Patents

Literature

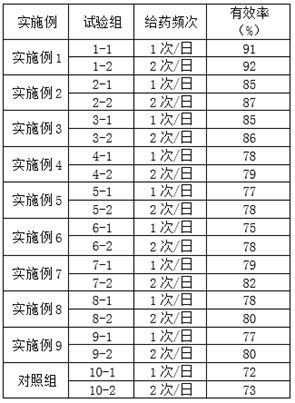

37results about How to "Lower injection costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

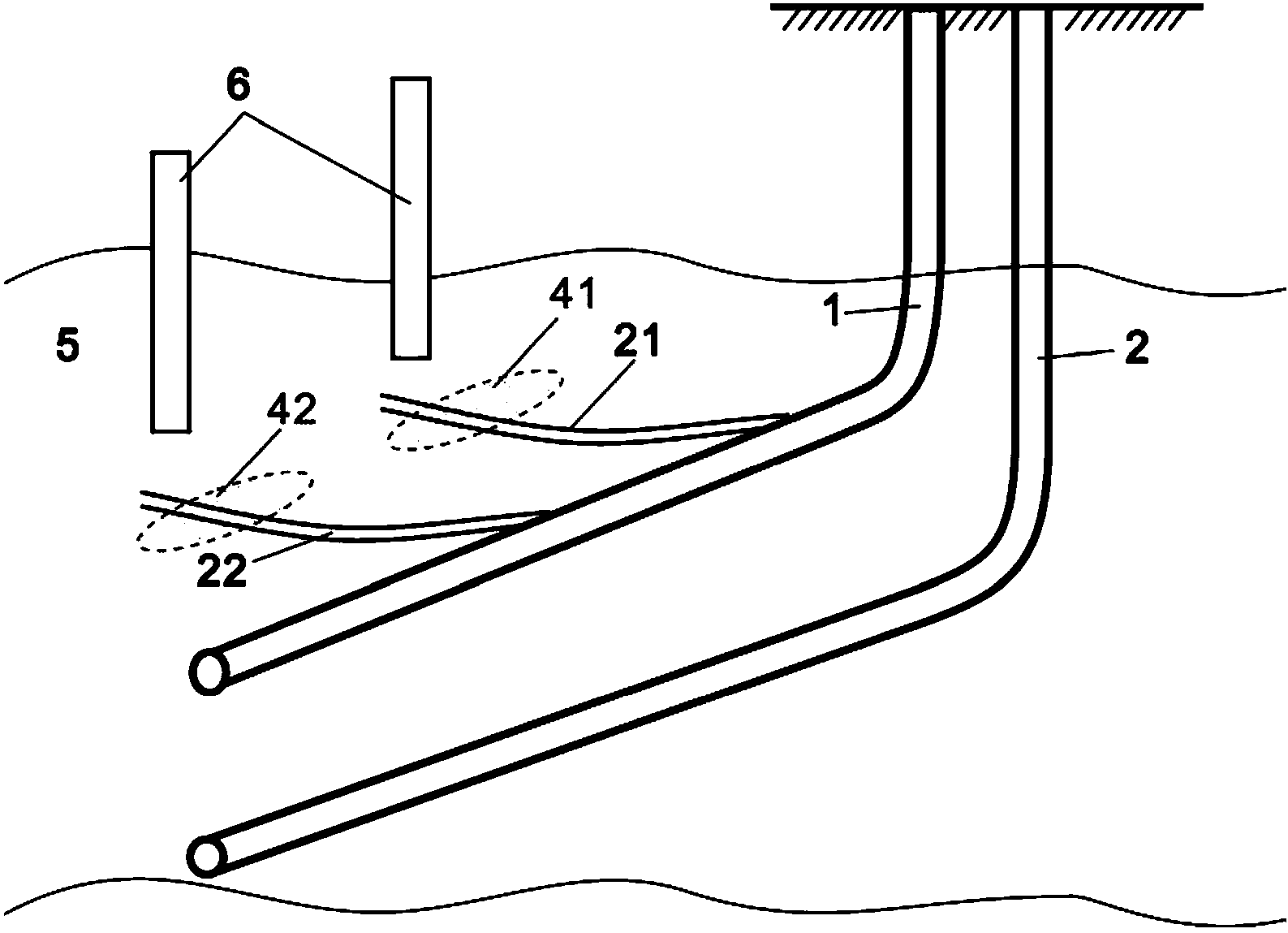

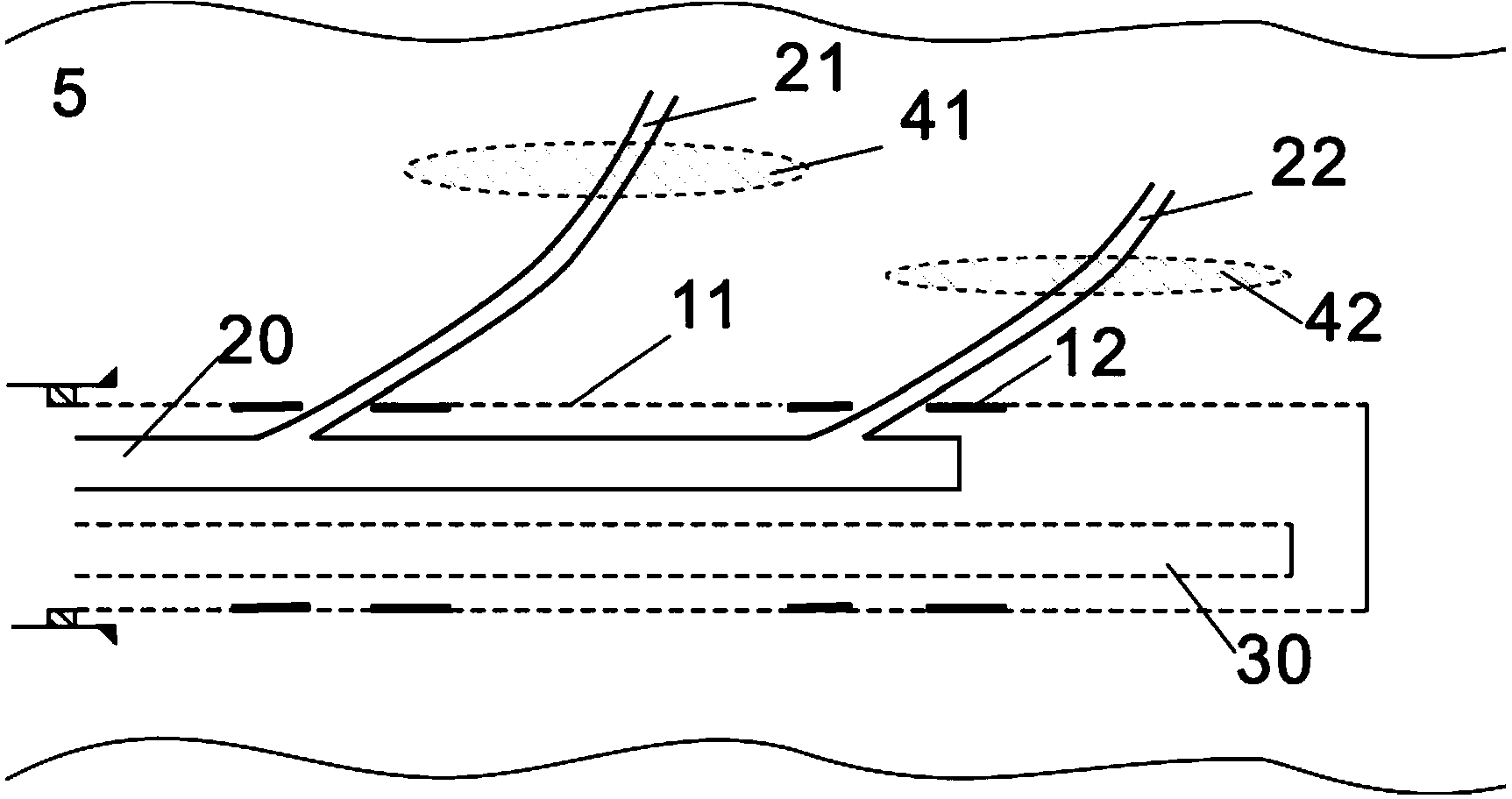

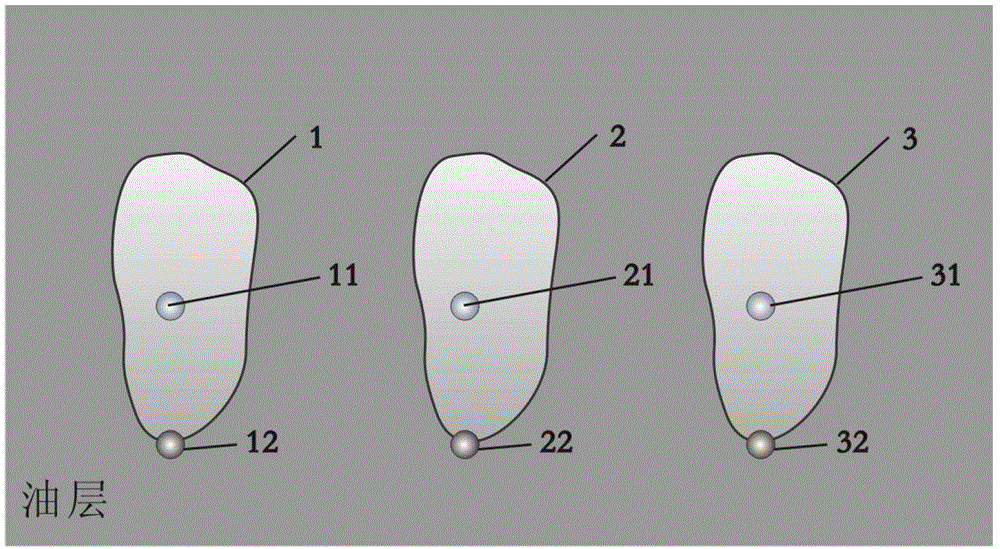

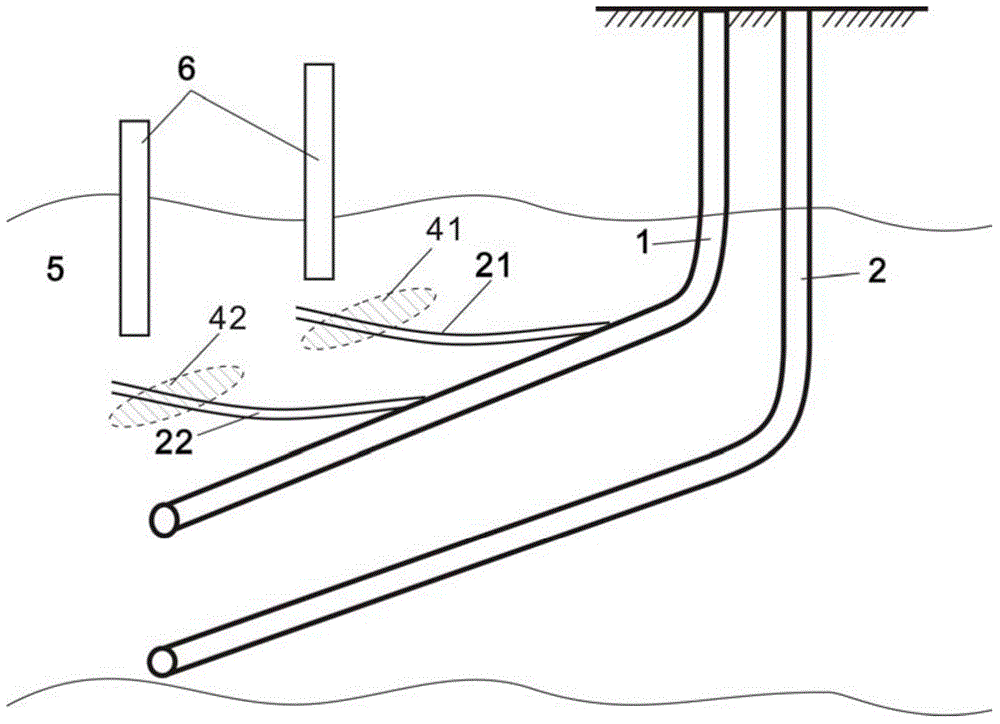

Fire-flooding exploitation method used in later period of steam assisted gravity drainage (SAGD) of heavy oil reservoir

ActiveCN102747997AExtended production timeIncrease profitFluid removalInjection wellSteam-assisted gravity drainage

The invention relates to a fire-flooding exploitation method used in a later period of steam assisted gravity drainage (SAGD) of a heavy oil reservoir. At a steam chamber expansion phase of the SAGD, when steam chambers of adjacent injection and production well pairs are subjected to coalescence, a injection and production well of the middle injection and production well pair is used for injecting air to ignite, a production well of the middle well pair and production wells of the left and right adjacent well pairs are used for producing, and injection wells of the left and right adjacent well pairs are converted into fire-flooding ventilation wells. The exploitation method can utilize a high-temperature fire-flooding front edge to effectively drive remaining reserves at the lower part of an oil layer between the adjacent SAGD well pairs, avoids the steam play of in the later period of the regular SAGD or the gas-assisted SAGD, prolongs the SAGD production time, and obviously improves the oil recovery. The method disclosed by the invention combines the advantages of the SAGD and fire flooding; the output at an SAGD production phase is high, and the oil exploitation speed is high; and the fire flooding is utilized at an output declination phase after the adjacent stream cavities are subjected to the coalescence, so that the injection cost can be reduced, and the heat energy utilization rate and the oil recovery are improved.

Owner:PETROCHINA CO LTD

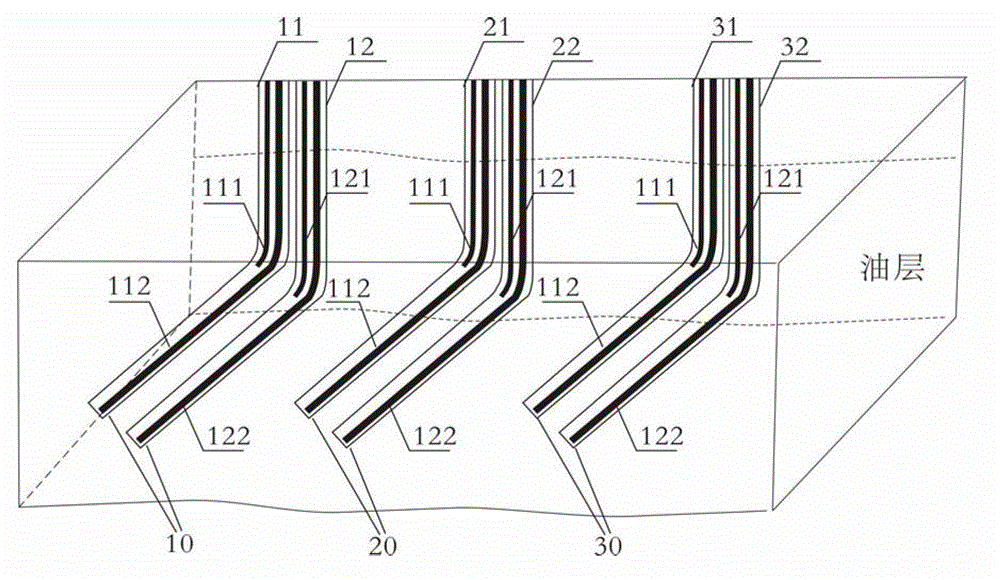

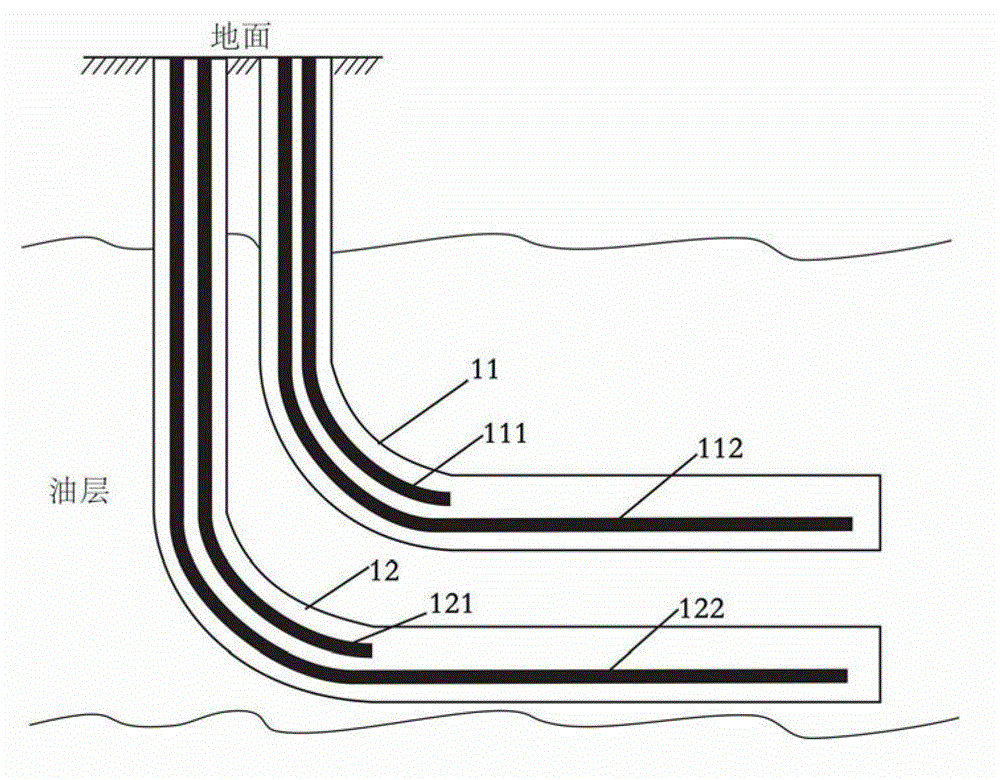

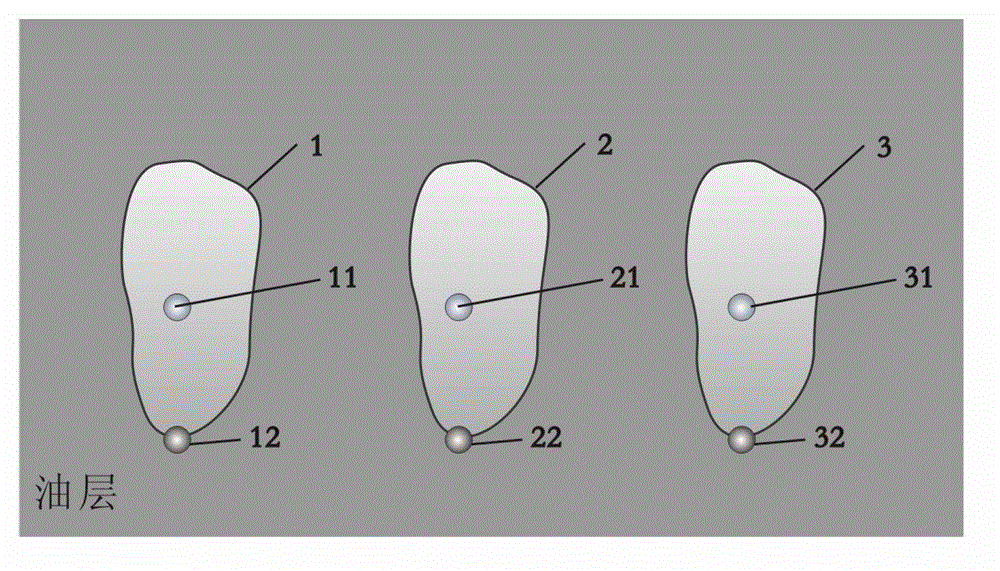

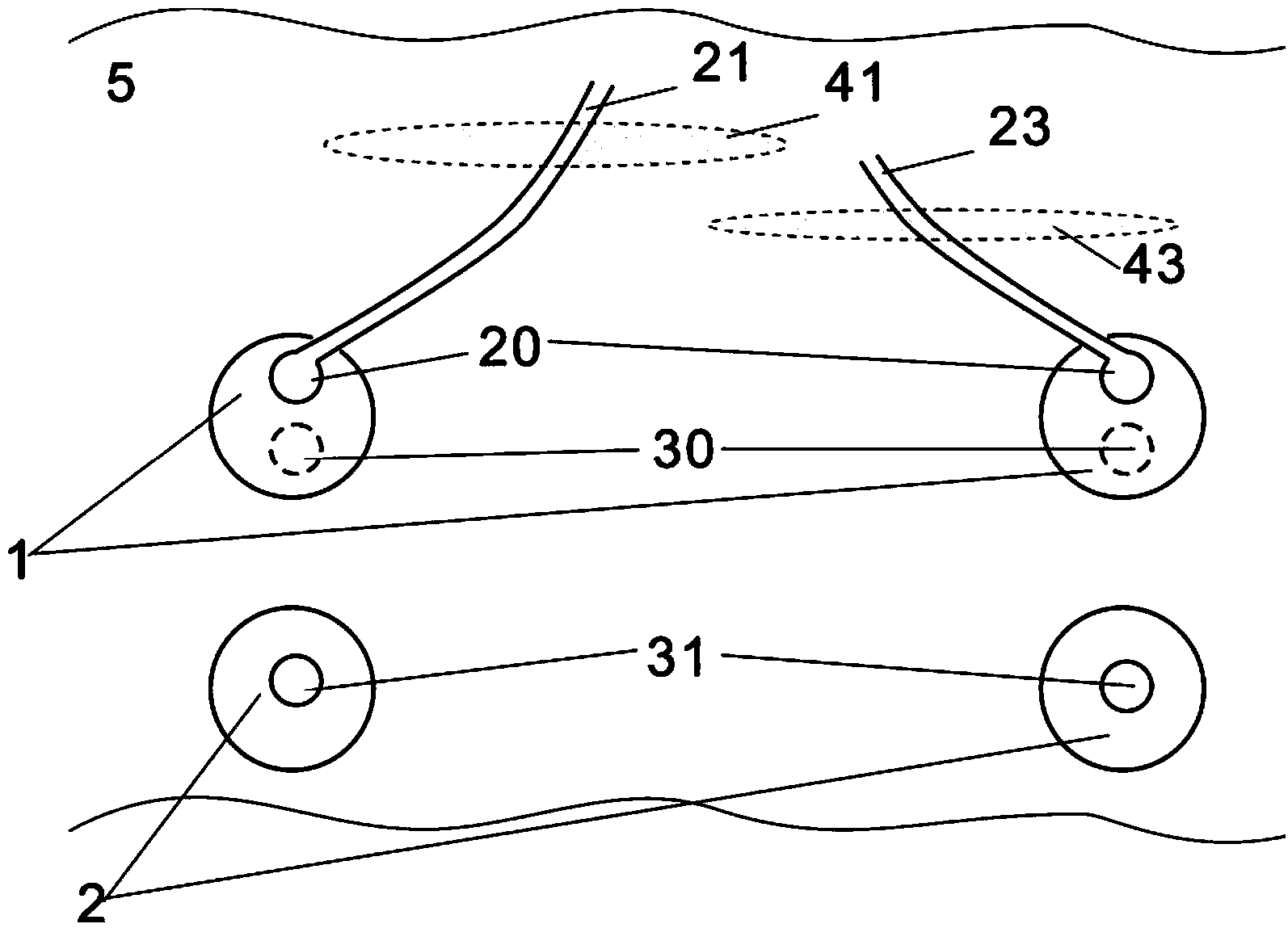

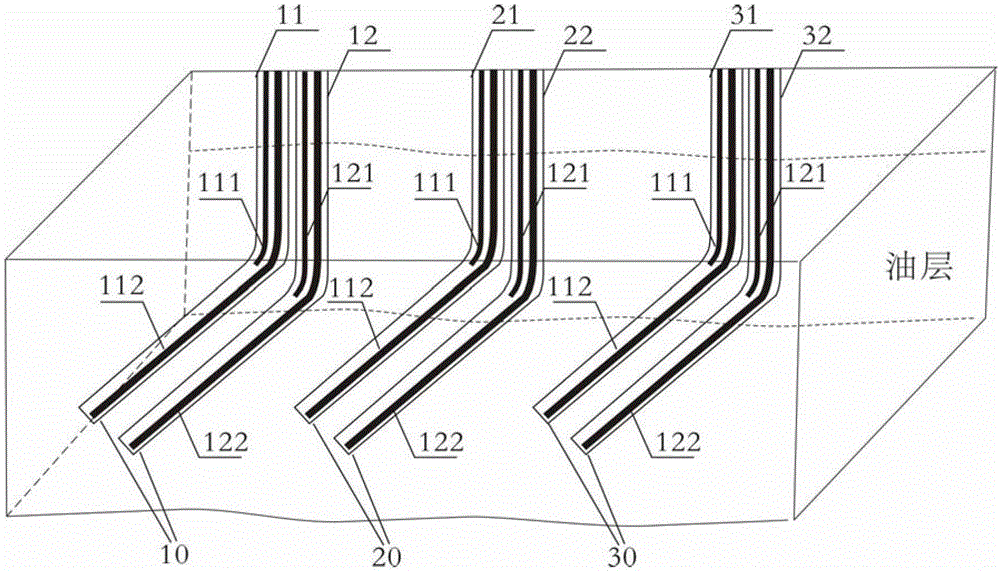

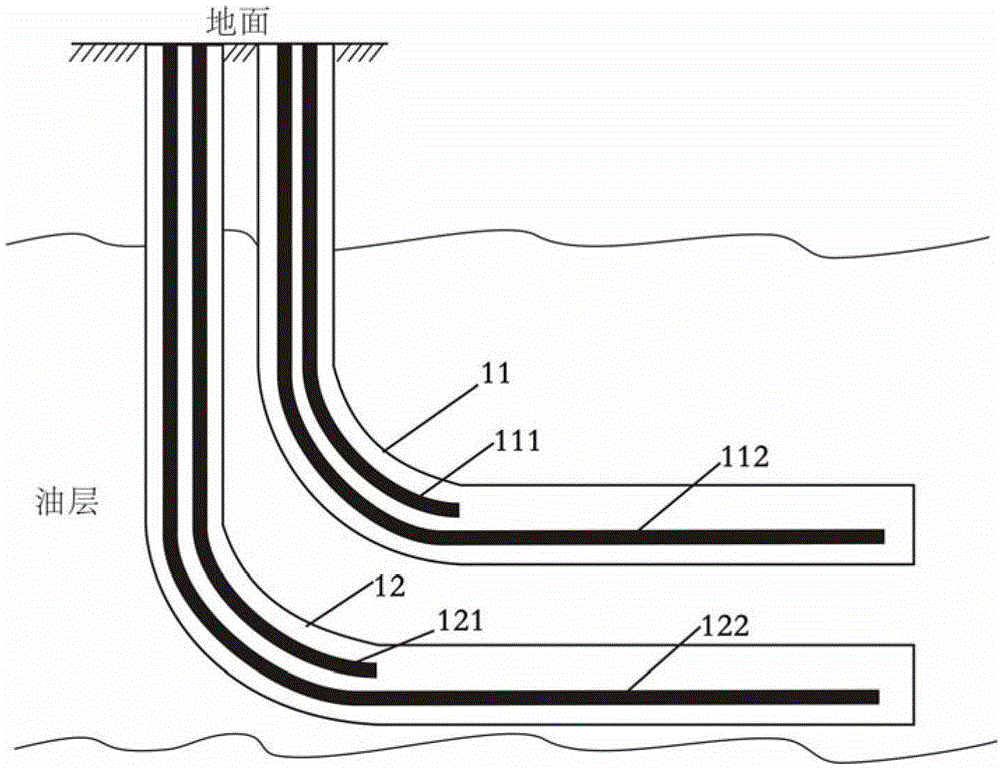

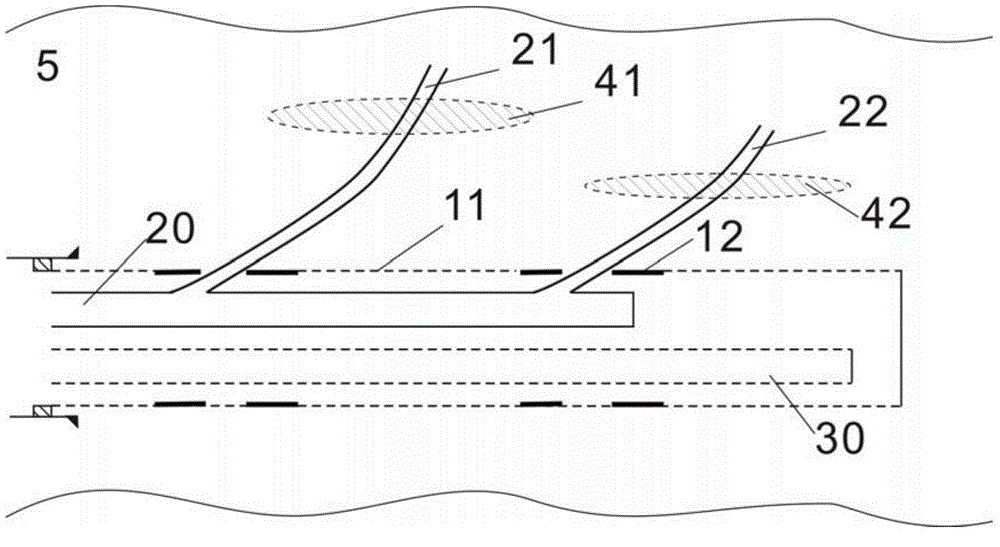

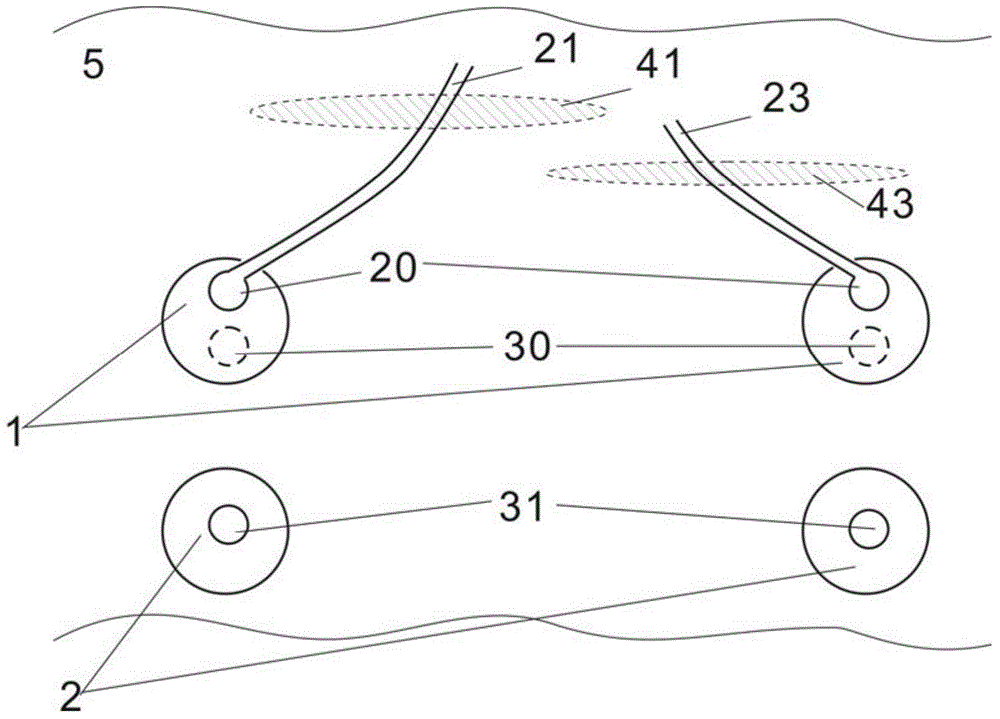

Method and well network structure for improving steam assisted gravity drainage for extracting heavy oil reservoirs by aid of solvents

The invention discloses a method and a well network for improving steam assisted gravity drainage for extracting heavy oil reservoirs by the aid of solvents. The well network comprises SAGD (steam assisted gravity drainage) horizontal well pairs; horizontal sections of steam injection wells are subjected to well completion by the aid of slotted screen pipes; branched well sections are drilled in the horizontal sections of the steam injection wells and penetrate the middles of inner sandwich layers in oil layers; the various branched well sections are subjected to well completion by the aid of tail pipes; first long oil pipes which extend to toes of the steam injection wells descend into screen pipes of the steam injection wells; solvent injection main pipes which are parallel to the first long oil pipes descend into the screen pipes of the steam injection wells and are hermetically connected with the tail pipes in the various branched well sections by tail pipe hangers; second long oil pipes descend into production wells and reach the tail ends of horizontal sections of the production wells; vertical monitoring wells are further deployed in the well network. The method and the well network have the advantages that steam flows into the oil layers to upwardly develop steam cavities, and the hot solvents and steam mixed systems flow into the oil layers on the upper portions of the sandwich layers from the main pipes via the tail pipes, so that heat communication and fluid communication among the oil layers and the steam cavities can be accelerated, the sandwich layers can be forcedly broken through, development of the steam cavities on the upper portions of the sandwich layers can be promoted, and the recovery efficiency can be greatly improved.

Owner:PETROCHINA CO LTD

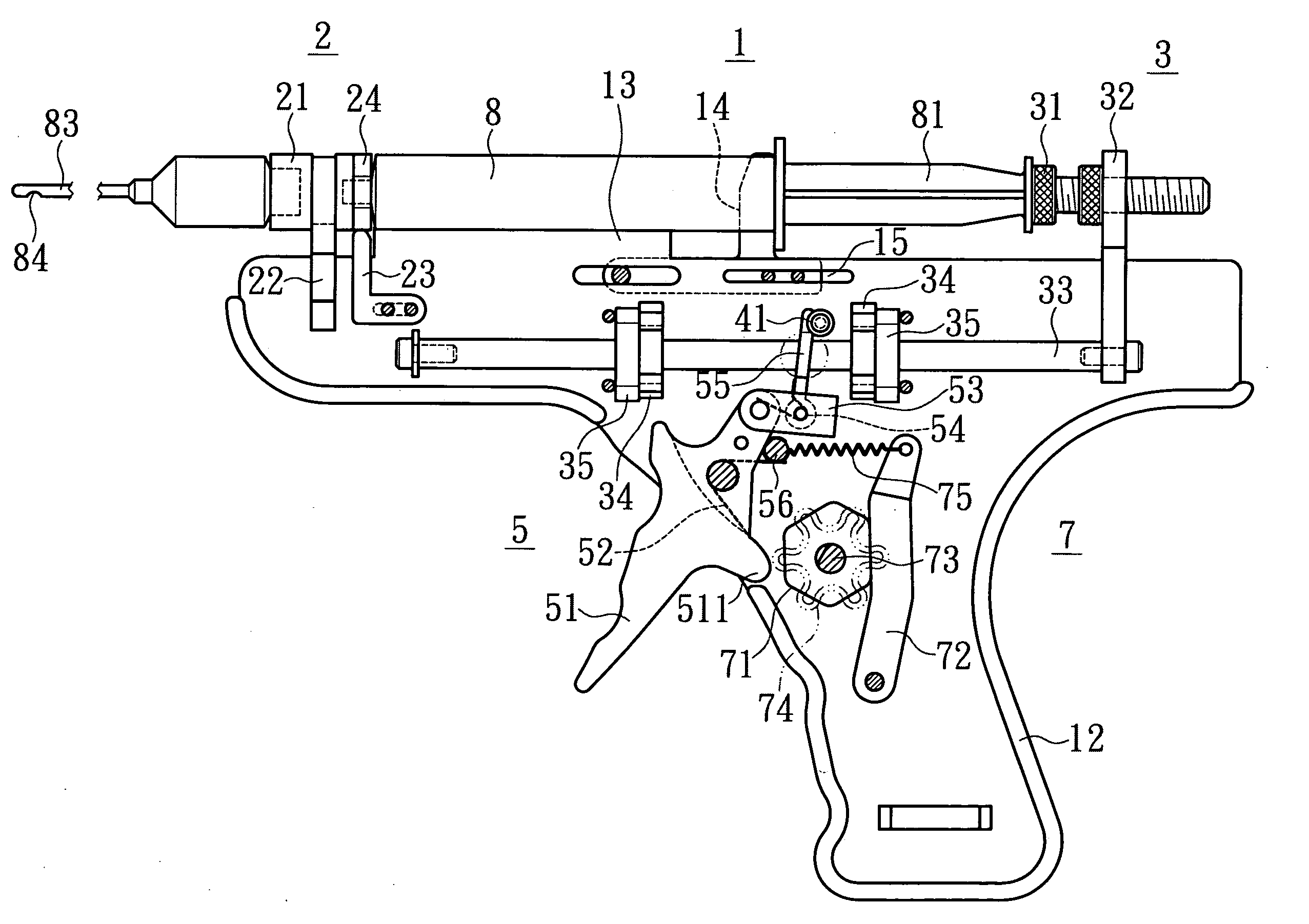

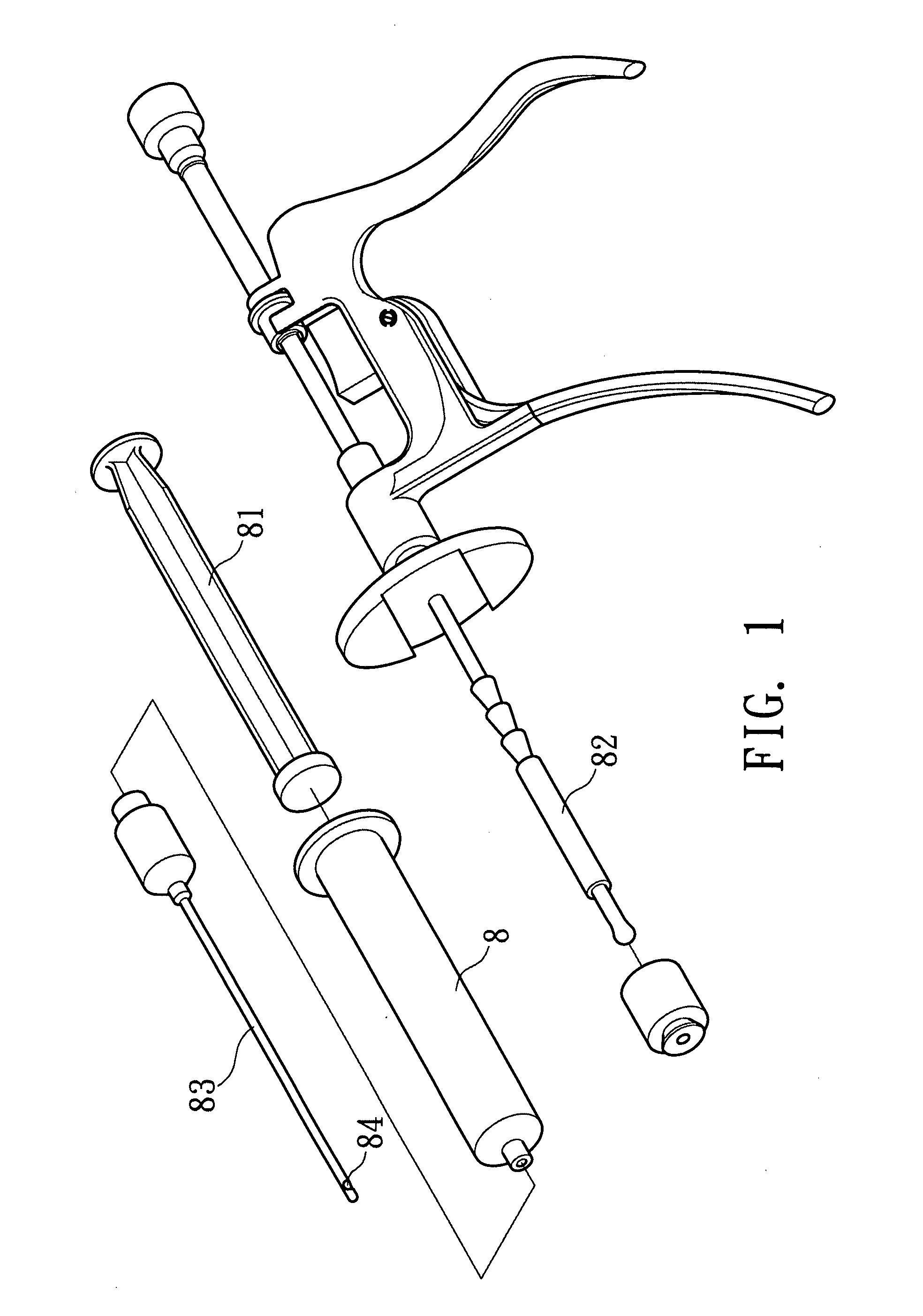

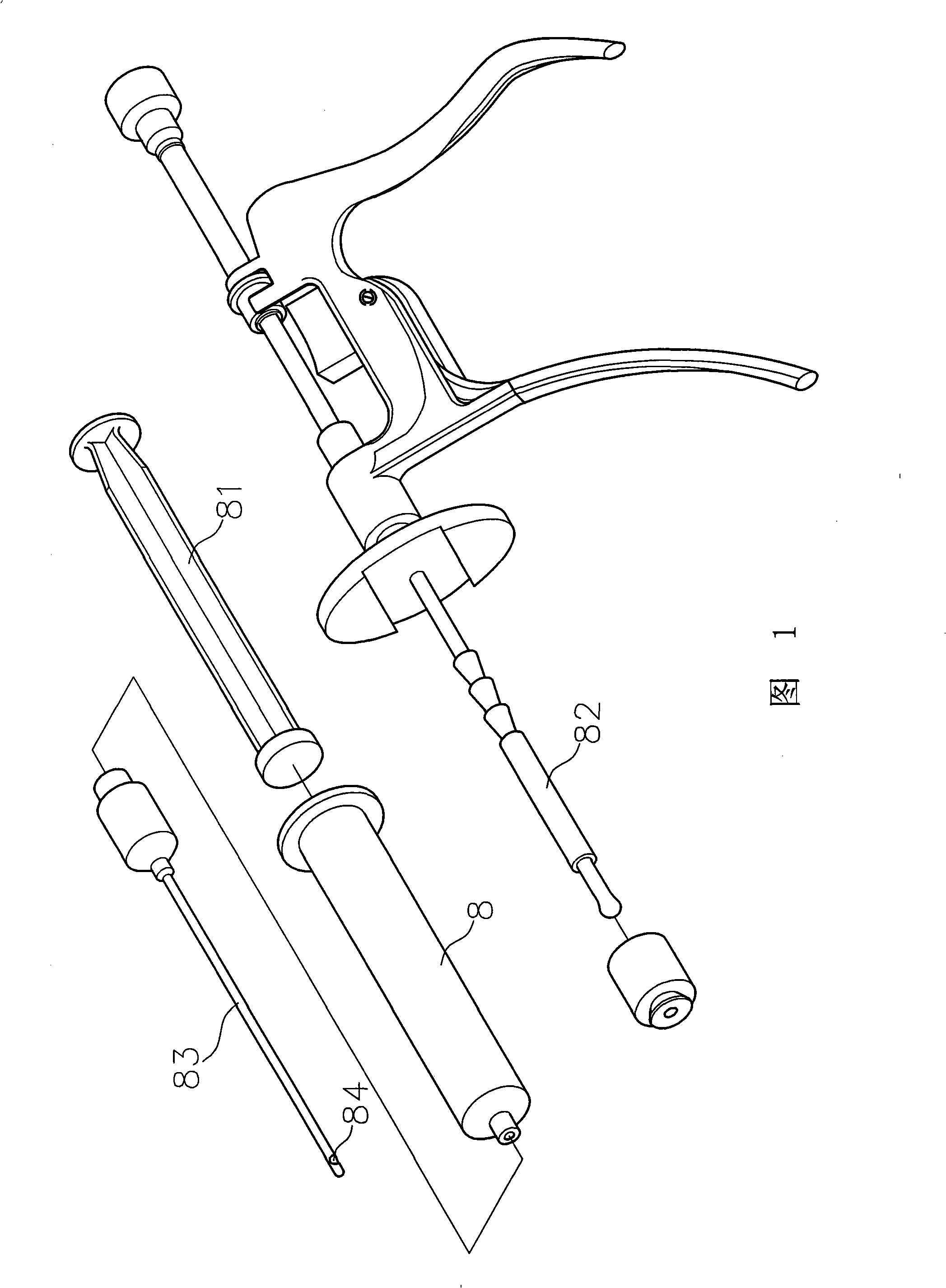

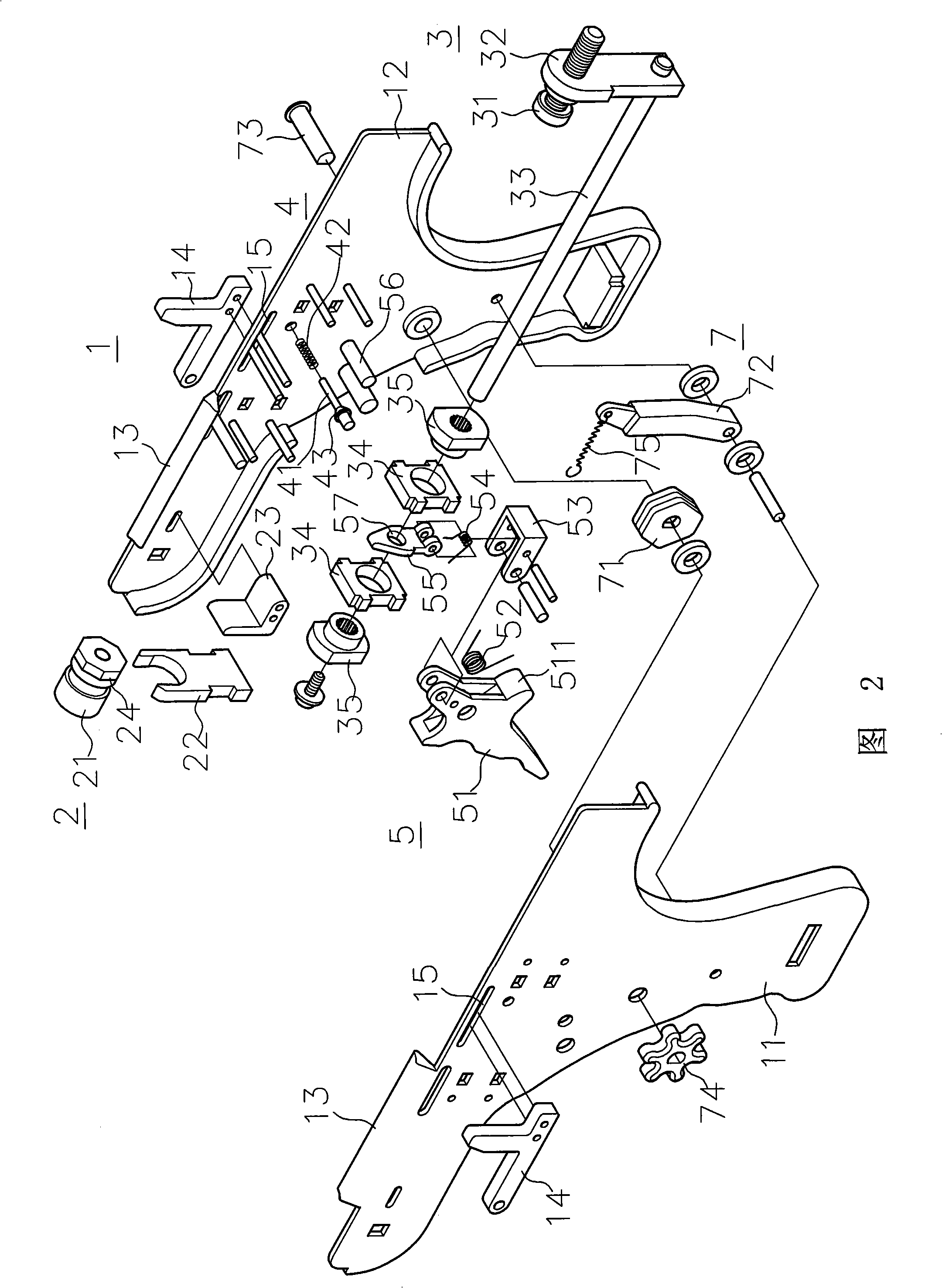

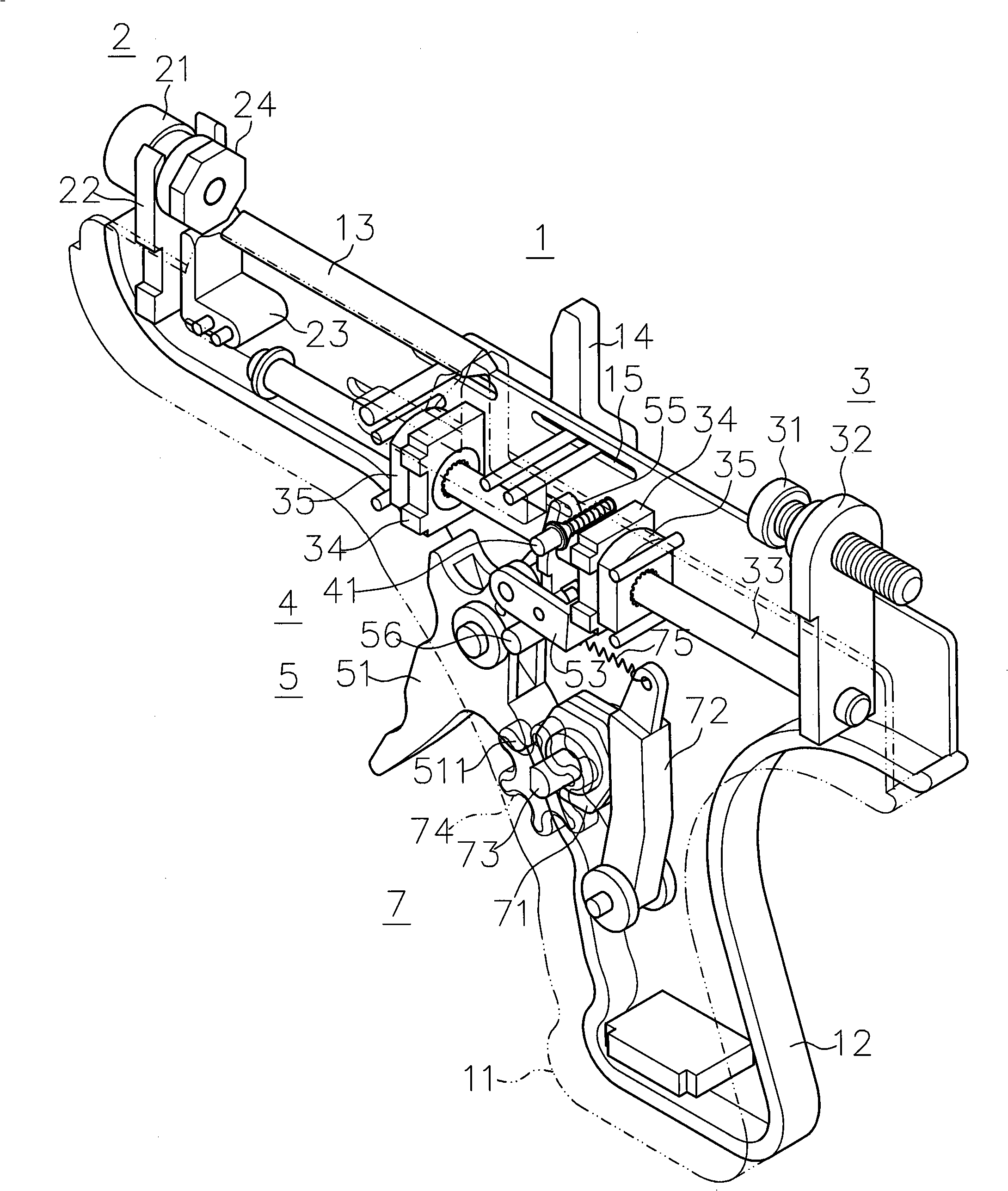

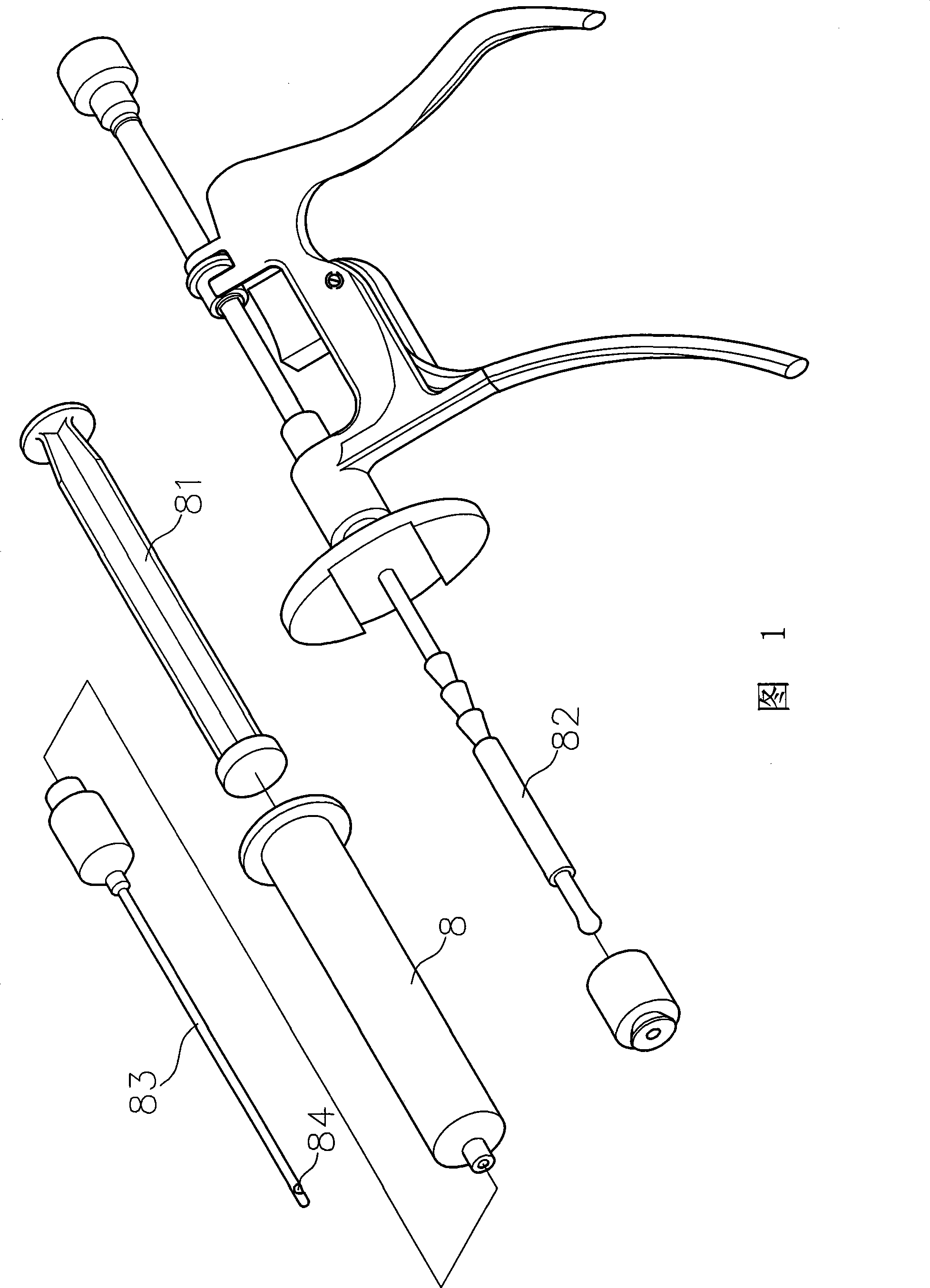

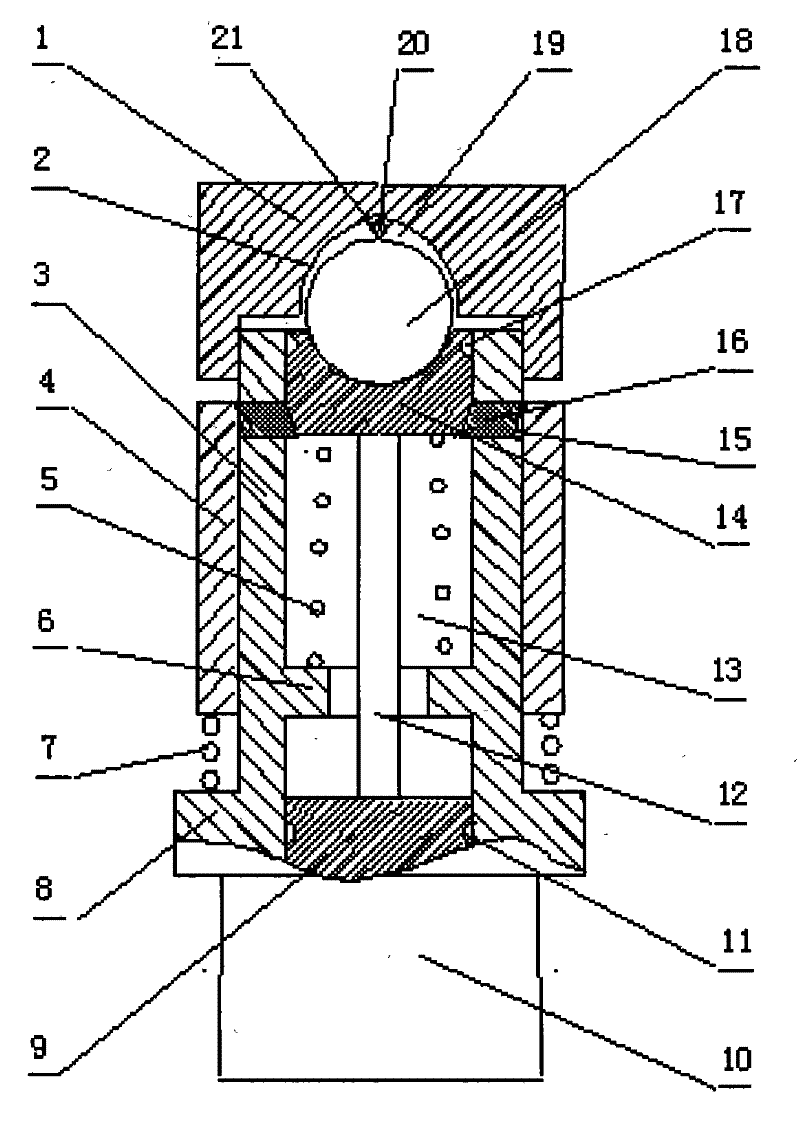

Volume adjustable, micro-injection device

ActiveUS20080269671A1Easy to operateImprove accuracyAmpoule syringesMovable measuring chambersAir exposureInjection volume

The present invention relates to a volume-adjustable micro-injection device. The device includes a base structure having a syringe positioning structure and a grip, in which the syringe positioning structure can flexibly accommodate injection syringes with different volumes; a holding structure capable of flexibly adjusting an injection angle of syringe content for easier operation; a qualitative controller capable of accurately controlling injection volume; a pressure pushing structure to hold and push a plunger; an injection controller interlinked with the qualitative controller and the pressure pushing structure; and an eject structure facilitating simple operation and easy replacement of injection syringes. In contrast to conventional structures, the present invention provides advantages that control injection volume more accurately, address better injection angle control, allow for the syringe contents to be free from air exposure, require no special syringes, and allow for single-handed replacement of the injection syringe.

Owner:DERMATO PLASTICA BEAUTY DPB

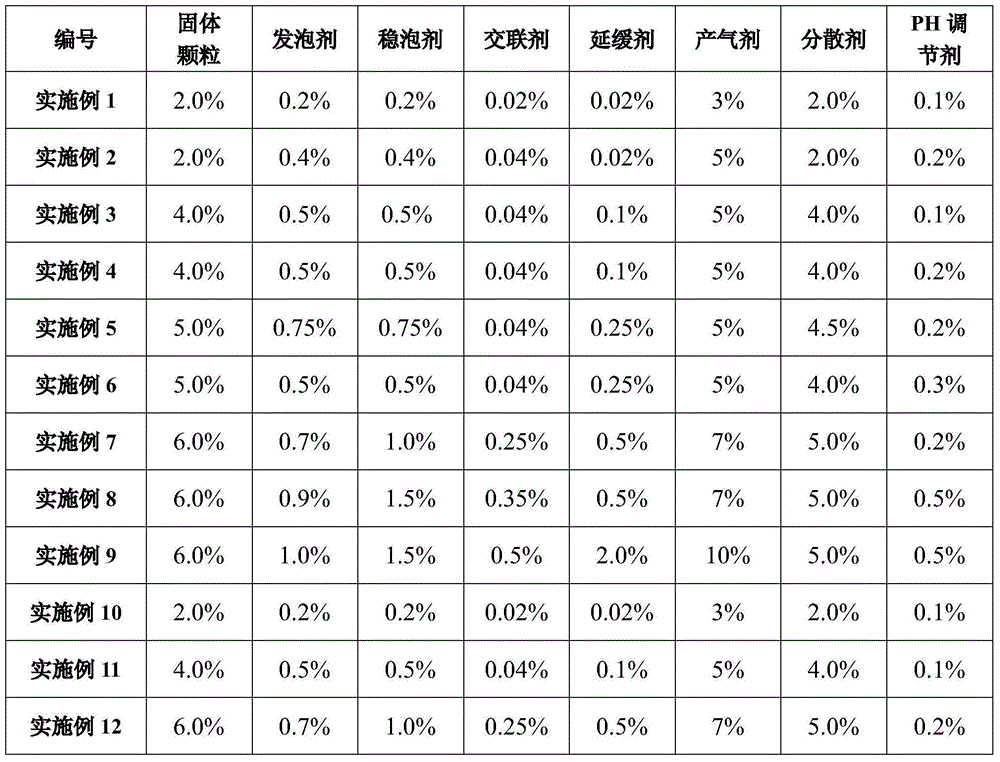

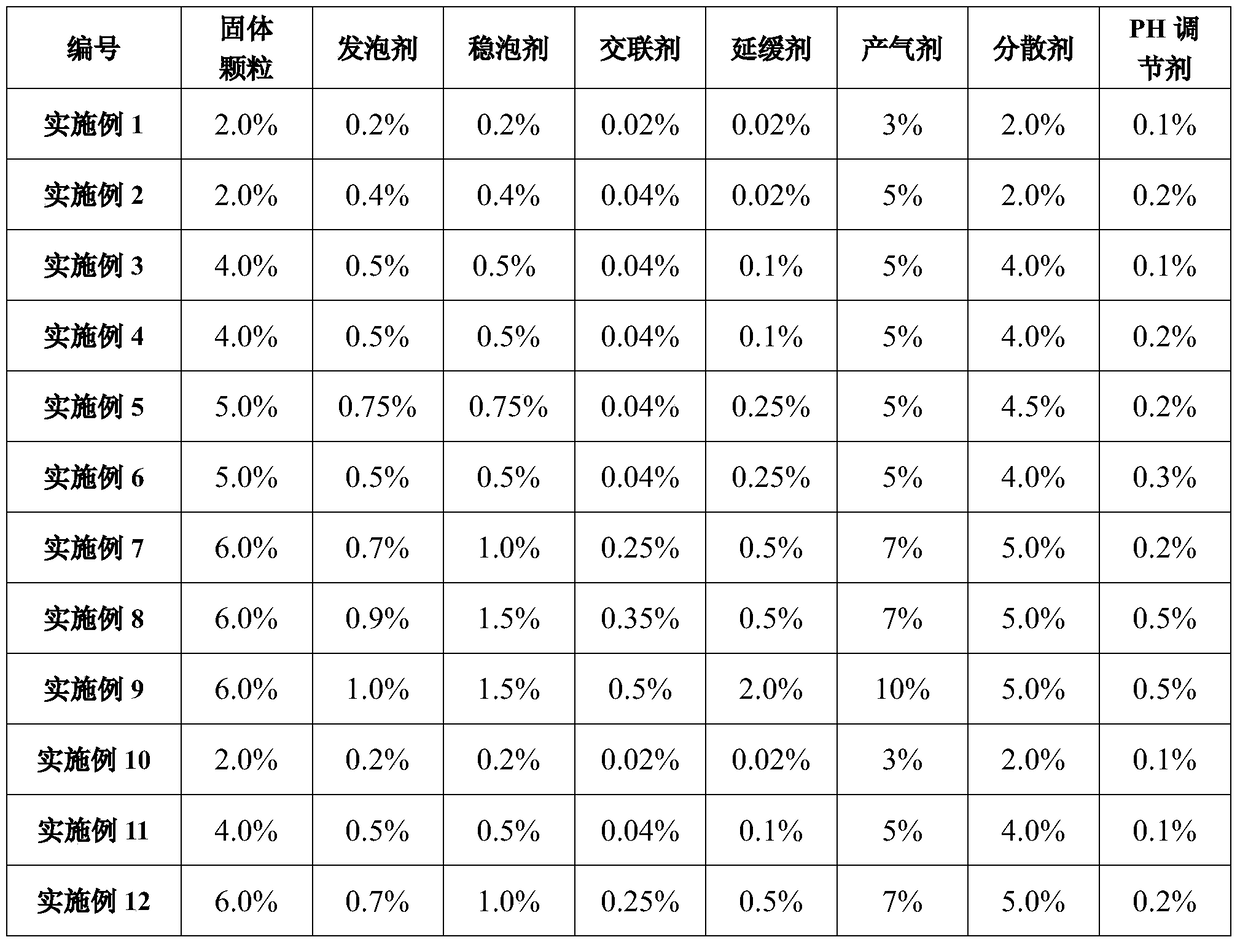

Three-phase self-foaming water-plugging agent

The invention discloses a three-phase self-foaming water-plugging agent, and belongs to the field of petroleum chemistry. The provided water-plugging agent comprises the following components: solid particles, a foaming agent, a foam stabilizing agent, a crosslinking agent, a delaying agent, and a gas producing agent. Compared with the prior art, the provided water-plugging agent has the advantages of high foam quality and good stability, the gel crosslinking and gas production can be achieved at the same time, the water-plugging agent can tolerate high temperature, has a strong residue blocking performance and a long water-plugging period, and can achieve efficient plugging and depth profile control. Moreover, the preparation technology of the provided water-plugging agent is simple, the injection cost is low, and the water-plugging agent is safe and reliable, thus has a good market prospect and high economic value, and is especially suitable for the development of high temperature heavy oil steam stimulation wells.

Owner:CHINA PETROLEUM & CHEM CORP +1

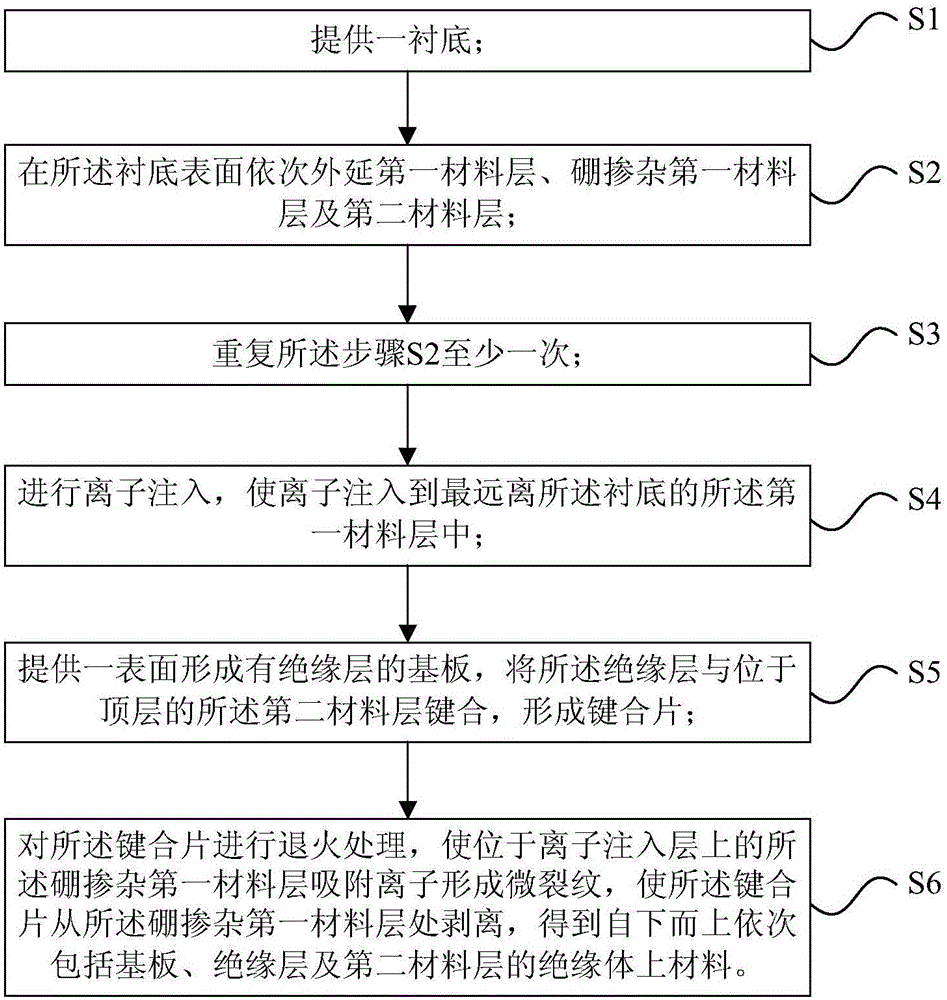

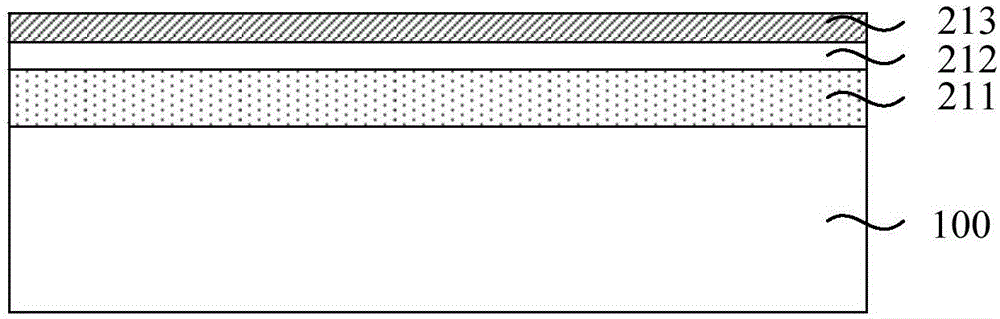

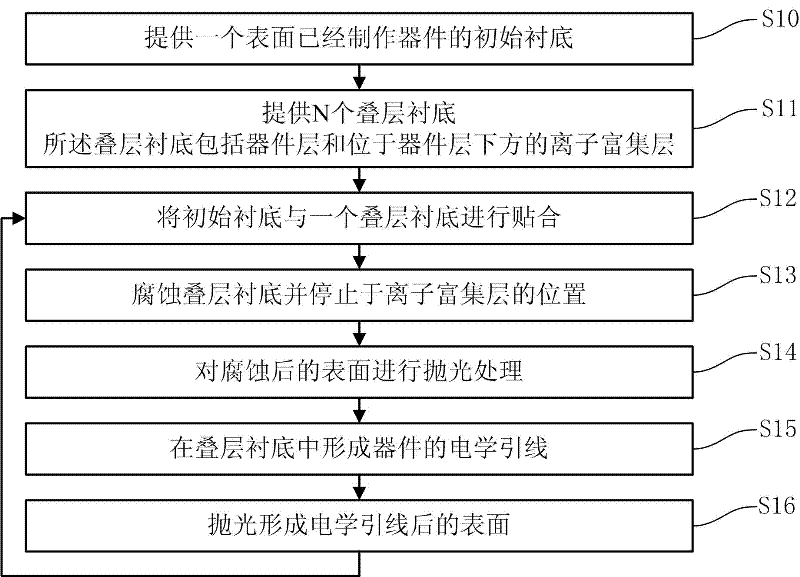

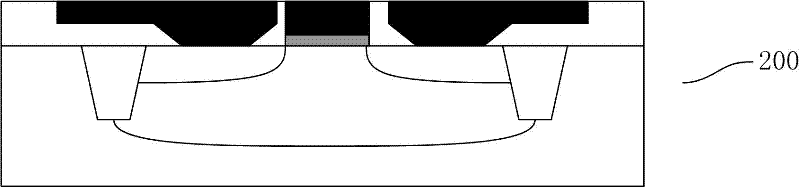

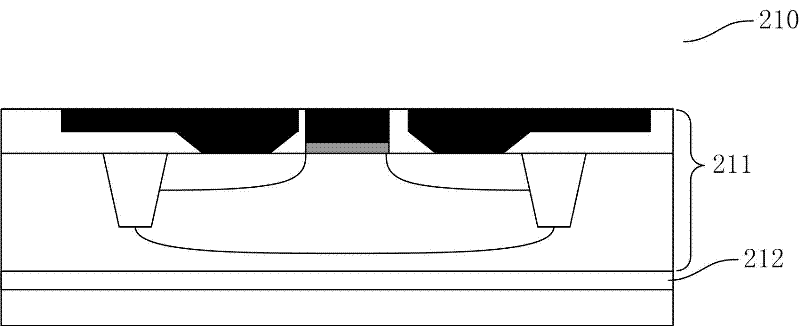

Preparation method of material-on-insulator

ActiveCN105140171ALow costQuality improvementSemiconductor/solid-state device manufacturingBoronIon implantation

The invention provides a preparation method of a material-on-insulator. The method comprises the following steps: (S1) a substrate is provided; (S2) a first material layer, a boron-doped first material layer and a second material layer sequentially extend on the surface of the substrate; (S3) the step (S2) is repeated at least once; (S4) ion implantation is carried out, so that the ions are injected into the first material layer which is the furthest to the substrate; (S5) a base plate formed with an insulating layer on the surface is provided; and the insulating layer and the second material layer on the top layer are bonded to form a bonding wafer; and (S6) annealing treatment is carried out on the bonding wafer; and the boron-doped first material layer on an ion implantation layer absorbs the ions to form microcracks for stripping, so as to obtain the material-on-insulator. According to the preparation method, the substrate can be repeatedly utilized, so that the cost of the production material is reduced; the technological process is simplified; the ion implantation dosage is relatively low; improvement of the crystal quality is facilitated; the implantation cost is reduced; and the obtained material-on-insulator is very smooth in surface and does not need to be polished.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

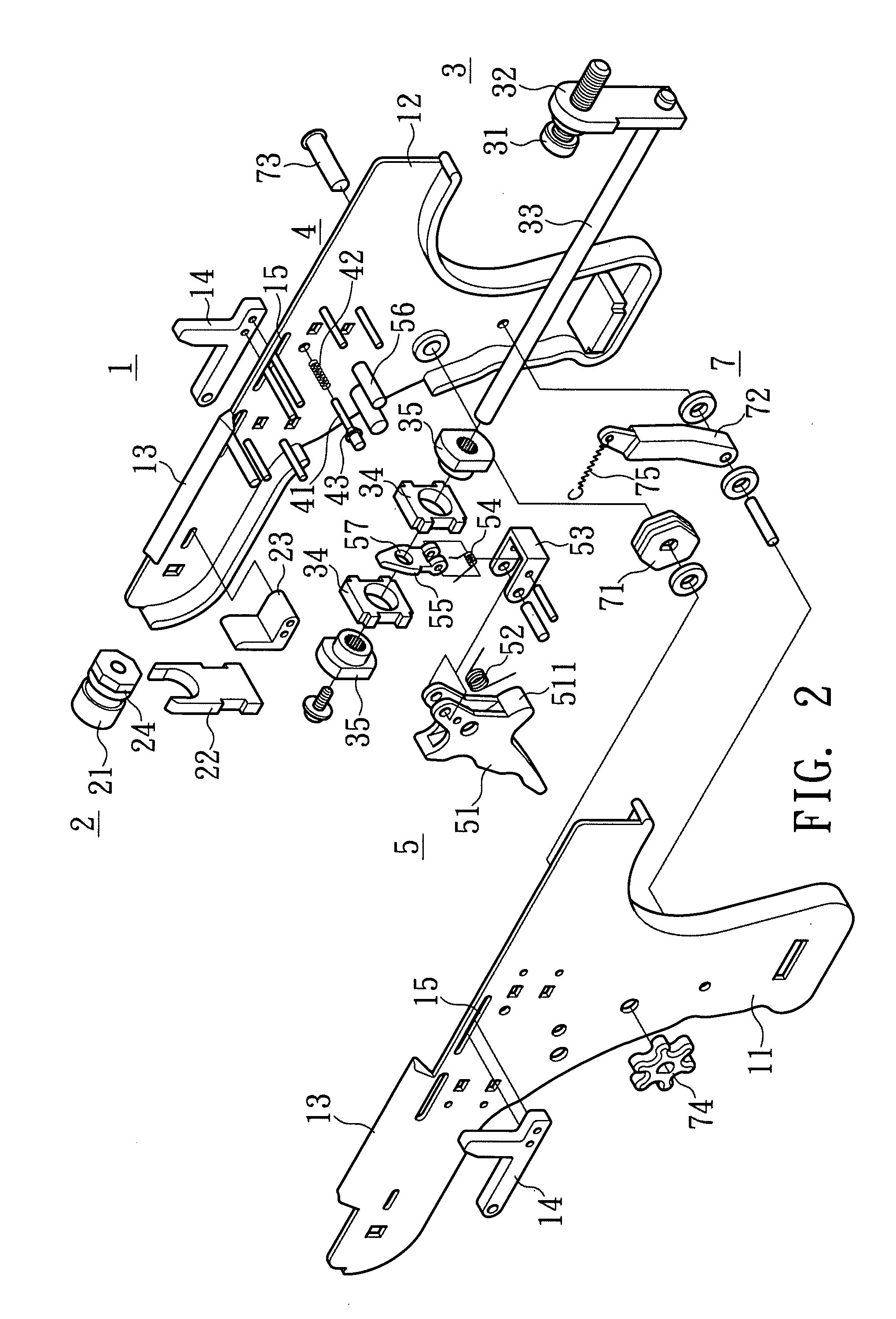

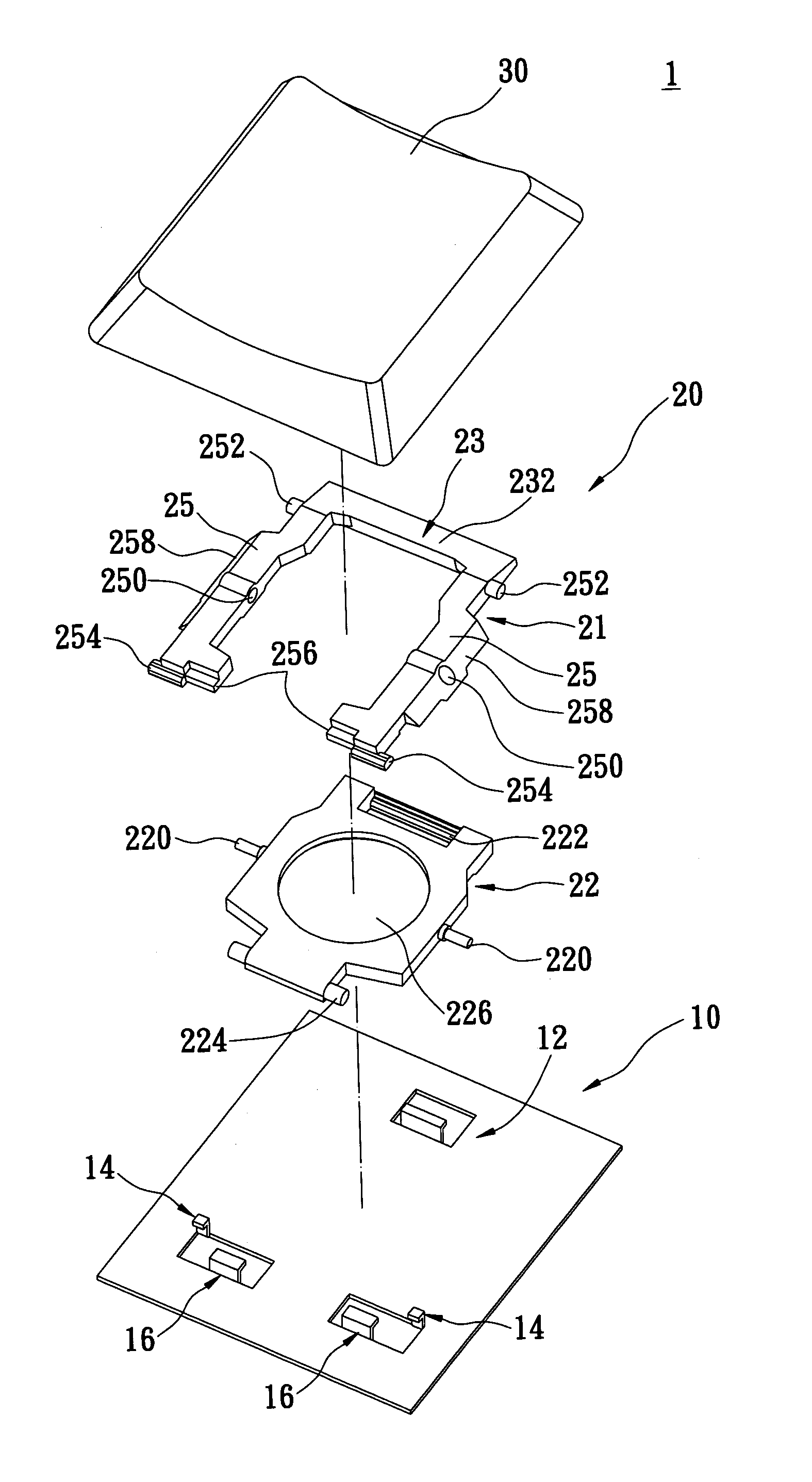

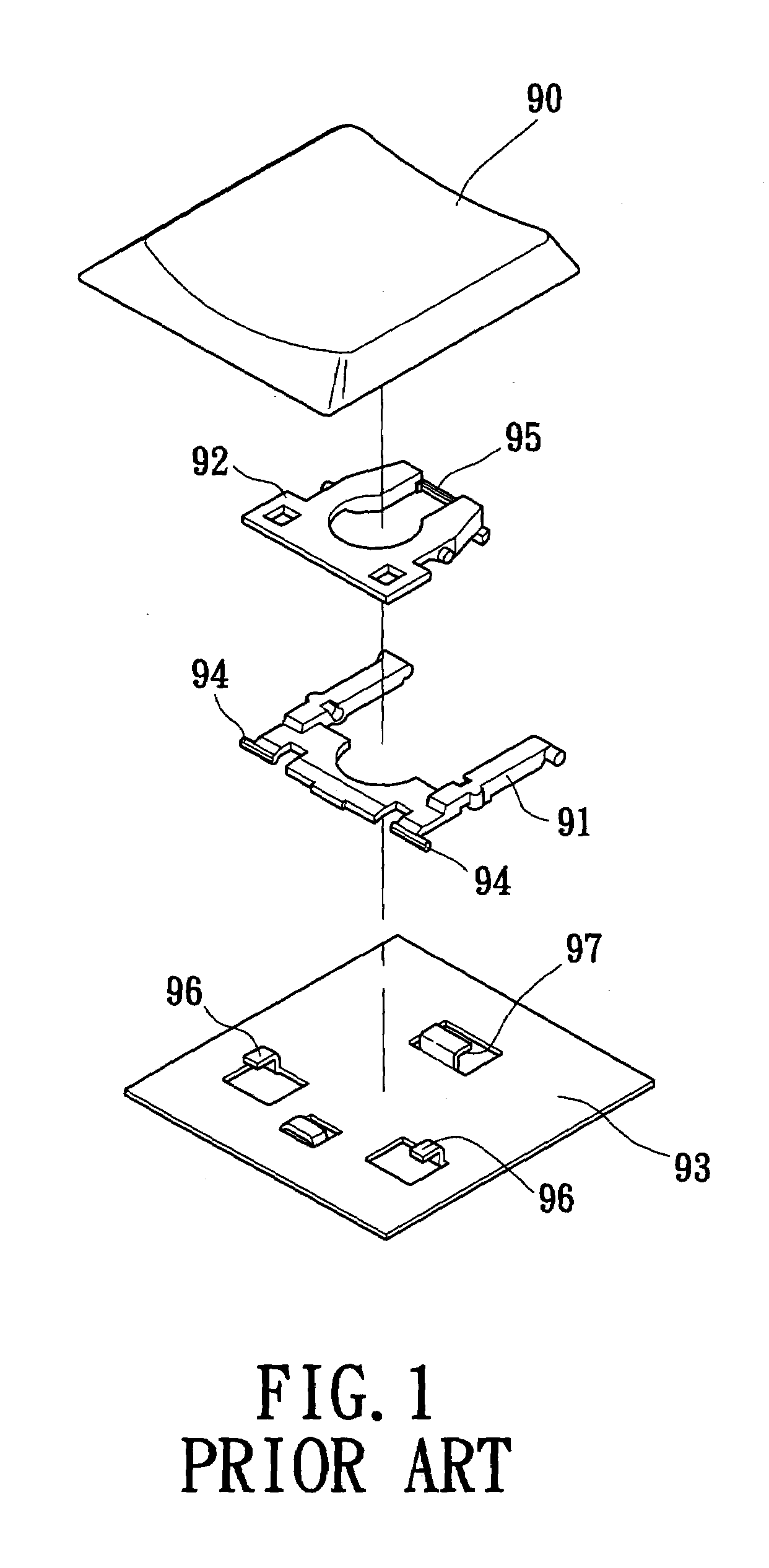

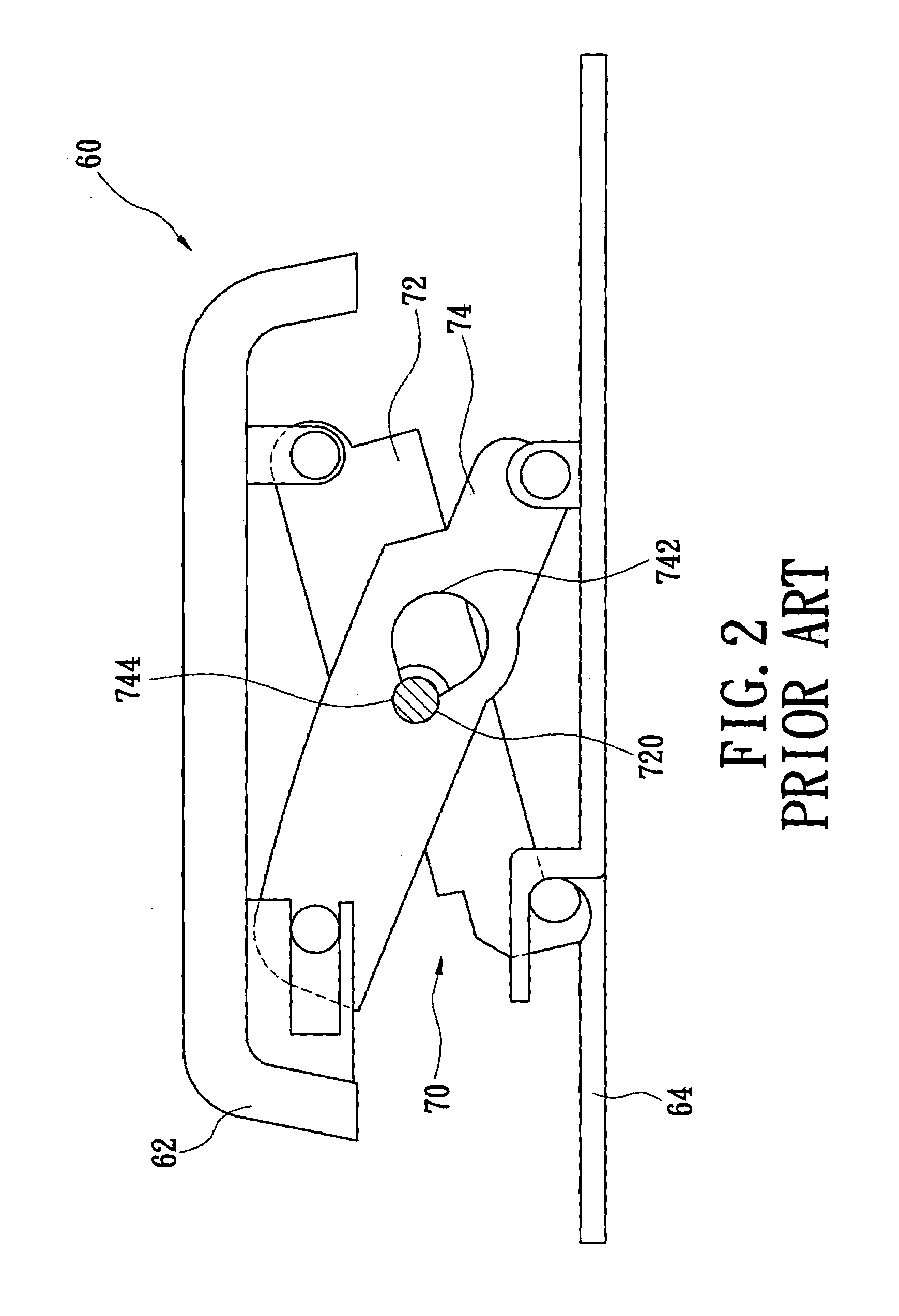

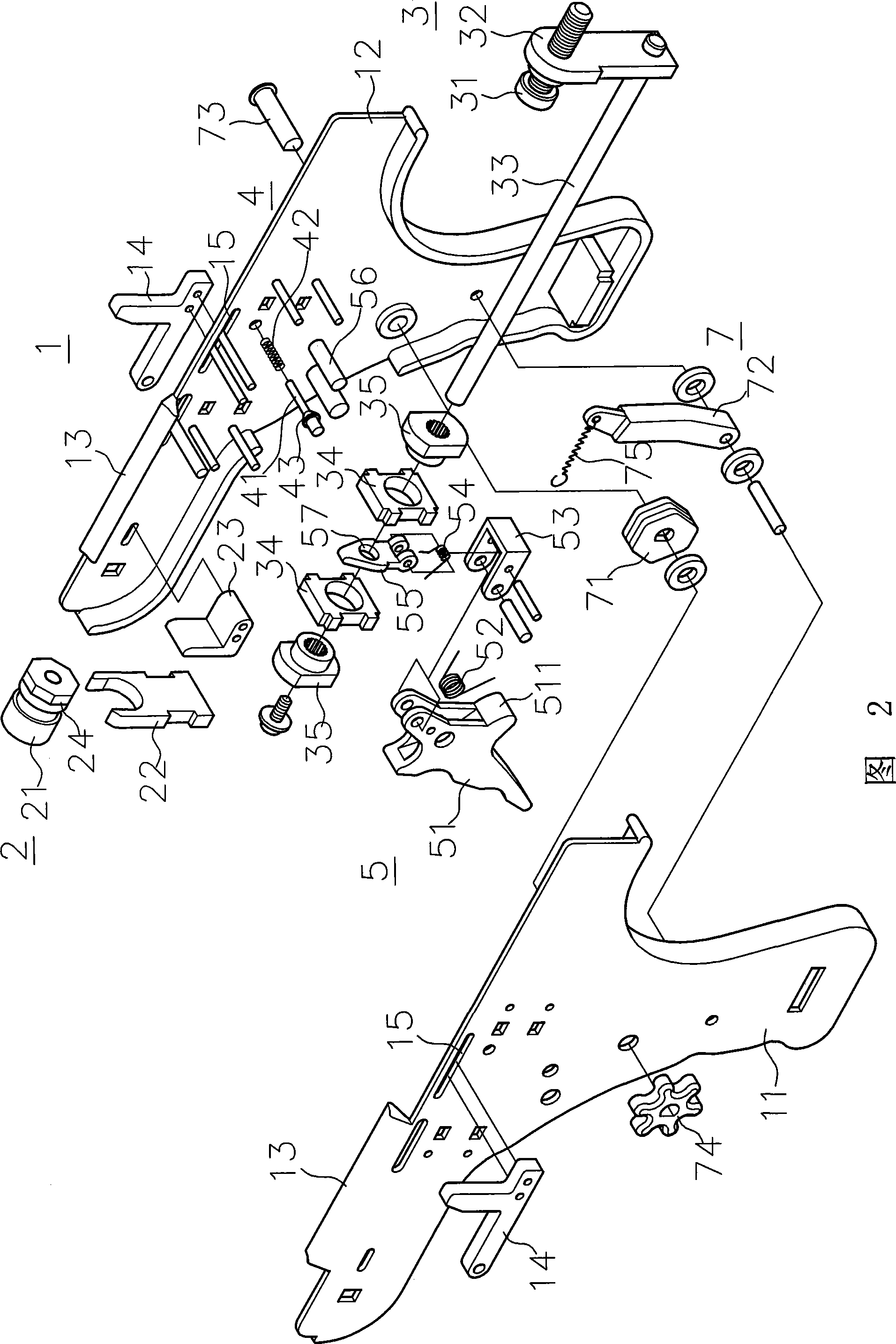

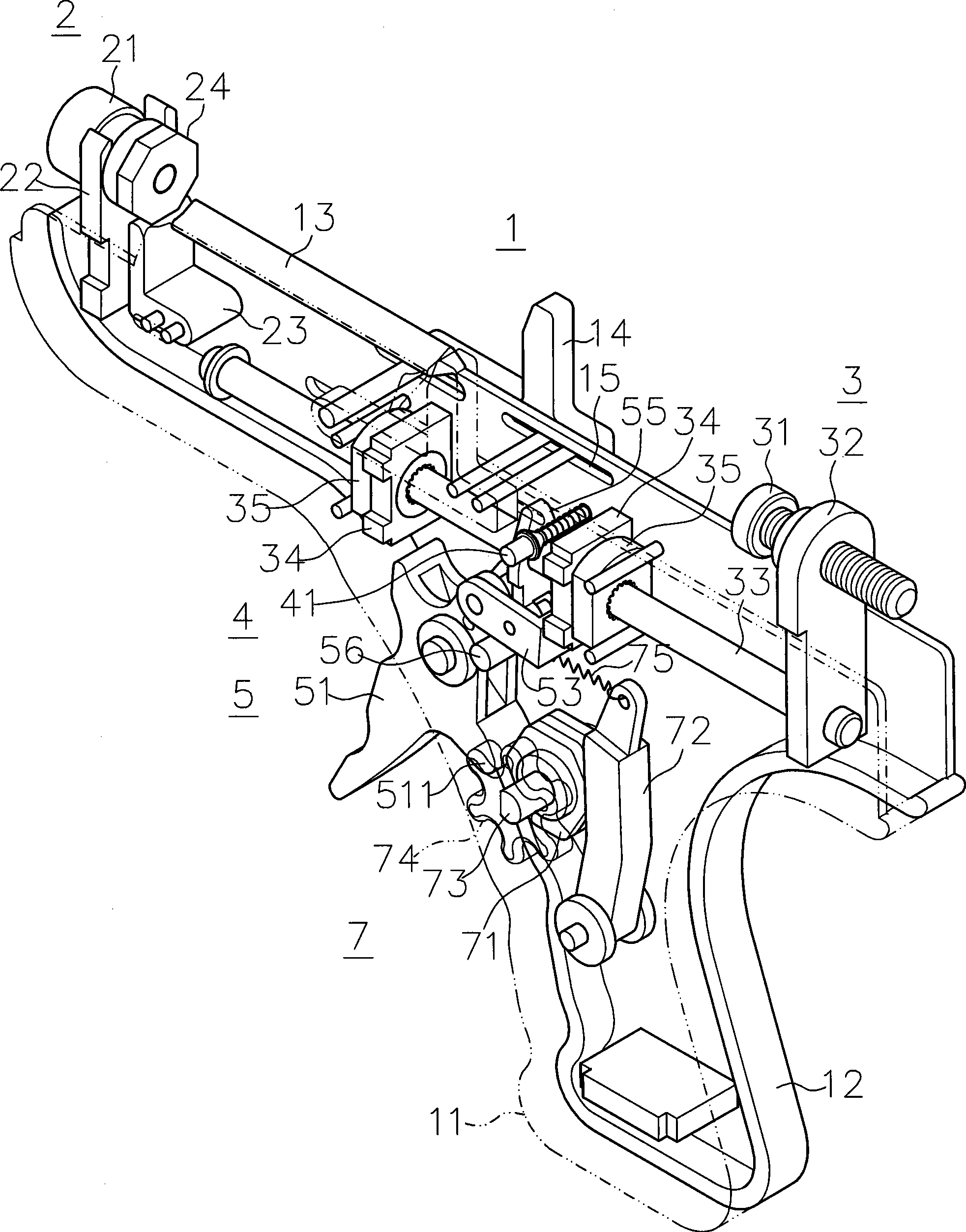

Key structure

ActiveUS7183512B2Reduce the overall heightLower injection costsContact operating partsEngineeringMechanical engineering

A key structure has a support member that reduces manufacturing costs, assembly costs, and the total height of the manufactured product. The support member is mounted between a base and a key cap. The support member has a first frame and a second frame, which are both formed in a united manner by injection. The first frame has a base portion and a pair of side arms connected with the base. The side arms both have a penetrated transverse pivotal hole formed therein. The second frame is disposed between the side arms and has a pair of pivots protruded respectively from two sides thereof. The pivots are formed and mounted directly in the pivotal holes during ejection molding, and an annular channel is formed for receiving a tubular mold during ejection molding.

Owner:LITE ON IT TECH CORP +1

Viscosity adjustable crosslinked polymer displacement agent and preparation method thereof

InactiveCN102127411AApplicable to a wide range of reservoirsLower injection costsDrilling compositionPolymer scienceCrosslinked polymers

The invention discloses a viscosity adjustable crosslinked polymer displacement agent and a preparation method thereof. The displacement agent comprises polymer, a crosslinking agent, a viscosity regulator and water for preparation, wherein the concentration of the polymer in the prepared crosslinked polymer displacement agent is 500-1,000mg / L; the concentration of the crosslinking agent is 30-120mg / L; the concentration of the viscosity regulator is 0-8mg / L; and the pH value of the water for preparation is 7.5-8.5. The preparation method comprises the following steps of: adding solution of crosslinking agent into solution of polymer, and uniformly stirring; adding solution of viscosity regulator and uniformly stirring; and regulating the viscosity of the crosslinked polymer displacement agent by regulating the using amount of the crosslinking agent and a crosslinking aid. Experiments show that: compared with 1,200mg / L polymer solution contrast, the displacement agent can improve the recovery ratio by 0 to 5 percent, and saves raw material cost by 10 to 20 percent.

Owner:BEIJING HAIEN RUNDE CHEM SCI & TECH

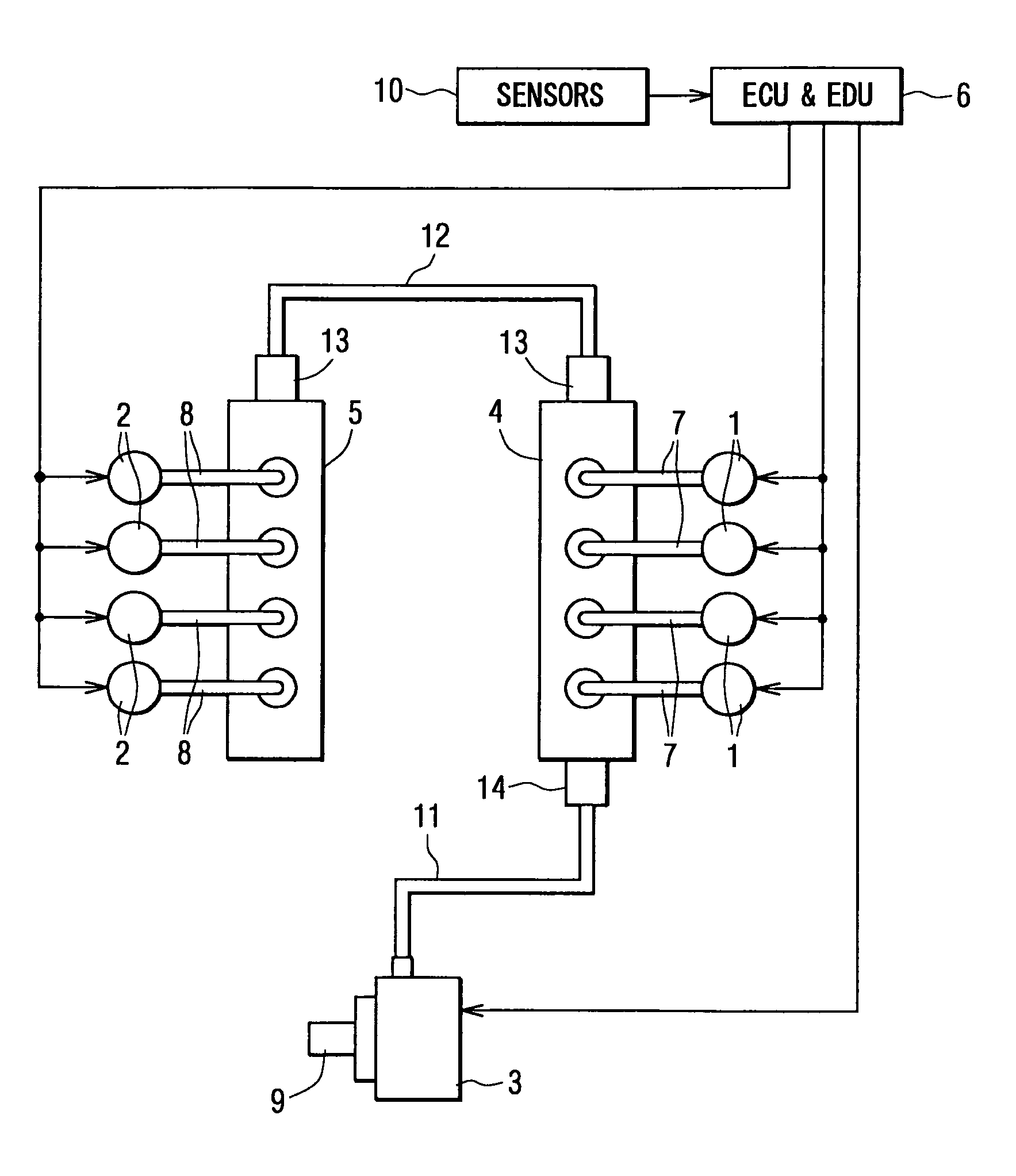

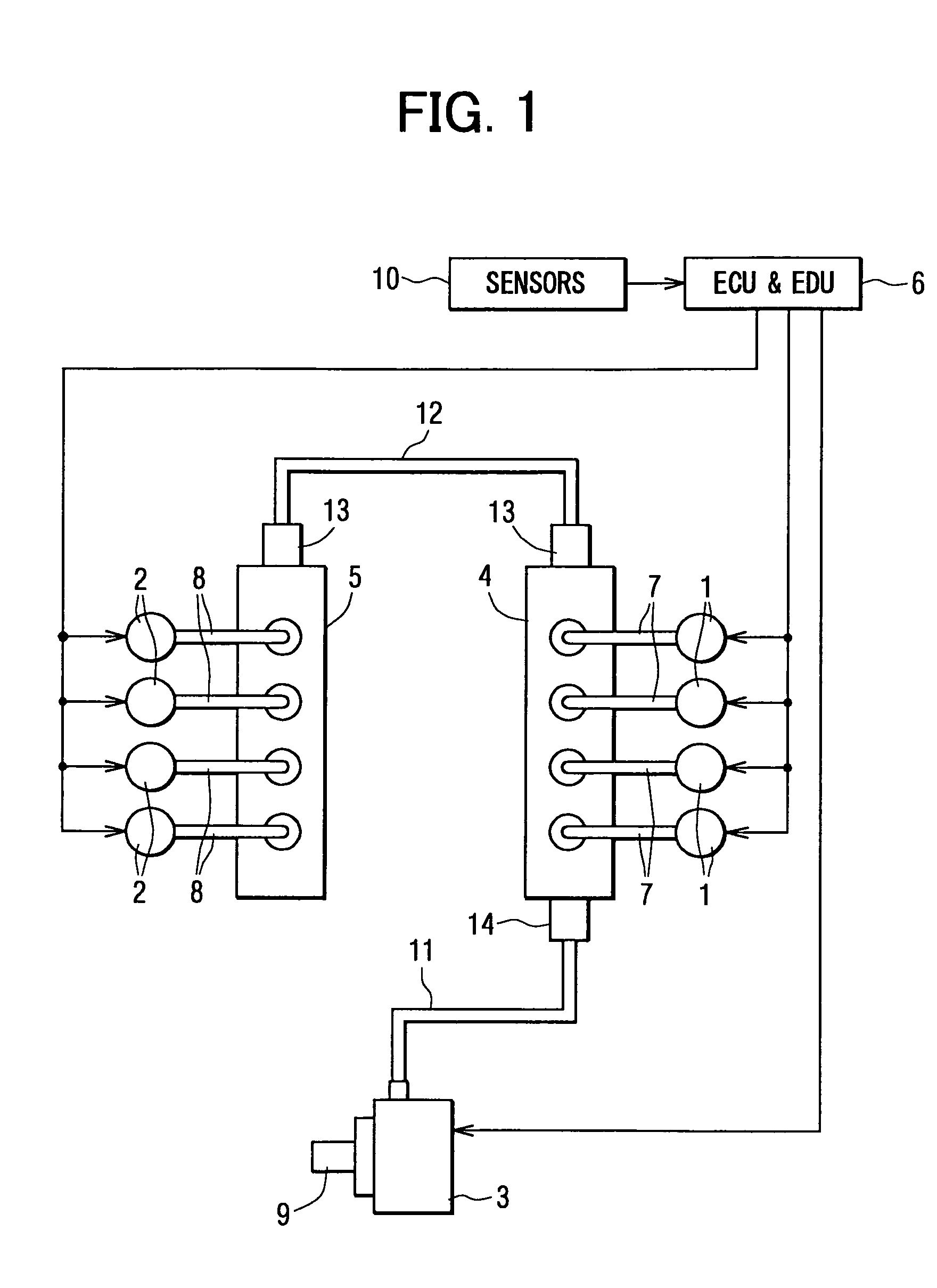

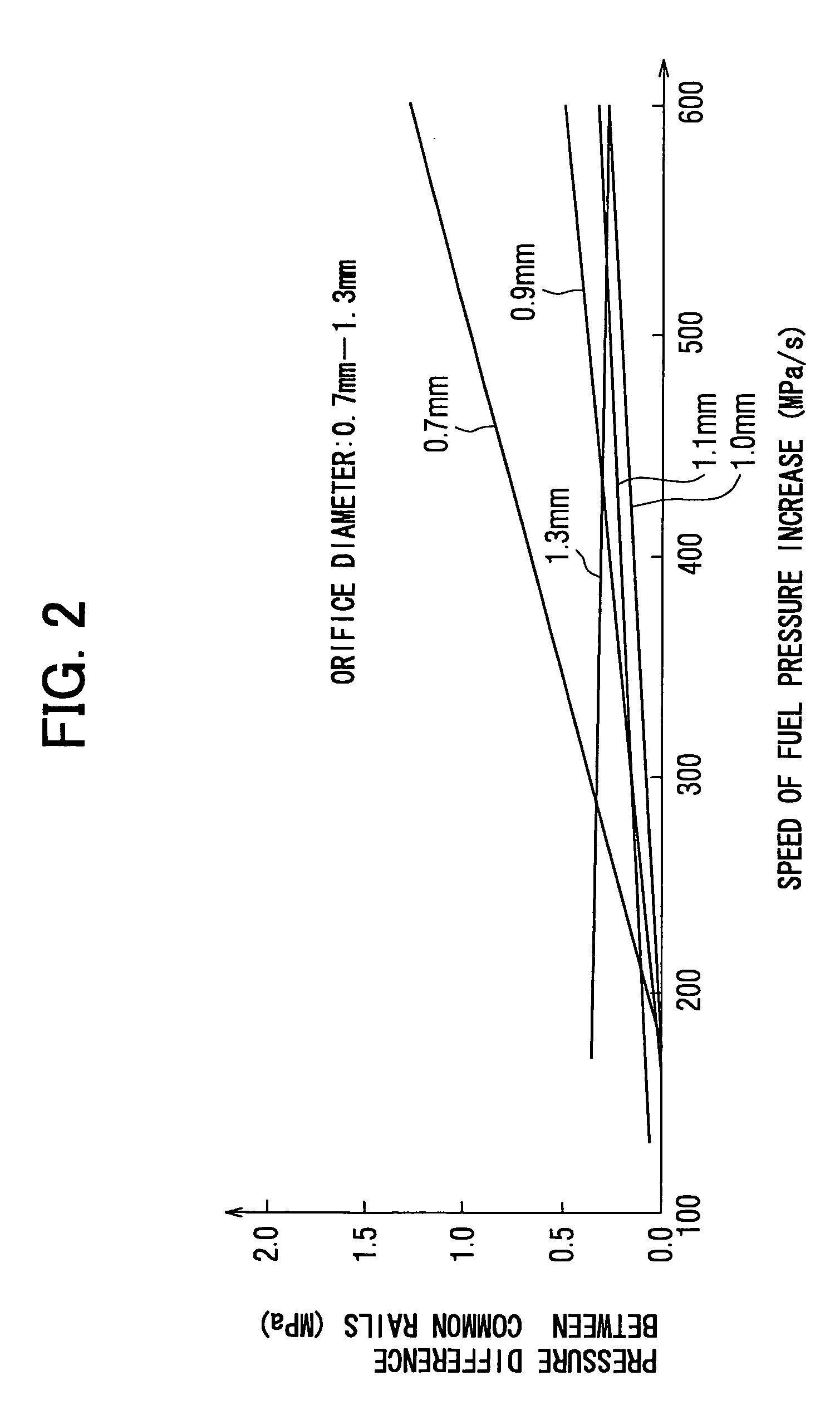

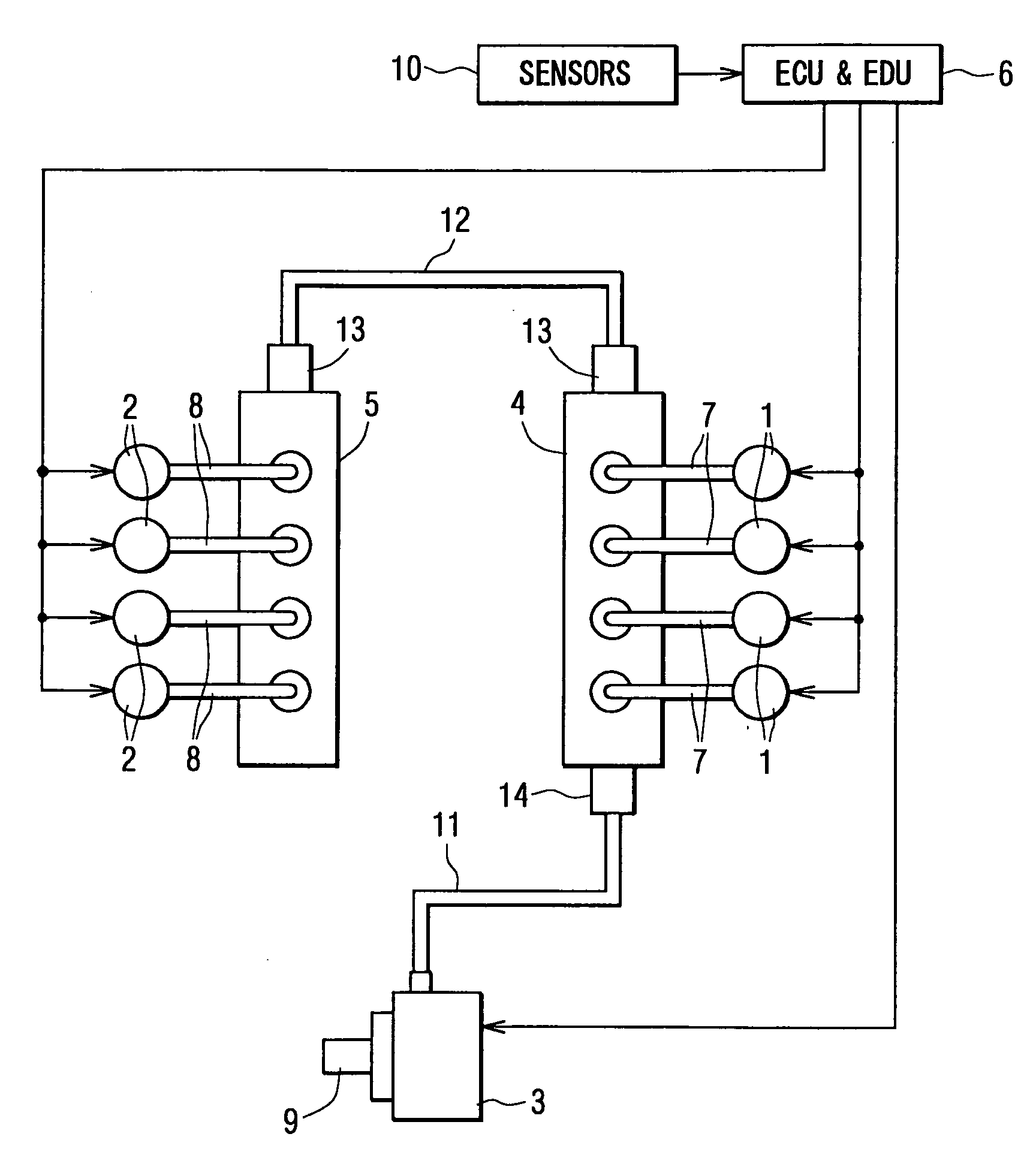

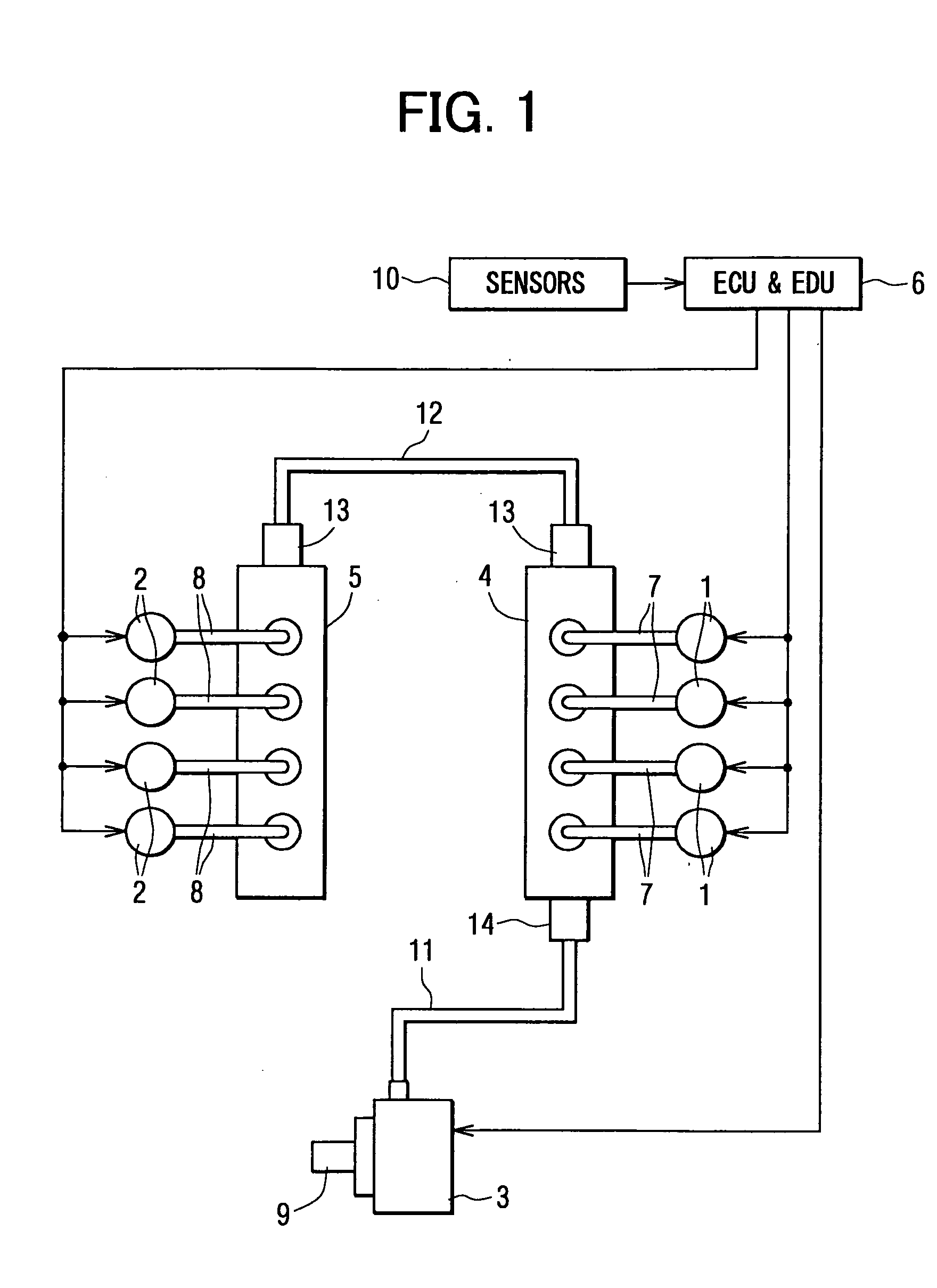

Fuel injection device having two separate common rails

InactiveUS7131427B2Easy to installIncrease flow resistanceLow pressure fuel injectionMachines/enginesControl mannerCommon rail

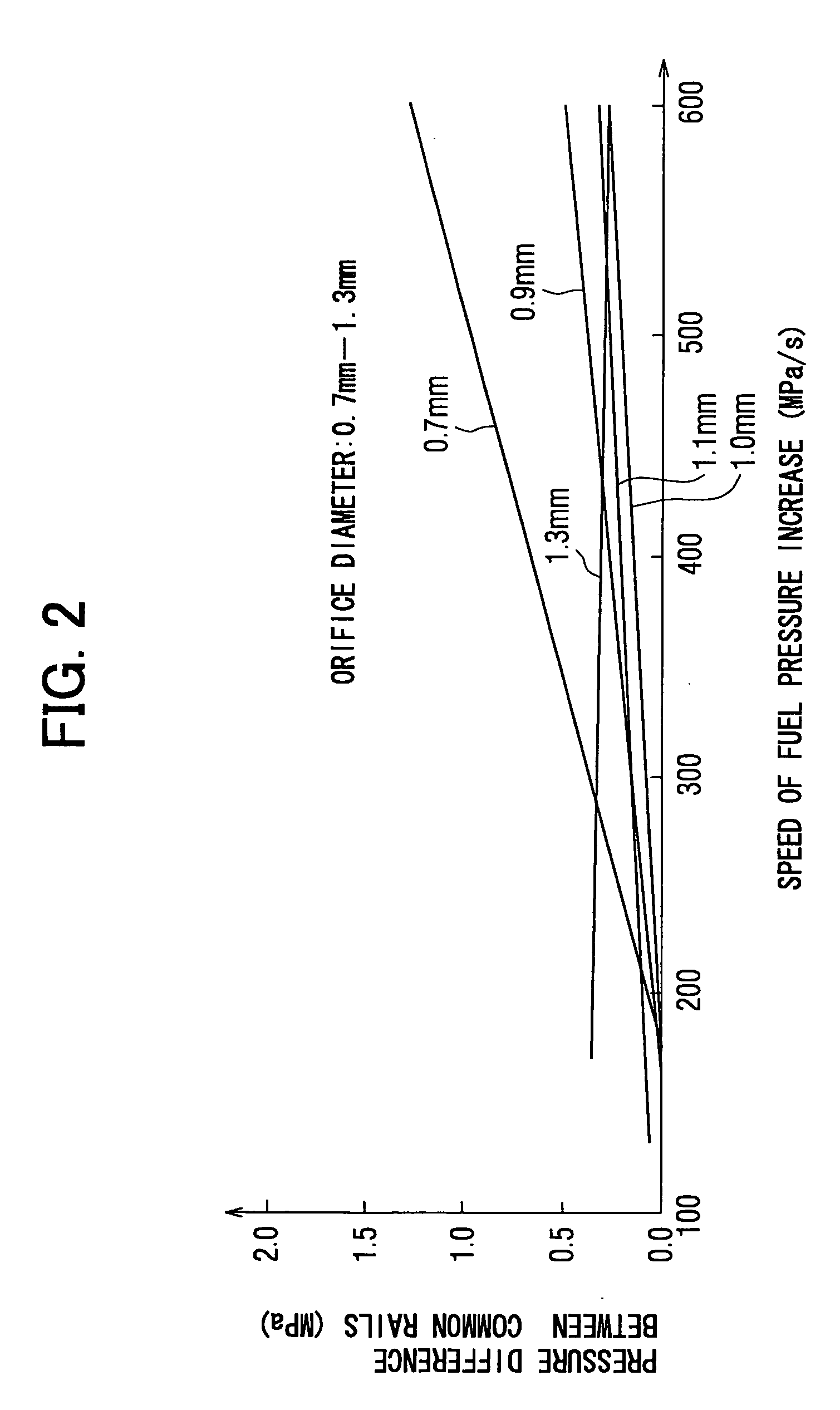

A fuel injection device for supplying high-pressure fuel to an internal combustion engine includes a fuel supply pump, a first common rail and a second common rail. High-pressure fuel is directly supplied to the first common rail and then to the second common rail from the first common rail through a connecting passage having an orifice. The high-pressure fuel accumulated in the common rails is supplied to injectors and is injected into cylinders in a controlled manner. To suppress pressure wave propagation from the first common rail to the second common rail while providing an appropriate flow passage size, a passage diameter of the orifice is set to 0.9 mm–1.3 mm. In this manner, a pressure difference between the first common rail and the second common rail is minimized.

Owner:DENSO CORP

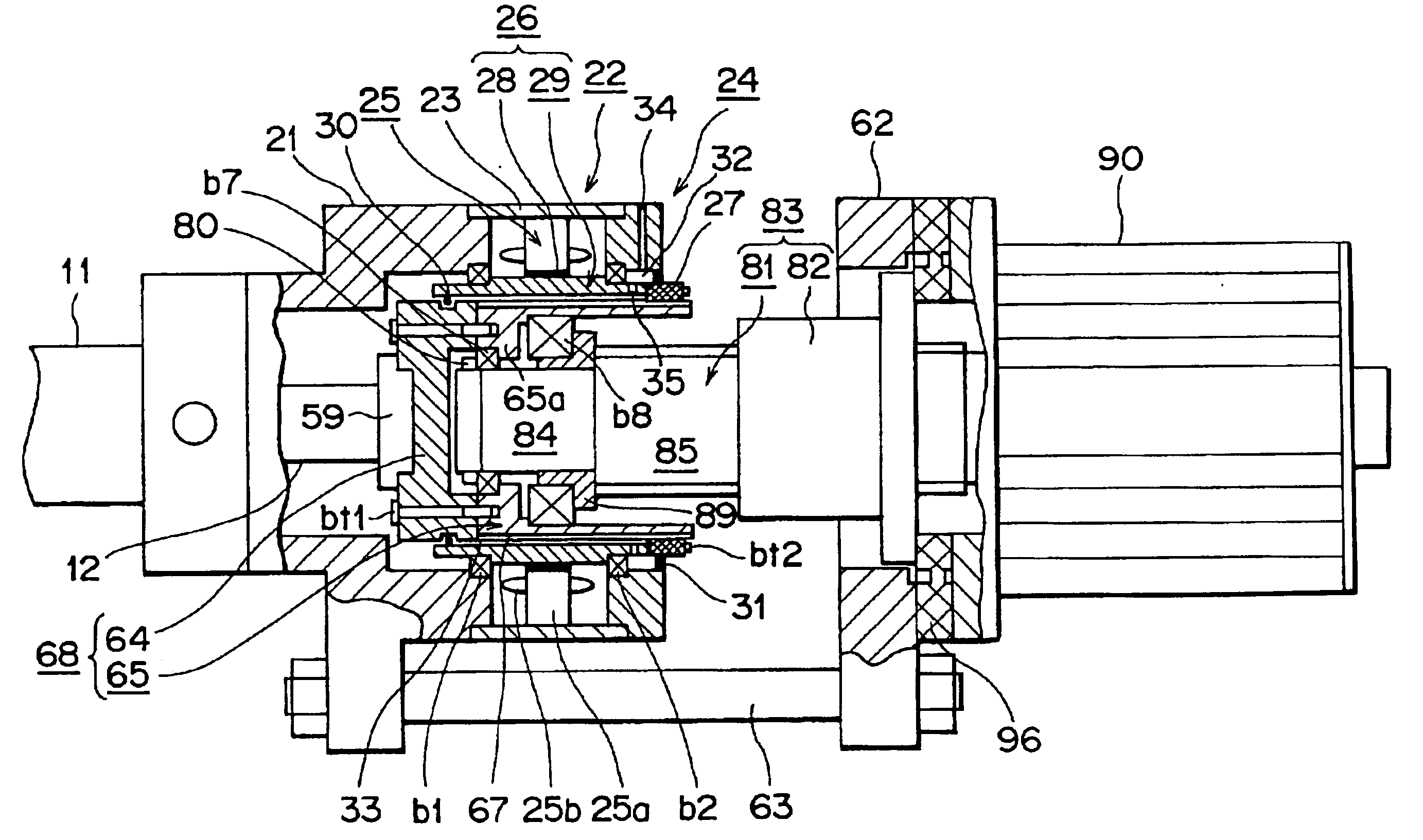

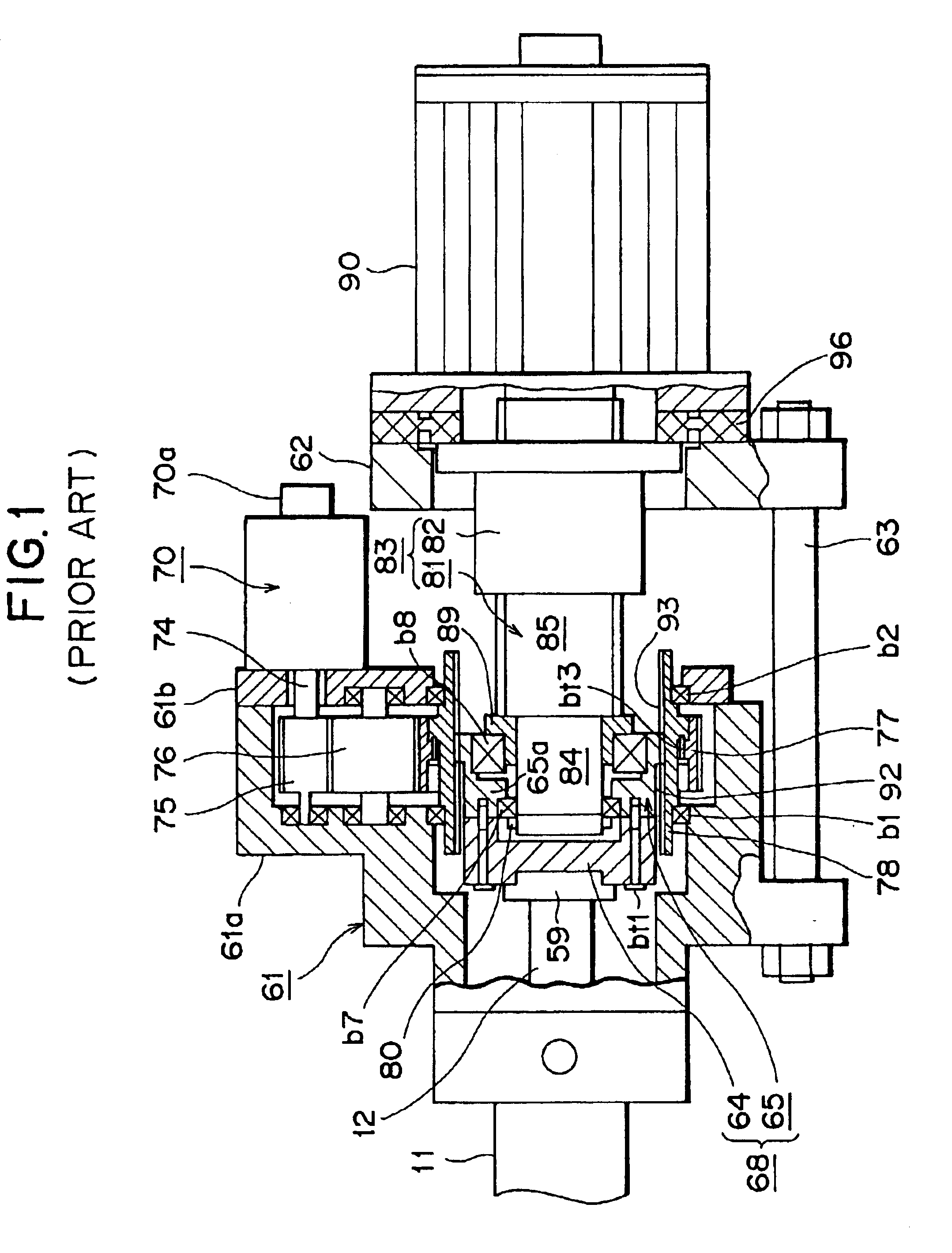

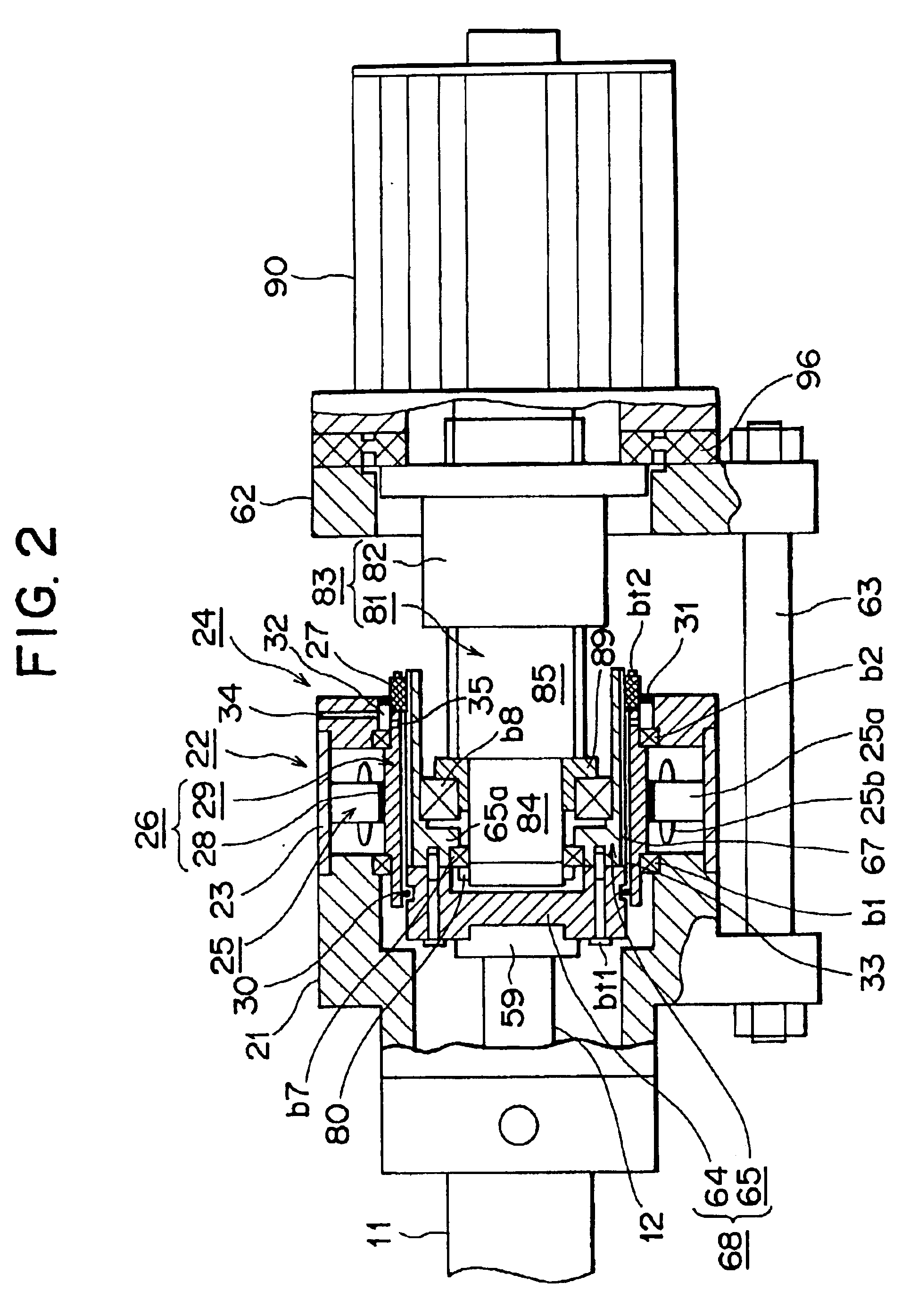

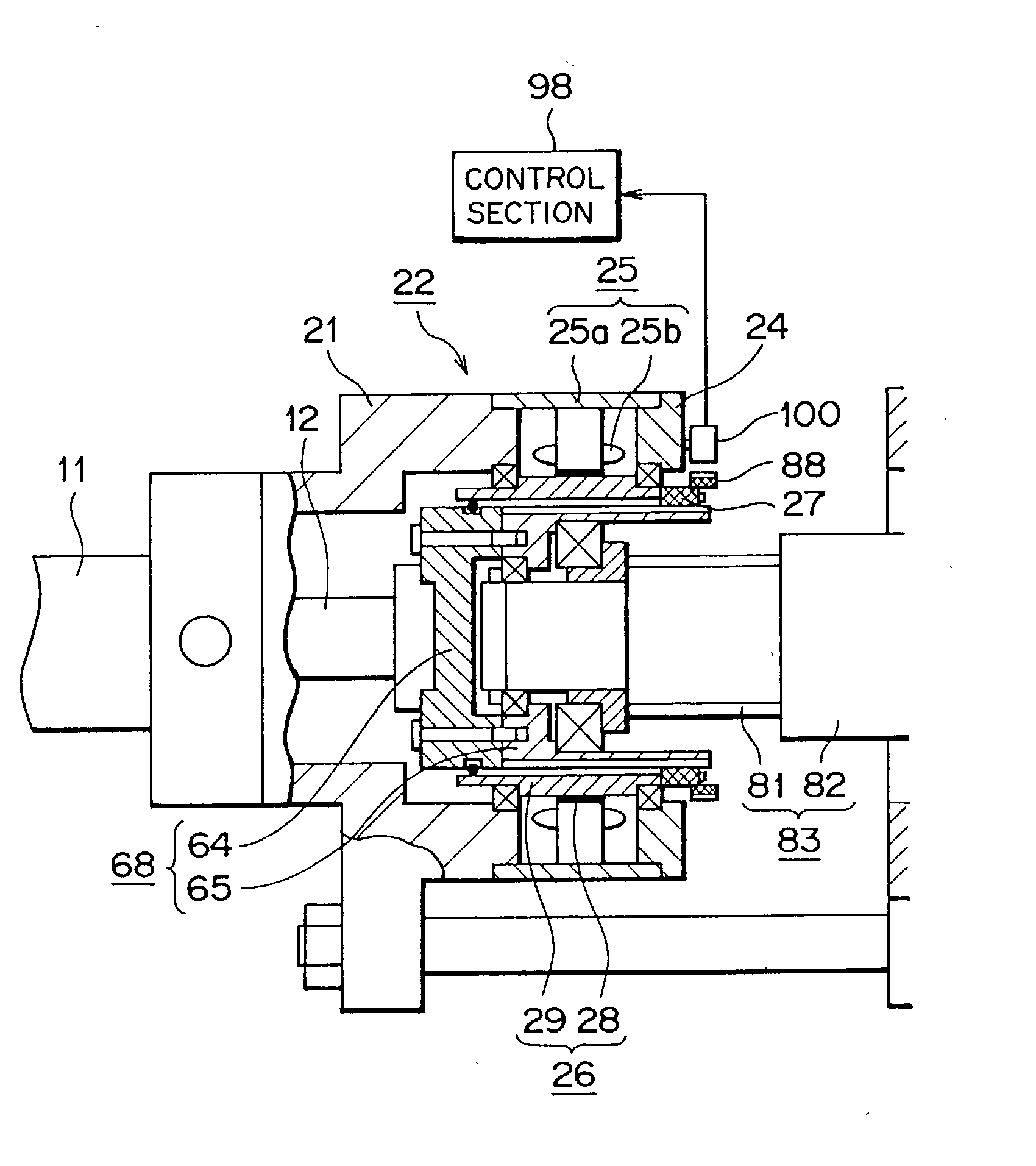

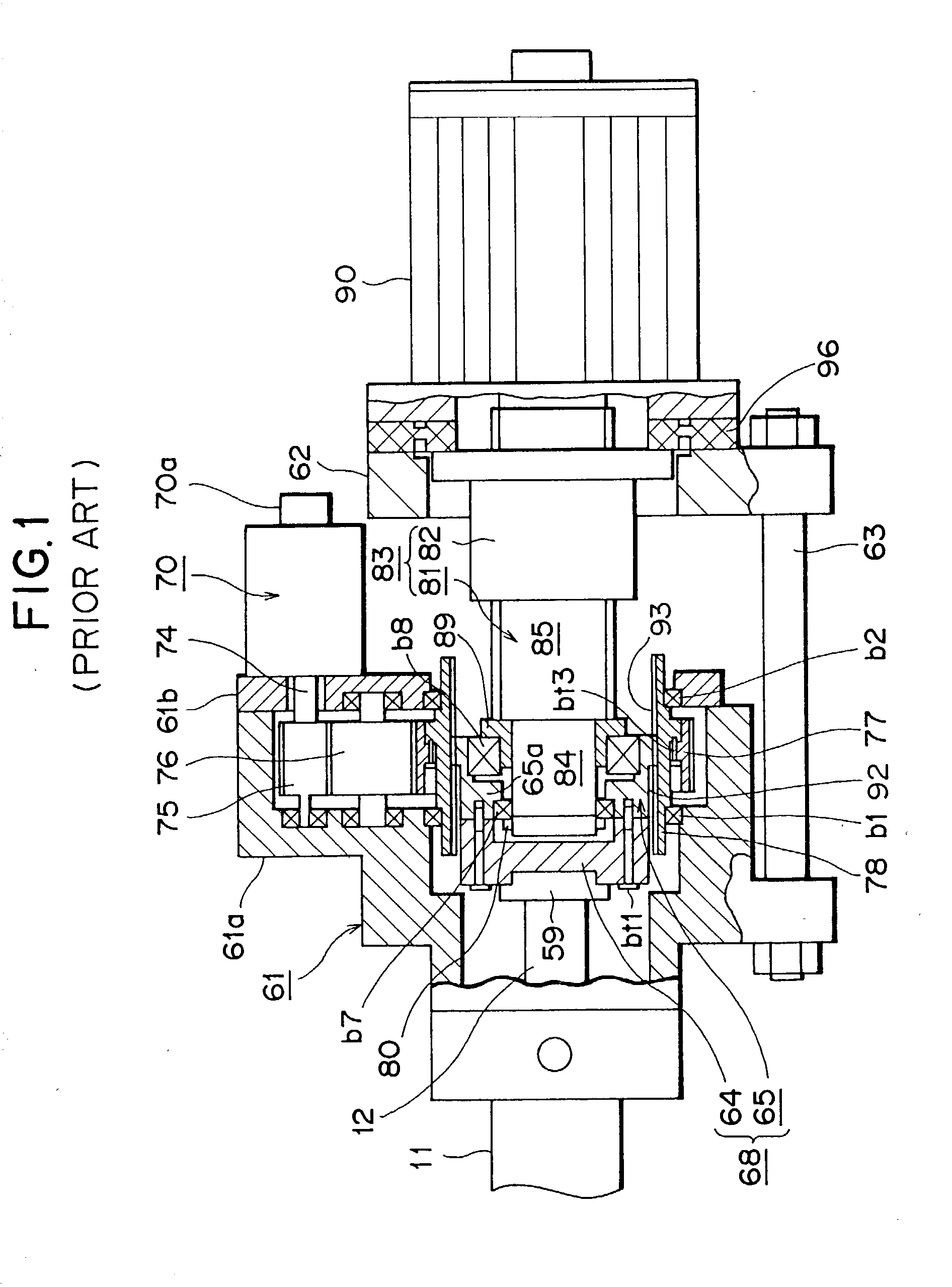

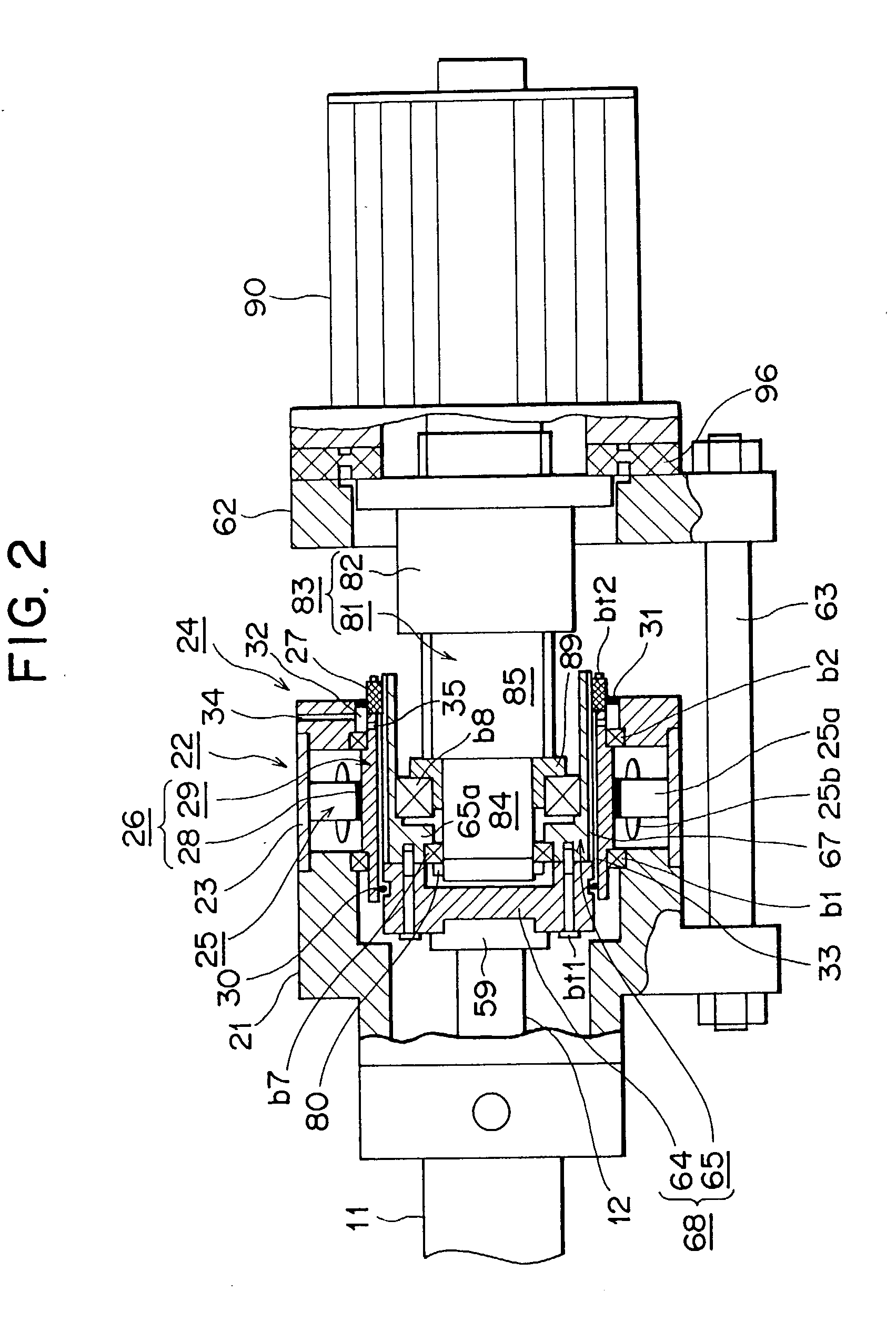

Injection apparatus

InactiveUS6755636B2Avoid noiseReduce component countAuxillary shaping apparatusGear wheelInjection device

An injection apparatus includes an injection frame; a cylinder member attached to the injection frame; an injection member disposed within the cylinder member such that the same can rotate and can advance and retreat; a rotary slide member attached to the injection member; a stator attached to the injection frame, and a rotor disposed radially inward of the stator to be rotatable relative to the stator. The rotor includes a hollow, cylindrical member disposed radially outward of the rotary slide member and movably relative to the rotary slide member, and a magnet attached to the cylindrical member. In this case, the rotor has a cylindrical member and a magnet and can transmit generated rotation directly to the rotary slide member. Therefore, a transmission mechanism which consists of an output gear, a counter drive gear, a counter driven gear, a rotary member, etc. becomes unnecessary; and generation of noise due to meshing engagement of gears and other components can be prevented. Accordingly, the number of components can be reduced, generation of torque loss can be prevented, and cost of the injection apparatus can be reduced.

Owner:SUMITOMO HEAVY IND LTD

Fuel injection device having two separate common rails

InactiveUS20050115545A1Easy to installIncrease flow resistanceLow pressure fuel injectionMachines/enginesCommon railControl manner

A fuel injection device for supplying high-pressure fuel to an internal combustion engine includes a fuel supply pump, a first common rail and a second common rail. High-pressure fuel is directly supplied to the first common rail and then to the second common rail from the first common rail through a connecting passage having an orifice. The high-pressure fuel accumulated in the common rails is supplied to injectors and is injected into cylinders in a controlled manner. To suppress pressure wave propagation from the first common rail to the second common rail while providing an appropriate flow passage size, a passage diameter of the orifice is set to 0.9 mm-1.3 mm. In this manner, a pressure difference between the first common rail and the second common rail is minimized.

Owner:DENSO CORP

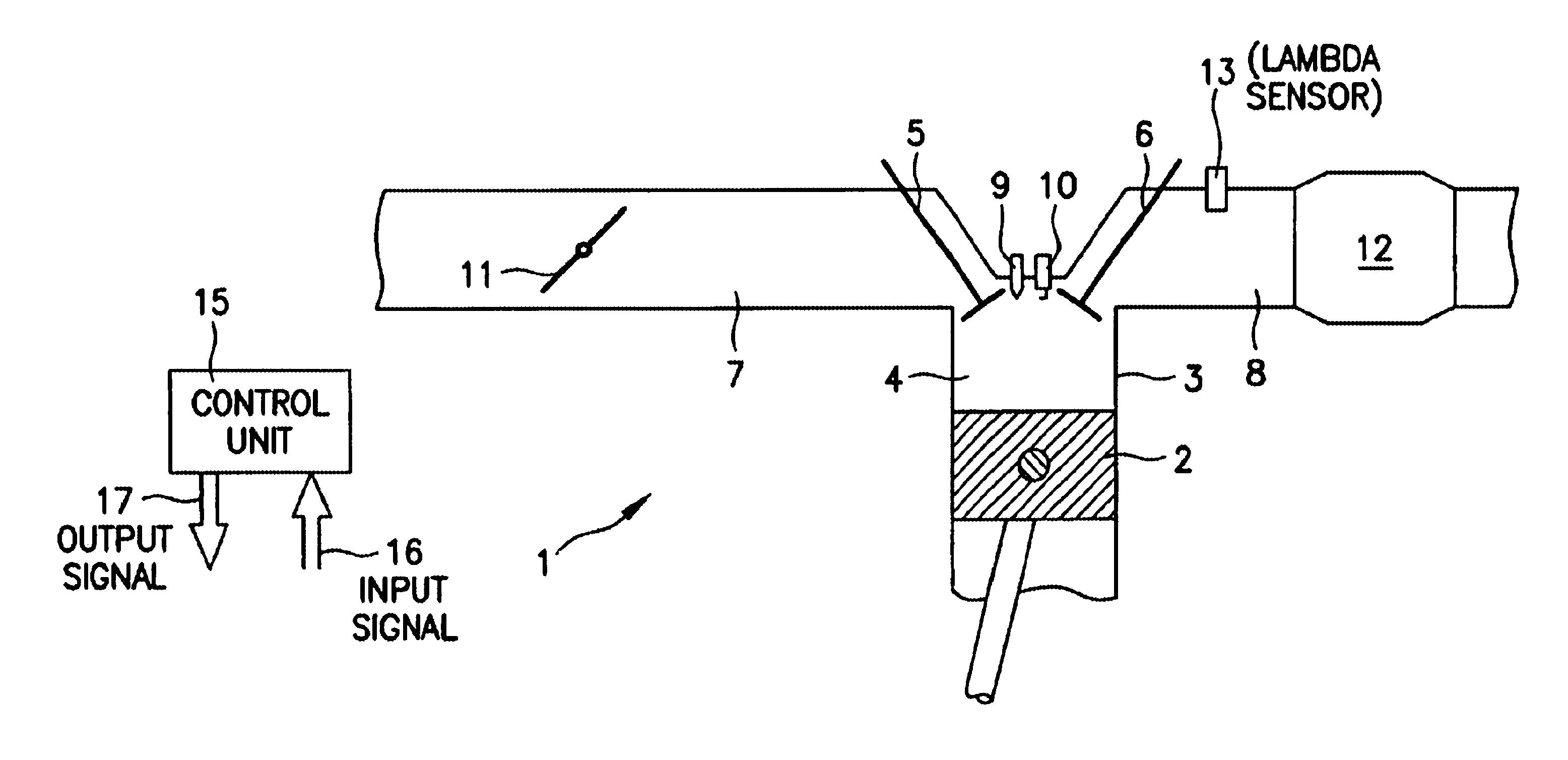

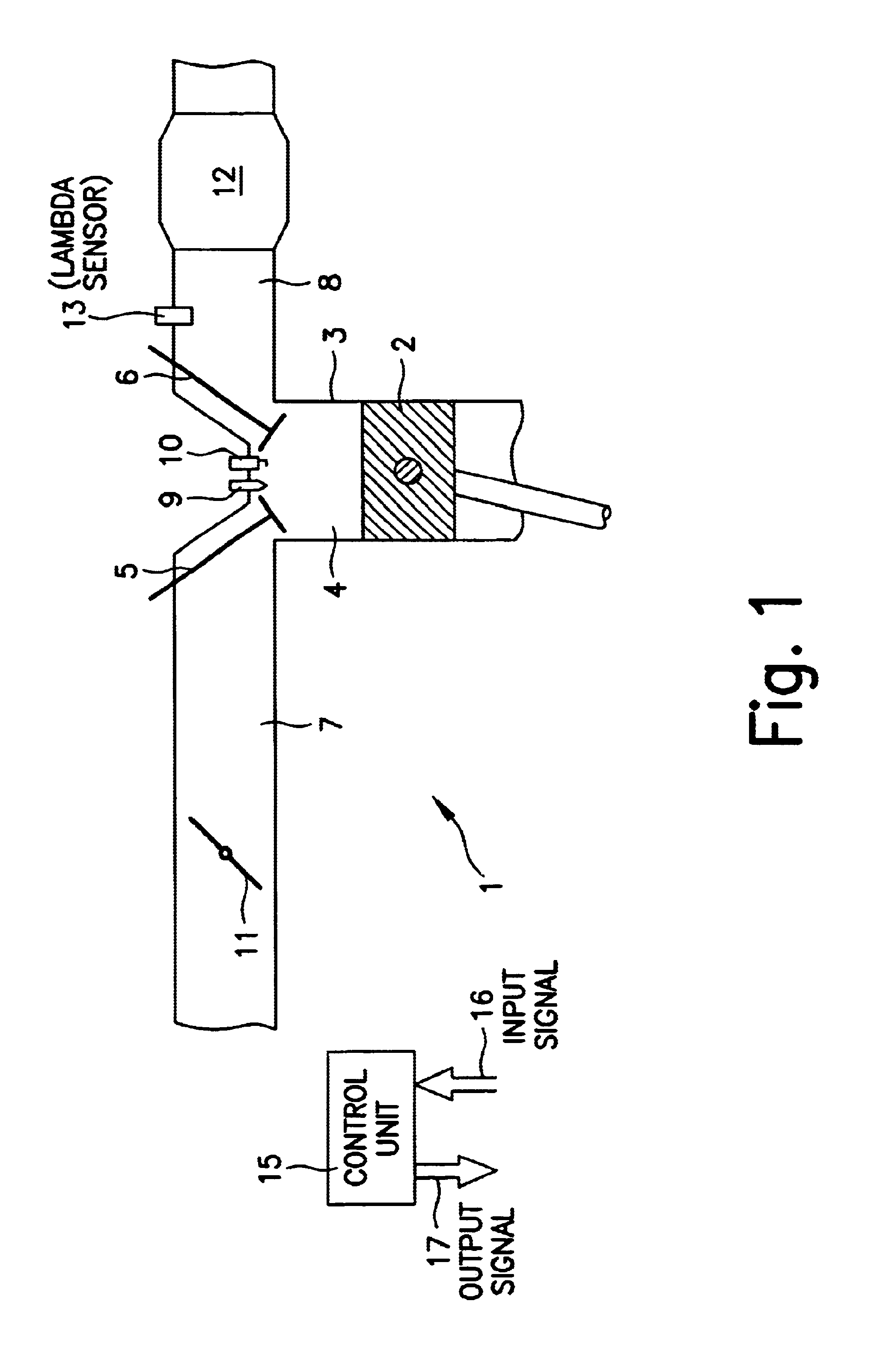

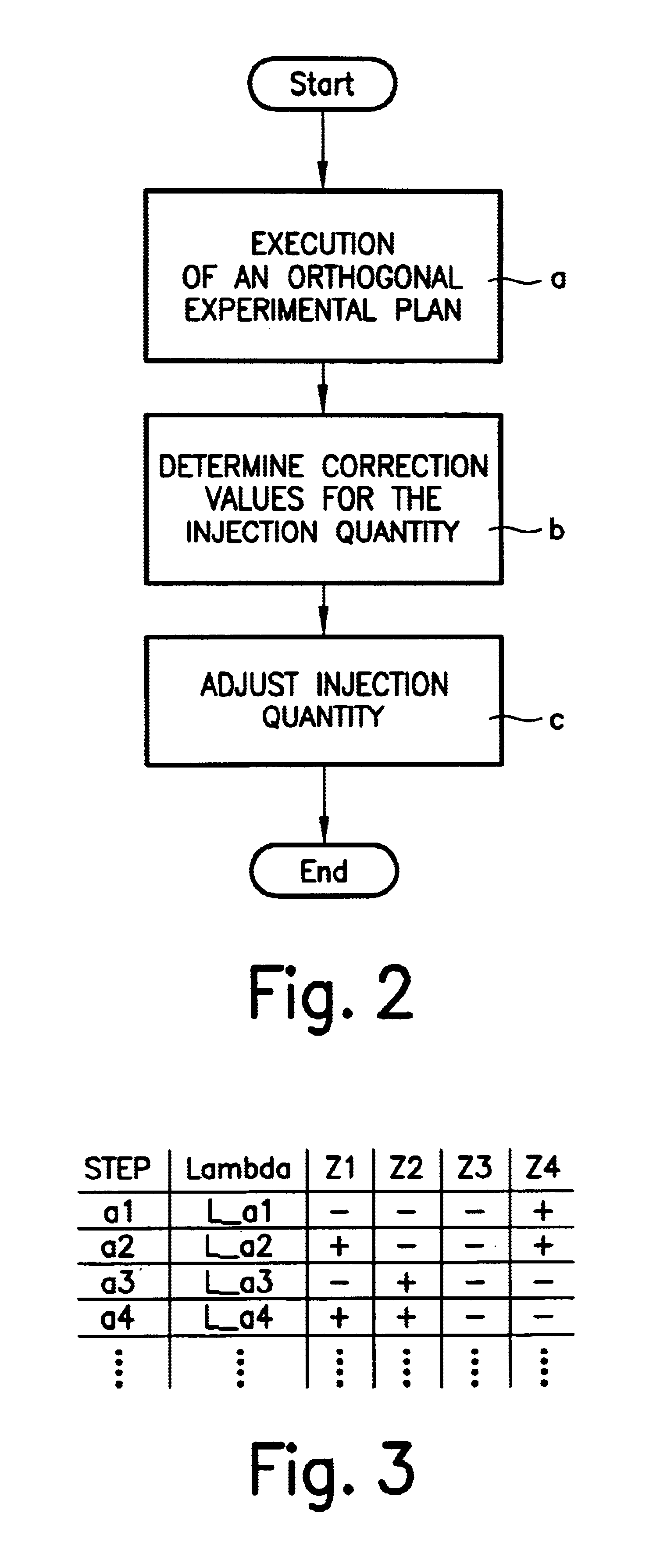

Method for compensating injection quality in each individual cylinder in internal combustion engines

InactiveUS6947826B2Avoid smallImprove liquidityElectrical controlDigital data processing detailsCombustionExternal combustion engine

A method for cylinder-specific adjustment of the injection quantity in internal combustion engines is provided, as well as an internal combustion engine with which the method may be implemented. The injection quantity per cylinder selected by the engine management is changed in a controlled manner following an orthogonal experimental plan. The effect of this change on the excess-air factor “lambda” is analyzed, allowing the formulation of a regression polynomial to determine necessary corrections of the injection quantity, which injection quantity is adjustable individually for each cylinder with a view to optimum combustion.

Owner:ROBERT BOSCH GMBH

Injection apparatus

InactiveUS20030054059A1Avoid noiseReduce component countDough homogenizationFrozen sweetsGear wheelEngineering

An injection apparatus includes an injection frame; a cylinder member attached to the injection frame; an injection member disposed within the cylinder member such that the same can rotate and can advance and retreat; a rotary slide member attached to the injection member; a stator attached to the injection frame, and a rotor disposed radially inward of the stator to be rotatable relative to the stator. The rotor includes a hollow, cylindrical member disposed radially outward of the rotary slide member and movably relative to the rotary slide member, and a magnet attached to the cylindrical member. In this case, the rotor has a cylindrical member and a magnet and can transmit generated rotation directly to the rotary slide member. Therefore, a transmission mechanism which consists of an output gear, a counter drive gear, a counter driven gear, a rotary member, etc. becomes unnecessary; and generation of noise due to meshing engagement of gears and other components can be prevented. Accordingly, the number of components can be reduced, generation of torque loss can be prevented, and cost of the injection apparatus can be reduced.

Owner:SUMITOMO HEAVY IND LTD

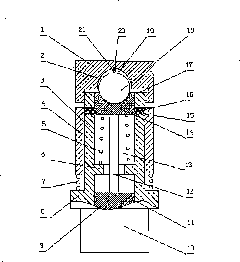

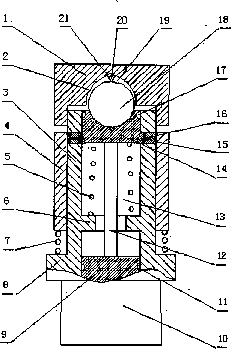

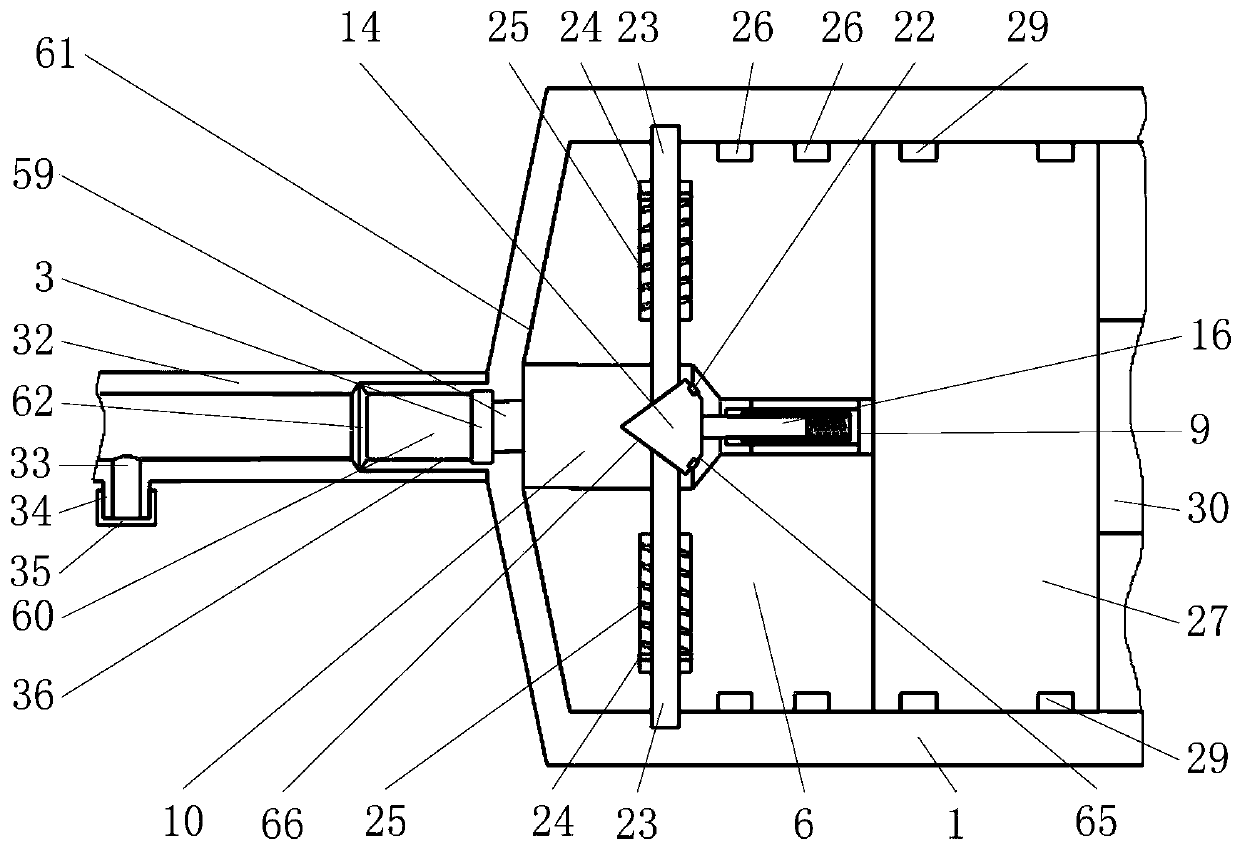

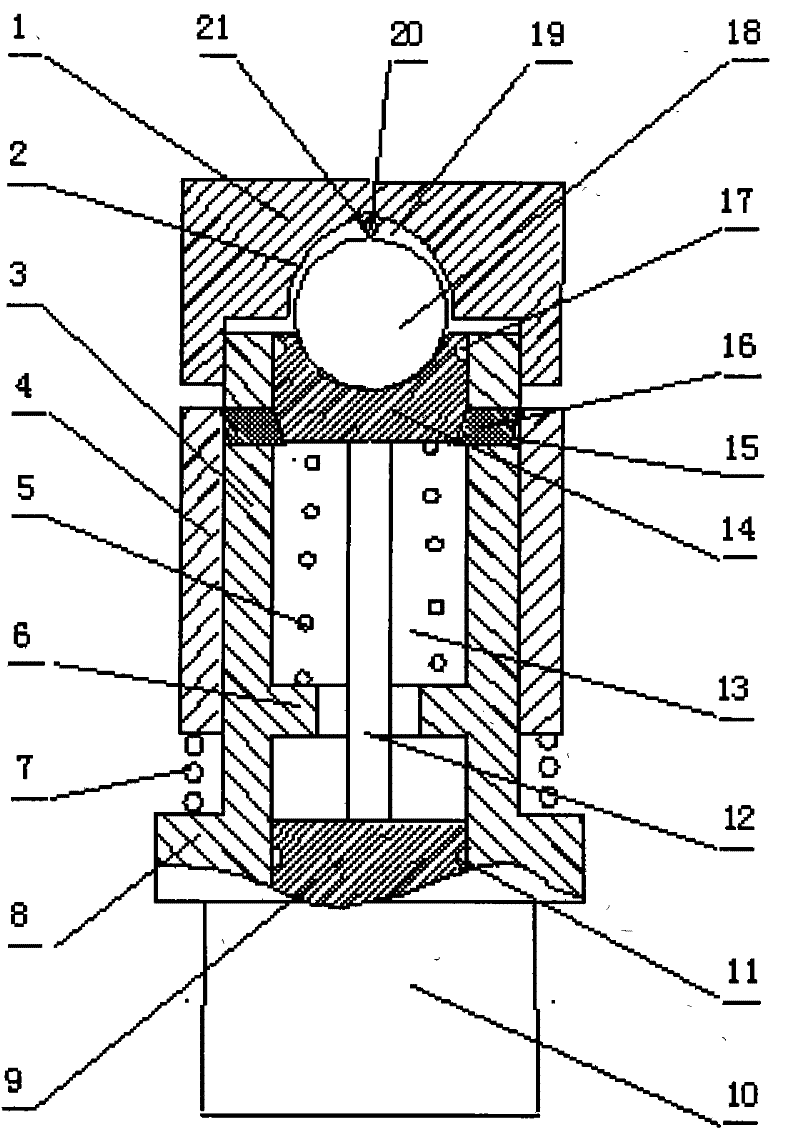

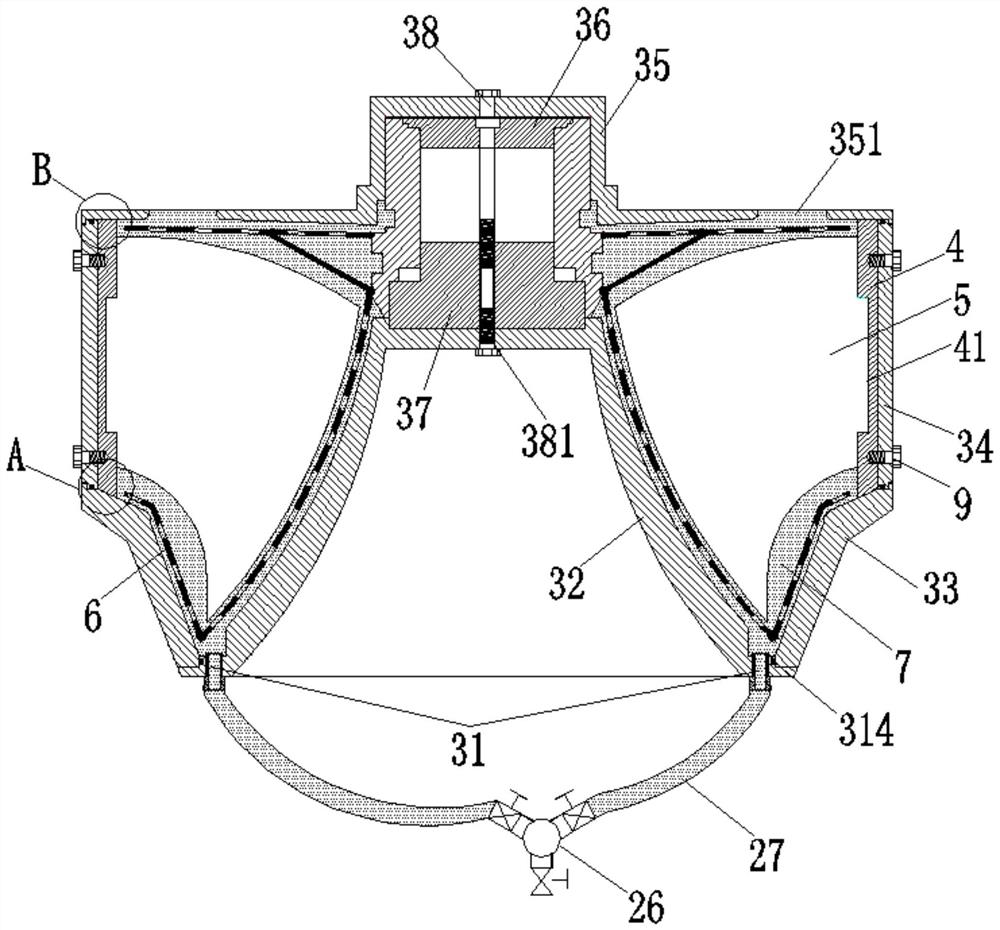

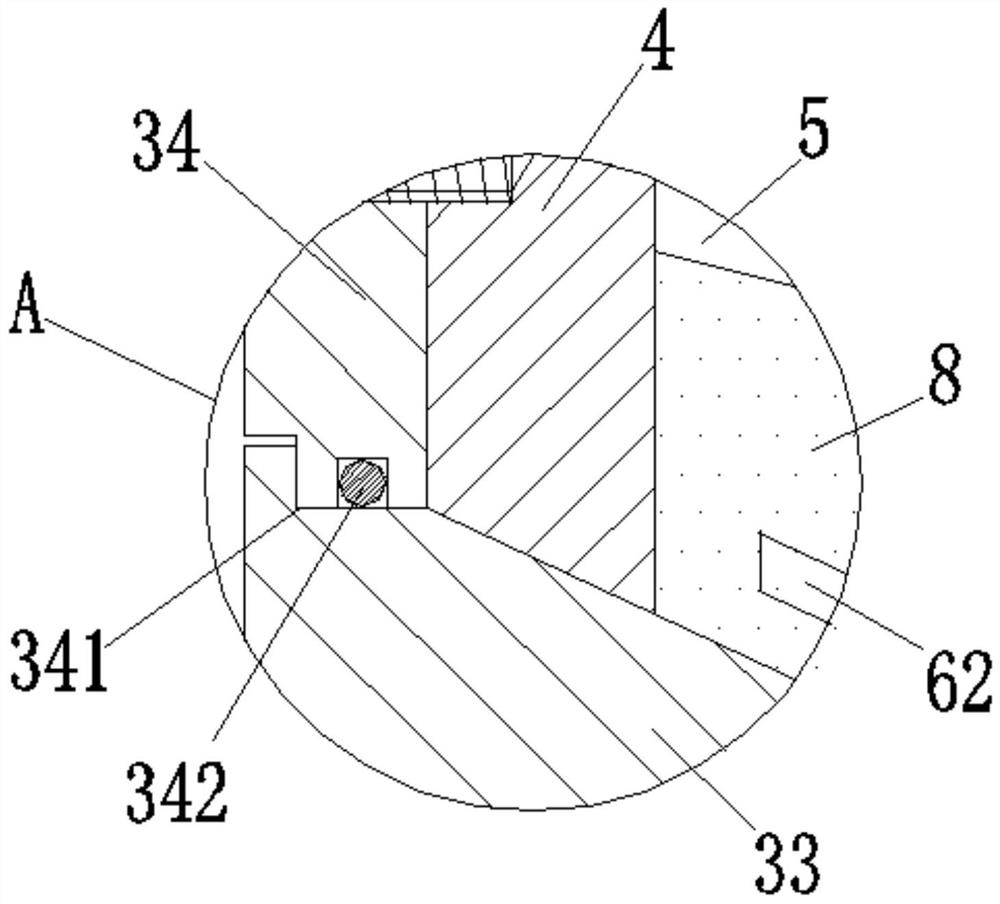

Air-pressure type needleless injector power head

ActiveCN101797411AAchieve needle-free injectionFor long-term storageIntravenous devicesNeedle Free InjectionPiston

The invention discloses an air-pressure type needleless injector power head comprising a barrel. A nut cap is sealedly screwed on the upper part of the barrel, and the lower part of the barrel is connected with a medicine injection head; a set of piston assembly with a resetting device is arranged in a barrel bore, the barrel is provided with a movable stop pin which controls the piston to move downwards, a sliding sleeve which controls the movable stop pin is arranged outside the barrel, and the sliding sleeve is connected with a return spring. The air-pressure type needleless injector power head is characterized in that high-pressure air serving as a power source is packaged in a metal thin-wall globule which is arranged in a cavity between the upper part of the piston assembly in the barrel bore and the nut cap; and a pointed drill with a groove, which is fixed in the nut cap, is arranged above the metal thin-wall globule. The power head can ensure that the air-pressure type needleless injector can be stored for a long term.

Owner:扬中市检验检测中心

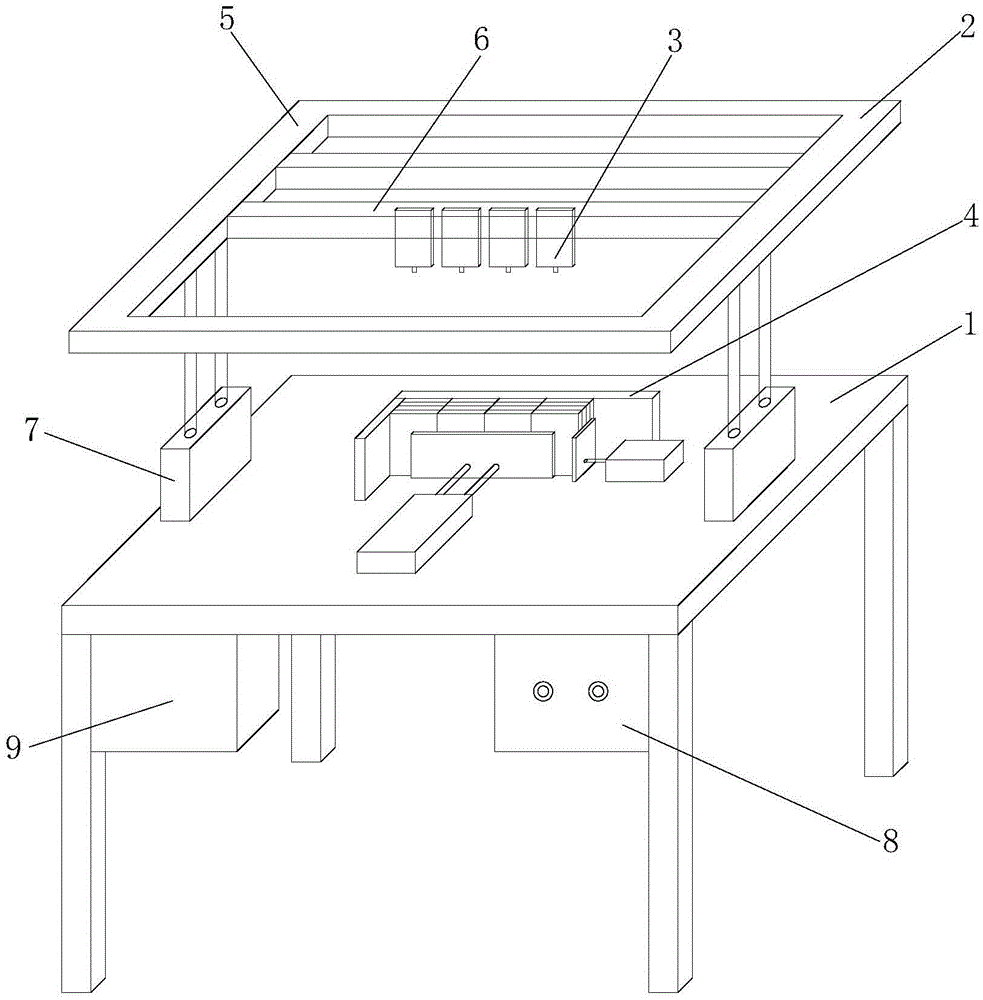

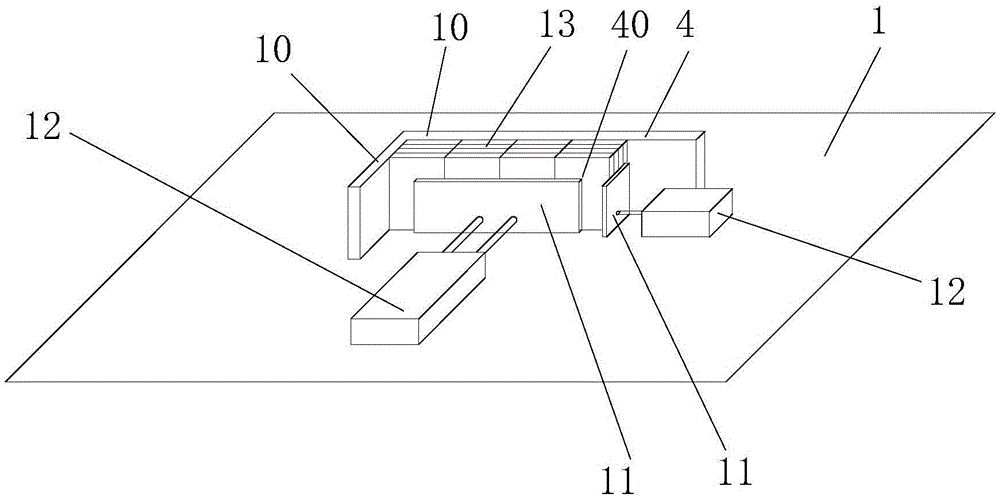

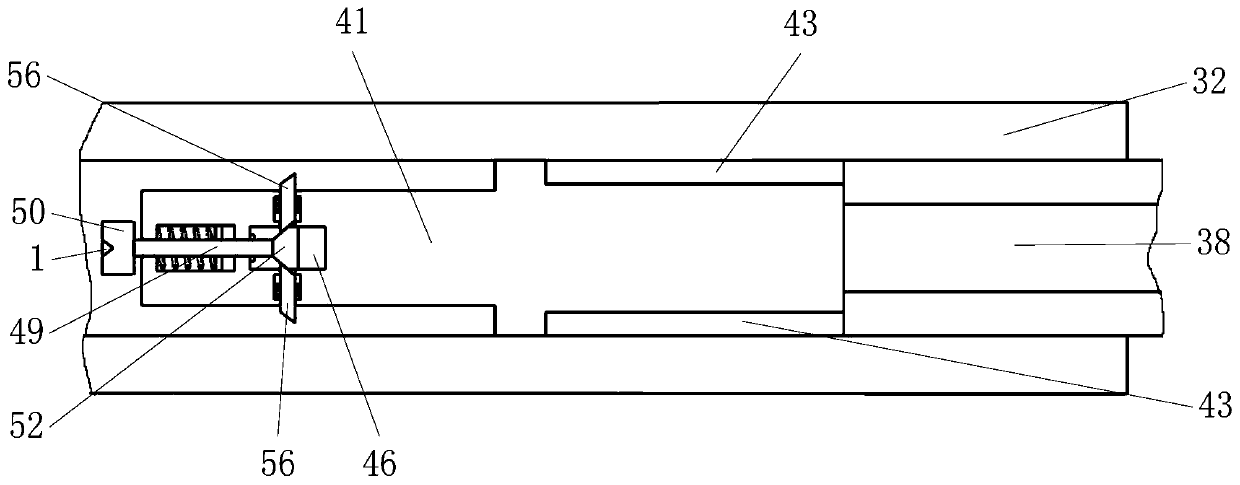

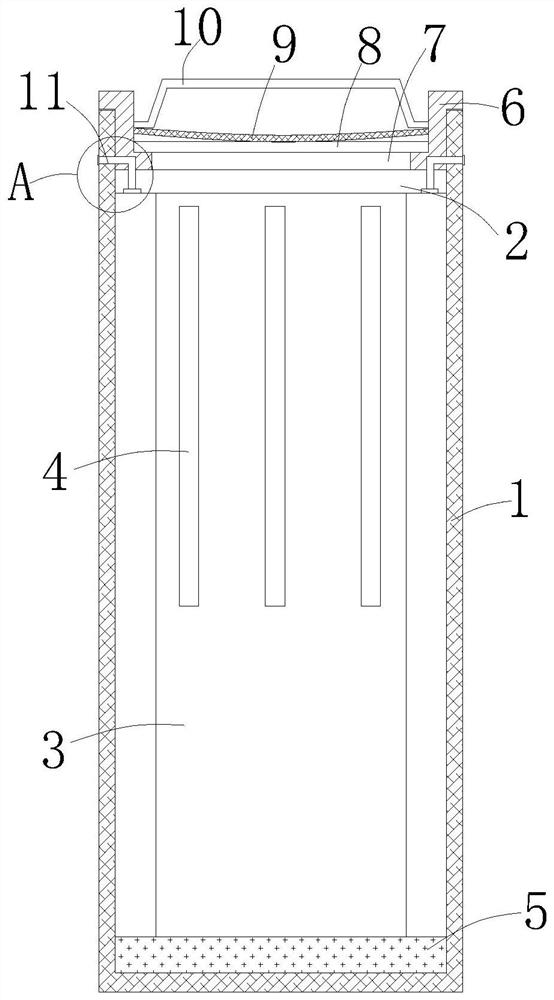

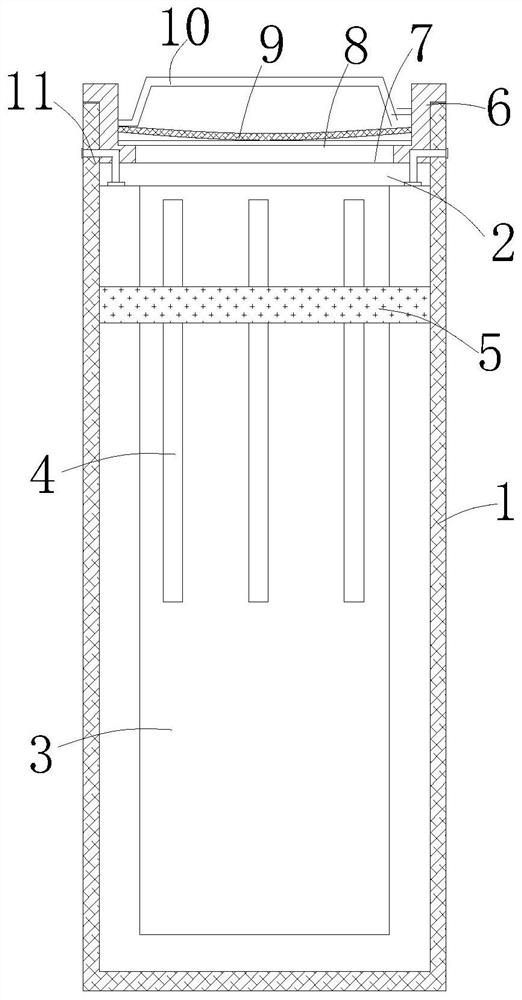

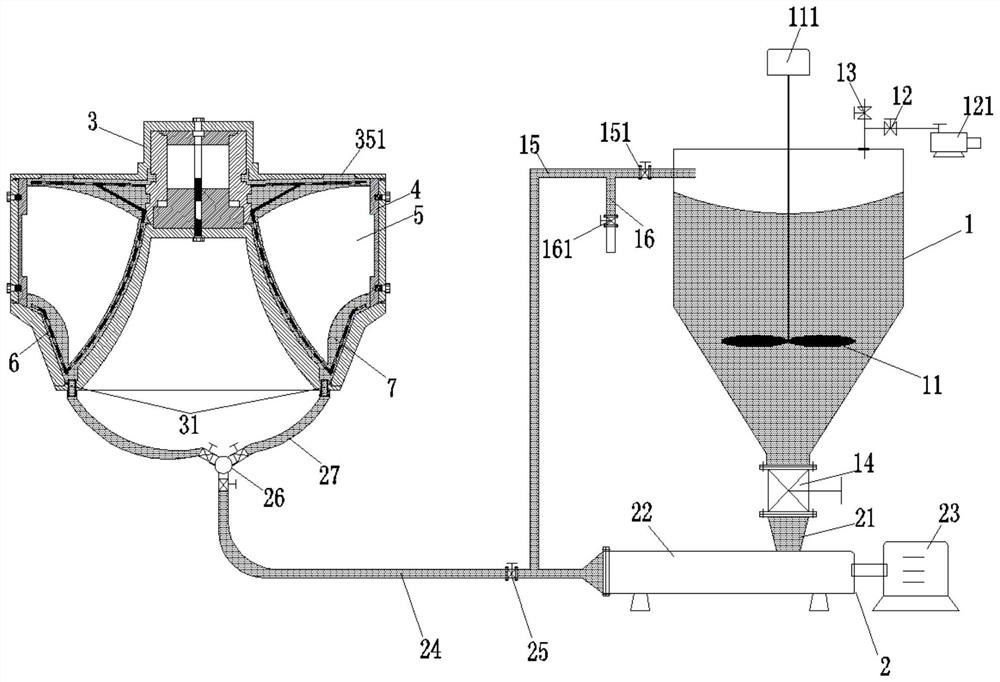

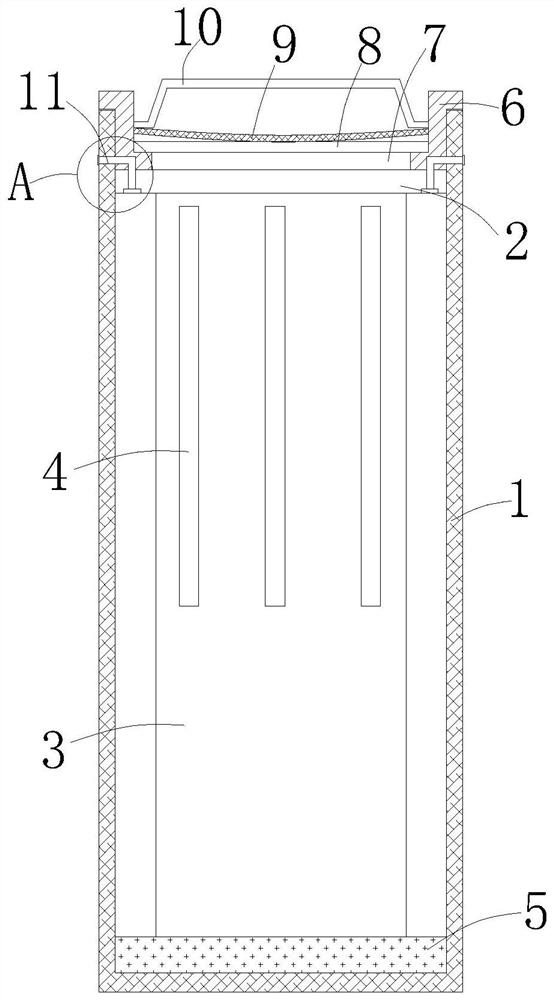

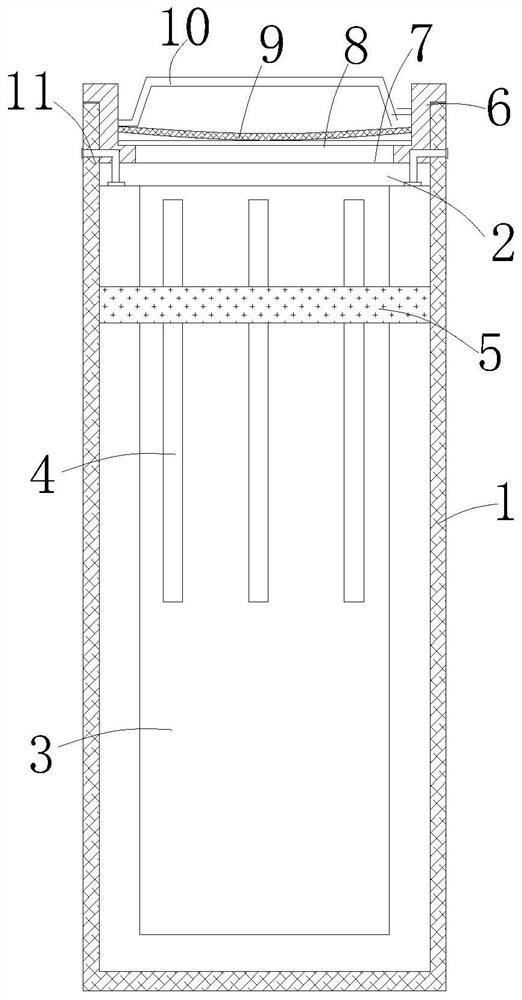

Liquid injection machine and liquid injection units thereof

ActiveCN105552299AImprove injection efficiencyLower injection costsFinal product manufactureNon-aqueous electrolyte cellsBiomedical engineeringElectromagnetic valve

The invention discloses a liquid injection machine and liquid injection units thereof. The liquid injection machine comprises a machine table, a lifting device, an electromagnetic valve bank, a battery core positioning clamp, at least two liquid injection units and a liquid injection pump, wherein the liquid injection pump is used for injecting liquids into the liquid injection units; the liquid injection units are located at the upper part of the battery core positioning clamp; the lifting device drives the liquid injection units to lift and drop; each liquid injection unit comprises an injection nozzle, a volume chamber, a liquid pipe and a gas hole; the lower part of each volume chamber is communicated with the corresponding injection nozzle; the upper part of each volume chamber is communicated with the corresponding gas hole; the upper part of each liquid pipe extends outside upwards; the lower part of each liquid pipe extends into the corresponding volume chamber downwards; each liquid pipe, each gas hole and each volume chamber are communicated with one another; the gas holes of the liquid injection units are sequentially connected end to end in series to form a gas channel; the electromagnetic valve bank comprises a plurality of electromagnetic valves; and the battery core positioning clamp comprises a positioning space. The liquid injection machine can accurately inject the liquids into battery cores in large quantities by a common pump within a cycle, so that the liquid injection efficiency is greatly improved; and the liquid injection cost is reduced.

Owner:常熟东南高新技术创业服务有限公司

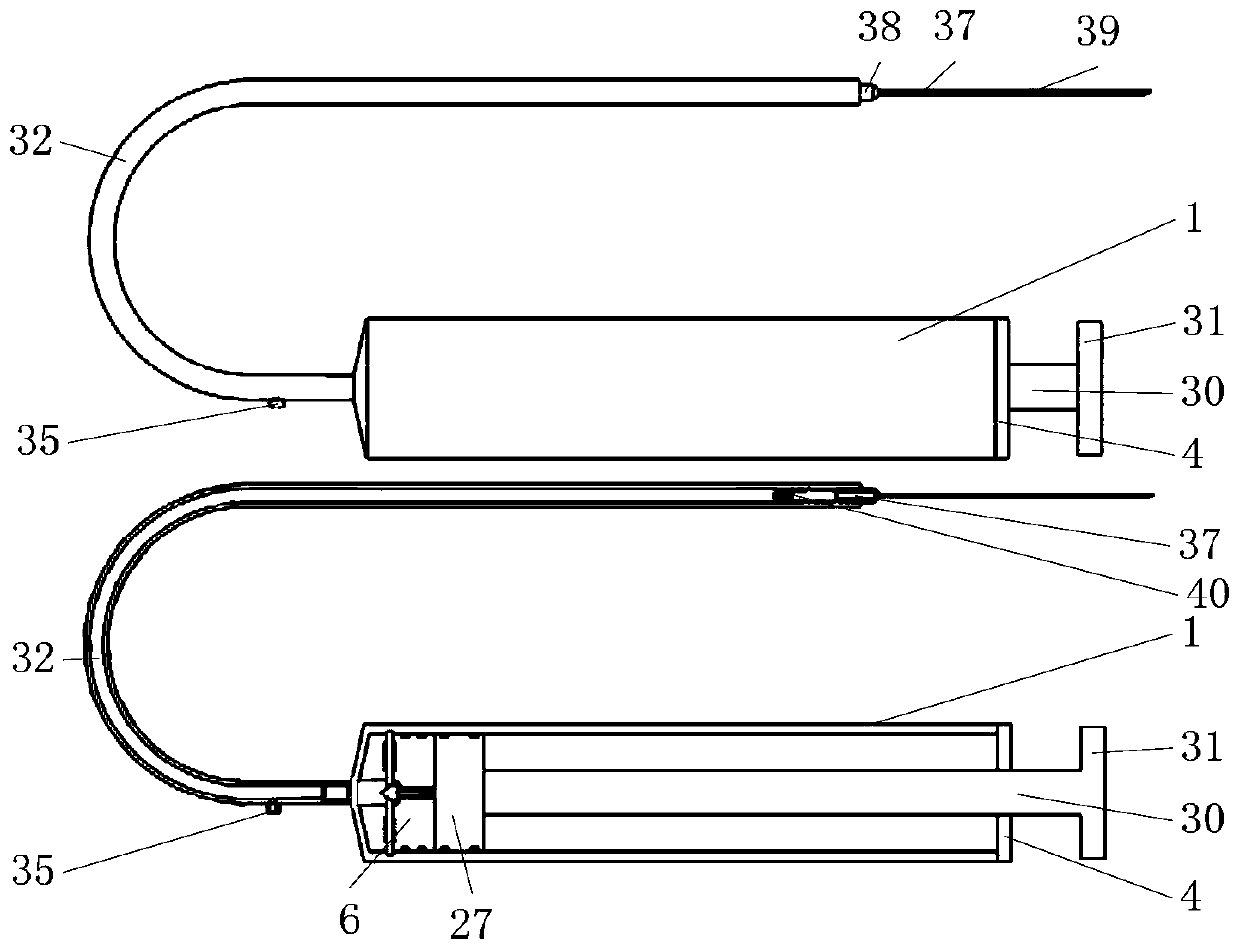

Adjustable microinjection apparatus

InactiveCN101314060AImprove surgical precisionEasy to operateInfusion syringesIntravenous devicesHand heldEngineering

The present invention relates to an adjustable micro-injection device, comprising a base structure, a clamping structure, a pressurizing impulse structure, a withdrawing structure, an injection controller and a quantitive controller, wherein the base structure is provided with a syringe positioning structure for accommodating an injection syringe and at least one holding part for hand holding operation; the clamping structure is positioned at one end of the injection syringe positioning structure for successively connecting the injection syringe and a injector needle tube; the pressurizing impulse structure is positioned at the other end of the injection syringe positioning structure and is connected with the base structure; the withdrawing structure is combined with the base structure and is positioned at the position of an adjacent pressurizing impulse structure; the injection controller is combined with the base structure and drives the pressurizing impulse structure to apply propelling pressure on a push barrel piston of the injection syringe via at least one driving structure; the quantitive controller is combined with the injection controller to move so as to control tolerance displacement quantity of drive of the driving structure to the pressurizing impulse structure. Compared with the prior structure, the bracket has the advantages that the bracket has more precise injection quantity control, better injection angle control, no contact with air for substances in the injection syringe, no requirement on special injection syringe and no replacement of the injection syringe by single hand.

Owner:DERMATO PLASTICA BEAUTY DPB

Three-dimensional packaging method

InactiveCN102214613ALower injection costsEasy to integrateSolid-state devicesSemiconductor/solid-state device manufacturingIonEngineering

The invention relates to a three-dimensional packaging method which comprises the following steps: providing an initial substrate of which a device is made on the surface; providing N laminated substrates, wherein the laminated substrate comprises a device layer and an ion collection layer below the device layer; gluing the initial substrate and a laminated substrate; etching the laminated substrate and stopping at the position of the ion collection layer; forming an electricity lead in the laminated substrate; repeating the steps and bonding the N laminated substrates in sequence to form a three-dimensional packaging structure with N+1 device layers, wherein N is an integer greater than one.

Owner:SHANGHAI SIMGUI TECH

Fire-flooding exploitation method used in later period of steam assisted gravity drainage (SAGD) of heavy oil reservoir

The invention relates to a fire-flooding exploitation method used in a later period of steam assisted gravity drainage (SAGD) of a heavy oil reservoir. At a steam chamber expansion phase of the SAGD, when steam chambers of adjacent injection and production well pairs are subjected to coalescence, a injection and production well of the middle injection and production well pair is used for injecting air to ignite, a production well of the middle well pair and production wells of the left and right adjacent well pairs are used for producing, and injection wells of the left and right adjacent well pairs are converted into fire-flooding ventilation wells. The exploitation method can utilize a high-temperature fire-flooding front edge to effectively drive remaining reserves at the lower part of an oil layer between the adjacent SAGD well pairs, avoids the steam play of in the later period of the regular SAGD or the gas-assisted SAGD, prolongs the SAGD production time, and obviously improves the oil recovery. The method disclosed by the invention combines the advantages of the SAGD and fire flooding; the output at an SAGD production phase is high, and the oil exploitation speed is high; and the fire flooding is utilized at an output declination phase after the adjacent stream cavities are subjected to the coalescence, so that the injection cost can be reduced, and the heat energy utilization rate and the oil recovery are improved.

Owner:PETROCHINA CO LTD

Adjustable microinjection apparatus

InactiveCN101314060BImprove surgical precisionEasy to operateInfusion syringesIntravenous devicesHand heldEngineering

The present invention relates to an adjustable micro-injection device, comprising a base structure, a clamping structure, a pressurizing impulse structure, a withdrawing structure, an injection controller and a quantitive controller, wherein the base structure is provided with a syringe positioning structure for accommodating an injection syringe and at least one holding part for hand holding operation; the clamping structure is positioned at one end of the injection syringe positioning structure for successively connecting the injection syringe and a injector needle tube; the pressurizing impulse structure is positioned at the other end of the injection syringe positioning structure and is connected with the base structure; the withdrawing structure is combined with the base structure and is positioned at the position of an adjacent pressurizing impulse structure; the injection controller is combined with the base structure and drives the pressurizing impulse structure to apply propelling pressure on a push barrel piston of the injection syringe via at least one driving structure; the quantitive controller is combined with the injection controller to move so as to control tolerance displacement quantity of drive of the driving structure to the pressurizing impulse structure. Compared with the prior structure, the bracket has the advantages that the bracket has more precise injection quantity control, better injection angle control, no contact with air for substances in the injection syringe, no requirement on special injection syringe and no replacement of the injection syringe by single hand.

Owner:DERMATO PLASTICA BEAUTY DPB

A three-phase self-generating foam water blocking agent

The invention discloses a three-phase self-foaming water-plugging agent, and belongs to the field of petroleum chemistry. The provided water-plugging agent comprises the following components: solid particles, a foaming agent, a foam stabilizing agent, a crosslinking agent, a delaying agent, and a gas producing agent. Compared with the prior art, the provided water-plugging agent has the advantages of high foam quality and good stability, the gel crosslinking and gas production can be achieved at the same time, the water-plugging agent can tolerate high temperature, has a strong residue blocking performance and a long water-plugging period, and can achieve efficient plugging and depth profile control. Moreover, the preparation technology of the provided water-plugging agent is simple, the injection cost is low, and the water-plugging agent is safe and reliable, thus has a good market prospect and high economic value, and is especially suitable for the development of high temperature heavy oil steam stimulation wells.

Owner:CHINA PETROLEUM & CHEM CORP +1

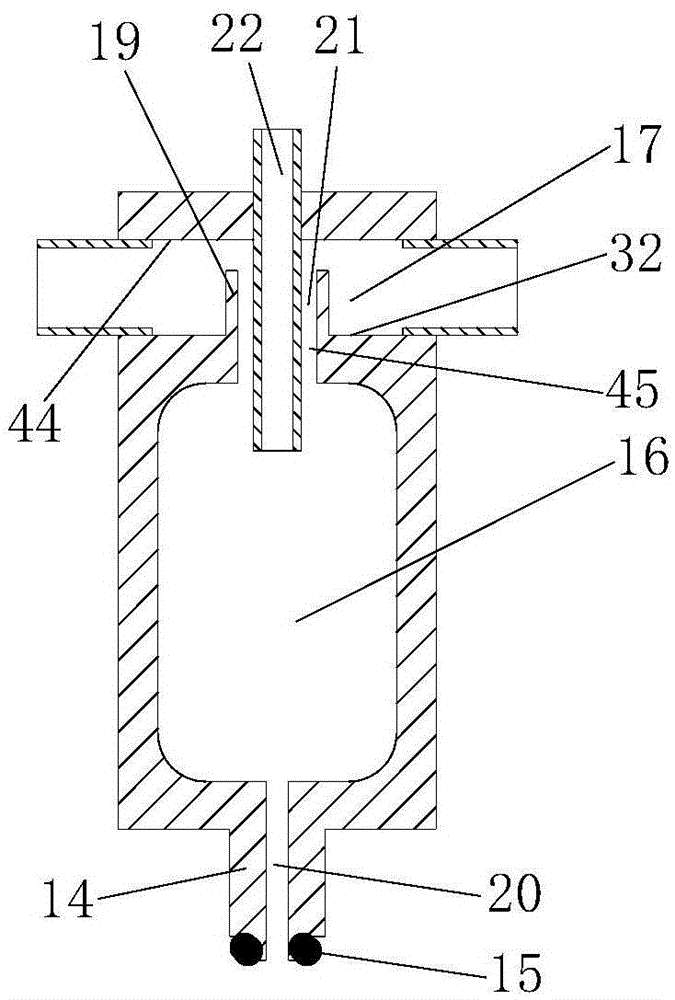

Thrombolytic agent syringe

PendingCN109731183AEasy to operateLower injection costsInfusion syringesIntravenous devicesEngineeringThrombolytic Agent

The invention relates to a thrombolytic agent syringe, and relates to the technical field of medical equipment so as to solve the technical problem that operation of an existing syringe is inconvenient. The thrombolytic agent syringe includes a syringe barrel, a push rod and a piston installed in the syringe barrel. The front end of the syringe barrel is provided with a needle connector connectedwith a needle for injection, the push rod is fixedly connected with the piston, a rod body of the push rod stretches backwards to the outside of the syringe barrel, the front end of the piston is fixedly provided with an integrally closed saline storage chamber, the saline storage chamber is filled with normal saline, and the front end of the piston is fixedly provided with a spike which can pierce the wall of the saline storage chamber. The provided syringe can reduce the injection cost of a thrombolytic agent.

Owner:SHANGHAI EAST HOSPITAL EAST HOSPITAL TONGJI UNIV SCHOOL OF MEDICINE

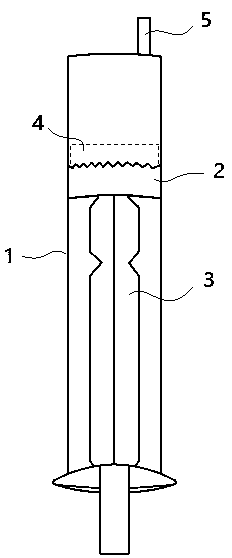

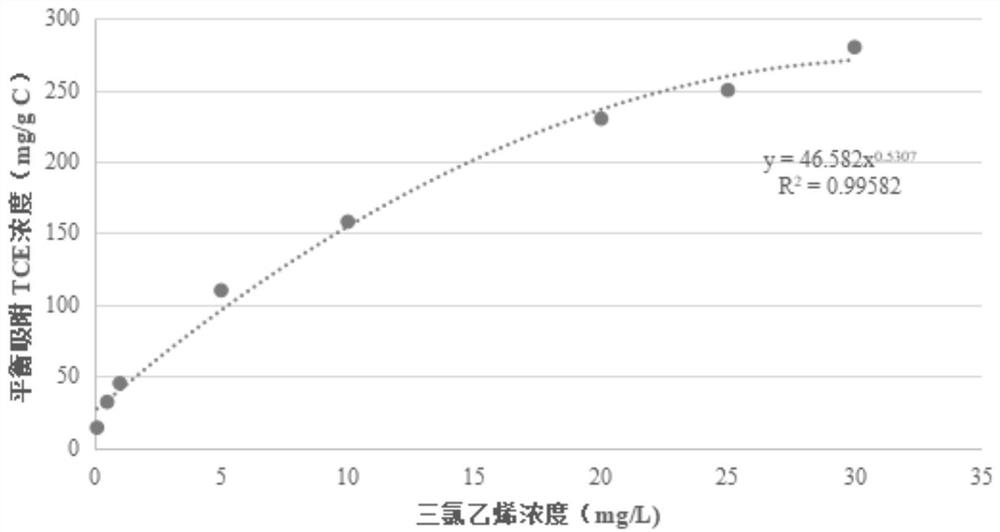

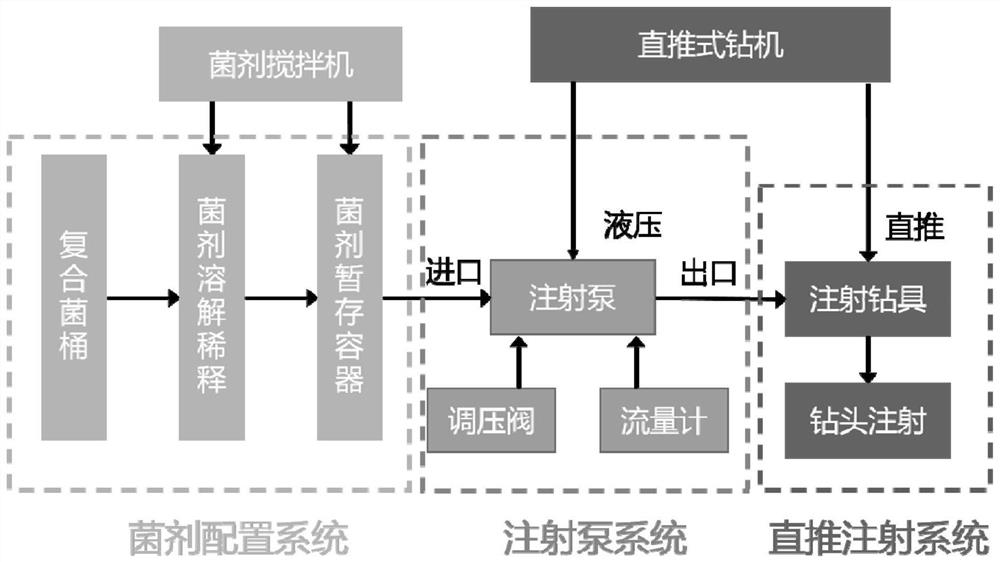

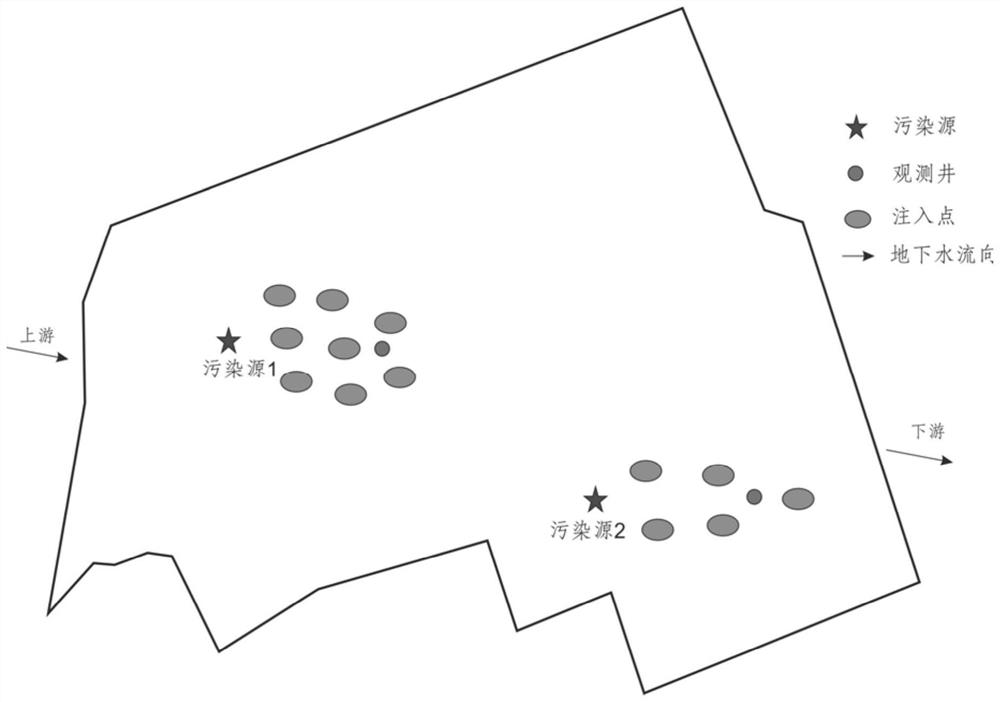

In-situ reinforced remediation method for chlorohydrocarbon-polluted underground water

PendingCN112875874AMake the most of your mobilityImprove adsorption capacityWater contaminantsWater/sewage treatment by sorptionActivated carbonMicrobial agent

The invention discloses an in-situ reinforced remediation method for chlorohydrocarbon-polluted underground water. The method comprises the following steps: (1) investigating hydrogeological conditions and pollutant distribution conditions of a polluted site; (2) calculating the size of an underground water pollution plume, and delimiting a pollution area according to the size of the pollution plume; (3) preparing nano colloid activated carbon-based compound bacteria, and mixing the nano colloid activated carbon-based compound bacteria with water according to a ratio of (1:10)-(1:1000) to prepare a mixed bacterial agent; and (4) establishing injection points in each pollution area, pushing the mixed microbial agent to a target pollution layer through a direct push drilling machine injection system, and injecting the mixed microbial agent into each injection point in sequence under a certain pressure. The method is easy to operate, the injection depth can be greatly reduced, the injection cost is reduced, and the method has the advantages that the removal speed of chlorohydrocarbon in underground water is high, degradation is thorough, the repair period is shortened, and the adsorption and degradation capacity is reproducible.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI +1

Syringe capable of preventing needle from falling off

The invention, which belongs to the field of syringes, particularly relates to a syringe capable of preventing a needle from falling off. The syringe comprises a syringe barrel with a syringe head, apiston mechanism, a cylindrical piston A, a hose, a sliding plug mechanism and the like. The syringe head on the syringe barrel is connected with a needle sleeve with a needle head structure through the hose. Because of cooperation of the sliding plug mechanism, the piston mechanism and the piston A, the injector filled with the liquid medicine can completely inject the liquid medicine in the hoseand the syringe barrel into the livestock and poultry body in the injection process and no more liquid medicine is left in the hose after injection is finished. Compared with simple modification of connecting a needle head structure and an injection head in a common injection device by using a hose, the designed structure of the provided syringe enables no liquid medicine to be left in the hose basically after injection completion, so that the liquid medicine wasting is reduced substantially and thus the syringe size or length that is increased because the residual liquid medicine in the hoseis supplemented to cause insufficient standard injection dosage of the syringe is reduced; the injection cost is reduced, and flexible operation is facilitated.

Owner:曹苏玲

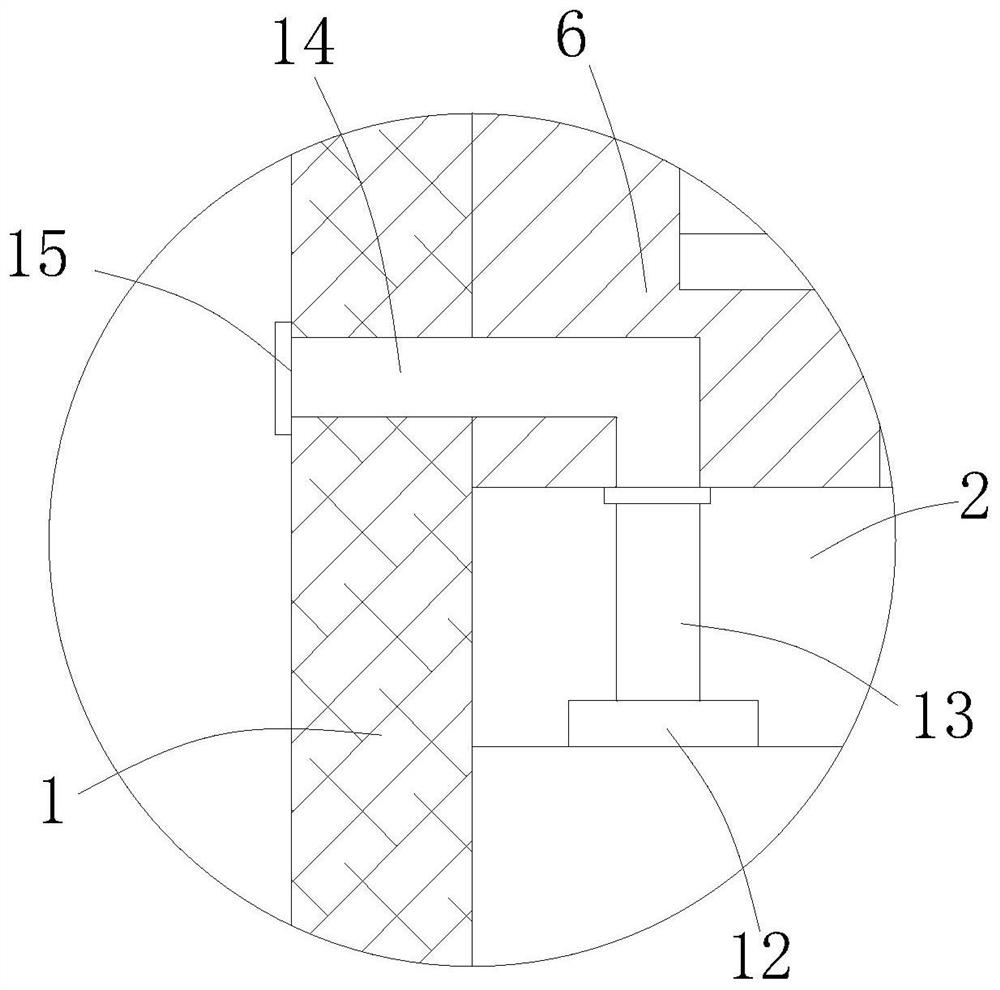

Lithium-ion battery steel case and method for improving liquid injection efficiency of steel case

ActiveCN112803115BImprove injection efficiencyPrevent leakageSmall-sized cells cases/jacketsSecondary cellsStructural engineeringLithium-ion battery

The invention relates to the technical field of lithium ion batteries, and discloses a lithium ion battery steel case and a method for improving the liquid injection efficiency of the steel case. The lithium ion battery steel shell includes a steel shell body. A fixing ring is fixed on the upper side wall of the steel shell body. A connection cover is provided at the lower part of the fixing ring. The lower part of the connection cover extends to the steel shell body. In the lower part of the inner part, a plurality of vents are evenly arranged on the outer wall of the connecting cover, and a floating pad is set on the lower outer wall of the connecting cover. A sealing ring is provided on the outer wall of the opening of the steel shell body. An exhaust mechanism is provided in the sealing ring. One end of the exhaust mechanism is connected to the inside of the steel shell body, and the other end passes through the fixed ring, the sealing ring, and the side wall of the steel shell body to communicate with the outside. The exhaust mechanism of the present invention can be used to exhaust gas in real time during liquid injection. At the same time, the floating pad can move with the height of liquid injection to exhaust the air in the upper part and improve the air outlet efficiency.

Owner:SINOWATT DONGGUAN

Health care method for improving immunity of nursery piglets under subtropical monsoon climate

InactiveCN108812543AImprove immunityImprove survival rateTetracycline active ingredientsAccessory food factorsLivestock breedingEconomic benefits

The invention discloses a health care method for improving the immunity of nursery piglets under the subtropical monsoon climate and relates to the technical field of livestock breeding. The problem is solved that in the prior art, under the subtropical monsoon climate condition, vaccine injection of nursery piglets is reduced, and the survival rate of the nursery piglets cannot be guaranteed. Thehealth care method comprises the steps of vaccine injection and medicine health care. Vaccine injection comprises the steps that one dose of triple vaccine is intramuscularly injected into each 50-day-old piglet; one dose of pseudorabies vaccine is intramuscularly injected into each 60-day-old piglet; each 70-day-old piglet takes 2 ml of foot-and-mouth disease vaccine orally; each 100-day-old piglet takes 2 ml of foot-and-mouth disease vaccine orally. Medicine health care comprises the steps that an immune reagent capable of improving the immunity of the piglets is added to feeding fodder atdifferent day ages. According to the technical scheme, the dose of the vaccine injection can be effectively reduced, medicine health care is adjusted adaptively to improve the immunity of the pigletsin the growth and development stages, immune success is guaranteed, and the survival rate of fattening pigs can be obviously increased; the cost of vaccine injection is reduced, and the economic benefit of enterprises can be effectively improved.

Owner:邛崃驰阳农牧科技有限公司

Veterinary radix scutellariae powder injection and preparation method thereof

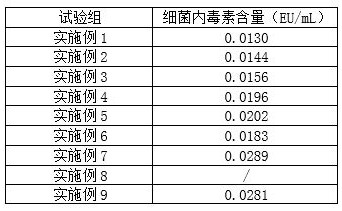

InactiveCN112516193AControl concentrationHigh purification ratePowder deliveryAntiviralsUltrafiltrationPharmaceutical Substances

The invention provides a veterinary radix scutellariae powder injection and a preparation method thereof. after a controlled release agent and auxiliary material medicine are added and injected into an animal body, the medicine absorption speed can be effectively controlled, the medicine use frequency is reduced while the medicine effect is improved, and the influence of the stress reaction of theanimal on the medicine effect is reduced. In the processes of filtration purification and filtration sterilization, an ultrafiltration membrane of the invention is used, and the filter membrane is prepared from a ceramic support body and an organic filter membrane which are prepared by a unique formula and a specific process, so that the filtration effect is good, the bacteria removal capabilityis high; and the purity of baicalin is effectively improved to 80%-85% and is remarkably improved in comparison with the purity of 75% of the national standard; and meanwhile, bacterial endotoxin is controlled to be about 0.014 EU / mL, so that heat source reaction and veterinary stress reaction are correspondingly reduced, and the healing effect is good.

Owner:JIANGXI ZHONGCHENG MEDICINE GROUP

A Pneumatic Needle-Free Injector Power Head

ActiveCN101797411BAchieve needle-free injectionFor long-term storageIntravenous devicesNeedle freeCylinder head

Owner:扬中市检验检测中心

A kind of manufacturing method of composite ceramic closed impeller containing metal skeleton

ActiveCN110053157BEasy to clean upReduce the difficulty of operationCeramic shaping apparatusMaterials preparationImpeller

Owner:上海邦聚工程材料技术有限公司

Lithium ion battery steel shell and method for improving liquid injection efficiency of steel shell

ActiveCN112803115AImprove injection efficiencyPrevent leakageSmall-sized cells cases/jacketsSecondary cellsStructural engineeringLithium-ion battery

The invention relates to the technical field of lithium ion batteries, and discloses a lithium ion battery steel shell and a method for improving the liquid injection efficiency of the steel shell. The lithium ion battery steel shell comprises a steel shell body, a fixing ring is fixed to the side wall of the upper portion in the steel shell body, a connecting cover is arranged on the lower portion of the fixing ring, the lower portion of the connecting cover extends to the lower portion in the steel shell body, and a plurality of ventilation openings are evenly formed in the outer wall of the connecting cover. The outer wall of the lower portion of the connecting cover is sleeved with a floating pad, a sealing ring is arranged on the outer wall of the through opening of the steel shell body, an exhaust mechanism is arranged in the sealing ring, one end of the exhaust mechanism is connected with the interior of the steel shell body, and the other end of the exhaust mechanism sequentially penetrates through the fixing ring, the sealing ring and the side wall of the steel shell body to be communicated with the outside. According to the invention, air can be exhausted in real time during liquid injection through the arranged exhaust mechanism, meanwhile, the arranged floating pad can move along with the liquid injection height, pressure of air on the upper portion is exhausted, and the air outlet efficiency is improved.

Owner:SINOWATT DONGGUAN

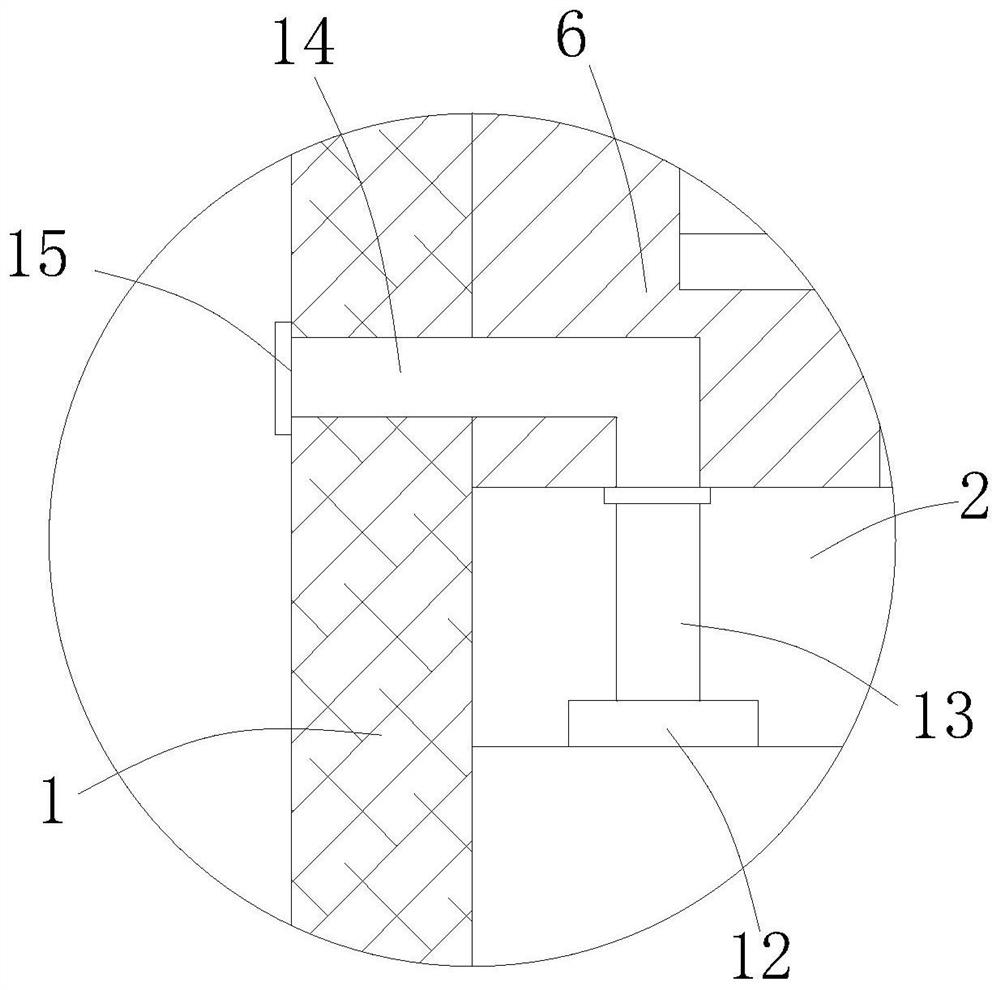

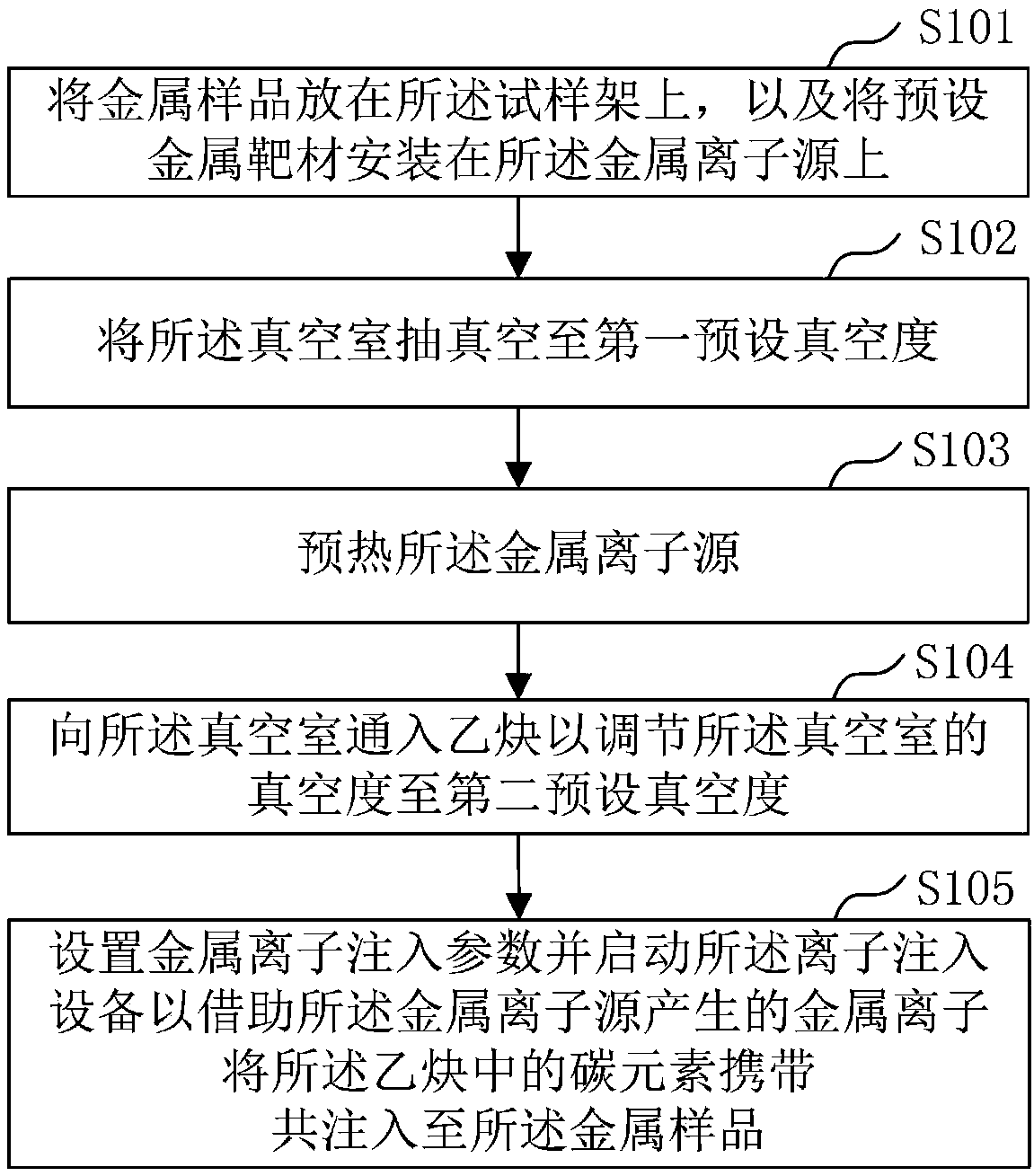

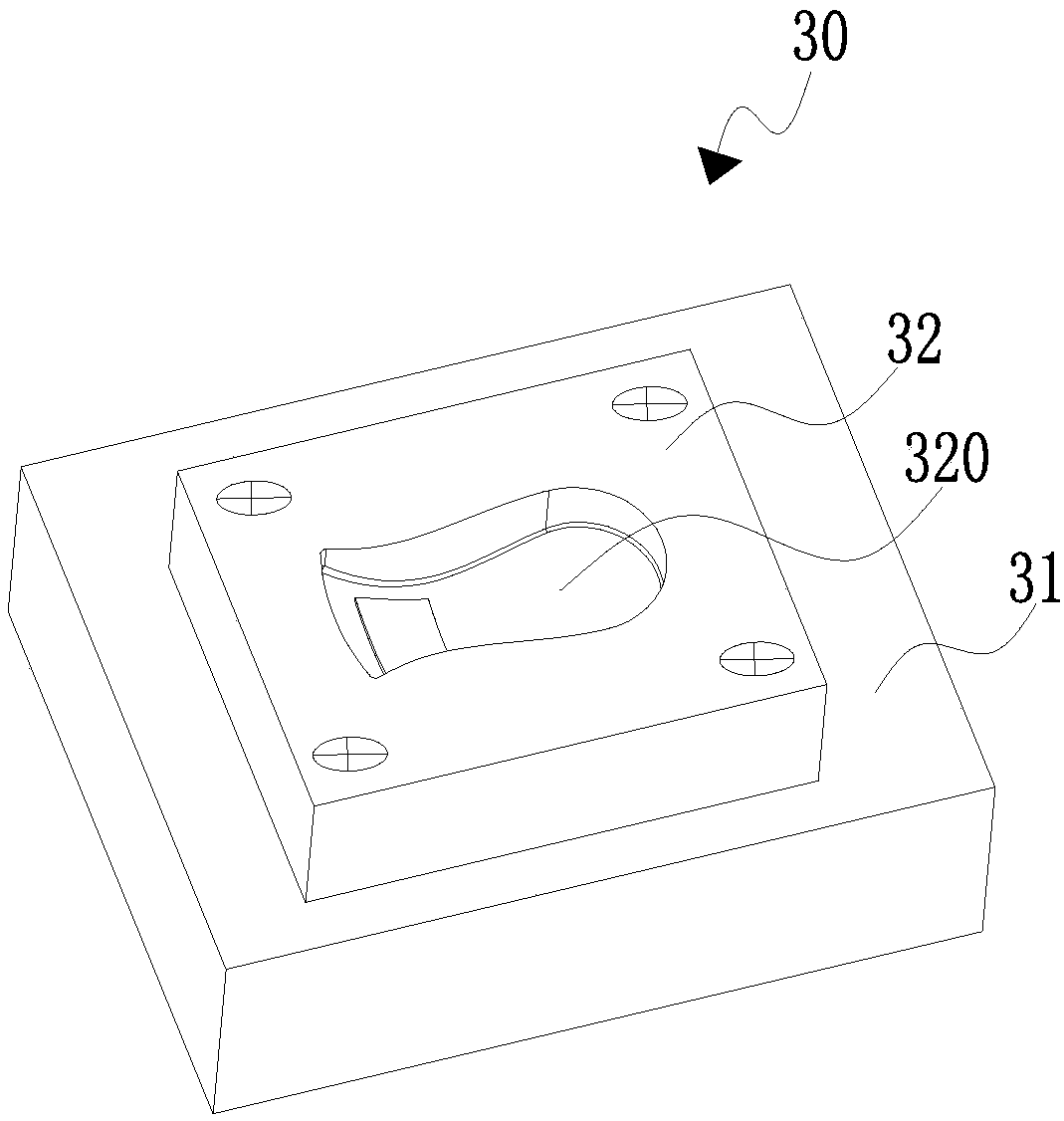

Carbon element injection method and modifying tool and mold thereof

ActiveCN108342708ALower injection costsSimple processVacuum evaporation coatingSputtering coatingVacuum chamberIon implantation

The invention discloses a carbon element injection method and a modifying tool and mold thereof. The carbon element injection method comprises the steps that a metal sample is put on a sample holder,and a preset metal target material is installed on a metal ion source; a vacuum chamber is vacuumized to the first preset vacuum degree; the metal ion source is preheated; acetylene is introduced intothe vacuum chamber to adjust the vacuum degree of the vacuum chamber to the second preset vacuum degree; and metal ion injection parameters are set, ion injection equipment is started, and carbon elements in acetylene are carried and injected into the metal sample by virtue of metal ions generated by the metal ion source. The carbon element injection method has the advantages of being low in injection cost, easy to operate and the like.

Owner:SHENZHEN UNIV

Method and Well Pattern Structure of Solvent Improving Heavy Oil Reservoir Recovery by Steam-Assisted Gravity Drainage

The invention discloses a method and a well network for improving steam assisted gravity drainage for extracting heavy oil reservoirs by the aid of solvents. The well network comprises SAGD (steam assisted gravity drainage) horizontal well pairs; horizontal sections of steam injection wells are subjected to well completion by the aid of slotted screen pipes; branched well sections are drilled in the horizontal sections of the steam injection wells and penetrate the middles of inner sandwich layers in oil layers; the various branched well sections are subjected to well completion by the aid of tail pipes; first long oil pipes which extend to toes of the steam injection wells descend into screen pipes of the steam injection wells; solvent injection main pipes which are parallel to the first long oil pipes descend into the screen pipes of the steam injection wells and are hermetically connected with the tail pipes in the various branched well sections by tail pipe hangers; second long oil pipes descend into production wells and reach the tail ends of horizontal sections of the production wells; vertical monitoring wells are further deployed in the well network. The method and the well network have the advantages that steam flows into the oil layers to upwardly develop steam cavities, and the hot solvents and steam mixed systems flow into the oil layers on the upper portions of the sandwich layers from the main pipes via the tail pipes, so that heat communication and fluid communication among the oil layers and the steam cavities can be accelerated, the sandwich layers can be forcedly broken through, development of the steam cavities on the upper portions of the sandwich layers can be promoted, and the recovery efficiency can be greatly improved.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com