Cold heading machine straightening device

A cold heading machine and straightening technology, applied in the direction of operating devices, forging/pressing/hammer devices, metal processing equipment, etc., can solve the problems that cold heading machines cannot meet product quality requirements, high scrap rate, and economic losses of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

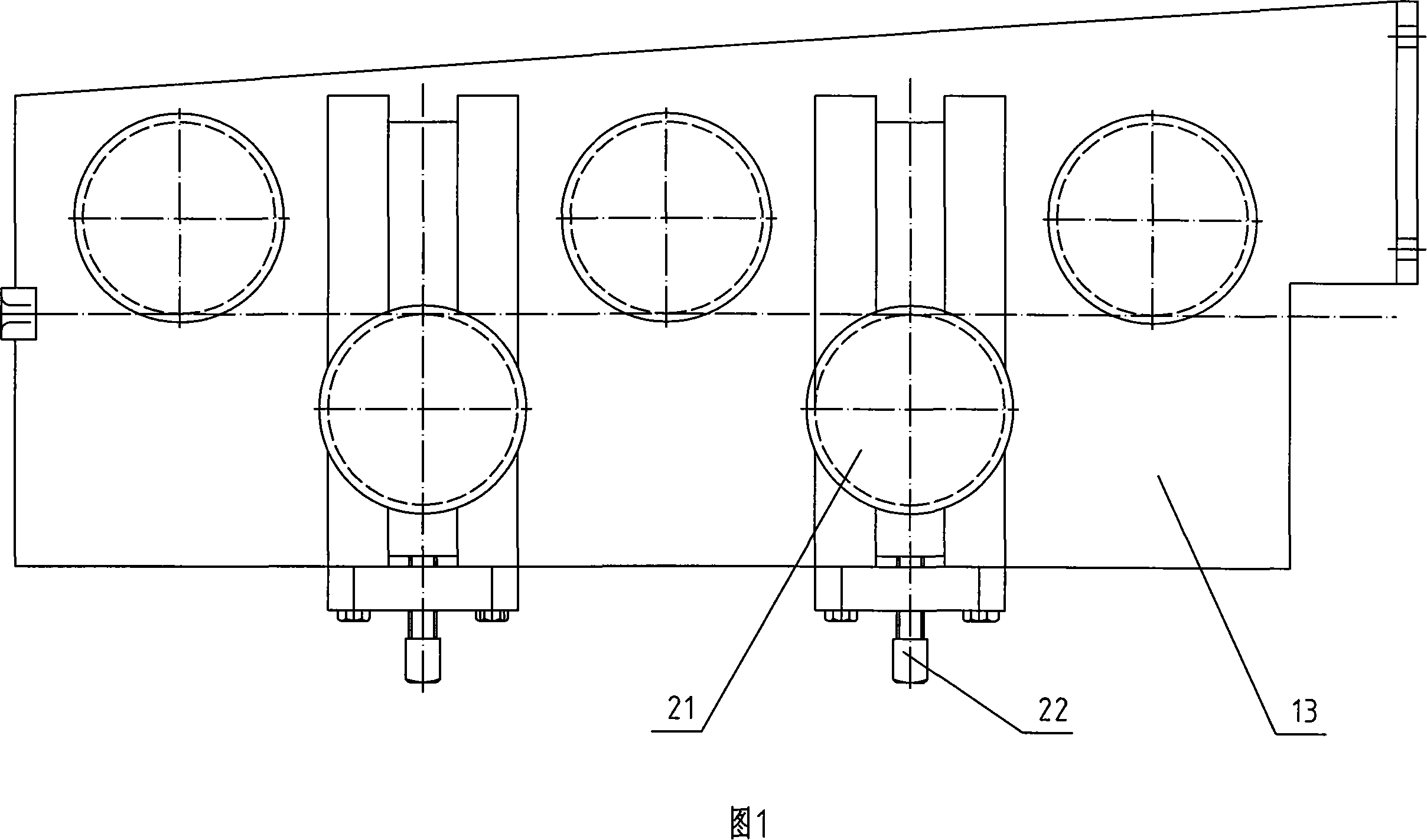

[0017] It can be known from the top view of the straightening device of the prior art cold heading machine shown in FIG. The several rollers 21 described are installed on the horizontal support 13, equidistant and staggered in two rows and distributed on the horizontal support 13 of the cold heading machine. One row of rollers 21 is connected with a screw 22, and the relative position of the other row of rollers 21 is adjusted by manually adjusting the screw 22, that is, the diameter of the blank determines the relative position of the two rows of rollers. When the cold heading machine is working, the billet is fed in from the first roller for straightening in advance, and the bent billet is straightened through the force of the feed wheel that drives the billet forward linearly and several rollers. Since the blank is only subjected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com