Patents

Literature

88results about How to "Improve dehydration ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation technology of efficient polymeric aluminum chloride for wastewater treatment

InactiveCN103738992AGood processing effectImprove protectionAluminium chloridesWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateWastewater

The invention relates to a preparation technology of efficient polymeric aluminum chloride for wastewater treatment. The preparation technology is mainly technologically characterized by comprising the following steps: with hydrochloric acid, aluminum hydroxide and a polymerization regulator as main raw materials, producing a liquid solution by a high-temperature, low-pressure and alkaline adjustment two step method; and producing powdery solid by a centrifuging or pressure spray drying and curing environment-friendly technology. The preparation technology disclosed by the invention is advanced in process, high in production efficiency, fast in purification speed, good in treatment effect, wide in application field, low in treatment cost, energy-saving and environment-friendly, and has important application and popularization values by adjusting the raw material ratio in production.

Owner:TIANJIN SHUIJIE PURIFICATION MATERIAL CO LTD

Alkylation waste sulfuric acid resource recycling method

InactiveCN105858622AHigh removal rateReduce operating energy consumptionBiofuelsSolid fuelsRecovery methodActivated carbon

A method for recycling waste sulfuric acid from alkylation, comprising the following steps: (1) mixed impregnation: mixed impregnation according to the liquid-solid weight ratio of waste sulfuric acid and condensation carbonization agent of 1:1-10:1; (2) condensation carbonization Reaction: The waste sulfuric acid after mixing and impregnation and the condensation carbonization agent are subjected to condensation carbonization reaction at a temperature of 95-145°C and a pressure of normal pressure-0.05MPa for 1-10 minutes to obtain carbides and waste liquid; (3) Washing: put The carbides are washed countercurrently for many times, and after filtration and separation, the carbides and filtrate are finally obtained; (4) Decolorization and deodorization: add decolorization and deodorization agent according to 1-10% of the weight of the filtrate, and decolorize and deodorize at a temperature of 50-100°C , recycling to obtain regenerated sulfuric acid; (5) carbon material recovery: the carbide obtained in step (3) is used for fuel or further processed into activated carbon. The method of the invention is carried out under relatively small pressure and low temperature when processing waste sulfuric acid from alkylation, the device has mild operating conditions, low energy consumption, low investment, simple operation and low device maintenance cost.

Owner:GUANGXI NANNING DHXY ENTECH

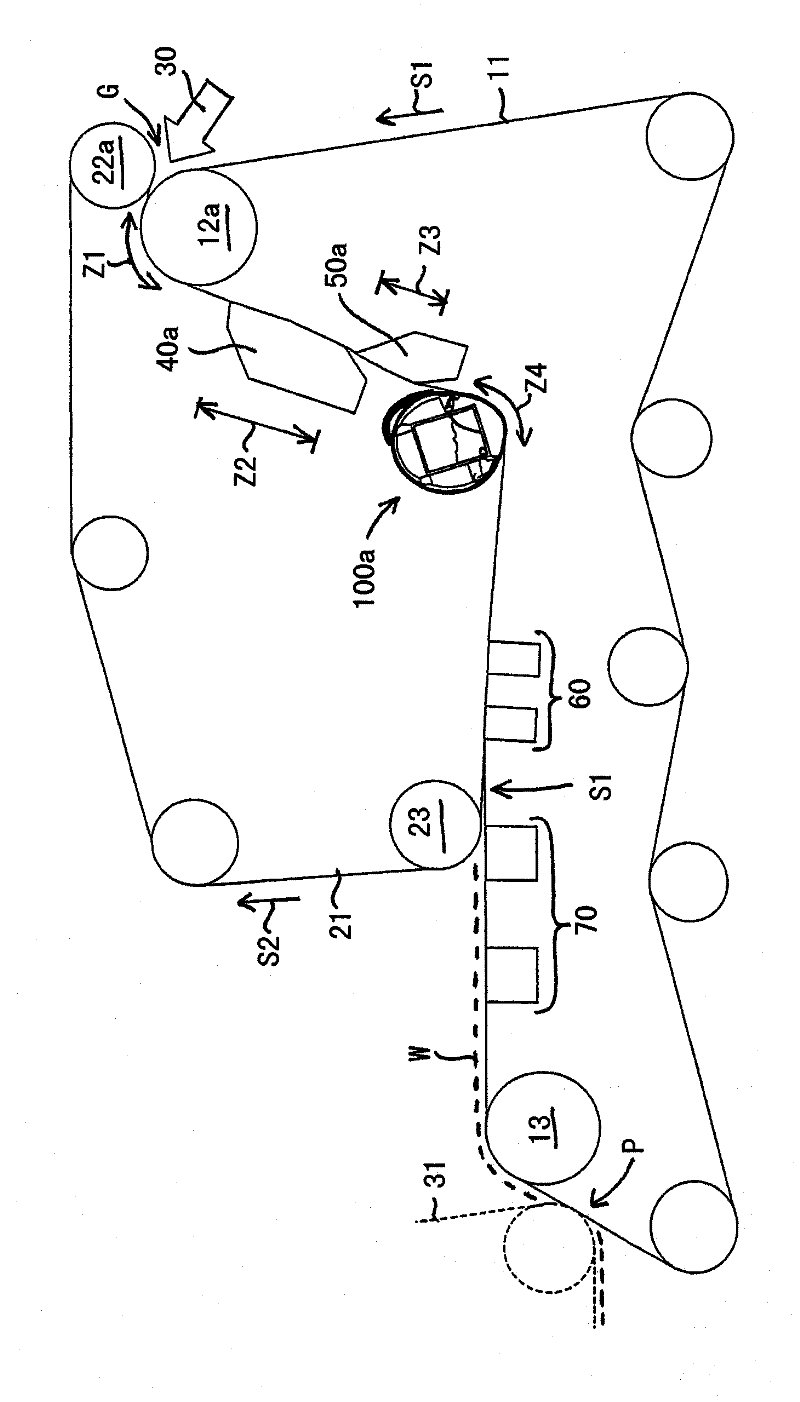

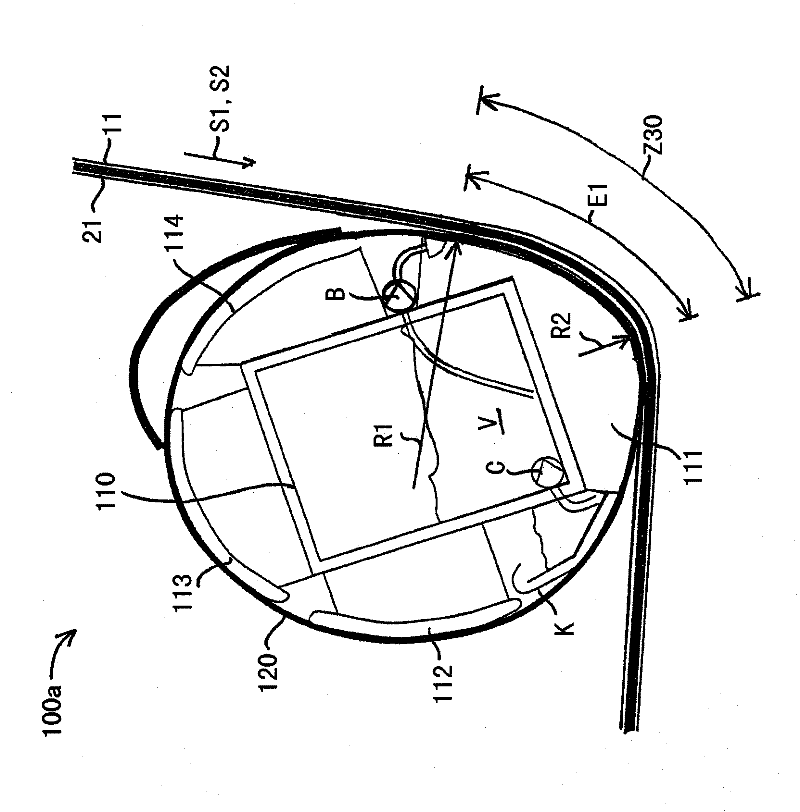

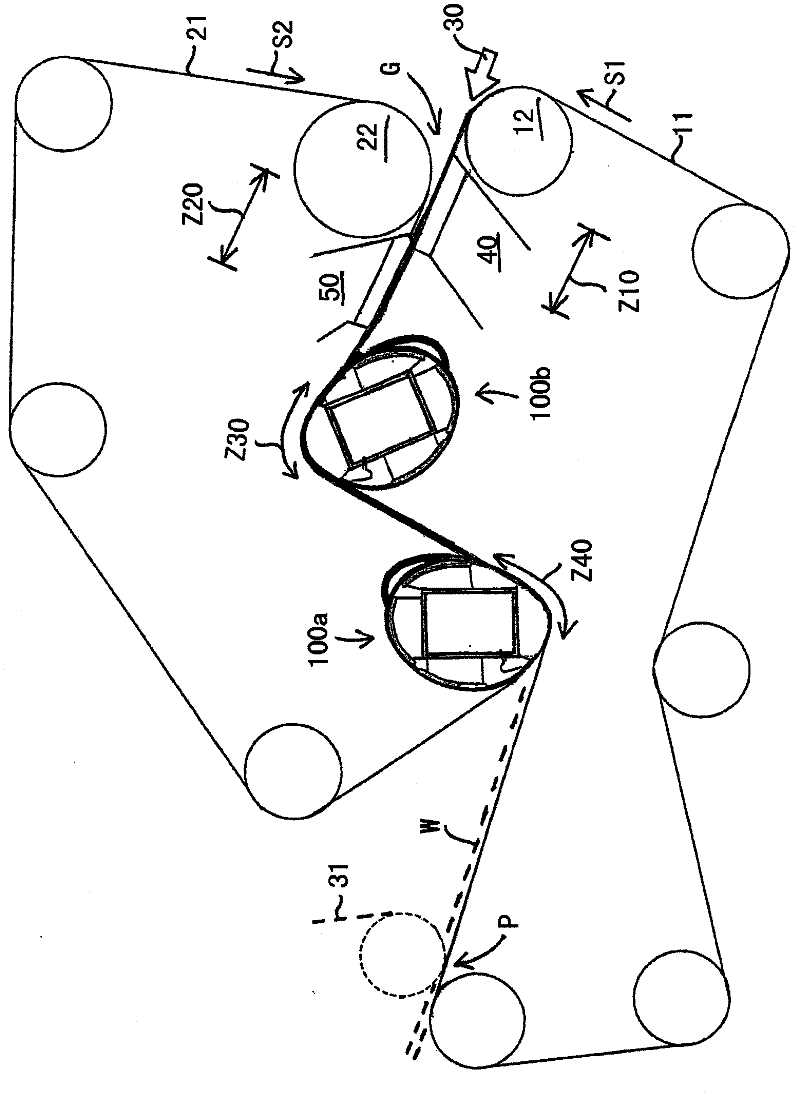

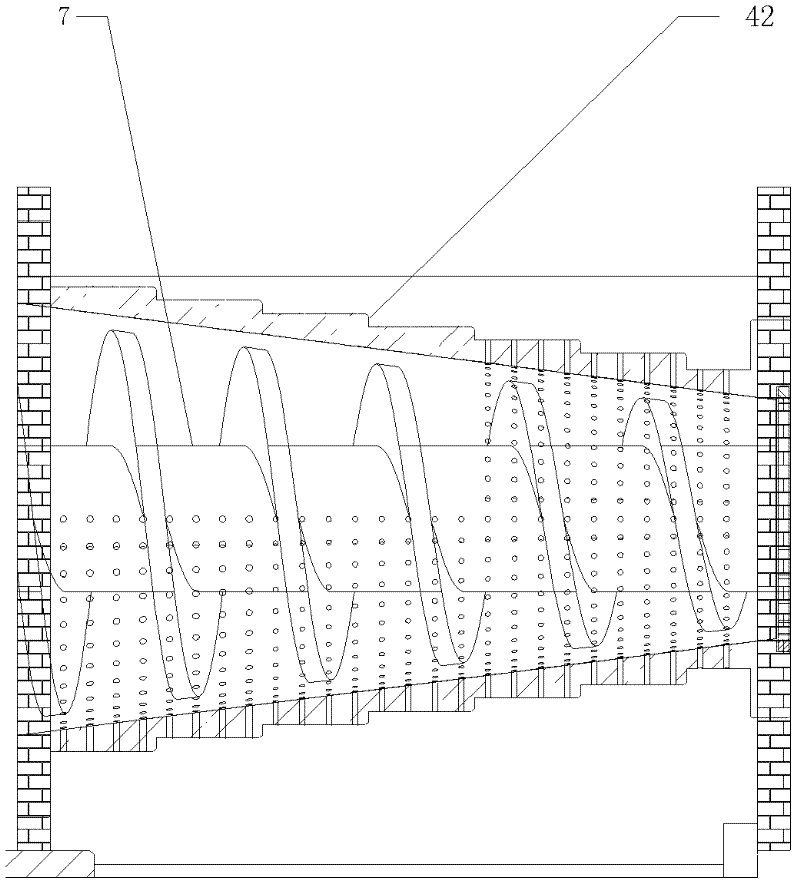

Forming section

ActiveCN102197177AExcellent quality and strength propertiesReduce splashMachine wet endWire loopDewatering

The forming section comprises two wire loops (11, 21) which form a twin- wire zone which comprises a dewatering element (40) performing initial dewatering and a dewatering device (100b) following it. The dewatering device (100b) comprises a stationary support shaft (110) on which are supported support elements (111, 112, 113, 114) around which circles an impermeable belt loop (120). The dewatering device (100b) further comprises a curvilinear dewatering zone (Z30) over which the wires (11, 21) travel supported by the belt loop (120). The degree of curvature of the curve of the curvilinear dewatering zone (Z30) increases in the travel direction of the belt (120) such that increasing dewatering pressure is applied to pulp suspension travelling between the wires (11, 21) on the curvilinear dewatering zone (Z30).

Owner:METSO PAPER INC

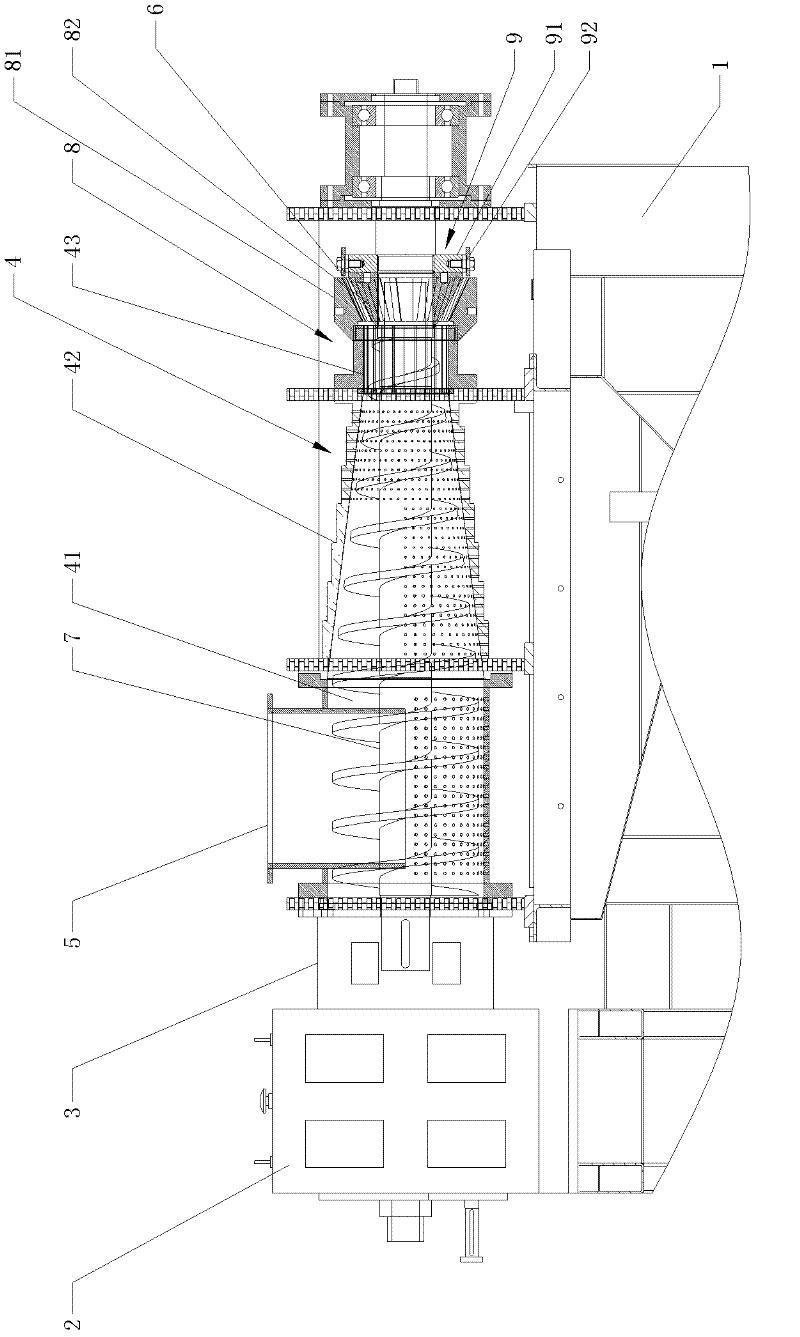

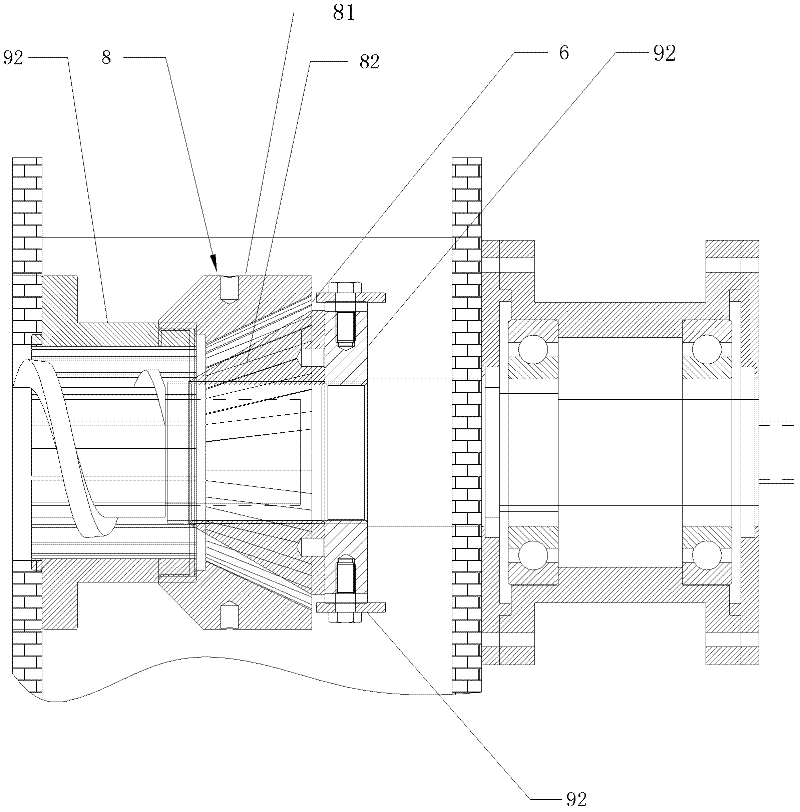

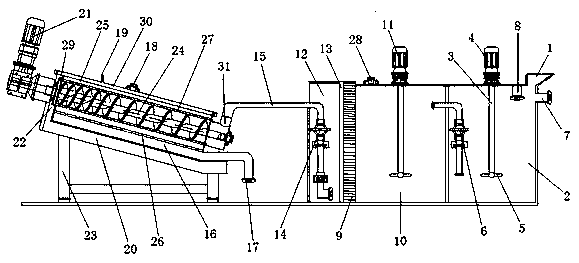

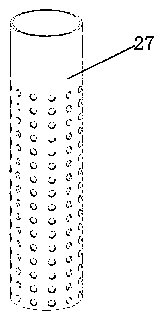

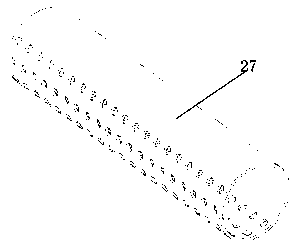

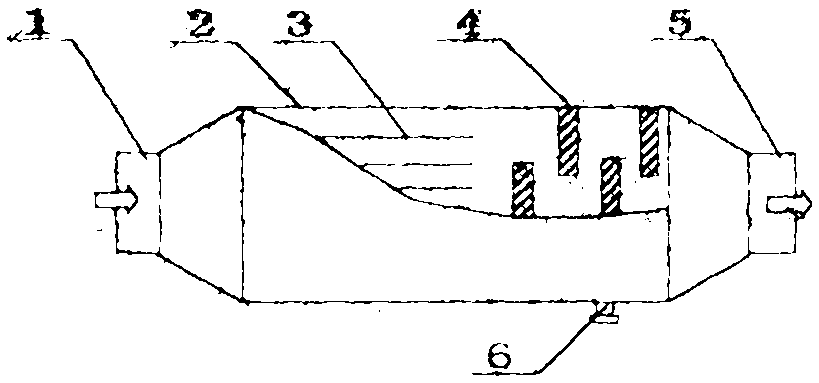

Squeezing type dewatering machine

The invention discloses a squeezing type dewatering machine, which comprises a frame. A filter cylinder with filtering holes is fixed onto the frame, a conical screw rod with a helical blade is mounted in the filter cylinder, the filter cylinder comprises a primary filter cylinder body and a secondary filter cylinder body which are connected with each other, the primary filter cylinder body is provided with a feeding port, the secondary filter cylinder body is conically contracted along the pushing direction, and a squeezing cylinder is connected to the tail end of the secondary filter body. The conical screw rod penetrates through the primary filter cylinder, the secondary filter cylinder and the squeezing cylinder, a discharging device is arranged at the tail end of the squeezing cylinder, and the conical screw rod is driven by a power device. Materials can be dewatered for three times by means of the squeezing type dewatering machine, and since the conical screw rod is conical and the secondary filter cylinder body is conically contracted along the pushing direction, the space between the conical screw rod and the secondary filter cylinder body is small, and materials can be better dewatered. The squeezing type dewatering machine is low in required centrifugal rotation speed, high in dewatering capacity, low in noise pollution and environment-friendly.

Owner:JIANGSU FANGSHENG MACHINERY

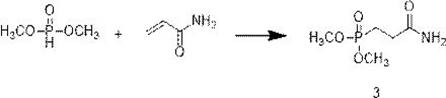

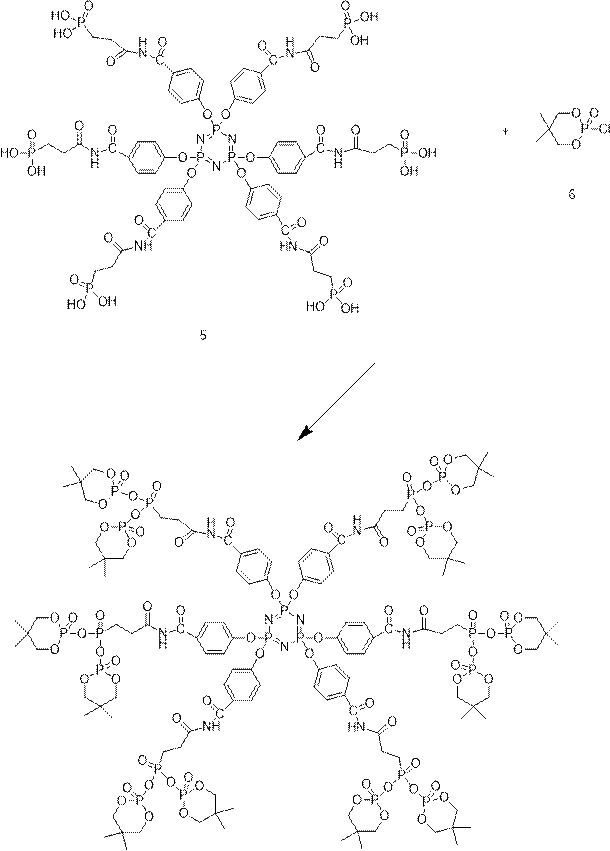

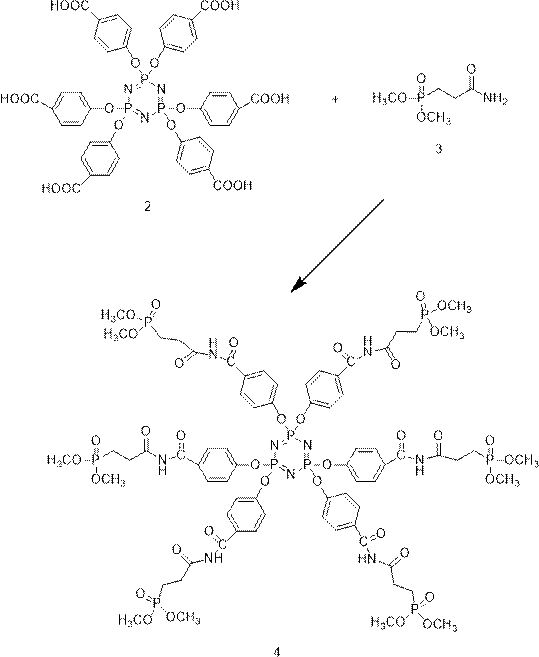

Efficient PP flame-retardant master batch and preparation method thereof

InactiveCN113248831AGood compatibilityImprove dehydration abilityOrganic structureAluminium hydroxide

The invention discloses an efficient PP flame-retardant master batch which is prepared from the following raw materials in parts by weight: 60.5 to 78.6 parts of PP resin, 10.4 to 16.7 parts of talcum powder, 20.2 to 24.6 parts of modified nano aluminum hydroxide, 7.5 to 11.3 parts of an auxiliary flame retardant, 0.5 to 1.1 parts of a coupling agent, 0.6 to 1 part of a stabilizer, 1.5 to 2 parts of an antioxidant and 20.8 to 35.6 parts of isopropyl ether. The invention also discloses a preparation method of the flame-retardant master batch. The modified nano aluminum hydroxide plays a role of a main flame retardant, the structure that the aluminum hydroxide coats the red phosphorus contains two flame-retardant components of the aluminum hydroxide and the red phosphorus, meanwhile, the disadvantage of poor stability caused by small enough granularity of the red phosphorus is solved, in addition, the auxiliary flame retardant is added to further consolidate the flame-retardant performance, the auxiliary flame retardant is of a pure organic structure, has better compatibility with the base material and is more resistant to migration, and meanwhile, the auxiliary flame retardant is matched with the inorganic flame retardant to achieve the gain effect.

Owner:苏州羽凡工程塑料有限公司

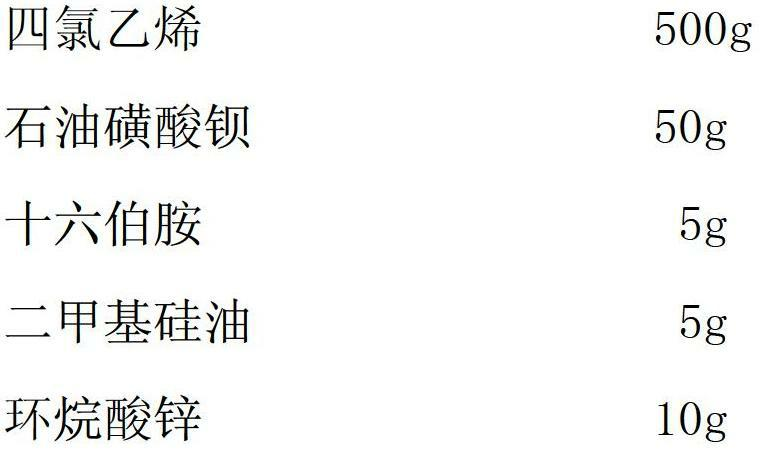

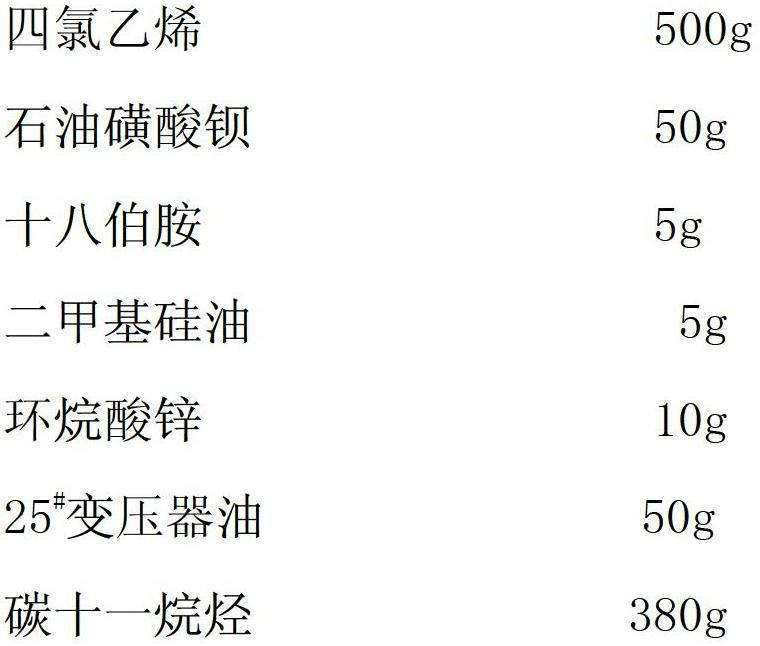

Electric equipment moisture resistance, corrosion resistance and insulation protection agent and preparation method thereof

The invention relates to an electric equipment moisture resistance, corrosion resistance and insulation protection agent and a preparation method thereof. The protection agent contains the raw materials by weight percentage: 20-50 percent of tetrachloroethylene, 1-10 percent of rust inhibitor, 0.1-1 percent of dehydrating agent, 0.5-2 percent of film-forming agent, 5-10 percent of transformer oil and the balance of hydrocarbonic solvent. After being sprayed on a piece of electric equipment, the protection agent can not only remove the moisture and the damp on the electric equipment, but also form a half-dry protective film on the surface of the electric equipment, and the protective film does not hamper the connection of the circuit of the equipment. The protective film protects the electric equipment against the encroachment of damp and corrosive gases and can improve the insulation intensity of the electric equipment. The protective film can endure the voltage of 20KV and can be used when the electric equipment is in work. The invention has simple and scientific action mechanism, and through the reasonable combination such as the solvent, the dehydrating agent, the rust inhibitor and the film-forming agent, the protection agent reaches the functions of dispersing water, resisting damp and corrosion and improving the insulation intensity of the electric equipment.

Owner:华阳新兴科技(天津)集团有限公司

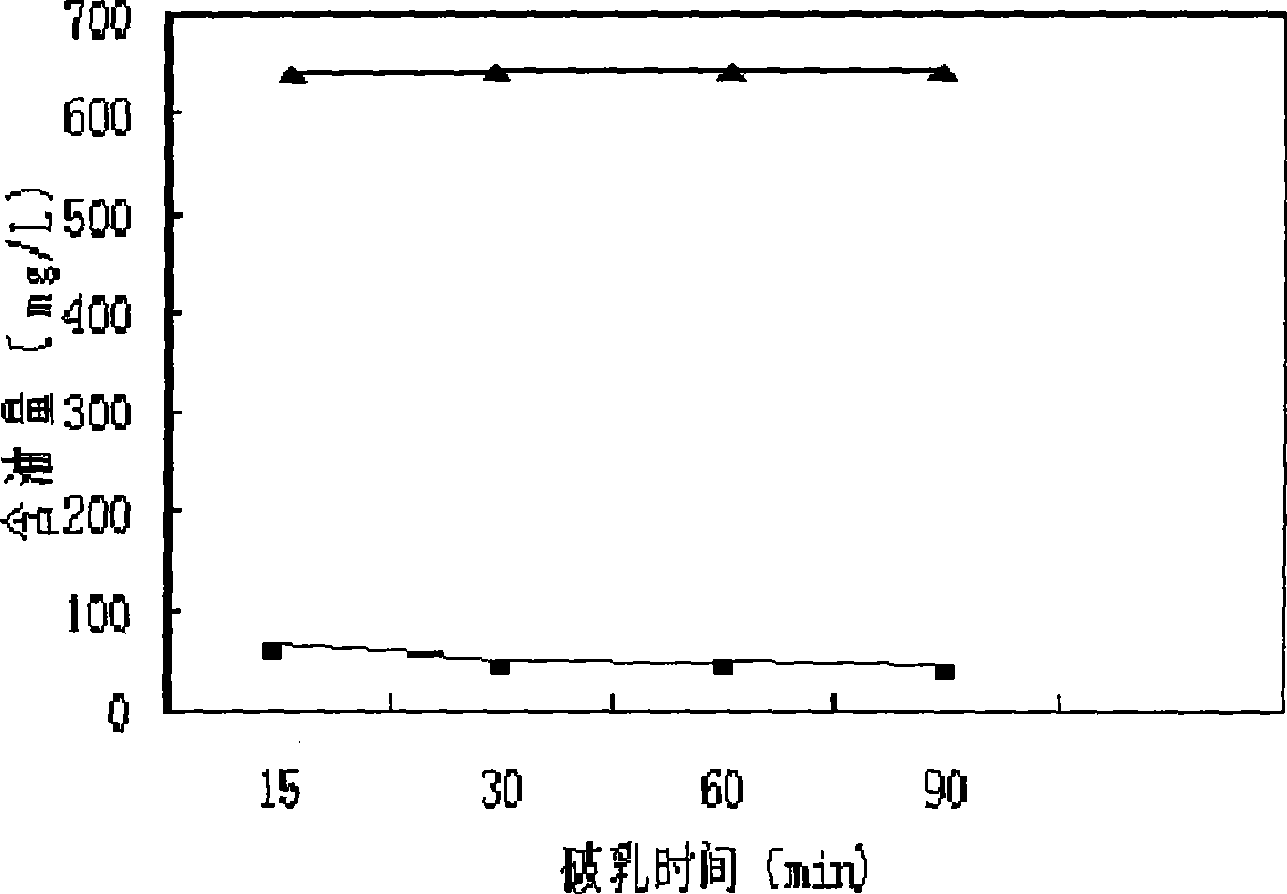

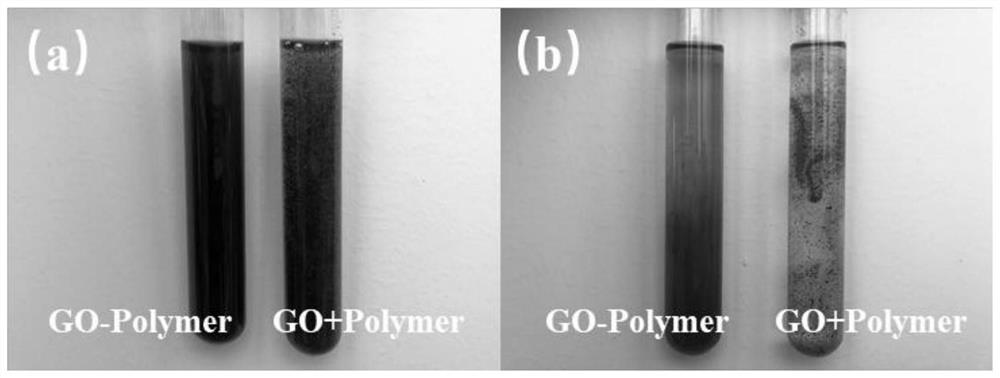

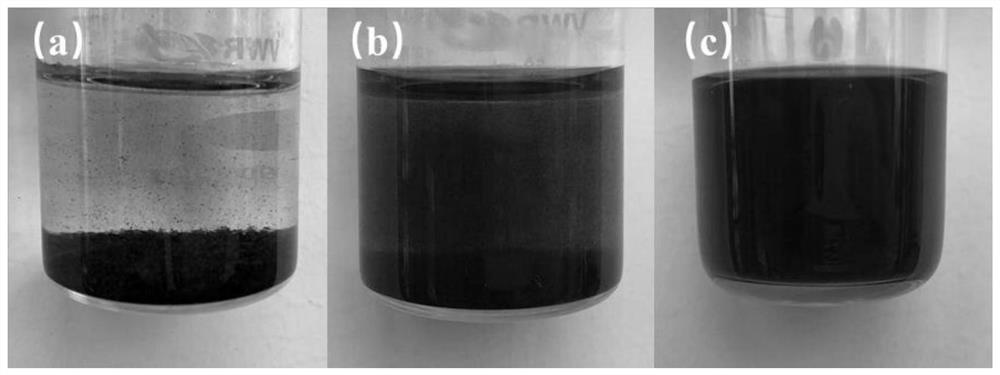

Composite type biological emulsion splitter

InactiveCN101530758AImprove dehydration abilityReduce negative impactTransportation and packagingMicroorganism based processesEmulsionDistilled water

Owner:HARBIN INST OF TECH

Zinc phosphomolybdate flame retarding and smoke suppressing PVC sheet material

InactiveCN107286494APromote cross-linking into charReduce generationPhosphorus compoundsPlasticizerPhosphate

The invention discloses a zinc phosphomolybdate flame retarding and smoke suppressing PVC sheet material which is prepared from the following components in parts by weight: 100 parts of PVC resin, 4 to 5 parts of a heat stabilizer, 5 to 20 parts of a plasticizer, 3 to 7 parts of a flame retarding and smoke suppressing agent, 0.5 to 3 parts of a phosphate coupling agent and 0.4 to 0.6 part of PE wax. According to the PVC sheet material, by the flame retarding action of phosphorus and the smoke suppressing action of molybdenum and zinc, the synergistic effect of phosphorus, molybdenum and zinc can effectively improve the flame retarding and smoke suppressing performance of the PVC sheet material.

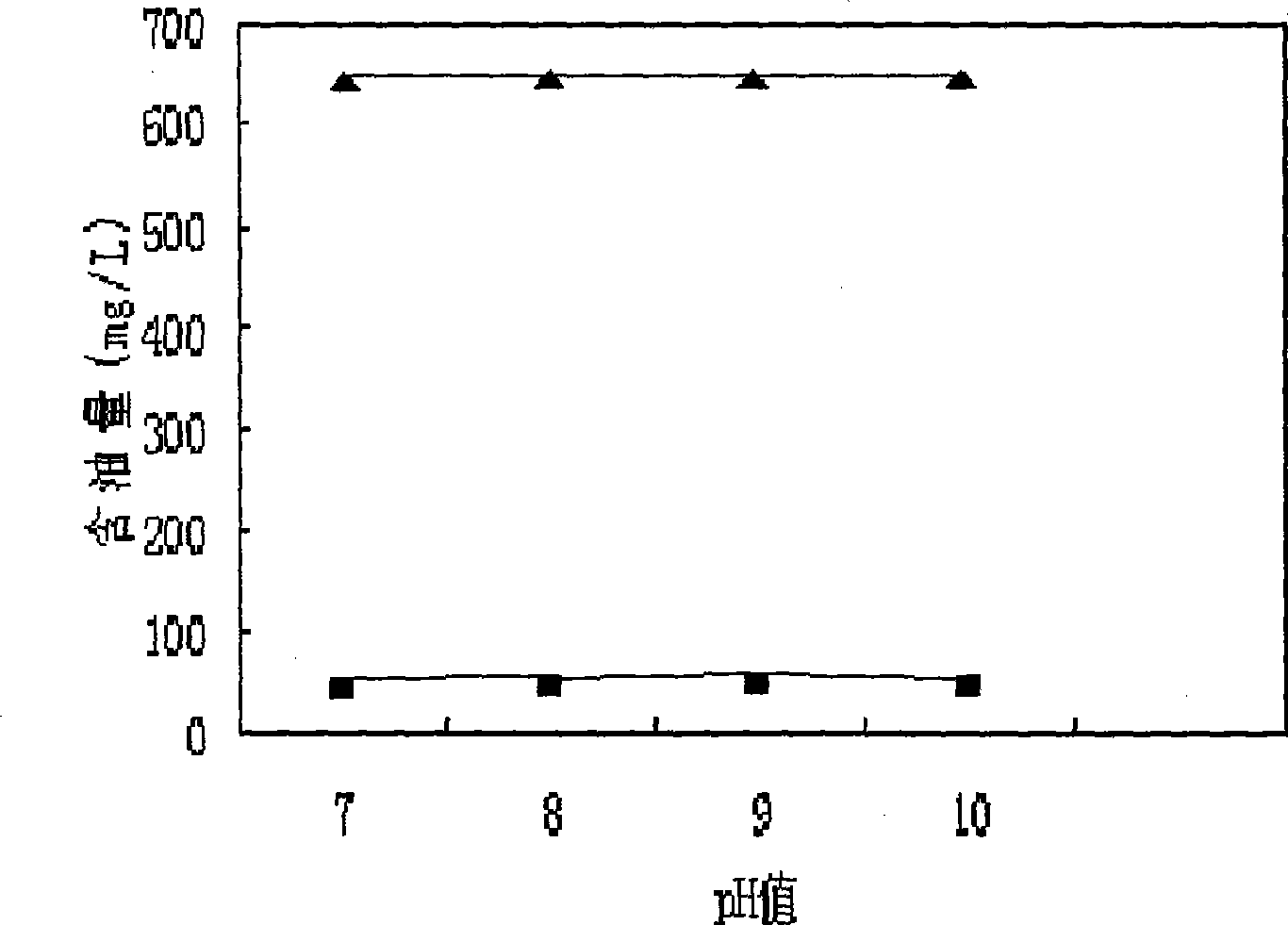

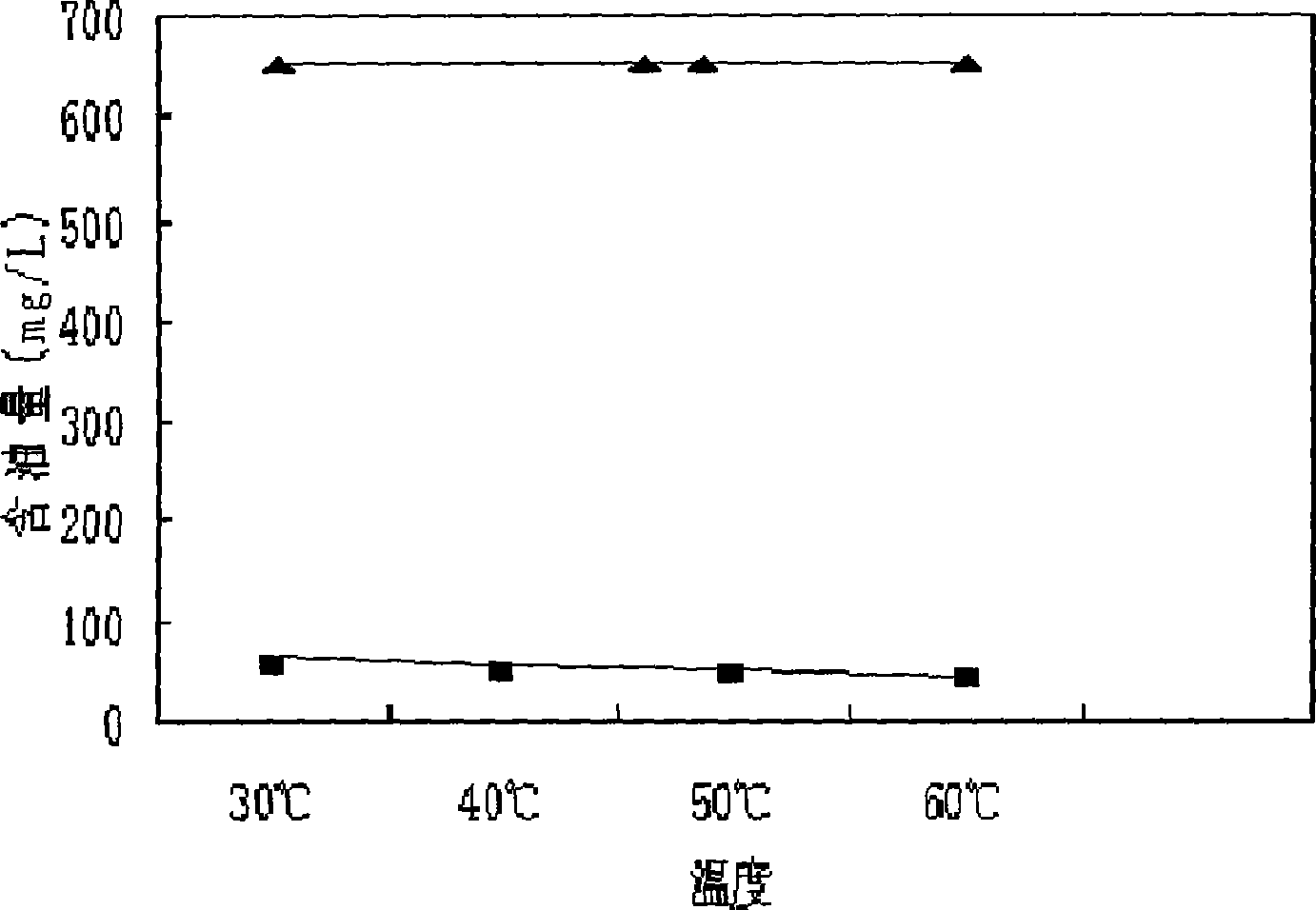

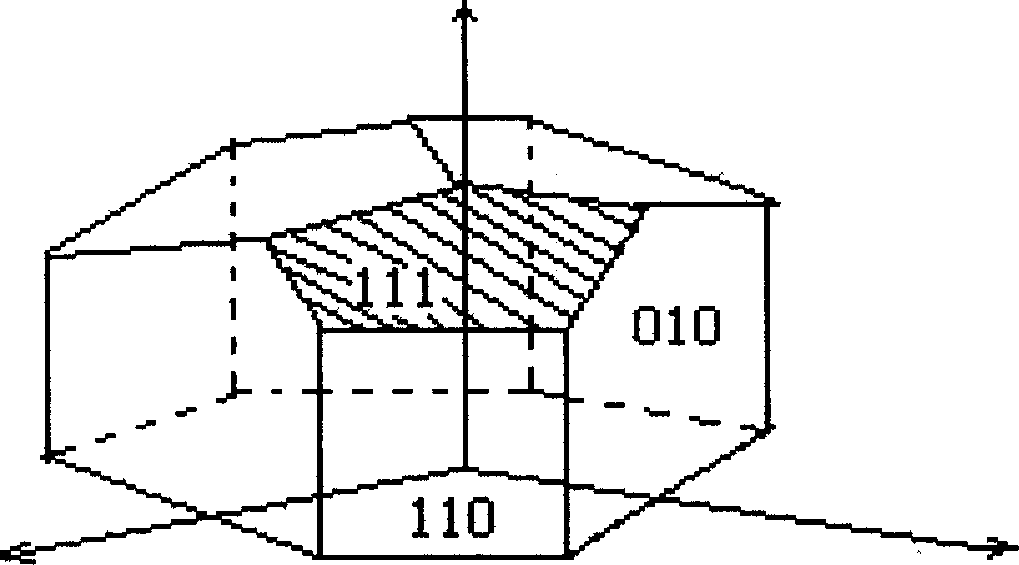

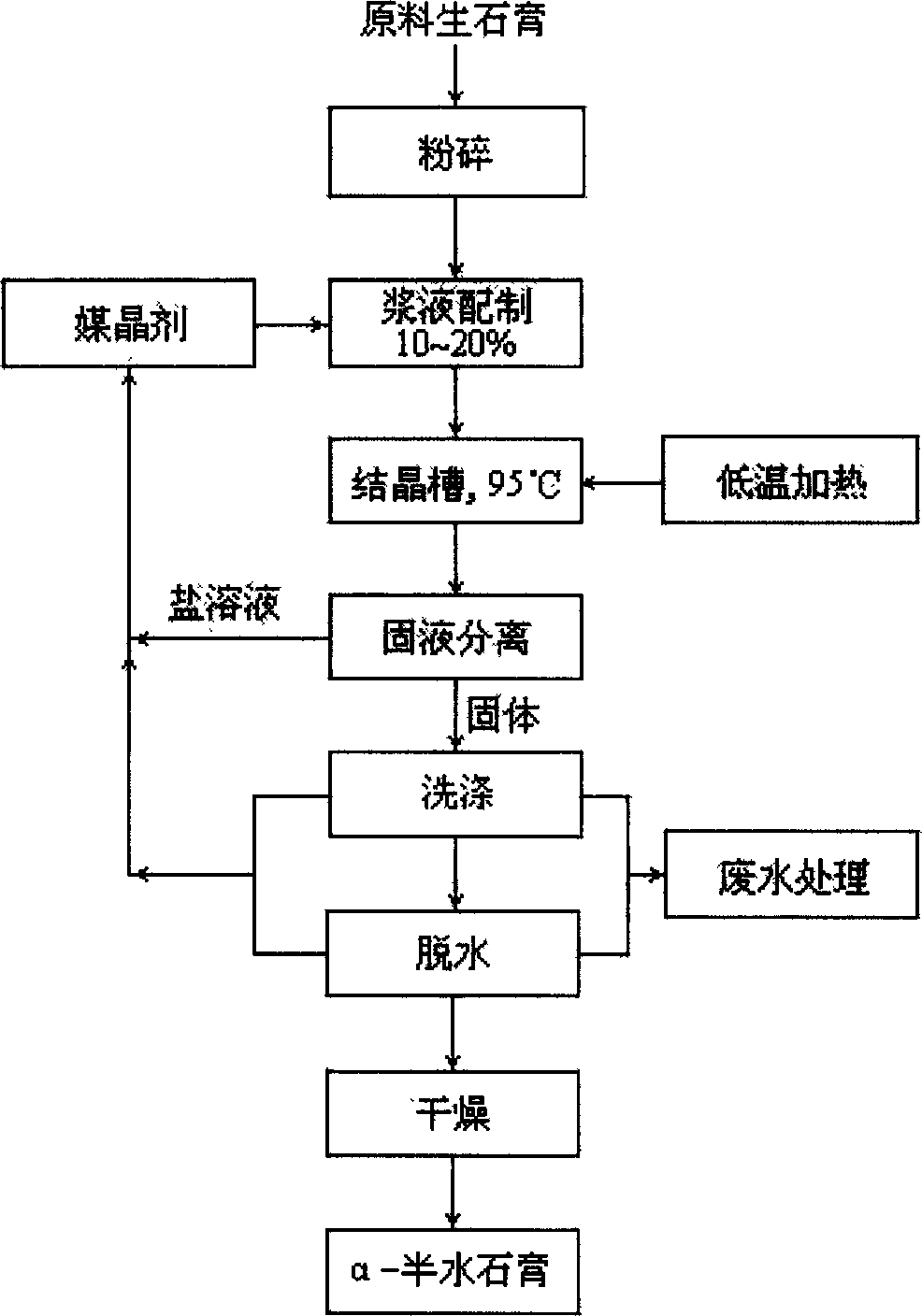

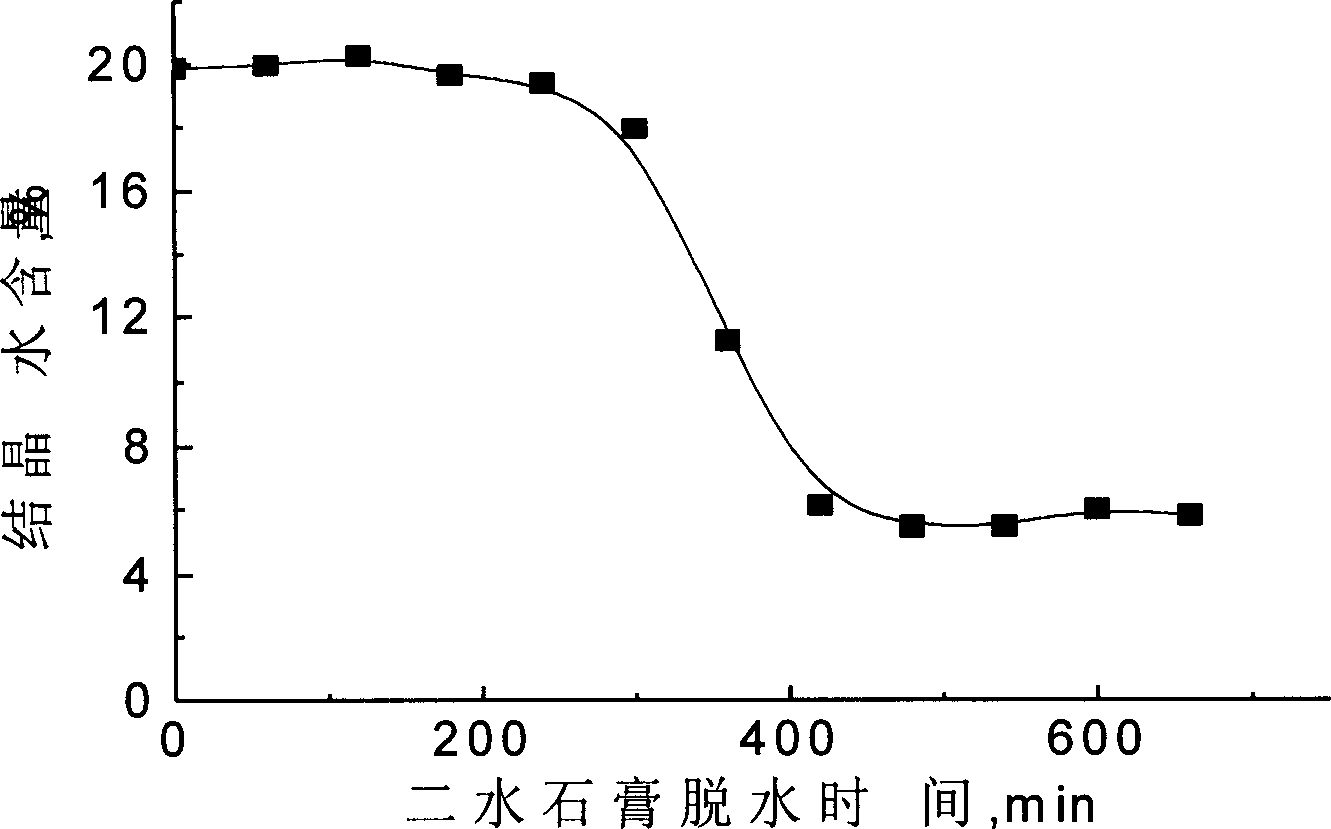

Process for preparing alpha-semi-hydrated gypsum from modified gypsum at normal pressure

ActiveCN1569642AImprove adsorption capacityReduced growth rateCalcium/strontium/barium sulfatesGypsumLiquid solid

The disclosed semi-hydrated gypsum preparing process consists of, charging a finite proportion or salt solution into crude gypsum for crystallization under normal pressure, separating liquid-solid phase, subjecting the separated alpha-semi-hydrated gypsum to washing, drying, and packaging. Said salt solution comprises alkali metal chloride, the soluble salts of alkaline-earth metal and borax.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

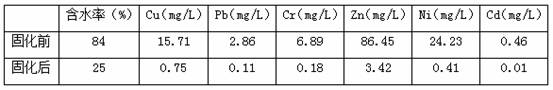

Sludge curing agent and production method thereof

InactiveCN112341127AReduce moisture contentHigh curing strengthWater contaminantsFixation/solidifcation sludge treatmentAluminateSlag

The invention discloses a sludge curing agent and a production method thereof. The sludge curing agent is prepared from the following raw materials in parts by weight: 60-100 parts of sulphoaluminatecement, 10-40 parts of Portland cement, 40-70 parts of superfine slag micro-powder, 20-40 parts of fly ash, 2-10 parts of dispersible latex powder, 2-10 parts of sodium silicate, 4-12 parts of hydroxyl calcium phosphate and 4-12 parts of modified nano montmorillonite. The preparation method comprises the following steps: grinding the sulphoaluminate cement, the Portland cement, the fly ash, the sodium silicate and the hydroxyl calcium phosphate, performing sieving with a 200-300-mesh sieve, adding the superfine slag micro-powder, the dispersible latex powder and the modified nano montmorillonite, and performing sufficient and uniform mixing to obtain a finished product. The sludge curing agent provided by the invention has strong dehydration property, and can effectively adsorb heavy metals in sludge and fix the heavy metals, so that the cured sludge can be recycled.

Owner:广西云燕特种水泥建材有限公司

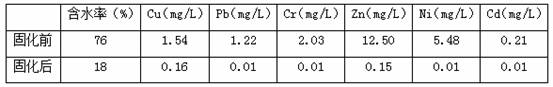

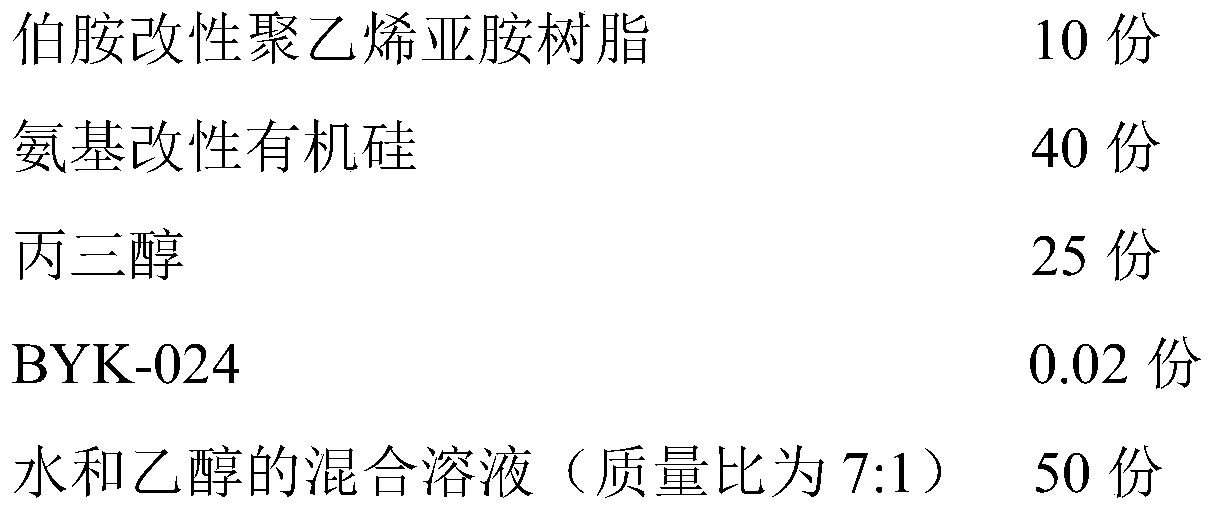

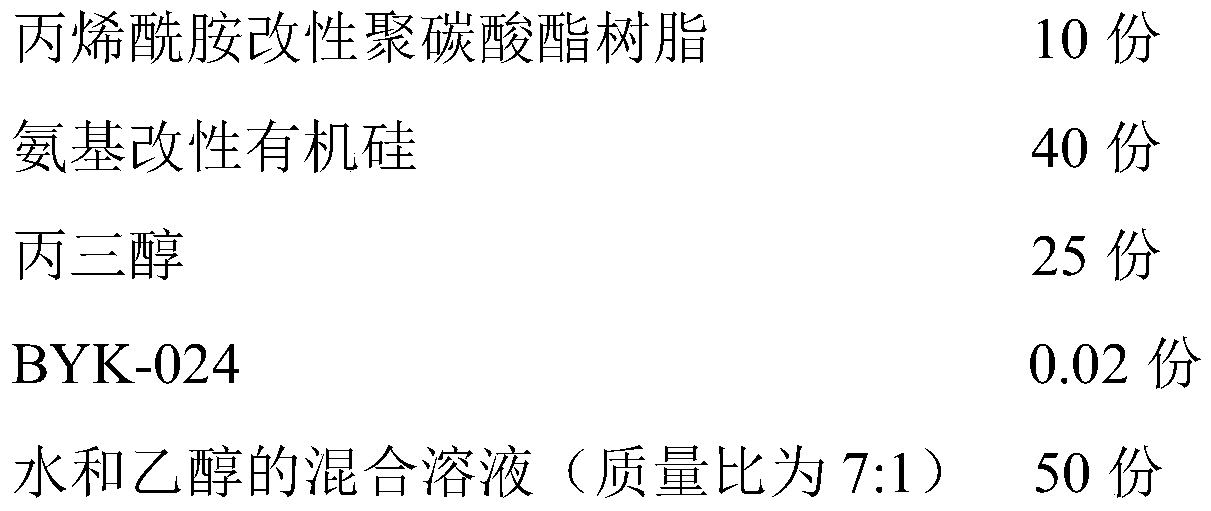

Back coating material for tipping paper for cigarettes, tipping paper for cigarettes, and preparation method of tipping paper

ActiveCN110644280ALow flatnessEasy to slideSurface covering paperNon-fibrous pulp additionPolymer sciencePolycarbonate

The invention relates to a back coating material for tipping paper for cigarettes. The back coating material comprises, by weight, 1-10 parts of a resin, 10-50 parts of a softener and 5-25 parts of awater-retaining agent; and the resin is primary amine modified polyethyleneimine and / or acrylamide modified polycarbonate, and the softener is amino modified organosilicon. The invention also relatesto the tipping paper for cigarettes. The invention further relates to a preparation method of the tipping paper for cigarettes.

Owner:ANHUI GENUINE PAPER PACKING

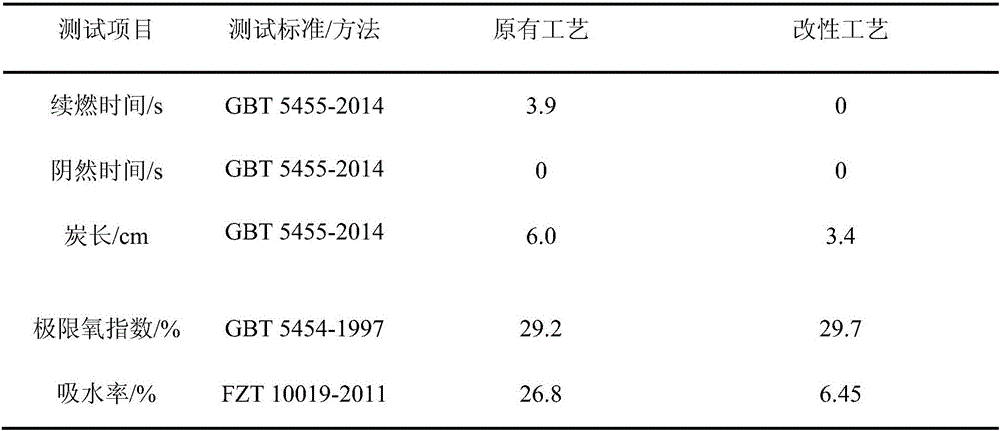

Method for solving problems of moisture absorption and stickiness of phosphorus coated fabric by adding inorganic components

ActiveCN105907210AImprove dehydration abilityTogether produce flame retardant effectFireproof paintsTextiles and paperFrostEmulsion

The invention discloses a method for solving problems of moisture absorption and stickiness of phosphorus flame-retardant coated fabric by adding inorganic components. The method is characterized by coating, drying and baking nap face fabric for chairs, wherein the coating comprises the components in proportion by weight: 40-55% of acrylic ester emulsion, 35-50% of phosphorus flame retardant, 4-10% of inorganic flame retardant synergist and 4-8% of thickener and water, and the glue amount of the fabric is 200-260g / m<2>. The method reduces the usage of the phosphorus flame retardant by adopting the inorganic flame retardant synergist, the flame retardant efficiency and water resistance of the phosphorus intumescent flame-retardant coating are improved, and simultaneously the defects of frost on the surface, satiny hand feeling, stickiness and the like of the original phosphorus flame-retardant coated fabric are improved.

Owner:SHANDONG TAIYANGNIAO SAFETY TECH CO LTD

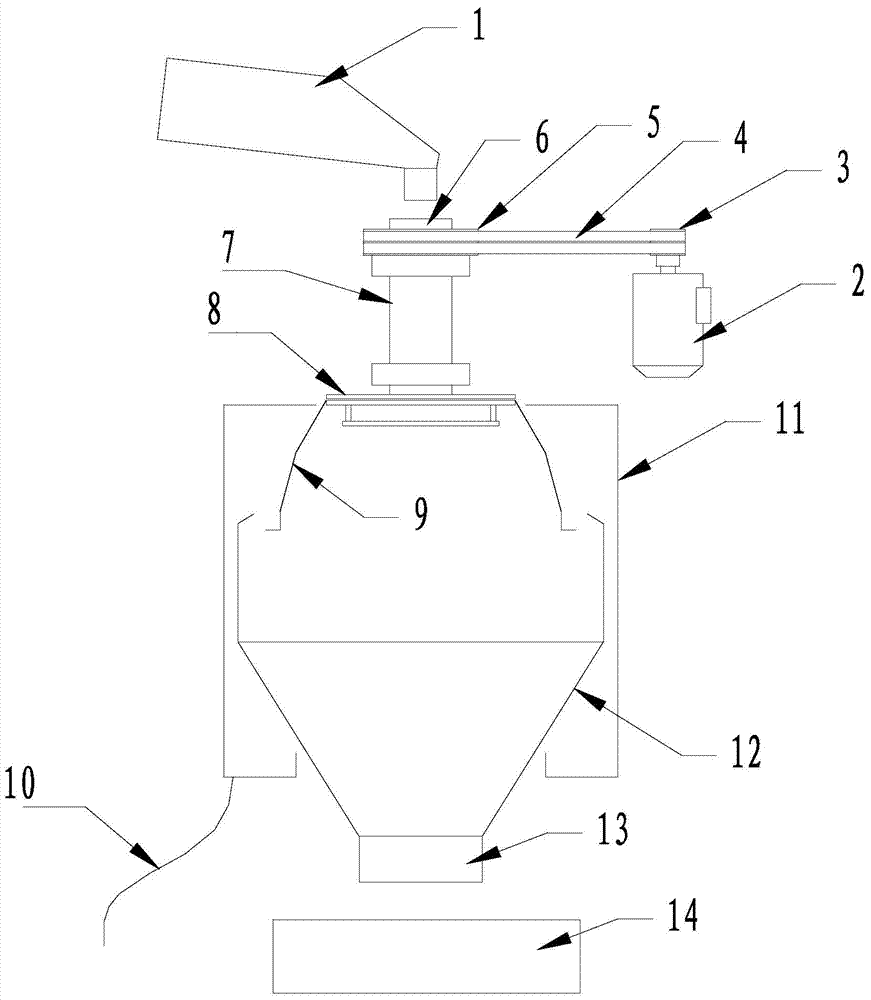

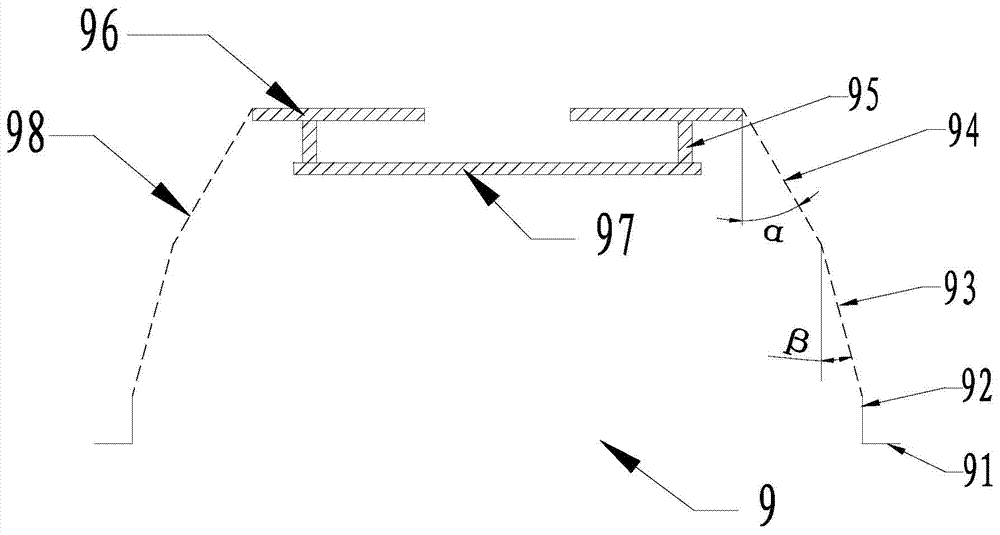

Hot pickled mustard tuber continuous dehydration centrifugal separator with bottom upwards

ActiveCN104741248AEasy to produceHigh degree of dehydrationRotary centrifugesDraining tubeEngineering

The invention discloses a hot pickled mustard tuber continuous dehydration centrifugal separator with the bottom upwards. The centrifugal separator comprises a vibration hopper used for conveying hot pickled mustard tubers, and a hollow shaft used for collecting materials, and a motor transmits rotating power to the hollow shaft through a power transmitting device; the lower end of the hollow shaft is provided with a hollow rotary table, a rotary drum is installed at the lower end of the hollow table with the bottom upwards, and the rotary drum rotates along with the hollow shaft and the hollow rotary table through rotary power provided by the motor; an inner barrel is outside the lower end of the rotary drum and used for receiving the hot pickled mustard tuber materials thrown out of the rotary drum, and the materials fall into a finished product groove through a material falling port in the bottom of the inner barrel; an outer barrel is further arranged outside the rotary drum and the inner barrel and used for collecting water thrown out of the rotary drum, and the water is drained out through a drainage pipe. The hot pickled mustard tuber continuous dehydration centrifugal separator has the advantages of being convenient to use, efficient, capable of achieving continuous production and low in cost. The hot pickled mustard tuber continuous dehydration centrifugal separator is stronger in dehydration effect and higher in dehydration degree, and meanwhile, the materials can continuously go out without barriers, and cleaning is facilitated.

Owner:湖南省香味园食品股份有限公司

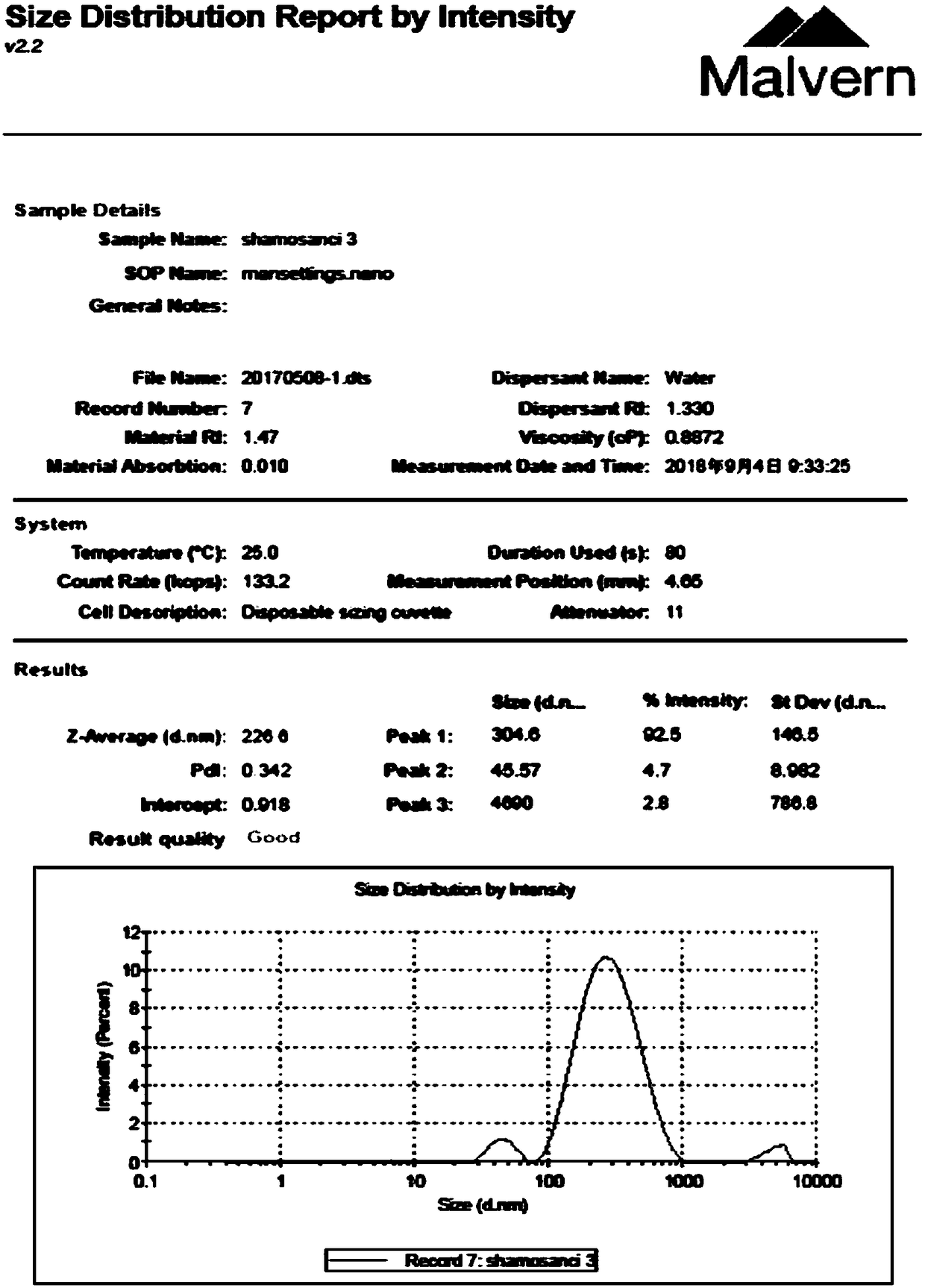

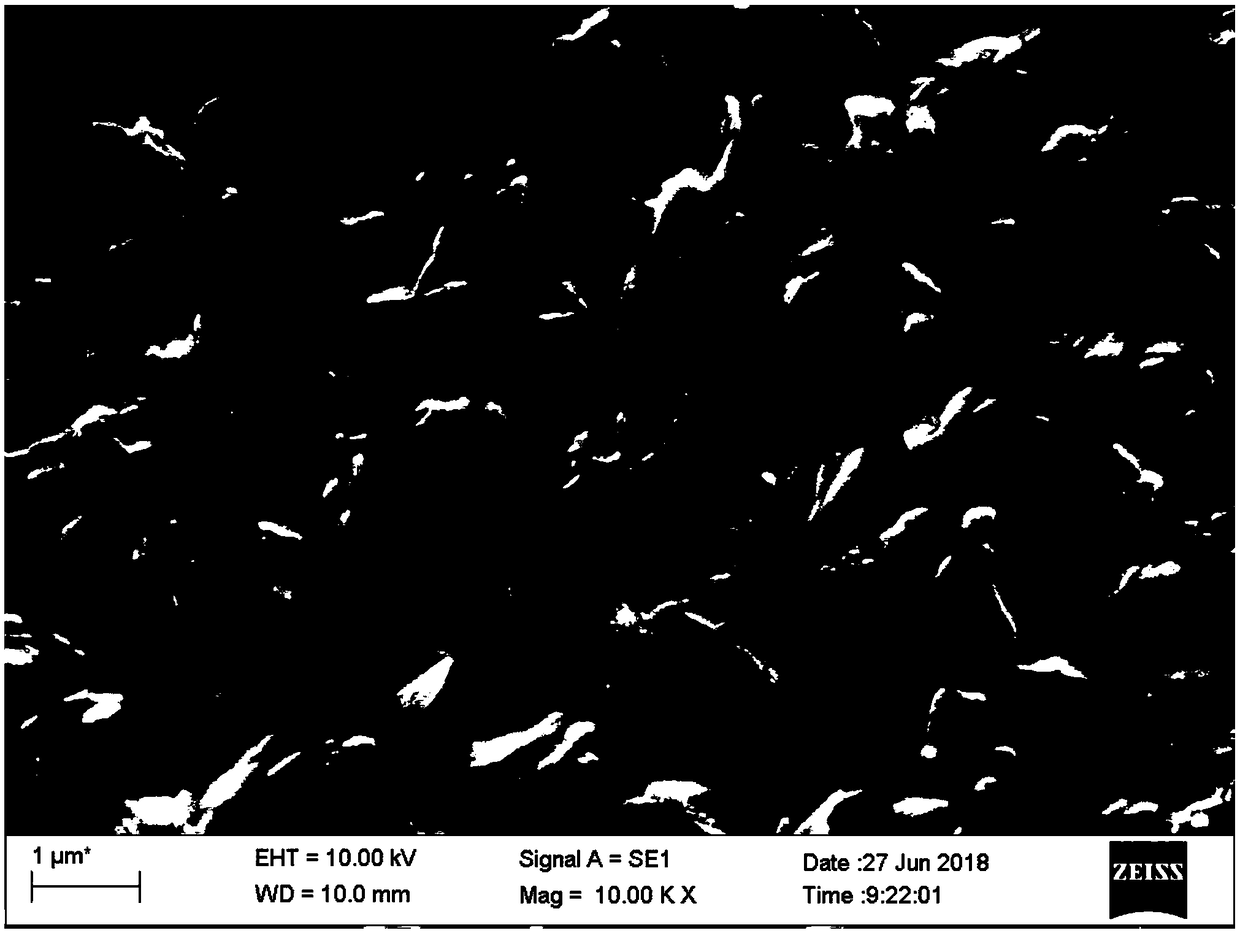

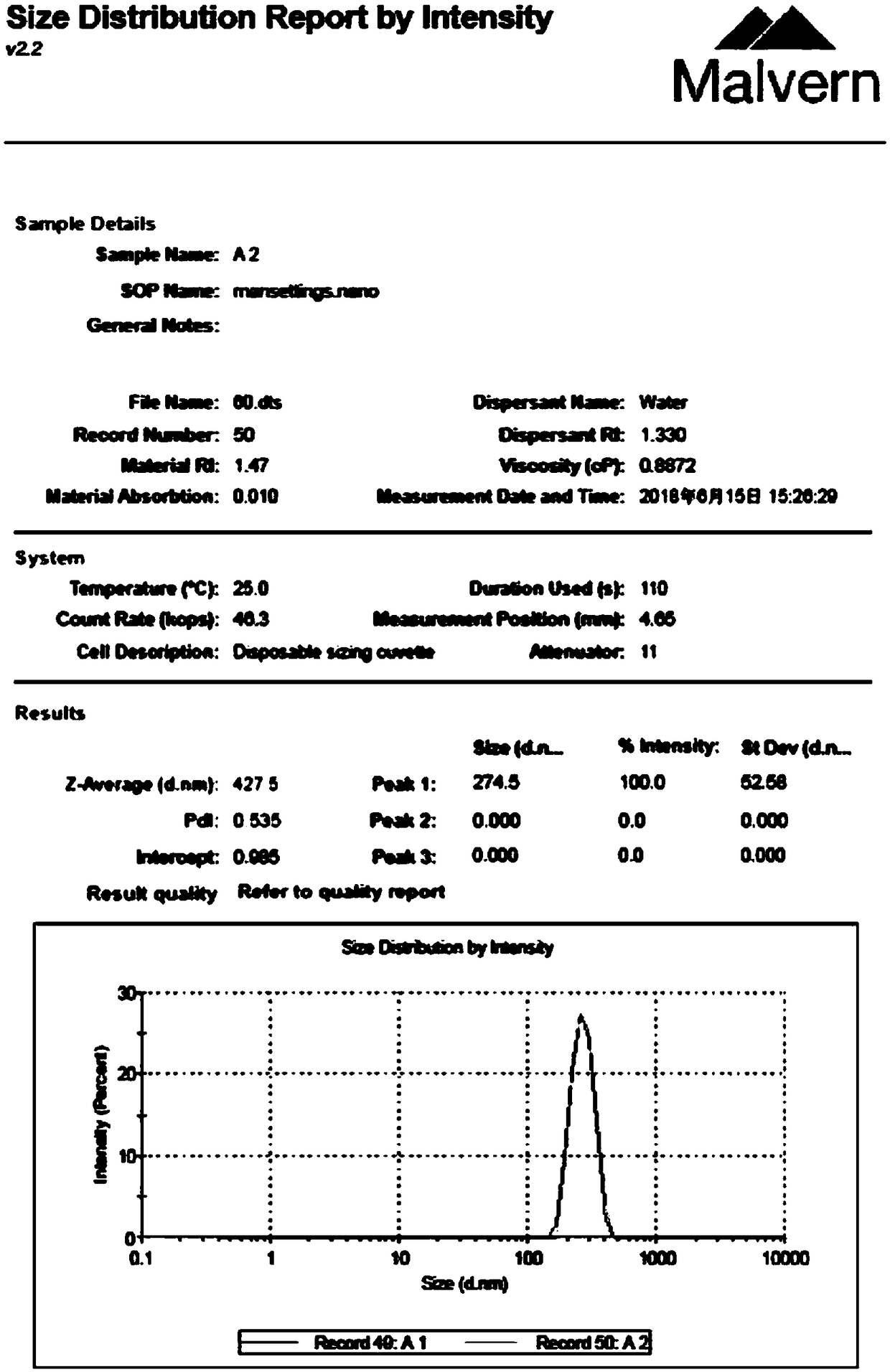

Preparation method and application of micro-nano cellulose

ActiveCN109208366AStrong oxidation abilityImprove dehydration abilityPaper material treatmentFiberCellulose

The invention discloses a preparation method and application of micro nano cellulose. The preparation method comprises the steps of: hydrolyzing plant fiber by a hydrolyzing agent to obtain the micronano cellulose; wherein the hydrolyzing agent is composed of (meth)sulfonic acid, sulfuric acid and water. The preparation method is thorough in reaction, and the prepared micro nano cellulose has good particle size uniformity, and the method can be applied in industrial production of the micro-nano cellulose.

Owner:刘永红 +2

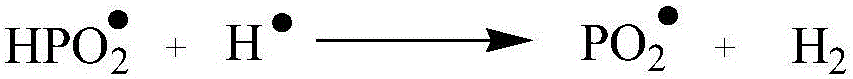

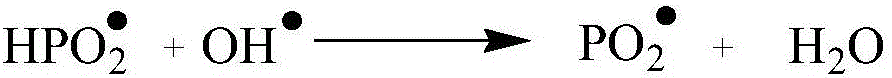

Preparation method of modified activated carbon material for capacitor

ActiveCN111320173AEasy to prepareSuitable for large-scale productionCarbon compoundsHybrid capacitor electrodesCapacitanceO-Phosphoric Acid

The invention discloses a preparation method of a modified activated carbon material for a capacitor. The preparation method comprises the following steps: (1) polishing, drying and crushing a carbonsource; (2) activating the raw materials through a phosphoric acid solution to obtain a primary activated product; (3) mixing the precursor powder with the primary activation product, and activating with potassium hydroxide to obtain a secondary activation product; and (4) adding the secondary activation product into a saturated lead nitrate solution, carrying out ultrasonic dispersion, stirring and performing vacuum filtration to obtain a filter cake, and carrying out heat treatment to obtain the material. The preparation method of the activated carbon is simple; the preparation method is simple in process, wide in raw material source and suitable for large-scale production, a secondary activation process is adopted in the preparation process, precursor powder with high content of heteroatoms such as nitrogen and oxygen is added into the activated carbon, the specific surface area is further increased, micropores are enriched in the surface, the specific capacitance of the material isimproved, and the use performance of the material is enhanced.

Owner:ZHEJIANG FORESTRY ACAD

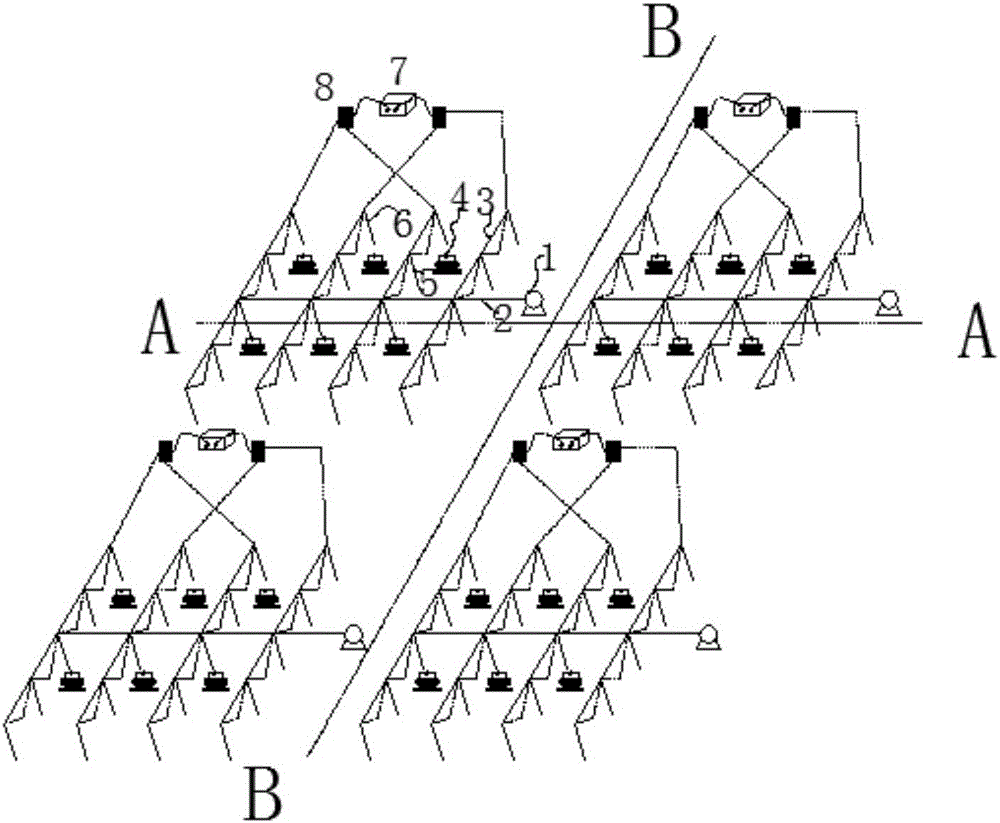

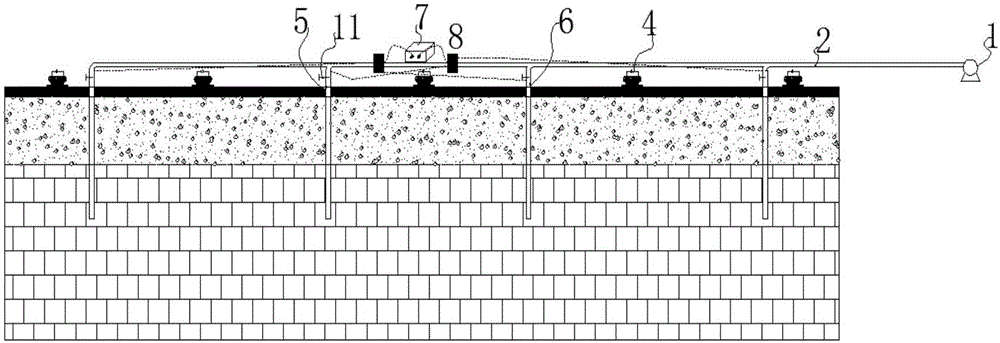

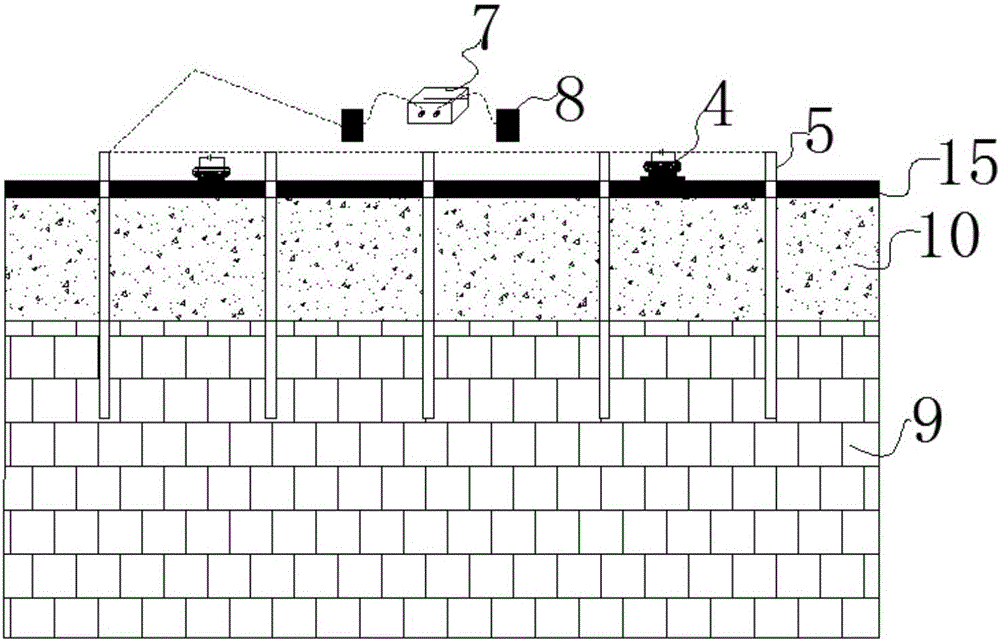

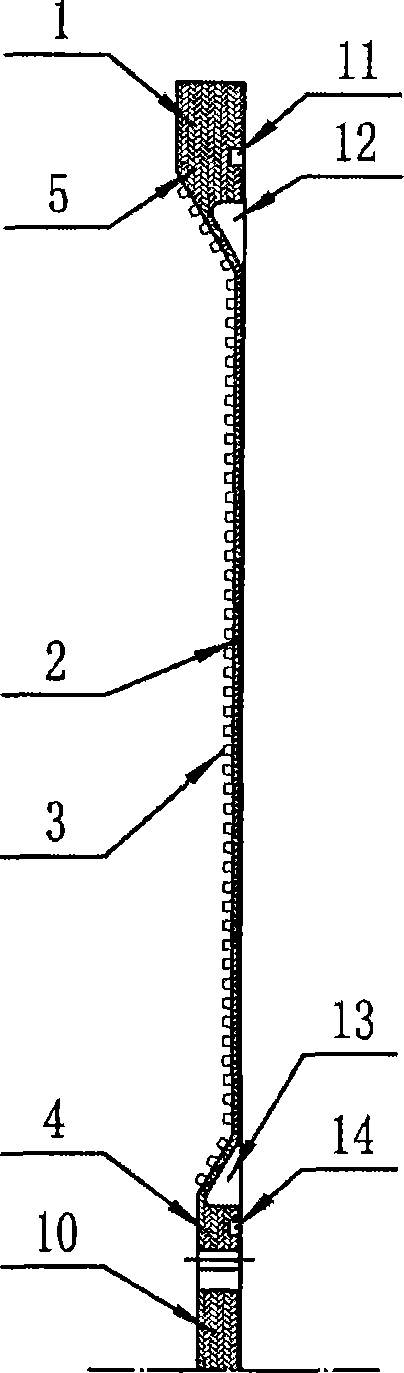

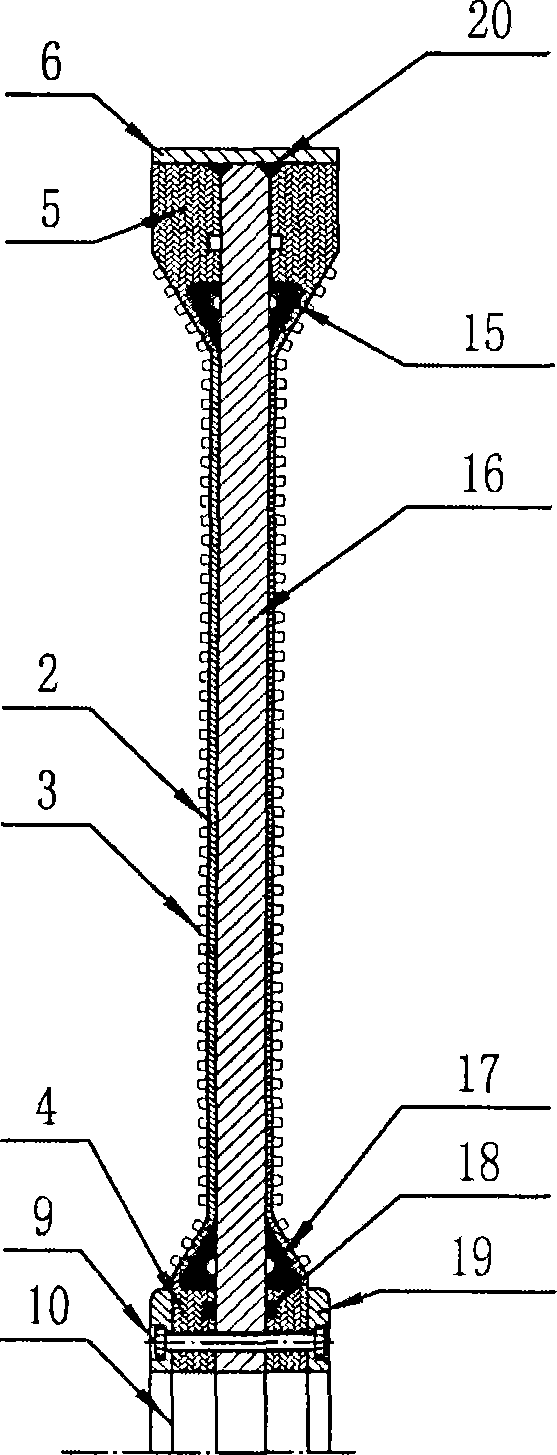

Fast curing system used for dredger fill of offshore reclamation and operation method of fast curing system

ActiveCN105839613ASignificant progressSave curing engineering cycleSoil preservationElectricityFiltration

The invention discloses a fast curing system used for dredger fill of offshore reclamation and an operation method of the fast curing system. The fast curing system comprises cathodes, anodes, plastic rigid main drain pipes, vacuum pumps, rectifiers, oscillators and the like. Alternating currents are converted into direct currents through the rectifiers. According to the fast curing system, curing of the dredger fill is enhanced through a combined process of vacuum negative pressure suction filtration drainage and electroosmosis reinforcement drainage, so that the curing effect of the dredger fill is improved. In the later period of vacuum-electroosmosis curing, grouting is conducted in generated cracks manually, thus the soil cracks are filled. Meanwhile, to-and-fro oscillation is conducted through an oscillation method, stress unevenness on the dredger fill is reduced, the number of the cracks generated in the base face of the dredger fill is reduced, the crack generation scale is reduced, and thus the curing effect of vacuum electroosmosis of the dredger fill is further improved. Through the combined process, the effect of reinforcement of dredger fill curing is achieved. Meanwhile, the fast curing system is simple in structure, the curing period is short, and through the process, curing of the dredger fill is achieved fast.

Owner:HOHAI UNIV

Method for dehydrating viscous waste by vacuum coupled physicochemical strengthening and device

InactiveCN109678319AStrong water absorptionImprove dehydration abilitySludge treatment by de-watering/drying/thickeningWater contaminantsBound waterPhosphoric acid

The invention discloses a method for dehydrating viscous waste by vacuum coupled physicochemical strengthening. The method comprises steps as follows: the viscous waste is prepared to form slurry withhigh water content firstly and is kept at certain temperature; phosphoric acid is formed by the aid of added auxiliary materials, and bound water and heavy metals are separated from viscous waste particles by the aid of phosphoric acid; phosphoric acid and the heavy metals are subjected to a reaction, and soluble metal salts are generated; the treated viscous waste is dehydrated by an improved dehydration device, finally, the harmless viscous waste with low water content is obtained, water obtained by dehydration is treated by ion exchange resin, and phosphoric acid is recovered. The problemsof low dehydration efficiency and high heavy metal content of a traditional viscous waste treatment mode are solved; the treated viscous waste can realize harmless discharge and recycling.

Owner:KUNMING UNIV OF SCI & TECH

Polylactic acid injection molding method

InactiveCN110938181AFacilitated catalytic polycondensationGood depolymerization effectCoatingsPolymer scienceButadiene Dioxide

The invention relates to the field of polylactic acid and particularly relates to a polylactic acid injection molding method. The method includes: 1, performing polycondensation on lactic acid to obtain a polylactic acid intermediate, and performing ring opening reaction on the polylactic acid intermediate to prepare a polylactic acid initial product; 2, polymerizing the polylactic acid initial product and 2-methyl-1,3-butadiene to obtain tri-blocked polylactic acid; 3, grafting the glycine on the tri-blocked polylactic acid by using a third initiator to obtain modified tri-blocked polylacticacid; 4, drying the modified tri-blocked polylactic acid in a drying box; 5, performing extrusion and granulation and injection molding on an injection molding machine. The invention solves the problem that polylactic acid prepared through conventional injection molding methods is high in brittleness and insufficient flexibility although the hardness is high. The method is beneficial to development of polylactic acid industry and wide application of polylactic acid resin.

Owner:无锡御束生物材料科技有限公司

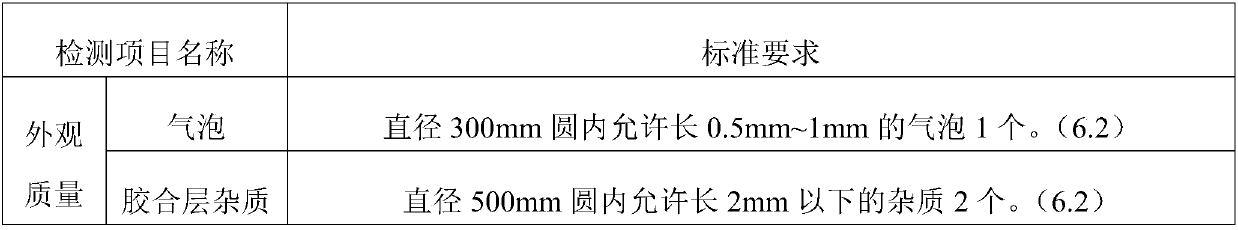

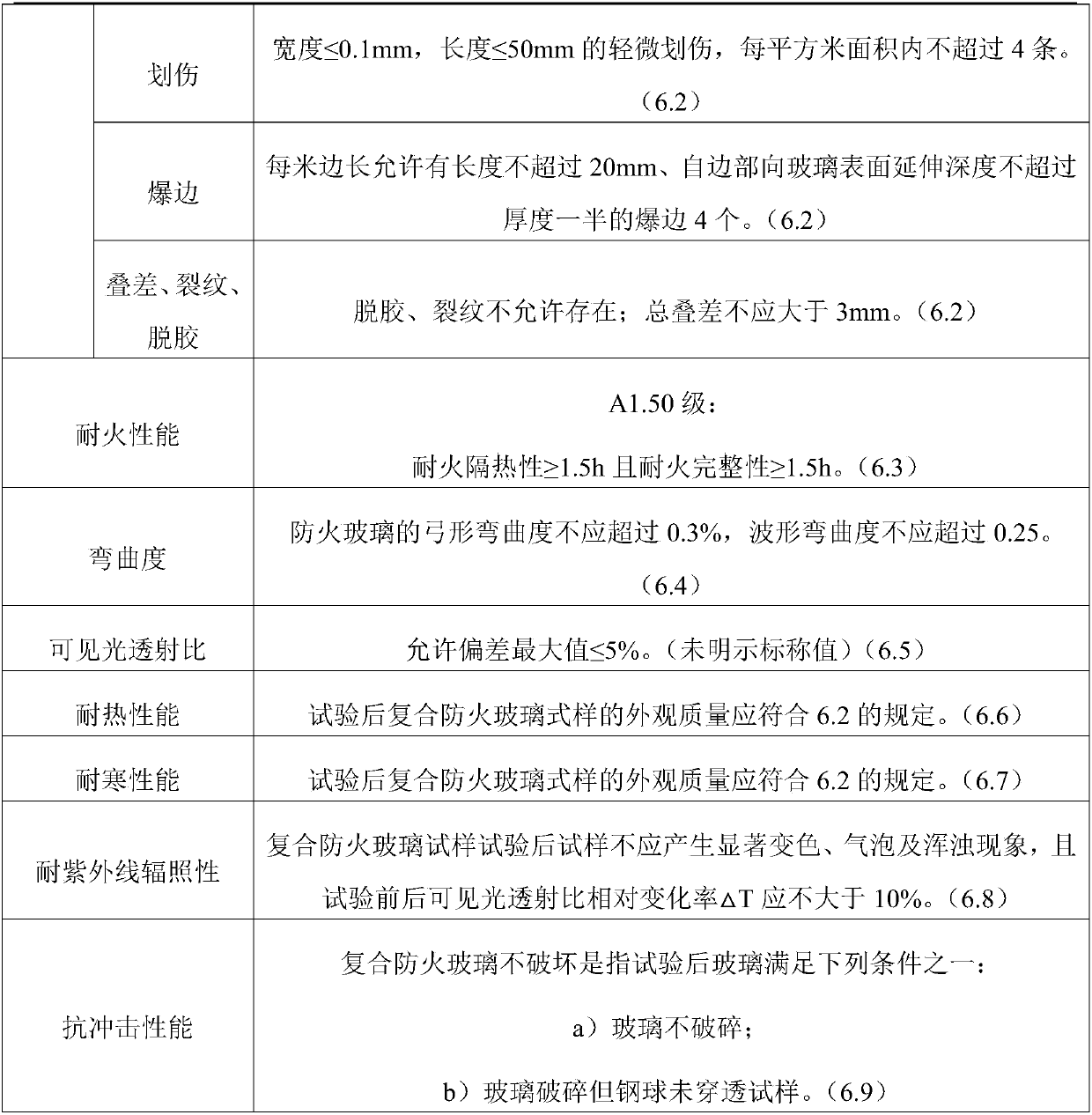

Composite fireproof glass and preparation method thereof

InactiveCN109605866AGood fire resistanceGood impact resistanceNon-macromolecular adhesive additivesSynthetic resin layered productsAmmonium sulfatePhosphoric acid

The invention belongs to the technical field of building material glass and provides composite fireproof glass and a preparation method thereof. The composite fireproof glass comprises two flat glasspieces and fireproof glue. The fireproof glue is arranged in a cavity formed by the two flat glass pieces and characterized by being prepared from, by weight, 125-134 parts of acrylamide,1,800-1,994 parts of water, 420-447 parts of sodium chloride, 1-2 parts of phosphoric acid, 5-10 parts of ammonium persulfate, 5-10 parts of sodium metabisulfite and 0.168-0.192 part of methylene bisacrylamide. The fireproof glass solves the problems that after being irradiated by ultraviolet rays outdoors, traditional fireproof glass can generate bubbles and is lower in light transmittance and the service performance of the traditional fireproof glass is thus seriously influenced.

Owner:河间市晶正玻璃有限公司

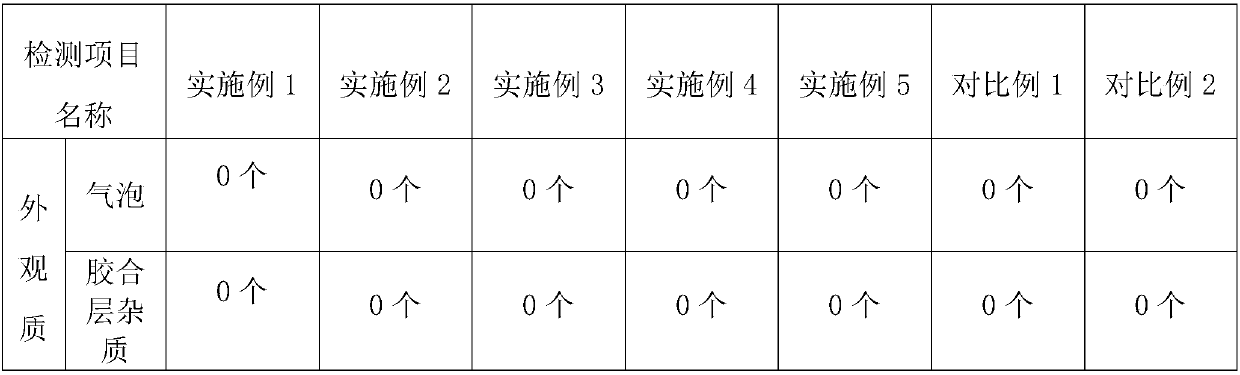

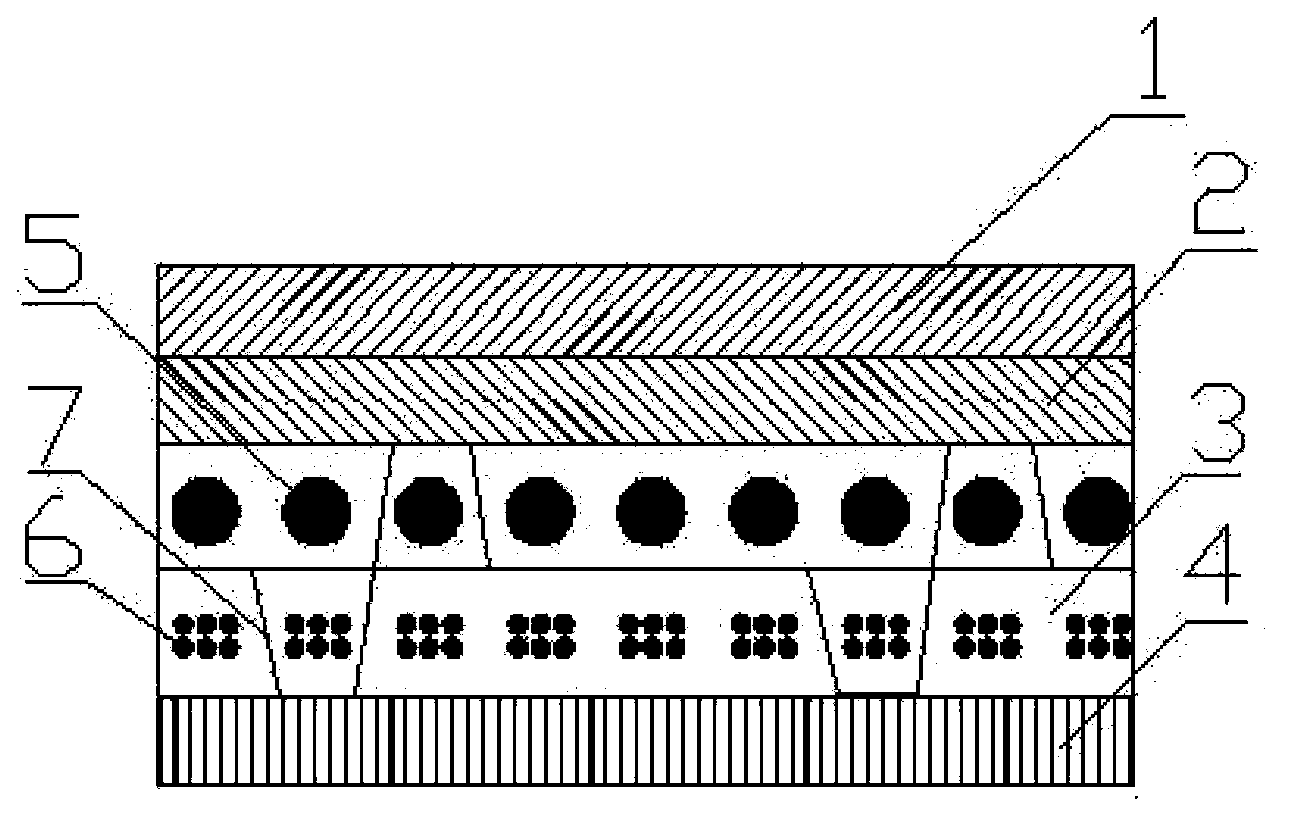

High-pressure diaphragm filter plate

InactiveCN104341085AImprove efficiencySimple structureSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesEngineeringTympanic Membranes

A novel high-pressure diaphragm filter plate is composed of two diaphragm plates 1, a middle supporting plate 16, a filter plate annular hoop 6 and the like. The filter plate is circular, a feeding hole is arranged in the center of the filter plate, and feeding is smooth and uniform; the diaphragm plates 1 have relatively high compressive strength and good deformation ability, and are fixed at two sides of the middle supporting plate 16 respectively; the filter plate annular hoop 6 tightly hoops the excircle of the diaphragm plates 1 and the middle supporting plate 16, so that the diaphragm plates 1 can bear higher feeding pressure and tympanic membrane pressure; the novel high-pressure diaphragm filter plate can bear the 3.0-8.0 MPa feeding pressure and tympanic membrane pressure; after a diaphragm movable plate 2 is trumped up, the filter chamber volume is reduced by 1 / 3 or more, so that a filter press adopting the filter plate has a super-strong dehydration ability, and moreover, has the advantages of simple structure, reliable performance, low cost, large specification and the like.

Owner:王树岩

Preparation method for flame-retardant polymethyl methacrylate foam

The invention relates to a preparation method for flame-retardant polymethyl methacrylate foam, belonging to the field of preparation of new materials. According to the invention, an initiator, a foaming agent, a cross-linking agent and a chain transfer agent are added into a mixture composed of methyl methacrylate and comonomers; after viscous slurry is formed after prepolymerization, a nucleating agent, a carbonizing agent, a nickel-based cadmium-free foaming accelerator, a flame retardant and a flame retardant synergist are added; and further polymerization is carried out and then foaming is performed so as to obtain the flame-retardant polymethyl methacrylate foam. The carbonizing agent used in the invention can carbonize the surface of a polymer in the process of combustion so as to form a carbonized layer having insulating effect. The added flame retardant can decompose with heat and absorbs heat to realize cooling effect, thereby achieving flame retarding effect. Thus, the polymethyl methacrylate foam prepared in the invention has the characteristics of light weight, high strength, easy foaming, capacity of being extinguished without fire and basically no generation of blacksmoke during combustion.

Owner:CASHEM ADVANCED MATERIALS HI TECH CO LTD ZHEJIANG

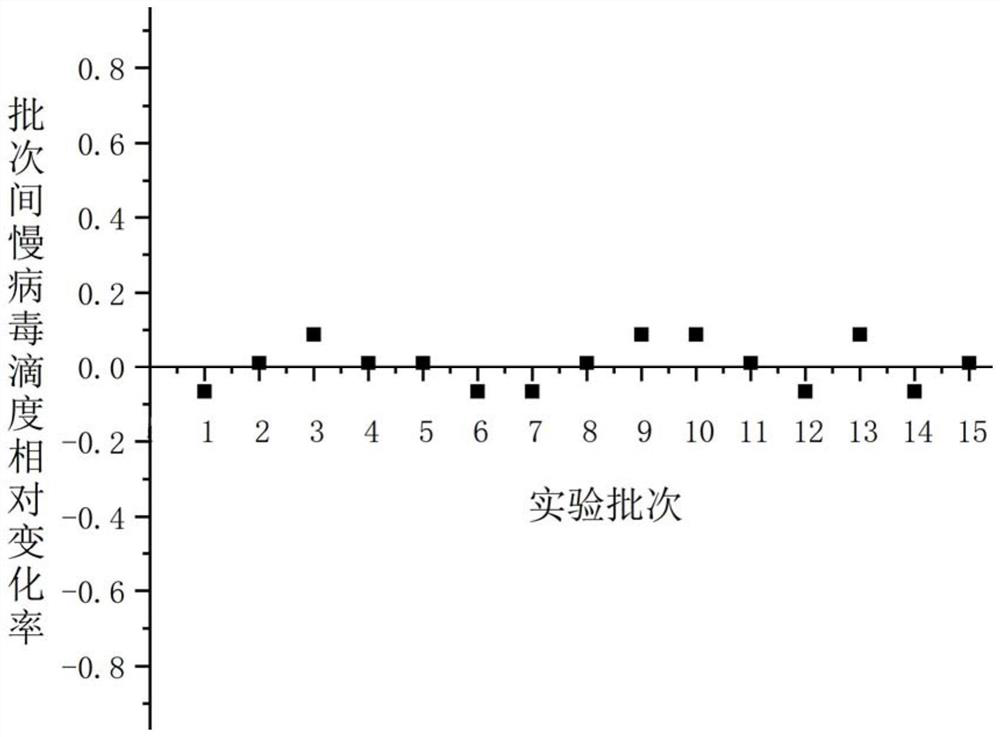

Lentivirus packaging method

The invention provides a lentivirus packaging method which comprises the following steps: (1) adding plasmids into a serum-free culture medium to obtain a plasmid mixture; the plasmids comprise lentivirus packaging plasmids and target expression plasmids; the lentivirus packaging plasmids comprise psPAX2 and pMD2. G; (2) adding the transfection medium into a serum-free culture medium to obtain a transfection reagent; and (3) uniformly mixing the plasmid mixture and a transfection reagent, adding the mixture into the tool cells, transfecting and culturing for 2-10 hours, replacing the culture medium with a serum-reduced culture medium, continuously culturing, collecting a supernatant, and concentrating to obtain the lentivirus. In the lentivirus packaging method provided by the invention, the target expression plasmid and the two packaging plasmids are utilized to carry out co-transfection on the tool cells, so that the lentivirus can stably package the tool cells, and the lentivirus packaging efficiency and the lentivirus titer are improved.

Owner:GUANGDONG PROCAPZOOM BIOSCIENCES CO LTD

Preparation method of flame-retardant artificial stone containing nano perovskite oxide MTiO3

ActiveCN105907034AImprove battery saving performanceChange transportHeat resistanceMetal-organic framework

The invention relates to a preparation method of a flame-retardant artificial stone containing nano perovskite oxide MTiO3. The nano perovskite oxide and a metal organic framework ZIF material are jointly added into a ternary polyene ester material (such as talcum powder, quartz and phenolic resin), therefore, the heat resistance and the strength of the artificial stone are improved, the aging time of the artificial stone is shortened, the artificial stone can not be degraded for a long time under the high temperature action, the good flame-retardant effect can be kept, and the loss-on-ignition (LOI) index is significantly increased.

Owner:浙江南塑合成材料有限公司

Novel papermaking felt

InactiveCN103669092AHigh strengthImprove dehydration abilityPaper-making machinesSurface layerStandard line

The invention provides a novel papermaking felt which is sequentially woven from a fiber surface layer, a fiber core layer, a base cloth layer and a fiber back layer from top to bottom in a needled mode. The base cloth layer is formed by a strong cloth layer which is integrally thickened and reinforced and woven from warps and wefts. Wraps on the upper layer of the base cloth layer are wool-like yarns, warps on the lower layer are polyamide piled yarns, and wefts are polyamide long filaments. A standard line colored tape is arranged on the front of the novel papermaking felt, penetrates two sides of the felt and intersects with the felt vertically with a 90-degree angle formed in between. An arrow indicting the running direction of a papermaking machine is arranged at each end of one side of the standard line colored tape. The novel papermaking felt is high in strength, high in dewatering capability and long in service life, and improves paper quality. In addition, the standard line colored tape is arranged on the papermaking felt to adjust the position of the papermaking felt on the papermaking machine and ensure that the felt runs normally on the papermaking machine, and the service life of the papermaking felt is prolonged.

Owner:天津滨海新区大港顺达造纸厂

Preparation method of flame-retardant artificial stone containing nano perovskite oxide

ActiveCN105907033AImprove battery saving performanceChange transportCobalt compoundsHeat resistanceMetal-organic framework

The invention relates to a preparation method of a flame-retardant artificial stone containing nano perovskite oxide. The nano perovskite oxide and a metal organic framework UIO material are jointly added into a ternary polyene ester material (such as talcum powder, quartz and phenolic resin), therefore, the heat resistance and the strength of the artificial stone are improved, the aging time of the artificial stone is shortened, the artificial stone can not be degraded for a long time under the high temperature action, the good flame-retardant effect can be kept, and the loss-on-ignition (LOI) index is significantly increased.

Owner:GUANGXI LISHENG STONE CO LTD

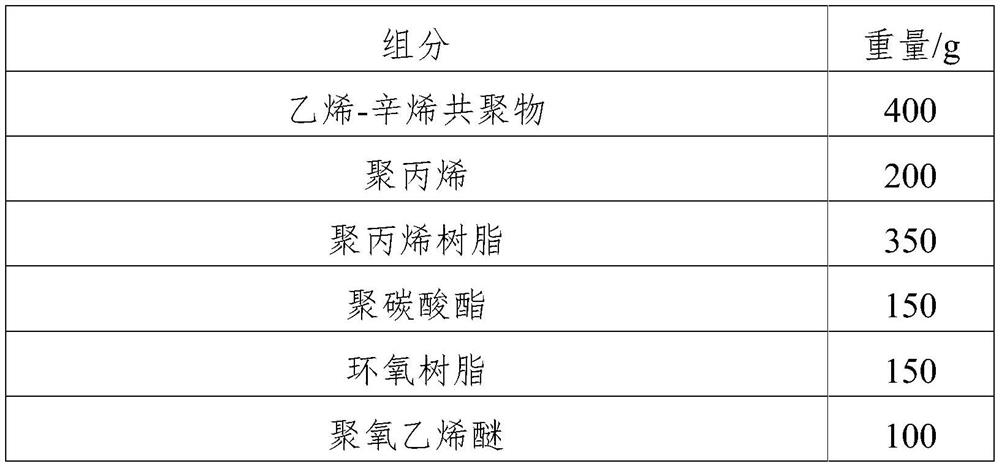

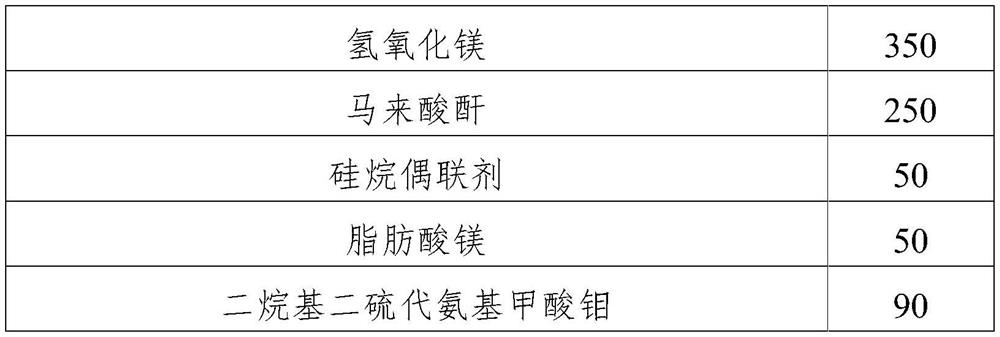

Halogen-free thermoplastic elastomer cable material for electric vehicle charging pile cable

InactiveCN114573940AImprove processing rheologyStrong shear sensitivityPlastic/resin/waxes insulatorsElectric vehicle charging technologyEpoxyElastomer

The invention provides a halogen-free thermoplastic elastomer cable material for an electric vehicle charging pile cable. The cable material comprises the following raw materials in parts by weight: 20-40 parts of an elastic composite material, 10-20 parts of polypropylene, 15-35 parts of polyolefin resin, 5-15 parts of polycarbonate, 5-15 parts of epoxy resin, 5-10 parts of polyoxyethylene ether, 15-35 parts of a halogen-free flame retardant, 15-25 parts of a compatilizer, 1-5 parts of a coupling agent, 1-5 parts of an auxiliary agent and 3-9 parts of an antioxidant. According to the invention, the impact resistance of polypropylene is poor, and after the elastic composite material is added, a crazing-shear band caused by elastic particles can fully play a role, so that the impact resistance of the mixed material is remarkably improved, and the impact resistance and structural strength of the cable material are favorably improved when the mixed material is used for preparing the cable material; the cable material disclosed by the invention has the advantages of environmental protection, low smoke amount, no halogen, no corrosive gas and the like.

Owner:昆山浩恩高分子材料有限公司

High-strength flame-retardant elastic fabric and preparation method thereof

PendingCN113089312AImprove dehydration abilityImprove hydrophobicityBiochemical fibre treatmentHeat resistant fibresPolyesterPolymer science

The invention discloses high-strength flame-retardant elastic fabric and a preparation method thereof, and belongs to the technical field of fabric. The high-strength flame-retardant elastic fabric mainly comprises the following raw materials: red phosphorus flame-retardant master batch, wherein the red phosphorus flame-retardant master batch mainly comprises red phosphorus, magnesium hydroxide and aluminum hydroxide; an epoxy resin flame retardant, wherein the epoxy resin flame retardant comprises epoxy resin, a flame-retardant curing agent and an active flame-retardant diluent; polyurethane; plant fibers; viscose fibers; hollow polyester fibers; and an antibacterial agent. By adding the red phosphorus flame-retardant master batch, the flame-retardant effect of the fabric can be improved; the epoxy resin is matched, the cured phosphorus-containing flame-retardant epoxy resin has high glass transition temperature and good thermal stability and flame retardance; and meanwhile, and moisture generated when magnesium hydroxide is heated can be formed into a water film on the surface of the fabric under the action of polyurethane with good hydrophobicity, so that the flame-retardant effect is further improved.

Owner:雷雨新

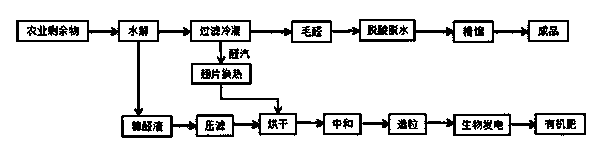

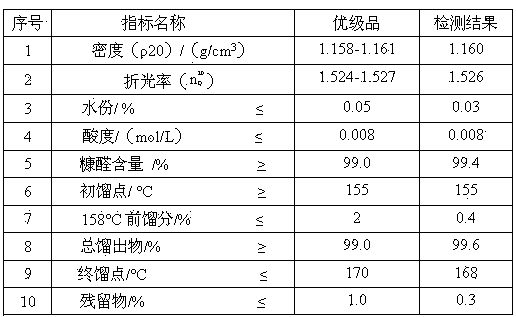

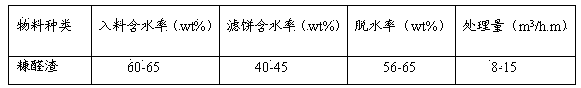

Novel process for comprehensively utilizing agricultural wastes

The invention belongs to the technical field of reutilization of agricultural wastes and particularly relates to a novel process for comprehensively utilizing the agricultural wastes. The novel process comprises the following steps: adding acid into the agricultural wastes and hydrolyzing to obtain aldehyde gas and furfural residues; carrying out filter pressing on the furfural residues and primarily reducing the water content of the furfural residues to be 40%-45%; then drying the furfural residues and further dehydrating the furfural residues; when the water content of the furfural residues is reduced to be 15%-20%, adding fly ash to neutralize; after neutralizing, granulating to obtain biomass fuel; combusting the biomass fuel to be used for biomass power generation; meanwhile, taking solid wastes generated by combustion as raw materials of an organic fertilizer to be reutilized; after filtering and condensing the aldehyde gas, condensing to obtain liquid, namely raw aldehyde; carrying out deacidifying and dehydrating on the raw aldehyde to obtain crude aldehyde; refining the crude aldehyde to obtain finished aldehyde; and carrying out heat exchange on the uncondensed aldehyde gas to replace aldehyde gas heat energy to be used as a heat source for drying the furfural residues, wherein all the percentages are mass percentages.

Owner:濮阳宏业生物质能源有限公司

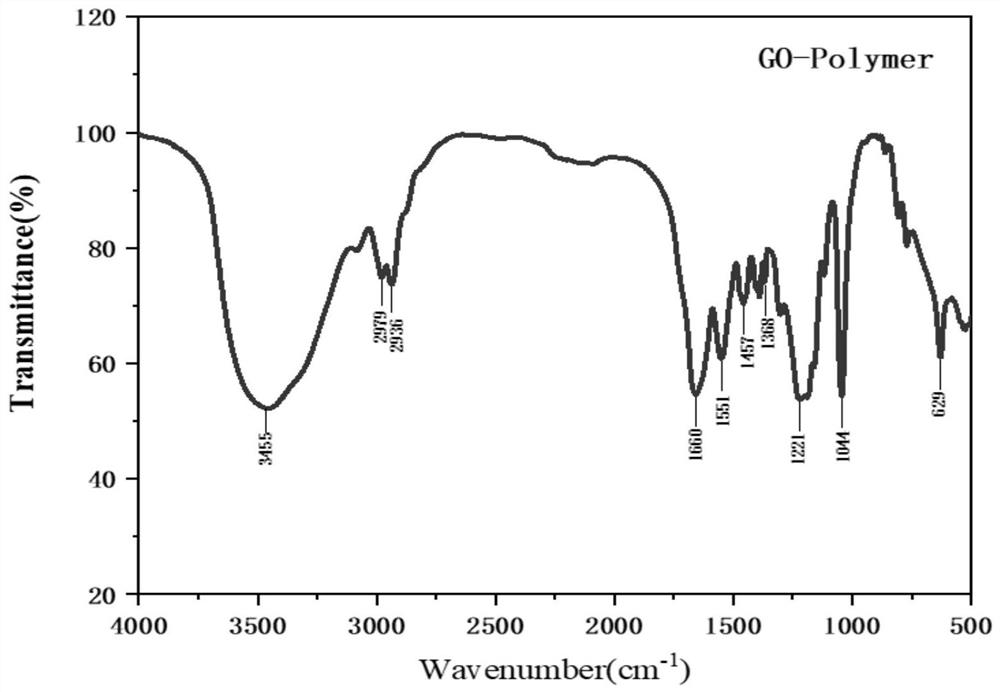

Ultrahigh-temperature modified polymer well cementation fluid loss agent as well as preparation method and application thereof

PendingCN113651931AImprove performanceImprove mechanical propertiesDrilling compositionMeth-Unconventional oil

The invention discloses an ultrahigh-temperature modified polymer well cementation fluid loss agent as well as a preparation method and application thereof, and belongs to the technical field of oil and gas well cementation admixtures. The ultrahigh-temperature modified polymer well cementation fluid loss agent is prepared from the following raw materials in parts by weight: 0.1 to 2 parts of graphene oxide, 0.1 to 1 part of initiator, 12 to 48 parts of 2-acrylamido-2-methylpropanesulfonic acid, 3 to 24 parts of unsaturated amide, 2 to 12 parts of unsaturated carboxylic acid and 130 to 170 parts of water. The fluid loss agent provided by the invention has the advantages of stable performance, high temperature resistance (30-240 DEG C), salt saturation resistance, excellent fluid loss performance, high adaptability, capability of remarkably improving mechanical properties (strengthening and toughening) of set cement and the like, and can meet the requirements of well cementation technologies under complex working conditions of deep wells, ultra-deep wells, complex natural gas wells, unconventional oil and gas wells, gas storage wells and the like.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Liquid-removing and demisting method and device for low pressure drop gas

InactiveCN106955531AImprove dehydration effectAvoid cloggingDispersed particle separationProduct gasSettling

A low-pressure-drop gas deliquoring and demisting method belongs to the technical fields of gas-liquid two-phase separation, environmental protection, and process equipment, and is used to solve the problem of gas carrying liquid. Including gas entry, purified gas discharge, and recovery liquid discharge, its features are: a wire mesh-strengthened separation maze is designed in the vertical or horizontal sedimentation separation space, and the fine liquid carried by the gas is adsorbed and captured by alternately overlapping the wire mesh and the gaps. Drops, and avoid the solid impurities carried by the gas from clogging the equipment. Also provided is a labyrinth screen apparatus for carrying out the method of the invention. It is used for gas-liquid two-phase separation, gas dehydration, and gas defogging, with low pressure drop and high efficiency.

Owner:刘英聚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com