An Electrostatic Hydraulic Actuator Driven by Double Butterfly Synergistic Distribution Pumps

An electrostatic hydraulic actuation and flow distribution pump technology, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, mechanical equipment, etc., can solve the problem of limited dynamic adjustment ability of system flow and pressure, internal transmission link of plunger pump, etc. And many friction pairs, unable to meet the high dynamic requirements of the pump control system, etc., to achieve the effect of short adjustment response time, good processing and assembly process, and increase the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

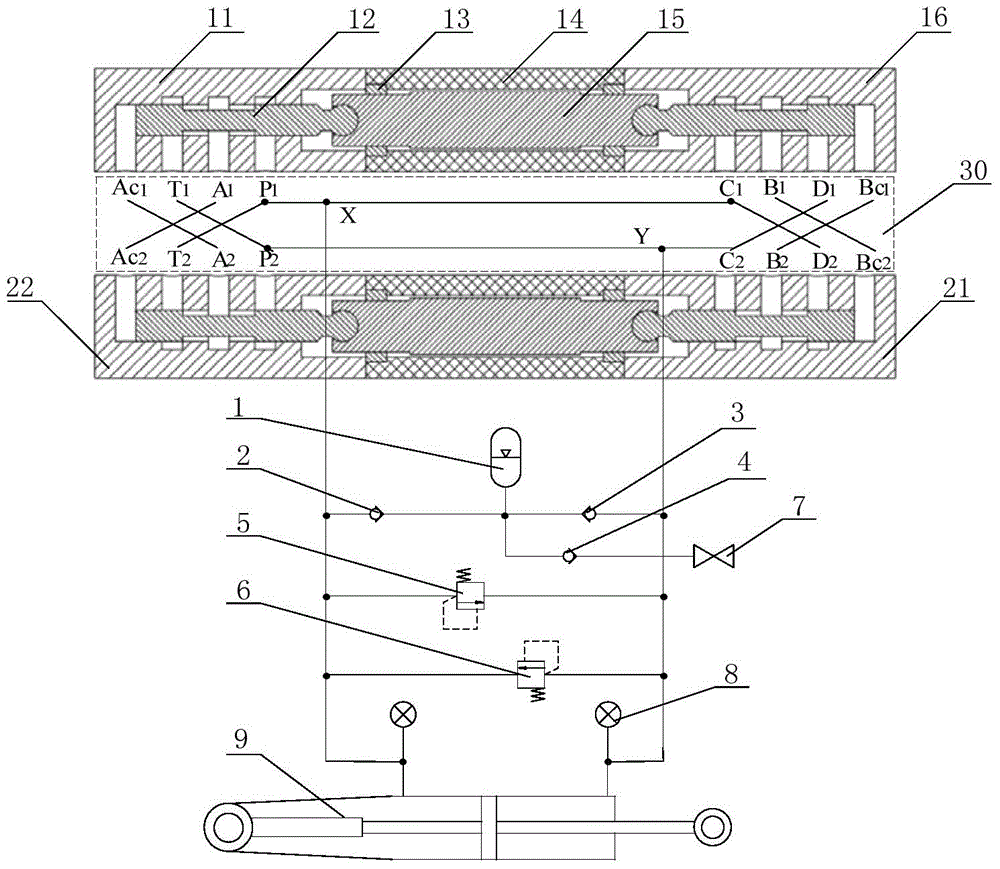

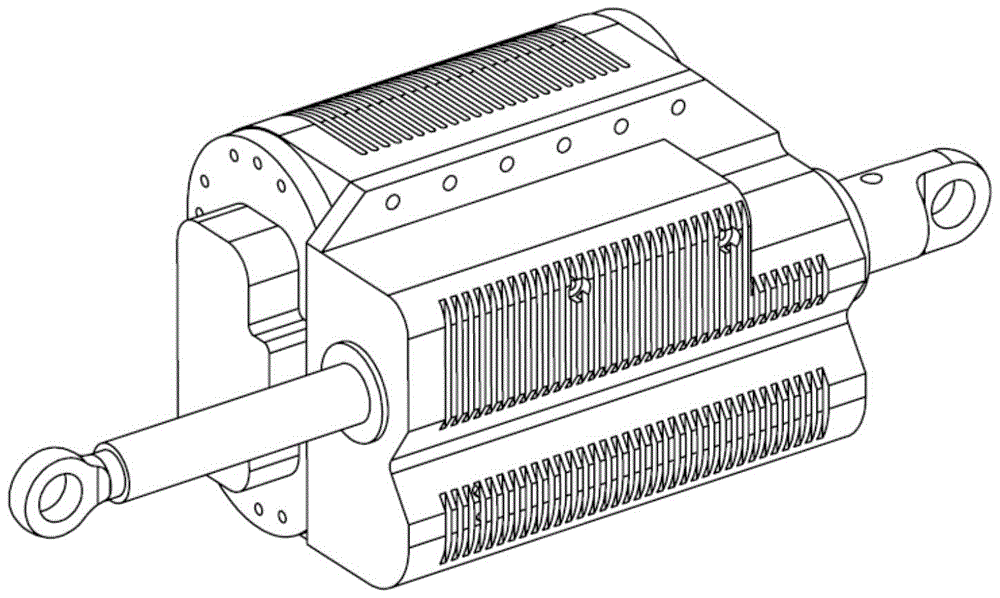

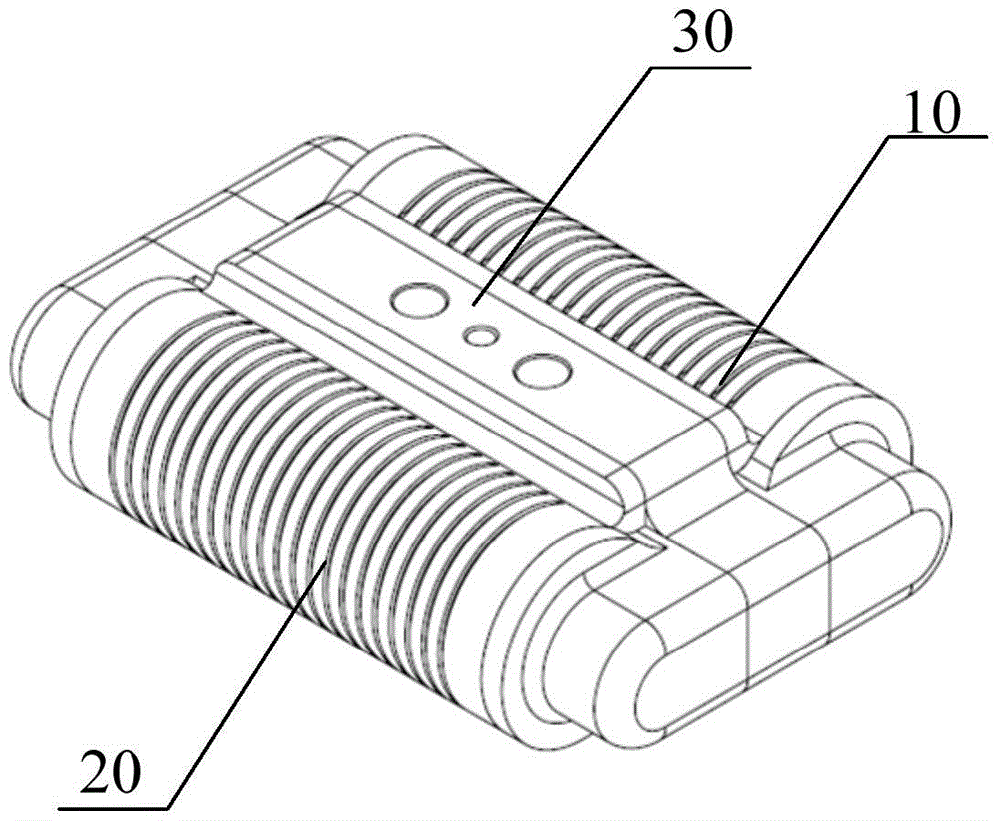

[0025] Such as figure 1 As shown, the embodiment of the present invention provides an electrohydrostatic actuator driven by a double-butterfly coordinated distribution pump, including at least one pump unit, an accumulator 1 and a hydraulic cylinder 9, the pump unit includes two pump modules, two The pump module is connected to the oil circuit through the double-butterfly distribution valve block 30. The pump module includes a linear motor. Both ends of the linear motor are connected with a distribution valve. The housing of the distribution valve i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com