Continuous preparation method of 1,4-butanediol

A technology of butanediol and succinic acid, which is applied in the field of continuous preparation of 1,4-butanediol, can solve problems such as high environmental protection pressure, large environmental pollution, and difference in reaction rate, and achieve the goal of reducing consumption and expanding the scope of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

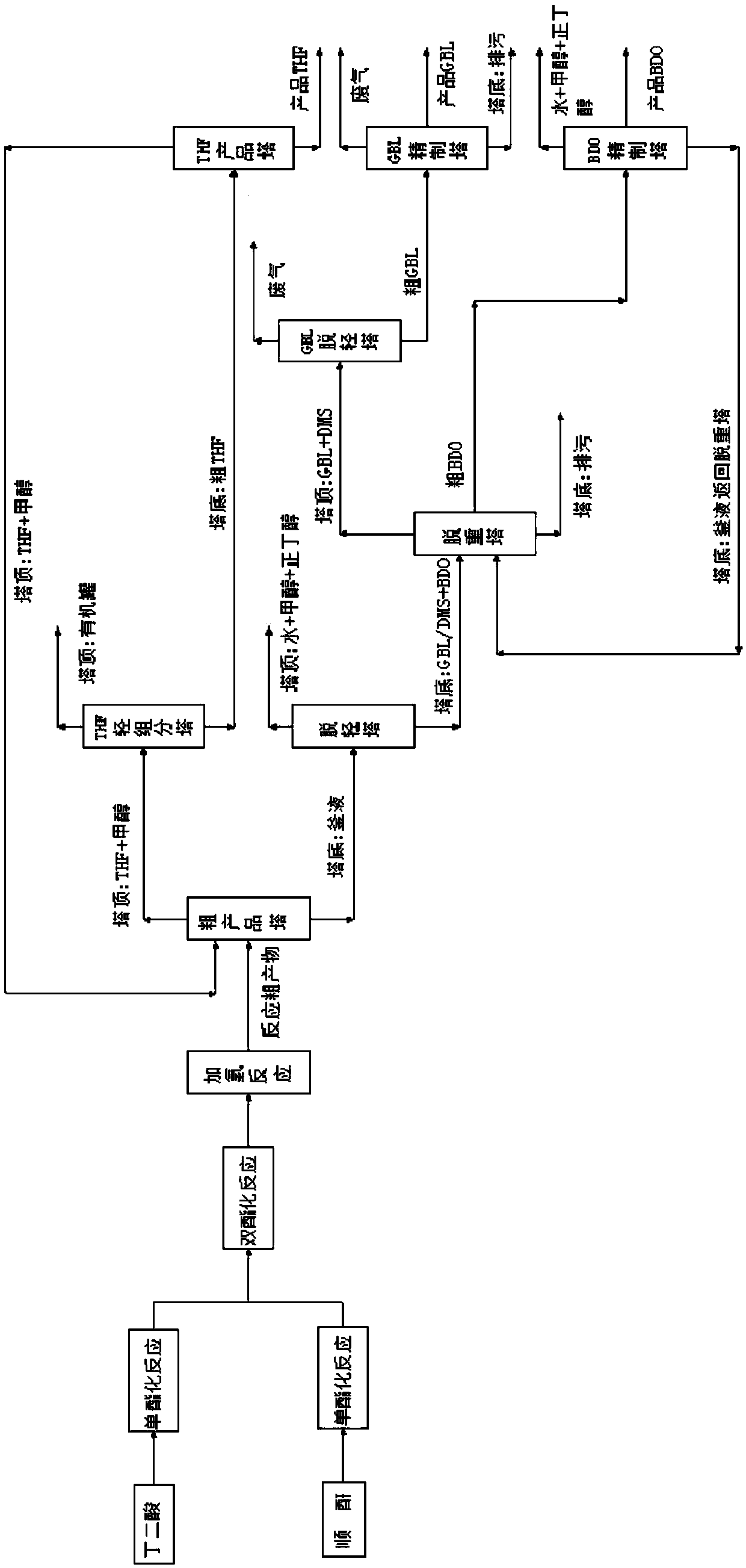

Method used

Image

Examples

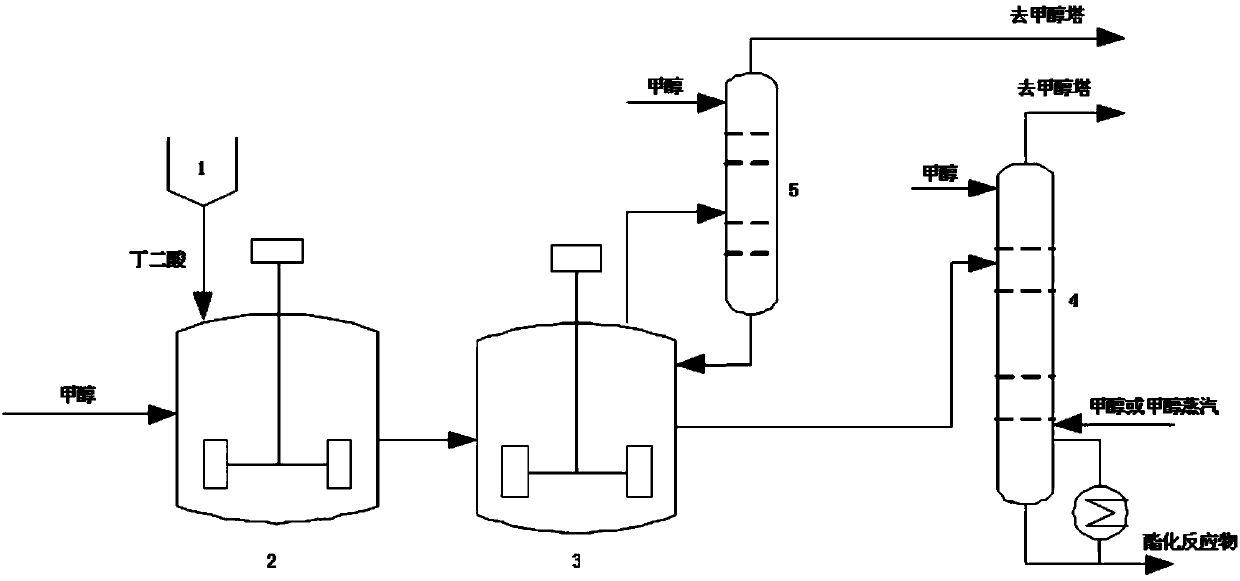

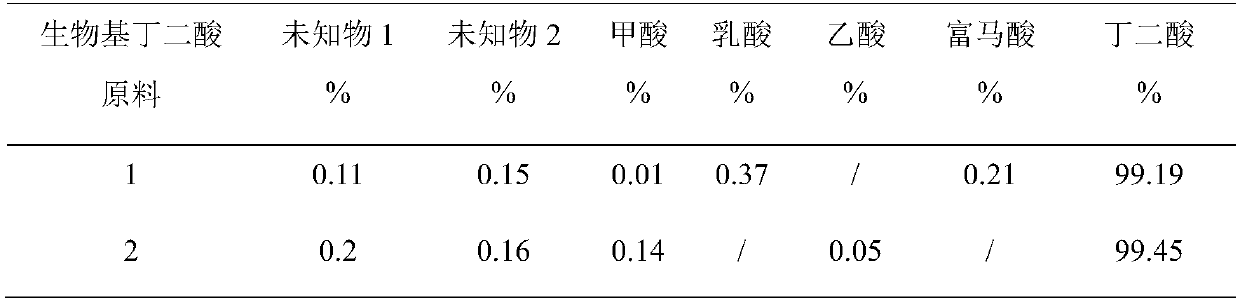

Embodiment 1

[0031] Succinic acid enters the beating tank from the silo 1 through the metering system. The molar ratio of bio-based succinic acid (calculated as succinic acid, bio-based succinic acid raw material 1) to methanol is 1:4. Slurry made in 2 enters the monoesterification reactor 3 for monoesterification reaction, the temperature is 130°C, the pressure is 3bar, and the residence time is 1hr to obtain succinic acid monoesterification liquid, the conversion rate of succinic acid is 95% .

[0032] The succinic acid monoesterification liquid flow and the maleic acid monoesterification liquid flow (the content of monomethyl maleate is 100%, the same below) from the maleic anhydride monoesterification reactor synthesize a fluid to enter the double esterification reaction Tower 4, the mass of succinic acid monoesterification liquid accounts for 1%, using KC105 maleic anhydride esterification catalyst, and the volume space velocity of esterification liquid flow is 0.7h -1 , methanol vapor...

Embodiment 2

[0035] The molar ratio of methanol to bio-based succinic acid (in terms of succinic acid, bio-based succinic acid raw material 2) is 4:1, and the slurry is beaten in the beating tank and entered into the monoesterification reactor for monoesterification For the reaction, the temperature was 130°C, the pressure was 3 bar, and the residence time was 1 hr to obtain a succinic acid monoesterification liquid, and the conversion rate of succinic acid was 95%. The succinic acid monoesterification liquid flow and the maleic acid monoesterification liquid flow from the maleic anhydride monoesterification reactor are synthesized into one stream and enter the double esterification reaction tower, and the succinic acid monoesterification liquid accounts for 20%. KC105 maleic anhydride esterification catalyst, esterification liquid flow volume space velocity 0.7h -1 , methanol vapor is introduced into the bottom of the tower, and a small amount of methanol is passed into the top of the tow...

Embodiment 3

[0037] The molar ratio of methanol to bio-based succinic acid (in terms of succinic acid, bio-based succinic acid raw material 1) is 4:1, and the slurry is beaten in the beating tank and entered into the esterification reactor for monoesterification reaction , a temperature of 130° C., a pressure of 3 bar, and a residence time of 1 hr to obtain a succinic acid monoesterification liquid, and the conversion rate of succinic acid is 95%. The succinic acid monoesterification liquid flow and the maleic acid monoesterification liquid flow from the maleic anhydride monoesterification reactor are synthesized into one stream and enter the double esterification reaction tower, and the succinic acid monoesterification liquid accounts for 50%. KC105 maleic anhydride esterification catalyst, esterification liquid flow volume space velocity 0.7h -1 , methanol vapor is introduced into the bottom of the tower, and a small amount of methanol is passed into the top of the tower at the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com