A kind of manufacturing method of composite ceramic closed impeller containing metal skeleton

A technology of composite ceramics and closed impellers, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of high processing costs and maintenance costs, increase costs, reduce product quality, etc., and achieve convenient waste cleaning, easy installation and The effect of reducing the difficulty of disassembly and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

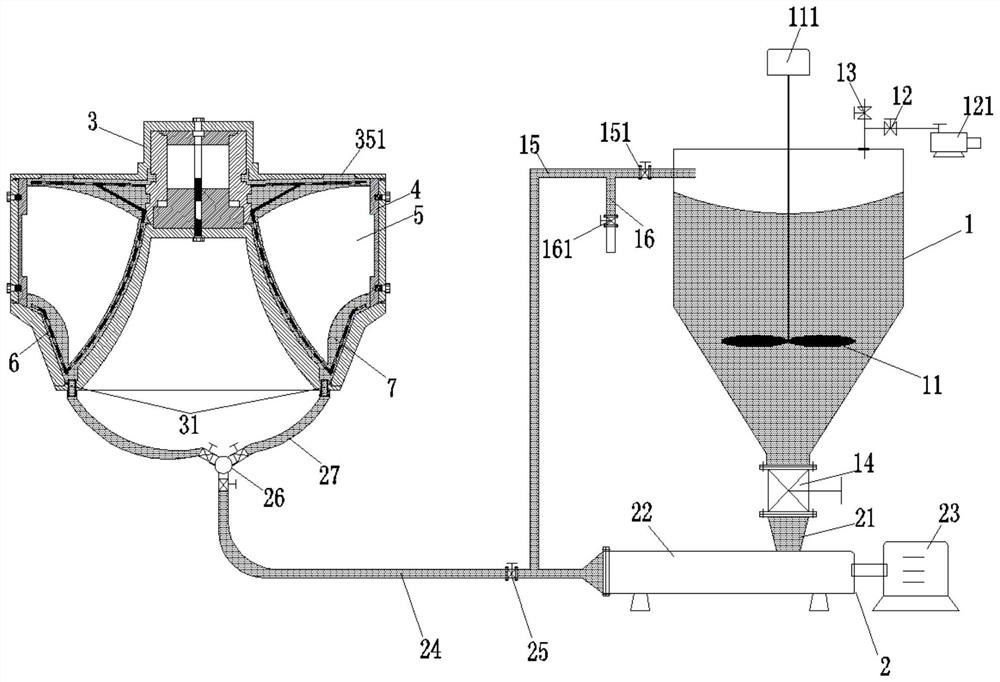

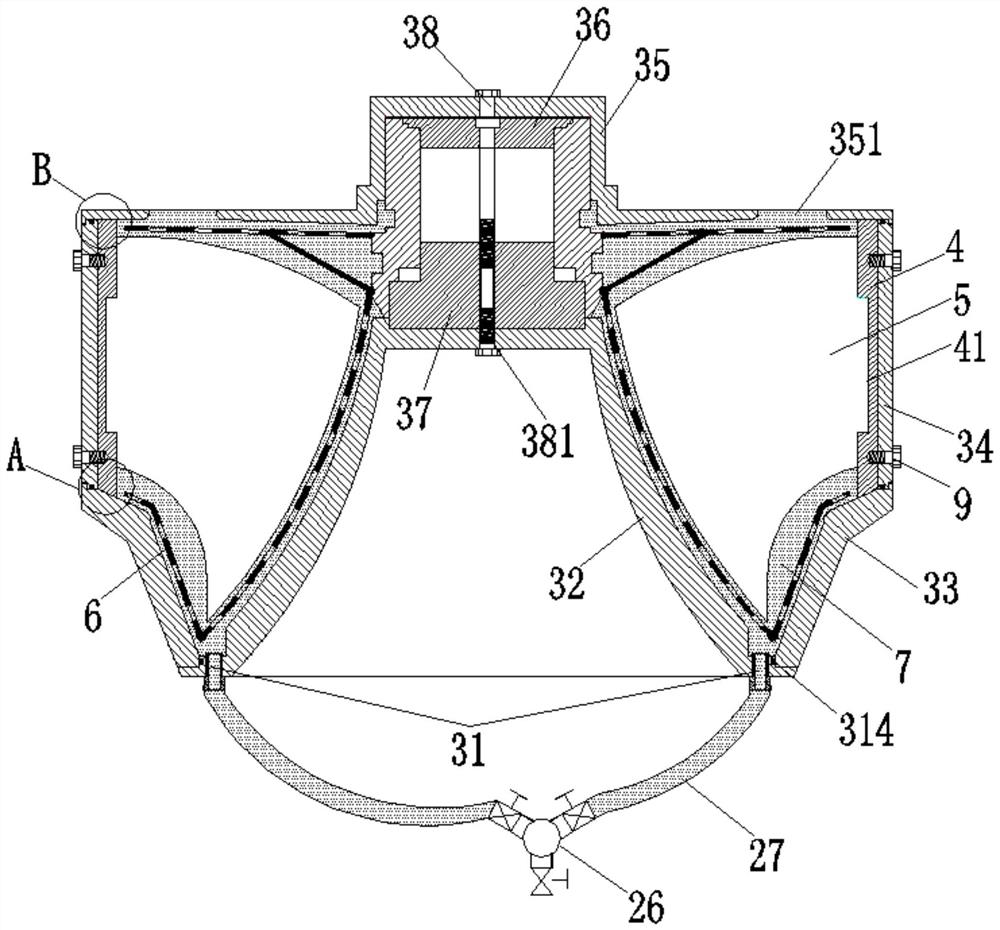

[0044] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0045] The operation steps of the manufacturing method of a composite ceramic closed impeller containing a metal skeleton according to the present invention are as follows.

[0046] (1) Preparation of the outer diameter mold 4 and the foam core mold 5 .

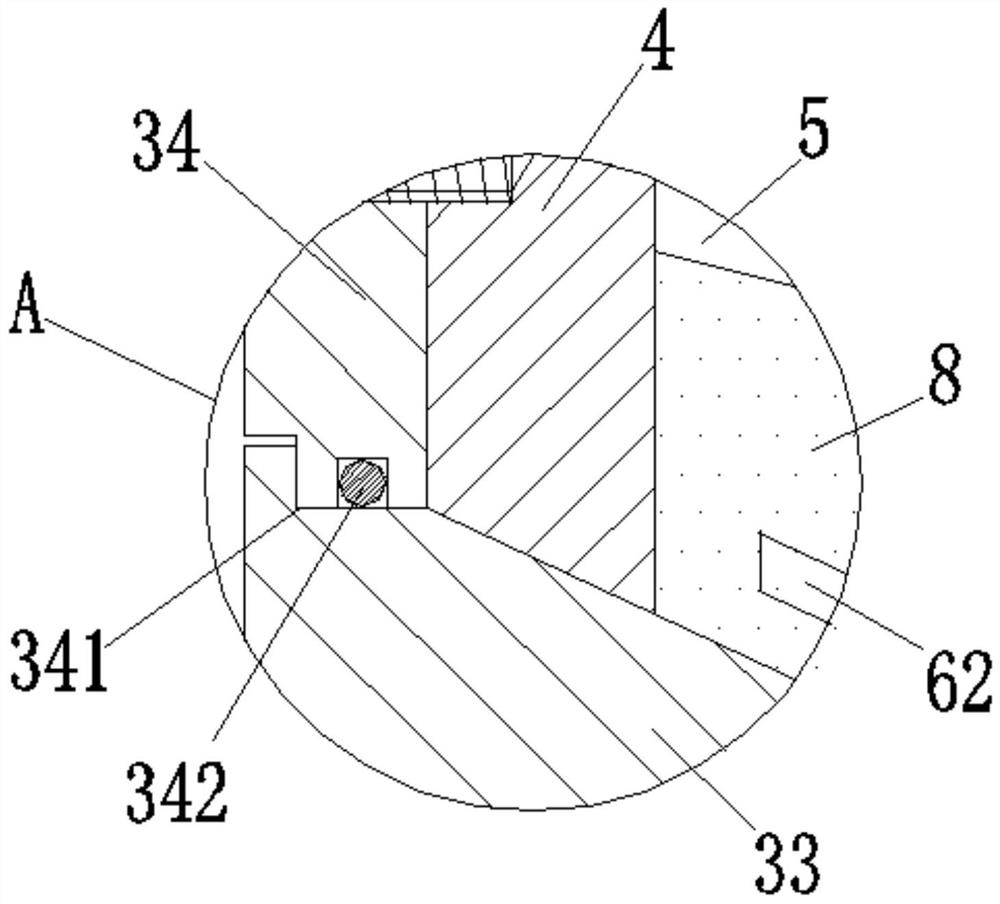

[0047] Such as figure 2 The shown outer diameter mold 4 has a plurality of core mold embedding grooves 41, which are evenly distributed on the inner surface of the outer diameter mold 4, and the outer surface of the corresponding foam core mold 5 is provided with corresponding embedding grooves. bit bumps. The number can be set to six, eight, etc. In this embodiment, the groove depth of the mandrel embedding groove 41 is set to 5mm to 10mm, the groove width is set to 15mm to 30mm, and the groove height is set to 30mm to 60mm to achieve Fixing of the foam core mold 5.

[0048] In the prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com