Patents

Literature

168results about How to "Reduce magnetic field" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

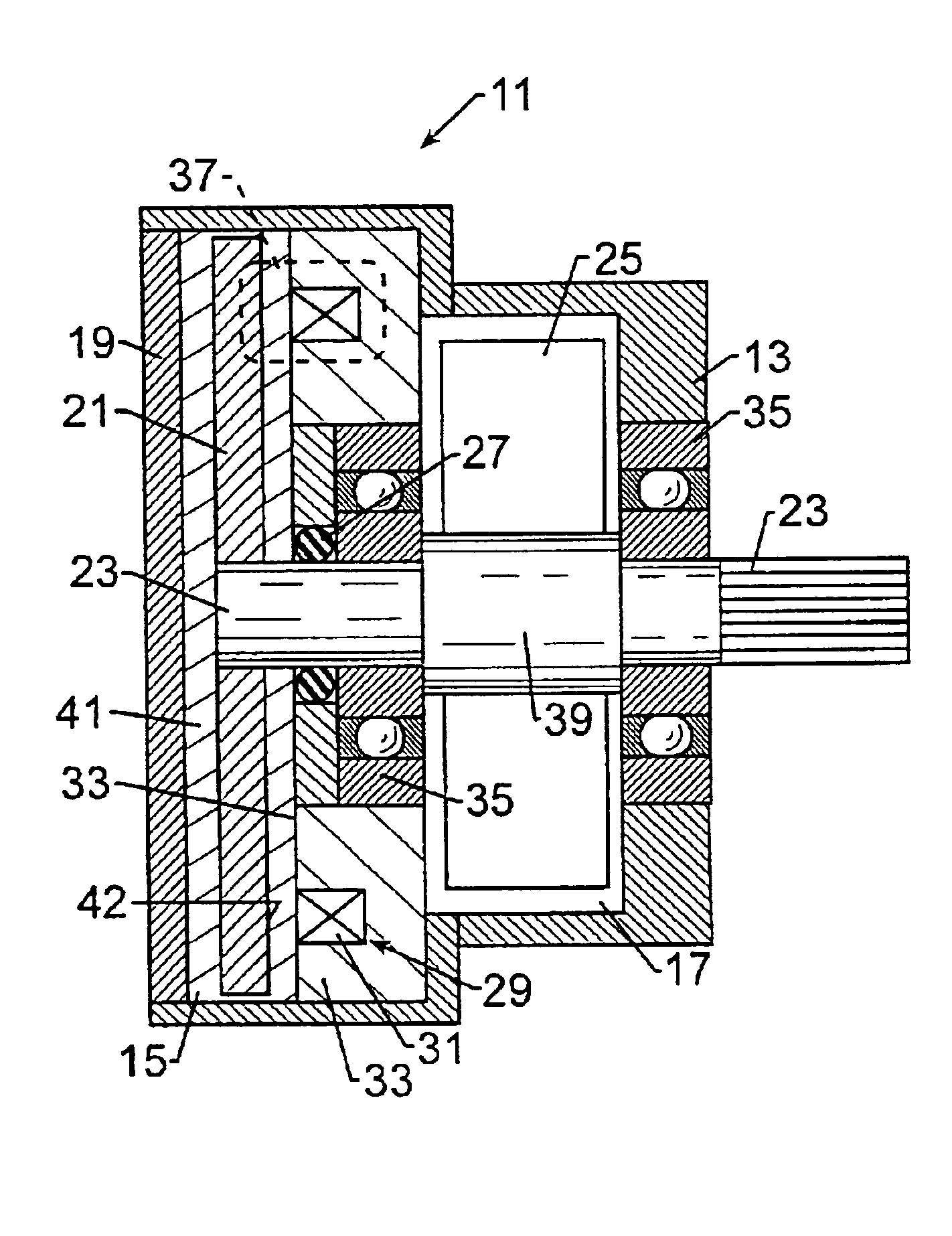

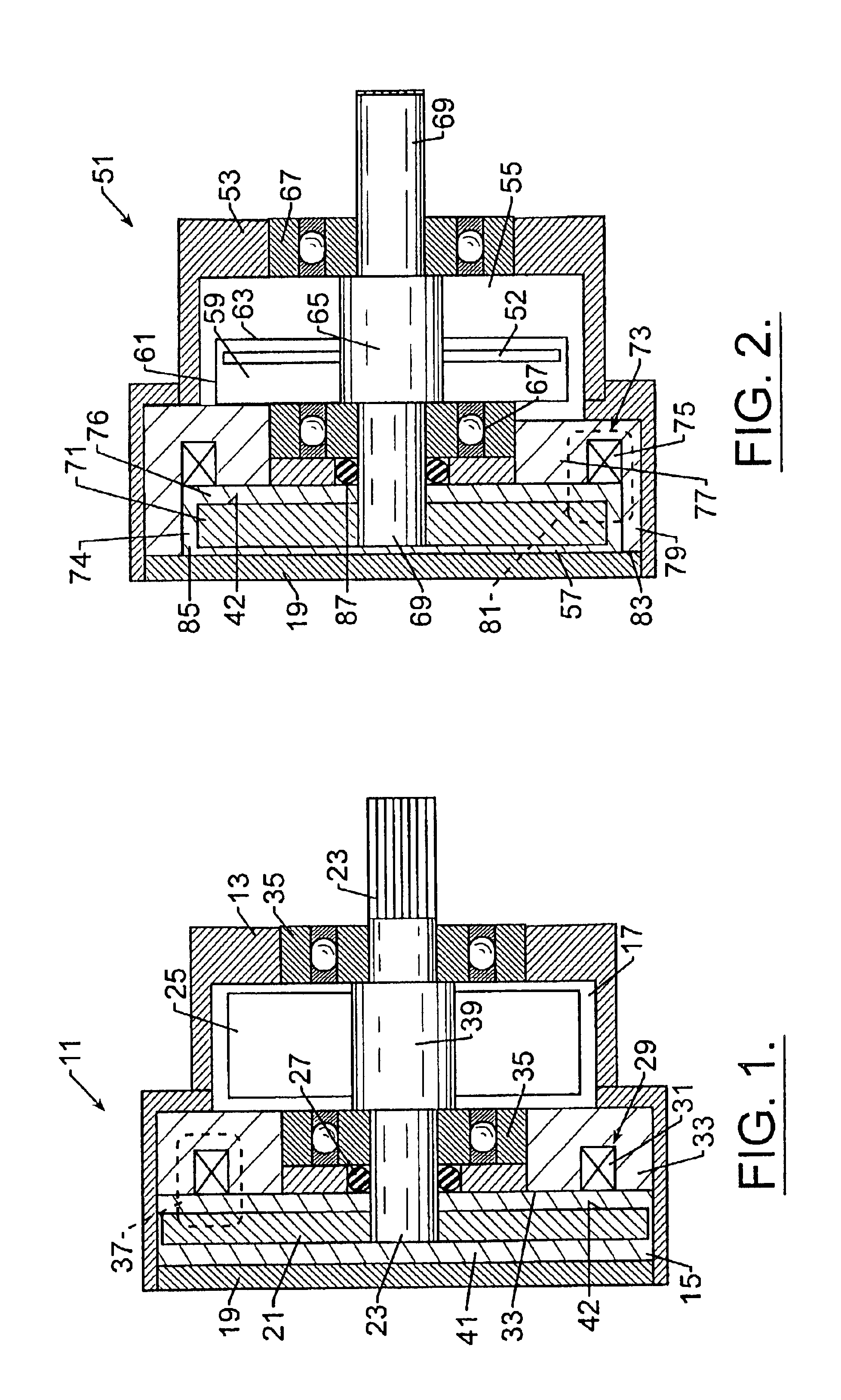

Brake with field responsive material

InactiveUS6854573B2Prevent rotationSome backlashLiquid resistance brakesSpringsEngineeringMechanical engineering

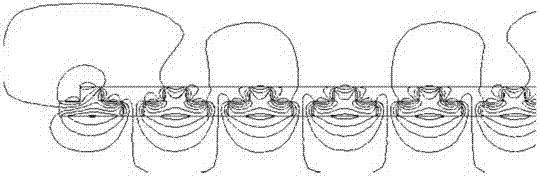

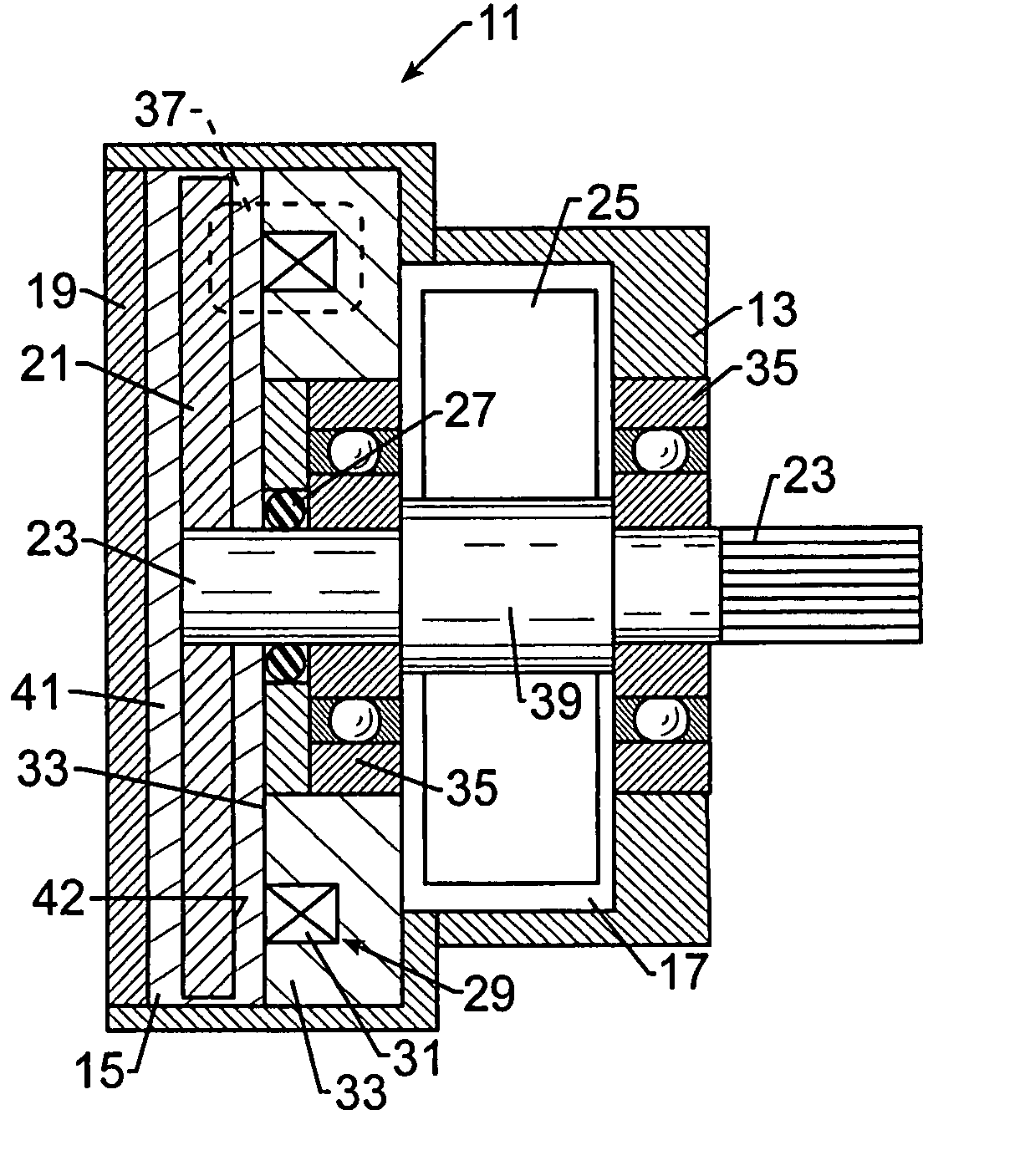

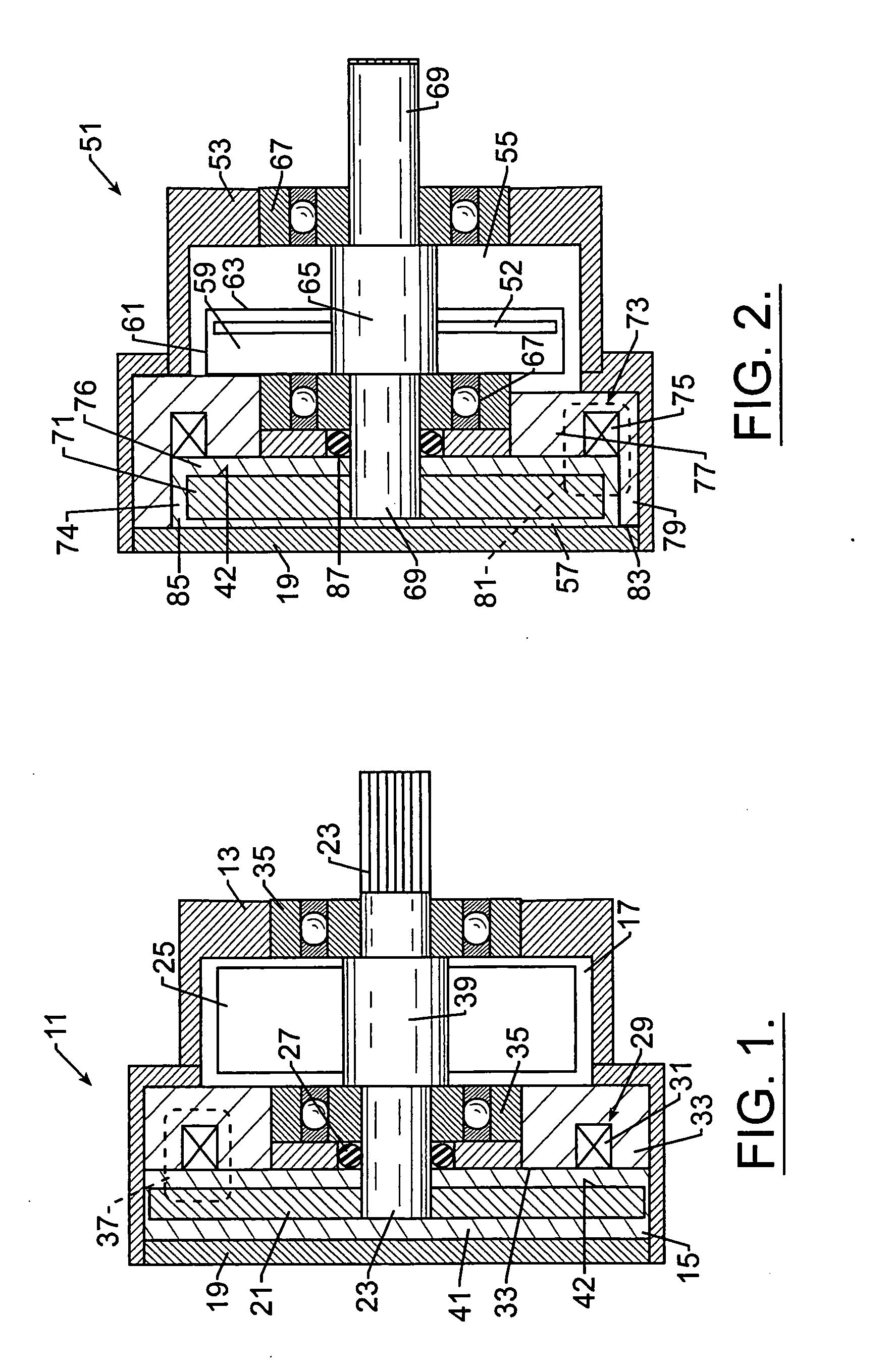

A controllable brake includes a rotor supported on one shaft end. The rotor is housed within a chamber containing a field controllable material which is acted upon by a magnetic field generator to change the rheology of the material and thereby impede movement of the rotor. The shaft is supported by two bearings which, in combination with the housing define a second housing chamber adapted to enclose means for monitoring and / or controlling the brake and in this way, an integrated, compact controllable brake is provided.

Owner:LORD CORP

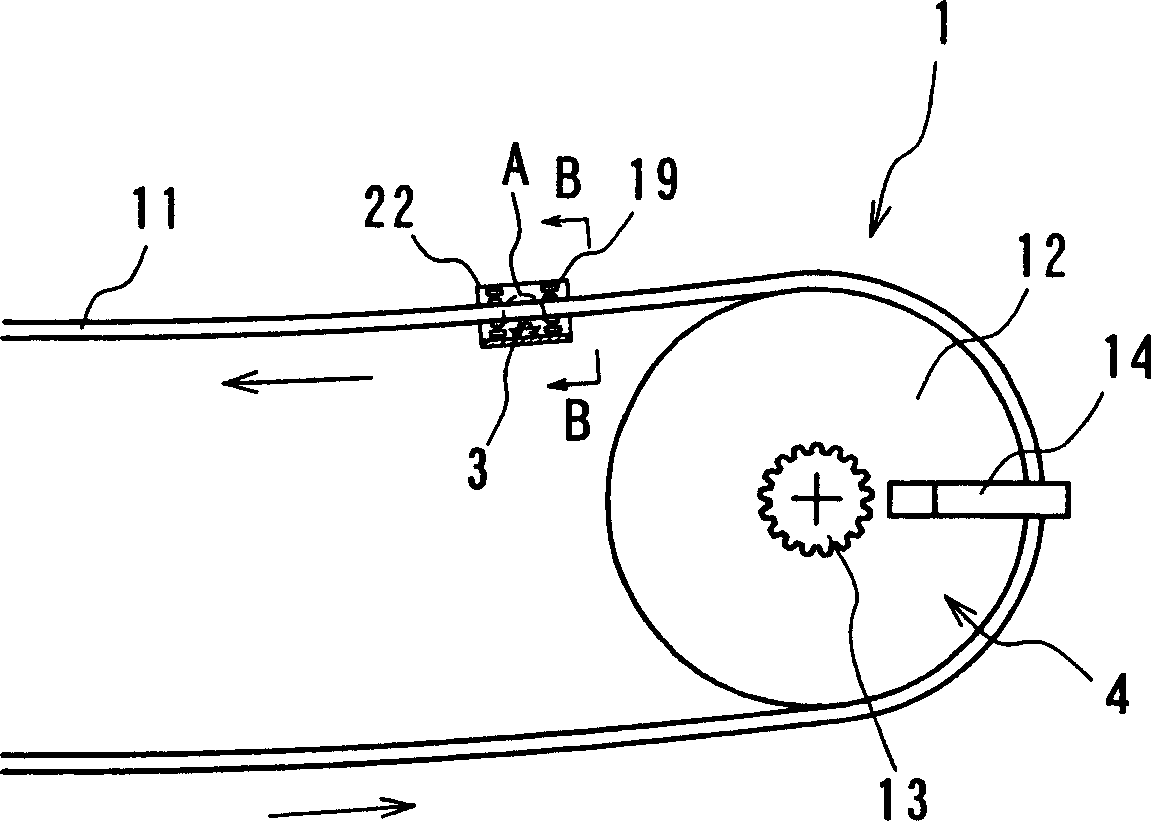

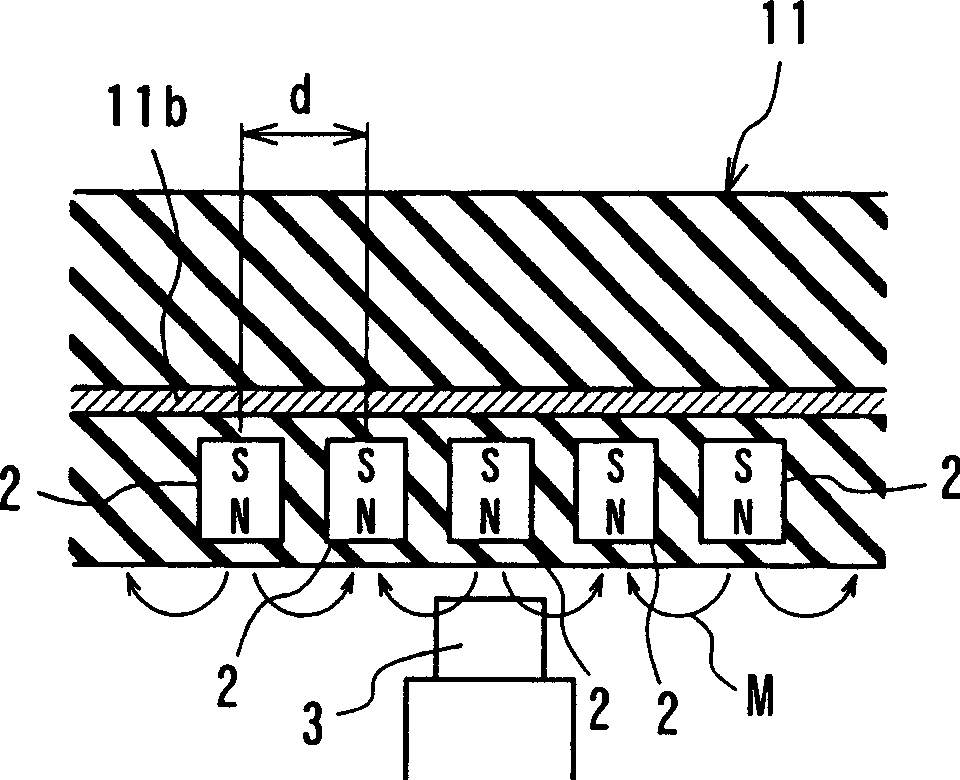

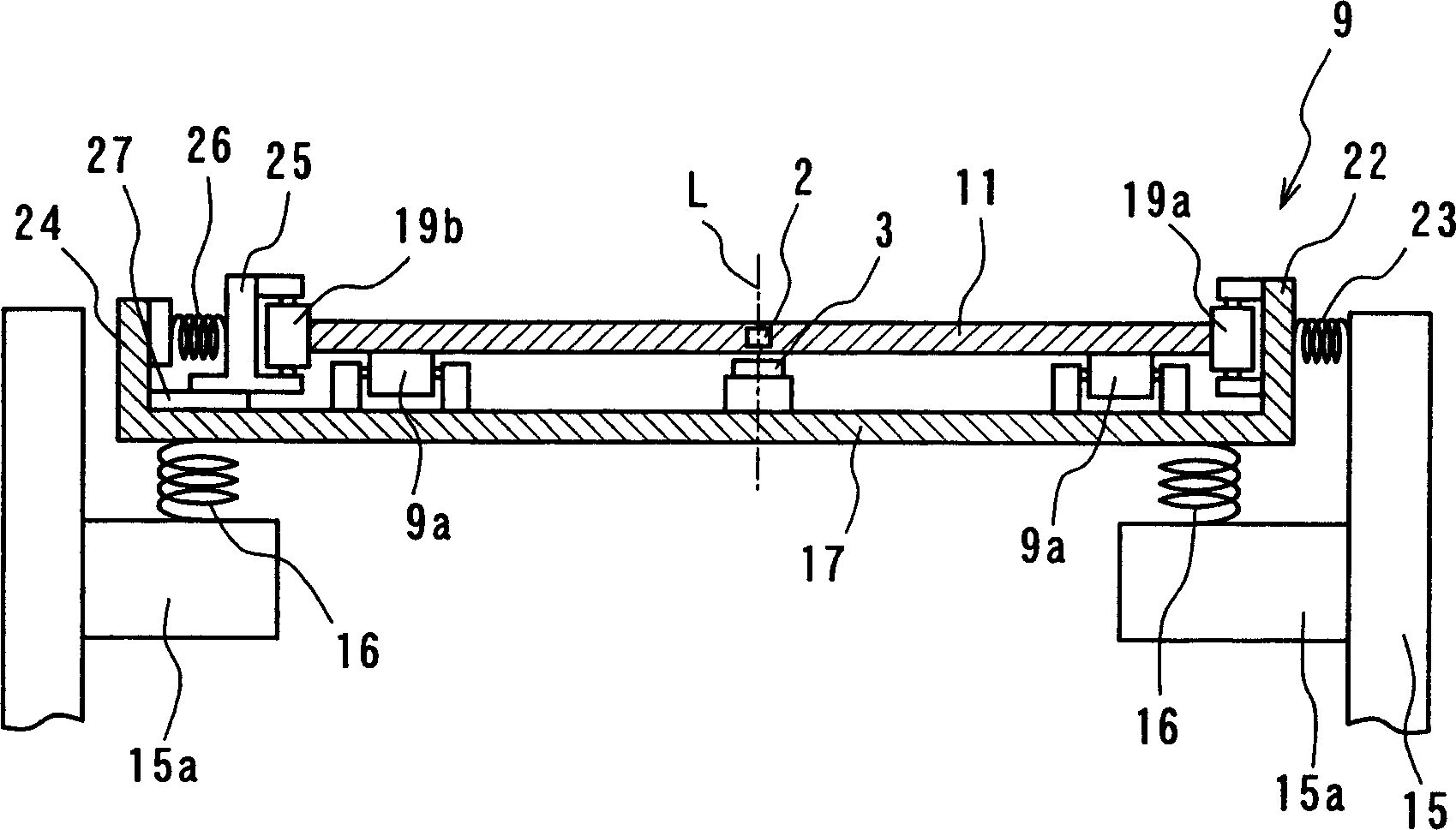

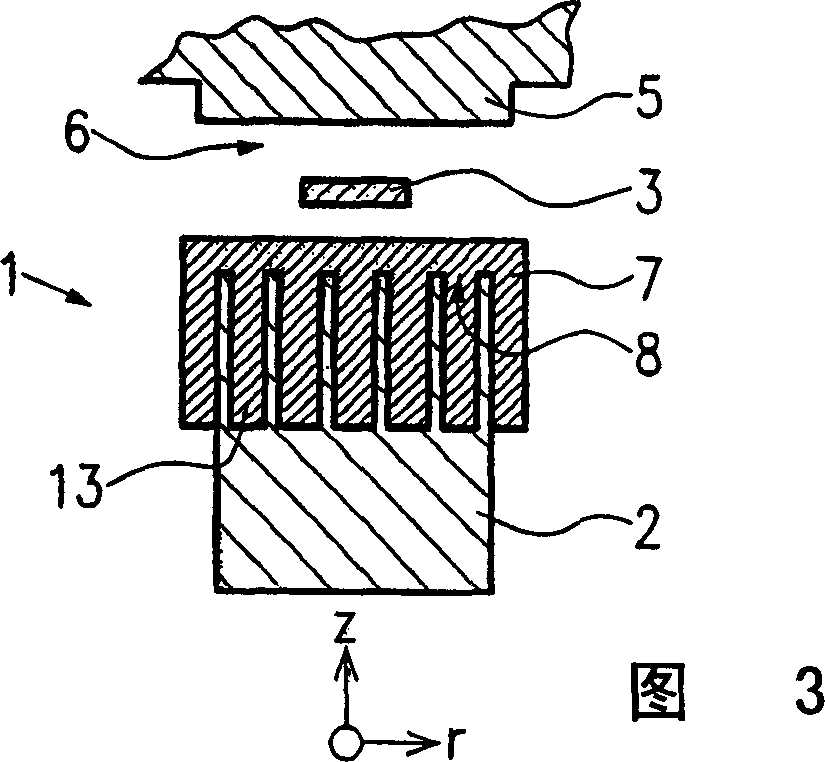

Method and device for measuring conveyor belt elongation, method and device for measuring conveyor belt wear extent, method and device for measuring conveyor belt temperature, rubber magnet sheet, and

InactiveCN1835881AShort lifeAccurate elongationConveyorsThermometers using electric/magnetic elementsConveyor beltInternal temperature

Methods and devices for measuring elongation, wear, and internal temperature of a conveyor belt to catch signs of conveyor belt failure such as breakage by detecting a magnetic field from a magnetic body by using a magnesium sensor, as well as a rubber magnet sheet as a magnetic body and a method of producing the sheet, the rubber magnet sheet being able to be used while it is embedded in the conveyor belt. To measure elongation of a running conveyor belt ( 11 ), a magnetic field of a magnetic body ( 2 ) embedded in the belt ( 11 ) is detected by a magnetism sensor ( 3 ) fixed to the earth, and elongation of the belt ( 11 ) is calculated from temporal variation of the detected magnetic field.

Owner:BRIDGESTONE CORP

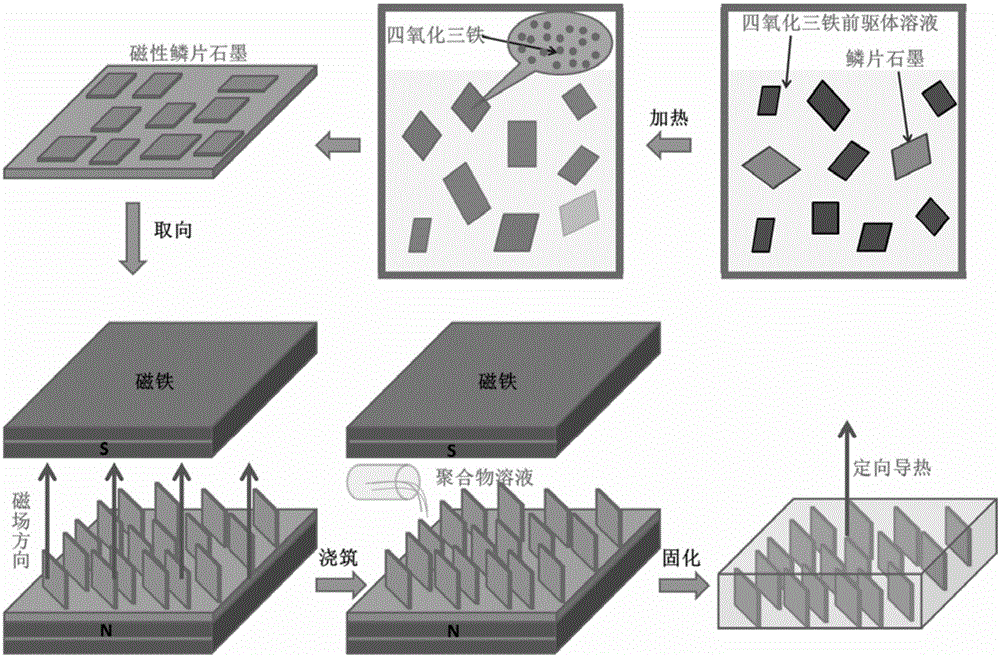

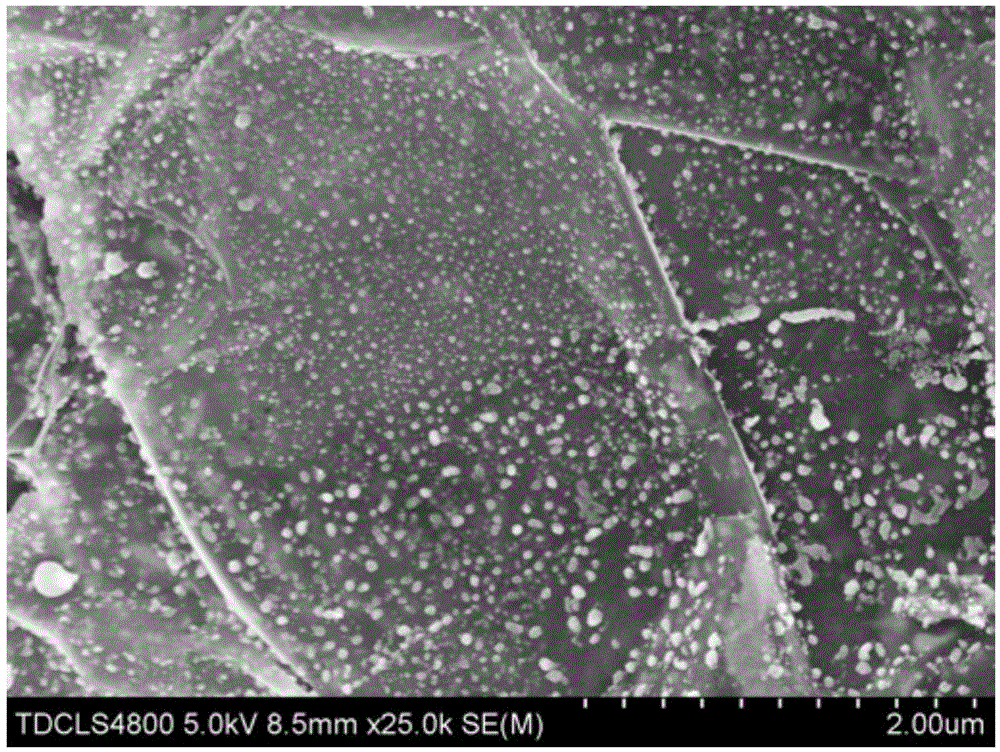

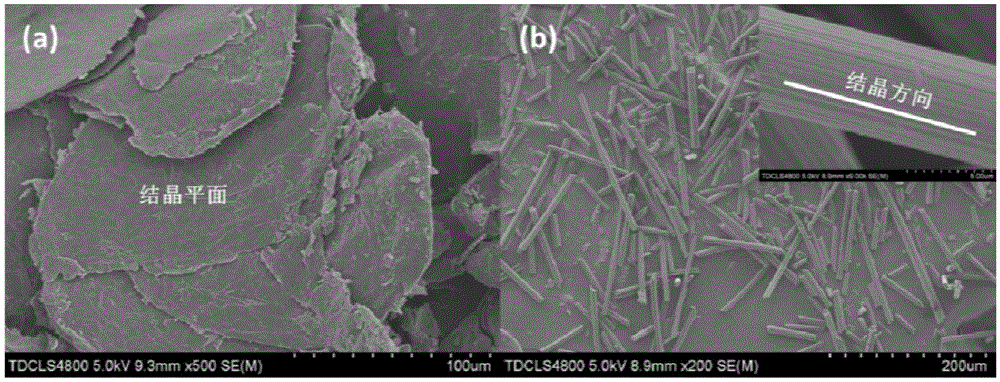

High-directional-thermal-conductivity carbon/polymer composite material and preparation method

The invention relates to a carbon / polymer composite material in a specific direction and a preparation method. A ferroferric oxide precursor solution containing 0.05-5% by mass of iron is prepared; a thermally conductive carbon material is uniformly mixed with the ferroferric oxide precursor solution, and reaction, filtration, washing and drying are performed to obtain a magnetic carbon material with ferroferric oxide uniformly dispersed on the surface of the carbon material; the magnetic carbon material is put in a magnetic field of 0.1-1 T, the direction of the magnetic field is from an N pole to an S pole, different magnetic field directions are obtained by regulating relative positions of the N pole and the S pole, and the magnetic carbon material is arranged in the magnetic field direction; and a polymer precursor solution is poured in a directional carbon material array and cured to obtain the carbon / polymer composite material with the carbon material directionally arranged in polymer. The surface of the carbon material is loaded with ferroferric oxide, and the carbon material is directionally arranged in the magnetic field direction in the magnetic field; and the thermal conductivity coefficient of the composite material in the carbon material direction is greater than or equal to 30 W / (m.K).

Owner:TIANJIN UNIV

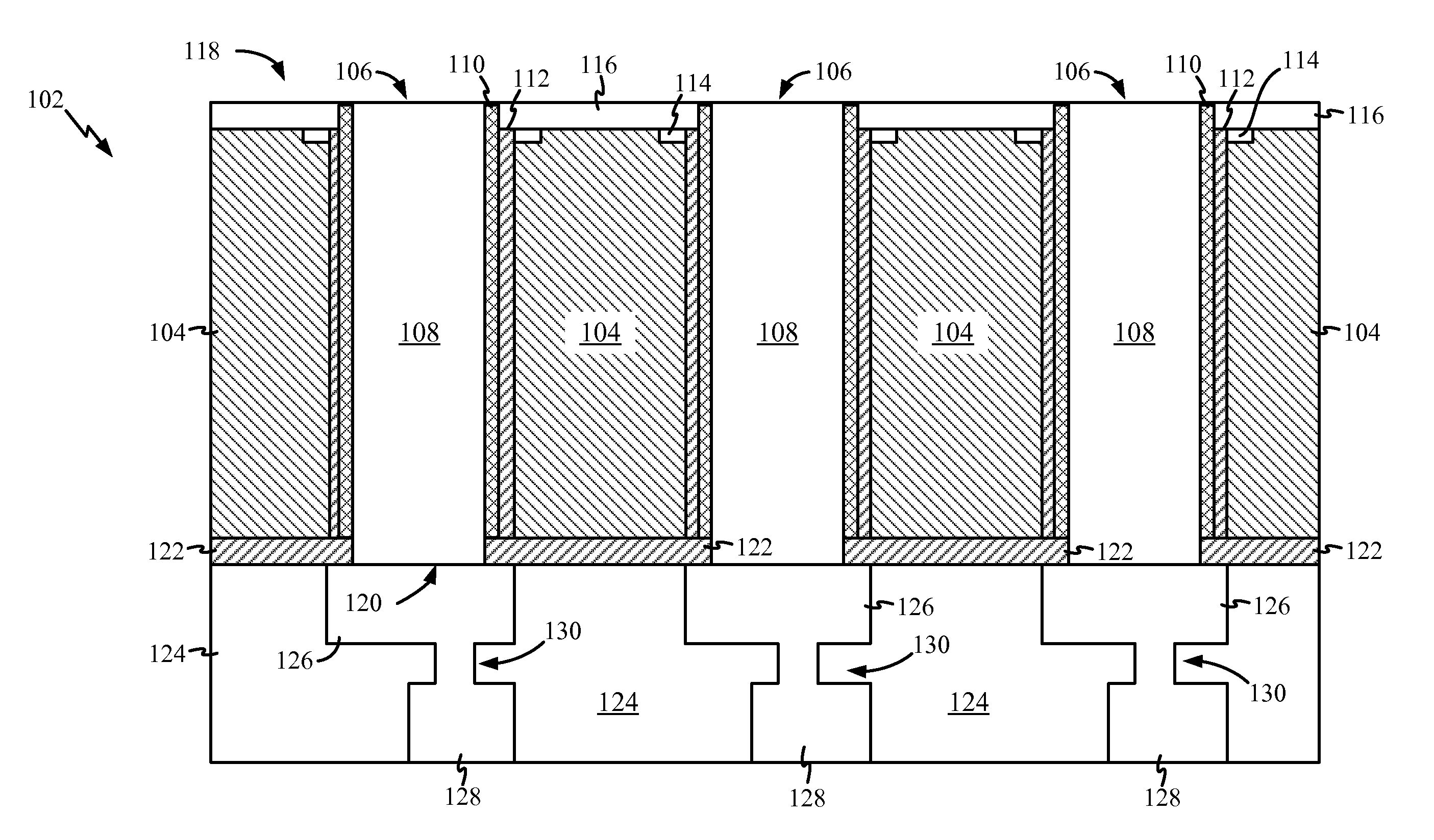

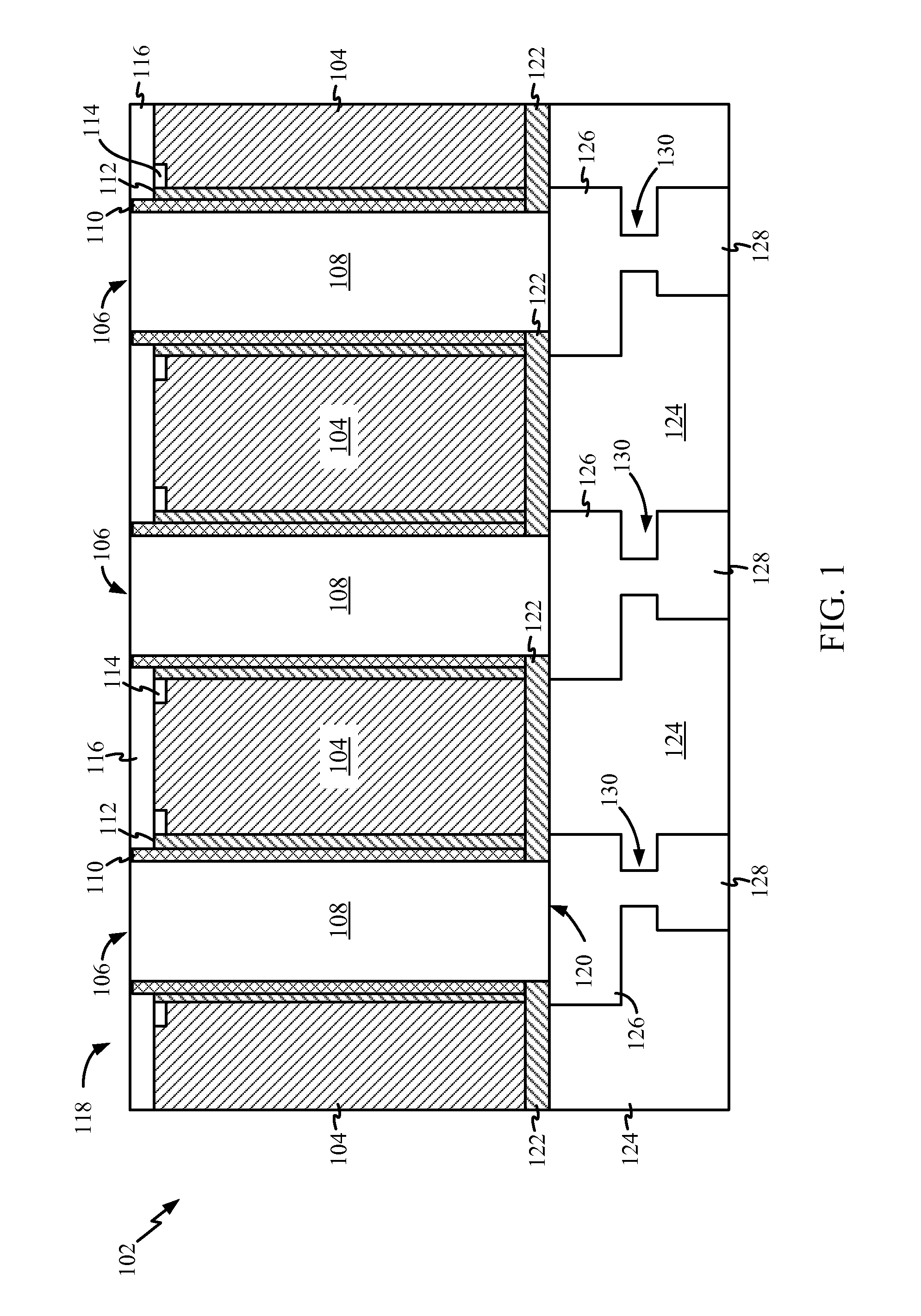

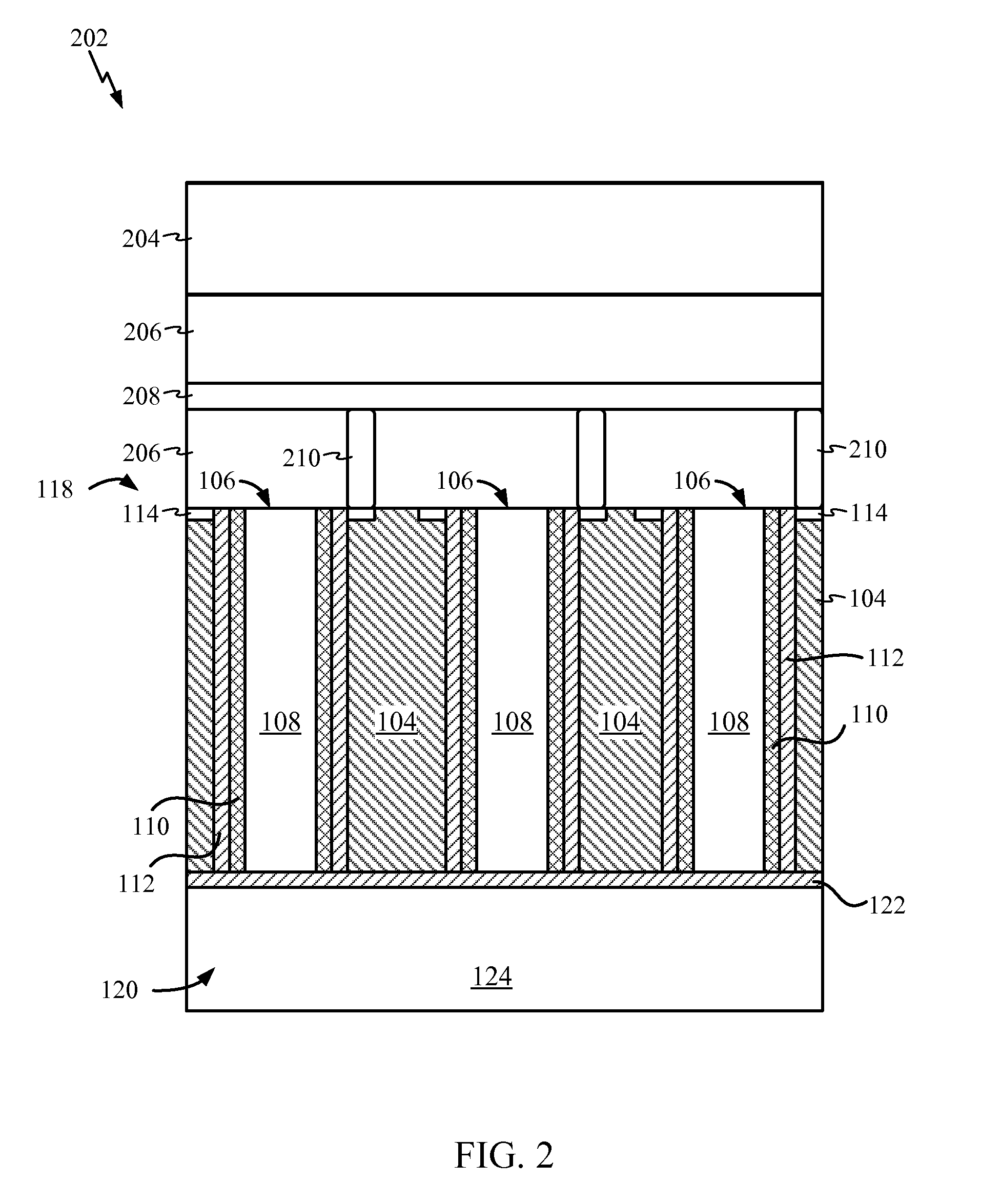

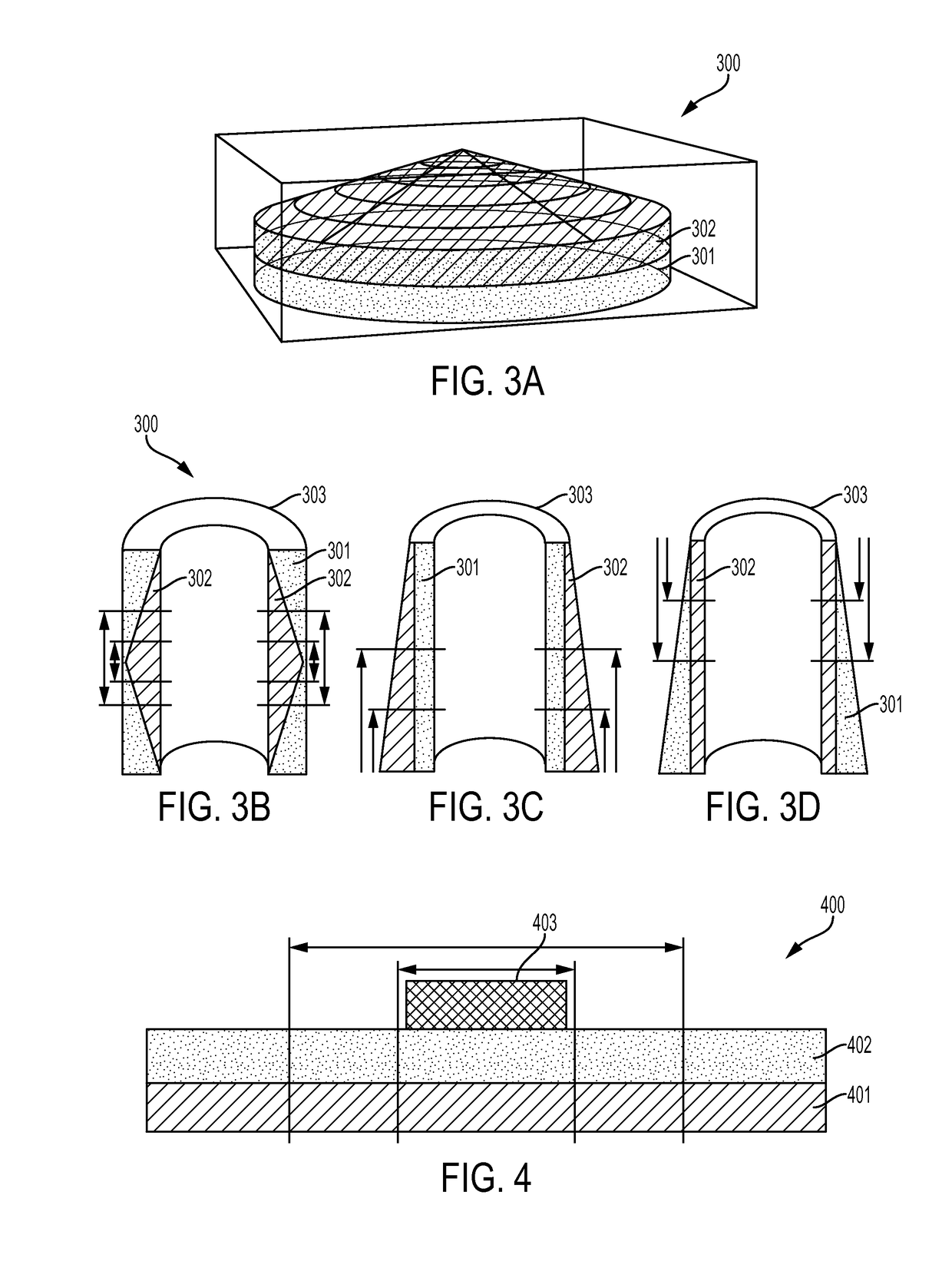

Via Structure Integrated in Electronic Substrate

ActiveUS20110139497A1Reducing electricalReducing magnetic fieldSemiconductor/solid-state device detailsSolid-state devicesComplementary pairOptoelectronics

A system of via structures disposed in a substrate. The system includes a first via structure that comprises an outer conductive layer, an inner insulating layer, and an inner conductive layer disposed in the substrate. The outer conductive layer separates the inner insulating layer and the substrate and the inner insulating layer separates the inner conductive layer and the outer conductive layer. A first signal of a first complementary pair passes through the inner conductive layer and a second signal of the first complementary pair passes through the outer conductive layer. In different embodiments, a method of forming a via structure in an electronic substrate is provided.

Owner:QUALCOMM INC

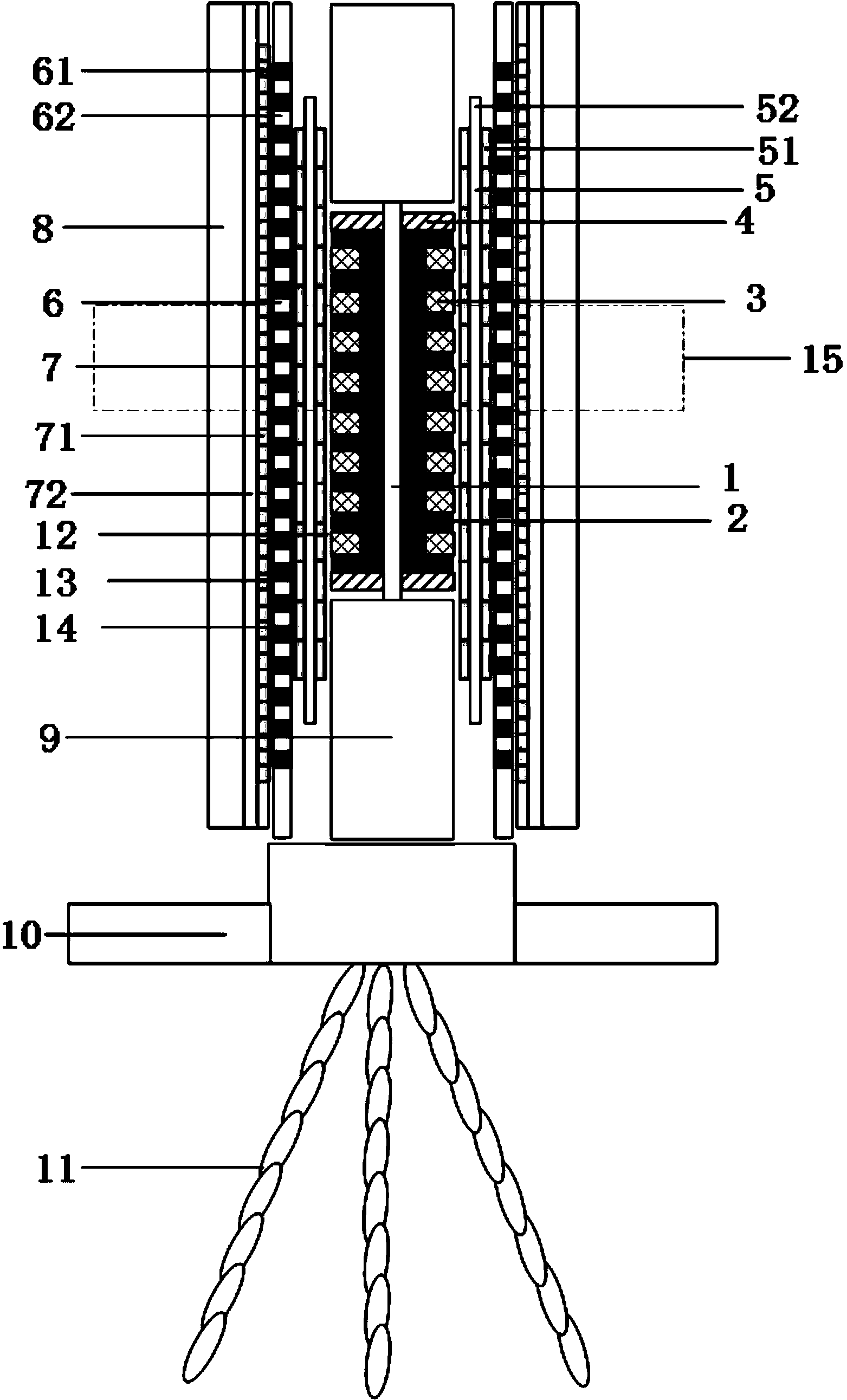

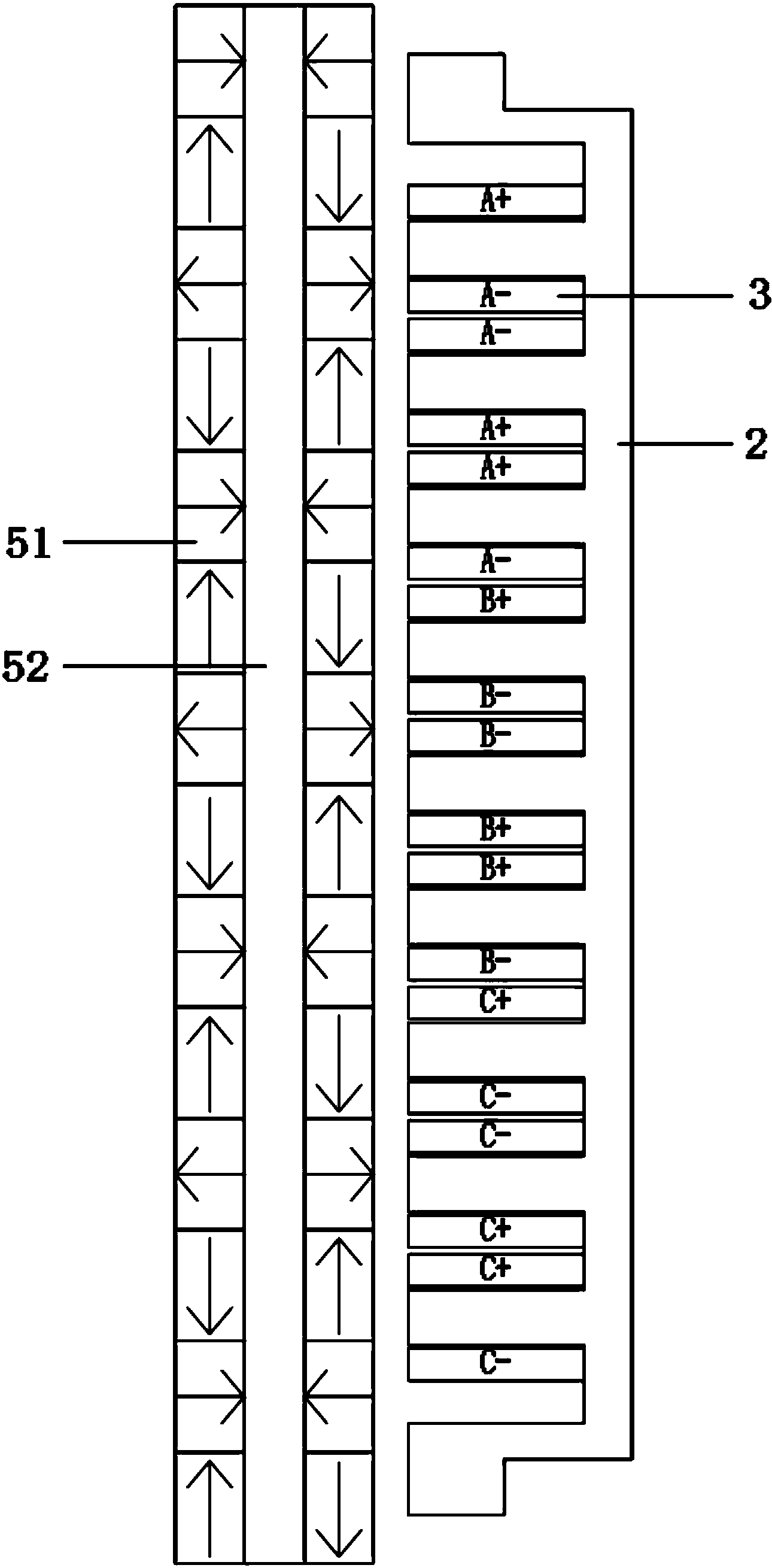

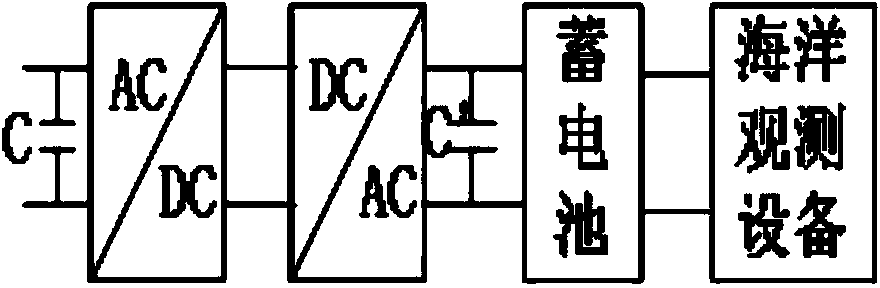

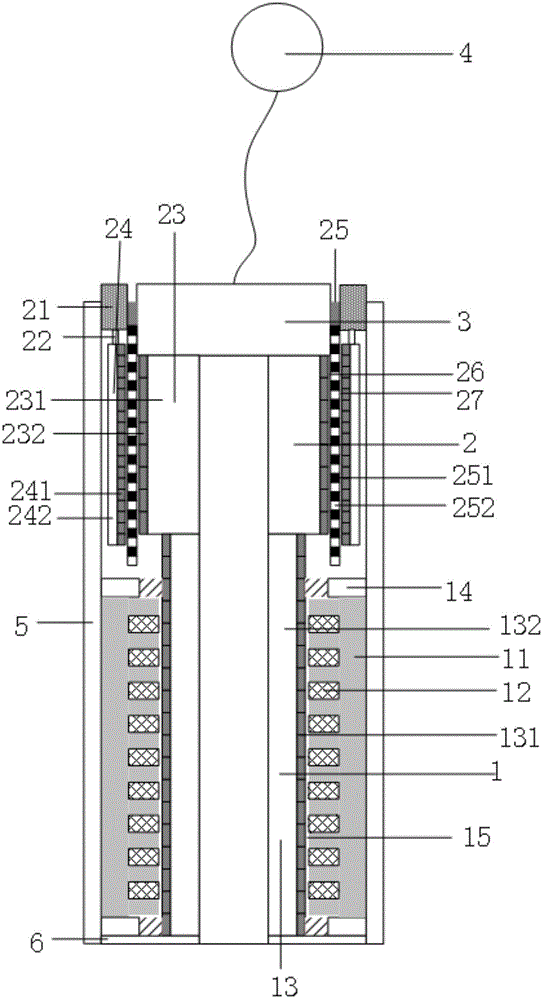

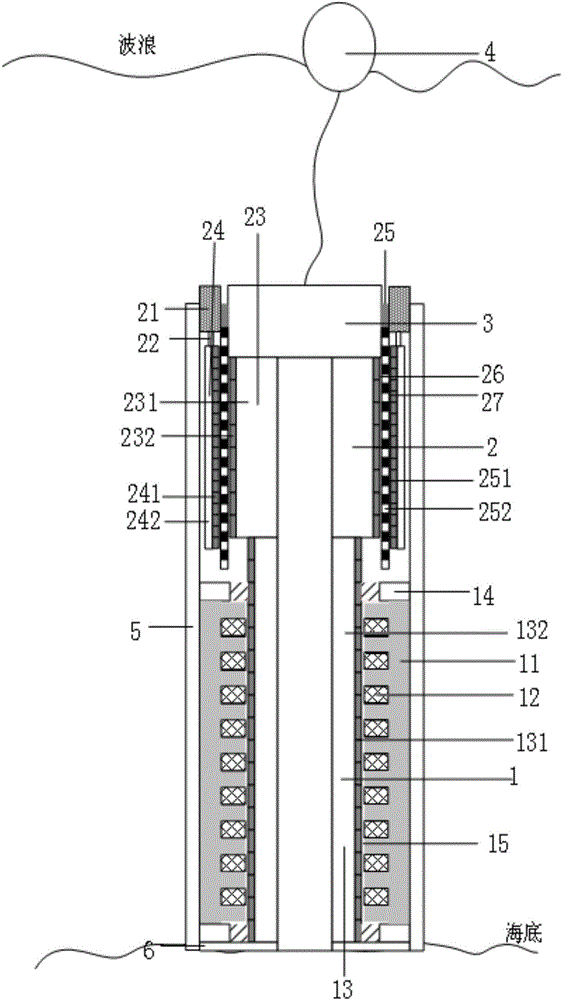

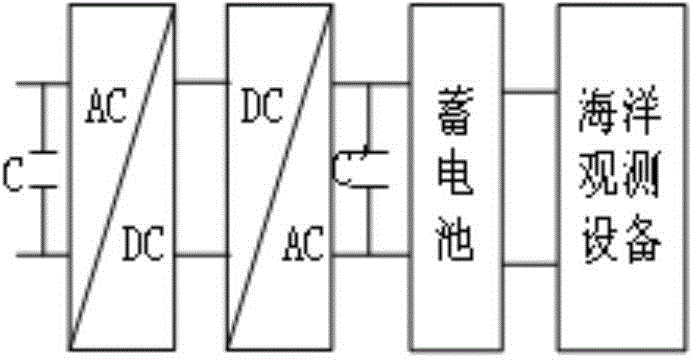

Wave power generation device based on linear magnetic gear motor

InactiveCN103807085AImprove power generation efficiencySimple structureMachines/enginesEngine componentsWave power generationLow speed

The invention discloses a wave power generation device based on a linear magnetic gear motor. The wave power generation device comprises a motor stator core, a motor converter, a magnetism regulating ring, a magnetic gear low-speed moving part, an inner floating barrel and an outer floating barrel. The motor stator core is sleeved with the motor converter, the motor converter is sleeved with the magnetism regulating ring, the magnetism regulating ring is sleeved with the magnetic gear low-speed moving part, the magnetic gear low-speed moving part is sleeved with the inner floating barrel, and the inner floating barrel is sleeved with the outer floating barrel. A first air gap is formed between the motor stator core and the motor converter, a second air gap is formed between the motor converter and the magnetism regulating ring, and a third air gap is formed between the magnetism regulating ring and the magnetic gear low-speed moving part. A motor stator shaft and the magnetism regulating ring are fixed in position, and the magnetic gear low-speed moving part and the inner floating barrel are fixed in position. The wave power generation device has the advantages that no huge speeders need to be additionally arranged, the size is small, energy capture and power generation efficiency is high, and convenience is brought to design, debugging and maintenance of an electrical control system through the whole floating suspended structure.

Owner:SOUTHEAST UNIV

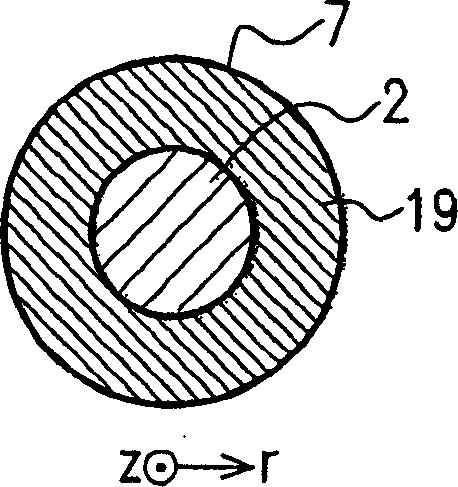

Synchronous induction motor

InactiveCN1447491AAvoid damageAvoid magnetizationMagnetic circuit rotating partsMagnetic/electric field screeningElectrical conductorInduction motor

A synchronous induction motor 2 comprises a stator 4 which has a stator winding 7, and the rotor 5 which is fixed to the rotary shaft 6, and rotates inside the stator 4. A secondary conductor disposed in the peripheral part of a rotor yoke part which constitutes the rotor 5, and permanent magnets, embedded in the rotor yoke part, are provided. The permanent magnets are disposed on both sides interposing the rotary shaft 6. The permanent magnets which pull in magnetic field constituted by the permanent magnets are disposed on both sides of a line which passes through the permanent magnets and the rotary shaft 6. Providing a synchronous induction motor, which largely prevents magnetization of a rotary shaft to which a rotor of the synchronous induction moor comprising two poles is fixed.

Owner:SANYO ELECTRIC CO LTD

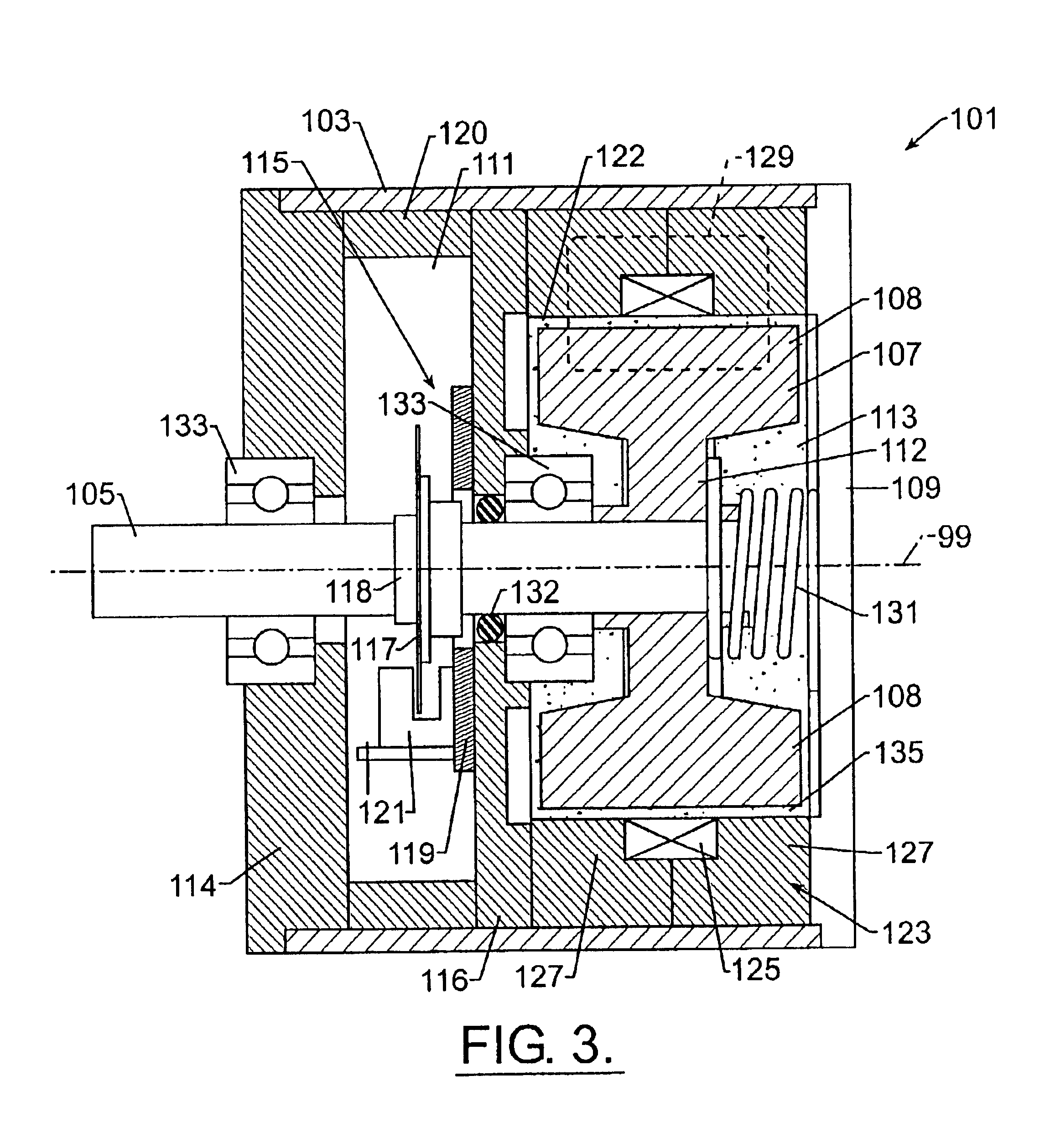

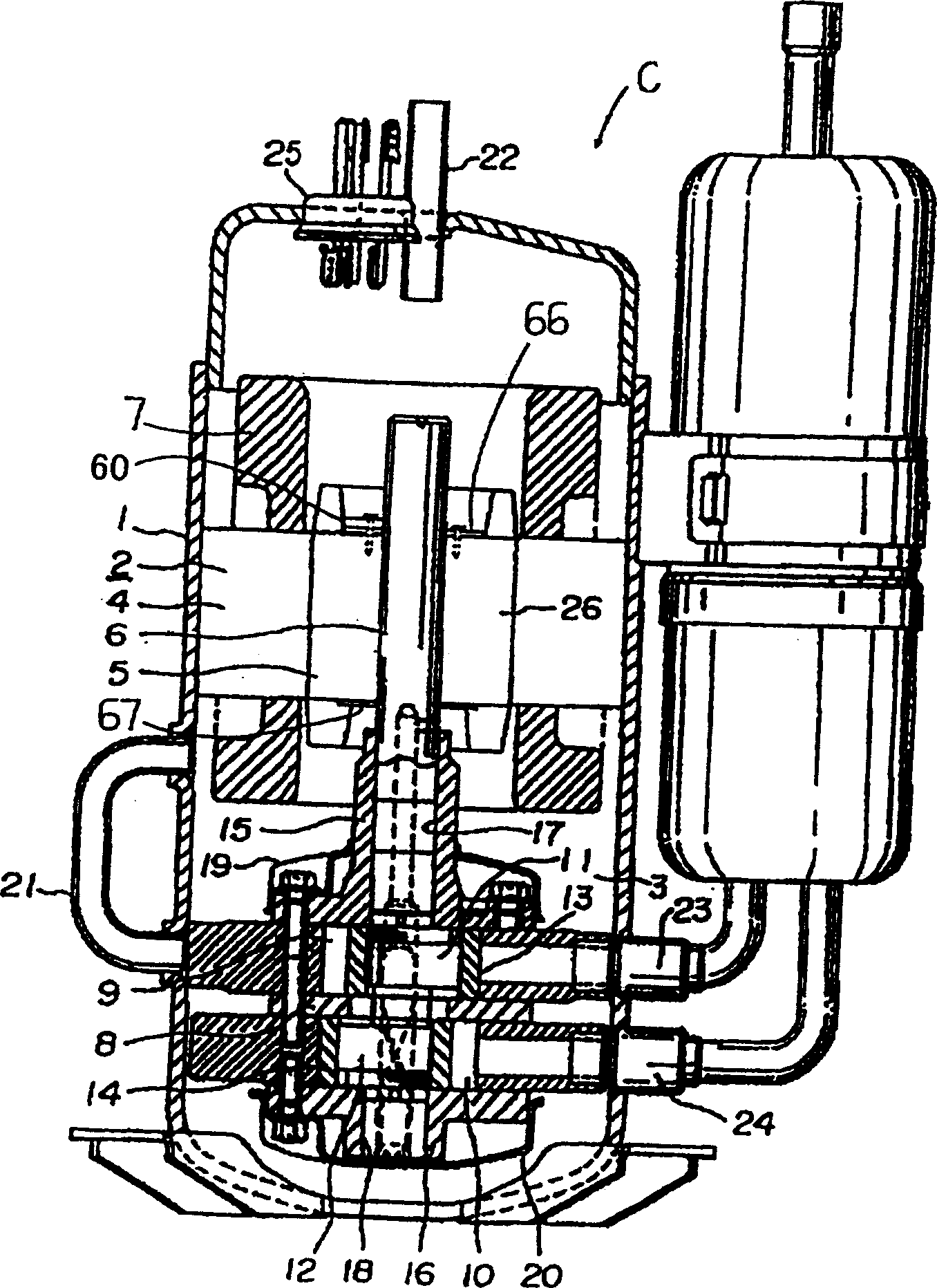

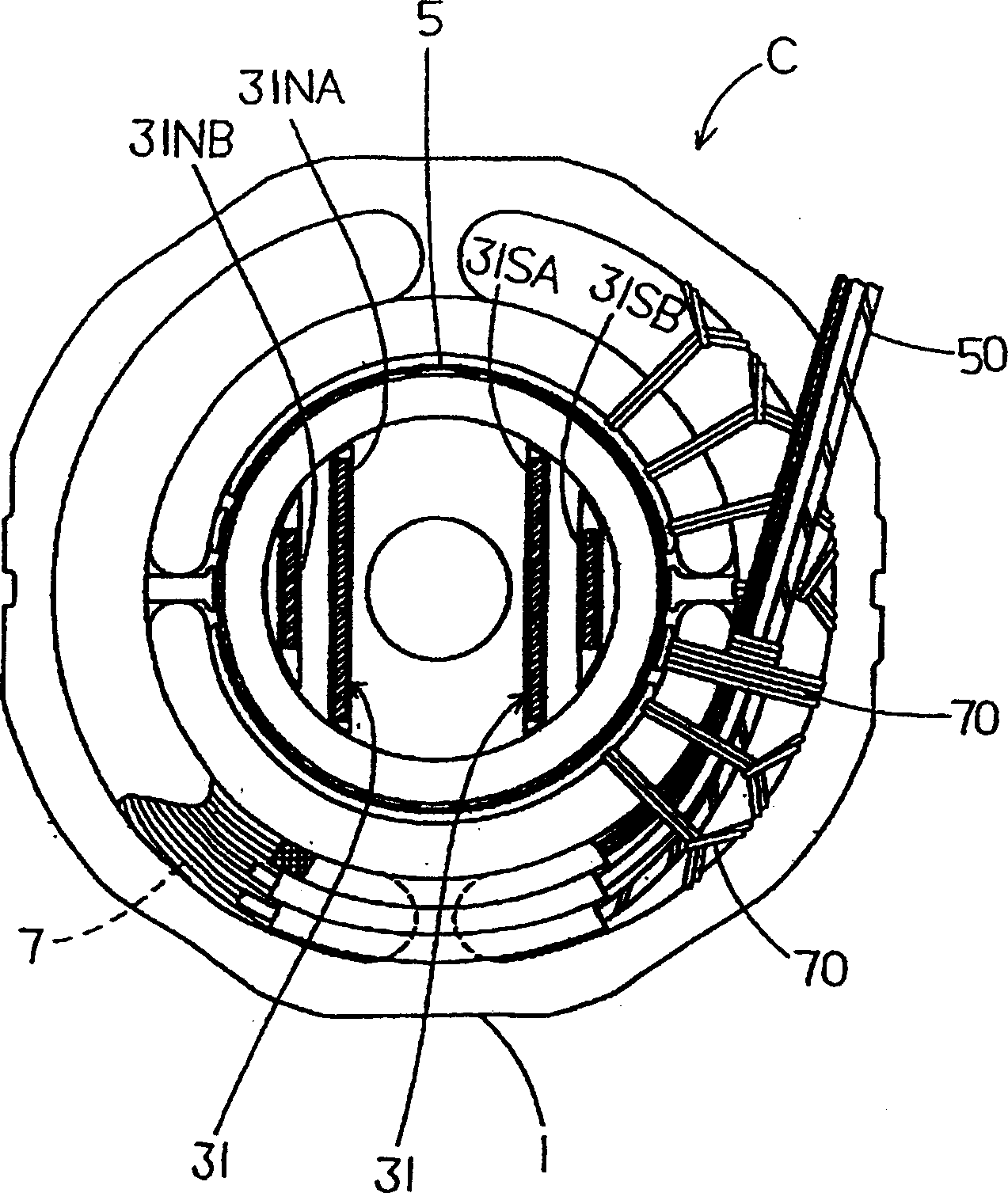

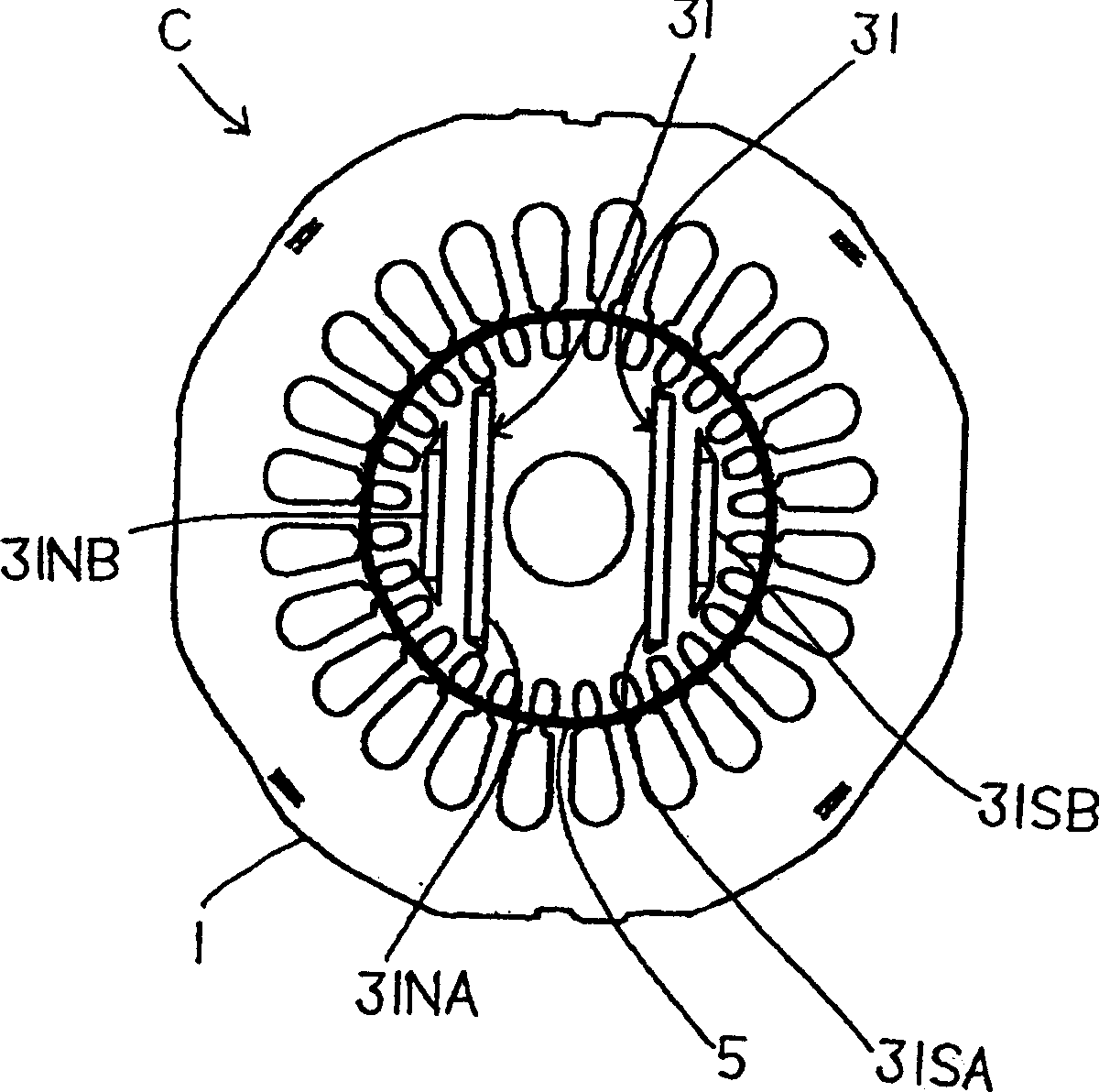

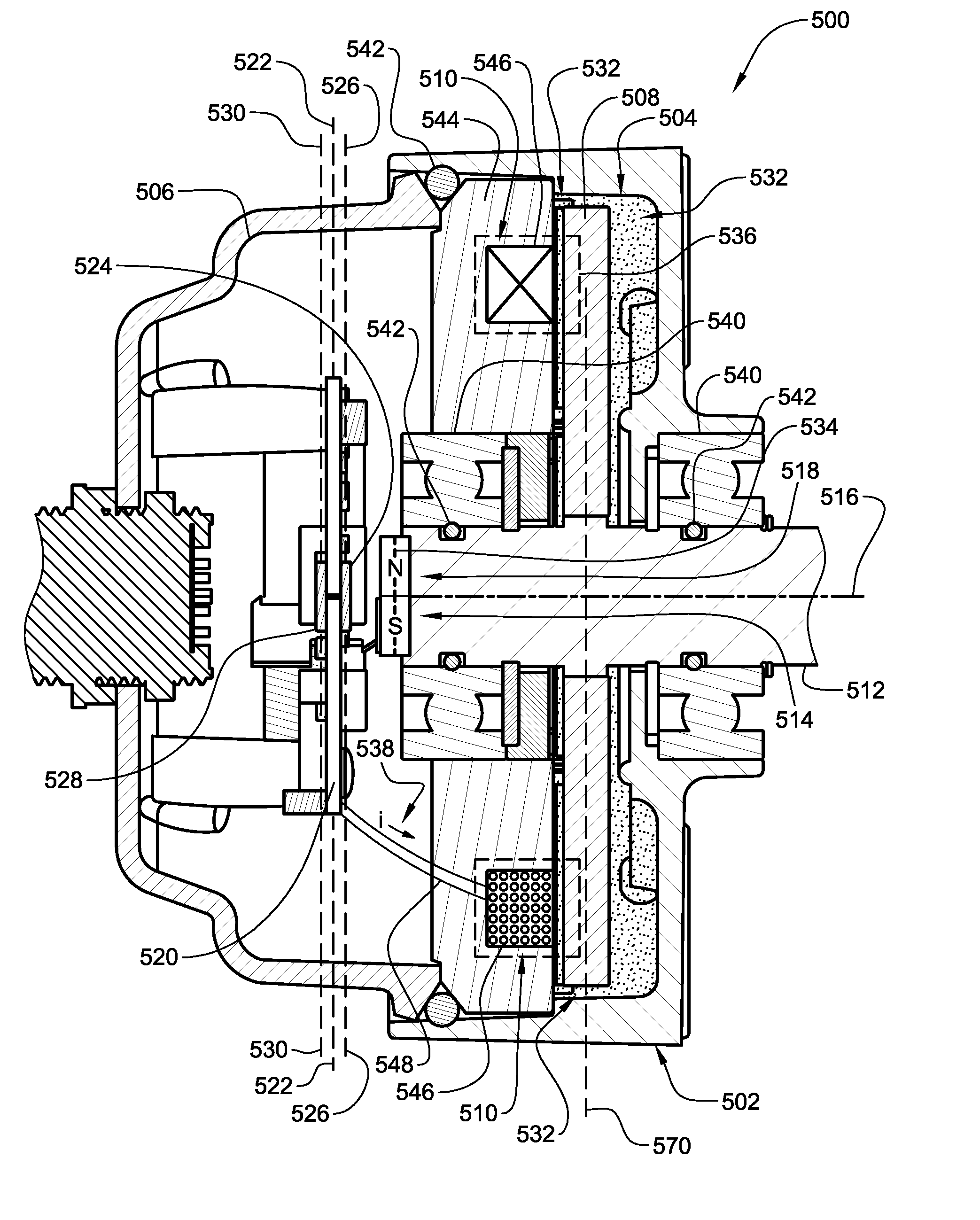

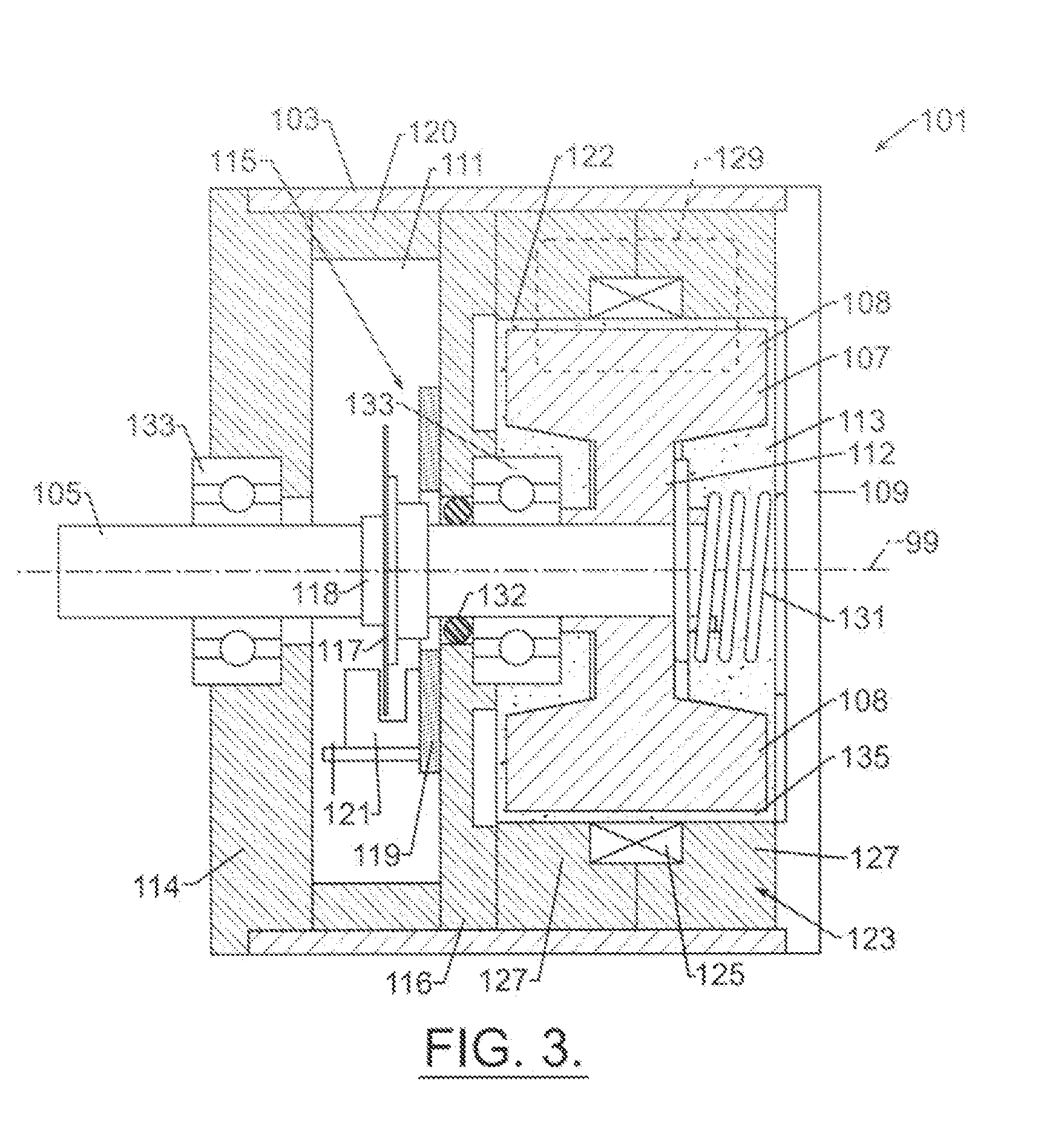

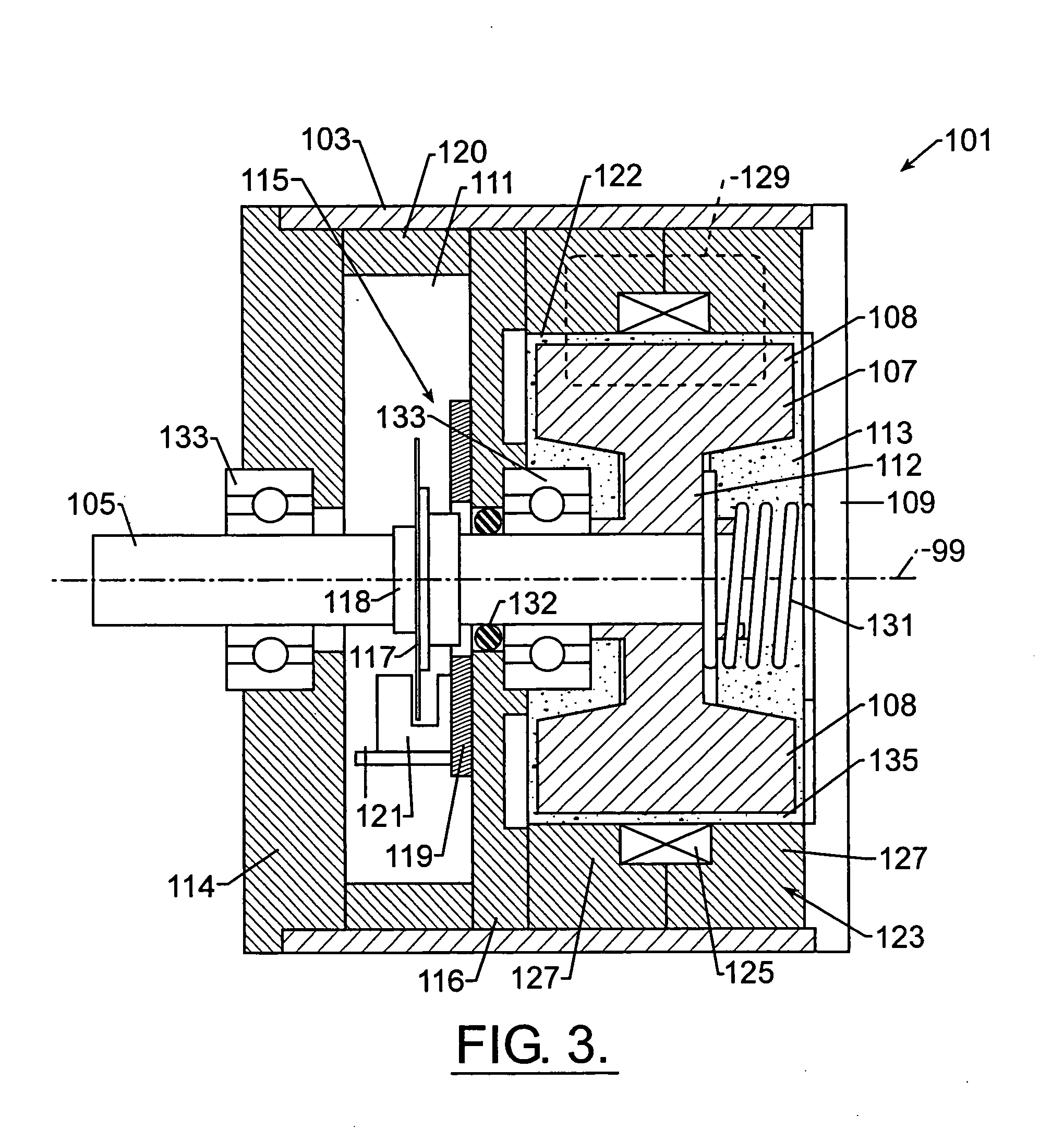

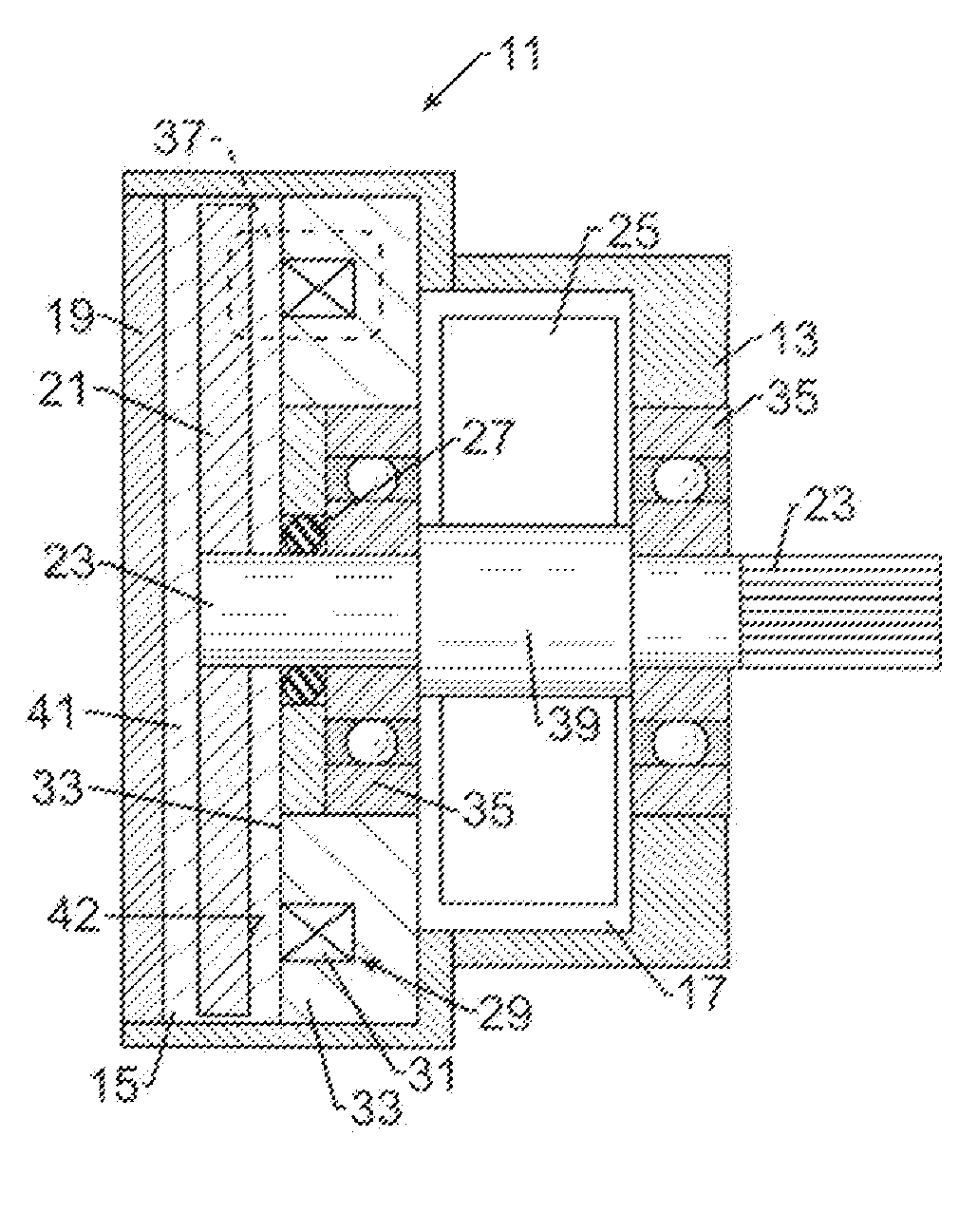

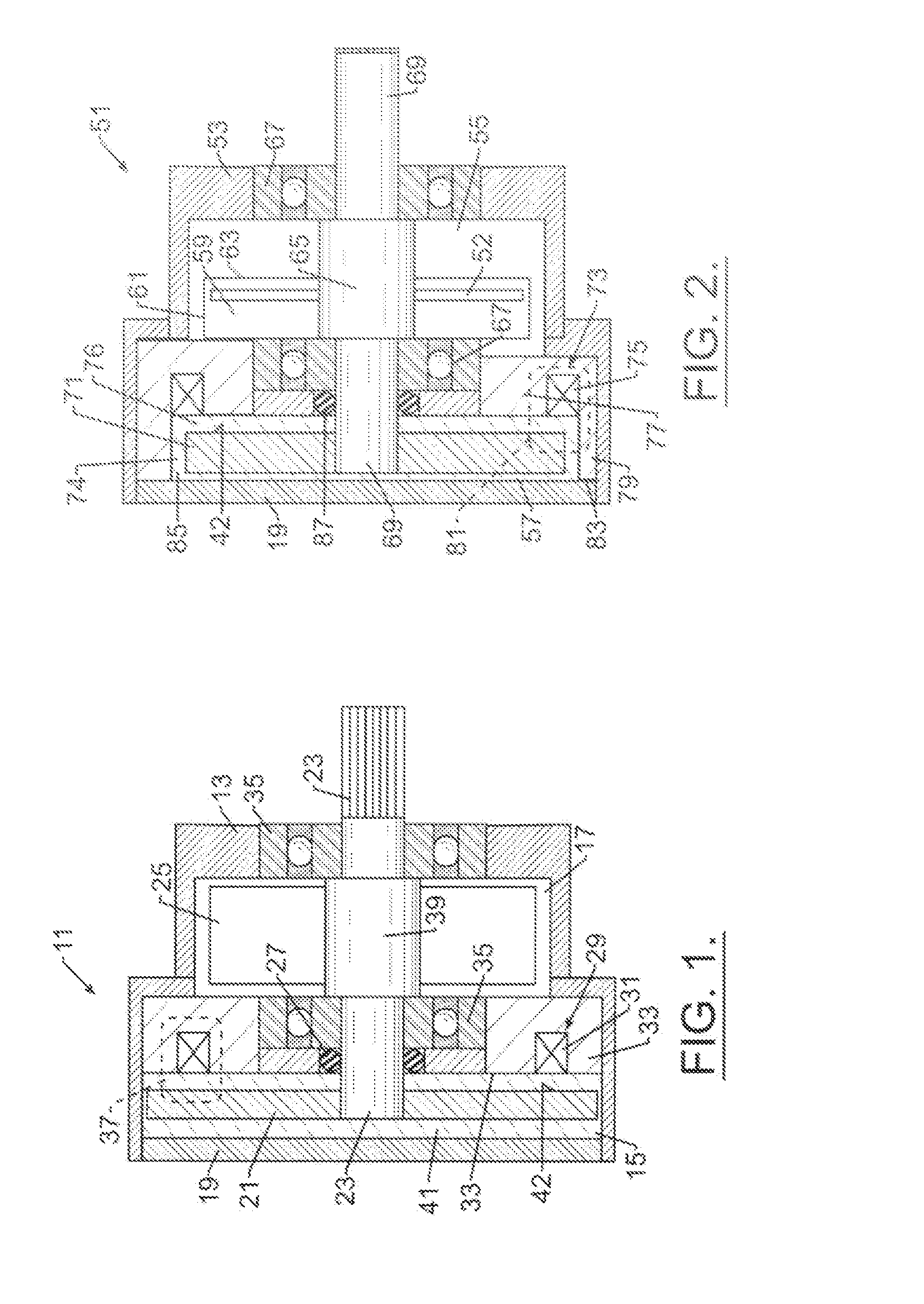

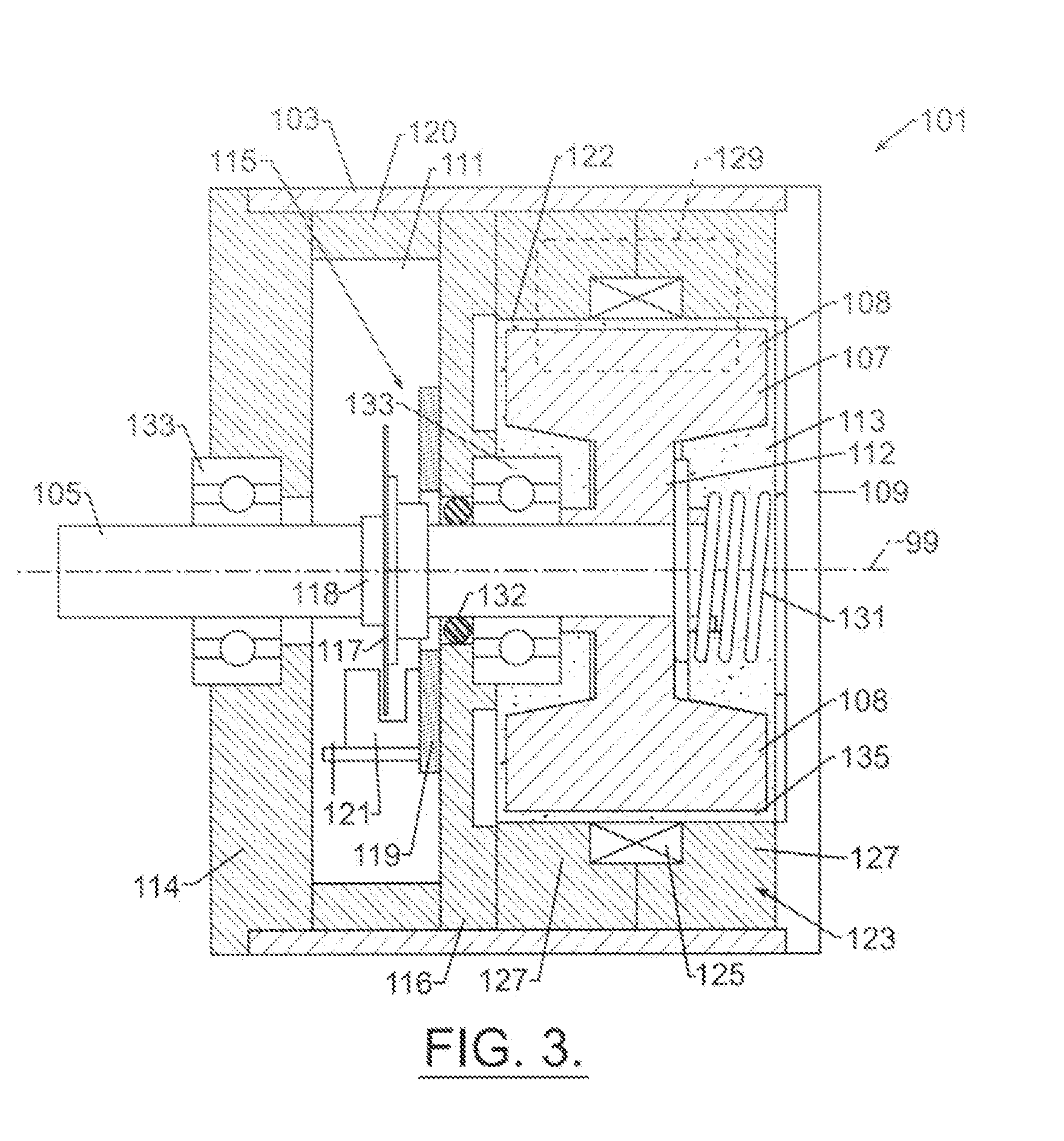

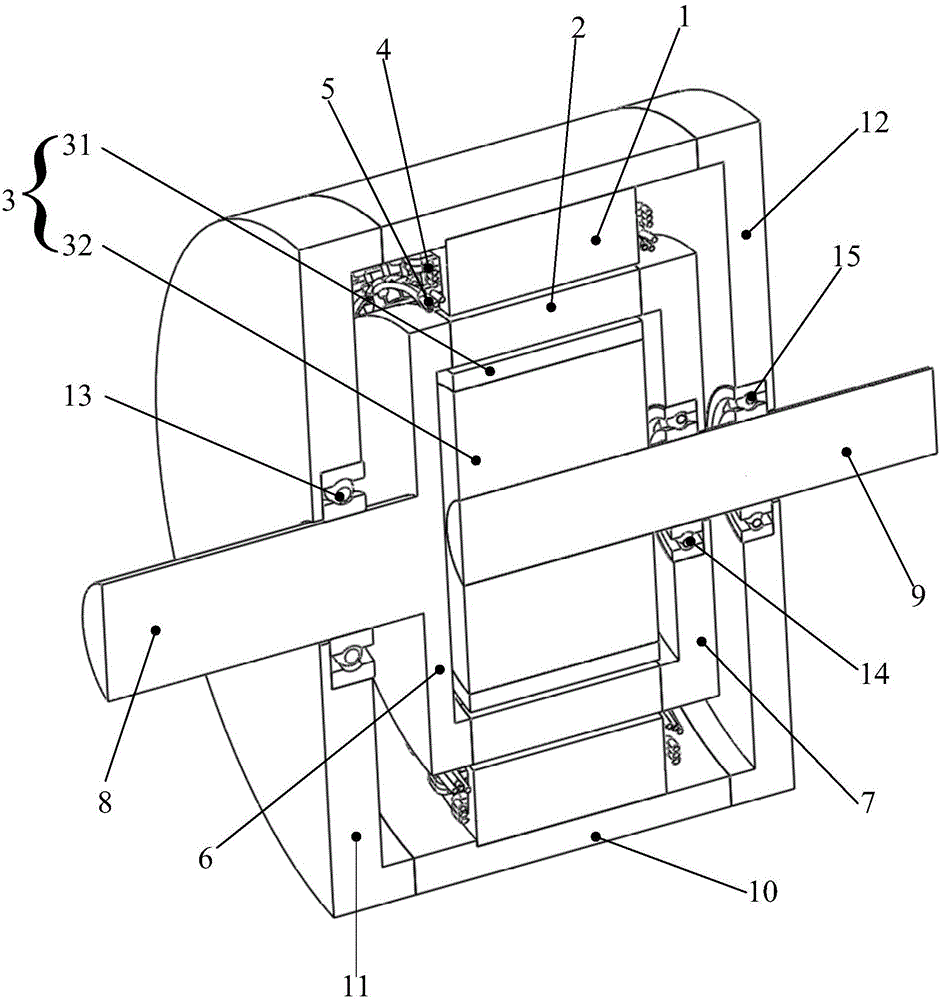

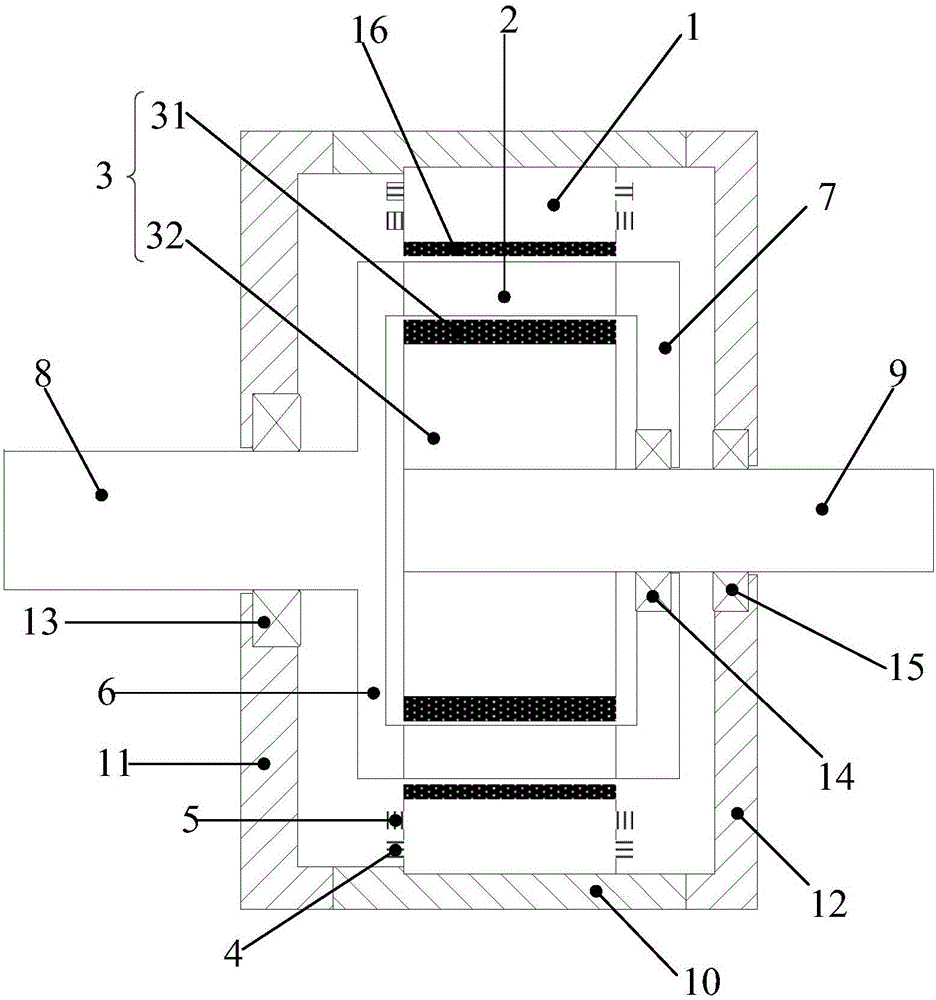

Brake with field responsive material

ActiveUS8397883B2Some backlashReduce magnetic fieldLiquid resistance brakesSpringsEngineeringMagnetic field

A controllable brake includes a housing and a rotor supported on a shaft. The rotor is housed within a chamber containing a field controllable material which is acted upon by a magnetic field generator to impede movement of the rotor. The shaft is supported by bearings. The controllable brake housing defines a second housing chamber adapted to enclose means for monitoring and / or controlling the brake and in this way, an integrated, compact controllable brake is provided.

Owner:LORD CORP

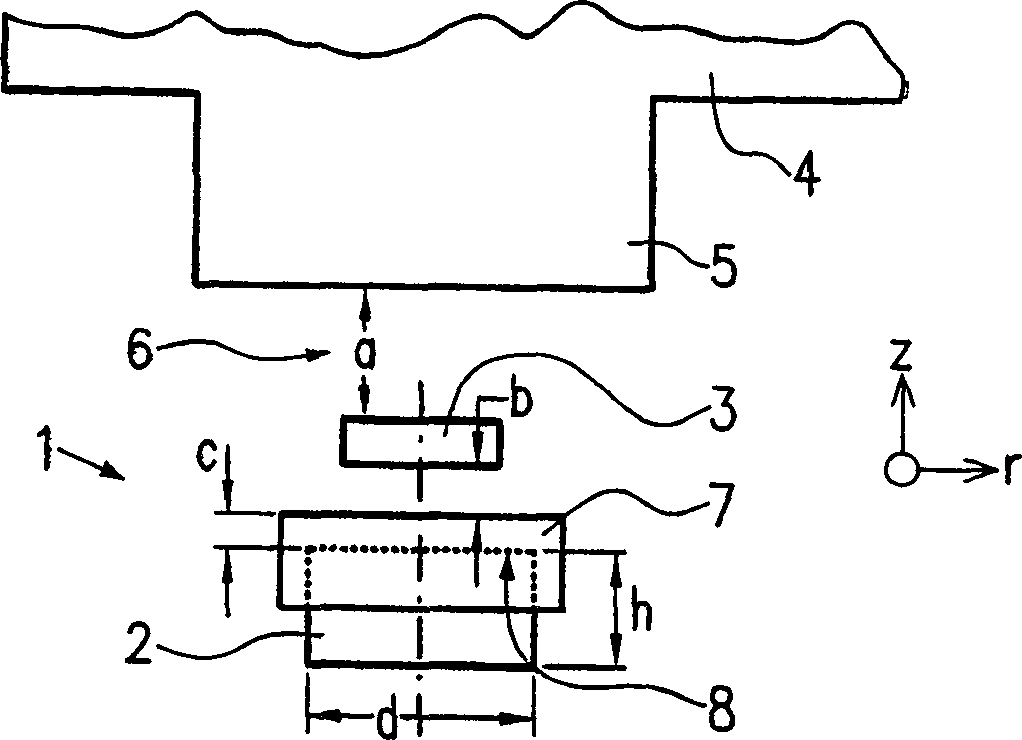

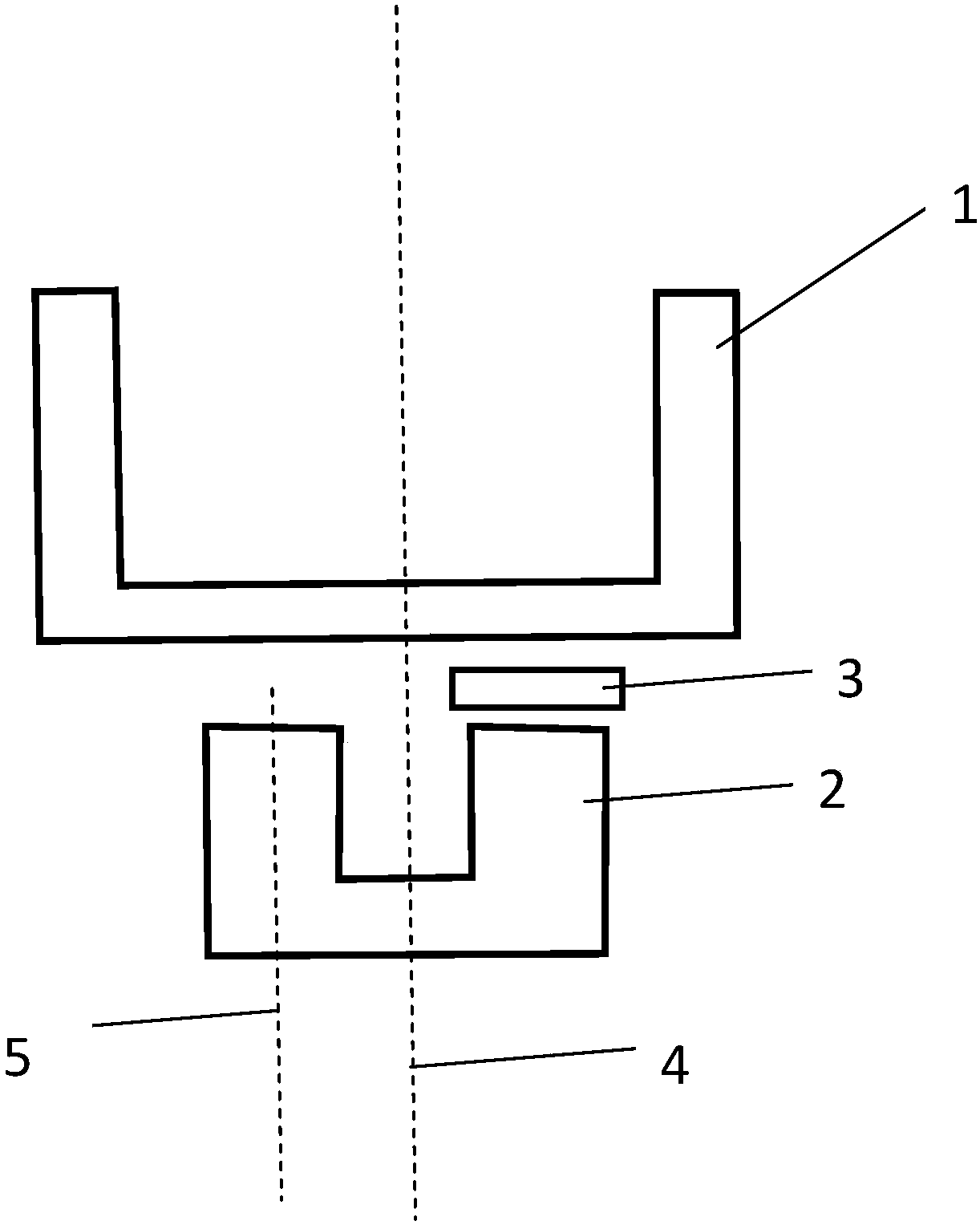

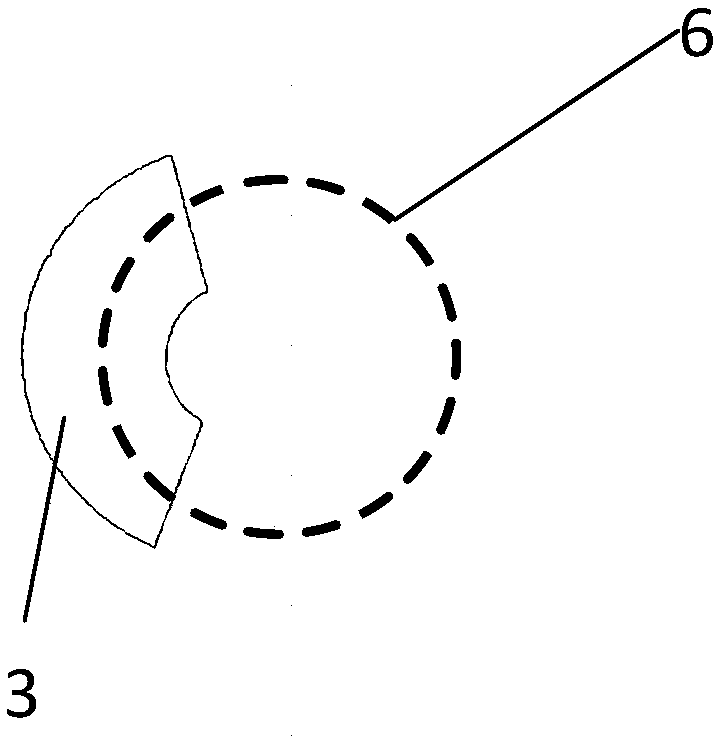

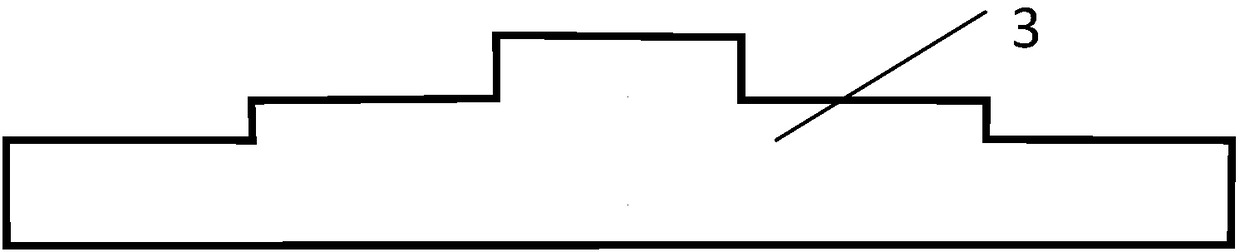

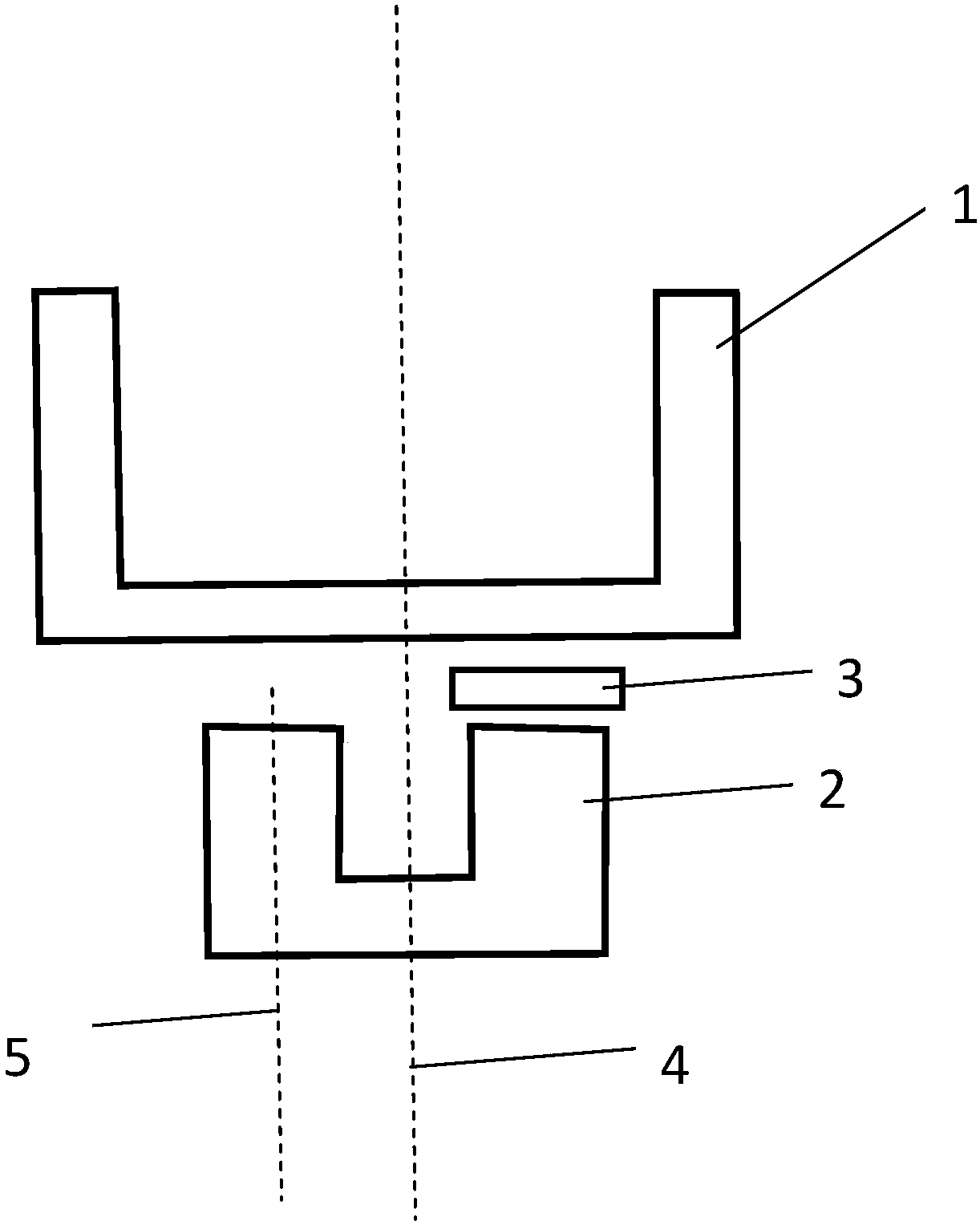

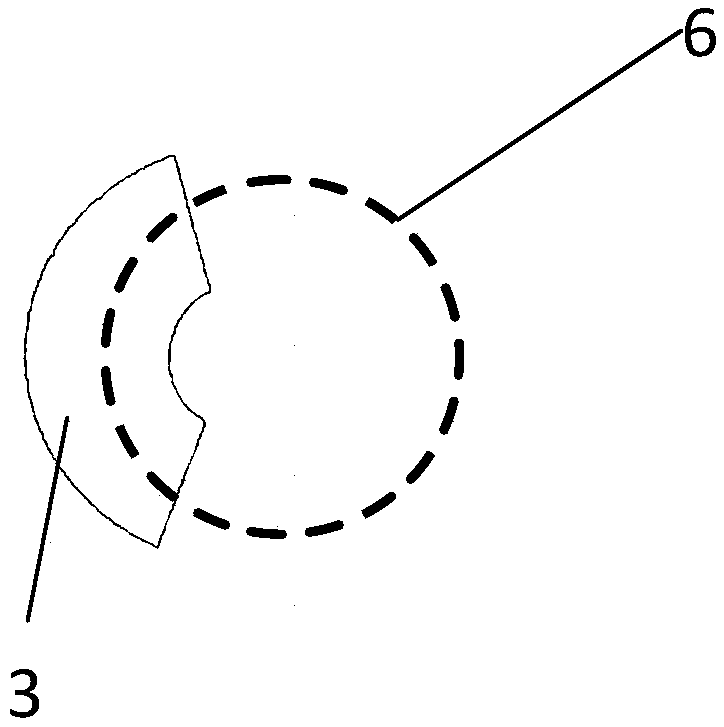

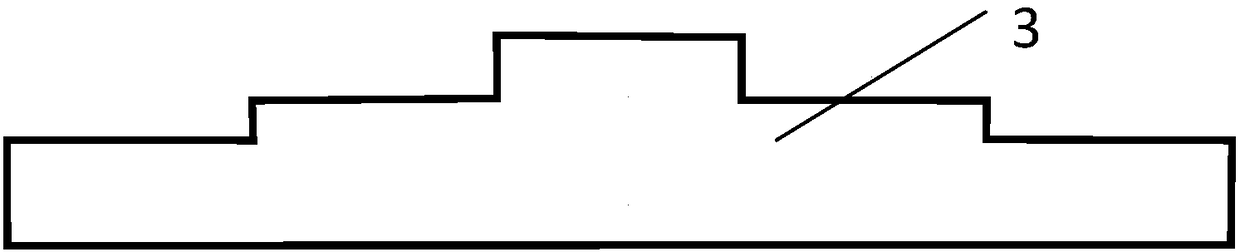

Measuring device for contactlessly detecting ferromagnetic object

InactiveCN1426530AReduce magnetic fieldGalvano-magnetic hall-effect devicesConverting sensor output electrically/magneticallyMeasurement deviceHall element

The invention relates to a measuring device (1) for contactlessly detecting a ferromagnetic object (4, 5). The measuring device comprises a Hall element (3) and at least one permanent magnet (2), an air gap (6) being located between said Hall element and said permanent magnet. The permanent magnet (2) also has a soft magnetic component (7) on at least one of its front sides, said component being located between the permanent magnet (2) and the Hall element (3).

Owner:ROBERT BOSCH GMBH

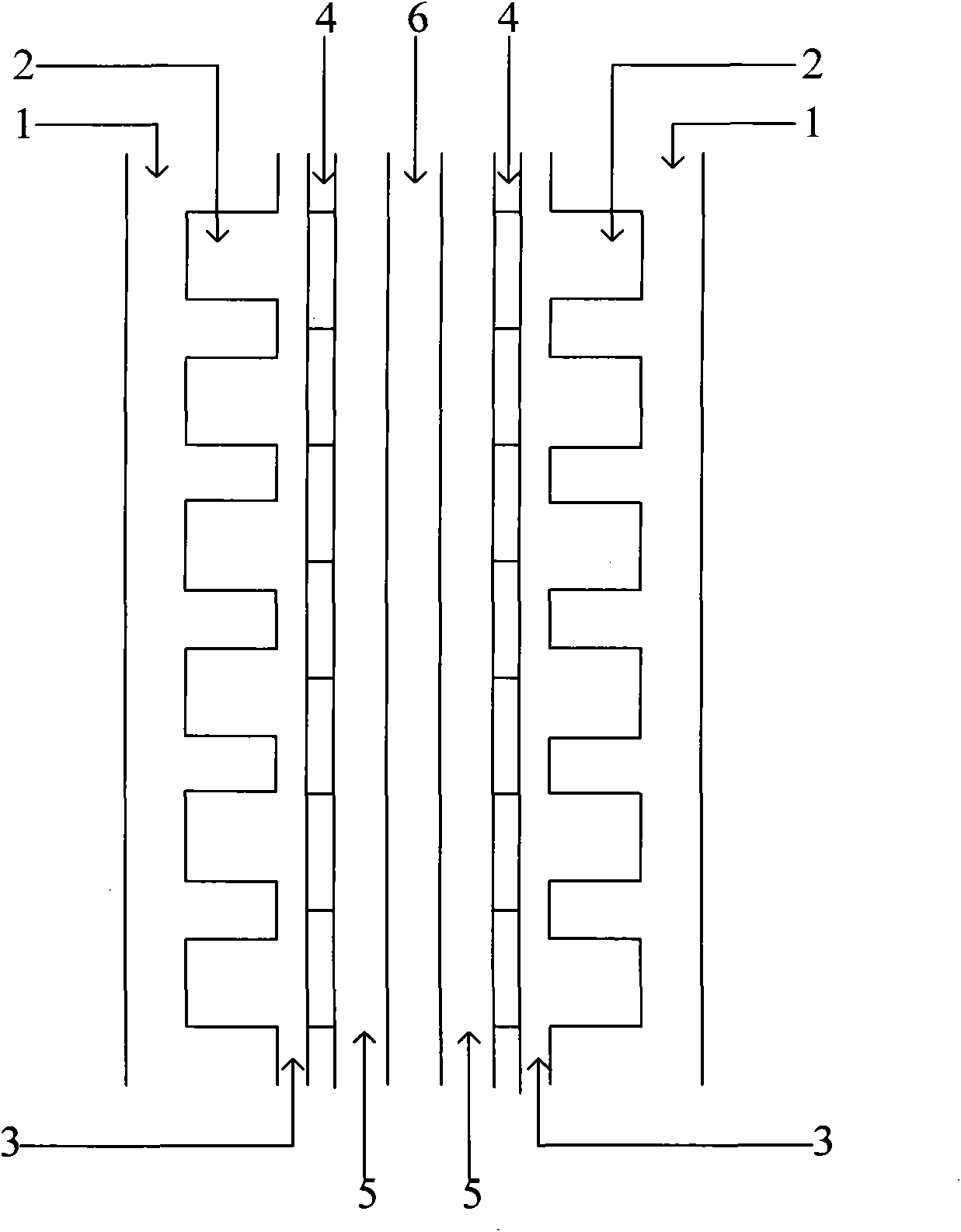

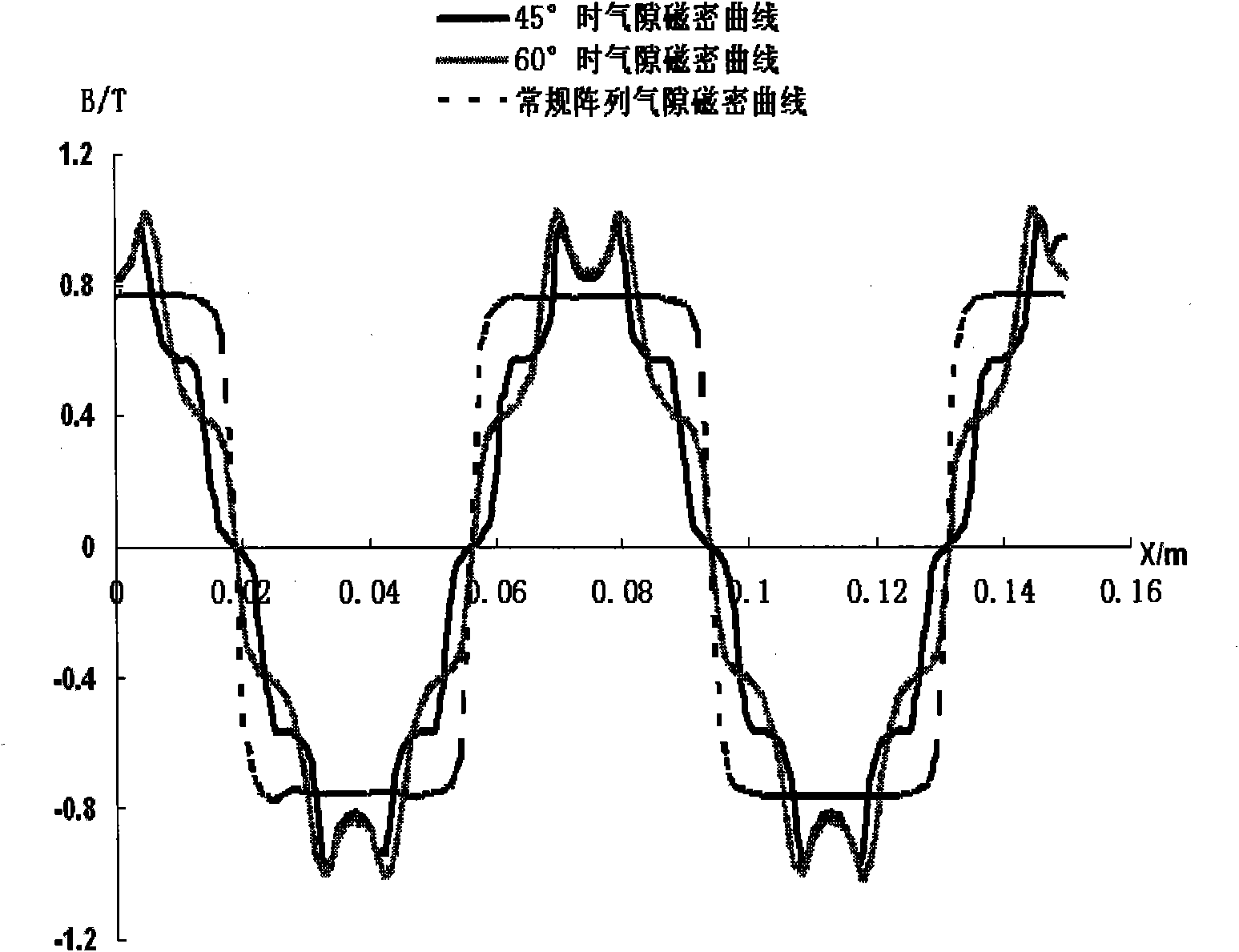

Linear permanent-magnet generator

The invention discloses a linear permanent-magnet generator, which comprises a primary iron core, a primary coil, a secondary iron core and a non-magnetic material shaft. The primary iron core, the primary coil, the secondary iron core and the non-magnetic material shaft are arranged in turn from the outside to inside; the primary coil is wound on the interior of the primary iron core; the non-magnetic material shaft is embedded in the secondary iron core; and a permanent magnet of a Halbach array is also sleeved outside the secondary iron core, and the permanent magnet enhances the magnetic field outside the permanent magnet and weakens the magnetic field inside the permanent magnet. The Halbach permanent-magnet array is applied to the linear generator and has the advantages of improving the power density of the generator, improving the utilization rate of the permanent magnet and simultaneously reducing eddy-current loss in the secondary iron core; therefore, the structure of an electric motor is simplified, the electric motor runs more stably, and the volume and weight of the generator are reduced.

Owner:SOUTHEAST UNIV

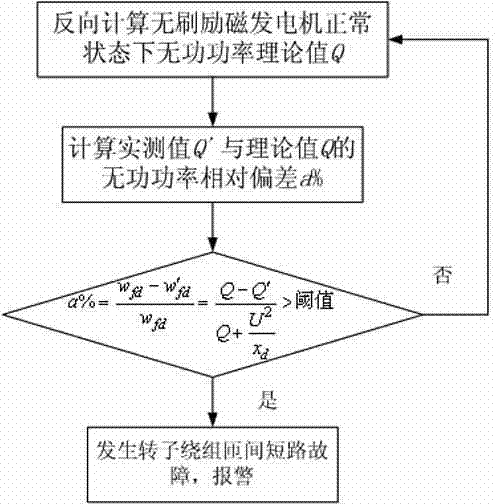

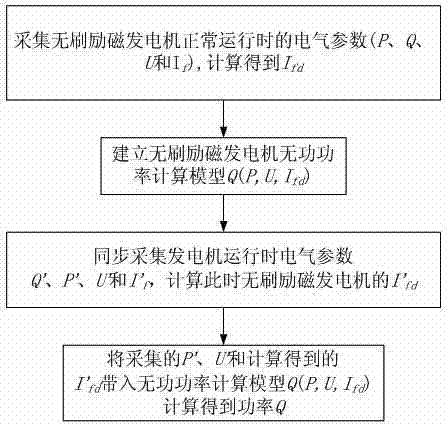

Turn-to-turn short circuit fault diagnosis method for rotor winding of brushless excitation generator

ActiveCN104764974AImprove accuracyReduce magnetic fieldElectrical testingConductor CoilSeverity/Intensity

The invention discloses a turn-to-turn short circuit fault diagnosis method for a rotor winding of a brushless excitation generator. The turn-to-turn short circuit fault diagnosis method comprises the steps that the theoretical reactive power value Q of the brushless excitation generator under the normal state is reversely calculated, the reactive power relative deviation a% of the measured reactive power value Q' and the theoretical reactive power value Q of the brushless excitation generator is calculated, the reactive power relative deviation a% and the preset threshold value are compared, and whether a turn-to-turn short circuit fault of the rotor winding occurs or not is judged. By means of the turn-to-turn short circuit fault diagnosis method, the accuracy on the aspect of the detection of the turn-to-turn short circuit of the rotor winding of the brushless excitation generator is improved. The defect that excitation currents cannot be detected when an excitation current method is adopted for the brushless excitation generator is overcome, faults under any working condition can be detected, the size is judged, and the severity degree of the short circuit fault can be directly reflected. New mentoring points do not need to be increased, operation is easy and convenient, sensitivity is high, and cost is saved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

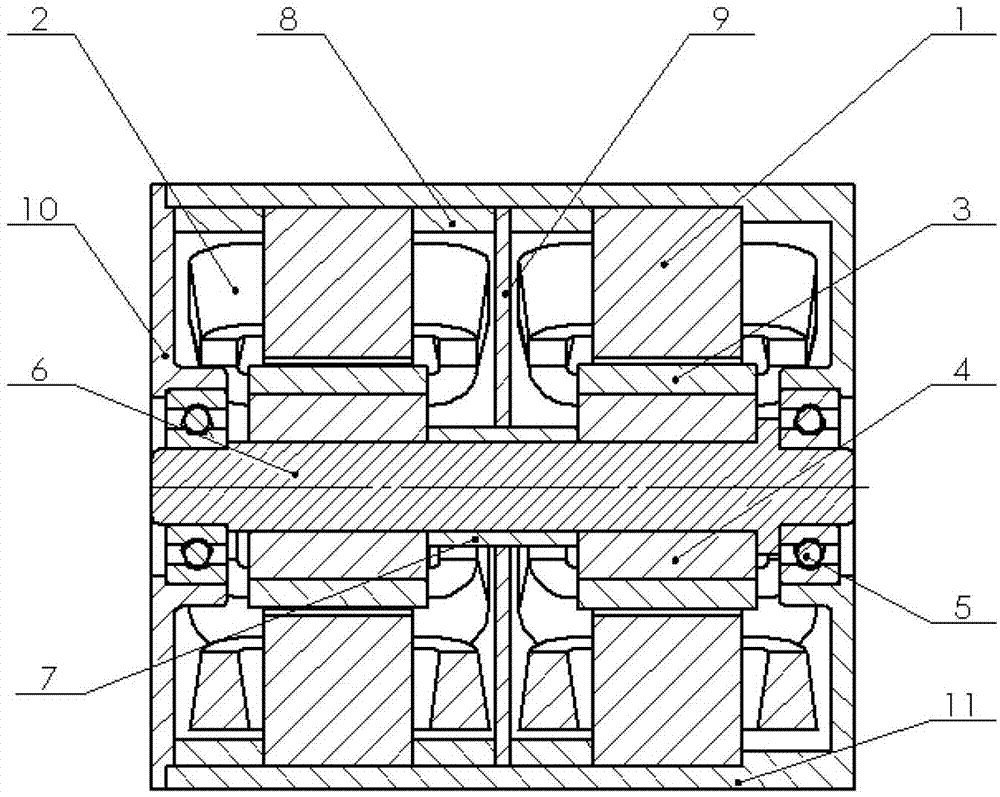

High-reliability permanent-magnet synchronous motor based on redundancy and fault-tolerant technology

InactiveCN102868266AGood physical isolationGood magnetic isolationMagnetic circuit rotating partsMagnetic circuit stationary partsThermal isolationFault tolerance

The invention relates to a high-reliability permanent-magnet synchronous motor based on redundancy and fault-tolerant technology, which comprises a shell, two rotor assemblies, two stator assemblies, rotating shafts, bearings, insulating sleeves, a magnetic isolation plate and an end cover, wherein the two stator assemblies are coaxially connected in series; windings in each stator assembly are centralized single-layer windings which are isolated by teeth and embedded in fractional slots, and an electrical fault-tolerance structure is formed among the phase windings; due to the structural dimension design of the stator tooth slot, the induction of the phase winding of the motor is enhanced, thereby effectively inhibiting the short-circuit current; the two rotor assemblies are connected in series on the same shaft and are respectively arranged in the two stator assemblies; magnetic steel in each rotor assembly is of a thickness-unequal magnetic steel structure; the magnetic isolation plate is arranged between the adjacent two stator assemblies and is used for isolating electromagnetic interference between the stators and rotors at both ends; the two bearings are respectively arranged in bearing chambers of the shell and the end cover; and all the assemblies are packaged by the shell and the end cover together. The permanent-magnet synchronous motor provided by the invention has favorable physical isolation, magnetic isolation, thermal isolation and electrical isolation capabilities, and the reliability of the motor is greatly enhanced.

Owner:BEIHANG UNIV

Wave energy power generating device based on serial connection linear magnetic gear motor

InactiveCN104061116AImprove power generation efficiencySimple structureDynamo-electric gearsMachines/enginesElectric machinePermanent magnet linear motor

The invention discloses a wave energy power generating device based on a serial connection linear magnetic gear motor, and belongs to a power generating device combining a linear magnetic gear and a permanent-magnet linear motor through serial connection. The wave energy power generating device comprises a permanent-magnet linear motor part, a linear magnetic gear part, a floating tube, a floater, an external encapsulation device and a base, wherein an outer rotor is driven by a driving motor and a mechanical transmission part to move in a certain moving range, the goal of variable transmission ratio is achieved, and the whole set of device has the advantages that the additional arrangement of a huge accelerator is not needed, the size is smaller, the energy capturing and power generating efficiency is high, no terminal winding is adopted, no radial force is exerted on a bearing, and the like.

Owner:SOUTHEAST UNIV

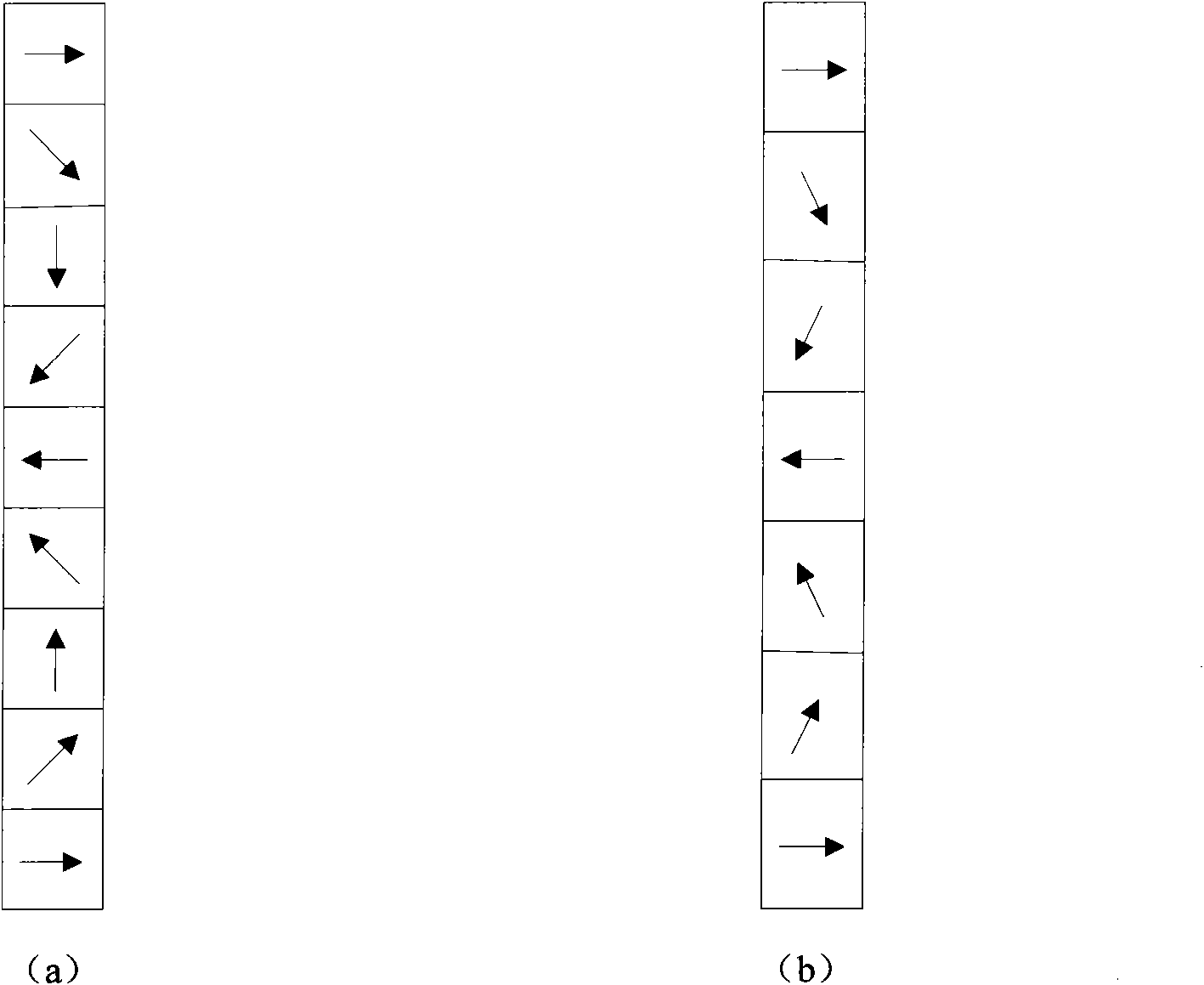

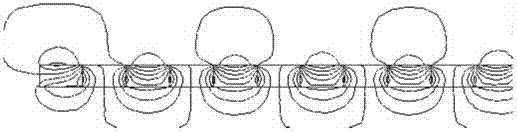

Halbach permanent magnet array of convex magnetic block

InactiveCN104333150AReduce distractionsLarge magnetic field space utilizationSalient polesPropulsion systemsDistribution characteristicPermanent magnet motor

The invention discloses a Halbach permanent magnet array of a convex magnetic block. The permanent magnet array is characterized in that the magnetism line distribution is closer to the sinusoidal distribution on the basis of keeping the basic characteristics of the Halbach permanent magnet array; meanwhile, the strength of a magnetic field is improved; the general Halbach permanent array is of a magnetic array structure which arranges and integrally combines the magnetic blocks with rectangular cross sections along the radial magnetizing direction and tangential magnetizing direction, and therefore, the strength of the magnetic field at one side of the permanent magnet array is highly increased and while the strength of the magnetic field at the other side is highly reduced; a large deviation occurs between the magnetic field distribution and sinusoidal distribution, so that the general Halbach magnetic field characteristics cannot meet the high-precision requirement of precise positioning and other application places. The Halbach magnet array of the magnetic block with the convex cross section is characterized in that each magnetic block is equipped with the convex sections and is arranged by the Halbach array mode; therefore, the sinusoidal distribution characteristic of the magnetic field is improved under the same size and rest magnetic induction intensity; moreover, the magnetic field strength is improved to some extent. The Halbach permanent magnet array of the convex magnetic block is mainly applied to the permanent array of a linear permanent magnet motor and a rotary permanent magnet motor.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Brake with field responsive material

InactiveUS20050126871A1Some backlashReduce magnetic fieldLiquid resistance brakesNon-rotating vibration suppressionEngineeringMechanical engineering

A controllable brake includes a rotor supported on one shaft end. The rotor is housed within a chamber containing a field controllable material which is acted upon by a magnetic field generator to change the rheology of the material and thereby impede movement of the rotor. The shaft is supported by two bearings which, in combination with the housing define a second housing chamber adapted to enclose means for monitoring and / or controlling the brake and in this way, an integrated, compact controllable brake is provided.

Owner:LORD CORP

Brake with field responsive material

ActiveUS20070181391A1Prevent rotationSome backlashLiquid resistance brakesSpringsEngineeringElectrical and Electronics engineering

A controllable brake includes a housing and a rotor supported on a shaft. The rotor is housed within a chamber containing a field controllable material which is acted upon by a magnetic field generator to impede movement of the rotor. The shaft is supported by bearings. The controllable brake housing defines a second housing chamber adapted to enclose means for monitoring and / or controlling the brake and in this way, an integrated, compact controllable brake is provided.

Owner:LORD CORP

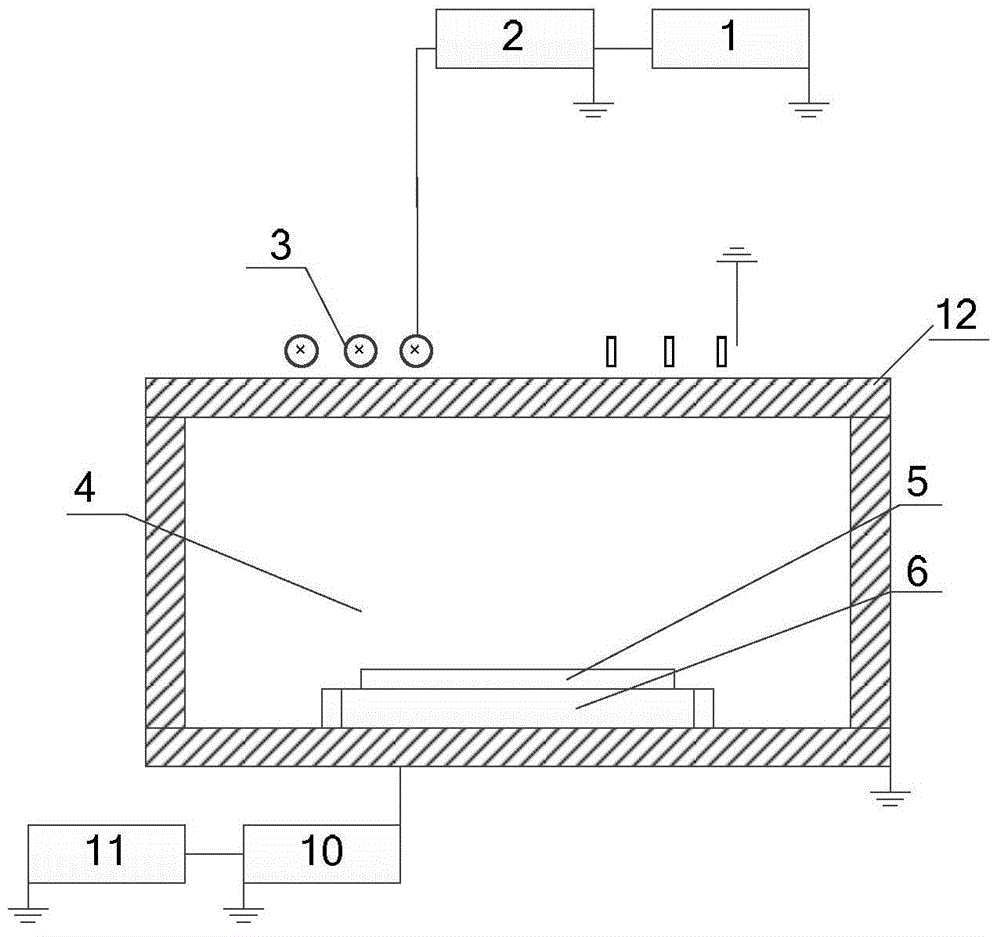

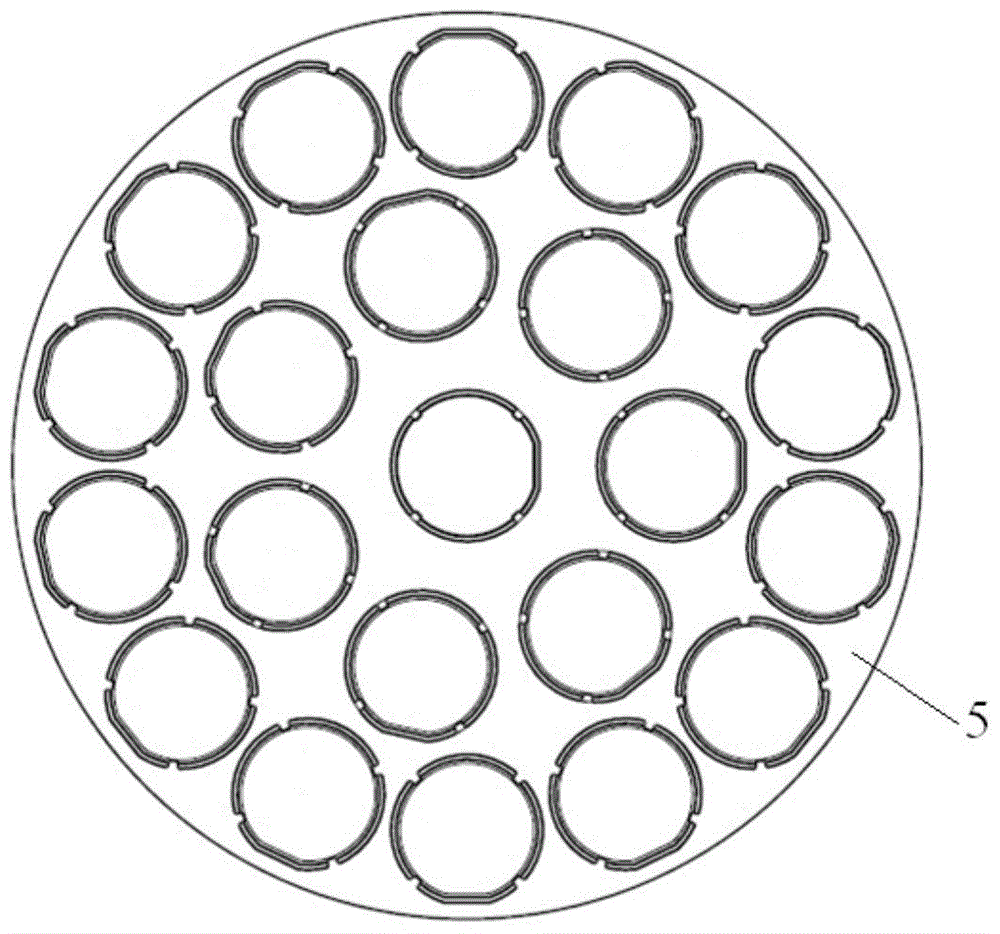

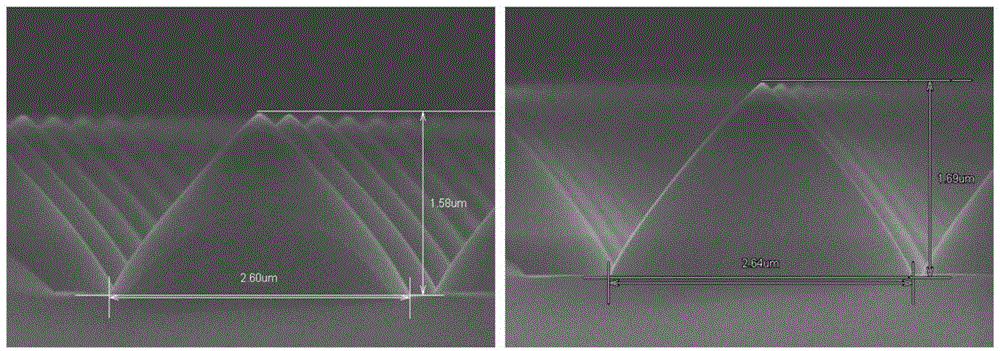

Plasma processing equipment

ActiveCN105632860ALow densityIncreased sheath thicknessElectric discharge tubesPhysicsRadio frequency

The invention provides plasma processing equipment, and the equipment comprises a reaction cavity, a substrate for carrying a machined workpiece, and a radio frequency antenna device. The radio frequency antenna device comprises an inductive coil, an electrode plate group, and a radio frequency source. The inductive coil and the electrode plate group are in parallel connection, and are electrically connected with the radio frequency source. Moreover, the inductive coil and the electrode plate group are disposed at the top of the reaction cavity, and are respectively corresponding to different positions of the substrate. The equipment employs the electrode plate group to generate plasma at the same time on the basis of employing the inductive coil to generate plasma, and can achieve the adjustment of the distribution density of plasma at different positions, so as to enable the etching results of various types of machined workpieces on the substrate to be uniform, thereby improving the etching uniformity.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

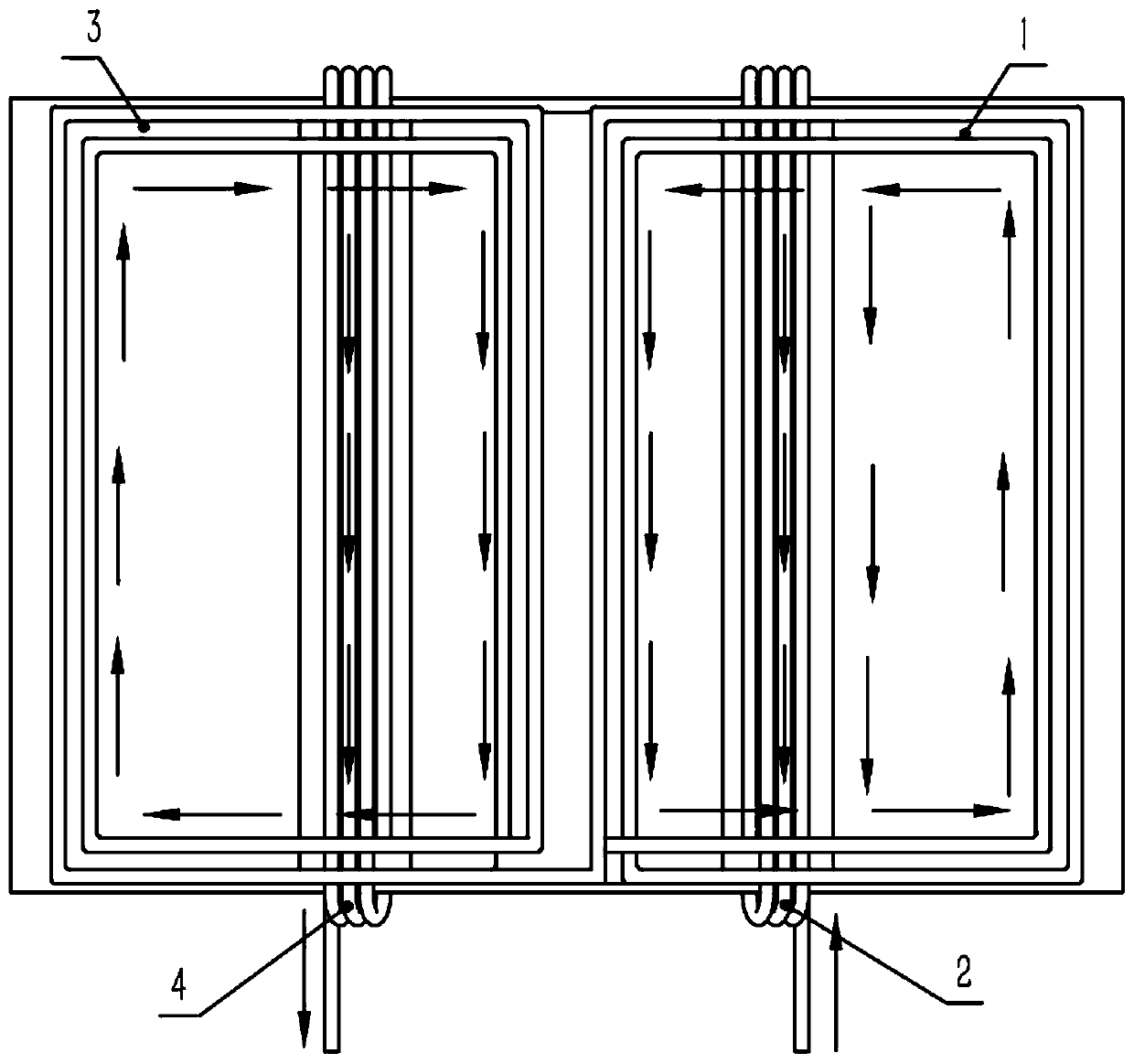

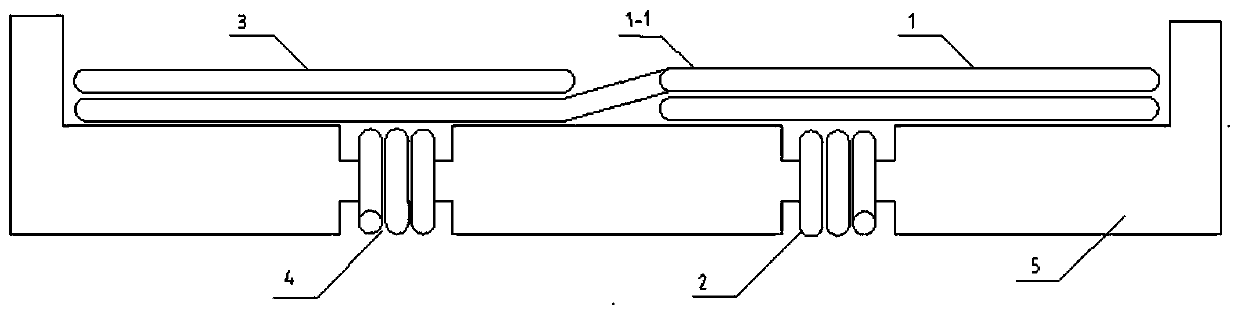

Wireless charging device

PendingCN110690038AIncrease the magnetic circuit areaIncrease the magnetic field strengthTransformersCircuit arrangementsPhysicsInductive charging

The invention relates to a wireless charging device, and belongs to the technical field of wireless charging. The wireless charging device comprises a wireless charging coils which comprises an excitation layer, a first coil annular loop and a second coil annular loop. The first coil annular loop is arranged in parallel on the upper end surface of the excitation layer. The periphery of the first coil annular loop is provided with an electromagnetic shielding plate formed by magnetic conductive materials.The electromagnetic shielding plate is fixed on the upper end surface of the excitation layer, and the height of the electromagnetic shielding plate on the upper end surface of the excitation layer is higher than that of the first coil annular loop and the third coil annular loop on the upper end surface of the excitation layer. The second coil annular loop is arranged around the upper and lower end surfaces and two side surfaces of the excitation layer. The side of the second coil annular loop on the upper end surface is disposed adjacent to the side of the first coil annular loop. The wireless charging device can improve the wireless charging efficiency and can also shield the radiation scattering generated by the charging coil in the process of transmitting energy and has a good electromagnetic shielding effect.

Owner:XJ POWER CO LTD +1

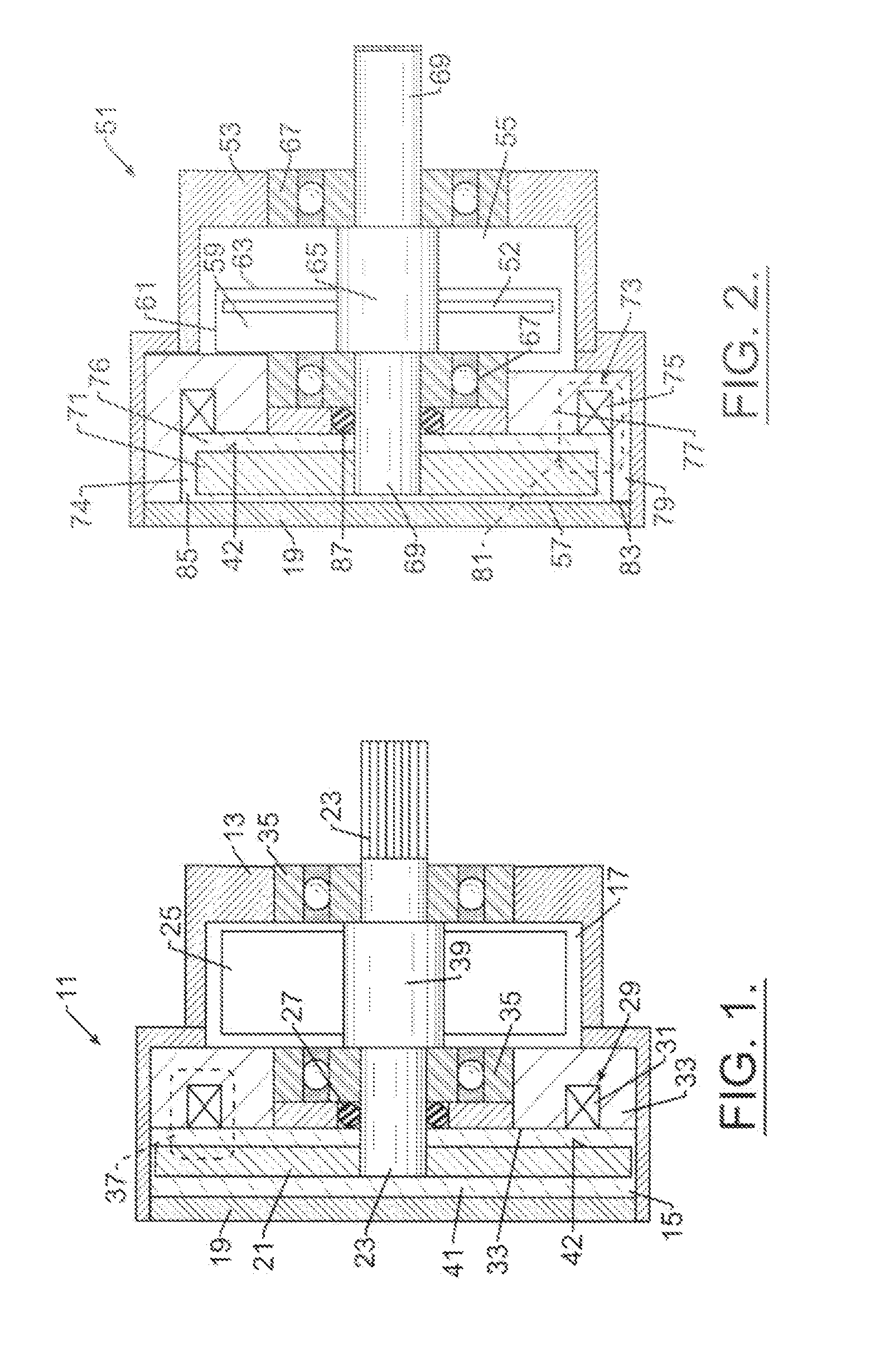

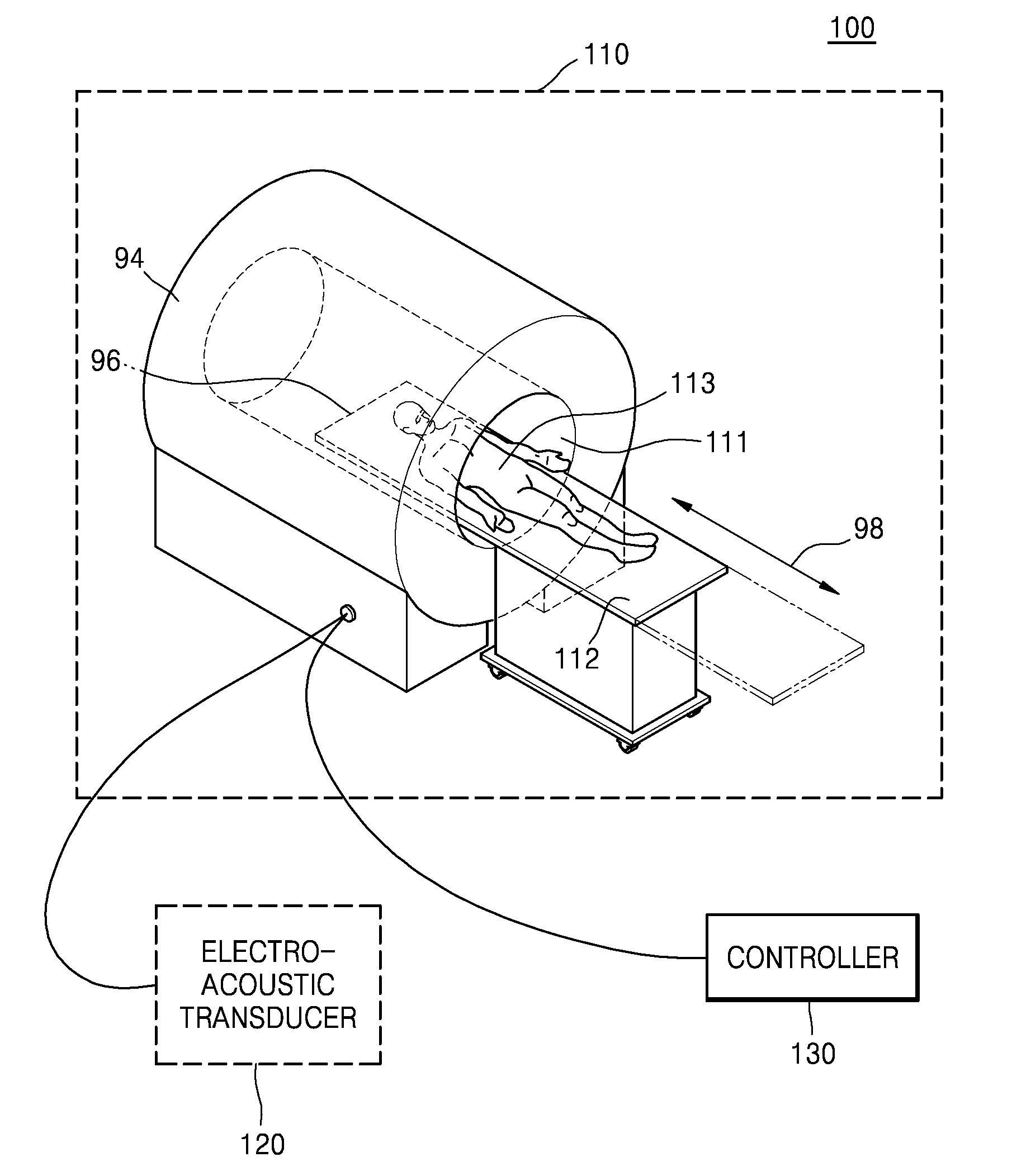

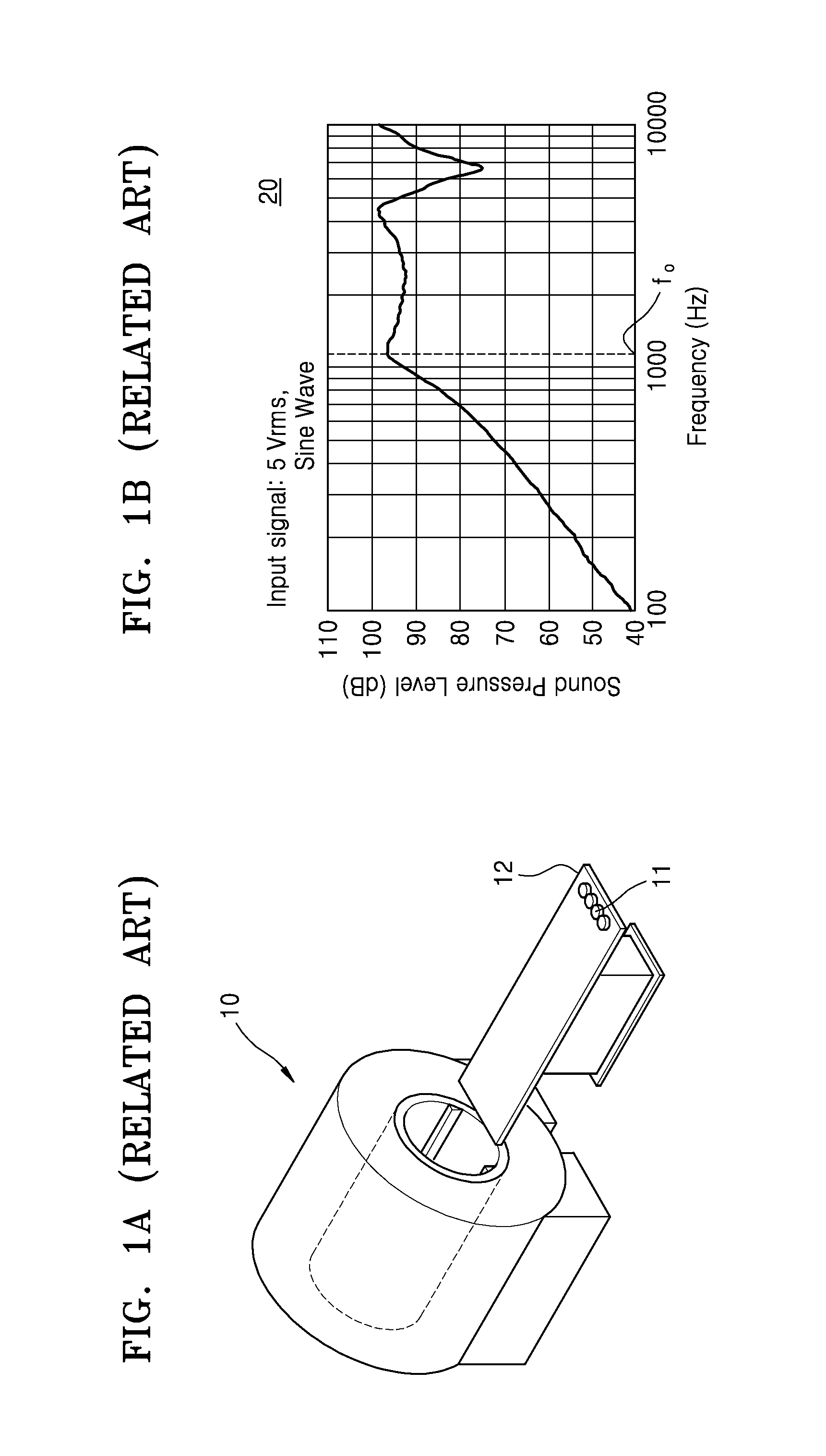

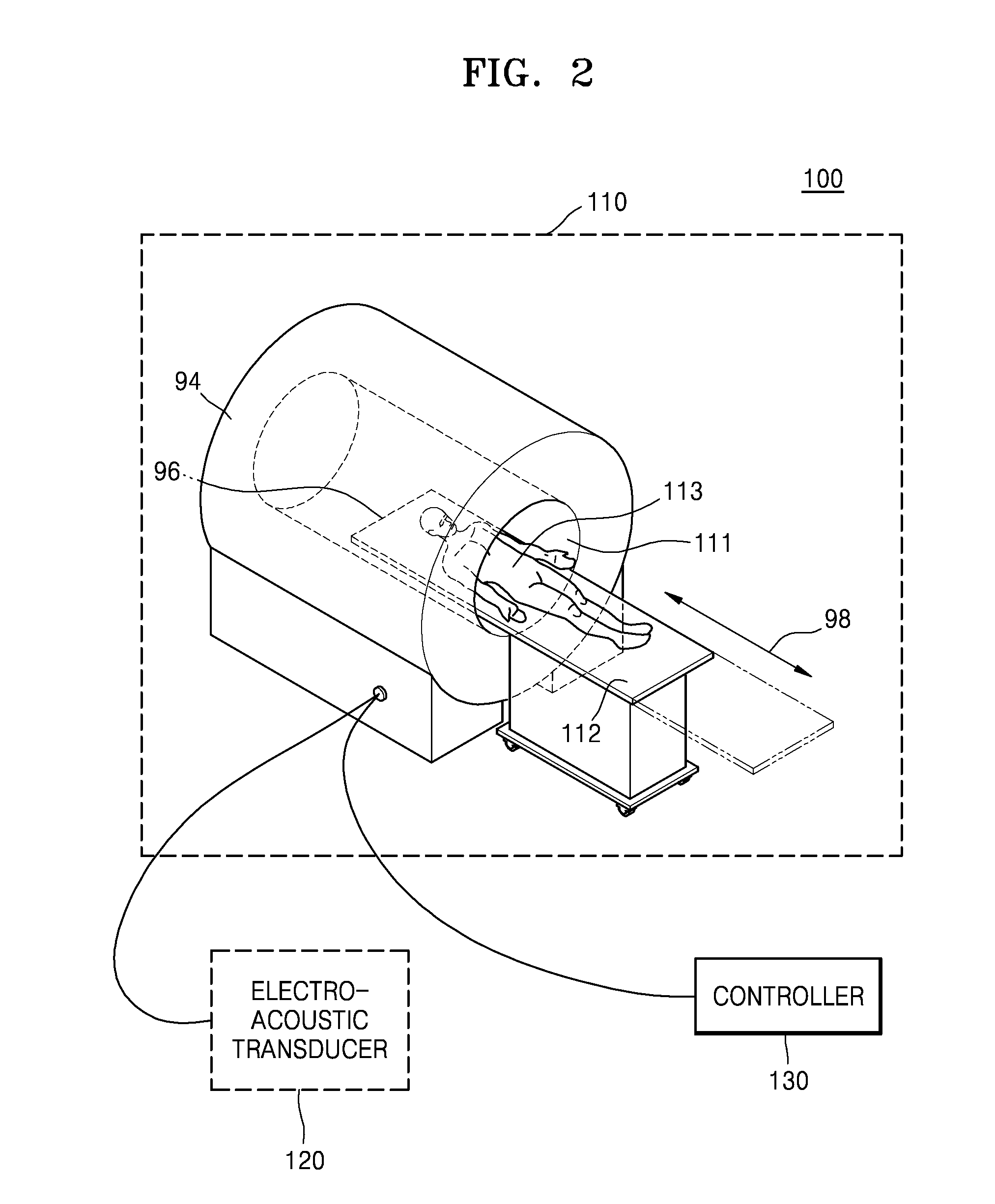

MRI acoustic system, acoustic output device, and electro-acoustic transducer

ActiveUS20140354283A1Reduce magnetic fieldAvoid interferenceDiagnostic recording/measuringMeasurements using NMR imaging systemsRepulsion forceTransducer

Provided is magnetic resonance imaging (MRI) acoustic system that includes a magnet that is included in a bore having an image-taking space where an object is able to be accommodated and that forms a magnetic field in the image-taking space to obtain an MR image of the object, an electro-acoustic transducer that is located outside of the bore, and includes coils through which a current for generating an attraction force or a repulsion force with respect to the magnetic field generated by the magnet and a vibrating plate that vibrates in response to the an attraction force or the repulsion force, and a controller that controls the intensity of the current inputted to the electro-acoustic transducer to generate a sound by using the magnetic field that is generated by the magnet.

Owner:SAMSUNG ELECTRONICS CO LTD

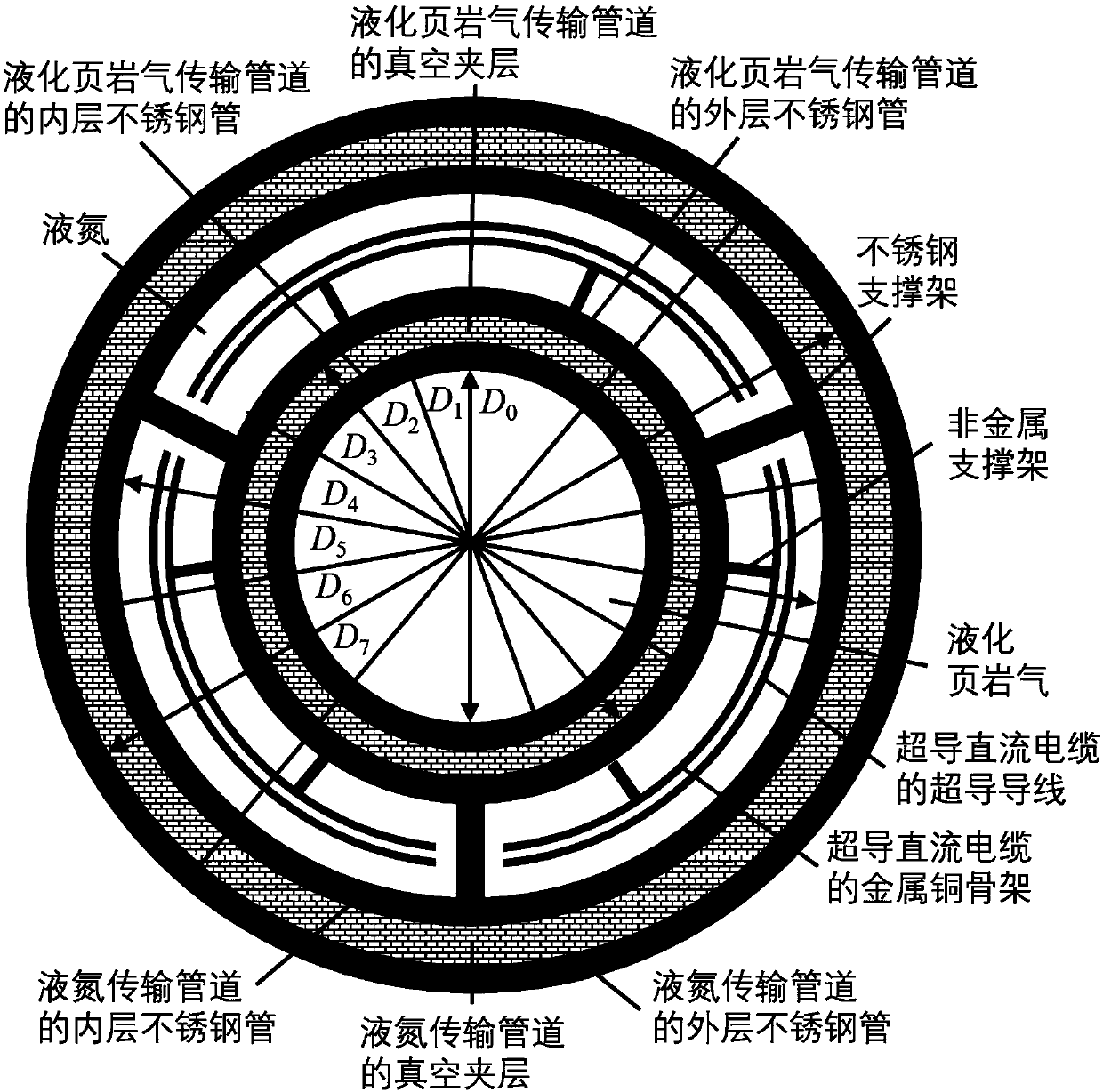

Design method of liquefied shale gas-liquid nitrogen superconducting direct current cable compound energy pipeline

ActiveCN107631104AIncreased power transmission capacityReduce magnetic fieldSuperconductors/hyperconductorsThermal insulationPower flowThermal insulation

The invention discloses a design method of a liquefied shale gas-liquid nitrogen superconducting direct current cable compound energy pipeline. The design method has the benefits as follows: three operation limiting conditions, namely the maximum allowable pressure drop, the maximum allowable temperature rise and the maximum allowable vacuum degree change rate, of the compound energy transmissionpipeline are met, and potential safety hazards as follows are avoided: as the vacuum and thermal insulation structural design is unreasonable, so that the vacuum maintenance time is too short, and theheat leakage of the pipeline is too large; meanwhile, the superconducting direct current cable arranged in the liquid nitrogen transmission pipeline is larger in diameter, the magnetic field generated by the running current of the cable is reduced, and the electric energy transmission capacity of the superconducting direct current cable is further improved.

Owner:SICHUAN NORMAL UNIVERSITY

High-yield-strength aluminum alloy formula and smelting key device thereof

The invention provides a yield strength pressure casting aluminum alloy. The yield strength pressure casting aluminum alloy has the good casting property, mechanical property and heat treatment property and meanwhile has the higher yield strength, a key device for smelting the alloy comprises a smelting furnace, a permanent magnetic stirring magnet and a permanent magnetic partition board, the permanent magnetic partition board is close to the bottom of the smelting furnace, and is located above the permanent magnetic stirring magnet, the magnetic direction of the permanent magnetic partitionboard is perpendicular to the plane of the permanent magnetic partition board, the area of the permanent magnetic partition board is smaller than the area of the bottom of the smelting furnace, the magnetic field strength of the permanent magnetic partition board is smaller than that of the permanent magnetic stirring magnet, space between the smelting furnace and the permanent magnetic stirring magnet is partly filled with the permanent magnetic partition board, a space non-uniform magnetic field and a time pulse magnetic field are provided, and through the space non-uniform magnetic field and the time pulse magnetic field, uneven drive force is generated in molten metal, and the surging effect is formed.

Owner:深圳市博锐专利新技术服务有限公司

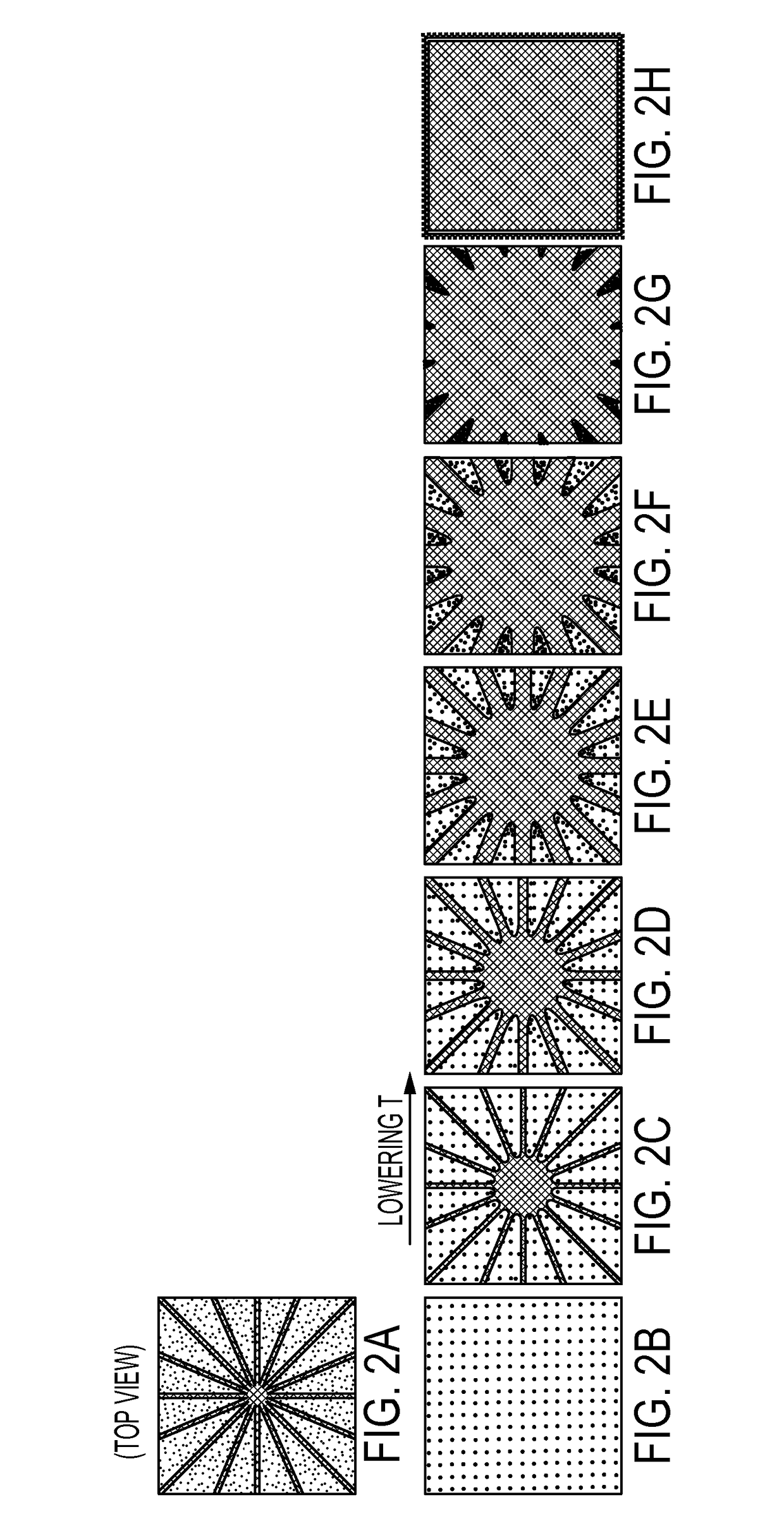

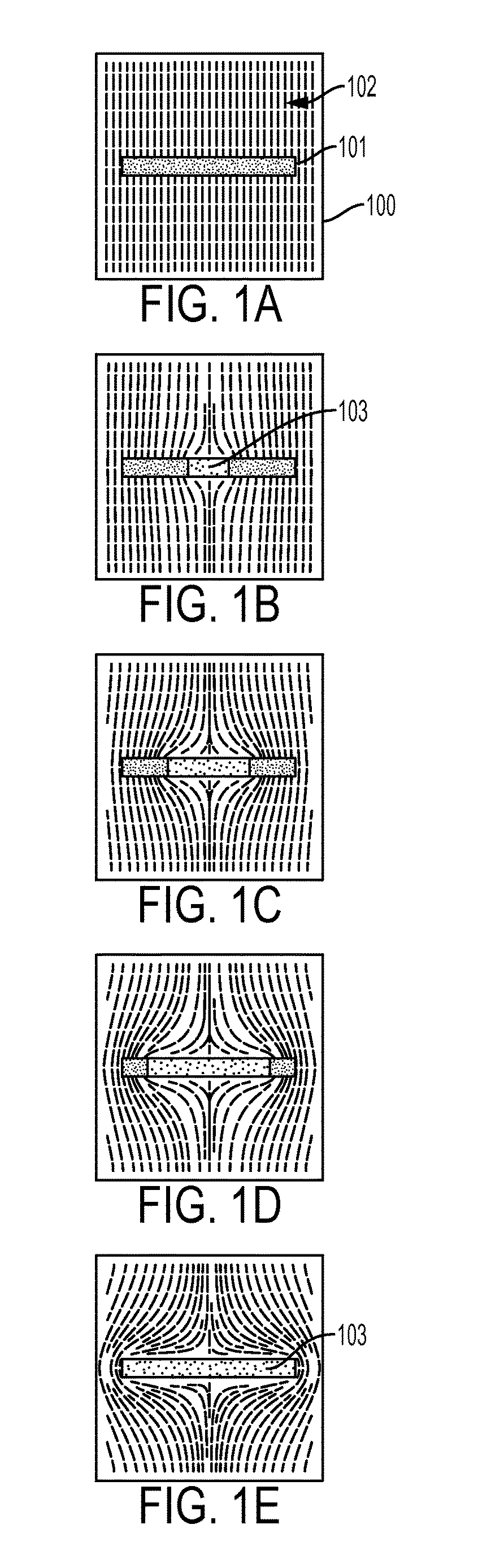

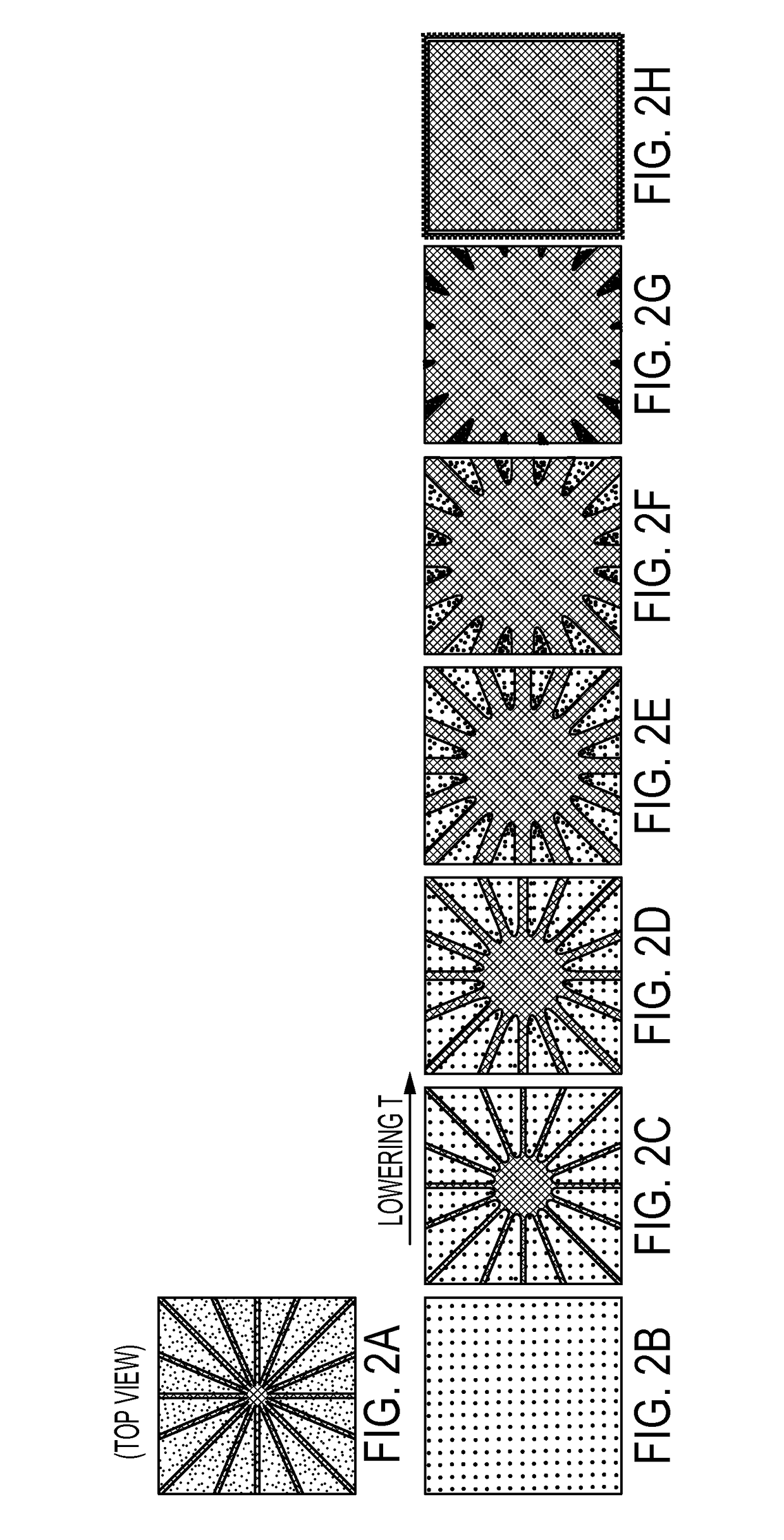

Method and apparatus of implementing a magnetic shield flux sweeper

ActiveUS20170071082A1Avoid changeAvoid pollutionShielding materialsActive shieldingCENBOLMagnetic shield

The present invention relates to a method and apparatus of protecting magnetically sensitive devices with a shield, including: a non-superconducting metal or lower transition temperature (Tc) material compared to a higher transition temperature material, disposed in a magnetic field; means for creating a spatially varying order parameter's |Ψ(r, T)|2 in a non-superconducting metal or a lower transition temperature material; wherein a spatially varying order parameter is created by a proximity effect, such that the non-superconducting metal or the lower transition temperature material becomes superconductive as a temperature is lowered, creating a flux-free Meissner state at a center thereof, in order to sweep magnetic flux lines to the periphery.

Owner:NASA

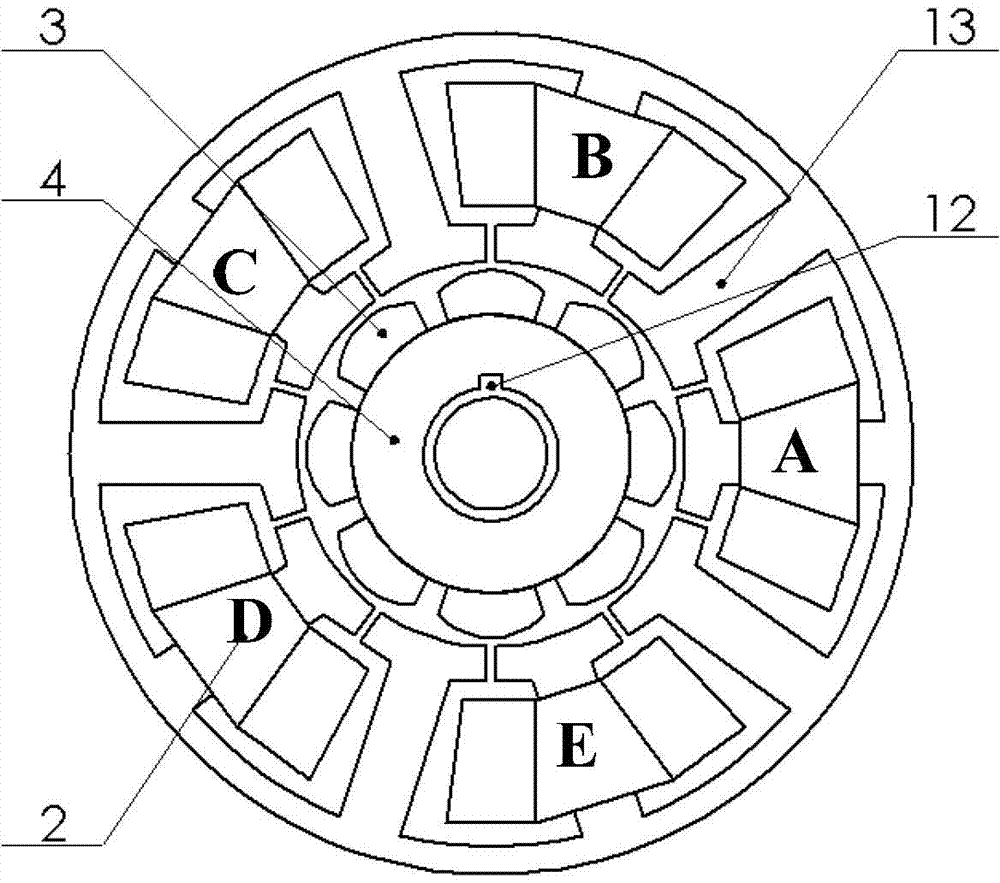

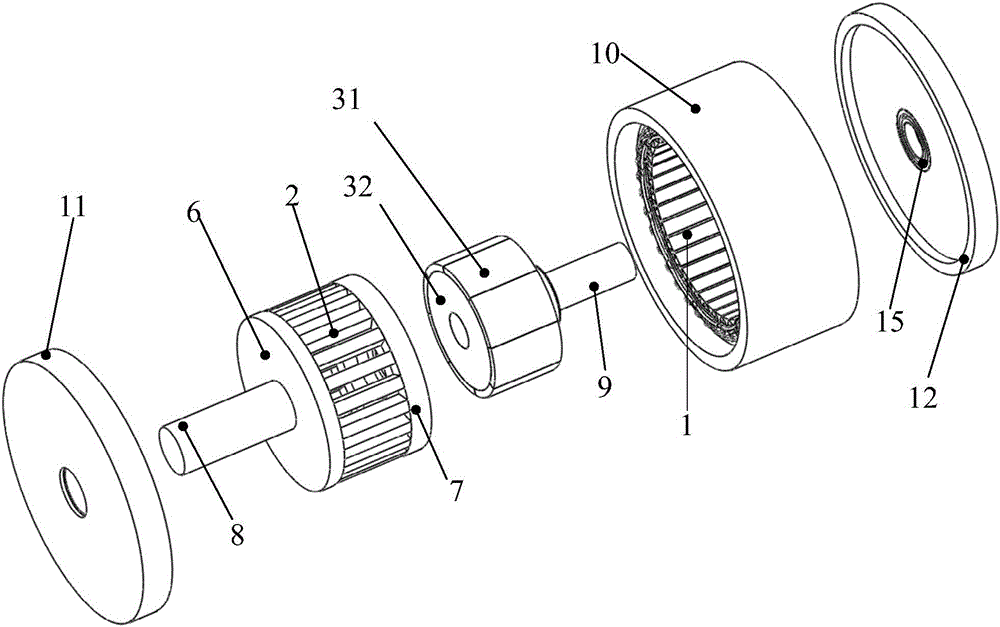

Low-speed and high-torque motor with magnetic gear

InactiveCN104953779AReduce dosageShorten the lengthMagnetic circuit rotating partsMagnetic circuit stationary partsLow speedCoupling

The invention provides a low-speed and high-torque motor with a magnetic gear. The low-speed and high-torque motor comprises an inner rotor, an adjustable magnetic ring and a stator which are coaxially and sequentially arranged from inside to outside, wherein a permanent magnet is arranged in the inner rotor; an armature winding for generating a rotating magnetic field and an electromagnet for generating a constant magnetic field are arranged in the stator. By adopting the electromagnet to generate the constant magnetic field in the stator and to replace a permanent magnet in the stator, the usage of the permanent magnet can be reduced, so that the length of an air gap on an outer layer is reduced, and further the coupling degree of an armature winding magnetic field and a permanent magnet magnetic field of the inner rotor is improved.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

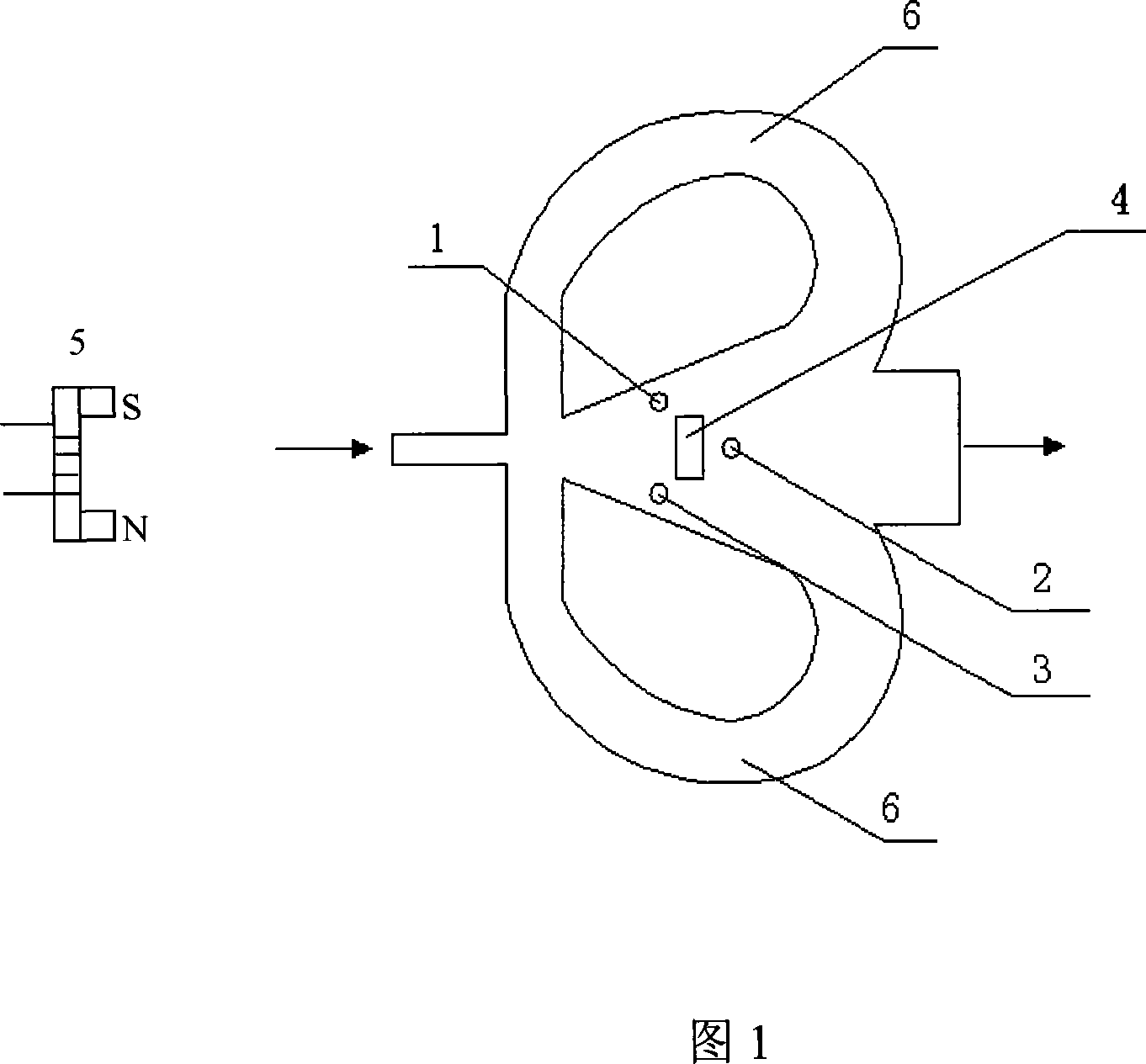

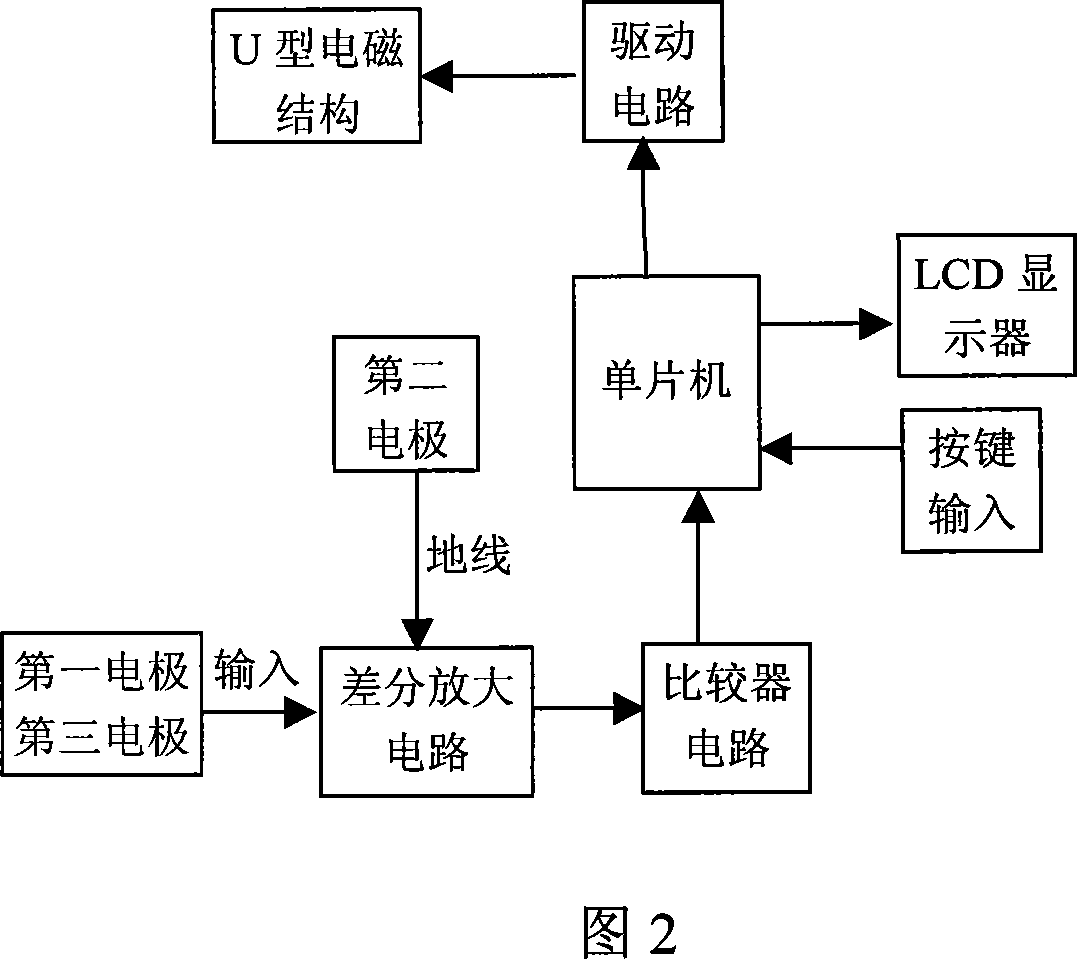

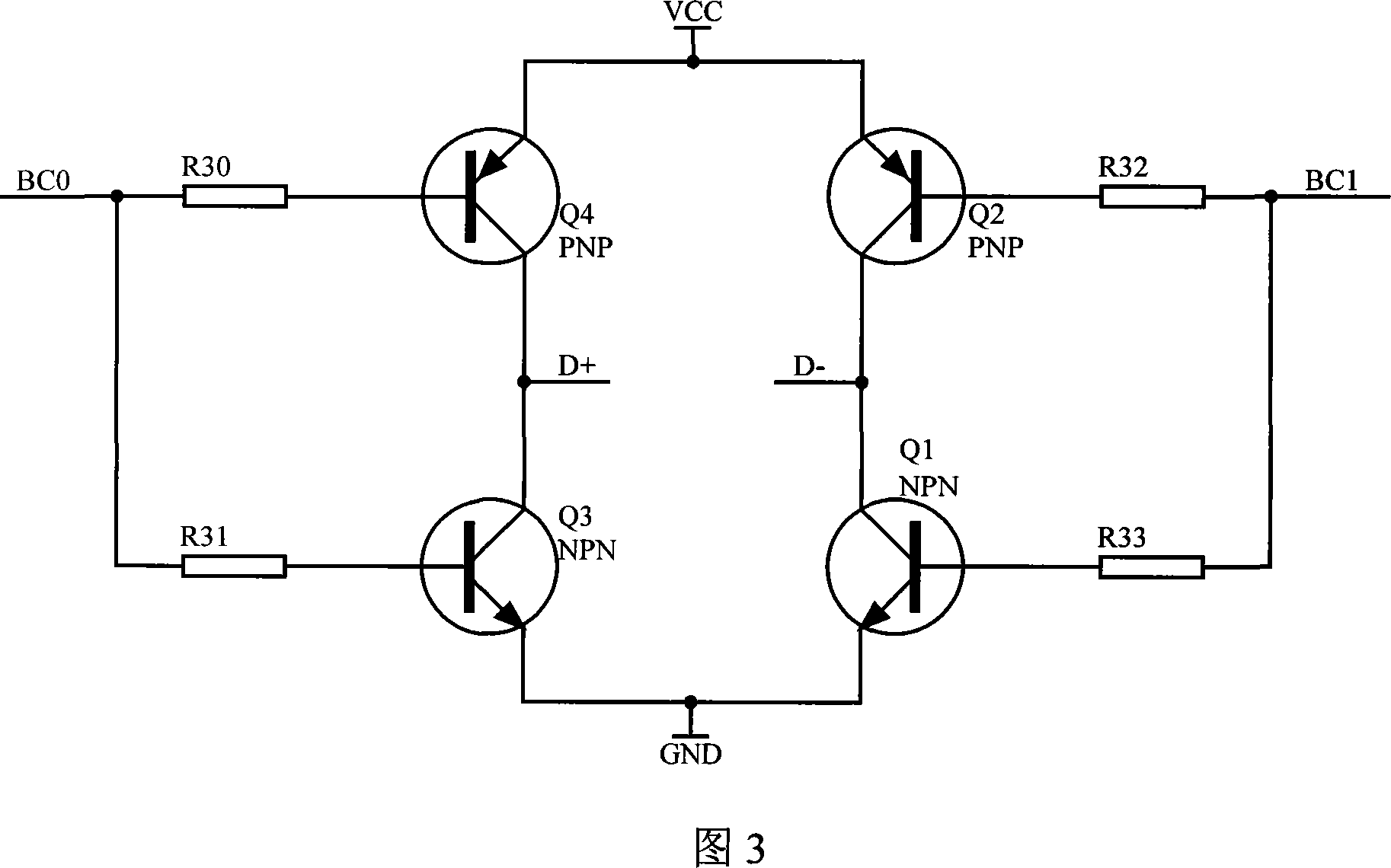

Electromagnetic jat-flow flowmeter

InactiveCN101067564ALow measurement limitReliable operationVolume/mass flow by electromagnetic flowmetersPhysicsComparators circuits

The invention discloses an electromagnetic jet flow flowmeter. It discloses a resist flow piece installs in the measuring tube of the jet flow flowmeter and a U type electromagnetism structure installs on the measuring tube, the first electrode, the second electrode, the third electrode installs on the measuring tube and resist flow side of the inferior of the U type electromagnetism structure. The U electromagnetism structure is composed by pair of permanent magnet and an exciting coil, controls by monolithic integrated circuit to strengthen or weaken the measuring tube magnetic field. The second electrode connects the grounding of the difference enlarge electric circuit by the wire, the first electrode, the third electrode connect the difference enlarge electric circuit input end by the wire, the difference enlarge electric circuit out-port connect the comparator electric circuit, the monolithic integrated circuit electric circuit in turn. The monolithic integrated circuit electric circuit also provides LCD monitor, pressed key input and so on electric circuit. The entire electric circuit uses a battery power supply. The merit of jet flow flowmeter is that the low power loss, the wide measuring range, the high exempt maintenance, reliable, high accuracy and so on.

Owner:ZHEJIANG UNIV +1

High-yield-strength aluminum alloy formula and smelting key device thereof

The invention discloses a high-yield-strength aluminum alloy formula and a smelting key device thereof. A provided yield-strength die-casting aluminum alloy has the good casting property, mechanical property and heat treatment property, and meanwhile has the high yield strength. The key device for smelting the alloy with the compositions comprises a melting furnace, a permanent magnet stirring magnet and a permanent magnet partition plate; the permanent magnet partition plate is close to the bottom of the melting furnace and located on the upper portion of the permanent magnet stirring magnet;and the magnetization direction of the permanent magnet partition plate is perpendicular to the plane of the permanent magnet partition plate, the area of the permanent magnet partition plate is smaller than that of the bottom of the melting furnace, and the magnetic field strength of the permanent magnet partition plate is smaller than that of the permanent magnet stirring magnet. A space between the melting furnace and the permanent magnet stirring magnet is partially filled with the permanent magnet partition plate, and thus a non-uniform magnetic field in space and a pulse magnetic fieldin time are provided; and through the non-uniform magnetic field in space and the pulse magnetic field in time, non-uniform driving force is applied to the interior of metal liquid, and thus the surgeeffect is formed.

Owner:东莞市金羽丰知识产权服务有限公司

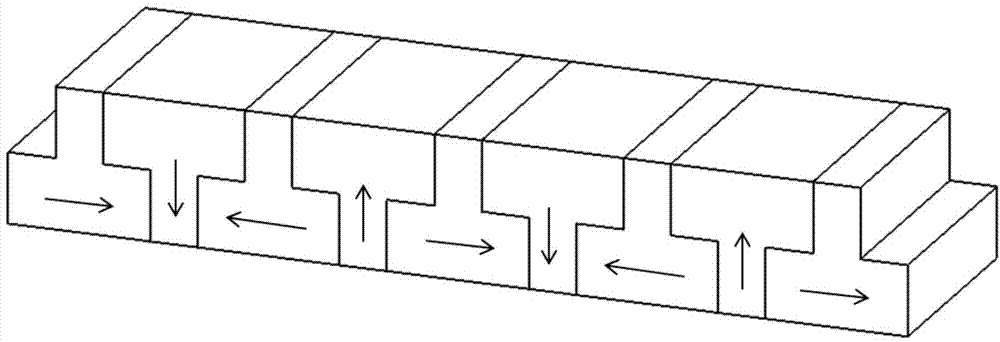

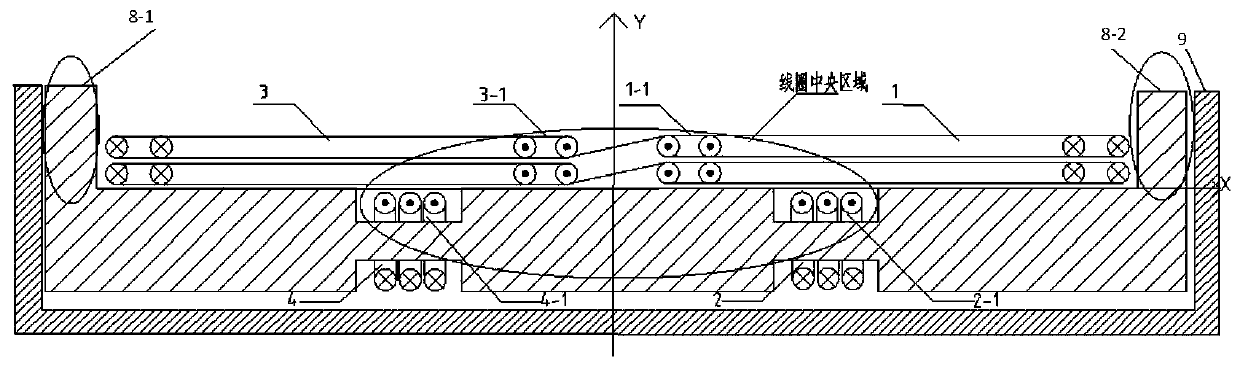

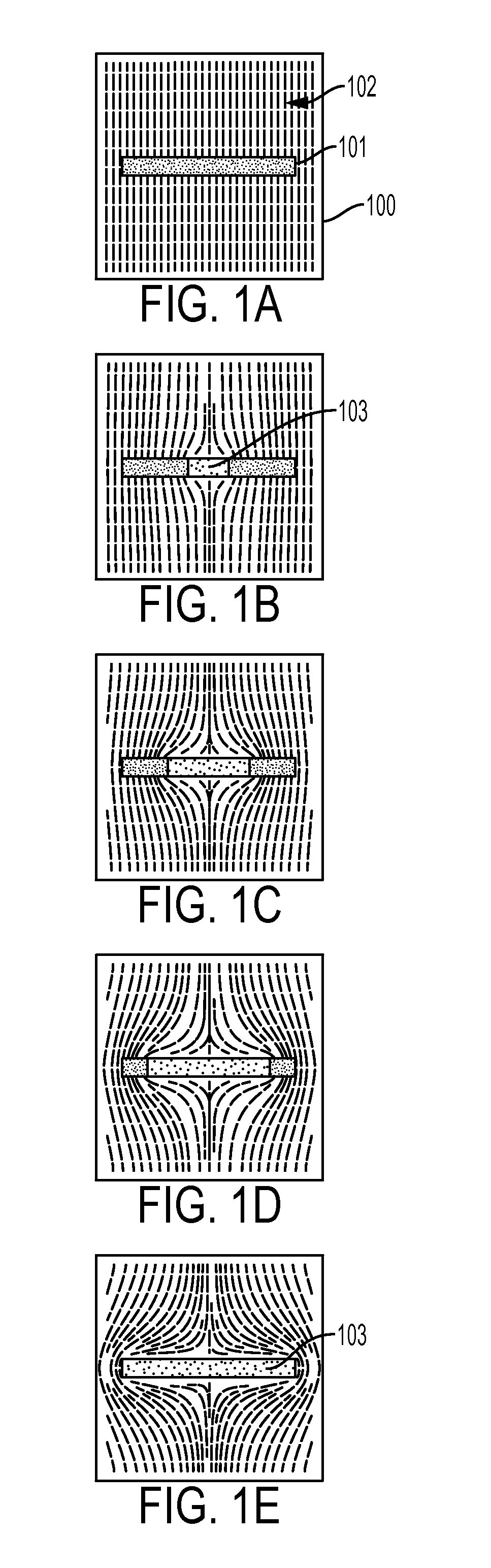

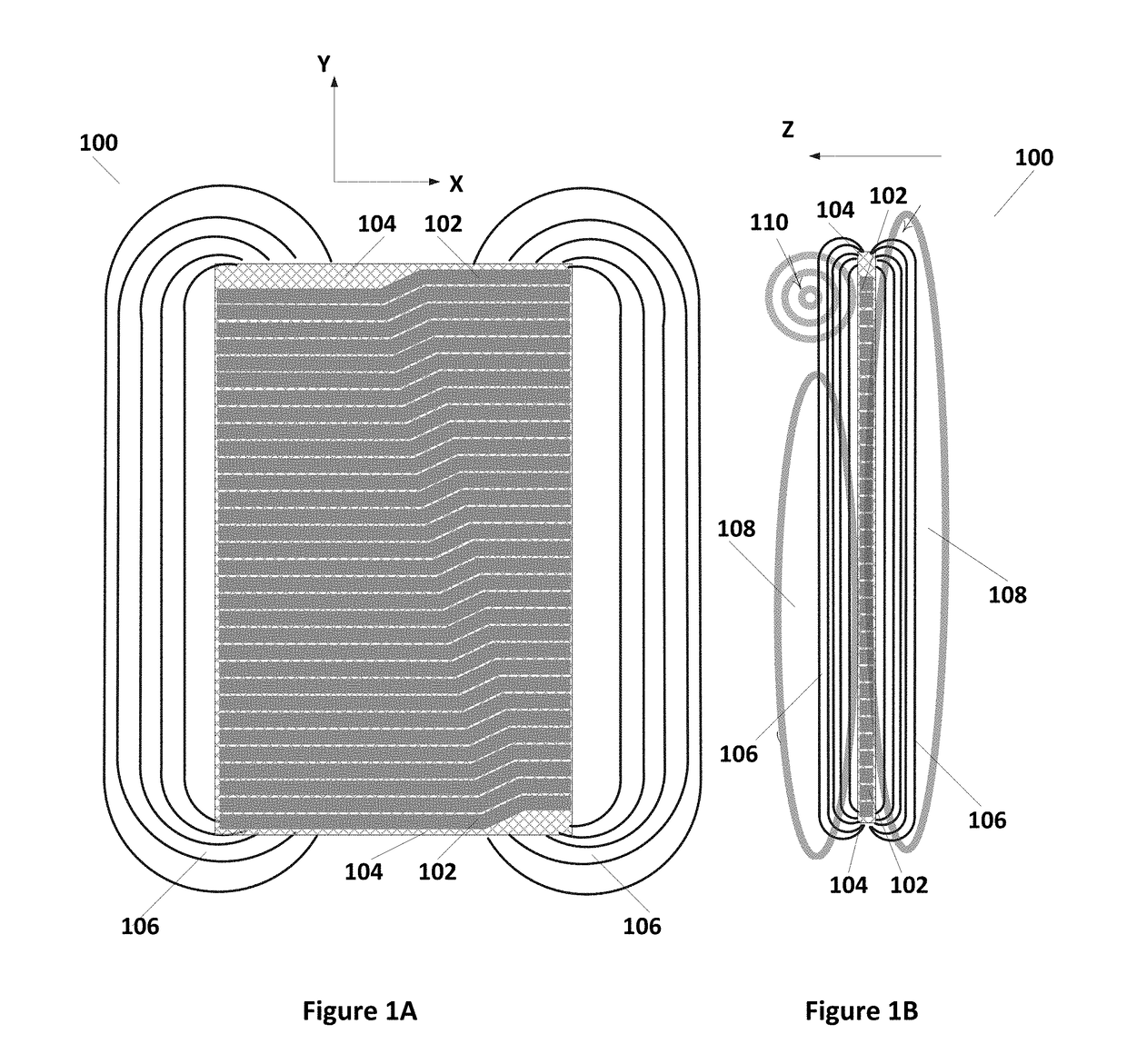

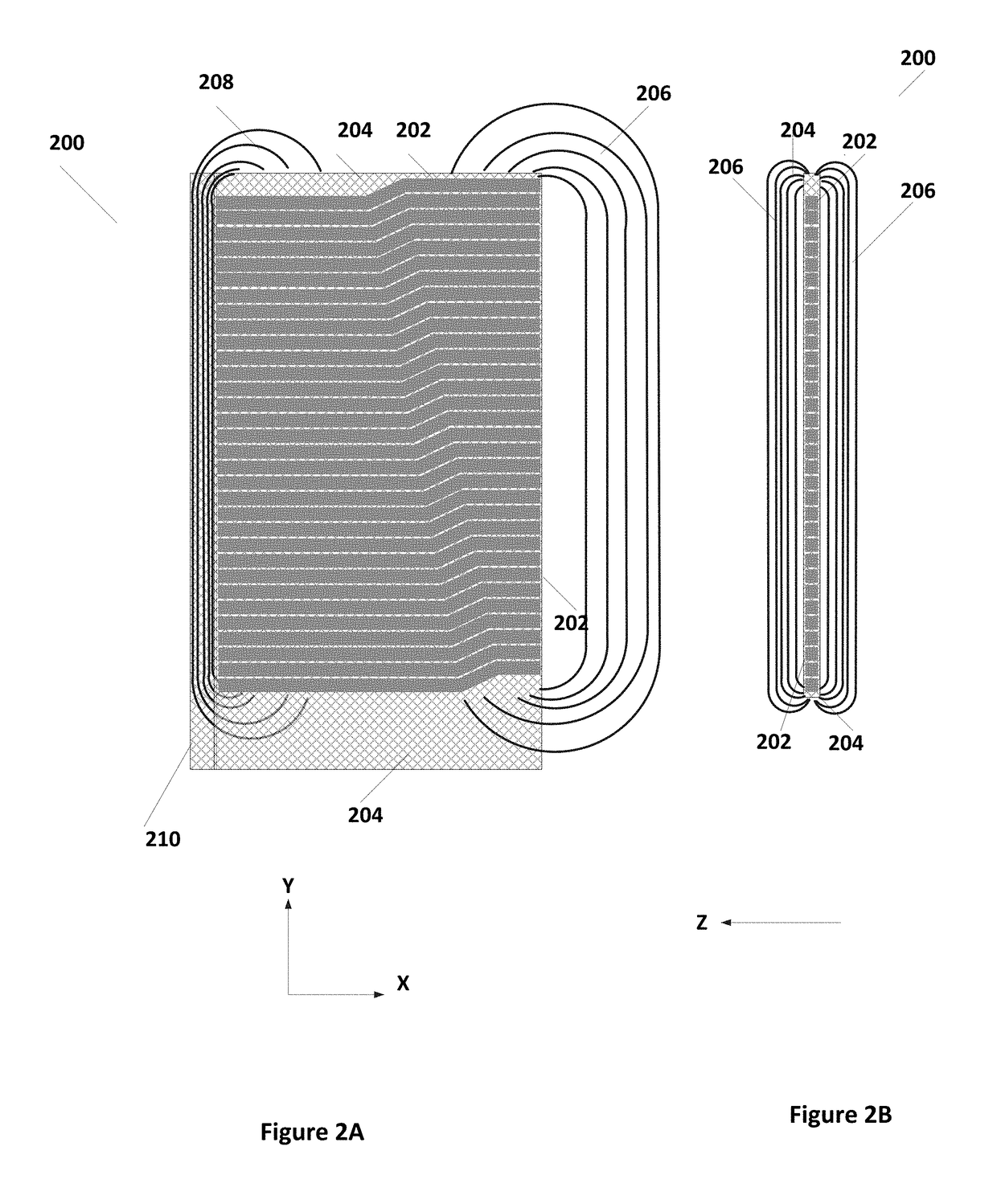

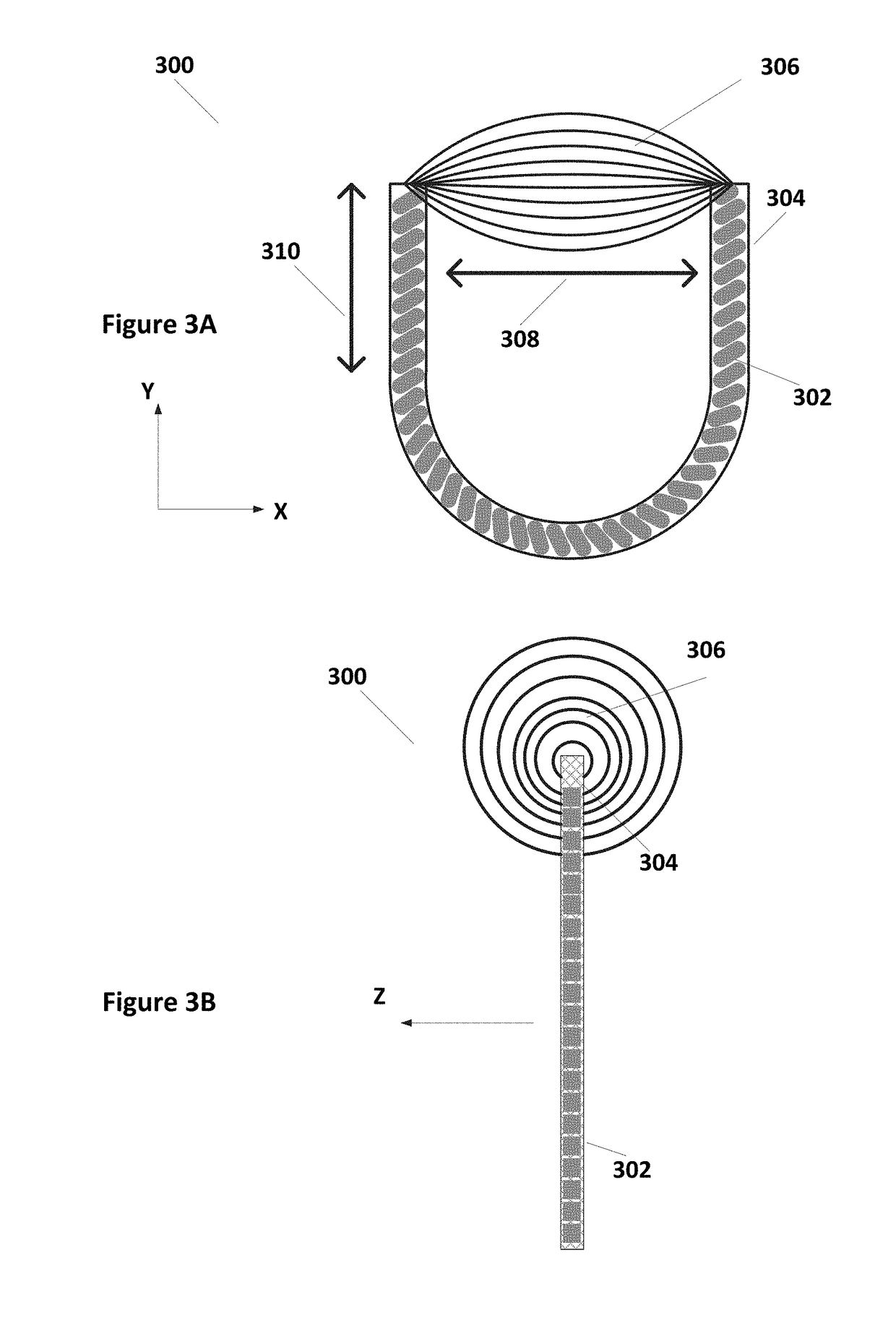

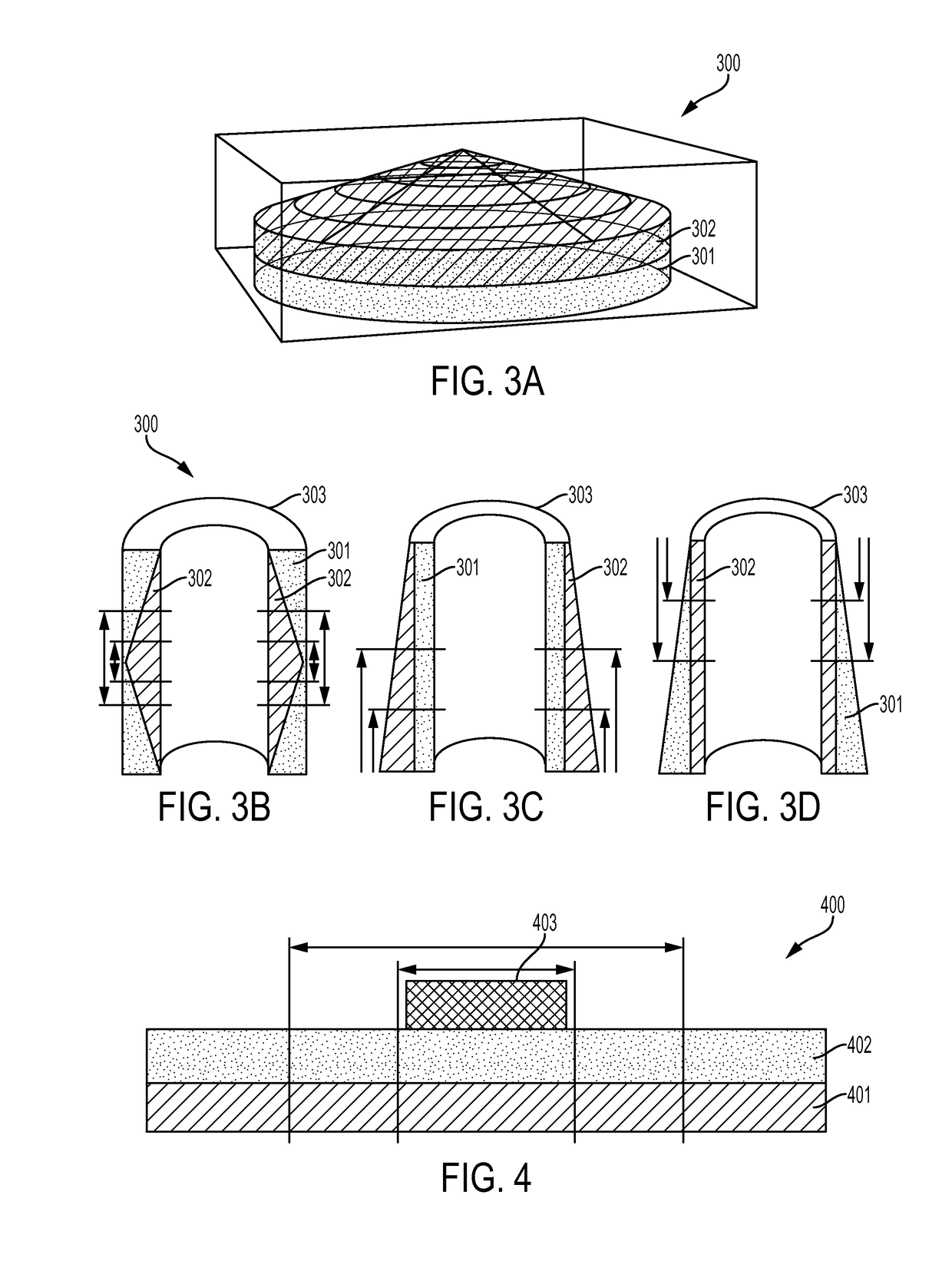

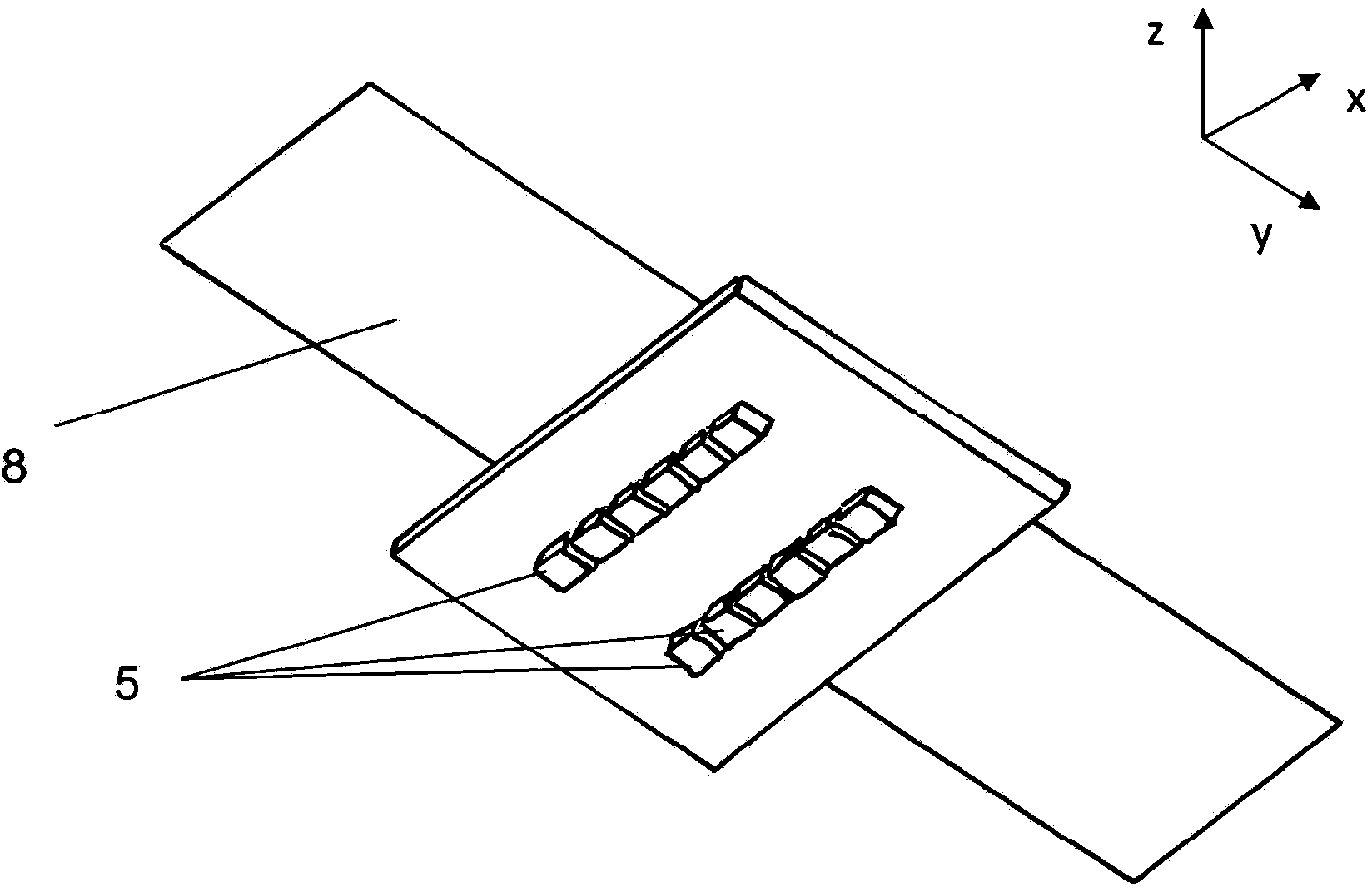

Directed magnetic field coil design

ActiveUS20190026411A1Reduce magnetic fieldNear-field transmissionTransformersEngineeringMagnetic flux

In accordance with aspects of the present invention, a coil arrangement is presented. A coil arrangement according to some embodiments includes at least one coil positioned to provide a magnetic field in a first area and configured to reduce the magnetic field in a second area outside of the first area. In some embodiments, the at least one coil includes a bent solenoid oriented in the X-Y plane, the bent solenoid localizing magnetic field flux at ends of the bent solenoid. In some embodiments, the bent solenoid can include end caps to further direct the magnetic flux. In some embodiments, the at least one coil includes a flattened solenoid with end caps to direct the magnetic flux. In some embodiments, the coil arrangement is a configuration of multiple coils.

Owner:INTEGRATED DEVICE TECH INC

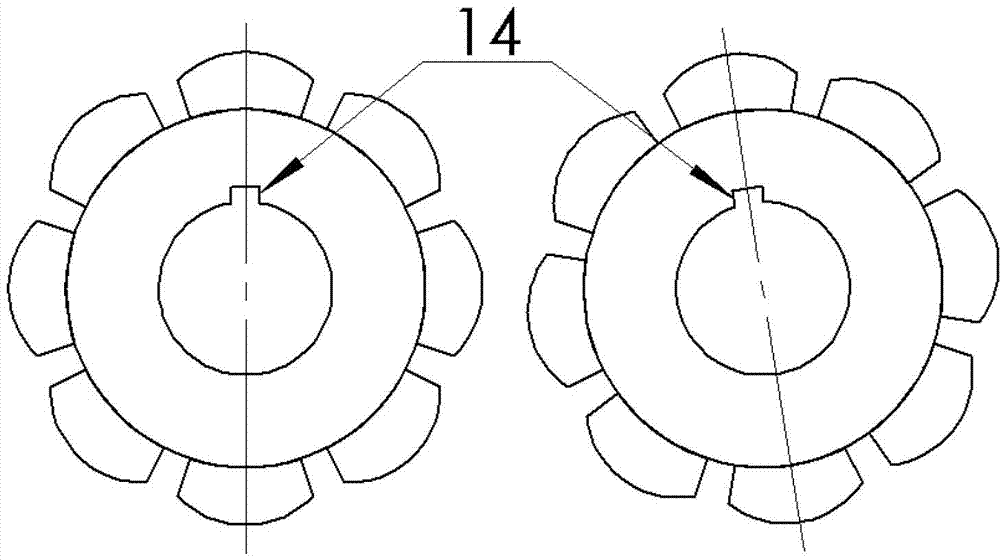

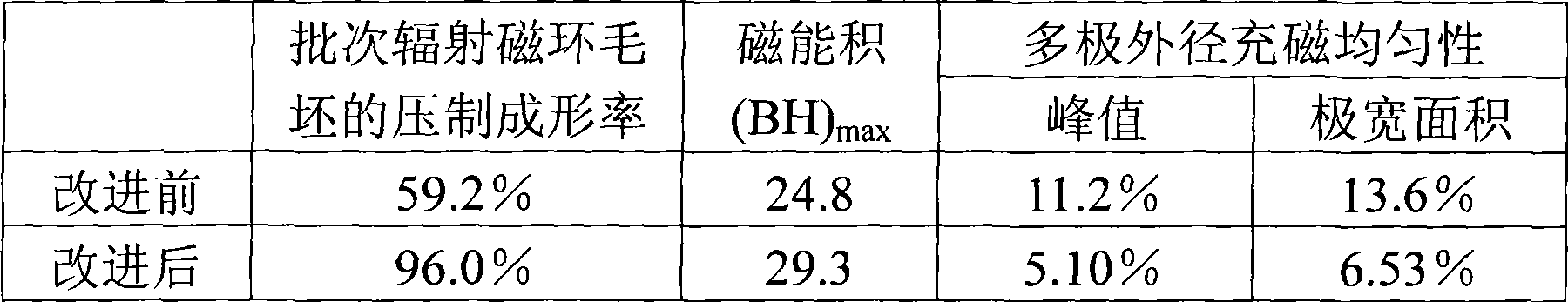

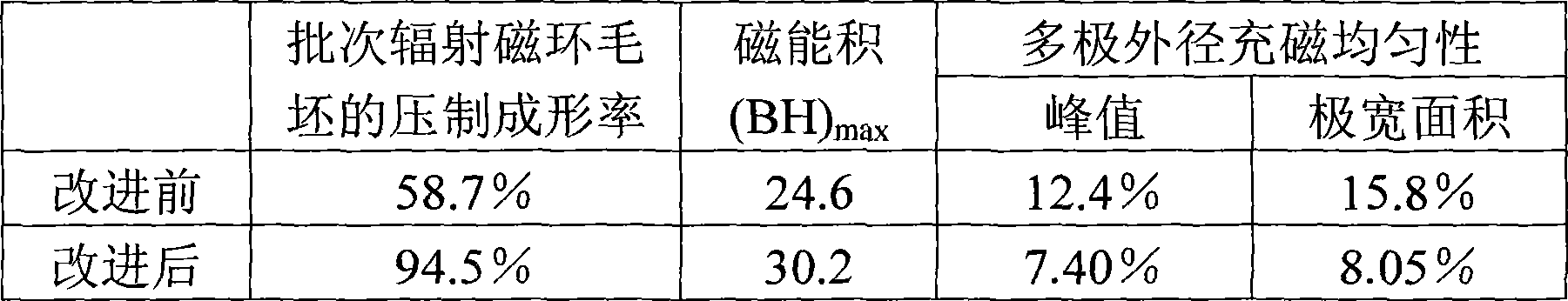

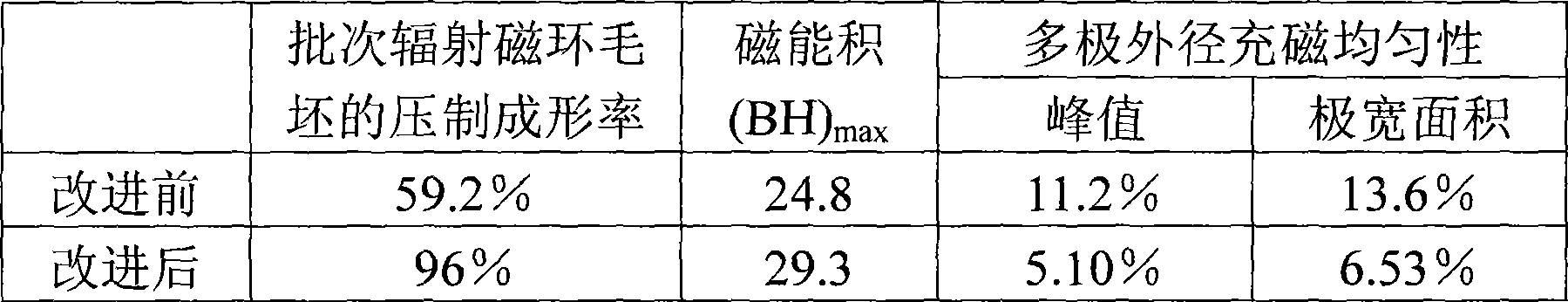

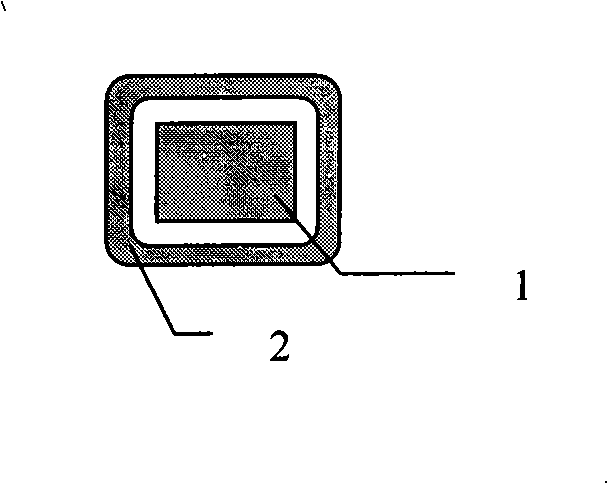

Processing method of R-T-B series alloy powder for radiation magnetic loop

ActiveCN101423902AUniform densityImprove one-shot molding rateFurnace typesHeat treatment furnacesPolyethylene oxideAlicyclic Hydrocarbons

The invention provides an R-T-B system alloy powder treatment method for radiation magnetic rings. The method comprises the following steps: raw alloy is melted in vacuum or inert gas so as to cast an ingot; a raw alloy ingot is subjected to coarse or hydrogen crushing in inert atmosphere; any two substances selected from polyethylene oxide composite polymers, fatty acid, fatty acid derivatives and hydrocarbon are added to and mixed with powder after coarse or hydrogen crushing; alloy coarse powder is subjected to micro-grinding in a nitrogen environment by use of a jet mill; the alloy powder is annealed in inert gas, vacuum or reducing atmosphere; carbonyl iron powder and at least one alicyclic hydrocarbon are added to and mixed with the annealed alloy powder; the mixed powder is taken to form an annular formed body in a magnetic field; the annular formed body is sintered in vacuum or inert gas atmosphere. The method has the advantages that the method is uniform in the density of the radiation ring, high in one-time molding rate and wide in pressure application range, increases the magnetic energy product of the radiation ring, and improves surface magnetic uniformity.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

Method for optimizing aluminium electrolysis slot field

ActiveCN101255567AOvercome the disadvantages of configurationReduce magnetic fieldSide effectConfiguration design

The invention provides a method for optimizing the in-cell magnetic field of aluminum electrolysis cell, relating to a magnetic field optimizing method for configuring bus of aluminum electrolysis cell. The method is characterized in that: on the way that the compensation bus goes to the object position, a ferromagnetic shielding cover is sheathed on a section where the bus has negative effect to the in-cell magnetic field in order to reduce side effect of the bus. The method effectively overcomes the drawback of the traditional compensation bus configuration by sheathing the shielding cover around part of the compensation bus located at the bottom of the electrolysis cell, thus, the compensation bus has little negative effect on the other magnetic field on the way for reducing the magnetic field of the object position, so that the magnetic field of the electrolysis cell can be easily reduced, especially applicable for the bus configuration design of large aluminum electrolysis cell with the advantages of being stable, high efficiency, long life.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method and apparatus of implementing a magnetic shield flux sweeper

ActiveUS9913414B2Ambient magnetic field will be reducedAvoid changeShielding materialsStray field compensationMagnetic shieldSpatial change

The present invention relates to a method and apparatus of protecting magnetically sensitive devices with a shield, including: a non-superconducting metal or lower transition temperature (Tc) material compared to a higher transition temperature material, disposed in a magnetic field; means for creating a spatially varying order parameter's |Ψ(r,T)|2 in a non-superconducting metal or a lower transition temperature material; wherein a spatially varying order parameter is created by a proximity effect, such that the non-superconducting metal or the lower transition temperature material becomes superconductive as a temperature is lowered, creating a flux-free Meissner state at a center thereof, in order to sweep magnetic flux lines to the periphery.

Owner:NASA

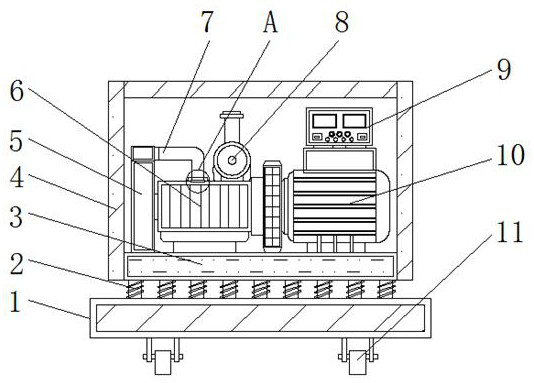

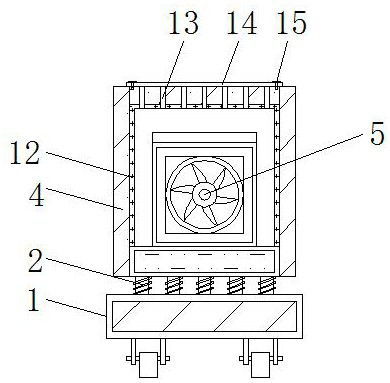

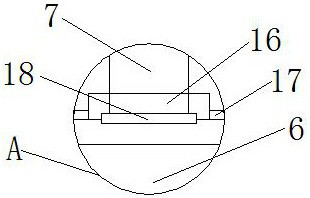

Anti-interference generator set with self-checking function

InactiveCN111894732AGuaranteed uptimePlay the role of anti-interferencePortable framesCombustion enginesInsulation layerInterference resistance

The invention discloses an anti-interference generator set with a self-checking function. The anti-interference generator set with the self-checking function comprises a base, a diesel engine and a control display screen, damping springs are fixedly arranged above the base, a seat plate is installed above the damping springs, the damping springs are distributed above the base at equal intervals, the damping springs and the base are welded, a sound insulation layer is arranged on the outer side of the upper portion of the seat plate and distributed in a rectangular hollow structure, the lower portion of the sound insulation layer is in threaded connection with the seat plate, a fan is installed on the left side of the upper portion of the seat plate, the diesel engine is fixed to the rightside of the fan, a pipeline is arranged on the left side of the upper portion of the diesel engine, a fuel tank is installed on the right side of the upper portion of the diesel engine, the upper portion of the diesel engine is fixedly connected with the fuel tank, and a generator is arranged on the right side of the diesel engine. The anti-interference generator set with the self-checking function is provided with the damping springs so that a uniform damping effect can be achieved on the seat plate.

Owner:张雪燕

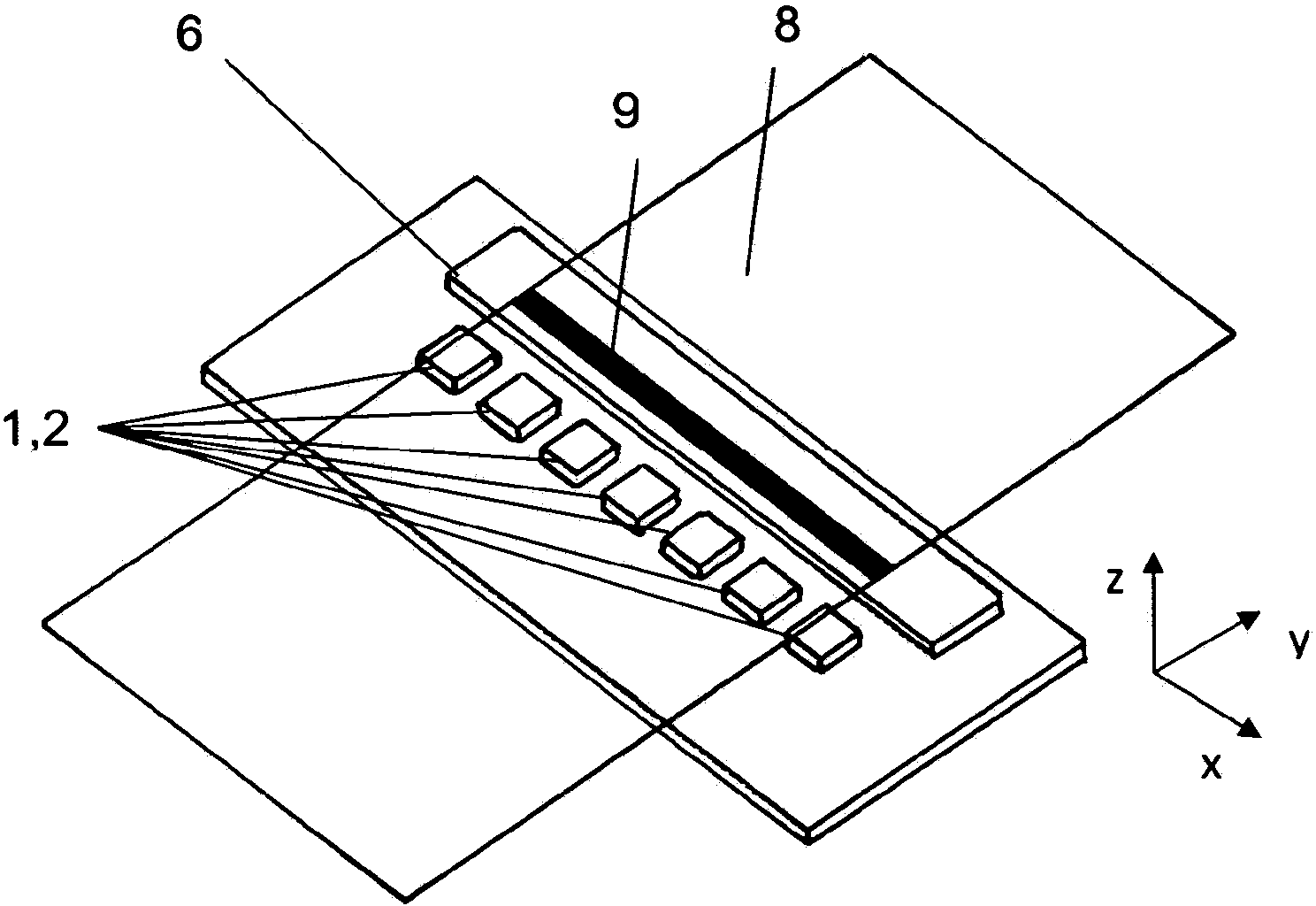

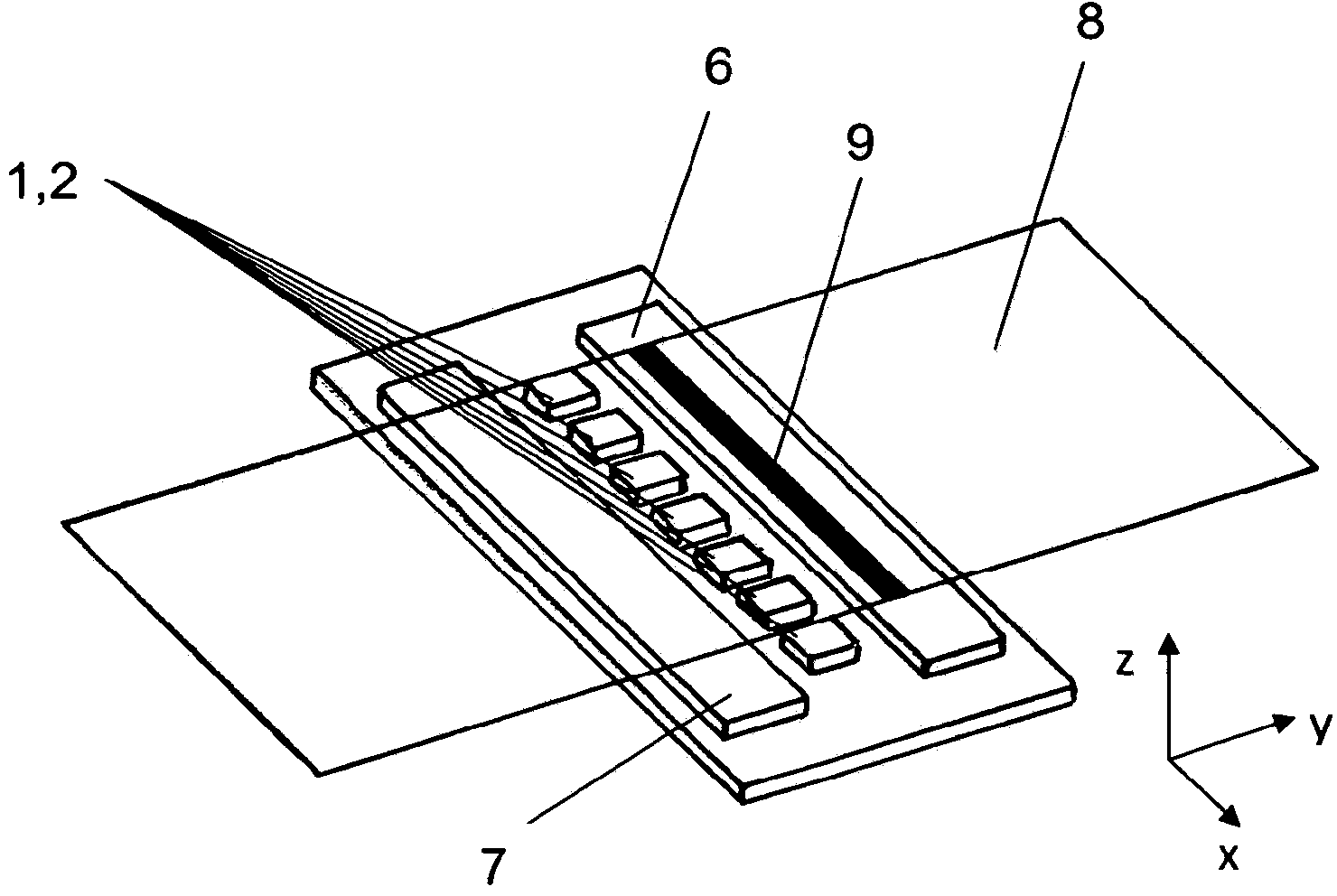

Measuring device for measuring magnetic properties of surroundings of measuring device

ActiveCN103814399ASensitive authenticationFull verificationMagnetic measurementsPaper-money testing devicesOrthogonal coordinatesMeasurement device

The invention relates to a measuring device for measuring the magnetic properties of the surroundings of the measuring device by means of a sensor line having at least one magnetoresistive sensor element extending in a line direction, which can measure the magnetic properties in the surroundings thereof, wherein the sensor element has a width and a length as well as a height, wherein the height is smaller than the width, and the height is smaller than the length, and the line direction points in the direction of the width or in the direction of the length of the sensor element, and having a support field device which generates a magnetic support field in the area over which the sensor line extends, having a premagnetization device which comprises a premagnetization magnet or several premagnetization magnets, wherein at least one premagnetization magnet is arranged in a direction which is perpendicular to the line direction, spaced from the sensor line, and extends in a direction parallel to the line direction, characterized in that magnetoresistive sensor element can measure the magnetic properties of the surroundings thereof substantially in only one direction, referred to as the measurement direction, of an orthogonal coordinate system, or substantially in only one plane, referred to as the sensor measurement plane, which is defined by two perpendicular measurement directions of an orthogonal coordinate system, in that, in the case of a premagnetization device which consists of only one premagnetization magnet, the properties of the premagnetization magnet, which influence the magnetic field generated by said magnet and the arrangement of said magnet relative to the sensor cell as well as the support field generated by the support field device are selected in such a manner that an overlap magnetic field forms due to the overlap of the magnetic field generated by the premagnetization device and of the support field, wherein the strength of the field component of said overlap magnetic field, which points in the line direction is, at least at one site on the sensor line, greater than the strength of the field component which is perpendicular to the line direction and does not point in the direction of the height of the sensor element, or in the case of a premagnetization device consisting of several premagnetization magnets, the properties of the premagnetization magnet, which influence the magnetic field generated by said magnets, and the arrangement of the premagnetization magnets relative to the sensor cell as well as the support field generated by the support field device are selected in such a manner that an overlap magnetic field forms due to the overlap of the magnetic field generated by the premagnetization device and of the support field, wherein the strength of the field component of said overlap magnetic field, which points in the line direction is, at least at one site on the sensor line, greater than the strength of the field component which is perpendicular to the line direction and does not point in the direction of the height of the sensor element.

Owner:精量电子(德国)公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com