Three-phase self-foaming water-plugging agent

A technology of water blocking agent and foaming agent, which is applied in the field of three-phase self-generated foam water blocking agent, which can solve the problems of poor foam stability, poor foaming effect, and low bubble efficiency, and achieve stable gel performance, convenient construction, and oil layer small damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In this embodiment, a three-phase self-generating foam water blocking agent includes the following components: by mass percentage, solid particles 2.0%, foaming agent 0.2%, foam stabilizer 0.2%, crosslinking agent 0.02%, retarder 0.02%, gas generating agent 3%, dispersant 2.0%, PH regulator 0.1%, and the balance is water.

[0047] Wherein, the solid particles are attapulgite, the foaming agent is a mixture of sodium dodecylbenzenesulfonate and fatty alcohol polyoxyethylene ether sodium sulfate in a weight ratio of 1:3, and the foam stabilizer has an average molecular weight of 1 ~×10 6 The polyacrylamide, the crosslinking agent is potassium dichromate, the retarder is sodium thiosulfate, the gas generating agent is a mixture of ammonium dichromate and sodium sulfite in a weight ratio of 1:1, and the dispersant is calcium lignosulfonate. The pH regulator is sodium acetate.

Embodiment 2~9

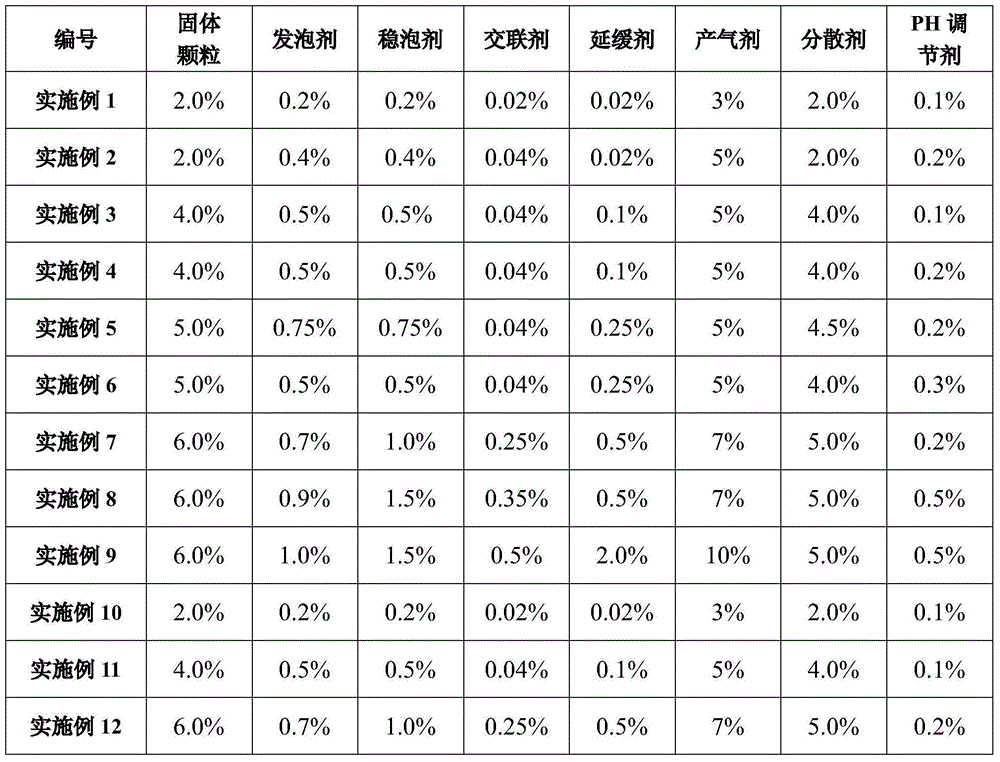

[0049] Same as Example 1, the difference lies in: the mass percentage content of each component included in the water shutoff agent is different, and the balance is water, see Table 1 for details.

Embodiment 10-12

[0051] Same as Example 1, the difference is that the attapulgite as a solid particle is replaced by bentonite, the mass percentage content of each component included in the water shutoff agent is different, and the balance is water, see Table 1 for details.

[0052] Table 1

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com