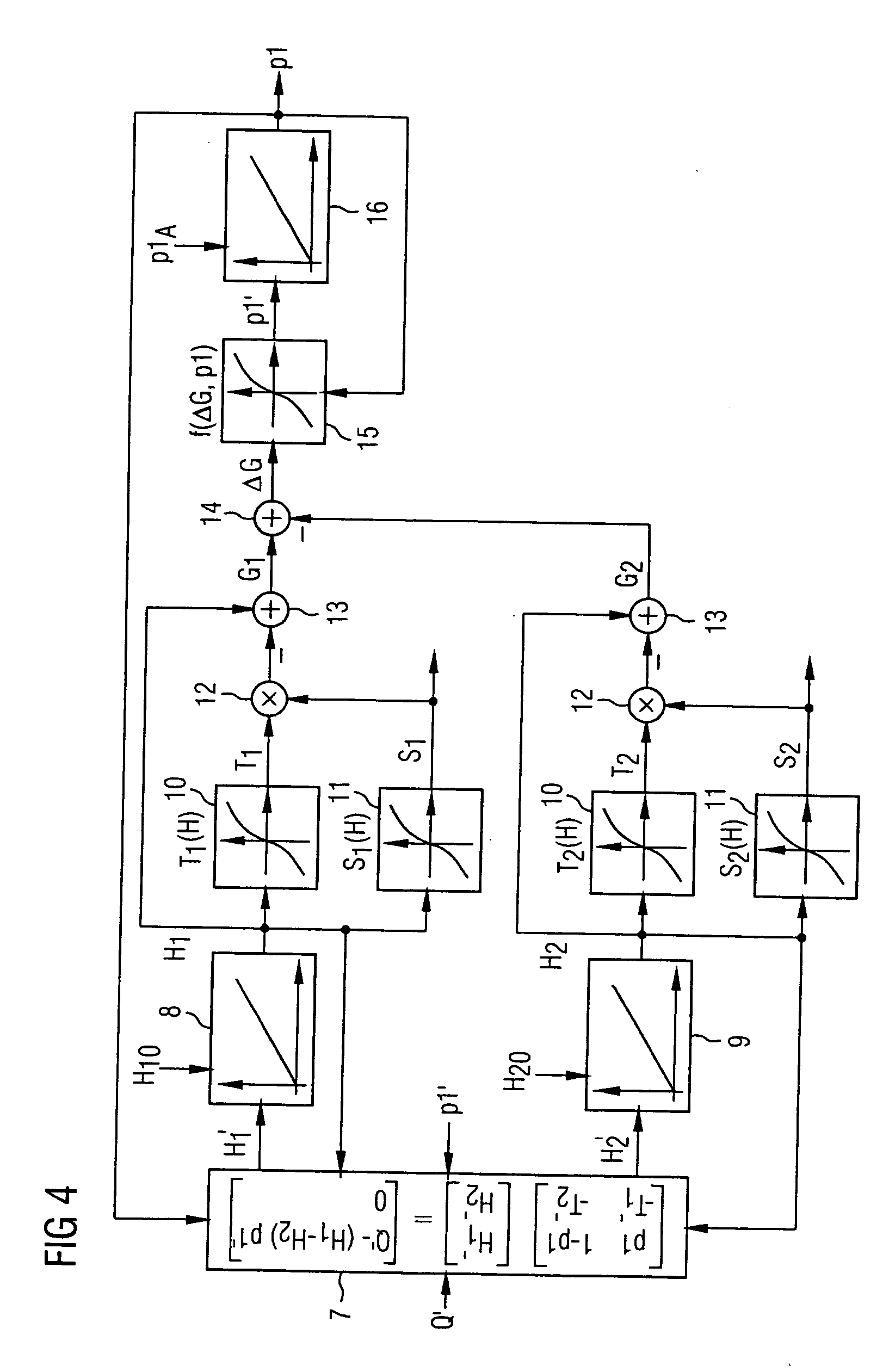

Modeling method for a metal

ActiveUS20050016712A1Modeling resultSimulator controlCasting safety devicesModel methodFree energies

The temperature (T) of a metal (1) can be influenced directly or indirectly by at least one actuator (2) which is actuated in accordance with a control variable (S). The control variable (S) and starting values (TA, p1A, p2A) for a temperature of the metal (1) and phase proportions in which the metal (1) is at least in a first phase or a second phase, respectively, are predetermined for a material model (5). A heat conduction equation and a transformation equation are solved in real time within the material model (5), taking account of these variables (TA, p1A, p2A) , and in this way expected values (TE, p1E, p2E) are determined for these variables. As part of the transformation equation, the Gibbs' free energies (G1, G2) of the phases of the metal (1) are determined, a transformation rate of the metal (1) from the first phase to the second phase is determined therefrom, and the expected proportions (p1E, p2E) are determined from the latter.

Owner:PRIMETALS TECH GERMANY

Apparatus for continuous strip casting

InactiveUS20100000705A1Promote oxidationImprove scaleCasting safety devicesMould controlling devicesStrip steelEngineering

An apparatus for continuously casting thin strip includes a caster having a pair of casting rolls having a nip there between capable of delivering cast strip downwardly from the nip and an first enclosure capable of forming a protective atmosphere into which the strip can be formed in loop to extend over a plurality of rollers into pinch rolls with the strip having a strain of less than 0.4%, which may be provided by a plurality of rollers at entry of the strip into the pinch rolls to carry the strip into the pinch rolls, with at least a first entry roller having a diameter between 200 and 650 millimeters and being below a majority of other rollers.

Owner:NUCOR CORP

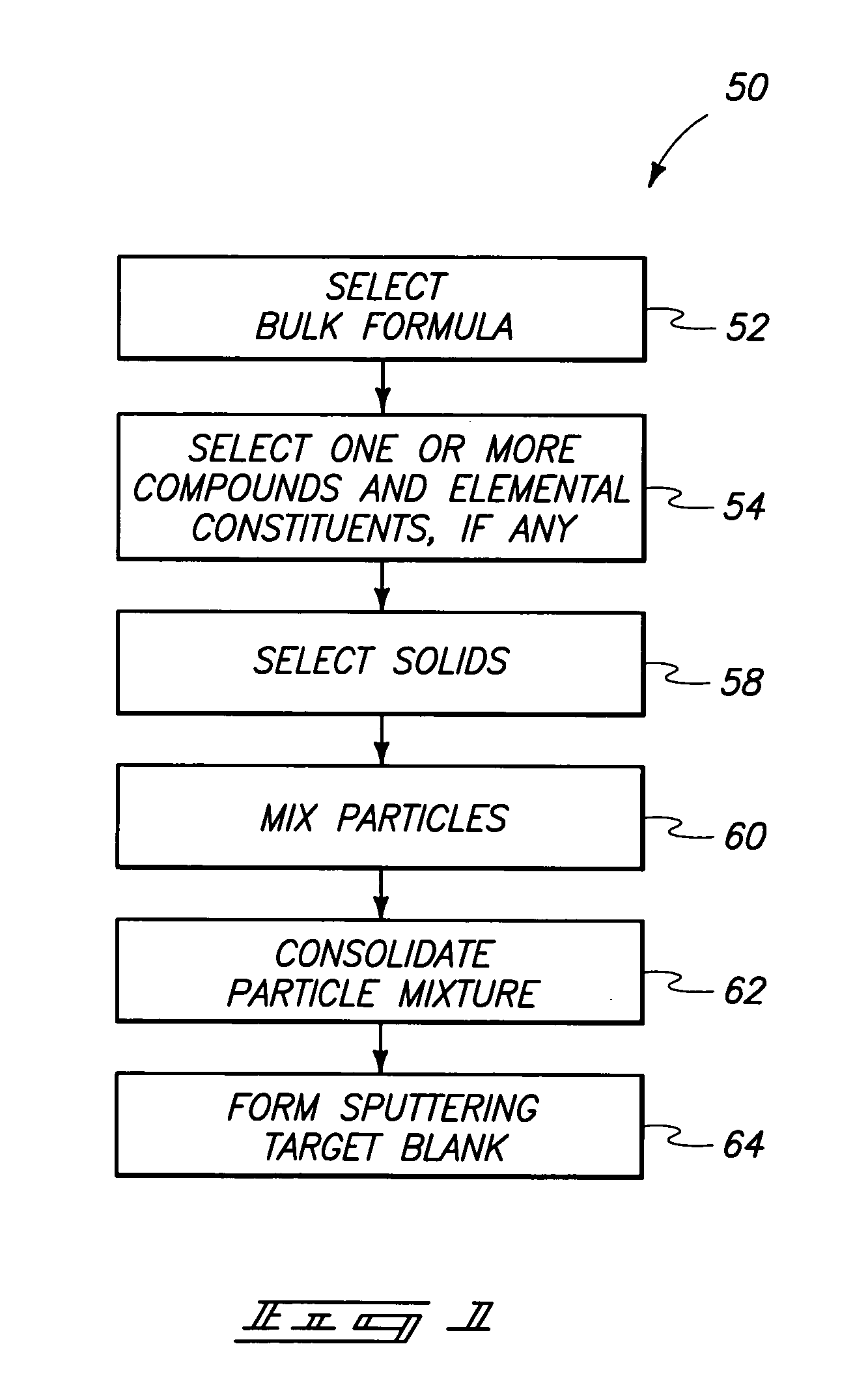

Alloy casting apparatuses and chalcogenide compound synthesis methods

A chalcogenide compound synthesis method includes homogeneously mixing solid particles and, during the mixing, imparting kinetic energy to the particle mixture, heating the particle mixture, alloying the elements, and forming alloyed particles containing the compound. Another chalcogenide compound synthesis method includes, under an inert atmosphere, melting the particle mixture in a heating vessel, removing the melt from the heating vessel, placing the melt in a quenching vessel, and solidifying the melt. The solidified melt is reduced to alloyed particles containing the compound. An alloy casting apparatus includes an enclosure, a heating vessel, a flow controller, a collection pan and an actively cooled quench plate. The heating vessel has a bottom-pouring orifice and a pour actuator. The flow controller operates the pour actuator from outside the enclosure. The quench plate is positioned above a bottom of the collection pan and below the bottom-pouring orifice.

Owner:HONEYWELL INT INC

Continuous casting machine for forming a lead alloy strip of large thickness

InactiveUS20110030914A1Low costHigh production output of productElectrode carriers/collectorsCasting safety devicesMolten stateSlice thickness

Continuous casting machine for forming a lead alloy strip of large thickness; which comprises a cooled rotating drum (4) having an annular seat (8) formed on the periphery thereof and a vat (10) for containing a molten lead bath, which is sealingly engaged on the peripheral surface (7) of the rotating drum (4). The machine (1) also comprises a fixed shoe (11) extending, from the vat (10), along an arc (25) around the rotating drum (4) and having an arc shape suitable for sealing engagement, in a sliding relationship, on the shoulders (90) of the annular seat (8). Heating means (26) are provided, these consisting of a plurality of torches acting on the shoe (11) along at least an initial section thereof (25) which extends from the vat (10), for heating to a temperature higher than the melting temperature of the lead alloy the free surface of the lead inside the annular seat (8). The bottom (9) of the annular seat (8) is knurled, while the inner surface (13) of the shoe (11) which slides on the lead is smooth and kept at a high temperature by the heating means (26). As a result of these characteristic features, the rotating drum (4) is able to transport in a rotationally integral manner the lead from a first angular position where it is inserted in the molten state inside the annular seat of the rotating drum (8) to a following angular position where it is extracted in the form of a continuous strip.

Owner:SOVEMA

Installation for filling a mould with liquid metal and process employing this installation

The installation according to the invention comprises at least one mould, a vessel intended to receive the liquid metal and means for directly determining the evolution of the level of molten metal in the impression of the mould. These determination means comprise means for detecting the presence of this liquid metal in the impression, particularly of electromagnetic nature, which are adapted to penetrate at least partially in the interior volume of this impression.

Owner:SOC DETUD & DE REALISATIONS TECHN S E R T

Control system, computer program product, device and method

InactiveUS7669638B2Improve productivityMinimizing emergenceCasting safety devicesMould controlling devicesControl systemLiquid metal

Owner:ABB (SCHWEIZ) AG

Popular searches

By pulling from melt Manufacturing converters Increasing energy efficiency From frozen solutions Heat treatment process control Single crystal growth details Special data processing applications Semiconductor/solid-state device manufacturing Semiconductor devices Casting parameters measurement/indication devices

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com