Straightening method and straightening device of short bar stock

A short bar, straightening technology, applied in other manufacturing equipment/tools, manufacturing tools and other directions, can solve the problems of unsatisfactory short bar straightening accuracy and straightening efficiency, and can not meet the short bar straightening needs, etc. The effect of improving the straightening accuracy and straightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

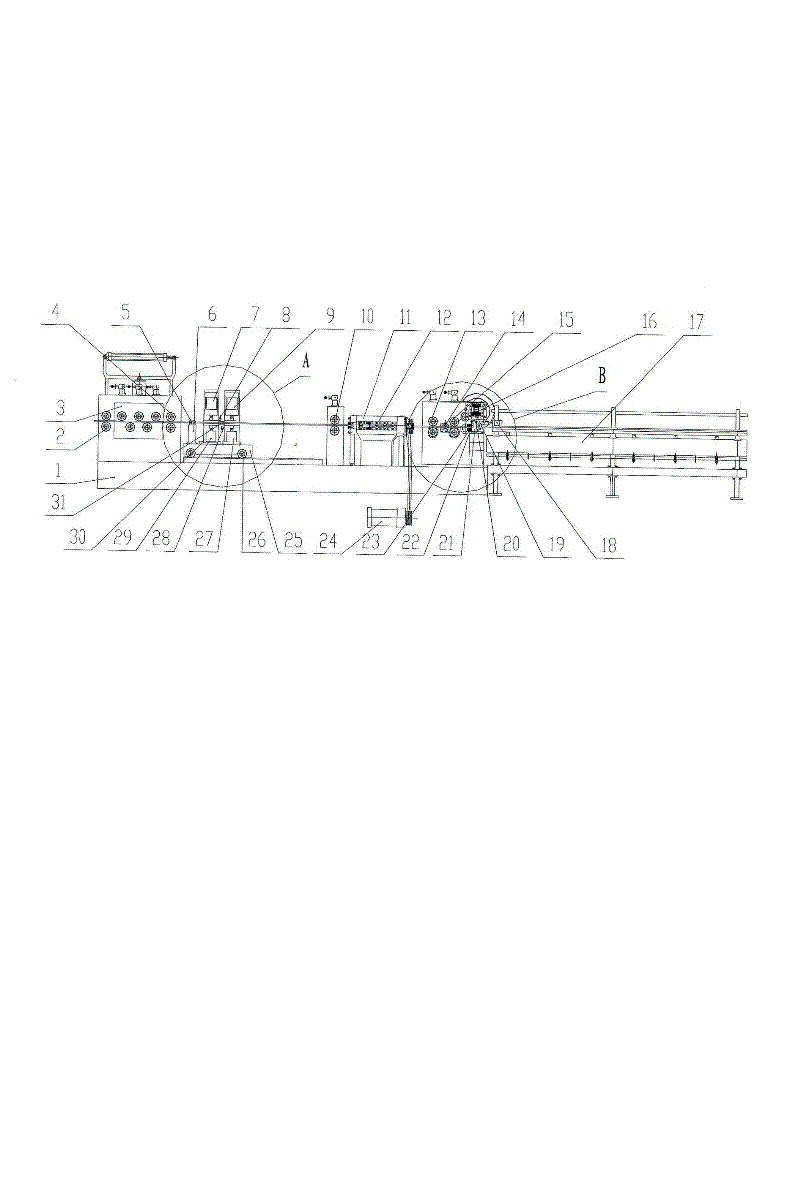

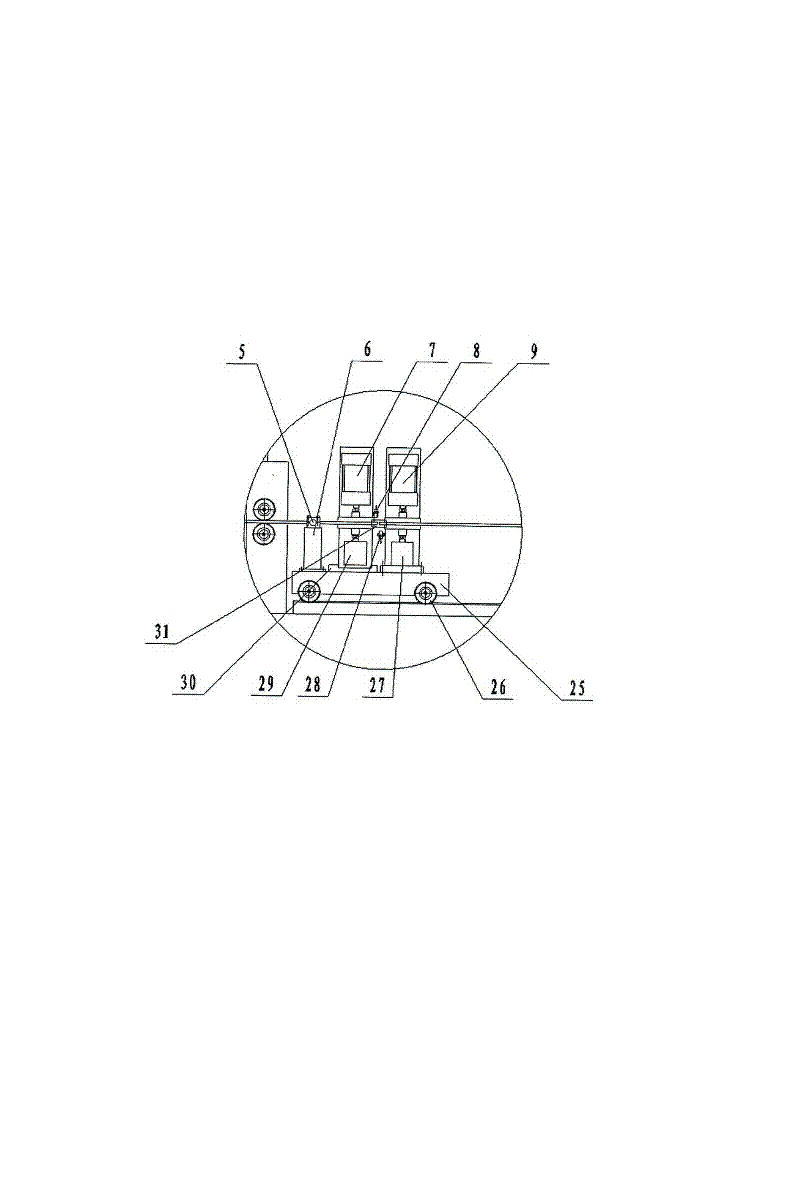

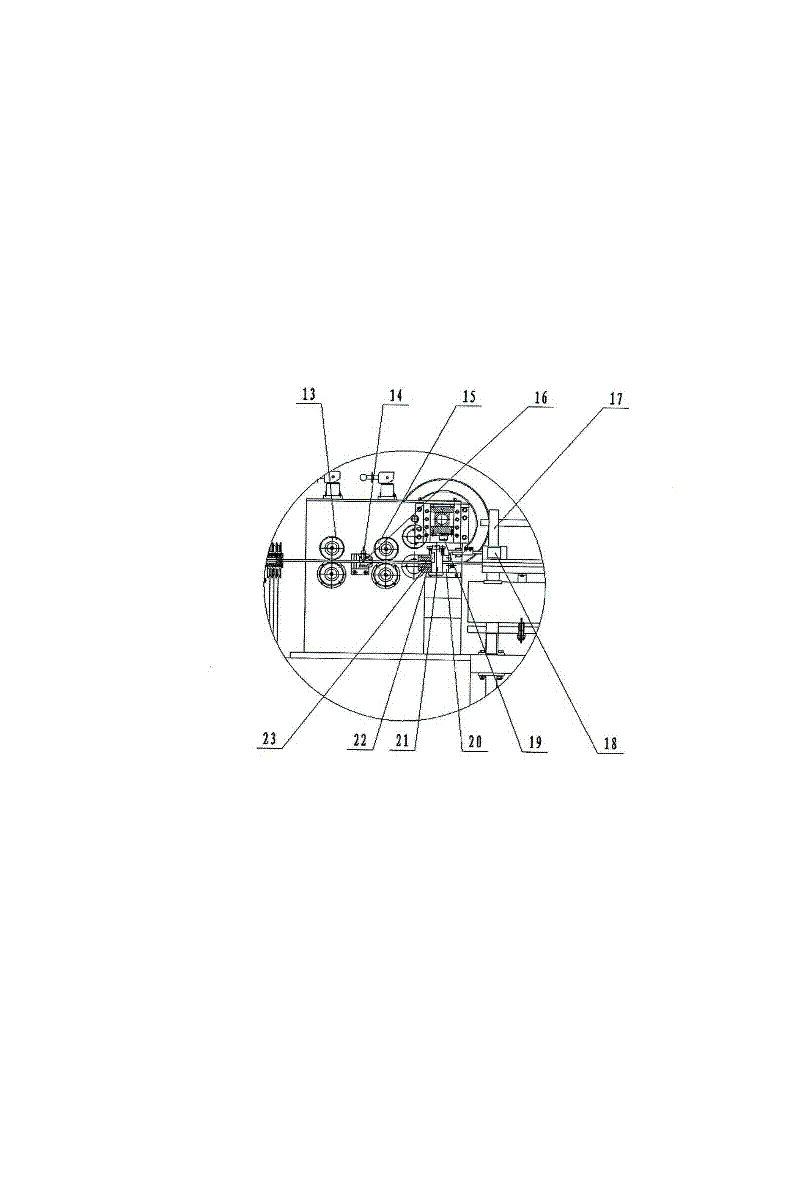

[0021] The present invention will be further described below in conjunction with accompanying drawing: adopt pre-straightening mechanism to carry out preliminary straightening to short bar stock first. exist figure 1 In the schematic diagram of the front view of the short bar straightening device of the present invention shown, the pre-straightening mechanism mainly includes a conventional parallel roller straightening machine, and its front and rear are respectively provided with front and rear pairs of pinch rollers, These two pinch rollers are connected with servo motors. A color spraying device is arranged behind the above-mentioned pre-straightening mechanism, and the paint nozzle of the color spraying device corresponds to the short bar pushed out by the pinch roller, and the base of the color spraying device is arranged on the welding base. Rollers are arranged under the welding base, and the rollers arranged on the slideway are connected with the stepping motor. Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com