Method and device for measuring conveyor belt elongation, method and device for measuring conveyor belt wear extent, method and device for measuring conveyor belt temperature, rubber magnet sheet, and

A conveyor belt, elongation technology, used in measuring devices, electromagnetic measuring devices, thermometers with directly sensitive electrical/magnetic components, etc., can solve the problem of not measuring internal temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

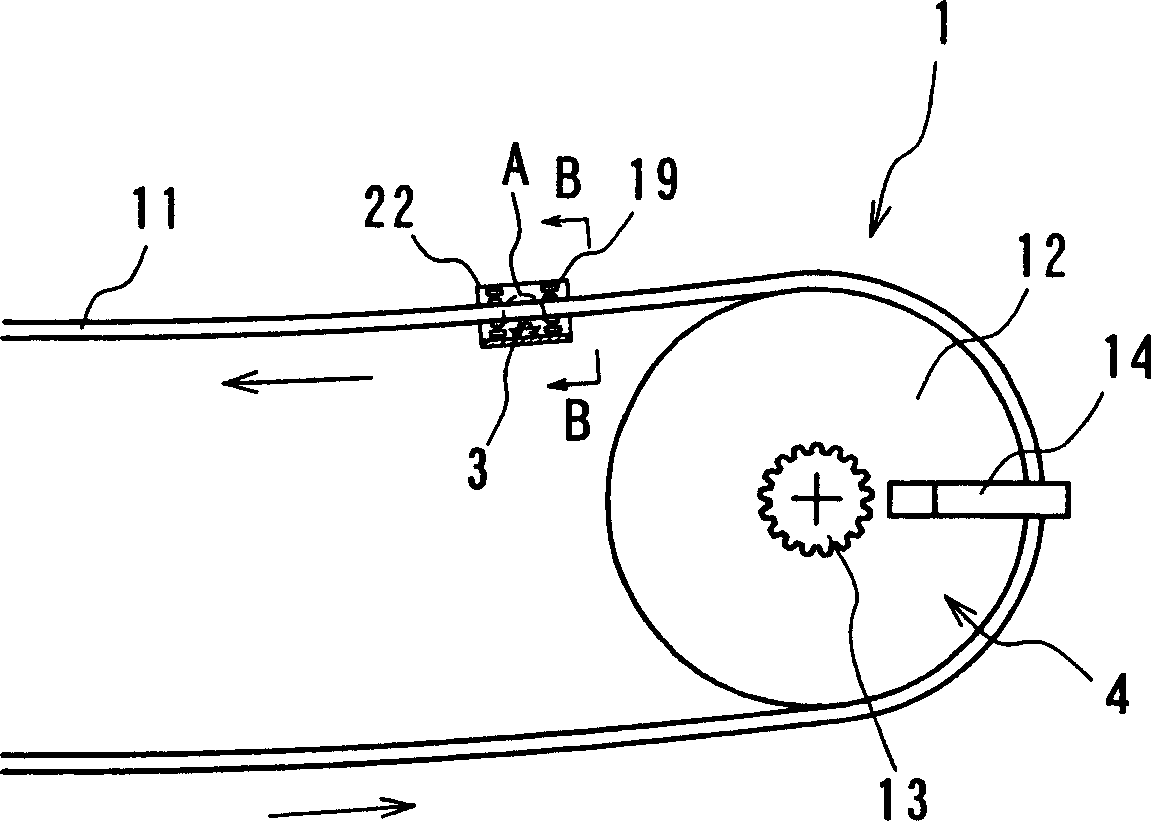

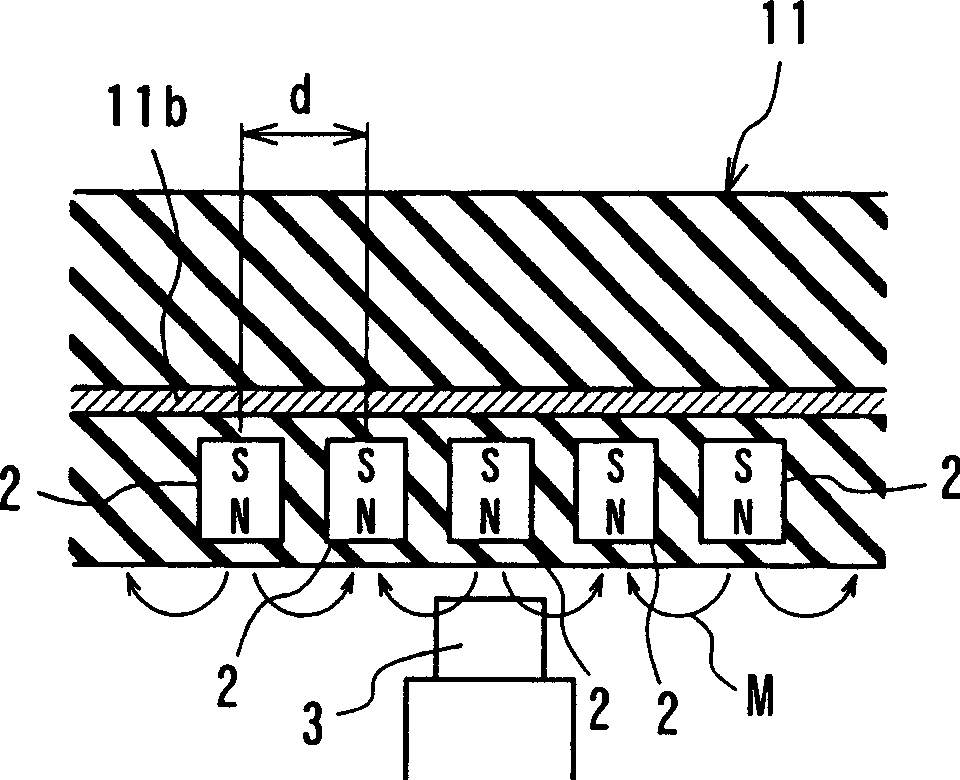

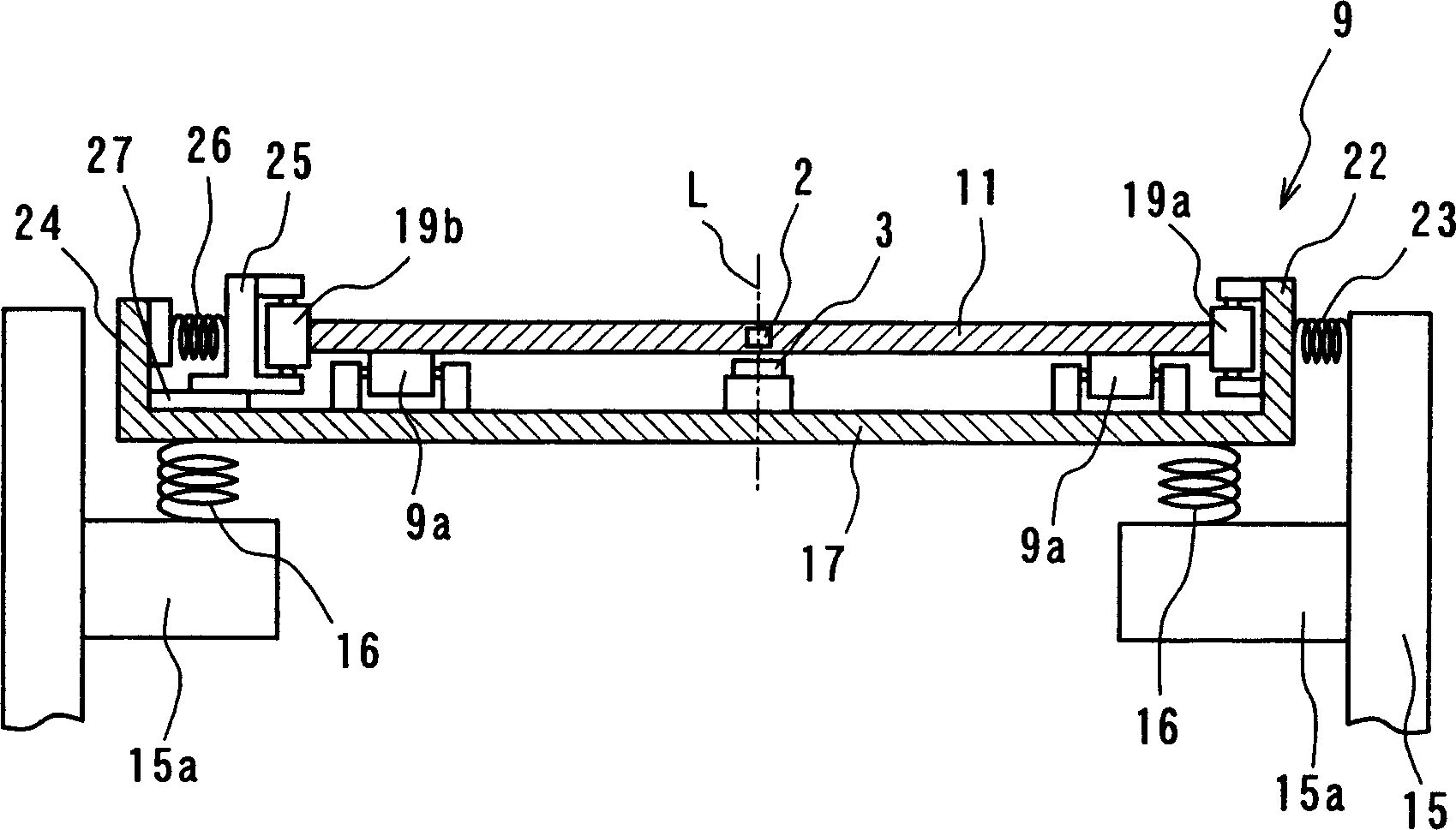

[0075] Embodiments of the present invention will be described below with reference to the accompanying drawings. figure 1 is a side view showing the conveyor belt elongation measuring device according to the first embodiment of the present invention, figure 2 yes figure 1 An enlarged cross-sectional view of part A in the image 3 is along figure 1 A partial cross-sectional view taken along line B-B in , viewed from the direction indicated by the arrow. The conveyor belt elongation measuring device 1 includes: a plurality of rubber magnets 2 embedded or arranged along the length direction of the conveyor belt 11, a magnetic sensor 3 fixed on the ground to detect the magnetic field generated from the rubber magnets 2, and a magnetic sensor 3 for measuring the conveyor belt 11. The belt speed measuring part 4 of the surface speed. The rubber magnets 2 are arranged such that the directions of their magnetic poles intersect the surface of the conveyor belt 11 at right angles, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com