Patents

Literature

49results about How to "Construction saves time and effort" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

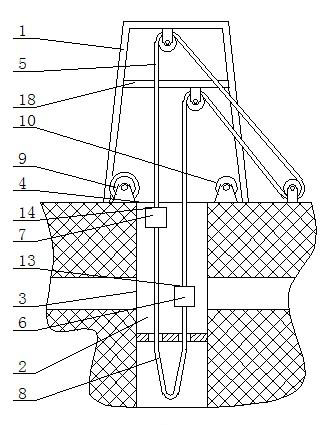

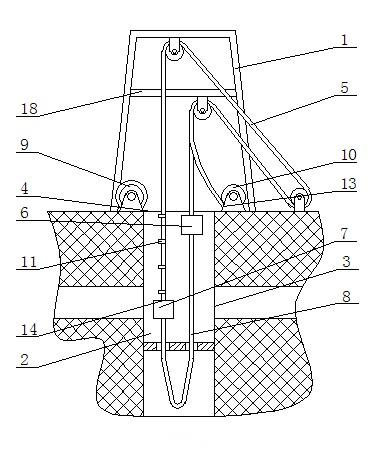

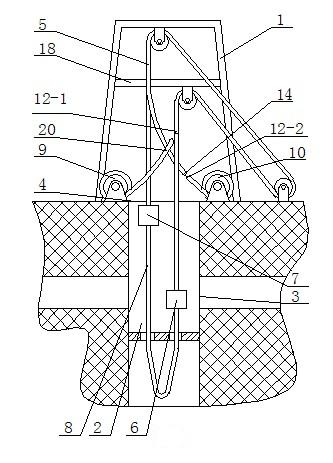

Process for replacing hoisting ropes

ActiveCN101786570AReduce usageSolve difficult problems that are easy to twistMine liftsPull forceEngineering

The invention discloses a process for replacing hoisting ropes, which comprises the steps of: 1, arranging new and old rope hoists at an upper wellhead, and lifting a second cage to the upper wellhead; 2, lowering the second cage, and arranging a pair of long boards on an old rope on the same side of the second cage at intervals of 50 meters; 3, separating the old rope from a first cage and connecting the old rope with an old rope take-up hoist; 4, when the second cage is lifted to the upper wellhead, taking up the old rope by the old rope take-up hoist, dismounting the long boards in the step 2, and breaking the old rope; 5, connecting the rope end of a new rope with an upper breaking point, and connecting a second end of the old rope with a lower breaking point; 6, driving the new rope by the old rope to wind two hoisting sheaves and a winch sequentially, breaking the new rope and the upper breaking point, and connecting the new rope with the second cage; and 7, driving the new rope to descend by the second cage, applying pull force to the new rope at intervals of 50 meters, arranging the long boards on the new rope and a to-be-replaced old rope, removing the pull force, breaking the new rope, and connecting the new rope with the first cage.

Owner:山东煤安矿山提升设备安装有限公司

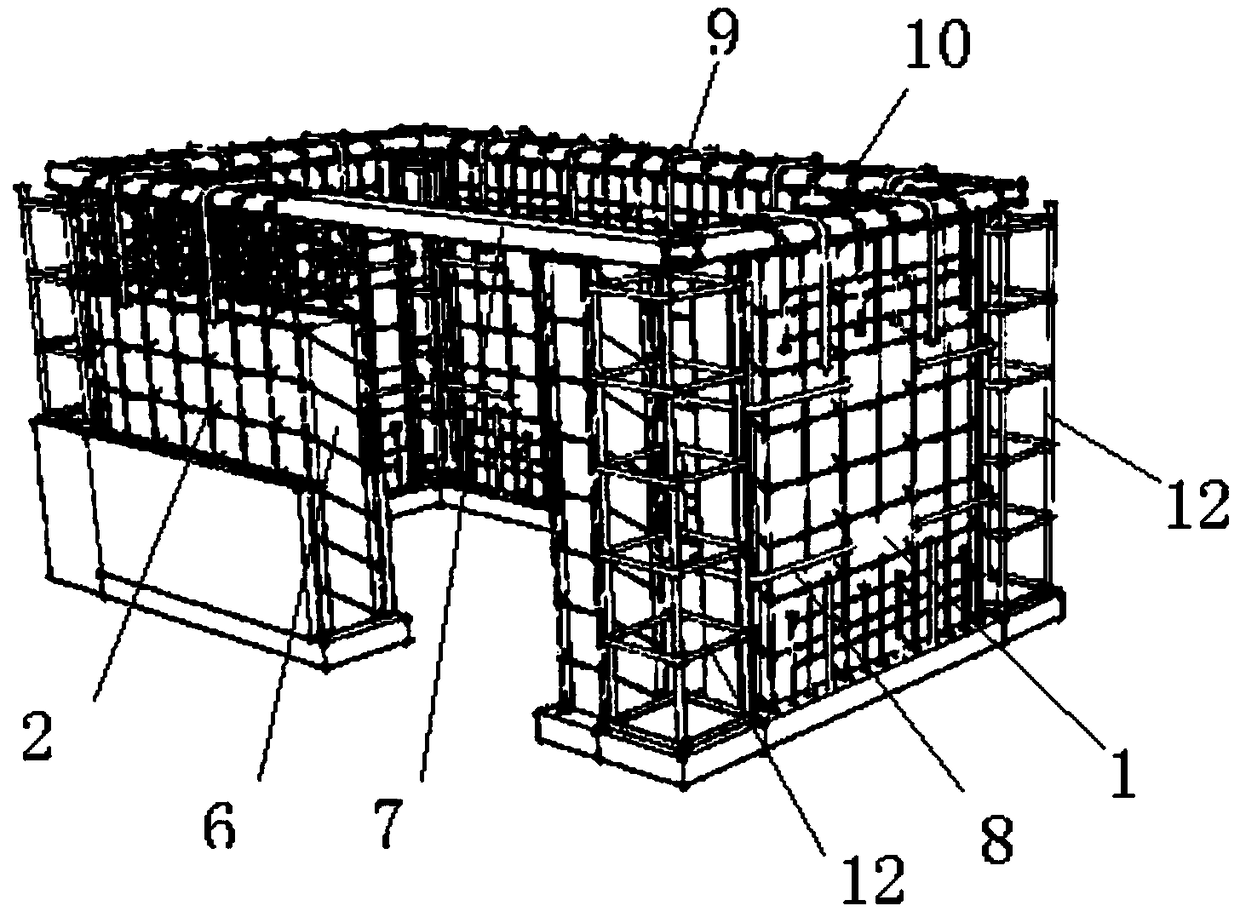

Multilayer long-span public building and industrial plant assembling integral box type structure and manufacture method

The invention discloses a multi-layer long-span public building, an industrial plant assembling integral box type structure and the manufacture method thereof, in advance, a planar type latticed steel open web girder is formed by connecting steel open web girders of all floor systems of all floors, namely all steel open web girders are connected to be latticed orthogonally, then latticed steel open web girders of all the floor systems of all floors are connected with an orthotropic and spatial steel latticed wall shelf, during connection, each open web girder is enabled to form an included angle of 45 degrees with the plane of the orthotropic and spatial steel latticed wall shelf, a planar type latticed steel open web girder which is formed by connecting orthogonally is connected with the orthotropic and spatial steel latticed wall shelf in a way of inclined placement at an angle of 45 degrees, namely an orthotropic inclined placement steel open web beam latticed floor system, and the orthotropic inclined placement steel open web beam latticed floor system is connected with an orthotropic right placement steel latticed wall shelf, namely an orthotropic inclined placement multi-layer spatial steel latticed box type building structure. According to the invention, advantages of low steel dosage and the like are achieved.

Owner:GUIZHOU UNIV +5

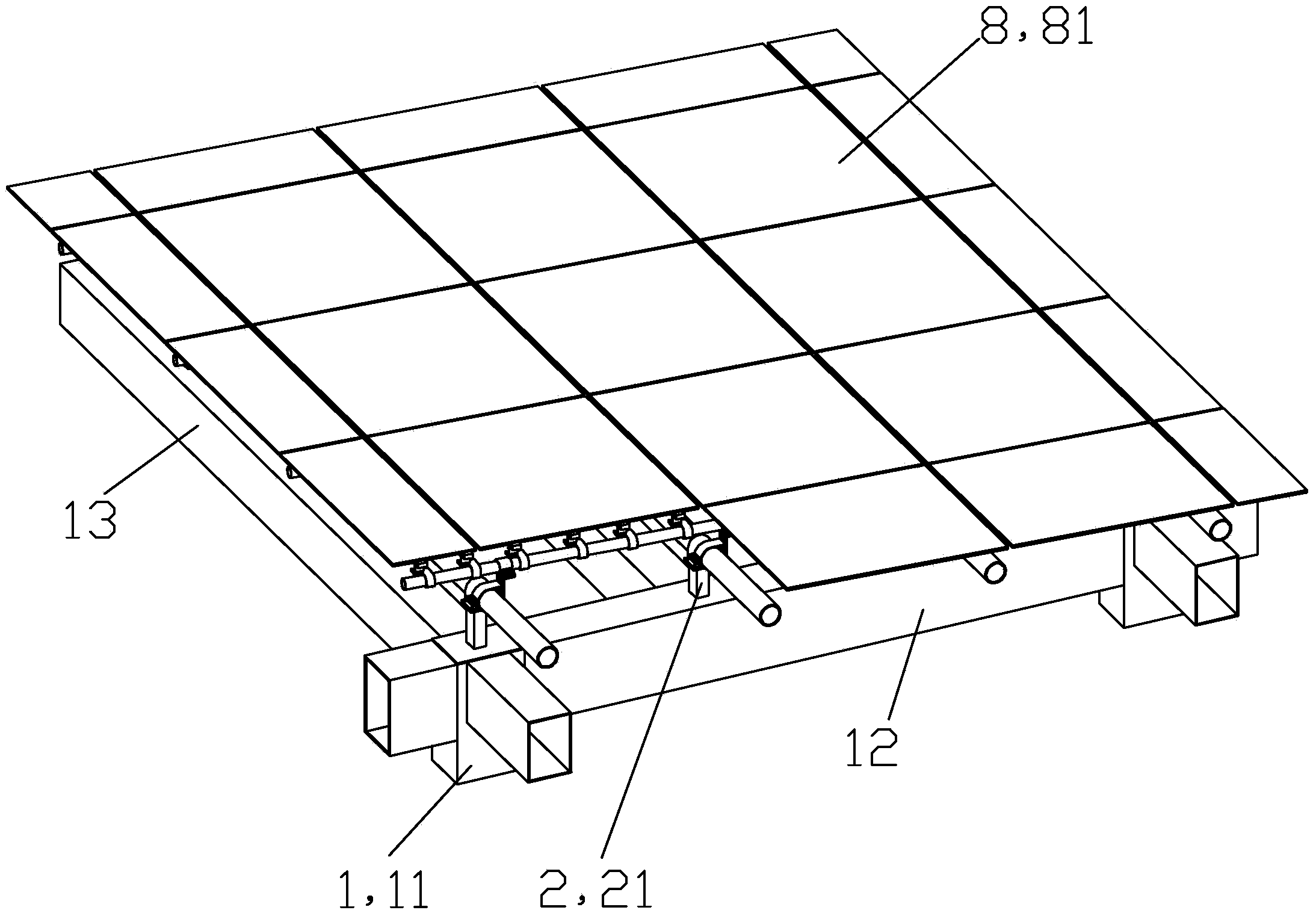

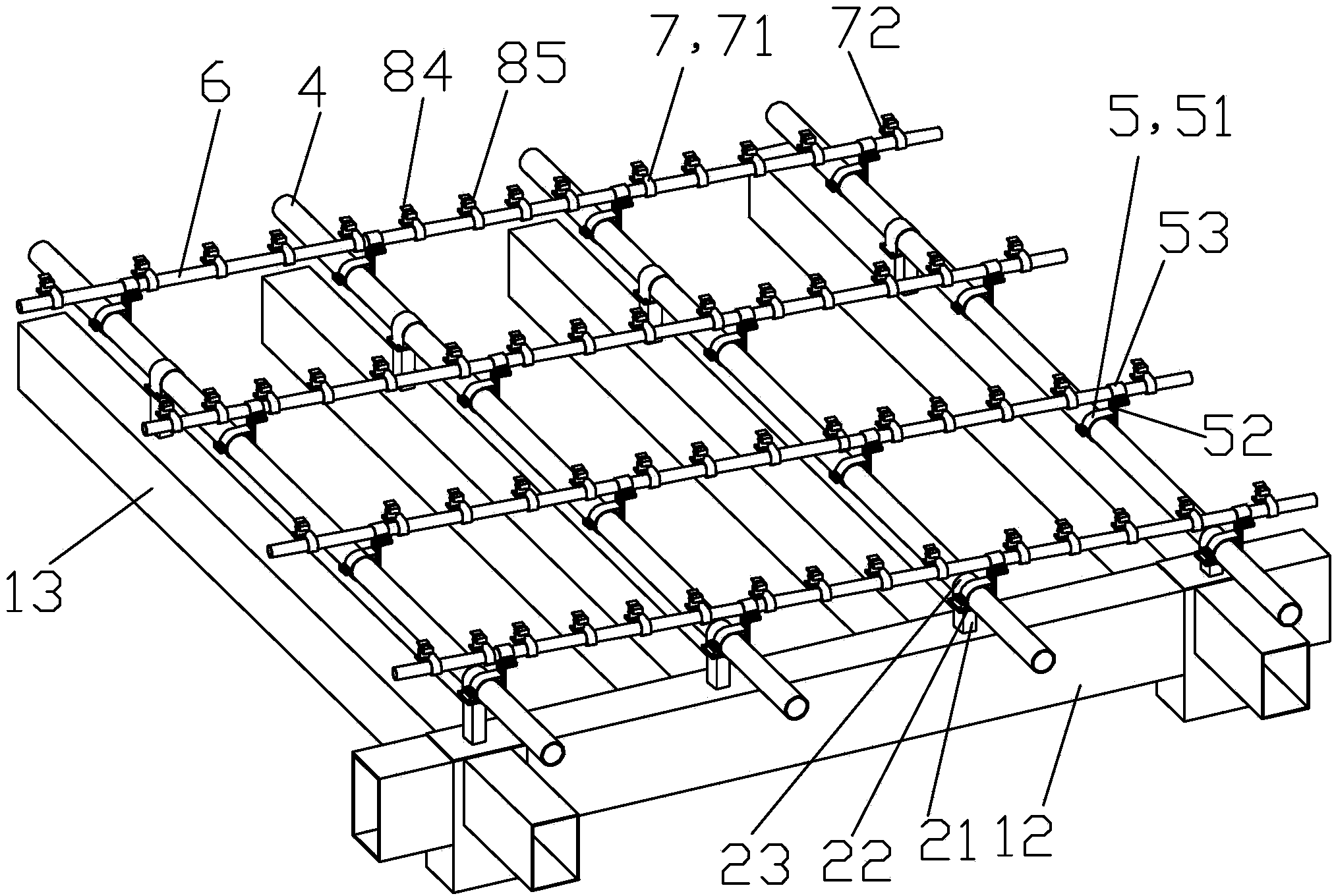

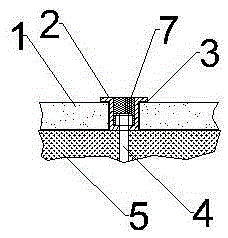

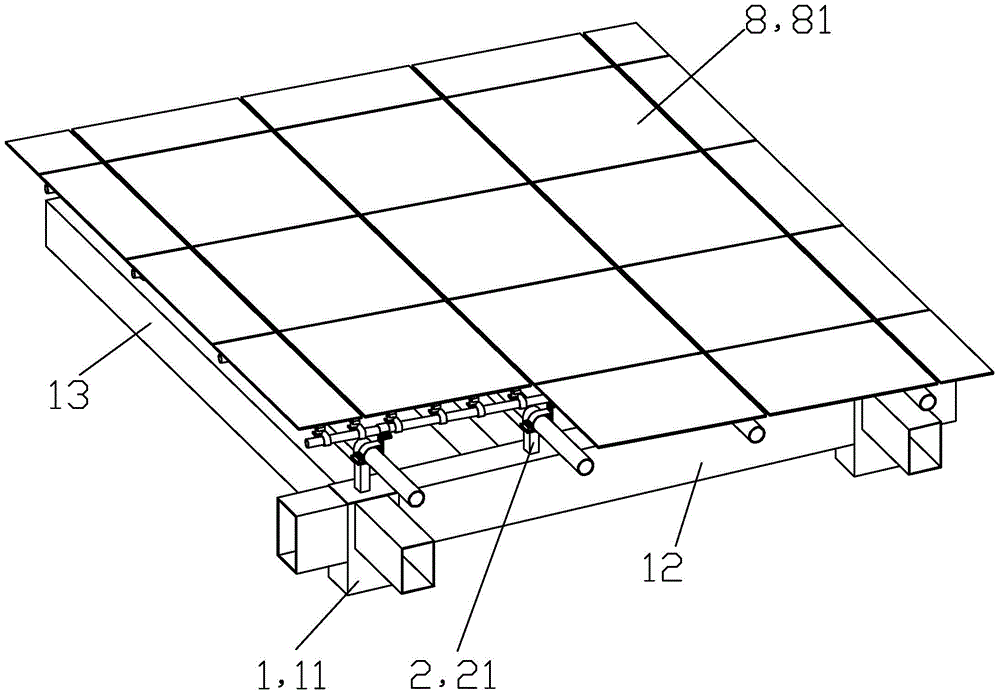

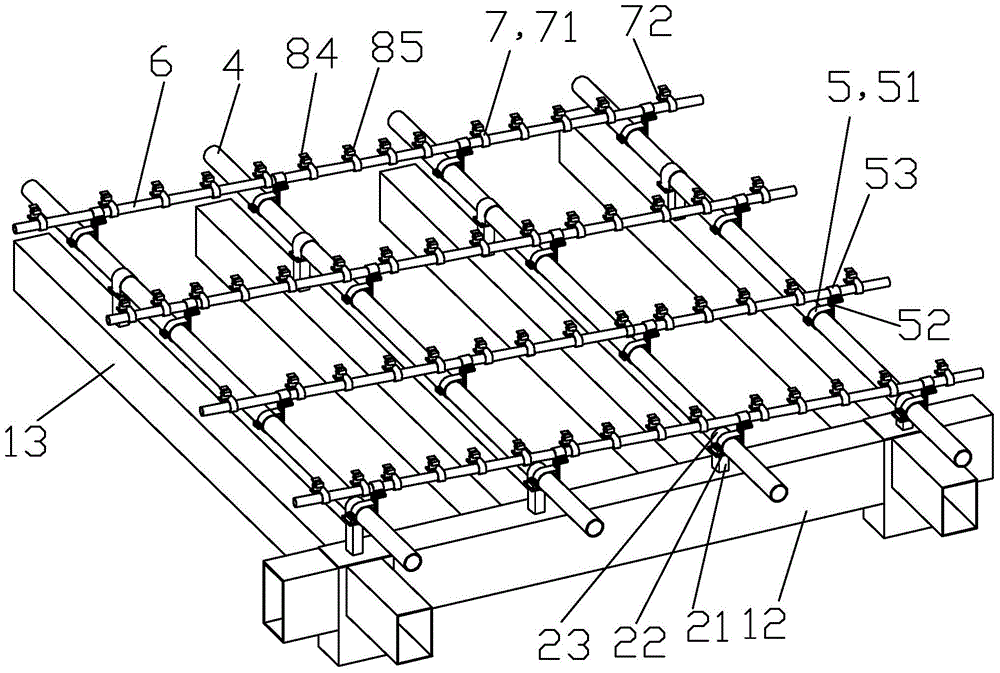

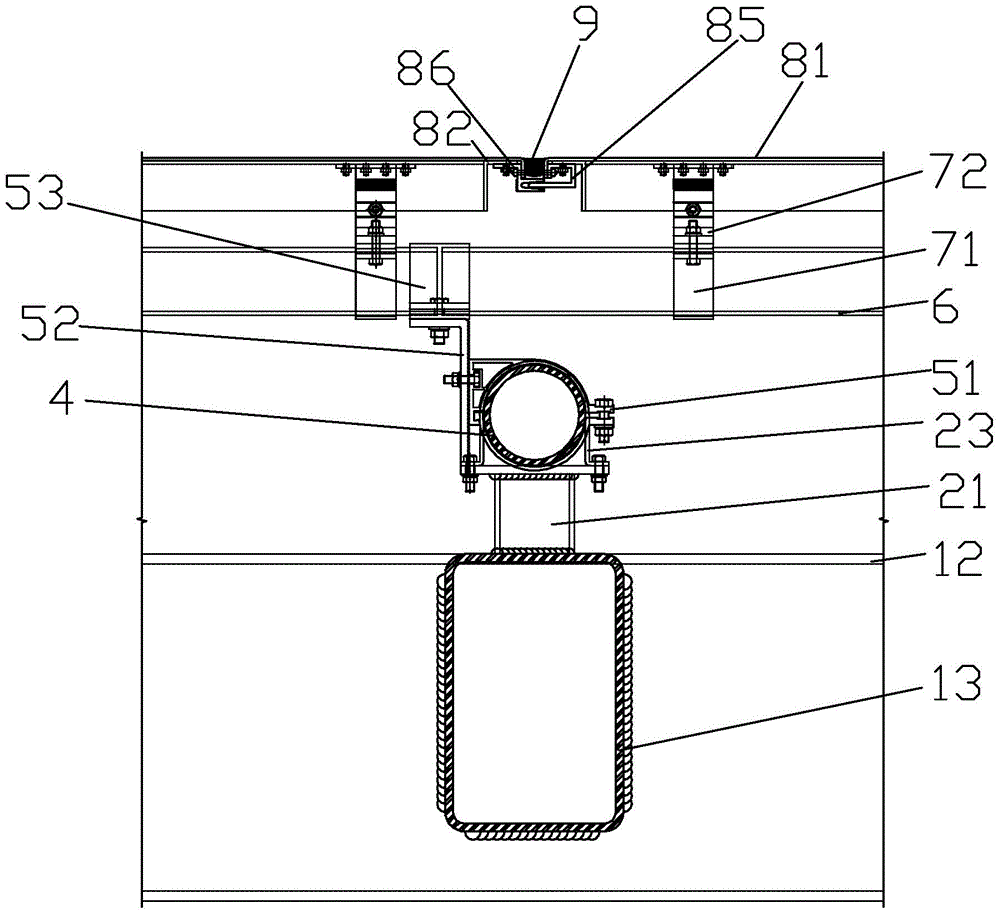

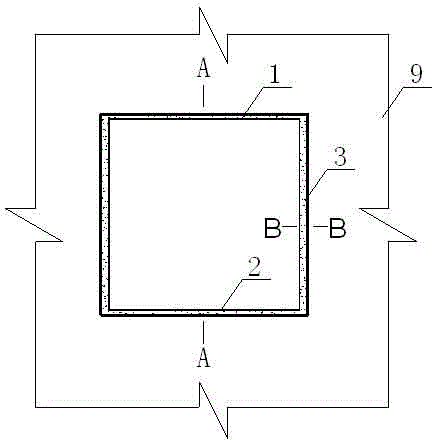

Fastener plug-in type curved surface metal roof and construction method thereof

ActiveCN103711258ASolve the odd-shaped surface problemGuaranteed free expansionRoof covering using slabs/sheetsBuilding material handlingArchitectural engineeringMetal roof

The invention provides a fastener plug-in type curved surface metal roof which comprises a base frame, primary purline supporting components, lengthening connecting fasteners, primary purlines, primary and secondary purline through connection components, secondary purlines, secondary purline panel through connection components, roof panel components and sealing components. The base frame is fixedly mounted on a civil engineering foundation roof face. The primary purlines are fixedly connected with the base frame through the primary purline supporting components. The secondary purlines are connected with the primary purlines through the primary and secondary purline through connection components. The secondary purline panel through connection components are connected with the secondary purlines. The roof panel components are connected with the secondary purline panel through connection components, two adjacent roof panel components are connected in an inserting mode, and the sealing components are arranged in the clearances of the roof panel components. A construction method mainly comprises the step that the base frame, the primary purline supporting components, the primary purlines, the primary and secondary purline through connection components, the secondary purlines, the secondary purline panel through connection components, the roof panel components and the sealing components are mounted in sequence. According to the fastener plug-in type curved surface metal roof and the construction method, steel and manpower cost can be effectively saved, the construction period can be shortened, and the new construction method of the curved surface metal roof is provided.

Owner:CHANGZHOU NO 1 CONSTR GRP

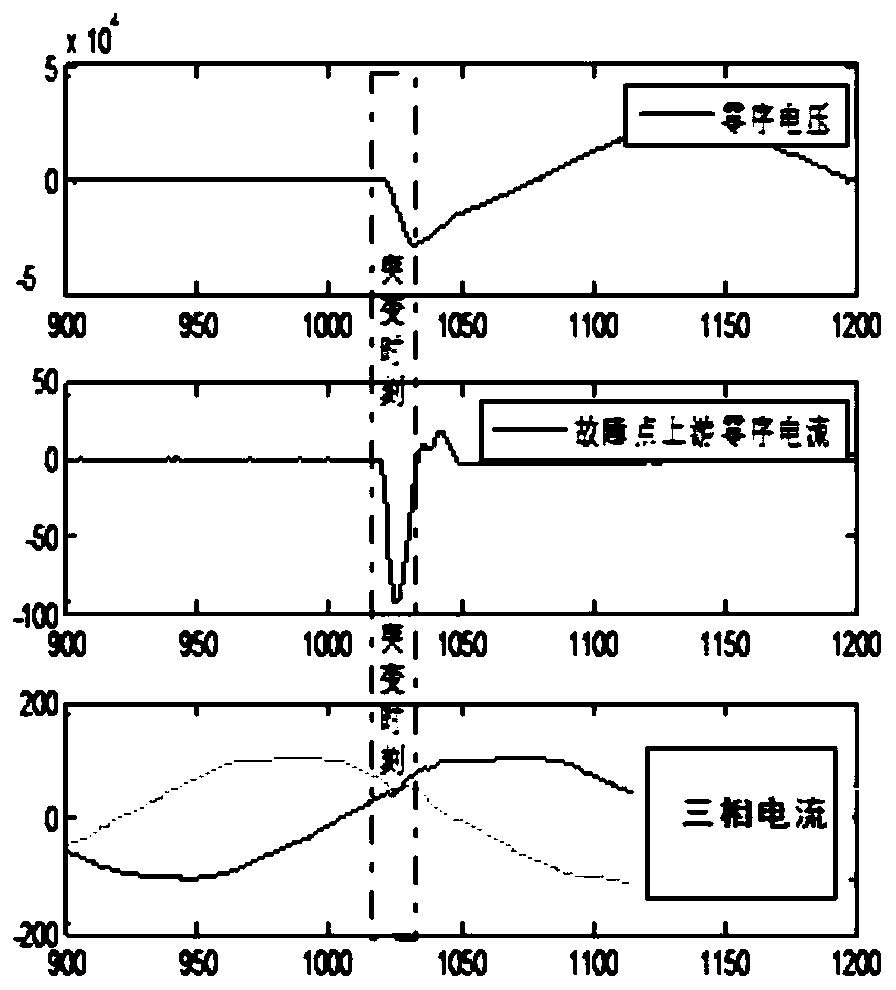

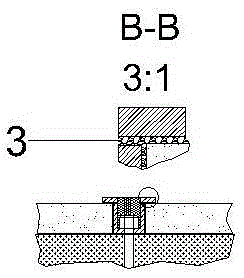

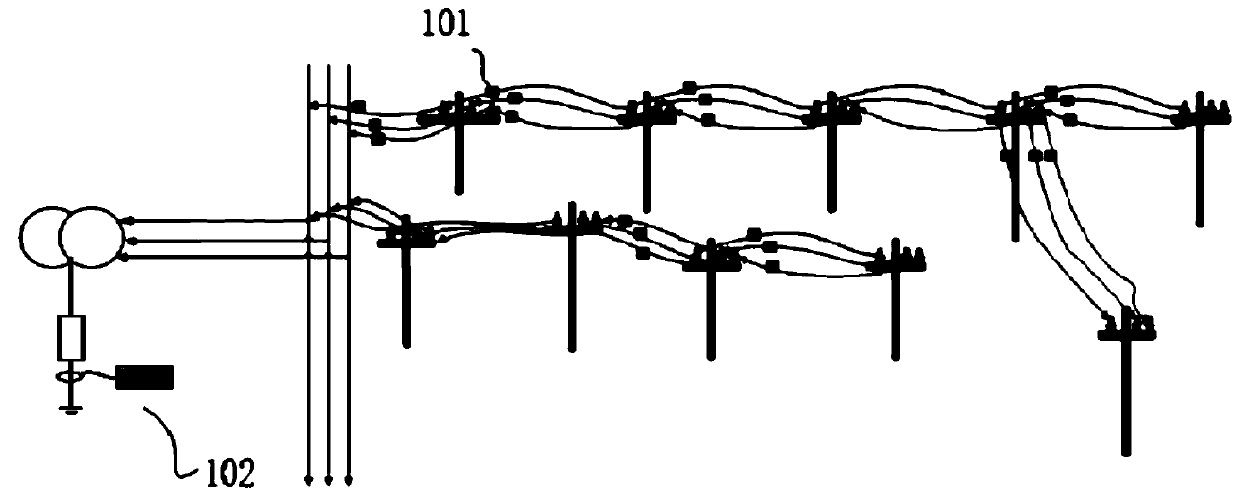

Single-phase ground fault locating method based on zero sequence voltage starting

InactiveCN110426593ANo wiring pull wires requiredConstruction saves time and effortFault location by conductor typesInformation technology support systemFault indicatorEngineering

The invention relates to a single-phase ground fault locating method based on zero sequence voltage starting. Zero sequence voltage is adopted as a single-phase ground fault break variable starting component, when a ground fault appears, a bus zero sequence voltage starting device can record zero sequence voltage waveforms at the break moment T, three-phase current waveforms of all high-precisiontransient wave recording type fault indicators installed along a transformer substation outgoing line at the same moment are called, and finally fault positioning is achieved based on wide area synchronous information. The purpose of single-phase ground fault locating in an existing power distribution network is achieved.

Owner:苏州银蕨电力科技有限公司

Repairing method for steel ladle wall permanent layer

InactiveCN105195723AAvoid the phenomenon of vibration deformationSimple processMelt-holding vesselsBrickSlag

The invention provides a repairing method for a steel ladle wall permanent layer. The repairing method is implemented after slag line bricks of a steel ladle wall working layer are dismantled, and comprises the specific operation steps that the wall permanent layer is cleaned, self-flow castable is prepared, new slag line bricks are laid several times, 1-2 layers are laid every time, the self-flow castable is poured between the new slag line bricks and heat preservation bricks after laying is finished, the steps are repeatedly executed till a 40-60 mm gap is reserved between new slag line bricks on the uppermost layer and a ladle edge opening swaged plate, the gap serves as an expansion gap and is filled with repairing materials, finally natural curing and baking are carried out, and therefore wall permanent layer repairing and new slag line brick laying are achieved. The self-flow castable is added with water and then stirred, vibration is avoided, and the constriction saves time and labor. In addition, the strength of the wall permanent layer is large after pouring due to the specific proportional range of Al2O3 and MgO, the repaired portion of the wall permanent layer is not likely to be poured out or damaged during ladle dismantling and overturning, the integrity is improved, and the service life is prolonged.

Owner:MCC BAOSTEEL TECH SERVICE

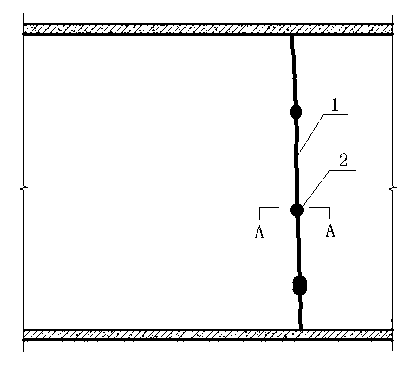

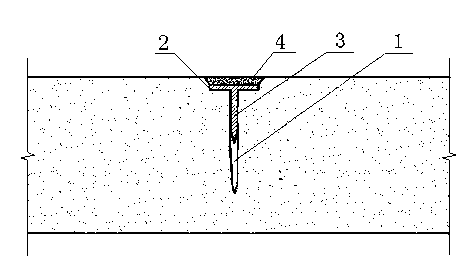

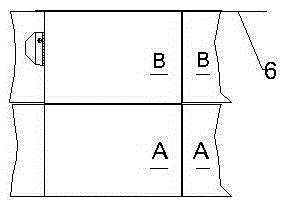

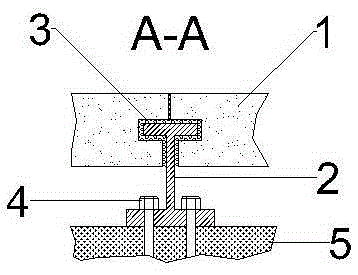

Repairing method and structure for building wall crack

InactiveCN103132707AAvoid deformationDeformation prevention or reductionBuilding repairsLacquerCement mortar

The invention discloses a repairing method and a structure for a building wall crack. At first, grooves (2) are polished in the crack along the length direction of the crack (1) at every 3-20 cm before the building wall crack is sealed, filled and leveled up through cement mortar or lacquer putty powder. Then, a metal nail (3) is used in each groove (2) to be embedded into the crack (1). The purposes of preventing deformation and narrowing the crack (1) are achieved by a manner that the metal nail (3) is embedded into the crack (1). At last, a nail head end of the metal nail is covered through the cement mortar (4) and the grooves are filled and leveled up. After the cement mortar is permanently set, the cement mortar or the lacquer putty powder is used for sealing, filling and leveling up rest wall building wall cracks. The repairing structure for the building wall crack not only has the advantages of being easy and convenient to construct, simple in structure and capable of preventing the crack from deforming continuously or narrowing the crack so as to prevent the crack from being produced again, but also has the advantages of being maintenance-free, low in construction cost, time-saving and labor-saving in construction and the like.

Owner:GUIZHOU CONSTR SCI RES & DESIGN INST OF CSCEC

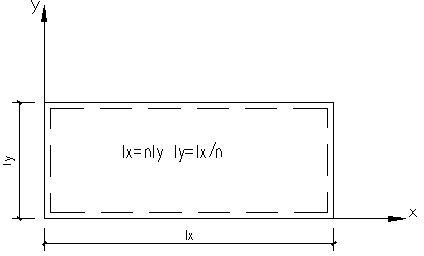

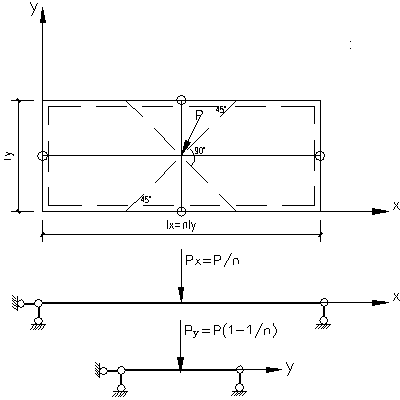

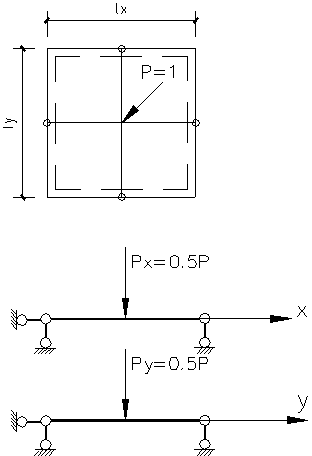

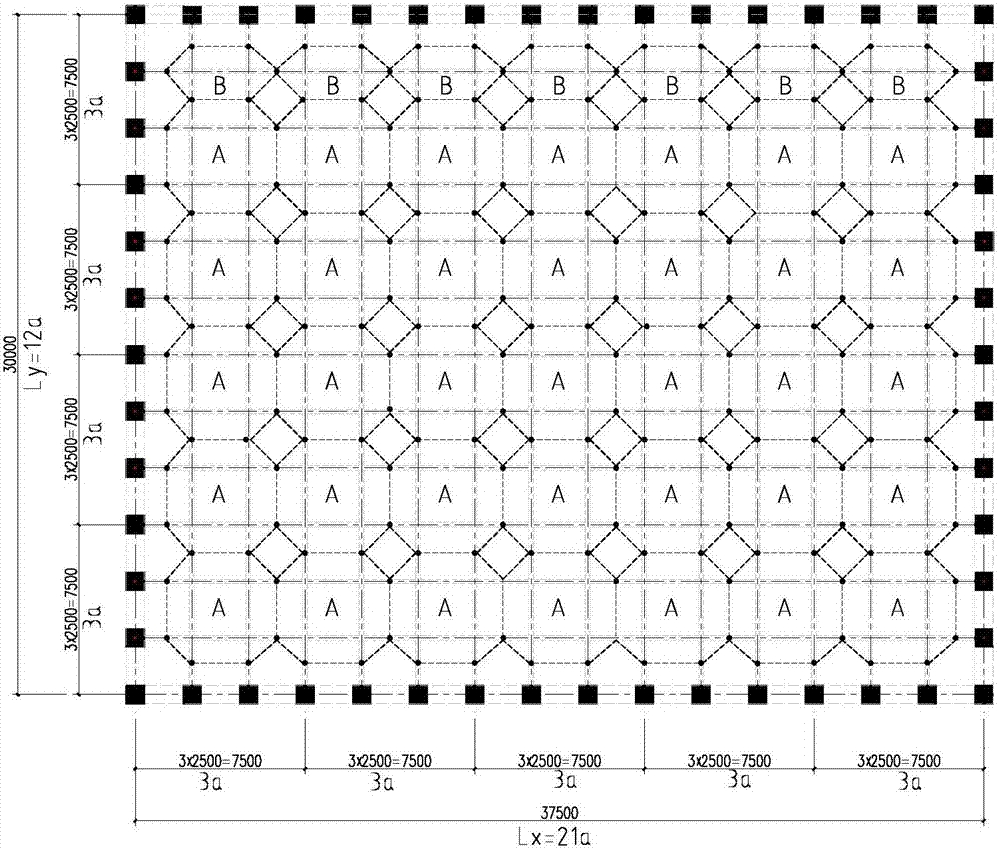

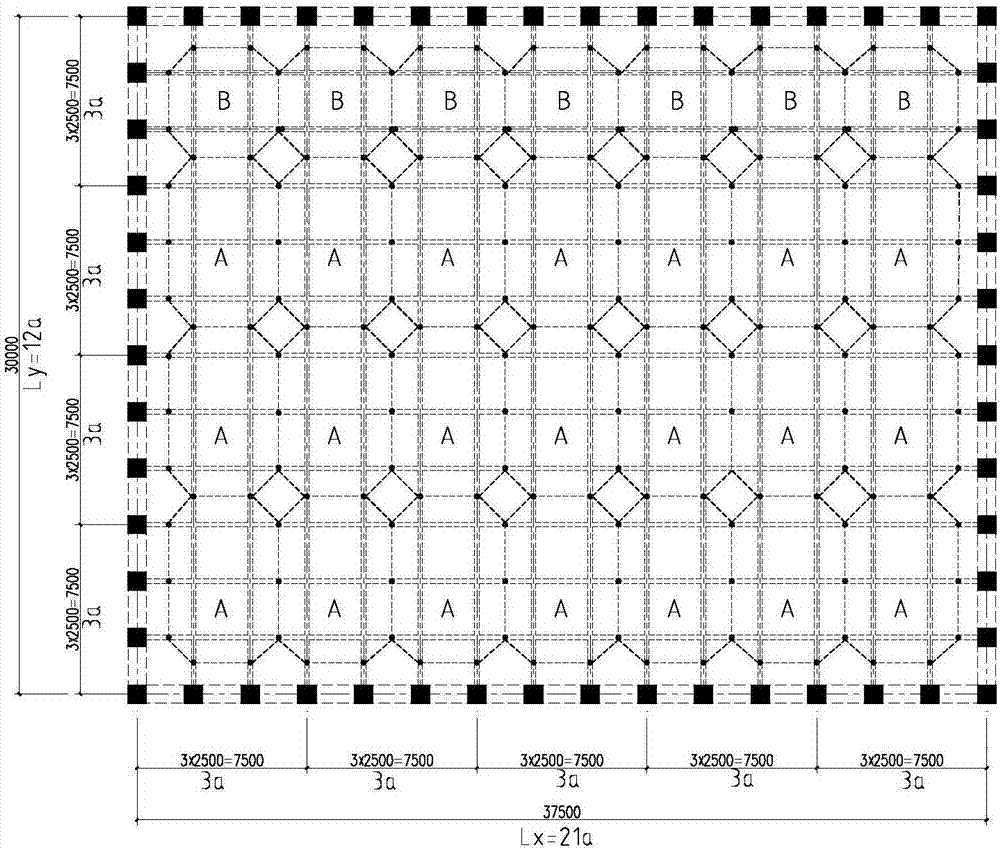

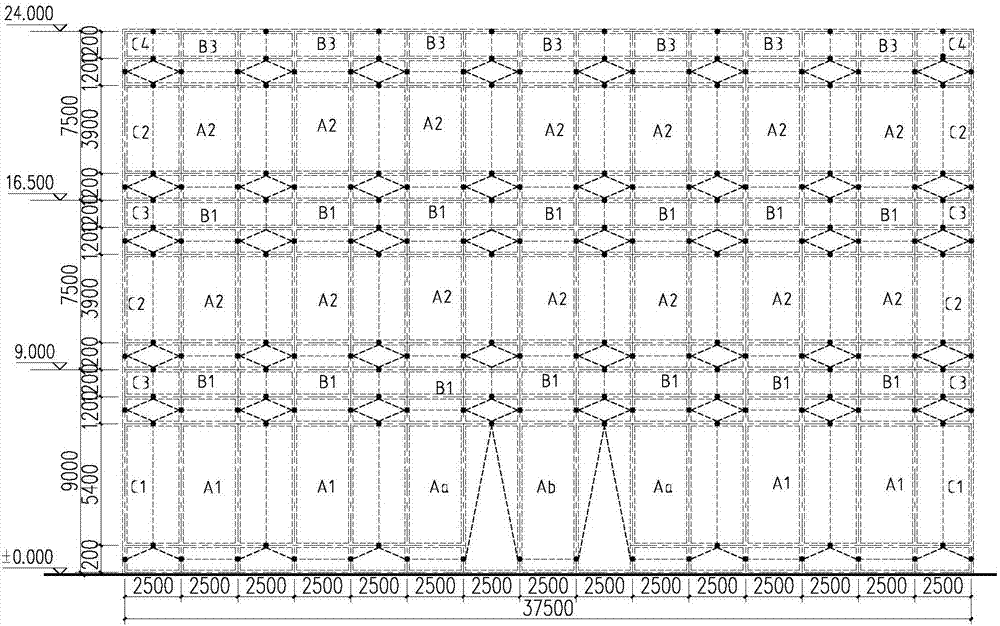

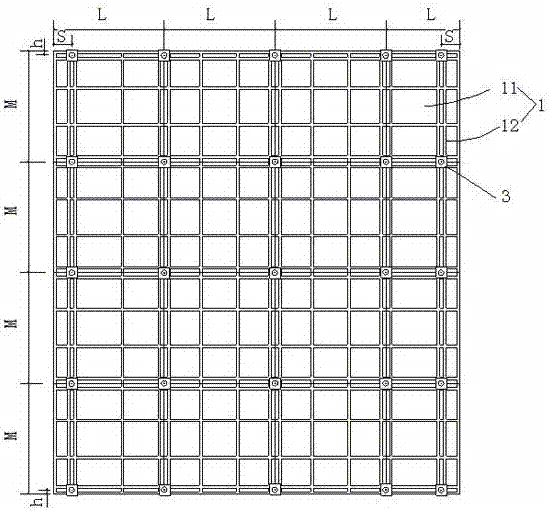

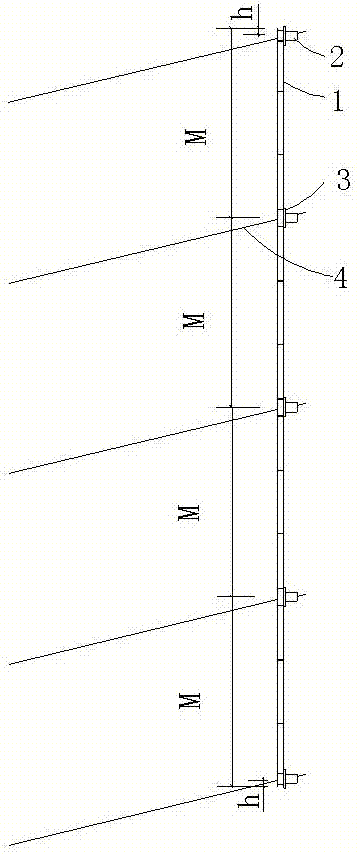

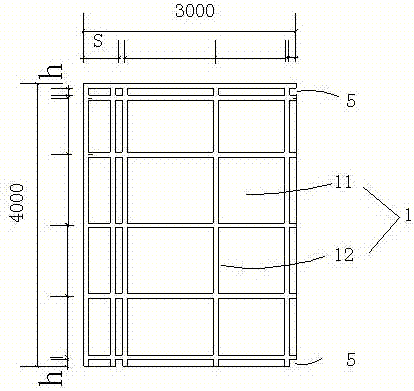

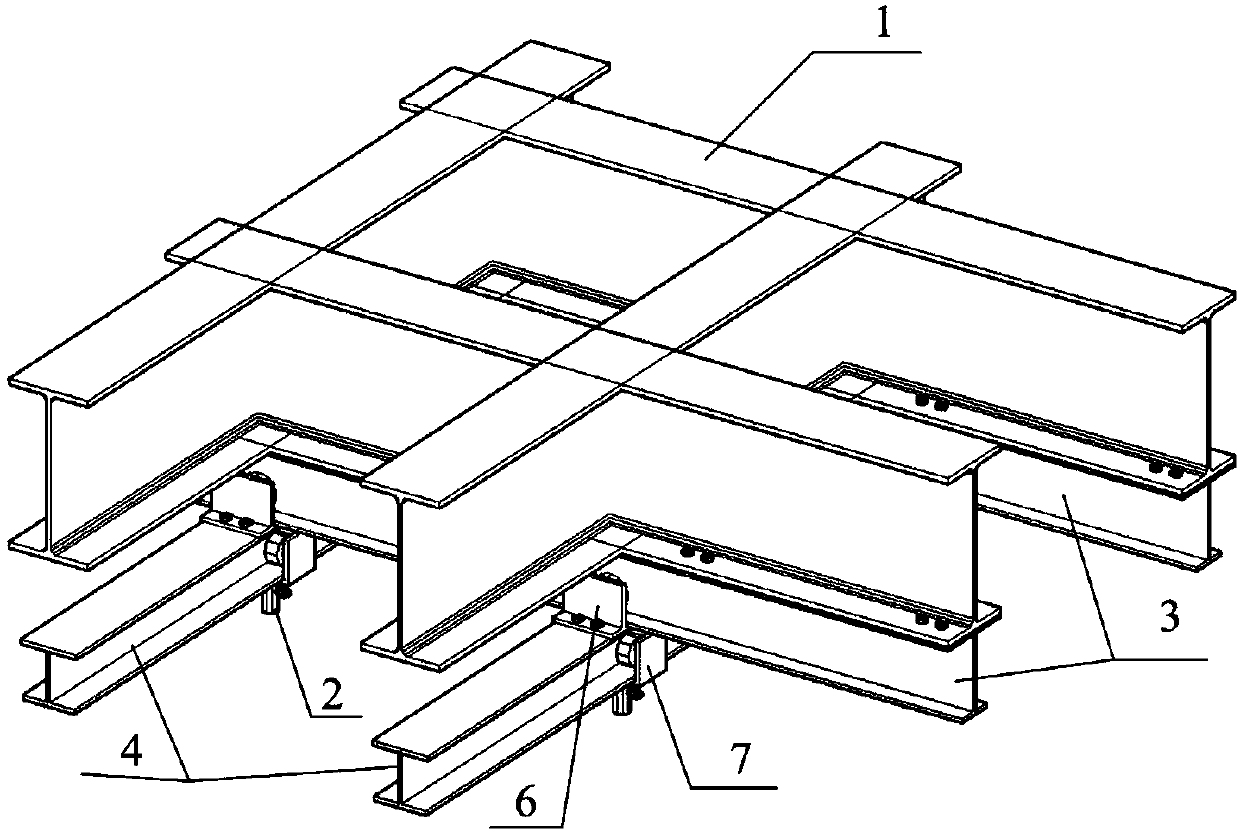

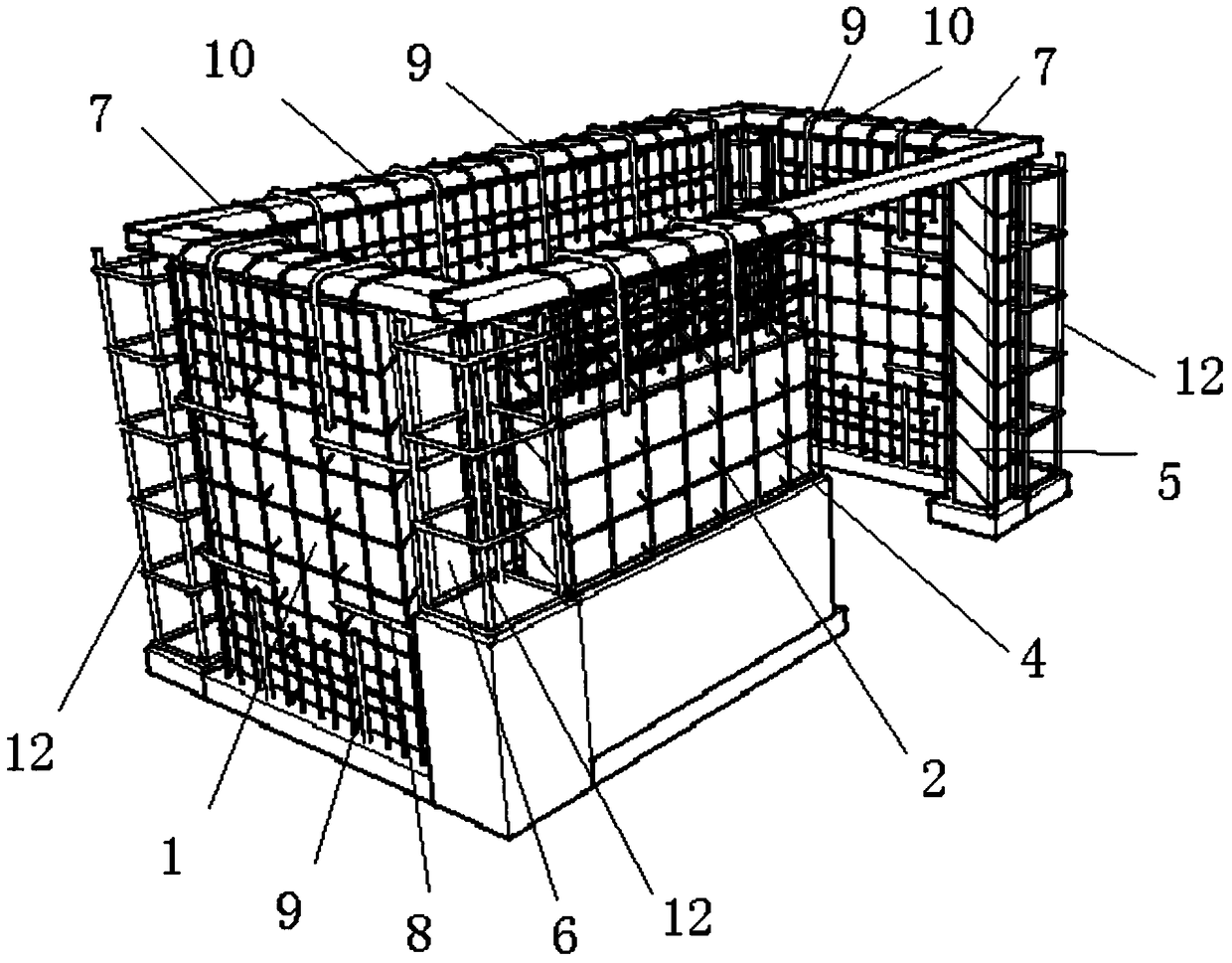

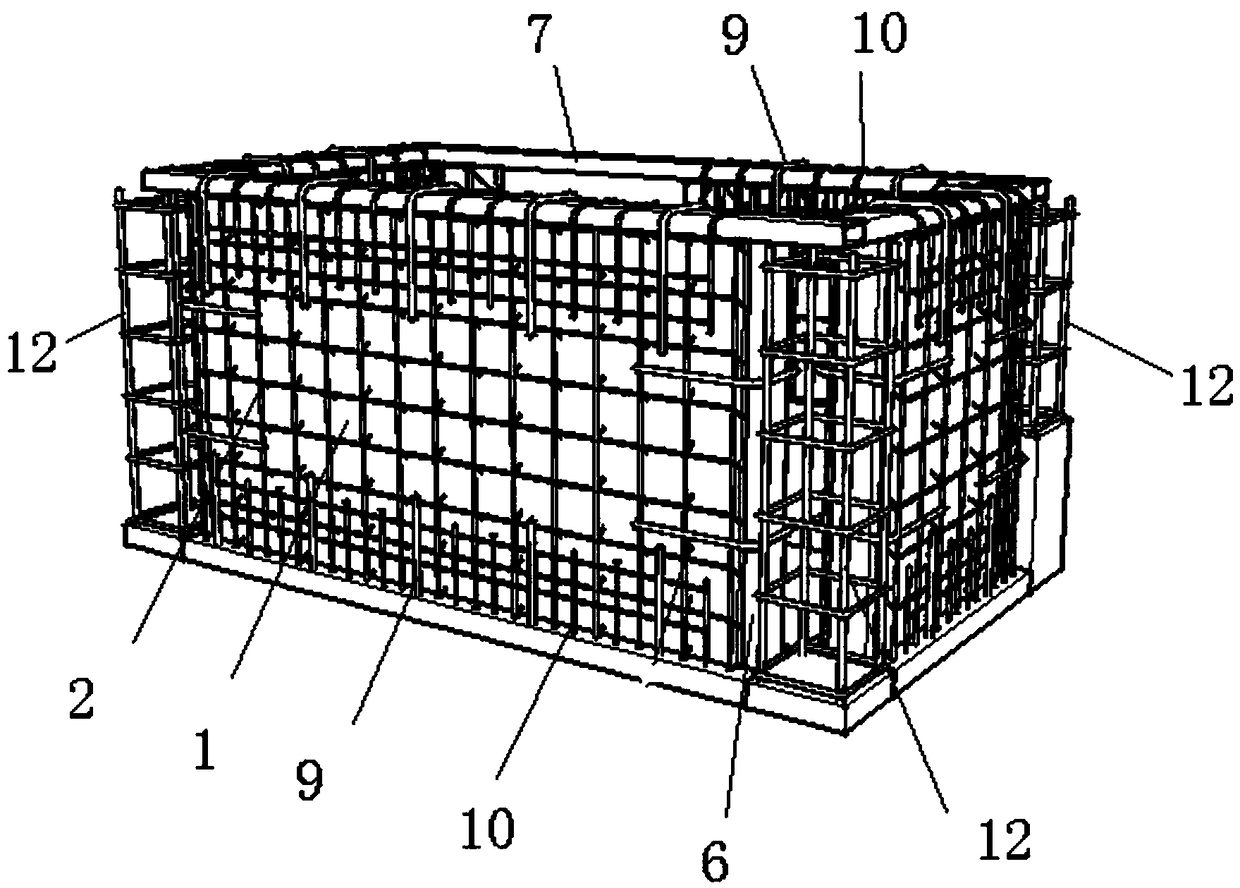

Multi-layer large-span fabricated orthogonal spatial concrete space grid box-type structure and manufacturing method

ActiveCN106996147ARealize the industrialization of prefabricationEvenly distributedFloorsSupporting systemMechanical models

The invention discloses a multi-layer large-span fabricated orthogonal spatial concrete space grid box-type structure and a manufacturing method. A peripheral supporting structure system of prefabricated large-span orthogonal spatial concrete hollow floors is changed into a concrete grid type framework with dense columns and dense beams from a concrete framework structure formed by casting of large column grids in site, and it is required that the sizes of floor grids are equal to the sizes of dense column grids. Small connecting beams are arranged at an upper window opening and a lower window opening of each layer of dense columns except connecting beams at the floor, so that the peripheral supporting structure system is changed into the grid type framework from the framework, and lateral resisting stiffness of the structure is improved by a large margin under the premise that structure materials are decreased. Because the transverse floors and the vertical supporting system both are composed of grids, the structure system is changed into the novel orthogonal spatial space grid box-type structure system of a mechanical model with plates.

Owner:SOUTHEAST UNIV +4

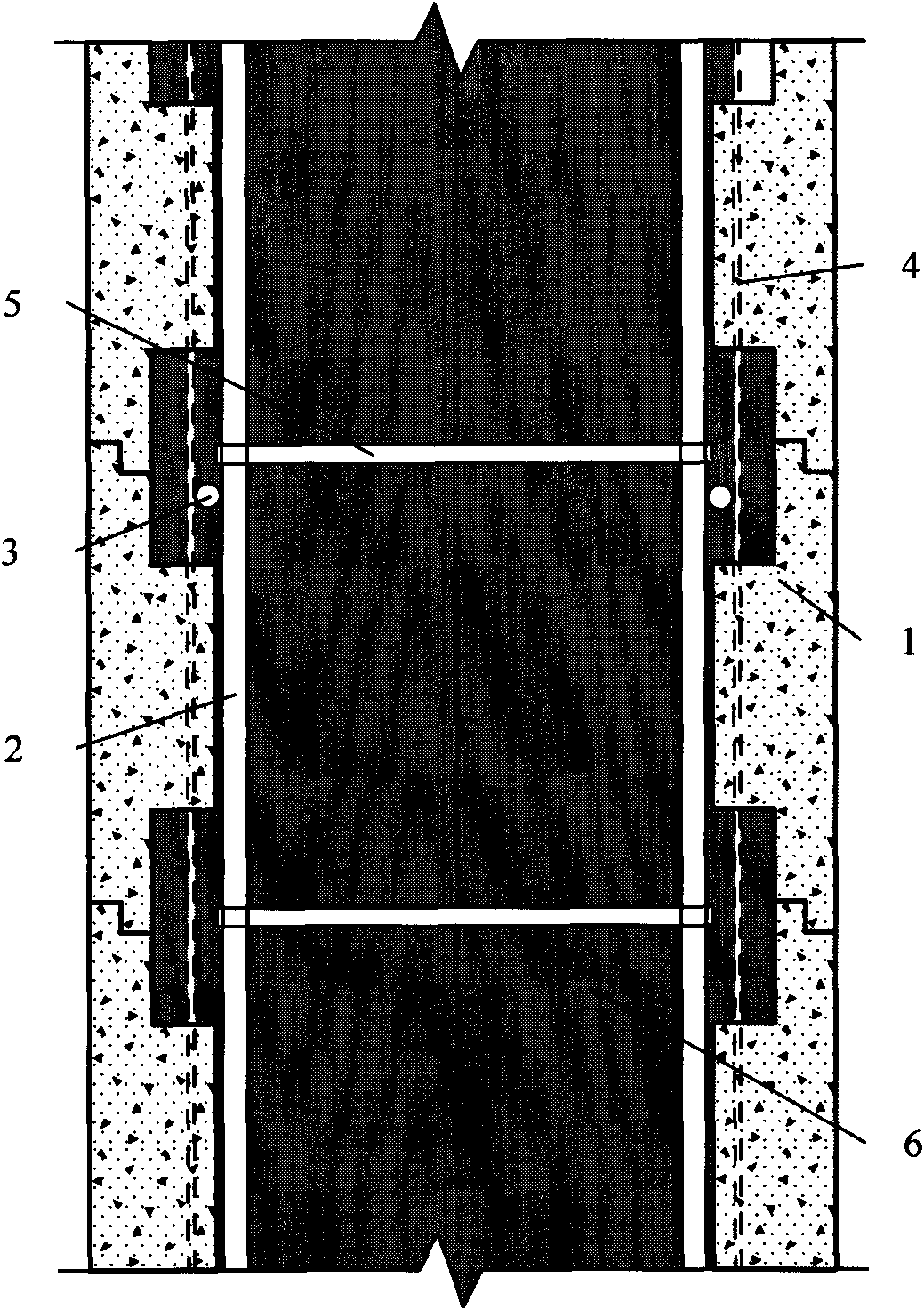

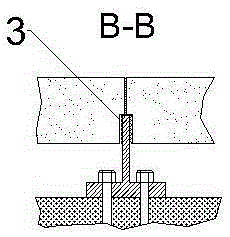

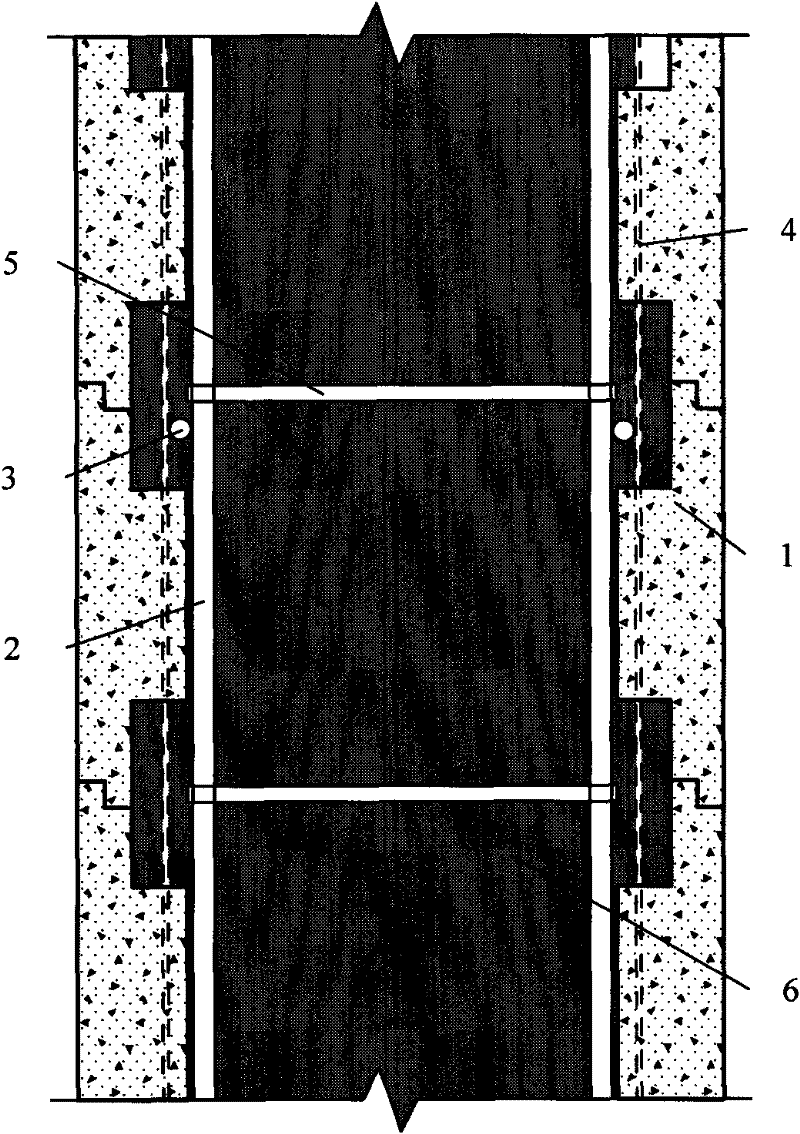

Precast spliced concrete slab wall body

InactiveCN101793068ASave time and effort in the construction processOverall goodConstruction materialWallsThermal insulationSurface plate

The invention discloses a precast spliced concrete slab wall body, which comprises an inner wall panel, an outer wall panel and an intermediate concrete layer. The inner wall panel and the outer wall panel are formed by splicing precast concrete slabs, the middle part of the concrete layer is provided with a steel reinforced frame, the steel reinforced frame is arranged along the whole length direction of the wall body and is connected with a bearing component on the wall edge, and horizontal steel wires are arranged at certain intervals along the height direction of the steel reinforced frame; and the inner surfaces of the inner wall panel and the outer wall panel are respectively provided with a prismatic table type bulge, and positioning steel wires parallel to the plate direction penetrate out of the prismatic table, are arranged in a triangular shape and are in clamping connection with the horizontal steel wires in the steel reinforced frame of the wall body. The invention has the advantages of good wall integrity, convenient construction, no need for formwork removal, low average density and good thermal insulation performance. Moreover, for the wall body constructed in the method, the manufacturing cost per unit area can be reduced.

Owner:叶翼翔 +2

Ceramic tile building block

The invention relates to a ceramic tile building block, which is characterized in that a splayed inclined edge is arranged in the middle of a horizontal hooked character stroke for forming a ceramic tile in a shape shown as the accompanying drawing, or the splayed inclined edge is arranged in the middle of a stroke formed by a right-falling character stroke and the horizontal hooked character stroke to form a ceramic tile in a shape shown as the accompanying drawing; after a metal strip in a shape like a Chinese character 'yu' is inserted into the back surface of the ceramic tile, the ceramic tile is put into a building block moulding press to be pressed together with a mixture of mineral slag, cement gel liquid and glass fiber short strips; the ceramic tile edge and acute angle spaces at the upper side of the ceramic tile building block can be firmly integrated with cement mortar; a plurality of trapezoidal spaces are formed in the built inner wall surface; hollowing and cracking phenomena cannot occur after cement mortar painting; the formed ceramic surface cannot generate loosening, falling or unexpected people injury phenomena; and the time and the labor are saved during construction.

Owner:施红

Recoverable and modular deep foundation pit construction process, recoverable module and deep foundation pit support

The invention provides a recoverable and modular deep foundation pit construction process, a recoverable module and a deep foundation pit support and belongs to the technical field of deep foundation pit excavation and supporting. The process comprises the following steps that a foundation pit is dug down; a first anchor cable hole is formed, a first anchor cable is put in, and a grouting stop plug is installed for grouting; a second anchor cable hole is formed, a second anchor cable is put in, and a grouting stop plug is installed for grouting; modules and connecting fasteners are installed; a prestressing force is exerted to the first anchor cable and the second anchor cable to for a first layer of supporting; the operations are repeated to form multiple layers of supporting; modules, anchor cables and connecting fasteners of the last layer of supporting are recovered, soil is backfilled to the bottom surface of the second layer of supporting till the first layer of supporting is recovered. A soil body surrounding a deep foundation pit is supported and retained by adopting the modules and anchor cables jointly, the modules can be recycled, and materials waste and construction cost are reduced.

Owner:河北建科唐秦建筑科技有限公司

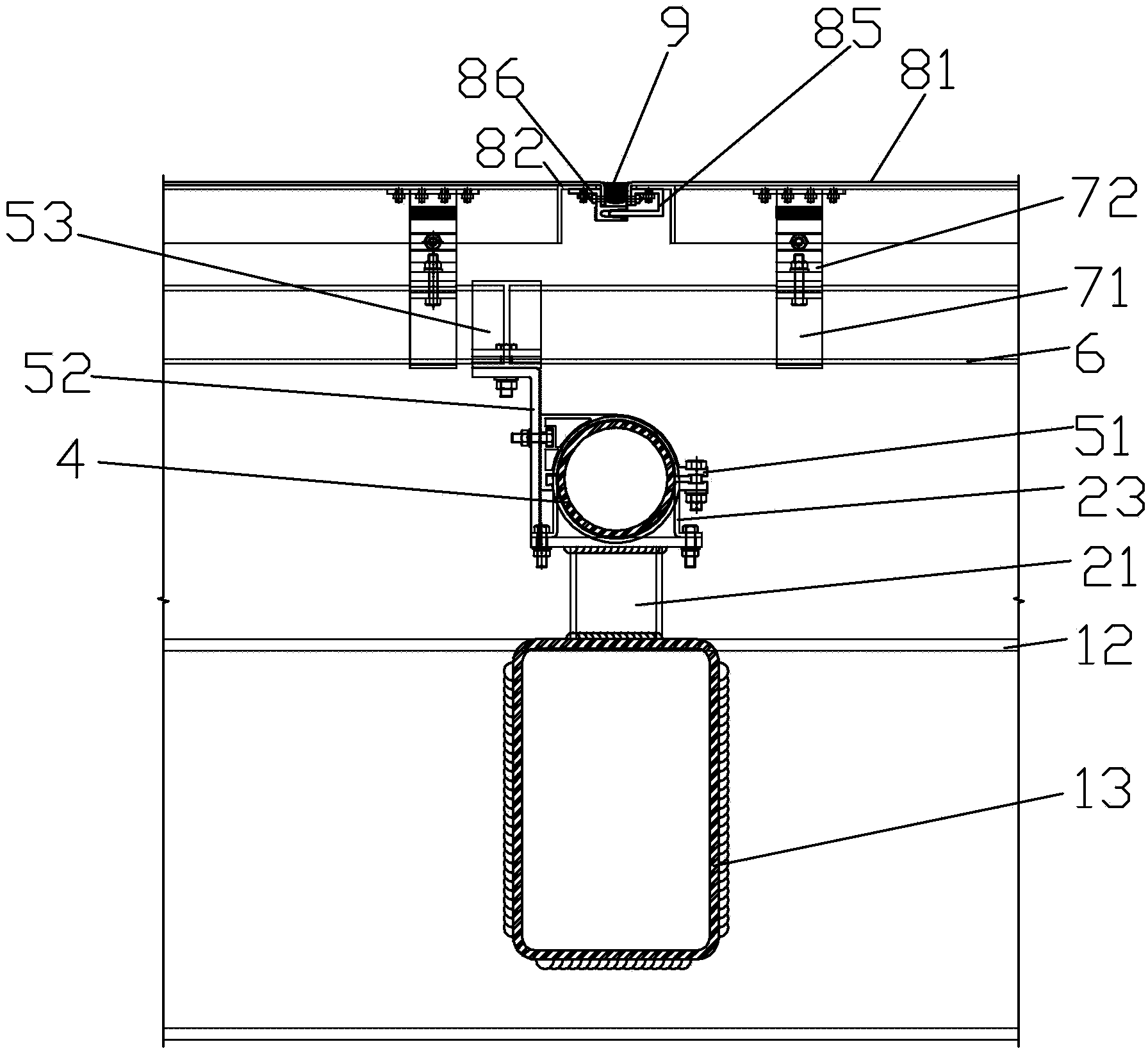

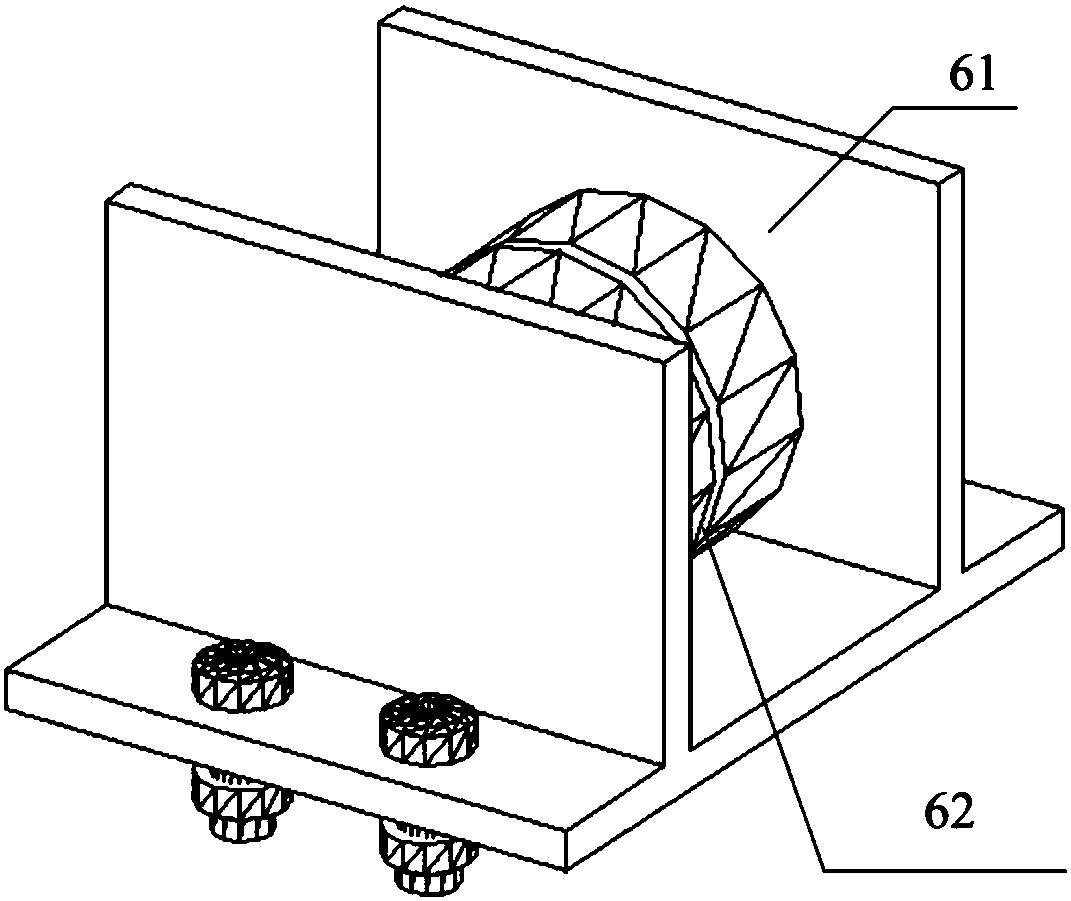

Contracting device for whole steel platform corner external scaffold system and construction method

ActiveCN107605141ANo collisionConstruction saves time and effortScaffold accessoriesBuilding support scaffoldsBeam directionThe Internet

The invention discloses a collection device and a construction method for an external hanging scaffolding system at the corner of an integral steel platform, which belongs to the field of super high-rise building construction, and solves the problem that the existing super high-rise core tube wall is closed outside the corner of the integral steel platform. The technical problem that the hanger cannot collect points at the same time. The retracting device includes a pair of orthogonally superimposed translating guide rail beams and retracting guide rail beams, the upper flange of the translating guide rail beams is closely fixed to the lower flange of the steel girder at the corner of the integral steel platform, and the retracting guide rail beams are It is arranged perpendicular to the direction of the translating guide rail beam and located below it, and the two are connected through the orthogonal superposition of the sliding node 1, and the external scaffolding system is connected with the retracting guide rail beam through the sliding node 2; The receiving guide rail beam can move in translation along the translation guide rail beam in the direction of the steel girder at the corner of the overall steel platform; with the help of the second sliding node, the external scaffolding system can move along the retracting guide rail beam to the inner direction of the core tube wall.

Owner:SHANGHAI CONSTRUCTION GROUP

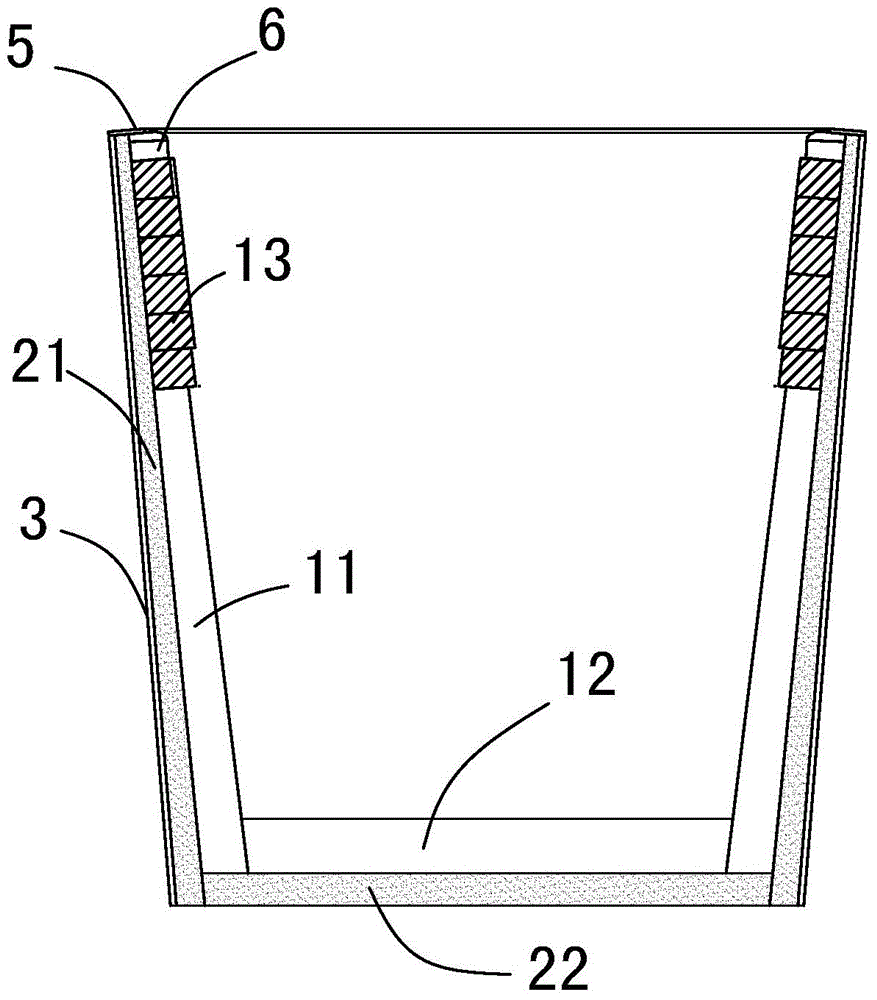

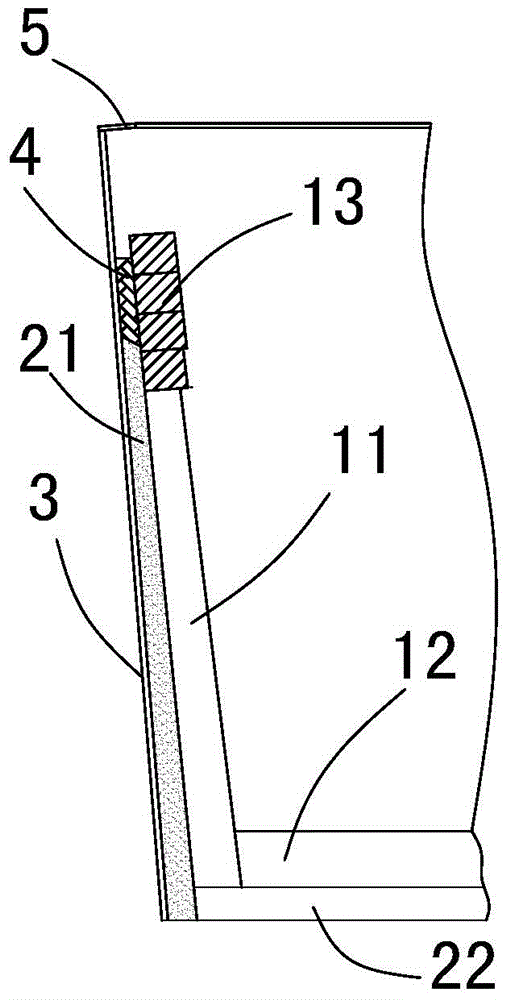

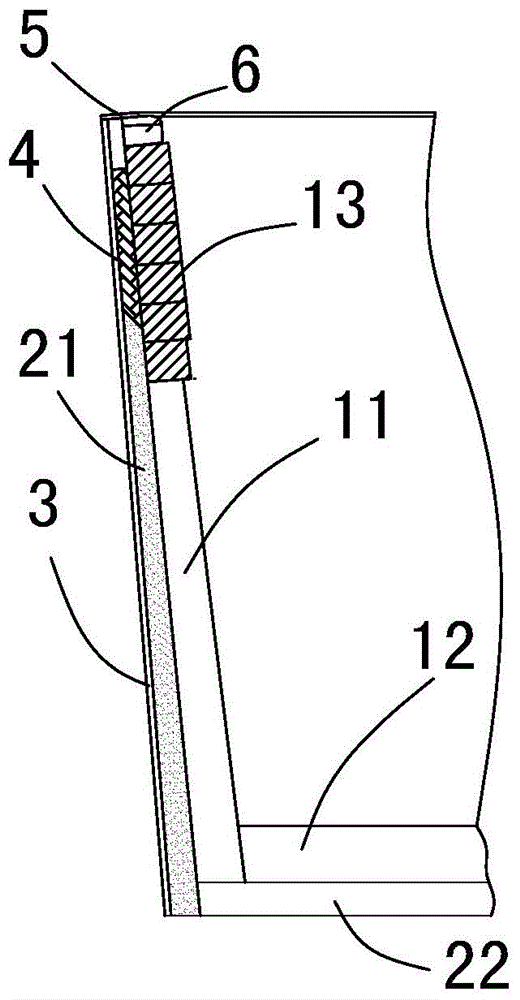

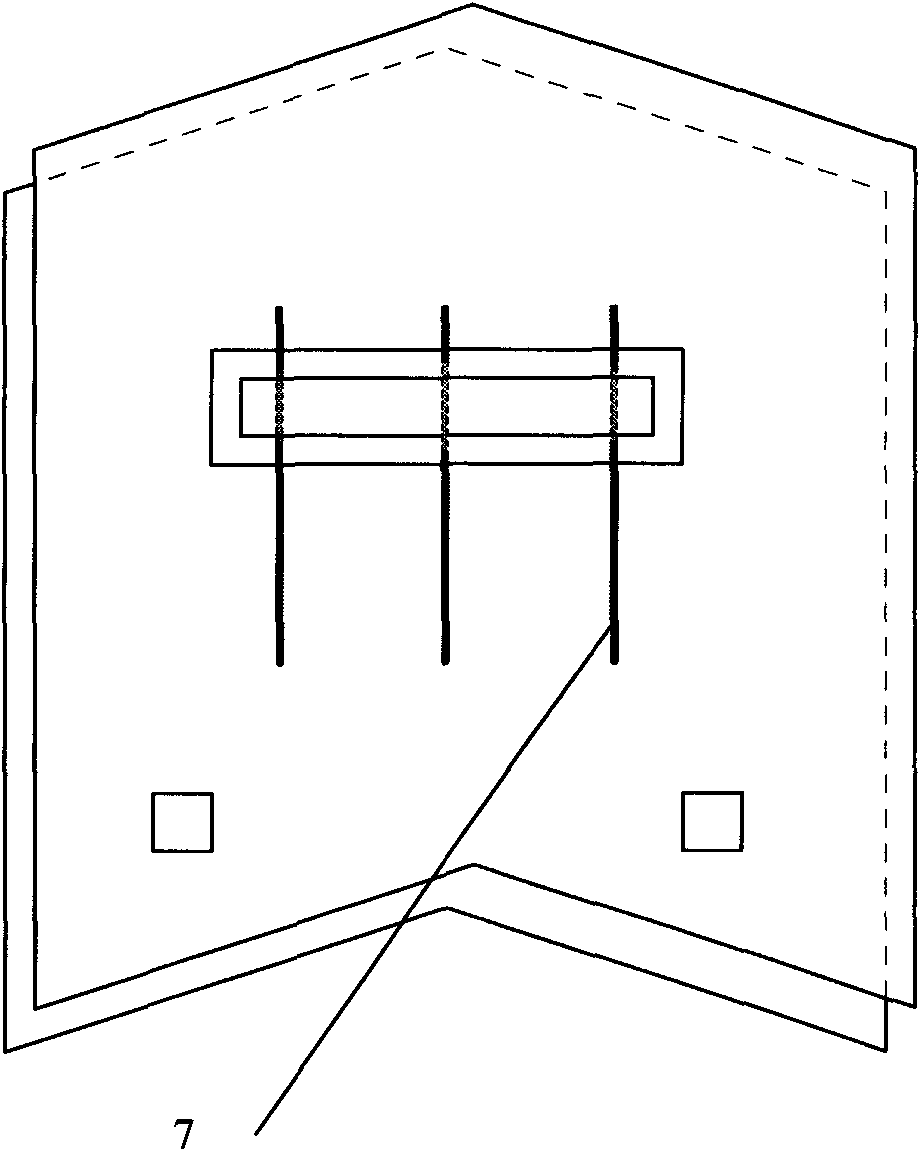

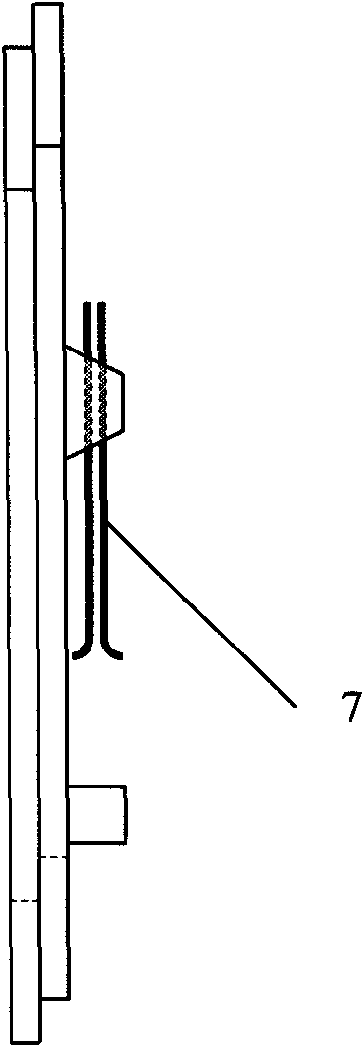

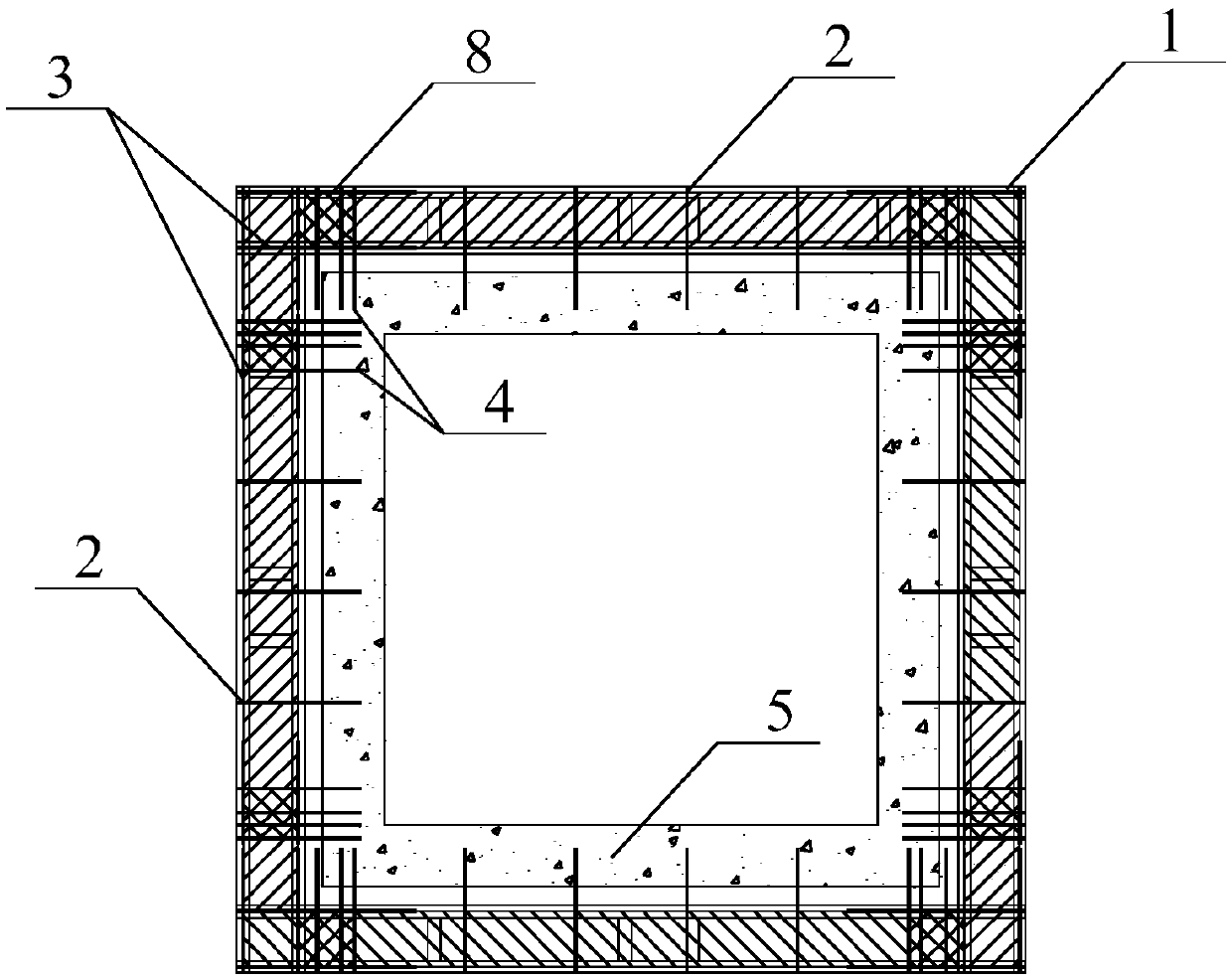

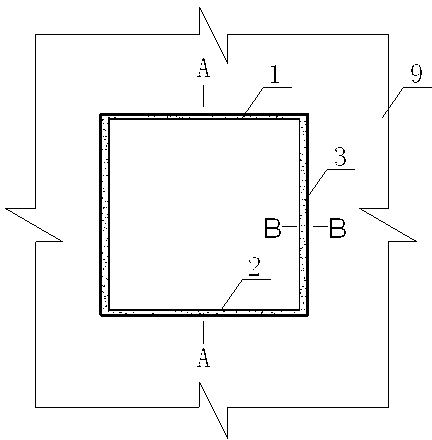

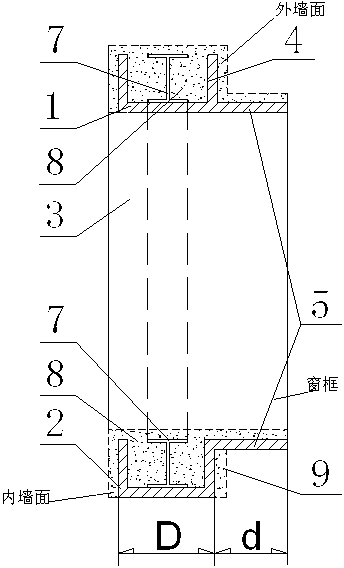

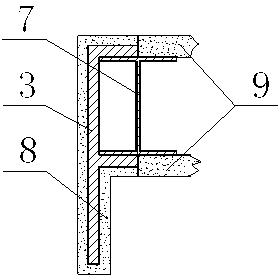

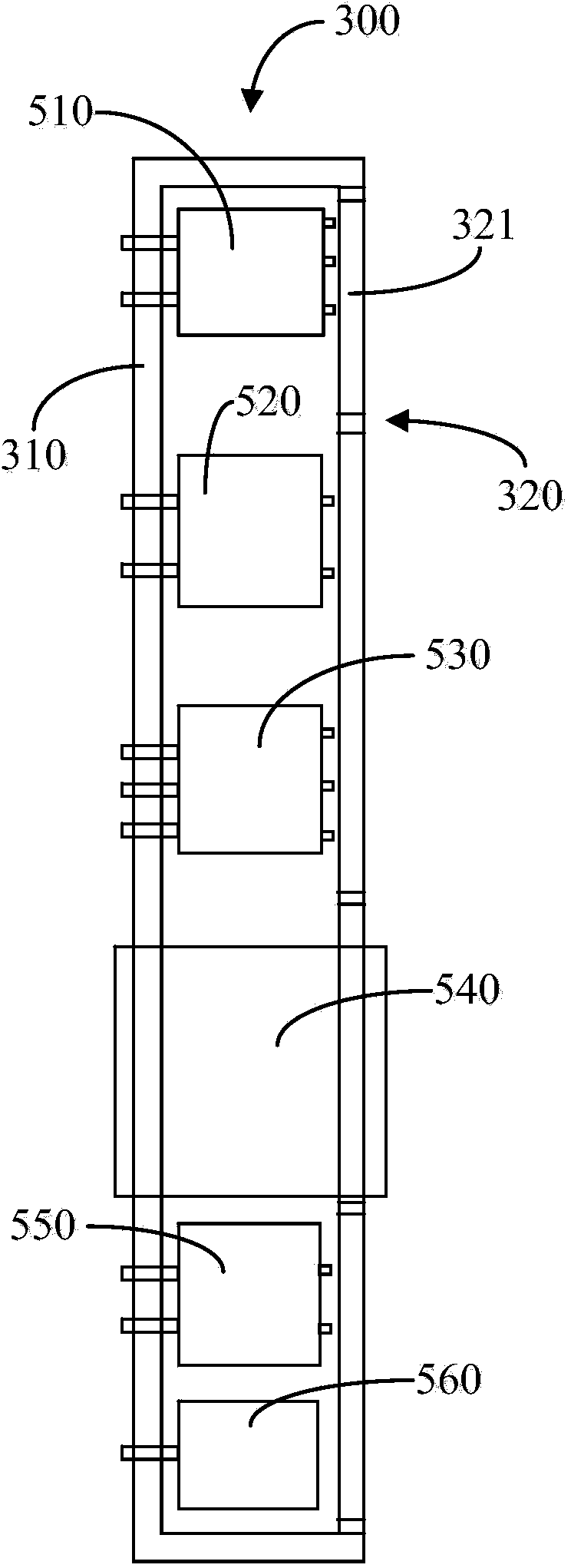

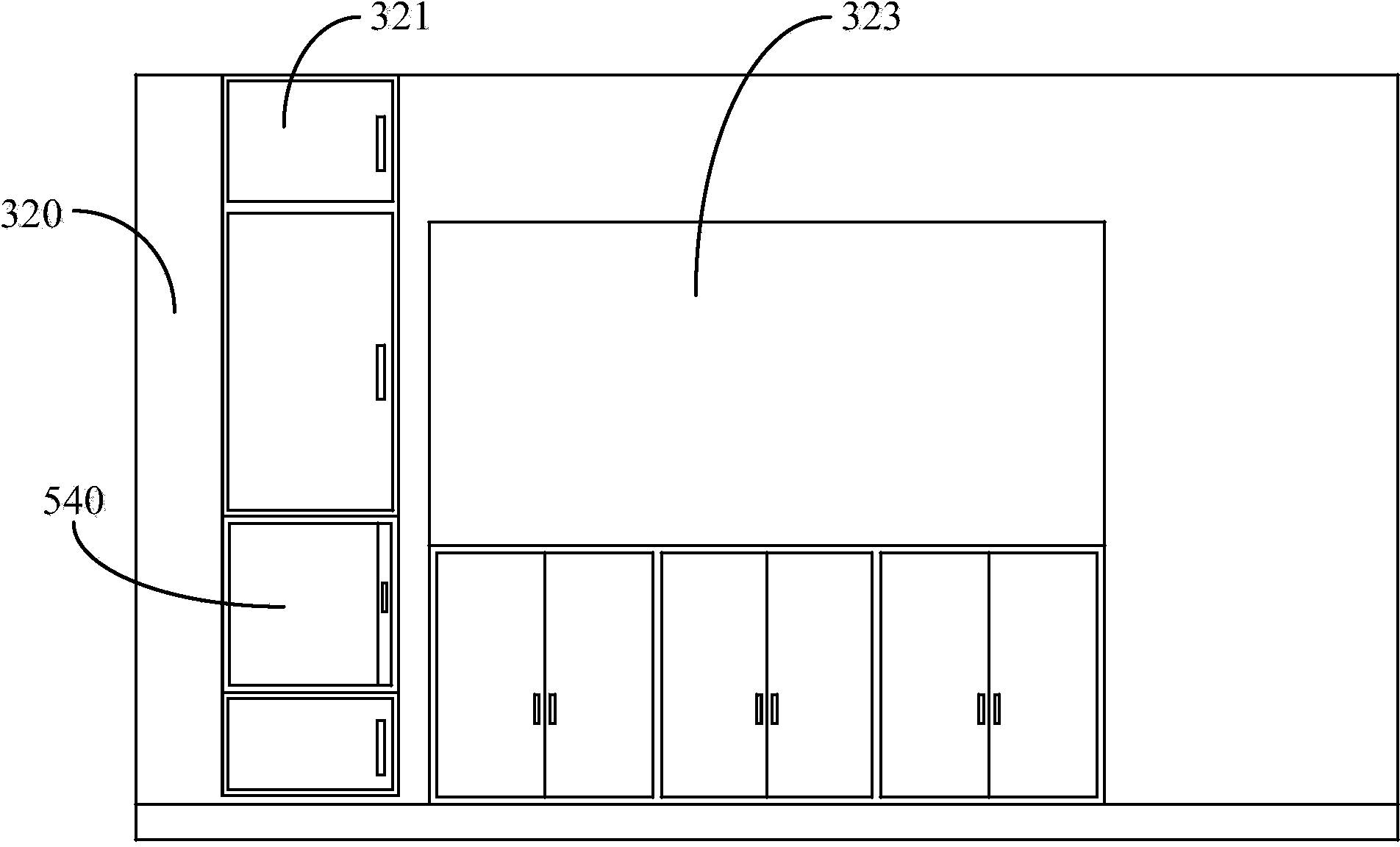

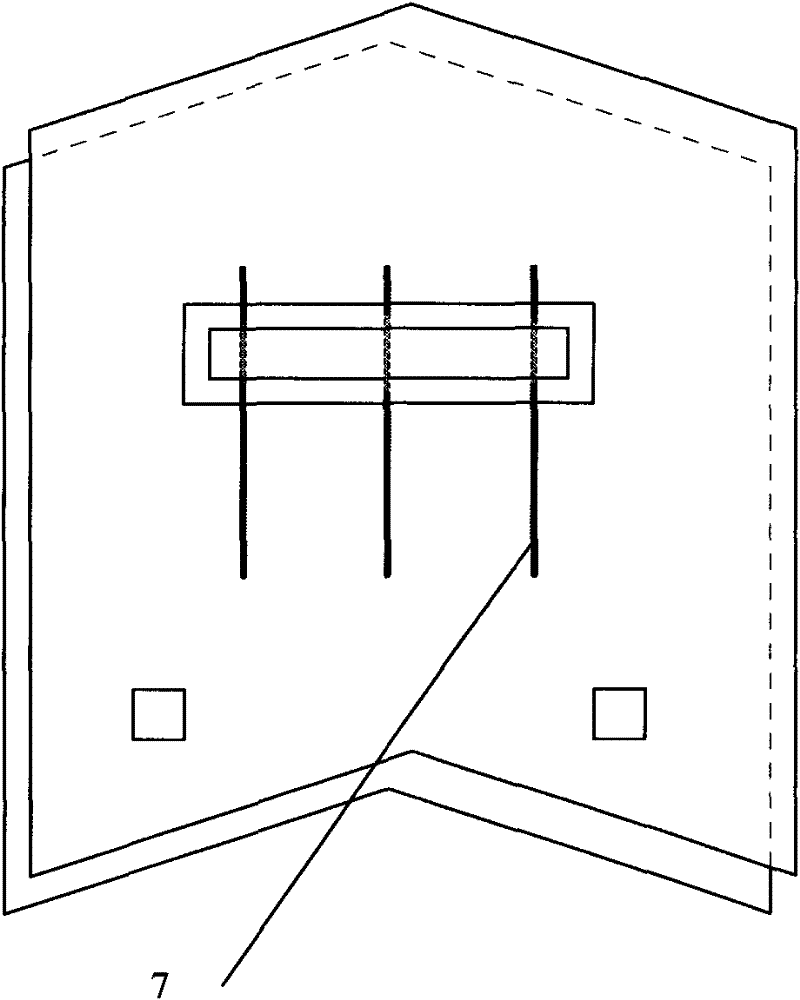

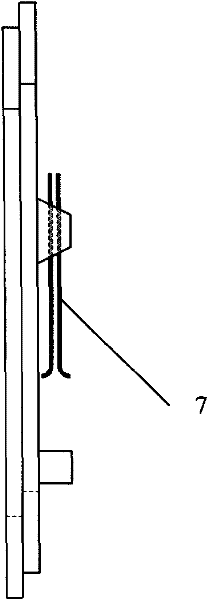

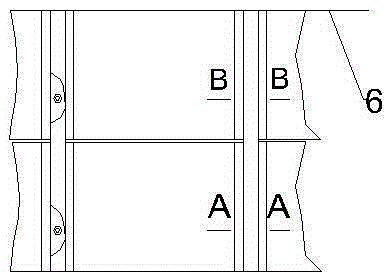

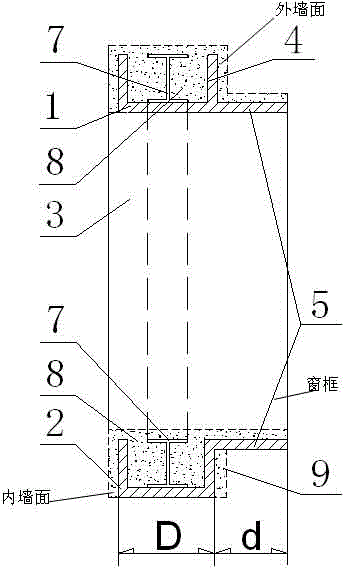

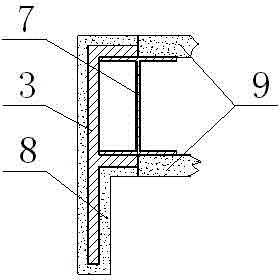

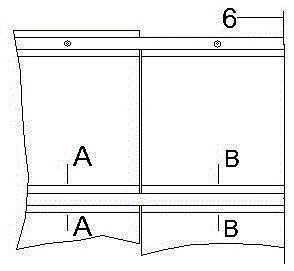

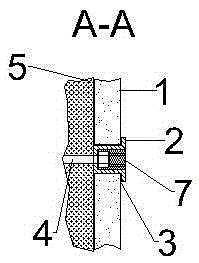

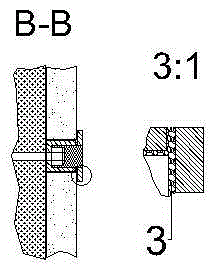

Assembling integrated type window frame for steel structure, and construction method of assembling integrated type window frame

The invention discloses an assembling integrated type window frame for a steel structure, and a construction method of the assembling integrated type window frame. The construction method comprises the following steps: producing components of the assembling integrated type window frame in a factory in advance and in batches; setting a clamping groove in the outer side of each component; conveying the components to an industrial or civil building construction site of the steel structure which is manufactured; and taking a hole of each steel grid consisting of vertical H-shaped steel and transverse H-shaped steel of a wall structure of the steel structure as a position where the building needs to open a window, buckling the clamping groove of each component on the H-shaped steel forming the hole, and pouring fine aggregate concrete into the clamping grooves of upper window frame and lower window frame components of the assembling integrated type window frame, so that the assembling integrated type window frame and the steel grid H-shaped steel of the steel structure can be connected into a whole, and construction of the assembling integrated type window frame for the steel structure is finished. The assembling integrated type window frame for the steel structure, and the construction method of the assembling integrated type window frame have the advantages of low manufacturing cost, easiness in manufacturing and construction, high production efficiency, high quality, long service life, high fireproof performance, avoidance of environmental pollution and the like.

Owner:GUIZHOU UNIV +2

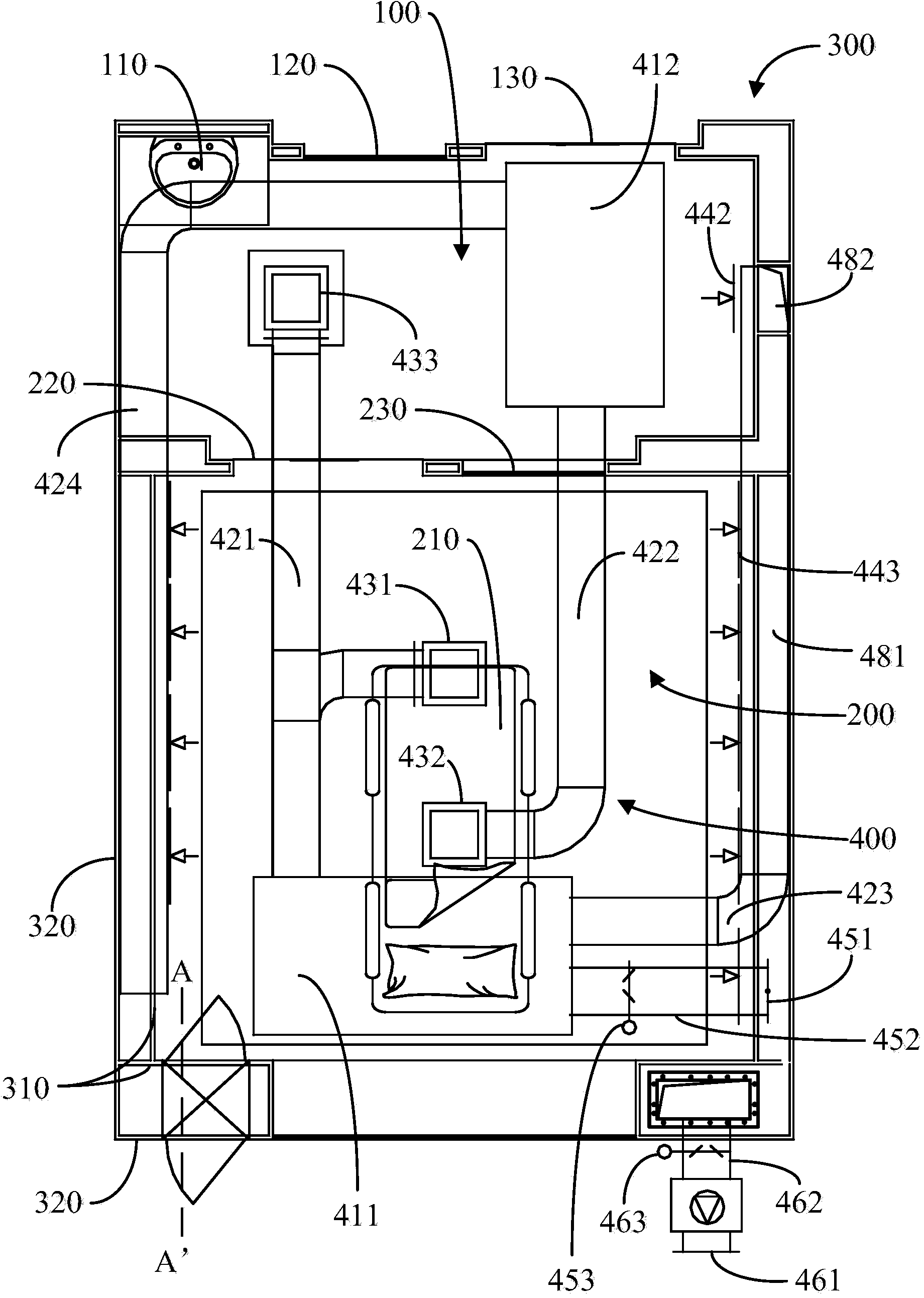

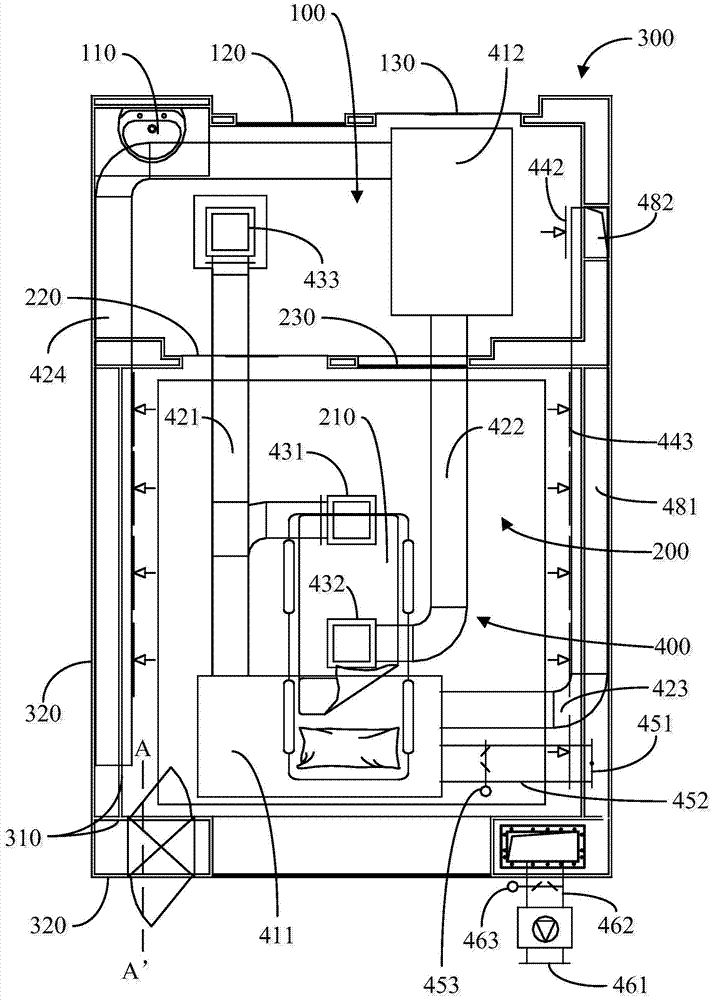

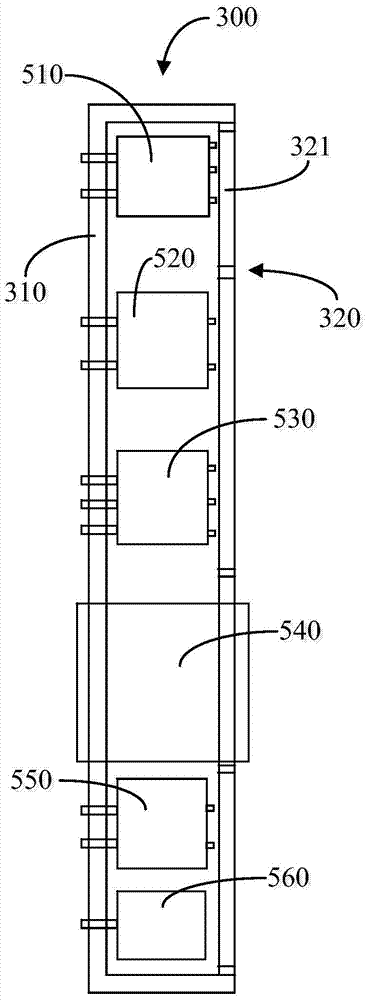

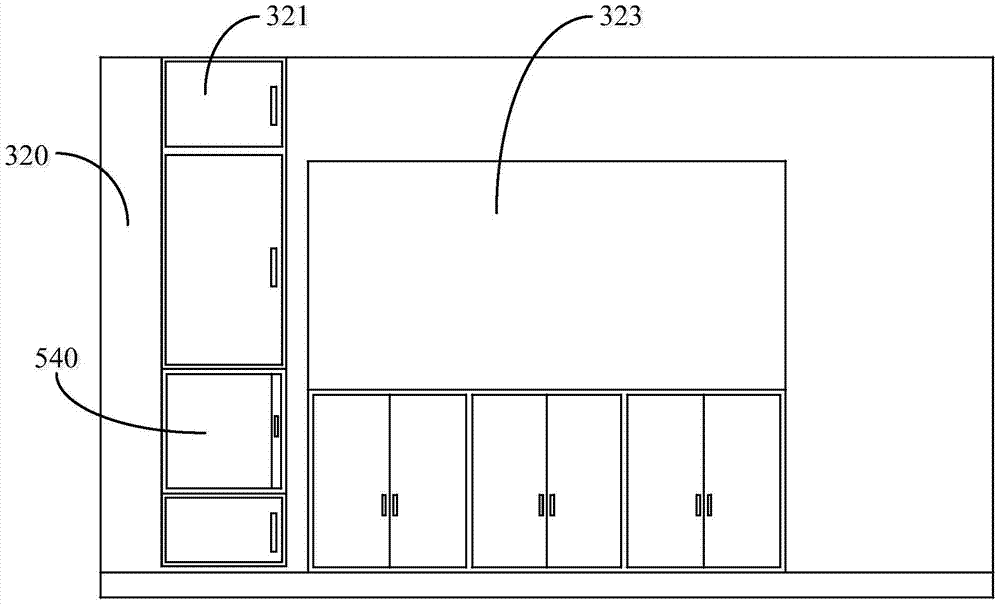

Integrated ward

ActiveCN104032984AConstruction saves time and effortEasy wiringDucting arrangementsLighting and heating apparatusMedical wardWeak current

The invention provides an integrated ward. The integrated ward comprises a sickbed and a partition wall, wherein the partition wall on at least one side comprises an inner wall and an outer wall; an accommodating space is formed between the inner wall and the outer wall; a medical gas valve box, a strong current box, a weak current box and an isolating transformer are arranged in the accommodating space; one end of the medical gas valve box is connected to a medical gas terminal inside the integrated ward, and the other end of the medical gas valve box is connected with a medical gas source pipeline outside the integrated ward; the strong current box is connected with an external power supply and used for supplying power to electrical equipment in the ward; a plurality of internal weak current equipment interfaces are formed in one end of the weak current box and connected to the interior of the integrated ward; a plurality of external weak current equipment interfaces are formed in the other end of the weak current box and used for connecting external lines; the isolating transformer is used for preventing electric leakage or voltage instability. By virtue of the mode, the integrated ward has the advantages that time and labor are saved in construction, and wire arrangement is simple and maintenance is convenient.

Owner:雷湛成

Indoor wall stone cladding

Indoor wall stone cladding comprises stone slabs, I-shaped steel racks, cladding glue, expansion screws, a wall and wall top corners. The I-shaped steel racks are vertically arranged and fixed to the wall with the expansion screws, the upper edges of vertical supports on the I-shaped steel racks are removed, grooves corresponding to the I-shaped steel racks are pre-cut in left and right sides of the stone slabs, inner terraces of these grooves need gaps for the vertical supports of the I-shaped steel racks to be cut, the stone slabs are wrapped and hoisted with strips during installation, the cladding glue is spread in the grooves, the stone slabs are inserted along two I-shaped steel racks into their opposing upper edges and lowered down, the strips are removed, with respect to the stone slabs at the wall top corners, the back of each stone slab can be cut gaps in left and right sides, and the stone slabs are pasted and fixed directly to the vertical supports of the I-shaped steel racks with the cladding glue.

Owner:刘卫东

Precast spliced concrete slab wall body

InactiveCN101793068BImprove integrityLow densityConstruction materialWallsClamp connectionThermal insulation

The invention discloses a precast spliced concrete slab wall body, which comprises an inner wall panel, an outer wall panel and an intermediate concrete layer. The inner wall panel and the outer wall panel are formed by splicing precast concrete slabs, the middle part of the concrete layer is provided with a steel reinforced frame, the steel reinforced frame is arranged along the whole length direction of the wall body and is connected with a bearing component on the wall edge, and horizontal steel wires are arranged at certain intervals along the height direction of the steel reinforced frame; and the inner surfaces of the inner wall panel and the outer wall panel are respectively provided with a prismatic table type bulge, and positioning steel wires parallel to the plate direction penetrate out of the prismatic table, are arranged in a triangular shape and are in clamping connection with the horizontal steel wires in the steel reinforced frame of the wall body. The invention has the advantages of good wall integrity, convenient construction, no need for formwork removal, low average density and good thermal insulation performance. Moreover, for the wall body constructed in the method, the manufacturing cost per unit area can be reduced.

Owner:叶翼翔 +2

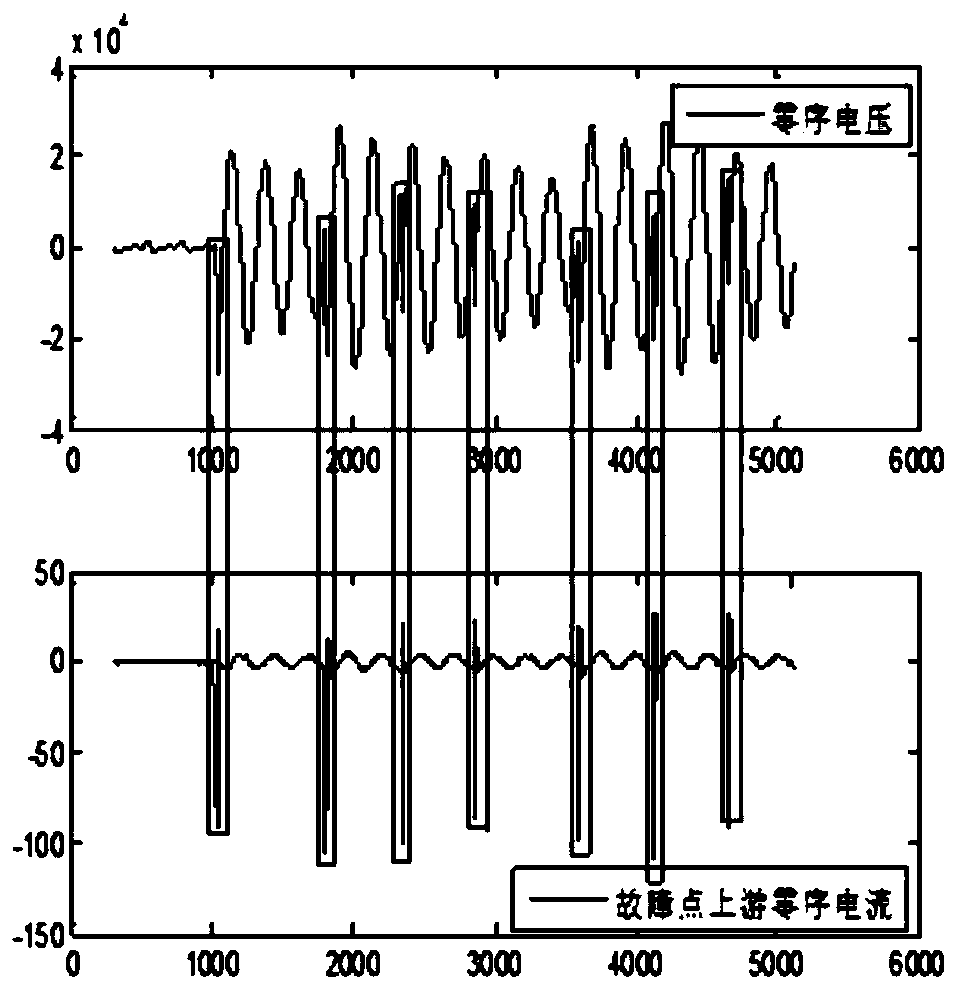

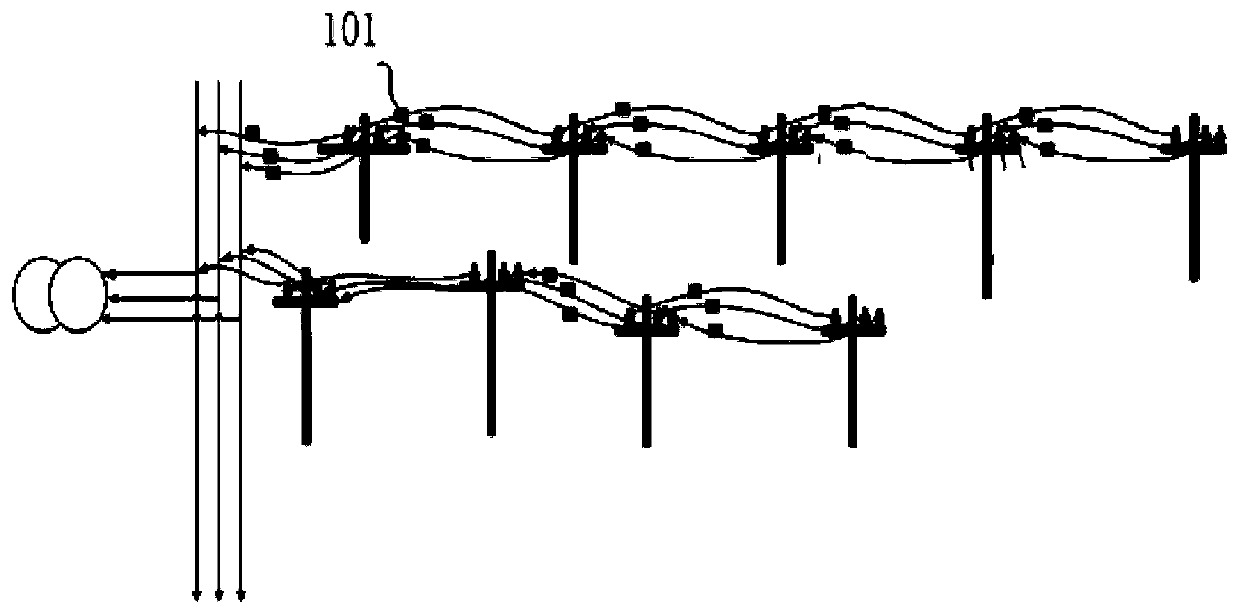

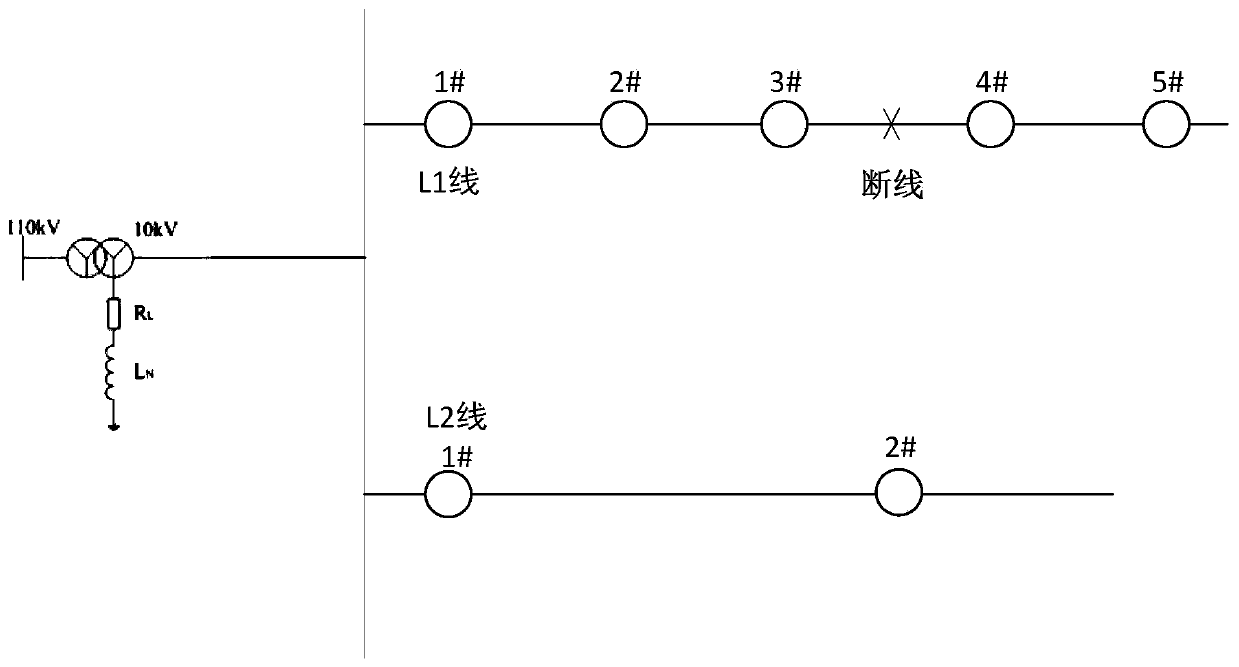

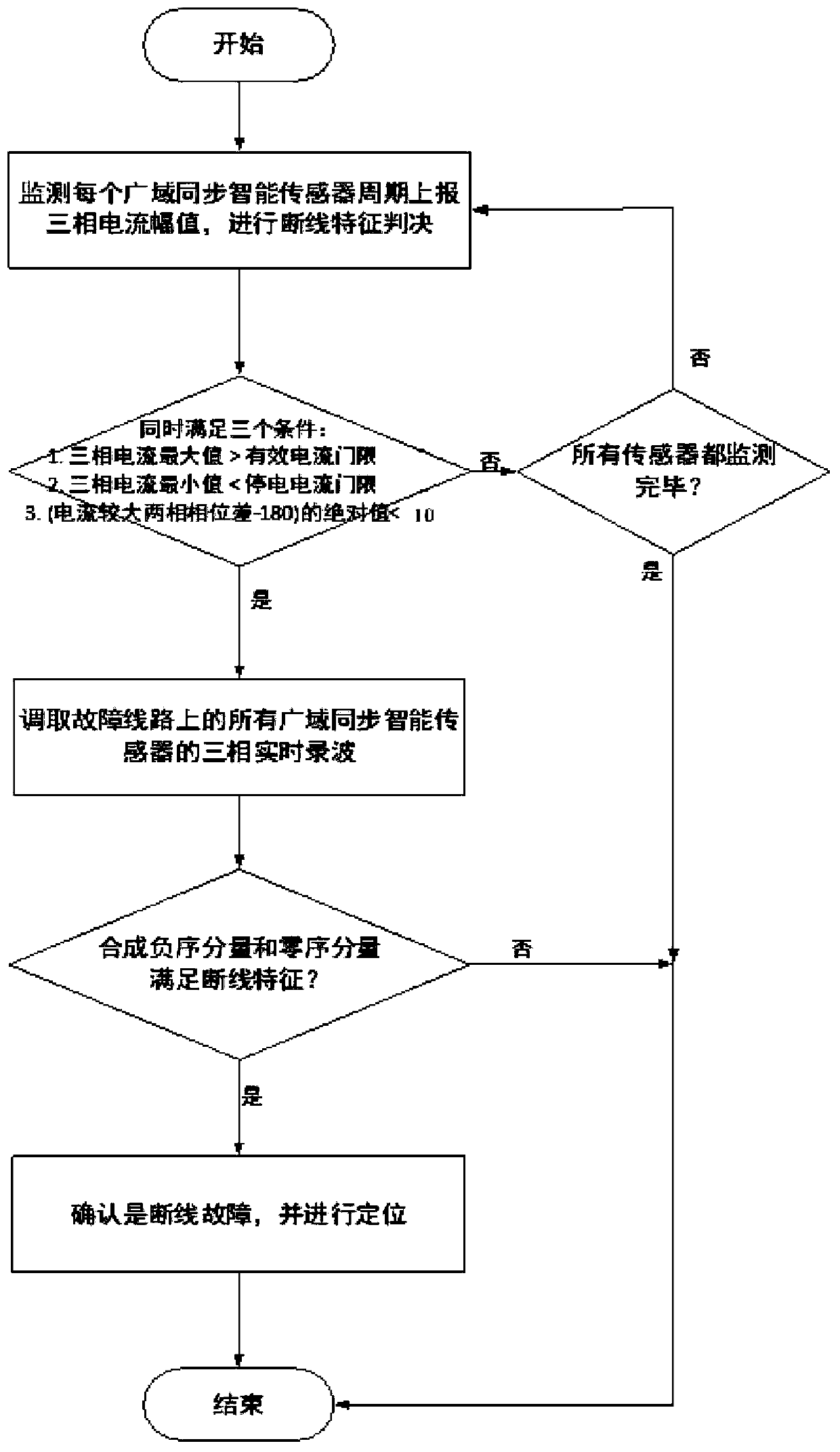

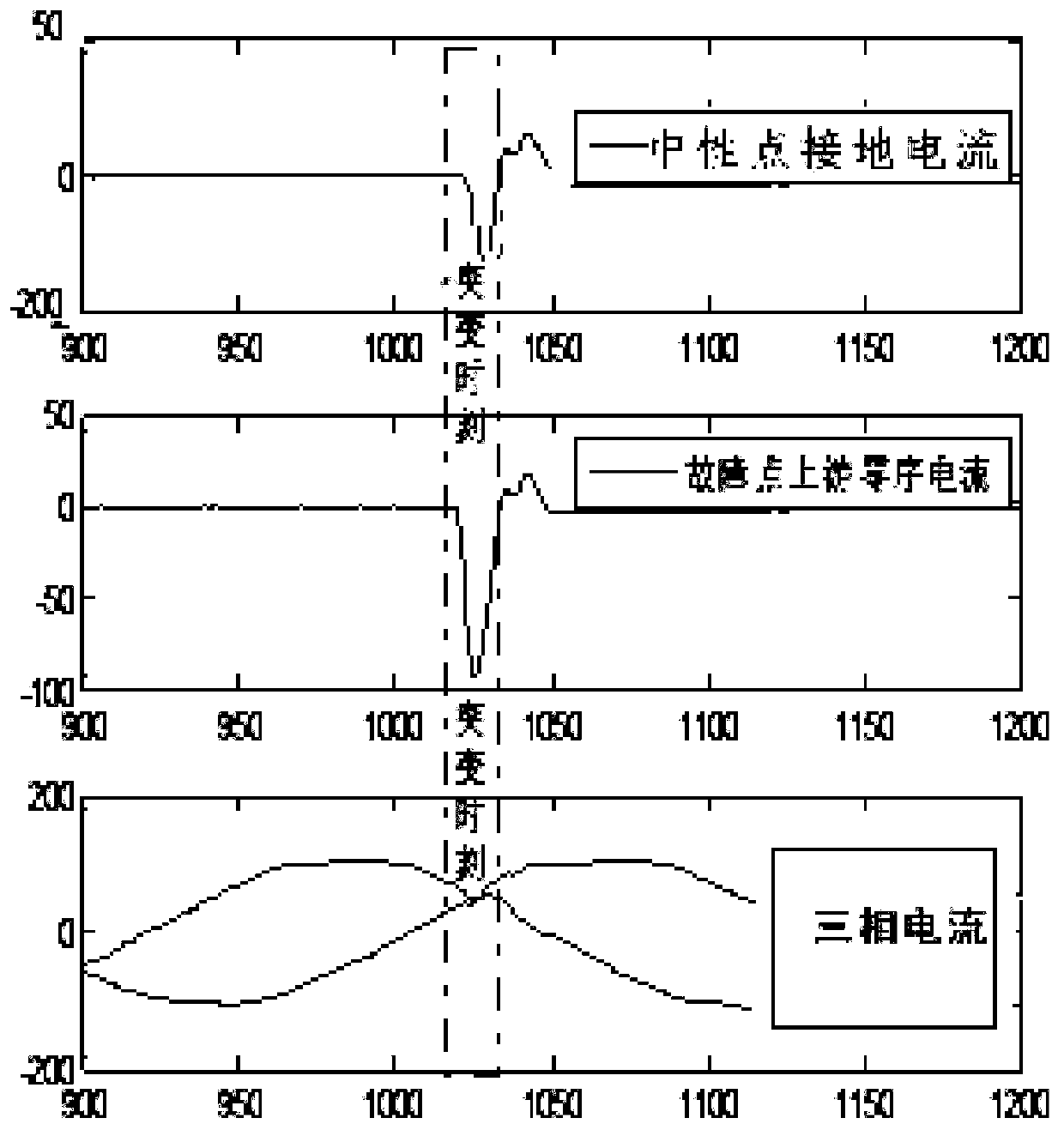

Disconnection fault detection method based on wide-area synchronous intelligent sensor

PendingCN111007355AConstruction saves time and effortRealize detection and localizationFault location by conductor typesContinuity testingEngineeringCurrent amplitude

The invention relates to a disconnection fault detection method based on a wide-area synchronous intelligent sensor. Three-phase current amplitude and phase periodically reported by a wide-area synchronous intelligent sensor are monitored in real time; once obvious disconnection fault characteristics occur, three-phase current waveforms of all wide-area synchronous intelligent sensors installed along a fault line with the disconnection characteristics at the current moment are called, automatic verification and confirmation are carried out, and finally a disconnection fault is detected and positioned. The method solves the problems of disconnection fault detection and positioning of the power distribution network at present.

Owner:苏州银蕨电力科技有限公司

Indoor wall surface stone dry hanging method

The invention discloses an indoor wall surface stone dry hanging method. According to the method, box iron is provided with an edge which is overturned outward, in another word, the channel iron is flanging box iron, the flanging box iron is vertically arranged, and expansion screws are arranged in grooves, so that the flanging box iron is fixed to the wall surface, in the installation process, a stone board is carried and hung with strips, the left side and the right side of the stone board are installed in a space between the edges, opposite to the stone board, of the upper ends of the two flanging box iron parts and the wall surface, dry hanging glue is applied to the position where a stone board is placed, the stone board is placed therein, the strips are drawn out, adjustment and alignment are conducted, and finally, the flanging box iron is decorated and sealed up with caulking plaster.

Owner:刘卫东

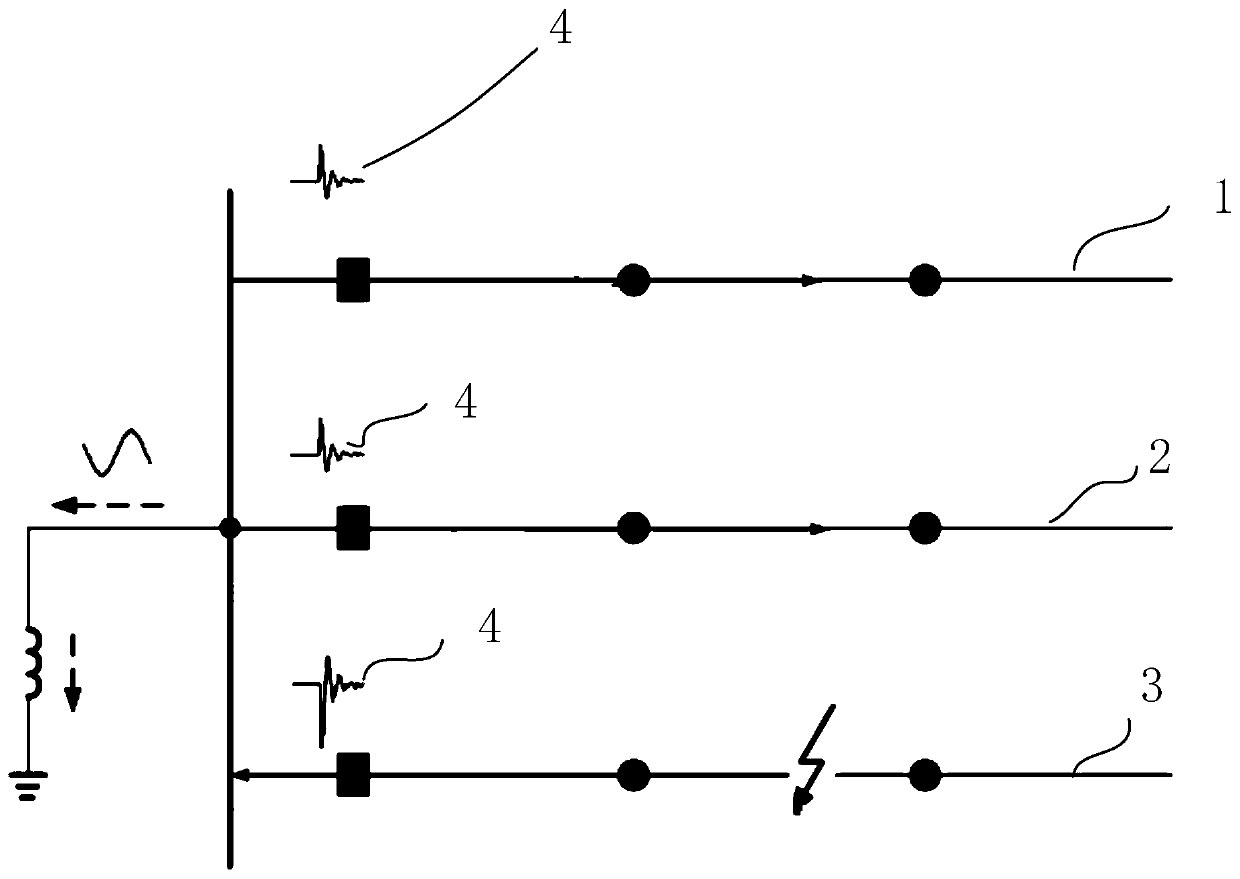

Single-phase earth fault positioning method based on neutral point earth current starting

PendingCN110865279ANo wiring pull wires requiredConstruction saves time and effortFault location by conductor typesShort-circuit testingPhase currentsEngineering

The invention relates to a single-phase earth fault positioning method based on neutral point earth current starting. The measured current of a current transformer installed at a bus neutral point earth resistor of a transformer substation is introduced, namely neutral point earth current. Neutral point earth current is used as a single-phase earth fault break variable starting element. A bus neutral point earth current starting device records the neutral point earth current waveform at the sudden change moment T, and calls the three-phase current waveforms of all wide-area synchronous intelligent sensors installed along the outgoing line of the transformer substation at the same moment T. Fault positioning is realized on the bus neutral point earth current starting device by using wide-area synchronous information. The method aims to solve the problem of single-phase earth fault positioning in the existing power distribution network small-resistance earth system, and especially medium-resistance and high-resistance earth faults.

Owner:苏州银蕨电力科技有限公司

Process method for insulation attaching type bonding of large-scale motor rotor magnetic pole body

ActiveCN110707886AGuaranteed stabilityPracticalApplying solid insulationInsulation layerControl theory

The invention discloses a process method for insulation attaching type bonding of a large-scale motor rotor magnetic pole body. The method is an innovation of a large-scale motor rotor magnetic pole body insulation bonding method, and the bonding area is effectively increased through the ultra-flat treatment of the edge gaps between the magnetic pole punching sheets and the core-penetrating screwwelding holes. During wrapping, the insulation paper is wound at an included angle of more than 30 degrees with the surface of the pole body, and a smoothing scraper and a magnetic cake support are combined to form smoothing extrusion propulsion, so that bubbles generated in the insulation layer are effectively reduced. According to the invention, mold shaping treatment is adopted, so that pole body insulation bonding is tighter. The pole body is insulated, heated and cured, so that the coating glue is accelerated to be cured, the mold is removed as soon as possible, and the mold use efficiency is improved. And the angle insulation adopts a glue brushing treatment mode, so that the construction is time-saving and labor-saving. And the integrity of pole body insulation bonding is improved,and the quality stability of the pole body is ensured. The method is a novel technical scheme which is high in practicability, simple and convenient to operate, cost-reducing, efficiency-increasing and easy to popularize.

Owner:HARBIN ELECTRIC MASCH CO LTD

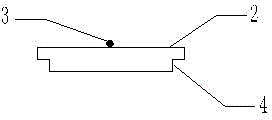

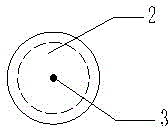

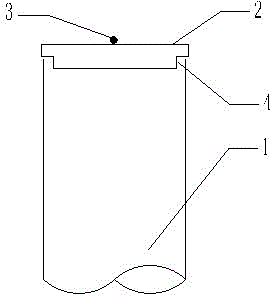

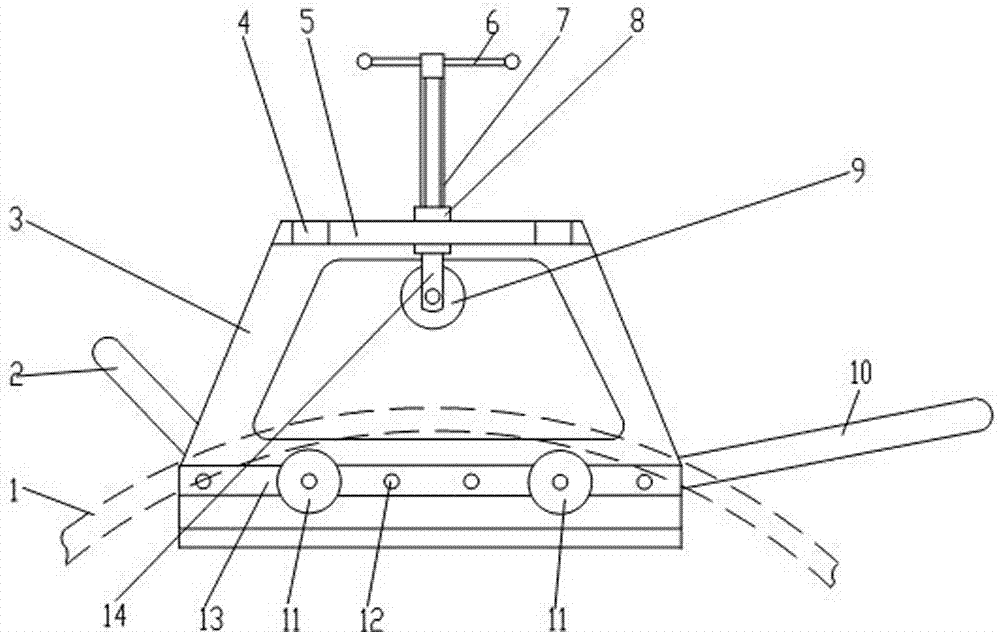

Mounting tool for coke oven sleeve and application of mounting tool for coke oven sleeve

The invention relates to a mounting tool for a coke oven sleeve, comprising an adjustment disc. The mounting tool is characterized in that the adjustment disc is a round lug boss part and has the thickness of 8-12 mm and the diameter same as the outer diameter of a sleeve to be mounted; the bottom part of the round lug boss part is a round lug boss with a stepped surface, the round lug boss part and the round lug boss are concentrically arranged, the diameter of the round lug boss is smaller than the inner diameter of the sleeve to be mounted, and the round lug boss has the height of equal to or more than 4mm so that the round lug boss of the round lug boss part can be mounted in the sleeve; and a central alignment point with the diameter of 2mm is arranged at the top part of the round lug boss part. The mounting tool for the coke oven sleeve and an application of the mounting tool for the coke oven sleeve disclosed by the invention have the advantages that the adjustment disc is simple in structure and convenient to manufacture; due to the use of the adjustment disc, the construction process is simple, the procedure is simplified, efficiency is improved and the entire construction is time-saving and labor-saving.

Owner:MCC5 GROUP CORP SHANGHAI

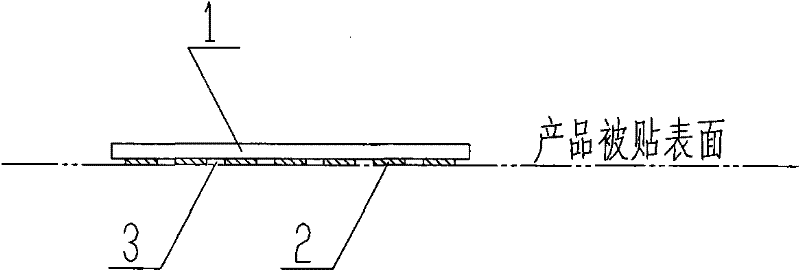

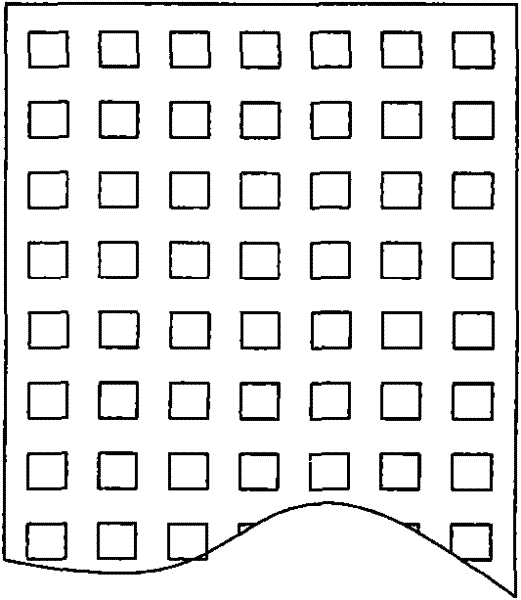

Membrane panel structure being easy to exhaust and convenient to glue

InactiveCN101752125AAvoid foamingConstruction saves time and effortElectric switchesEngineeringViscose fiber

The invention discloses a membrane panel structure being easy to exhaust and convenient to glue, which is characterized in that the back of the membrane panel is provided with a plurality of raised plate-form structures which are made by viscose glue and are not connected with each other, the raised plate can be in a round shape, a square shape and other shapes, and the original whole panel is replaced by the raised plates so as to make the gap between the raised plates become an exhaust passage when in gluing. Adopting the structure, when gluing the panel on the product surface, air can easily flow along the gap, and can not congregate to form cockle, thus avoiding the bubbling phenomena, the level gluing surface can be formed, the construction process is time and labor saving, and the membrane panel has better effect when gluing the membrane with larger width.

Owner:KUNSHAN XIONGFENG COLOR PRINTING

Steel wire mesh frame sandwich concrete load-bearing wall, building and construction method of building

The invention provides a steel wire mesh frame sandwich concrete load-bearing wall, a building and a construction method, and belongs to the technical field of construction. The load-bearing wall comprises a core plate and two layers of steel wire meshes correspondingly arranged on both sides of the core plate, and a plurality of rows of connecting steel wires penetrating through the core plate are arranged between the two layers of steel wire meshes; vertical edge steel members are correspondingly arranged on the left and right ends of the core plate, and horizontal edge steel members are correspondingly arranged on the lower bottom surface and the upper top surface of the core plate; the adjacent ends of the vertical edge steel members and the horizontal edge steel members are welded andfixed at joints to form a frame, and both ends of vertical steel wires are correspondingly welded to the corresponding horizontal edge steel members; and both ends of the horizontal steel wires are correspondingly welded to the corresponding vertical edge steel members. According to the steel wire mesh frame sandwich concrete load-bearing wall, the two steel wire meshes are connected through theconnecting steel wires penetrating through the core plate, the edge steel members are arranged around the core plate to enable a wall body to have good integrity and good seismic performance, the labor intensity is reduced, and the construction period is shortened.

Owner:河北羲杰发建筑工程有限公司

Process for replacing hoisting ropes

ActiveCN101786570BReduce usageSolve difficult problems that are easy to twistMine liftsPull forceEngineering

Owner:山东煤安矿山提升设备安装有限公司

Fastener plug-in curved metal roof and its construction method

ActiveCN103711258BSolve the odd-shaped surface problemGuaranteed free expansionRoof covering using slabs/sheetsBuilding material handlingArchitectural engineeringMetal

The invention provides a fastener plug-in type curved surface metal roof which comprises a base frame, primary purline supporting components, lengthening connecting fasteners, primary purlines, primary and secondary purline through connection components, secondary purlines, secondary purline panel through connection components, roof panel components and sealing components. The base frame is fixedly mounted on a civil engineering foundation roof face. The primary purlines are fixedly connected with the base frame through the primary purline supporting components. The secondary purlines are connected with the primary purlines through the primary and secondary purline through connection components. The secondary purline panel through connection components are connected with the secondary purlines. The roof panel components are connected with the secondary purline panel through connection components, two adjacent roof panel components are connected in an inserting mode, and the sealing components are arranged in the clearances of the roof panel components. A construction method mainly comprises the step that the base frame, the primary purline supporting components, the primary purlines, the primary and secondary purline through connection components, the secondary purlines, the secondary purline panel through connection components, the roof panel components and the sealing components are mounted in sequence. According to the fastener plug-in type curved surface metal roof and the construction method, steel and manpower cost can be effectively saved, the construction period can be shortened, and the new construction method of the curved surface metal roof is provided.

Owner:CHANGZHOU NO 1 CONSTR GRP

Assembling integrated type window frame for steel structure, and construction method of assembling integrated type window frame

The invention discloses an assembling integrated type window frame for a steel structure, and a construction method of the assembling integrated type window frame. The construction method comprises the following steps: producing components of the assembling integrated type window frame in a factory in advance and in batches; setting a clamping groove in the outer side of each component; conveying the components to an industrial or civil building construction site of the steel structure which is manufactured; and taking a hole of each steel grid consisting of vertical H-shaped steel and transverse H-shaped steel of a wall structure of the steel structure as a position where the building needs to open a window, buckling the clamping groove of each component on the H-shaped steel forming the hole, and pouring fine aggregate concrete into the clamping grooves of upper window frame and lower window frame components of the assembling integrated type window frame, so that the assembling integrated type window frame and the steel grid H-shaped steel of the steel structure can be connected into a whole, and construction of the assembling integrated type window frame for the steel structure is finished. The assembling integrated type window frame for the steel structure, and the construction method of the assembling integrated type window frame have the advantages of low manufacturing cost, easiness in manufacturing and construction, high production efficiency, high quality, long service life, high fireproof performance, avoidance of environmental pollution and the like.

Owner:GUIZHOU UNIV +2

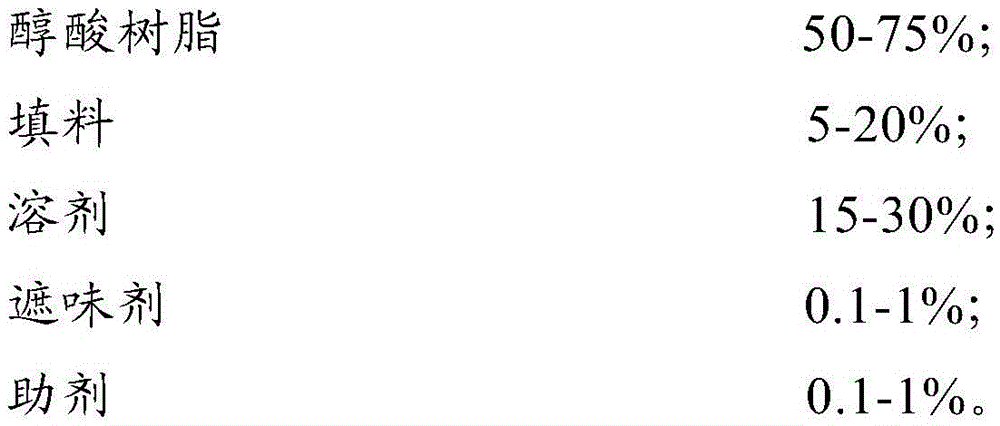

Color base paint for wood

The invention provides a color base paint for woodware, which comprises components and the weight content of each component are: 50%-75% of alkyd resin, 5%-20% of filler, 15%-30% of solvent, covering Flavoring agent 0.1%-1%%, auxiliary agent 0.1%-1%. The coloring base paint for woodware provided by the invention can be combined with color essence to produce woodware paints of various colors, and can be directly rubbed on the primer or topcoat of woodware. The construction is simple, the coloring is uniform, and natural leveling is achieved. Low odor and low VOC meet the requirements of environmental protection, so that after the wood is painted, it can achieve a decorative effect of bright and rich colors and clear textures.

Owner:ASIA PAINT SHANGHAI

an integrated ward

ActiveCN104032984BConstruction saves time and effortEasy wiringDucting arrangementsLighting and heating apparatusMedical wardWeak current

Owner:雷湛成

Indoor wall surface stone dry installation method

The invention discloses an indoor wall surface stone dry installation method. According to the method, box iron is provided with an edge which is overturned outward, in another word, the channel iron is flanging box iron, in the installation process, single H-shaped steel frames are vertically arranged from one end of the wall surface and horizontally fixed to the wall surface, dry hanging glue is applied to the position where a stone board is placed, then the stone board is placed in the ends of the two strips of flanging box iron and corresponds to the upper edges of the flanging box ion, the stone board is pushed to the end with hand, adjusted and aligned, after installation is completed, the corresponding single H-shaped steel frame is vertically arranged and fixed to the wall surface with joints arranged horizontally, the stone board is installed therein in a sleeved mode, when the stone board is installed to the other end of the wall surface, a section is removed from the upper edge located above a vertical support of the end of the corresponding box iron, then the stone board is placed therein in a sleeved mode from the section, finally, for the section, the stone board is directly bonded and fixed to the vertical support opposite to the space between the two strips of flanging box iron and the wall surface, and after installation is completed, finally, the flanging box iron is decorated and sealed up with caulking plaster.

Owner:江西亿仑建设工程有限公司

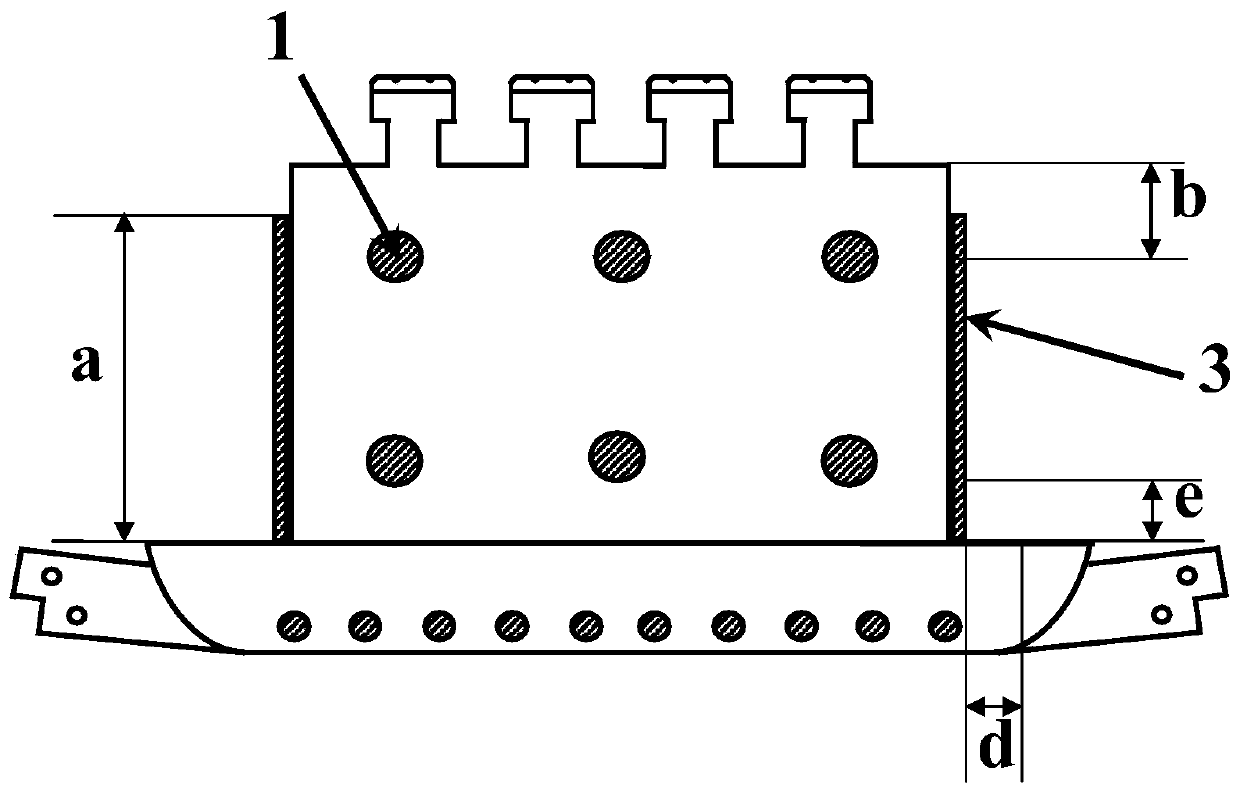

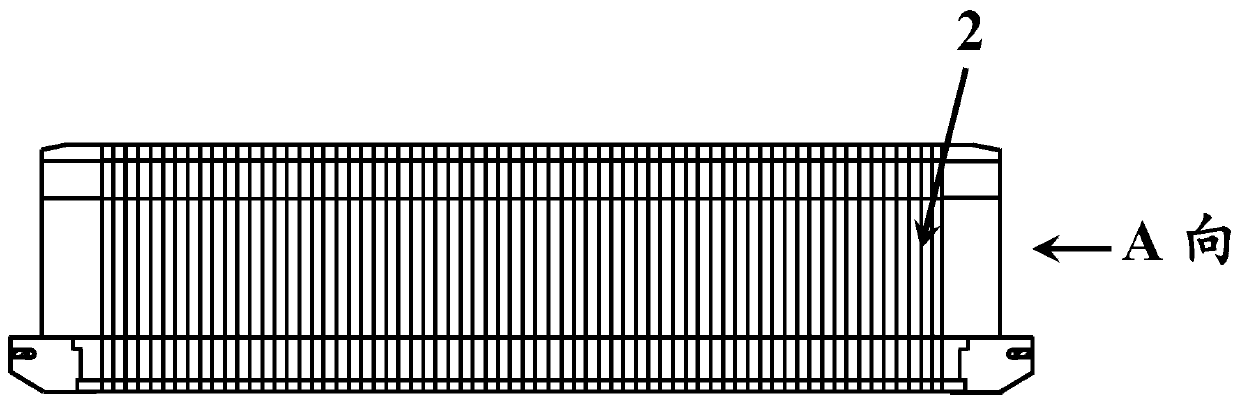

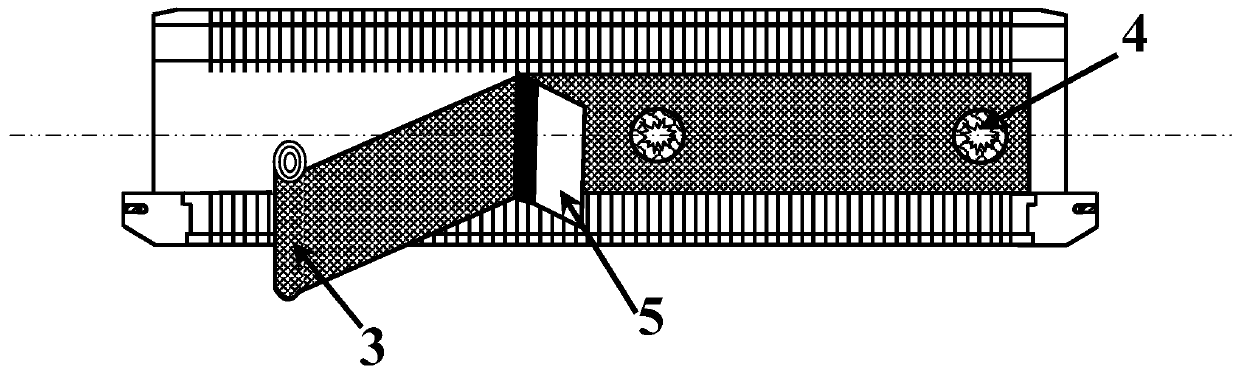

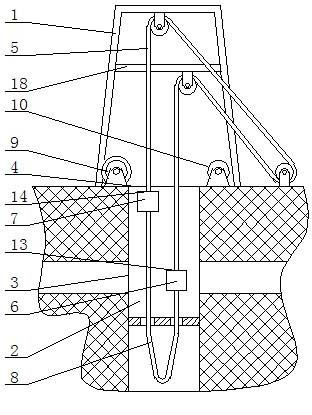

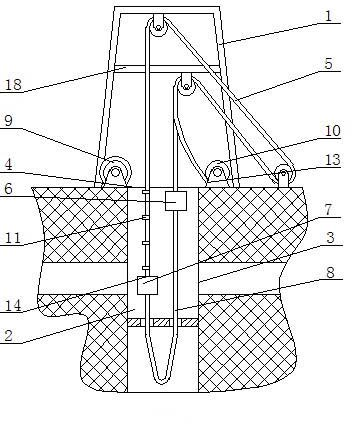

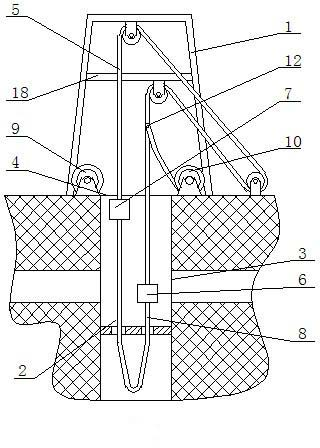

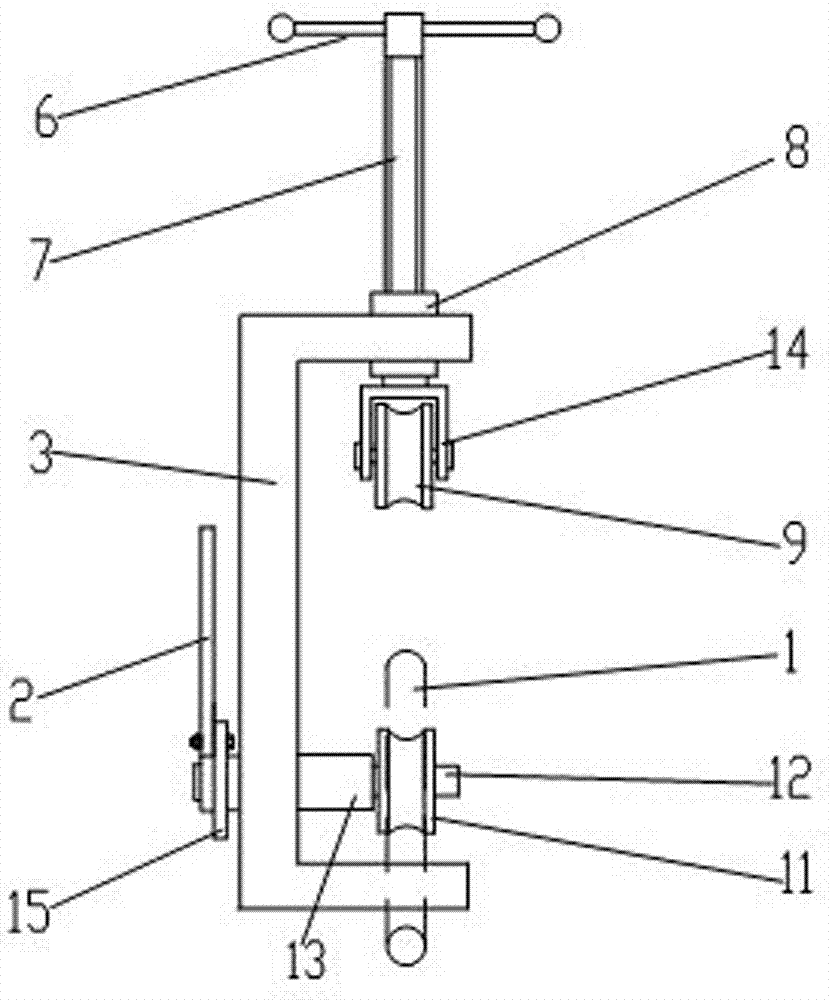

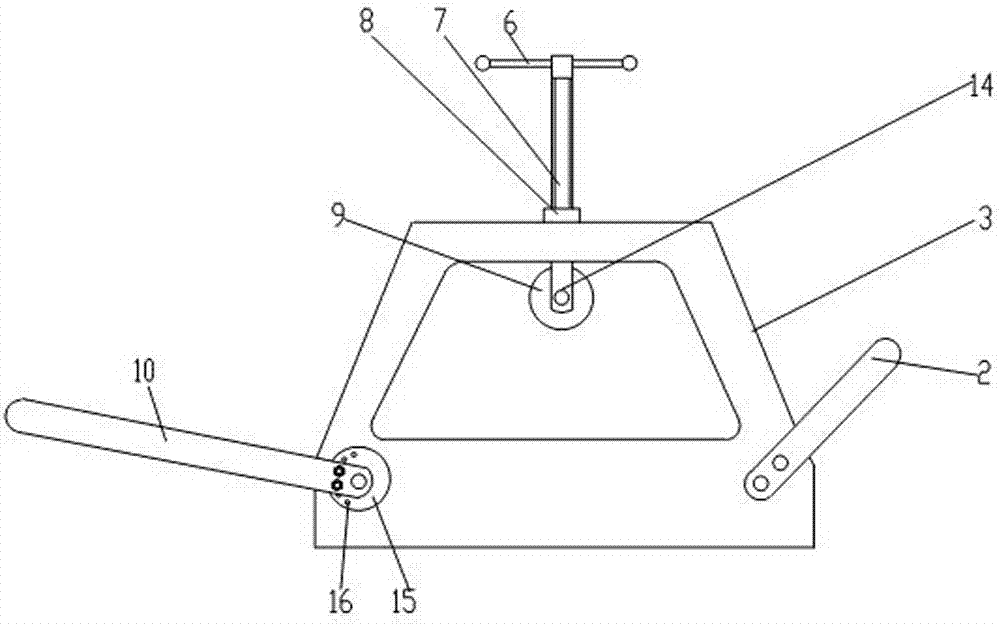

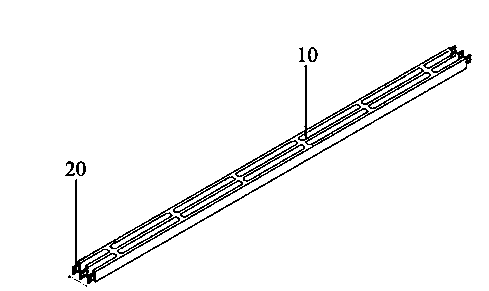

Cable straightening pulley bracket

InactiveCN105790150BEliminate operational defectsConstruction saves time and effortApparatus for laying cablesEngineeringUltimate tensile strength

The invention discloses a cable straightening pulley bracket which comprises a channel steel type frame, a transverse board, upper pulleys and lower pulleys. The transverse board is fixed above the lower edge of the channel steel type frame. More than two hanging shafts are arranged on the transverse board. The number of the lower pulleys is more than 2. The lower pulleys are hanged on the hanging shaft through central holes. Each upper pulley is provided with a central hole and is connected with the middle part of the upper edge of the channel steel type frame through a through shaft bracket and a lead screw pair. The cable straightening pulley bracket can perform straightening shaping on the cables with various kinds of bending shapes. Furthermore the cable straightening pulley bracket has advantages of saving time and labor in cable construction, reducing labor intensity, improving construction efficiency and ensuring high cable mounting quality.

Owner:STATE GRID CORP OF CHINA +2

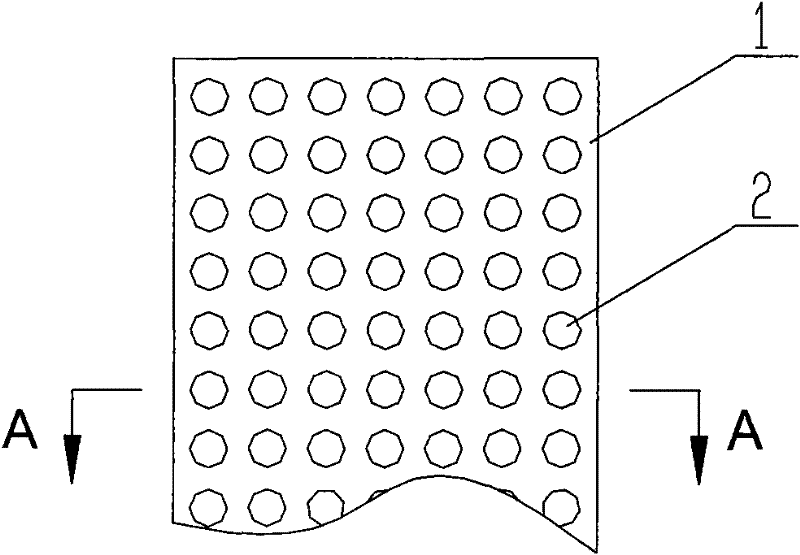

10-kilovolt full-poured medium-voltage bus

InactiveCN103515004ASimple structureReduce weightInsulated cablesInsulated conductorsElectrical conductorEngineering

The invention provides a 10-kilovolt full-poured medium-voltage bus which comprises a three-phase conductor and an insulator. The three-phase conductor is arranged in the insulator appropriately in parallel, the insulator is formed through full pouring, a plurality of rectangular radiating holes are formed between phases of the three-phase conductor, the length of each rectangular radiating hole is 940 millimeters, the width of each rectangular radiating hole is 80 millimeters, semicircle radiating holes are formed in the two ends of the three-phase conductor, and the diameter of each semicircle radiating hole is 80 millimeters. The distance between the rectangular radiating holes is increased to 120mm, so that the radiating volume is improved, and thermal stability and dynamic stability endurance are improved. Meanwhile, the radiating volume is improved by more than 260%, so that the copper using amount is reduced and energy conversation is achieved. In addition, the whole pouring amount is reduced, the whole weight of an assembly is relatively reduced, and time and labor are saved in construction and supporting of a hanging bracket.

Owner:江苏巴斯威节能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com