Patents

Literature

142results about How to "Increase the compression area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

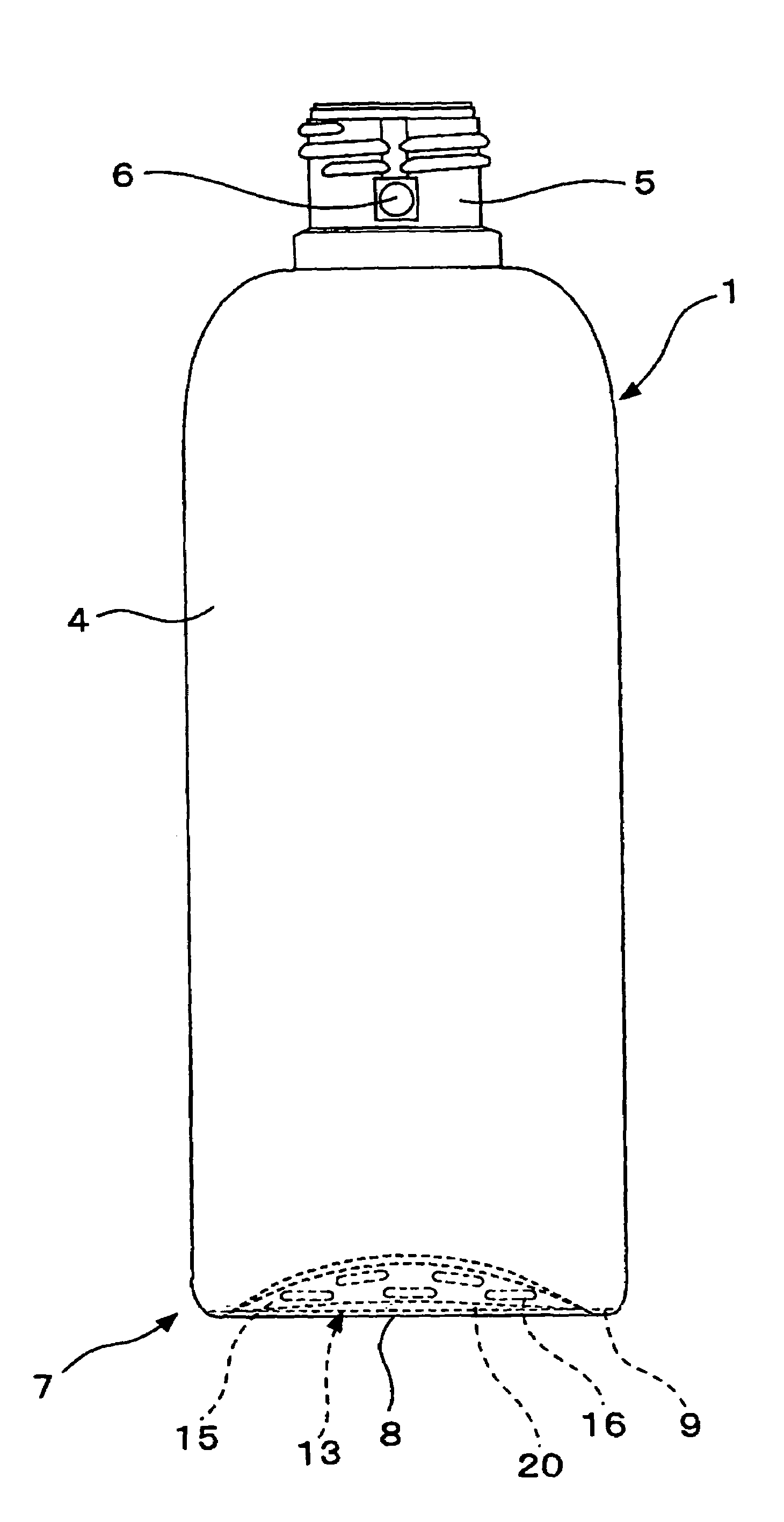

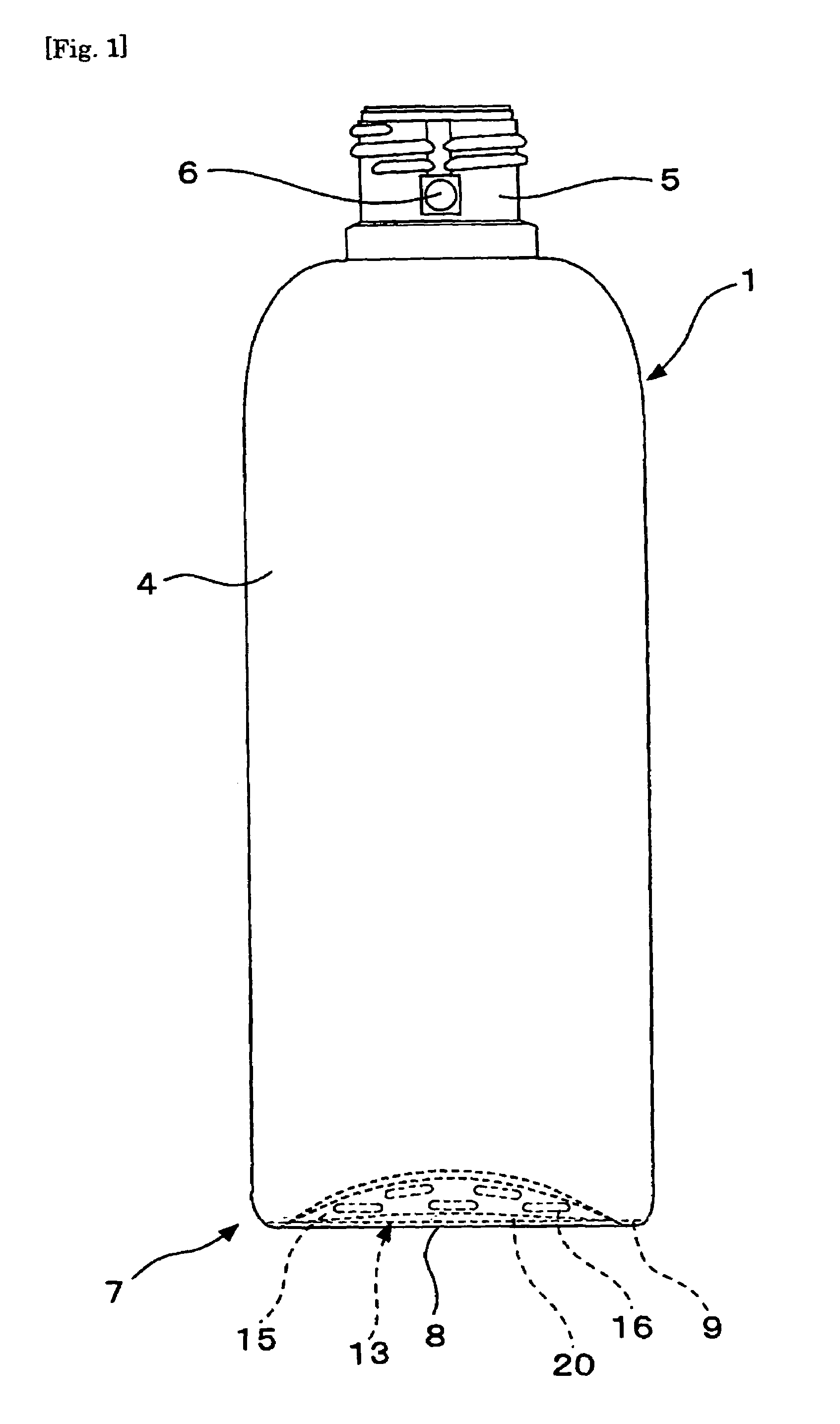

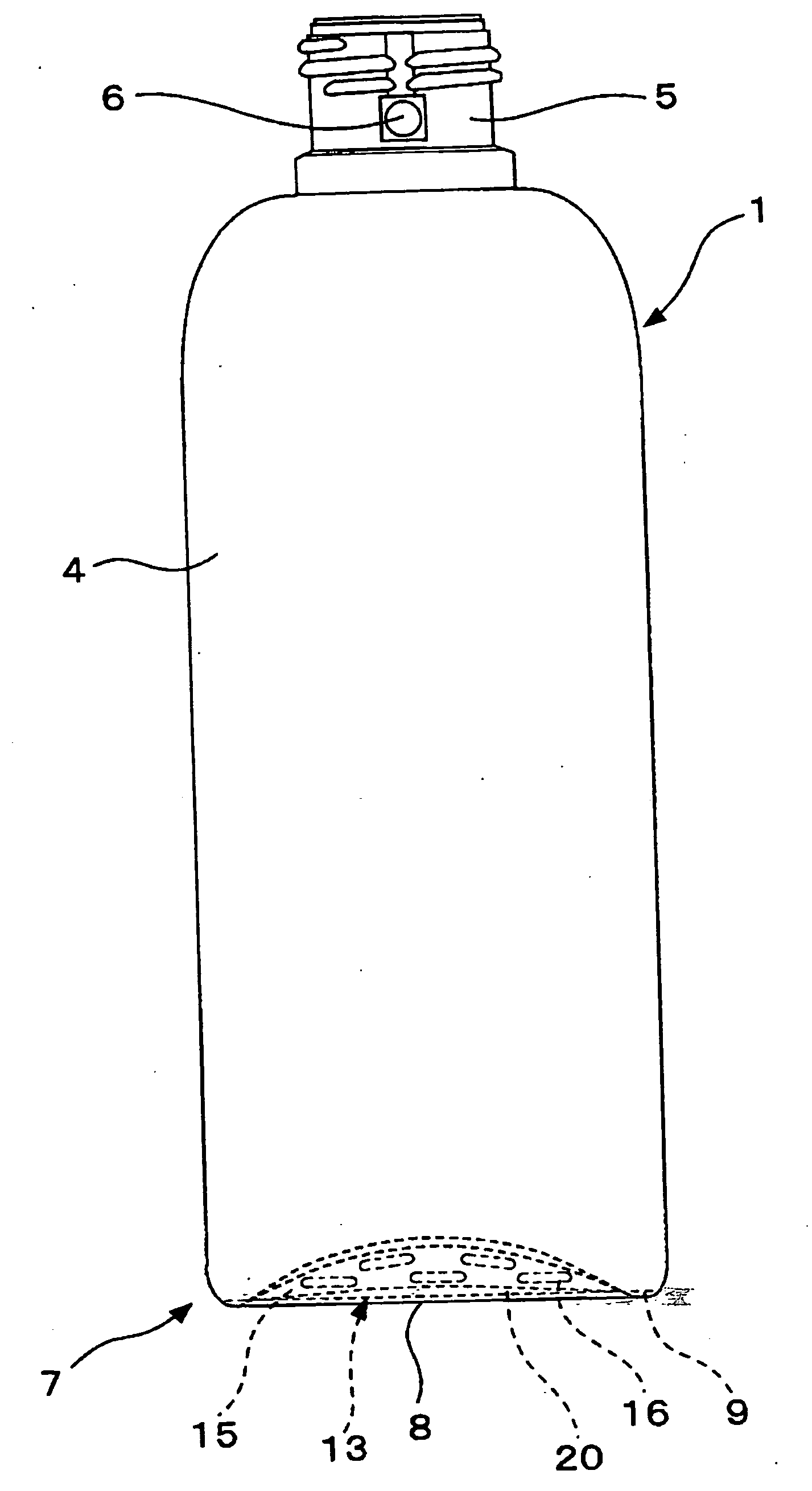

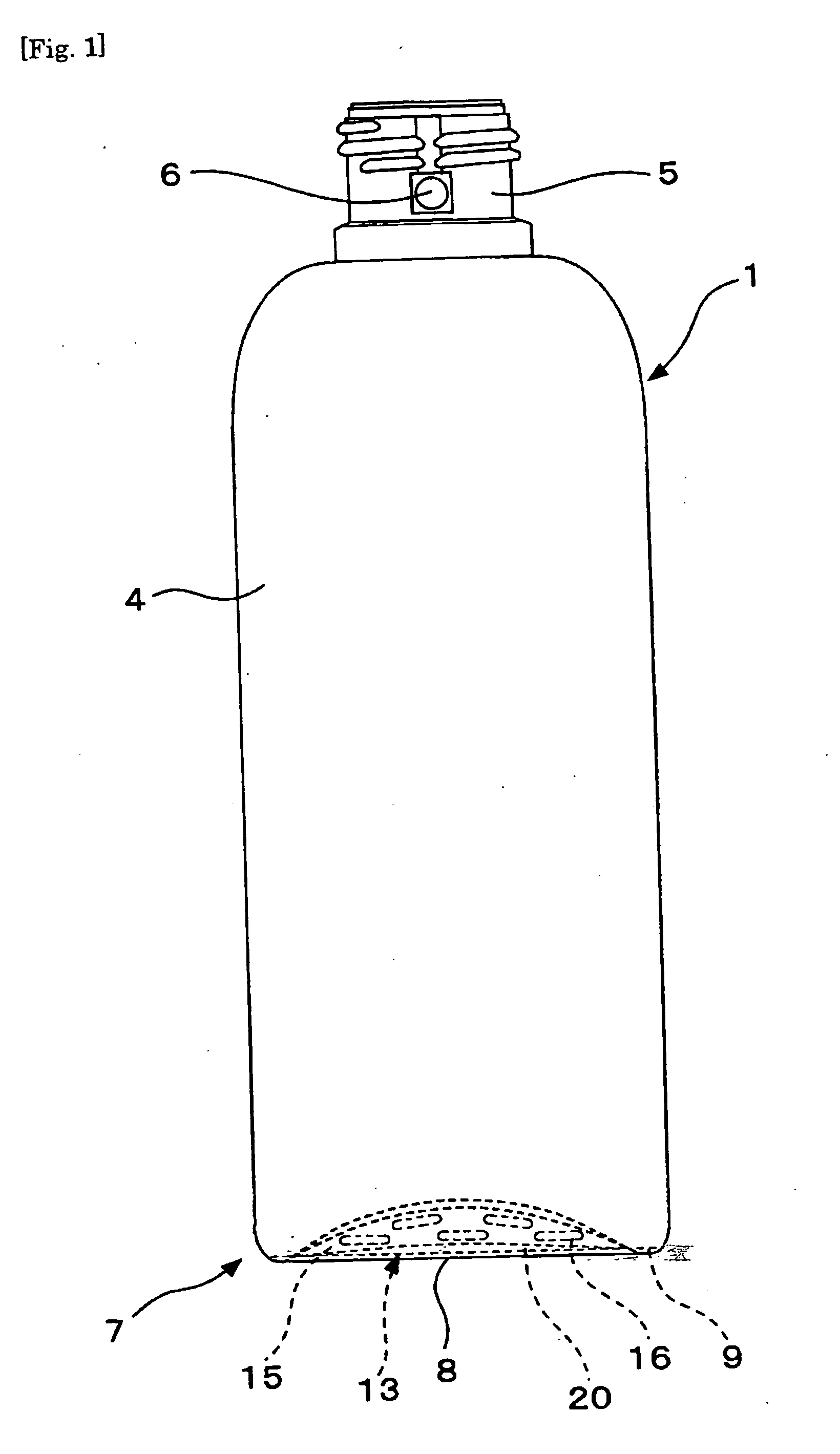

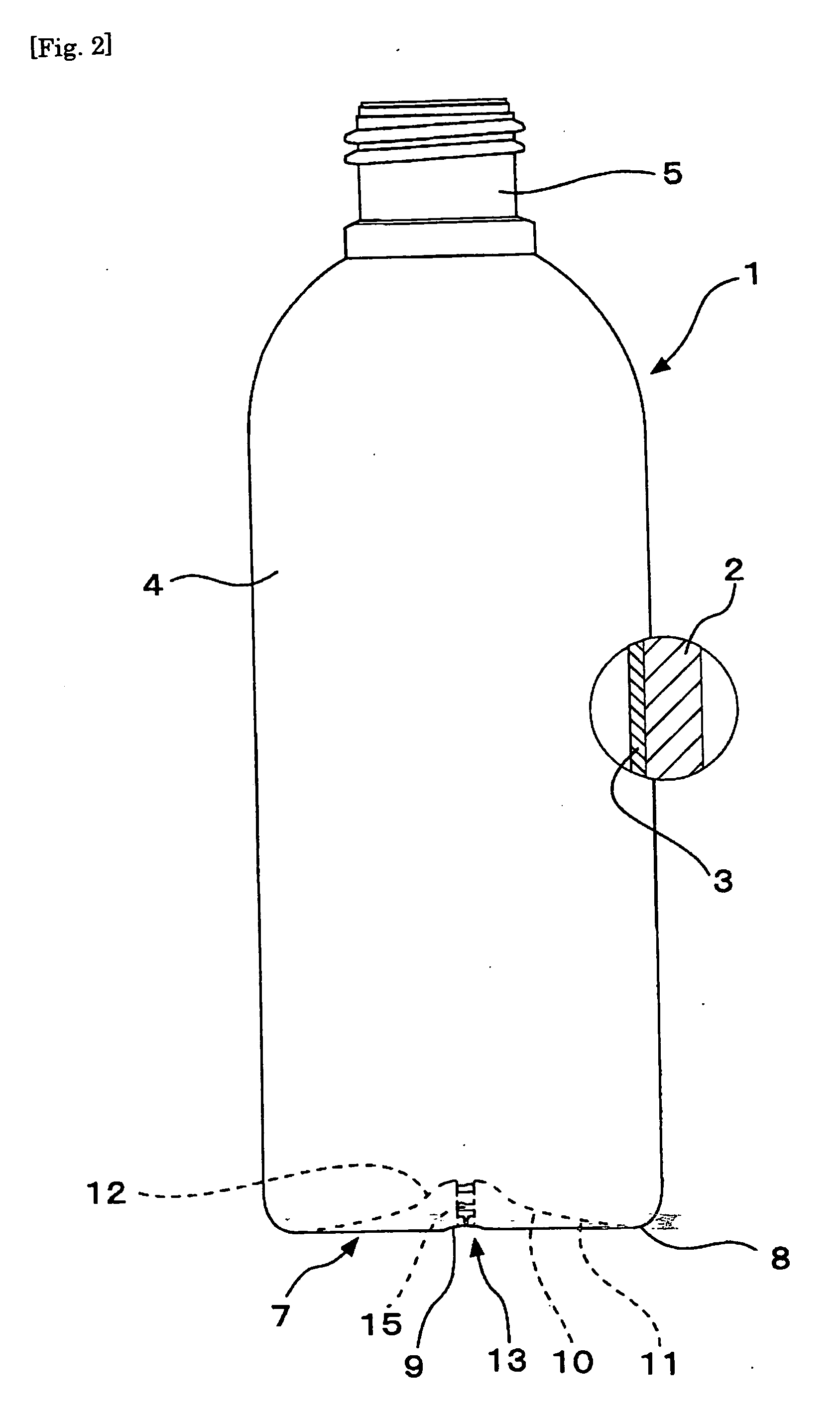

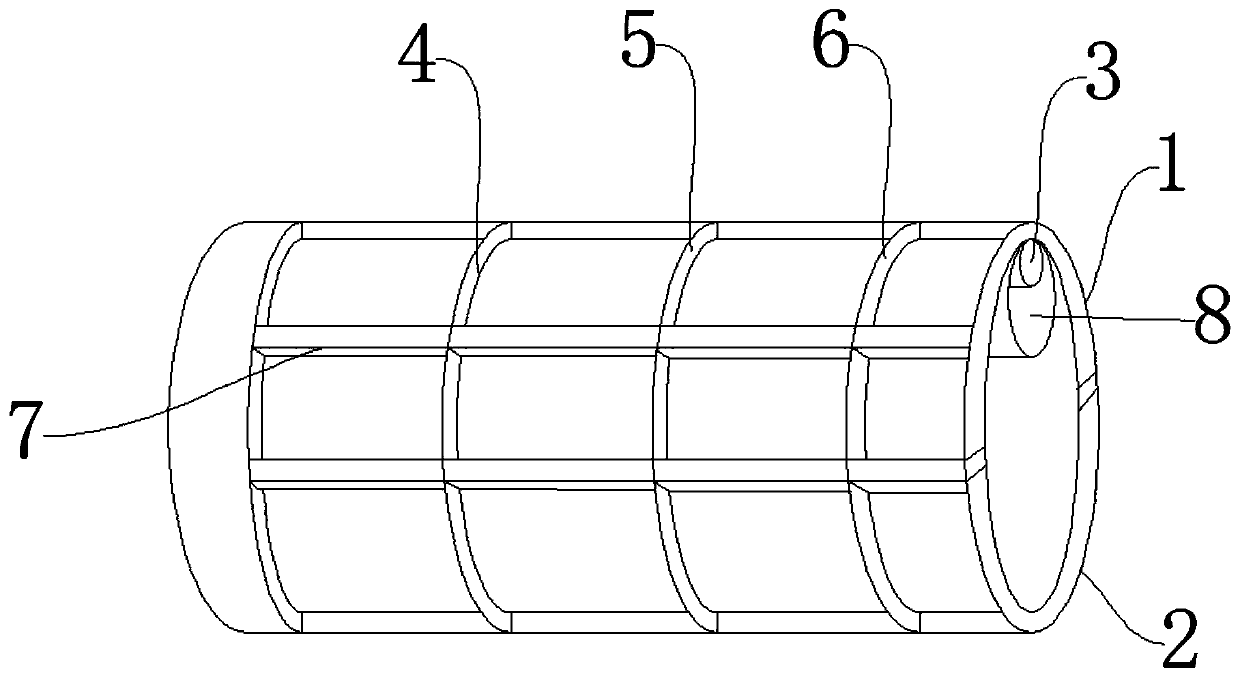

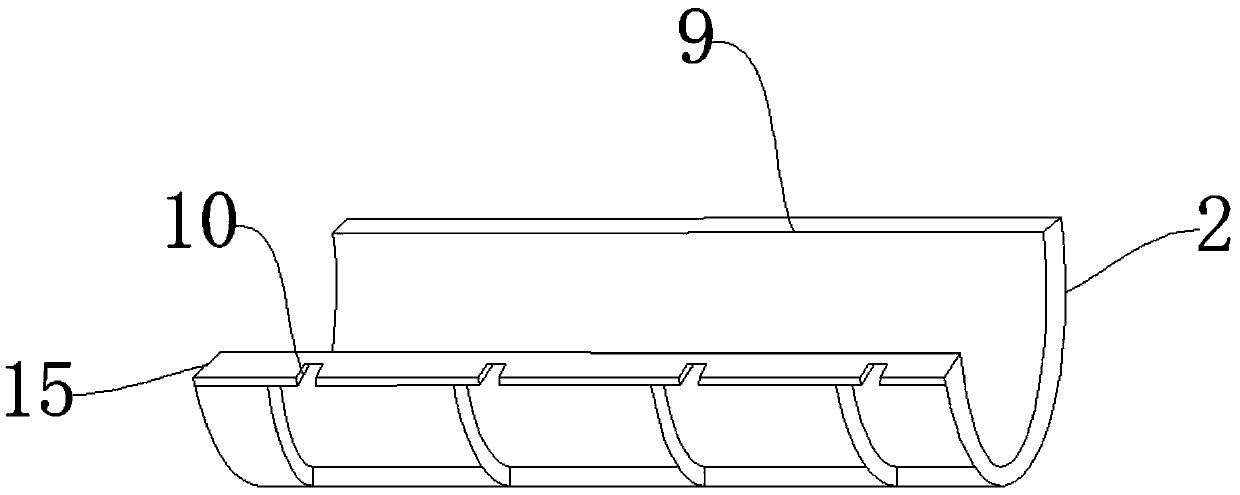

Blow molded container

ActiveUS7614515B2Improve the immunityIncrease the compression areaBottlesLarge containersEngineeringUltimate tensile strength

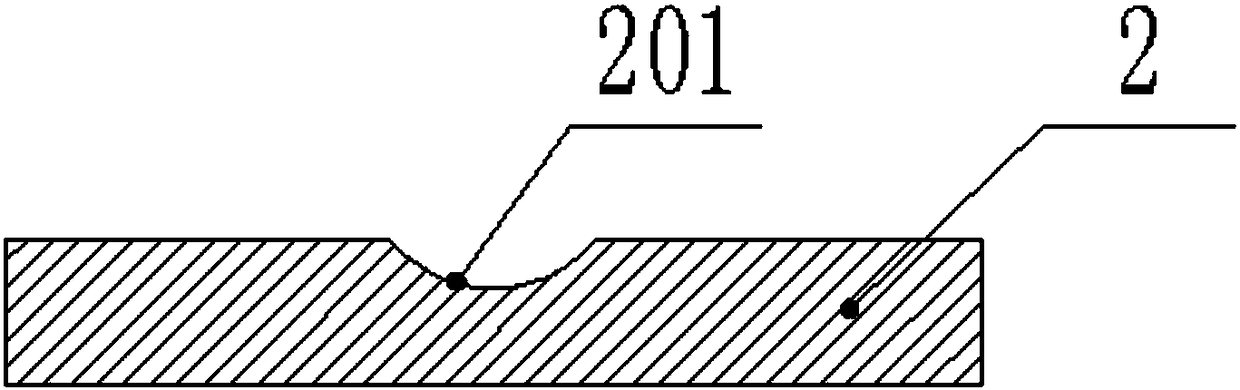

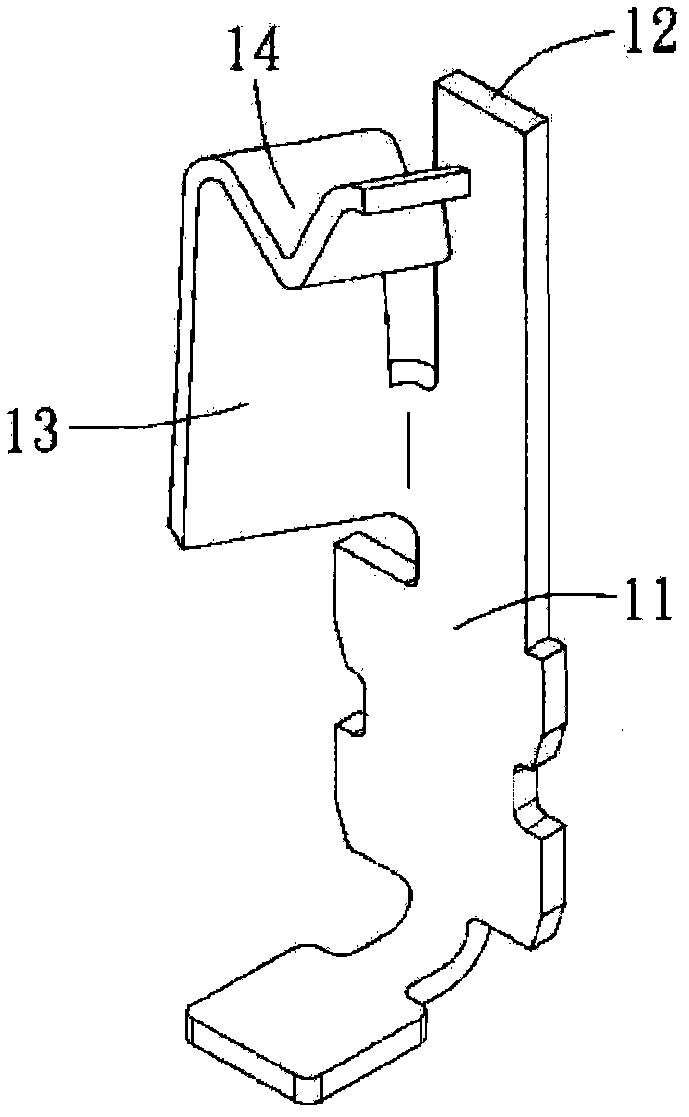

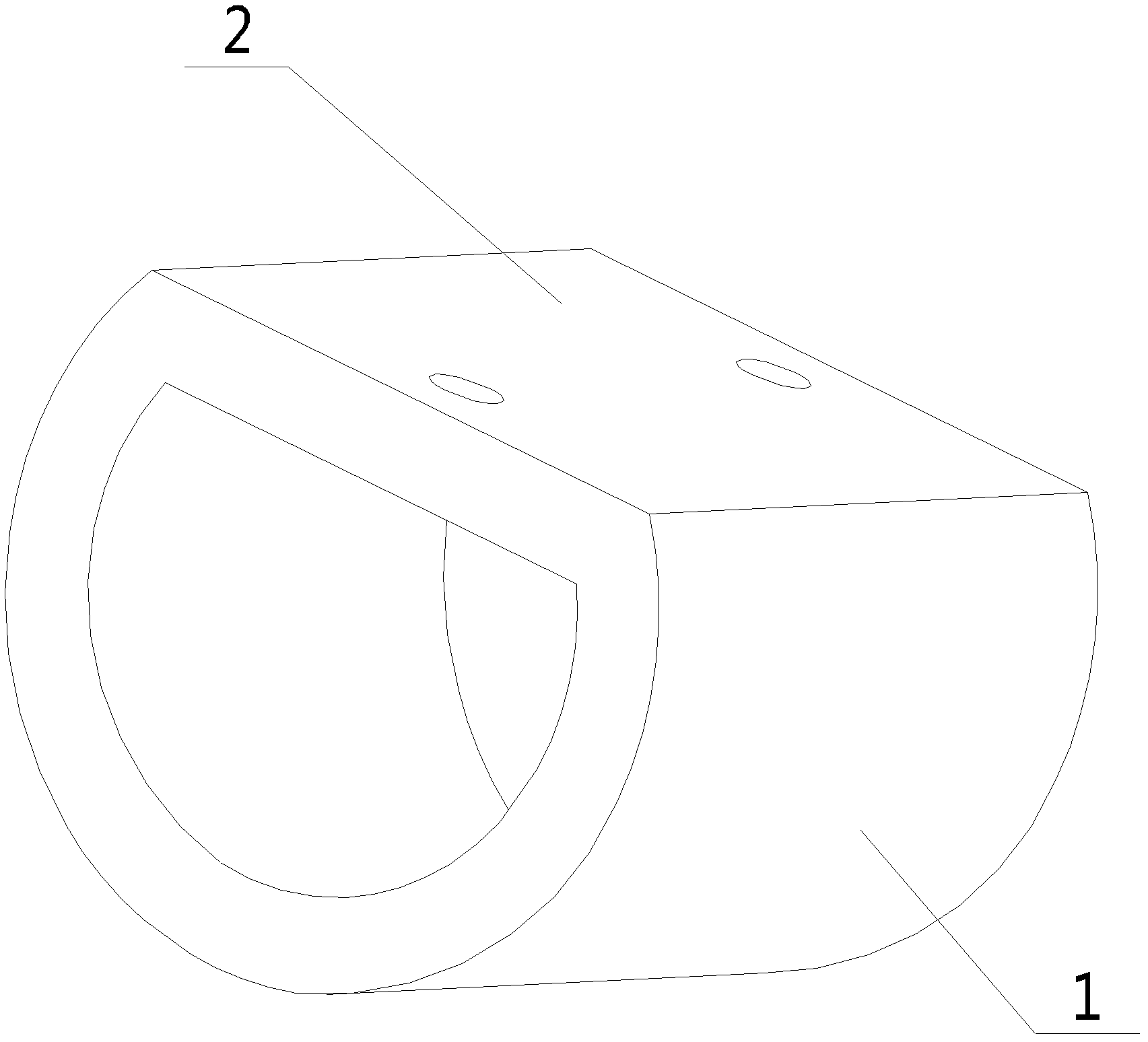

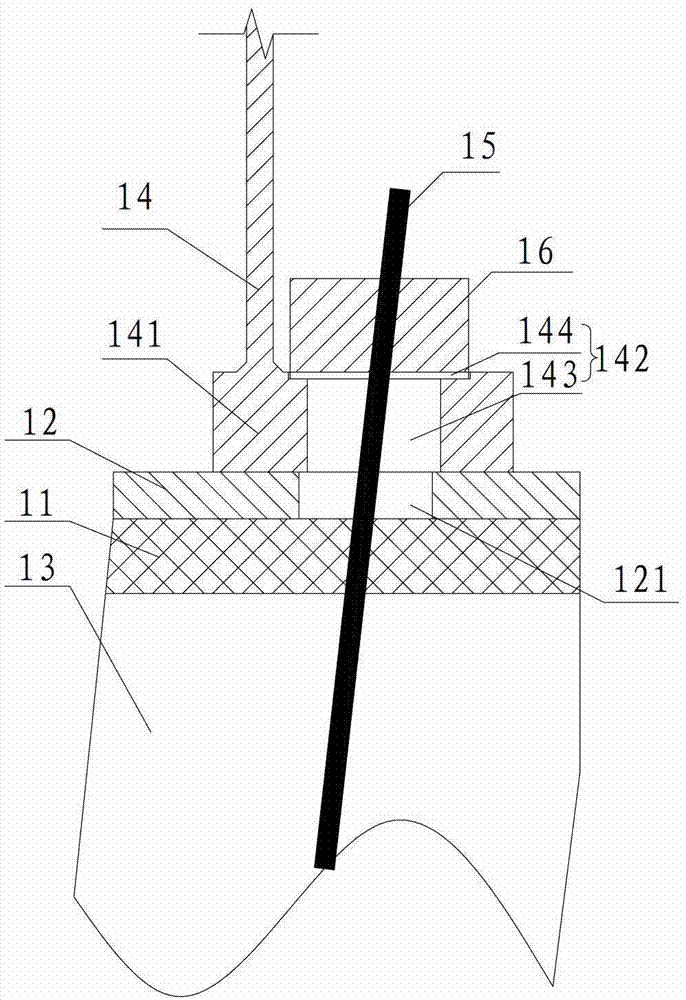

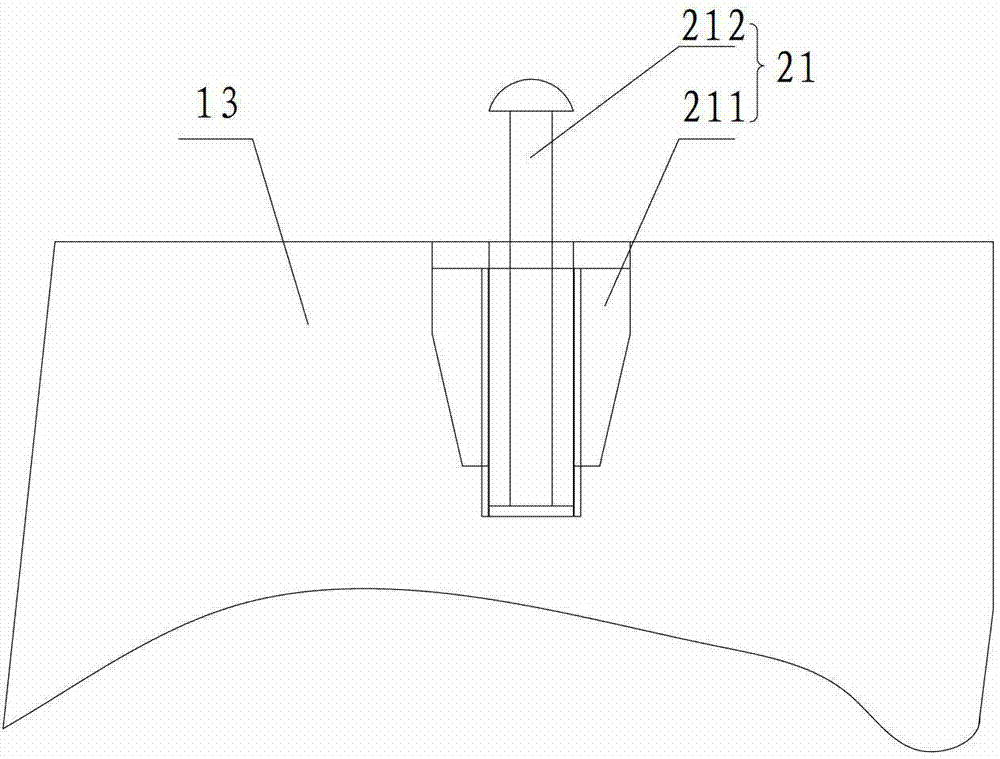

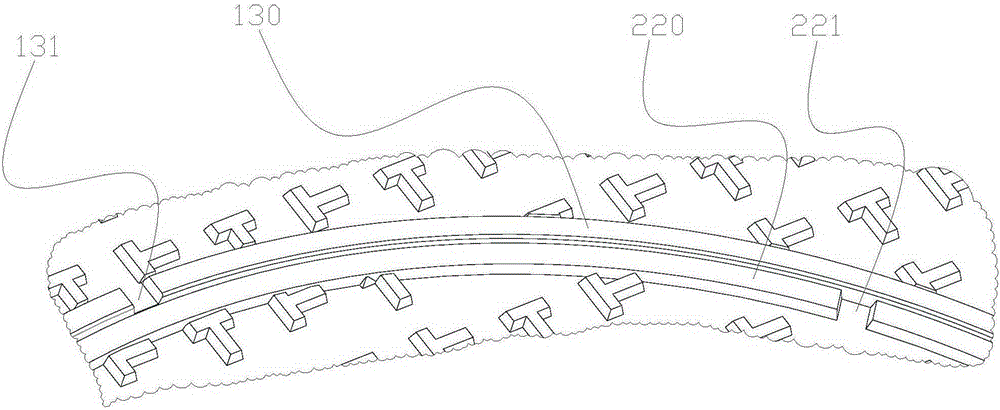

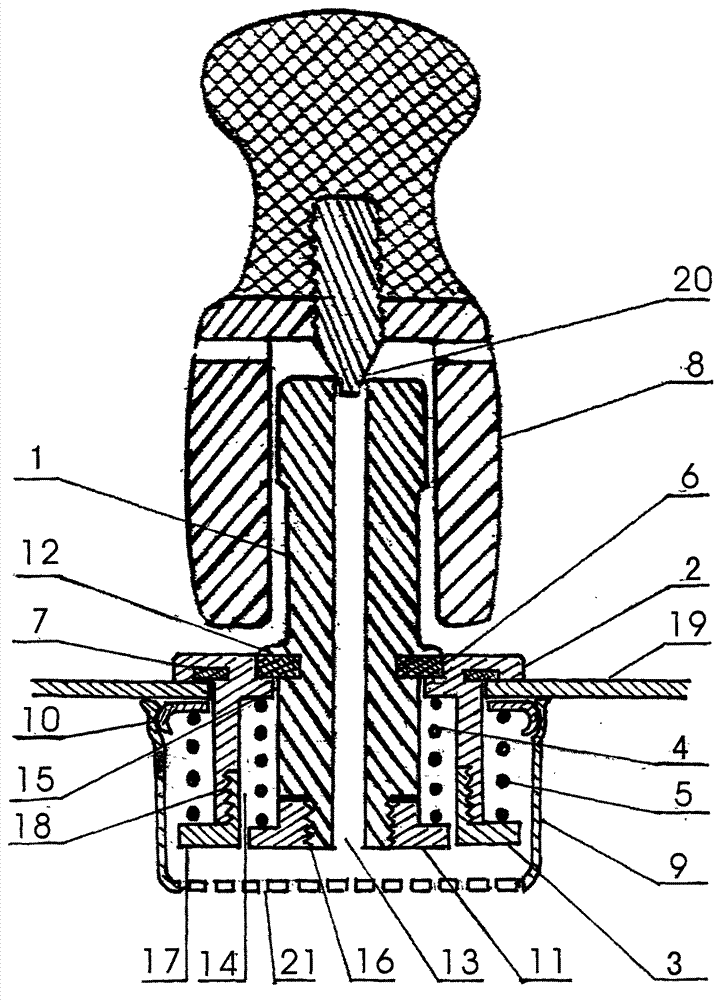

The invention is aimed at preventing bottom crack from occurring in a peelably laminated plastic container and maintaining the container stably in good in-use condition. This can be achieved by increasing the anti-peeling strength of a pair of rib strips, with which the bottom rib is formed, in the bottom seal that has been obtained by pinching off the parison at the bottom and molding the parison into a blow molded, peelably laminated plastic container.The bottom seal 13 of a blow molded, peelably laminated container 1 is reinforced by a pair of rib strips 14 which are pressed to each other to form the bottom rib 15. A multiple number of cavities 16 are formed in the bottom rib 15 in such a way that the rib strip 14 on one side is pushed toward, and caved into, the rib strip on the other side at several points, and vice verse. An expanded portion 18 is formed in the ceiling of each cavity 16. As a result, an undercut engagement portion 19 is formed along the contact faces of both rib strips 14 so that anti-cracking bottom strength of the bottom seal is enhanced.

Owner:YOSHINO KOGYOSHO CO LTD

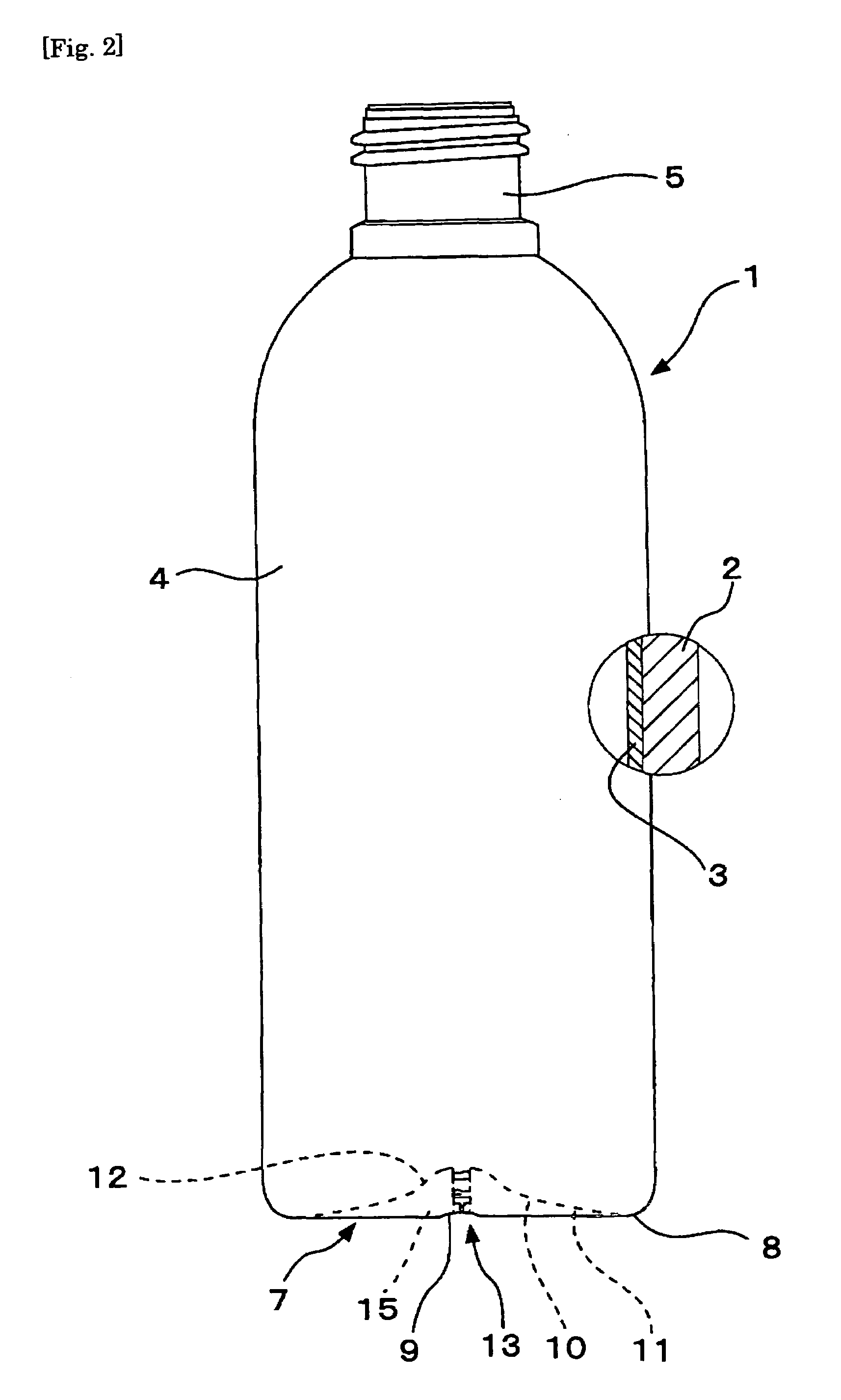

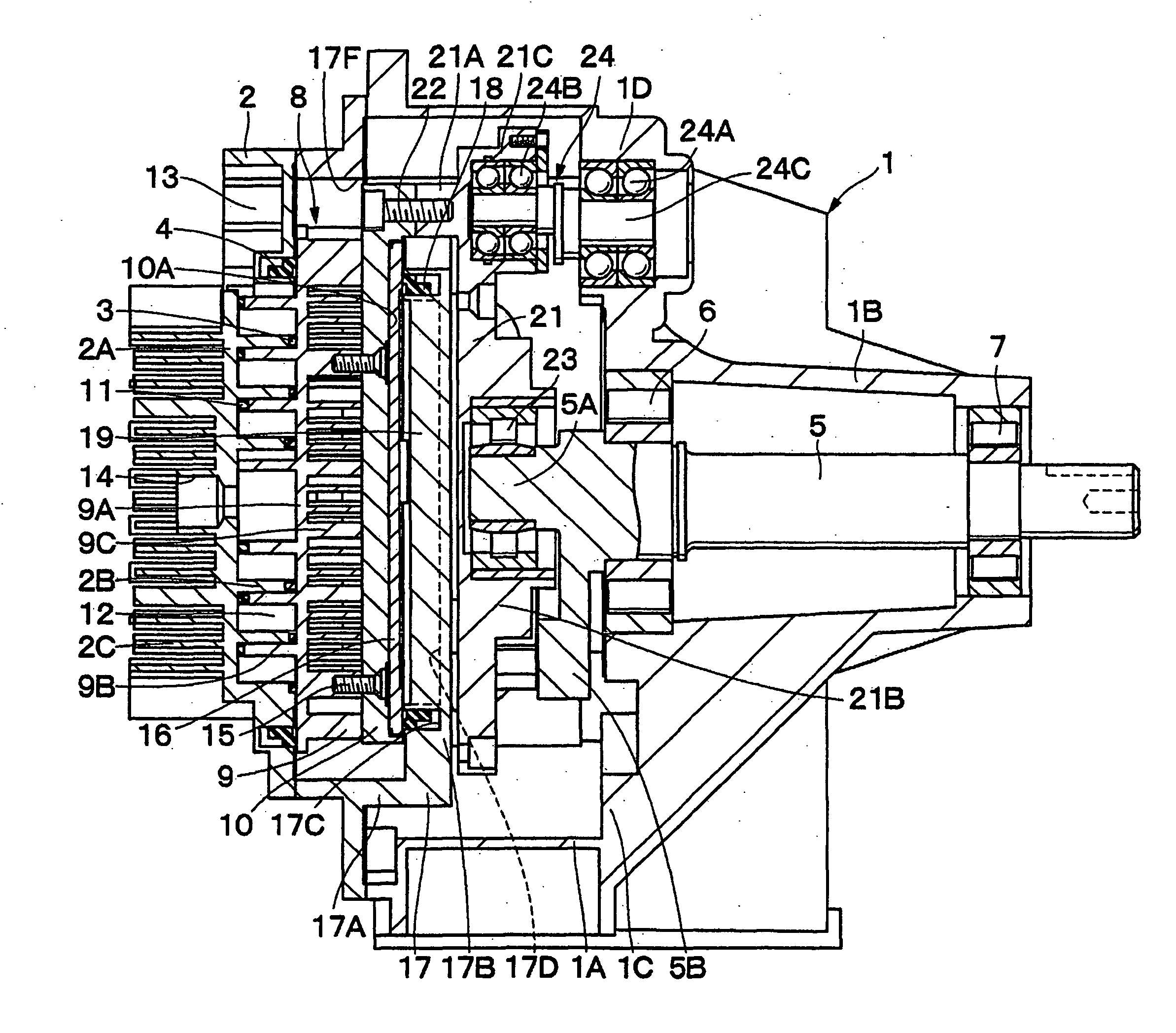

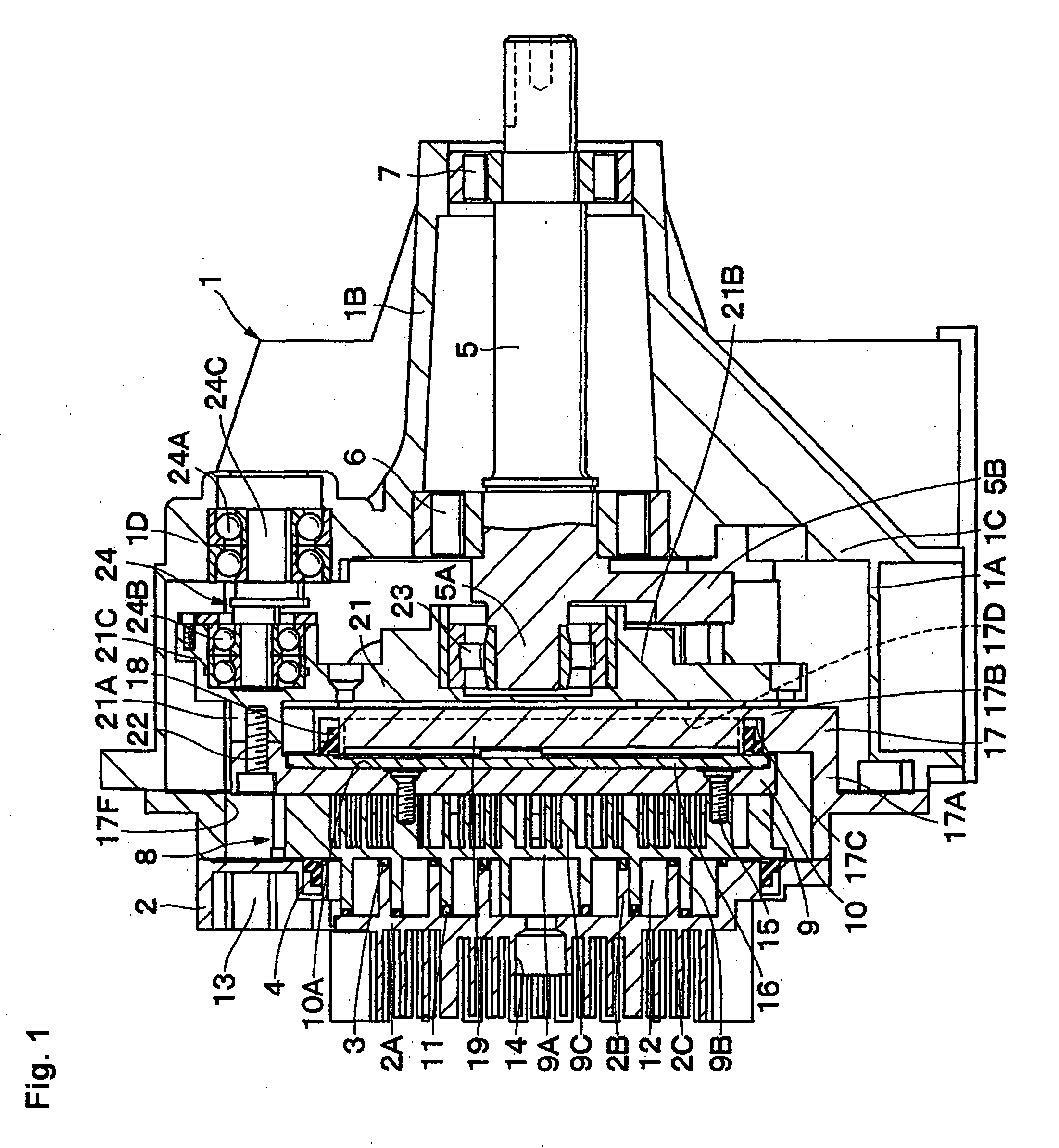

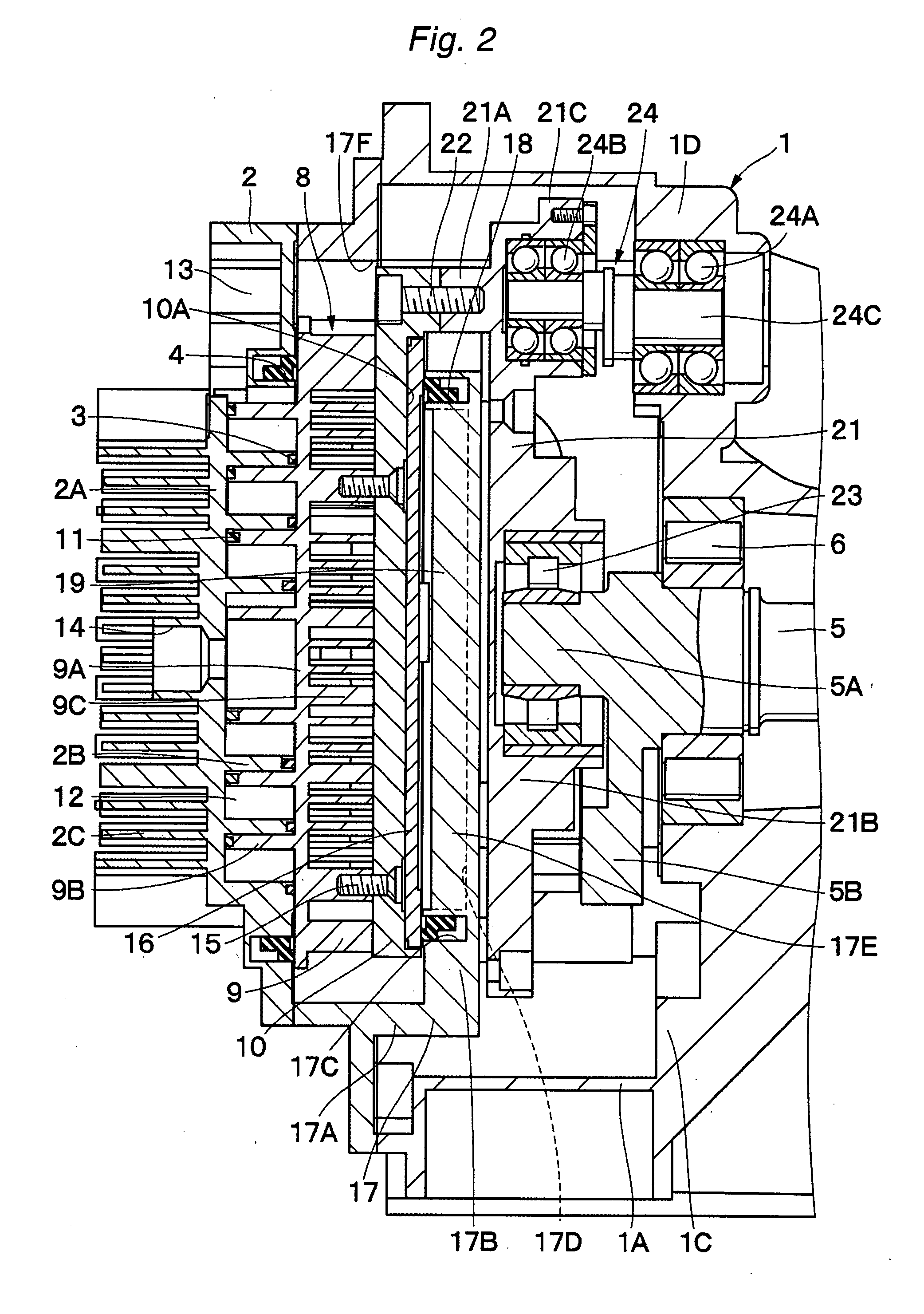

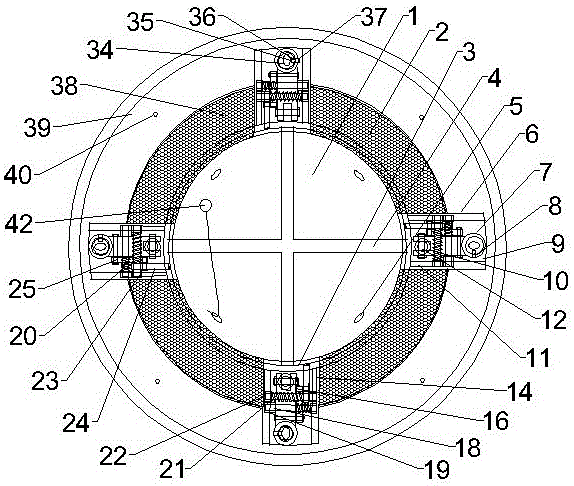

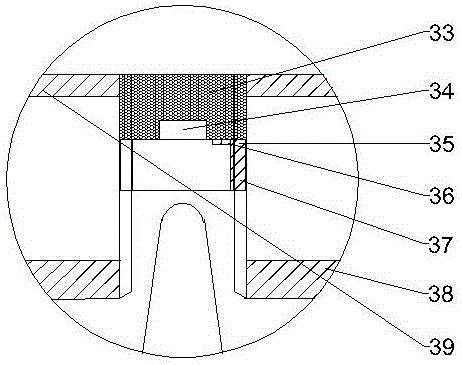

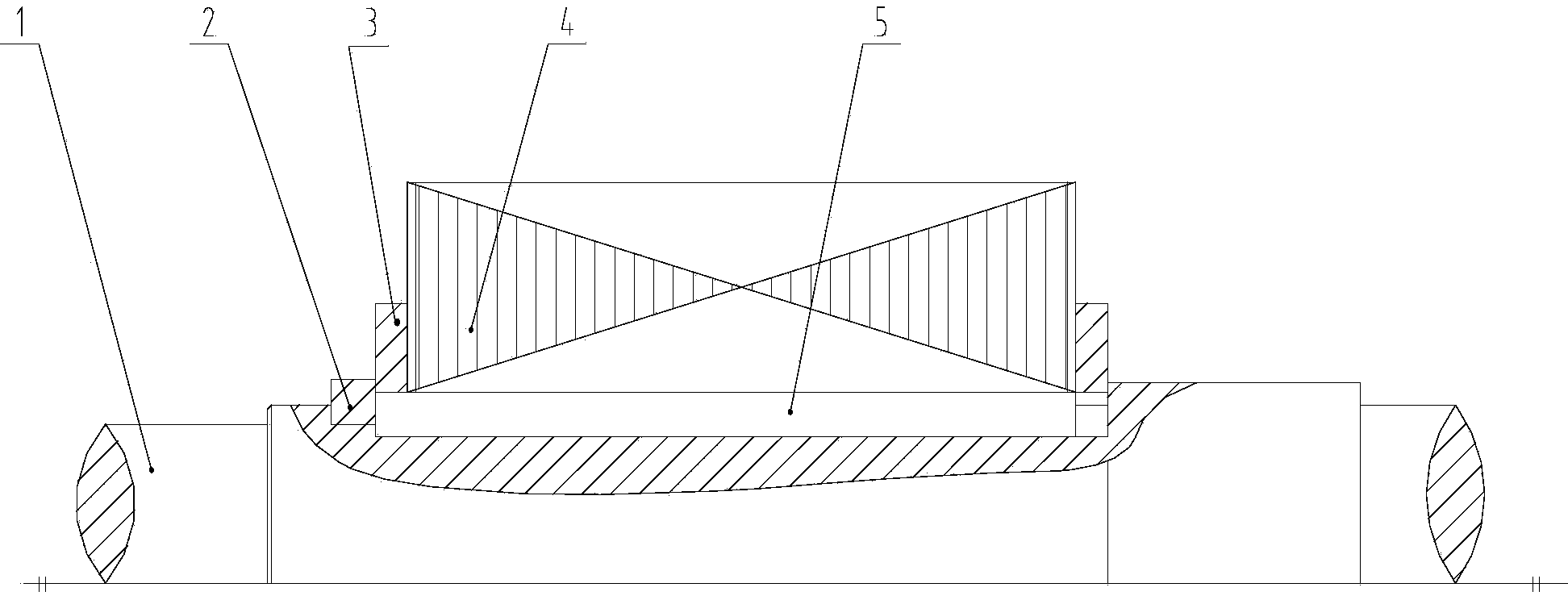

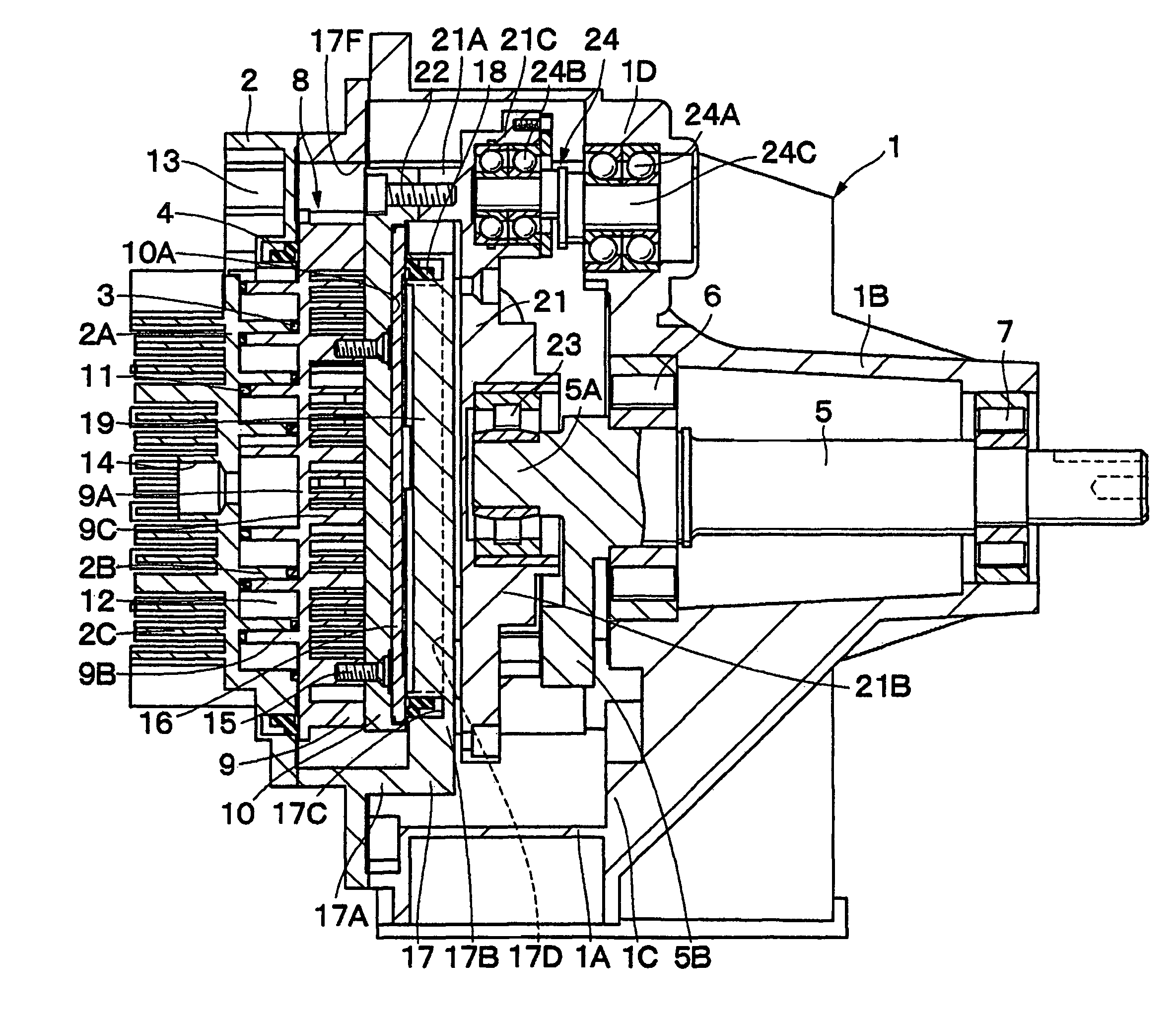

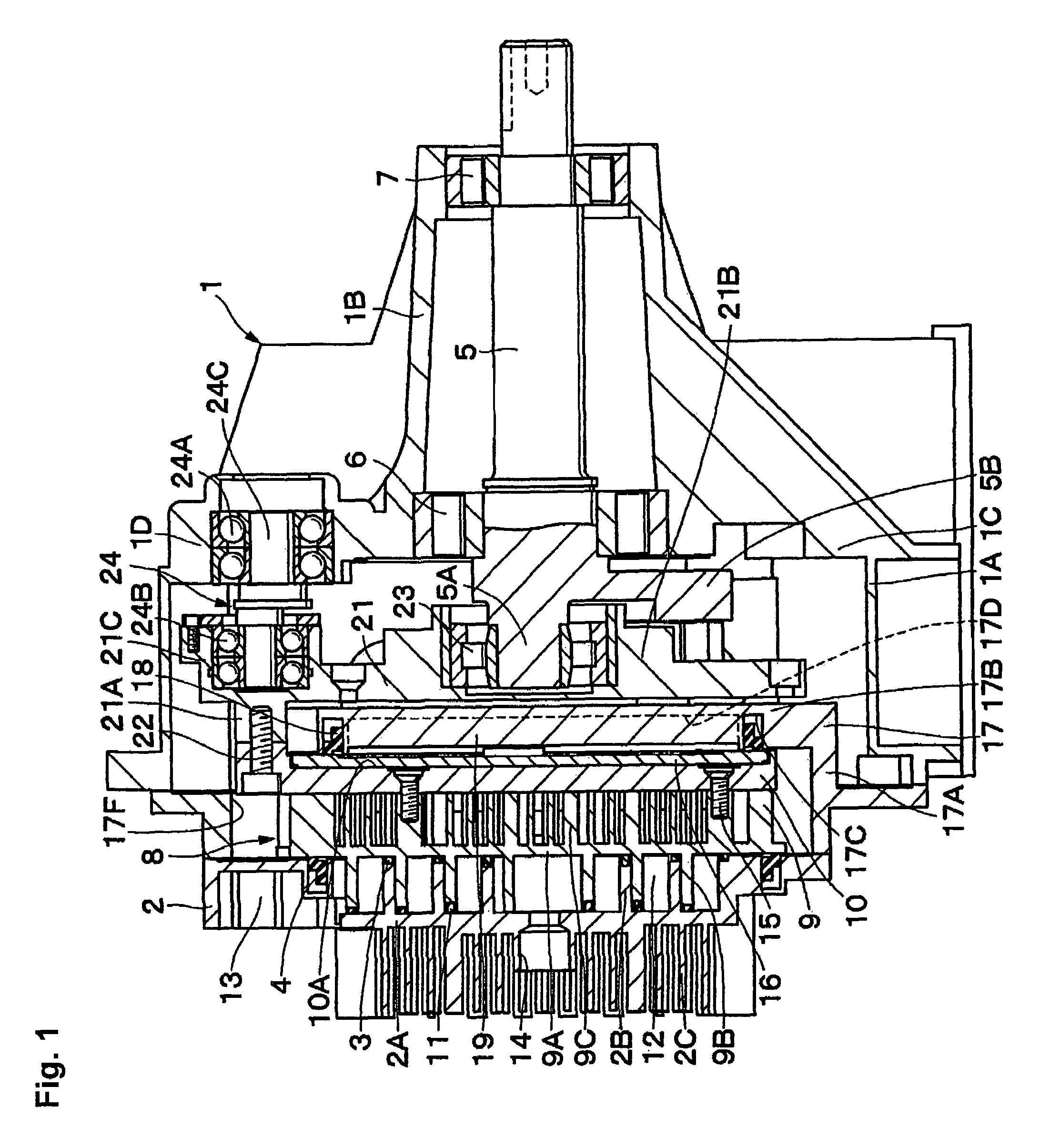

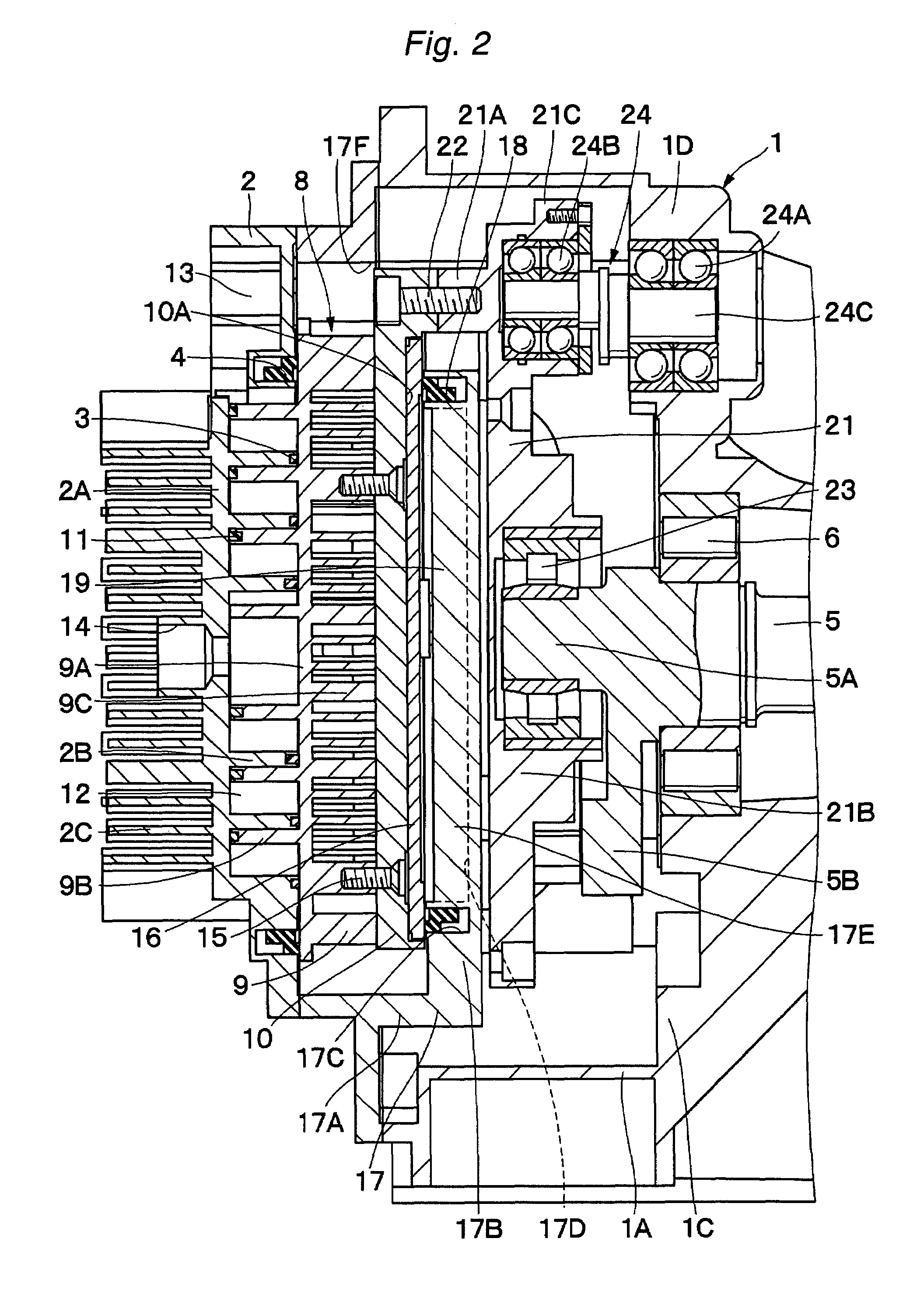

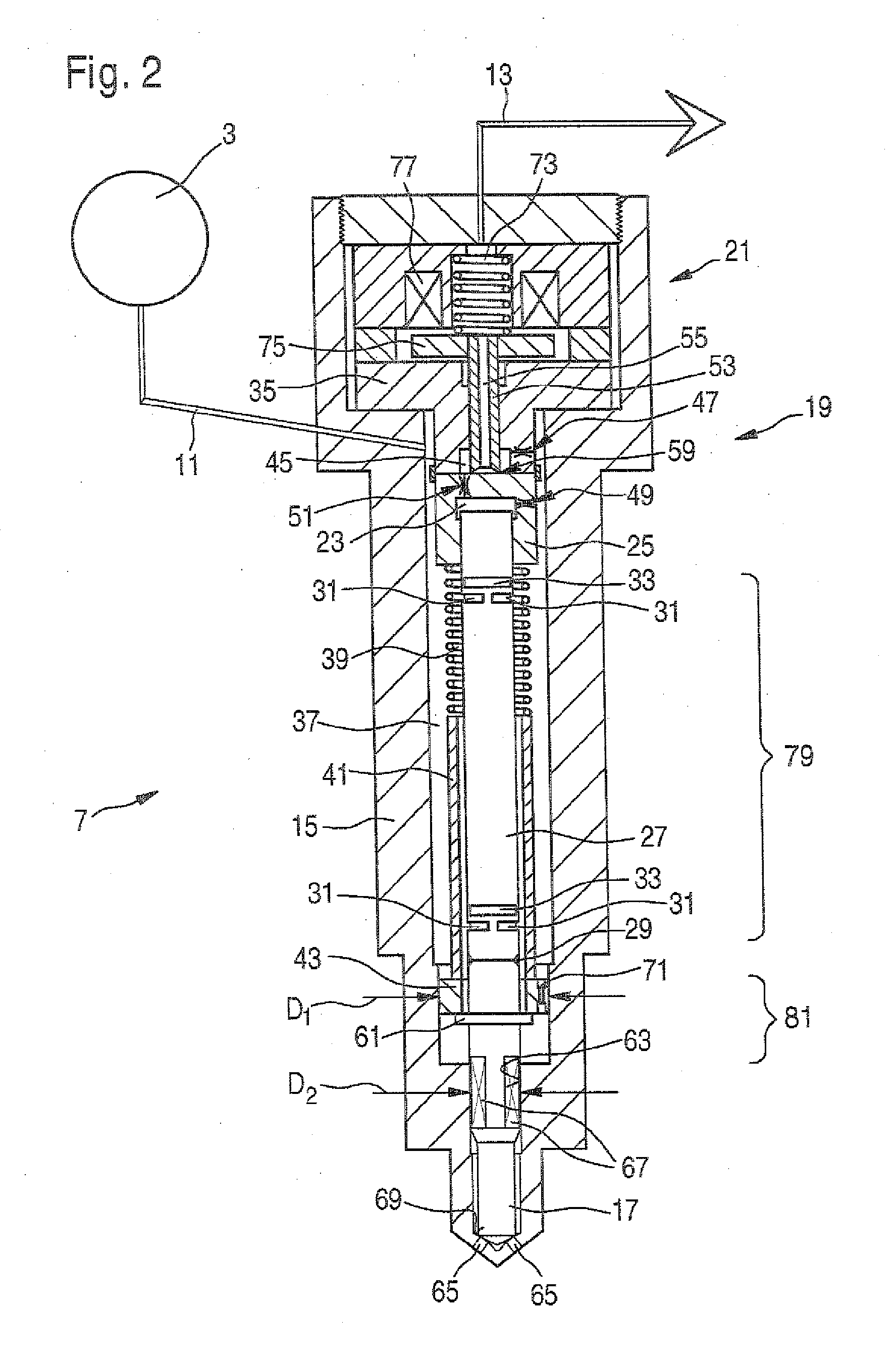

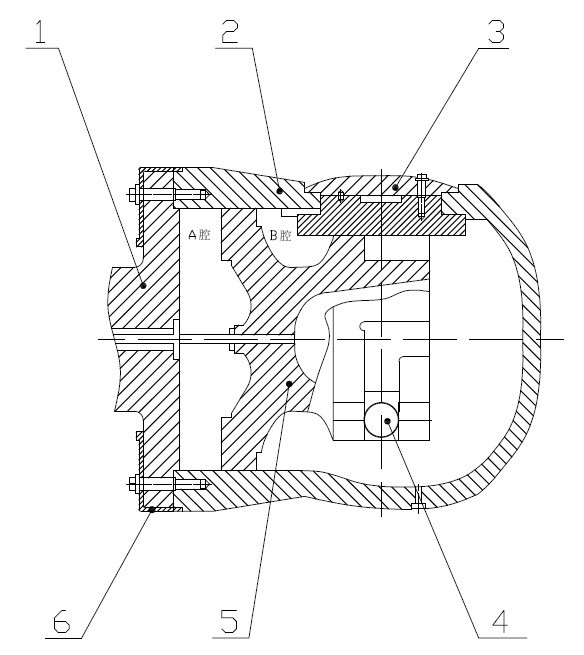

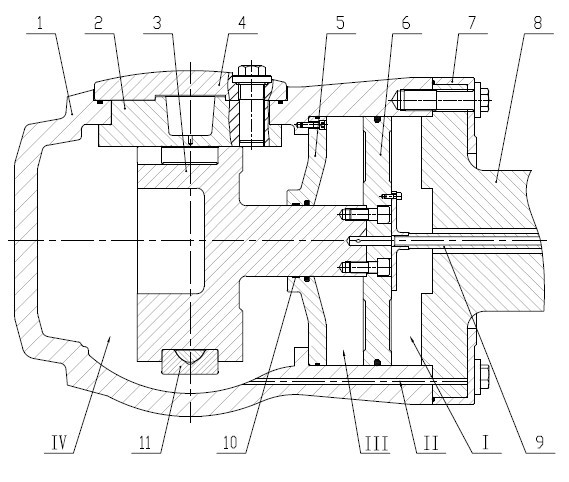

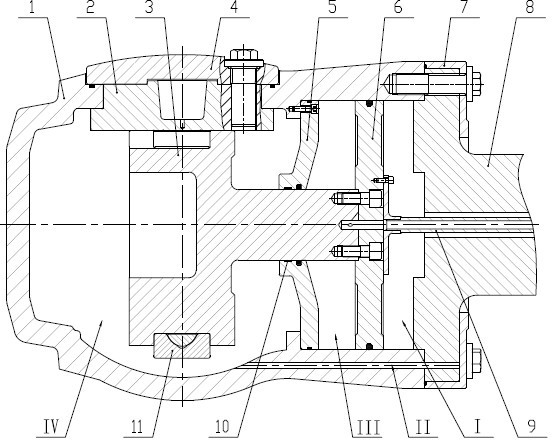

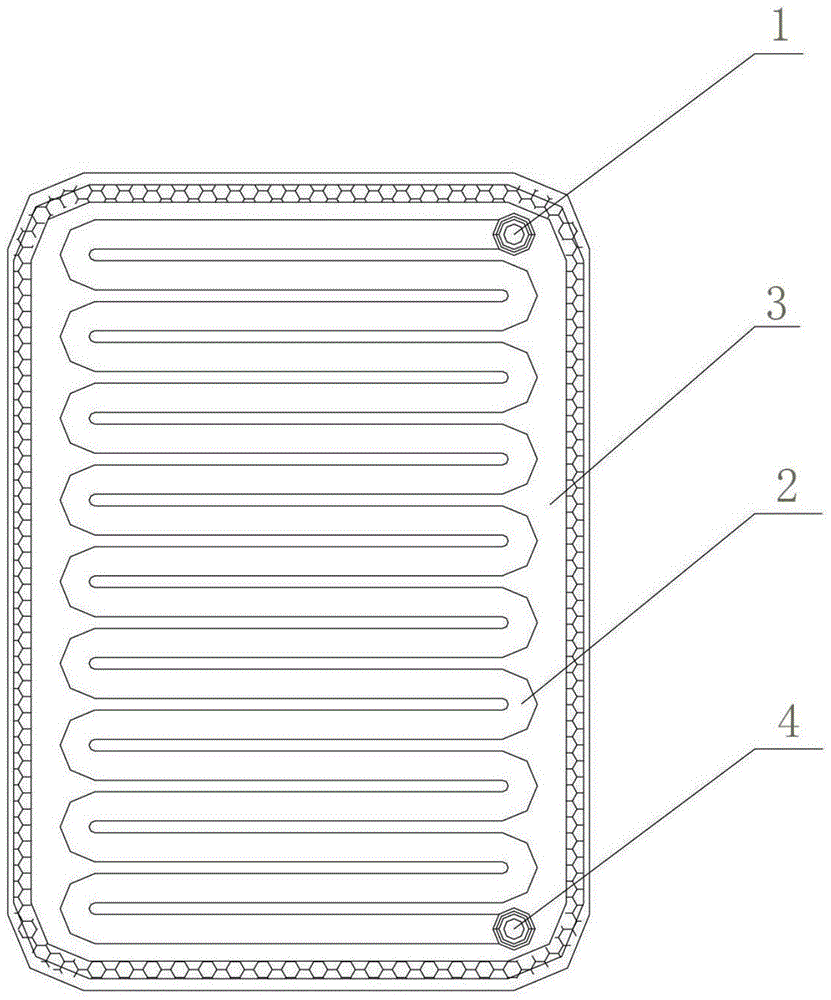

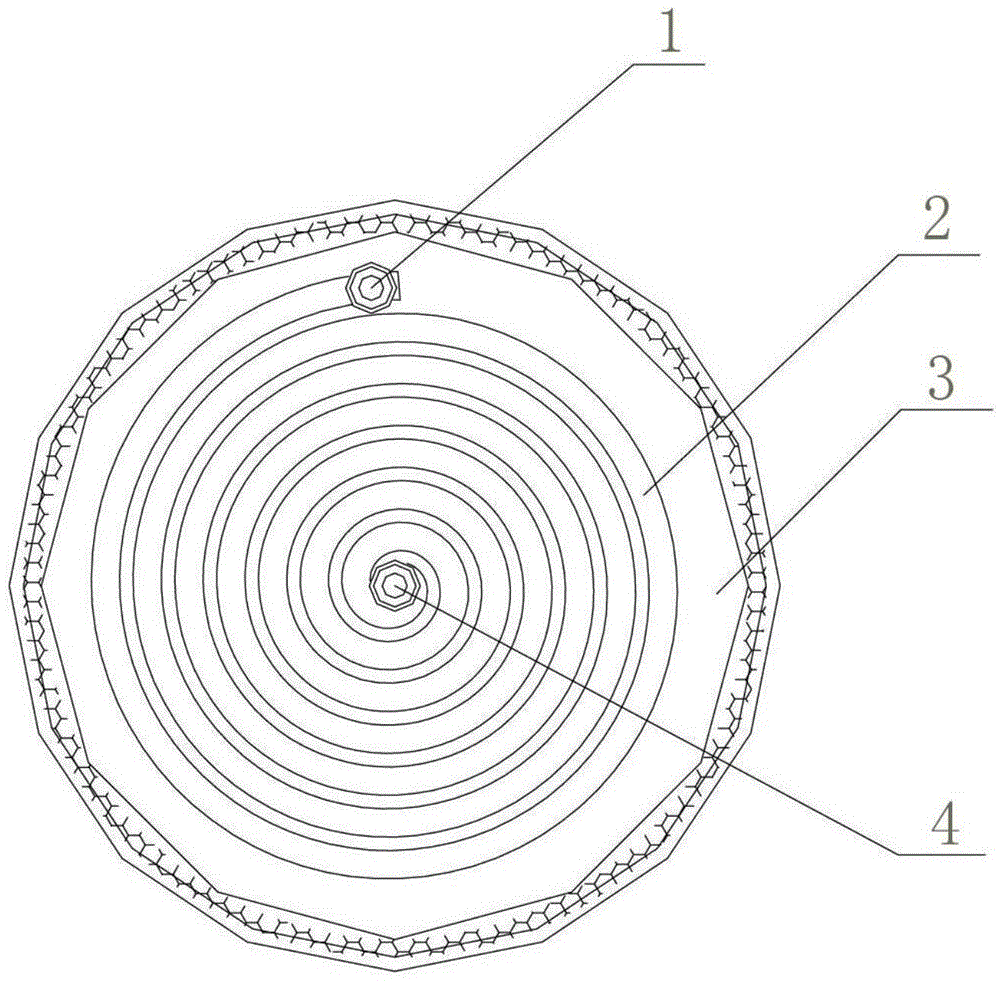

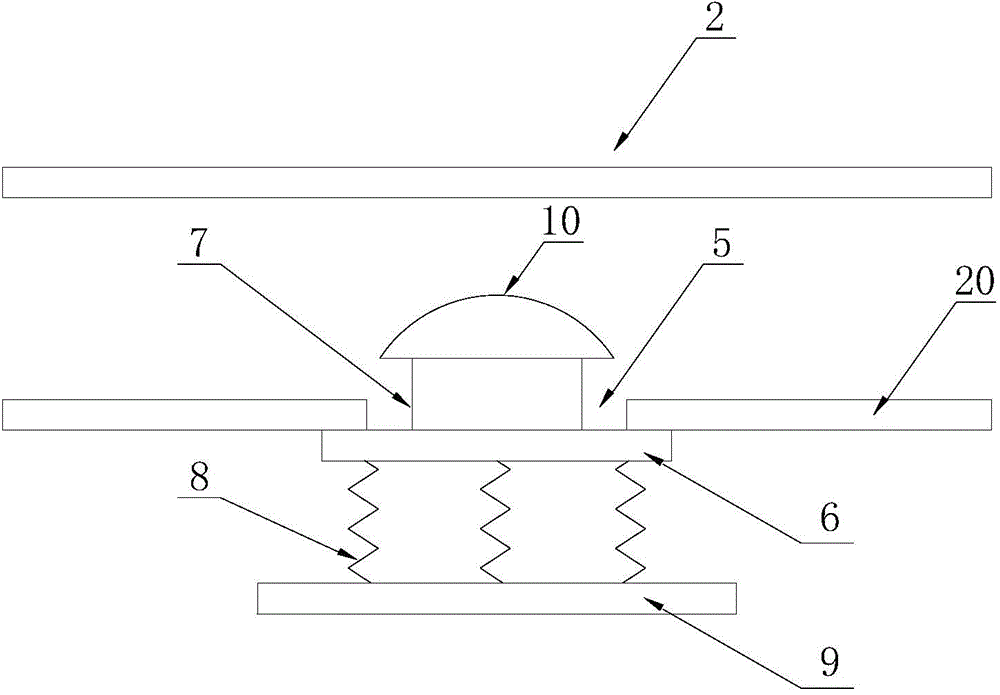

Scroll fluid machine

ActiveUS20080101973A1Small sizeIncrease the compression areaEngine of arcuate-engagement typeOscillating piston enginesDrive shaftIncrease pressure

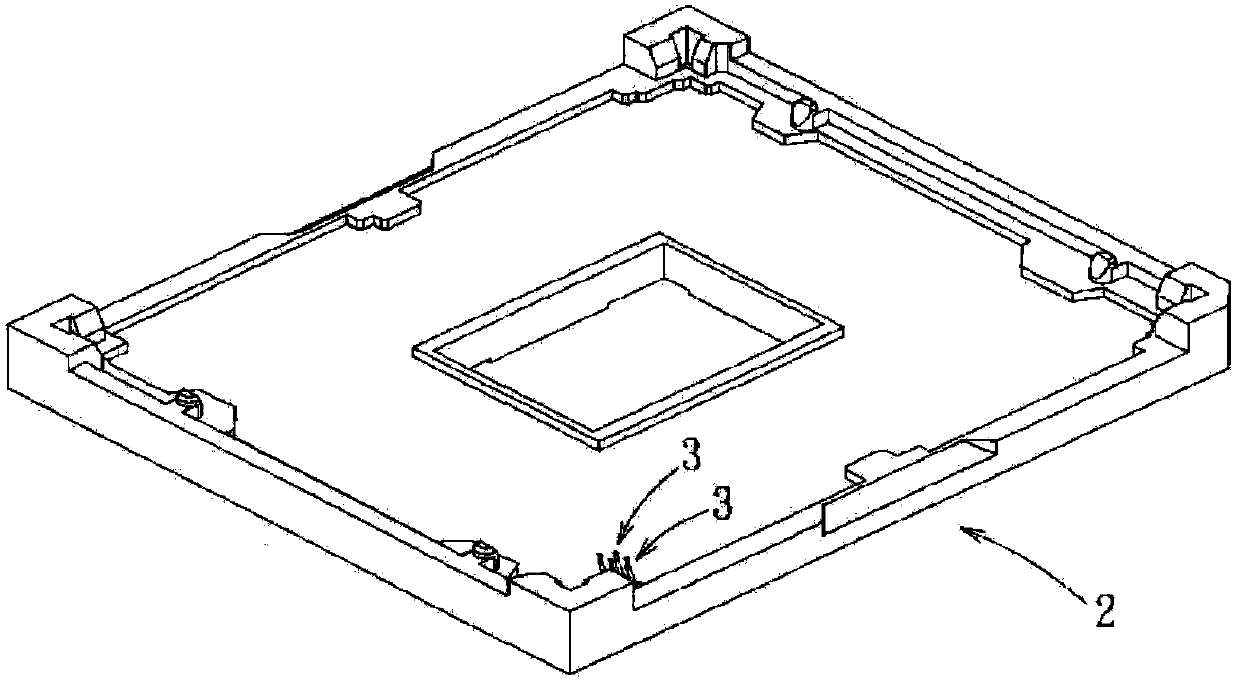

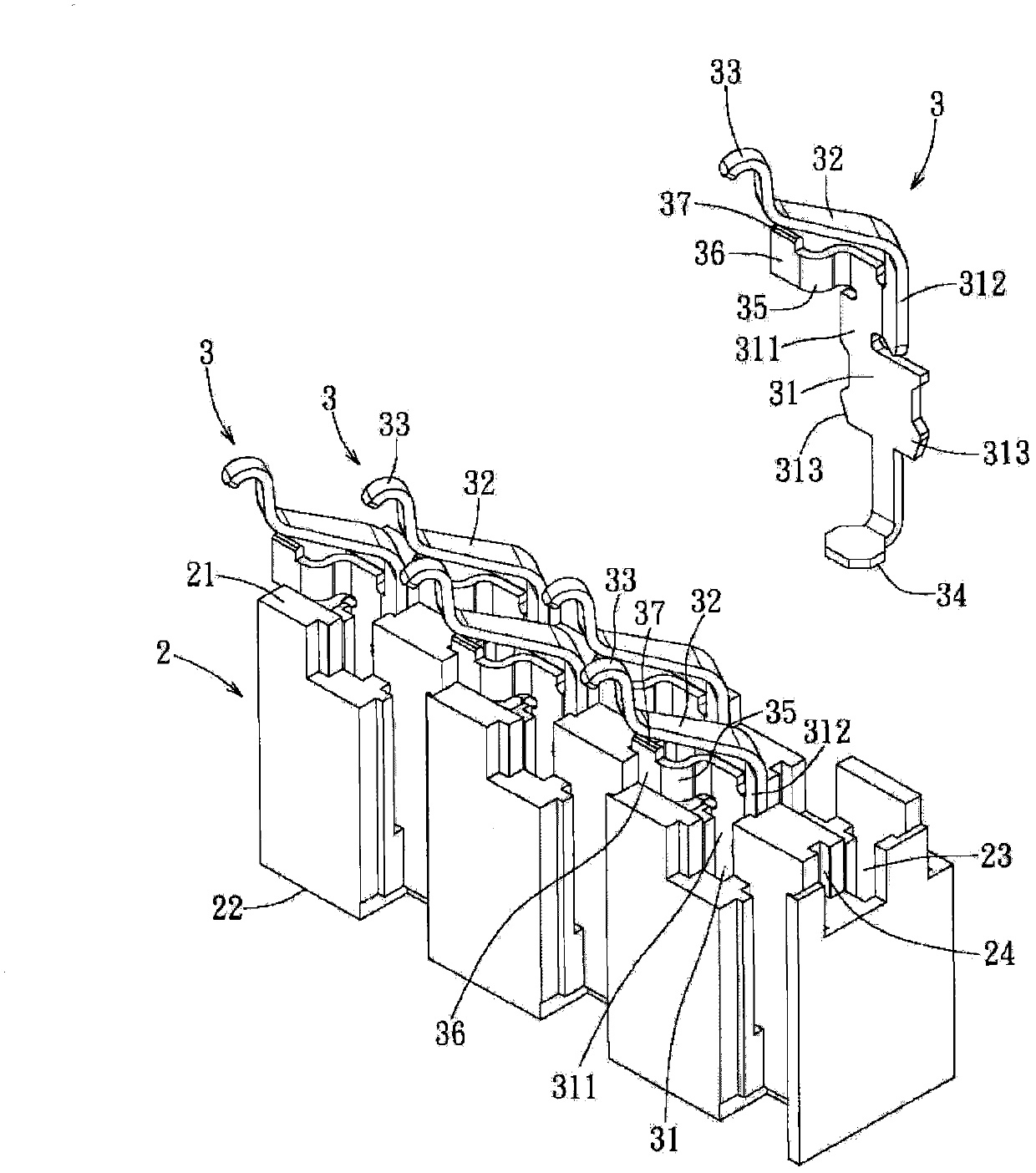

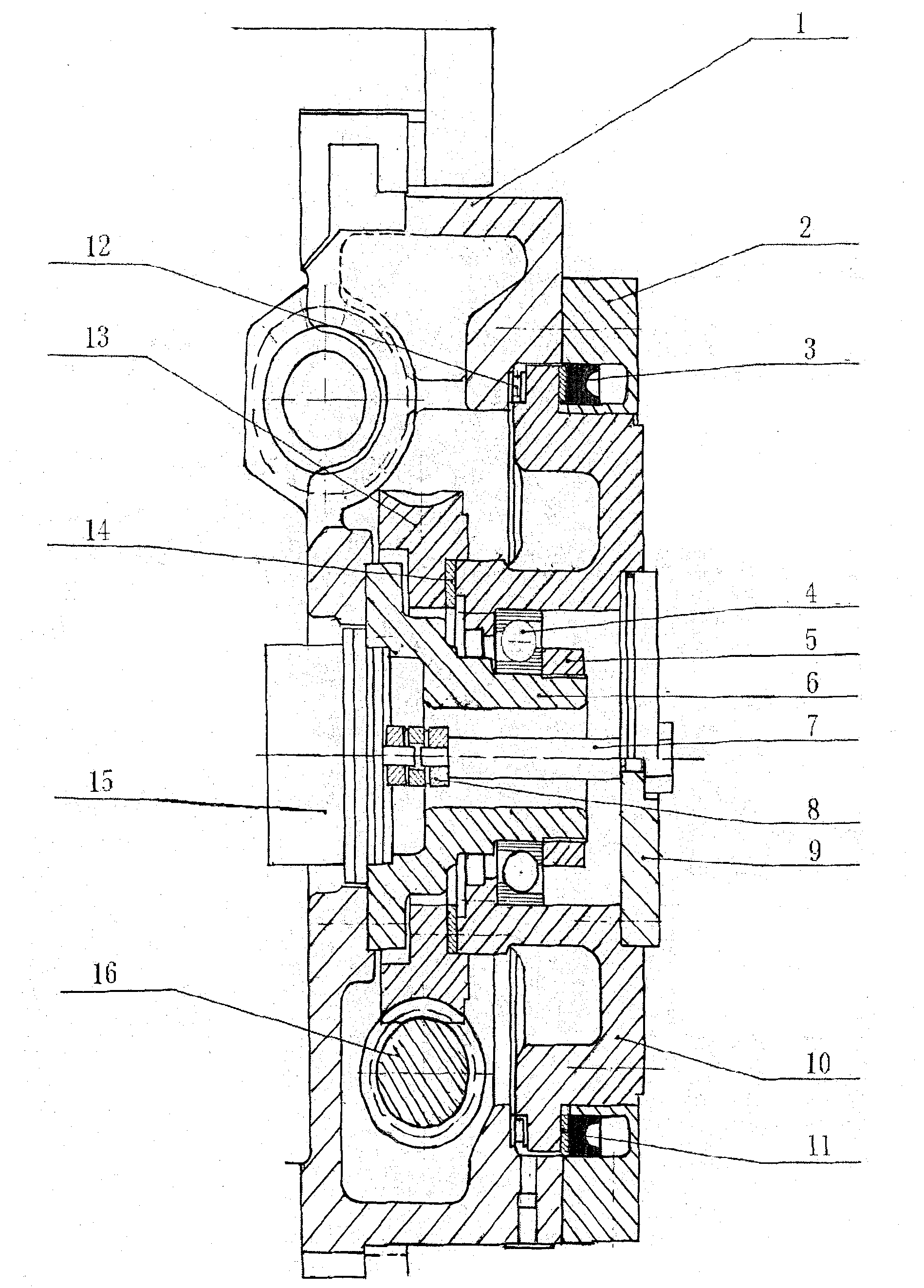

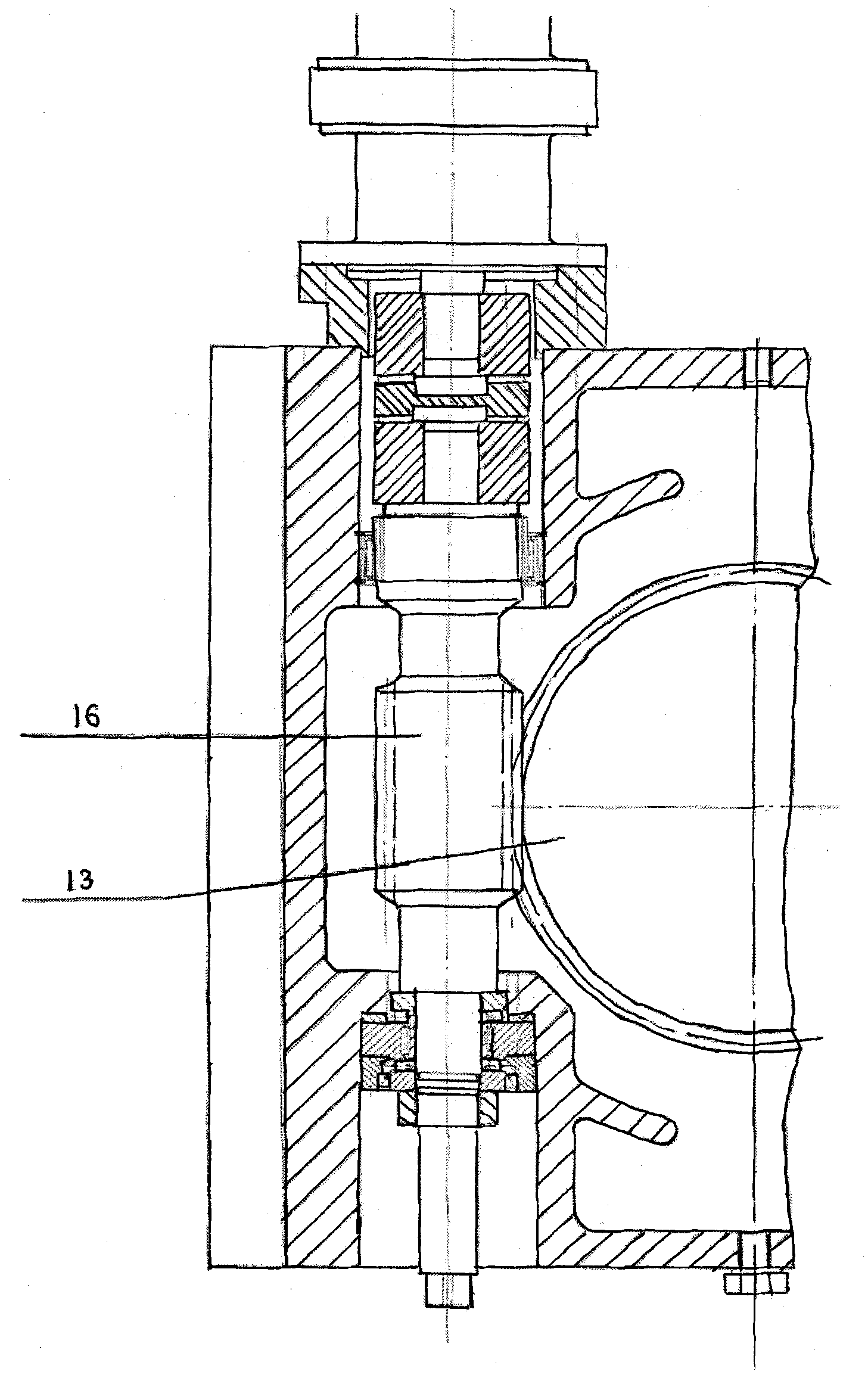

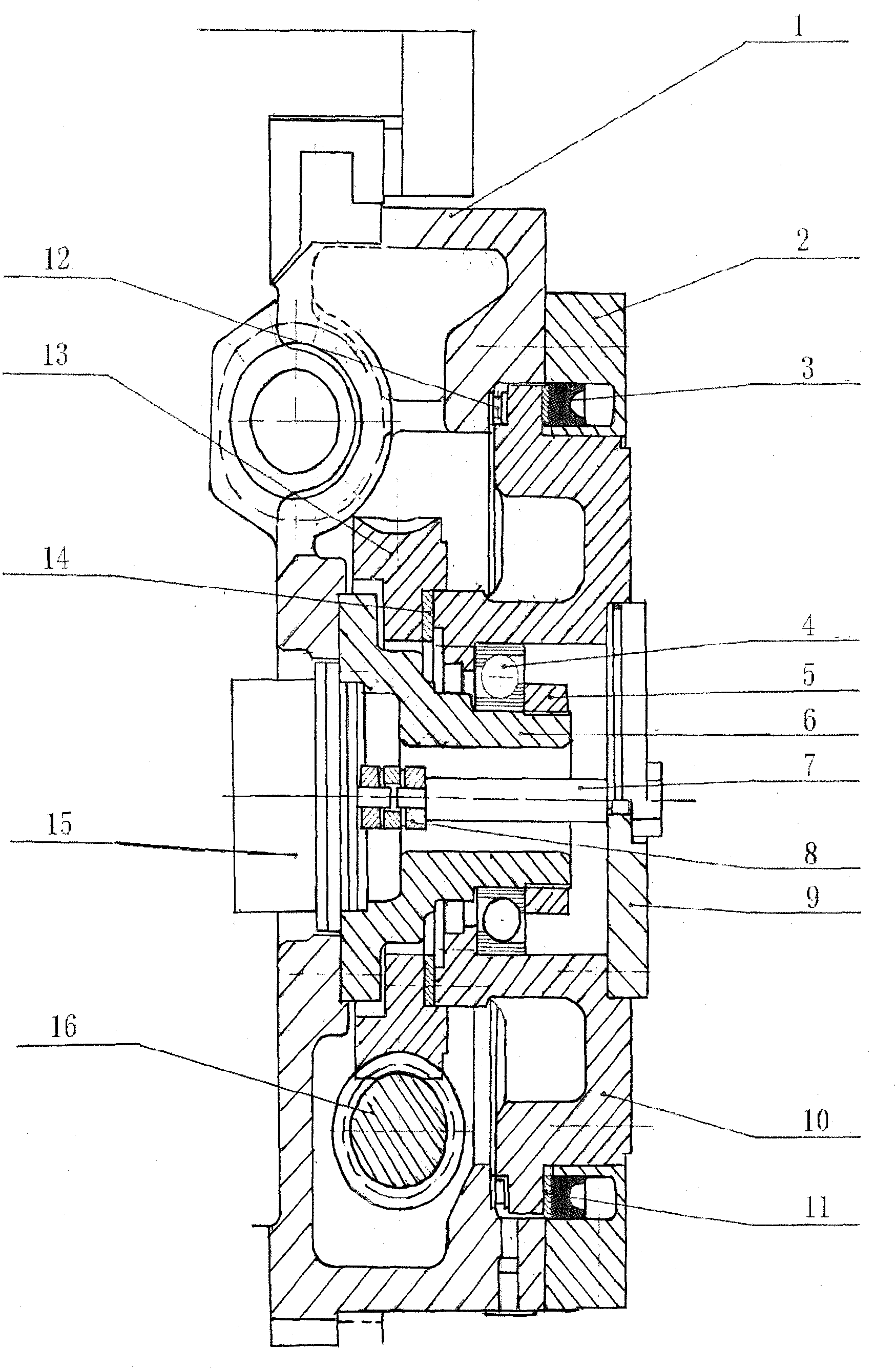

A scroll fluid machine is capable of readily providing a back-pressure chamber having an increased pressure-receiving area and yet capable of being reduced in size. A fixed scroll member is secured to a casing. An orbiting scroll member is provided at a position facing the fixed scroll member. A holder is provided at the back of the orbiting scroll member, and a coupling member is provided to face the orbiting scroll member across the holder. The coupling member couples together the orbiting scroll member and a driving shaft and performs an orbiting motion together with the orbiting scroll member. A back-pressure plate is provided at the back of the orbiting scroll member, and a back-pressure chamber is formed between the back-pressure plate and the holder.

Owner:HITACHI LTD

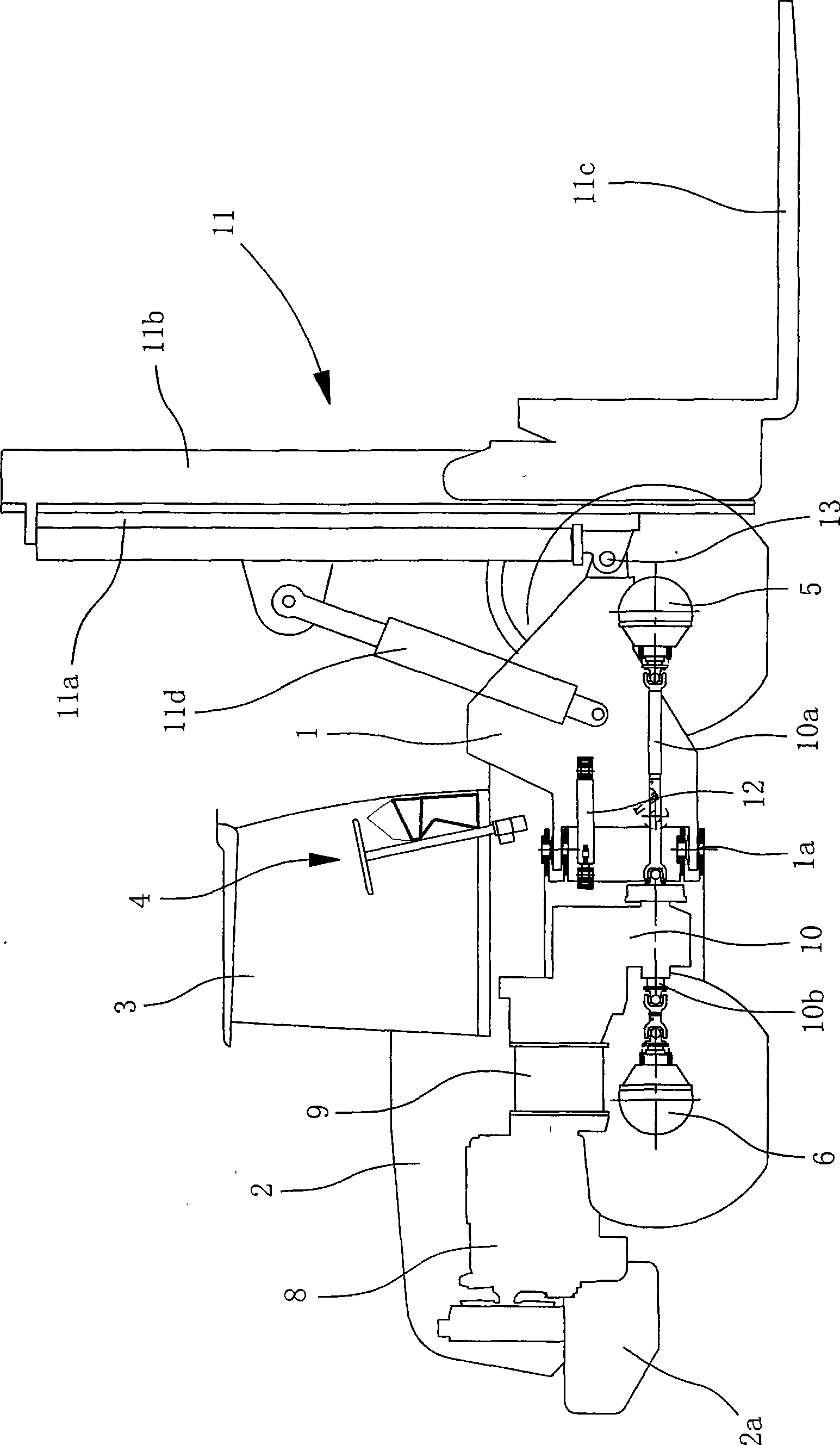

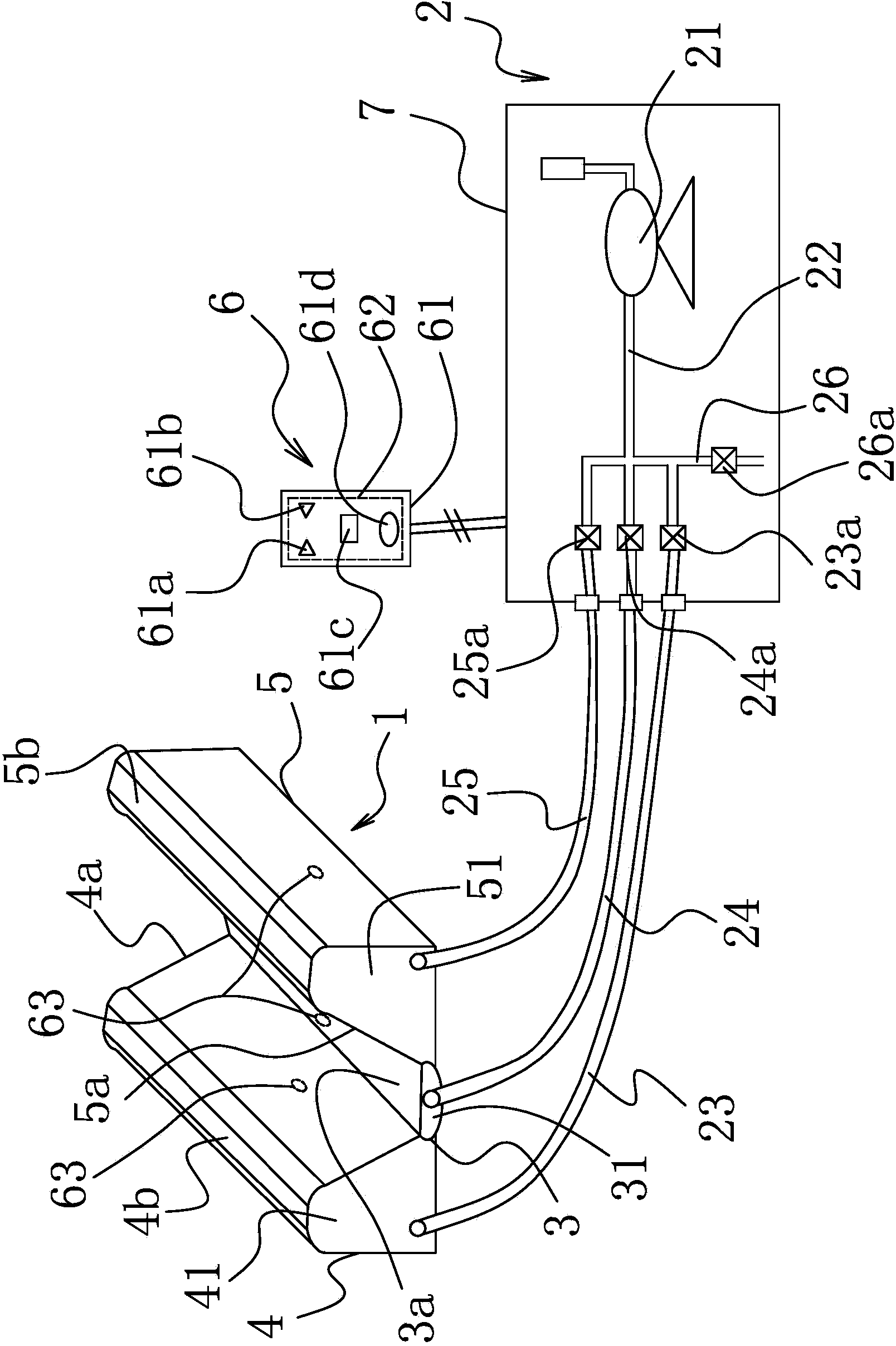

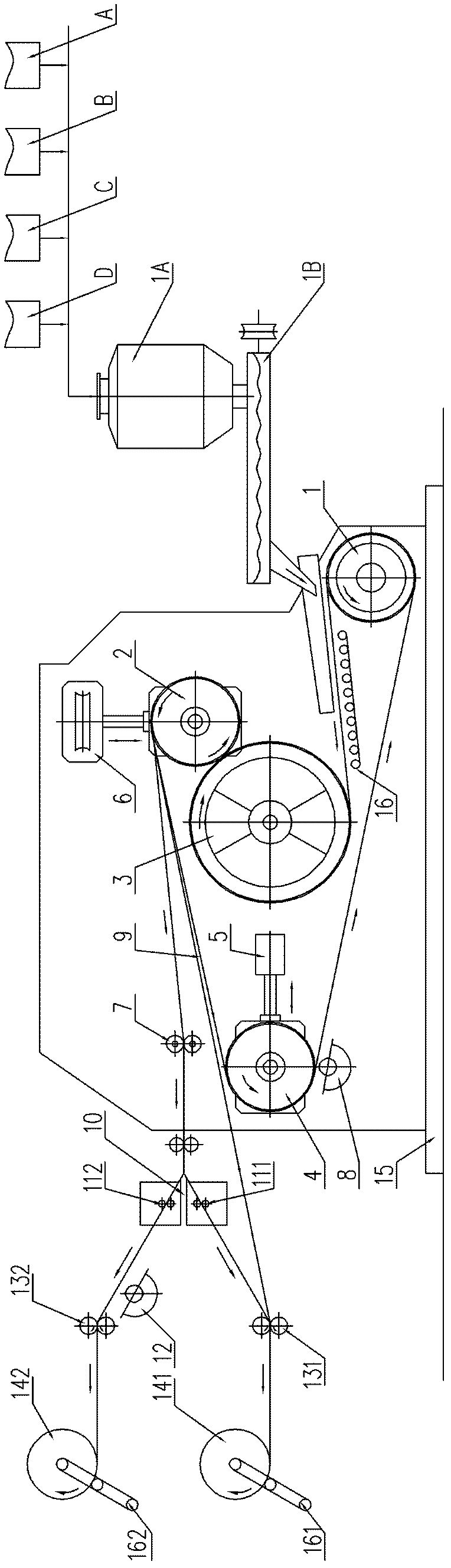

Engineering forklift truck

InactiveCN101519181AImprove off-road performanceGood value for moneyLifting devicesSuperstructure connectionsVehicle frameDrive shaft

The invention relates to an engineering forklift truck comprising a truck frame, an operator cabin in which an operating mechanism is arranged, a front driving axle, a rear driving axle, an engine, a torque converter, a variable speed case, door frame working mechanisms and balancing weights, wherein the door frame working mechanisms and the balancing weights are respectively arranged on the front end parts and the rear end parts of the truck frame. The engineering forklift truck is characterized in that the truck frame comprises a front truck frame and a rear truck frame, and the front truck frame and the rear truck frame are hinged together by pin shafts; a steering oil cylinder is installed between the front truck frame and the rear truck frame; the operator cabin is installed on the rear truck frame and generally positioned at the middle part of the entire truck; the engine, the torque converter and the variable speed case are installed on the rear truck frame, the engine is in transmission connection with the variable speed case by the torque converter, and a front transmission shaft and a rear transmission shaft of the variable speed case are correspondingly connected with the front driving axle and the rear driving axle by shaft couplings. The truck frame of the forklift truck adopts the mutually hinged front truck frame and the rear truck frame, uses the hinge steering to replace the rear wheel steering of the forklift truck and utilizes the two common driving axles of low cost to realize four-wheel driving, thereby enhancing the off-road performance of the forklift truck under adverse operating environment and being more adapted to the field operation of loading and unloading.

Owner:QUANZHOU WEISHENG MECHINE DEV

Blow Molded Container

ActiveUS20080302757A1Improve the immunityIncrease the compression areaBottlesLarge containersEngineeringUltimate tensile strength

[Problem] The invention is aimed at preventing bottom crack from occurring in a peelably laminated plastic container and maintaining the container stably in good in-use condition. This can be achieved by increasing the anti-peeling strength of a pair of rib strips, with which the bottom rib is formed, in the bottom seal that has been obtained by pinching off the parison at the bottom and molding the parison into a blow molded, peelably laminated plastic container.[Solution] The bottom seal 13 of a blow molded, peelably laminated container 1 is reinforced by a pair of rib strips 14 which are pressed to each other to form the bottom rib 15. A multiple number of cavities 16 are formed in the bottom rib 15 in such a way that the rib strip 14 on one side is pushed toward, and caved into, the rib strip on the other side at several points, and vice verse. An expanded portion 18 is formed in the ceiling of each cavity 16. As a result, an undercut engagement portion 19 is formed along the contact faces of both rib strips 14 so that anti-cracking bottom strength of the bottom seal is enhanced.

Owner:YOSHINO KOGYOSHO CO LTD

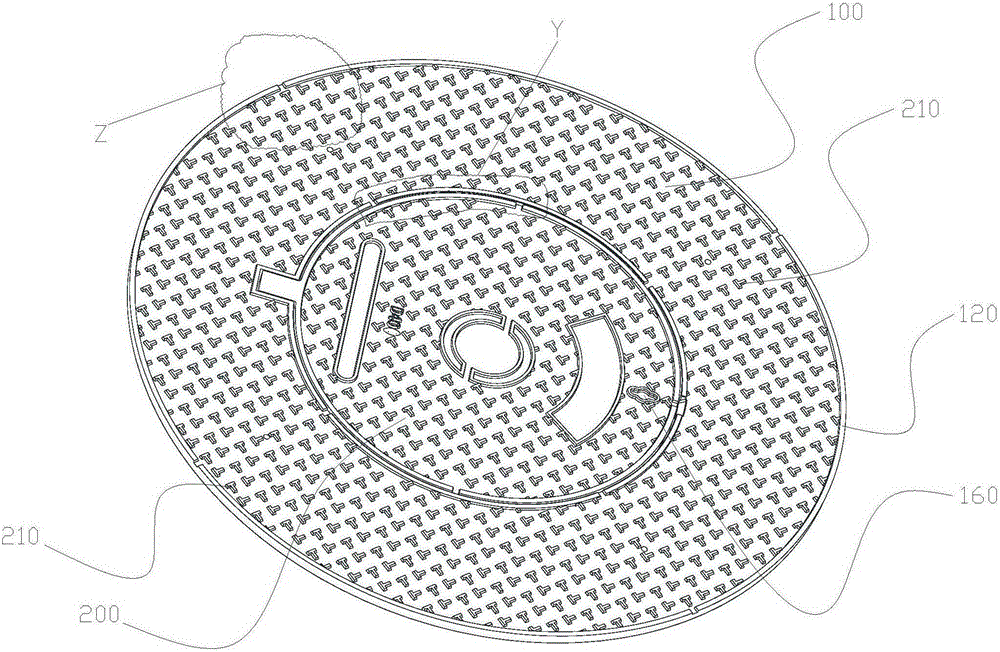

Manhole cover which is resistant to theft, noise, sedimentation and reverse gushing and opened in hidden mode

InactiveCN106065632AImprove the anti-theft effectImprove concealmentArtificial islandsUnderwater structuresRubber ringArchitectural engineering

The invention relates to the technical field of construction engineering pipelines. A manhole cover is composed of a manhole cover body, a base, pawls, cover opening ejector rods, elliptical reverse thread locking heads, unlocking opening reverse thread rods and the like. A trapezoid stopping ring on the bottom surface of the manhole cover body is sleeved with a pressure-proof rubber ring for preventing noise. When the manhole cover body is installed and placed on the base, the pawls are pressed down by the trapezoid stopping ring, and elastic force of ejector rod springs is transmitted to the pawls through levers and pawl connection rods to abut against and lock the trapezoid stopping ring so that an antitheft effect can be achieved. When the manhole cover body is opened, reverse thread pressure proof rubber plugs, gib headed keys and the elliptical reverse thread locking heads are taken out, the unlocking opening reverse thread rods are screwed into elliptical reverse thread locking holes, conical funnels and conical ejector rods are sleeved and connected, the levers are pushed, and the pawls are receded and unlocked through the pawl connection rods; and at the moment, the levers are just jacked to the upper ends of long-strip-shaped opening unlocking holes, and the manhole cover body is opened in a hidden mode by the pushing force of the unlocking opening reverse thread rods through the levers and the cover opening ejector rods. The contact surface between the manhole cover and a road is increased in a multilayer mode through a pawl mechanism box, a pressure-proof rubber ring flange face and a pavement flange face so that sedimentation can be prevented.

Owner:温兴亮

Novel anchor head structure used for slope support and construction method thereof

InactiveCN104963338AImprove securityIncreased hazardExcavationsBulkheads/pilesReinforced concreteRebar

The invention discloses a novel anchor head structure used for slope support. The structure comprises a reinforced concrete support and an anchor sealing body. The anchor sealing body comprises a steel cushion plate, an anchor head, a cast-in-place concrete panel and an anchor cable. The reinforced concrete support is arranged on the outer wall of the cast-in-place concrete panel, wherein the reinforced concrete support is internally provided with a load-bearing main rib. The reinforced concrete support is a regular trapezoid platform. The steel cushion plate is arranged on the outer wall of the reinforced concrete support, wherein the anchor cable extends out of the tail end of the steel cushion plate and is fastened by the anchor head. The external of the reinforced concrete support is provided with an outer cover which covers the anchor head, the steel cushion plate, and the reinforced concrete support. The inner wall of the outer cover is provided with a reinforcing steel mesh lining. Using the technical scheme, the invention provides a brand new anchorage device fixing mechanism, and through collocation of the concrete and the reinforcing steel mesh, a more steady protection system is formed.

Owner:DALIAN JIAOTONG UNIVERSITY

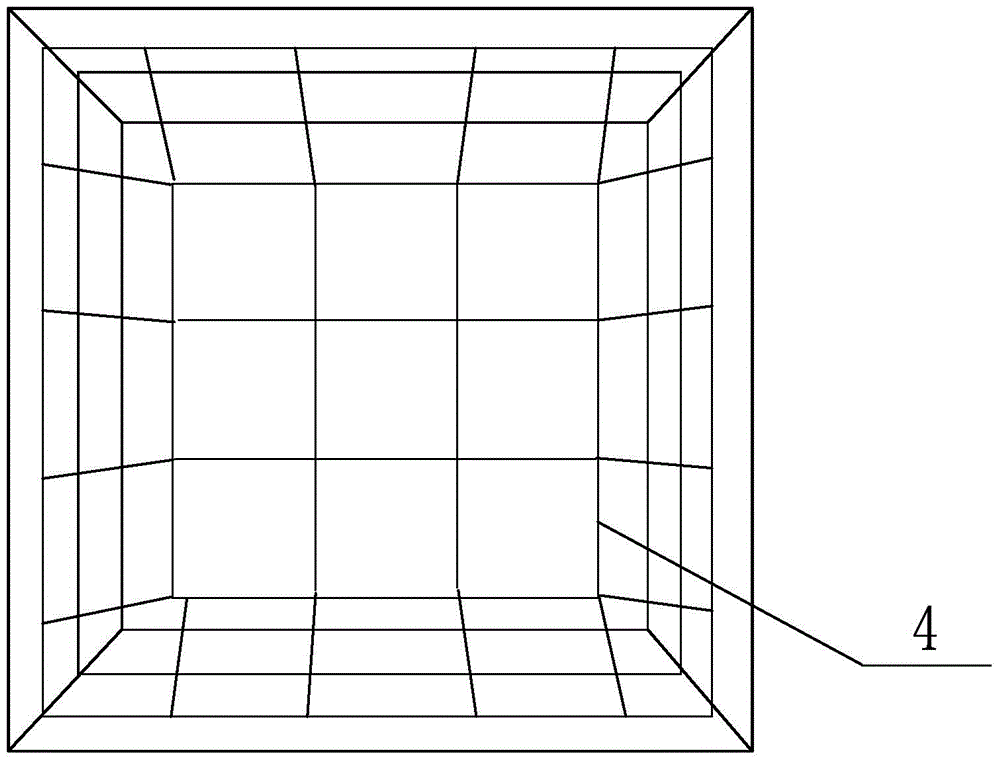

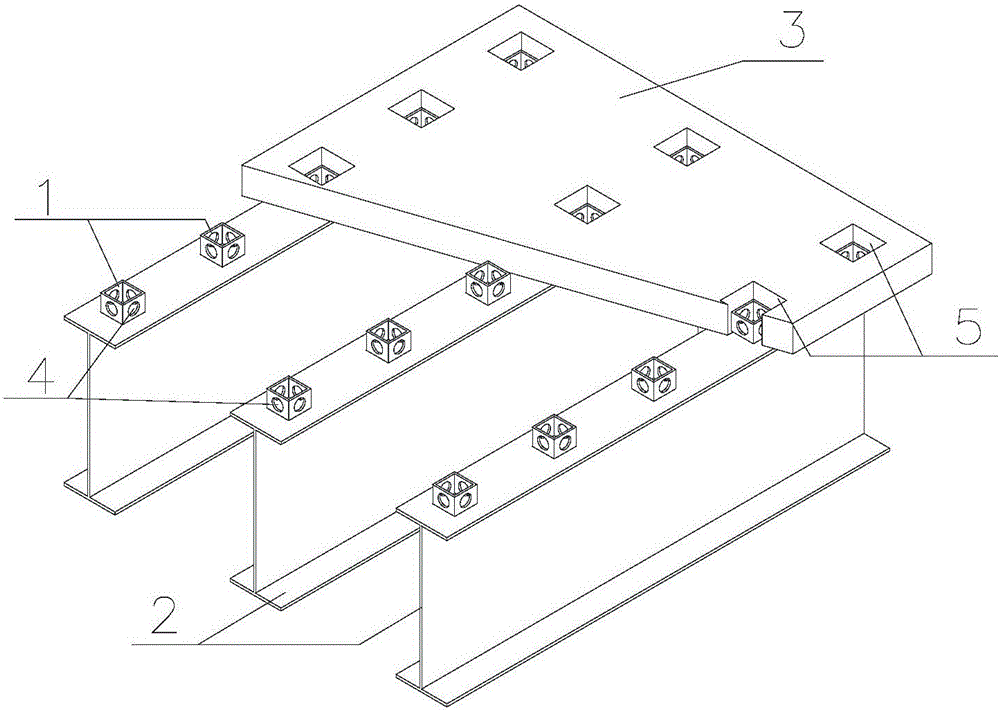

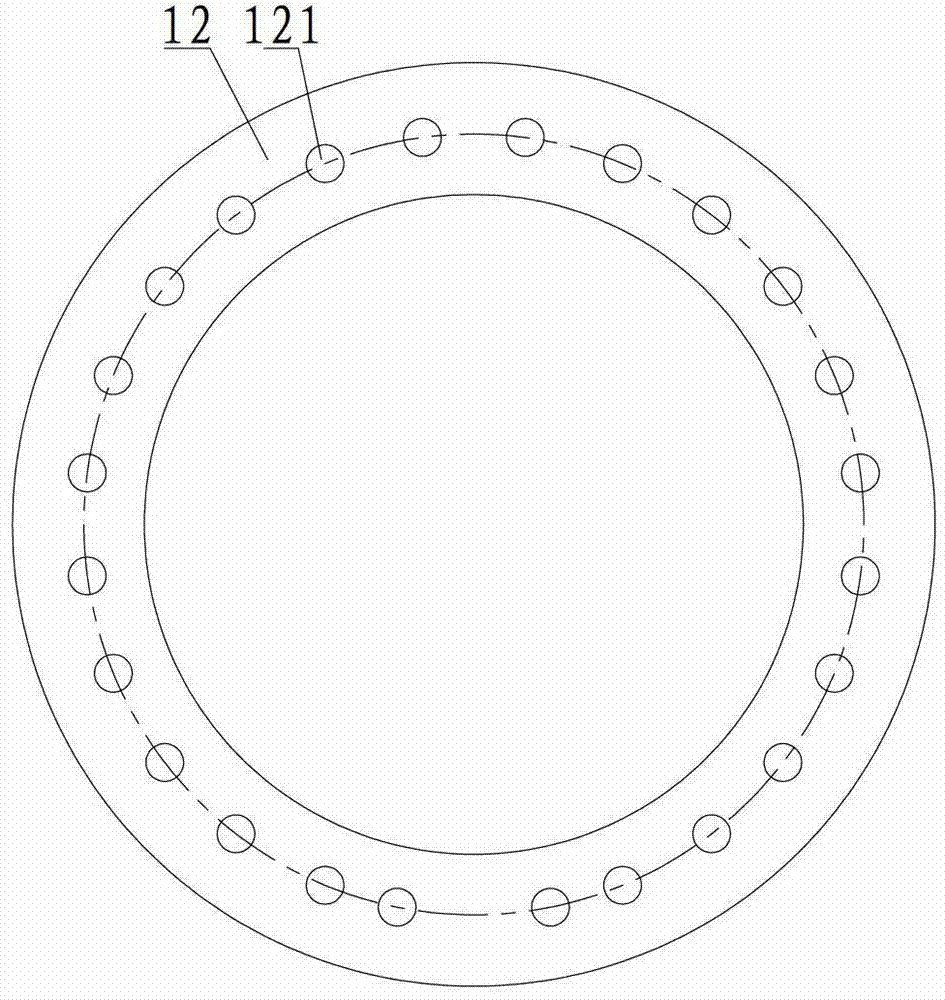

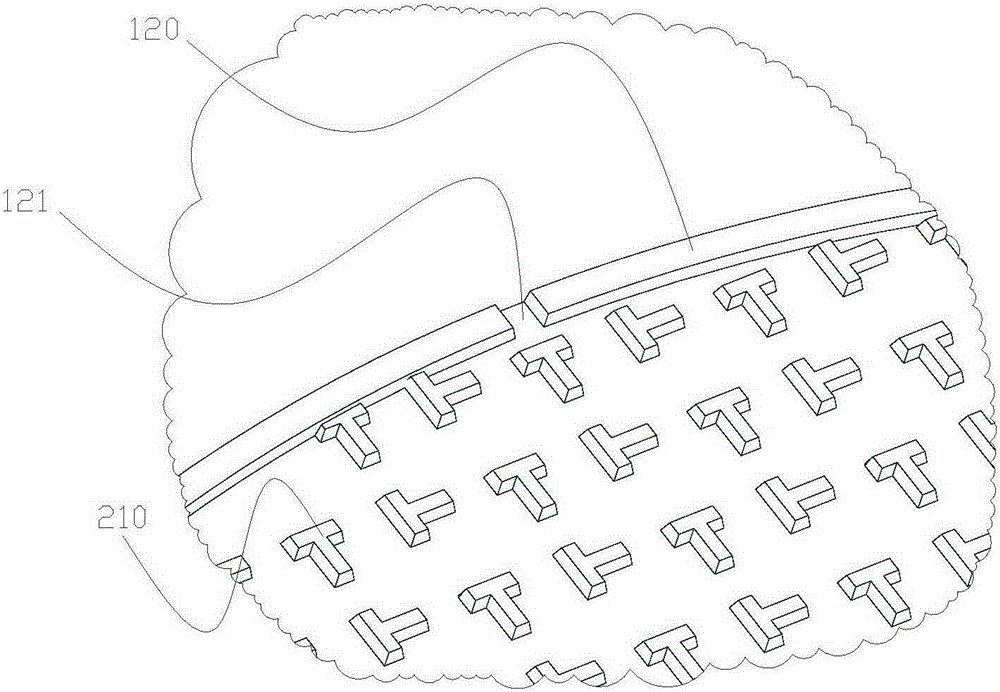

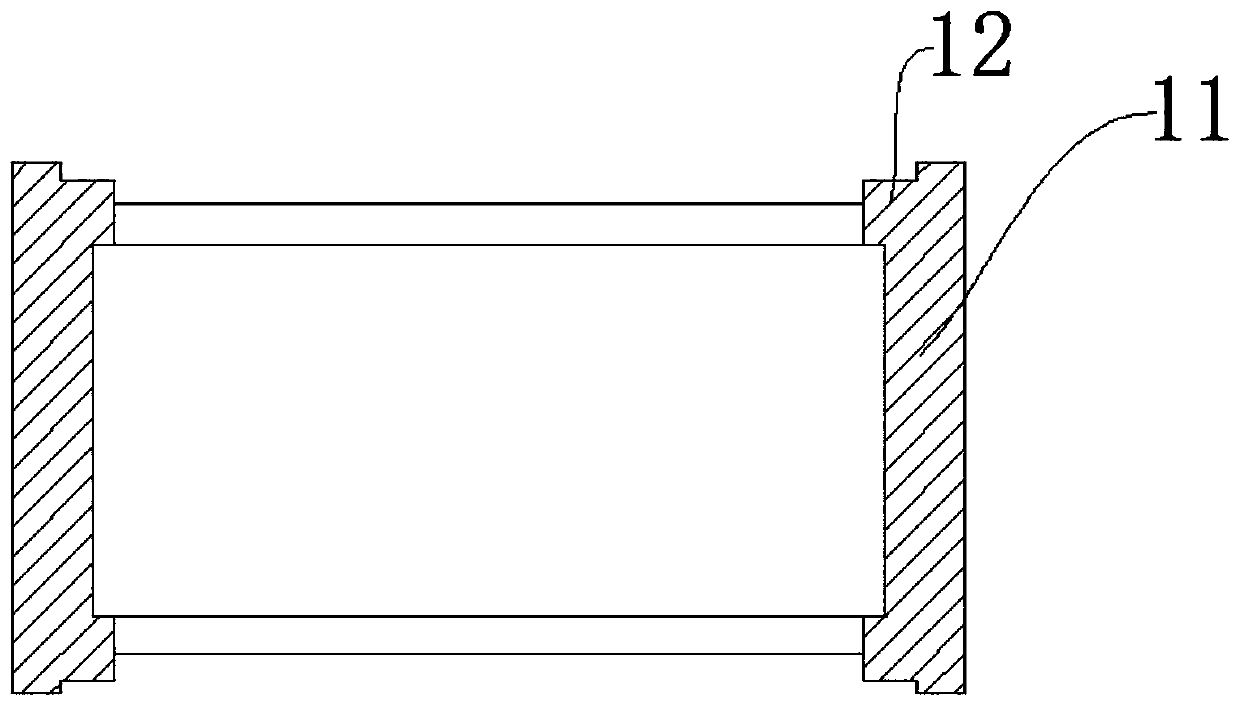

Universal type rotor core overlaying tool and method

ActiveCN104242568AImprove securityReduce the impactManufacturing stator/rotor bodiesEngineeringRadial clearance

The invention discloses a universal type rotor core overlaying tool which comprises a platen, a base and a mandrel. The mandrel is sleeved with rotor cores in an overlaid mode. The rotor cores are located between the platen and the base, and core laminations are overlaid through the platen and the base jointly. The universal type rotor core overlaying tool is characterized in that a plurality of pressing columns are connected with the lower portion of the platen and are evenly and annularly distributed at intervals, and the platen drives the pressing columns to enable the iron laminations to be overlaid. According to the universal type rotor core overlaying tool, the pressing column structure is adopted, and radial clearances exist between the pressing columns; compared with a traditional closed overlaying tool, rotor core end fixing keys can be installed when the rotor cores are compressed, the influences of the oil press stroke on rotor core overlaying specifications can be lowered, the security coefficients in the rotor core overlaying process are increased, working procedure tome is shortened, and production efficiency is improved by about 30%.

Owner:安徽金箔机电产业集团股份有限公司

Environment-friendly polybag heat packaging device and method

InactiveCN108582881AAvoid misalignmentAvoid mobilityBag making operationsPaper-makingEngineeringDislocation

The invention discloses an environment-friendly polybag heat packaging device and method. The device comprises a workbench. Multiple through holes are formed in the workbench. A cushion plate is embedded in the middle of the workbench. A pressure sensor mounted in the workbench is arranged on the lower portion of the cushion plate in an attached manner. A cover is fixed to the lower end of the workbench and is in an inverted table shape. A suction ventilator is fixed to the middle of the lower end of the cover. Supporting legs are fixed to the two sides of the lower end of the cover correspondingly. A first side plate is fixed to the side end of one supporting leg. A first support and a first motor are fixed to the upper end of the first side plate. The first support is on the front face of the first motor. A driven roller and a driving roller are rotationally connected to the first support. An output shaft of the first motor and the driving roller are fixed. A second side plate is fixed to the side end of the other supporting leg. According to the environment-friendly polybag heat packaging device and method, the situation that contact of a heat seal knife and the cushion plate istoo sudden, consequently, the heat seal knife is damaged, and the pressing area is increased can be avoided. A dual-layer film is attached to the workbench during transverse movement or heat packaging, and the situation that dislocation and movement happen to the dual-layer, and consequently defective goods appear is avoided.

Owner:NANAN CHUANGPEI ELECTRONICS TECH CO LTD

Electric connector and terminals thereof

InactiveCN103311695AIncrease the compression areaEasy to pushElectric discharge tubesSecuring/insulating coupling contact membersMechanical engineering

The invention provides an electric connector. The electric connector comprises an insulation body which comprises a number of terminal grooves and a number of limiting grooves, and a number of terminals which are respectively and correspondingly accommodated in a number of terminal grooves. Each terminal comprises a body which is located in the corresponding terminal groove and is fixedly arranged on the insulation body, an elastic arm which extends upward from the body, a first contact part which is formed on the tail end of the elastic arm, a second contact part which extends downward from the body, a curved arm which laterally bends and extends from the body, and a limiting part which is formed on the tail end of the curved arm and is partially accommodated in a limiting groove. Through the top surface of each curved arm, a number of terminals have large areas and can be pushed and pressed by a tool. Each limiting part is accommodated in each limiting groove, which can increase the auxiliary supporting of the terminals on the insulation body, so that the terminals can be easily pushed and pressed by the tool and are stable on the insulation body.

Owner:MOLEX INTERCONNECT SHANGHAI +1

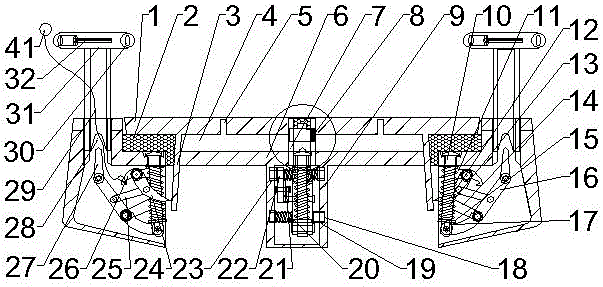

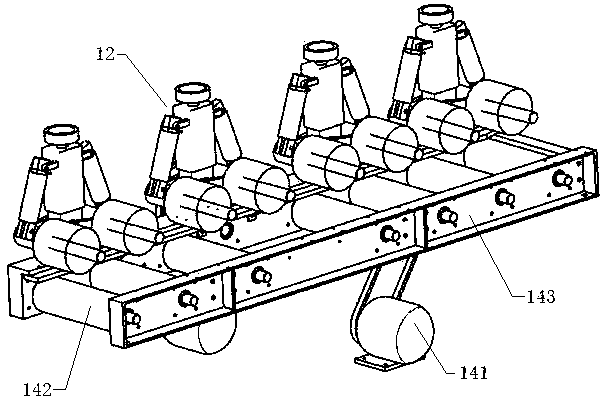

Multifunctional turnover device

InactiveCN104027214AExpand the pressure area of the bodyReduce pain levelsNursing bedsCushionEngineering

The invention belongs to the technical field of medical caring articles, and particularly relates to a multifunctional turnover device. The multifunctional turnover device solves the technical problem that practicability is poor in the prior art and comprises an inflatable air sac cushion made of flexible materials. The inflatable air sac cushion is connected with an inflating / deflating mechanism. The inflatable air sac cushion is provided with a middle cushion which is arranged in the middle and extends in the axial direction. A left wedge-shaped cushion and a right wedge-shaped cushion are arranged on the two sides of the middle cushion respectively. The middle cushion, the left wedge-shaped cushion and the right wedge-shaped cushion are respectively connected with the inflating / deflating mechanism. The middle cushion is provided with a horizontal middle plane when being in the inflated state, the left wedge-shaped cushion is provided with a left slope of which the height decreases gradually from the left side of the left wedge-shaped cushion to the middle cushion when the left wedge-shaped cushion is in the inflated state, and the right wedge-shaped cushion is provided with a right slope of which the height decreases gradually from the right side of the right wedge-shaped cushion to the middle cushion when the right wedge-shaped cushion is in the inflated state. The multifunctional turnover device has the advantages that practicability is high, pressure can be reduced effectively, and pressure sores can be effectively prevented.

Owner:HANGZHOU FIRST PEOPLES HOSPITAL

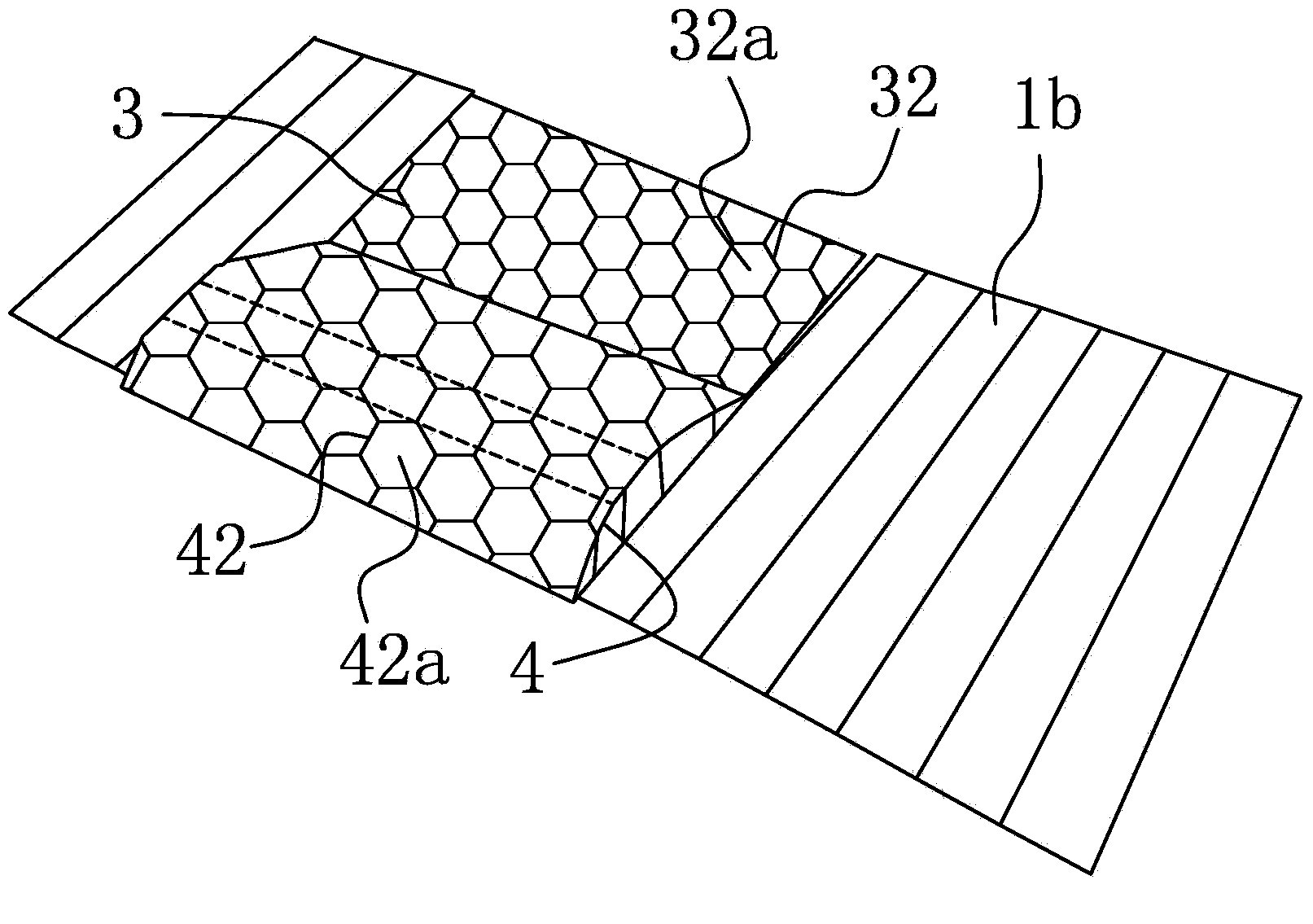

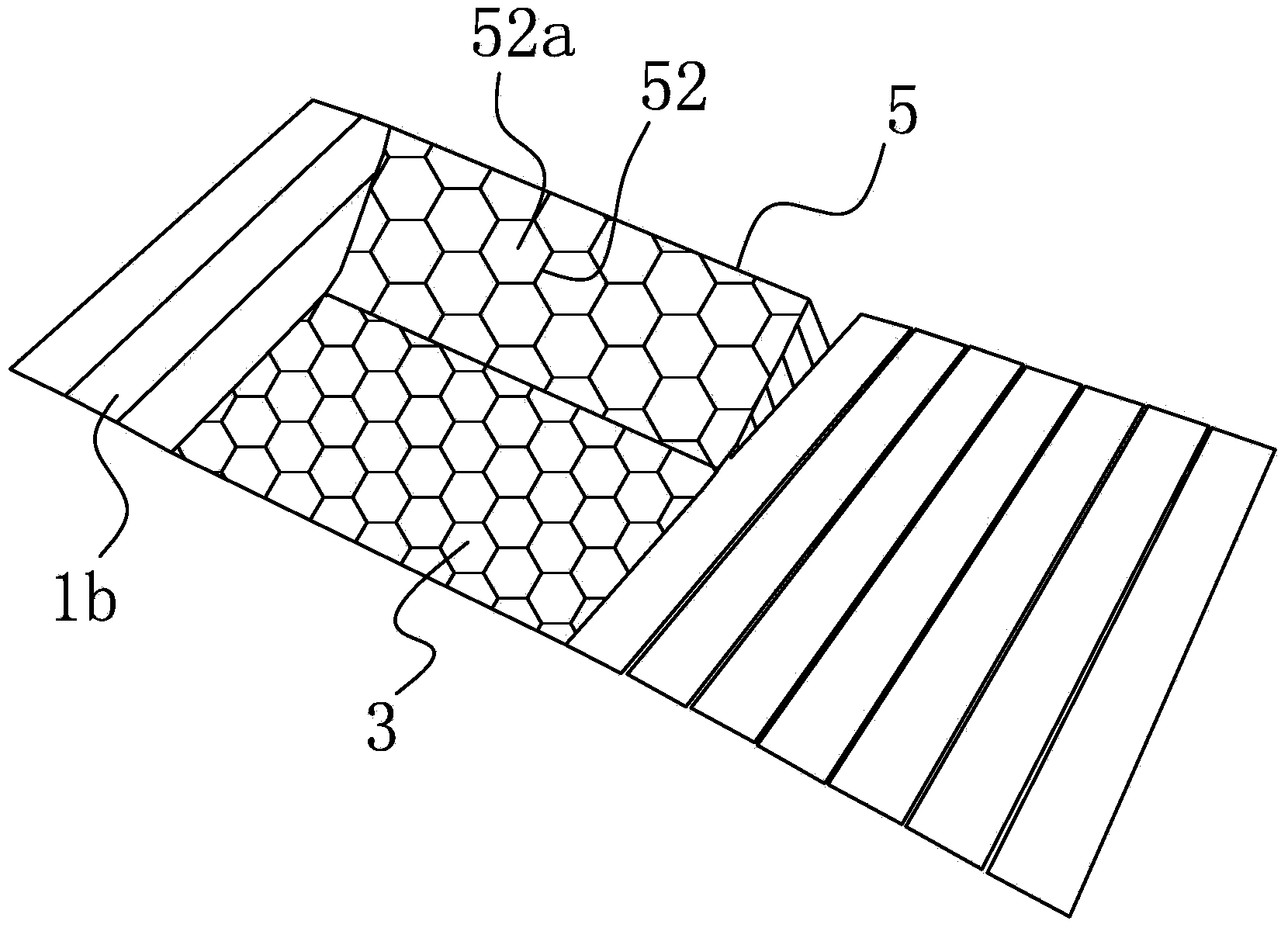

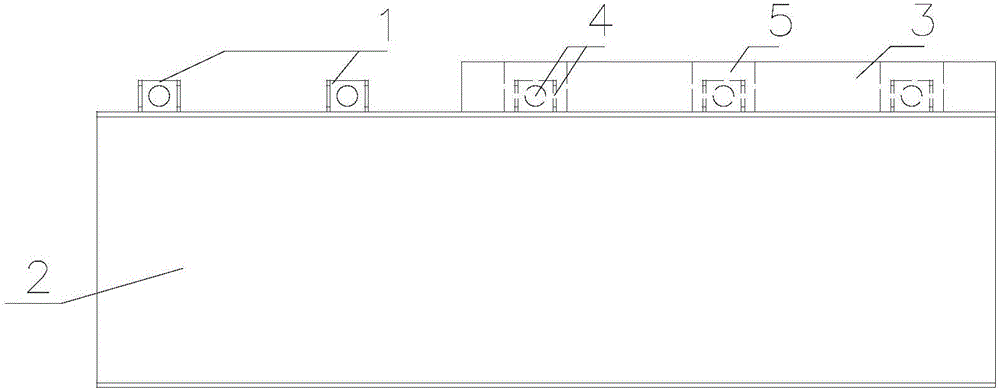

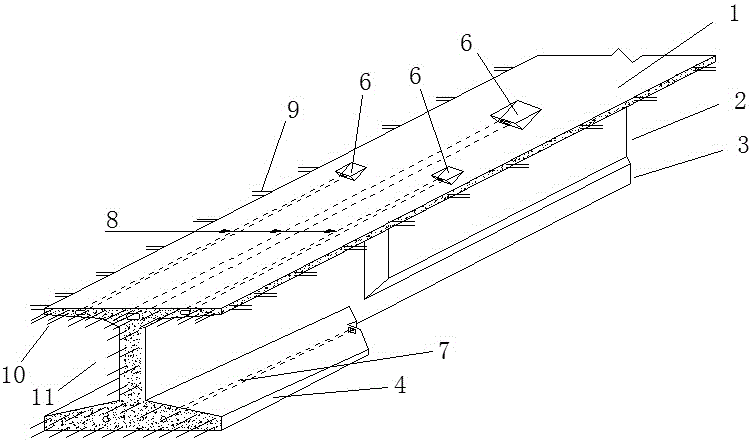

Open steel tube and reinforced-concrete combined girder bridge structure

InactiveCN105803939ASimple structureReasonable designBridge structural detailsBridge materialsStress concentrationReinforced concrete

The invention discloses an open steel tube and reinforced-concrete combined girder bridge structure. The structure comprises a concrete bridge deck slab, opening steel tube connecting pieces and multiple steel girders, each steel girder is provided with multiple steel tube connecting pieces, the concrete bridge deck slab is used for being erected on the steel girders, and the concrete bridge deck slab is provided with concrete pouring grooves matched with the steel tube connecting pieces and used for pouring concrete. The open steel tube and reinforced-concrete combined girder bridge structure is simple in structure, reasonable in design and convenient to construct. The structure has the advantages that the opening steel tube connecting pieces are simple in structure, convenient to manufacture and rapid to construct; by means of the opening steel tube connecting pieces, connection strength of the steel girders and the concrete bridge deck slab is increased, bearing areas of the connecting pieces are increased, and compared with bolt / screw connecting pieces, stress concentration can be effectively reduced; meanwhile, a single opening steel tube connecting piece is high in shear capacity, under the same situation, compared with the bolt / screw connecting pieces, a small number of opening steel tube connecting pieces are arranged, construction space is effectively saved, and it is beneficial to play the combination role of the concrete bridge deck slab and the steel girders.

Owner:CHANGAN UNIV

Scroll fluid machine including back-pressure chamber with increased pressure receiving area

ActiveUS7458788B2Small sizeIncrease the compression areaEngine of arcuate-engagement typeOscillating piston enginesDrive shaftEngineering

Owner:HITACHI LTD

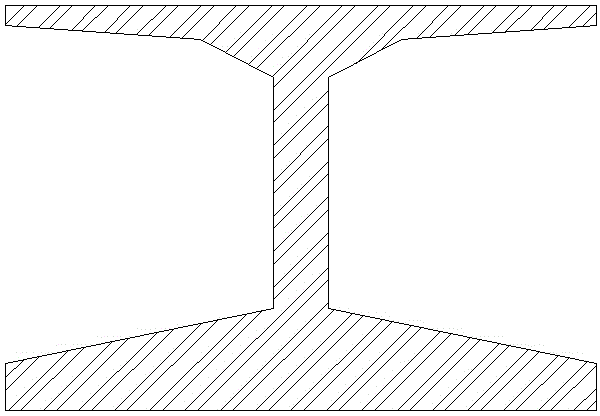

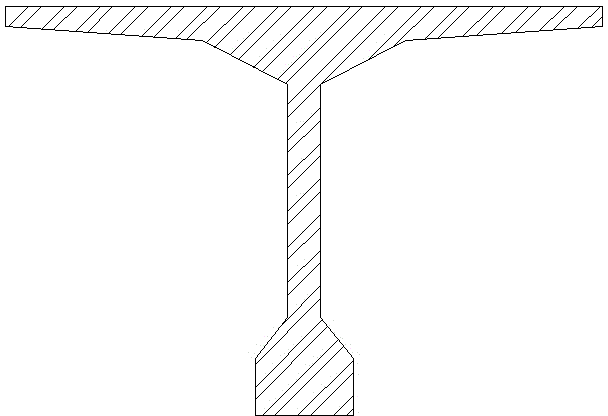

Prefabricated T-shaped beam and method of building continuous beam bridge by adopting prefabricated T-shaped beams

InactiveCN105019350AAvoid crackingReduces the possibility of crackingBridge structural detailsBridge erection/assemblyBridge engineeringTensile strain

The invention relates to a prefabricated T-shaped beam and a method of building a continuous beam bridge by adopting the prefabricated T-shaped beams, and belongs to the field of bridge engineering. The T-shaped beam is an improved form of the conventional prefabricated T-shaped beam, and bottom flanges are additionally arranged at the ends, so that the cross sections of the ends are I-shaped. Longitudinal prestressed ducts are formed in the bottom flanges, and the longitudinal prestressed ducts are also formed in top plates of the ends. The bridge is formed in a manner that the prefabricated T-shaped beams are spliced, simply supported and then connected. Longitudinal prestress is tensioned on the bottom flanges, and negative bending moment prestress is tensioned on the top plates. Certain prestress is exerted on compressed zones at the bottoms, so that cracks under the effects of temperature and the like can be avoided. The compression areas of the bottom flanges are increased, the compressive strain of the compressed zones is decreased under the effect of negative bending moment, correspondingly, the tensile strain at the tops is also decreased and thus the possibility of cracking of the bridge deck can be lowered. As the cross sections of the ends are changed to be I-shaped, transportation and installation are convenient, and the construction of the continuous beam bridge is also convenient. The method of building the continuous beam is convenient to construct, and cracks of the top plates at pier top areas are favorably decreased.

Owner:ZHENGZHOU UNIV

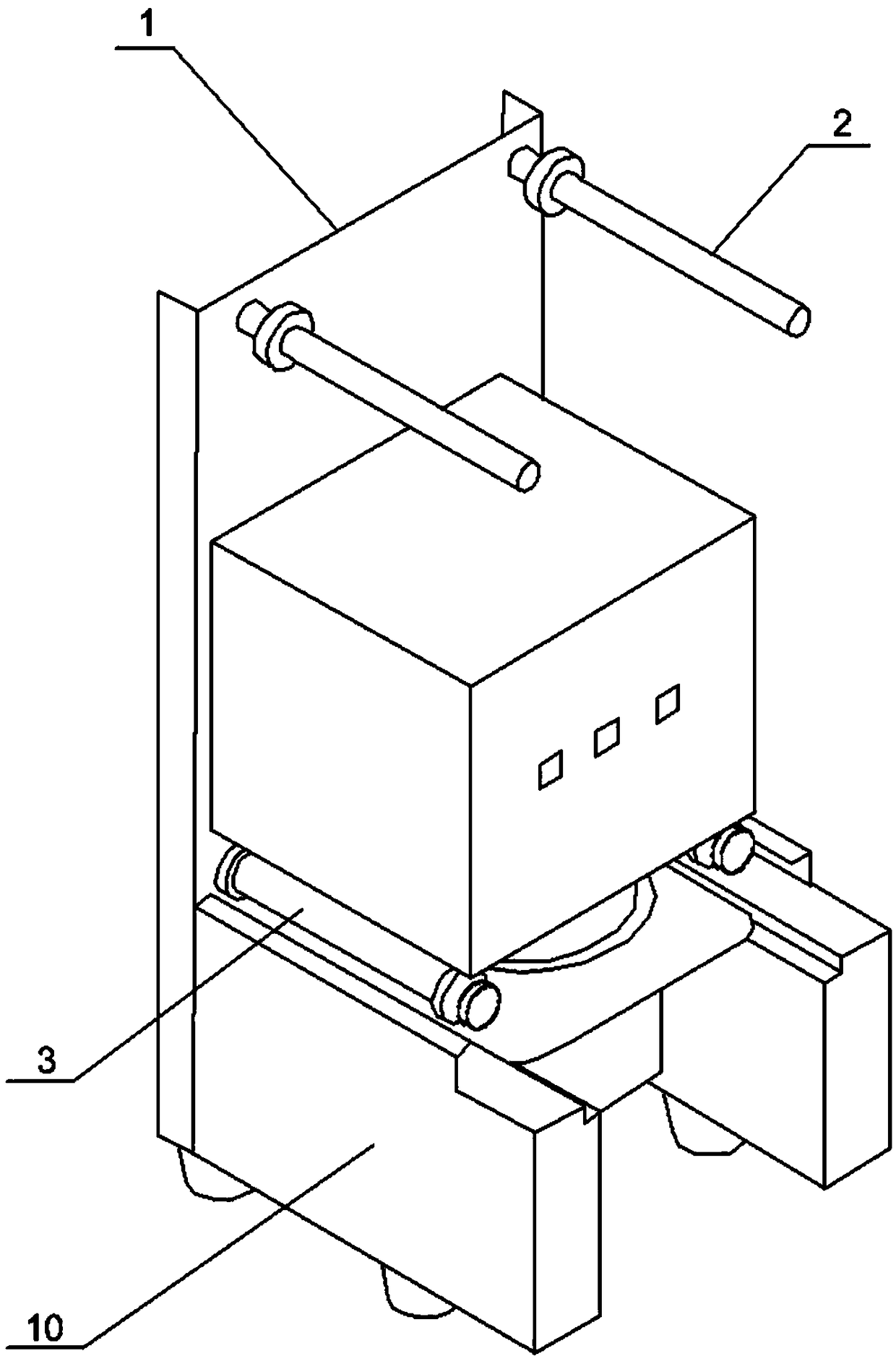

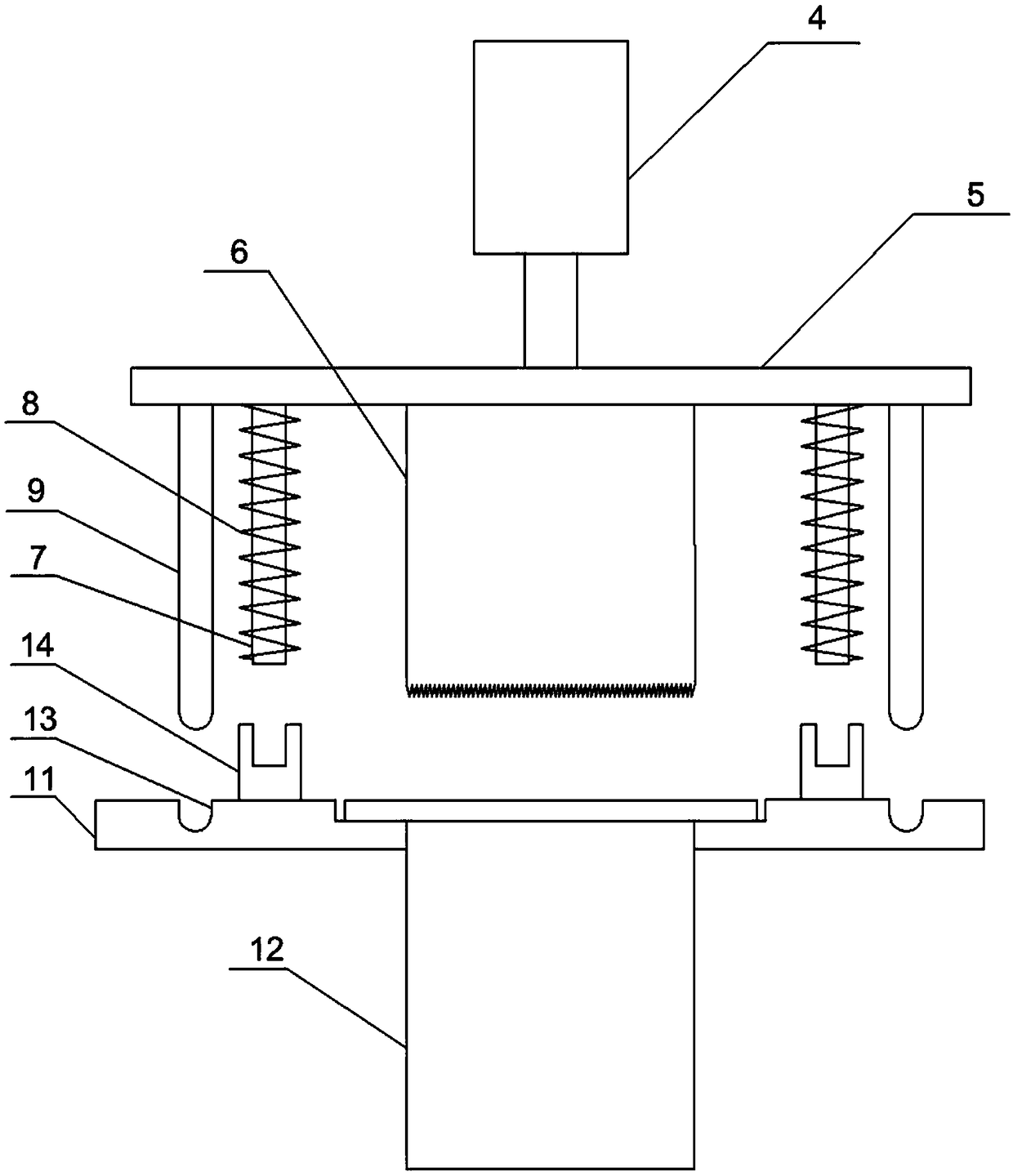

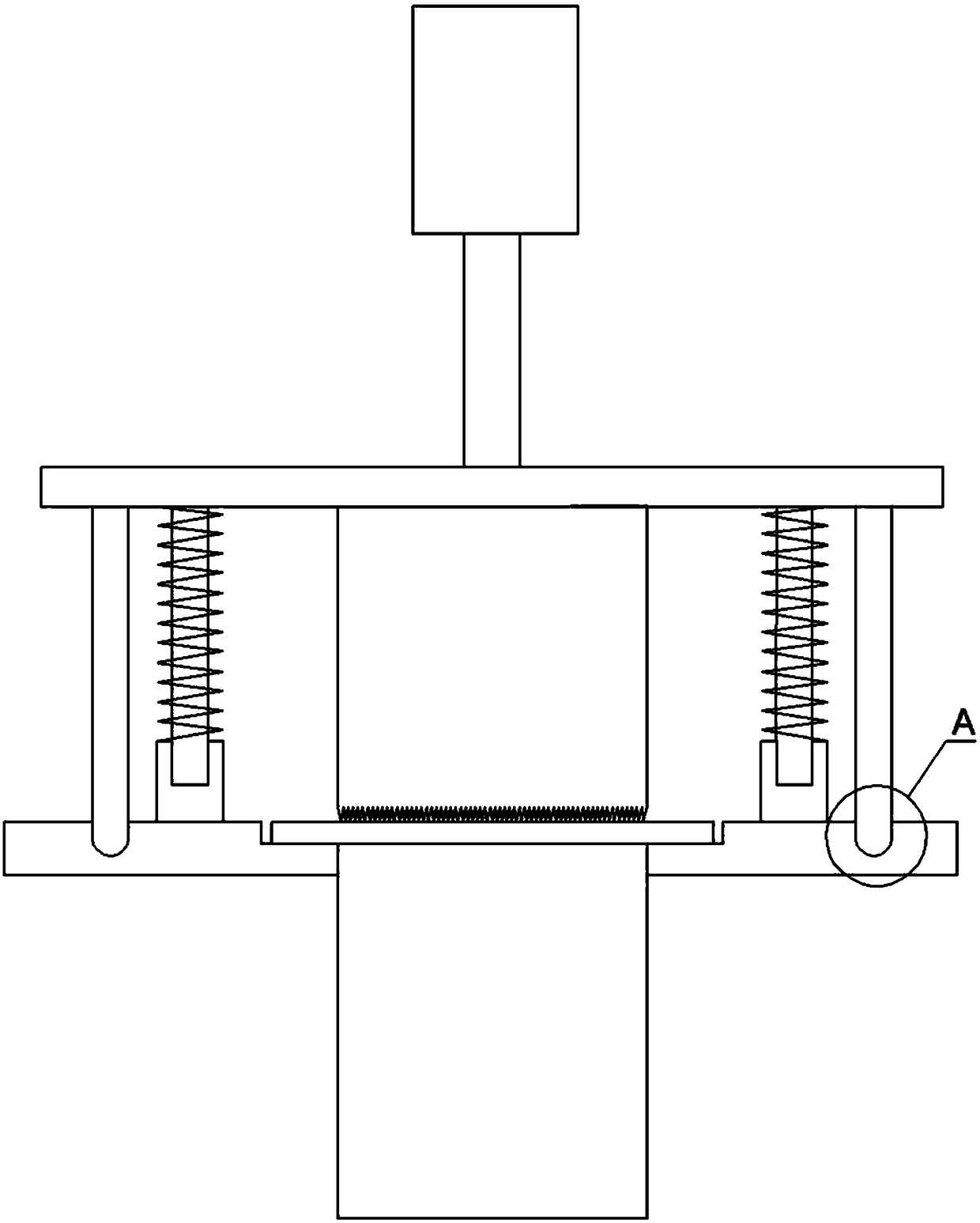

Shaft processing fixture

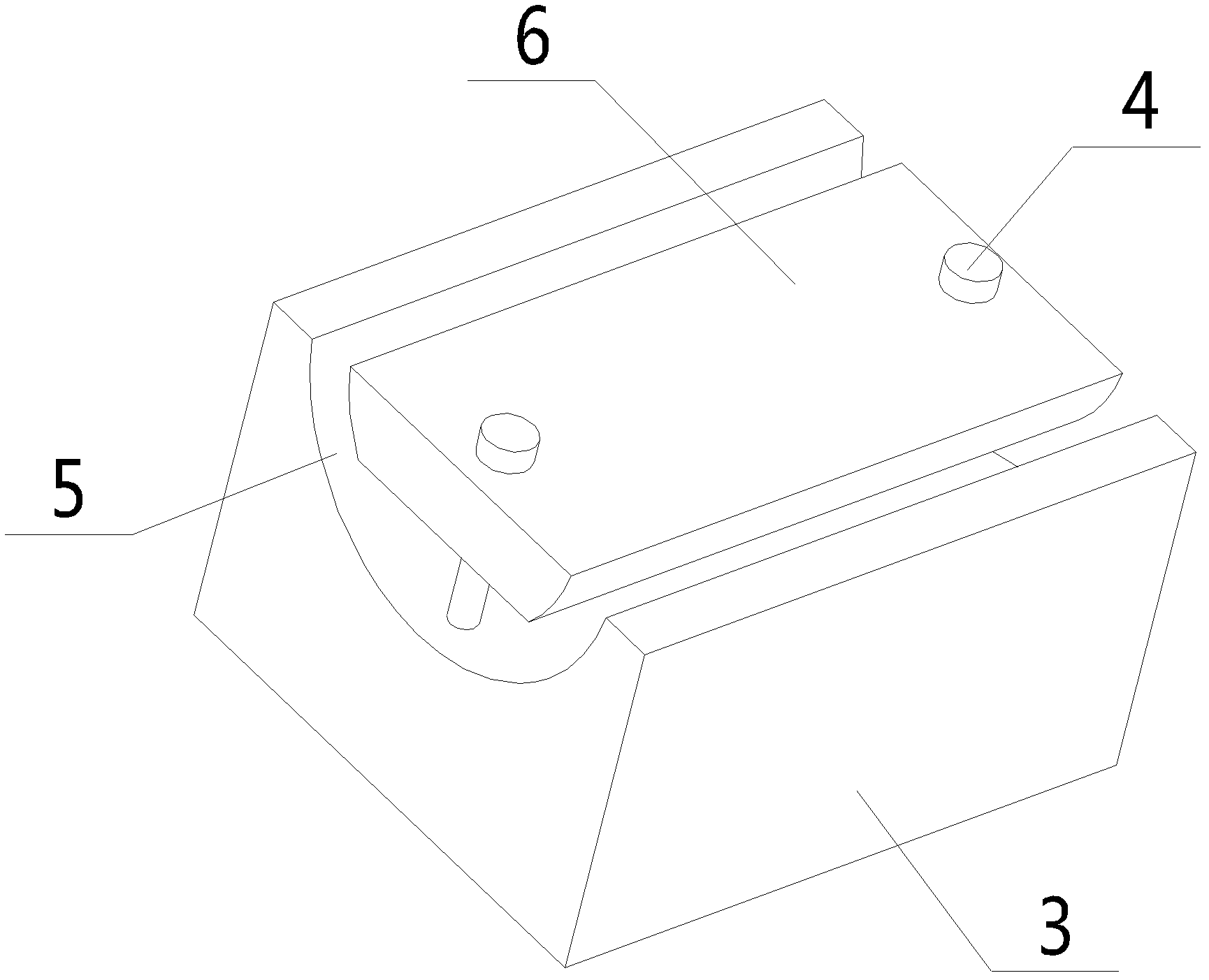

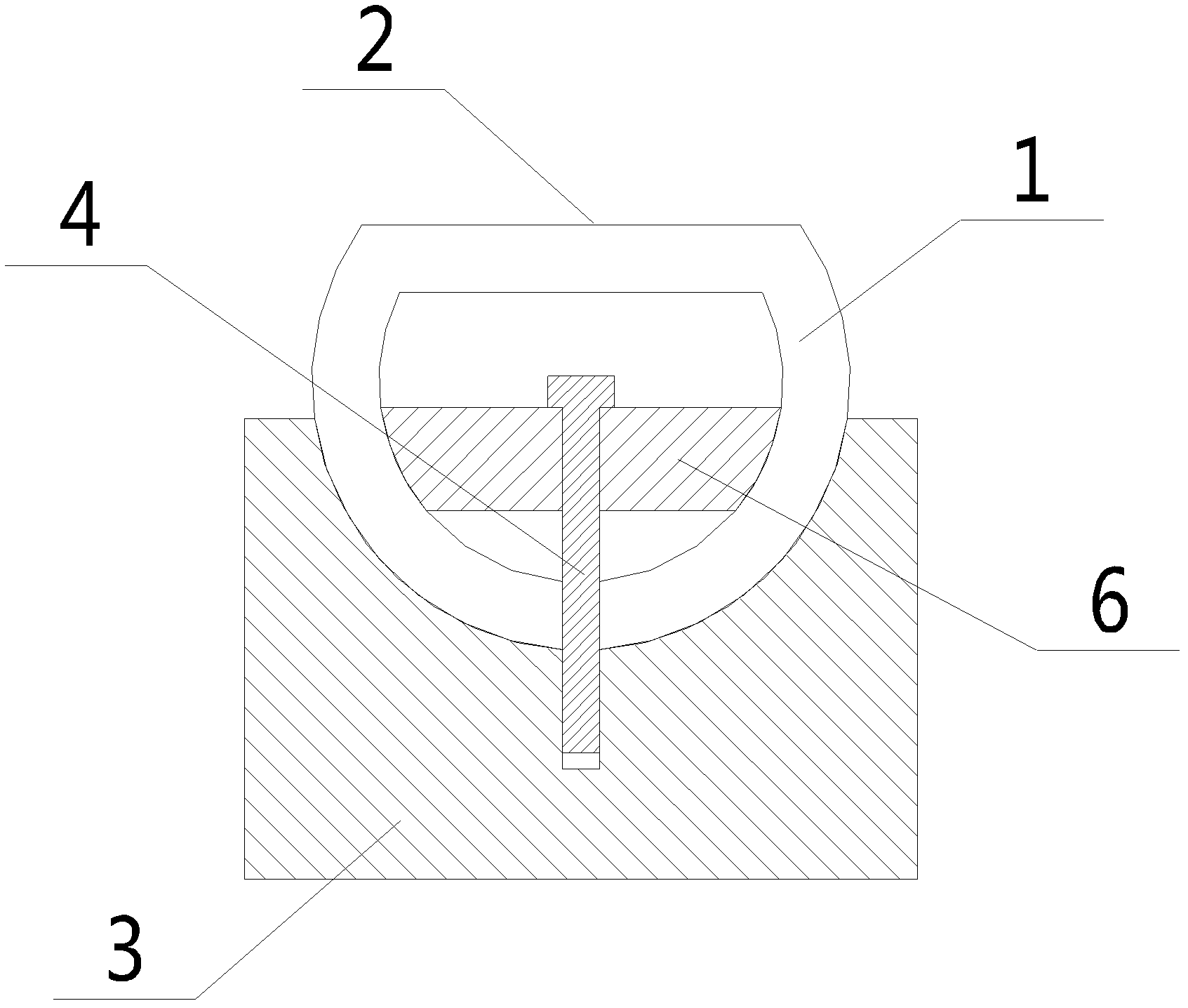

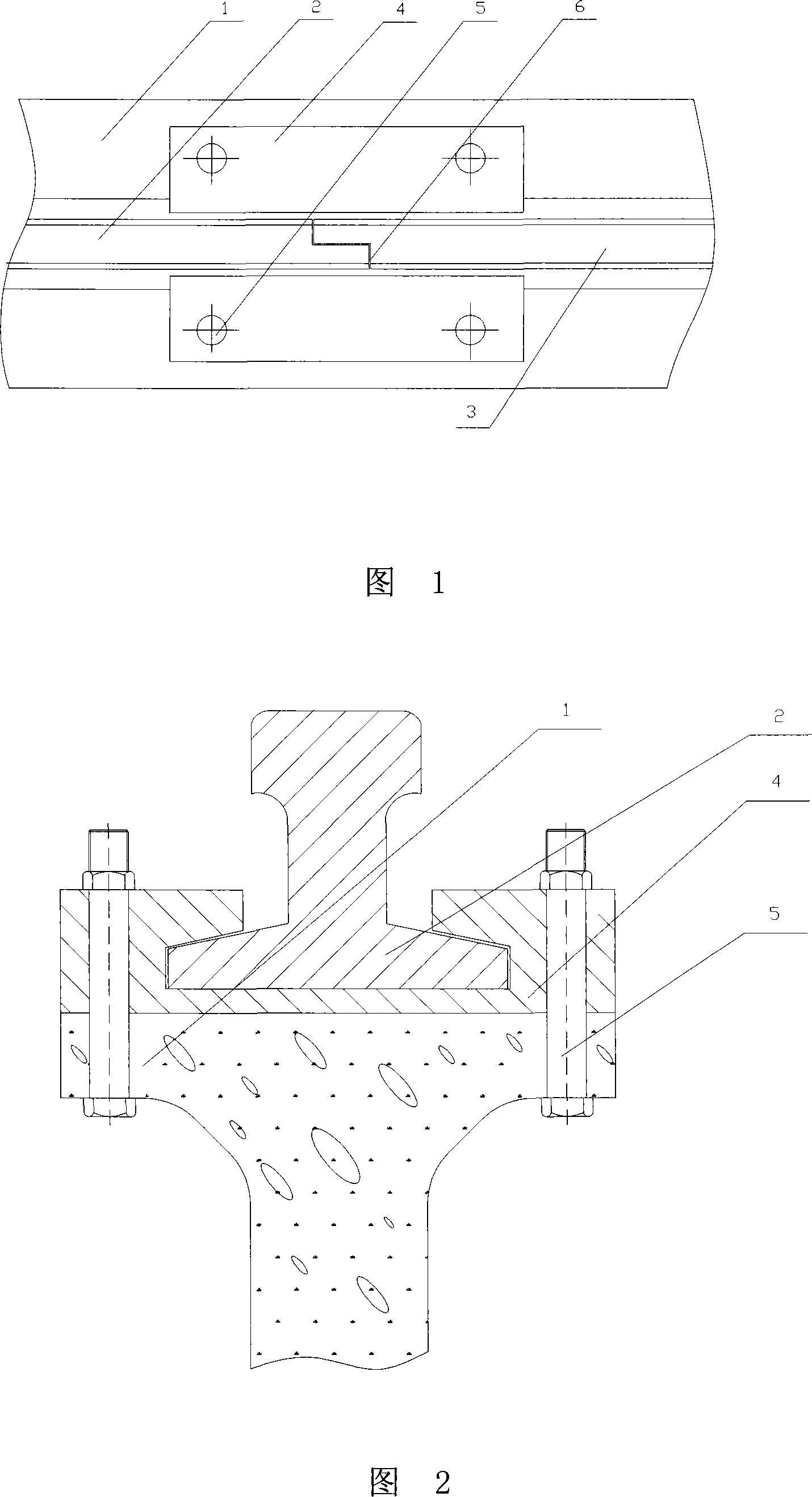

InactiveCN102601647AGuaranteed machining accuracyIncrease the compression areaPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a shaft processing fixture, which comprises a fixture body, a pressing piece and holddown bolts. A holding groove is arranged in the center of the top of the fixture body, the section of the holding groove is arc-shaped, a left side surface and a right side surface, which contact with the holding groove, of the pressing piece are arc-shaped surfaces, and the pressing piece is positioned on the upper side of the holding groove and fixedly presses a workpiece into the holding groove by the aid of the holddown bolts at the front end and the rear end of the pressing piece. By the aid of the shaft processing fixture, the pressing area of the workpiece is increased, clamping stability of the workpiece is improved, and processing precision of the workpiece is guaranteed.

Owner:SUZHOU TANGFENG METAL PROD

Connecting device for connecting concrete tower barrel and steel tower barrel

The embodiment of the invention provides a connecting device for connecting a concrete tower barrel and a steel tower barrel, which relates to the technical field of the wind power generation, and solves the problems by utilizing the prior art to connect the concrete tower barrel and the steel tower barrel, the stress mechanism and the failure form on the junction are complicated, the safety is low, the cost is high and the stress of the concrete tower barrel is not uniform. In the connecting device, since a steel base plate and a grouting layer are arranged between the concrete tower barrel and the steel tower barrel, the stress area can be increased, the pressure from the steel tower barrel can be scattered, so that the pressure is more uniformly applied onto the concrete tower barrel, the concrete tower barrel is simple and uniform to stress, the unfavorable situation that the local pressure is large can be avoided, meanwhile no shearing force exists inside the concrete tower barrel, the nonuniform situation of the stress on the concrete tower barrel is avoided, and the safety is improved; and in addition, since the concrete tower barrel is connected with the steel tower barrel only by adopting the steel base plate and the grouting layer, the cost is reduced.

Owner:BEIJING TIANBIN HIGH TECH WIND POWER TECH CO LTD

Pressure-resistant well lid for repair and method for mounting pressure-resistant well lid

ActiveCN105275018AHigh strengthDoes not cause unevennessArtificial islandsUnderwater structuresRepair materialRoad surface

The invention discloses a pressure-resistant well lid for repair and a method for mounting the pressure-resistant well lid. The outer sidewall of a ring body is provided with a first covered edge, and the inner sidewall of the ring body is provided with a second covered edge. The outer sidewall of a lid body is provided with a third covered edge. The width of the ring body is at least 16 cm. The method for mounting the pressure-resistant well lid sequentially comprises the following steps that firstly, a pit with the same shape as the outer edge of the ring body is cut in the road surface through a special device; secondly, the edge of the pit is evenly expanded outwards by a hoisting width, and the hoisting width is less than 6 cm; and thirdly, the lid body is hoisted onto the ring body and arranged on a through hole of the ring body in a covering mode. The pressure-resistant well lid for repair and the method for mounting the pressure-resistant well lid have the beneficial effects that the construction efficiency is improved; no repair mark and no obvious joint exist between the ring body and the road surface; the area of the ring body and the area of the lid body are expanded, and the well lid is high in strength and resistant to pressure; the surface of a well ring covers repair materials between the edge of the well lid and the edge of the cut pit, the appearance is attractive, the well ring protects the repair materials, and the well lid is not prone to secondary damage after being crushed by vehicles; the well lid is provided with anti-falling hooks and an anti-falling net, thereby being safer in use.

Owner:WUXI AILU CONSTR CO LTD

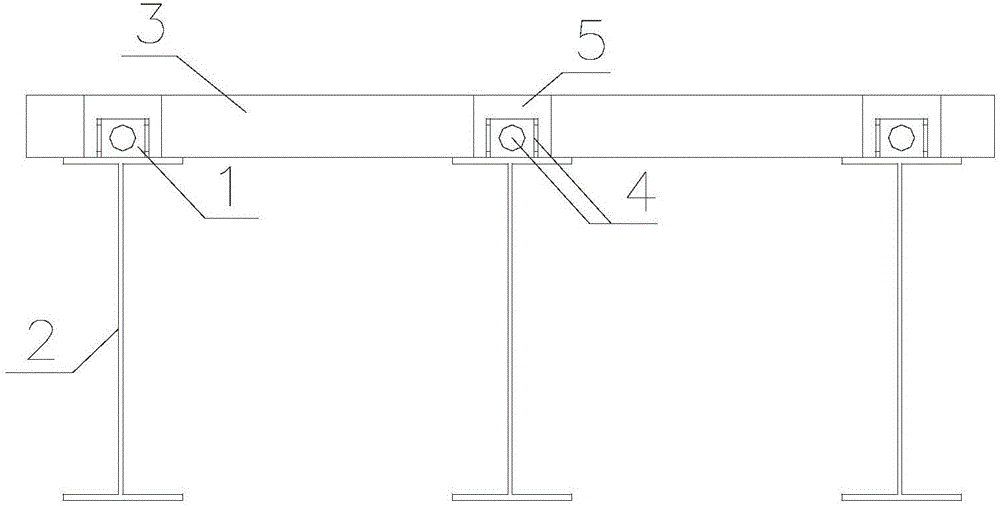

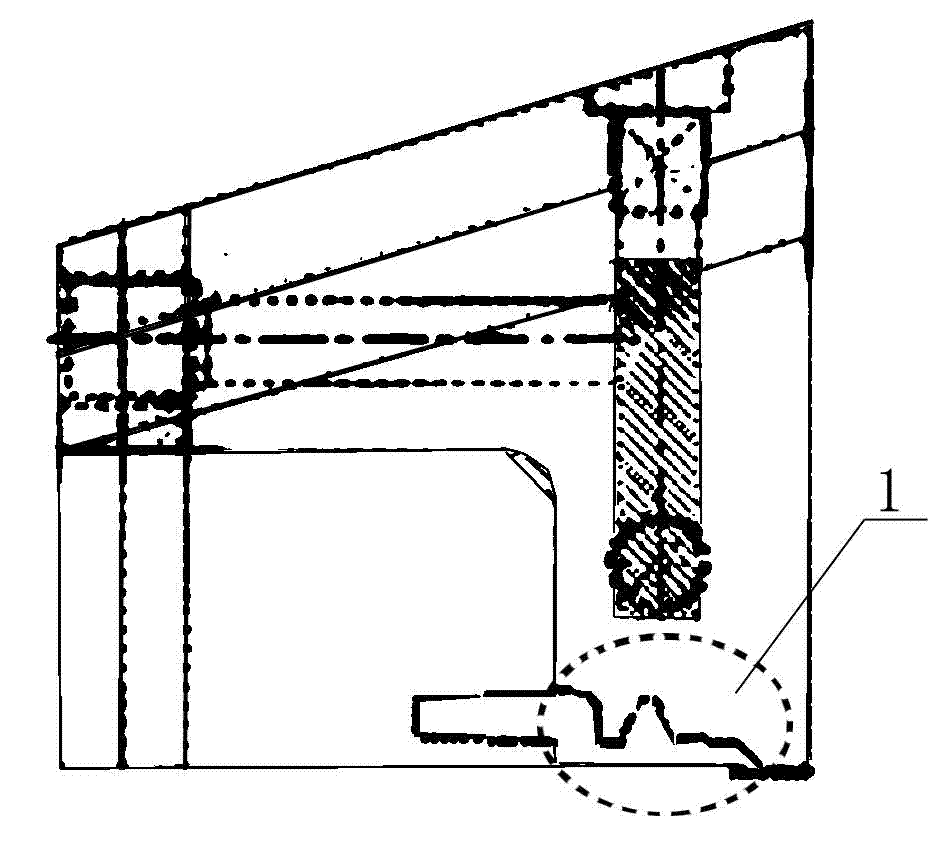

Method for connecting aluminum electrolysis multifunctional overhead crane orbit telescopic seam

InactiveCN101186263AEliminate rail gnawingPrevention of rail gnawingRunwaysFree expansionEngineering

The invention relates to an improved device in aluminium electrolysis industry, in particular to an aluminium electrolysis multifunction crown block rail expansion gap connecting method. The invention comprises a cement beam, a rail, a coattail-shaped trough, a fixed bolt, and an L-shaped rail expansion joint. The connecting method of the rail expansion gas is that two rails with L-shaped cut at the ends are mutually overlapped and sleeved in the coattail-shaped trough which is fixed on the cement beam by the fixed bolt. The invention eliminates the phenomenon of the rail gnawing of crown block caused by rail joint crushing; slight clearance is arranged on the side surfaces of the trough and the rail and the top surface of the rail base, so as to prevent the transverse staggering of the rail and ensure the free expansion when the rail is expanded by heat, solve the problem of the rail expansion gap coattail plate that the rail is not easy to slide or the rail is transversely staggered, and ensure the normal operation of the crown block. The aluminium electrolysis multifunction crown block rail expansion gap connecting method of the invention can be applied to the connection of the rail expansion gaps subject to heavy load, frequent and fatigue works in all industrial fields.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Novel pouring structure for mould

InactiveCN102814934AIncrease the compression areaReduce momentary momentumEngineeringMechanical engineering

The invention discloses a novel pouring structure for a mould, comprising a main flow channel, branch flow channels, and pouring gate flow channels for connecting the branch flow channels with the main flow channel. The novel pouring structure is characterized in that the pouring gate flow channels are provided with irregular cavities, and recesses or bulges are arranged on the wall surfaces of the cavities. According to the invention, the instantaneous flow acceleration during glue inlet is slowed down, and the partial impact pressure on the pouring gate flow channels during the glue inlet is reduced by increasing the areas of the tube walls of the pouring gate flow channels, thus preventing the mould from deforming.

Owner:SHENGYANG PRECISION MOLD KUSN

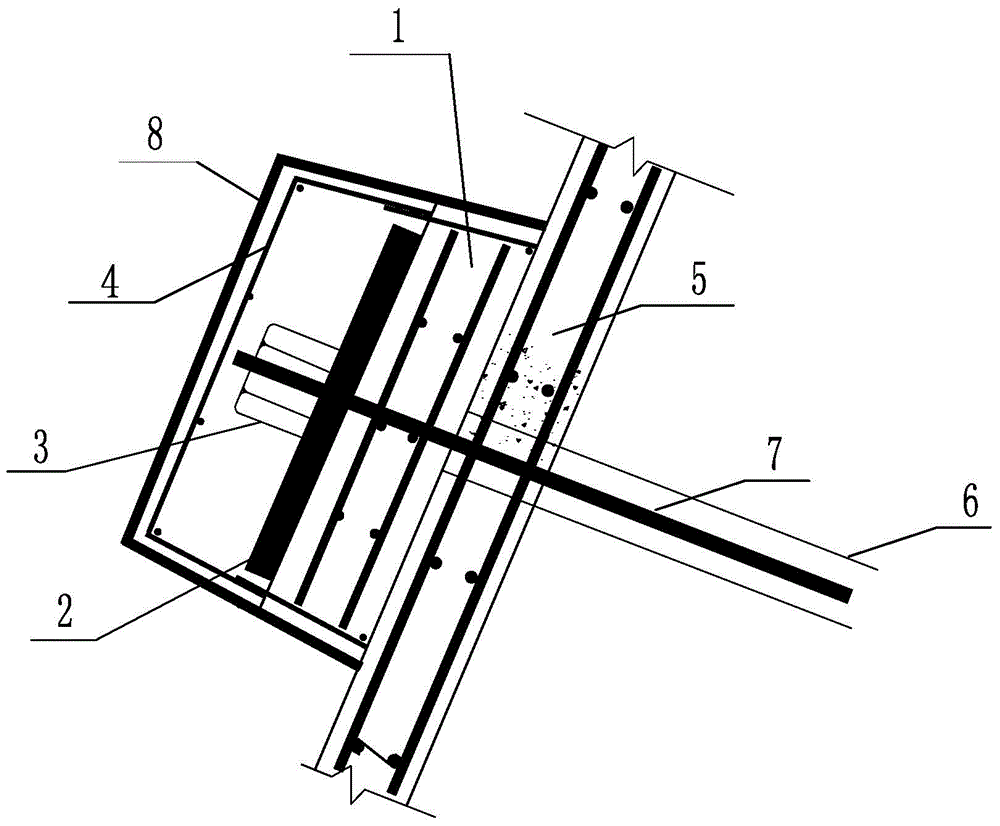

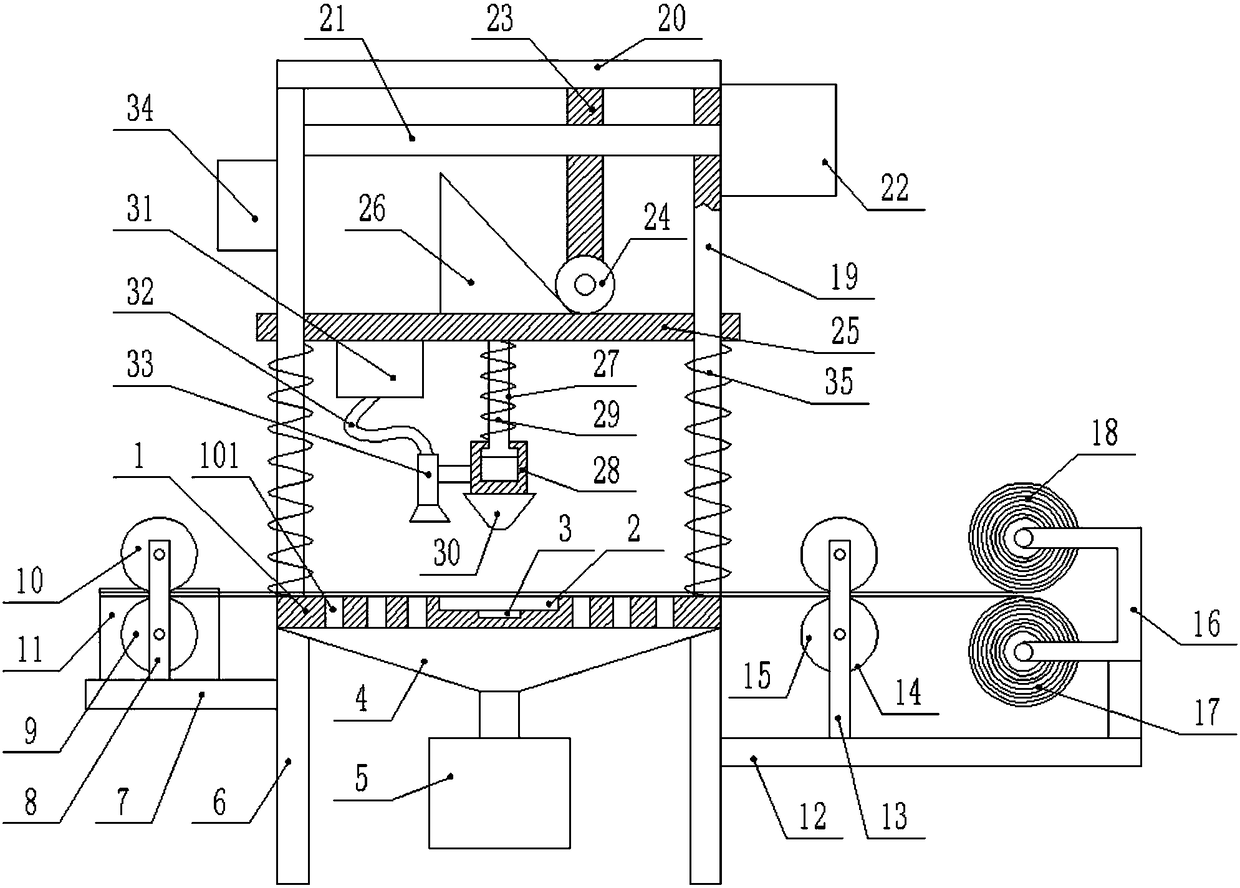

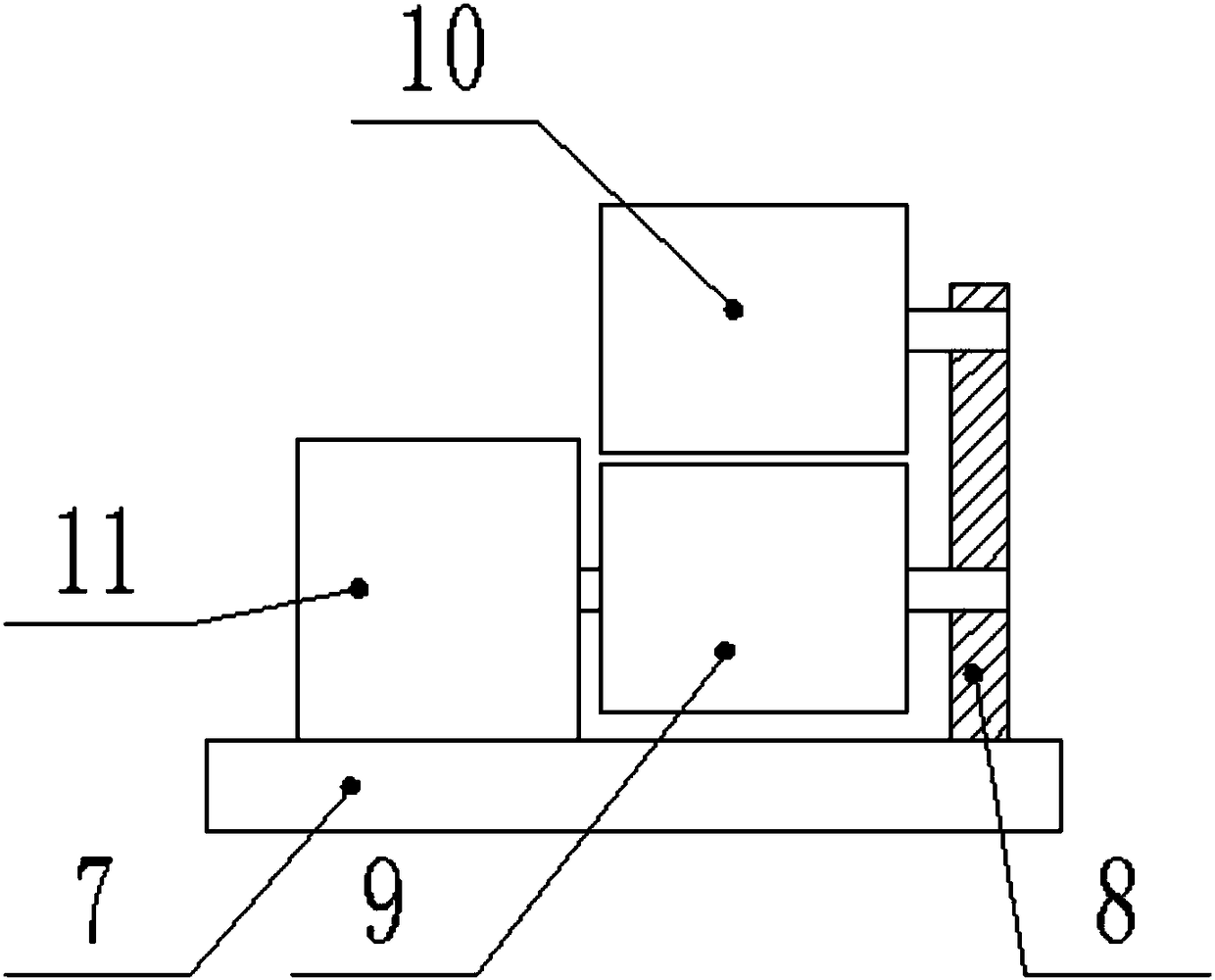

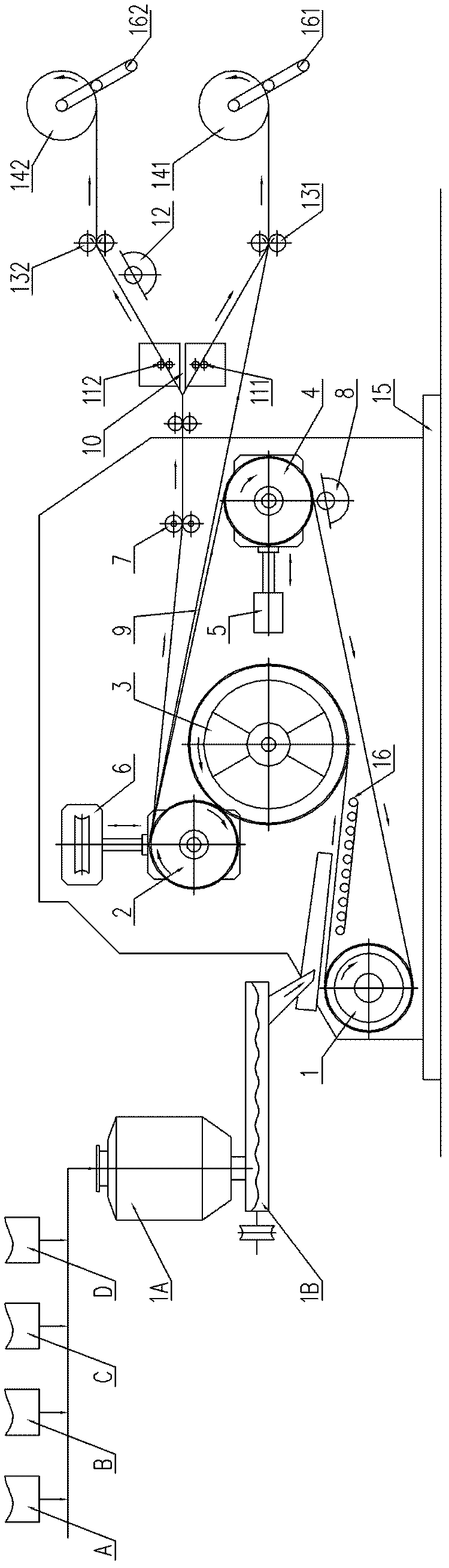

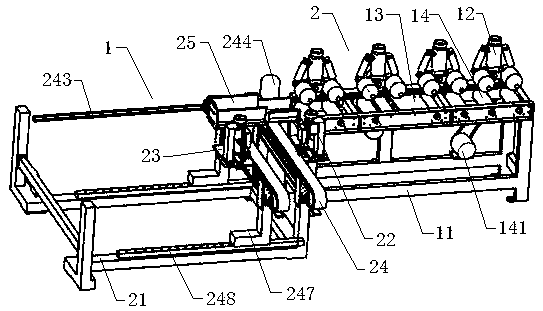

Color plastic floor continuous production device and color plastic floor continuous production method

ActiveCN102935688AReduce consumptionOvercome the shortcoming of contact pressurizationDomestic articlesCoatingsEngineeringContact position

In order to resolve the shortcomings existing in current color plastic floor production processes, the invention provides a color plastic floor continuous production device and a color plastic floor continuous production method. By means of a pressurization forming mechanism composed of multiple rolling wheels with an equal rotating linear speed and a sealed steel strip wound on the rolling wheels to roll. A color raw material conveyed by a material conveying mechanism moves on the steel strip along with it, and is subjected to pressurization forming at contact places of the steel strip and the rolling wheels so as to finish reeling finally. The device and the method provided in the invention can produce various color plastic floors with thickness of 1-10mm continuously. And the width of the color plastic floors is accomplished by the steel strip width and a main forming rolling wheel in one time. Thus, a pressurization steel strip new technology able to replace a calendaring process and a tape casting process is provided. Meanwhile, the forepart large equipment of an internal mixer and an open mill in the procedure is simplified, and the power energy consumption is reduced.

Owner:SHANGHAI FORWARD MASCH CO LTD

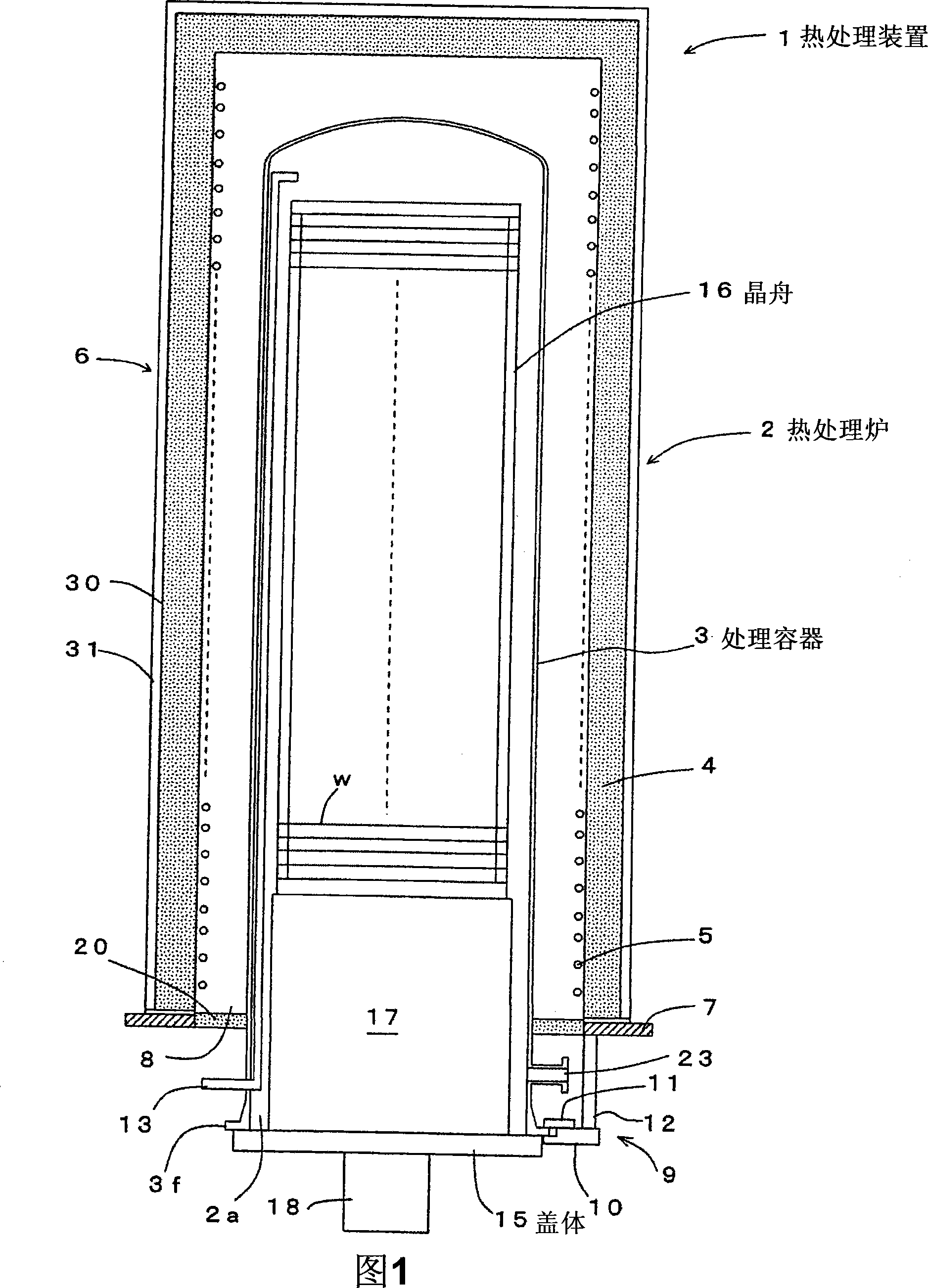

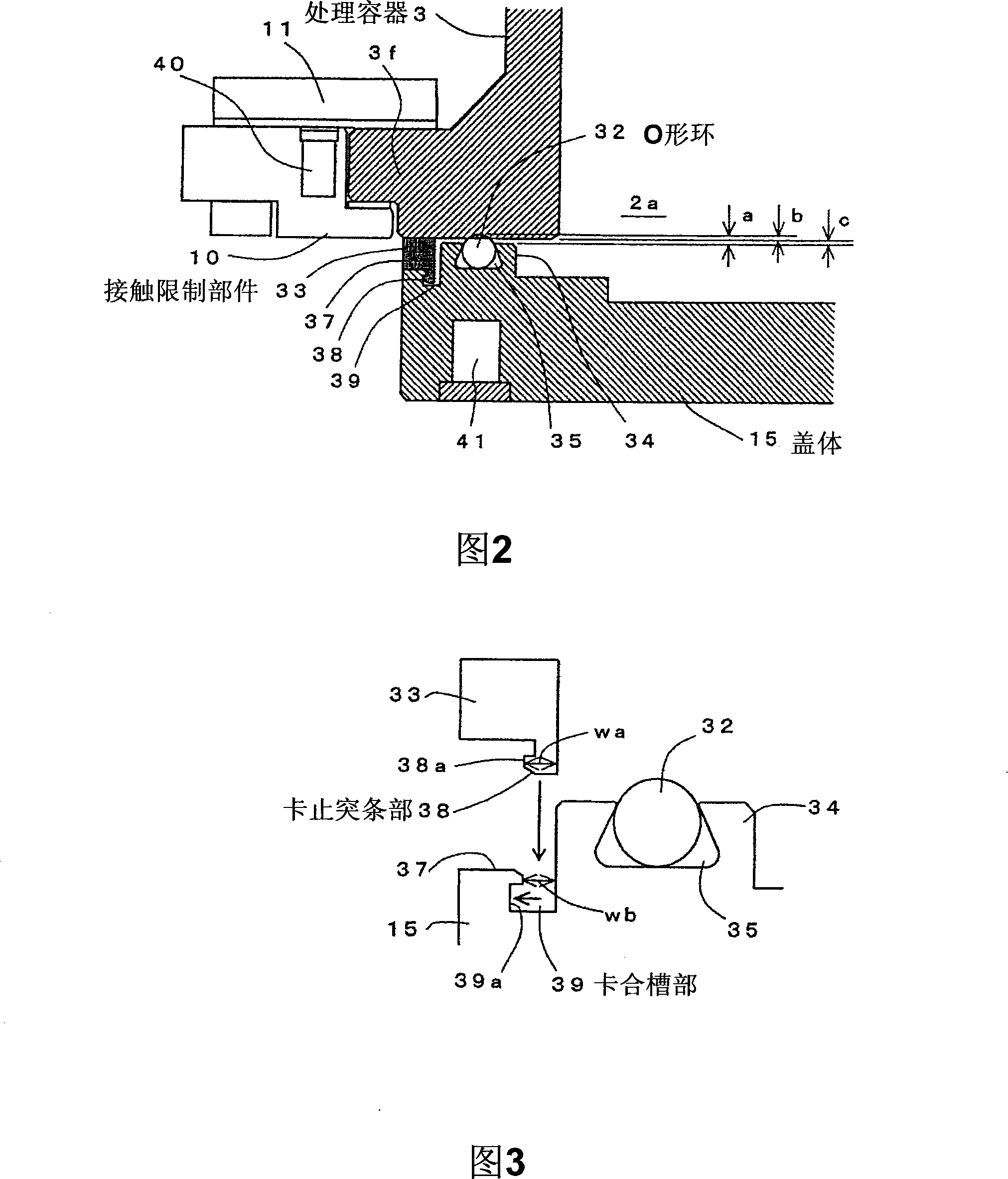

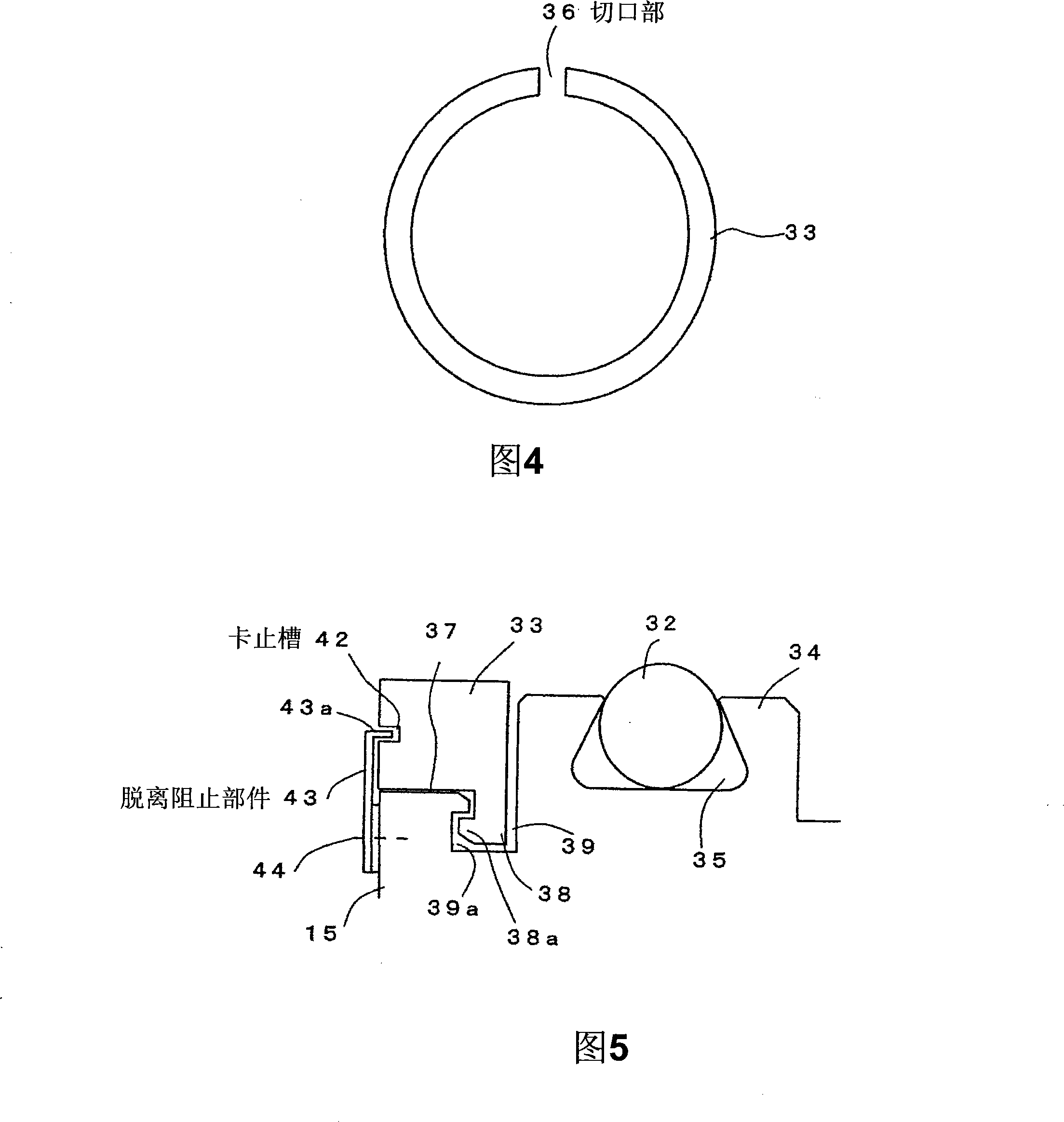

Heat treatment apparatus

ActiveCN101162686APrevent damage such as cracksAvoid damageSemiconductor/solid-state device manufacturingFurnace typesThroatInternal pressure

Owner:TOKYO ELECTRON LTD

Pressure limiting, safety and pressure relief integrated valve of pressure cooker

The invention discloses a pressure limiting, safety and pressure relief integrated valve of a pressure cooker. The pressure limiting, safety and pressure relief integrated valve comprises a pressure limiting exhaust pipe, an upper threaded connector, a lower threaded connector, a safety pressure spring, a relief pressure spring, a sealing ring, a pressure limiting valve, an anti-blocking cover and a clamping structure. The pressure limiting exhaust pipe, the upper threaded connector, the lower threaded connector, the safety pressure spring, the relief pressure spring, the sealing ring, the pressure limiting valve, the anti-blocking cover and the clamping structure are combined with one another and are mounted on a lid of the pressure cooker. The working pressure of the pressure cooker is controlled by the exhaust pipe and the pressure limiting valve, the safety exhaust pressure of the pressure cooker is controlled under the matched effect of the exhaust pipe and the safety pressure spring, and the relief pressure of the pressure cooker is controlled under the matched effect of the threaded connectors and the relief pressure spring. Compared with a conventional safety valve of a pressure cooker, the pressure limiting, safety and pressure relief integrated valve has the advantages that a narrow inner cavity can be omitted, and blocking or failure can be prevented. Besides, the basic difference between the pressure limiting, safety and pressure relief integrated valve and a conventional pressure relief structure is that the relief pressure of the pressure cooker can be precisely designed and controlled by the pressure limiting, safety and pressure relief integrated valve, injury to people due to high-temperature food which is ejected out of the pressure cooker during pressure relief can be completely eradicated, a protective cover can be omitted during detection, and safety can be completely guaranteed during operation.

Owner:欧明华

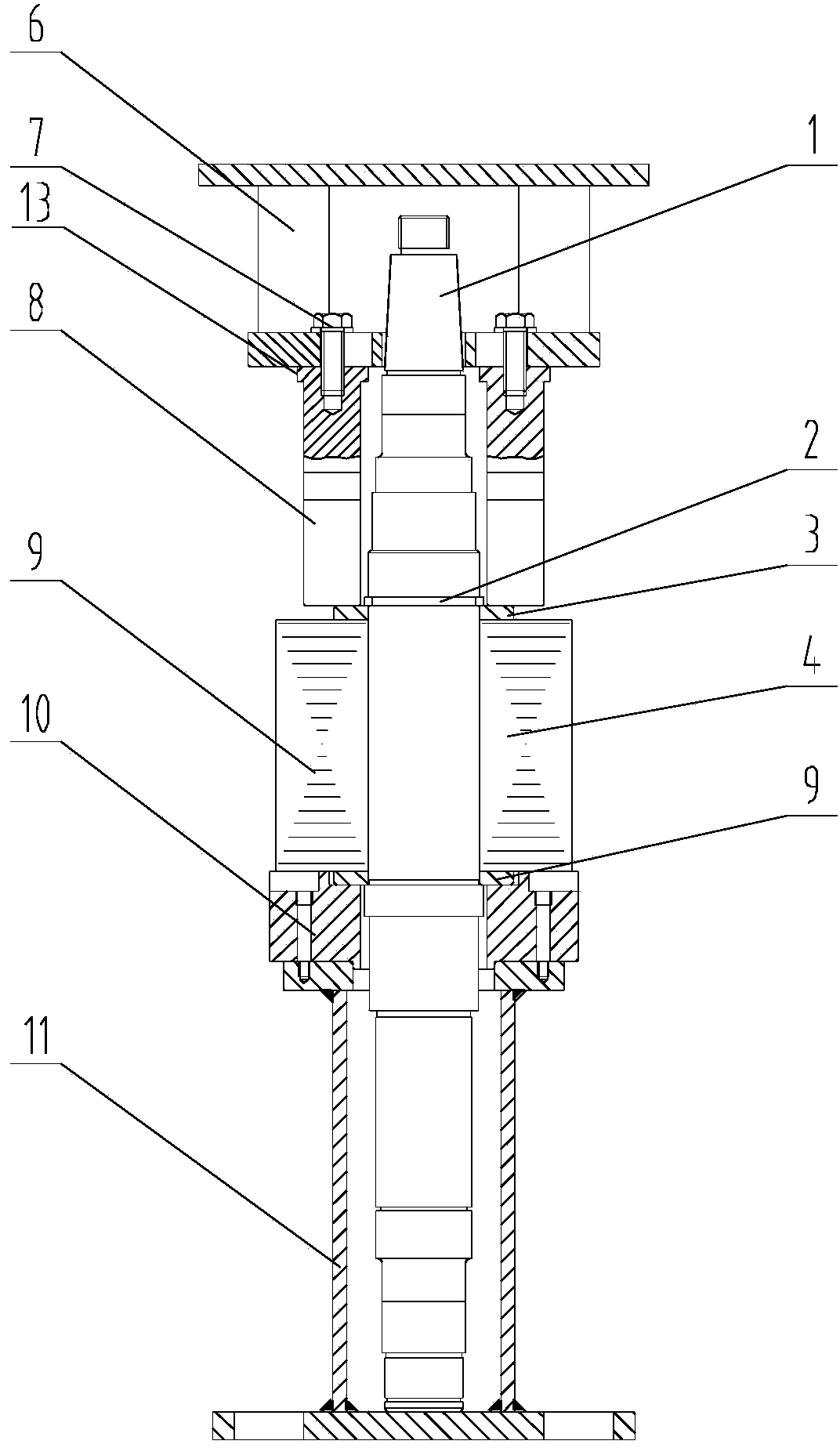

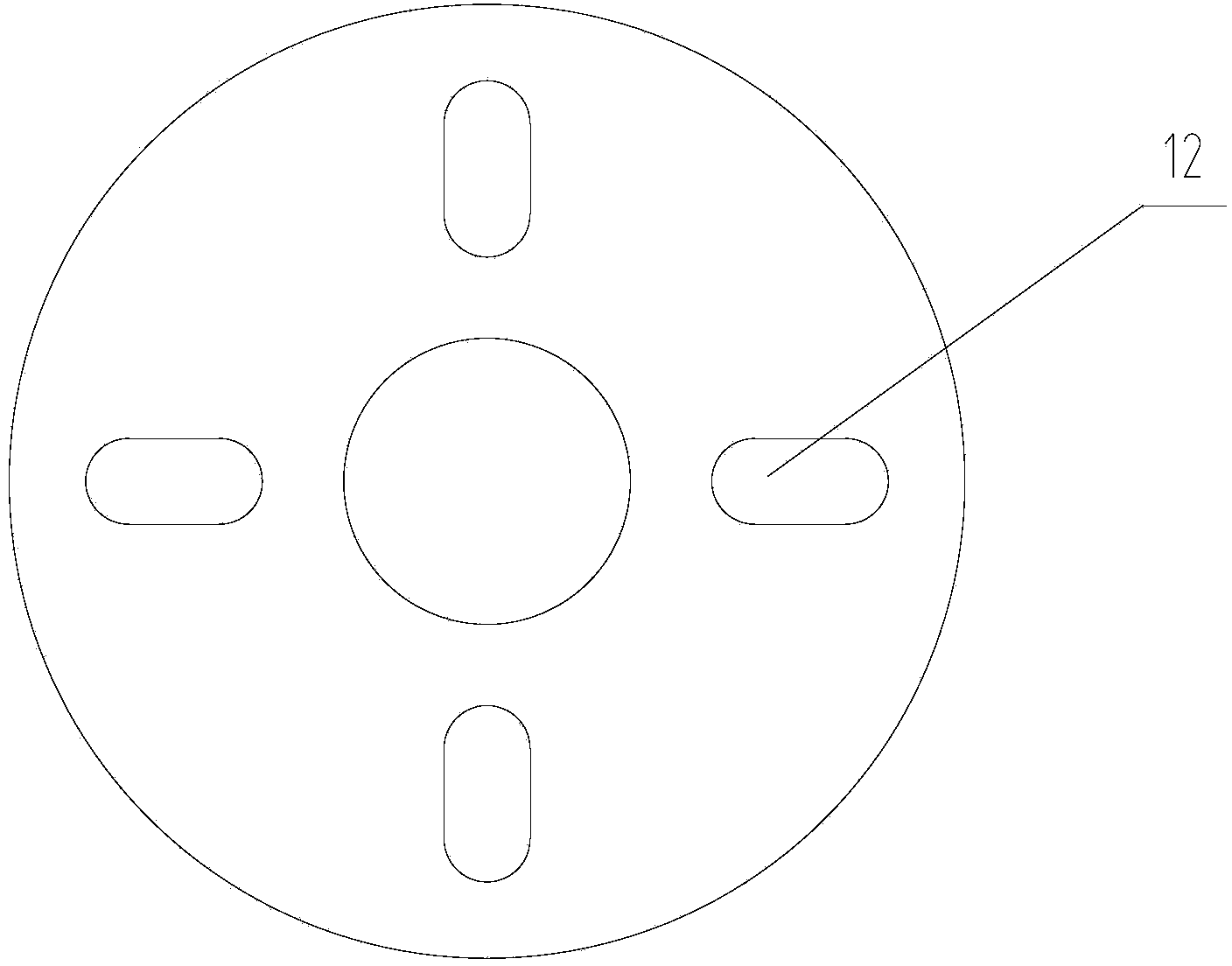

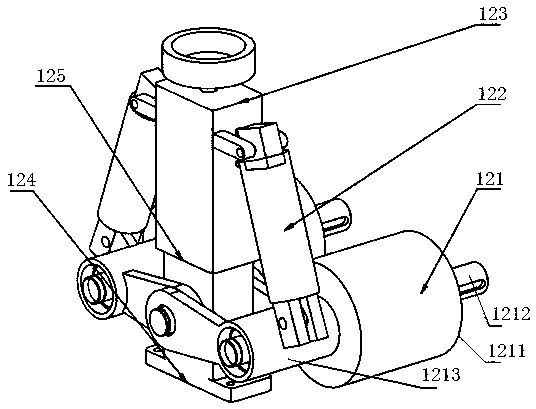

Hobbing cutter rest rotating device capable of locating accurately

InactiveCN101985183AIncrease the compression areaLarge torqueGear-cutting machinesGear teethHobbingCoupling

The invention discloses a hobbing cutter rest rotating device capable of locating accurately. A round hole is arranged on the upper end face of a shell (1), and the inner wall of the round hole is provided with an annular table raised inward; a plane bearing (12) is arranged on the annular table, and the plane bearing (12) is provided with a rotating piece (10); a center fixing piece (6) is arranged in the rotating piece (10), and the lower part of the center fixing piece (6) is fixedly provided with a worm gear (13) which is in gear transmission with a screw (16) arranged in the shell (1); the middle of the center fixing piece (6) is provided with an inner hole, and an encoder is fixedly arranged in the inner hole; an annular step is arranged above the through hole of the rotating piece (10), a centering plate (9) is arranged in the annular step, and the center of the centering plate (9) is fixedly provided with a center rod (7); and the center rod (7) passes through the inner hole, and the lower end of the center rod (7) is connected with the encoder (15) through a coupling (8). In the invention, the hobbing cutter rest rotating transmission mechanism is restructured, the one-stage transmission is used, and the encoder is arranged at the tail end of the rotating device, thereby enhancing the rotating accuracy greatly at the same time. The hobbing cutter rest rotating device is simple in structure, easy to realize and reliable to work.

Owner:ANHUI CHIZHOU WEISS ELECTROMECHANICAL

Sealing equipment

InactiveCN108146712AOptimize package structureEasy to cutWrapping material feeding apparatusWrapper twisting/gatheringEngineeringHot pressing

Owner:JINJIANG ZHIBAO ENTERPRISE MANAGEMENT CONSULTING CO LTD

Panel surface edge scraping machine

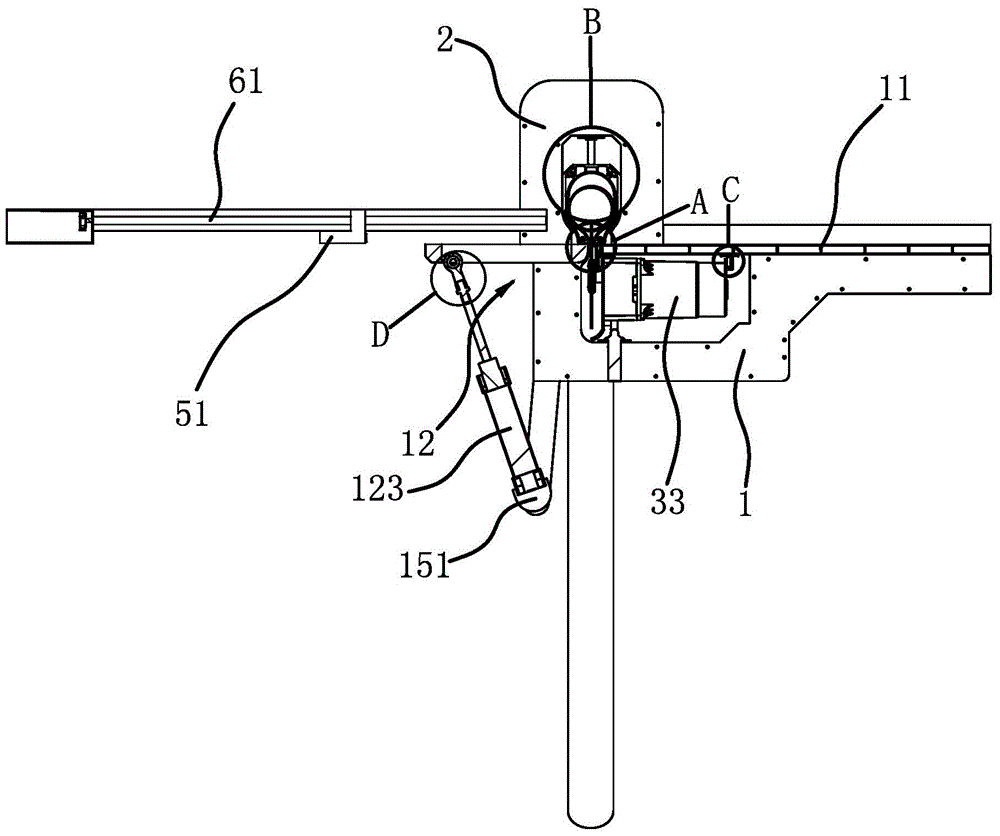

PendingCN109352754AEasy to adjust scraping depthVarious scraping effectsProfiling/shaping machinesEngineering

The invention discloses a panel surface edge scraping machine. The panel surface edge scraping machine comprises a longitudinal edge scraping device (1) and a transverse edge scraping device (2) perpendicular to the discharging direction of the longitudinal edge scraping device (1), wherein a feeding port of the transverse edge scraping device (2) is arranged below the end side of a discharging port of the longitudinal edge scraping device (1). The longitudinal edge scraping device (1) is provided with a scraping mechanism (3) capable of performing edge scraping on the long edge side wall of aplate. The transverse edge scraping device (2) is provided with a scraping mechanism (3) capable of performing edge scraping on the short edge side wall of the plate. When the panel surface edge scraping machine is used to perform edge scraping processing on the panel, the panel enters the feeding port of the longitudinal edge scraping device first to be subject to edge scraping processing in thelength direction and then enters the transverse edge scraping device from the discharging port of the longitudinal scraping device to be subject to edge scraping processing in the width direction, sothat panels with different thicknesses and lengths can be adapted to, the edge scraping depths of the panels can be adjusted conveniently, and the edge scraping effects are diversified.

Owner:盐城鼎恒机械有限公司

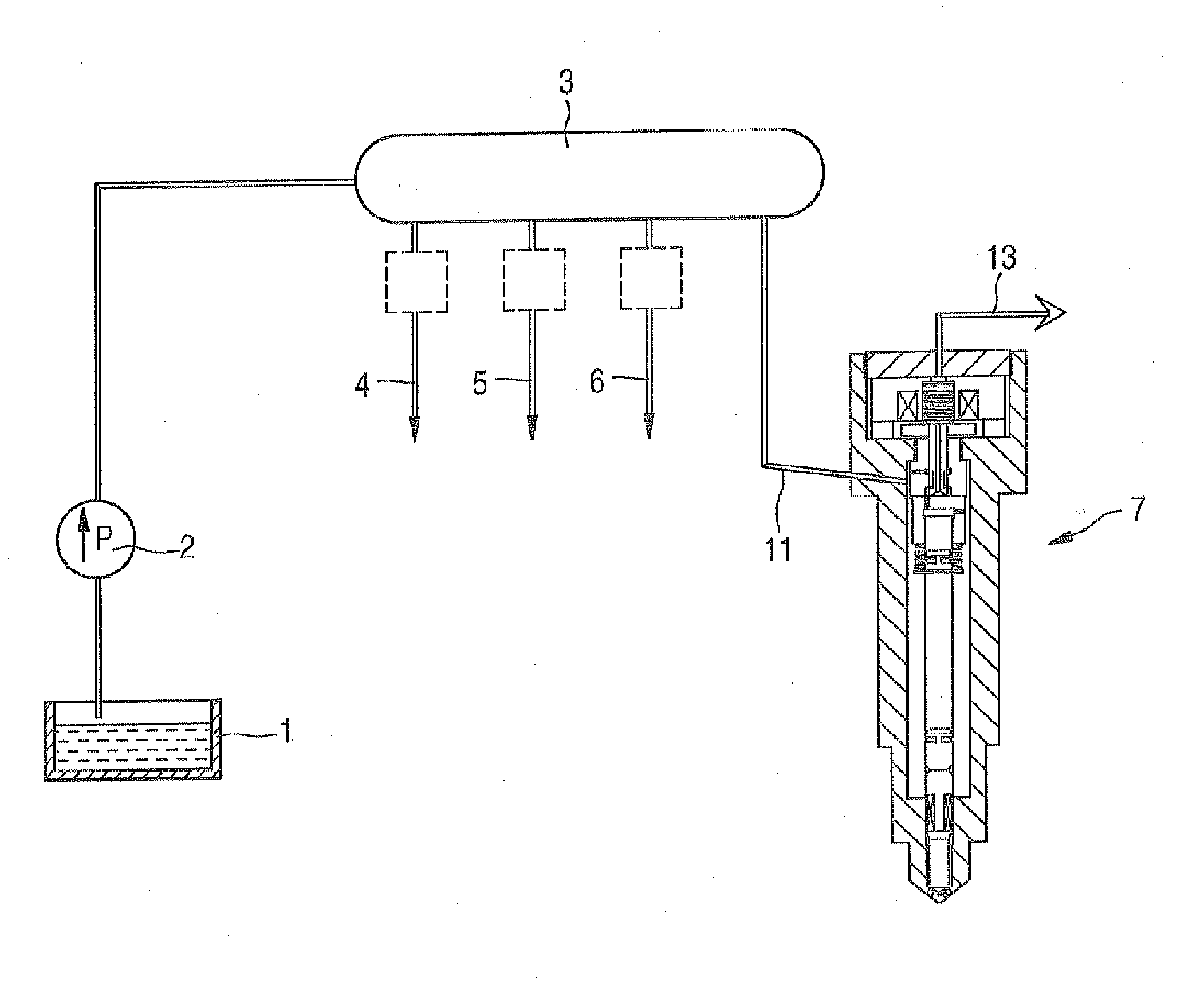

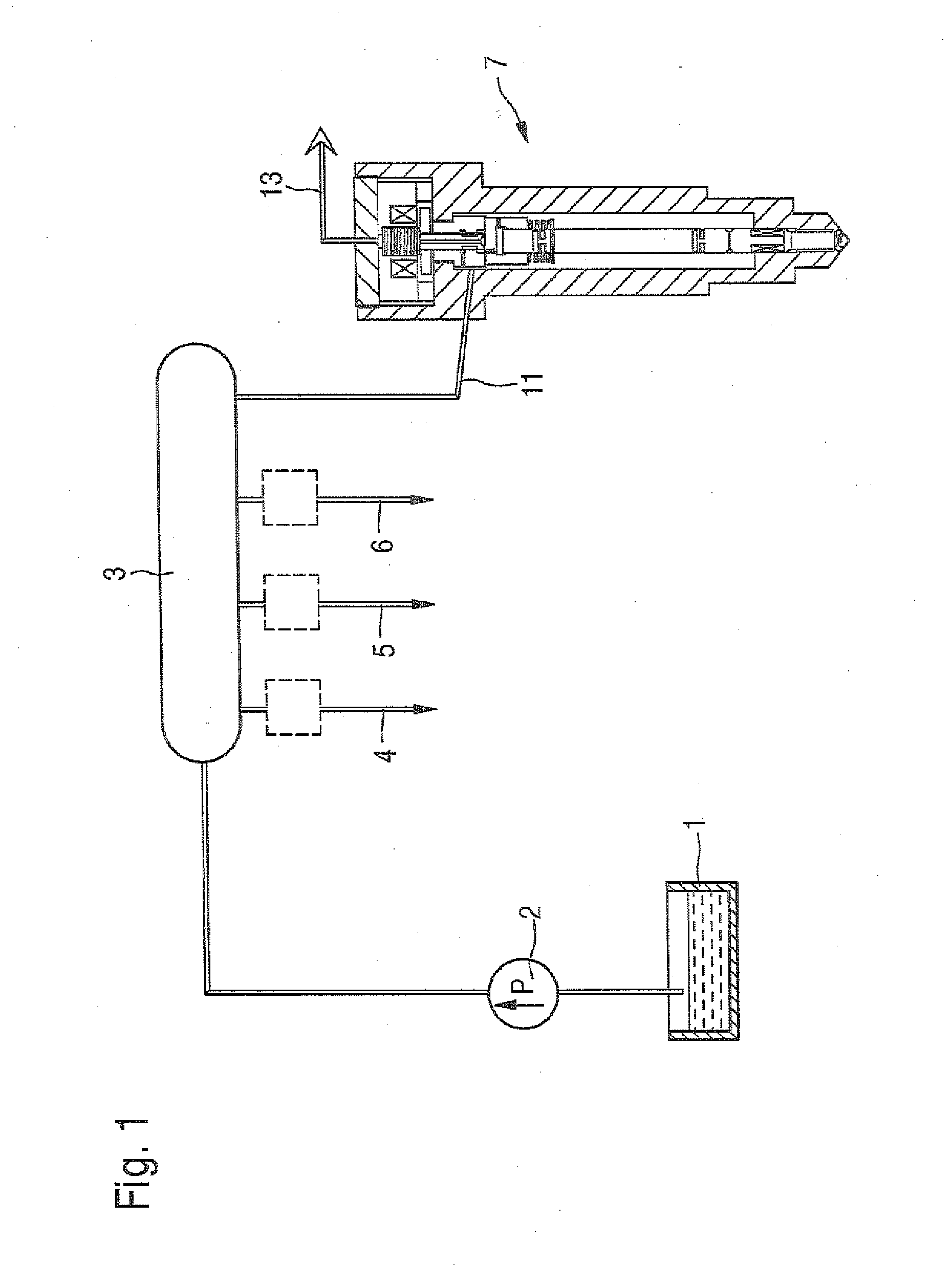

Injector for a fuel injection system

InactiveUS20090230220A1Promote combustionIncrease injection pressureSpray nozzlesFluid pressure injection controlEngineeringHigh pressure

A leak-free injector is proposed, the closing force of which is increased by a closing piston. An injector has a nozzle needle and a control valve, the nozzle needle being guided in an injector housing and cooperating with a nozzle needle seat of the injector housing. A high-pressure chamber is present between the control valve and the nozzle needle seat, and the closing piston is provided on the nozzle needle. The closing piston subdivides the high-pressure chamber into a first region and a second region. The two regions of the high-pressure chamber communicate hydraulically via a closing throttle restriction.

Owner:PROMISING GROUND +1

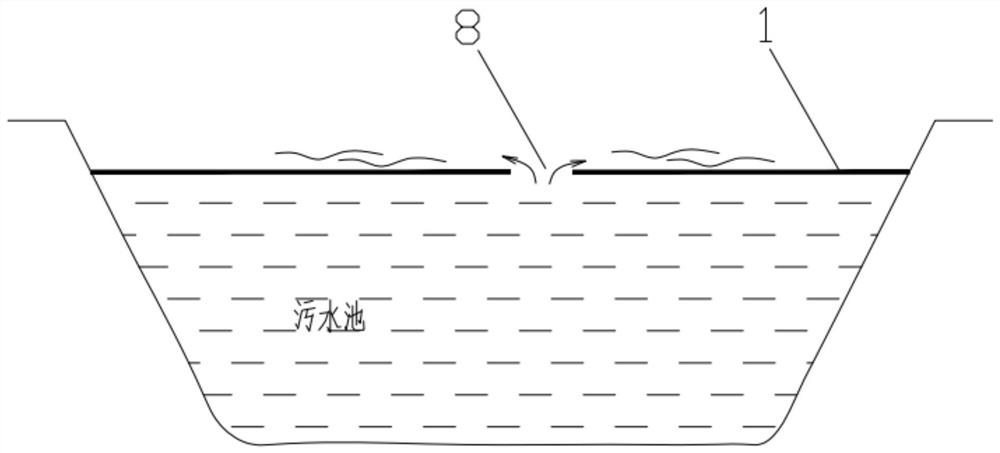

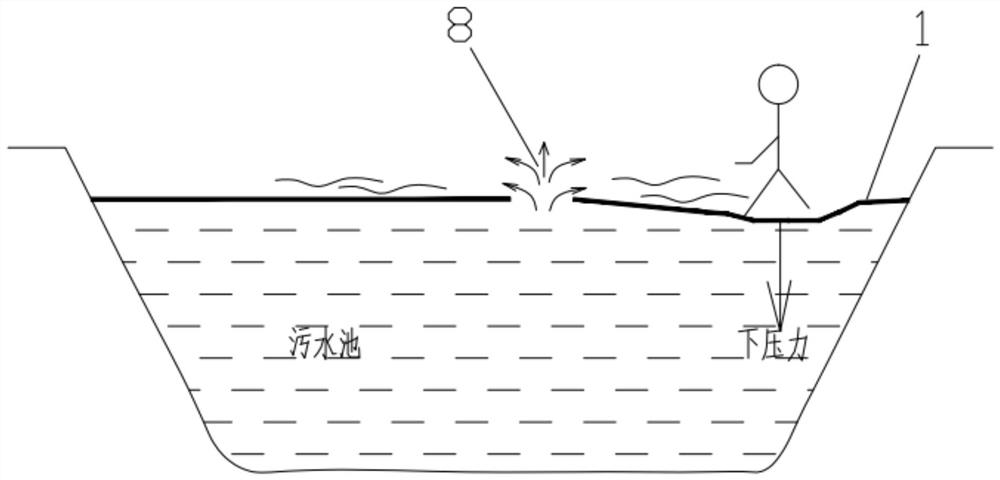

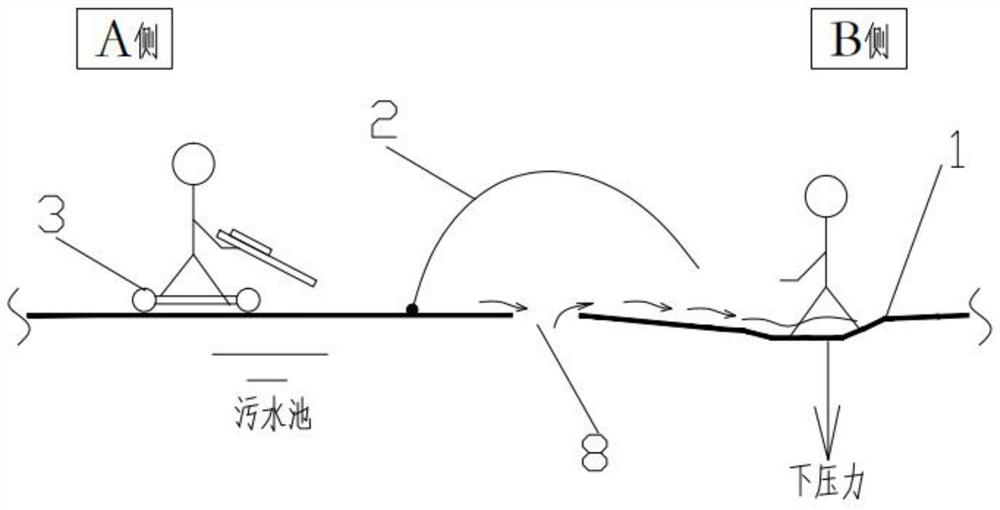

Operation method for repairing floating cover film with water

InactiveCN112624221AIncrease the compression areaSmall extrusion effectWater/sewage treatmentContaminated groundwater/leachate treatmentForeign matterSewage

The invention discloses an operation method for repairing a floating cover film with water. The operation method comprises the following steps: constructing an operation support platform for repairing a film surface broken hole by adopting a large-area buoyancy pad; enabling an operator to stand on the HDPE floating cover films on the two sides of the broken hole to weld HDPE film strips; slowly lifting the film strip, and lifting the HDPE floating cover film at the broken hole to be in a suspended state; temporarily sealing the film surface broken hole by adopting a strong adhesive tape; and carrying out extrusion welding repair on the film surface broken hole by adopting an HDPE repair block to form a permanent and firm HDPE repair block, so as to complete repair of the film surface broken hole of the HDPE floating cover film with water. The problem that in the operation process of a sewage pool, due to foreign matter entering or the action of external force or the like, holes occur in the film surface of the HDPE floating cover film covering the water surface of the sewage pool is solved.

Owner:中城建胜义(深圳)环境科技有限公司

Intensified reinforced concrete sewer pipe steel mold

InactiveCN110871495AUniform compacted roller compacted concreteImprove steel mold strengthMouldsRebarReinforced concrete

The invention discloses an intensified reinforced concrete sewer pipe steel mold which comprises an upper cylinder, a lower cylinder, a mounting hole, a first supporting flange, a second supporting flange and a third supporting flange. The lower end of the upper cylinder is provided with the lower cylinder, a steel cylinder is arranged inside the upper cylinder, the mounting hole is formed insidethe steel cylinder, the first supporting flange is arranged outside the upper cylinder, one side of the first supporting flange is provided with the second supporting flange, one side of the second supporting flange is provided with the third supporting flange, and a reinforcing cross bar is arranged on the front side of the upper cylinder. The intensified reinforced concrete sewer pipe steel moldhas the beneficial effect that the steel cylinder with the diameter smaller than the diameter of the reinforced concrete sewer pipe steel mold is additionally arranged, so that the inner wall pressure area of a pipe body is larger, rolled concrete is more uniform and dense, the inner wall is more smooth, the concrete slump is reduced, the dead time can be shortened, the production efficiency is improved, the production quality is also ensured, and the structure is simple.

Owner:JIANGSU HAI HENG BUILDING MATERIAL MACHINERY CO LTD

Ship propeller hub with front oil cylinder

The invention discloses a ship propeller hub with a front oil cylinder. The ship propeller hub mainly comprises a hub body, a guide frame, a slide block, a paddle holder, a piston, an oil cylinder supporting baffle and a paddle shaft provided with a single oil tube, wherein the piston is positioned at the front end in the hub body; the hub body is connected with the paddle shaft by bolts; the hub body and a front-end oil cylinder are integrated into a whole; the piston is installed at the end part of the guide frame in the hub by bolts; the front end of the piston, the inner wall of the hub body and the end part of the paddle shaft form a front chamber; the rear end of the piston, the inner wall of the hub body and the oil cylinder supporting baffle form a rear chamber; the rear end of the oil cylinder supporting baffle and the hub body form a lubricating oil chamber; the disk root of the paddle holder is provided with a crank pin; the slide block is sheathed on the crank pin and is arranged in a chute in the middle of the guide frame; the slide block is movably connected with the crank pin and the chute; and the oil tube is communicated with the rear chamber and moves together with the guide frame when working. The ship propeller hub has the characteristics of compact structure, good reliability, good stability of system operation and the like.

Owner:HANGZHOU ADVANCE GEARBOX GRP

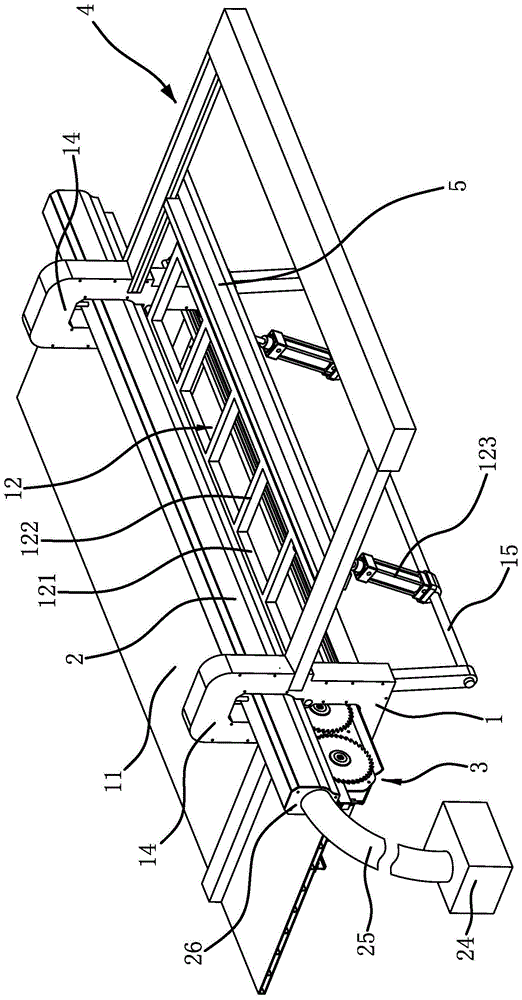

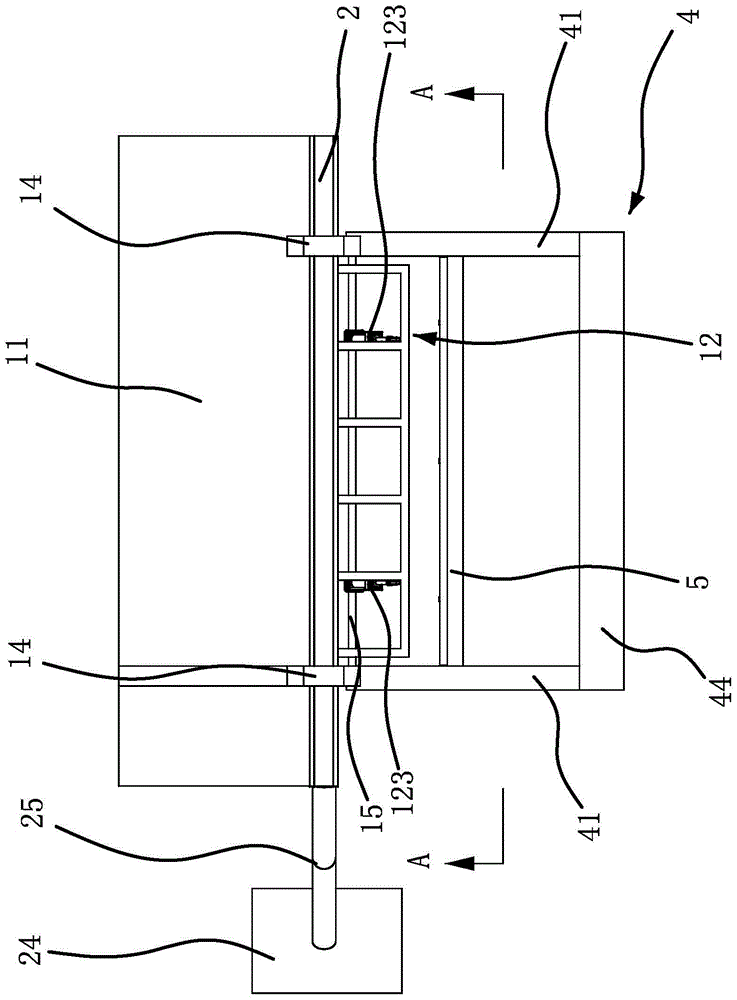

Material-pressing mechanism for sawing machine

ActiveCN105666591AImprove machining accuracyAvoid safety hazardsGuide fencesFeeding devicesEngineeringWoodworking machinery

The invention provides a material-pressing mechanism for a sawing machine and belongs to the technical field of woodworking machinery. The problem that an existing material-pressing mechanism for a sawing machine is poor in machining precision is solved. According to the material-pressing mechanism for the sawing machine, the sawing machine comprises a rack; a workbench plate is fixedly connected to the rack; the rack is further in swinging connection with a blanking frame; a receding clearance is formed between the blanking frame and the workbench plate; the material-pressing mechanism comprises a material-pressing base which is movably arranged on the rack; a dust collection cavity is formed in the material-pressing base and connected with an air pump; a dust collection notch communicating with the dust collection cavity is formed in the lower side surface of the material-pressing base; when the material-pressing base moves downwards and abuts against a workpiece, the upper edges of saw plates penetrate through the dust collection notch and stretch into the dust collection cavity. By means of the material-pressing mechanism for the sawing machine, the machining precision of the sawing machine can be made to be higher, scraps can be timely cleaned up, and the safety is higher.

Owner:浙江杭博电动工具有限公司

Oxygen supply device for fishpond

InactiveCN104396856AIncrease pressureIncrease the compression areaPisciculture and aquariaEngineeringOxygen supply

The invention discloses an oxygen supply device for a fishpond. The oxygen supply device for the fishpond comprises an oxygen supply machine and is characterized in that the oxygen supply machine is connected with an oxygen conveying pipeline, the other end of the oxygen conveying pipeline is closed, the oxygen conveying pipeline is firmly connected with the bottom of the fishpond and whirly arrayed along the bottom of the fishpond, and a plurality of automatic exhaust devices are arranged on the pipeline wall at intervals. The oxygen supply device for the fishpond is simple in structure, one oxygen supply machine can be used independently to supply oxygen to the whole fishpond, and the oxygen supply is uniform.

Owner:NINGBO FREE TRADE ZONE HUAMENG BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com