Magnetic induction current sensor for electric vehicle controller

A current sensor and electric vehicle technology, applied in voltage/current isolation, vehicle components, circuits or fluid pipelines, etc., can solve problems such as the influence of current detection accuracy, low production requirements, and brittle magnetic ring materials, making it difficult to purchase And cost reduction, solve the effect of magnetic permeability and linearity, good linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

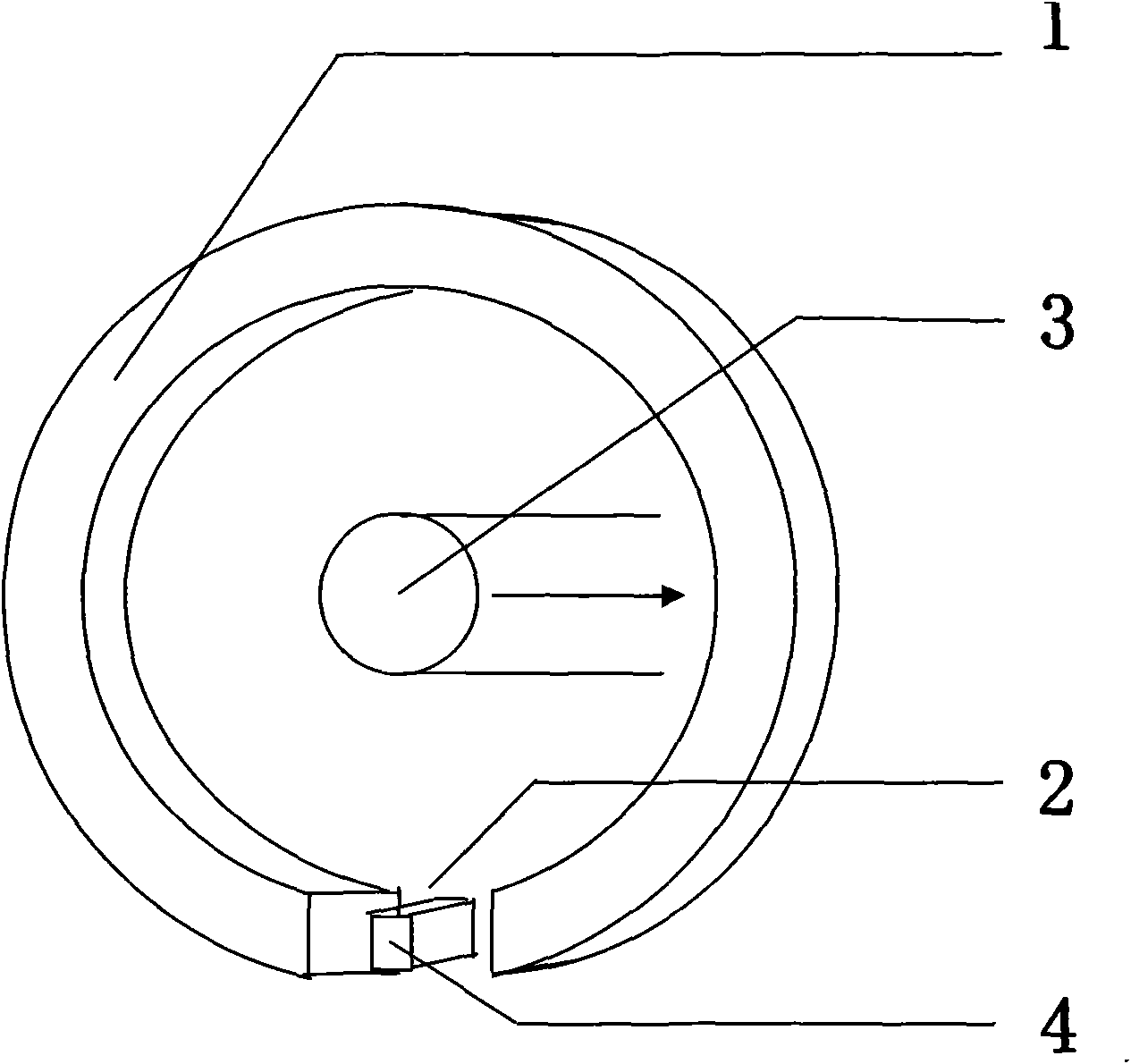

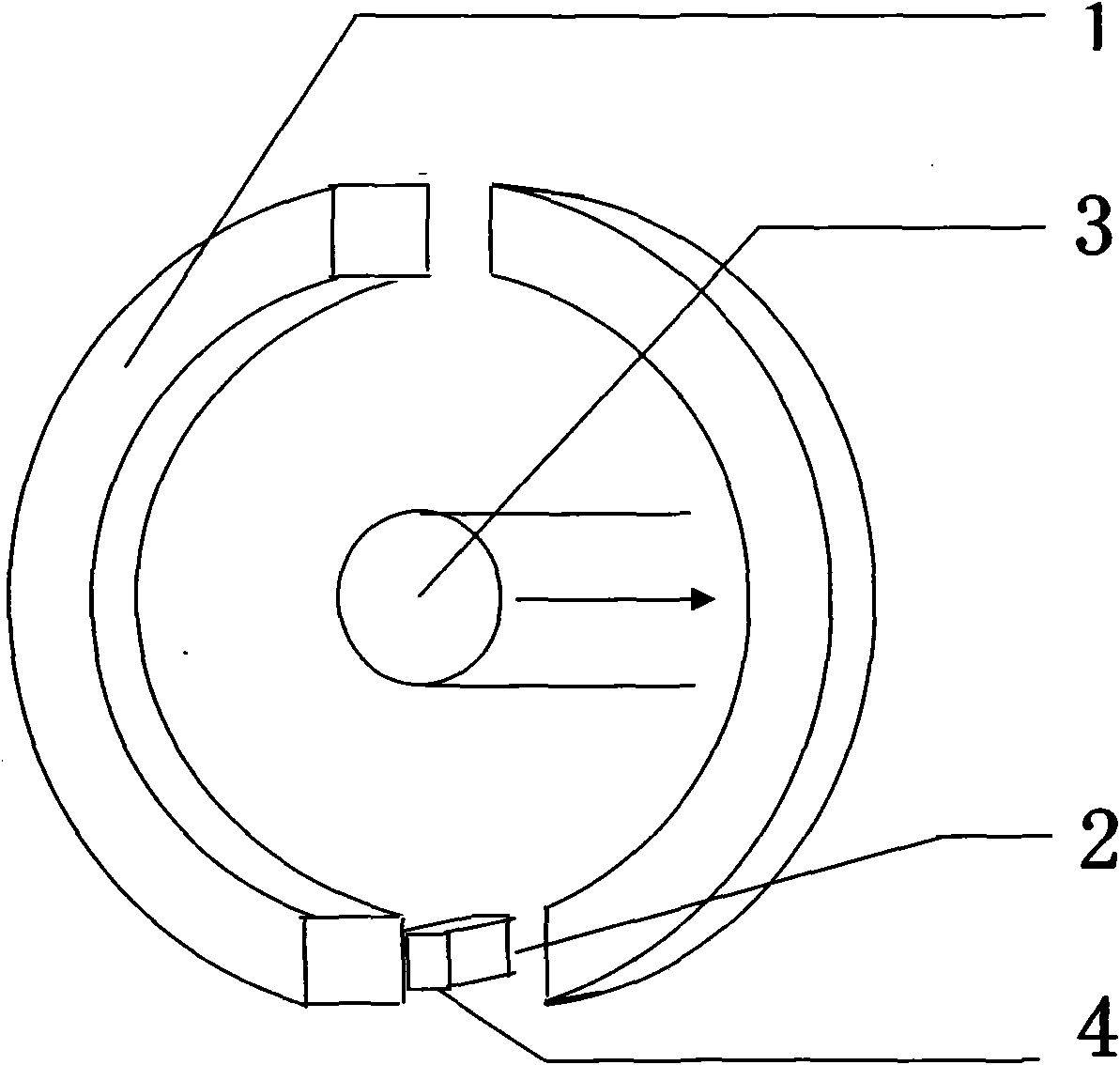

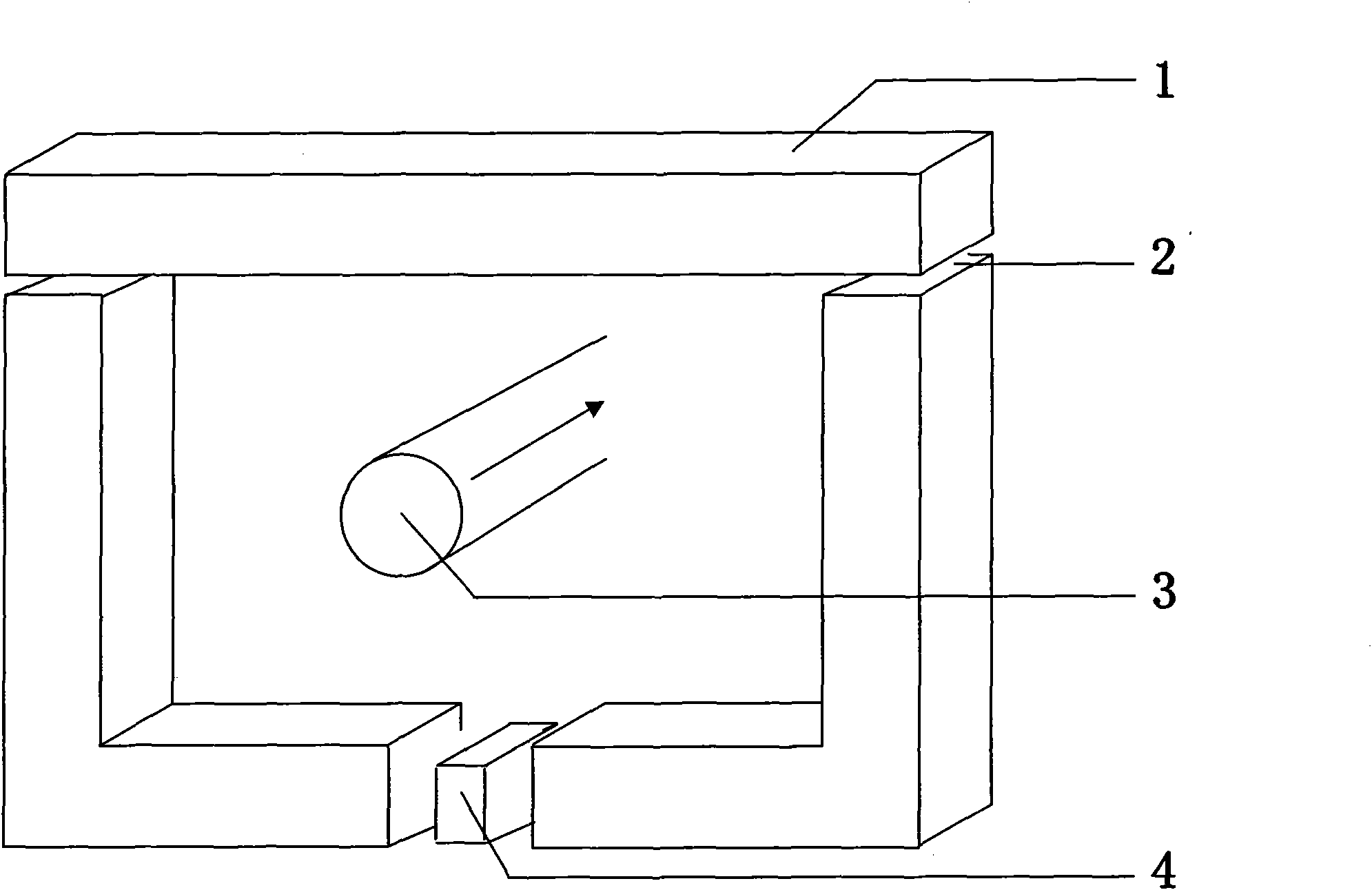

[0015] Such as Figure 1-4 : 1 is the magnetic ring segment, 2 is the magnetic gap, 3 is the external wire, and 4 is the magnetic sensor.

[0016] The present invention solves the above-mentioned technical problems by adopting the following scheme: the magnetic induction current sensor for the electric vehicle controller of the present invention is composed of a ferrite magnetic ring segment 1 and a magnetic sensor 4 to form a closed magnetic circuit, and the magnetic ring segment 1 is at least There are two, the magnetic sensor 4 is set in the magnetic gap 2 formed between the magnetic ring segments 1 , and the external wire 3 passes through the closed magnetic circuit formed by the magnetic ring segment 1 and the magnetic sensor 4 .

[0017] The technical solution of the present invention may also include: the cross section of the magnetic ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com