Patents

Literature

75results about How to "Dehydration achieved" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

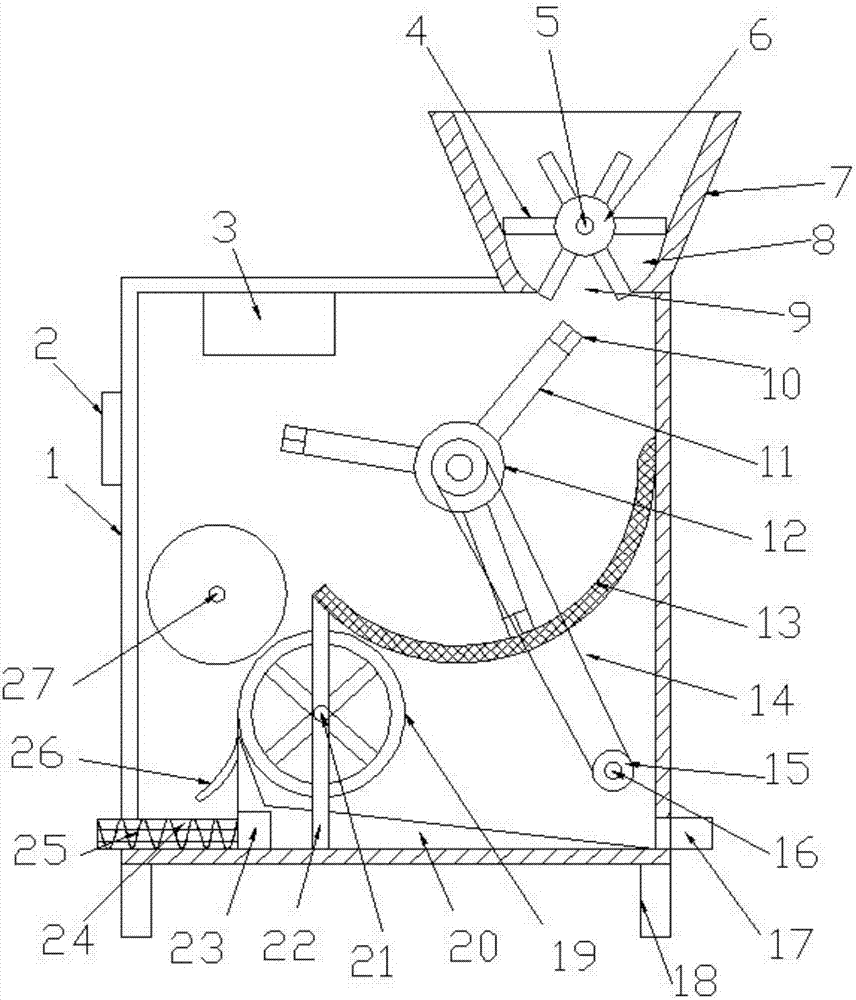

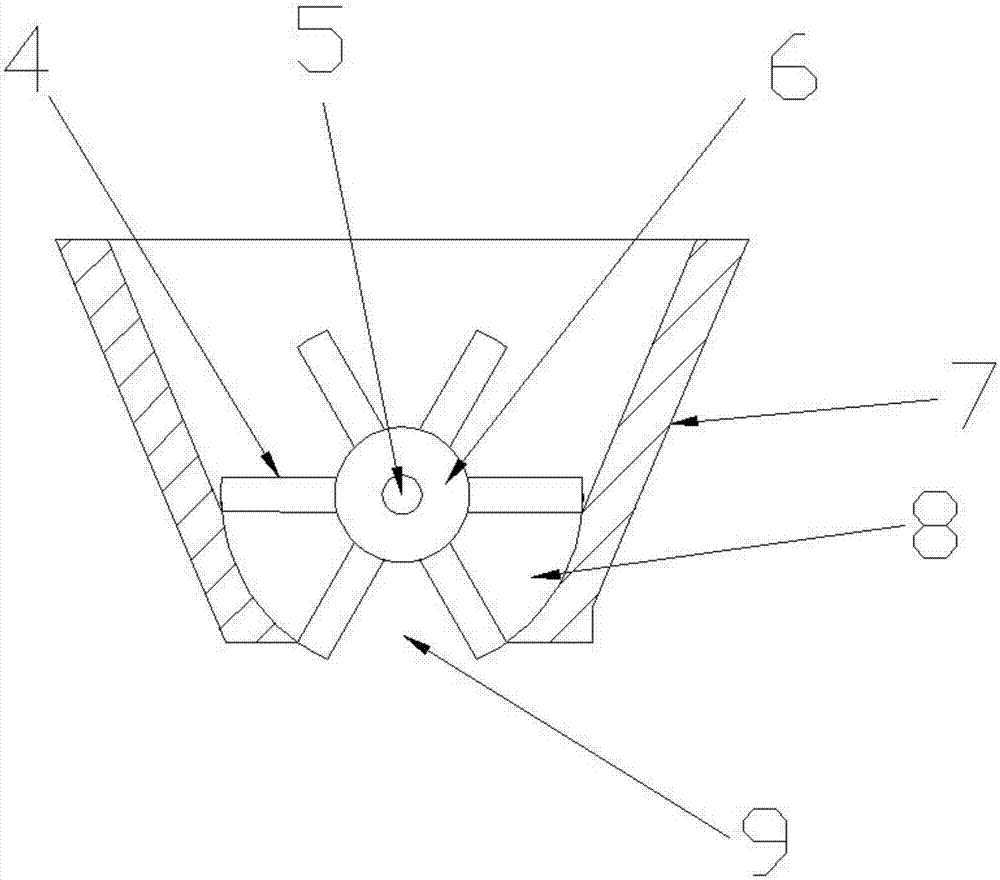

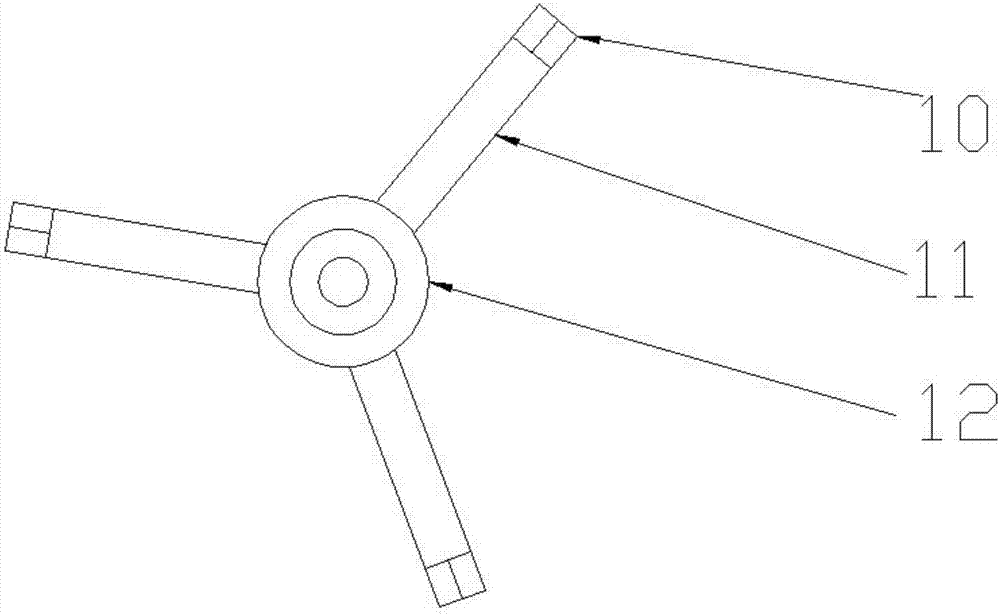

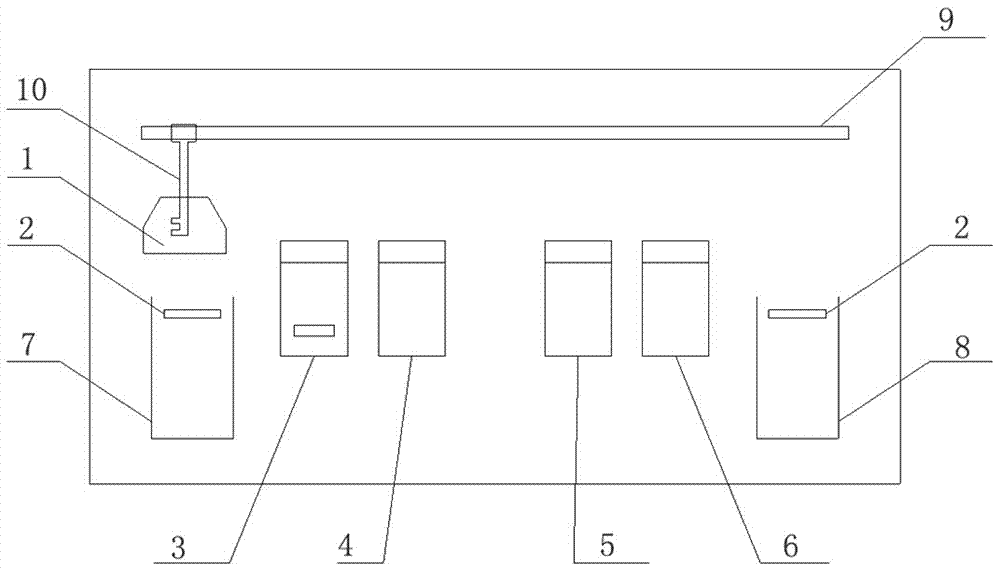

Quick efficient sludge dewatering device

InactiveCN107381992AImprove dehydration efficiencyDehydration achievedSludge treatment by de-watering/drying/thickeningSludge detoxificationPulp and paper industryDewatered sludge

The invention discloses a fast and high-efficiency sludge dewatering device, which comprises a shell, the bottom of the shell is symmetrically arranged with supporting feet, and a screen is arranged inside the shell, and the screen is in the shape of an arc groove. A turntable is set at the center of the arc, and the turntable is set on a rotating shaft in the casing. A rotating rod is arranged symmetrically on the center of the turntable, and a scraper is arranged at the end of the rotating rod. The top end of the right side of the screen is fixed on the casing. On the right side wall of the body, the left end of the screen is fixed to the inner bottom of the housing through a vertical rod; the top of the right side of the housing is provided with a feed port, and the housing on the left side of the screen is provided with an upper extrusion roller and a lower extrusion roller; The lower squeeze roller includes an outer drum, and the outer drum is a filter mesh drum; the invention skillfully arranges the screen structure and the scraping mechanism on the screen, which greatly improves the sludge dewatering efficiency, and at the same time, an upper squeeze roller is arranged corresponding to the bottom of the screen. The pressure roller and the lower squeeze roller, and clever use of the material hanging mechanism to scrape in the preliminary dewatered sludge to achieve further dehydration.

Owner:顾渠成

Chemical material extrusion dehydration and drying integration equipment

InactiveCN108151450ADehydration achievedReduce labor intensityDrying solid materials without heatDrying gas arrangementsEngineeringDehydration

The invention provides chemical material extrusion dehydration and drying integration equipment. The equipment comprises a tank; a top cover is arranged in a top opening of the tank; a bottom cover isarranged in a bottom opening of the tank; a feed pipe is fixedly welded on the edge of the top cover; a separation plate is fixedly welded at the middle part of the inner wall of the tank, and is annular; the inner wall is fixedly welded with the bottom of a dehydration cylinder; the top of the dehydration cylinder is fixedly welded with the bottom edge of a guide disc; a dehydration device is arranged in the dehydration cylinder; two limiting plates are symmetrically and fixedly welded on the lower surface of the separation plate; the limiting plates are L-shaped; baffle plates are arrangedbetween the limiting plates and the separation plate; and a crushing and drying device is arranged in the tank below the separation plate. The equipment uses the dehydration device for extruding addedchemical materials to realize dehydration of the chemical materials, uses the crushing and drying device for crushing the dehydrated chemical materials, and uses hot air for blow-drying of the dehydrated chemical materials.

Owner:ZHENGZHOU CHENGHE INFORMATION TECH CO LTD

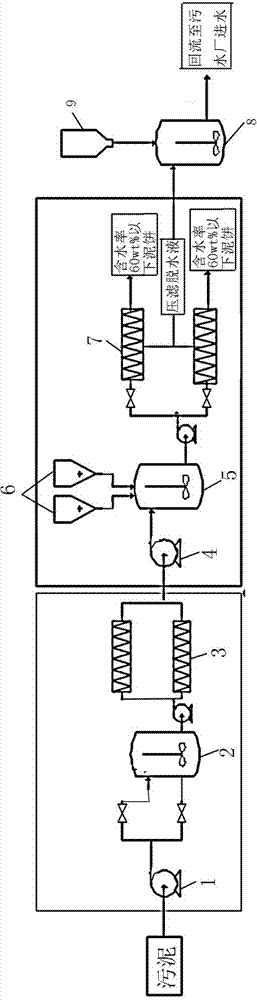

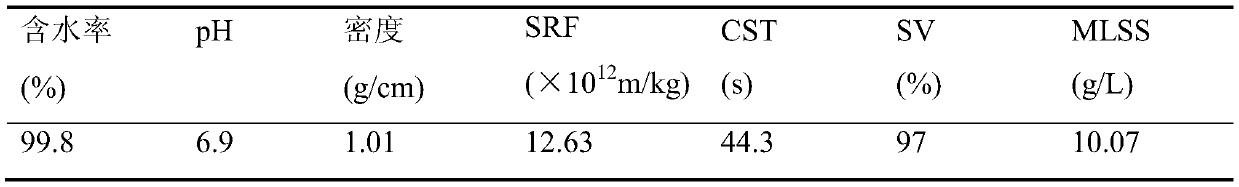

Inorganic conditioning based integrated sludge deep dehydration treatment process

InactiveCN103482844AReduce the ratioReach the smellSludge treatment by de-watering/drying/thickeningThermal energySocial benefits

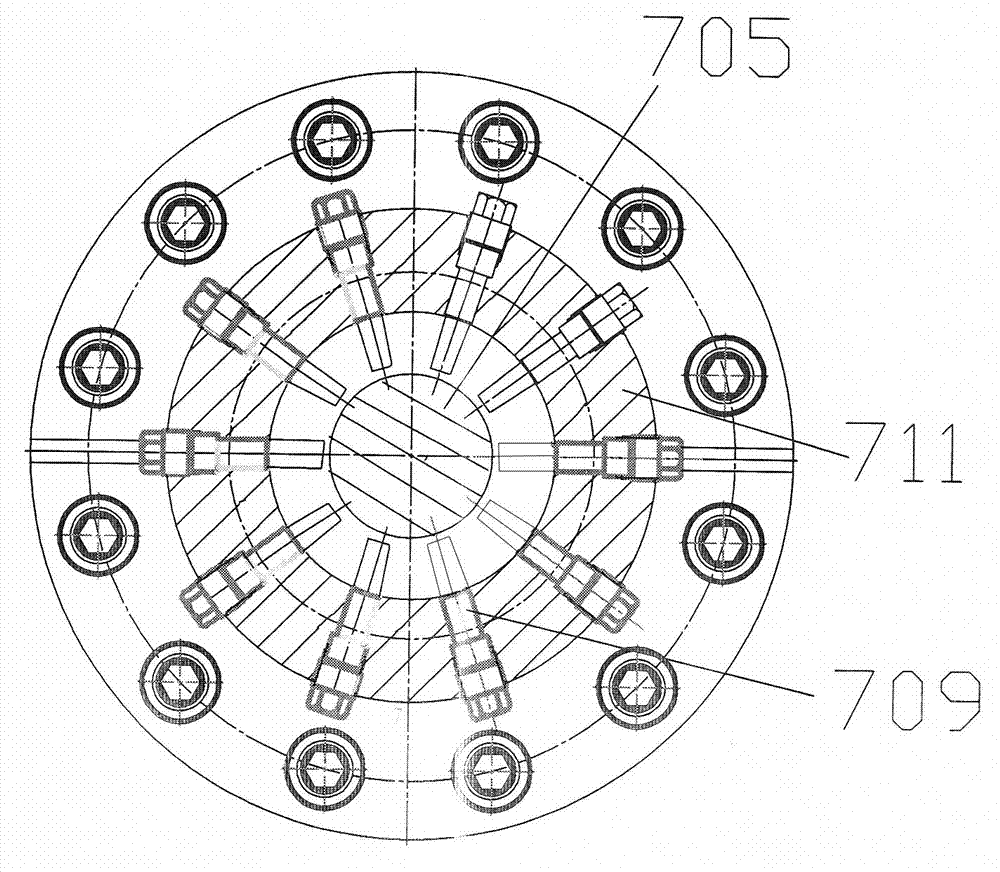

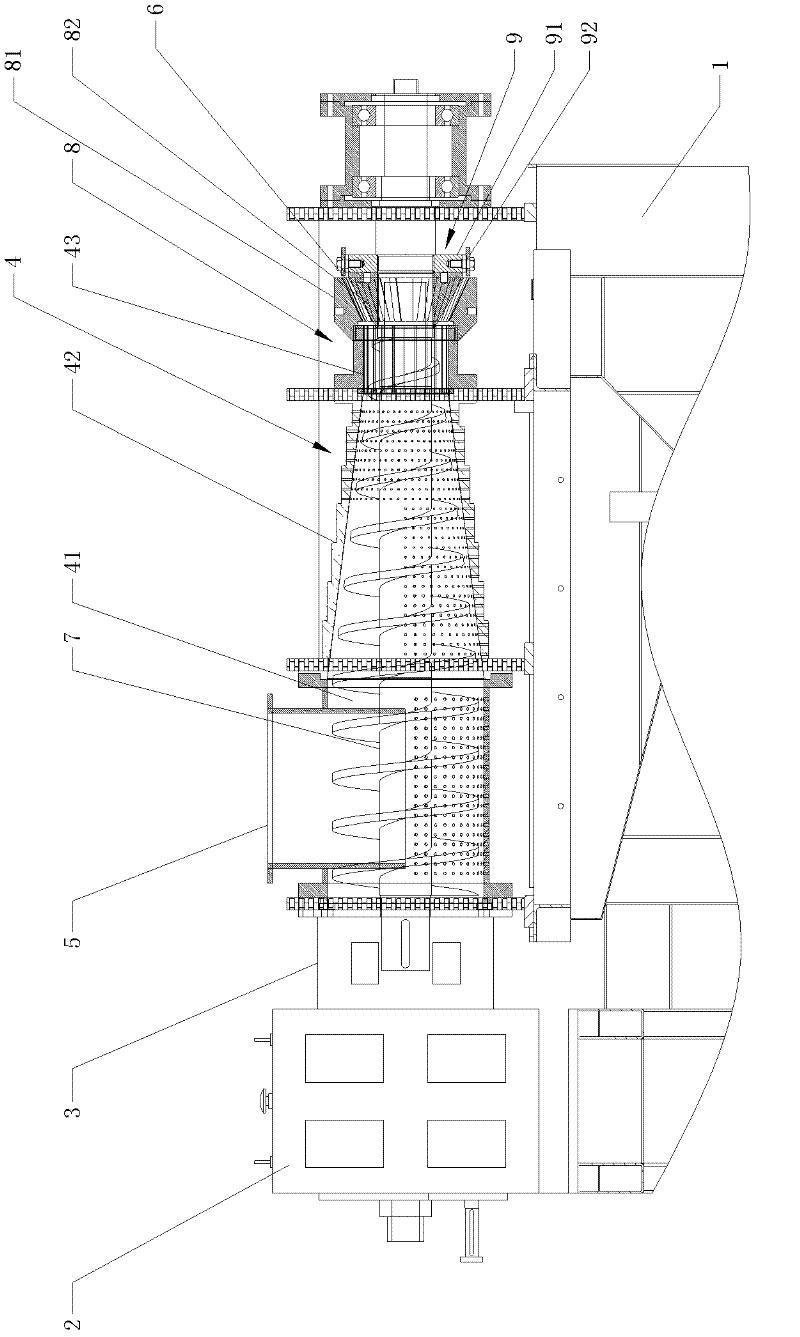

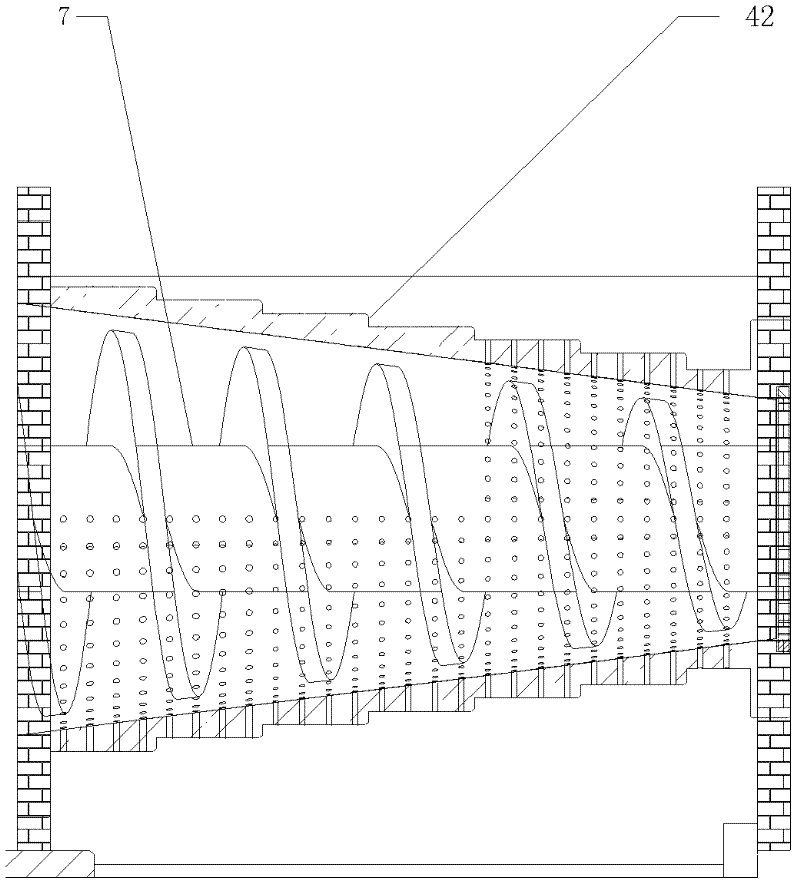

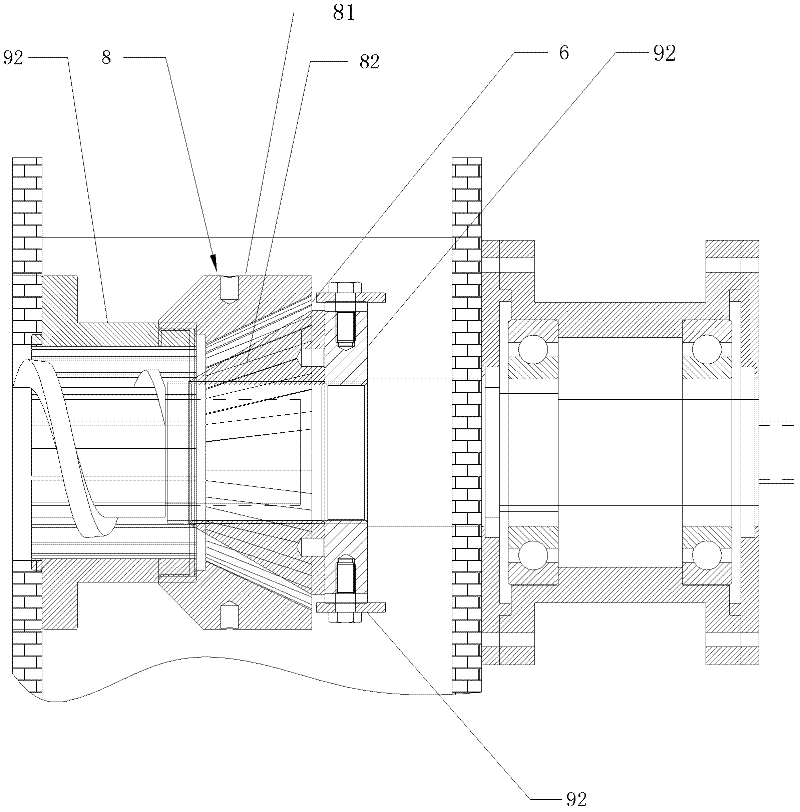

The invention relates to an inorganic conditioning and pin screw machine based integrated sludge deep dehydration treatment process. The process comprises the steps such as primary dehydration, deep dehydration, dehydrated sludge delivery and the like; the moisture content in the sludge is reduced from 99.7% to less than 60% once in two stages by only adopting medication modifying and pin screw machine filter pressing ways instead of depending on any external conditions such as thermal energy and the like. In the whole operation process, no smoke, odor and noise are generated, no external thermal sources are needed, no secondary pollution is caused, the clean production can be realized, and more importantly, an operable approach is provided for waste sludge recycling, so that the process has very important significance in handling a large-area and large-quantity sludge treatment situation on both economic and social benefits.

Owner:孙阳 +1

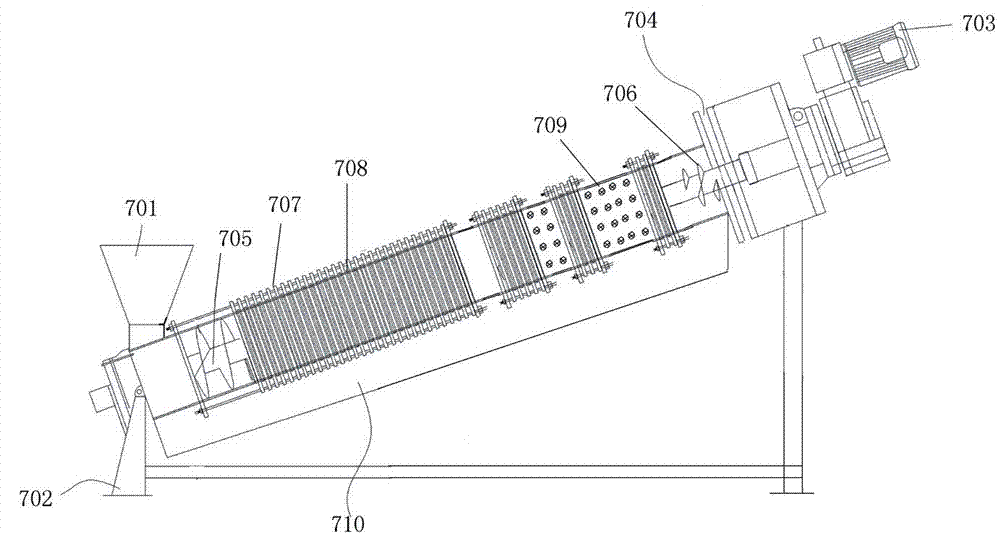

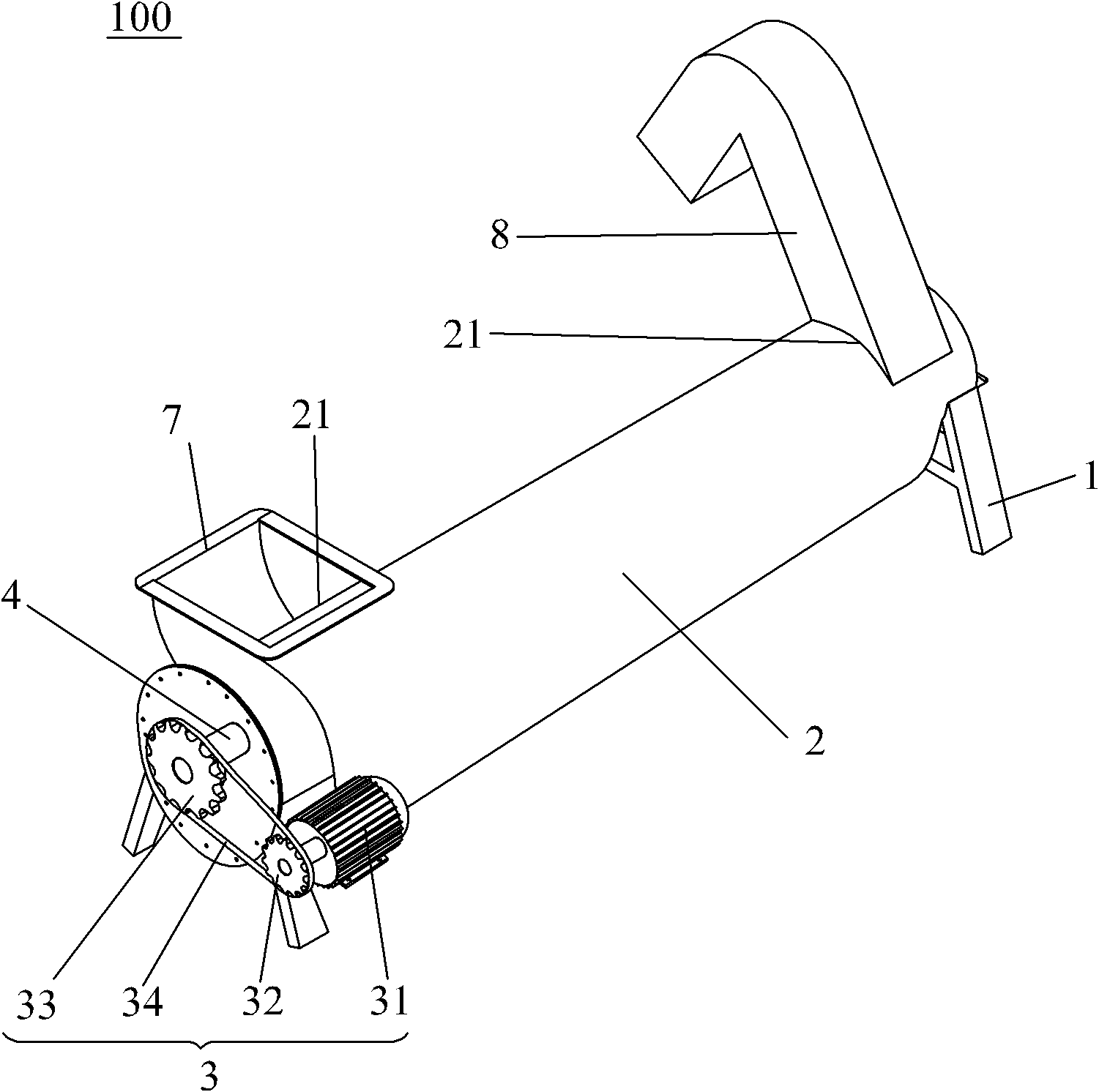

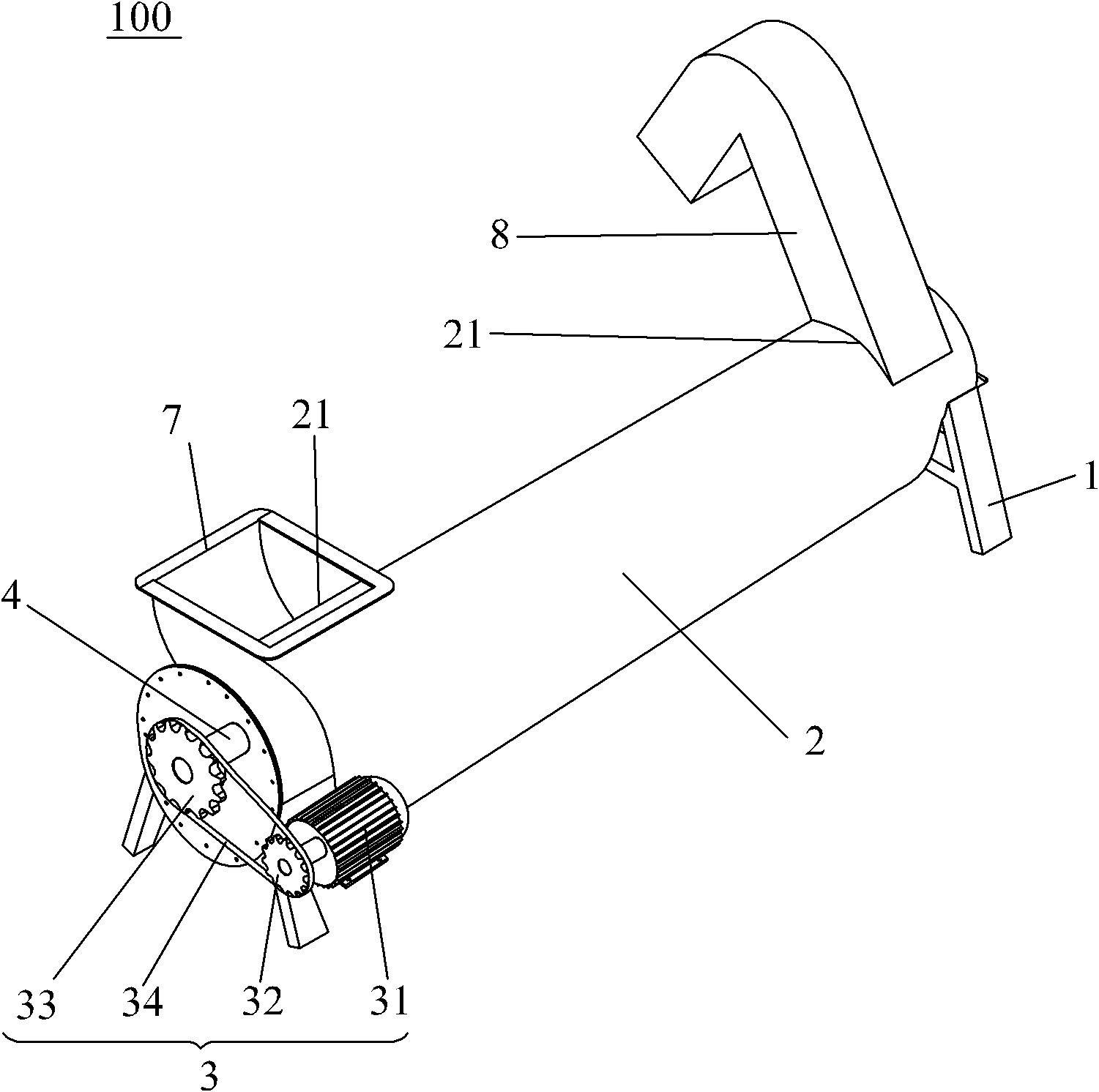

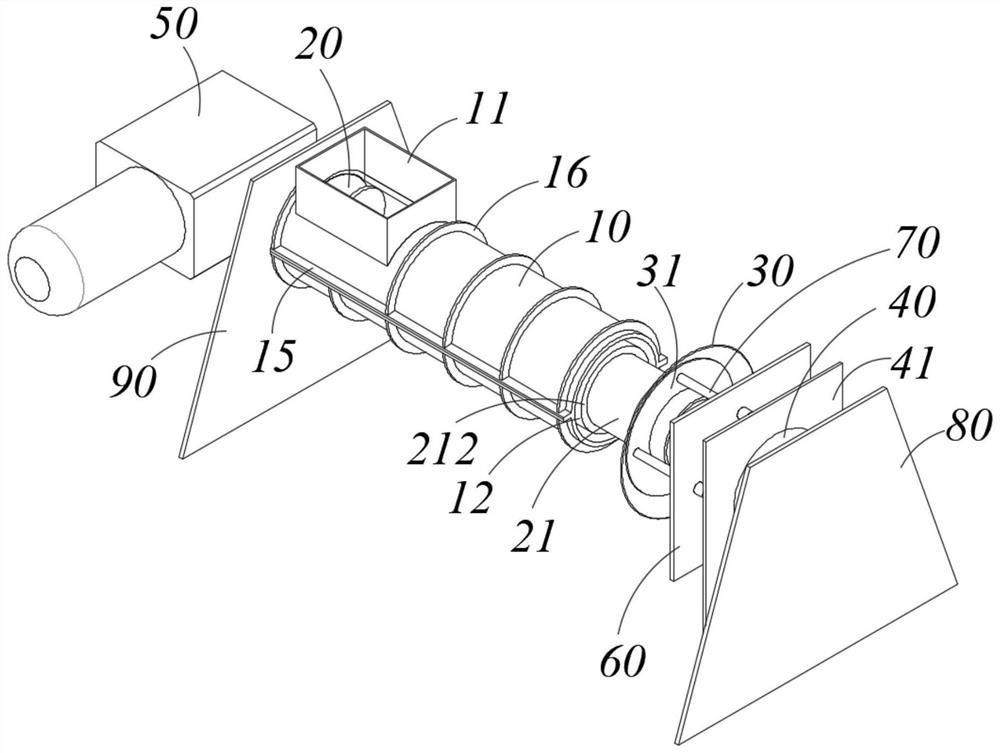

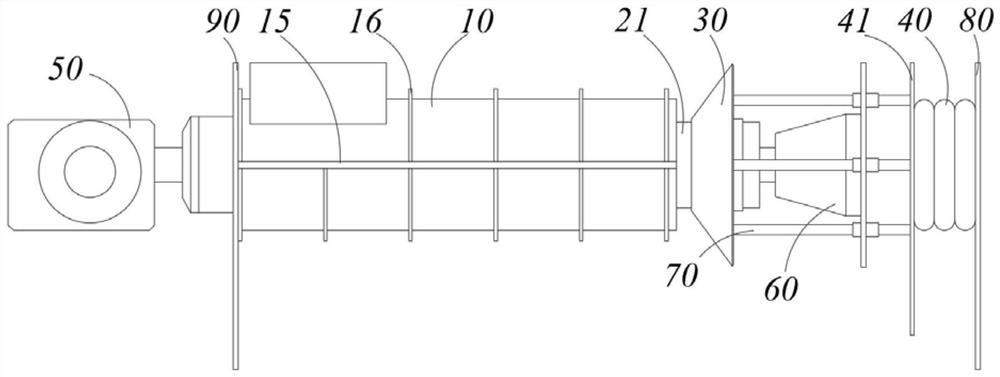

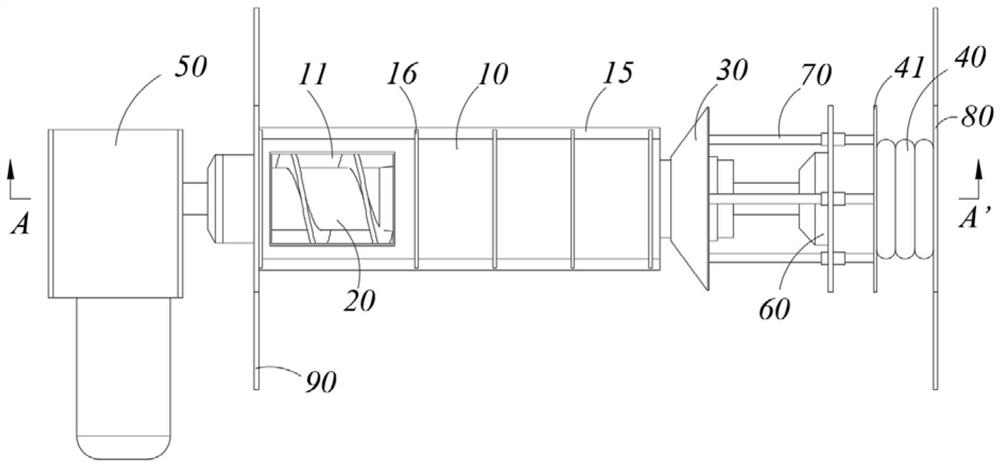

Squeezing type dewatering machine

The invention discloses a squeezing type dewatering machine, which comprises a frame. A filter cylinder with filtering holes is fixed onto the frame, a conical screw rod with a helical blade is mounted in the filter cylinder, the filter cylinder comprises a primary filter cylinder body and a secondary filter cylinder body which are connected with each other, the primary filter cylinder body is provided with a feeding port, the secondary filter cylinder body is conically contracted along the pushing direction, and a squeezing cylinder is connected to the tail end of the secondary filter body. The conical screw rod penetrates through the primary filter cylinder, the secondary filter cylinder and the squeezing cylinder, a discharging device is arranged at the tail end of the squeezing cylinder, and the conical screw rod is driven by a power device. Materials can be dewatered for three times by means of the squeezing type dewatering machine, and since the conical screw rod is conical and the secondary filter cylinder body is conically contracted along the pushing direction, the space between the conical screw rod and the secondary filter cylinder body is small, and materials can be better dewatered. The squeezing type dewatering machine is low in required centrifugal rotation speed, high in dewatering capacity, low in noise pollution and environment-friendly.

Owner:JIANGSU FANGSHENG MACHINERY

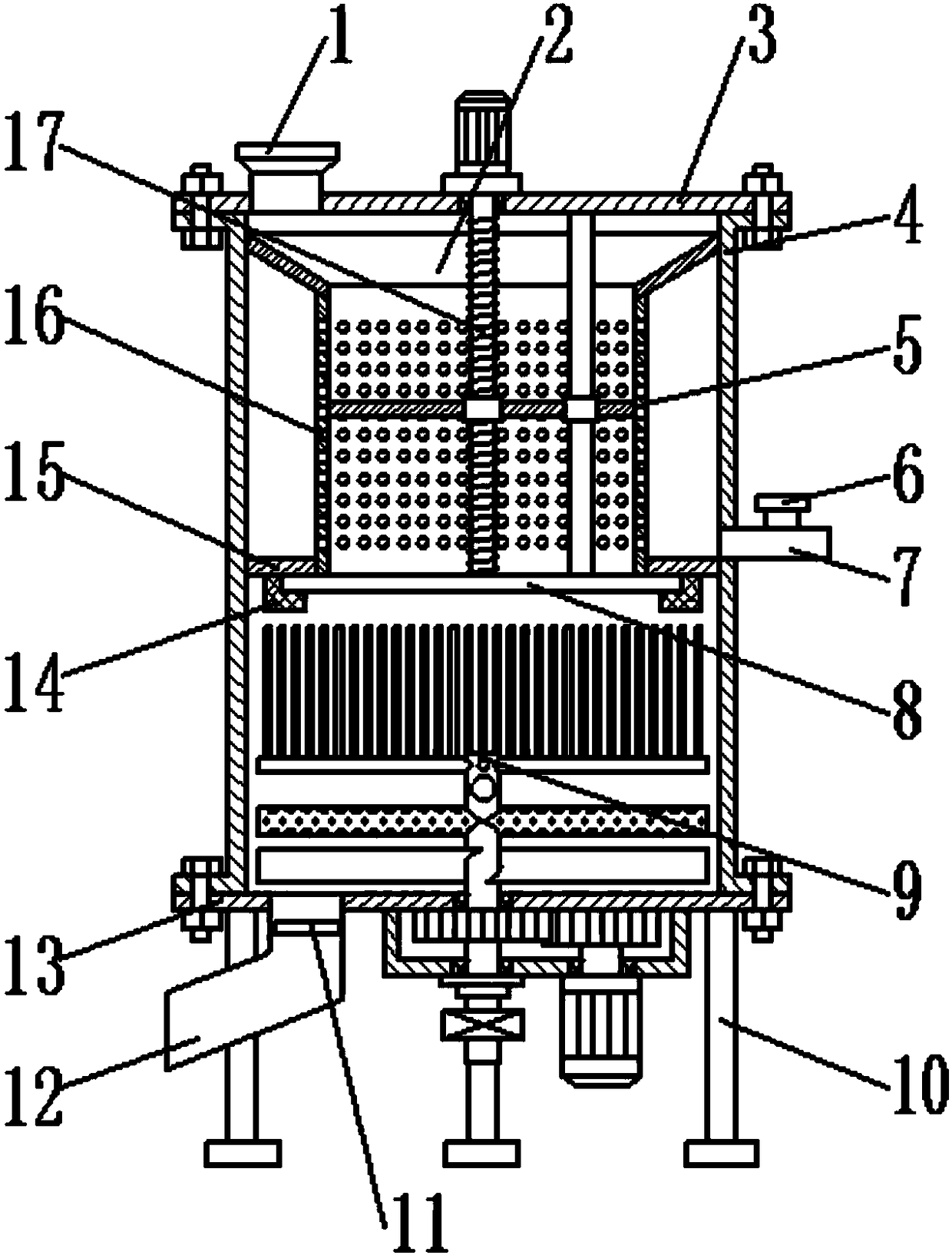

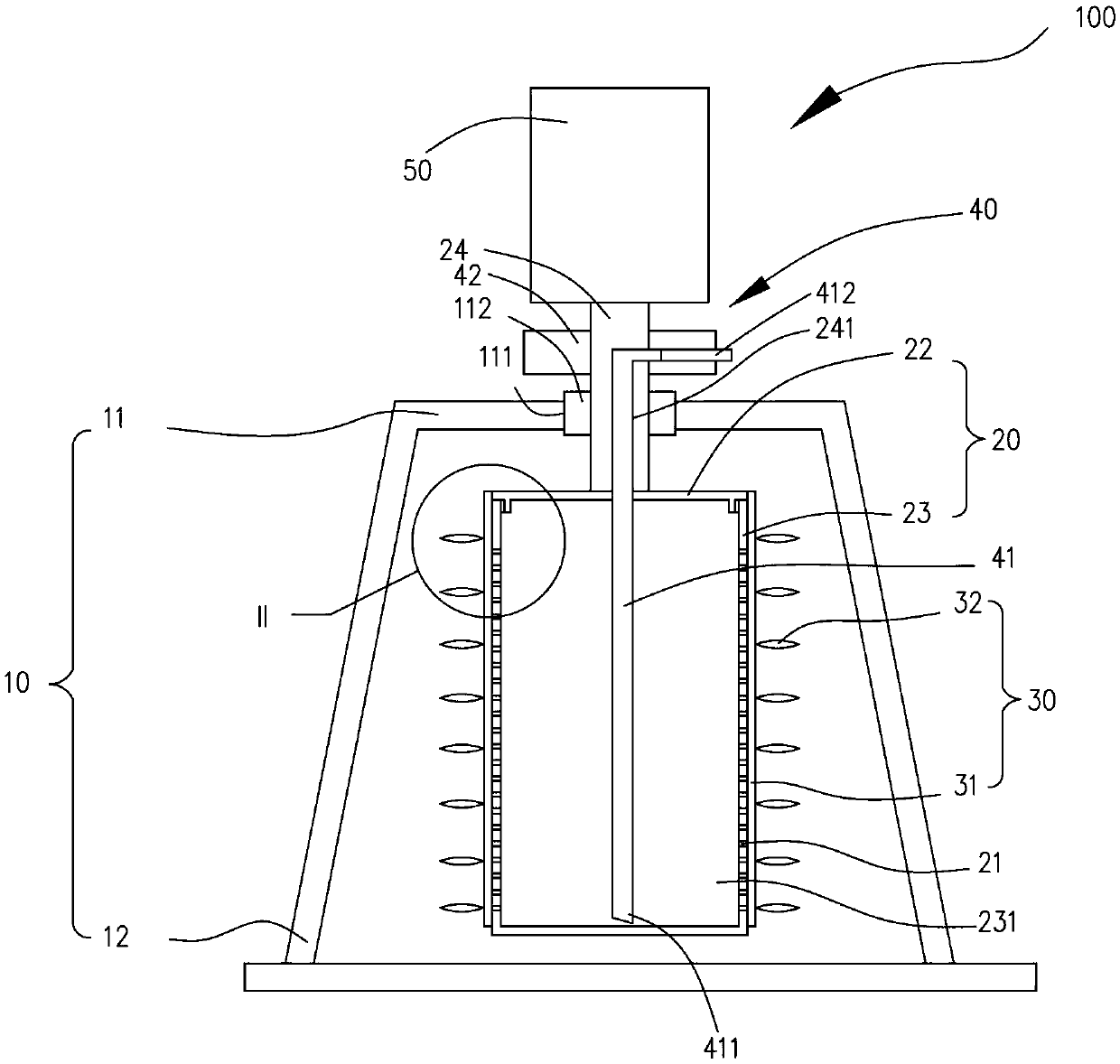

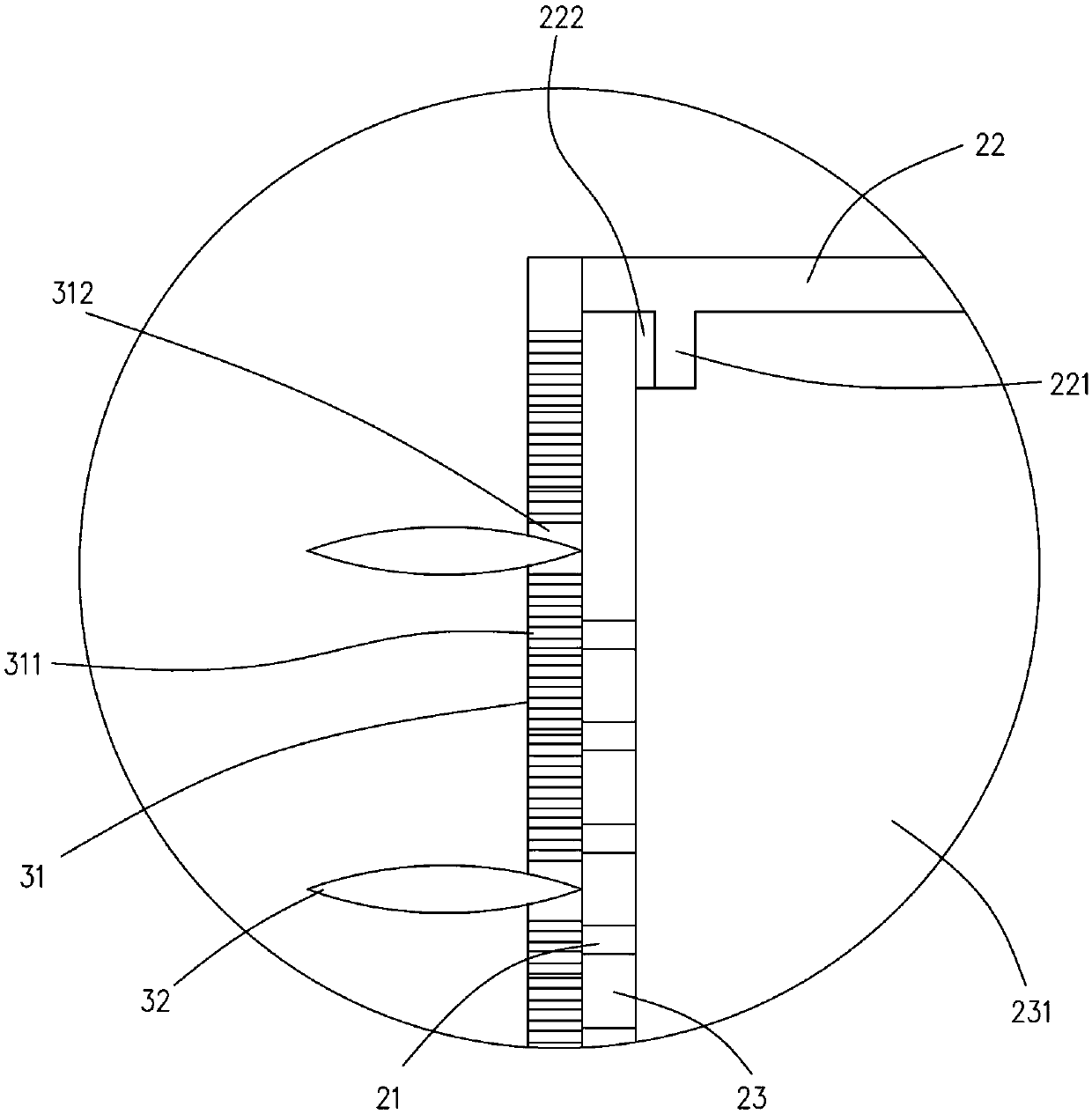

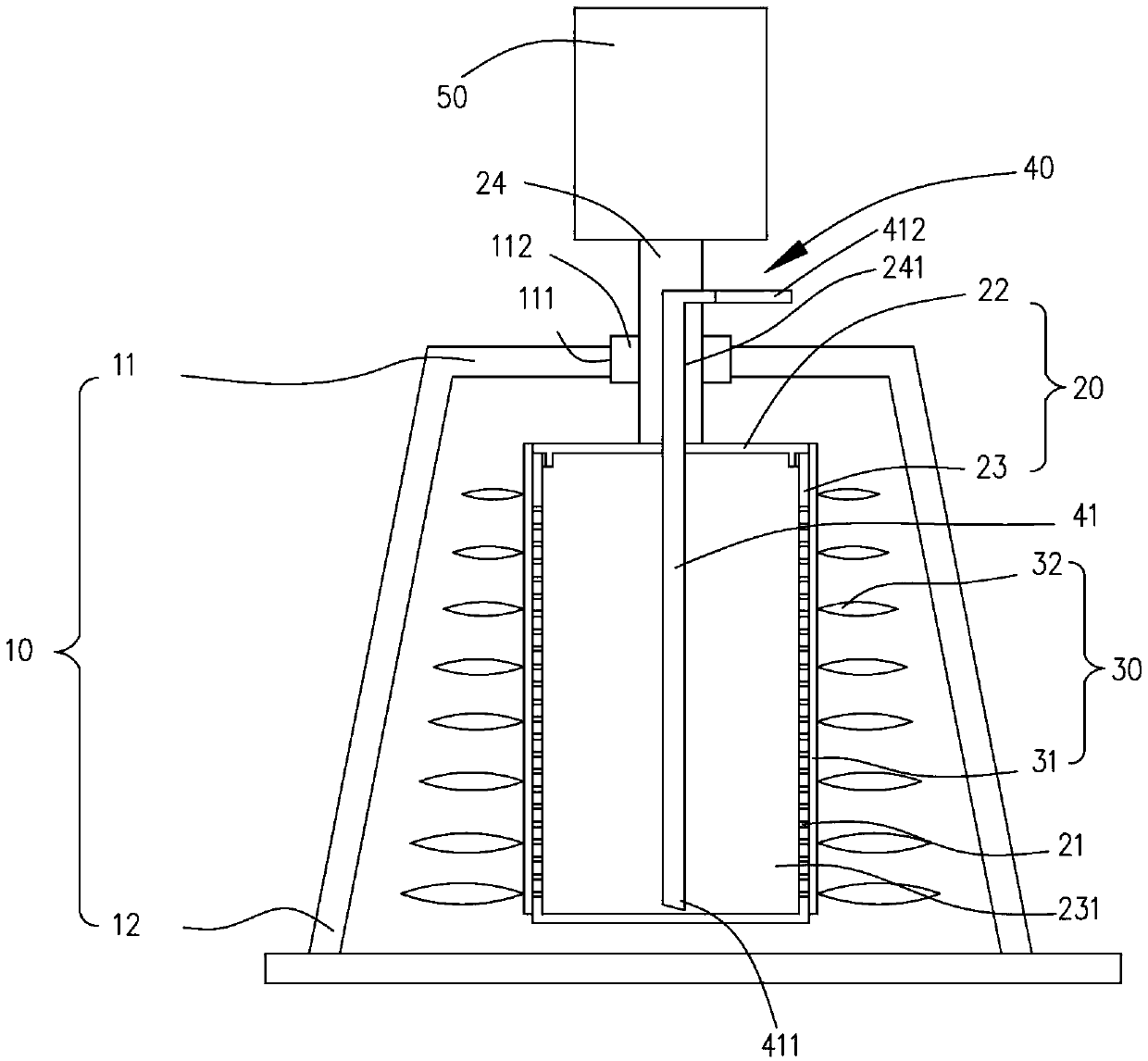

Hydraulic dewatering machine, and sludge dewatering system and method

InactiveCN109179949AImprove dehydration rateReduce labor intensitySludge treatmentStart upSludge dewatering

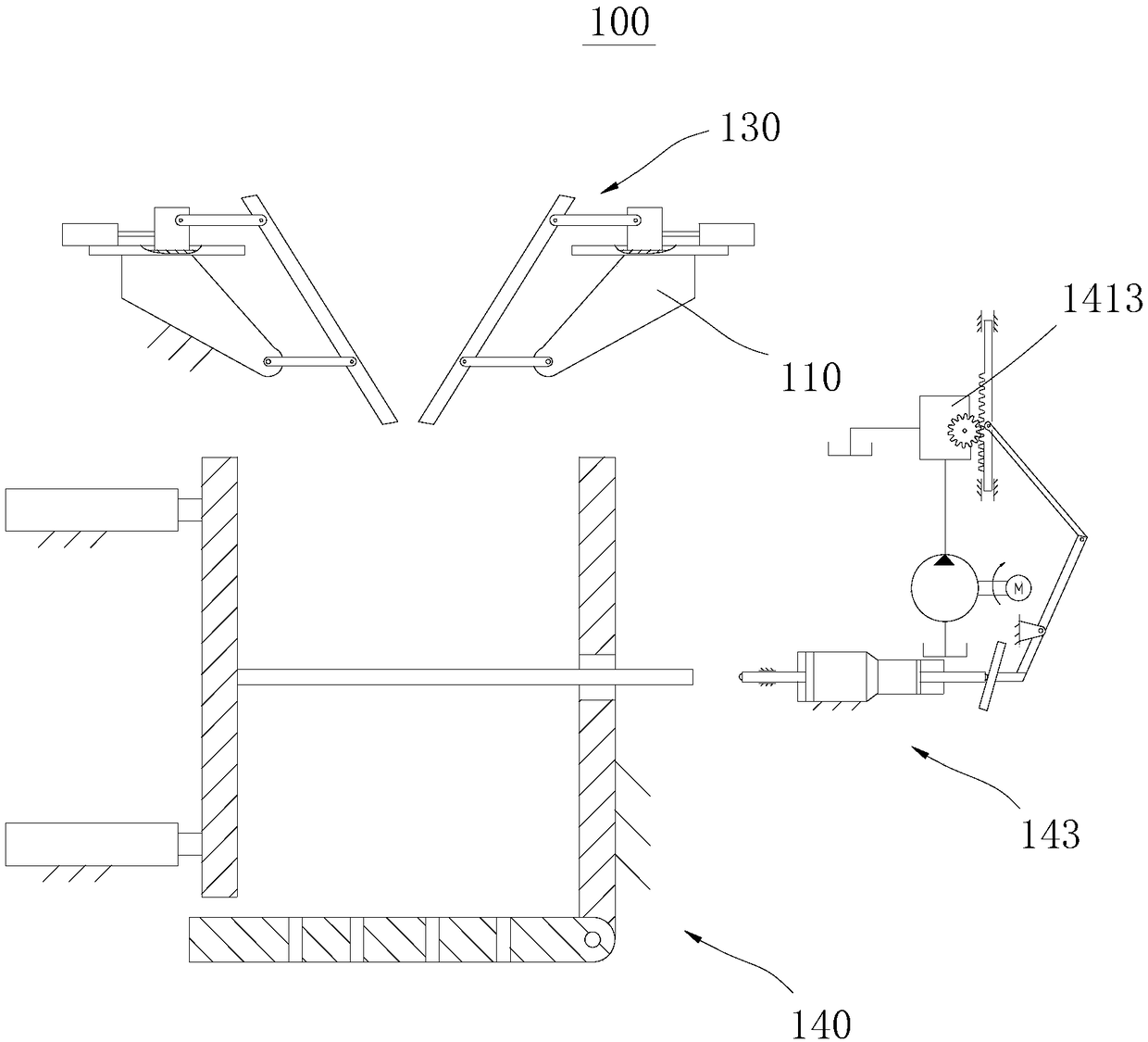

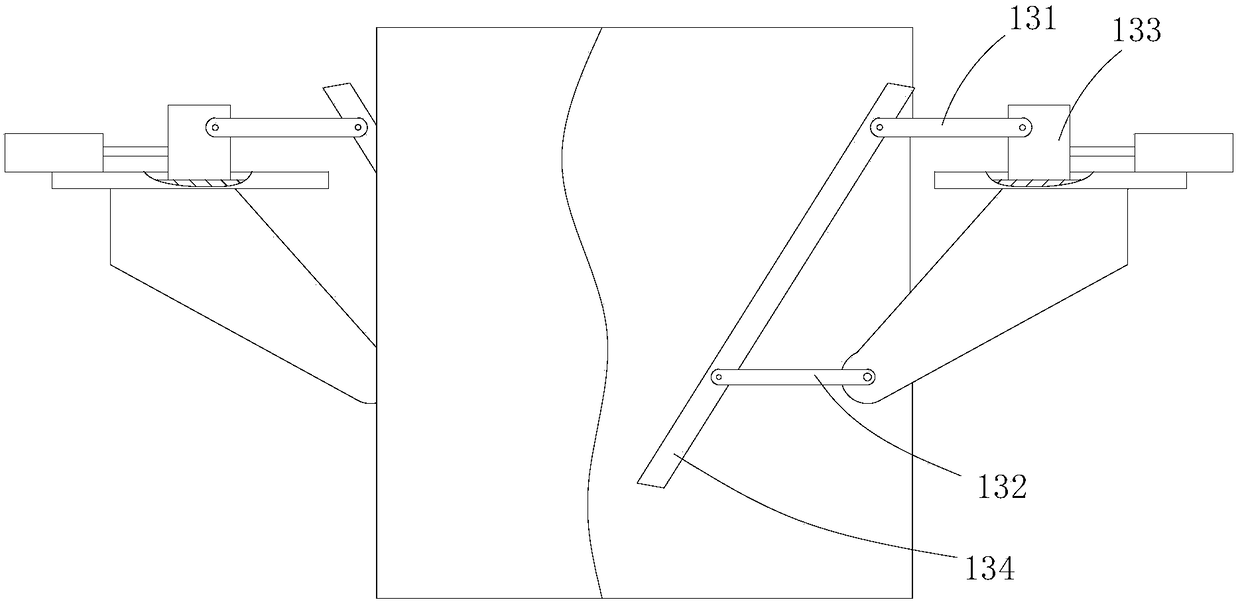

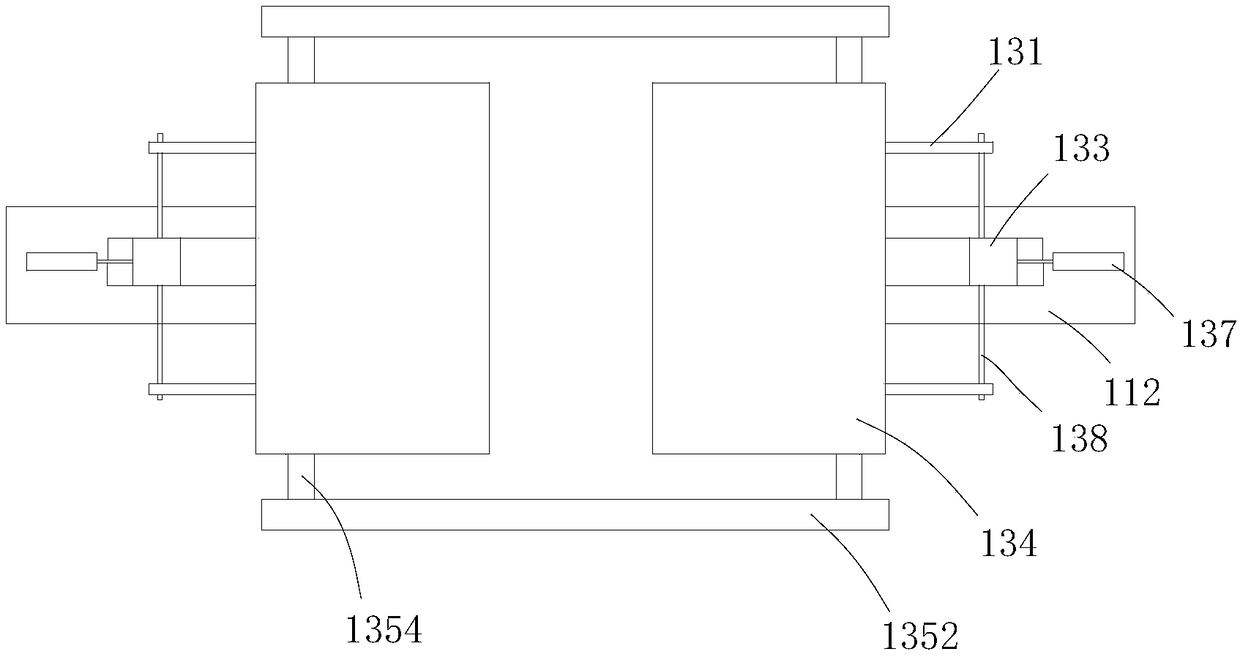

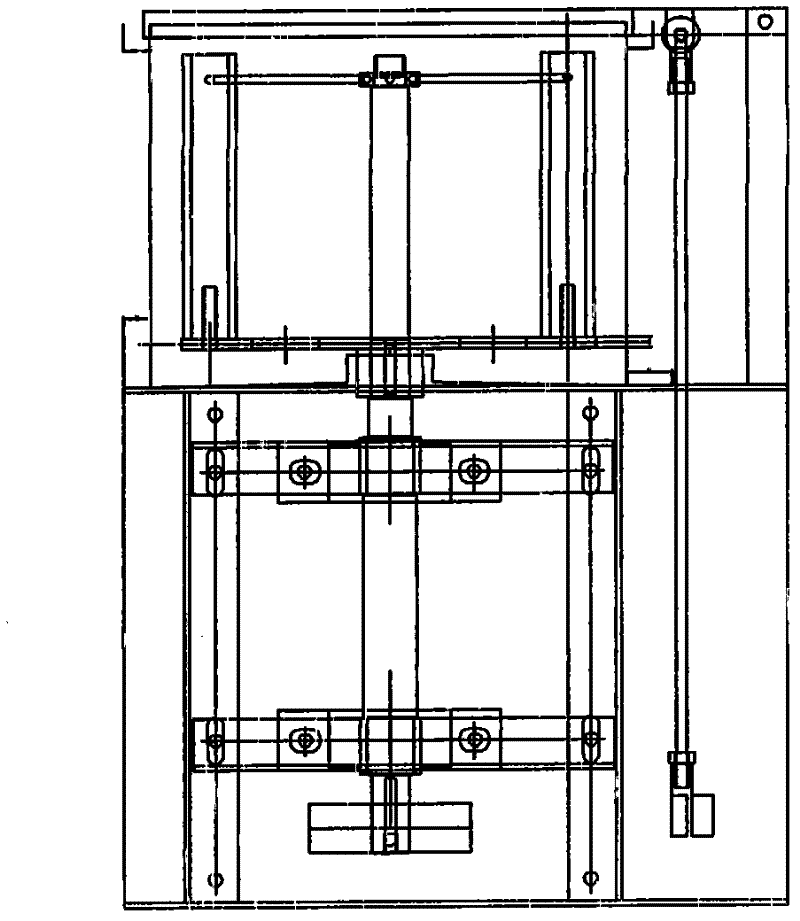

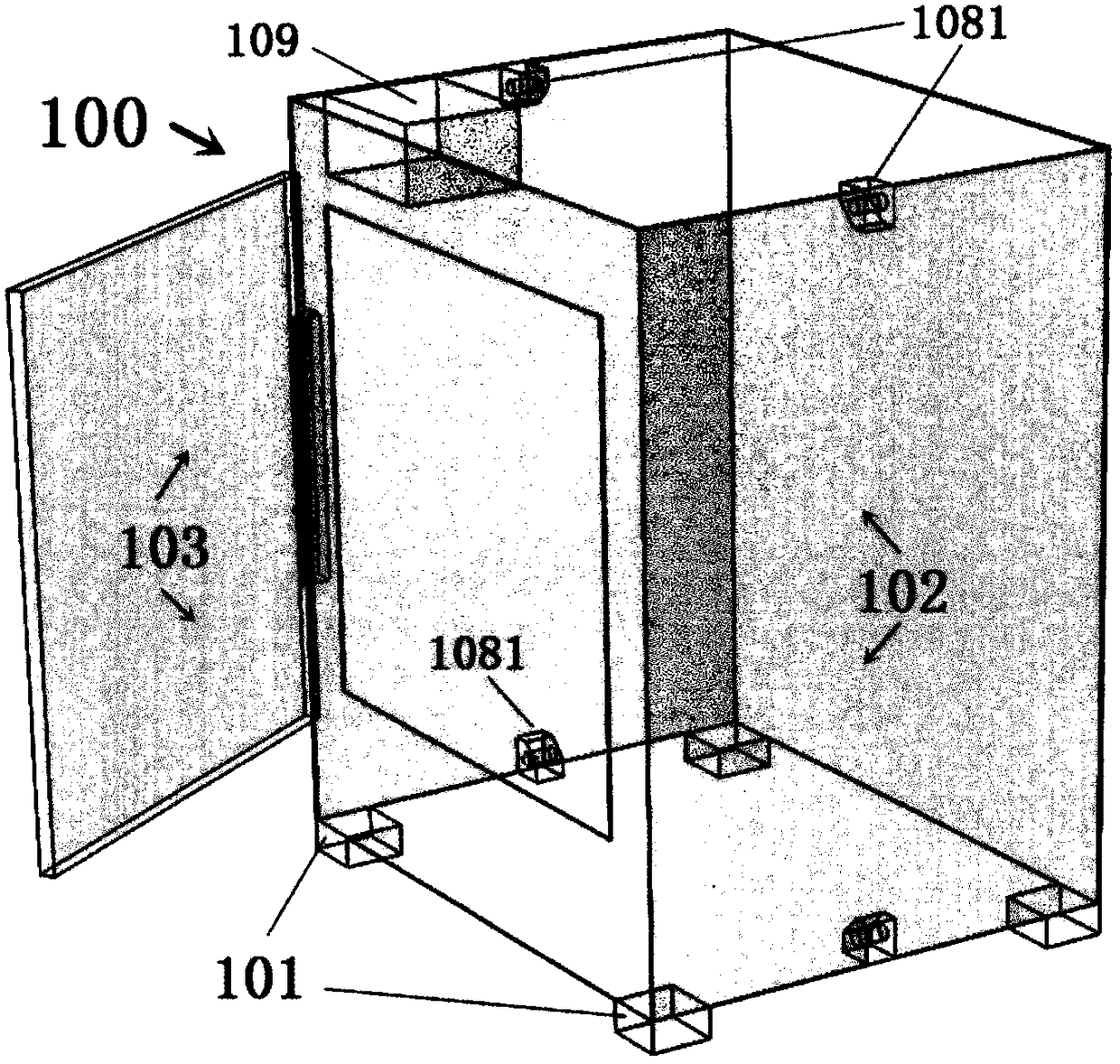

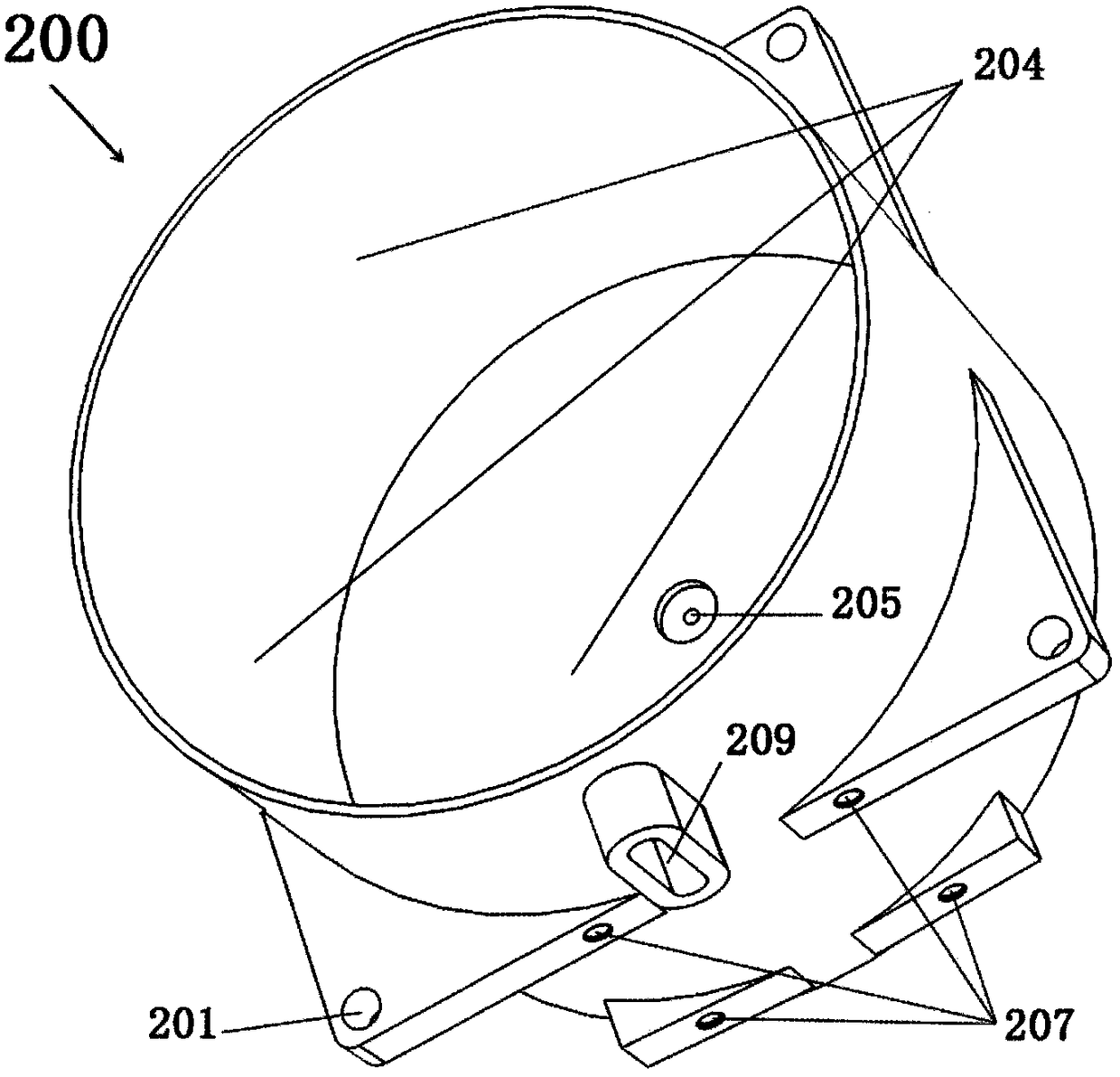

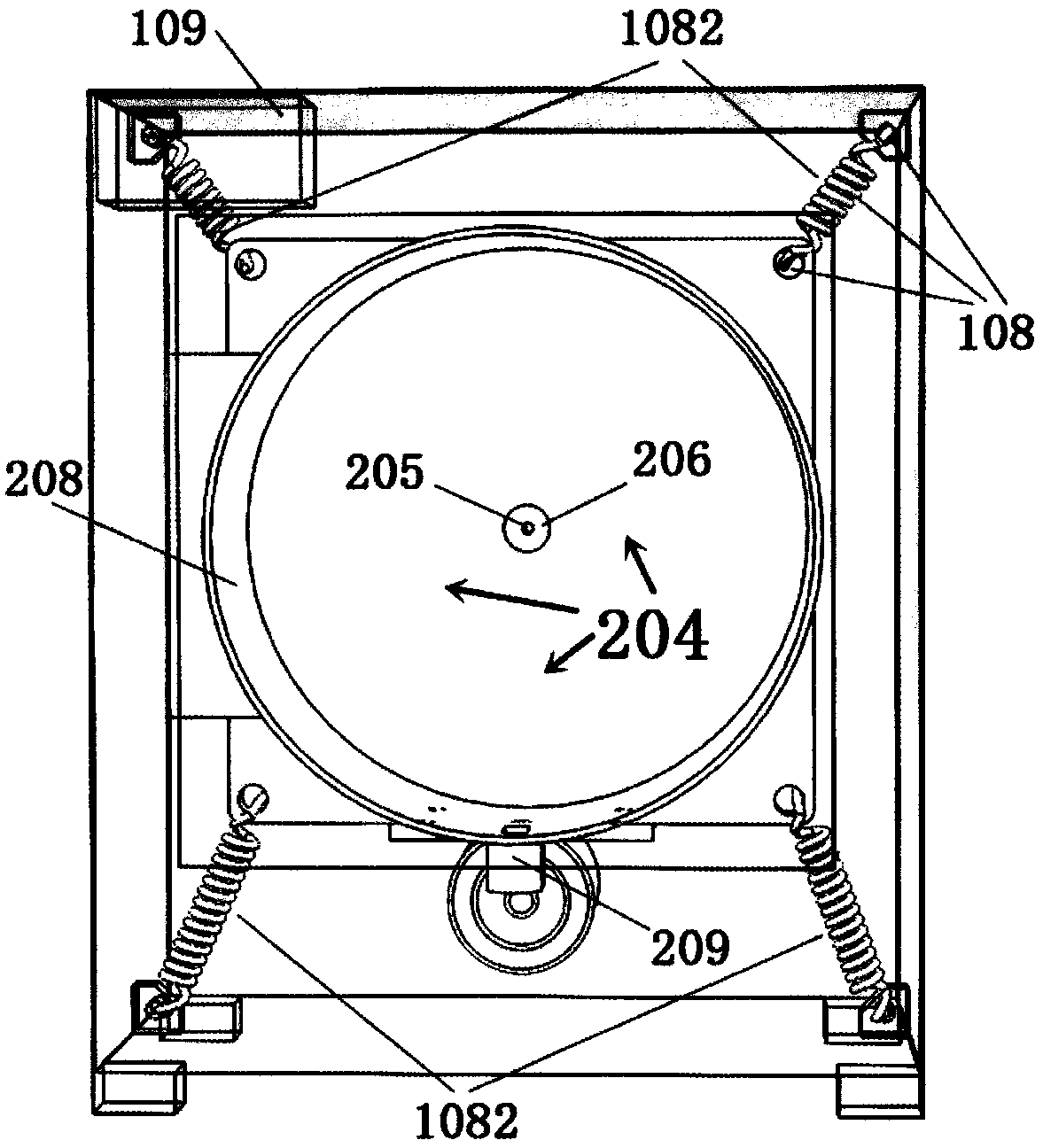

The invention provides a hydraulic dewatering machine, and a sludge dewatering system and method, and belongs to the field of environmental protection equipment. The hydraulic dewatering machine comprises a rack, a hydraulic system, a dewatering device and a starting-up device; the hydraulic system provides the pressure for the dewatering device; the dewatering device is used for extruding sludgeto dewater; the starting-up device is used for driving to start up the dewatering device to make sludge fall. The sludge dewatering system includes the hydraulic dewatering machine and a plate overturning dewatering machine. The plate overturning dewatering machine is used for preliminary dewatering, and the hydraulic dewatering machine is used for deep dewatering. The dewatering system is adoptedin the method. With adopting of the hydraulic dewatering machine, and the dewatering system and method, the dewatering rate is high, the labor intensity of workers is reduced and the dewatering efficiency is improved.

Owner:李文静

Energy-saving sump oil dehydration device and treatment method thereof

ActiveCN107880930AAchieve deep dehydrationLess waterTreatment with plural serial refining stagesEvaporationOil water

The invention provides an energy-saving sump oil dehydration device and a treatment method thereof. The energy-saving sump oil dehydration device comprises a sump oil dehydration tower, a sump oil atomizer, a Venturi rod layer, a circulating heater, a pump for sump oil to be dehydrated and a circulating sump oil pump. A circulating heating and atomizing technologies are used; low-temperature afterheat of an oil refining device is fully utilized; heated sump oil is atomized into fine fogdrop, so that the oil-water boundary tension is reduced; the oil-water evaporation area is increased; the deep dehydration of the sump oil is realized. The energy-saving sump oil dehydration device has the advantages that the flow process is simple; the operation is simple and convenient; the energy consumption is low; the dehydration effect is good; the applicability is wide. The energy-saving sump oil dehydration device can be used for light sump oil dehydration, can also be used for heavy sump oil dehydration and is particularly applicable to deep dehydration of seriously emulsified sump oil; the water content in the sump oil can be lowered to 2 percent or less; the requirement of sump oil refining on the water content is met.

Owner:SHANGHAI YOUHUA PROCESS INTEGRATED TECH CO LTD +1

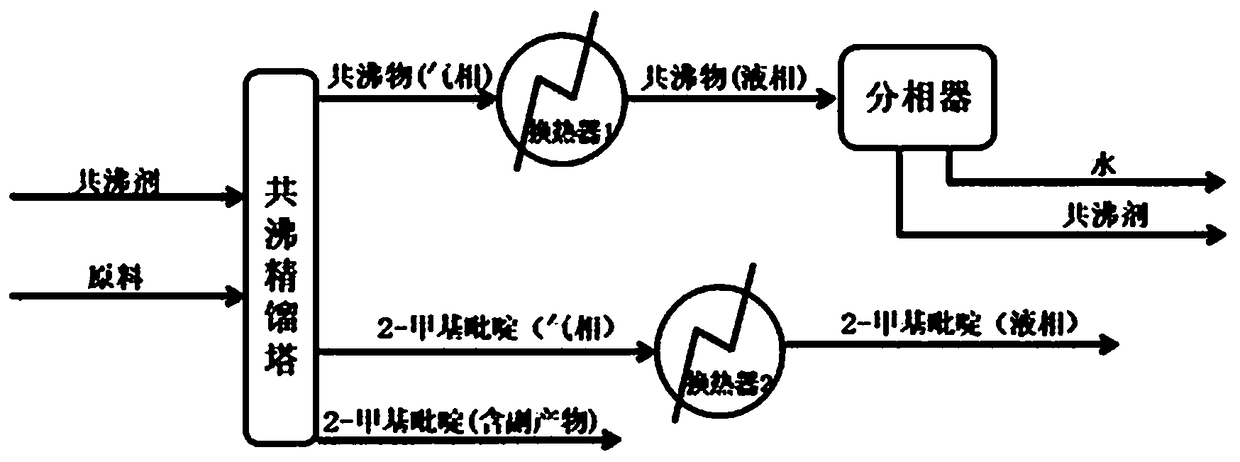

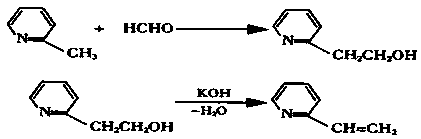

Method for realizing 2-picoline dehydration by side withdrawal from azeotropic distillation column

ActiveCN108191743AEasy to operateReduce cost inputOrganic chemistryChemical industryDistillation methodAzeotropic distillation

The invention provides a method for realizing 2-picoline dehydration by side withdrawal from an azeotropic distillation column. According to the method, cyclohexane is taken as an entrainer, a new lowazeotrope is formed from cyclohexane and water and breaks azeotropy of 2-picoline and water. A cyclohexane and water gas-phase mixture is obtained from top of the azeotropic distillation column, vapor rich in 2-picoline is withdrawn from the side of a column plate close to the column bottom and condensed into a liquid by a heat exchanger, a small amount of 2-picoline containing impurities is withdrawn from the column bottom, and accordingly, separation of 2-picoline and water is realized with the distillation method. The method is applicable to continuous distillation operation, 2-picoline with higher purity can be obtained by side withdrawal, 2-picoline is prevented from being heated at the column bottom for too long time to produce side effects, only one substance, namely, the entraineris introduced in the whole process, the entrainer can be efficiently recycled, and the method is a separation method with high efficiency and low energy consumption and cost.

Owner:淄博高新技术产业开发区精细化工和高分子材料研究院 +1

Fe3+ loading composite catalyst, preparation method of catalyst and dewatering pretreatment method for Fenton-like sludge

ActiveCN110314687ADehydration achievedReflect the concept of "treating waste with waste"Sludge treatmentWater treatment compoundsPretreatment methodClay minerals

The invention discloses a Fe3+ loading composite catalyst, a preparation method of the catalyst and a dewatering pretreatment method for Fenton-like sludge, and belongs to the field of treatment of urban solid waste and resource utilization. Carriers of the Fe3+ loading composite catalyst are sludge particles and clay minerals, wherein the mass ratio of the sludge particles to the clay minerals is(3-5):1; the average loading amount of Fe3+ in the Fe3+ loading composite catalyst is 5-10 mmol / g. The preparation method of the catalyst comprises the steps that after the carriers are mixed, a FeCl3 solution is added, prilling and dry calcination are conducted, and the catalyst is prepared. Fe3+ in the Fe3+ loading composite catalyst replaces Fe2+, the Fe3+ and H2O2 are subjected to a Fenton-like reaction under the original sludge pH condition, and therefore the sludge is subjected to efficient and economical intensified sludge dewatering pretreatment. The Fe3+ loading composite catalyst can be recycled. According to the dewatering pretreatment method, the sludge can be quickly and efficiently dewatered, later treatment cost of the sludge is reduced, waste is treated by waste, and the economical efficiency and the effectiveness are achieved.

Owner:SHENYANG LIGONG UNIV

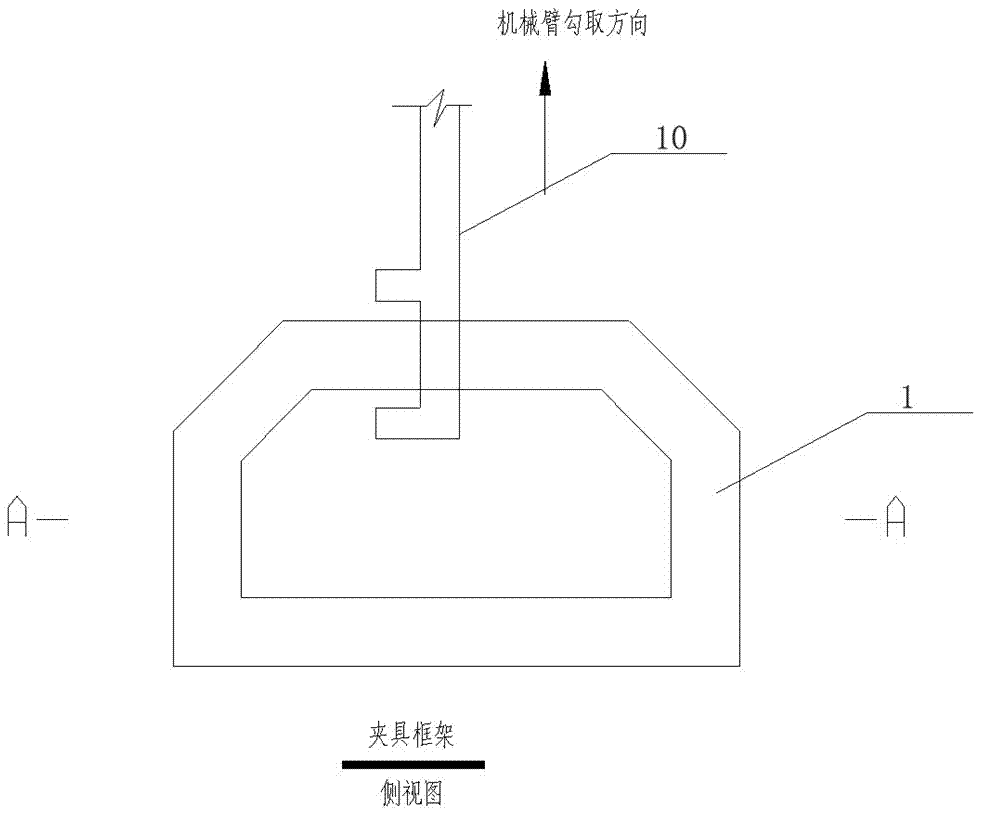

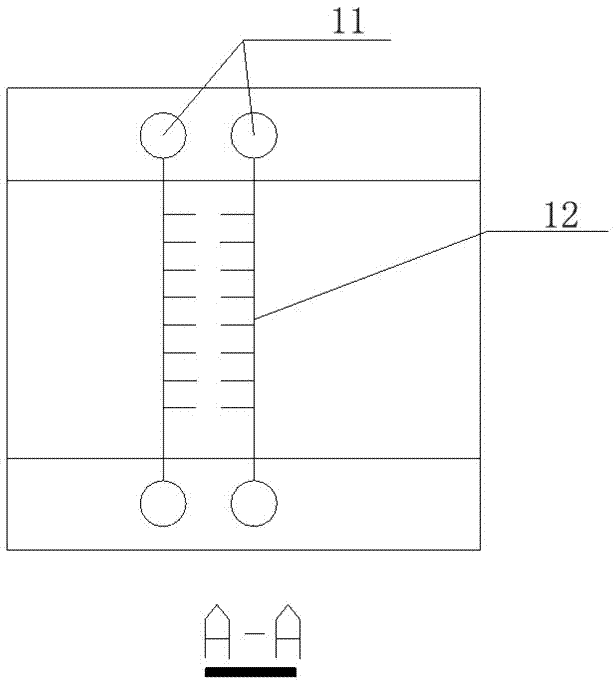

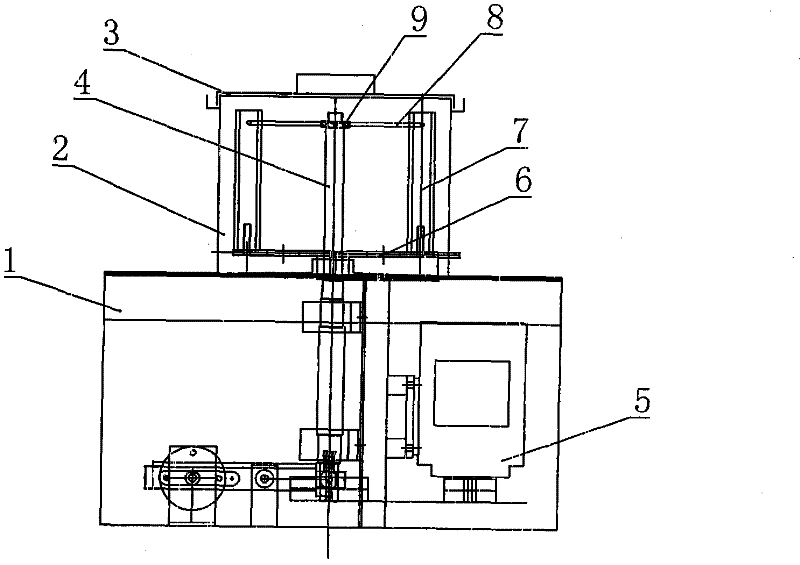

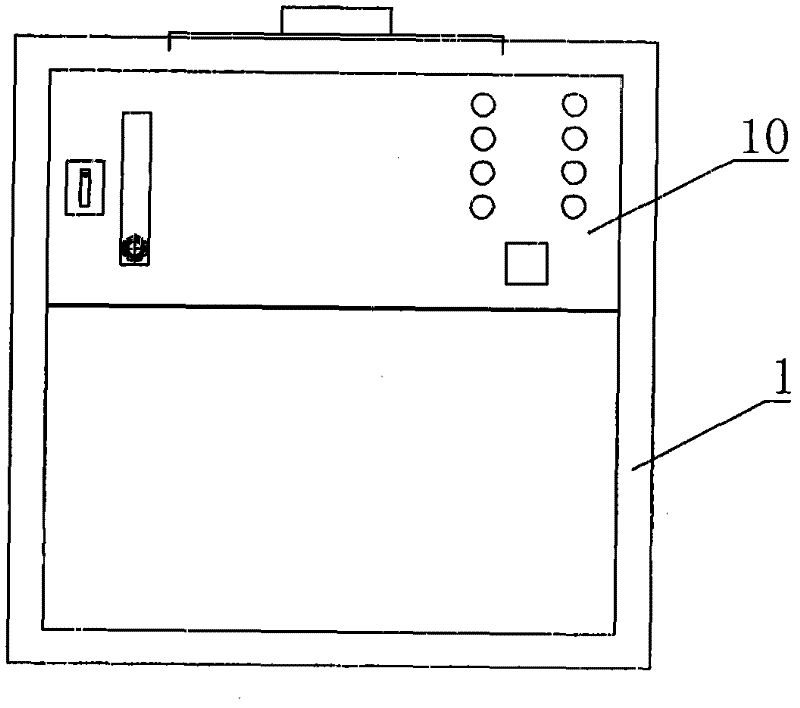

Water-based environment-friendly cleaning method and cleaning device of soldering flux on radar electronic module

ActiveCN107413760AEasy to cleanMeet the highest cleanliness class requirementsDrying gas arrangementsDrying machines with progressive movementsWater basedAlcohol

The invention provides a water-based environment-friendly cleaning method of soldering flux generated in the welding process of a radar electronic module. The cleaned object is the radar electronic module of which a ceramic substrate and a related connector are installed and welded. A cleaning system comprises a cleaning clamp, a moving mechanism, a soaking ultrasonic flow spraying cleaning mechanism, a reverse spraying rinsing mechanism, a solvent dehydration bubbling mechanism, a baking mechanism and a feeding and discharging table. According to the operation steps, 1, the radar electronic module to be cleaned is clamped; 2, soaking ultrasonic flow spraying cleaning is carried out, and a multi-component composite water-based cleaning solution is adopted as a soaking cleaning solution; 3, pure water is used for carrying out reverse spraying rinsing; 4, solvent dehydration bubbling treatment is carried out, and dehydration solvent is ethyl alcohol with concentration being over 95% or other alcohol solutions easy to volatilize; and 5, hot wind baking is carried out.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Light-emitting diode dehydrator

ActiveCN102410711APrevent oxidationEasy to operateDrying solid materials without heatDrying machines with non-progressive movementsDrive motorNitrogen gas

The invention relates to a light-emitting diode dehydrator, which comprises a rack, and has the innovative points that: the light-emitting diode dehydrator further comprises a dehydration outer barrel, a rotating shaft, a dehydration inner container and a control system, wherein the dehydration outer barrel is fixedly arranged at the top end of the rack, and a barrel cover for sealing is arranged at the barrel top; the rotating shaft is vertically arranged on the rack, the upper part of the rotating shaft extends into the center of the dehydration outer barrel, and the rear end of the rotating shaft is connected with a drive motor through a transmission mechanism; the dehydration inner container is used for installing a light-emitting diode acid-washing mould to be dehydrated, and is arranged in the dehydration outer barrel, and the center of the dehydration inner container is fixed with the rotating shaft which extends into the dehydration outer barrel; and the control system comprises a programmable controller and a control panel thereof, and the programmable controller is connected with the drive motor. The invention has the advantages that: when the dehydration is carried out, the two ends of the light-emitting diode acid-washing mould are inserted into an installation groove of the light-emitting diode acid-washing mould of the vertical rack of the dehydration inner container, then the barrel cover is closed, the drive motor is started through the control panel, the rotating shaft drives the dehydration inner container to rotate, the water in the light-emitting diode is dehydrated through the centrifugal force, so the dehydration is realized. The gas inlet of the side wall of the dehydration outer barrel can be filled with nitrogen, so the light-emitting diode is prevented from being oxidized during the dehydration.

Owner:RUGAO DACHANG ELECTRONICS

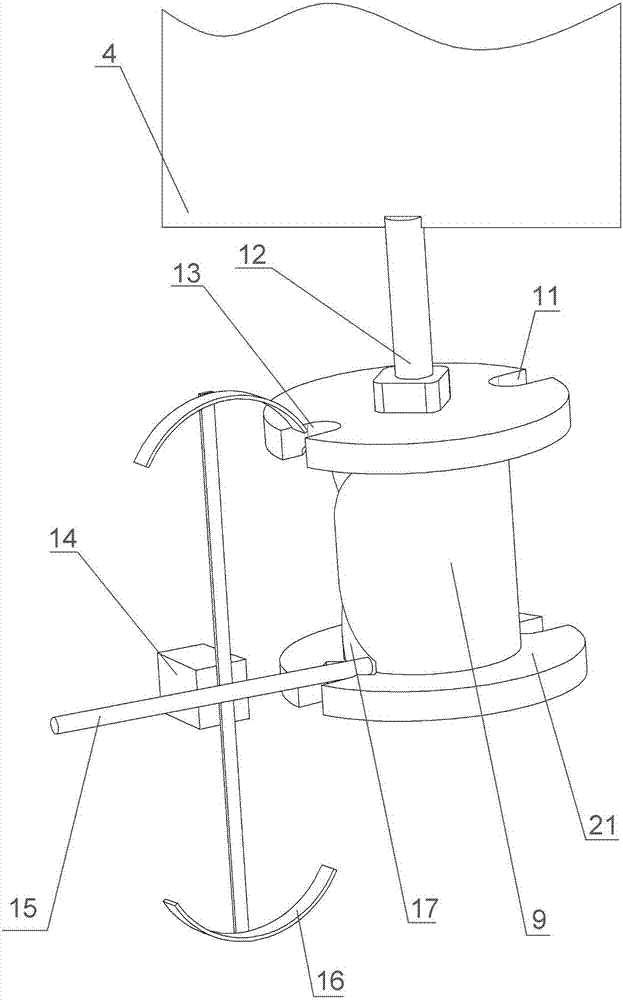

Dewatering device for inner chamber of hose and operation method thereof

PendingCN108452956ADehydration achievedLow costDrying solid materials without heatCentrifugesEngineeringCentrifugal force

The invention discloses a dewatering device for an inner chamber of a hose. The device comprises a centrifugal device, a rotor device and a power system, wherein the centrifugal device comprises a centrifugal shaft which is connected to the power system, and a centrifugal rack which is connected to the centrifugal shaft; the rotor device comprises a rotor which is connected to the power system, and a rotor shaft which is fixedly connected to the centrifugal shaft through the centrifugal rack; axes of the rotor shaft and the centrifugal shaft are parallel to each other and are distributed at acertain interval. According to the dewatering device, the rotor loaded with a material is driven by the power system to revolute to produce centrifugal force and synchronously revolve on own axis to change the direction of the centrifugal force, thus water in the empty chamber of the material continuously changes the position to seek for an open end port in order to be drained, and thus the dewatering of the inner chamber of the hose is achieved. The invention also provides a dewatering operating method of the inner chamber of the hose. The method comprises the steps of classifying the hose; fixing the hose into the rotor through a clamping device; and starting the abovementioned device to drive the rotor to move. The device and the method are low in cost, high in efficiency, and convenient to use.

Owner:刘一成

Manual treadle-type rectangular mop cleaning and dehydrating barrel

PendingCN107569194ADehydration achievedRealize environmental protectionCarpet cleanersFloor cleanersWater levelRubbing

The invention discloses a manual treadle-type rectangular mop cleaning and dehydrating barrel which comprises a cleaning tank, a storage tank and a treadle device. A rubbing plate translation mechanism is arranged inside the cleaning tank. The rubbing plate translation mechanism is provided with a rubbing plate which is horizontally and movably arranged in the cleaning tank. The rubbing plate translation mechanism is in transmission connection with the treadle device through a connecting rod crank mechanism. The rubbing plate performs rounding and rubbing operation on the whole. The cleaning tank has a cleaning upper water level and a dehydration lower water level for controlling a cleaning liquid level. The cleaning tank is communicated with the storage tank. A dehydration control component for controlling the transfer of cleaning liquid to the storage tank so as to make the water level in the cleaning tank drop from the cleaning upper water level to the dehydration lower water levelis provided between the cleaning tank and the storage tank. A pump component for controlling the transfer of cleaning liquid to the cleaning tank so as to make the water level in the cleaning tank rise from the dehydration lower water level to the cleaning upper water level is further provided between the cleaning tank and the storage tank. The manual treadle-type rectangular mop cleaning and dehydrating barrel has novel and simple structural design, achieves simple and effective cleaning and dehydration cycle operation with zero carbon emission in rectangular mop and has good environmental friendliness.

Owner:QUANZHOU INST OF INFORMATION ENG

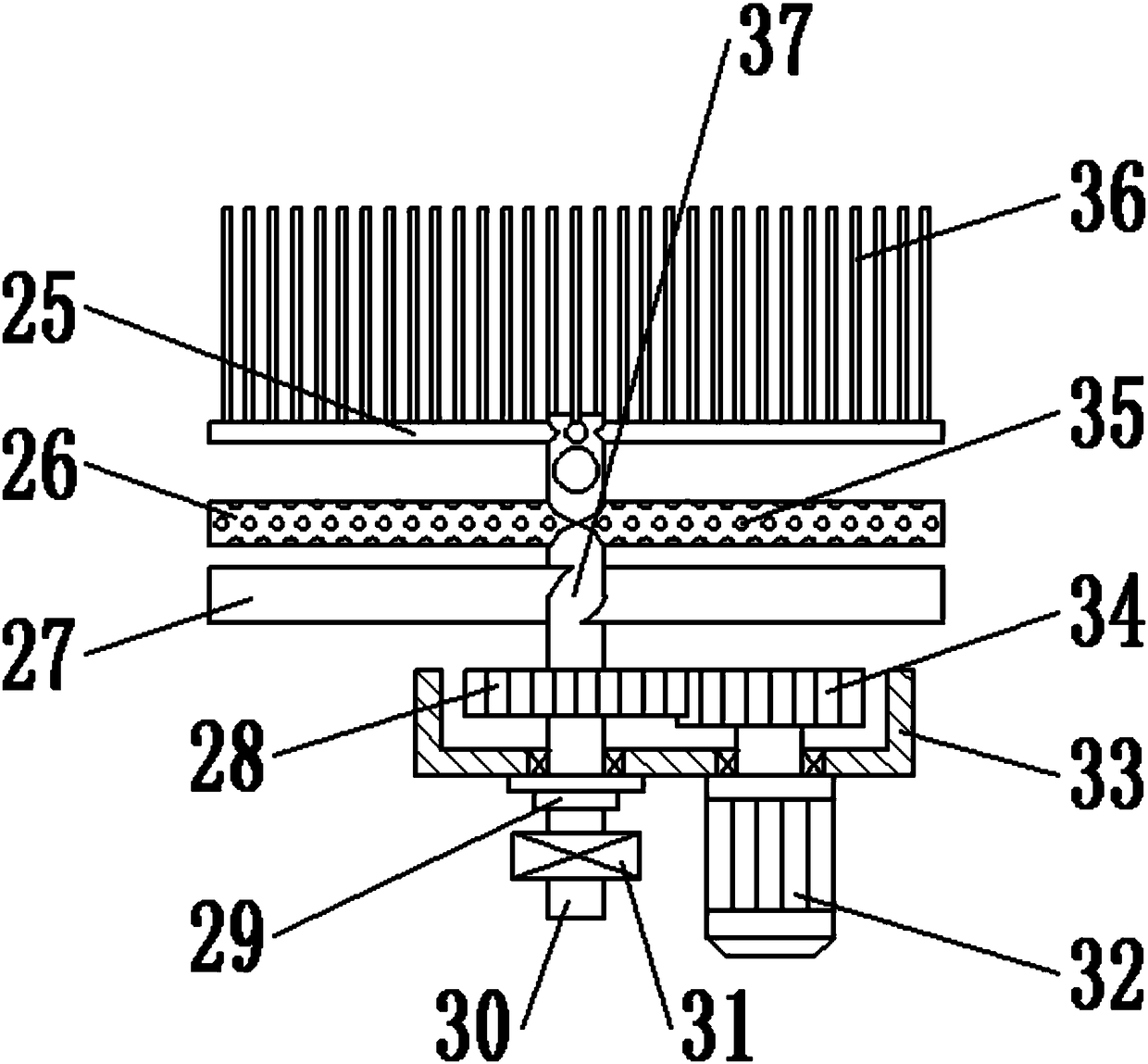

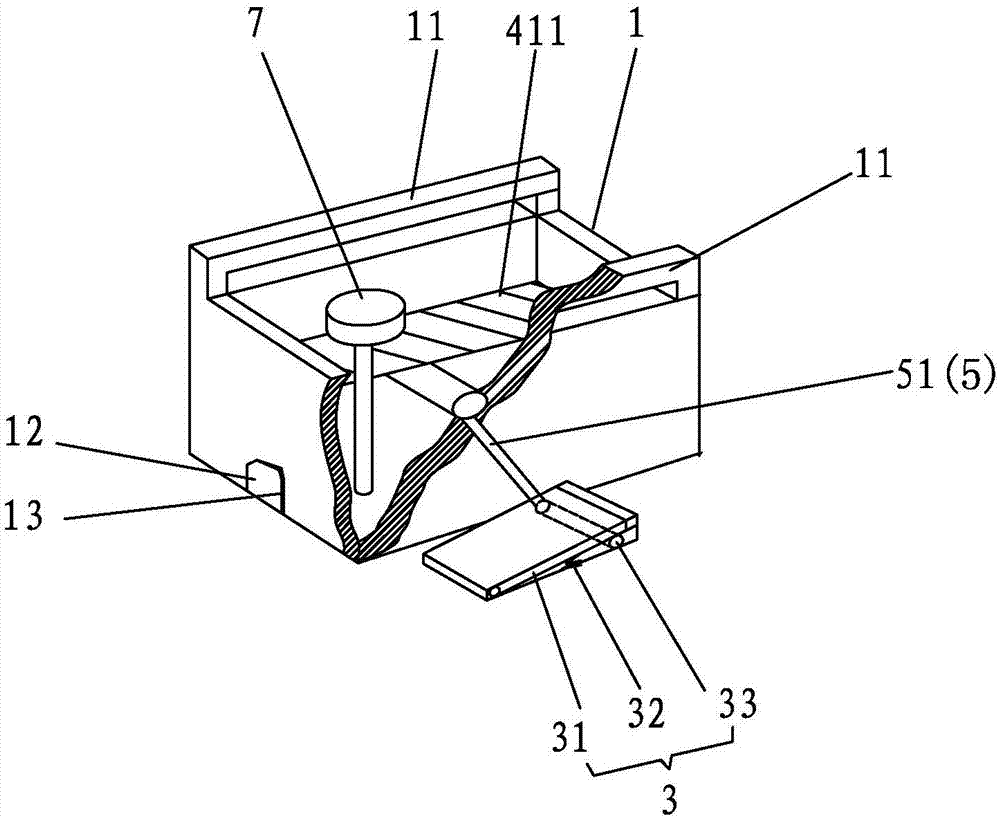

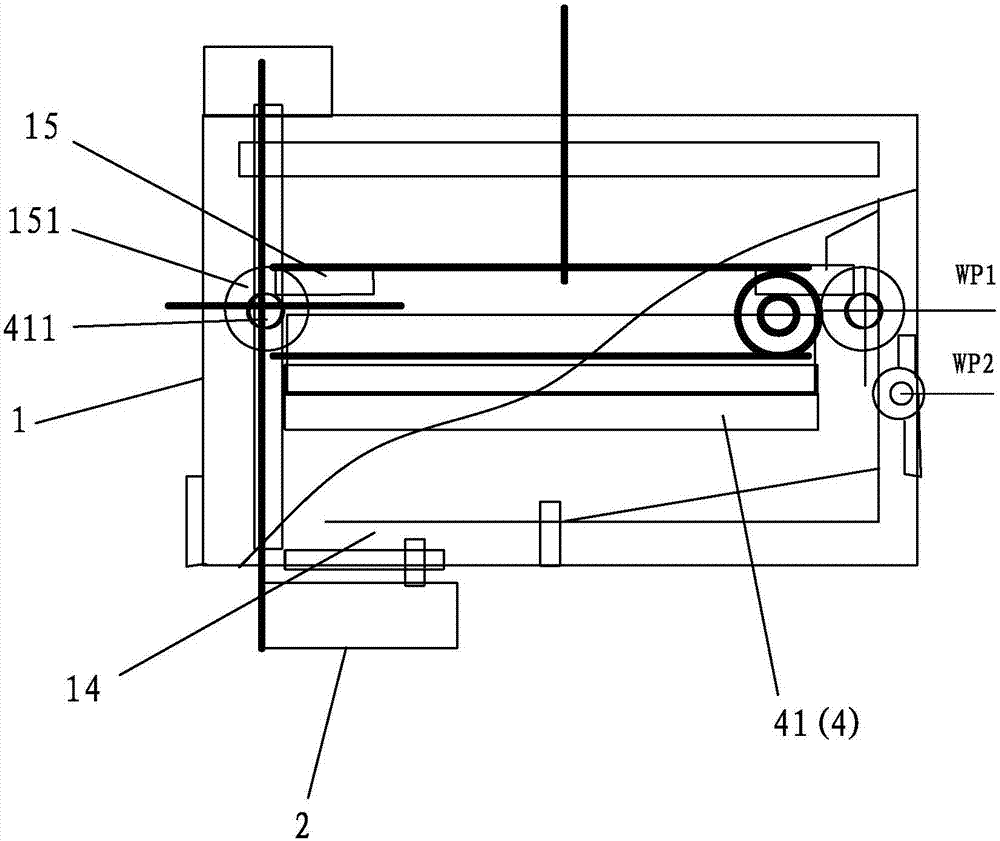

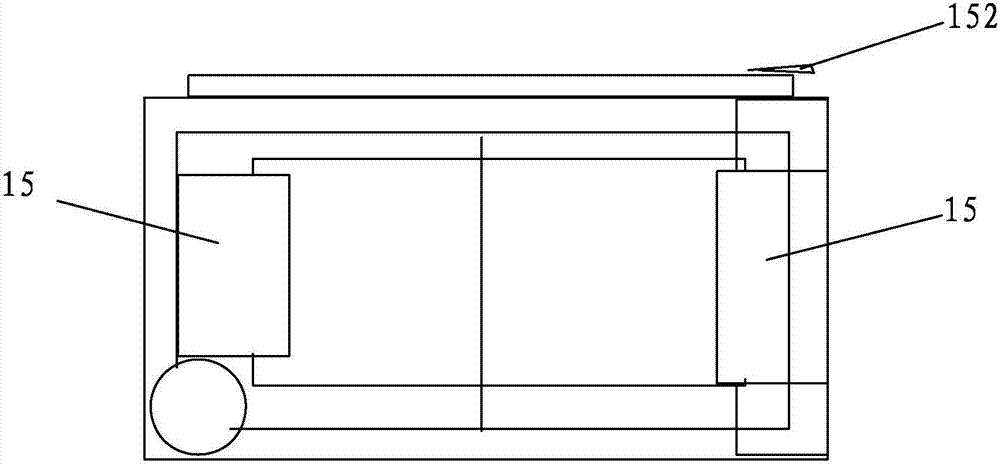

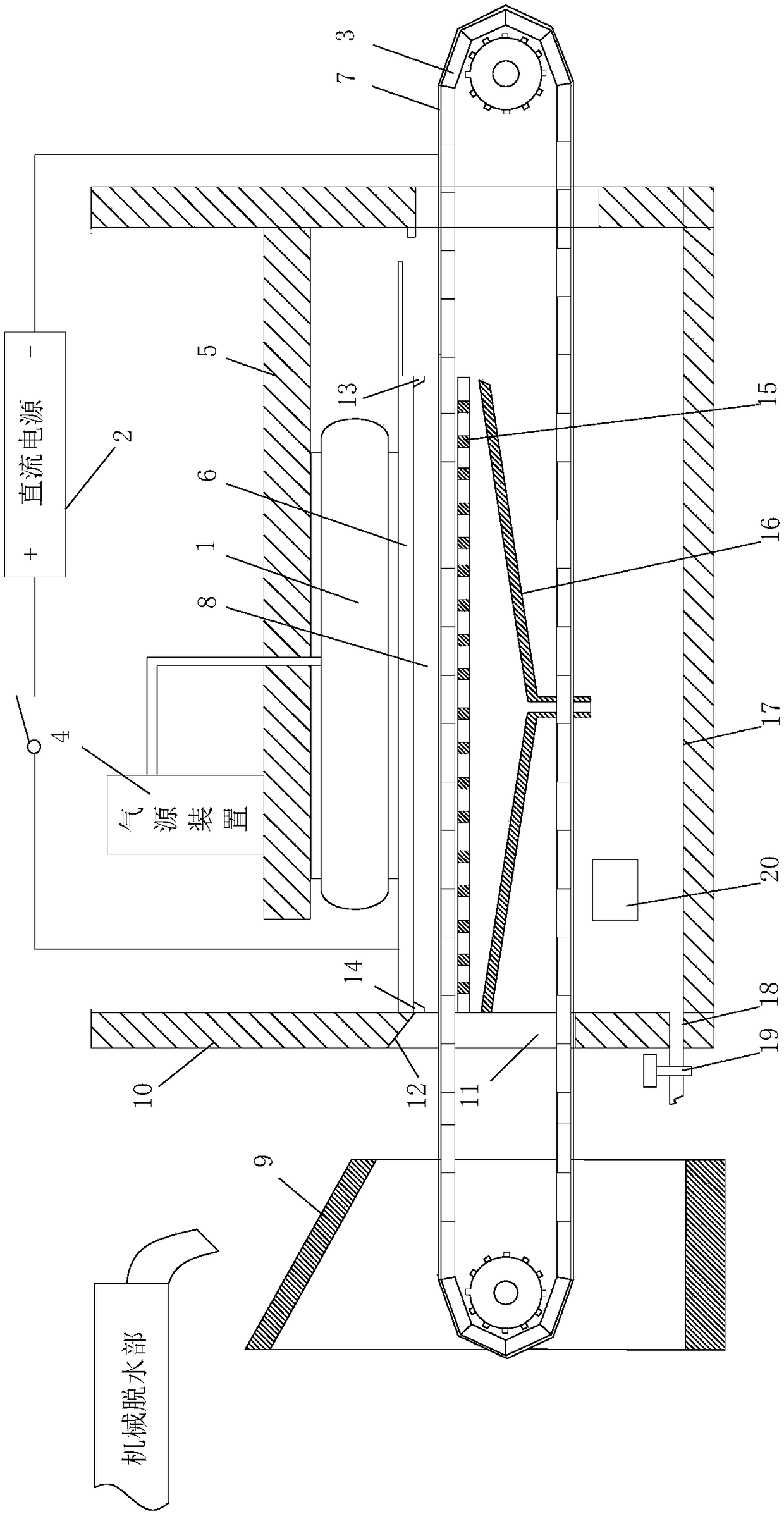

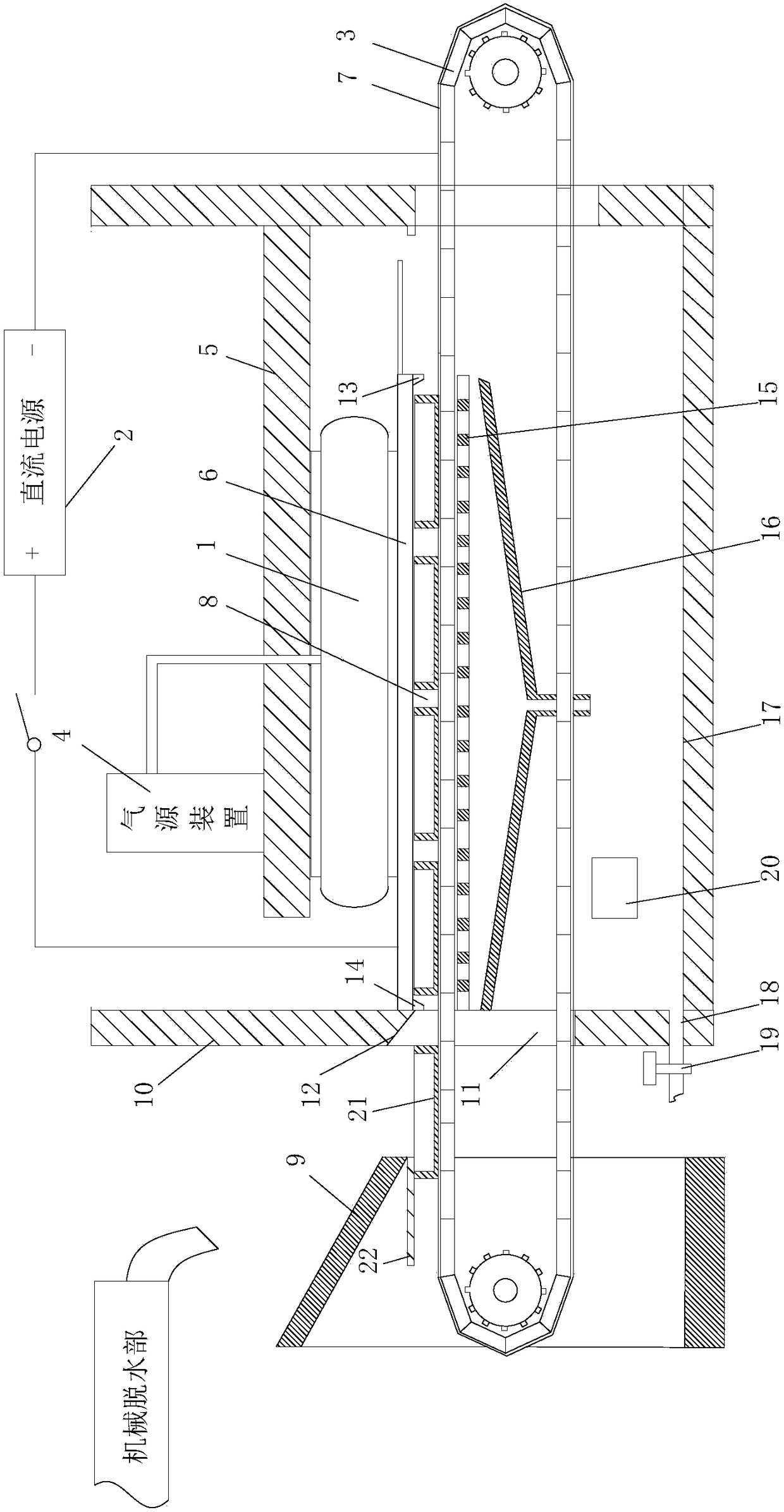

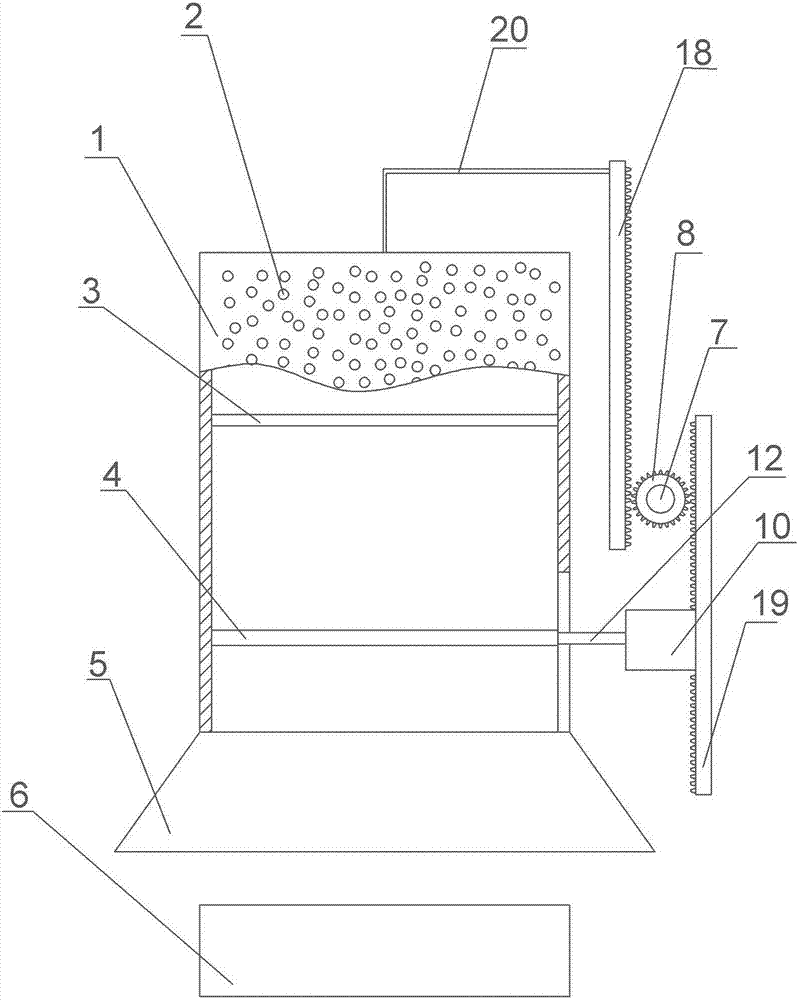

Electroosmosis sludge treatment device

PendingCN108483863AReduce energy consumptionLow costSludge treatment by de-watering/drying/thickeningElectrochemical sludge treatmentElectricityHigh energy

The invention aims to provide an electroosmosis sludge treatment device to solve the problem of high energy consumption in an electroosmosis dewatering process of an existing technical scheme. The electroosmosis sludge treatment device comprises an electroosmosis dewatering part, wherein the electroosmosis dewatering part comprises an air spring, a direct current power supply, a conveying belt, anair source device which is connected with the air spring and is used for inflating and deflating the air spring, and a fixing part for fixing the air spring; the upper end of the air spring is fixedly connected with the fixing part, and the lower end of the air spring is provided with an electrode plate; the electrode plate is connected with a positive electrode of the direct current power supply; the conveying belt is arranged below the electrode plate; a metal filter net is laid on the outer surface of the conveying belt; the metal filter net is connected with a negative electrode of the direct current power device; a dewatering cavity for accommodating sludge is formed between the electrode plate and the conveying belt under the electrode plate. In a sludge dewatering process, in caseof changes in the thickness of sludge, the sludge still can be stressed by the acting force of the air spring without inflating the air spring by the air source device, thereby reducing the energy consumption.

Owner:CHINA JILIANG UNIV

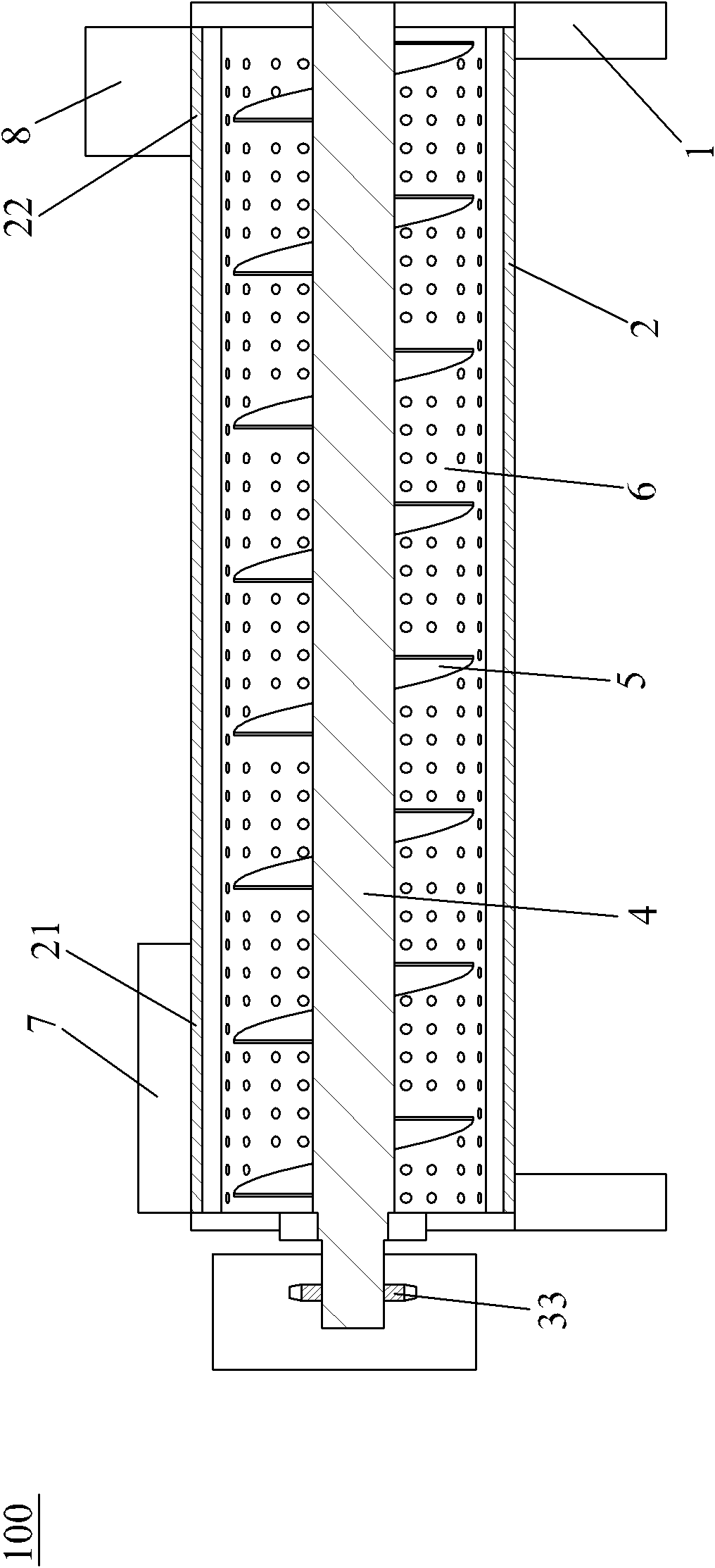

Horizontal type paper-film dehydration equipment

InactiveCN102032765ADehydration achievedImprove work efficiencyDrying solid materials without heatDrying machines with non-progressive movementsEngineeringPulp and paper industry

The invention discloses horizontal type paper-film dehydration equipment, which is suitable for cleaning film-like plastic sheets. The equipment comprises a machine frame, a dehydration drum, a driving mechanism, a main shaft, blades and a separation screen in a cylindrical shape, wherein the dehydration drum is transversely and horizontally fixed on the machine frame; the separation screen is arranged in the dehydration drum; a feed inlet is formed at one end of the dehydration drum, and a discharge hole is formed at the other end of the dehydration drum; the feed inlet and the discharge hole are communicated with the separation screen; the main shaft is arranged in the separation screen, and both ends of the main shaft are pivoted to both ends of the dehydration drum; the blades wind the main shaft spirally; and the driving mechanism is arranged on the machine frame and is connected with one end of the main shaft and drives the main shaft to rotate. The horizontal type paper-film dehydration equipment has the advantages of automatic feeding, automatic discharging and high work efficiency, does not need manual operation in the integral process, and improves the yield greatly.

Owner:东莞市英豪机械有限公司

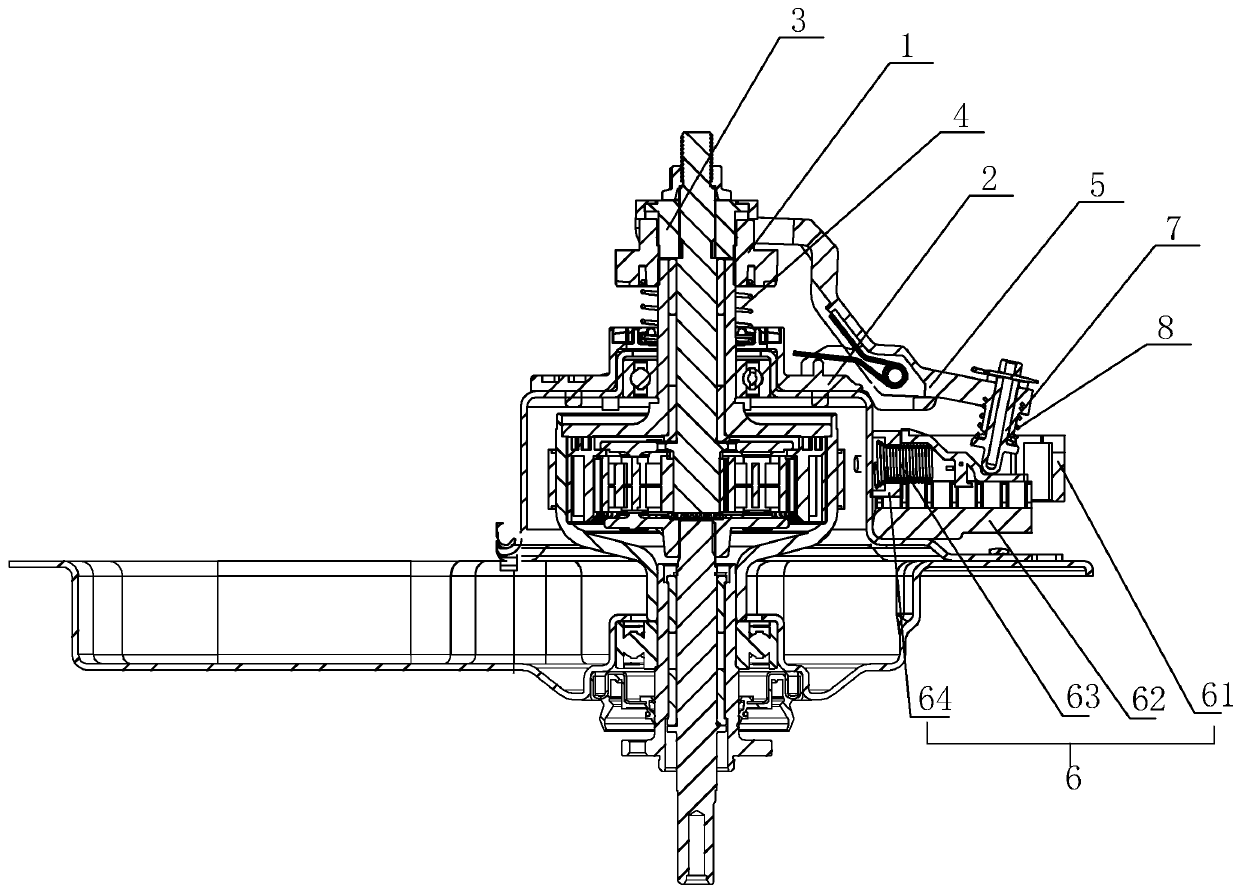

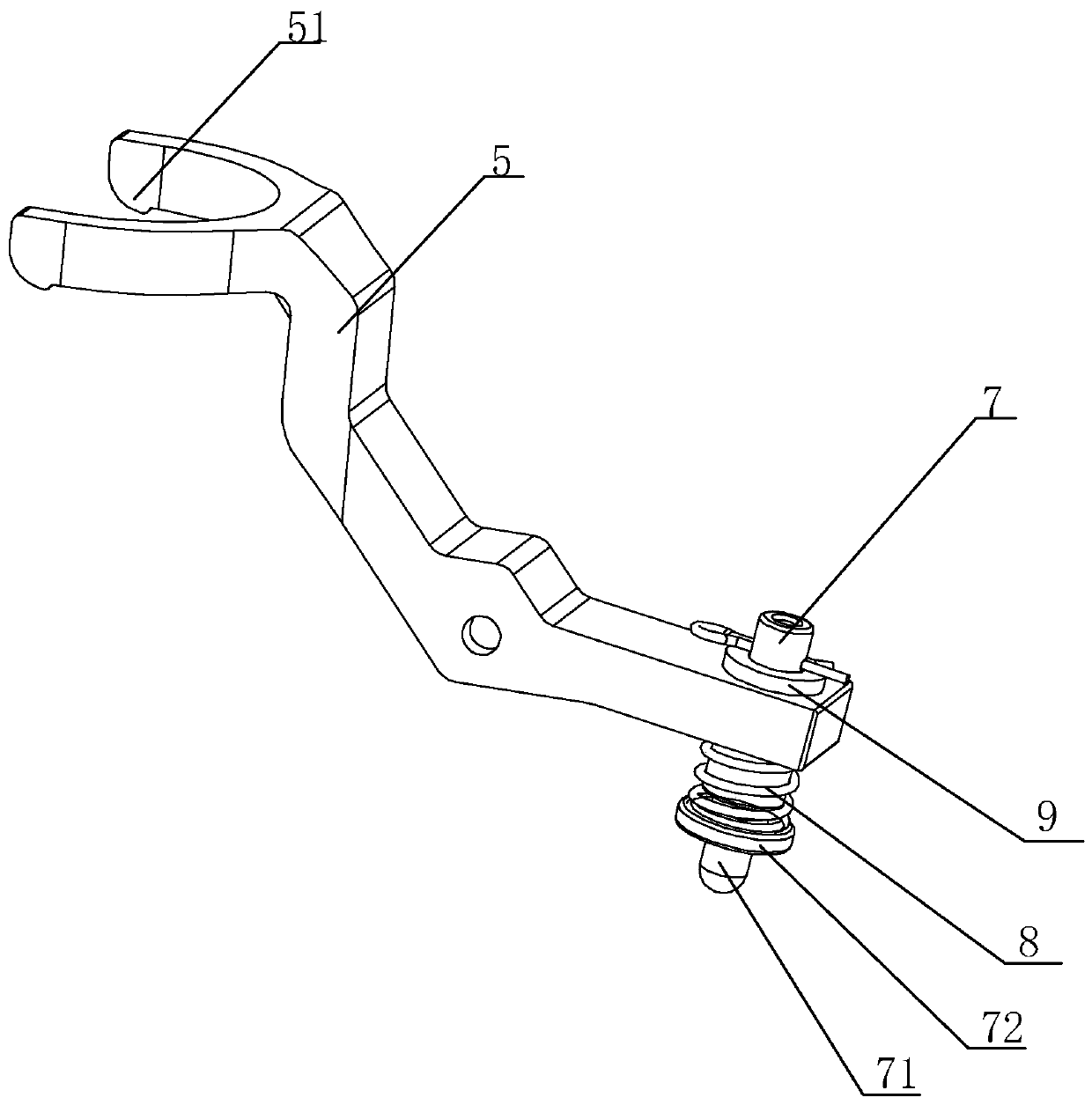

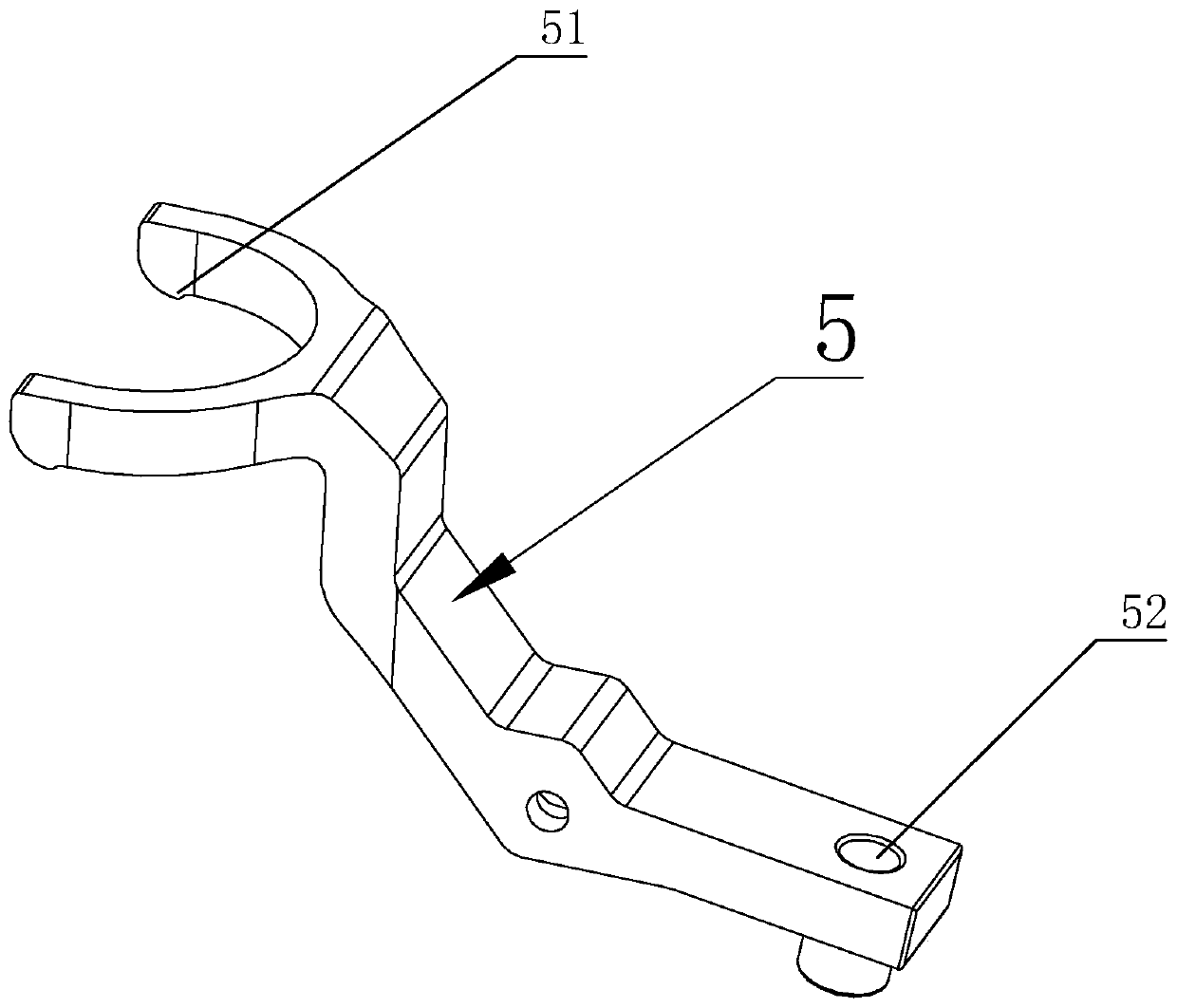

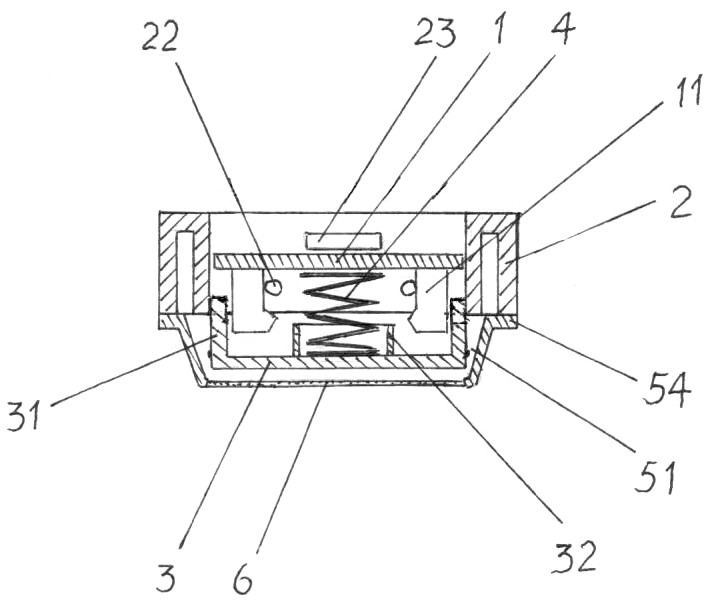

Shifting fork switching mechanism for clutch of washing machine

PendingCN111560740ADehydration achievedRealize clutchOther washing machinesTextiles and paperElectric machineryTraction motor

The invention discloses a shifting fork switching mechanism for a clutch of a washing machine. The shifting fork switching mechanism comprises a connecting disc, a positioning disc and a torque transmission shaft sleeve, a clutch spring is arranged between the connecting disc and the positioning disc, and the clutch spring drives the connecting disc to be matched with the torque transmission shaftsleeve; the shifting fork switching mechanism further comprises a shifting fork arranged on the positioning disc in a rotating mode and a shifting fork driving device for driving the shifting fork torotate, and a boss is arranged at one end of the shifting fork and abuts against the connecting disc; the shifting fork driving device comprises a sliding block, a sliding rail and a tension spring,one end of the tension spring is fixed to a clutch shell, and the other end of the tension spring is connected with the sliding block; when the traction motor drives the sliding block to move along the sliding rail, a dewatering plane, a hand-rubbing washing plane and a common washing plane can be sequentially matched with the shifting fork, so that the shifting fork drives the connecting disc tomove to three different positions, and three different working conditions of the clutch are achieved; and therefore, a deceleration clutch can be switched among a hand-rubbing type washing mode, a common type washing mode and a dewatering mode.

Owner:ZHEJIANG SANXING MECHANICAL & ELECTRONICSAL STOCK

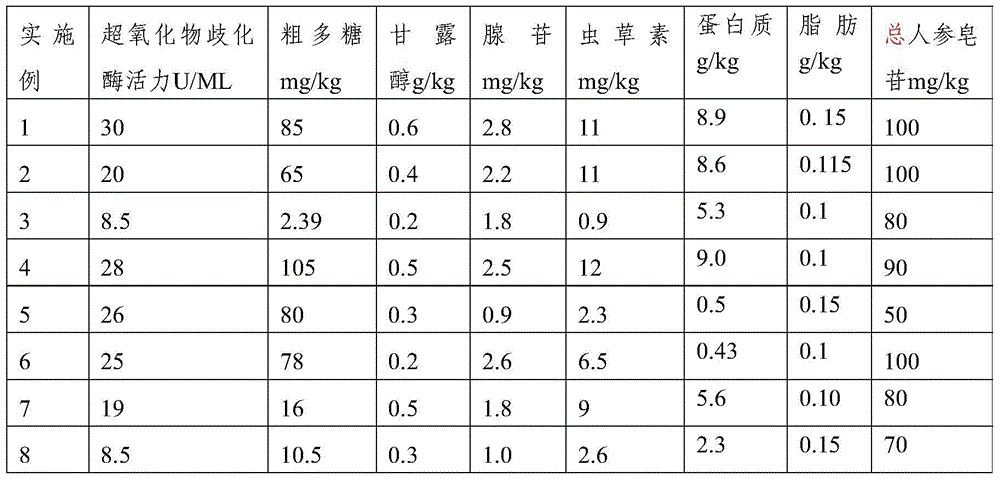

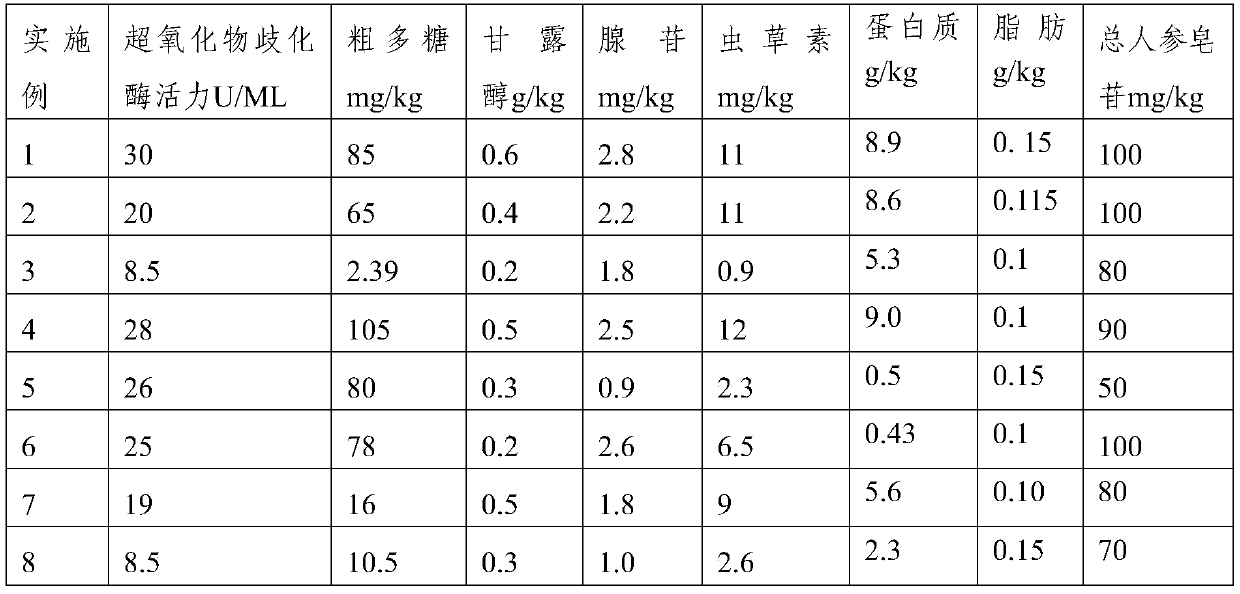

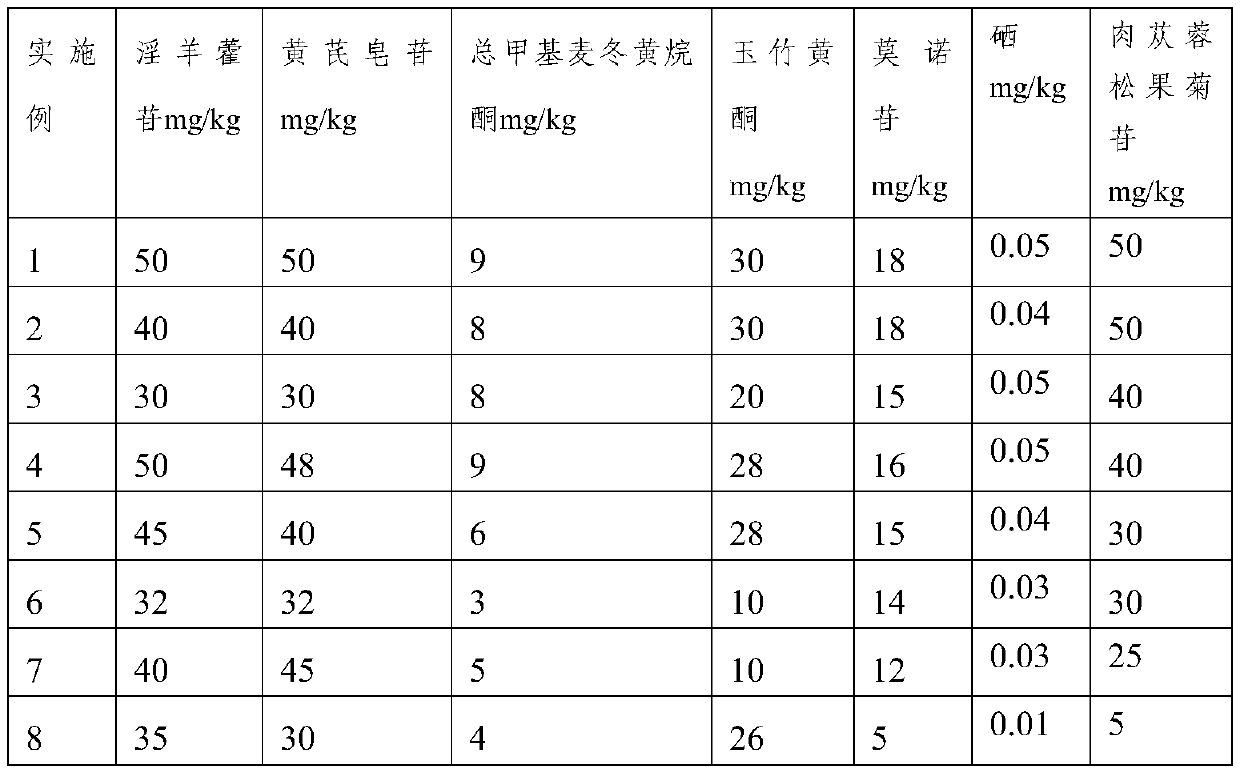

Organic selenium-rich original wine with Tibetan cordyceps and method for industrially producing organic selenium-rich original wine

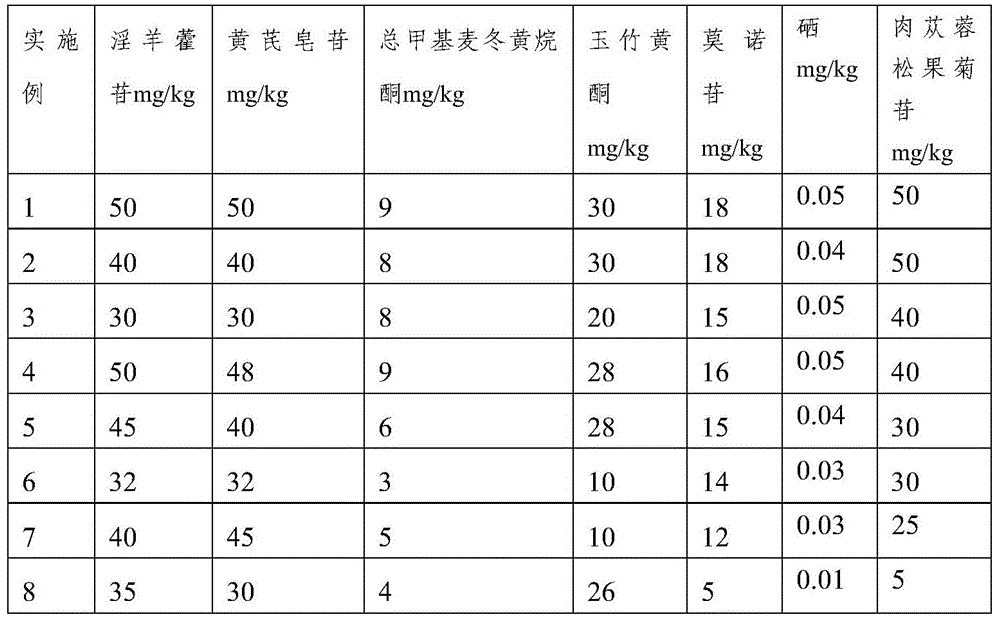

ActiveCN105754809AHigh active ingredientUse strain innovationDigestive systemMicroorganism based processesAdditive ingredientGrape wine

The invention provides a method for industrially producing organic selenium-rich original wine with Tibetan cordyceps.The method includes steps of 1), carrying out slant strain cultivation on the Tibetan cordyceps and cultivating seed solution; 2), carrying out submerged fermentation and enlarge cultivation on the seed solution by the aid of water cultivation media, proportionally adding wine into the seed solution and continuing to ferment the seed solution; 3), breaking walls of cells of active mycelia of the Tibetan cordyceps, alternately, soaking and sealing the Tibetan cordyceps by the aid of wine, aging the Tibetan cordyceps and producing aroma; 4), preparing traditional Chinese medicine extract; 5), breaking the walls of mycelia of fermentation liquor of the Tibetan cordyceps, proportionally adding the high-purity traditional Chinese medicine extract and fermentation wine into the fermentation liquor of the Tibetan cordyceps and blending the high-purity traditional Chinese medicine extract, the fermentation wine and the fermentation liquor of the Tibetan cordyceps with one another to obtain the organic selenium-rich original wine.The method has the advantages that the mycelia of the Tibetan cordyceps are subjected to submerged liquid fermentation, baijiu, the sweet wine, the yellow rice wine and the grape wine are respectively added into the Tibetan cordyceps when the sufficient mycelia are obtained, the mycelia of the Tibetan cordyceps continues to be fermented, the walls of the mycelia are broken when active components are sufficient, the mycelia are mixed with the fermentation wine and the extract of radix ophiopogonis, rhizoma polygonati odorati, fructus corni, herba cistanches, herba epimedii, selenium-rich sweet herba gynostemmatis pentaphylli, radix astragali and radix panacis quinquefolii, and accordingly the organic selenium-rich original wine with the Tibetan cordyceps and effects of improving the immunity, resisting kidney gland and thymus gland atrophy, prolonging lives and tendering skins can be produced.

Owner:锬酃藏虫草生物科技(深圳)有限公司

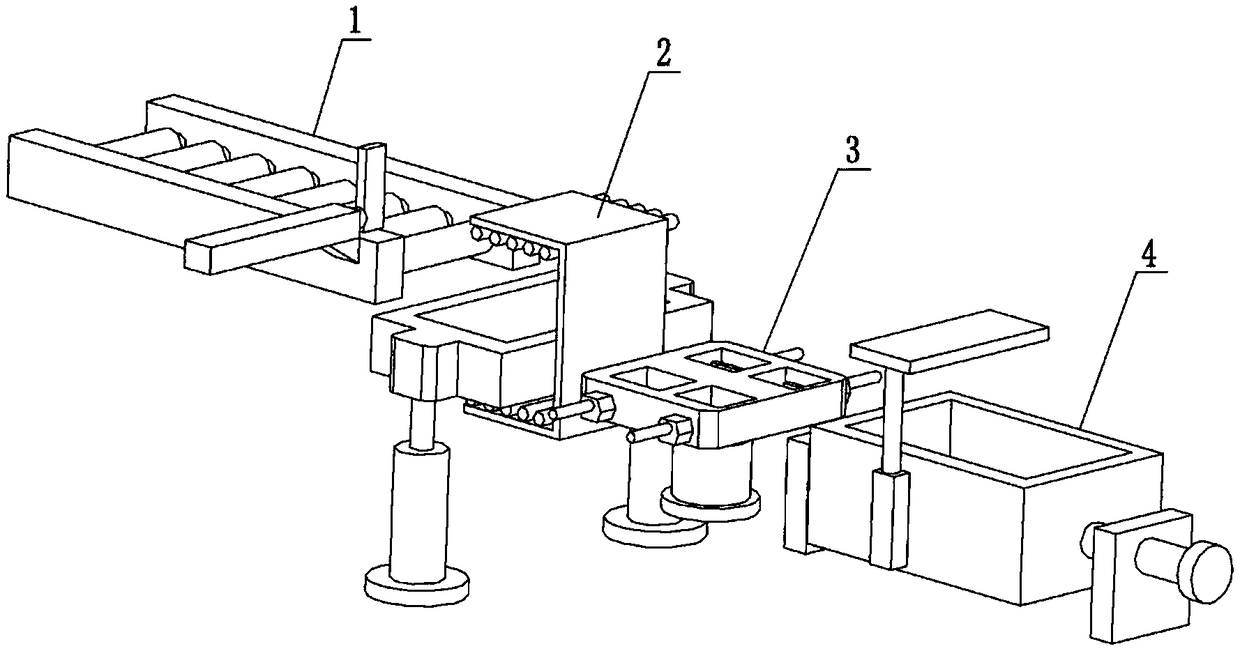

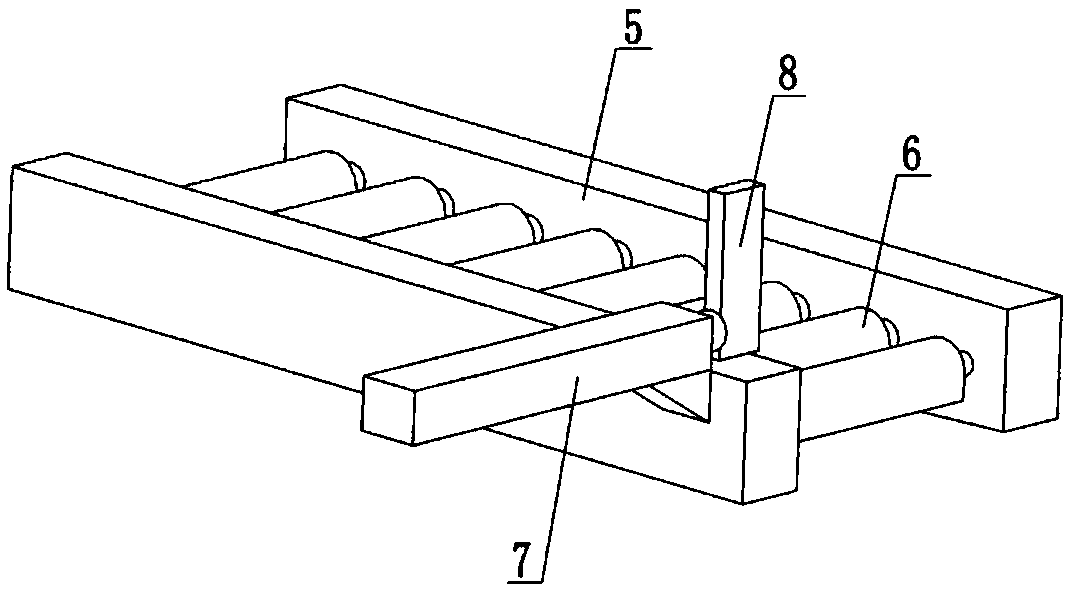

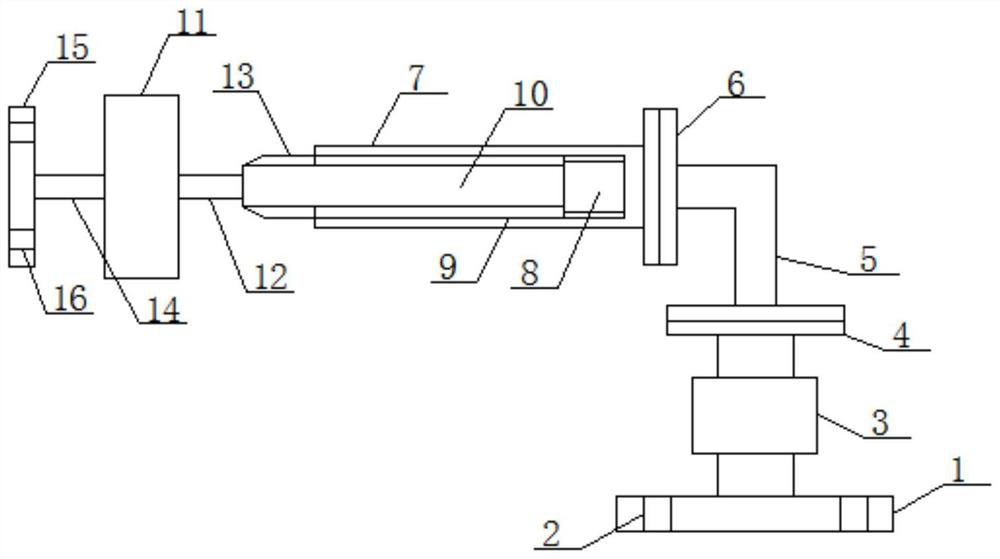

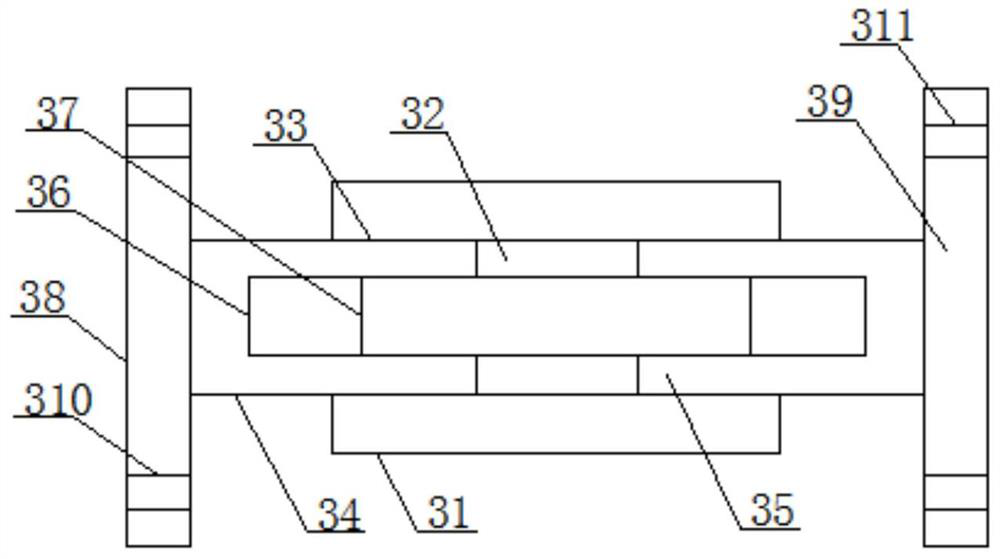

Bottle cleaning equipment and cleaning process thereof

The invention discloses bottle cleaning equipment comprising a conveying device (1), a spraying cleaning device (2), a bottle outer surface dewatering device (3) and a bottle inner surface dewateringdevice (4) which are arranged sequentially from left to right. The conveying device (1) comprises a rack (5), rollers (6), an intercept cylinder (7) and a baffle (8). The multiple rollers (6) are rotationally installed in the rack (5) through rotary shafts in the length direction of the rack (5). The intercept cylinder (7) is fixedly installed at the top of the rack (5) and is parallel to the rollers (6). The baffle (8) is fixedly arranged on a piston rod of the intercept cylinder (7). A chain is installed between the rotary shafts of every two adjacent rollers (6). Any one rotary shaft is connected with an output shaft of a driving motor through a coupling. The bottle cleaning equipment has the technical characteristics that the cleaning effect is good, oil dirt and impurities on the inner surface and outer surface of a bottle can be cleaned away thoroughly, labor intensity of workers is relieved, and cleaning efficiency is improved.

Owner:临沂高新文旅发展有限公司

Semiconductor monocrystalline silicon cleaning agent and cleaning method thereof

InactiveCN108753478AStable efficacyGood effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsMegasonic cleaningCleansing Agents

The invention discloses a semiconductor monocrystalline silicon cleaning agent and a cleaning method thereof, belongs to the technical field of monocrystalline silicon manufacturing and aims to solvethe problem of low monocrystalline silicon cleaning quality in the prior art. The semiconductor monocrystalline silicon cleaning agent is prepared from, by weight, 3 parts of non-ionic surface activeagent, 3 parts of triethanolamine, 9 parts of sulfonic acid and 45 parts of deionized water. The cleaning method utilizes the semiconductor monocrystalline silicon cleaning agent for monocrystalline silicon cleaning, mainly comprises the steps of clear water soaking, acid soaking, clear water soaking, spraying, ultrasonic cleaning and the like and produces the very good cleaning effect on monocrystalline silicon. Rough grains are firstly removed, and then fine grains are cleaned through ultrasonic waves, so that the good monocrystalline silicon cleaning effect and reasonable utilization of thecleaning agent are guaranteed, and the production cost is reduced.

Owner:CHENGDU QINGYANG ELECTRONICS MATERIAL CO LTD

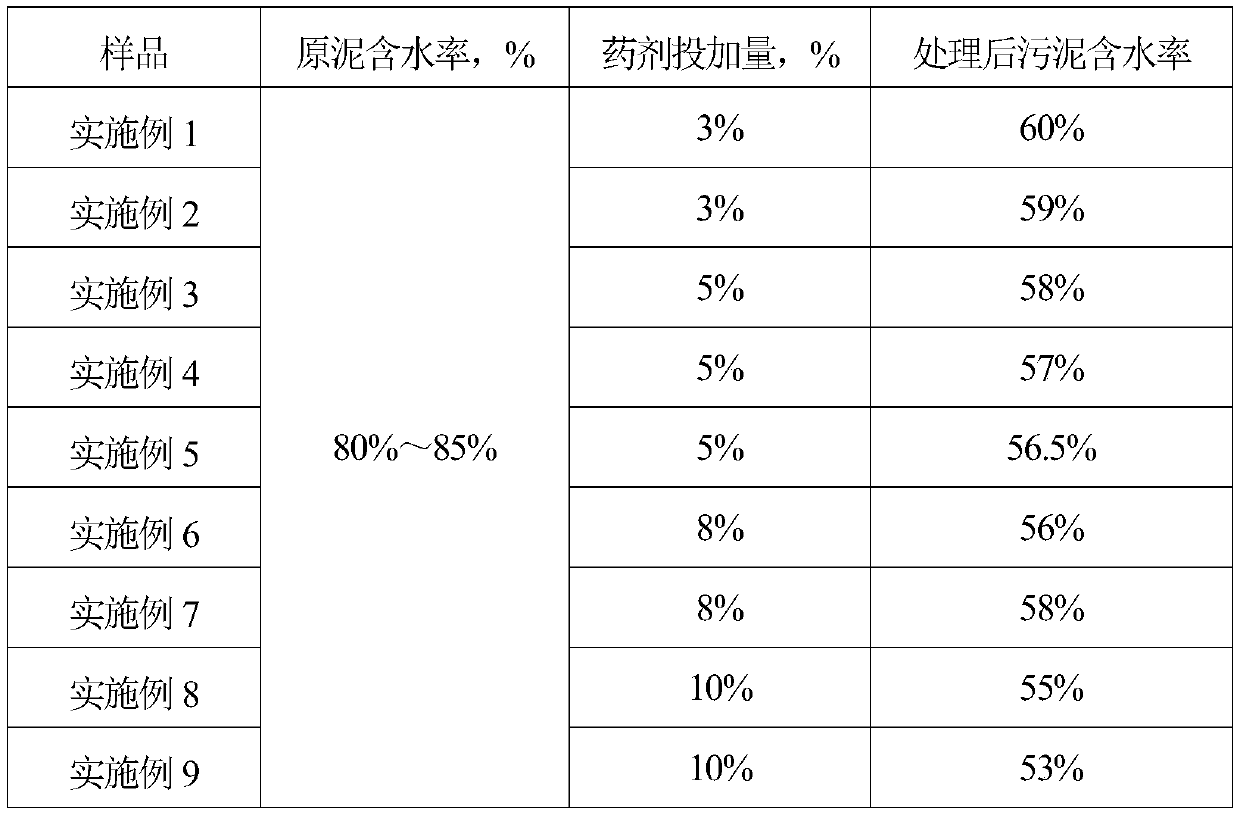

Deep dehydration reagent for solid-phase sludge

ActiveCN110526550AAvoid double dilutionDehydration achievedSludge treatmentPolyethylene oxidePotassium permanganate

The invention discloses a deep dehydration reagent for solid-phase sludge. The dehydration reagent is composed of the following components: in percent by mass, 5-20% of an inorganic flocculant, 0.1-1%of a seepage drag-reducing agent, 79-94% of a curing proppant and 0.1-3% of a wall breaking agent, wherein the inorganic flocculant comprises polyaluminum chloride, polyiron sulfate, ferric chloride,aluminum sulfate, polyaluminum ferric silicate and other components, and the seepage drag-reducing agent comprises polyethylene oxide, polydiallyldimethylammonium chloride, acrylamide / sodium acrylate / diallyldimethylammonium chloride copolymer, humic acid and other components, and the curing proppant comprises fly ash, diatomaceous earth, perlite and other components; and the wall breaking agent comprises potassium permanganate, potassium dichromate, calcium perchlorate, sodium percarbonate and other components. The dehydration reagent is suitable for secondary squeeze dehydration of the solid-phase sludge from a water content of about 80% to 60% or below through direct adoption of a high-pressure belt machine and other squeeze dehydration devices, the technical problem of secondary dilution of the solid-phase sludge can be solved, and no lime and other components which have corrosion and pollution to high-temperature equipment are contained.

Owner:北京恒润慧创环境技术有限公司 +1

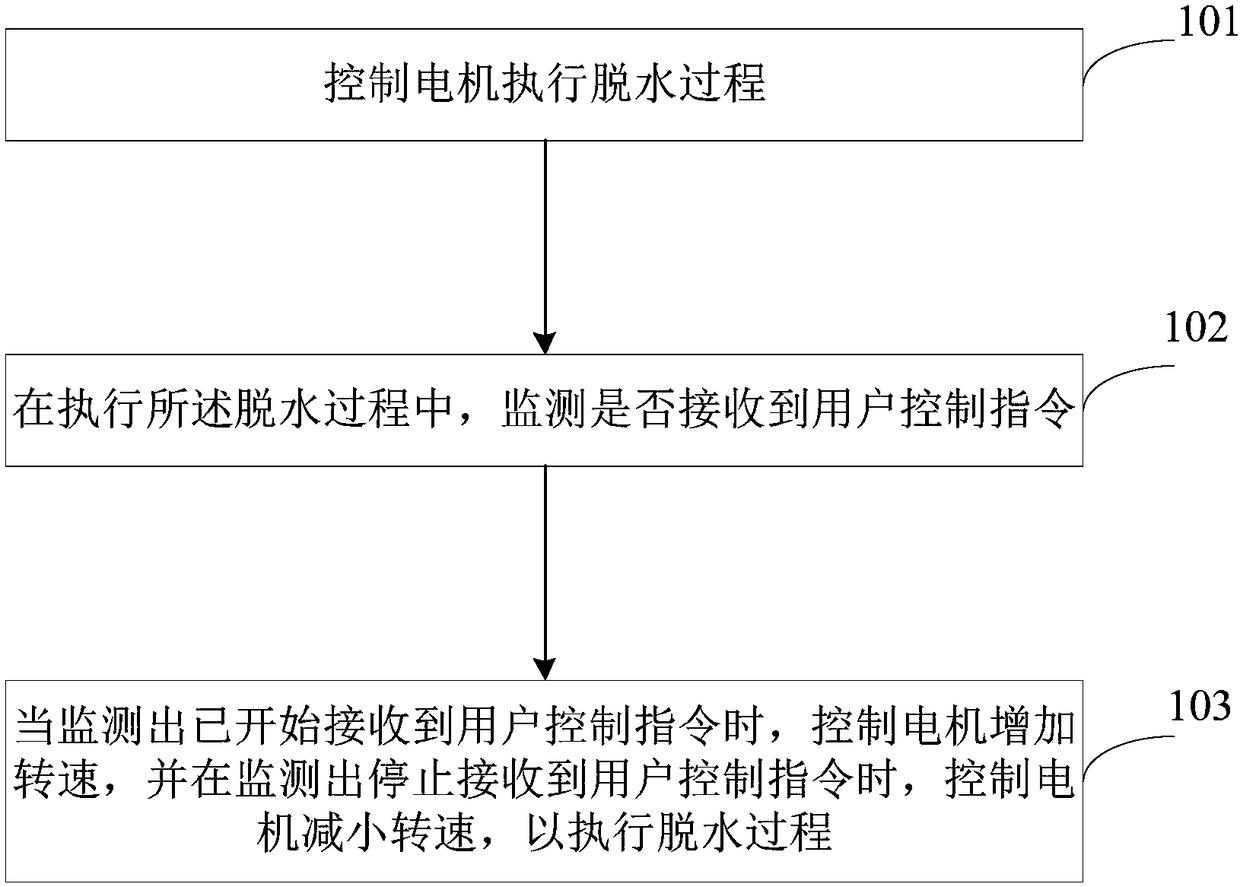

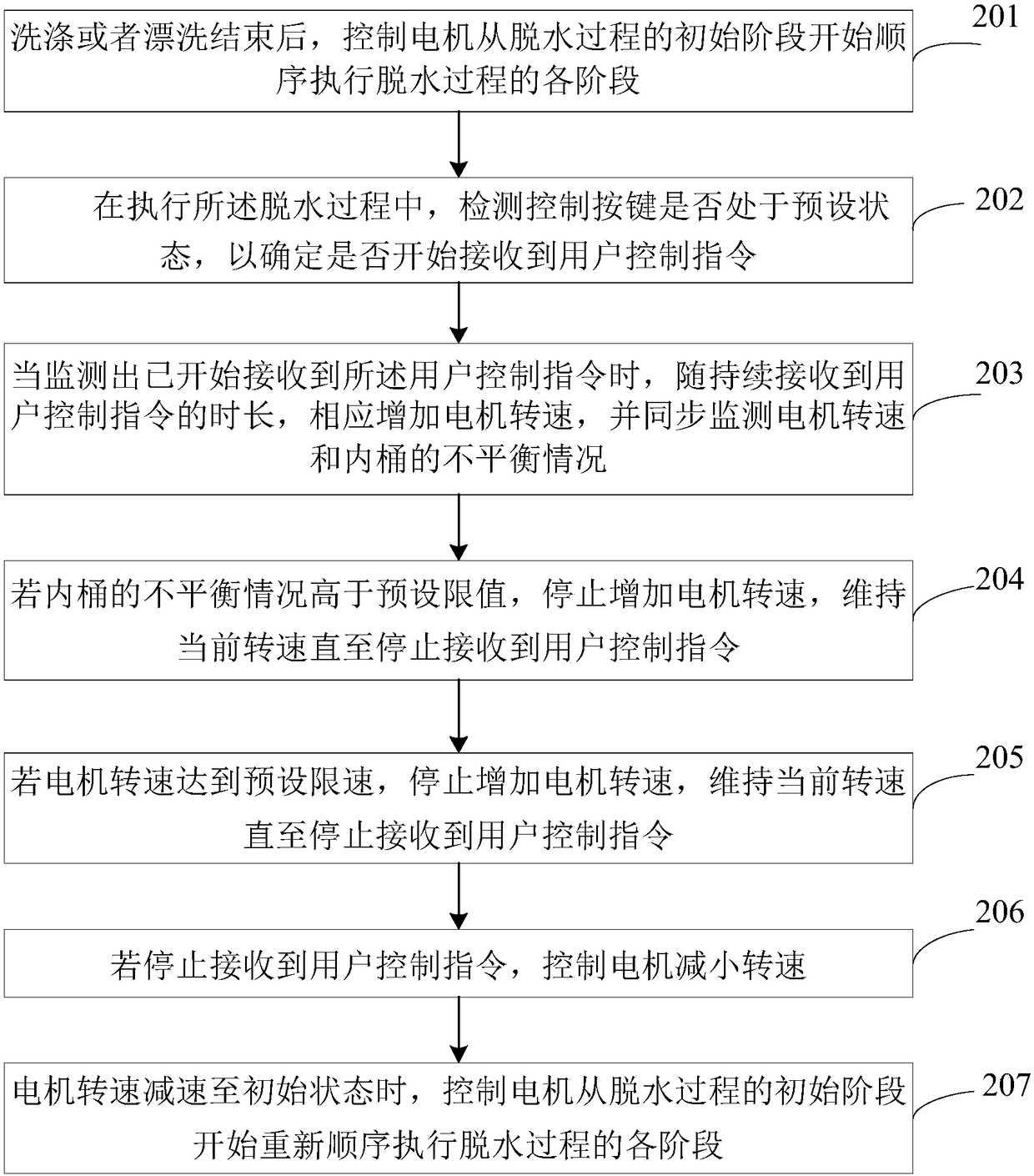

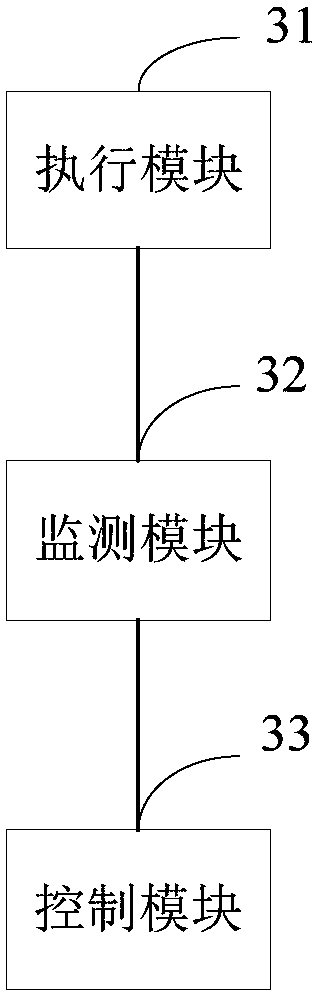

Spinning method and device and clothes treatment device

ActiveCN108221301AIncrease balanceReduce speedTextiles and paperSpin-dryersElectric machineControl theory

The invention provides spinning method and device and a clothes treatment device. The method comprises the following steps: controlling a motor to execute a spinning process; in the spinning process,monitoring whether a user control instruction is received; if the start of receiving the user construction instruction is monitored, controlling the motor to increase the rotation speed; after the stop of receiving the user control instruction is monitored, controlling the motor to reduce the rotation speed, to execute the spinning process. According to the invention, the rotation speed of the motor is controlled by the user control instruction; the water content is lowered properly by the high rotation speed monitored by the user, so as to increase the balance degree of the inner drum; and with the inner drum balance, spinning is performed at a relatively high rotation speed, thereby increasing the spinning efficiency, and solving the technical problems of the prior art that the clothes are spun at a relatively low rotation speed in the case of inner drum imbalance and consequently the spinning efficiency is quite low.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

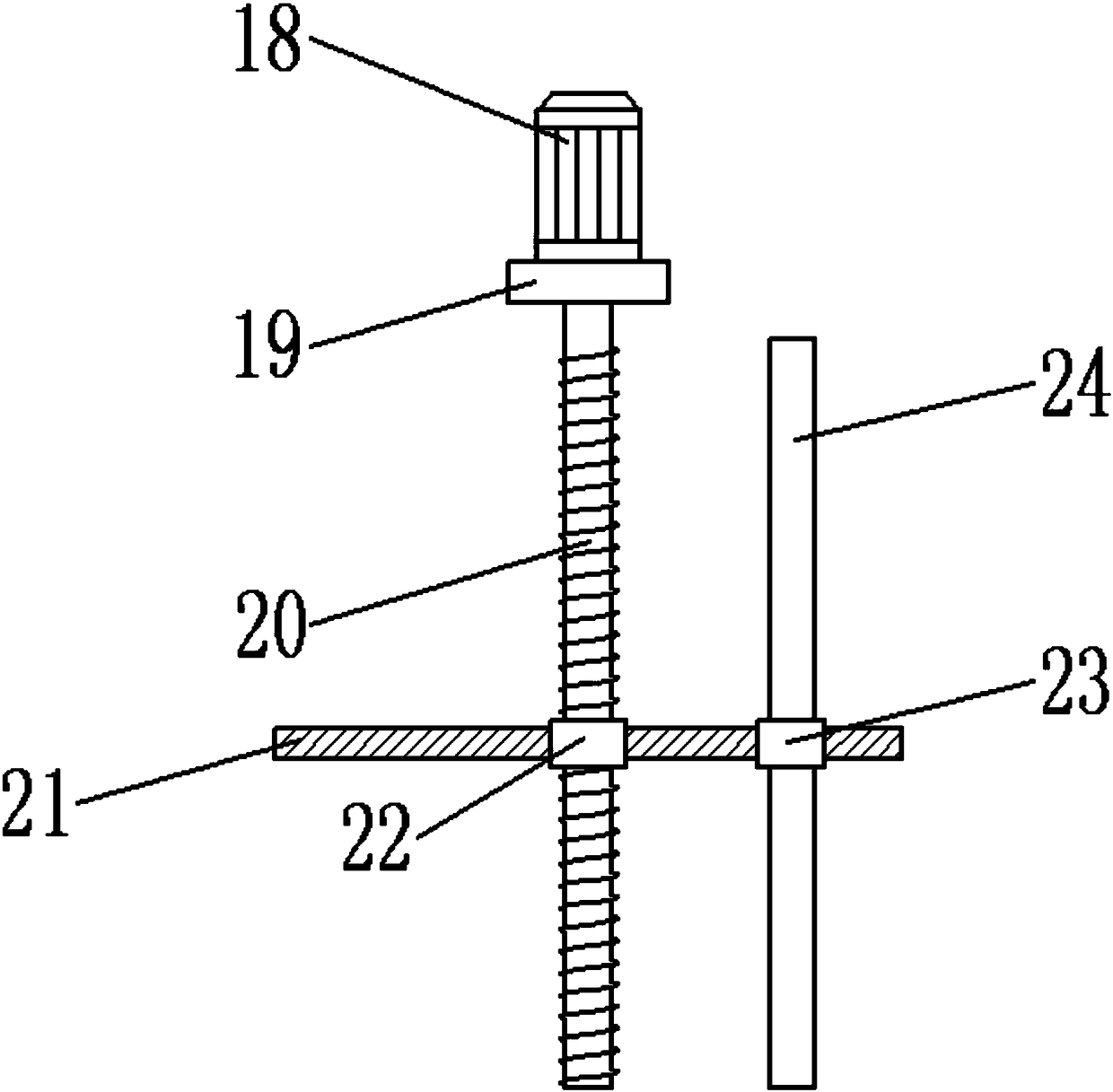

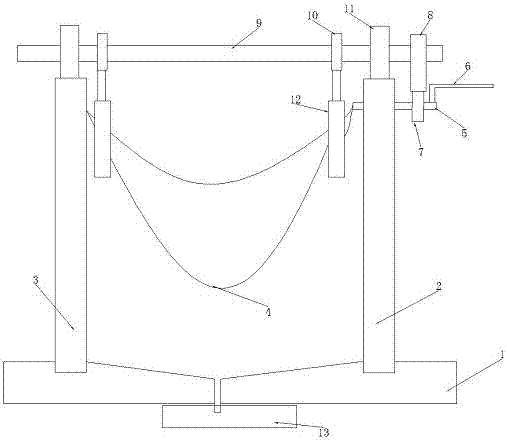

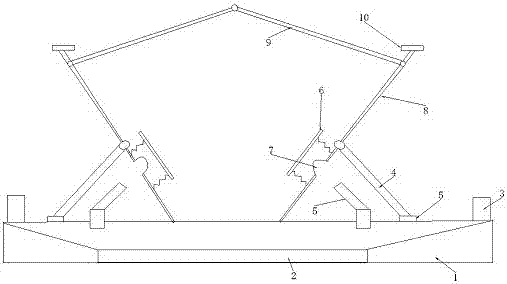

Vegetable dehydrating device

The invention belongs to the field of vegetable processing devices, and specifically relates to a vegetable dehydrating device. The vegetable dehydrating device comprises a base; a left pole and a right pole are arranged on the base; a lateral shaft is arranged at a top of the right pole, and penetrates through the right pole; bearings are arranged on the left pole and the right pole; a screw rod is arranged in the bearings in rotary connection; mutually opposite threads are arranged along the screw rod in a symmetrical way to the center of the screw rod; nuts are installed on the screw rod between the two bearings; press rings are installed at the bottom of the nuts in a fixed way; a cloth bag is arranged in the press rings in a penetrating way; one end of the cloth bag is connected to the left pole in a fixed way, and the other end of the cloth bag is connected to the lateral shaft in a fixed way; a first gear is installed on the lateral shaft in a fixed way; a second gear is installed at an end part of the screw rod in a fixed way, and is meshed with the first gear; and a handle used for performing rotating is further arranged at an end part of the lateral shaft. The vegetable dehydrating device is simple in structure and beneficial for manual control; moreover, the vegetable dehydrating device is capable of realizing device control at anytime according to dehydration state of the vegetables so as to prevent crushing or even squashing of the vegetables.

Owner:CHONGQING ZHOUYI FOOD CO LTD

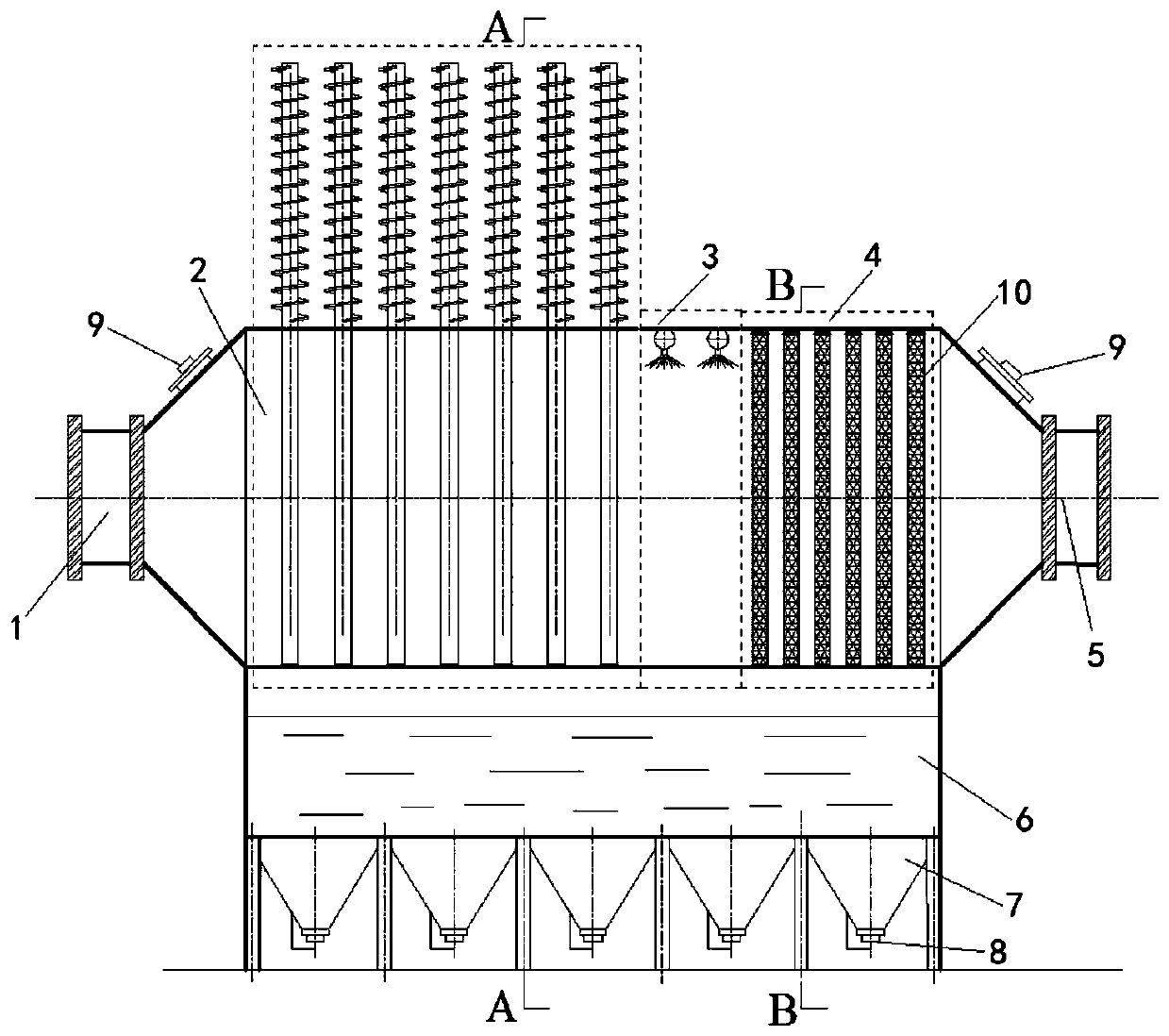

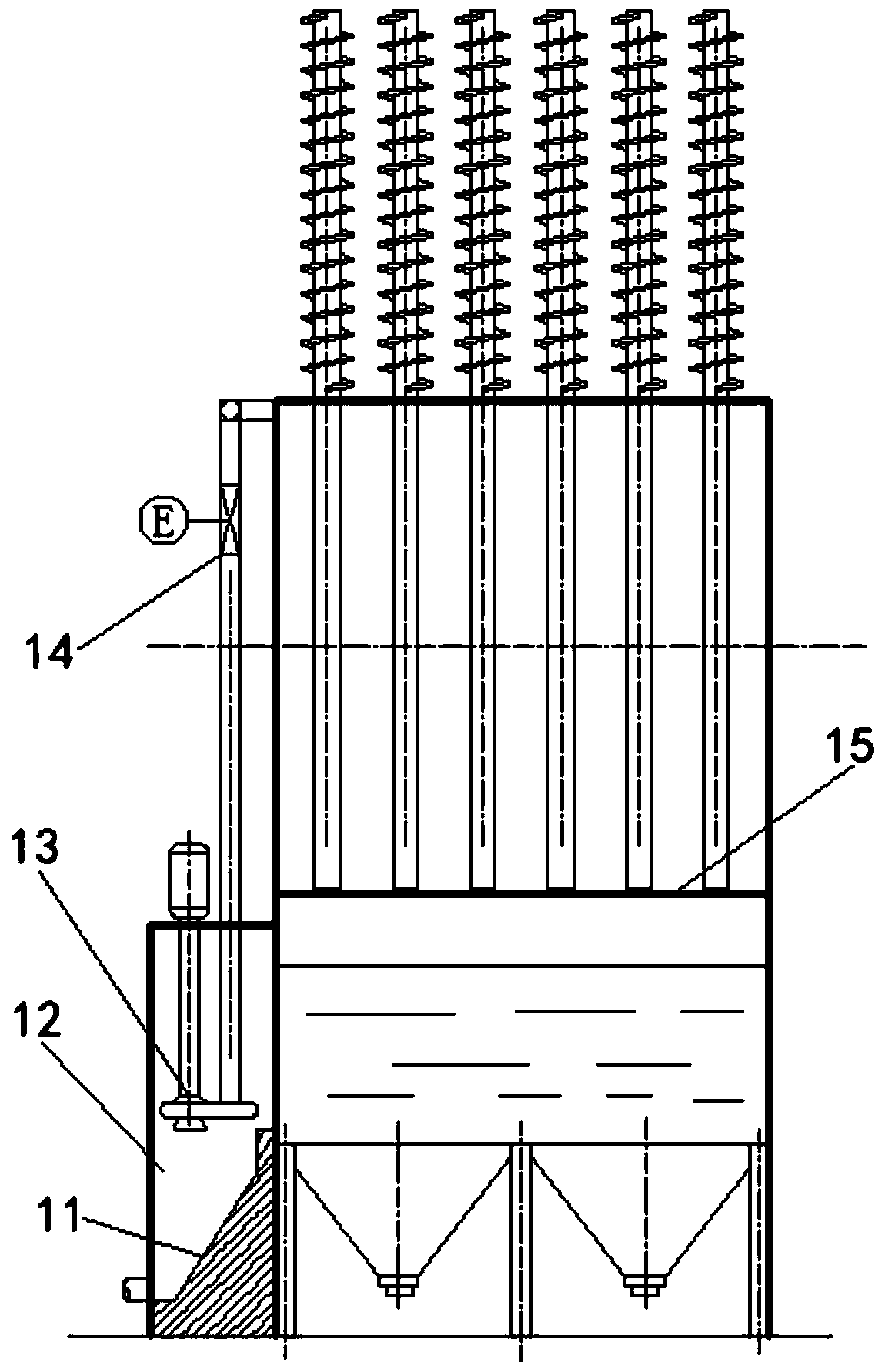

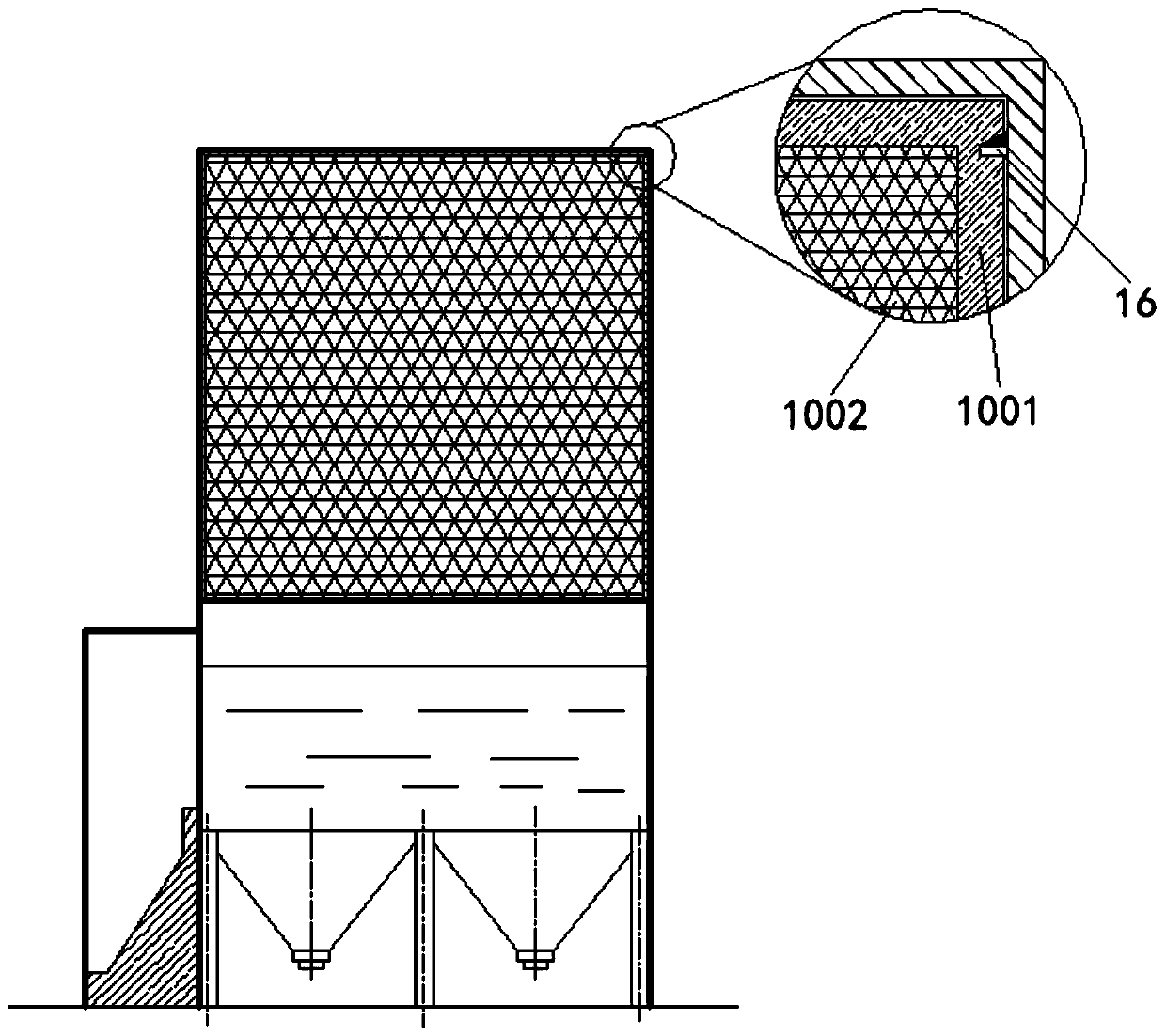

Phase change-based flue gas end dehydration fine dust removal device

PendingCN110090519AReduce dust contentReduce moisture contentHuman health protectionCombination devicesEvaporationEngineering

The invention discloses a phase change-based flue gas tail end dehydration fine dust removal device and relates to the field of air pollution control. The phase change-based flue gas tail end dehydration fine dust removal device comprises a horizontally arranged dedusting box body and a sedimentation tank, wherein a phase change cooling area, a spray cooling area and a filter screen dedusting areaare sequentially arranged in the dedusting box body from the flue gas inlet flue direction to the flue gas outlet flue direction. The phase change cooling area comprises a plurality of layers of heatpipe heat exchange layers, each layer of heat pipe heat exchange layer comprises a plurality of heat pipes which are arranged in parallel with each other, the evaporation sections of the heat pipes are positioned inside the dedusting box body, and the condensation sections of the heat pipes are positioned outside the dedusting box body. The spray cooling area comprises a plurality of atomizing nozzles. The filter screen dedusting area comprises a plurality of vertically arranged filter screen dust removal units, wherein each filter screen dust removal unit comprise a support frame, and the support frame is paved with a filter screen. The sedimentation tank is positioned below the opening on the bottom surface of the dedusting box body. The phase change-based flue gas tail end dehydrationfine dust removal device aims at further dedusting industrial flue gas under the conditions of low cost and low energy consumption to achieve near zero emission and eliminate white smoke.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Sludge dewatering device for sewage treatment

InactiveCN109928594ADehydration achievedRealize dehydration reduction treatmentSludge treatmentSpiral bladeCentrifugal force

The invention provides a sludge dewatering device for sewage treatment. The sludge dewatering device for sewage treatment comprises an outer cylinder, a first inner cylinder, a separation component, awater pumping component and a first driving mechanism, the first inner cylinder is contained in the outer cylinder, the first inner cylinder is rotationally connected to the outer cylinder, a plurality of through holes are formed in the peripheral side of the first inner cylinder, and the separation component comprises a filter cloth wrapping the peripheral side of the first inner cylinder and aplurality of spiral blades fixed to the filter cloth. The water pumping component comprises a water pumping pipe, wherein one end of the water pumping pipe extends into the first inner cylinder, and the other end of the water pumping pipe extends out of the outer cylinder; and the first driving mechanism is fixed on the top of the outer cylinder to drive the first inner cylinder to rotate. Sludgeis separated from water under the action of centrifugal force, water enters the first inner cylinder through the filter cloth and the through holes, and the water in the first inner cylinder is pumpedout by a pumping pipe to realize sludge dehydration and improve dehydration efficiency.

Owner:深圳市汉境环境科技有限责任公司

Pickled vegetable dewatering device

ActiveCN107041560AImprove dehydration effectImprove dehydration efficiencyFood treatmentGear wheelPulp and paper industry

The invention discloses a pickled vegetable dewatering device, which comprises a rack, a dewatering drum, a turnover mechanism, a squeezing plate, a squeezing motor, a gear, a first rack and a second rack. A plurality of dewatering holes are formed in the circumferential direction of the dewatering drum; a strip-shaped notch is formed in the lower part of the dewatering drum; the squeezing plate is located at the upper part in the dewatering drum and is slidably connected with the dewatering drum; the turnover mechanism comprises a connecting rod and a turnover plate; the turnover plate is connected with one end of the connecting rod; the turnover plate is located in the dewatering drum; the connecting rod is in sliding fit to the dewatering drum through the strip-shaped notch; the squeezing motor is fixed on the rack; an output shaft of the squeezing motor is connected with the gear; the gear is respectively engaged with the first rack and the second rack; the first rack is connected with the squeezing plate; the second rack is connected with the turnover mechanism. According to the device, a dewatering effect of pickled vegetable can be improved, and the dewatering efficiency is improved.

Owner:CHONGQING ZHOUYI FOOD CO LTD

Vegetable dehydrating device

InactiveCN106954824ADehydration achievedIncrease the compression areaFood scienceVegetable processingEngineering

The invention belongs to the field of vegetable processing devices, and specifically relates to a vegetable dehydrating device. The vegetable dehydrating device comprises a base; a sliding rail is arranged on the base; sliders are arranged on the sliding rail, and can be pushed by an external force; a cone-shaped dehydration box is arranged on the base, and side walls of the dehydration box are hinged to the base; holes used for discharging water are formed on surfaces of the dehydration box; connecting rods are connected with the side walls of the dehydration box in a sliding way; the bottoms of the connecting rods are connected to the sliders in a fixed way; percussion holes are formed on the side walls of the dehydration box, and are sleeved with plastic film; elastic plates are arranged on inner walls of the dehydration box along percussion holes, and are connected with the dehydration box in a fixed way via springs; percussion rods capable of stretching into the percussion holes are further arranged on the base; and a cover plate is hinged to the top of the dehydration box, wherein the central part of the cover plate is collapsible. The vegetable dehydrating device is simple in structure, and capable of increasing movement of space position of the vegetable to be dehydrated, increasing compression area, improving dehydration effects and preventing crushing or even squashing of the vegetables.

Owner:CHONGQING ZHOUYI FOOD CO LTD

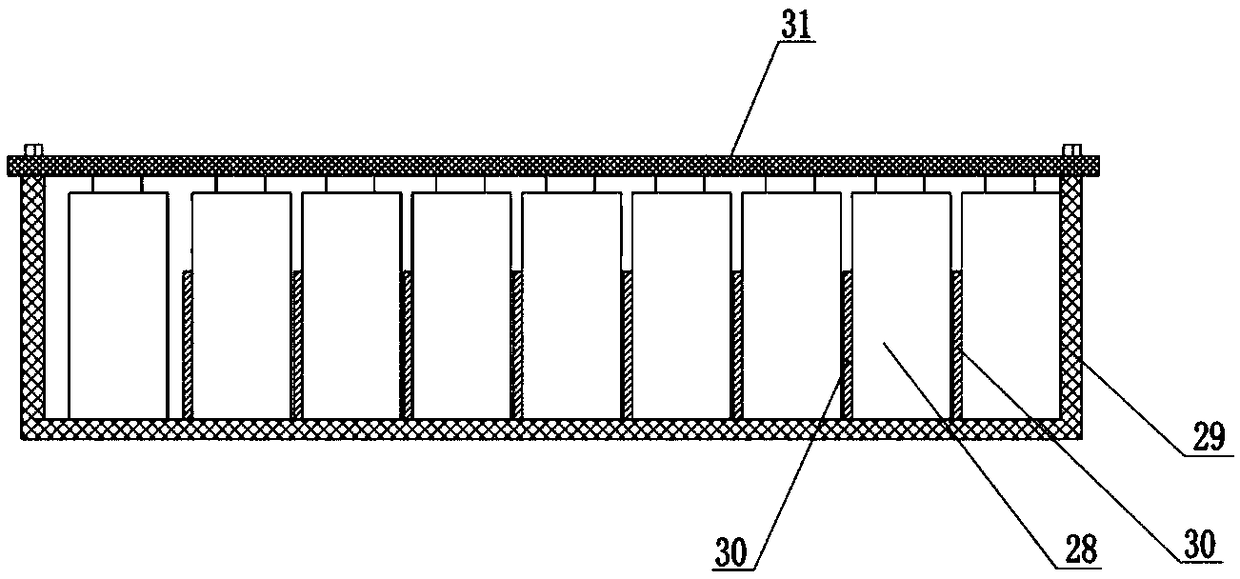

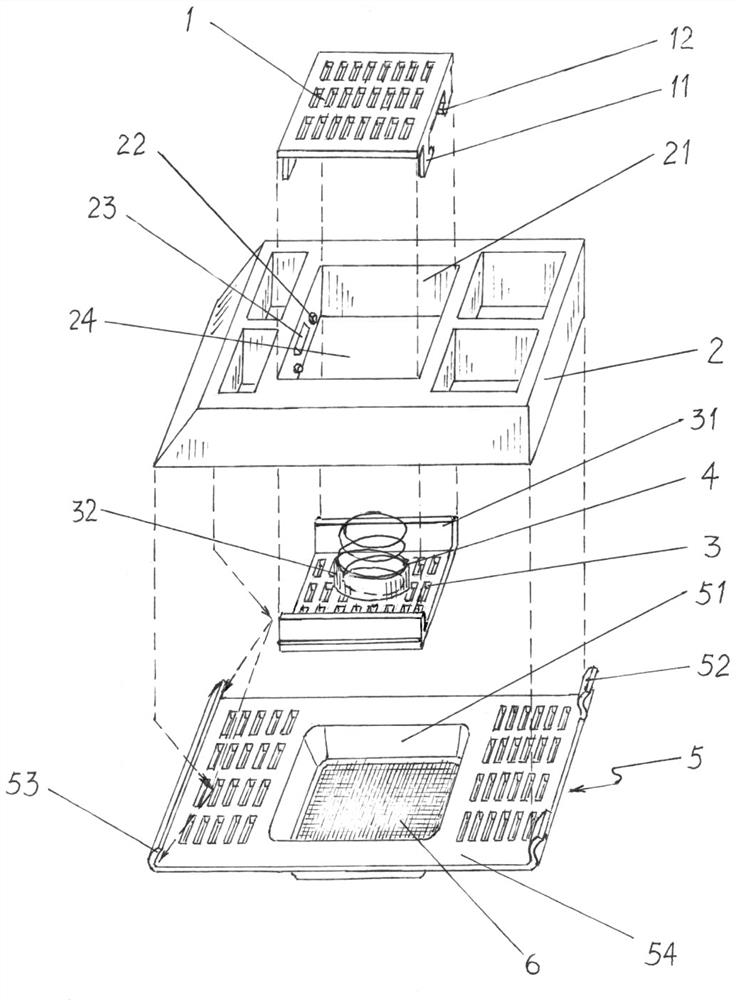

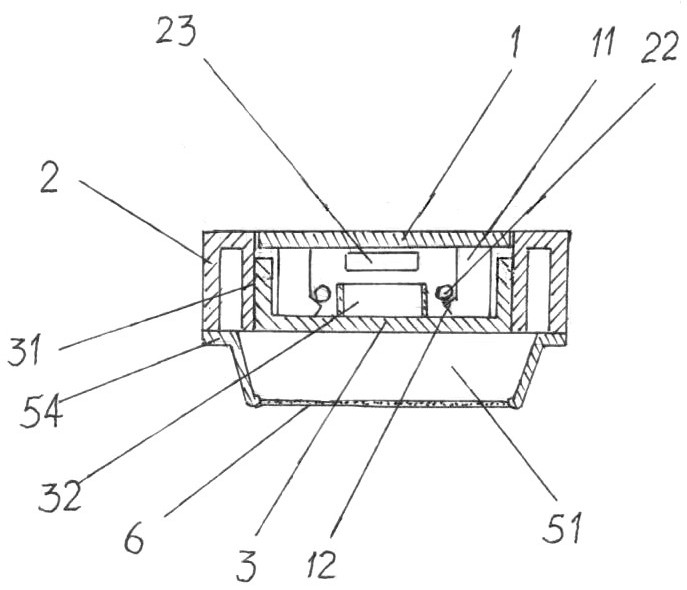

Dehydration embedding box for human tissue specimen inspection

ActiveCN112161857AAvoid transfer operationsAvoid specimen deformationPreparing sample for investigationHuman bodyStructural engineering

The invention relates to a dehydration embedding box for human tissue specimen inspection. The dehydration embedding box structurally comprises an upper cover body, an upper pressing plate, a lower pressing plate, a spring, a box body and the like, wherein the upper pressing plate comprises a top plate and a pressing rod; the lower pressing plate comprises a bottom plate and a side wall; and an inner through opening for bearing the upper pressing plate and the lower pressing plate is formed in the middle of the upper cover body, and the box body comprises a containing bin and a bearing plate.According to the dehydration embedding box, an integrated operation processing mode of dehydration and embedding of the human tissue specimen is realized, so that the transfer operation of the human tissue specimen between the dehydration box and the embedding box and the cross contamination caused by the transfer operation can be avoided; specimen deformation and section deformation caused by thefact that the human tissue specimen cannot be shaped in the dehydration and paraffin soaking process can be avoided, the human tissue specimen section soaked in paraffin is attached to a mesh membrane at the bottom part of the box and is flatly exposed, condensation of redundant paraffin is avoided, section trimming treatment is not needed, the operation flow of dehydration and embedding is simplified, and the inspection accuracy is improved.

Owner:胡盛博

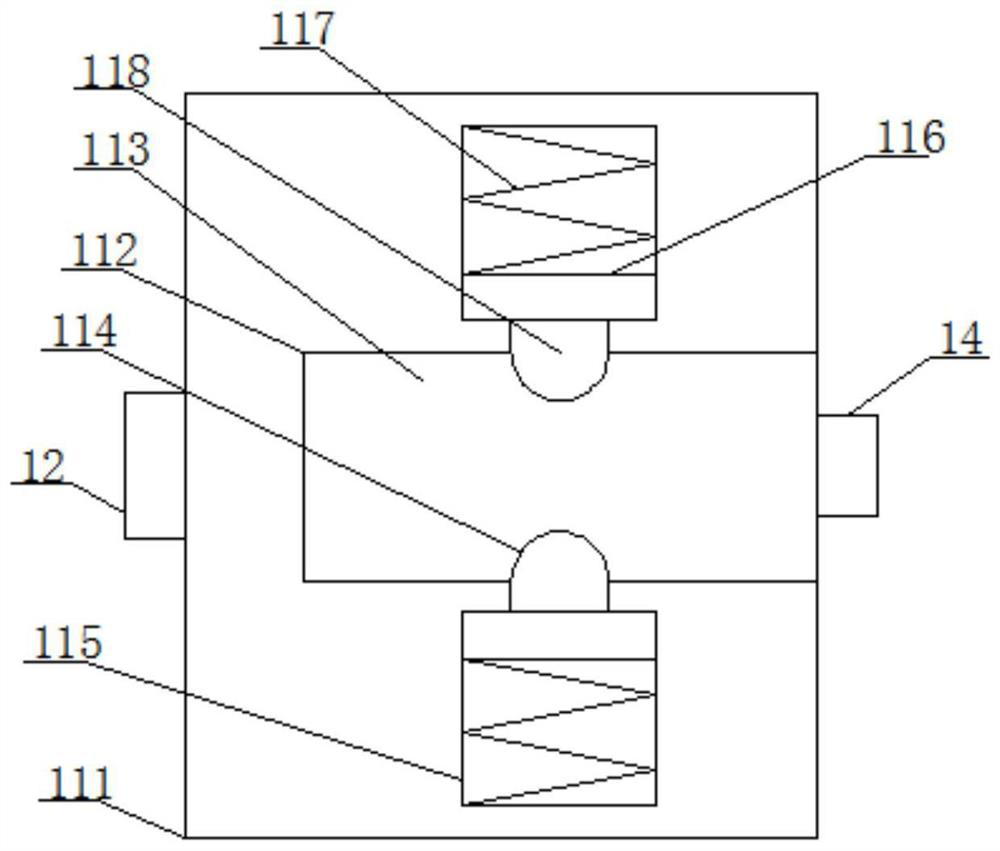

Dehydration equipment

InactiveCN112611170ADehydration achievedWon't clogDrying solid materials without heatDrying chambers/containersEngineeringMechanical engineering

The invention discloses dehydration equipment, which comprises a screen drum, and a feeding port and a discharging port are arranged on the screen drum; a material conveying mechanism comprising a conveying part arranged between the feeding port and the discharging port; an extension piece, wherein gap is formed between the extrusion part and the discharging port; a driving piece connected with one end, far away from the discharging port, of the extrusion piece; and the driving piece drives the extrusion piece to move away from or close to the discharging port. Materials are moved from the feeding port to the discharging port through the material conveying mechanism, the extension piece extrudes the materials at the discharging port to dehydrate the materials, the driving piece drives the extension piece to move, so that the distance between the extension piece and the discharging port is changed, the materials with large particle sizes and the materials with small particle sizes can be dehydrated, and the discharging port cannot be blocked.

Owner:SUZHOU JONO RECYCLING RESOURCES EQUIP

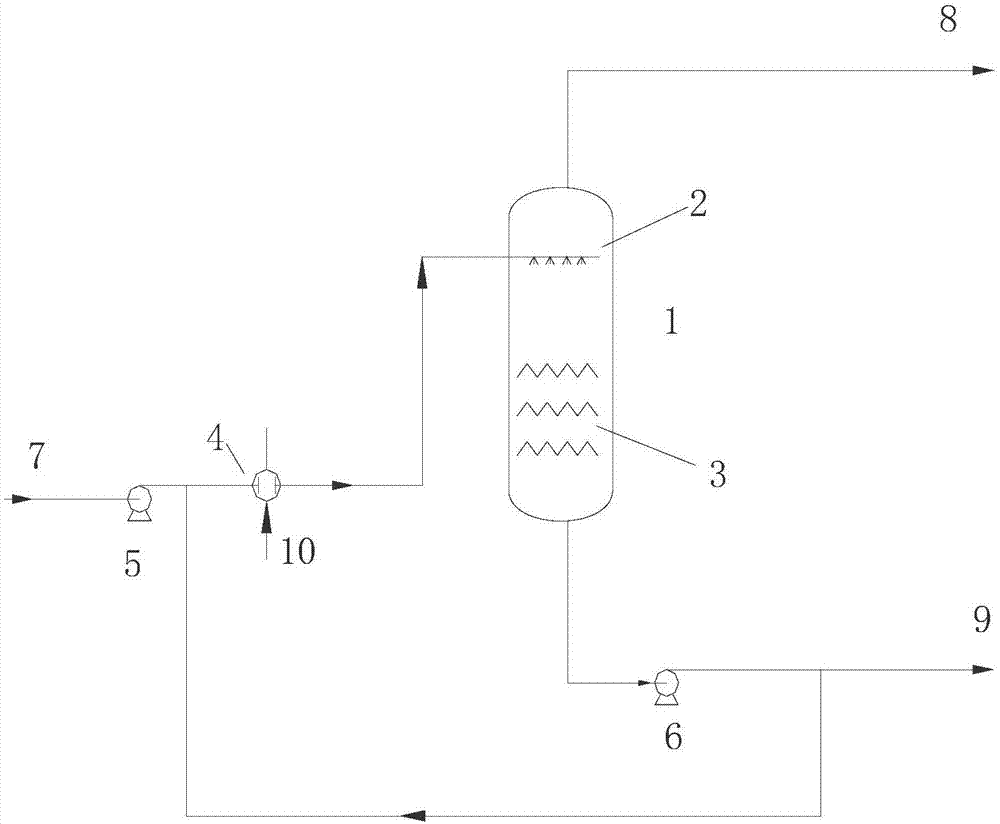

Method for dehydrating polyether initiator

ActiveCN105859523BDehydration achievedImprove dehydration efficiencyOrganic compounds purification/separation/stabilisationOrganic compound preparationNitrogenNitrogen gas

The invention relates to the field of chemistry, in particular to a method for dewatering a polyether initiator. The method for dewatering the polyether initiator, provided by the invention, comprises the following steps: spraying the polyether initiator into fog drops through arranging a spraying system at the top of a reactor, introducing nitrogen from the bottom of the reactor, enabling the polyether initiator fog drops and the nitrogen to form a uniform gas-liquid dispersion system taking the nitrogen as a continuous phase and taking away water generated by the reaction of the polyether initiator with a base catalyst from the top of the reactor through the dry nitrogen, so that the dewatering of the polyether initiator is realized. Compared with a traditional vacuum distillation method, the method for dewatering the polyether initiator, provided by the invention, has the advantages of being high in dewatering efficiency and lower in moisture content of the dewatered initiator.

Owner:眉山海螺新材料科技有限公司

A method for industrialized production of organic selenium-enriched Tibetan Cordyceps pulp wine and the resulting product

ActiveCN105754809BHigh active ingredientUse strain innovationDigestive systemAlcoholic beverage preparationBiotechnologyCordyceps

The invention provides a method for industrially producing organic selenium-rich original wine with Tibetan cordyceps.The method includes steps of 1), carrying out slant strain cultivation on the Tibetan cordyceps and cultivating seed solution; 2), carrying out submerged fermentation and enlarge cultivation on the seed solution by the aid of water cultivation media, proportionally adding wine into the seed solution and continuing to ferment the seed solution; 3), breaking walls of cells of active mycelia of the Tibetan cordyceps, alternately, soaking and sealing the Tibetan cordyceps by the aid of wine, aging the Tibetan cordyceps and producing aroma; 4), preparing traditional Chinese medicine extract; 5), breaking the walls of mycelia of fermentation liquor of the Tibetan cordyceps, proportionally adding the high-purity traditional Chinese medicine extract and fermentation wine into the fermentation liquor of the Tibetan cordyceps and blending the high-purity traditional Chinese medicine extract, the fermentation wine and the fermentation liquor of the Tibetan cordyceps with one another to obtain the organic selenium-rich original wine.The method has the advantages that the mycelia of the Tibetan cordyceps are subjected to submerged liquid fermentation, baijiu, the sweet wine, the yellow rice wine and the grape wine are respectively added into the Tibetan cordyceps when the sufficient mycelia are obtained, the mycelia of the Tibetan cordyceps continues to be fermented, the walls of the mycelia are broken when active components are sufficient, the mycelia are mixed with the fermentation wine and the extract of radix ophiopogonis, rhizoma polygonati odorati, fructus corni, herba cistanches, herba epimedii, selenium-rich sweet herba gynostemmatis pentaphylli, radix astragali and radix panacis quinquefolii, and accordingly the organic selenium-rich original wine with the Tibetan cordyceps and effects of improving the immunity, resisting kidney gland and thymus gland atrophy, prolonging lives and tendering skins can be produced.

Owner:锬酃藏虫草生物科技(深圳)有限公司

One-way rotary extruding device for textile fabric dewatering device

InactiveCN111649560AAvoid damageRealize extrusion dehydrationDrying solid materials without heatDrying machines with non-progressive movementsStructural engineeringCentrifugal force

The invention discloses a one-way rotary extruding device for a textile fabric dewatering device. The one-way rotary extruding device comprises a main mounting plate. The one-way rotary extruding device is used in cooperation with a centrifugal dewatering device for the textile fabric dewatering device, high-speed rotation can be generated on a textile fabric to form centrifugal force, so that centrifugal dewatering is achieved, and a threaded extendable structure can be controlled according to the rotating direction to achieve extruding dewatering of the internal textile fabric, so that the dewatering effect in two aspects is achieved; the device is provided with a rotary longitudinal height adjusting mechanism with a reverse thread structure to be capable of achieving the longitudinal height adjusting effect, so that the device can be more conveniently connected with the centrifugal dewatering device for the textile fabric dewatering device; and in addition, the device is provided with an annular array spiral spring abutting type maximum-rotating-strength control mechanism to avoid the phenomenon that the thread structure is damaged due to too large rotation resistance.

Owner:WEIFANG ENG VOCATIONAL COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com