Patents

Literature

74results about How to "Improve straightening accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

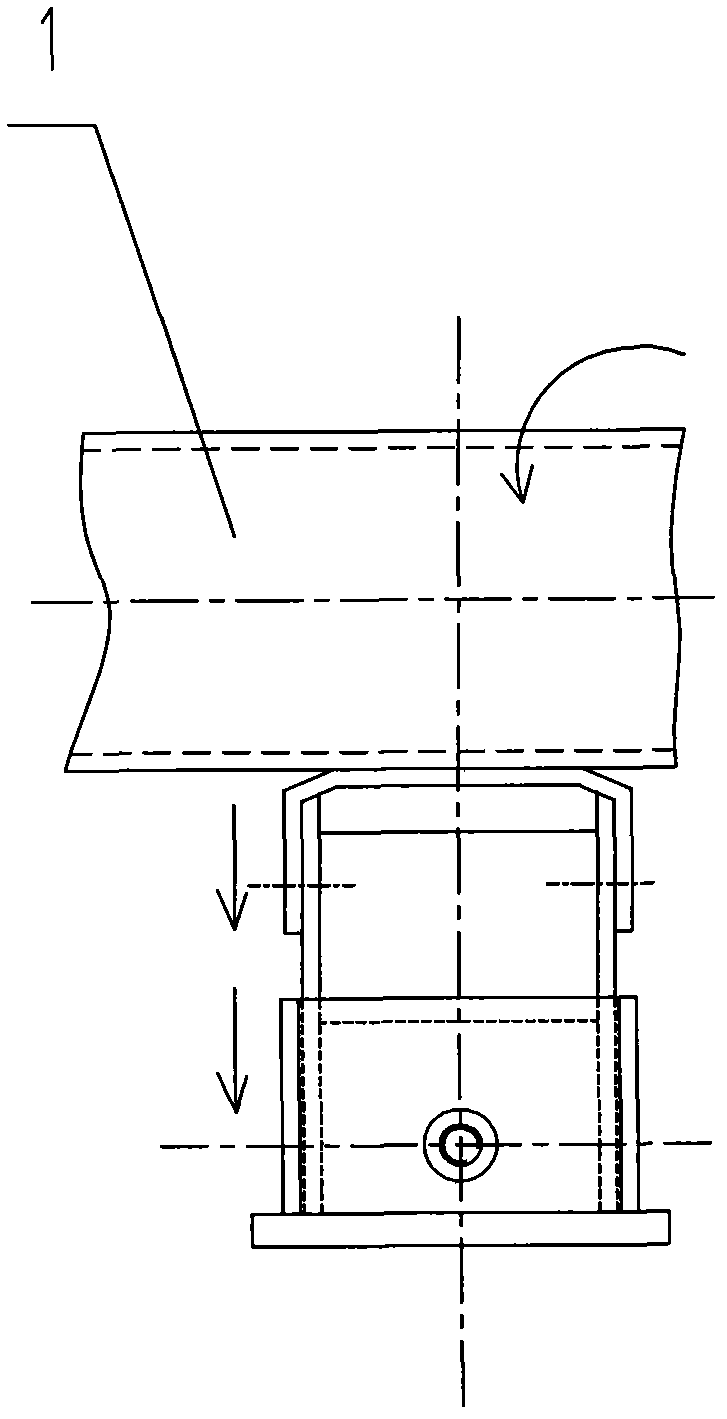

Transverse straightener

Owner:广州市力鼎汽车零部件有限公司

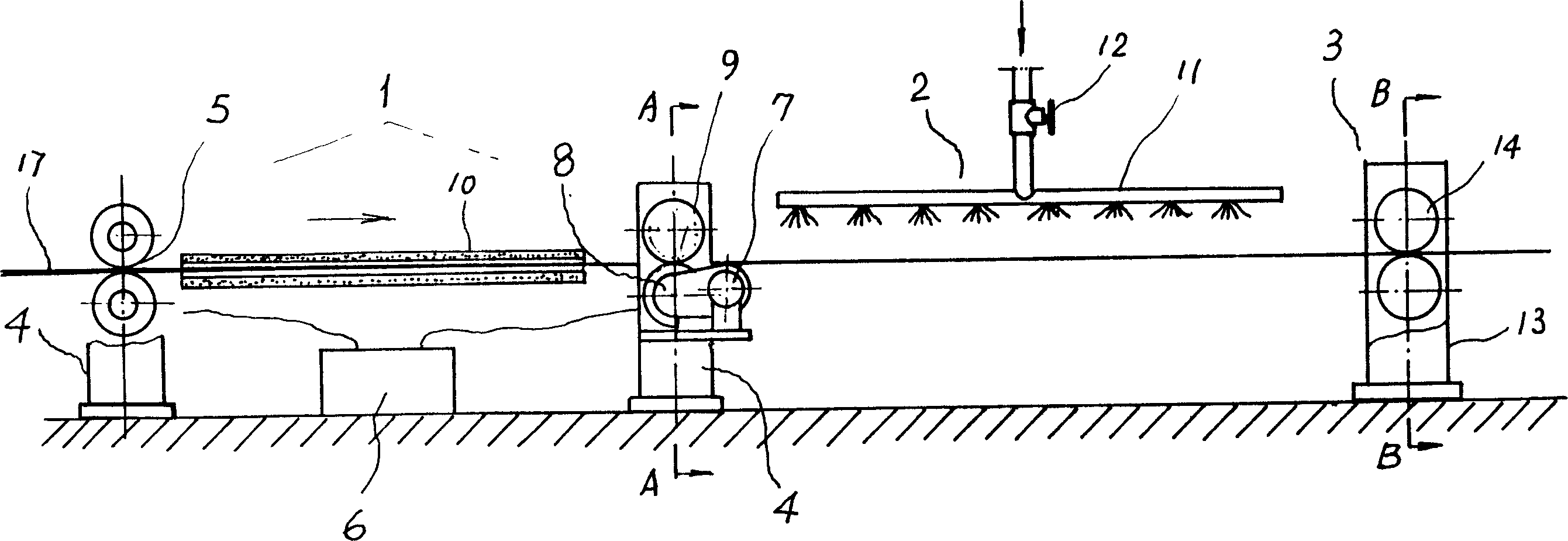

Composite working technology of steel wire heat treatment and straigthening and device thereof

InactiveCN1450181AImprove adaptabilityImprove straightening accuracyFurnace typesHeat treatment furnacesElectricityLow voltage

The present invention provides a steel wire heat treatment and straightening composite working process and its equipment. Said process includes the following steps: making steel wire pass through an electric heating device with two electric contacts, heating steel wire to required heat-treatment temp., then making said steel wire pass through a control cooling device to coal it, finally, making the steel wire pass through a tension device to straighten said steel wire. Said invented equipment includes a tension device, and is characterized by that it also has an electric heater formed from two supporting frames, two electric contacts and a low-voltage high-current transformer, and a cooling control device which is placed in the rear end of the electric heater and equipped with spray pipe with several cooling fluid spray heads and valve.

Owner:GUANGDONG IRON & STEEL INST

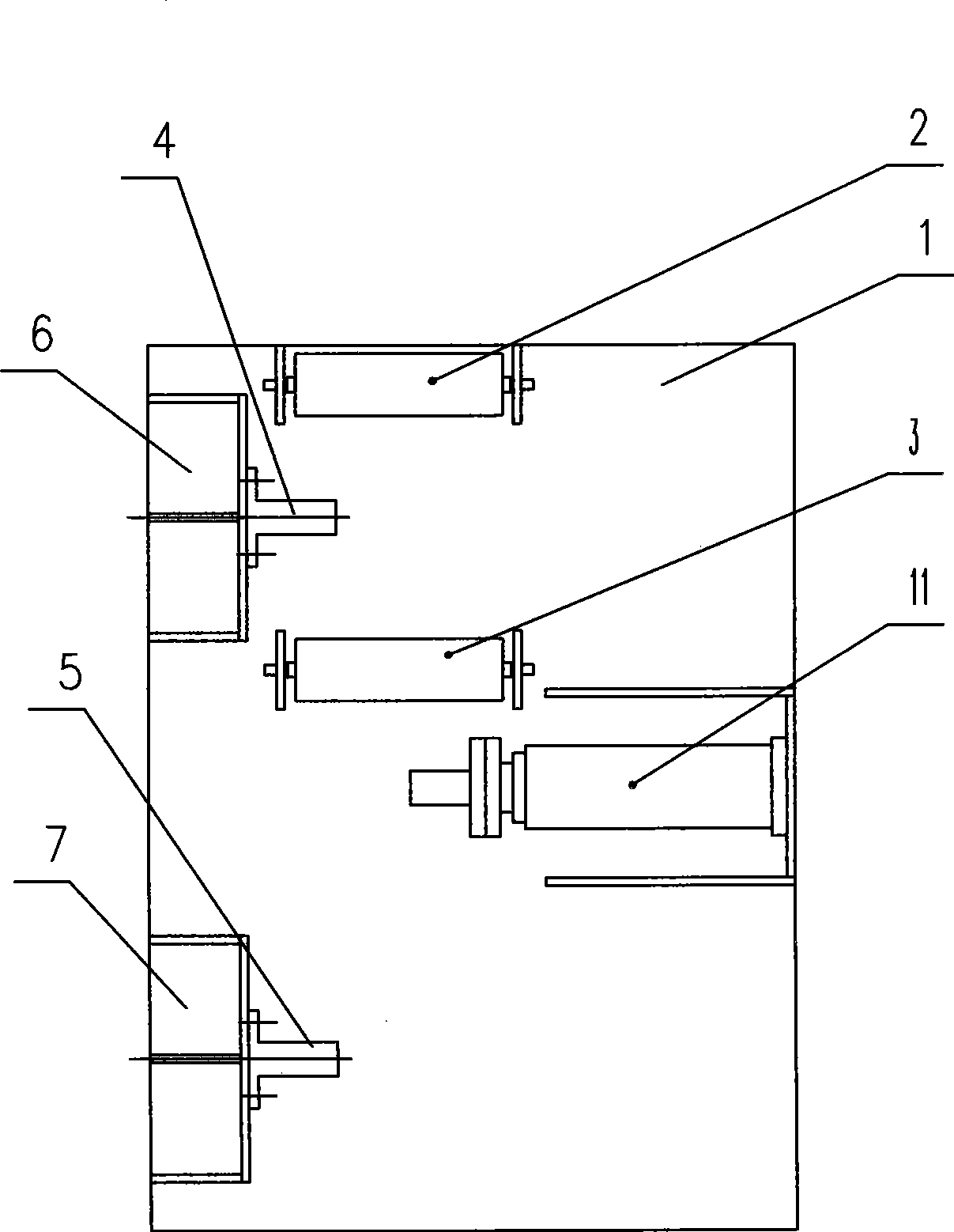

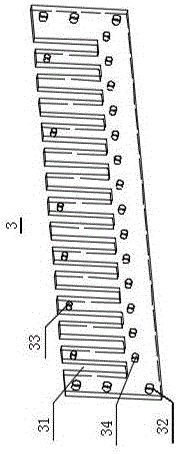

Rectangular pipe straightener

The invention discloses a rectangular pipe straightener comprising a frame, a motor and a reducer. The motor and the reducer are fixed under the frame. Two parallel wall plates are arranged above the frame. A rectangular pipe straightening mechanism set is arranged between the wall plates and comprises carrier rollers and a plurality of compression rollers. The carrier rollers are arranged at the bottoms of the wall plates. The compression rollers are arranged on the lower portions of the tops of the wall plates. Clearances between the upper faces of the carrier rollers and the lower faces of the compression rollers form straightening passages to allow the rectangular pipes to pass. The motor drives the reducer to drive the carrier rollers to rotate, and meanwhile, a transmission mechanism is arranged between two carrier rollers and two compression rollers which are arranged at two ends of the rectangular pipe straightener mechanism. Each transmission mechanism drives the two compression rollers to rotate. The compression rollers are connected with the wall plates through bearing seats. Adjusting mechanisms are arranged between the wall plates and the bearing seats to drive the bearing seats to move vertically. The rectangular pipe straightener is convenient to operate and adjust, capable of straightening the rectangular pipes with different sizes and high in straightening accuracy.

Owner:上海奉贤钢管厂有限公司

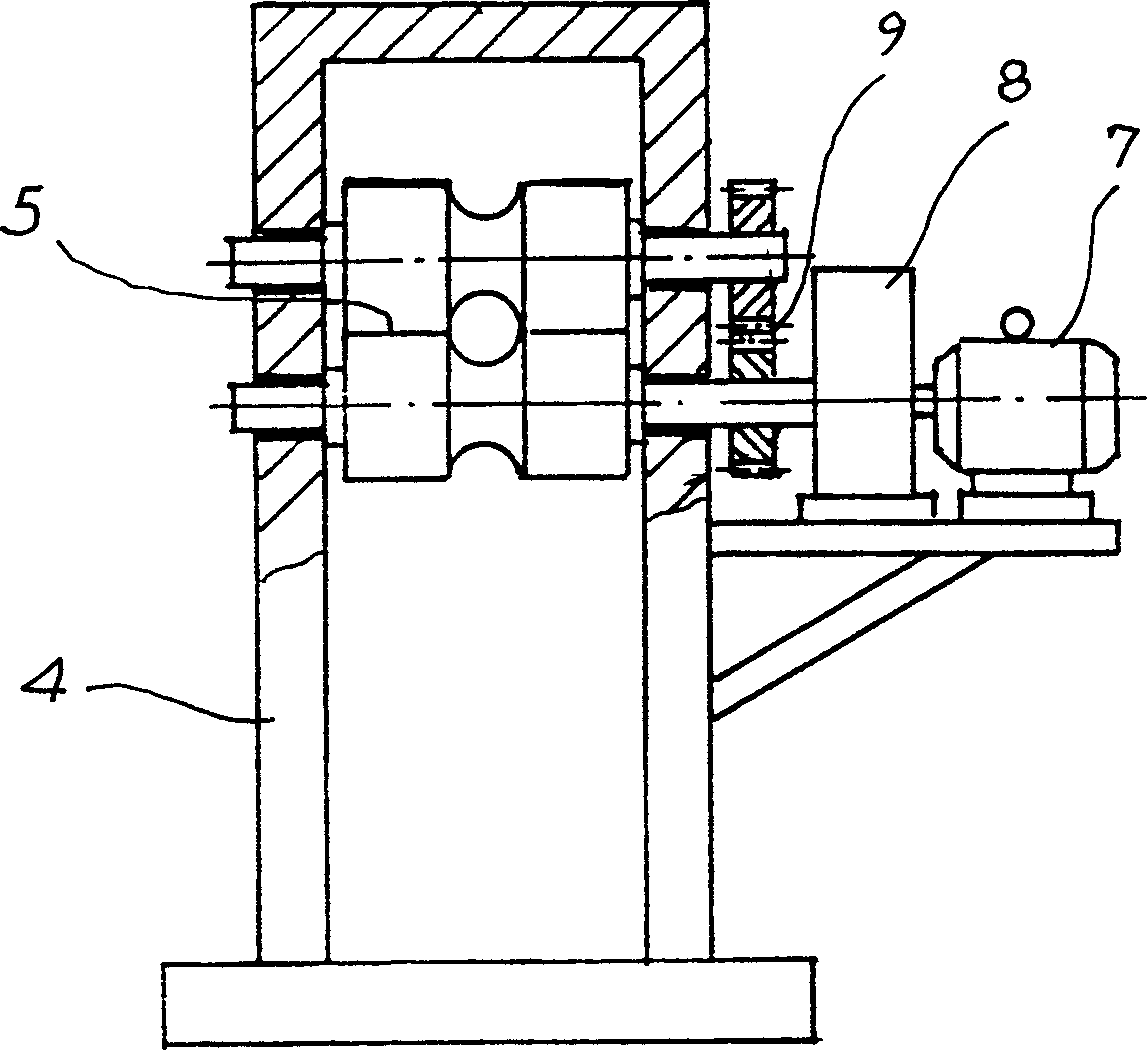

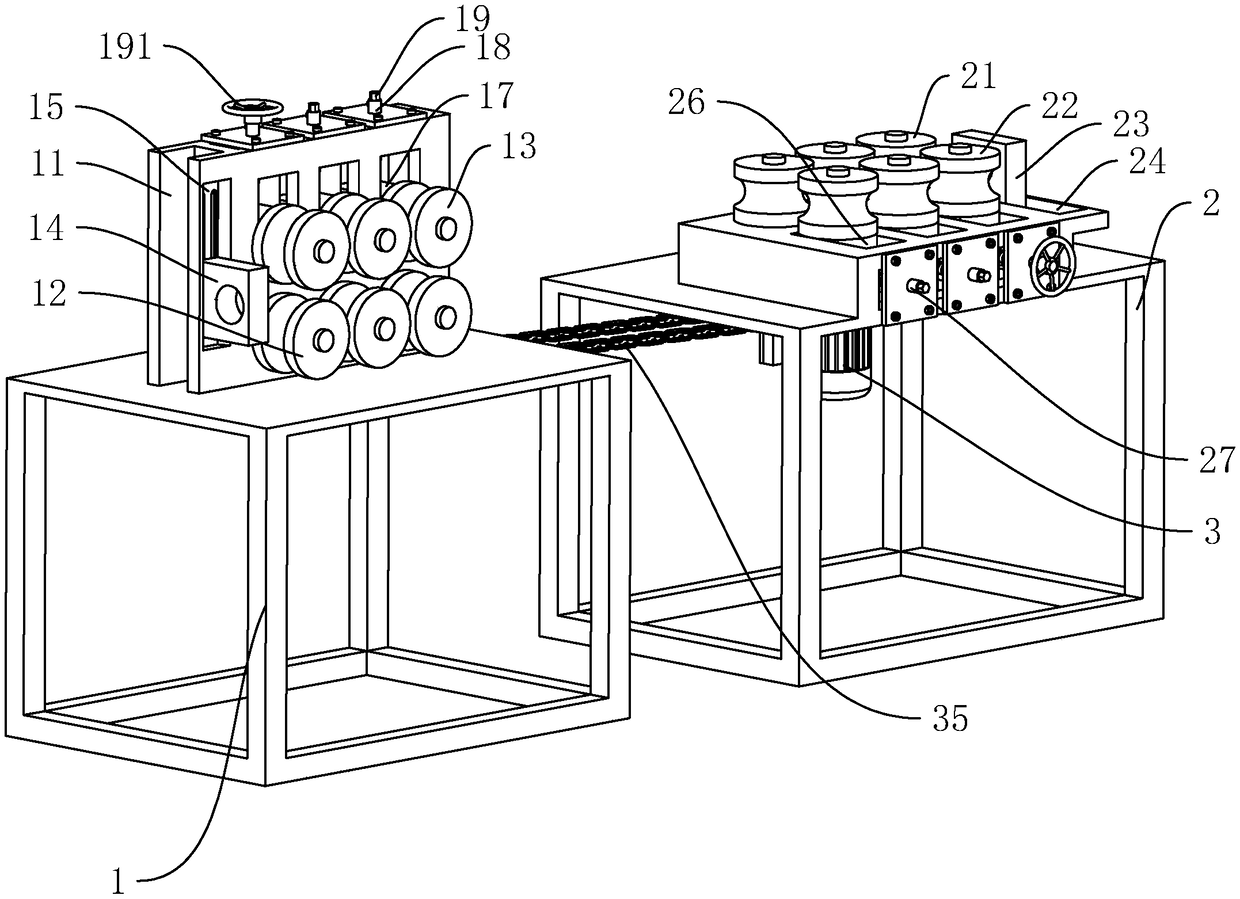

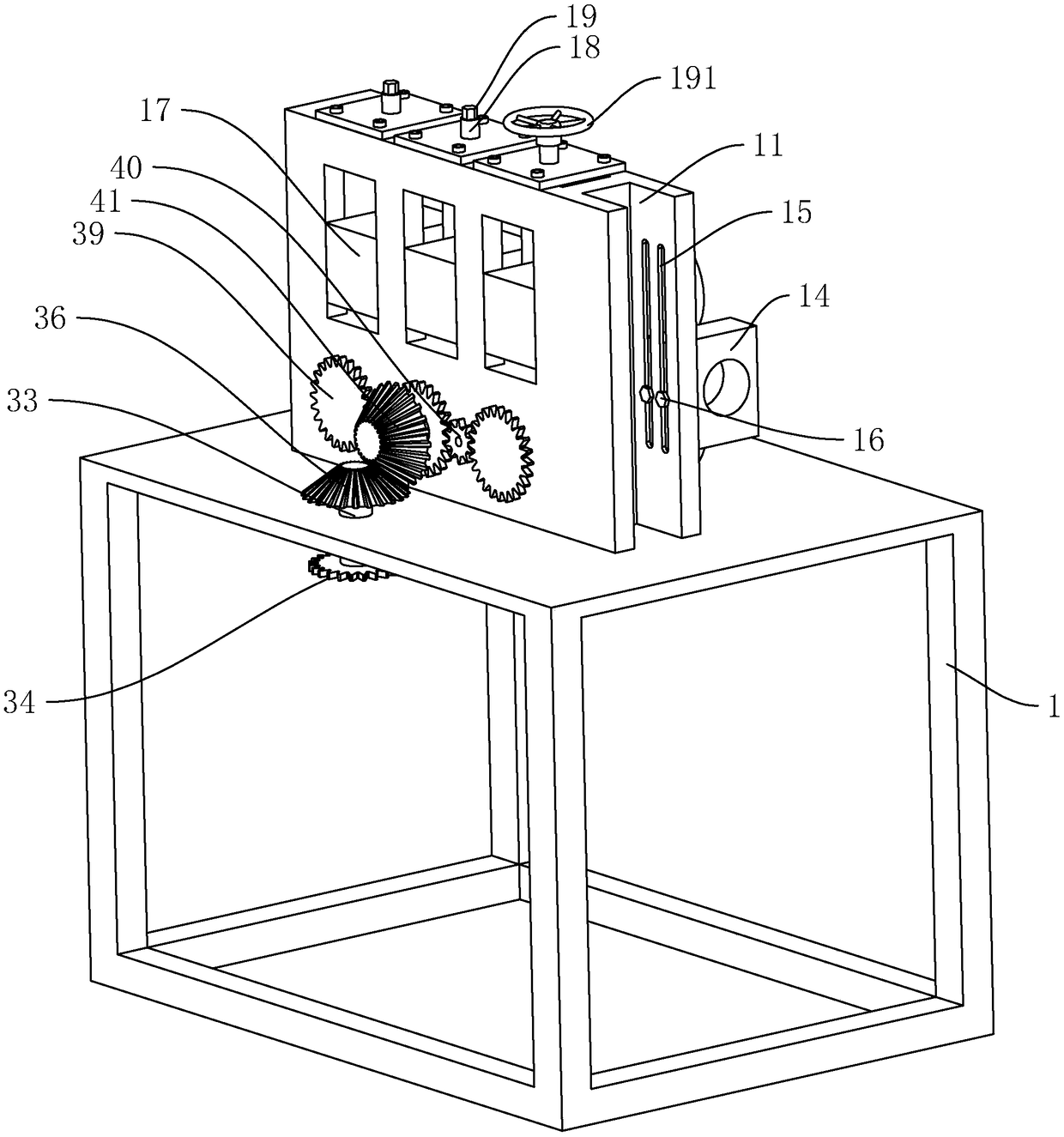

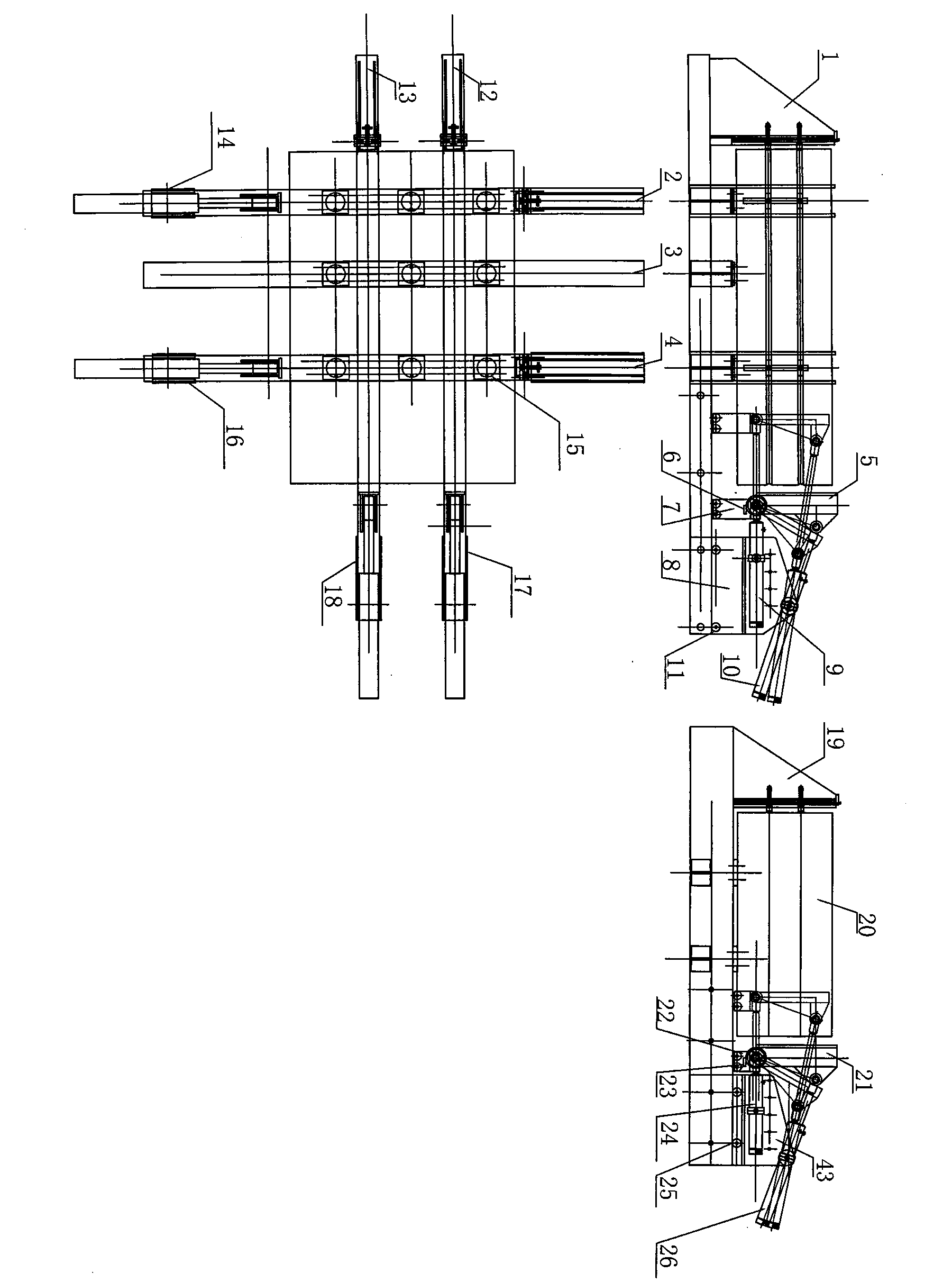

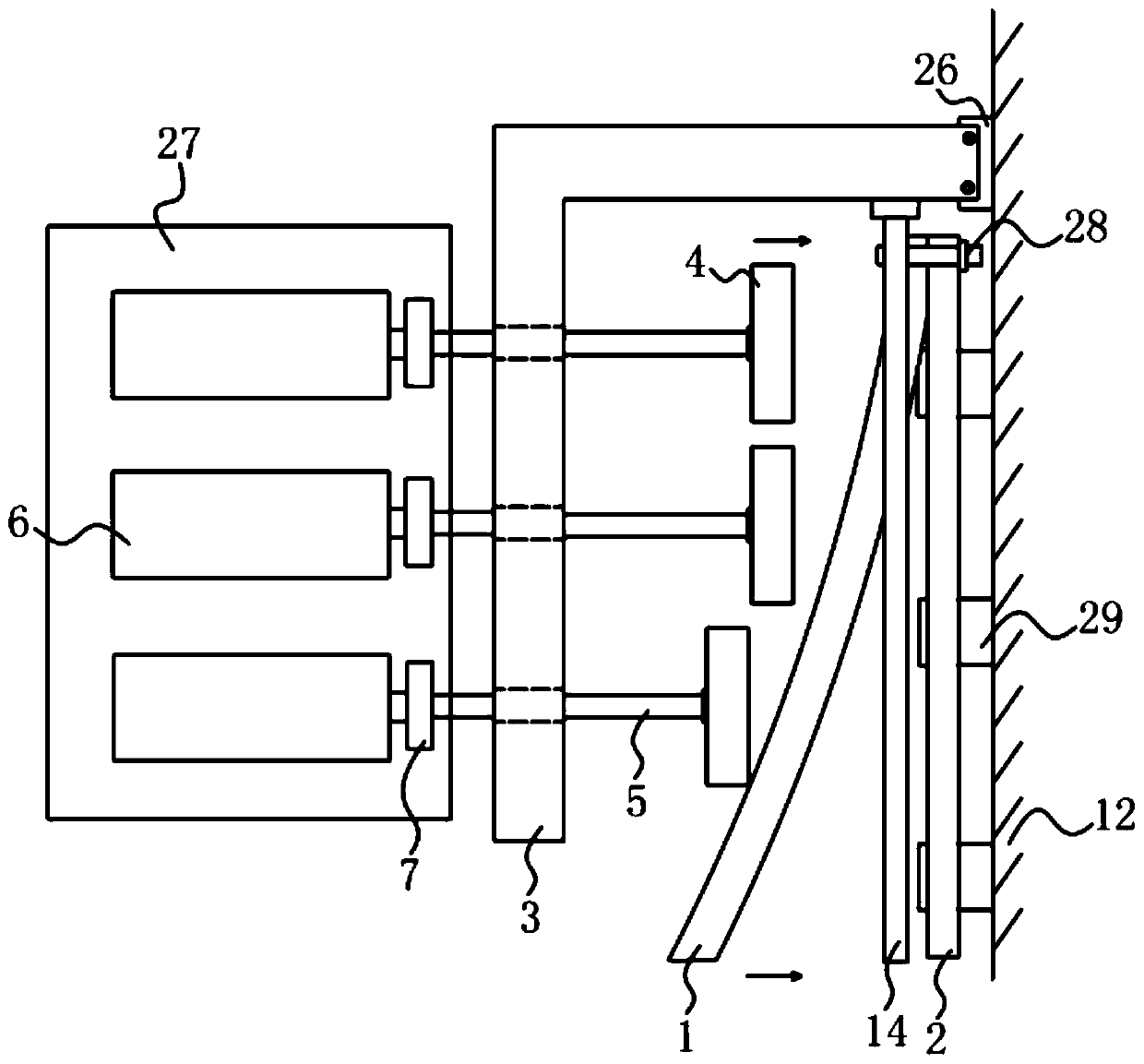

Two-way straightening machine driven by single power source

InactiveCN108906918APrevent abnormal slidingImprove operational coordinationGearingAlternating currentGear transmission

The invention discloses a two-way straightening machine driven by a single power source and relates to steel processing equipment, aiming at solving the problem of inadequate straightening accuracy. The key point of the technical scheme includes: the two-way straightening machine driven by the single power source includes a vertical straightening mechanism, a horizontal straightening mechanism anda power mechanism. The vertical straightening mechanism includes a first workbench, a vertical mounting plate and a plurality of vertical power wheels. The vertical mounting plate corresponds to eachvertical power wheel which slips longitudinally and is connected with a vertical pressure wheel in rotation. The horizontal straightening mechanism includes a second workbench and a plurality of horizontal power wheels. The surface of the second workbench corresponds to each horizontal power wheel which slips horizontally and is connected with a horizontal pressure wheel in rotation. The power mechanism includes an alternating current motor, a horizontal gear transmission unit and a vertical gear transmission unit. The two-way straightening machine driven by the single power source effectively improves the straightening accuracy of steel, while ensuring the coordination of the two straightening mechanisms.

Owner:JIAXING JIECHENG MACHINERY

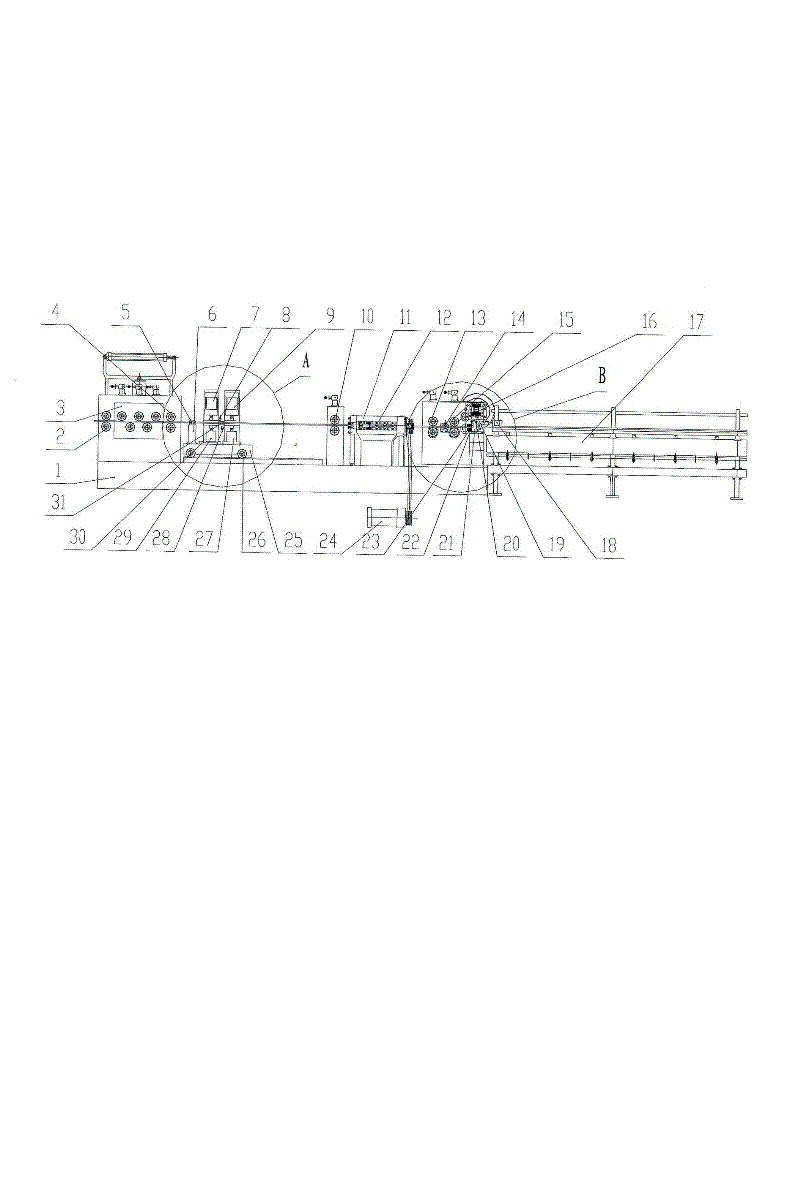

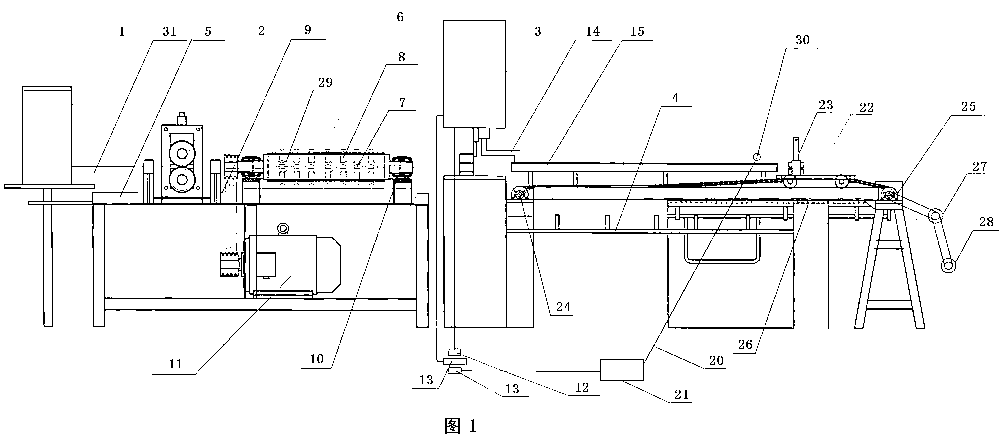

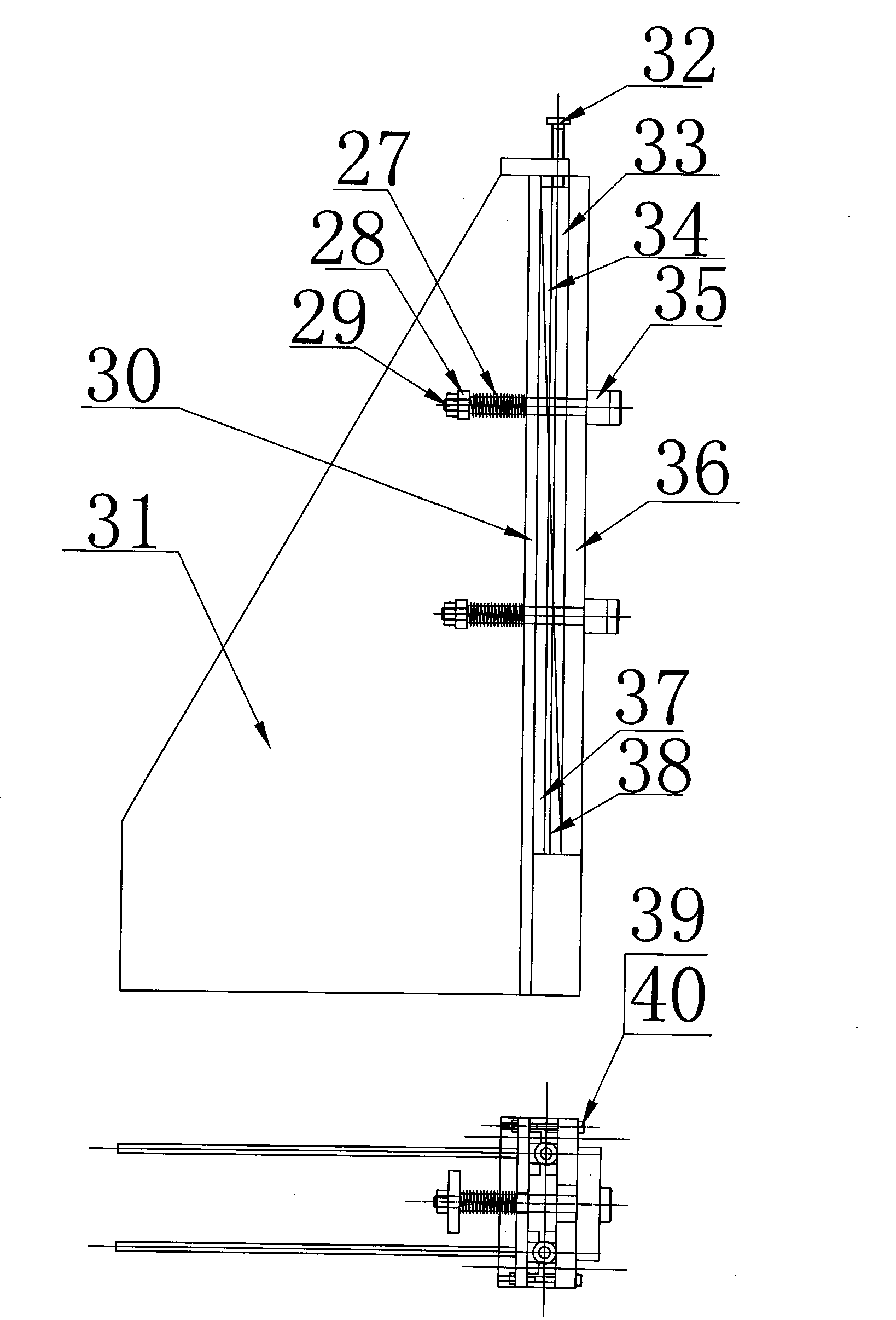

Straightening method and straightening device of short bar stock

InactiveCN102653054AReduce the proportionImprove straightening accuracyOther manufacturing equipments/toolsButt weldingEngineering

The invention provides a straightening method and a straightening device of a short bar stock. The method comprises the following main steps of: sequentially welding dispersed short bar stocks end to end to form a continuous long bar stock; straightening by a precise straightening mechanism; and cutting the bar stocks in front and back of a straightened welding line to obtain the straightened short bar stocks. According to the device corresponding to the method disclosed by the invention, a color spraying and butt welding mechanism is additionally arranged between a conventional roller straightening mechanism and the precise straightening mechanism; and a welding line detecting and cutting mechanism is additionally arranged at the back of the precise straightening mechanism. According to the invention, the straightening efficiency and the straightening precision of the short bar stock can be effectively improved.

Owner:YANSHAN UNIV

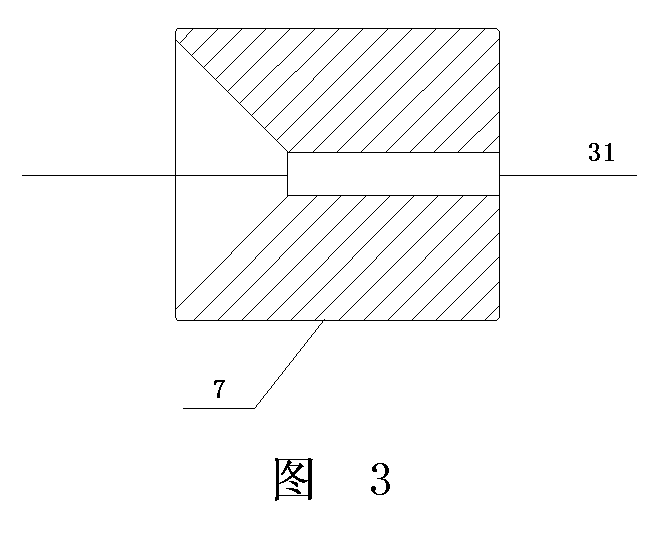

End-thickened steel-tube straightening device

InactiveCN101507991AStraightening up toObvious axial stretching phenomenonHydraulic cylinderMechanical equipment

The invention provides a method for straightening steel tubes with thickened end parts, which relates to the technical field of metal tube material processing in the metallurgy industry, in particular to finishing mechanical equipment for the metal tube materials. A base is provided with at least two sets of carrier rollers along the length direction; two steel tube pivot seats capable of sliding along the length direction of the base are arranged on the same side along the length direction of the base; jacking blocks which are positioned on the same plane as the two steel tube pivot seats are arranged on the other side of the base opposite to the steel tube pivot seats; and the rear ends of the jacking blocks are connected with hydraulic cylinders vertical to the length direction of the base. The method overcomes the defects of high labor intensity, low efficiency, poor quality and large deviation of the conventional manual pressure straightening machine, and has the characteristics of less investment, simple operation, high efficiency, high straightening precision, and the like.

Owner:江苏诚德钢管股份有限公司

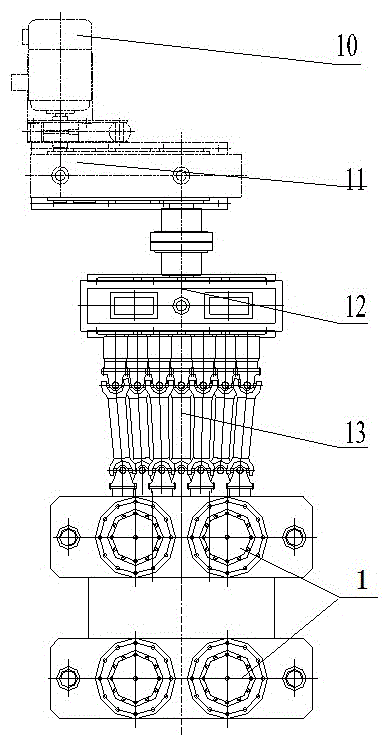

Stretch straightening machine and stretch straightening method

ActiveCN104399783AImprove straightening effectImprove straightening accuracySingle degree of freedomEngineering

The invention discloses a stretch straightening machine and a stretch straightening method. The stretch straightening machine comprises a primary stretching device and a secondary stretching device, wherein the primary stretching device comprises a primary machine base and a guide rail supporting slide base arranged on the primary machine base, and a primary stretching chuck sliding with a single degree of freedom and a stretching oil cylinder for driving the primary stretching chuck to slide are arranged on the guide rail supporting slide base; slide rails which are matched with one another are arranged between the guide rail supporting sliding base and the primary stretching chuck; the secondary stretching device comprises a secondary machine base, and a secondary stretching chuck for clamping section bars is arranged on the secondary machine base; a first jaw and a second jaw for fixing the section bars are correspondingly arranged on the opposite side surfaces of the primary stretching chuck and the secondary stretching chuck; the primary stretching chuck further comprises a straightening channel which comprises a straightening clamping opening. The straightening machine and the straightening method disclosed by the invention can be used for performing pre-straightening and stretch straightening in sequence, thereby achieving a relatively good straightening effect and guaranteeing high precision; during the operation, only one ends of the section bars need to be put into the straightening machine, and thus the straightening machine is convenient to use.

Owner:LIAONING ZHONGWANG MACHINERY EQUIP MFG

Method for straightening drill rod

InactiveCN101733309AAvoid destructionReduce work intensityNumerical controlEngineeringPressure sensor

The invention discloses a method for straightening a drill rod. The method comprises the following steps of: 1) detecting the initial bending modulus of the drill rod and axially and circumferentially positioning the drill rod needing straightening; 2) obtaining a straightening feeding amount in a computing device through a straightening mathematical model; 3) starting a feed cylinder of a pressure straightening machine to start feeding; 4) as the pressure of an oil inlet loop of the feed cylinder rises when a piercing head of the feed cylinder contacts the surface of the drill rod, when a pressure sensor detects a set value, feeding the set value to the computing device; 5) starting a displacement sensor by the computing device to start detecting the straightening feeding amount; 6) when detecting that the piercing head of the feed cylinder reaches the straightening feeding amount of the straightening mathematical model, rapidly returning the piercing head; and 7) ending automatic straightening control.

Owner:BAOSHAN IRON & STEEL CO LTD

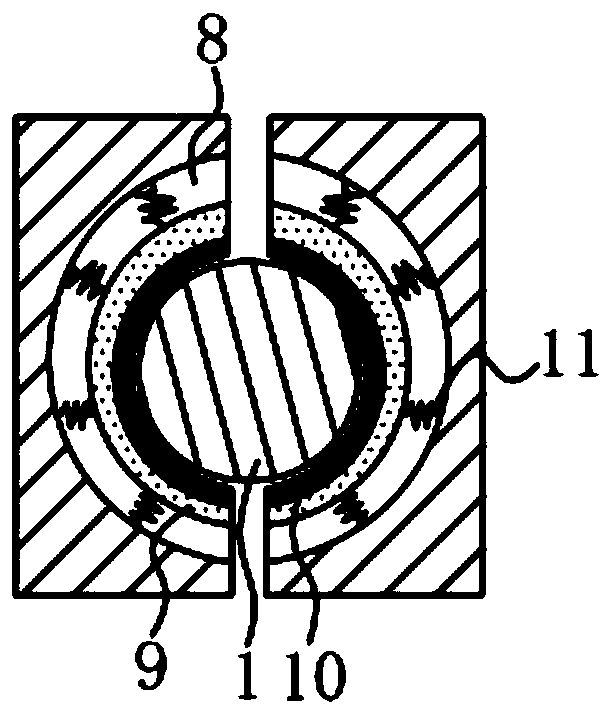

Valve steel plate element straightener

The invention discloses a valve steel plate element straightener which comprises a pay-off reel, a pinch roll, a straightening mechanism and a cut-off mechanism, wherein the straightening mechanism comprises a straightening barrel which is horizontally arranged, at least one straightening model is arranged in the straightening barrel, the straightening model is horizontally fixed in the straightening barrel by two adjustable jacking bolts symmetrical to each other vertically and has a cylinder structure, the outer sides of two ends of the straightening barrel are provided with rotating shafts with through holes at the center, the rotating shafts are arranged on a support frame, the support frame is fixed on a main frame table, and any of the rotating shafts is connected with the shaft of the motor by a transmission mechanism. The valve steel plate element straightener has the advantages of simple structure, low cost, easy operation, convenient overhauling, no scratch on the surface of wire, high straightening precision, automatic sizing, cutting-off and blanking, high sizing precision, low labor intensity, high efficiency, no balance of straightening steel wires, and high yield.

Owner:JIANGSU SHENYUAN SPECIAL STEEL

Centered guiding device of bars for straightening machine

PendingCN108160840AImprove operational reliabilityAvoid breakingMetal-working feeding devicesPositioning devicesEngineeringOperational reliability

The invention discloses a centered guiding device of bars for a straightening machine. The centered guiding device comprises two bar limiting units symmetrically arranged on the two sides of a roll gap, wherein each bar limiting unit comprises a guiding plate door, a guiding strip, a guiding plate and two locking cylinders; the lower part of each of the guiding plate doors is rotatably connected with a straightening machine base through a rotating shaft; each of the guiding strips is blocked on the side part of the roll gap and is connected with each of the guiding plate doors through each ofthe guiding plates; the two locking cylinders are respectively positioned on the left side upper part and the right side upper part of each of the guiding plate doors; and cylinder bodies of the locking cylinders are supported on each of the guiding plate doors. According to the centered guiding device of the bars for the straightening machine disclosed by the invention, the guiding plate doors are pressed tightly by the cylinder bodies of the locking cylinders, and because the mass of the cylinder bodies is large, slight vibration is only produced when the guiding plate doors are impacted, sothat sealing of the locking cylinders is difficultly damaged; and therefore, oil leakage failure is reduced, the operation reliability of the centered guiding device is improved, the maintenance costof the equipment is reduced, and a normal operation of production is ensured.

Owner:SHIJIAZHUANG IRON & STEEL

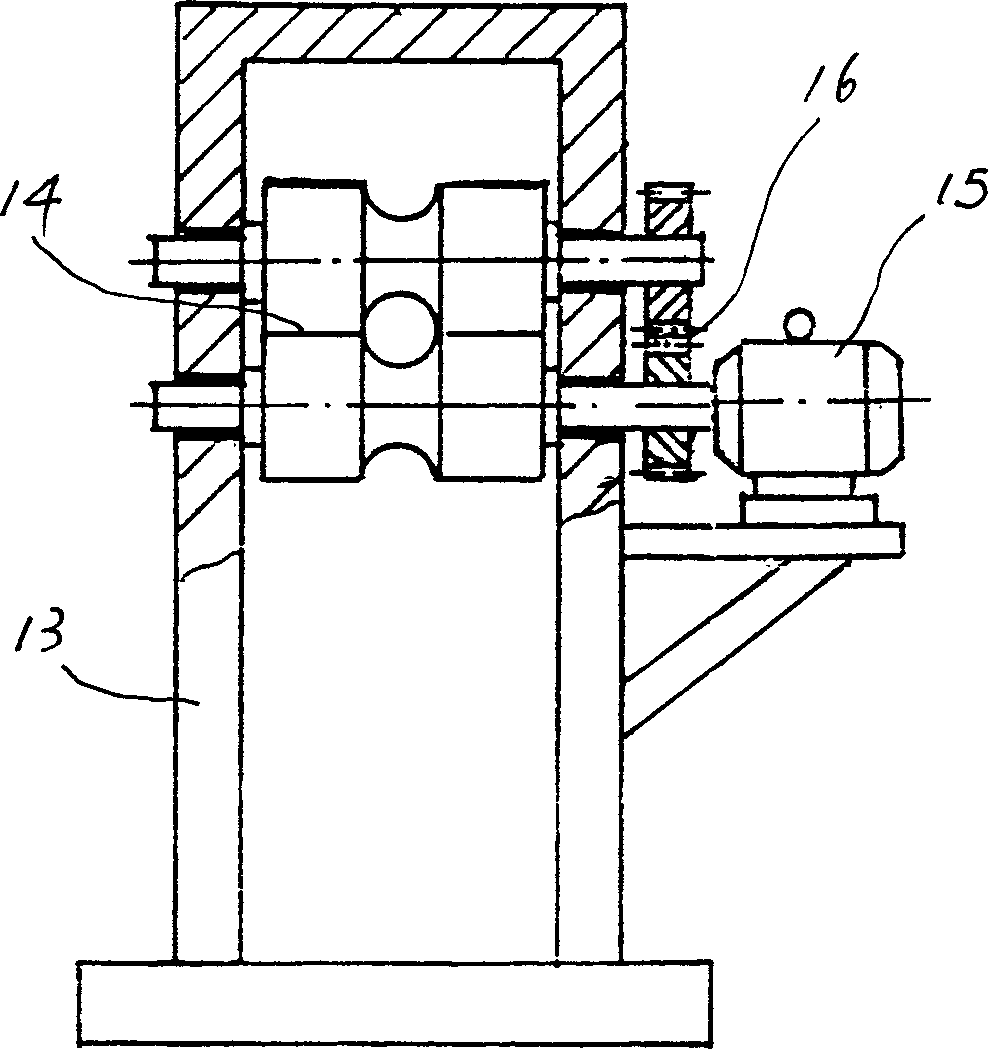

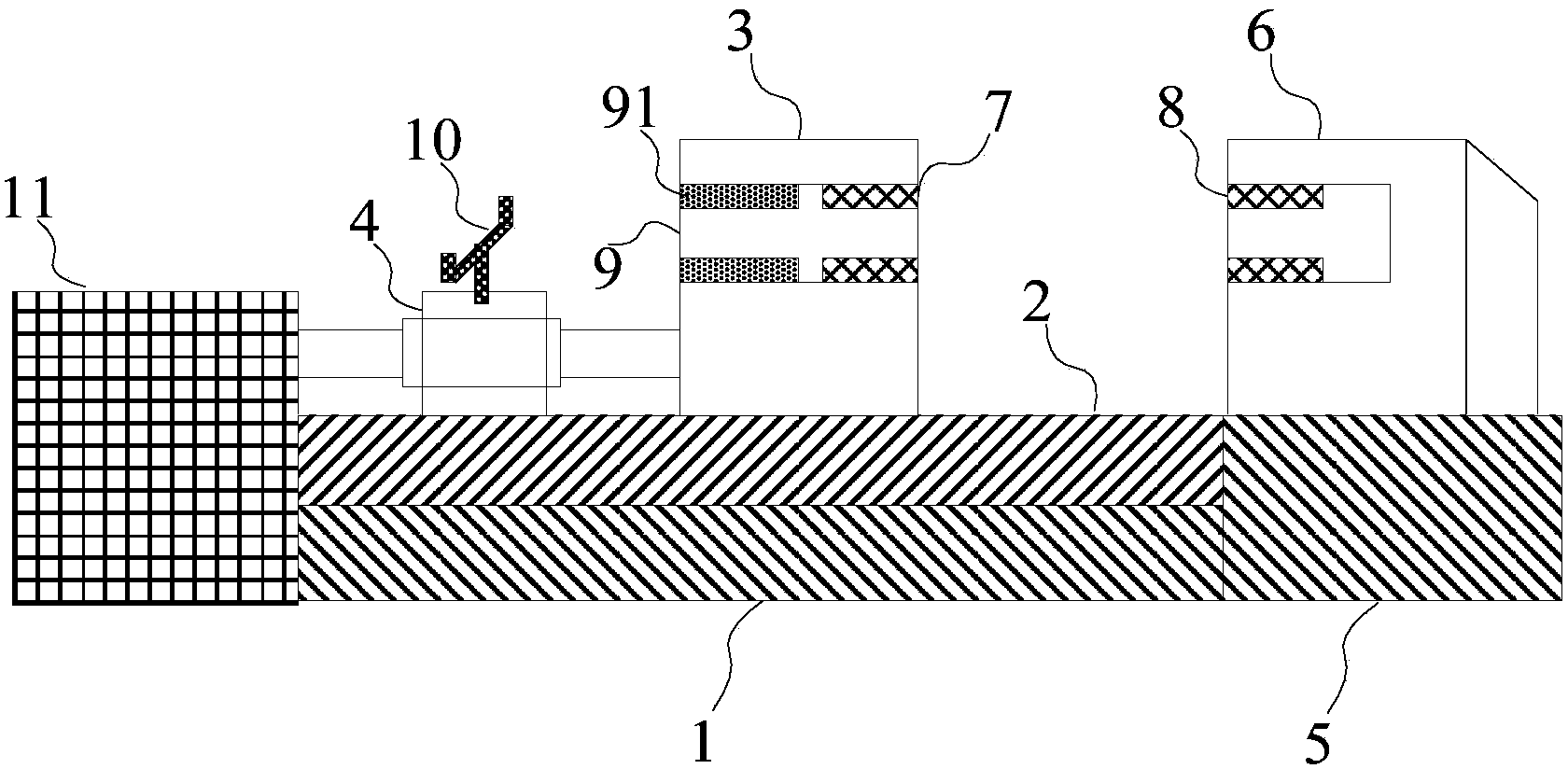

Roller type straightener for steel pipe

PendingCN105728505AImprove straightening accuracyExpand the scope of applicationSteel tubeEngineering

The invention discloses a roller type straightener for a steel pipe. The roller type straightener comprises a first straightening device used for straightening the steel pipe in the first direction, a second straightening device used for straightening the steel pipe in the second direction, and an adjustable supporting device connected with the second straightening device and used for adjusting the distance between the steel pipe conveying direction of the first straightening device and the steel pipe conveying direction of the second straightening device and the included angle between the first direction and the second direction. The roller type straightener for the steel pipe has the beneficial effects that the surface of the steel pipe is not damaged, the structure is stable, the straightening precision is high, and operability is high, and has good mechanical performance.

Owner:QINGDAO HANHE CABLE DMAR MARINE EQUIP MFG CO LTD

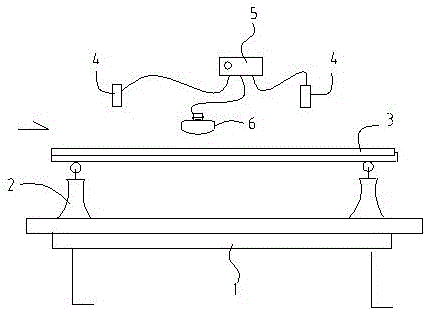

Hydraulic straightening platform

The invention provides a hydraulic straightening platform which can straighten and align overlapped workpieces. A set of shape steel bottom beams which are arranged in a criss-cross mode and meet the requirement for the height difference, adjustable end socket columns, movable end socket bases, tilt angle detection devices, T-shaped movable centers, movable pushing and straightening columns, track idler wheels, abrasion resistance blocks, straight-movement oil cylinders and inclined-pushing oil cylinders are stably connected together through hinge pins and rib plates to form the hydraulic straightening platform. The two ends of each shape steel bottom beam are connected with the corresponding adjustable end socket column and the corresponding movable straightening end socket base respectively, the straight-movement oil cylinders and the inclined-pushing cylinders are simultaneously hinged to the straightening end socket bases, the track idler wheels and the tilt angle detection devices are simultaneously hinged to the piston rod ends of the straight-movement oil cylinders, the T-shaped movable centers are arranged on the adjustable end socket columns, and the piston rod end of the corresponding straight-movement oil cylinder and the piston rod end of the corresponding inclined-pushing oil cylinder are hinged to the two ends of each movable pushing and straightening column respectively.

Owner:YANGZHOU LISHEN ELEVATORING EQUIP

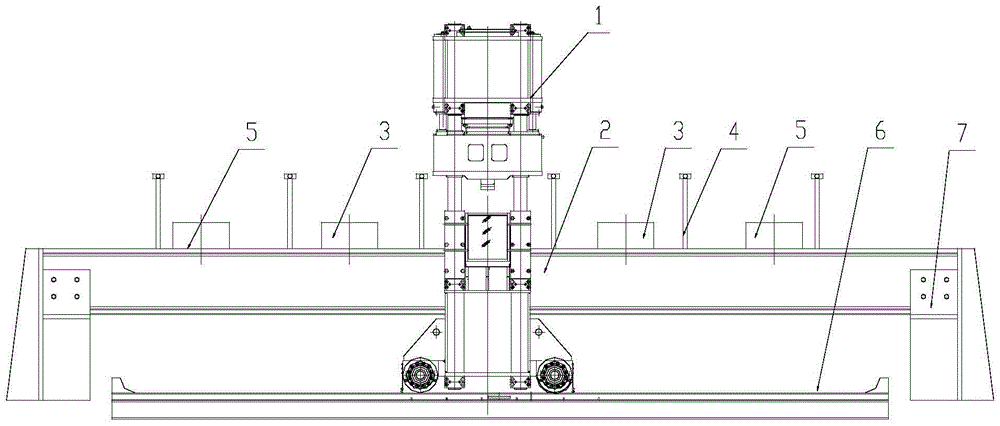

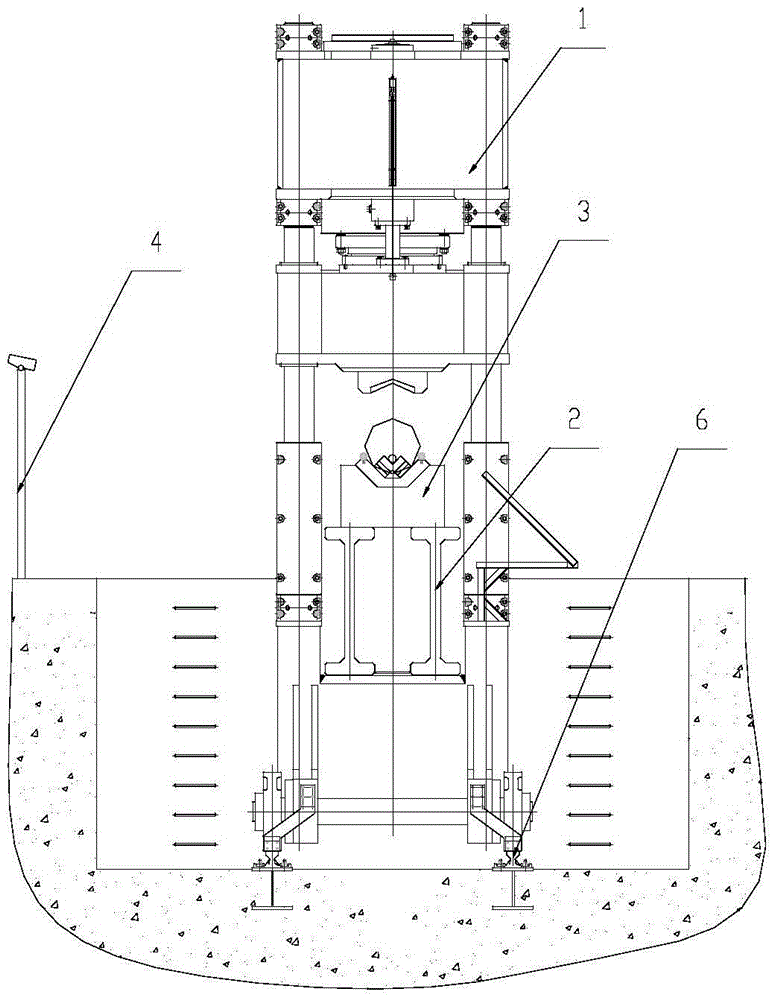

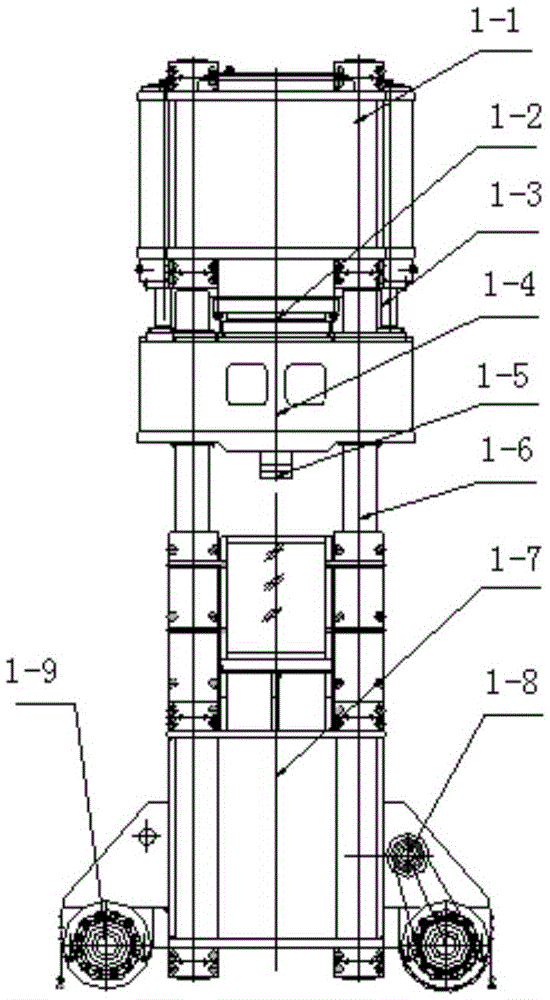

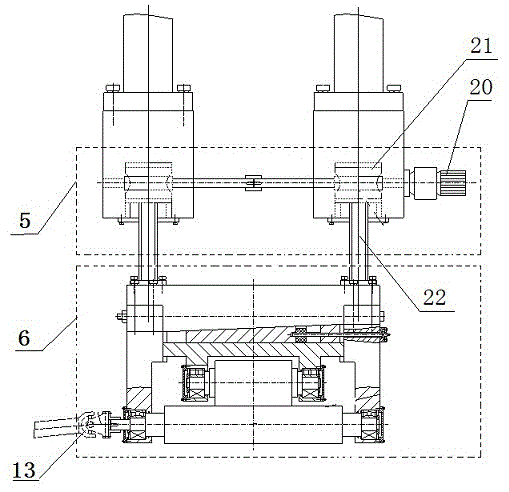

Self-propelled automatic pressure straightening machine for gantry

ActiveCN105458041ASimple structureCompact structureMetal working apparatusEngineeringUltimate tensile strength

The invention discloses a self-propelled automatic pressure straightening machine for a gantry. The self-propelled automatic pressure straightening machine for the gantry comprises a track steel beam; the two ends of the track steel beam are mounted on a base; the overall track steel beam passes through a gantry frame of a main machine; two mobile anvil beds and two mobile steel tilters both move inside the track steel beam; the two mobile anvil beds are mounted between the two mobile steel tilters; the main machine travels on steel rails; the steel rails are laid on a foundation; a straightness detection system is arranged close to the steel rails; the main machine is of a gantry type three-beam four-column structure; the main machine, the mobile anvil beds and the mobile steel tilters can all move so that more convenient and quicker steel tilting and straightening can be realized; meanwhile, the bending degree of a received material can be detected automatically, so the labor intensity of operation is alleviated, and the straightening precision of the equipment is improved; the self-propelled automatic pressure straightening machine is simple and compact in structure and has the advantages of reducing the floor area of the equipment and lowering the equipment investment.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

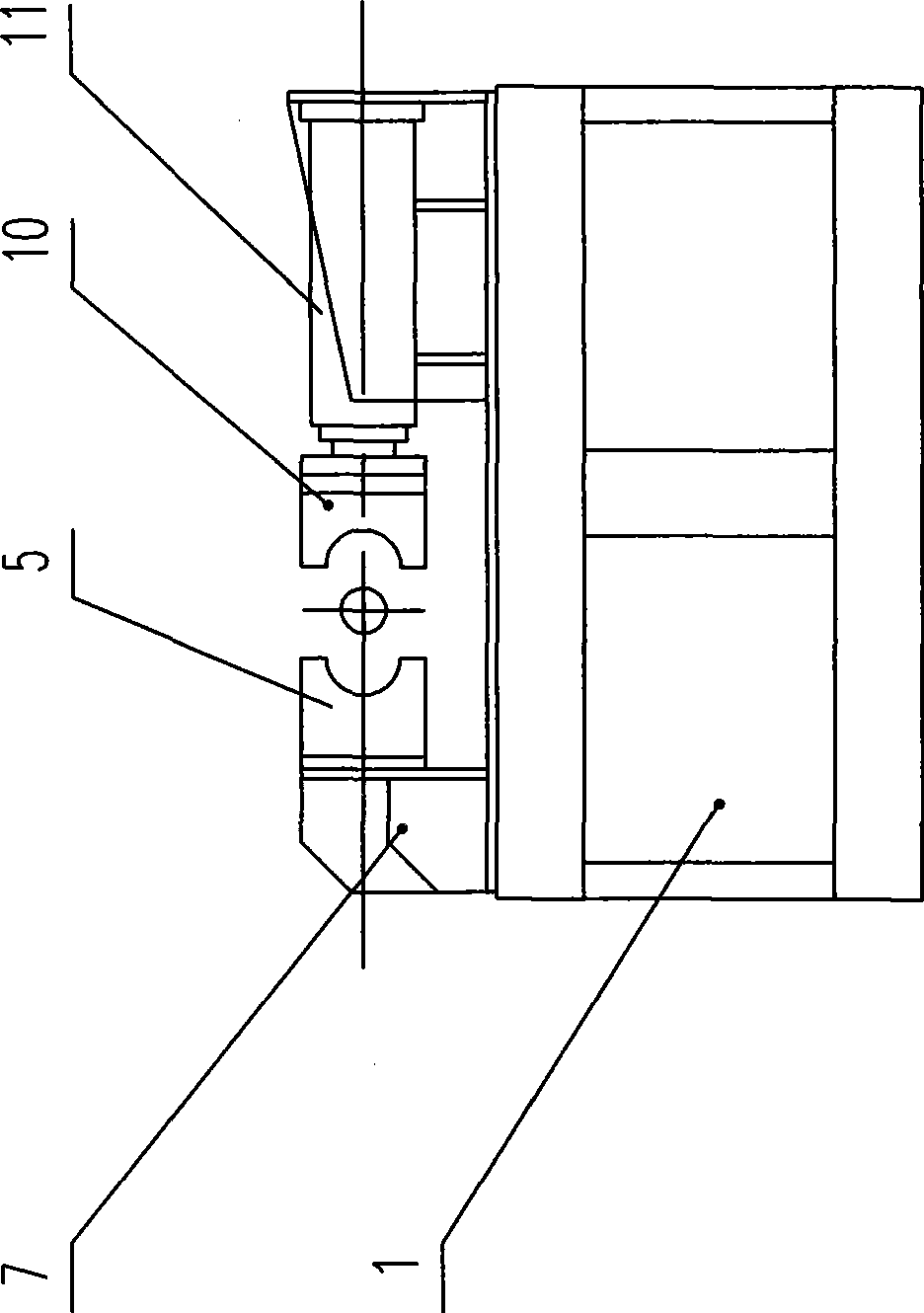

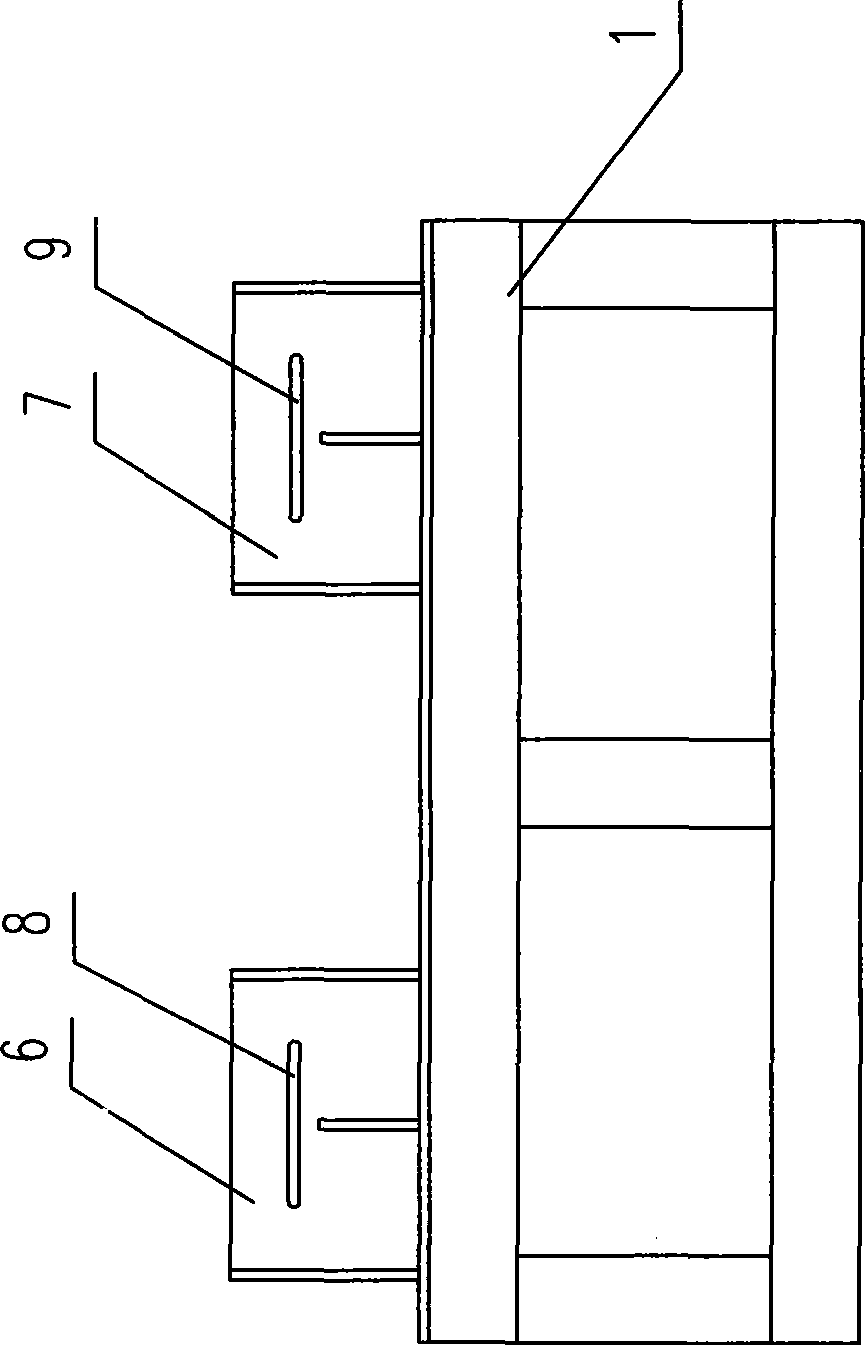

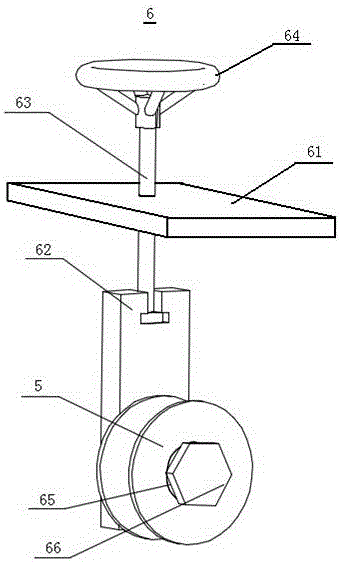

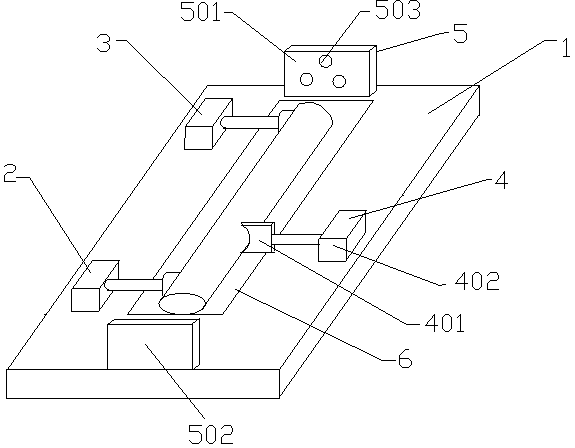

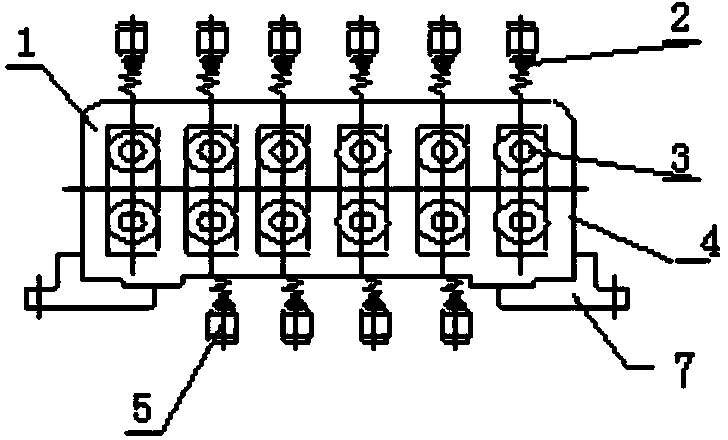

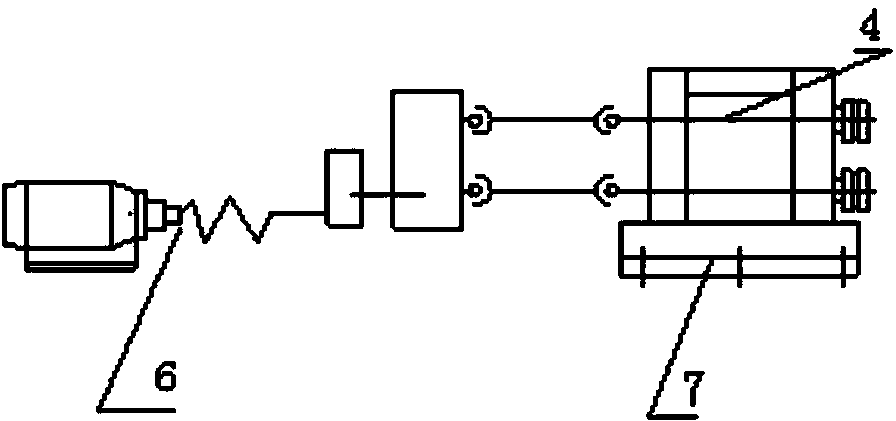

Elbow pressing-straight device

InactiveCN103736780AA Quick Look at Bend OrientationSimple designMetal working apparatusOptoelectronicsLaser source

The invention discloses an elbow pressing-straight device. The elbow pressing-straight device comprises a base (1), a left pressing-straight support (2), a right pressing-straight support (3), a pressing-straight support (4), a laser device (5) and a liner plate (6). The laser device (5) comprises a laser emitting device (501) and a laser receiving device (502). The surface, facing the laser receiving device (502), of the laser emitting device (501) is provided with at least three laser sources (503), and the lower surface of the liner plate (6) is provided with a plurality of horizontal balls. Compared with the prior art, the elbow pressing-straight device has the advantages of being simple in design, fast, convenient to use, high in precision and suitable for being popularized and used, and the steel pipe pressing-straight effect is detected through a laser beam.

Owner:HAILONG ZHANGJIAGANG IND

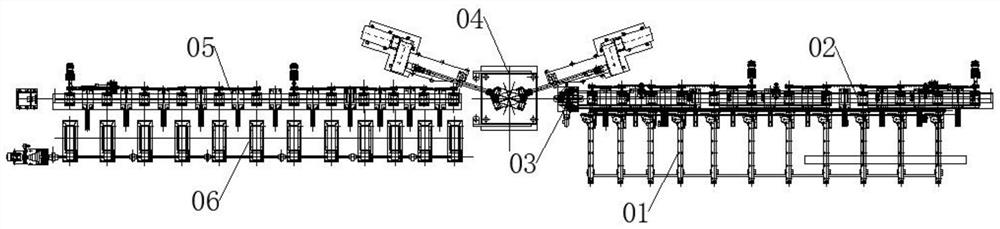

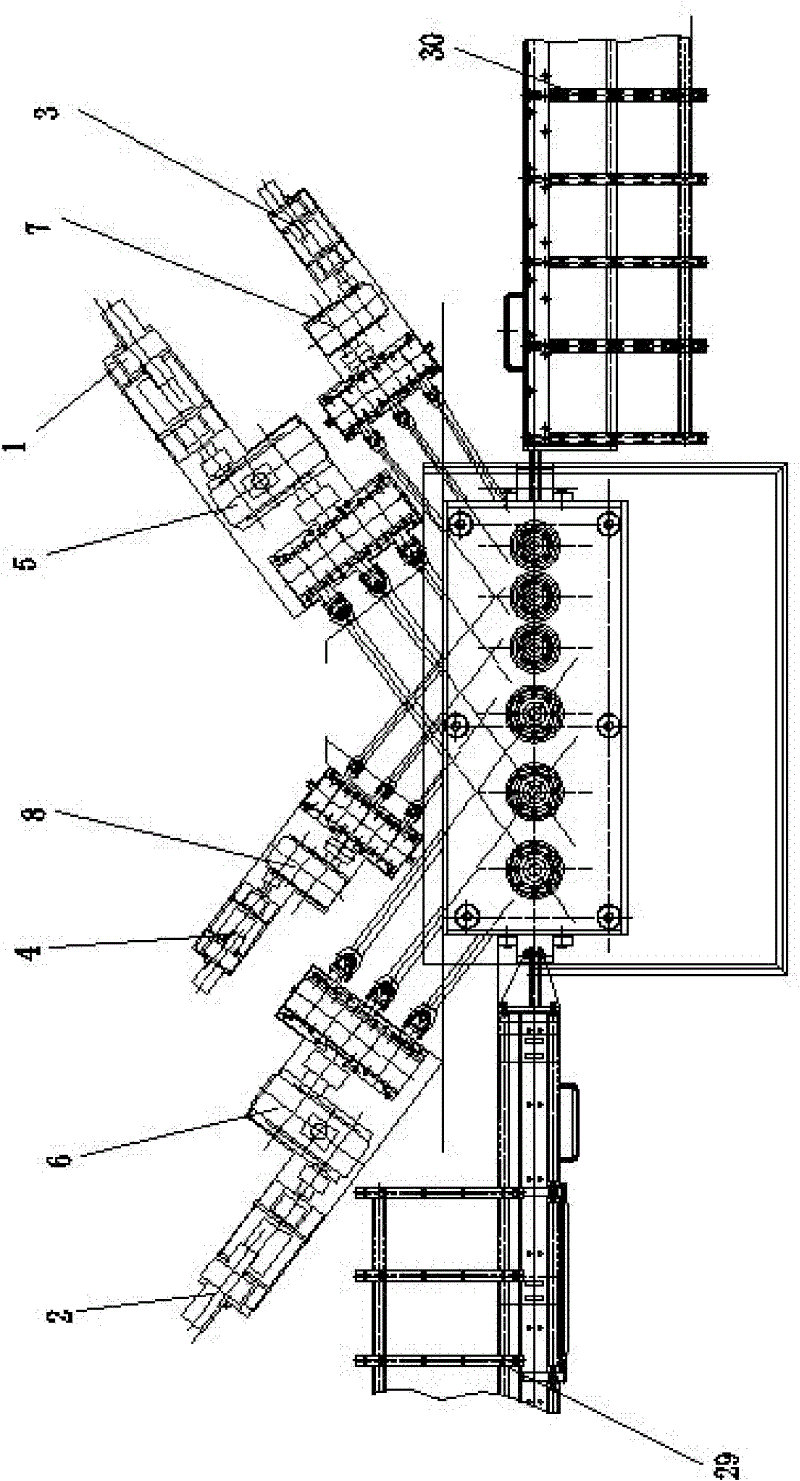

Efficient straightening unit for small-bore thick-wall metal tubes

PendingCN111804765ALow input costSimple structureShaping toolsMetal-working feeding devicesStraight tubeStructural engineering

The invention belongs to the technical field of metal straightening machines, and particularly relates to an efficient straightening unit for small-bore thick-wall metal tubes. The efficient straightening unit comprises a loading device, a feeding device, an entrance limiting device, a straightening host, a discharging device and a collection device, wherein the loading device is arranged on one side of the feeding device, and is used for conveying unbaled tubes to be strengthened to the feeding device; the feeding device, the entrance limiting device, the strengthening host and the discharging device are arranged in sequence; the feeding device is used for feeding the tubes to the strengthening host; the strengthening host is used for strengthening the tubes; the discharging device is used for moving the tubes strengthened by the straightening host out of a strengthening production line; and the collection device is used for collecting the tubes sliding down after strengthening. In the strengthening process, the contact areas between an upper strengthening roller and the tubes as well as between a lower strengthening roller and the tubes are large, so that the strengthening accuracy of the small-bore thick-wall tubes can be improved, and the residual stress distribution condition inside the small-bore thick-wall tubes is improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Circumference-symmetrical automatic pressure straightening machine for slender shaft

ActiveCN110369561AComprehensive detection effectImprove completion rateMetal-working feeding devicesMetal working apparatusButt jointEngineering

The invention relates to the field of machining, in particular to a circumference-symmetrical automatic pressure straightening machine for a slender shaft. The circumference-symmetrical automatic pressure straightening machine for the slender shaft comprises a positioning plate, a straightening and bearing device and a bearing drive device, wherein the bearing drive device is in transmission connection with the straightening and bearing device; a positioning and pressure-supplying device and a positioning and taking device are arranged on the positioning plate; a loading support table in buttjoint with the straightening and bearing device is arranged in front of the positioning plate; a blanking support table is arranged under the positioning and taking device; a through slot is formed inthe positioning plate; a controller is arranged beside the positioning plate; a contact displacement sensor is arranged on the straightening and bearing device; and under a work state, a sensing endof the contact displacement sensor is in butt joint with the middle part of a rod piece to be straightened. According to the circumference-symmetrical automatic pressure straightening machine for theslender shaft provided by the invention, the rod piece is automatically rotated, so that an effect on comprehensively detecting and straightening the rod piece can be improved; the rod piece is blanked through the blanking support table; and the straightness of the rod piece is detected through the positioning sensor, so that the accuracy and the efficiency on straightening the rod piece can be improved.

Owner:泰州市津达电子科技有限公司

Intelligent rebar straightening device for building construction

PendingCN110280692AAchieve protectionExtended service lifeMetal working apparatusControl systemEngineering

The invention relates to the technical field of building construction, in particular to an intelligent rebar straightening device for building construction. The intelligent rebar straightening device comprises a straightening rod, a rebar straightening mechanism and a guide rod, wherein the rebar straightening mechanism comprises a plurality of groups of straightening device bodies and further comprises a control system; the control system controls the working states of the straightening device bodies according to the rebar bending position and comprises a controller, a detecting element and a mobile device; after detecting a rebar bending part, the detecting element sends a detecting signal to the controller; after receiving the detecting signal, the controller sends a signal for controlling the operating states of the straightening device bodies to the straightening device bodies and also sends a signal for controlling the operating state of the mobile device; and after straightening, the controller sends the signal for controlling the operating state of the mobile device to the mobile device. The intelligent rebar straightening device is simple in structure and convenient to use, adopts part of driving devices for driving according to the rebar bending part, is low in energy consumption, can automatically and rapidly straighten the rebar on a construction site, and is high in straightening precision and construction efficiency.

Owner:QINGDAO NO 1 CONSTR GRP

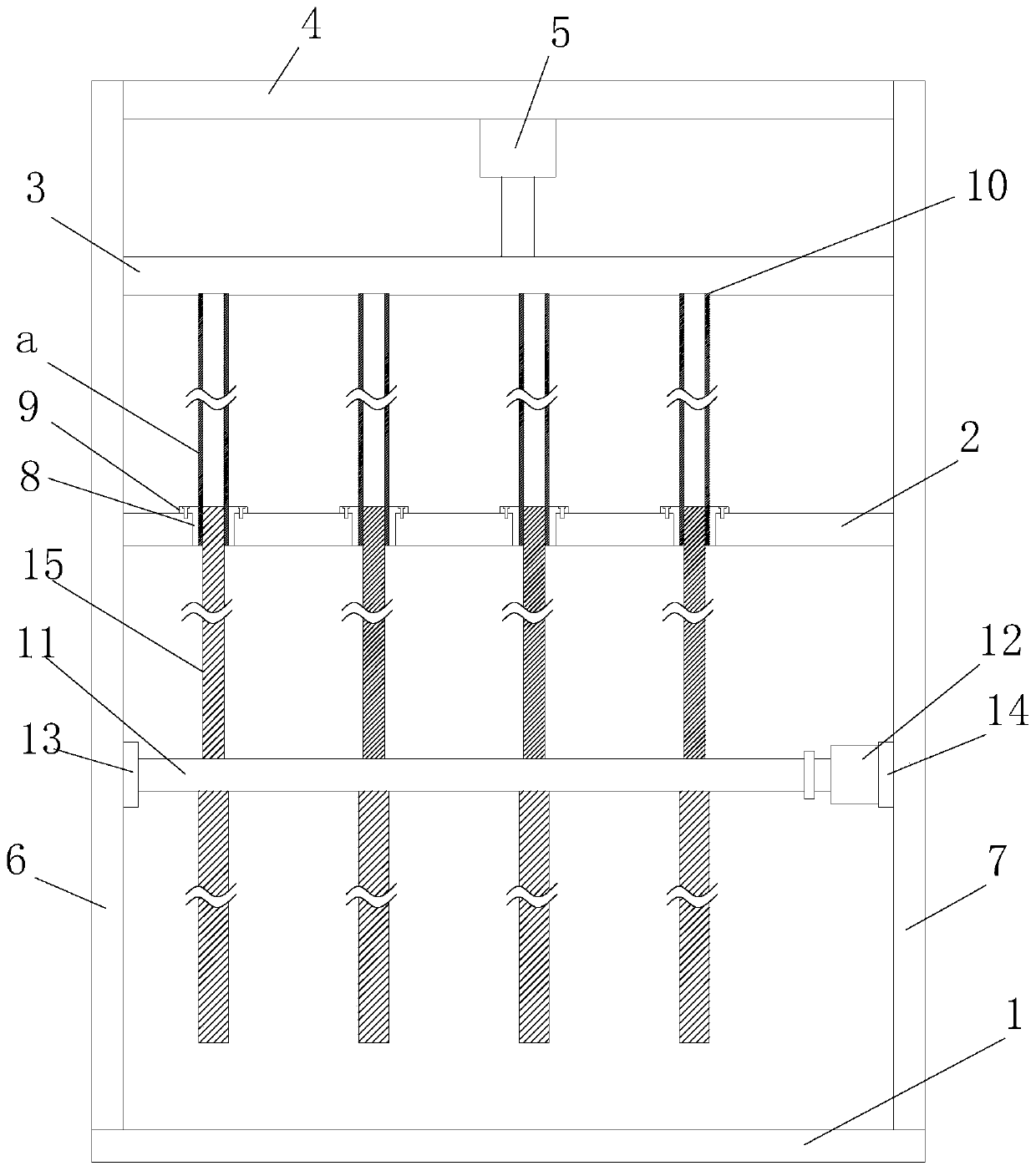

Seamless steel pipe straightening equipment

The invention provides seamless steel pipe straightening equipment. The seamless steel pipe straightening equipment comprises a receiving plate, a straightening plate, a pressing plate, a mounting plate and a first air cylinder. A first support and a second support are vertically arranged at the two ends of the receiving plate. The straightening plate is located above the receiving plate and parallel to the receiving plate, and the two ends of the straightening plate are connected with the first support and the second support correspondingly. Multiple mounting holes penetrating through the upper surface and the lower surface of the straightening plate are formed in the straightening plate, straightening dies are mounted in the mounting holes, and the straightening dies are provided with straightening holes penetrating through the upper surfaces and the lower surfaces of the straightening dies. The pressing plate is located above the straightening plate and parallel to the straightening plate, and the two ends of the pressing plate are connected with the first support and the second support in a sliding fit manner correspondingly. The mounting plate is located above the pressing plate, and the two ends of the mounting plate are connected with the first support and the second support correspondingly. The first air cylinder is mounted on the mounting plate, and the first air cylinder is connected with the pressing plate. The seamless steel pipe straightening equipment is simple in structure and convenient to operate, multiple steel pipes can be straightened simultaneously, the steel pipes with different sizes can be straightened, and the straightening precision is high.

Owner:安徽中山金属有限公司

Reserved steel bar correction device and application construction method thereof

The invention relates to a reserved steel bar correction device and an application construction method thereof. The reserved steel bar correction device comprises an outer frame, a transverse beam, a sleeve, a first guide rail, a second guide rail, a limiting plate and at least two stretching parts. The outer frame comprises a first outer frame body and a second outer frame body. The sleeve penetrates the transverse beam, the first guide rail is arranged on the surface, close to the transverse beam, of the first outer frame body, and the transverse beam is connected with the first outer frame body through the first guide rail and slides along the first outer frame body. The limiting plate is vertical to a plane where the outer frame is located. The second guide rail is arranged on the surface, close to the limiting plate, of the second outer frame body, and the limiting plate is connected with the second outer frame body through the second guide rail and slides along the second outer frame body. The at least two stretching parts are located on the first outer frame body, one end of each stretching part is connected with the first outer frame body, and the other end of each stretching part is provided with a clamping plate in a hung manner. The reserved steel bar correction device is high in straightening accuracy and is good in straightening effect. According to the application construction method adopting the above reserved steel bar correction device, operation is simple, and the straightening effect is good.

Owner:SHANGHAI CONSTRUCTION GROUP +1

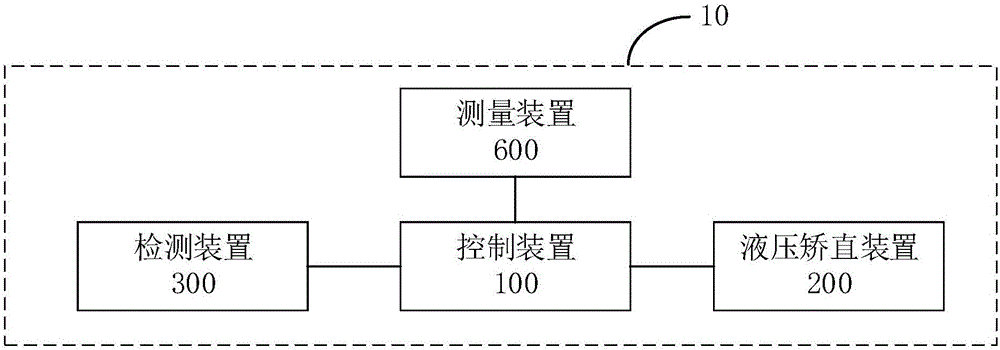

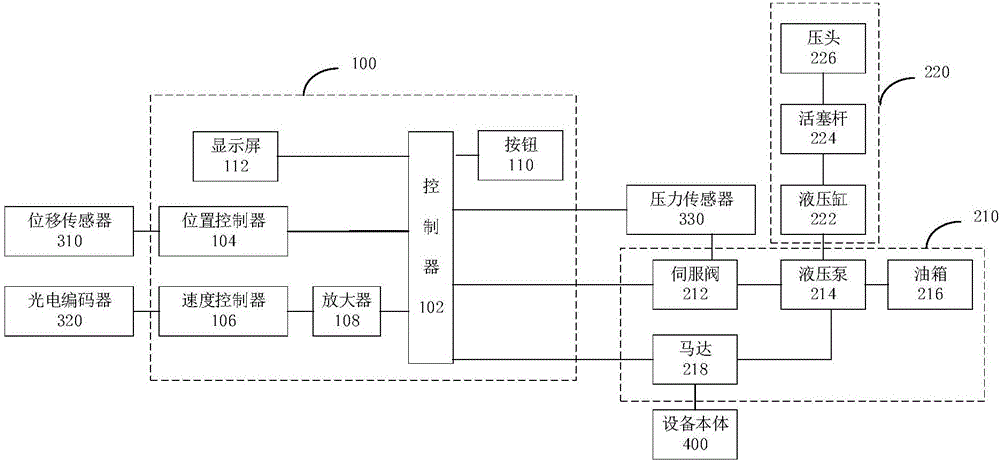

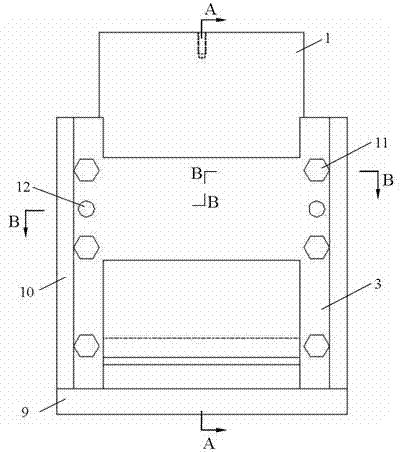

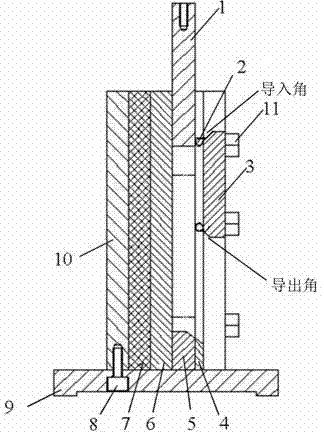

Hydraulic straightening method and system

The invention provides a hydraulic straightening method and system, and the hydraulic straightening method is applied to a hydraulic straightening system. The hydraulic straightening method comprises the following steps that: firstly, a control device generates a first control signal according to an obtained information instruction and sends the first control signal to a hydraulic straitening device; then, the hydraulic straightening device performs straightening on a to-be-straightened object according to the first control signal; in a straightening process, a detecting device detects straitening parameters between the to-be-straightened object and the hydraulic straightening device and feeds back the straitening parameters to a control device; and the control device generates a corresponding control signal according to the received straitening parameters to regulate straitening parameters in a straitening process in real time. According to the embodiment of the invention, automation of a hydraulic straightening process can be realized, working efficiency is effectively improved, and object straightening precision is high.

Owner:YANCHENG INST OF TECH

Slight and flexible straightening device for small-diameter round tubes

The invention discloses a slight and flexible straightening device for small-diameter round tubes. The slight and flexible straightening device for the small-diameter round tubes comprises a base and a U-shaped limiting frame, wherein the U-shaped limiting frame is arranged on the base through screws; an elastic gasket, an interface gasket and a fixed rubbing plate are sequentially arranged in the limiting frame; the elastic gasket is close to a back plate; a partition and a tube diameter limiting gasket are arranged between each of two vertical plates and the interface gasket; the partitions are close to the interface gasket; a movable rubbing plate is arranged between the two partitions; and the elastic gasket, the interface gasket, the movable rubbing plate, the partitions, the tube diameter limiting gaskets, the vertical plates of the fixed rubbing plates and the back plate are connected to one another in a pre-tightening manner through a plurality of adjusting screws and a plurality of cylindrical pins. In a straightening process of the slight and flexible straightening device, small-diameter round tube blanks are straightened gradually under the effect of elastic pressure, rolling diameters of the small-diameter round tube blanks are reduced, the size of a gap between the movable rubbing plate and the fixed rubbing plate is reduced, and influences on straightening precision due to the rigid gap are prevented effectively. The slight and flexible straightening device is simple in structure, convenient to operate, high in straightening precision and low in cost.

Owner:CHINA NUCLEAR TIANJIN TECH DEV

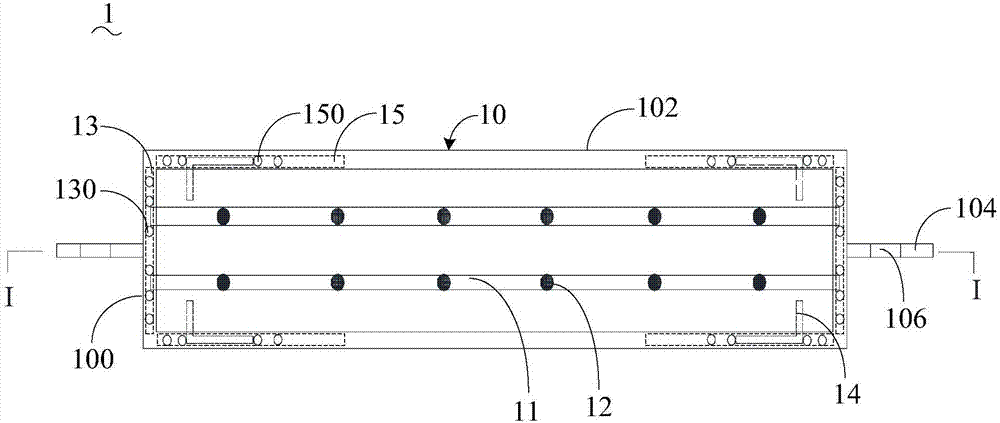

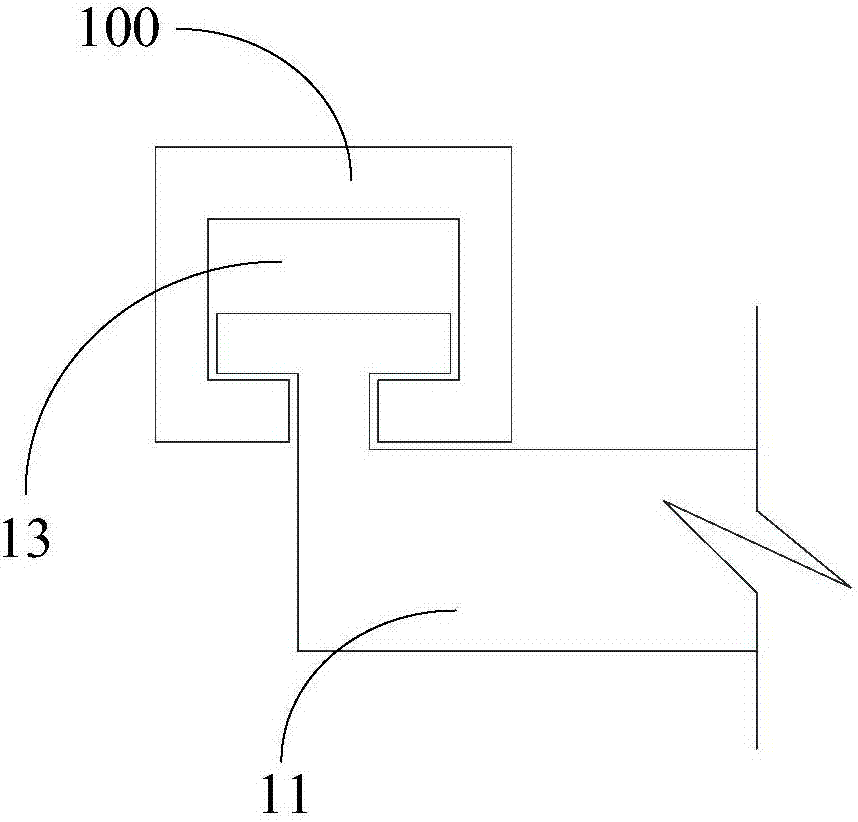

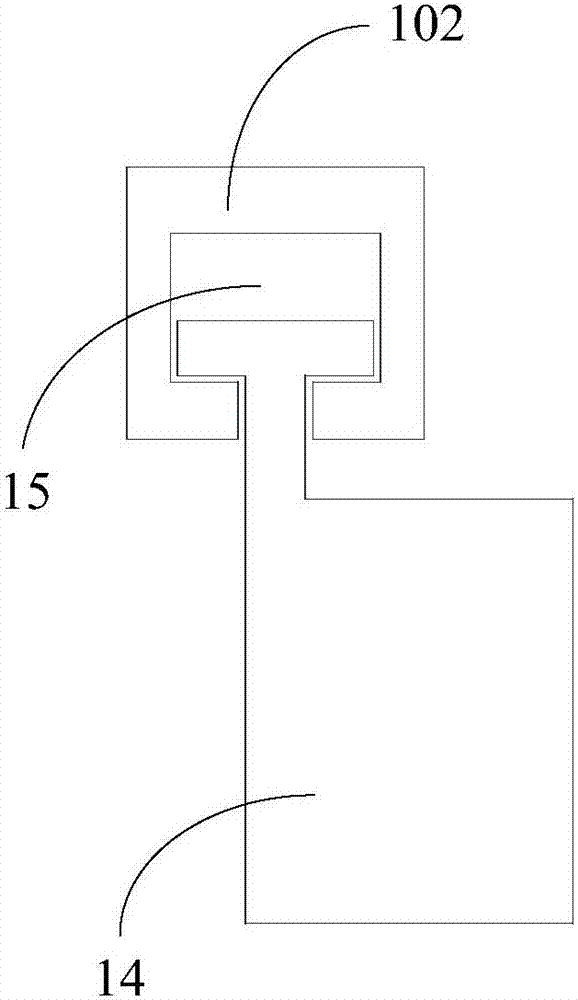

Welding strip adjusting device and series welding machine

PendingCN108637545ASolve Welding ProblemsSimple structureAssembling battery machinesFinal product manufactureEngineeringMechanical engineering

The invention provides a welding strip adjusting device and a series welding machine, and relates to the technical field of battery manufacturing equipment. The welding strip adjusting device comprises a rack, a first adjusting mechanism, a second adjusting mechanism, a third adjusting mechanism and a shifting aligning mechanism, wherein the first adjusting mechanism, the second adjusting mechanism and the third adjusting mechanism are sequentially connected between the shifting aligning mechanism and the rack and are correspondingly used for adjusting the position of the shifting aligning mechanism relative to the rack, so that the position of the shifting aligning mechanism is corresponding to the position of a welding strip to be shifted and aligned; and the welding strip to be shiftedand aligned is shifted and aligned through the shifting and aligning mechanism. The series welding machine comprises the welding strip adjusting device and solves the problem that the end part of thewelding strip moves away from a target position and the series welding quality of a battery is influenced.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

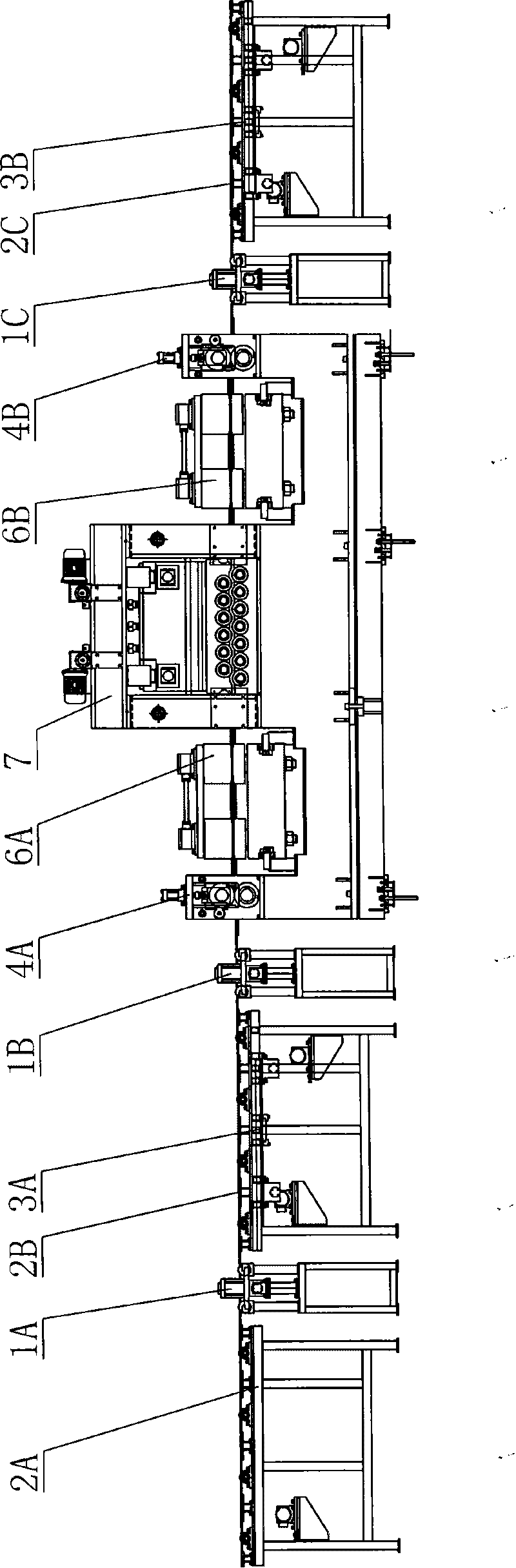

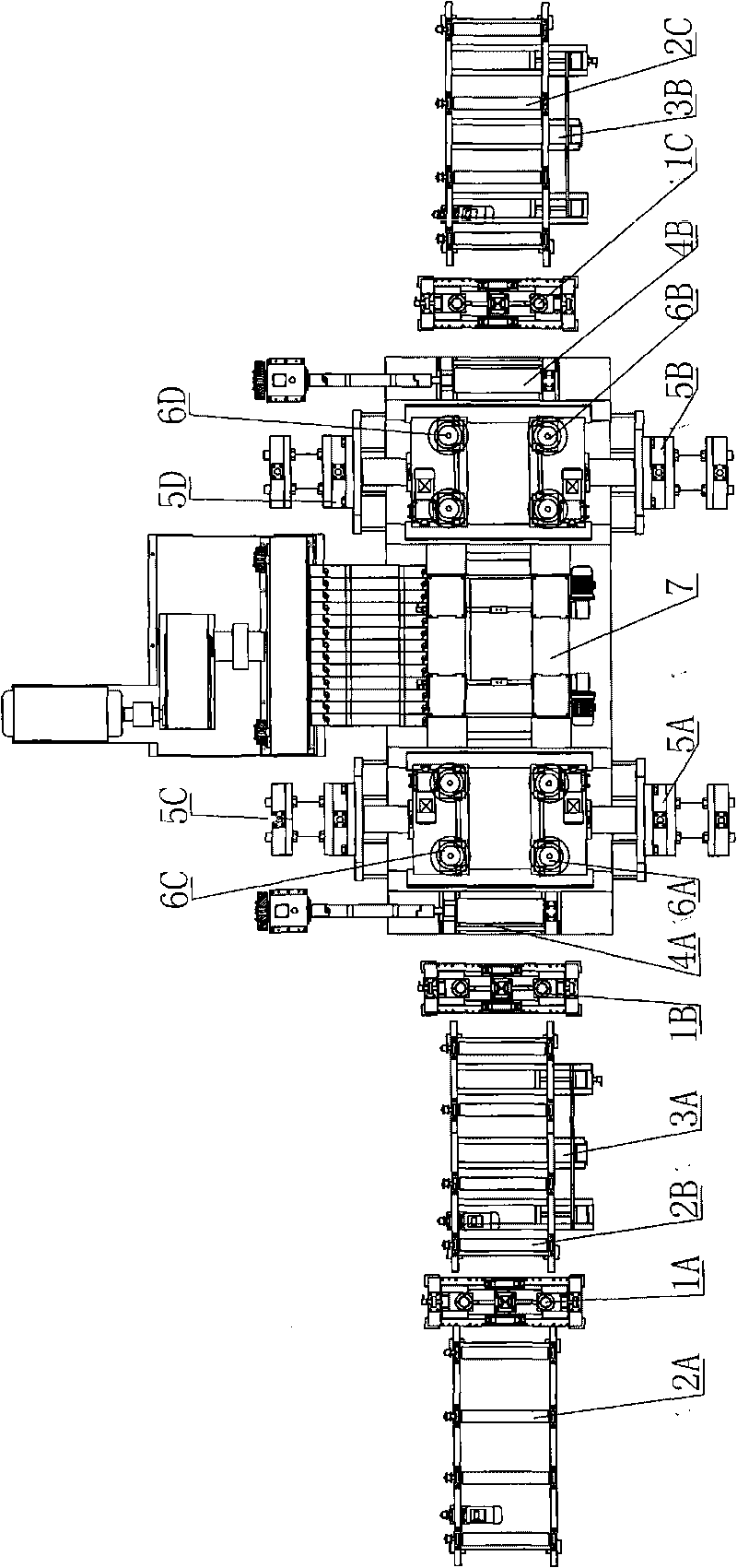

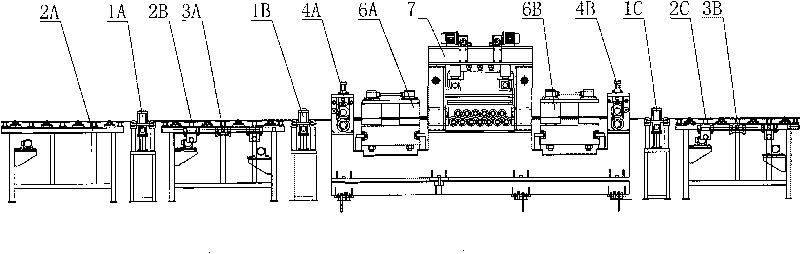

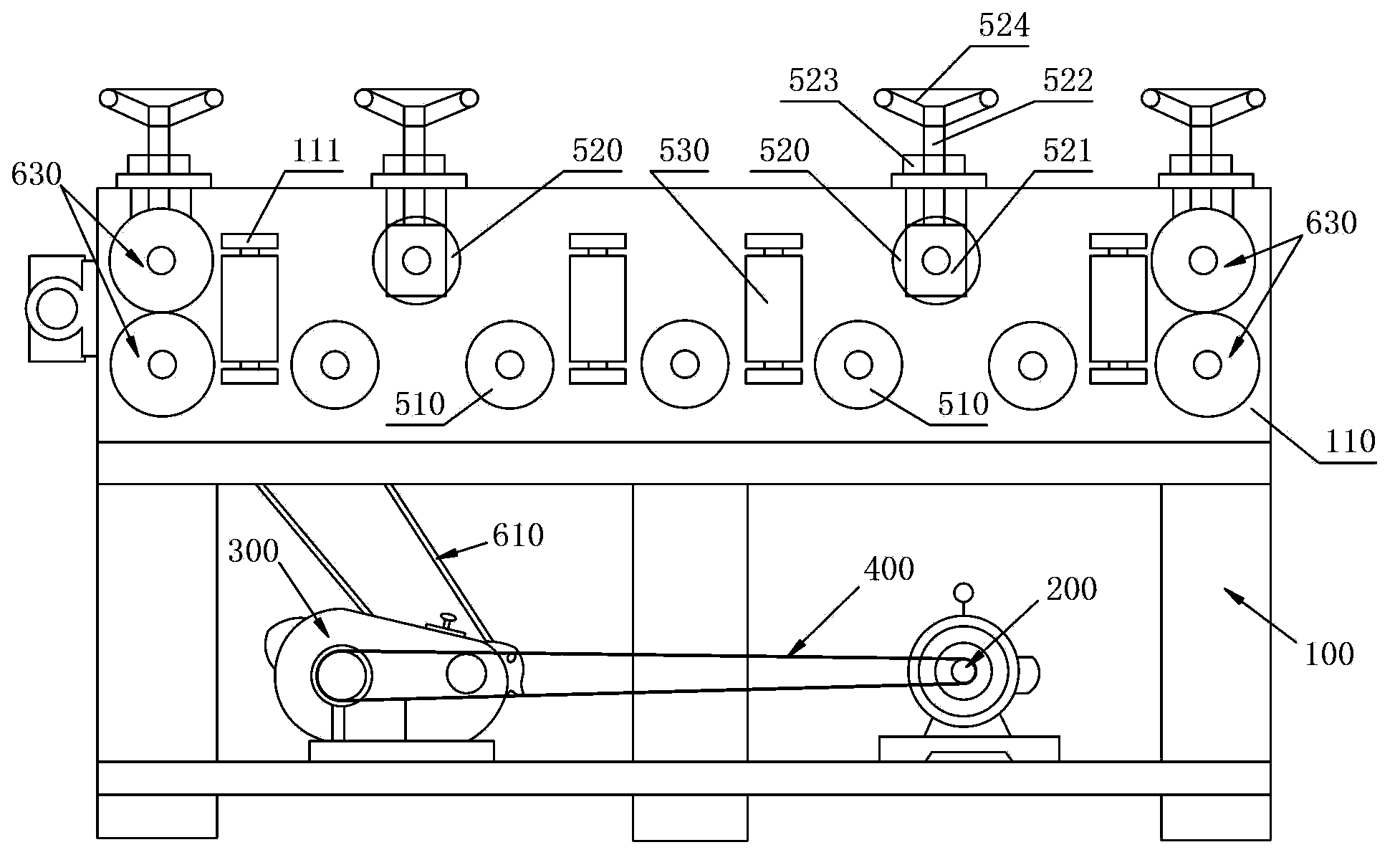

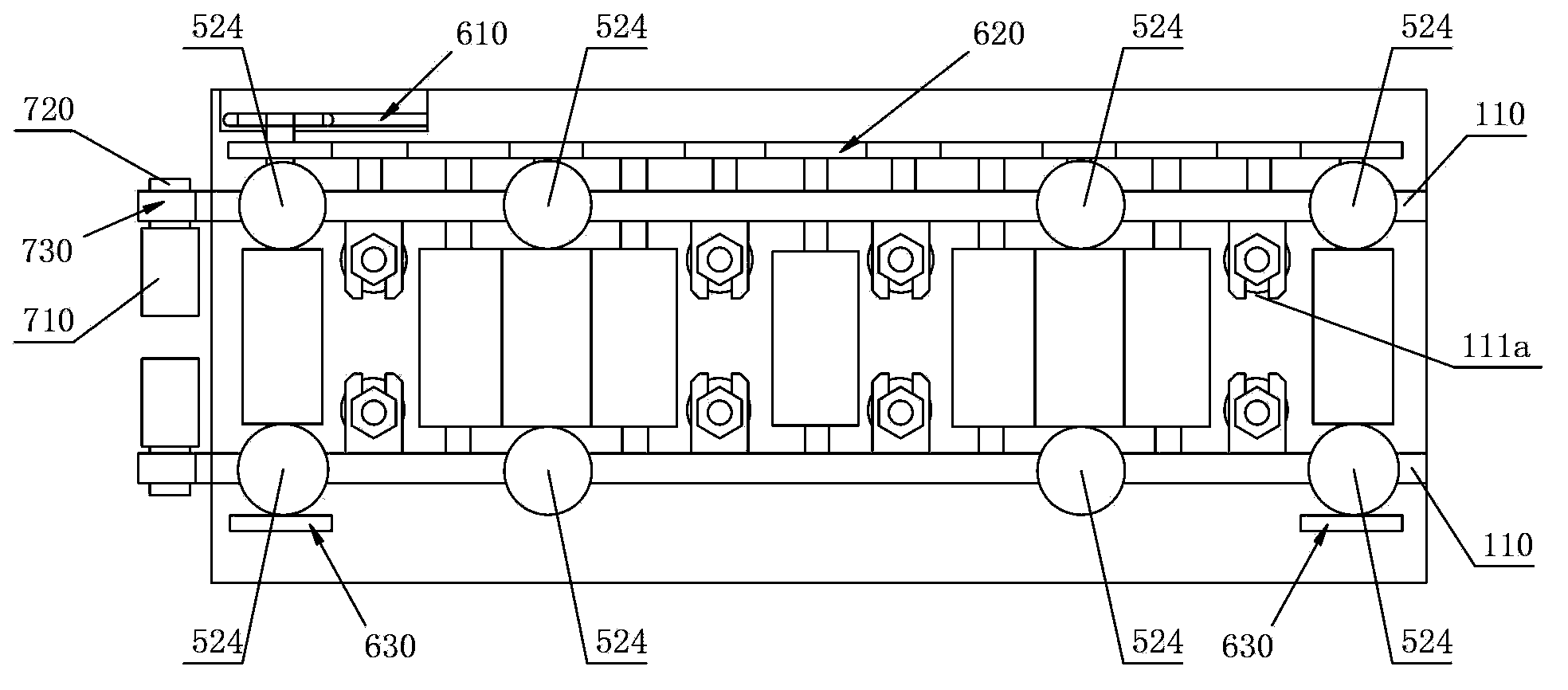

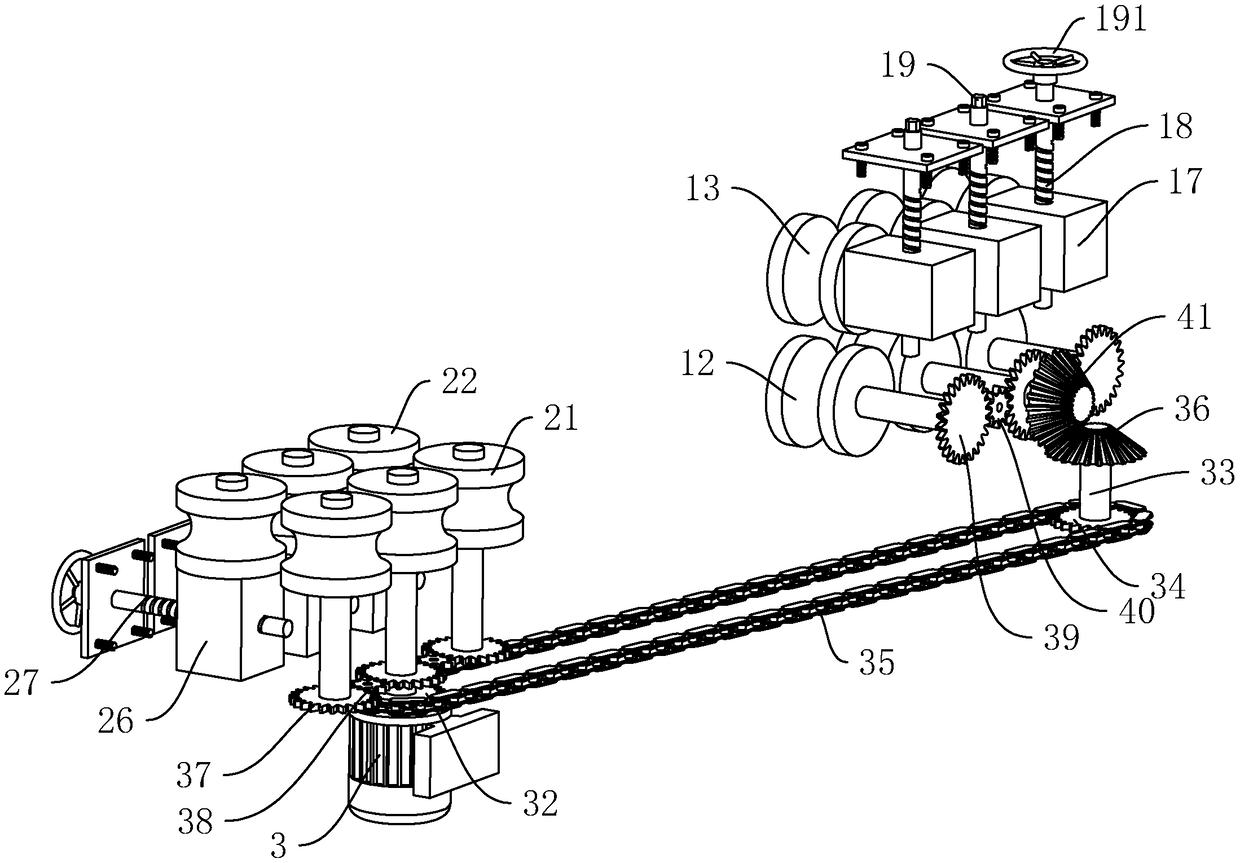

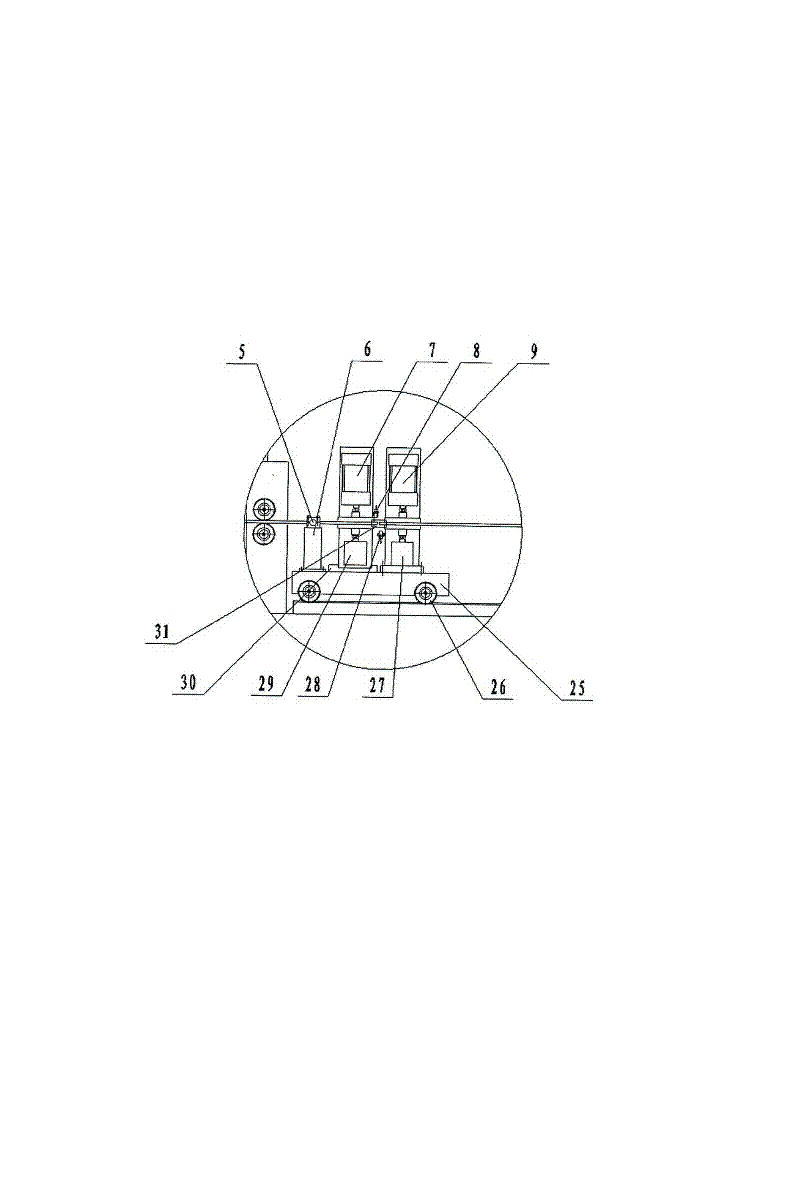

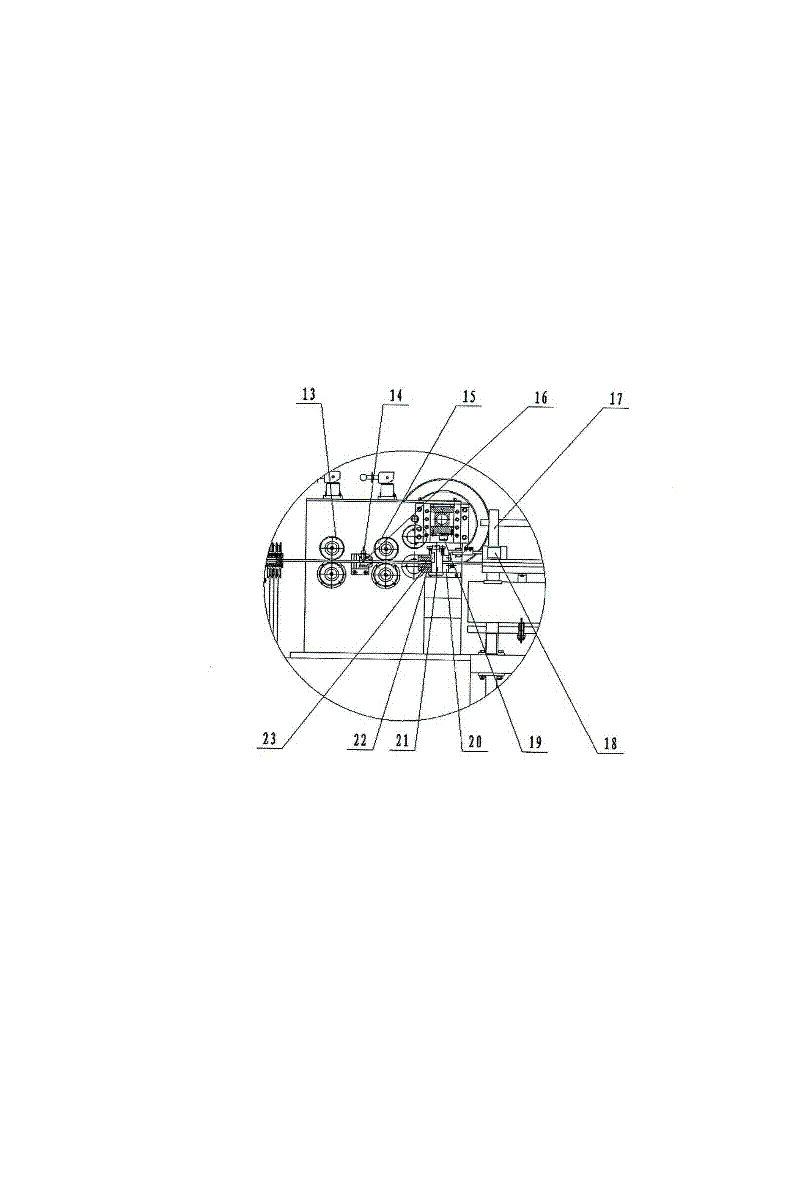

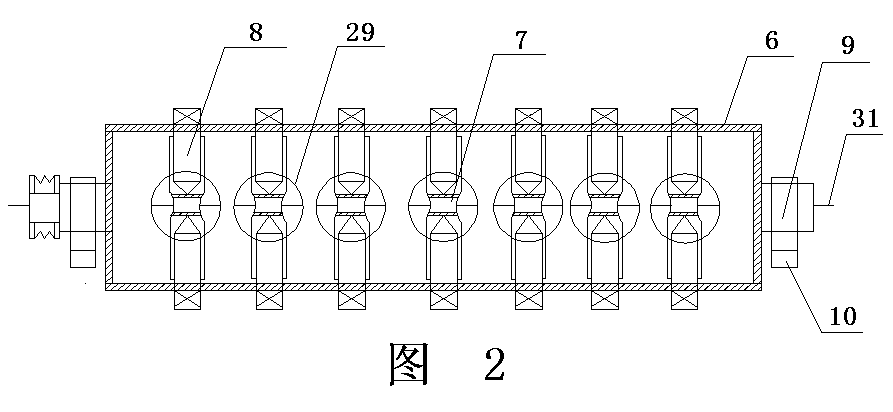

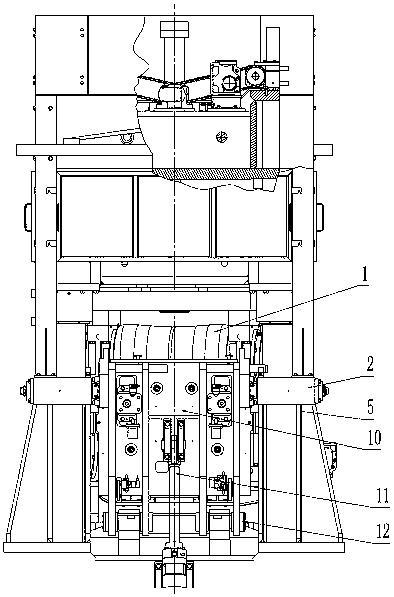

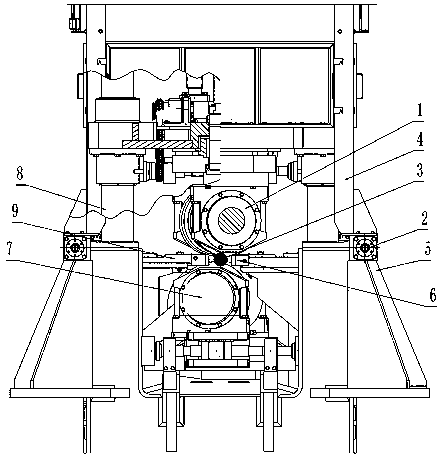

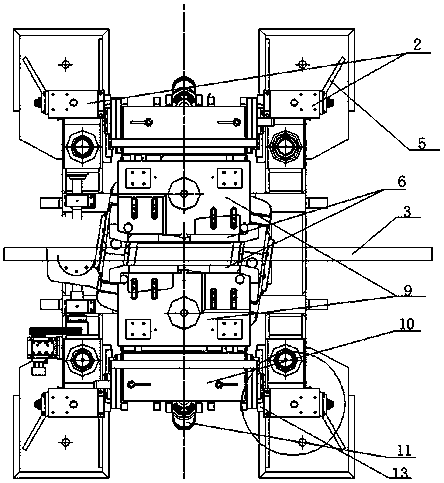

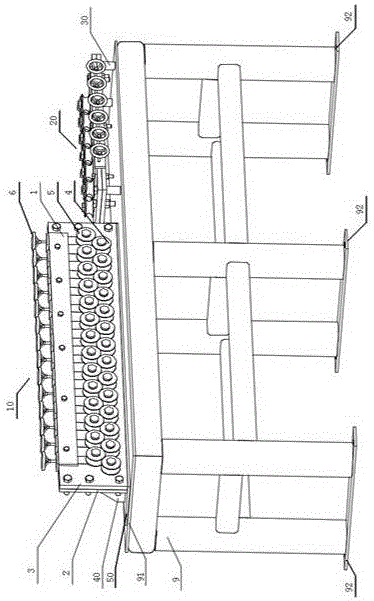

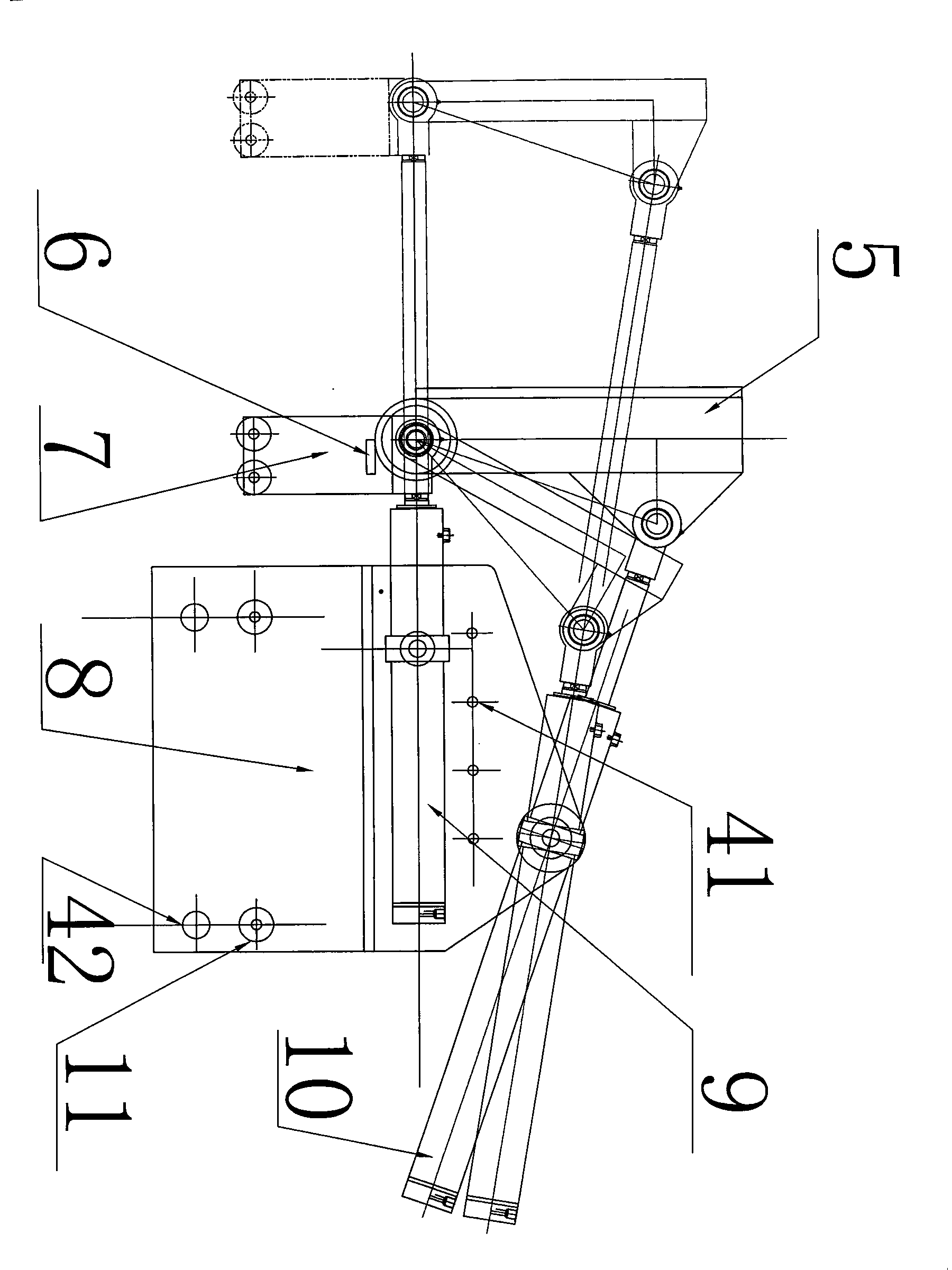

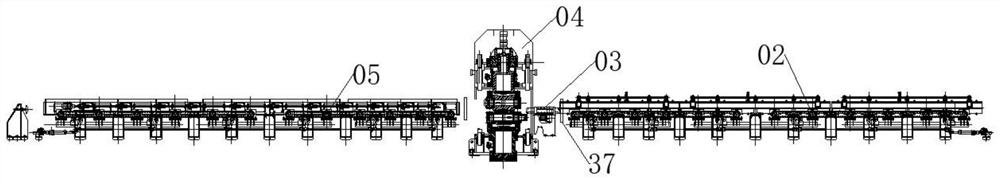

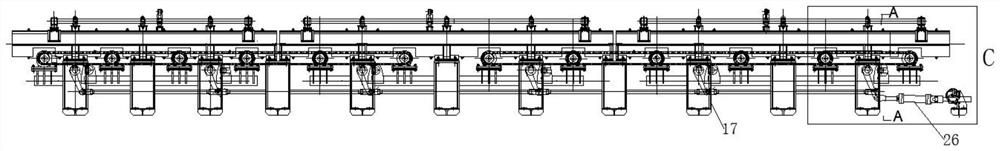

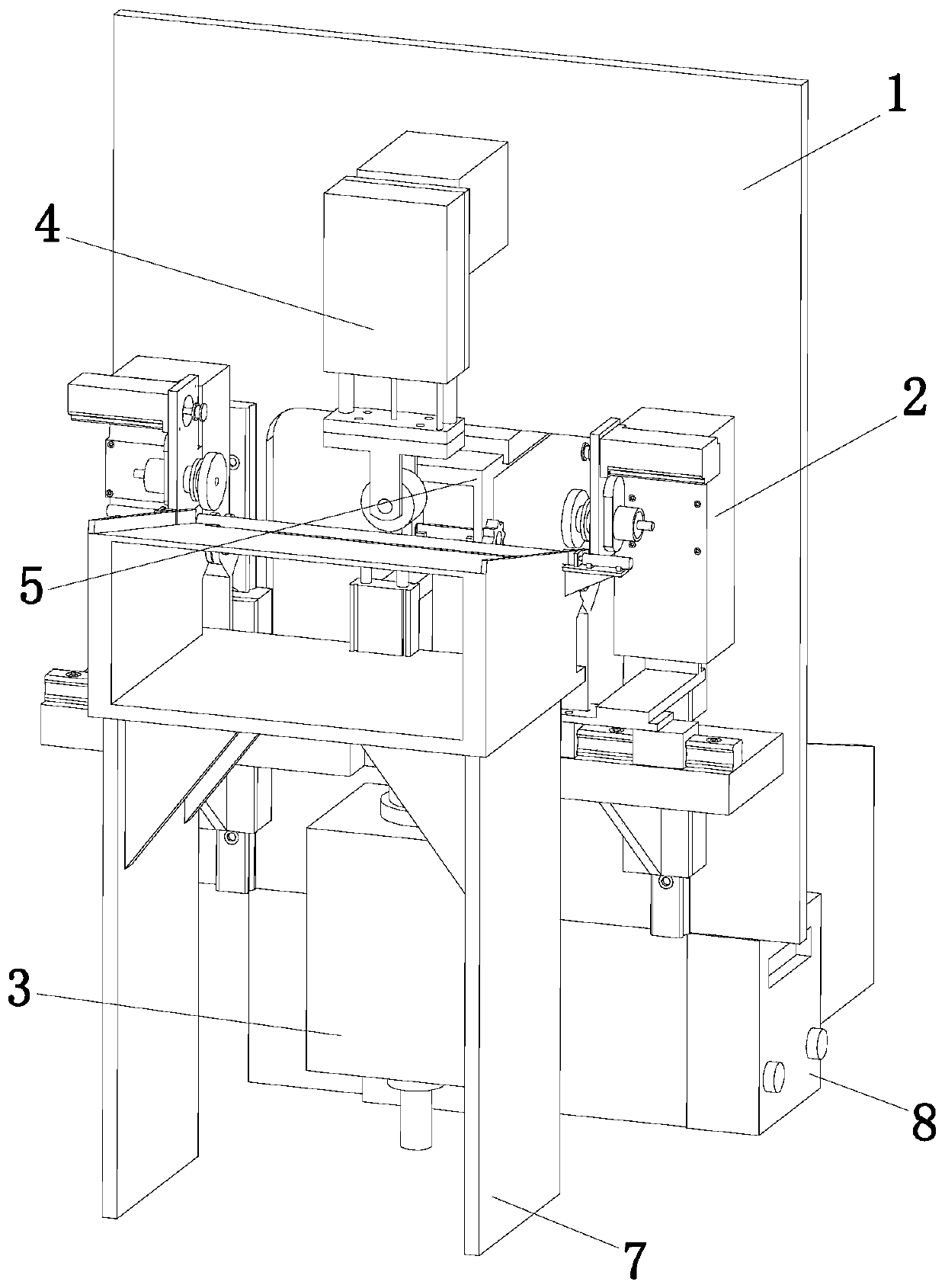

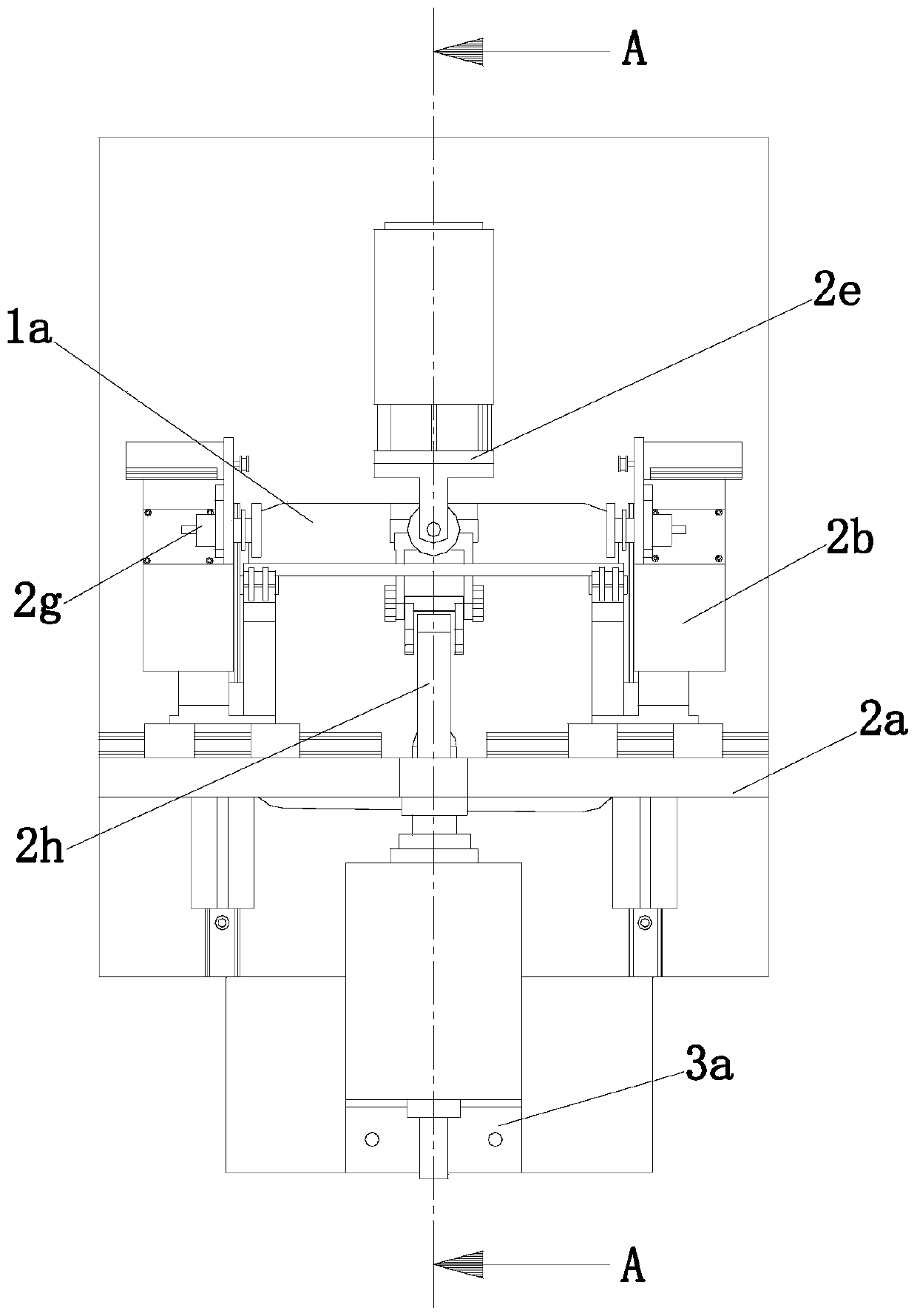

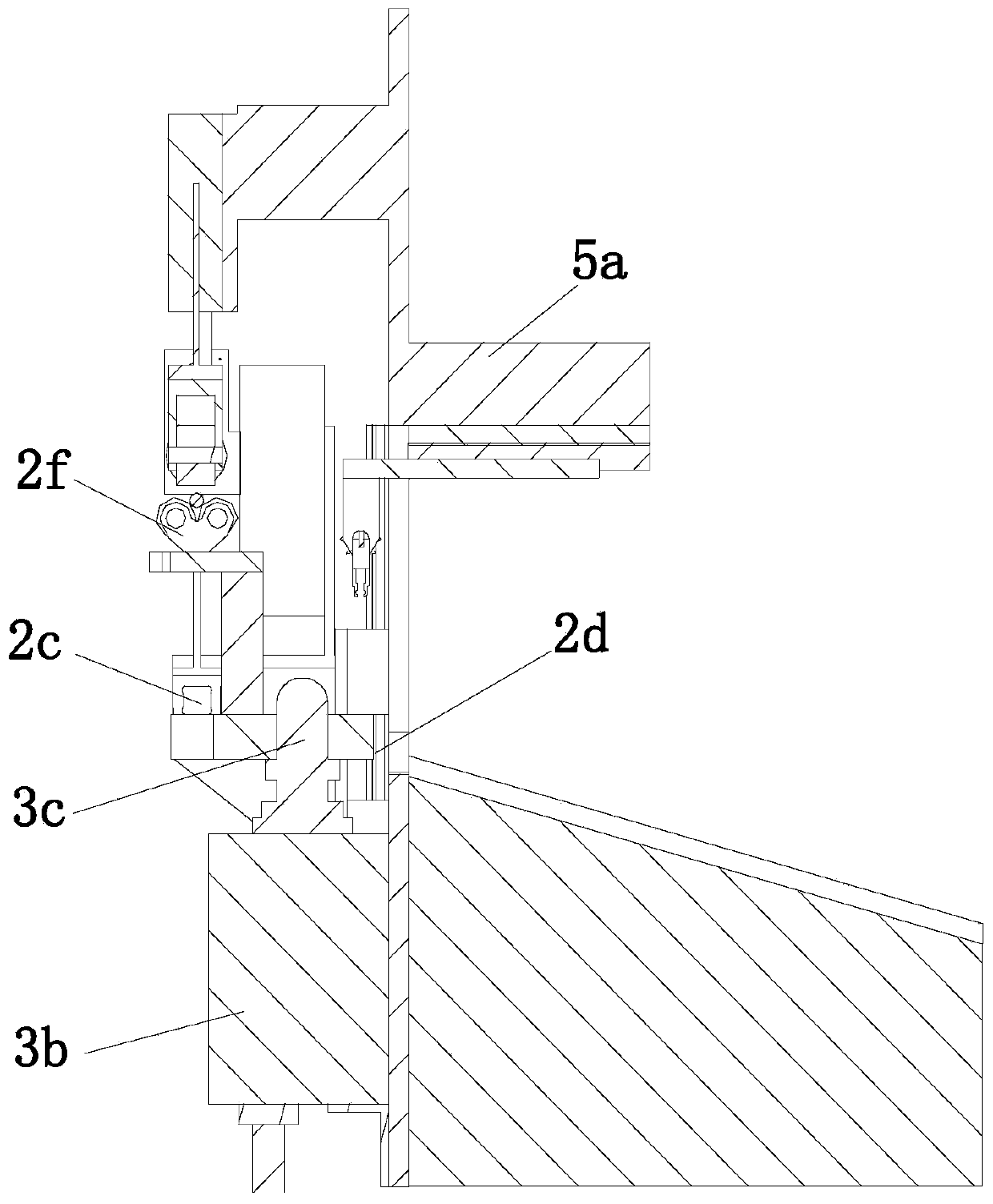

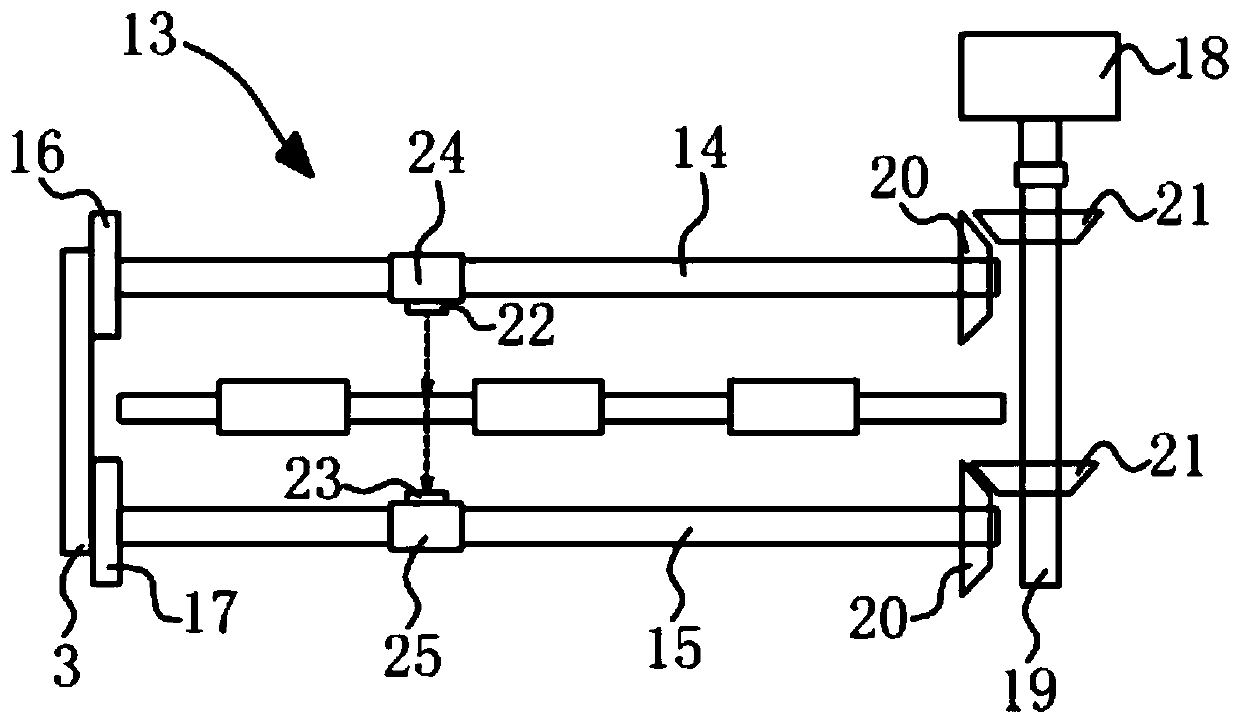

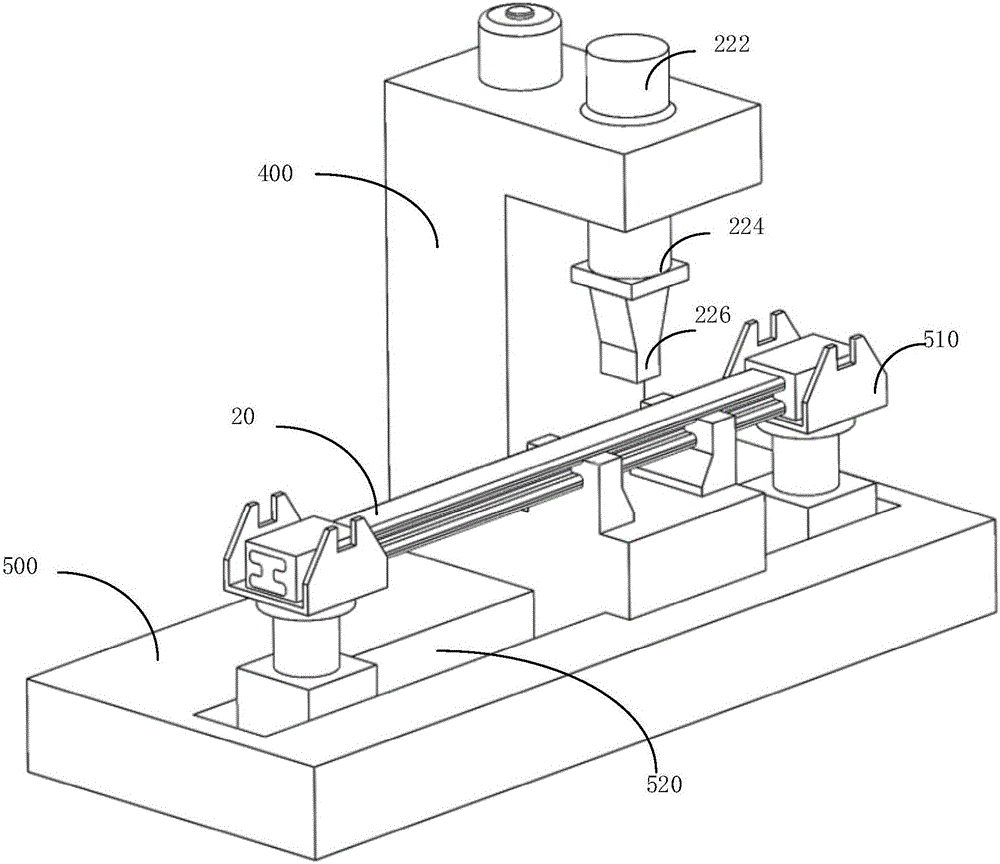

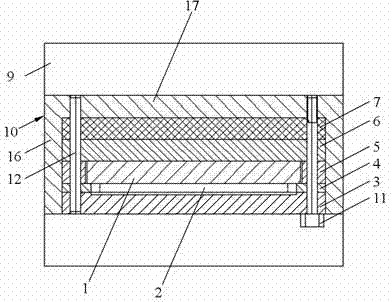

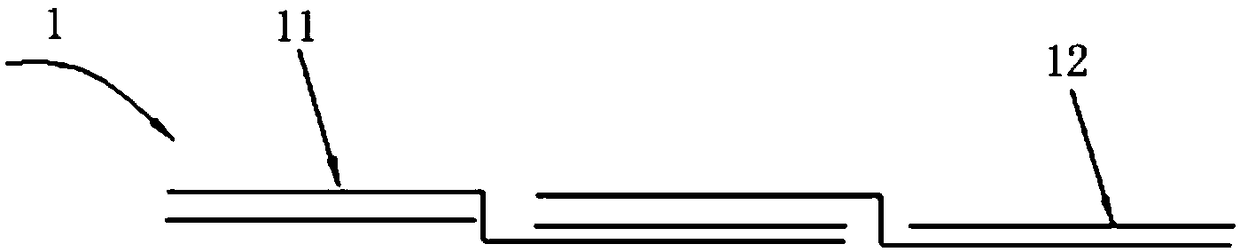

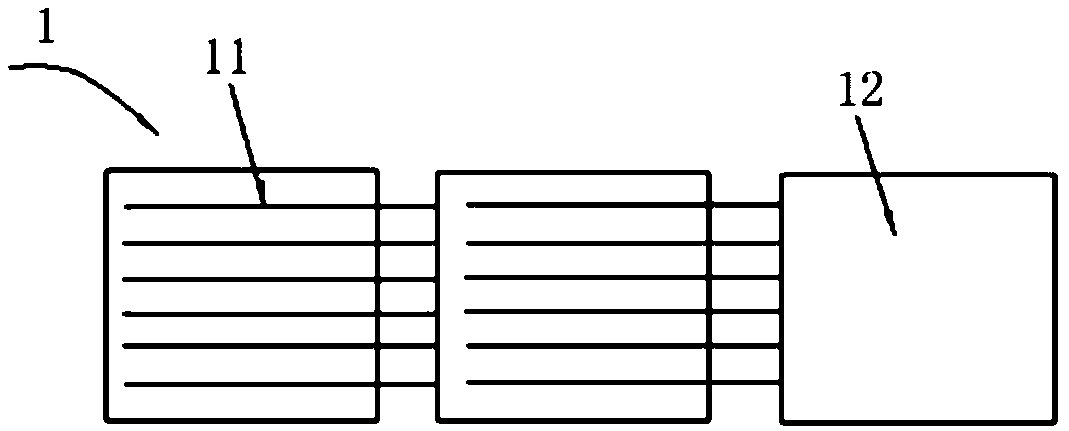

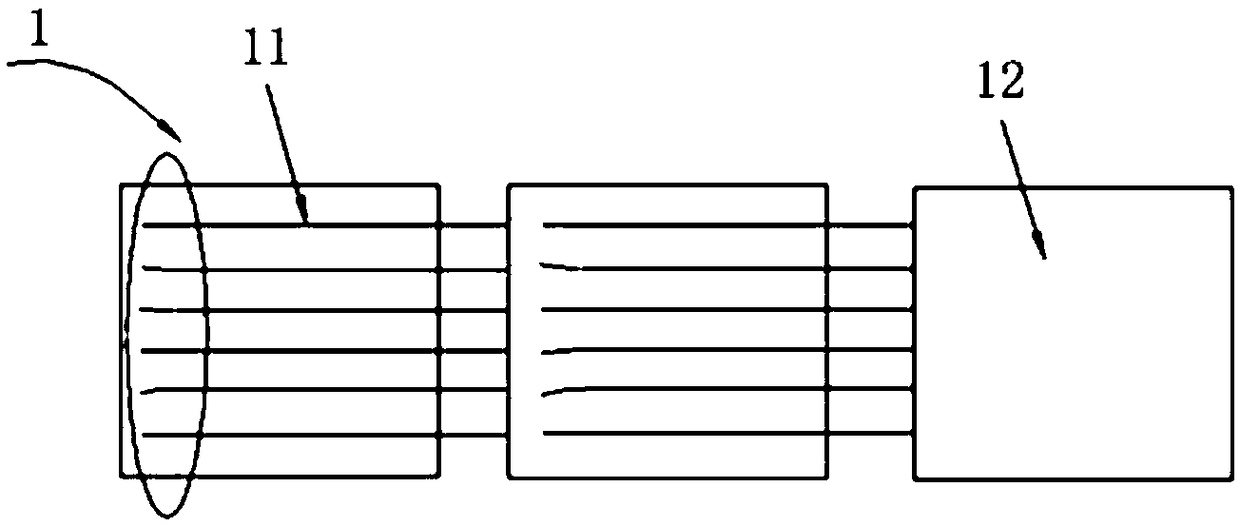

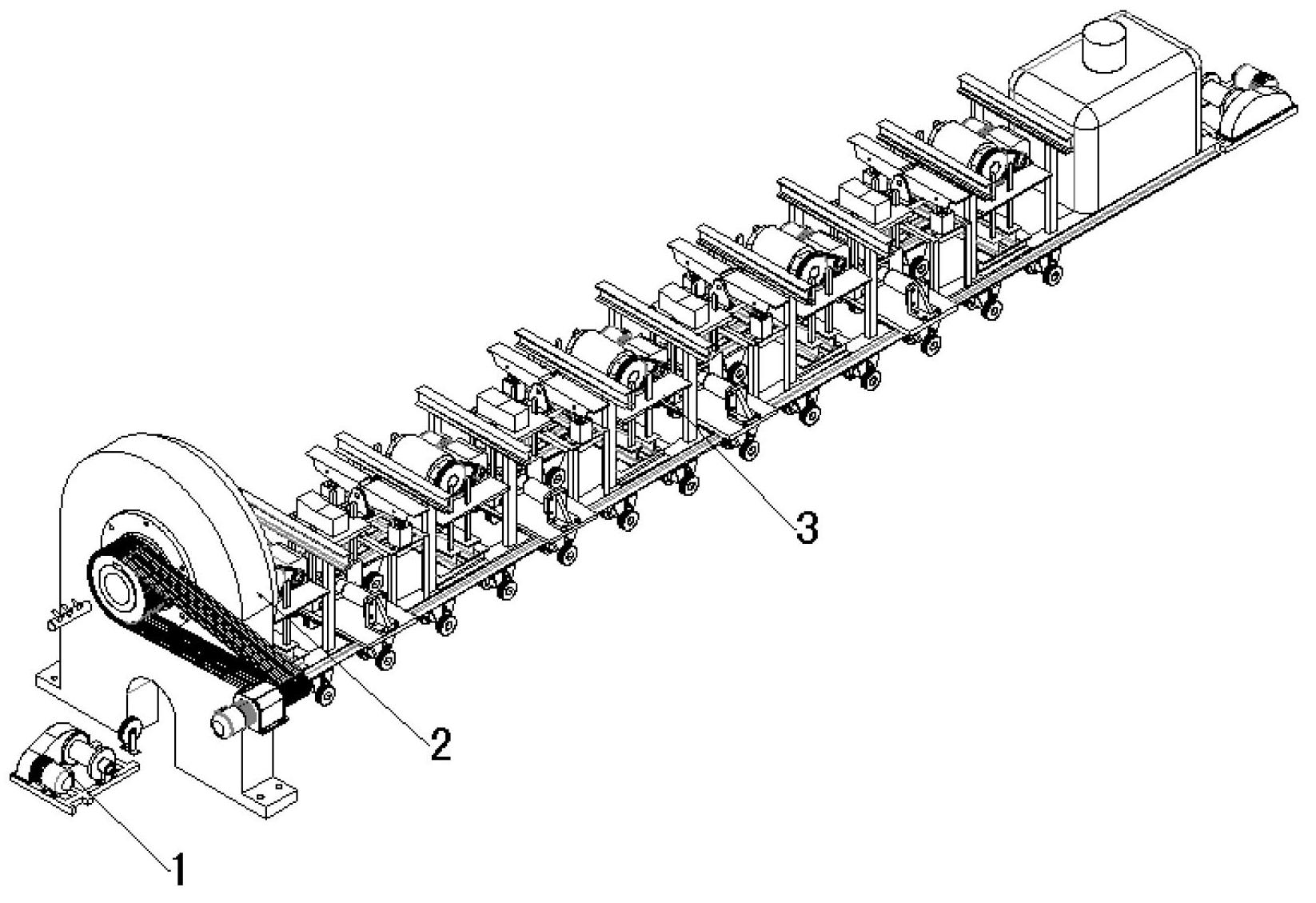

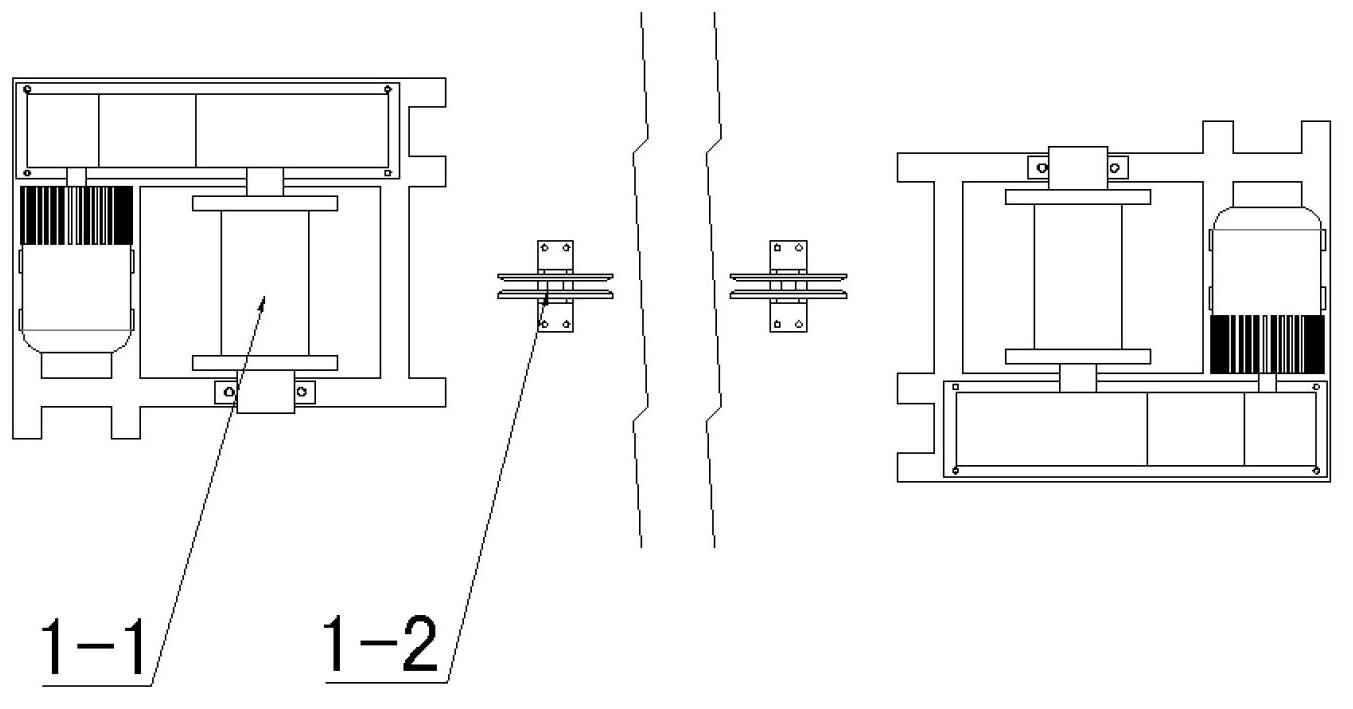

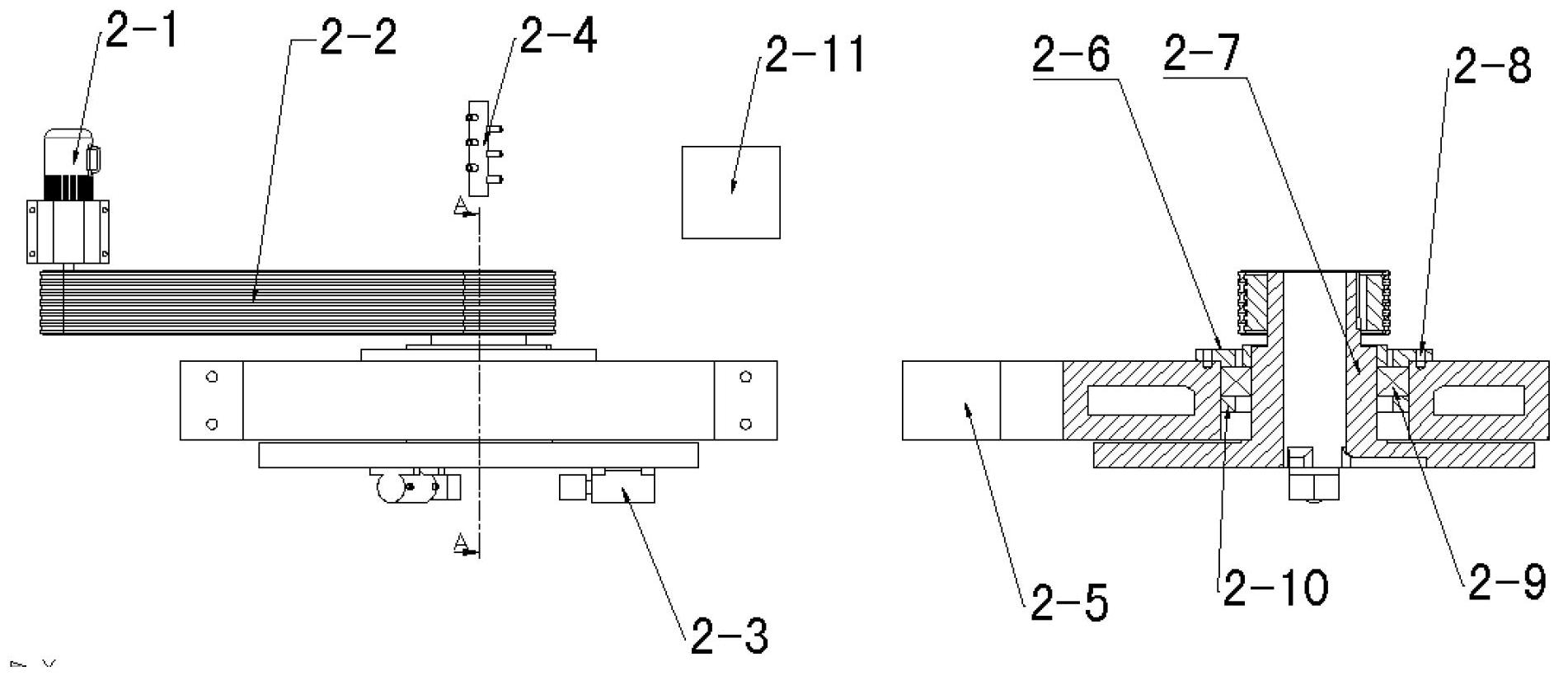

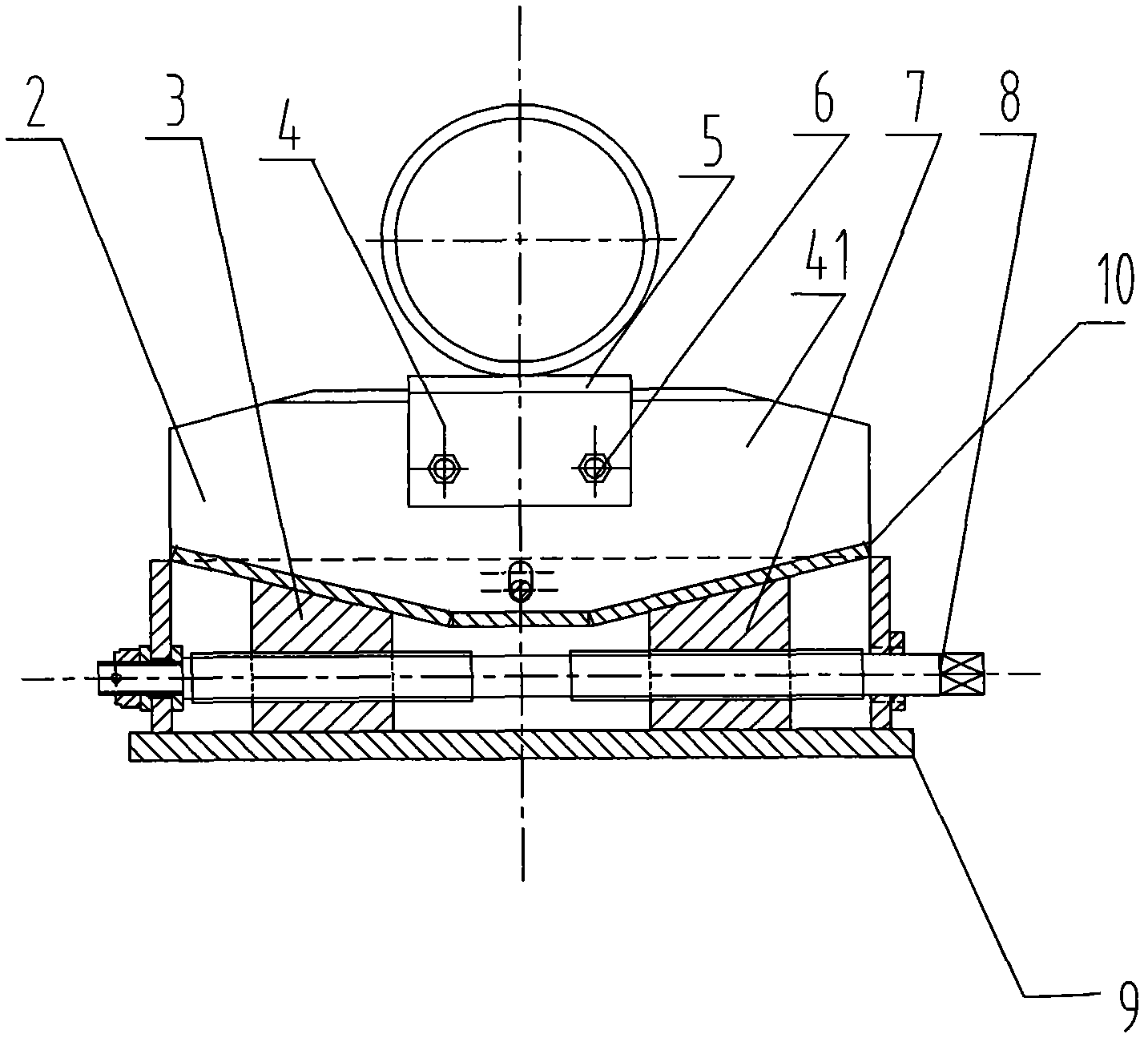

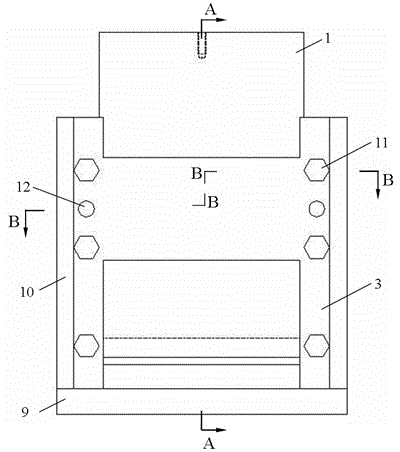

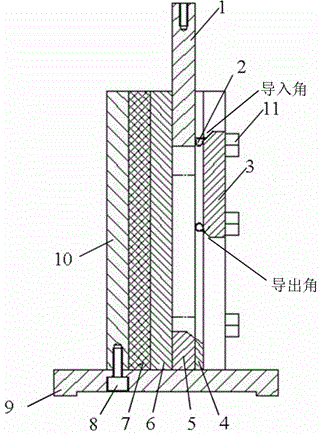

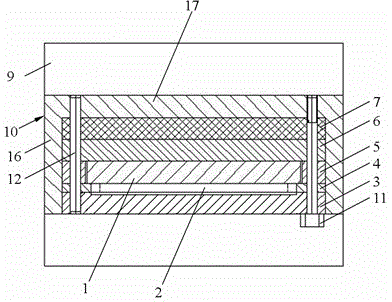

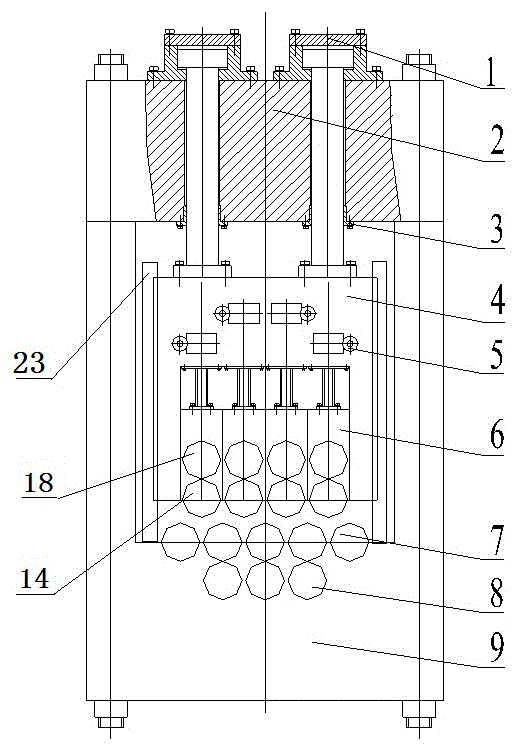

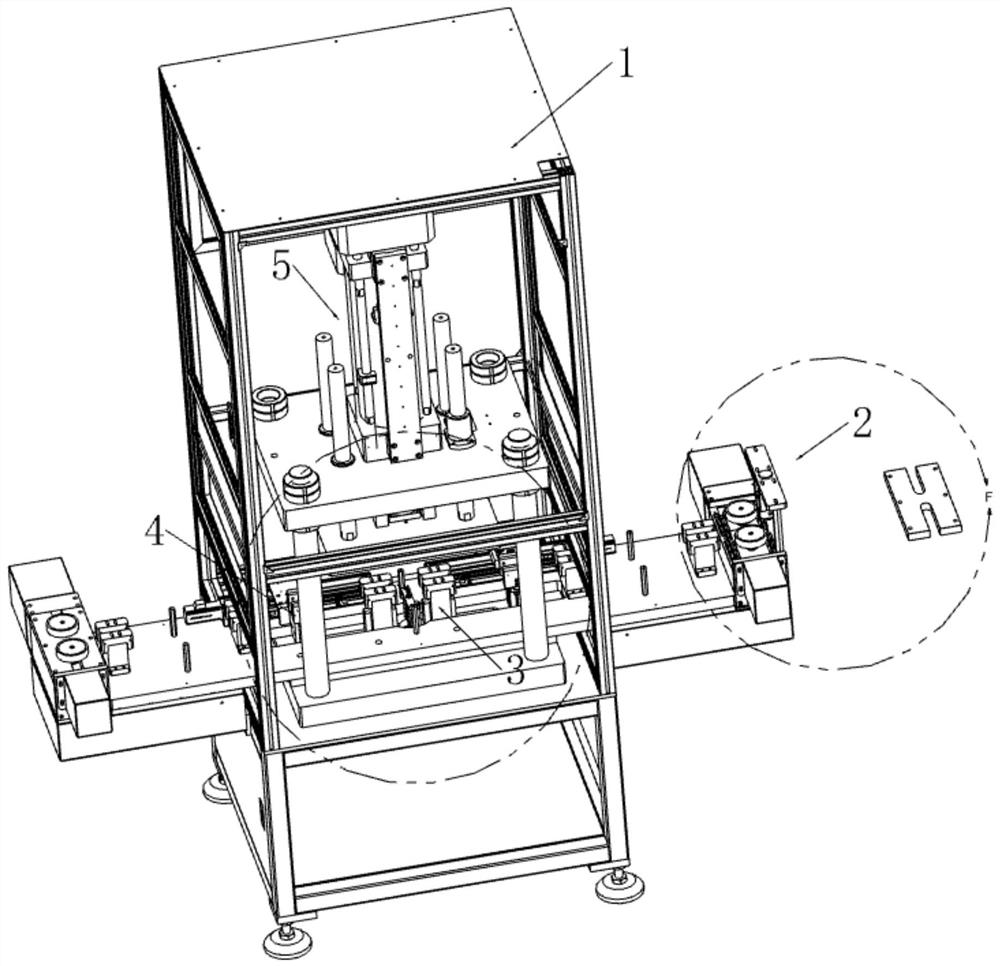

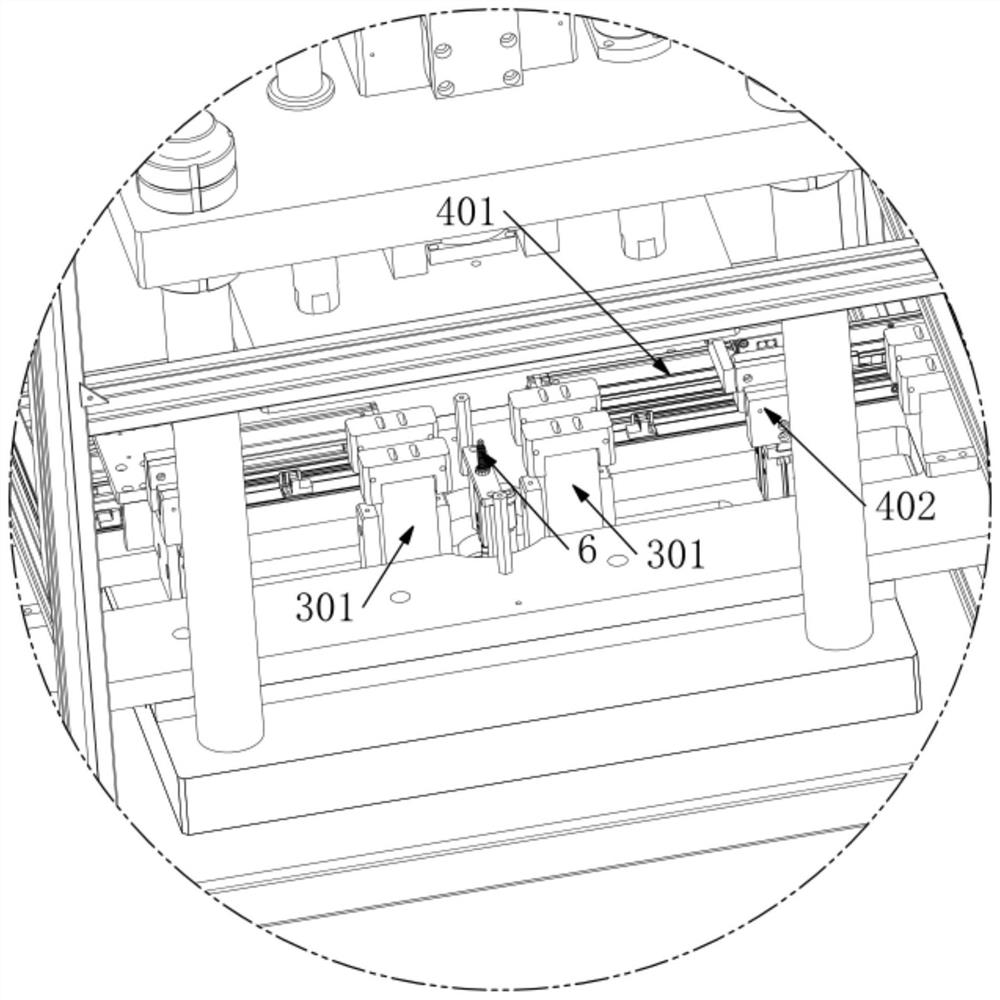

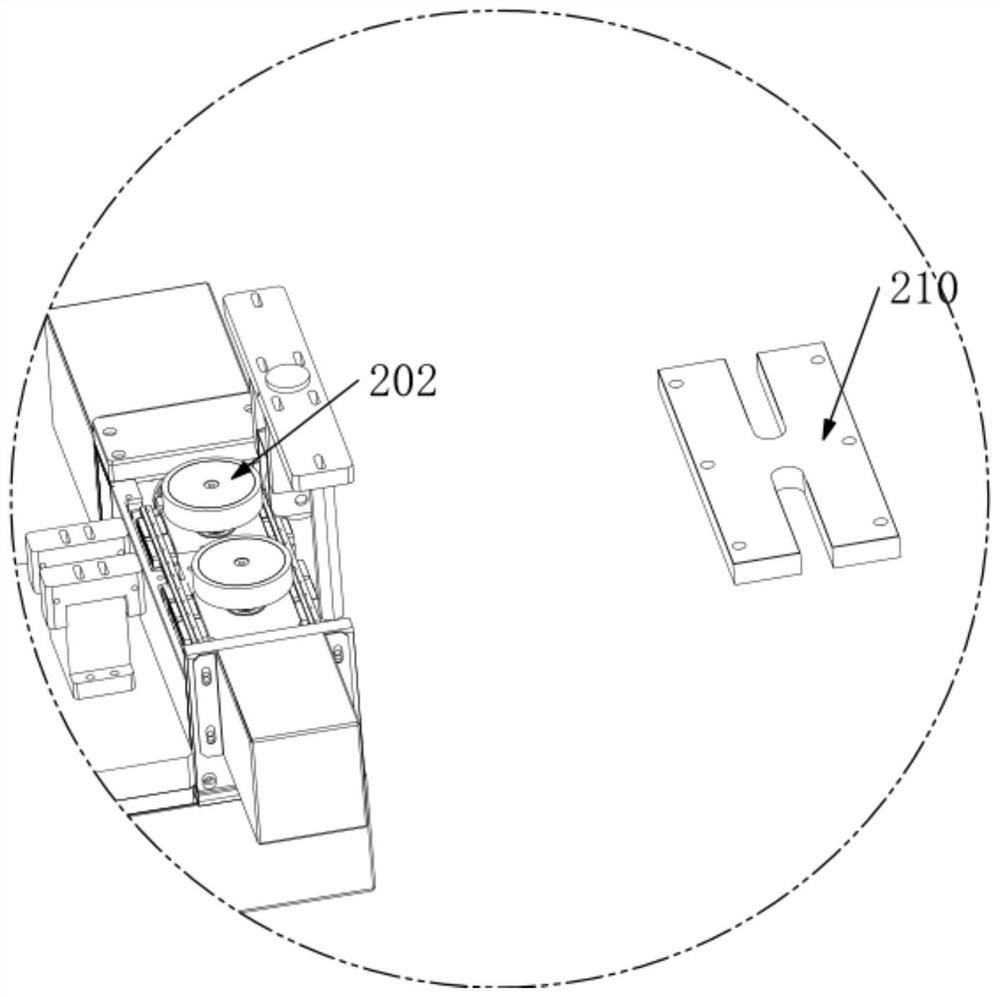

Bar overturning mechanism and conveying trolley for bar straightening machine

ActiveCN102672009AImprove straightening accuracyAvoid the effects of inaccurate positioningMetal-working feeding devicesPositioning devicesMotor speedHydraulic pump

The invention discloses a bar overturning and conveying device for a bar straightening machine. The bar straightening machine consists of a traction mechanism (1), the bar overturning mechanism (2) and the conveying trolley (3), an oil inlet and outlet tube of a hydraulic clamping jaw (2-3) of the bar overturning mechanism penetrates through a rotating shaft (2-7) through three grooves of the rotating shaft (2-7) to be connected with a hydraulic rotary joint (2-4), and a motor speed reducer (2-1) drives the rotating shaft (2-7), the hydraulic clamping jaw (2-3) and the hydraulic rotary joint (2-4) to rotate together via a sprocket chain (2-2); and a bar side push raising positioning device (3-2), a bar rolling raising device (3-3), a bar positioning device (3-4), a roller train (3-5) and a hydraulic pump station (3-6) of the conveying trolley are fixed on a support frame (3-1). The bar side push raising positioning device (3-2), the bar rolling raising device (3-3) and the bar positioning device (3-4) are respectively arranged independently, and the numbers of the bar side push raising positioning device (3-2), the bar rolling raising device (3-3) and the bar positioning device (3-4) are determined according to the lengths of bars required to be straightened.

Owner:SICHUAN UNIV

Diagonal roll tubing straightener oil coating device with function of auxiliary straightening

The invention discloses a diagonal roll tubing straightener oil coating device with the function of auxiliary straightening. A base seat with the functions of guiding and supporting is fixed on a rack of a straightener, wherein a machine body is fixed on the base seat, an oil coating block is arranged on the machine body, a left-right spin adjusting screw rod is arranged inside the machine body, the left-right spin adjusting screw rod drives a left oblique iron and a right oblique iron to form a height adjusting mechanism, and a bolt fastening auxiliary is arranged on the oil coating block to fix an oil absorbing band. The diagonal roll tubing straightener oil coating device with the function of auxiliary straightening is not only capable of removing processing lubricating oil remained on the surface of a tubing after straightening, but also thanks to a special structure and an oil scraping mechanism of a new device, the diagonal roll tubing straightener oil coating device with the function of auxiliary straightening is capable of having certain auxiliary function of improving accuracy of the straightening when a thin walled tube is straightened by a diagonal roll tubing straightener.

Owner:海亦(河南)机械有限公司

Minor-diameter round tube micro-scale flexible straightening method and device

The invention discloses a minor-diameter round tube micro-scale flexible straightening method and device. The minor-diameter round tube micro-scale flexible straightening device comprises a base and a U-shaped limiting frame installed on the base through screws. An elastic mat, an interposed mat and a fixed twisting plate are sequentially arranged in a frame body of the limiting frame, the elastic mat is close to a back plate, the portions between two vertical plates and the interposed mat are each provided with a partition plate and a tube diameter limiting mat, the partition plates are close to the interposed mat, and a movable twisting plate is arranged between the two partition plates. The elastic mat, the interposed mat, the movable twisting plate, the partition plates, the tube diameter limiting mats and the vertical plates of the fixed twisting plate are connected with the back plate in a pre-tightened mode through a plurality of adjustment screws and a plurality of cylindrical pins. According to the minor-diameter round tube micro-scale flexible straightening method and device, in the straightening process, under the elastic pressure, a minor-diameter round tube blank is gradually straightened, the rolling diameter is accordingly decreased, a gap between the movable twisting plate and the fixed twisting plate is accordingly decreased, influences of a rigid gap on the straightening accuracy are effectively prevented, and the minor-diameter round tube micro-scale flexible straightening device is simple in structure, convenient to operate, high in straightening accuracy and low in cost.

Owner:CHINA NUCLEAR TIANJIN TECH DEV

Fully-automatic specially-shaped pipe straightening machine

InactiveCN105642708AReduce the difficulty of homeworkHigh degree of automationMetal working apparatusFully automaticWorkbench

The invention relates to a fully-automatic specially-shaped pipe straightening machine which comprises a workbench and a die pressing mechanism for straightening a specially-shaped material; the workbench is provided with movable supporting points, the movable supporting points transversely support a specially-shaped pipe, a plurality of laser detectors are arranged above the workbench, the laser detectors are used for detecting the interval with the specially-shaped material and transmitting the detected data to a control center, and accordingly the control center controls the die pressing mechanism to work on the bent portion of the specially-shaped material. According to the fully-automatic specially-shaped pipe straightening machine, the laser distance detectors which are quite high in precision are adopted for straightening in a matched mode, straightening is conducted while detection is conducted, straightening precision and efficiency are effectively improved, the automated degree is high, and work difficulty of workers is lowered.

Owner:江苏界达特异新材料股份有限公司

Tool-die steel plate straightening machine

InactiveCN105057401AImprove straightening accuracyImprove one-shot molding rateSteel platesEngineering

The invention belongs to the technical field of metallurgical equipment, in particular to a tool-die steel plate straightening machine. A classic three-beam four-column prestress rack is used, and a roller system with four rollers at the top and five rollers at the bottom is arranged. Opening degrees of the four straightening rollers at the top can all be adjusted independently, all the top straightening rollers are provided with independent support rollers, and each top straightening roller and the corresponding support roller form an independent compound roller system to perform adjustment. Hydraulic load cylinders are arranged above an upper beam, a movable beam can be lifted rapidly while overload protection is achieved, and accordingly maintenance can be performed conveniently. According to the tool-die steel plate straightening machine, because the opening degrees of all the top straightening rollers can be adjusted independently, the opening degrees can be adjusted flexibly from small to large according to original bends, thickness, width and materials of plates, the rolling reduction of the top straightening rollers is changed from large to small, straightening accuracy is improved, and meanwhile the one-step forming rate of the plates is greatly improved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

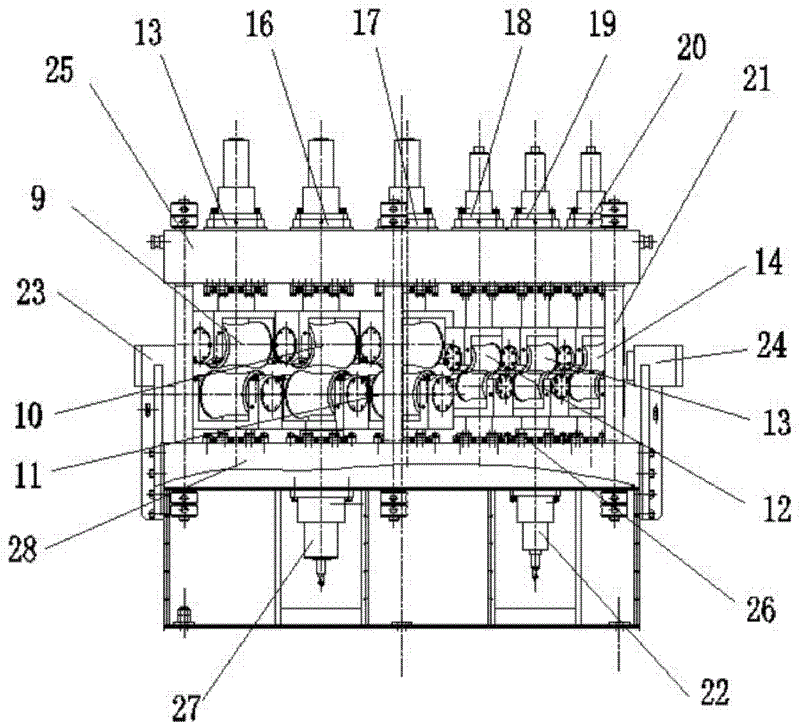

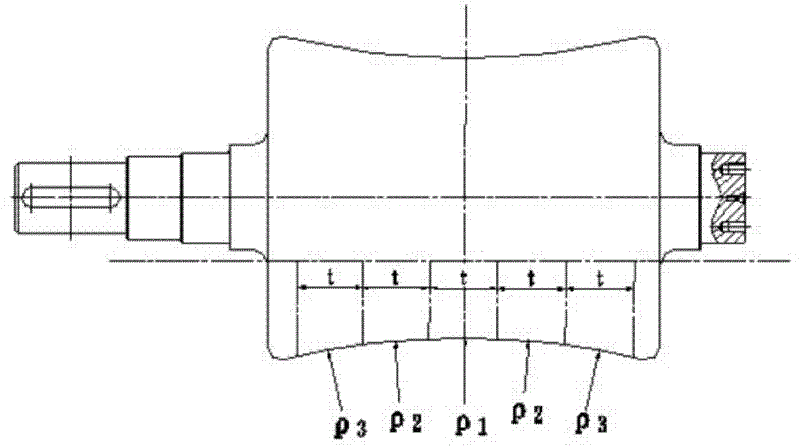

High-accuracy straightening machine for tantalum-niobium alloy pipe

The invention relates to a high-accuracy straightening machine for a tantalum-niobium alloy pipe, comprising a straightening main machine, a hydraulic servo system and an electrical control system, wherein the straightening main machine adopts a structure of 2-2 (12) composite rolls and is provided with 6 pairs of straightening rolls which are symmetrically arranged up and down in all, wherein the first pair of straightening rolls, the second pair of straightening rolls and the third pair of straightening rolls are large rolls, the fourth pair of straightening rolls, the fifth pair of straightening rolls and the sixth pair of straightening rolls are small rolls, the shapes of the straightening rolls are all segmental equal-curvature reverse bending roll shapes, and roll spacings are differential roll spacings; and the hydraulic servo system and the electrical control system carry out closed-loop control on the displacement quantities of the straightening rolls and the pressure of the straightening main machine and carry out stepless speed regulation on a straightening speed. The high-accuracy straightening machine can achieve the diameter ratio of a straightened pipe at 1:5; the diameter of the straightened pipe is phi 15-phi 70 mm, a wall thickness is 0.254-0.381 mm, and the straightening accuracy can achieve 0.3 mm / m; in addition, the high-accuracy straightening machine can also be used for straightening the pipes made of high-strength alloy materials, such as high-quality alloy steel and the like.

Owner:辽宁银捷装备科技股份有限公司

Straightening equipment

PendingCN114130861AImprove automationHigh degree of intelligenceMetal-working feeding devicesMetal working apparatusStructural engineeringIndustrial engineering

The invention discloses straightening equipment which comprises a frame body, horizontal conveying devices, a clamping device and a straightening device, a platform is arranged on the frame body, the horizontal conveying devices, the clamping device and the straightening device are all arranged on the platform, the number of the horizontal conveying devices is two, the two horizontal conveying devices are arranged on the two sides of the clamping device, and the clamping device is arranged between the two horizontal conveying devices. The number of the clamping devices is two, and the two clamping devices are arranged on the two sides of the straightening device. The full-automatic precise straightening equipment can be used for full-automatic precise straightening of guide rails of different models, is systematized straightening equipment with transmission, detection, positioning and straightening functions, and is high in automation and intelligence degree, and meanwhile, the straightening efficiency and the straightening precision of the equipment are high; the multiple positioning blocks are arranged, so that deviation of the linear guide rail in the straightening process is avoided; the guide rail straightening span can be adjusted, and efficient and accurate straightening is achieved.

Owner:LISHUI UNIV +1

Rectifying device for large-sized unstable aluminum alloy sections

A rectifying device for large-sized unstable aluminium alloy sections comprises a symmetric arrangement roll system comprising 12 straightening rolls, the straightening rolls are connected with straightening roll full-transmission driving devices and are mounted in a combined rack in a top-bottom symmetric arrangement manner, upper ends of the straightening rolls are equipped with six upper roll press-down devices, four lower roll press-up devices are arranged at the lower ends of the straightening rolls, two ends of the rack are connected with a fixing support in a matched manner, the fixing support is connected with a foundation screw, the adjustment of the upper roll press-down devices and the lower roll press-up devices allow for the adjustment of roll gaps and inflection amount, the straightening roll full-transmission driving devices drive the straightening rolls to realize gripping and straightening of sections via the twelve straightening rolls and rectification of cross section of the can be realized through the symmetric straightening rolls. Straightening accuracy and section size accuracy of the existing sections can be increased, and scrap from instability and surface strain caused during straightening process can be avoided for large-sized irregular aluminium and aluminum alloy sections.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com