Metal steel pipe straightening machine

A technology for straightening machines and steel pipes, which is applied in the field of metal steel pipe straightening machines, can solve the problems that steel pipes are difficult to enter the straightening machine, labor-intensive, and cannot be straightened, so as to increase the pre-straightening function, protect from damage, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

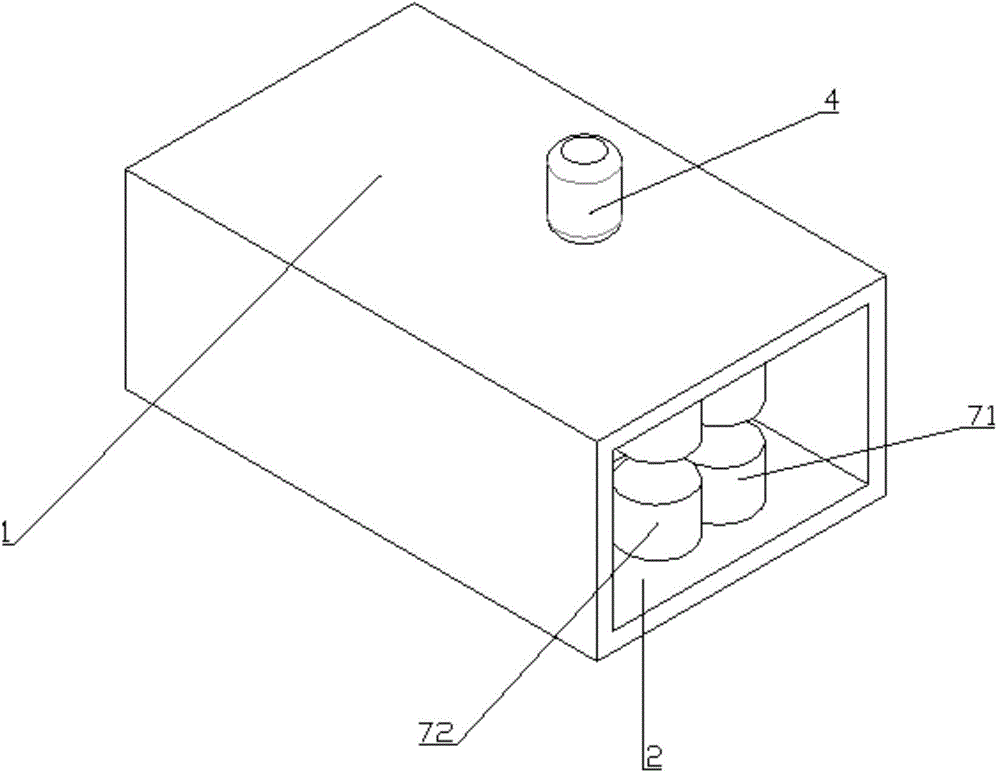

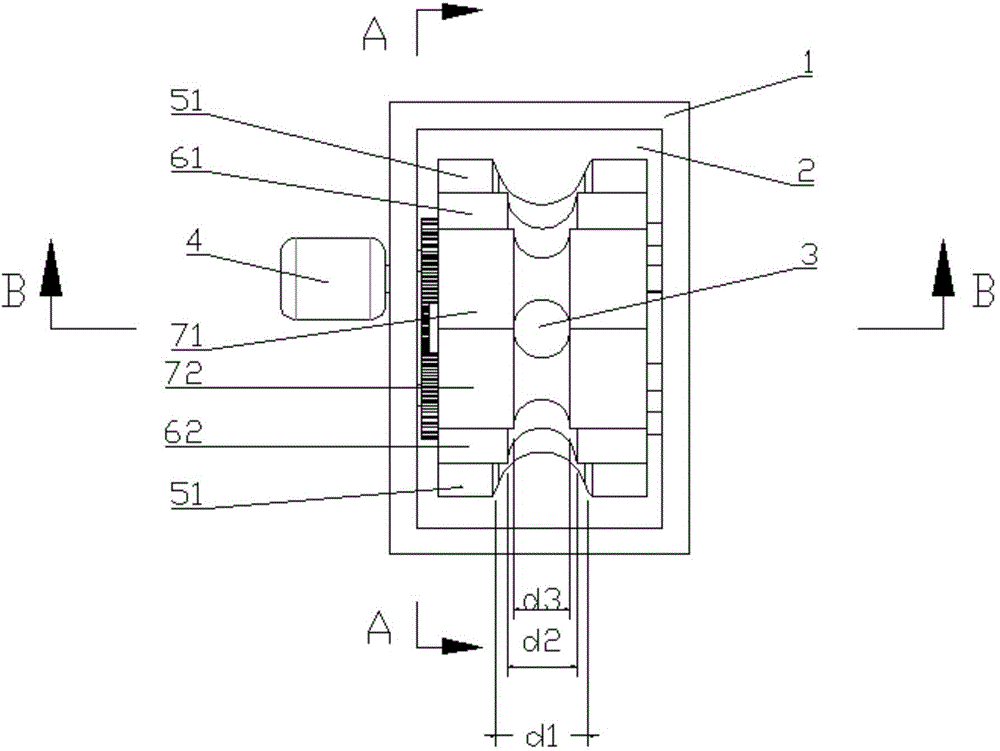

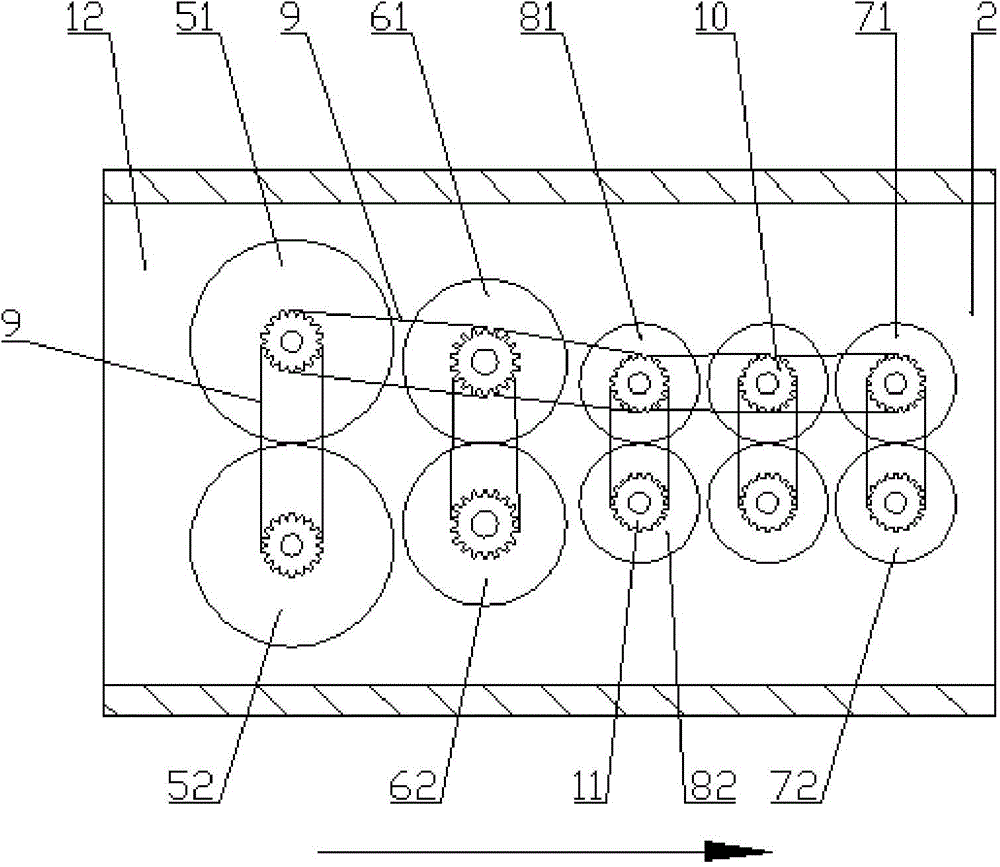

[0023] like Figure 1-Figure 4 As shown, the present invention provides a metal steel pipe straightening machine, including a casing 1, and a roller and a roller locker (not shown in the figure) are arranged under the casing 1, which can facilitate the movement and fixing of the casing 1. The cabinet 1 includes a material inlet 12 and a discharge port 2. There are multiple groups of corresponding upper and lower rollers rotatably arranged in the cabinet 1. The upper and lower rollers in each group are provided with corresponding rollers in the circumferential direction. Corresponding to the groove 13, a straightening channel 3 is formed between the upper roller and the lower roller, and the diameter of the straightening channel 3 gradually decreases from the feed port 12 to the discharge port 2, and then remains constant.

[0024] In order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com