Injection device for die casting machine

a technology of injection device and die casting machine, which is applied in the direction of mould control device, manufacturing tool,foundry moulding apparatus, etc., can solve the problems of limiting the reduction in size and weight of electric mechanism, affecting the production efficiency of injection system, and increasing speed, so as to reduce the necessary maximum torque, reduce the manufacturing cost of injection system, and reduce the size of injection system itself.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

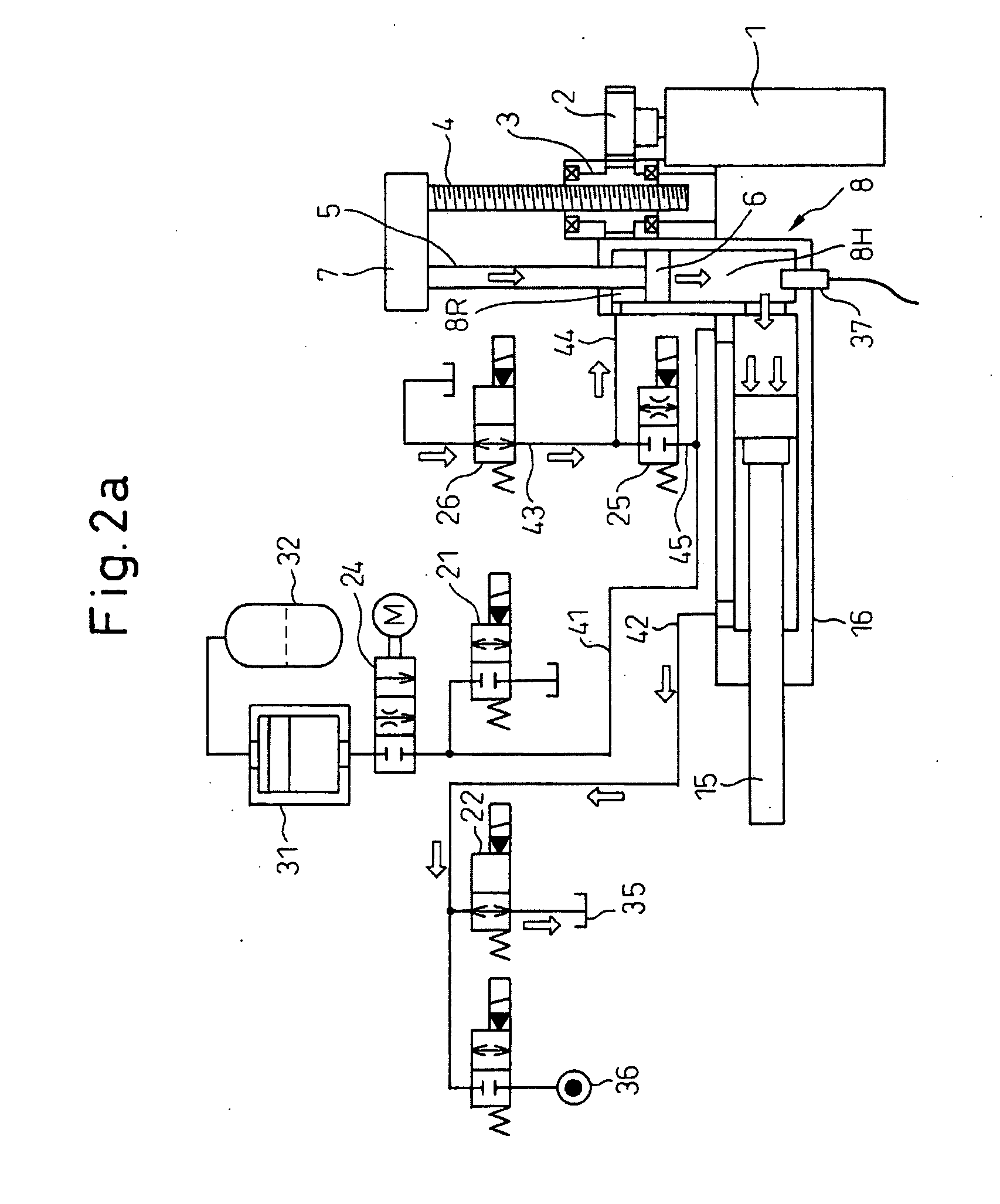

[0128]Next, an injection system 100 for a die casting machine in a second embodiment of the present invention is explained. FIG. 7 and FIGS. 8a to 8g show the injection system 100 for a die casting machine according to the second embodiment of the present invention, wherein FIG. 7 is an explanatory diagram showing a general configuration of a hydraulic circuit in the second embodiment of the injection system for a die casting machine, and FIGS. 8a to 8g are explanatory diagrams showing a state of the hydraulic circuit in various working processes in a die casting machine, The constituent parts in FIG. 7 and FIGS. 8a to 8g that are the same as or similar to the constituent parts in the first embodiment shown in FIG. 1 and FIGS. 2a to 2f are designated by the same reference symbols.

[0129]In the first embodiment, there is no description of the leak of hydraulic oil from the injection piston accumulator 31 (that is, the leak through the valve M 24), and no explanation is given as to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com