Synthesis method of alkyl block polyether quaternary ammonium salt surfactant

A technology of surfactants and alkyl blocks, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems that cationic surfactants cannot be used in combination, the viscosity of polymers is reduced, and they cannot be used. Excellent emulsifying and wetting properties, strong compounding ability and low adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Synthesis of alkyl block polyether quazene salt surfactants using different bases

[0037] 1) Sodification reaction: 0.5 mol of alkyl block polyether and 0.55 mol "base" (sodium methanol, sodium ethanol, sodium hydroxide, potassium hydroxide, potassium hydroxide, and potassium hydroxide) are added to the three bottles, and then the reaction phase The medium is introduced into nitrogen, the flow rate of nitrogen is 2 l / min, and stirred at the stirring, and the stirring speed is 250 r / min, the oil bath temperature is 80 ° C, the reaction time is 6 h, to obtain an alkyl block polyether sodium salt or potassium salt.

[0038] 2) Williamson into an ether reaction: After the first step is completed, the nitrogen is closed, and the reaction temperature is reduced to 50 ° C, 1 mol of 1,2-dichloroethane is added, and the electric stirring is activated, and the rotation speed is 200R / min. Under 55 ° C, the reaction was reacted for 4 h to give chlorolymethyl alkyl blo...

Embodiment 2

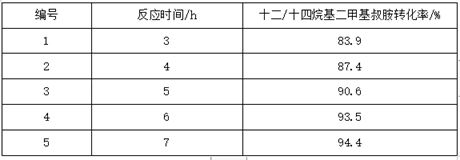

[0044] Example 2: Synthesis of an alkyl block polyether quazene salt surfactant using different reaction times

[0045] 1) Sodium reaction: 0.5 mol of alkyl block polyether and 0.55 mol sodium sodium sodium were added to the three flasks, and then nitrogen gas in the reaction phase, the stirring was opened, and the flow rate of nitrogen was 2 l / min, set the stirring speed. It was 250 r / min, the oil bath temperature was 80 ° C, the reaction time was 6 h, and the alkyl block polyether sodium salt was obtained.

[0046] 2) Williamson into an ether reaction: After the first step is completed, the nitrogen is closed, and the reaction temperature is reduced to 50 ° C, 1 mol of 1,2-dichloroethane is added, and the electric stirring is activated, and the rotation speed is 200R / min. Under 55 ° C, the reaction was reacted for 4 h to give chlorolymethyl alkyl block polyethers.

[0047] 3) Quaternization Reaction: Reaction 2) After the end, the remaining 1,2-dichloroethane is rotated wi...

Embodiment 3

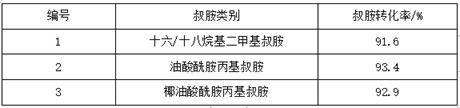

[0051] Example 3: Synthesis of alkyl block polyether quazene salt surfactants using different tertiary amine reactants

[0052] 1) Sodium reaction: 0.5 mol of alkyl block polyether and 0.55 mol sodium sodium sodium were added to the three flasks, and then nitrogen gas in the reaction phase, the stirring was opened, and the flow rate of nitrogen was 2 l / min, set the stirring speed. It was 250 r / min, the oil bath temperature was 80 ° C, the reaction time was 6 h, and the alkyl block polyether sodium salt was obtained.

[0053] 2) Williamson into an ether reaction: After the first step is completed, the nitrogen is closed, and the reaction temperature is reduced to 50 ° C, 1 mol of 1,2-dichloroethane is added, and the electric stirring is activated, and the rotation speed is 200R / min. Under 55 ° C, the reaction was reacted for 4 h to give chlorolymethyl alkyl block polyethers.

[0054] 3) Quaternization reaction: Reaction 2) After the end, the remaining 1,2-dichloroethane is ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com