Dynamic Control Method of Electric Loading System of Linear Steering Gear

A loading system and dynamic control technology, applied in the direction of computer control, program control, general control system, etc., can solve the problems of unmeasurable linear steering gear loading, affecting loading accuracy, weakly damped pneumatic system, etc., to shorten the dynamic tracking process. , Guarantee force tracking accuracy, improve the effect of loading accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

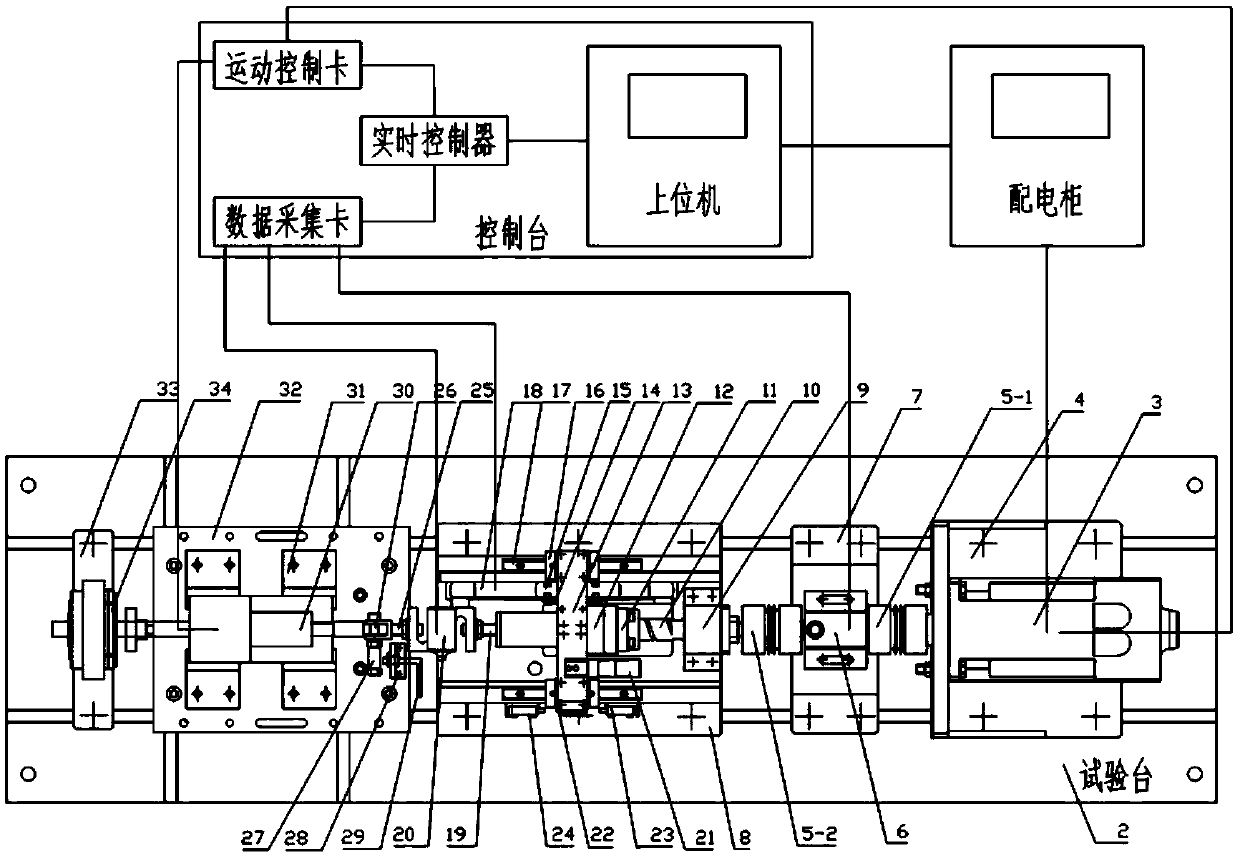

[0110] In order to verify the present invention, the components selected in the embodiment are shown in Table 1, and the parameters of the electric loading system of the linear steering gear are shown in Table 2.

[0111] Table 1 Selection of each component of the test bench

[0112]

[0113]

[0114] Table 2 System parameters

[0115] parameter

parameter value

unit

significance

K t

1.75

Nm / A

Electromagnetic torque constant

K e

112

V / Krpm

back emf constant

K L

6000

Nm / rad

elastic stiffness constant

J L

8.81×10 -5

Kgm 2

load moment of inertia

L m

11.4

mH

Inductance constant

R m

2.1

Ω

Stator winding resistance

J m

9.1×10 -4

Kgm 2

Moment of inertia of PMSM

B m

0.052

Nm / Krpm

Motor damping constant

P

25

mm

screw lead

[0116] Secondly, to analyze whether the system is stable, use MATLAB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com