High-inhibition amino silanol drilling fluid and preparation method thereof

An aminosilanol and drilling fluid technology, applied in chemical instruments and methods, drilling compositions, etc., to achieve the effects of good inhibition, strong inhibition and reduction of expansion pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

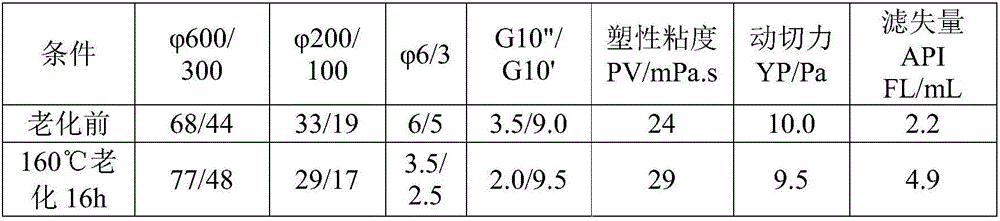

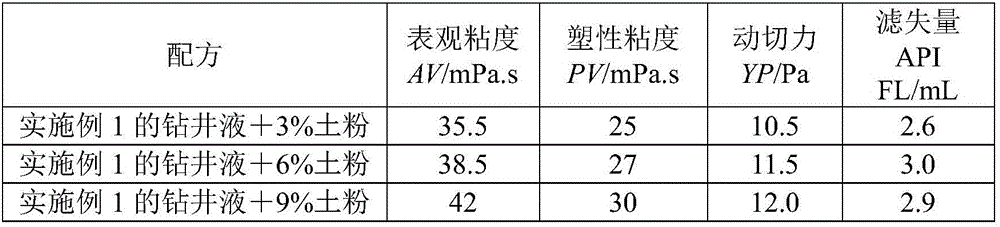

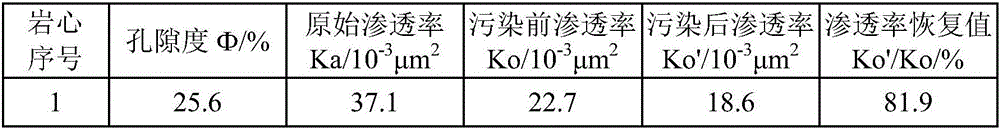

[0033] This embodiment provides a kind of highly inhibited aminosilanol drilling fluid suitable for coal seams, which includes 3% bentonite, 0.3% Na 2 CO 3 , 0.5% potassium polyacrylamide (KPAM), 2% lignite resin (SPNH), 1% sulfonated bitumen FT1, 1% shale inhibitor KAHm, 2% sulfonated phenolic resin SMP-Ⅱ, 1% non-fluorescent anti- Slump fluid loss agent KH-9311, 0.5% zwitterionic polymer viscosity reducer XY27 and 1.0% aminosilanol, the balance is water, and then add barite to adjust the density of the strongly inhibited aminosilanol drilling fluid to 1.2 g / cm 3 .

[0034] This example also provides the above-mentioned strong inhibitory aminosilanol drilling fluid used in tight sandstone reservoir inhibition experiments, temperature resistance, anti-pollution experiments, oil and gas layer protection effect evaluation experiments, to further illustrate the strong inhibition provided by this embodiment. Excellent performance of aminosilanol drilling fluid.

[0035] 1. Basi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| filtration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com