Patents

Literature

31 results about "Petroleum chemistry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

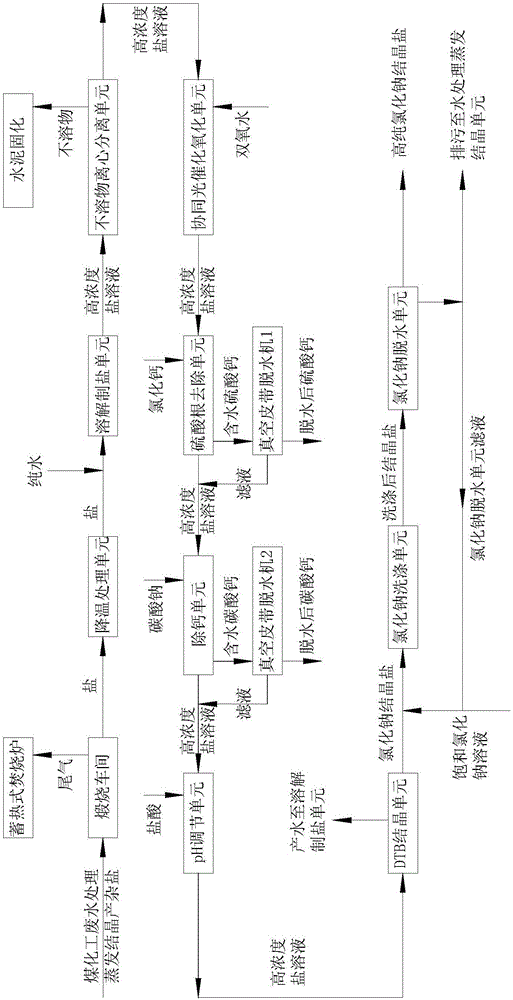

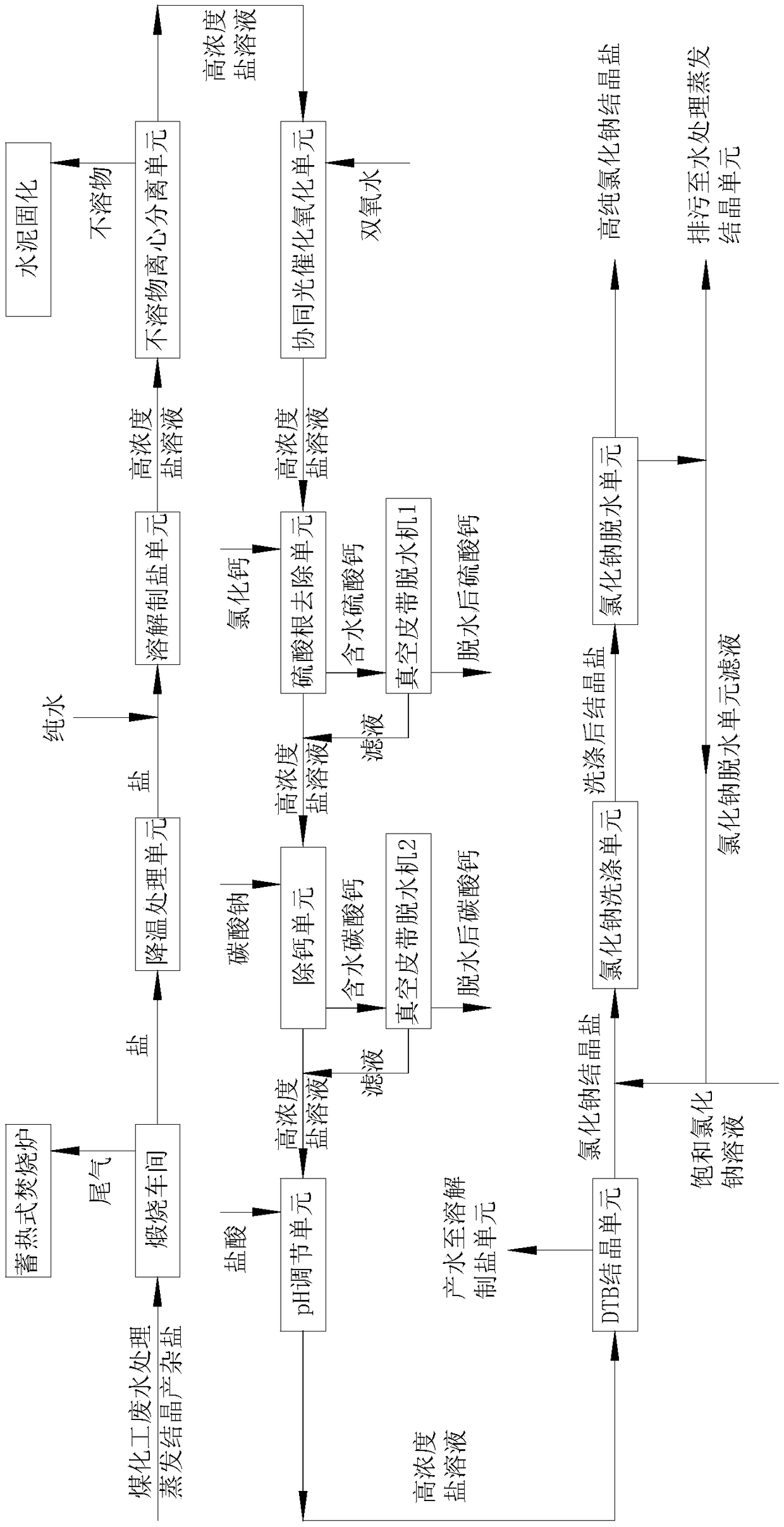

Method for recycling impurity salts generated in industrial wastewater treatment

ActiveCN106745076AEasy to handleWide operating conditionsCalcium/strontium/barium carbonatesCalcium/strontium/barium sulfatesHigh concentrationSulfate radicals

The invention provides a method for recycling impurity salts generated in industrial wastewater treatment. The method comprises the following steps: (1) calcining impurity salts generated in an industrial wastewater treatment process, cooling, dissolving in pure water, and obtaining a high-concentration sodium chloride solution; (2) performing solid-liquid separation, and removing residual organisms in the solution; (3) successively removing sulfate radicals and calcium ions, adjusting the pH of the solution to neutral, and obtaining a high-purity sodium chloride solution; and (4) crystallizing the high-purity sodium chloride solution obtained in step (3), obtaining a sodium chloride crystal product, and washing to obtain the high-purity sodium chloride crystal product. By adopting the method, the effective treatment and recycling of impurity salts generated in the industrial wastewater zero emission process of electric power, petroleum chemistry, coal chemistry and the like; moreover, the method is simple in treatment process and moderate in operation conditions, and is a high-efficiency and stable impurity salt recycling method; and a final product sodium chloride is high in recycling rate and purity.

Owner:DATANG INT CHEM TECH RESINST

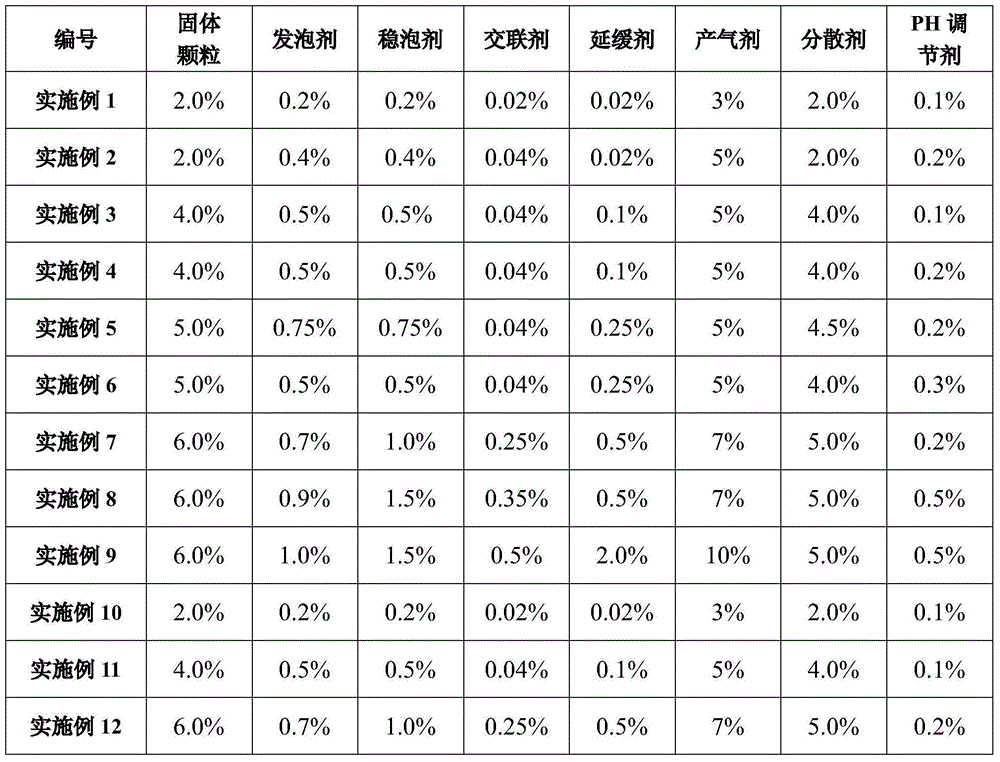

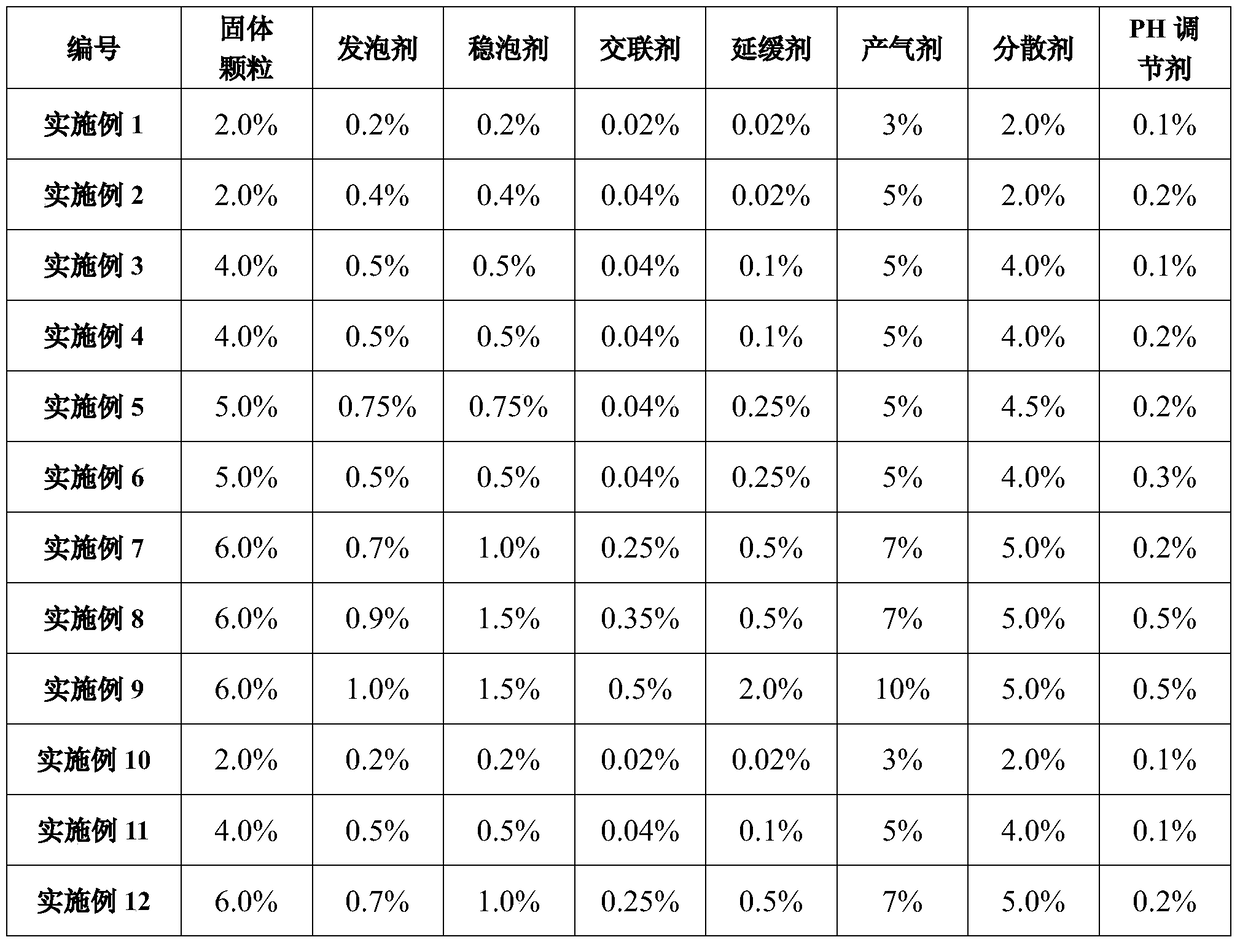

Three-phase self-foaming water-plugging agent

The invention discloses a three-phase self-foaming water-plugging agent, and belongs to the field of petroleum chemistry. The provided water-plugging agent comprises the following components: solid particles, a foaming agent, a foam stabilizing agent, a crosslinking agent, a delaying agent, and a gas producing agent. Compared with the prior art, the provided water-plugging agent has the advantages of high foam quality and good stability, the gel crosslinking and gas production can be achieved at the same time, the water-plugging agent can tolerate high temperature, has a strong residue blocking performance and a long water-plugging period, and can achieve efficient plugging and depth profile control. Moreover, the preparation technology of the provided water-plugging agent is simple, the injection cost is low, and the water-plugging agent is safe and reliable, thus has a good market prospect and high economic value, and is especially suitable for the development of high temperature heavy oil steam stimulation wells.

Owner:CHINA PETROLEUM & CHEM CORP +1

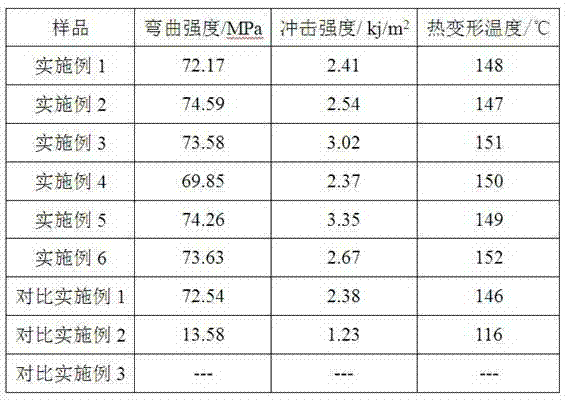

Method for preparing friction-resistant composite material by modifying solvent type lignin

ActiveCN101891933ARetain chemical activityHigh purityOther chemical processesSolvent basedChemical activity

The invention provides a new method for preparing a friction-resistant material by taking lignin as a modifying raw material. The new method is used for preparing the friction-resistant material by taking the solvent type lignin as the modifying raw material. The method can utilize the renewable lignin and has the advantages of strong chemical activity, high purity and the like, the solvent type lignin is taken for replacing phenols for preparing lignin-modified phenolic resin, and the resin has more polar groups in comparison with the traditional phenolic resin and stronger affinity in comparison with other components for preparing the friction-resistant material, thereby not only improving the performances of the friction-resistant material, but also fully utilizing the renewable resource and reducing the consumption of petroleum chemicals; simultaneously, the method can reduce the cost of preparing the friction-resistant material, save energy, reduce emission and produce great social benefits; furthermore, the process for preparing the friction-resistant material is simple and easy to implement and can produce good effects.

Owner:FUZHOU UNIV

Molding compound modified by organosolv lignin or derivative thereof and preparation method thereof

The invention provides a molding compound modified by organosolv lignin or a derivative thereof and a preparation method thereof. The organosolv lignin or the derivative thereof, a plasticizer, a filling agent, a curing agent, a curing accelerator, a plasticizing agent, a toughening agent and a lubricating agent are blended, and the molding compound modified by the organosolv lignin or the derivative thereof is prepared by a hot-press curing process or an injection molding process. The organosolv lignin or the derivative thereof can replace phenolic resin partially and even completely and the lignin modified molding compound of which the performance is similar to that of a phenolic molding compound is prepared; petroleum chemicals such as phenols, aldehydes and the like are used seldom or are not used, the consumption of petroleum resources and the production cost of the molding compound are reduced and particularly when the phenolic aldehyde is replaced by the lignin or the lignin derivative completely, the phenolic resin is not needed to be synthesized in advance, water and energy are saved, the pollution of phenol-containing sewage is reduced, and significant social benefits are achieved; and a processing technology is simple, easy to perform and good in effect.

Owner:程贤甦

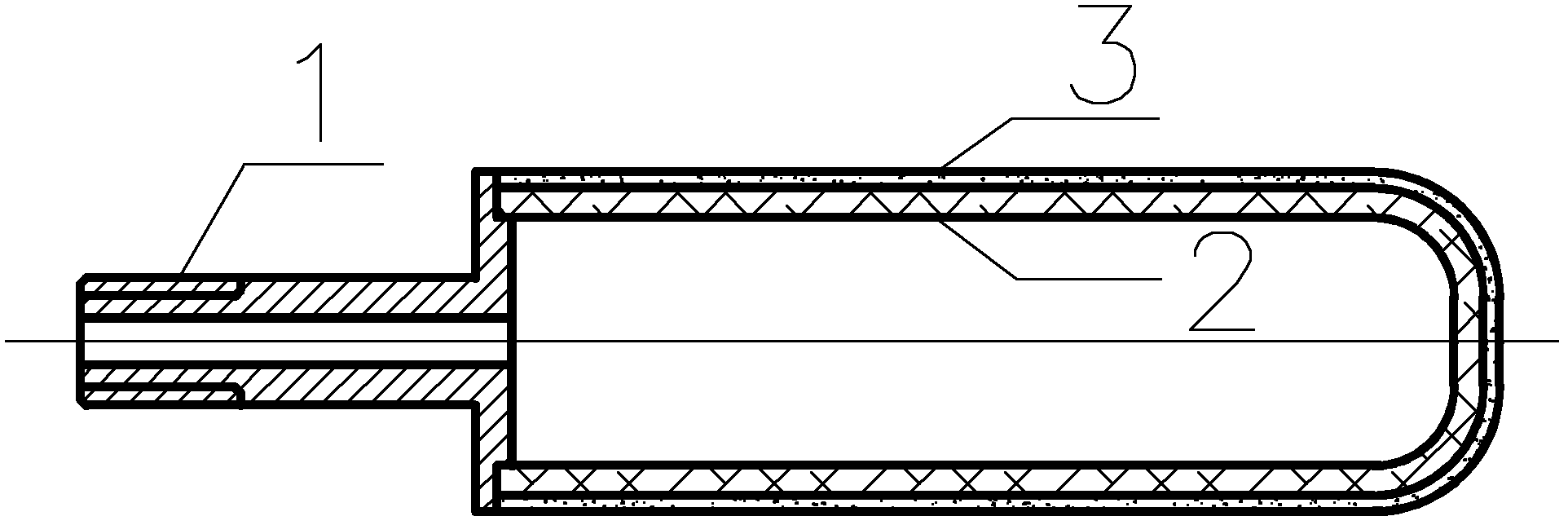

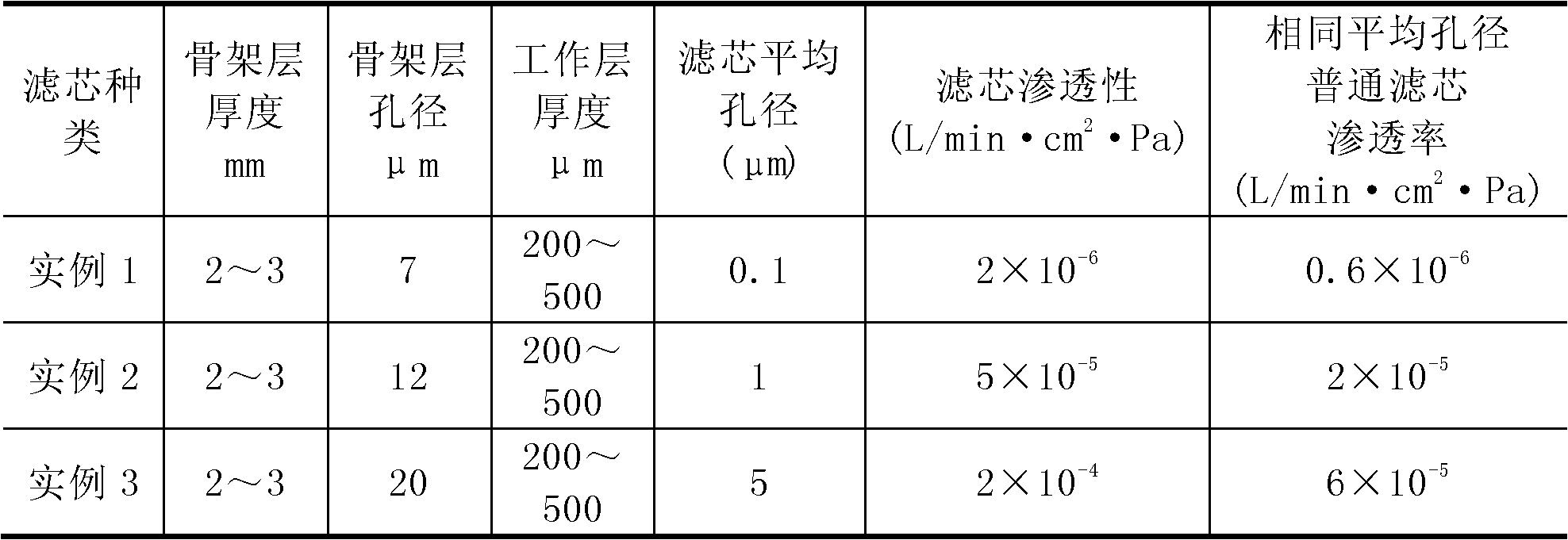

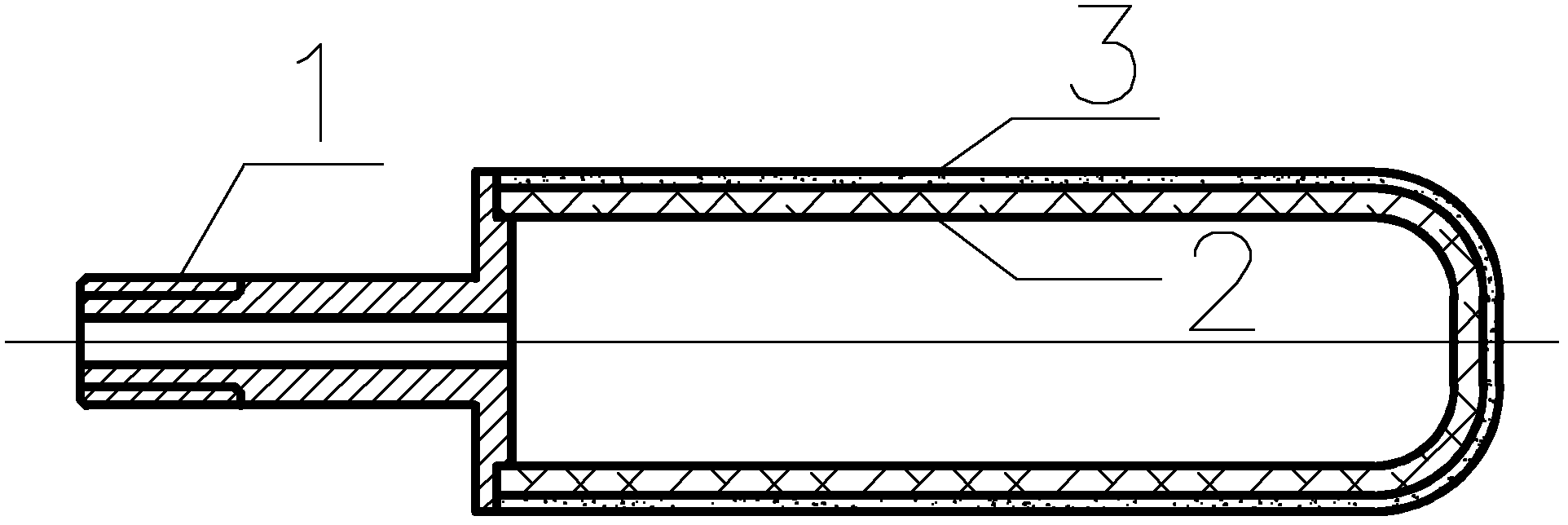

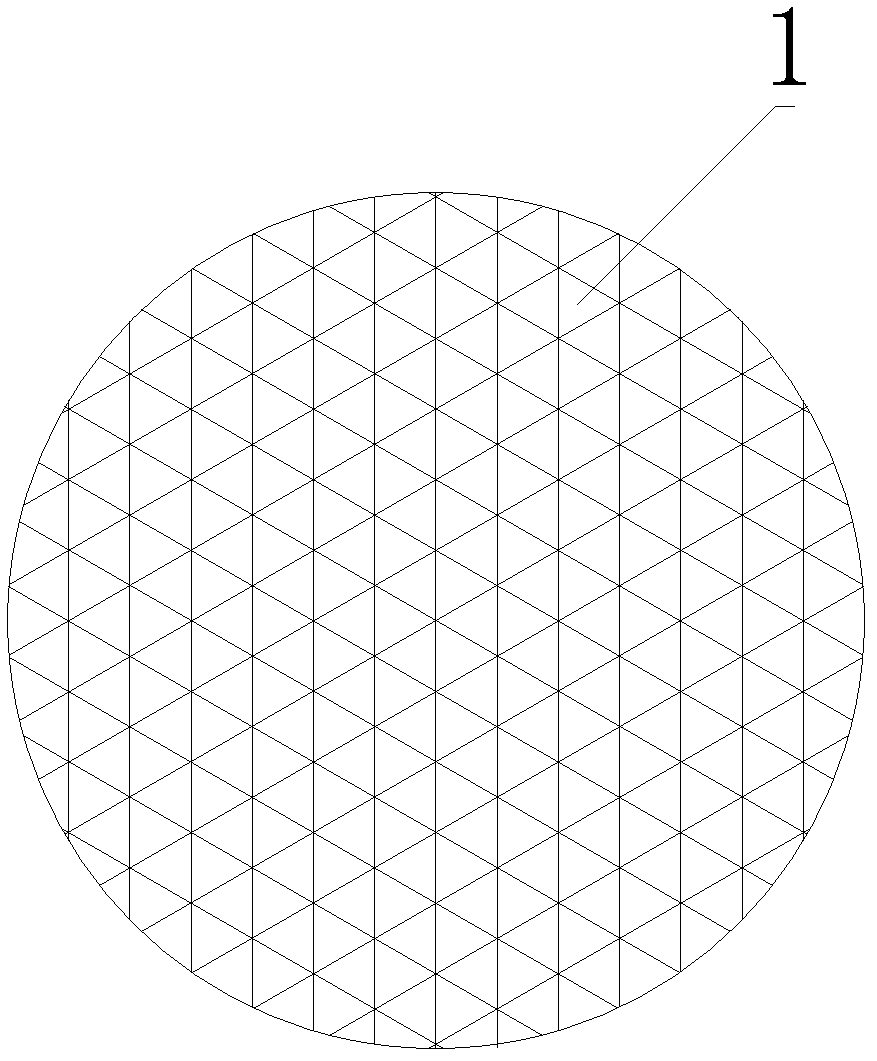

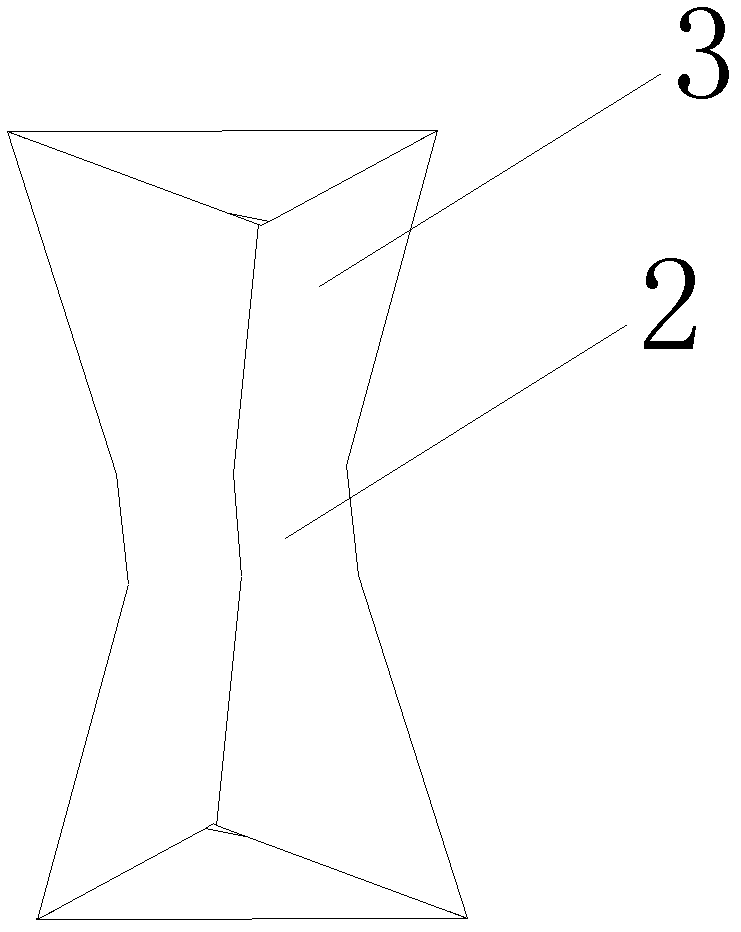

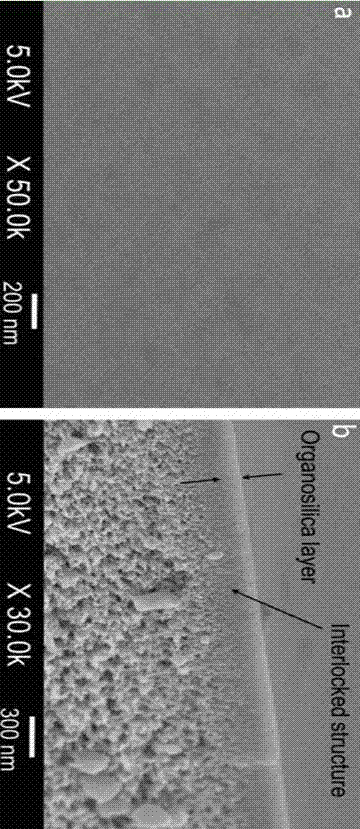

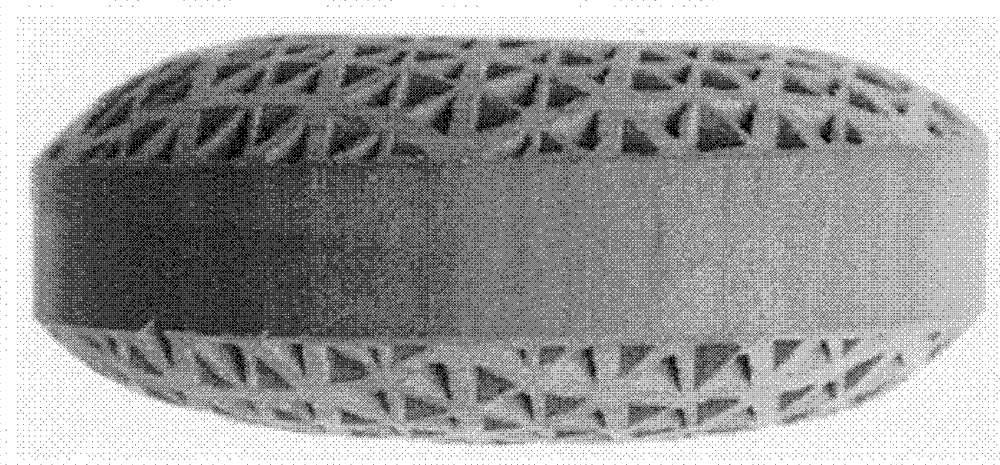

Asymmetric metal filter core and preparation method thereof

The invention provides an asymmetric metal filter core and a preparation method thereof. The asymmetric metal filter core is prepared by carrying out composite sintering on powder and comprises a tubular skeleton layer and an operational layer. The operational layer is covered above an external surface of the skeleton layer; the metal filter core has a dimension of d*l* delta equal to phi (30-100)*(100-2000)*(1.7-5.5)mm, wherein d*l* delta respectively represent an external diameter, a length and a wall thickness of the metal filter core; the skeleton layer of the metal filter core has an average aperture of 5-35 mum; the asymmetric metal filter core has an aperture of 0.1-10 mum and an amount of porosity of 25-60%; and the aperture of the skeleton layer is 5-25 mum larger than that of the operational layer. Compared with a homogeneous filter core with a same aperture, the asymmetric powder composite filter core has advantages of high permeability, good regeneration performance and long service life, etc., applies to gas-solid separation and liquid-solid separation and has good application prospects in the fields of gas purification, petroleum chemistry and energy and environmental protection, etc.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

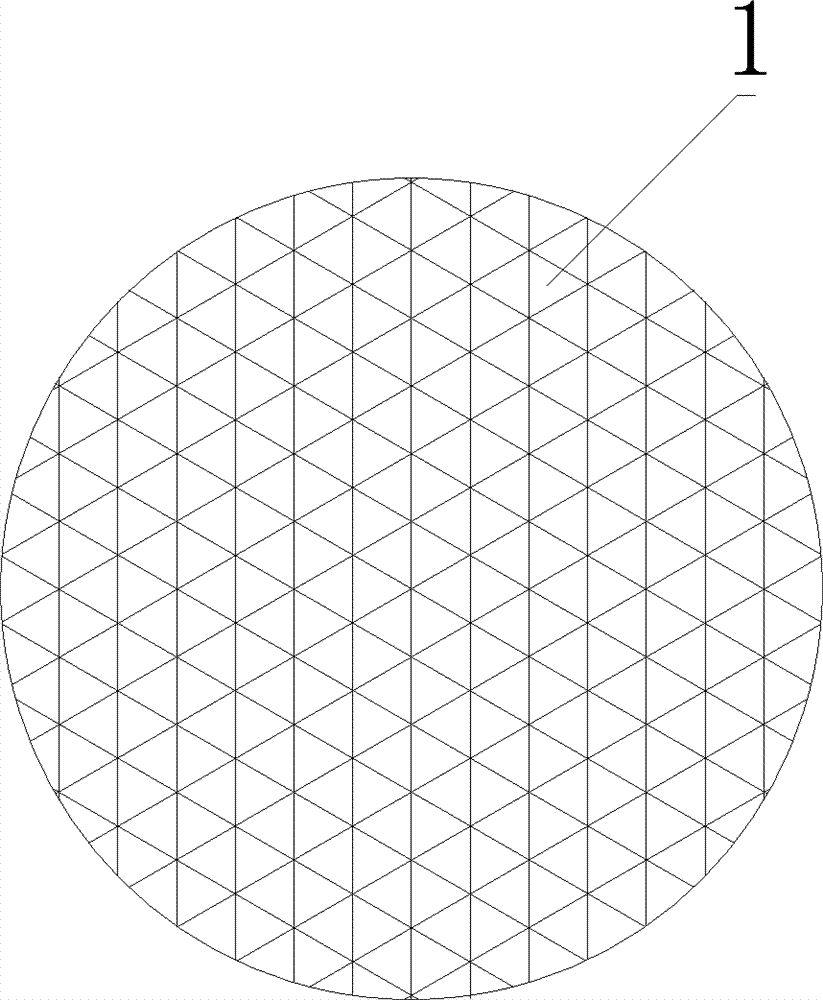

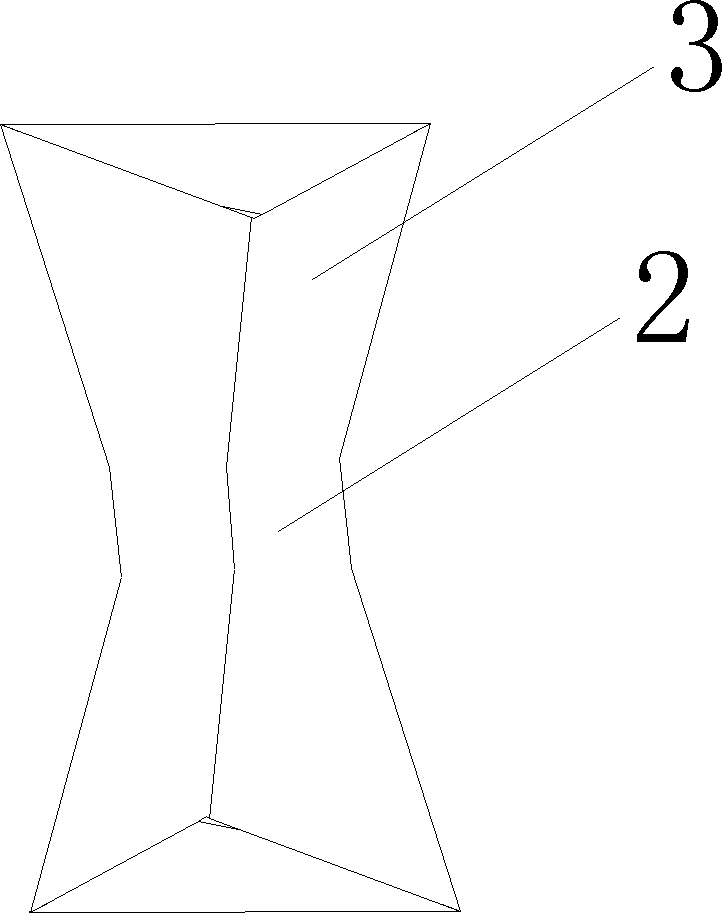

Catalyst carrier, and preparation method and application thereof

InactiveCN103041867AEnhanced mass transferImprove heat transfer performanceCatalyst carriersOther chemical processesReaction rateAlkali metal oxide

The invention relates to a catalyst carrier used for generating gas pulse in a reactor. The outer shape of the catalyst carrier is in a circular cake shape (flying saucer shape). The catalyst carrier is composed of a plurality of unit holes. The structure of each unit hole is that two ends of unit hole are prismoids and the middle portion of the unit hole is a hollow neck (weir groove), wherein the prismoids are preferably triple prismoids, quadruple prismoids or pentagonal prismoids, hexagonal prismoids, regular circular truncated cones, etc. The catalyst carrier is made of chemical ceramic materials. The chemical ceramic materials comprise the following raw materials of, by weight, gibbsite, 25-35 parts of kaolin, 10-20 parts of Guizhou soil, 5-10 parts of talcum, 8-12 parts of feldspar and 8-12 parts of alkali metal oxide. The catalyst carrier is suitable for being used as a carrier for the catalyst of the field of petroleum chemistry or as filling materials in the reactor. The carrier with the structure enhances a mass transfer effect and a heat transfer effect between gas and liquid, and further increases catalytic effect of the catalyst and reaction rate. The catalyst carrier has high hardness, high strength, large specific surface area, good high temperature resistance and good acid and alkali resistance.

Owner:刘一序

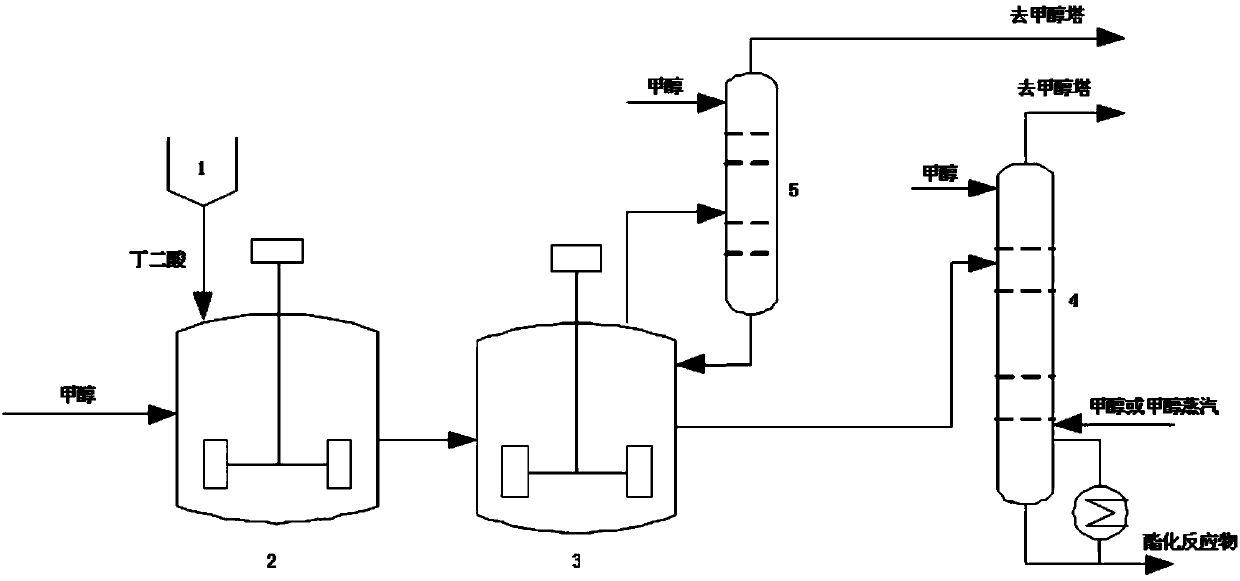

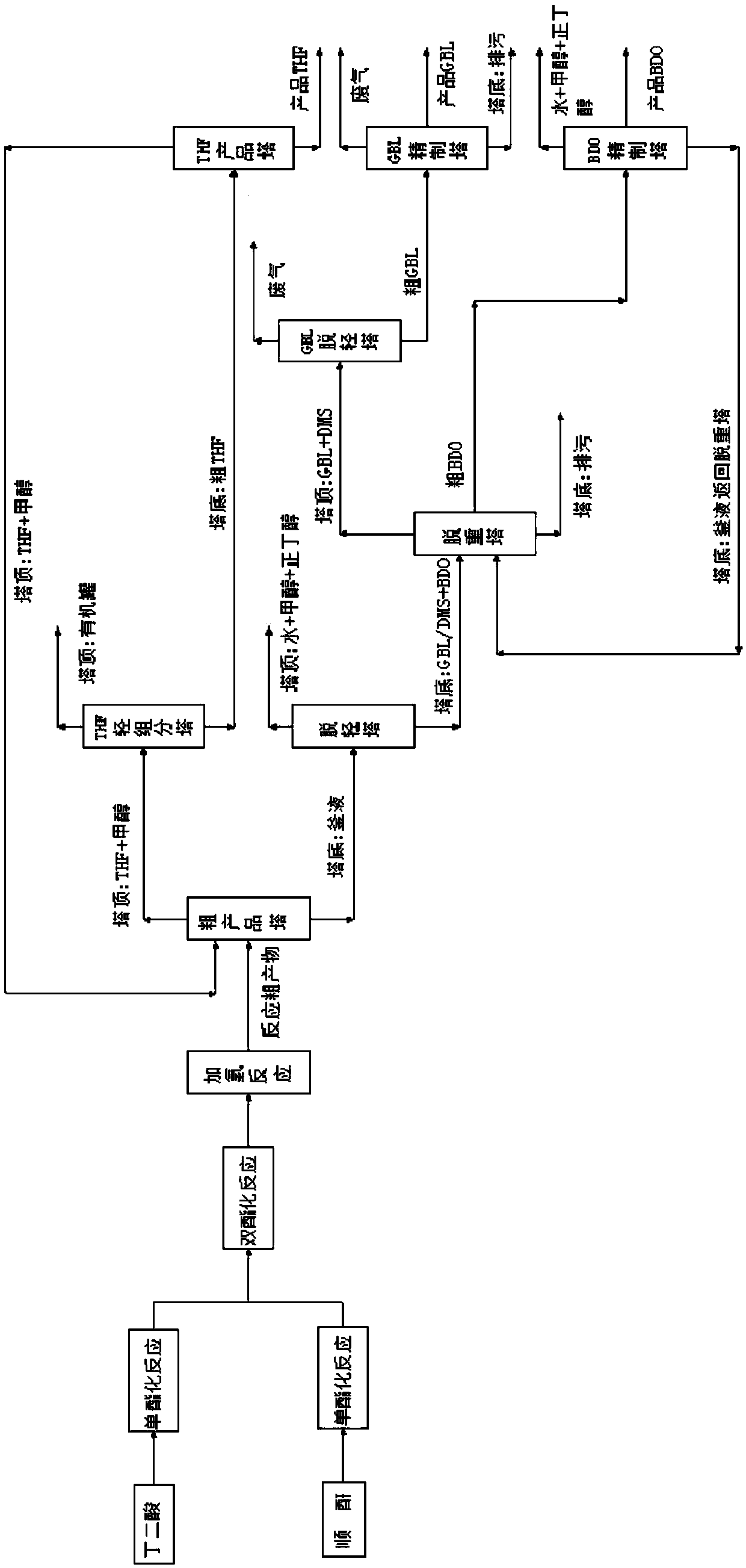

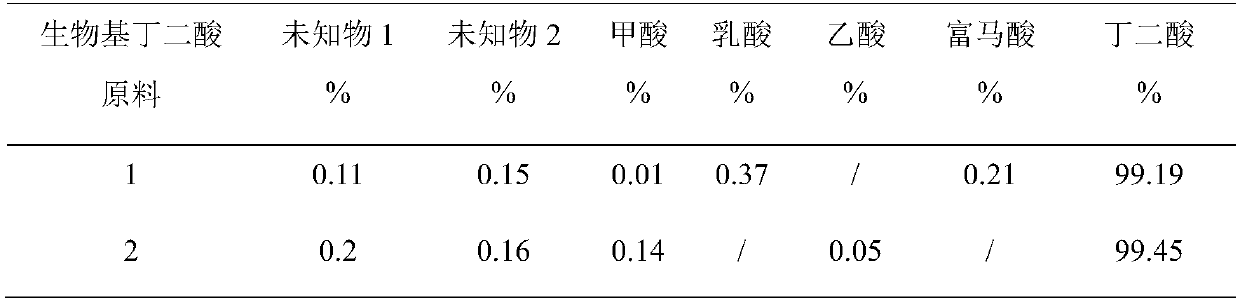

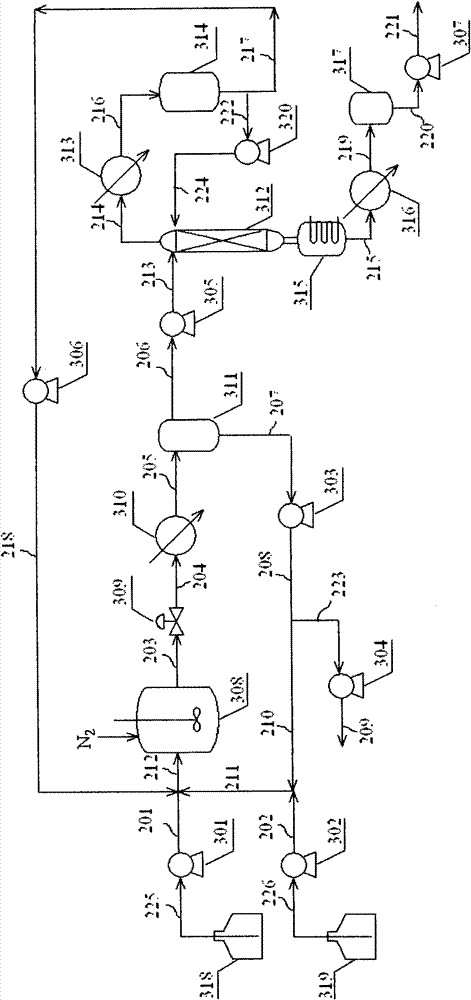

Continuous preparation method of 1,4-butanediol

ActiveCN111018669AAvoid mutual influence of co-monoesterificationAvoid interactionOrganic compound preparationCarboxylic acid esters preparationSuccinic acid monomethyl esterButanedioic acid

The invention discloses a continuous preparation method of 1,4-butanediol. The method comprises the following steps: carrying out a monoesterification reaction on bio-based succinic acid and methanolto obtain a succinic acid monoesterification liquid containing succinic acid monomethyl ester; mixing with monomethyl maleate to obtain a mixed esterification liquid; feeding into a double esterification reaction tower, and carrying out a double esterification reaction to generate a mixture of dimethyl succinate and dimethyl maleate; feeding the mixture into a hydrogenation reactor, and carrying out a hydrogenation reaction, wherein the the dimethyl maleate in the mixture is hydrogenated to generate dimethyl succinate; and performing a cascade reaction to convert into an intermediate product gamma-butyrolactone, and then generating 1,4-butanediol and tetrahydrofuran. According to the method, the bio-based succinic acid is adopted to partially replace monomethyl maleate to produce 1,4-butanediol, so that the consumption of petroleum chemicals is reduced, and the production cost of 1, 4-butanediol is reduced; and bio-based succinic acid and methanol are subjected to a monoesterificationreaction, and then mixing is performed with monomethyl maleate, so that the mutual influence caused by co-monoesterification of succinic acid and maleic anhydride is avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

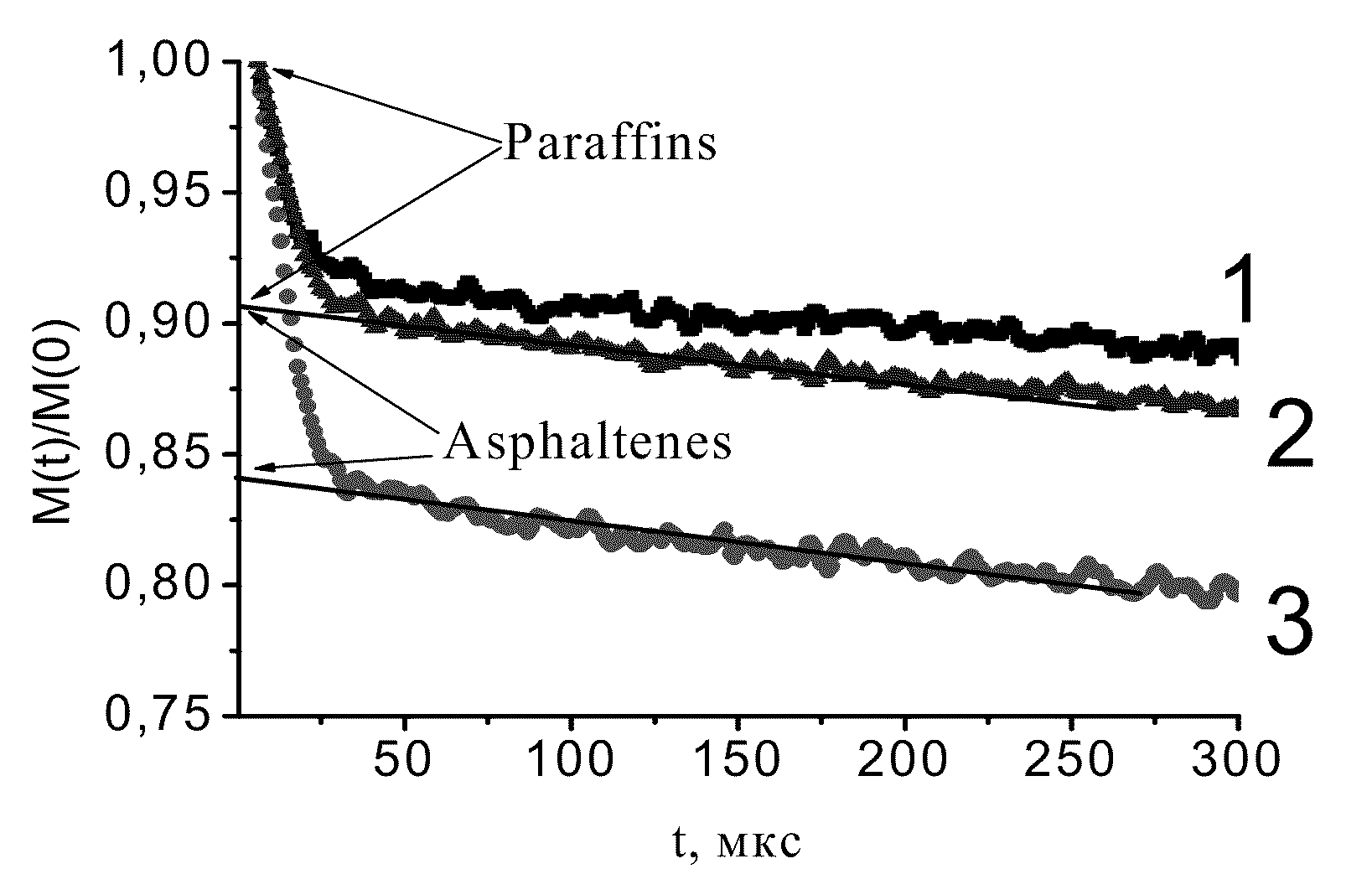

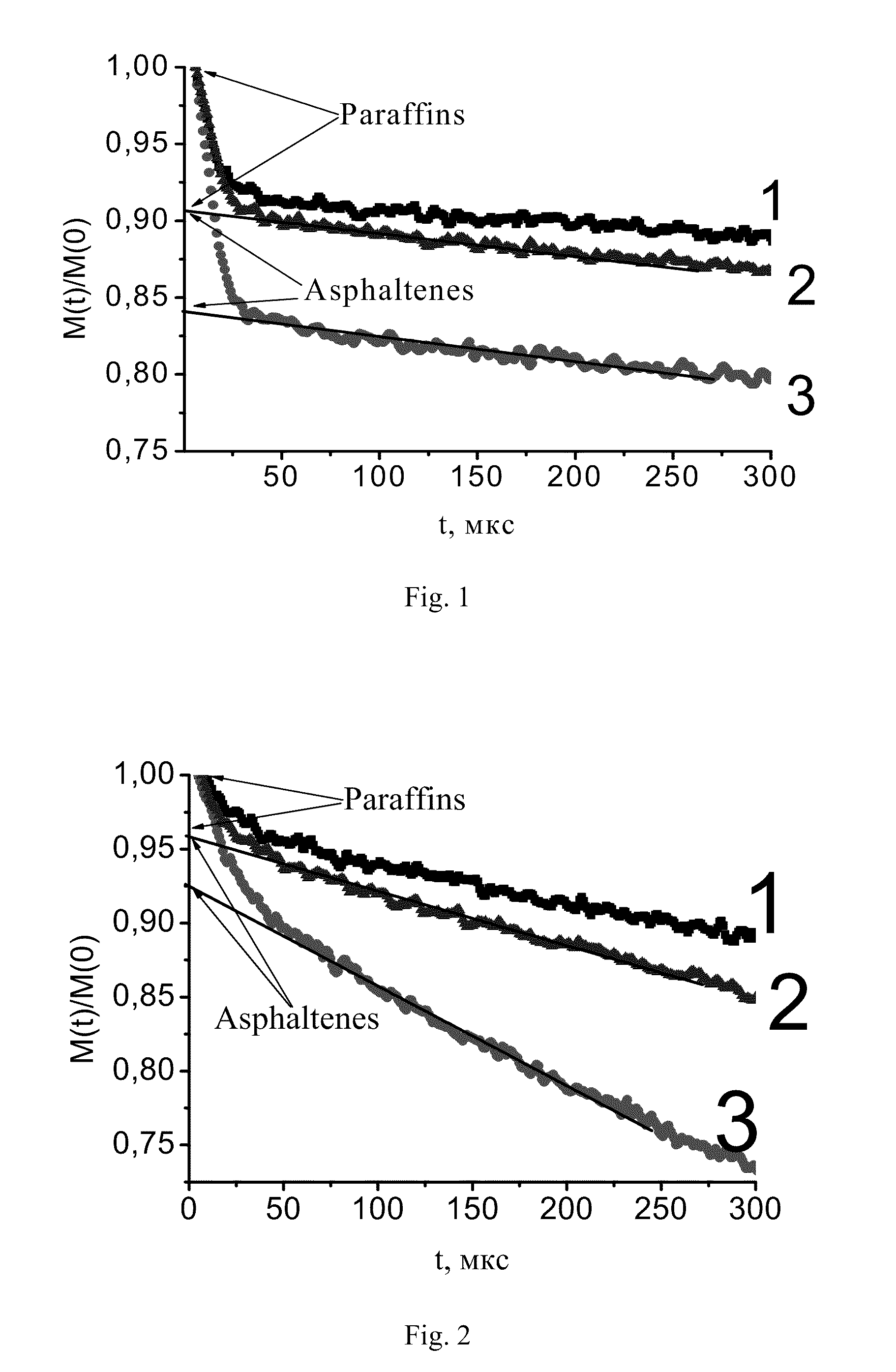

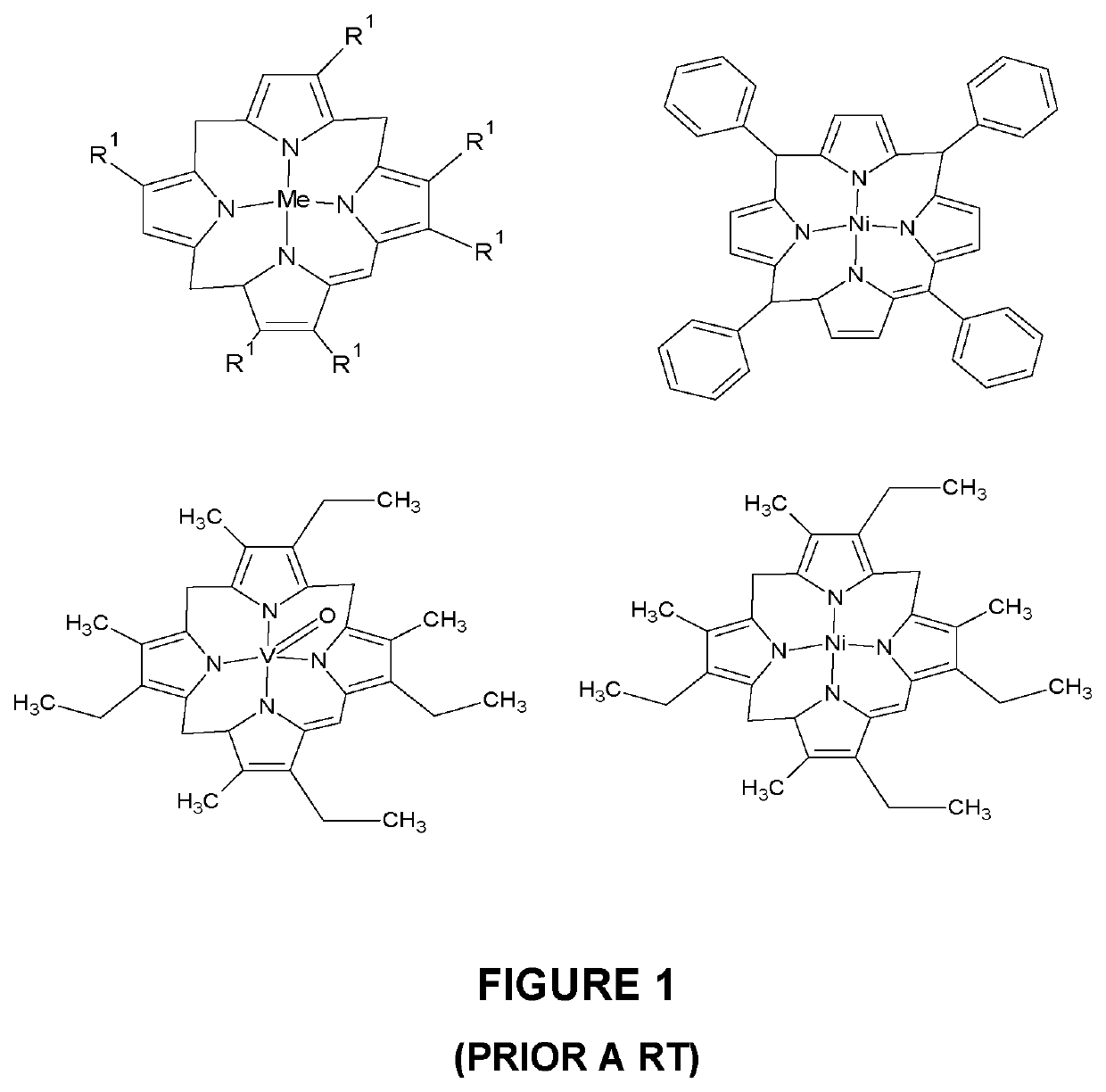

Method for detecting paraffin wax and asphaltene content in oil

InactiveUS20100085047A1Measurements using NMR imaging systemsAnalysis using nuclear magnetic resonanceParaffin waxAlkane

This invention relates to geology, geochemistry, oil refinery and petroleum chemistry and can be implemented for determination of paraffin and asphaltene concentration in oil, in particular, for analysis of heavy oils and bitumens. To determine concentration of paraffins and asphaltenes in oil, three crude oil samples are extracted; two extracted samples are dissolved in a solvent and the solvent alongside with light oil fractions is then removed; meanwhile, asphaltenes are removed from one of the solvent-treated samples. A nucleic magnetic resonance method is employed for measuring free inductance drop-down curves for all three samples; thereafter, a ratio of solid hydrogen-containing fractions suspended in oil, to liquid hydrogen-containing fractions is defined. The paraffin concentration is judged by the content of solid hydrogen-containing fractions in the solvent-treated sample, from which asphaltenes have been removed. The asphaltene concentration is judged by the content of solid hydrogen-containing fractions in the other solvent-treated sample, with the consideration of the defined concentration of paraffins. The concentration of paraffins and asphaltenes in original oil is determined based on the defined paraffin-to-asphaltene ratio in solid hydrogen-containing fractions.

Owner:SCHLUMBERGER TECH CORP

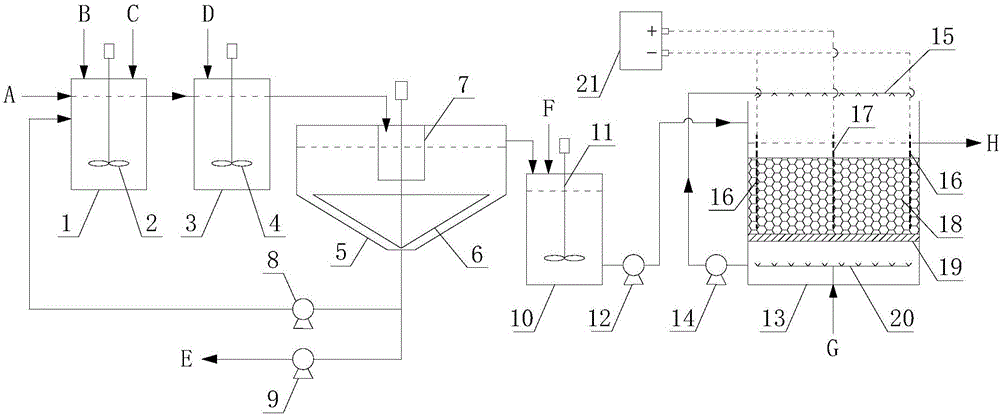

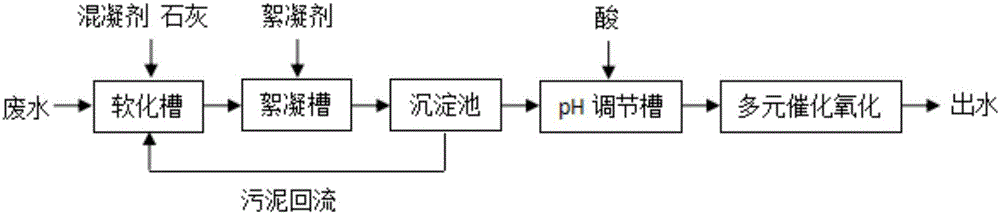

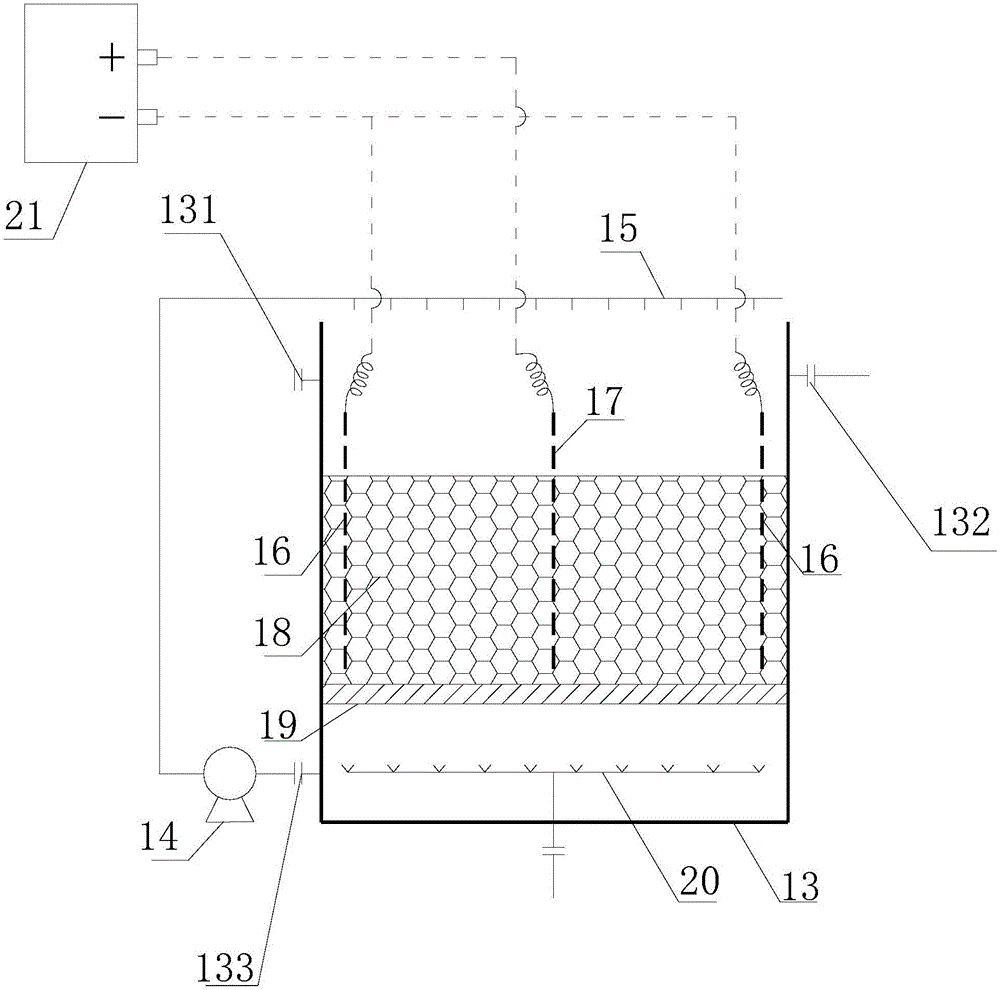

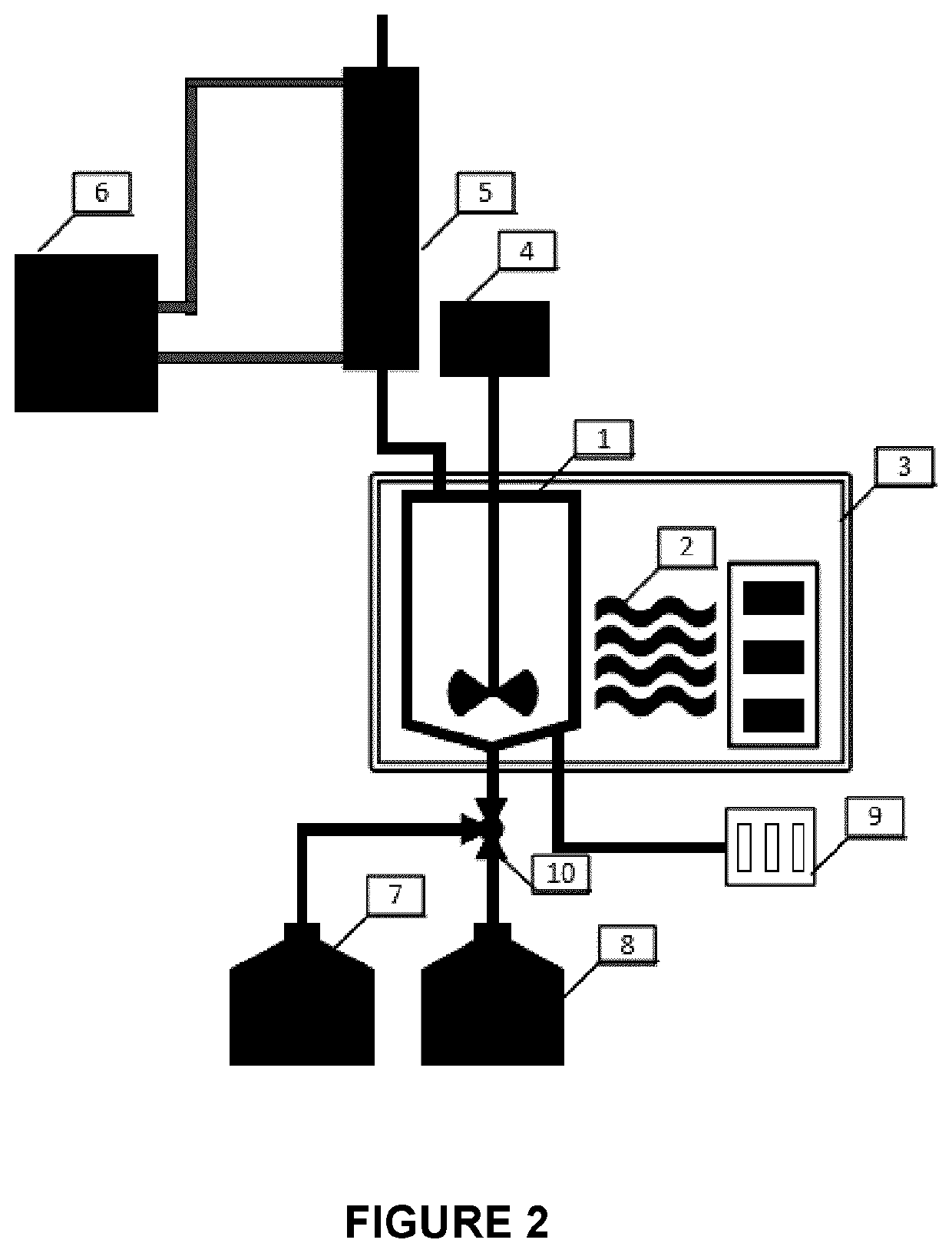

Treatment system for organic matters in petrochemical sewage reverse osmosis concentrated water and treatment method thereof

PendingCN106630314AMild reaction conditionsGood removal effectWater contaminantsWater/sewage treatment by magnetic/electric fieldsChemical oxygen demandSludge

The invention provides a treatment system for organic matters in petrochemical sewage reverse osmosis concentrated water and a treatment method thereof. The system comprises a softening tank, a flocculating tank, a settling pond, a pH regulation tank and a multi-element catalytic oxidation device which are sequentially communicated, wherein the settling pond is communicated with the softening tank through a sludge return pump, and a softening tank stirrer and a flocculating tank stirrer are respectively arranged in the softening tank and the flocculating tank. The method comprises the following steps: sequentially softening, flocculating and settling the petrochemical sewage reverse osmosis concentrated water; inputting the water into the pH regulation tank, and regulating the pH value to 4-5; inputting the water into the multi-element catalytic oxidation device through a multi-element catalytic oxidation water inlet pump, and performing multi-element catalytic oxidation treatment; and discharging the water after reaching the standard. The actual treatment effect proves that when the petrochemical sewage reverse osmosis concentrated water is treated by the multi-element catalytic oxidation device, the COD (chemical oxygen demand) in the reverse osmosis concentrated water can be reduced from 76-116mg / L to 31-42 mg / L, and the requirements of Emission Standard of Pollutants for Petroleum Chemistry Industry (GB 31571-2015) are met.

Owner:上海东振环保工程技术有限公司

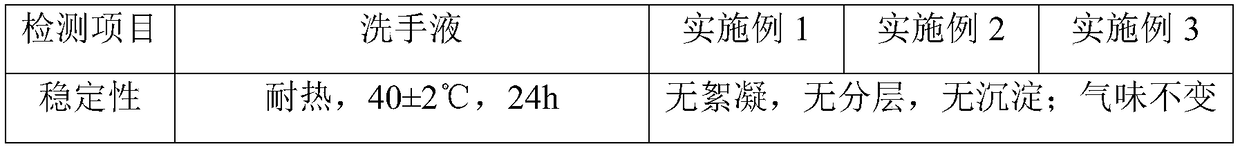

Dull polish type hand cleaner used for industrial heavy oil stain removing, and preparation method thereof

ActiveCN109288727ANo irritation and allergiesGood heat and cold resistanceCosmetic preparationsToilet preparationsSodium metasilicateBetaine

The invention relates to a dull polish type hand cleaner used for industrial heavy oil stain removing, and a preparation method thereof. The dull polish type hand cleaner comprises fatty alcohol polyoxyethylene ether, sodium lauryl diphenyl ether disulfonate, iso-tridecanol polyoxyethylene ether, sodium disec-octyl sulfosuccinate, cocoamidopropyl betaine, anionic polyacrylamide, dull polish particle, sodium metasilicate, a chelating agent, ethanol, an aseptic, and the balance a thickening agent, a pH conditioning agent, and water. The dull polish type hand cleaner is stable in properties, mildin effect, and high in heavy stain removing efficiency; after hand washing, no grease stain is left, and washing is convenient; after washing with the hand cleaner, no skin dry or stretching feelingis caused, no adverse reaction such as irritation or allergy is caused, the hand washing effect is excellent, and the dull polish type hand cleaner is suitable to be used for removing heavy oil stainson the hands of workers in industry such as machine maintenance, vehicle repairing, oil extraction, printing ink, printing, petroleum chemistry, and machining.

Owner:巩义市宏盛稀有金属有限公司

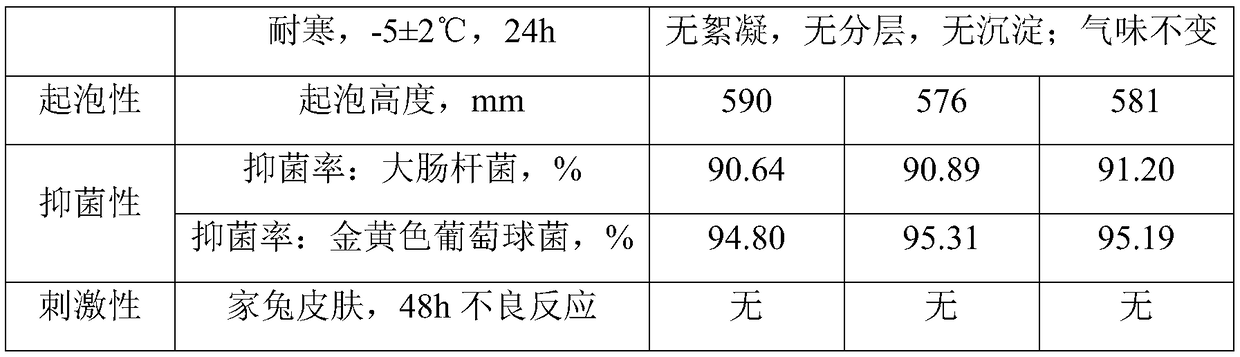

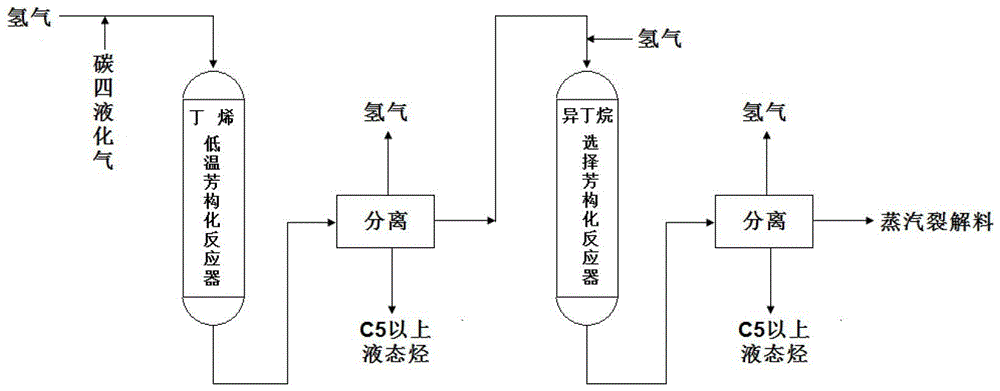

Two-stage reaction process of hydro-aromatization of C4 liquefied gas

ActiveCN103834435ALow reaction temperatureReduce yieldLiquid hydrocarbon mixtures productionTreatment with hydrotreatment processesButeneAromatization

The invention belongs to the field of petroleum chemistry, and relates to a two-stage reaction process of hydro-aromatization of C4 liquefied gas in a fixed bed reactor. The reaction process is mainly formed by a butene low-temperature aromatization reactor and an iso-butane selective aromatization reactor, so that the C4 liquefied gas can be processed into gasoline fraction with high octane value and a steam cracking material. The operation flexibility can be improved due to two-stage reactors, the quality of the gasoline product with high octane value and the steam cracking material can be guaranteed, and dry gas, coke and other side products can be reduced; the two reactors are under a hydrogenating condition, so that the one-way operation cycle and total service life of the catalyst can be prolonged.

Owner:PETROCHINA CO LTD +1

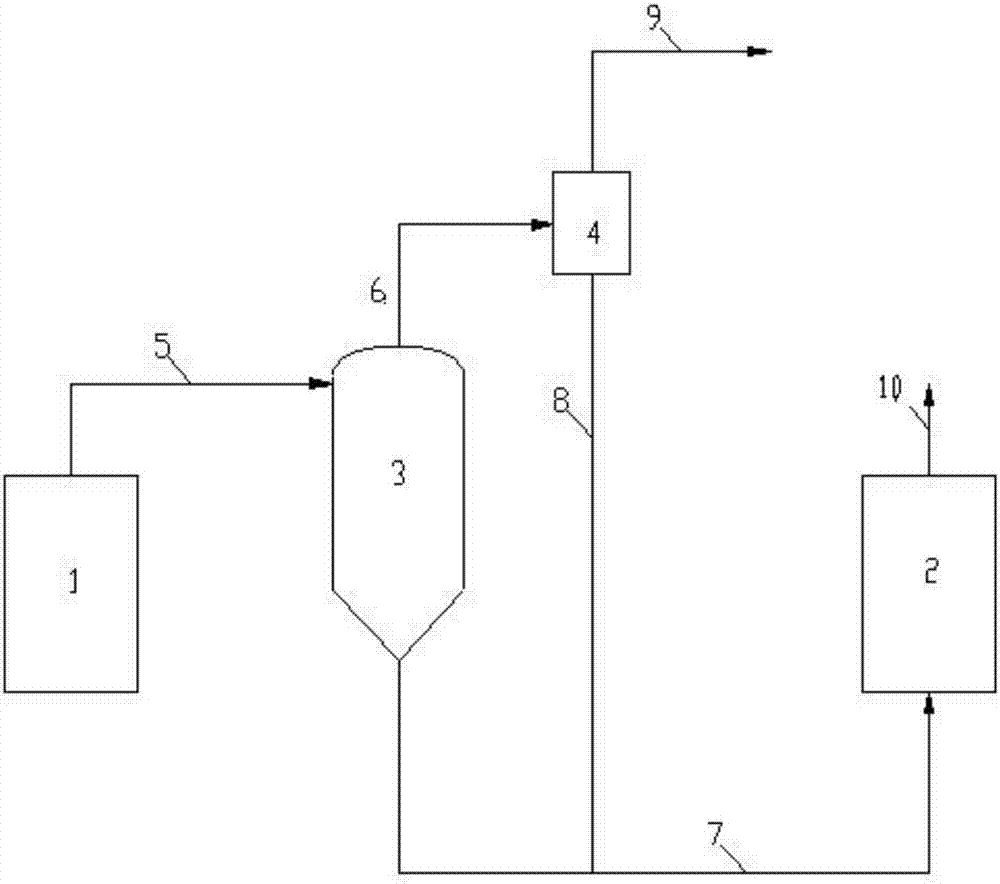

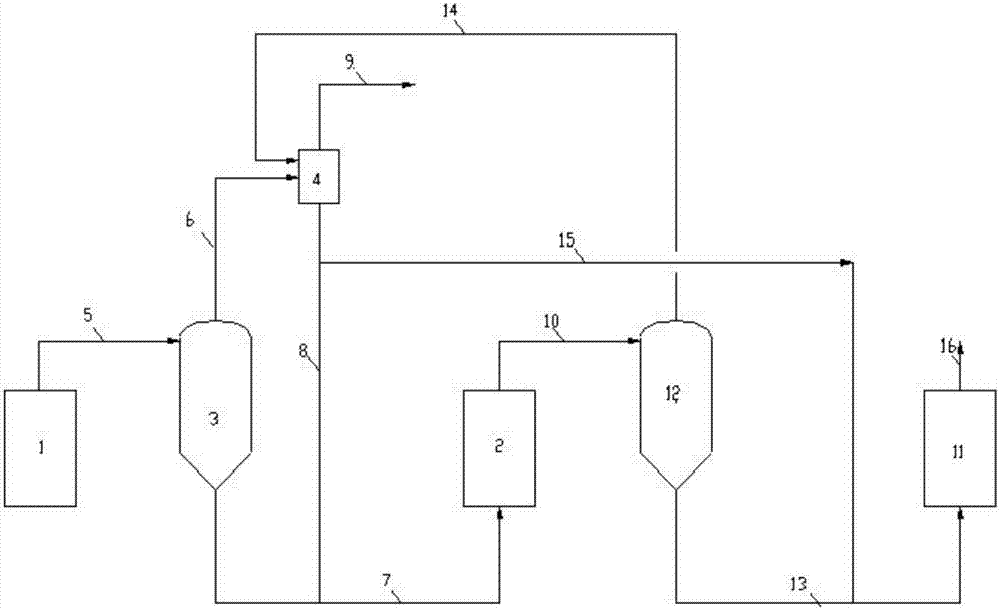

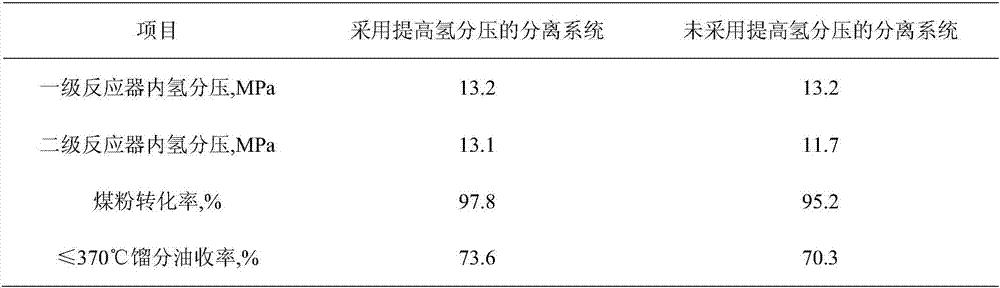

Method for increasing partial hydrogen pressure of hydrogenation reaction system, and design method and application thereof

InactiveCN106957681AImprove conversion rateHigh yieldTreatment with hydrotreatment processesGas phaseHydrogen pressure

The invention provides a method for increasing the partial hydrogen pressure of a hydrogenation reaction system, and a design method and an application thereof, which are used for increasing the partial hydrogen pressure of the hydrogenation reaction system and belong to the fields of petroleum chemistry and coal chemistry. The hydrogenation reaction system comprises at least two reactors. The method comprises the following steps that materials discharged from the former-stage reactor firstly enter a separating system for increasing the partial hydrogen pressure to conduct separation, then non-hydrogen components obtained are separated and discharged, and hydrogen components and liquid-solid phases enter the next-stage reactor. The materials from an outlet of the former-stage reactor are effectively separated by the separating system, the liquid-solid phase enters the next-stage reactor, and the gas phase is separated again, so that after the concentration of the hydrogen in the gas phase is increased, and the hydrogen enters the next-stage reactor. The method provided by the invention has the advantages that the partial hydrogen pressure of the next-stage reactor can be increased, the reaction depth can be effectively increased, the material conversion ratio and the light-oil yield can be increased, the space speed of the next-stage reactor also can be increased and the energy consumption can be reduced.

Owner:CATECH TECH

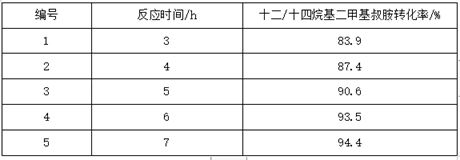

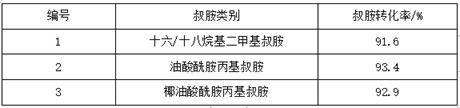

Synthesis method of alkyl block polyether quaternary ammonium salt surfactant

ActiveCN113980260AEnhanced overall recoveryCorrosion resistanceDrilling compositionActive agentEthyl group

The invention discloses a synthesis method of an alkyl block polyether quaternary ammonium salt surfactant, and mainly belongs to the field of petroleum chemistry. The synthesis method comprises the following steps of: making alkyl block polyether react with alkali to obtain alkyl block polyether sodium salt or alkyl block polyether potassium salt; adding 1, 2-dichloroethane, and reacting for 4-5 hours to obtain chloroethyl alkyl block polyether; and recovering the unreacted 1, 2-dichloroethane, adding tertiary amine of which the molar weight is 1-1.2 times of the molar weight of the alkyl block polyether, adding a NaOH aqueous solution when the conversion rate of the tertiary amine reaches 70-75%, raising the reaction temperature to 100 DEG C, and continuously reacting for 6-7 hours. The product obtained by the method of the invention has the advantages of strong compounding capacity, good emulsifying property, temperature resistance, salt resistance and corrosion resistance.

Owner:SHANDONG DAMING FINE CHEM CO LTD

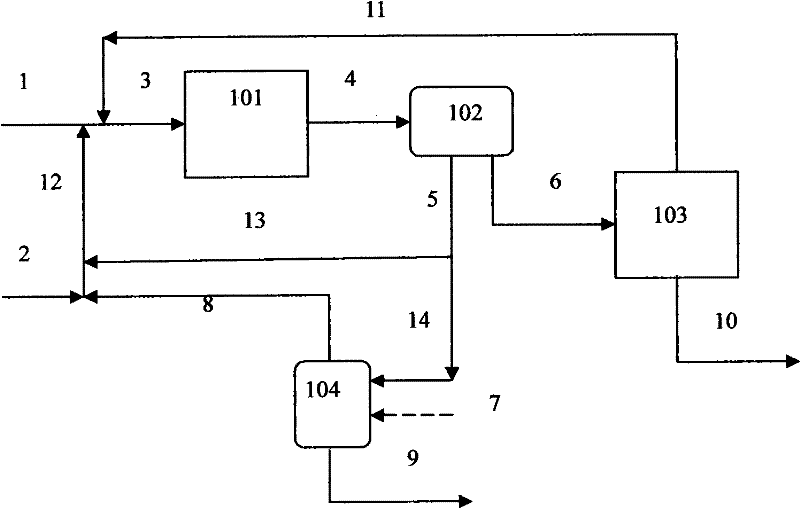

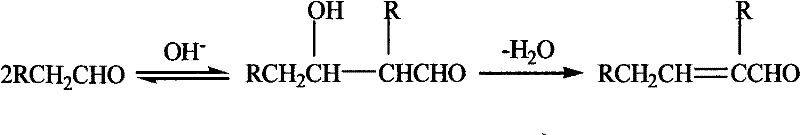

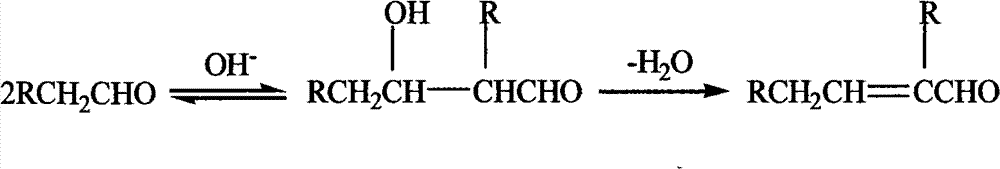

Preparation method of unsaturated aldehyde by aldehyde condensation

ActiveCN102442892AReduce the possibilityReduce the burden onOrganic compound preparationCarbonyl compound preparationChromatographic separationDistillation

The invention relates to a preparation process of an unsaturated aldehyde in the field of petroleum chemistry, and in particular relates to a preparation method of the unsaturated aldehyde by aldehyde condensation. The method comprises the following steps: performing chromatographic separation after a reaction mixed substance leaves a reaction region; separating the water phase containing a catalyst from an organic phase; and distilling and separating the organic phase in a distillation region so as to reduce the possibility that the mixed substance circularly undergoes a side reaction, namely cannizzaro reaction, in the process and lighten the load of the distillation region. According to the preparation method of the unsaturated aldehyde by aldehyde condensation, the water phase containing the catalyst is separated from the organic phase, so that the possibility that the mixed substance circularly undergoes the side reaction, namely cannizzaro reaction, is reduced, the reaction mixed substance is subjected to chromatographic separation before entering the distillation region, and only the organic phase is fed into the distillation region for distillation and separation, so that the load of the distillation region is lightened.

Owner:CHINA PETROLEUM & CHEM CORP +1

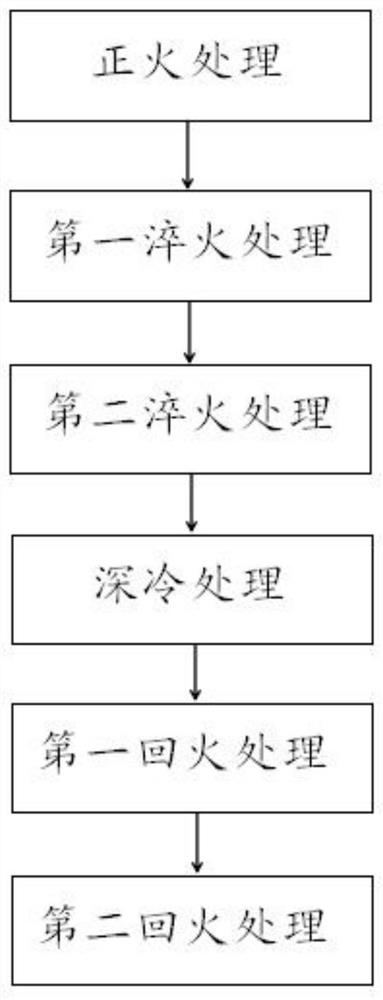

A heat treatment method for ultra-low temperature high-strength steel for compressors

Owner:SHENYANG TURBO MASCH CORP

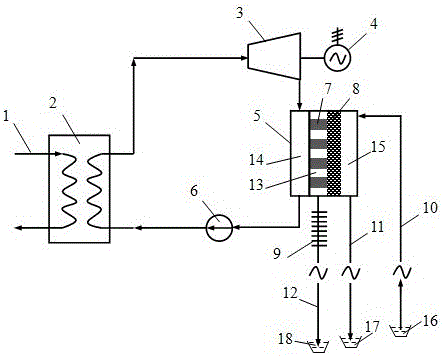

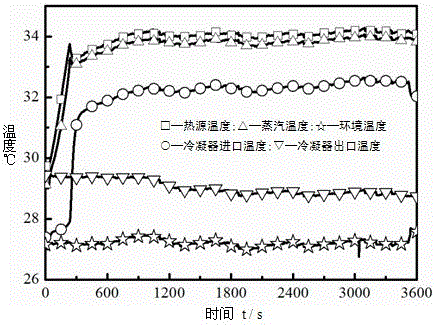

A cogeneration system of waste heat, electricity and water

InactiveCN104445481BWatered down realizationImprove the problem of low thermal efficiencyGeneral water supply conservationSeawater treatmentSuction forceEngineering

The invention discloses a waste heat electricity-water coproduction system. The water heat electricity-water coproduction system comprises a low-temperature Rankine cycle power generation system and a steam exhaust seawater desalting system. An energy staircase-type utilization system for generating the electric power by utilizing the primary waste heat and desalting the seawater by utilizing the secondary waste heat can be realized by utilizing a great amount of exhaust steam and smoke discharged from enterprises such as iron and steel, cement and petroleum chemistry. The waste heat electricity-water coproduction system is characterized in that the low-temperature seawater desalting technology for establishing a vacuum environment by utilizing the water column height and sucking the seawater by utilizing the capillary force is combined with the low-temperature Rankine cycle power generation. In the seawater desalting system, the discharge of the concentrated salty water utilizes a siphon effect, and the seawater replenishment utilizes the capillary suction force, so that no additional pump power input is needed for operating the desalting system. According to the technical scheme, a seawater desalting evaporator is used for substituting the traditional Rankine circulating condenser, so that the Rankine circulation low-temperature exhaust steam is further recycled, not only is the electricity-water coproduction realized, but also the problem of the low heat efficiency in a waste heat power generation system can be solved, and energy conservation and emission reduction can be realized.

Owner:WUHAN UNIV

A three-phase self-generating foam water blocking agent

The invention discloses a three-phase self-foaming water-plugging agent, and belongs to the field of petroleum chemistry. The provided water-plugging agent comprises the following components: solid particles, a foaming agent, a foam stabilizing agent, a crosslinking agent, a delaying agent, and a gas producing agent. Compared with the prior art, the provided water-plugging agent has the advantages of high foam quality and good stability, the gel crosslinking and gas production can be achieved at the same time, the water-plugging agent can tolerate high temperature, has a strong residue blocking performance and a long water-plugging period, and can achieve efficient plugging and depth profile control. Moreover, the preparation technology of the provided water-plugging agent is simple, the injection cost is low, and the water-plugging agent is safe and reliable, thus has a good market prospect and high economic value, and is especially suitable for the development of high temperature heavy oil steam stimulation wells.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for recycling miscellaneous salt produced in industrial wastewater treatment

ActiveCN106745076BEasy to handleWide operating conditionsCalcium/strontium/barium carbonatesCalcium/strontium/barium sulfatesHigh concentrationSulfate radicals

Owner:DATANG INT CHEM TECH RESINST

Tetrafluoroethylene composite punched teeth steel sealing gasket and method for making same

This invention discloses a tetrafluoro complex sealed shim and its facture. In the shim is the tooth-rushing steel disk upward and downward alternatively. The colophony around is suppressed and sintered under the high temperature from 370 deg. C to 430 deg. C. This invention is suitable for all kinds of pressure container and pipe flange airproof, especially the industries such as the FI chemistry, medical chemistry, biological pharmacy, and petroleum chemistry under the mid-pressure 2.0MPa~10.0MPa, the temperature of minus 196 deg. C~250 deg. C, and has good effect of airproof.

Owner:ZHEJIANG UNIV

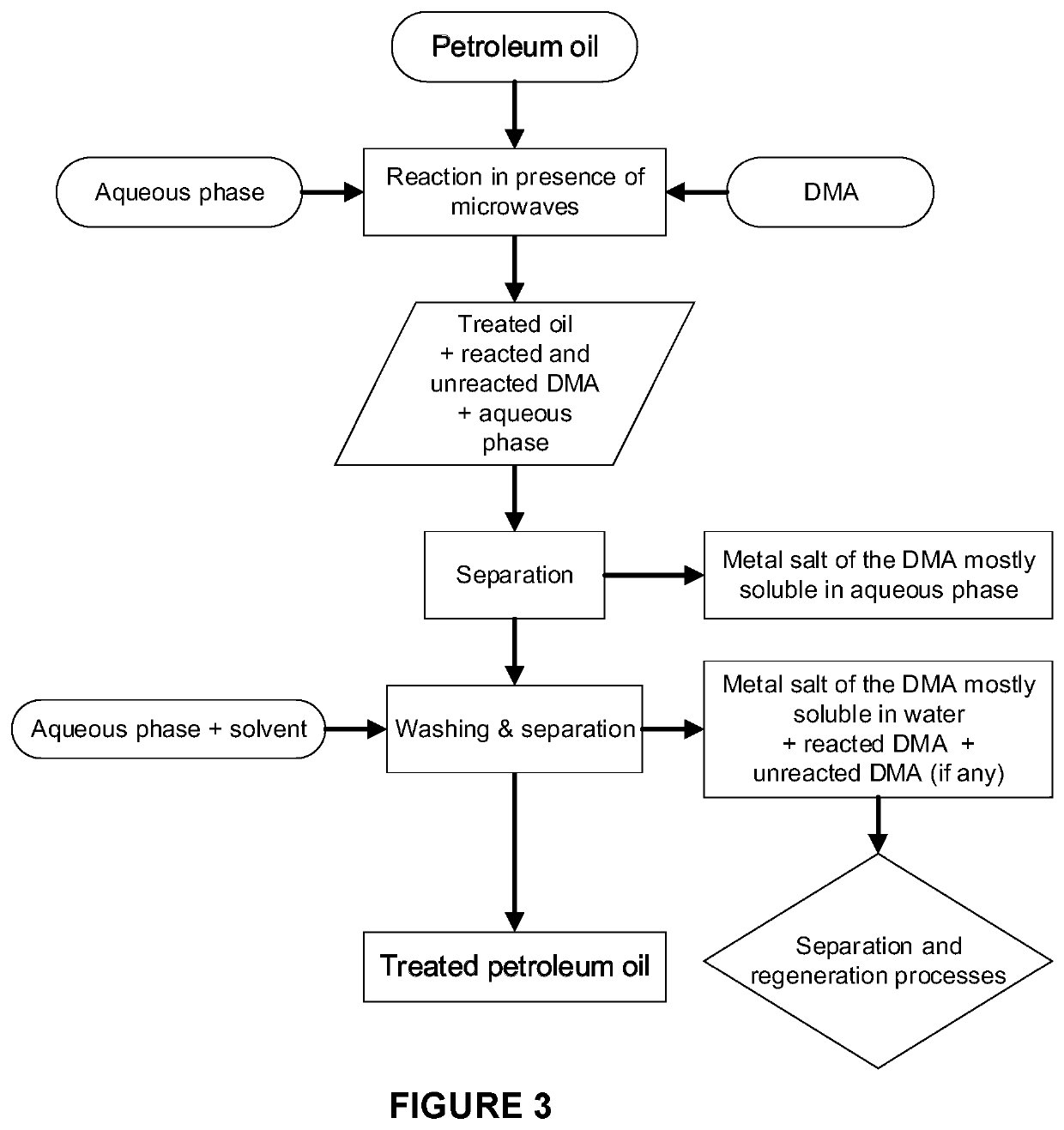

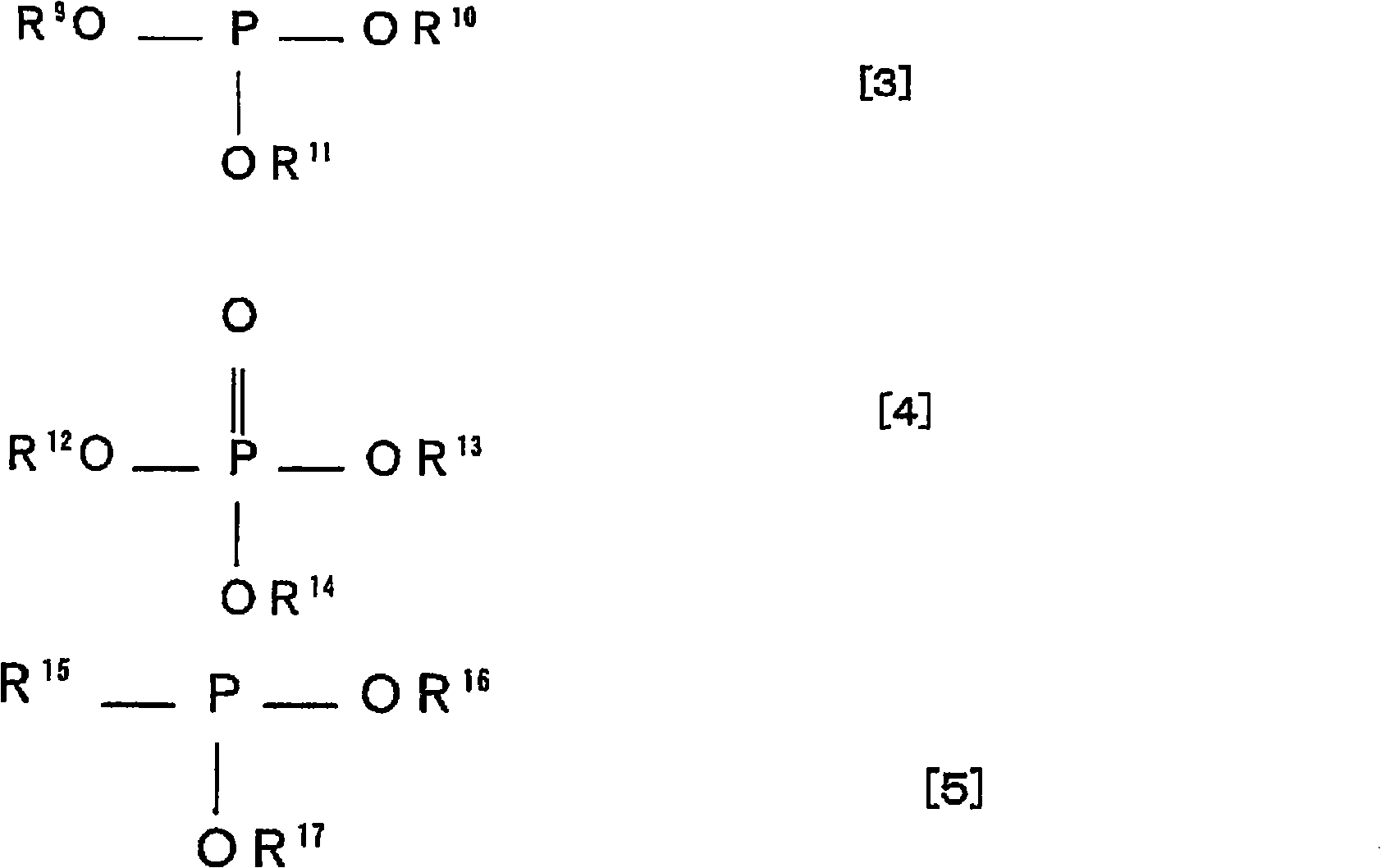

Process for removing metals in petroleum oil using an organophosphorus compound and microwaves

ActiveUS20220033715A1Readily scaledEasy to integrateTreatment with plural serial refining stagesRefining with acid-containing liquidsPhosphoric Acid EstersOrganophosphorous compounds

A process for removing metals in a petroleum oil material. The process comprises causing the petroleum oil material to react with a removing agent which comprises a phosphoric acid ester. A microwave irradiation environment was created during the reaction to provide the required energy essential for separating such contaminations from the oil chemical network. The process of the invention is applied at ambient pressure and low temperature compared to the conventional metal removal processes. The process of the invention can be readily scaled up and integrated into an industrial facility.

Owner:GREENOVEL INC

Treating method of high-salt waste water

InactiveCN107445378ASave energyEasy to handleSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisUltrafiltrationSalt-wasting

The invention discloses a treating method of high-salt waste water. The treating method comprises the following steps that: (1) alkali liquor is added into the high-salt waste water, stirred uniformly and then keeps standing; and the solution after standing is filtered by an ultrafiltration membrane; (2) the solution after filtering is heated and then pumped into an organic-silicon membrane component by a pump, and after separation of the organic-silicon membrane component, concentrated water solution and pure-water solution are obtained;and (3) the concentrated water solution entering an evaporation device is primarily evaporated, evaporated steam flows back into the evaporation device by a condensing device to carry out secondary evaporation, and is condensed after secondary evaporation to obtain waste water reaching the emission standard. The treating method disclosed by the invention has the advantages that the alkali liquor is added for pretreatment, the organic-silicon membrane is adopted for concentration, one part of waste water can be discharged directly, and another part of waste water is secondarily evaporated and then discharged, so that the energy is saved, the treating effect is good and the treating method is suitable for treating the high-salt waste water in the industries of petroleum chemistry, pharmacy and food.

Owner:苏州赛比膜分离科技有限公司

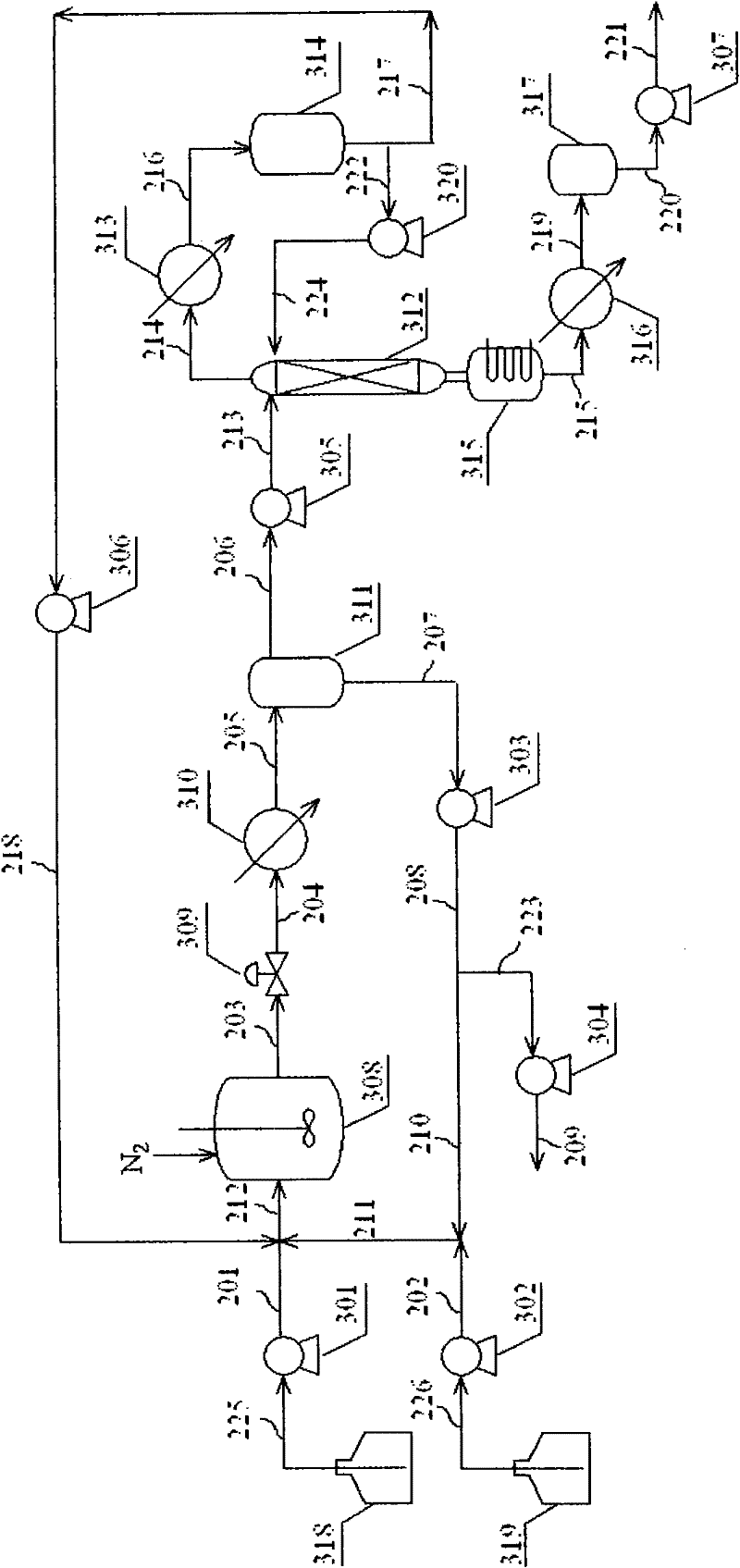

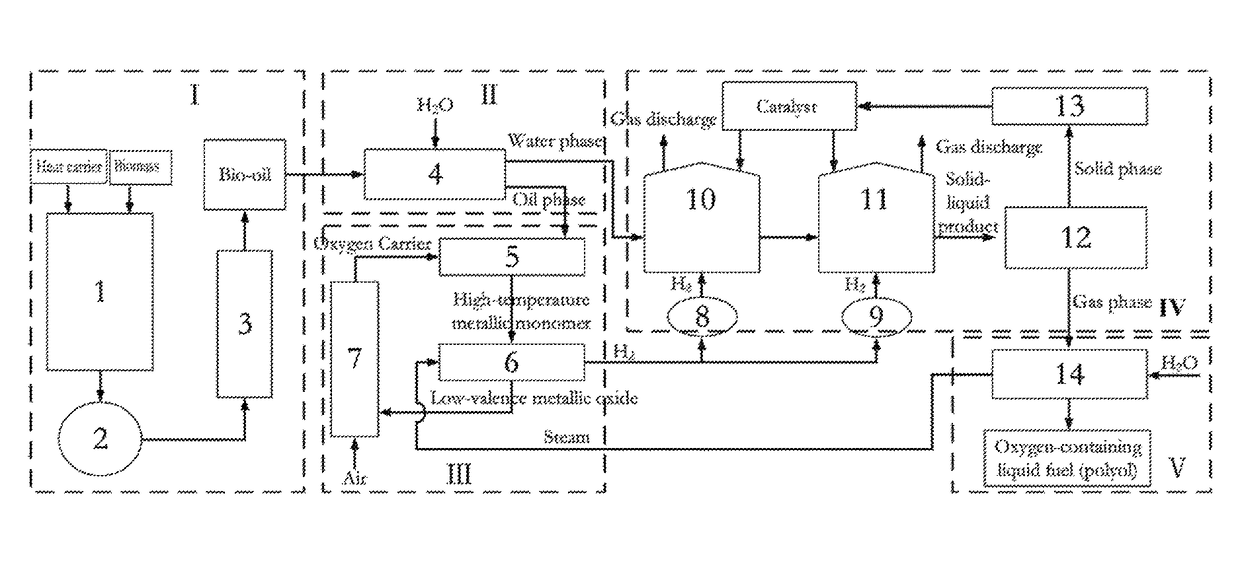

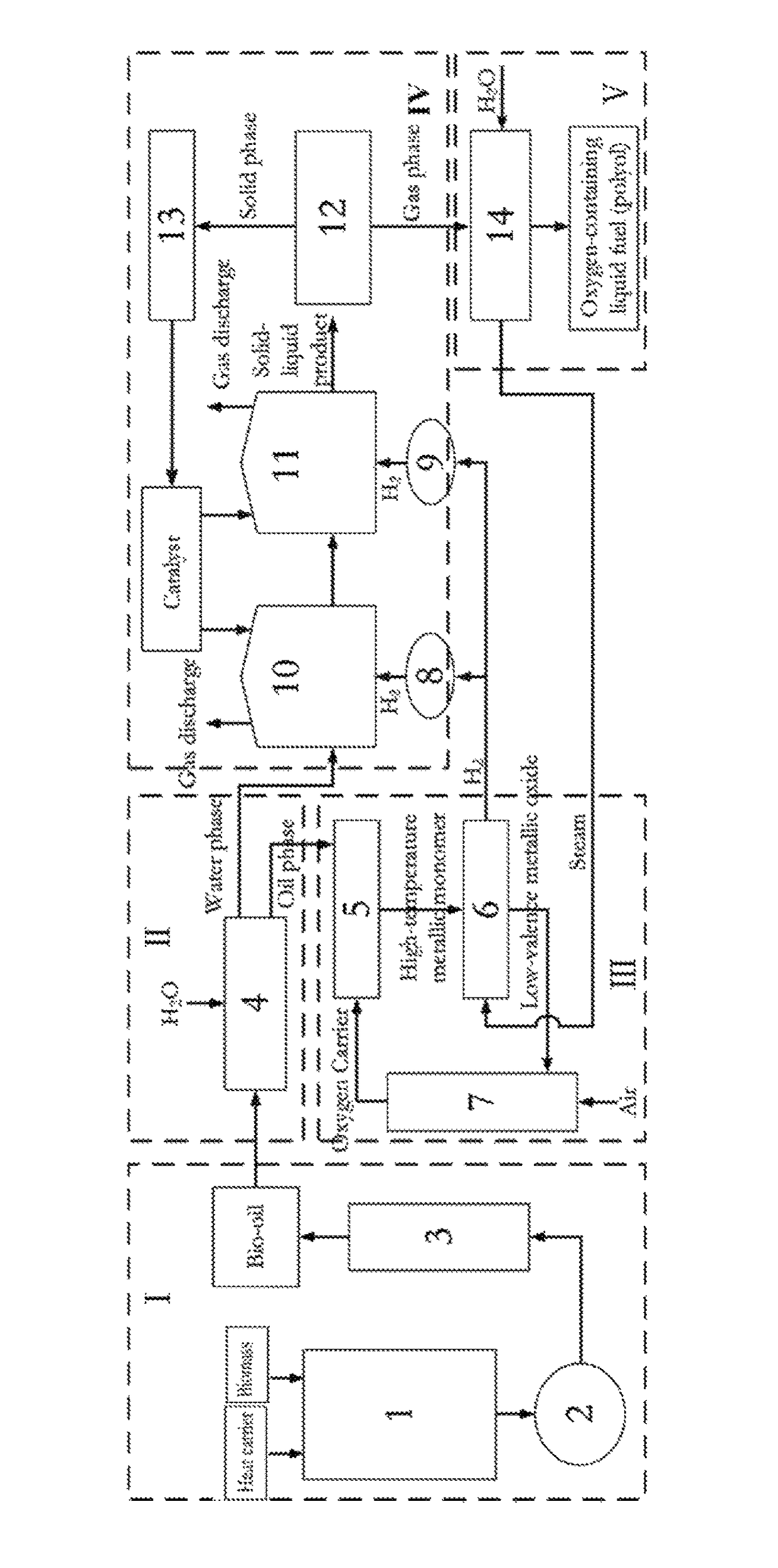

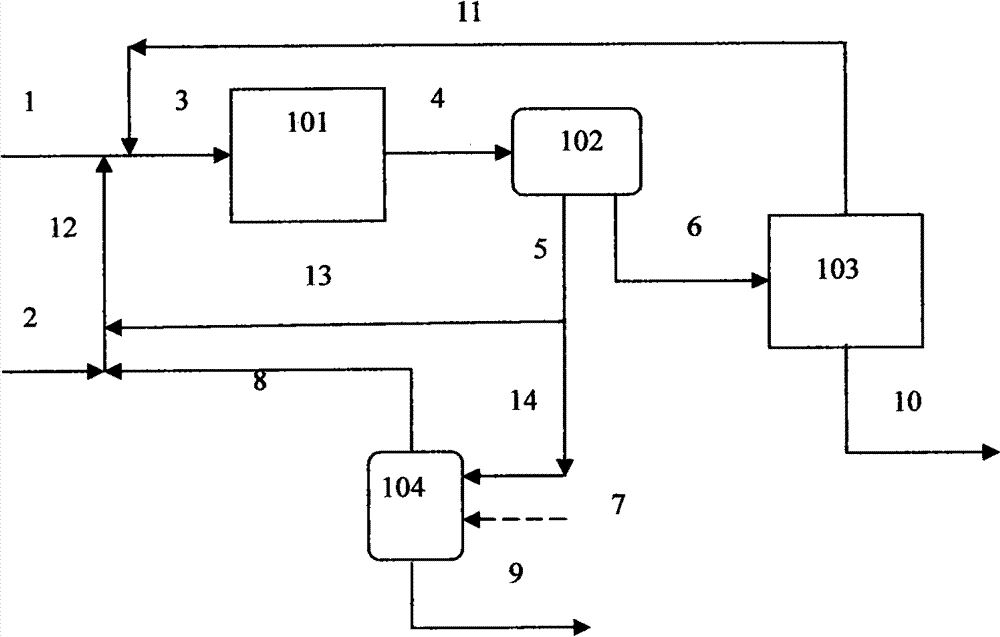

Device and method for preparing oxygen-containing liquid fuel by bio-oil catalytic conversion

ActiveUS9725653B2Easy to condenseReduce processing costsProductsReagentsCatalytic transformationLiquid fuel

Devices and methods for preparing oxygen-containing liquid fuel by bio-oil catalytic conversion. A device includes a biomass fast thermal cracking system for preparing bio-oil, a bio-oil oil-water separating system for separating the bio-oil into oil phase bio-oil and water phase bio-oil that is output to an oil phase bio-oil chemical chain hydrogen production system, and a water phase bio-oil catalytic hydrogenation system. The hydrogen production system outputs produced hydrogen to the water phase bio-oil catalytic hydrogenation system to prepare a liquid fuel. A method includes the steps: thermally cracking the biomass to prepare bio-oil, separating the water phase and the oil phase, producing hydrogen from the oil phase bio-oil through a chemical chain method so as to provide a hydrogen source for the water phase bio-oil to carry out two-stage catalytic hydrogenation in a slurry bed, and separating and purifying the hydrogenated products to obtain an oxygen-containing liquid fuel.

Owner:SOUTHEAST UNIV

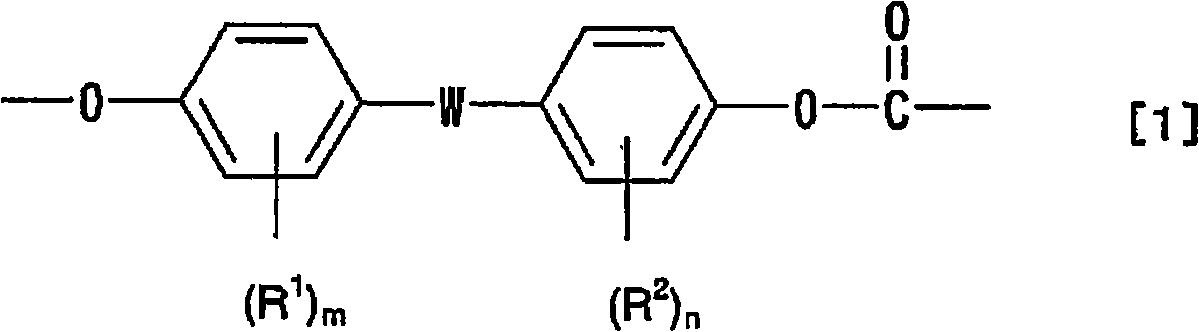

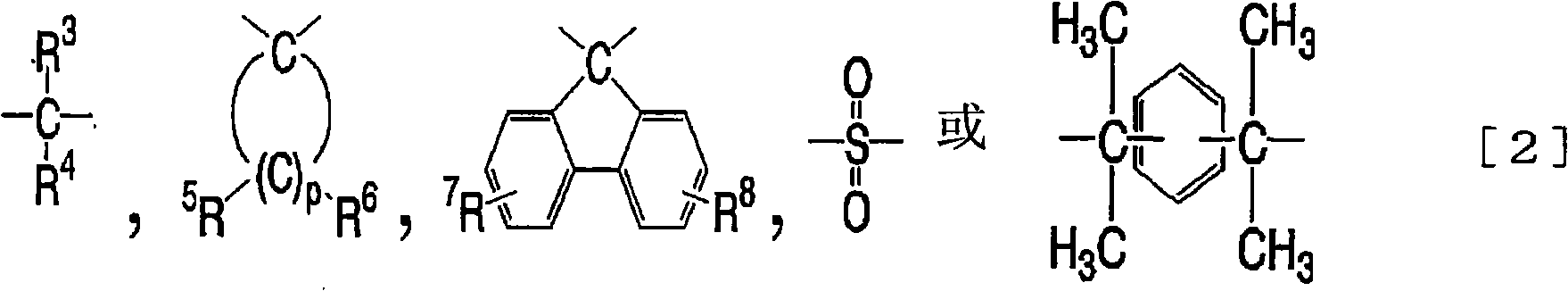

Polycarbonate resin combination

InactiveCN101284935AHigh transparencyImprove heat resistanceOptical record carriersRecord information storagePolycarbonateResin composite

The purpose of the invention is providing a polycarbonate resin composite. The transparence, high thermal stability and anti-hydroscopicity of the resin composite are great; the resin composite is the new oil chemical resin with low environment load and reproducible resource. The polycarbonate resin composite contains poly butane diacid acid poly butanediol ester with 1-3 weight% relative to the polycarbonate resin with 100 weight parts.

Owner:TEIJIN KASEK KK

A two-stage reaction process for hydrogen aromatization of C4 liquefied petroleum gas

ActiveCN103834435BLow reaction temperatureReduce yieldLiquid hydrocarbon mixtures productionTreatment with hydrotreatment processesButeneHydrogen

Owner:PETROCHINA CO LTD +1

Prodn. of olefins

A process for cracking an olefin-rich hydrocarbon feedstock which is selective towards light olefins in the effluent, the process comprising contacting a hydrocarbon feedstock containing olefins having a first composition of one or more olefinic components with a crystalline silicate catalyst to produce an effluent having a second composition of one or more olefinic components, the feedstock and the effluent having substantially the same olefin content by weight therein as the feedstock.

Owner:FINA RES SA

Tetrafluoroethylene composite punched teeth steel sealing gasket and method for making same

This invention discloses a tetrafluoro complex sealed shim and its facture. In the shim is the tooth-rushing steel disk upward and downward alternatively. The colophony around is suppressed and sintered under the high temperature from 370 deg. C to 430 deg. C. This invention is suitable for all kinds of pressure container and pipe flange airproof, especially the industries such as the FI chemistry, medical chemistry, biological pharmacy, and petroleum chemistry under the mid-pressure 2.0MPa~10.0MPa, the temperature of minus 196 deg. C~250 deg. C, and has good effect of airproof.

Owner:ZHEJIANG UNIV

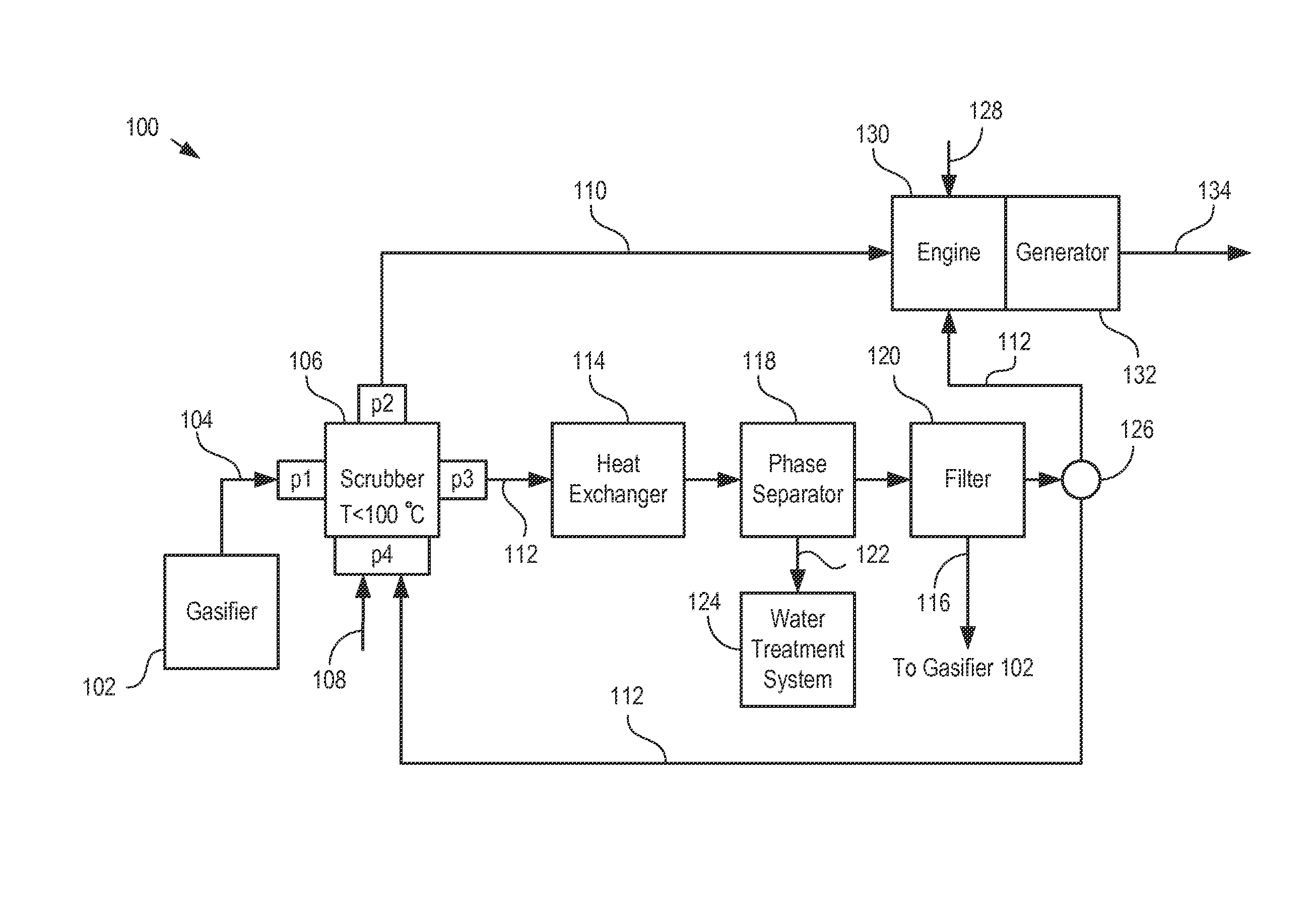

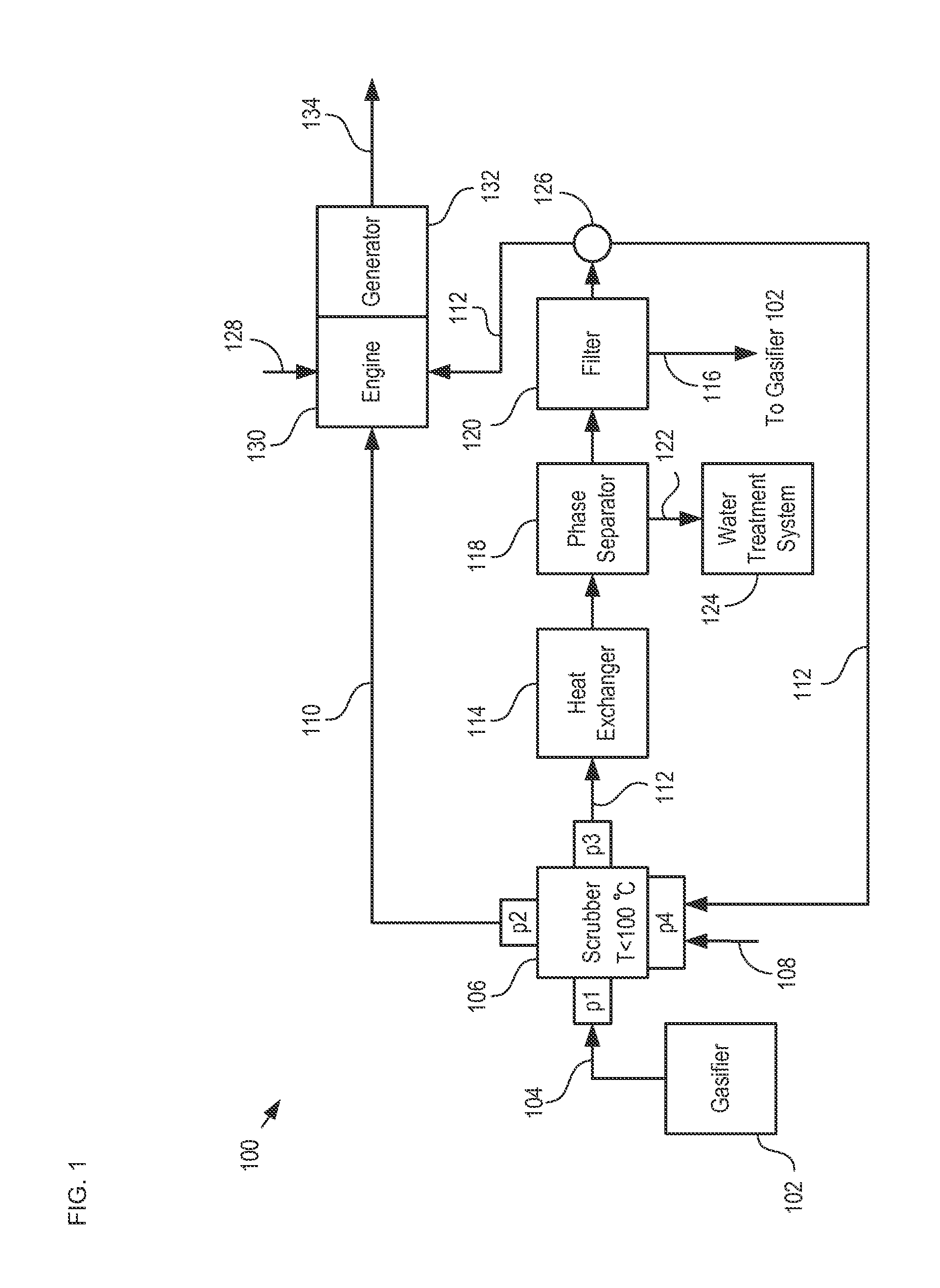

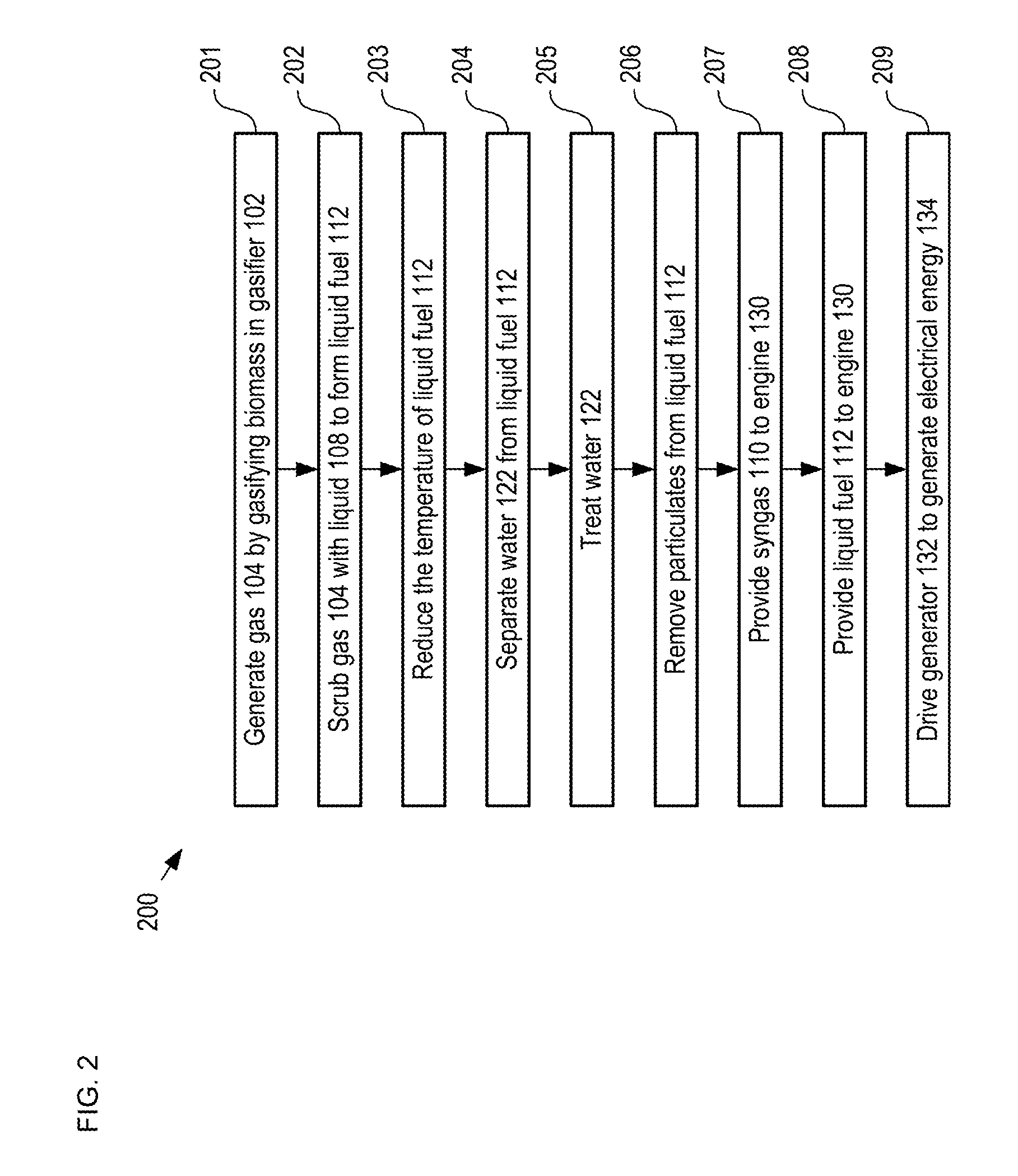

Tar scrubber for energy recovery from gasification operations

ActiveUS8783215B2Improve availabilityPromote generationChemical industryDispersed particle separationUpdraft gasifierGas phase

A method and apparatus for generating electrical energy from combustion of biomass is provided. The present invention provides both liquid-phase and gas-phase fuel to an internal combustion engine that is designed to run on both types of fuel. Scrubbing syngas generated in an updraft gasifier with a first petrochemical-based liquid fuel reduces the concentration of tars in the syngas stream and also enables absorption of tars from the syngas into the first liquid fuel. After absorption, the tars form a second liquid fuel that is suitable for direct use in the internal combustion engine. As a result, the syngas provided to the engine is substantially free of tars and the volume of liquid fuel available to the engine is increased.

Owner:LOCKHEED MARTIN CORP

Preparation method of unsaturated aldehyde by aldehyde condensation

ActiveCN102442892BReduce generationReduce lossesOrganic compound preparationCarbonyl compound preparationChromatographic separationDistillation

The invention relates to a preparation process of an unsaturated aldehyde in the field of petroleum chemistry, and in particular relates to a preparation method of the unsaturated aldehyde by aldehyde condensation. The method comprises the following steps: performing chromatographic separation after a reaction mixed substance leaves a reaction region; separating the water phase containing a catalyst from an organic phase; and distilling and separating the organic phase in a distillation region so as to reduce the possibility that the mixed substance circularly undergoes a side reaction, namely cannizzaro reaction, in the process and lighten the load of the distillation region. According to the preparation method of the unsaturated aldehyde by aldehyde condensation, the water phase containing the catalyst is separated from the organic phase, so that the possibility that the mixed substance circularly undergoes the side reaction, namely cannizzaro reaction, is reduced, the reaction mixed substance is subjected to chromatographic separation before entering the distillation region, and only the organic phase is fed into the distillation region for distillation and separation, so that the load of the distillation region is lightened.

Owner:CHINA PETROLEUM & CHEM CORP +1

Chemical flooding method of medium-permeability oil reservoir

PendingCN111648741AHigh viscoelasticityGood suspensionFluid removalDrilling compositionRock corePhysics

The invention relates to a chemical flooding method of a medium-permeability oil reservoir, and belongs to the technical field of petroleum chemical flooding development. The chemical flooding methodincludes the following steps that 1), a first heterogeneous dispersion system is injected into a reservoir stratum, and a front slug is formed; 2), then a polymer water solution is injected into the reservoir stratum, a main plug is formed, or a polymer water solution and a profile control system are alternately injected into the reservoir stratum, and the main slug and a profile control slug areformed correspondingly; and 3), a second heterogeneous dispersion system is injected into the reservoir stratum, and a protective slug is formed. The first heterogeneous dispersion system is mainly composed of a first polymer, a viscoelastic particle oil displacement agent and water. The polymer water solution is mainly composed of a second polymer and water. The second heterogeneous dispersion system is mainly composed of a third polymer, a viscoelastic particle oil displacement agent and water. By means of the chemical flooding method, the rock core stemming ratio of the medium-permeabilityoil reservoir can be increased, remaining oil in a strong flooding region and a medium-permeability rock core is effectively started, and the effect of greatly increasing the raw oil recovery rate isachieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst carrier, and preparation method and application thereof

InactiveCN103041867BEnhanced mass transferImprove heat transfer performanceCatalyst carriersOther chemical processesPtru catalystMetallurgy

The invention relates to a catalyst carrier used for generating gas pulse in a reactor. The outer shape of the catalyst carrier is in a circular cake shape (flying saucer shape). The catalyst carrier is composed of a plurality of unit holes. The structure of each unit hole is that two ends of unit hole are prismoids and the middle portion of the unit hole is a hollow neck (weir groove), wherein the prismoids are preferably triple prismoids, quadruple prismoids or pentagonal prismoids, hexagonal prismoids, regular circular truncated cones, etc. The catalyst carrier is made of chemical ceramic materials. The chemical ceramic materials comprise the following raw materials of, by weight, gibbsite, 25-35 parts of kaolin, 10-20 parts of Guizhou soil, 5-10 parts of talcum, 8-12 parts of feldspar and 8-12 parts of alkali metal oxide. The catalyst carrier is suitable for being used as a carrier for the catalyst of the field of petroleum chemistry or as filling materials in the reactor. The carrier with the structure enhances a mass transfer effect and a heat transfer effect between gas and liquid, and further increases catalytic effect of the catalyst and reaction rate. The catalyst carrier has high hardness, high strength, large specific surface area, good high temperature resistance and good acid and alkali resistance.

Owner:刘一序

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com