Patents

Literature

2396results about How to "Improve construction safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ecological protection method for high steep side slope

The invention relates to an ecological protection method for a high steep side slope. The method mainly comprises the steps of slope surface treatment, concrete shotcrete and rock bolt support, vegetating hole arrangement, net spreading, spray material preparation, granule spray sowing, maintenance, management, and the like. In the method, guest soil materials such as humus loam rich in organic matters and clay are utilized to undergo a granule reaction after mixed with a granule agent at the moment of spray sowing so as to form a greening template which has the same high order granule structure as natural soil and strong erosion resistance and can suppress water and soil loss. After a diversified mature plant community which is in harmony with surrounding vegetation environment is formed, the slope surface can be protected, which can effectively resist diseases and insect pests and maintain the ecological balance. Post maintenance management and expenses can be saved. All used materials can be naturally degraded, have no pollution to the environment and can purify air and beautify the environment. Equipment of the method does not need to be hung on the slope surface for construction, and spray sowing operations are carried out only below the slope surface, thus the method has high construction speed and safety. The method is suitable for slope surfaces which are difficult to green, and the like, such as various high steep and unstable slope surfaces, bare slope surfaces having high greening expected values, and the like.

Owner:河南国网宝泉抽水蓄能有限公司

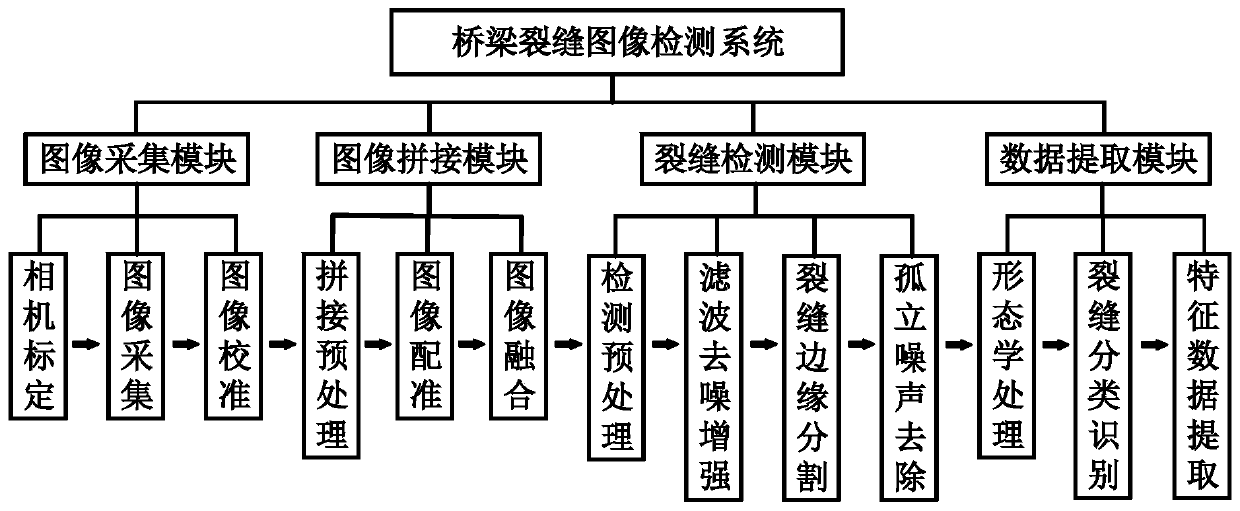

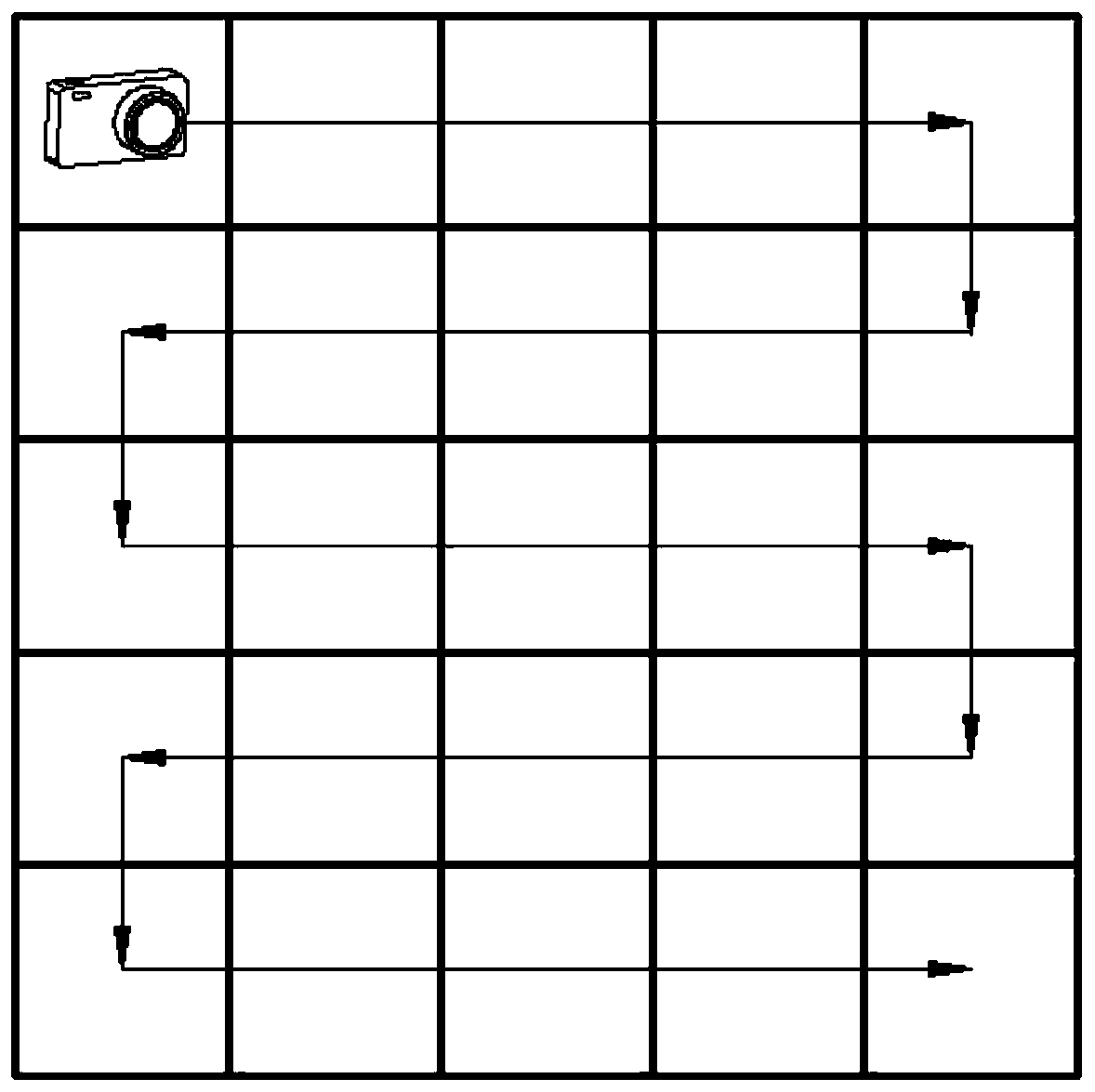

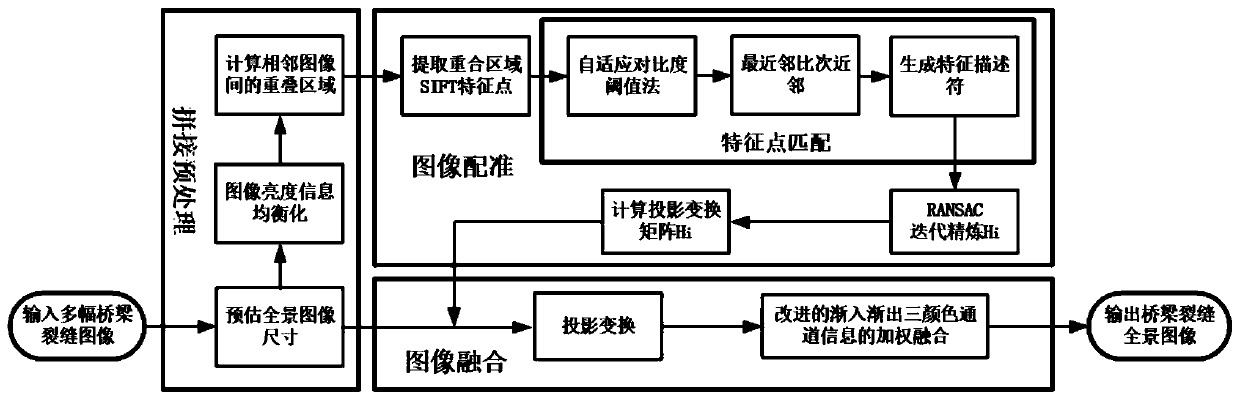

Bridge crack detection method

ActiveCN110378879AImprove mobilityIncrease flexibilityImage enhancementImage analysisTerrainBridge deck

The invention discloses a bridge crack detection method. Due to the fact that manual marking has certain subjectivity, the pavement crack detection precision depends on experience knowledge of experts, and experience lacks objectivity in quantitative analysis. The method comprises the following steps: 1, collecting images of a detected bridge floor one by one to obtain a bridge floor image set; 2,splicing images; 3, detecting crack; 4, extracting crack parameter. According to the invention, the image acquisition and processing technology replaces human eyes to complete automatic nondestructive detection of the bridge crack, and has very important practical significance for research of the bridge crack detection technology in a complex terrain environment. On one hand, the construction safety is enhanced, and on the other hand, the operation maneuverability and flexibility are improved. According to the invention, fidelity splicing of multiple groups of bridge deck images is realized,the image splicing precision and efficiency are improved, a working foundation is laid for subsequent bridge crack image detection, and a technical reference is provided for image splicing detection in other fields.

Owner:HANGZHOU DIANZI UNIV

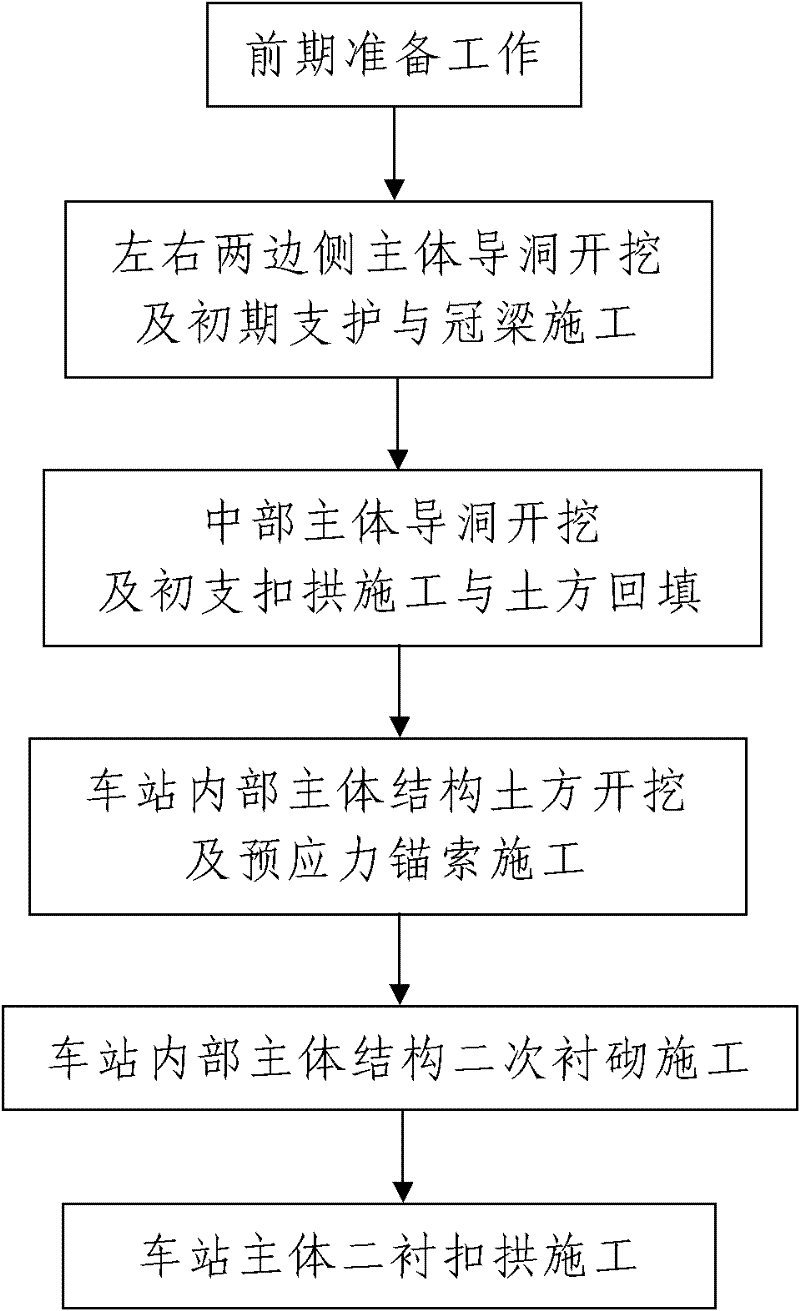

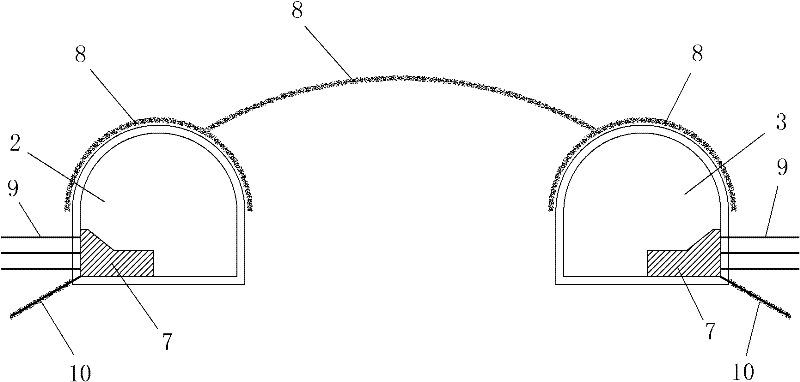

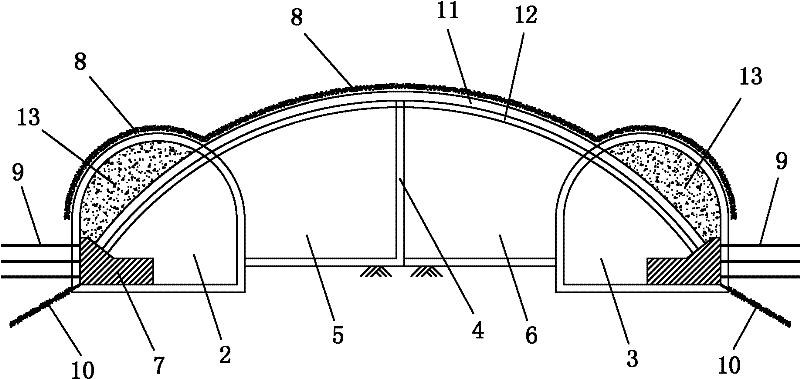

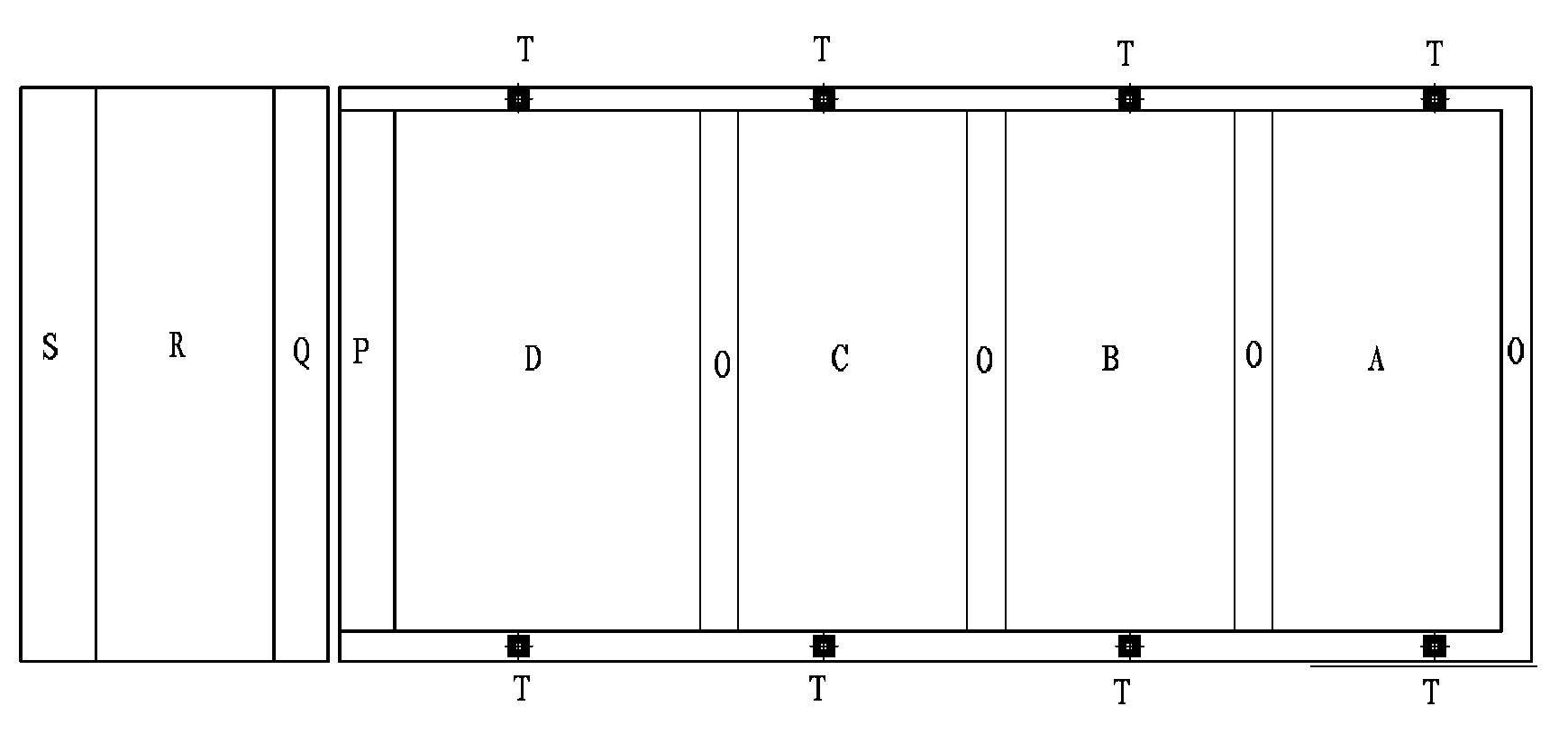

Construction method of large-span subway station main body by using arched cover method and station main body structure

ActiveCN102226403ASimplify construction stepsEasy constructionUnderground chambersSupporting systemArchitectural engineering

The invention discloses a construction method of a large-span subway station main body by using an arched cover method and a station main body structure. The construction method comprises the following steps: 1. making first-phase preparations; 2. excavating main body pilot tunnels at the left side and the right side, and carrying out primary support and top beam construction; 3. excavating a middle-part main body pilot tunnel, carrying out primary support and arch buckling construction, and refilling the earthwork; 4. carrying out earthwork excavation on a main body structure in the station, and prestressing force anchor cable construction; 5. carrying out secondary lining construction on the main body structure in the station; and 6. carrying out secondary lining and arch buckling construction on the station main body. The station main body structure comprises the main body structure in the station, a central post, a central plate and a main body arch part, wherein, the main body arch part comprises a middle arch fragment and two side arch fragments respectively arranged in the two side main body pilot tunnels formed by excavation in advance; and the main body arch part comprises a primary support system and a station main body arch buckling secondary lining structure from the outside to the inside. The station main body structure provided by the invention has reasonable design, simple construction steps, convenience in realization, small construction difficulty and rapid construction speed; the subway station formed by the construction method has a stable structure and a good use effect.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

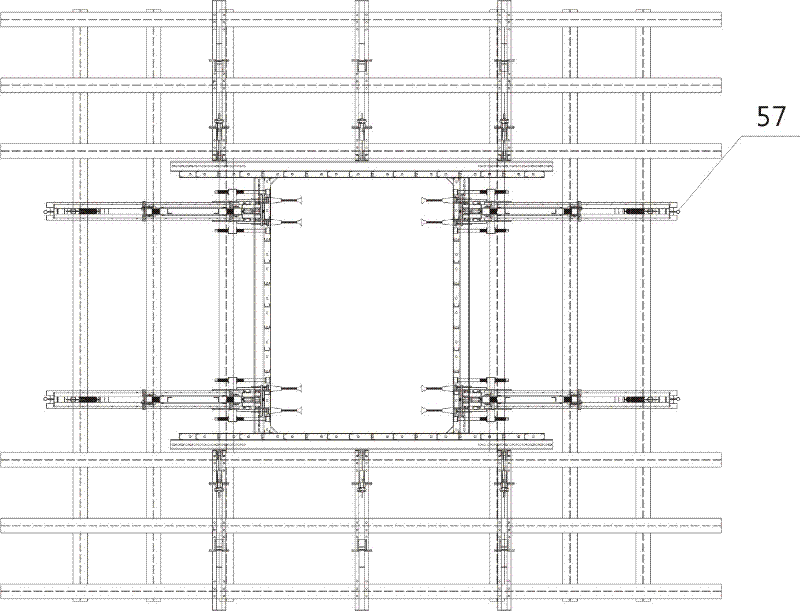

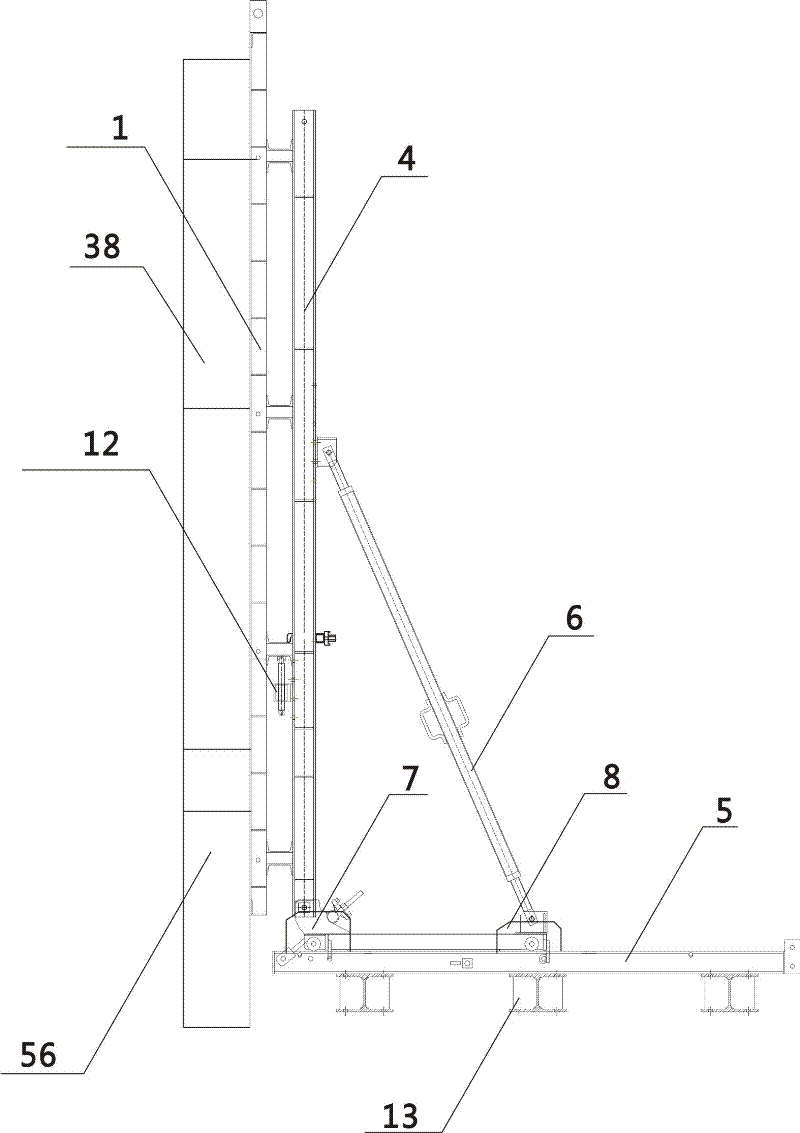

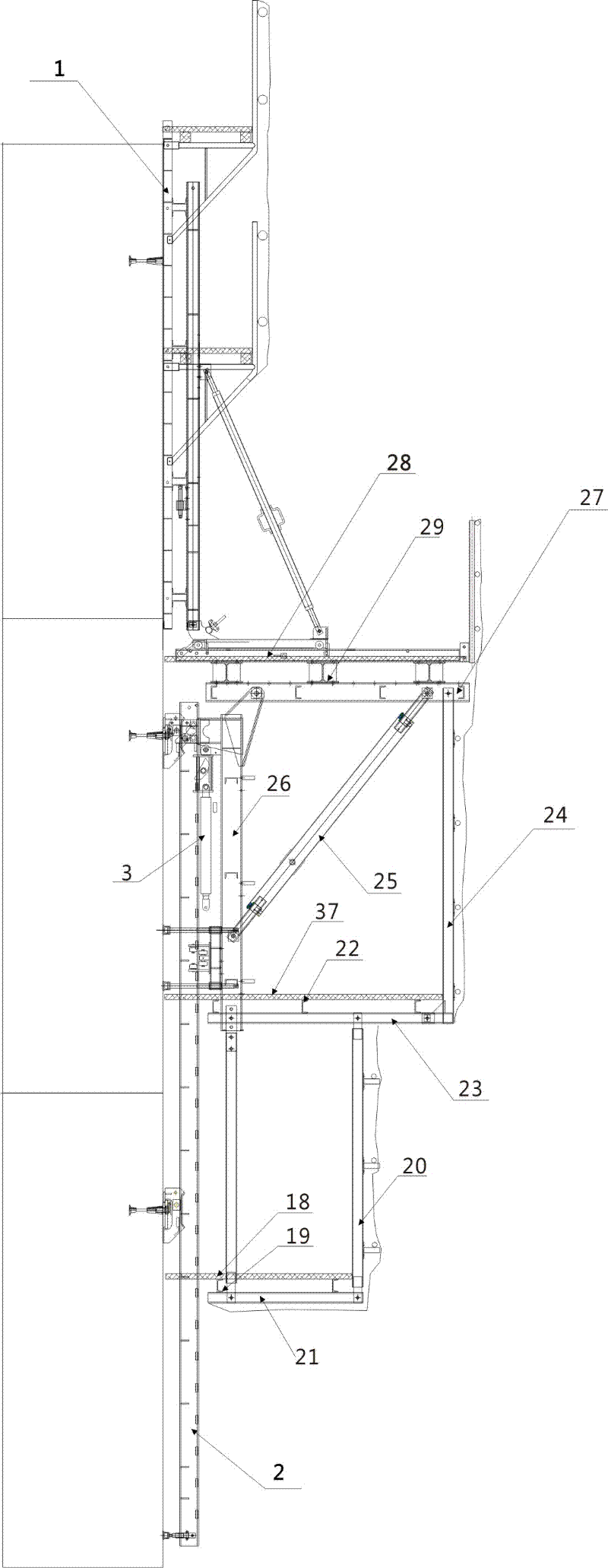

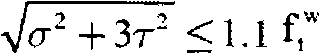

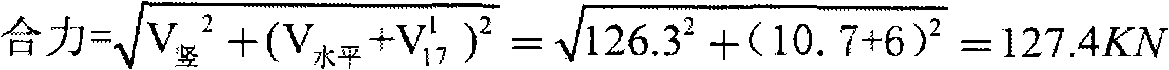

Hydraulic creeping formwork system and creeping formwork construction method

ActiveCN102345381AEasy maintenanceReduce labor costsForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksStructural engineering

Owner:重庆市超强钢结构制造有限公司

Connecting device of steel column butt joint and installing method

InactiveCN101906849ASpeed up the installation processReduce temporary fixturesStrutsBuilding material handlingButt jointSteel columns

The invention discloses a connecting device of a steel column butt joint and an installing method, belonging to the field of steel structure construction. The connecting device comprises two lug plates, two connecting clamp plates and bolts, wherein bolt holes are arranged on the two lug plates; the two connecting clamp plates are provided with bolt holes corresponding to the bolt holes on the two lug plates; and the two lug plates are arranged between the two connecting clamp plates and are fixedly connected into an integral structure through the bolts and the connecting clamp plates. The invention also provides an installing method of an incline steel column butt joint. The connecting device can be used in the butt joint of incline steel columns and is fixed on the butt joint of an upper steel column and a lower steel column to ensure that the upwards-inclining upper steel column is temporally fixed on the lower steel column through the connecting device without arranging a rigid support and pulling a cable wind rope and other temporary fixed facilities, thereby reducing the temporary fixed facilities used in the butt joint of incline steel column members, improving the installation progress of the construction of the steel structure, and shortening the construction period.

Owner:CHINA CONSTR SCI & IND CORP LTD

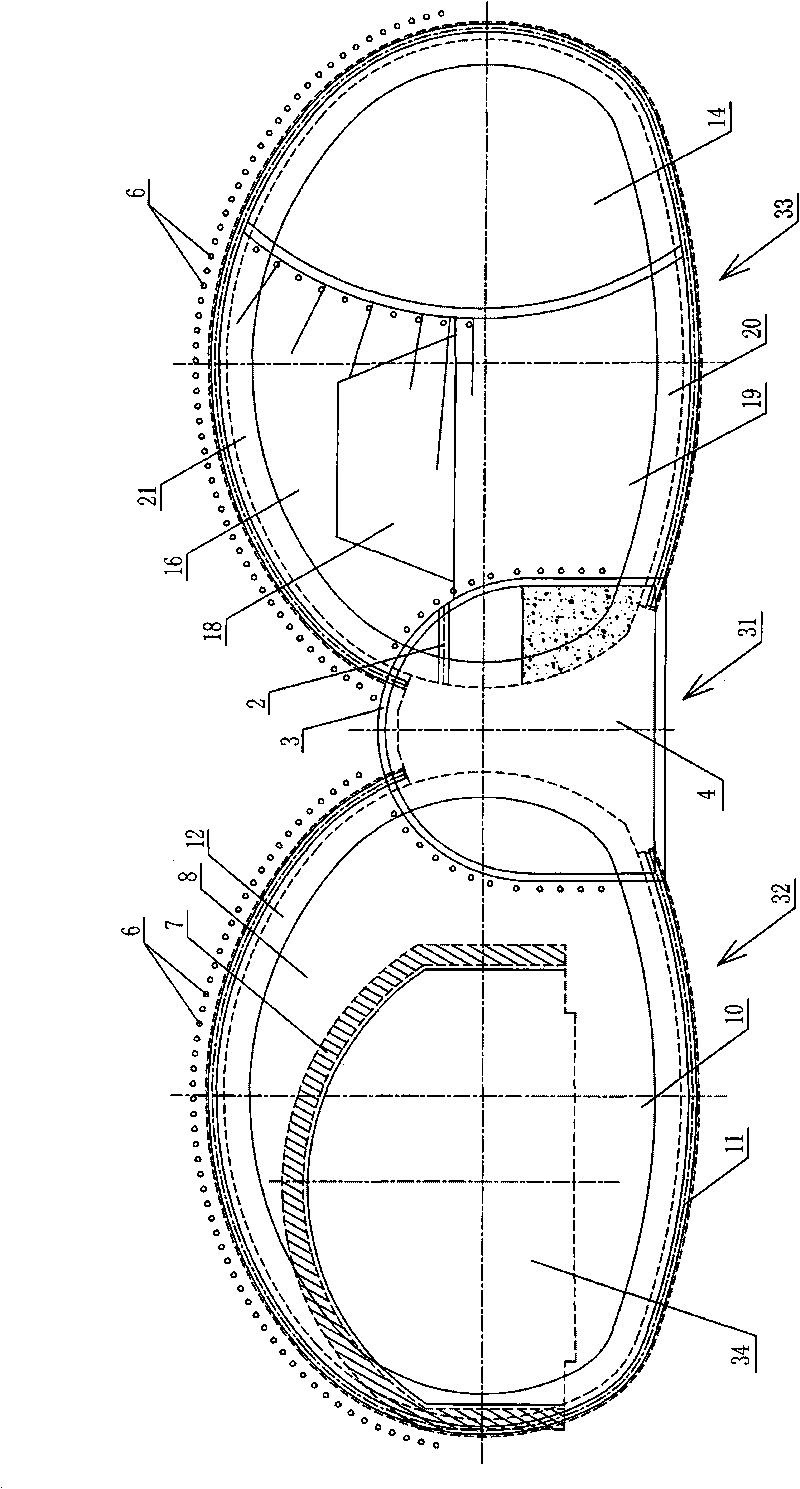

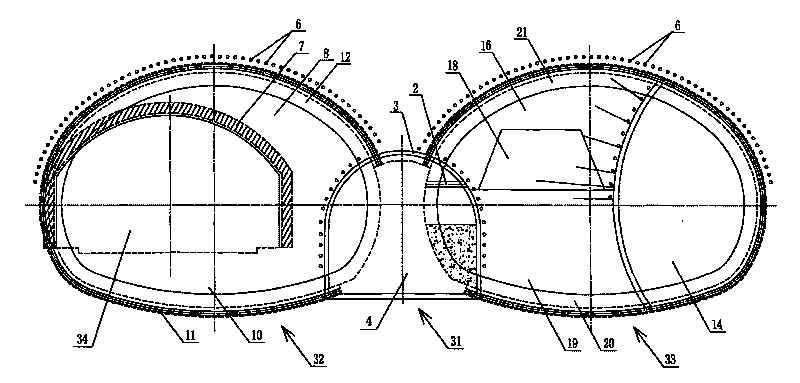

Method for constructing double-arch tunnel by rebuilding and expanding existing single-hole tunnel

InactiveCN101737061AIncrease the construction work areaImprove construction efficiency and construction safetyUnderground chambersTunnel liningSingle holeEngineering

The invention relates to a method for constructing a double-arch tunnel by rebuilding and expanding an existing single-hole tunnel. The technical problem to be solved by the invention is to provide a method for constructing the double-arch tunnel by rebuilding and expanding the existing single-hole tunnel, which adopts a ' middle pilot hole, the existing tunnel and a right hole' three pilot pit construction scheme, enlarges construction face and reduce excavation face and surrounding rock disturbed zone. To solve the technical problem, the invention adopts a technical scheme that the method for constructing the double-arch tunnel by rebuilding and expanding the existing single-hole tunnel comprises the following steps: 1.1 constructing the middle pilot hole parallel to the existing single-hole tunnel on one side of the existing single-hole tunnel and completing supporting construction; 1.2, constructing a left hole by sequence and zone on the basis of the existing single-hole tunnel and communicating the left hole and the middle pilot hole; and 1.3, after excavating the left hole to a certain size, constructing the right hole by sequence and zone and communicating the right hole with the middle pilot hole. The method is mainly used in highway traffic engineering and municipal traffic engineering.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Whole high-cleanliness electronic plant steel structure slippage and detachment method

ActiveCN103806658AImprove construction efficiencyImprove construction safetyBuilding material handlingSynchronous controlEngineering

The invention discloses a whole high-cleanliness electronic plant steel structure slippage and detachment method. A construction route of the ground assembly of a single truss, the aerial assembly and accumulative slippage of a slippage unit, the whole slippage of the slippage unit, and the synchronous detachment of the slippage unit is adopted, a long-span and large plant steel structure is mounted in high altitude above two layers of wafer boards. The method is characterized by comprising the following steps of a, the confirmation of a slippage and detachment scheme and the simulating calculation of the slippage and the detachment of the slippage unit; b, the accumulative slippage and the whole slippage construction of the slippage unit; c, the synchronous detachment and construction of the slippage unit in batches and in levels; d, the synchronous control on the whole slippage and detachment of the steel structure. By using the whole high-cleanliness electronic plant steel structure slippage and detachment method, the problems that a large-size crane cannot enter a hoisting field and reserved holes of wafer board floors, and the circumjacent construction plant of the field is limited are solved, the construction efficiency is greatly improved, the construction safety is ensured, and the engineering construction cost is reduced.

Owner:MCC5 GROUP CORP SHANGHAI

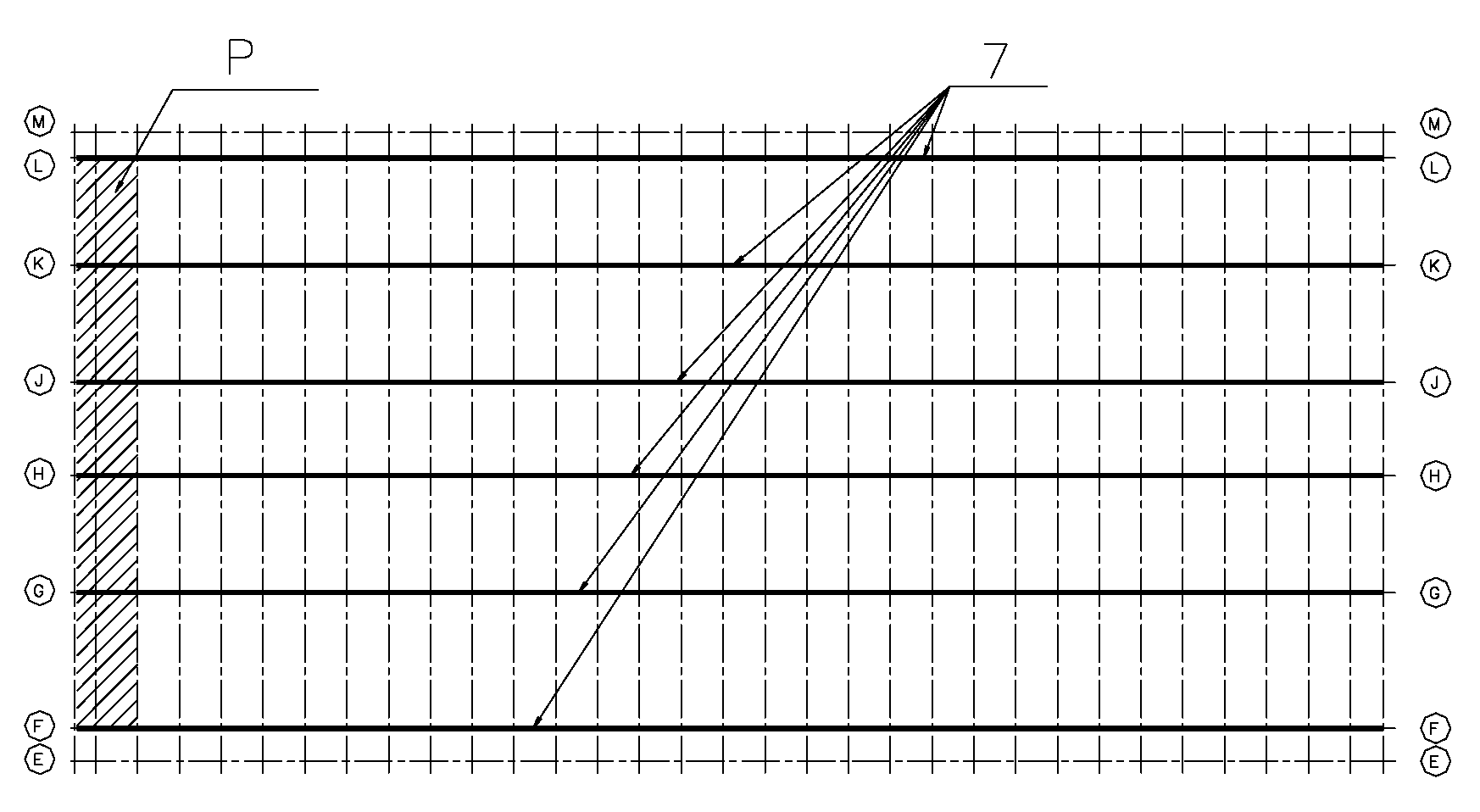

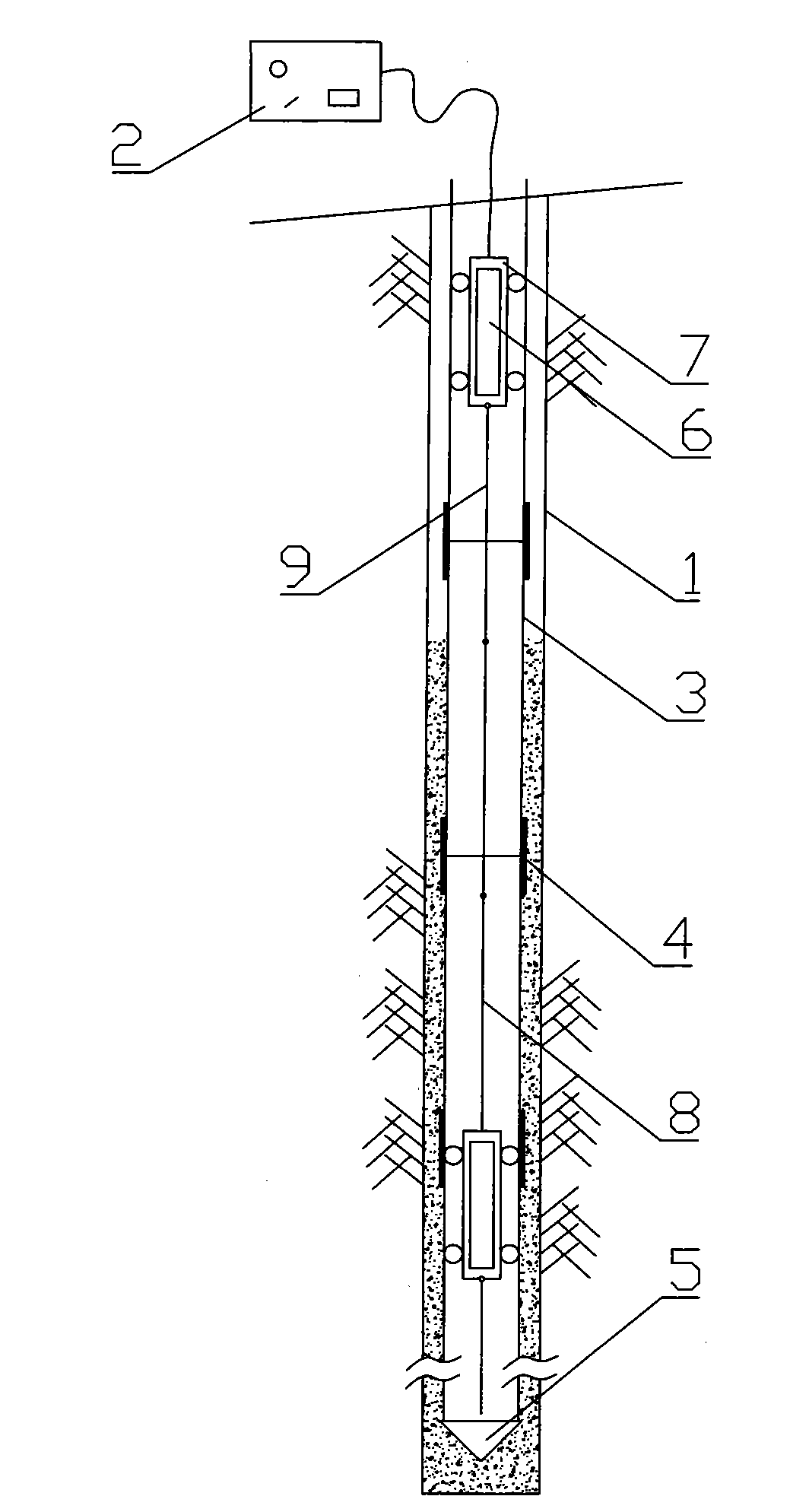

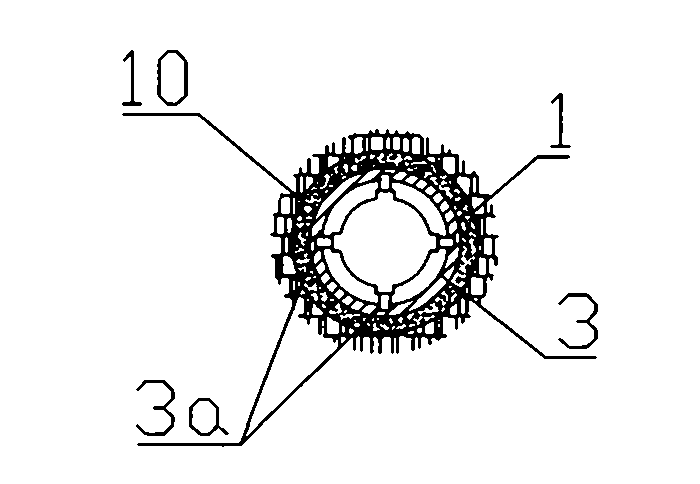

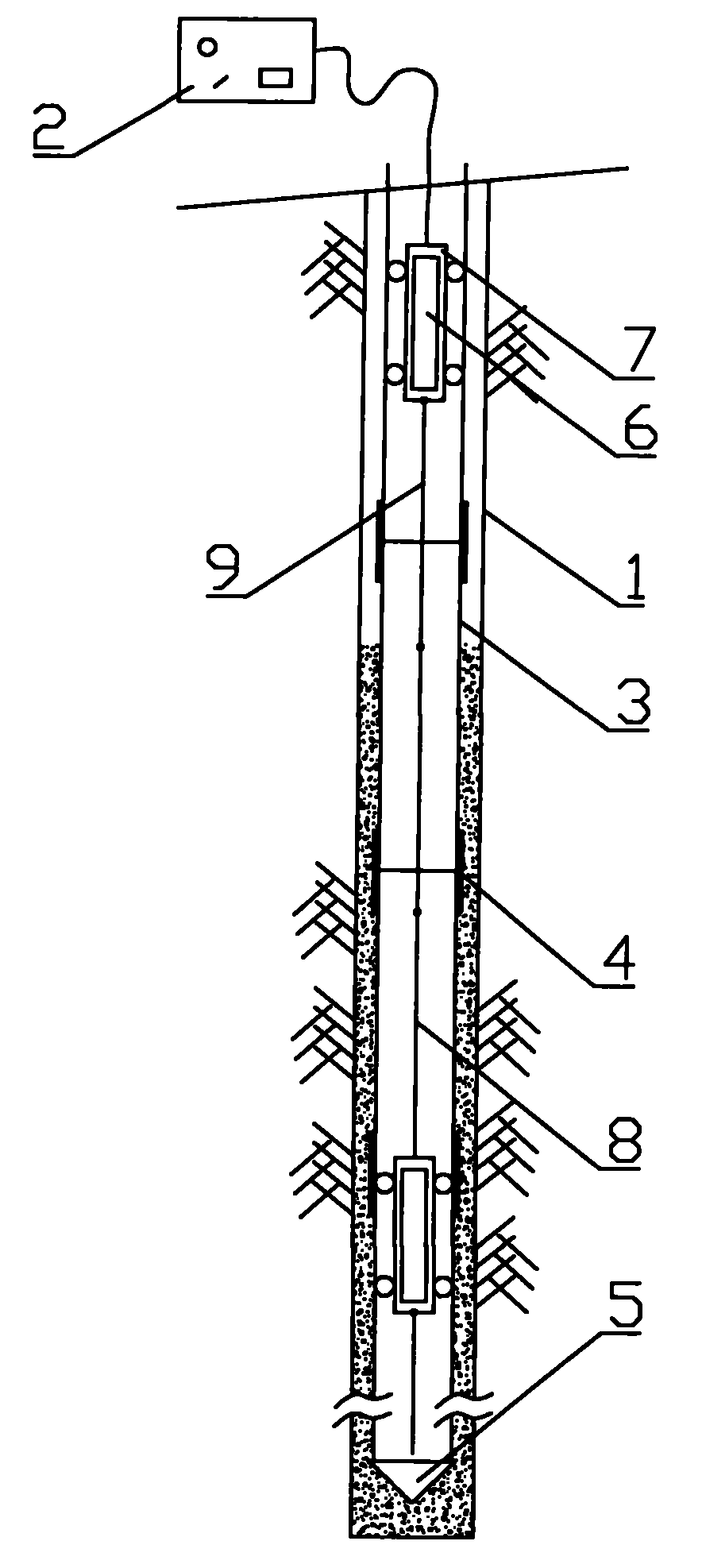

Continuous monitoring system of overburden rock displacement in ore bed mining process and structuring method thereof

ActiveCN101915094ARealize the whole process of continuous monitoringAvoid damageSurveyOverburdenChain structure

The invention discloses a continuous monitoring system of overburden rock displacement in an ore bed mining process, which comprises an inclination measuring drilling hole, an inclination measuring pipe assembly, a monitoring device and a monitoring station. When in use, a plurality of fixed inclinometers are arranged at different positions as required so as to realize the continuous whole-coursemonitoring on mined overburden rock displacement; meanwhile, the monitoring device for a flexible chain structure can be used for preventing the damage of overburden rock movement on instruments so as to ensure monitoring is carried out smoothly; and the monitoring system is used for evaluating the space-time influence degree of the mining to overburden rock so as to provide a basis for the judgment of the influenced degree and the safety of deep mining operation execution, facilities in an overburden rock stratum, ground facilities, and the like. In addition, the invention also discloses a method for structuring the monitoring system, wherein methods for embedding an inclination measurement pipe, carrying out anti-sliding safety protection during lowering the inclination measurement pipe, lowering the inclination measurement pipe when water or no water exists in the drilling hole, fixing the inclination measurement pipe by deep hole grouting, and the like not only effectively solve the problem of huge difficulty on installing deep-hole inclination measurement pipes, but also effectively improve the construction efficiency and the safety.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

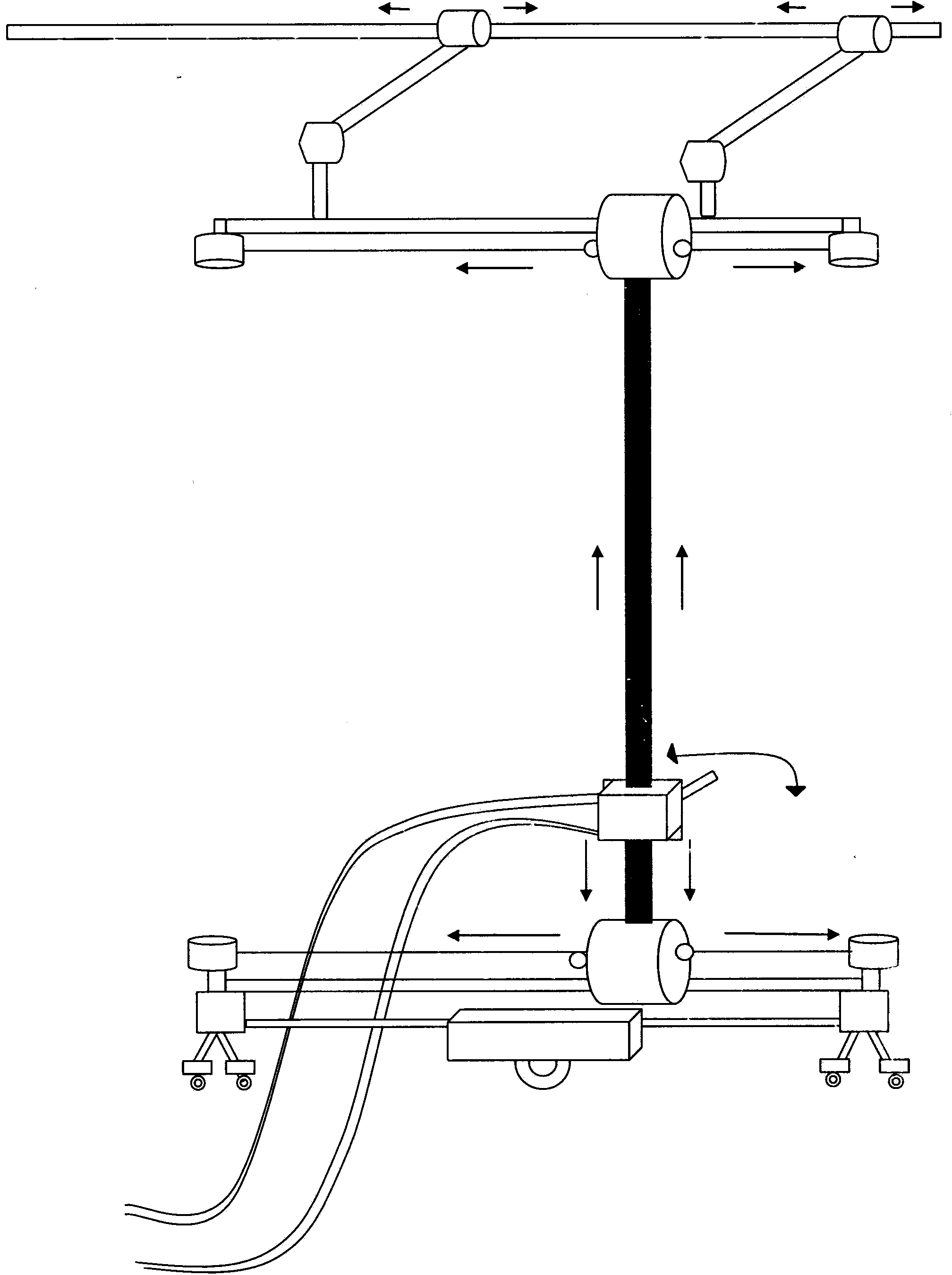

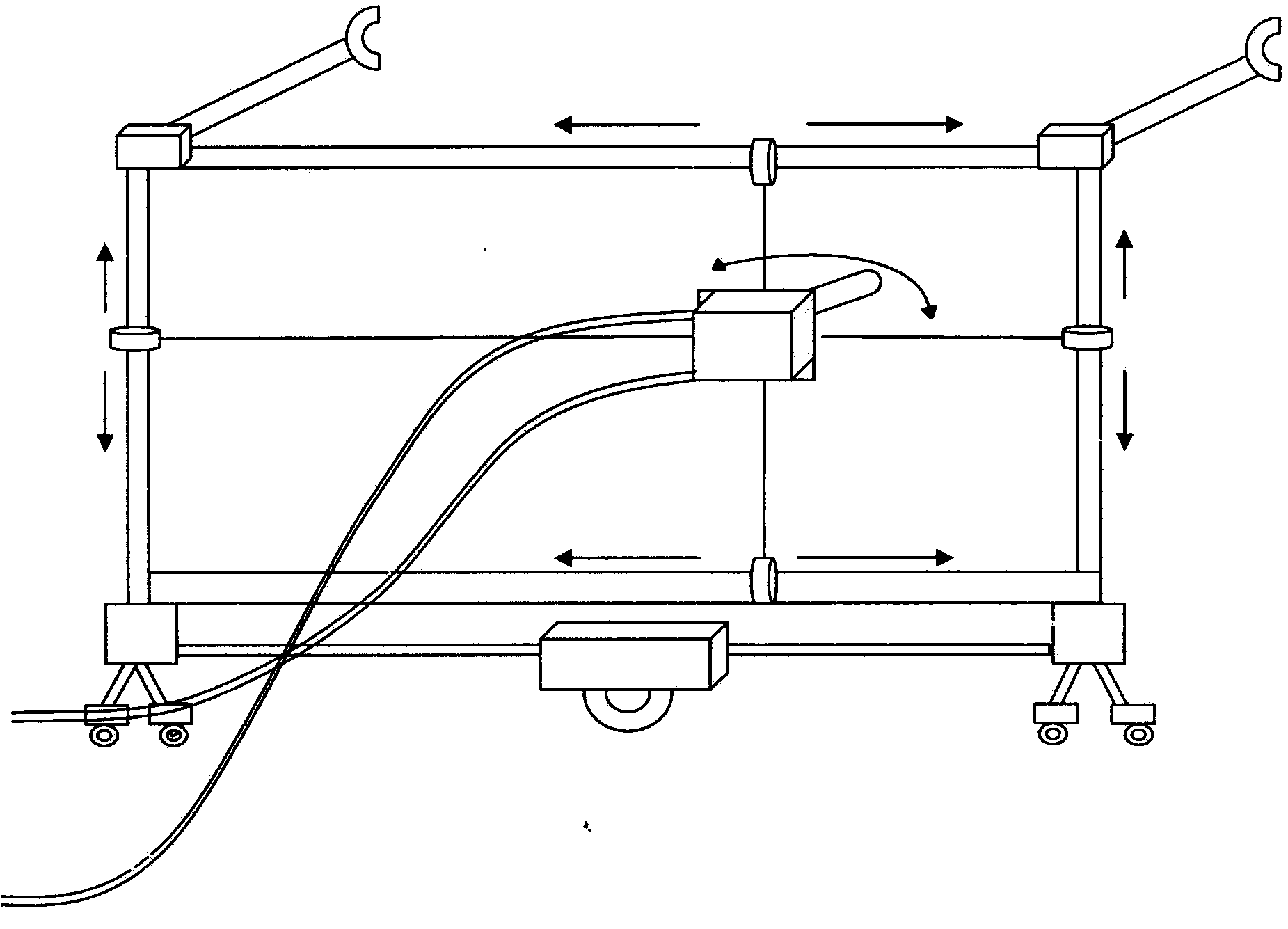

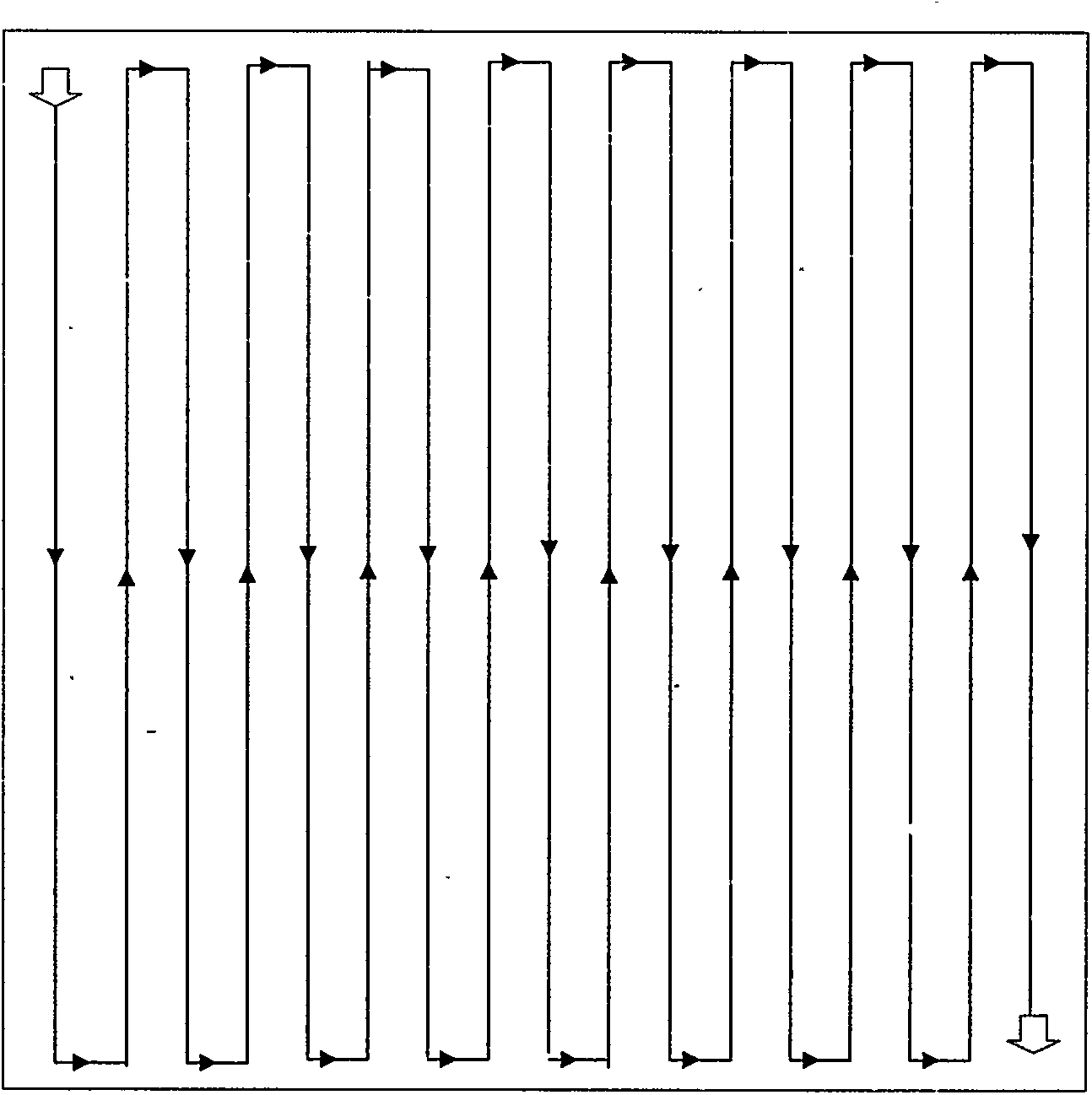

Surface spraying and rendering robot for building

InactiveCN104343230AImprove construction efficiencyApply evenlyBuilding constructionsGraphicsAngular velocity

The invention provides a surface spraying and rendering robot for a building. The robot can be used for automatically spraying and rendering cement mortar, lime mortar, putty mortar and other materials, and can also be used for spraying embossed graphics. The robot is of two structures according to the height of a wall body of the building. The robot is characterized in that a spraying and rendering head is fixed through a transverse and longitudinal moving device and used for accurately moving and spraying and rendering in the transverse and longitudinal directions; the spraying and rendering head is equipped with a camera device; the self-cleaning function is brought, so that the camera shooting picture cannot be influenced by the spraying of mortar, and a worker can remotely monitor the spraying and rendering effect; the spraying thickness is controlled through the swinging angular velocity and moving rate of the spraying head; a spraying and rendering device is equipped with a touch part and a distance sensor which enables uniform coating and rendering, and the efficiency and reliability are higher than manual operation. According to the robot, a plurality of spraying heads or rendering knives can be arranged and switched by program control; different building materials can be loaded; the colorful embossed graphics can be sprayed based on the computer picture; the working scope and route of the robot can be set by the computer program, and the learning can be performed automatically through the teaching program.

Owner:郑西涛

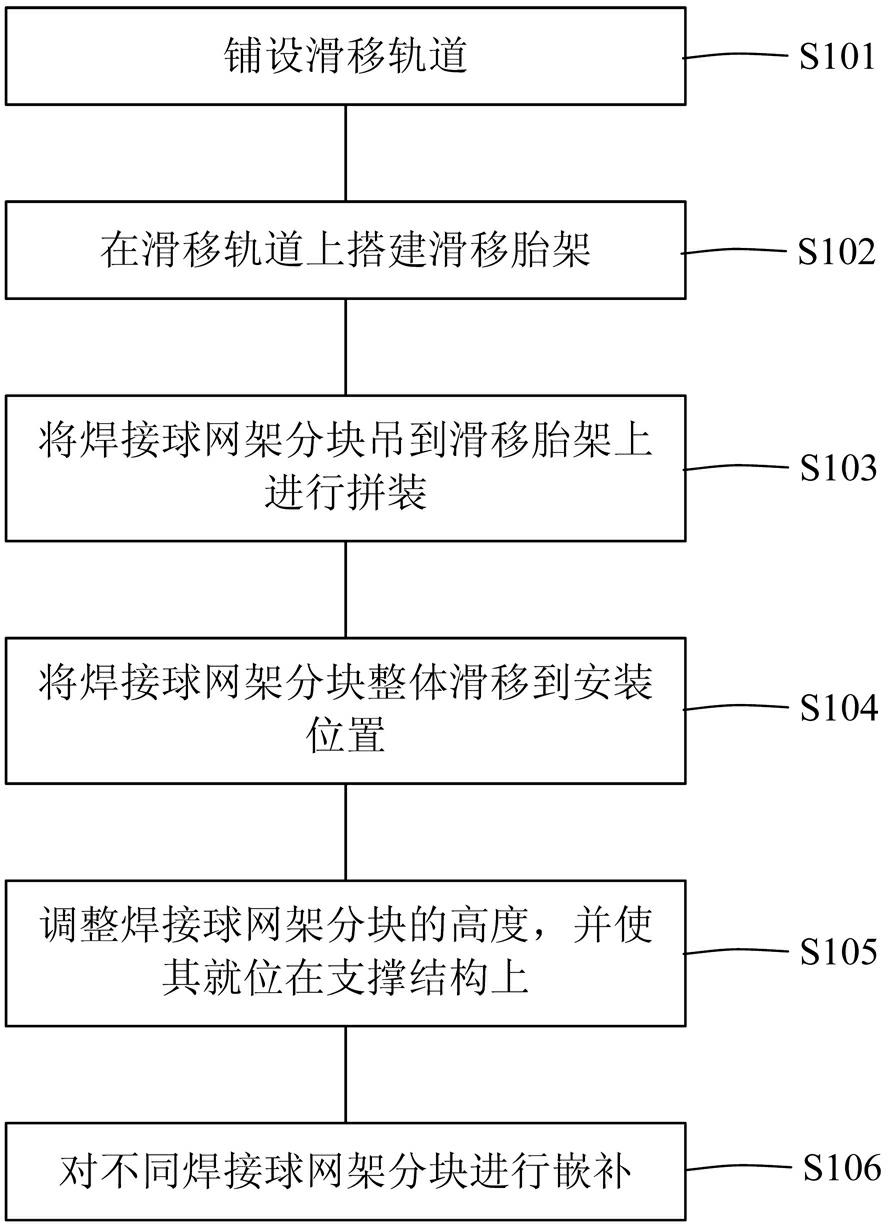

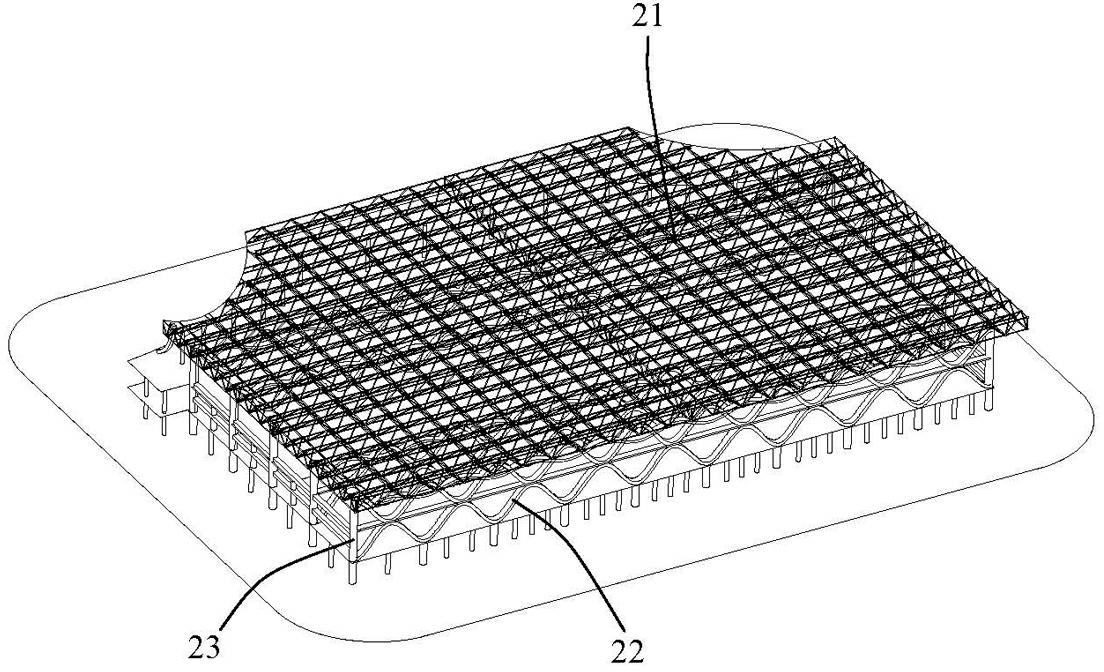

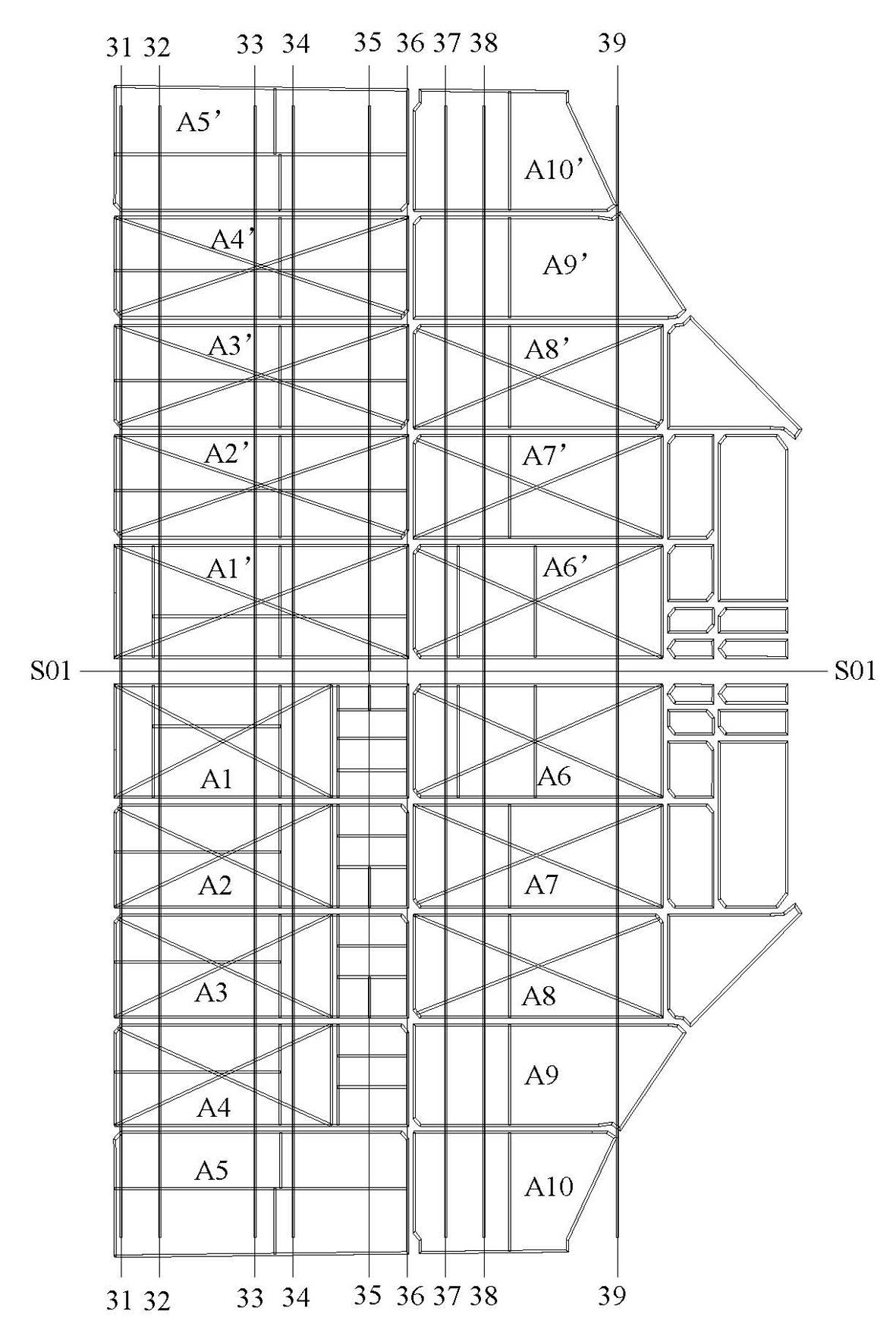

Extra-large-area hyperboloid welding ball network frame sliding construction method

ActiveCN102146732ASolve construction difficultiesEasy constructionBuilding material handlingHyperboloidEngineering

The invention provides an extra-large-area hyperboloid welding ball network frame sliding construction method, which comprises the following steps of: (1) laying a sliding rail; (2) building a sliding jig frame on the sliding rail; (3) hoisting welding ball network frame blocks to the sliding jig frame; (4) wholly sliding the welding ball network frame blocks to a mounting position; (5) adjustingthe heights of the welding ball network frame blocks and positioning the welding ball network frame blocks on a supporting structure; and (6) inlaying different welding ball network frame blocks to form an extra-large-area welding ball network frame. The invention has the advantages that: the method solves the problem that the extra-large welding ball network frame structure is difficult to construct, the construction is convenient and the safety is high.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

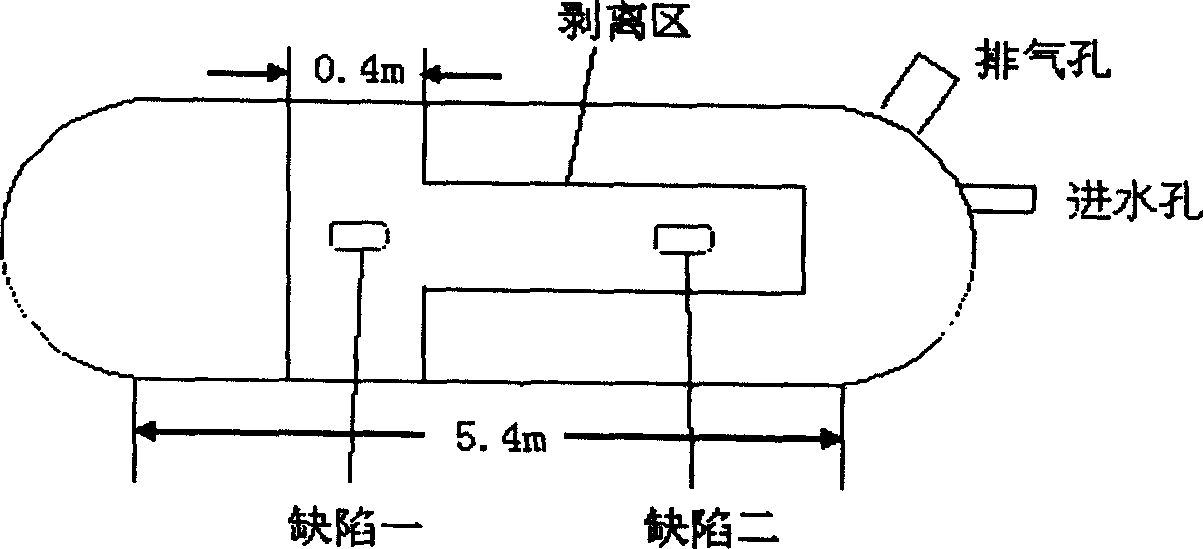

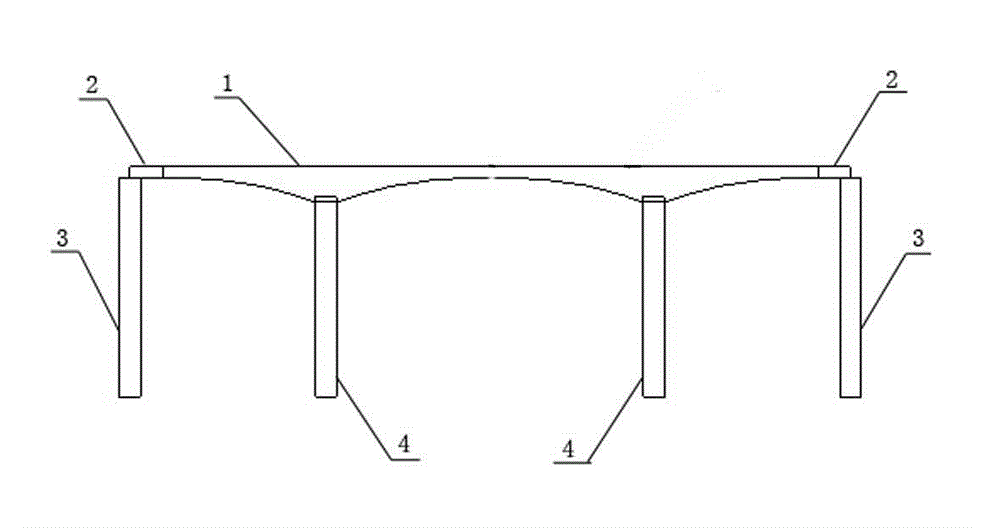

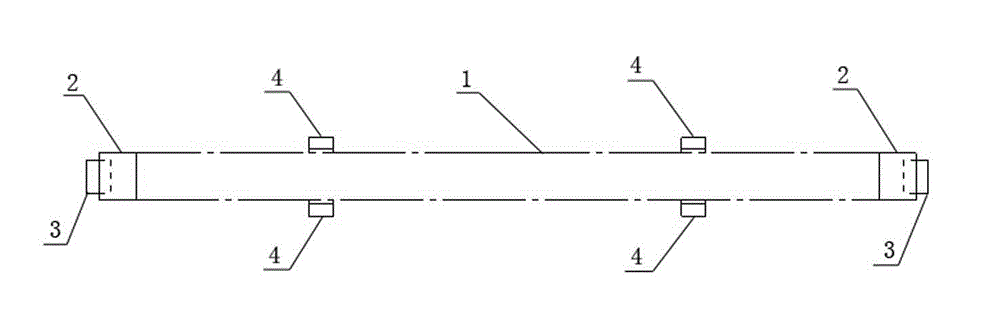

Strengthening carbon fiber composite material and method for repairing defective pipeline

The pipeline repairing and reinforcing material includes repairing glue layer for repairing and leveling the outer pipeline fault; carbon fiber sheet painted or dipped with glue for restoring and raising the bearing strength of the fault part; and anticorrosive material layer for the outer surface. The repairing and reinforcing material of the present invention has specific strength and specific module near that of the metal pipe material, can bear the pressure inside the pipe together with the pipe and reach or even exceed the bearing capacity of the pipe. The present invention may be used in repairing pipeline without stopping conveyance.

Owner:UNIV OF SCI & TECH BEIJING +1

Bridge and construction method thereof

ActiveCN102747677AImprove construction safetyShorten working timeBridge erection/assemblyButt jointArchitectural engineering

The invention relates to the field of construction, in particular to a bridge and a construction method thereof. The bridge and the construction method of the bridge are provided to overcome shortcomings in construction methods of existing bridges, a conventional sequence construction method of performing cast-in-place construction of a beam body after bridge pier construction is finished is changed into a parallel construction operation method of a bridge pier and the beam body. The bridge comprises the bridge pier and the beam body, and the beam body comprises a precast beam body and two side span connecting segments respectively in butt joint with the head end and the tail end of the precast beam body. The bridge pier comprises side piers supported on end sides of the side span connecting segments and main piers symmetrically arranged on two sides of the end of the precast beam body, and a load-bearing beam for supporting the precast beam body is connected between the two main piers positioned on two sides of the end of the precast beam body. The construction method has the advantages of achieving the effects of shortening operating time and reducing cost at once, being high in work efficiency, being not subjected to limitation of a conventional construction process, reducing high-altitude operation difficulty and dangerous sources and improving construction safety for workers.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

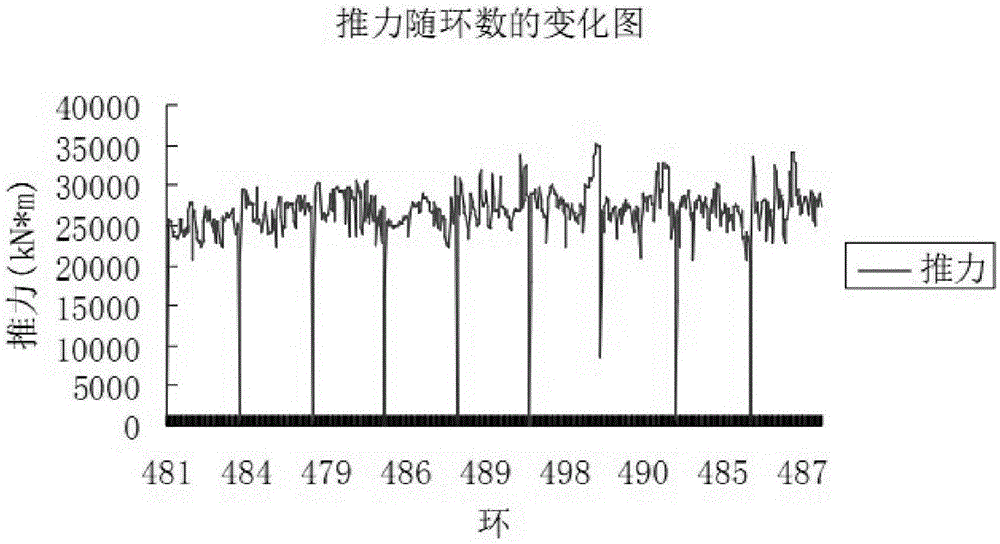

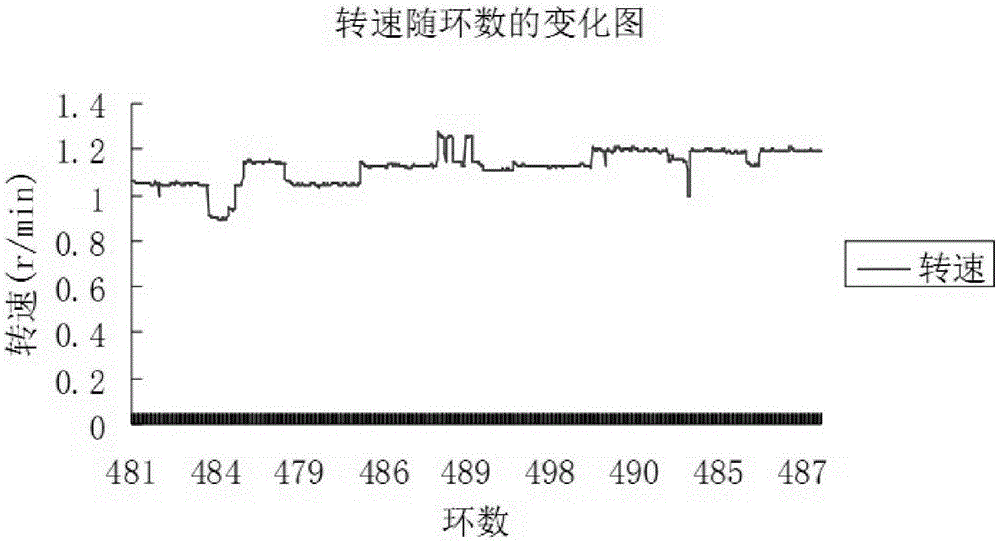

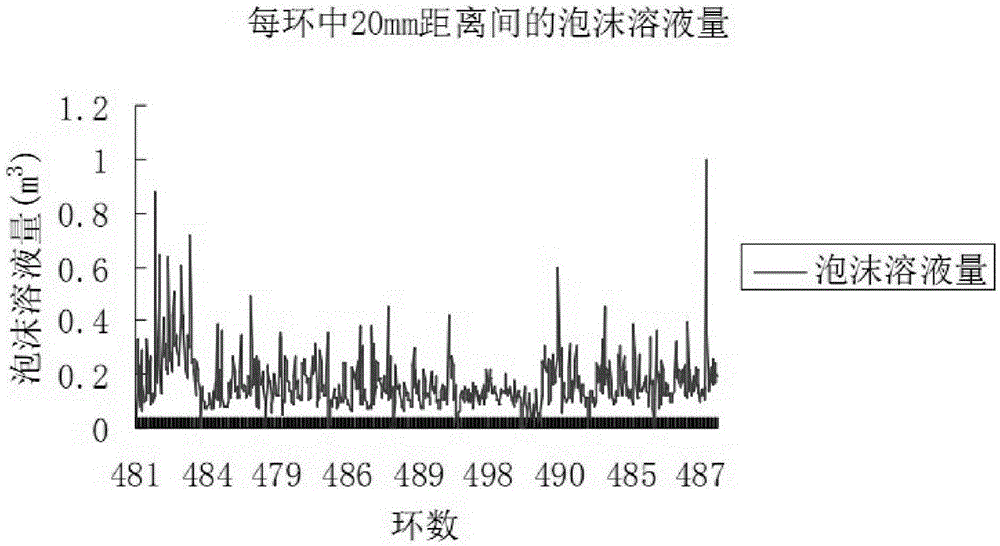

Optimization method of shield excavation parameters under condition of compound stratum

InactiveCN105631150AImprove construction safetyExtended service lifeSpecial data processing applicationsMathematical modelData acquisition

The invention discloses an optimization method of shield excavation parameters under the condition of a compound stratum. The method is characterized by comprising the following steps of (1) carrying out shield excavation orthogonal experimental design; (2) collecting excavation data; utilizing a data collection and storage system of a shield tunneling machine to collect and record experimental data; collecting the thrust, the rotating speed of a cutter, the excavation speed, the foam solution adding amount, the foam concentration and the cutter torque by the data collection system during the experiment process; collecting data at a time after excavating 20mm every time, wherein the experimental excavation length of each group is 1.6m; (3) building a shield excavation parameter mathematical model; designing an orthogonal experimental model according to the shield construction process, carrying out nonlinear regression analysis on data collected by the orthogonal experiment, respectively building an excavation speed model and a cutter torque model of earth pressure balance shield, confirming the reasonable excavation parameters under the condition of the compound stratum through resolving, and optimizing the excavation parameters, so that the safety of shield construction is improved, and the service life of the shield tunneling machine is prolonged.

Owner:SHIJIAZHUANG TIEDAO UNIV

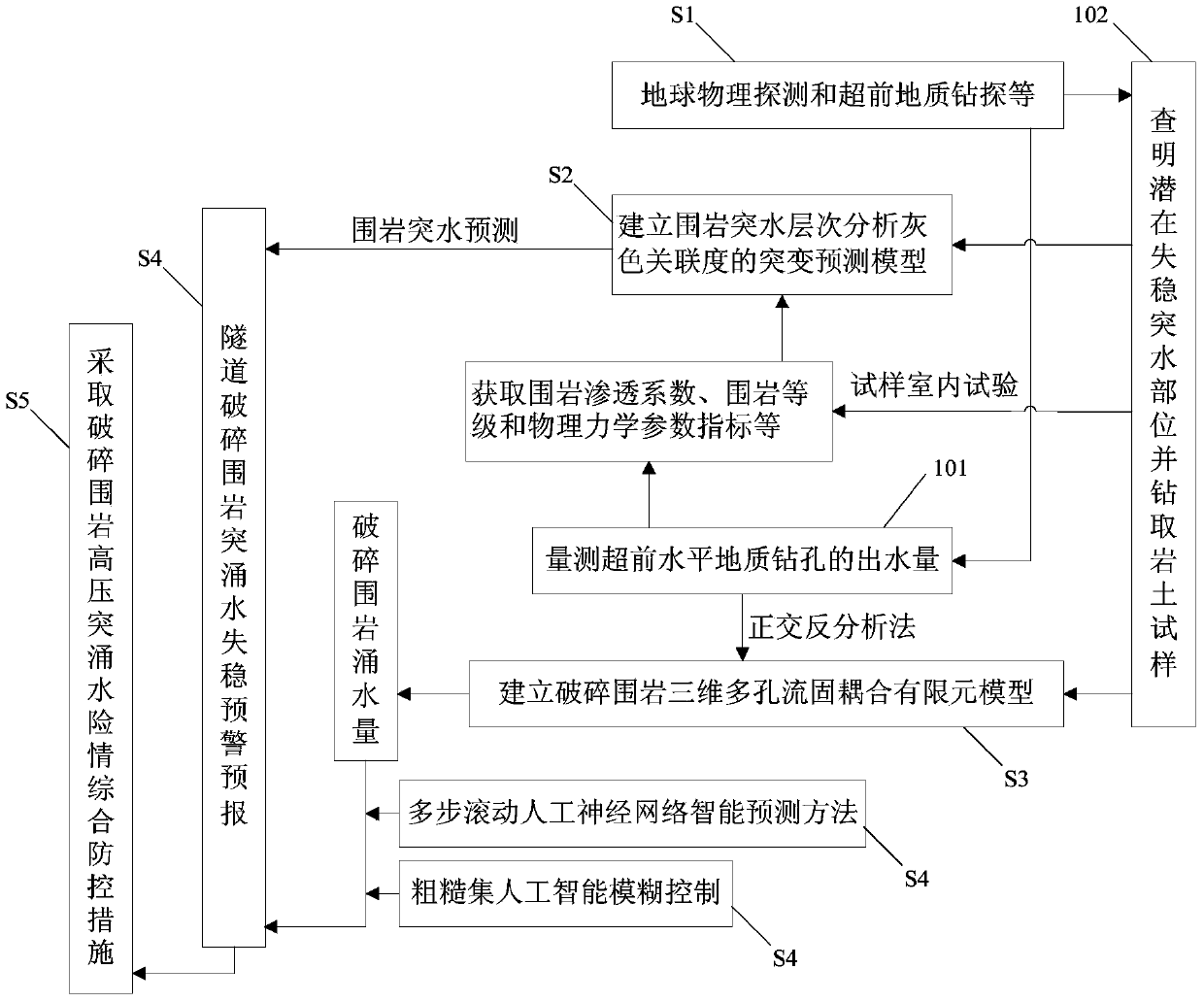

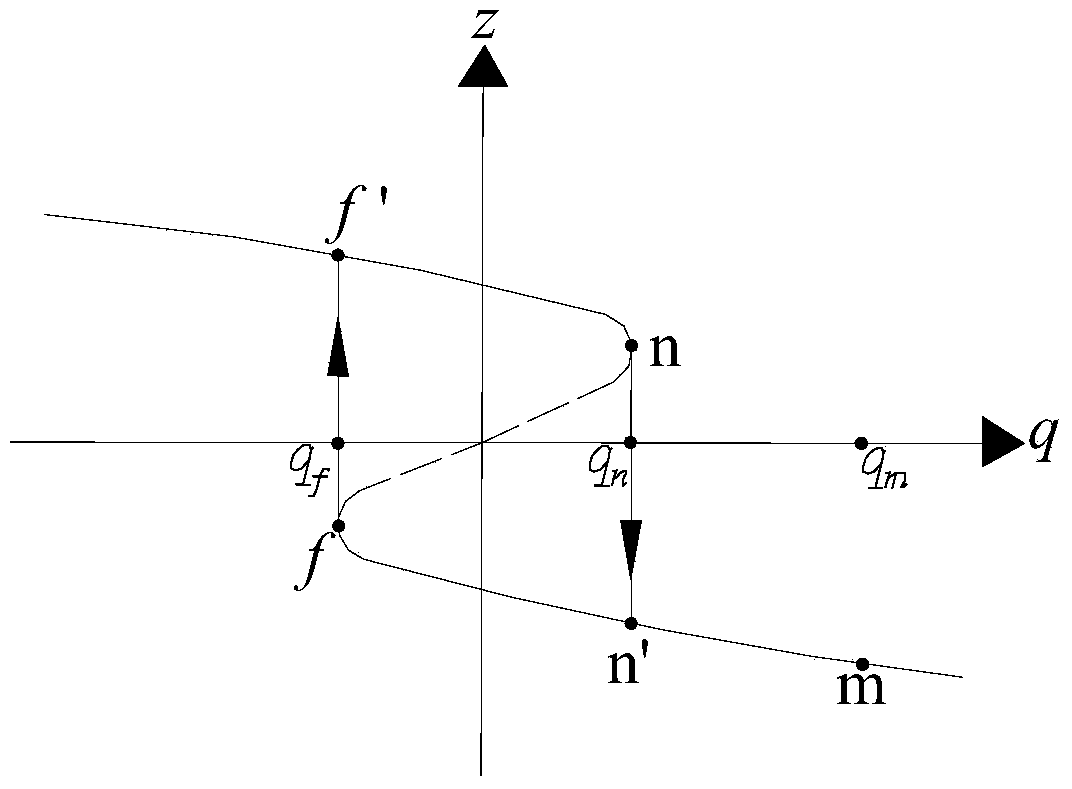

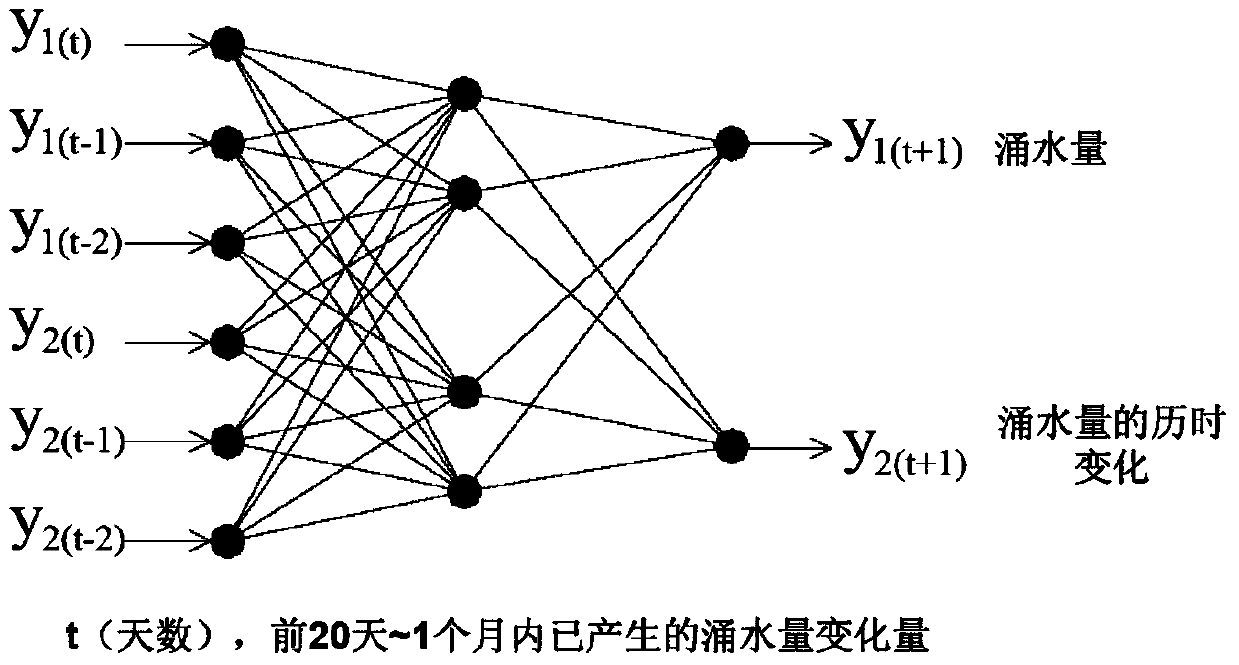

Method for water inrush prediction and seepage control for underwater-tunnel broken surrounding rocks

InactiveCN104179514ARealize surrounding rock water inrush predictionImprove rational designUnderground chambersTunnel liningElement modelInstability

The invention relates to a method for water inrush prediction and seepage control for underwater-tunnel broken surrounding rocks. The method includes the steps of S1), exploring by adopting a geophysical exploration and advanced-level geological drilling method and performing tests; S2), establishing a saltation prediction model of analytic hierarchy grey correlation of water inrush of the surrounding rocks by adopting an analytic hierarchy grey correlation method; S3), establishing a three-dimensional porous continuous medium fluid-structure coupled finite element model of the underwater-tunnel broken surrounding rocks by adopting an orthogonal back-analysis method; S4), performing dynamic prediction and seepage control on water inflow of the broken surrounding rocks and performing intelligent fuzzy logic control and instability early-warning forecast on high-pressure water inrush of the broken surrounding rocks; S5), adopting comprehensive prevention and control measures. Compared with the prior art, the method has the advantages that instability of water inrush of the underwater-tunnel broken surrounding rocks under high water pressure can be predicted and subjected to economical, reasonable, safe and reliable comprehensive seepage control.

Owner:TONGJI UNIV

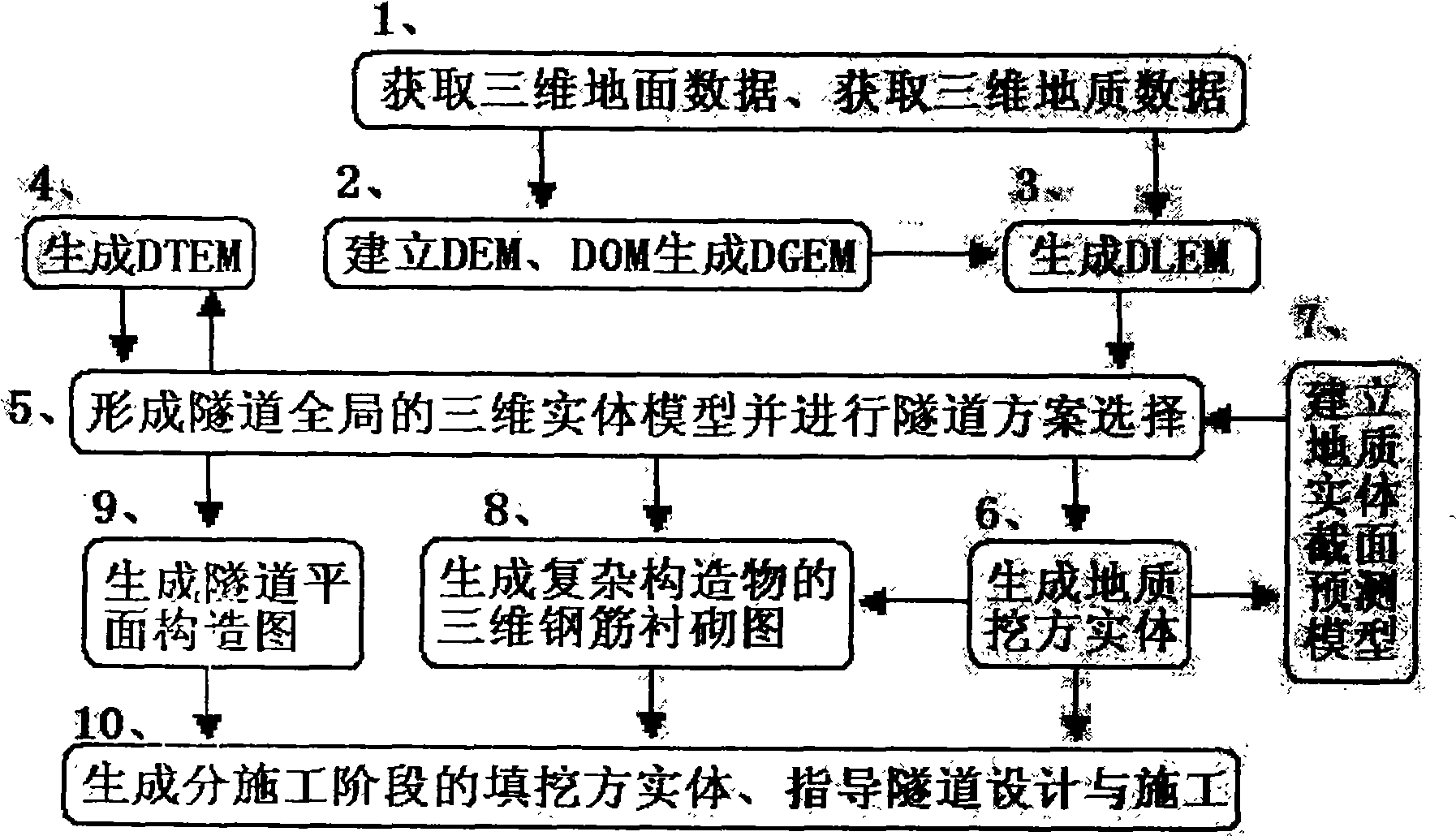

Tunnel surveying method

The invention relates to a method for investigating a tunnel, comprising the following steps: 1) obtaining 3-dimensional data on ground and geology; 2) generating DGME; 3) generating DLEM; 4) generating DTEM; 5) forming an overall 3-dimensional hardware model of the tunnel and selecting a tunneling solution; 6) generating a geological excavation entity; 7) establishing a forecasting model for geological entity section; 8) generating a 3-dimensional steel bar lining diagram of a complex structure; 9) generating a tunnel plane structure diagram: 10) generating a cut and fill entity with different construction stages, guiding tunnel design and construction. By the method of the invention, 3-dimensional effect and geological conditions of the tunnel can be directly obtained for exact, intuitive and convenient selection of the tunneling solution, thus effectively reducing rework, improve investigating quality, construction safety and tunnel stability, coordinating the tunnel mouth with the environment, remarkably improving design effects of a tunnel portal, a tunnel face and a tunnel trunk. As a result, the method of the invention can be widely applied to tunnel investigation, and in terms of engineering application, related softwares can be configured according to actual needs.

Owner:COMM DESIGN INST CO LTD OF JIANGXI PROV

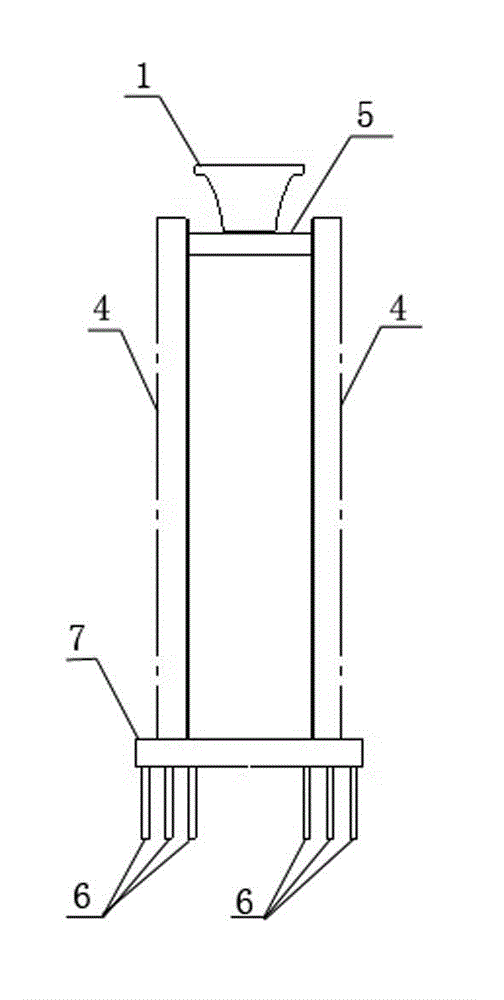

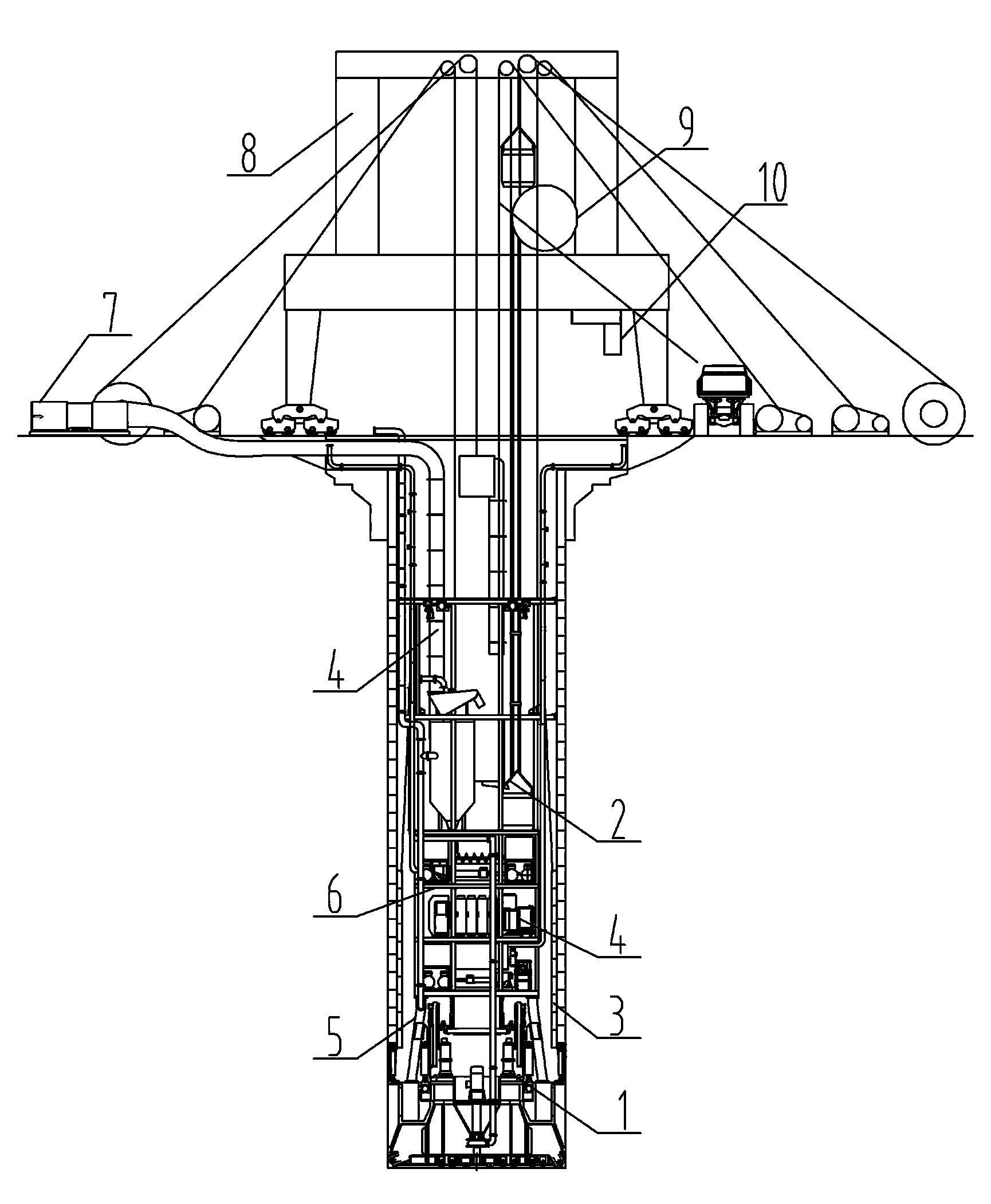

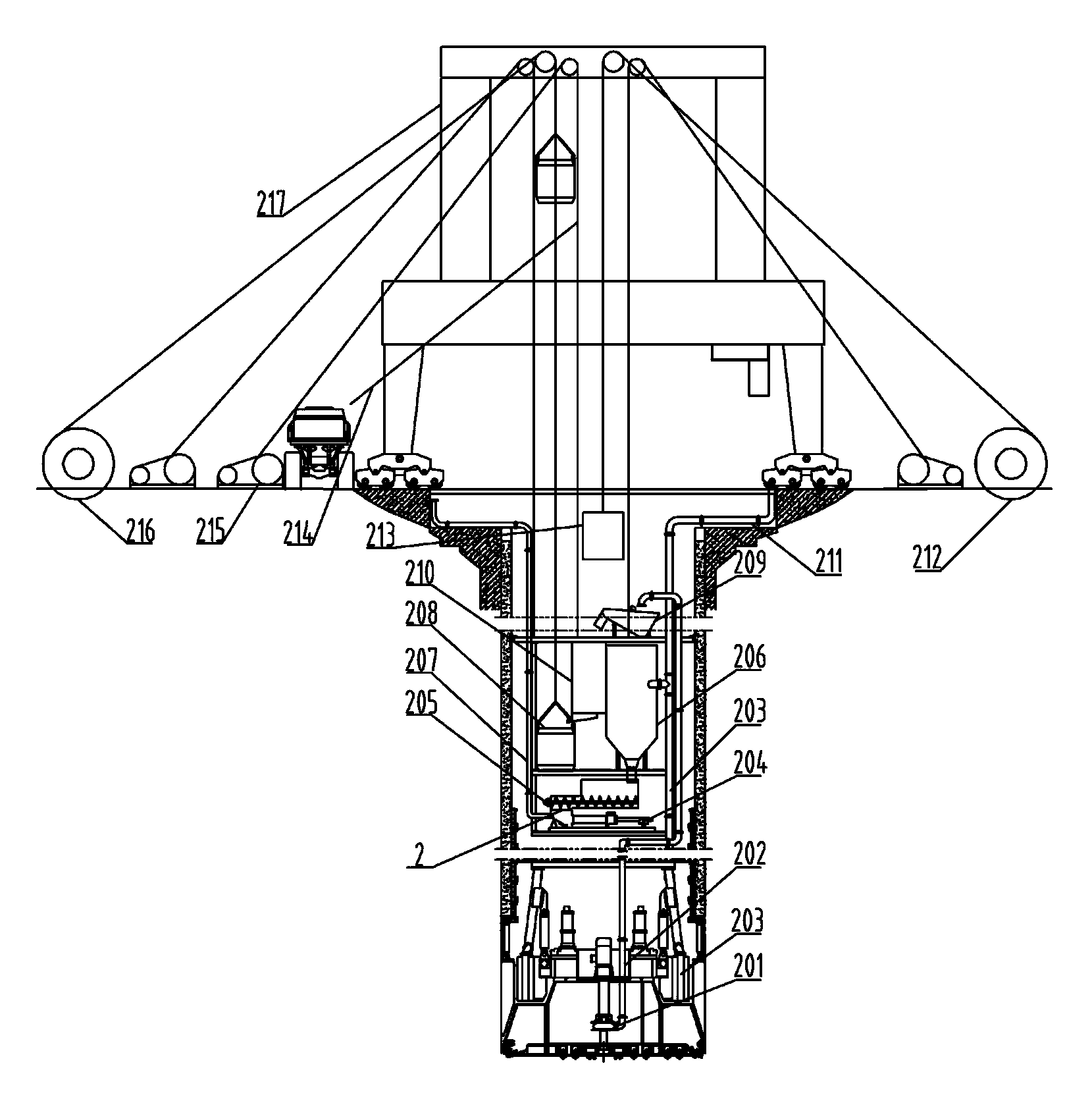

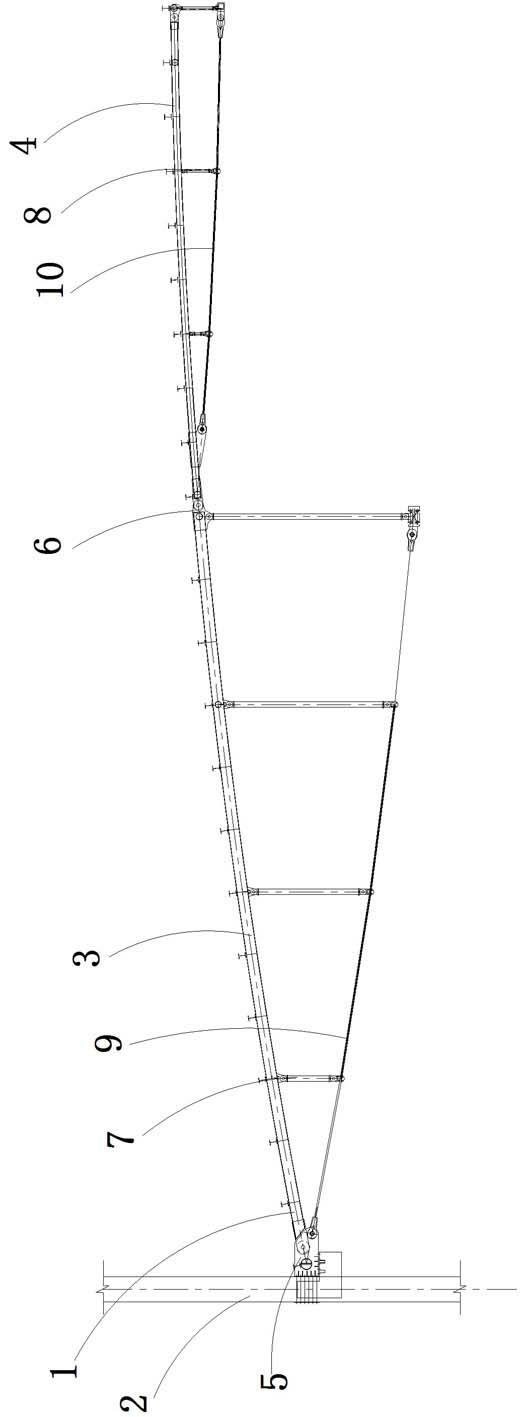

Full-fracture-surface vertical shaft drilling machine

ActiveCN103670420AEfficient constructionImprove construction efficiencyShaft sinkingShaft liningSlagControl engineering

The invention belongs to the technical field of mineral product machinery and discloses a full-fracture-surface vertical shaft drilling machine which comprises a device main girder, device platforms, a head frame, a tunneling system, a personnel and material conveying system, a shaft wall supporting and protecting system, a guaranteeing system and a manipulating chamber. The tunneling system is installed at the front end of the device main girder, the device platforms are installed at the rear end of the device main girder, the head frame is arranged on a shaft mouth, the manipulating chamber is arranged on the head frame, the personnel and material conveying system and the guaranteeing system are installed on the rear portion of the tunneling system, the shaft wall supporting and protecting system is arranged on the rear portion of the tunneling system and the periphery of the tunneling system, the personnel and material conveying system comprises a hoister, a first-level separation station, a slag storage cabin, a second-level separation station, a feeding mechanism and a conveying pump, the shaft wall supporting and protecting system comprises an auxiliary crane, a hoister, an underground concrete mixing tank, a concrete pump and an anchoring system, and the auxiliary crane, the hoister, the underground concrete mixing tank, the concrete pump and the anchoring system are installed on the device platforms respectively. The full-fracture-surface vertical shaft drilling machine solves the construction problems of large-scale vertical shafts such as coal mines, complete equipment of automation, mechanization and integration of the functions of shaft tunneling, slag tapping, supporting, protection, water discharging, ventilation and the like, the construction efficiency is improved, the construction cost is reduced, the construction safety is improved, and the application range is wide.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

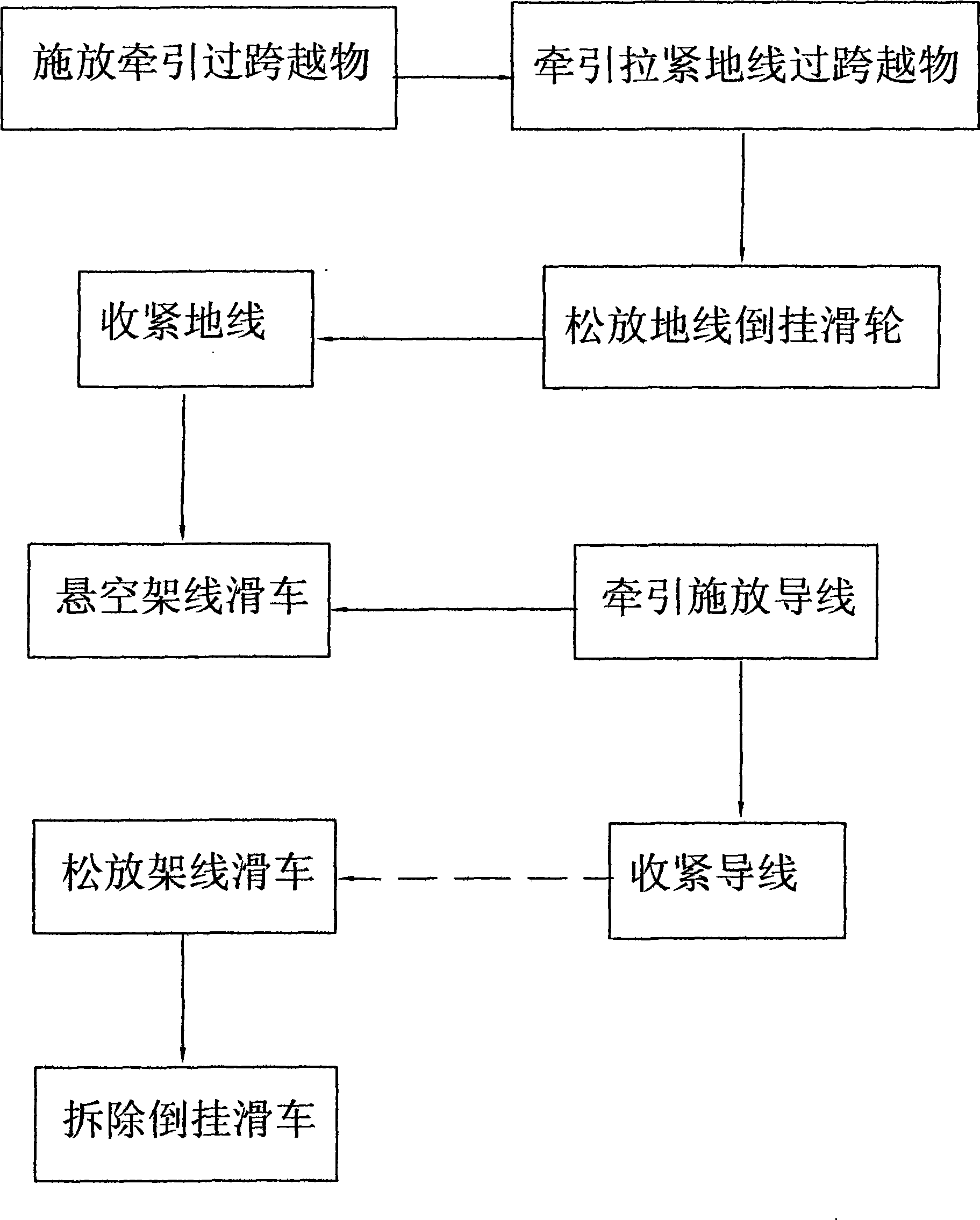

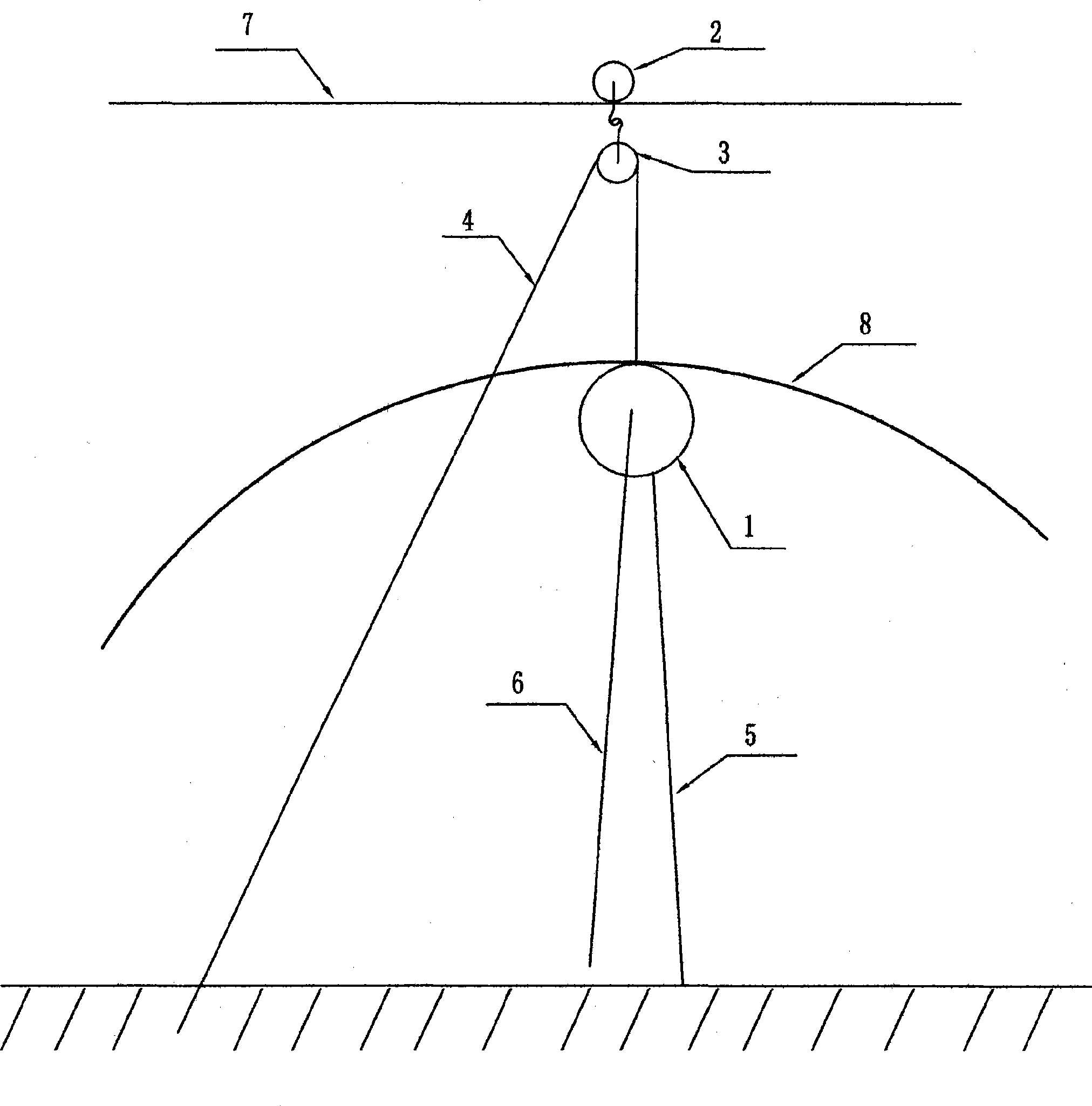

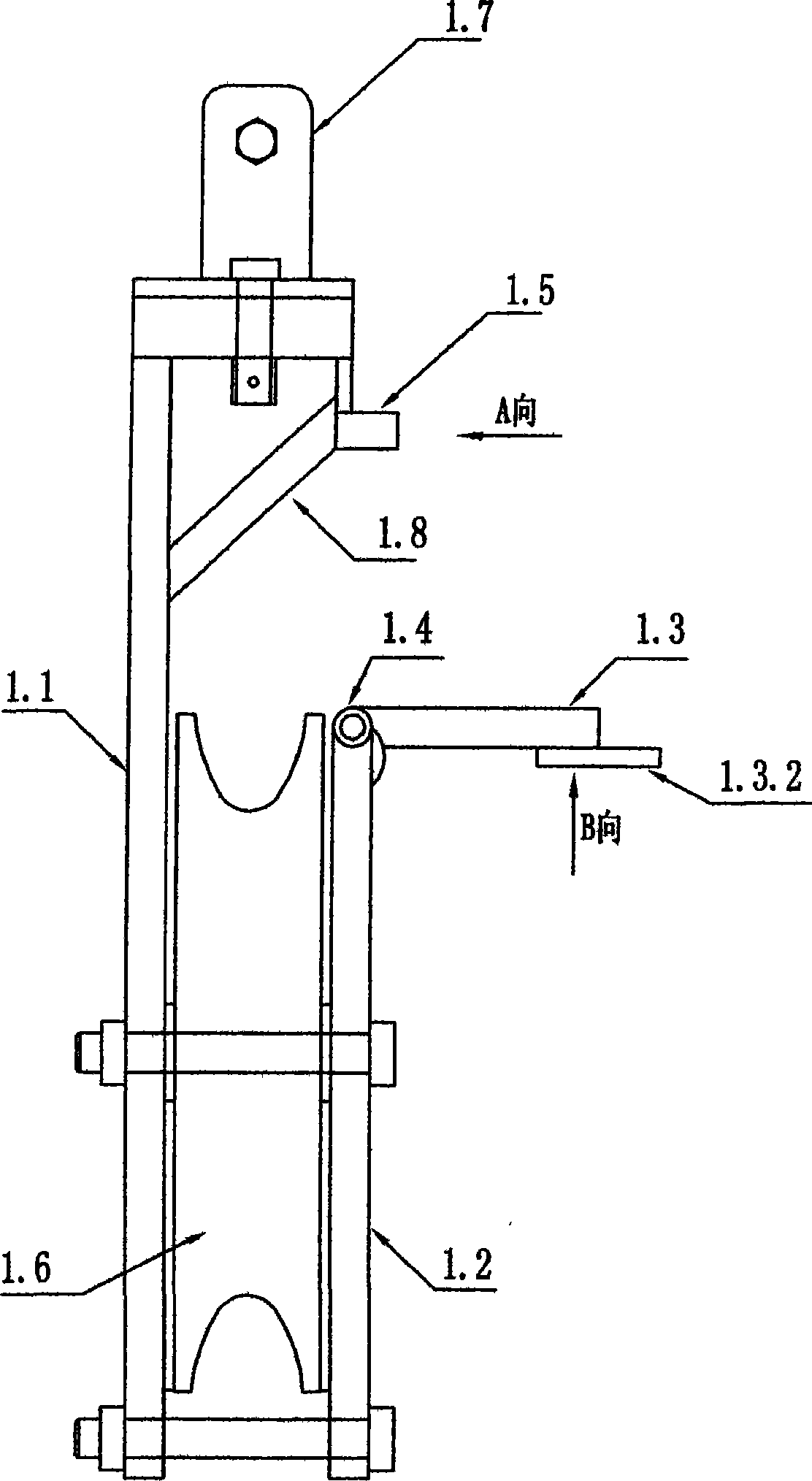

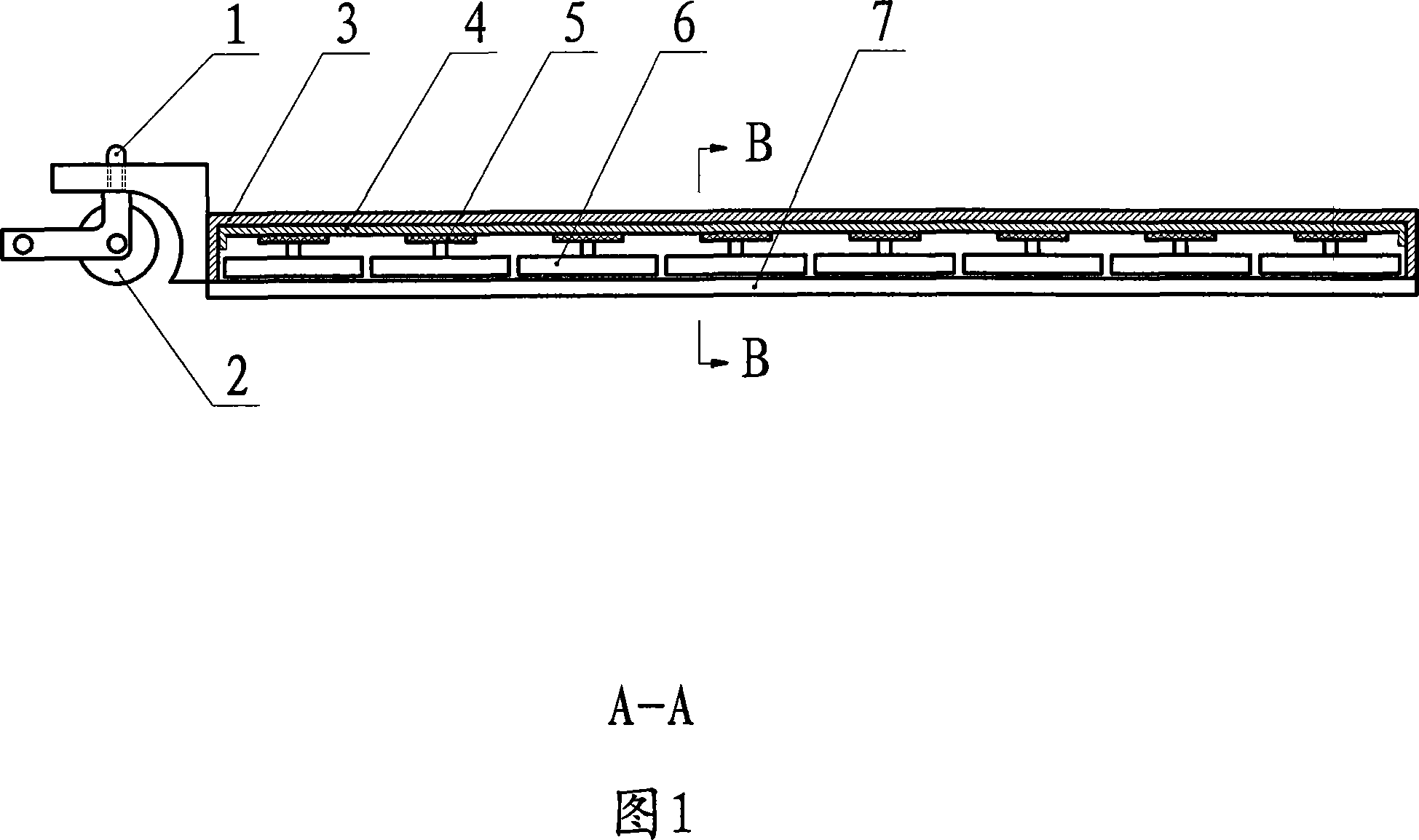

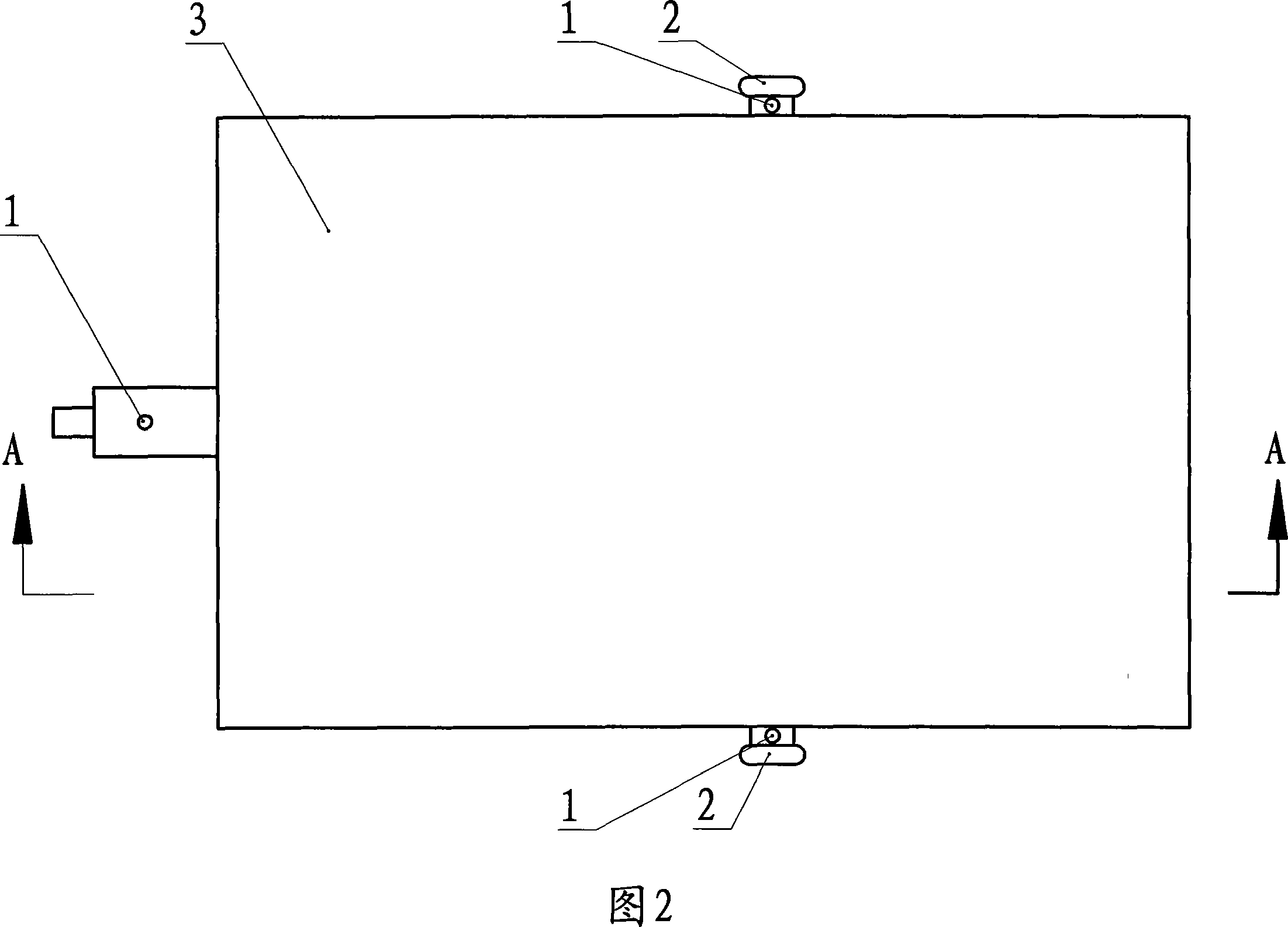

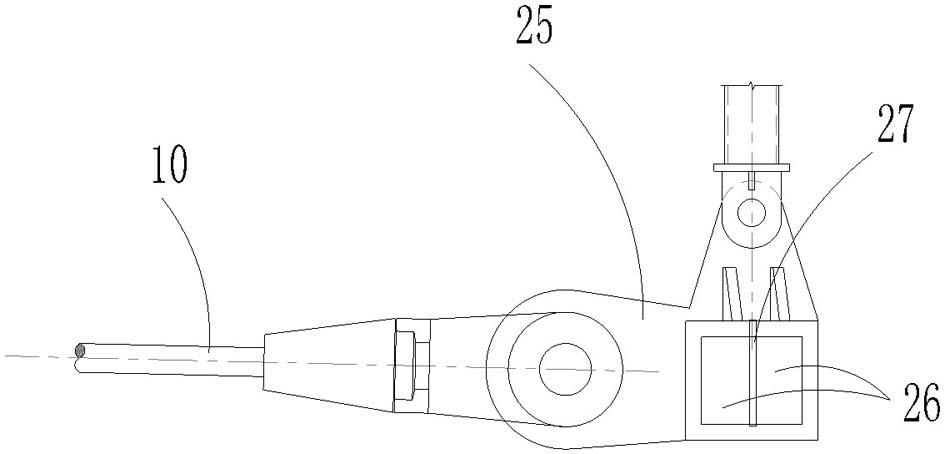

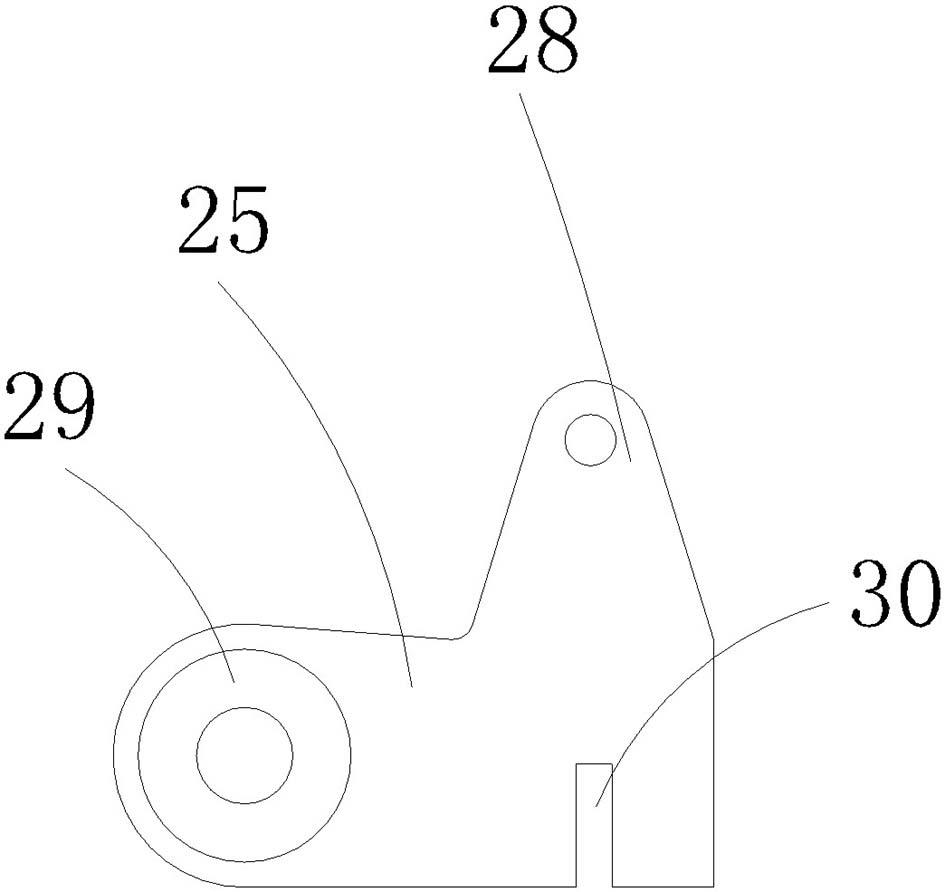

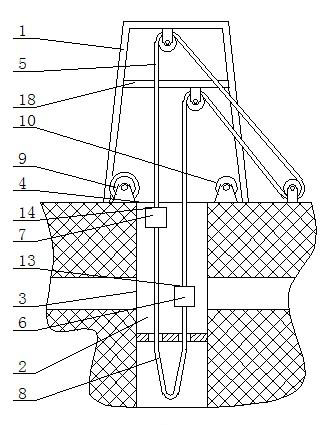

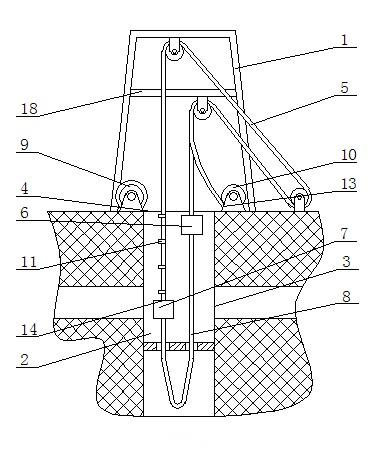

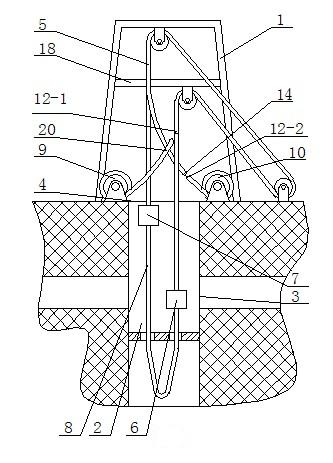

Crossover stringing method for overhead line and stringing sheave pulley

InactiveCN101436764AEasy to implementImprove construction safetyApparatus for overhead lines/cablesLocking mechanismTower

The invention discloses a method for crossing stringing of overhead line and improvement on stringing tackle. The method comprises the following steps: a pulling cable is released and extends across an spanning object; the pulling cable is communicated with towers at two sides of a span; one end of the pulling cable is connected with a groundwire at a cable releasing side, while the other end pulls an overhead ground wire to cross the spanning object; when reaching a pulling end, the ground wire is loosened, so that at least one point in the span is lowered to or close to the ground; a pulley with a surrounding cable is hung upside down on the ground wire to tighten the ground wire; one end of the surrounding cable is pulled to make a trip stringing tackle which holds the pulling cable and a conducting wire and is hung on the other end of the surrounding cable lift and positioned over the spanning object; the pulling cable or the conducting wire on the stringing tackle is pulled to cross the spanning object till the spanning conducting wire is completely released or tightened; a strip door of the stringing tackle is pulled to be open to separate the conducting wire and the stringing tackle to complete the crossing stringing; after the cable releasing is completed, the strip stringing tackle is landed; and the surrounding cable is pulled to allow the pulley hung upside down to move to a tower on one side of the span to remove the pulley. A closable opening is arranged above a pulley of a pulley frame on at least one side of the strip stringing tackle. A movable door which can be turned down to be opened is arranged at the opening. The movable door is provided with a self-lock mechanism for preventing automatic opening. The self-lock mechanism is provided with a downward-pulled door chain.

Owner:国网江苏省电力有限公司宜兴市供电分公司 +3

Microwave heating device for asphalt pavement and repairing machine thereof

InactiveCN101058970AImprove construction safetyEffective isolationRoads maintainenceMicrowaveRoad surface

A microwave asphalt pavement heating device and its repairing machine. The microwave asphalt pavement heating repairing machine includes traction power vehicle, microwave asphalt heating device connecting fore-and-aft and rotary tillaging flattening device, said asphalt heating device includes frame body and many microwave generators installed and fixed under the frame body according certain rules, the frame body is installed moving wheel, a non-corrodible steel shielding layer with certain thickness and downward mouth is covered on the said frame body; the lower edge near the ground surface of said non-corrodible steel shielding layer; said microwave generators are installed under the frame body through rubber buffer blocks, hydraulic absorber is installed between said moving wheel and frame body; the construction safety performance of the invention is improved greatly, it saves pavement repairing materials, the damping effect is good, and it is not easy to be shocked and damaged, the construction efficiency is improved; it is worth being applied in road construction department.

Owner:王仕亮 +1

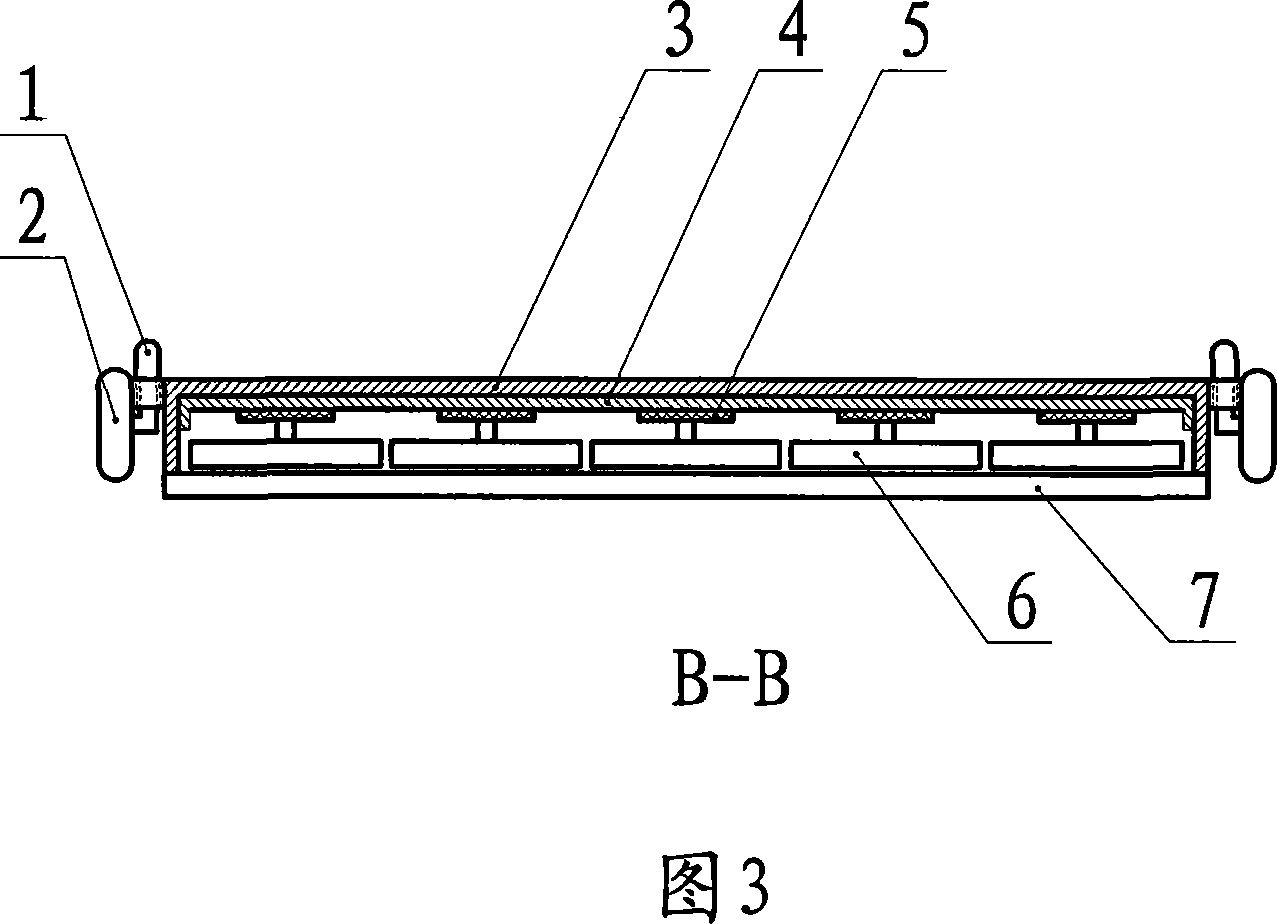

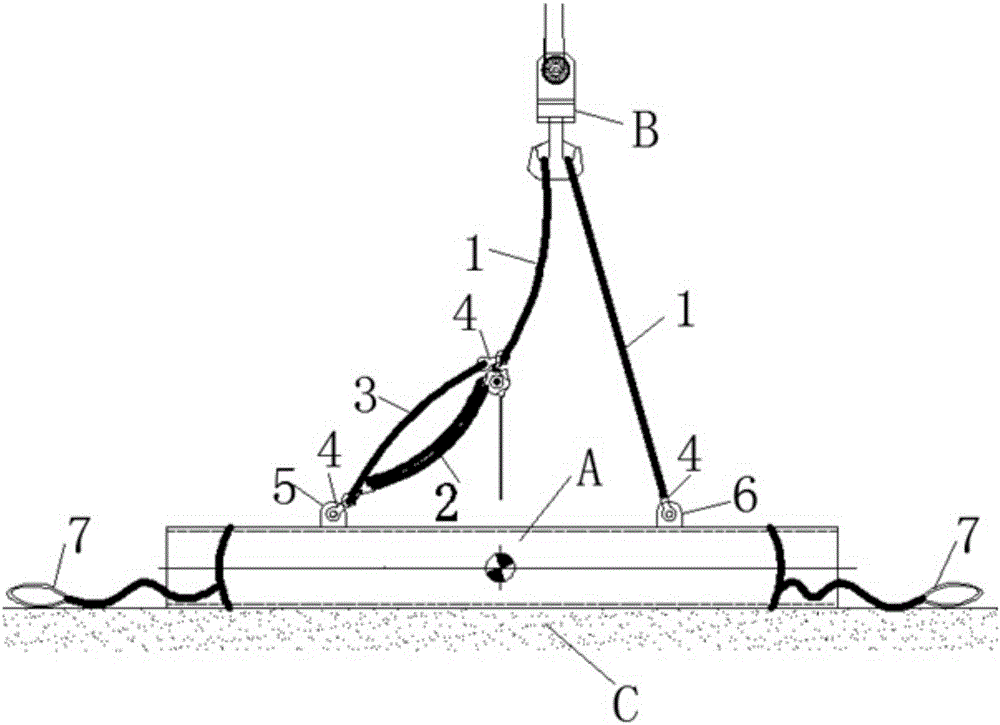

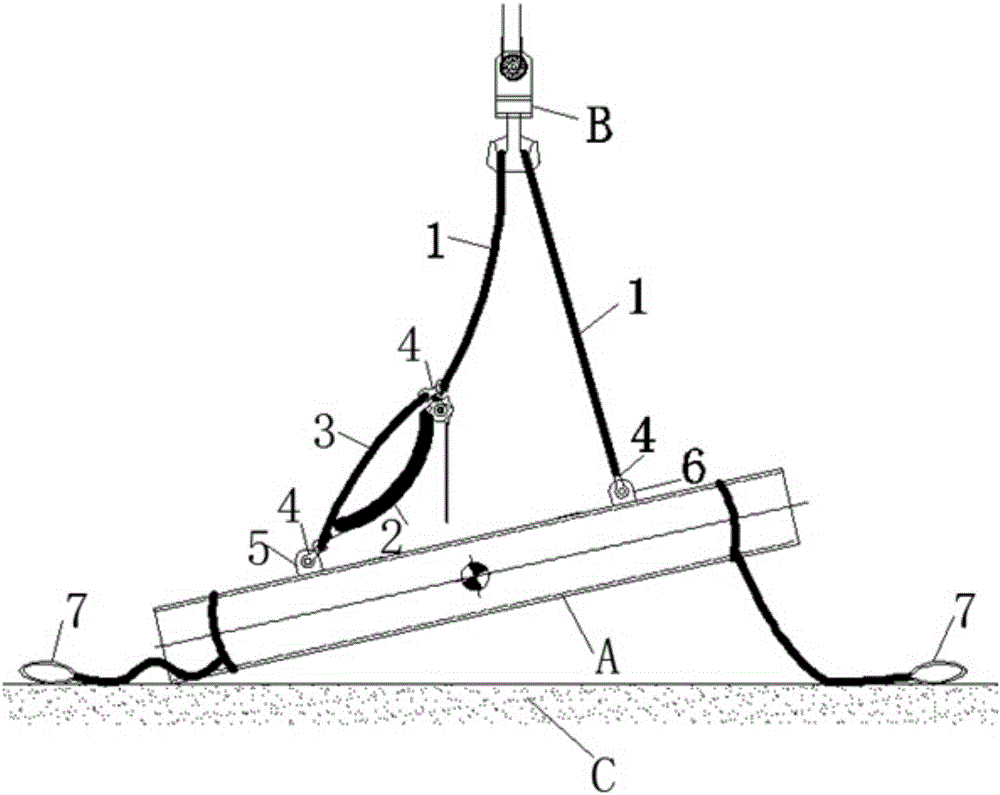

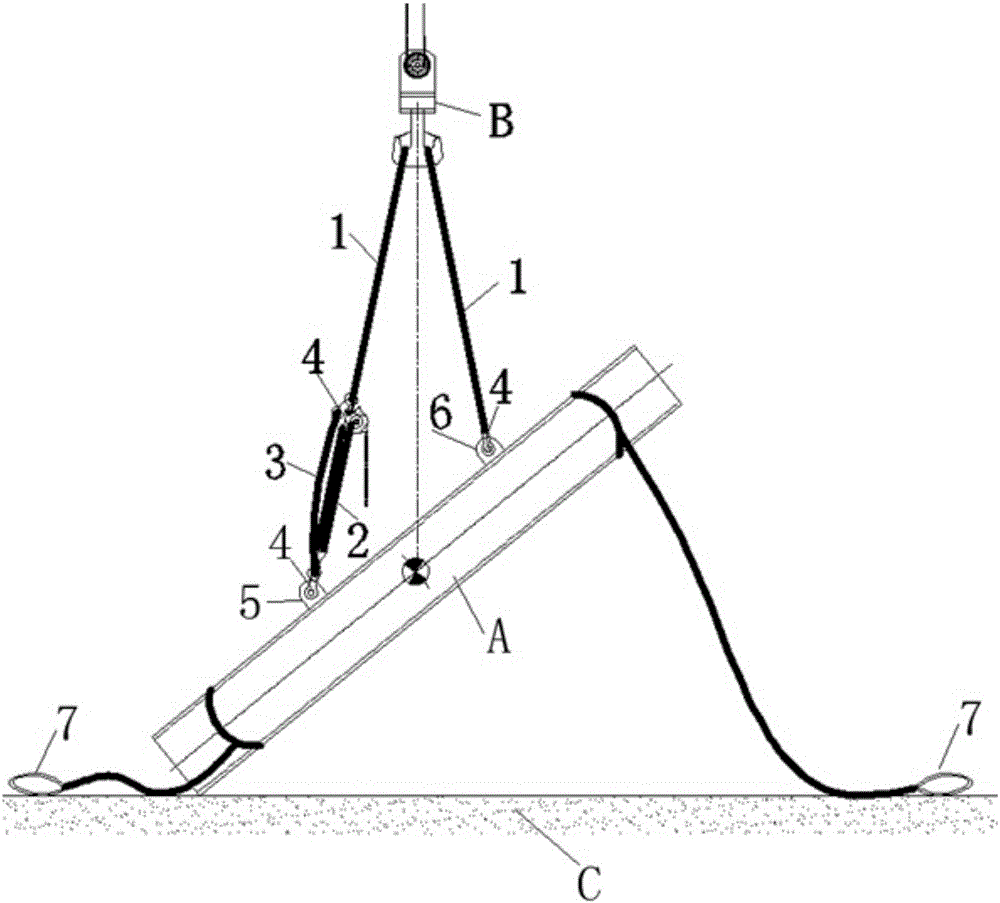

Technology for hoisting strip-shaped inclined steel structures in place through single crane

InactiveCN105858435ASolve the problem of tilt angleReduce construction costsLoad-engaging elementsEngineeringGravity center

A technique for hoisting a strip-shaped inclined steel structure into place by a single crane, the following steps are adopted: 1. Calculate the weight and center of gravity position of the inclined tie bars; 3. Connect the upper ends of the slings with the hooks, and set sliding tail ropes at both ends of the inclined ties; 4. Set safety ropes at both ends of the chain hoist; 5. Slowly lift the crane and place The whole inclined ties slowly leave the ground; 6. After the slanted ties are lifted half a meter from the ground, they should stay for a few minutes; 7. Put the slanted ties in place to the installation position, and assemble the slanted ties accurately; 8; The hoisting is completed by welding and fixing the inclined tie bars. The present invention can complete the precise hoisting and positioning of the strip-shaped inclined steel structure by using a single crane, which solves the problem of using two cranes to adjust the inclination angle of the steel structure with a lighter tonnage; not only greatly reduces the construction cost, Moreover, the efficiency and safety of construction are also improved.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Double-layer spoke type space string-structure steel roof truss and pre-stressed tension method thereof

ActiveCN102635186AAvoid local damagePrevent bucklingBuilding roofsBuilding material handlingPre stressPre stressing

The invention relates to a steel roof truss, particularly relates to a double-layer spoke type space string-structure steel roof truss and a pre-stressed tensions method thereof, and belongs to the field of a steel structure. The side wall of a stand column is fixedly connected with an outer ring truss through an outer ring support; the outer ring truss is fixedly connected with an inner ring truss through an inner ring support; the bottom of the outer ring truss is provided with outer supporting rods which can be continuously distributed at intervals, wherein the bottom of the outer supporting rod at the innermost end is provided with an outer annular cable fastening device and the bottoms of the other outer supporting rods are provided with outer lower-chord radial fastening devices; the bottom of the inner ring truss is provided with inner supporting rods which are continuously distributed at intervals, wherein the bottom of the inner supporting rod at the innermost end is provided with an inner lower-chord ring beam fastening device; and the bottoms of the other inner supporting rods are provided with inner lower-chord radial fastening devices. The double-layer spoke type space string-structure steel roof truss and the pre-stress tensioning method thereof disclosed by the invention have the advantages of high construction precision, high construction efficiency and low construction cost, and improve the construction safety.

Owner:浙江东南网架股份有限公司

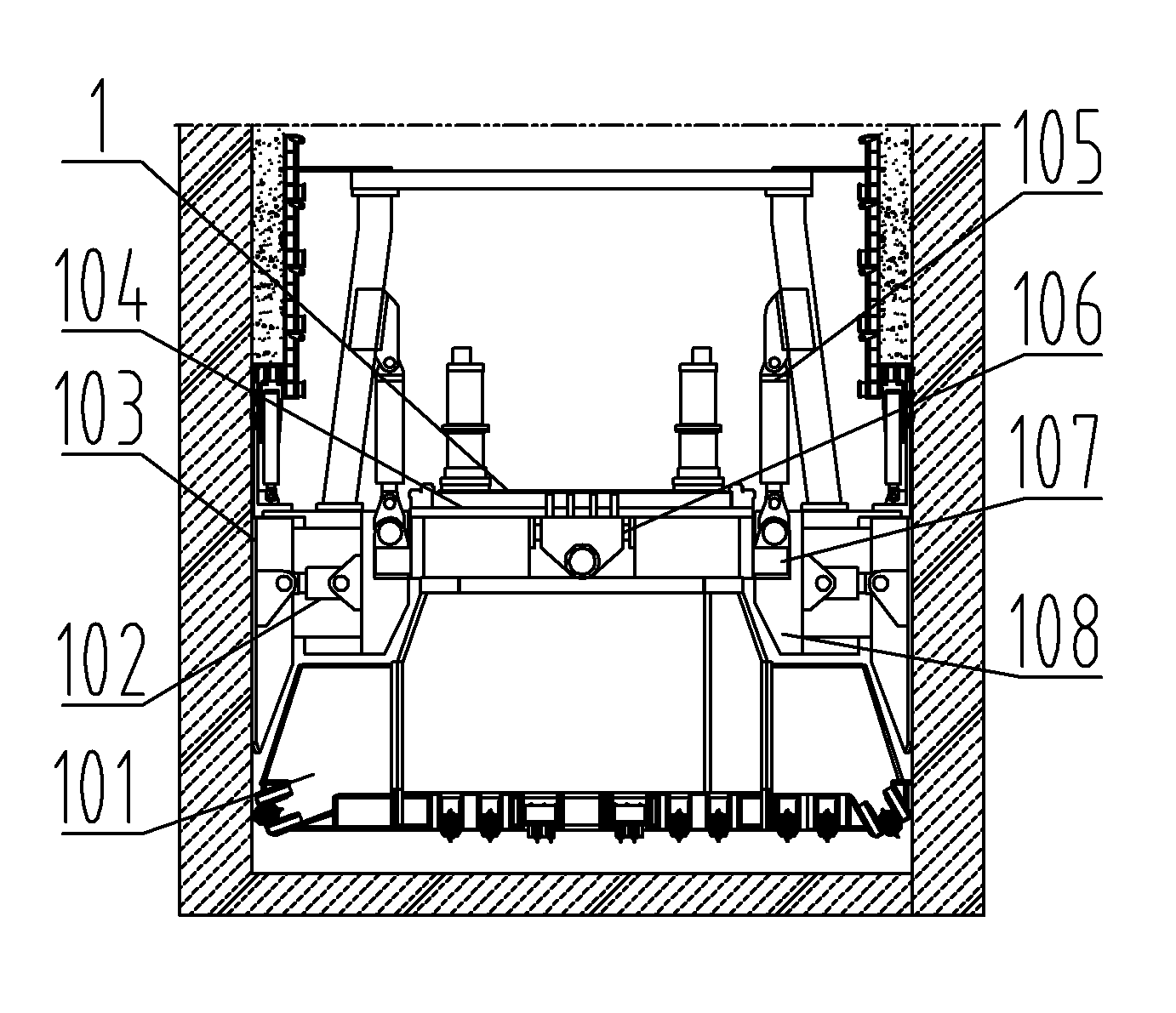

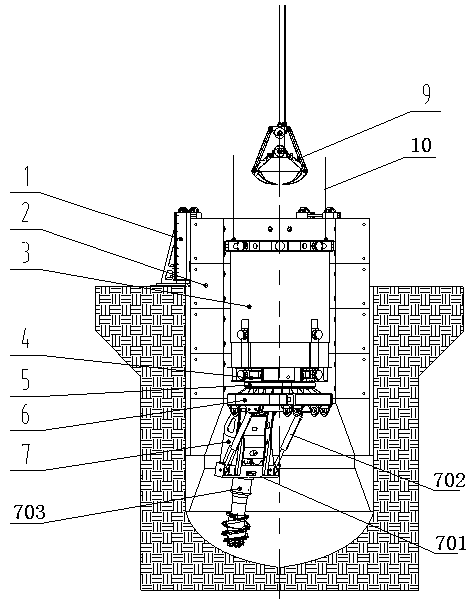

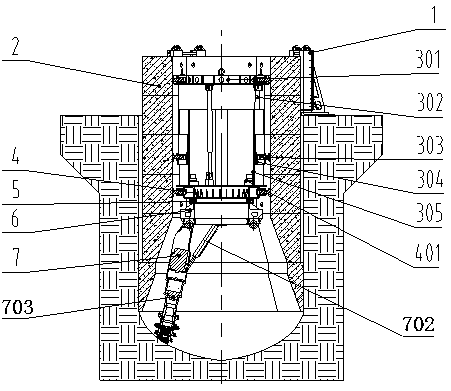

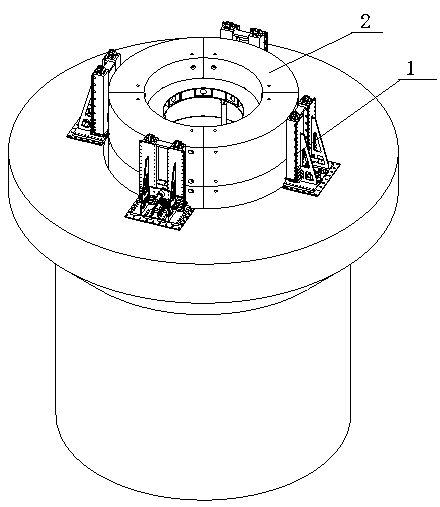

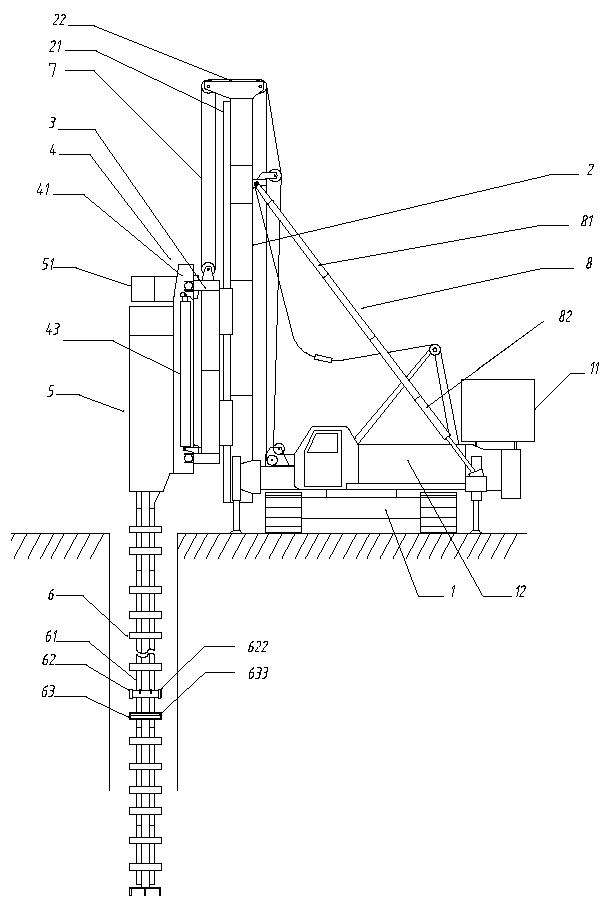

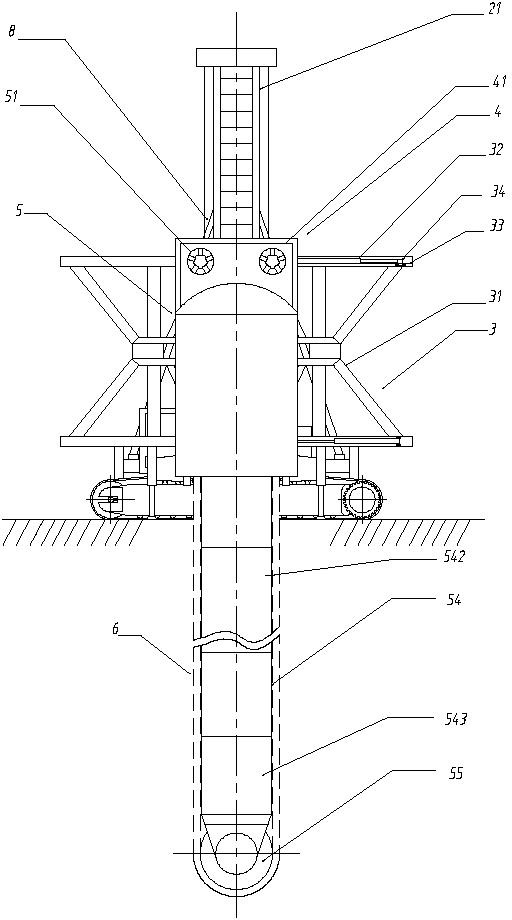

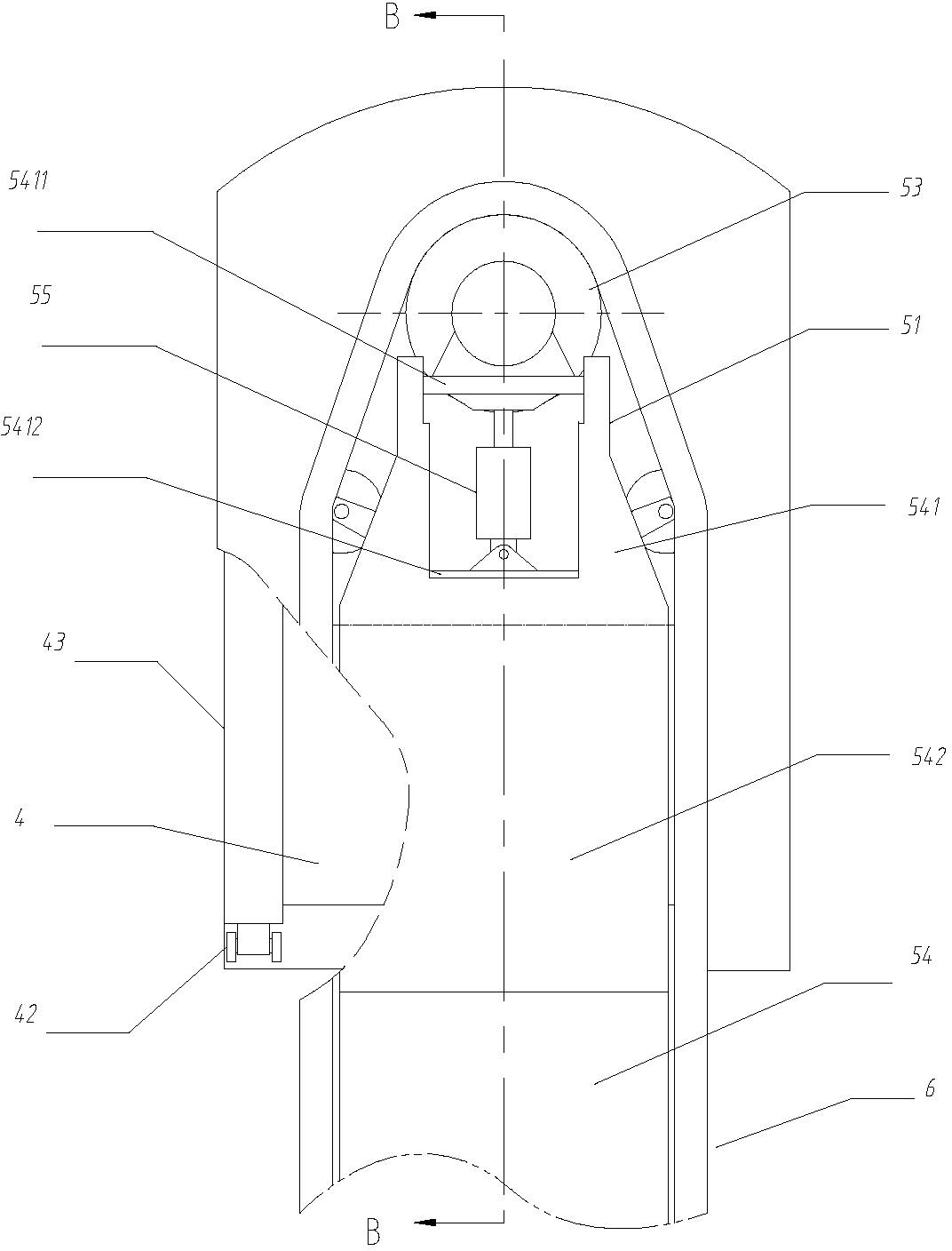

Shaft boring machine by open caisson method and construction method thereof

PendingCN109630124AImprove securityImprove construction safetyDrilling rodsShaft sinkingSlagMechanization

The invention discloses a shaft boring machine by an open caisson method and a construction method thereof, and solves the problems of low mechanization degree, difficult disassembly and assembly andlow working efficiency of a shaft excavation device in the prior art. The shaft boring machine by the open caisson method comprises a tunneling system, a control detection system and a slag dischargesystem. A pipe joint pressure lifting device is arranged on a wellhead ring beam on the ground. The tunneling system comprises a propulsion device, a rotary support, a rotary platform and an excavation device. The upper part of the propulsion device is connected with a hydraulic power system on the ground, and the lower part of the propulsion device is provided with an equipment platform. The equipment platform is connected with the rotary support, and the rotary support is connected with a driving device arranged on the equipment platform. The upper part of the rotary platform is connected with the rotary support, and the excavation device is arranged at the lower part of the rotary platform. According to the shaft boring machine by the open caisson method, the step-by-step excavation ofthe excavation device is realized through the propulsion device, and the efficient and safe excavation is realized through the tightening and stabilization of the excavation device. The shaft boring machine can be quickly disassembled and assembled in the process of entering and exiting the well, thereby saving the construction period and improving the well-forming efficiency.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

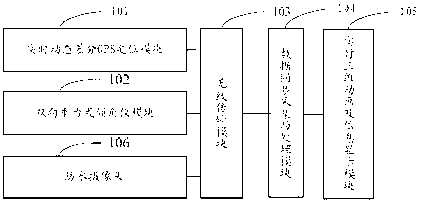

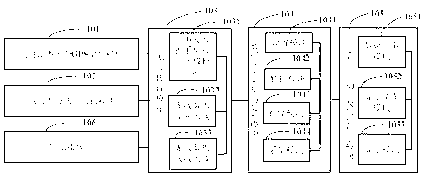

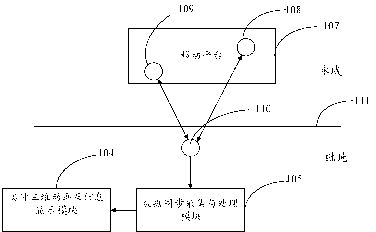

Monitoring and display system for position and three-dimensional attitude of floating and semi-submersible type mobile platform

ActiveCN103018757AImprove engineering efficiencyHigh degree of automationAngle measurementHeight/levelling measurementData transmissionReal Time Kinematic

A monitoring and display system for a position and a three-dimensional attitude of a floating and semi-submersible type mobile platform comprises an RTK (real time kinematic) DGPS (differential global position system) positioning module which is used for obtaining positioning data of the mobile platform; a bidirectional gravity type inclinometer module which is used for obtaining longitudinal and transverse inclination data of the mobile platform; a wireless transmission module which is used for transmitting the positioning data and the inclination data to a synchronous collection and processing module; the synchronous collection and processing module which is used for collecting the positioning data and the inclination data synchronously and converting the positioning data into a presupposed type coordinate system; and a real-time three-dimensional animation and information display module which is used for dynamically displaying the position and the three-dimensional attitude of the mobile platform in real time in a three-dimensional simulation mode. By means of the GPS (global position system) and the animated simulation, the monitoring and display system for the position and the three-dimensional attitude of a floating and semi-submersible type mobile platform displays dynamically the position and attitude information of the mobile platform in real time, and has the advantages of being intuitional, efficient and highly-accurate, thereby largely improving the safety in construction and engineering efficiency, and having a high automaticity, an accurate measurement during work process and a wide prospect.

Owner:SUN YAT SEN UNIV

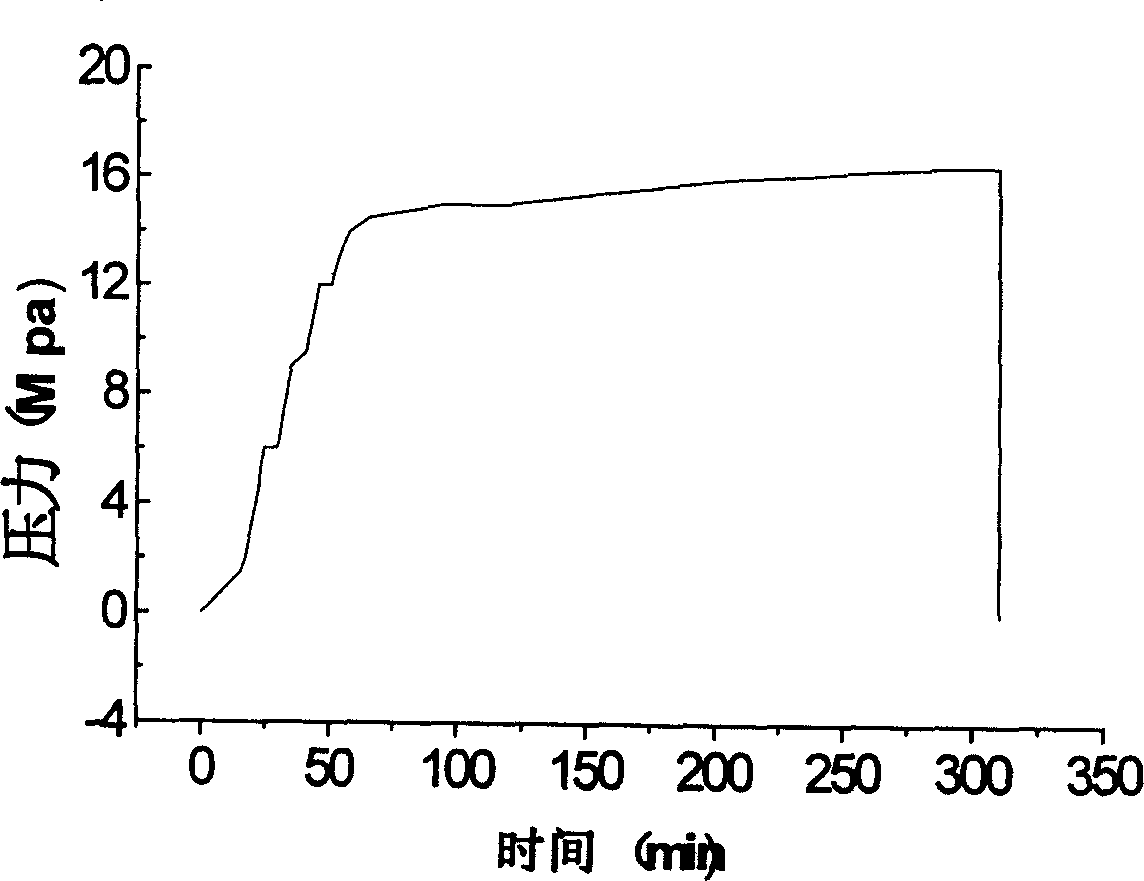

High flashing point environment-friendly soluble polyurethane chemical grouting material

The invention relates to a high flashing point environment-friendly soluble polyurethane chemical grouting material, aiming at solving the technical problem of providing the high flashing point environment-friendly soluble polyurethane chemical grouting material which has the characteristics of high flashing point, non-flammability and good environmental protection performance on the basis of maintaining the original comprehensive performance of soluble polyurethane grouting material. The high flashing point environment-friendly soluble polyurethane chemical grouting material has the technical proposal for solving the technical problem: the material is characterized by comprising the components based on parts by weight: 10-35 parts of isocyanate, 30-80 parts of hydrophilic polyether, 5-30 parts of plasticizer, 10-50 parts of high boiling point composite solvent and 0.5-3 parts of foam stabilizer. The chemical grouting material is applicable to foundation seepage prevention treatment of large dams and other buildings, water burst treatment of subway and tunnel, etc.

Owner:POWERCHINA HUADONG ENG COPORATION LTD +1

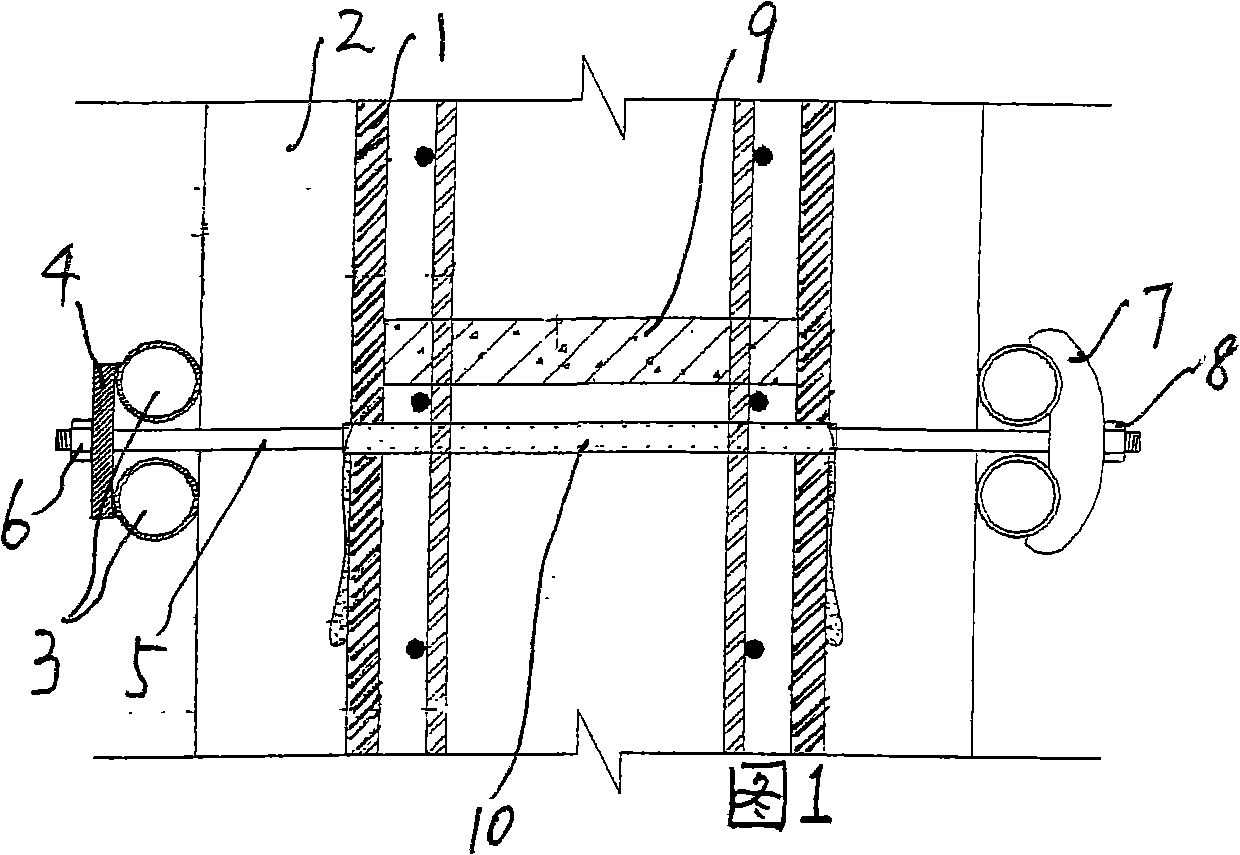

Dual-shear force wall deformation slit formwork

InactiveCN101349106AReasonable structureLow costForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksKeelEngineering

The invention discloses a novel double shear wall deformation joint mould plate. Forming mould plate system on each side comprises a panel, wherein vertical wood keels are fixed outside the panel by iron nails, horizontal keels are arranged outside the vertical wood keels, the horizontal keels are made of steel pipes, and each two steel pipes are closely arranged; the two adjacent steel pipes of the forming mould plate system on one side are welded with a steel plate provided with a screw rod hole, a nut of a double-pulling screw rod is welded in the screw rod hole; the horizontal keels of the forming mould plate system on the other side are provided with a reverse M-shaped clip used to fix the double-pulling screw rod; the double-pulling screw rod passes through the forming mould plate system on the left side and the forming mould plate system on the right side, and is fixed by the steel plates and the nut in the reverse M-shaped clip; a wall plate thickness limitation support is arranged between the panels of the forming mould plate system on the left side and the forming mould plate system on the right side; the double-pulling screw rod is sleeved by a plastic sleeve, both ends of which are inserted in the panels of the forming mould plate system on the left side and the forming mould plate system on the right side respectively. The mould plate of the invention has the advantages of reasonable structure, cost conservation, short construction period, convenient use, flexible assembly, high repeated use rate and good constructional safety.

Owner:JIANGSU NANTONG NO 2 CONSTR ENG GRP

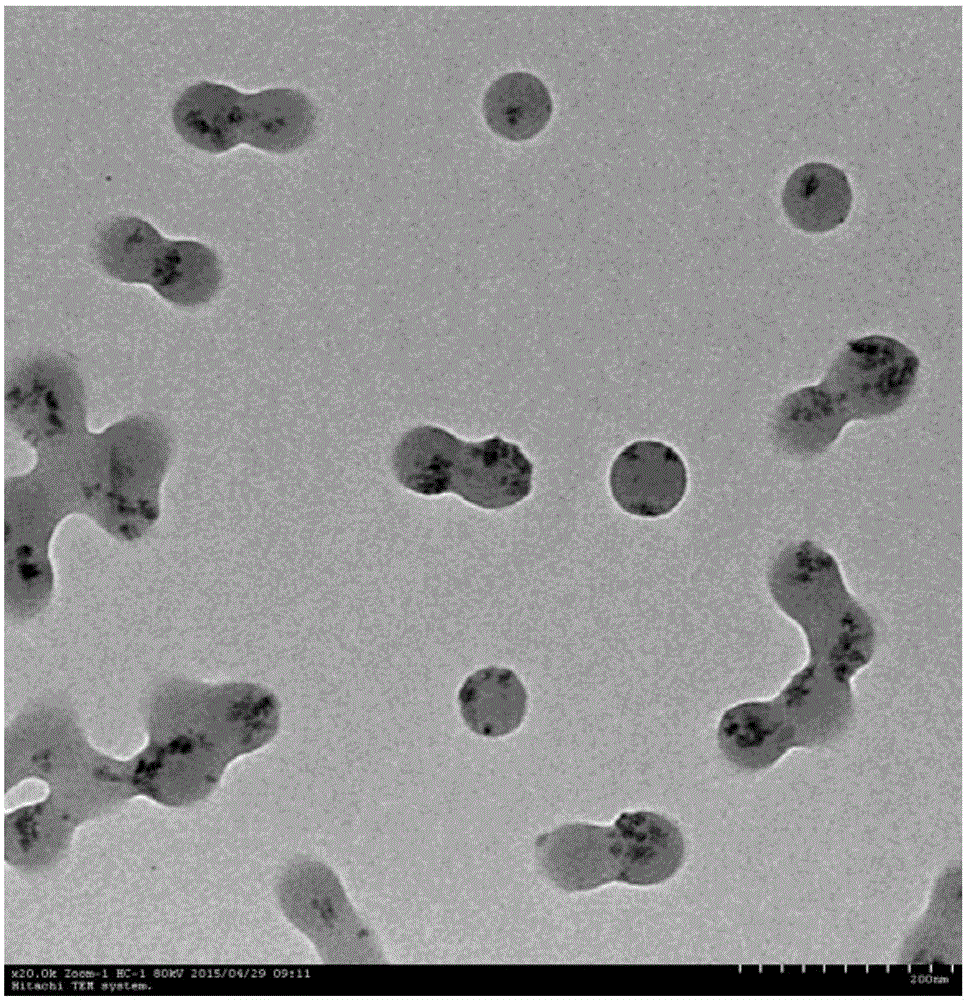

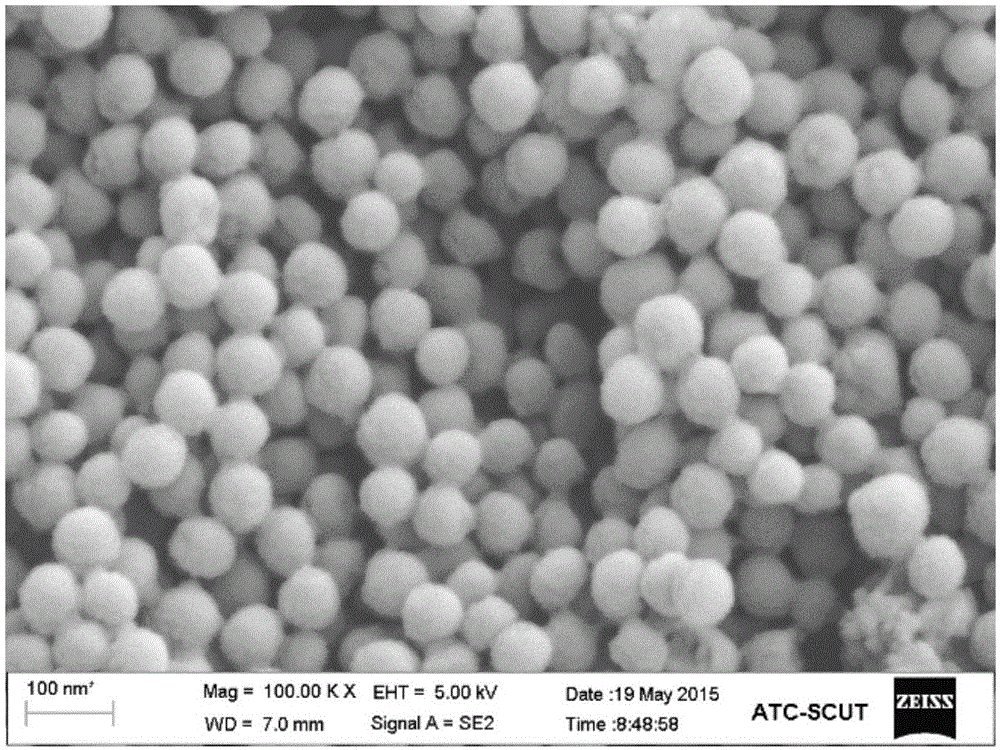

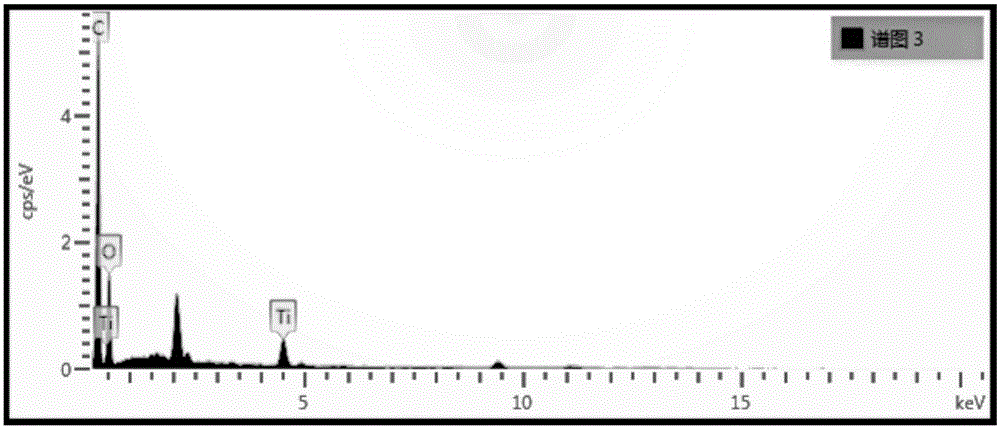

Ultraviolet-proof exterior wall coating and preparation method therefor

The invention discloses ultraviolet-proof exterior wall coating and a preparation method therefor. The preparation method comprises: coating a nano titanium dioxide surface with a layer of acrylate polymer to obtain nano titanium dioxide / acrylate polymer to obtain compound emulsion; and then, sufficiently mixing the compound emulsion with acrylate polymer exterior wall emulsion to obtain mixed emulsion, and adding pigments, auxiliaries and water into the mixed emulsion. According to the coating, the nano titanium dioxide surface is coated with one layer of acrylate polymer, so that dispersion and stability of nano titanium dioxide in coating are remarkably improved, and therefore, nano titanium dioxide aggregates are avoided, and anti-ultraviolet property of the aggregates is greatly reduced or even avoided. The coating not only has characteristics such as excellent water resistance, excellent alkali resistance, excellent scrubbing resistance and the like of the acrylate polymer exterior wall coating, but also has improved hardness and anti-ultraviolet property, so that the service life of the coating is prolonged; and the preparation method is simple, low in production cost and beneficial for industrial production.

Owner:HEBEI CARPOLY PAINT CO LTD

Process for replacing hoisting ropes

ActiveCN101786570AReduce usageSolve difficult problems that are easy to twistMine liftsPull forceEngineering

The invention discloses a process for replacing hoisting ropes, which comprises the steps of: 1, arranging new and old rope hoists at an upper wellhead, and lifting a second cage to the upper wellhead; 2, lowering the second cage, and arranging a pair of long boards on an old rope on the same side of the second cage at intervals of 50 meters; 3, separating the old rope from a first cage and connecting the old rope with an old rope take-up hoist; 4, when the second cage is lifted to the upper wellhead, taking up the old rope by the old rope take-up hoist, dismounting the long boards in the step 2, and breaking the old rope; 5, connecting the rope end of a new rope with an upper breaking point, and connecting a second end of the old rope with a lower breaking point; 6, driving the new rope by the old rope to wind two hoisting sheaves and a winch sequentially, breaking the new rope and the upper breaking point, and connecting the new rope with the second cage; and 7, driving the new rope to descend by the second cage, applying pull force to the new rope at intervals of 50 meters, arranging the long boards on the new rope and a to-be-replaced old rope, removing the pull force, breaking the new rope, and connecting the new rope with the first cage.

Owner:山东煤安矿山提升设备安装有限公司

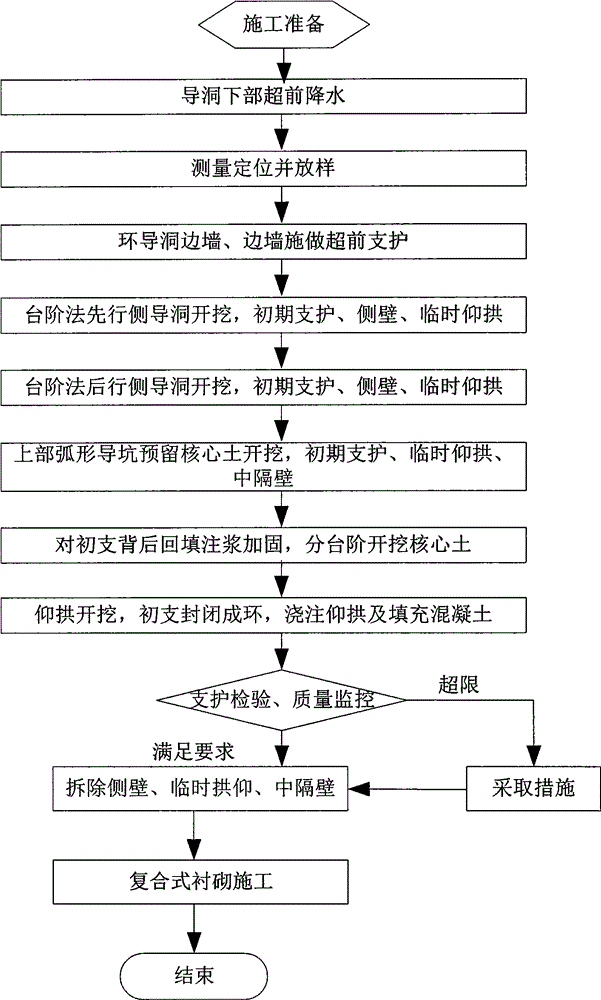

Advance precipitation construction method of oversized-section double-side lower pilot tunnels of water-rich tunnel

InactiveCN104373128AFast structure speedOne splicing construction deviation is smallTunnelsClerestoryPrecipitation

The invention relates to an advance precipitation construction method of oversized-section double-side lower pilot tunnels of a water-rich tunnel. Pilot tunnels on two side walls of a lower half section of a tunnel are adopted, and are partially closed to form rings; the advance precipitation is performed for the tunnel; the stability of arching legs of primary supports of the tunnel is guaranteed; the upper half section of the tunnel is dig by an arch pilot tunnel reserved core soil method; the arch part is dig in place once; the primary steel supports at the upper part of the tunnel are once spliced in place for closing to rings; the disturbance to surrounding rocks due to multiple splices is reduced; and the whole structure of the primary supports of the tunnel is quickly built. Compared with a traditional CD method, CRD method and double-side wall pilot tunnel method, the construction method is high in construction safety, quick in construction progress, short in construction period, low in part mechanical and labor resource configuration, low in once splicing construction deviation of the steel supports, high in construction quality of the primary supports, quick in building of the whole structure of the primary supports of the tunnel and low in vault crown settlement.

Owner:CHINA ROAD & BRIDGE

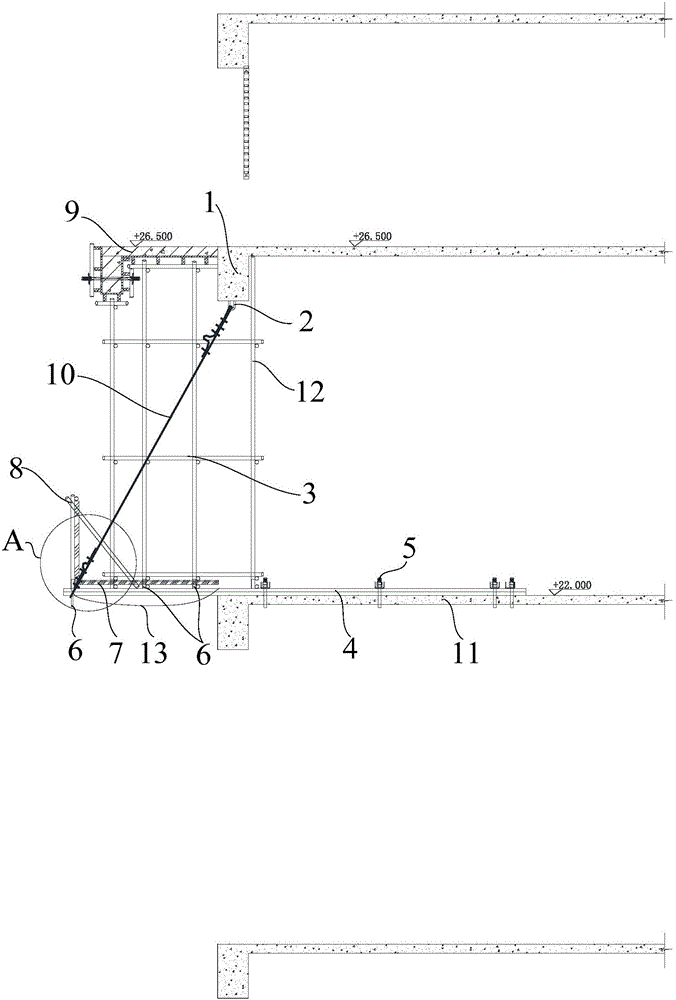

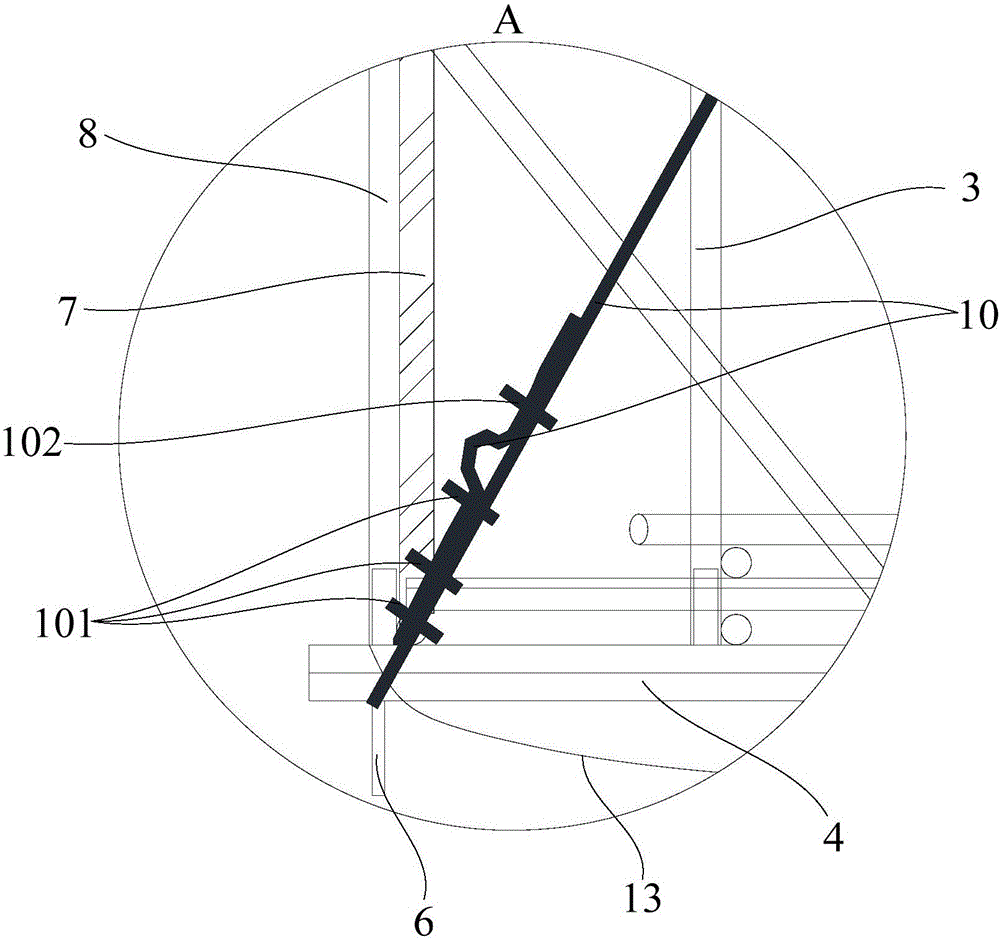

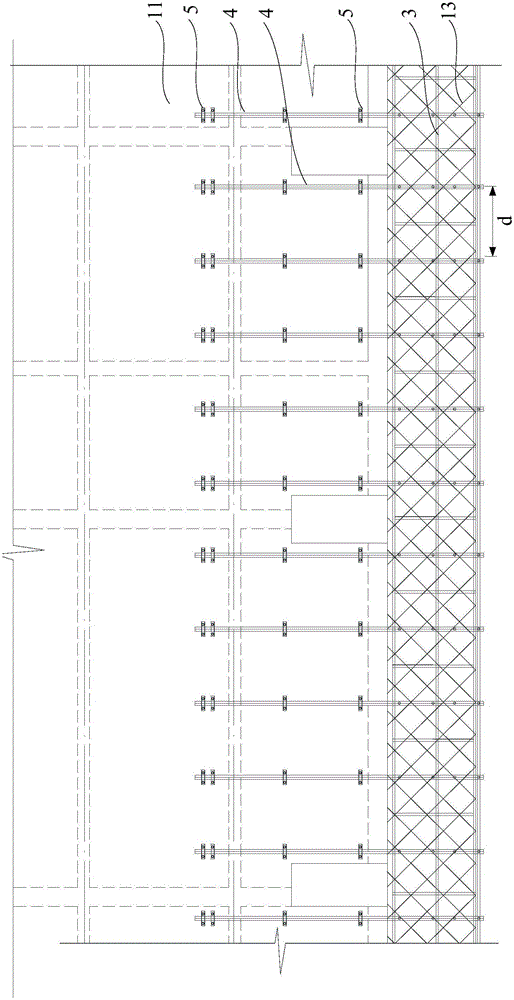

Overhanging support frame formwork system and construction method thereof

InactiveCN105971274AImprove reliabilityImprove construction safetyForms/shuttering/falseworksBuilding material handlingFloor slabBuilding construction

The invention provides an overhanging support frame formwork system and a construction method thereof. The overhanging support frame formwork system is used for pouring of overhanging members on an outer wall of a building. The overhanging support frame formwork system comprises a plurality of overhanging beams, pulling pieces and a whole-hall scaffold. The overhanging beams are fixed to a floor on the lower layer of a floor layer where the outer wall of the building is located through connecting pieces, the multiple overhanging beams are arranged side by side, and the space between the adjacent overhanging beams is smaller than or equal to a preset value. The pulling pieces are fixedly connected with structural beam built-in fittings of the floor layer where the overhanging members are located and overhanging sections respectively. The whole-hall scaffold is arranged on the overhanging sections of the overhanging beams to support a formwork for the overhanging members so that concrete pouring of the overhanging member can be achieved. According to the overhanging support frame formwork system, the space between the adjacent overhanging beams is not larger than the preset value, it is guaranteed that the overhanging beams cannot be broken off by loads, and therefore it is guaranteed that cost cannot be increased due to the large number of the overhanging beams, it is also guaranteed that the overhanging beams cannot be broken off by loads, and safety of building construction is improved.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Continuous wall milling machine

InactiveCN102155035AExtended service lifeReduce maintenance costsSoil-shifting machines/dredgersBulkheads/pilesMilling cutterEngineering

The invention discloses a continuous wall milling machine, which comprises a host machine base plate, an upright post, a gantry frame, a guide frame, a milling box, a milling and stirring chain, a steel wire rope, an inclined strut and a correcting mechanism, wherein a milling frame adopts a box structure and can be extended to a set length; the milling and stirring chain comprises a chain, and multiple groups of crossed milling cutter bodies and multiple groups of stirring bodies which are fixedly arranged on the chain at certain intervals; after the chain is arranged on a driving chain wheel and a driven chain wheel, a chain transmission mechanism is formed; a transmission case is positioned on the upper part of the milling box; a driving head is fixedly arranged at an installation position above the transmission case; the driving chain wheel is arranged on an output shaft at the lower end of the transmission case; the output shaft is arranged on a supporting platform; one end of a tension oil cylinder is hinged with the lower part of the supporting platform, and the other end of the tension oil cylinder is connected with a lower rod piece; the correcting mechanism is used for obliquely correcting the front, back, left and right of the milling frame; multiple groups of grout pipes are arranged inside the milling frame along the length direction of the milling frame; and the end parts of the grout pipes are provided with spray heads. The continuous wall milling machine is suitable for underground facilities of large buildings, deep foundation excavation and cut-off wall construction of water conservancy dams.

Owner:上海工程机械厂有限公司

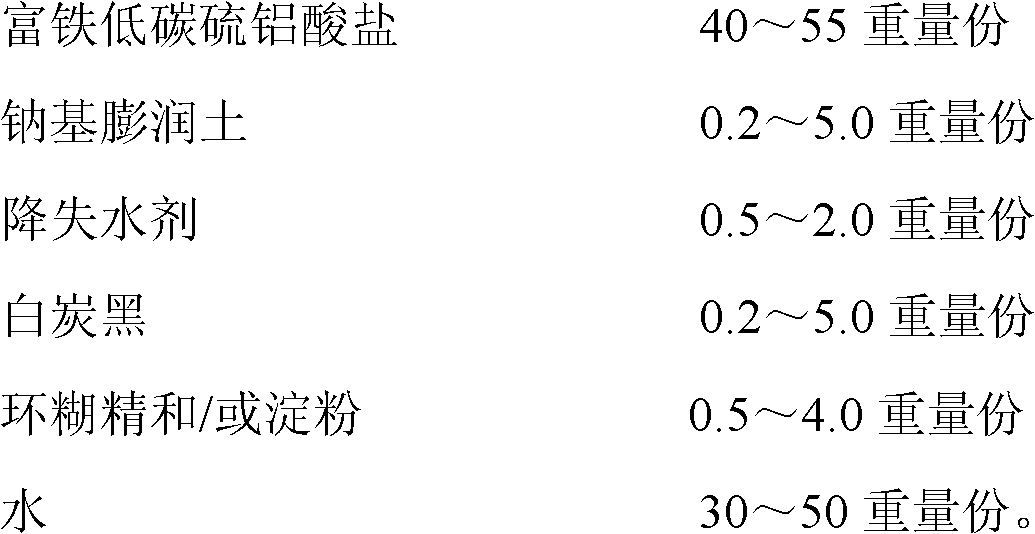

Thixotropic chemical sealing channeling agent

ActiveCN102181274AFormation damage is smallImprove construction safetyDrilling compositionSealing/packingChemistryCarbon black

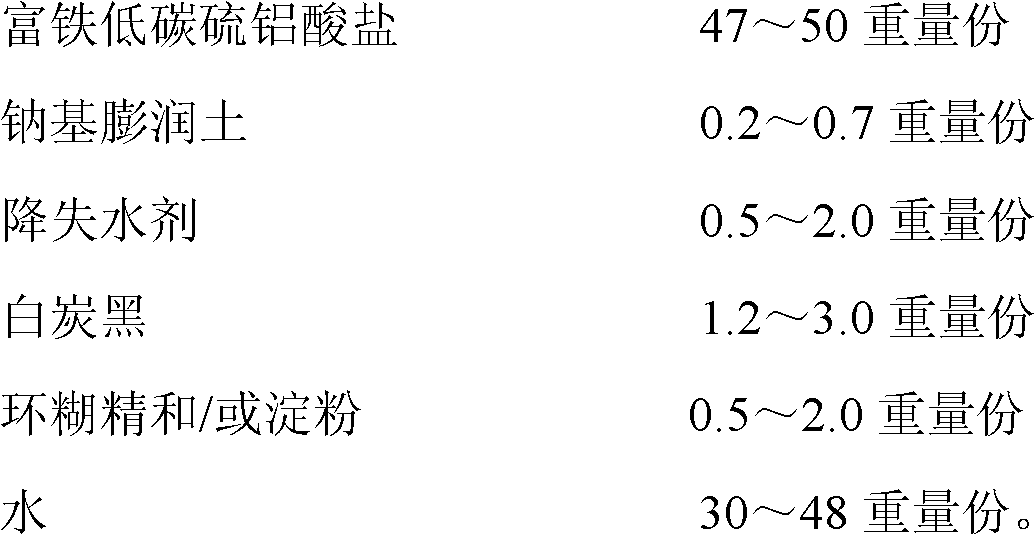

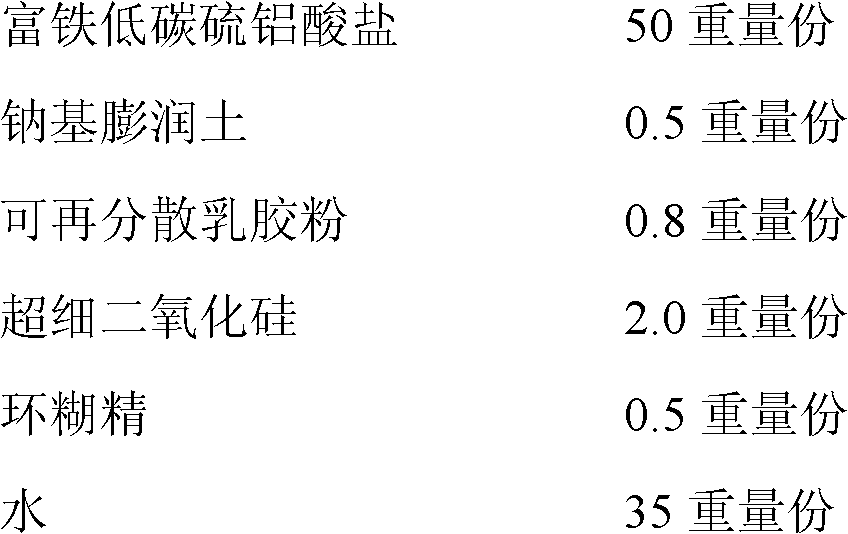

The invention provides a thixotropic chemical sealing channeling agent. The sealing channeling agent comprises the following raw materials: 40 to 55 weight parts of iron rich low-carbon sulfur aluminate, 0.2 to 5.0 weight parts of sodium-based bentonite, 0.5 to 2.0 weight parts of fluid loss agent, 0.2 to 5.0 weight parts of white carbon black, 0.5 to 4.0 weight parts of cyclodextrin and / or starch and 30 to 50 weight parts of water. The chemical sealing channeling agent has the characteristics of strong adhesion and thermal stability, good durability, prominent cracking resistance and the like; the linear expansion rate reaches over 0.2 percent, the compressive strength reaches over 30MPa, and the shearing strength reaches over 10MPa; and by adding dispersant, fluid loss agent and thixotropic regulator, the sealing channeling agent has high thixotropic property and loss resistance.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com