Process for replacing hoisting ropes

A steel wire rope and process technology, applied in the field of lifting steel wire rope replacement technology, can solve the problems of long construction period, poor construction safety, endangering the safety of construction personnel, etc., and achieve the effect of saving time and labor, saving construction time and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

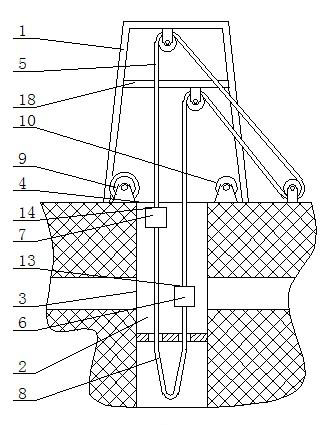

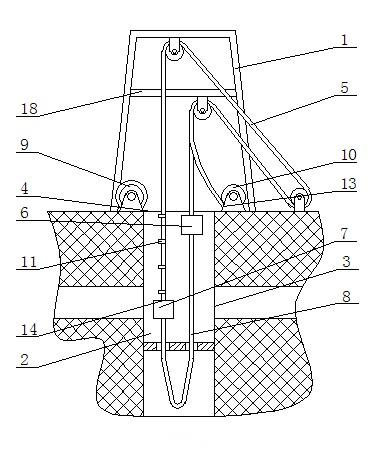

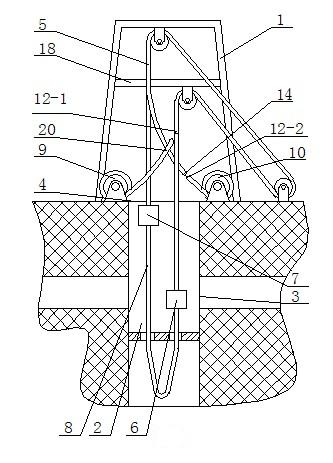

[0017] Usually the first cage 6 and the second cage 7 are jointly suspended by four old steel wire ropes 5 side by side. In order to quickly replace the old steel wire ropes 5 on the premise of ensuring safety, the outermost two old steel wire ropes 5 can be replaced at the same time. Replace the two in the middle again, or replace the two old steel ropes 5 in the middle and then replace the two old steel ropes 5 in the outermost side. Take the well shaft 2 with four old steel ropes 5 in total as an example. Figures 1 to 6 Specifically describe the hoisting wire rope replacement process steps of the present invention as follows:

[0018] Such as figure 1 As shown, 1. first place two new rope cars 9 and two old rope cars 10 near the upper wellhead 4 of the well shaft 2, and start the winch 15 to raise the second cage 7 to the upper wellhead 4, and the first cage 6 is lowered to the upper wellhead 4. The lower wellhead 3 of the shaft 2 completes the positioning work;

[0019]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com