Patents

Literature

1002results about How to "Reduce permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

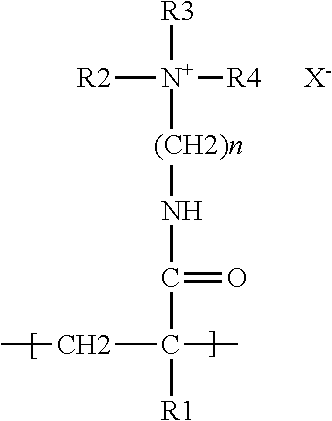

Delivery particles

ActiveUS20110269658A1Strong adhesionReduce permeabilityBiocideCosmetic preparationsPolymer chemistryMaterials science

Owner:THE PROCTER & GAMBLE COMPANY

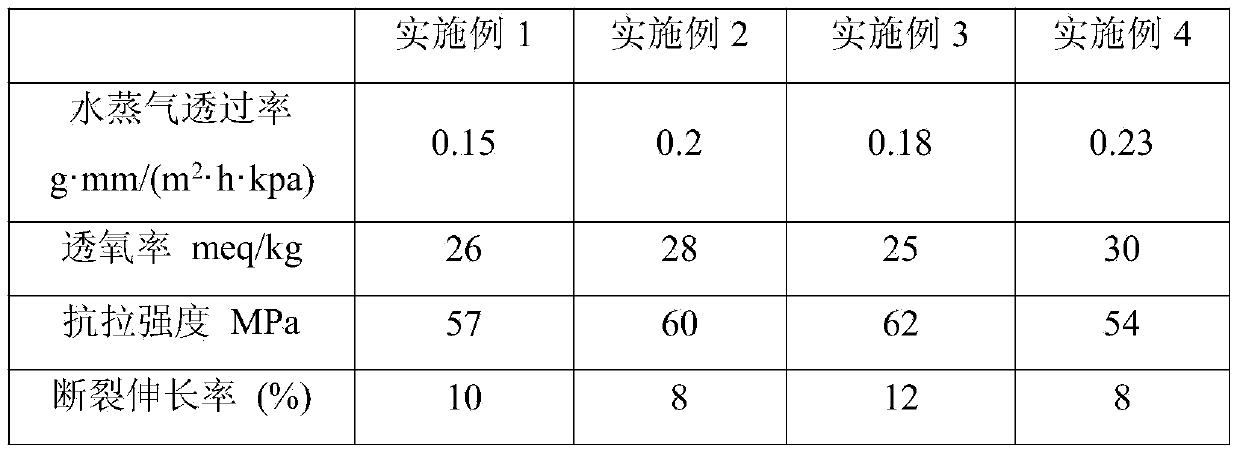

Edible biological preservative film and preparation method thereof

ActiveCN104194354AImprove mechanical propertiesImprove barrier propertiesFlexible coversWrappersAntioxidantPlasticizer

The invention discloses an edible biological preservative film and a preparation method thereof. The edible biological preservative film comprises the following components in parts by weight: 30-60 parts of a film former, 1-10 parts of a natural antioxidant, 1-10 parts of a natural bacterial inhibitor, 1-4 parts of a plasticizer and 0.5-4 parts of an emulsifier. The preparation method comprises the following steps: mixing the components in proportion to form preservative film liquid, and preparing the preservative film by adopting a tape-casting process. According to the preservative film, excellent film forming performances of materials such as marine polysaccharides, chitosan, gelatin and the like are utilized, the natural antioxidant and the natural bacterial inhibitor are selected and used, and the modification process is carried out through the plasticizer, the emulsifier and the like, so that the prepared preservative film is good in mechanical property, delays the spoilage of an aquatic product and can effectively prolong the shelf life of the aquatic product.

Owner:MARINE BIOLOGY INST OF SHANDONG PROVINCE

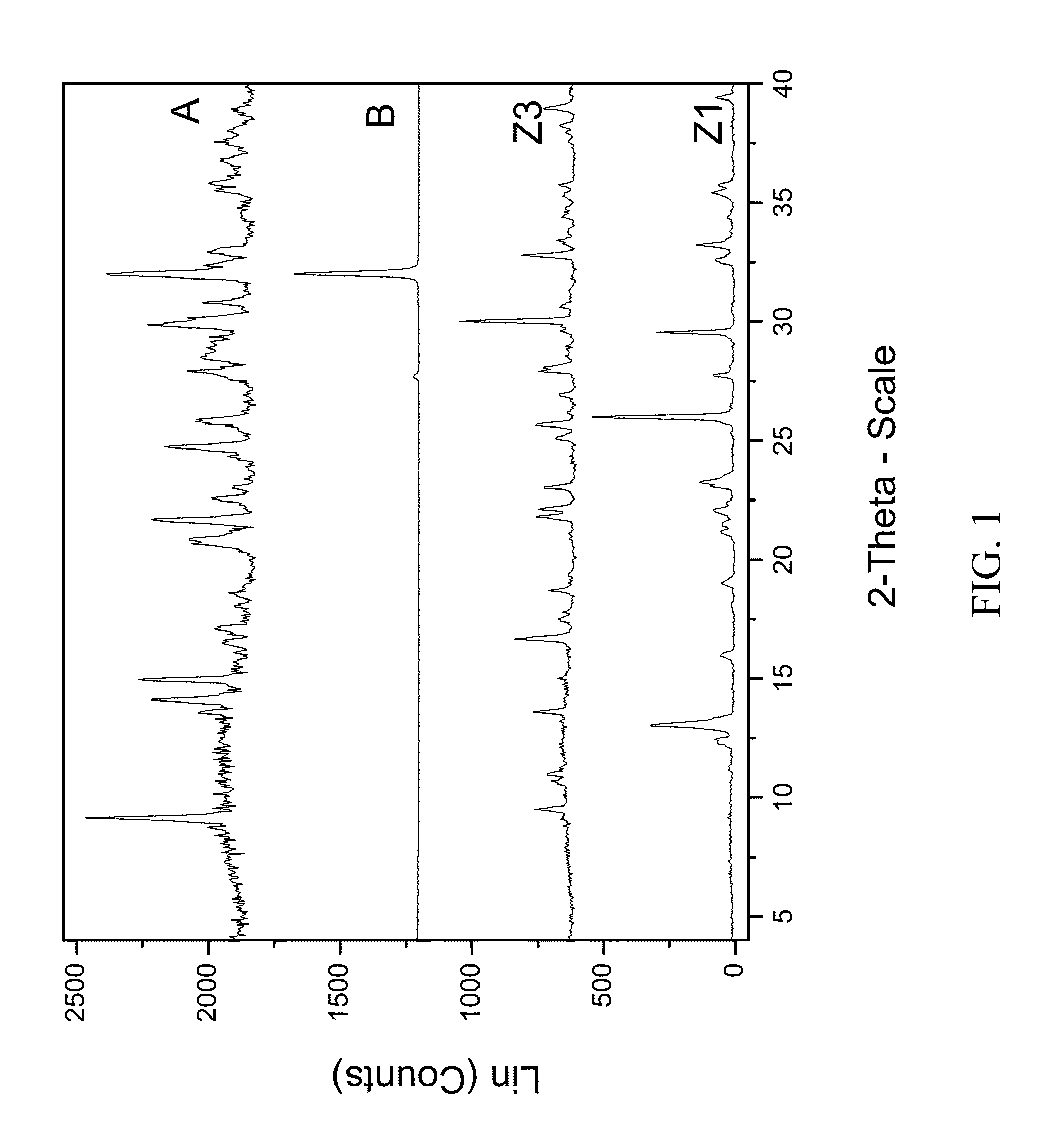

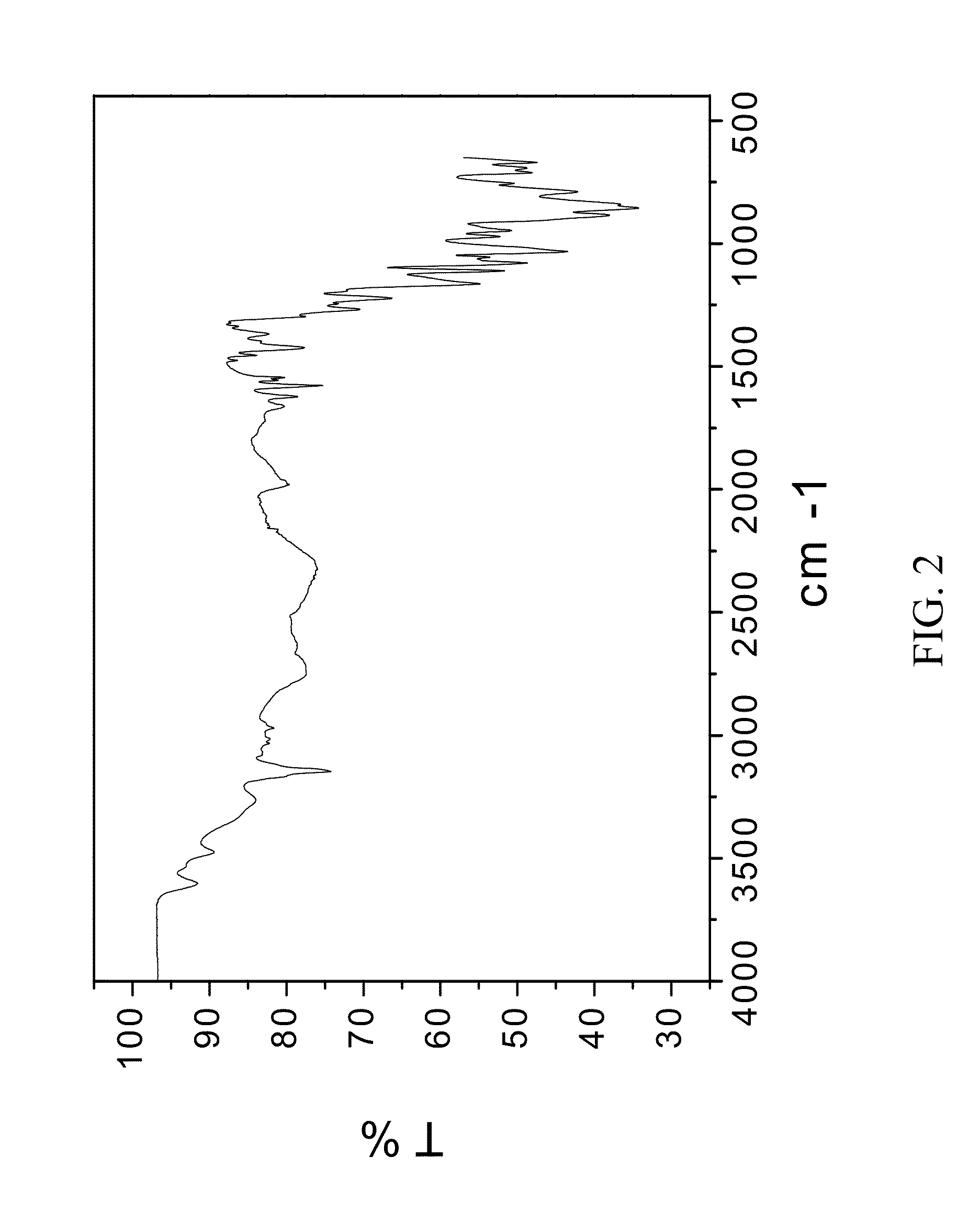

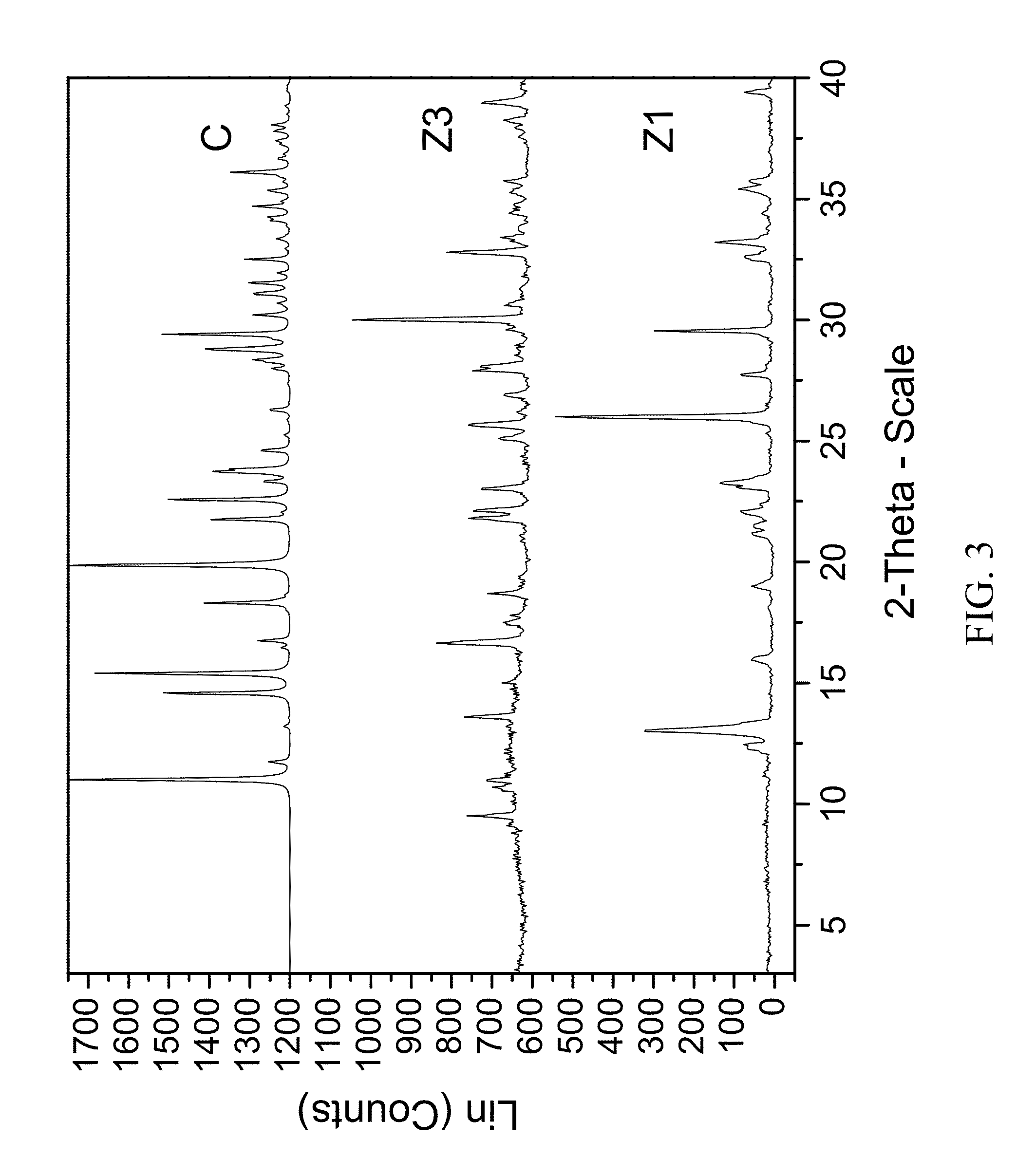

Crystallization method and bioavailability

ActiveUS20130035315A1Improve bioavailabilityPoor blend/physical mixture uniformityPowder deliveryBiocideDrug deliveryDrug

Owner:THAR PHARMA

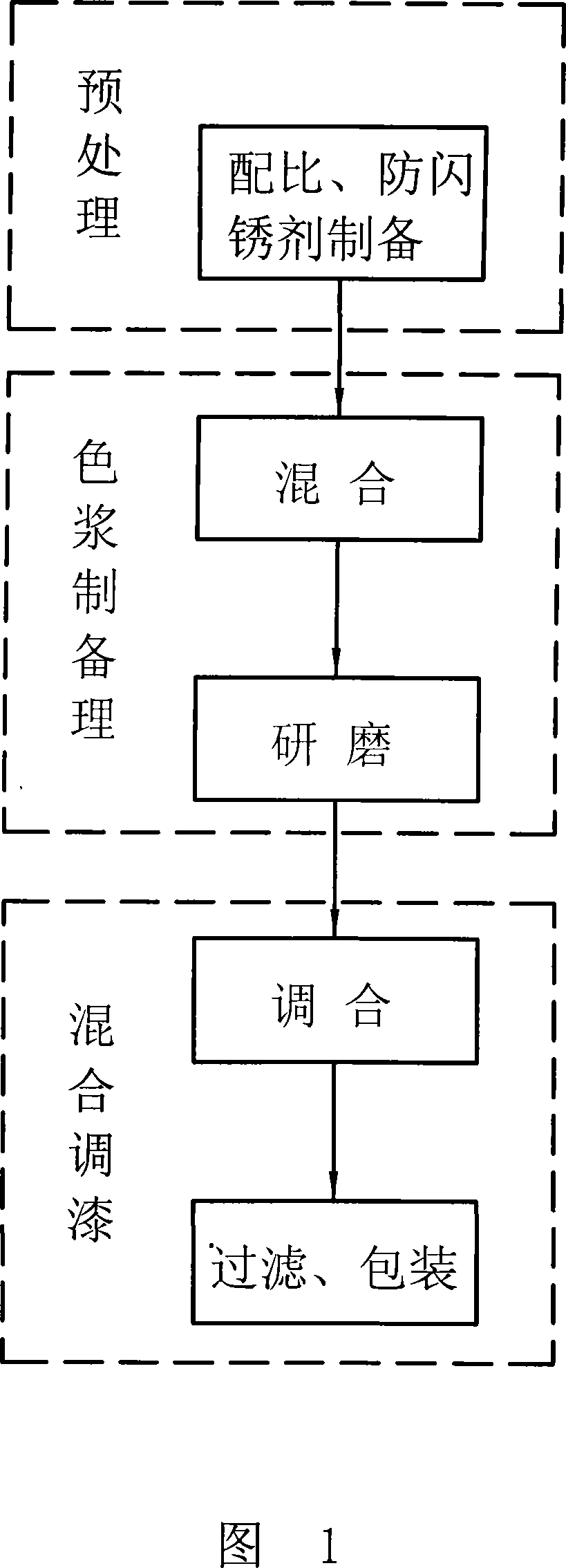

Water industrial antirust paint and preparation method thereof

InactiveCN101045843AHigh hardnessStrong adhesionAnti-corrosive paintsEmulsion paintsEpoxyALUMINUM PHOSPHATE

This invention relates to a aquosity industry anti-rust paint and its preparation method. According to weight it includes 8 to 11% aquosity acroleic acid modified epoxy, 33 to 40% acroleic acid latices, 0.1 to 0.3% defoamer, 0.05 to 0.15% wetting agent, 0.3 to 0.5% dispersant, 0.3 to 0.5% rust-resistant agent, 7.5 to 9% iron oxide red, 6 to 8% French chalk, 5 to 10% modified zinc phosphate, 2.5 to 10% trimerization aluminum phosphate, 3 to 3.5% precipitated baryte , 0.5 to 1% zinc oxide, 3 to 5% mica ferric oxide, alcohol ester twelve 1 to 2%, triethanolamine 1 to 2%, thickening agent 0.3 to 0.6%, preservative 0.05 to 0.1%, 5 to 20% de-ionized water, through pretreatment, color paste preparation and blending and adjusting to gain product.

Owner:邹磊

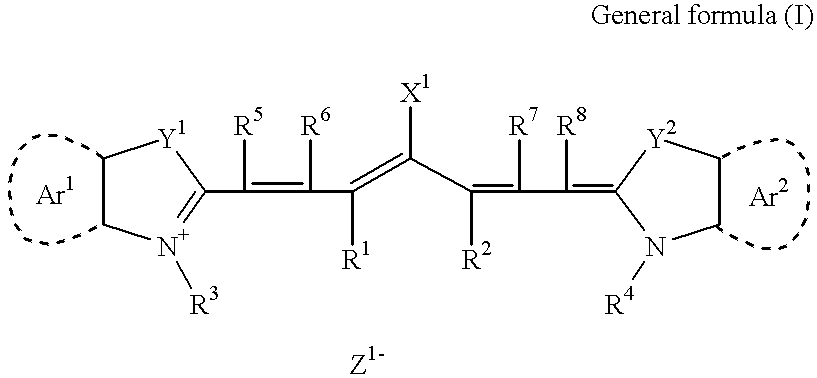

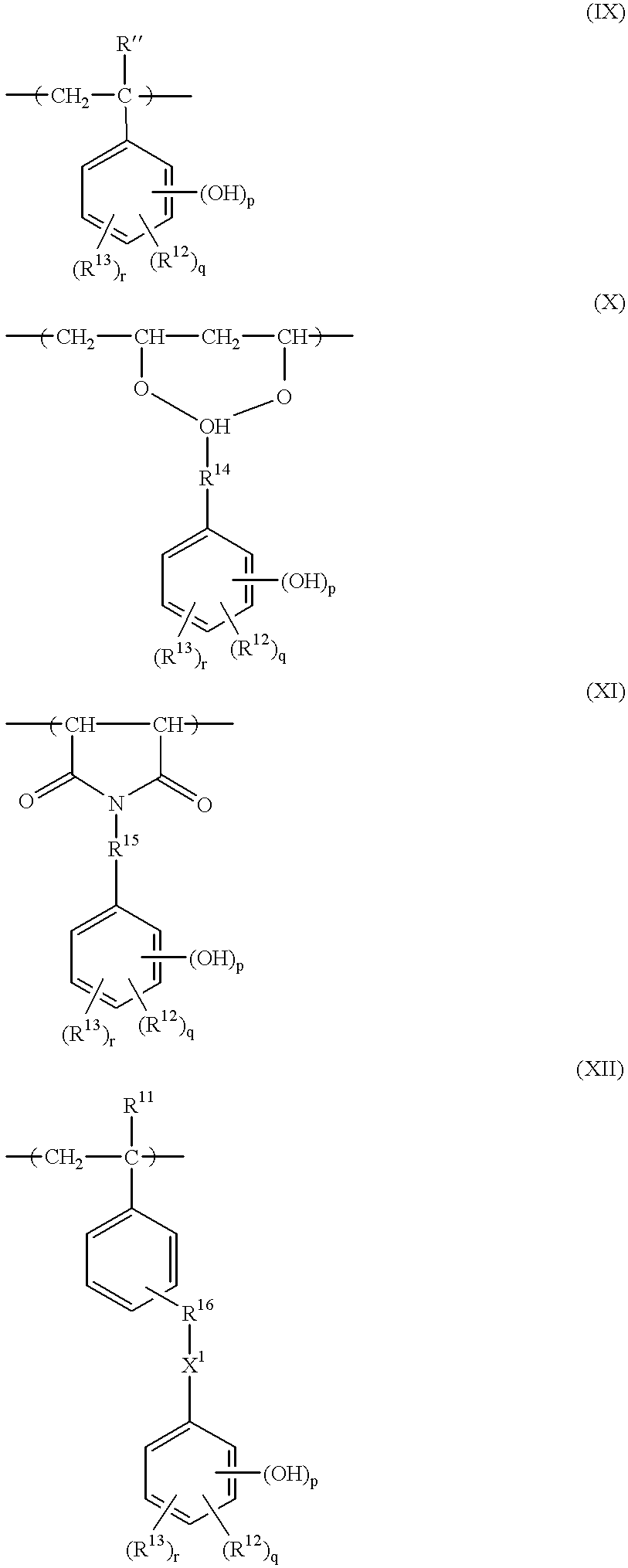

Cationic microcapsule particles

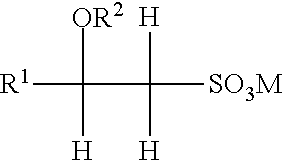

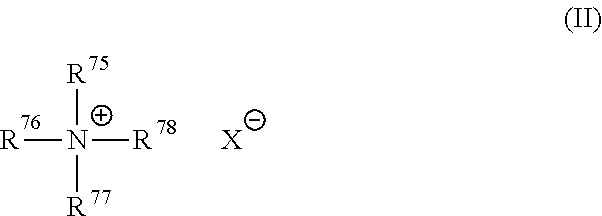

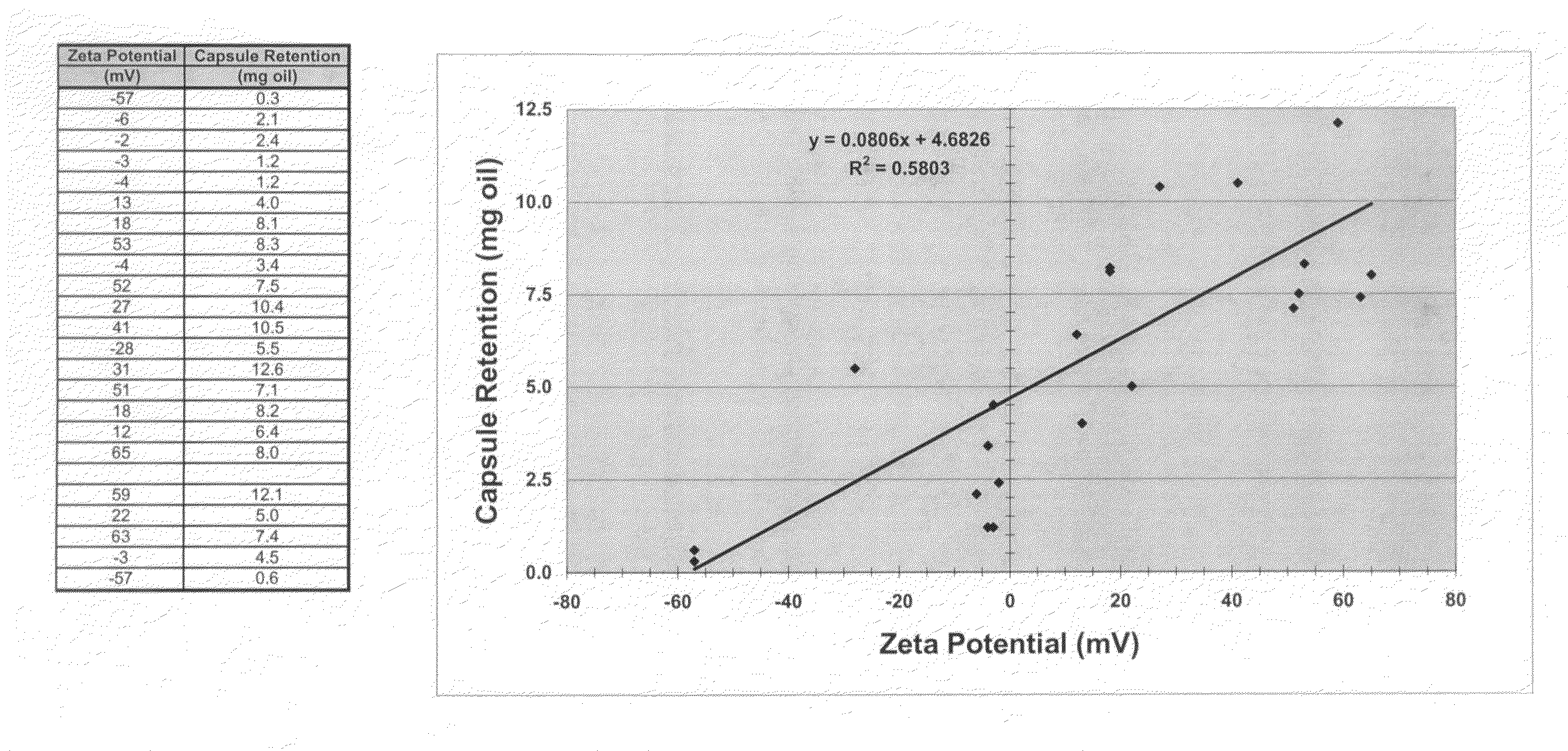

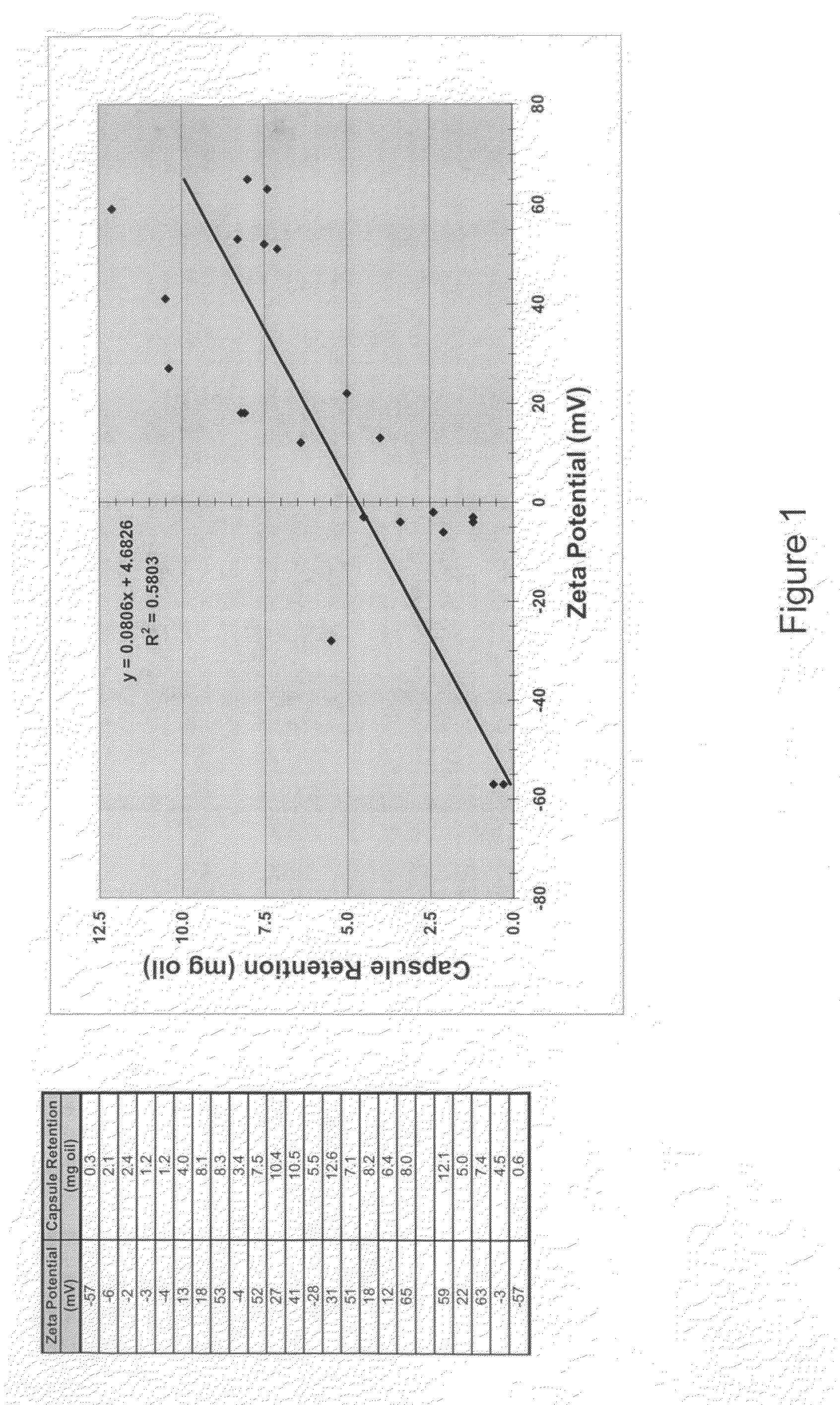

ActiveUS20090274905A1Strong adhesionReduce permeabilityCosmetic preparationsLiquid surface applicatorsZeta potentialMethacrylate

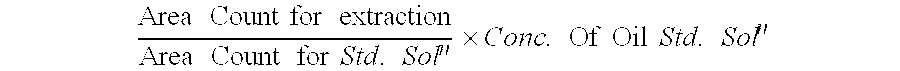

The present invention teaches a cationically charged or neutral microcapsule particle comprising an oil soluble or dispersible core material and a wall material at least partially surrounding the core material, the microcapsule wall material comprising the reaction product of a first composition in the presence of a second composition comprising an emulsifier which is cationic or nonionic, the first composition comprising a reaction product of i) an oil soluble or dispersible amine with ii) a multifunctional acrylate or methacrylate monomer or oligomer, an oil soluble acid and an initiator. The cationic or nonionic emulsifier comprises a water soluble or water dispersible material and optionally a water phase initiator. The first composition initiator and the water phase initiator is an energy-activated initiator. The reaction product of the first composition and second composition results in the formation of a population of microcapsules having a microcapsule wall of low permeance to the core material and having a zeta potential of−5 millivolts or greater. The resulting microcapsules have adherence to anionic surfaces.

Owner:ENCAPSYS LLC

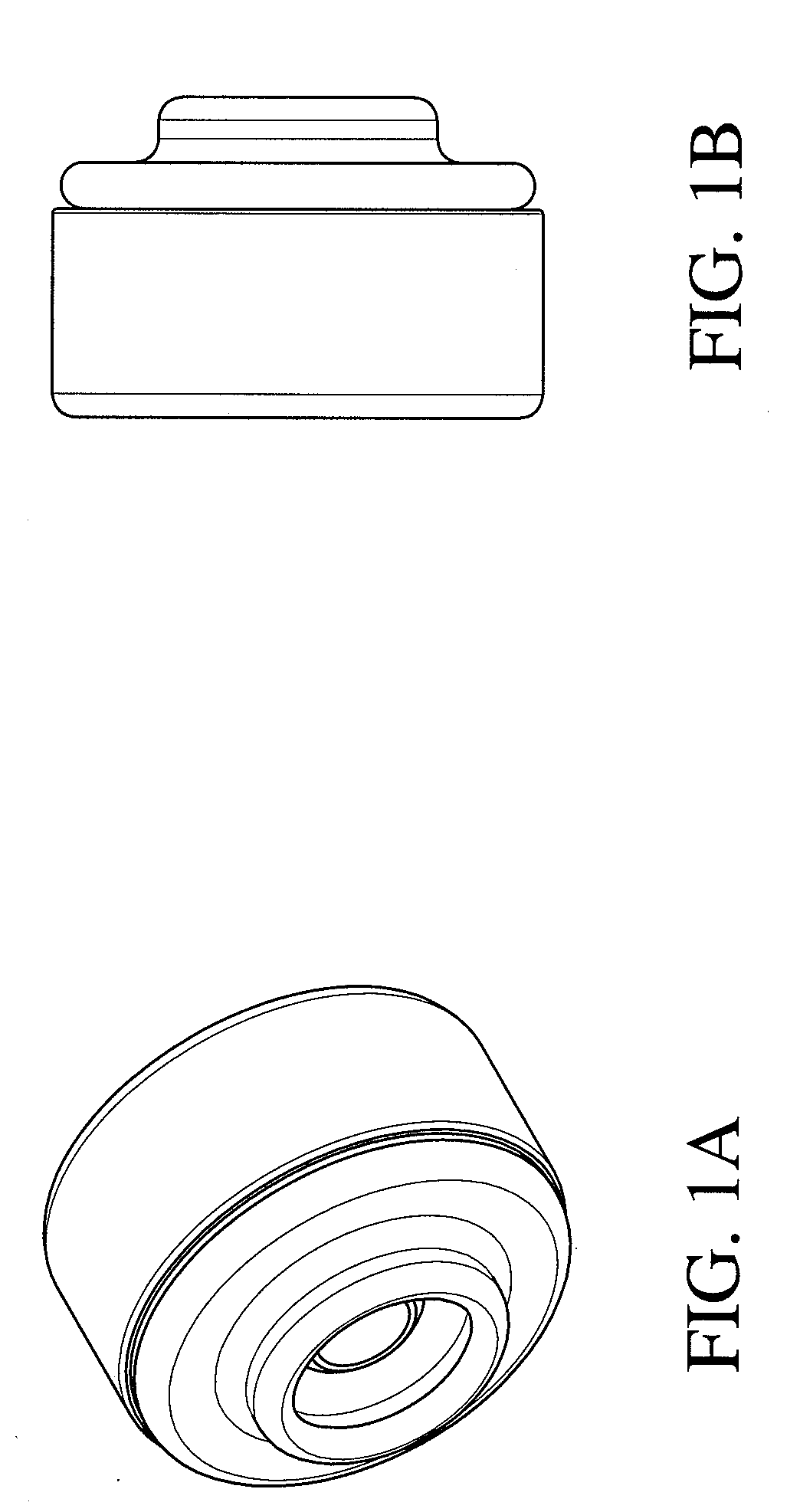

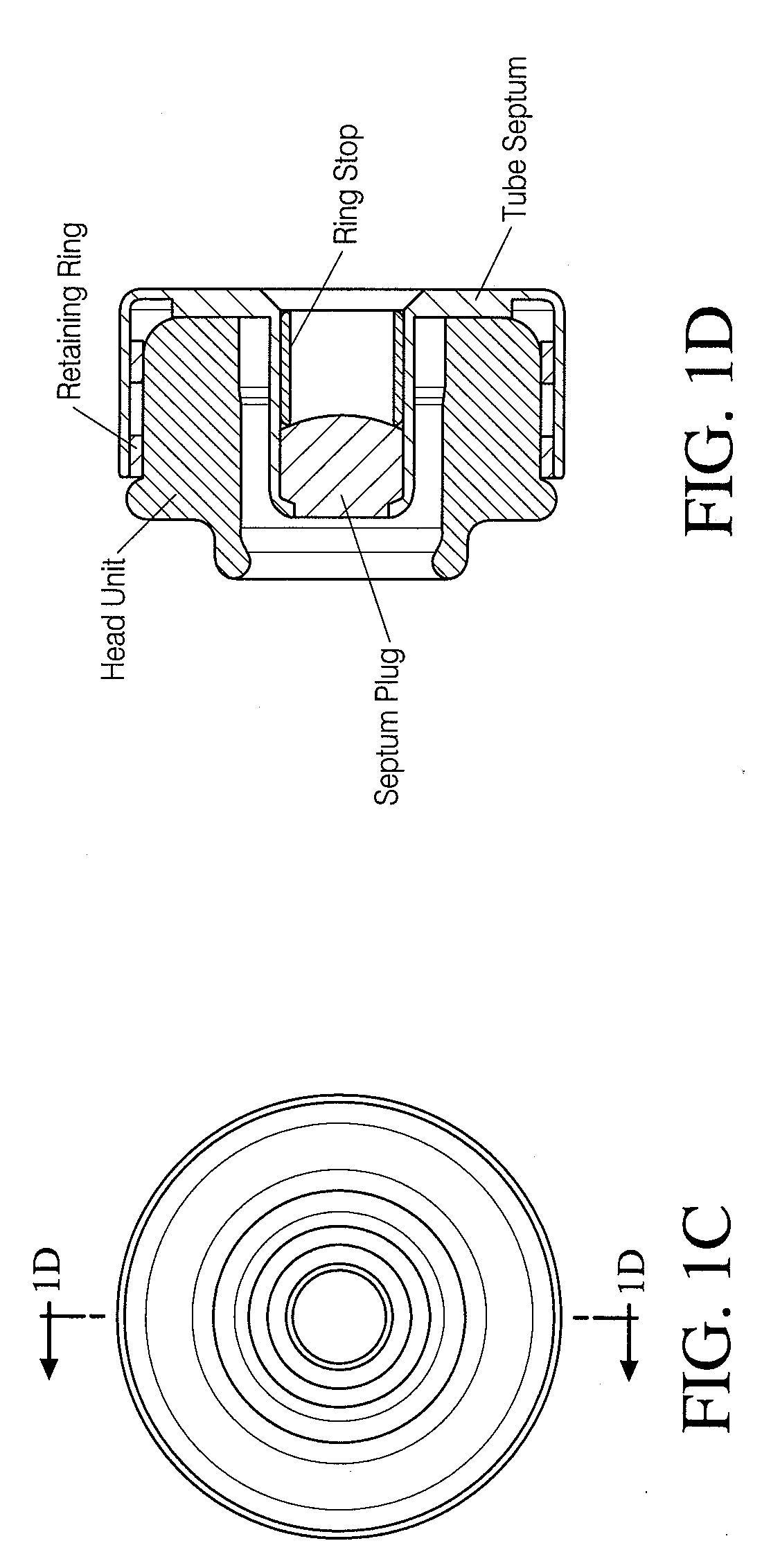

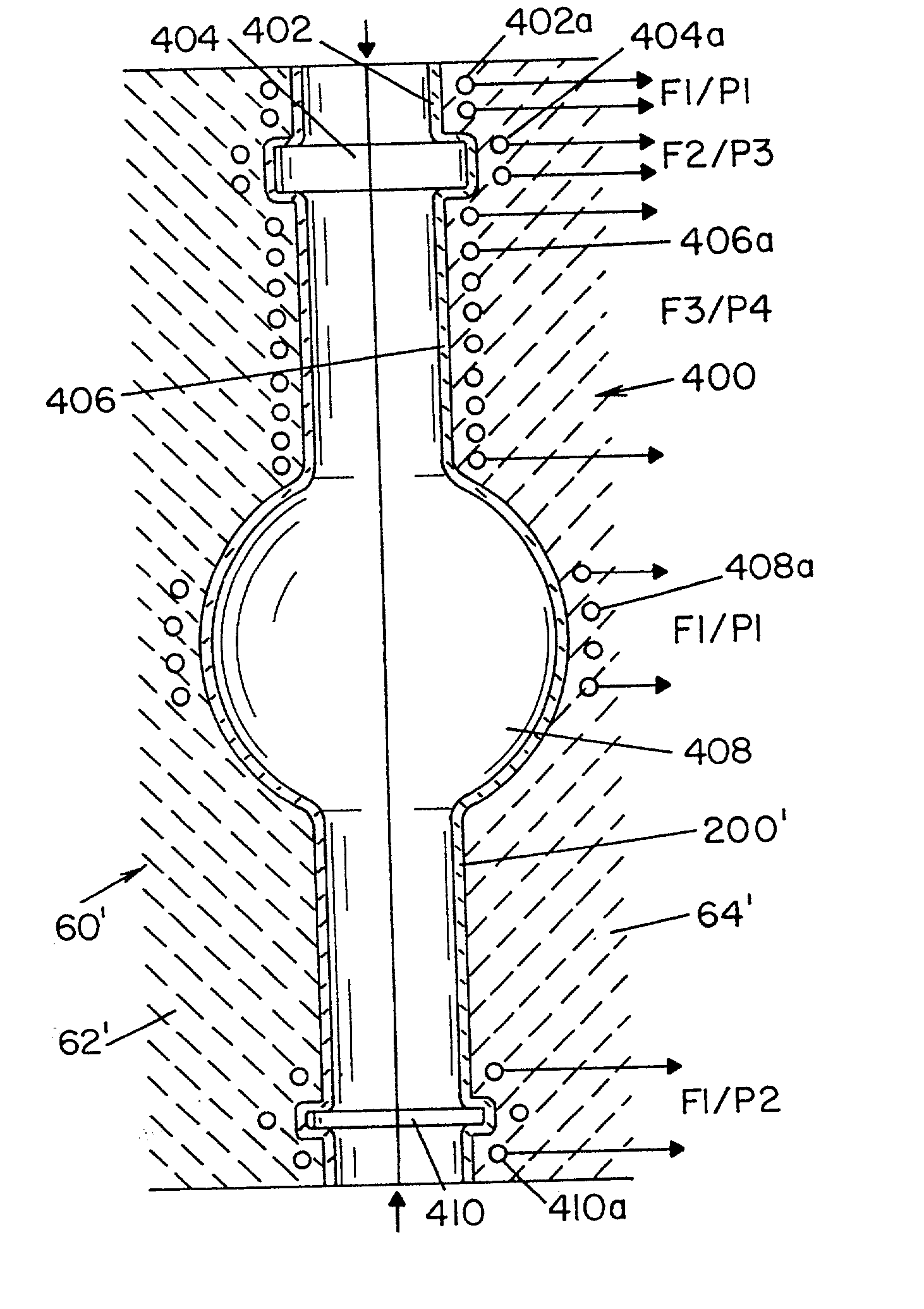

Intragastric device

ActiveUS20120191123A1Reduce permeabilityEnhance gas impermeable characteristicBalloon catheterSurgeryBiomedical engineeringStomach

Devices and methods for treating obesity are provided. More particularly, intragastric devices and methods of fabricating, deploying, inflating, monitoring, and retrieving the same are provided.

Owner:RESHAPE LIFESCIENCES INC

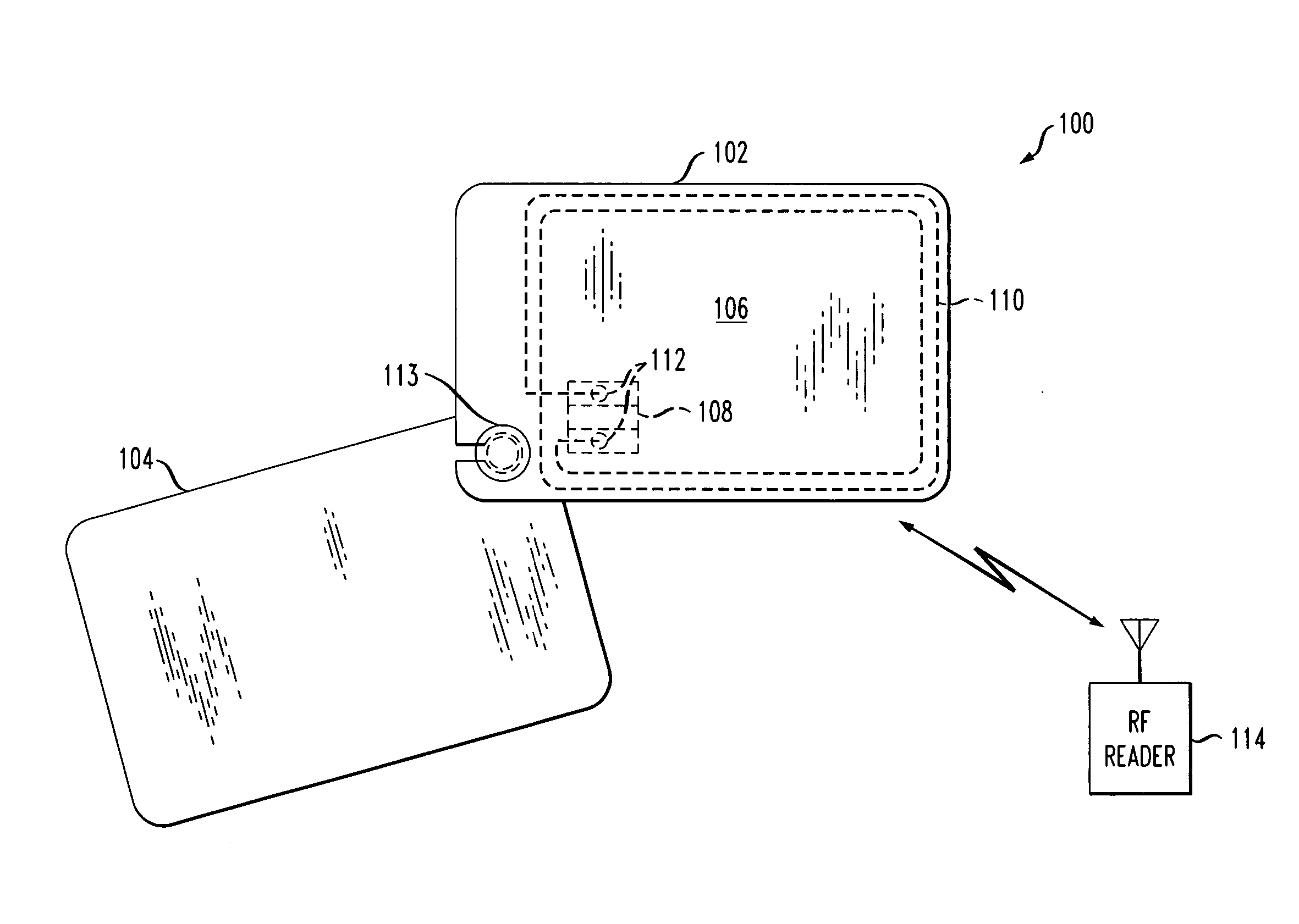

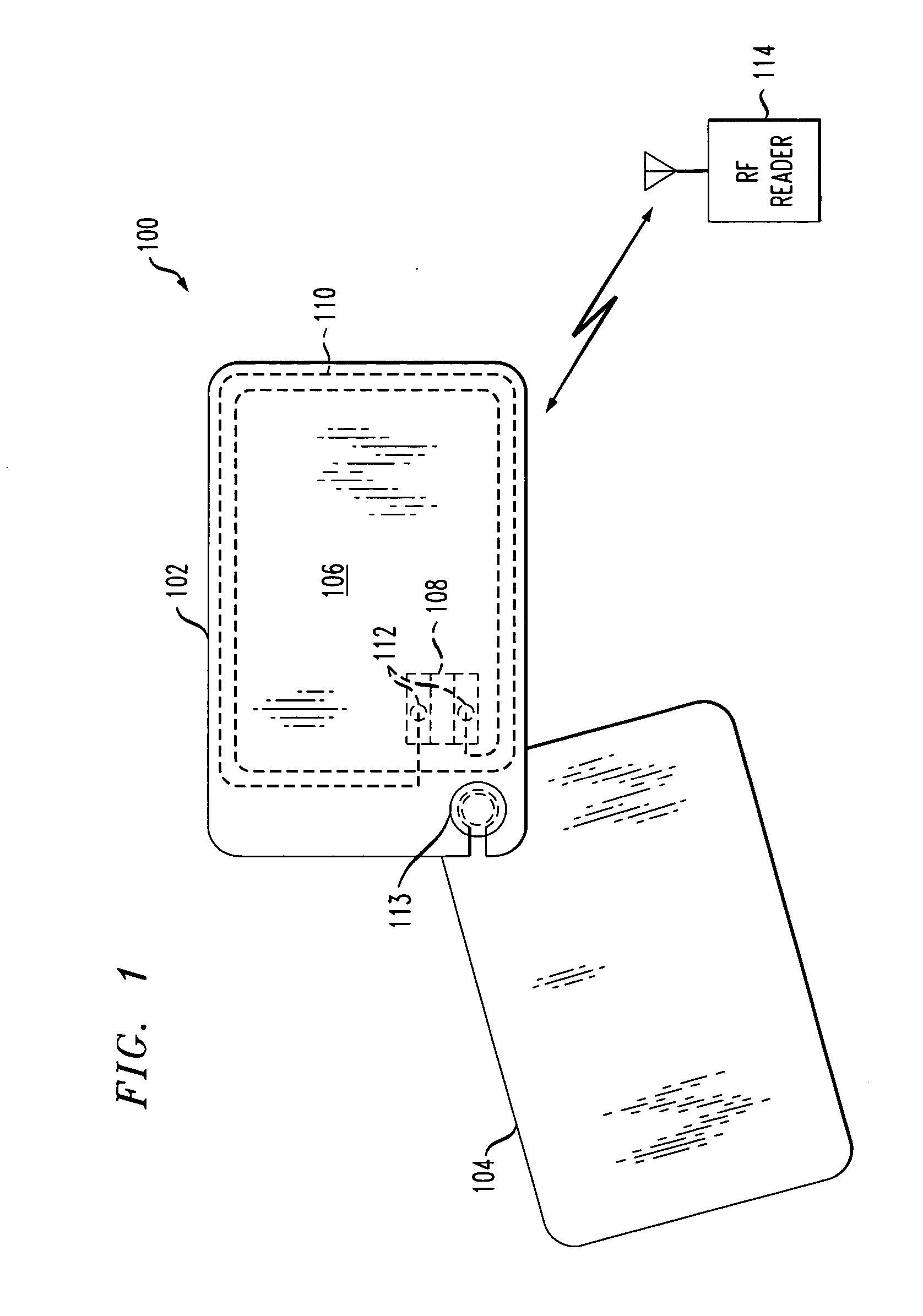

Contactless proximity communications apparatus and method

InactiveUS20070040030A1Reduce permeabilityNear-field systems using receiversSensing record carriersLinear motionEngineering

Techniques for reducing or eliminating the likelihood of fraud in a contactless proximity communications apparatus are provided. The apparatus can include a body portion with a body, a communications circuit, and an antenna. The apparatus can also include a signal-disrupting portion that is mounted for motion, such as rotary or linear motion, with respect to the body portion and configured to substantially disrupt RF signals in a first position, and to move to a second position where RF communication is possible.

Owner:MASTERCARD INT INC

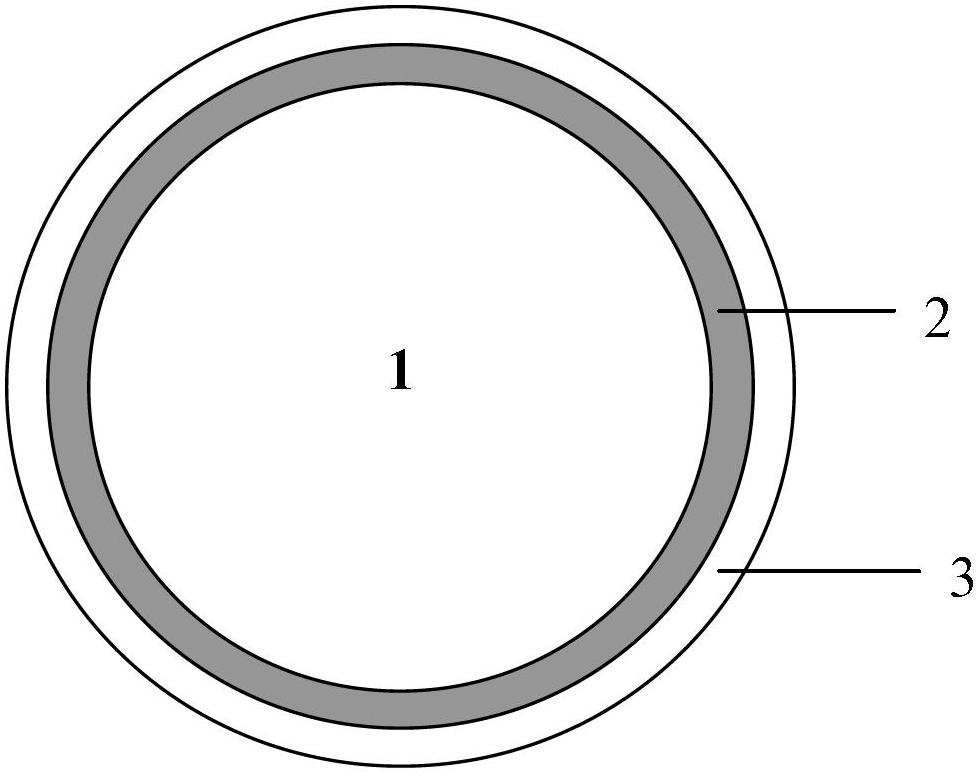

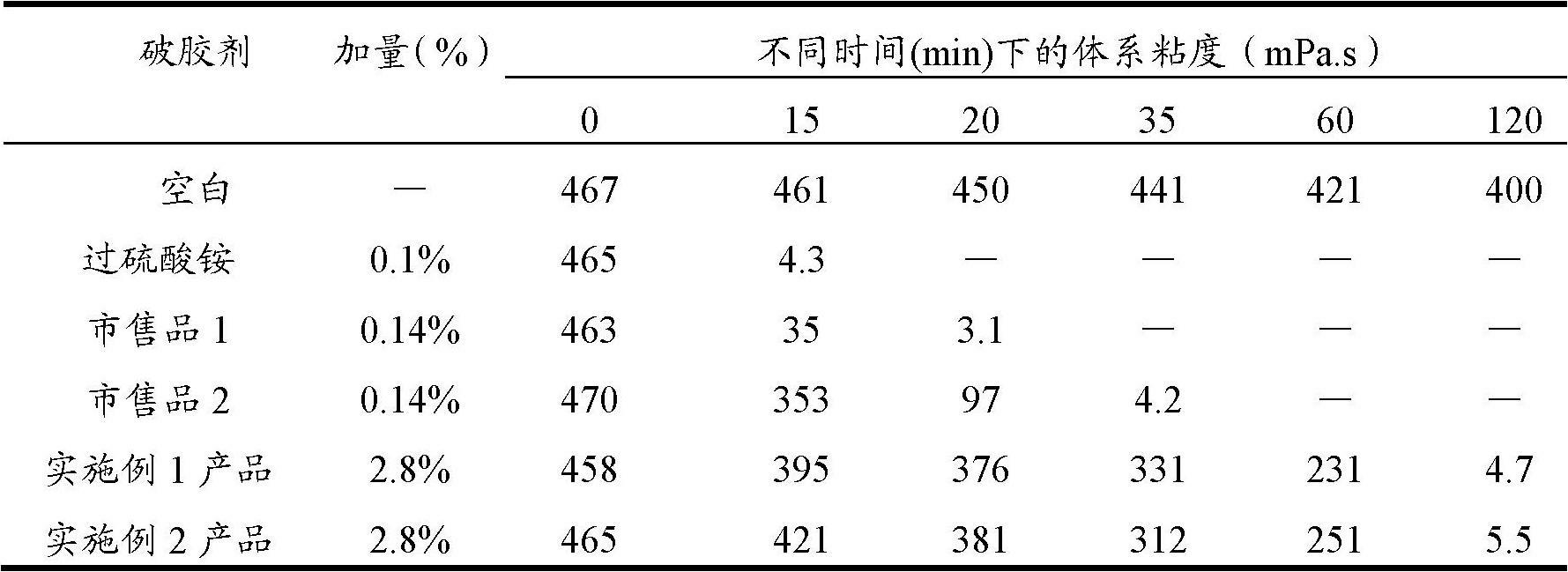

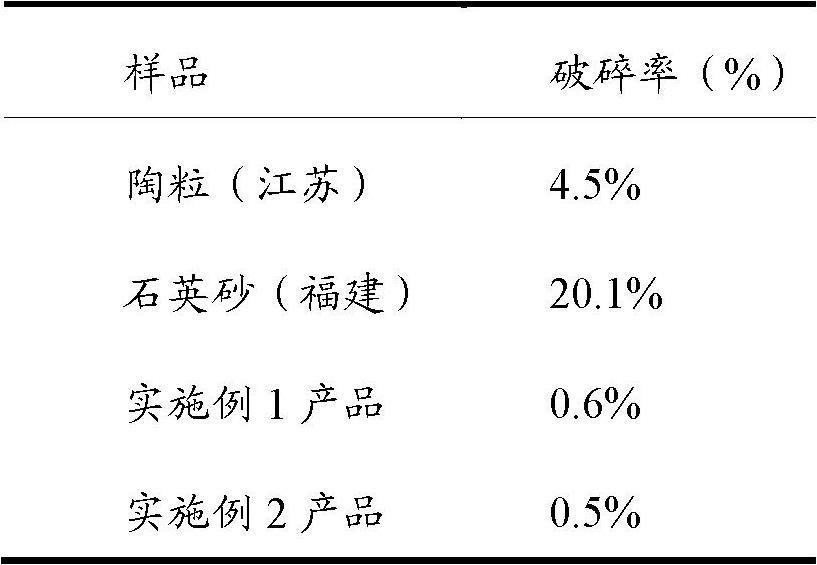

Sustained-release gel-breaking type fracturing propping agent and preparation method thereof

The invention discloses a sustained-release gel-breaking type fracturing propping agent for fracturing an oilfield. The propping agent sequentially comprises a base material, a medicament carrying layer and a sustained release layer from inside to outside, wherein the medicament carrying layer comprises a gel breaking agent and a filling agent, and the sustained release layer comprises a film forming material and a pore forming agent. The invention further provides a preparation method of the sustained-release gel-breaking type fracturing propping agent. In an actual application, the sustained-release gel-breaking type fracturing propping agent disclosed by the invention can enter the stratum along with fracturing fluid, and the gel breaking agent can be released slowly under the stratum conditions; and as the propping dosage is great, the gel breaking agent is distributed uniformly, and gel breaking can be realized to the greatest extent. Simultaneously, a chemical material coating the gel breaking agent can be stilly firmly coated on matrix particles, thus the problems of breaking, reflux and stratum embedding of the propping agent can be reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +2

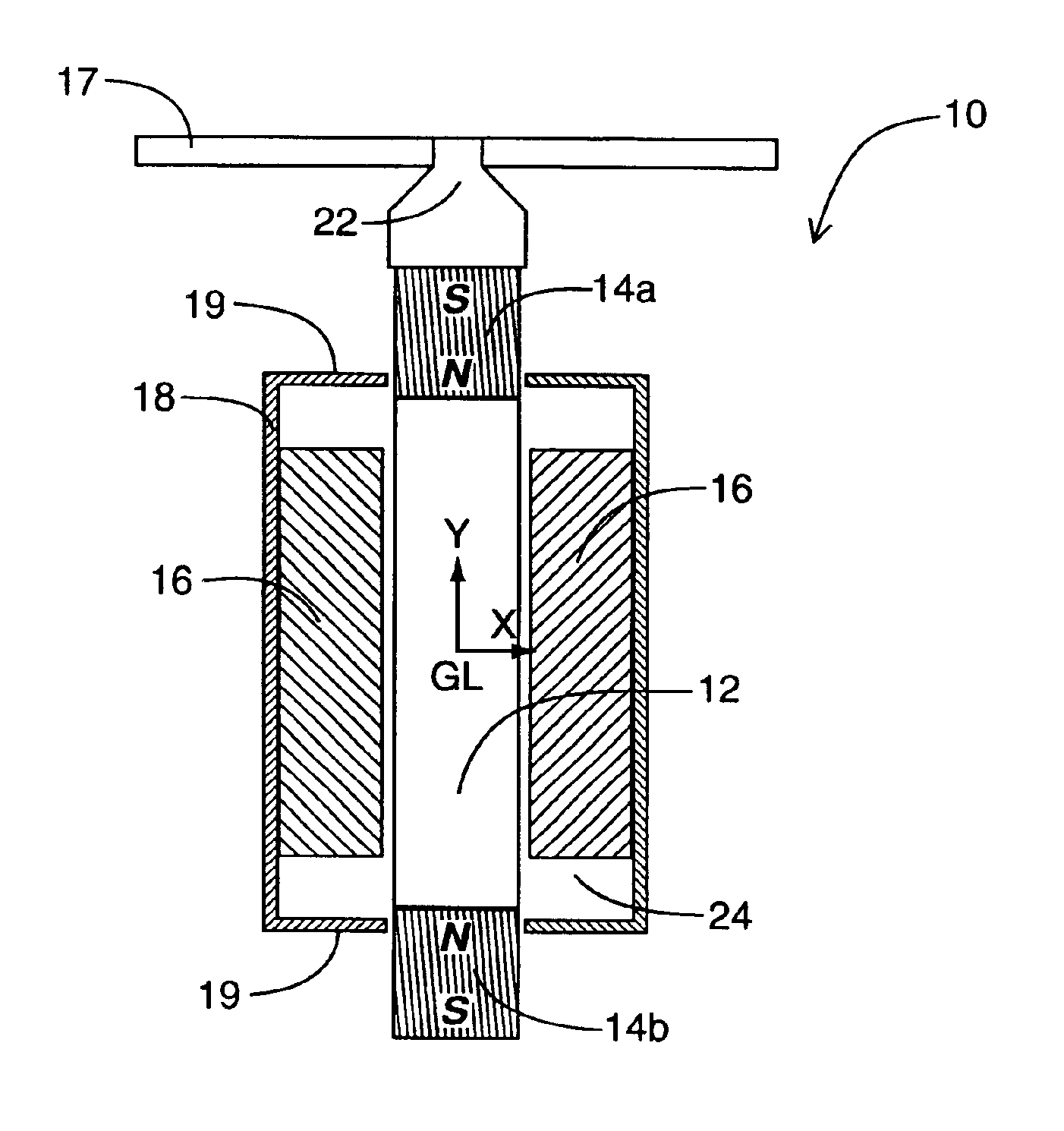

Linear switch actuator

A linear switch actuator for actuating a movable element within a microwave switch includes a ferromagnetic shield, a coil positioned within, and a movable armature assembly positioned within the coil. The armature assembly is coupled to the movable element and includes a ferromagnetic rod and first and second permanent magnets. The permanent magnets are coupled on either end of the rod and have opposite pole orientations. The armature assembly moves between first and second stroke end positions. When one of the permanent magnets is positioned substantially outside the shield, the magnetic permeance of the armature assembly is maximized, and the armature assembly experiences bi-stable latching between the two stroke end positions. When the coil is energized, the armature assembly moves between these positions due to magnetic interaction between the energized coil and the field associated with the permanent magnets and the solenoid magnetic field associated with the coil which reduces the magnetic permeance associated with said armature assembly.

Owner:HONEYWELL LIMITED HONEYWELL LIMITÉE

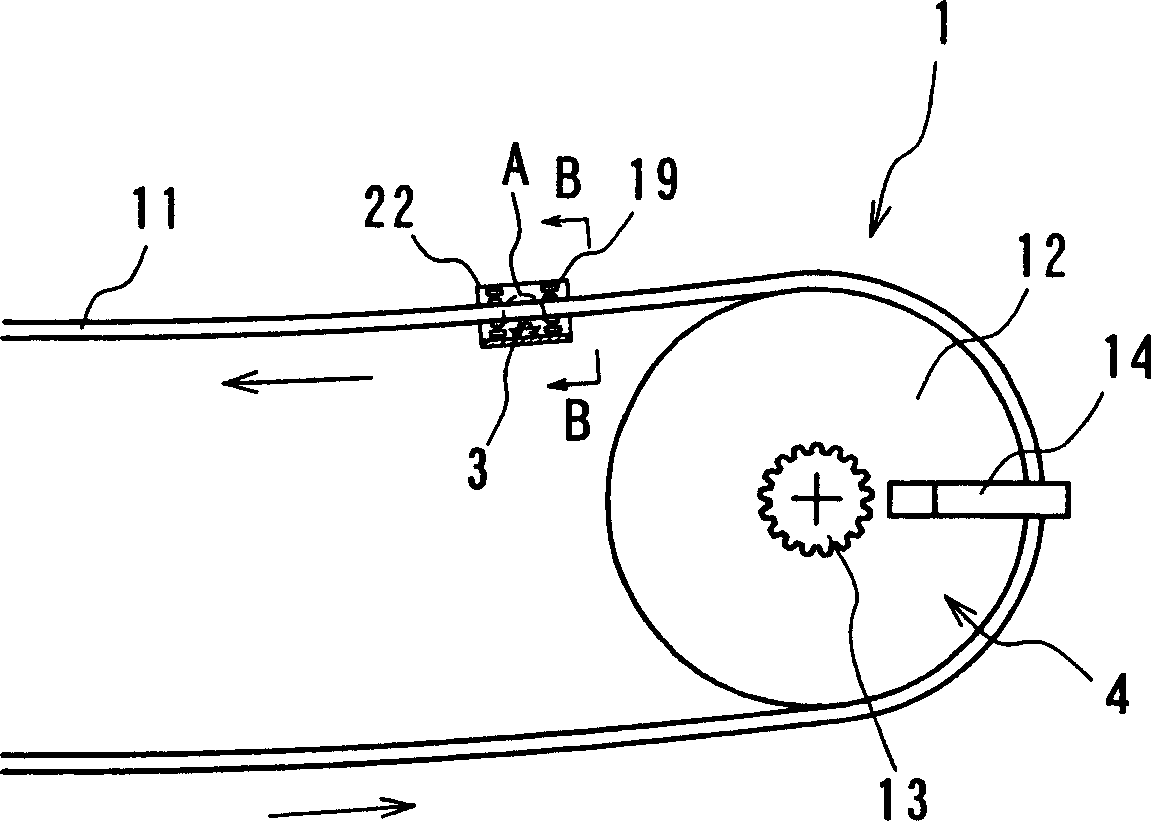

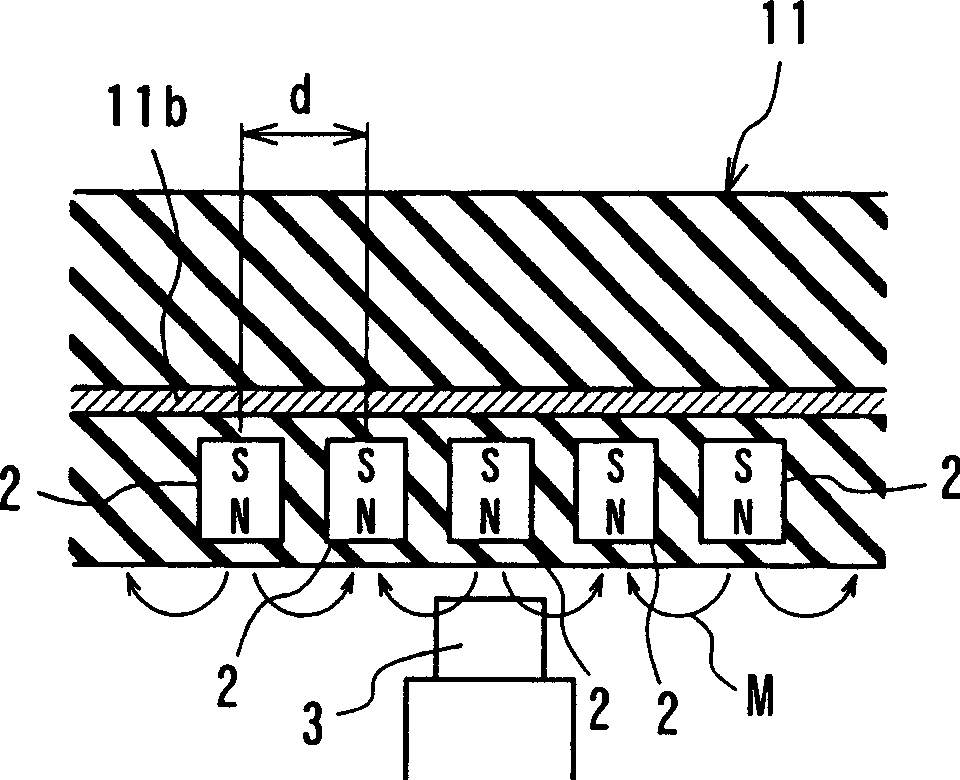

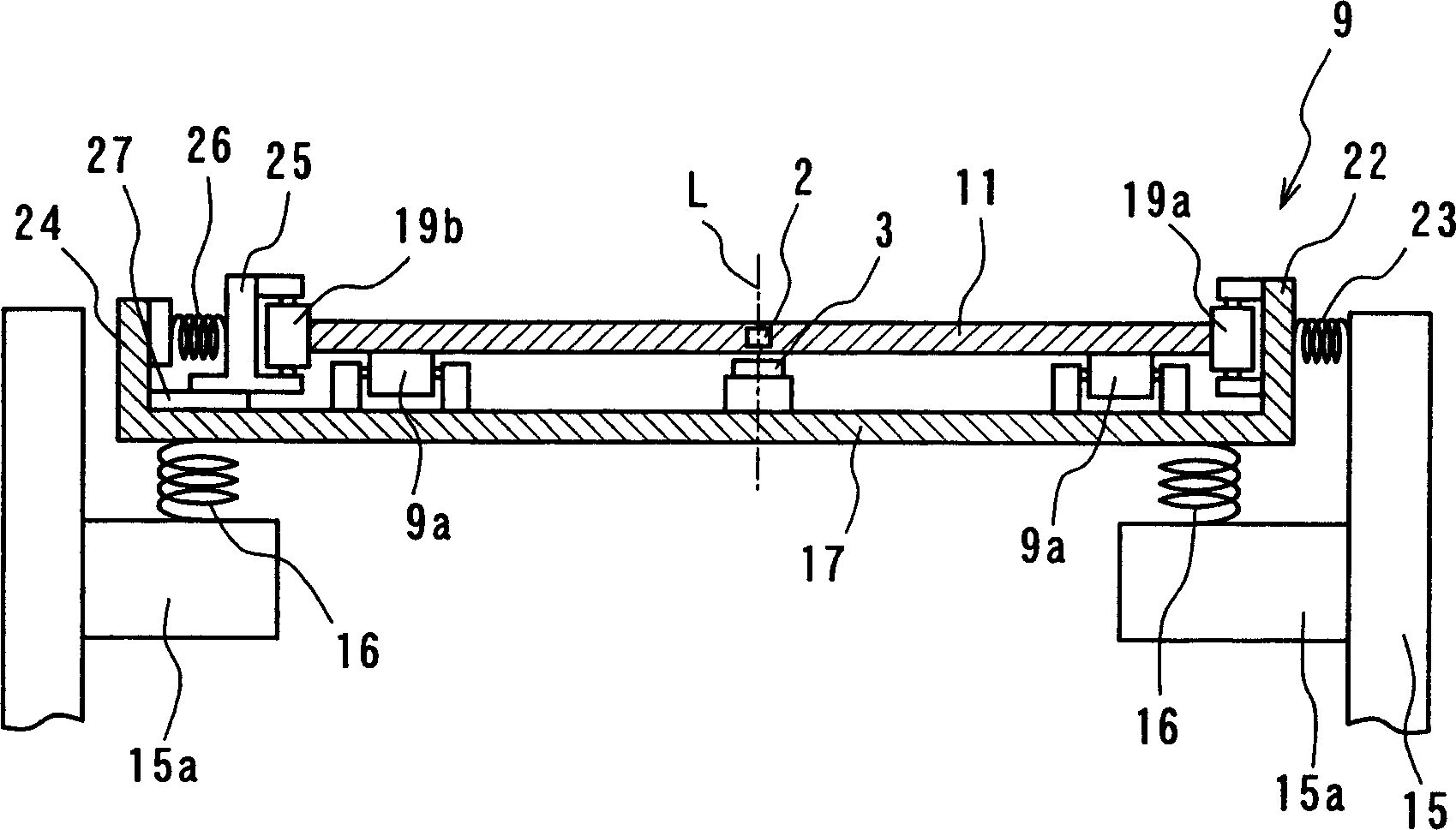

Method and device for measuring conveyor belt elongation, method and device for measuring conveyor belt wear extent, method and device for measuring conveyor belt temperature, rubber magnet sheet, and

InactiveCN1835881AShort lifeAccurate elongationConveyorsThermometers using electric/magnetic elementsConveyor beltInternal temperature

Methods and devices for measuring elongation, wear, and internal temperature of a conveyor belt to catch signs of conveyor belt failure such as breakage by detecting a magnetic field from a magnetic body by using a magnesium sensor, as well as a rubber magnet sheet as a magnetic body and a method of producing the sheet, the rubber magnet sheet being able to be used while it is embedded in the conveyor belt. To measure elongation of a running conveyor belt ( 11 ), a magnetic field of a magnetic body ( 2 ) embedded in the belt ( 11 ) is detected by a magnetism sensor ( 3 ) fixed to the earth, and elongation of the belt ( 11 ) is calculated from temporal variation of the detected magnetic field.

Owner:BRIDGESTONE CORP

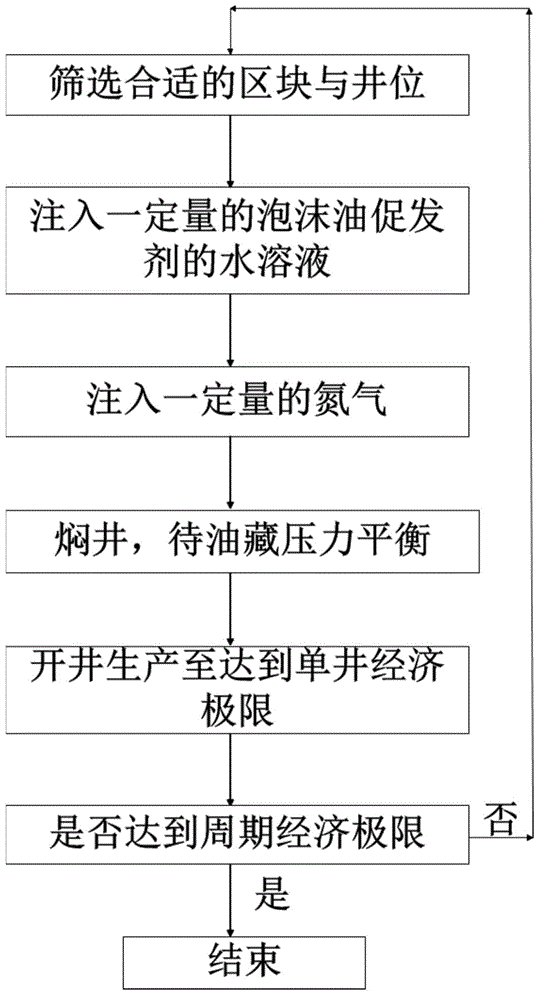

Artificial foaming-oil huff and puff oil production method for heavy oil reservoir

ActiveCN104314539AReduce interfacial tensionImprove liquidityFluid removalMass ratioDifferential pressure

The invention provides an artificial foaming-oil huff and puff oil production method for a heavy oil reservoir. The method comprises the following steps: filling aqueous solution of foaming oil accelerant and nitrogen into the heavy oil reservoir, wherein the foaming oil accelerant comprises a foaming oil accelerant A, a foaming oil accelerant B and a foaming oil accelerant C of which the mass ratio is 1:1:1; soaking for 1 to 5 days; opening a well to produce oil in a certain production differential pressure range and stopping producing oil when the single-well daily oil production reaches single-well economic limit; repeating the step 1 to the step 3 and stopping production until the single-well cyclic oil production reaches cyclic economic limit, wherein the heavy oil reservoir has a reservoir thickness of over 2m, reservoir permeability of over 10*10<-3> mu<m2>, a reservoir temperature of lower than 120 DEG C, viscosity of crude oil of over 50mPas, oil saturation of over 30 percent and water saturation of over 50 percent. According to the artificial foaming-oil huff and puff oil production method for the heavy oil reservoir, which is provided by the invention, the viscosity of crude oil can be reduced and elastic energy of fluid can be increased so as to increase single-well productivity and a recovery ratio of an oil field.

Owner:PETROCHINA CO LTD

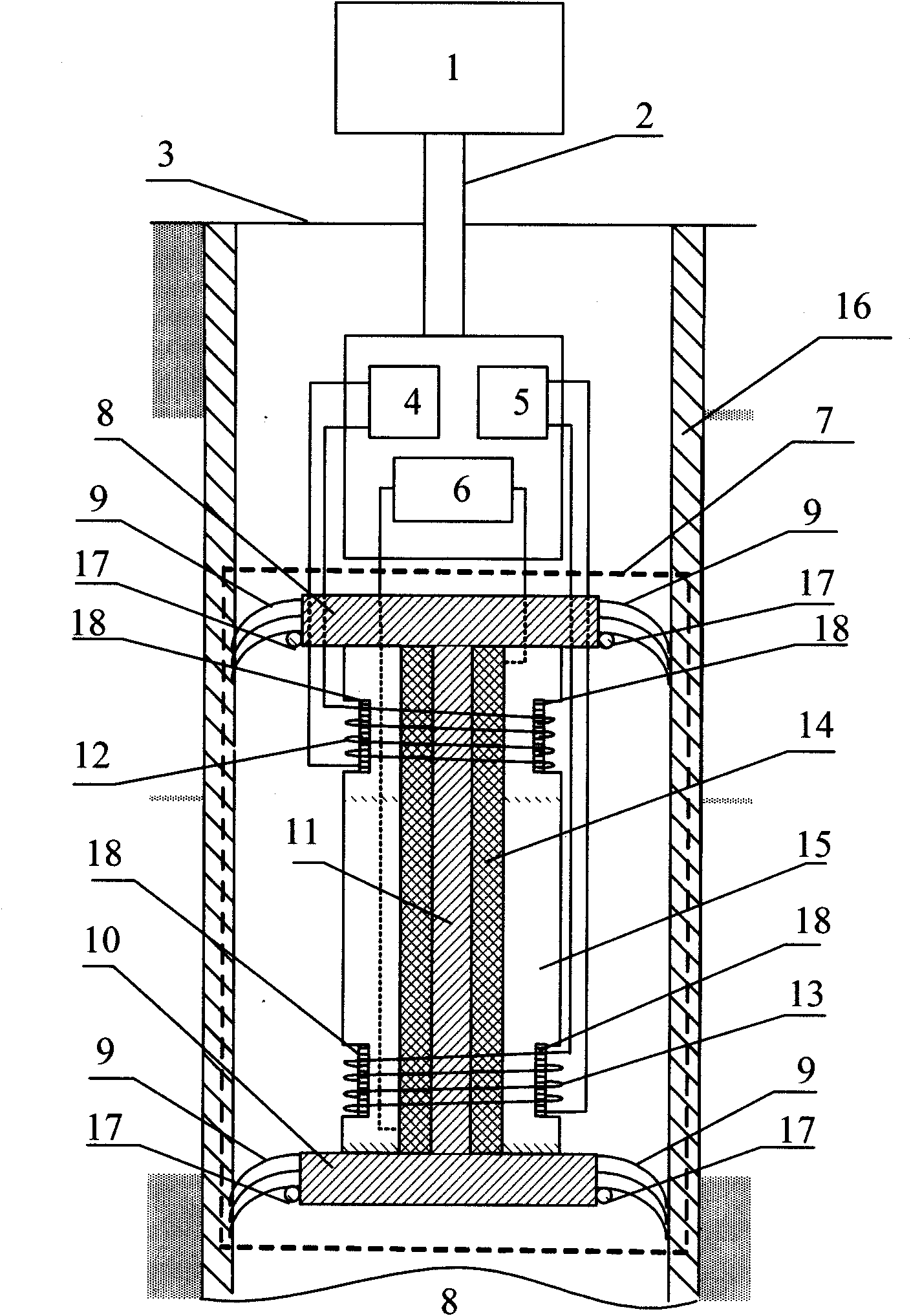

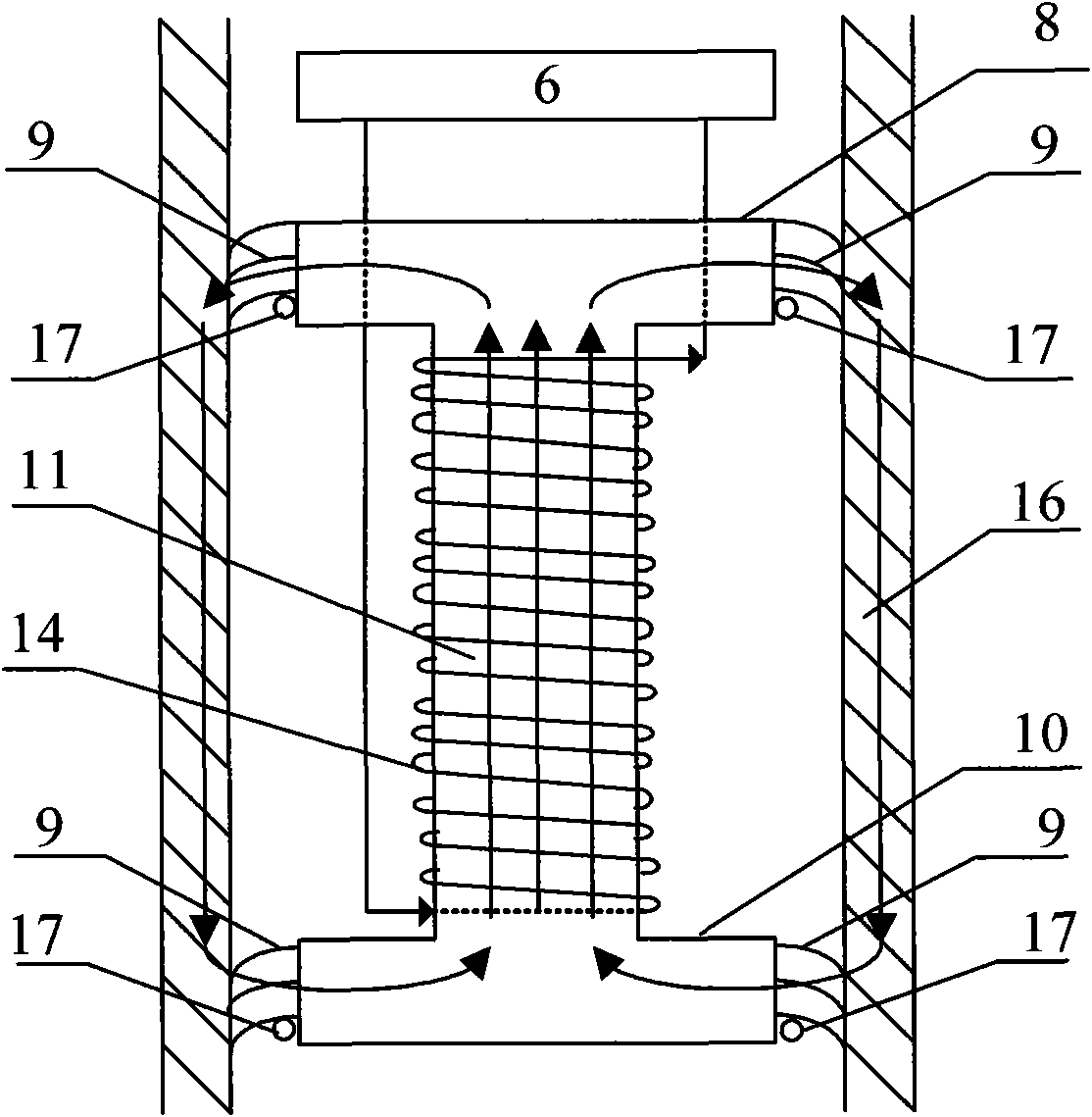

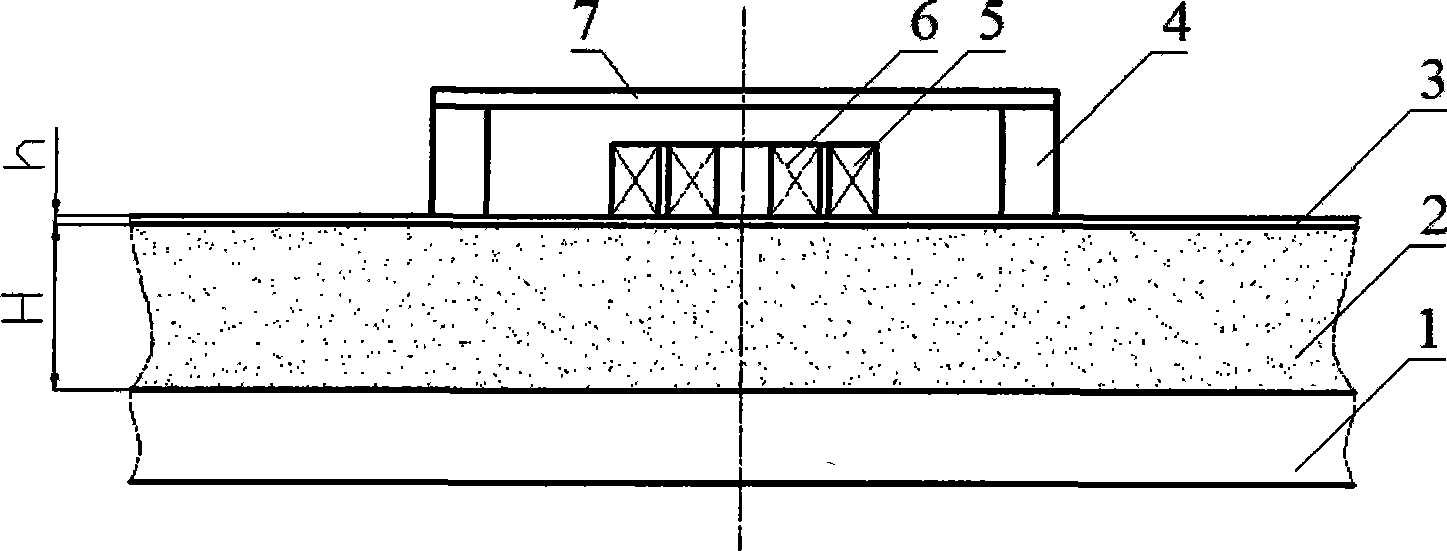

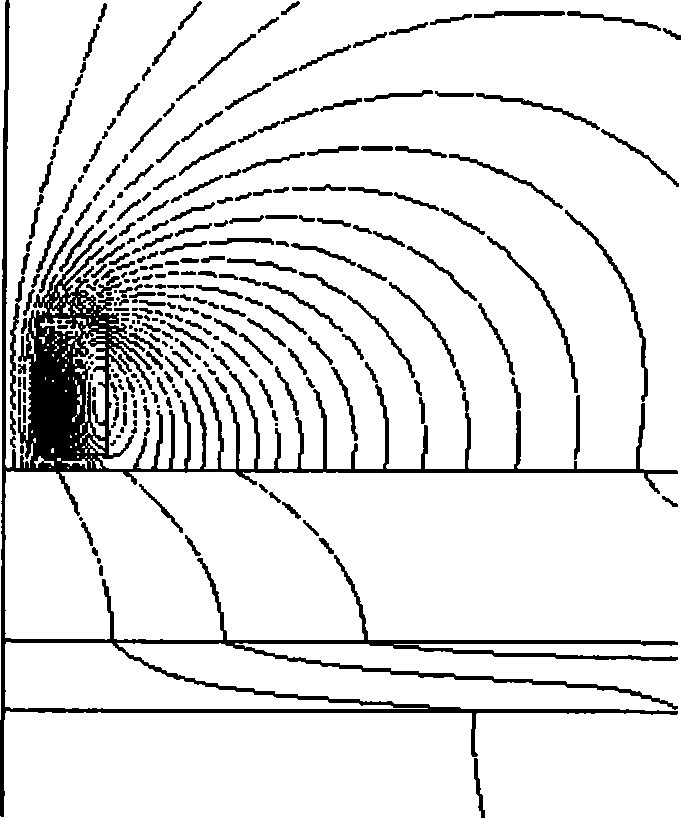

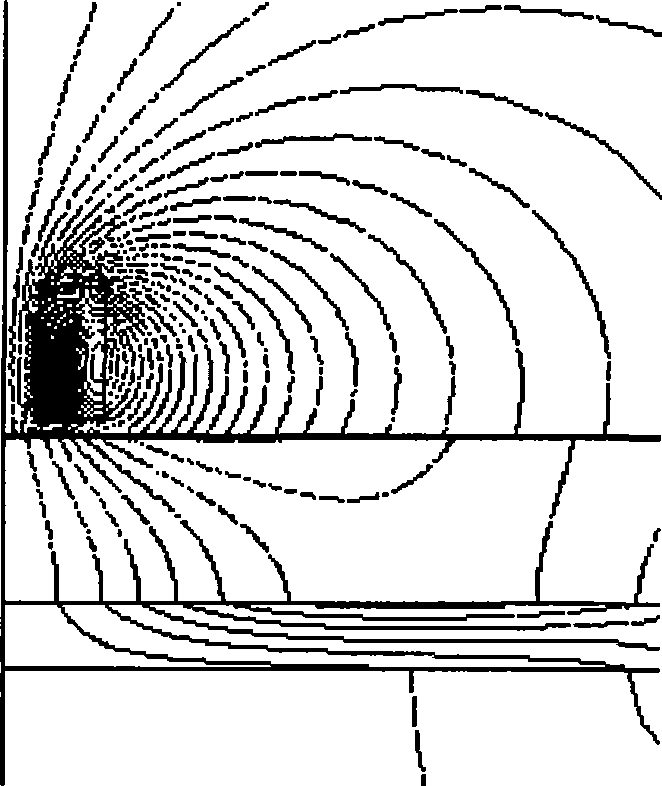

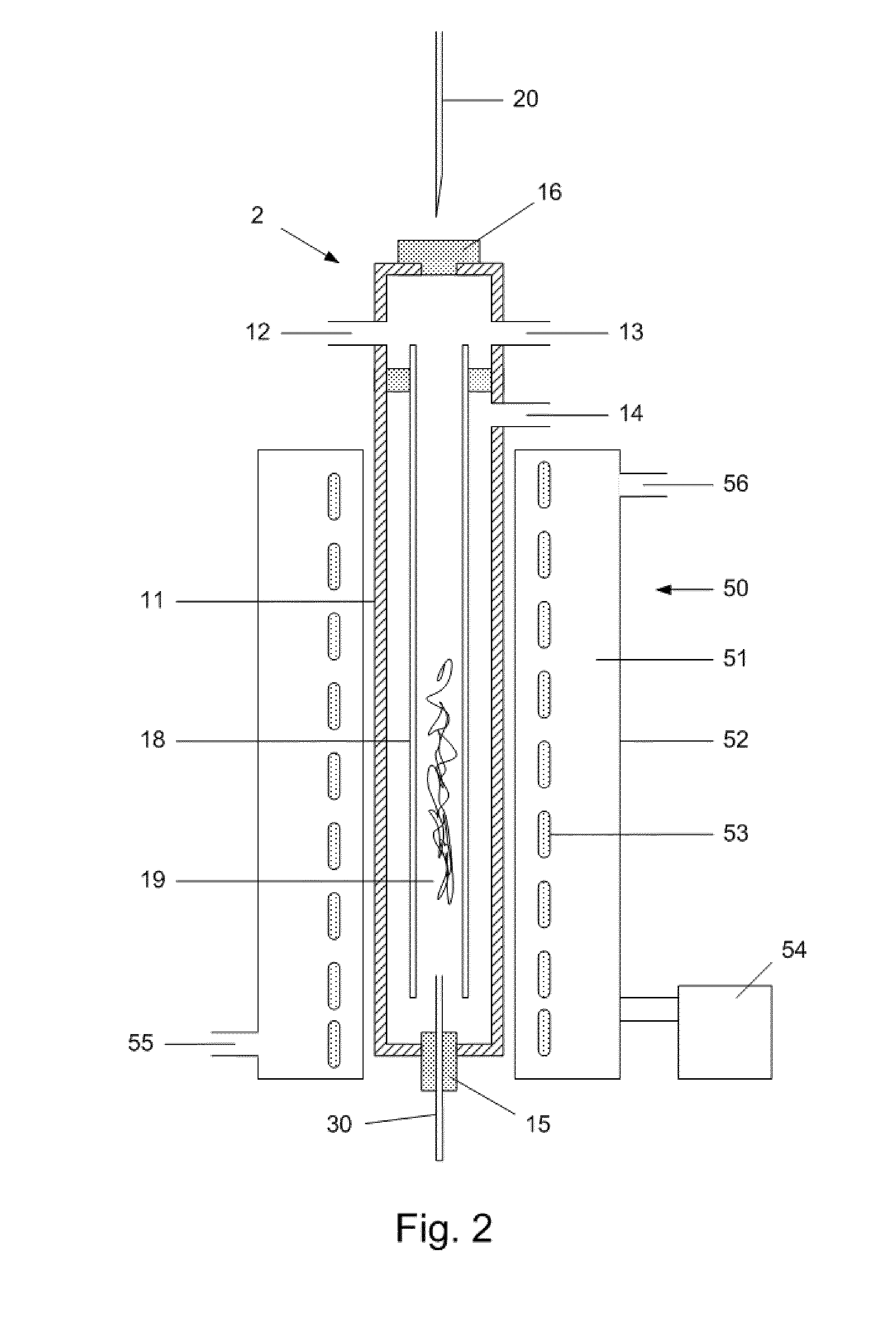

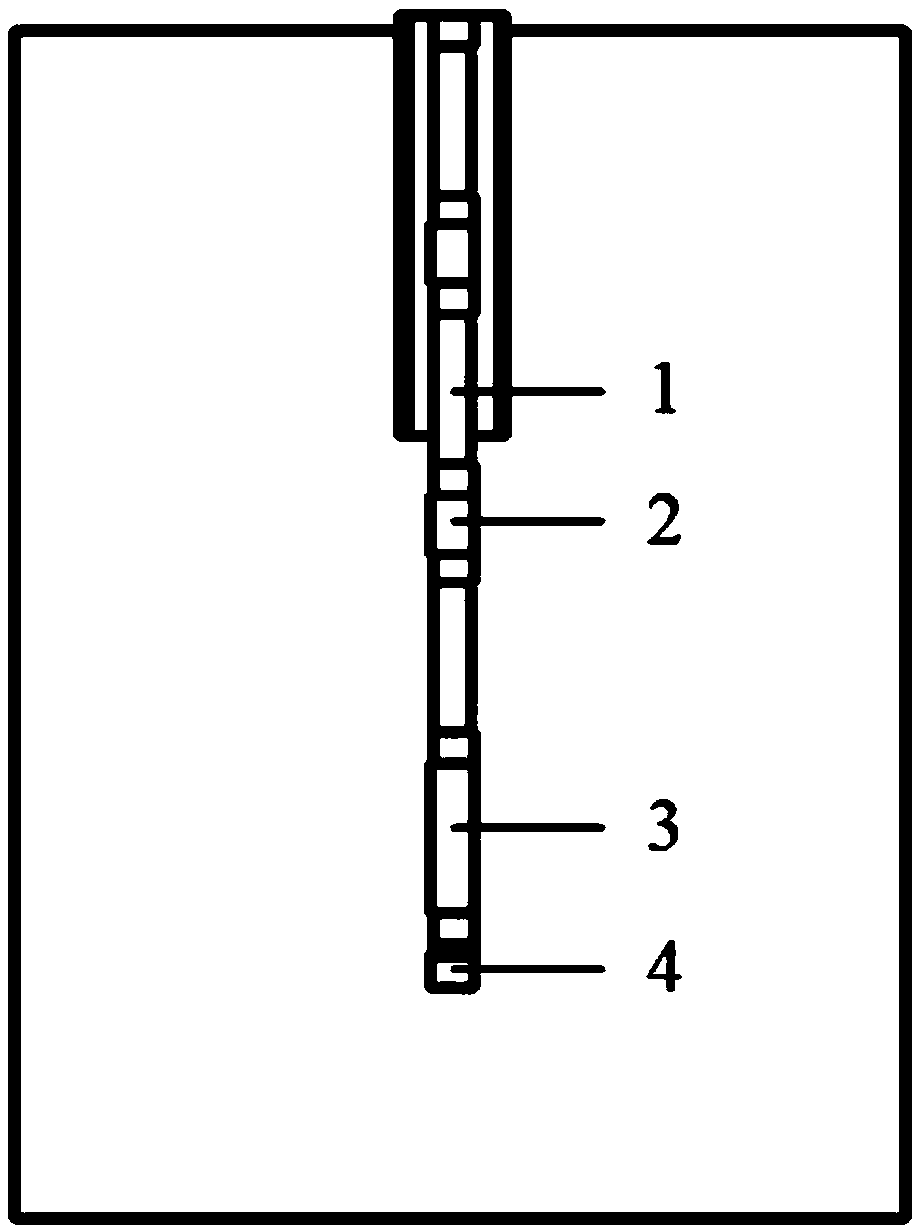

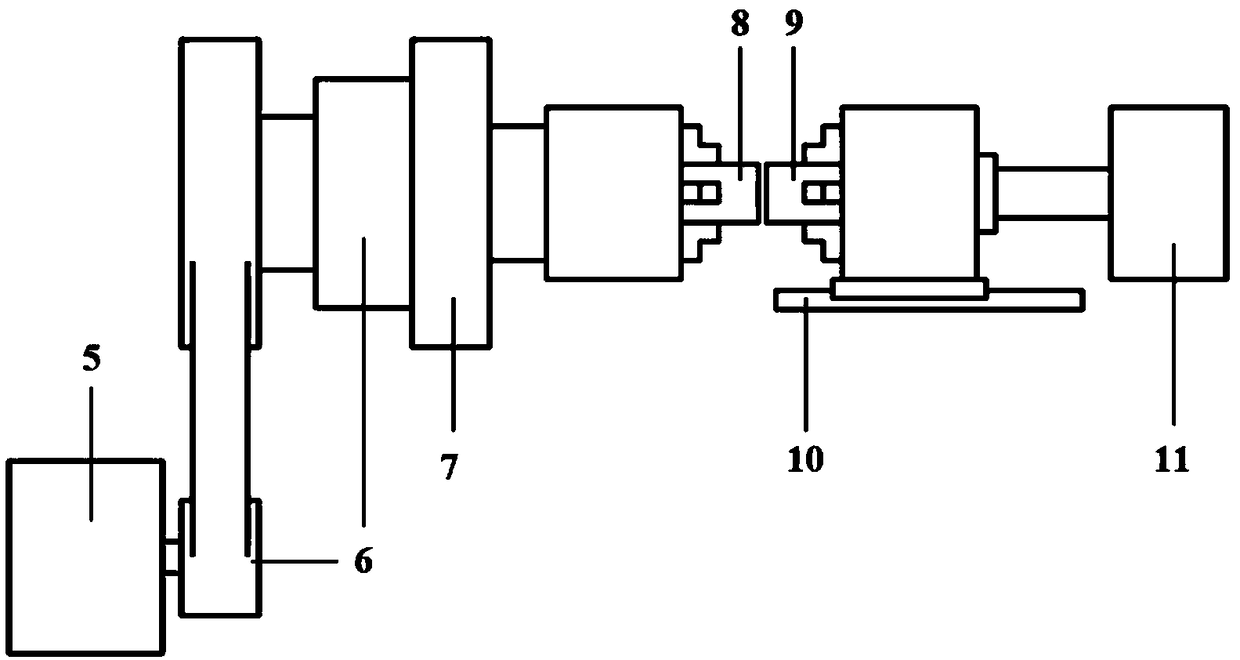

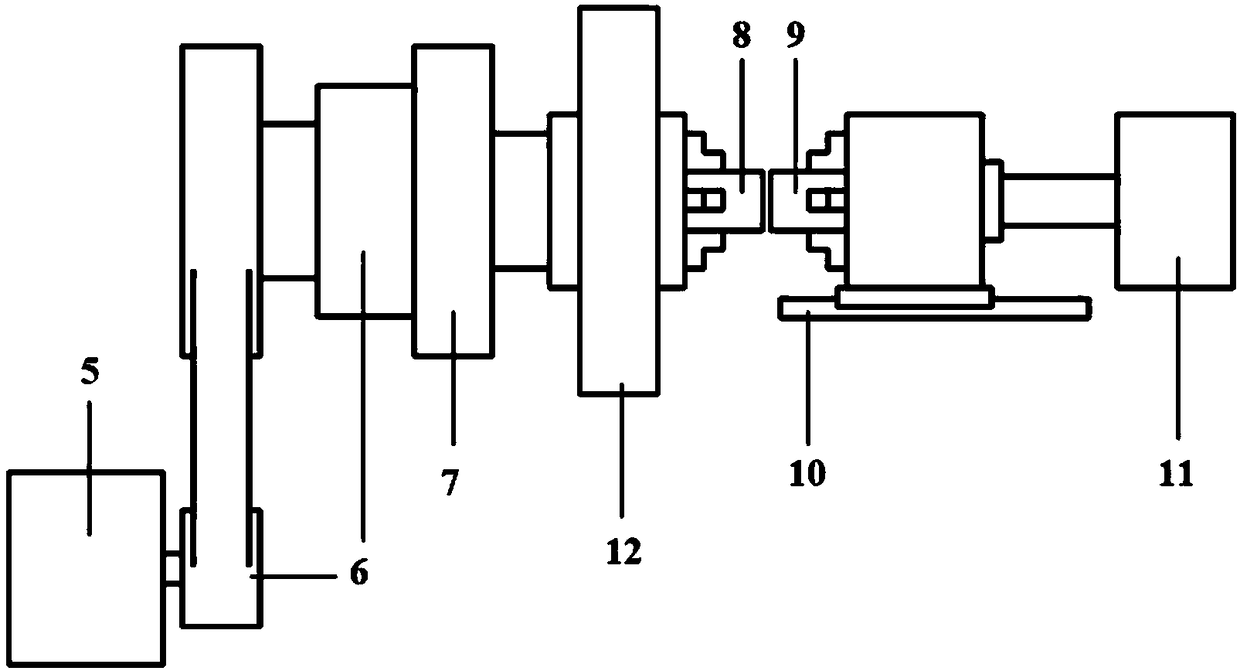

Transient electromagnetic logging device in through-casing well

InactiveCN101581214AAchieve signal identification formation characteristicsReduce permeabilitySurveyEngineeringElectromagnetic field

The invention discloses a transient electromagnetic logging device in a through-casing well, which comprises ground monitoring equipment 1, wherein the ground monitoring equipment 1 is connected with a downhole logging instrument 3 through a cable 2, and the downhole logging instrument 3 consists of a transmitting control unit 4, a receiving control unit 5, a magnetized power supply 6, a magnetizer 7, a transmitting coil 12 and a receiving coil 13. The device utilizes transient electromagnetic technology to transmit low-frequency high-power electromagnetic signals; according to Faraday law of electromagnetic induction, a variable magnetic field produces a variable electric field; the characteristics of an electromagnetic field are determined by the characteristics of medium; and the magnetic field which embodies the characteristics of the detected medium is received by the downhole logging instrument 3, so that the aim of identifying stratum characteristics through the signals detected by the receiving coil is achieved. The device has the characteristics of high efficiency, quickness and non-contact.

Owner:XI'AN PETROLEUM UNIVERSITY

Main acid for oil well drilling and multi-hydrogen acid acidulating system with main acid

The invention relates to a main acid for oil well drilling and a multi-hydrogen acid acidulating system with the main acid. A multi-hydrogen acid is prepared by blending HCl, villiaumite, multi-hydrogen acid, an acidization corrosion inhibitor, a ferric ion stabilizer, a clay stabilizer, a demulsifier, a discharge aiding agent and water. Based on 100mg of water, the multi-hydrogen acid comprises 8 to 15g of HCl, 2 to 4g of villiaumite, 3 to 6g of multi-hydrogen acid, 1 to 3g of acidization corrosion inhibitor, 0.5 to 2g of ferric ion stabilizer, 1 to 2g of clay stabilizer, 0.5 to 1g of demulsifier, 0.5 to 1g of discharge aiding agent and 1 to 2g of mutual solvent, wherein the multi-hydrogen acid acidulating system comprises a front acid, the main acid and a back acid. The main acid and the multi-hydrogen acid acidulating system which contains the main acid is applicable for oil wells with the disadvantages of low oil well permeability, low oil recovery, no oil and the like and can effectively solve the problem of blockage caused by sedimentation.

Owner:北京奥凯立科技发展股份有限公司

Planographic printing plate and method of producing the same

InactiveUS20020048722A1Reduce penetrationHigh sensitivityPhotosensitive materialsSemiconductor/solid-state device manufacturingSolubilityHardness

A negative planographic printing plate comprising a substrate carrying thereon a recording layer which contains a polymerizable compound and an infrared absorbing agent, and in which a polymerization reaction caused the action of light or heat decreases solubility in an alkali developer, wherein the optical density of said recording layer is from 0.4 to 2.0, and the film hardness of the upper part of said recording layer after reduction in solubility in an alkali developer due to the action of light or heat is higher than the average film hardness of the whole recording layer, and a preferable method of producing the same.

Owner:FUJIFILM CORP

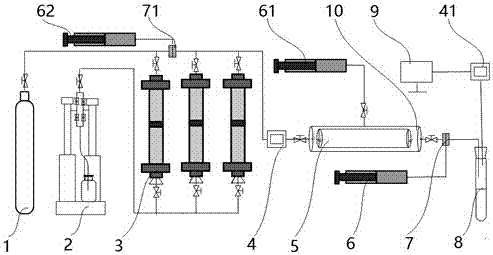

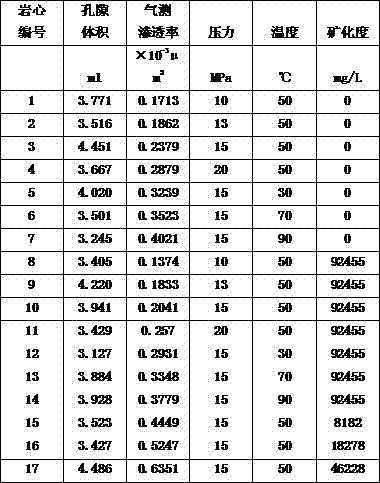

Experimental device researching influence of formation water with high degree of mineralization on CO2 flooding

InactiveCN106908579AImprove securityAvoid corrosionEarth material testingFluid removalPorosityGas cylinder

The invention provides an experimental device researching influence of formation water with a high degree of mineralization on CO2 flooding. The experiment device comprises a gas cylinder, a core holding unit and a gas-liquid separating device. The gas cylinder is connected to a piston container, the top of the piston container is connected to a back-pressure valve and a pressure gage, the bottom of the piston container is connected to an ISCO pump, the pressure gage is connected to the core holding unit, the outlet end of the core holding unit is connected to the gas-liquid separating device, and the gas-liquid separating device is connected to an upper computer through a gas flowmeter. The back-pressure valve is connected to the back-pressure valve, the side face of the core holding unit is connected to a circular pressing pump and the suction lift is high, the outlet of the core holding unit is connected to the back-pressure valve, and the back-pressure valve is connected to a back-pressure pump. The designed device can compare changes of core permeability after and before CO2 flooding, porosity, pore structures, contents of core minerals, surface shapes of the cores, masses of the core and the recovery rates and research influence of CO2 flooding on reservoir physical property and development parameters.

Owner:ZHEJIANG OCEAN UNIV

Cotton seedling raising transplantation method

InactiveCN101379919ALow costImprove structural performanceCultivating equipmentsSoilless cultivationFungicideAntitranspirant

The invention relates to a method for transplanting cotton seedlings. The method comprises three steps of preparation of a matrix, sowing and transplanting sequentially. Step 1, cotton stalks, rape stalks, corn stalks, soybean stalks or wheat straws are crushed, added with a nitrogenous fertilizer, and mixed with human excrement or livestock and poultry manure bio-fertilizer or other fertilizers to obtain a mixture which is treated to obtain a prepared material, then the prepared material is sun-dried or baked, added with a fungicide and bagged for spare use; step 2, the prepared cotton stalk matrix or the matrixes prepared from other stalks are filled in a seedling raising aperture disk or flatly spread on a plastic film laid on the ground as a seedbed, seeds are sown, watered and covered with an agricultural film, and seedlings are raised under heat insulation condition; step 3, an antitranspirant and a rooting agent are applied before transplanting; the taken seedlings are bound, put in the watered rooting agent solution for root soaking, and then taken out and put in a watered gel containing a water retention agent to dip the roots; when in transplantation, the water retention agent is applied to planting furrows; after transplantation, the seedlings are covered with soil, and irrigated with adequate water for fixing the roots. The method is characterized by high seedling survival rate, stable effect, short rejuvenation period, low cost and environmental protection.

Owner:操宇琳

Method and device for detecting corrosion of component with permeability magnetic material protective layer

InactiveCN101520435ALow permeabilityIncreased penetration depthMaterial magnetic variablesPhysicsUltrasound attenuation

The invention provides a method for detecting the corrosion of a component with a permeability magnetic material protective layer. The method comprises the following steps: the permeability magnetic material protective layer is magnetized to be saturated or deeply saturated, a reference area and a area to be detected are selected on the surface of a detected component, pulsed eddy current sensors are arranged on the protective layers of the two areas, the square-wave exciting is applied to exciting coils of the pulsed eddy current sensors, the attenuation curve of the induced voltage in the detecting coils of pulsed eddy current sensors is measured after the level of square waves is reduced to the low level, and the difference between the attenuation curves of the induced voltage in the two areas is compared, thus the corrosion condition of the area to be detected relative to the reference area can be further distinguished. The invention also provides a device for realizing the method, which comprises a pulsed eddy current sensor, a square-wave signal exciting circuit, a signal processing circuit, an A / D conversion circuit and a computer which are connected in sequence, wherein the pulsed eddy current sensor is provided with a magnetization unit. The invention improves the sensitivity of corrosion detection of the component with the permeability magnetic material protective layer and is suitable for detecting the corrosion of the component on-line without dismounting the protective layer and the cladding layer.

Owner:HUAZHONG UNIV OF SCI & TECH

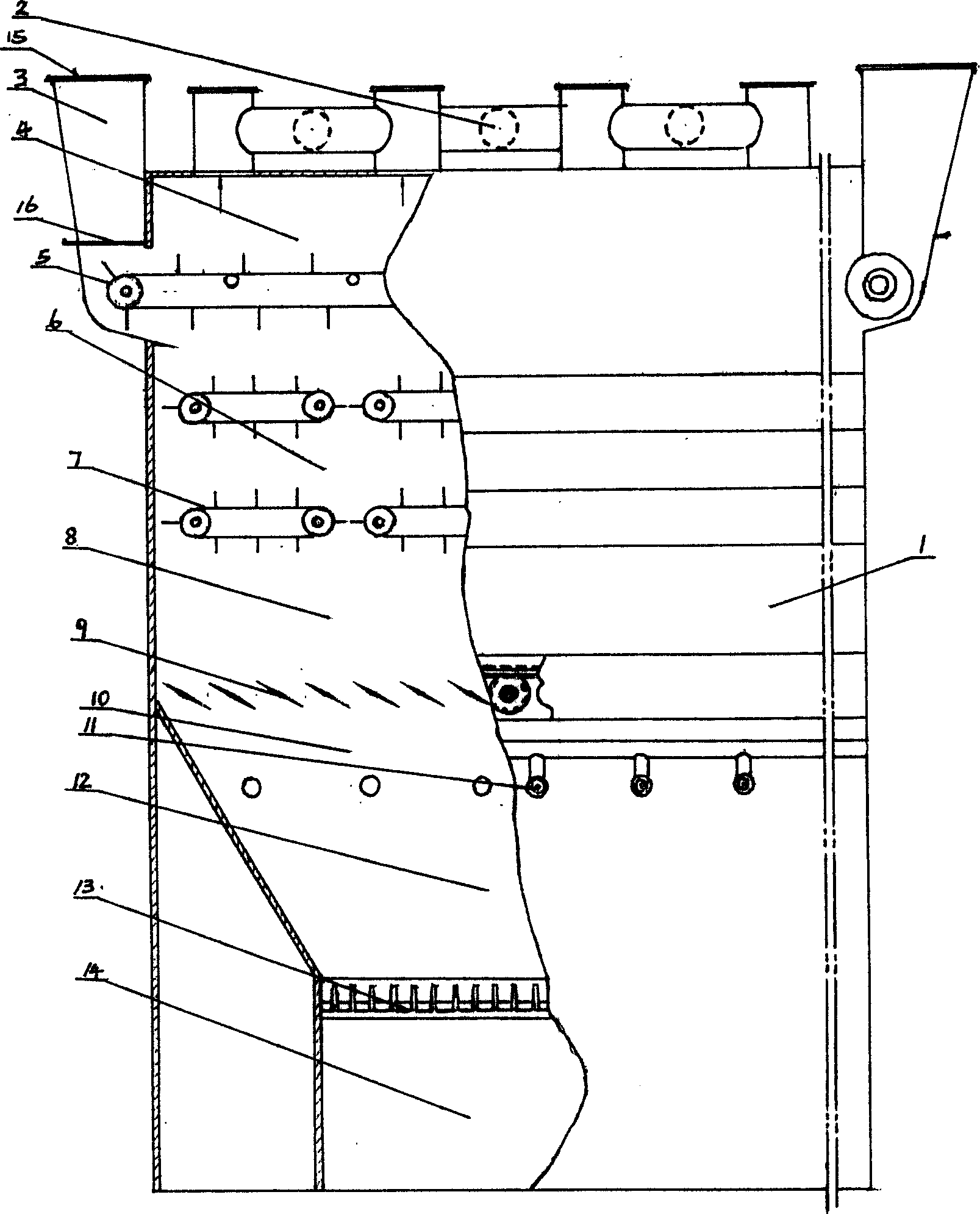

Thermal cracking gasification oven for city domestic garbage

InactiveCN1687646AIncreasing the thicknessReduce permeabilityIncinerator apparatusCombustible gas productionCombustion chamberBurn treatment

The invention relates to the hot cracking gasifying treatment of the urban rubbish and the equipment. The method can adopts the non-selected rubbish to burn and gasify directly, uses the heat energy produced by the organics of the rubbish to crack the organics, the residual heat of the cracking gas to remove the water in the rubbish and the physical form characteristic of the rubbish to purify the furnace gas. The rectangle gasifying furnace (1) comprises eight main structural parts: the burner gas lead-out assembly (2), the feed cabin (3), the rectangle suction cabin (4), the rectangle drying chamber (6), the rectangle gasifying chamber (8), the fuel return heating combustion chamber (10), the melting combustion chamber (12), the slurry cabin (14). The invention can effectively prevent the producing of dioxin and does not have the high-cost and complex exhaust treatment processes of the usual rubbish burning treatment.

Owner:郭炜明

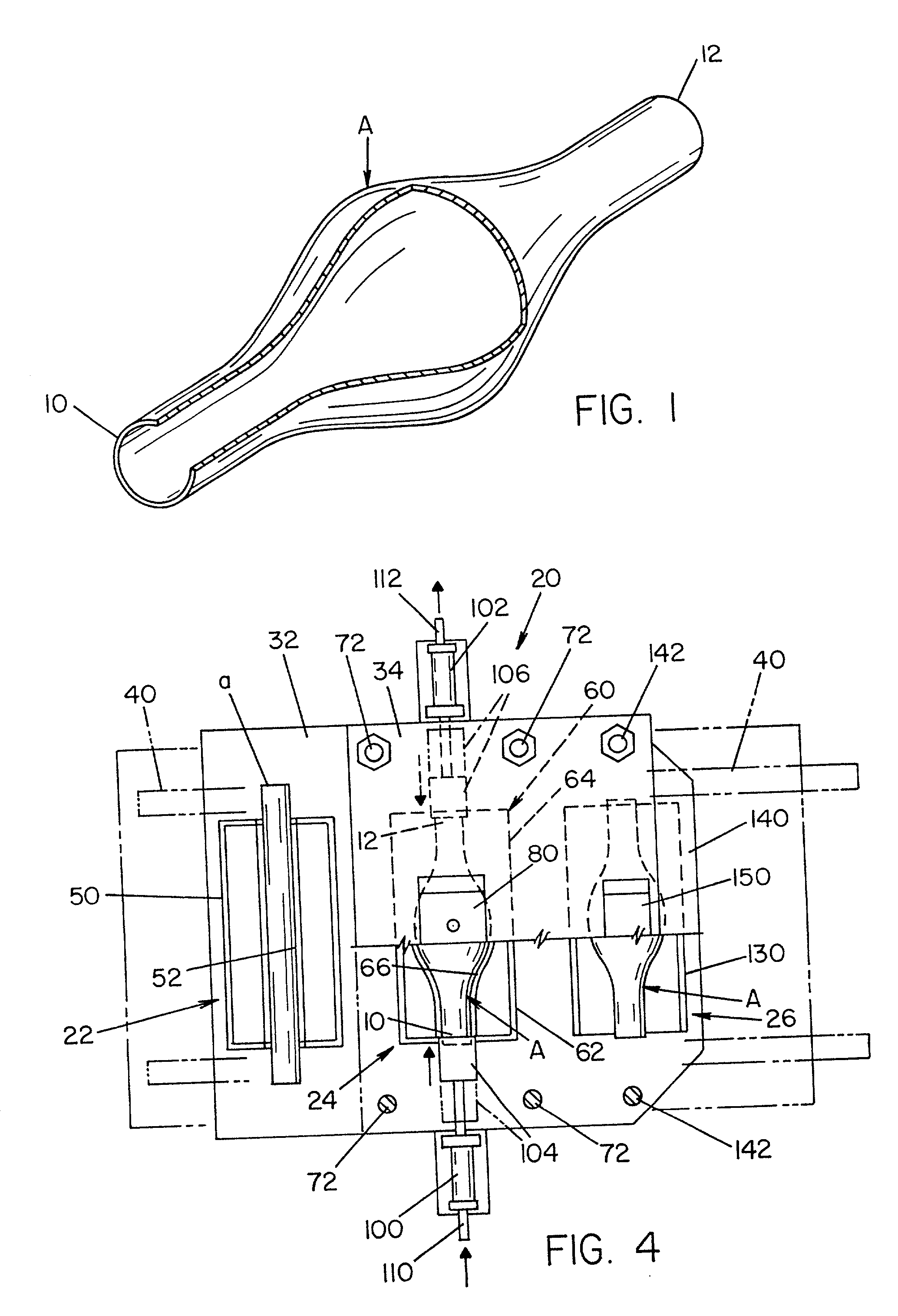

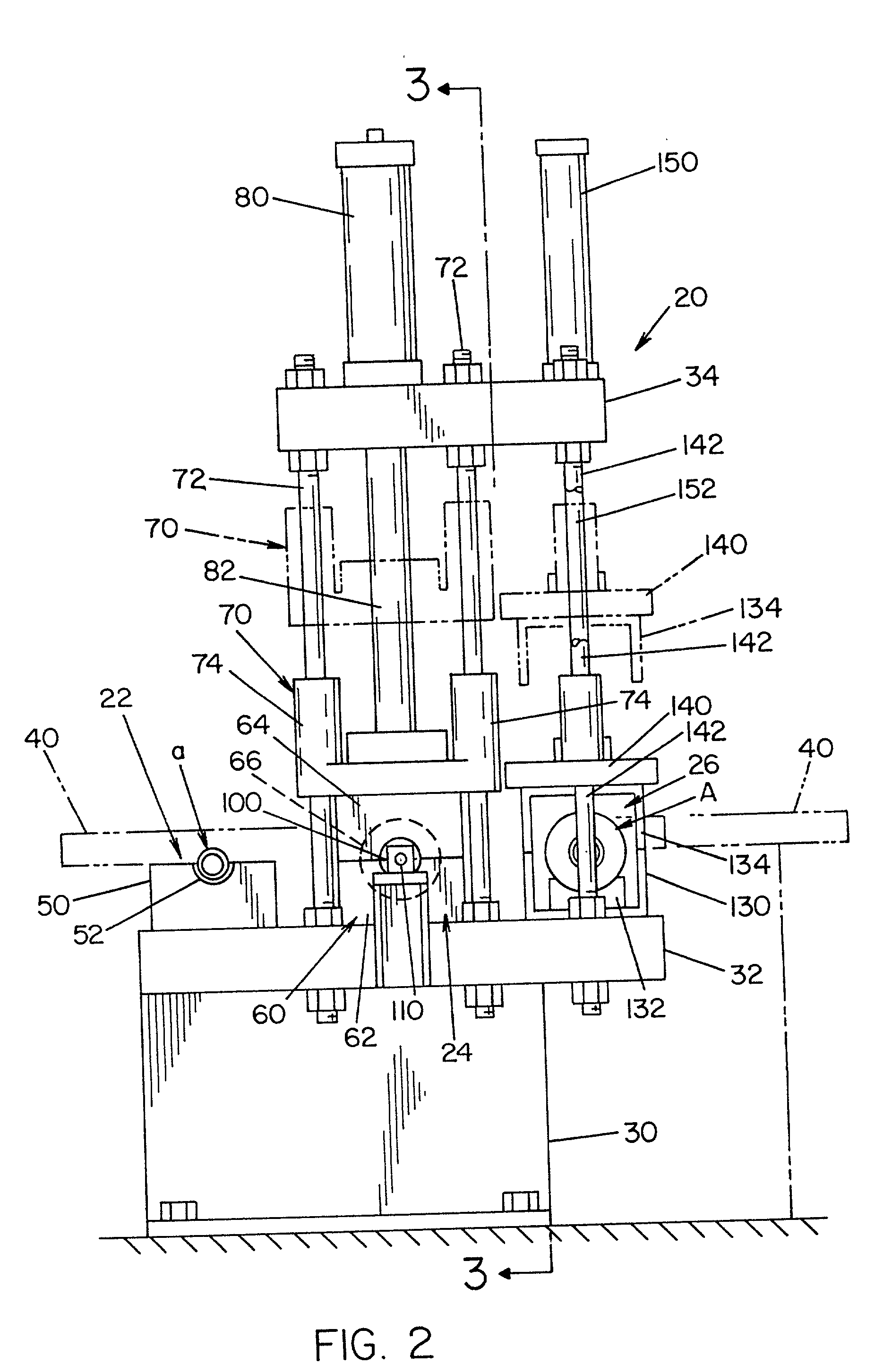

Method of forming a tubular blank into a structural component and die therefor

InactiveUS20020003011A1Quick upgradeImprove mechanical propertiesShaping toolsFurnace typesElectrical conductorEngineering

Owner:TEMPER IP

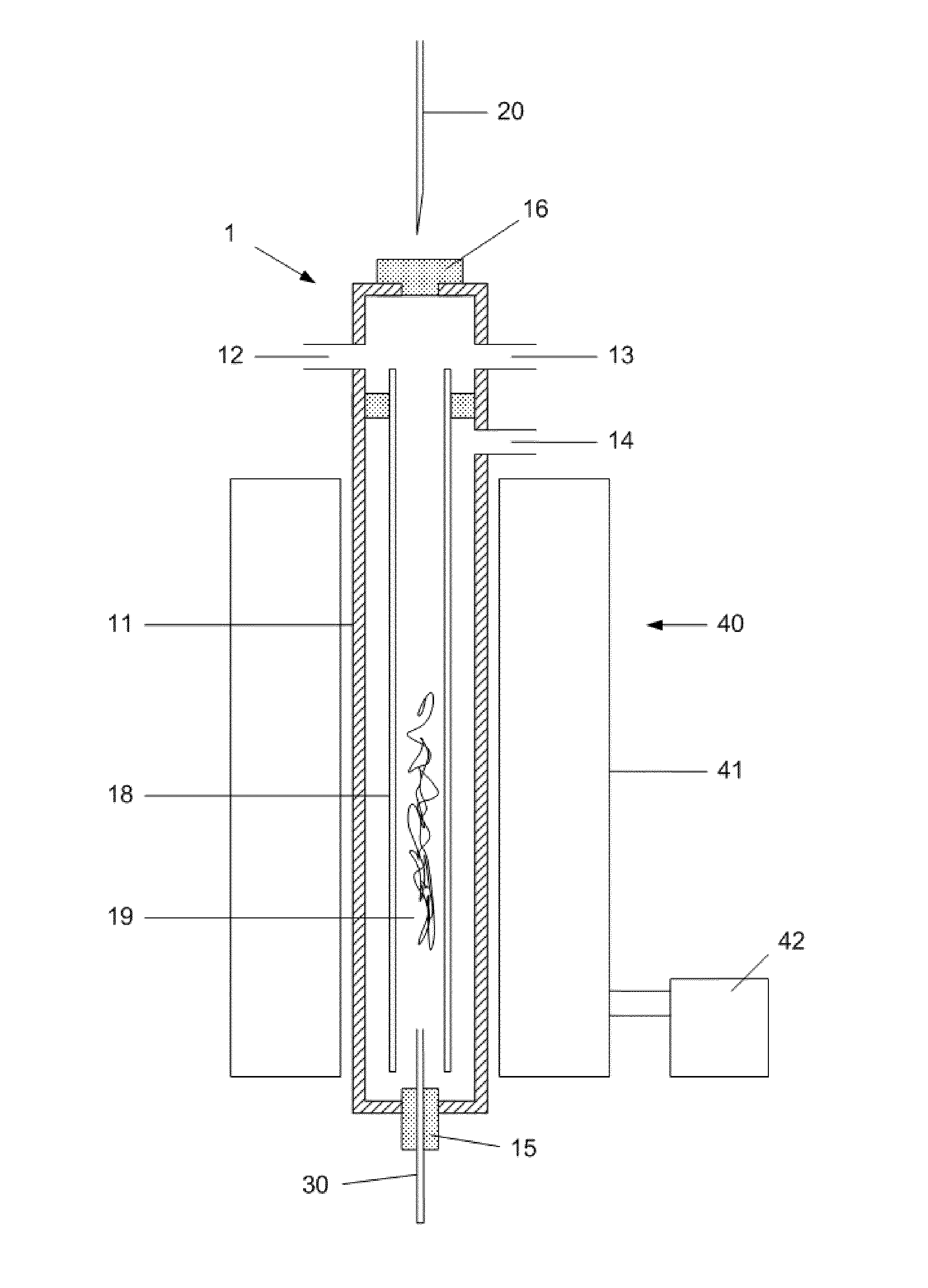

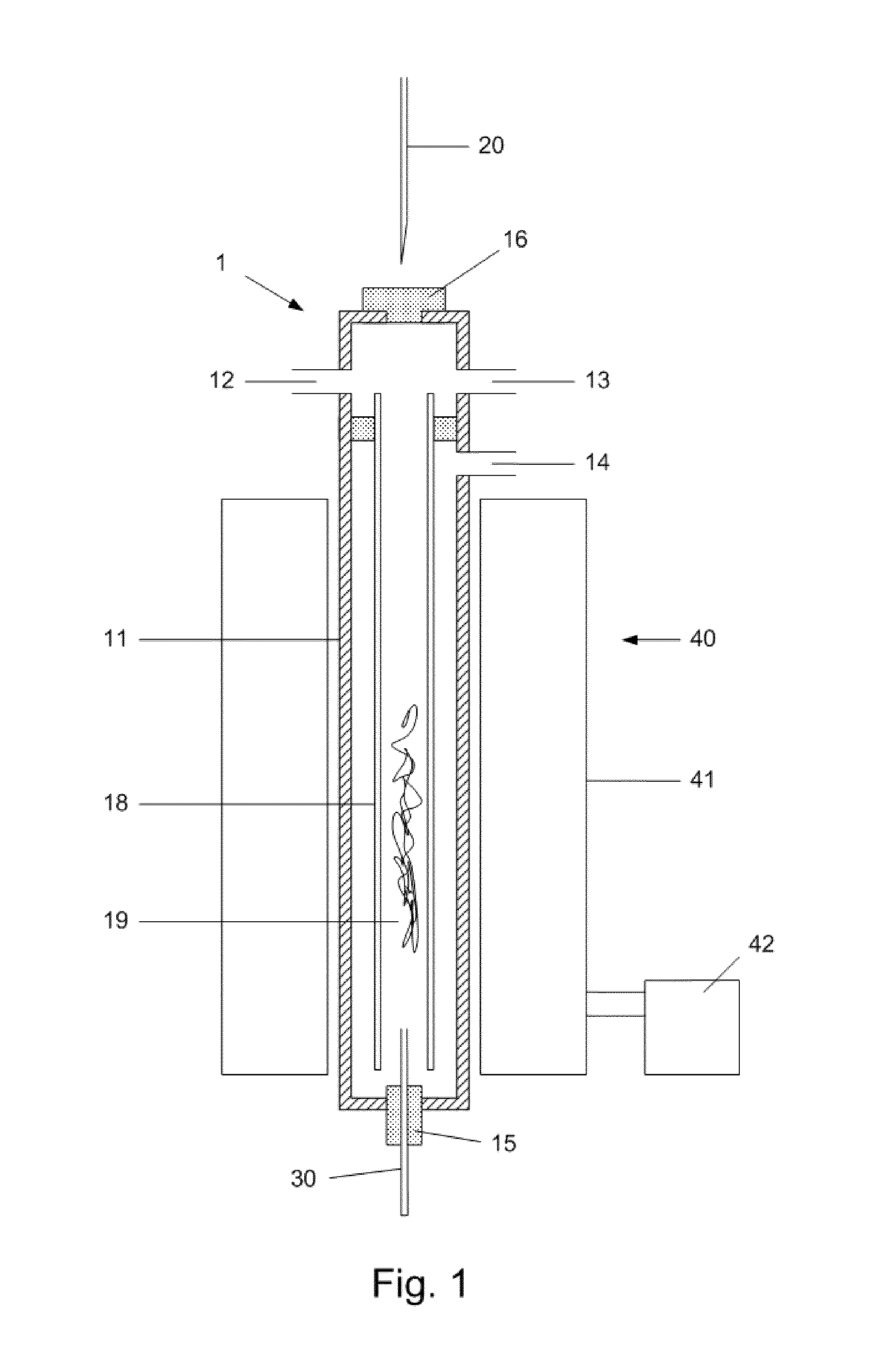

Sample introduction device and method

InactiveUS20140331744A1Reduced discriminationHeating rates and programmes can be varied widelySamplingComponent separationGas analysisGas phase

The present invention relates to an injector for use in gas phase analytical systems and methods comprising a metal housing, provided with a carrier gas inlet, a split outlet, a column outlet of the injector, a sample inlet, a liner, and a heater device comprising at least one coil for radio frequency inductive heating the housing with a predetermined temperature program and for providing a predetermined spatial temperature profile in the injector. The injector according to the invention allows performing gas phase analyses, especially GC analyses with reduced discrimination. Advantages of heating with a heater device comprising a coil for inductive heating include a homogeneous heating profile of the housing including parts connected thereto, with heating rates that can be varied widely. A further advantage is that the injector can be operated as a conventional S / SL injector at a predetermined temperature, or as PTV injector or thermal desorption injector with certain predetermined temperature programs. The invention also relates to a process of making an injector according to the invention, and to a process of refitting an existing S / SL injector. The invention further concerns a gas analytical system comprising an injector according to the invention, and to a process of analysing a sample with such gas analytical system.

Owner:DSM IP ASSETS BV

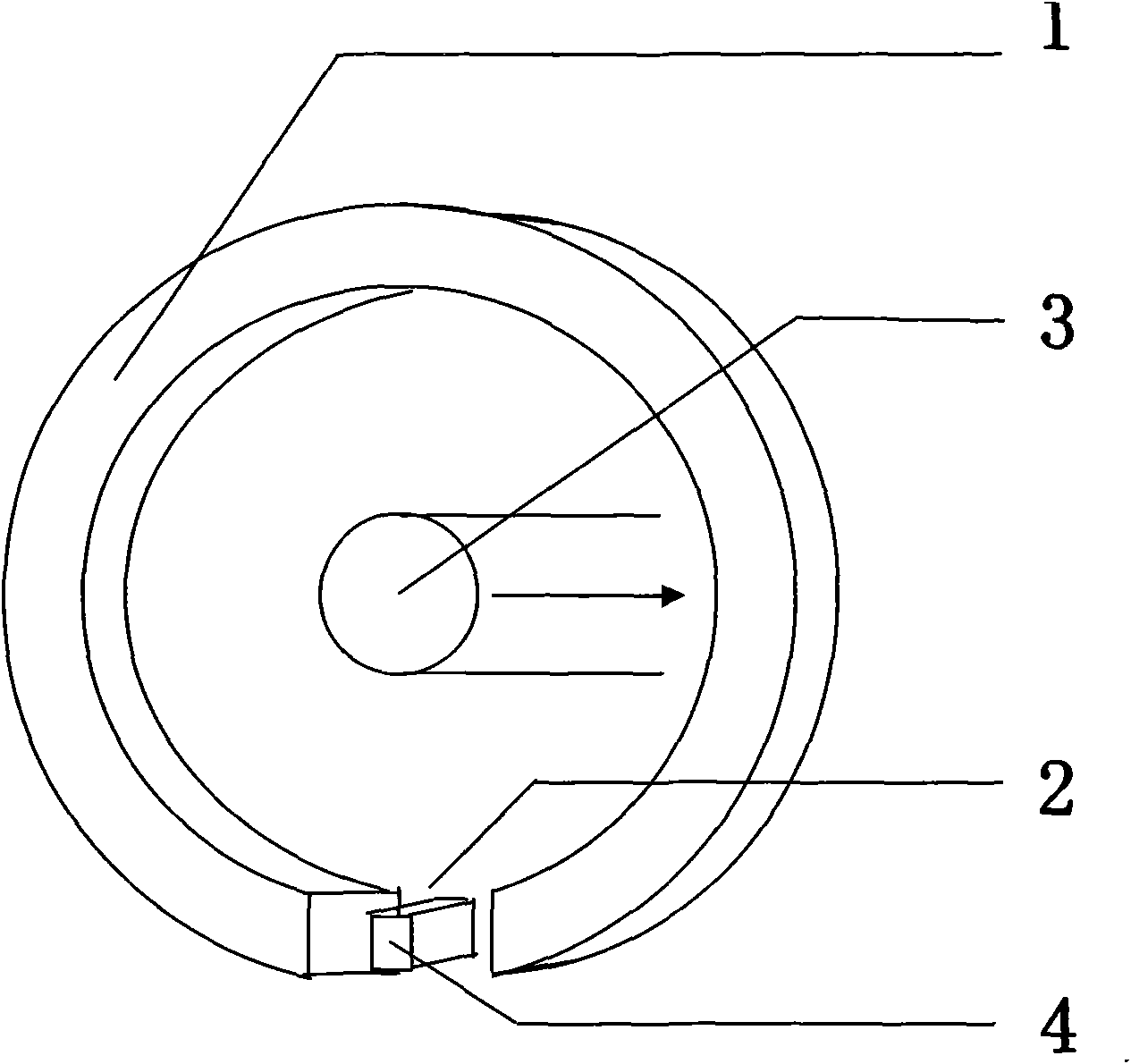

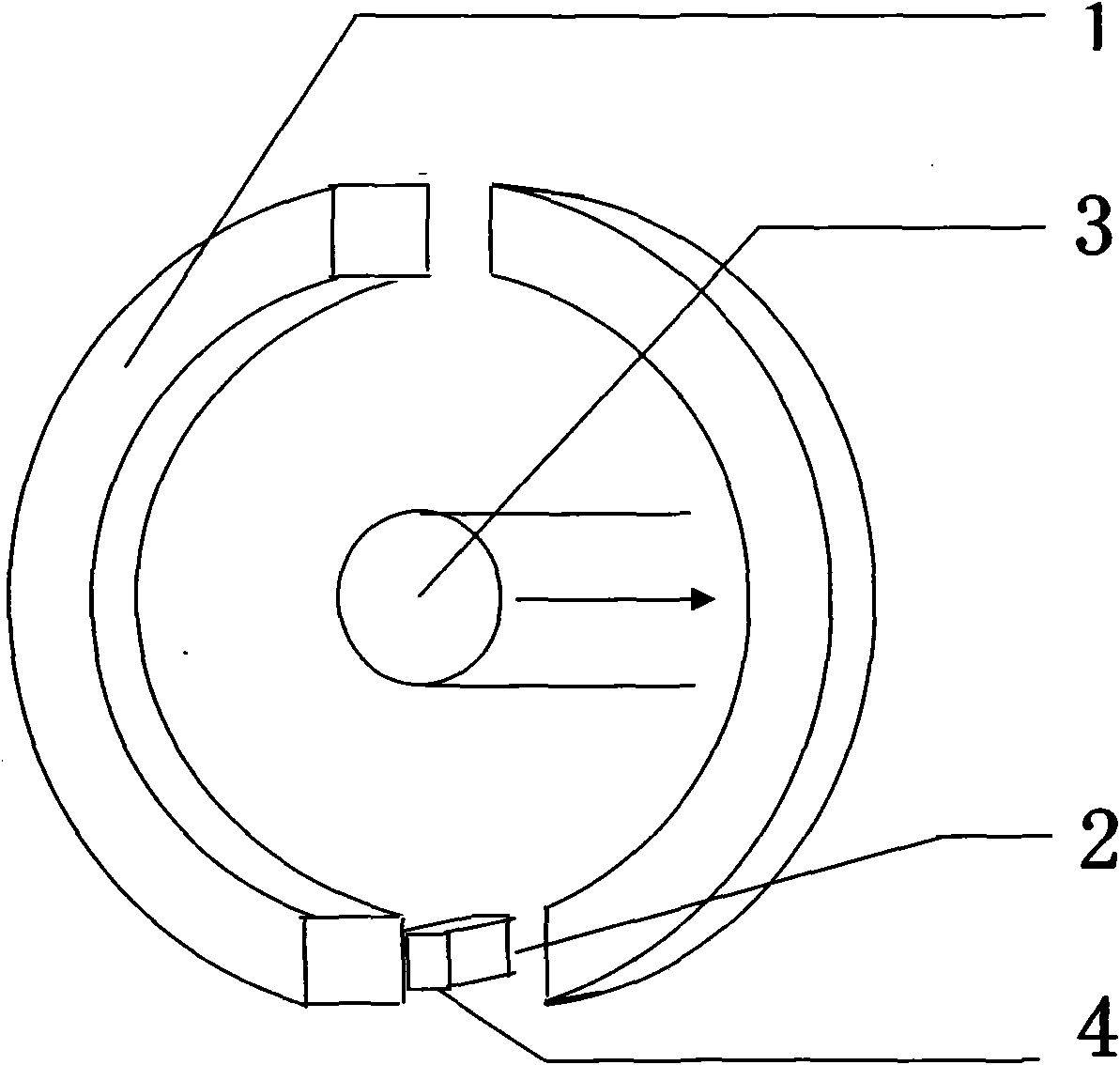

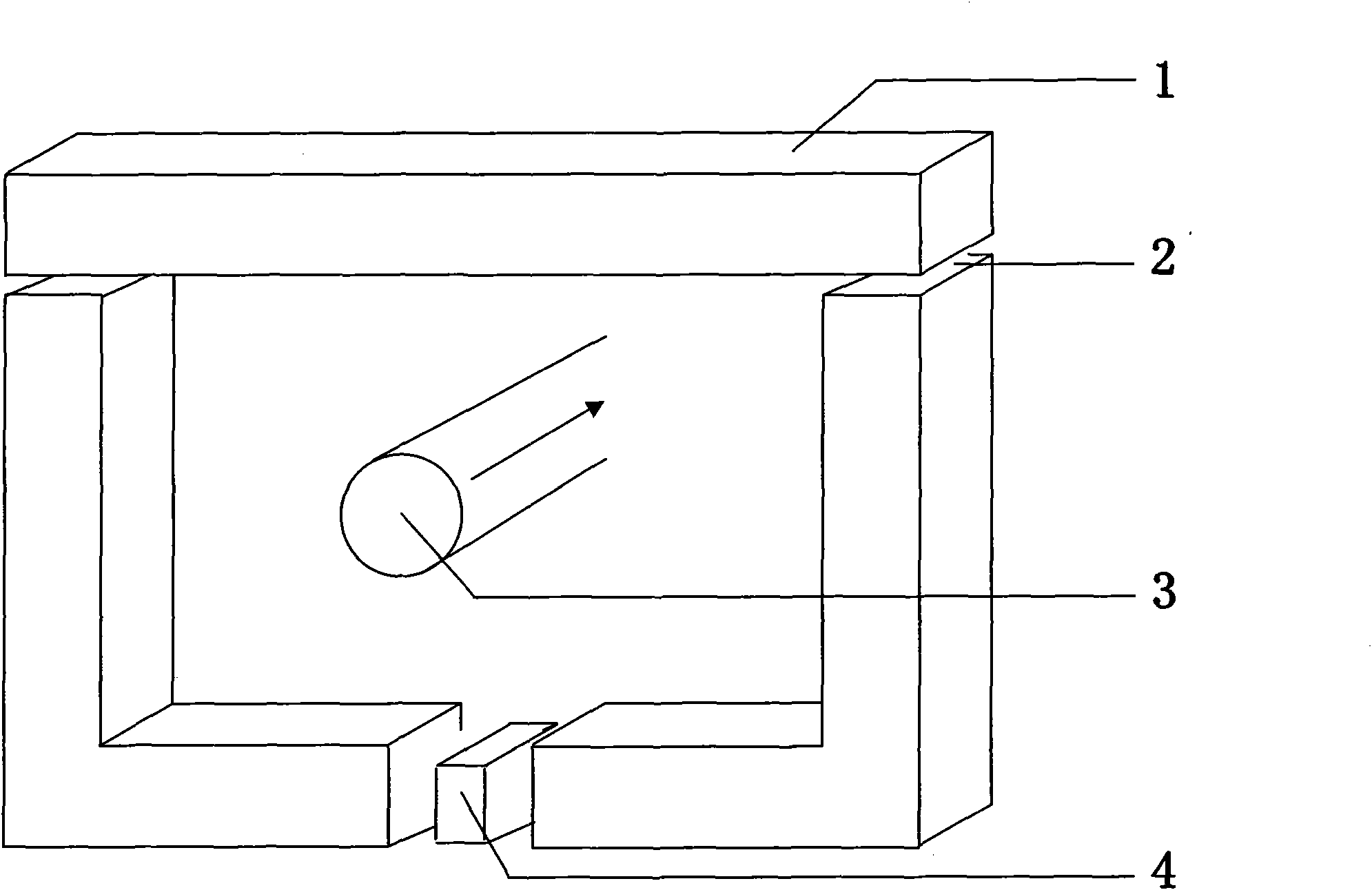

Magnetic induction current sensor for electric vehicle controller

InactiveCN102004179AImprove linearityReduce permeabilityCurrent/voltage measurementVoltage/current isolationCurrent sensorLinearity

The invention relates to a magnetic induction current sensor for an electric vehicle controller, wherein a closed magnetic circuit is formed by a magnetic sensor, at least two magnetic ring sections are comprised, the magnetic sensor is arranged in a magnetic gap between the two magnetic ring sections, and an external lead wire passes through the closed magnetic circuit formed by the magnetic ring sections and the magnetic sensor. The invention provides the magnetic induction current sensor, which has the advantages of lower material cost, lower manufacturing requirements, better seismic resistance, better linearity and higher precision, and is more convenient to install and easier to regulate.

Owner:TIANJIN SANTROLL ELECTRIC SCI & TECH

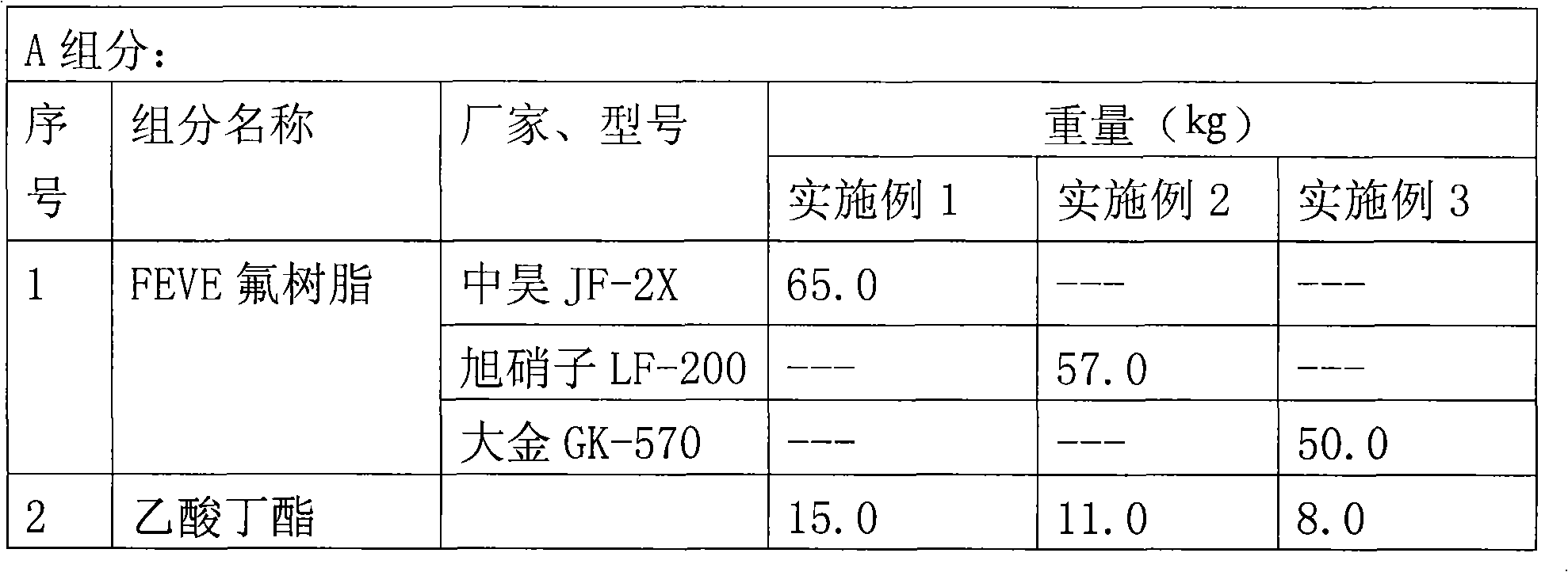

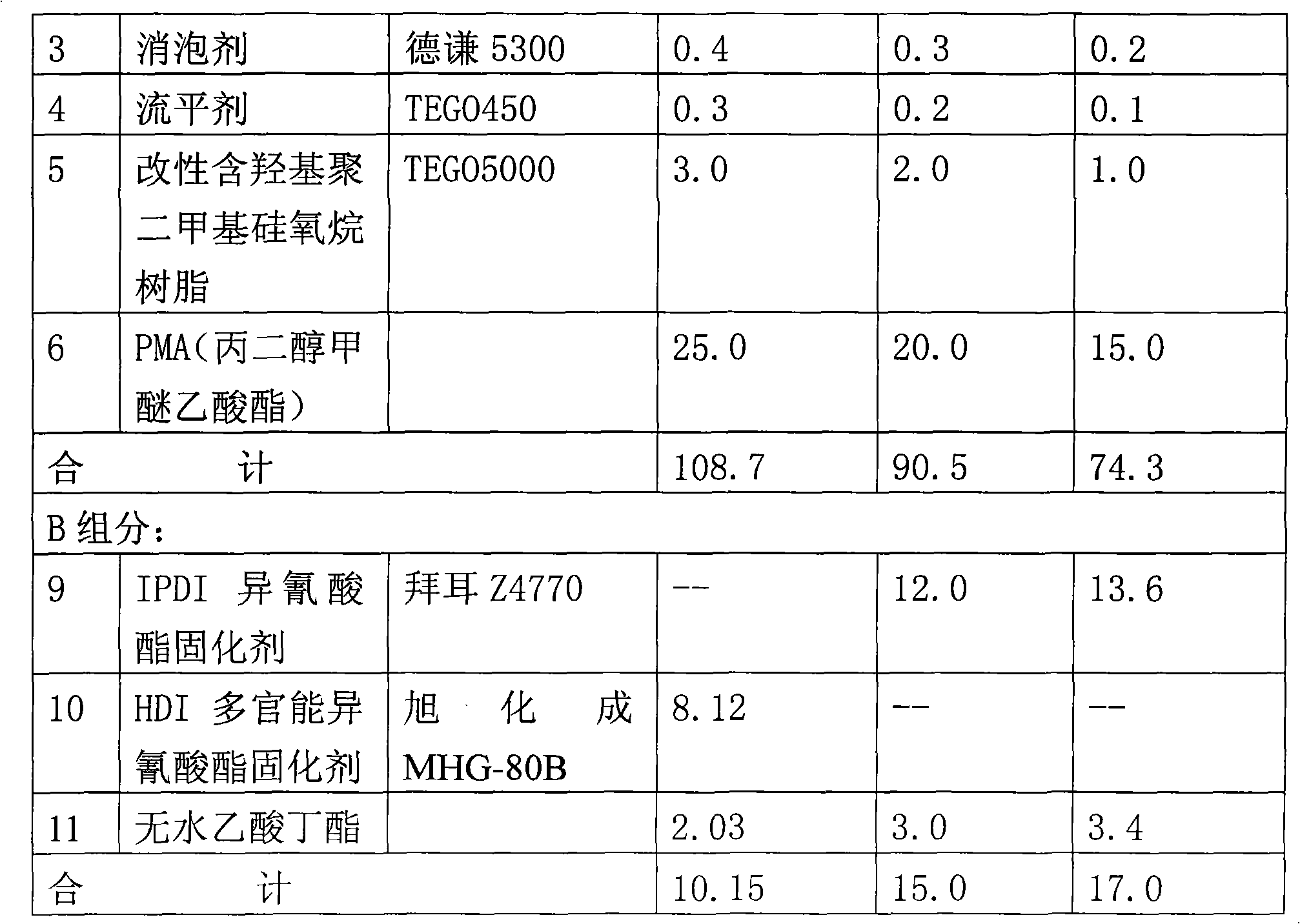

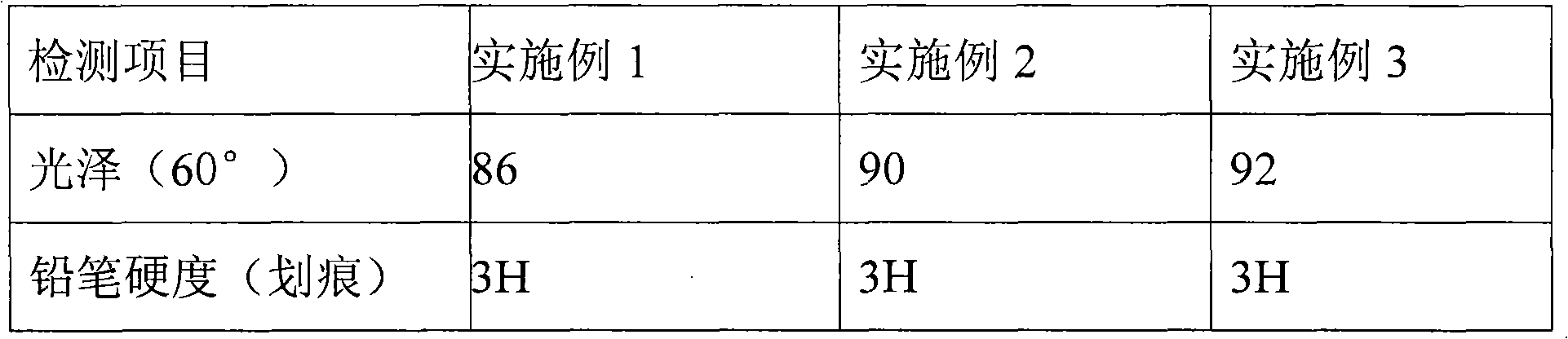

Anti-paste and anti-graffiti fluorocarbon coating and use method thereof

ActiveCN101629049AIncrease crosslink densityImprove the compactness of the paint filmPolyurea/polyurethane coatingsChemistryHardness

The invention relates to an anti-paste and anti-graffiti fluorocarbon coating which is prepared by mixing a component A and a component B in a proportion of OH / NCO=1:(1.0-1.1), wherein the component A comprises the following components in percentage by weight: 50-65 percent of FEVE fluororesin, 1-3 percent of modified polydimethylsiloxane resin containing hydroxide radicals, 8-15 percent of butyl acetate, 15-25 percent of propylene glycol methyl ether acetate, 0.2-0.4 percent of defoaming agent and 0.1-0.3 percent of flatting agent; and the component B is prepared by mixing 80 parts of IPDI isocyanate curing agent or GDI multifunctional isocyanate curing agent by weight and 20 parts of anhydrous butyl acetate by weight. The coating has high film crosslinking density and hardness, low surface tension, extremely strong permeability resistance and excellent anti-paste and anti-graffiti performance, and intractable oil pen graffiti can also be easily and completely wiped out. The coating also has excellent wear-resistant, scouring resistant and weather resistant properties and is suitable for long-term outdoor use. The coating can be painted and can also be sprayed after being diluted by adding 10-20 percent of PMA or polyurethane coating diluent.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

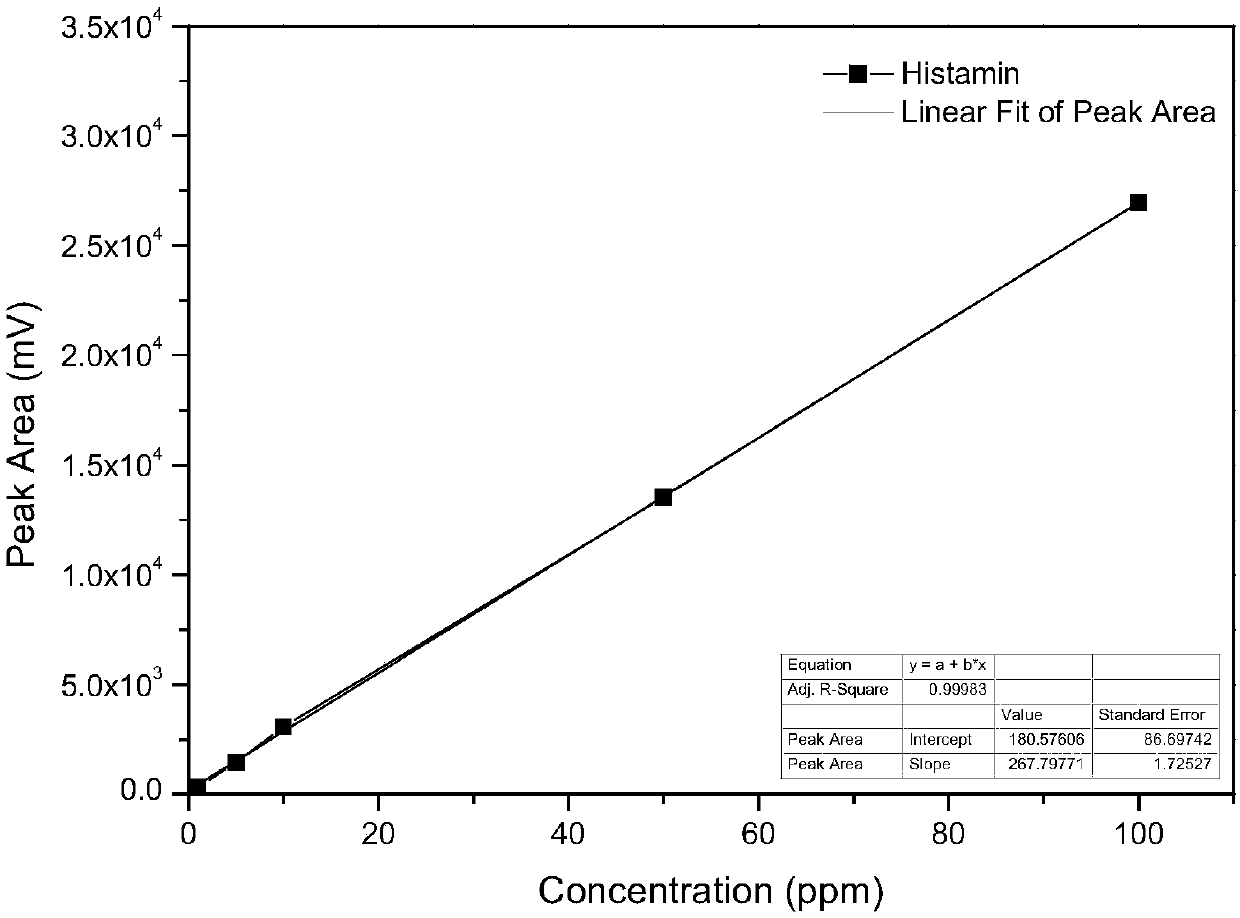

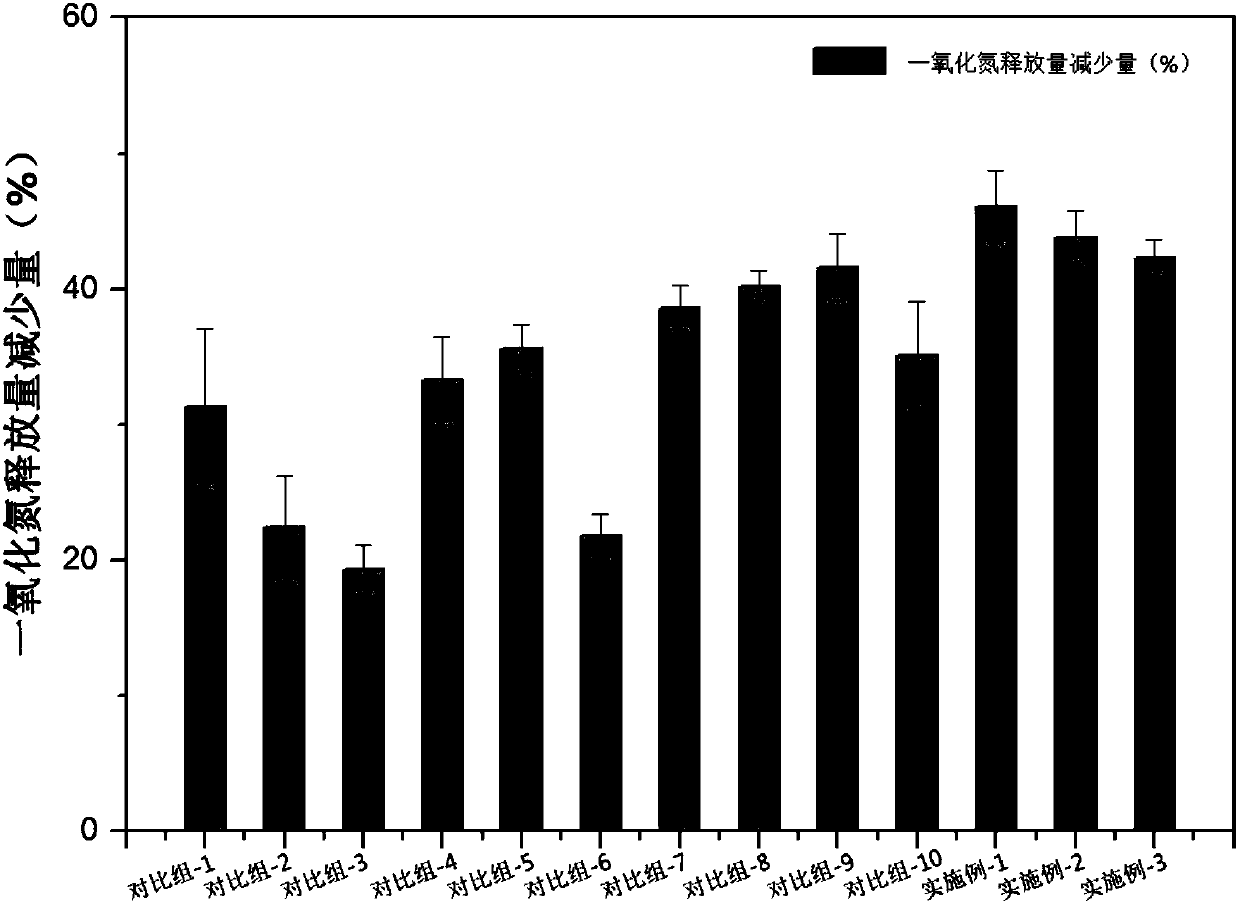

Anti-allergic composition for relieving as well as application thereof

ActiveCN107714531AEnhanced Tolerance ThresholdReduce trafficCosmetic preparationsToilet preparationsAdemetionineNitric oxide

The invention relates to an anti-allergic composition for relieving as well as an application thereof. The anti-allergic composition for relieving comprises the following components: a first anti-allergic composition, a second anti-allergic composition, an anti-allergic peptide composition, Crambe abyssinica seed oil, bisabolol, and a Cardiospermum halicacabum extract product; the active componentof the first anti-allergic composition comprises 4-tert-butylcyclohexanol and 2-(3-(4-hydroxyphenyl)propanamido)benzoic acid; the active components of the second anti-allergic composition comprise anextract product of Stephania tetrandra, potassium lactate, phenoxyethanol, and dipotassium glycyrrhizinate; the active components of the anti-allergic composition comprise palmitoyl tripeptide-8 andacetyl tetrapeptide-15. The anti-allergic composition for relieving is evaluated by a macrophage nitric oxide inflammation releasing model, inhibition rate of nitric oxide releasing reaches 46.07%, and inhibition rate of histamine reaches 61.59%.

Owner:HUNAN YUJIA COSMETICS MFG CO LTD

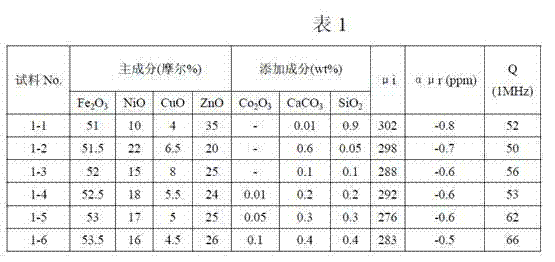

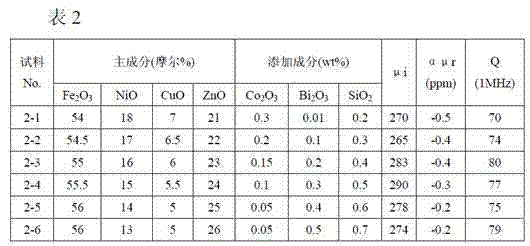

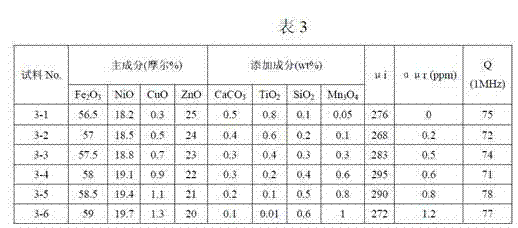

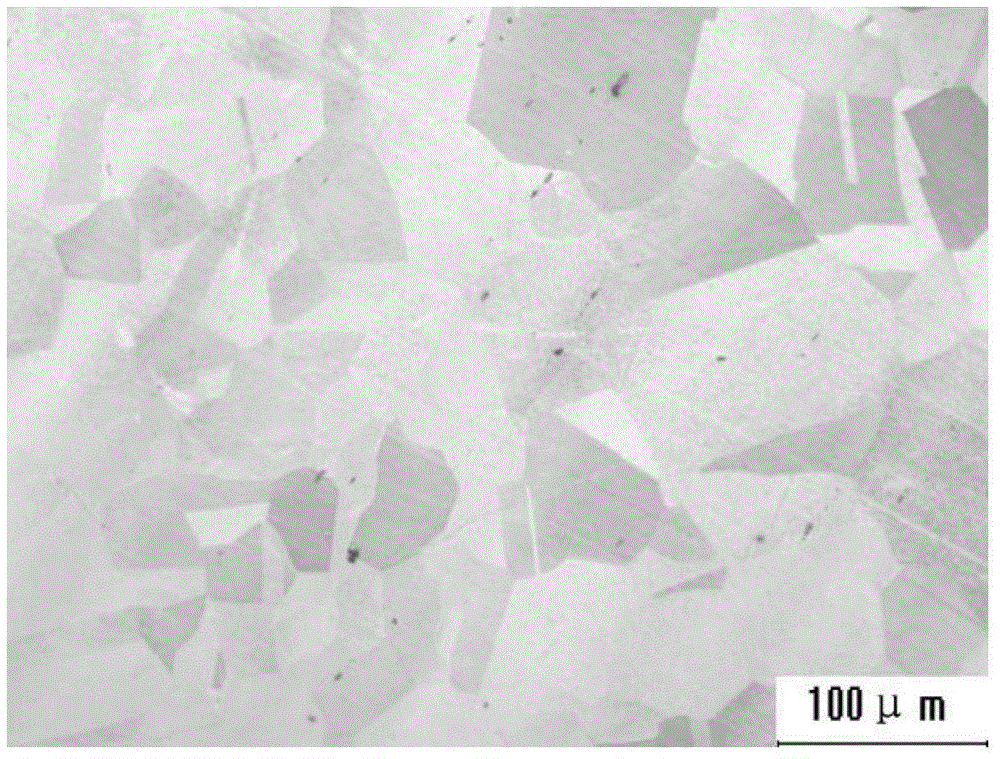

Soft magnetic NiCuZn ferrite material with characteristics of wide temperature range, low temperature coefficient, high frequency and low loss, and preparation method thereof

ActiveCN103693949ASmall temperature coefficientSmall temperature changeInorganic material magnetismTemperature coefficientFerrite (magnet)

The present invention discloses a soft magnetic NiCuZn ferrite material with characteristics of wide temperature range, low temperature coefficient, high frequency and low loss, and a preparation method thereof. The soft magnetic NiCuZn ferrite material comprises a main component and a sub-component, wherein the main component comprises 51-59 mol% of Fe2O3, 10-22 mol of NiO, 20-35 mol% of ZnO, and 0.3-8 mol% of CuO, and the sub-component comprises (by the total weight of the main component) two or more than two components selected from 0.05-1.0 wt% of Mn3O4, 0.05-0.9 wt% of SiO2, 0.01-0.5 wt% of Bi2O3, 0.01-0.8 wt% of TiO2, 0.01-0.6 wt% of CaCO3, and 0.01-0.3 wt% of Co2O3. The soft magnetic NiCuZn ferrite material can be used in the wide temperature range of -40 to 120 DEG C, and has characteristics of low temperature coefficient, low magnetic permeability change along with temperature change, and low loss.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

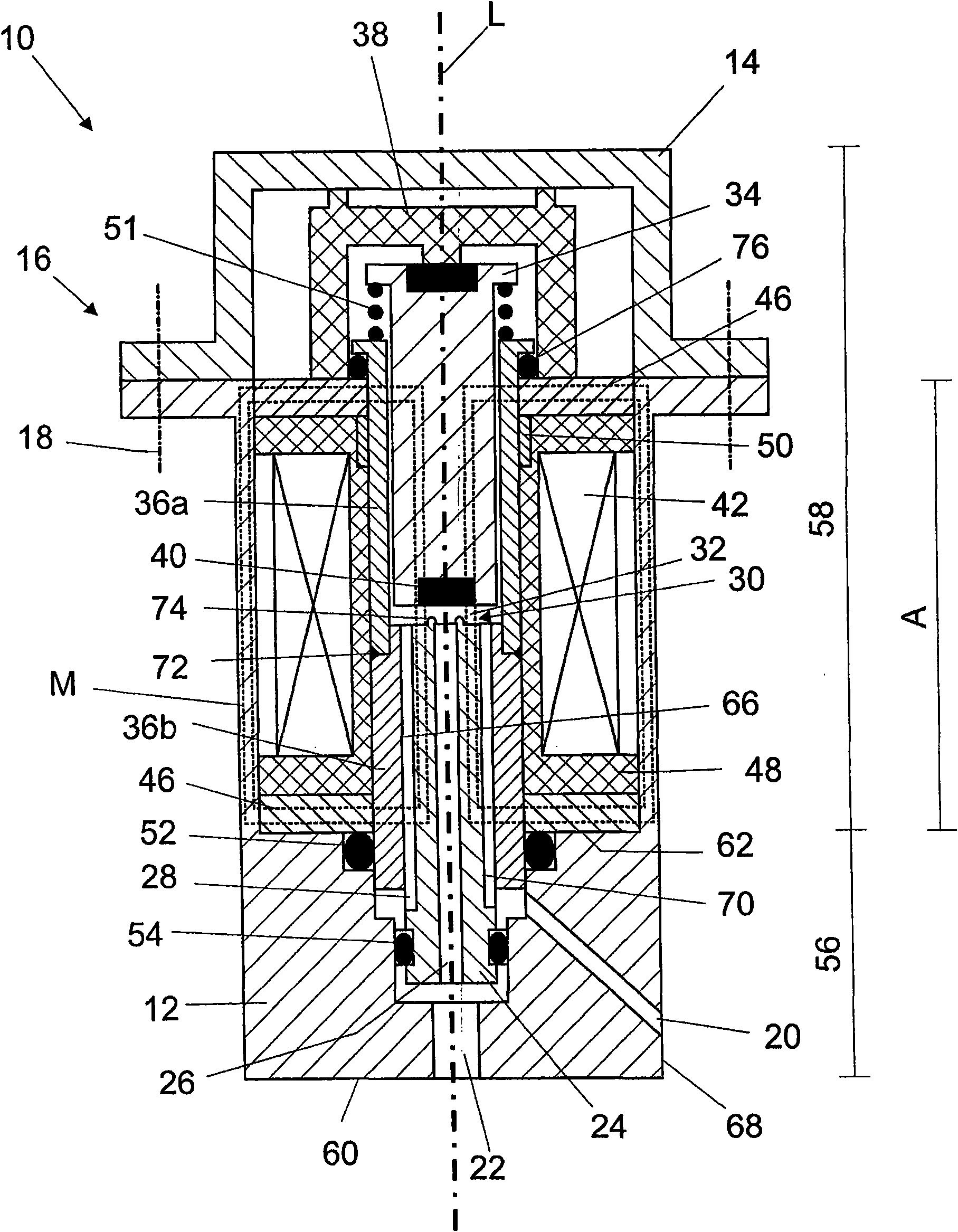

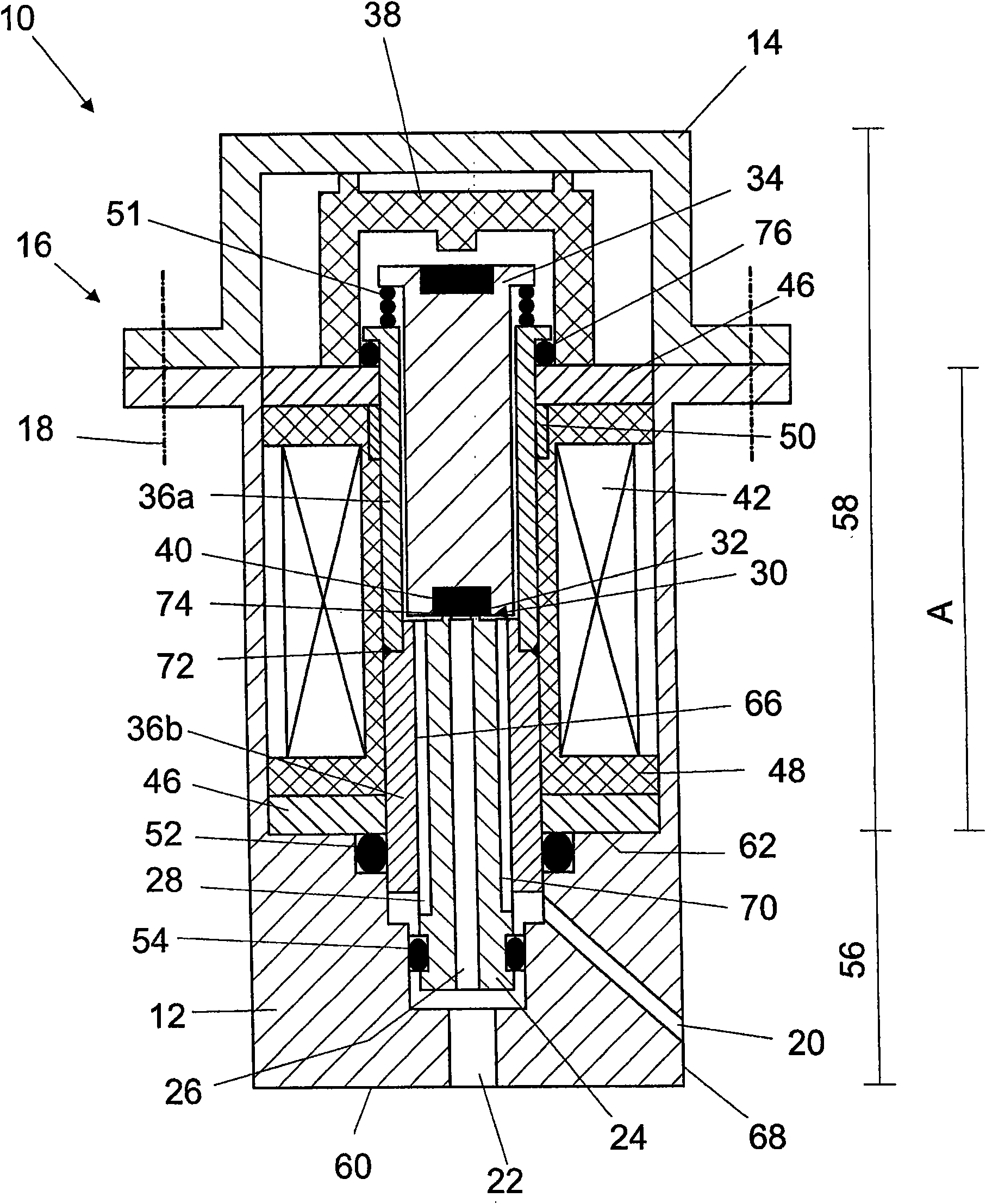

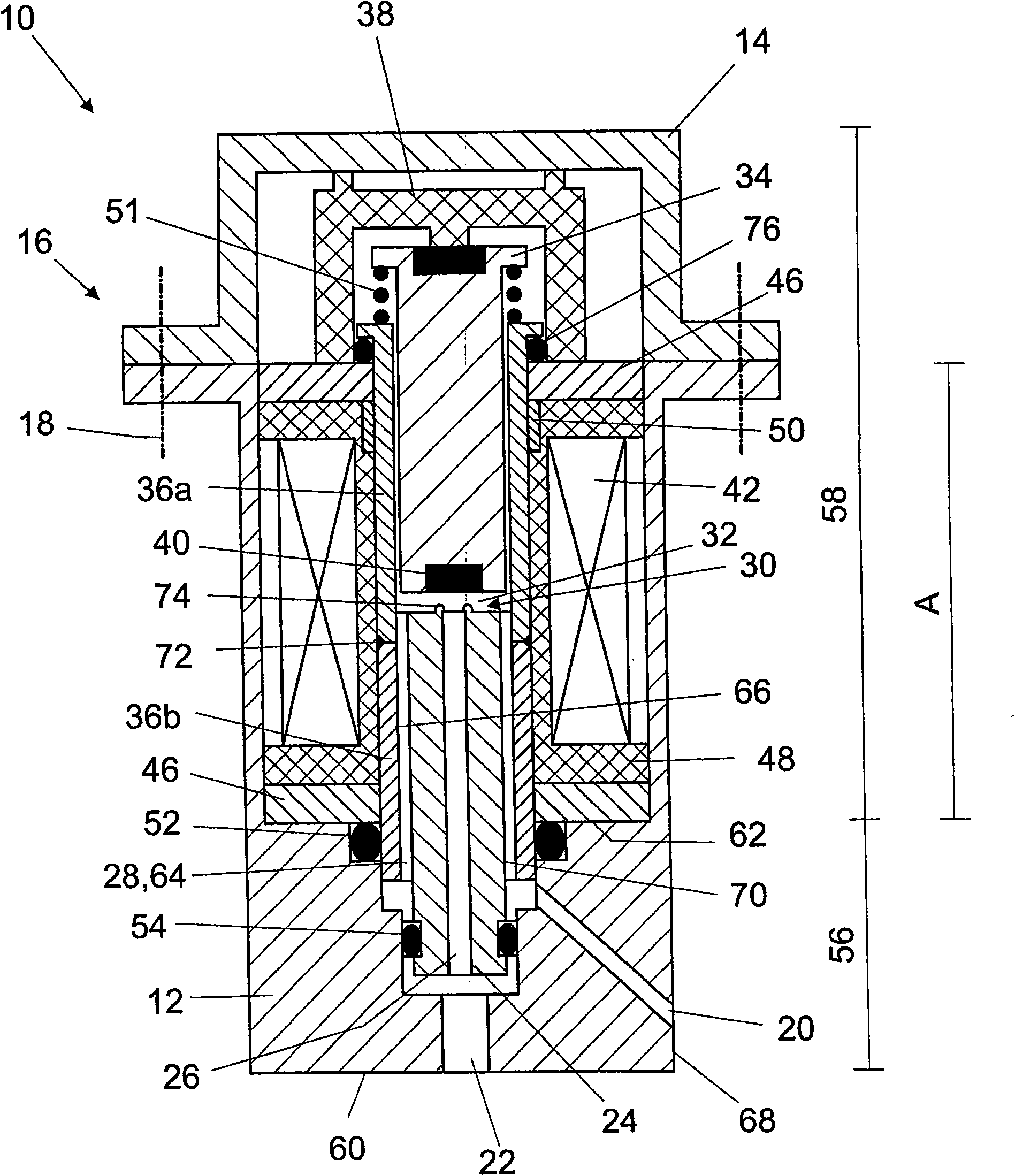

Switching magnetic valve

InactiveCN101555958AEasy to driveCheap manufacturingOperating means/releasing devices for valvesApplication and release valvesIn vehicleMagnetic valve

The present invention relates to a switch magnetic valve, which is taken as a pre-control valve to generate and control pressure in vehicle pneumatic braking system, wherein the switch magnetic valve comprises a first passage, used for introducing compressed-air into the switch magnetic valve or export compressed-air from the switch magnetic valve; a second passage, used for introducing compressed-air into the switch magnetic valve or export compressed-air from the switch magnetic valve; a valve chamber including a valve seat for selectively release and break off compressed-air stream; and a valve core, provided with an outer housing surface and a hole used let the compressed-air pass through. According to the invention, the valve chamber (32) is provided with a flow path (28); the flow path (28) neighbors with housing surface (70) of the valve core (24); the flow path (28) is formed by at least one gap on housing surface (70) of the valve core (24) in preference.

Owner:WABCO GMBH

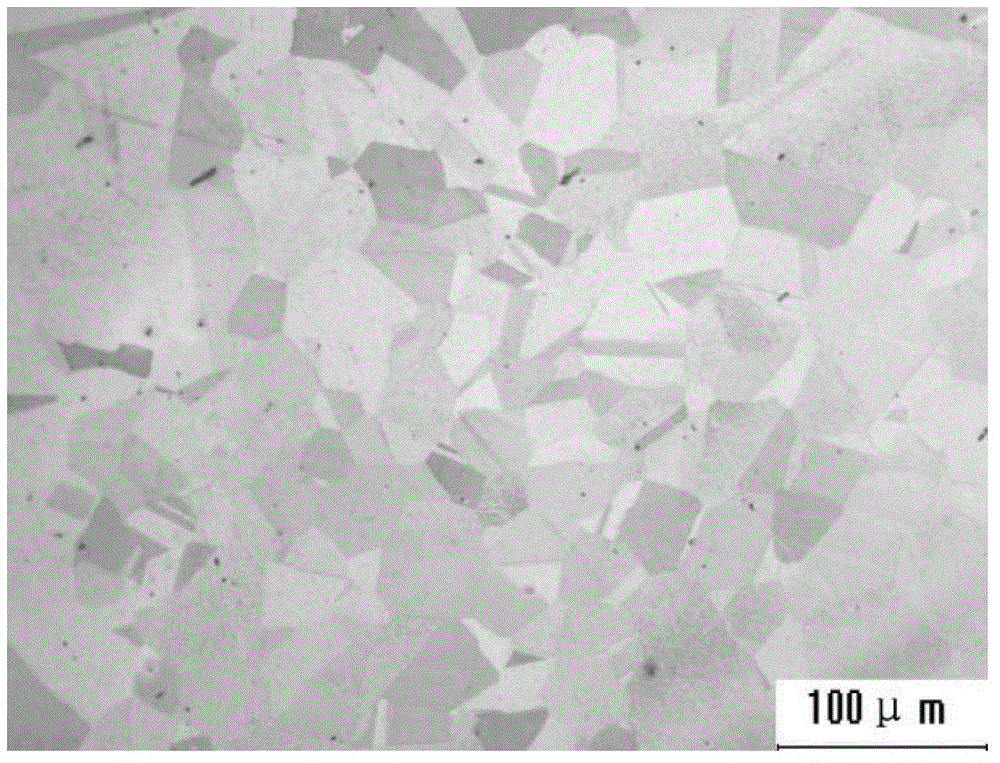

Axial friction welding process method of high-nitrogen austenitic stainless steel and non-magnetic drill collar

InactiveCN108907447AAchieve weldingGuaranteed normal work requirementsTubular articlesHollow articlesFriction weldingNon magnetic

The invention relates to an axial friction welding process method of a high-nitrogen austenitic stainless steel and non-magnetic drill collar and belongs to the field of preparation of oil-gas drilling tools. The method comprises the application steps: workpieces made from high-nitrogen austenitic stainless steel are clamped into a friction welding machine, then, workpieces in a clamp of a rotating end and a clamp of a moving end are welded, the workpiece of the moving end moves towards the workpiece of the rotating end when welding is started, at this time, the workpiece of the rotating end starts to rotate, the workpiece of the rotating end and the workpiece of the moving end start to produce heat due to friction under the action of frictional pressure after contact, rotation is stoppedwhen a friction amount of deformation reaches a set value, upset forging is started, upset forging pressure is applied to the workpieces along the axial direction of the workpieces and is maintained,and a workpiece is taken out after the upset forging pressure is unloaded, thereby obtaining the non-magnetic drill collar. According to the method, the non-magnetic drill collar is processed and repaired by an axial friction welding method, so that the problems, i.e., material waste, relatively high cost and relatively low production efficiency of the existing processing methods are improved, andthe problem that a failed drill collar is difficult to repair is solved.

Owner:SHANDONG UNIV

High-manganese non-magnetic steel containing niobium and preparation method thereof

A high-manganese non-magnetic steel containing niobium and a preparation method thereof belong to the technical field of non-magnetic steel production. Components of the high-manganese non-magnetic steel containing niobium comprises, by mass percent, 10 to 15 % of Mn, 0.8 to 1.2 % of C, 0.3 to 0.5 % of Si, less than 0.008 % of P, less than 0.005 % of S, 0.01 to 0.02 % of Nb, and the balance being Fe. The preparation method comprises steps of smelting, forging, hot rolling, water toughening, and water quenching after the hot-rolled plate is kept in a heating furnace for 15 minutes at 1000 DEG C. The method is advantageous in that the high manganese steel is pre-deformed by using a rolling method, thereby being capable of refining grain size and improving organization and performance, and a finished product has tensile strength of 900 to 1100 MPa, elongation percentage of 50 to 60%, Rockwell hardness of 15 to 22 HRC and magnetic permeability of less than 1.0002. According to the invention, the non-magnetic steel is superior in magnetic, mechanical and processing properties, and the method is simple in production, low in economic cost, and is applicable in the fields of mechanical production and transportation, such as nonmagnetic structural members and nonmagnetic molds used for magnetic shielding in large and medium-sized transformer oil tanks, train tracks, etc.

Owner:UNIV OF SCI & TECH BEIJING

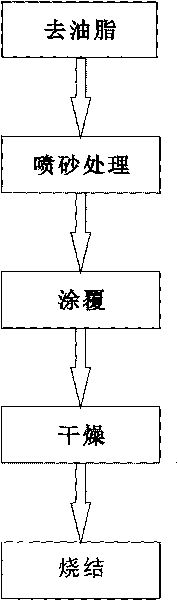

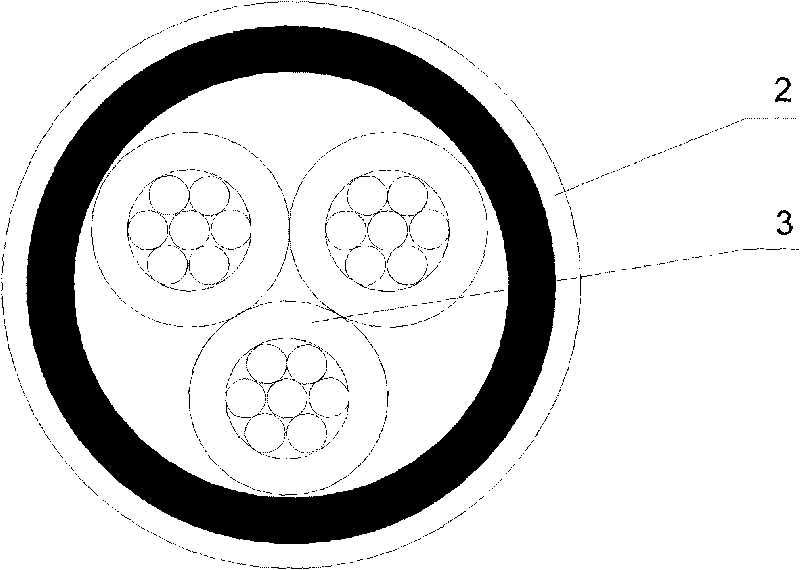

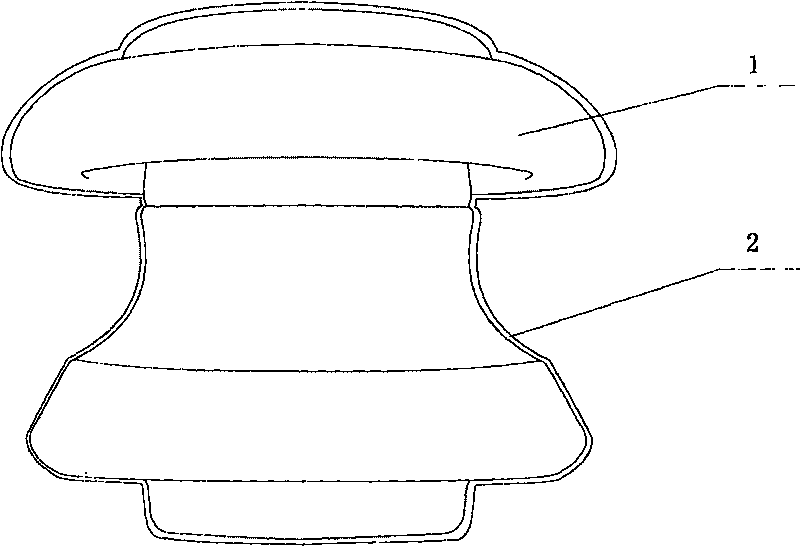

Coating method for wire or electrical insulator with teflon coating

InactiveCN101707103AExcellent heat and low temperature resistanceReduce permeabilityInsulatorsInsulating conductors/cablesTemperature resistanceTransmission line

The invention relates to a coating method for a wire or an electrical insulator with a teflon coating, which relates to the technical field of transmission lines. The coating method for the electrical insulator (3) comprises the steps of degreasing, sand-blasting treatment, coating, drying and sintering. The coating method for the wire (1) comprises the steps of degreasing, coating adhesives and spraying the coatings. As the teflon has inadhesion property and moisture resistance, the aim of preventing serious icing can be fulfilled by spraying the teflon on the outsides of the wire and the electrical insulator, and the aim of preventing the pollution flashover can be fulfilled by spraying the teflon on the outside of the electrical insulator. As the teflon coating film has excellent heat resistance and low temperature resistance, the wire or electrical insulator sprayed with the teflon can work normally in a high-temperature environment in summer or a low-temperature environment in winter.

Owner:河南省电力公司洛阳供电公司输电公司

MIM manufacturing process for weak-magnetism 17-4PH material part

ActiveCN108380888AControl Nitriding DepthControl the nitriding depth to meet the magnetic requirementsTransportation and packagingMetal-working apparatusNitrogenRoom temperature

The invention discloses an MIM manufacturing process for a weak-magnetism 17-4PH material part. The MIM manufacturing process comprises the following technological steps of: preparing an MIM injection-molded blank; degreasing; sintering; and discharging, wherein in a sintering process, the temperature is increased from the room temperature to 550-650 DEG C at a temperature rise speed of 3-3.5 DEGC / min in negative-pressure sintering; the temperature is increased from 550-650 DEG C to 950-1050 DEG C at a temperature rise speed of 3.8-4.5 DEG C / min in vacuum sintering; the temperature is increased from 950-1050 DEG C to 1270-1300 DEG C at a temperature rise speed of 2-2.5 DEG C / min in partial-pressure sintering; in a first-stage cooling process, the temperature is reduced from 1270-1300 DEGC to 1050-1150 DEG C; in a first-stage cooling temperature-maintaining process, the temperature is maintained for 60 min to 360 min at 1050-1150 DEG C, and nitrogen is charged; in a second-stage cooling process, the temperature is reduced from 1050-1150 DEG C to 550-650 DEG C; and in a third-stage forced cooling process, the temperature is reduced from 550-650 DEG C to 70 DEG C or lower in a forced cooling manner. A product manufactured by the manufacturing method disclosed by the invention is high in dimensional accuracy, high in strength, good in weak magnetism and corrosion resistance, andsmaller than 1.2H / M in magnetic conductivity.

Owner:QUJING ZHONGMING TECH

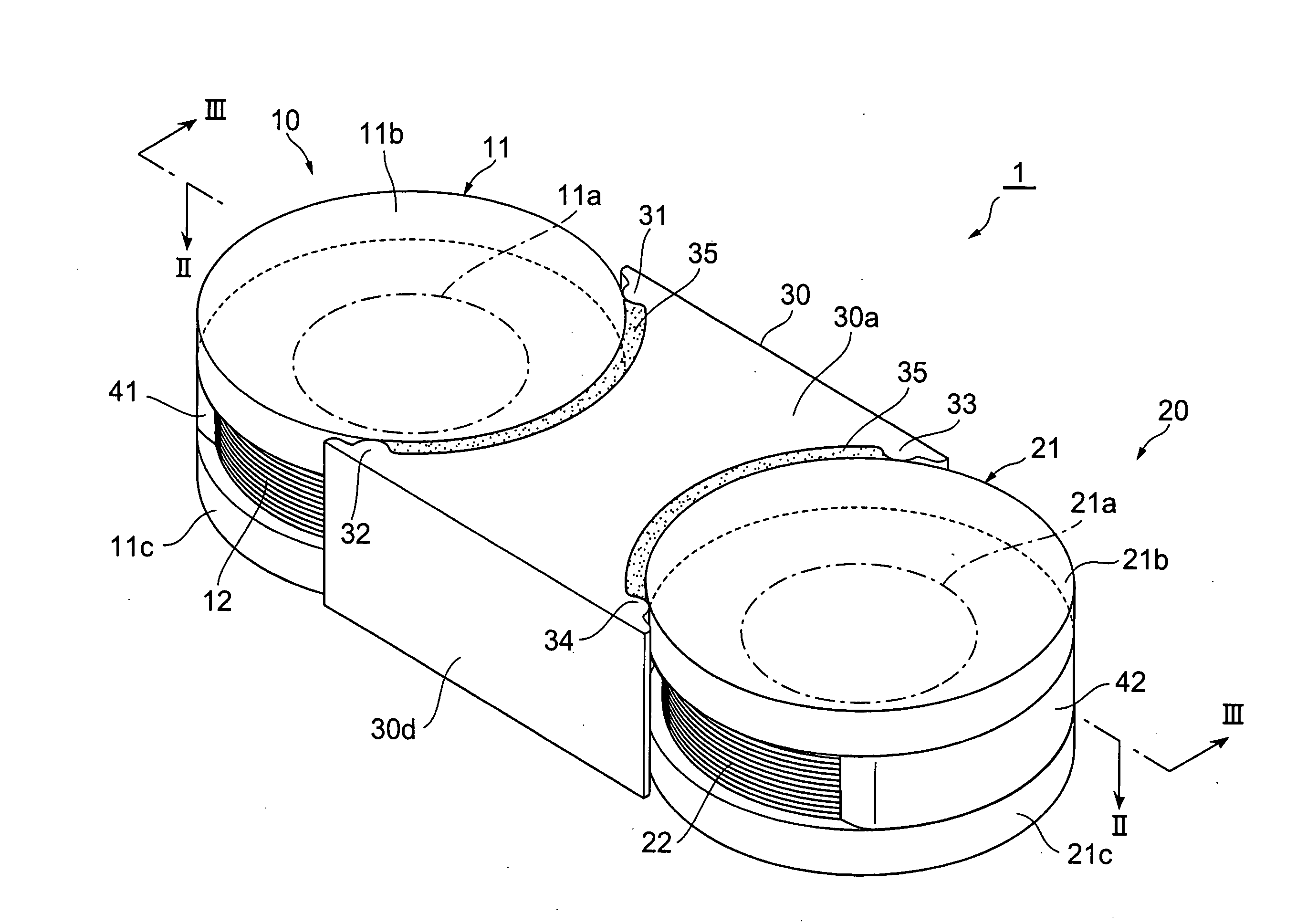

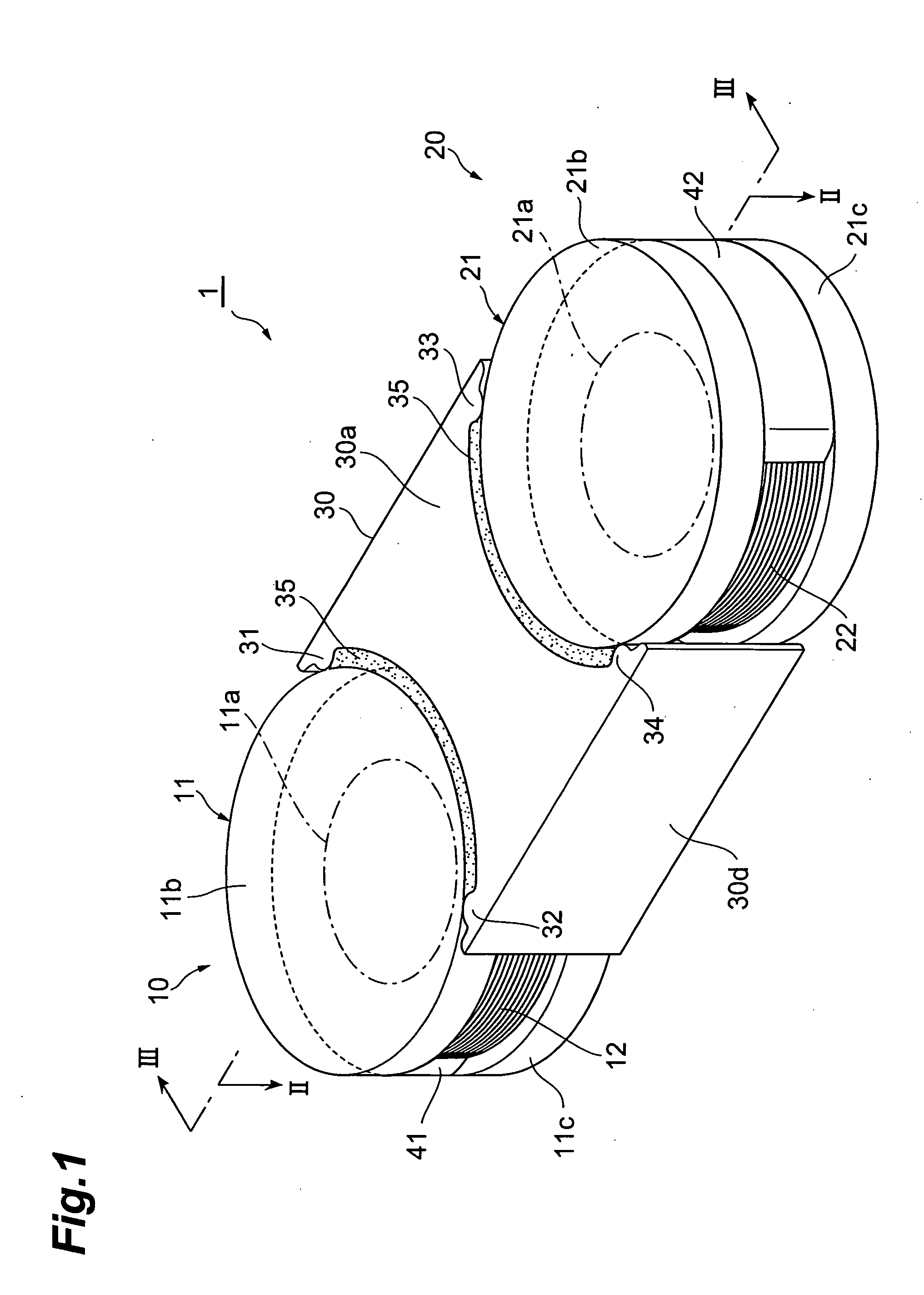

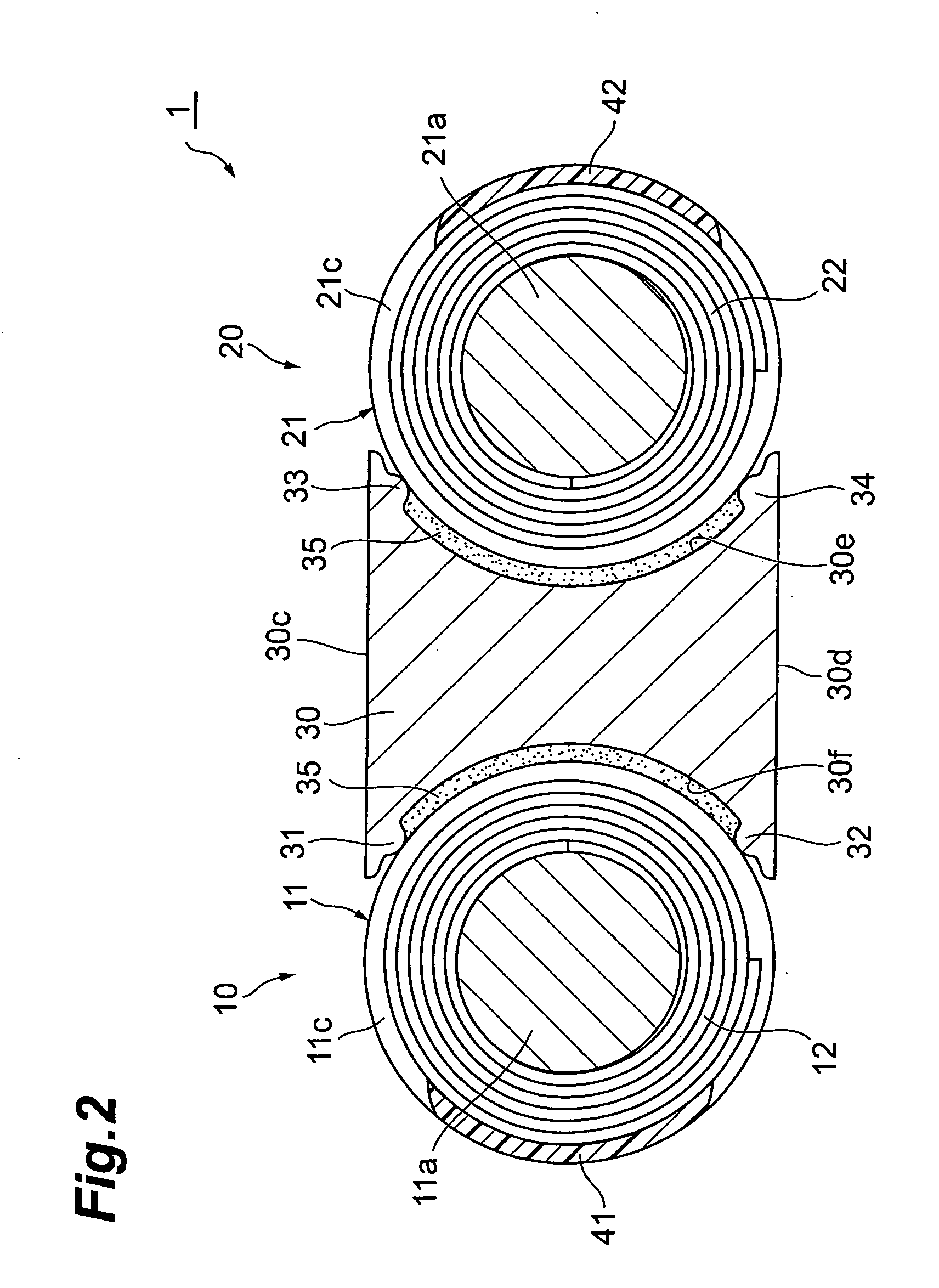

Coil component

ActiveUS20080179445A1Reduce crosstalkImprove shielding effectTransformers/inductances coils/windings/connectionsFilament handlingEngineeringConductor Coil

A coil component has a first coil part and a second coil part, a middle member, and a shield member. Each of the first and second coil parts includes a drum core and a winding. The middle member is located between the first and second coil parts arranged in a state in which axes of winding drums in the respective first and second coil parts are parallel to each other. The shield member is formed at least in part of an outside surface of the winding in each of the first and second coil parts and is a resin containing a magnetic material powder. The magnetic permeability of the middle member is lower than that of the core and the shield member.

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com