Method for straightening a metal strip and straightening machine

A metal strip and straightening machine technology, applied in the field of straightening machines, can solve problems such as difficulties, fluctuations in the thickness of the head or tail of the strip, fluctuations in the thickness of the strip, etc., and achieve a good straightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

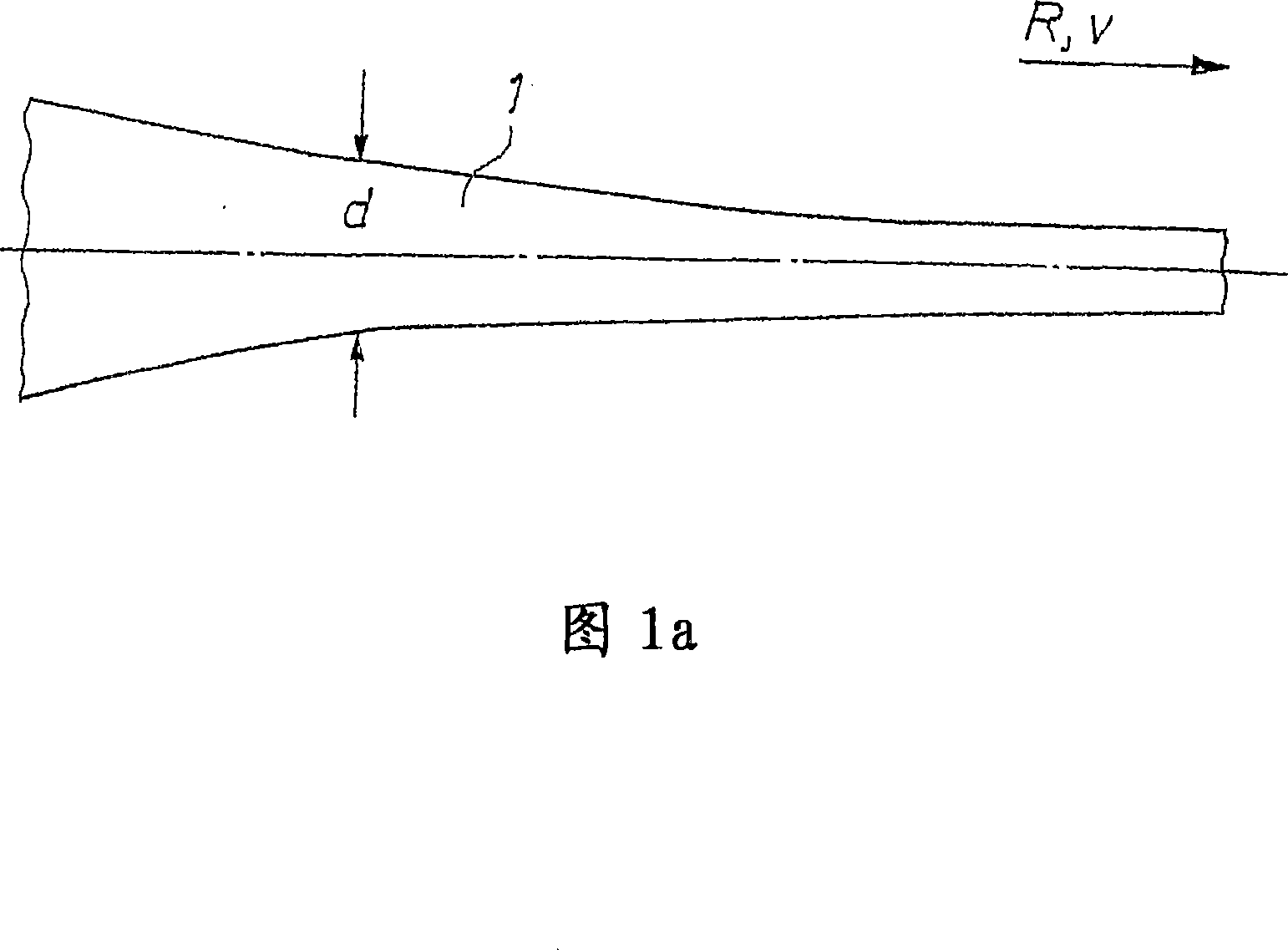

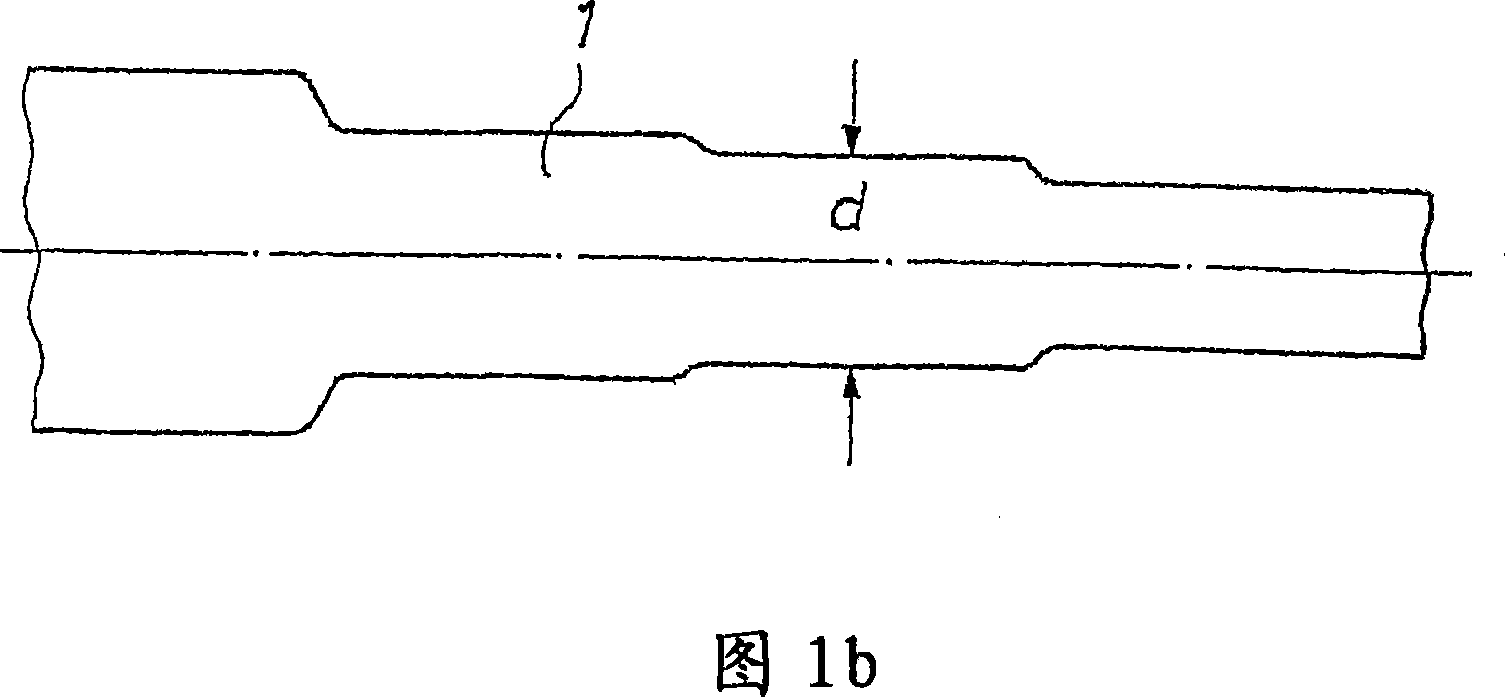

[0029] Figures 1a and 1b show a side view of a metal strip 1 which is to be straightened, showing the region of the head of an unrolled strip. Typically, the thickness d of the metal strip 1 is not constant over the entire longitudinal axis of the strip corresponding to the conveying direction R. In the case of FIG. 1a, the metal strip 1 extends in a wedge shape, while FIG. 1b shows the case in which the thickness of the metal strip extends in steps.

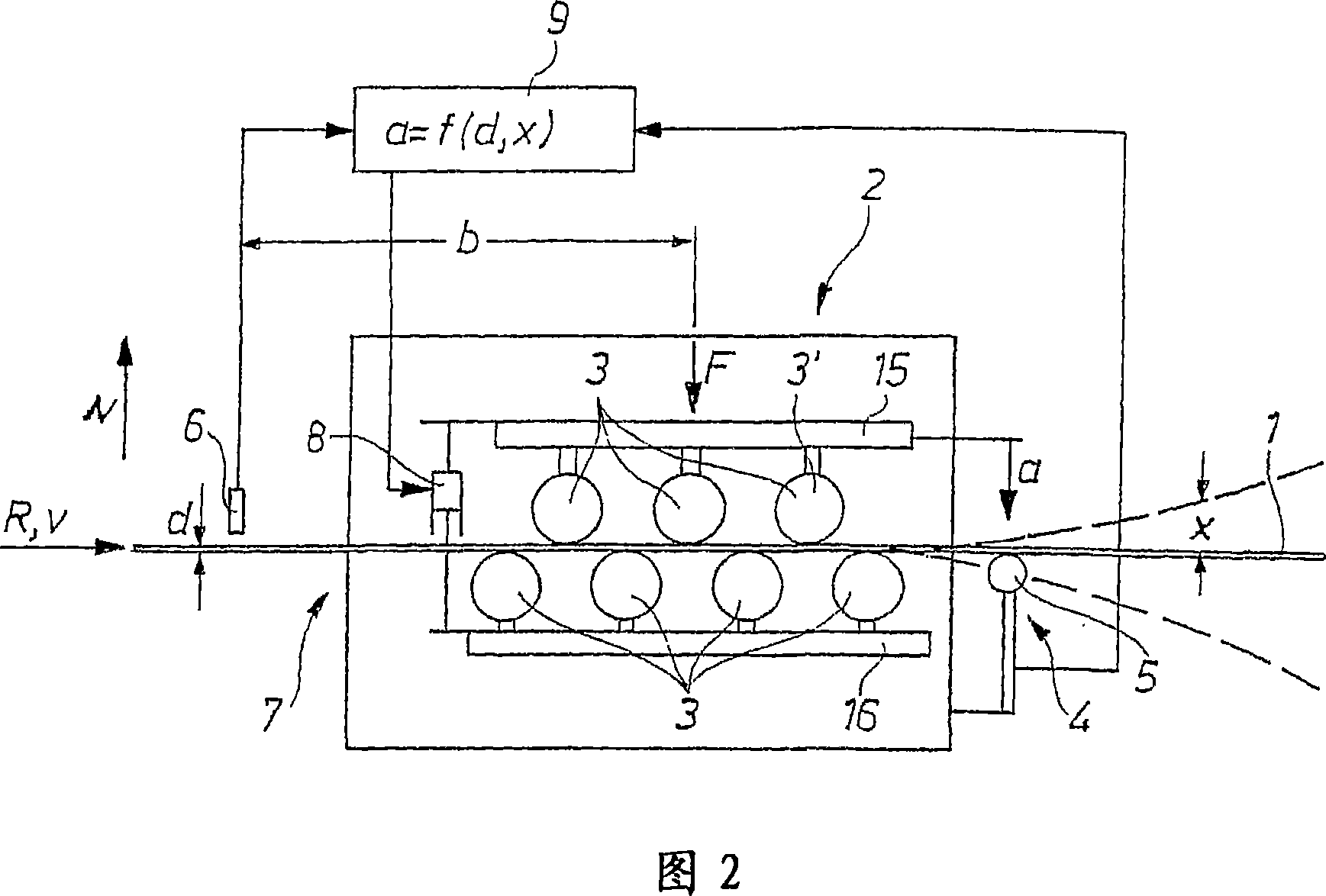

[0030] Straightening of such metal strips is particularly difficult and effective straightening is only possible with the straightening machine 2 shown in FIG. 2 .

[0031] The metal strip 1 is fed into the straightening machine 2 at a constant speed V in the conveying direction R. The straightening machine 2 is a roller straightening machine and has a plurality of straightening rollers 3 . Four lower straightening rollers 3 and three upper straightening rollers 3 are respectively arranged on a beam 15 and 16 which are relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com