High-flow safety valve

A large-flow safety valve and spool technology, which is applied in mining equipment, earthwork drilling, pillars/supports, etc., can solve the problem that the safety valve affects the normal operation of the hydraulic support and personnel safety, affects the dynamic response time of the safety valve, and the overshoot of the valve body. Liquid and seal diameter problems, etc., to prevent random disassembly structure, improve dynamic response time, improve the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

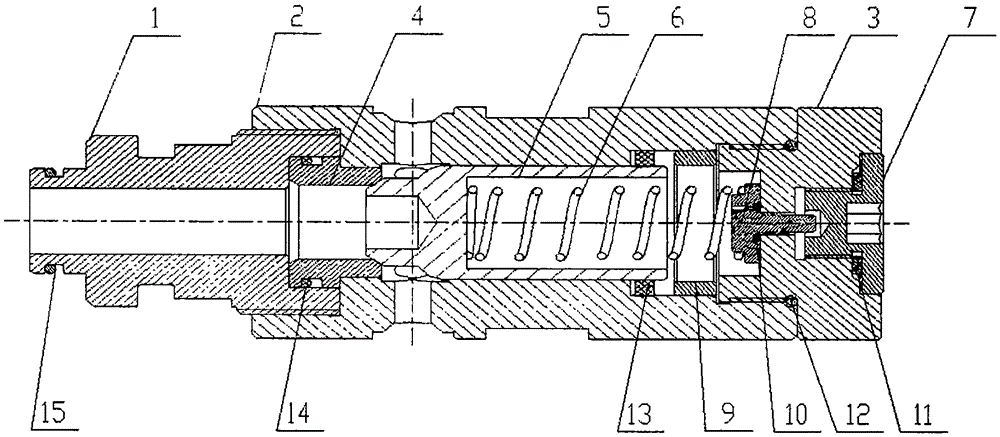

[0024] Attached below figure 1 An exemplary detailed description of the invention is given.

[0025] See attached figure 1 , which describes a preferred embodiment of the high flow safety valve according to the invention. The high-flow safety valve includes a valve body, a valve seat, a joint, a terminal, a valve core, a spring, and a floating sleeve. The joint and the terminal are respectively threaded at both ends of the valve body. The seat is set on the side close to the joint, the valve core is set on the side close to the end, and the line sealing contact between the valve seat and the valve core; the valve core is connected to the end through a spring, one end of the spring is connected to the inner surface of the inner hole of the valve core, and the other end There is a floating sleeve between the end and the valve body, which is used to prevent the back pressure from being greater than the inflation pressure and cause the third sealing ring to recoil to the inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com