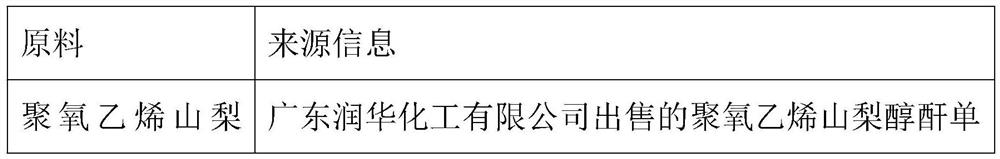

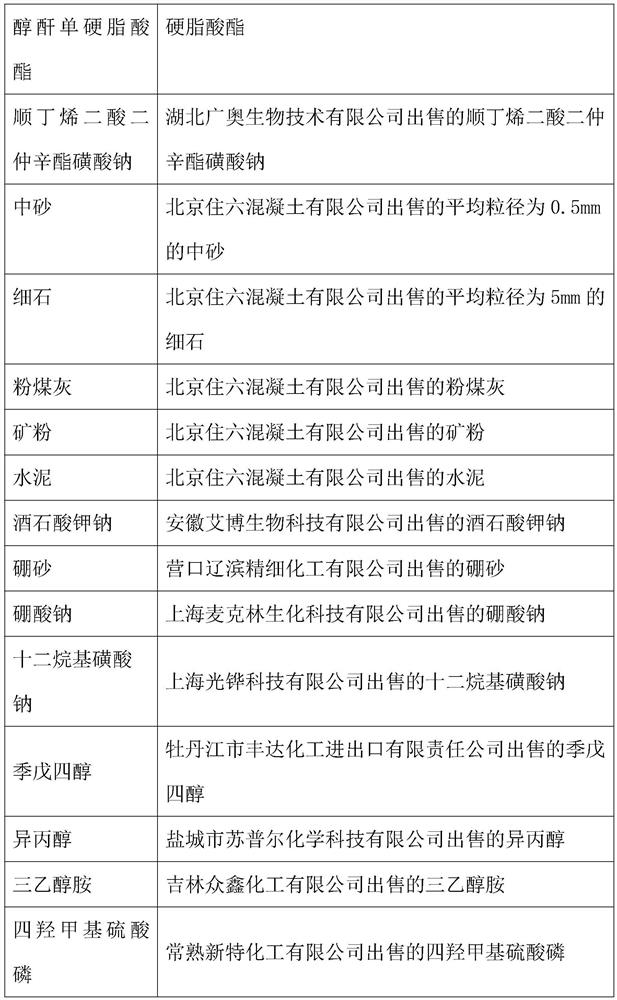

Patents

Literature

52results about How to "Reduce inflation pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

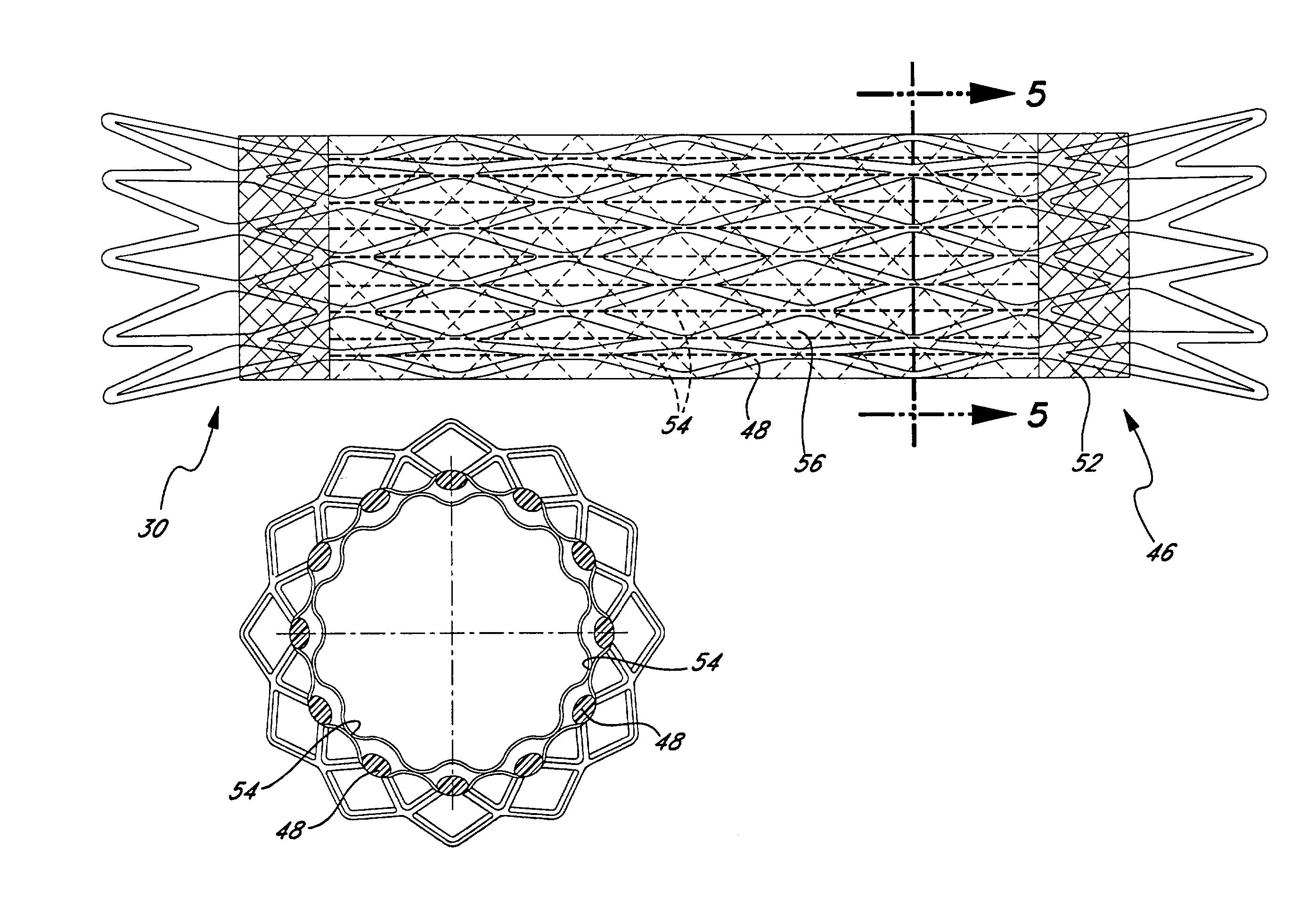

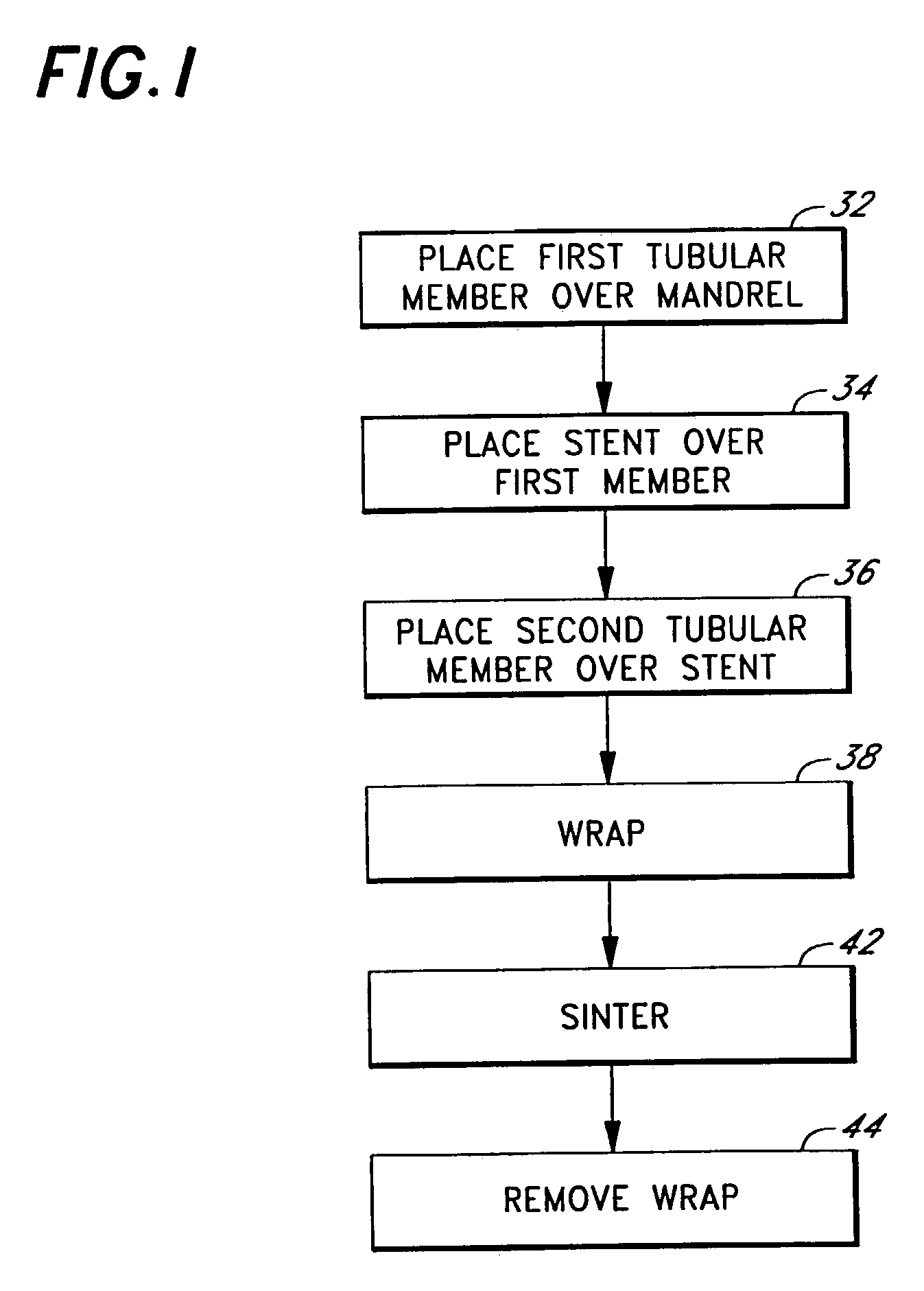

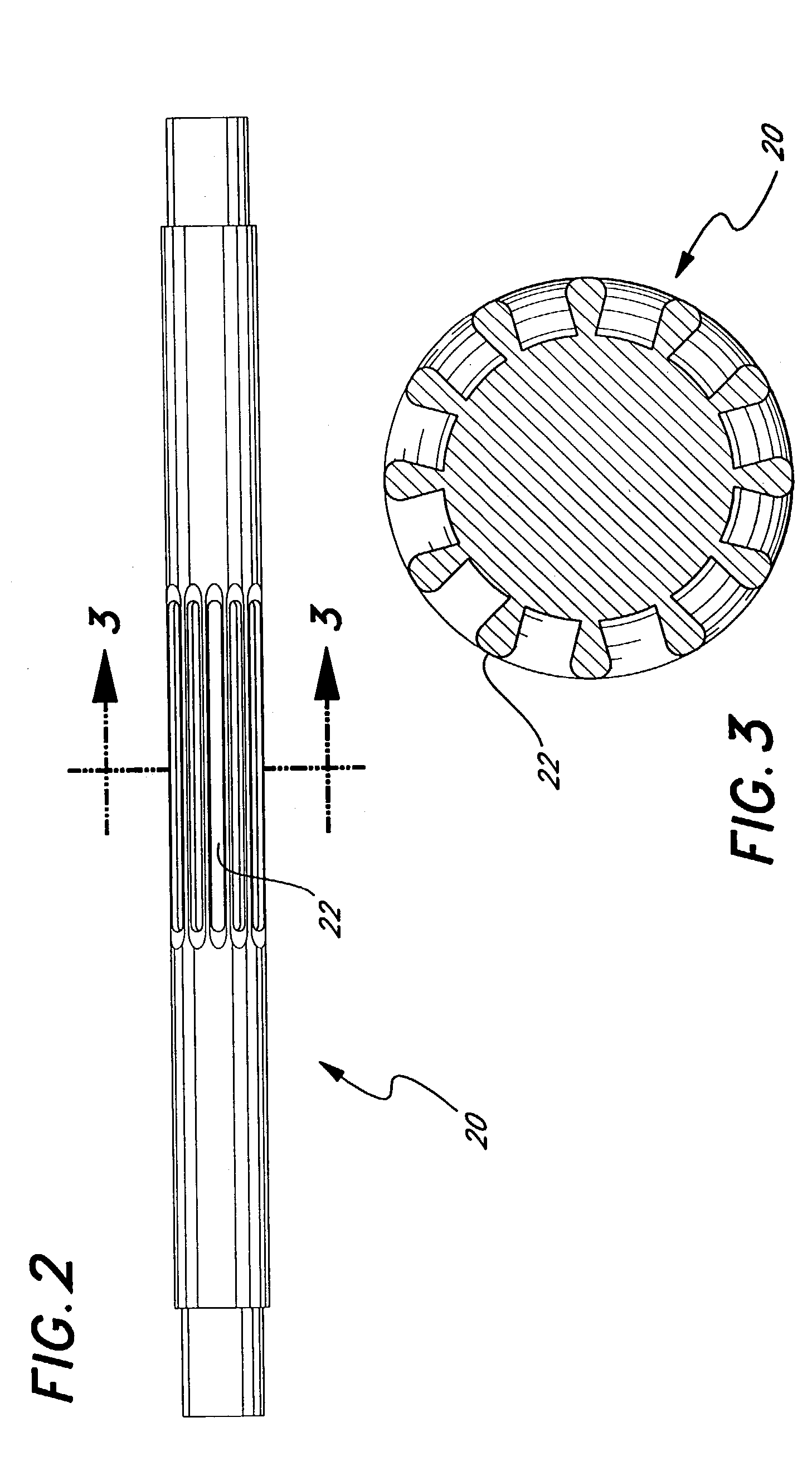

Selective adherence of stent-graft coverings

InactiveUS7004966B2Little strengthReduce inflation pressureStentsDomestic articlesStent graftingVascular device

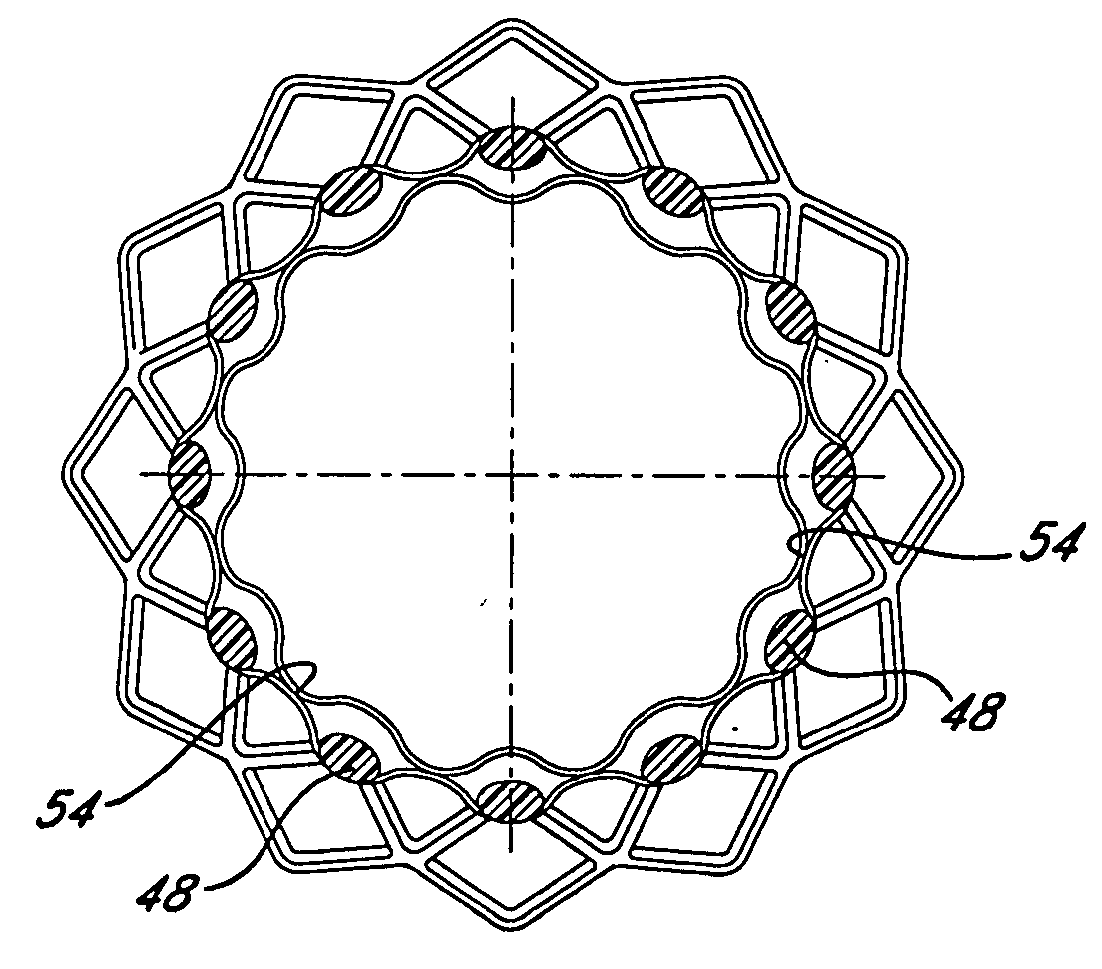

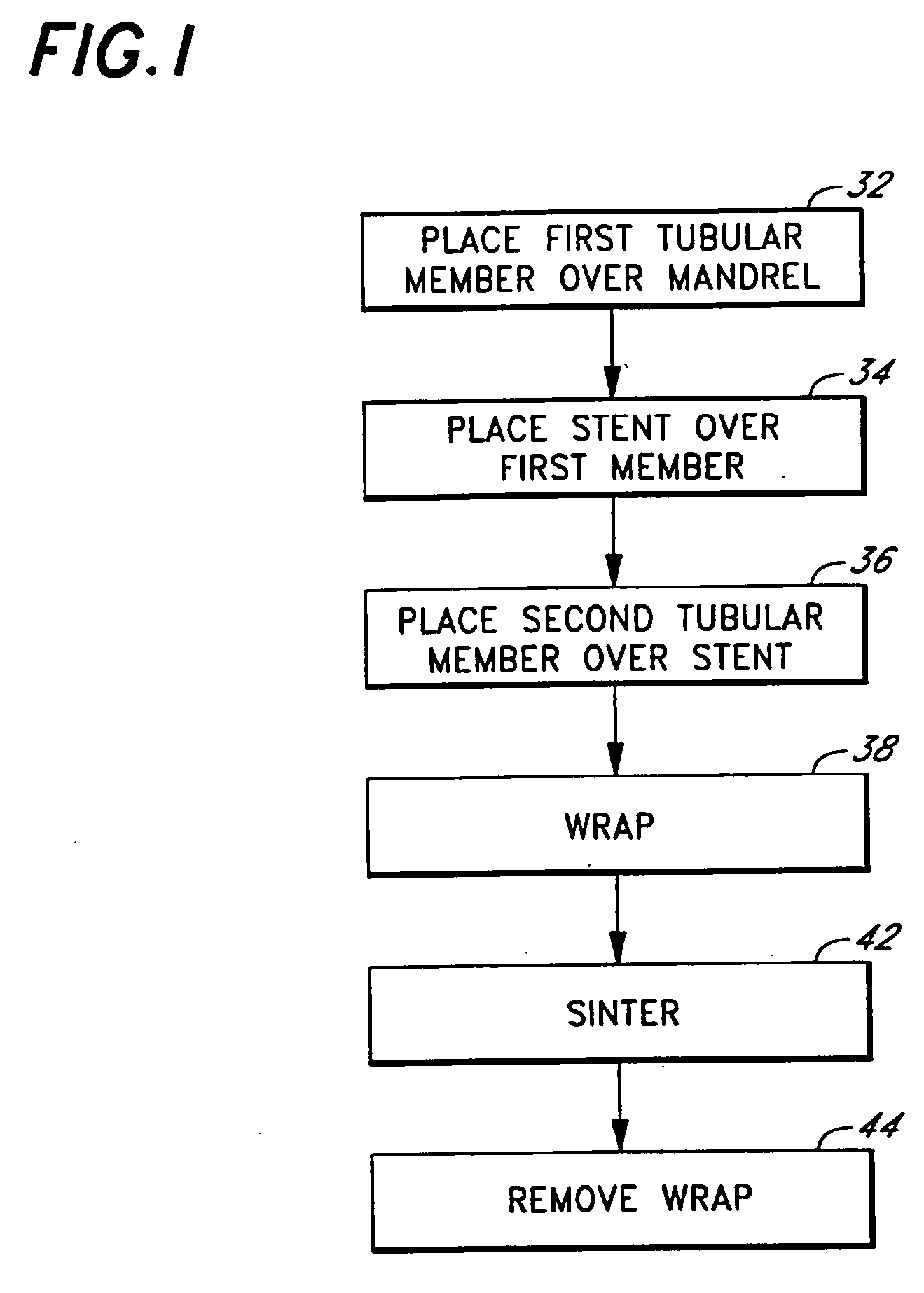

An endoluminal vascular device having a plurality of predetermined boding locations between respective first and second covering members to selectively encapsulate a support member. Selective bonding between the first and second covering members results in unbonded slip pockets to accommodate movement of the support member. Such a configuration allows compression of the support member with minimal force and also promotes a low profile of the compressed device. Unbonded regions of the covering members also encourage enhanced cellular penetration for rapid healing and can be configured to hold bioactive substances that diffuse through the covering members.

Owner:BARD PERIPHERAL VASCULAR

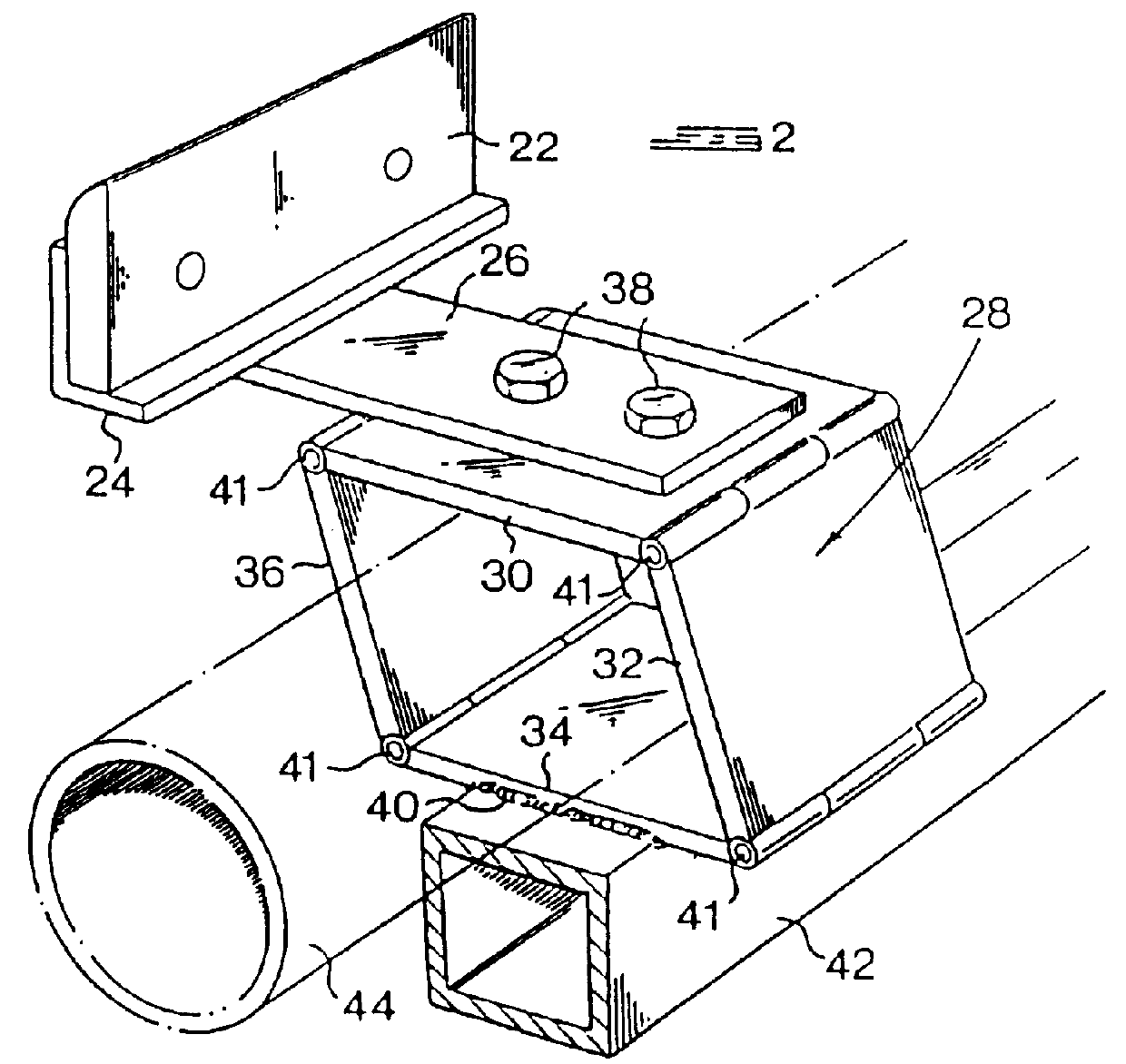

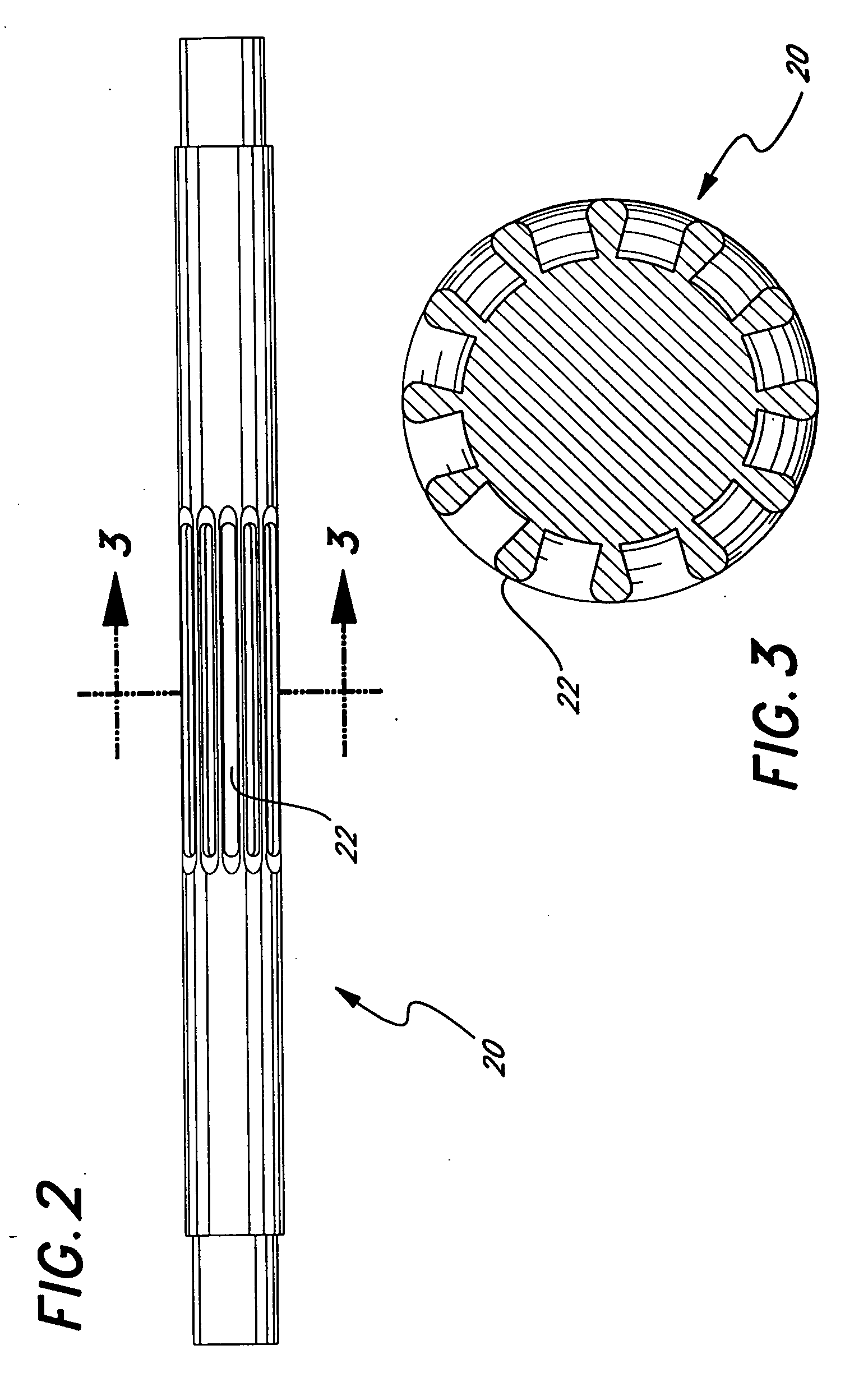

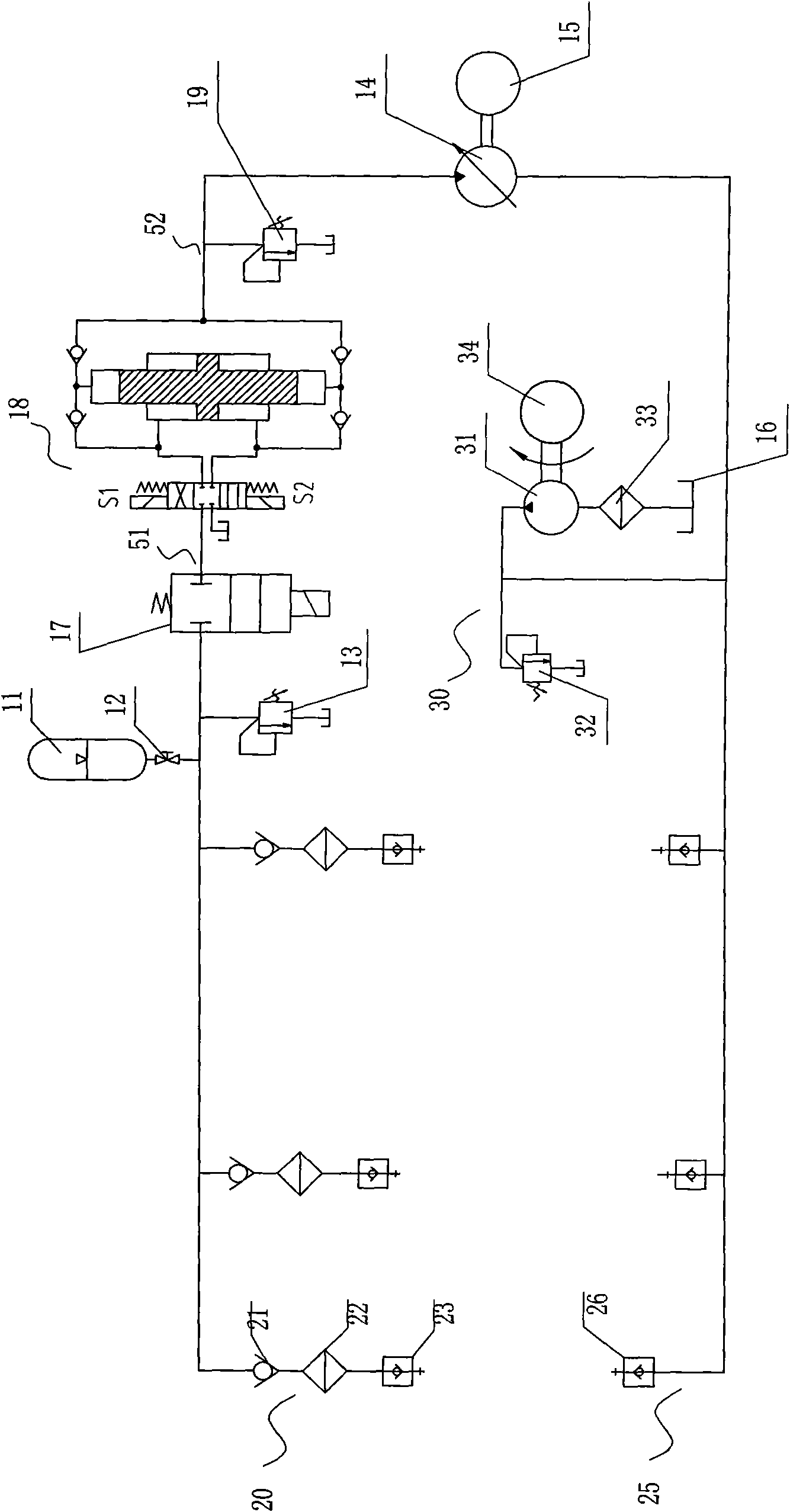

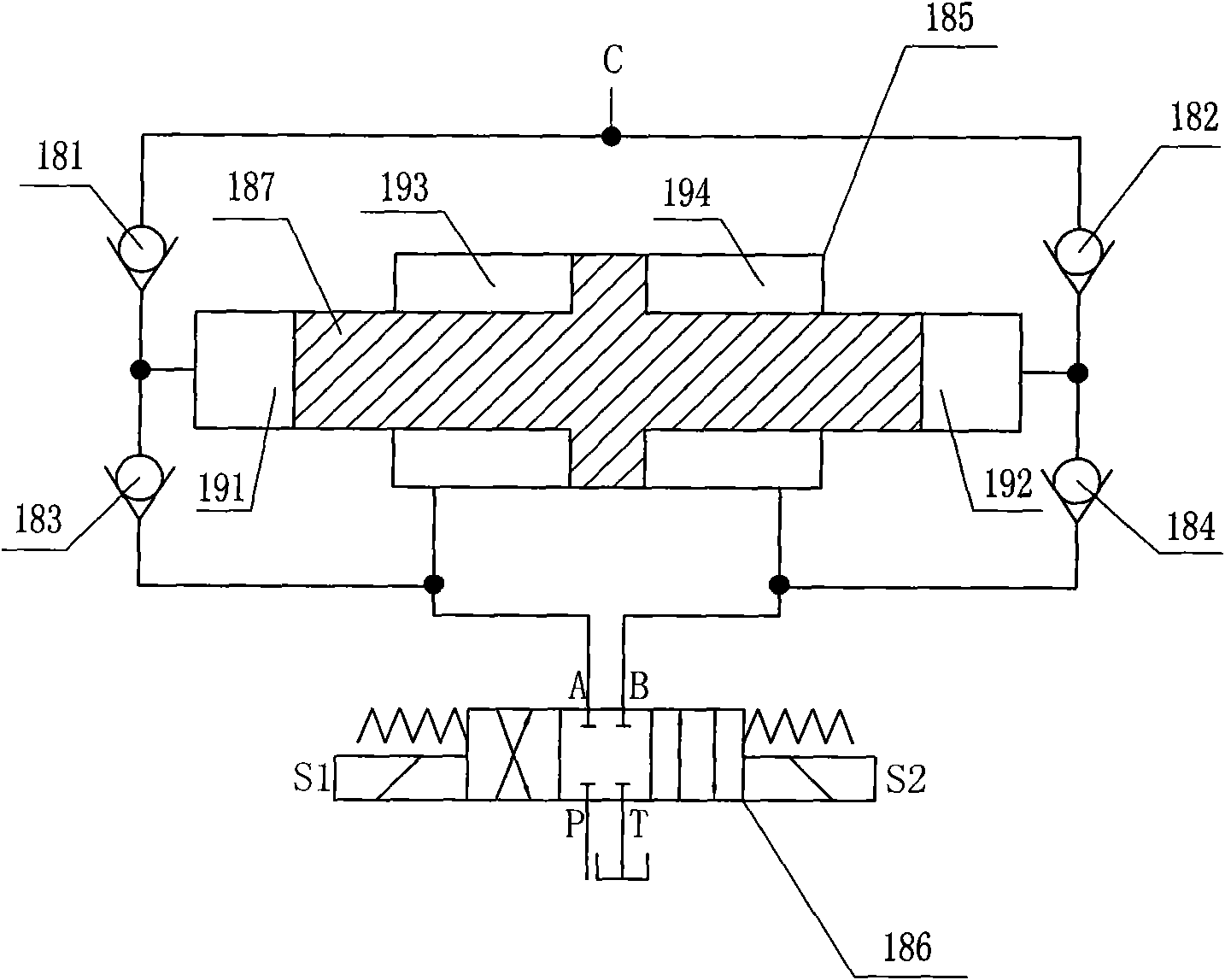

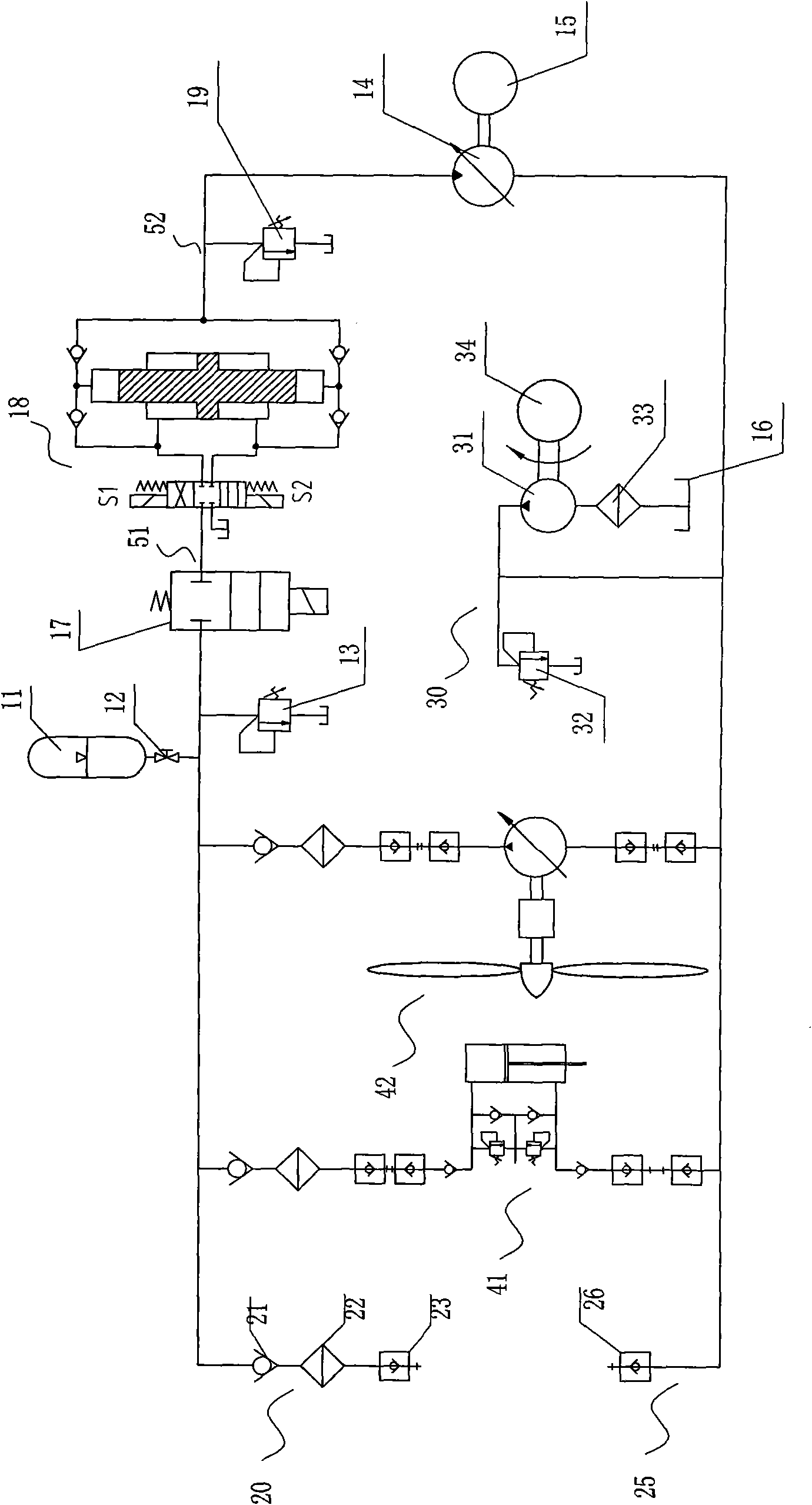

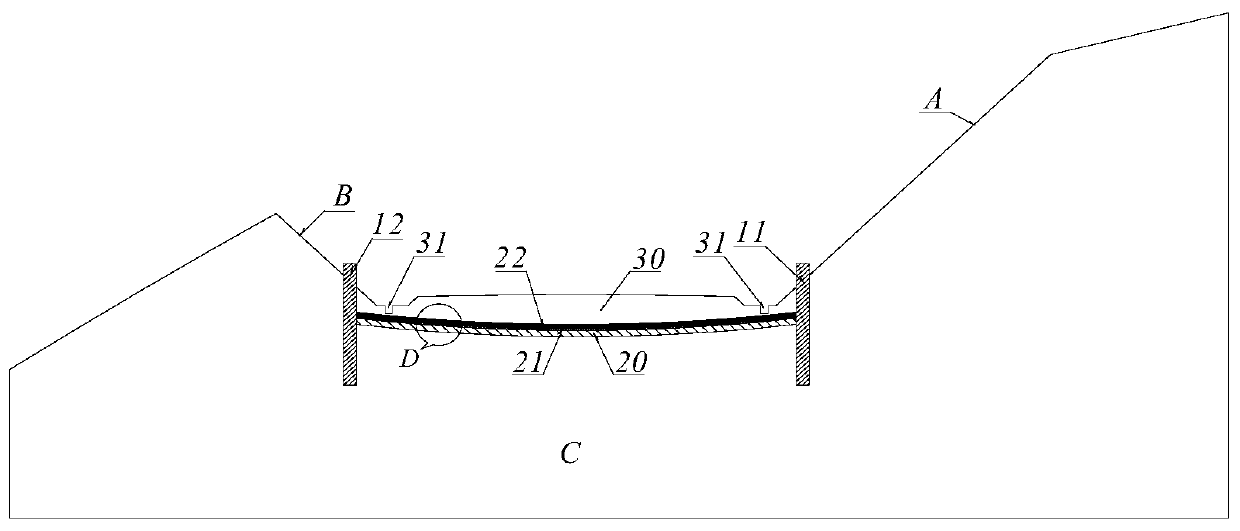

Conveyor belt scrapers

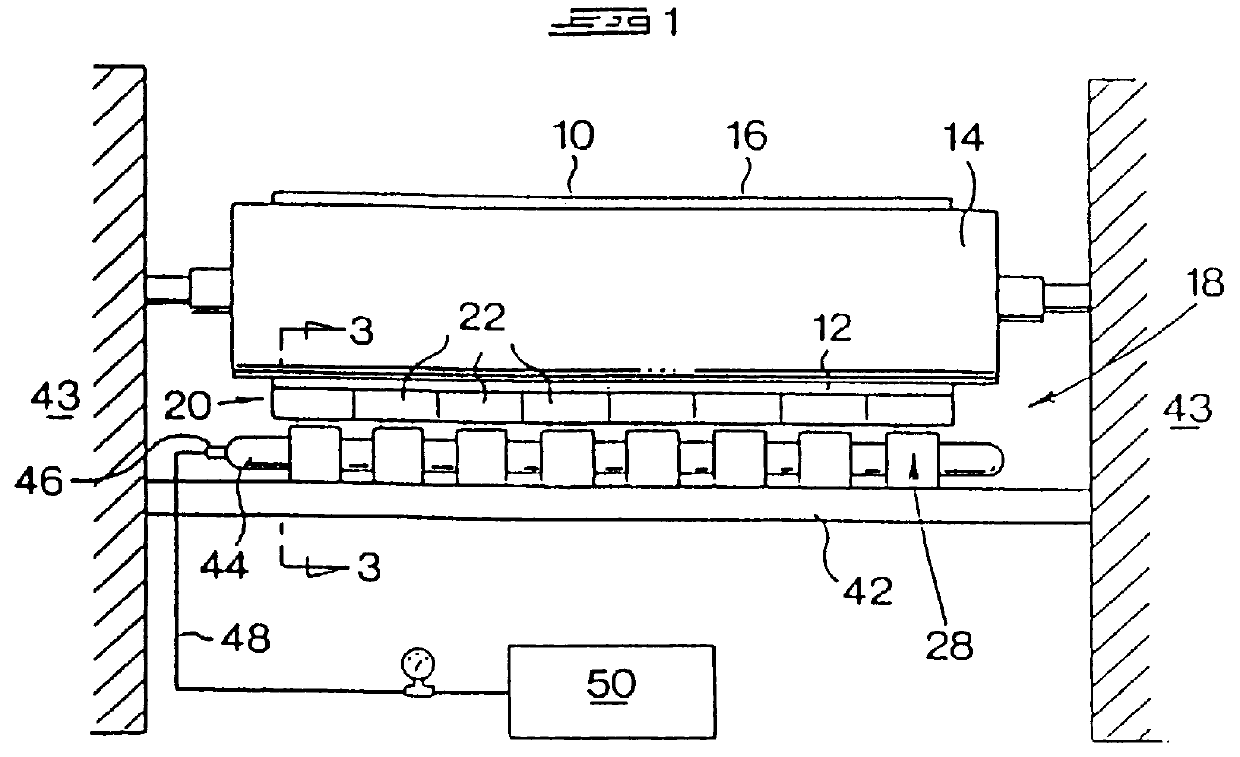

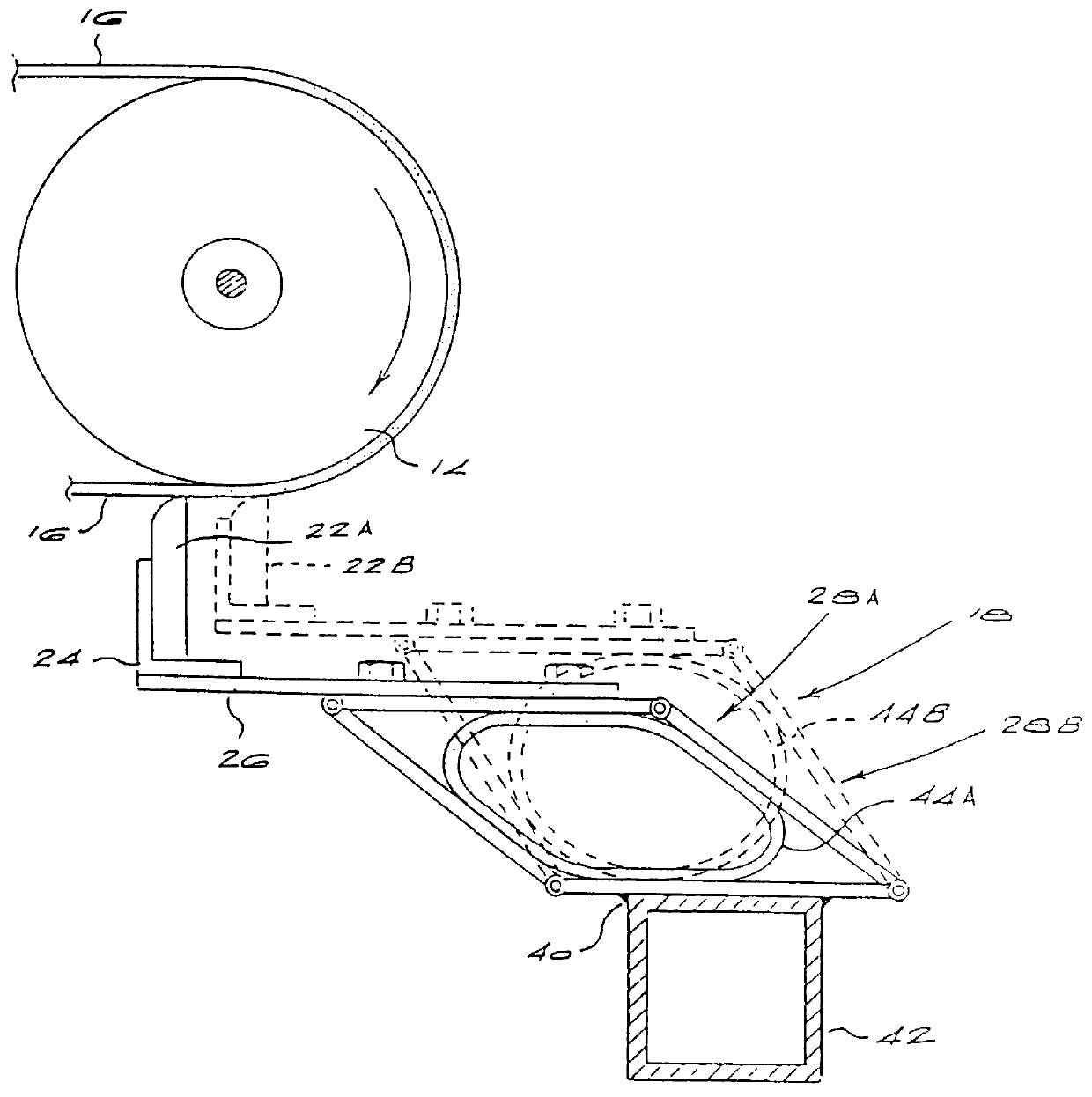

PCT No. PCT / EP96 / 04228 Sec. 371 Date Feb. 20, 1998 Sec. 102(e) Date Feb. 20, 1998 PCT Filed Sep. 27, 1996 PCT Pub. No. WO97 / 14635 PCT Pub. Date Apr. 24, 1997The invention concerns a conveyor belt scraper used to scrape debris from the surface of a conveyor belt (10). The scraper incorporates a segmented scraper blade which includes individual blade segments (22) arranged side by side with one another such that in use each blade segment scrapes a portion of the width of the belt surface. For blade segment there is a blade segment support (28) on which the associated blade segment (22) is supported. Each blade segment support (28) includes pivotally interconnected links (30, 32, 34, 36) forming a closed parallelogram linkage. A support structure (42, 82) is provided to support the parallelogram linkages in side by side relationship adjacent the belt surface. Gas-inflatable biasing means (44, 58) act on the parallelogram linkages such that inflation thereof causes the linkages to deform in a manner to displace the blade segments (22) in a direction lengthwise of the belt (10) and towards the belt surface. During such displacement, each blade segment (22) moves parallel to itself and maintains a constant inclination to the vertical.

Owner:MAT GHISLAIN JUSTIN MARIE

Selective adherence of stent-graft coverings

InactiveUS20060155369A1Little strengthReduce inflation pressureStentsDomestic articlesMedicineStent grafting

An endoluminal prosthesis including a first polymer member bonded to a second polymer member to selectively encapsulate a stent. Selective bonding between the first and second polymer members results in unbonded regions or pockets that accommodate movement of the stent, permitting compression of the prosthesis using minimal force and enabling collapse of the prosthesis to a low profile. The pockets are believed to encourage enhanced cellular penetration for rapid healing and may contain bioactive substances.

Owner:BARD PERIPHERAL VASCULAR

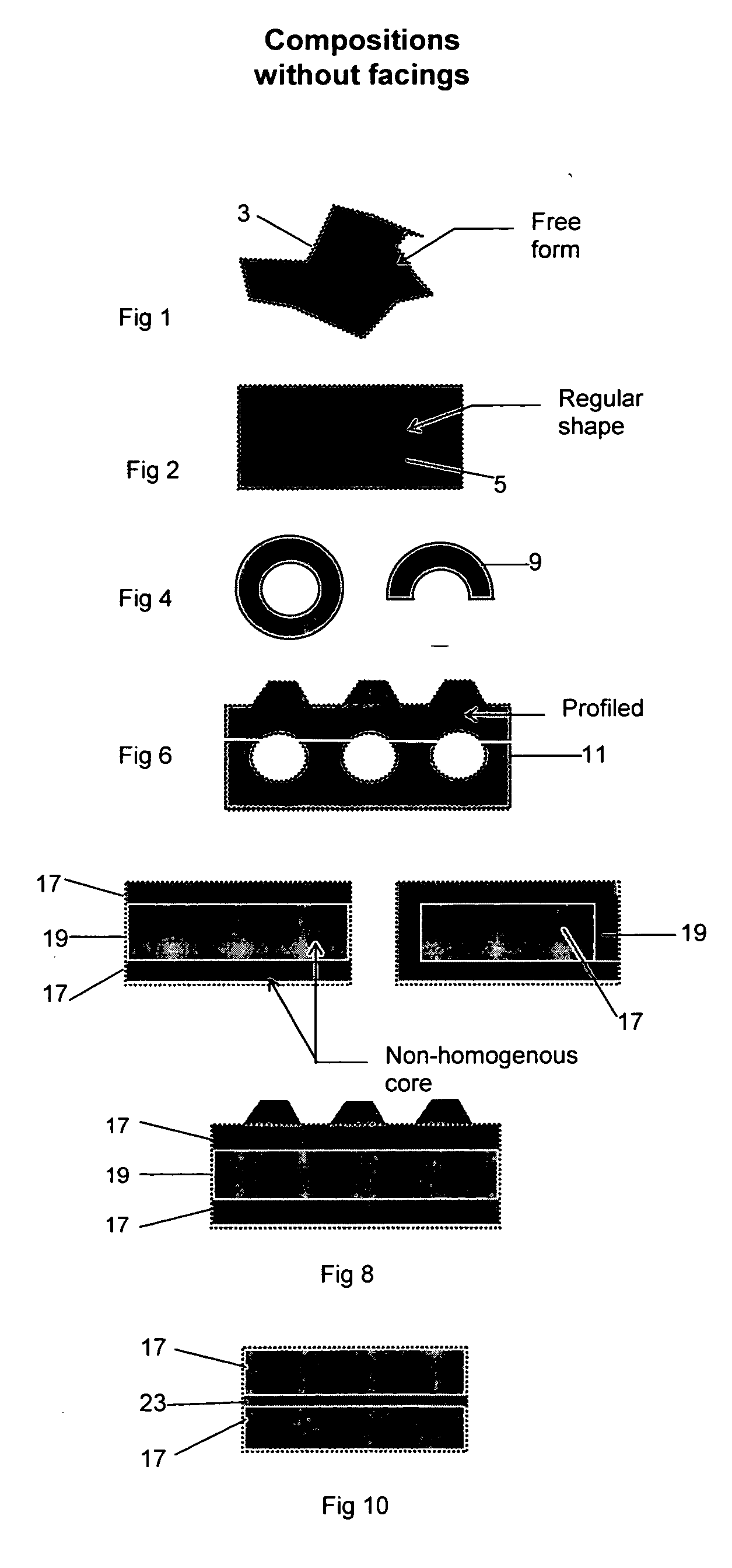

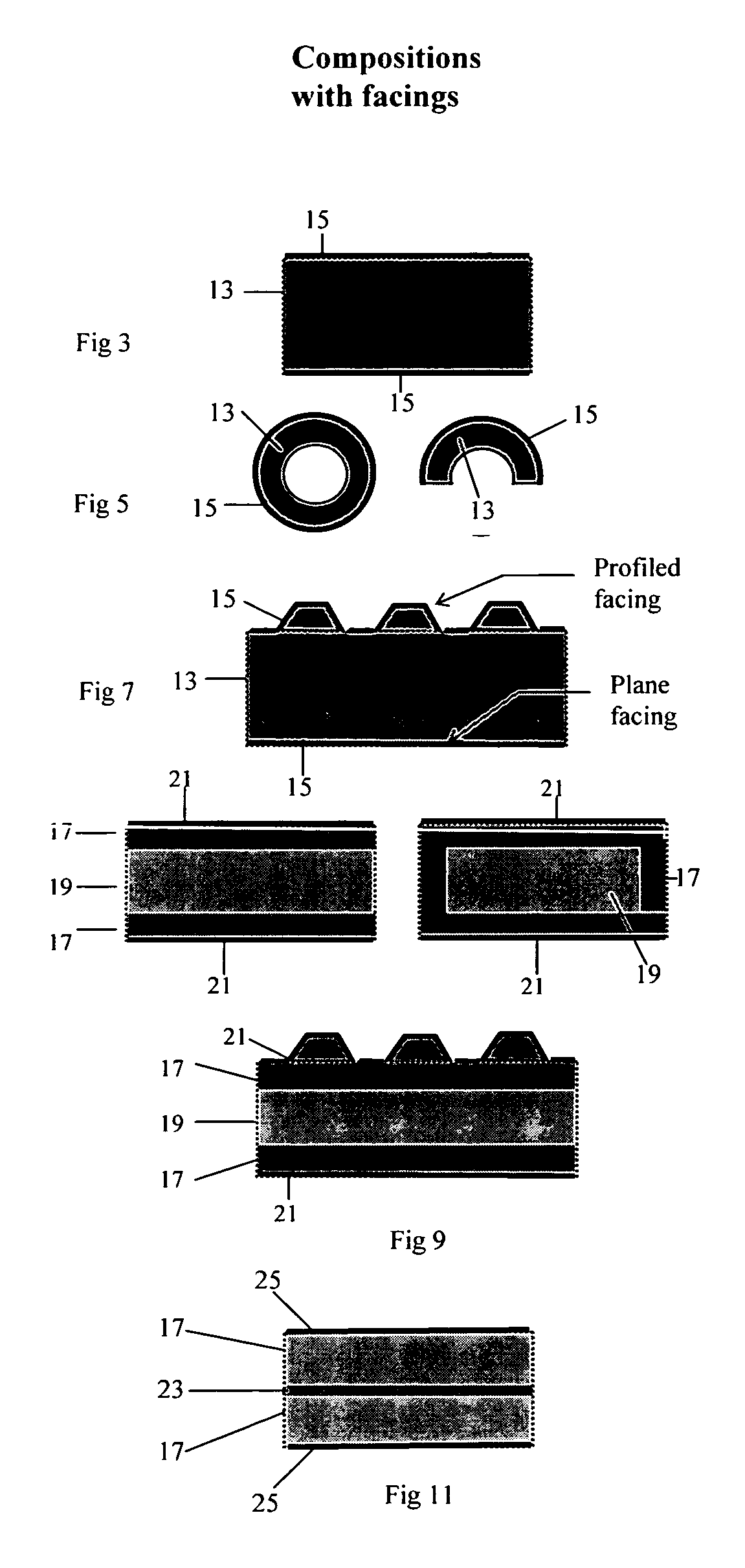

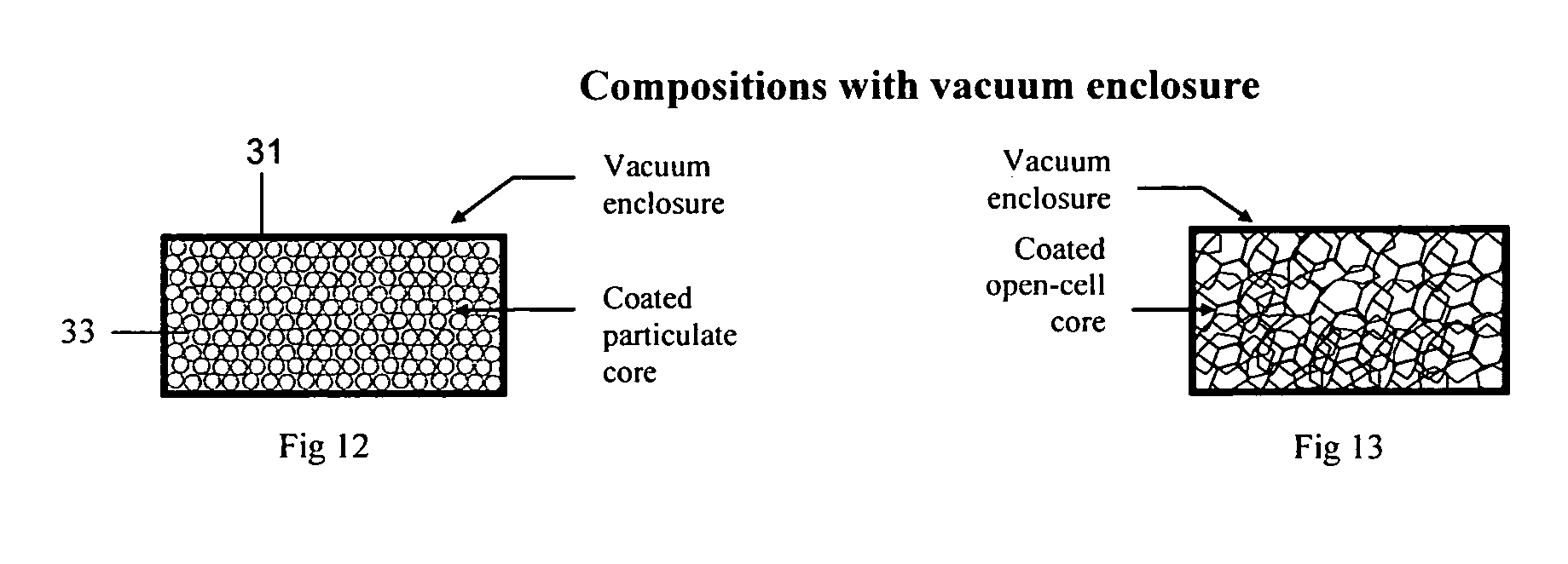

Fire resistant insulation material

InactiveUS20050176833A1Improve fire resistanceEnhance layeringSolid waste managementThermal insulationRefractory

Owner:TAY CHONG HAK

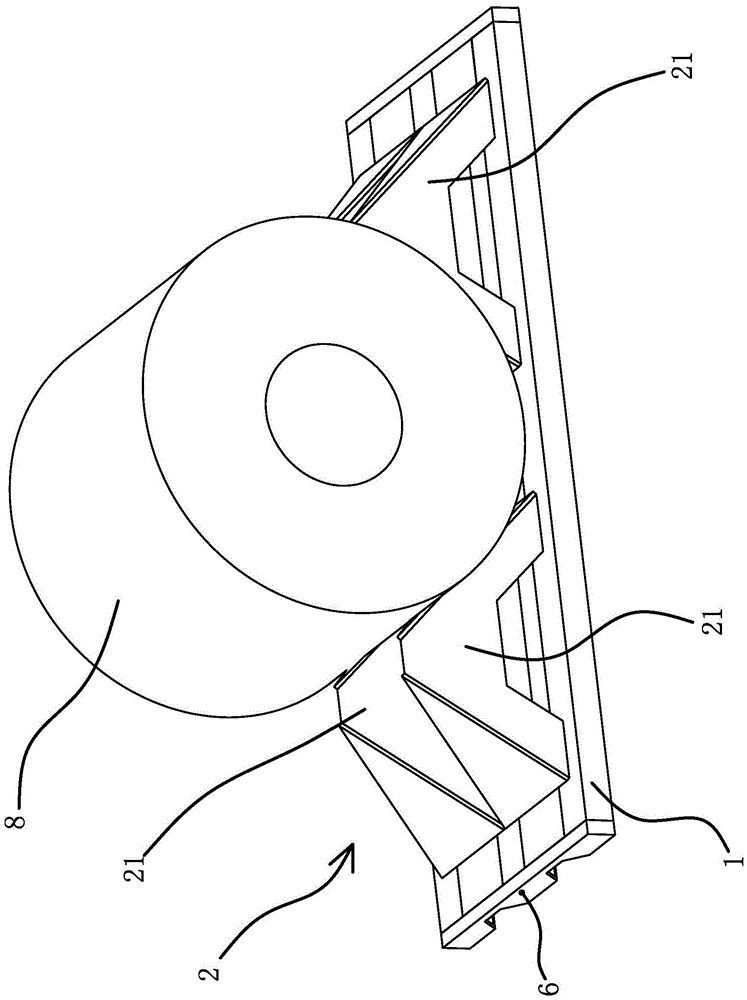

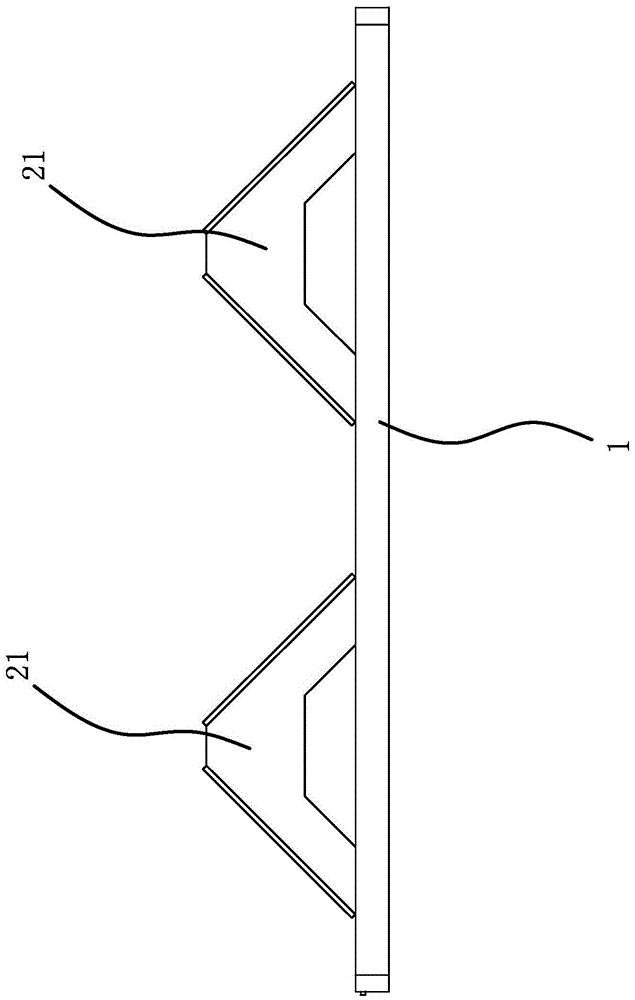

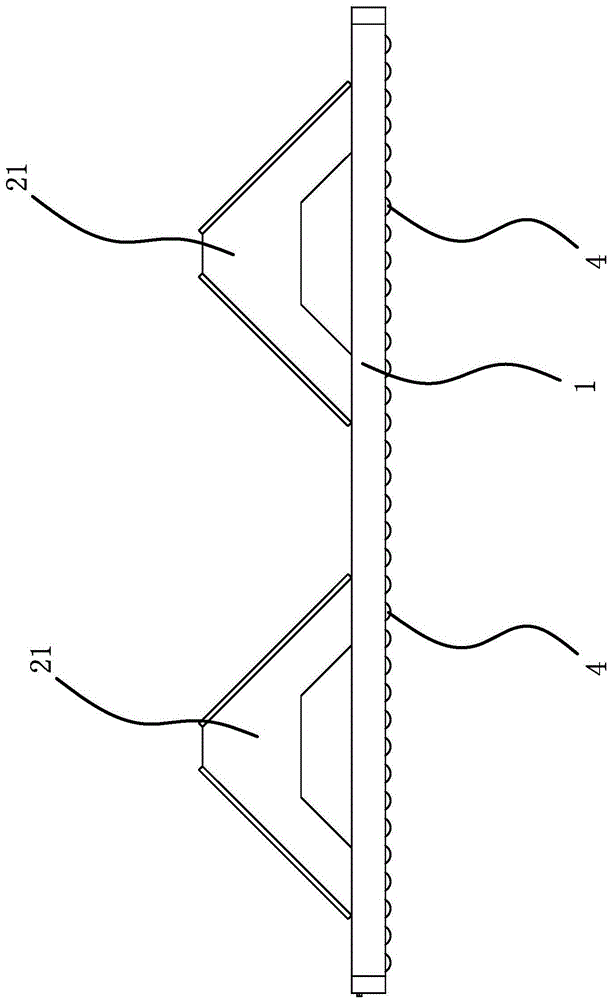

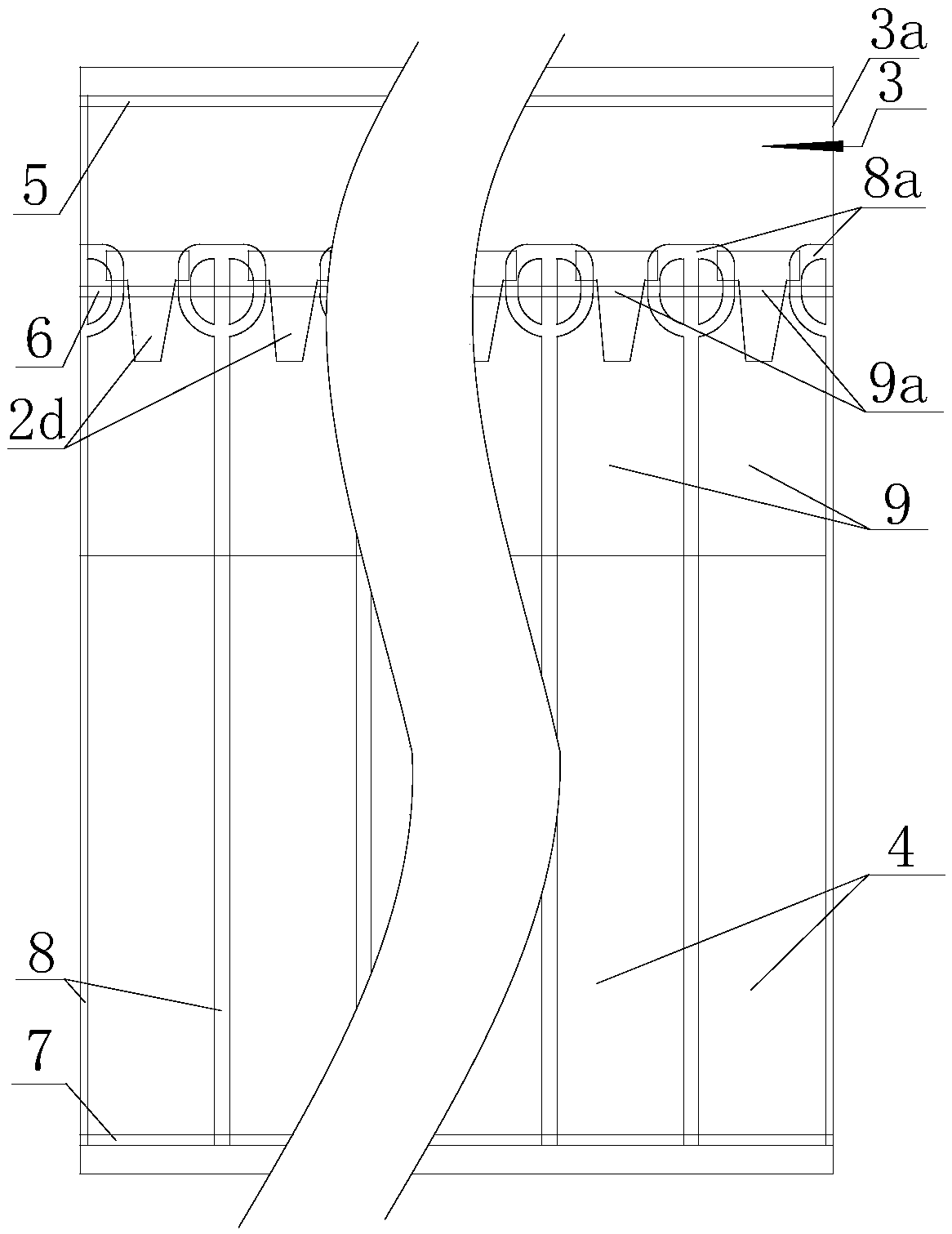

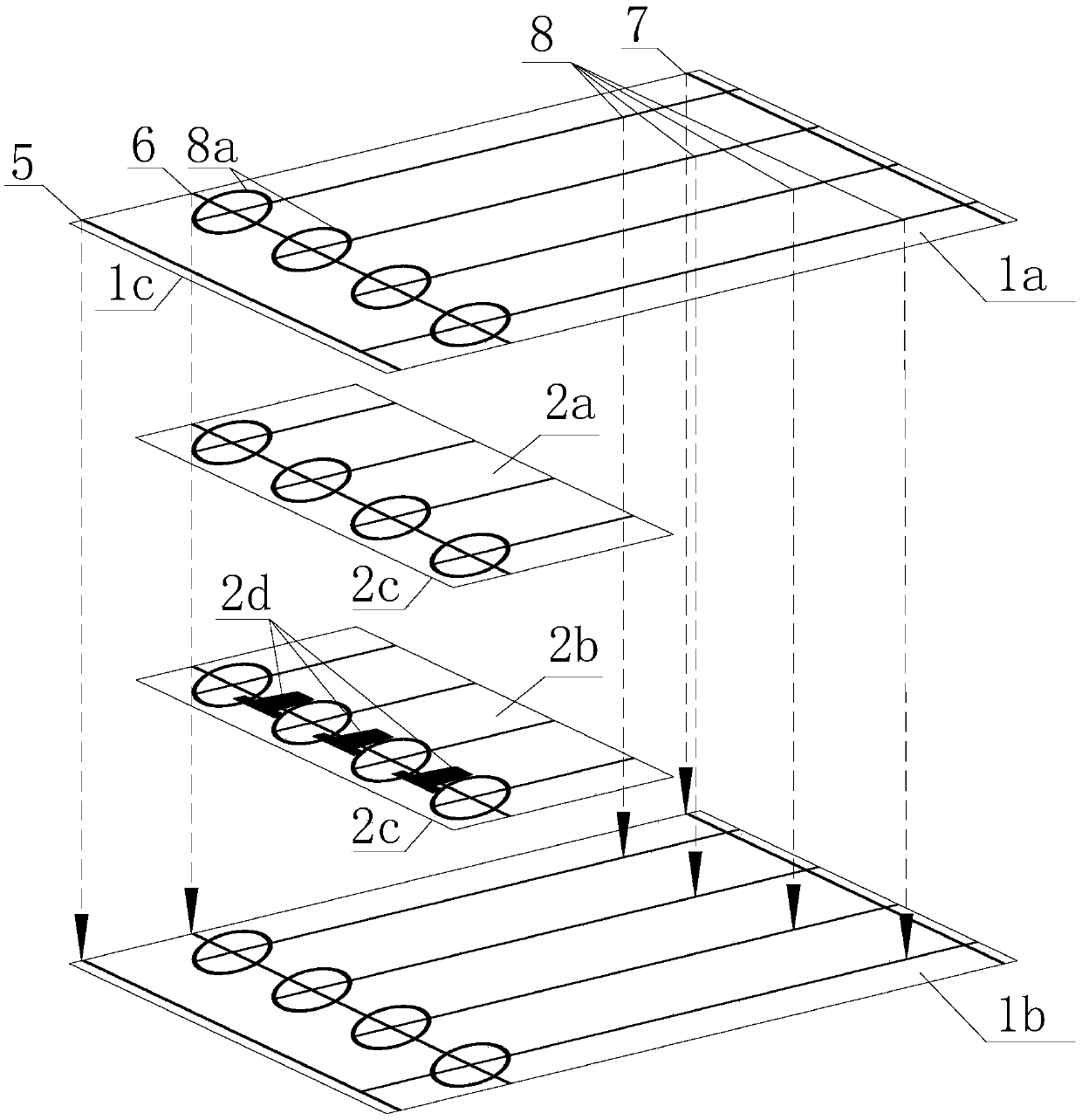

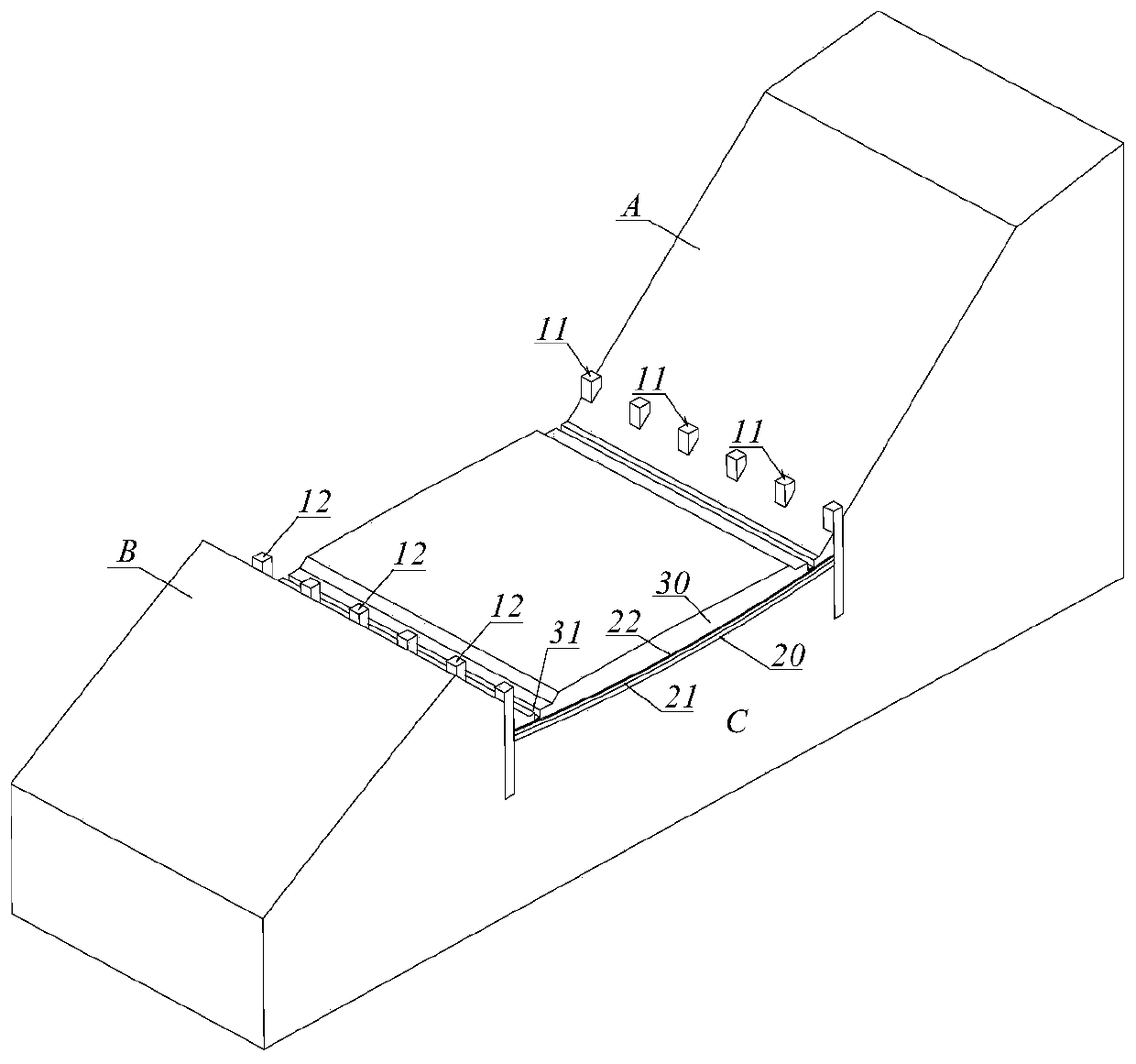

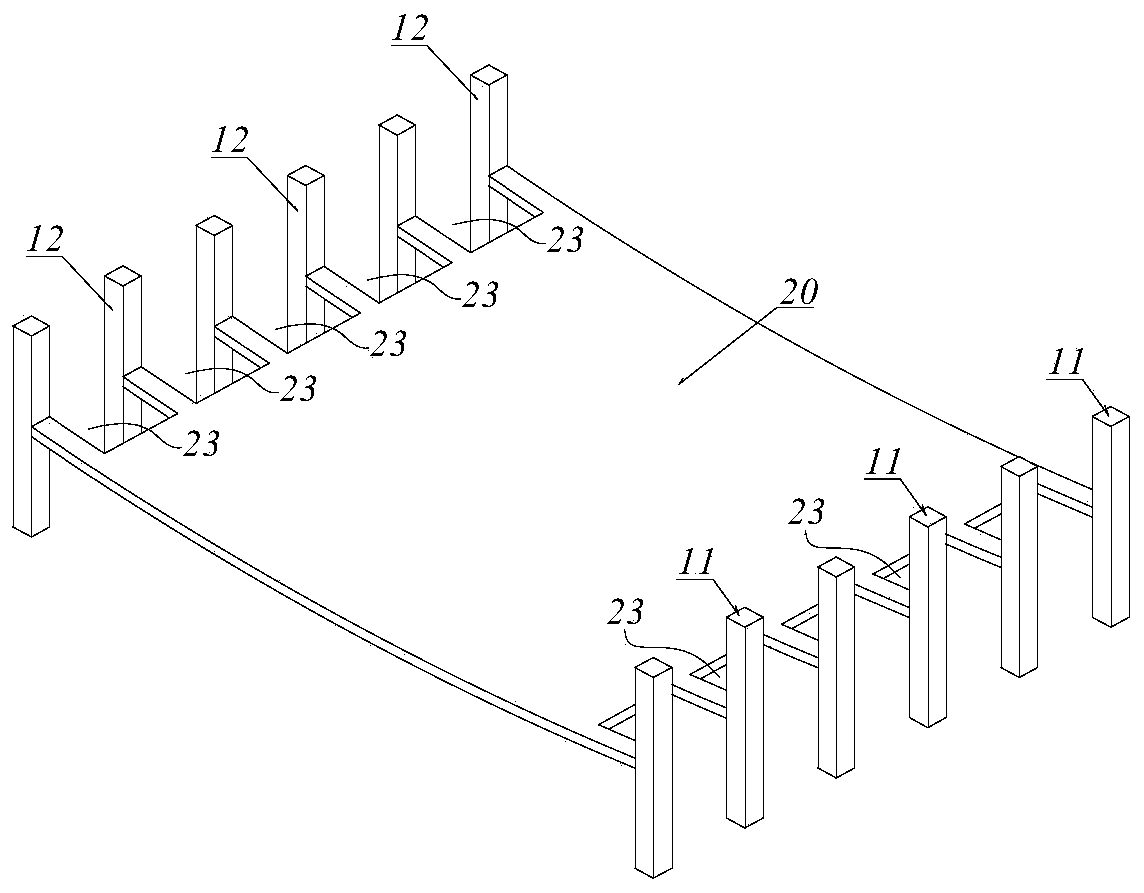

Tray used for steel coil transportation

ActiveCN105600134AEasy to transfer and transportEasy to transportExternal framesRigid containersEngineeringMechanical engineering

The invention provides a tray used for steel coil transportation, and belongs to the technical field of transportation. The tray solves the technical problem that an existing movable tray is not suitable for bearing steel coils. The tray comprises a tray frame and a limiting frame arranged on the tray frame and used for positioning a steel coil. At least two long-strip-shaped installation grooves are formed in the bottom of the tray frame. Long-strip-shaped rolling wheel frames are arranged in the installation grooves. A plurality of rolling wheels are connected to the rolling wheel frames in the length direction of the rolling wheel frame. Guide structures capable of guiding the rolling wheel frames to move up and down relative to the tray frame and limiting structures capable of preventing the rolling wheel frames from being disengaged from the installation grooves are arranged on the portions, located in the installation grooves, on the tray frame. Gas bags are arranged in the installation grooves and located above the rolling wheel frames. The whole rolling wheels can be located in the installation grooves when the gas bags are not inflated. The gas bags can act on the rolling wheel frames to make the rolling wheels stretch out of the installation grooves when the gas bags are inflated and expanded. The tray has the advantage that the steel coil can be stably transported.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

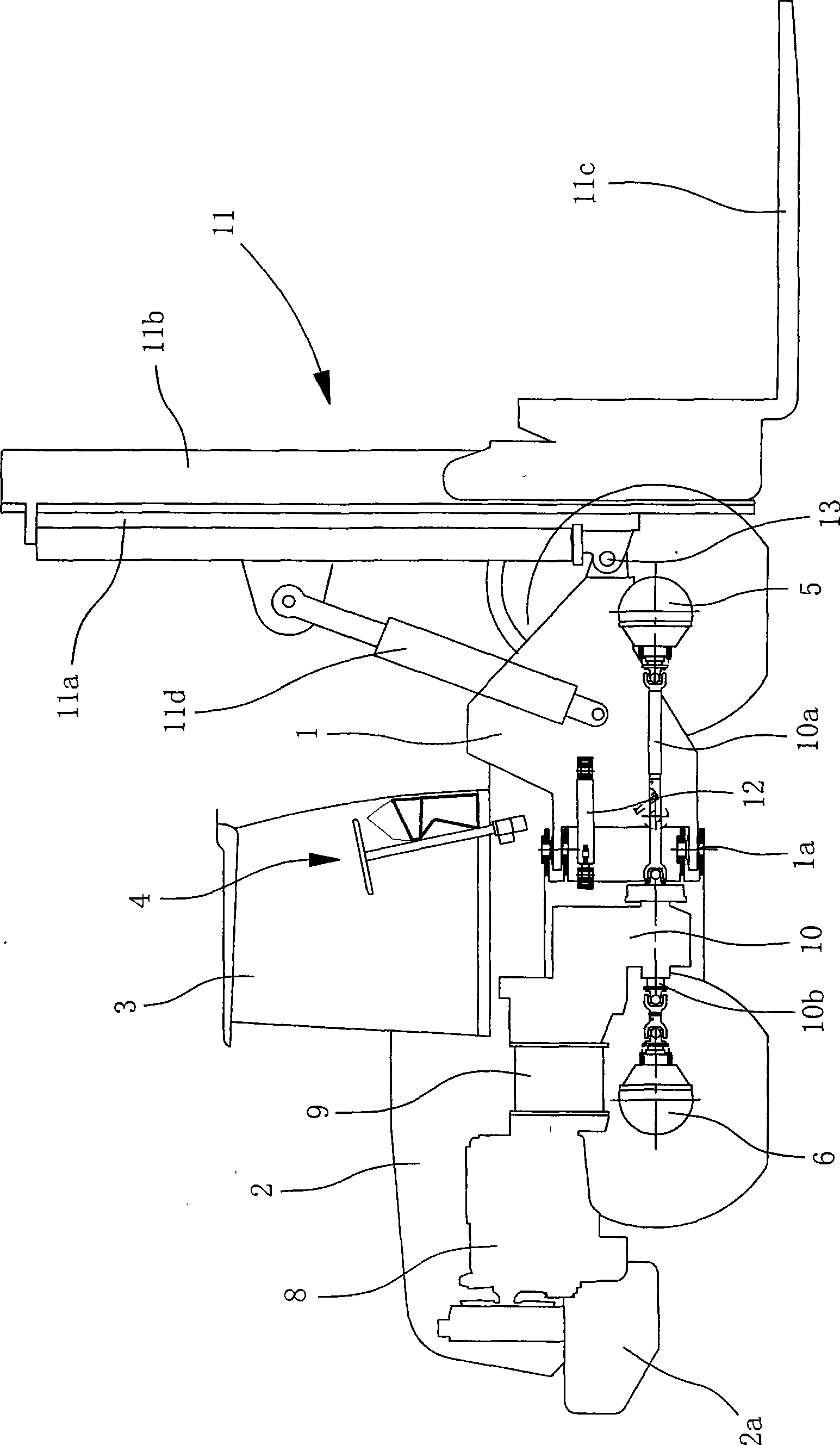

Engineering forklift truck

InactiveCN101519181AImprove off-road performanceGood value for moneyLifting devicesSuperstructure connectionsVehicle frameDrive shaft

The invention relates to an engineering forklift truck comprising a truck frame, an operator cabin in which an operating mechanism is arranged, a front driving axle, a rear driving axle, an engine, a torque converter, a variable speed case, door frame working mechanisms and balancing weights, wherein the door frame working mechanisms and the balancing weights are respectively arranged on the front end parts and the rear end parts of the truck frame. The engineering forklift truck is characterized in that the truck frame comprises a front truck frame and a rear truck frame, and the front truck frame and the rear truck frame are hinged together by pin shafts; a steering oil cylinder is installed between the front truck frame and the rear truck frame; the operator cabin is installed on the rear truck frame and generally positioned at the middle part of the entire truck; the engine, the torque converter and the variable speed case are installed on the rear truck frame, the engine is in transmission connection with the variable speed case by the torque converter, and a front transmission shaft and a rear transmission shaft of the variable speed case are correspondingly connected with the front driving axle and the rear driving axle by shaft couplings. The truck frame of the forklift truck adopts the mutually hinged front truck frame and the rear truck frame, uses the hinge steering to replace the rear wheel steering of the forklift truck and utilizes the two common driving axles of low cost to realize four-wheel driving, thereby enhancing the off-road performance of the forklift truck under adverse operating environment and being more adapted to the field operation of loading and unloading.

Owner:QUANZHOU WEISHENG MECHINE DEV

Condensate water and cooling water regenerating device of thermal power plant and nuclear power plant

InactiveCN102094744ANo reduction in massRelieve pressureSteam useEngine componentsLiquid waterWater storage tank

The invention relates to a waste steam, condensate water and cooling water regenerating device of a thermal power plant and a nuclear power plant. The device provided by the invention is characterized in that after steam drives a turbine to generate power, the swelling pressure of the turbine is reduced, but the steam quality of the turbine is not reduced; the waste steam is pressed into a platform with a certain height relative to the ground through a pipeline under 3 to 4 atmospheric pressures (while the higher height is better but according to actual conditions); after being cooled through a highly vacuum condenser, the waste steam is changed into liquid water at a temperature of about 40 DEG C; after being exhausted and stored into an upper water storage tank at the lower part, the liquid water leaks downwards through a pressure pipeline to drive the turbine; the turbine drives a generator to generate the power; the cooling water is lifted to the height which is the same to the condenser through a circulating water pump; the waste heat is taken away by the condenser; after being exhausted and stored into another upper water storage tank at the lower part, the waste heat leaks downwards through the pressure pipeline to drive the turbine; and the turbine drives the generator to generate the power (while the cooling of the condenser is divided into water cooing and air cooling, if the air cooling is adopted, a cooling water generating device is not provided).

Owner:侯创新

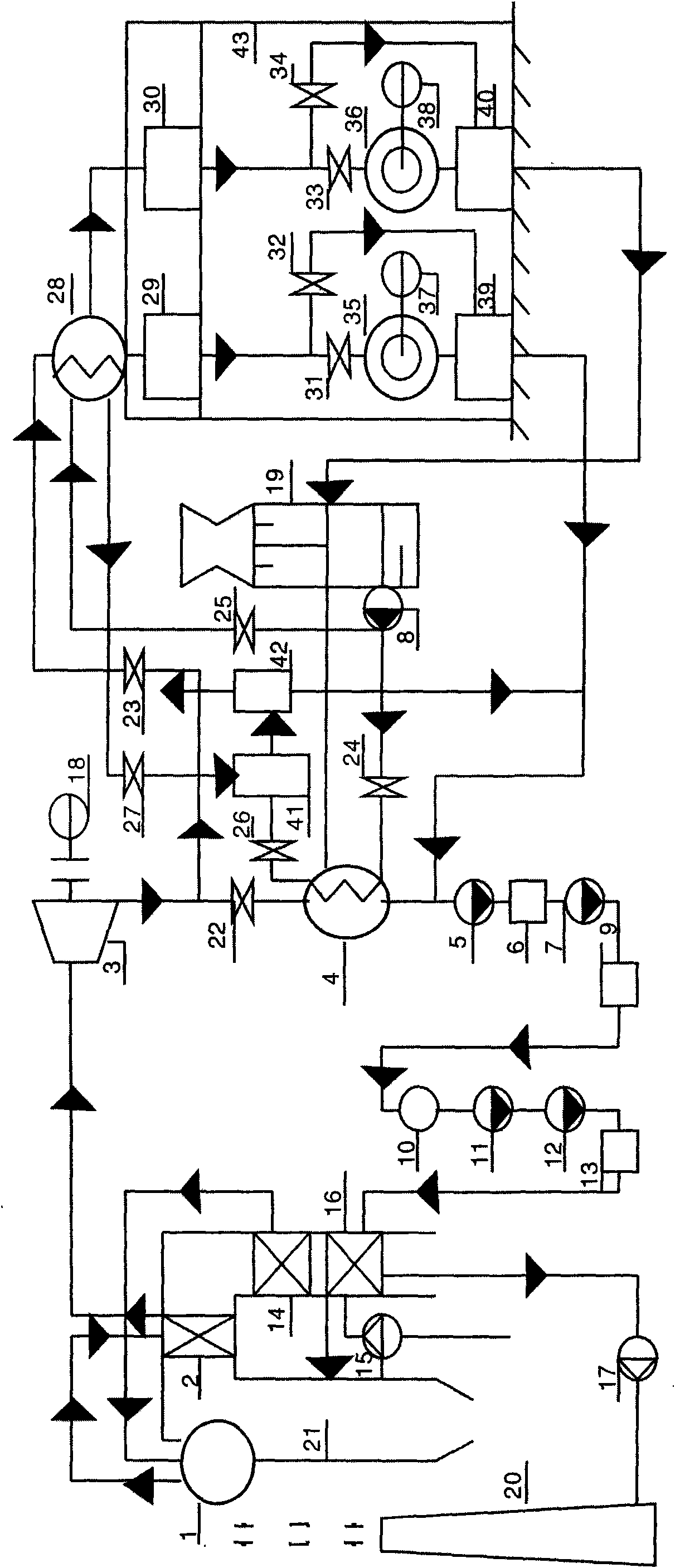

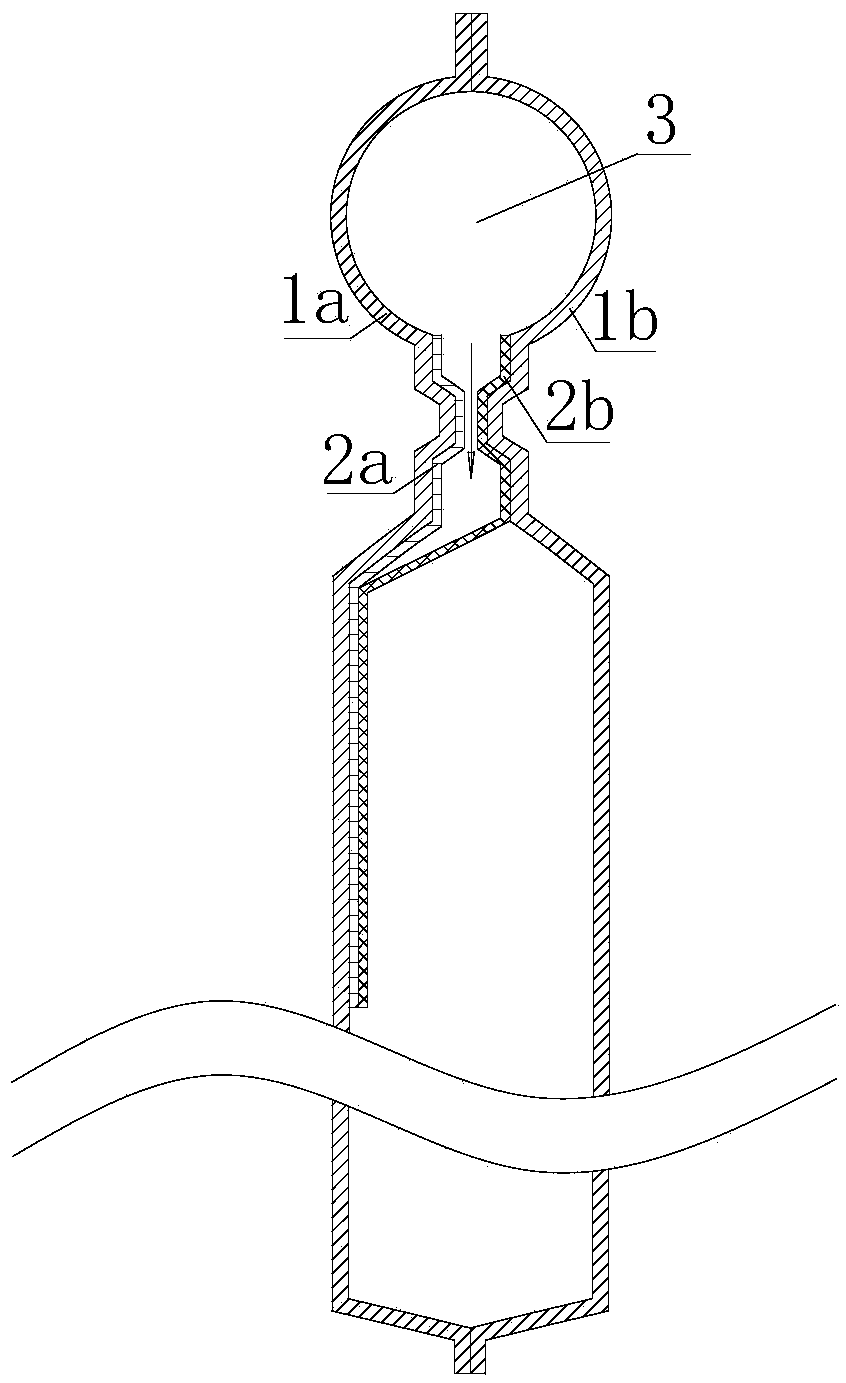

Marine fluid kinetic energy integrated generating system

InactiveCN101871416AReduce inflation pressureReduce volumeMachines/enginesEngine componentsHigh energyMechanical energy

The invention discloses a marine fluid kinetic energy integrated generating system, which comprises energy capturing devices converting fluid kinetic energy into mechanical energy, a mechanical energy transmission mechanism and a generating mechanism converting the mechanical energy into electrical energy. The system is connected with a pressure increasing valve. The flow at an inlet of the pressure increasing valve is controlled by a switch valve. The hydraulic branch circuit is a hydraulic branch circuit group formed in a mode that at least more than two hydraulic branch circuits are connected in parallel. Each hydraulic branch circuit is connected with one energy capturing device. The marine fluid kinetic energy integrated generating system adopting the structure not only can capture high-energy marine fluid kinetic energy, but also can capture weak marine fluid kinetic energy and is particularly suitable for the integrated generating system for capturing the weak marine fluid kinetic energy.

Owner:ZHEJIANG UNIV

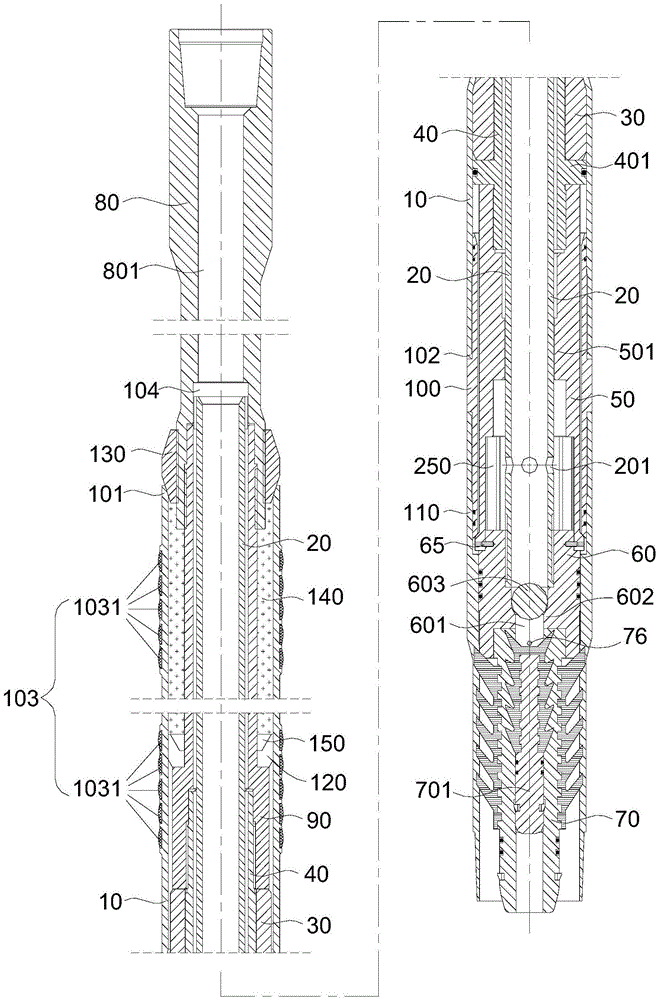

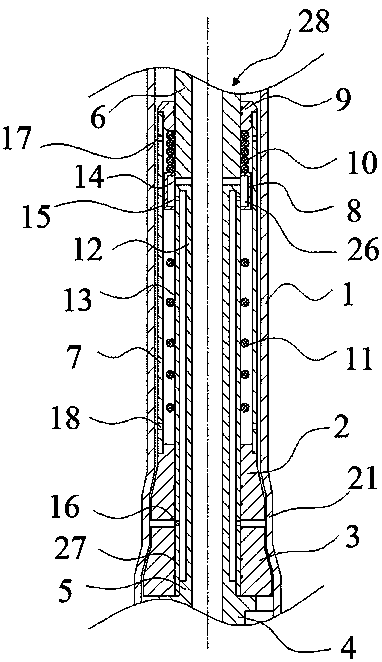

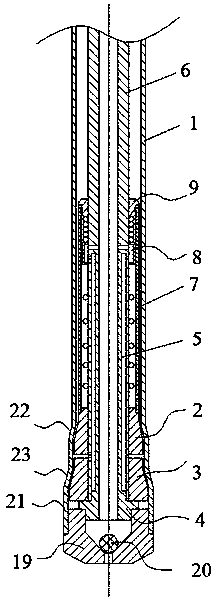

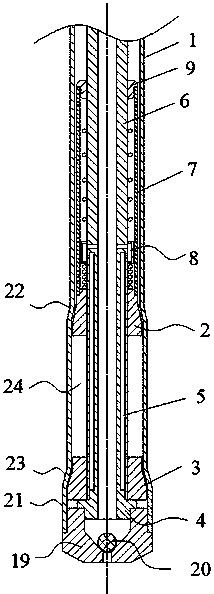

Liner hanger

The invention provides a liner hanger. The liner hanger comprises an expansion pipe with a hanging portion, a central pipe, an expansion cone seat, an expansion cone, a locking claw, a ball valve bottom plug and a well cementation rubber plug; the central pipe is arranged in the expansion pipe in a penetrating mode, a first annular cavity is formed between the expansion pipe and the central pipe, and through holes are formed in the side wall of the central pipe; the expansion cone seat is arranged in the first annular cavity and provided with a protrusion; the expansion cone is arranged on the expansion cone seat in a sleeving mode, and the end of the expansion cone is fixed to the upper end of the protrusion in an abutting mode; the locking claw is arranged in the first annular cavity, the end of the locking claw is fixed to the lower end of the protrusion in an abutting mode, and a second annular cavity is formed between the locking claw and the central pipe and communicated with the central pipe through the through holes; the ball valve bottom plug is provided with a fluid channel and a valve seat, the valve seat is located in the fluid channel, the end of the central pipe stretches into the fluid channel and is connected with the inner wall of the fluid channel, and the outer side wall of the ball valve bottom plug is connected with the end of the locking claw through a first shear pin; the well cementation rubber plug is connected with the ball valve bottom plug through a second shear pin; the shear strength of the first shear pin is higher than that of the second shear pin.

Owner:PETROCHINA CO LTD

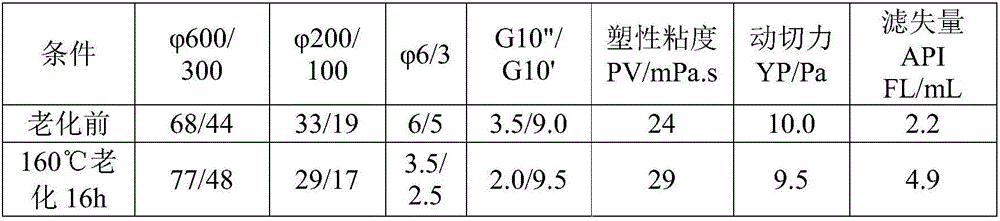

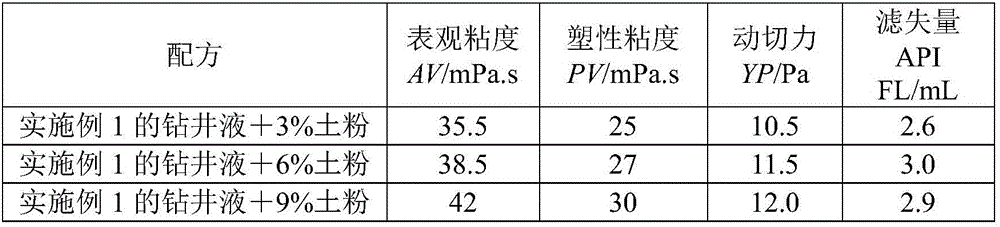

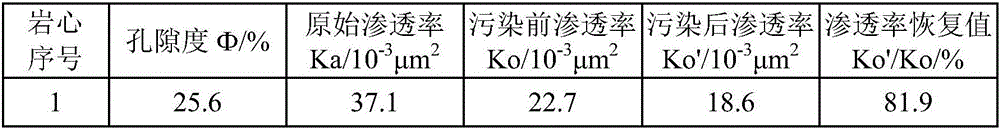

High-inhibition amino silanol drilling fluid and preparation method thereof

InactiveCN107177349AEnhanced inhibitory effectInhibit hydration swelling dispersionDrilling compositionSodium BentonitePotassium

The invention provides high-inhibition amino silanol drilling fluid and a preparation method thereof. The high-inhibition amino silanol drilling fluid is prepared from the following components in percentage by mass: 2 percent to 5 percent of bentonite, 0.2 percent to 0.5 percent of sodium carbonate, 0.3 percent to 0.5 percent of potassium polyacrylamide, 1 percent to 2 percent of valchovite, 2 percent to 3 percent of anti-collapse inhibitor, 2 percent to 3 percent of fluid loss agent, 0.5 percent to 1 percent of viscosity reducer, 1.0 percent to 1.5 percent of amido silanol and weighting agent, and the balance of water. The dosage of the weighting agent is used for adjusting the density of the high-inhibition amino silanol drilling fluid to be 1.1g / cm<3> to 1.6g / cm<3>. The high-inhibition amino silanol drilling fluid has a higher lubricating ability, so that the drilling speed can be effectively improved, meanwhile, the effects on improving reservoir protection, controlling drilling fluid rheology, improving drilling fluid pollution resistance and reducing downhole complex accident occurrence are remarkable, and the collapse problem of coal seam and carbonaceous mudstone is effectively solved.

Owner:PETROCHINA CO LTD

Air sealing body

InactiveCN105501673AWill not affect the openingDoes not affect the phenomenon of openingContainers to prevent mechanical damageEngineeringMechanical engineering

Owner:珠海徐太日用品有限公司

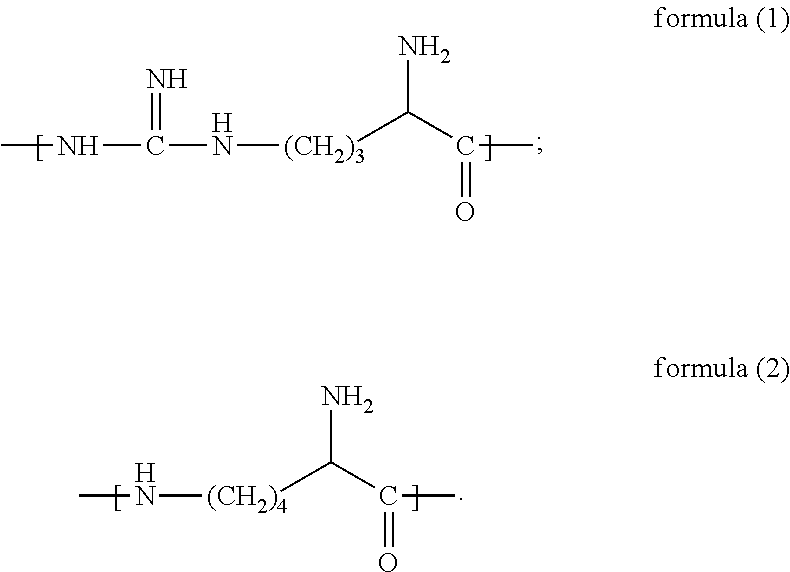

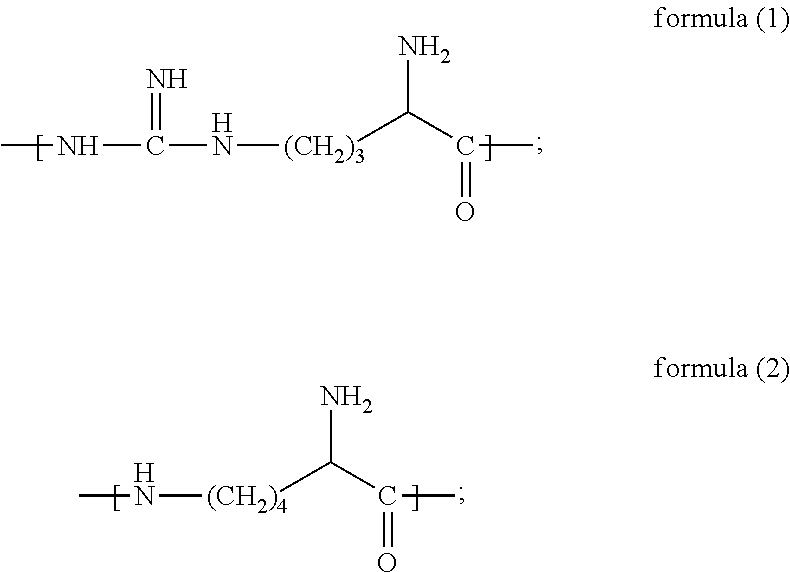

Bionic shale inhibitor and preparation method thereof and drilling fluid

InactiveUS20160230063A1High shale inhibition capabilityFriendly to environmentDrilling compositionChemistryStructural unit

The present invention discloses a bionic shale inhibitor, consisting of structural units denoted by formula (1) and structural units denoted by formula (2), wherein, the molar ratio of the structural units denoted by formula (1) to the structural units denoted by formula (2) is 0.2-6:1, and the weight-average molecular weight of the shale inhibitor is 800-4,000 g / mol. The present invention further provides a method for preparation of a bionic shale inhibitor. The present invention further provides a drilling fluid containing the bionic shale inhibitor. The bionic shale inhibitor disclosed in the present invention has high shale inhibition capability, and is environment-friendly and pollution-free.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

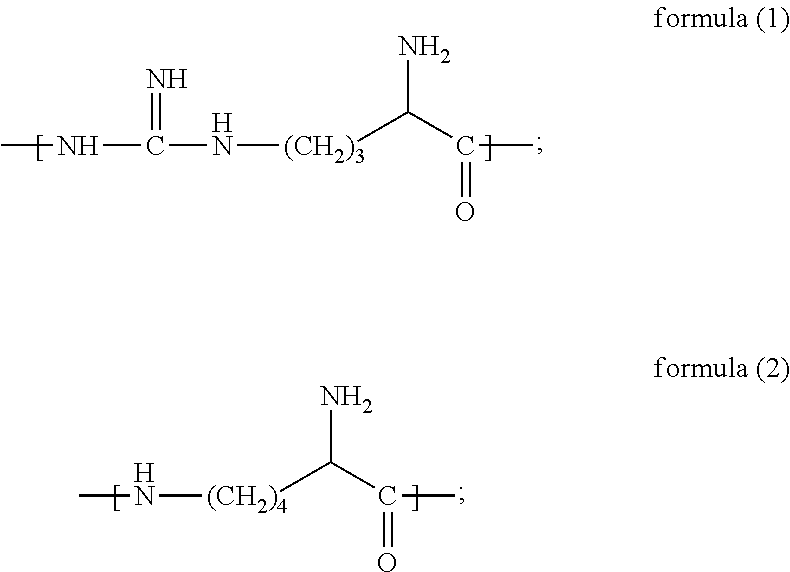

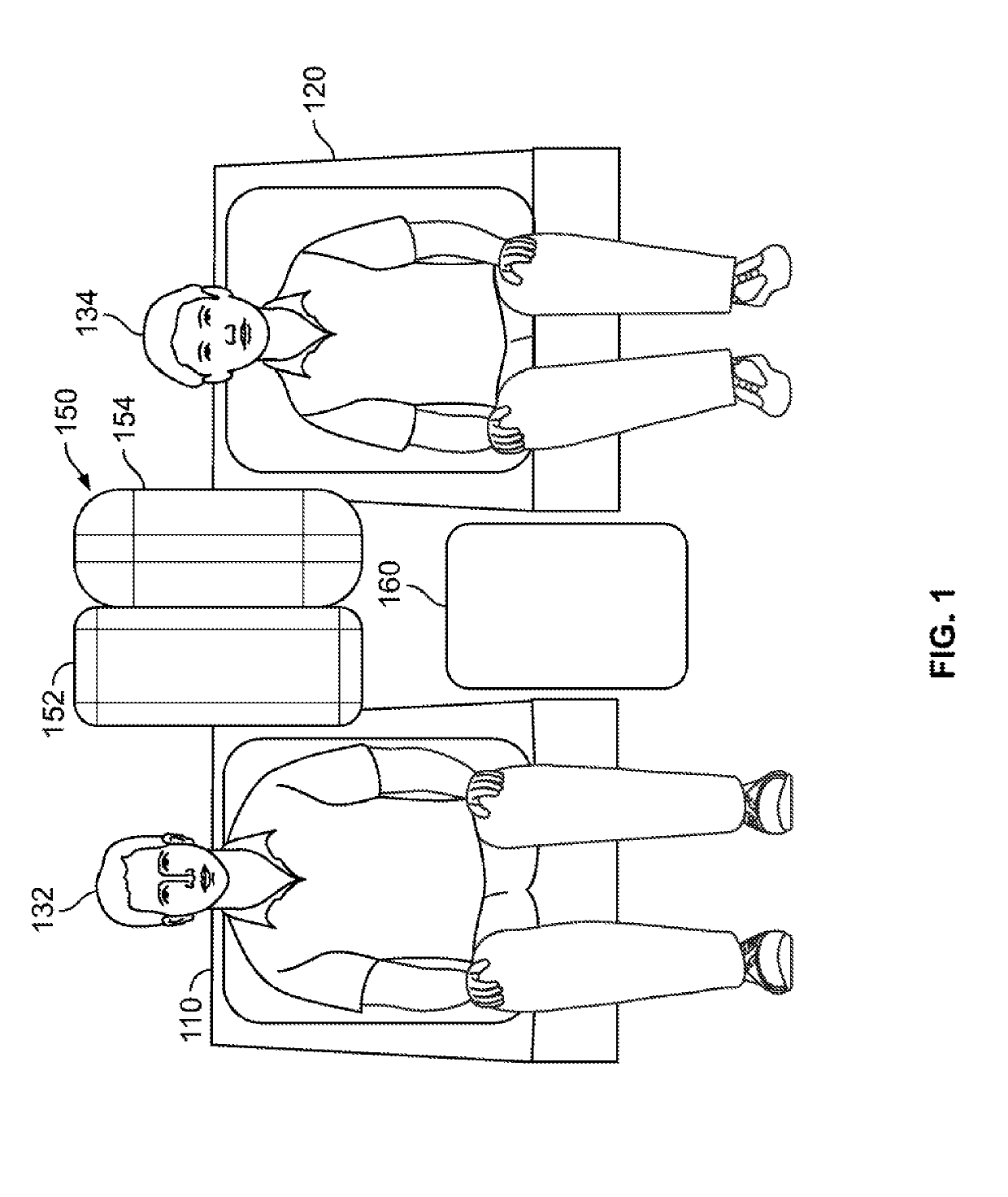

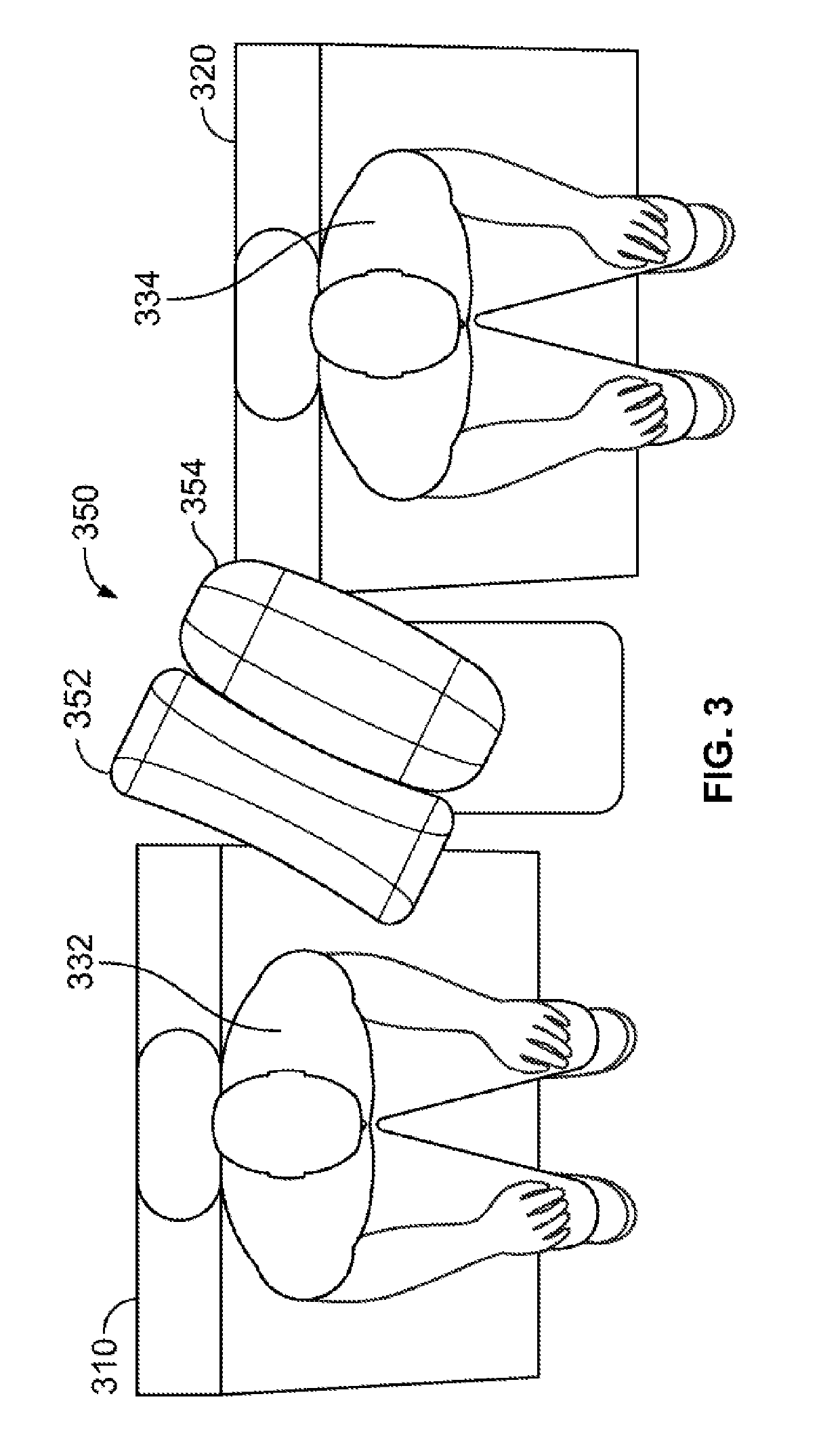

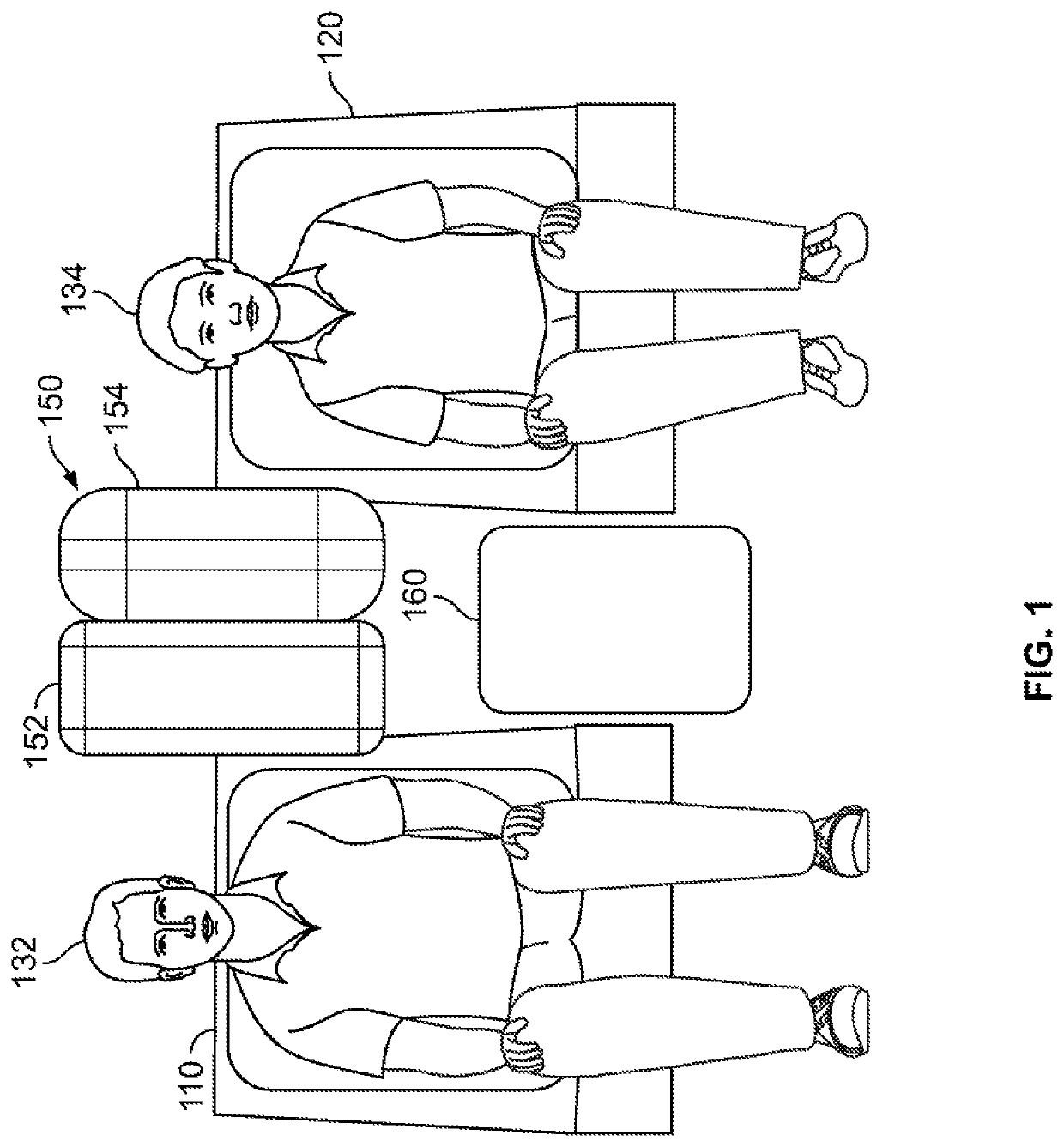

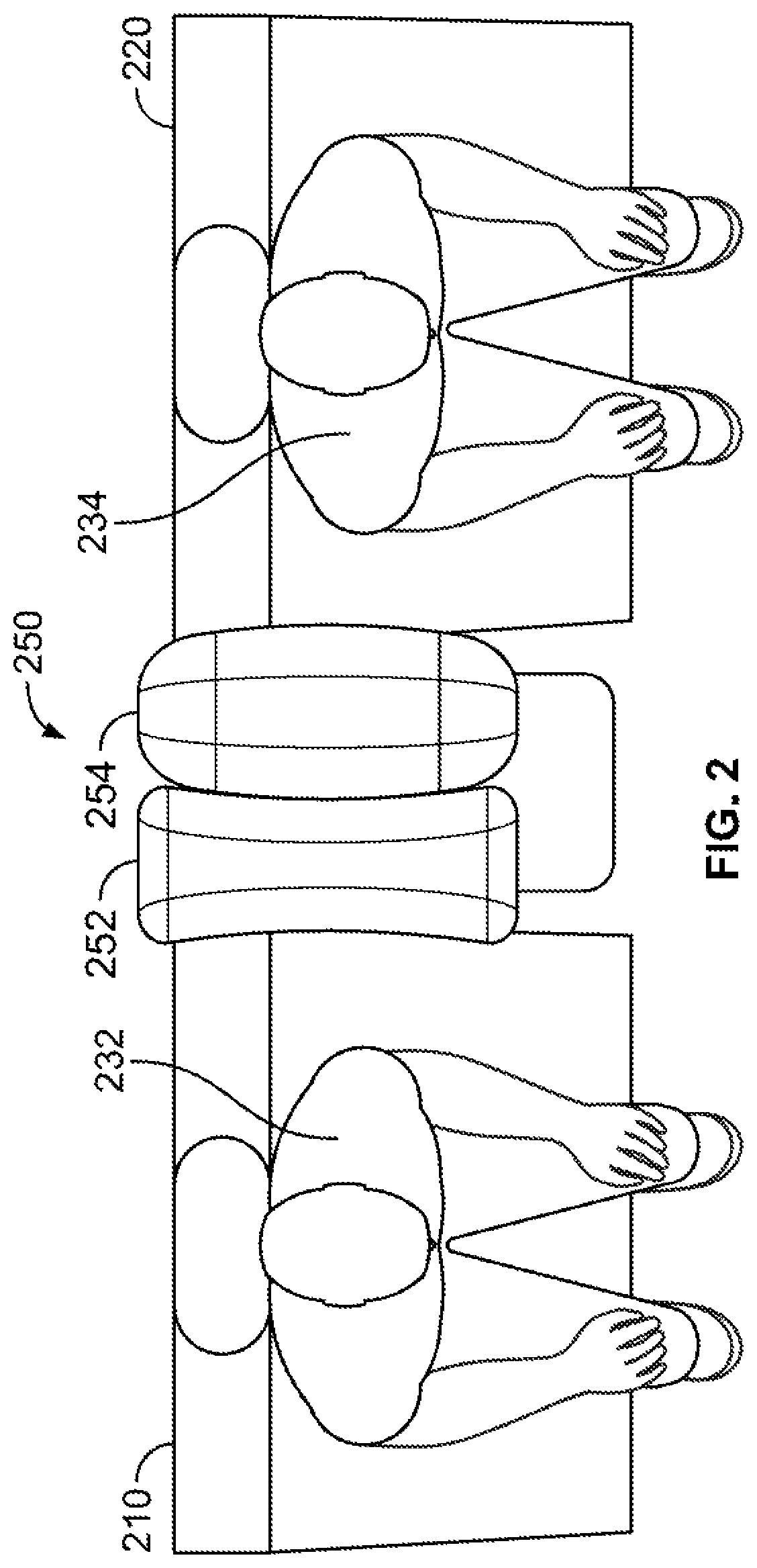

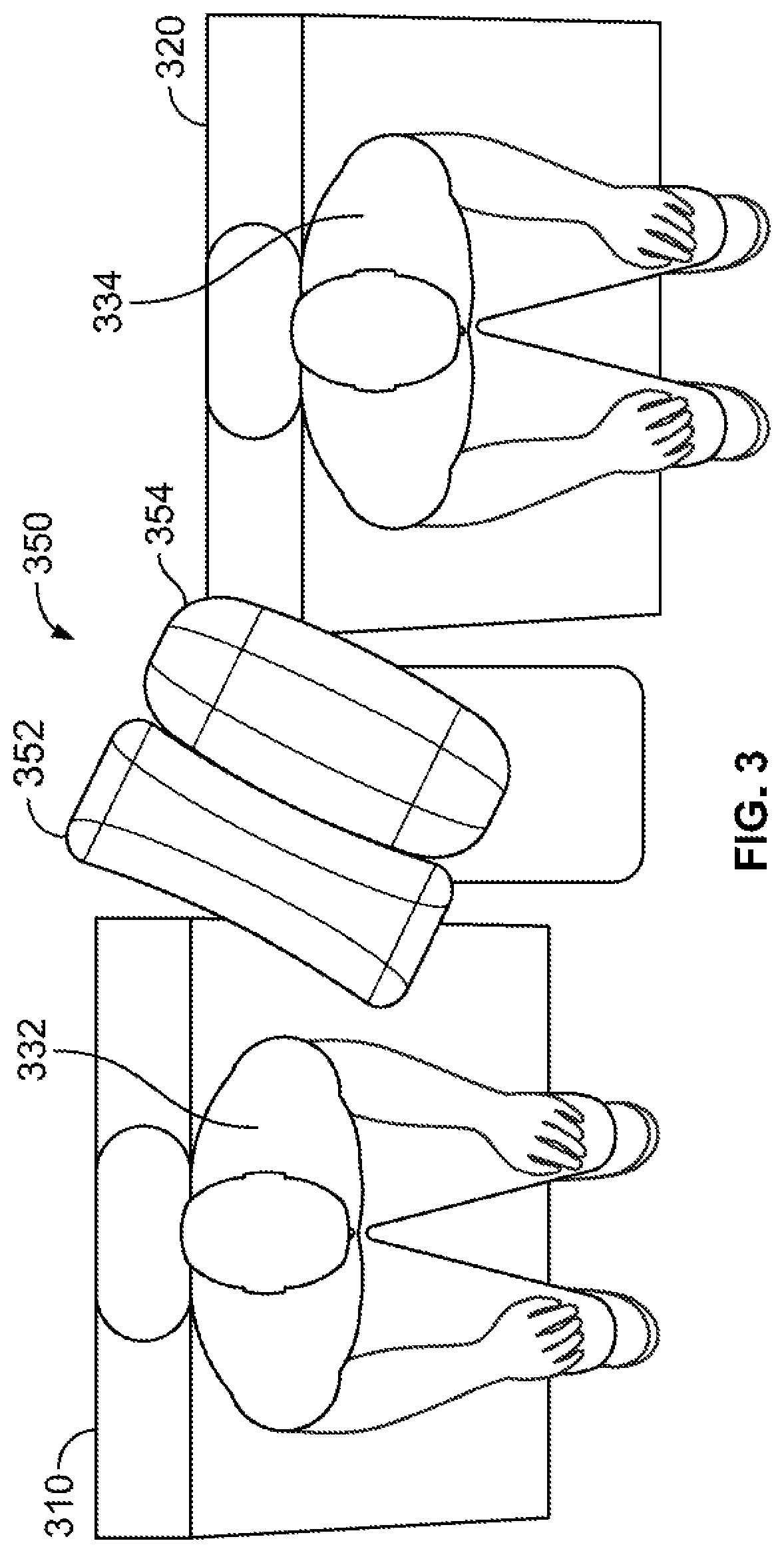

Airbag arrangement for protection in a far-side vehicular crash

ActiveUS20190283703A1Improve securityProvide supportPedestrian/occupant safety arrangementEngineeringAirbag

An arrangement of two airbags located in a respective seatback for two adjacent seats. The two airbags are configured to deploy in a center area between the two adjacent seats and provide support and protection for an occupant in a vehicle involved in a far-side crash.

Owner:RIVIAN IP HLDG LLC

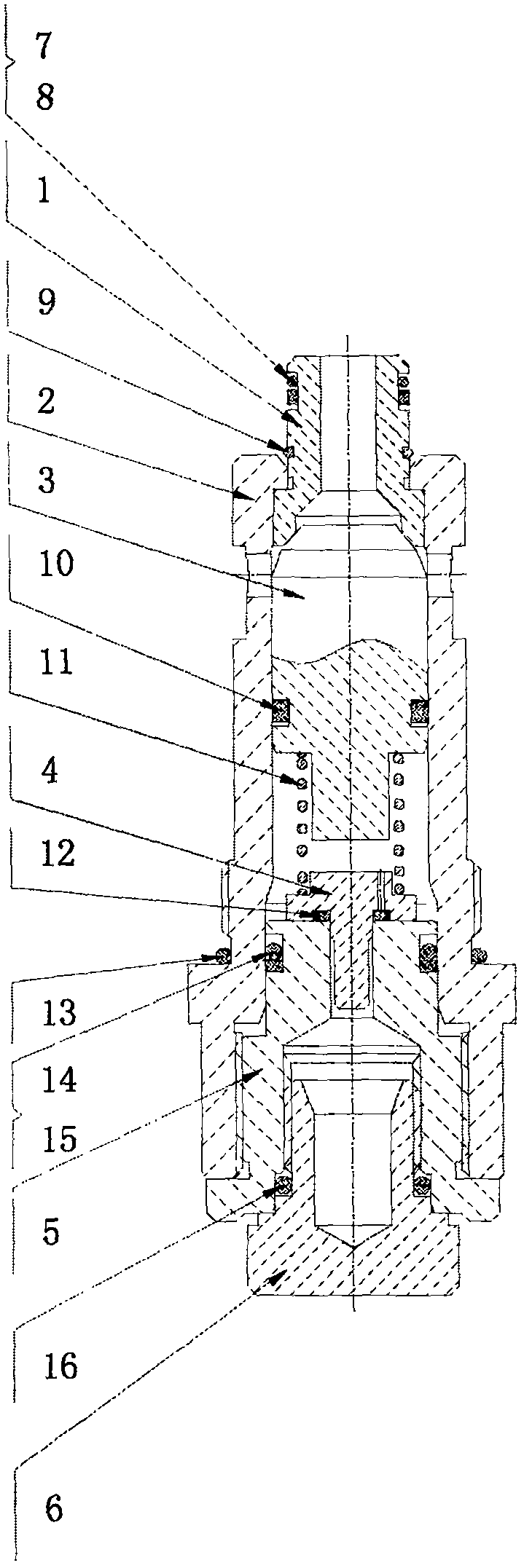

High-flow safety valve

A high-flow safety valve comprises a valve body, a valve seat, a connector, an end, an ejector rod, a valve element, a spring and a floating sleeve. The connector and the end are in threaded connection with the two ends of the valve body respectively. The valve seat and the valve element are arranged in the valve body. A sealing gasket is arranged between the end and a tail end screw. A first sealing ring is arranged between the ejector rod and the end. An inner counter bore is formed in the end face of the side, facing the connector, of the valve element. The valve seat and the valve element are in linear sealing contact. A sealing ring is arranged between the valve element and a spring cavity. The valve element is connected with the end through the spring. The floating sleeve is arranged between the end and the valve body. A metal hard sealing structural form is adopted for replacing a traditional O ring soft seal form; a sealing gas spring form is adopted for replacing a traditional mechanical spring structure; inflation pressure is lowered, and inflation sealing reliability is improved; the end is in a smooth cylinder shape, and the structural form is prevented from being freely demounted; and meanwhile it is guaranteed that in the process of forcefully loosening the end, before a thread is not screwed out of the valve body, gas is leaked, and the operation safety of personnel is guaranteed.

Owner:BEIJING TIANMA INTELLIGENT CONTROL TECH CO LTD

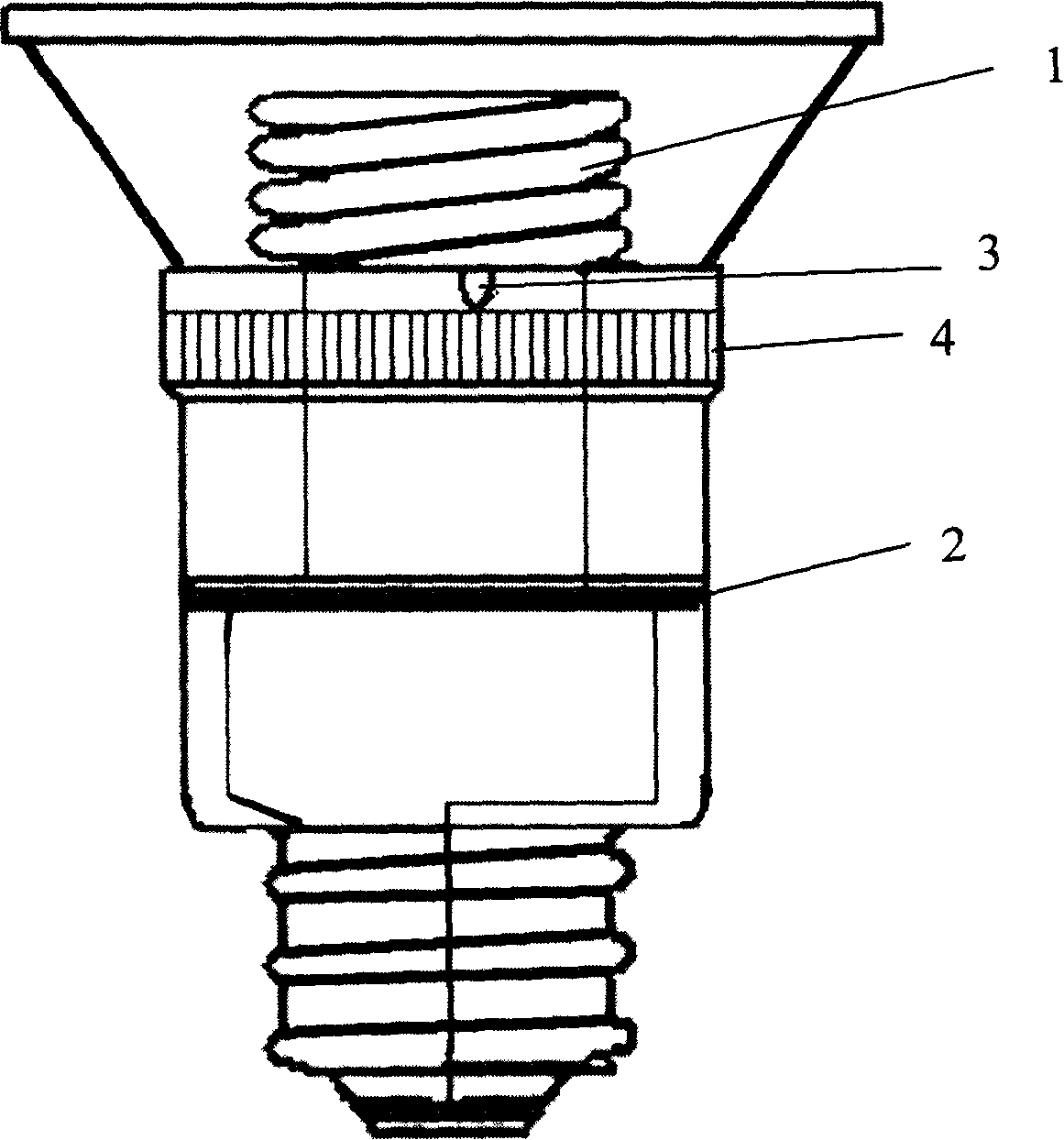

New type non-filament florescent lamp working in brightness arc transition zone

InactiveCN101202198AImprove reliabilityExtend your lifeElectric lighting sourcesVacuum evaporation coatingSurface brightnessInsulation layer

The invention relates to a novel wireless fluorescent lamp which works in a bright arc transition zone, comprising a lamp tube, an electrode, a drive, a lamp casing and a lamp cup or lampshade. The electrode consists of tungsten, or molybdenum or iron. More than one layers of anti cathode sputtering films are arranged on the surface of the electrode. Super-pure argon air is filled into the lamp tube with an air-filling pressure ranging from 800 Pa to 6665Pa. The work current of the lamp tube is between 7MA and 60MA. A cold end is arranged in the lamp tube and a titanium mercury zirconium aluminum 16 alloy amalgam or an indium mercury zirconium aluminum 16 alloy amalgam is arranged in the cold end. An insulation layer is arranged between the lamp cup or lampshade and the lamp casing. The cold end extends from the lamp cup or lampshade to the insulation layer. The invention enhances light effect and surface brightness, and has small volume, high flux, enhanced reliability and long service life. The manufacture of the drive is easy, the manufacturing cost is low and the cost performance is high, furthermore, the proposal of the EMC is easy, the cost for restraining electromagnetic interference wires is low and the effect for restraining electromagnetic interference is good.

Owner:陈宗烈

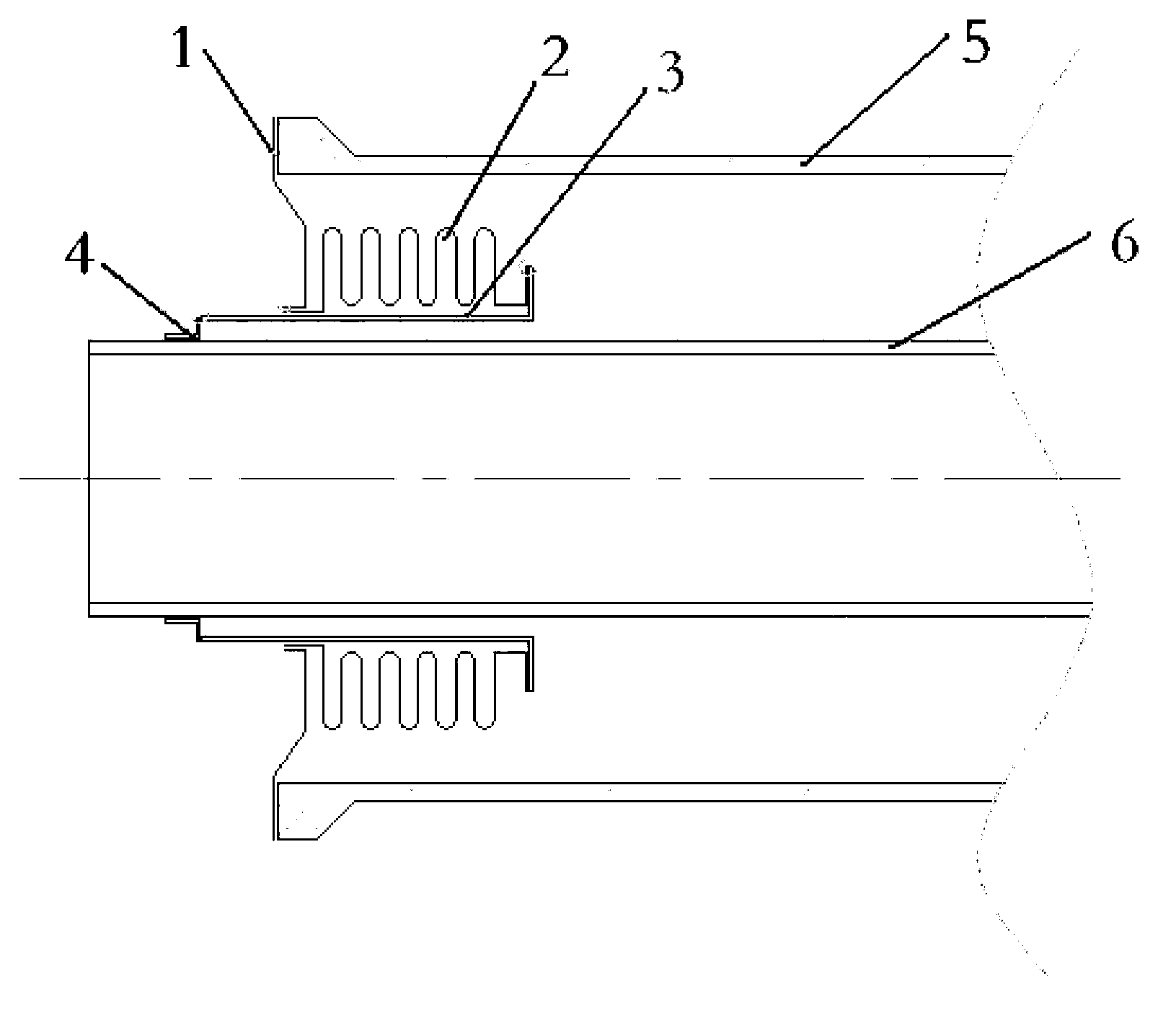

Tight connecting device of glass tube and metal tube

InactiveCN102840703AAvoid heat dissipationAvoid corrosionSolar heat devicesPipe connection arrangementsAlloyEngineering

The invention discloses a tight connecting device of a glass tube and a metal tube. The metal tube is sleeved inside the glass tube. The tight connecting device comprises a transition tube, a metal end cover, and a corrugated tube; the metal tube is sleeved outside the metal tube; one end of the transition tube is connected to the metal tube and the other end of the transition tube is provided with an outward edge and extends into the glass tube; the metal end cover is made of an expansion alloy material and sleeved on the transition tube; the peripheral edge is sealed on the end face of an opening of the glass tube in a hot pressing manner; the corrugated tube is sleeved on the transition tube at the inner side of the metal end cover; one end and the inner peripheral edge of the metal end cover are welded together, and the other end of the metal end cover is welded on the outward edge of the transition tube. The tight connecting device has the beneficial effects that assembling components are reduced; the production cost is reduced; the quantity of welded junctions is halved; the production technology difficulty is reduced; the yield is improved; and the heat collecting efficiency and the service life of a vacuum tube are effectively improved and prolonged.

Owner:山东威特人工环境有限公司

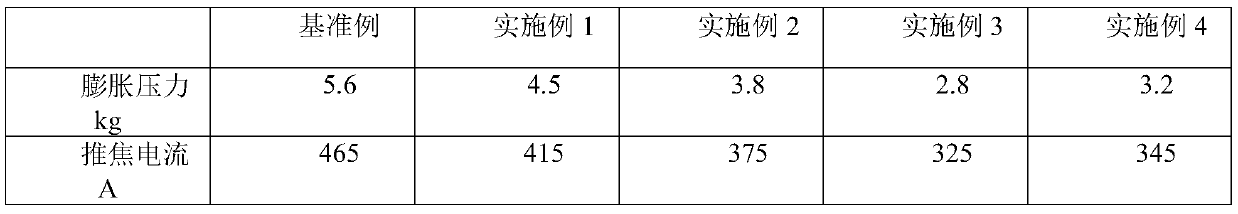

Control method of tamping coking resistance

InactiveCN110713842AReduce resistanceReduce inflation pressureCoke ovensProcess engineeringCoke oven

The invention relates to the field of coking, and discloses a control method of tamping coking resistance. The method comprises the following steps: (1) measuring the maximum expansion pressure of single coal for tamping coking; and (2) adjusting the structure of the coal blending for tamping coking according to the measurement result. According to the method, the maximum expansion pressure of thesingle coal for tamping coking is detected, and the expansion pressure of the blended coal is reduced by reasonably adjusting the structure of the blended coal according to the detection result, so that the tamping coking resistance is reduced, the pressure on the furnace wall in the tamping coking process is further reduced, and the service life of the tamping coke oven is prolonged.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

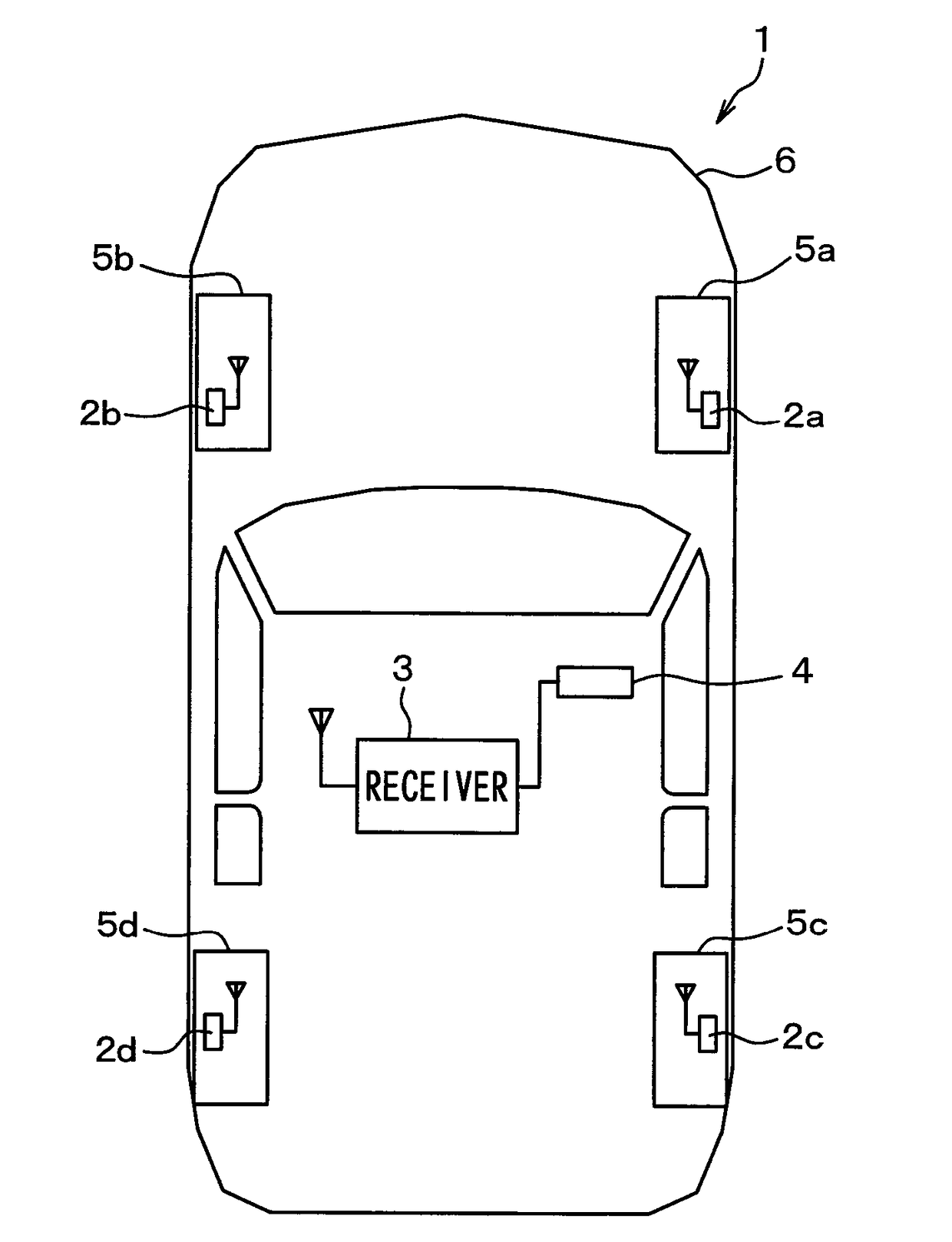

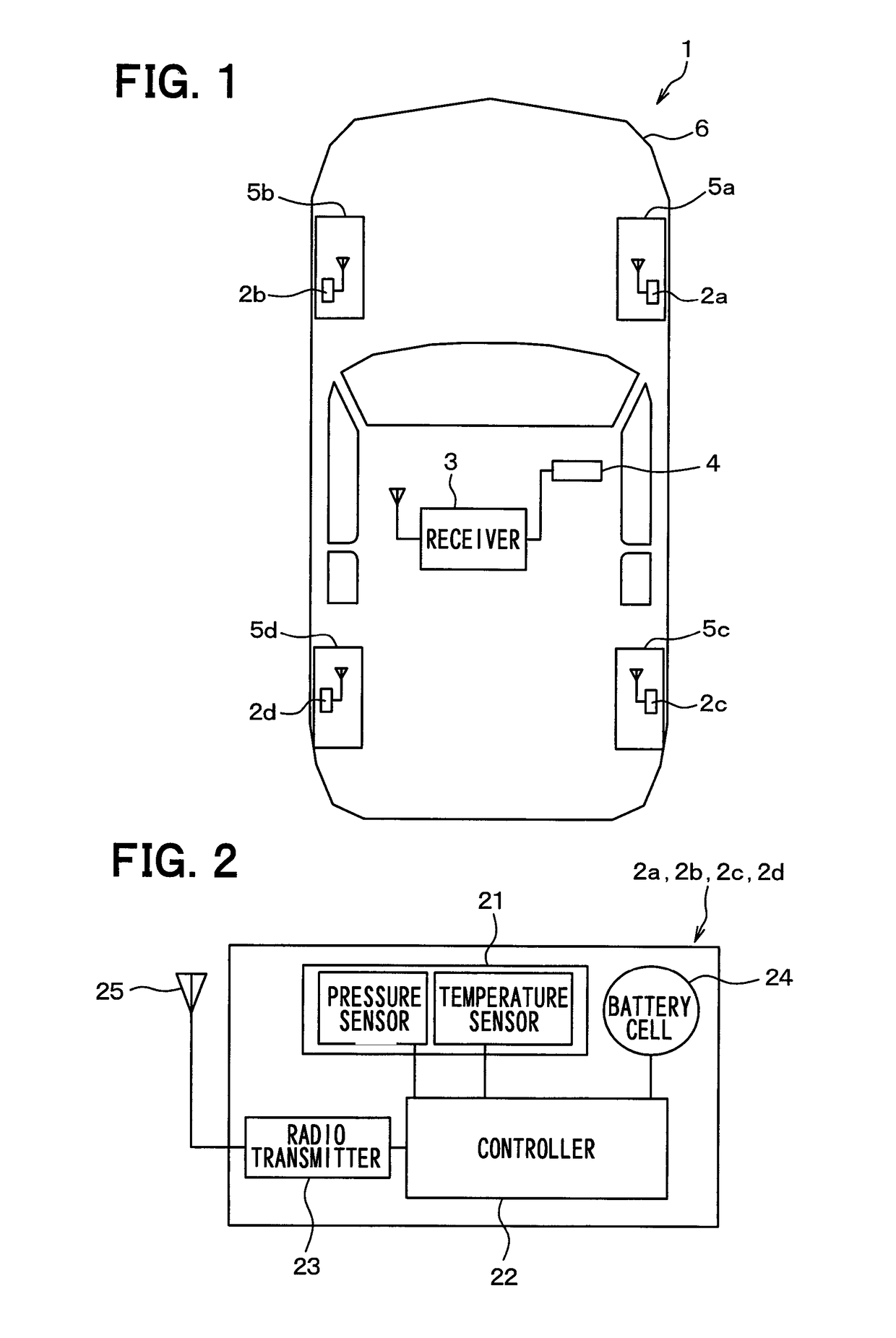

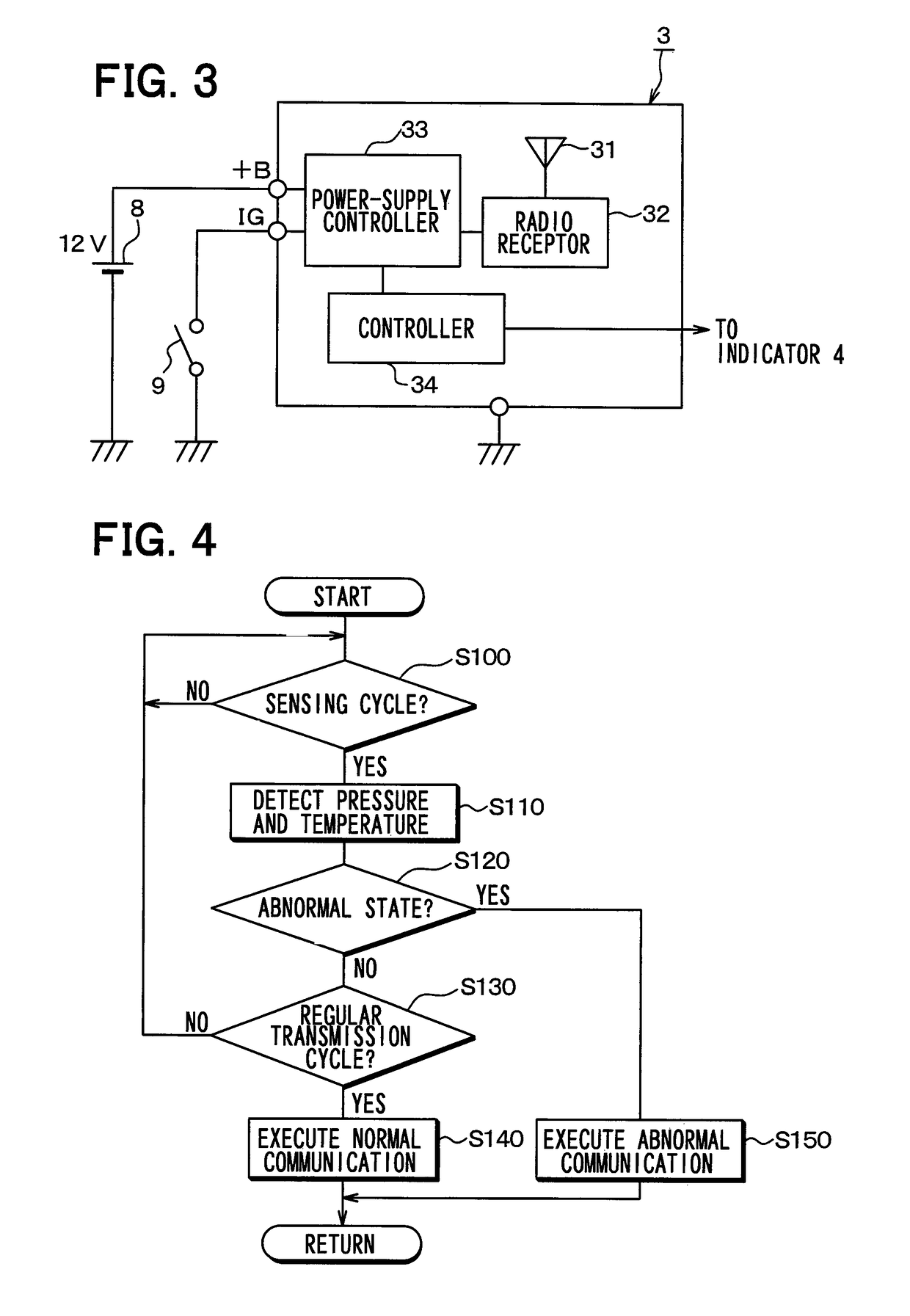

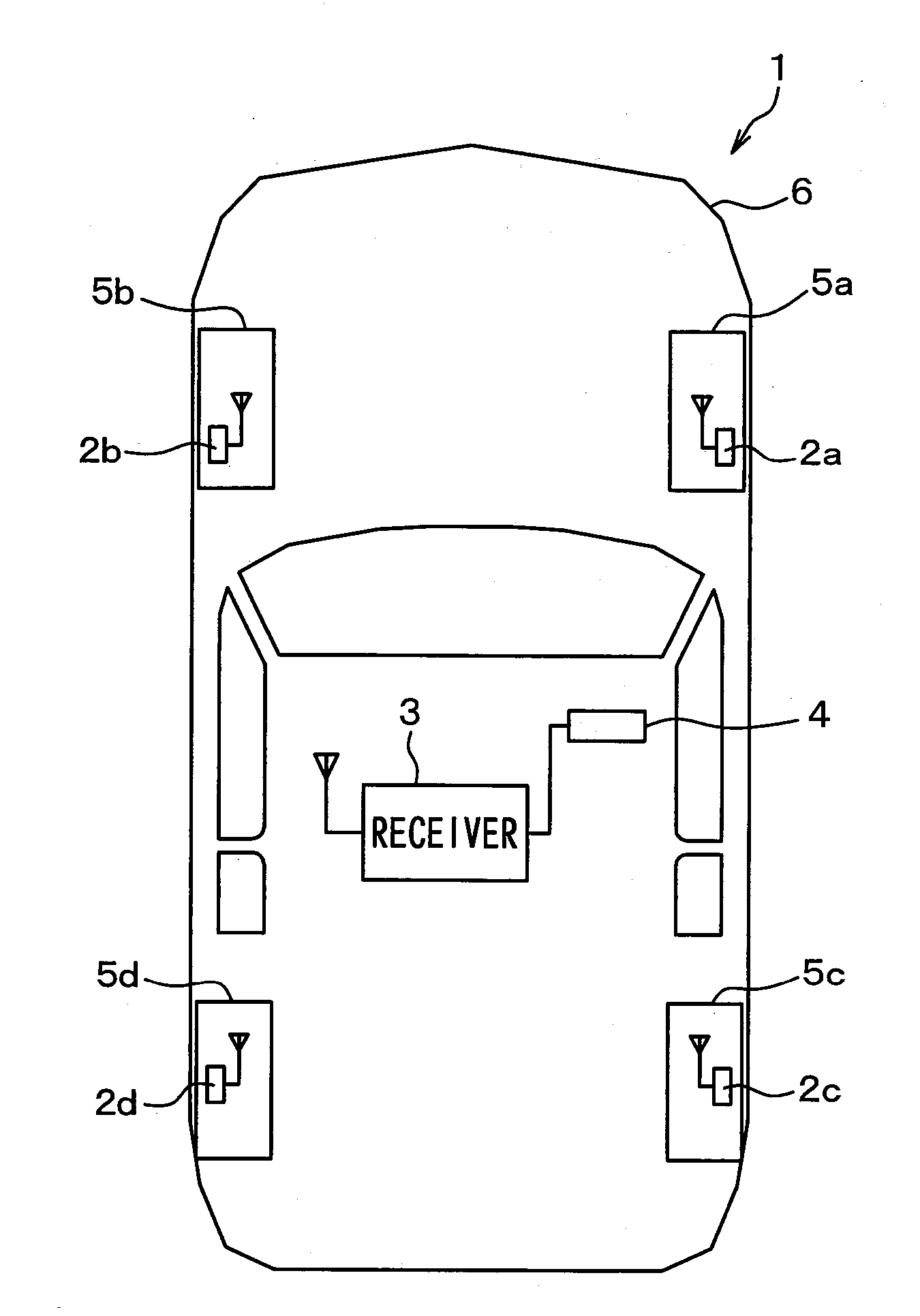

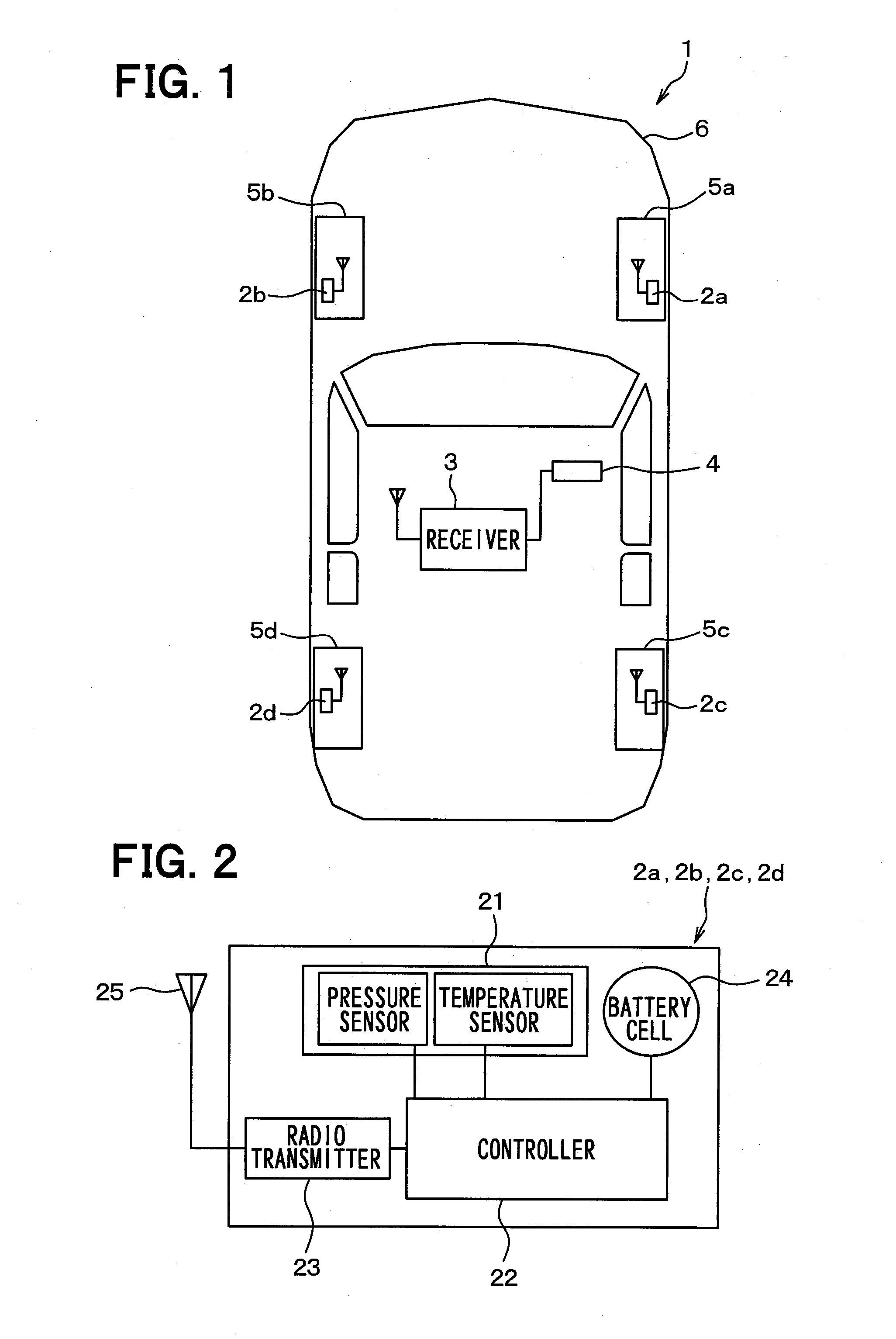

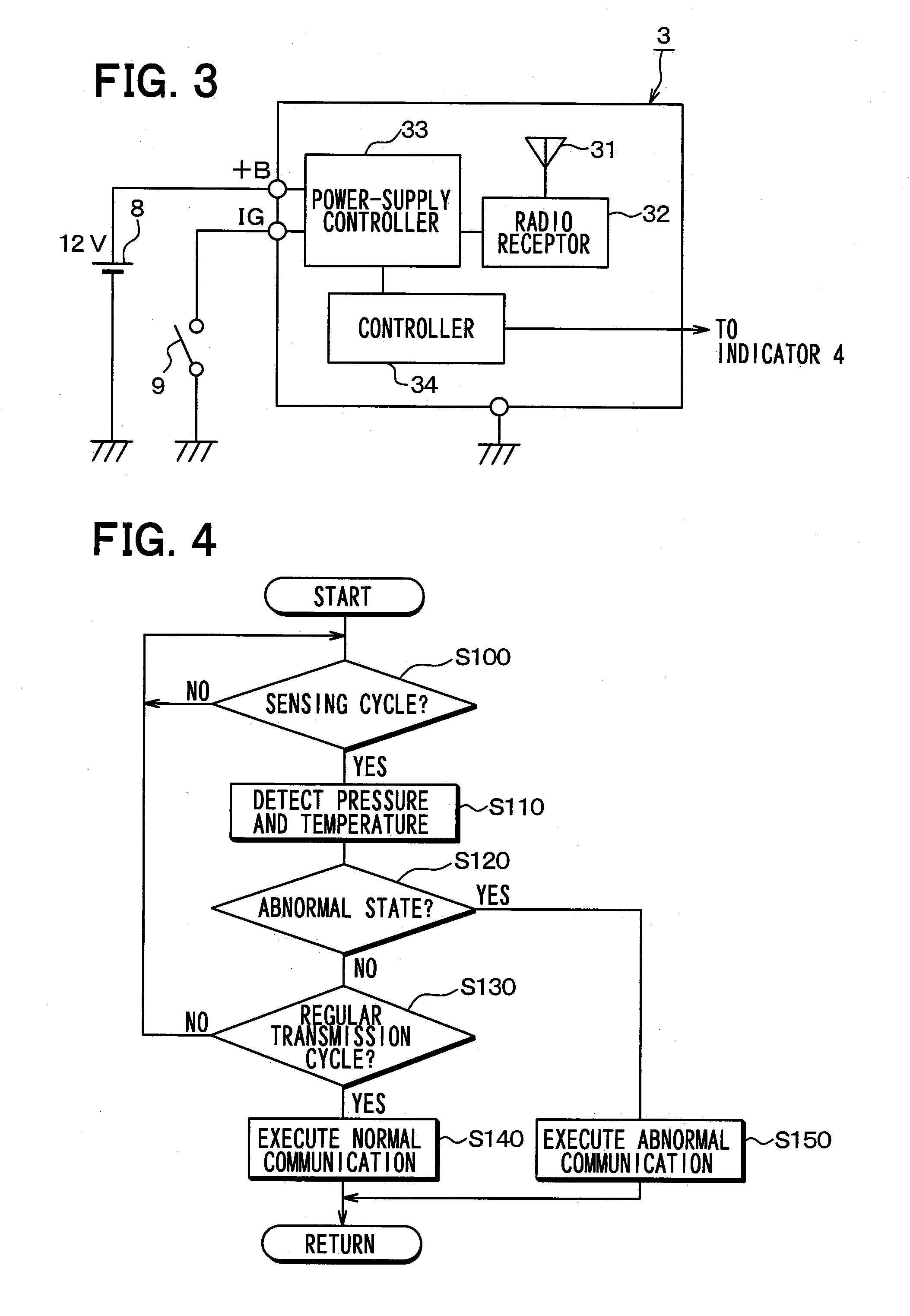

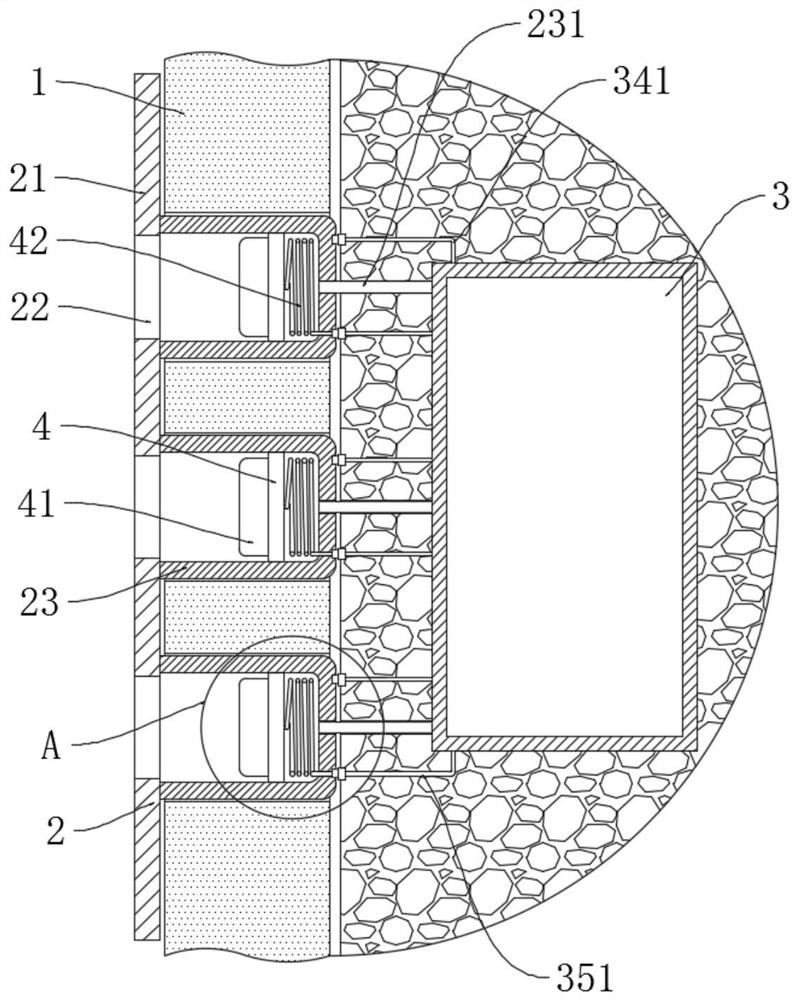

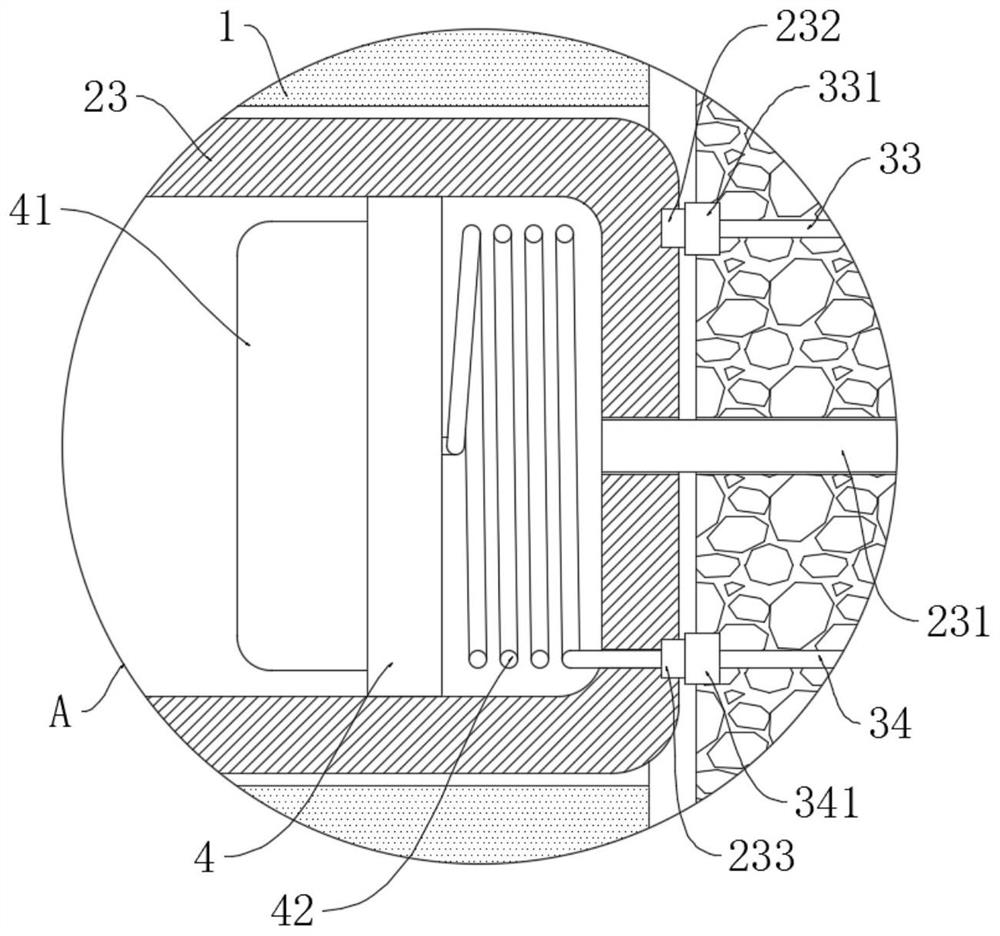

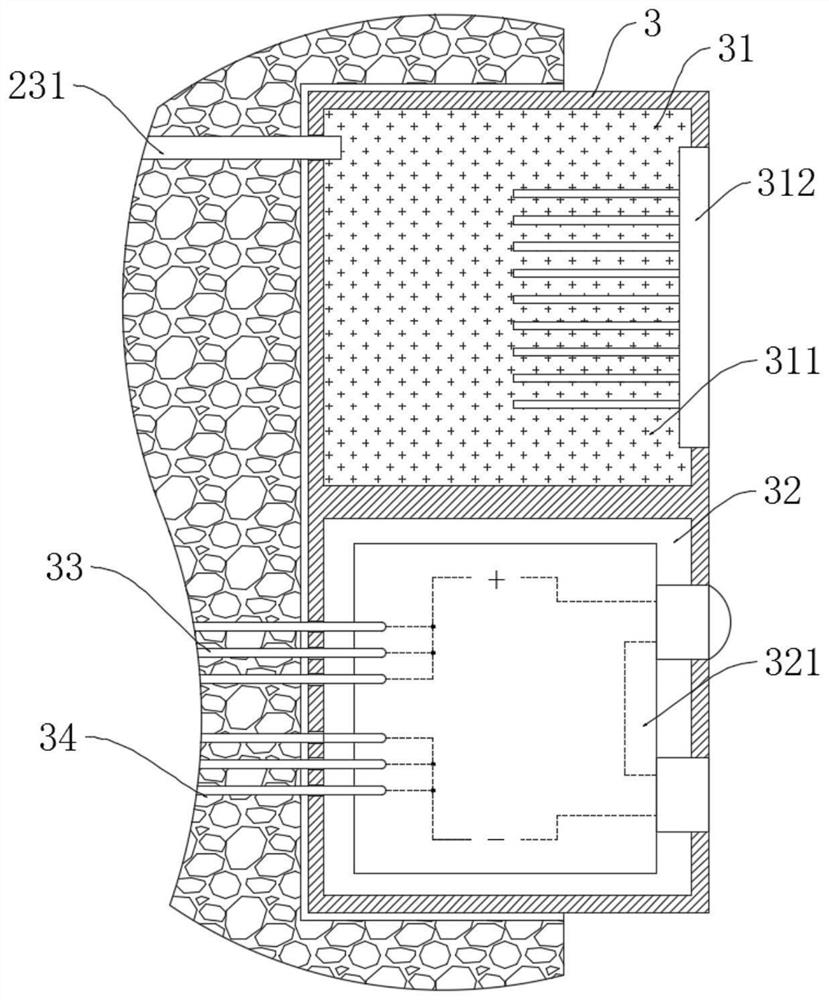

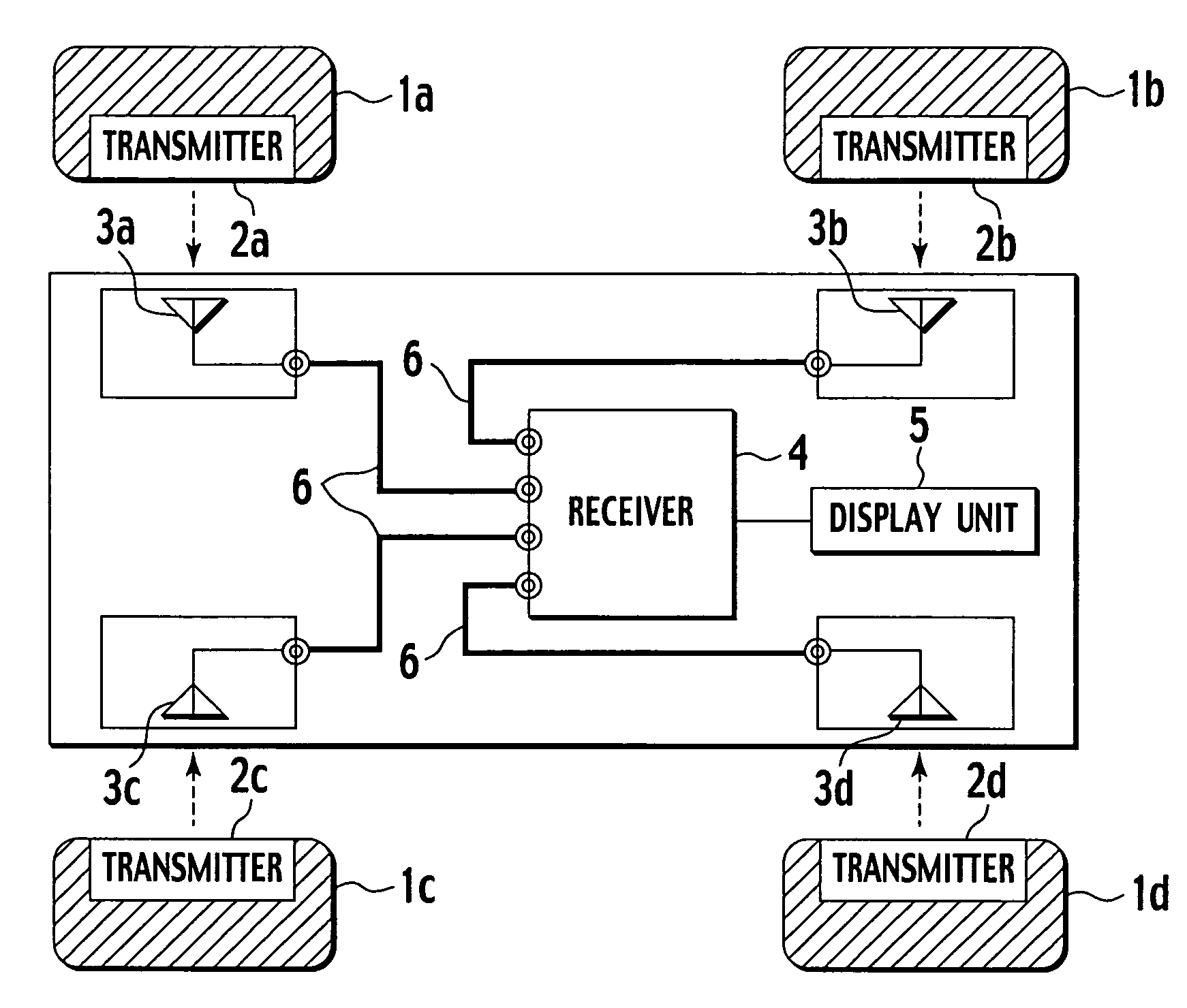

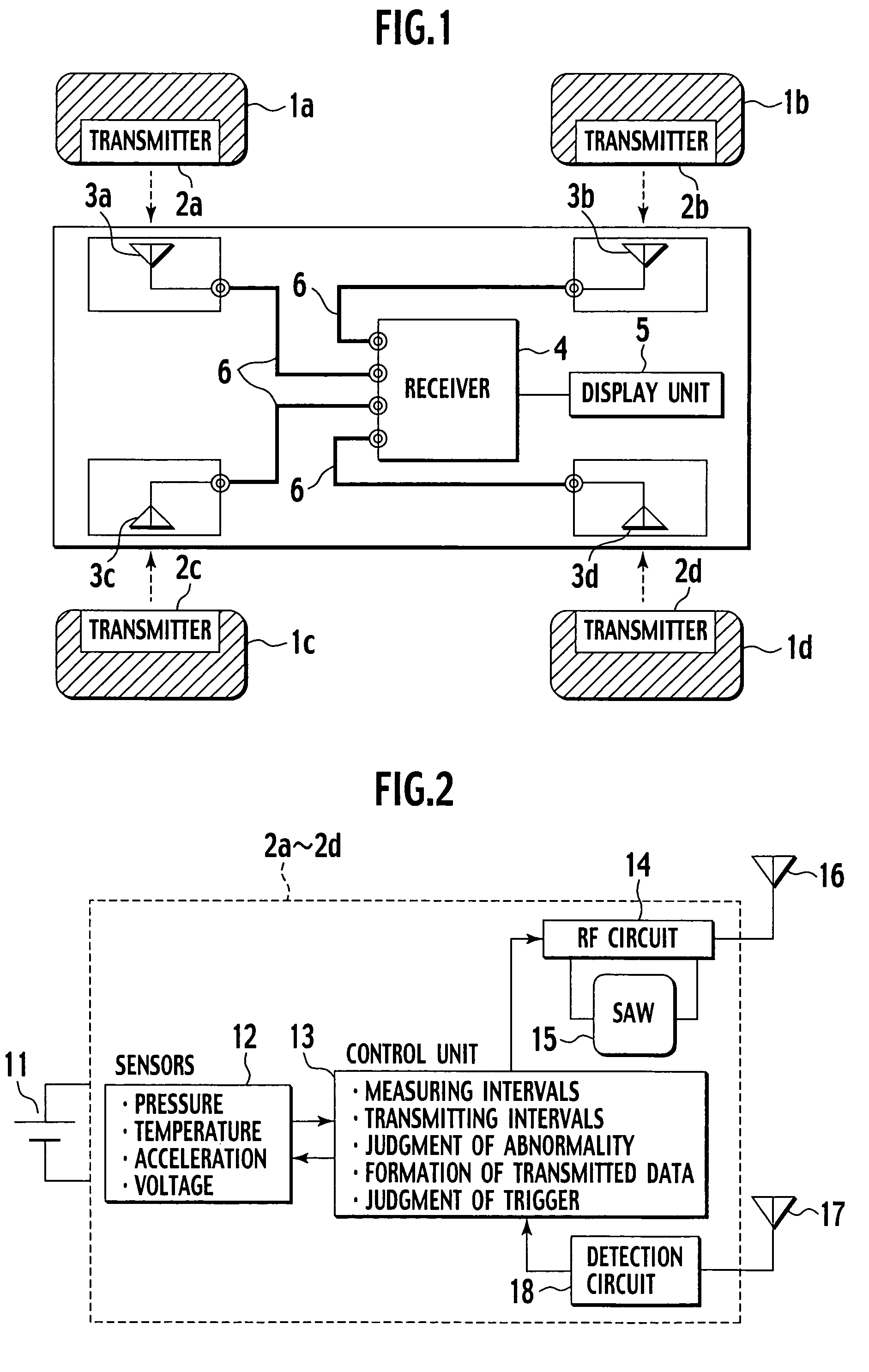

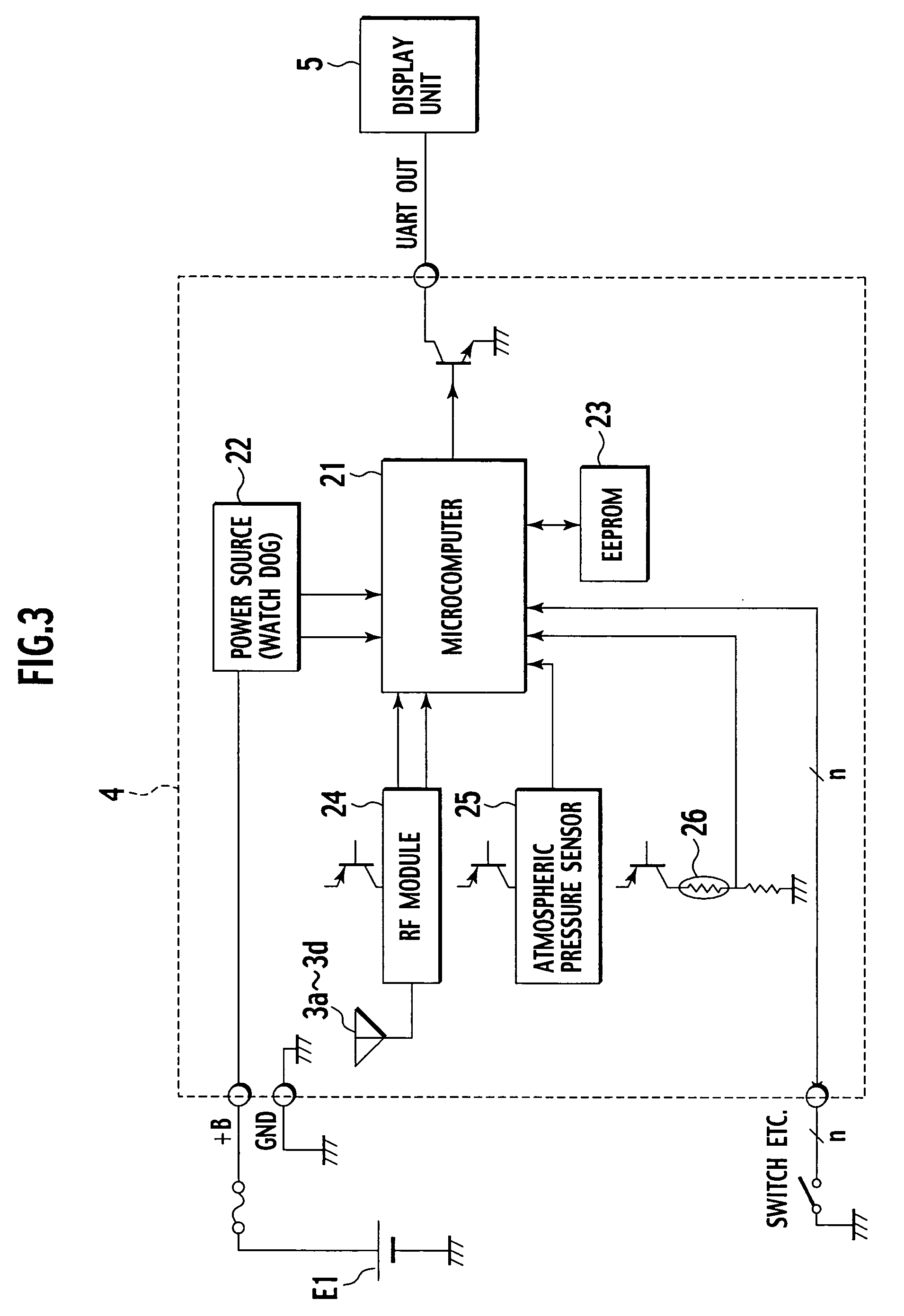

Tire inflation pressure detection device

ActiveUS9776461B2Reduce inflation pressureEasy to limitInflated body pressure measurementTyre measurementsReceiver functionElectric power

In a tire inflation pressure detection device, a receiver functions such that, when an ignition switch is on, power is generated by a power supply controller to set the power supply state of the receiver to one in which frame reception is enabled to detect the inflation pressure of a tire, and such that, when the IG is off, in each predetermined intermittent cycle power is generated by the power supply controller to set the power supply state of the receiver to one in which frame reception is enabled to detect the inflation pressure of the tire. A transmitter determines whether a decrease in tire inflation pressure occurs, and when the decrease occurs, the transmitter transmits frames more frequently than before the occurrence of the decrease in tire inflation pressure at a shorter frame transmission time interval than a regular transmission cycle during a high-frequency transmission period.

Owner:DENSO CORP

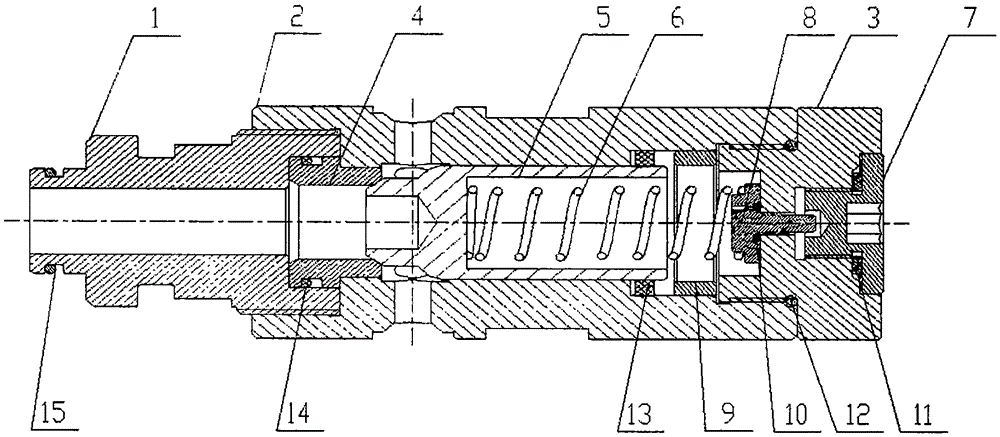

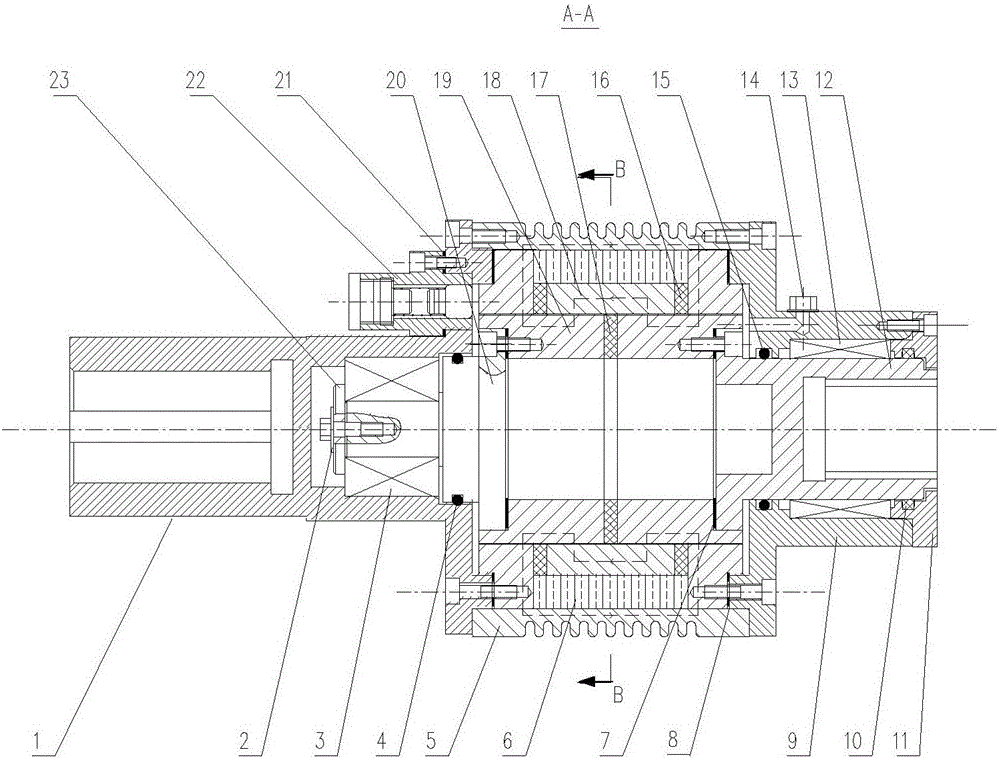

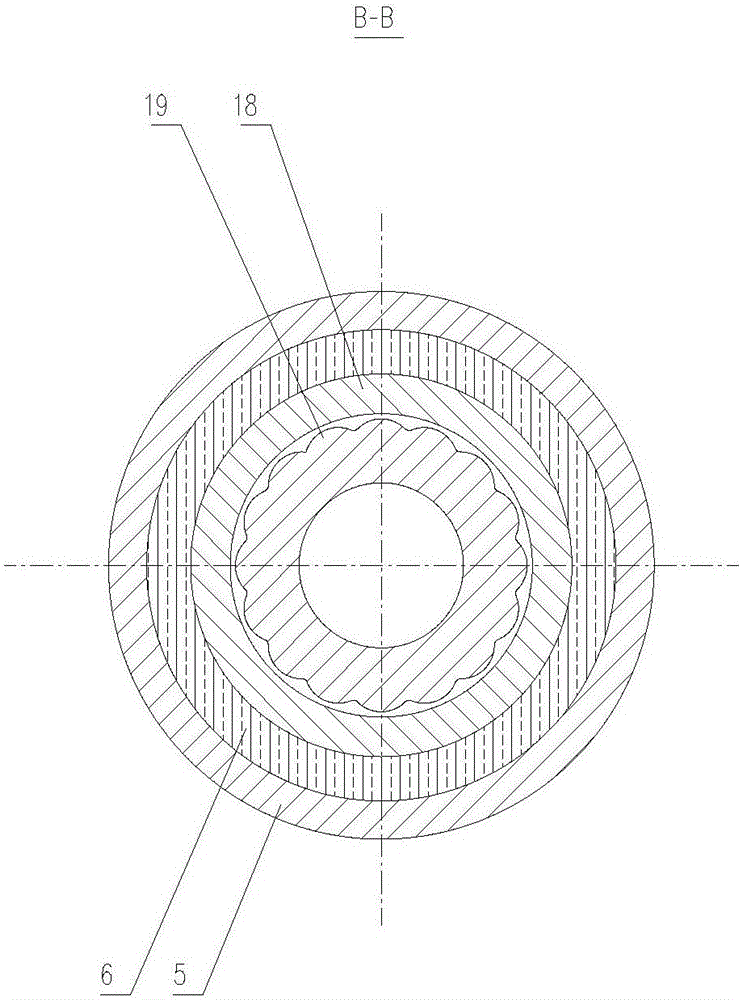

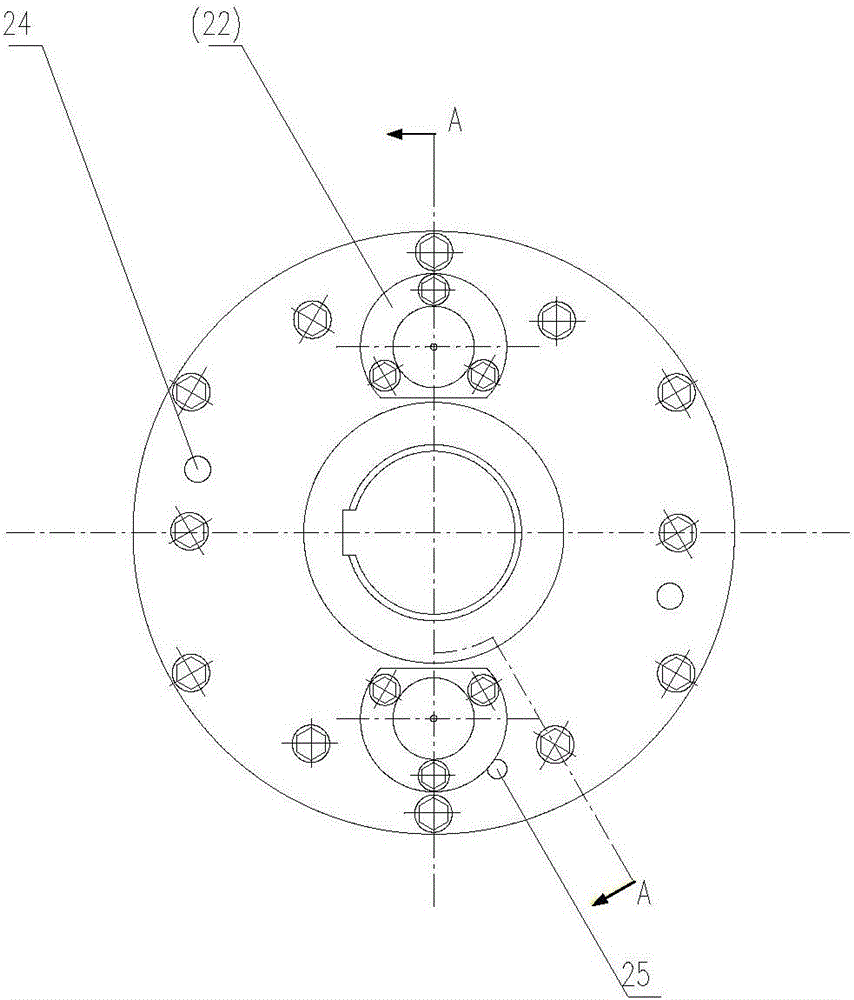

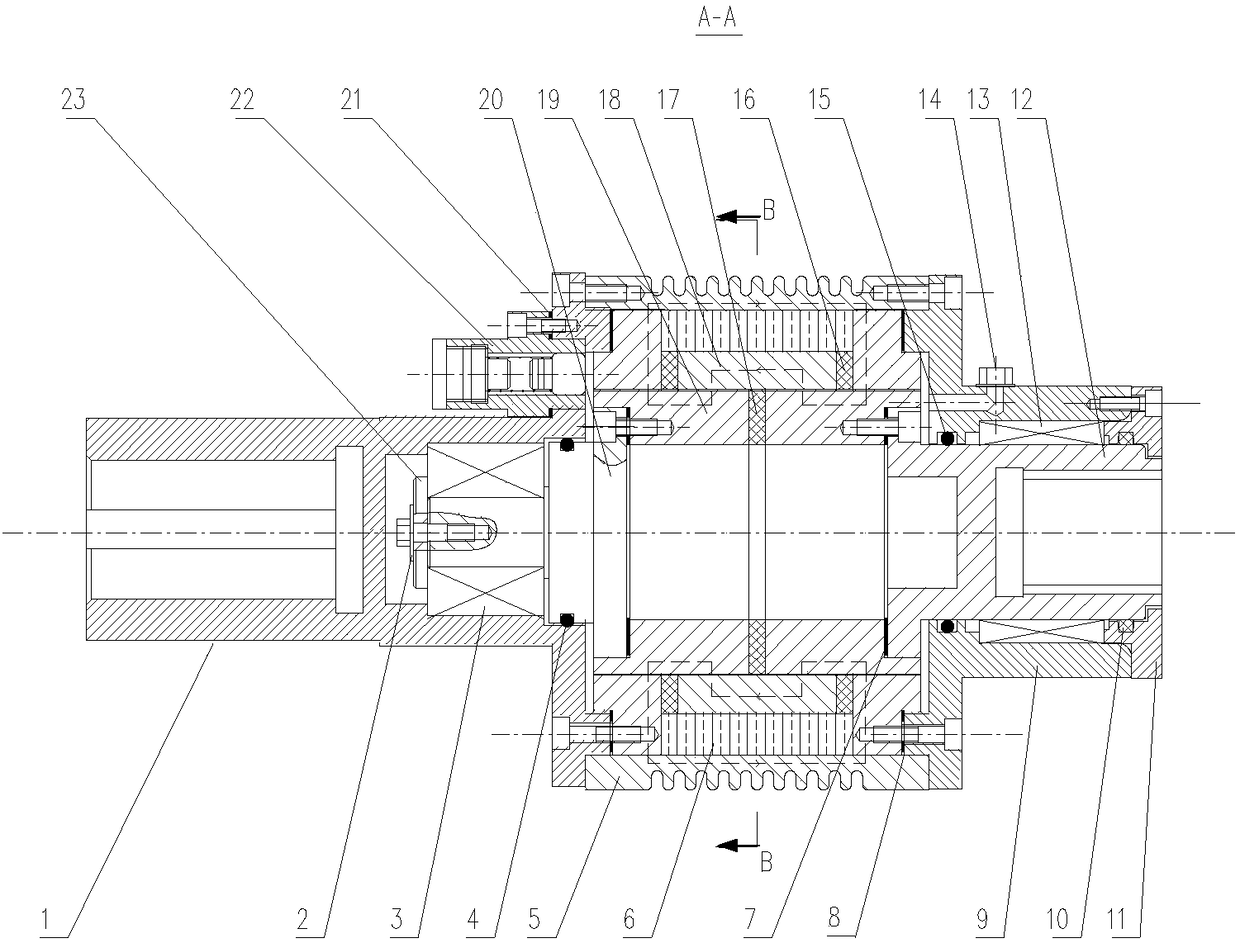

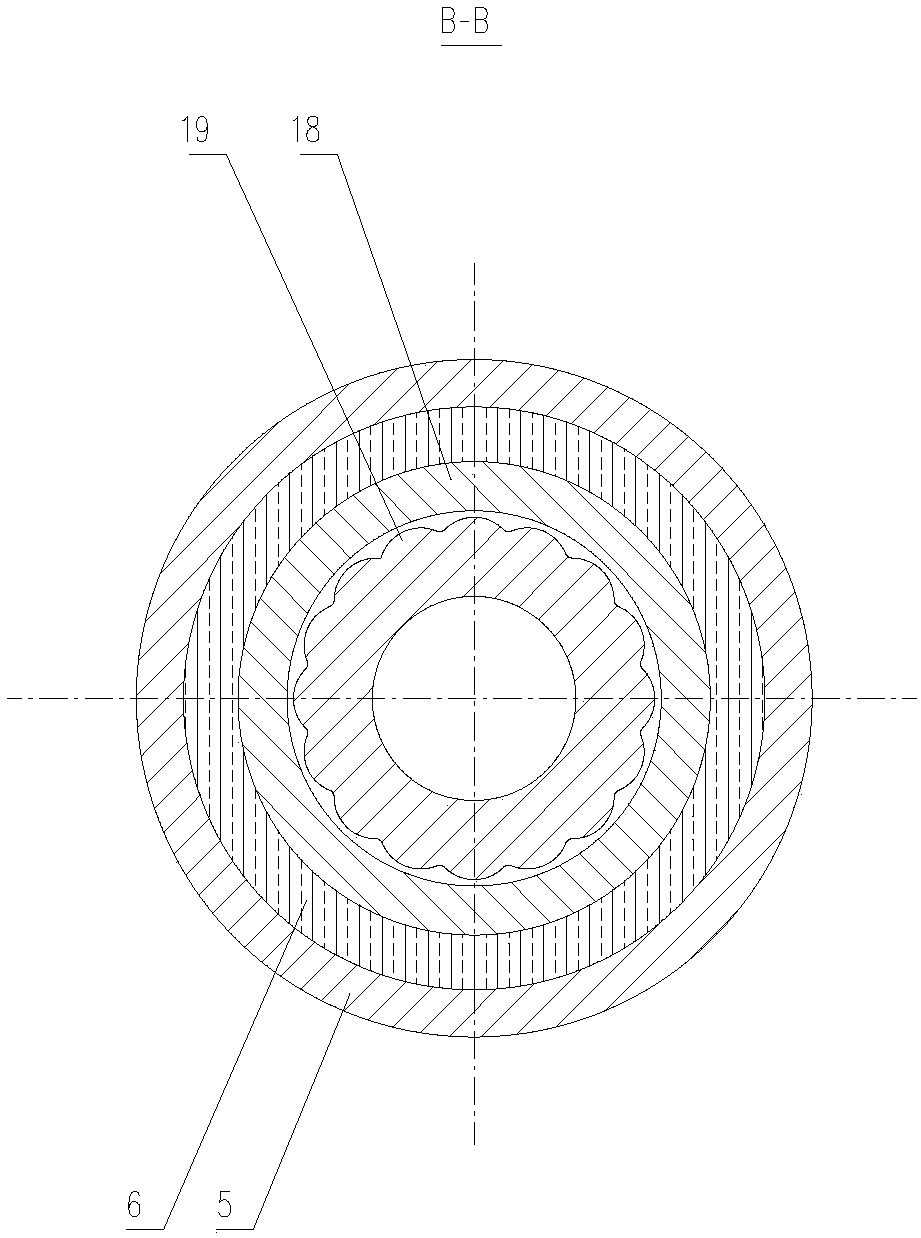

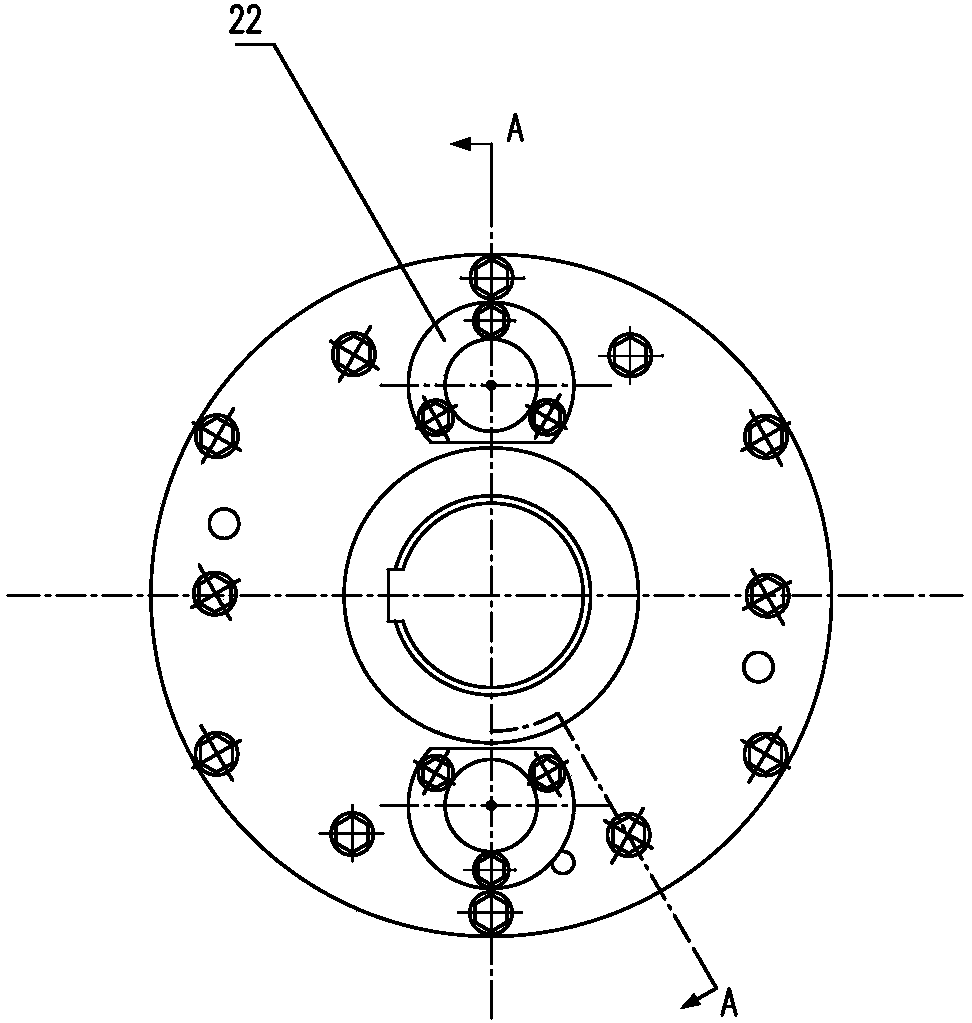

Compact cycloidal wheel magnetorheological coupling

ActiveCN106499747AIncrease the effective contact areaUniform magnetic field distributionFluid clutchesCouplingHeat sink

The invention discloses a compact cycloidal wheel magnetorheological coupling. The compact cycloidal wheel magnetorheological coupling is composed of an outer rotary component and an inner rotary component. An outer sleeve is formed by fixedly connecting a magnetizer and magnetism isolating rings which are symmetrically distributed on the two sides in the axial direction, and a multi-turn electromagnetic coil is wound in an annular groove of the outer sleeve. An outgoing line of the electromagnetic coil and a wiring terminal are guided out from the axial side face of an input-end coupling and connected with a power supply slip ring, and the input end is sleeved with the power supply slip ring. The outer-diameter portion of the outer sleeved is sleeved with cooling fins, and the two ends of the outer sleeve are connected with the input end of the coupling and a transparent cover through magnetism isolating screws. Oil injection plug screws are symmetrically distributed and mounted on the axial outer-diameter portion of the transparent cover. Pressure release valves which are symmetrically distributed are mounted at the input-end coupling in the circumferential direction. An outer cycloidal wheel sleeve is formed by fixedly connecting a cycloidal wheel and an inner magnetism isolating ring and is of a hollow barrel-shaped structure, and the two ends of the outer cycloidal wheel sleeve are connected with a rotary flange and an output-end coupling through magnetism-isolating stainless steel screws correspondingly. The inner rotary component and the outer rotary component are connected through a bearing. The compact cycloidal wheel magnetorheological coupling has the advantages of being compact in structure, low in manufacturing cost, convenient to maintain, and capable of transmitting a large torque.

Owner:WUHAN UNIV OF TECH

Tire inflation pressure detection device

ActiveUS20160167459A1Facilitate warningReduce inflation pressureInflated body pressure measurementTyre measurementsReceiver functionEngineering

In a tire inflation pressure detection device, a receiver functions such that, when an ignition switch is on, power is generated by a power supply controller to set the power supply state of the receiver to one in which frame reception is enabled to detect the inflation pressure of a tire, and such that, when the IG is off, in each predetermined intermittent cycle power is generated by the power supply controller to set the power supply state of the receiver to one in which frame reception is enabled to detect the inflation pressure of the tire. A transmitter determines whether a decrease in tire inflation pressure occurs, and when the decrease occurs, the transmitter transmits frames more frequently than before the occurrence of the decrease in tire inflation pressure at a shorter frame transmission time interval than a regular transmission cycle during a high-frequency transmission period.

Owner:DENSO CORP

Downhole casing twin-stage cone expansion device and operating method thereof

PendingCN108240205AReduce single stage expansionReduce inflation pressureFluid removalWell drillingEngineering

The invention discloses a downhole casing twin-stage cone expansion device and an operating method thereof. The downhole casing twin-stage cone expansion device comprises a first-stage expansion cone,a second-stage expansion cone, a central tube, a connecting outer tube, a limiting mechanism, a top check block and the like; and the central tube is mainly composed of a spline shaft, a double-deckinner tube, a connecting inner tube and the like, and the double-deck inner tube comprises a central inner tube and a central outer tube. When an expansion casing is subjected to first-stage expansion, the first-stage expansion cone together with the connecting outer tube and the top check block move up along the central tube, and the first-stage expansion is completed after limiting displacement;when second-stage expansion occurs, the second-stage expansion cone, the central tube and the limiting mechanism move up relative to the first-stage expansion cone, and single-stroke expansion ends after second-stage limiting displacement; and hydraulic expansion of the expansion casing is completed in stages by repeating twin-stage expansion stroke until the expansion casing is fully expanded. According to the downhole casing twin-stage cone expansion device and the operating method thereof, the expansion force of the casing can be effectively reduced at downhole, the possibility of expanding the expansion casing can be achieved to a larger extent, and construction risks are reduced; and the downhole casing twin-stage cone expansion device can be used in the expansion casing operation inthe fields of expansion casing subsidy well repair, well completion, and well drilling and plugging and the like.

Owner:中石化石油工程技术服务有限公司 +2

Airbag arrangement for protection in a far-side vehicular crash

ActiveUS10717405B2Improve securityProvide supportPedestrian/occupant safety arrangementAirbagControl theory

An arrangement of two airbags located in a respective seatback for two adjacent seats. The two airbags are configured to deploy in a center area between the two adjacent seats and provide support and protection for an occupant in a vehicle involved in a far-side crash.

Owner:RIVIAN IP HLDG LLC

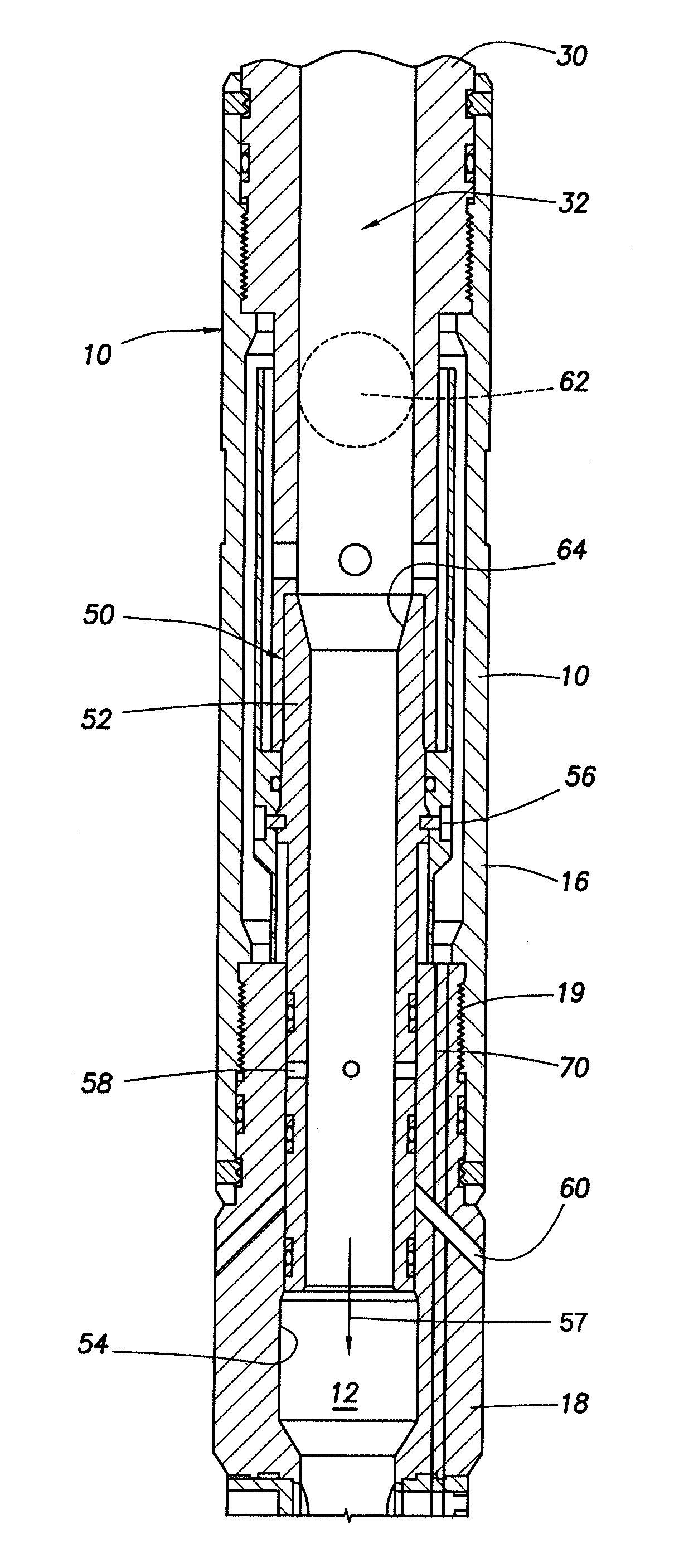

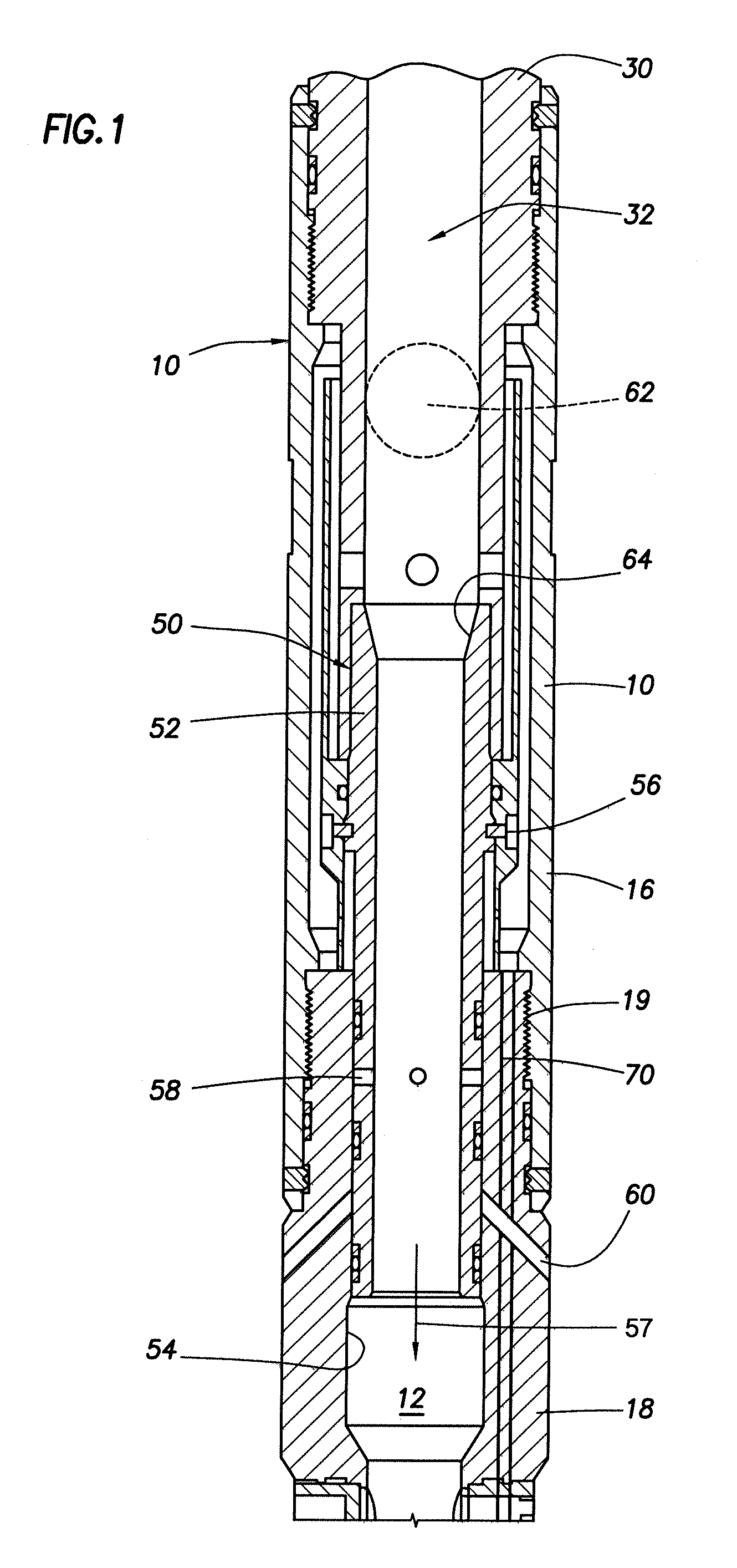

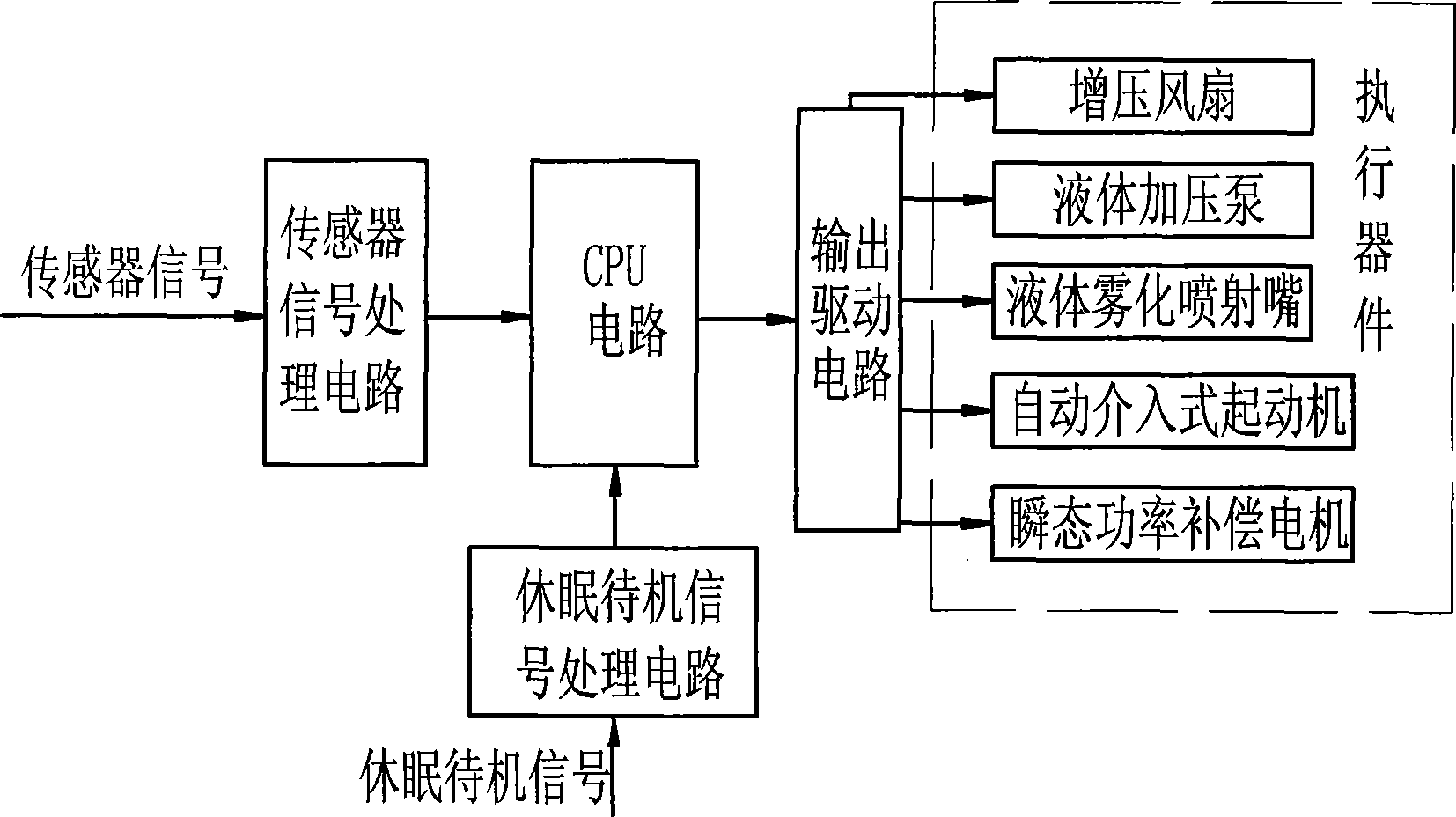

Stepped liner hanger expander

ActiveUS9476288B2Reduce inflation pressureReduce tool lengthConstructionsFluid removalShortest distanceEngineering

Disclosed is a tubular expansion tool which includes a plurality of stackable piston / slip / spring assemblies that are used to radially expand a liner against well casing along a longitudinal distance “L.” The pistons are repeatedly stroked a short distance “S” with the application of hydraulic pressure. As the pistons are stroked, they move a mandrel-expansion die sub assembly in successive steps a distance “S” to perform the tubular expansion over a longer distance “L.”

Owner:HALLIBURTON ENERGY SERVICES INC

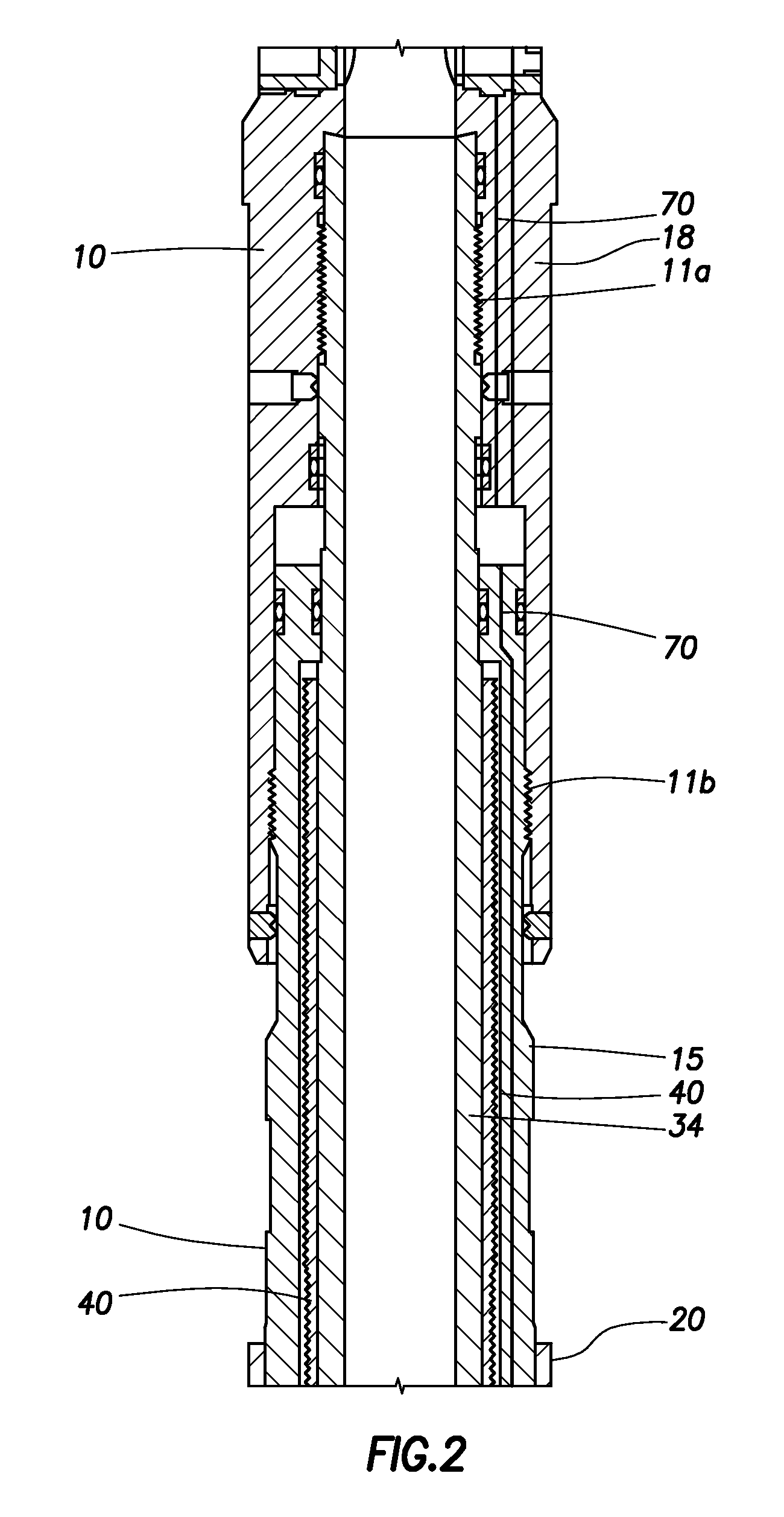

Energy-saving synergistic device for automobile

InactiveCN101503085AHigh expansion pressureOptimize fuel supply modeNon-fuel substance addition to fuelCombustion enginesCombustion chamberFuel oil

The invention discloses an automobile energy-saving and efficiency-increasing system, comprising an ECU control circuit, a sensor, an expander ECU control circuit, an engine air-entering and a pressure-increasing compensating mechanism, an engine liquid atomization compensating mechanism, an automatic intrusive starter, a transient power compensating mechanism and an electric machinery, wherein, the engine air-entering and pressure-increasing compensating mechanism, the engine liquid atomization compensating mechanism, the automatic intrusive starter, the transient power compensating mechanism and the electric machinery are controlled by the expander ECU control circuit. The invention can improve transient required ratio precision between air and fuel oil, transient transporting proportioning precision and the power of original automobile engine; the invention has the advantages of fast start and acceleration; the engine liquid atomization compensating mechanism can be used for increasing the expansion pressure of a combustion chamber after combusting, thereby the kinetic energy of the engine can be correspondingly improved and large amount of fuel oil can be saved when the engine outputs equivalent power; and the invention not only improves engine power but also reduces oil consumption, which is excellently characterized in that the purification degree of exhaust emission is high and has the rate of economizing gasoline which is more than 10%. The power is improved by more than 5% and the environmental protection function is superior to the original state-IV Europe.

Owner:HEBEI FEIER POWER SCI & TECH DEV

Anti-freezing cracking concrete and preparation method thereof

InactiveCN112358252AReduce heat of hydrationImprove frost cracking resistanceSorbitan monostearateSulfonate

The invention relates to the field of concrete, and particularly discloses anti-freezing cracking concrete and a preparation method. The concrete comprises polyoxyethylene sorbitan monostearate, sodium di-sec-octyl maleate sulfonate, coarse aggregate, fine aggregate, cement and water. The preparation method of the concrete comprises the following steps: 1) adding the polyoxyethylene sorbitan monostearate and the sodium di-sec-octyl maleate sulfonate into water, and heating to 75-80 DEG C to obtain a first mixture; and 2) adding the first mixture, the cement and the fine aggregate into the coarse aggregate, and uniformly mixing to obtain the anti-freezing cracking concrete. The anti-freezing cracking concrete provided by the invention can improve the freezing resistance and impermeability of the concrete, and the preparation method provided by the invention can improve the workability of a concrete mixture.

Owner:广州市广丰混凝土有限公司

Inflatable safety valve for emulsion pump

The invention discloses an inflatable safety valve for an emulsion pump. The inflatable safety valve is mainly used for safety protection of emulsion pumps in order to prevent the situation that overall system pressure is too high since unloading valves of the emulsion pumps are broken and cannot be used for normal unloading. The inflatable safety valve adopts high-pressure nitrogen for replacingmechanical springs to serve as elastic elements. Under the condition that the drift diameter for liquid drainage is increased, the size of the safety valve is reduced, and the response time of the safety valve is shortened. A liquid cavity sealing pair adopts a steel-steel hard sealing mode and has the advantages of long service life and great antifouling performance. The area of a liquid cavity sealing port is 50% of the airtight area of a valve core, the inflation pressure is decreased, and the sealing reliability is improved.

Owner:ZHEJIANG ZHONGMEI HYDRAULIC MACHINERY

Automatic unlocking door opening system for fire

ActiveCN111894363ARescue time shortenedReduce threatNon-mechanical controlsAlarm locksStructural engineeringMechanical engineering

The invention discloses an automatic unlocking door opening system for fire. The automatic unlocking door opening system comprises a lock catch body embedded in a door frame and a controller embeddedin a wall, wherein the lock catch body comprises a lock catch plate and a plurality of lock groove boxes; a plurality of lock holes are formed in the positions, corresponding to the lock groove boxes,of the lock catch plate; a piston plate is installed in each lock groove box in a sealed and sliding manner; an ejection column is installed on the side, close to the corresponding lock hole, of eachpiston plate; and a spring wire is installed on the side, away from the corresponding lock hole, of each piston plate. According to the automatic unlocking door opening system, fire heat is transmitted to thermal expansion liquid through a heat conduction plate so that the thermal expansion liquid can expand, the piston plates and the ejection columns are pushed to move towards the lock holes through drainage of guide pipes so that lock tongues can be pushed out of the lock groove boxes to be unlocked, and the automatic unlocking function for fire is achieved; and in addition, the ejection columns enter the lock holes so that an alarm circuit can be connected to give out alarm sounds to disperse surrounding personnel, an effective rescue channel is provided for firefighters, and the rescue time is saved.

Owner:SHENZHEN HOLISH INTELLIGENT TECH CO LTD

Tire inflation pressure detecting device for vehicle

InactiveUS7140243B2Simple structureReduce inflation pressureInflated body pressure measurementTransmission systemsTransmitterAutomotive engineering

A tire inflation pressure detecting device includes sensors provided in respective tires of a vehicle to detect various kinds of measured data involving a tire inflation pressure, transmitters for transmitting the measured data and a receiver for receiving the measured data transmitted from the transmitters. In operation, each of the transmitters of the tires transmits the measured data plural times at certain transmitting intervals in a predetermined cycle. Among the transmitters, the respective transmitting intervals are different from each other.

Owner:YAZAKI CORP

High-speed railway soft rock deep cutting arch-up deformation control structure and construction method

PendingCN110453542AAvoid excessive deformationAvoiding damage such as cracking and damageBallastwayStress distributionReinforced concrete

The invention discloses a high-speed railway soft rock deep cutting arch-up deformation control structure and a construction method. Continuous arch-up deformation of a high-speed railway deep cuttingin a soft rock area can be effectively controlled, rock body stress distribution can be adjusted, adjacent slopes can be reinforced, and then the construction cost can be reduced. The high-speed railway soft rock deep cutting arch-up deformation control structure comprises a ballastless track roadbed constructed on a soft rock base bed, the two sides of the ballastless track roadbed are providedwith right-side resisting piles and left-side resisting piles at intervals on a right-side slope body and a left-side slope body in the line direction, and the right-side resisting piles and the left-side resisting piles go deep into a certain depth under the base bed elevation. A reinforced concrete arc-shaped plate which is symmetrical along the central line of the roadbed and concaved downwardsis arranged on the top face of the soft rock base bed, and the two transverse sides of the reinforced concrete arc-shaped plate are rigidly connected with the right-side resisting piles and the left-side resisting piles to form a whole; and a water isolating cushion layer is arranged on the top face of the reinforced concrete arc-shaped plate, and the ballastless track roadbed is arranged on thewater isolating cushion layer in a filling manner.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Compact Cycloidal Magnetorheological Couplings

ActiveCN106499747BIncrease the effective contact areaUniform magnetic field distributionFluid clutchesCouplingBarrel Shaped

The invention discloses a compact cycloidal wheel magnetorheological coupling. The compact cycloidal wheel magnetorheological coupling is composed of an outer rotary component and an inner rotary component. An outer sleeve is formed by fixedly connecting a magnetizer and magnetism isolating rings which are symmetrically distributed on the two sides in the axial direction, and a multi-turn electromagnetic coil is wound in an annular groove of the outer sleeve. An outgoing line of the electromagnetic coil and a wiring terminal are guided out from the axial side face of an input-end coupling and connected with a power supply slip ring, and the input end is sleeved with the power supply slip ring. The outer-diameter portion of the outer sleeved is sleeved with cooling fins, and the two ends of the outer sleeve are connected with the input end of the coupling and a transparent cover through magnetism isolating screws. Oil injection plug screws are symmetrically distributed and mounted on the axial outer-diameter portion of the transparent cover. Pressure release valves which are symmetrically distributed are mounted at the input-end coupling in the circumferential direction. An outer cycloidal wheel sleeve is formed by fixedly connecting a cycloidal wheel and an inner magnetism isolating ring and is of a hollow barrel-shaped structure, and the two ends of the outer cycloidal wheel sleeve are connected with a rotary flange and an output-end coupling through magnetism-isolating stainless steel screws correspondingly. The inner rotary component and the outer rotary component are connected through a bearing. The compact cycloidal wheel magnetorheological coupling has the advantages of being compact in structure, low in manufacturing cost, convenient to maintain, and capable of transmitting a large torque.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com