Water-based conducting sizing agent for coating on surface of current collector of high-safety lithium battery and preparation method application thereof

A conductive paste, surface coating technology, applied in battery electrodes, electrode carriers/current collectors, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problem of poor adhesion between electrode material and current collector, thermal runaway There are no problems such as prevention and limited contact area, which can increase the cruising range, improve the consistency of dynamic internal resistance, and reduce the internal resistance of the battery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

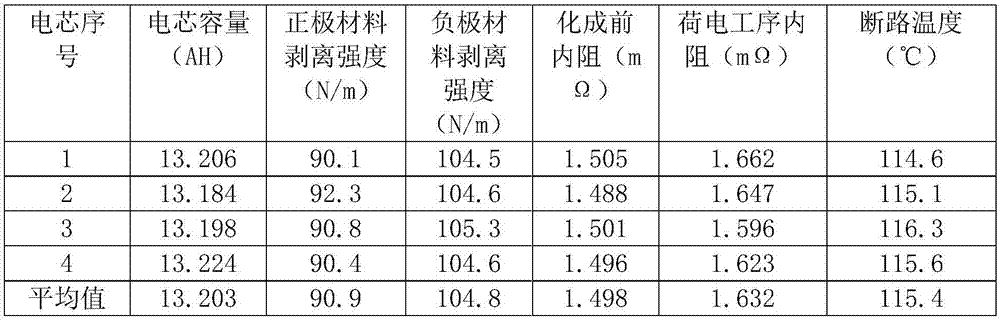

Embodiment 1

[0032] A high-safety lithium battery current collector surface coating water-based conductive paste, including the following components by weight percentage: graphene: conductive carbon black: 10%, dispersant: 2%, cellulose CMC: 2%, moistening Wet agent: 0.5%, thermoplastic acrylic resin: 20%, polyolefin microsphere emulsion: 10%, deionized water: the balance.

[0033] The preparation process of polyolefin microsphere emulsion is: using supercritical ethane / carbon dioxide pulverization process, dissolving ethylene-propylene block copolymer and ethylene-methacrylic acid copolymer in ethane / carbon dioxide mixed critical In the liquid, the mass ratio of ethane to carbon dioxide is 1:1.5, the spray velocity of the control solution is 380m / s, and the expansion time is 10 -8 s, to obtain polyolefin microsphere aggregates with a particle size of 3 μm; mix the above polyolefin microsphere aggregates with high molecular weight acrylic acid additives, and perform surface modification in...

Embodiment 2

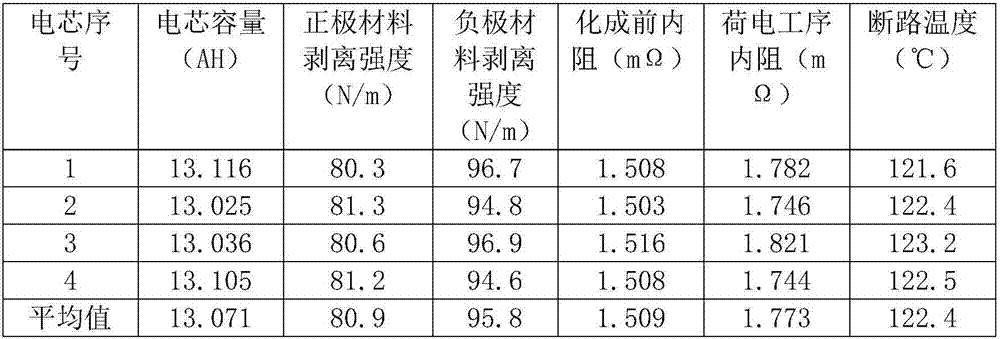

[0043] A high-safety lithium battery current collector surface coating water-based conductive paste, including the following components in weight percentage: SP-Li: 5%, dispersant: 4%, cellulose HEC: 1%, wetting agent: 1%, styrene-acrylic emulsion: 15%, polyolefin microsphere emulsion: 5%, deionized water: the balance.

[0044] Preparation process of polyolefin microsphere emulsion:

[0045] Using supercritical ethane / carbon dioxide crushing process, the ethylene-propylene block copolymer and ethylene-methacrylic acid copolymer are dissolved in the ethane / carbon dioxide mixed critical liquid according to the mass ratio of 2:1, the mass ratio of ethane to carbon dioxide The ratio is 1:1.5, the spray velocity of the control solution is 420m / s, and the expansion time is 10 -8 s, to obtain polyolefin microsphere aggregates with a particle size of 2 μm; mix the above polyolefin microsphere aggregates with high molecular weight acrylic acid additives, and perform surface modificati...

Embodiment 3

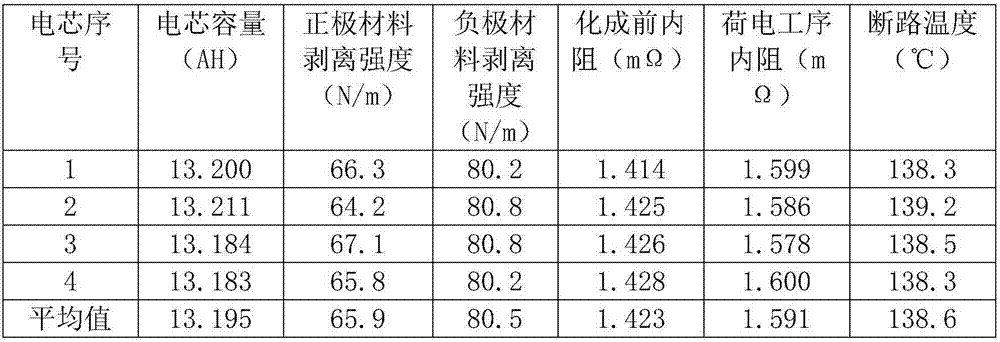

[0055] A high-safety lithium battery current collector surface coating water-based conductive paste, including the following components in weight percentage: graphene: 0.5%, dispersant: 10%, cellulose HPMC: 0.2%, wetting agent: 0.1 %, binder epoxy resin: 2%, polyolefin microsphere emulsion: 0.5%, deionized water: the balance.

[0056] Preparation process of polyolefin microsphere emulsion: using supercritical ethane / carbon dioxide pulverization process, dissolving ethylene-propylene block copolymer and ethylene-methacrylic acid copolymer in ethane / carbon dioxide mixed critical liquid according to the mass ratio of 2:1 , the mass ratio of ethane to carbon dioxide is 1:1.5, the spray velocity of the control solution is 480m / s, and the expansion time is 10 -9 s, Polyolefin microsphere aggregates with a particle size of 1 μm were prepared. Mix the above-mentioned polyolefin microsphere aggregates with high-molecular-weight acrylic acid additives evenly, and perform surface modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com