Patents

Literature

42results about How to "Composite strong" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

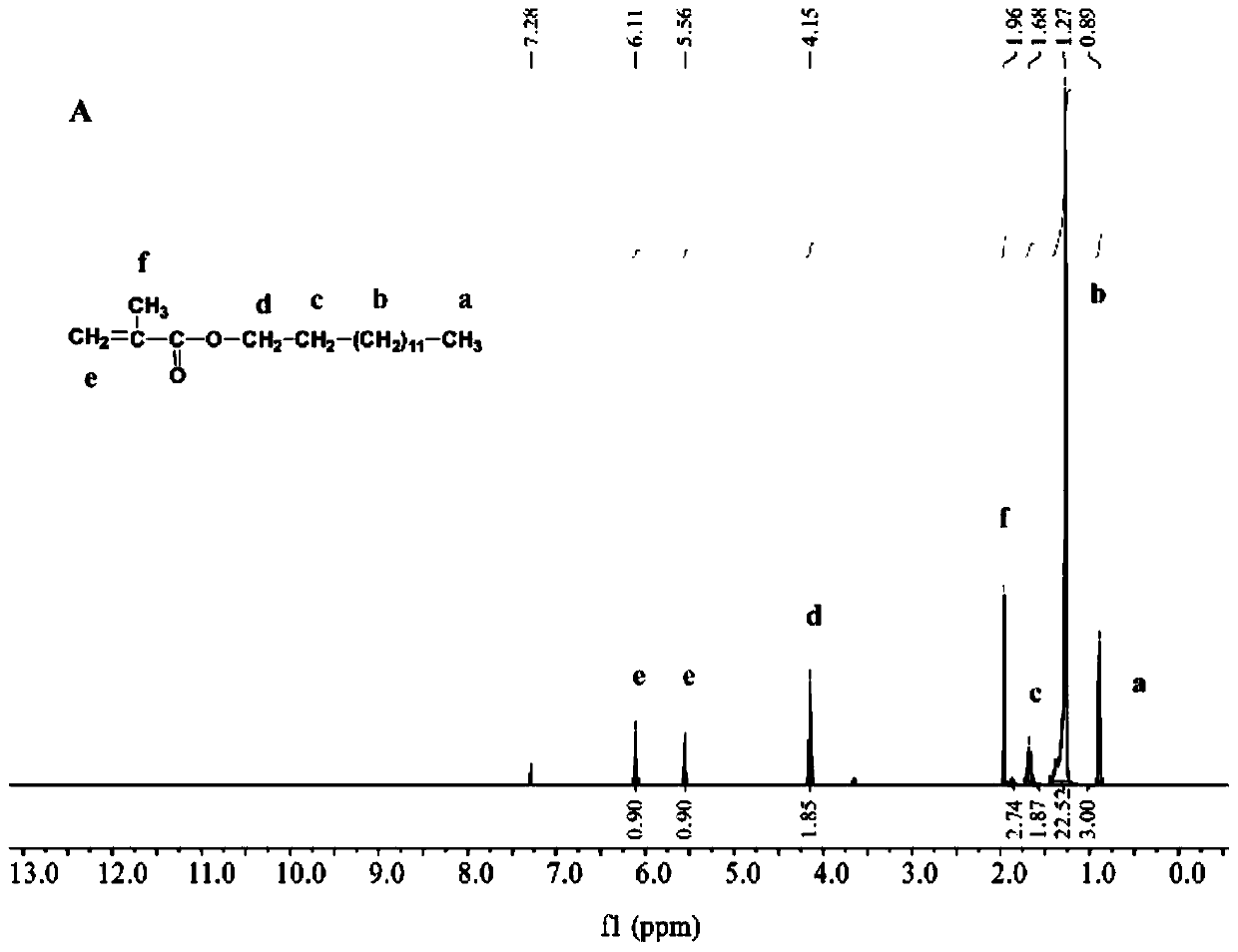

Diesel oil pour-point depressant and preparation method and application thereof

InactiveCN104530305ASolve the problem of poor broad spectrumComposite strongLiquid carbonaceous fuelsMethacrylatePtru catalyst

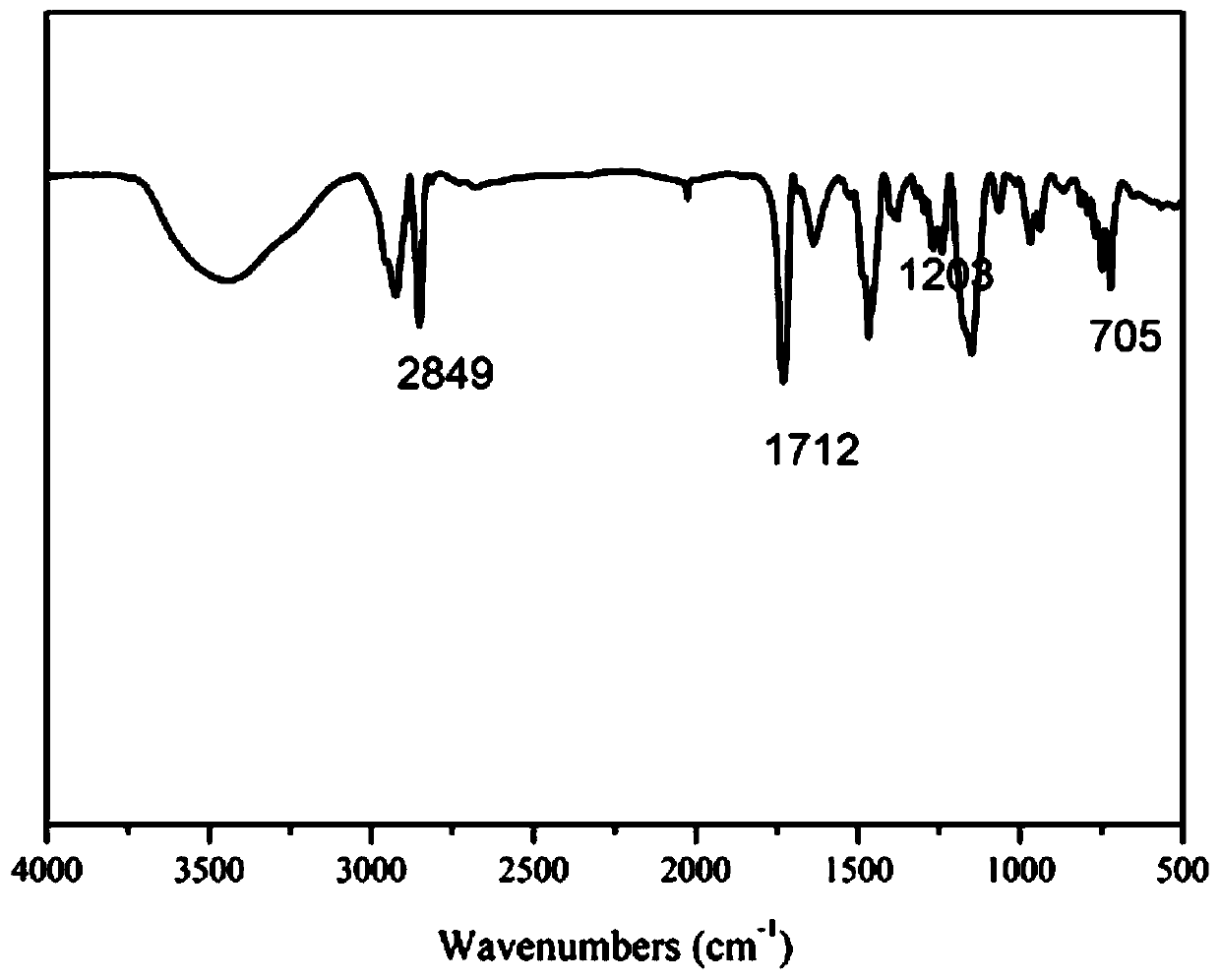

The invention discloses a diesel oil pour-point depressant and a preparation method thereof, wherein the diesel oil pour-point depressant is prepared by the steps: carrying out an aminolysis reaction on a methacrylate maleic anhydride copolymer and higher fatty amine for 6 h with toluene as a solvent and p-toluenesulfonic acid as a catalyst and at a reflux temperature, adding methanol having the same volume as the reaction liquid volume into the obtained reaction liquid, producing a white precipitate, removing a supernatant, washing the obtained white precipitate with toluene, carrying out methanol precipitation to remove the catalyst p-toluenesulfonic acid, then controlling the temperature at 50 DEG C, and carrying out vacuum drying to obtain the diesel oil pour-point depressant. The diesel oil pour-point depressant solves the problems that a (methyl) acrylate pour-point depressant has poor adaptability with diesel oils with different carbon chains, at the same time, makes the reaction of maleic anhydride more diversified, provides another possibility for combination of a maleic anhydride pour-point depressant with the (methyl) acrylate pour-point depressant, effectively improves the condensation point and the cold filter plugging point of No.0 diesel oil, and enables the cold filter plugging point to be superlatively reduced by 11-12 DEG C.

Owner:SHANGHAI INST OF TECH

Preparation technology of efficient polymeric aluminum chloride for wastewater treatment

InactiveCN103738992AGood processing effectImprove protectionAluminium chloridesWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateWastewater

The invention relates to a preparation technology of efficient polymeric aluminum chloride for wastewater treatment. The preparation technology is mainly technologically characterized by comprising the following steps: with hydrochloric acid, aluminum hydroxide and a polymerization regulator as main raw materials, producing a liquid solution by a high-temperature, low-pressure and alkaline adjustment two step method; and producing powdery solid by a centrifuging or pressure spray drying and curing environment-friendly technology. The preparation technology disclosed by the invention is advanced in process, high in production efficiency, fast in purification speed, good in treatment effect, wide in application field, low in treatment cost, energy-saving and environment-friendly, and has important application and popularization values by adjusting the raw material ratio in production.

Owner:TIANJIN SHUIJIE PURIFICATION MATERIAL CO LTD

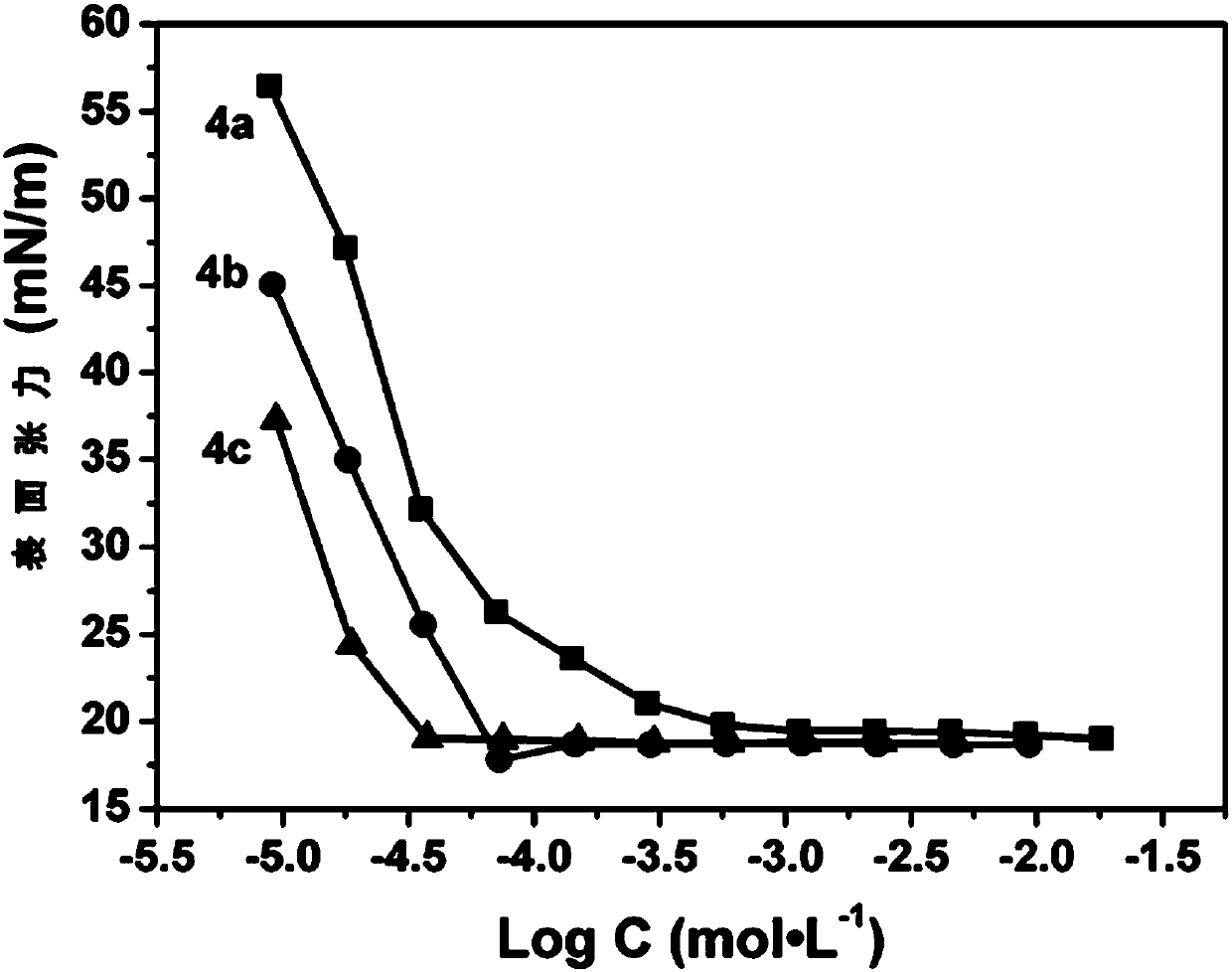

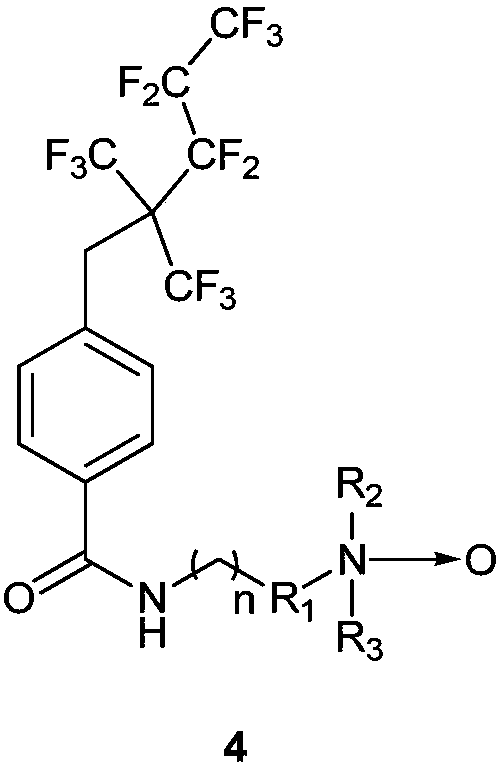

Ampholytic fluorine-containing surfactant as well as preparation method and application thereof

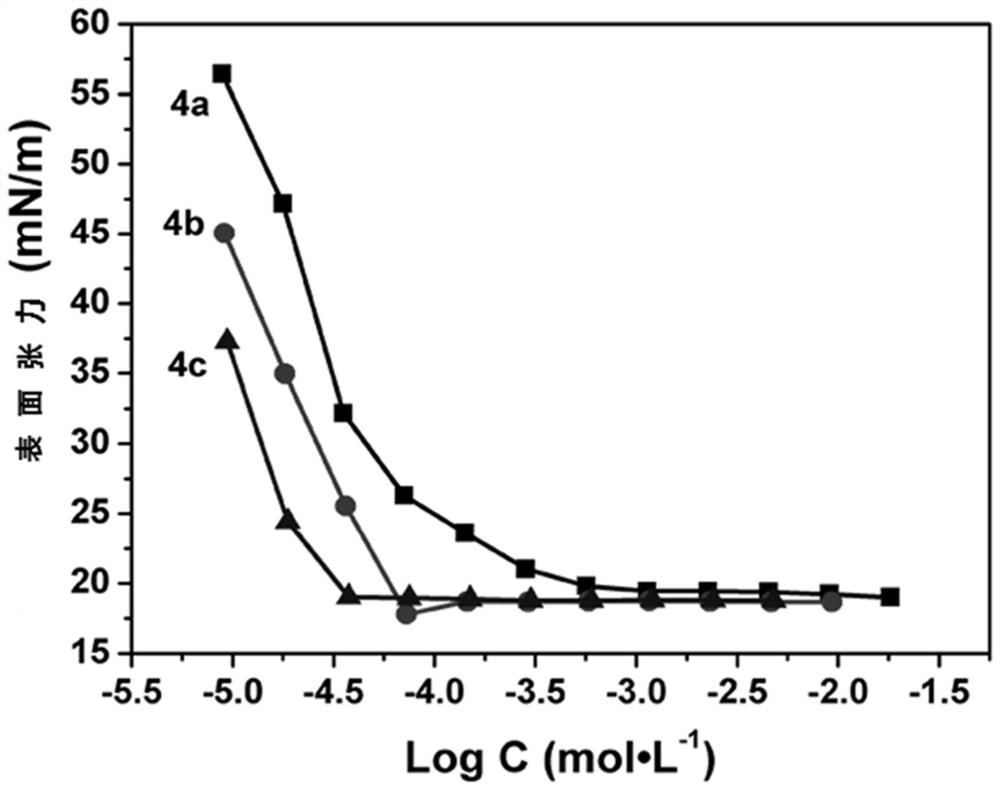

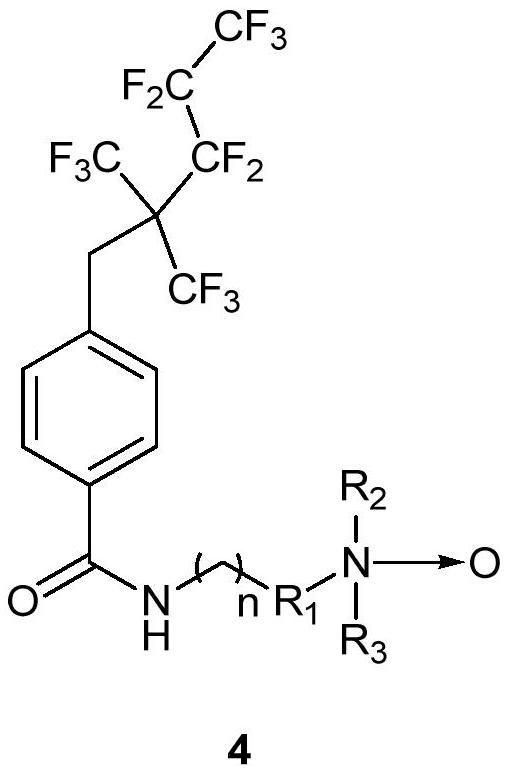

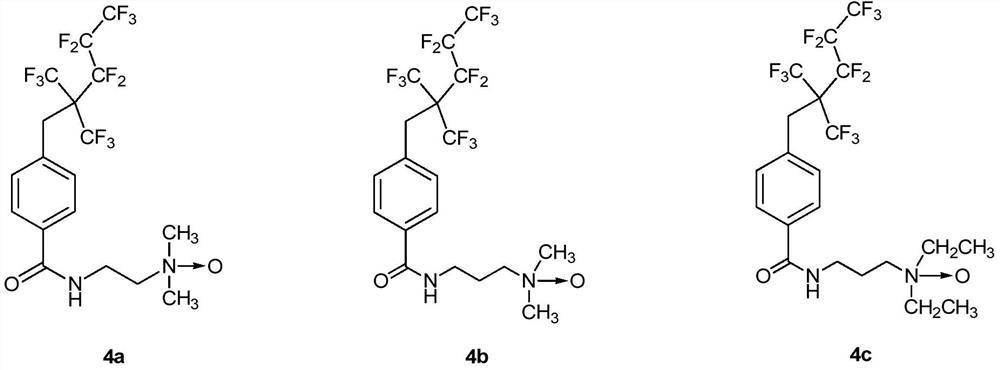

ActiveCN109851529AComposite strongReduce surface tensionOrganic chemistryTransportation and packagingSynthesis methodsHigh surface

The invention discloses an ampholytic fluorine-containing surfactant as well as a preparation method and application thereof. The structure of the ampholytic fluorine-containing surfactant disclosed by the invention is shown as a formula 4, wherein n is selected from any one integer in a range of 1 to 4, R1 is -CH2- or -CH(OH)- and R2 and R3 are independently selected from -CH3- or -CH2CH3. The ampholytic fluorine-containing surfactant disclosed by the invention is easy to degrade, is easily dissolved in water and has high surface activity and good compounding performance; a synthesis method of the ampholytic fluorine-containing surfactant provided by the invention is simple and the total yield is high; the cost problem of an aqueous film-forming foam fire extinguishing agent can be extremely reduced; and the ampholytic fluorine-containing surfactant has relatively high actual value and a wide market prospect. The formula 4 is shown in the description.

Owner:SHANGHAI INST OF ORGANIC CHEMISTRY - CHINESE ACAD OF SCI

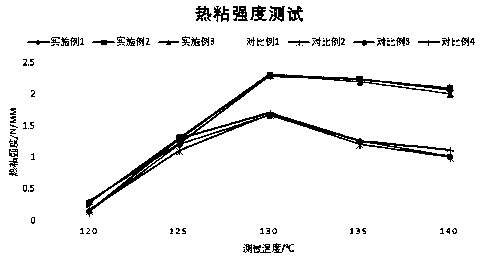

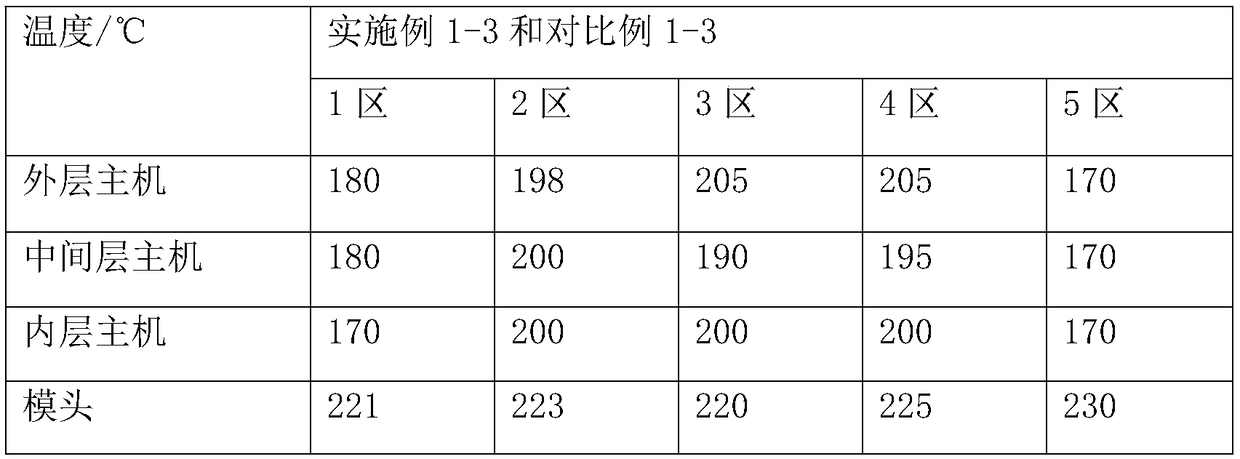

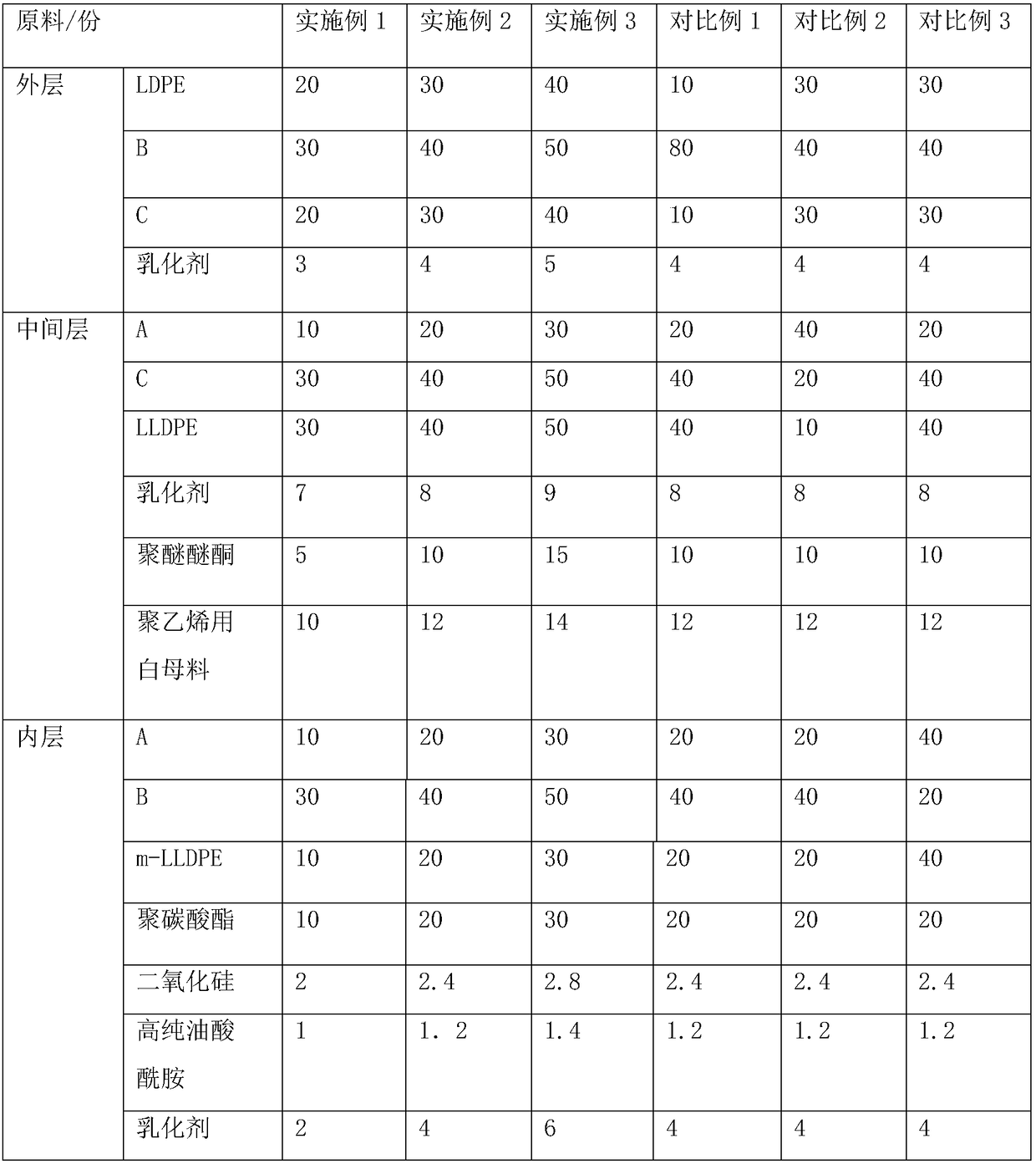

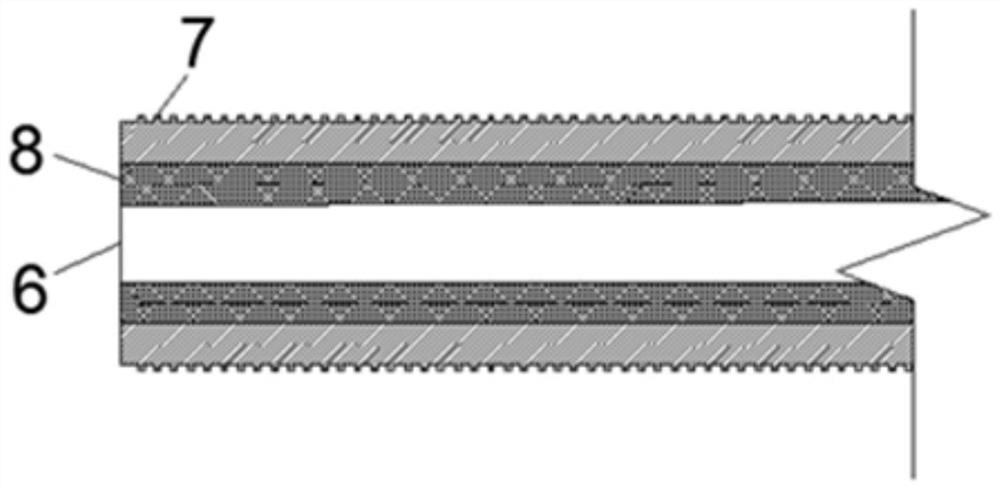

Polyethylene film for automatic packaging and preparation method thereof

ActiveCN108773137AAnti-pollutionComposite strongSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

The invention discloses a polyethylene film for automatic packaging. The polyethylene film comprises an outer layer, an intermediate layer and an inner layer which are sequentially laminated. The outer layer is prepared from the following substances in parts by weight: 20-40 parts of low density polyethylene (LDPE), 30-50 parts of linear low density polyethylene (LLDPE), and 20-40 parts of LLDPE with melt index of 1.1 g / 10 min and density of 0.920 g / cm<3>. The intermediate layer is prepared from the following substances in parts by weight: 10-30 parts of LDPE, 30-50 parts of LLDPE with melt index of 1.1 g / 10 min and density of 0.920 g / cm<3>, and 30-50 parts of LLDPE with melt index of 2.4 g / 10 min and density of 0.921 g / cm<3>. The inner layer is prepared from the following substances in parts by weight: 10-30 parts of LDPE, 30-50 parts of LLDPE, and 10-30 parts of LLDPE. The invention solves the problem that the polyethylene film has lower thermal viscosity and higher bag breaking rate.

Owner:青岛东海包装产业有限公司

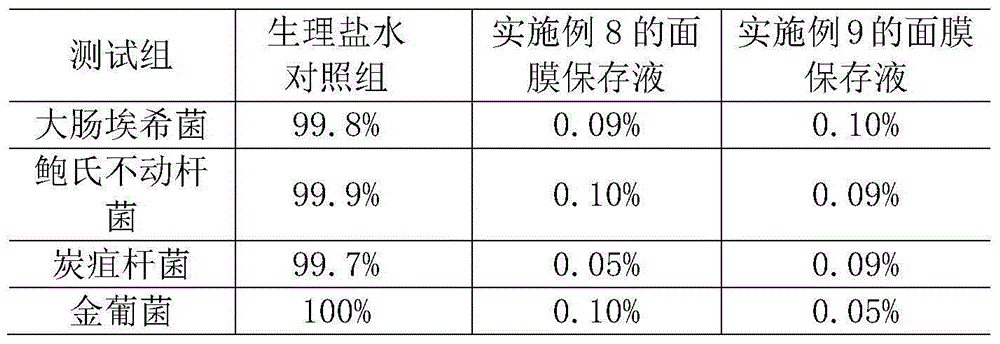

Preserving fluid of collagen mask

InactiveCN105616309AQuick killLower resistanceCosmetic preparationsToilet preparationsAdditive ingredientWhitening Agents

The invention discloses a preserving fluid of a collagen mask. According to a formula of the preserving fluid of the collagen mask, each 100 mL of distilled water contains the following ingredients: 0.10-10.00 g of a bonded compound of hyaluronic acid and antibacterial peptide, 0.05-0.4 g of a skin-whitening agent, 0.05-0.4 g of a cutin softener, 0.05-0.4 g of a skin anti-wrinkling agent, 0.2-1.2 g of a skin repairing agent and 0.2-2 g of aromatic. The collagen mask of the invention can be used along with existing collagen masks in the market and also can be marketed alone; the bonded compound of hyaluronic acid and antibacterial peptide in the formula is a non-irritating broad-spectrum antibacterial disinfector, is safe and nonirritating, and has high stability; and the collagen mask obtained after being immersed in the preserving fluid will not produce irritating feelings such as stabbing pain and the like on face and has a moisturizing function and can perform a beauty treatment effect to the greatest extent.

Owner:刘志刚

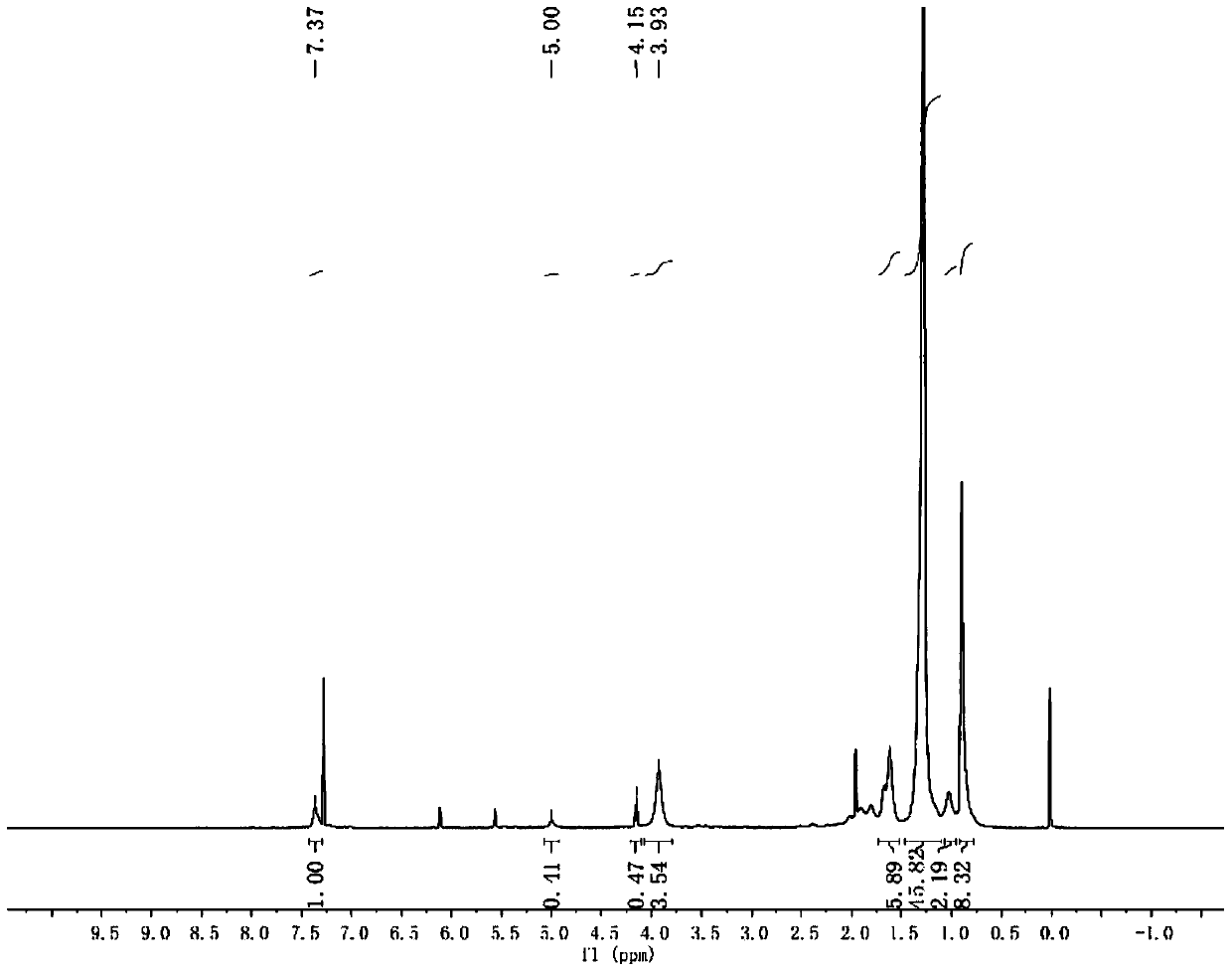

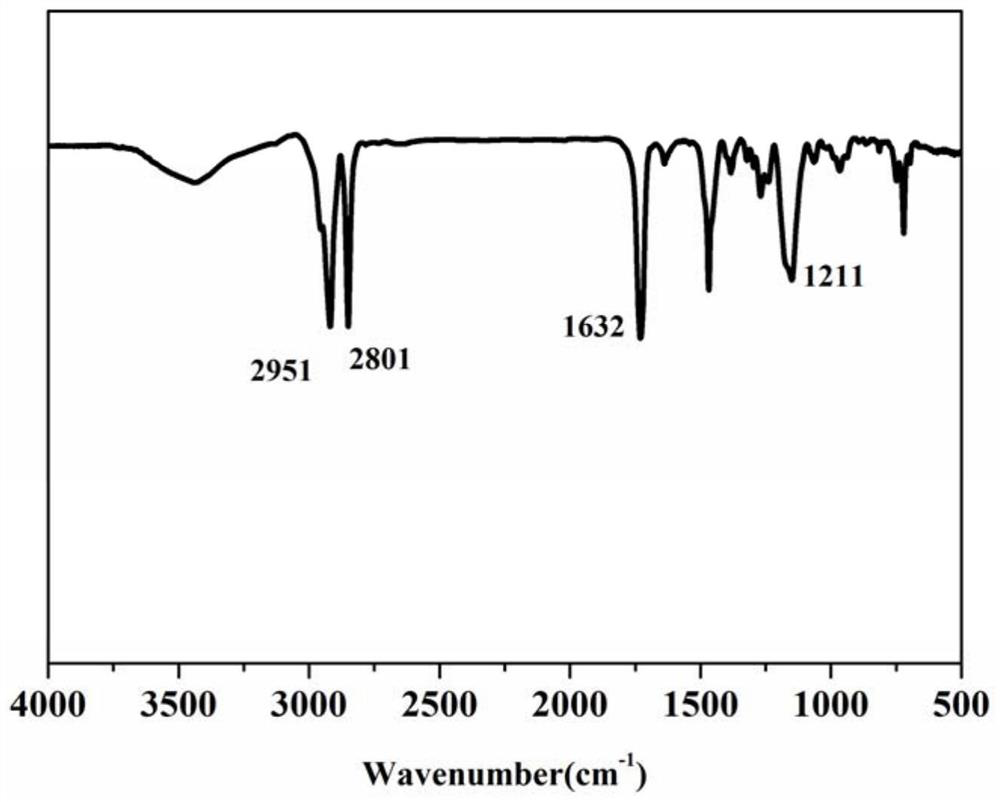

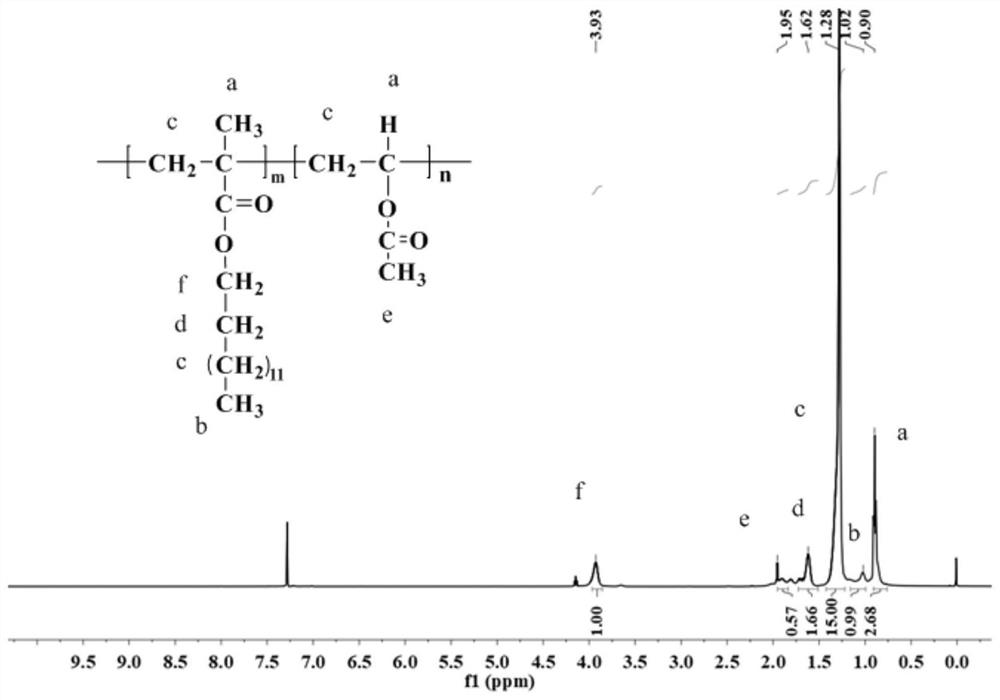

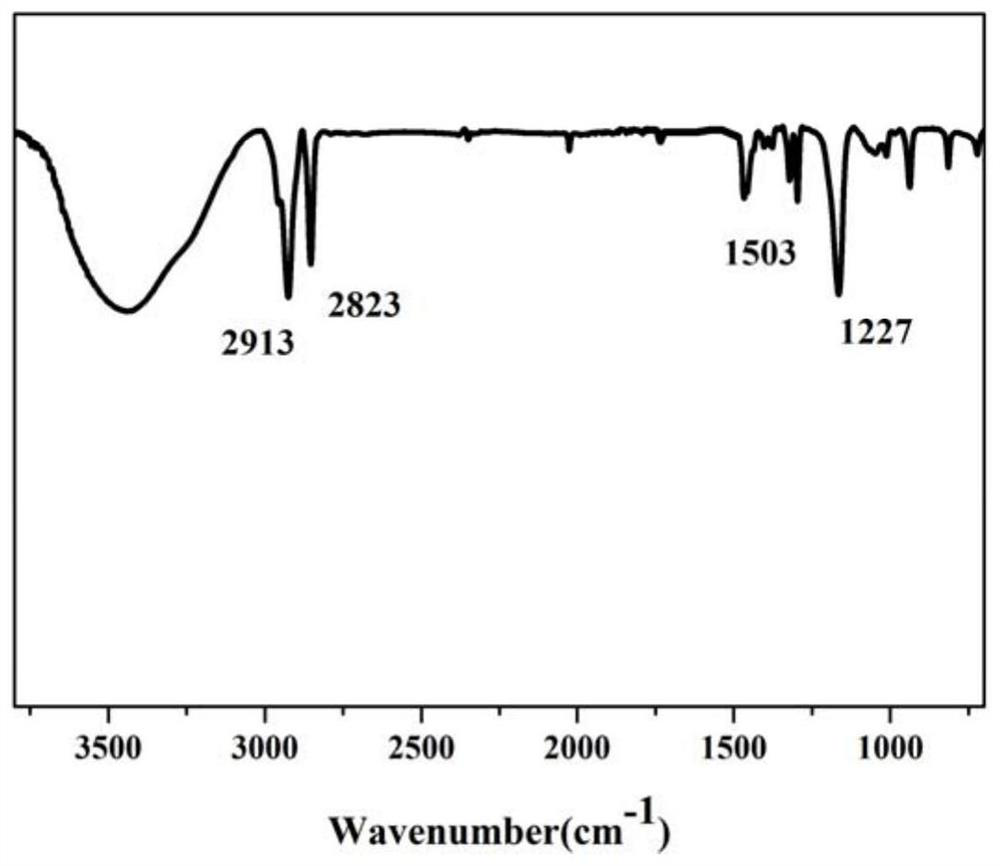

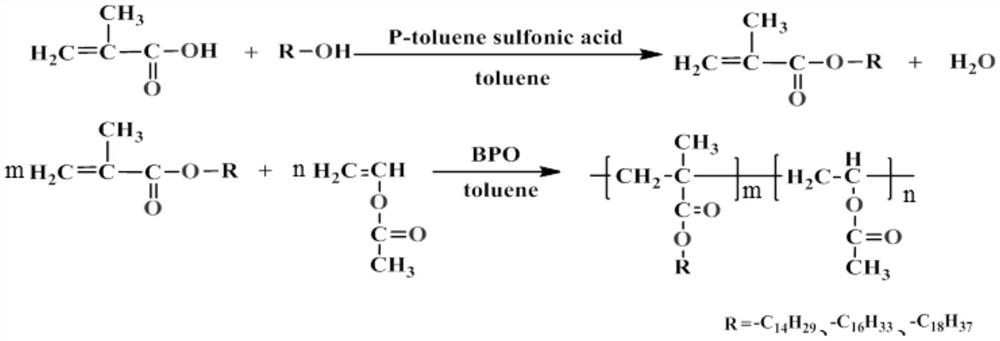

Ternary polymer biodiesel pour point depressant, preparation and application thereof

ActiveCN110172366AGood depressing effectImprove cold flow propertiesLiquid carbonaceous fuelsFuel additivesSolventSolubility

The invention provides a preparation method of a ternary polymer biodiesel pour point depressant. The preparation method of the ternary polymer biodiesel pour point depressant is characterized by comprising the following steps: dissolving methylacrylic acid high carbon ester, benzyl methacrylate and N-vinyl pyrrolidone in a solvent, and carrying out polymerization reaction under the action of an initiator to obtain the ternary polymer biodiesel pour point depressant. The ternary polymer raw material is cheap and easy to obtain, a synthesis method is simple, the ternary polymer raw material notonly has high oil solubility, but also can effectively improve the low-temperature fluidity of biodiesel, and has a good effect on reducing a condensation point and a cold filtration point, and a newpossibility is provided for research and development of novel biodiesel.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

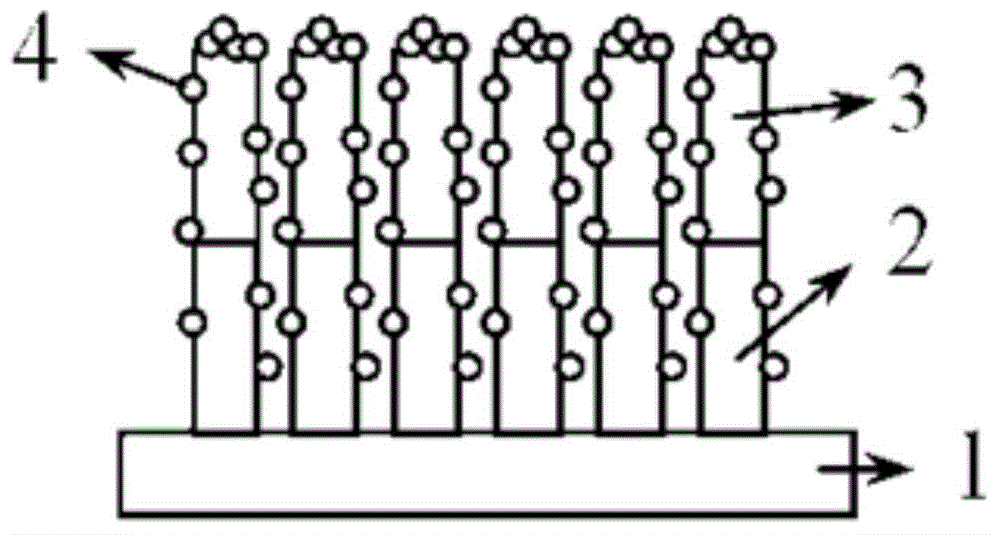

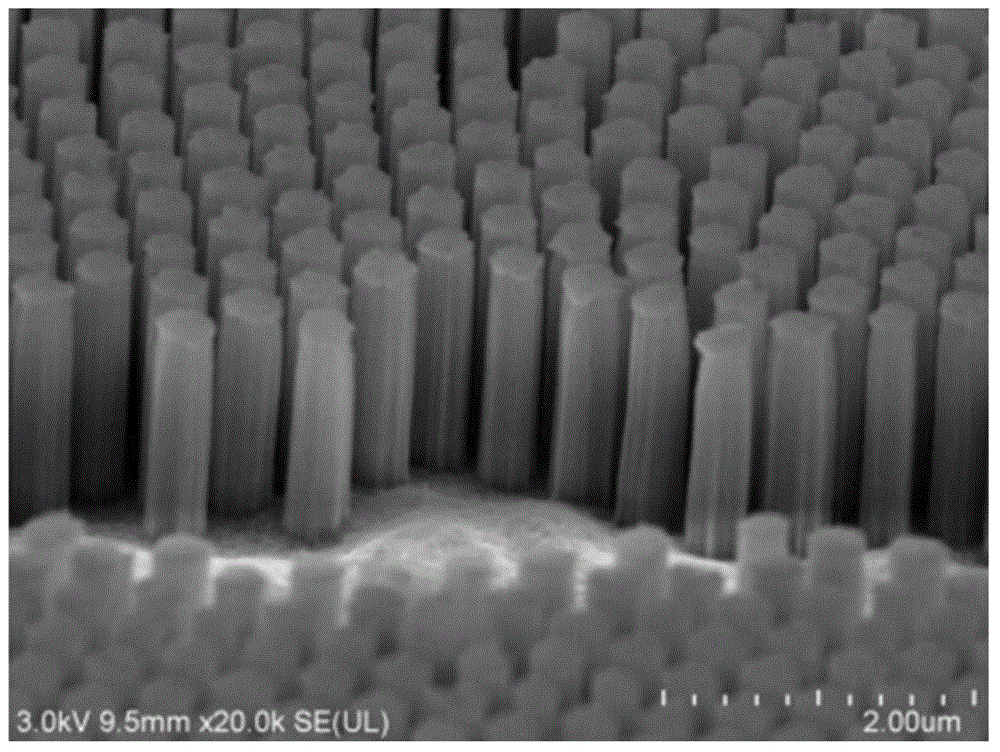

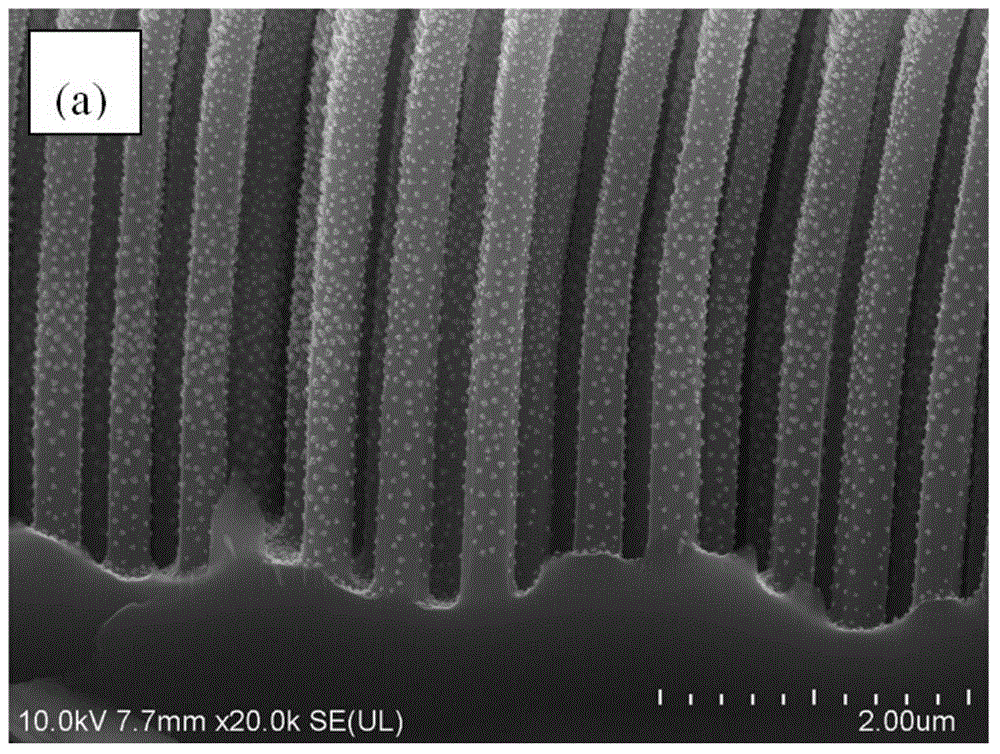

Preparation method of Si-ITO composite nanowire ordered array

InactiveCN104947043ARealize seamless splicingUniform diameterAfter-treatment detailsVacuum evaporation coatingAutocatalysisField emission display

The invention discloses a preparation method of a Si-ITO composite nanowire ordered array. The method comprises the following steps: etching a structured and ordered Si nanowire array on a clean monocrystalline silicon chip by using a dry-wet etching combination process, and growing ITO nanowires in an ITO electron beam vapor plating mode according to an autocatalysis principle to realize seamless combination of Si nanowires and the ITO nanowires in order to obtain the Si-ITO composite nanowire ordered array. The obtained Si-ITO nanowires have the advantages of uniform diameter, adjustable proportion, and coverage of the surface and the front of the Si-ITO nanowires by ITO grains. The method has the characteristics of simple operation, concise preparation process, good repeatability, stable performance and strong compounding property. The composite nanowires have good application prospects in the fields of nanocrystalline solar batteries, nanometer sensors and field emission display.

Owner:XI AN JIAOTONG UNIV

Degradable waterproof aluminium foil paper

ActiveCN106978765AComposite strongAntifoulingCoatings with pigmentsSpecial paperPaper basedAluminum foil

The invention discloses degradable waterproof aluminium foil paper which comprises base paper and an aluminium foil layer. The aluminium foil layer is obtained by plating a layer of aluminium foil on the surface of the base paper by adopting a direct vapour plating method, and then a layer of degradable waterproof film with a specification of 5 to 10mum is compounded on the surface of the aluminium foil layer. The aluminium foil layer is prepared by the following preparation process of: (1) uniformly spraying a layer of degradable hot melt adhesive on one surface of the base paper, then placing the coated base paper in a vacuum aluminizing machine to carry out aluminizing, compounding an aluminized layer and the base paper by the hot melt adhesive, and carrying out press-polishing by a press-polishing machine; (2) uniformly coating the surface of the aluminium foil layer with degradable waterproof colloid by a coating roller, then drying the aluminium foil paper in an electric heating constant-temperature fan dryer with a temperature of 120 DEG C for 15s, and then carrying out press-polishing by the press-polishing machine. According to the degradable waterproof aluminium foil paper disclosed by the invention, aluminizing is directly carried out on the surface of the base paper, and then the degradable waterproof film is compounded on the surface of the aluminium foil layer, so that the prepared aluminium foil paper is easy to degrade.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

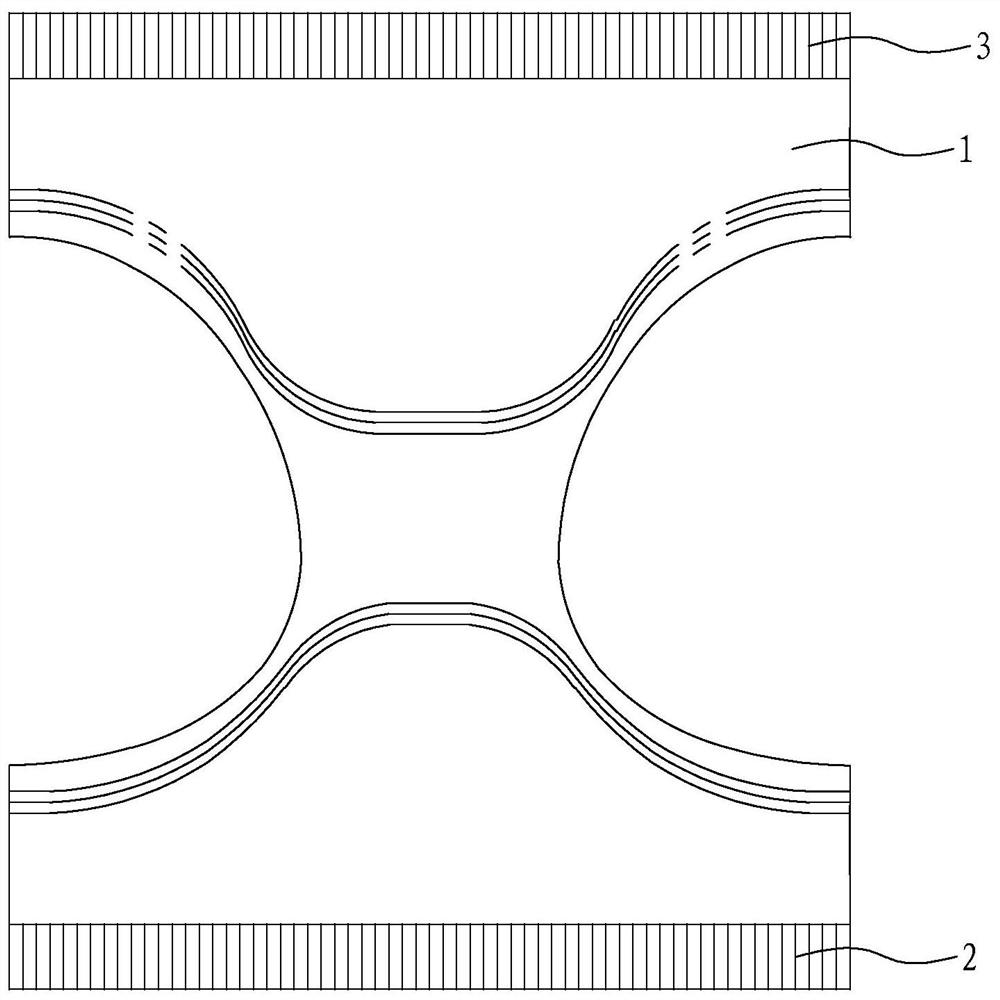

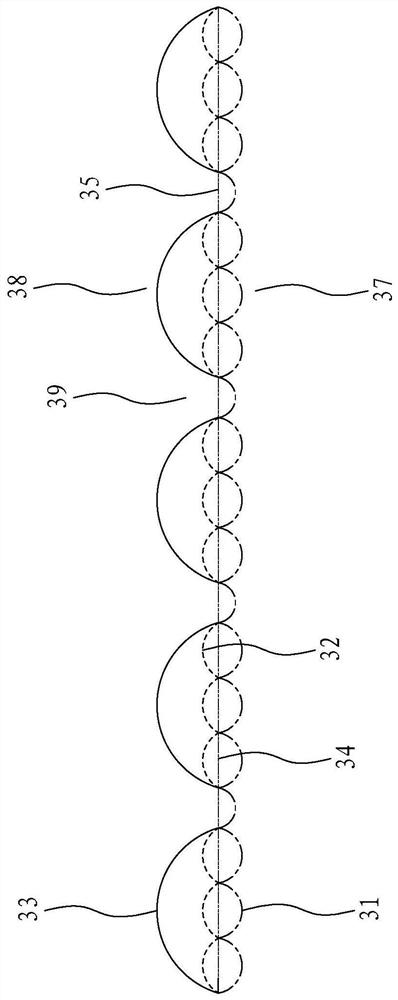

Breathable adult pull-ups and production process thereof

ActiveCN111821105ATightly boundRelieve tensionLaminationLamination apparatusMechanical engineeringWaist

The invention relates to the field of disposable sanitary products, in particular to breathable adult pull-ups. The breathable adult pull-ups comprise a body, a front waist and a back waist, the backwaist comprising an outer layer, a middle layer, an inner layer and elastic rubber strings, the elastic rubber strings are clamped between the outer layer and the middle layer, the elastic rubber strings are fastened to the outer layer and the middle layer, the lower end of the inner layer is lower than the lower end of the elastic rubber strings, and the inner layer is compounded with the middlelayer, a plurality of hot pressing parts are formed and extend in the vertical direction, when the elastic rubber strings contract, the outer layer and the middle layer form outer folding bulges withthe same folding state, the inner layer forms inner folding bulges, the width of the inner folding bulges in the transverse direction covers at least two outer folding bulges, and a ventilation channel is formed between two adjacent inner folding bulges. The breathable adult pull-ups solve the technical problems that existing pull-ups cause tightening marks at waist parts and have poor breathability. At the same time, a production process of the breathable adult pull-ups is provided.

Owner:FUJIAN HENGAN HLDG CO LTD +2

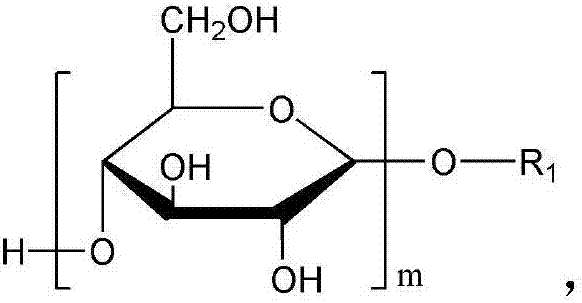

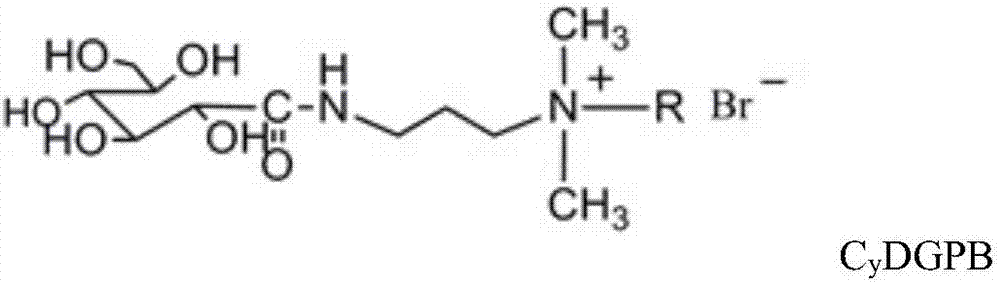

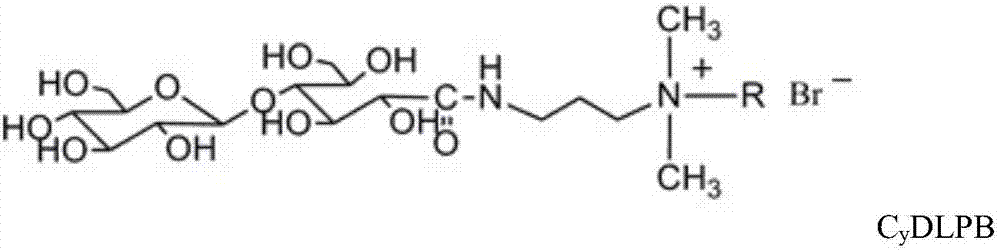

Green antibacterial skin-care hand sanitizer and preparation method thereof

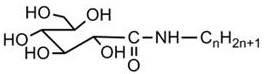

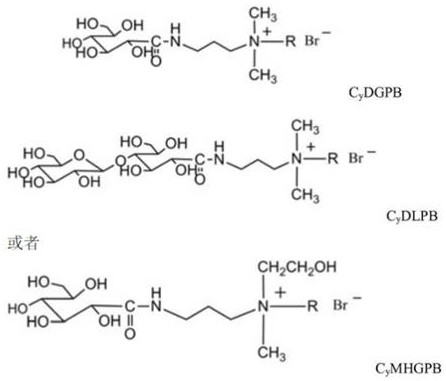

ActiveCN107468545ARaw greenRaw material environmental protectionCosmetic preparationsToilet preparationsGlycerolHand sanitizer

The invention belongs to the technical field of personal daily clean care products, and specifically relates to a green antibacterial skin-care hand sanitizer and a preparation method thereof. The green antibacterial skin-care hand sanitizer consists of the following components in parts by weight: 1 to 5 parts of modified grease ethoxylate, 5 to 10 parts of alkyl glycoside, 0.5 to 3 parts of a glycosyl amide cationic surface active agent, 0.5 to 1 part of alkyl glucose amide, 0.1 to 1 part of edible glycerinum, 0.01 to 0.1 part of flavoring rose essence and the balance of deionized water. The antibacterial skin-care hand sanitizer can be used for deep decontamination, is high in antibacterial property, fine in foam, easy to wash and easy for biodegradation, and has the effects of preserving moisture and moistening skin.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

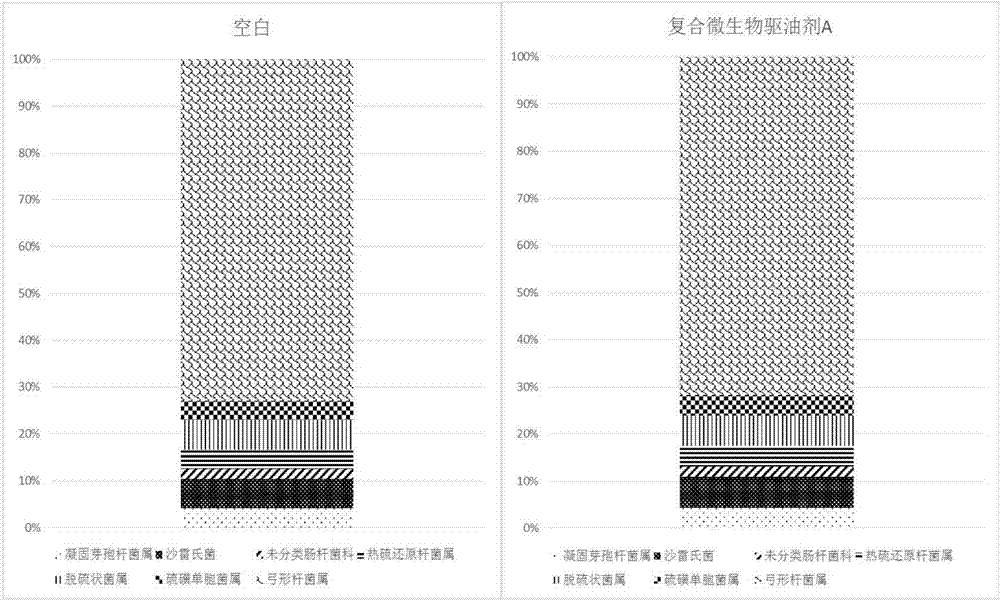

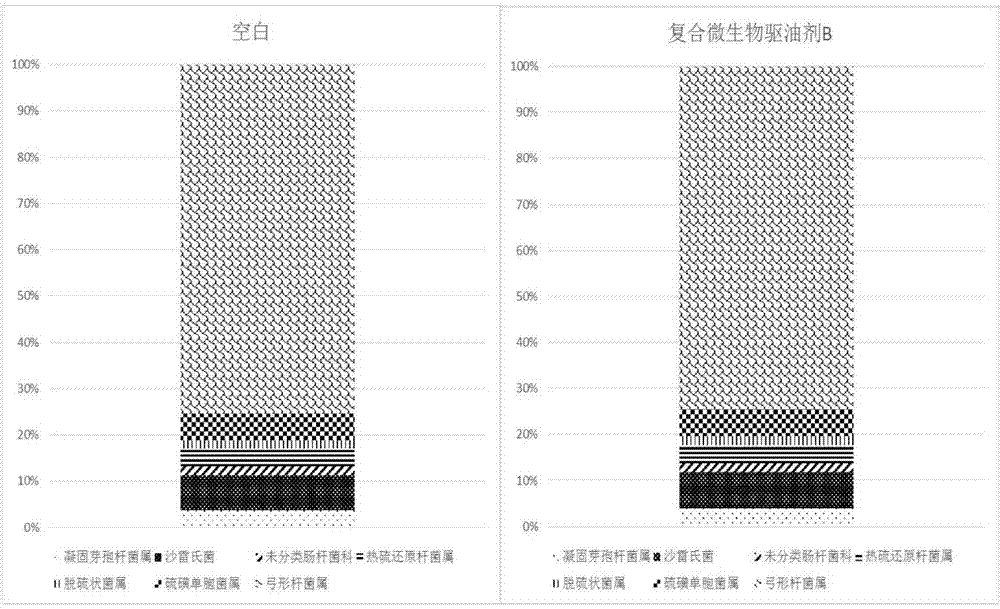

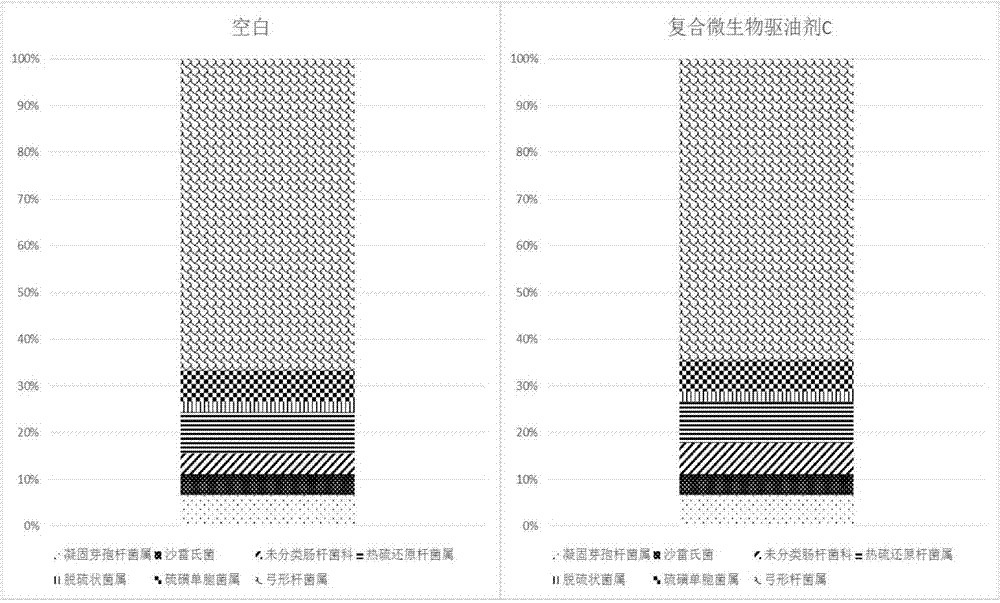

Compound microorganism oil-displacing agent for oil production and compounding method thereof

InactiveCN104263343AEnhanced overall recoveryHigh recovery rateDrilling compositionMicroorganismNitrogen source

The invention discloses a compound microorganism oil-displacing agent for oil production and a compounding method thereof. The oil-displacing agent is prepared from the following components in percentage by weight: 2-5 percent of an oligomeric surfactant, 5-9 percent of an activator and the balance of water, wherein the oligomeric surfactant is alkyl polyoxyethylene ether polymer, and the activator is prepared from a carbon source, a nitrogen source and a phosphorus source. The compounding method of the oil-displacing agent comprises the following steps: sampling oil-reservoir formation water, separating oil and water, and filtering the formation water; adding the activator into a closed reaction kettle according to the components and proportion, and stirring for 0.5-1.0 hour; adding the filtered formation water into the uniformly stirred activator, heating to 30-40 DEG C, and stirring for 2-3 hours to form an activator solution; and adding the oligomeric surfactant into the activator solution according to the component and proportion, heating to 40-50 DEG C, stirring for 4-6 hours, and standing for 0.5-2 hours. The oil-displacing agent has the characteristics of high displacement efficiency, low interfacial tension, wide oil reservoir application range, large scope of enhanced oil recovery, strong compounding performance, simple compounding method and strong operability, thus the oil-displacing agent can be widely applied to field testing of enhanced oil recovery.

Owner:CHINA PETROLEUM & CHEM CORP +1

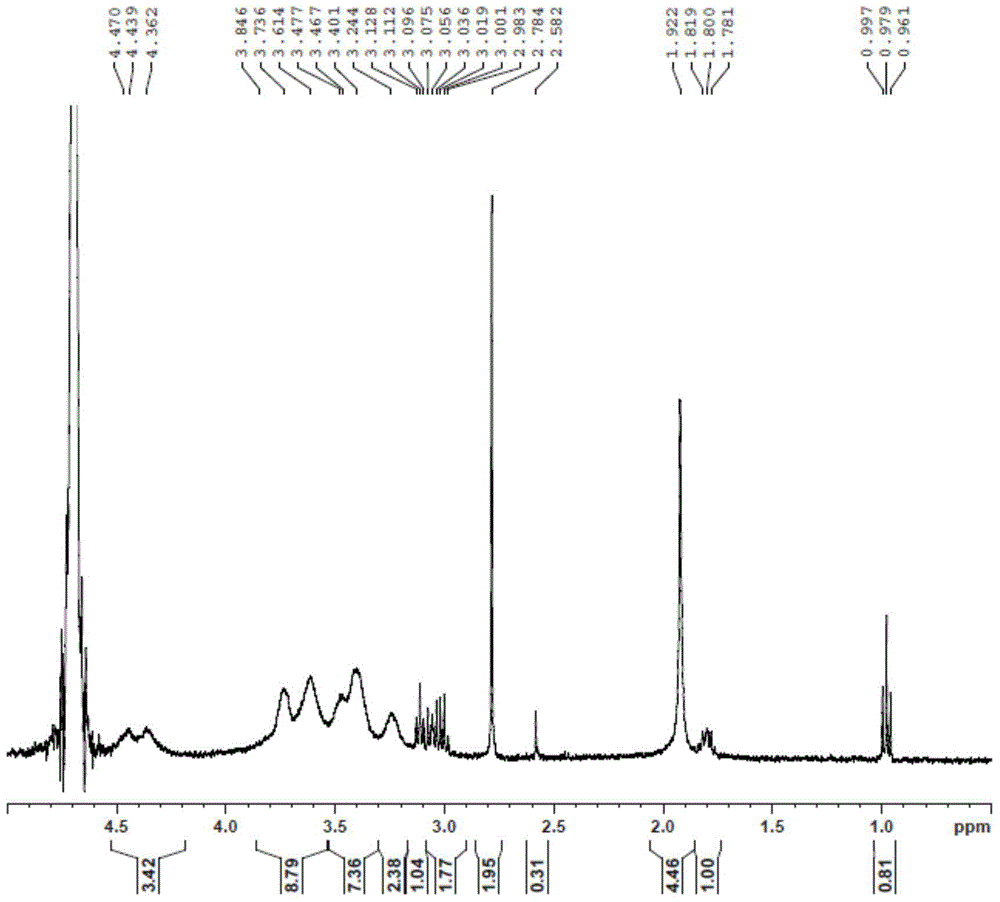

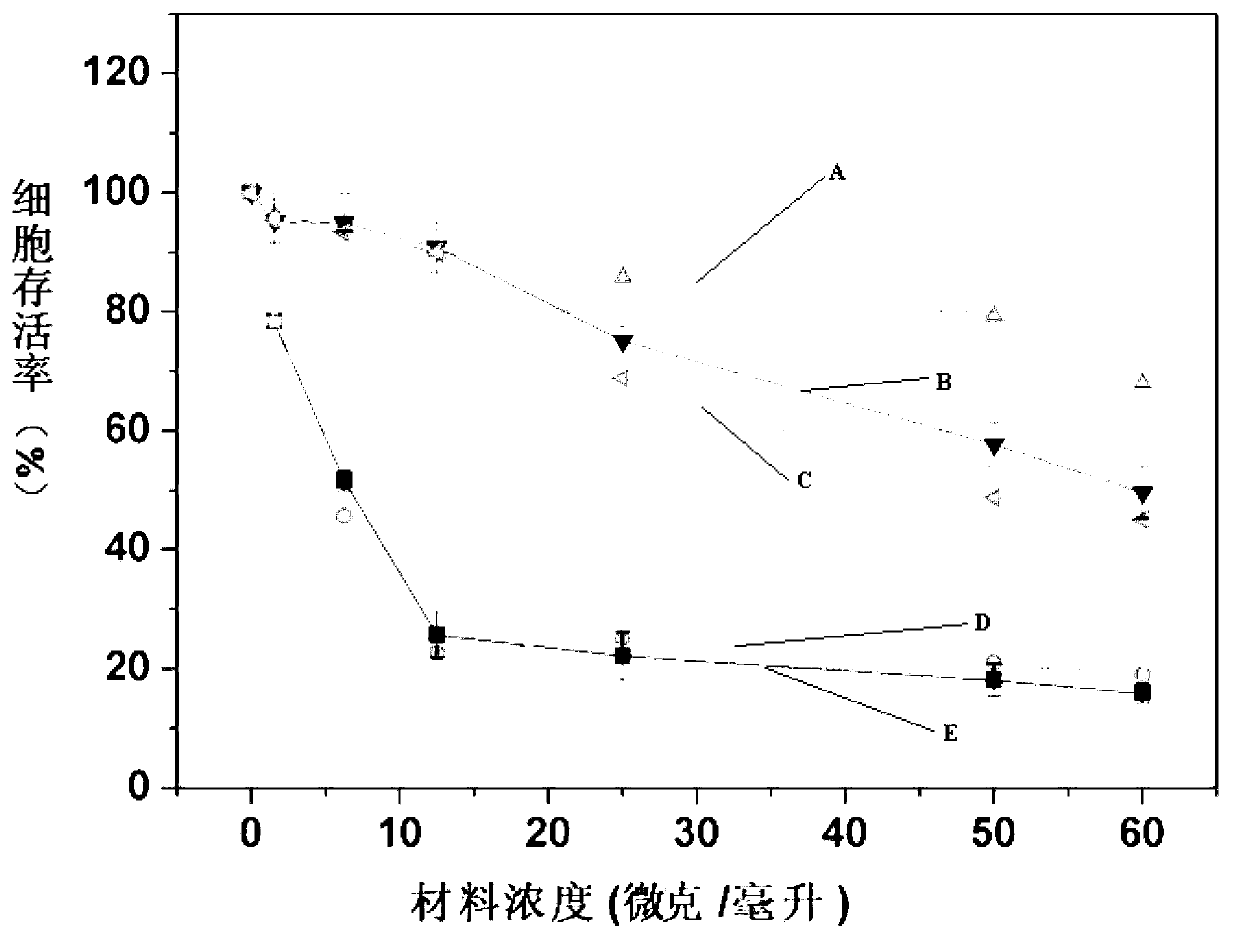

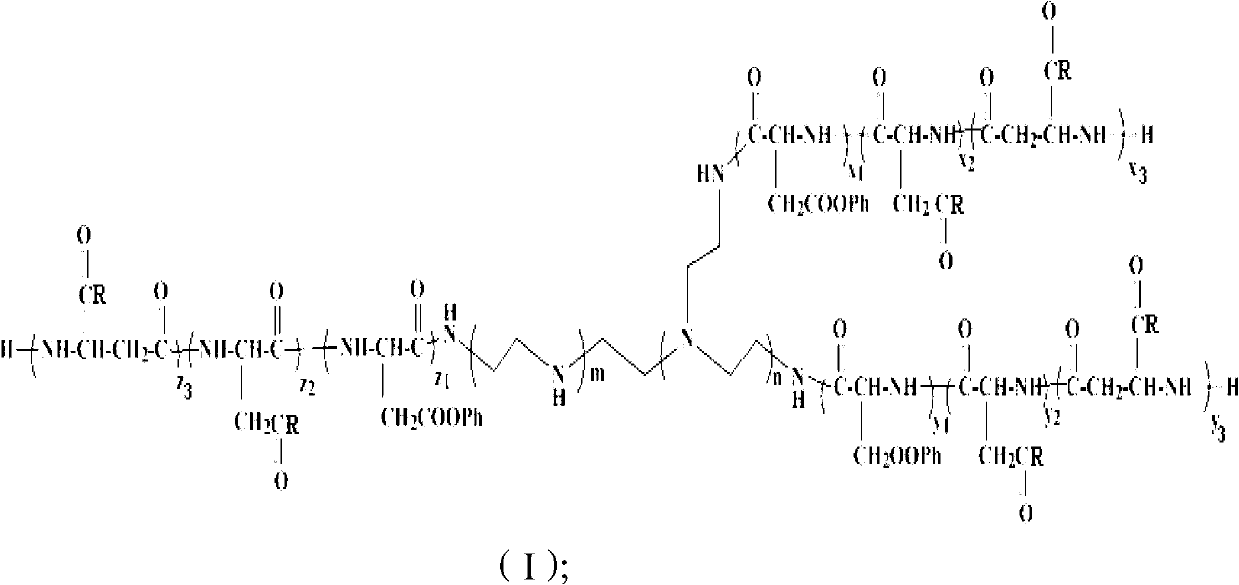

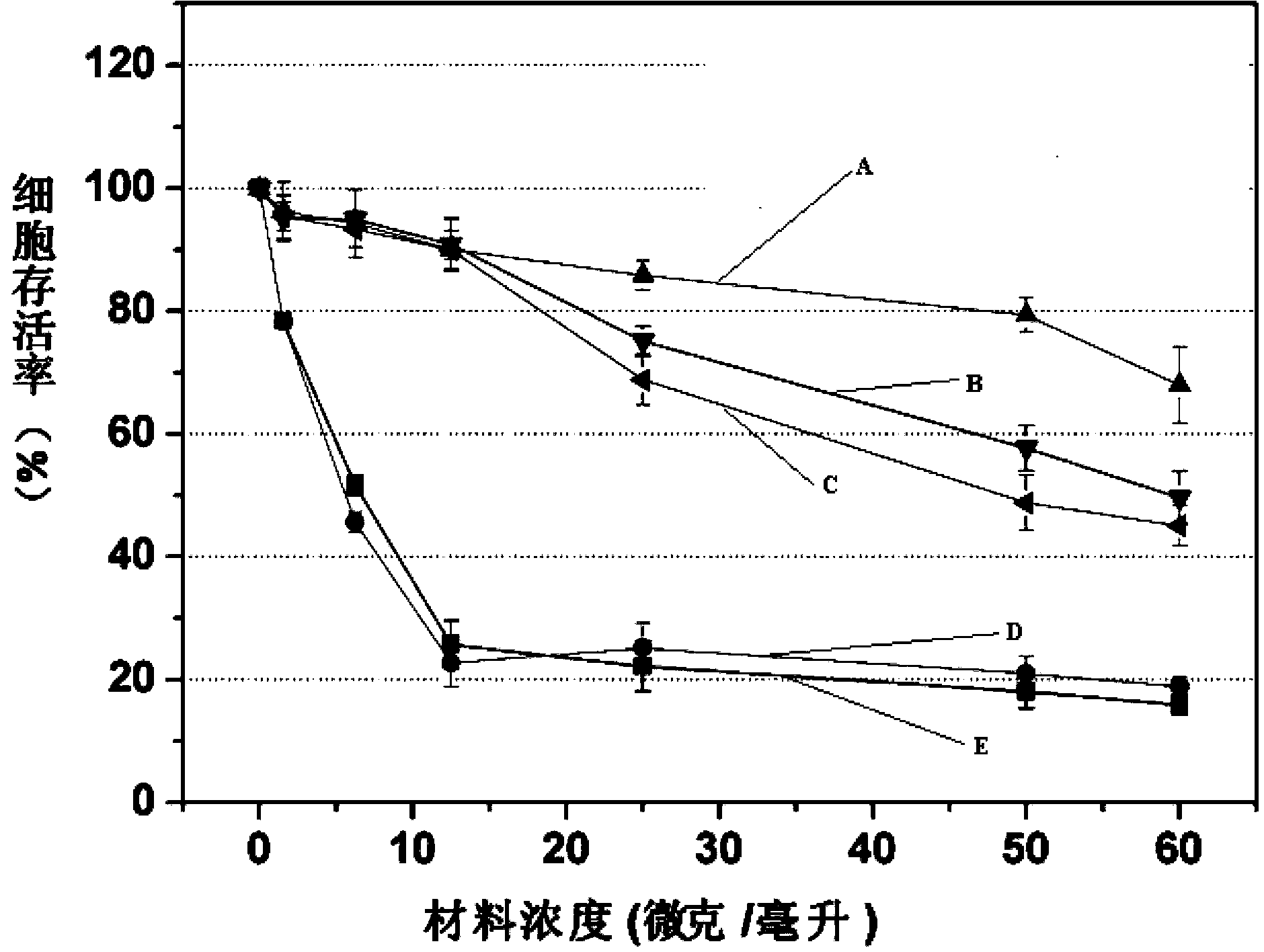

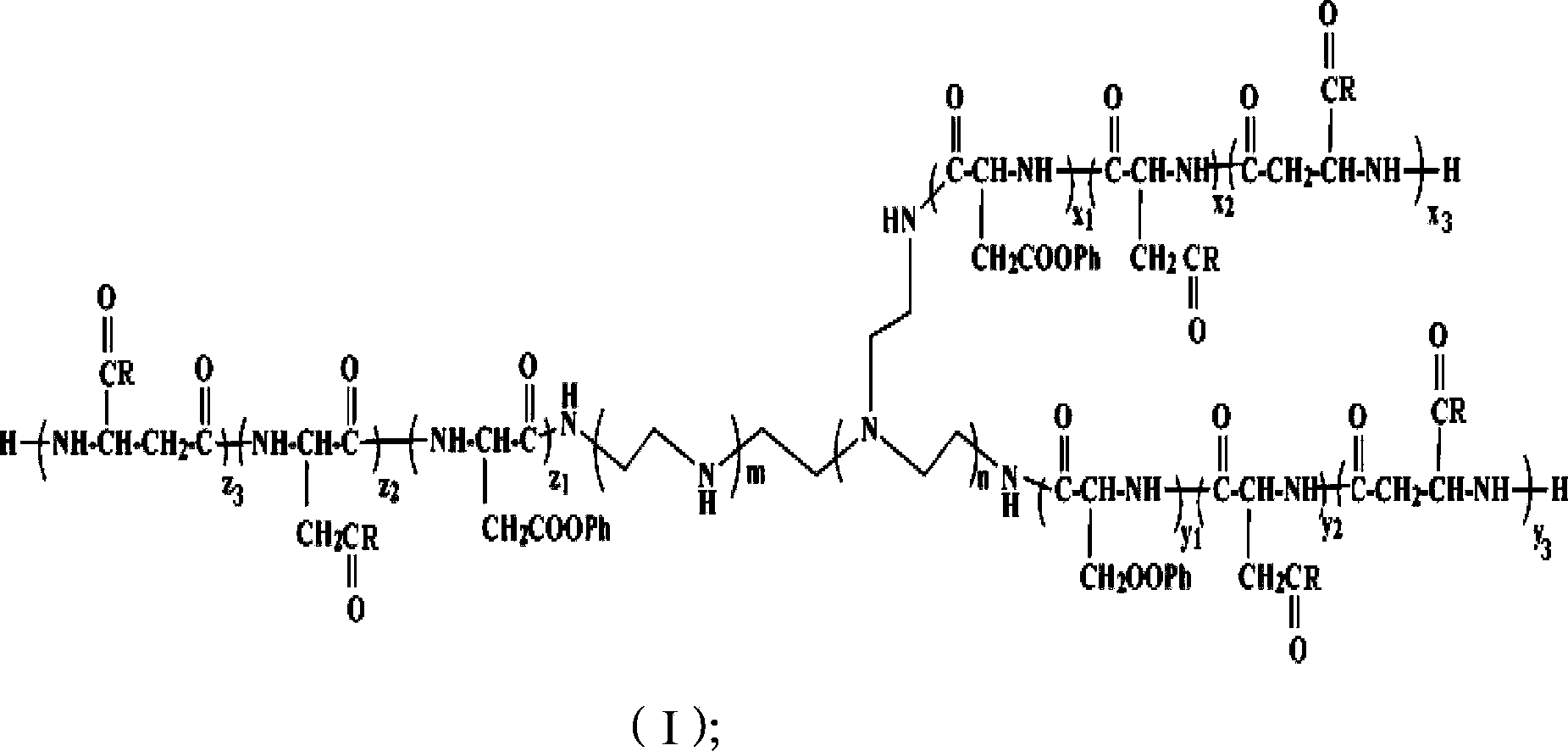

Polyamino acid segmented copolymer serving as siRAN carrier and preparation method as well as composite particle

ActiveCN102746513AComposite strongLow toxicityOther foreign material introduction processesOrganic solventL-Aspartate

The invention provides a polyamino acid segmented copolymer serving as a siRAN carrier shown in a formula (I). A preparation method for the polyamino acid segmented copolymer comprises the following steps of: enabling beta-benzyl-L-aspartic acid-N-carboxylic acid anhydride to react with cladodification polyethyleneimine in an organic solvent under the protection of inert gas to obtain an intermediate product; enabling the obtained intermediate product to react with polyethyleneimine under the action of a catalytic agent to obtain the polyamino acid segmented copolymer serving as the siRAN carrier. The invention provides a composite particle which comprises the polyamino acid segmented copolymer serving as the siRAN carrier and siRNA; and the siRNA is the Luc siRNA of silent luciferase. The polyamino acid segmented copolymer serving as the siRAN carrier provided by the invention has concentrated electric charge density, strong composite capacity and good biological compatibility; and the toxicity of the polyamino acid segmented copolymer is effectively reduced.

Owner:长春金传科技有限公司

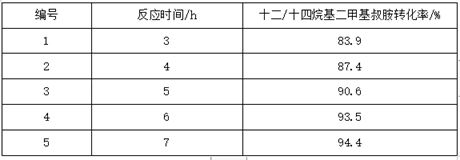

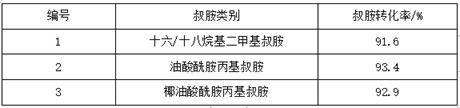

Synthesis method of alkyl block polyether quaternary ammonium salt surfactant

ActiveCN113980260AEnhanced overall recoveryCorrosion resistanceDrilling compositionActive agentEthyl group

The invention discloses a synthesis method of an alkyl block polyether quaternary ammonium salt surfactant, and mainly belongs to the field of petroleum chemistry. The synthesis method comprises the following steps of: making alkyl block polyether react with alkali to obtain alkyl block polyether sodium salt or alkyl block polyether potassium salt; adding 1, 2-dichloroethane, and reacting for 4-5 hours to obtain chloroethyl alkyl block polyether; and recovering the unreacted 1, 2-dichloroethane, adding tertiary amine of which the molar weight is 1-1.2 times of the molar weight of the alkyl block polyether, adding a NaOH aqueous solution when the conversion rate of the tertiary amine reaches 70-75%, raising the reaction temperature to 100 DEG C, and continuously reacting for 6-7 hours. The product obtained by the method of the invention has the advantages of strong compounding capacity, good emulsifying property, temperature resistance, salt resistance and corrosion resistance.

Owner:SHANDONG DAMING FINE CHEM CO LTD

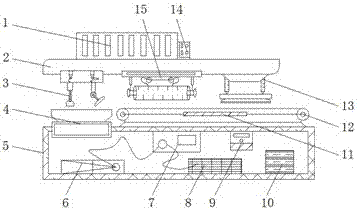

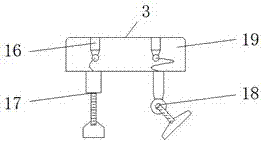

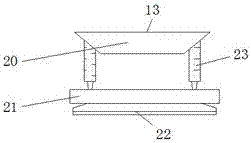

Wood product die cutting marking press

InactiveCN107234679AWill not affect the quality of useEasy to useWood compressionProfiling/shaping machinesNumerical controlFixed frame

The invention discloses a wood product die cutting marking press. The wood product die cutting marking press comprises a work supporting rod, conveying equipment, a work machine case, a power device, a conveying belt and an impressing roller. A servo motor is arranged on one side of the upper end of the work supporting rod, and a control panel is arranged on the other side of the upper end of the work supporting rod. The conveying equipment is fixedly arranged on one side of the bottom end of the work supporting rod. A material bearing plate is arranged on one side of the upper end of the work machine case. The power device is arranged on one side of the bottom end in the work machine case. The conveying belt is fixedly arranged at the upper end of the center of the outer portion of the work machine case. Roller impressing equipment is fixedly arranged in the center of the lower end of the work supporting rod and fixed to the bottom end of the work supporting rod through a fixing frame at the upper end. Die cutting equipment is fixedly connected to one side of the bottom end of the work supporting rod. According to the wood product die cutting marking press, wood product impressing and die cutting are automatic, the impressing pressure and conveying speed can be adjusted in a numerical control manner, using is simple and convenient, and the work efficiency is improved.

Owner:鱼珠湾智能科技(广州)有限公司

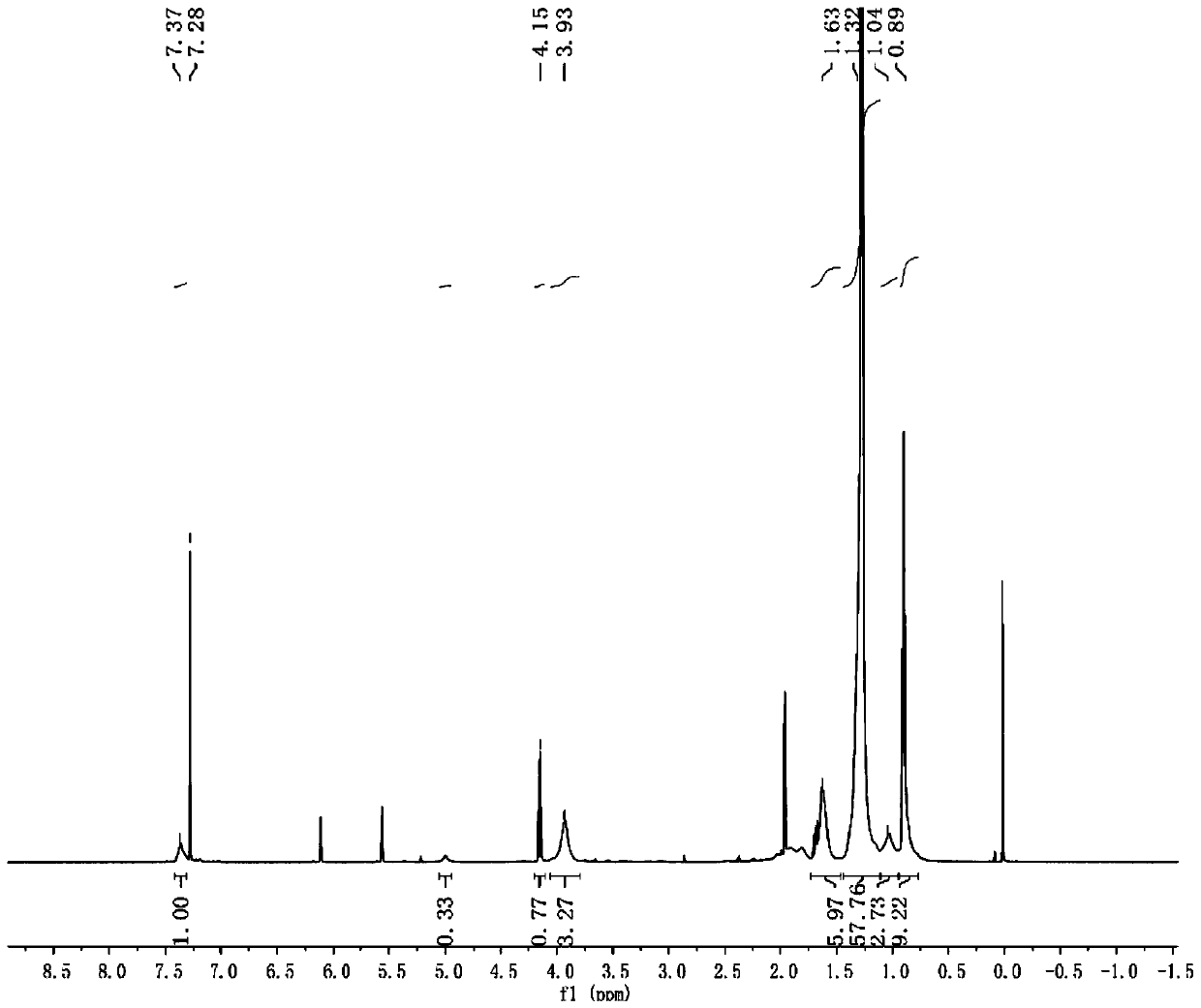

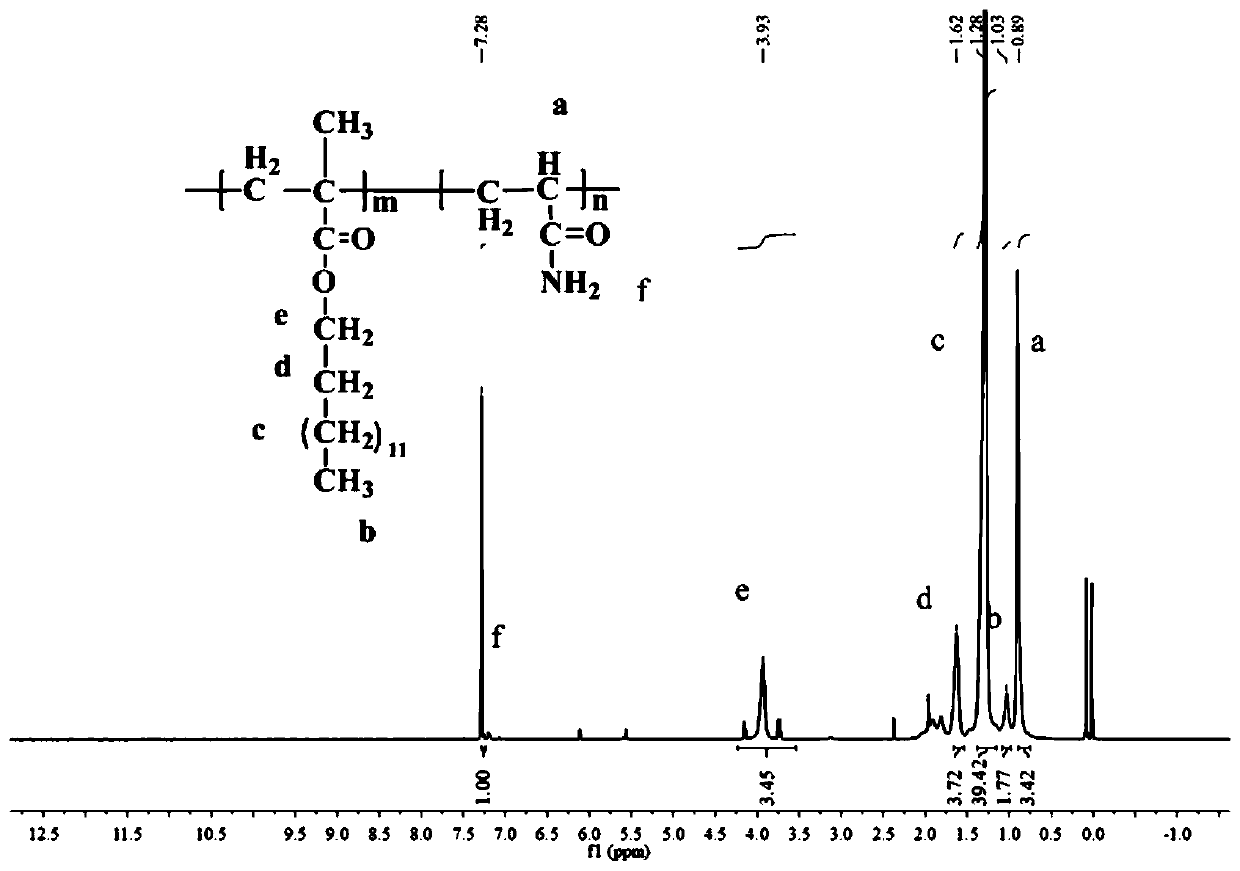

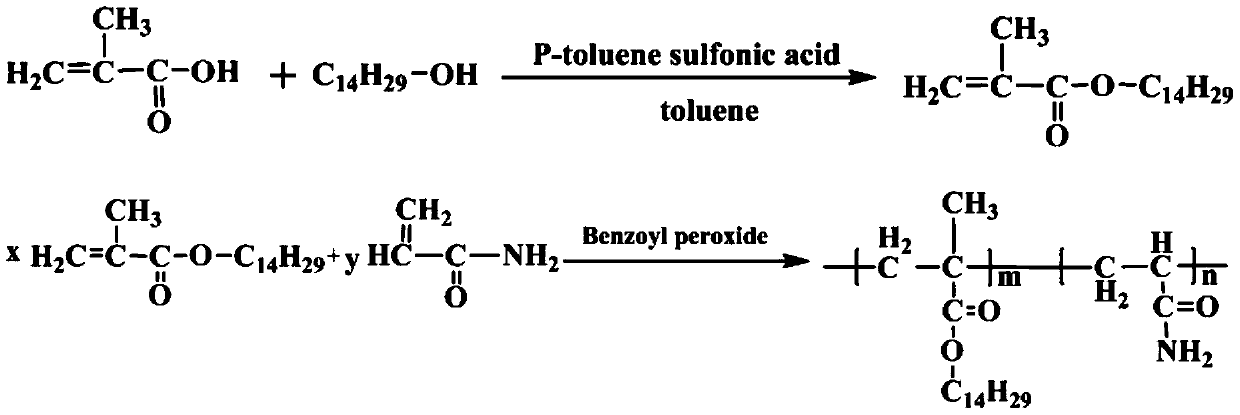

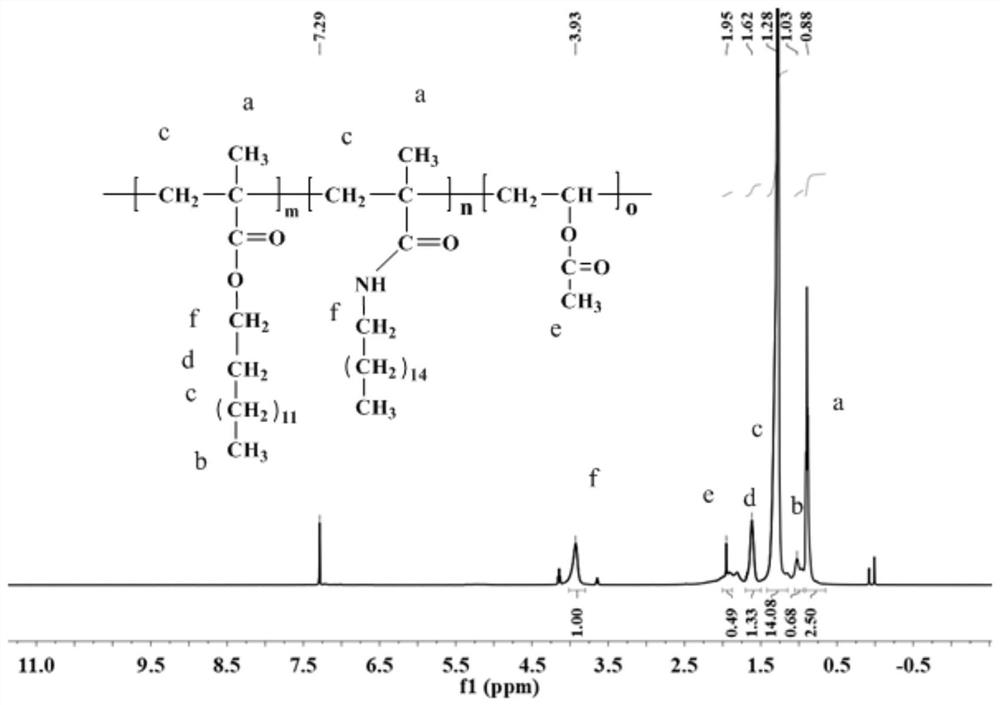

Binary nitrogen-containing polymer diesel pour point depressant, and preparation method and application thereof

InactiveCN111269352AImprove low temperature fluidityLowering the freezing pointLiquid carbonaceous fuelsFuel additivesMethacrylatePtru catalyst

The invention relates to a binary nitrogen-containing polymer diesel pour point depressant, and a preparation method and an application thereof. The preparation method of the diesel pour point depressant comprises the following steps: 1) adding methacrylic acid, higher alcohol and a polymerization inhibitor into a solvent, fully dissolving, adding a catalyst, and carrying out a catalytic reactionto obtain high-carbon methacrylate; and 2) adding the high-carbon methacrylate and acrylamide into a solvent, then adding an initiator, and carrying out a polymerization reaction to obtain the high-carbon methacrylate-acrylamide binary polymer. When applied, the binary nitrogen-containing polymer diesel pour point depressant and EVA are mixed and then added into 0# diesel. The binary nitrogen-containing polymer diesel pour point depressant is low in raw material cost and simple in synthesis method, has high oil solubility after being compounded with EVA, can effectively improve the low-temperature flowing property of diesel, has a good effect in the aspect of reduction of a condensation point and a cold filter plugging point, and has excellent market value.

Owner:SHANGHAI INST OF TECH

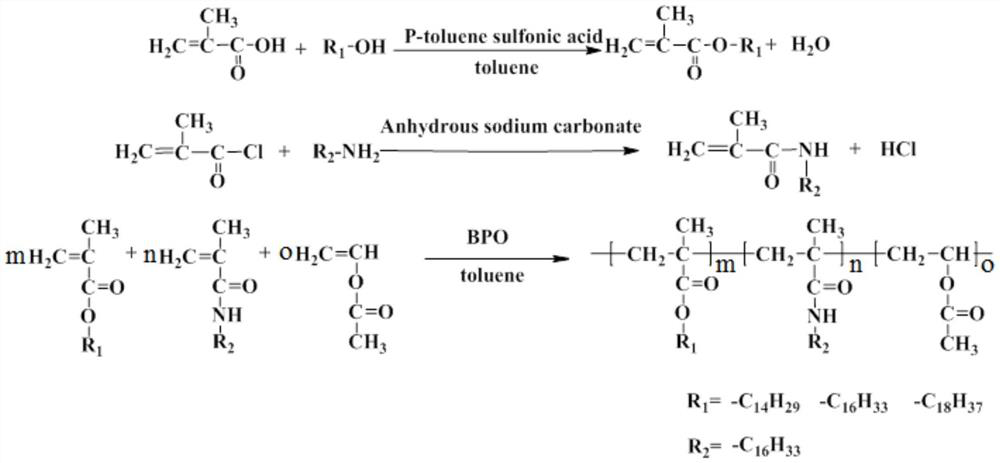

Nitrogen-containing ternary polymer biodiesel pour point depressant, preparation method and application thereof

ActiveCN111826222AImprove low temperature fluiditySimple preparation processBiofuelsLiquid carbonaceous fuelsPolymer scienceBiodiesel

The invention relates to a nitrogen-containing ternary polymer biodiesel pour point depressant, a preparation method and application thereof. The preparation method comprises the following steps of: 1) respectively preparing methacrylic acid high-carbon ester and N-hexadecyl methacrylamide; and 2) adding methacrylic acid high-carbon ester, N-hexadecyl methacrylamide and vinyl acetate into a solvent, then adding an initiator, and carrying out polymerization reaction to obtain a methacrylic acid high-carbon ester-N-hexadecyl methacrylamide-vinyl acetate ternary polymer, i.e., the nitrogen-containing ternary polymer biodiesel pour point depressant. Compared with the prior art, the nitrogen-containing ternary polymer biodiesel pour point depressant solves the problem of poor broad spectrum ofa single methacrylic acid pour point depressant, the N-hexadecyl methacrylamide and the vinyl acetate are introduced to expand the composition of the pour point depressant, the pour point depression effect is improved, and the pour point depressant is simple in preparation process and convenient in experimental operation.

Owner:SHANGHAI INST OF TECH

Multifunctional wet tissue and preparation method

InactiveCN112006584AFine foamReduced breaking strengthCosmetic preparationsKitchenware cleanersEnvironmental engineeringMaterials science

The invention belongs to the field of daily chemical production, and provides a multifunctional wet tissue, which comprises a packaging body, a wet tissue body and a washing bag. The wet tissue body and the washing bag are wrapped in the packaging body, the wet tissue body comprises a wet tissue base material and wet tissue liquid, the wet tissue base material is soaked in the wet tissue liquid, the washing bag is composed of an outer package and washing components wrapped in the outer package, and the outer package and the wet tissue liquid are immiscible. According to the multifunctional wettissue, washing components are newly added and matched while common wiping cleaning and antibacterial functions are achieved, deep cleaning of two hands or utensils is achieved, convenience is brought to life, and the multifunctional wet tissue is easy to degrade and beneficial to environmental protection.

Owner:JIANGSU PROVINCE JIANERKANG MEDICAL DRESSING CO LTD

Soluble hydrofluoride pesticide preparation

InactiveCN101953374BSignificantly restorative growthRestorative growth is goodBiocideDisinfectantsPlant virusDrug resistance

The invention belongs to agrochemicals and pesticides and in particular relates to a soluble hydrofluoride pesticide preparation which is suitable for plant virus diseases and bleeding diseases. The soluble hydrofluoride pesticide preparation is characterized in that after soluble hydrofluoride is mixed and dissolved in clear water, fluorinion molar concentration in the solution is 0.0093-0.0156mol / L and 0.071-0.119mol / L, wherein the fluorinion molar concentration of 0.0093-0.0156mol / L is foliage spraying concentration, and the fluorinion molar concentration of 0.071-0.119mol / L is wound smearing concentration. The invention has no drug resistance to plat viruses and has the advantages of reusability, low use level and quite strong compatibility.

Owner:陈本建

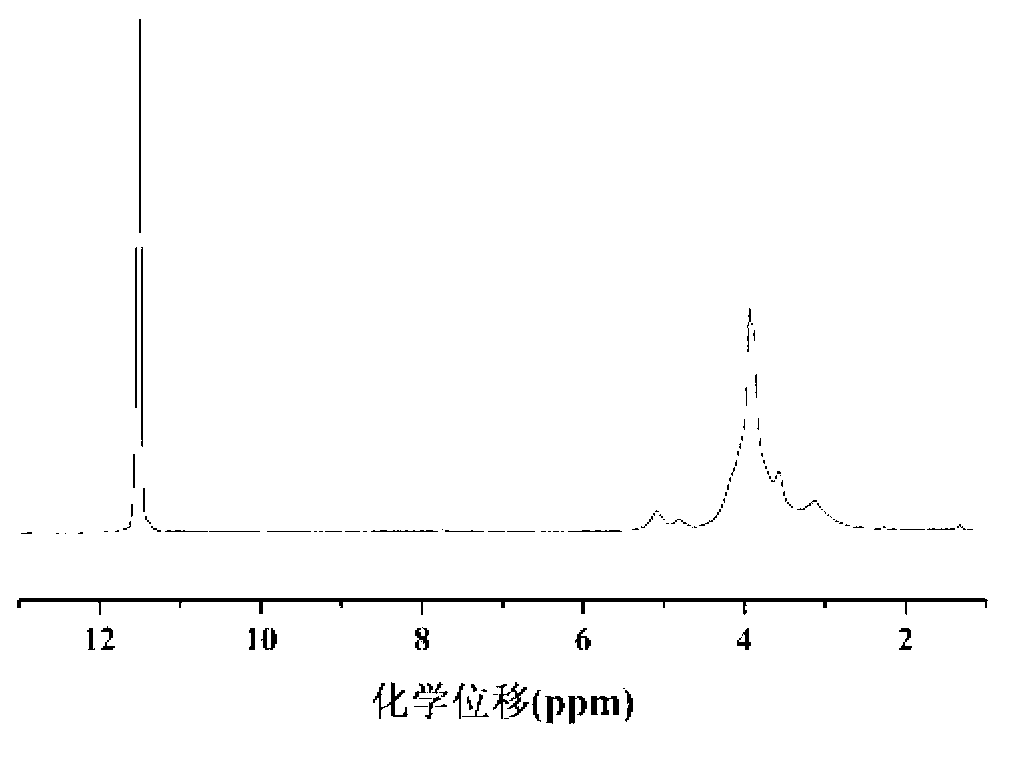

Polymethacrylate-vinyl acetate diesel pour point depressant as well as preparation and application thereof

InactiveCN111748385AImprove low temperature fluidityStrong oil solubilityLiquid carbonaceous fuelsFuel additivesAcetic acidPolymer science

The invention relates to a polymethacrylate-vinyl acetate diesel pour point depressant as well as preparation and application thereof. The preparation method of the diesel pour point depressant comprises the following steps: 1) adding methacrylic acid, higher alcohol and a polymerization inhibitor into a solvent, heating the components to 55-65 DEG C to be fully dissolved, then adding a catalyst,and carrying out a catalytic reaction to obtain methacrylic acid high-carbon ester; and 2) adding high-carbon methacrylate and vinyl acetate into a solvent, then adding an initiator, and carrying outa polymerization reaction to obtain a high-carbon methacrylate-vinyl acetate binary polymer, i.e., the polymethacrylate-vinyl acetate diesel pour point depressant. Compared with the prior art, the polymethacrylate-vinyl acetate diesel oil pour point depressant solves the problem that a single methacrylic acid pour point depressant is poor in broad spectrum, wherein the composition of the pour point depressant is expanded by introducing vinyl acetate, so that the pour point depression effect is improved, and the diesel oil pour point depressant is simple in preparation process and convenient inexperimental operation.

Owner:SHANGHAI INST OF TECH

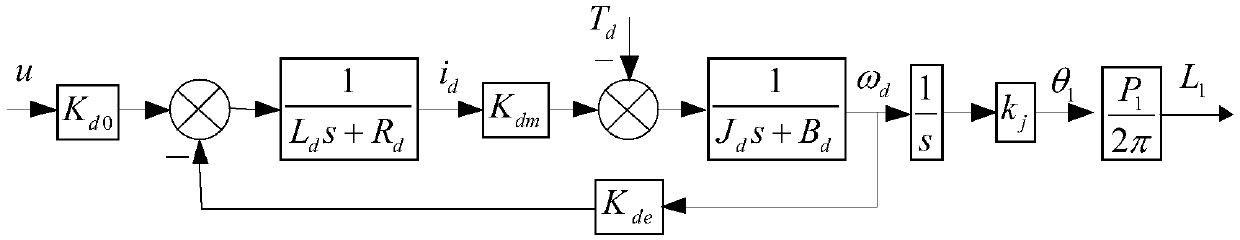

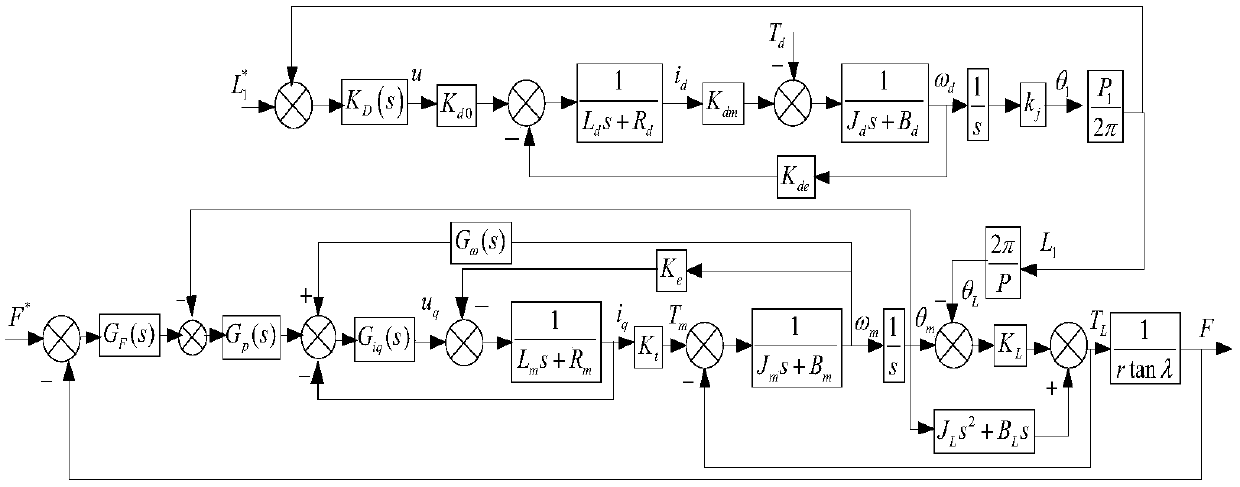

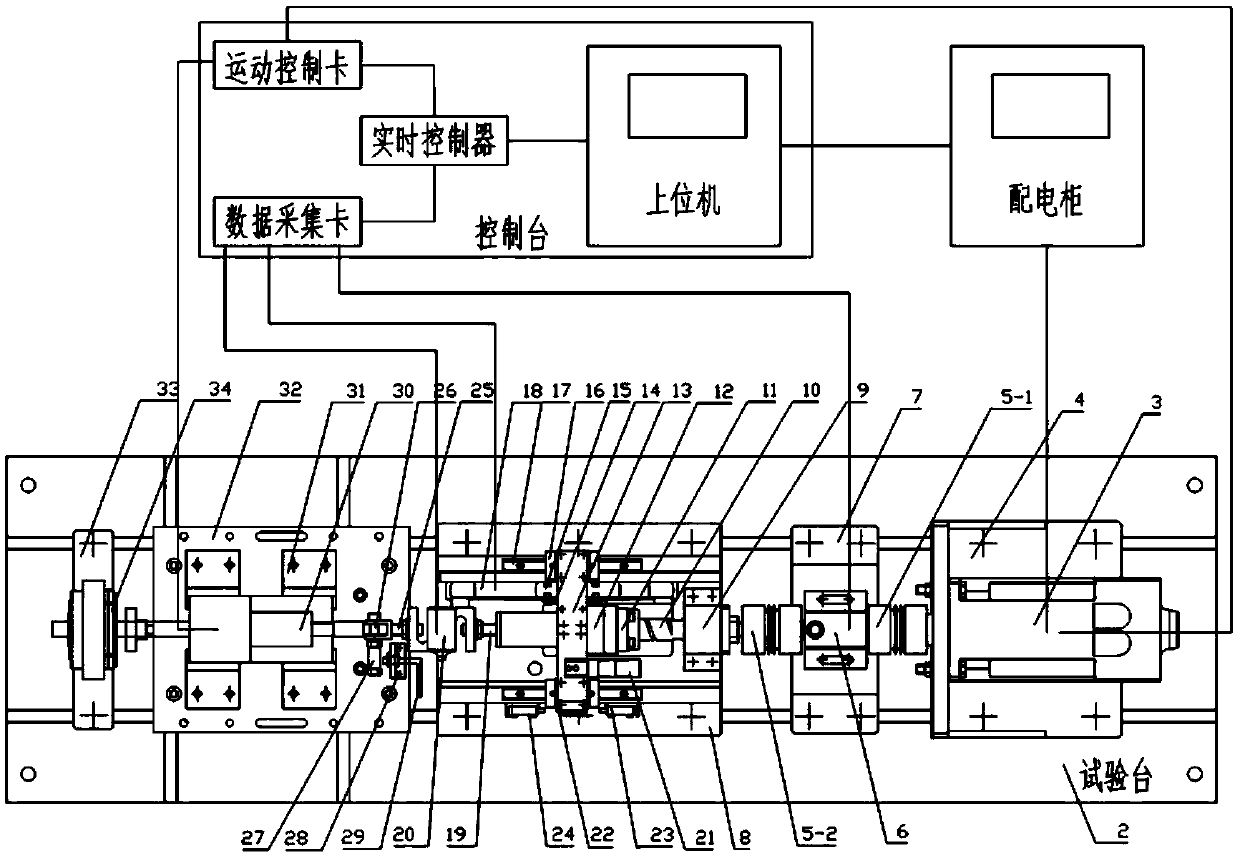

Dynamic Control Method of Electric Loading System of Linear Steering Gear

ActiveCN107203184BReliable controlHigh loading accuracyProgramme controlComputer controlValidation methodsPermanent magnet synchronous motor

The invention discloses a dynamic control method of a linear steering engine electric loading system, comprising the following steps: modeling a servo loading motor, constructing a torque balance equation, and constructing a linear steering engine mechanism model; building a ball screw pair motion model; analyzing the transfer function of the electric loading system, designing a three-closed-loop control method based on a current inner loop, a position outer loop and a force outer loop, and applying complex vector PI control in the current inner loop to enable the current of the servo loading motor to track instruction signals quickly and accurately; and finally, making feed-forward compensation for angular velocity, and verifying the control method. The method takes an electric loading system driven by a permanent magnet synchronous motor as a specific object, and considers the impact of the characteristics of the linear steering engine and the coupling degree between the linear steering engine and the electric loading system. The active force of active displacement of the linear steering engine is inhibited, and the loading precision of the linear loading system is improved. Moreover, a verification method is put forward, which makes a linear load simulator better evaluated.

Owner:NANJING UNIV OF SCI & TECH

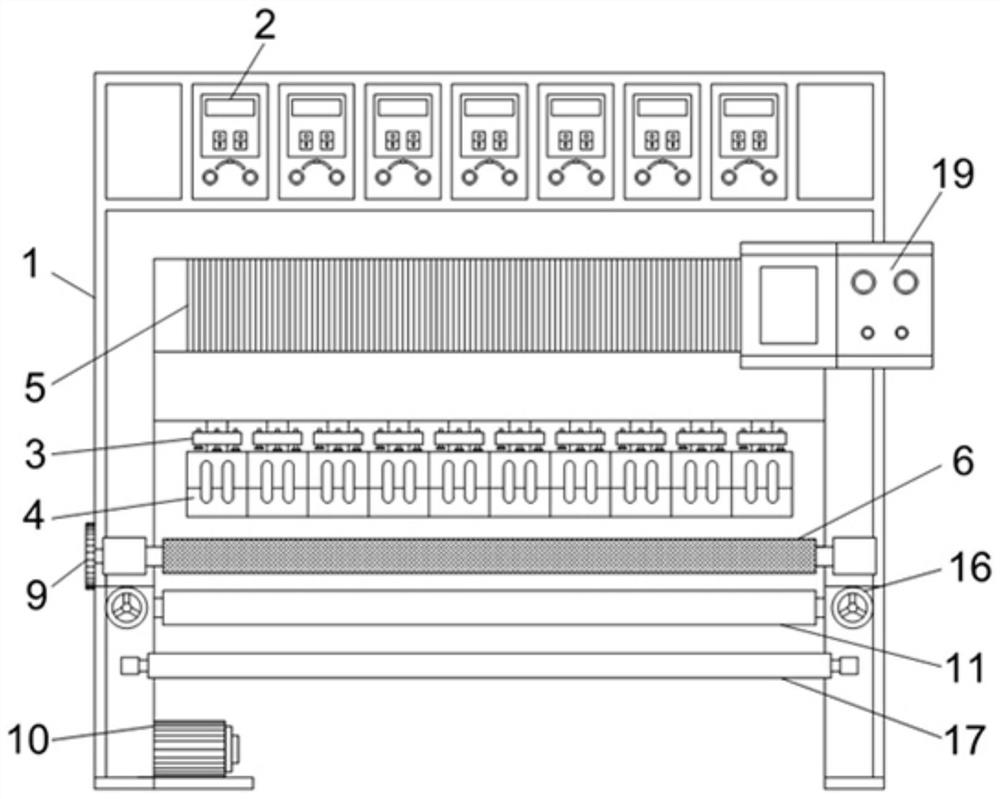

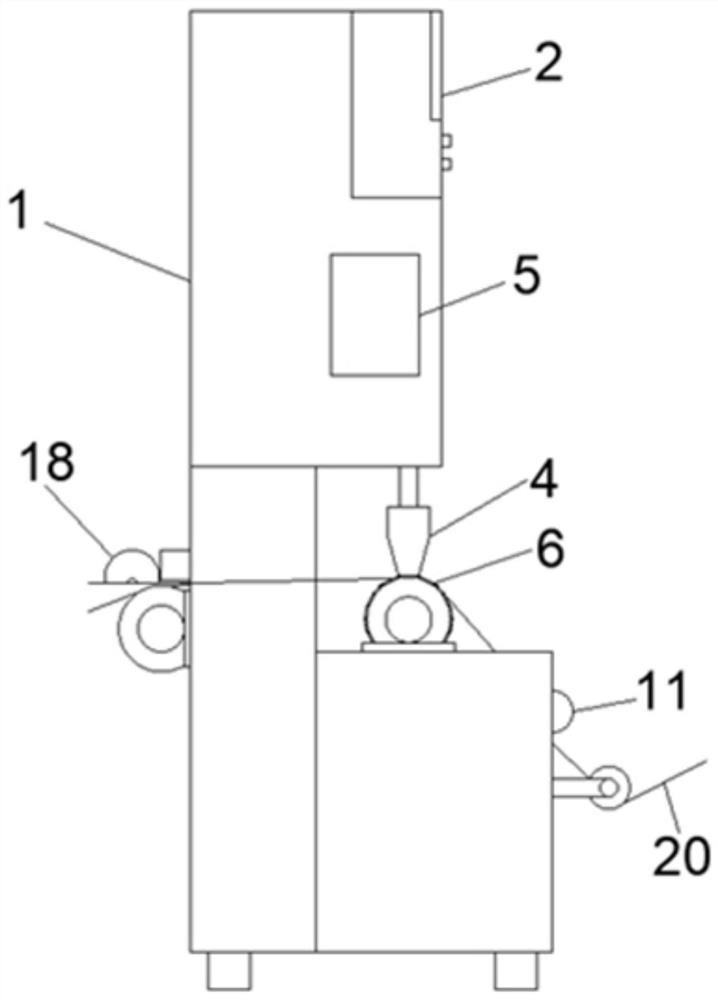

Ultrasonic composite perforating machine

PendingCN112406251AComposite strongNo crackLamination ancillary operationsLaminationComposite effectEngineering

The invention relates to the technical field of filter material manufacturing equipment, and discloses an ultrasonic composite perforating machine, which comprises a rack, a plurality of ultrasonic generators are arranged above the rack, the output ends of the ultrasonic generators are connected with a hot pressing block, sound waves are transmitted by the hot pressing block, a perforated paper roller is arranged below the rack, protruding points used for perforating the composite filter paper are arranged on the outer wall of the perforating paper roller, and a chain wheel mechanism is further arranged on the rack and driven by a motor to drive the perforating paper roller to rotate. The ultrasonic composite perforating machine has the advantages that the ultrasonic composite perforatingmachine can be suitable for composite work of an environment-friendly supporting composite material which is researched and developed by a company and used for manufacturing filter paper for a filter,the composite effect is strong, cracking and gaps are not generated after folding, required discrete holes can be perforated during composite work, and the ultrasonic composite perforating machine isconvenient to use, safe and easy to adjust; and the compounding steps are reduced.

Owner:杭州特种纸业有限公司

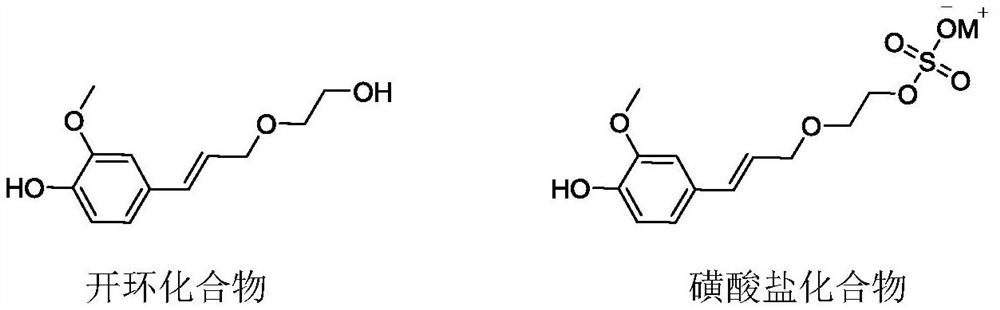

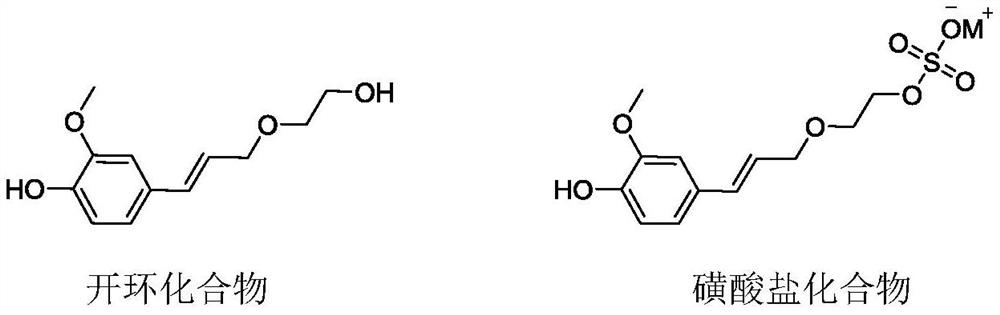

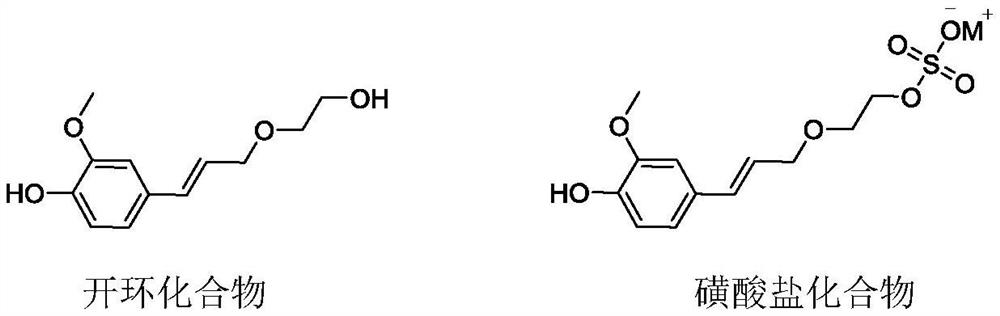

Oil-displacing discharge aiding agent as well as preparation method and application thereof

ActiveCN113684013AComposite strongHigh thermodynamicsOrganic compound preparationFluid removalSulfonateActive agent

The invention provides an oil-displacing discharge aiding agent as well as a preparation method and application thereof. The preparation method comprises the steps of S1, carrying out ring-opening reaction on coniferyl alcohol, ethylene oxide and a first solvent under an alkaline condition to obtain a product system containing a ring-opening compound; S2, carrying out sulfonation reaction on the product system containing the ring-opening compound, SO3 and a second solvent to obtain a sulfonate compound; and S3, mixing the sulfonate compound and a surface active substance to obtain the oil-displacing discharge aiding agent, wherein the surface active substance is a mixture of a fluorocarbon surfactant and ammonium bicarbonate, and the ring-opening compound and the sulfonate compound respectively have structural formulas shown in the description, and M < + > is a monovalent cation. The method is simple, low in cost and remarkable in effect of solving the problem that the multi-cycle steam huff and puff harvesting effect becomes poor.

Owner:PETROCHINA CO LTD

Release liner coating material for four-way elastic synthetic leather for clothing

ActiveCN106400597BComposite strongImprove composite effectPaper/cardboardRelease paperOrganic solventHigh intensity

The invention discloses a four-side elastic synthetic leather functional release paper coating material applicable to clothes, and relates to the technical field of synthetic leather processing. Face coating agent, middle coating layer and following coating agent are used as the coating material of the release paper; a film layer is formed on the release paper through synergistic effect, wherein water is used as solvent of the coating agent; the coating material is safe and toxic-free, and strong in environmental protection property; the invention can avoid the problem that the easy volatile existed in organic solvent can pollution environment and hurt human body health; meanwhile, the compositeness of the prepared film layer and a synthetic leather base cloth is good, and the film layer can easily and completely peel from the release paper; after compounding the prepared film layer and the synthetic leather base cloth, the synthetic leather has excellent elasticity, and is also featured by high intensity, good in both hydrolysis resistance and flame retardance; therefore, the coating material is applicable to process the clothes with four-side elasticity.

Owner:福建宏正利合成革有限公司

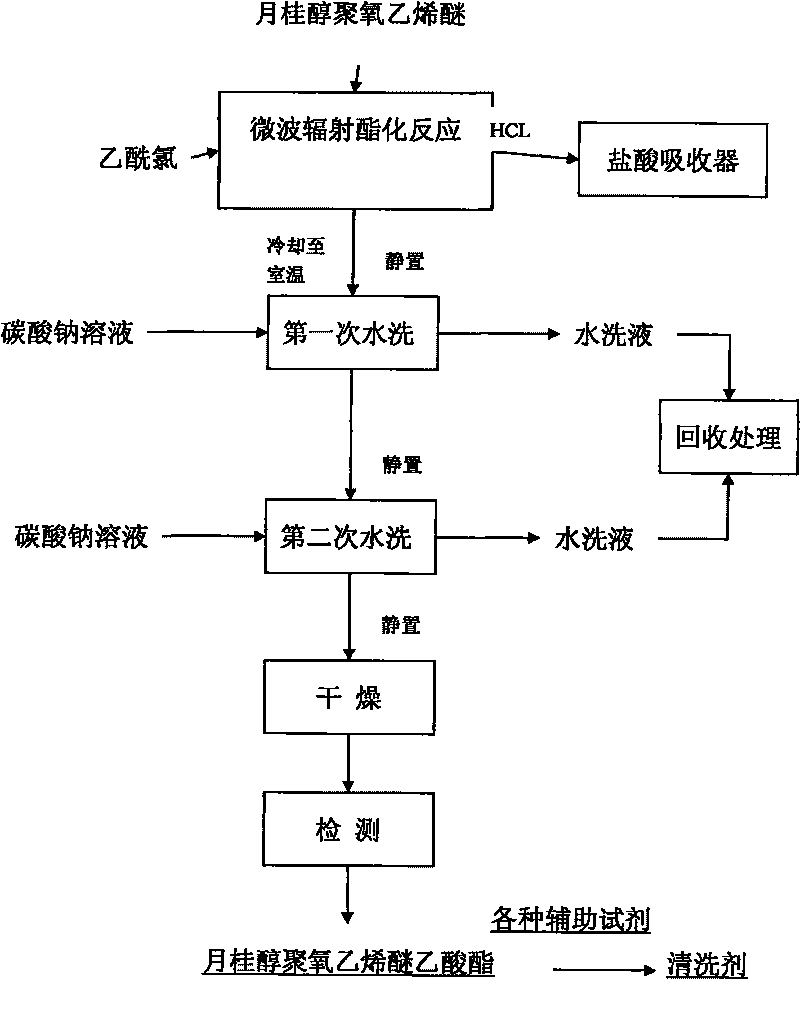

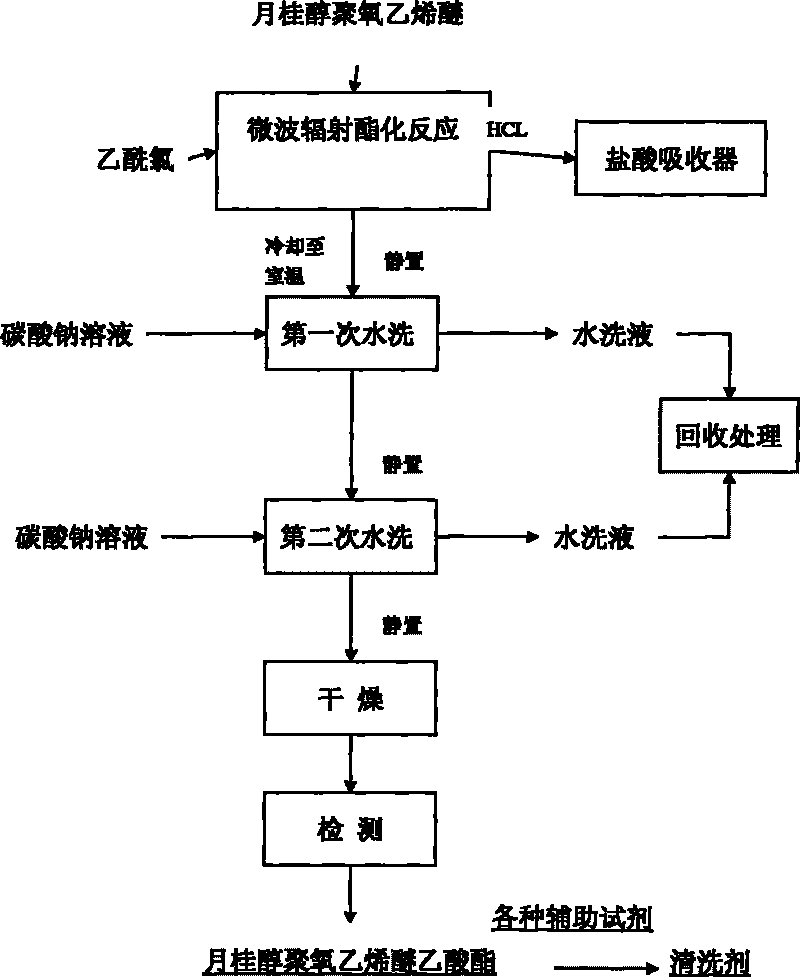

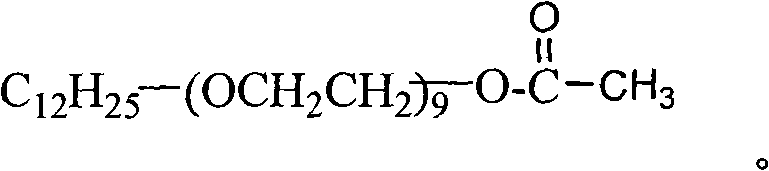

Lauryl alcohol polyoxyethylene ether acetate and cleaning agent taking lauryl alcohol polyoxyethylene ether acetate as main component

InactiveCN101709032AComposite strongFully reflect the synergistic effectInorganic/elemental detergent compounding agentsPreparation from carboxylic acid halidesSolventChemistry

The invention discloses lauryl alcohol polyoxyethylene ether acetate. A preparation method comprises the following steps of: performing esterification reaction of lauryl alcohol polyoxyethylene and acetyl chloride under the conditions of microwave radiation and no solvent, wherein process conditions include: the ratio of raw materials is 1: 1.00-1.10, the microwave emissivity is 375W, and the reaction time is 5min; extracting a reaction product by chloroform, washing the obtained product for two times by using 5 percent sodium carbonate solution, drying the obtained product, and obtaining a lauryl alcohol polyoxyethylene ether acetate product through detection analysis; and then adding 8 to 10 percent of propylene glycol n-propyl ether, 4 to 5 percent of hydroxypropyl sodium cellulosate, 5 to 6 percent of sodium chloride and 45 to 50 percent of water into the product to obtain a non-ionic cleaning agent product by high-speed stirring. The product has special degreasing ability and excellent wettability, can be compatible with cationic and anionic surfactants, and has larger solubility in the water, which ensures that the product has broad application prospect.

Owner:LIAOCHENG UNIV

A method for manufacturing a multi-cavity ceramic composite thermal insulation material

ActiveCN110746199BWith high temperature heat insulation performanceImprove performanceCeramicwareFiberCeramic composite

The invention proposes a method for manufacturing a multi-cavity ceramic composite thermal insulation material. Pour the prepared slurry A into the vacuum water absorption mold for dehydration treatment. After the water drops, spread the prepared slurry B on the surface and continue dehydration to make the product form a thermal insulation composite layer. After drying, it will be used as a felt-like thermal insulation package material used. The thermal insulation felt sheet made by the method of the present invention uses the combination of existing thermal insulation materials, utilizes the different thermal conductivity coefficients of different materials at different temperature sections to exert their respective advantages, forms a composite structure, and produces composite properties , not only has many advantages over traditional fiber materials in terms of structural strength, toughness and thermal insulation performance, especially it is divided into upper and lower layers. The upper layer has high strength and can withstand general impact, while the lower layer has good thermal insulation properties, making the material have excellent performance . It is suitable for application as a ceramic multi-cavity composite thermal insulation material.

Owner:中海润达新材料股份有限公司

A kind of green antibacterial skin care hand sanitizer and preparation method thereof

ActiveCN107468545BRaw greenRaw material environmental protectionCosmetic preparationsToilet preparationsGlycosideActive agent

The invention belongs to the technical field of personal daily cleaning and care products, and in particular relates to a green antibacterial and skin-care hand sanitizer and a preparation method thereof. A green antibacterial skin care hand sanitizer, consisting of the following components in percentage by weight: modified oil ethoxylate 1-5, alkyl glycoside 5-10, sugar-based amide cationic surfactant 0.5-3, alkyl glucose Amide 0.5‑1, edible glycerin 0.1‑1, rose essence 0.01‑0.1, and the balance is deionized water. The antibacterial skin care hand sanitizer of the present invention can decontaminate deeply, has strong antibacterial power, fine foam, easy to rinse, easy to biodegrade, and has the effect of moisturizing and moisturizing the skin.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

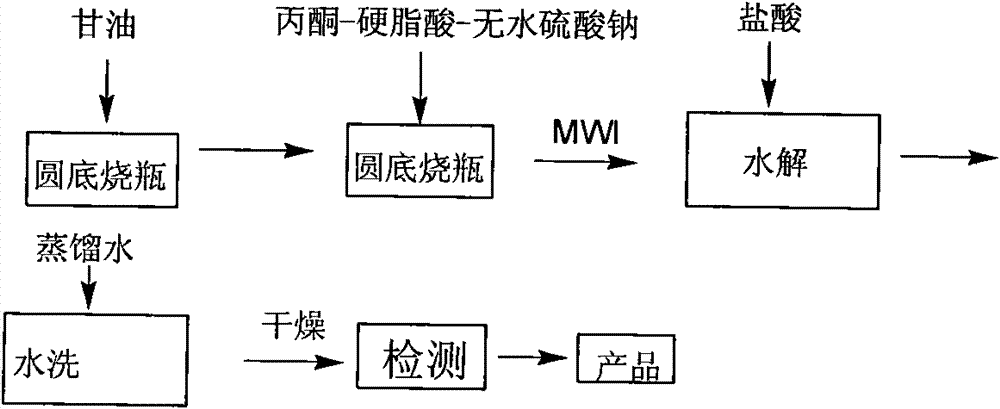

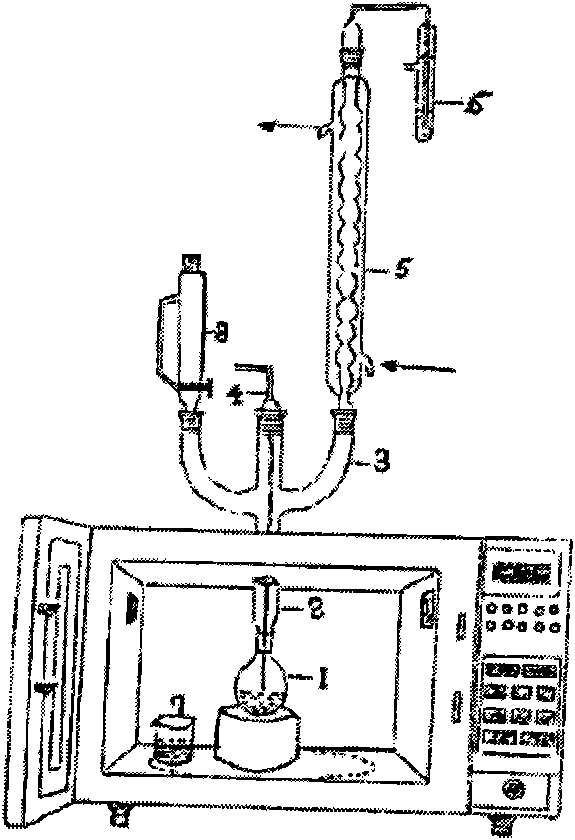

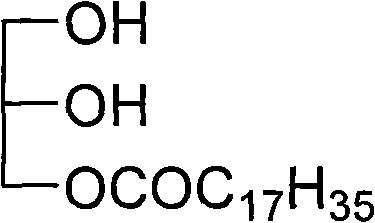

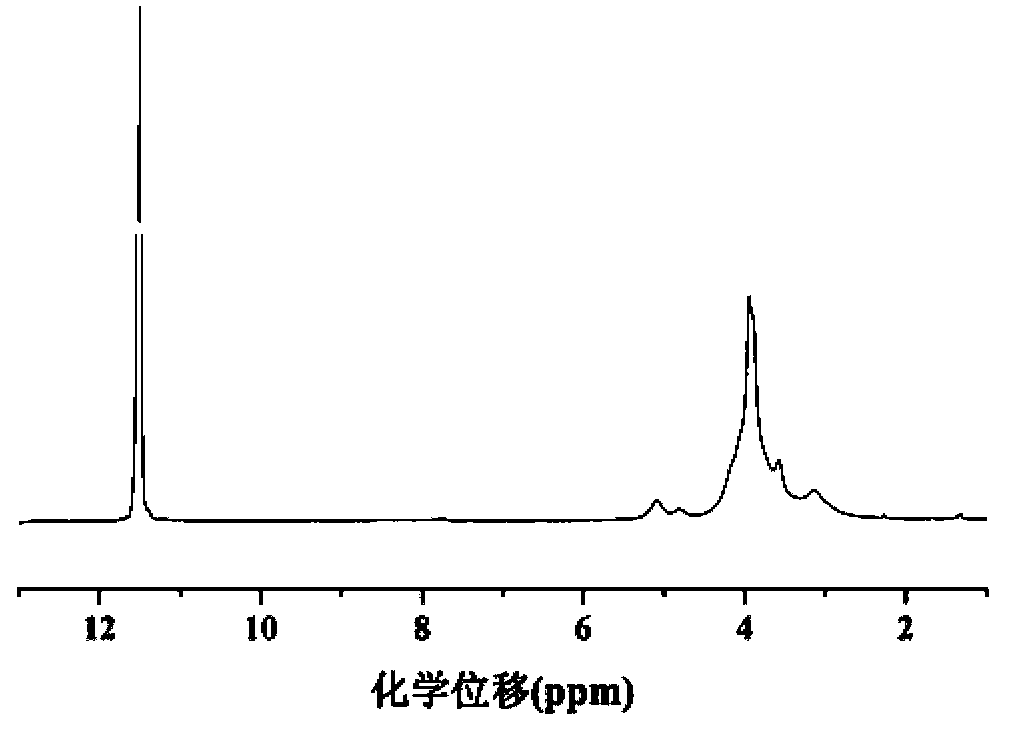

Quick preparation method of glycerin monostearate

InactiveCN101914016BHigh reaction yieldLess side effectsOrganic compound preparationCarboxylic acid esters preparationOrganic synthesisSolvent free

The invention discloses a quick preparation method of glycerin monostearate. In the method, the glycerin monostearate is prepared by placing glycerol, copper p-toluene sulfonate, stearic acid, anhydrous sodium sulfate and acetone into a reactor and placing the reactor in a microwave radiation heating device for microwave heating; wherein the microwave radiation power is 220 to 400 W; and the heating reaction time is 4 to 5 min. The quick preparation method for the glycerin monostearate adopts a microwave radiation solvent-free coupling organic synthesis technology and has the advantages of high reaction speed, simple reaction course, high product purity and simple post processing.

Owner:LIAOCHENG UNIV

Polyamino acid segmented copolymer serving as siRAN carrier and preparation method as well as composite particle

ActiveCN102746513BComposite strongLow toxicityOther foreign material introduction processesOrganic solventL-Aspartate

The invention provides a polyamino acid segmented copolymer serving as a siRAN carrier shown in a formula (I). A preparation method for the polyamino acid segmented copolymer comprises the following steps of: enabling beta-benzyl-L-aspartic acid-N-carboxylic acid anhydride to react with cladodification polyethyleneimine in an organic solvent under the protection of inert gas to obtain an intermediate product; enabling the obtained intermediate product to react with polyethyleneimine under the action of a catalytic agent to obtain the polyamino acid segmented copolymer serving as the siRAN carrier. The invention provides a composite particle which comprises the polyamino acid segmented copolymer serving as the siRAN carrier and siRNA; and the siRNA is the Luc siRNA of silent luciferase. The polyamino acid segmented copolymer serving as the siRAN carrier provided by the invention has concentrated electric charge density, strong composite capacity and good biological compatibility; and the toxicity of the polyamino acid segmented copolymer is effectively reduced.

Owner:长春金传科技有限公司

A kind of amphoteric fluorine-containing surfactant and its preparation method and application

ActiveCN109851529BComposite strongReduce surface tensionOrganic chemistryTransportation and packagingActive agentCombinatorial chemistry

The invention discloses an amphoteric fluorocarbon surfactant, a preparation method and application thereof. The amphoteric fluorocarbon surfactant structure of the present invention is shown in formula 4, wherein, n is selected from any integer in 1 to 4, R 1 for-CH 2 ‑or‑CH(OH)‑, R 2 and R 3 each independently being ‑CH 3 or-CH 2 CH 3 . The amphoteric fluorocarbon surfactant of the present invention is easy to degrade; easily soluble in water and has high surface activity; good compounding performance; and the synthesis method of the amphoteric fluorosurfactant of the present invention is simple, the total yield is high, The cost problem of the aqueous film-forming foam fire extinguishing agent can be greatly reduced, and it has high practical application value and broad market prospect.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

A kind of degradable waterproof aluminum foil paper

The invention discloses a degradable waterproof aluminum foil paper, which comprises a base paper and an aluminum foil layer. The aluminum foil layer is coated with a layer of aluminum foil on the surface of the base paper by a direct evaporation method, and then a layer of 5-10um is compounded on the surface of the aluminum foil layer. The degradable waterproof film; the preparation process of the aluminum foil layer is as follows: (1) uniformly spray a layer of degradable hot melt adhesive on one side of the base paper, and then place the coated base paper in a vacuum aluminum coating machine for aluminum transfer , the aluminum layer and the paper base are compounded by hot melt adhesive, and calendered with a calender; (2) Use a coating roller to evenly coat the degradable waterproof colloid on the surface of the aluminum foil layer, and then heat the aluminum foil paper at 120 ° C Dry it in a constant temperature blast dryer for 15 seconds, and then use a calender to perform calendering. In the invention, aluminum is directly coated on the surface of the base paper, and then a degradable waterproof film is compounded on the surface of the aluminum foil layer, so that the prepared aluminum foil paper is easy to degrade.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com