Water industrial antirust paint and preparation method thereof

An anti-rust paint, industrial technology, applied in latex paint, anti-corrosion paint, coating and other directions, can solve the problems of danger caused by production and construction sites, heavy metal ions exceeding the standard, high VOC content, achieve excellent stability and penetration function, strengthen Anti-corrosion performance, complete conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

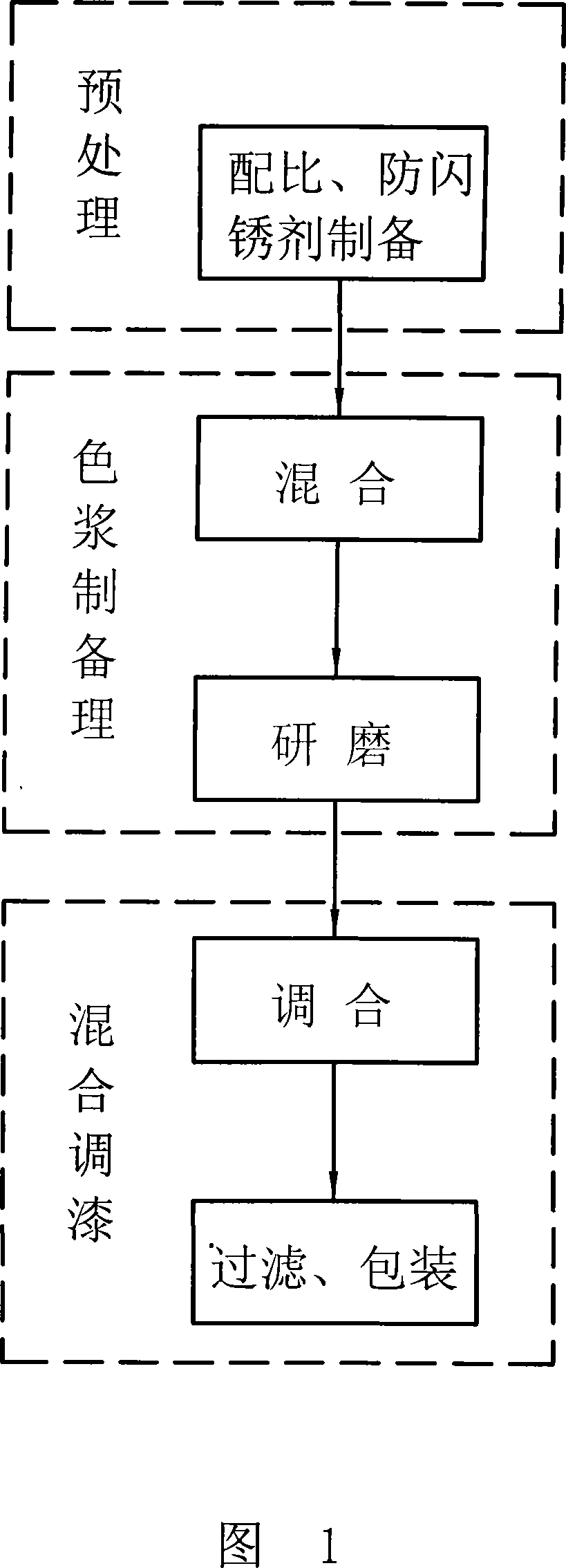

[0015] The preparation method of water-based industrial anti-rust paint: prepare according to the following steps: (1) Pretreatment According to the weight of the water-based industrial anti-rust paint to be prepared, weigh the following raw materials by weight percentage: water-based acrylic acid modified epoxy resin 8%, acrylic acid emulsion 40%, defoamer 0.3%, wetting agent 0.05%, dispersant 0.5%, anti-flash rust agent 0.3%, iron oxide red 7.5%, talcum powder 6%, modified zinc phosphate 5%, aluminum tripolyphosphate 2.5% %, precipitated barium sulfate 3%, zinc oxide 0.5%, micaceous iron oxide 3%, alcohol ester 12%, triethanolamine 1%, thickener 0.3%, preservative 0.05%, deionized water 20%. Slowly stir the weighed water-based acrylic modified epoxy resin and acrylic emulsion, and fully mix; prepare the anti-flash rust agent: according to the weight to be prepared, the following components are prepared by weight percentage, polyglycol 0.5%, sub Cyclohexylamine nitrate 0.5%, ...

Embodiment 2

[0017] The preparation method of water-based industrial antirust paint: prepare according to the following steps: (1) Pretreatment According to the weight of the water-based industrial antirust paint to be prepared, weigh the following raw materials by weight percentage: water-based acrylic acid modified epoxy resin 10%, acrylic acid emulsion 36%, defoamer 0.2%, wetting agent 0.1%, dispersant 0.4%, anti-flash rust agent 0.4%, iron oxide red 8.5%, talcum powder 7.5%, modified zinc phosphate 8.0%, aluminum tripolyphosphate 8.0 %, precipitated barium sulfate 3.2%, zinc oxide 0.6%, micaceous iron oxide 3.5%, alcohol ester dodecane 1.5%, triethanolamine 1.5%, thickener 0.5%, preservative 0.1%, deionized water 10%. Slowly stir the weighed water-based acrylic modified epoxy resin and acrylic emulsion, and fully mix; prepare the anti-flash rust agent: according to the weight to be prepared, the following components are prepared by weight percentage, polyglycol 6%, sub Cyclohexylamine ...

Embodiment 3

[0019]The preparation method of water-based industrial antirust paint: prepare according to the following steps: (1) Pretreatment According to the weight of the water-based industrial antirust paint to be prepared, weigh the following raw materials by weight percentage: water-based acrylic acid modified epoxy resin 11%, acrylic acid emulsion 33%, defoamer 0.1%, wetting agent 0.15%, dispersant 0.3%, anti-flash rust agent 0.5%, iron oxide red 9%, talcum powder 8%, modified zinc phosphate 10%, aluminum tripolyphosphate 10% %, precipitated barium sulfate 3.5%, zinc oxide 0.8%, micaceous iron oxide 5%, alcohol ester twelve 1%, triethanolamine 2%, thickener 0.6%, preservative 0.05%, deionized water 5%. Slowly stir the weighed water-based acrylic modified epoxy resin and acrylic emulsion, and fully mix; prepare anti-flash rust agent: according to the weight to be prepared, the following components are prepared by weight percentage, polyglycol 8%, sub- Cyclohexylamine nitrate 3%, sodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com