Patents

Literature

40results about How to "Improve one-shot molding rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

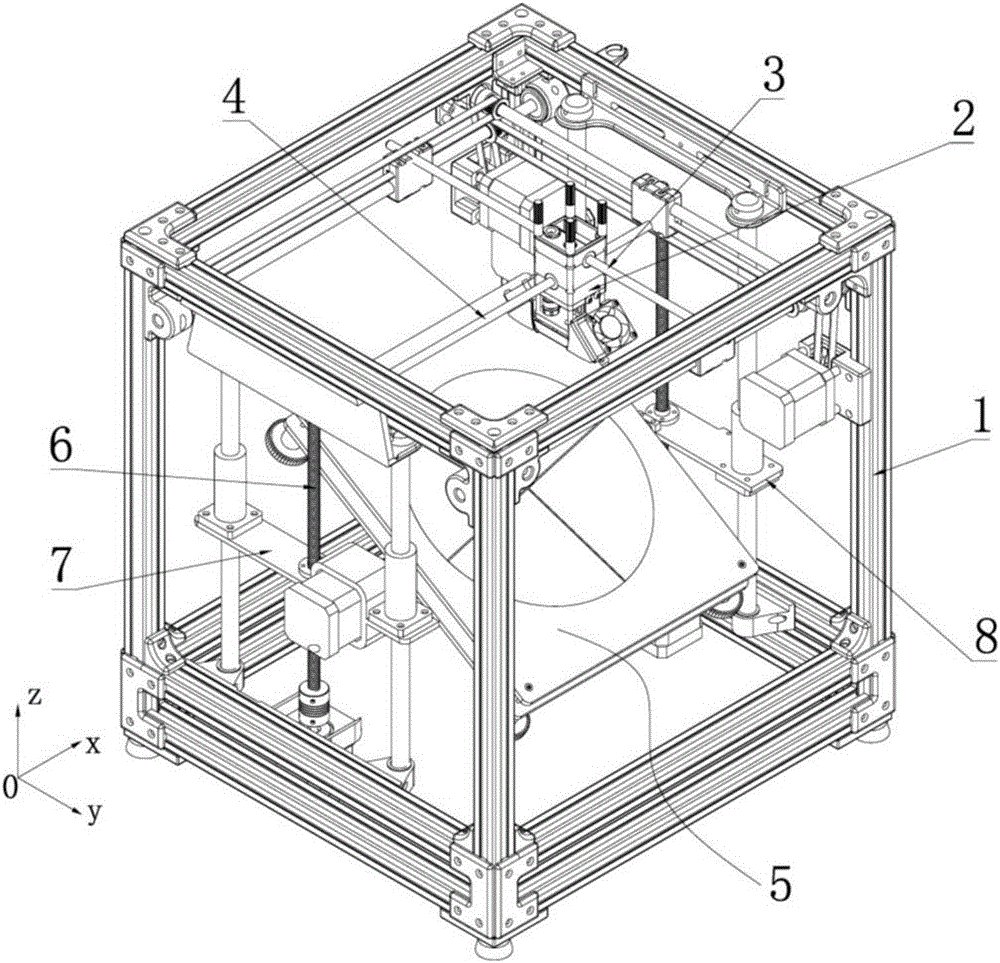

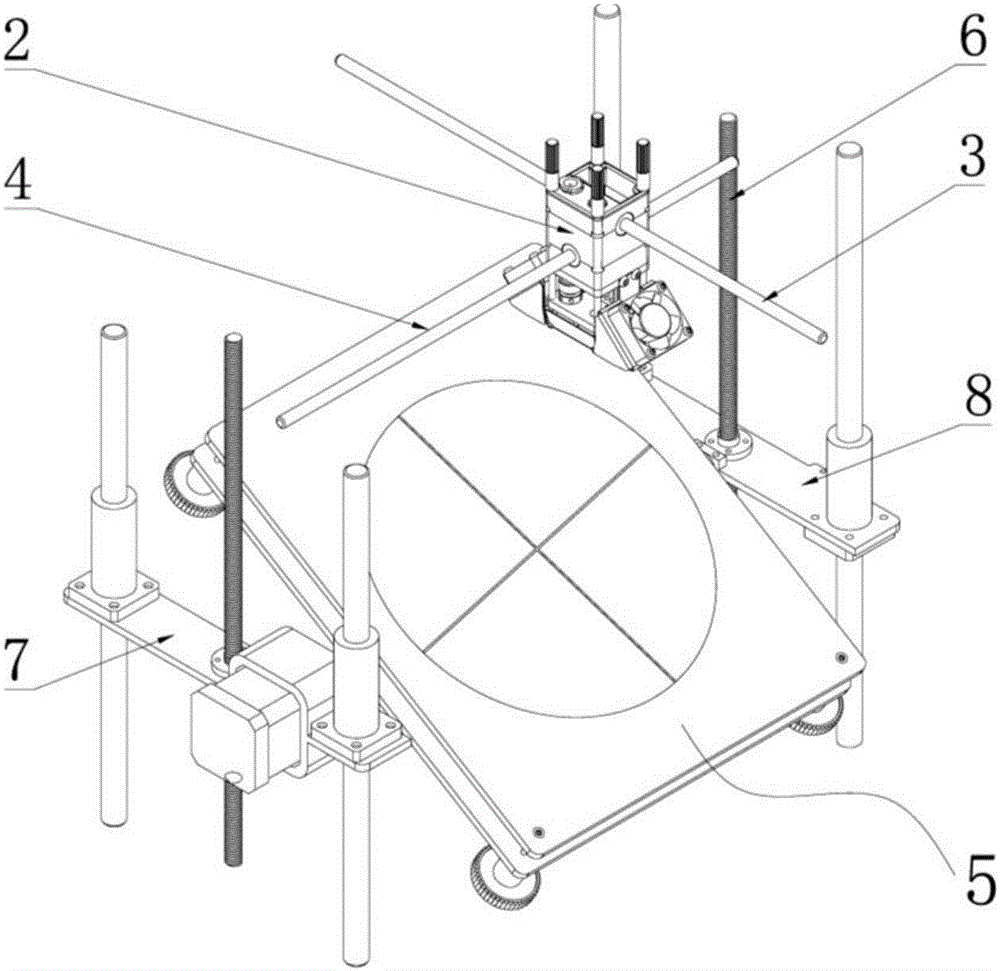

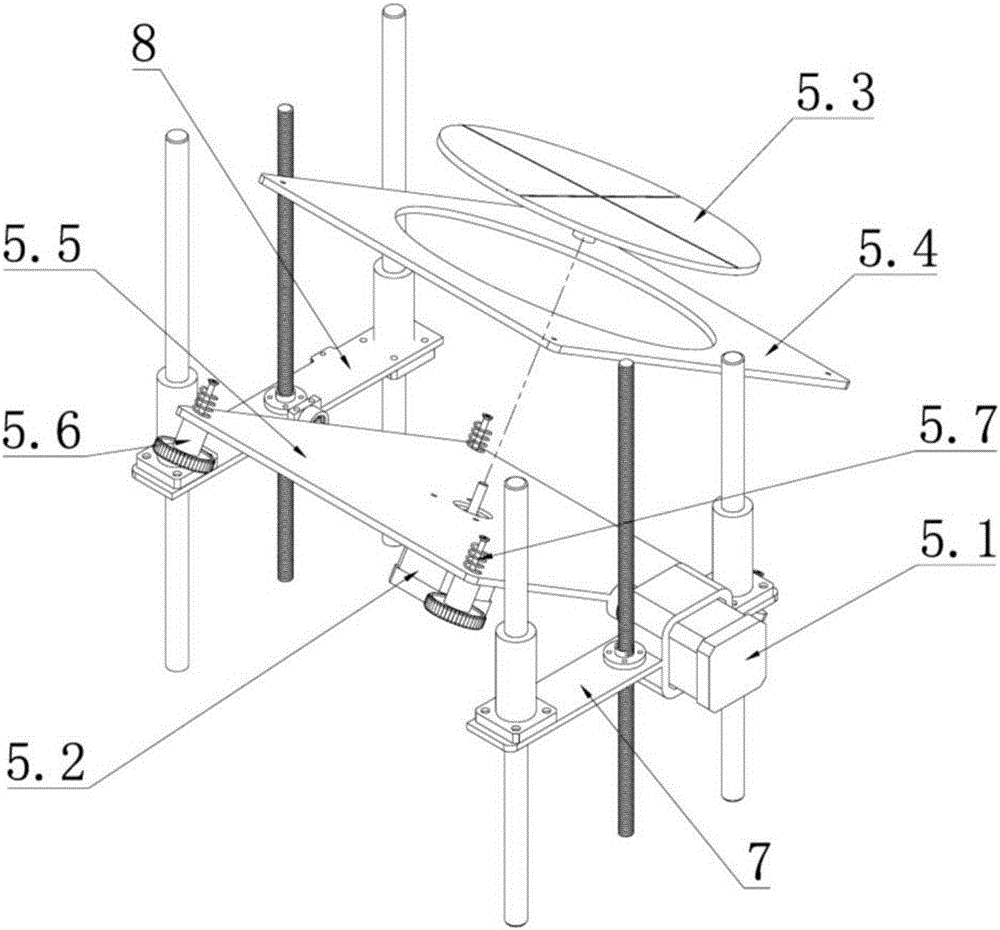

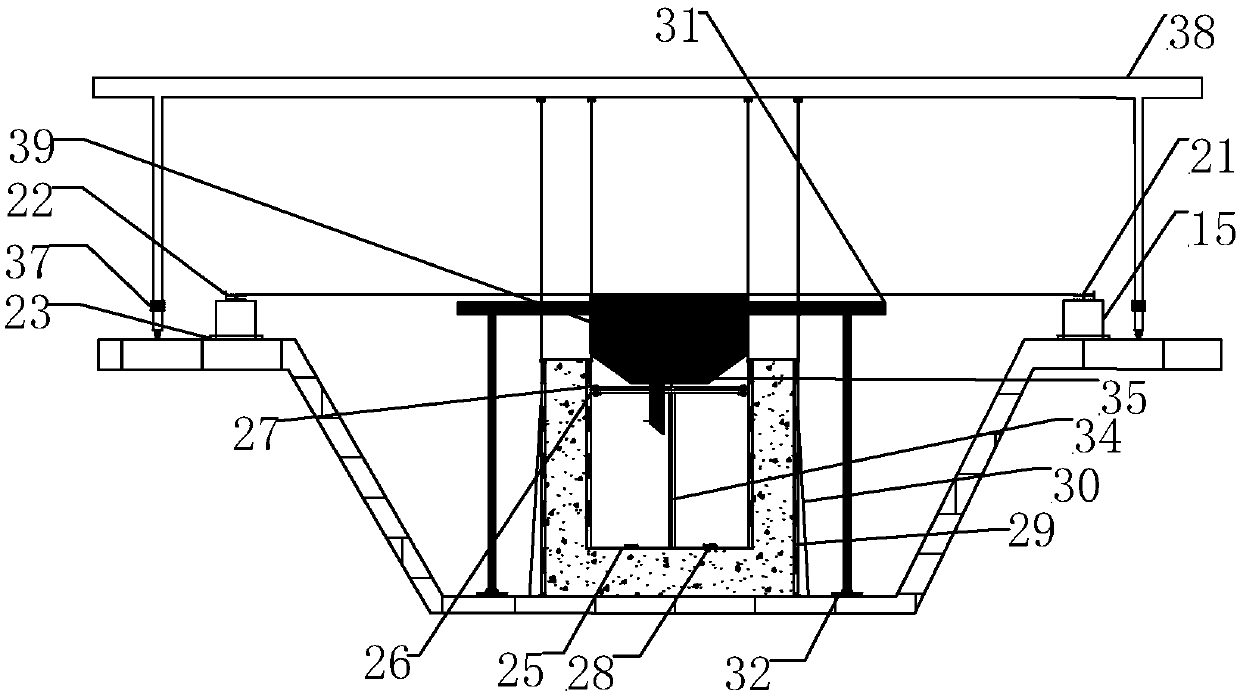

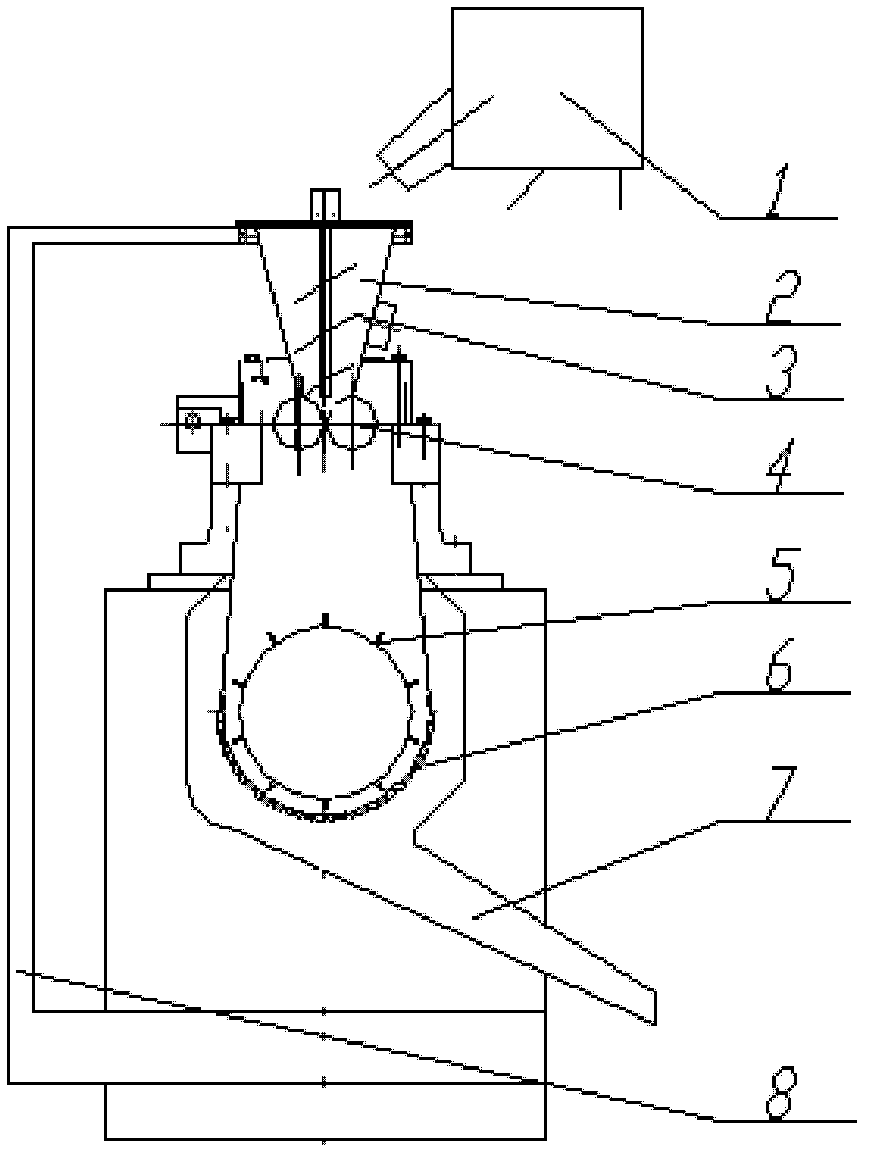

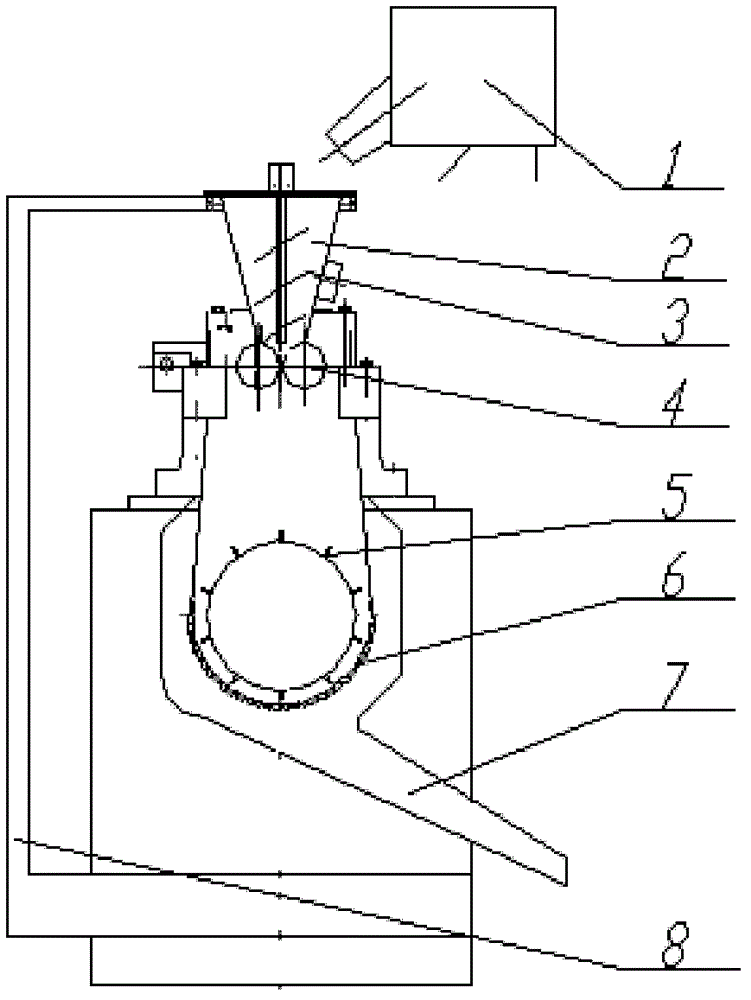

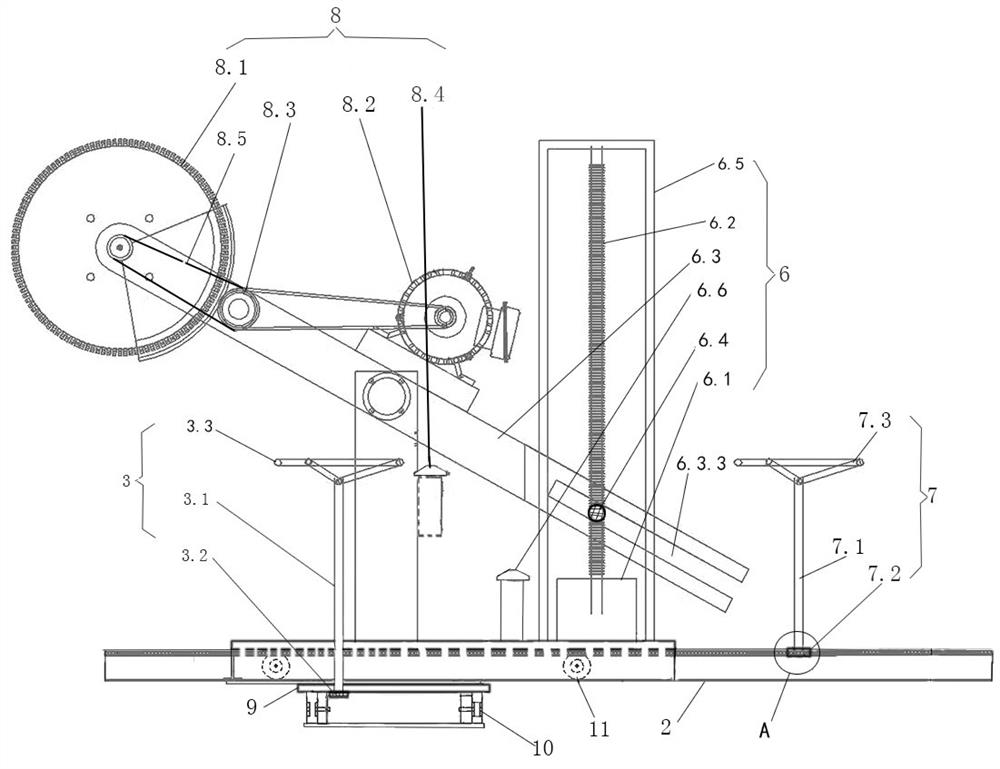

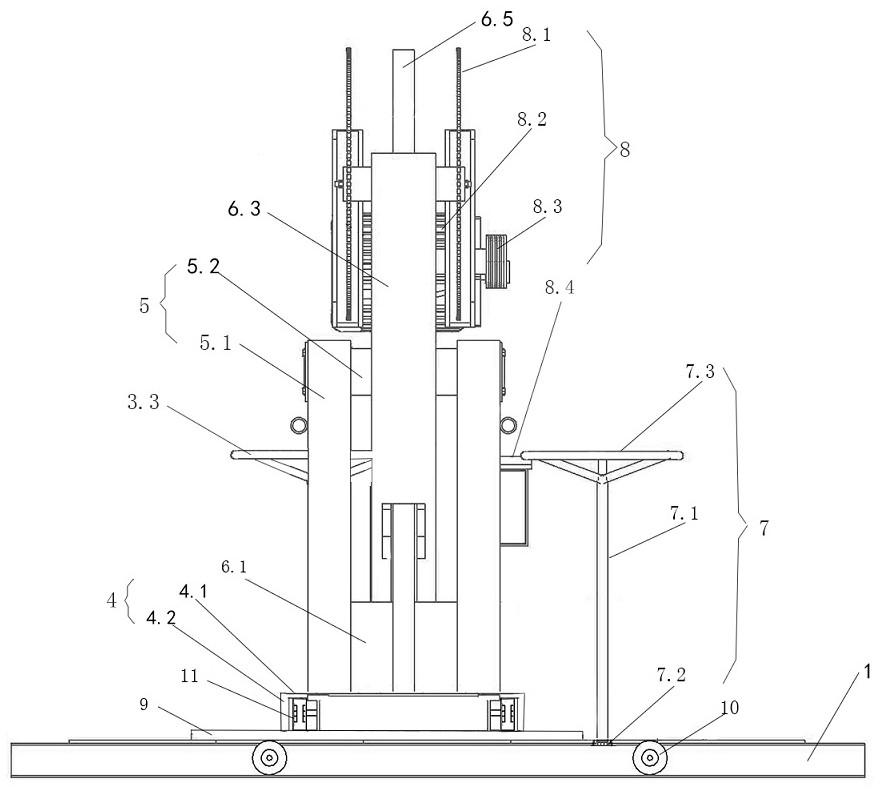

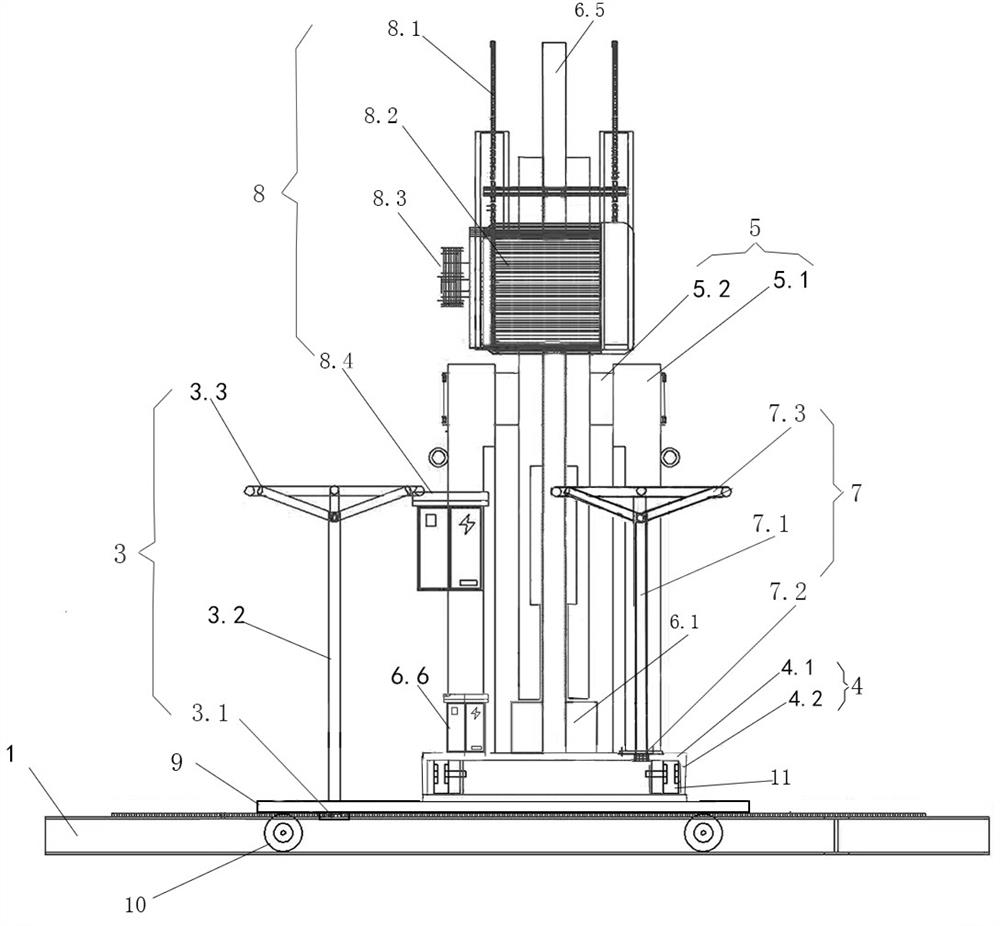

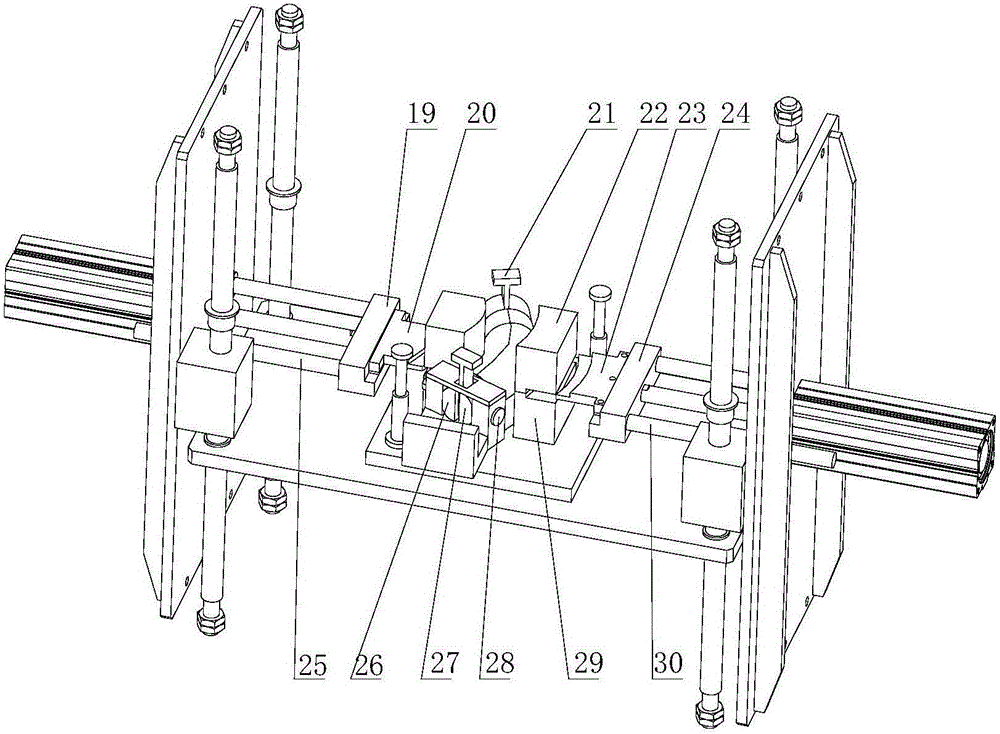

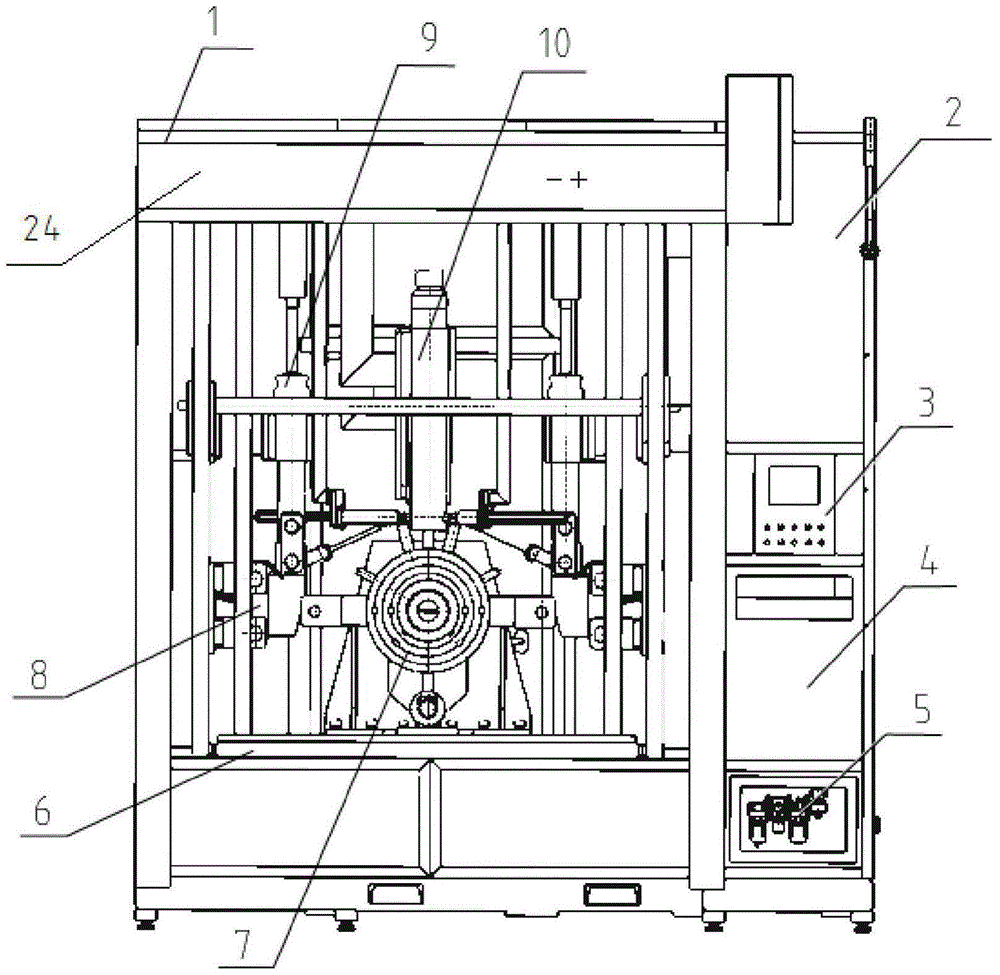

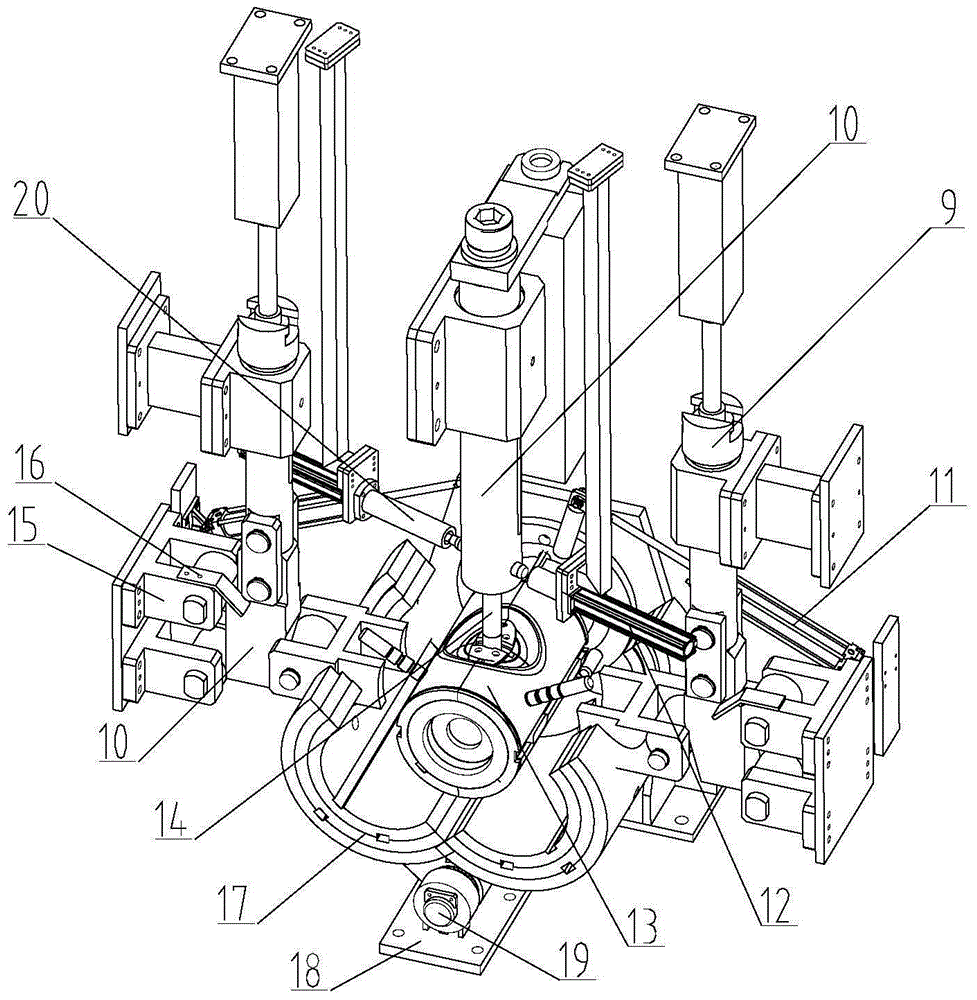

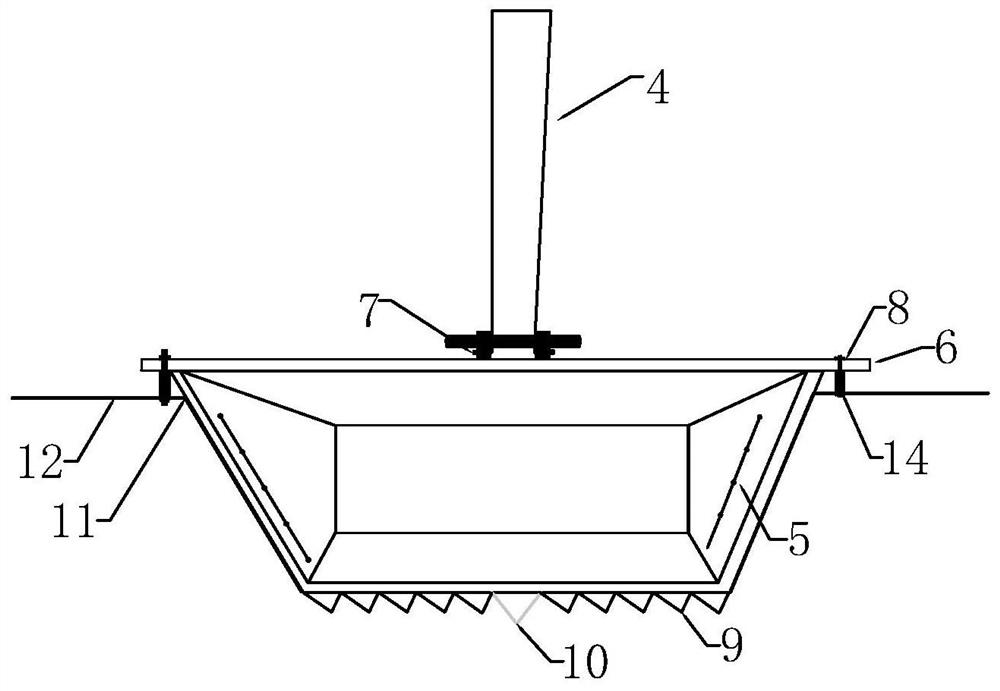

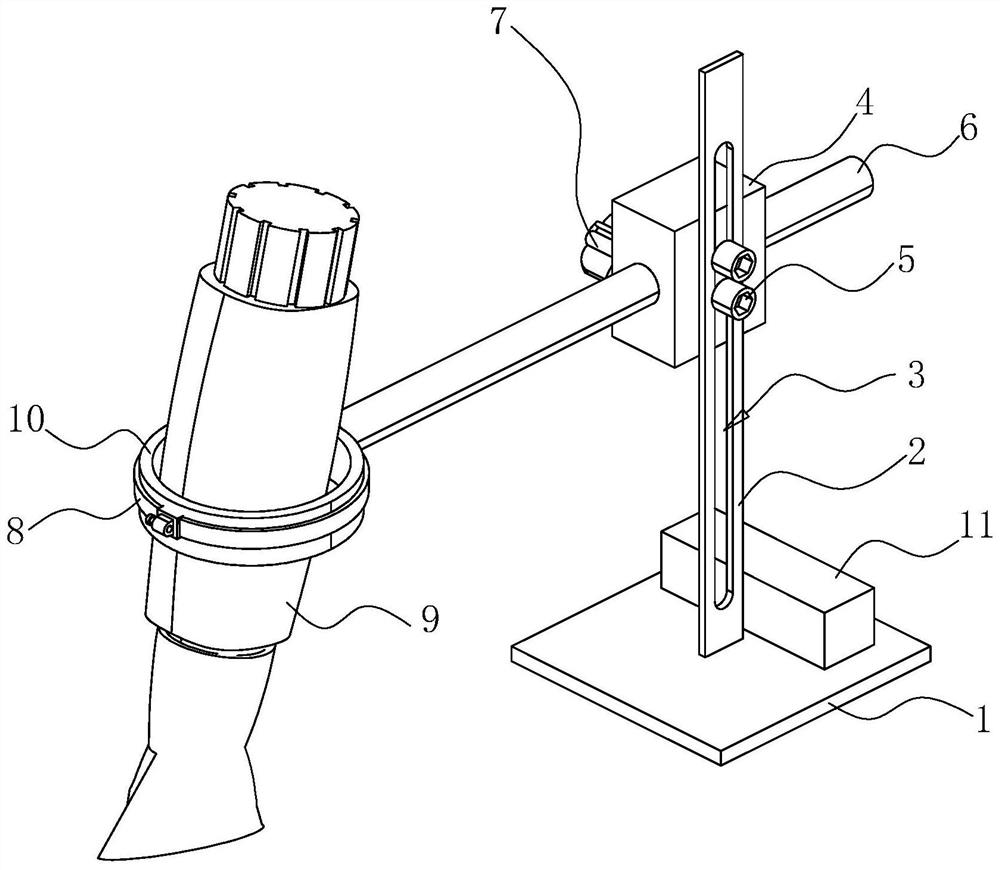

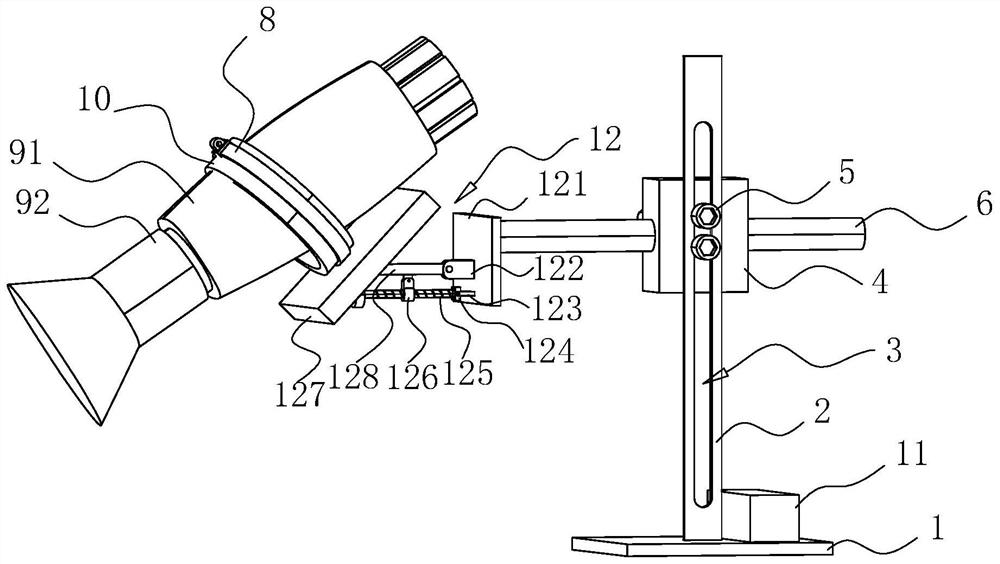

Double-rotating-shaft 3D printing platform

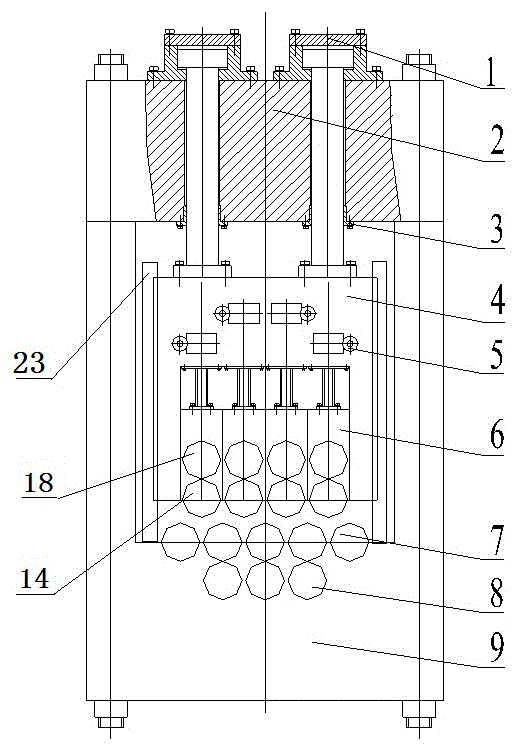

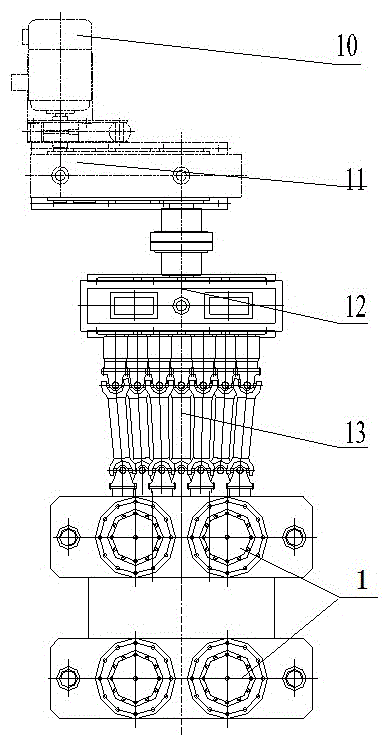

InactiveCN106239918ARealize printingImprove one-shot molding rateAdditive manufacturing apparatusBall screwEngineering

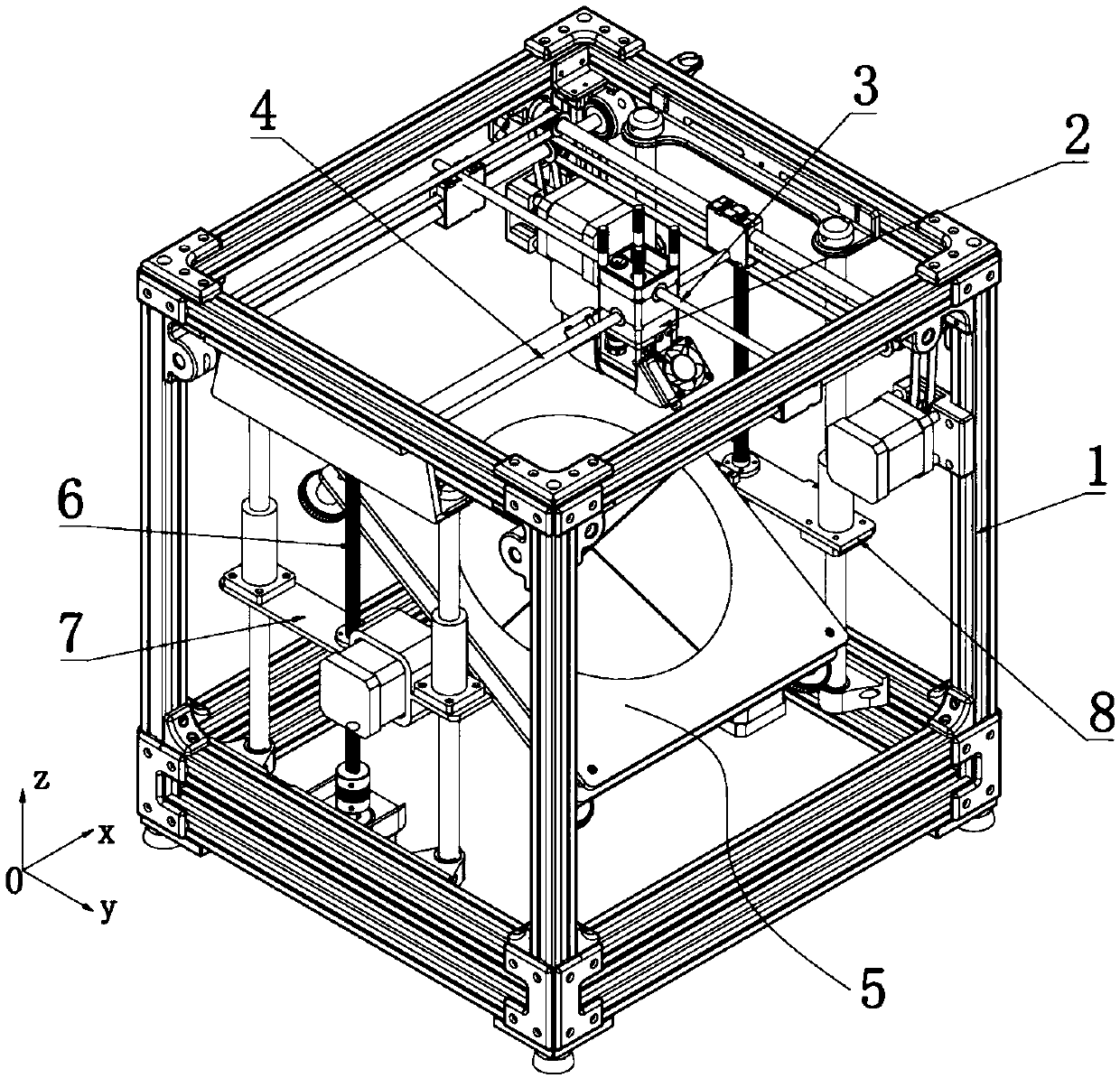

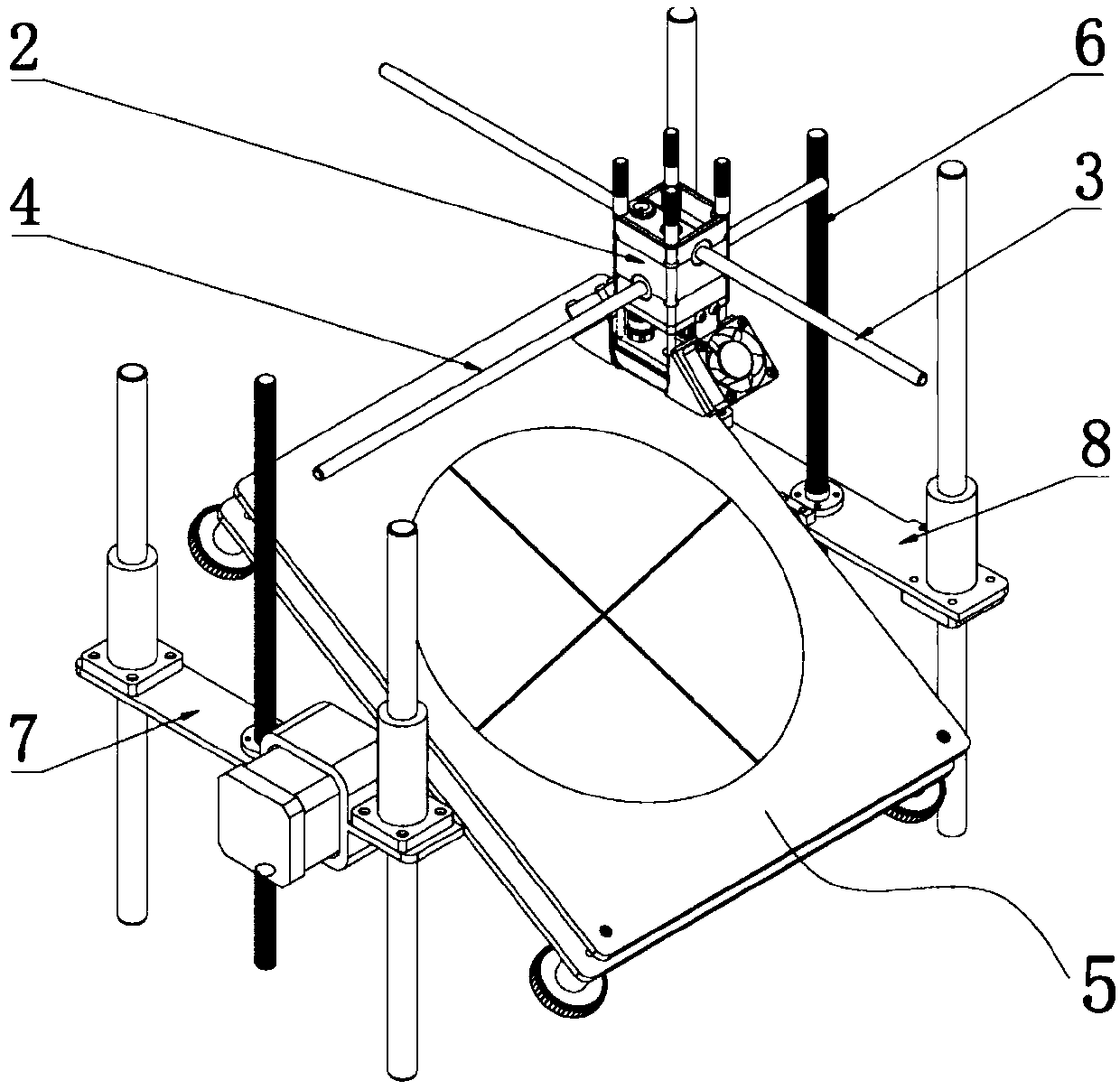

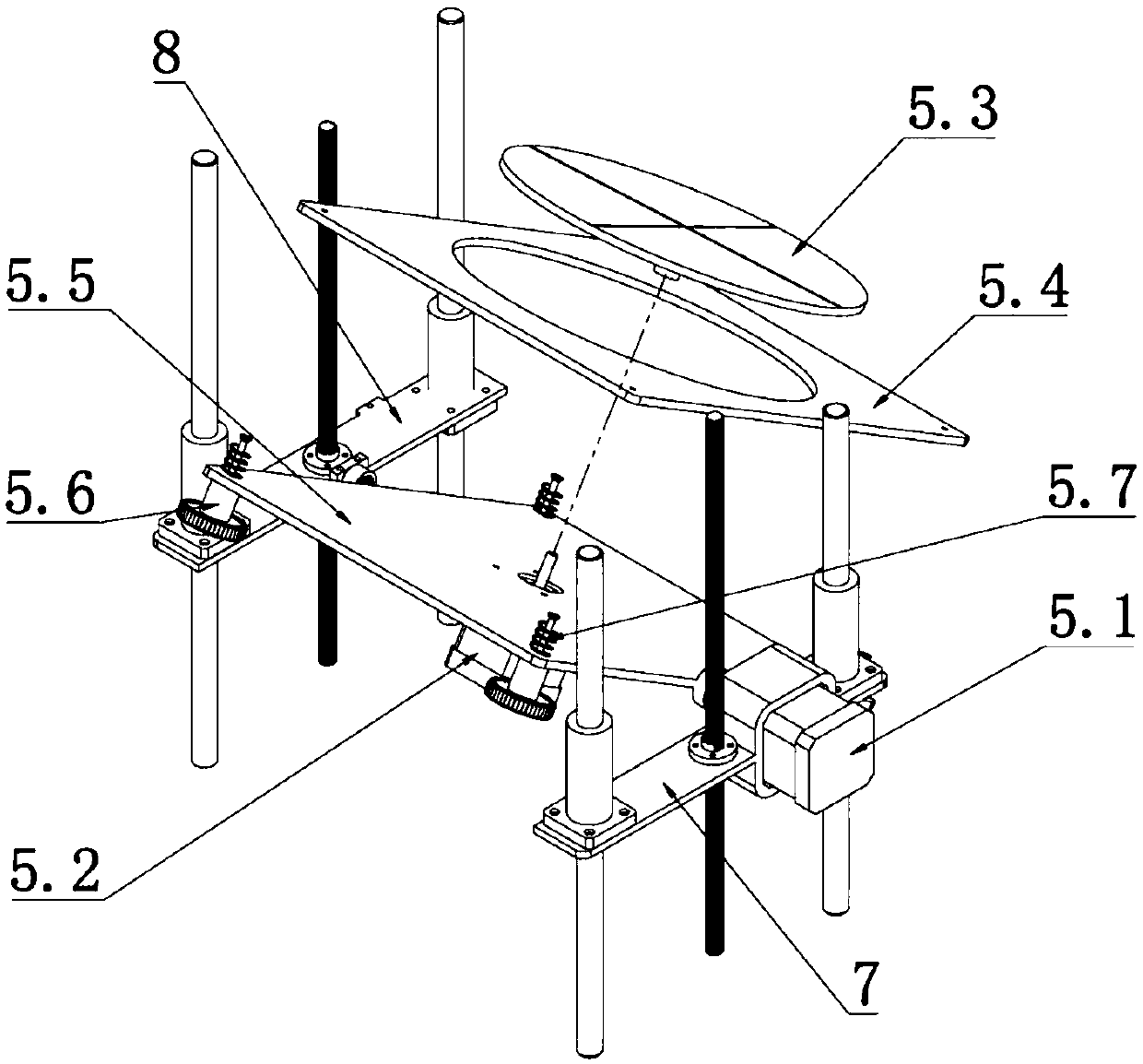

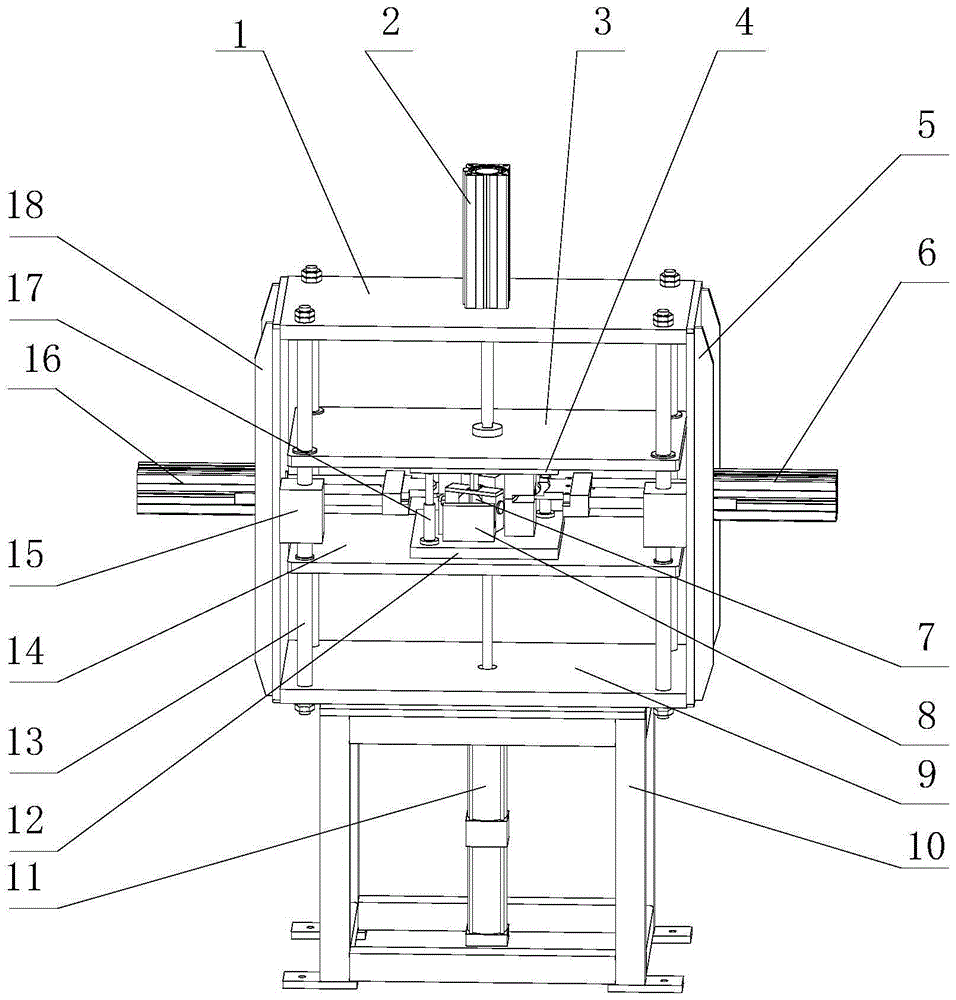

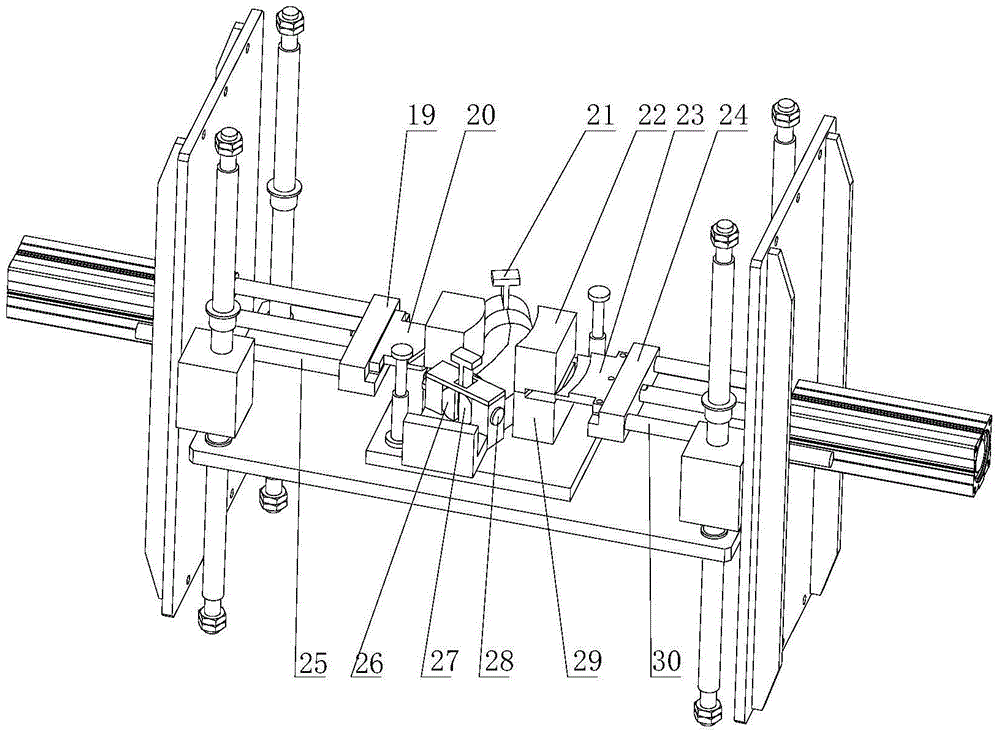

The invention discloses a double-rotating-shaft 3D printing platform capable of completing printing of the lateral side parts of components. According to the double-rotating-shaft 3D printing platform, by means of two stepping motors, a working table can be driven to rotate around the vertical axis of the working table itself and can pitch and incline up and down around the horizontal central axis of the platform during rotation; and on the other hand, the 3D printing platform is driven by a ball screw to rise and fall along the Z axis, and therefore precise and complete printing of the lateral side parts of the printed parts is achieved. The double-rotating-shaft 3D printing platform is simple in structure, reasonable in design and convenient to control, no supporting materials need to be added during printing, the pretreatment and aftertreatment procedures required by conventional printers are reduced, the quality of printed pieces is improved, and the application field of printers of the type is expanded.

Owner:HUBEI UNIV OF TECH

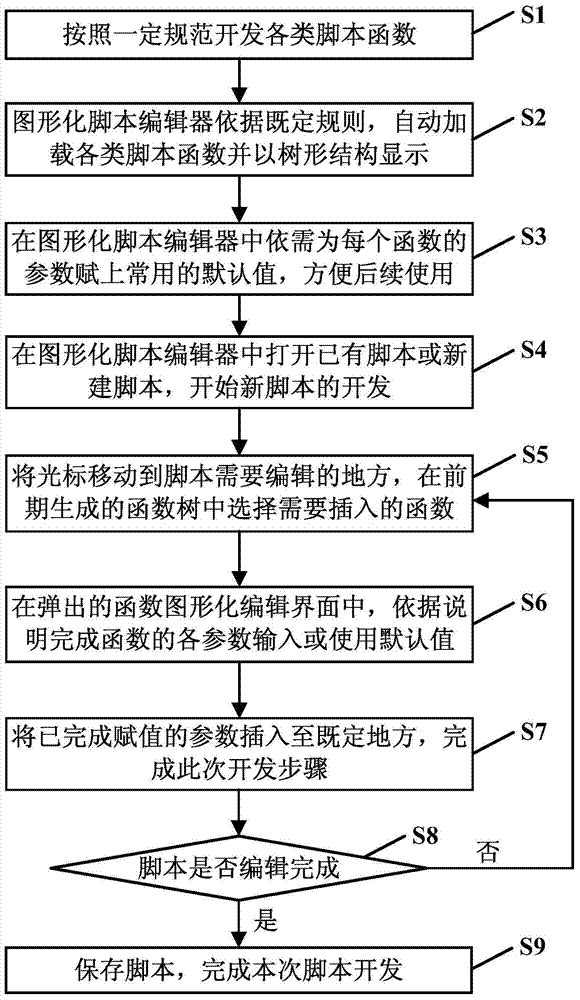

Graphical script editor and method for fast developing communication equipment testing script

ActiveCN104268072AImprove development efficiencyImprove one-shot molding rateSoftware testing/debuggingPersonalizationFunction tree

The invention discloses a graphical script editor and a method for fast developing a communication equipment testing script, and relates to the field of graphical interface development. The graphical script editor comprises a function information document library forming unit, an automatic function loading unit, a function tree generating unit, a tree structure display unit, a function assignment unit, an individual graphical interface display unit and a script development unit. In the whole compiling process of the communication equipment testing script, developers only need to complete input of communication equipment testing script parameters according to the prompt of a graphical interface, and do not need to know compiling grammar or the writing format, and error-free development of the communication equipment testing script can be completed. Through a large number of tests, it is proved that the graphical script editor can effectively improve the development efficiency of the communication equipment testing script.

Owner:FENGHUO COMM SCI & TECH CO LTD

Biological desiccant and preparing method of biological desiccant

InactiveCN105032135ALow cost situationIncrease diversityOther chemical processesDispersed particle separationAdditive ingredientSorbent

The invention relates to a biological desiccant, which is characterized by comprising the following ingredients including a water retention agent, a water absorbent, an anti-sticking agent and an adsorbent, wherein the water retention agent is konjak flying powder or konjak full powder; the water absorbent is one or a mixture of several materials from anhydrous calcium chloride, magnesium chloride and L-carnitine-L-tartrate; the anti-sticking agent is one or a mixture of several materials from silicon dioxide, white carbon black and talcum powder; the adsorbent is bamboo charcoal or active carbon. The biological desiccant and a preparing method of the biological desiccant have the advantages that the effects of safety, no toxicity and no pollution are achieved; the water absorbing capacity is high; the biological desiccant is suitable for being applied to environments with any humidity; in the environment with T being 25 DEG C and RH being 90 percent, the moisture absorption rate can reach 70 to 200 percent; the prepared desiccant finished product also has the function of odor adsorption; the preparing process is simple; the one-step forming rate of the product is high; the problem of low profits since the konjak flying powder is only used as feed for a long time is solved; the application value of konjak by-products and the diversity of drying agent products are improved.

Owner:WUHAN POLYTECHNIC UNIVERSITY +1

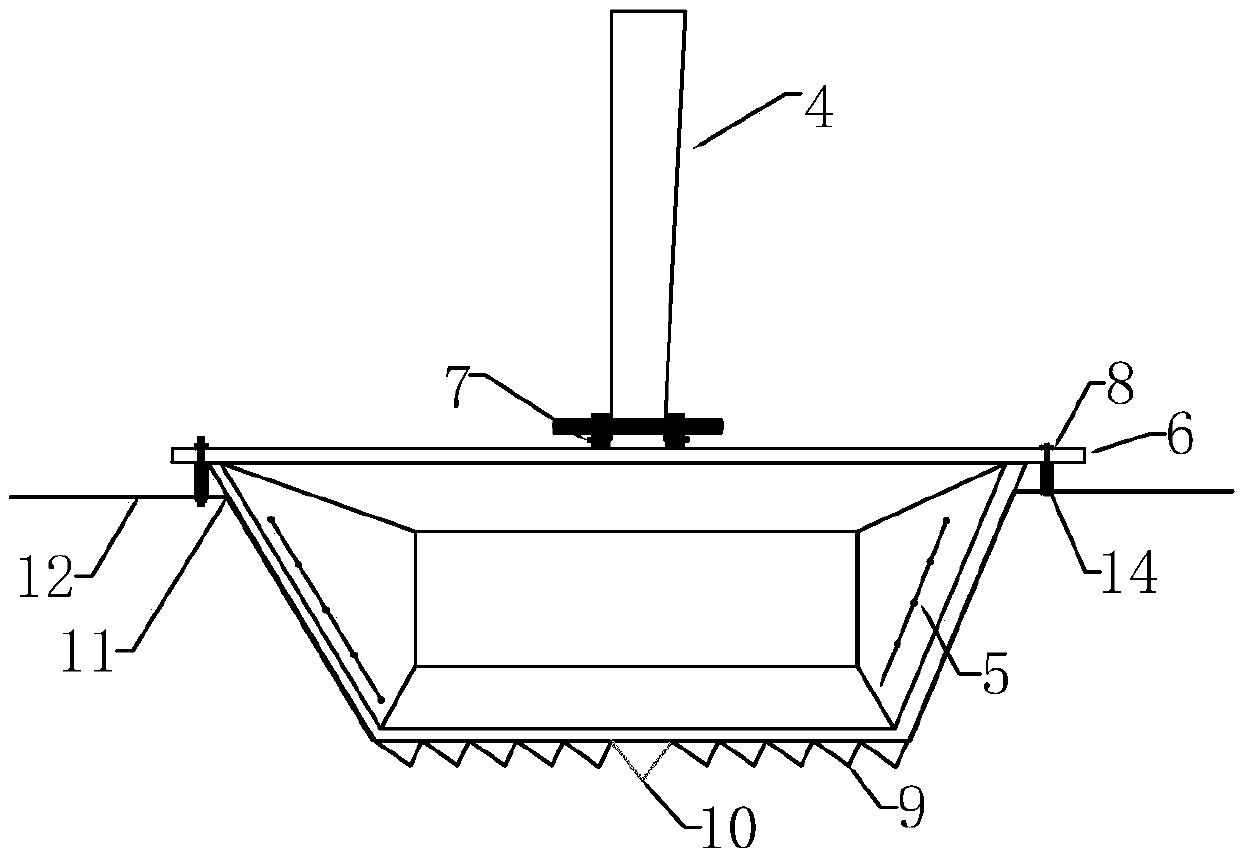

Integrally-formed drainage ditch and construction method thereof

The invention discloses an integrally-formed drainage ditch, which comprises a drainage ditch body, a shaped digging bucket, a shaped slope scraper, sliding mold rails, a shaped side mold and a bottomscraping cross beam frame, wherein the sliding mold rails are assembled on two sides of the drainage ditch body; the shaped side mold is arranged in the drainage ditch body; the bottom scraping crossbeam frame is arranged at the bottom of the drainage ditch body; the shaped side mold can be fixedly arranged on the bottom scraping cross beam frame; the bottom scraping cross beam frame is connected with a sliding cross beam gantry and is dragged and slid by the sliding cross beam gantry; and the shaped side mold is connected with a side mold gantry and is dragged and slid by the side mold gantry. The drainage ditch simplifies the construction steps, saves the construction time, reduces the construction cost, is easy to excavate and form, has low operation difficulty, so that the safety inthe construction process can be effectively ensured; and the drainage ditch has beautiful appearance and good quality. The second object of the invention is the construction method of the integrally-formed drainage ditch, the method is applied to the integrally-formed drainage ditch, and further has the advantages of high safety, high convenience and the like.

Owner:HANGZHOU JIANGRUN TECH LIMITED

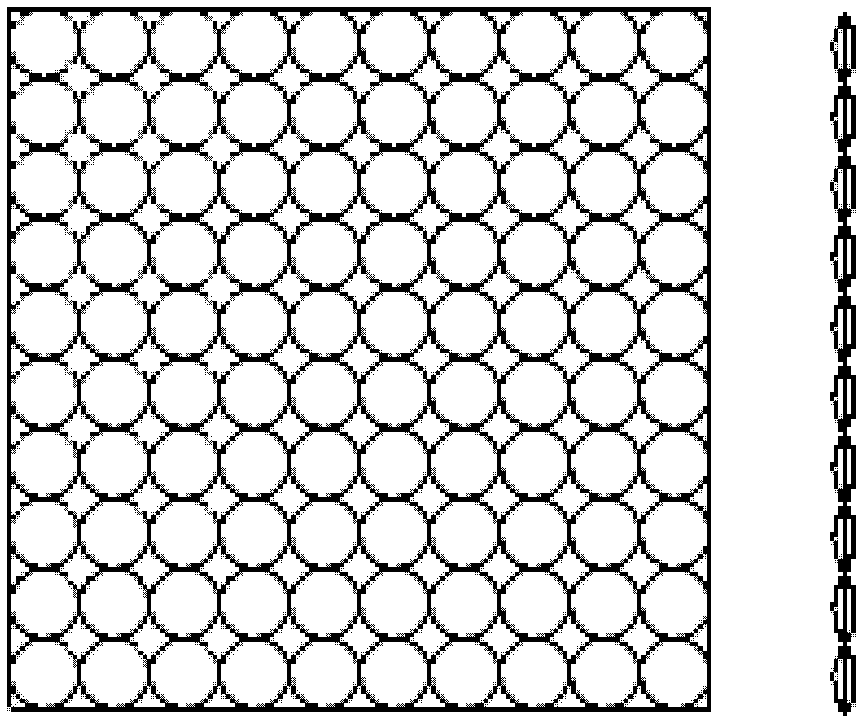

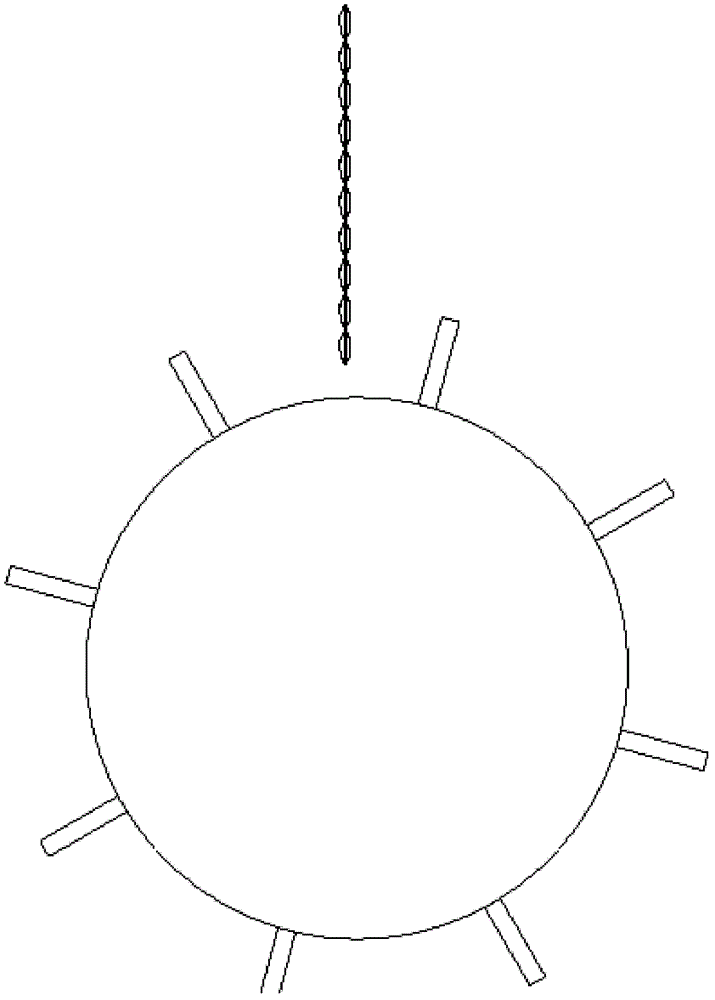

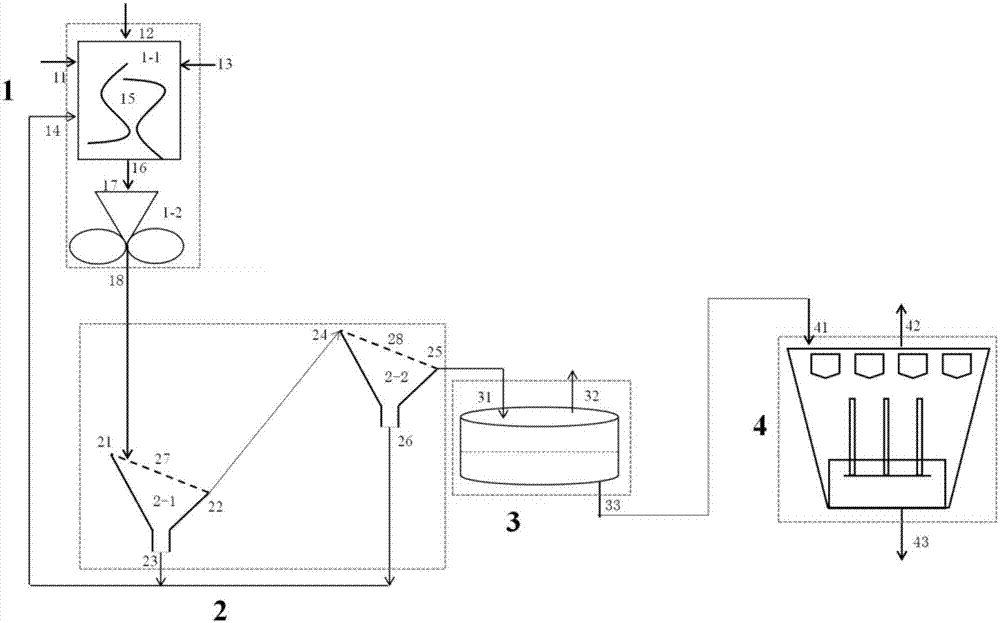

One-step molding technology and device for spherical soldering tin

ActiveCN1657226AAdaptableGood sphericityWelding/cutting media/materialsSoldering mediaSolderingVertical cylinder

A technology for preparing the spherical soldering tin used for packing ICs (BAG, CSP, etc) includes such steps as smelting the soldering tin, delivering the molten soldering tin via tube to a container with laser perforated plate, electromechanical longitudinal and transverse oscillasion to make the molten soldering tin pass through the pinholes on plate while vacuum sucking downward to become drops, rounding and antioxidizing treating in a vertical cylinder, and screening. Its apparatus is composed of smelting furnace, liquid drop shaper, and sphere shaper.

Owner:云南锡业研究院有限公司研究设计院

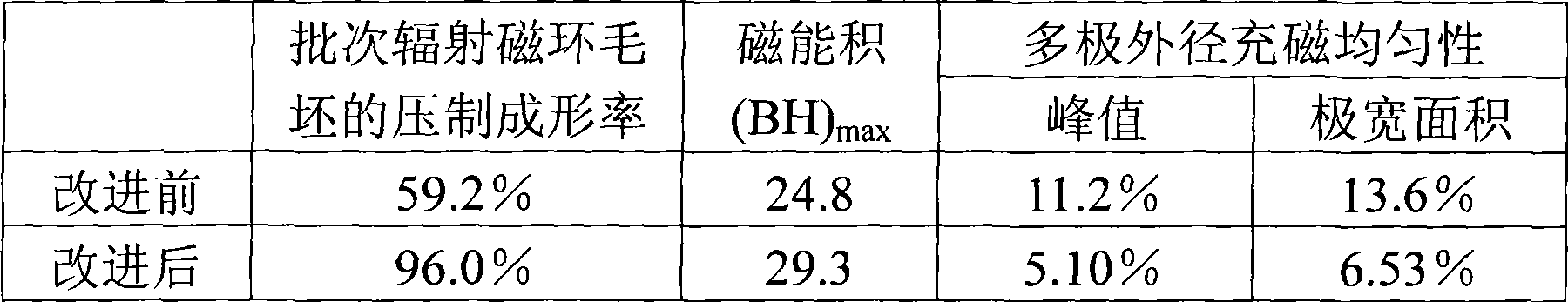

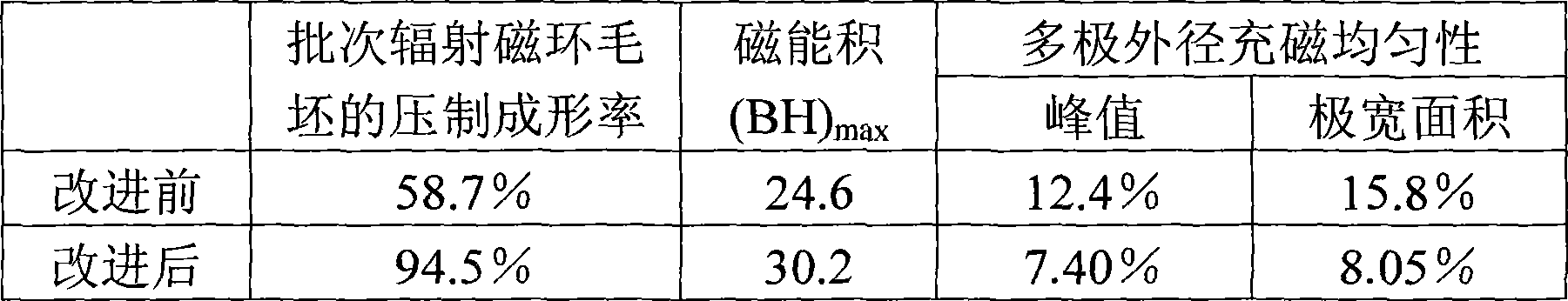

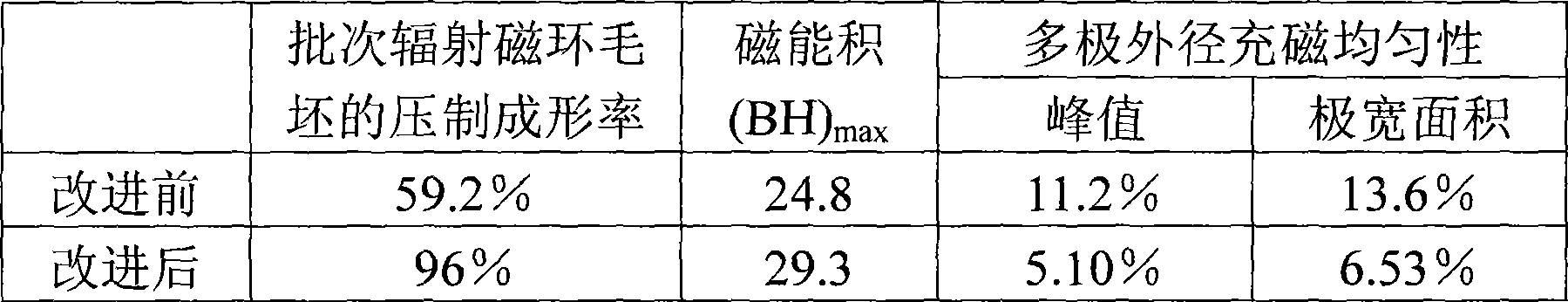

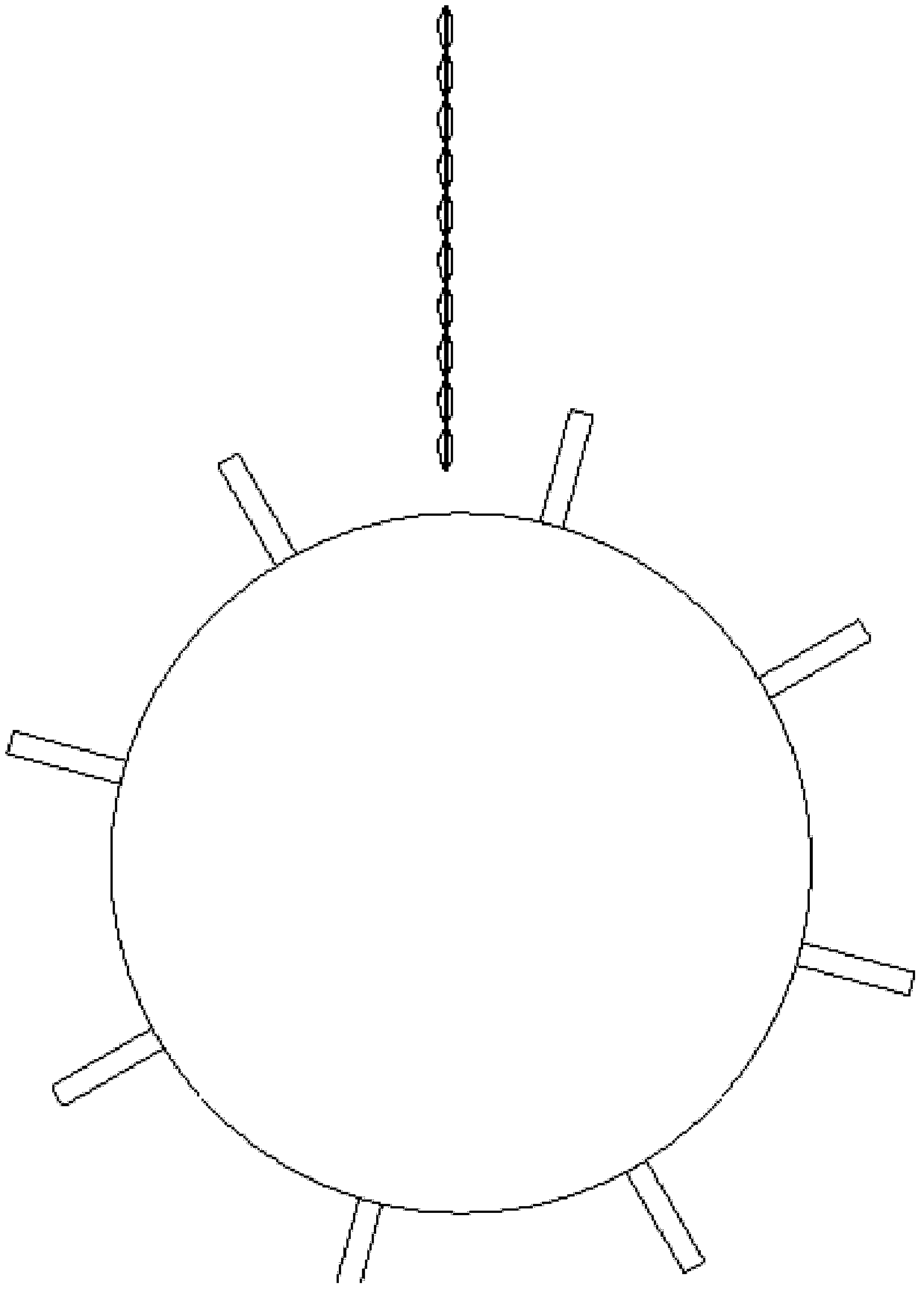

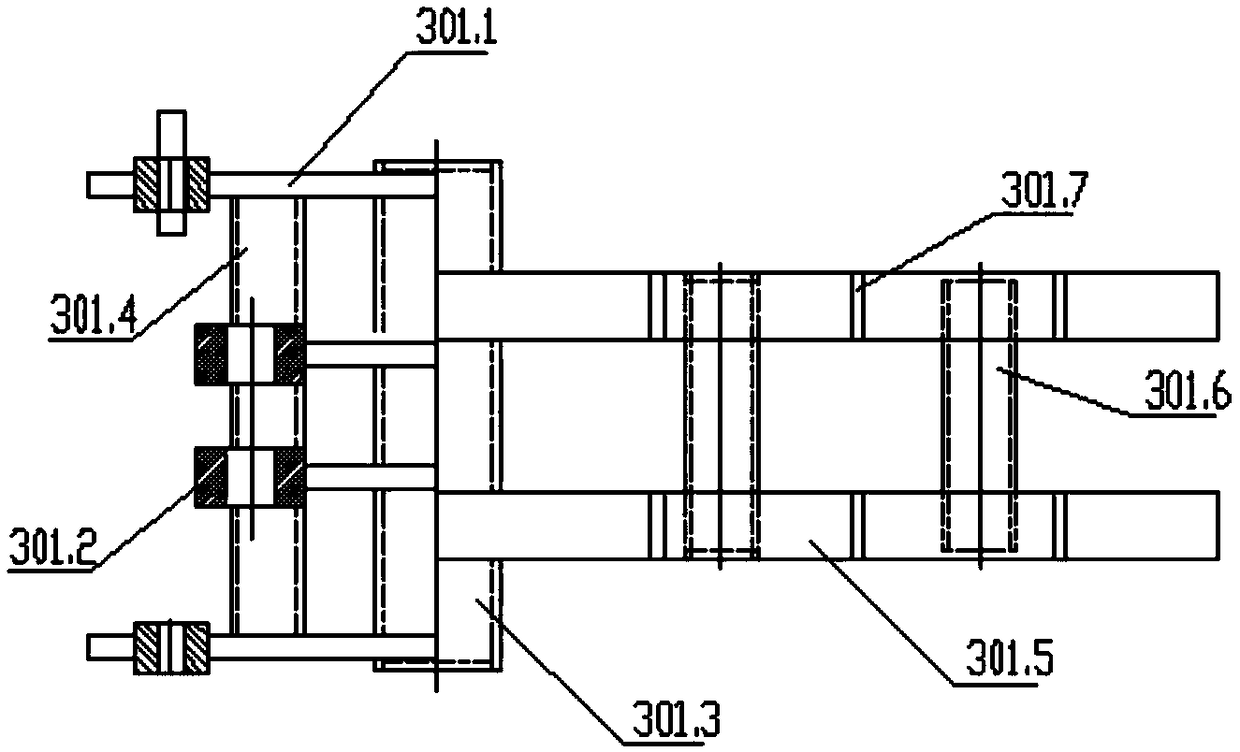

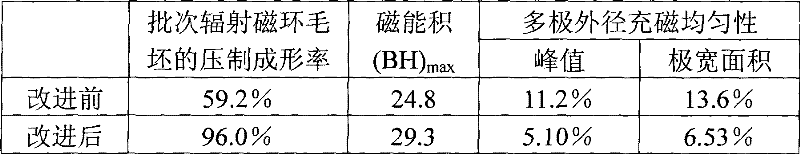

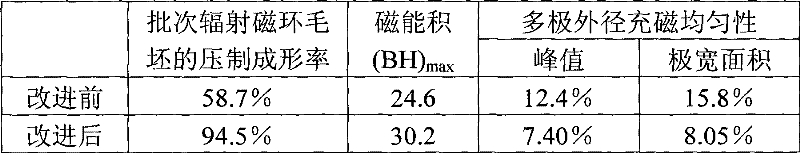

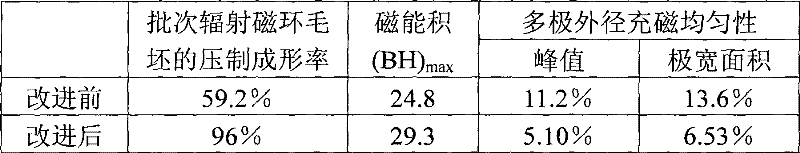

Processing method of R-T-B series alloy powder for radiation magnetic loop

ActiveCN101423902AUniform densityImprove one-shot molding rateFurnace typesHeat treatment furnacesPolyethylene oxideAlicyclic Hydrocarbons

The invention provides an R-T-B system alloy powder treatment method for radiation magnetic rings. The method comprises the following steps: raw alloy is melted in vacuum or inert gas so as to cast an ingot; a raw alloy ingot is subjected to coarse or hydrogen crushing in inert atmosphere; any two substances selected from polyethylene oxide composite polymers, fatty acid, fatty acid derivatives and hydrocarbon are added to and mixed with powder after coarse or hydrogen crushing; alloy coarse powder is subjected to micro-grinding in a nitrogen environment by use of a jet mill; the alloy powder is annealed in inert gas, vacuum or reducing atmosphere; carbonyl iron powder and at least one alicyclic hydrocarbon are added to and mixed with the annealed alloy powder; the mixed powder is taken to form an annular formed body in a magnetic field; the annular formed body is sintered in vacuum or inert gas atmosphere. The method has the advantages that the method is uniform in the density of the radiation ring, high in one-time molding rate and wide in pressure application range, increases the magnetic energy product of the radiation ring, and improves surface magnetic uniformity.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

Flat die casting method for silver bullion

The invention relates to a method for casting a silver ingot flat die. The method adds charcoal during melting of silver powder or silver ingots as a reducer and uses high-temperature high-speed air flow to protect a casting mold under the condition of cooling so as to realize prevention of oxygen in the air from being dissolved and entering a fused silver mass and smooth separation of oxygen in the fused silver mass, solve the problem of oxygen absorption of silver during melting and the high-temperature fused mass by adoption of protective measures, and adopt liquid-level heat insulation to make the oxygen in the fused mass smoothly separated out. Moreover, the method has the advantages of small investment, simple operation and high forming rate.

Owner:HENAN YUGUANG GOLD & LEAD

High-content high-universality talcum powder master filler and production equipment and method thereof

The invention discloses a high-content high-universality talcum powder master filler and production equipment and a method thereof. The talcum powder master filler is prepared by 90 to 98 parts of talcum powder, 1 to 2 parts of stearate, 1 to 3 parts of sodium silicate and 3 to 5 parts of water. The content of talcum powder of the master filler can reach 90% to 95%, a great quantity of energy forfusion and plasticization is saved, production cost of the master filler is reduced greatly, and the problem of high-temperature operation environments caused by high temperature equipment is solved.Talcum powder filling content is high, and adding content of the master filler is low in subsequent use, so that adding cost of the master filler is reduced, universality of the talcum powder master filler is realized thoroughly. Since the talcum powder master filler prepared by the method contains no plastic resin, the problem about consistency of matrix during subsequent use can be ignored, andthe high-content high-universality talcum powder master filler can be widely added and used in various talcum powder filling modified plastic products.

Owner:KINGFA SCI & TECH CO LTD +1

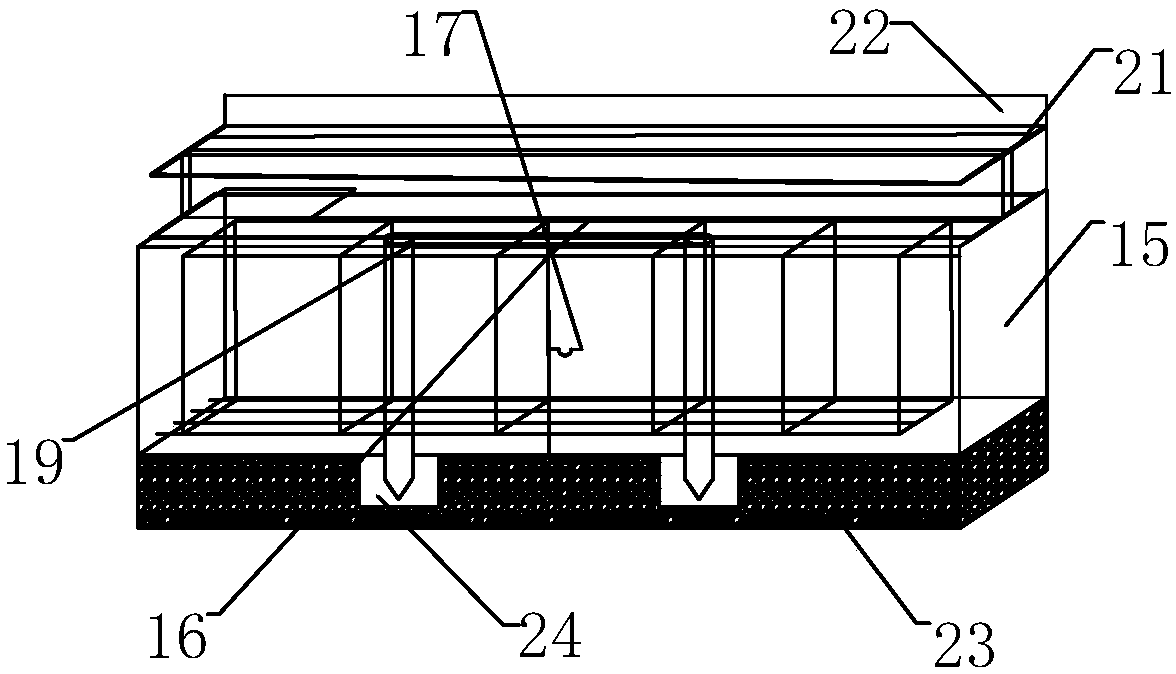

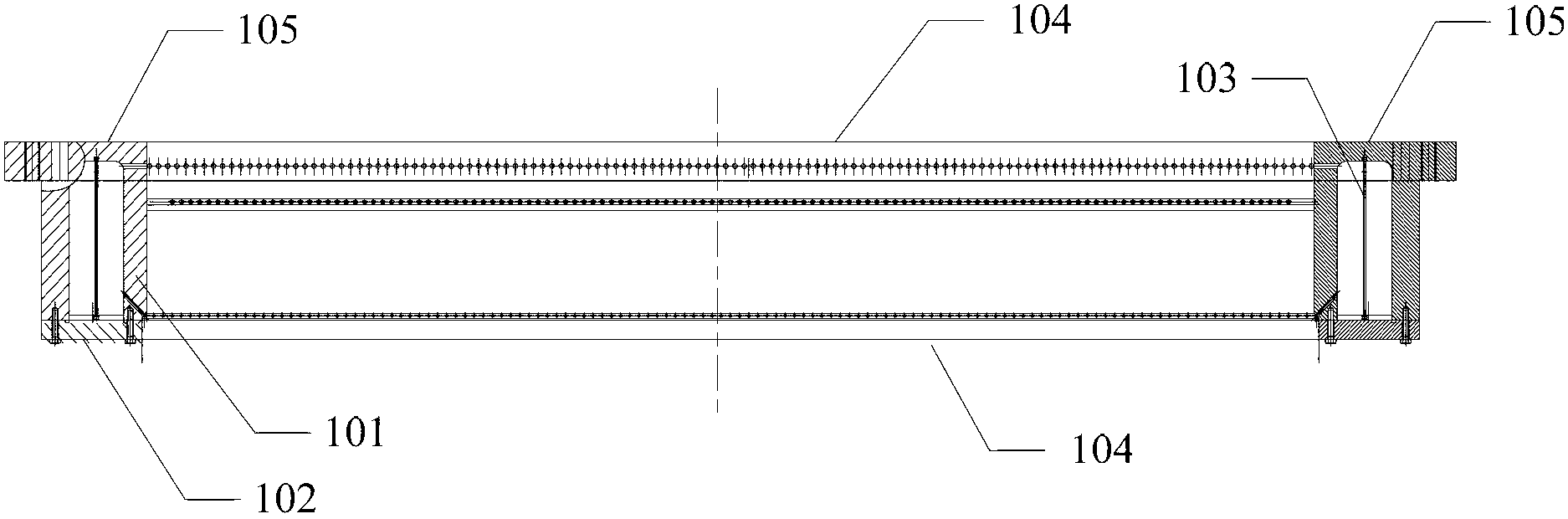

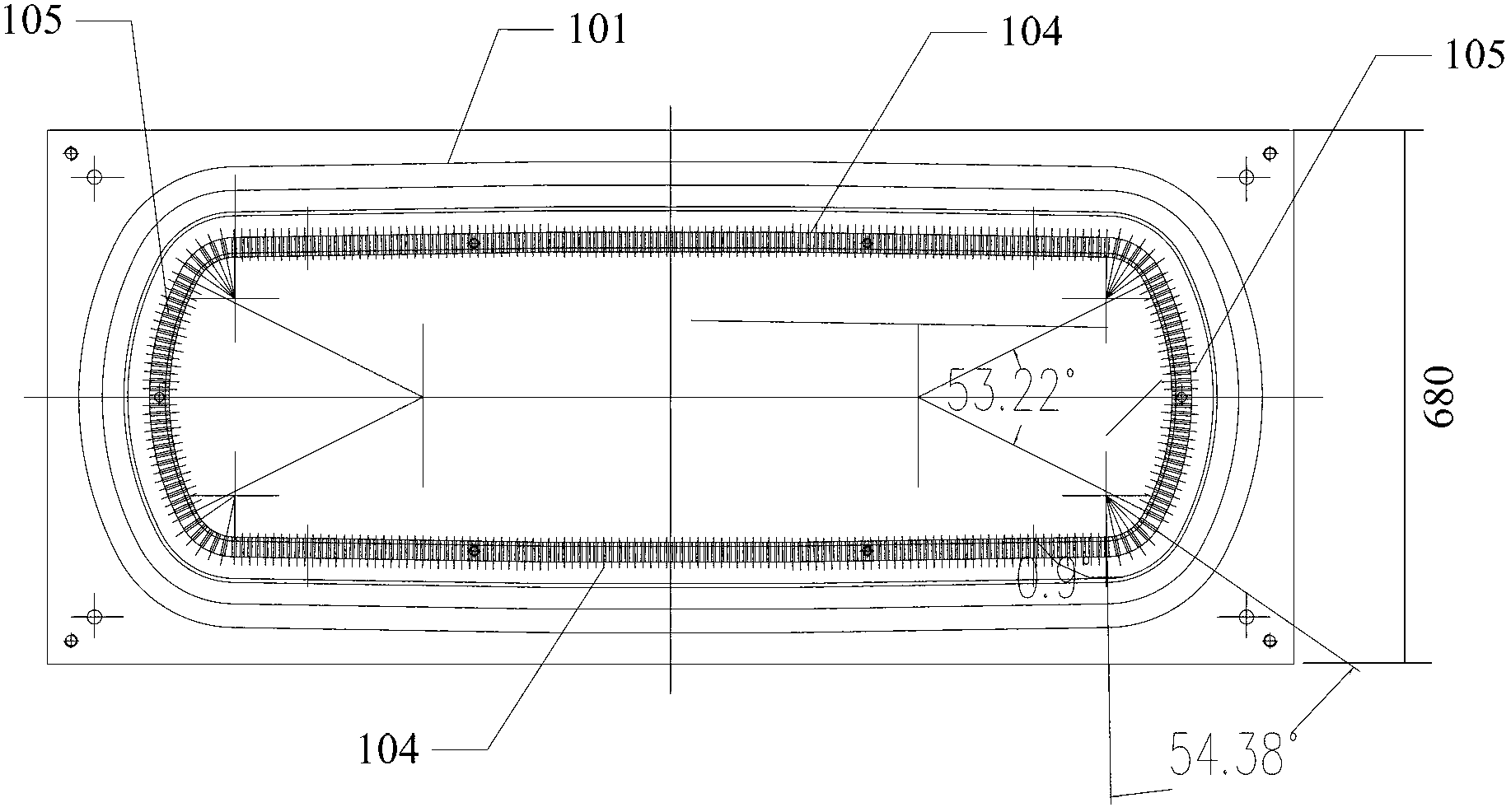

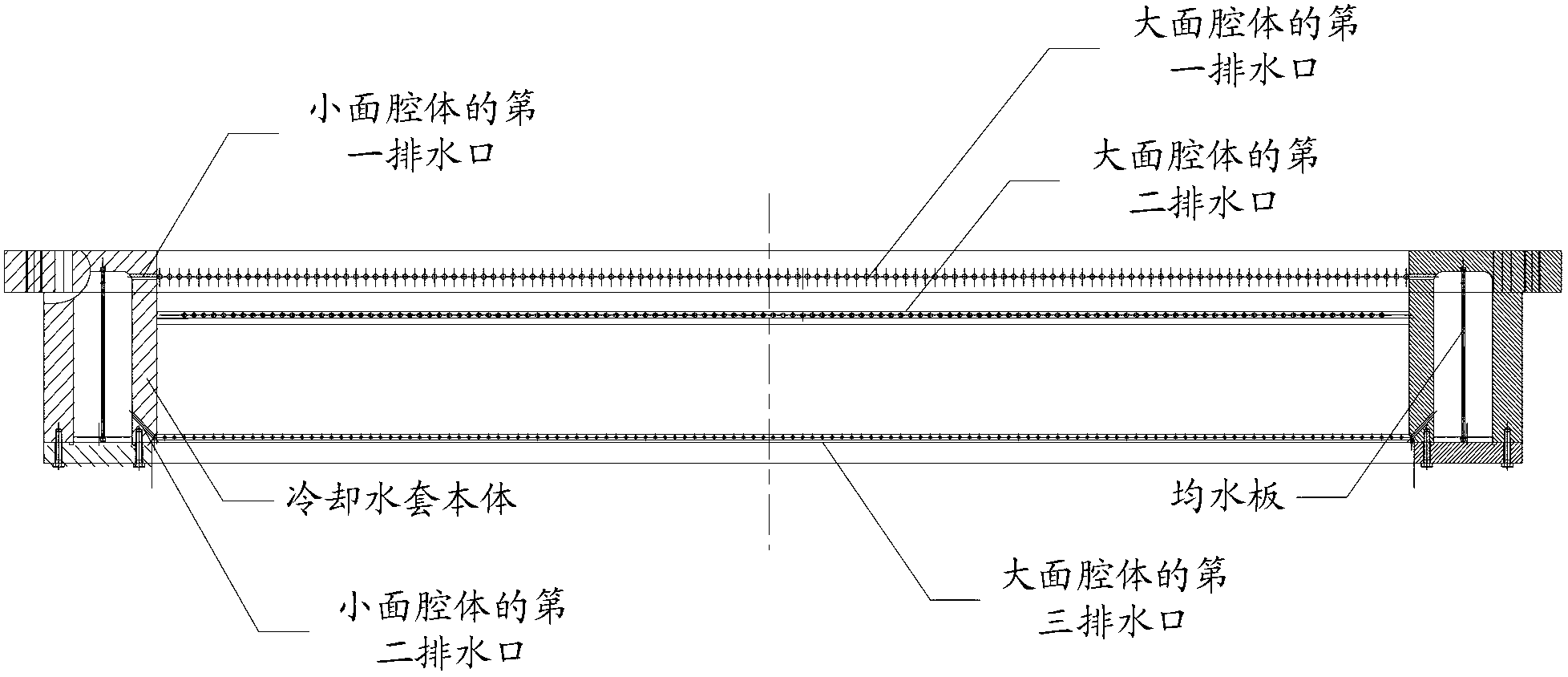

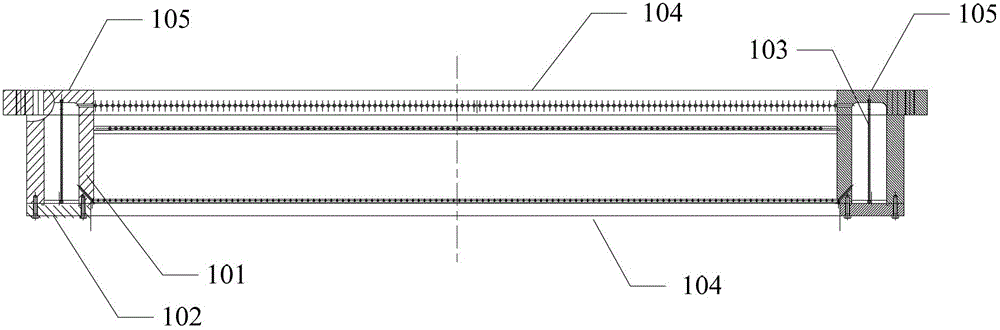

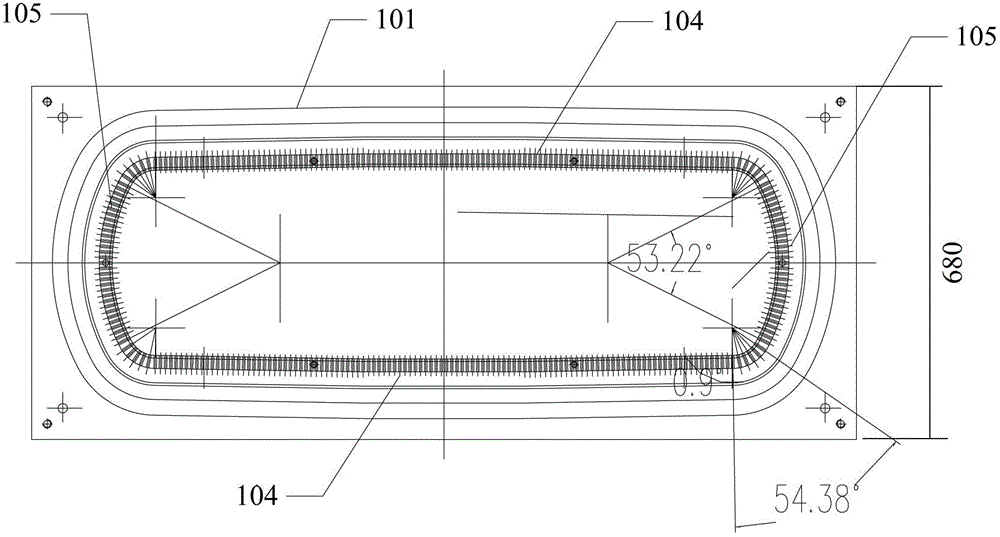

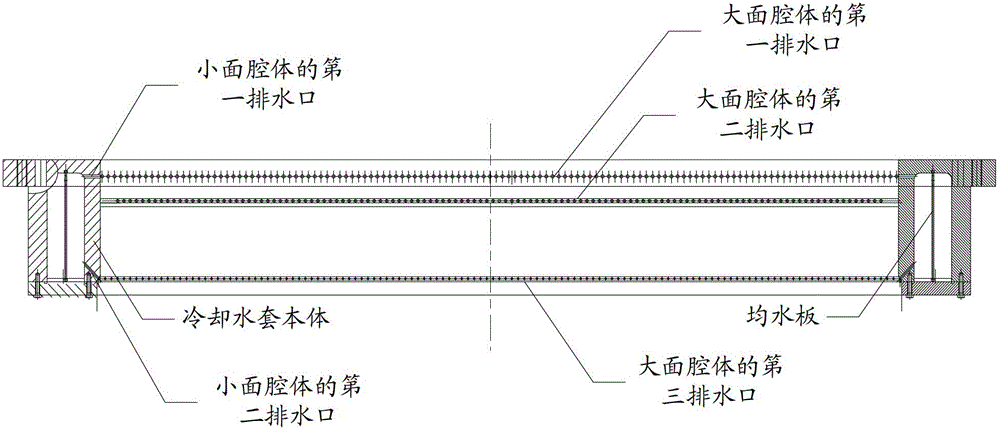

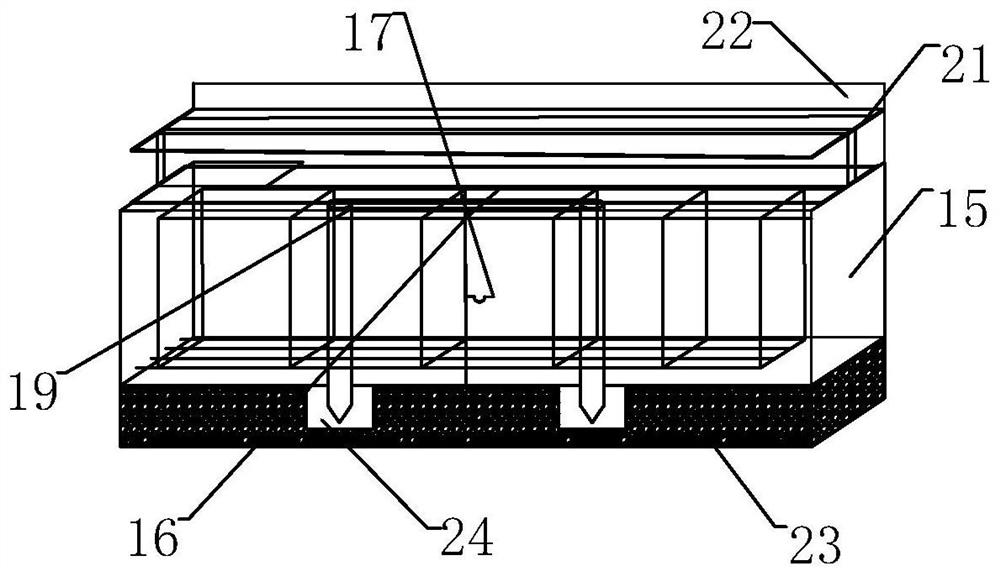

Cooling device for casting aluminum-lithium alloy slab ingot and application method thereof

The embodiment of the invention disclose a cooling device for casting an aluminum-lithium alloy slab ingot and an application method thereof, which are used for improving the uniformity of the water yield of a cooling water jacket during casting. The cooling device in the embodiment of the invention comprises a cooling water jacket body, a cooling water jacket water sealing plate and a cooling water jacket water balancing plate, wherein the cooling water jacket body comprises pairwise large-area cavities and pairwise small-area cavities; the bottom of the cavity of the cooling water jacket body is sealed by using the cooling water jacket water sealing plate; the cooling water jacket water balancing plate is arranged between the outer side face and the inner side face of the cavity of the cooling water jacket body; the cooling water jacket water balancing plate is used for averagely isolating cooling water in the water cooling jacket body into two parts; and the primary cooling water outlet and the secondary cooling water outlet of the cooling water jacket body are positioned on the cooling water jacket body.

Owner:SOUTHWEST ALUMINUM GRP

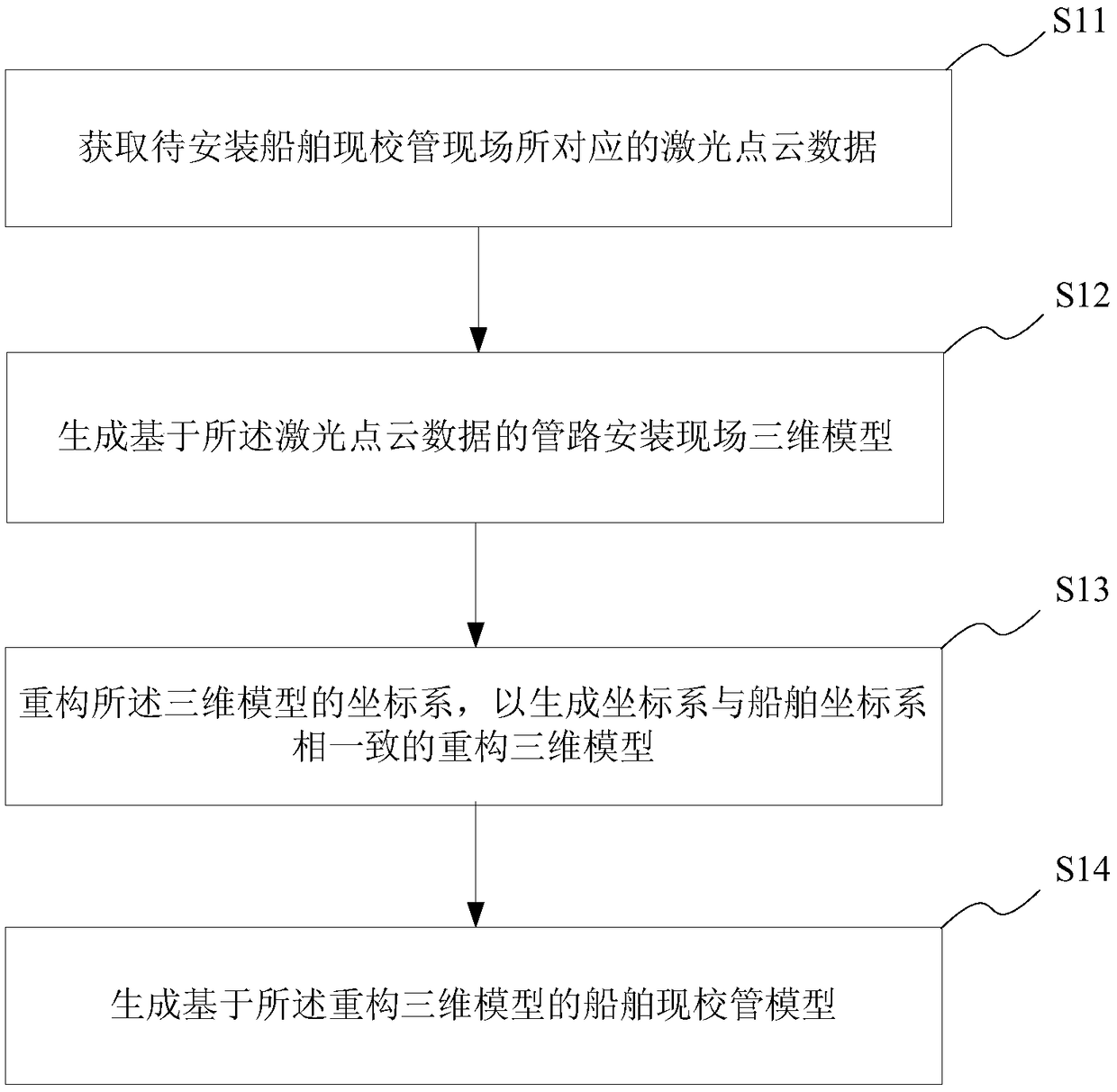

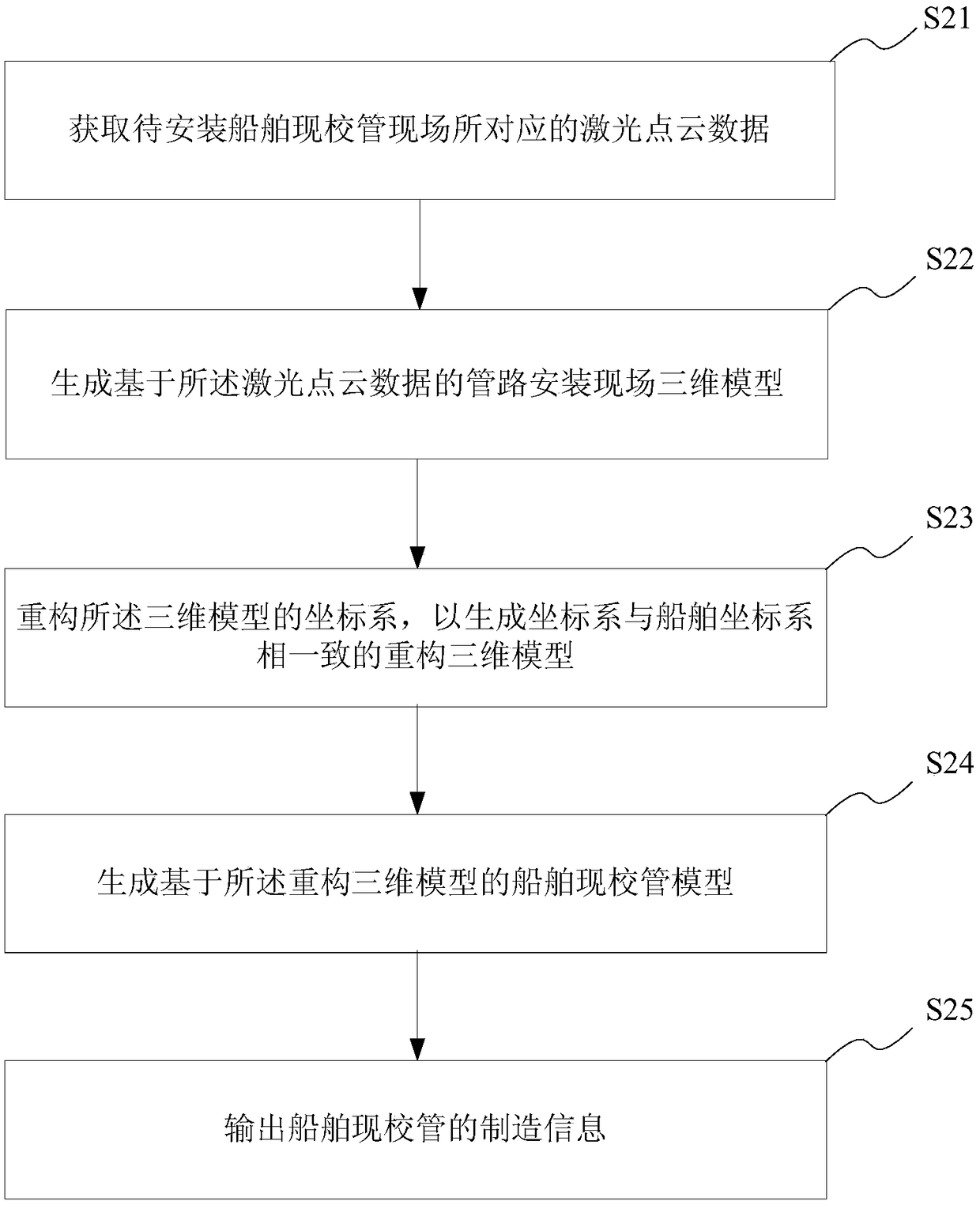

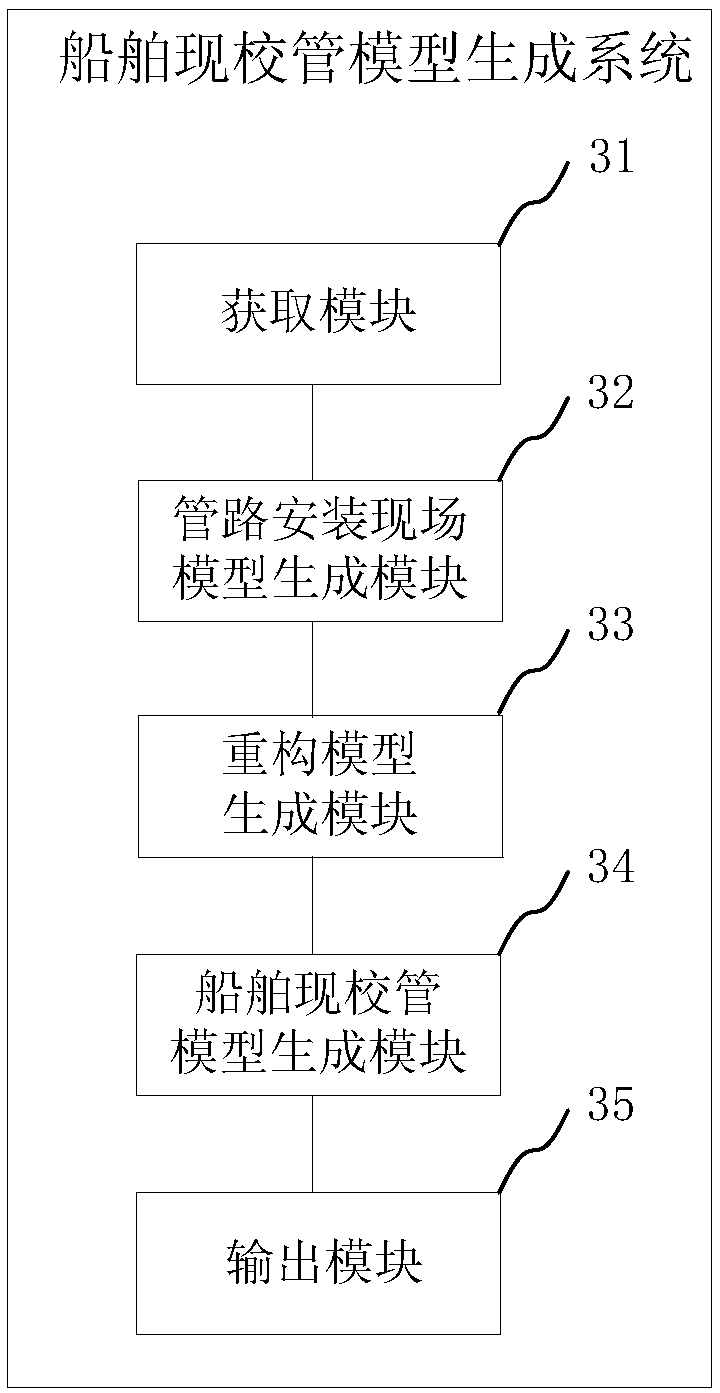

Method, system, terminal and medium for generating ship calibration pipe model based on laser scanning

PendingCN109377559AImprove one-shot molding rateClearly design the production processGeometric CADDesign optimisation/simulationLaser scanningPhysical model

The invention provides a method, a system, a terminal and a medium for generating a ship calibration pipe model based on laser scanning. The invention utilizes laser scanning to measure accurately andimproves measurement accuracy and efficiency. The present calibration tube is created based on the on-site physical model, and the primary forming rate of the present calibration tube is high, and the waste reflection rate is reduced; the connectors at the end of the pipe section are clear, the flange angle can be defined accurately by the current calibration pipe, and the pipe section can be installed directly on the berth after the design and processing is completed, which greatly simplifies the design and production process of the current calibration pipe and shortens the construction period. One measurement can create multiple calibration tube, greatly improve the efficiency of the design of the current calibration tube; the present calibration tube is modeled with reference to the real object background model, avoiding collision interference, improving the design accuracy and ensuring the manufacturability of the model; Incorporating the current school management into the designdata management system to manage it.

Owner:JIANGNAN SHIPYARD GRP CO LTD

High-content high-universality talcum powder master filler and production equipment and method thereof

Owner:KINGFA SCI & TECH CO LTD +1

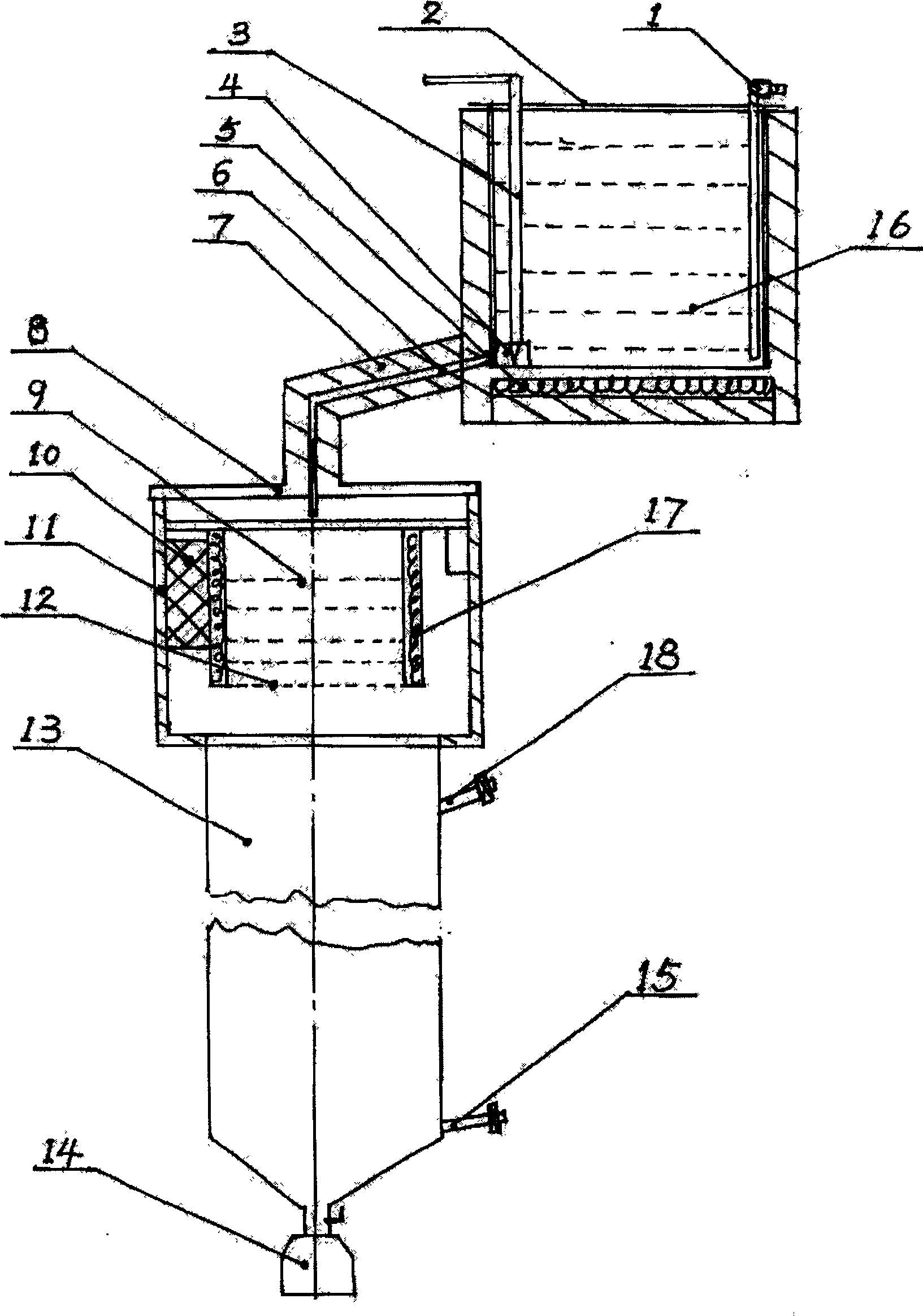

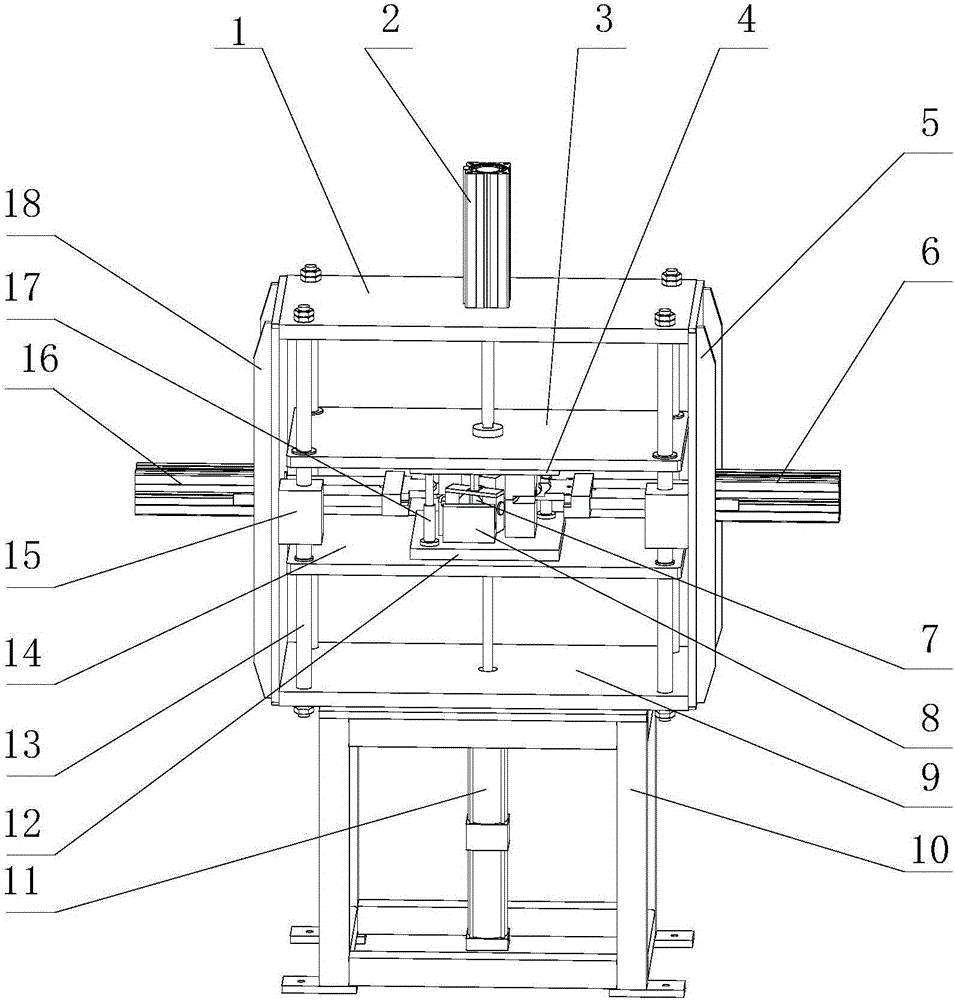

Vertical liftable rock cutting machine and use method thereof

PendingCN114012903AAdjustable widthExpand the cutting rangeWorking accessoriesStone-like material working toolsRock cuttingMachine

The invention discloses a vertical liftable rock cutting device and a use method thereof. The vertical liftable rock cutting device comprises a first sliding rail, a second sliding rail, a first sliding control device, a base, a bracket, an angle control device, a second sliding control device and a cutting device, wherein the first sliding rail is longitudinally arranged on one side of a rock to be cut; first sliding grooves are formed in the two outer longitudinal side faces of the first sliding rail; sawteeth are arranged on one inner longitudinal side face of the first sliding rail in the longitudinal direction in a full-length mode; and the second sliding rail is longitudinally and adjustably connected to the first sliding rail, and a connecting plate is fixed to the bottom of the second sliding rail. The rock cutting machine is particularly suitable for outdoor operation; by arranging the first sliding rail and the second sliding rail, the cutting machine can be transversely and longitudinally adjusted on one side of a rock to be cut, and the width of the rock to be cut can be adjusted according to field requirements. The double-blade type saw blade is adopted and can be vertically lifted, the cutting range is expanded, convenience is provided for the follow-up construction process, the cutting quality is guaranteed, and the construction efficiency is improved.

Owner:中国建筑土木建设有限公司

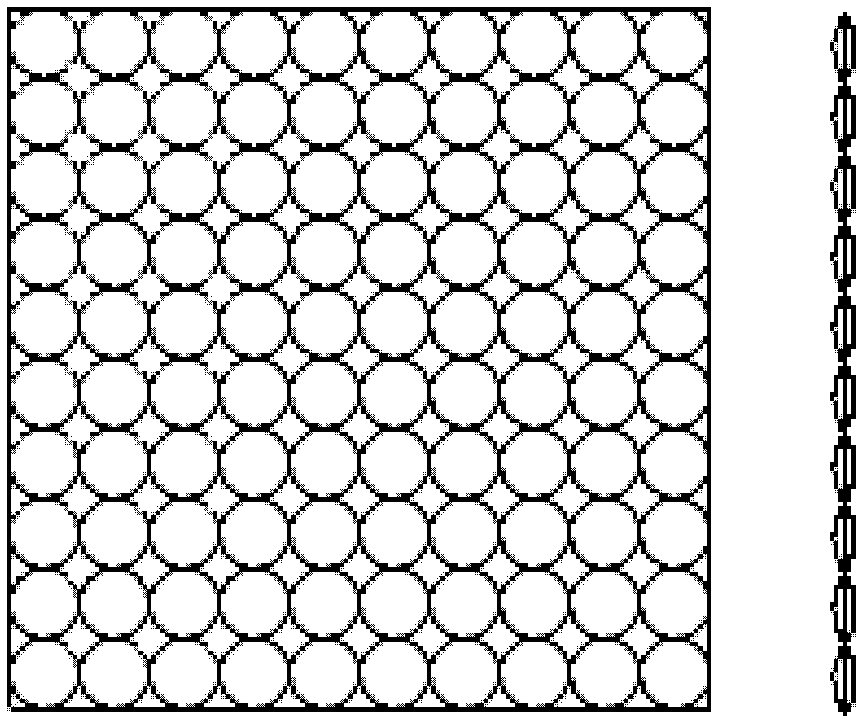

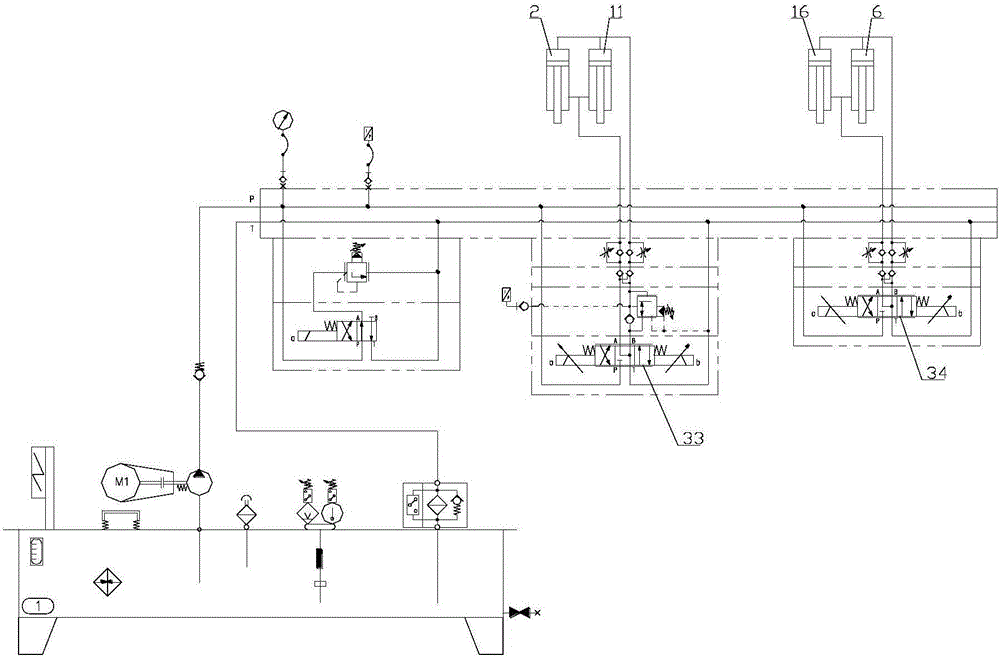

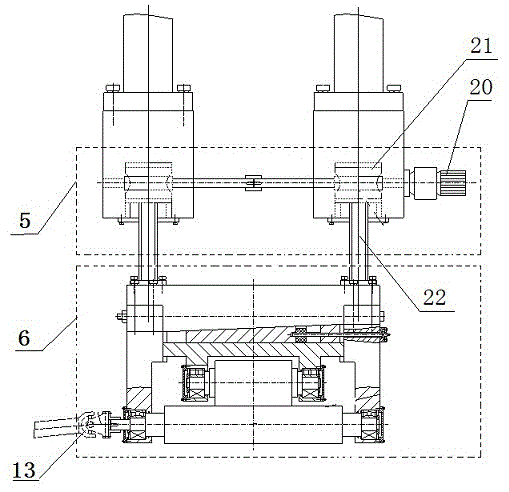

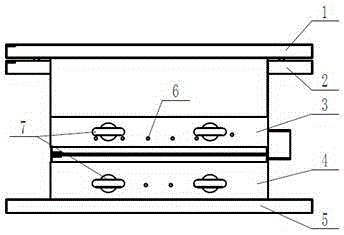

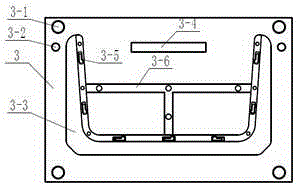

Full-automatic seam buckling device

ActiveCN105033079AImprove appearance qualityHigh degree of automationShaping toolsHydraulic cylinderControl system

The invention relates to a full-automatic seam buckling device. The full-automatic seam buckling device comprises an upper mold mechanism, a lower mold mechanism, a left push mechanism, a right push mechanism, core molds and a control system. An upper mold of the upper mold mechanism and a lower mold of the lower mold mechanism are oppositely arranged and driven by corresponding hydraulic cylinders to bend edges of a workpiece. The left push mechanism and the right push mechanism are oppositely arranged on the two sides of a mold combining position and driven by the corresponding hydraulic cylinders to bend the edges of the workpiece again. The upper mold and the lower mold are each of a split structure, and the shape of the split position of the upper mold and the lower mold is matched with the shape of the core molds arranged in the upper mold and the lower mold. The shape of the core molds is matched with the shape of the workpiece. The upper mold mechanism, the lower mold mechanism, the left push mechanism and the right push mechanism can be controlled by the control system to achieve sequential actions. According to the full-automatic seam buckling device, seam buckling machining can be achieved on longitudinal closed seams of a special-shaped sheet metal part, and machining of workpieces in different shapes can be finished after the core molds are replaced; and the automation degree of the full-automatic seam buckling device is high, the appearance quality of a finished product is good, the one-time molding rate is high, the machining efficiency can be greatly improved, and the machining cost is reduced.

Owner:ANSHAN SONGYI ROBOT MFG

One-step molding technology and device for spherical soldering tin

ActiveCN1309529CAdaptableGood sphericityWelding/cutting media/materialsSoldering mediaSolderingVertical cylinder

A technology for preparing the spherical soldering tin used for packing ICs (BAG, CSP, etc) includes such steps as smelting the soldering tin, delivering the molten soldering tin via tube to a container with laser perforated plate, electromechanical longitudinal and transverse oscillasion to make the molten soldering tin pass through the pinholes on plate while vacuum sucking downward to become drops, rounding and antioxidizing treating in a vertical cylinder, and screening. Its apparatus is composed of smelting furnace, liquid drop shaper, and sphere shaper.

Owner:云南锡业研究院有限公司研究设计院

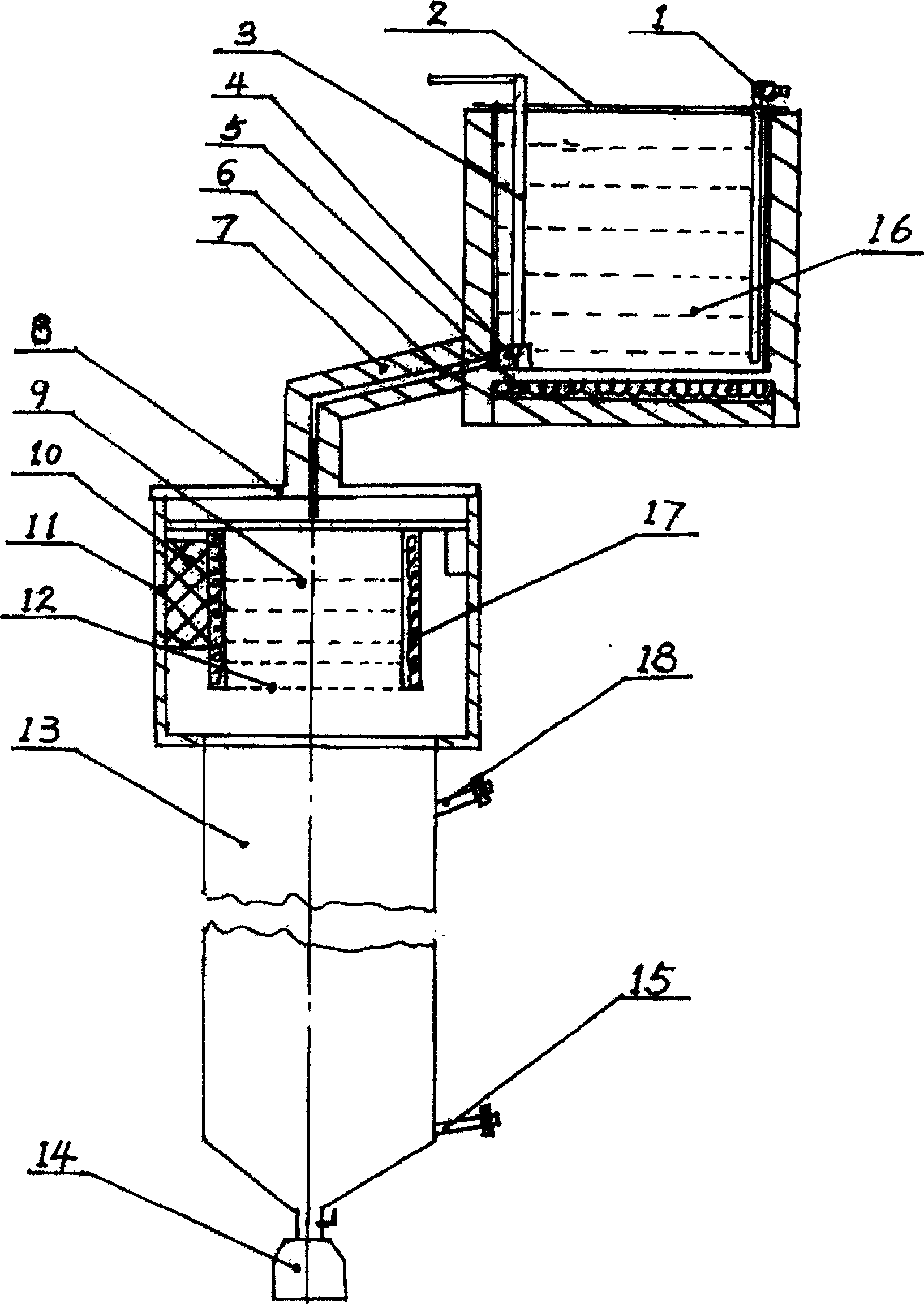

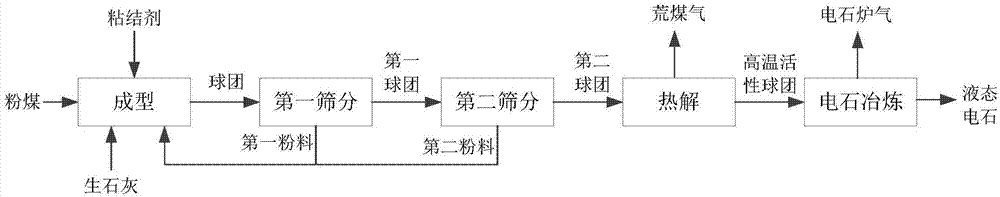

Method and system for preparing calcium carbide

The invention discloses a method and system for preparing calcium carbide. The method comprises the following steps of mixing pulverized coal, quicklime and a binder and then conducting compression moulding to obtain a pellet; sifting the pellet to obtain a first pellet and a first powder material; sifting the first ball pellet for the second time to obtain a second pellet and a second powder material; adding the first powder material and the second powder material into the pulverized coal, the quicklime and the binder for preparing the pellet; conducting pyrolysis on the second pellet to obtain coke-oven gas and a high-temperature active pellet; conducting calcium carbide smelting on the high-temperature active pellet to obtain liquid calcium carbide and calcium carbide furnace gas. According to the method and system for preparing calcium carbide, grizzly devices are arranged at an outlet of a ball-pressing device and an inlet of a ball material pyrolysis unit, the content of powder materials in the pellets is reduced before pyrolysis, the problems of being inflammable and easily damaged because of sifting of the high-temperature pellet are avoided, and safe and stable running of a calcium carbide smelting unit is ensured.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

Tool-die steel plate straightening machine

InactiveCN105057401AImprove straightening accuracyImprove one-shot molding rateSteel platesEngineering

The invention belongs to the technical field of metallurgical equipment, in particular to a tool-die steel plate straightening machine. A classic three-beam four-column prestress rack is used, and a roller system with four rollers at the top and five rollers at the bottom is arranged. Opening degrees of the four straightening rollers at the top can all be adjusted independently, all the top straightening rollers are provided with independent support rollers, and each top straightening roller and the corresponding support roller form an independent compound roller system to perform adjustment. Hydraulic load cylinders are arranged above an upper beam, a movable beam can be lifted rapidly while overload protection is achieved, and accordingly maintenance can be performed conveniently. According to the tool-die steel plate straightening machine, because the opening degrees of all the top straightening rollers can be adjusted independently, the opening degrees can be adjusted flexibly from small to large according to original bends, thickness, width and materials of plates, the rolling reduction of the top straightening rollers is changed from large to small, straightening accuracy is improved, and meanwhile the one-step forming rate of the plates is greatly improved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Prewelding method of thin-wall longitudinal submerged-arc welded (LSAW) pipes with small bore diameter

InactiveCN105171208AImprove one-shot molding rateReduce welding flashArc welding apparatusWelding/cutting media/materialsPower flowEngineering

The invention discloses a prewelding method of thin-wall longitudinal submerged-arc welded (LSAW) pipes with a small bore diameter, and relates to the technical field of steel products welding. The prewelding method lies in that prewelding is carried out by adopting CO2 and Ar mixed gas protective automatic welding, and further comprises the following steps: firstly, determining welding technological parameters, determining the diameter of a welding wire as 2.0 mm and the welding speed as 1.8-2.9 m / min, and determining the proportion and flow of mixed gas, then carrying out preparation before welding, preparing a groove, determining the grade of the welding wire and the welding parameters. During the process of producing thin-wall steel pipes with a small bore diameter, prewelding is carried out by utilizing a shielding welding wire with the diameter of 2.0 mm, welding is carried out by adopting low current, the prewelding seam is plump, the overlaps of an internal groove are greatly reduced, the occurrence probability of defects like burning through and weld misalignment is reduced, and at the same time, the prewelding failure discharge regulation times is reduced, the prewelding once-shaping ratio is increased, and the production efficiency is improved.

Owner:CNPC BOHAI EQUIP MFG +1

A dual-axis 3D printing platform

InactiveCN106239918BRealize printingImprove one-shot molding rateManufacturing platforms/substratesManufacturing driving meansBall screwEngineering

The invention discloses a double-rotating-shaft 3D printing platform capable of completing printing of the lateral side parts of components. According to the double-rotating-shaft 3D printing platform, by means of two stepping motors, a working table can be driven to rotate around the vertical axis of the working table itself and can pitch and incline up and down around the horizontal central axis of the platform during rotation; and on the other hand, the 3D printing platform is driven by a ball screw to rise and fall along the Z axis, and therefore precise and complete printing of the lateral side parts of the printed parts is achieved. The double-rotating-shaft 3D printing platform is simple in structure, reasonable in design and convenient to control, no supporting materials need to be added during printing, the pretreatment and aftertreatment procedures required by conventional printers are reduced, the quality of printed pieces is improved, and the application field of printers of the type is expanded.

Owner:HUBEI UNIV OF TECH

Cooling device and application method for cast aluminum-lithium alloy flat ingot

The embodiment of the invention disclose a cooling device for casting an aluminum-lithium alloy slab ingot and an application method thereof, which are used for improving the uniformity of the water yield of a cooling water jacket during casting. The cooling device in the embodiment of the invention comprises a cooling water jacket body, a cooling water jacket water sealing plate and a cooling water jacket water balancing plate, wherein the cooling water jacket body comprises pairwise large-area cavities and pairwise small-area cavities; the bottom of the cavity of the cooling water jacket body is sealed by using the cooling water jacket water sealing plate; the cooling water jacket water balancing plate is arranged between the outer side face and the inner side face of the cavity of the cooling water jacket body; the cooling water jacket water balancing plate is used for averagely isolating cooling water in the water cooling jacket body into two parts; and the primary cooling water outlet and the secondary cooling water outlet of the cooling water jacket body are positioned on the cooling water jacket body.

Owner:SOUTHWEST ALUMINUM GRP

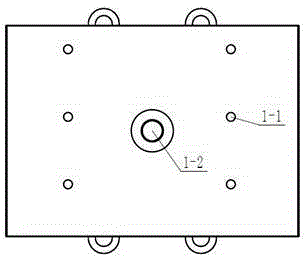

Injection mold for automobile door frame

Owner:JIANGSU KEXIN AUTOMOBILE DECORATION PARTS

Fully automatic pipe fitting flanging equipment and flanging processing technology

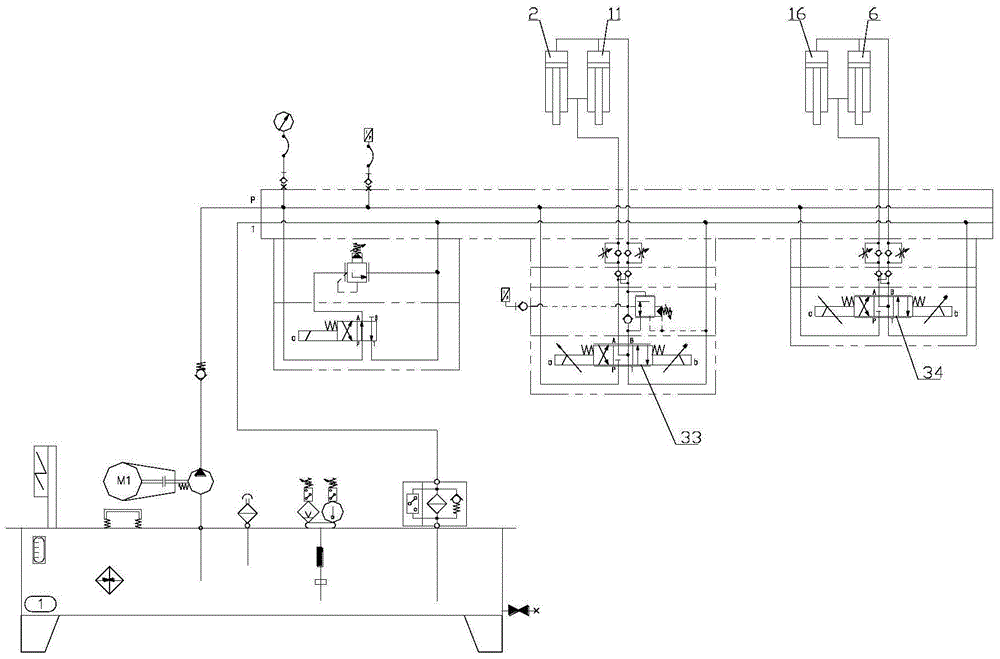

ActiveCN105033007BEnsure safe operationEnsure safetyMetal-working feeding devicesShaping safety devicesButt jointControllability

The invention relates to a full-automatic pipe edge turning device. The full-automatic pipe edge turning device comprises a safety protective system, a hydraulic station, a pneumatic triple connection piece, a PLC, a power device, a pneumatic device, dead point mechanisms, a pressing device, an edge turning mechanism and a workpiece positioning inner mold. The safety protective system comprises a safety room. The safety room is provided with a roller shutter door. The PLC, the hydraulic station and the pneumatic triple connection piece are arranged on the right side of the safety room. The safety room is internally provided with a workbench which is provided with the pressing device. The pressing device is connected with the dead point mechanisms on the two sides. The workpiece positioning inner mold is arranged in the pressing device. The edge turning mechanism is arranged above the workpiece positioning inner mold. The full-automatic pipe edge turning device is an automatic device which is easy to operate, safe, convenient to use and high in controllability, and is high in one-time forming rate. The domestic blank is really filled in. A T-shaped pipe butt joint technology does not need a welding mode, production cost is low, and the quality and the appearance of the product are prominent.

Owner:ANSHAN SONGYI ROBOT MFG

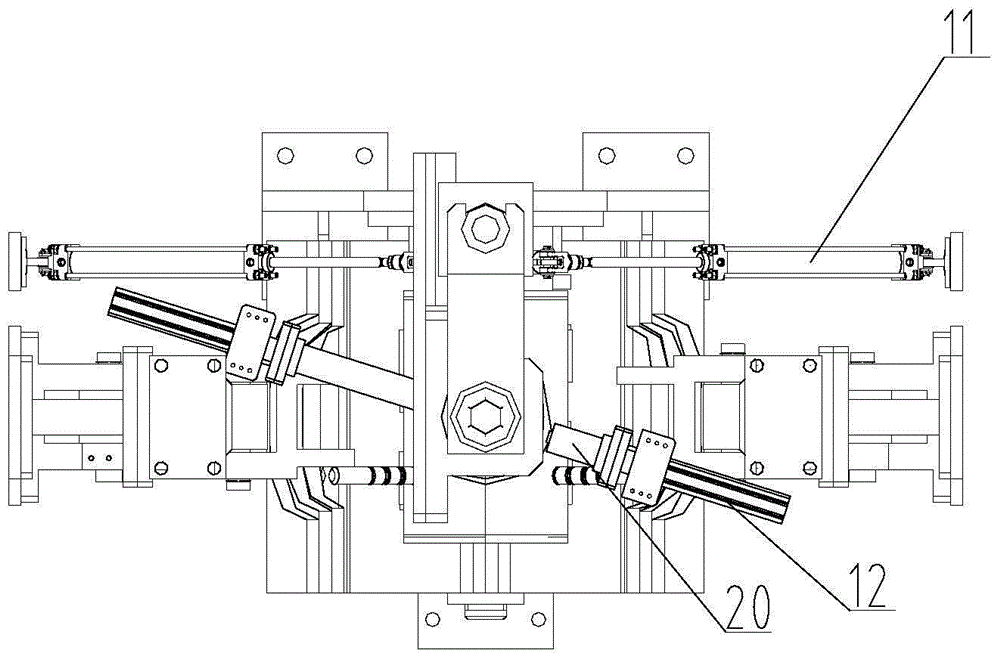

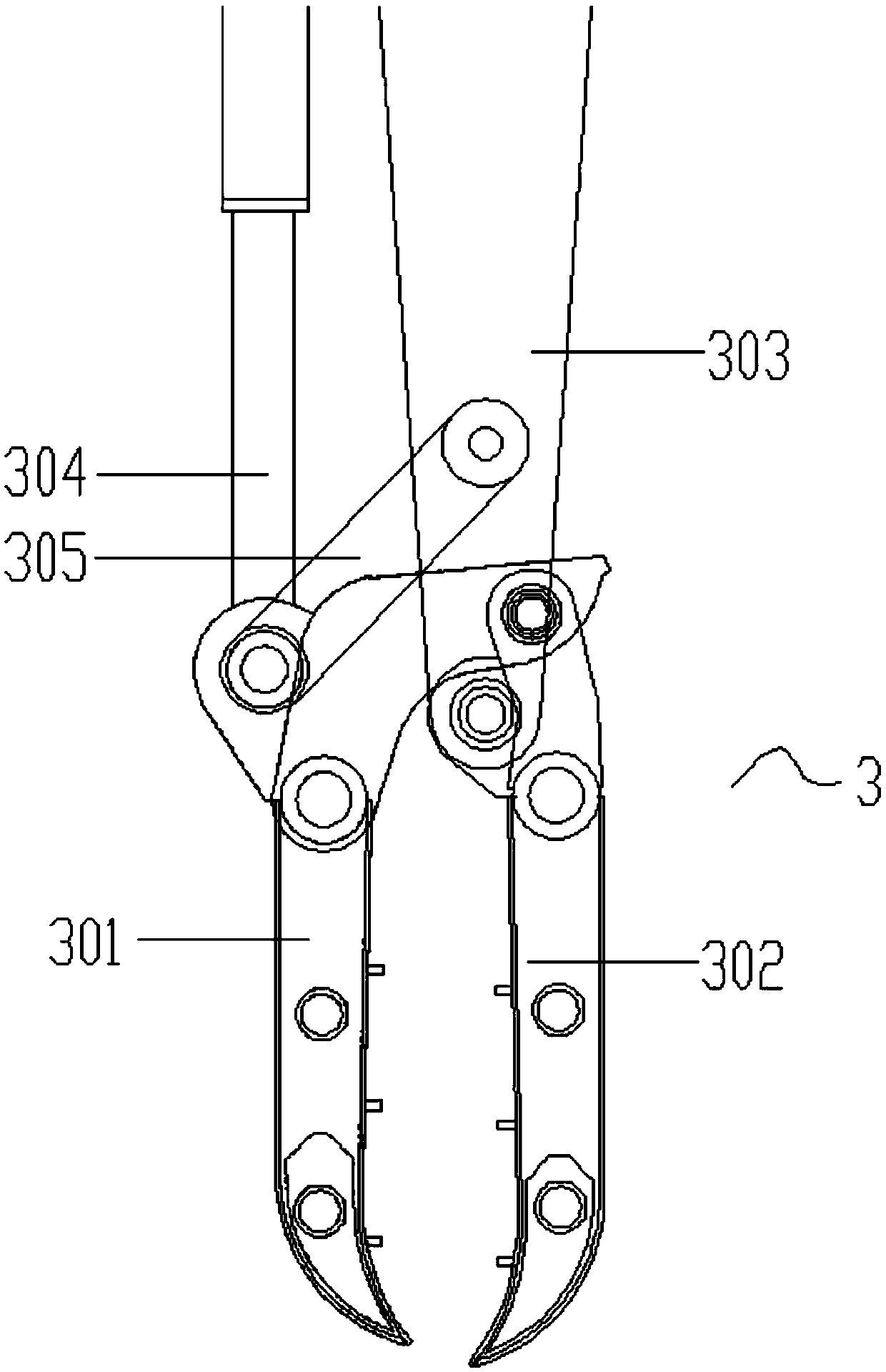

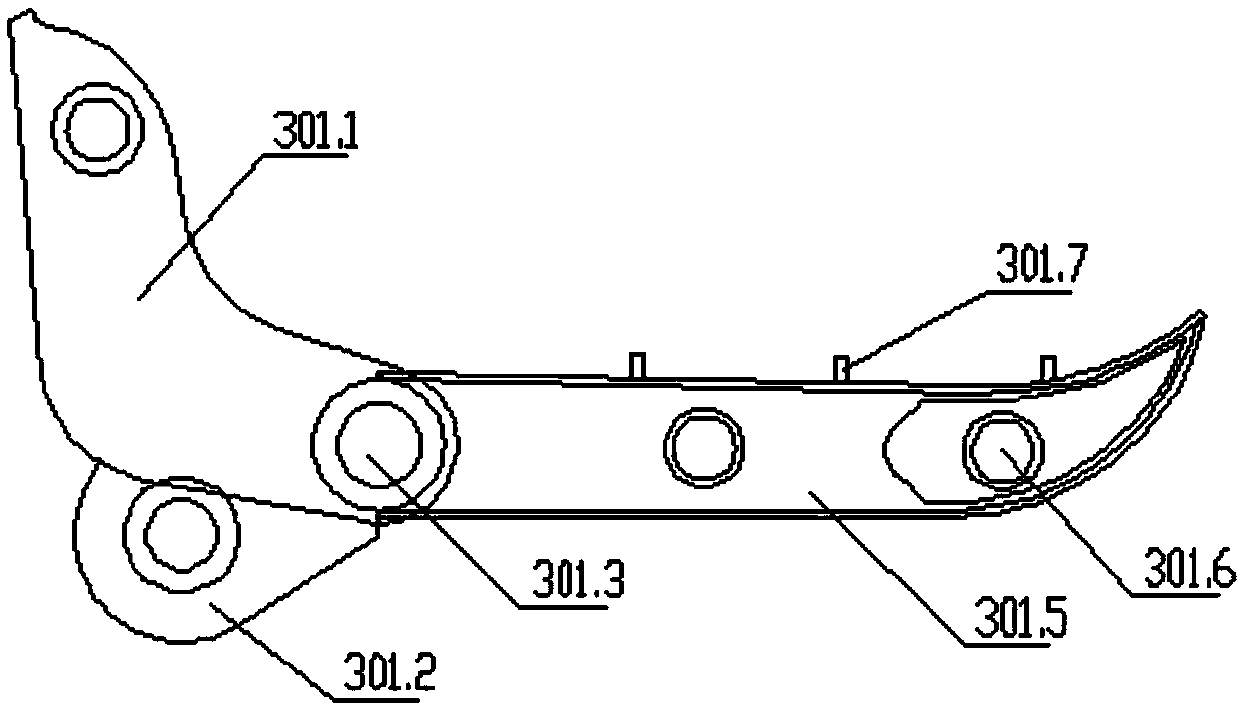

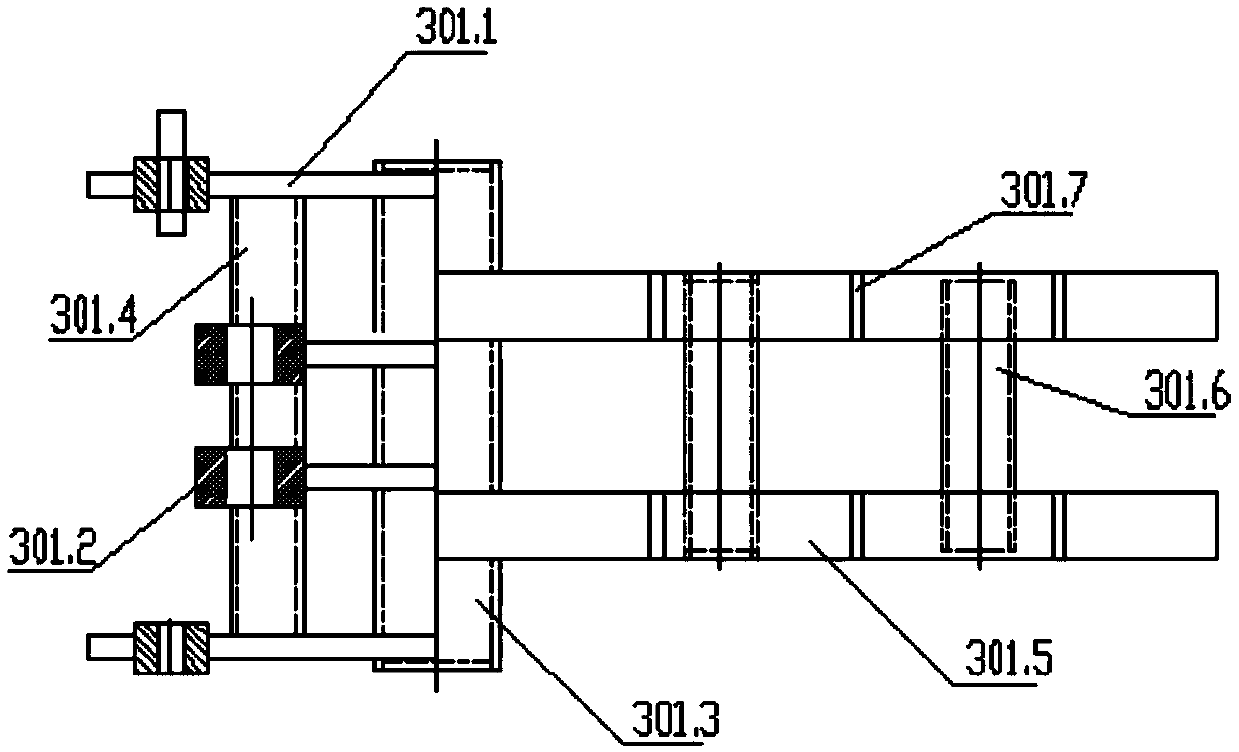

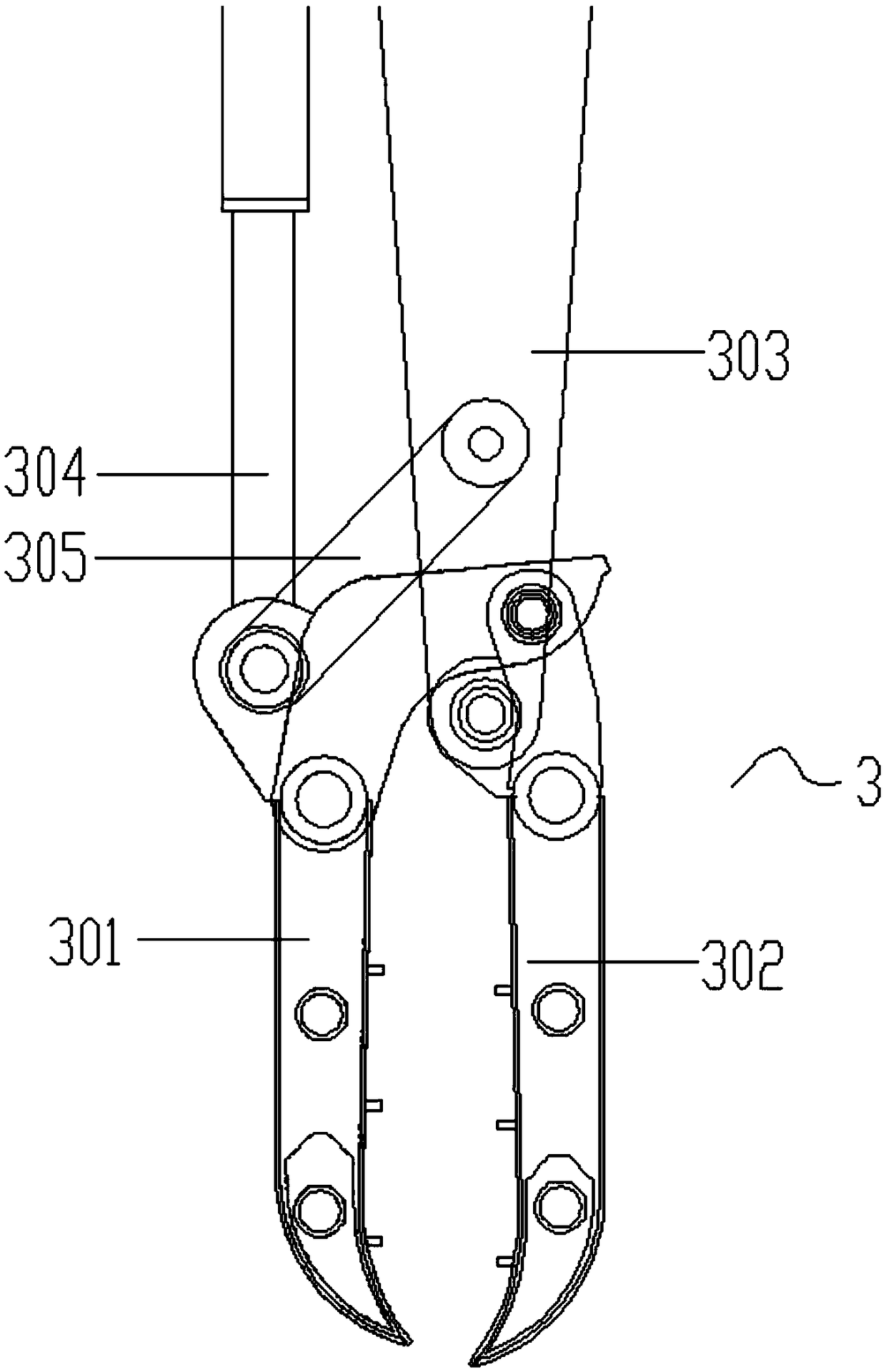

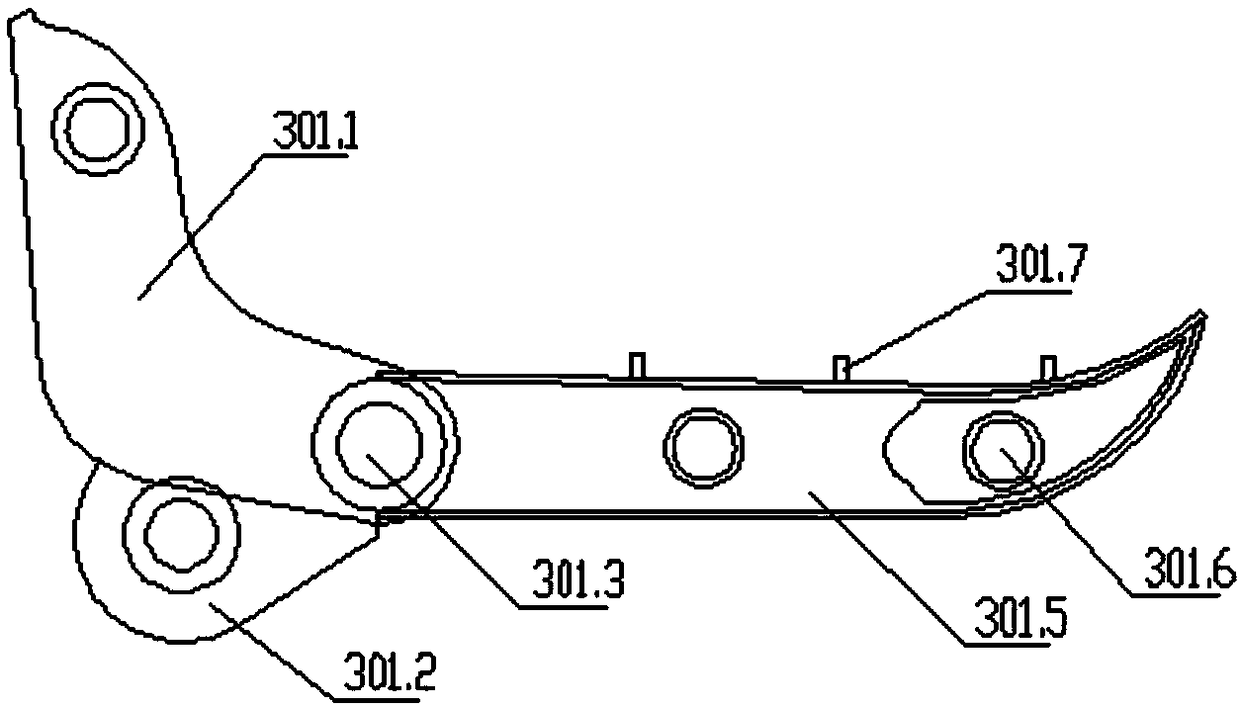

Two-jaw die

ActiveCN108673023AImprove matchAdaptableWelding/cutting auxillary devicesAuxillary welding devicesEngineeringOlecranon

The invention relates to a two-jaw die. The two-jaw die comprises a two-jaw die bottom plate. The two-jaw die bottom plate is a horizontally-put rectangular plate. A longitudinally-arranged two-jaw die right supporting strip is arranged on the right section of the front face of the two-jaw die bottom plate, a longitudinally-arranged two-jaw die left supporting strip is arranged on the left sectionof the front face of the two-jaw die bottom plate, and each of the rear section and the front section of the top face of the two-jaw die bottom plate is connected with two two-jaw die outer limitingplates leftwards. A two-jaw mechanism manufactured from the two-jaw die is used for an olecranon clip for engineering machinery,the olecranon clip can be conveniently assembled on and cooperate with excavators of various types, the manufacturing process of the olecranon clip depends on an olecranon clip die, the olecranon clip die is adopted for manufacturing, and a manufacturing method has the beneficial effects of being high in adaptability, good in universality, easy to operate and high in one-time forming rate.

Owner:江苏高德液压机械有限公司

Flat die casting method for silver bullion

Owner:HENAN YUGUANG GOLD & LEAD

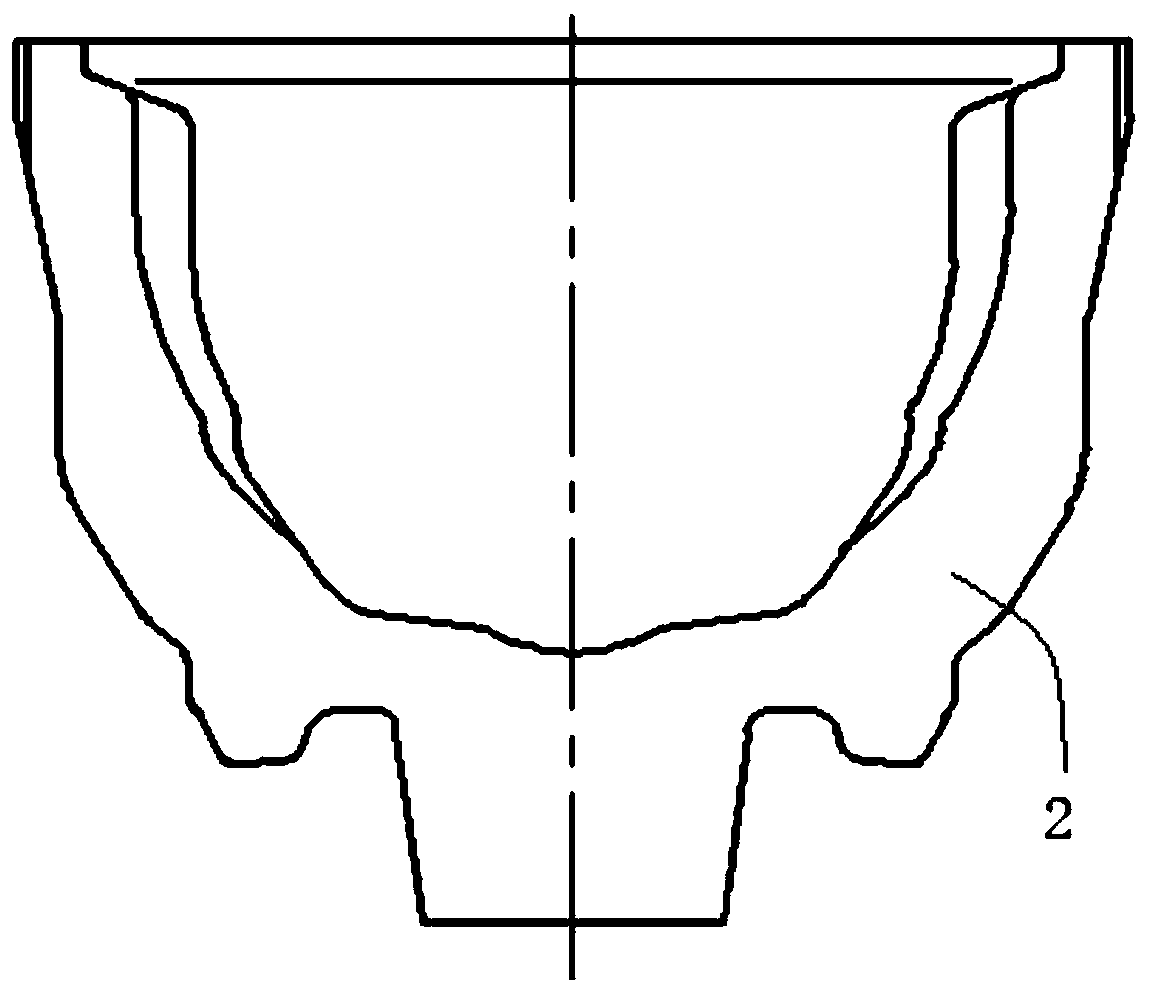

Manufacturing method for eagle beak shaped clamp used for engineering machinery

ActiveCN108643270AEasy to assembleAdaptableWelding/cutting auxillary devicesSoil-shifting machines/dredgersBeak shapeExcavator

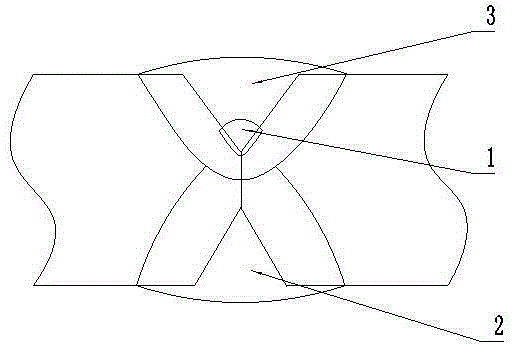

The invention relates to a manufacturing method for an eagle beak shaped clamp used for engineering machinery. The manufacturing method is characterized in that an eagle beak shaped mould is adopted to manufacture, wherein the eagle beak shaped mould comprises a two-claw mould (1) and a three-claw mould (2); an eagle beak shaped two-claw mechanism (301) and an eagle beak shaped three-claw mechanism (302) are separately manufactured through the two-claw mould (1) and the three-claw mould (2). The eagle beak shaped clamp used for the engineering machinery disclosed by the invention can be used for conveniently assembling and matching excavators of various models, and a manufacturing process of the manufacturing method depends one eagle beak shaped clamp mould which is adopted to manufacture.The manufacturing method has the advantages of being strong in adaptive capacity, good in universality, simple in operation and high in once forming yield.

Owner:江苏高德液压机械有限公司

A kind of traditional Chinese medicine tablet and preparation method thereof

ActiveCN104547616BSolve the problem of poor formabilityImprove one-shot molding ratePill deliveryFood scienceFreeze-dryingDissolution

Owner:YICHANG SHANCHENGSHUIDU CORDYCEPS

Processing method of r-t-b alloy powder for radiation magnetic ring

ActiveCN101423902BUniform densityImprove one-shot molding rateFurnace typesHeat treatment furnacesPolyethylene oxideNitrogen gas

The invention provides a method for processing R-T-B series alloy powders for radiant magnetic rings, which comprises the following steps: the raw material alloy is smelted and cast in a vacuum or an inert gas; the raw material alloy ingot is subjected to rough / hydrogen crushing in an inert atmosphere; Add any two substances selected from polyethylene oxide composite polymers, fatty acids, fatty acid derivatives, and hydrocarbons to the powder after hydrogen crushing; use a jet mill to finely grind the alloy coarse powder under a nitrogen environment Pulverizing; annealing the alloy powder in an inert gas, vacuum or reducing atmosphere; adding carbonyl iron powder and at least one alicyclic hydrocarbon to the annealed alloy powder for mixing; forming the mixed powder into a ring shape in a magnetic field body; the ring shaped body is sintered in vacuum or inert gas atmosphere. The method of the invention has the advantages of uniform radiation ring density, high one-time molding rate, wide application range of pressure, increased magnetic energy product of the radiation ring, and improved surface magnetic uniformity.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

A fully automatic seaming device

ActiveCN105033079BRealize buckle seam processingImprove appearance qualityShaping toolsHydraulic cylinderControl system

The invention relates to a full-automatic seam buckling device. The full-automatic seam buckling device comprises an upper mold mechanism, a lower mold mechanism, a left push mechanism, a right push mechanism, core molds and a control system. An upper mold of the upper mold mechanism and a lower mold of the lower mold mechanism are oppositely arranged and driven by corresponding hydraulic cylinders to bend edges of a workpiece. The left push mechanism and the right push mechanism are oppositely arranged on the two sides of a mold combining position and driven by the corresponding hydraulic cylinders to bend the edges of the workpiece again. The upper mold and the lower mold are each of a split structure, and the shape of the split position of the upper mold and the lower mold is matched with the shape of the core molds arranged in the upper mold and the lower mold. The shape of the core molds is matched with the shape of the workpiece. The upper mold mechanism, the lower mold mechanism, the left push mechanism and the right push mechanism can be controlled by the control system to achieve sequential actions. According to the full-automatic seam buckling device, seam buckling machining can be achieved on longitudinal closed seams of a special-shaped sheet metal part, and machining of workpieces in different shapes can be finished after the core molds are replaced; and the automation degree of the full-automatic seam buckling device is high, the appearance quality of a finished product is good, the one-time molding rate is high, the machining efficiency can be greatly improved, and the machining cost is reduced.

Owner:ANSHAN SONGYI ROBOT MFG

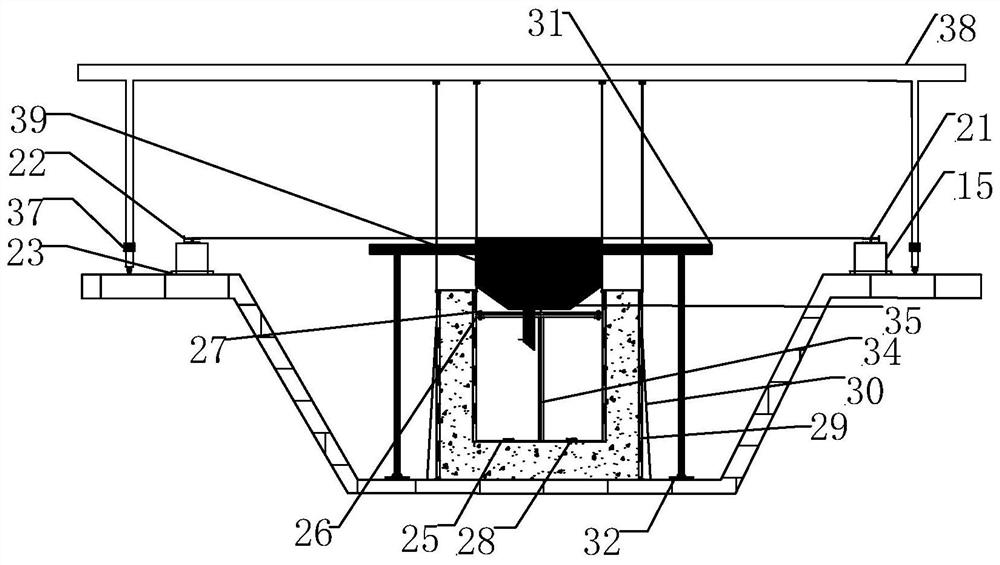

Integral forming drainage ditch construction system and its construction method

ActiveCN109577453BFast formingShort timeSewer pipelinesArchitectural engineeringStructural engineering

The invention discloses an integrally formed drainage ditch, including a drainage ditch body, a shaped bucket, a shaped slope scraper, a sliding form track, a shaped side form and a bottom scraping beam frame, and the sliding form track is assembled on both sides of the drainage ditch body , the shaped side form is set in the drain body, the bottom scraping beam is erected at the bottom of the drain body, the shaped side form can be fixed on the bottom scraping beam frame, and the bottom scraping beam frame is connected to the sliding beam gantry frame and formed The sliding beam gantry pulls and slides, and the finalized side formwork is connected to the sideform gantry and is pulled and slipped by the sideform gantry. The drainage ditch simplifies construction steps, saves construction man-hours, reduces construction costs, is easy to excavate and form, and has low operation difficulty, can effectively ensure safety during construction, and the drainage ditch has beautiful appearance and good quality. The second object of the present invention is the construction method of integrally formed drainage ditch, which is applied to the above-mentioned integrally formed drainage ditch, which also has the advantages of high safety and high convenience.

Owner:HANGZHOU JIANGRUN TECH LIMITED

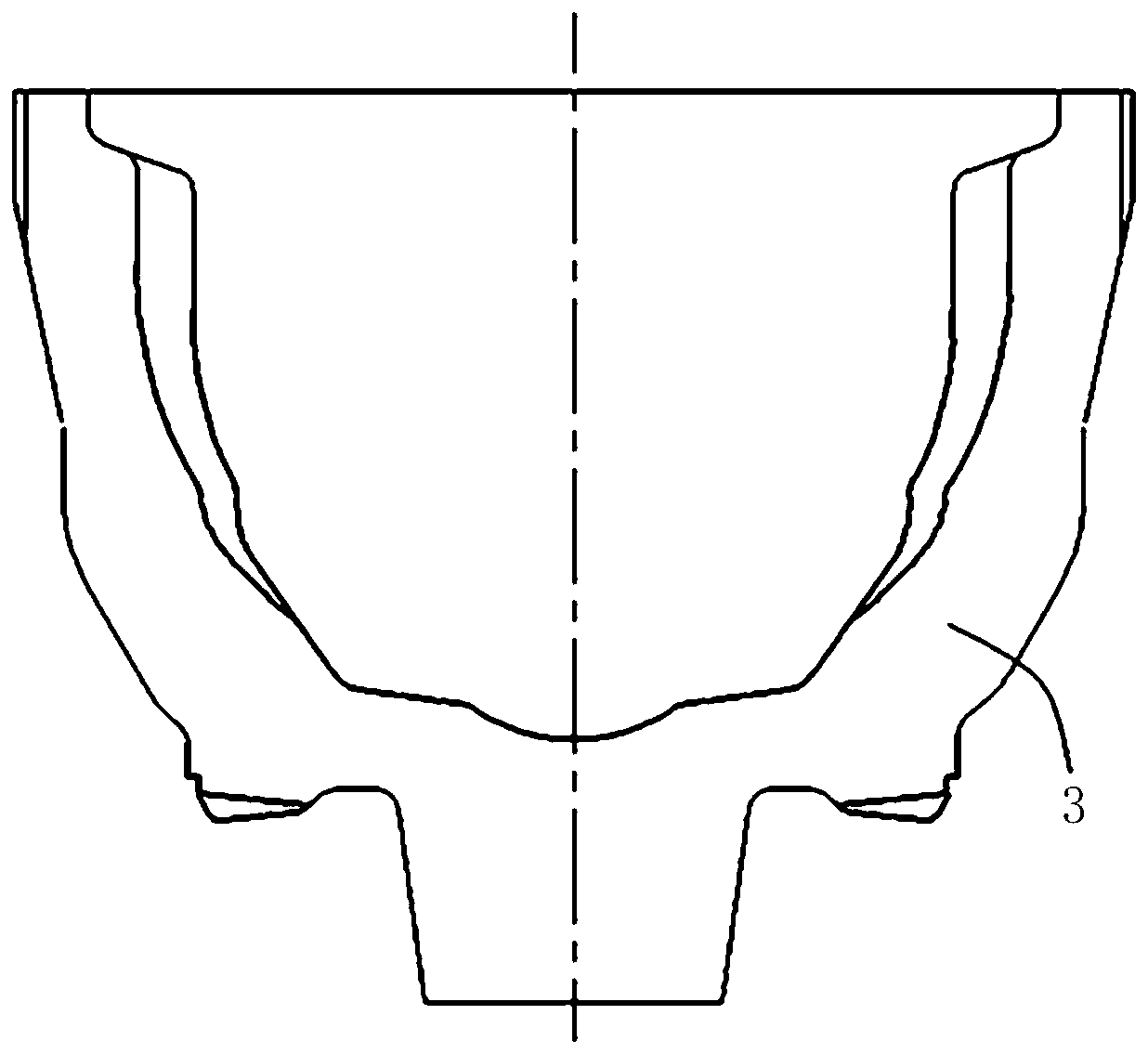

End face tooth bell-shaped shell and manufacturing method thereof

InactiveCN111015134AReduce deformation resistanceDeformation resistance fully utilizedManufactured materialBar stock

The invention relates to an end face tooth bell-shaped shell and a manufacturing method thereof. The method comprises the following steps that a bar stock is firstly forged to obtain a blank; surfacetreatment is carried out on the obtained blank to obtain a blank without scale on the surface; then phosphating treatment is carried out on the obtained blank without the scale on the surface to obtain a blank with a phosphating film on the surface; then saponification treatment is carried out on the obtained blank with the phosphating film on the surface, and cold extrusion is carried out to obtain a blank with a tooth shape; and finishing is carried out on the obtained blank with the tooth shape to obtain the end face tooth bell-shaped shell. According to the manufacturing method, processingprocedures such as warm forging, shot blasting, the cold extrusion, the finishing and the like are used for replacing milling procedures applied in a traditional production process, raw materials aresaved, the integral strength and rigidity of a part after forming are further guaranteed, and the one-time processing forming rate is increased.

Owner:JIANGSU SUNWAY PRECISION FORGING

A heating device for powder paste filling and a powder paste production process using the device

ActiveCN112208877BReduce temperature differenceReduce the phenomenon of concavePackagingHeat gunComposite material

The application discloses a heating device for powder paste filling, which includes a base, a vertical plate is fixedly arranged on the top of the base, a waist-shaped hole is opened on the side wall of the vertical plate, and a lifting block is arranged on the side wall of the vertical plate. A positioning bolt is installed in the shaped hole, and the positioning bolt passes through the waist-shaped hole and is threaded with the lifting block. A sliding rod is installed in the lifting block. The side wall of the lifting block is threaded with a positioning screw. A heat gun is held in the sleeve. The present application also discloses a powder paste production process, including S1: placing the container on a jig; S2: filling the container; S3: heating the container to 98°C-102°C; S4: heating the container to 108℃‑112℃; S5: Heat the container to 98℃‑102℃; S6: Check whether the products are qualified; S7: Freeze the products to 13℃‑17℃; S8: Select qualified products and cover them. The present application reduces the problem of the concave surface of the powder paste, and improves the flatness of the surface of the powder paste when it is finally formed.

Owner:上海致新生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com