Ultrahigh-temperature modified polymer well cementation fluid loss agent as well as preparation method and application thereof

A fluid loss reducing agent and polymer technology, which are applied in drilling compositions, chemical instruments and methods, etc., to achieve the effects of mild conditions, simple preparation methods, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

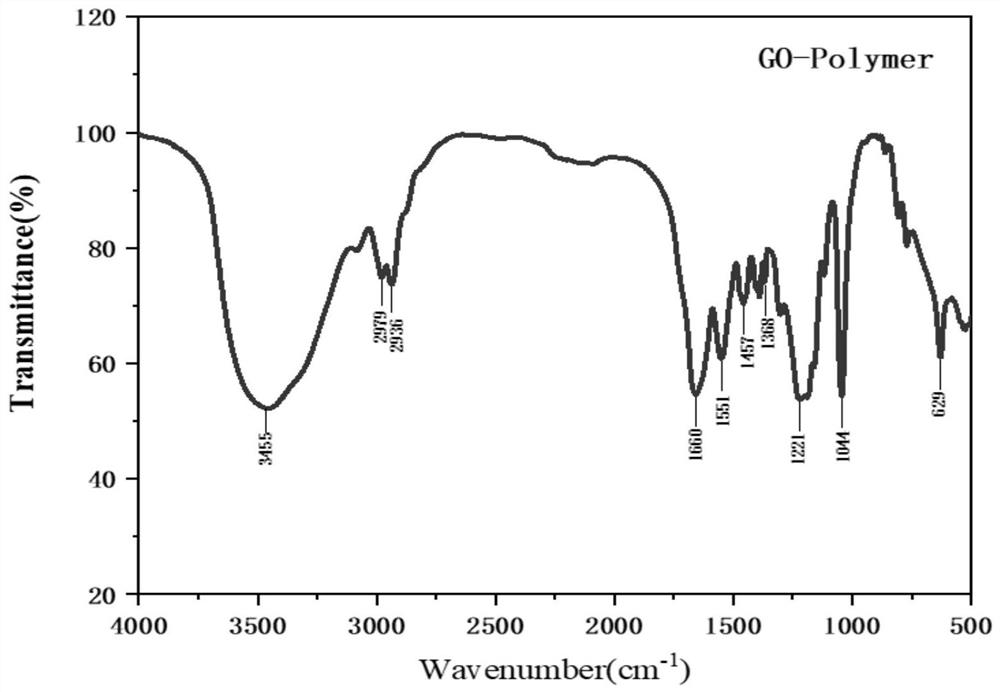

[0042] The reaction process is as Figure 8 shown, including the following steps:

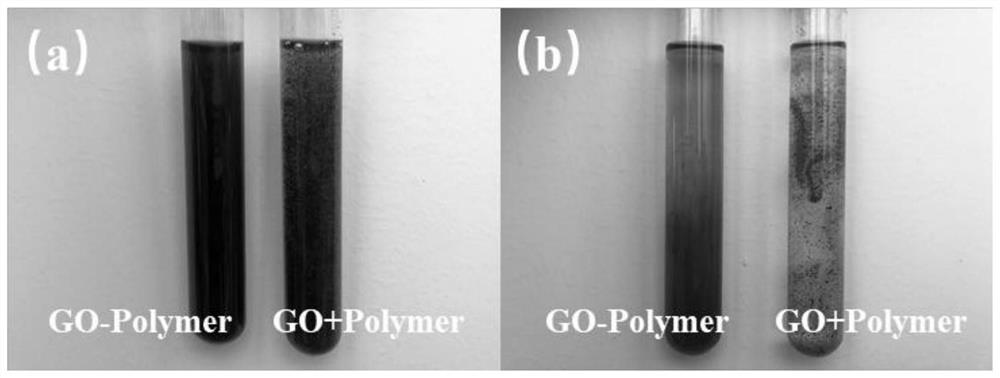

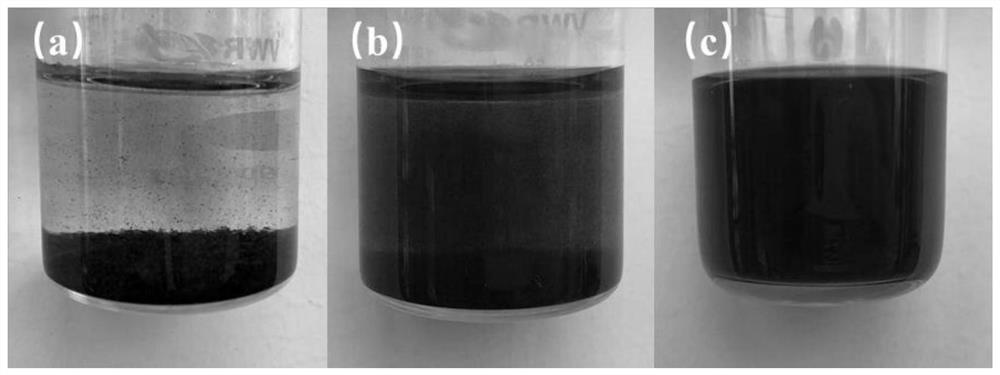

[0043] Weigh 1 g of graphene oxide (GO) into 100 g of water, and ultrasonically disperse at a frequency of 100 Hz for 30 min. After the ultrasonication was completed, 0.3 g of azobisisobutylamidine hydrochloride was added to the above solution, and the pH of the solution was adjusted to 10 with sodium hydroxide, and placed in a rotary stirrer at 30° C. for 4 h. Weigh 40g of 2-acrylamido-2-methylpropanesulfonic acid, 7.5g of N,N-dimethylacrylamide and 2.5g of itaconic acid, add 50g of water to dissolve completely, add 10g of sodium hydroxide to adjust the system When the pH reaches 6, add the solution to the graphene oxide solution after the reaction, raise the temperature to 80°C at a rate of 2°C / min at a speed of 200rpm, and keep this temperature for 2 hours, then cool naturally to room temperature to obtain a black Viscous graphene oxide graft modified polymer fluid loss reducer, that is, u...

Embodiment 2

[0045] Weigh 1 g of graphene oxide (GO) into 100 g of water, and ultrasonically disperse at a frequency of 100 Hz for 1 h. After the ultrasonication was completed, 0.3 g of azobisisobutylamidine hydrochloride was added to the above solution, and the pH of the solution was adjusted to 9 with sodium hydroxide, and placed in a rotary stirrer at 35° C. for 3 h. Weigh 40g of 2-acrylamido-2-methylpropanesulfonic acid, 5g of N,N-dimethylacrylamide and 5g of itaconic acid, add 50g of water to dissolve completely, add 14g of sodium hydroxide to adjust the pH of the system to 6. Add the solution to the graphene oxide solution after the reaction, raise the temperature to 60°C at a rate of 1°C / min at a rotation speed of 250rpm, and keep this temperature for 4 hours, then cool naturally to room temperature to obtain an ultra-high temperature improved Permanent polymer cementing fluid loss reducer (GO-Polymer).

Embodiment 3

[0047] Weigh 0.5 g of graphene oxide (GO) into 100 g of water, and ultrasonically disperse at a frequency of 60 Hz for 10 min. After the ultrasonication was completed, 0.3 g of azobisisobutylamidine hydrochloride was added to the above solution, and the pH of the solution was adjusted to 9 with sodium hydroxide, and placed in a rotary stirrer at 25° C. for 3 h. Weigh 30g of 2-acrylamido-2-methylpropanesulfonic acid, 15g of N-vinylcaprolactam and 5g of maleic acid and add 50g of water to dissolve completely, add 12.5g of sodium hydroxide to adjust the pH of the system to 7, and then Add this solution to the graphene oxide solution after the reaction, raise the temperature to 90°C at a rate of 3°C / min at a rotation speed of 150rpm, and keep this temperature for 1 hour, then cool naturally to room temperature to obtain an ultra-high temperature modified polymer Cementing fluid loss reducer (GO-Polymer).

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com