Patents

Literature

474results about How to "Improve straightening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

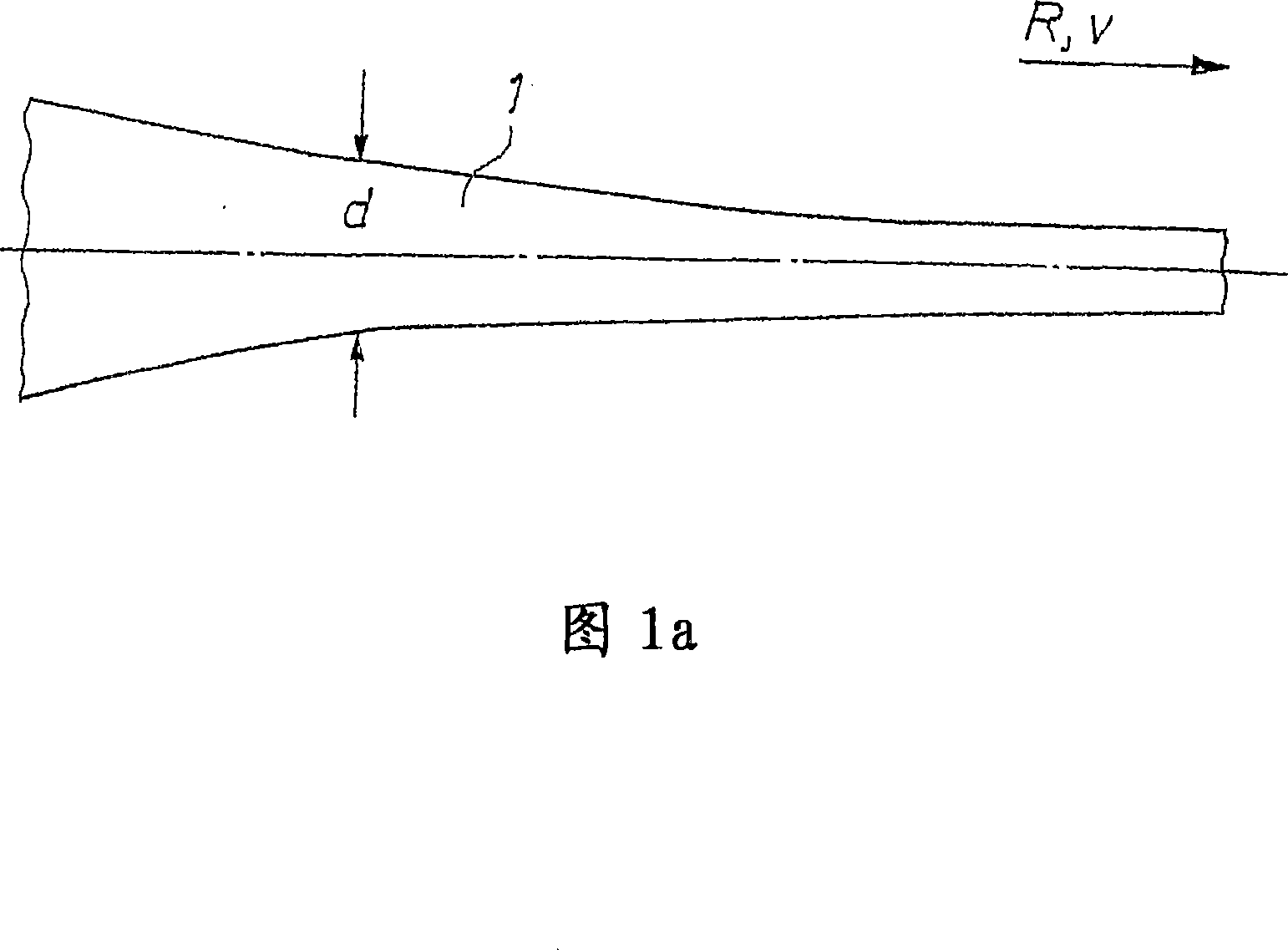

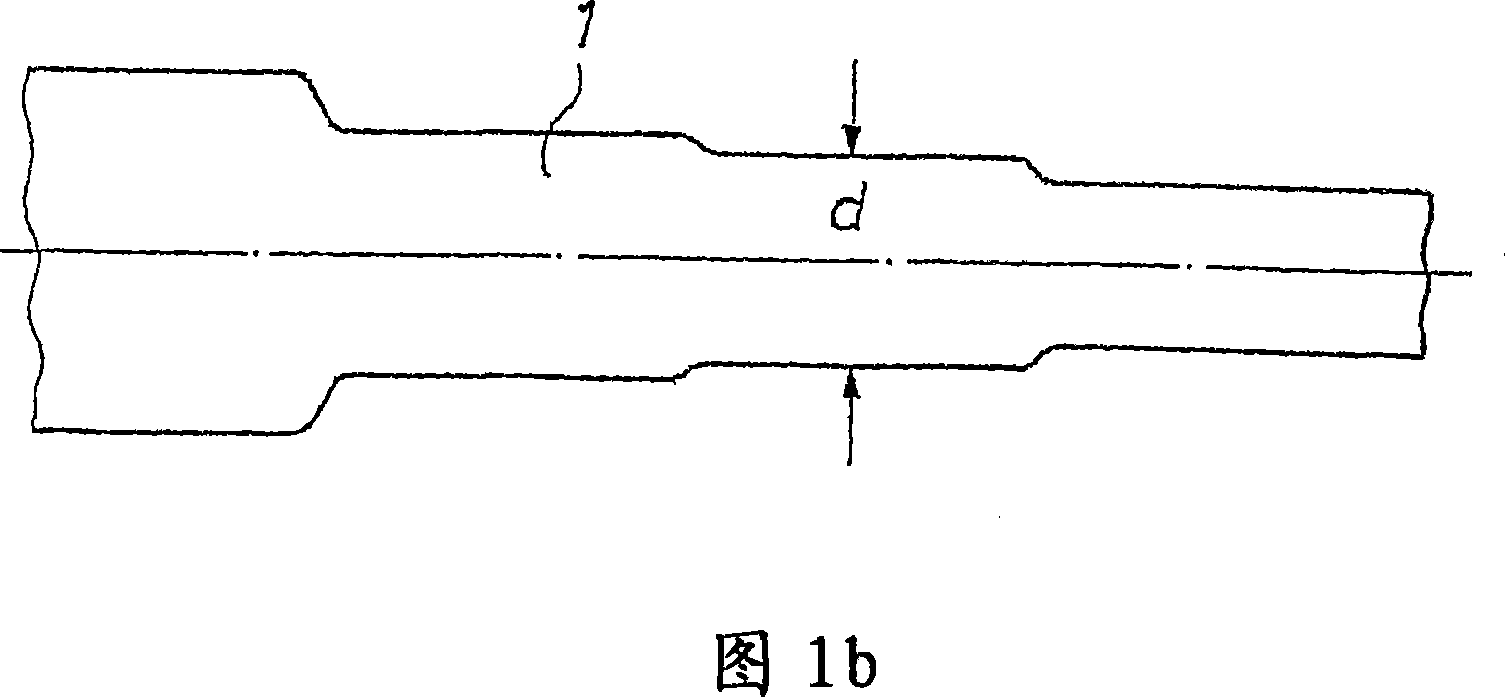

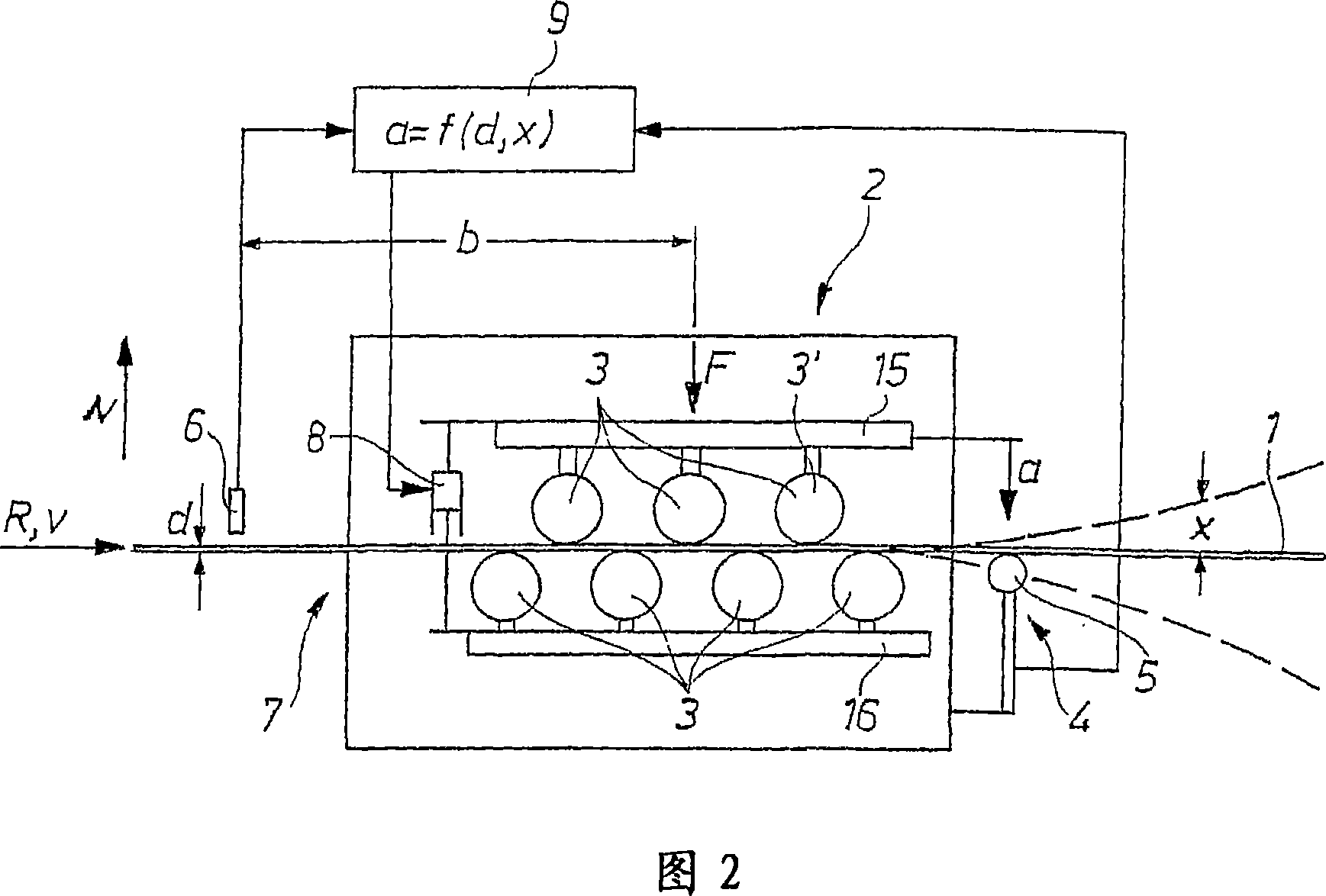

Method for straightening a metal strip and straightening machine

An improved medical treatment and medicine is provided to quickly and safely resolve HIV and other microbial infections. The inexpensive medicine can be self administered and maintained for the prescribed time. The attractive medicine comprises an antimicrobial concentrate comprising microbe inhibitors, phytochemicals or isolates. Desirably, the effective medicine comprises a surfactant and an aqueous carrier or solvent and a nutrient. In the preferred form, the medicine comprises: Echinacea and Commiphora myrrha phytochemicals, benzalkonium chloride, a sterile water solution, and folic acid.

Owner:SMS DEMAG AG

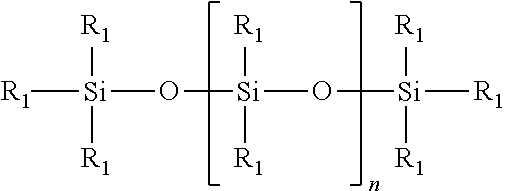

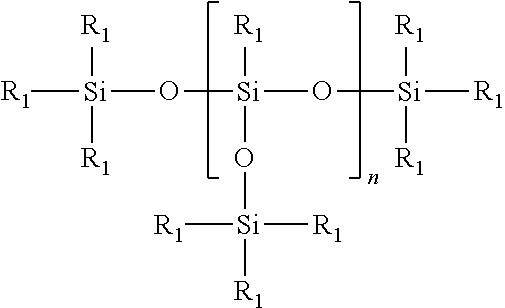

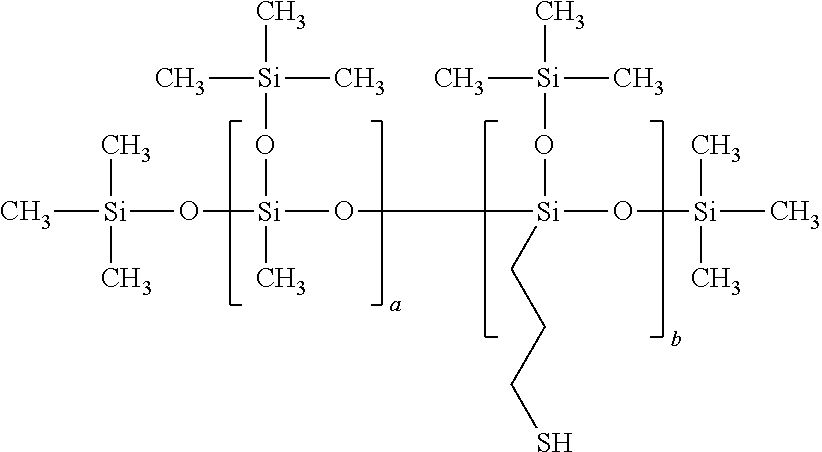

Composition and method for thermally activated hair treatment

ActiveUS20120031420A1Excellent semi-permanent straightening resultFree aldehydeCosmetic preparationsHair cosmeticsThermal conditioningHair treatment

A formulation is disclosed useful for semi-permanent, thermal conditioning and styling of the hair comprising a mercaptosilicone polymer derived from greater than 25 mole percent mercaptosilicone monomer. A method of straightening the hair is also disclosed which comprises the steps of applying the mercaptosilicone polymer formula to the hair and then styling the hair at an elevated temperature with a flat iron to achieve a lasting straight style that remains after more than one shampoo cycle.

Owner:GRANT INDS

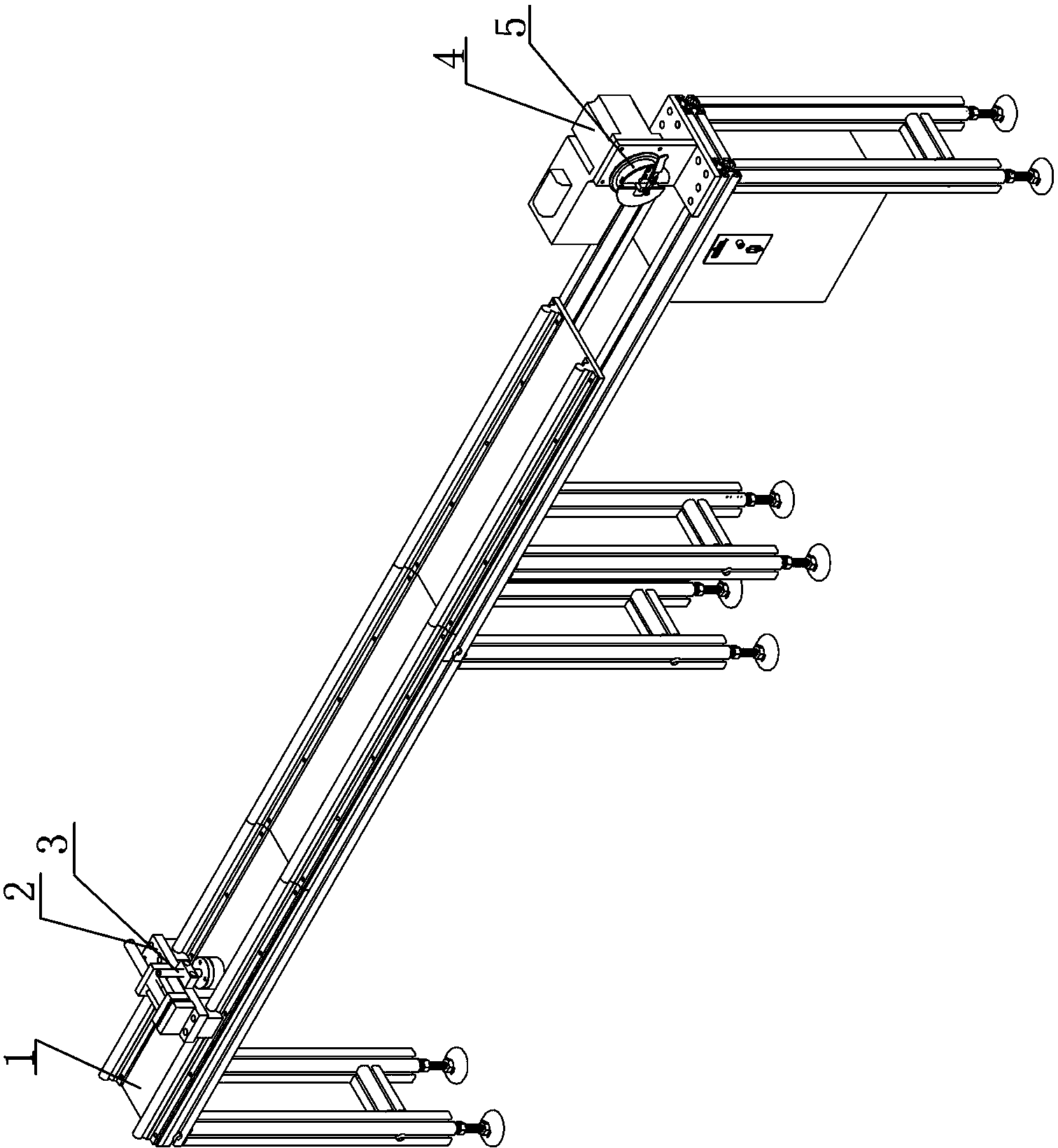

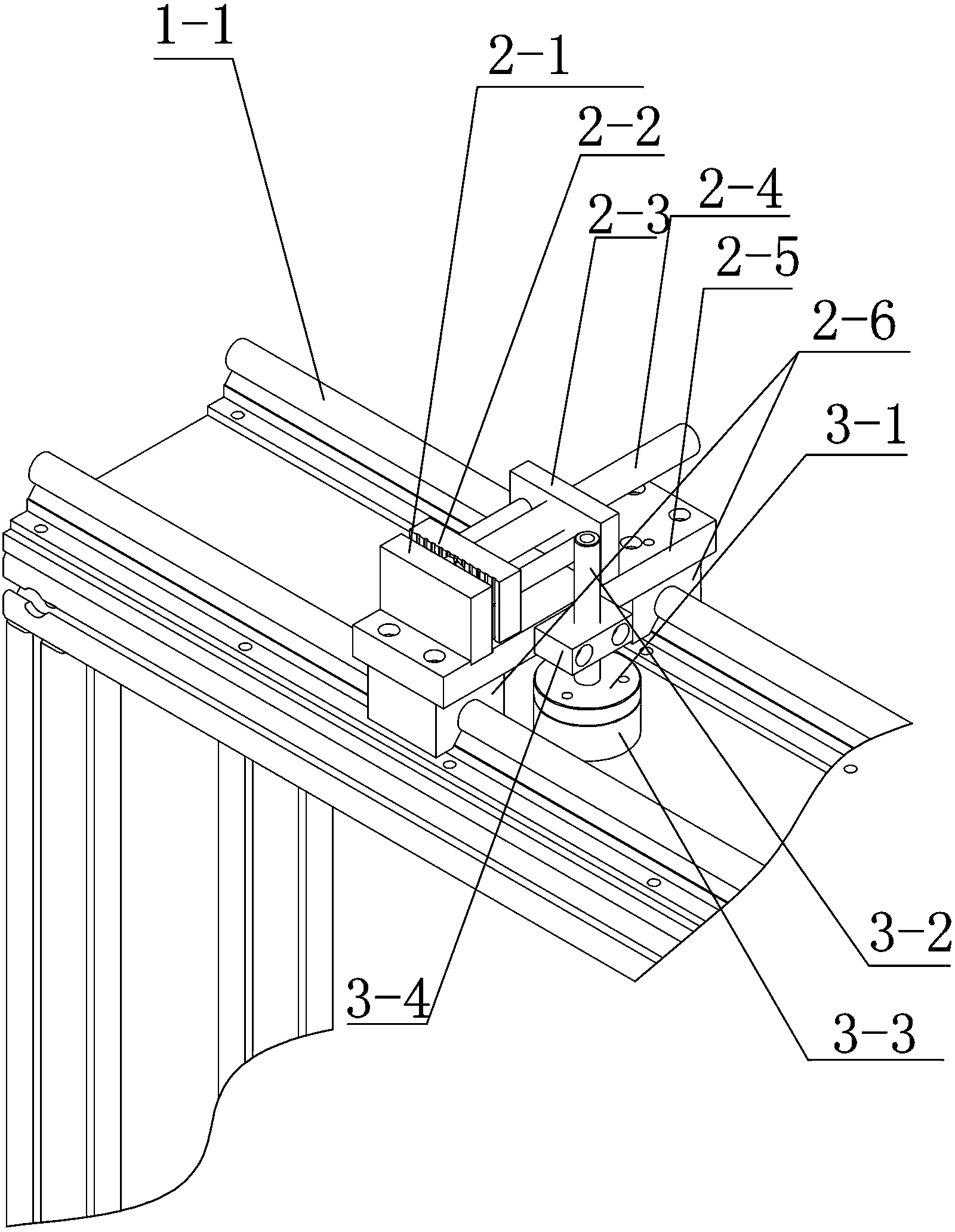

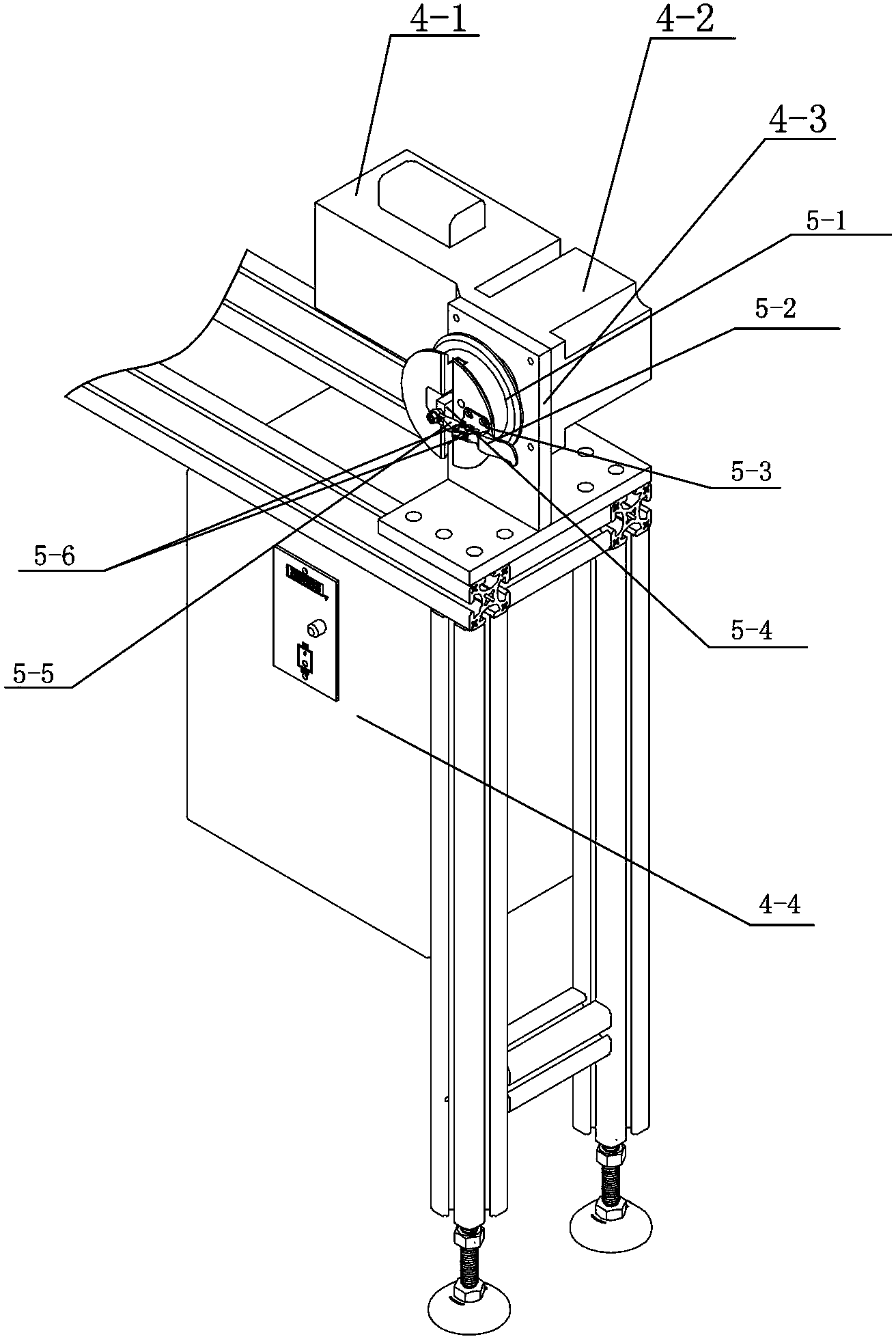

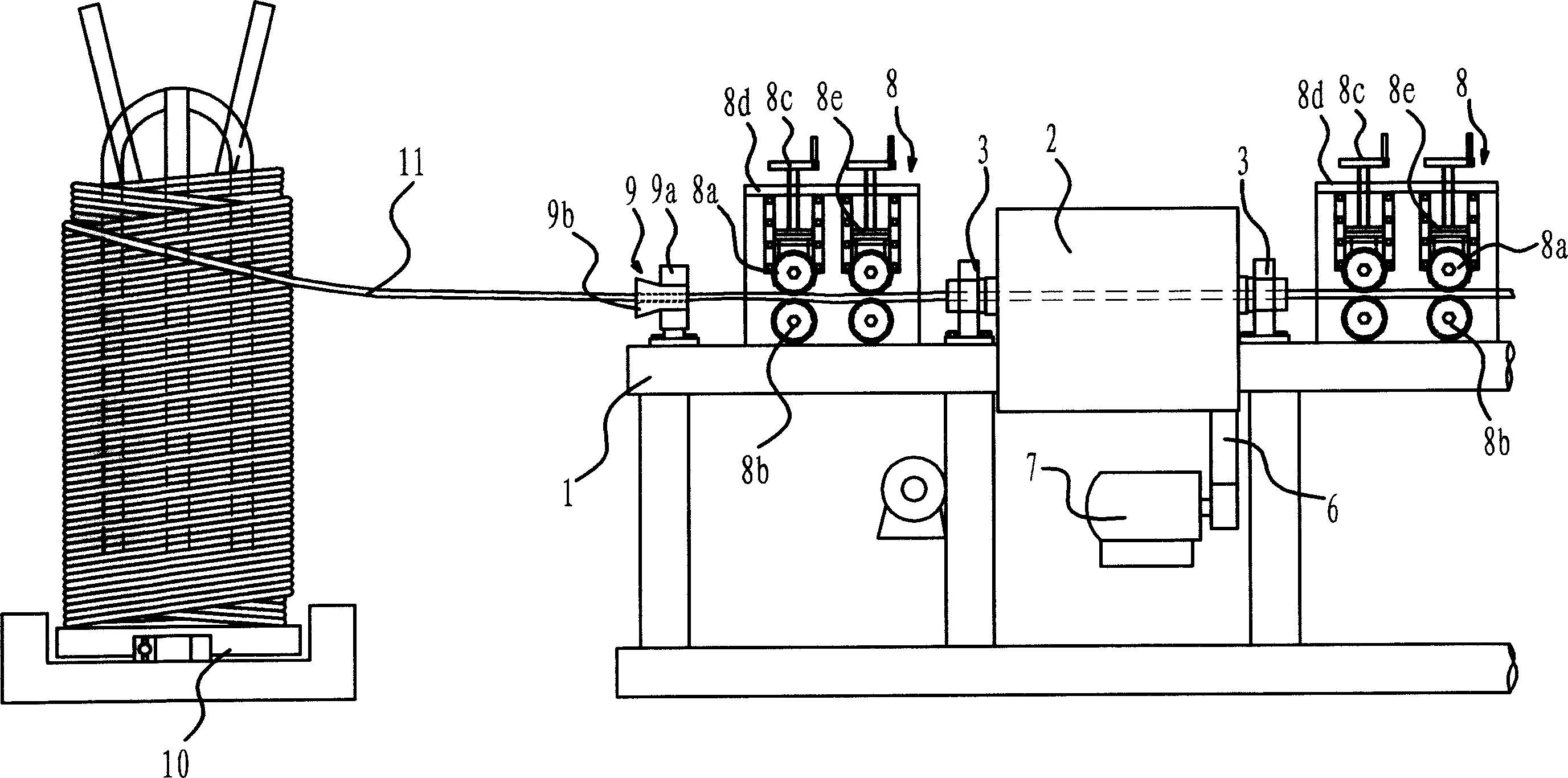

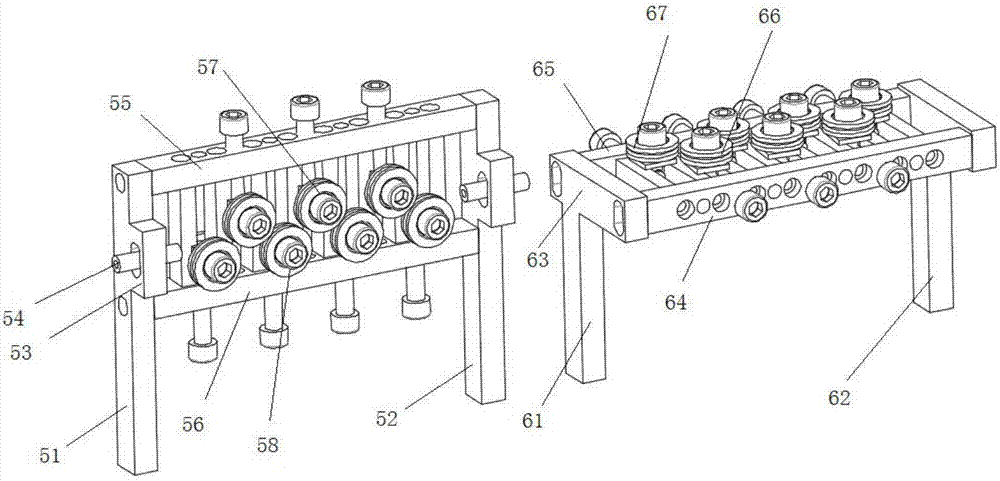

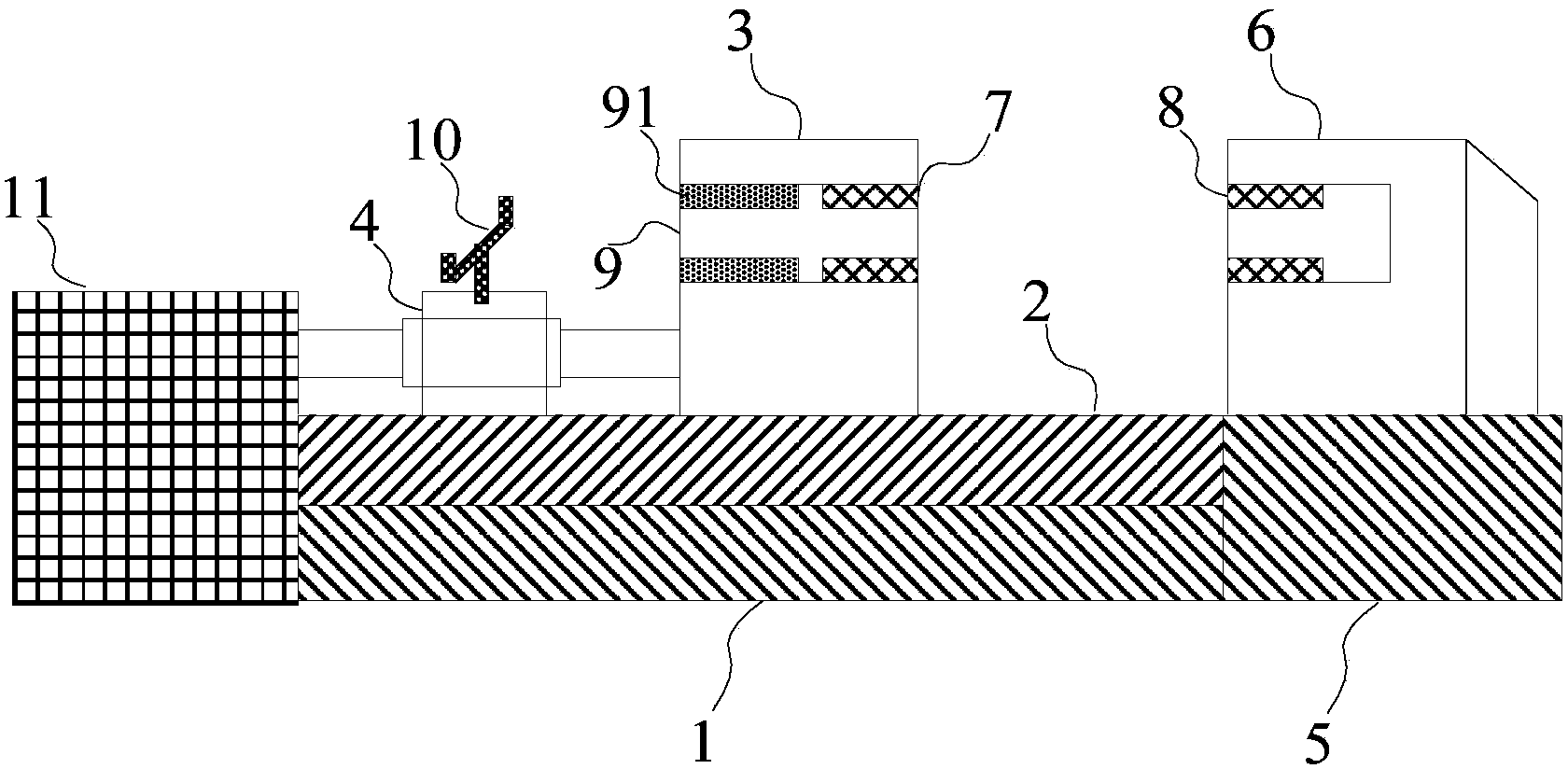

Cable core automatic straightening device

InactiveCN103928877AProcessing speedImprove straightening effectApparatus for joining/termination cablesSlide plateEngineering

The invention provides a cable core automatic straightening device which is formed by a machine frame part, a sliding base part, a sliding base fixing device, a power transmission part and a cable core winding part. The machine frame is of a rectangular frame structure capable of being spliced in a segmented mode, a linear guide rail is arranged on the upper portion of the machine frame, the sliding base part comprises the sliding base matched with the guide rail, a sliding plate fixed to the sliding base and a cable end fixing device installed on the sliding plate, the cable end fixing device comprises a fixed clamping plate, a movable clamping plate, a fixed nut plate and a lead screw, the fixed clamping plate and the fixed nut plate are fixed to the sliding plate, the fixed nut plate and the lead screw form a lead screw pair, and the movable clamping plate is fixed to one end of the lead screw. The cable core automatic straightening device is convenient and flexible to operate, high in cable processing speed and good in straightening effect and solves the problems that a cable core cannot continuously operate when being straightened by workers, the speed is low and the workers are tired due to long-time strength exertion.

Owner:STATE GRID CORP OF CHINA +1

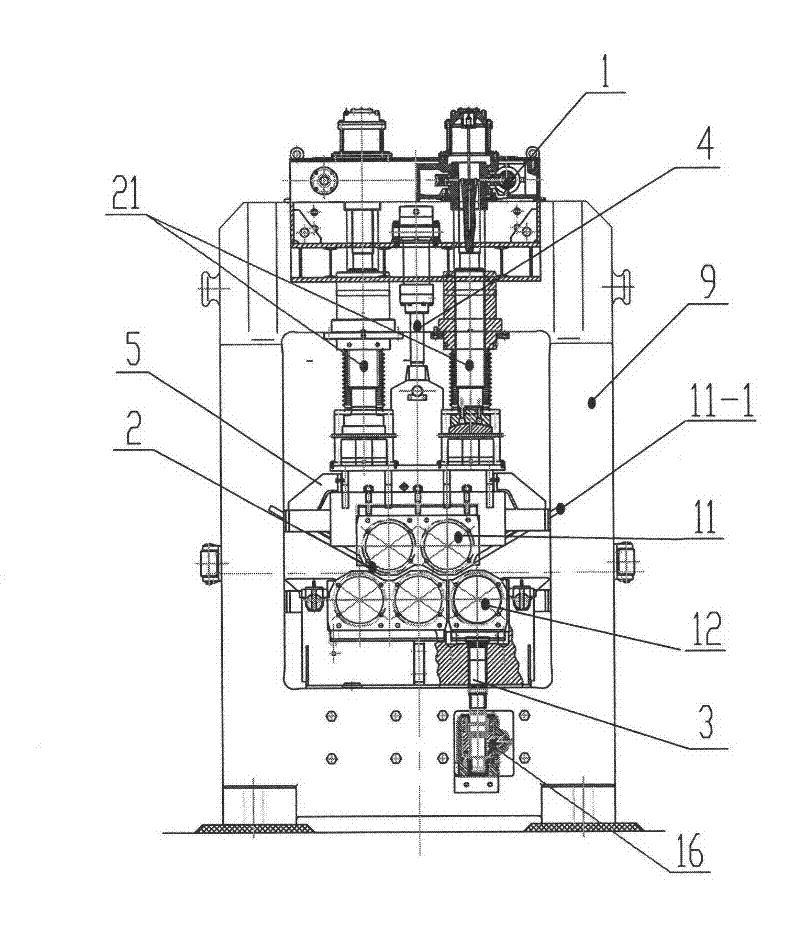

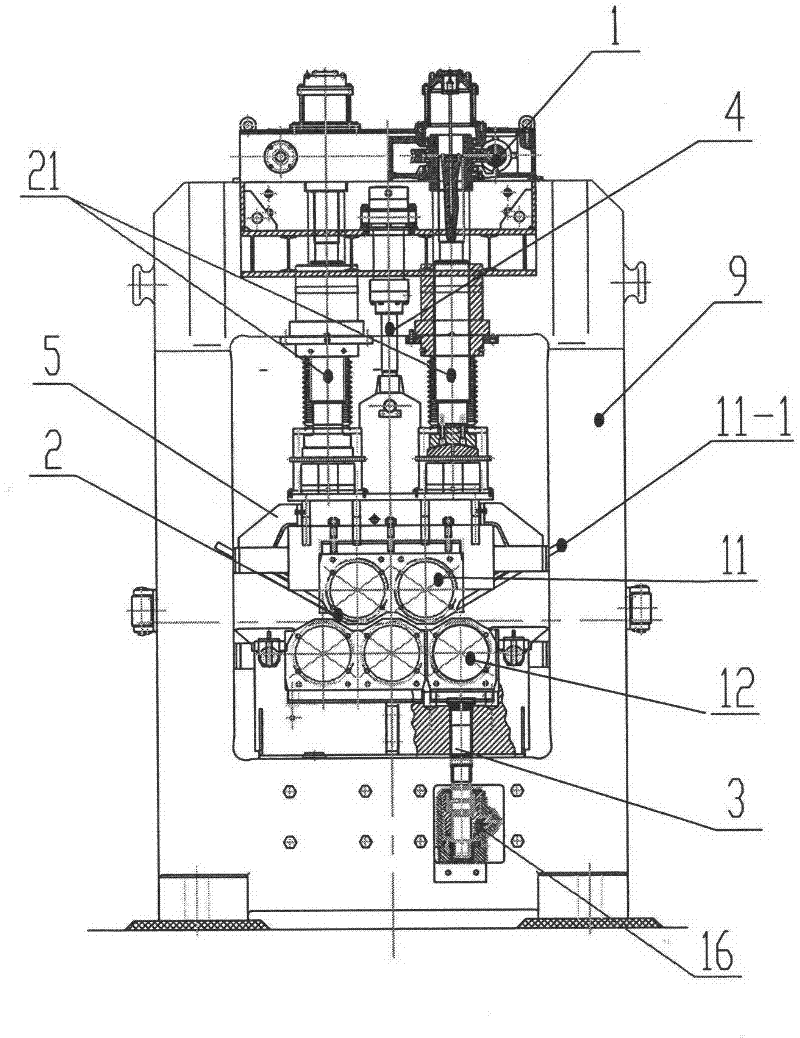

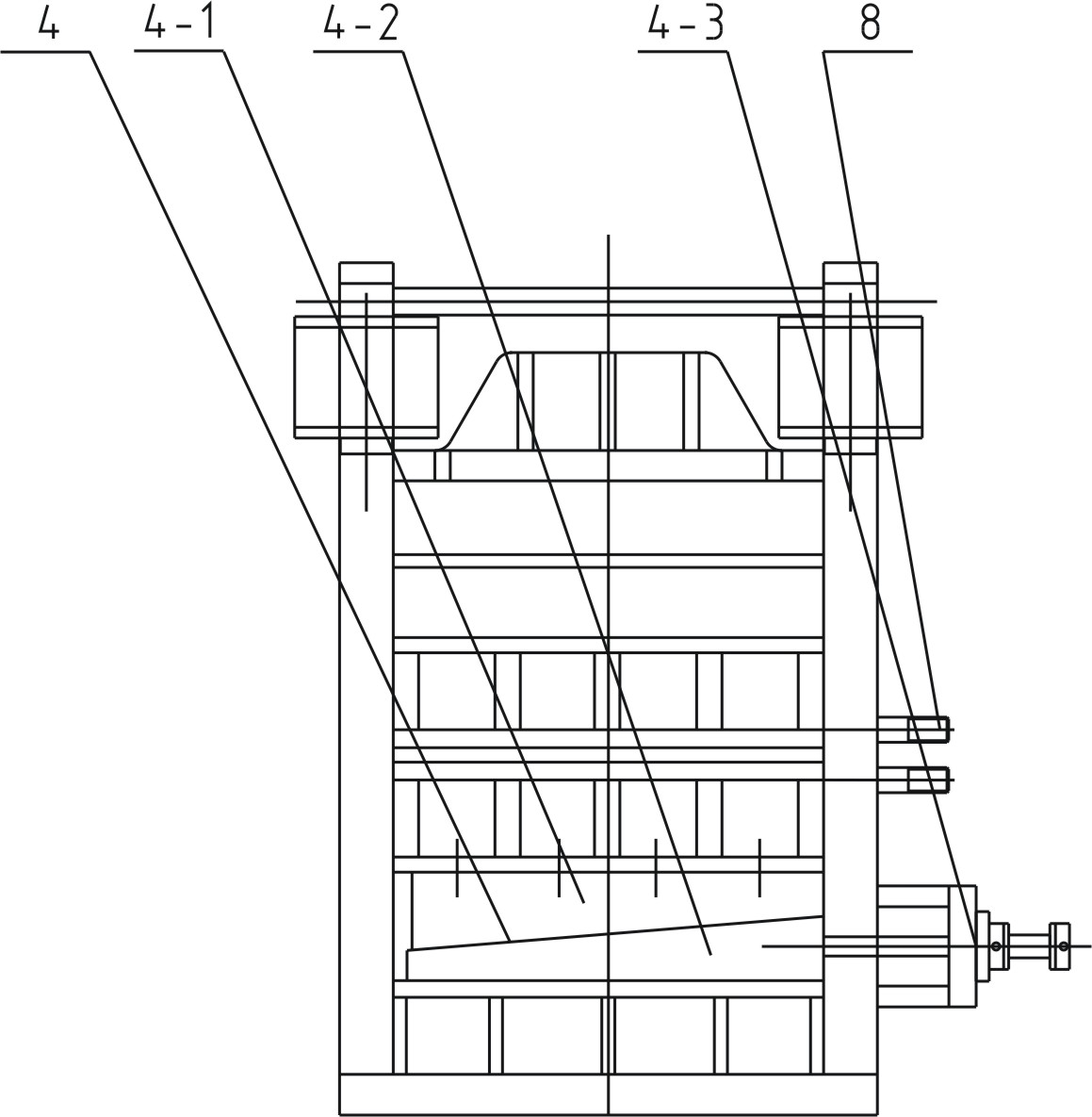

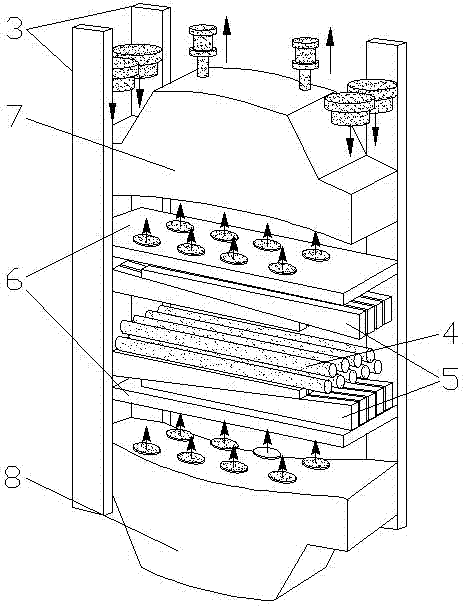

Pre-straightener for medium and thick plates

ActiveCN102248029AGuaranteed uptimeMeet the straightening process requirementsThick plateWater source

The invention discloses a pre-straightener for medium and thick plates, and relates to a thermal straightener. The invention solves the problems that the conventional thermal straightener has an unreasonable structure, is provided with a large number of rolls and has overhigh straightening force. The thermal straightener is characterized in that: a frame is fixed on a foundation through foundation bolts, a fast screwdown system is arranged on the upper part of the frame, and a balancing device is connected with the frame and a movable beam through hinged earrings respectively; an outlet edge roll lifting system is arranged inside the outlet side of the frame, and is connected with outlet edge rolls of a five-roll system device through a screw elevator; a high-efficiency cooling system is arranged inside the five-roll system device and on the upper part of the movable beam, and is connected with an external water source through a pipeline; a fast roll replacement device consists of a roll system lifting device, a connecting shaft positioning and clamping device, and a roll system dragging device; and a main transmission device is arranged on the foundation, and is connected with the five-roll system device through a universal spindle. The thermal straightener can continuously pre-straighten hot-rolled high-temperature steel plates; and equipment guarantee is provided for the progress of a medium and thick plate production process and the development of novel varieties of steel.

Owner:TAIYUAN HEAVY IND

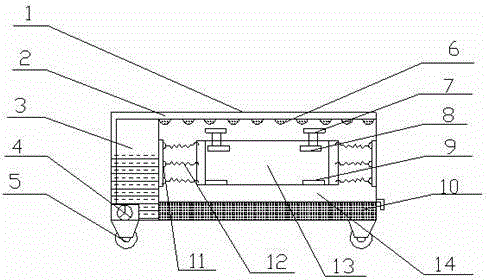

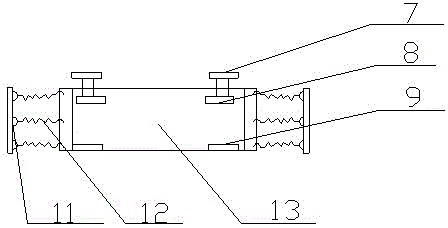

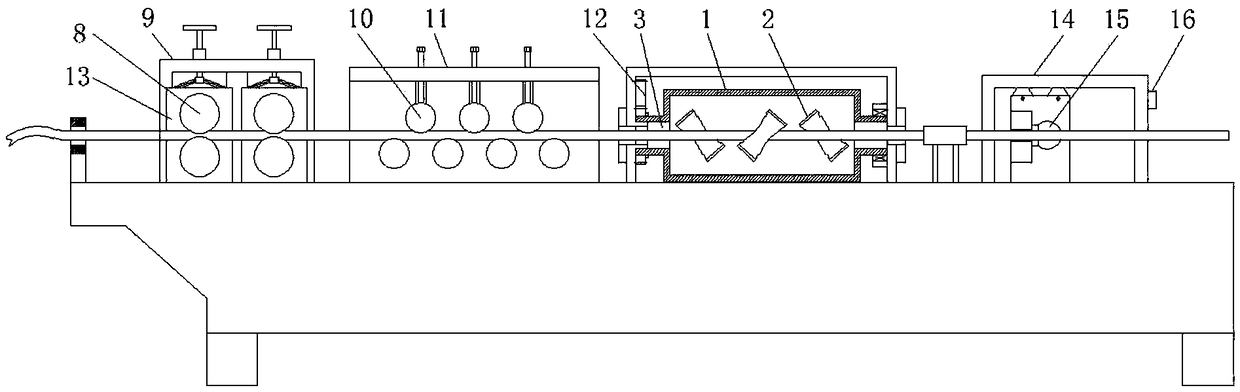

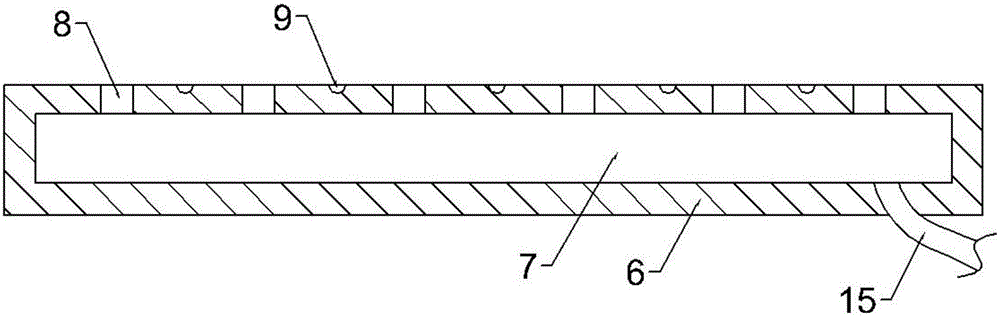

Cable straightening machine for power equipment

InactiveCN104362494ASimple structureEasy to operateLine/current collector detailsPipingWater delivery

The invention discloses a cable straightening machine for power equipment. The cable straightening machine comprises a machine case, a straightening box and a water delivery mechanism, wherein the water delivery mechanism is composed of a water tank, a water pump and a water delivery pipe; the water pump is arranged at the bottom of the water tank; the extension end of the water delivery pipe is arranged on the horizontal part at the upper end of the machine case in an extension manner; the downward surface of the horizontal water delivery pipe is provided with a plurality of nozzles in parallel; a work bench is arranged in the straightening box; two groups of upper pressure blocks and lower pressure blocks are arranged on the upper part and the lower part of the work bench; two groups of fixing plates are arranged on the left part and the right part of the inner wall of the straightening box; three groups of strong springs are arranged on the fixing plates; suspension links matched with the strong springs are arranged on two sides of the work bench; and the upper pressure blocks are connected to locking bolts. The cable straightening machine has the advantages of being simple in structure, convenient to operate, excellent in straightening effect and the like.

Owner:STATE GRID CORP OF CHINA +1

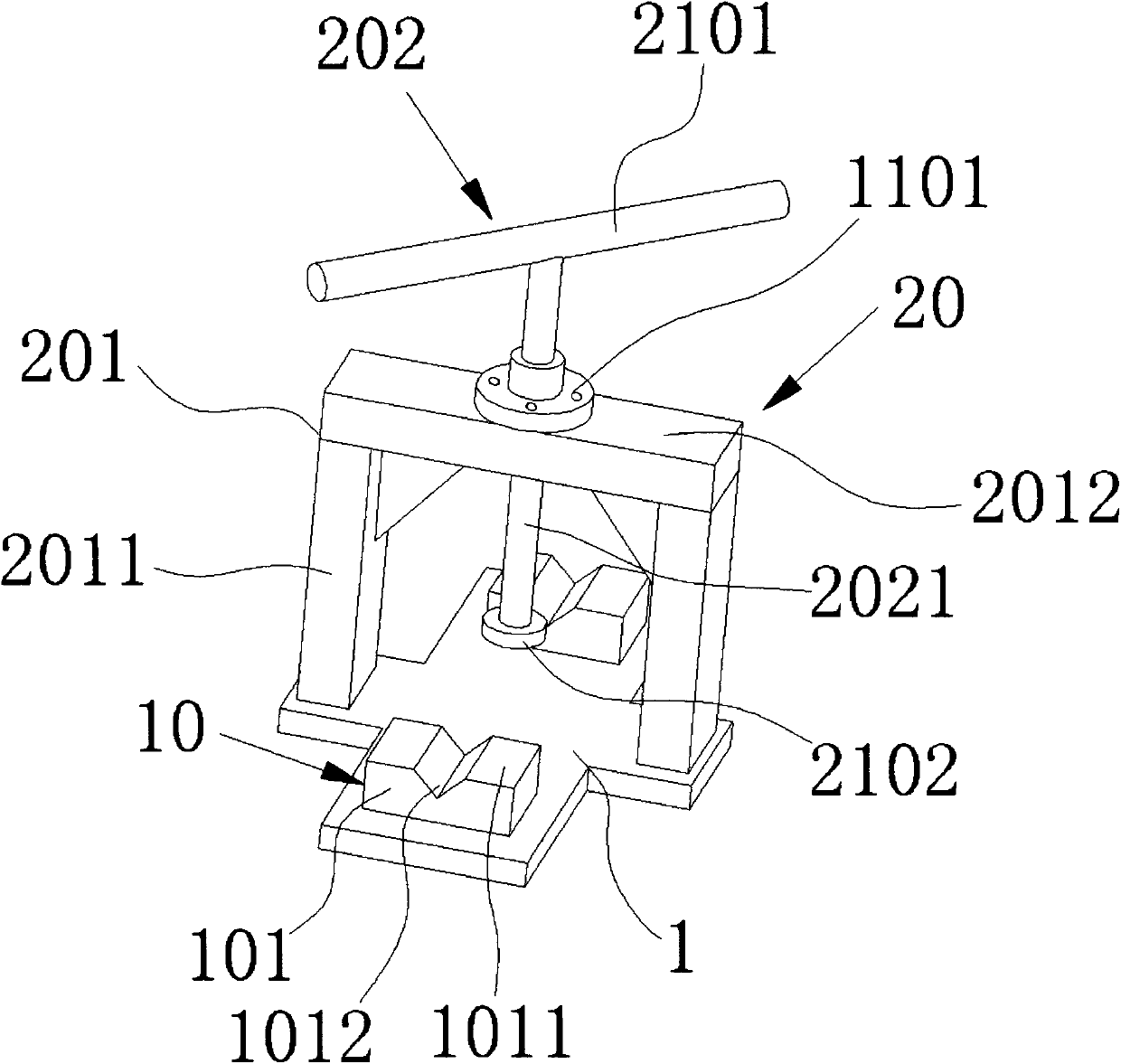

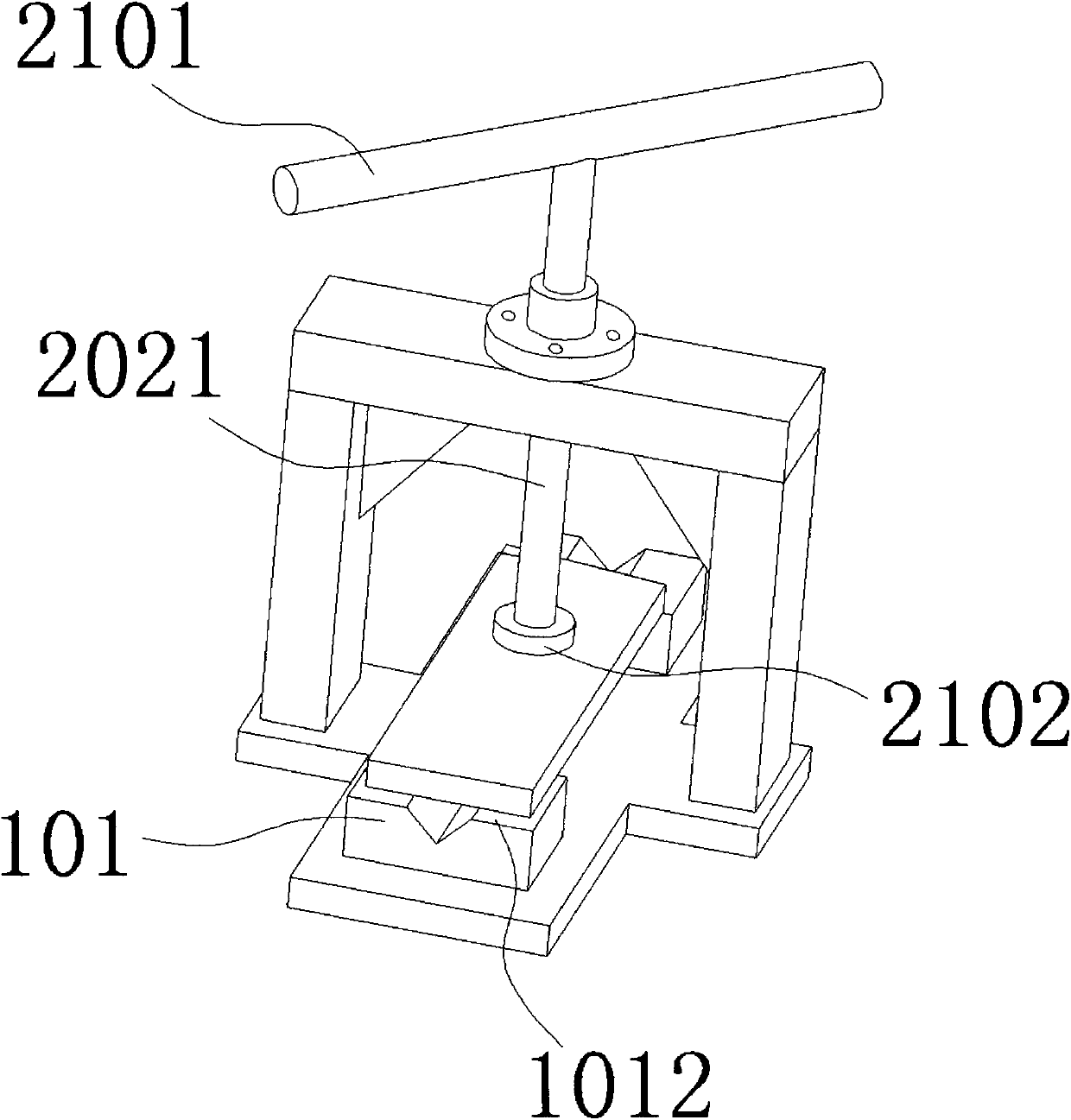

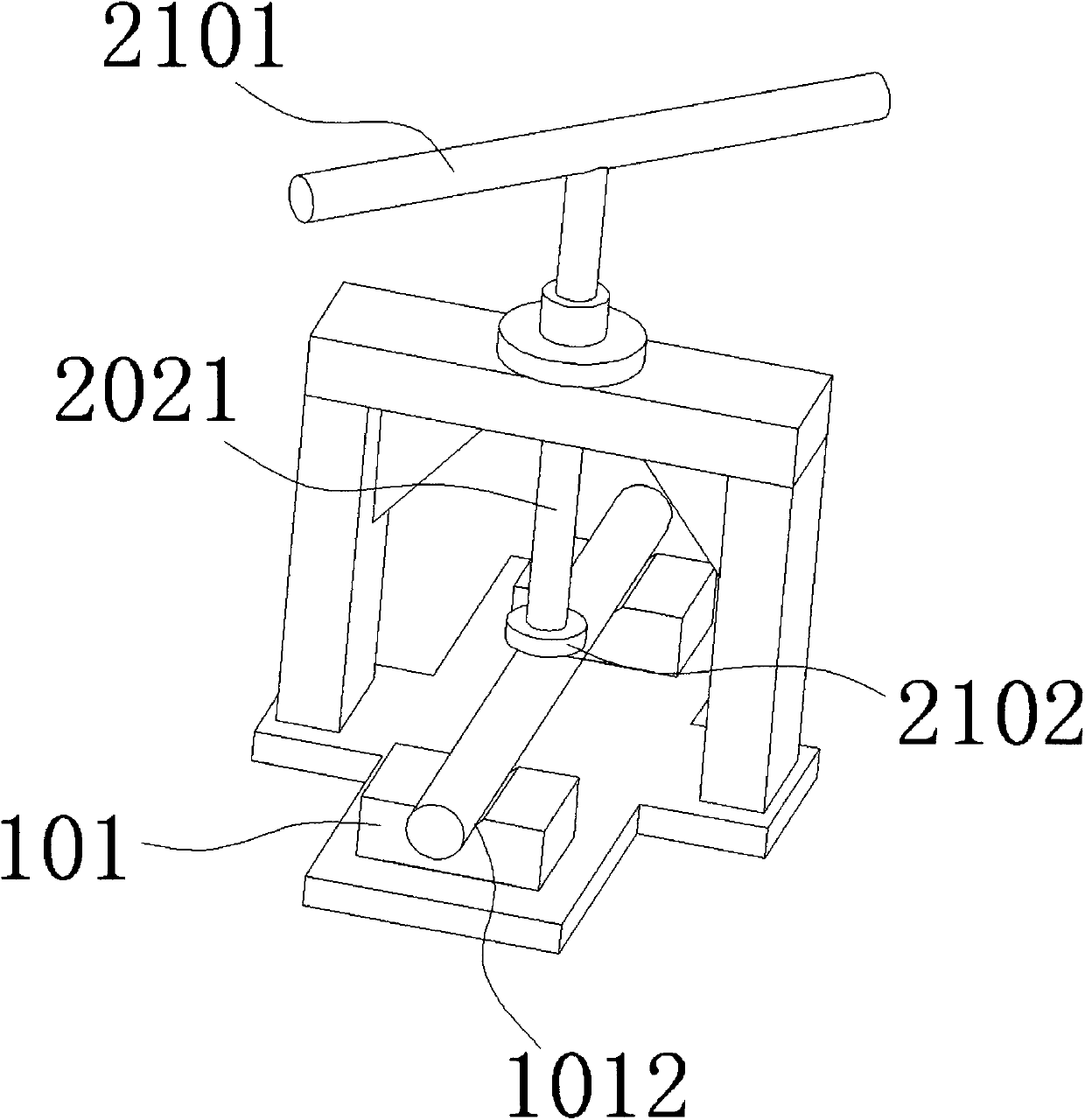

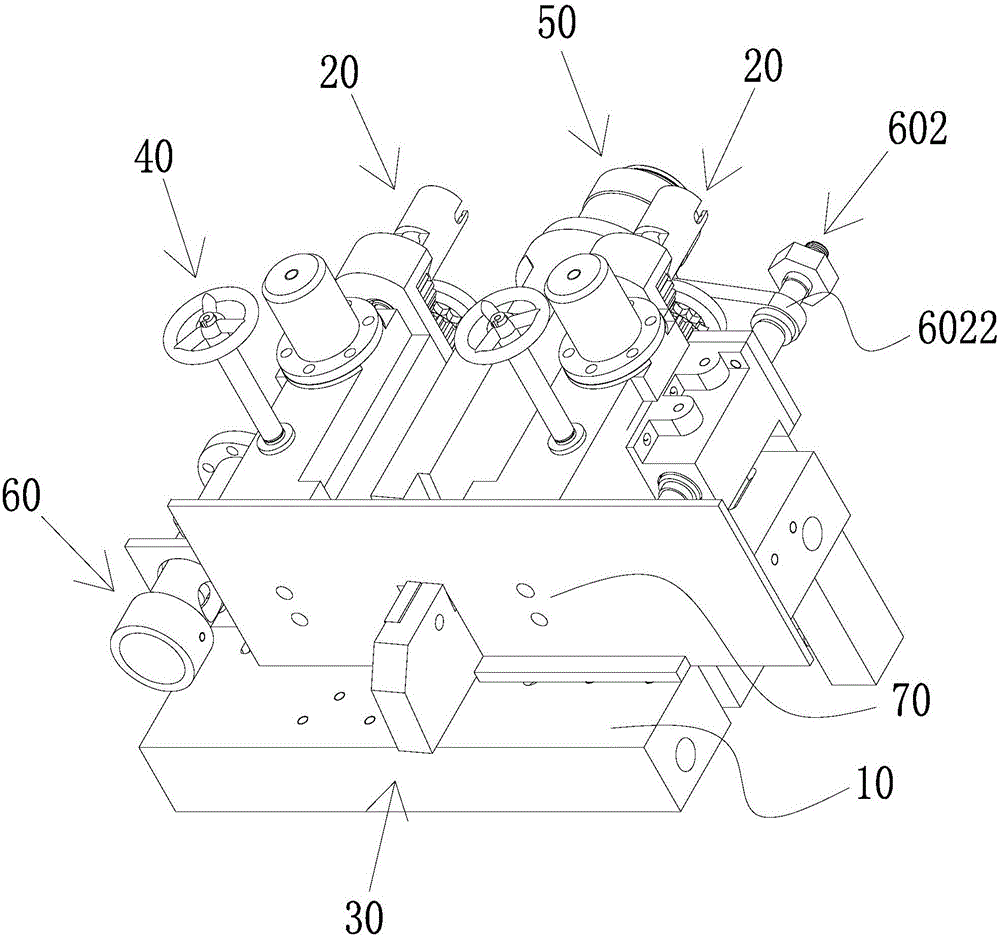

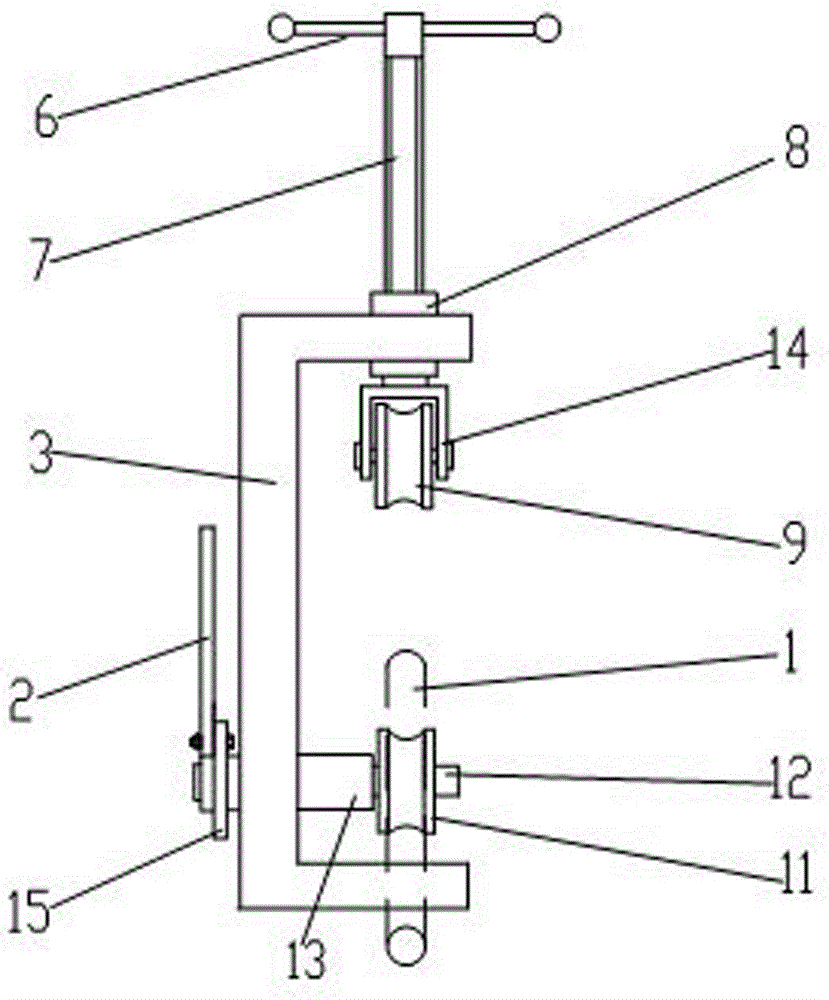

Straightening mechanism

The invention provides a straightening mechanism which comprises a positioning part and a pressing part. The pressing part is arranged above the positioning part. The straightening mechanism can effectively prevent a workpiece from being damaged, and the straightening effect is obvious. In addition, operation is simple and convenient, long-plate type and shaft type workpieces can be straightened easily, straightening time is greatly saved, labor intensity is lowered, the production rate is improved, manufacturing is simple, and cost is saved.

Owner:苏州市合昌电器有限公司

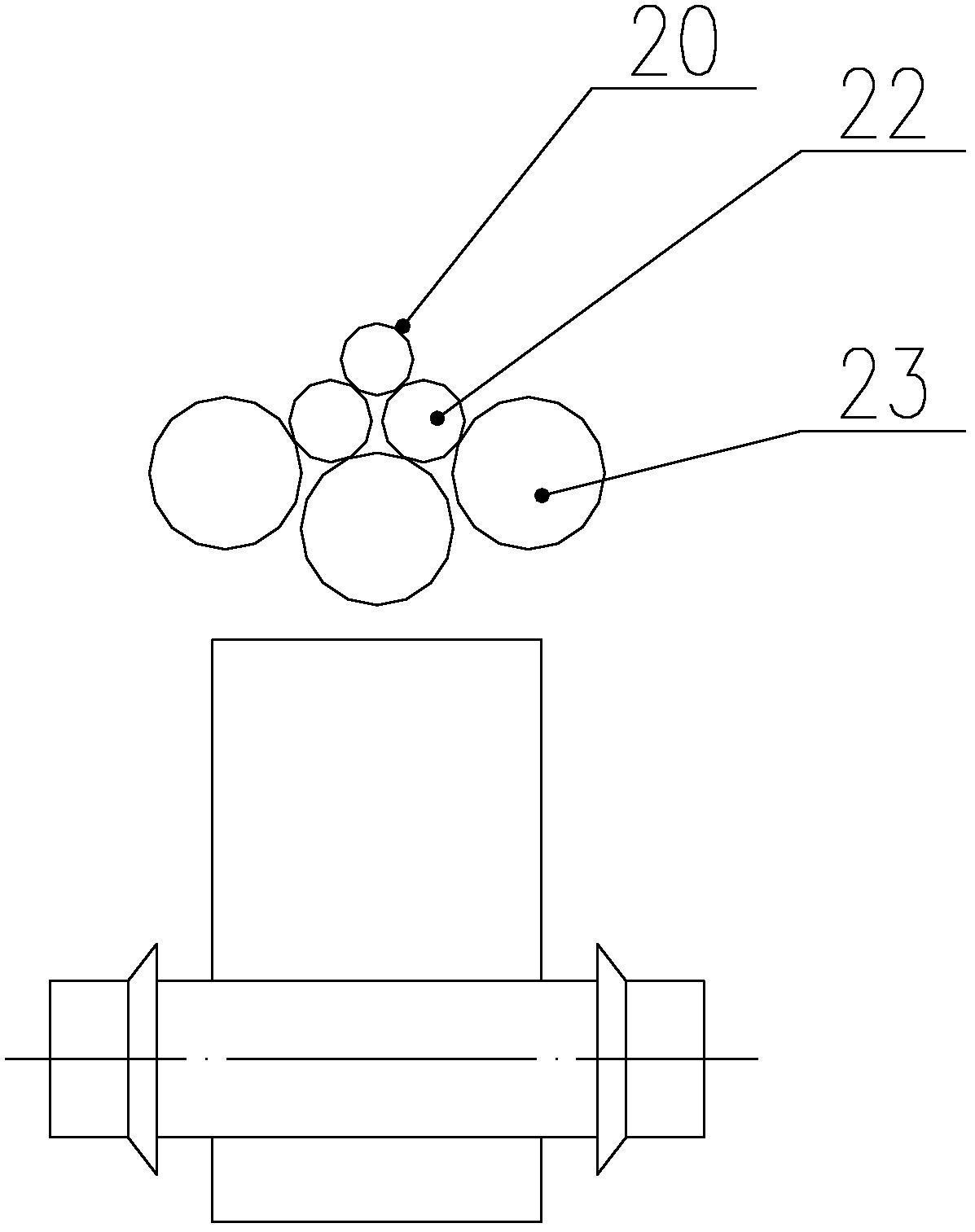

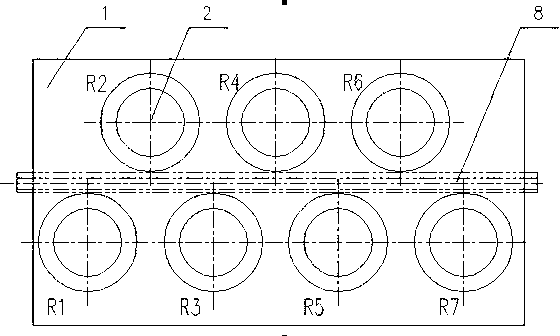

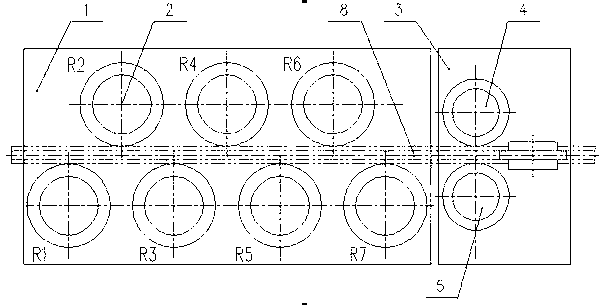

Wire rod straightener for wire hook formation machine

A wire straightening machine for the wire hook forming machine has a rotary drum supported by two bearings, and several straightening blocks which are serially and coaxially arranged in said rotary drum and have a hole for each block. All the holes are coaxial and the wire passes through the rotary holes for straightening it.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

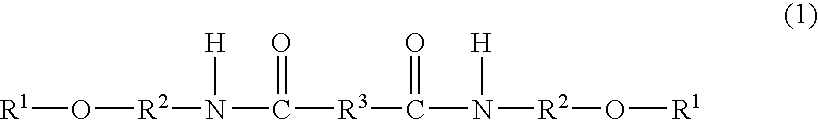

Hair straightener composition

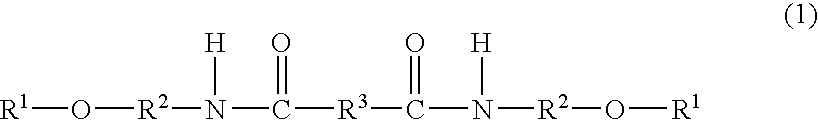

InactiveUS20030215410A1Reduce hair damageImprove straightening effectCosmetic preparationsHair cosmeticsHydrogen compoundsPolymer chemistry

Provided is a hair straightener composition comprising a diamide compound (1) and an alkali agent and having a pH of from 12 to 14 when diluted to 10 times with water. wherein, R<1>: a C1-12 hydrocarbon group which may be substituted by a hydroxy and / or alkoxy group, R<2>: a divalent C1-5 hydrocarbon group, and R<3>: a divalent C1-22 hydrocarbon group. The hair straightener composition of the present invention causes little hair damage upon treatment therewith.

Owner:KAO CORP

Plate strip straightening equipment and precision adjusting method thereof

InactiveCN102632112A"Straightening edge waves" defectThe edge wave defect reachesHydraulic cylinderMechanical engineering

Owner:武汉钢铁有限公司

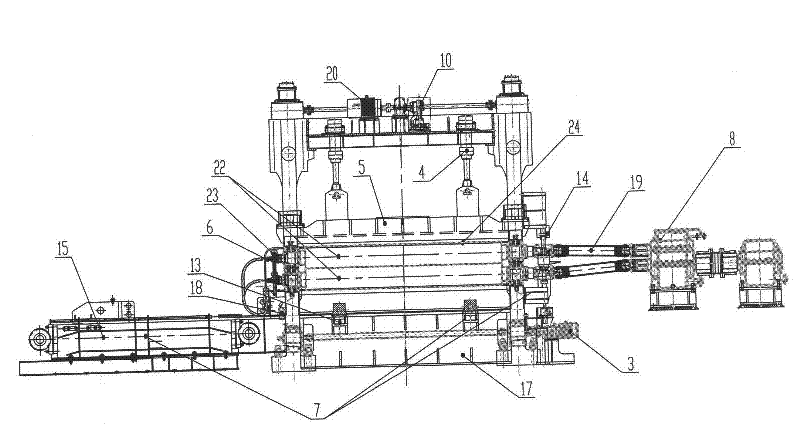

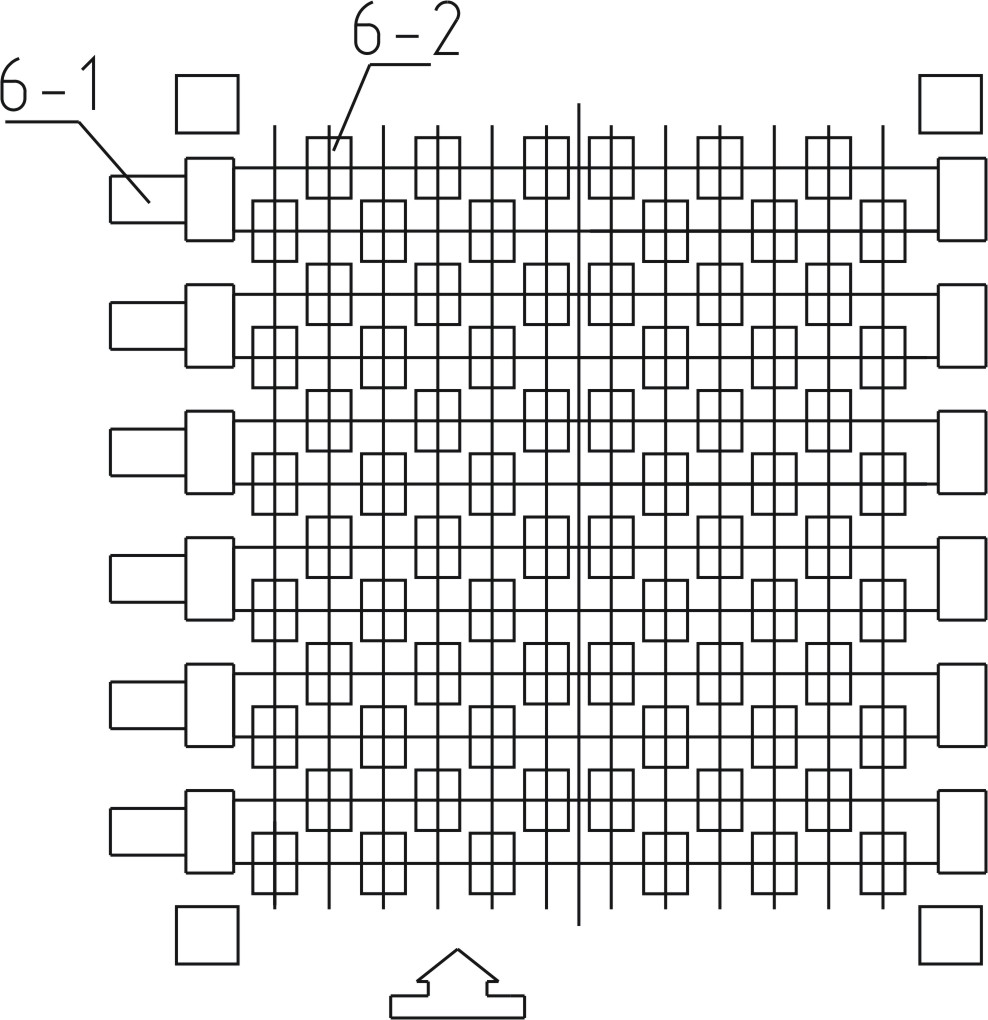

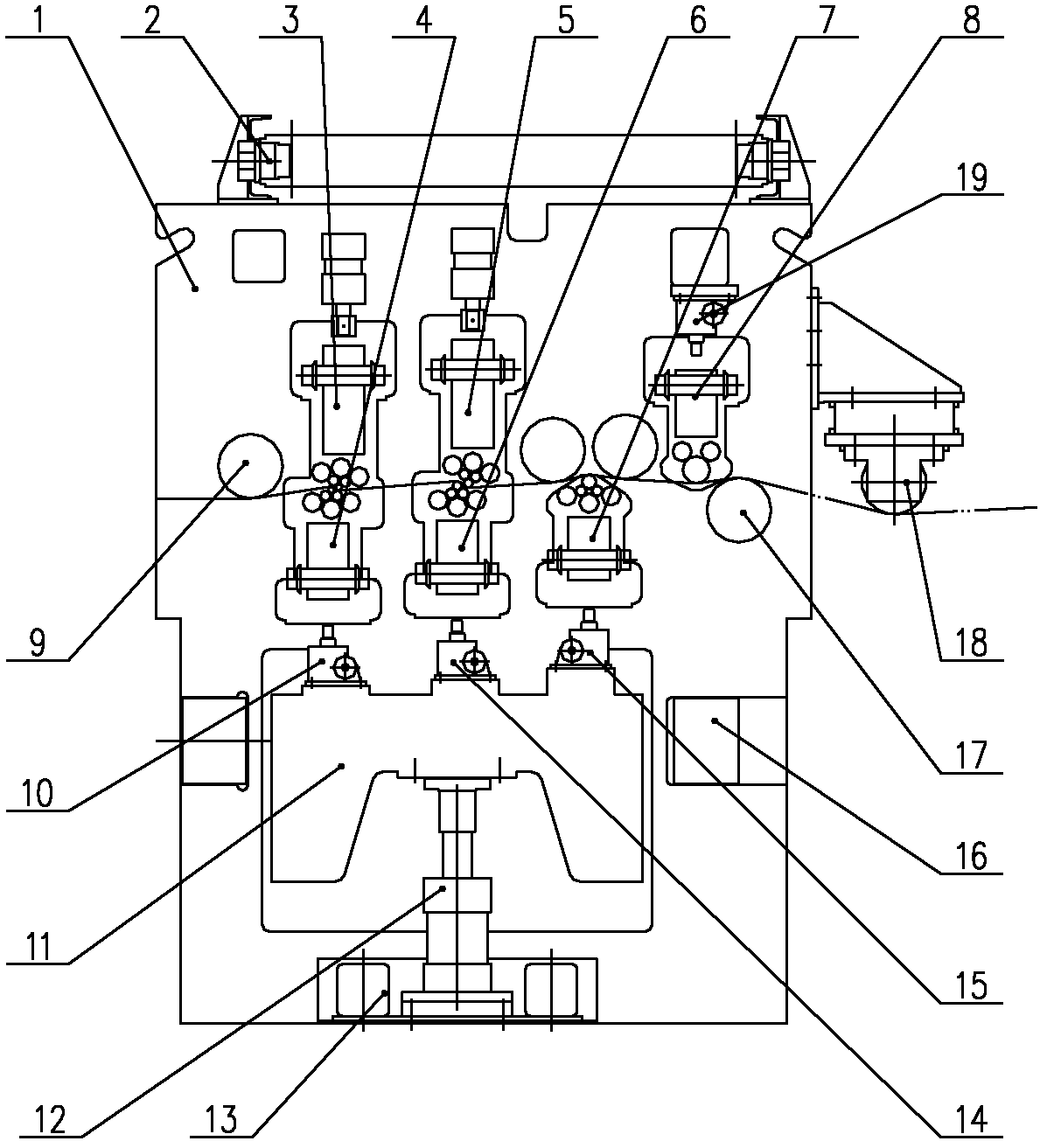

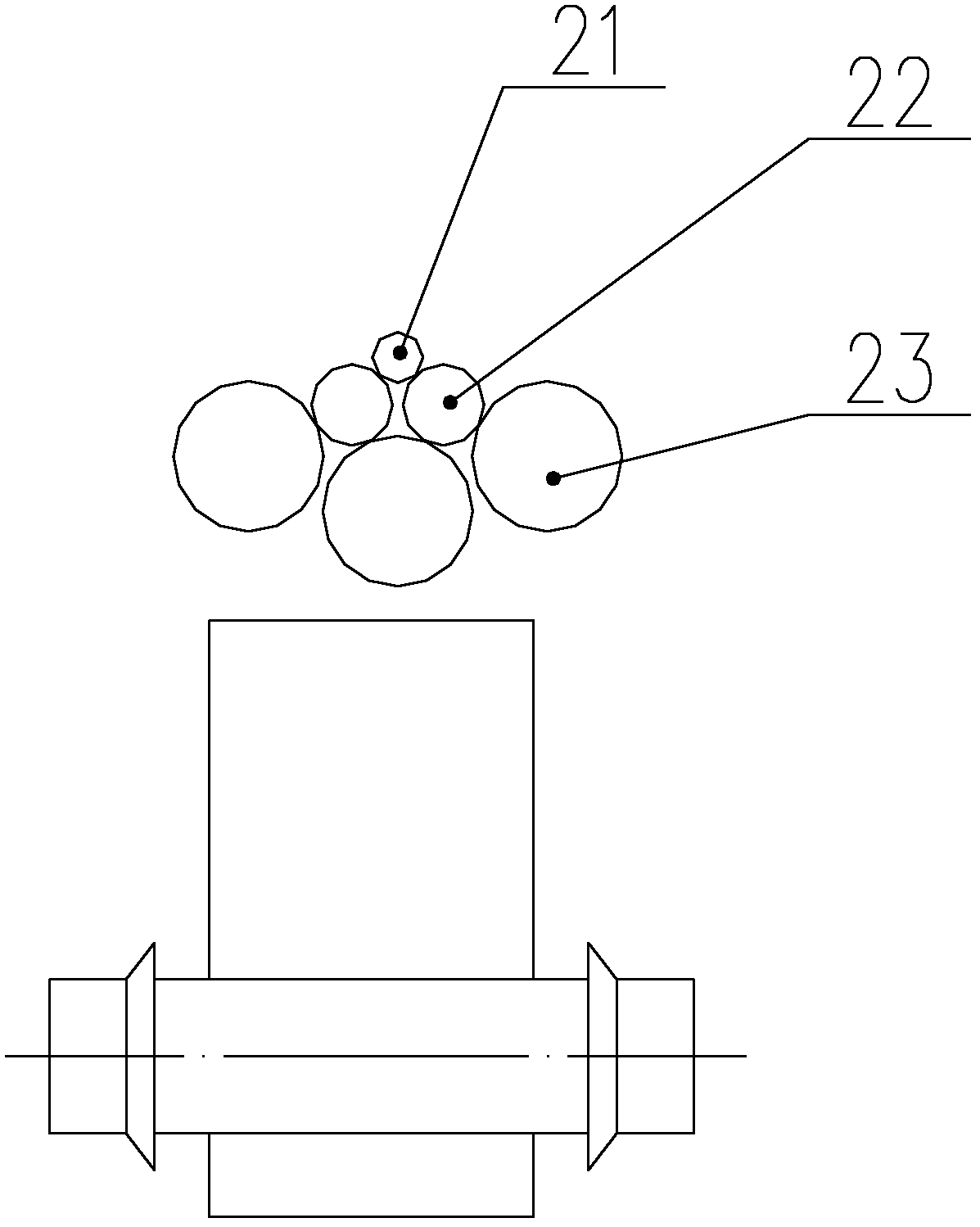

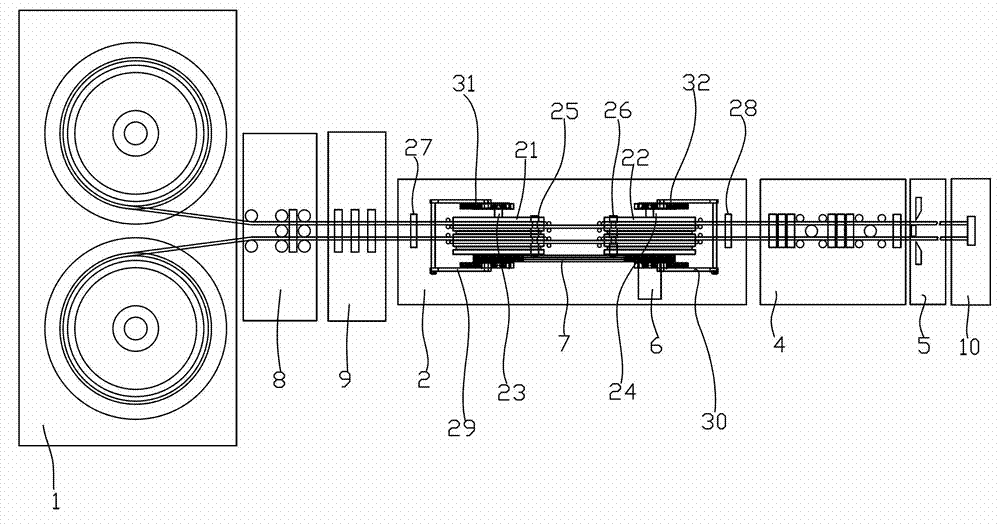

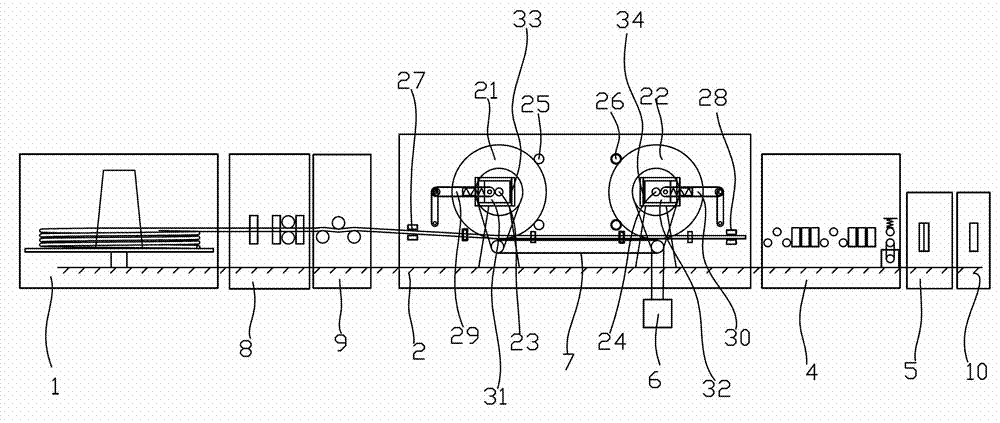

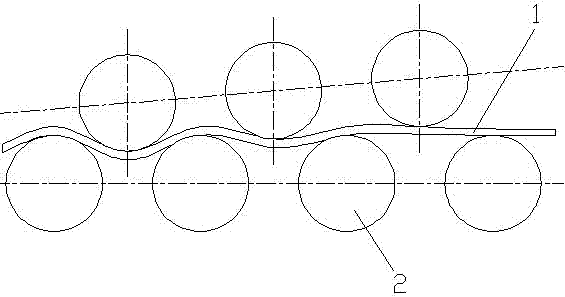

Strip stretch bending leveller

The invention discloses a strip stretch bending leveller. The leveller comprises a stand housing, two bending roll systems, two levelling roll systems, four roll system gap adjusting mechanisms, roll change devices, quick opening devices, guide rolls and a tension measuring roll, wherein six windows are arranged in the stand housing and are respectively correspondingly provided with a 1# upper bending roll set, a 1# lower bending roll set, a 2# upper bending roll set, a 2# lower bending roll set, a 1# levelling roll set and a 2# levelling roll set up and down from left to right; the machine is provided with standby roll sets with diameters different from the diameters of the two bending rolls; the roll change devices are arranged on the top of the stand housing; and connecting rods are arranged between the ends of the roll change devices and the ends of the two bending roll systems. The leveller has the following effects: the working rolls in the bending roll sets have different diameters and can be freely combined; the thickness range of the levelled strip is wider and the levelling effect is better; the roll sets have longer lives; only the working rolls in the bending roll sets have different diameters and the intermediate rolls, supporting rolls and shaft end supports are shared; and the leveller is equipped with the roll change trolleys, thus realizing quick roll change.

Owner:WISDRI ENG & RES INC LTD

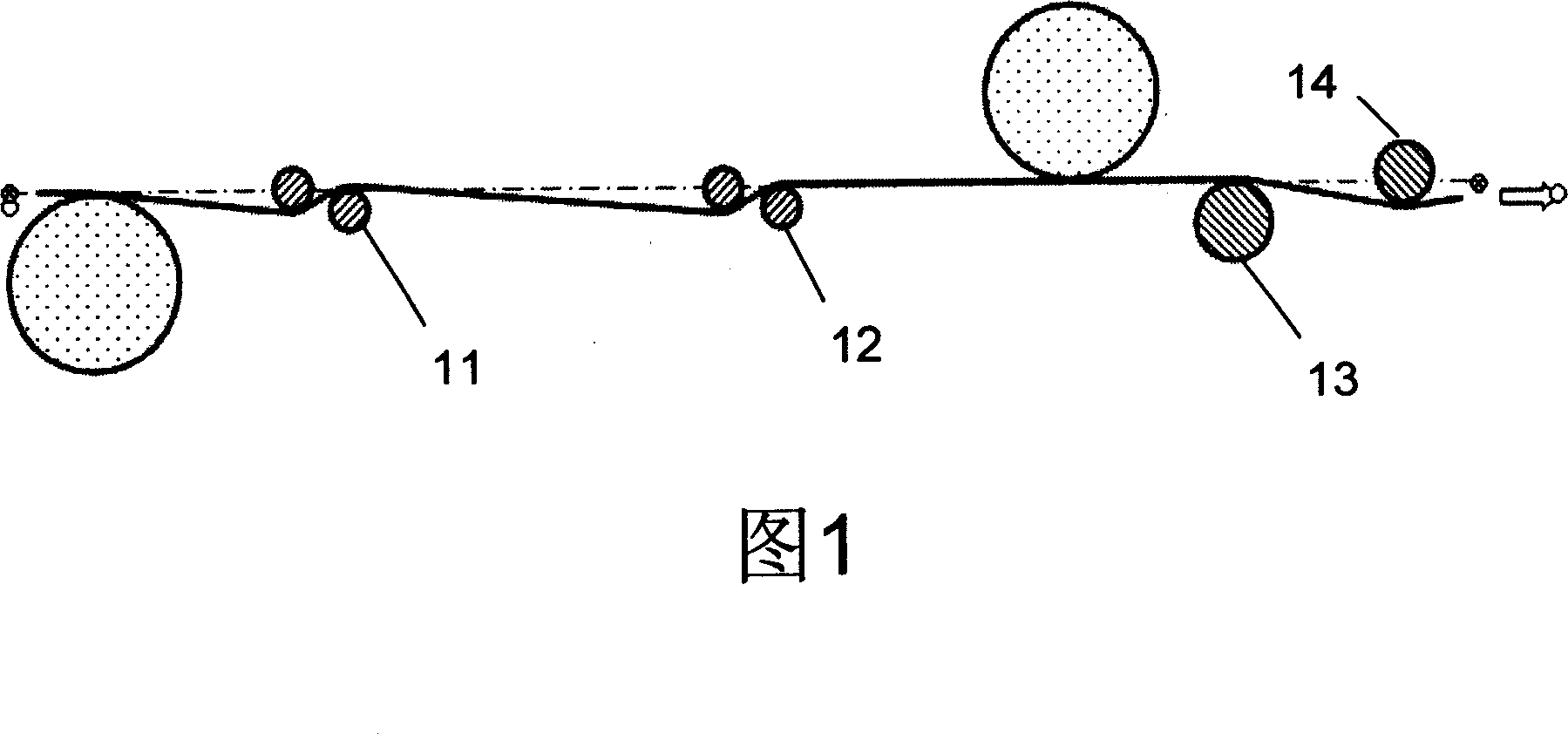

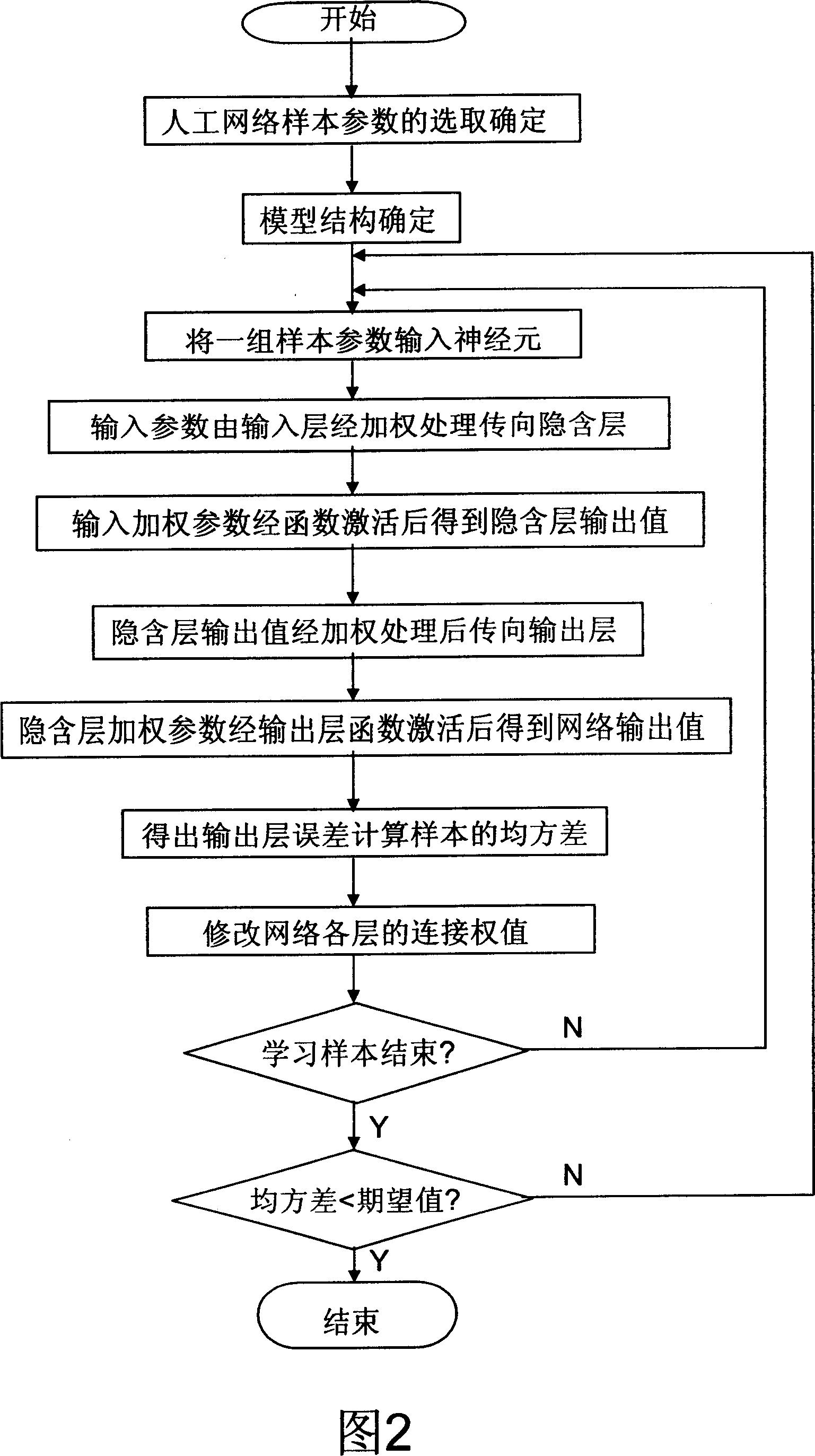

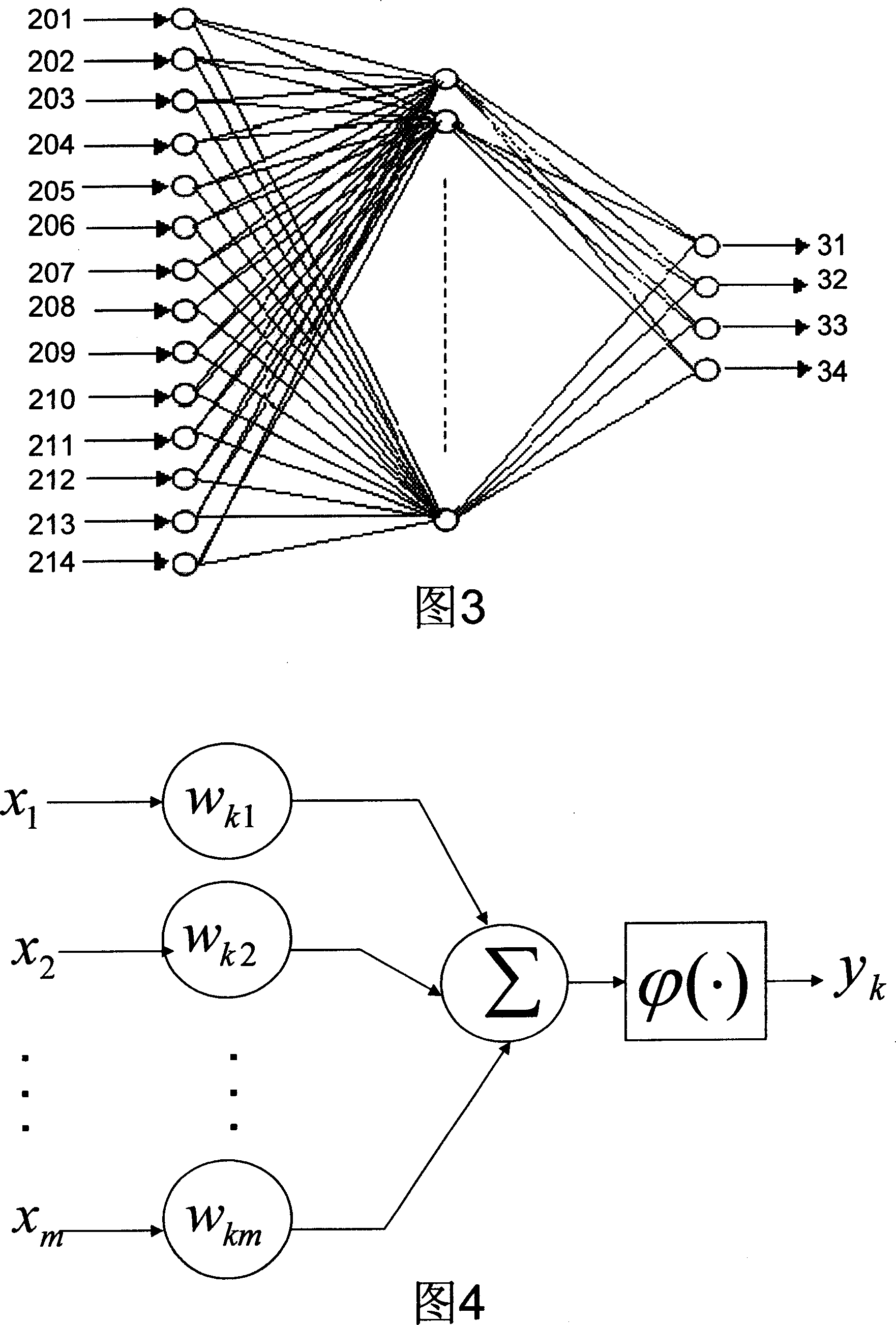

Processing parameter setting method of tension straightening machine set correct roller

ActiveCN101097581AGood straightening effectImprove straightening effectSpecial data processing applicationsBack propagation neuralNerve network

The invention discloses a kind of setting method for processing parameter of correct roller of withdrawal straightening stands based on spot measured data and analysis result, and the shape of steel sheet at the export of withdrawal straightening stands is good as standard, and it chooses the relative data with representation as the training sample parameter of artificial nerve network, and combines the characteristics of withdrawal straightening stands to choose the skilled and general reversing transmission nerve network. The good operation experience is converted into mathematical model to build the setting method for processing parameter under different steel rule and material. The invention can overcome the problems that the setting of processing parameter of traditional spot withdraw is short of theory, and the result is not ideal, and the invention fits for the production characteristics, it has good withdraw effect and satisfy the requirement for producing the production with high quality.

Owner:BAOSHAN IRON & STEEL CO LTD +1

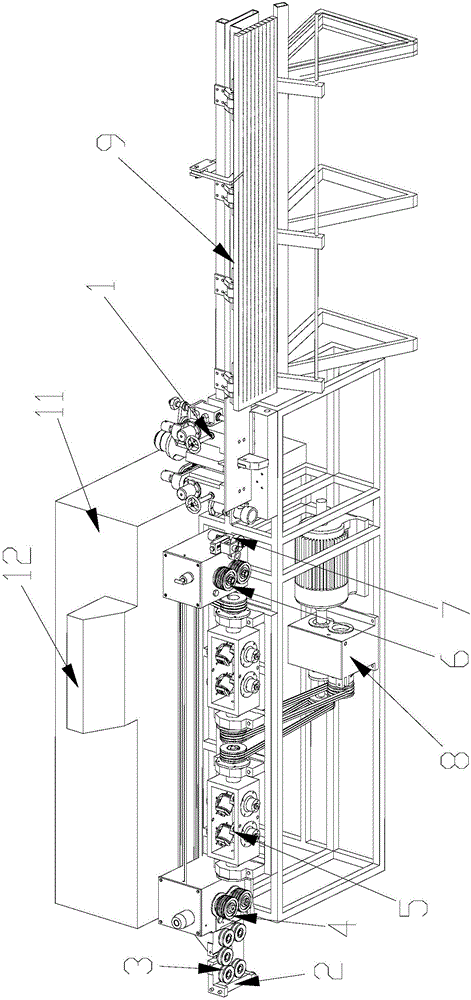

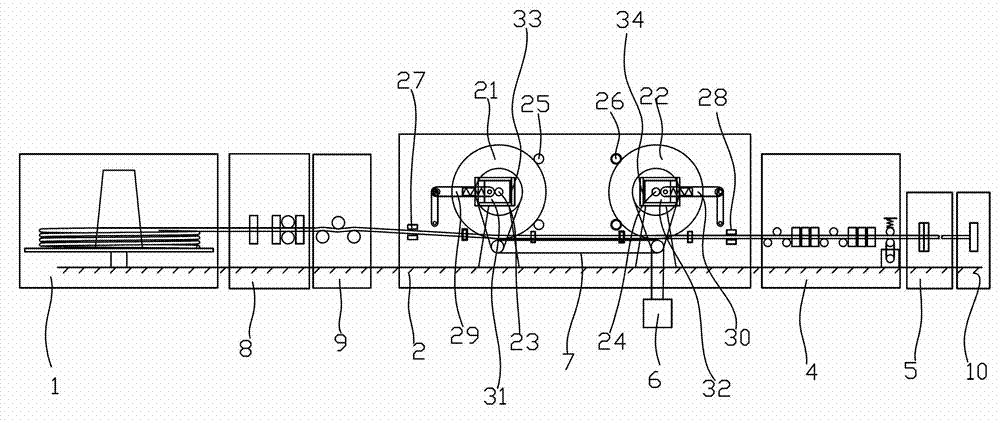

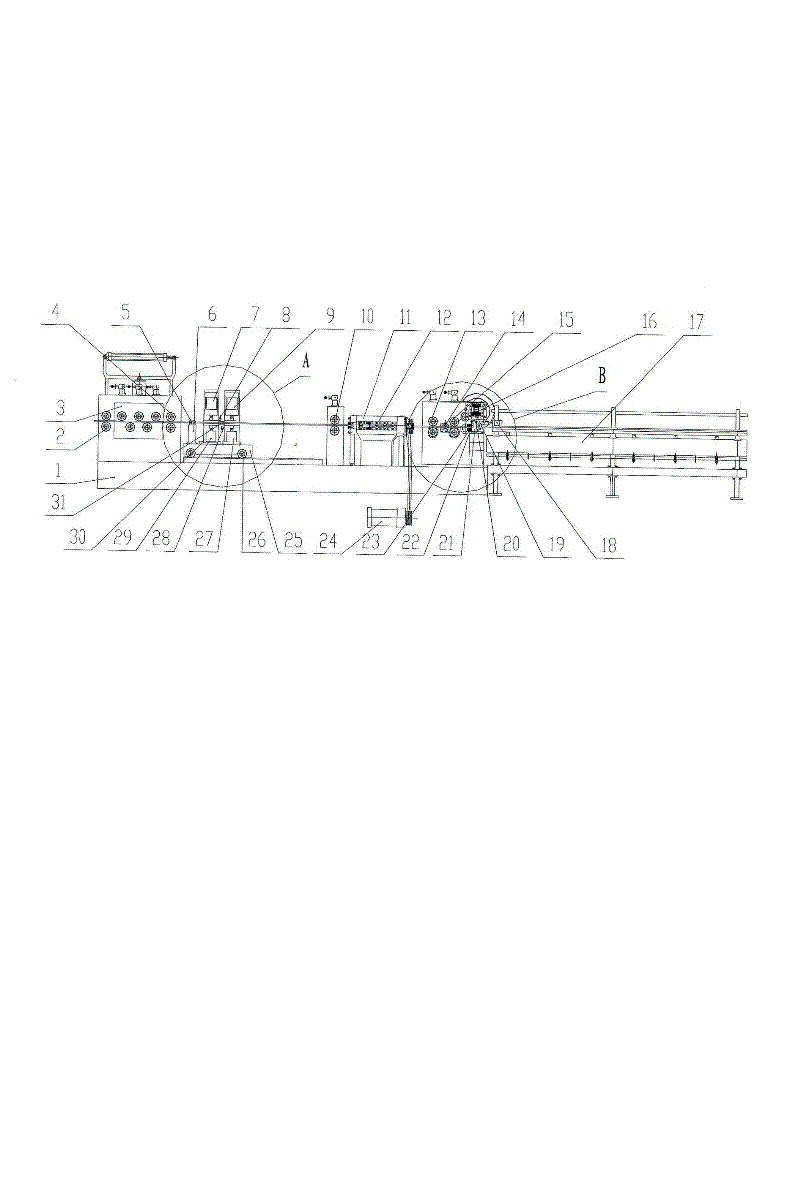

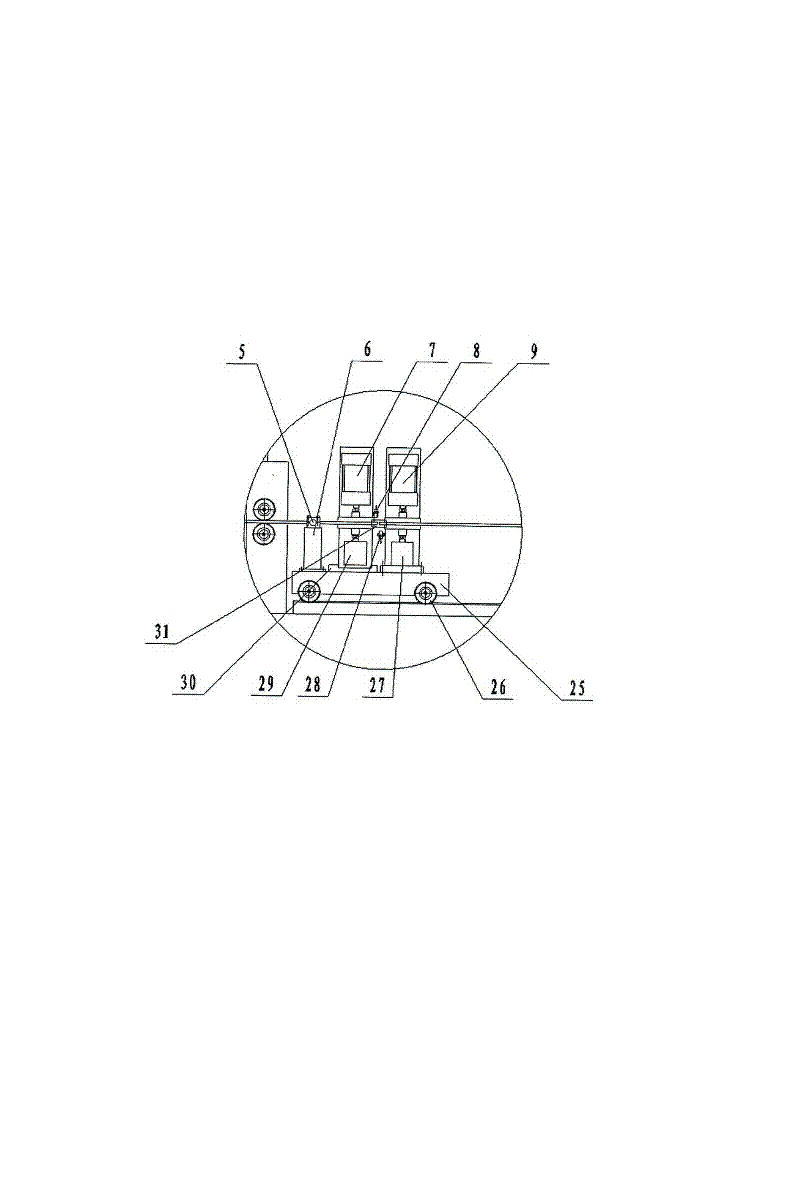

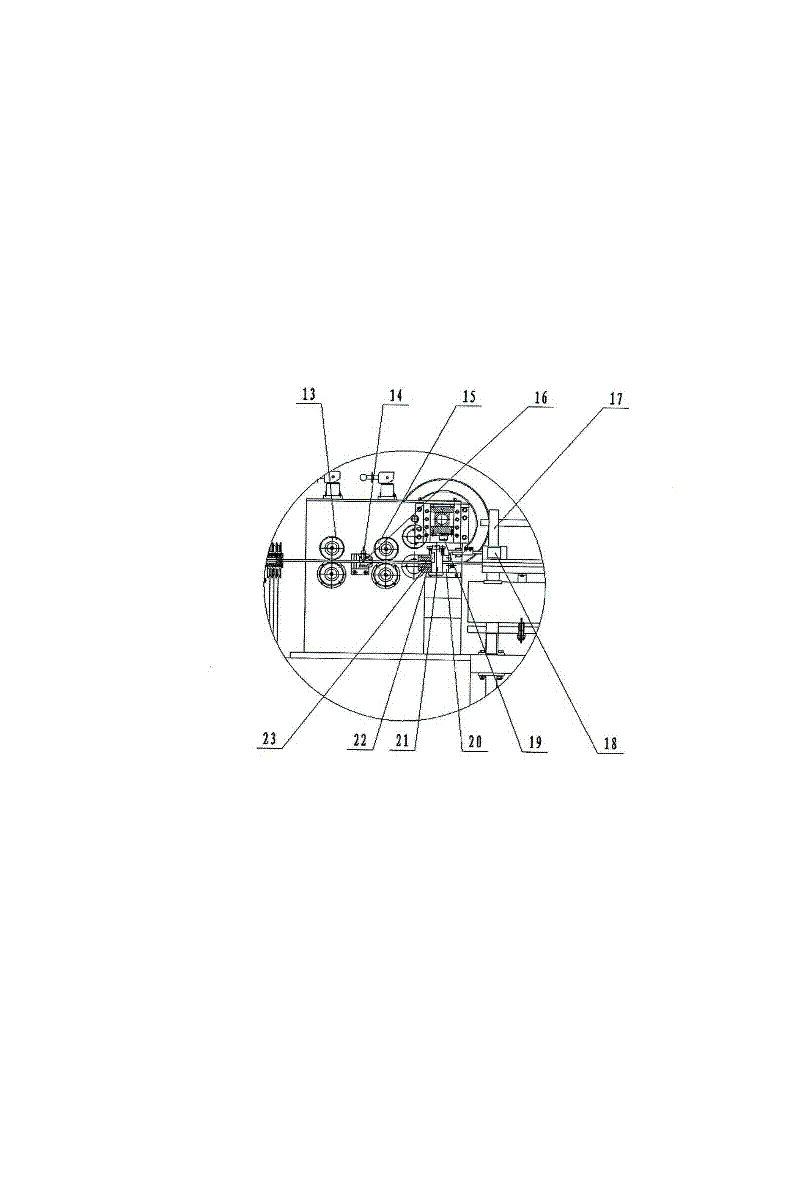

Adjustable numerically-controlled plate-type rebar machine

The invention relates to an adjustable numerically-controlled plate-type rebar machine. The adjustable numerically-controlled plate-type rebar machine comprises a machine frame and further comprises a guiding mechanism, a preset mechanism, a drawing device, a straightening mechanism, a drawing mechanism, a length measuring device, an adjustable two-machine-head shearing and bending machine and a stripping mechanism which are sequentially arranged on the machine frame. The guiding mechanism guides rebars, the preset mechanism presets the rebars, the drawing device draws the rebars, and the straightening mechanism conducts high-precision straightening through two reversely-arranged centrifugal straightening barrels; and the drawing mechanism continues to conduct drawing, the length measuring device measures the required length of the rebars, the adjustable two-machine-head shearing and bending machine conducts movable shearing and bending, and the stripping mechanism limits the rebars, so that the rebars cannot be rotated. According to the adjustable numerically-controlled plate-type rebar machine, the continuity of the rebar machining process is achieved, and bending deformation caused by the shearing resistance in the machining process is avoided; a straightener, a shearer and a bending machine are integrally combined; and operation is easy, and the machining efficiency is high.

Owner:PUTIAN TIANMA MACHINERY MFG

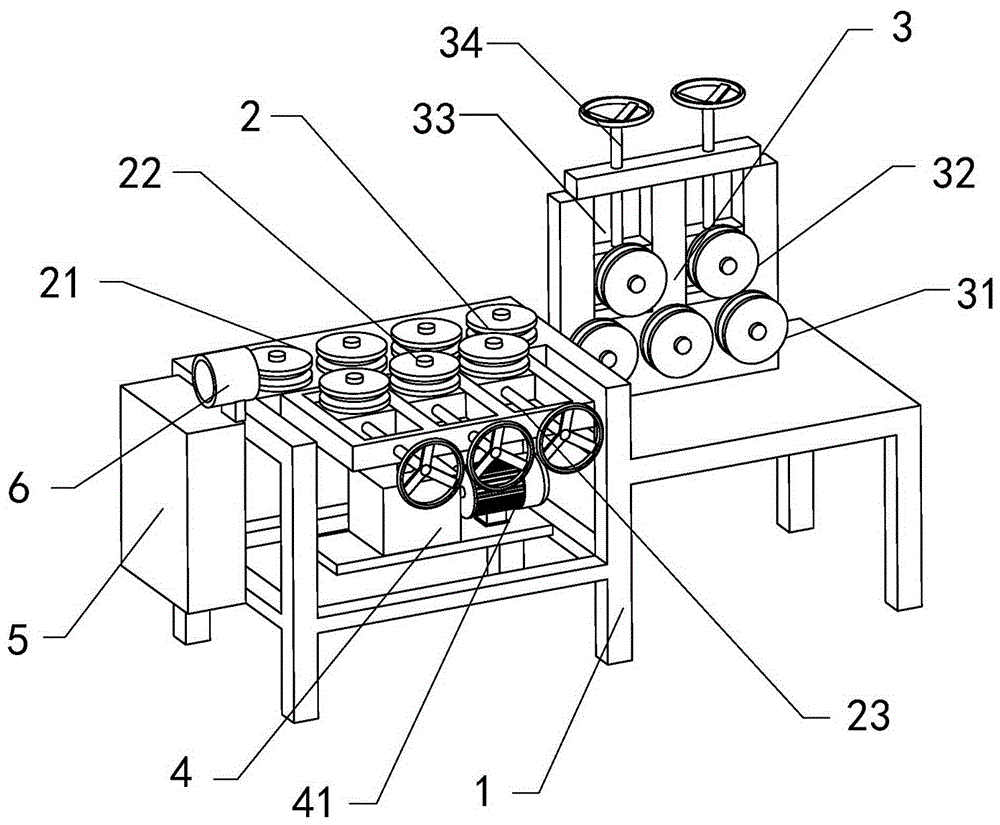

Steel tube straightening machine

The invention relates to steel tube manufacturing equipment, and particularly relates to a steel tube straightening machine. The steel tube straightening machine comprises a rack, wherein a transverse straightening area and a longitudinal straightening area which are connected end to end as well as a driving device which is used for driving and a control box which is used for controlling are arranged on the rack; the transverse straightening area comprises a plurality of transverse fixed wheels which are horizontally arranged, a plurality of transverse sliding wheels and a plurality of transverse sliding ways which are used for the transverse sliding wheels to slide, and the spacing between the transverse sliding wheels and the transverse fixed wheels is adjusted by sliding; the longitudinal straightening area comprises a plurality of longitudinal fixed wheels which are vertically installed, a plurality of longitudinal sliding wheels and a plurality of longitudinal sliding ways which are used for the longitudinal sliding wheels to slide, and the spacing between the longitudinal sliding wheels and the longitudinal fixed wheels is adjusted by sliding. The steel tube straightening machine has the advantages of simple structure, high straightening speed and good straightening effect.

Owner:湖州水晶宫管业科技有限公司

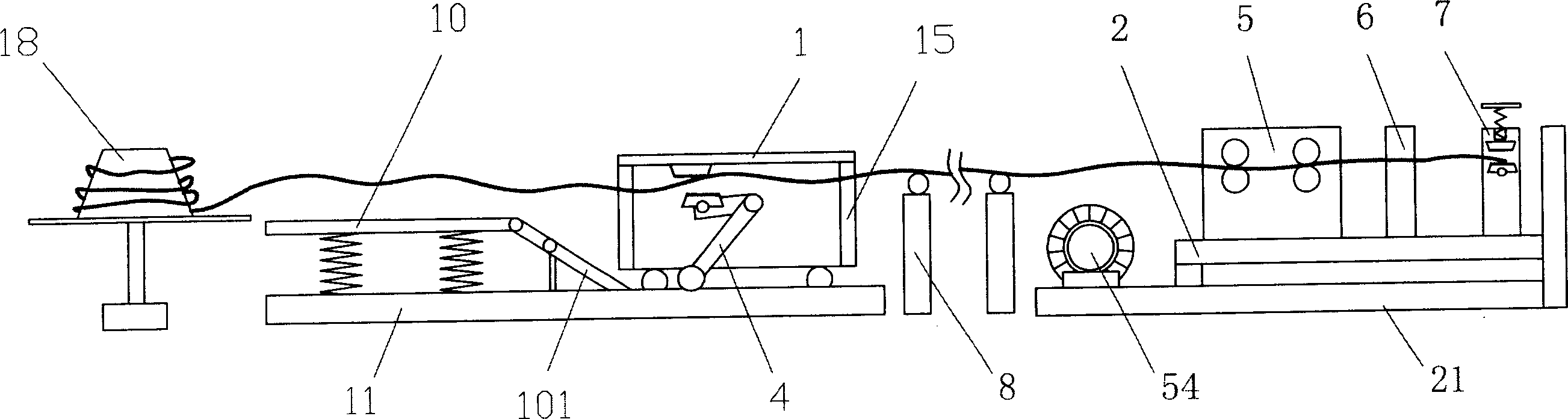

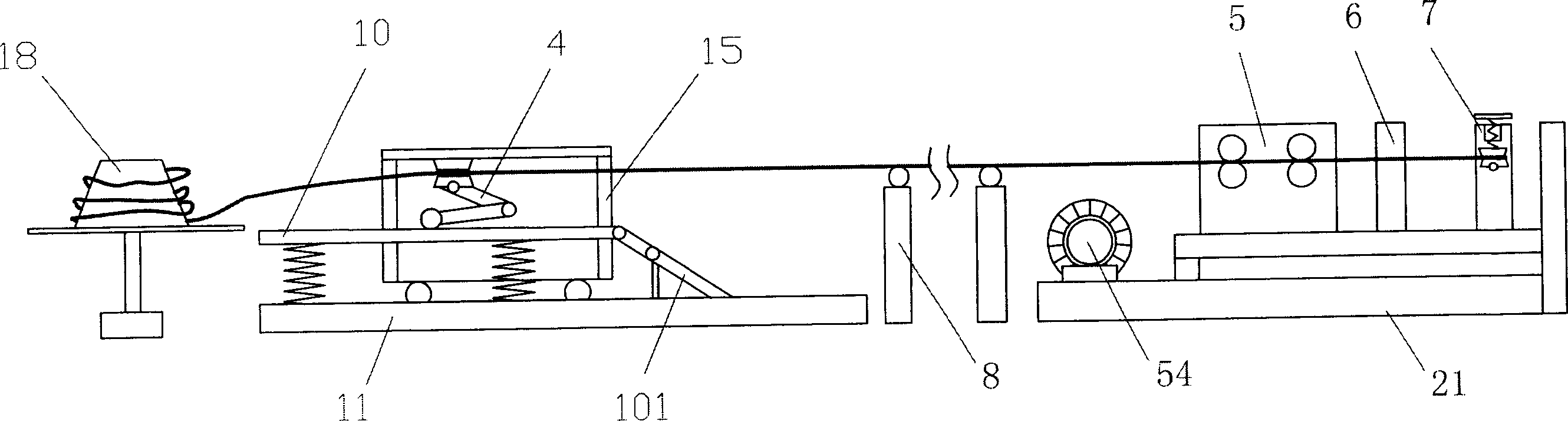

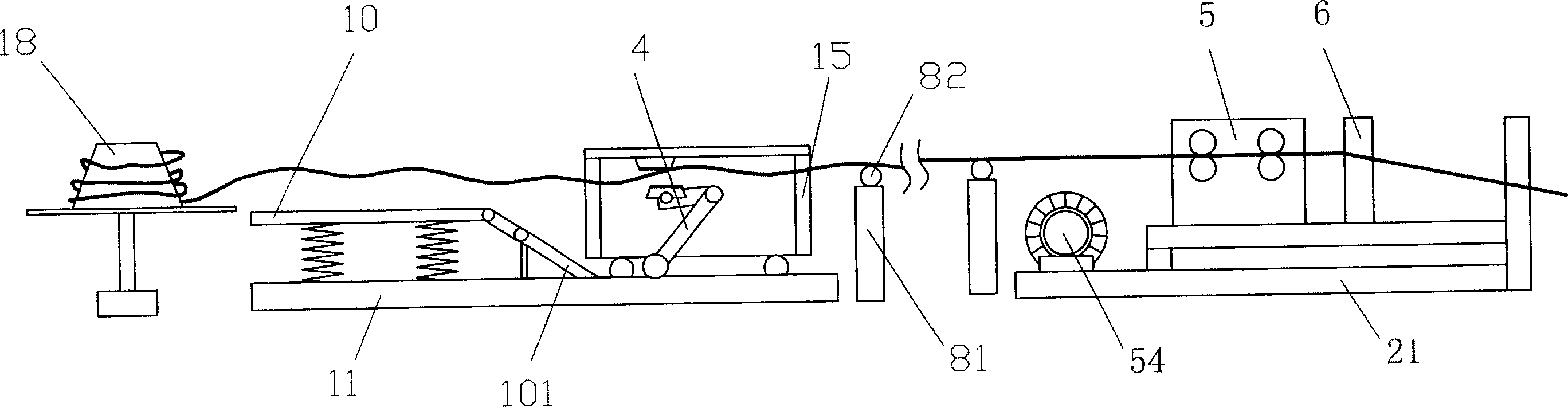

Concrete-bar straightening cutting machine

The invention discloses a steel-bar drawing-in and cutting machine. This device comprises a device for holding the disc-form steel bar, to-and-fro automatic clamping and stretching mechanism, feeding, cutting and locking devices. The to-and-fro mechanism comprises a base which is fixed on the ground and is fitted with a guiding device having and is also fitted with guide slot which has a moving frame driven by power device. The frame comprises an upper toothed plate fitted on upper part of the frame and a rocker which has a crank lever whose middle part in hinged oh the frame and at the two ends of the crank lever are respective movably fitted with a lower toothed plate matched with the upper toothed plate and a guide wheel moving along the guide device. Advantages: it needs no sectional cutting so as to fully utilize raw material and it has better drawing-in effect.

Owner:冯广建

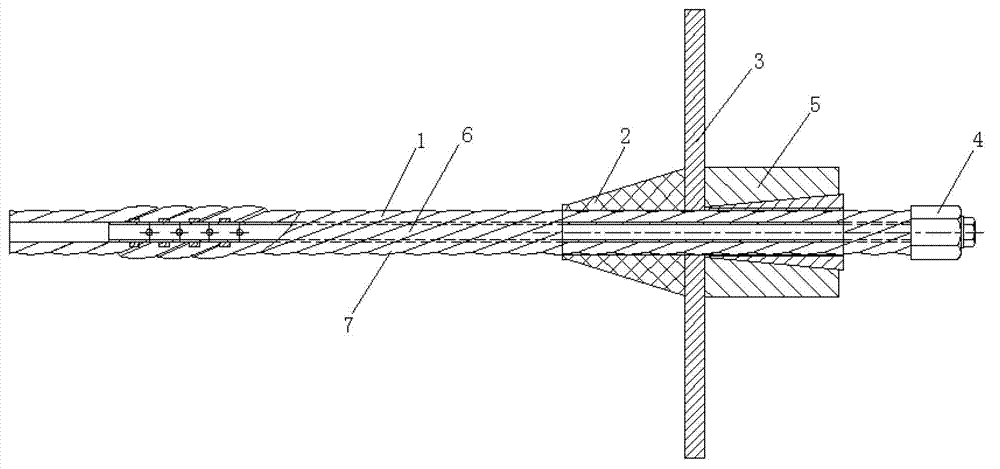

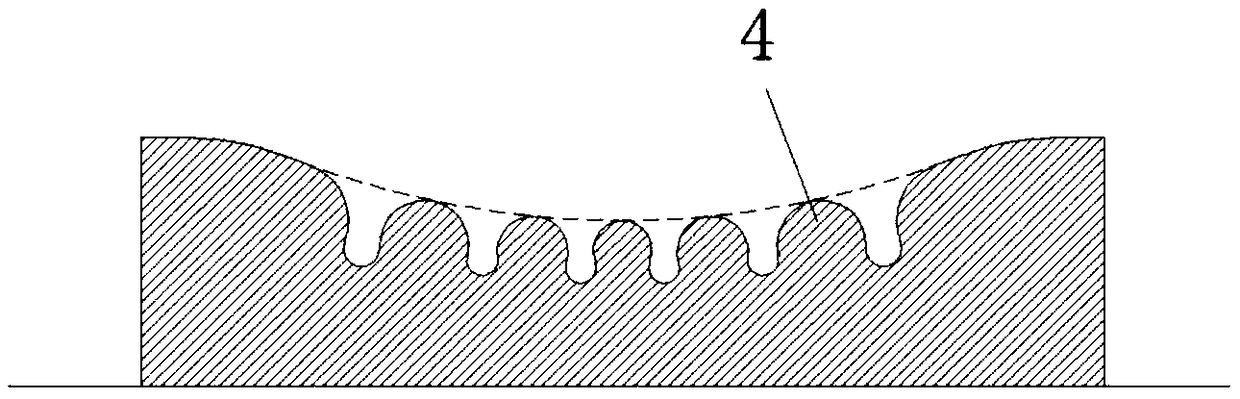

Pre-stress spiral rib hollow grouting anchor rope

The invention discloses a pre-stress spiral rib hollow grouting anchor rope which comprises an anchor rope body which stretches into a rock-soil drilling hole; the anchor rope body is formed by weaving and twisting a plurality of high-strength spiral rib pres-stress steel wires; a rope tool is fixedly connected with the rear end of the anchor rope body; a grouting core tube penetrates through the anchor rope body and the anchor tool; a support disc is sleeved on the anchor tool; a locking nut is screwed on the anchor tool at the rear end of the support disc; the locking nut props against the rear end face of the support disc; and a slurry stopping plug which aligns with the rock-soil drilling hole is sleeved at the rear end of the anchor rope body. According to the grouting anchor rope, by increasing the grouting pressure, while being filled into the drilling hole so as to realize the overall-length anchoring, slurry spreads into the rock fractures around the drilling hole at the same time, so that the bonding and curing functions to the surrounding rock are achieved, and the deep hole anchoring grouting is realized.

Owner:淮南市顺辉锚固有限公司

Steel bar straightening machine

PendingCN109365684AEliminate internal stressImprove straightening effectMetal working apparatusSteel barMultiple point

The invention discloses a steel bar straightening machine. The steel bar straightening machine straightening cylinder and a plurality of inclined rolling wheels which are arranged in the straighteningcylinder and are used for eliminating internal stress of a steel bar, the multiple inclined rolling wheels are arranged on the two radial sides of the steel bar in a staggered mode, the axis of the inclined rolling wheels is arranged at an angle with the axis of the straightening cylinder, the outer peripheral surfaces of the inclined rolling wheels are provided with hemispherical touch protrusions which protrude outwards in the radial direction of the inclined rolling wheels, the axial middle of the inclined rolling wheels is gradually increased towards the radius of the contact protrusionsat the two ends of the inclined rolling wheels, the contact protrusions distributed on the outer peripheral surfaces of the inclined rolling wheels are externally cut into inwards-concave annular cutting surfaces, and the annular sections are arranged coaxial with the inclined rolling wheels. According to the steel bar straightening machine, the internal stress of the steel bar is eliminated through interaction of multiple points with different friction force and torque; and by correction of the multiple inclined rolling wheels located on the two sides of the steel bar, the stress in the steelbar reaches a stress balance state, and the straightening effect of the steel bar is improved.

Owner:重庆宏扬电力器材有限责任公司

Section steel straightening device and method

The invention discloses a section steel straightening device, which comprises a straightening roll system, wherein the straightening roll system is arranged on a body; an output end of the straightening roll system is also provided with a rolling and straightening roll system; the rolling and straightening roll system comprises at least one pair of upper and lower rolling and straightening rolls and at least one pair of left and right rolling and straightening rolls; the upper and lower rolling and straightening rolls are symmetrically arranged on the upper and lower sides of a pass steel wire and a roll gap I for passing through section steel is formed between the two rolls; and the left and right rolling and straightening rolls are symmetrically arranged on the left and right sides of the pass steel wire and a roll gap II for passing through the section steel is formed between the two rolls. According to the section steel straightening device and a section steel straightening method, lateral bending of straightened section steel can be effectively improved, and the length of a straightening blind zone of a main bend of the section steel is reduced, so that the section size of the section steel is better, the flatness is higher, the residual stress is smaller, and particularly height difference existing in rail level of the straightening blind zone and a straightening zone can be effectively reduced and the yield of a steel rail is increased when the steel rail is straightened.

Owner:CISDI ENG CO LTD

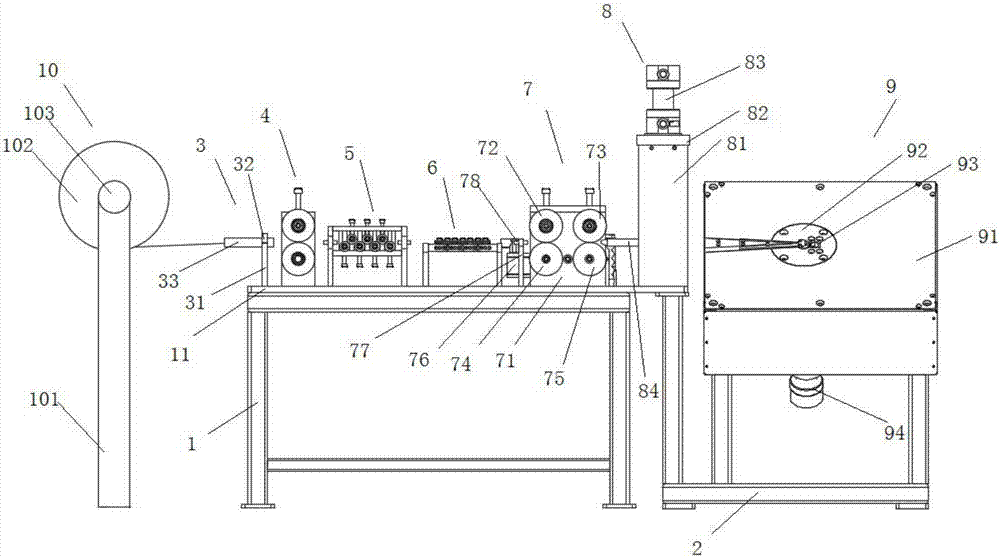

Rebar wire straightening and tailoring mechanism

The invention relates to a rebar wire straightening and tailoring mechanism, which comprises an emptying device, an affecting wheel set, a straightening device and a tailoring device which are sequentially connected with one another, wherein the affecting wheel set comprises at least two affecting wheels, and a rebar wire is sequentially winded on the affecting wheels; the rebar wire straightening and tailoring mechanism also comprises a power device used for providing power for the affecting wheel set; and the linear speed of the affecting wheel positioned in the rear along the conveying direction of the rebar wire in the affecting wheel set is greater than that of the affecting wheel positioned in front. According to the rebar wire straightening and tailoring mechanism, the technical characteristic that the linear speed of the affecting wheel which is passed through first by the rebar wire is less than that of the affecting wheel which is passed through later by the rebar wire is utilized, so that the affecting wheel set can continuously take drawing and straightening work on wires winding two affecting wheels such as rebar and the like, and the efficiency is high; at the same time, the mechanism causes small damage to the wire, does not destroy an oxidized protective layer on the surface of the wire, causes little loss on the wire and has good economic benefits.

Owner:冯广建

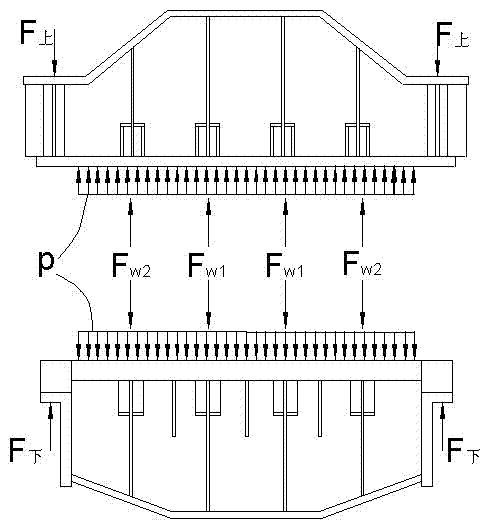

Roll bending compensation method for wide and thick metal plates straightening machine

The invention relates to the field of controlling straightened plate shape of metal plates, and particularly relates to a method for controlling the straightened roll gap shape of multiple rolls of the wide and thick metal plates. A roll bending compensation method for wide and thick metal plates straightening machine comprises the following steps of: firstly determining a deflection model of a beam of the straightening machine, then collecting parameters of the straightened metal plates, calculating to obtain a deflection of an initial upper beam and a deflection of an initial lower beam, and increasing corresponding compensation in a bending roll model for compensation; acquiring oil pressure through an oil pressure sensor, calculating to obtain measured values of the parameters, calculating differential values of the parameters and calculating to obtain a modified value of the deflection of the upper beam and a modified value of the deflection of the lower beam respectively by combining the parameters of the upper beam and the lower beam, and increasing the corresponding compensation in the bending roll model for compensation. According to the invention, corresponding modification control is increased in a control system of the straightening machine, the change of the on-load roll gap of the straightening machine is determined, so that the roll gap control of the straightening machine is not affected by the change of the state of the supplied materials, so that the index of the straightened plate shape is guaranteed, and the straightening effect is effectively improved.

Owner:BAOSHAN IRON & STEEL CO LTD

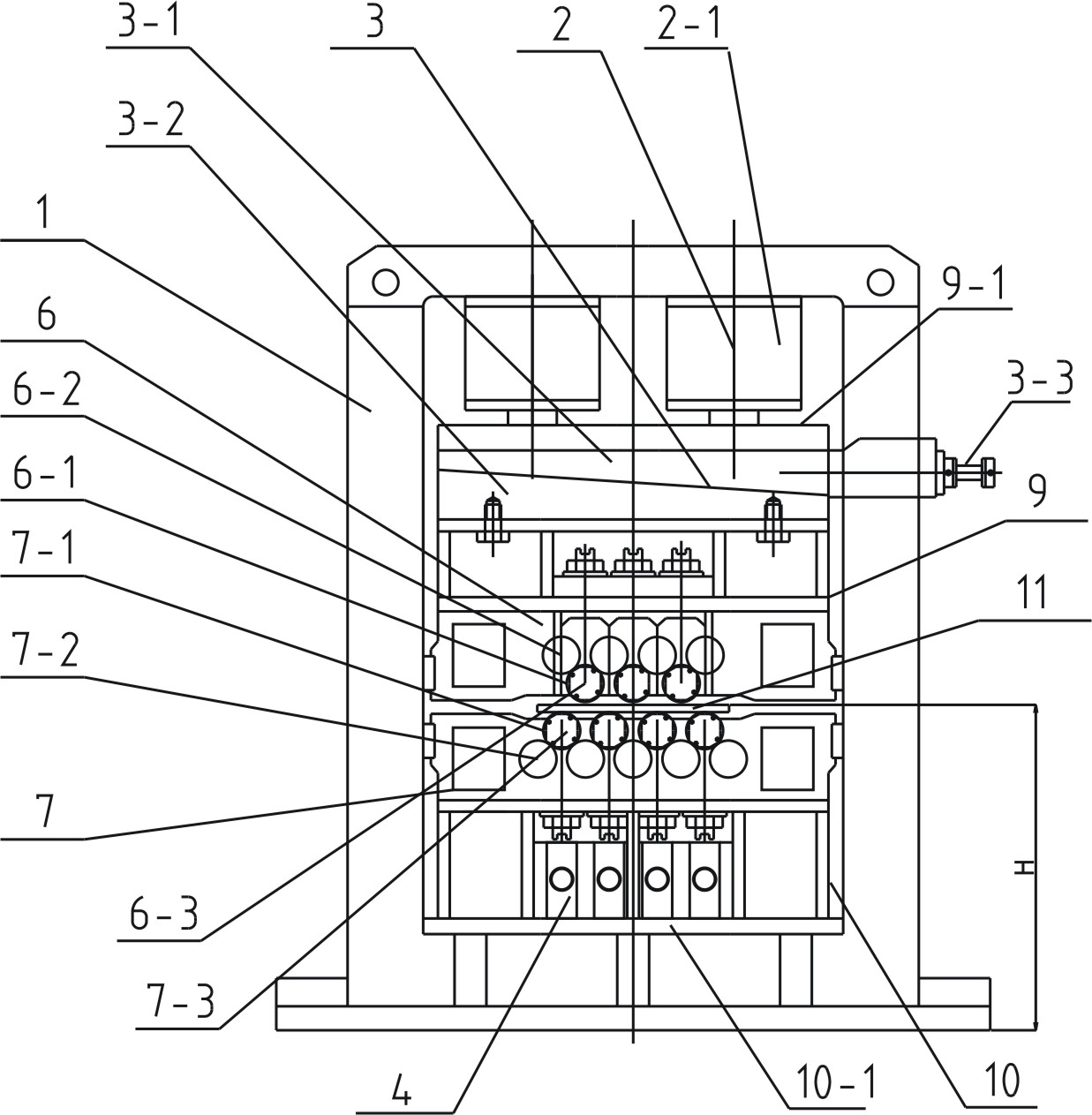

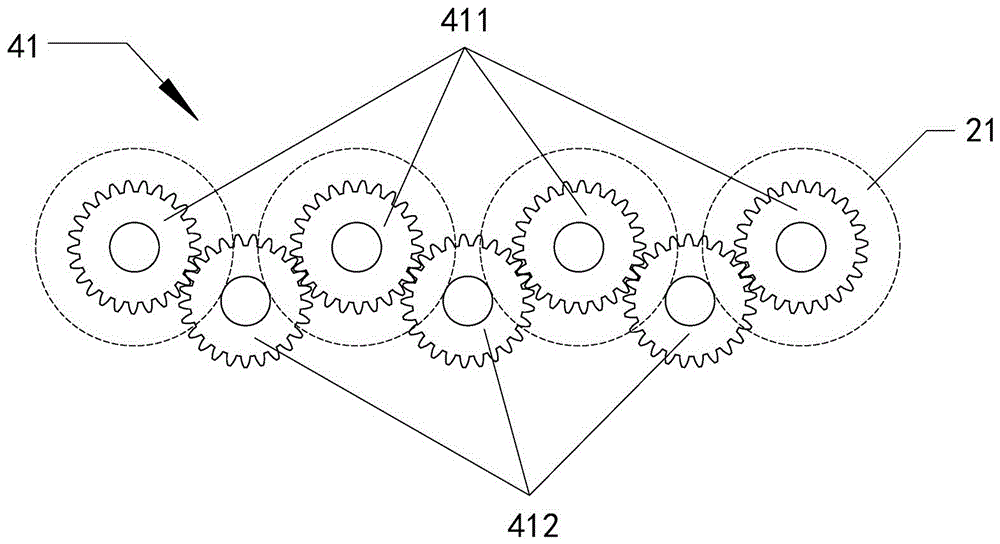

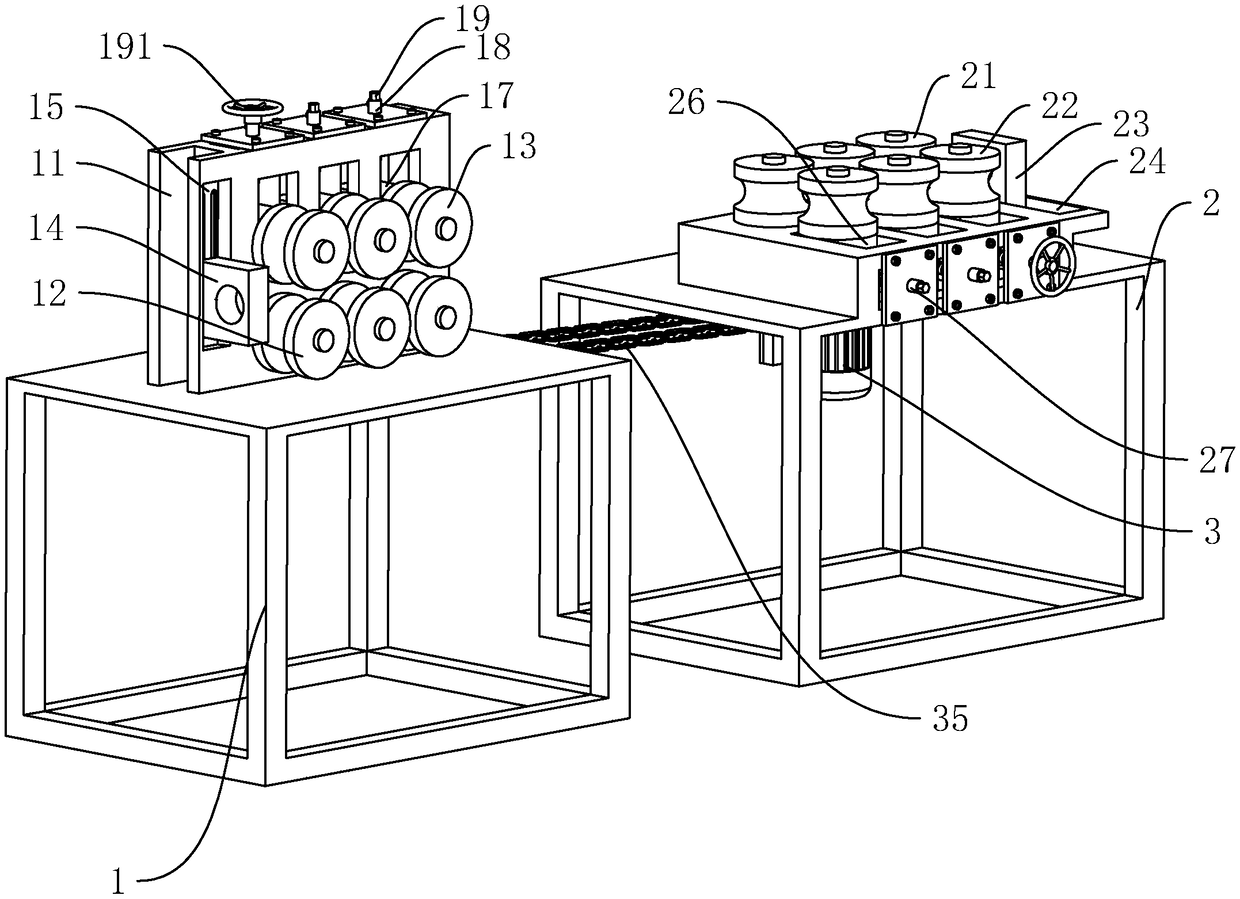

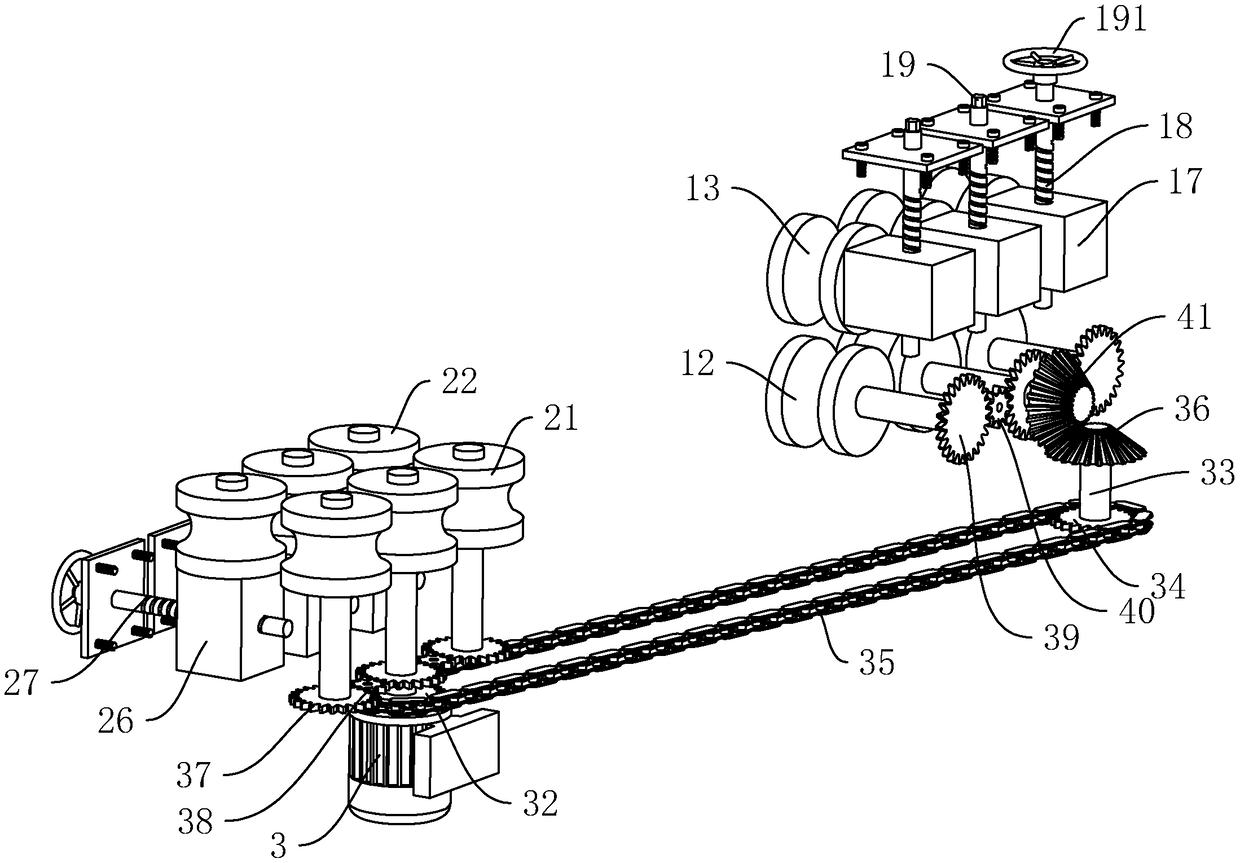

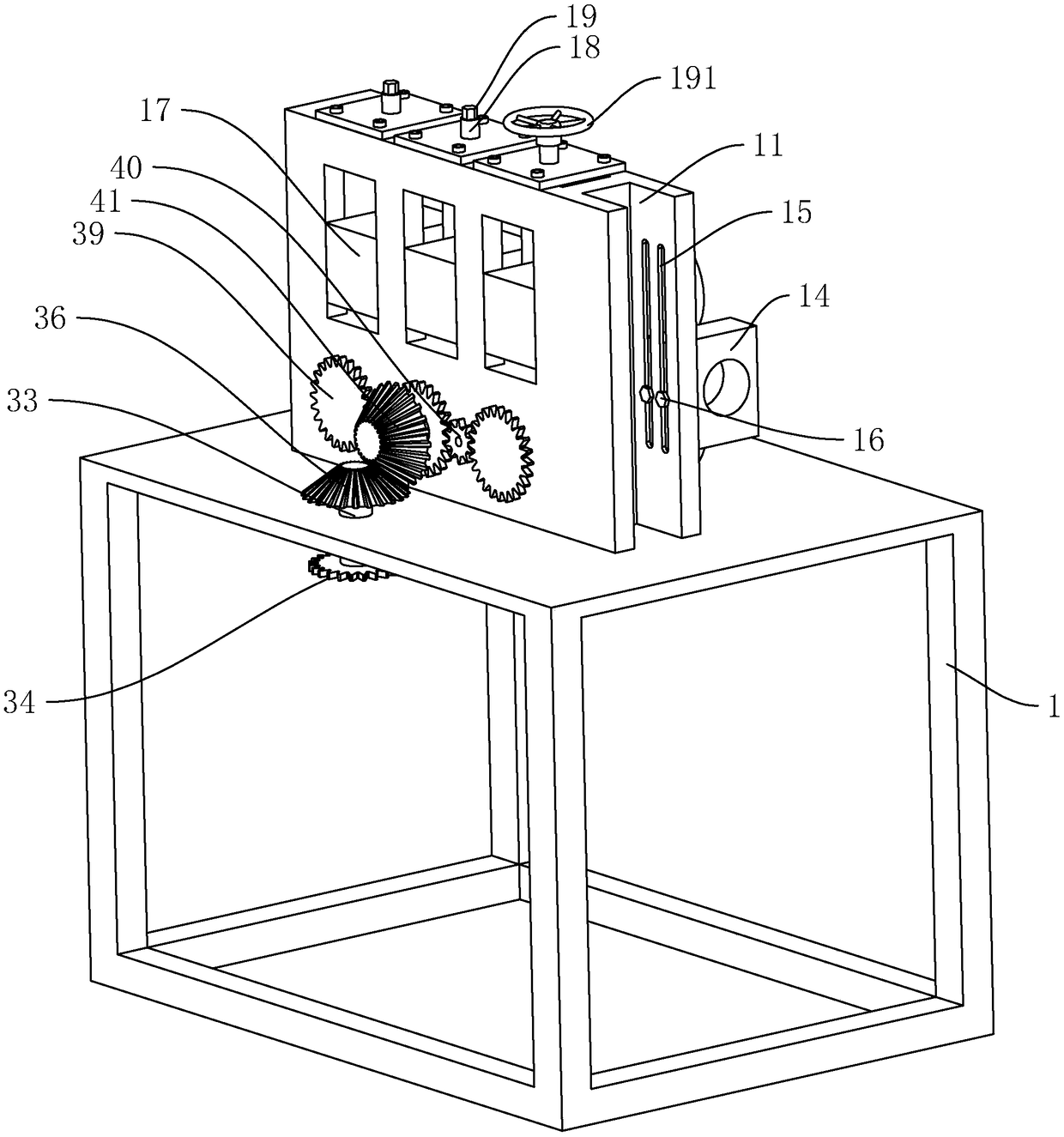

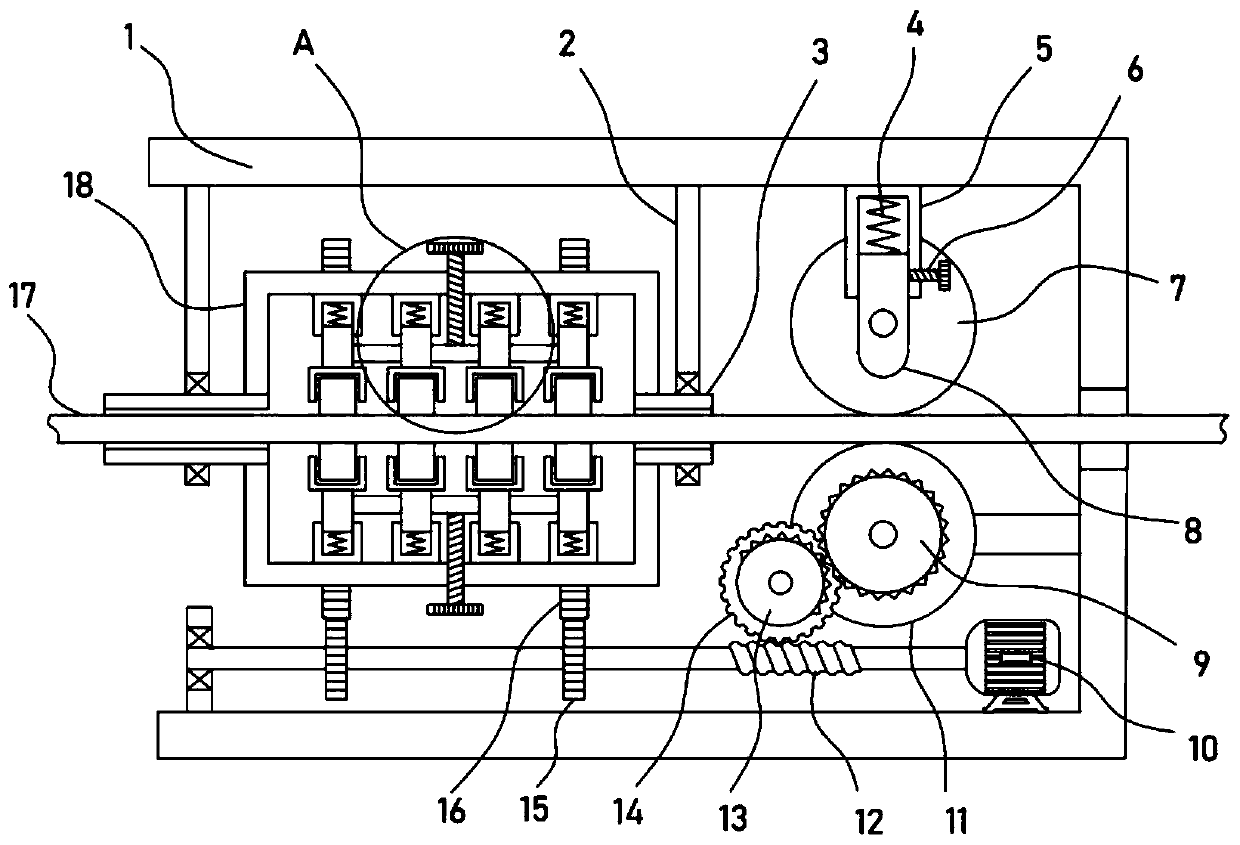

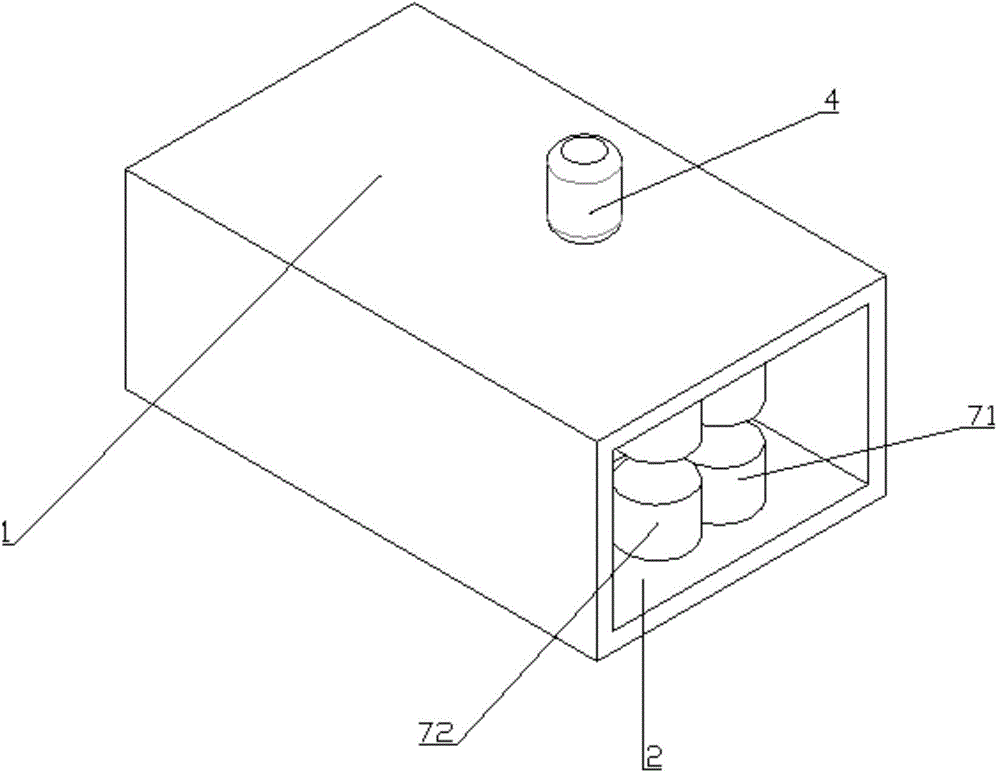

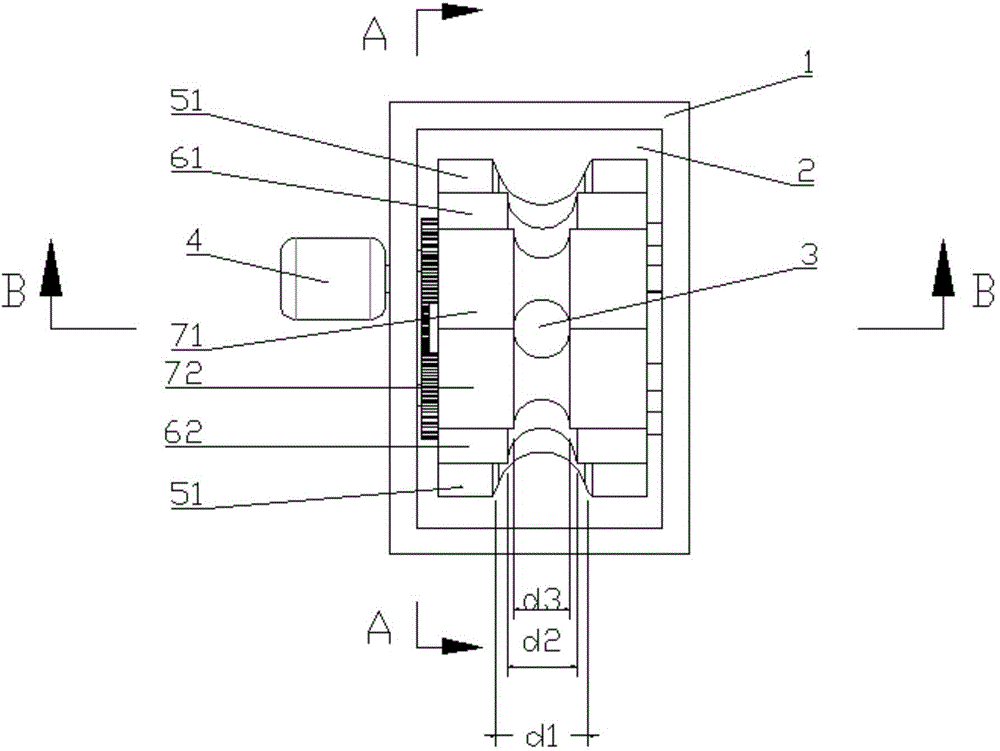

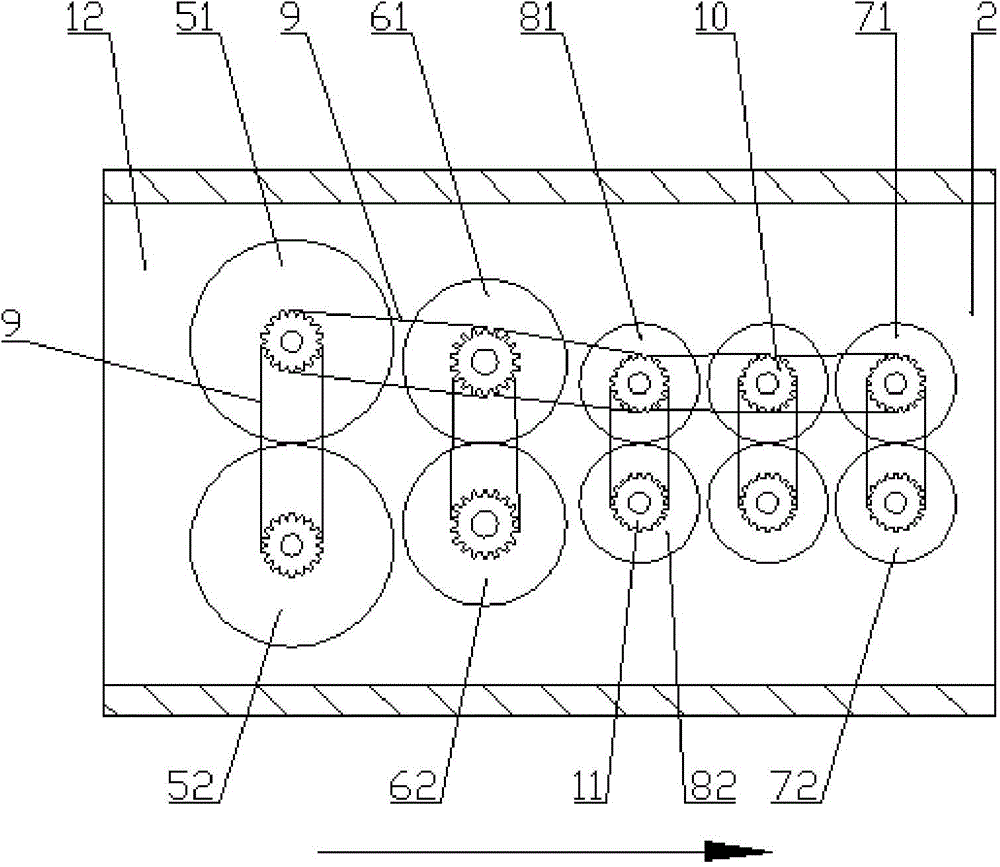

Two-way straightening machine driven by single power source

InactiveCN108906918APrevent abnormal slidingImprove operational coordinationGearingAlternating currentGear transmission

The invention discloses a two-way straightening machine driven by a single power source and relates to steel processing equipment, aiming at solving the problem of inadequate straightening accuracy. The key point of the technical scheme includes: the two-way straightening machine driven by the single power source includes a vertical straightening mechanism, a horizontal straightening mechanism anda power mechanism. The vertical straightening mechanism includes a first workbench, a vertical mounting plate and a plurality of vertical power wheels. The vertical mounting plate corresponds to eachvertical power wheel which slips longitudinally and is connected with a vertical pressure wheel in rotation. The horizontal straightening mechanism includes a second workbench and a plurality of horizontal power wheels. The surface of the second workbench corresponds to each horizontal power wheel which slips horizontally and is connected with a horizontal pressure wheel in rotation. The power mechanism includes an alternating current motor, a horizontal gear transmission unit and a vertical gear transmission unit. The two-way straightening machine driven by the single power source effectively improves the straightening accuracy of steel, while ensuring the coordination of the two straightening mechanisms.

Owner:JIAXING JIECHENG MACHINERY

Steel wire straightener

The invention relates to metal straightening equipment, in particular to a steel wire straightener. The steel wire straightener comprises a base. An upper pressing frame and a lower bracket which are parallel to each other are arranged on the base, and a straightening wheel and a straightening block are arranged at the opposite position of the upper pressing frame and the lower bracket. When the steel wire straightener is used, all-steel cords pass through the straightening wheel and the straightening block of the lower bracket and the upper pressing frame through wire-passing wheels, all-steel cord straightening effect is achieved through adjustment of interval and displacement of the wheels, the straightening effect is good, whole structure is simple, and adjustment and replacement of components are easy.

Owner:ZHANGJIAGANG JINCAIYANG MACHINERY

Wire bending device with straightening function

The present invention proposes a wire bending device with straightening function, which includes a first frame and a second frame, the first frame is arranged at the left end of the second frame, and the surface of the first frame is fixed There is a working platform board, and the working platform board is equipped with a wire feeding assembly, a straightening assembly, a straightening assembly, a straightening assembly, a straightening assembly, a straightening assembly and a wire discharge positioning assembly from left to right. Assemblies, a wire bending assembly is fixed at the second frame, and a wire reel is also provided on the left side of the first frame. This kind of wire bending device with straightening function is beneficial to increase production capacity through automatic straightening and bending, and the bending component with high automation integration can improve bending efficiency and significantly improve product quality.

Owner:嘉善中正电子科技有限公司

Pipe straightening machine

The invention discloses a pipe straightening machine, and aims to provide a pipe straightening machine which can improve the straightening effect and prolong the service life of an abutting piece. According to the technical scheme, the pipe straightening machine is characterized by comprising a placement table; a straightening machine support, placement supports where a raw material central spindle pipe to be straightened is placed and abutting mechanisms used for abutting against grooves in the ends of the raw material central spindle pipe are fixedly arranged on the placement table; an abutting part capable of abutting against the raw material central spindle pipe placed on the placement supports is arranged on the straightening machine support; each abutting mechanism comprises an abutting base and an abutting head; the abutting bases are transversely connected with the placement supports in a sliding mode, and the abutting heads are connected with the abutting bases in a rotating mode; second limiting parts are arranged on the abutting bases and used for limiting sliding motion of the abutting bases, and tips are arranged on the abutting heads; driving pieces used for driving the abutting heads to rotate and first limiting parts used for limiting rotation of the abutting heads are arranged on the abutting bases. When the first limiting parts are in a limiting state, the length direction of the tips is parallel with the horizontal direction.

Owner:ZHEJIANG HONGDA GRP WENLING DAFENG ELECTRONICS

Straightening method and straightening device of short bar stock

InactiveCN102653054AReduce the proportionImprove straightening accuracyOther manufacturing equipments/toolsButt weldingEngineering

The invention provides a straightening method and a straightening device of a short bar stock. The method comprises the following main steps of: sequentially welding dispersed short bar stocks end to end to form a continuous long bar stock; straightening by a precise straightening mechanism; and cutting the bar stocks in front and back of a straightened welding line to obtain the straightened short bar stocks. According to the device corresponding to the method disclosed by the invention, a color spraying and butt welding mechanism is additionally arranged between a conventional roller straightening mechanism and the precise straightening mechanism; and a welding line detecting and cutting mechanism is additionally arranged at the back of the precise straightening mechanism. According to the invention, the straightening efficiency and the straightening precision of the short bar stock can be effectively improved.

Owner:YANSHAN UNIV

Wear-resistant straightening machine for steel rib processing

The invention discloses a wear-resistant straightening machine for steel rib processing and relates to the technical field of steel rib processing. The wear-resistant straightening machine comprises arack, wherein driven rotating rollers used for pressing a steel rib are arranged on the rack, driving rotating rollers driven by a conveying mechanism are arranged at the bottom of the steel rib in an abutting manner, a straightening drum through which the steel rib runs is arranged on the rack in a rotating manner, two straightening mechanisms connected through a regulating mechanism are symmetrically arranged in the straightening drum, each straightening mechanism comprises a plurality of straightening pinch wheels arranged in a rotating manner, and the straightening pinch wheels are arranged in a manner of forming pressure abutting with the steel rib. Through the regulating mechanism, the straightening mechanisms used for straightening the steel rib can be rapidly regulated so as to ensure that the straightening pinch wheels in the straightening mechanisms tightly press the steel rib, a full straightening effect is realized, and the straightening of steel ribs with different diameter sizes can be adapted. By additionally arranging the conveying mechanism, the intermittent conveying of the steel rib into the straightening drum can be realized, the steel rib can intermittently stop in the straightening drum, time required by the straightening of the steel rib is ensured, and the straightening effect of the steel rib is better.

Owner:张海燕

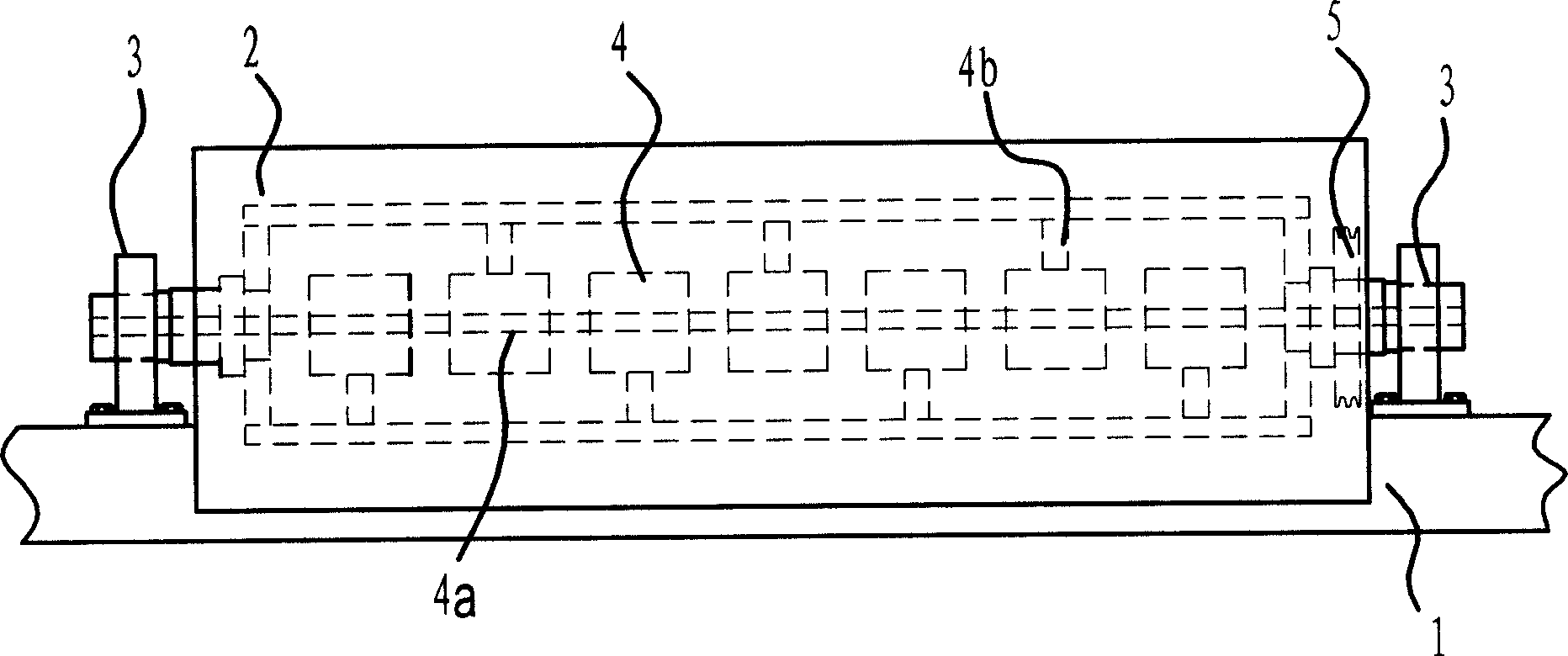

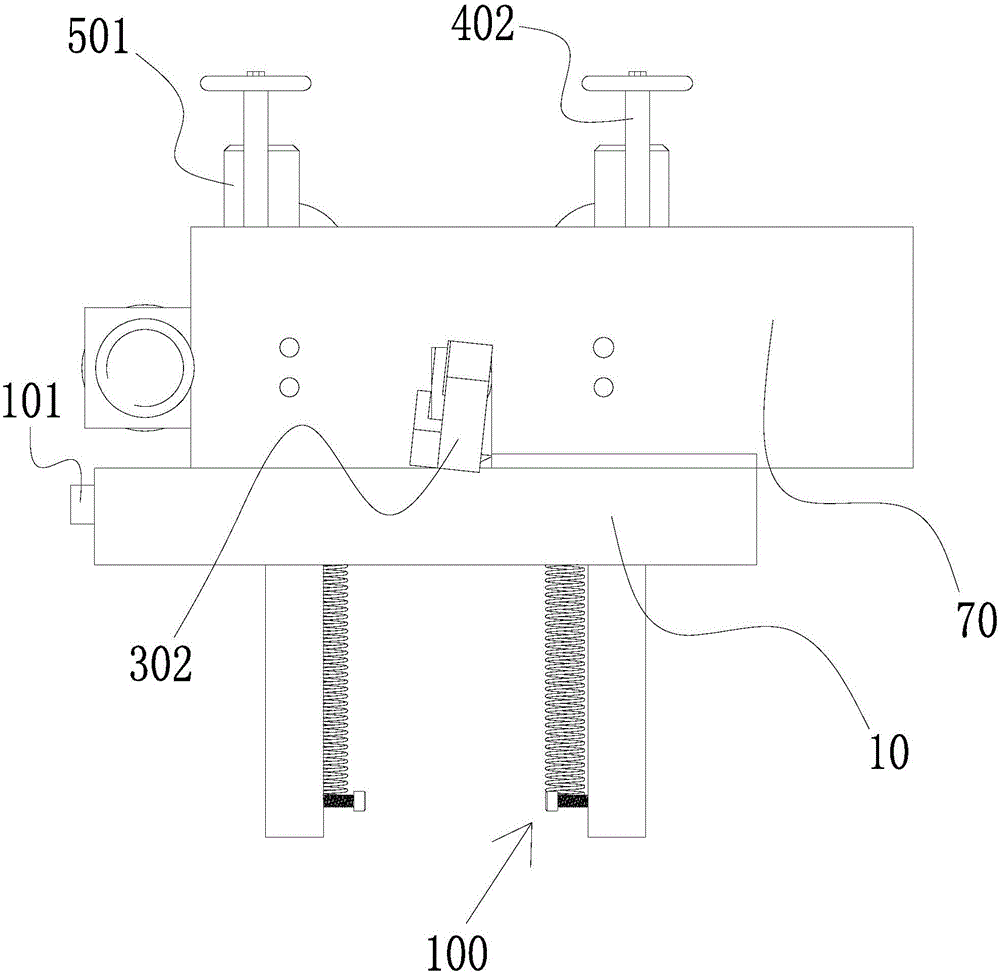

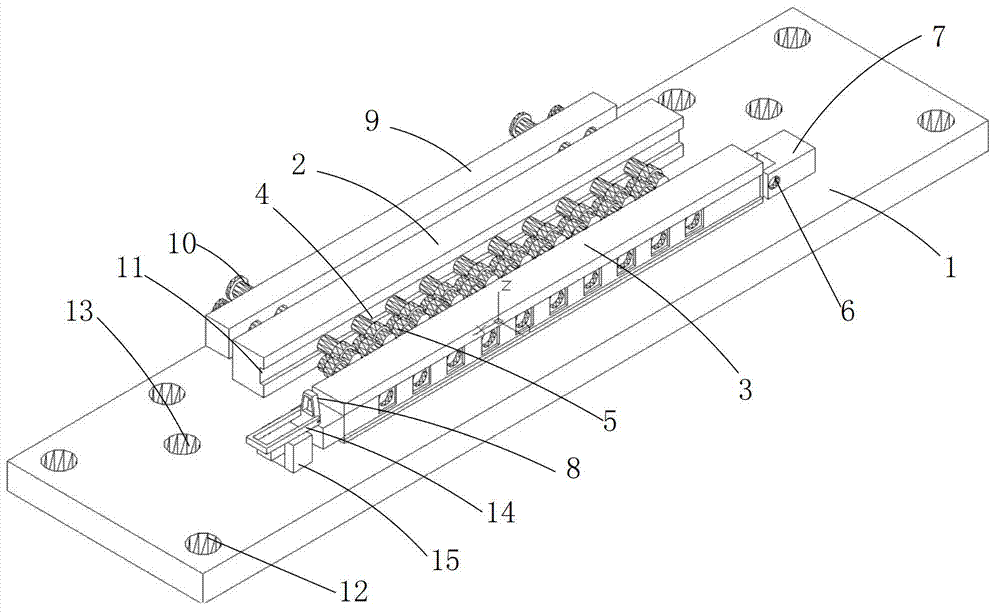

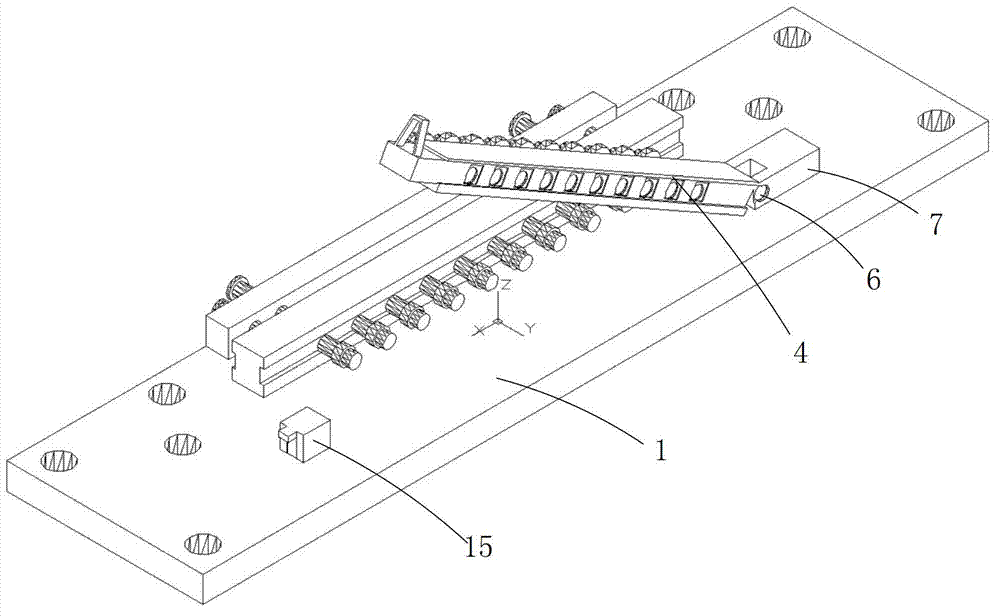

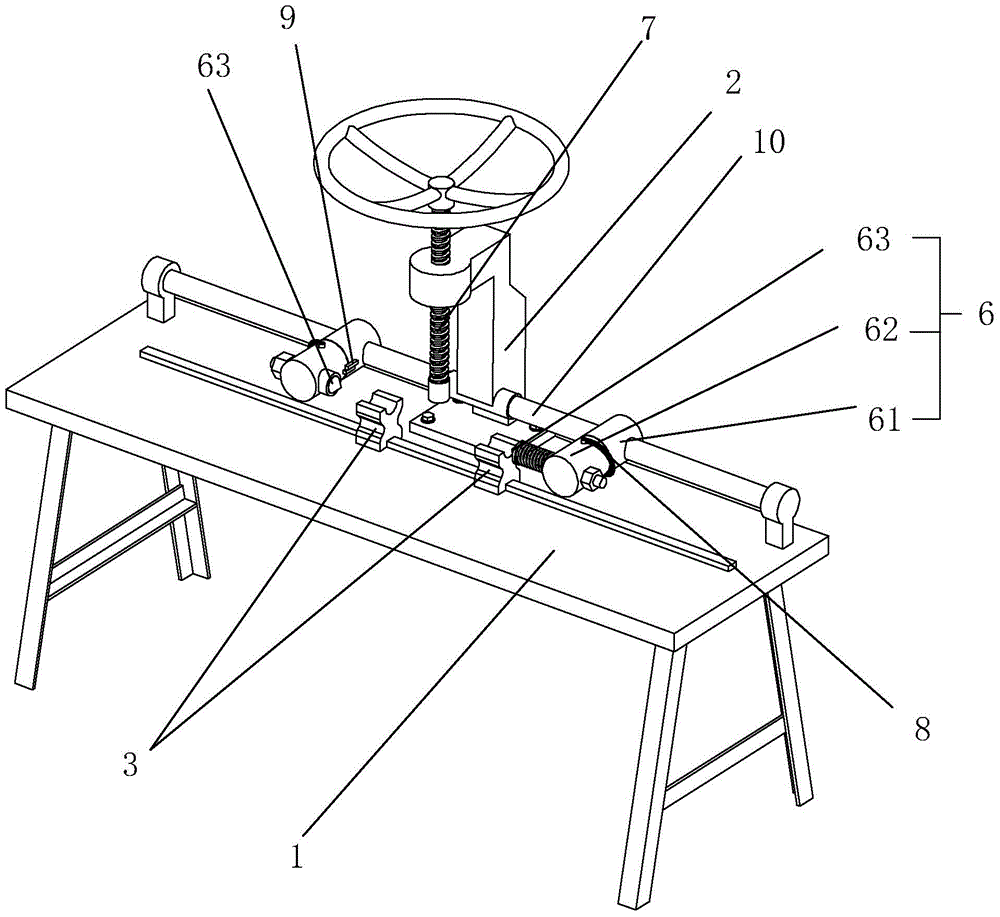

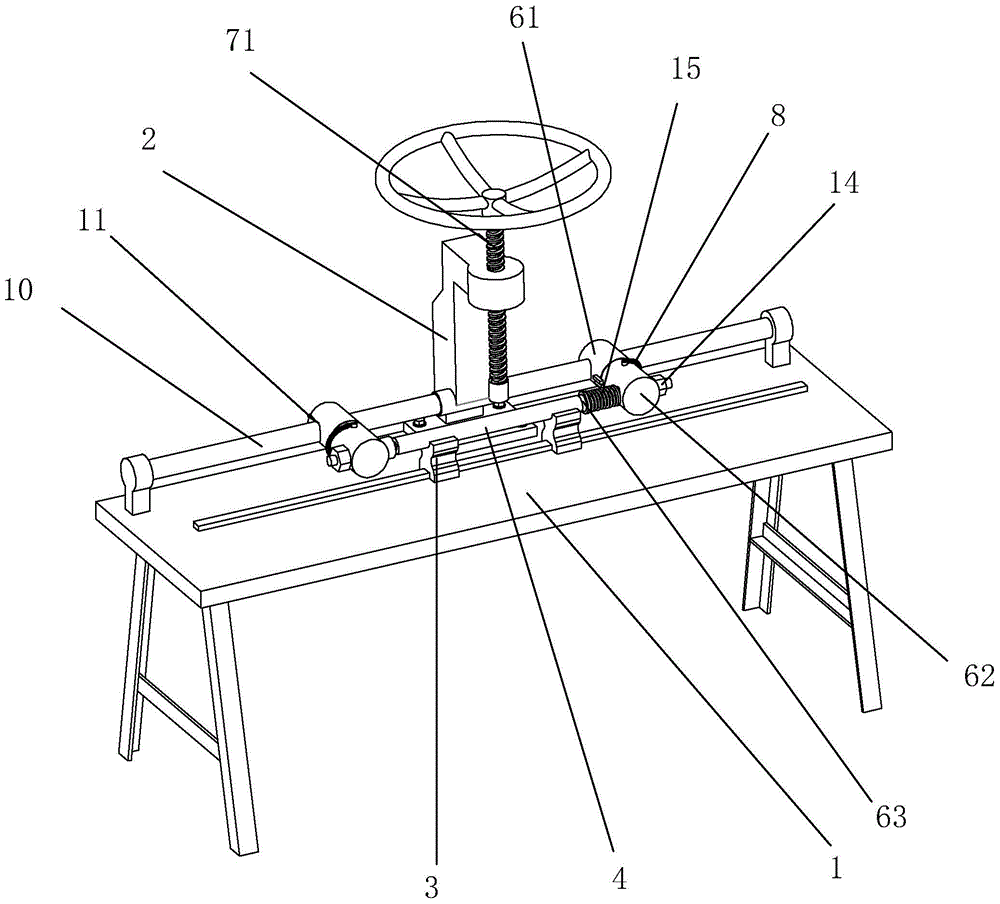

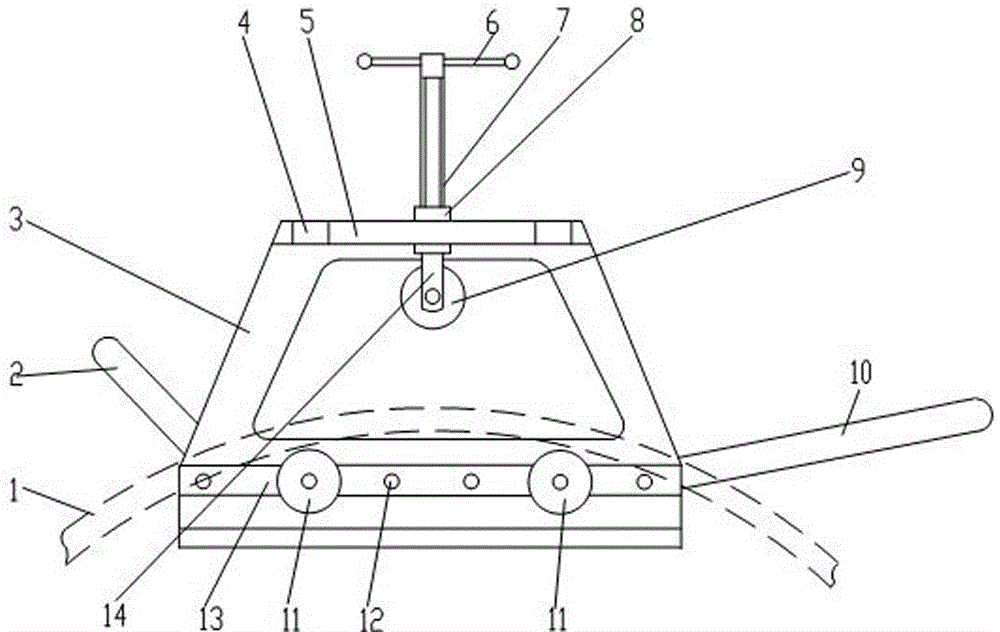

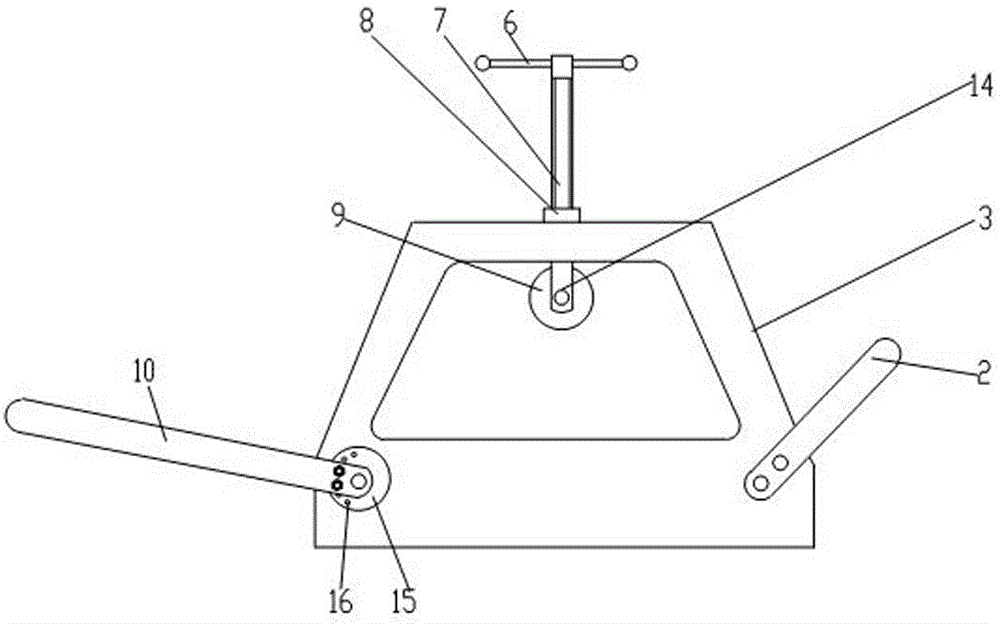

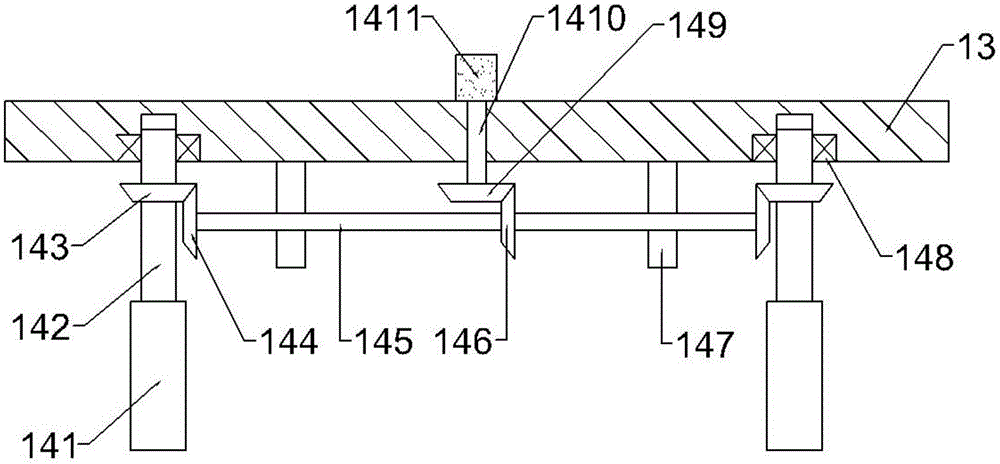

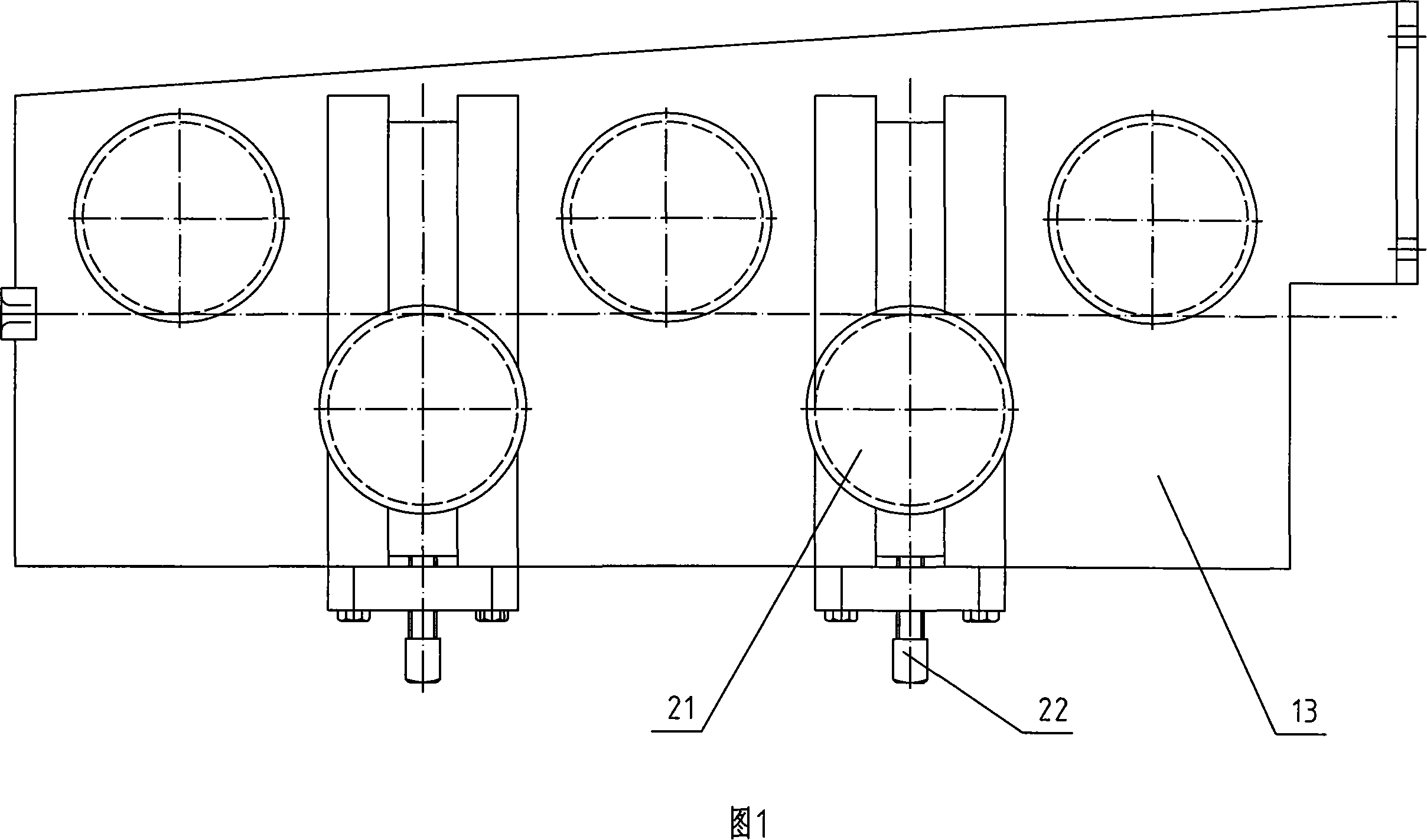

Stretch straightening machine and stretch straightening method

ActiveCN104399783AImprove straightening effectImprove straightening accuracySingle degree of freedomEngineering

The invention discloses a stretch straightening machine and a stretch straightening method. The stretch straightening machine comprises a primary stretching device and a secondary stretching device, wherein the primary stretching device comprises a primary machine base and a guide rail supporting slide base arranged on the primary machine base, and a primary stretching chuck sliding with a single degree of freedom and a stretching oil cylinder for driving the primary stretching chuck to slide are arranged on the guide rail supporting slide base; slide rails which are matched with one another are arranged between the guide rail supporting sliding base and the primary stretching chuck; the secondary stretching device comprises a secondary machine base, and a secondary stretching chuck for clamping section bars is arranged on the secondary machine base; a first jaw and a second jaw for fixing the section bars are correspondingly arranged on the opposite side surfaces of the primary stretching chuck and the secondary stretching chuck; the primary stretching chuck further comprises a straightening channel which comprises a straightening clamping opening. The straightening machine and the straightening method disclosed by the invention can be used for performing pre-straightening and stretch straightening in sequence, thereby achieving a relatively good straightening effect and guaranteeing high precision; during the operation, only one ends of the section bars need to be put into the straightening machine, and thus the straightening machine is convenient to use.

Owner:LIAONING ZHONGWANG MACHINERY EQUIP MFG

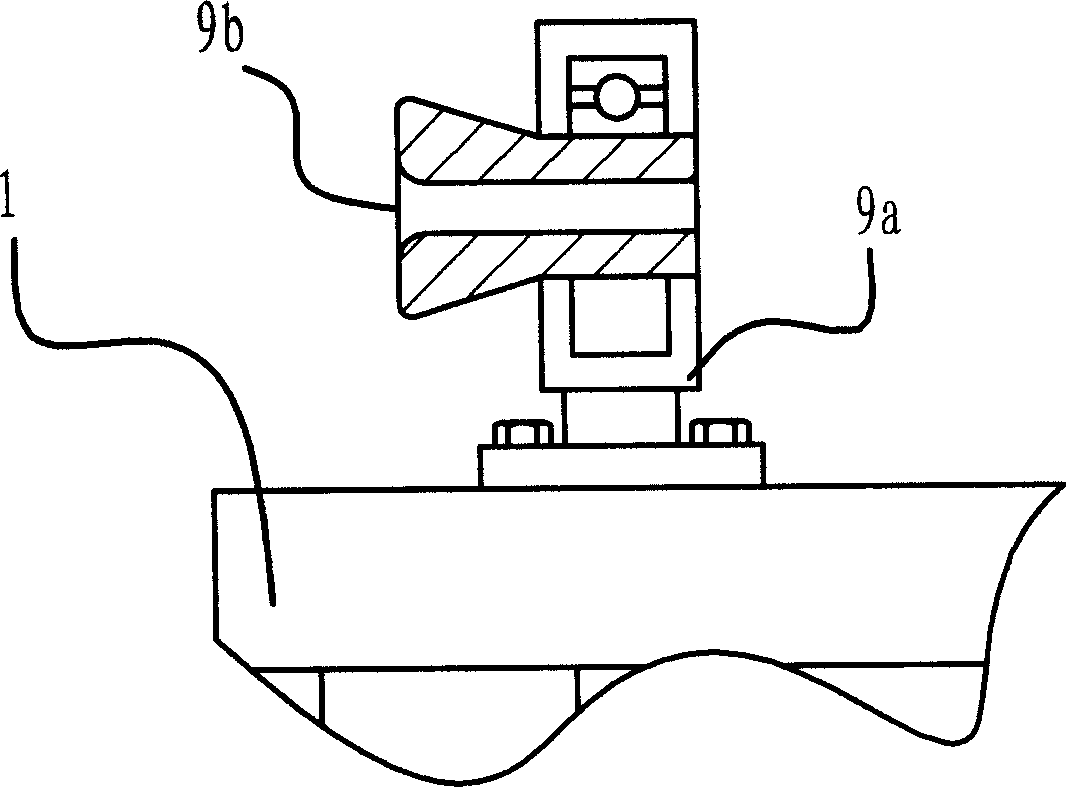

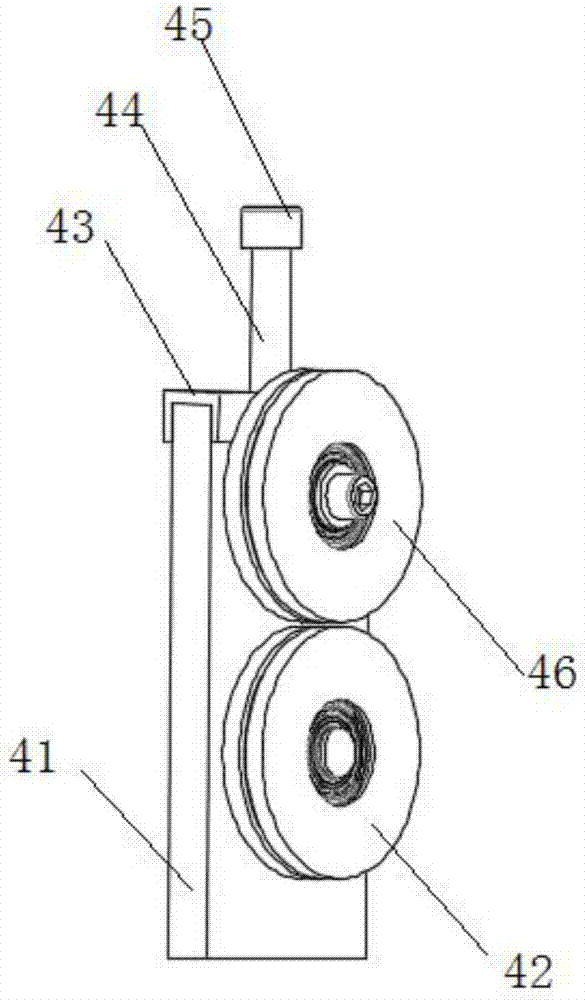

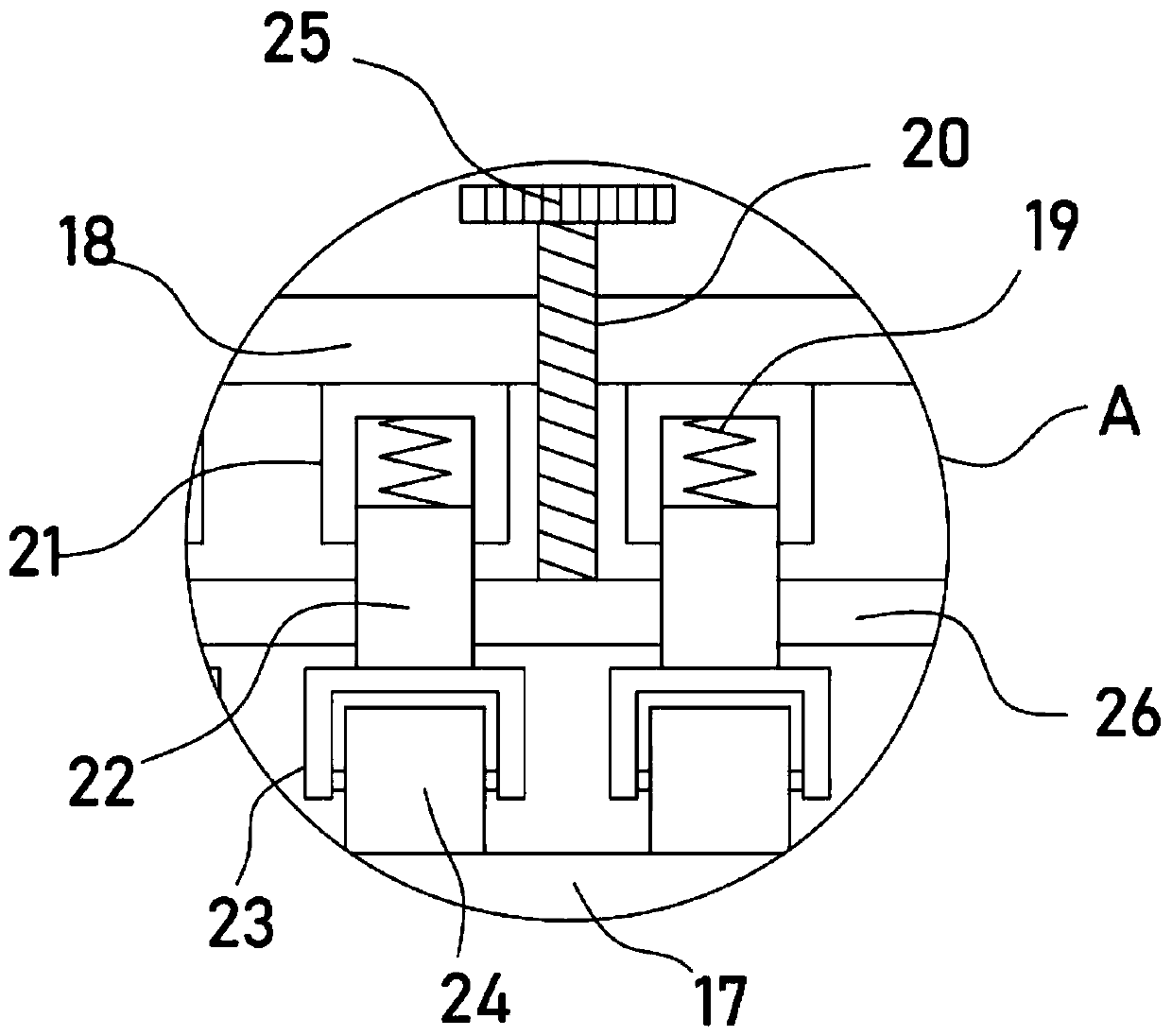

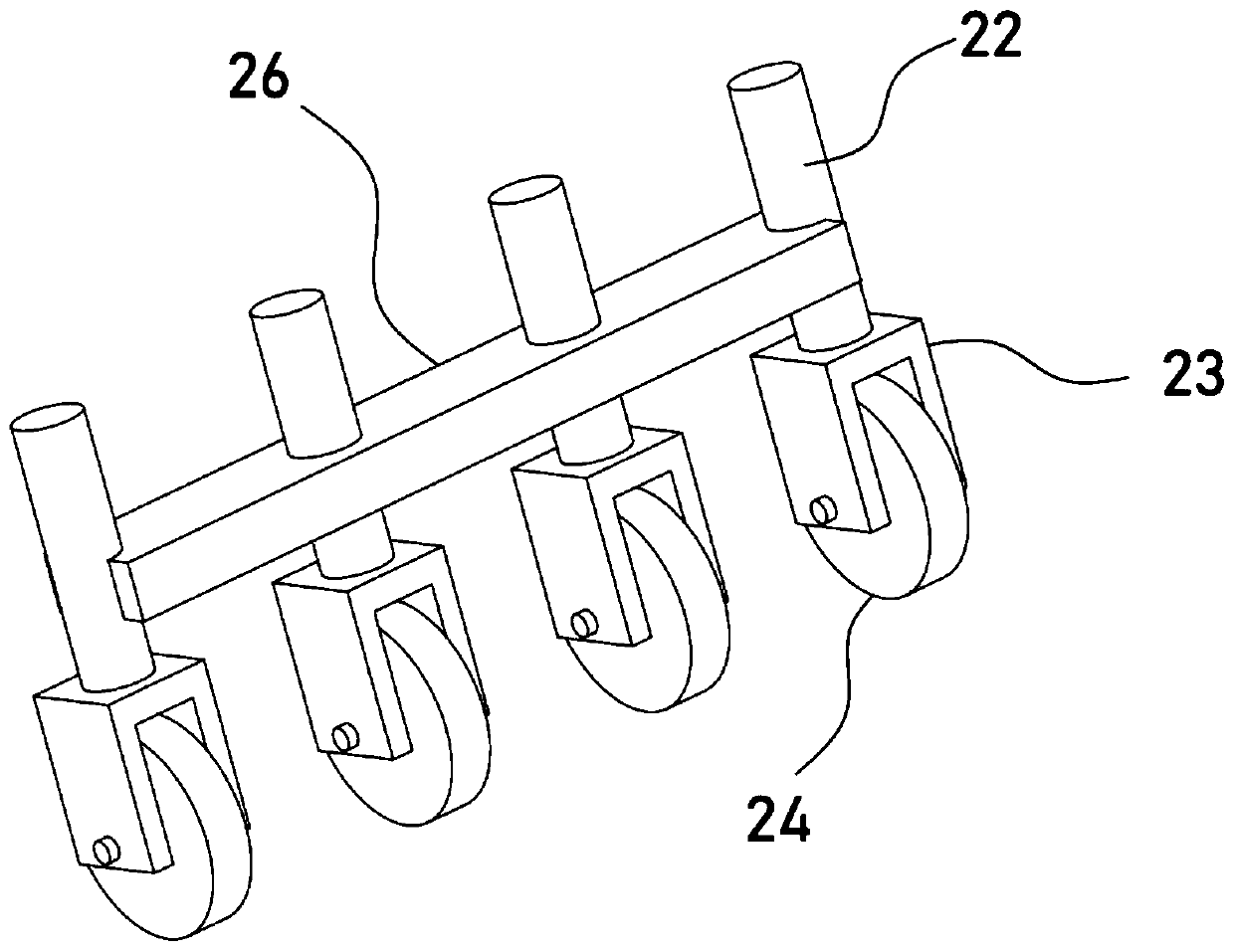

Cable straightening pulley bracket

InactiveCN105790150AEliminate operational defectsConstruction saves time and effortApparatus for laying cablesEngineeringUltimate tensile strength

The invention discloses a cable straightening pulley bracket which comprises a channel steel type frame, a transverse board, upper pulleys and lower pulleys. The transverse board is fixed above the lower edge of the channel steel type frame. More than two hanging shafts are arranged on the transverse board. The number of the lower pulleys is more than 2. The lower pulleys are hanged on the hanging shaft through central holes. Each upper pulley is provided with a central hole and is connected with the middle part of the upper edge of the channel steel type frame through a through shaft bracket and a lead screw pair. The cable straightening pulley bracket can perform straightening shaping on the cables with various kinds of bending shapes. Furthermore the cable straightening pulley bracket has advantages of saving time and labor in cable construction, reducing labor intensity, improving construction efficiency and ensuring high cable mounting quality.

Owner:STATE GRID CORP OF CHINA +2

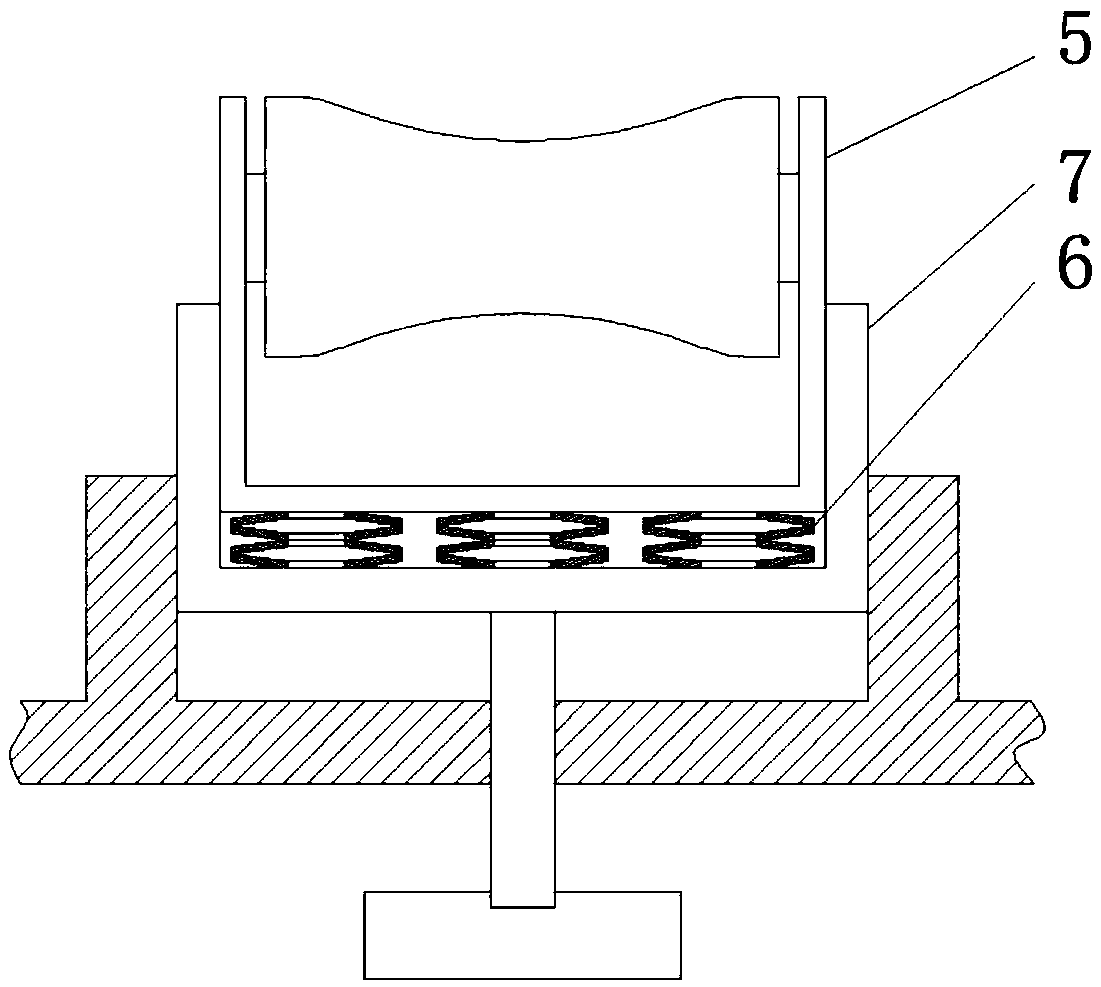

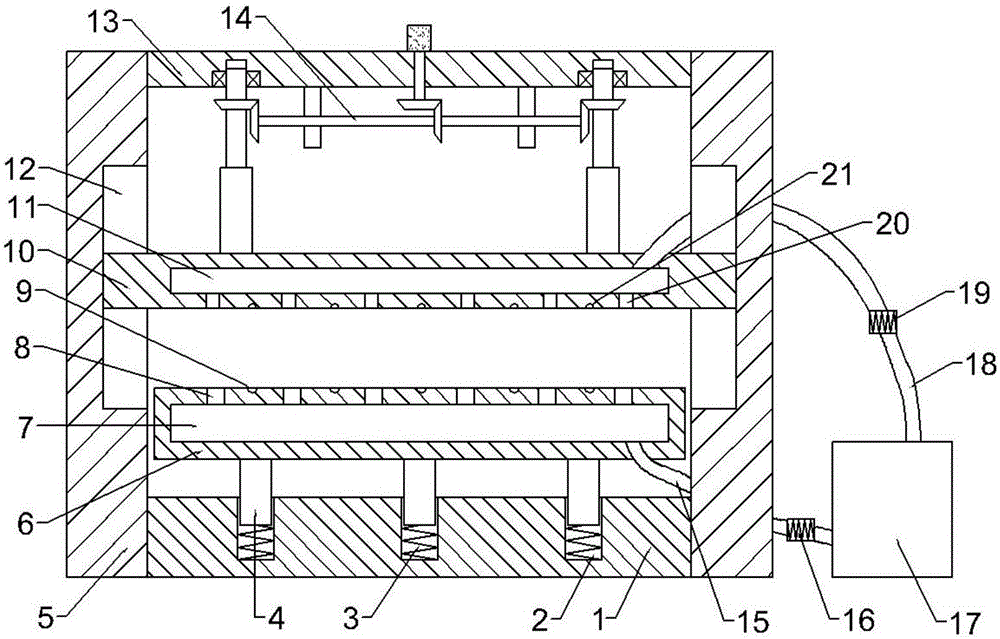

Feather straightening device for badminton production with steam-assisted function

The invention relates to a feather straightening device for badminton production with a steam-assisted function, which comprises a base, wherein support frames are arranged on two sides of the base; a plurality of grooves with upward openings are formed in the upper side of the base; springs are arranged on the bottom parts in the grooves; support pillars are also arranged in the grooves; the bottom ends of the support pillars are fixedly connected with the upper ends of the springs; a lower straightening plate is fixedly connected to the top ends of the support pillars; a lower cavity is arranged in the lower straightening plate; a plurality of lower through holes are formed in the upper side of the lower straightening plate; a steam generation device is arranged on one side of the base, and is connected with the lower cavity in the lower straightening plate through a lower steam inlet pipe. The feather straightening device provided by the invention has the beneficial effects that an upper straightening plate and the lower straightening late are utilized for straightening feathers, and steam is cooperated for steam-assisting the feathers, so that the feathers cannot be too dry and have higher toughness, and a straightening effect is effectively improved.

Owner:同码信息科技(常州)有限公司

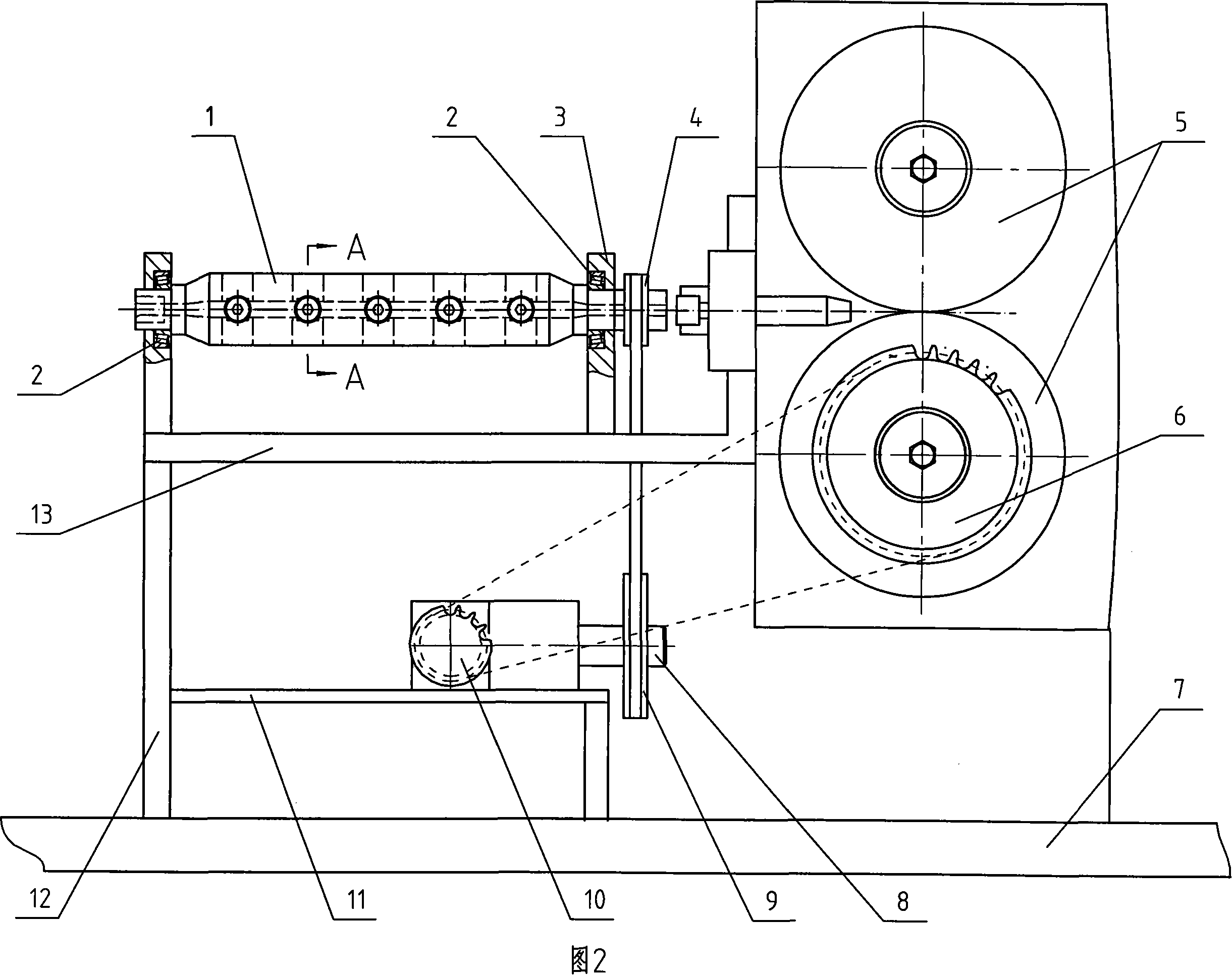

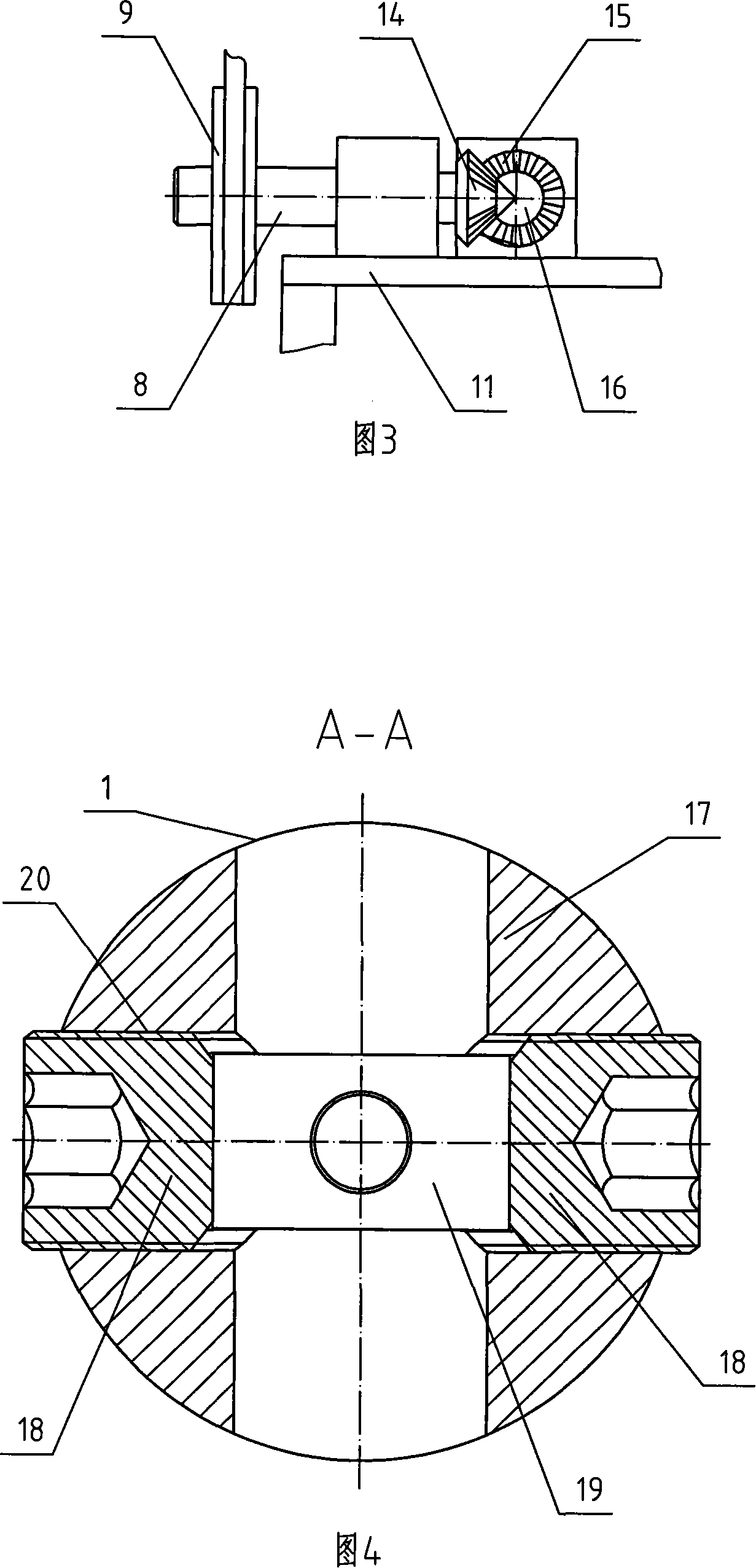

Cold heading machine straightening device

InactiveCN101125353AImprove straightening effectImprove pass rateHandling devicesPass rateEngineering

The invention discloses a cold header aligning device, which comprises a level supporting frame(13), a feeding wheel(5) that drives the blank to go forward linearly; one end of the level supporting frame(13) is fixed with a machine frame girder(12) that is fixed on the machine frame(7); another end is fixed on the feeding mechanism of the cold header. The aligning device also includes a hollow aligning shaft(1), and a transmission mechanism. A supporting frame girder(3) is fixed on the level supporting frame(13); one end of the hollow aligning shaft(1) is rotatably connected with the machine frame girder(12), another end is rotatably connected with the supporting frame girder(3); one end of the hollow aligning shaft(1) that sticks out of the supporting frame girder(3) is connected with the transmission mechanism; the transmission mechanism is connected with the machine frame(7) and both of them are fixed on a level plate(11). The cold header aligning device in this structure has excellent aligning effect, can improve the passing rate of finished products, therefore can improve the economic benefit.

Owner:NINGBO EASTPORT FASTENER MFG

Metal steel pipe straightening machine

The invention provides a metal steel pipe straightening machine. The machine comprises a case, and the case comprises a feeding opening and a discharging opening. A plurality of sets of upper rotating rollers and lower rotating rollers which correspond to the upper rotating rollers are rotatably arranged in the case. Grooves are circumferentially formed in the upper rotating rollers and the lower rotating rollers, and straightening channels are formed between the upper rotating rollers and the lower rotating rollers. The diameter of the straightening channels is gradually decreased in the direction from the feeding opening to the discharging opening, and then is kept constant. Compared with an existing straightening machine, the pre-straightening function is added, and the metal steel pipe straightening machine can reduce manual pre-straightening operation, and is convenient; troubles and labor are saved, and the surface of a steel pipe can be effectively protected against damage; and meanwhile, the service life of the straightening machine can be prolonged.

Owner:TIANJIN CHENGTIANFENG METAL PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com